Method for preparing high-nickel concentrate from low-grade red soil nickel ore

A laterite nickel ore, low-grade technology, applied in chemical instruments and methods, solid separation, magnetic separation, etc., can solve the problems of non-extraction technology, achieve strong process adaptability, fine embedded particle size, and improve the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

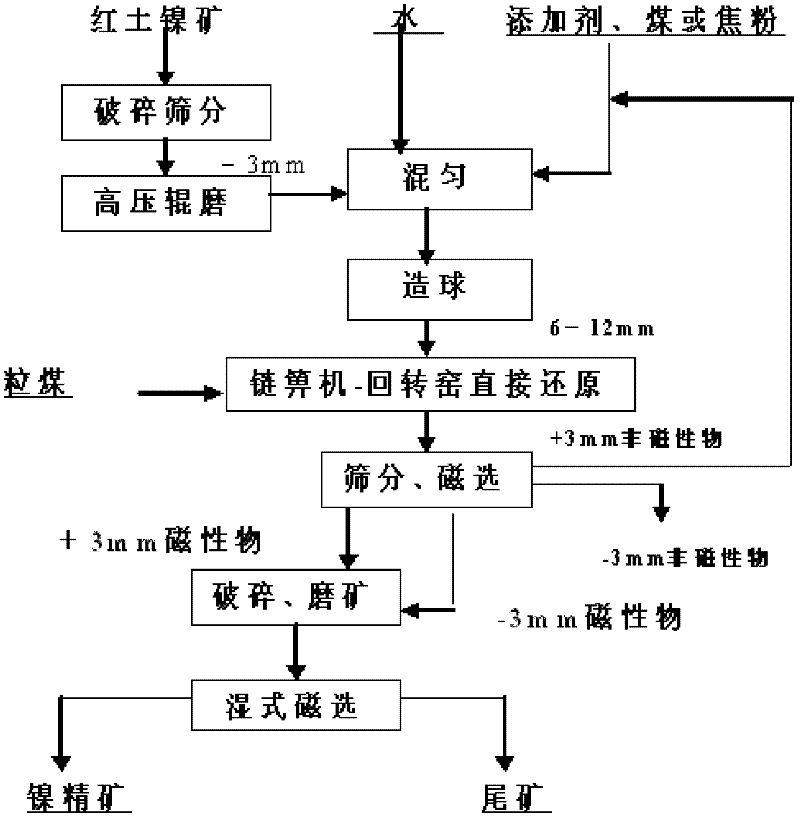

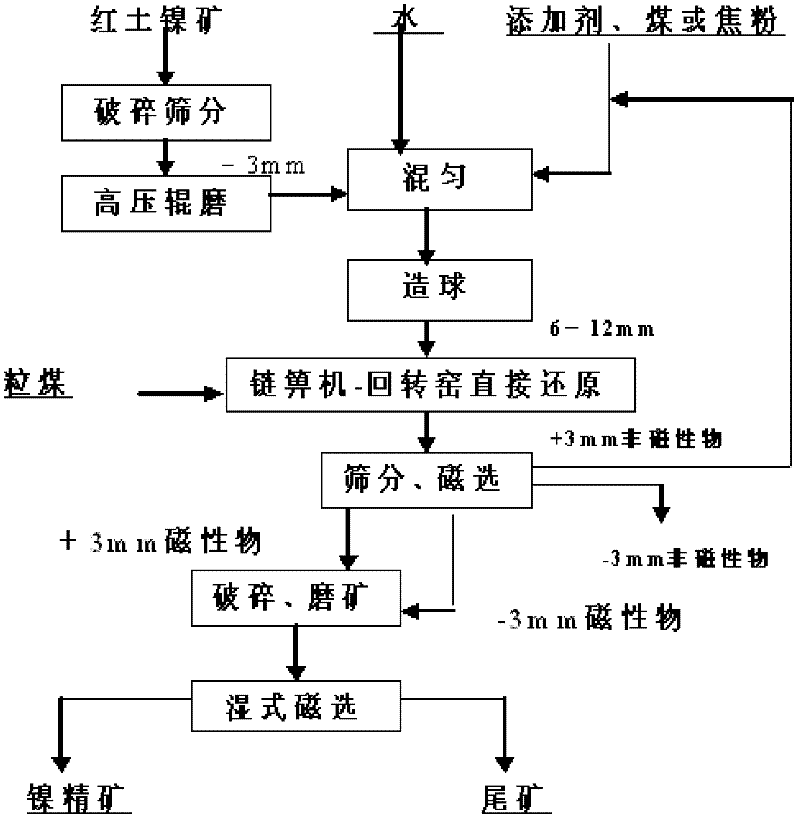

[0020] see figure 1 , low-grade silicate-type laterite nickel ore is dried to a moisture content of 15%, crushed to 100% less than 3mm, crushed and high-pressure roller milled to -0.074mm80%, mixed with 1% coal and 15% compound additives , pelleting water 25%, pelletizing time 8min, raw pellet 6-16mm. The green pellets are dried and preheated on the chain grate machine. The preheating temperature is 1000°C and the preheating time is 20 minutes. The compressive strength of the pellets is greater than 500N. The preheated pellets enter the rotary kiln for reduction, and the amount of reduced coal (5mm-30mm) added The mass ratio of reduced coal to pellets is 0.8. The reduction temperature in the first stage is 800°C, the reduction time is 30 minutes, and the amount of reduced coal accounts for 30% of the total amount; the reduction temperature in the second stage is 1100°C, the reduction time is 90 minutes, and the amount of reduced coal added accounts for 70% of the total amount...

Embodiment 2

[0022] see figure 1 , low-grade silicate-type laterite nickel ore is dried to a moisture content of 14%, crushed to 100% less than 3mm, crushed and high-pressure roller milled to -0.074mm80%, mixed with 3% coal and 15% compound additives , pelleting water 25%, pelletizing time 8min, raw pellet 6-16mm. The green pellets are dried and preheated on the chain grate machine. The preheating temperature is 1100°C and the preheating time is 15 minutes. The compressive strength of the pellets is greater than 500N. The preheated pellets enter the rotary kiln for reduction, and the amount of reduced coal (5mm-30mm) added It is reduced coal, and the mass ratio of pellets is 1.0. The reduction temperature in the first stage is 900°C, the reduction time is 30 minutes, and the amount of reduced coal accounts for 30% of the total amount; the reduction temperature in the second stage is 1200°C, the reduction time is 60 minutes, and the amount of reduced coal added accounts for 70% of the tota...

Embodiment 3

[0024] see figure 1 , low-grade silicate-type laterite nickel ore is dried to a moisture content of 15%, crushed to 100% less than 3mm, crushed and high-pressure roller milled to -0.074mm80%, mixed with 3% coal and 20% compound additives , pelleting water 25%, pelletizing time 8min, raw pellet 6-16mm. The green pellets are dried and preheated on the chain grate machine. The preheating temperature is 1050°C and the preheating time is 18 minutes. The compressive strength of the pellets is greater than 500N. The preheated pellets enter the rotary kiln for reduction, and the amount of reduced coal (5mm-30mm) added It is reduced coal, and the mass ratio of pellets is 1.0. The reduction temperature of the first stage is 1050°C, the reduction time is 20 minutes, and the amount of reduced coal accounts for 30% of the total amount. The reduction temperature of the second stage is 1250°C, and the reduction time is 80 minutes. The amount of reduced coal added accounts for 70% of the tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com