Patents

Literature

75 results about "Coke rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for preparing composite carbon carrier noble metal dehydrogenation catalyst

InactiveCN1844324AImprove stabilityImprove anti-coking performanceRefining to eliminate hetero atomsCoke rateActive component

The invention relates to a method for preparation of precious-metal dehydrogenation catalyst with compound carbon as carrier, which adopts compound carbon material and allocates precious-metal active component on with the said material to prepare new precious-metal dehydrogenation catalyst with compound carbon as carrier. Compared with homogeneous precious-metal catalyst, the said catalyst not only can reduce the coking rate by 25 % but also can increase the dehydrogenation activity by 5-10 %, and is of high cryogenic activity and good stability. The invention provides unitary implementation procedure for preparation technology of compound carbon material and precious-metal dehydrogenation catalyst and activity evaluation, which changes the conventional technical thoughts using active components and catalyst promoter in the past time and improves the coking resistance of the catalyst beginning with carrier.

Owner:PETROCHINA CO LTD +1

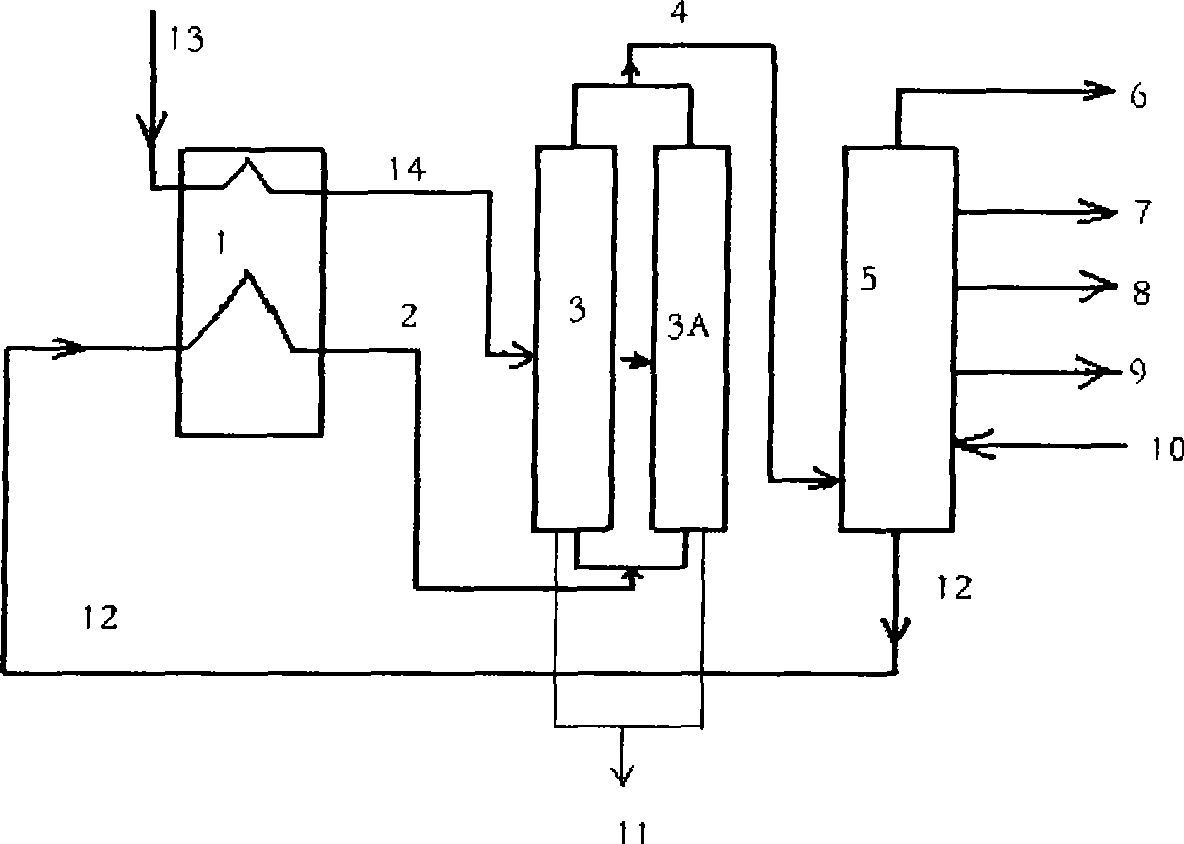

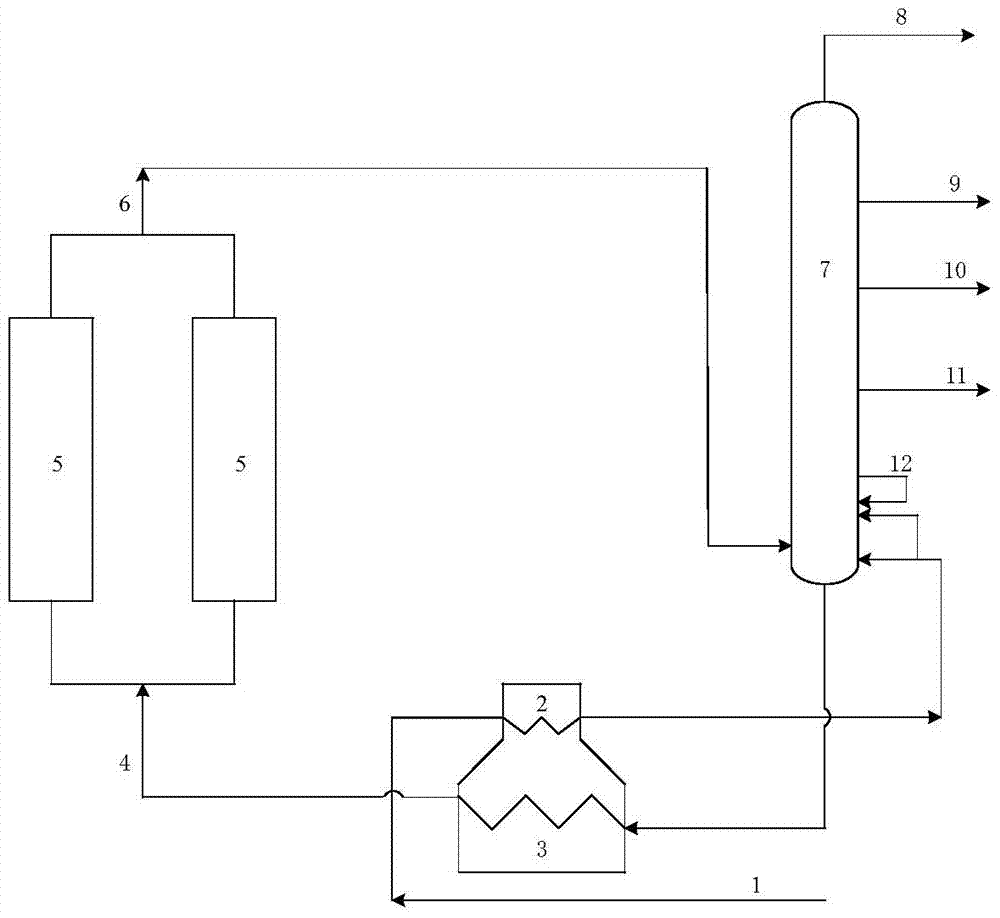

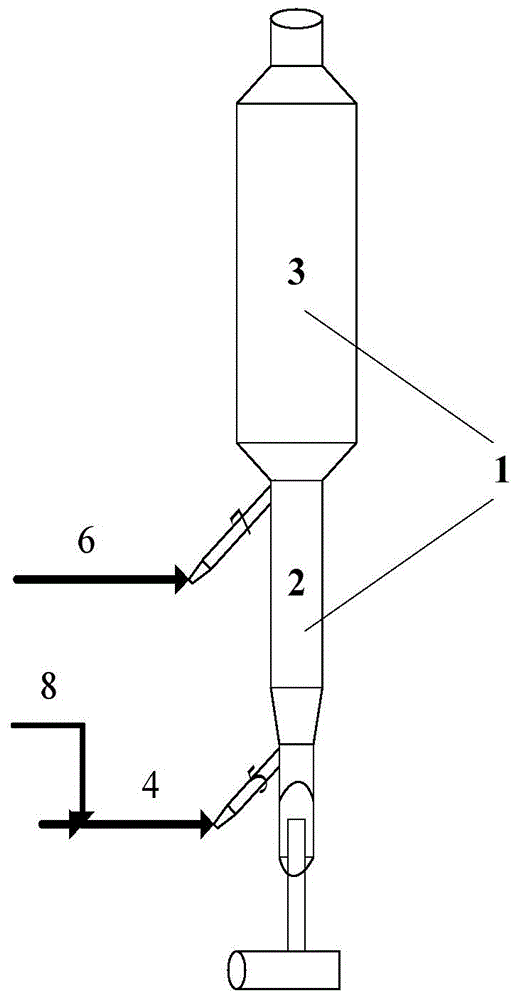

Production method of needle coke raw material

ActiveCN101724420AExpand sourceThe method flow is simpleCoking carbonaceous materialsDecompositionCoke rate

The invention discloses a method of needle coke raw material by using delay coking technique to treat FCC slurry oil and conventional coking raw material. The method comprises: introducing FCC slurry oil with low temperature into a delay coking tower from the upper part inside the tower, leading the introduced FCC slurry oil to be contacted with high temperature oil gas generated by the conventional coking raw material which is introduced into the tower from the bottom and treated by high temperature decomposition, and reacting under the condition of delay coking; and separating the generated oil gas in a coking fractionating tower, and obtaining the needle coke raw material. In the method, as the FCC slurry oil enters into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for restraining cracking furnace pipe from coking

ActiveCN103421531AThe method is simpleSimple technologyThermal non-catalytic crackingCoke ratePre treatment

The invention provides a method for restraining a cracking furnace pipe from coking. The method comprises the following steps: pre-treating the inner surface of the cracking furnace pipe before a coking restraining coating of the inner surface of the cracking furnace pipe is coated; coating a coking resistant coating on the inner surface of the cracking furnace pipe; adding a coking inhibitor into cracking raw materials. According to the invention, the coke formation is reduced through the recombination of the coking resistant technology, so that the hydrocarbon high-temperature cracking coking rate is greatly reduced, and the use cycle of hydrocarbon cracking equipment is prolonged.

Owner:内蒙古冠泰环保科技有限公司

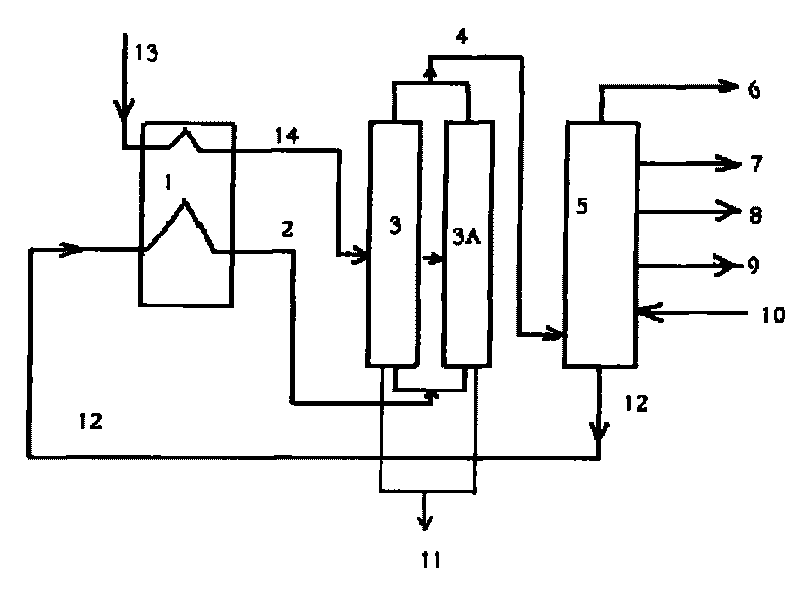

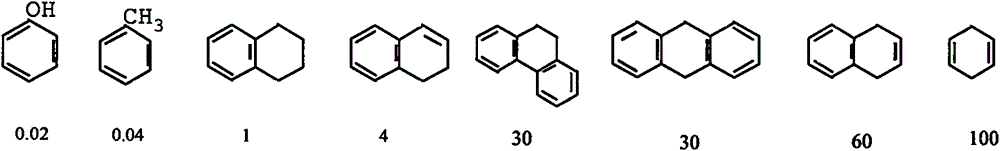

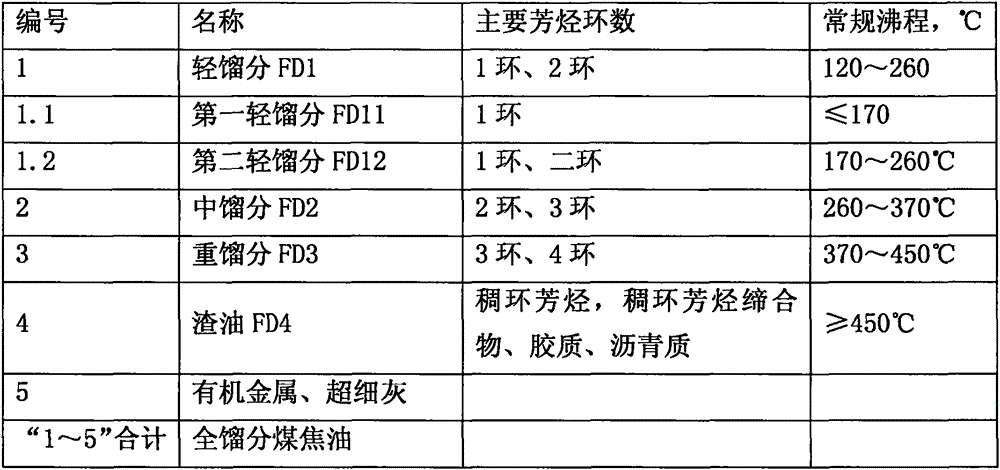

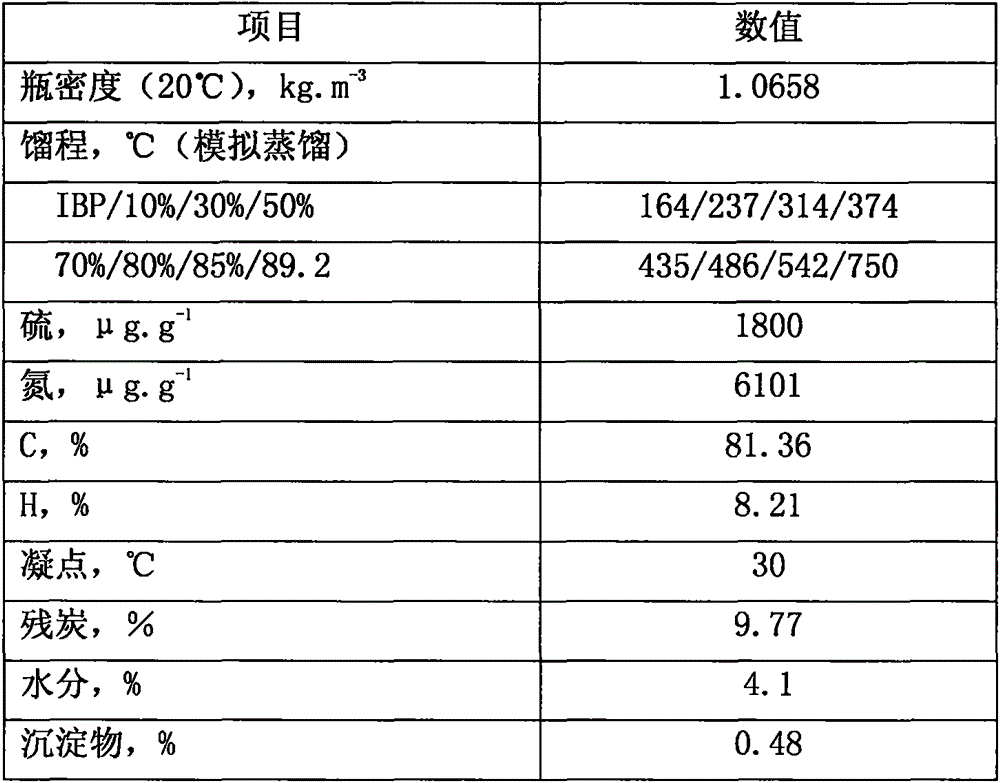

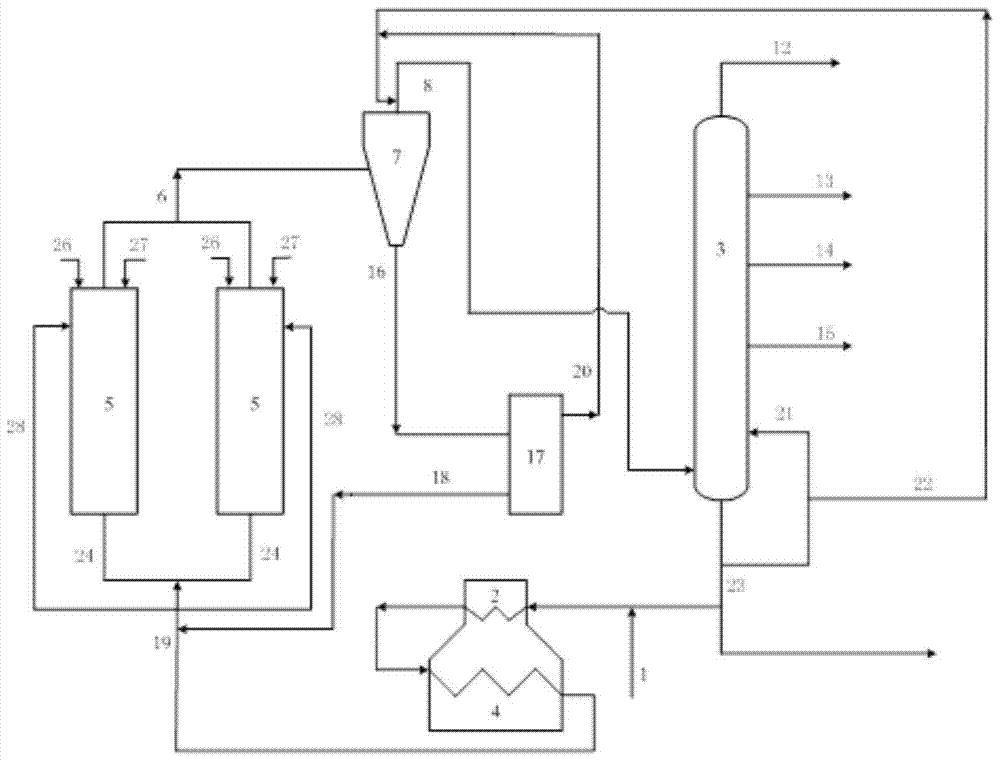

Upflow type hydrogenation thermal cracking method with characteristic of high-aromatic-carbon-rate poor-quality hydrocarbon branching feeding

The invention relates to an upflow type hydrogenation thermal cracking method with a characteristic of high-aromatic-carbon-rate poor-quality hydrocarbon branching feeding. According to the present invention, the upflow type hydrogenation thermal cracking method is suitable for the suspension bed hydrogenation thermal cracking process R10 of coal tar heavy oil having the high contents of metals, polycyclic aromatic hydrocarbons, colloid and asphaltene and having the conventional boiling point of higher than 450 DEG C, wherein the R10 comprises two or a plurality of operation series connecting sub-hydrogenation reaction zones such as a first sub-hydrogenation reaction zone R101, a second sub-hydrogenation reaction zone R102 and the like, poor-quality hydrocarbon HDS is divided into the two-branch raw material such as HDS1 and HDS2 or multi-branch raw material, the HDS1 enters the R101, and the obtained reaction effluent R101P or the stream R101PX containing the hydrogenation generation oil of the R101P enters the R102 and contacts the HDS2, such that the concentration of the fresh raw material HDS2 in the R102 liquid phase can be reduced, the ratio of the hydrogen supply hydrocarbon weight to the fresh raw material HDS weight in the SHS flowing-through reaction zone can be significantly increased when the R101 uses the hydrogen supply hydrocarbon stream SHS, and the thermal condensation coking rate can be reduced.

Owner:洛阳瑞华新能源技术发展有限公司

Production method of needle coke raw material

ActiveCN101724420BHigh reactivityExpand sourceThermal non-catalytic crackingCoking carbonaceous materialsCoke rateDecomposition

Owner:CHINA PETROLEUM & CHEM CORP +1

Furnace-protecting material for blast furnaces and preparation and application methods thereof

ActiveCN103468840AReduce titanium contentReduce the impact of liquidityBlast furnace componentsBlast furnace detailsCoke rateSlag

The invention provides a furnace-protecting material for blast furnaces and preparation and application methods thereof. The furnace-protecting material for the blast furnaces comprises the following components: 30-39% of ilmenite concentrate, 5-8% of CDQ (Coke Dry Quenching), and 51-65% of pulverized coal. The preparation method of the furnace-protecting material for the blast furnaces is implemented through uniformly mixing the CDQ powder with the pulverized coal in proportion so as to obtain a mixture, heating the mixture, dehydrating the mixture, and grinding and separating the mixture; uniformly mixing the ilmenite concentrate with the mixture so as to obtain the furnace-protecting material for the blast furnaces. When the temperatures of bottom and basque detecting couples rise or the temperature difference of cooling water rises, the furnace-protecting material for blast furnaces is injected; the furnace-protecting material is injected after roughing slags in the process of tapping, and after normal coal blending is performed for 2 hours, the furnace-protecting material is injected again; oxygen-enriched injection is performed in the process of injecting the furnace-protecting material. According to the invention, the influence of the titanium content of scrap iron in the slags on the flowability of the scrap iron in the slags can be reduced, so that while the disposal capacity of metallurgical wastes is reduced, the furnace-protecting cost and coke rate of blast furnaces are lowered, the efficiency and effect of furnace protecting are improved, and the service cycle of a furnace hearth is relatively extended.

Owner:ANGANG STEEL CO LTD

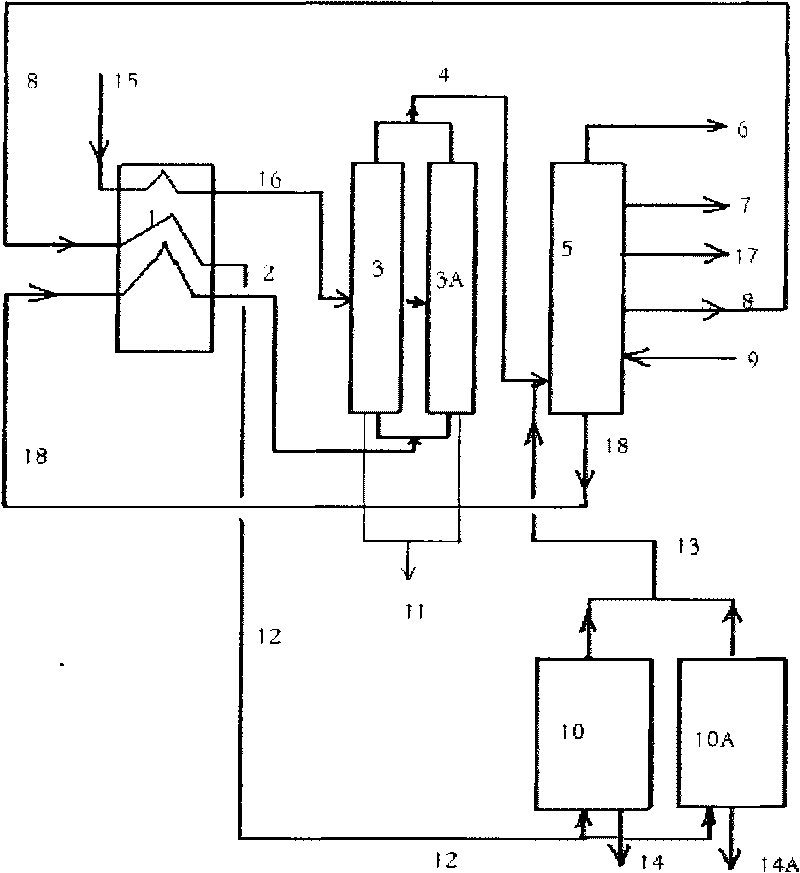

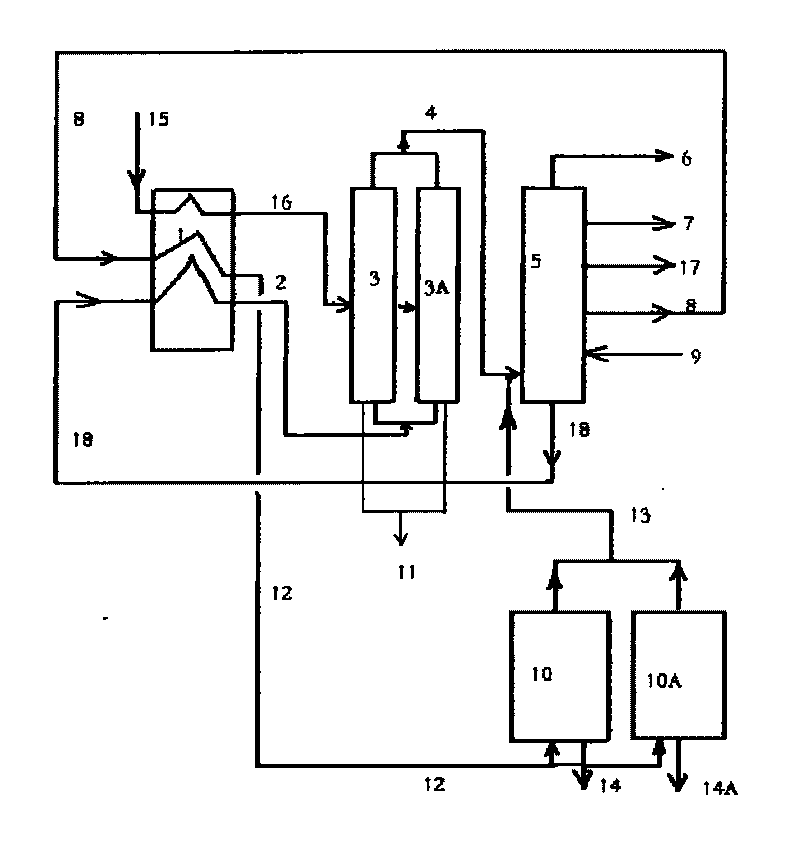

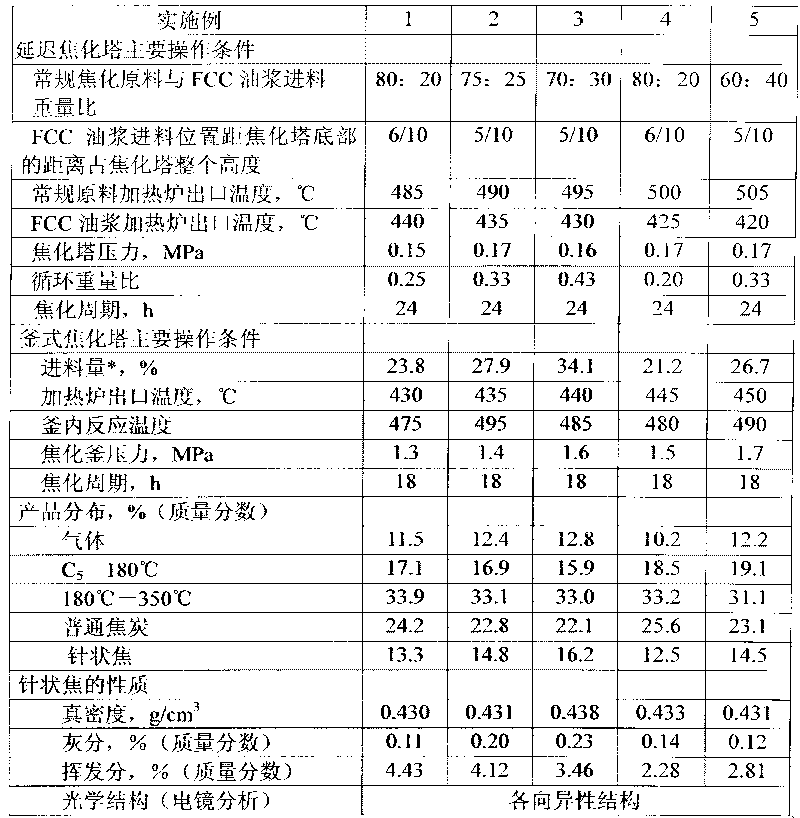

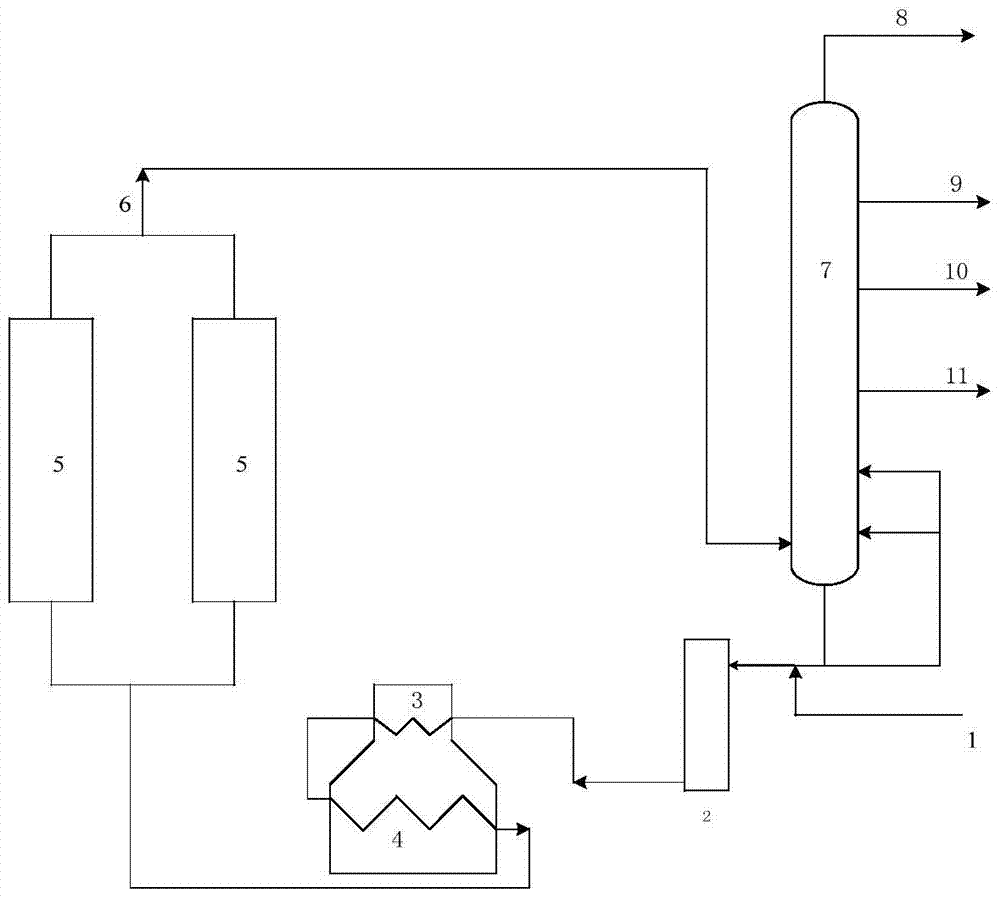

Production method of needle coke

The invention discloses a method for producing needle coke by adopting the technique combining delay coking and kettle-type coking. The method comprises: when treating the conventional coking raw material by using the delay coking technique, introducing FCC slurry oil into a delay coking tower from the upper part inside the tower at the low temperature, and obtaining needle coke raw material by fractionating high temperature oil gas obtained by the reaction; and then, treating the needle coke raw material by using the kettle-type coking technique, and obtaining high quality needle coke. In the method, as the FCC slurry oil is injected into the coking tower at the lower temperature, the decomposition temperature of the conventional coking raw material is lowered, the high temperature decomposition time of the raw material is shortened, the occurrence of secondary reaction is reduced, green coke rate is reduced, the stable operation cycle of a signal tower is prolonged, and light components which have high reaction activity and are not beneficial to producing the needle coke, heavy components with high polymerization activity, and a great deal of impurities such as catalyst powder, heavy metal and the like can be removed. The obtained needle coke has high yield and good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

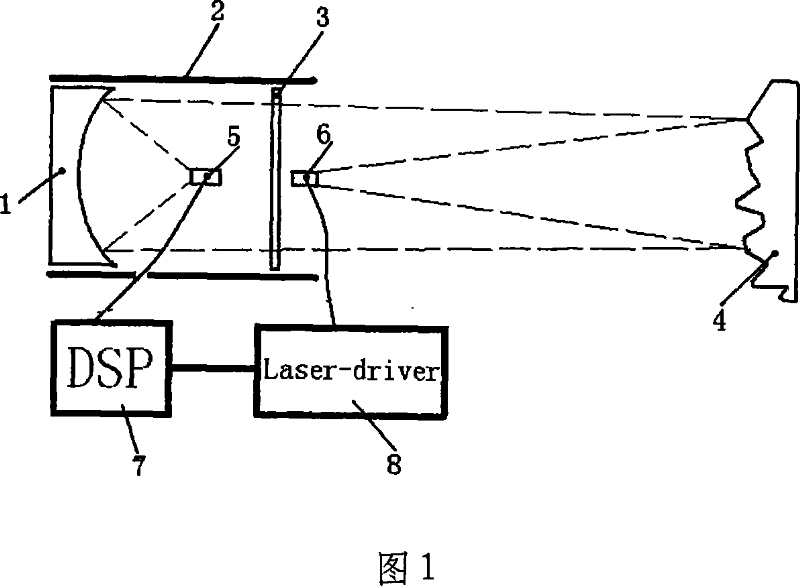

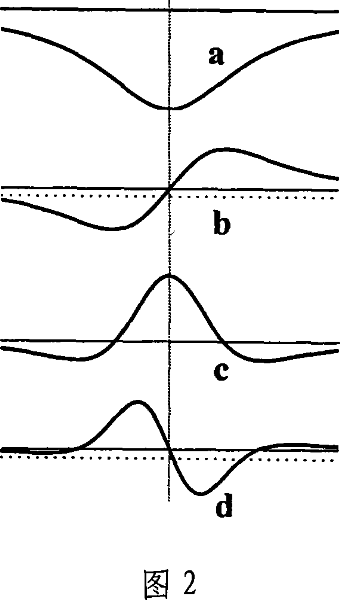

Method for detesting natural gas and toxic gas with real-time mobile remote sensor

Disclosed is a detecting method of natural gas and poisonous gas, utilizing a real-time mobile remote measuring sensor, wherein a multiple harmonic modulated semiconductor laser absorption spectroscopy method, an photoelectricity receiving system, a DSP software / hardware technology and a laser driving circuit are utilized. A laser beam emitted from an infrared laser emitting / receiving unit formed by a semiconductor laser, fibers, collimating mirrors, filters, photoelectric detectors and micro coke rate reflectors is output after it is collimated by the collimating mirrors through fibers, and then is scattered when it meets an objective. After a frequency selection and filtration by the filters, the scattered laser is then focused, by a reflector, to the photosensitive surface of the photoelectric detector where it is received. The analog signals of a photoelectric detection are digitalized and then sent to the DSP signals processor for a processing to provide concentration information of natural gas and poisonous gas to be tested between the emitting laser and the objective. Therefore, a continuous mobile detection of natural gas and poisonous gas invading into a production locale or a non-production locale is achieved to maintain the safety of the production locale or a non-production locale.

Owner:SINOPEC PETROLEUM ENG DESIGN

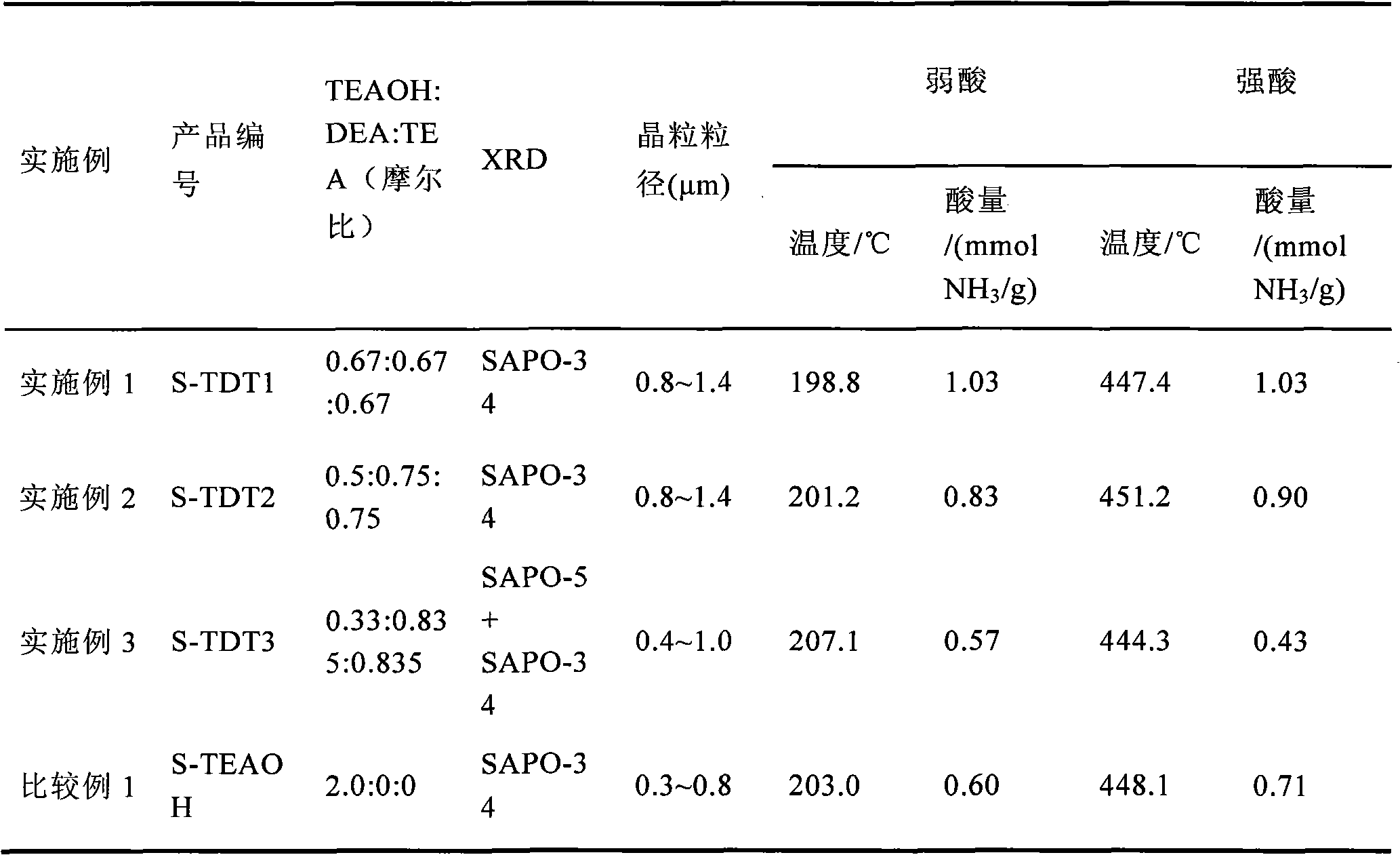

Silicoaluminophosphate molecular sieve and preparation method and application thereof

ActiveCN101857244ASolution to short lifeExtend your lifeMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveCoke rate

The invention relates to a silicoaluminophosphate molecular sieve and a preparation method and application thereof. The structure formula of the molecular sieve is (0.2-3.0) R: (Si0.01-0.3Al0.01-1P0.01-0.9 ):(10-400) H2O, and three templates, a silicon source, an aluminum source and a phosphorus source are mixed with water to form gel, and then the silicoaluminophosphate molecular sieve can be obtained by the steps of crystallization and drying. Compared with the preparation methods of the molecular sieve with single template and double templates in the prior art, the invention is taken as a catalyst and is applied to the reaction of light olefins from methanol, can improve the conversion rate of raw materials, delay coking rate, prolong reaction activity time, and improve the selectivities of ethylene and propylene, and simultaneously solve the problem that the synthesis cost of the silicoaluminophosphate molecular sieve is high in the prior art.

Owner:YANKUANG ENERGY R&D CO LTD

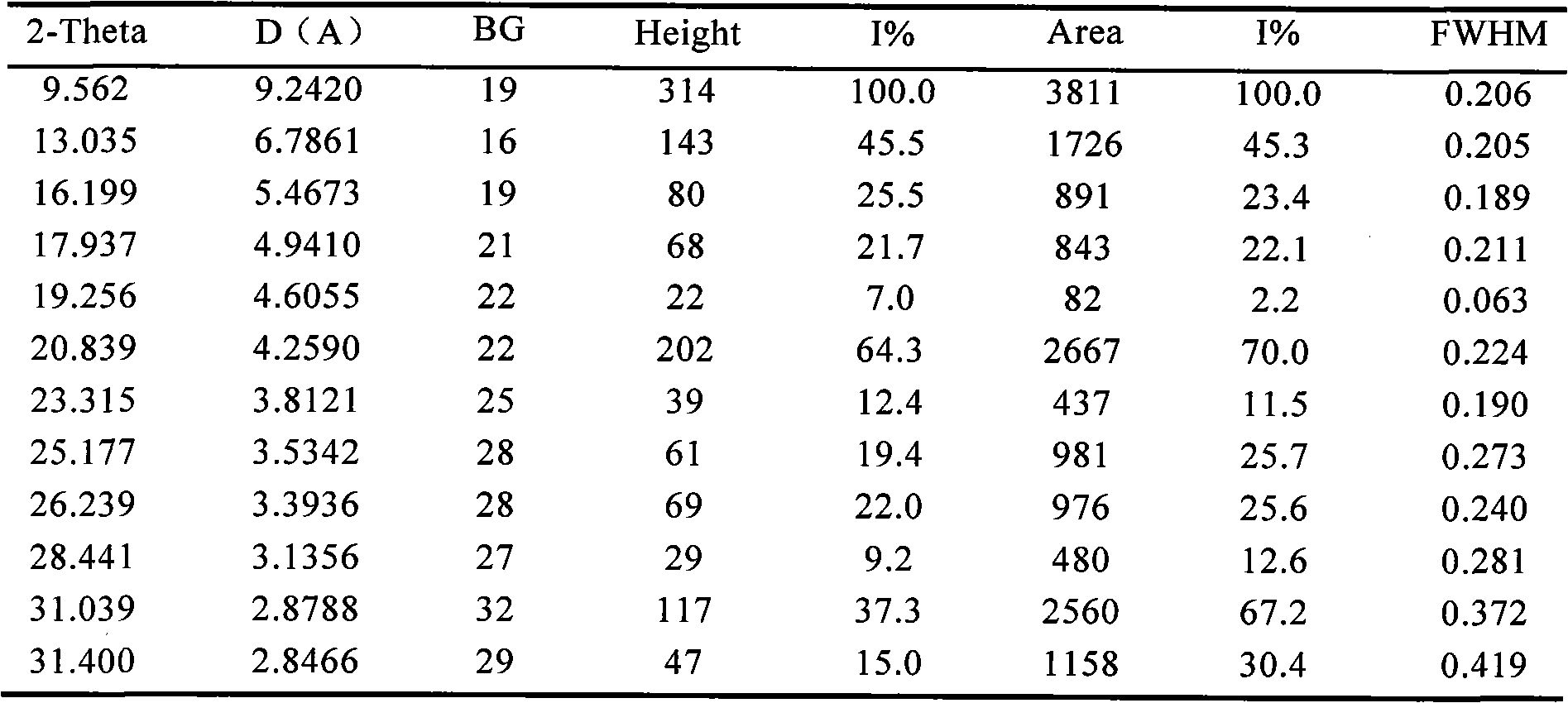

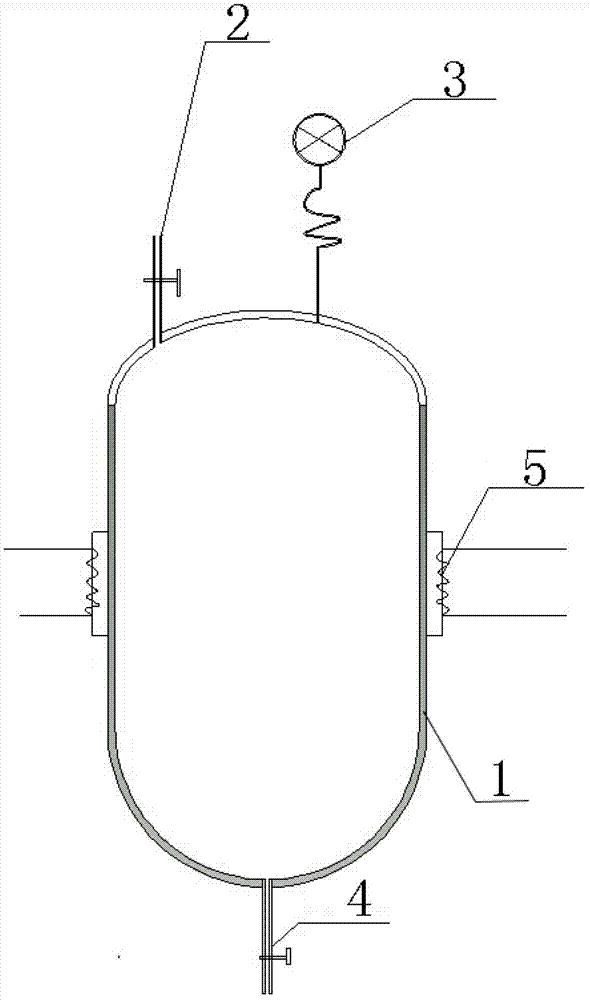

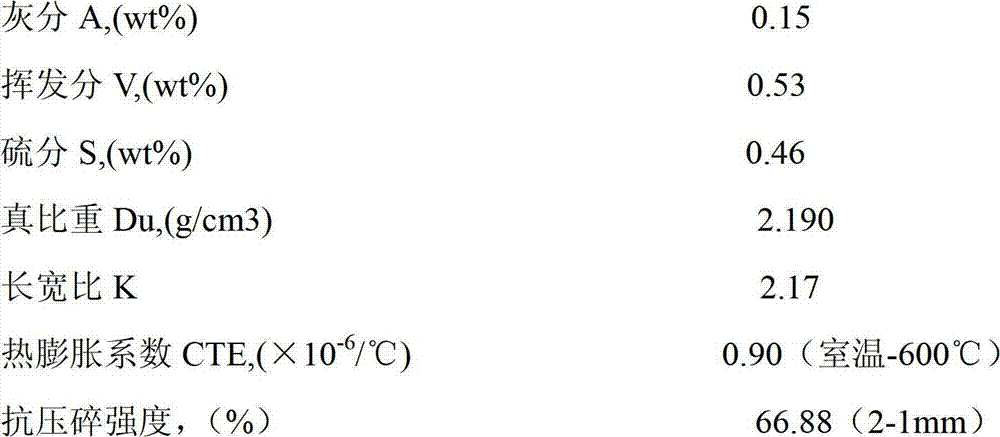

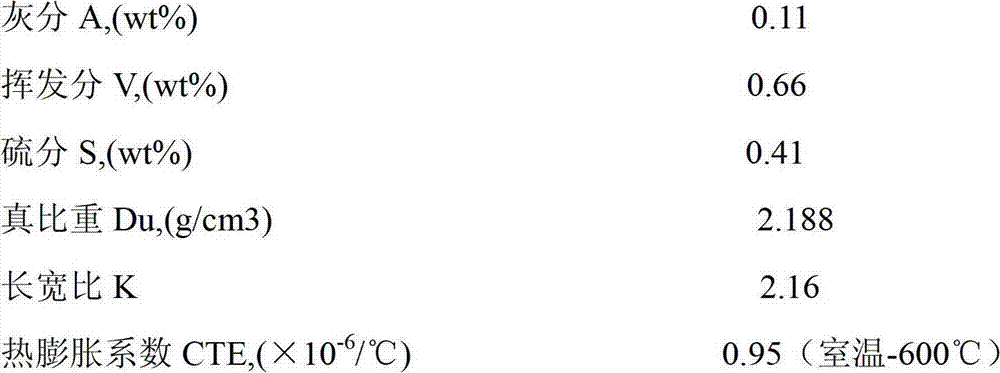

Method for preparing needle coke by magnetization reaction kettle

InactiveCN102965132ARelieve pressureEasy to controlEnergy based chemical/physical/physico-chemical processesCoking carbonaceous materialsCoke rateMagnetization

The invention relates to a device and a method for preparation of needle coke. A magnetization reaction kettle comprises a reaction kettle body, which is equipped with a pressure release valve, a pressure gauge, and an inert gas inlet. The reaction kettle is mainly characterized in that magnetization device are symmetrically arranged on two sides of the reaction kettle body. The device and the method provided in the invention have the advantages that: (1) the system has a small pressure, easy controllability, and high security; (2) the prepared needle coke has a good needle structure, a low thermal expansion coefficient, and high strength; and (3) the prepared needle coke has significantly improved appearance and coking rate, and the graphitization property at the later period can be improved.

Owner:FANGDA CARBON NEW MATERIAL CO LTD

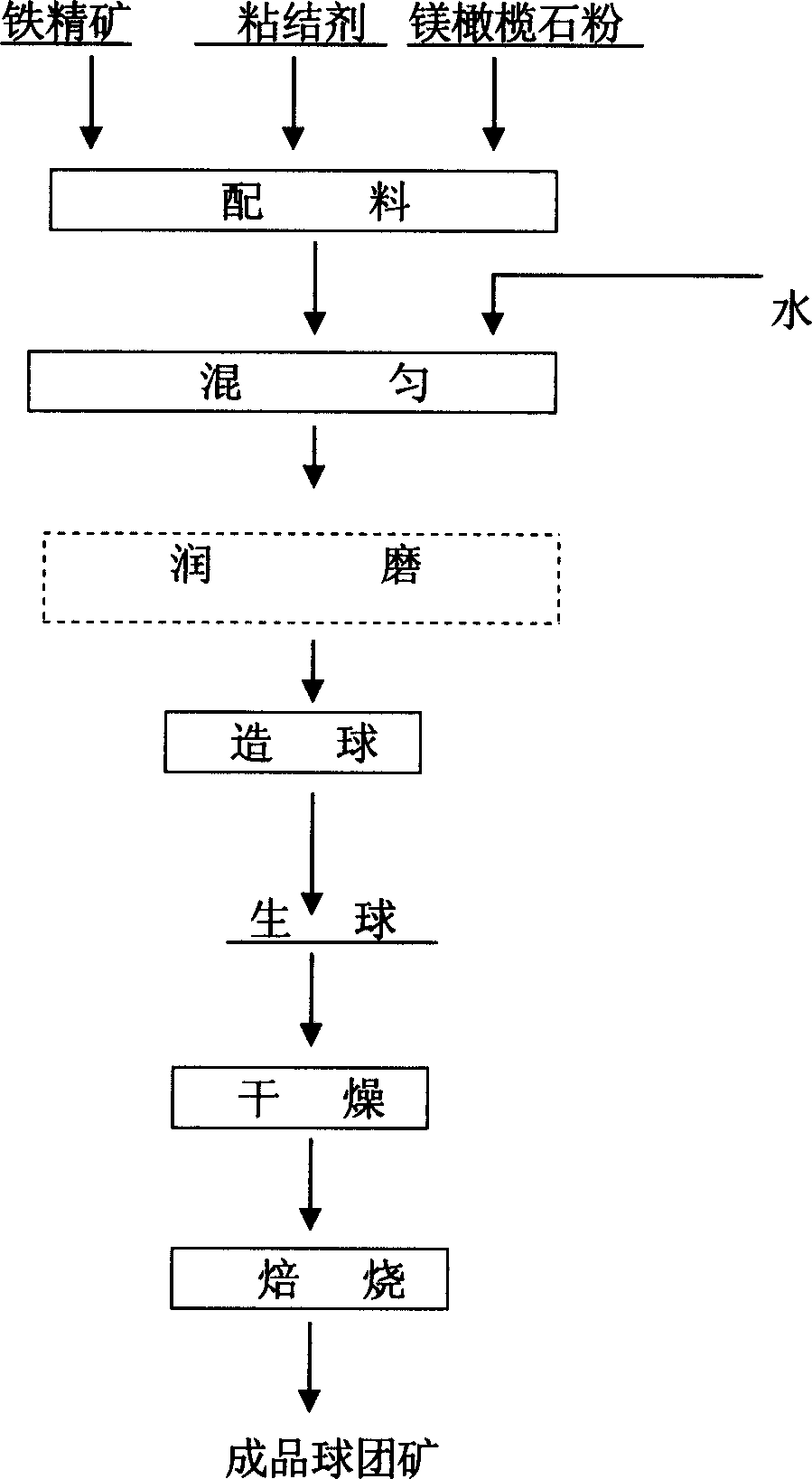

Method for producing magnesium olivine iron pellet

A process for preparing the forsterite-type iron ore ball includes such steps as proportionally mixing the powder of forsterite containing MgO (more than 43%) with bentone or wkd, grinding, spheroidizing, drying and calcining. It can increase the flowability of slog and the soft heat temp of burden, and decrease soft heat band, drop band, SiO2 activity and coke rate.

Owner:YICHANG KEBO OLIVINE

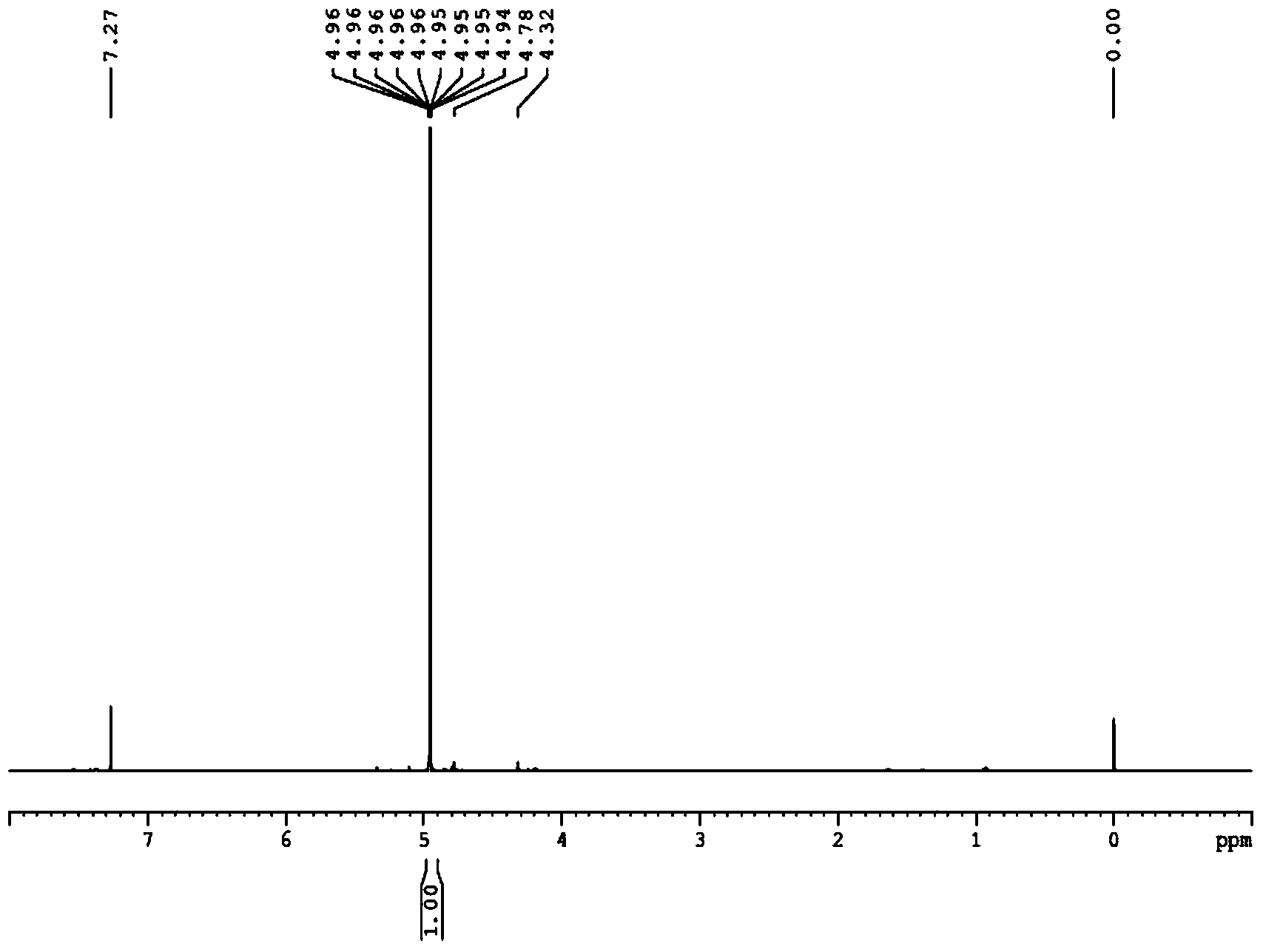

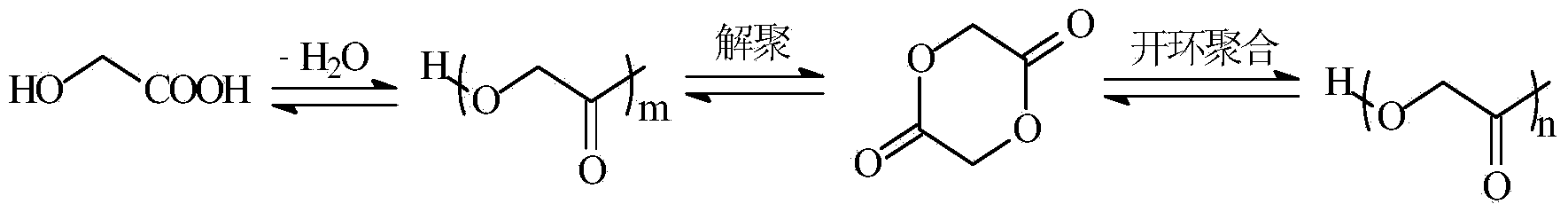

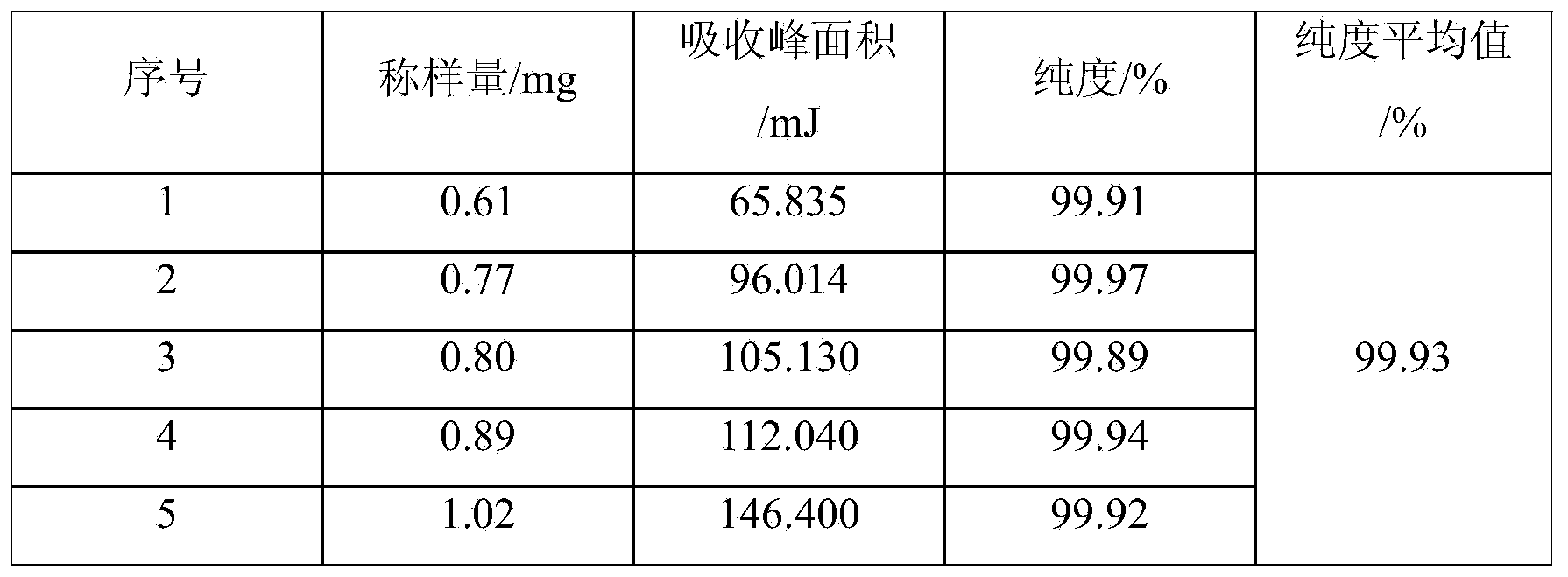

Low-temperature high-efficiency glycolide preparation method based on catalytic depolymerization

ActiveCN104163810AAvoid thermal degradation problemsDepolymerization temperature decreasedOrganic chemistryDepolymerizationCoke rate

The invention belongs to the field of preparation of glycolide monomers, and particularly relates to a low-temperature high-efficiency preparation process which is beneficial to increase the glycolide yield. The process can obviously reduce the depolymerization temperature of PGA oligomers, increase the glycolide yield and reduce the coking rate of a reaction system. The technical scheme is as follows: under the catalytic action of metal acetoacetonate, polyglycolic acid oligomers, or a mixture of polyglycolic acid and azeotropic solvent, or a mixture of polyglycolic acid, azeotropic solvent and cosolvent is depolymerized to prepare the glycolide monomer; and the reaction temperature of the glycolide monomer preparation based on depolymerization can be reduced to 160-210 DEG C.

Owner:CHANGZHOU UNIV

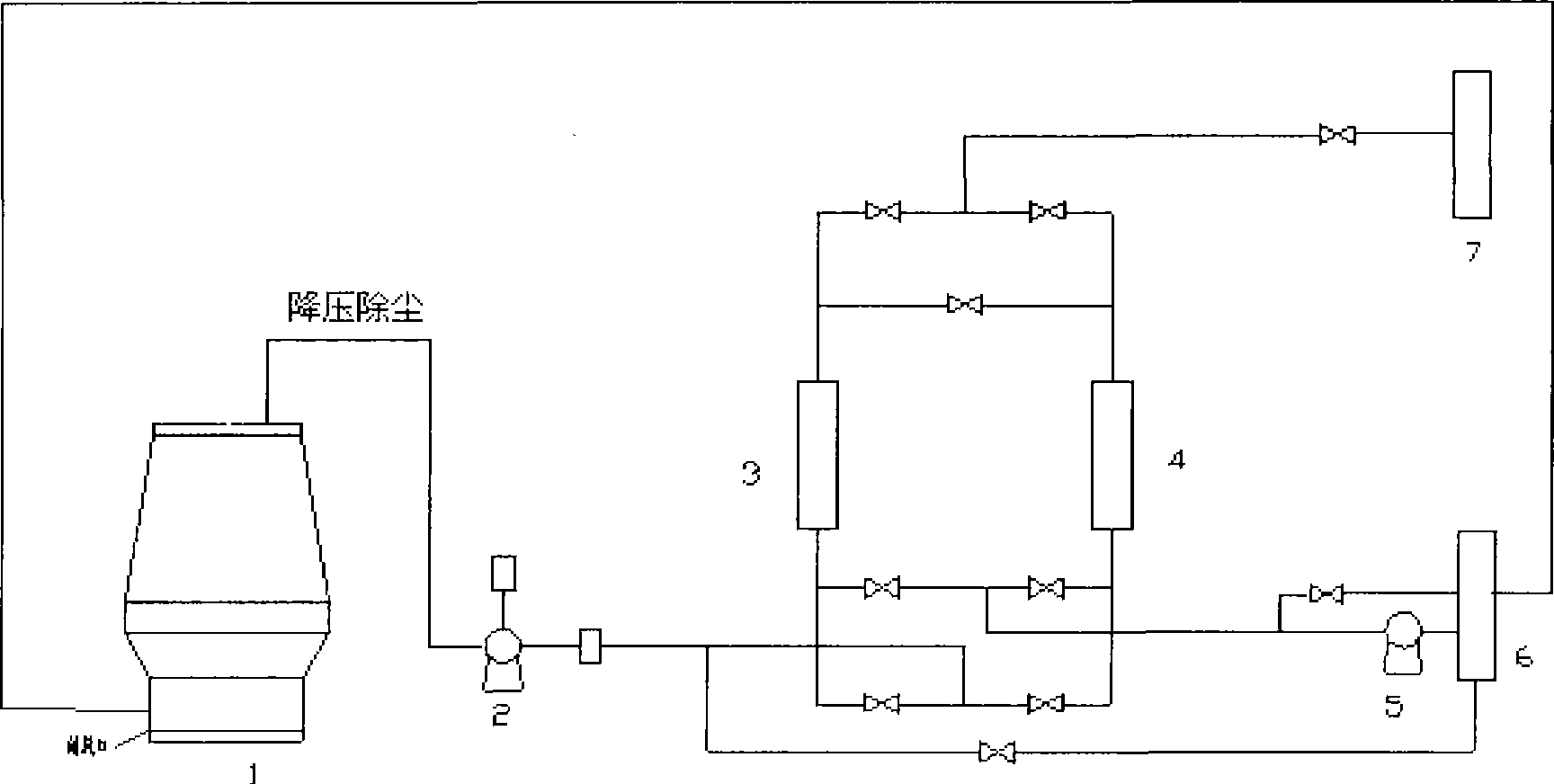

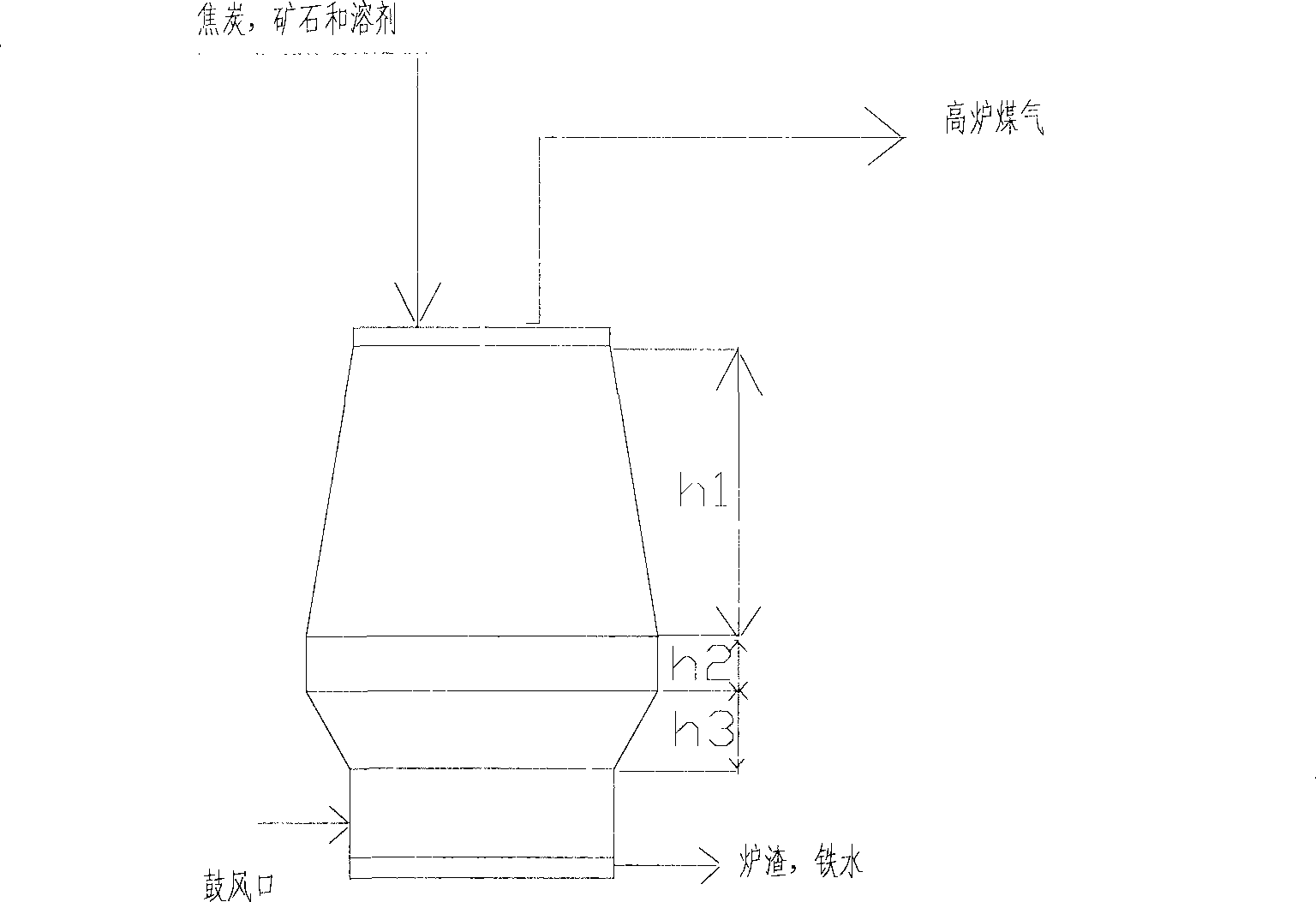

Blast furnace iron manufacturing process

The invention relates to a method for ironmaking by a novel blast furnace. A pressure-swing absorption apparatus and a blast furnace ironmaking device are combined and applied. Carbon monoxide is enriched from blast furnace coal gas by the pressure-swing absorption apparatus after cooling and removing dust, and the enriched carbon monoxide returns to the blast furnace from different parts of the blast furnace. The invention not only lowers coke consumption during the ironmaking process and reduces the coke rate and the energy consumption for ironmaking by the blast furnace, but also solves the problem that utilization rate of the blast furnace coal gas is low. The invention reduces the emission of harmful gas, such as the carbon monoxide, carbon dioxide and the like and is good for the environmental protection. Under proper condition, the coke rate can be reduced from 420kg / t to 180kg / t by the method to the maximum.

Owner:BEIJING PEKING UNIV PIONEER TECH

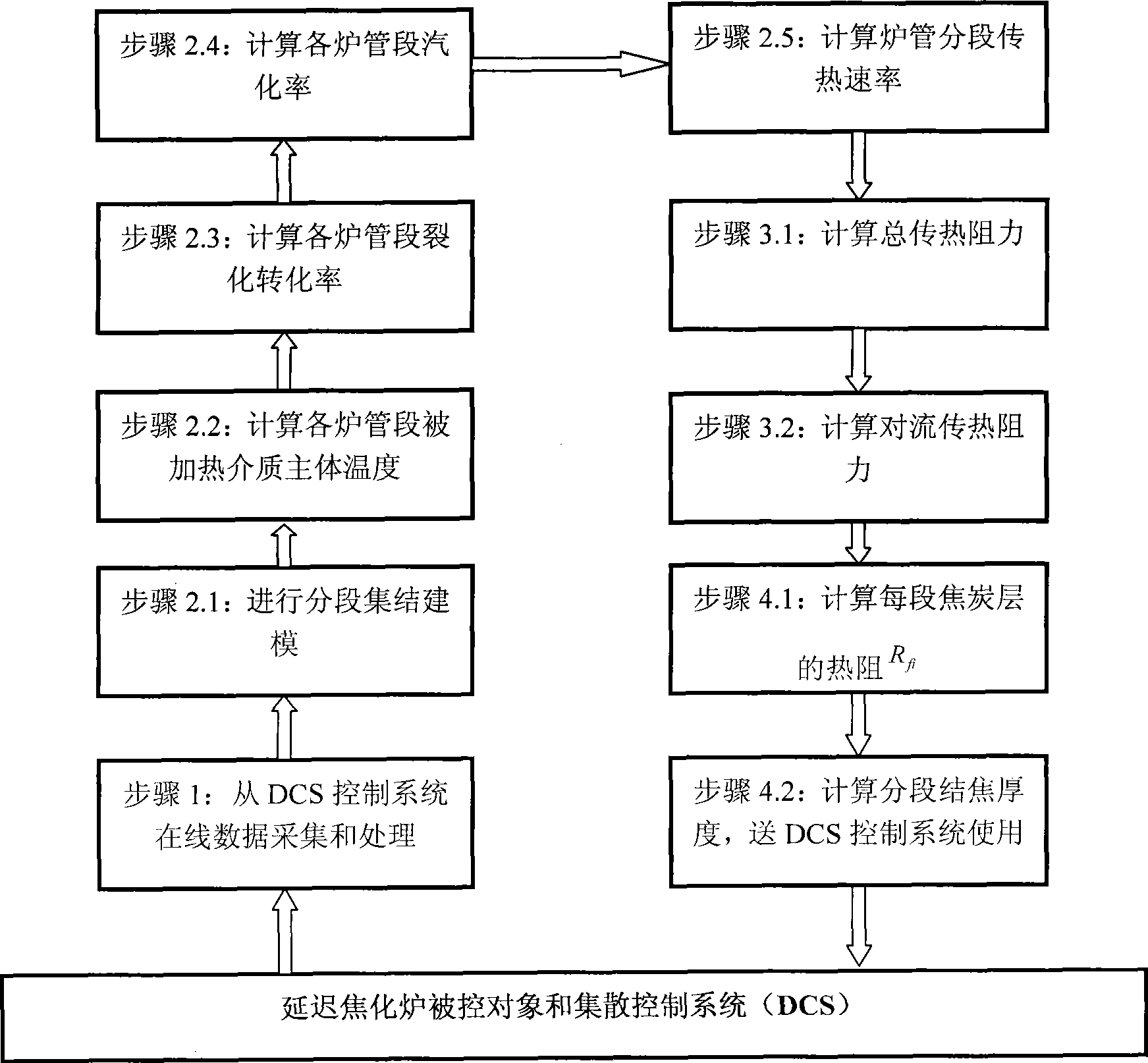

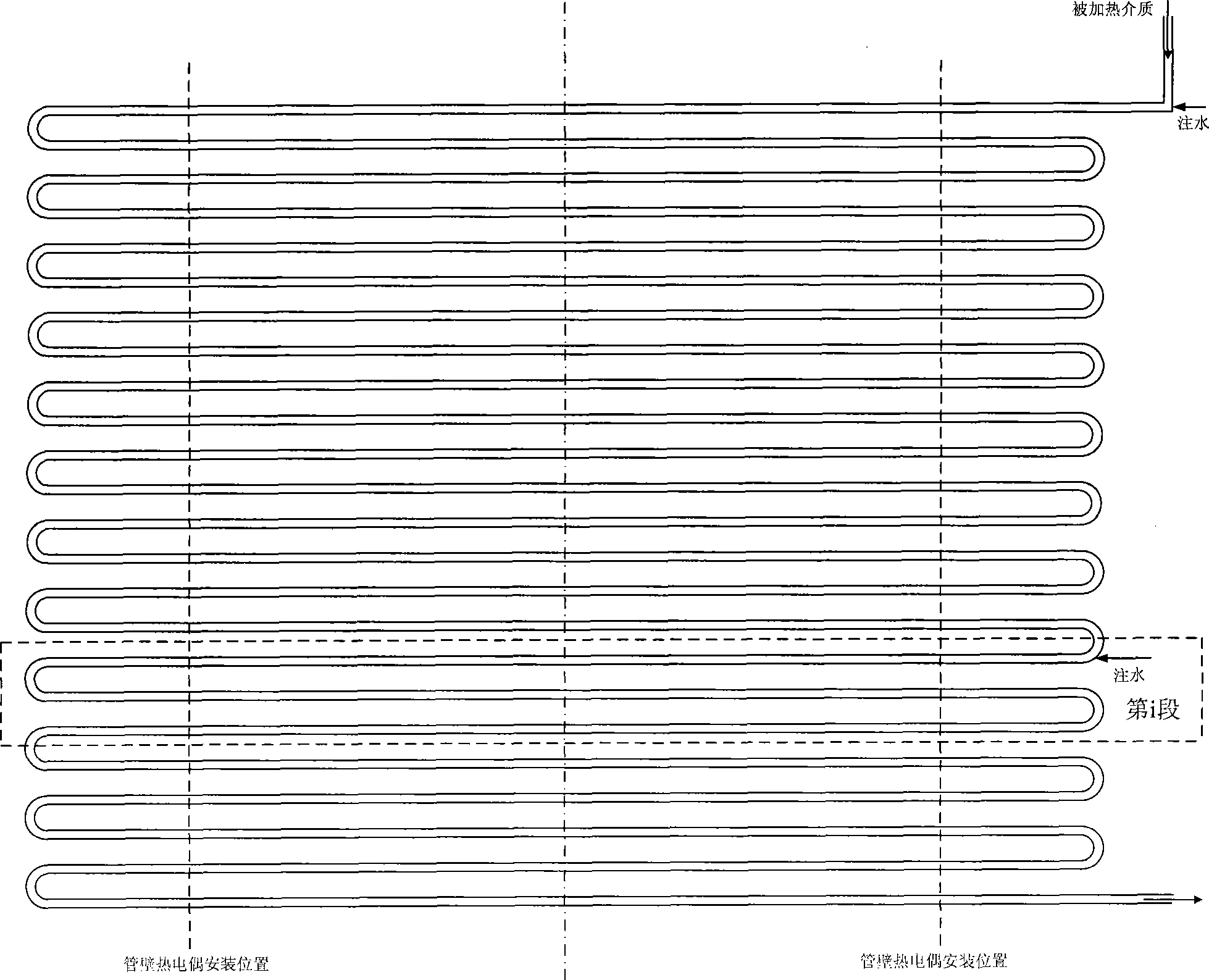

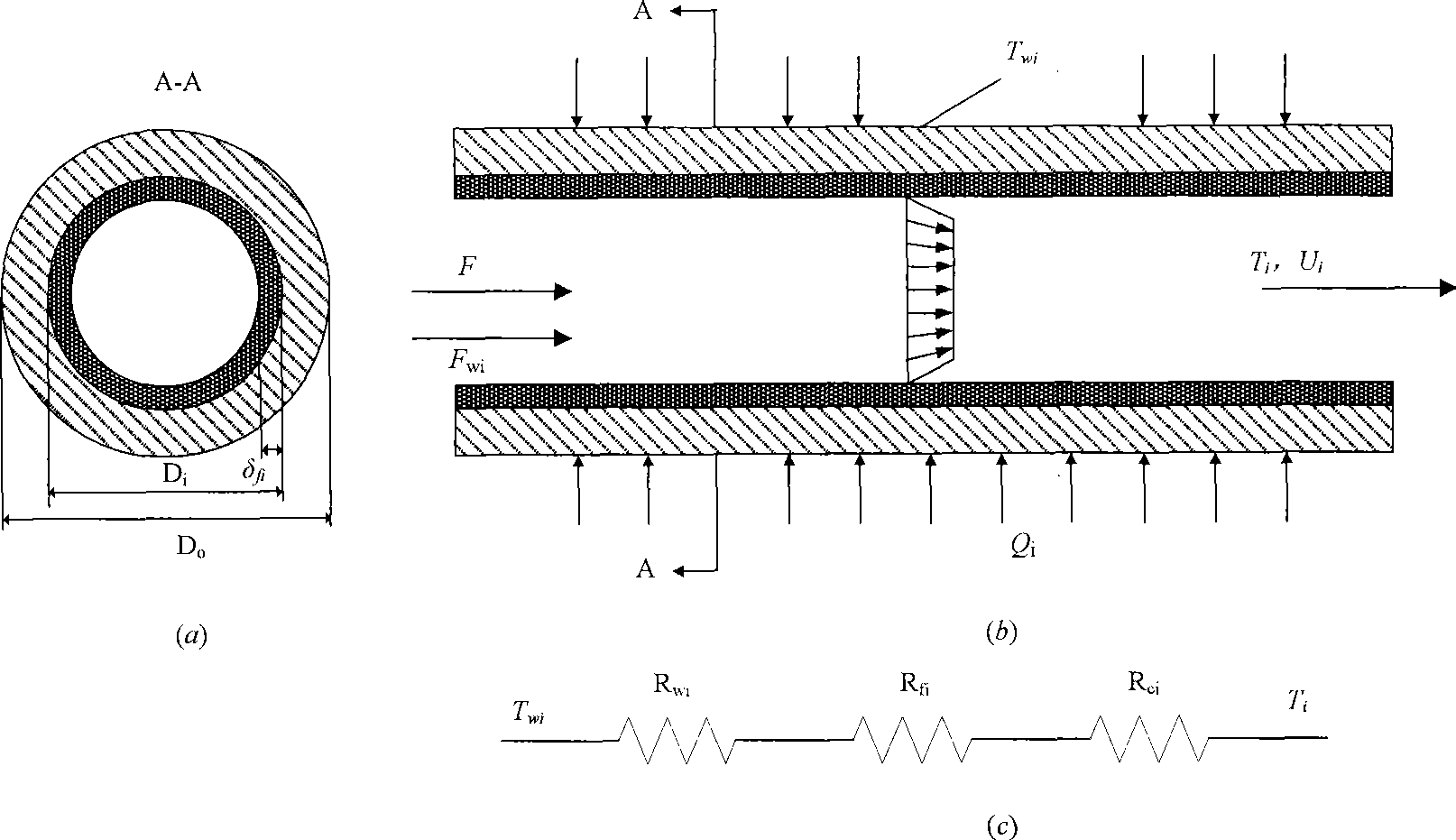

On-line detection method for tube coking thickness of delay coking heating stove

InactiveCN101498578ASuitable for online monitoringReduce dependenceThermal non-catalytic crackingMeasurement devicesAutomatic controlCoke rate

The invention relates to an on-line detecting method for delaying the coking of a furnace tube in a radiation chamber of a coking heating furnace, belonging to the technical field of automatic control of heating furnaces. The method is characterized in that the furnace tube is segmented according to the tube wall temperature measuring position and the water injection position of the heating furnace; process variables which are actually measured are collected, the total heat transmission resistance and the convection heat transmission resistance in different positions of the furnace tube of the heating furnace are obtained by on-line computation through process calculation and mathematical models such as heat transmission, reaction, and the like in the furnace tube of the heating furnace, and then, the coking thicknesses of the furnace tube in different positions are determined. The observed coking result can provide reference for production operation and decoking so as to improve the security and the economical efficiency in the process of the operation of devices. On the basis of the method, the relationship between the coking rate and each operating parameter of the furnace tube can be researched, the coking rate can be forecast, and reasonable controlling and optimizing methods are designed to delay the coking of the furnace tube.

Owner:TSINGHUA UNIV

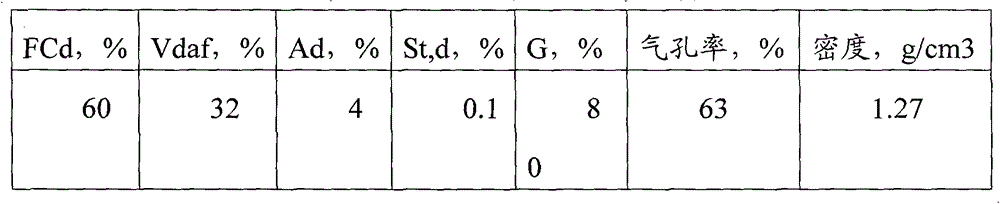

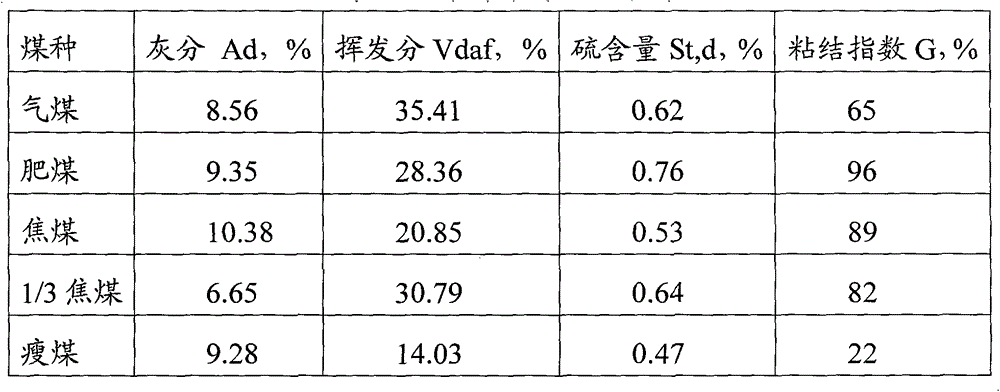

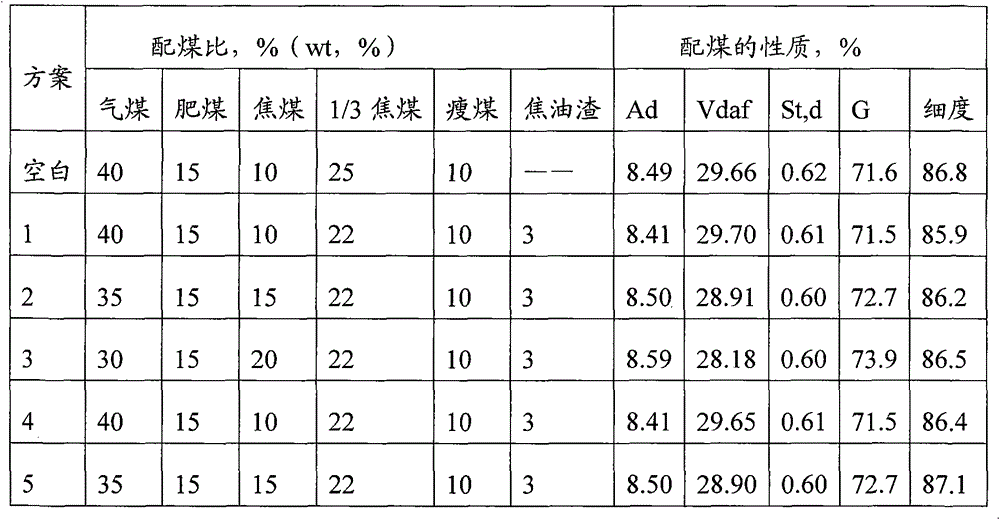

Method for coking tar residue in coal blending manner

The invention relates to a method for coking tar residue in a coal blending manner. According to the technical scheme, the method comprises the steps of selecting a coal blending ratio, carrying out the coking experiment for blending the tar residue by utilizing a 20kg small coke oven and analyzing the quality of coke. The raw material consists of gas coal, fat coal, coking coal, 1 / 3 coke coal, lean coal and tar residue, wherein the gas coal accounts for 35 to 40 percent by mass, the fat coal accounts for 15 percent by weight, the coking coal accounts for 10 to 20 percent by weight, the 1 / 3 coke coal accounts for 19 to 25 percent by weight, the lean coal accounts for 10 percent by weight, the tar residue accounts for 3 to 6 percent by weight, and the tar residue is firstly independently crushed and then blended with the raw material to be coked. The method is used for coking the coal, so that not only is the environmental pollution problem caused by the tar of a coking plant be solved, but also the coal source is saved, the secondary utilization of the energy is realized; and moreover, by adding the tar residue, the lump coke rate of the coke can be obviously increased, and a novel way for reducing the cost and improving the efficiency can be provided for the coking plant.

Owner:田秀文

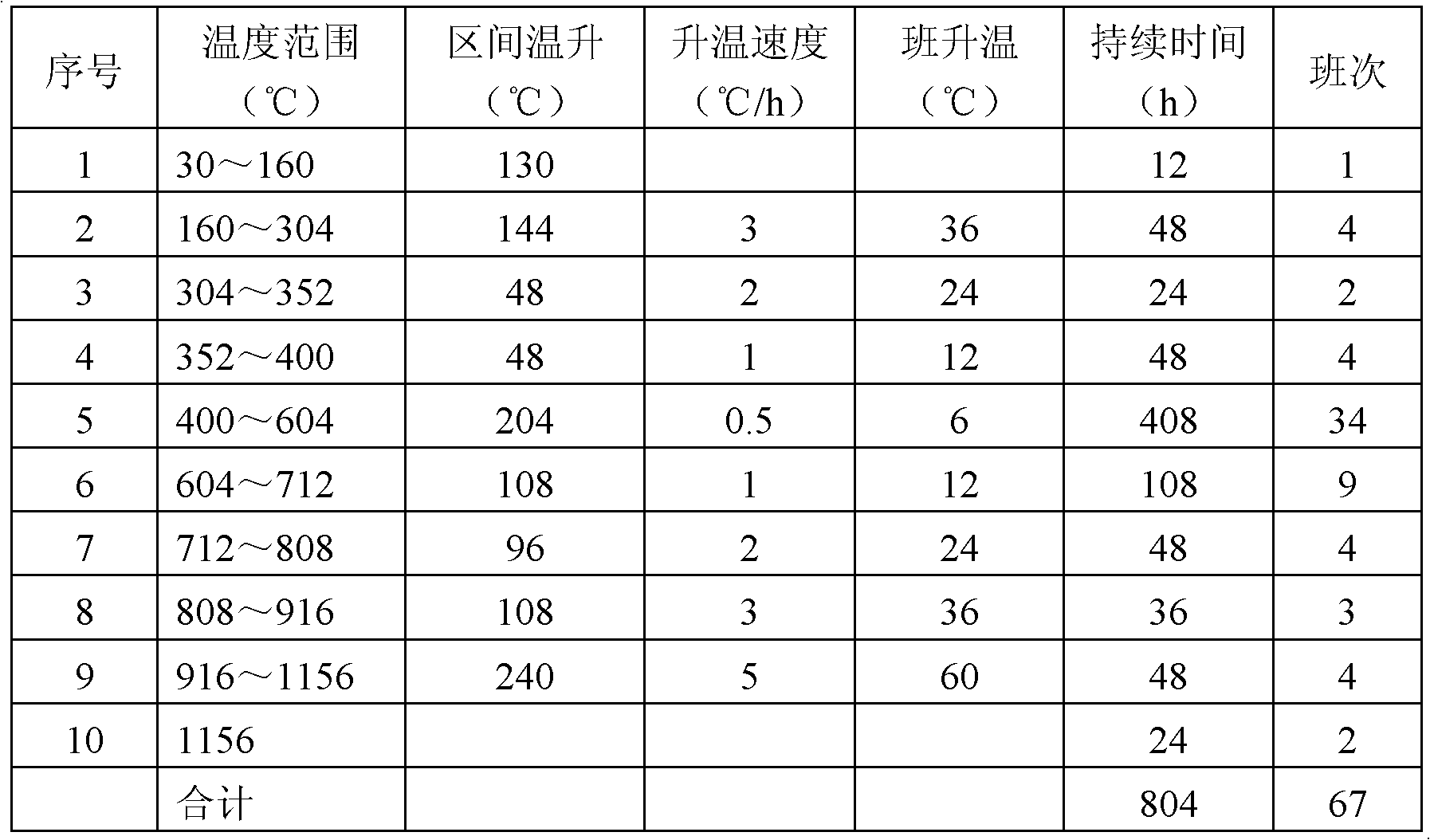

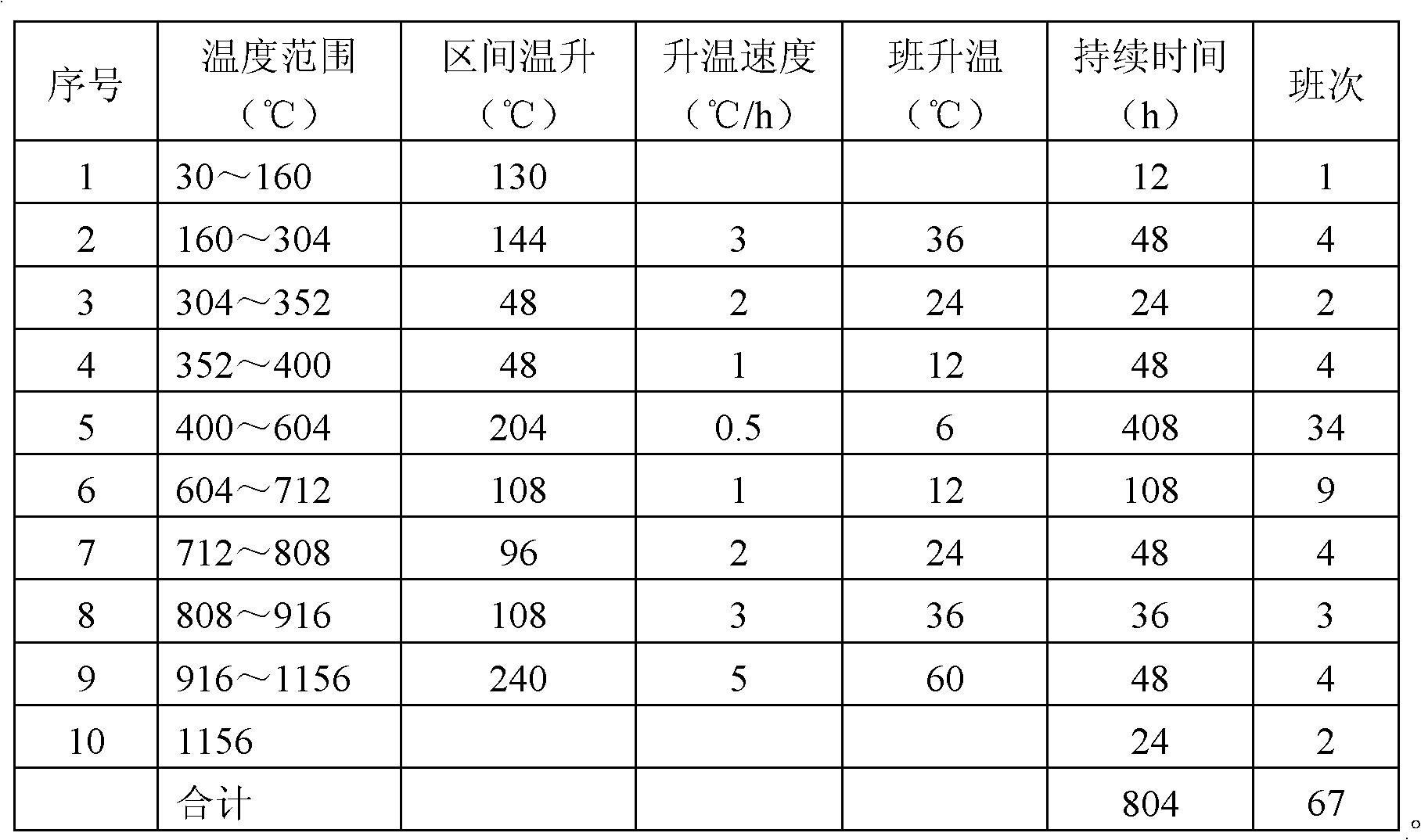

Pressurization roasting method for carbon

The invention provides a pressurization roasting method for carbon, and relates to a carbon roasting process. The pressurization roasting method for the carbon can avoid shell wastes, reduce the crack wastes caused by temperature difference and shorten the roasting time. The method comprises the following steps of: placing a compression green body product in a saggar, and filling a filler betweenthe product and the saggar; and after the product is filled in the saggar, sealing and vacuumizing, inflating nitrogen, placing in a roasting furnace, and heating, wherein the pressure is kept 2.5 to1.5 MPa, and when the pressure exceeds an upper limit, the pressure can be released through a valve and the valve is closed when the pressure is close to the lower limit. By using the anaerobic state, the shell wastes are avoided. By using the saggar, the periphery of the product is heated uniformly, the temperature difference among positions of the product can be reduced and the crack wastes caused by the temperature difference are reduced. An 804-hour roasting curve is performed for roasting and the roasting time can be reduced by about 12 percent. Through experiment, under the same condition, compared with the conventional carbon roasting method, the pressurization roasting method can obviously improve the product yield, coking rate, volume density and recovery yield.

Owner:福建兴朝阳硅材料股份有限公司

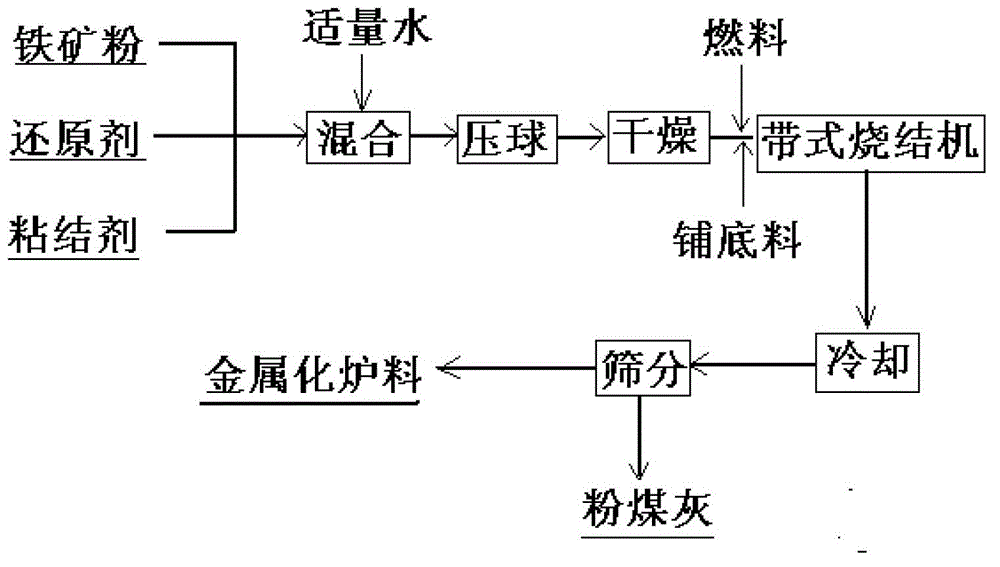

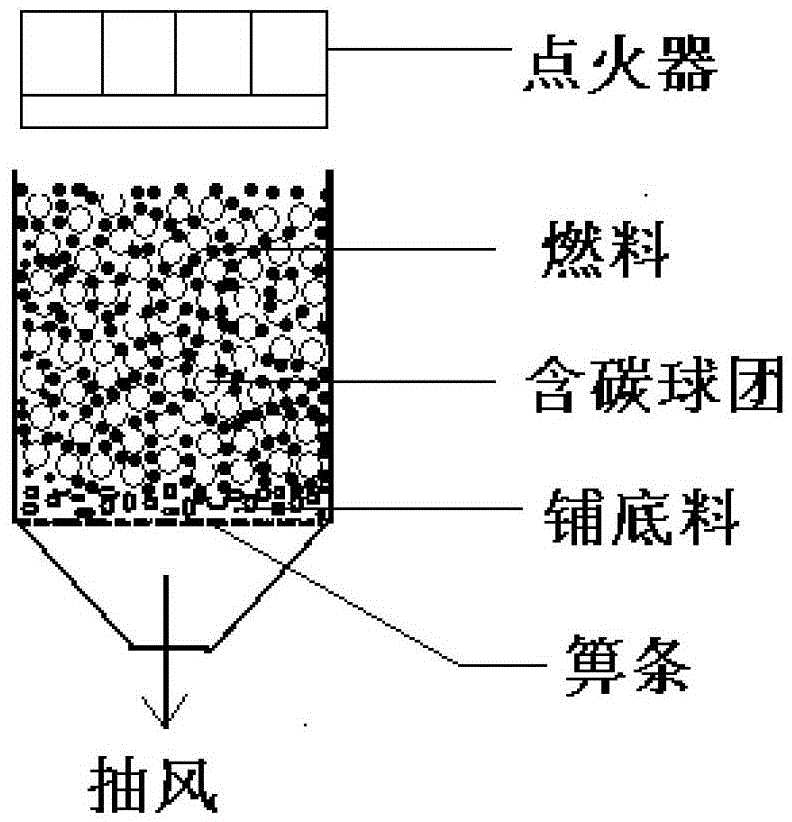

Production process for metalized burden suitable for blast furnace ironmaking

ActiveCN104004905AReduce focal ratioReduce the burden onBlast furnace detailsProduction rateAlkalinity

The invention discloses a production process for metalized burden suitable for blast furnace ironmaking. The production process comprises the steps of (1) mixing iron ore powder, a reducing agent and a binder according to a mass ratio of 100:4-25:2-5, wherein the reducing agent is one or two selected from coke powder or anthracite duff and the binder is a binder capable of adjusting alkalinity; (2) mixing the above raw materials thoroughly, wetting the mixture by adding water, pressing the uniformly mixed raw materials on a twinroller machine to obtain pellets; (3) mixing the pellets with fuels, carrying out high temperature reduction of the pellets on a belt-type sinter machine, the addition amount of the fuels being 7-20% that of the pellets; and (4) screening sintered products and applying parts fitting to requirements of the metalized burden in blast furnace ironmaking. When in use, the metalized burden obtained by the process can reduce blast furnace coke rate by 10-30%, significantly reduce burden of direction reduction at the lower part of the blast furnace and increase capacity factor of the blast furnace, thereby greatly increasing production rate of the blast furnace and increasing competitive power of a blast furnace ironmaking process.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method for 2-hydroxy-4-methylthio-calcuim butyrate

ActiveCN104356035ARaise the reaction temperatureNo decompositionSulfide preparationCalcium hydroxideCoke rate

The invention discloses a preparation method for 2-hydroxy-4-methylthio-calcuim butyrate. The method is characterized by comprising the following step of reacting reaction raw materials comprising a 2-hydroxy-4-methylthio-butyric acid solution and one or more of calcium hydroxide, calcium oxide and calcium carbonate with ammonium bisulfate introduced as an organic reaction catalyst to obtain the 2-hydroxy-4-methylthio-calcuim butyrate. The method has the advantages of being mild in reaction, free of specific stirring tools, high in universality, less in equipment investment, low in production cost, convenient to use, mild and controllable in the whole reaction process, low in probability of product decomposition or coking rate, complete in reaction, time-saving, high in product yield, purity and yield, energy-saving and more environment-friendly.

Owner:宁波它世界生物科技有限公司

Metallurgical coke briquette

InactiveCN1337441ANo dischargePollution controlSpecial form destructive distillationCoke rateSmall footprint

The present invention relates to a method for producing industrial metallurgical formed coke by using binding coal, weak caking coal, fat coal and gas fat coal. It is made up by using the following raw materials: (by weight portion) coal 100 0portions, humate (powder) 2-5 portions and detackifier 4-9 portions, in which the detackifier is made up by using the following raw materials: (by weight portion) mixture of corn starch 3-9 portions and water 100-200 portions, sodium hydroxide 4-12 portions, liquid mixture of polyvinyl acetate and water according to the ratio of 1:5, 2-8 portions and starch paste. As compared with existent technology, it is short in coking time, can effectively control environmental pollution, its block coke rate is high, production cost is low, and it can a handred per cent extract tar and lots of gas.

Owner:李志远 +1

A method of delayed coking

Owner:CHINA PETROLEUM & CHEM CORP +1

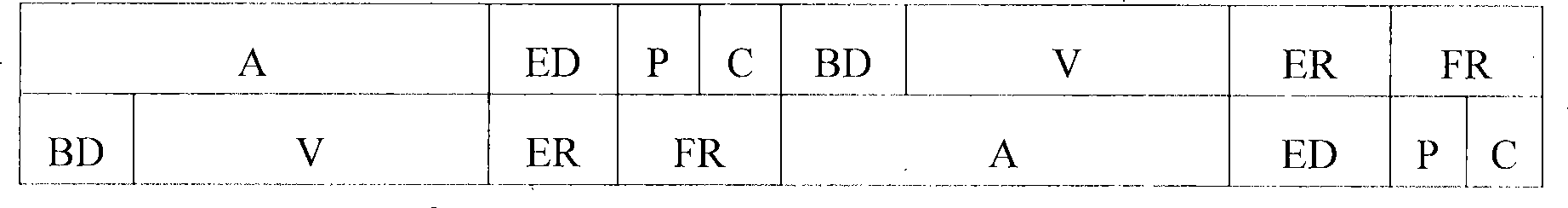

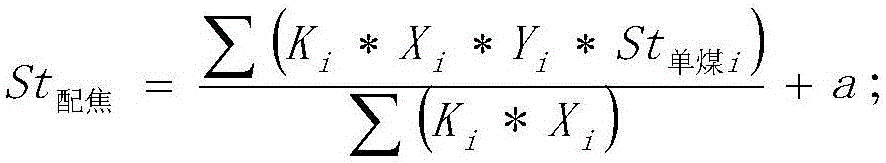

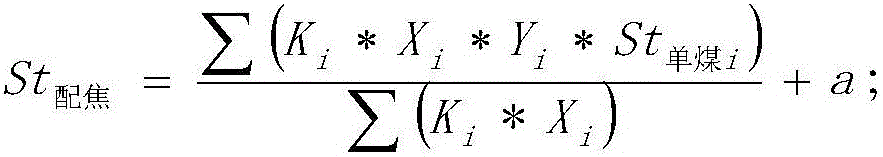

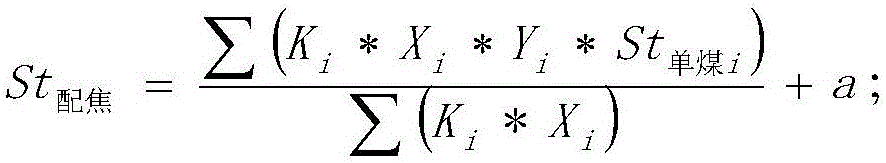

Method for predicting sulfur contents in mixed coal coking

ActiveCN106190209AUniversally applicableImprove forecast accuracyCoke ovensCoke rateConversion coefficients

The invention provides a method for predicting sulfur contents in mixed coal coking. According to the method, the sulfur contents of single-kind coal, the sulfur content conversion coefficient of the single-kind coal in the coking process, the total coke rate and the use proportion in the mixed coal are used as parameters for predicting the sulfur content in the mixed coal coking. According to a prediction calculation method of the sulfur contents in the mixed coal coking, the formula shown as the accompanying drawing is used. The method provided by the invention has the advantages that the differences of different single-kind coal after the coke smelting are sufficiently considered; the defect that in the prior art, the sulfur content conversion coefficient of different kinds of coals are determined into a fixed value in a certain interval according to an empirical formula is overcome; meanwhile, the errors between the small coke oven coking test results and a production coke oven are considered, the prediction results are corrected; the prediction precision is greatly improved; the prediction model has general applicability; the prediction precision reduction caused by too great coal distribution scheme change is avoided.

Owner:SHOUGANG CORPORATION

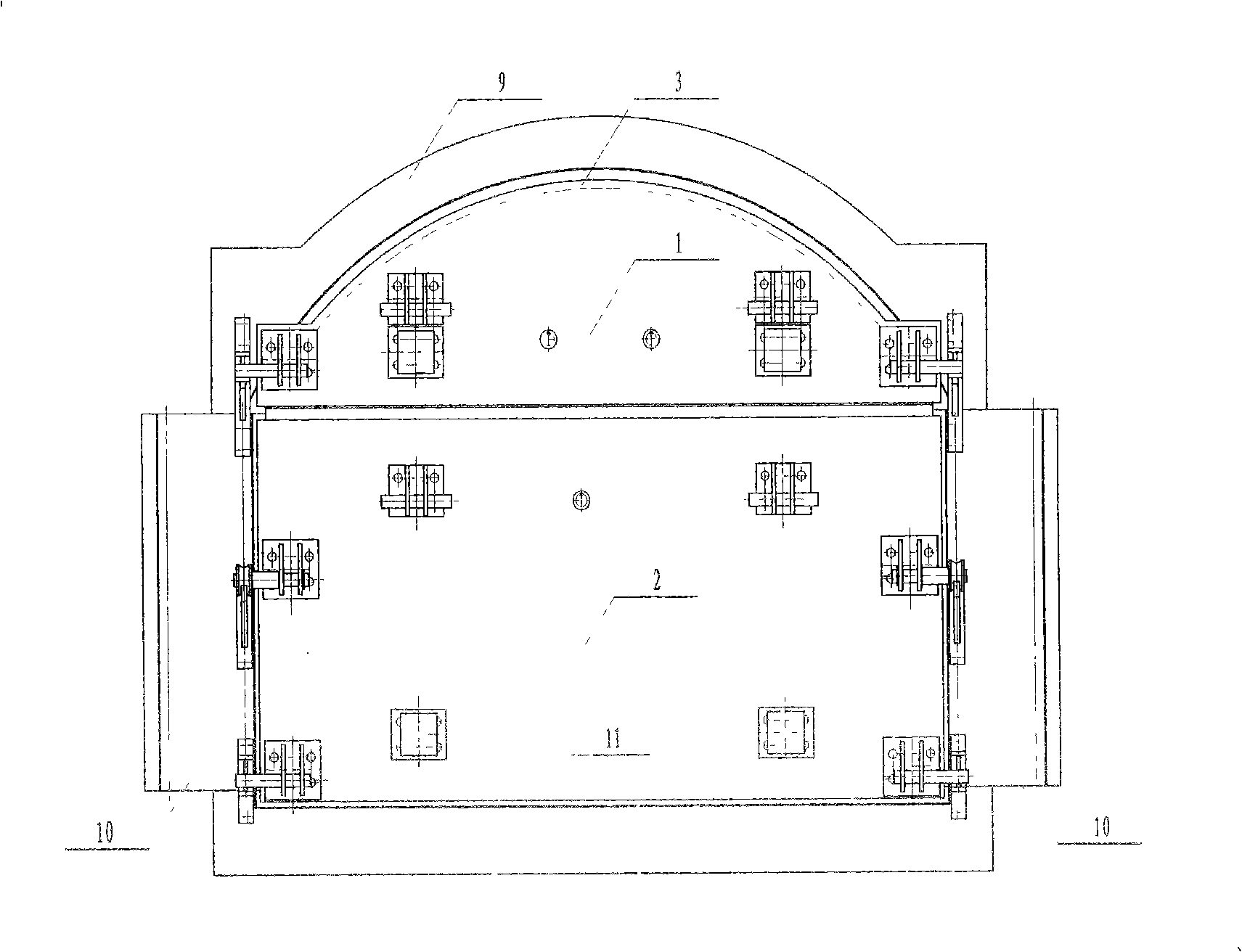

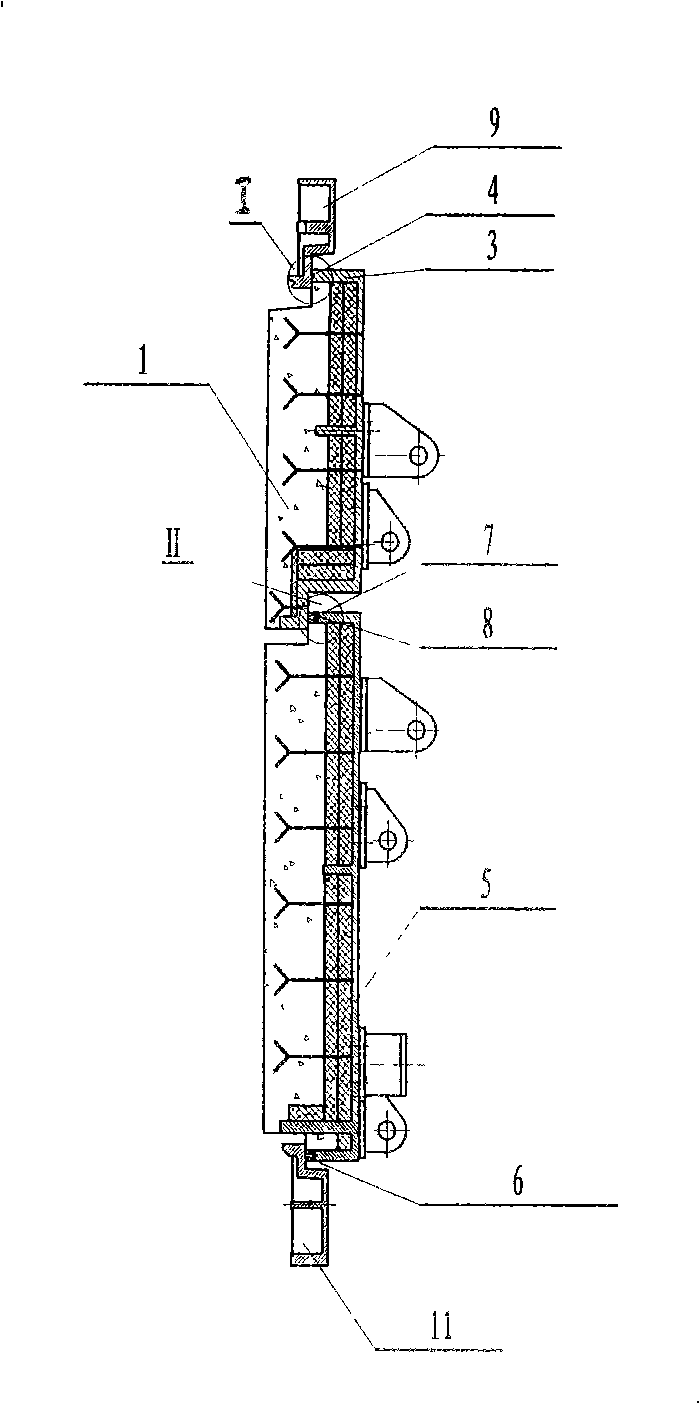

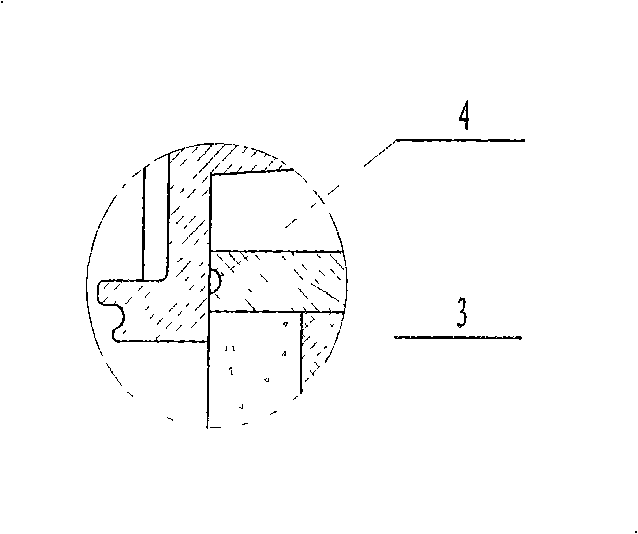

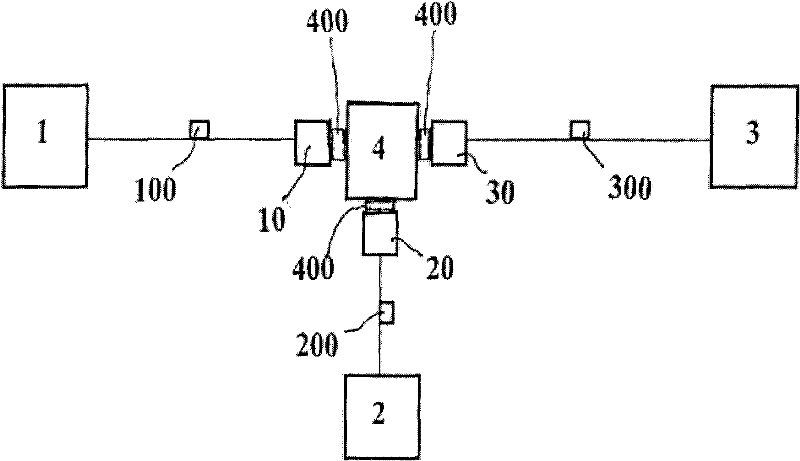

Cleaning type heat reclamation coke oven door

The invention relates to a clean heat recovery coke oven door, which comprises an upper oven door 1, a lower oven door 2, an upper guard plate 9, intermediate guard plates 10 and a lower guard plate 11, wherein, the upper guard plate 9 is arranged on the upper oven door 1; both sides of the lower oven door 2 are provided with the intermediate guard plates 10; the lower guard plate 11 is arranged under the lower oven door 2; the width of the lower edge of the upper oven door 1 is equal to the width of a carbonization chamber; the height of the lower edge of the upper oven door 1 is parallel tothe upper guard plate 9; an upper segmental arc 3 is arranged on the upper edge of the upper oven door 1; a semicircular groove 4 is arranged on the upper segmental arc 3; a braided asbestos round packing is arranged inside the semicircular groove 4; the lower oven door 2 consists of an oven door body 5 and four detachable cast iron bars 6 provided with dovetail grooves 7; and flat ceramic fiber ropers are arranged inside the dovetail grooves 7. The clean heat recovery coke oven door changes the sealing form of the oven door from rigid surface contact to flexible seal, solves the problems of unprecise seal and inorganized air inlet of a coke oven during the coking process, reduces the coke rate, improves the overall coke yield, and reduces the resource waste.

Owner:山西沁新能源集团股份有限公司

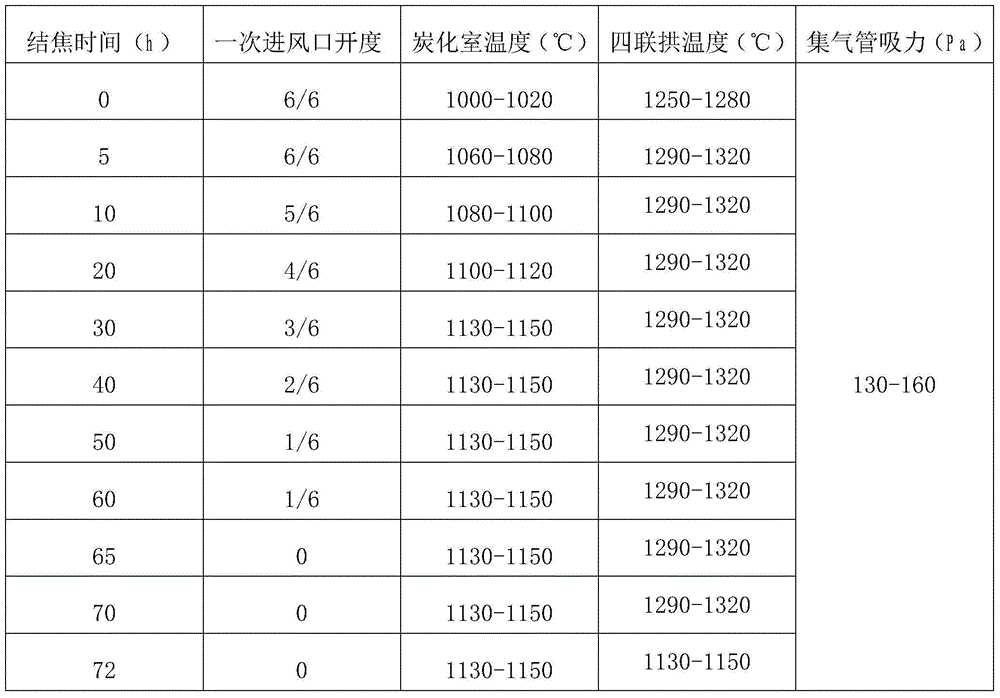

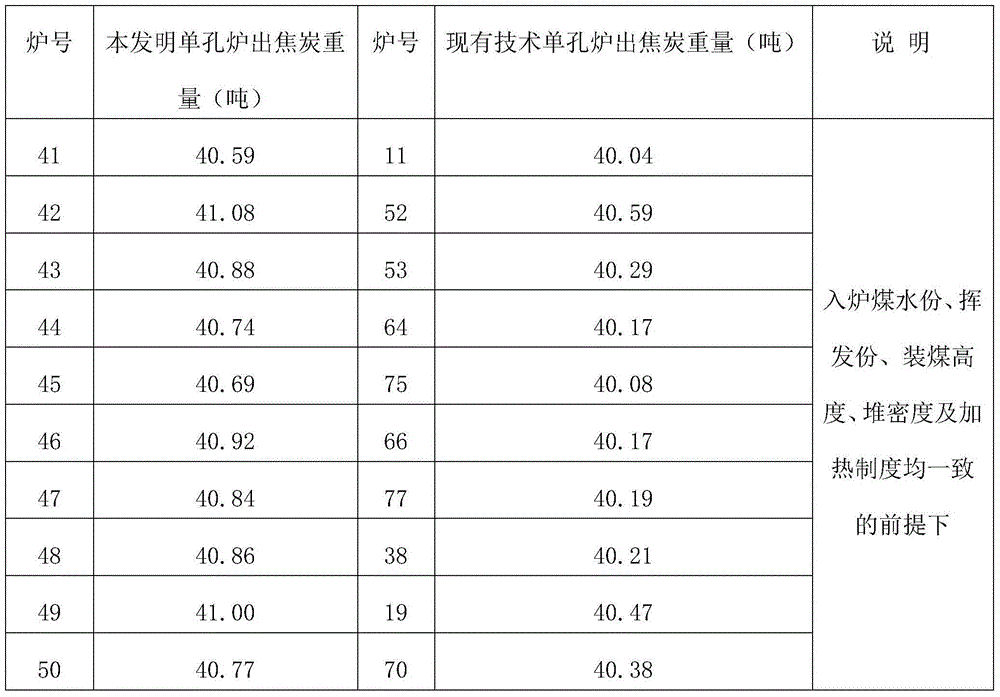

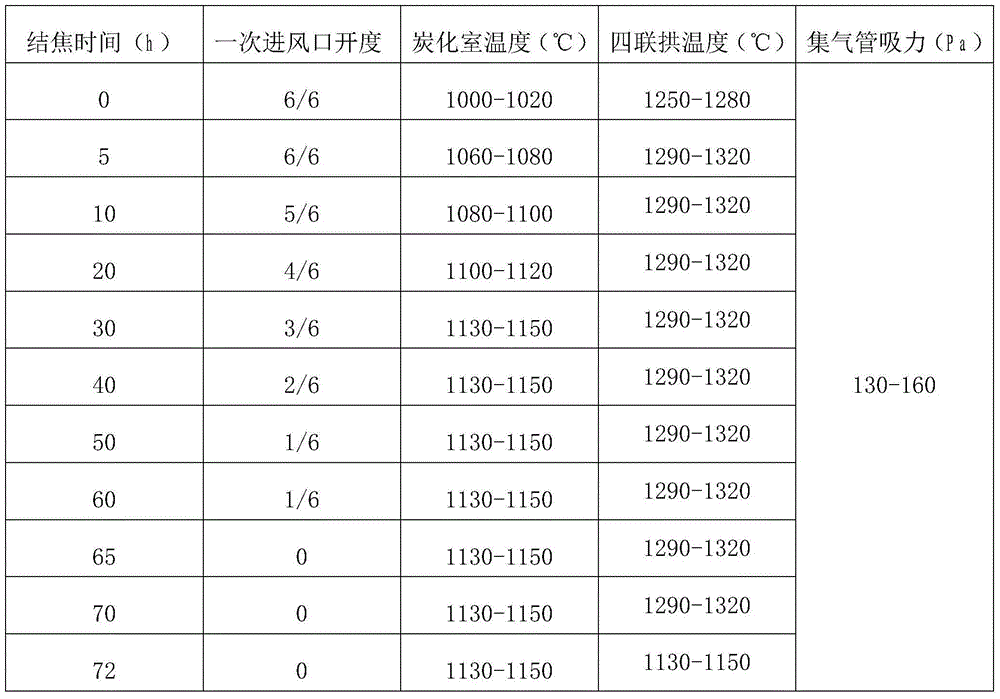

Method of improving total coke rate of heat recovery coke oven

InactiveCN104449767AIncrease productionImprove qualityCombustible gas coke oven heatingCoke rateCoke oven

The invention belongs to the technical field of the coking method and specifically relates to a method of improving a total coke rate of a heat recovery coke oven. The method mainly solves technical problems that the coking of coke cake surfaces easily gets out of control, the coking temperature is difficult to control, the coking of the coke cakes is easily increased and the over-coking of the coke occurs easily in the present heat recovery coke oven. The technical scheme is as follows: five primary air inlets are arranged at the top of the heat recovery coke oven; after coal cakes are placed in a coking chamber of the heat recovery coke oven, the openness of the four primary air inlets at the top of the heat recovery coke oven are set as an full-open state; the openness of the primary air inlets is adjusted according to the coking time, and meanwhile, the temperature of the coking chamber of the heat recovery coke oven and the temperature of a four-joint arched fire channel are adjusted; after the coking of 72 hours, the burning in the coking chamber of the heat recovery coke oven is observed; once the flame in the coking chamber disappears, the coked cakes are discharged out of the oven immediately. The method of improving the total coke rate of the heat recovery coke oven has the advantages of easy control of the coking temperature, high quality of the coked cakes and high yield of single oven of the coked cakes.

Owner:山西兴高能源集团股份有限公司

Hot delivery and hot charging process of blast furnace iron making raw material and device thereof

InactiveCN102191344AReduce production energy consumptionImprove strength qualityBlast furnace detailsCoke rateMetallurgy

Owner:SHANDONG TIEXIONG METALLURGICAL TECH CO LTD

Suspended bed hydrocracking catalyst for coal tar and preparation method thereof

ActiveCN111420671ALow costImprove conversion rateHydrocarbon oil crackingChemical recyclingPtru catalystCoke rate

The invention discloses a suspended bed hydrocracking catalyst for coal tar and a preparation method thereof. The preparation method comprises the following specific steps: adding a ferrous sulfate solution into semi-coke powder suspension, conducting stirring, adjusting a pH value through ammonia water, and then introducing air for an oxidation reaction so as to obtain a semi-coke powder suspension b loaded with an iron compound; then adding regenerated powder of a waste cobalt-molybdenum-nickel series hydrocracking catalyst into the suspension b, successively carrying out stirring, filteringand drying to obtain solid powder containing semi-coke, the iron compound and the regenerated powder of the waste cobalt-molybdenum-nickel series hydrocracking catalyst; and finally, uniformly mixingthe solid powder with red mud powder to obtain the suspended bed hydrocracking catalyst for coal tar. The catalyst prepared by using the method provided by the invention can effectively improve the conversion rate of heavy oil in coal tar and increase the yield of light oil, and is low in coking rate and relatively low in catalyst cost, so the economic benefit of a device can be obviously improved.

Owner:YANAN UNIV

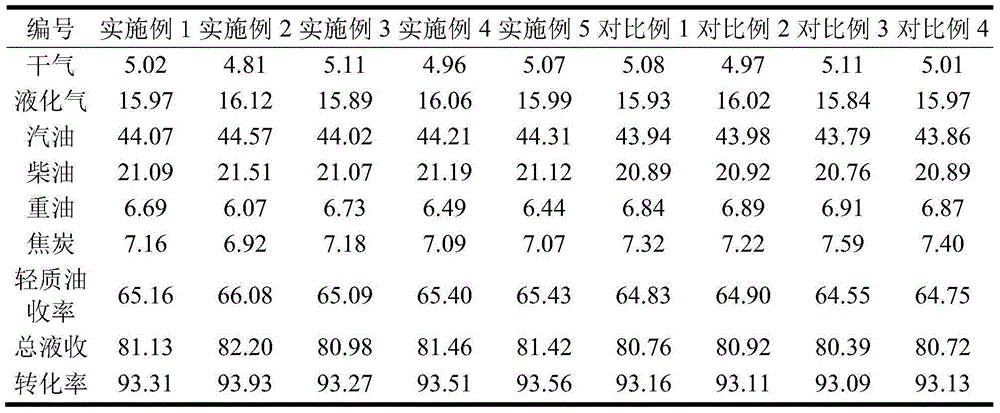

Method for improving catalytic cracking product distribution by using heavy C9

ActiveCN105567298ADecreased catalytic cracking coke production rateProperties No adverse effectsCatalytic crackingIsomerizationCoke rate

The present invention relates to a method for improving the catalytic cracking product distribution by using heavy C9, and belongs to the technical field of petroleum refining. According to the method, a MIP process is used; the method comprises that raw material oil passes through a first reaction zone adopting a cracking reaction as the main and a second reaction zone adopting a hydrogen transfer reaction and an isomerization reaction as the main in the riser of a catalytic cracking reactor so as to be subjected to catalytic cracking; and the method is characterized in that heavy C9 adopted as quenching oil is injected into the riser of the catalytic cracking reactor, and a coking inhibitor is added to the raw material. According to the present invention, the liquefied gas yield, the gasoline yield and the diesel oil yield are increased, the catalytic cracking coking rate of the catalysis apparatus is reduced with the addition of the coking inhibitor, no adverse effect is generated on the product property, the catalytic cracking benefits are increased, the added value is increased, and the environmental pollution caused by the heavy C9 combustion is avoided.

Owner:CHINA PETROLEUM & CHEM CORP

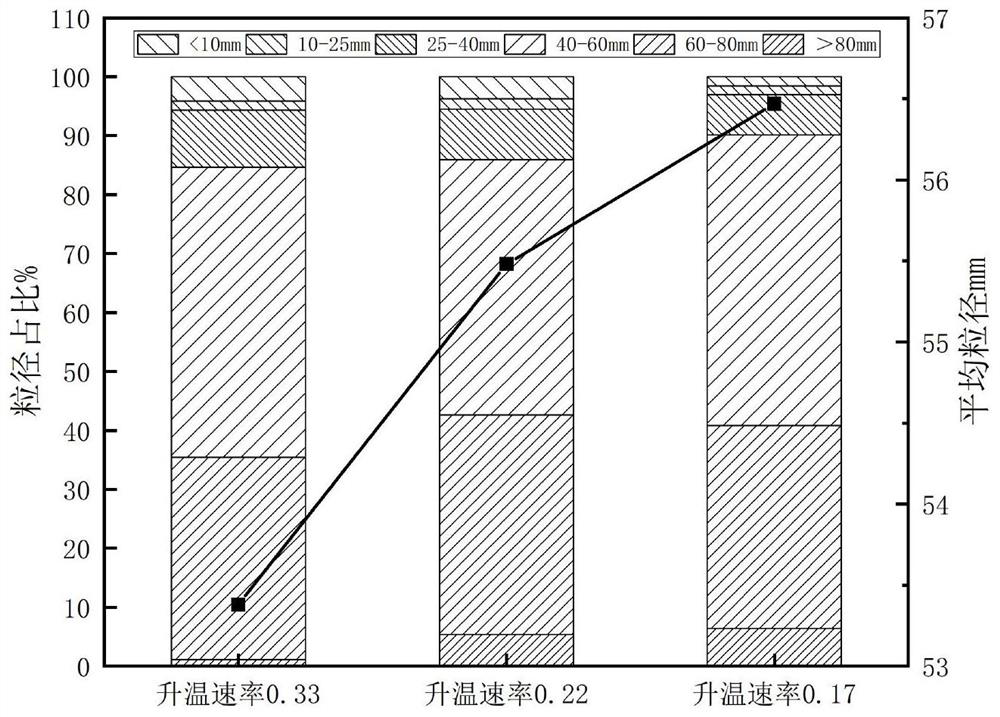

Coking method for improving lumpiness of tamping coke and tamping coke prepared by same

ActiveCN113604238AReduce outputHigh strengthSpecial form destructive distillationThermodynamicsCoke rate

The invention provides a coking method for improving lumpiness of tamping coke and the tamping coke prepared by the method. According to the method, the coking time, the coking rate and the heating standard temperature in the tamping coking process are adjusted according to the actual index of as-fired coal relative to a reference index and a coke quenching mode, so that the lumpiness of the tamping coke is improved. According to the method, the lumpiness of the tamping coke can be improved, the method is also suitable for coking production of tamping coke ovens of any furnace type, the phenomenon of difficult coke pushing does not exist in coking production, and the wall of the coke oven cannot be damaged.

Owner:河北中煤旭阳能源有限公司

Suspended bed hydrocracking catalyst for inferior heavy oil and preparation method of catalyst

ActiveCN107970952AAdjust the amount addedFacilitates hydrocracking reactionsMolecular sieve catalystsHydrocarbon oil crackingIronstoneCoke rate

The invention discloses a suspended bed hydrocracking catalyst for inferior heavy oil and a preparation method of the catalyst. The catalyst comprises zinc oxide powder, vulcanized kaolin powder and vulcanized iron-containing ore powder, wherein the content of the vulcanized kaolin powder is 15.0-60.0 wt%, the content of the vulcanized iron-containing ore powder is 15.0-55.0 wt%, the content of zinc oxide powder is 15.0-50.0 wt%, and the kaolin powder, the iron-containing ore powder and the zinc oxide are mixed dryly. The catalyst has low coke rate, high desulfurization rate, strong resistanceto impurities such as sulfur, metal, nitrogen, carbon residues and the like, and is used for the suspended bed hydrocracking reaction of the inferior heavy oil.

Owner:FUZHOU UNIV

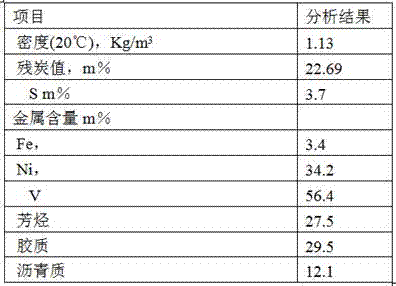

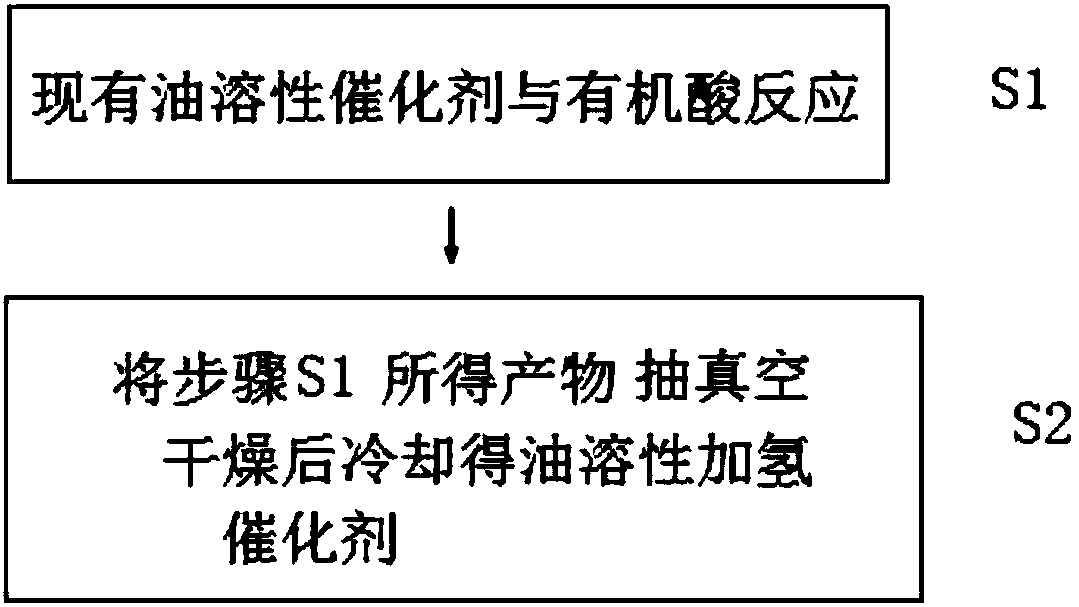

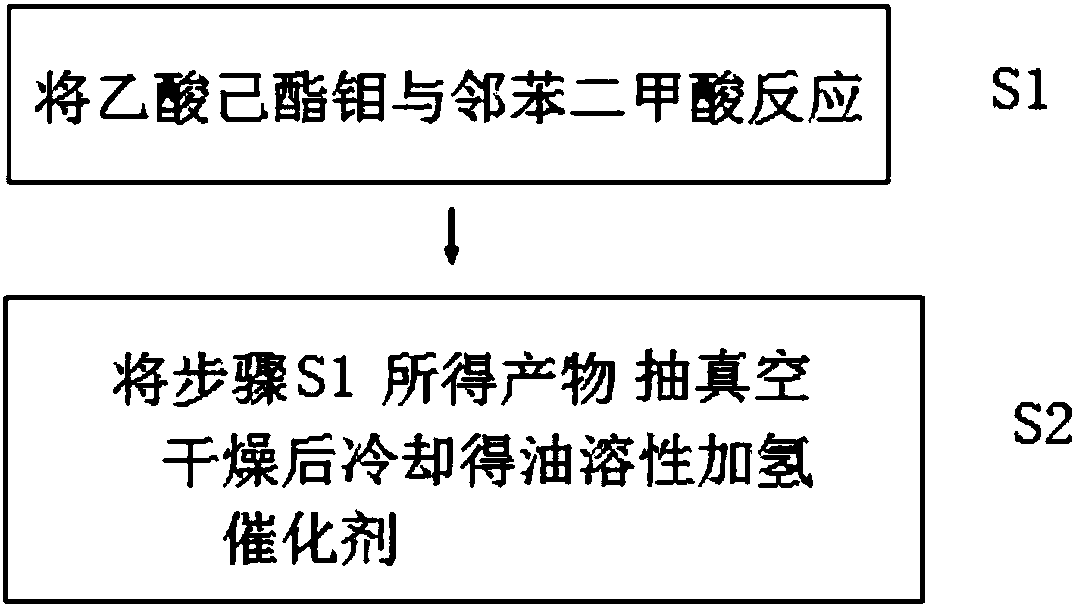

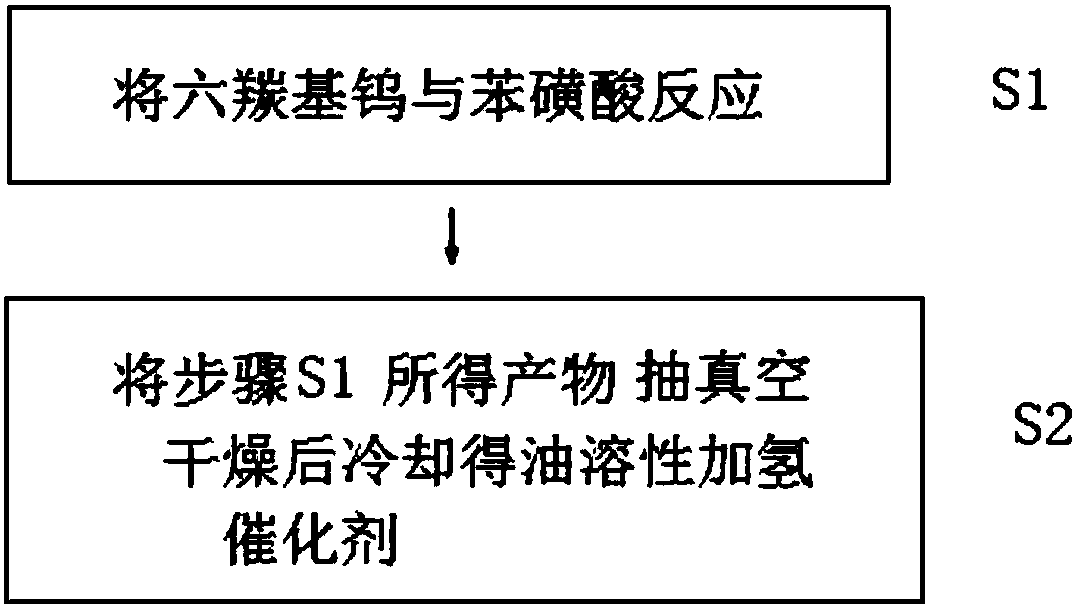

Preparation method of hydrocracking catalyst and inferior heavy oil/residue slurry bed hydrogenation reaction method

InactiveCN110237861AHigh purityProcess environmental protectionOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oil crackingCoke rateFuel oil

The invention relates to a preparation method of a hydrocracking catalyst. The method comprises the following steps: enabling the existing oil-soluble catalyst to react with organic acid compounds for 1-6h at 50-260 DEG C until the reaction is complete; then, carrying out vacuum drying at 30-80 DEG C, and cooling to the room temperature to obtain an oil-soluble hydrogenation catalyst, wherein the existing oil-soluble catalyst is an alcohol amine-based organometallic compound, an amine-based metal complex, a carbonyl organometallic compound or an ester organometallic compound. The oil-soluble catalyst has a higher hydrocracking capacity when being used for processing inferior heavy or residue oil, can obtain a higher conversion rate, and can reduce raw coke rate to the utmost extent. The invention also provides an inferior heavy oil / residue slurry bed hydrogenation reaction method.

Owner:PETROCHINA CO LTD

Blast-furnace coke colloid composite anticatalyst and spraying device

InactiveCN101235425AGuaranteed effectImprove spraying effectSolid fuelsBlast furnace detailsSodium BentoniteCoke rate

The invention relates to blast furnace coke colloid compound negative catalyst and a spraying device which belong to the blast furnace ironmaking field and are suitable for lowering the coke rate in blast furnace ironmaking. The supporting role of the coke to a stock column in a blast furnace can be increased through lowing the reactivity of the coke and increasing the strength after reaction, the permeability of the lower portion of the blast furnace is improved, and the purpose for increasing the smelting intensity, increasing the blast furnace output and lowering coke rate the is reached. The negative catalyst and a spraying device are characterized in that the colloid compound negative catalyst is composed of silica sol and bentonite, the ratio between the silica sol and the bentonite in solution is 1:1, the ratio between boric acid and magnesium chloride in solute is equal to 2:8-8:2, and the ratio between dissolvent and the solute is 9:1. The colloid compound negative catalyst is diluted to the concentration of 2%-8% with clean water under the temperature of 60DEG C-80DEG C and mixed sufficiently, a rustless steel ball valve nozzle whose pressure (1-10kg) can be adjusted is used to spray the colloid compound negative catalyst to the surface of rolling coke in a fog shape, the purpose for spraying evenly is achieved, and the spraying amount is controlled within 1%-5%, namely 10-50 kilograms catalyst are sprayed on one ton coke. The coke rate is lowered by 15-30 kilograms for iron each ton, the blast furnace utilization coefficient is increased by 0.15-0.3t / m3.d, and the invention is suitable for the coke with different specifications and quality.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com