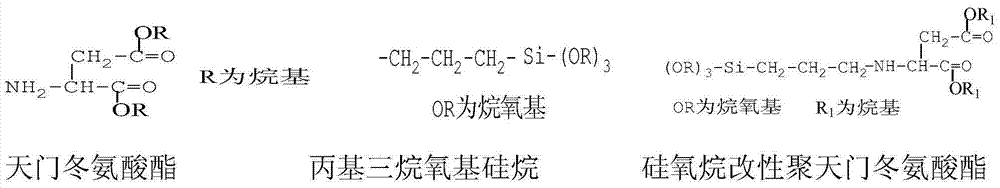

Preparation method of siloxane modified polyaspartic acid ester

An aspartate and siloxane modification technology, which is applied in the field of chemical product synthesis, can solve the problems of low double bond activity, less double bond steric hindrance, and increased resin viscosity, and achieves low production cost and single composition. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Mix 3.5g of 3A molecular sieve with 110g of diethyl maleate, keep the temperature at 90°C, stir at 500°C, keep warm for 70 minutes, heat up to 120°C, turn on the vacuum pump and adjust the vacuum degree to 300Pa to start vacuum rectification, rectification Carry out after 60min, after temperature rises to 150 ℃, promptly there is no rectification product, stop rectification, obtain the diethyl maleate that water content is 400ppm; Add 110g gamma-aminopropyltriethoxy in the reaction kettle Silane and pass nitrogen gas for 10 minutes, raise the temperature to 40°C, start stirring and maintain the stirring speed at 500r / min, and start to drop 86g of diethyl maleate that has been dehydrated, and control the dropping speed to 1 drop / S, with the reaction Exothermic, control the temperature not to exceed 80°C, dropwise is completed in about 50-80 minutes, that is, maintain the temperature and the reaction temperature at 80°C and continue the reaction for 24 hours to obtain the ...

example 2

[0025]Mix 6.0g of 3A molecular sieve with 160g of diisobutyl maleate, keep the temperature at 90°C, stir at 500°C, keep warm for 70 minutes, raise the temperature to 140°C, turn on the vacuum pump and adjust the vacuum degree to 300Pa to start rectification under reduced pressure. After distillation for 60min, when the temperature rises to 180°C, there is no rectification product, stop the rectification, and obtain a maleic acid ester with a water content of 200ppm; add 110g of γ-aminopropyltriethoxysilane to the reaction kettle And pass through nitrogen for 8 minutes, heat up to 40°C, start stirring and maintain the stirring speed at 500r / min, and start to drop 114g of diisobutyl maleate after dehydration, control the dropping speed to 2 drops / S, with the reaction Exothermic, control the temperature not to exceed 80°C, the dropwise addition is completed in about 50-80 minutes, that is, maintain the temperature and the reaction temperature at 80°C and continue the reaction for ...

example 3

[0027] Mix 6.0g of 3A molecular sieve with 160g of dipropyl maleate, keep the temperature at 90°C, stir at 500°C, keep warm for 70 minutes, raise the temperature to 120°C, turn on the vacuum pump and adjust the vacuum degree to 300Pa to start vacuum rectification, rectification After 60 minutes, when the temperature rises to 160°C, there is no rectification product, stop the rectification to obtain dipropyl maleate with a water content of 200ppm; add 90g of γ-aminopropyltrimethoxysilane to the reaction kettle And feed nitrogen gas for 8 minutes, heat up to 40°C, start stirring and maintain the stirring speed at 500r / min, and start to drop 102g of dipropyl maleate after dehydration, control the dropping speed to 1-2 drops / S, with The reaction is exothermic, and the temperature is controlled not to exceed 80°C. The dropwise addition is completed in about 50-80 minutes, that is, the temperature is maintained at 80°C and the reaction is continued for 24 hours to obtain the crude pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com