Early strength composite admixture and preparation method thereof

A composite admixture and admixture technology, which is applied in the field of concrete admixtures, can solve the problems of no contribution to concrete work performance, no significant improvement in strength, and small improvement, and achieve significant economic and social benefits. The effect of improving workability and reducing cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below with reference to the examples, but the embodiments of the present invention are not limited thereto.

[0040] Preparation Example 1 Preparation Example 2 Preparation Example 3 Preparation Example 4 Preparation Example 5 Sodium sulfate (unit: kg) 20 70 25 65 45 Calcium nitrate (unit: kg) 45 60 50 55 55 Potassium nitrite (unit: kg) 20 50 25 45 35 Urea (unit: kg) 10.6 64 40 66 45 Silica fume (unit: kg) 797 720 800 935 765

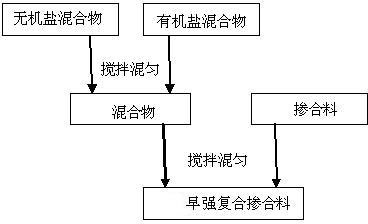

[0041] Mix sodium sulfate, calcium nitrate and potassium nitrite according to the above ratio to prepare an inorganic salt mixture; urea according to the above ratio as an organic salt mixture; take the silicon powder of the above ratio as an admixture; then mix the above organic salt mixture , the inorganic salt mixture and the admixture are mixed, mixed and stirred for 8 to 10 minutes to make them evenly stirred, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com