Upflow type hydrogenation thermal cracking method with characteristic of high-aromatic-carbon-rate poor-quality hydrocarbon branching feeding

A high aromatic carbon rate, up-flow technology, applied in hydrotreating process, treatment of hydrocarbon oil, petroleum industry, etc., can solve the problems of large reaction heat, unreported, high gas yield and condensate yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

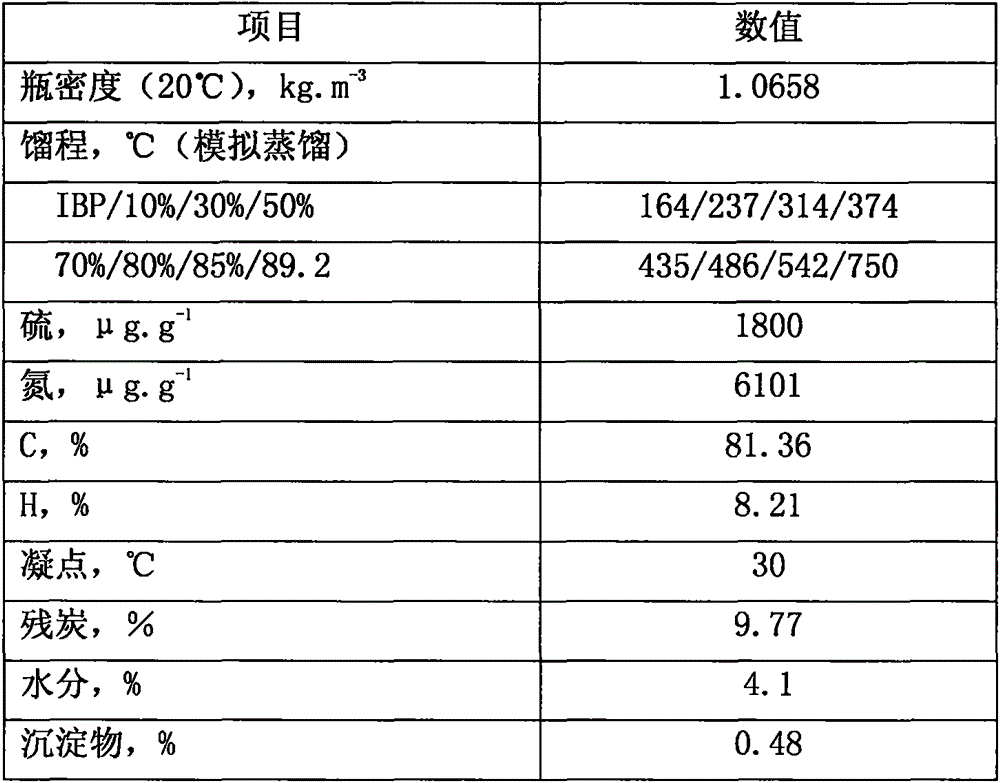

[0491] Based on Comparative Example 1, according to the present invention, the distillate oil of coal tar F00 with a conventional boiling point greater than 355° C. is used as inferior hydrocarbon HDS, and the inferior hydrocarbon HDS is divided into the first one with a volume ratio of 50:50. The first path of inferior hydrocarbons HDS1 and the second path of inferior hydrocarbons HDS2.

[0492] Based on Comparative Example 1, add the suspended bed pre-hydrocracking reactor R101E of the first inferior hydrocarbon HDS1, and the space velocity of the reactor R101E is: 2.0h for the first inferior hydrocarbon HDS1 -1 , HDS space velocity for total inferior hydrocarbons is 4.0h -1 , so the total space velocity of the three suspended bed hydrogenation reactors R101E, R102E, R103E operated in series is: the total inferior hydrocarbon HDS is 0.8h -1 .

[0493] Table 6 shows the reaction temperature of hydrothermal cracking in Example 1.

[0494] The effect of this embodiment is: ...

Embodiment 2

[0501] Embodiment 1 was improved by adopting Chinese patent ZL201210022921.9, a method for hydrogenation and lightening of heavy oil with low hydrogen content using hydrogen-donating hydrocarbons.

[0502] In the coal tar F00 separation part FRAC, coal tar F00 is separated into a light fraction F0L mainly composed of hydrocarbons with a conventional boiling point of 60-355°C, and a medium-low temperature coal tar middle fraction F0M mainly composed of hydrocarbons with a conventional boiling point of 355-435°C And the heavy fraction F0D mainly composed of hydrocarbons with a conventional boiling point greater than 435°C, the heavy fraction F0D is used as inferior hydrocarbon HDS; the middle fraction F0M enters the pre-hydrogenation process RF0M to be converted into hydrogenation reaction effluent RF0M-P, hydrogenation reaction effluent RF0M-P enters the first hydrogenation reaction process R10.

[0503] The operating conditions of the pre-hydrogenation process RFOM are: temper...

Embodiment 3

[0514] Combined application of a hydrothermal cracking method disclosed in Chinese patent application CN105623724A to produce low-carbon single six-membered ring hydrocarbons from high aromatics, to form a second product solution for Example 2. Compared with Example 2, the hydrocarbon components in the first hydrogenation reaction effluent R10P with a conventional boiling point of 290-355°C are returned to the first hydrogenation reaction process R10 as cracked cycle oil instead of being used as a deep hydrogenation upgrading reaction Process R20 raw materials are used, the effect is:

[0515] ① For the first hydrogenation reaction process R10, the total amount of hydrogen-donating hydrocarbons is increased, which can further increase the ratio KSH of "weight of hydrogen-donating hydrocarbons / weight of coal tar heavy oil HDS1";

[0516] ② Utilize the "selective cracking function" of the hydrothermal cracking reaction process to maximize the production of cyclohexane-based hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com