Preparation of complete stable cubic phase zircite crystal fibre

A technology of phase zirconia and crystal fiber, which is applied in the field of refractory materials and heat preservation, can solve the problems of being short, can only be used in environments below 1600 °C, has little practical significance, and is easy to pulverize, etc., and achieves moderate strength and high temperature The effect of stable performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

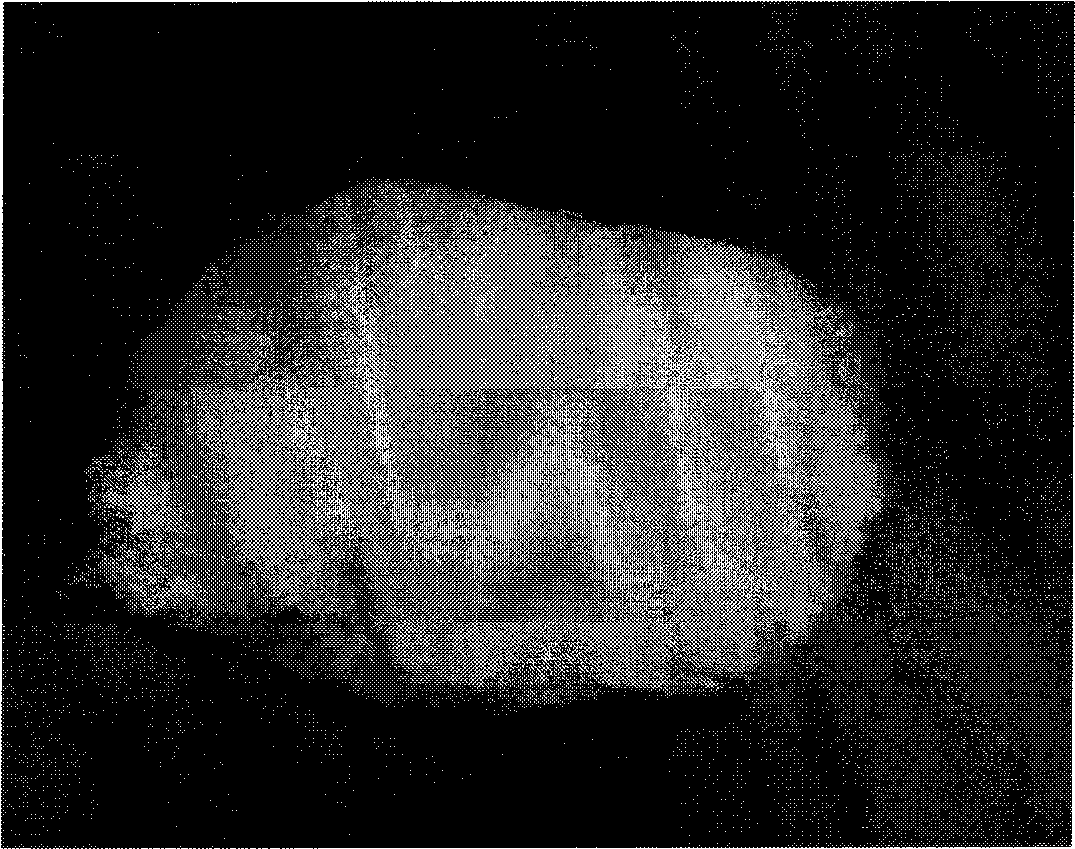

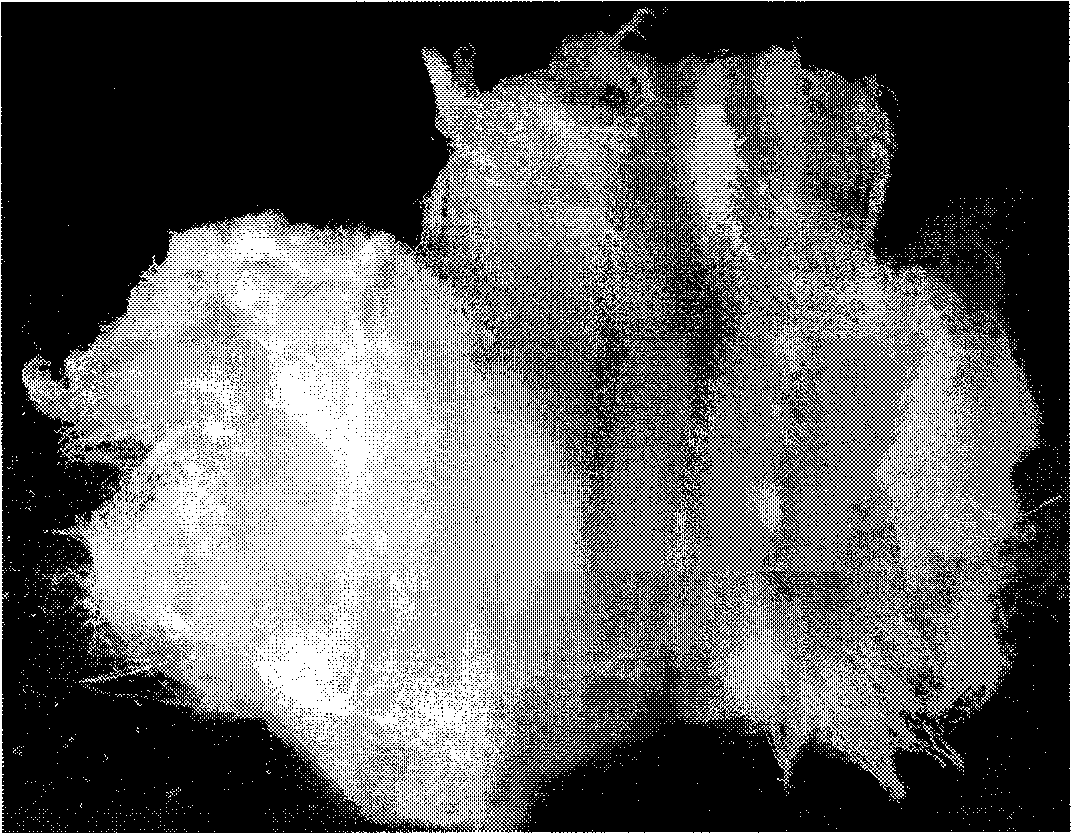

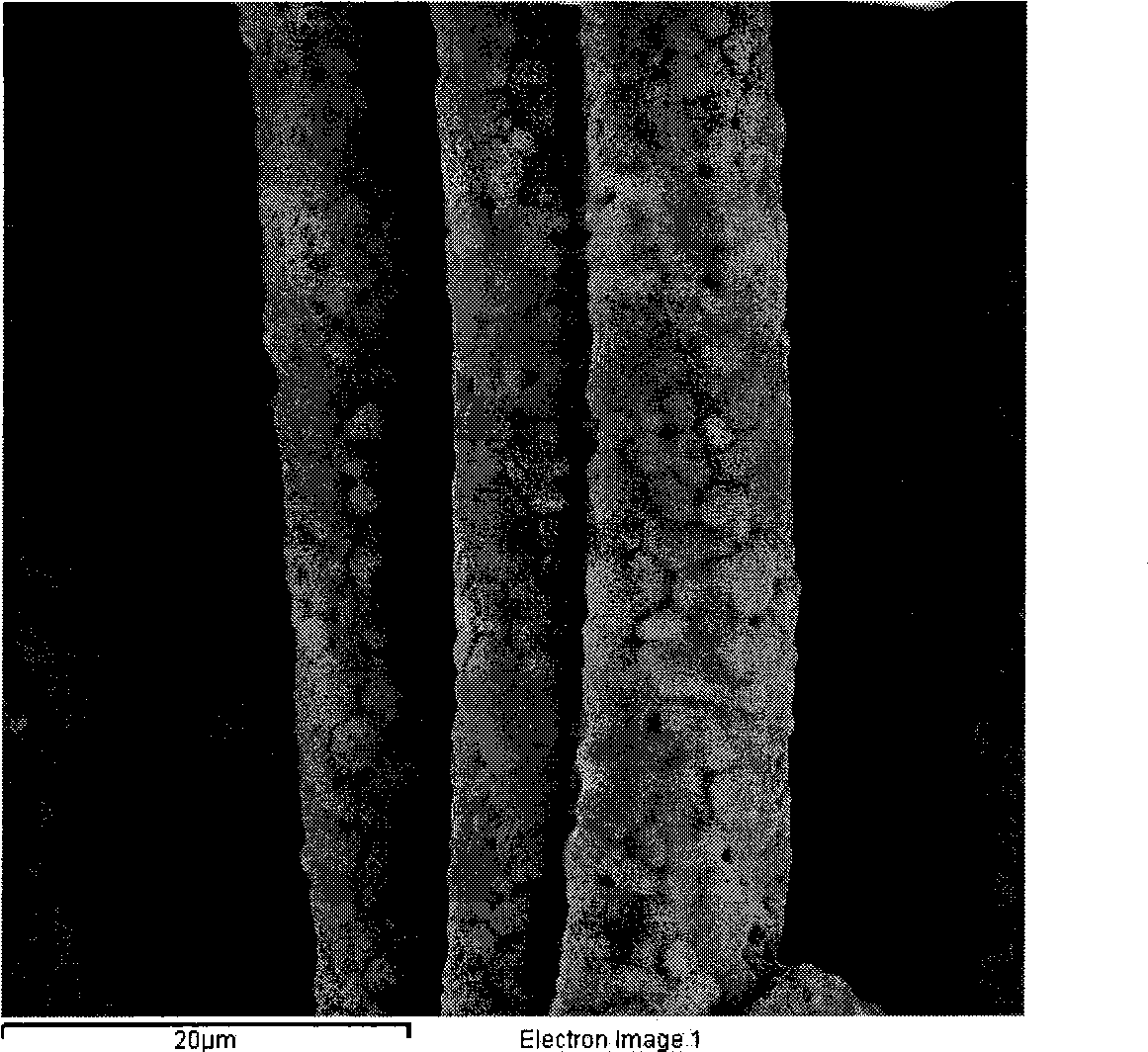

[0035] The preparation method of the fully stable cubic phase zirconia crystal fiber of the present invention adopts the following steps:

[0036] (1) Weigh zirconium oxychloride (ZrOCl 2 ·8H 2(2) 100g, be dissolved in 800ml ethanol, be zirconium oxychloride according to molar ratio: acetylacetone: the ratio of triethylamine=1:1.8:2.5, measure 60ml acetylacetone and 110ml triethylamine, be dissolved in 800 milliliters jointly In ethanol, under stirring conditions at 5°C, atomize the ethanol dilution of acetylacetone and triethylamine into the ethanol dilution of zirconium oxychloride, and continue stirring for 3 hours after the addition to obtain a golden yellow transparent reaction solution. Remove the solvent ethanol by rotary evaporation at 40°C until it is nearly dry, and obtain a light yellow sticky substance. Add 500ml of acetone according to the ratio of zirconium oxychloride: acetone = 100g:500ml, stir to dissolve the soluble matter, and press filter to remove the ins...

Embodiment 2

[0042] As described in Example 1, the difference is that 100 grams of zirconium oxychloride (ZrOCl) was weighed in step (1). 2 ·8H 2 O) be dissolved in 800ml ethanol instead be dissolved in 900ml ethanol, and change the ratio of zirconium oxychloride: the mol ratio of acetylacetone=1:1.8 to 1:2.0, be about to change 60 milliliters of acetylacetone into 67 milliliters of acetylacetone , be dissolved in 900 milliliters of ethanol together with 110ml triethylamine, simultaneously with reactant zirconium oxychloride in step (2): the ratio of ethanol=100g: 20ml, 70g of gained product are dissolved in 20ml ethanol, change according to Reactant zirconium oxychloride: the ratio of ethanol=100g:30ml, 70g of the product obtained is dissolved in 30ml ethanol.

Embodiment 3

[0044] As described in Example 1, the difference is that 100 grams of zirconium oxychloride (ZrOCl) was weighed in step (1). 2 ·8H 2 O) be dissolved in 800ml ethanol instead be dissolved in 1000ml ethanol, and zirconium oxychloride: the mol ratio of acetylacetone=1:1.8 is changed into 1:1.9, is about to change 60 milliliters of acetylacetones into 63 milliliters of acetylacetones , and 110ml triethylamine are dissolved in 1000 milliliters of ethanol, simultaneously with reactant zirconium oxychloride: ethanol=100g: 20ml ratio in the step (2), the obtained product zirconium polyacetylacetonate 70g is dissolved in 20ml ethanol In the present invention, according to the ratio of the reactant zirconium oxychloride: ethanol=100g: 40ml, 70g of the obtained product was dissolved in 40ml of ethanol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com