Lithium-titanium oxide type lithium ion sieve absorbent and method for preparing precursor thereof

A lithium titanium oxide, lithium ion technology, applied in titanium compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of uneven powder contact, large powder particle size, insufficient reaction, etc., and shorten the grinding time. time, large adsorption capacity, and the effect of increasing the contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

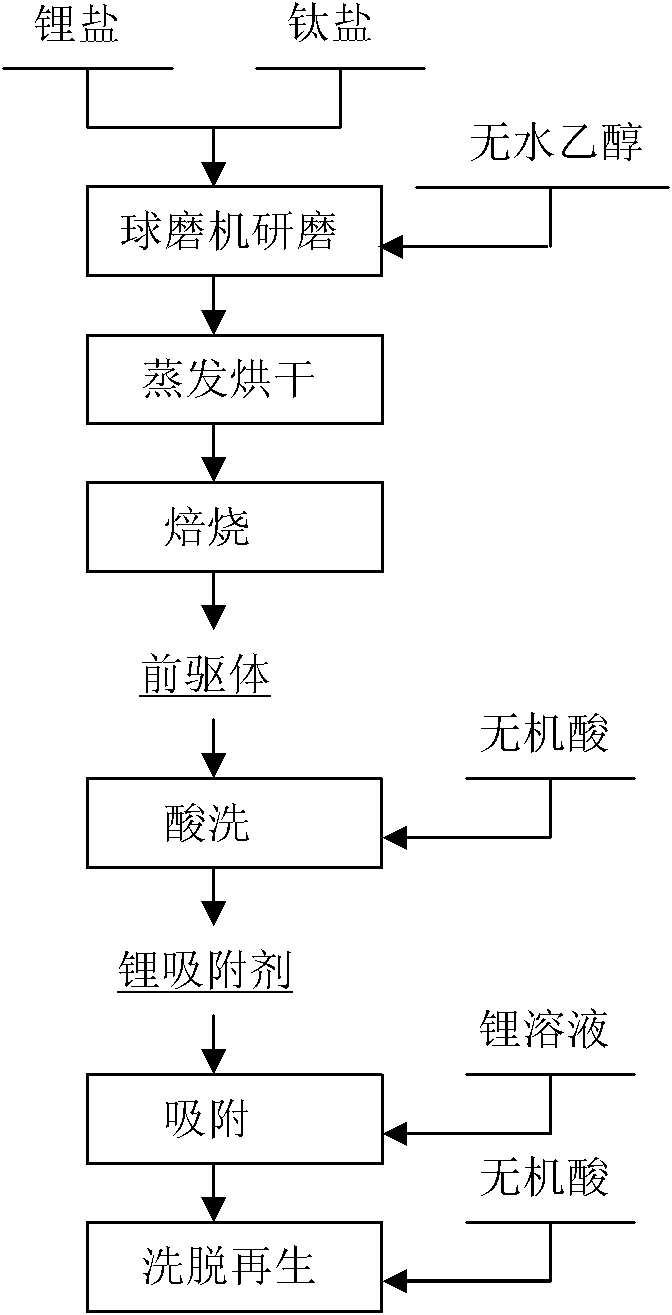

[0029] (1) Preparation of precursor

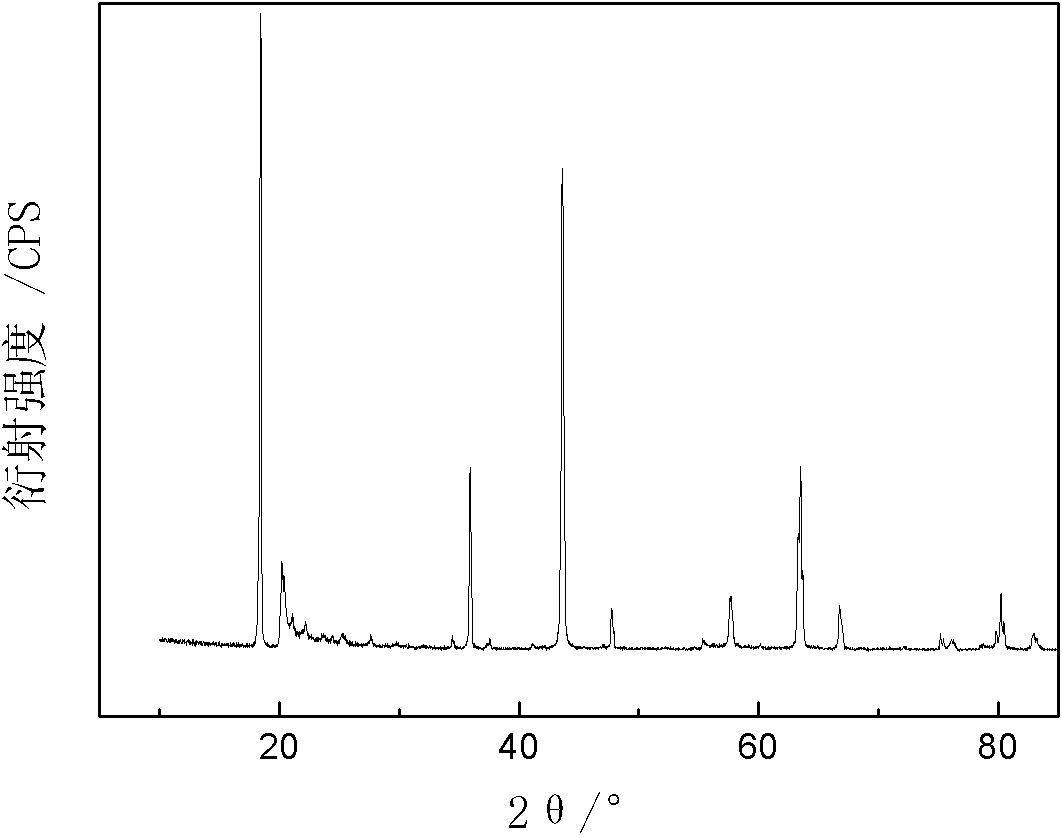

[0030] 40g of mixed crystal titanium dioxide, according to the molar ratio of lithium element and titanium element is 2: 1, add lithium carbonate, use absolute ethanol as the dispersion medium, grind in a ball mill for 2 hours; the product after grinding is dried at 100 ° C for 4 hours; in an air atmosphere, the mixture was calcined at 800°C for 12 hours to obtain the lithium adsorbent precursor Li 2 TiO 3 . Its X-ray diffraction pattern and SEM pattern are shown in figure 2 and image 3 .

[0031] (2) Preparation of ion sieve

[0032] Weigh 10g lithium adsorbent precursor Li 2 TiO 3 , at 60°C, with a concentration of 0.25mol L -1 pickling with hydrochloric acid, filtered under magnetic stirring for 24 hours, washed the filter residue with deionized water until the pH of the filtrate was about 7, and then dried at 100°C for 4 hours to obtain the lithium adsorbent H 2 TiO 3 , and its X-ray diffraction pattern is shown in Figure...

Embodiment 2

[0038]With 40g of mixed crystal titanium dioxide, according to the molar ratio of lithium element and titanium element is 2:1, add lithium hydroxide, use acetone as dispersion medium, grind in ball mill machine for 3 hours; The product after grinding is dried at 100 DEG C for 4 hours; in the air atmosphere, the mixture was calcined at 850°C for 12 hours to obtain the lithium adsorbent precursor Li 2 TiO 3 .

[0039] The preparation, adsorption, analysis and regeneration of the ion sieve are the same as in Example 1.

Embodiment 3

[0041] With 40g of mixed crystal titanium dioxide, according to the molar ratio of lithium element and titanium element is 2:1, add lithium hydroxide, use acetone as dispersion medium, grind in ball mill machine for 3 hours; The product after grinding is dried at 100 DEG C for 4 hours; in an air atmosphere, the mixture was calcined at 550°C for 15 hours to obtain the lithium adsorbent precursor Li 2 TiO 3 .

[0042] The preparation, adsorption, analysis and regeneration of the ion sieve are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com