Method for preparing bio-oil through hydrogenation degradation of lignin

A technology of hydrodegradation and lignin, which is applied in the preparation of ether, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of consuming more hydrogen sources and energy, the conversion rate is only about 50%, and the yield of bio-oil is low. and other problems, to achieve the effects of alleviating the economic crisis, easy large-scale production, and less bio-oil components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Ni-VS 2 Preparation of the catalyst: Weigh 1.80g of sodium orthovanadate, 1.65g of thioacetamide and 0.13g of nickel nitrate, dissolve them in 60mL of ethanol, stir them magnetically for 1 hour and put them into a polytetrafluoroethylene hydrothermal kettle. Reaction at 160°C for 24h. Cool to room temperature, wash with ethanol and distilled water several times, and dry in vacuum at 60°C for 6h. The resulting catalyst contains 5% nickel, expressed as 5% Ni-VS 2 .

[0019] Other conditions remain the same, only changing the quality of nickel nitrate added, can get nickel-containing vanadium disulfide catalysts of different components, respectively 0.1% Ni-VS 2 , 0.5%Ni-VS 2 , 1%Ni-VS 2 , 2%Ni-VS 2 , 10%Ni-VS 2 , 30%Ni-VS 2 .

Embodiment 2

[0021] Co-VS 2 、Mo-VS 2 , Ag-VS 2 Preparation of the catalyst: the preparation process is similar to that of Example 1, the difference being that the nickel nitrate was replaced with cobalt nitrate, sodium molybdate, and silver nitrate before the preparation. The mass content of Co, Mo, and Ag in the catalyst is 5%, respectively recorded as 5% Co-VS 2 , 5% Mo-VS 2 , 5% Ag-VS 2

Embodiment 3

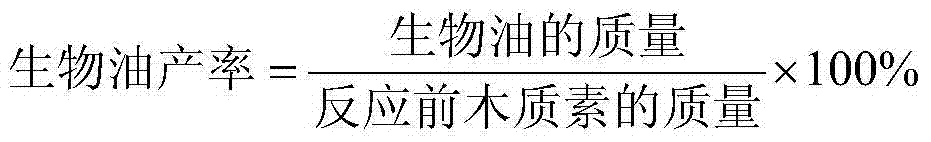

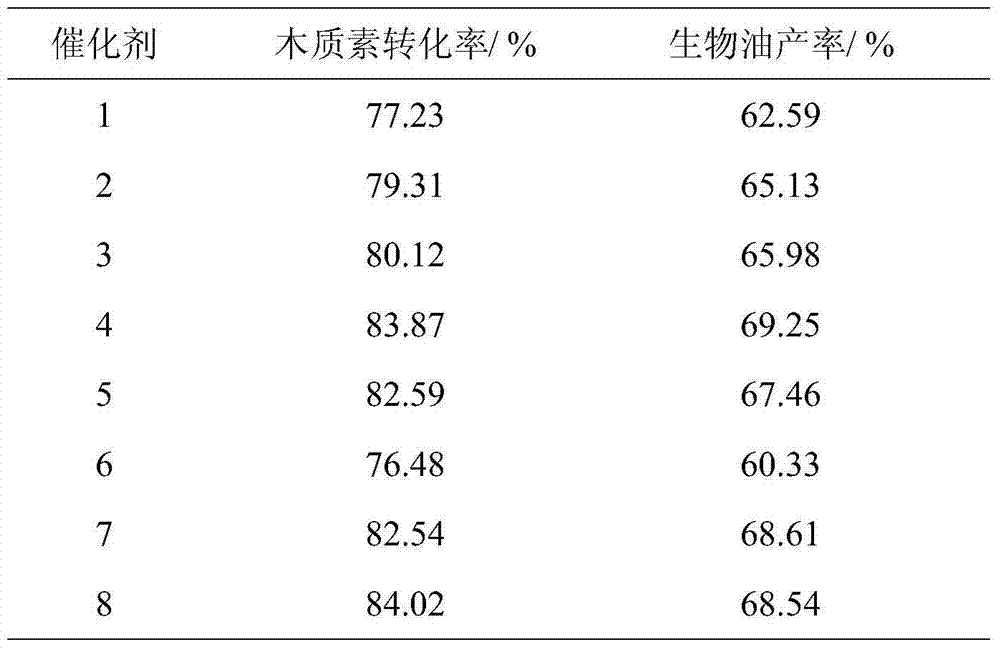

[0023] Hydrocracking of lignin with different vanadium-based catalysts: 4g of lignin, 0.2g of catalyst and 40ml of ethanol were weighed into the autoclave, and the autoclave was tightly sealed. Introduce 2MPa nitrogen, vent, and repeat three times to get rid of the air in the reactor. Then, 3MPa hydrogen gas was introduced, the stirring speed was 800 rpm, the temperature was raised to 290° C. and the temperature was maintained for 1 h. Cool to room temperature after the reaction, and collect liquid bio-oil and solid residue. The catalyst used is respectively in table 1: (1) 0.5%Ni-VS 2 , (2) 1% Ni-VS 2 , (3) 2% Ni-VS 2 , (4) 5% Ni-VS 2 , (5) 10%Ni-VS 2 , (6) 30%Ni-VS 2 , (7) 5% Co-VS 2 , (8) 5% Mo-VS 2 , (9) 5% Ag-VS 2 . The liquid product was analyzed for its chemical composition by GC-MS.

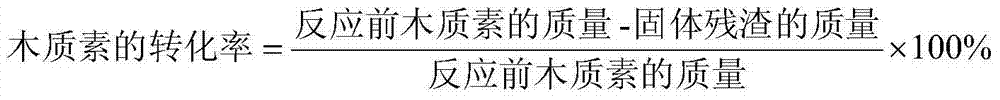

[0024]

[0025]

[0026] Table 1 Performance comparison of different vanadium-based catalysts for hydrocracking lignin

[0027]

[0028]

[0029] It can be seen fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com