Three-layer co-extruded lithium-ion battery separation membrane and production method thereof

A lithium-ion battery, three-layer co-extrusion technology, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., can solve the problems of complex components and production methods, increased production costs, etc., to achieve Good promotion and application value, good mechanical strength, single ingredient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

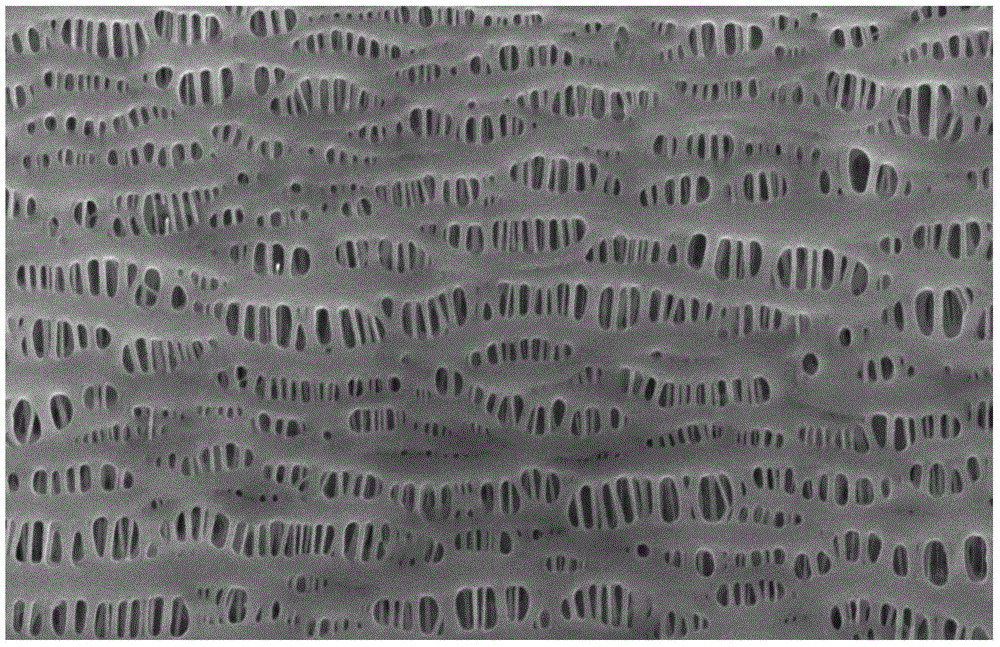

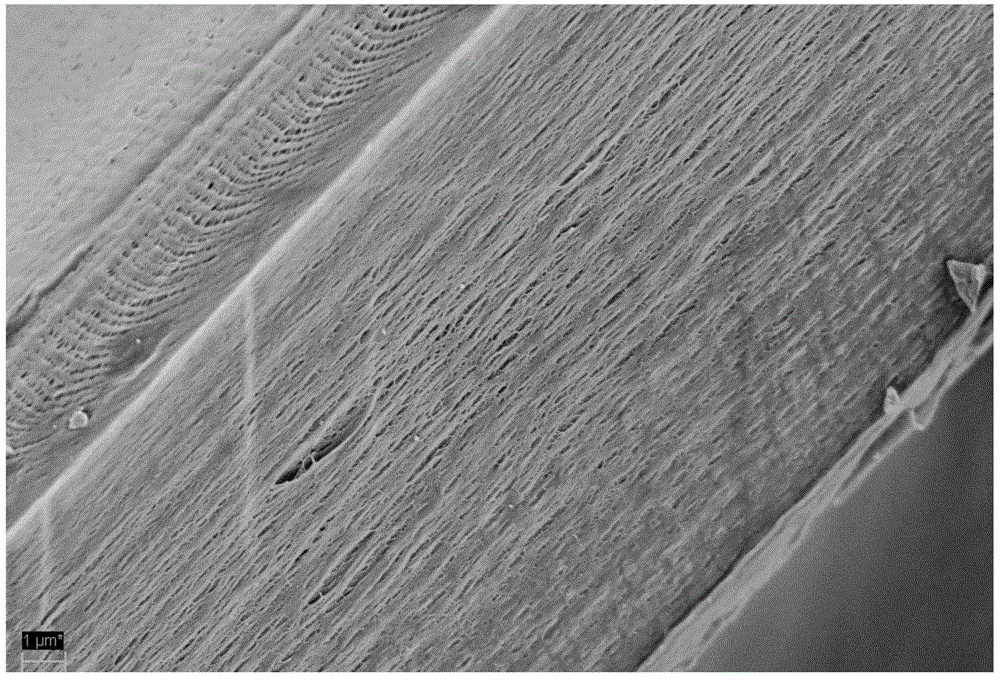

Image

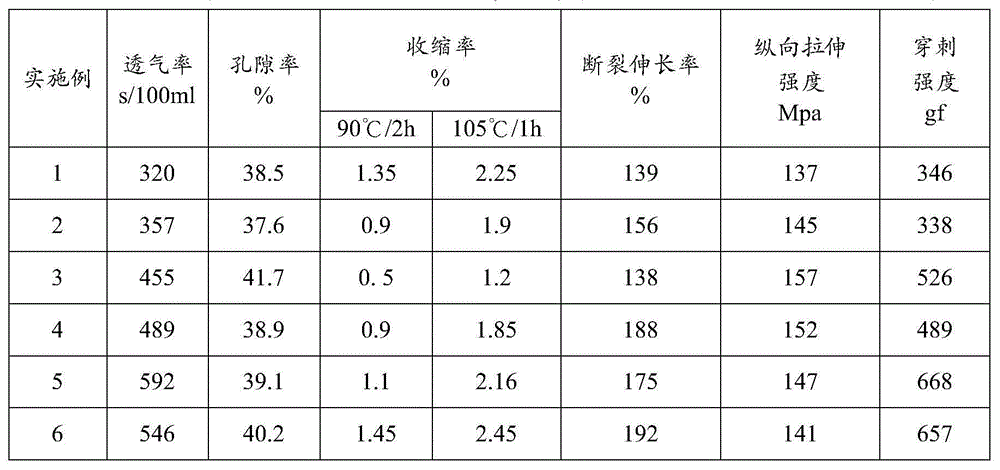

Examples

Embodiment 1

[0023] The three-layer co-extruded lithium-ion battery separator provided in this example has a thickness of 16 μm and includes three layers of A / B / A. The raw material of layer A is H5300 polypropylene resin, the isotacticity is above 98%, and the melt index is : 3.4g / 10min (2.16kg, 230°C); B layer is T30S polypropylene resin, the isotacticity is also above 98%, and the melt index is 2.5g / 10min (2.16kg, 230°C); The thickness of the A layer is the same, and the thickness of the B layer is 2.5 times of the single A layer thickness.

[0024] The preparation method of the three-layer co-extruded lithium-ion battery diaphragm provided in this embodiment comprises the following steps:

[0025] a. Melting step: Add H5300 and T30S polypropylene resin to two different extruder inlets to melt and plasticize. The temperature of the conveying section is 50°C, the temperature of the compression section is 170°C, the temperature of the metering section is 200°C, and the rotation speed is 6...

Embodiment 2

[0030] The three-layer co-extruded lithium-ion battery separator provided in this example has a thickness of 16 μm and includes three layers of A / B / A. The raw material of layer A is H5300 polypropylene resin, the isotacticity is above 98%, and the melt index is : 3.4g / 10min (2.16kg, 230°C); B layer is T30S polypropylene resin, the isotacticity is also above 98%, and the melt index is 2.5g / 10min (2.16kg, 230°C); The thickness of the A layer is the same, and the thickness of the B layer is twice the thickness of a single A layer.

[0031] The preparation method of the three-layer co-extruded lithium-ion battery diaphragm provided in this embodiment comprises the following steps:

[0032] a. Melting step: Add H5300 and T30S polypropylene resin to two different extruder inlets to melt and plasticize respectively, where the temperature of the conveying section is 65°C, the temperature of the compression section is 190°C, the temperature of the metering section is 220°C, and the rot...

Embodiment 3

[0037] The three-layer co-extruded lithium-ion battery separator provided in this example has a thickness of 32 μm and includes three layers of A / B / A. The raw material of layer A is H5300 polypropylene resin, the isotacticity is above 98%, and the melt index is : 3.4g / 10min (2.16kg, 230°C); B layer is T30S polypropylene resin, the isotacticity is also above 98%, and the melt index is 2.5g / 10min (2.16kg, 230°C); The thickness of the A layer is the same, and the thickness of the B layer is 3 times of the thickness of a single A layer.

[0038]The preparation method of the three-layer co-extruded lithium-ion battery diaphragm provided in this embodiment comprises the following steps:

[0039] a. Melting step: Add H5300 and T30S polypropylene resin to two different extruder inlets to melt and plasticize respectively, where the temperature of the conveying section is 75°C, the temperature of the compression section is 210°C, the temperature of the metering section is 235°C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com