Patents

Literature

339results about How to "Single ingredient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

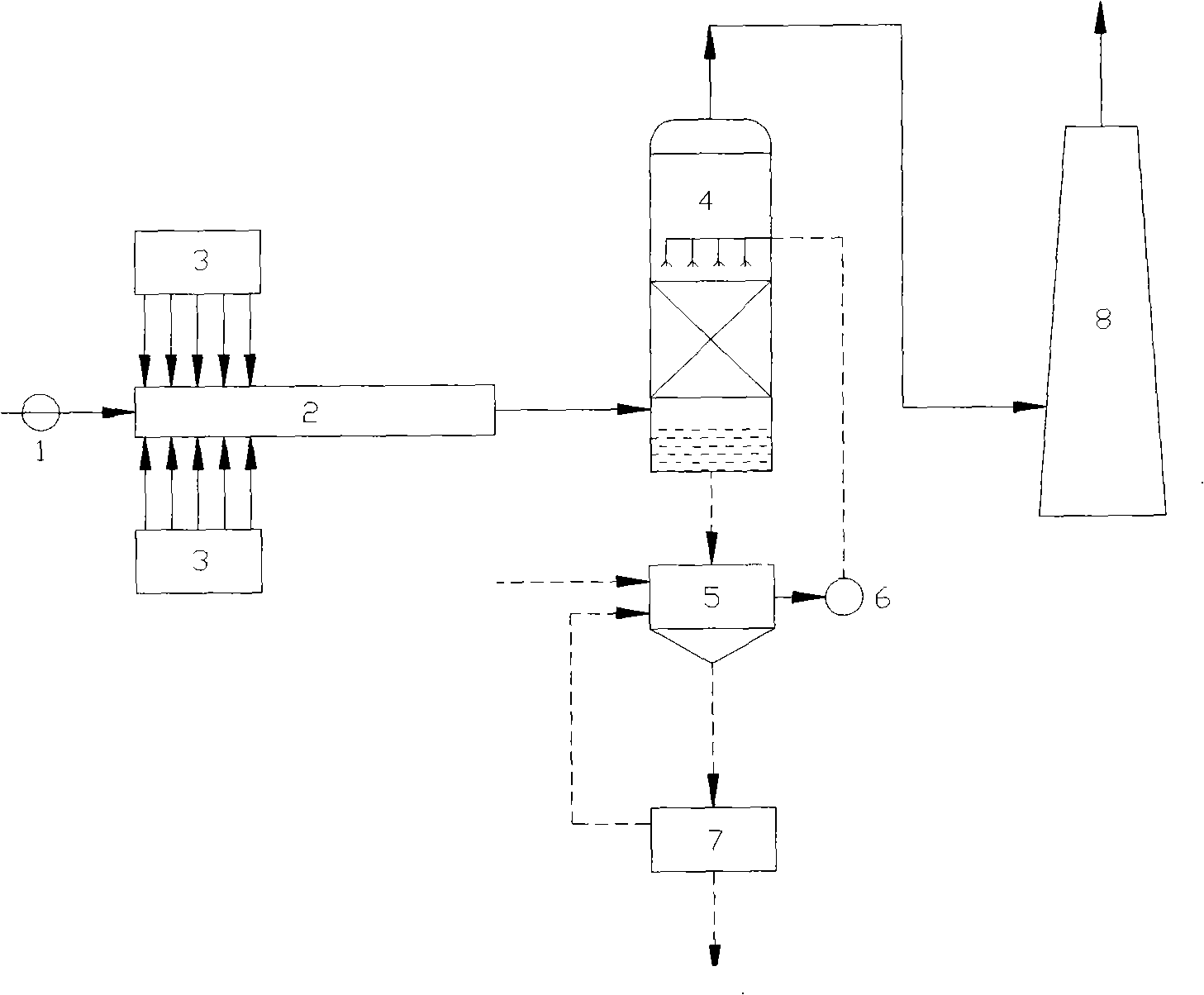

Wet flue gas denitration technique for nitrite recovery

ActiveCN101352644AHigh economic valueIncrease profitDispersed particle separationAir quality improvementNitriteResource utilization

The invention discloses a wet-method smoke denitration process used for recovering nitrite, comprising the steps as follows: hydrogen peroxide or ozone is taken as oxidant; the oxidant is uniformly sprayed into smoke disposed by pre-dedusting and desulfurizing so as to carry out gas oxidation reaction and lead the NO in the smoke to be oxidated as NO2; subsequently, alkali liquid is taken as absorbent so as to absorb the mixture of the oxidated NO and NO2 and generate the nitrite; the absorbent is concentrated after absorbing the NO and NO2 and cooled and crystallized; after centrifuging separation, the nitrite crystal is gained. The process of the invention can effectively remove the NOx in the smoke, gains the nitrite with high economic values at the same time, and realizes the resource utilization of denitration outgrowth.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

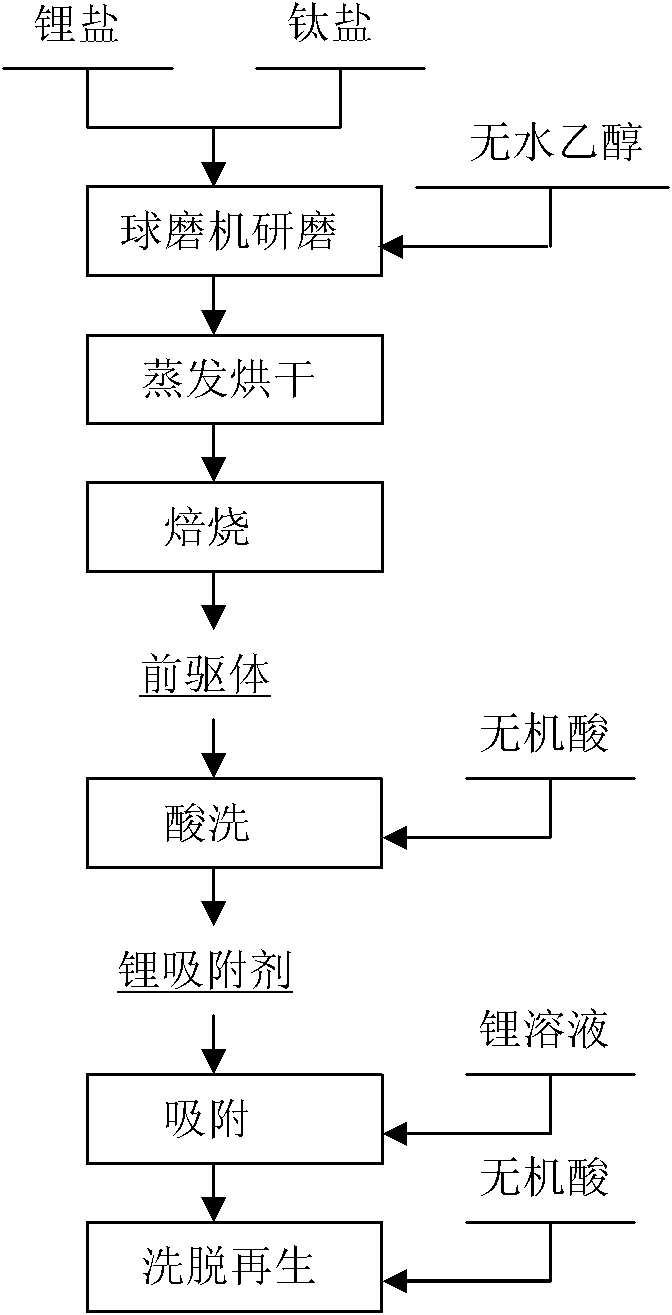

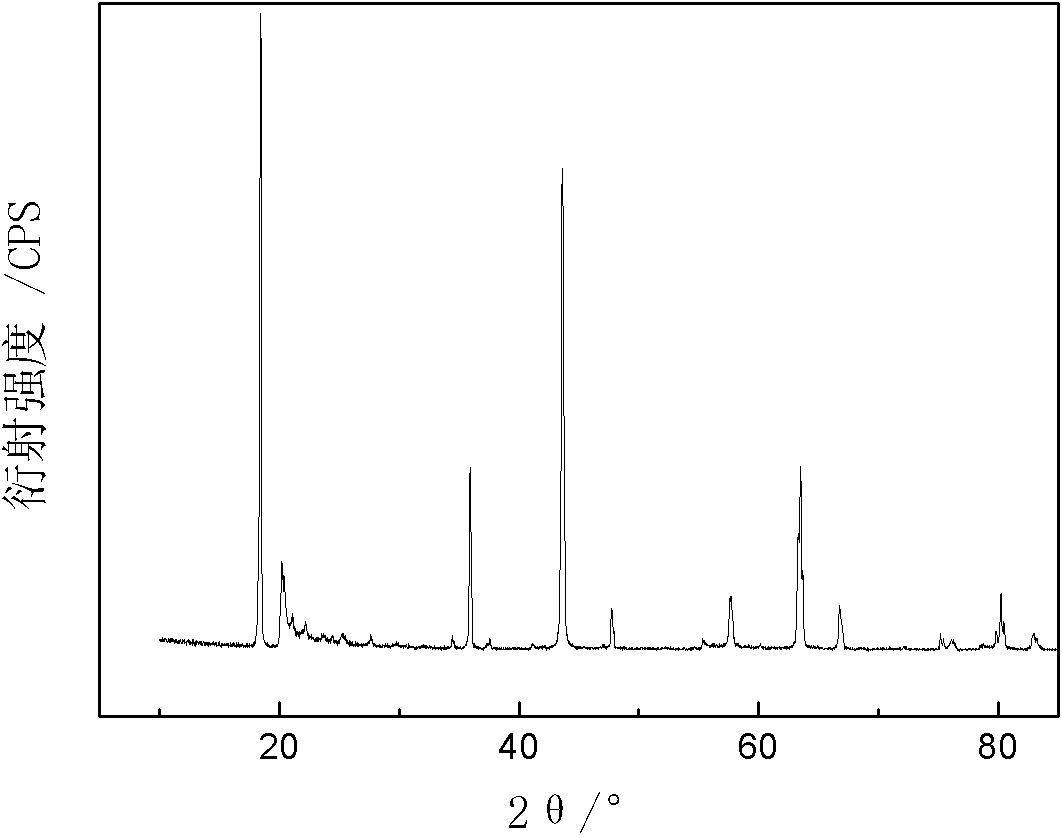

Lithium-titanium oxide type lithium ion sieve absorbent and method for preparing precursor thereof

InactiveCN101944600AWell mixedIncrease contact surfaceCell electrodesTitanium compoundsSalt lake brineTitanium oxide

The invention discloses a lithium-titanium oxide type lithium ion sieve absorbent and a method for preparing a precursor thereof, and relates to a method for preparing an inorganic absorbent for absorbing enriched lithium from salt lake brine, seawater and other liquid lithium resources. The method is characterized in that: titanium dioxide and lithium salt are taken as raw materials, ground by a ball grinder and dried so as to prepare a precursor Li2TiO3 of an ion sieve through a high-temperature solid-phase roasting method; and the lithium is eluted from the precursor Li2TiO3 by inorganic acid to prepare an ion sieve H2TiO3. The method has the advantage of simple technology, and the obtained ion sieve has the advantages of low solution loss and high adsorption capacity.

Owner:CENT SOUTH UNIV

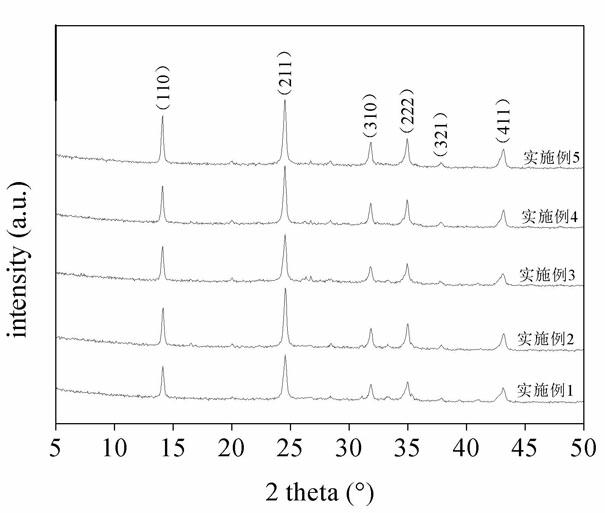

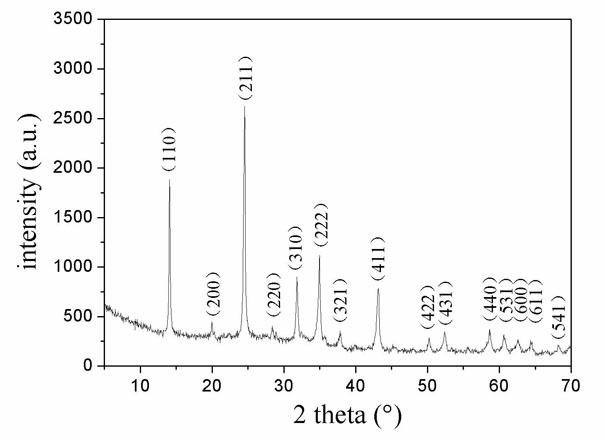

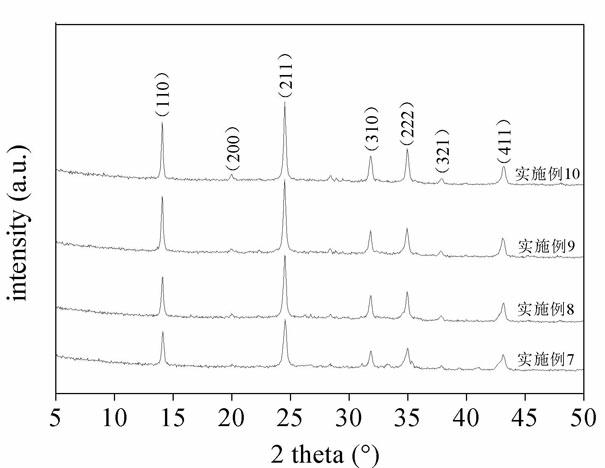

Preparation of complete stable cubic phase zircite crystal fibre

InactiveCN101498063AGood effectSimple processFibre chemical featuresZirconium oxidesFiberPolymer solution

The invention relates to a method of preparing full-stable and cubic-phase zirconia crystal fibers, which mainly comprises the following steps: using zirconium oxychloride, acetylacetone and triethylamine as main raw material and using ethanol as diluent solvent to directly react at a temperature of 0 DEG C to 50 DEG C under a stirring condition so as to generate an organic polymer solution comprising zirconium; evaporating the ethanol and using acetone as solvent to dissolve soluble substances and filter and remove an undissolved substance of triethylamine hydrochloride; recycling the acetone, dissolving the obtained products and yttrium salt to the ethanol to prepare a spinning solution which is centrifugally flung at a high speed to obtain organic polymer fibers comprising zirconium; and carrying out heat treatment in a special atmosphere and ultra-high temperature treatment of the organic polymer fibers comprising zirconium. The invention has simple preparation technology and can recycle the solvent, and the prepared crystal fibers have single ingredients, high purity and stable high-temperature performance and can be used in a range from 1700 DEG C to 2150 DEG C for a long time.

Owner:SHANDONG UNIV +1

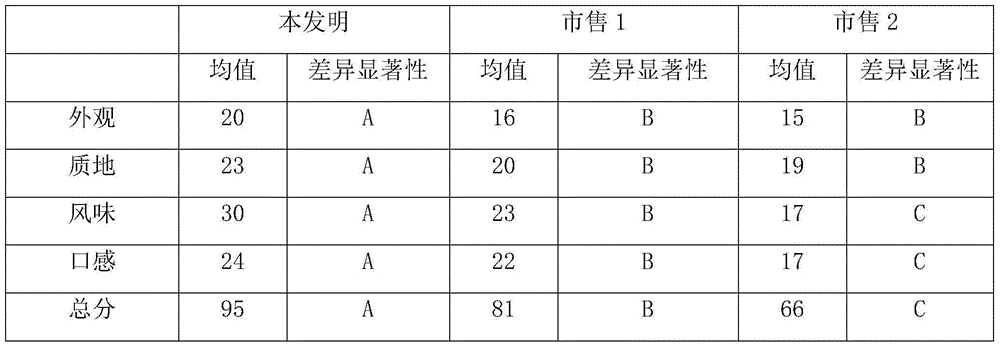

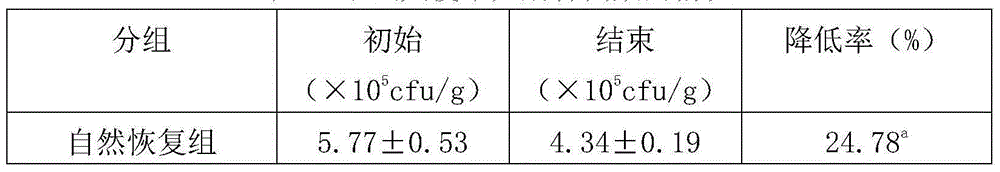

Probiotics troche and preparation method thereof

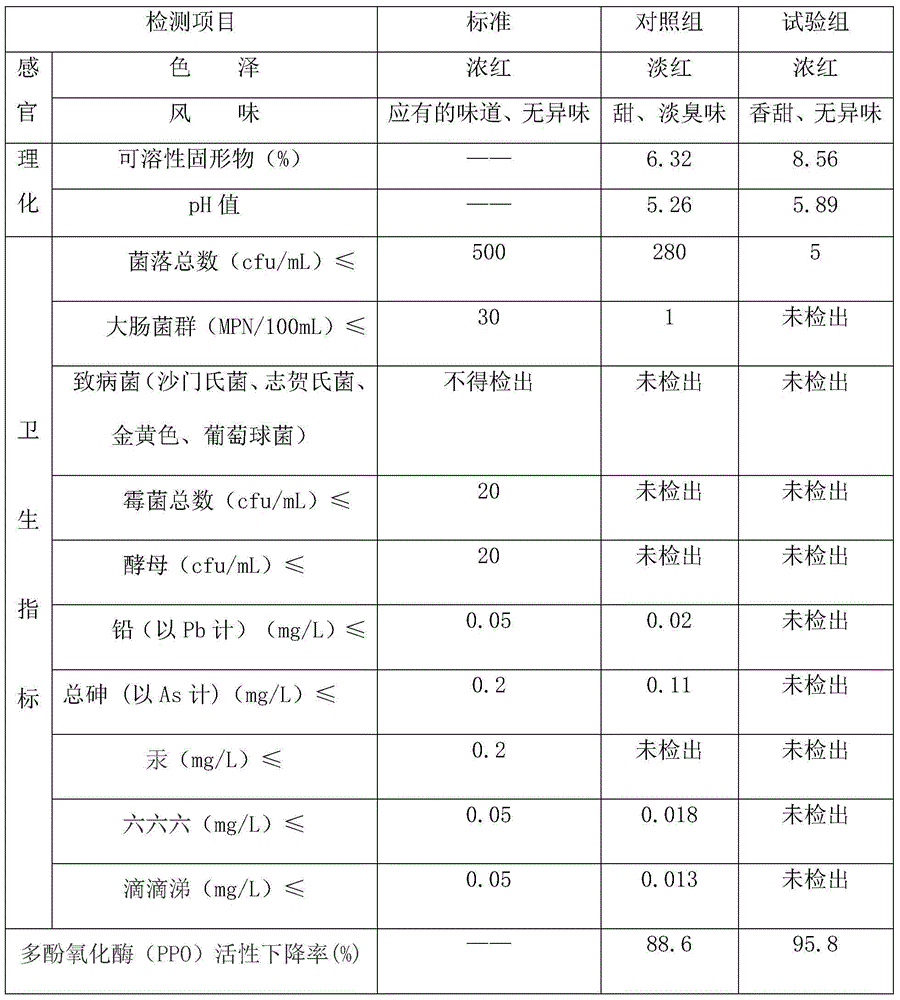

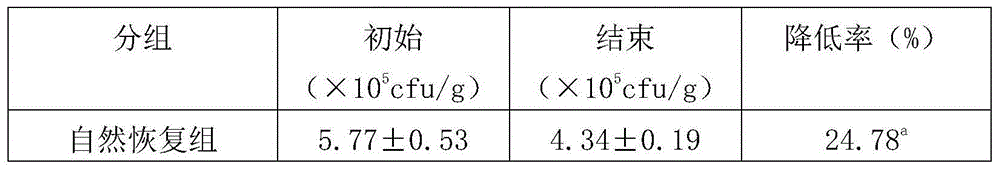

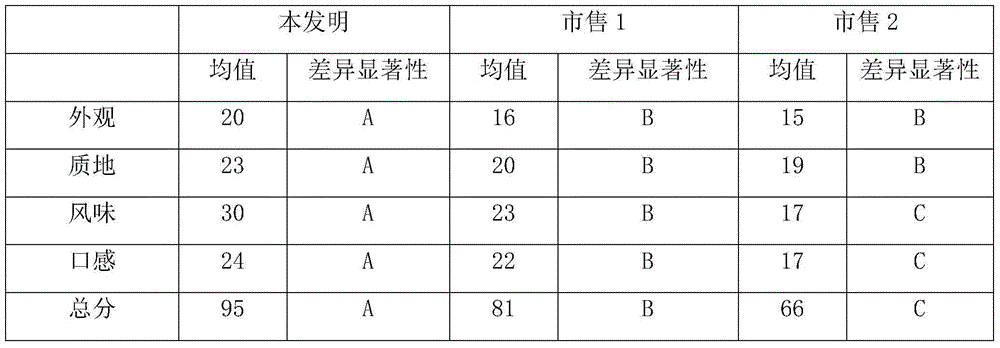

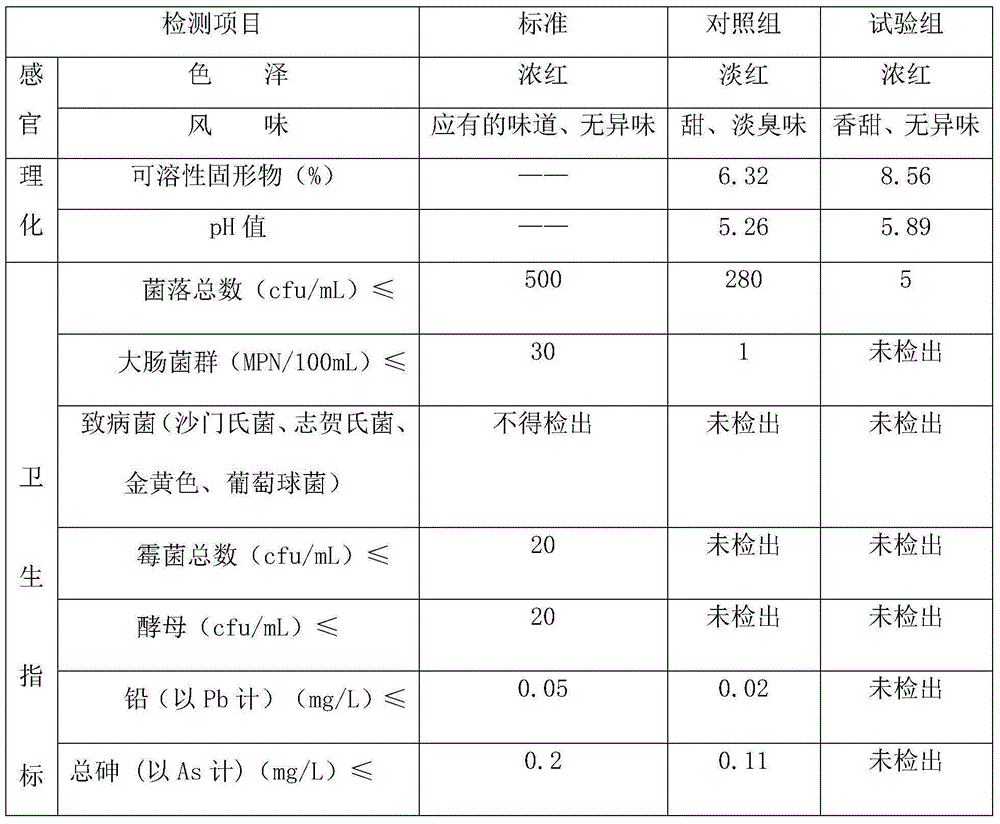

The invention discloses a probiotics troche and a preparation method thereof. Functional leavening agents and germinated brown rice, Chinese herb medicine extract with anti-cold and hot irritability and a stabilizer capable of effectively enhancing the stability are added into a yoghourt fermenting process; poikilothermal yogurt fermentation enables proliferation of lactic acid bacteria to the maximum extent, so that the anti-cold and hot irritability of lactic acid bacteria is improved. yogurt and fruit and vegetable slurry are pre-treated by using a non-hot-working technology so as to prevent infectious microbe infection in the process, improve the juice yield of the fruit and vegetable slurry, increase the content of soluble cellulose of the fruit and vegetable slurry and prevent the fruit and vegetable slurry from brown stain. Moreover, when the fruit and vegetable slurry and the yogurt are mixed, a scientifically compounded freezing protecting agent which is relatively good in anti-freezing effect is added. Finally, the probiotics troche which is smooth in taste, uniform in texture, stable in state, natural in quality, high in viable count, strong in functionality and long in expiration data is prepared. The viable count is (1.75-2.55)x10<11> CFU / g. At normal temperature, the expiration data is 30-36 months.

Owner:TIANJIN ZHONGTIAN JINGKE SCI & TECH

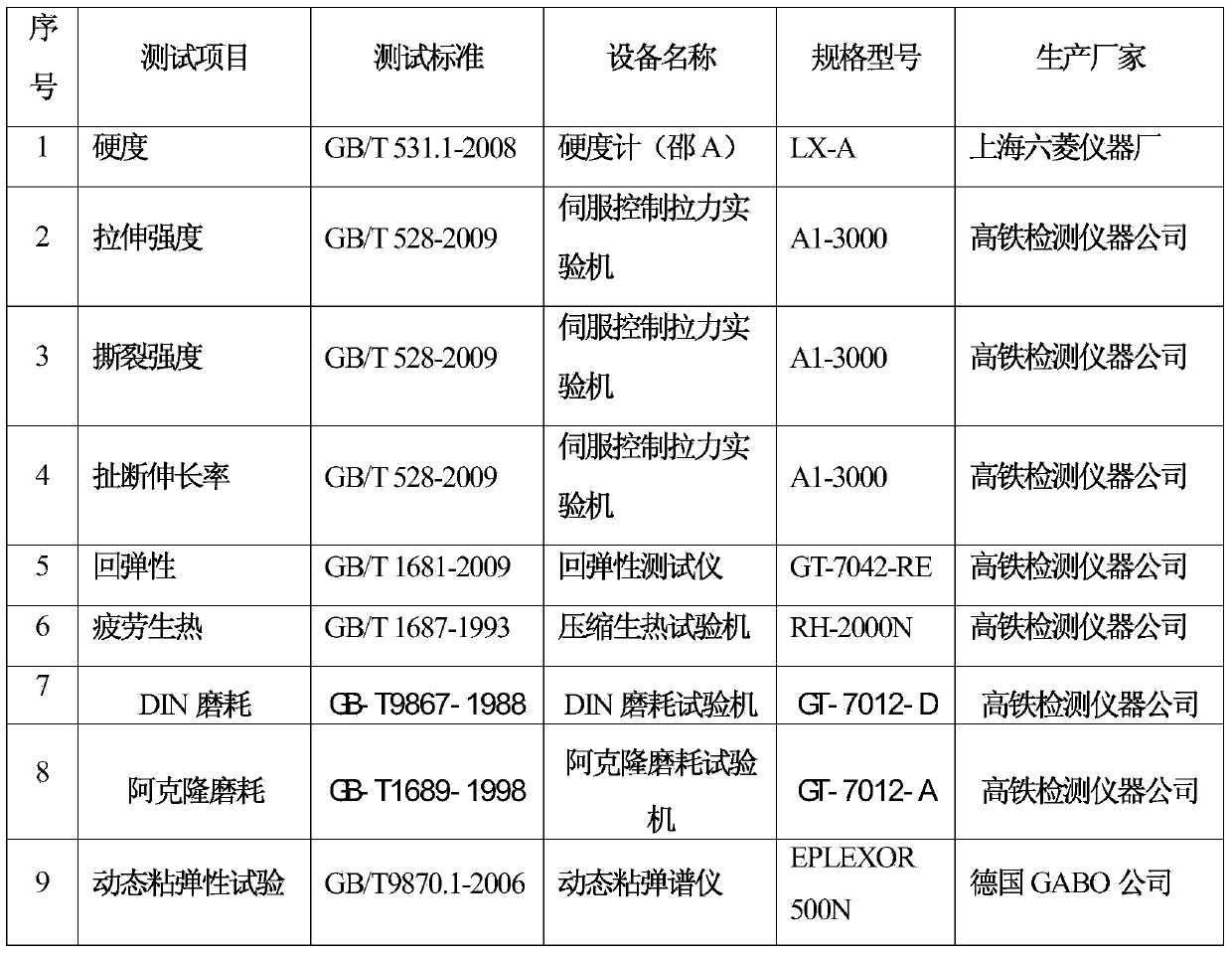

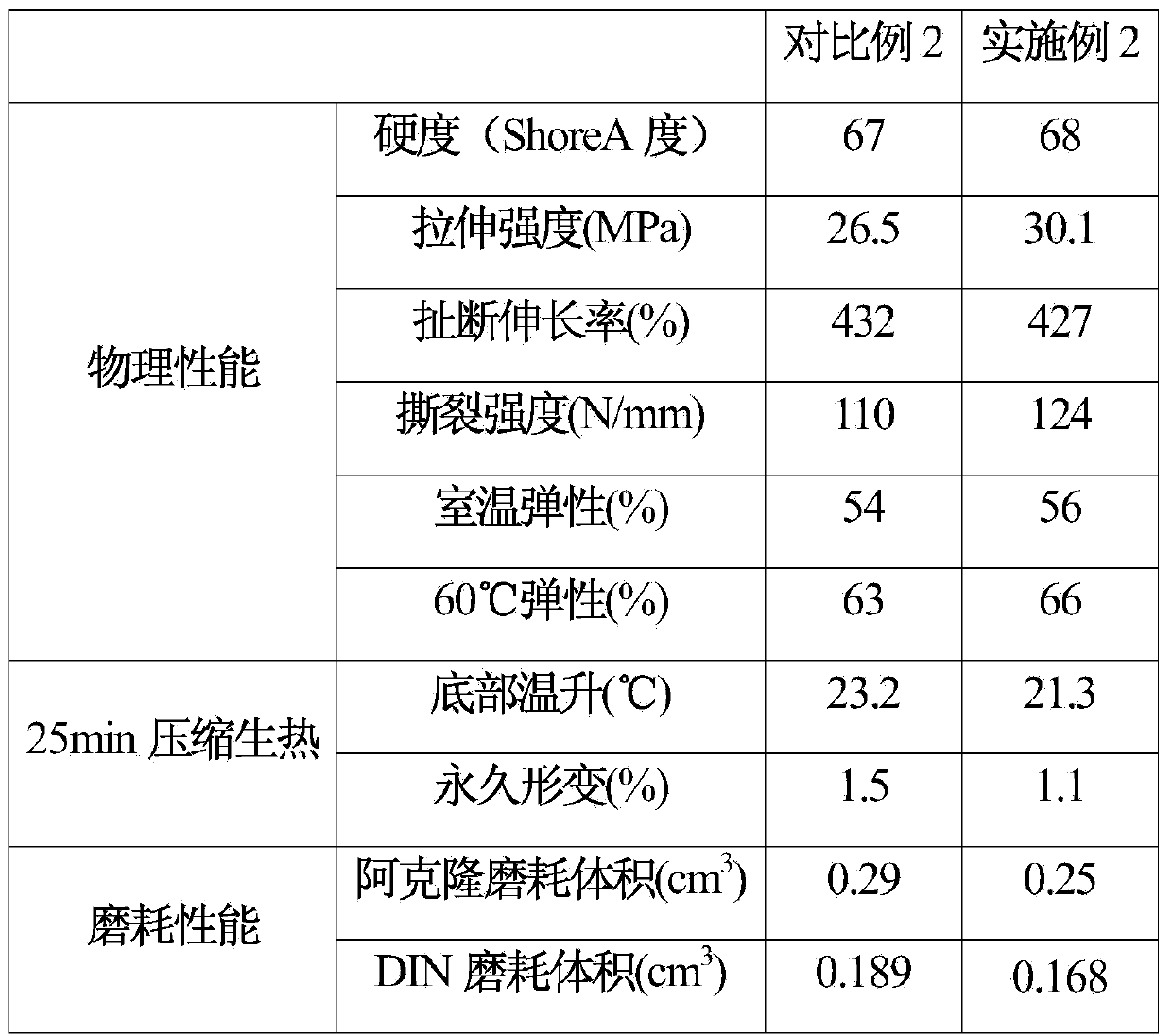

Rubber composition taking natural rubber/carbon black and synthesized isoprene rubber/white carbon black as rubber master batch and preparation technique thereof

The invention relates to a rubber composition taking natural rubber / carbon black and synthesized isoprene rubber / white carbon black as rubber master batch and a preparation technique thereof. Natural rubber / carbon black and synthesized isoprene rubber / white carbon black are premixed to prepare rubber master batch, and then rubber aids are added according to the composition ratio to prepare rubber compound. The carbon black master batch of the compound is prepared from the following raw materials in parts by weight: 100 parts of natural rubber, 5-120 parts of carbon black, preferentially 20-80 parts of carbon black, the ratio of the natural rubber to the synthesized isoprene rubber is 1:3-5:1, a certain ratio of the carbon black to the white carbon black and a certain ratio of the natural rubber to the synthesized isoprene rubber are kept, and the ratio of the two fillers is consistent with the ratio of the two kinds of rubber. The rubber compound prepared by the preparation technique has the advantages of good abrasive resistance, high elasticity and low heat generation, and can be used in a tire formula and used for other rubber products.

Owner:EVE RUBBER RES INST

Process for preparing nano vanadium carbide powder

The invention discloses a preparing method of nanometer vanadium carbide powder, which is characterized by the following: dissolving raw material of powder-shaped ammonium vanadate, carbonaceous reducer and micro-dose rare earth as catalyst according to certain proportion in the deionized water or distilled water; stirring evenly; preparing solution; heating solution; drying; producing priority powder with vanadium source and carbon source; carbonizing priority powder in the high-temperature reactor protected by vacuum or gas for 30-60 min at 800-950 deg.c; obtaining vanadium carbide powder with even distributing grain (even grain is less than 100 nm).

Owner:SICHUAN UNIV

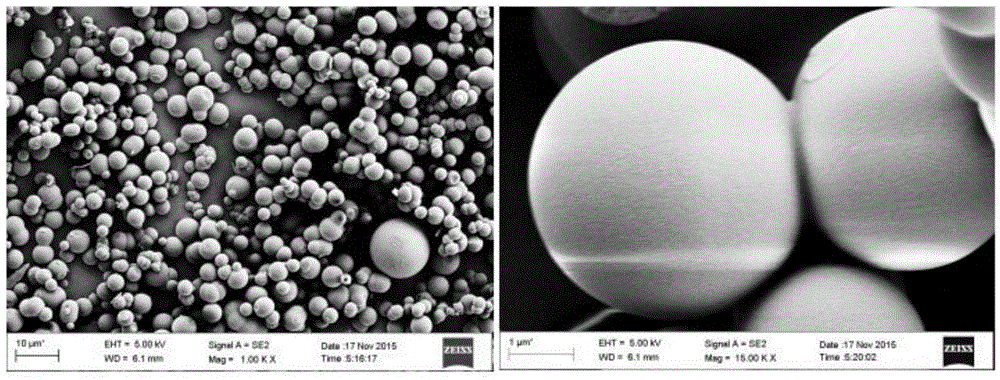

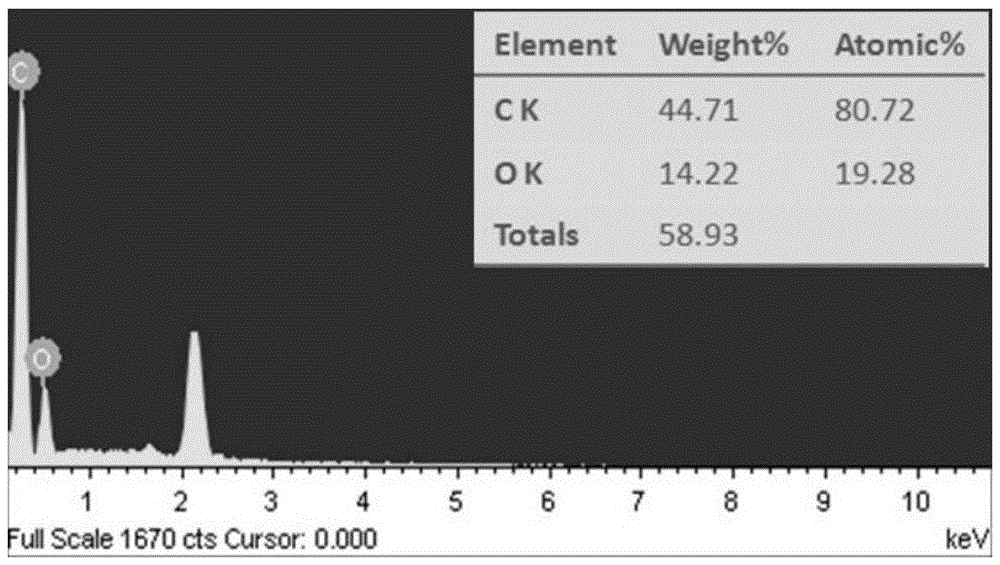

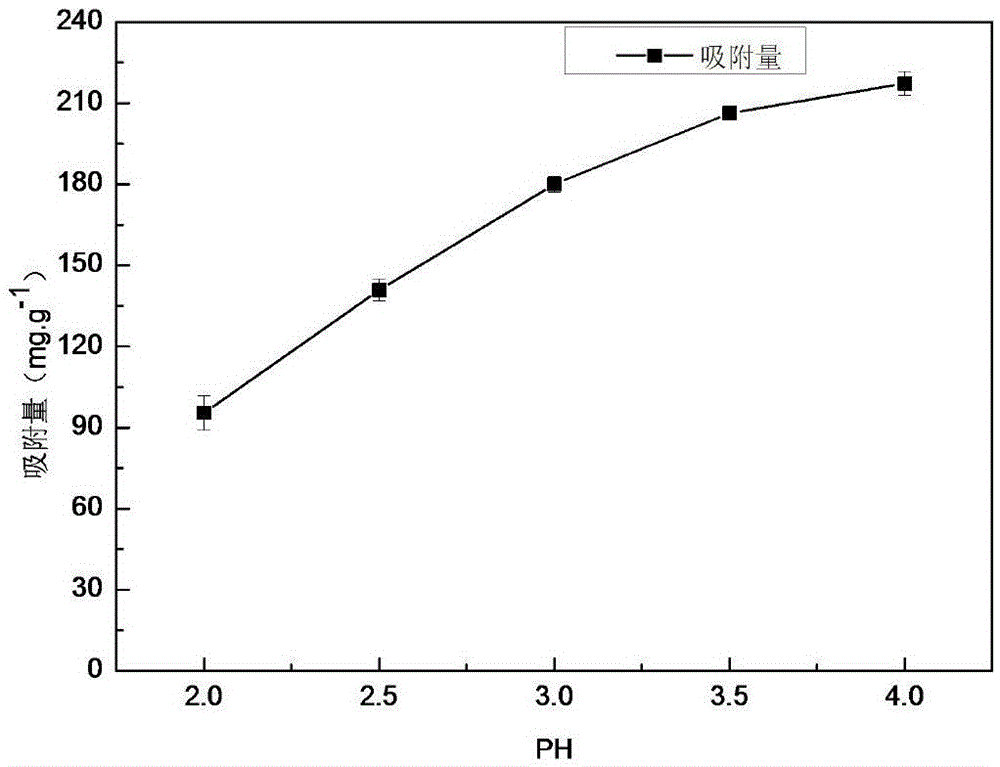

Method for preparing carbon microsphere adsorbent under catalysis of metal salt with low-temperature hydrothermal method

ActiveCN105582888AEasy disposalReduce energy consumptionOther chemical processesAlkali metal oxides/hydroxidesAir atmosphereSorbent

The invention discloses a method for preparing a carbon microsphere adsorbent under catalysis of metal salt with a low-temperature hydrothermal method. The method comprises steps as follows: (1) a biomass solution with the concentration being 2wt%-20wt% and a metal salt solution with the concentration being 0.5wt%-2wt% are prepared, then mixed in the mass ratio being (2-5):1 and stirred for 5-10 min, and a reaction solution is obtained; (2) the reaction solution is transferred to a stainless steel reaction kettle, the volume of the reaction solution accounts for 60%-80% of that of the reaction kettle, the reaction solution is heated to 100-160 DEG C at a certain heating speed, reacts at the constant temperature for 8-20 hours and is naturally cooled, separated and dried in vacuum, and hydrothermal carbon microspheres are obtained; (3) the hydrothermal carbon microspheres are calcined and carbonized at the air atmosphere, and the carbon microsphere adsorbent is obtained. The preparation process of the adsorbent is simple, energy consumption is low, the reaction time is shortened to be within 24 hours, and the adsorbent has high adsorption performance for part of positive ions, particularly, uranyl ions, has excellent radioresistance, thermal stability and acid stability and can be widely used for treatment of radioactive wastewater.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Recombinant human collagen containing hydroxyproline and hydroxylysine and production method of recombinant human collagen

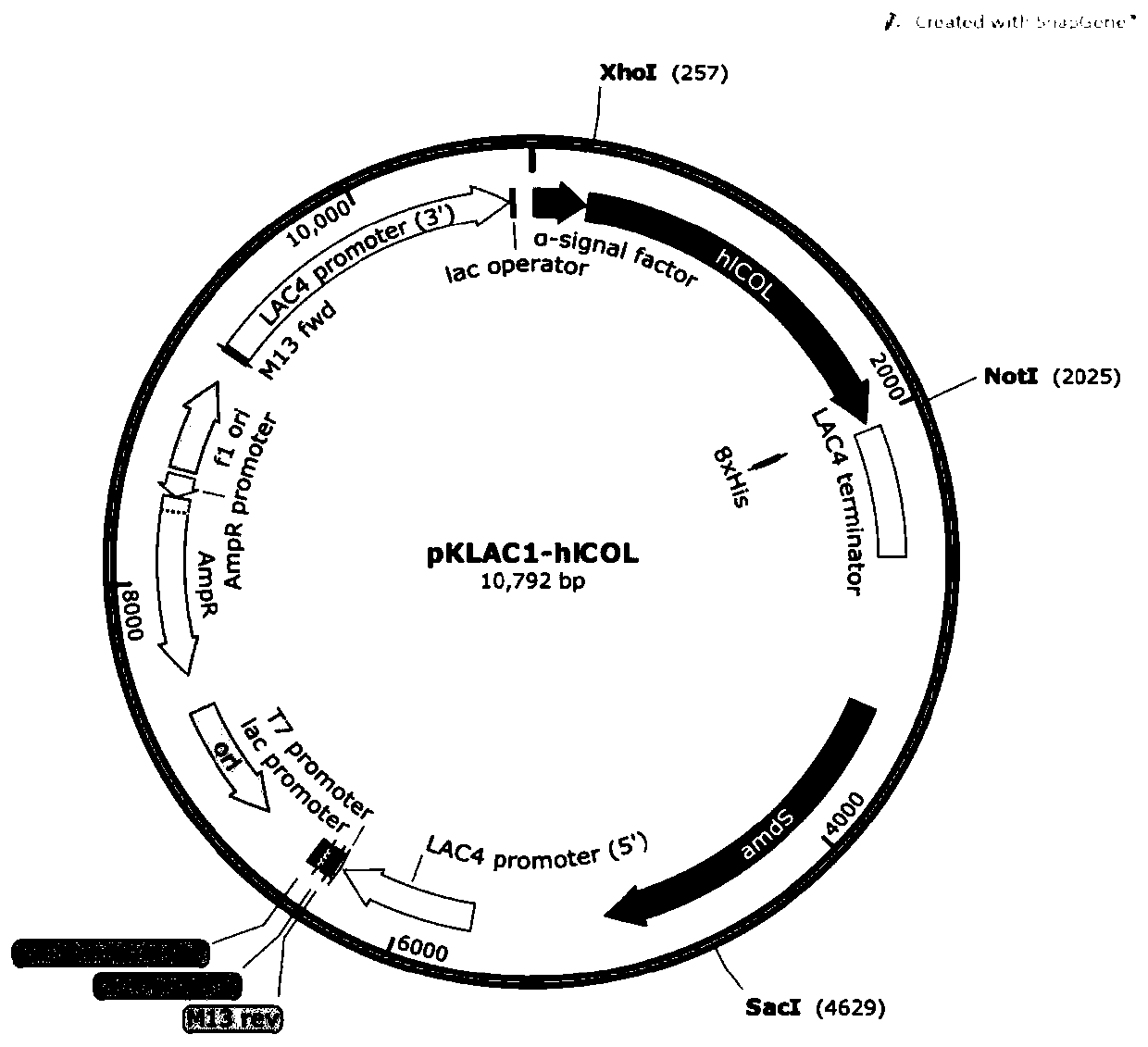

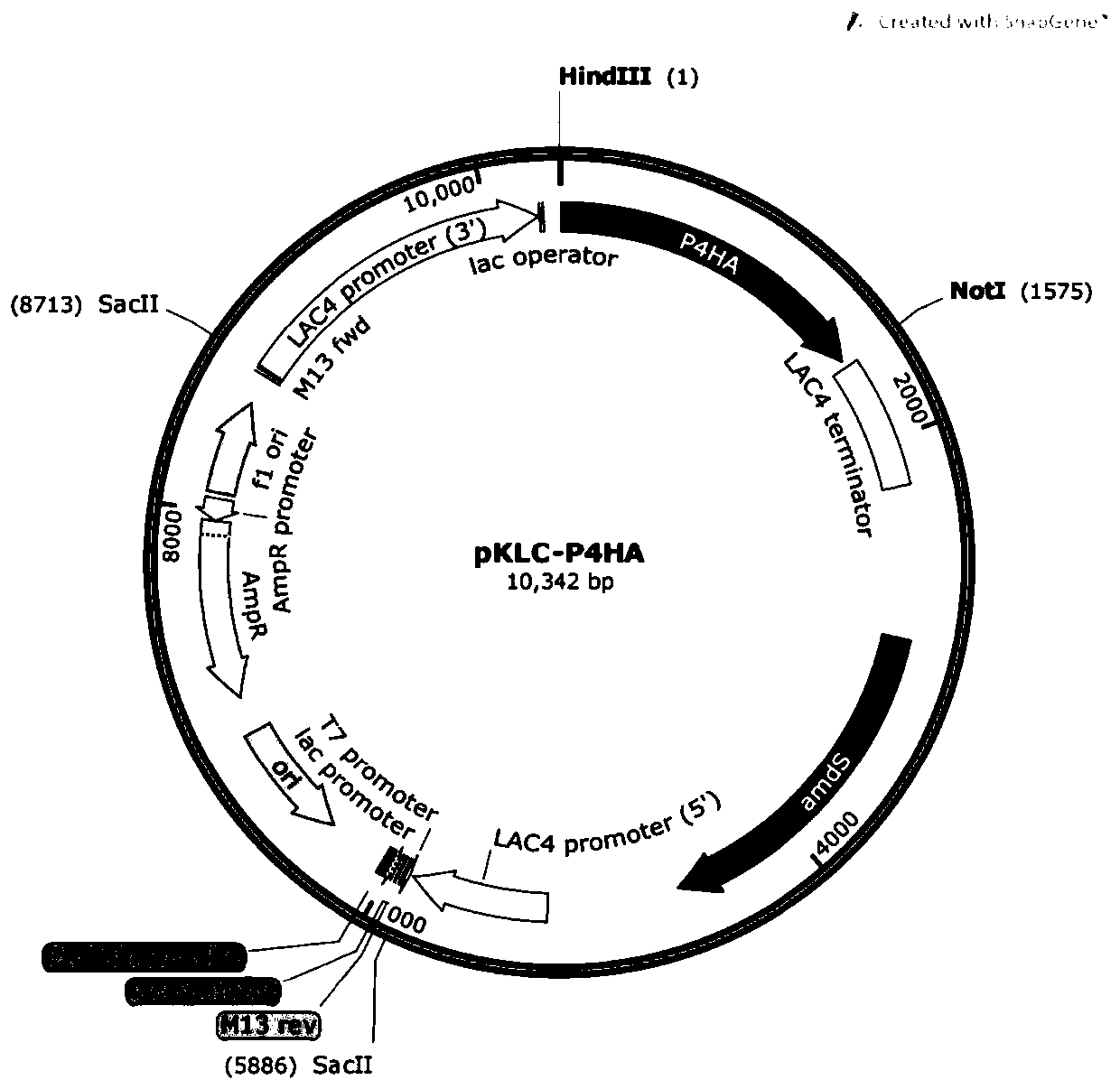

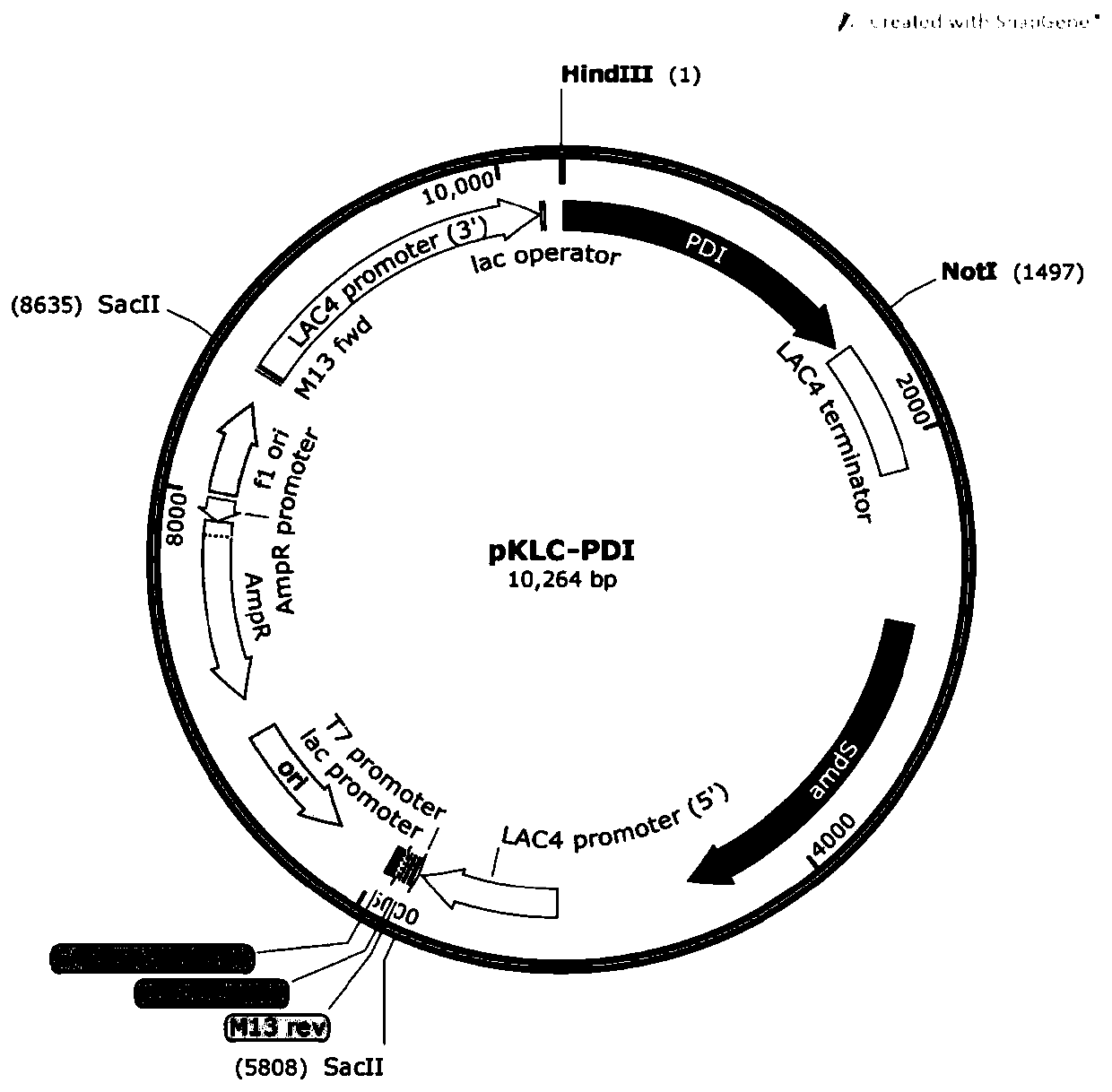

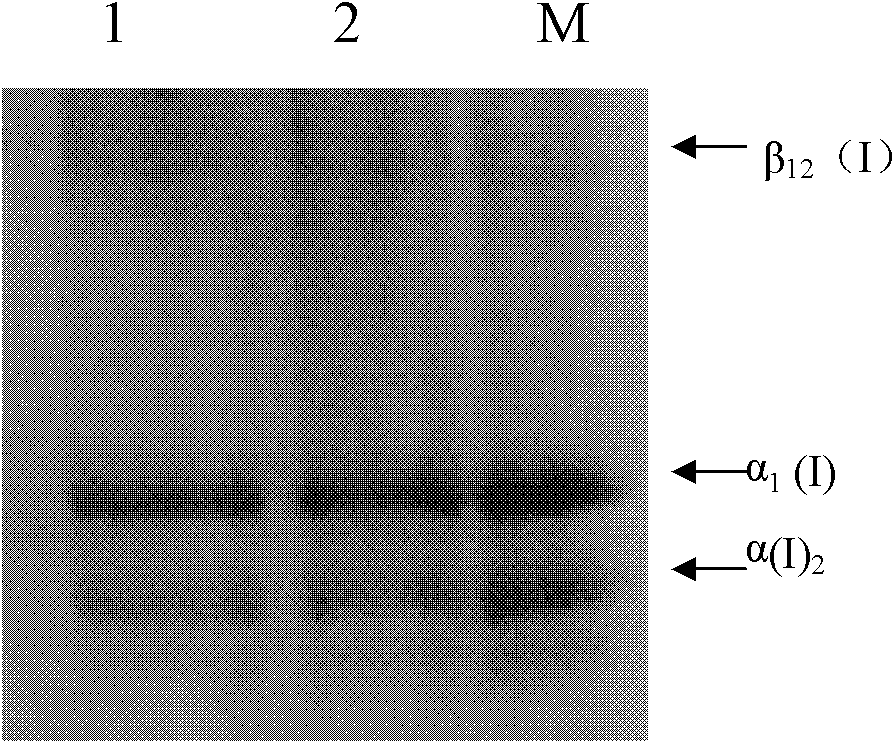

ActiveCN111334512AAchieve secretory expressionDomain definitionCosmetic preparationsConnective tissue peptidesHydroxyprolineCell adhesion

The invention discloses a recombinant human collagen containing hydroxyproline and hydroxylysine and a production method of the recombinant human collagen. The nucleotide sequence of the recombinant human collagen containing the hydroxyproline and the hydroxylysine is shown as SEQ ID NO.1; and the amino acid sequence of the recombinant human collagen containing the hydroxyproline and the hydroxylysine is shown as SEQ ID NO.5. The recombinant human collagen is obtained by performing co-expression on four different vectors pKLAC1-hlCOL, pKLC-P4HA, pKLC-PDI and pKLC-LH respectively by using Kluyveromyces as a base cell through a series of fermentation and purification manners. The hydroxylation rates of proline and lysine of the recombinant human collagen are similar to those of natural humantype I collagen, and reaches 30.7% and 43.1%, respectively; and compared with unhydroxylated recombinant human collagen, the recombinant human collagen provided by the invention has better functionsof promoting cell adhesion and wound healing.

Owner:肽源(广州)生物科技有限公司

Collagen gel and preparation method thereof

ActiveCN101829320AHigh puritySingle ingredientCosmetic preparationsOrganic active ingredientsDissolutionAntibacterial agent

The invention provides a collagen gel and a preparation method thereof. The collagen gel comprises collagen and an antibacterial agent, wherein the antibacterial agent is at least one of chitosan and nano silver. The collagen gel also comprises a preservative, a substrate, a dispersing agent, a film-forming agent and water; and 1g of gel comprises 0.5 to 8.0mg of collagen, 0.001 to 15mg of antibacterial agent, 1 to 50mg of preservative, 10 to 50mg of matrix, 50 to 100mg of dispersing agent, 1 to 10mg of film-forming agent, and the balance of water. The method for preparing the collagen gel comprises the following steps of: performing dispersion and dissolution on the substrate by adopting the dispersing agent under ten-thousand grade clean environment; adding the dispersing agent, the substrate, the preservative, the antibacterial agent, and collagen solution into a vacuum emulsified homogenizer one by one; after fully mixing, standing and defoaming, filling the product. The collagen gel is applied to various open wounds and infected wounds, lightens hyperpigmentation, has good effect of accelerating wound healing, and can maintain long-term anti-bacteria function.

Owner:GUANGZHOU TRAUER BIOTECH

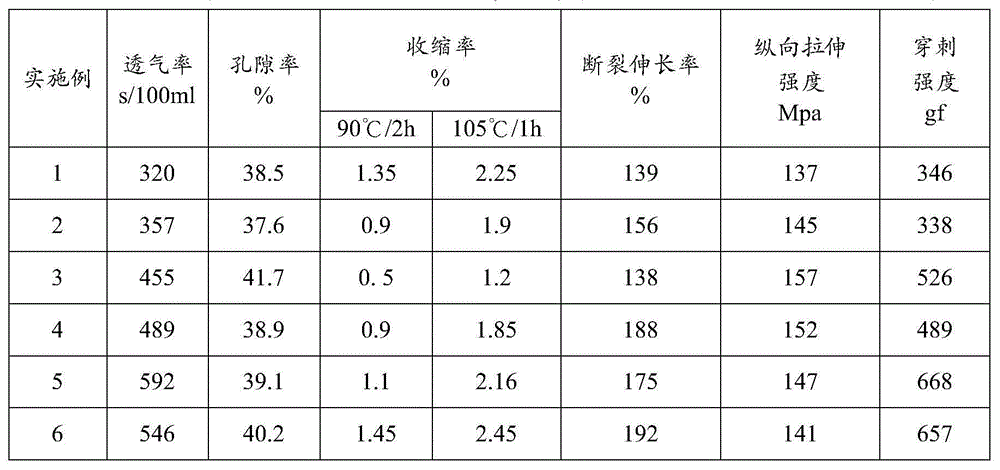

Three-layer co-extruded lithium-ion battery separation membrane and production method thereof

ActiveCN104979513ASingle ingredientImprove heat resistanceCell seperators/membranes/diaphragms/spacersPorosityHeat resistance

The present invention belongs to the technical field of lithium-ion battery separation membrane production, and particularly relates to a three-layer co-extruded lithium-ion battery separation membrane and a production method thereof. The three-layer co-extruded lithium-ion battery separation membrane comprises an A / B / A three-layer coextruded polypropylene resin microporous film, wherein the layer A and the layer B are two different polypropylene resins, the separation membrane thickness is 12-50 [mu]m, and the tensile strength in the longitudinal direction is more than or equal to 130 Mpa. According to the present invention, the tensile strength of the separation membrane can achieve more than or equal to 130 Mpa so as to meet requirements of most users; the separation membrane puncture strength achieves more than or equal to 300 gf, such that the piercing phenomenon during the battery assembly can be well avoided; the heat resistance is good, such that the separation membrane can work in the high temperature environment; the thermal shrinkage is low, such that the separation membrane can not produce the short circuit phenomenon caused by the high shrinkage during the use; and the permeability and the porosity are in the appropriate range so as to well meet the lithium-ion battery performance requirements.

Owner:HUIQIANG WUHAN NEW ENERGY MATERIAL TECH

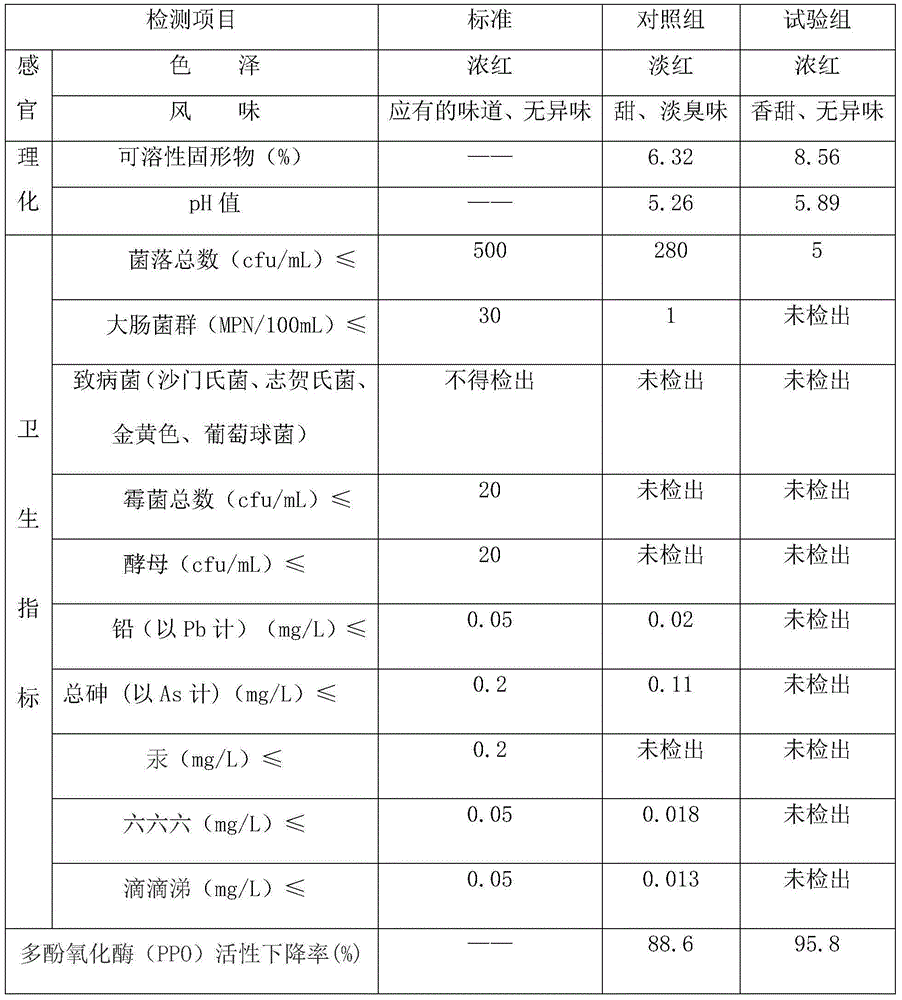

Probiotic foodstuff and preparation method thereof

The invention discloses a probiotic foodstuff and a preparation method thereof. In the fermentation process of yoghourt, a functional starter, germinated brown rice, Chinese herbal medicine extract with anti-heat-and-cold irritability and a stabilizing agent capable of effectively enhancing stability are added; temperature-varying yoghurt fermentation enables propagation of lactic acid bacteria to be maximized and anti-heat-and-cold stress capability of lactic acid bacteria to be improved; non-thermal processing technology is employed for pretreatment of yoghurt and fruit and vegetable pulp so as to prevent infection with infectious microbes in preparation process, improve juice yield of the fruit and vegetable pulp, increase the content of soluble cellulose in the fruit and vegetable pulp and prevent browning of the fruit and vegetable pulp; and a scientifically compounded cryoprotectant with good anti-refrigeration effect is added during mixing of the fruit and vegetable pulp and the yoghurt. Eventually, the prepared probiotic foodstuff has fine mouthfeel, uniform texture, stable state, natural quality, a great number of live bacteria, strong functionality and long shelf life, wherein the content of the live bacteria is 1.75 * 10<11> to 2.55 * 10<11> CFU / g, and the shelf life is 30 to 36 months at normal temperature.

Owner:邵素英

Process for synthesizing single-phase sodalite from fly ash

ActiveCN102173433ASolve the reuse problemExpand sourceSolid waste disposalCrystalline aluminosilicate zeolitesPre treatmentFly ash

The invention belongs to the field of production and preparation of inorganic functional materials, and particularly relates to a process for preparing single-phase sodalite from fly ash, which comprises the following steps: pretreating fly ash by an alkaline fusion method; proportionally adding the activated fly ash, aluminum hydroxide and sodium hydroxide solution into a polytetrafluoroethyleneinner container, evenly mixing, and carrying out hydrothermal crystallization in a sealed constant-temperature drying oven; and finally, filtering the product, washing until the product becomes neutral, and drying to obtain the single-phase sodalite material. The invention successfully synthesizes the low-cost single-phase sodalite zeolitization material by using solid waste-fly ash as the raw material for production. The process has the advantages of low cost, abundant sources of raw material, controllable product performance, no secondary pollution and the like, is simple and easy to operate, and thus, has great industrial application potential.

Owner:NANJING UNIV OF SCI & TECH

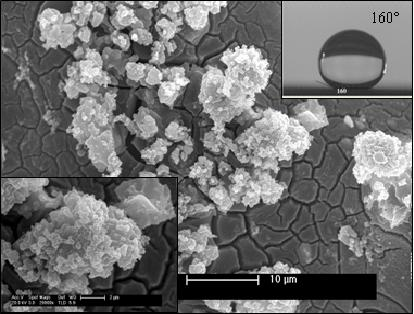

Compound method for preparing magnesium alloy having superhydrophobic surface

The invention relates to a compound method for preparing a superhydrophobic surface of magnesium alloy, which comprises the following steps: carrying out chemical etching on the surface of the magnesium alloy with sulfuric acid to construct a primary minute structure, and then simultaneously constructing a secondary structure and carrying out low-surface energy modification on the surface of the magnesium alloy by an anodic oxidation process to obtain the magnesium alloy surface which enables water drops not to adhere easily and has fine superhydrophobicity. The technical method of the invention has the following advantages: 1) the contact angle between the prepared magnesium alloy surface and water is up to 160 degrees, and the surface has low adhesion and excellent superhydrophobicity; 2) the superhydrophobic surface is prepared by combining chemical etching and electrochemical processes, thereby achieving better hydrophobicity and stability; 3) the construction of the secondary structure and the low-surface energy modification are simultaneously carried out by using the anodic oxidation process, thereby further optimizing the minute structure and ensuring prefarably bonding force between film and substrate; and 4) the invention has the characteristics of simple preparation process and required equipment, high preparation process efficiency, easy operation, high controllability, low combined cost and easy industrialized application.

Owner:SOUTHEAST UNIV

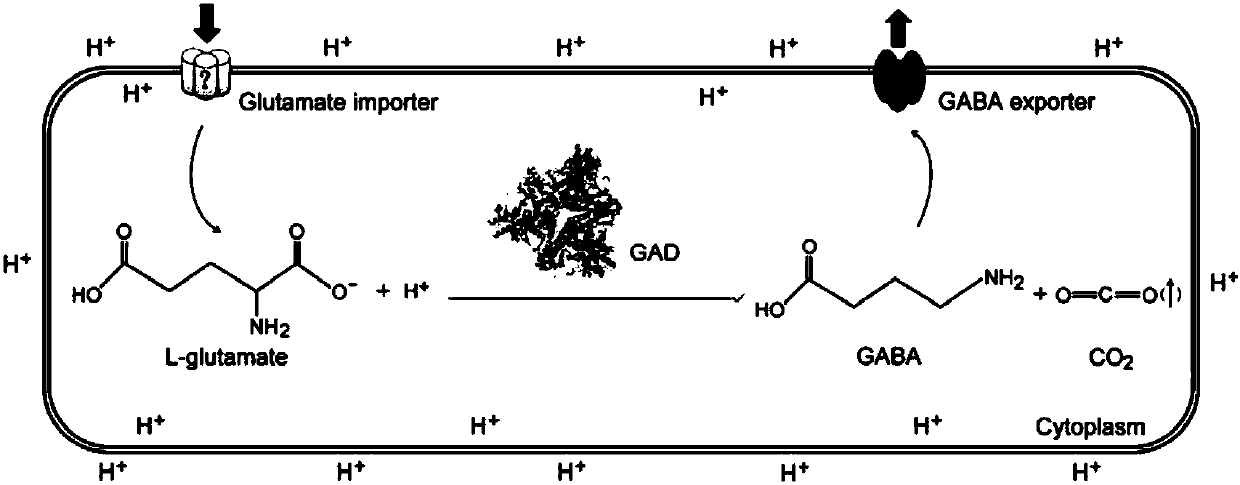

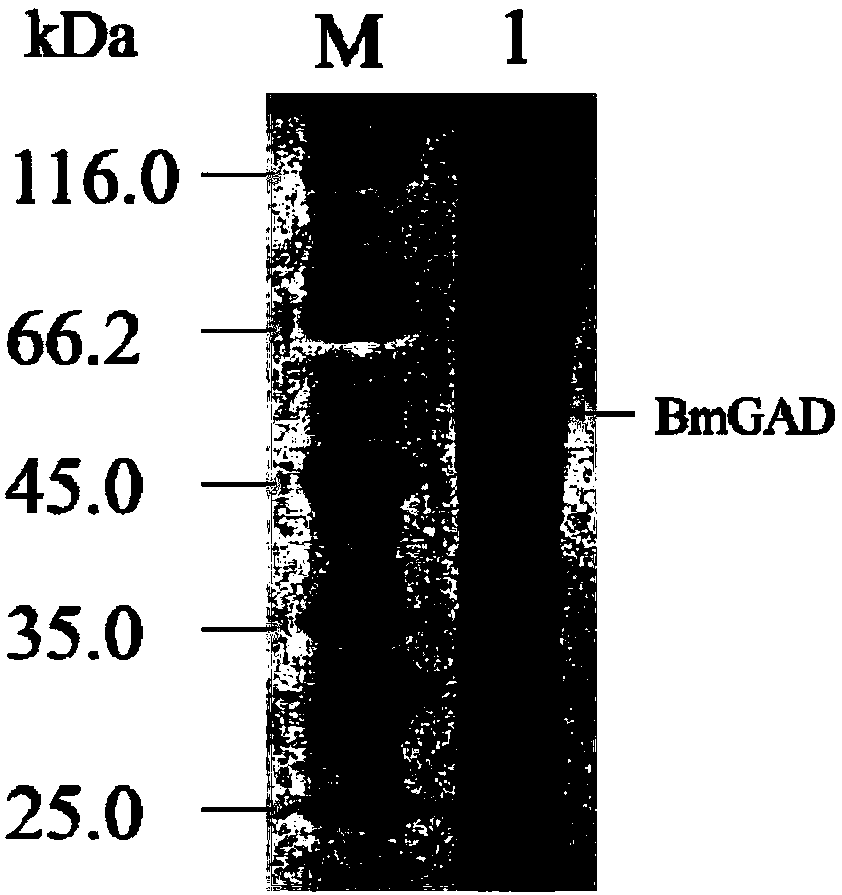

Method for producing gamma-aminobutyric acid by whole cell transformation method

InactiveCN109722402AEasy to operateLow costBacteriaMicroorganism based processesHeterologousBacillus megaterium

The invention discloses a method for producing gamma-aminobutyric acid by a whole cell transformation method. Corynebacterium glutamicum is used as a production bacterial strain, glutamate decarboxylase of bacillus megaterium is in heterologous expression, and through high-density fermentation culture, protein over-expressed corynebacterium glutamicum thalli cells are obtained. L-glutamic acid orL-glutamate is used as a substrate, and the gamma-aminobutyric acid is produced through corynebacterium glutamicum whole cell catalyzing. According to the method disclosed by the invention, glutamatedecarboxylase high in catalytic activity and a production bacterial strain namely the corynebacterium glutamicum in food safety grade are used for producing the gamma-aminobutyric acid, and the methodhas the advantages that the yield of the gamma-aminobutyric acid is high, transformation liquid is single in ingredients, the production cycle is short, the operation is simple, the production cost is low, and potential safety hazard does not exist.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Functional peptide segment of epididymis protease inhibitors and uses thereof

InactiveCN101402674AImproving immunogenicityStimulationImmunoglobulins against animals/humansAntibody medical ingredientsEpididymal protease inhibitorBlood plasma

The invention discloses an epididymis protease inhibitor which is a functional peptide segment of Eppin. The inhibitor is any one selected from amino acid sequences shown from SEQ ID No.1 to SEQ ID No.7 and has advantages of single component, simple structure and strong pertinence of immunoreaction inspired; polypeptide with at least 80 percent of sequences the same as the functional peptide segment of Eppin can be used for constructing immunogen which can improve the immunogenicity of the functional peptide segment of Eppin, stimulate an organism to generate a specific antibody, reduce Eppin level in blood plasma and induce high-efficient, safe and reversible antifertility effect. The immunogen of the epididymis protease inhibitor can form a medicament composite with medically acceptable carriers, and the composite can be used for preparing male contraception vaccines, therefore, the epididymis protease inhibitor has broad application prospect.

Owner:ARMY MEDICAL UNIV

Method for raising service life of coat layer of heat barrier by surface modification of metal binder course

InactiveCN101050515AExtended service lifeImprove thermal shock resistanceMolten spray coatingAlloyThermal shock

This invention discloses a method for increasing the service life of thermal barrier coating layer by surface modification of metal bonding layer. The method comprises: washing and sand-blasting the matrix surface, depositing a metal bonding layer of MCrAlY series alloy onto the matrix surface by supersonic flame spray or plasma spray, performing surface modification on the metal bonding layer by supersonic coolant air injection of Al2O3 particles, and depositing conventional ZrO2-Y2O3 ceramic surface layer onto the metal bonding layer by plasma spray to obtain the thermal barrier coating layer. The method utilizes supersonic coolant air injection of Al2O3 particles to change the surface grain / particle structure, surface morphology and surface stress of the metal bonding layer. The method can realize finer surface grains / particles, and more uniform composition distribution, which can improve the thermal shock resistance of the thermal barrier coating layer, and increase its service life.

Owner:CIVIL AVIATION UNIV OF CHINA

Slaked lime plugging method in process of exploiting in-situ combustion oil layer

The invention provides a slaked lime plugging method in the process of exploiting an in-situ combustion oil layer. The slaked lime plugging method includes the following steps: injecting slaked lime emulsion into an oil exploitation well of an in-situ combustion oil layer needing to be plugged, wherein consumption Q of slaked lime in the emulsion is equal to nFh, n refers to injection coefficient, and is equal to 1 when gas yield of the oil well is 5000-10000m<3> / d, equal to 1.1 when the gas yield is 10000-20000m<3> / d and equal to 1.2 when the gas yield is greater than 20000m<3> / d, F refers to injection strength of the slaked lime and ranges from 0.1 to 0.2, and h refers to thickness of a gas producing layer of the oil layer needing to be plugged. The slaked lime emulsion can be composed of 20-150g / L of slaked lime, 0.1-0.5wt% of water glass and the balance of water. The slaked lime plugging method has the advantages that construction cost is low, injection liquid is unitary in component and easy to control, and selectivity is high; only the gas producing layer is plugged, and reaction with a non-gas-producing layer is avoided, so that no lime stone is generated; plugging can be released easily.

Owner:PETROCHINA CO LTD

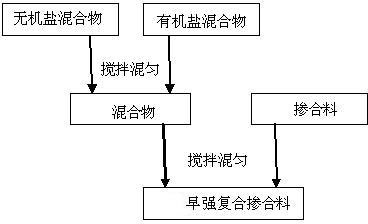

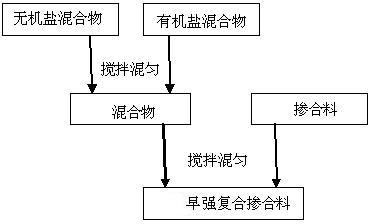

Early strength composite admixture and preparation method thereof

Owner:中铁岩锋成都科技有限公司

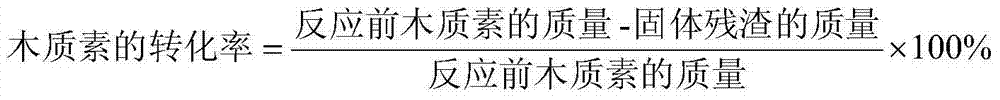

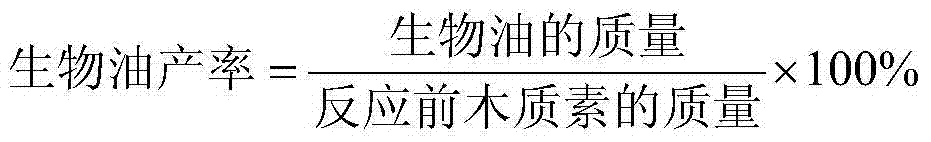

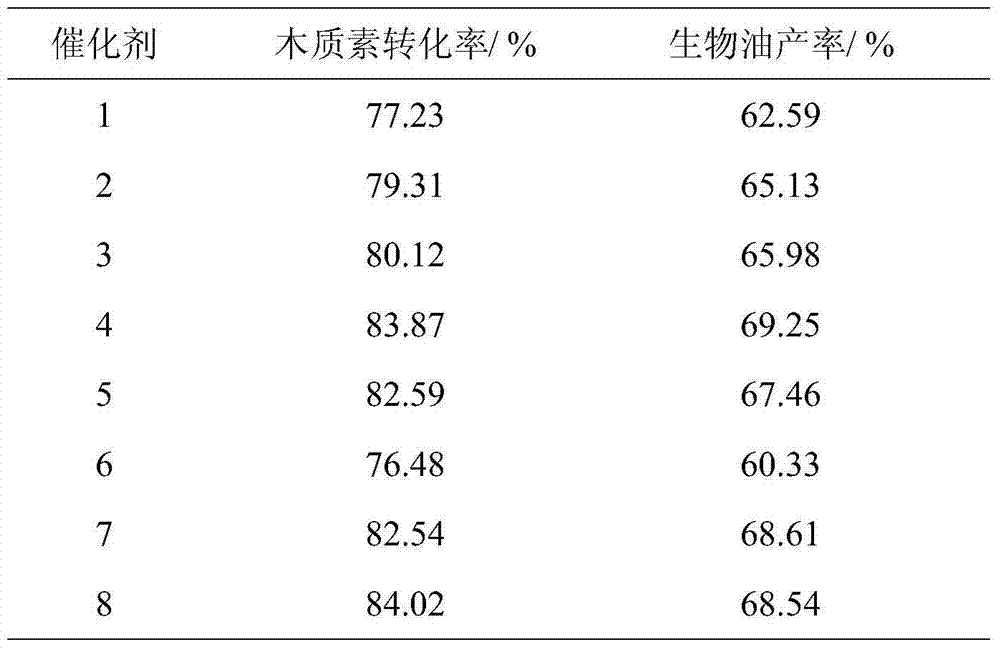

Method for preparing bio-oil through hydrogenation degradation of lignin

InactiveCN104326875AWide variety of sourcesReduce consumptionOrganic compound preparationEther preparationChemical industryReaction temperature

The invention relates to a method for preparing bio-oil through hydrogenation degradation of lignin. The method comprises the following steps: uniformly mixing lignin, a vanadium-based catalyst and a solvent, sealing the obtained mixture in an autoclave, and carrying out hydrogenation catalysis degradation to prepare the bio-oil. A mass ratio of the lignin to the vanadium-based catalyst is 100:1-10:1, a mass / volume ratio of the lignin to the solvent is 1:5-1:30, the reaction temperature is 150-400DEG C, the reaction time is 0.5-5h, the H2 pressure in the reaction is 0.5-6Mpa, and the main components of the prepared bio-oil are aromatic compounds and phenolic compounds. The method has the advantages of cheap catalyst, environmental protection, easy large-scale production, mild reaction conditions, high lignin conversion rate and high bio-oil yield; and the bio-oil contains few components and is an important chemical industry raw material.

Owner:SOUTHEAST UNIV

Freeze-dried foodstuff and preparation method thereof

The invention discloses a freeze-dried foodstuff and a preparation method thereof. In the fermentation process of yoghourt, a functional starter, germinated brown rice, Chinese herbal medicine extract with anti-heat-and-cold irritability and a stabilizing agent capable of effectively enhancing stability are added; temperature-varying yoghurt fermentation enables propagation of lactic acid bacteria to be maximized and anti-heat-and-cold stress capability of lactic acid bacteria to be improved; non-thermal processing technology is employed for pretreatment of yoghurt and fruit paste so as to prevent infection with infectious microbes in preparation process, improve fruit juice yield, increase the content of soluble cellulose in the fruit paste and prevent browning of the fruit paste; and a scientifically compounded cryoprotectant with good anti-refrigeration effect is added during mixing of the fruit paste and the yoghurt. Eventually, the prepared freeze-dried foodstuff has fine mouthfeel, uniform texture, stable state, a great number of live bacteria, strong functionality and long shelf life, wherein the content of the live bacteria is 1.55 * 10<11> to 2.52 * 10<11> CFU / g, and the shelf life is 30 to 36 months at normal temperature.

Owner:TIANJIN ZHONGTIAN JINGKE SCI & TECH

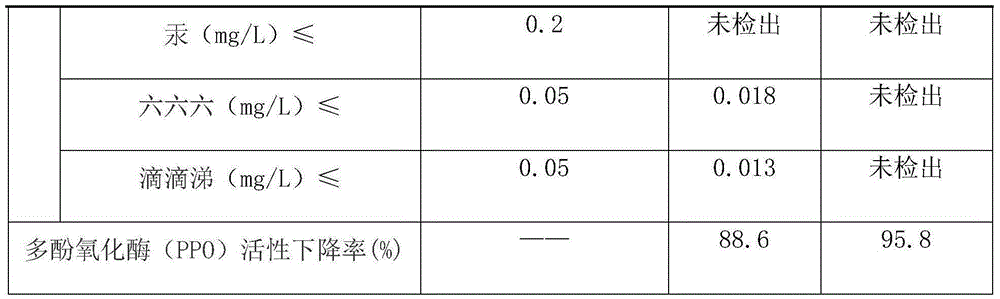

Preparation method of siloxane modified polyaspartic acid ester

The invention discloses a preparation method of siloxane modified polyaspartic acid ester. The method comprises the step of adding primary amine in gamma-aminopropyl trialkoyl saline to a carbon-carbon double-bond in a maleate monomer to generate the siloxane modified polyaspartic acid ester. The method specifically comprises the following steps: dropwise adding maleate to the gamma-aminopropyl trialkoyl saline at 30-80 DEG C for 50-80 minutes; and then insulating and reacting for 12-24 hours at 60-100 DEG C to obtain the siloxane modified polyaspartic acid ester. The preparation method disclosed by the invention is free of side reactions, simple to operate and low in production cost, and the product has the advantages of being single in component, good in stability, low in viscosity, high in purity (the purity can reach over 99.5%) and the like. The prepared siloxane modified polyaspartic acid ester can be applied to any filed of gamma-aminopropyl trialkoyl saline, and particularly, the siloxane modified polyaspartic acid ester has a relatively remarkable application performance in polyurethane waterproof field.

Owner:广东坚派新材料有限公司

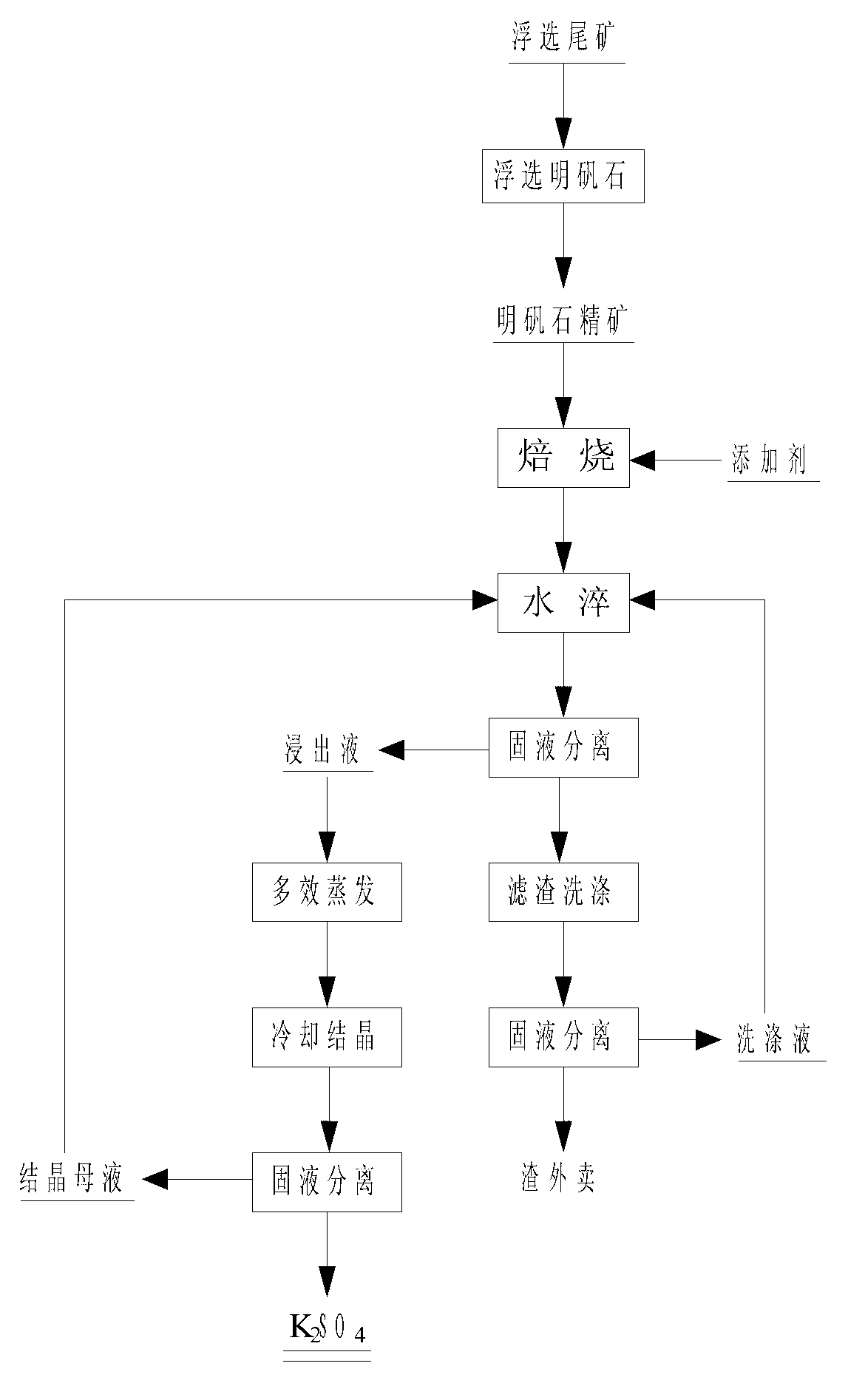

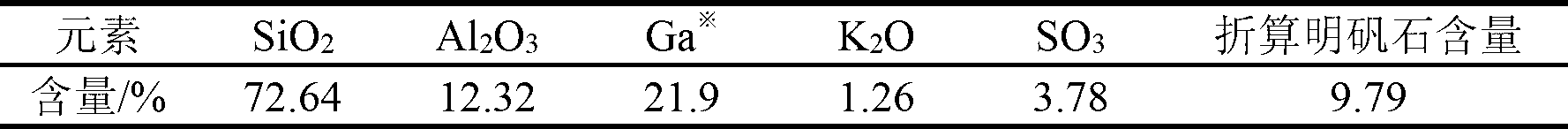

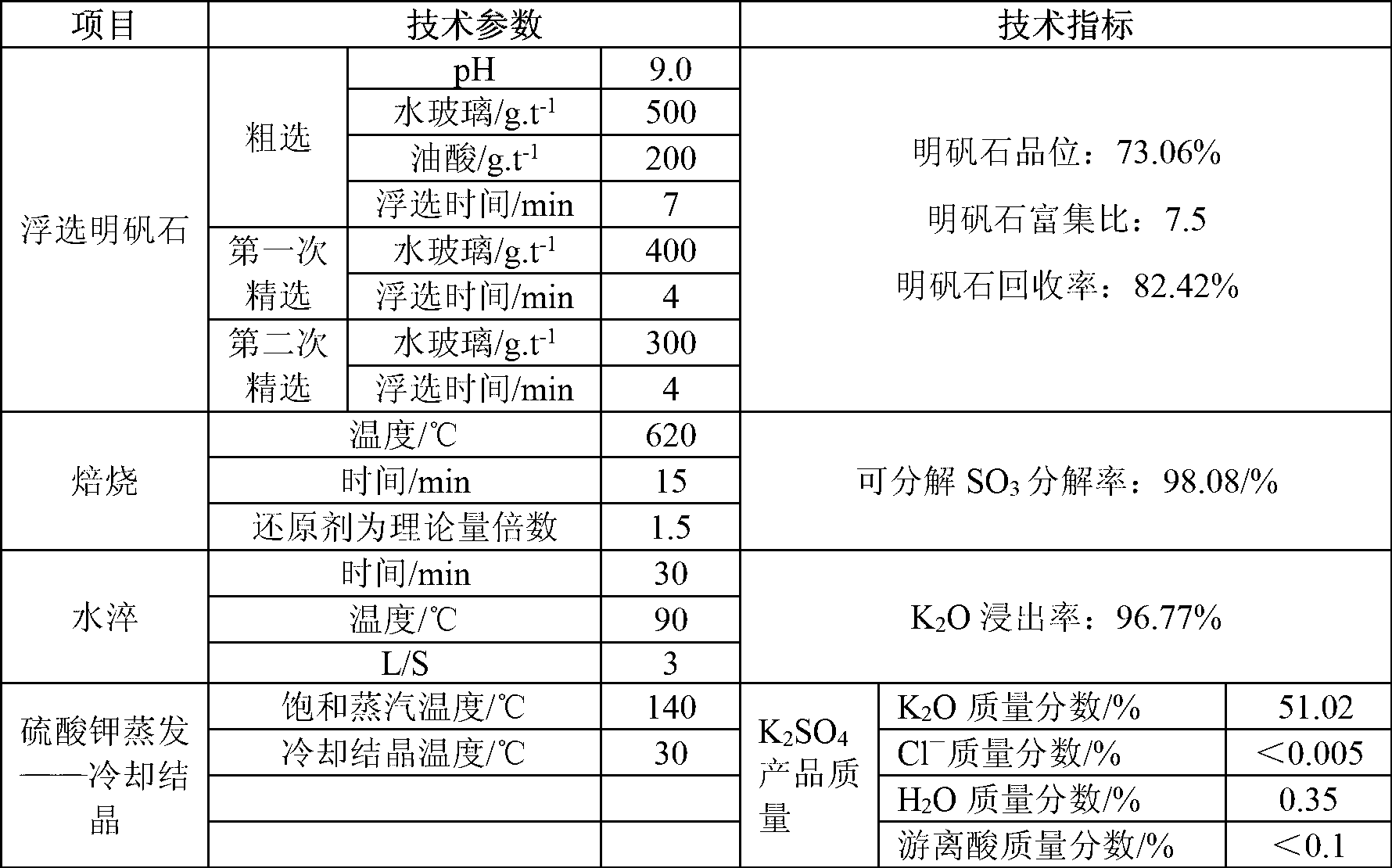

Method utilizing alunite in flotation tailing to produce potassium sulfate and auxiliary products thereof

ActiveCN103011206AImprove the level of comprehensive utilizationAlleviate the contradiction between supply and demandSulfate/bisulfate preparationEngineeringPotassium sulfate

The invention provides a method utilizing alunite in flotation tailing to produce potassium sulfate and auxiliary products thereof. The method fully utilizes secondary resources, changes waste into treasure, achieves minimizing, harmlessness and recycling of solid waste, improves comprehensive utilizing level of tailings in China, relieves an acute contradiction of supply and demand of potassium sulfate, reduces loss on foreign exchange caused by mass importation of the potassium sulfate, improves guarantee age limit of kalium and the international competitiveness of the kalium salt industry, completely solves the key scientific and technical problem of economic, clean efficient and comprehensive utilization of the alunite in flotation, the tailings are utilized as resources, establishes tailing comprehensive utilization technical demonstration project, and promotes the development of the comprehensive utilization technique of the tailing in China.

Owner:ZIJIN MINING GROUP

Method for preparing nano chrome/vanadium carbide composite powder

InactiveCN101857196AAbundant raw materialsRich sourcesNanostructure manufactureHydrogen atmosphereCarbonization

The invention discloses a method for preparing nano chrome / vanadium carbide composite powder. The preparation method comprises the following steps of: taking 4.20 to 10.90 grams of powdery chrome salt, 3.70 to 7.70 grams of ammonium vanadate and 2.20 to 8.40 grams of carbonaceous reducing agent in a weight ratio, putting the materials into deionized water or distilled water, and stirring the mixture uniformly to obtain solution or mixed liquid; putting the solution or the mixed liquid obtained in the step a into a drying oven, heating the solution or the mixed liquid for 1 to 3 hours at the temperature of between 100 and 200 DEG C, and drying the heated substance for 1 to 5 hours at the temperature of between 50 and 100 DEG C to finally obtain precursor powder containing chrome source, vanadium source and carbon source; and putting the precursor powder obtained in the step b into a high-temperature reaction furnace, and performing carbonization reduction on the precursor powder for 0.5 to 2 hours at the temperature of between 800 and 1,100 DEG C under the protection of vacuum, argon or hydrogen atmosphere to obtain the nano chrome / vanadium carbide composite powder with average grain diameter of less than 100 nanometers and uniform granularity distribution. The method has the characteristics of low reaction temperature, short reaction time, low production cost, simple process and the like, and is suitable for industrialized production of the nano chrome / vanadium carbide composite powder.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

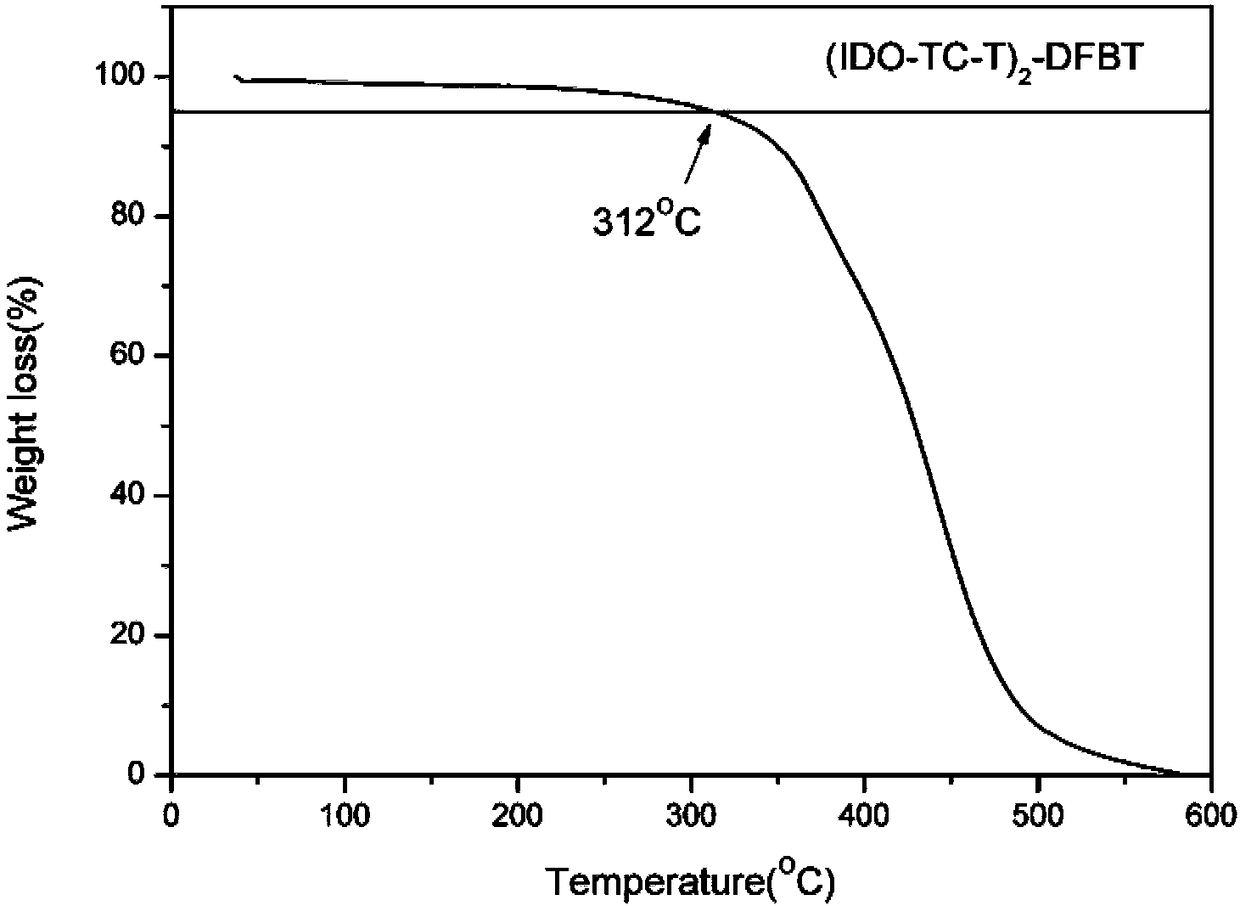

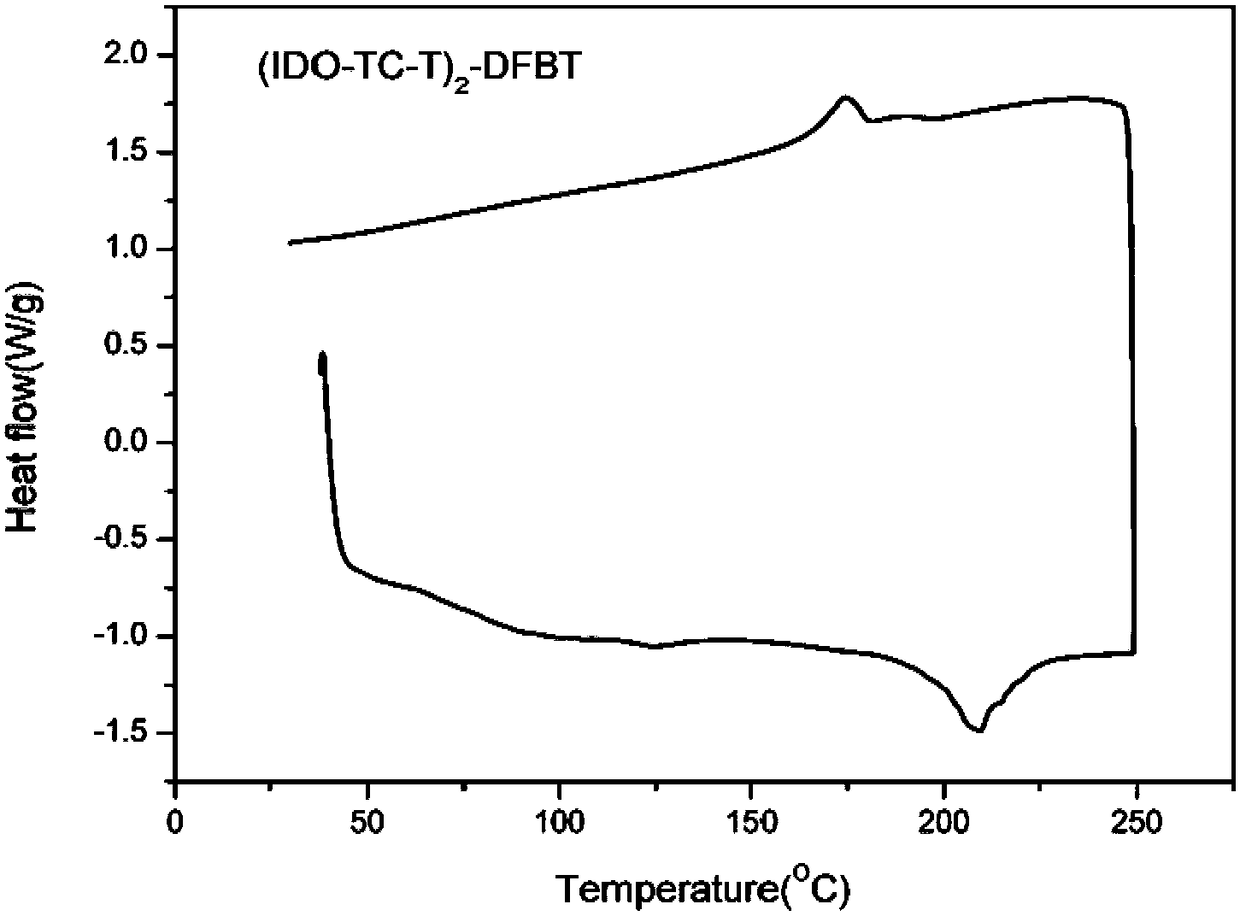

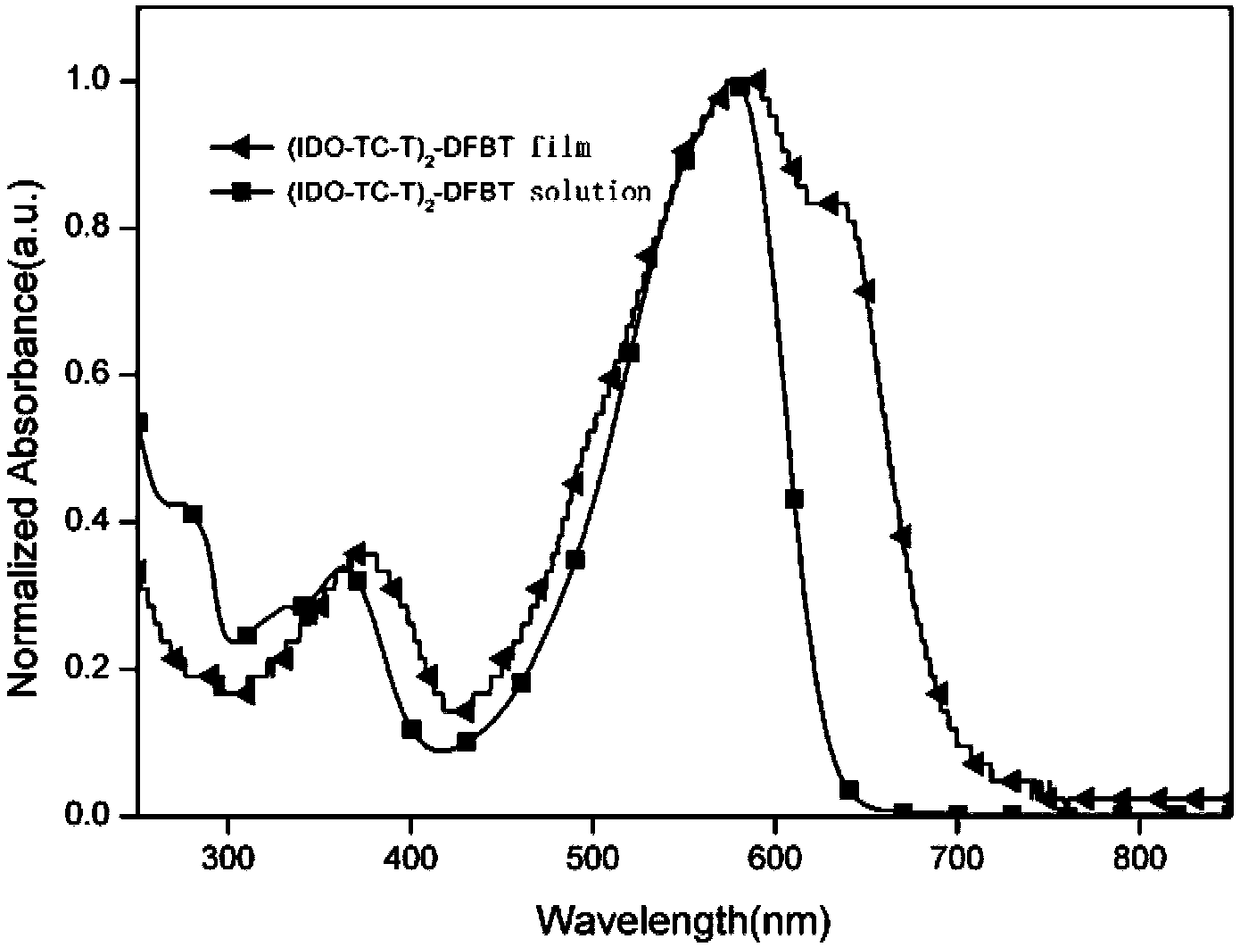

Zigzag type medium wide-band-gap small molecule electron donor materials based on thienobenzopyran and application of zigzag type medium wide-band-gap small molecule electron donor materials

ActiveCN108586496AHigh puritySingle ingredientOrganic chemistrySolid-state devicesHeterojunctionElectron donor

The invention relates to synthesis of zigzag type medium wide-band-gap small molecule photovoltaic materials based on thienobenzopyran and application of the zigzag type medium wide-band-gap small molecule photovoltaic materials in small molecule photovoltaic devices. An electron donor (D) unit of each medium wide-band-gap small molecule material is a thienobenzopyran derivative, a center acceptor(A) unit is 5,6-bis(benzothiadiazole), and a terminal group acceptor (A1) unit is rhodanine, indandione and derivatives of the indandione. The thienobenzopyran derivative, 5,6-bis(benzothiadiazole),rhodanine, indandione and the derivatives of the indandione can be widely used as donor materials in high-efficiency solution-processed small molecule solar cells. When the acceptor material of the device is fullerene (PC71BM), the maximum energy conversion efficiency and the open circuit voltage of the bulk heterojunction small molecule solar cells are respectively up to 7.55 percent and 0.9V. According to the invention, high efficiency energy conversion of the medium wide-band-gap small molecule photovoltaic materials in the small molecule solar cells is realized.

Owner:CHANGZHOU UNIV

Method used for chrome tanning waste water treatment and chrome recovery

ActiveCN103922521ASimple processHigh degree of automationWaste water treatment from animal processingMultistage water/sewage treatmentChromiumElectricity

The invention discloses a method used for chrome tanning waste water treatment and chrome recovery. The method comprises the steps of pretreatment, pH adjustment, electric flocculation treatment, aeration sedimentation treatment, sludge reaction pool treatment, electro-catalysis oxidization treatment and the like. A novel method for treating chrome-contained waste water through an electrochemical method is provided for the field of leather water treatment, a technology for recovering chrome in sludge is studied and developed, chrome resource consumption is lowered, the purposes of up-to-standard discharging of the chrome-contained waste water and recycling and reusing of chrome resources are realized, and meanwhile, the problem of after-treatment of a large amount of chrome sludge in waste water treatment is solved.

Owner:POWERCHINA ZHONGNAN ENG +1

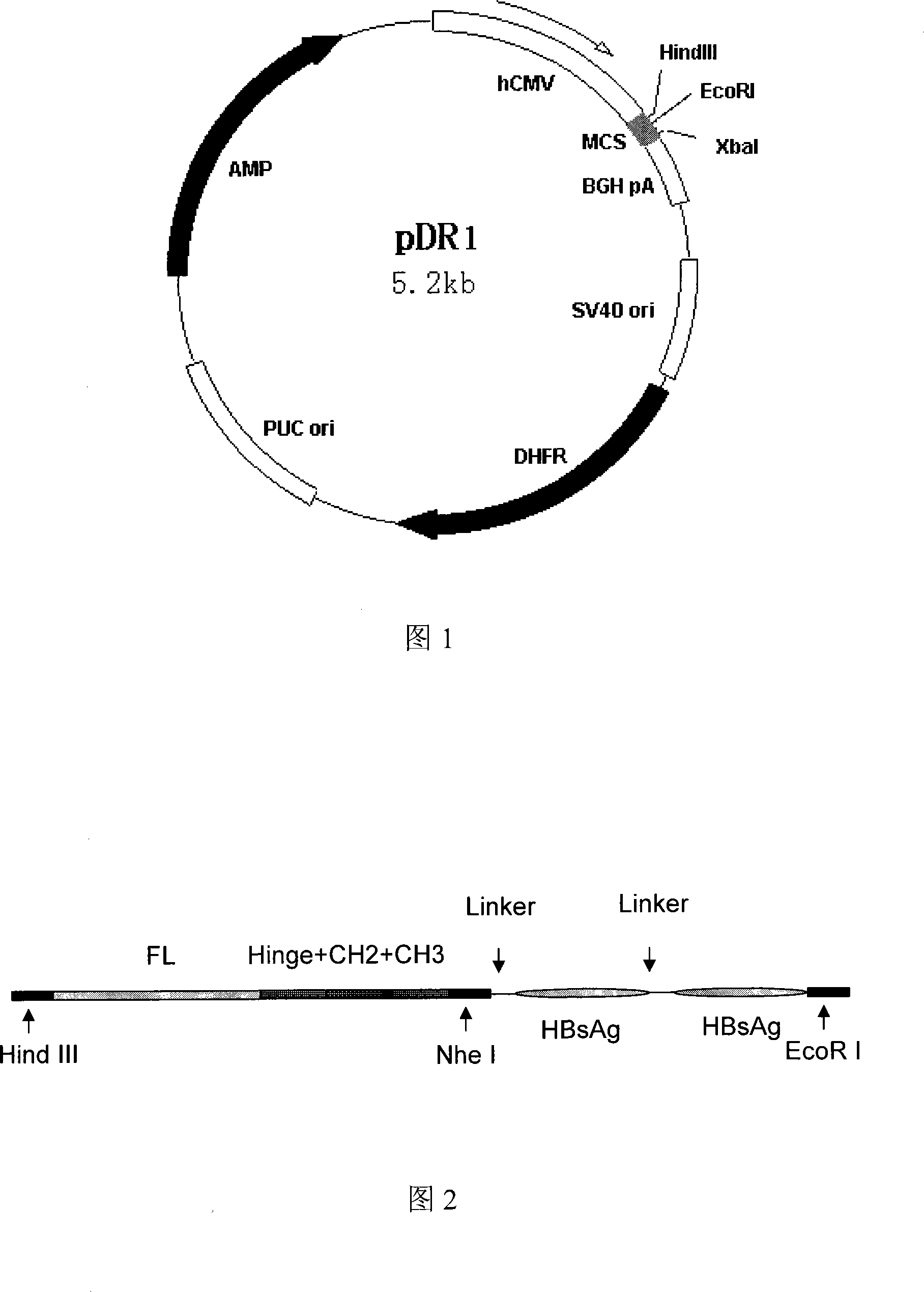

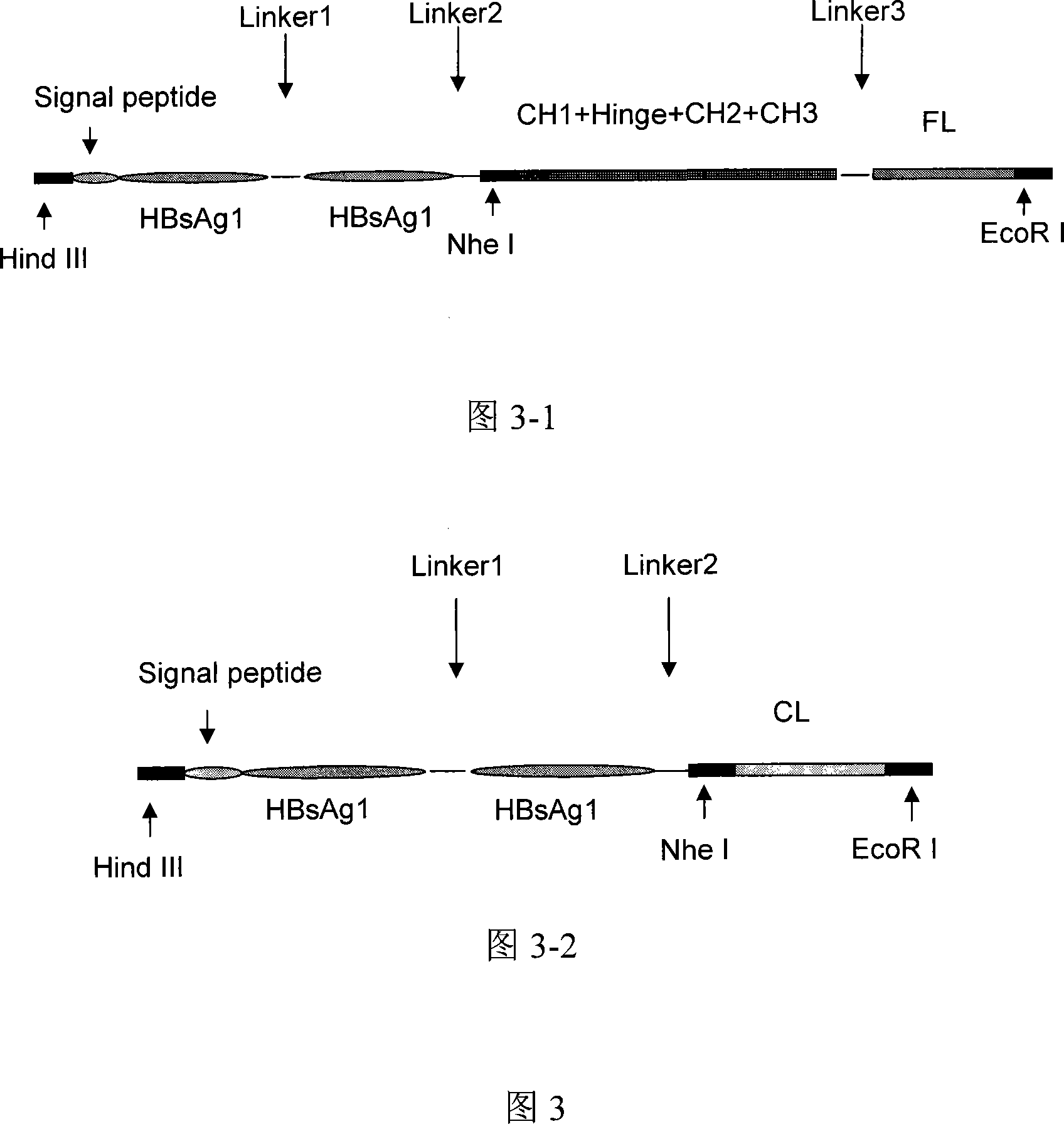

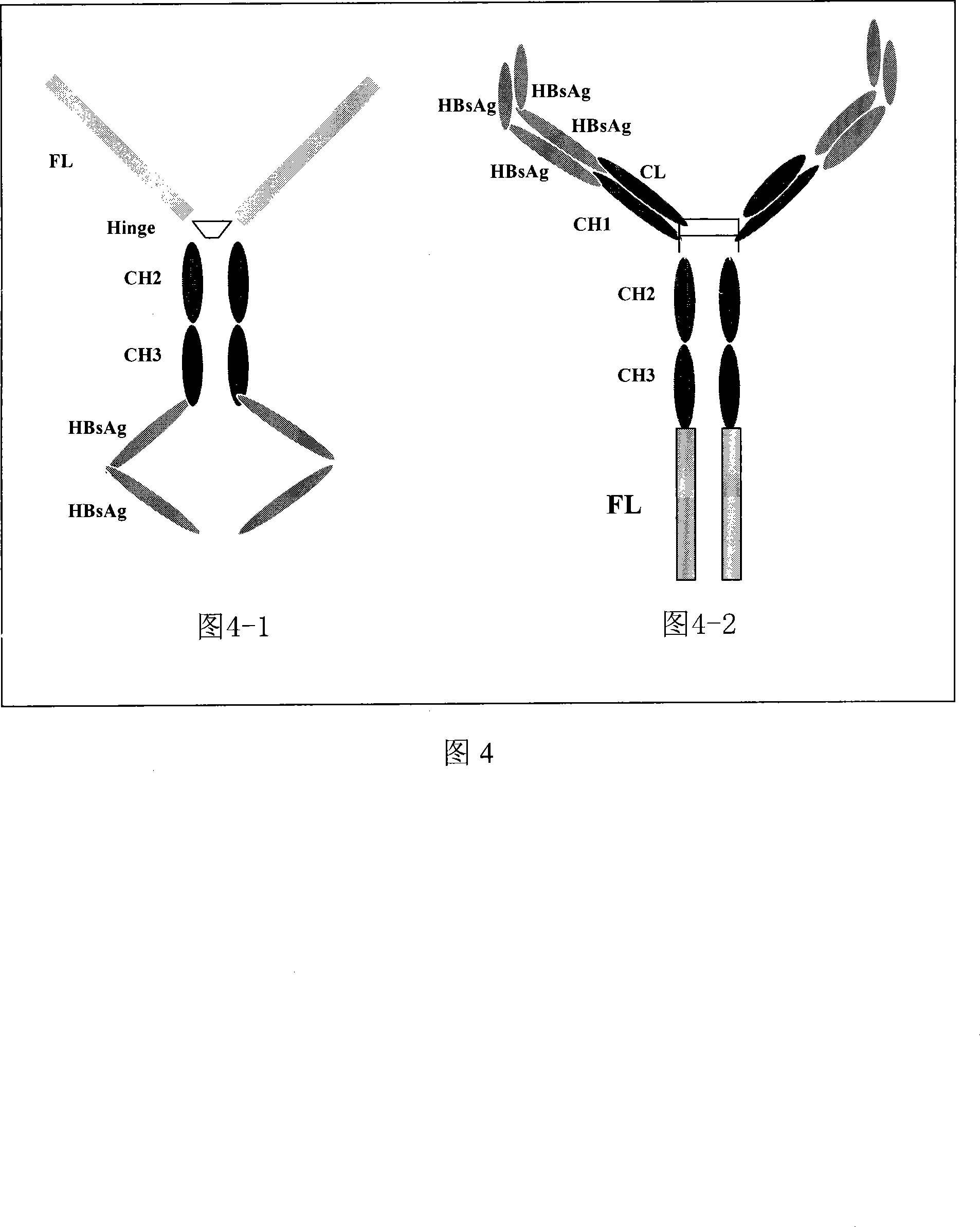

Hepatitis B fusion protein multiva lentvaccine, preparation method and uses thereof

This invention discloses a multivalence hepatitis B fusion protein targeting adjuvant vaccine, a preparation method and an application thereof. Particularly, the invention discloses a quadrivalence hepatitis B fusion protein targeting adjuvant vaccine (FL-CH-HBsAg-HbsAg)2, an octivalence hepatitis B fusion protein targeting adjuvant vaccine (HBsAg-HBsAg-CH-FL, HBsAg-HBsAg-CL)2, a relevant preparation method, and an application in preparation of preventative pharmaceuticals, and in treatment and / or prevention of hepatitis B.

Owner:SHANGHAI NAT ENG RES CENT OF ANTIBODY MEDICINE +1

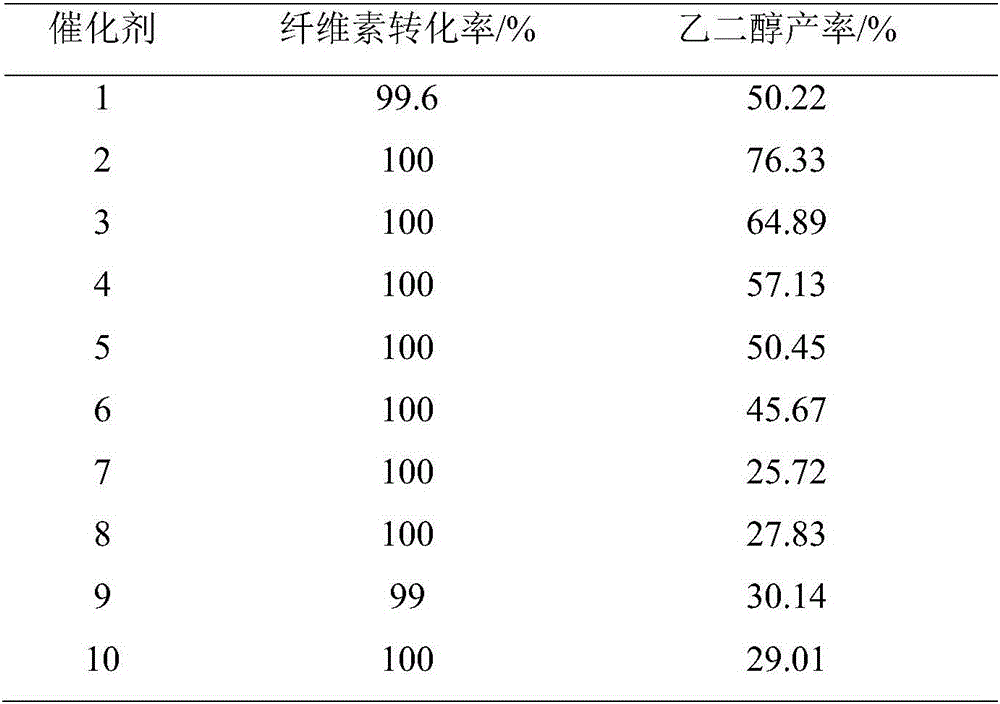

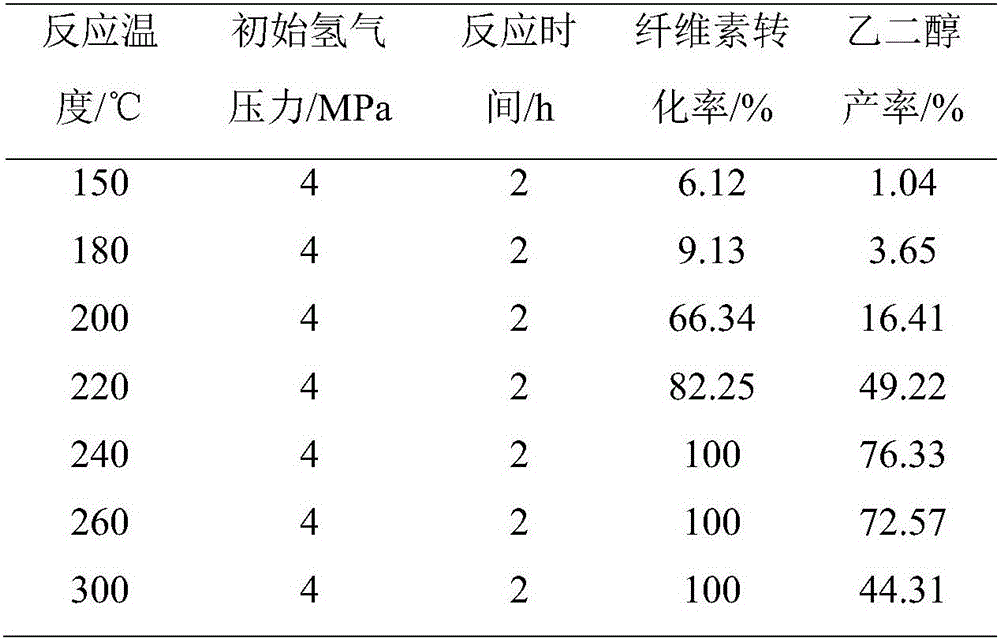

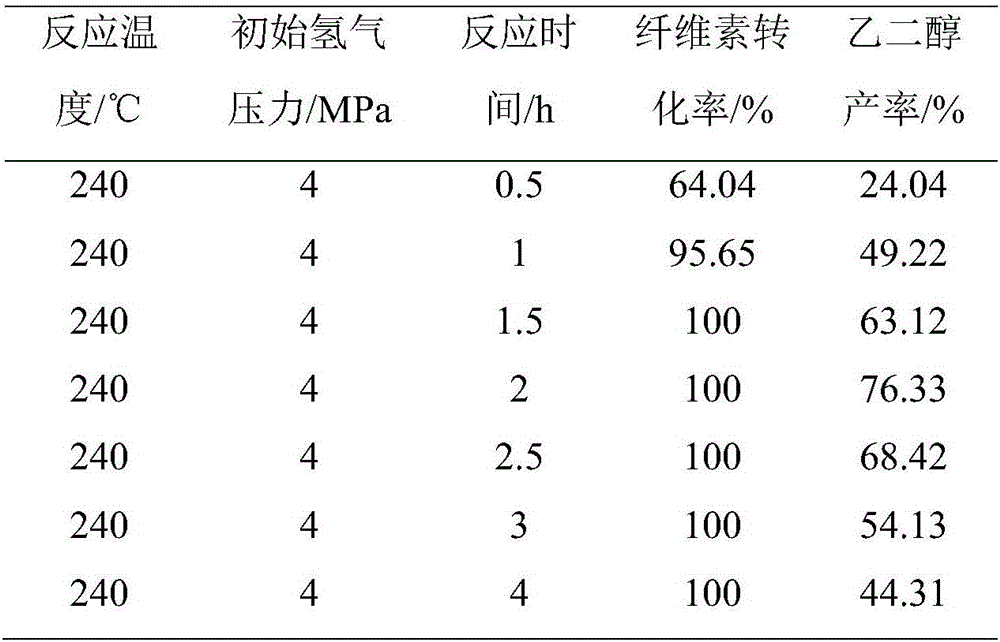

Preparation and application methods of transition-metal-supported tungsten-base catalyst

InactiveCN106824188AWide variety of sourcesReduce consumptionMaterial nanotechnologyOrganic compound preparationCelluloseInorganic compound

The invention relates to preparation and application methods of a transition-metal-supported tungsten-base catalyst. The method comprises the following steps: preparing a tungsten-base catalyst by low-temperature liquid-phase hydrothermal synthesis, and directly supporting one or more transition metals onto the support surface by sodium borohydride chemical reduction to obtain the supported tungsten-base catalyst; and uniformly mixing the tungsten-base catalyst with cellulose and water, and carrying out hydrogenation catalytic degradation in a closed high-pressure reaction kettle to prepare ethanediol. The cellulose can be catalytically converted into ethanediol in a high-efficiency high-selectivity high-yield way, and the ethanediol yield is up to 76.3%. The method has the advantages of simple technique, favorable reproducibility, mild reaction conditions, high cellulose conversion rate and high ethanediol yield; all the raw materials are inorganic compounds; and the reaction raw materials in the application direction are renewable resources. The ethanediol is an important chemical raw material.

Owner:SOUTHEAST UNIV

Method for preparing nanometer vanadium/chromium carbide composite powder by reduction with microwave method

InactiveCN102674844ASimple processSimple production processNanotechnologyMicrowave methodCarbonization

A method for preparing nanometer vanadium / chromium carbide composite powder by reduction with a microwave method is characterized by comprising the following steps: a, taking 5.60-7.35 g of nanometer vanadium oxide, 5.40-7.10 g of nanometer chromium oxide and 5.40-6.20 g of carbonaceous reducing agent in proportion by weight, placing the materials into a ball mill, and fully mixing the materials by taking absolute ethyl alcohol or acetone as a ball-milling medium, so as to obtain a mixed material; b, placing the mixture obtained in the step a into a drying box, drying the mixture at the temperature of 100-200 DEG C for 1-3 hours, and then compressing the dried mixture into blocks for standby; and c, placing the blocks obtained in the step b into a microwave sintering furnace, performing carbonization reduction on the blocks at the temperature of 700-1000 DEG C for 5-30 minutes under the protection condition of vacuum, argon or hydrogen environment, so as to obtain the nanometer vanadium / chromium carbide composite powder with the average grain diameter of 100 nm and uniform grain fineness distribution.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Method for preparing porous metal with mixed gas

The invention provides a method for preparing porous metal with mixed gas in order to solve the problems that an existing micro-nano-porous metal preparation technology mainly concentrates on the initial formation process of metal materials, the method is complex and seriously relies on a die template, and the requirements for production equipment are high. The method for preparing the porous metal includes the steps that firstly, the metal materials are cleaned with acetone firstly and then cleaned with absolute ethyl alcohol and deionized water sequentially; and secondly, the temperature of the cleaned metal is raised to 550-850 DEG C under the protection of inert gas, then the mixed gas composed of fuel gas and oxidation gas is introduced into a carrier to carry out porous processing. A porous structure is formed on the surface of and inside the metal by directly using the expansion and overflowing of H2O gas and CO2 gas formed by the fuel gas and the oxidation gas inside the metal. The method has the advantages that the technology is simple, preparation is convenient, and pollution is avoided. Secondary processing can be achieved on a prepared complex metal device, and the requirements for the equipment are low.

Owner:HARBIN INST OF TECH

Method for improving ternary lithium battery positive-electrode material temperature resistance by evaporating aluminum fluoride

ActiveCN106848252AImprove high temperature resistanceImprove conductivityCell electrodesSecondary cellsAluminum fluorideFluidized bed

The invention discloses a method for improving ternary lithium battery positive-electrode material temperature resistance by evaporating aluminum fluoride. According the method, a fluidized bed serves as an evaporation device, the aluminum fluoride is sublimated, nano-scale nickel and cobalt lithium manganate ternary materials and the aluminum fluoride are evaporated in a contacting and suspending manner in the sublimating atmosphere of the aluminum fluoride, an ultrathin aluminum fluoride protection film uniformly wraps the surfaces of micro-particles of the nano-scale nickel and cobalt lithium manganate ternary materials after the materials are cooled, and the high-temperature resistance of nickel and cobalt lithium manganate is improved to 300 DEG C by wrapping the aluminum fluoride. By the aid of a pure physical coating mode, the method overcomes the technical shortcomings that a coating layer acquired by chemical coating of the aluminum fluoride is nonuniform, battery efficiency is affected, effect processing period is long, cost is high, pollution exists and the like in the prior art. The method is good in coating effect and simple in preparation process and can achieve large-scale industrial production modes.

Owner:东营睿港管道工程有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com