Patents

Literature

1313results about How to "Expand source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

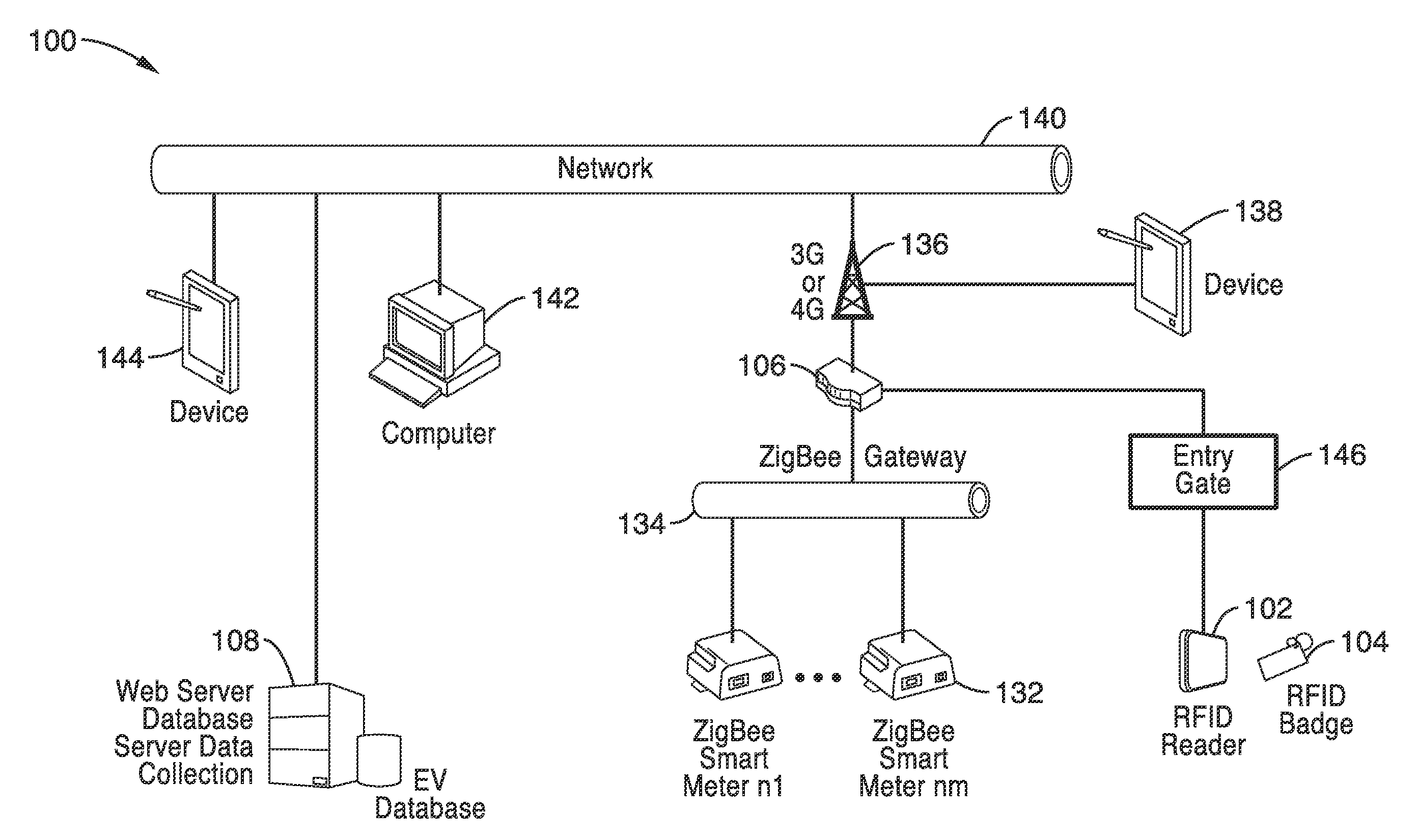

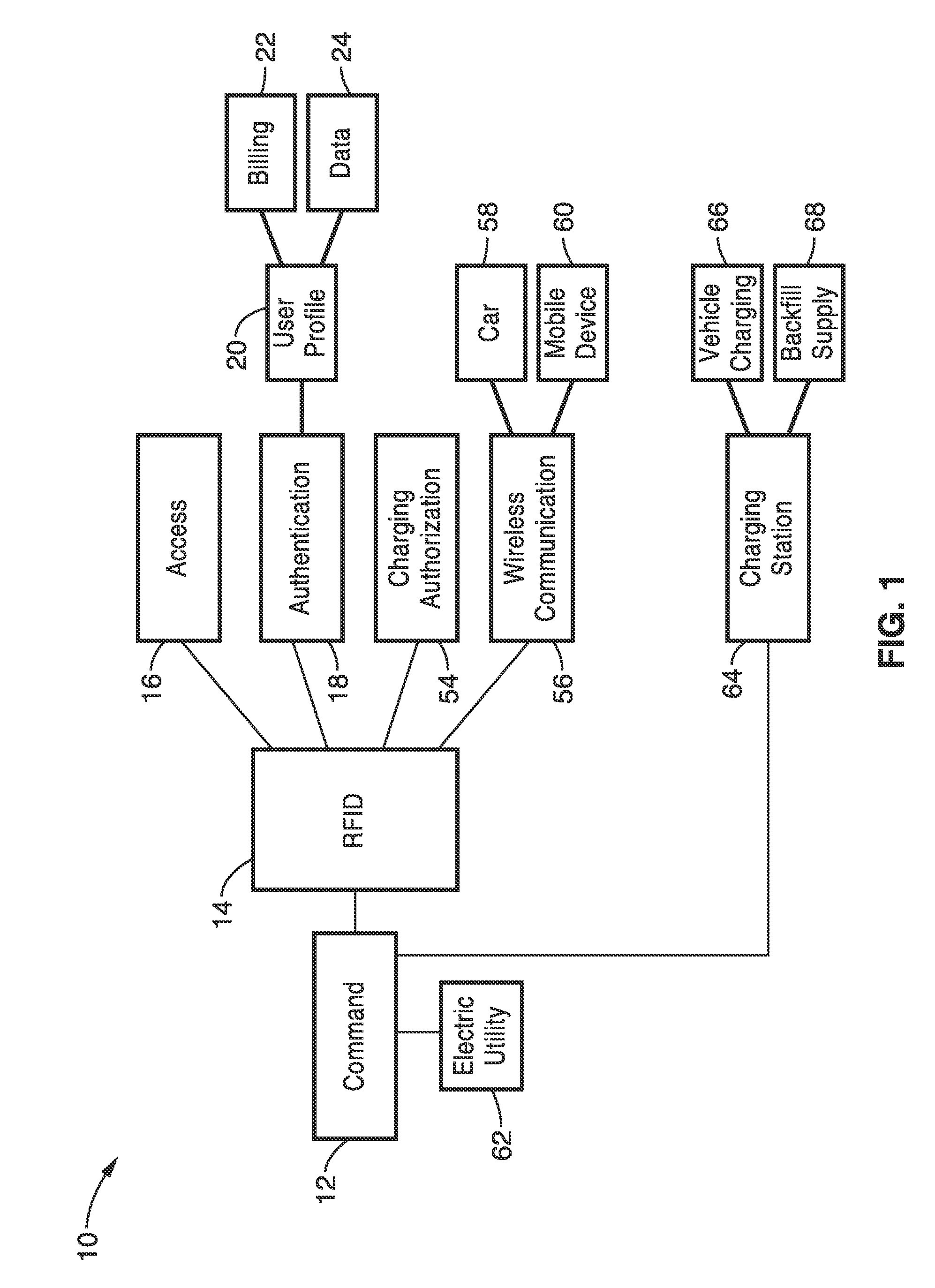

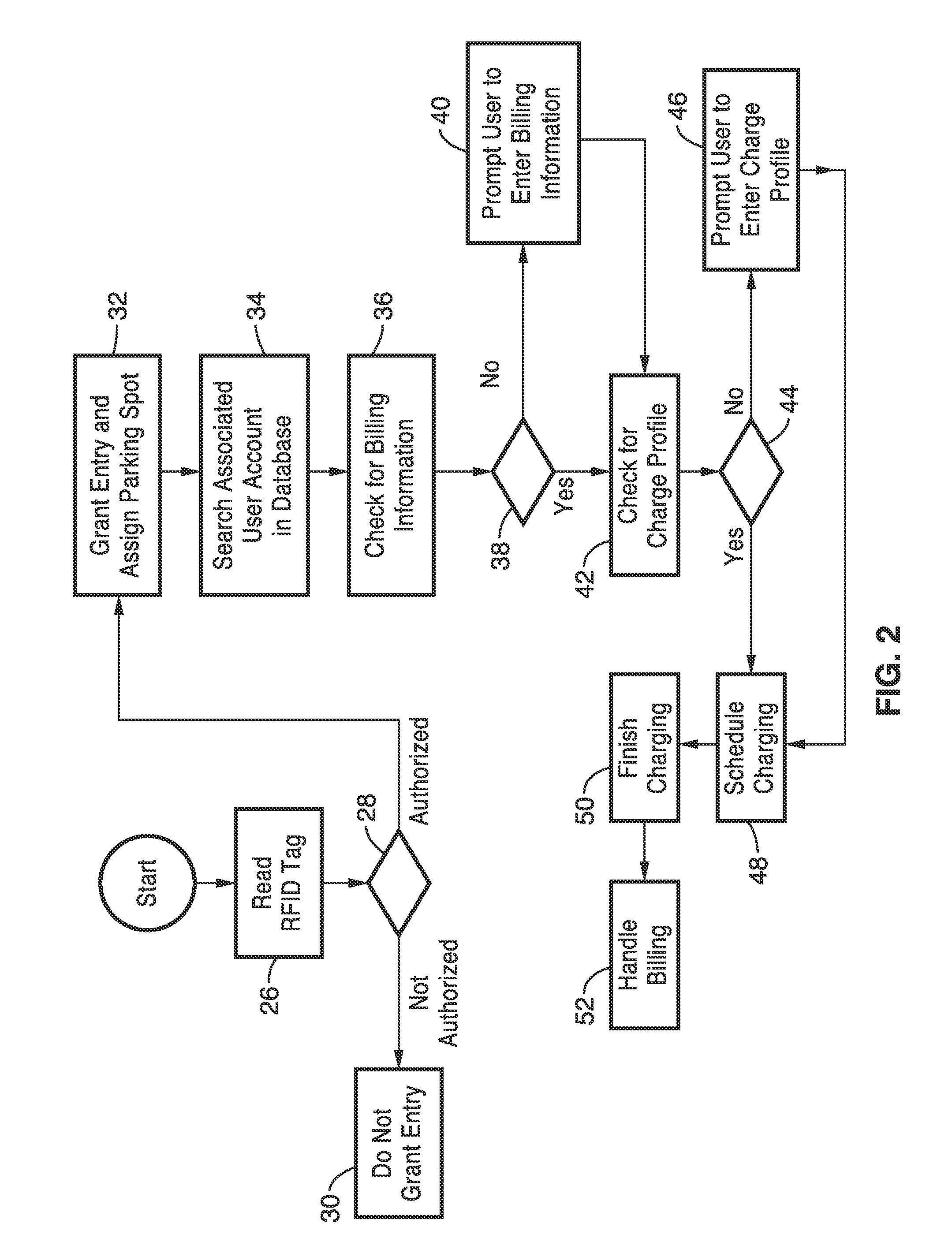

Intelligent electric vehicle charging system

InactiveUS20140203077A1Reduce energy costsAvoid prolonged useCircuit authenticationCircuit monitoring/indicationTelecommunications linkElectrical battery

A battery charging system for an electric vehicle in which an addressable RFID tag, an RFID receiver, an electrical charger, and a controller operate to charge the battery of an electric vehicle according to a user profile and a charging profile in response to a signal received by the RFID reader from the RFID tag. In an interconnected system, multiple charging stations are connected to the electrical power grid and communicate with a central controller through communications links. A grid converter can be provided to allow for backfilling power from an electric vehicle to the power grid in response to a command from the central controller.

Owner:RGT UNIV OF CALIFORNIA

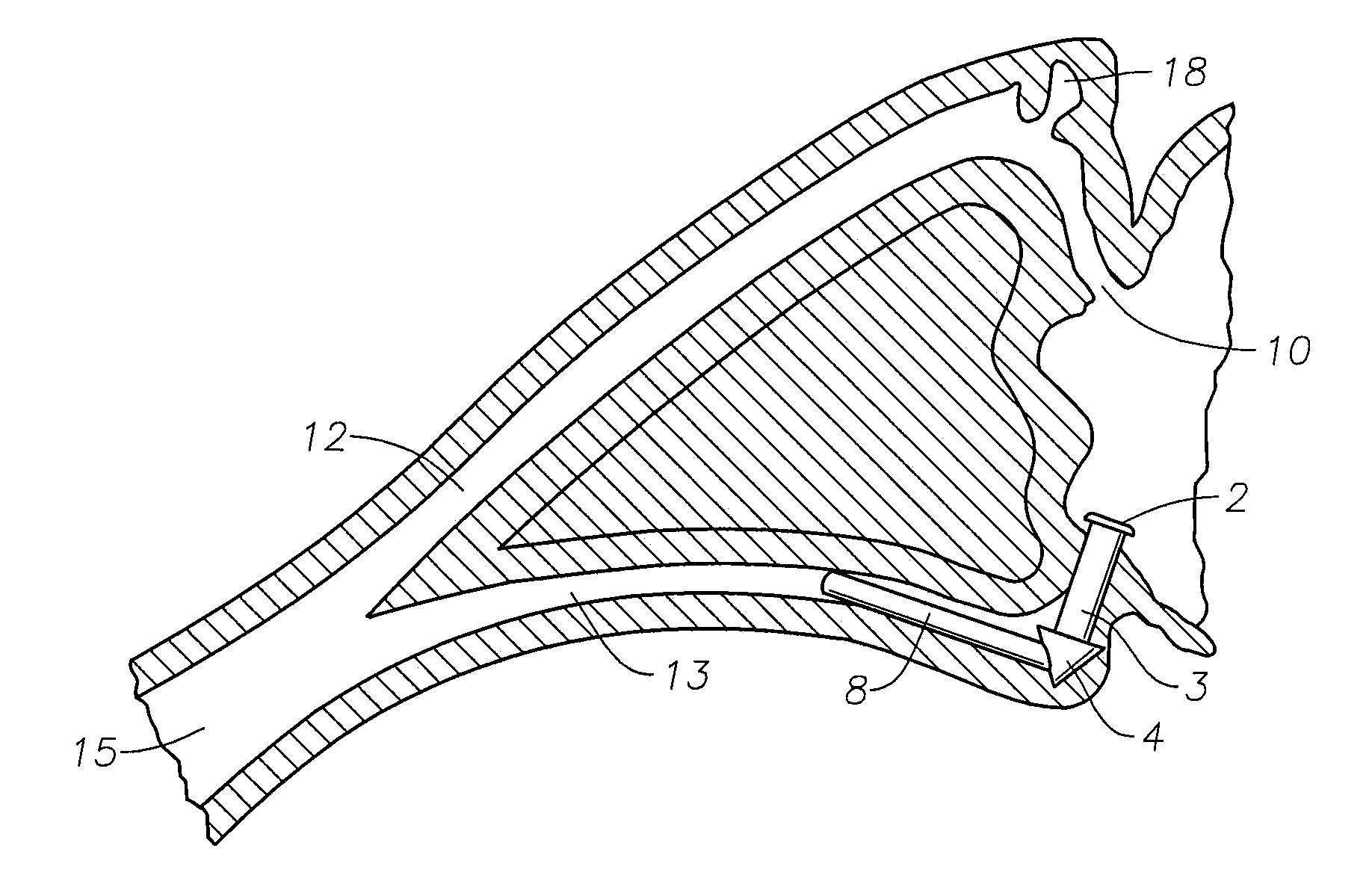

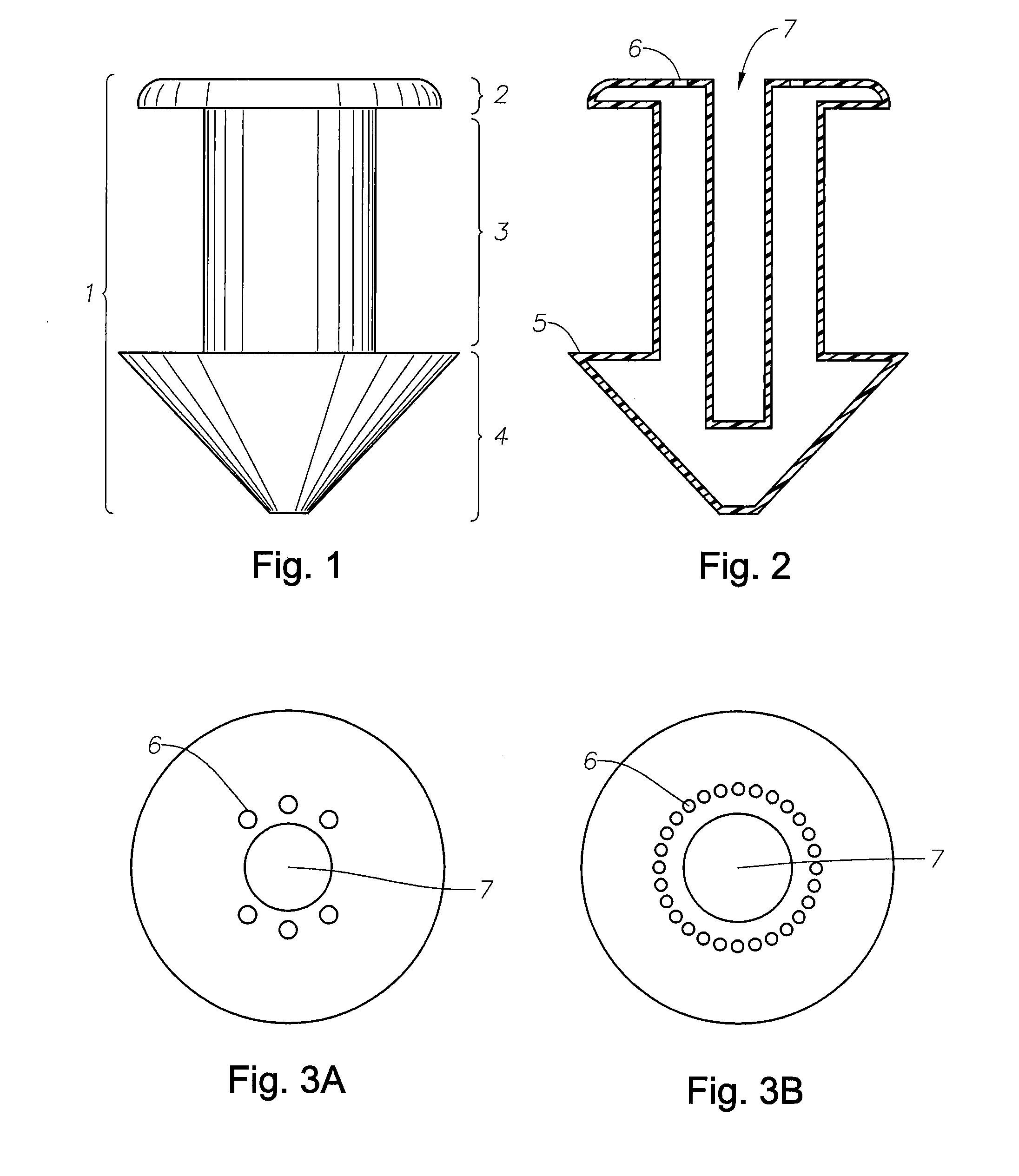

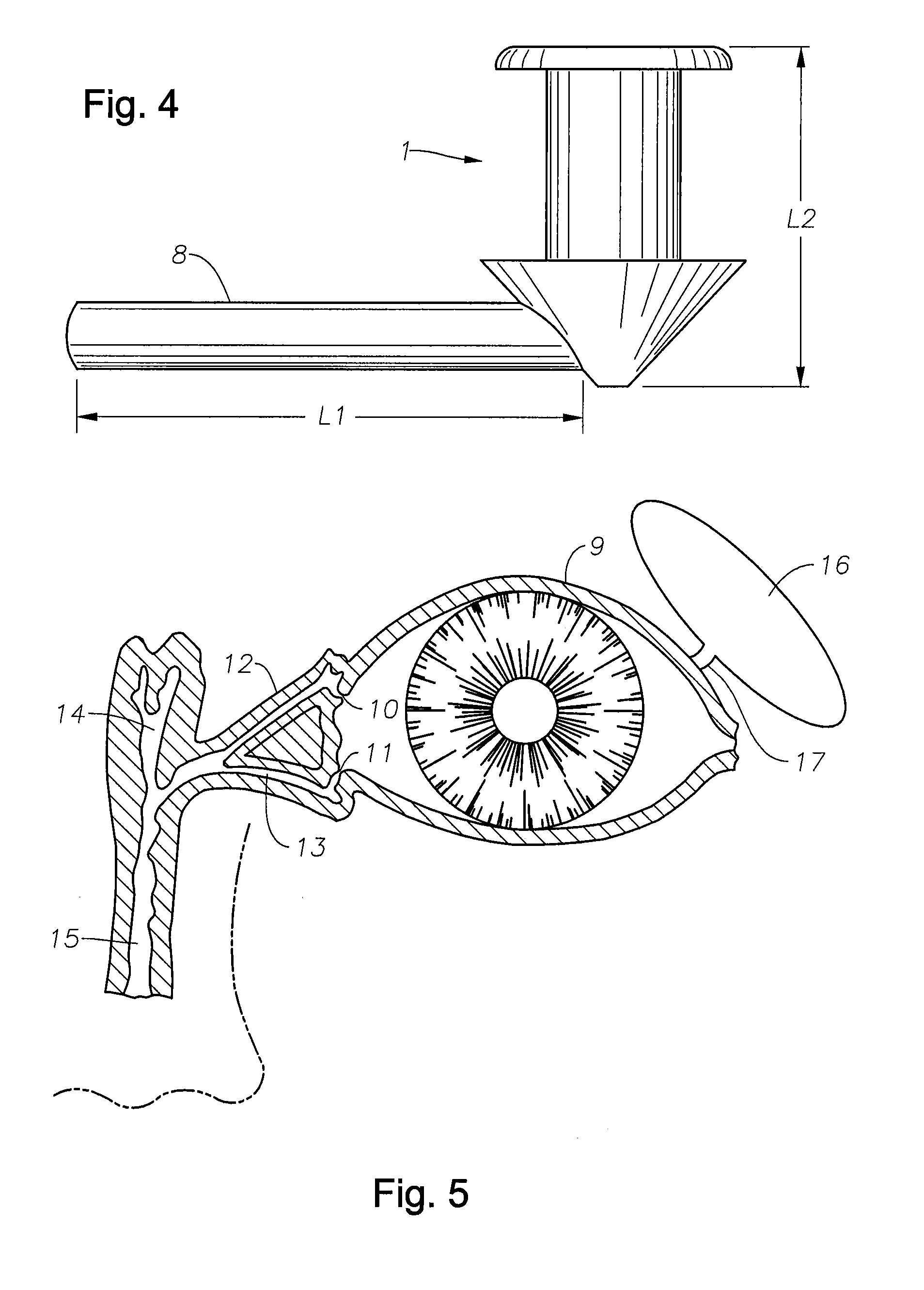

Punctal Plugs and Methods of Delivering Therapeutic Agents

ActiveUS20080181930A1High retention rateIncrease stiffnessBiocideSenses disorderCollagen Punctal PlugsParylene coating

The present invention concerns implantable ocular devices for the sustained release of medication to the eye, and methods for manufacturing and using such devices. In one embodiment, the present invention provides a device comprising: (a) a body comprising a matrix of a prostaglandin and a silicone; (b) a parylene coating on the outer surface of the body; and (c) one or more pores extending from the outer surface of the parylene coating to the outer surface of the body.

Owner:NOVARTIS AG

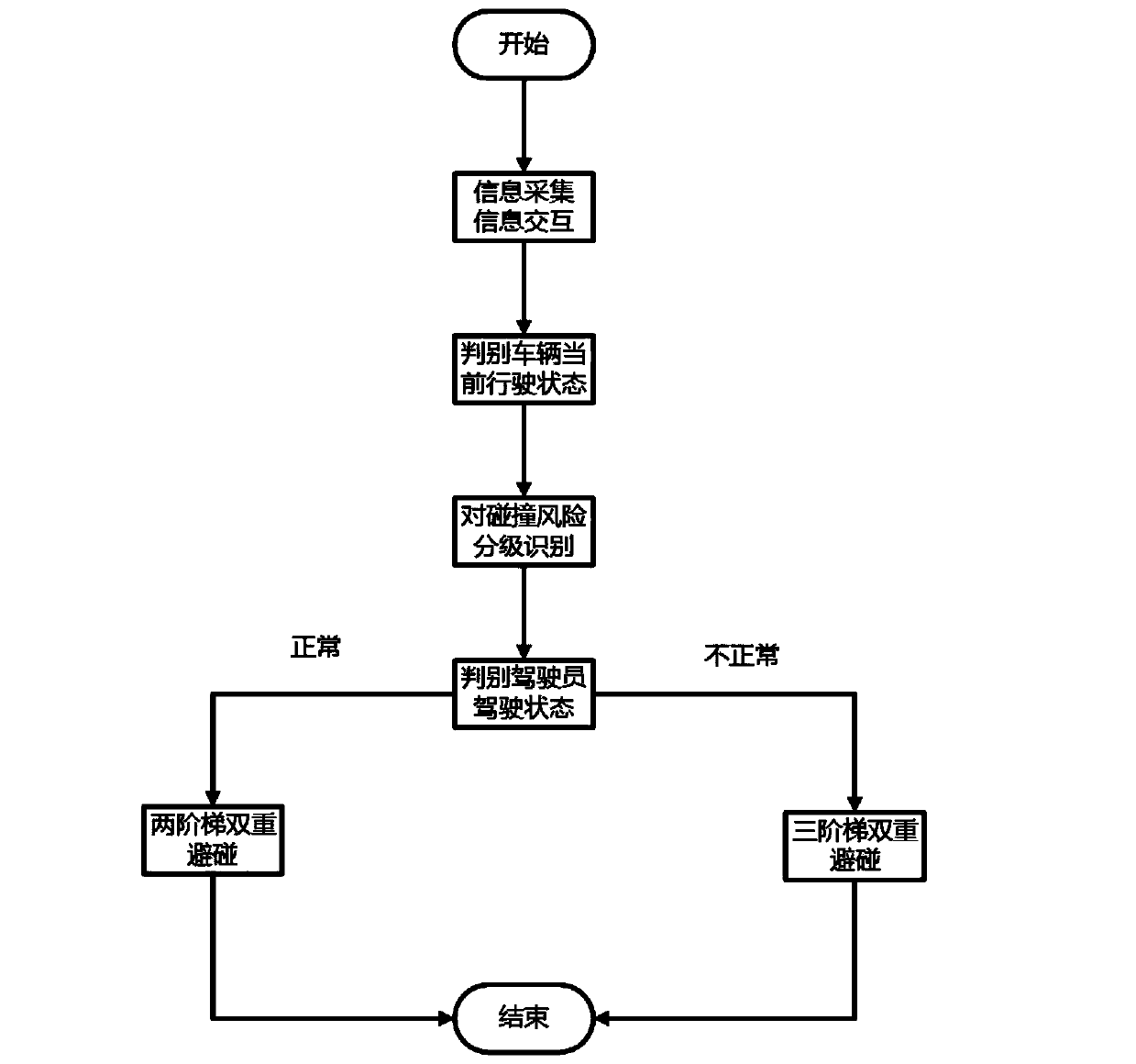

Method and system for avoiding vehicle and pedestrian collision in road-vehicle coordination environment

ActiveCN104210489AExpand sourceReduce computational workloadExternal condition input parametersDriver/operatorEngineering

The invention discloses a method and a system for avoiding the vehicle and pedestrian collision in road-vehicle coordination environment. The method comprises the following steps including (1) information collection: information used for identifying collision risk is collected; (2) driving state discrimination: the current driving state of a vehicle is discriminated; (3) collision risk identification: whether the collision risk exists or not is identified according to the collected collision risk information and the current driving state of the vehicle; (4) driving state discrimination: if the collision risk exists, whether the current driving state of a driver is normal or not is discriminated; (5) collision avoiding: a targeted avoiding method is adopted according to the driving state of the driver for implementing the collision avoidance. The method provided by the invention has the advantage that the in-time adaptation to the actual driving condition can be realized for realizing effective avoidance on different dangerous conditions.

Owner:WUHAN UNIV OF TECH

Method for treating and regenerating reuse building waste

ActiveCN101099974AAvoid excessive cement slurry contentAvoid Excessive Water DemandSolid waste managementSolid waste disposalPrillBrick

The present invention discloses building waste treating and reusing process, which includes the following steps: classifying building wastes into waste concrete, waste stone material, waste ceramic, waste sintered brick and waste lime-sand brick; crushing separately into coarse grains and eliminating metal, timber and other impurity; milling into 5 mm below regenerated fine aggregate; sorting 0.15 mm below high quality fine aggregate and milling into regenerated fine powder material of 250-600 sq m / kg specific surface area; and preparing mortar, concrete, asphalt concrete and other building material with the regenerated fine aggregate and the regenerated fine powder.

Owner:SOUTH CHINA UNIV OF TECH

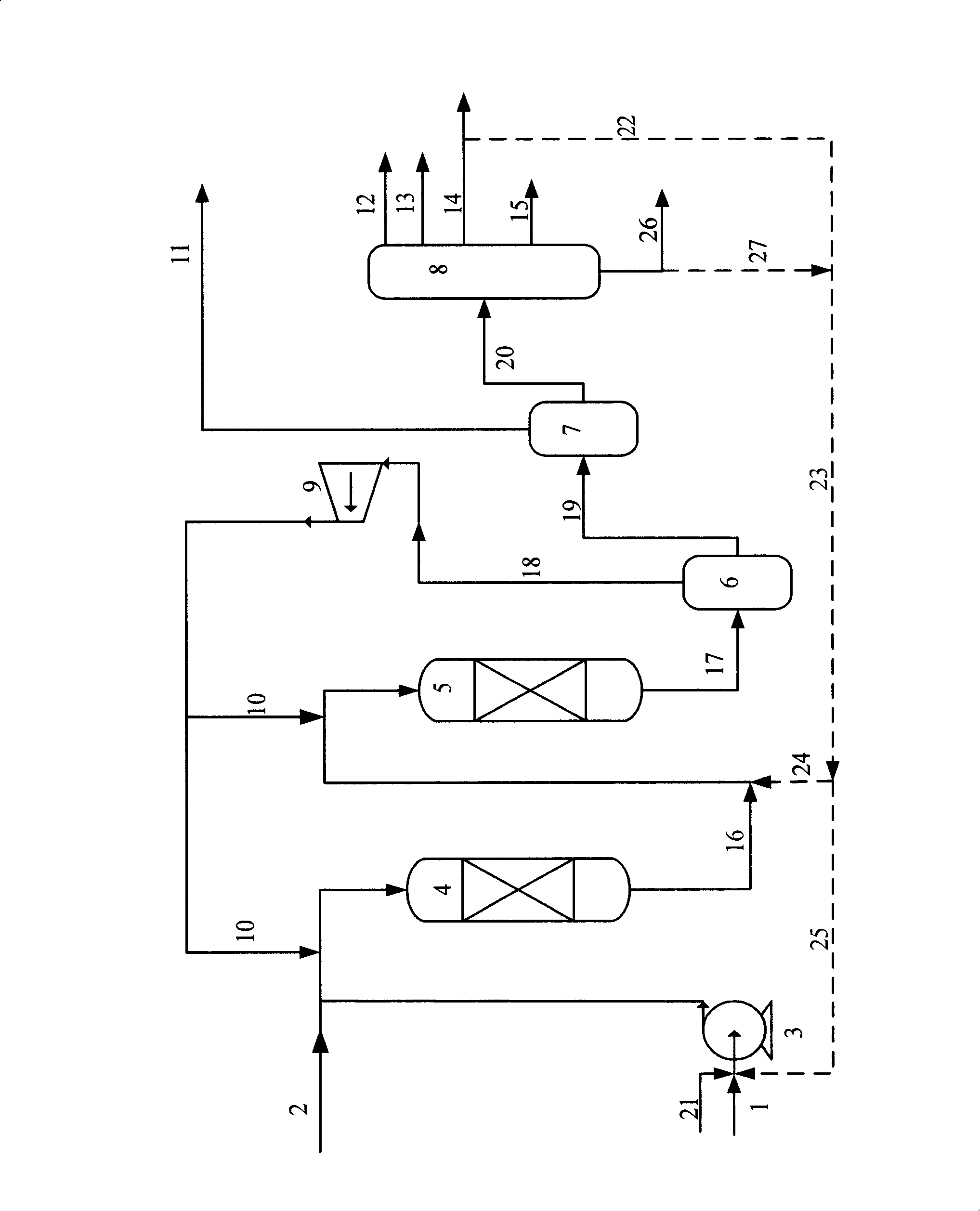

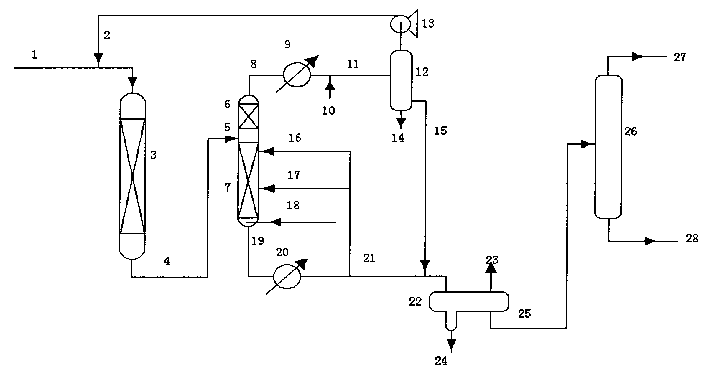

Hydrogenation method for producing high grade diesel oil and high grade reforming raw material

ActiveCN101210198AHigh saturation activityImprove hydrodesulfurization activityHydrocarbon oil crackingTreatment with hydrotreatment processesWaxHydrogen

A hydrogenation method for producing high-quality diesel oil and high-quality reforming materials comprises the following steps of: mixing diesel oil and / or a light wax oil material with hydrogen gas, and sequentially contact-reacting with a hydrorefining catalyst and a hydrocracking catalyst without middle separation, cooling the reaction result, and separating to obtain a light naphtha fraction, a heavy naphtha fraction, a kerosene fraction, a diesel oil fraction and a tail oil fraction, wherein the kerosene fraction and / or the tail oil fraction can be directly extracted or partially or completely recycled back to the reaction system. By adopting single-stage once-through process and a non-noble metal catalyst, the invention can produce the reforming materials with high aromatic content and the diesel oil fraction with high cetane number, wherein the yield of the reforming material is larger than 20wt%, and the cetane number of the diesel oil fraction can be improved by more than 15 units. The method provided by the invention has high operation flexibility and can flexibly adjust the technical scheme according to different raw materials and different product scheme requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

Compound bio-fertilizer containing ardealite and application thereof

InactiveCN101693641AFacilitate absorption and utilizationImprove the immunityBio-organic fraction processingOrganic fertiliser preparationGypsumWater content

The invention provides a compound bio-fertilizer containing ardealite and application thereof. Compound bio-fertilizer is obtained through following steps: adjusting pH value of the ardealite to 4-5 via lime water, drying and crushing to 200-400 sections; drying animal manure, cutting crop straws into sections and then drying; mixing and fermenting the ardelite, the animal manure and the crop straws; controlling cultivation temperature to be at 28-32 DEG C after medium sterilization, sequentially inoculating various beneficial microorganisms, respectively cultivating the same, mixing mixed bacteria with prepared fermenting mixture by weight ratio of 1:300-1000 after completing cultivation, adding water to adjust water content to 35-45%, stirring the water , stacking the mixture for 3-5 days for co-fermentation, further adding water to adjust water content to 20-30%, and then crushing to obtain the compound bio-fertilizer. The compound bio-fertilizer is mainly applied to field crops and applied to improving saline-alkali soil, acid soil and coastal soil structures.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

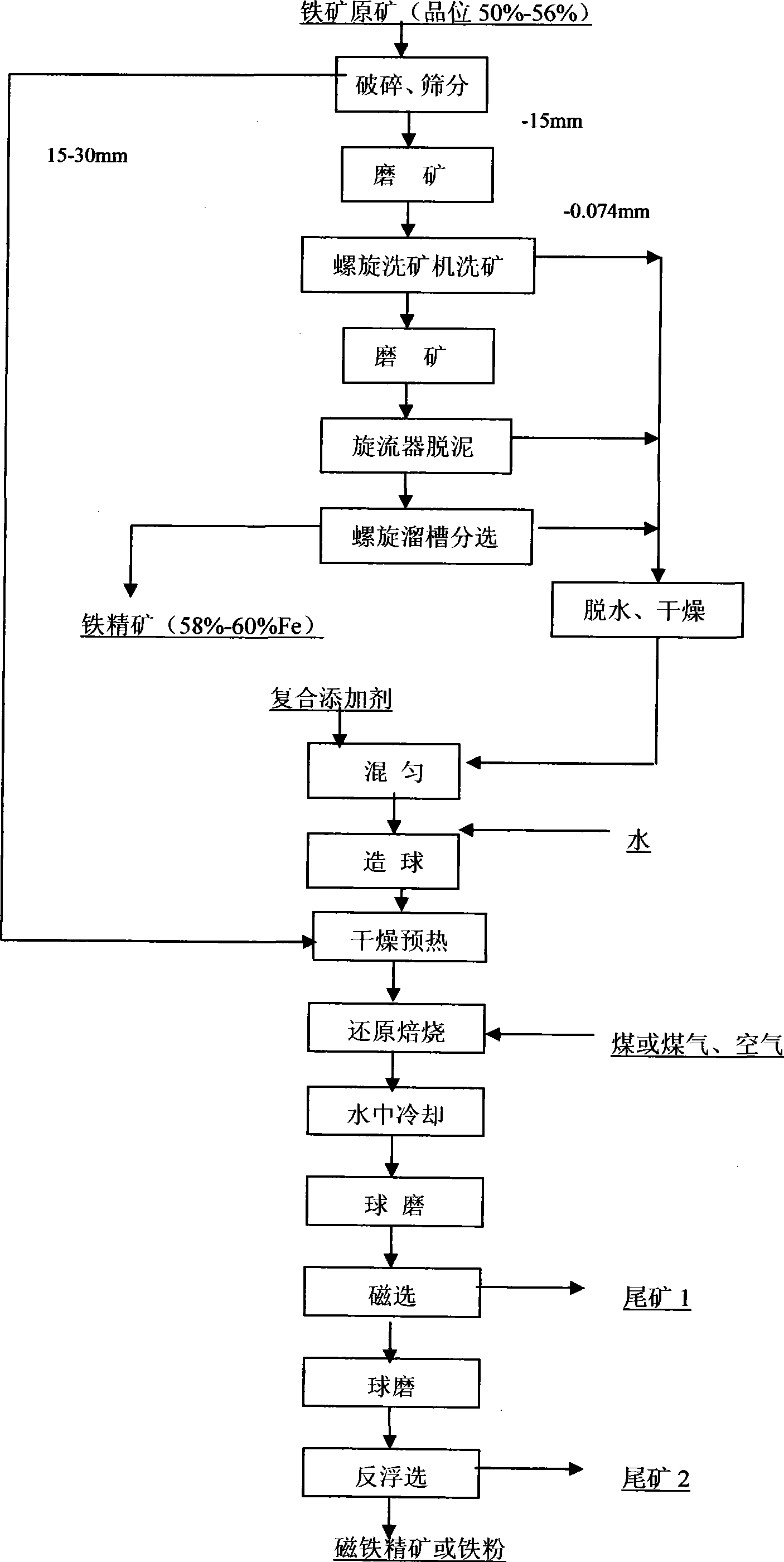

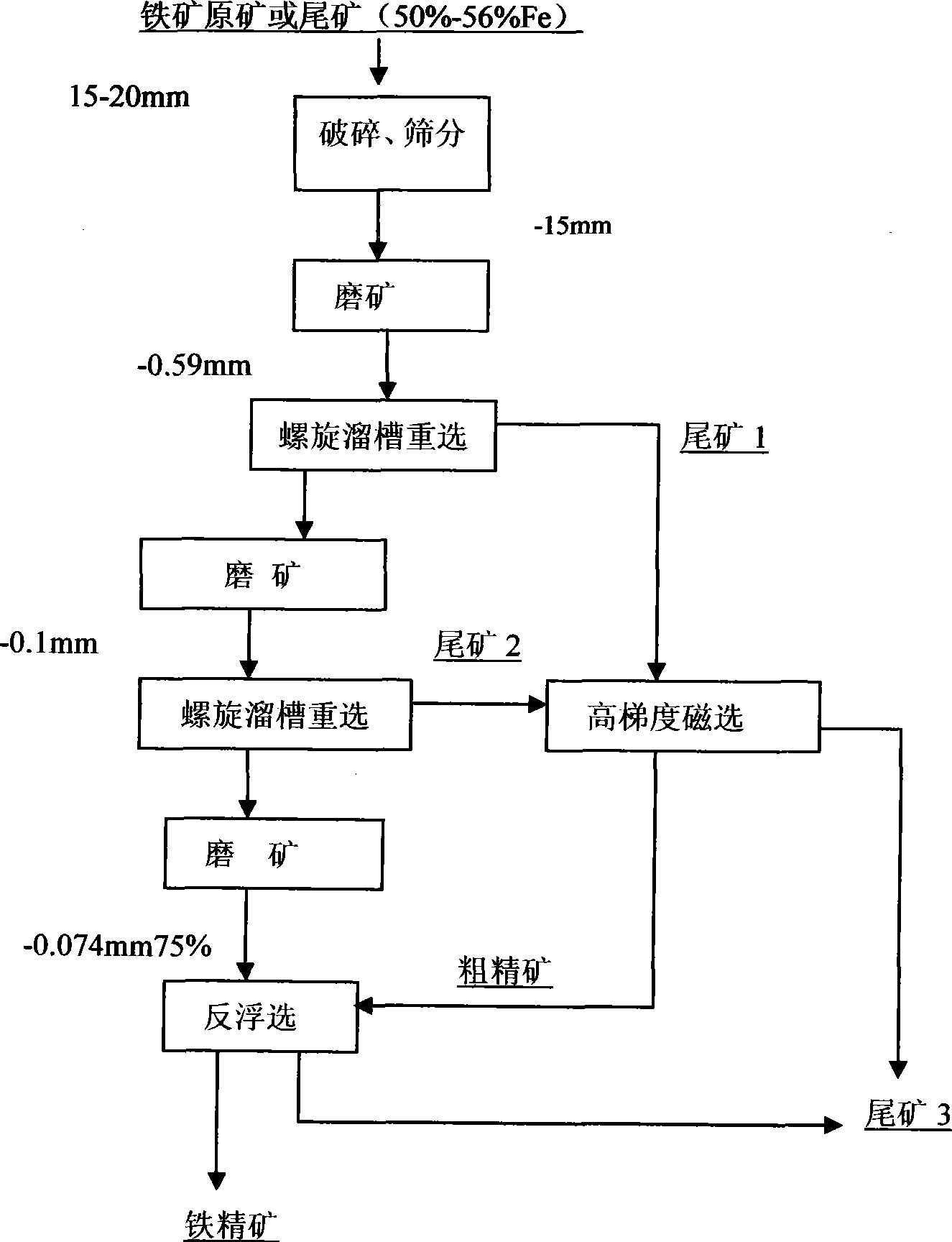

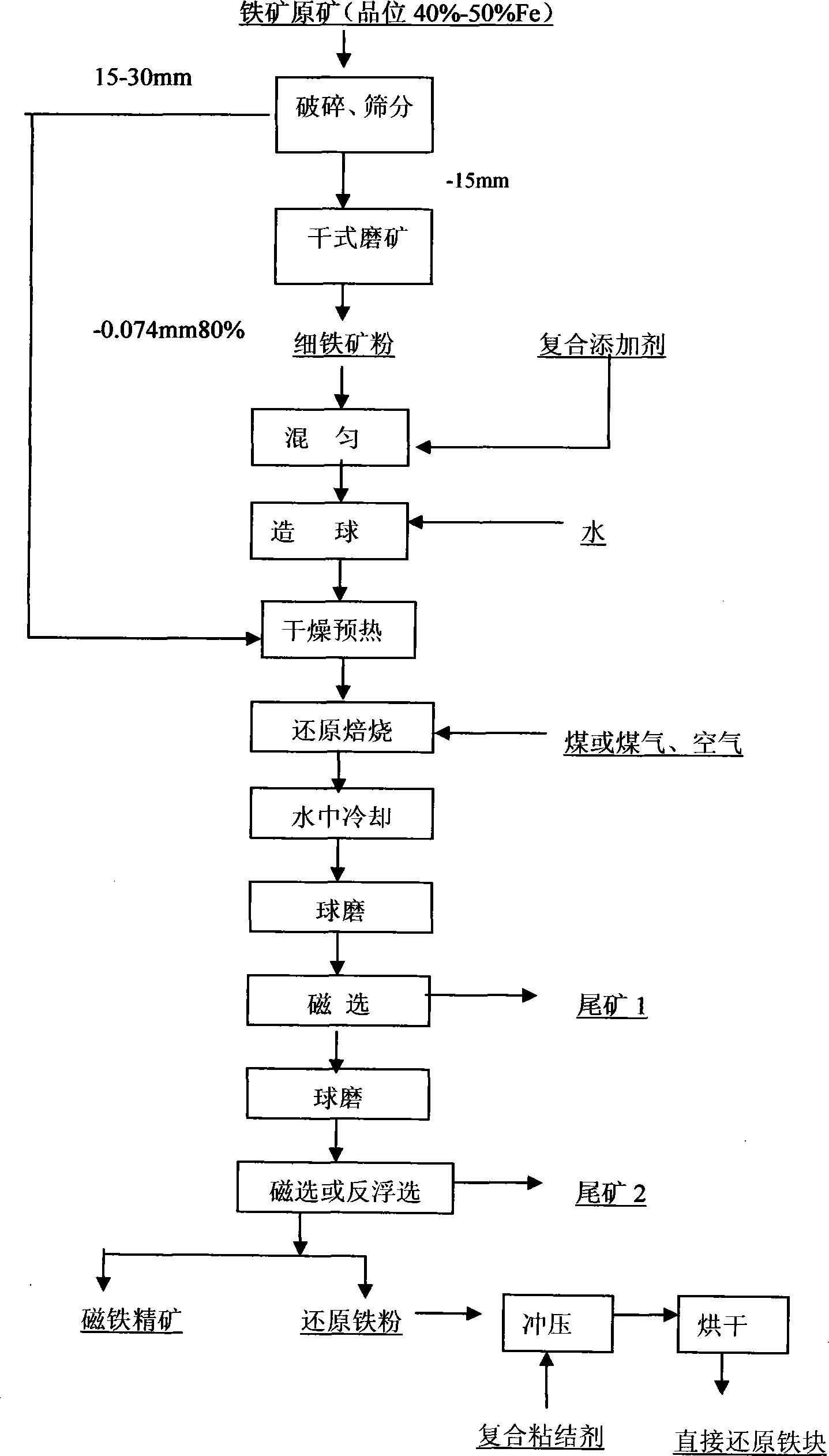

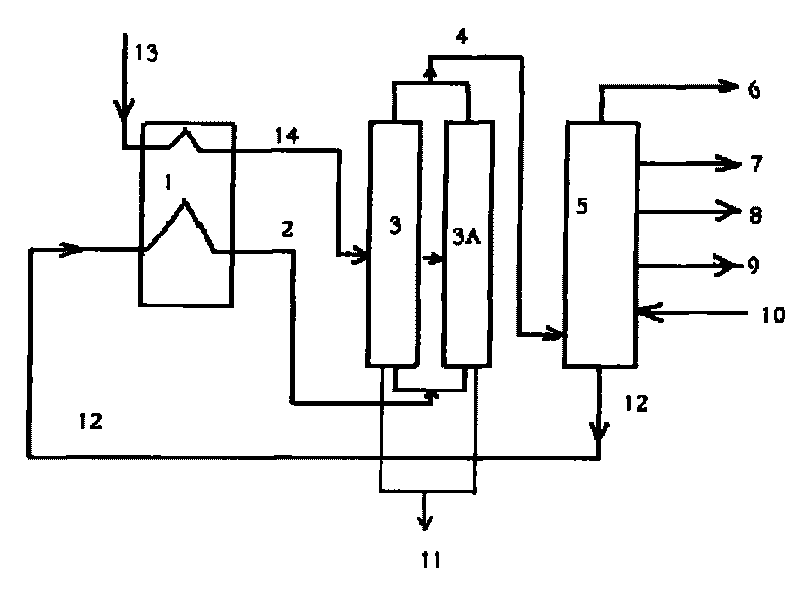

Method for efficiently separating low-ore grade and complicated iron ore

ActiveCN101413057ALow grain sizeHigh content of water of crystallizationProcess efficiency improvementIronstoneIron powder

The invention provides an efficient separation method for low-grade and complex iron ores. The method is characterized in that the complex iron ores of different grades and species are classified, so as to obtain lump ores and mineral powder which are balled, dried and preheated; reduction roasting, cooling, ball milling, magnetic separation, ball milling and magnetic separation or reverse flotation are performed in turn, so as to obtain iron ore concentrate or reduced iron powder; classification treatment is to crush and screen the iron ores with iron-containing grade between 50 and 56 percent and then dry and preheat obtained ores; fine-grained mineral powder is ground, washed, ground, deslimed and separated so as to obtain the iron ore concentrate and slime containing 58 to 60 percent of iron; the slime which is washed, deslimed, and separated is dewatered and dried and is added to and well mixed additives, so as to be balled then; the iron ores with the iron-containing grade between 40 and 50 percent are crushed and screened so as to obtain the lump ores which are directly dried and preheated, while the fine-grained mineral powder is obtained through dry-type grinding and then is added to and well mixed the additives so as to be balled then; and the iron ores with the iron-containing grade between 25 and 40 percent are crushed and screened so as to obtain the lump ores which are dried and preheated, while the fine-grained mineral powder is subjected to grinding, gravity separation or high-gradient magnetic separation and reverse flotation, so as to obtain coarse iron concentrate powder which is added to and well mixed with the additives and then is balled.

Owner:CENT SOUTH UNIV

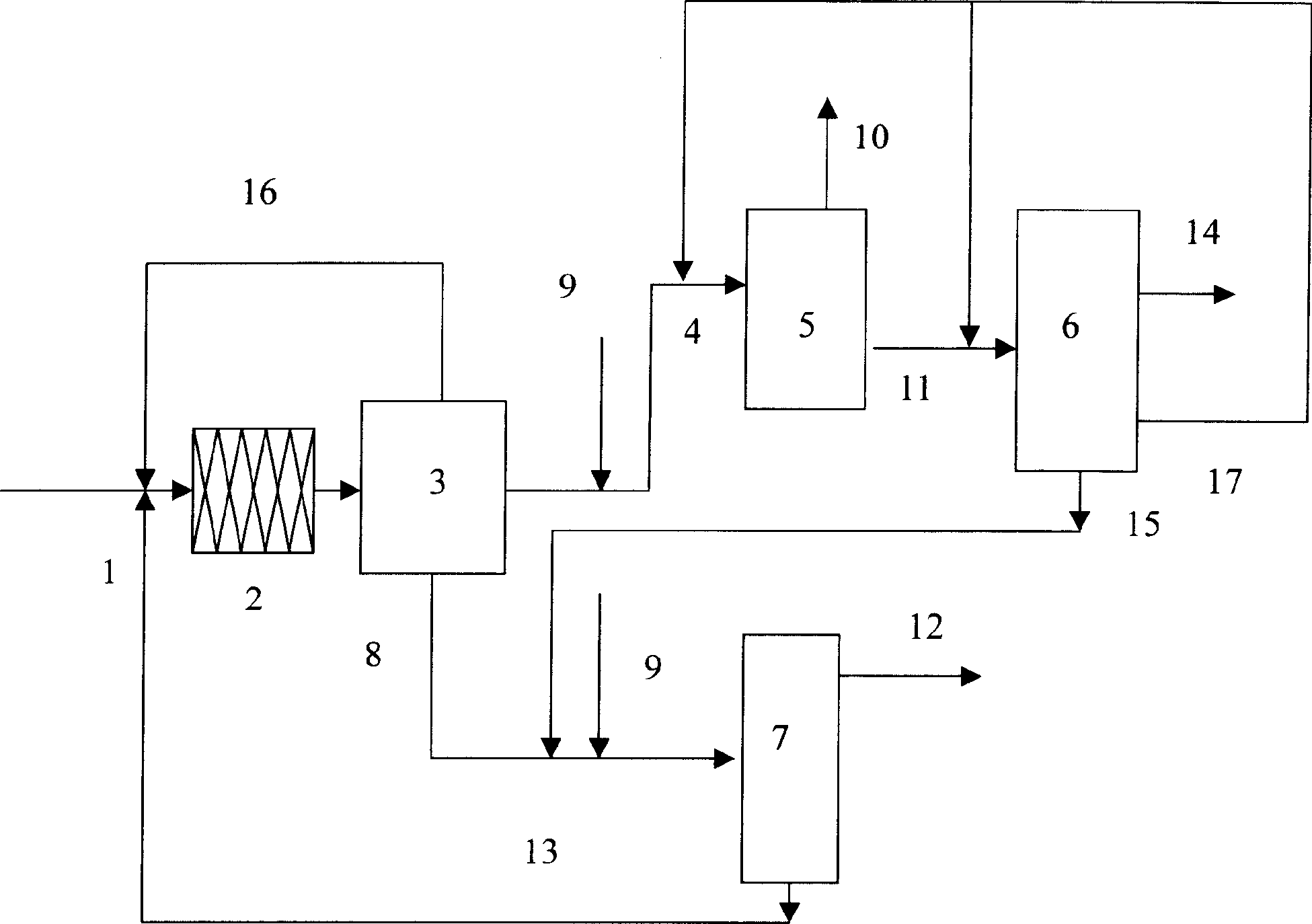

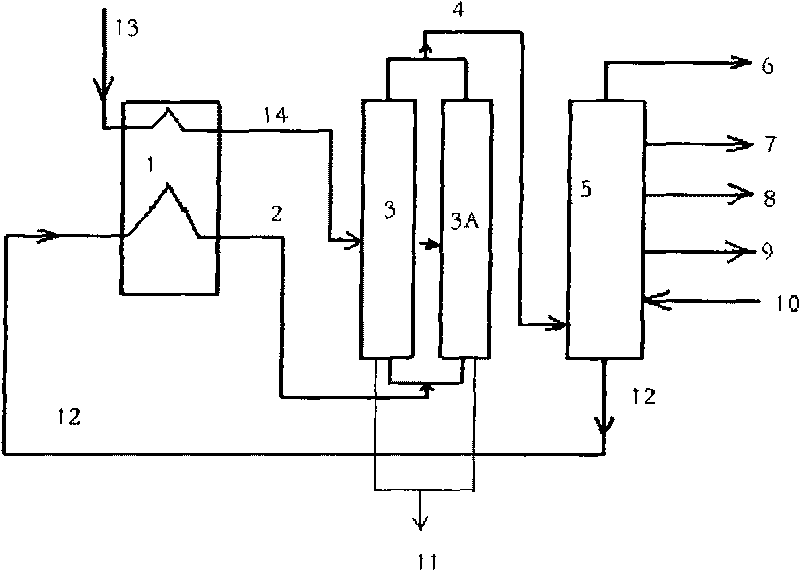

Treatment method for inferior heavy oil and residual oil

ActiveCN1766059ABroaden sources of raw materialsReduce production operating costsTreatment with hydrotreatment processesSolventChemistry

The invention discloses a process for treating inferior heavy oil and residual oil comprising the following steps: loading heavy oil and petroleum residue into a solvent extraction apparatus, charging the obtained deasphalted oil into a fixed bed for hydrotreatment, entering the obtained tail oil into a catalytic cracking device, loading part or total slurry oil and de-oiled asphalt into a floating bed hydrogenation unit, separating the outcome yield to obtain lightweight fraction and untransformed tail oil, which is circulated to the solvent extraction device.

Owner:CHINA PETROLEUM & CHEM CORP +1

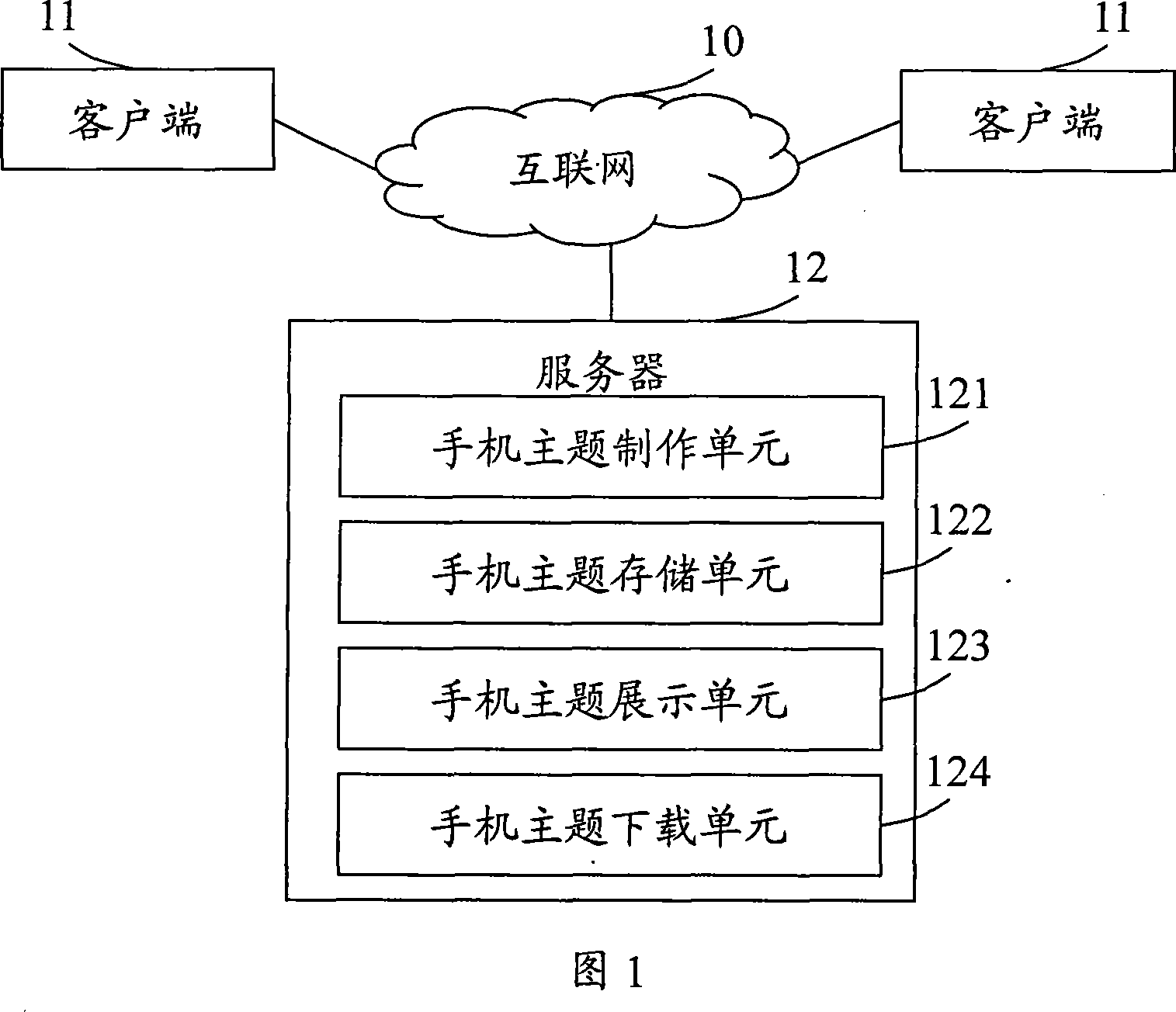

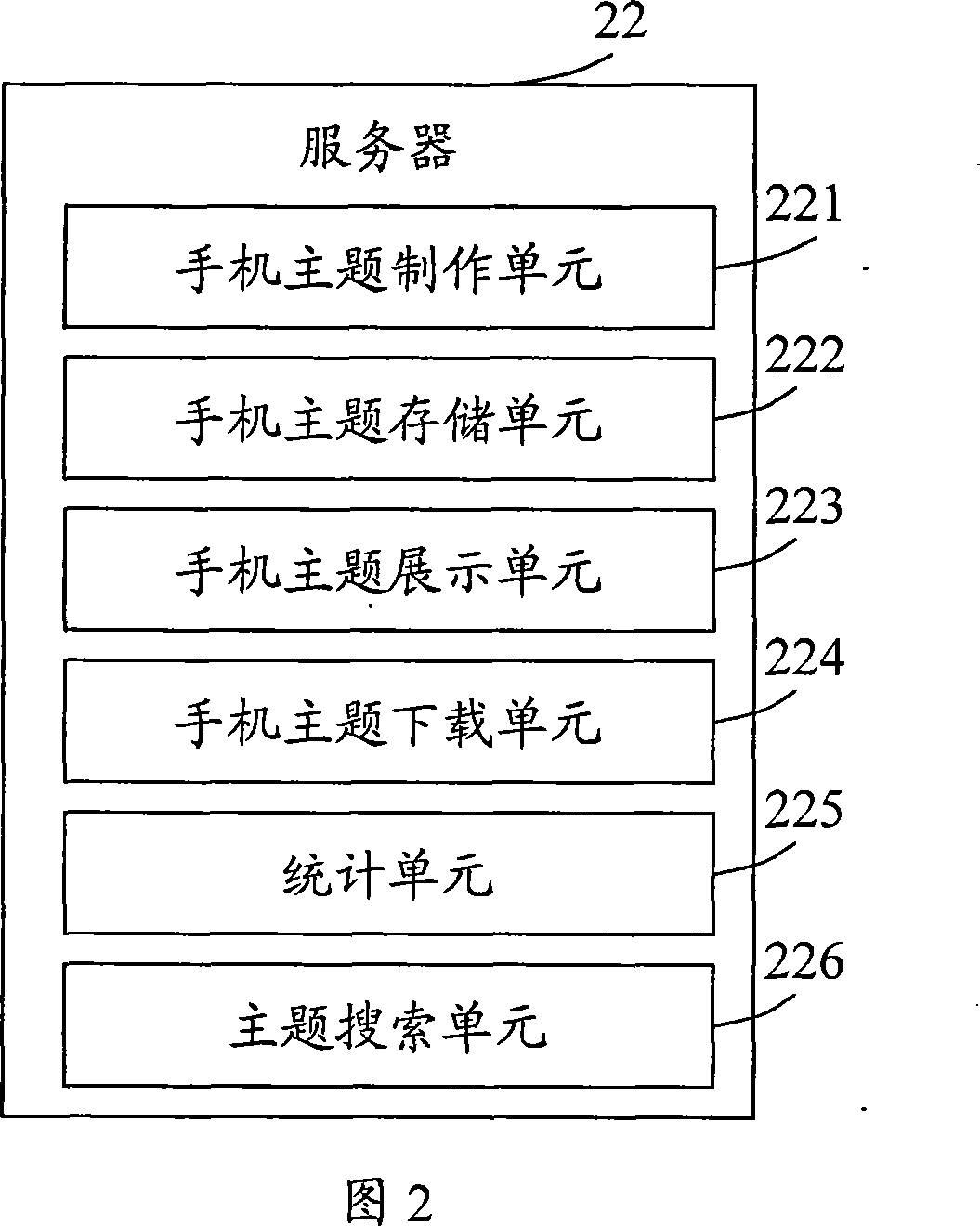

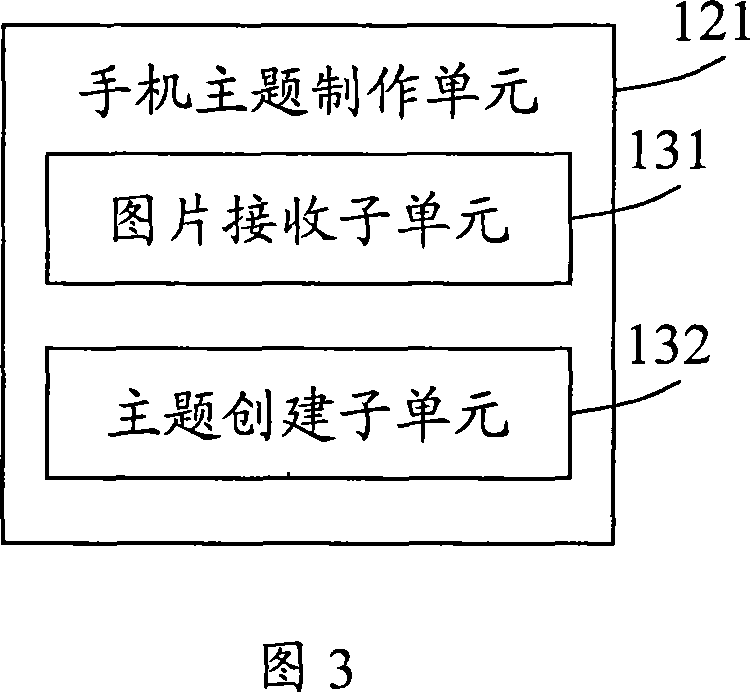

A subject interaction system and method of mobile phone

ActiveCN101080095AAchieve interactionExpand sourceSpecial service provision for substationSubstation equipmentInteraction systemsClient-side

This invention discloses an interaction system of cell phone topics including a server and a customer end, in which, the server includes: a cell phone topic processing unit used in taking pictures input by the customer end as the background one or ico of the topic to generate topic mounting files, a topic storage unit used in storing the topic mounting files generated by the processing unit, a display unit reading and analyzing the mounting files stored in the storing unit and bringing forth pictures and words in the files, a download unit used in transmitting the mounting files in the storing unit according to the request of the customer end. This invention also provides a corresponding method.

Owner:TENCENT TECH (SHENZHEN) CO LTD

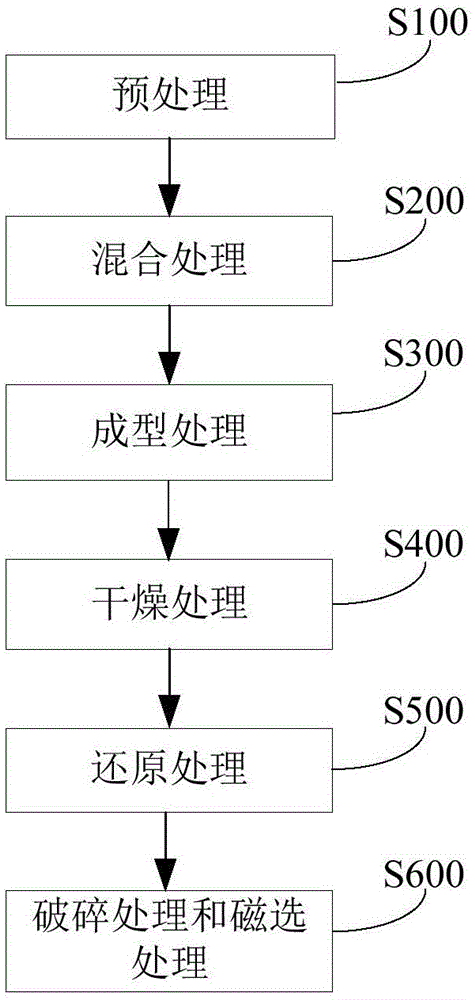

Direction reduction and electric furnace smelting-separation preparation process of vanadium-titanium magnetite cold bound pellet

The cooled agglomerated carbon-contained pellet prepared with vanadium titano magnetite concentrate and opposite direct reduction with former pellet comprises: mixing the concentrate, reducer and bonding agent, drying, grinding, and pelletizing to obtain the cooled agglomerated carbon-contained pellet drying and sieving into the reduction furnace with reducer for reduction atmosphere; loading the reduced pellet into electric furnace to melt and separate the iron liquid, V, Ti and Cr. This invention is fit to the pellet on wide application temperature and low energy consumption, has well efficiency and low running cost, and can also extract V, Ti Fe and Cr from electric furnace with high yield and obvious environmental protection.

Owner:鲜帆 +2

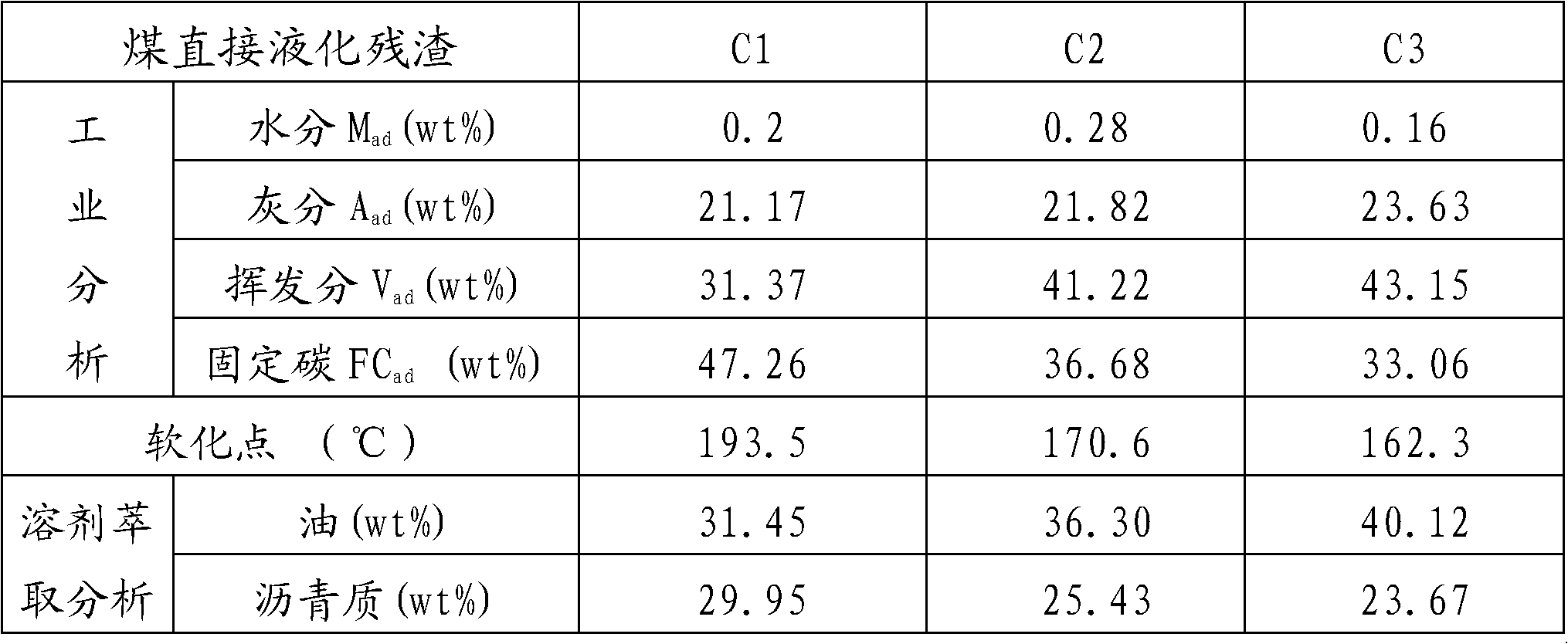

Method for preparing activated carbon by utilizing direct coal liquefaction residue

InactiveCN102153081AExpand sourceImprove coal liquefaction technologySolid waste disposalAcid washingCarbonization

The invention provides a method for preparing activated carbon by utilizing direct coal liquefaction residue as a raw material. The method includes the steps as follows: (1) adding smashed direct coal liquefaction residue together with KNO3, KOH and absolute alcohol into water, stirring to be uniform under room temperature, and later drying the obtained mixture to obtain a dry material; (2) placing the prepared dry material in a carbonization furnace, conducting preoxidation in the atmosphere of air, conducting carbonization-activation in the atmosphere of inertia gas, and then obtaining coarse activated carbon; and (3) acid-washing and deashing the prepared coarse activated carbon to obtain finished activated carbon. The method is simple in preparation process route, uses conventional equipment and has universality to the raw material. The obtained activated carbon has not only characteristics of high specific surface area, developed micropores and low ash content, but also controllable output, higher productivity, suitability for production in batches, and better technological and economic benefits.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

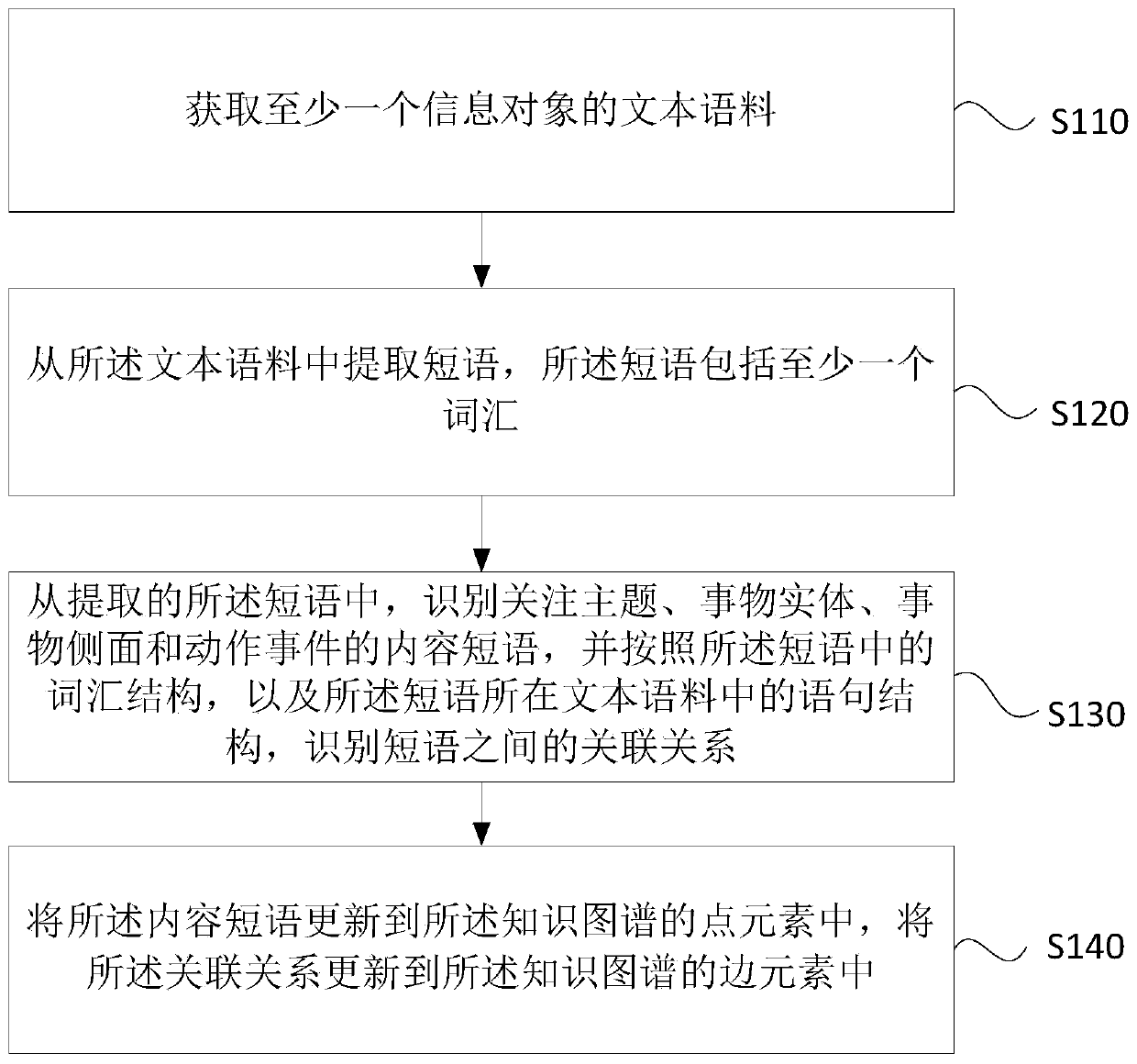

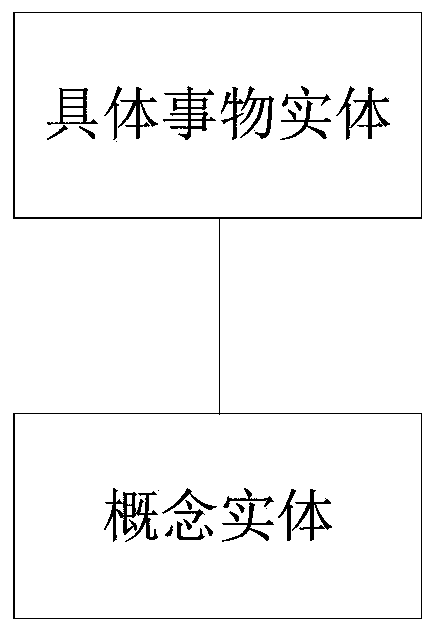

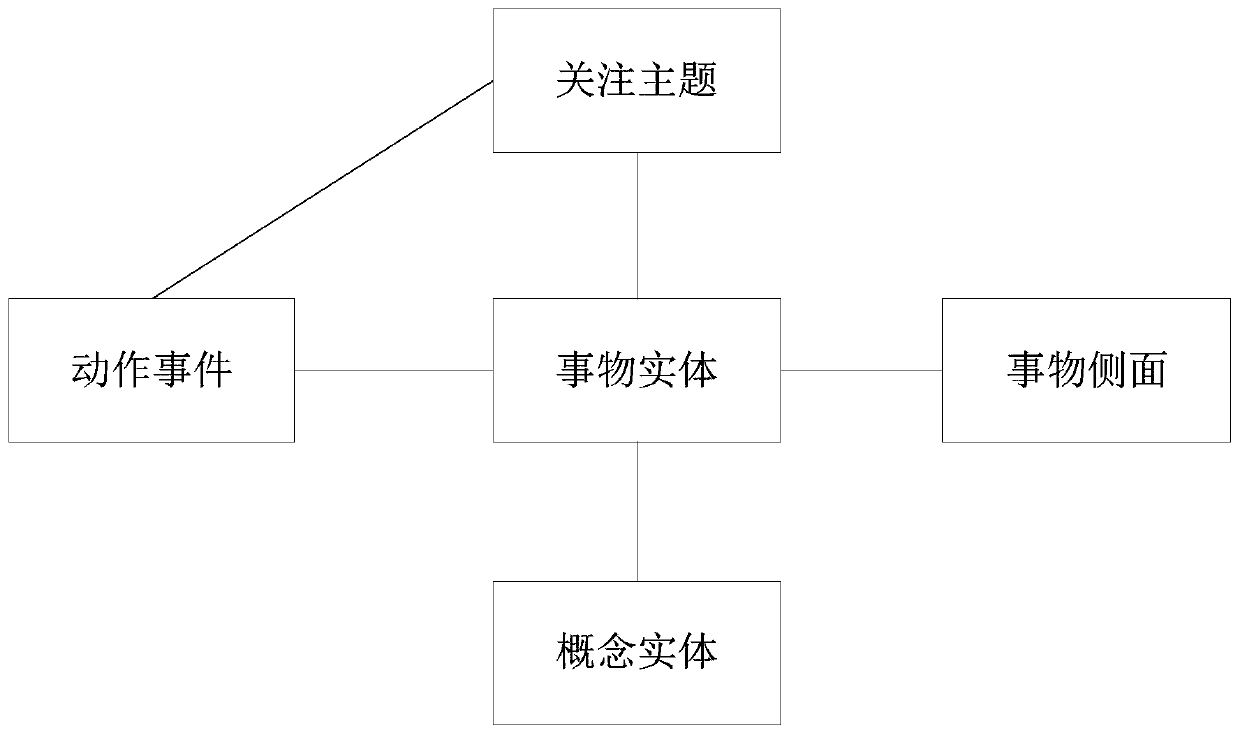

Knowledge graph construction method and device, equipment and medium

ActiveCN110543574ARich composition elementsRealize information expansionSpecial data processing applicationsSemantic tool creationInformation objectKnowledge graph

The embodiment of the invention discloses a knowledge graph construction method and device, equipment and a medium. The method comprises the steps of obtaining a text corpus of at least one information object; extracting phrases from the text corpus; from the extracted phrases, identifying content phrases of an attention theme, an object entity, an object side surface and an action event, and identifying an association relationship between the phrases; and updating the content phrases to point elements of the knowledge graph, and updating the association relationship to edge elements of the knowledge graph. According to the technical scheme of the embodiment of the invention, the information object text corpus is extracted, the knowledge graph of the information object is constructed, a plurality of point elements and corresponding side elements such as attention topics, action events and object side surfaces are added, information extension of existing object entities in the knowledgegraph is realized, and new object entities are continuously mined from the information object to continuously expand and supplement the composition of the knowledge graph.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

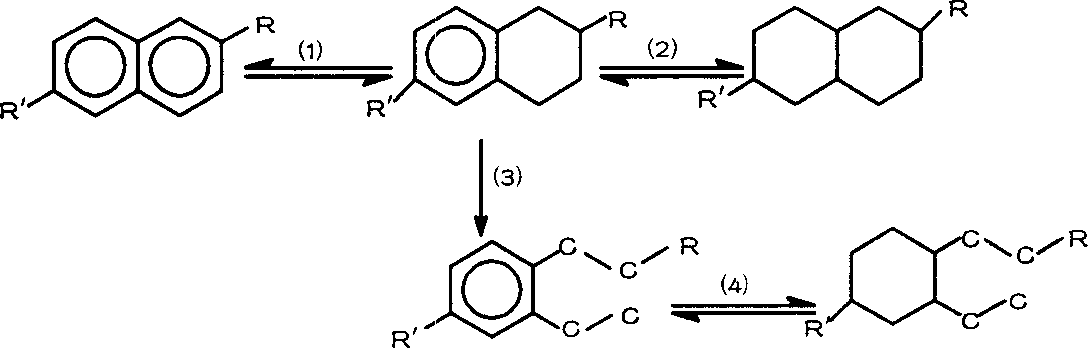

Hydro-cracking method for blending ethylene bottom oil

The invention discloses a hydro-cracking method for blending ethylene bottom oil, which is different from the method for processing the conventional ethylene bottom oil and comprises the following steps: blending an ethylene bottom oil light end into a conventional hydro-cracking raw material for hydro-cracking, in the presence of hydrogen, sequentially contacting the ethylene bottom oil light end with a hydro-guard catalyst, a hydro-refining catalyst, a hydro-residue carbon removing catalyst and a hydro-cracking catalyst; separating an effluent of hydro-cracking reaction to obtain light fuel oil. The method of the invention adopts a method of grading the hydrogenation catalyst, can process the ethylene bottom oil light end and produce diesel oil having a high cetane number and a low condensation point and a naphtha having high arene, and is not obviously changed in a BMCI value of tail oil and a smoke point of a jet fuel when compared with the conditions before blending the ethylene bottom oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing alumina supporter

ActiveCN1768946AWide variety of sourcesExpand sourceCatalyst carriersCatalyst activation/preparationChemical industryPore distribution

The invention discloses a method for preparing AL2O3 carrier. Said invention uses the farina as pore-expansion agent, which is added as powder after mixing other raw materials uniformly, and its added amount is 10-20wt% of alumina. Compared to present technique, said inventive alumina carrier has high strength, larger pore diameter, and centralized pore distribution, while said inventive method has simple process without special raw material and the cost of material and production are lower. The invention can be used as catalyst in the areas of oil refining, chemical industry and environmental protection, especially as the hydrogenation catalyst of heavy and residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of producing C8 arene isomerization catalyst

ActiveCN101134171AExpand sourceReduce lossesHydrocarbon by isomerisationMolecular sieve catalystsAlkaneMolecular sieve

The process of preparing catalyst for C8 arene isomerization includes forming the mixture of EUO type molecular sieve and adhesive to obtain carrier, introducing VIII metal, drying, roasting and reducing with reductant gas. The catalyst contains EUO type molecular sieve in 5-90 wt%, adhesive 10-90 wt%, and VIII metal 0.1-5.0 wt%. The EUO type molecular sieve is prepared through mixing compound containing element X, compound containing element T, alkali metal compound and water, hydrothermal crystallization reaction in the presence of template agent precursor compounded with coarse dibromoalkane and monamine, collecting the solid and drying, where X is Si and Ge, T is Al, Fe, Ga or B, and the coarse dibromoalkane is mixture of dibromoalkane in the content of 80-95 wt%, Monobromoalkane and paraffin hydrocarbon diol. The catalyst has high ethyl benzene converting rate and low arene losing rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ceramic polished brick and method for producing the same

The invention discloses a ceramic polished tile, which uses magnesian clay as a main plastic raw material, and mainly uses a SiO2-MgO-CaO-Al2O3 quaternary phase as a formulation system, wherein the SiO2 is between 65 and 85 percent, the MgO is between 5 and 20 percent, the CaO is between 3 and 15 percent, the Al2O3 is between 3 and 15 percent, KNa2O is between 0 and 3 percent, and Fe2O3 and TiO2 are between 0 and 2 percent. The invention also discloses a method for producing the ceramic polished tile. The ceramic polished tile uses the magnesian clay as the plastic raw material so that the source of the raw material is broadened,; and with the addition of talc and quartz, the ceramic polished tile has the characteristics of high brightness, high strength, high hardness, good wear resistance and the like, and has the advantages of wide range of firing temperature, small shrinkage, low product proportion, reduced production cost, low price and high quality, improved product competitive power, and great promoting function for the development of the ceramic polished tile industry.

Owner:况学成 +1

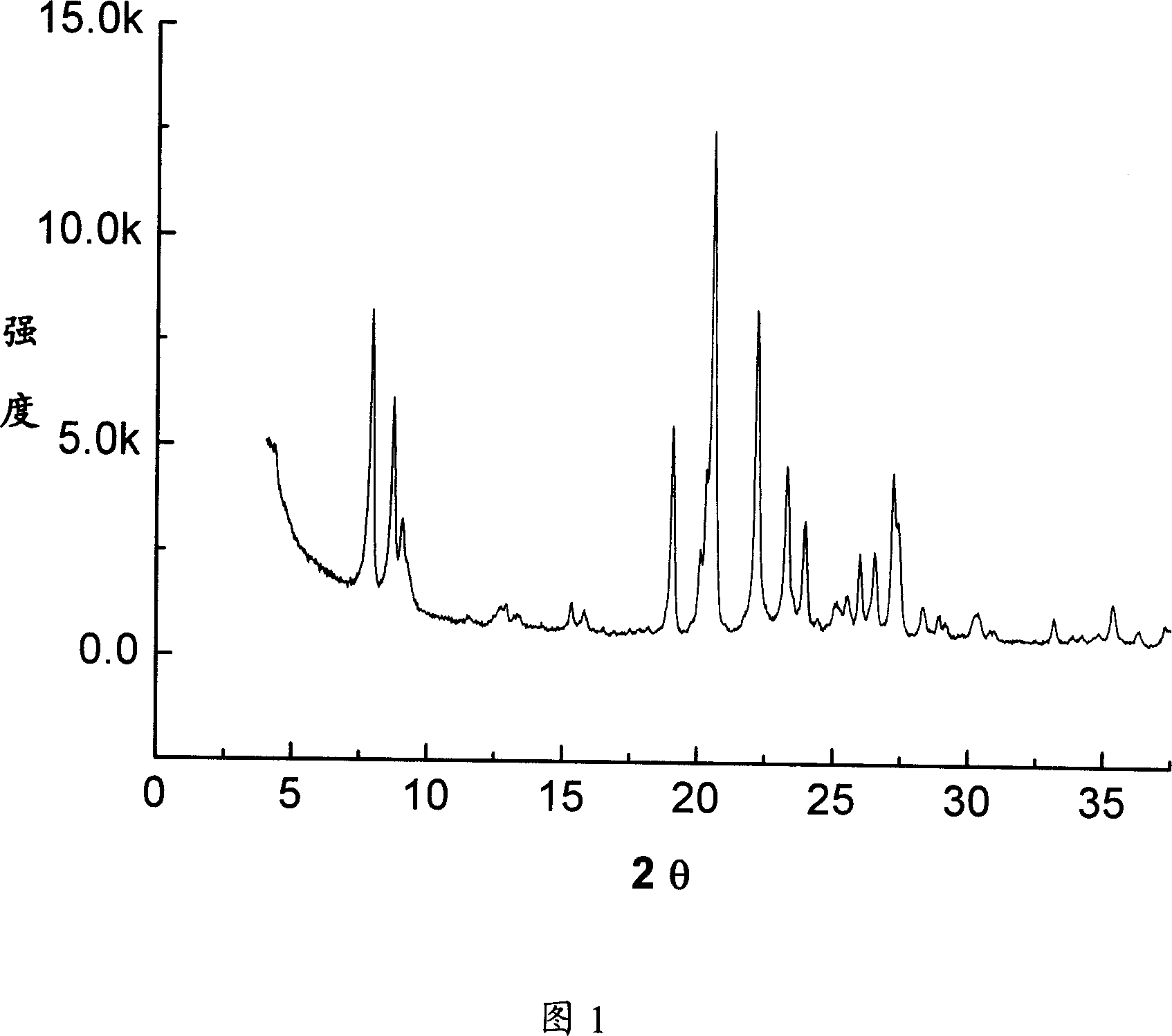

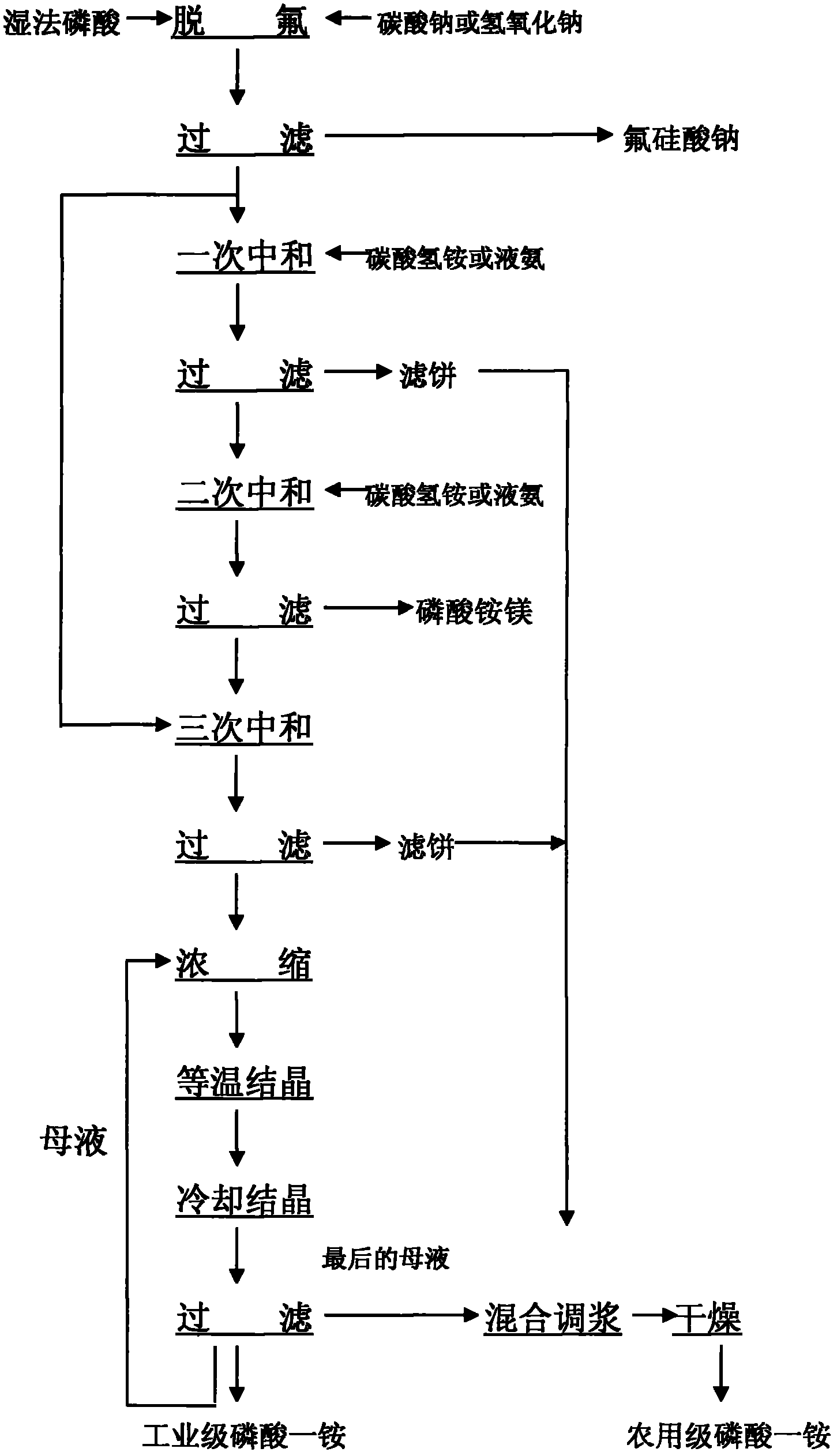

Method for producing industrial and agricultural monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid

ActiveCN102020256AImprove purification effectTroubleshoot follow-up issuesPhosphatesO-Phosphoric AcidAgricultural engineering

The invention provides a method for producing industrial and agricultural grade monoammonium phosphate and magnesium ammonium phosphate with wet-process phosphoric acid. The wet-process phosphoric acid is taken as a raw material. Sodium fluosilicate, monoammonium phosphate solution, monoammonium phosphate filter cakes and magnesium ammonium phosphate are respectively obtained through defluorination and a three-section substep neutralization process, wherein the monoammonium phosphate solution is concentrated and crystallized to obtain high-quality water soluble industrial monoammonium phosphate, and the monoammonium phosphate filter cakes and the monoammonium phosphate mother solution subjected to repeated crystallization are subjected to size mixed and dried to obtain qualified agricultural monoammonium phosphate. The magnesium ammonium phosphate is a good slow release nitrogenous fertilizer per se. The process has the advantages of little investment of equipment, good adaptability of raw material, low production cost and good product quality. The water soluble industrial monoammonium phosphate with low cost can provide a cheap and good water soluble phosphatic fertilizer for modern facility agriculture.

Owner:昆明隆祥化工有限公司

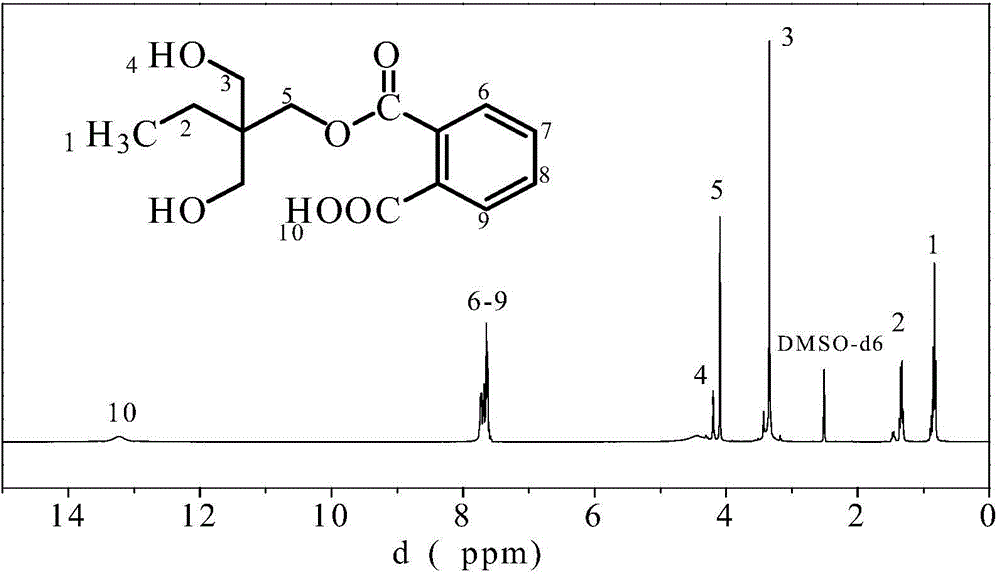

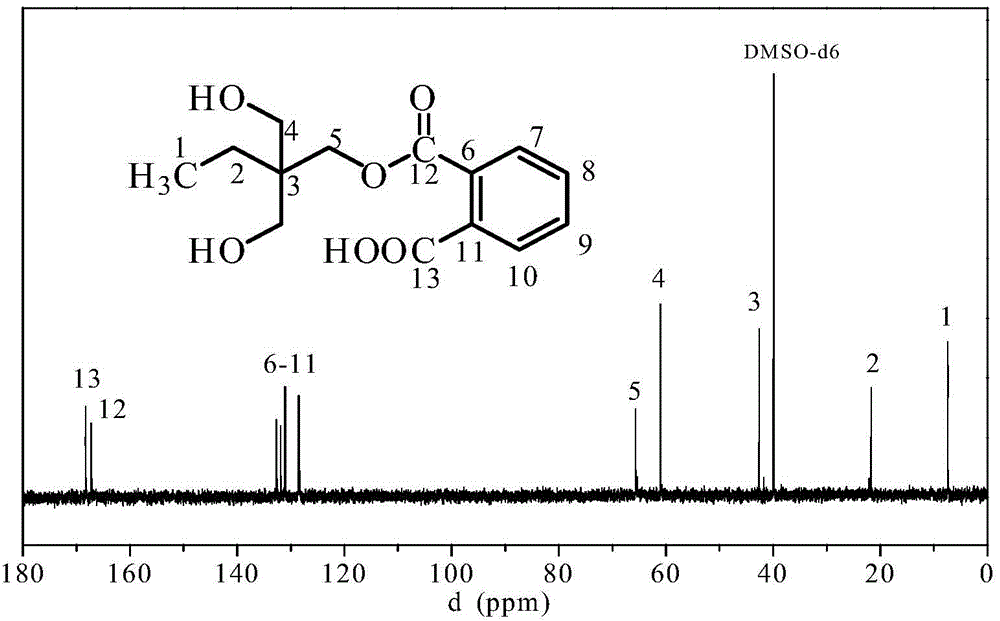

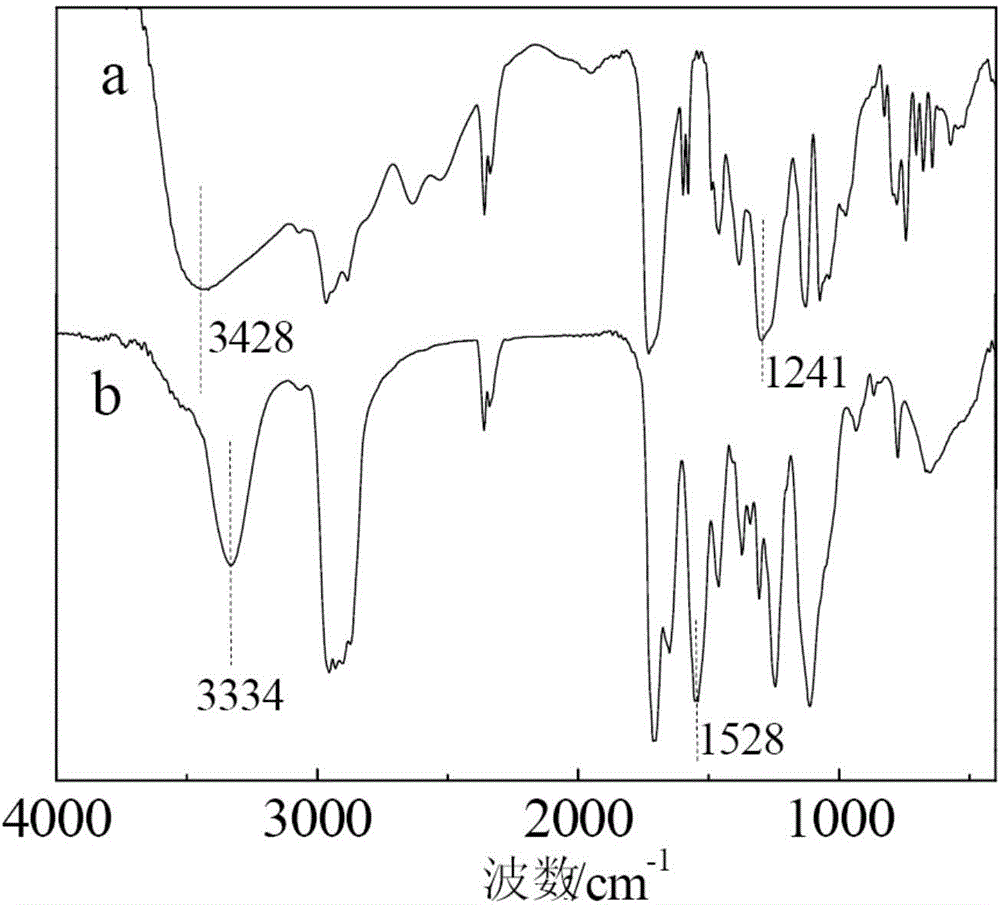

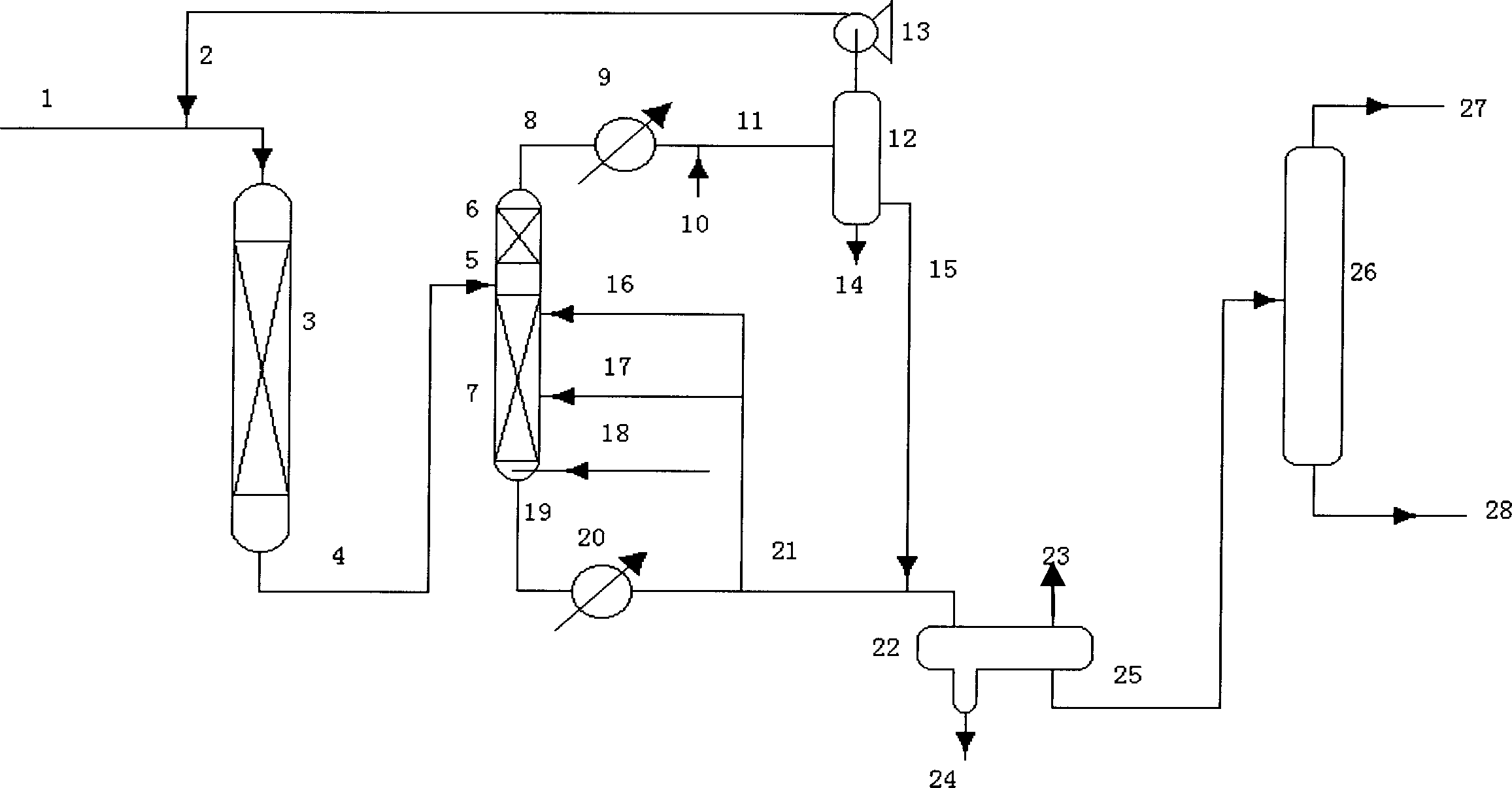

Polyurethane aqueous dispersion and preparation method thereof

InactiveCN104311778AReduce manufacturing costLow priceOrganic compound preparationCarboxylic acid esters preparationCross-linkHydrophilic monomer

The invention discloses a polyurethane aqueous dispersion and a preparation method thereof. The preparation method comprises the following steps: firstly, mixing trimethylolpropane or glycerol and acid anhydride and preparing a carboxylic acid type hydrophilic monomer; on the basis of molar parts, adding 20-60 parts of polymer dibasic alcohol, 4-10 parts of carboxylic acid type hydrophilic monomer and 30-60 parts of a diisocyanate monomer into a reactor, heating to 60 DEG C-100 DEG C and carrying out heat preservation; adding1-10 parts of small-molecular dibasic alcohol, 2-10 parts of a non-ionic hydrophilic chain extender and 1-6 parts of a cross-linking agent and reacting until the content of NCO is less than 5%; and adjusting the viscosity of the reactant, cooling, adding a neutralizing agent for neutralizing, adding water for emulsifying, adding an amine chain extender and removing the solvent by distillation to obtain the polyurethane aqueous dispersion. The carboxylic acid type hydrophilic monomer has stable performance and low cost, the polyurethane aqueous dispersion prepared from the carboxylic acid type hydrophilic monomer has high content of solids and the coating has relatively high hardness and excellent chemical product resistance.

Owner:SOUTH CHINA UNIV OF TECH

Method for producing the clean diean diesel oil with low sulfur and low arene

InactiveCN1415706AExpand sourceImprove adaptabilityTreatment with hydrotreatment processesSulfurImpurity

A process for preparing low-sulfur low-arylhydrocarbon clean diesel oil includes such steps as hydrorefining / hydrocracking raw hydrocarbon to obtain intermediate fraction oil, catalytic stripping to separate light fraction from heavy fraction, hydrorefining the light fraction to remove residual S and impurities, and catalytic stripping of heavy fraction for removing sulfure and arylhydrocarbon to obtain final product. Its advantage is cyclic use of two reactino segments for low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

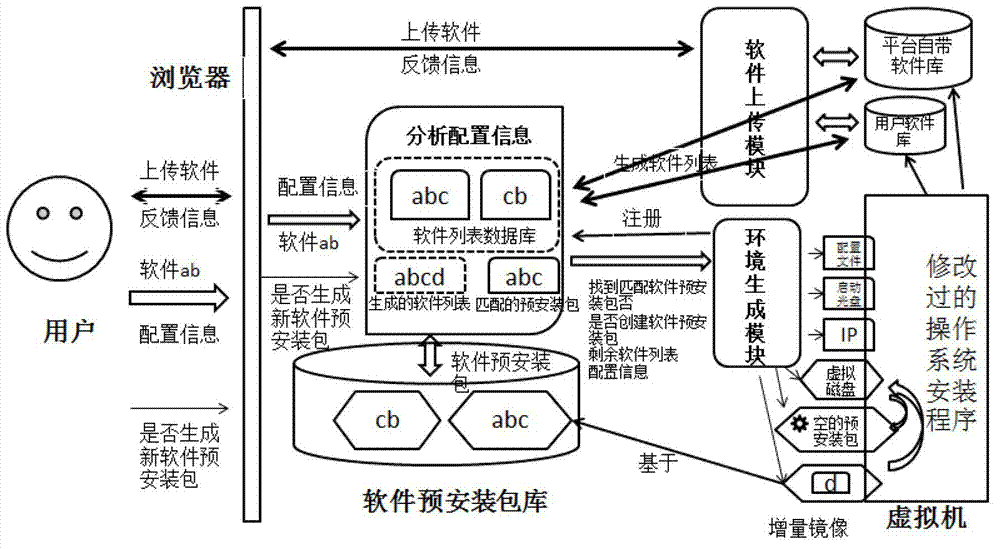

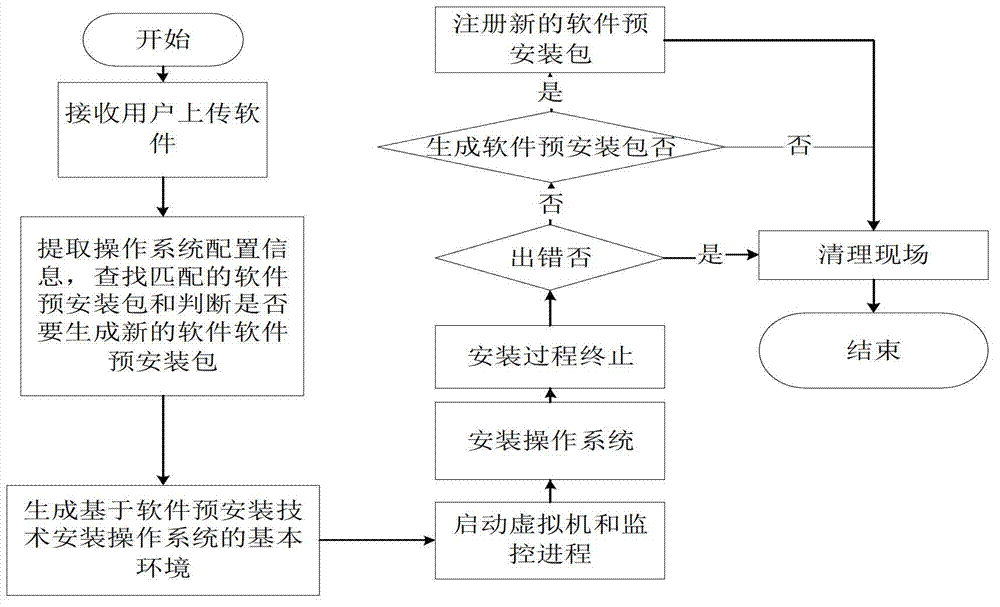

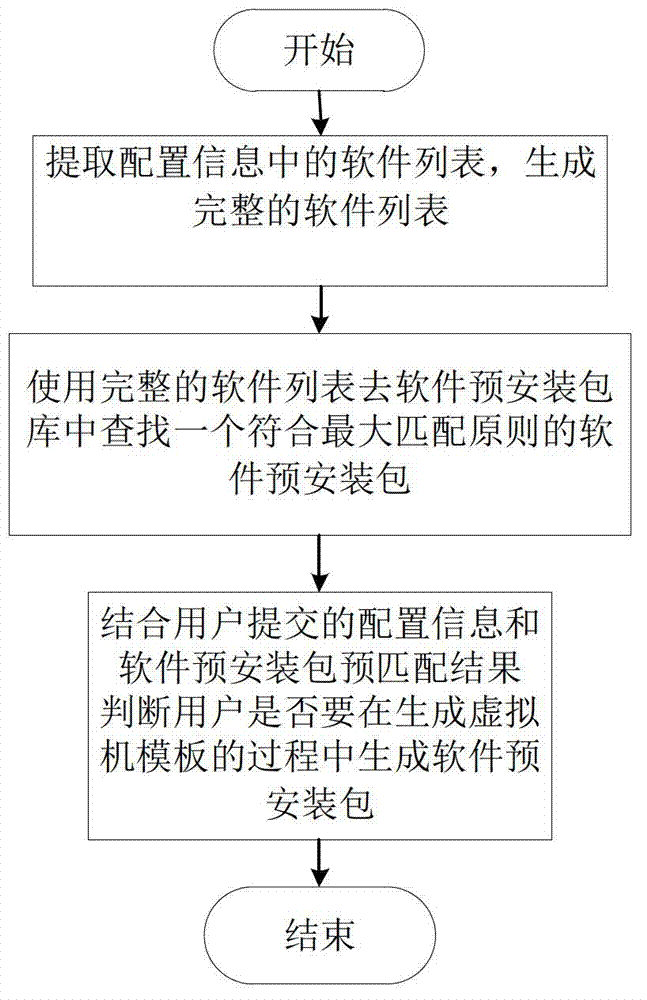

Virtual machine mirror image generating method and device based on software preinstallation in cloud environment

ActiveCN103092650AIncrease generation speedAvoid duplicate installationsProgram loading/initiatingIp addressSystem configuration

The invention discloses a virtual machine mirror image generating method and a device based on software preinstallation in cloud environment. The virtual machine mirror image generating method and the device based on the software preinstallation in the cloud environment comprise that softwares which are uploaded by users are received and dependency of the uploaded softwares are checked, operating system configuration information which is submitted by the users is received and analyzed to obtain analysis results of the operating system configuration information. Basic environment which is necessary to install an operating system based on the software preinstallation technology is generated according to the analysis results of the operating system configuration information. A virtual machine start is started by using a virtual machine start configuration file in the generated environment and a monitoring progress is started at the same time. An operating system installation program is operated in the virtual machine and the operating system is installed in a non-interactive mode. Meanwhile, the monitoring progress judges whether the installation of the operating system is wrong or accomplished or not. When the installation of the operating system is wrong, the virtual machine is closed and temporary files in the basic environment are cleaned and internet protocol (IP) address is returned to an IP address pool. The virtual machine mirror image generating method and the device based on the software preinstallation in the cloud environment can solve defects of an existing manner, wherein the defects of the existing manner are insufficient in flexibility, low in speed, serious in source consumption and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

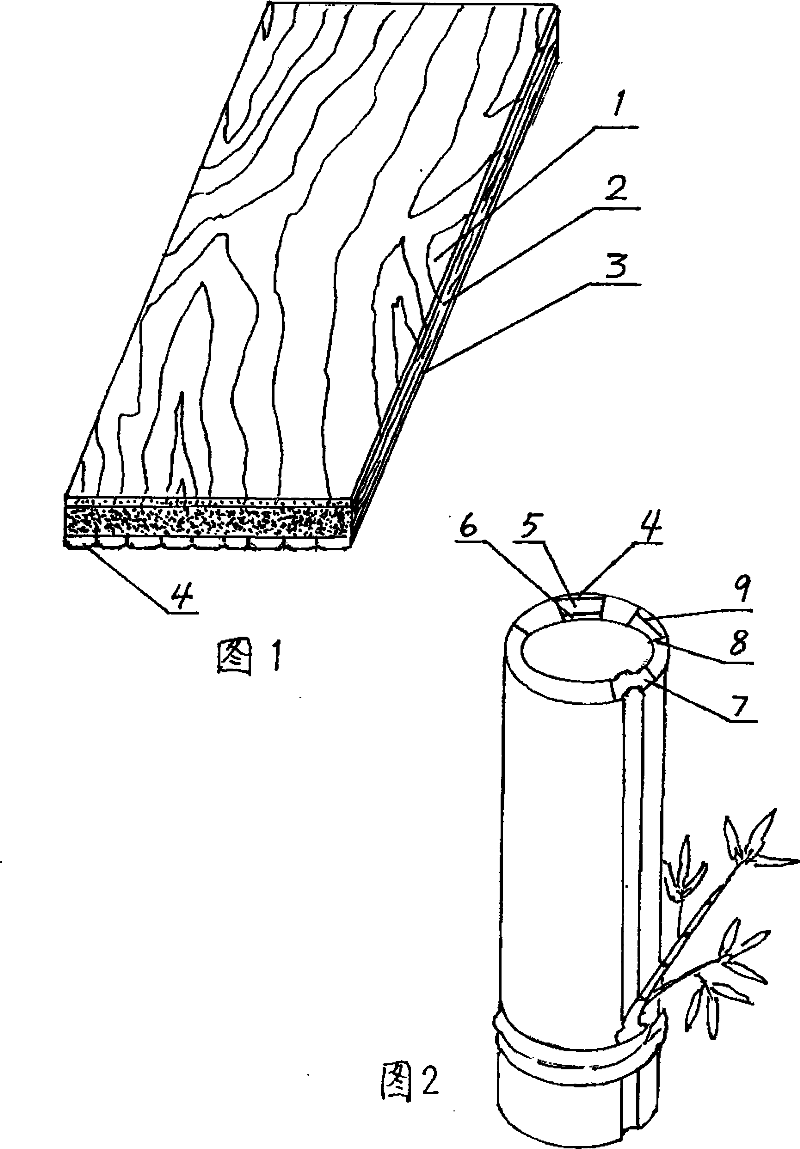

Laminated sheets of tabasheer core layer and the outer bamboo bottom layer and the processing method

InactiveCN101036994ALow costExpand sourceOther plywood/veneer working apparatusWood treatment detailsFiberEconomic benefits

A laminated sheet of tabasheer core layer and bamboo green base layer includes a core layer, a base layer, characterized in that the core layer is composed of the connecting thread sheets cleaved by the raw materials of tabasheer, bamboo base part, bamboo tip part, concave thickness sheet and the glue, the base layer is arranged vertically with bamboo fiber of the base layer, core layer, side jointed board of bamboo green sheet cleaved to inner plane and outer arc face by the raw materials of bamboo green; the manufacturing method of the laminated sheet has following steps made by working procedures of pretreating, cooking, glue blending and drying of the raw material, vertical jointing board, paving and hot pressing of the bamboo green sheet, which can widely use as floor, wallboard, furniture panel, wrapper plate and so on, with advantages of high mechanical strength, high utilization rate, less procedure, quick work efficiency, low cost, remarkable economic benefit and ecological benefit of bamboo material.

Owner:浙江坚林林业股份有限公司

Cementing agent for producing pellet ore and preparing process thereof

InactiveCN101008046ASolve the problem that the burst rate of raw balls also increases significantlyHigh strengthPolyvinyl alcoholEther

The invention discloses a new bonding agent for producing pellet ore and the method for preparing said bonding agent, belonging to metallurgy field. The comprised bonding agent and their proportion by weight are as follows: water soluble organic matter 1- 50, clay 10- 30, borax 1- 2, active calcium 10- 40, active carbon 10- 25, and magnesium lime cement 8- 15; said water soluble is selected from one of starch ether, cellulose ether or polyvinyl alcohol or mixture of them at any ratio. The bonding agent is added into process producing pellet ore, and the physical property and metallurgy performance are dramatically increased, and it is characterized by saving production cost and reducing environmental pollution.

Owner:周德聪 +1

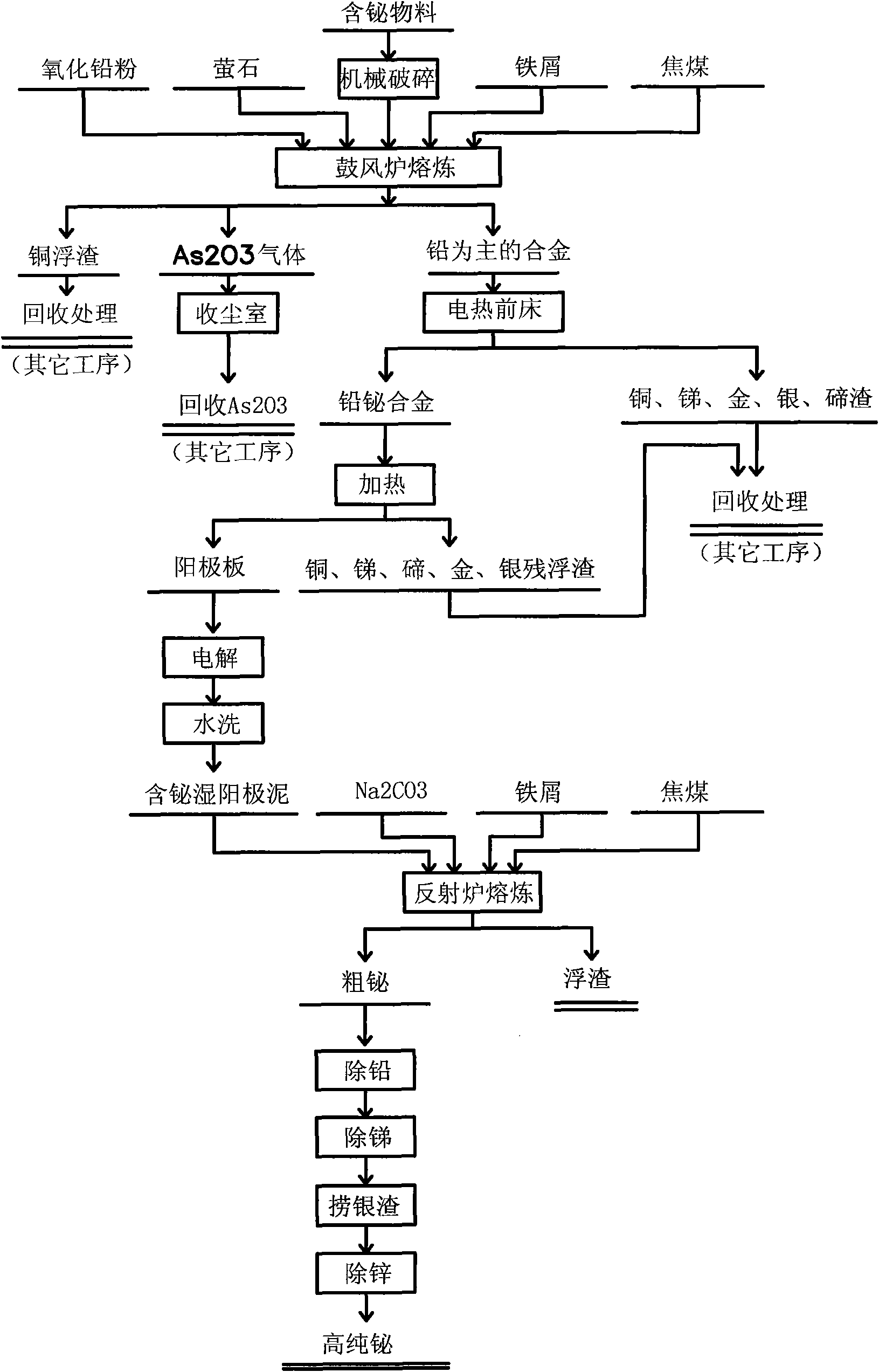

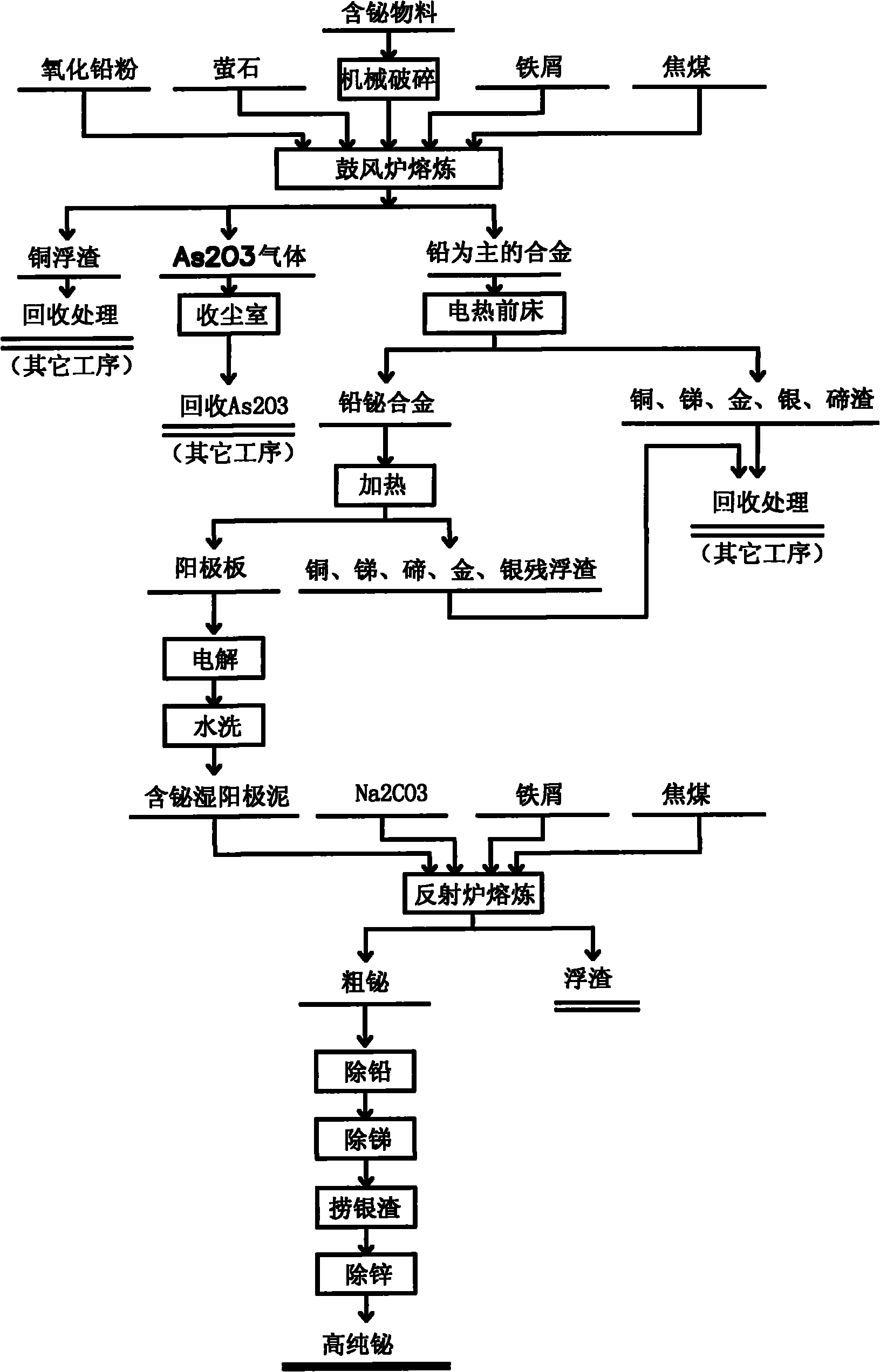

Process for refining high-purity bismuth from bismuth-containing material generated from anode mud recovery

ActiveCN101886174AReduction of Bismuth Content RequirementsExpand sourcePhotography auxillary processesProcess efficiency improvementTemperature controlBismuth

The invention relates to a process for refining high-purity bismuth from bismuth-containing materials generated from anode mud recovery, belonging to the technical field of processes of recovering smelting bismuth by combining a wet process and a pyrogenic process of non-ferrous metal. The process comprises the following steps of: firstly increasing the content of bismuth contained in the bismuth-containing materials to obtain crude bismuth by adopting an enrichment process; and then further refining and purifying the crude bismuth into the high-purity bismuth by adopting a selective accurate temperature-control smelting method according to different melting points of compounds between bismuth metal and impurity-containing metal. Compared with the prior art, the invention reduces the requirements for the content of the bismuth contained in raw materials and can realize the economic and high-efficiency recovery of the bismuth metal, refine the high-purity bismuth and reduce the environmental pollution.

Owner:郴州雄风环保科技有限公司

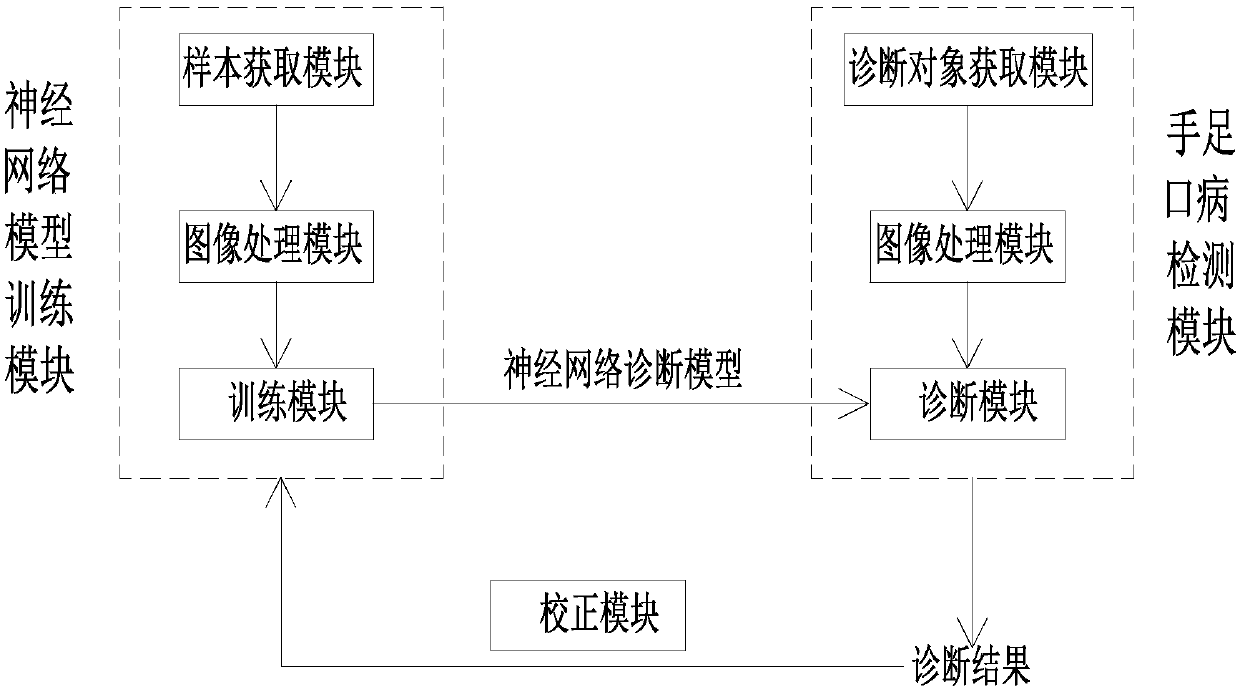

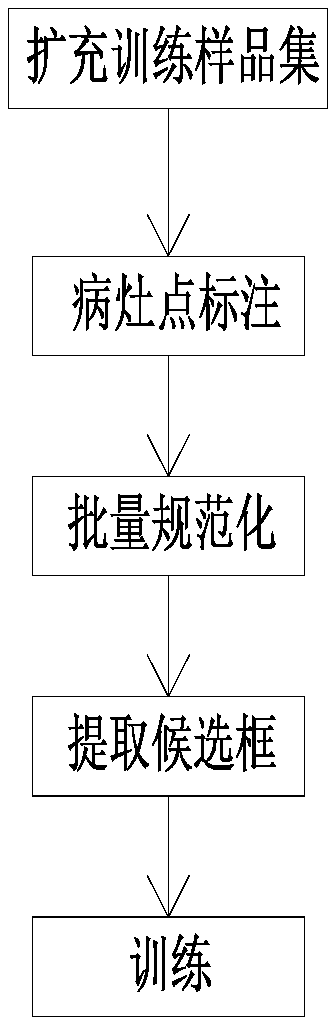

Deep learning based hand-foot-and-mouth disease detection system

PendingCN107862694AImprove accuracyRealize online self-diagnosisImage enhancementImage analysisMedicineHand foot mouth disease

A deep learning based hand-foot-and-mouth disease detection system comprises a neural network model training module and a hand-foot-and-mouth disease detection module. A convolutional neural network model is constructed through the neural network model training module on the basis of a hand-foot-and-mouth disease sample set, and a hand-foot-and-mouth disease neural network diagnosis model is obtain by analysis of images in the hand-foot-and-mouth disease sample set. On the basis of input images, the hand-foot-and-mouth disease detection module judges to obtain hand-foot-and-mouth disease diagnosis results through the neural network diagnosis model. By application of the deep learning technology to automatic diagnosis of the hand-foot-and-mouth disease, a hand-foot-and-mouth disease detection core problem is transformed into a target detection problem, and detection result accuracy is improved by autonomous optimization.

Owner:济南大象信息技术有限公司

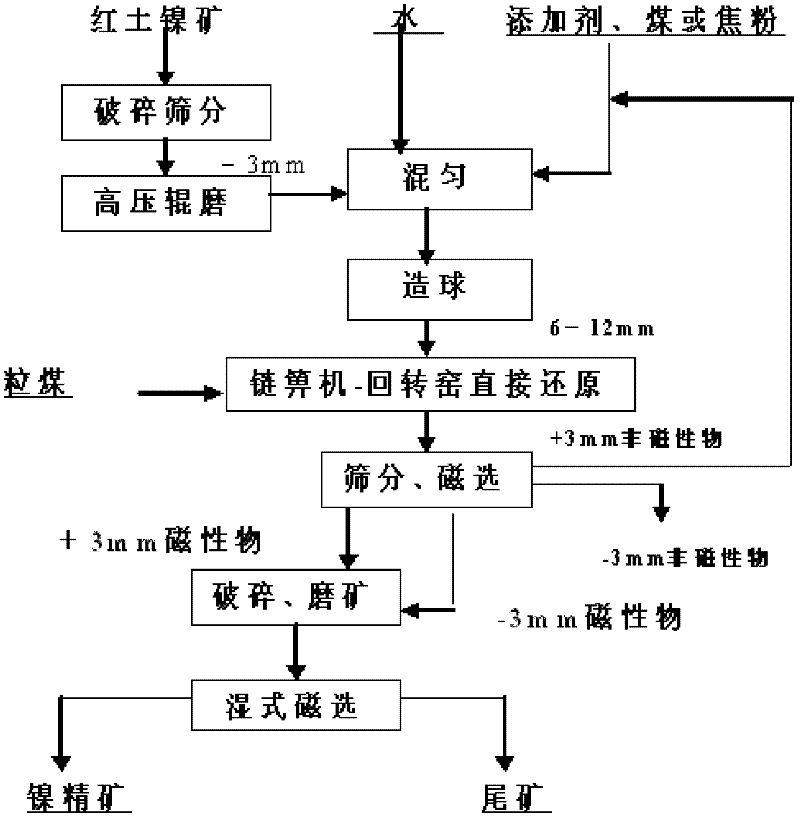

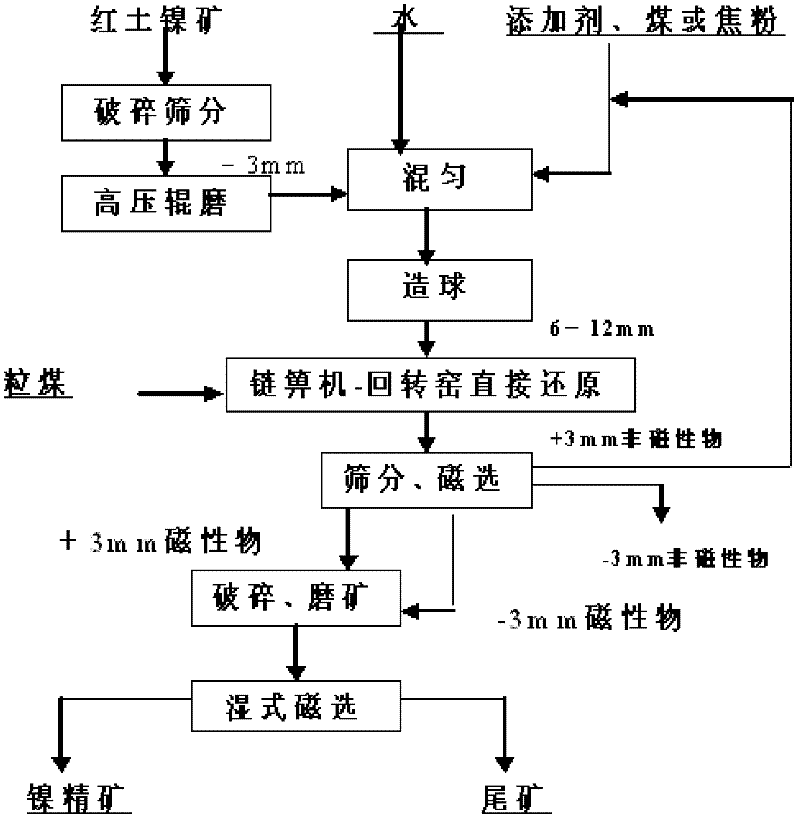

Method for preparing high-nickel concentrate from low-grade red soil nickel ore

InactiveCN102242252ALarge specific surface areaGood ball formingMagnetic separationMass ratioHigh pressure

The invention discloses a method for preparing a high-nickel concentrate from a low-grade red soil nickel ore, which comprises the following steps of: drying the low-grade red soil nickel ore until water content is 13 to 16 percent, crushing to ensure that the size of all particles is less than 3mm, grinding by using a high-pressure roller mill to ensure that particles with the size of less than 0.074mm account for 80 percent and specific surface area is not less than 2,000cm<2> / g, adding 15 to 20 percent of composite binder and 1 to 5 percent of coal powder, and pelletizing by using a disc pelletizer to obtain green pellets with the size of 6 to 16mm; drying and preheating the green pellets on a chain grate for water removal and solidification to ensure that each piece of pellet entering a kiln has the compression strength of over 500N; directly adding the preheated and solidified pellets into a rotary kiln, and reducing at the temperature of between 1,100 and 1,250 DEG C for 60 to 120 minutes by using pea coal as a reducing agent in a mass ratio of the reducing coal to the pellets of 0.8-1.0; and cooling a reduction product, sieving, performing magnetic separation to obtain a magnetic product, crushing, grinding, and performing magnetic separation to obtain the high-nickel concentrate, wherein the composite additive comprises the following components: Na2CO3 and CaO, iron oxide powder, the coal powder and sodium humate in a ratio of (30-60):(20-30):(20-30):(5-10). The method is high in adaptability and nickel recovery rate and suitable for mass production.

Owner:CENT SOUTH UNIV

Production method of needle coke raw material

ActiveCN101724420AExpand sourceThe method flow is simpleCoking carbonaceous materialsDecompositionCoke rate

The invention discloses a method of needle coke raw material by using delay coking technique to treat FCC slurry oil and conventional coking raw material. The method comprises: introducing FCC slurry oil with low temperature into a delay coking tower from the upper part inside the tower, leading the introduced FCC slurry oil to be contacted with high temperature oil gas generated by the conventional coking raw material which is introduced into the tower from the bottom and treated by high temperature decomposition, and reacting under the condition of delay coking; and separating the generated oil gas in a coking fractionating tower, and obtaining the needle coke raw material. In the method, as the FCC slurry oil enters into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating copper slag

InactiveCN105039728AAchieve recyclingReduce consumptionProcess efficiency improvementProduct containing ironMixed materials

The invention discloses a method for treating copper slag. The method includes the steps that (1) the copper slag, a reducing agent and additives are pre-treated respectively; (2) the pre-treated copper slag, the pre-treated reducing agent and the pre-treated additives are mixed so that a mixed material can be obtained; (3) the mixed material is formed so that copper slag pellets can be obtained; (4) the copper slag pellets are dried so that the dried copper slag pellets can be obtained; (5) at the temperature of 1,350-1,550 DEG C, the dried copper slag pellets are reduced so that a solid reduced product containing iron-copper alloy particles and smoke containing lead and zinc can be obtained; and (6) the solid reduced product containing the iron-copper alloy particles is broken and magnetically separated so that the iron-copper alloy particles and tailings can be obtained respectively. According to the method, multiple metal elements in the copper slag can be comprehensively recycled, and the higher recovery rate is achieved.

Owner:SHENWU TECH GRP CO LTD

Non-sintered ceramic aggregate with stone coal vanadium extraction tailings as main raw material and preparation method thereof

InactiveCN102617097AEffective way to useExpand sourceSolid waste managementThermal insulationExpanded clay aggregate

The invention relates to a non-sintered ceramic aggregate with stone coal vanadium extraction tailings as a main raw material and a preparation method thereof. The non-sintered ceramic aggregate comprises the following raw material components in percentage by weight: 45-60 percent of stone coal vanadium extraction tailings, 10-30 percent of fly ash, 7-15 percent of solid alkali exciter, 5-10 percent of cement, 5-10 percent of quick lime, 2-5 percent of gypsum and 5-15 percent of water. The preparation method comprises the following steps of: according to the raw materials and the contents thereof, uniformly mixing the stone coal vanadium extraction tailings and the solid alkali exciter and grinding to be below 0.074 mm to prepare a prefabricated material; adding the fly ash, the cement, the quick lime, the gypsum and the water into the prefabricated material and uniformly stirring to prepare a mixture; aging the mixture for 1-3 hours; pelletizing; aging for 3-7 days; holding in an autoclave; and autoclaving under the condition of 0.8-1.2 MPa for 6-10 hours. The non-sintered ceramic aggregate has the advantages of environmental friendliness, simple process, low energy consumption and high utilization rate of tailings; and a prepared non-sintered ceramic aggregate product has high strength and good thermal insulation performance.

Owner:WUHAN UNIV OF SCI & TECH

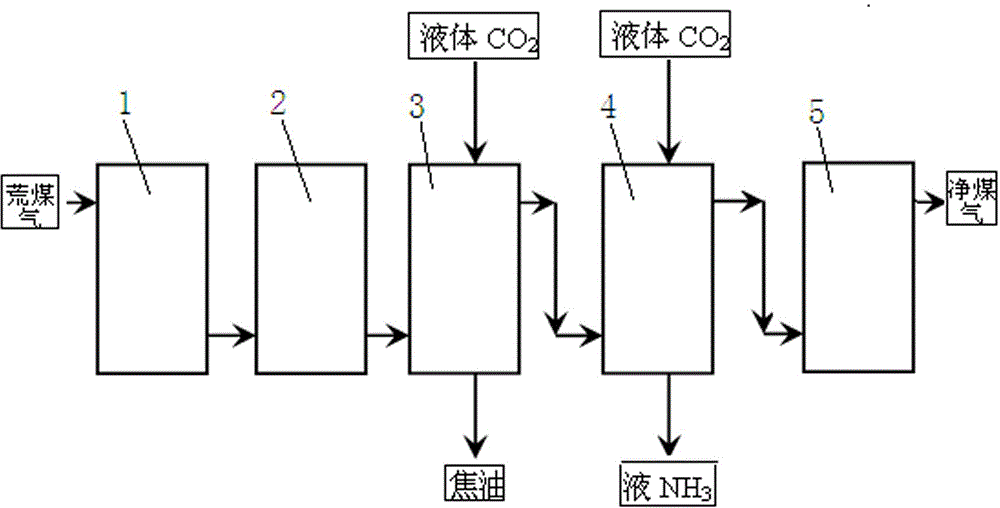

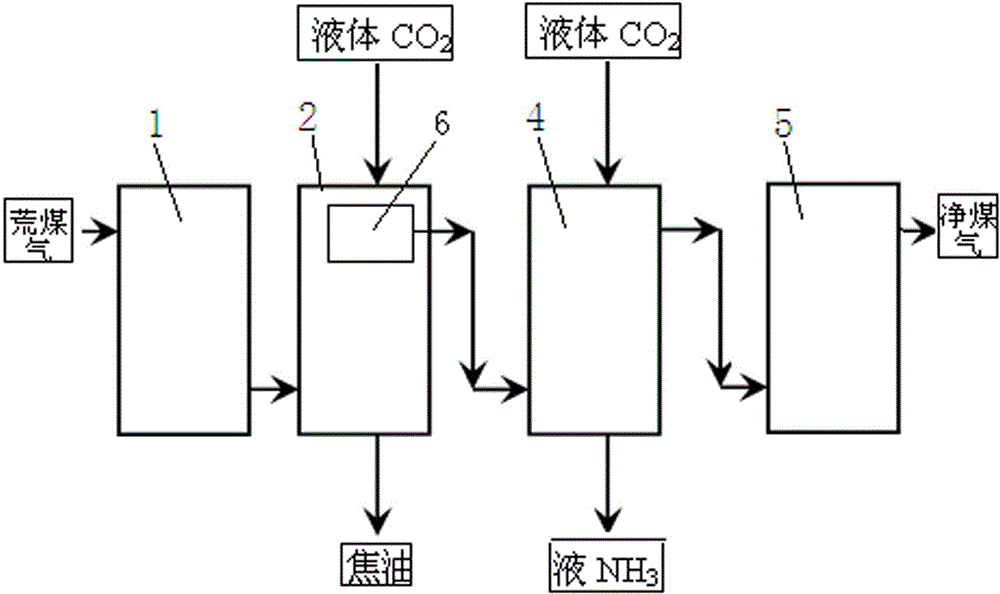

Method and device for purifying coke oven gas

ActiveCN104388127AExpand sourceQuality improvementGas purification by non-gaseous materials condensationHazardous substanceMoisture

The invention relates to a method for purifying coke oven gas. The method comprises the following steps of indirectly cooling coke oven gas to 300-500 DEG C through water in a primary cooler, dehydrating coke oven gas by virtue of a dehydrating tower until the moisture content is 5-10ppm, enabling dehydrated coke oven gas to enter a tar recovery tower, discharging precipitated liquid tar obtained after condensing to the outside, enabling the gas to enter a liquid ammonia recovery tower, cooling to -30 to -50 DEG C and discharging precipitated liquid ammonia to the outside, removing impurities by virtue of a methanol washing tower and enabling the purified coke oven gas to enter a purified coke oven gas tank. The device for purifying coke oven gas comprises the primary cooler, the dehydrating tower, the tar recovery tower, the liquid ammonia recovery tower and the methanol washing tower which are sequentially connected, wherein the tar recovery tower and the liquid ammonia recovery tower are respectively connected with liquid carbon oxide pipelines, the outlet formed in the bottom of the tar recovery tower is connected with a tar recovery device and the outlet formed in the bottom of the liquid ammonia recovery tower is connected with a liquid ammonia recovery device. By cooling, dehydrating, separating tar and liquid ammonia and washing with methanol, impurities and harmful substances in gas are removed, sources of clean fuels are expanded, and thus being conductive to improving the quality of high-quality fuels and reducing the air pollution.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

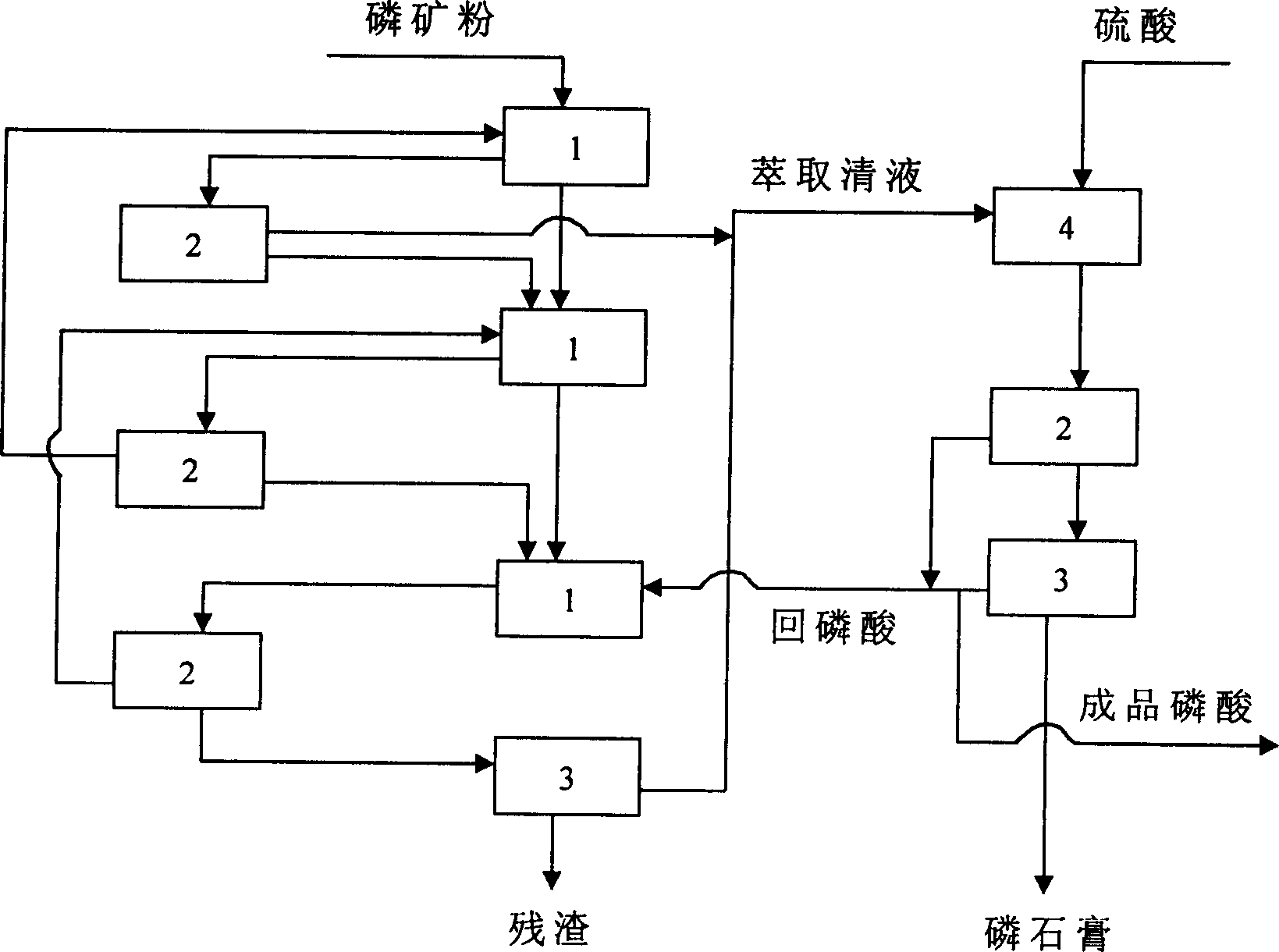

Process for producing wet method phosphoric acid by medium low grade phosphorus mine

A process for preparing phosphoric acid from low-and medium-grade phosphorus ore by wet method includes such steps as countercurrent decomposing of P core by excessive phosphoric acid to generate the solution of calcium dihydrogen phosphate, liquid-solid separation to obtain liquid extract, reacting on sulfuric acid to obtain bihydrated calcium sulfate crystal and phosphoric acid solution, liquid-solid separation to obtain phosphoric acid and phosphogypsum, returning the most of phosphoric acid back to decomposing step, and using the rest as finished product.

Owner:SINOPEC NANJING ENG & CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com