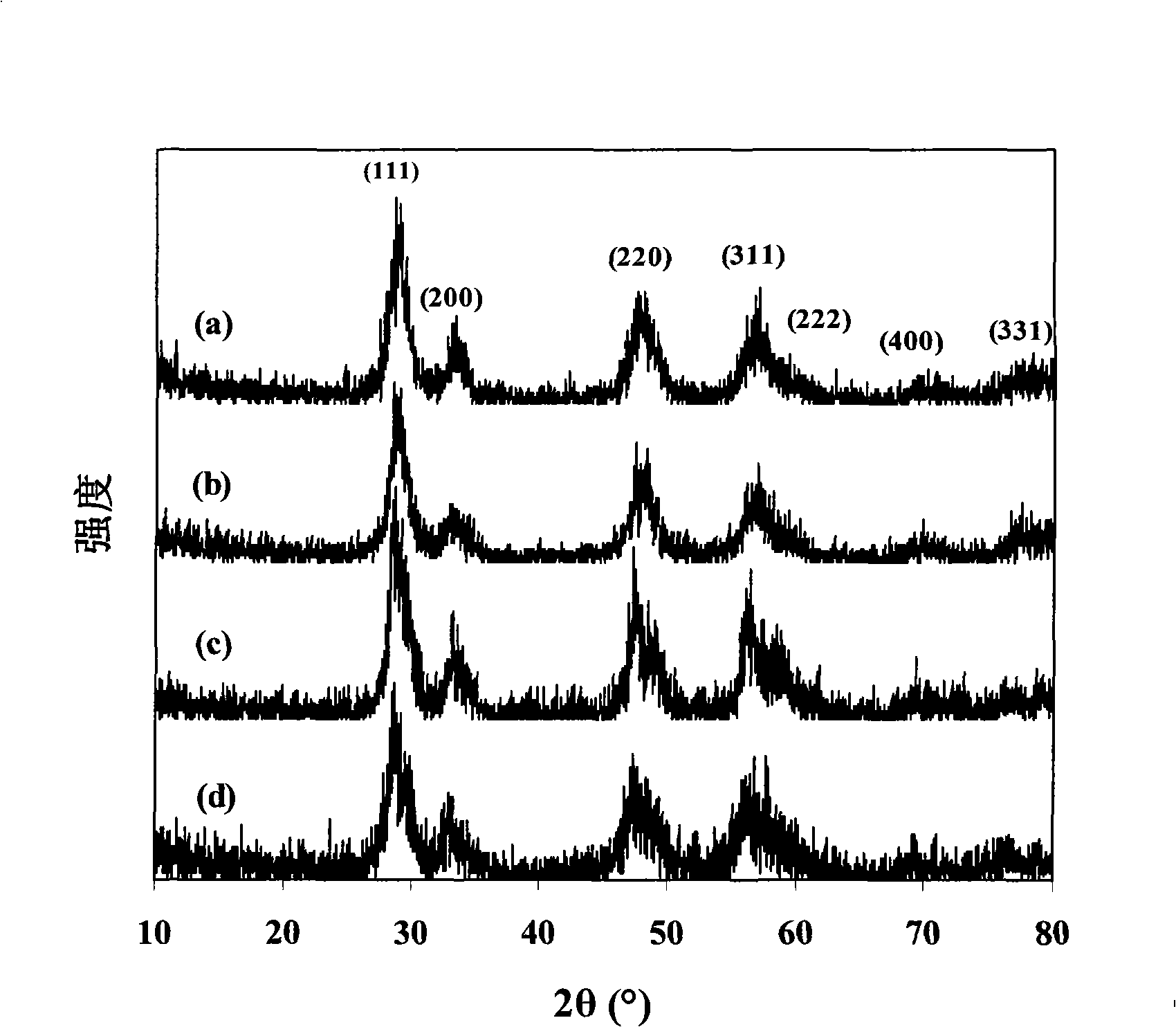

Method for preparing macropore-mesopore Ce1-xZrxO2 solid solution

A solid solution, mesoporous technology, applied in ceramic products, other household appliances, household appliances, etc., to achieve the effect of large mass transfer characteristics and good oxygen storage and release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

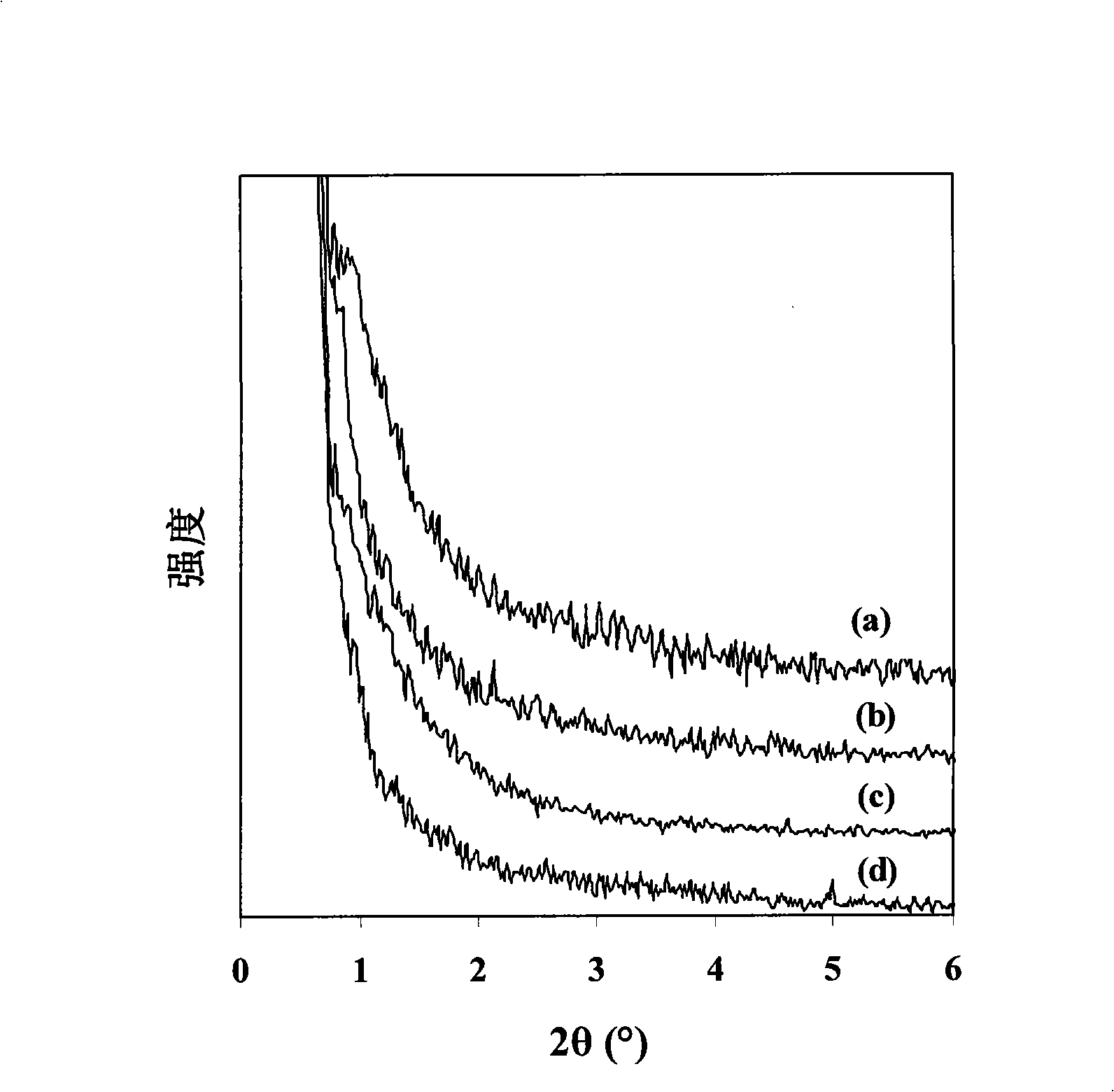

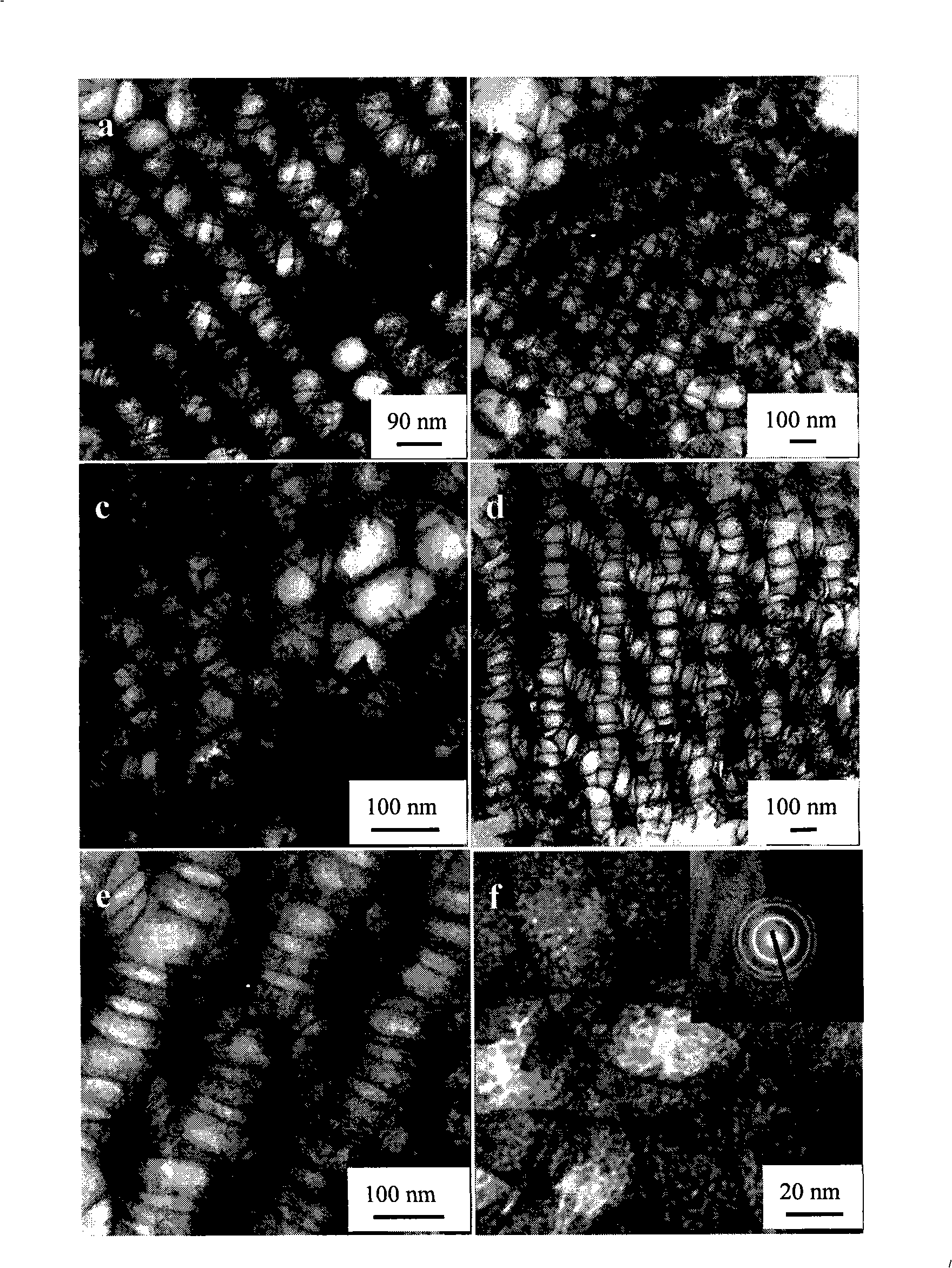

Embodiment 1

[0020] At normal temperature and pressure, 1g of EO 20 PO 70 EO 20 Dissolve in 15g absolute ethanol, that is, 100% ethanol aqueous solution; add 6mmol CeCl after complete dissolution 3 ·7H 2 O and 4 mmol ZrOCl 2 ·8H 2 O, keep stirring for 1h; place 5g of hard template in the Buchner funnel, add the prepared solution dropwise until it is completely soaked, filter to remove excess liquid, and place it in air at room temperature with a relative humidity below 40% for 48h; at 1°C / min After burning at 300°C and 500°C for 3h and 5h respectively, the three-dimensional ordered macropore-wormlike mesoporous Ce 0.6 Zr 0.4 o 2 solid solution.

[0021] The specific surface area of the solid solution is 64m 2 / g, the pore volume is 0.23m 3 / g; Among them, the specific surface area of macropores with a pore diameter of 36-200nm is 14m 2 / g, the pore volume is 0.13m 3 / g; and the specific surface area of mesopores with a pore diameter of 2-36nm is 50m 2 / g, the pore volume...

Embodiment 2

[0023] At room temperature and pressure, 1 g of EO 20 PO 70 EO 20 Dissolve in 15g of 60% ethanol aqueous solution, add 6mmol CeCl after complete dissolution 3 ·7H 2 O and 4 mmol ZrOCl 2 ·8H 2 O, keep stirring for 1h; place 5g of hard template in the Buchner funnel, add the prepared solution dropwise until it is completely soaked, filter to remove excess liquid, and place it in air at room temperature with a relative humidity below 40% for 48h; at 1°C / min After burning at 300°C and 500°C for 3h and 5h respectively, the three-dimensional ordered macropore-wormlike mesoporous Ce 0.6 Zr 0.4 o 2 solid solution.

Embodiment 3

[0025] At normal temperature and pressure, 1g of EO 20 PO 70 EO 20 Dissolve in 15g of water (i.e. 0% ethanol aqueous solution), add 7mmol CeCl after complete dissolution 3 ·7H 2 O and 3 mmol ZrOCl 2 ·8H 2 O, keep stirring for 1h; place 5g of hard template in the Buchner funnel, add the prepared solution dropwise until it is completely soaked, filter to remove excess liquid, and place it in air at room temperature with a relative humidity below 40% for 48h; at 1°C / min After burning at 300°C and 500°C for 3h and 5h respectively, the three-dimensional ordered macropore-wormlike mesoporous Ce 0.7 Zr 0.3 o 2 solid solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com