Patents

Literature

1839 results about "Hydrogen supply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen Supply. Air Products offers complete flexibility in the supply of hydrogen. We can provide hydrogen sourced from natural gas, waste off-gas recovery or power, either delivered to the site or produced on-site.

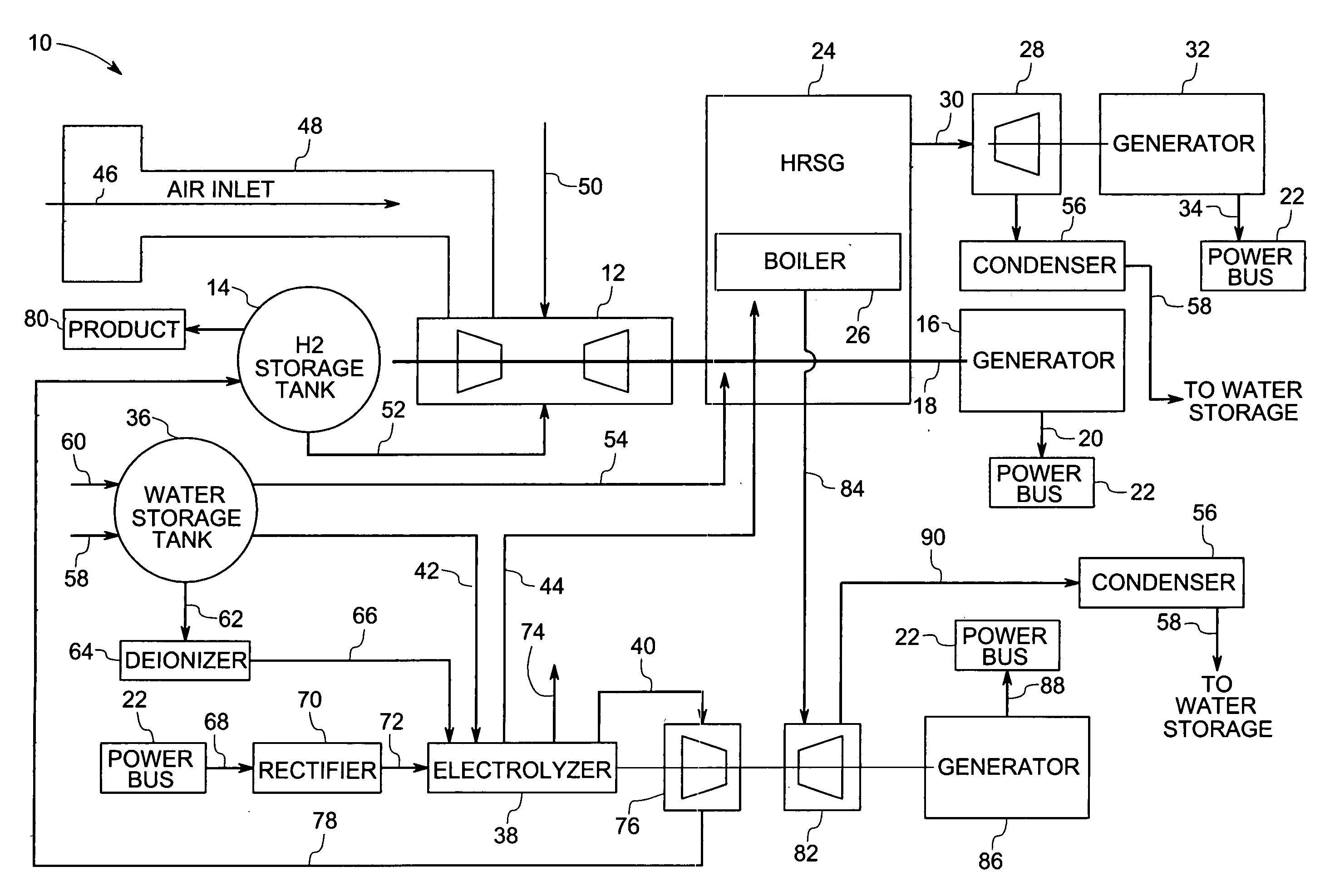

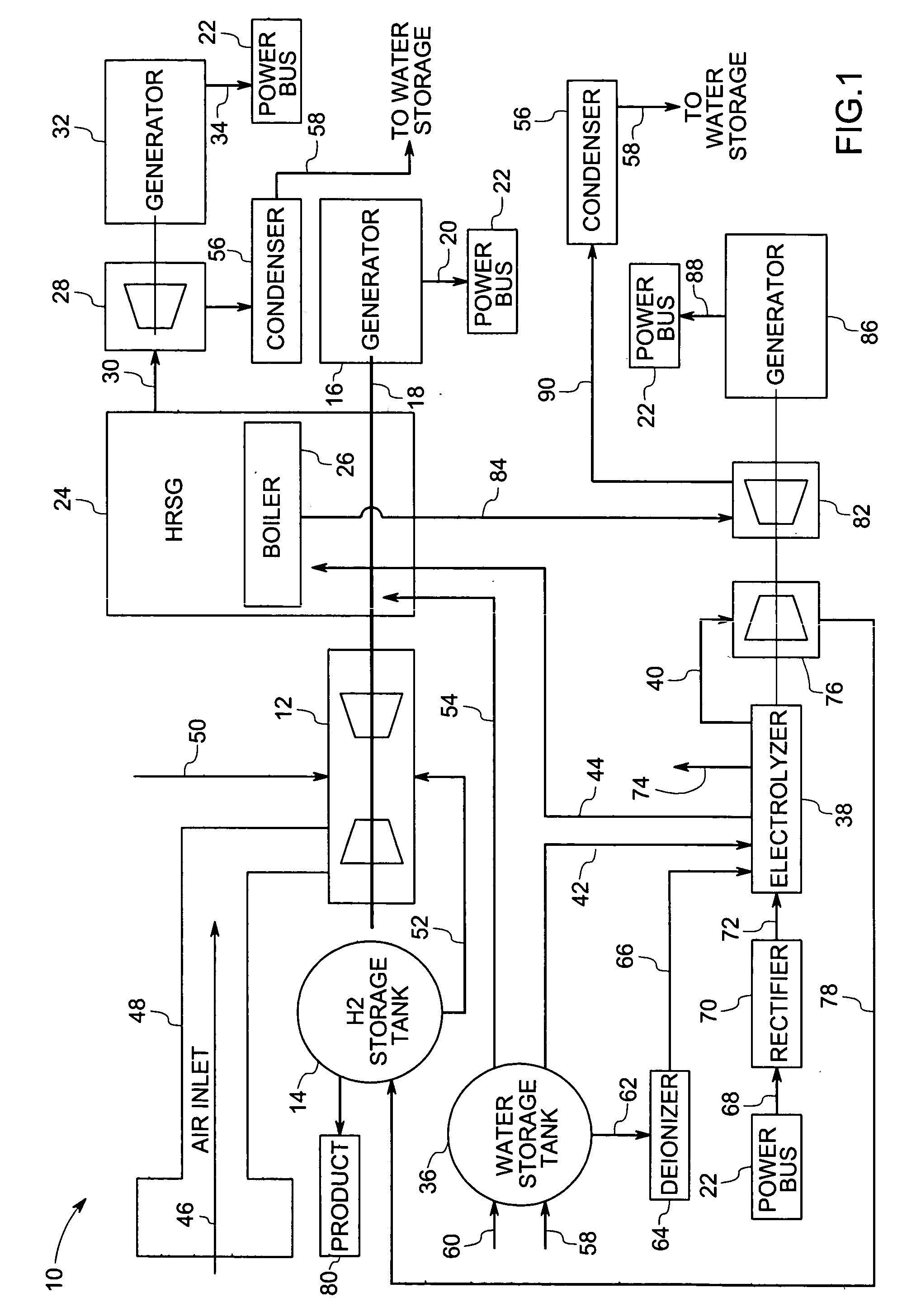

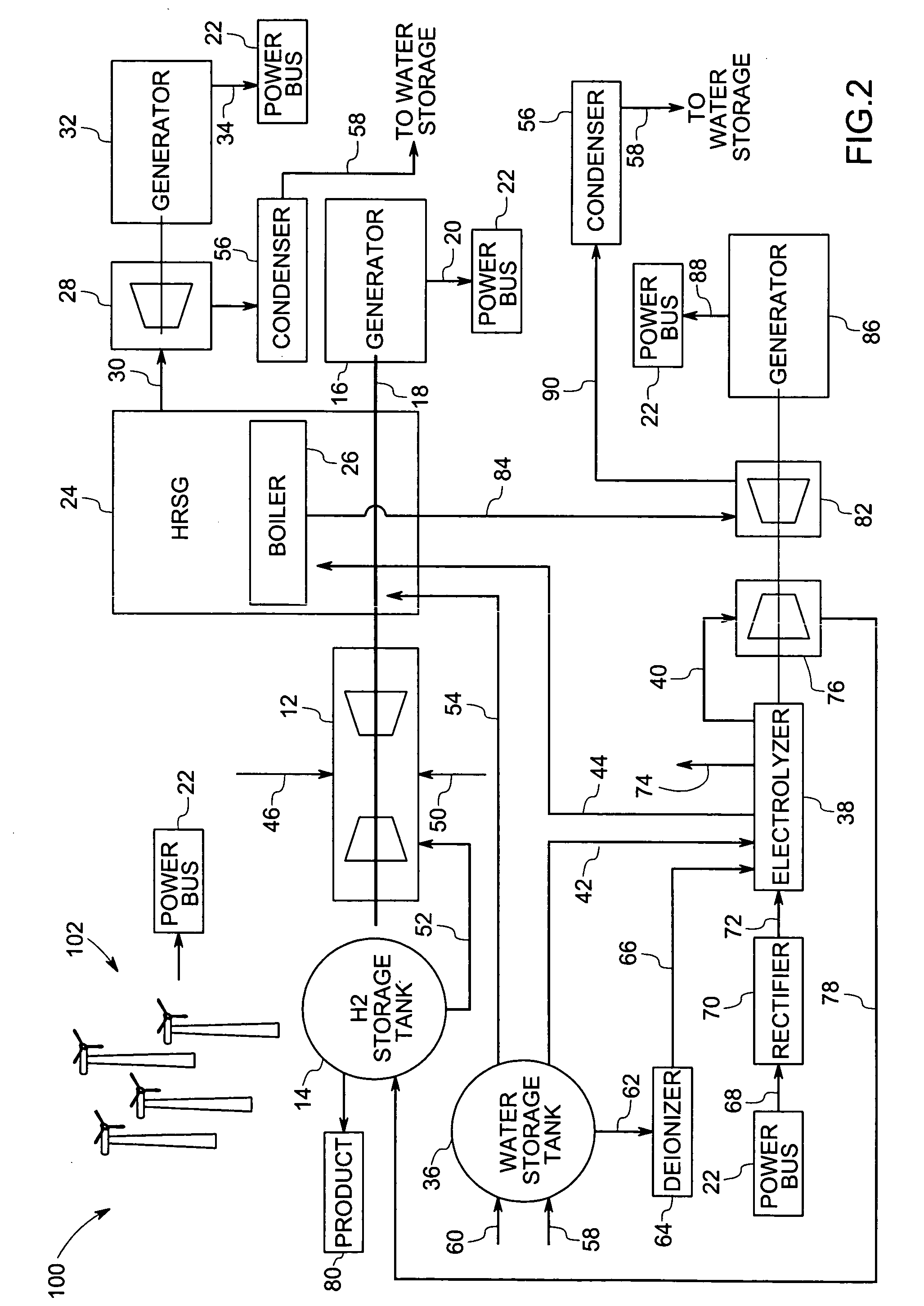

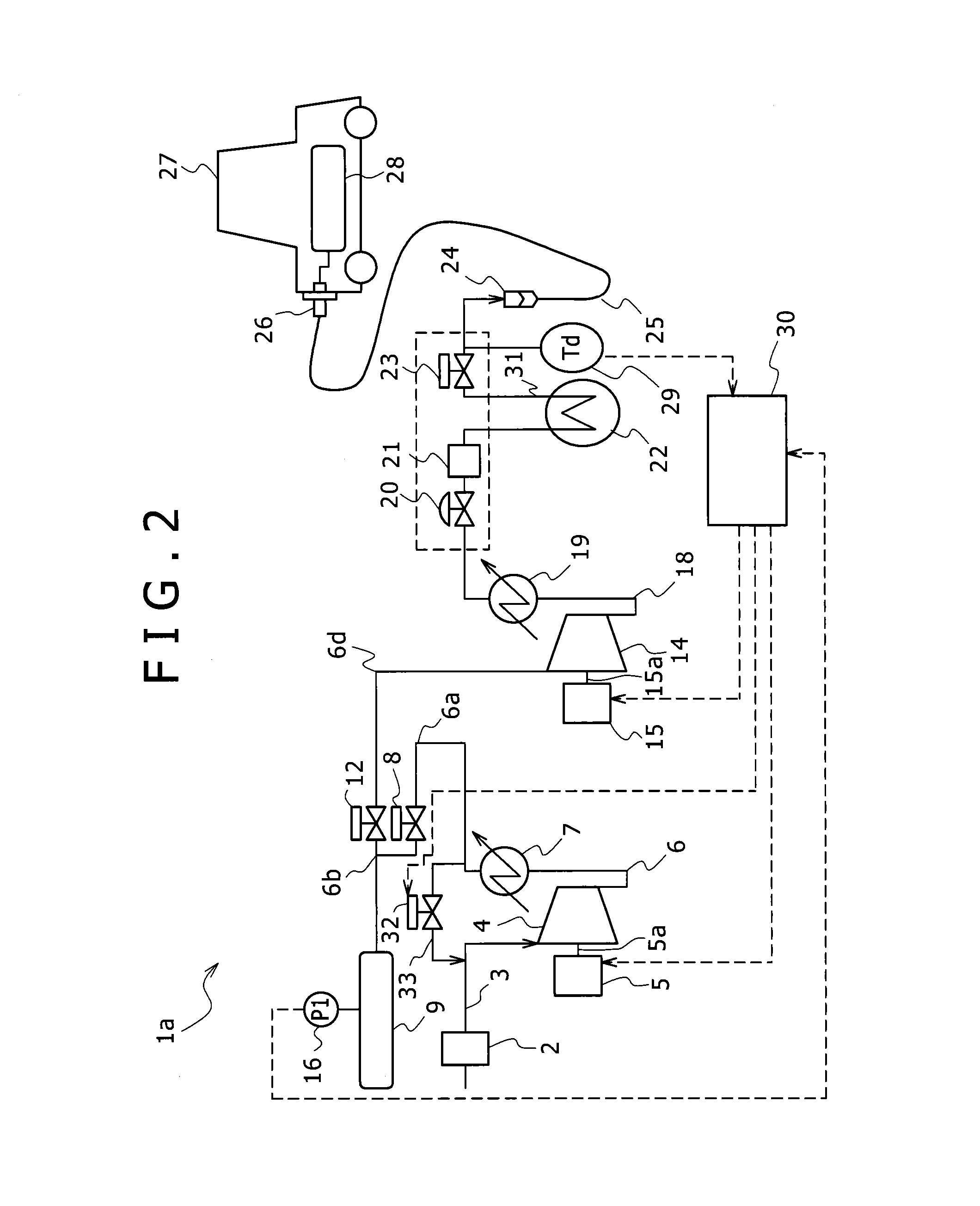

Power generation system and method of operating same

A power generation system comprising a liquid-cooled electrolyzer operable to produce a supply of hydrogen from water is provided. The power generation system may also comprise a steam turbine and a steam production device operable to produce a supply of steam to the steam turbine. The power generation system may also comprise a system operable to provide cooling liquid to the liquid-cooled electrolyzer and to couple heated cooling liquid from the liquid-cooled electrolyzer to the steam production device.

Owner:GENERAL ELECTRIC CO

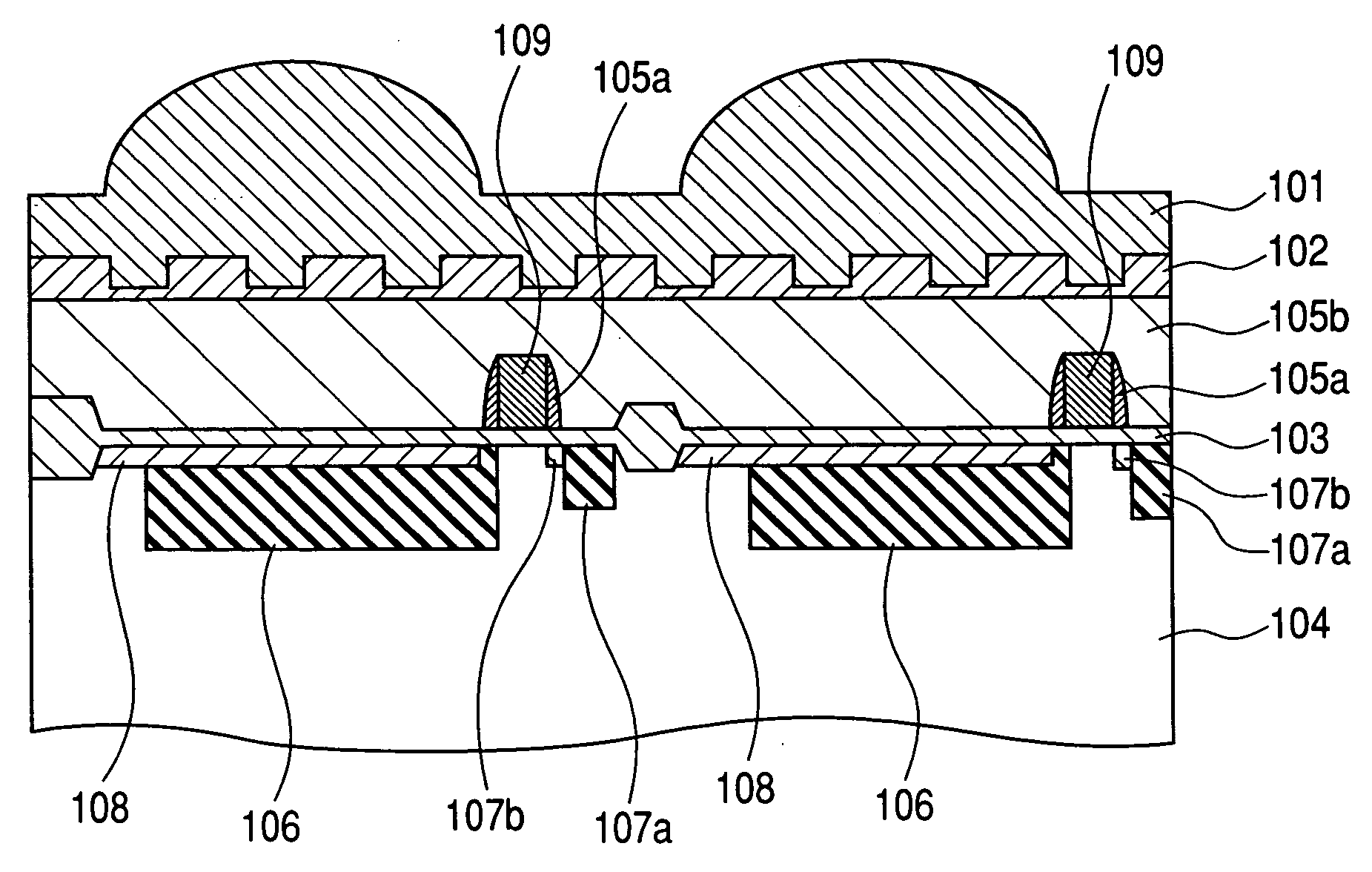

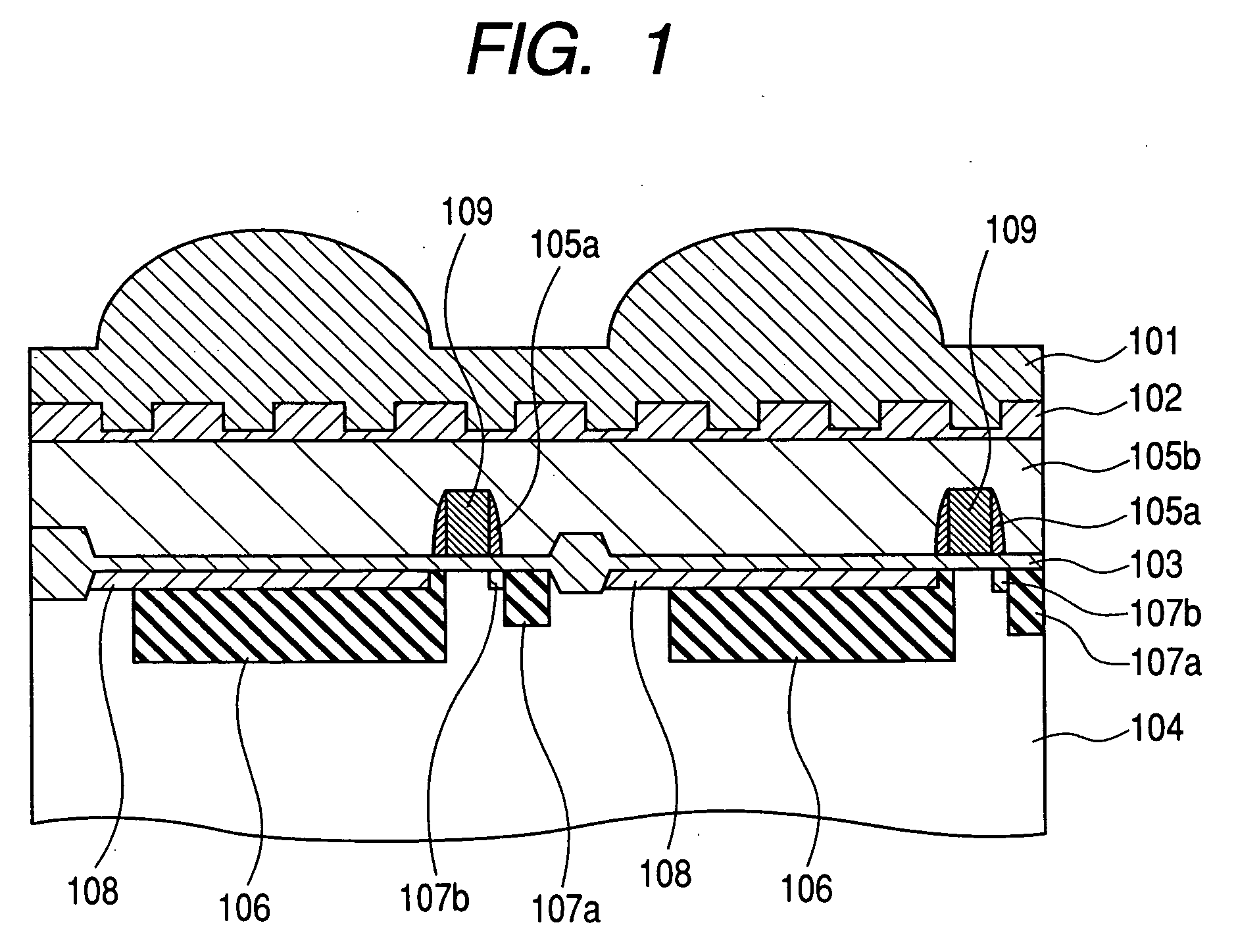

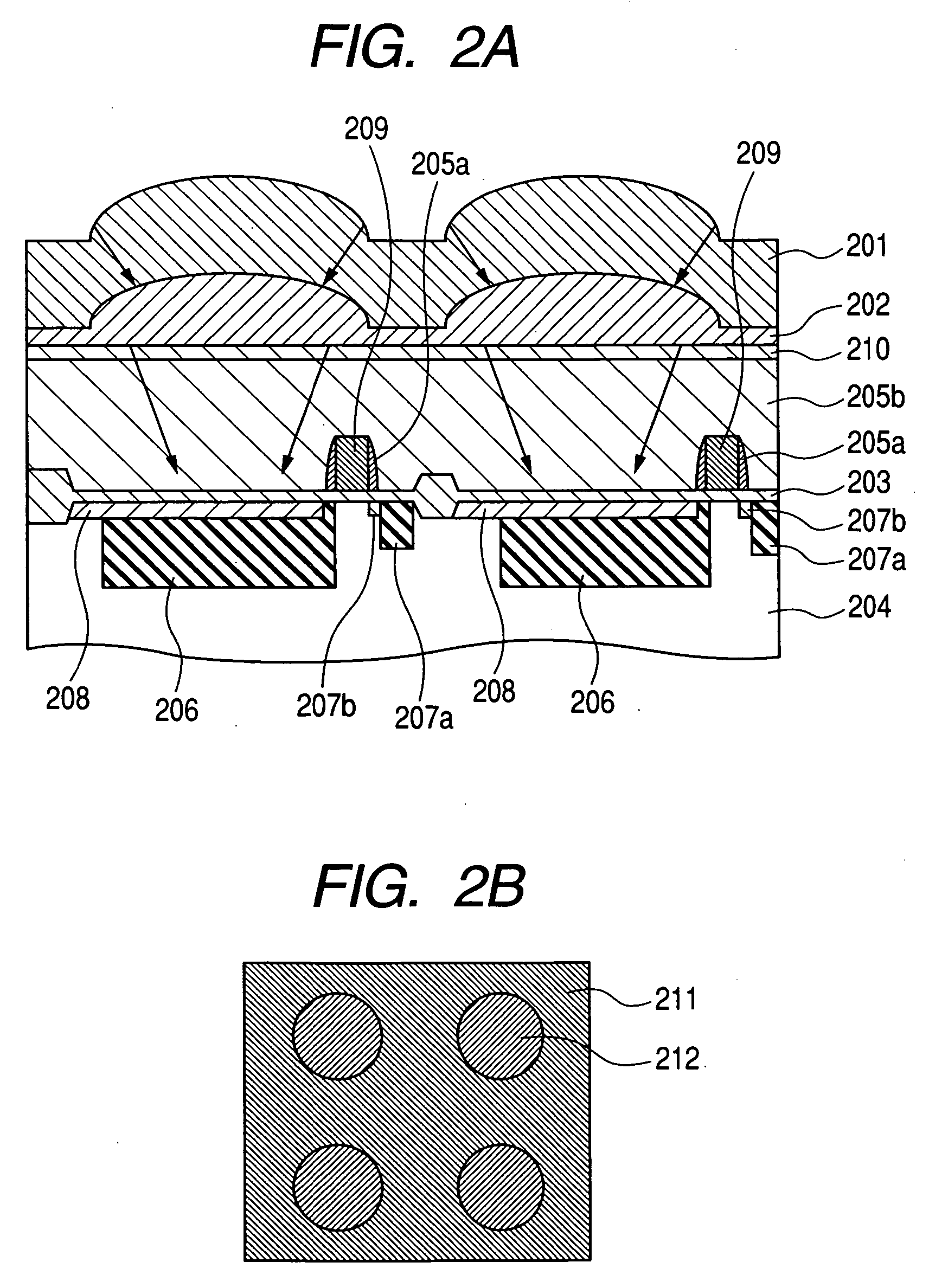

Solid state imaging device, method of manufacturing same, and digital camera

InactiveUS20060061674A1Improve hydrogen supply capacityInhibit the generation of cracksTelevision system detailsTelevision system scanning detailsEngineeringHydrogen supply

Provided is a MOS type solid state imaging device, including a semiconductor substrate, a plurality of pixels arranged on the semiconductor substrate, each pixel having a light receiving element for generating a signal charge due to incident light, and a MOS transistor for reading the signal charge, and a hydrogen supply film arranged on the semiconductor substrate over the plurality of pixels and having a region corresponding to the light receiving element at least a part of which has a film thickness greater than the other part of the region.

Owner:CANON KK

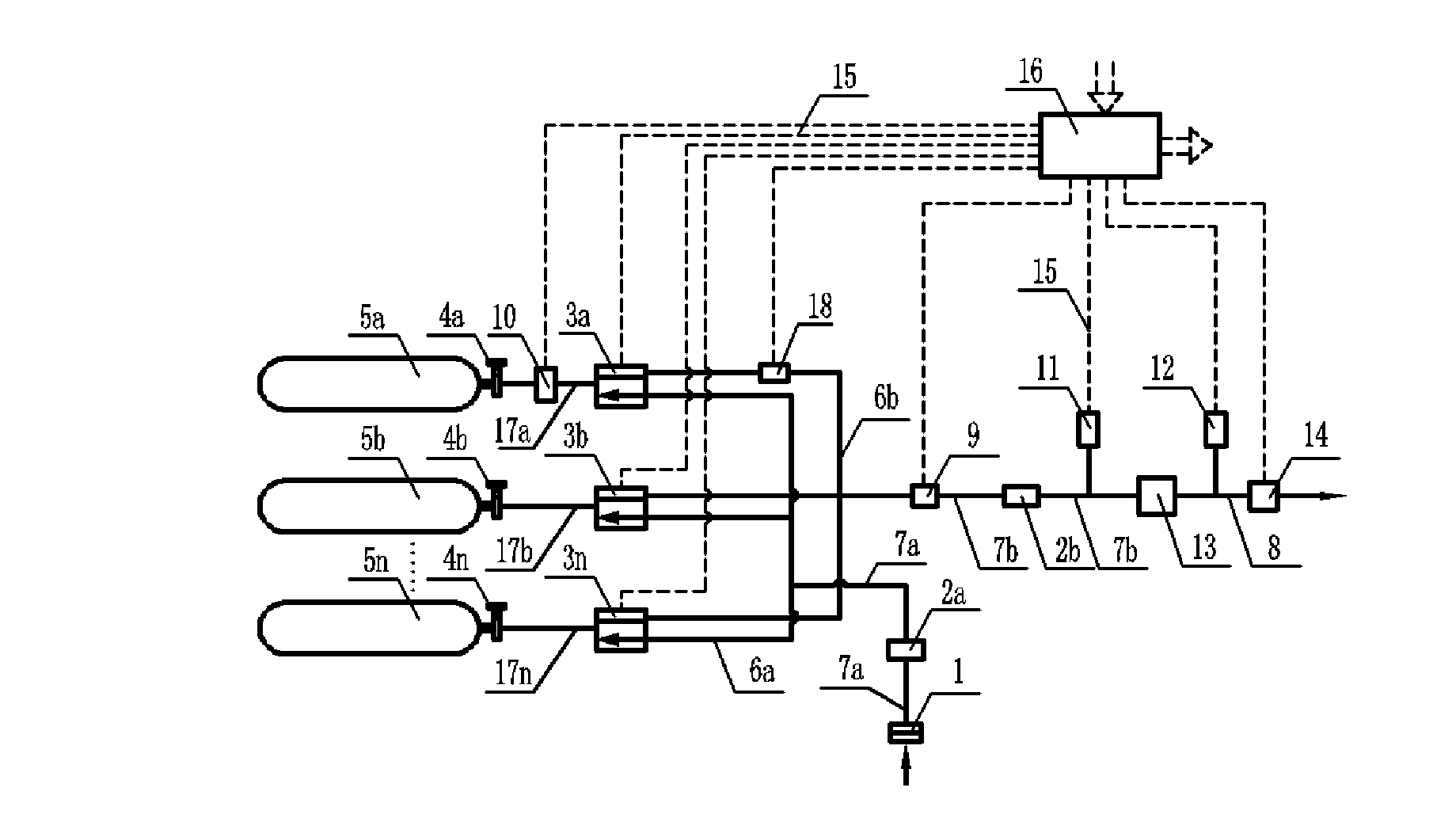

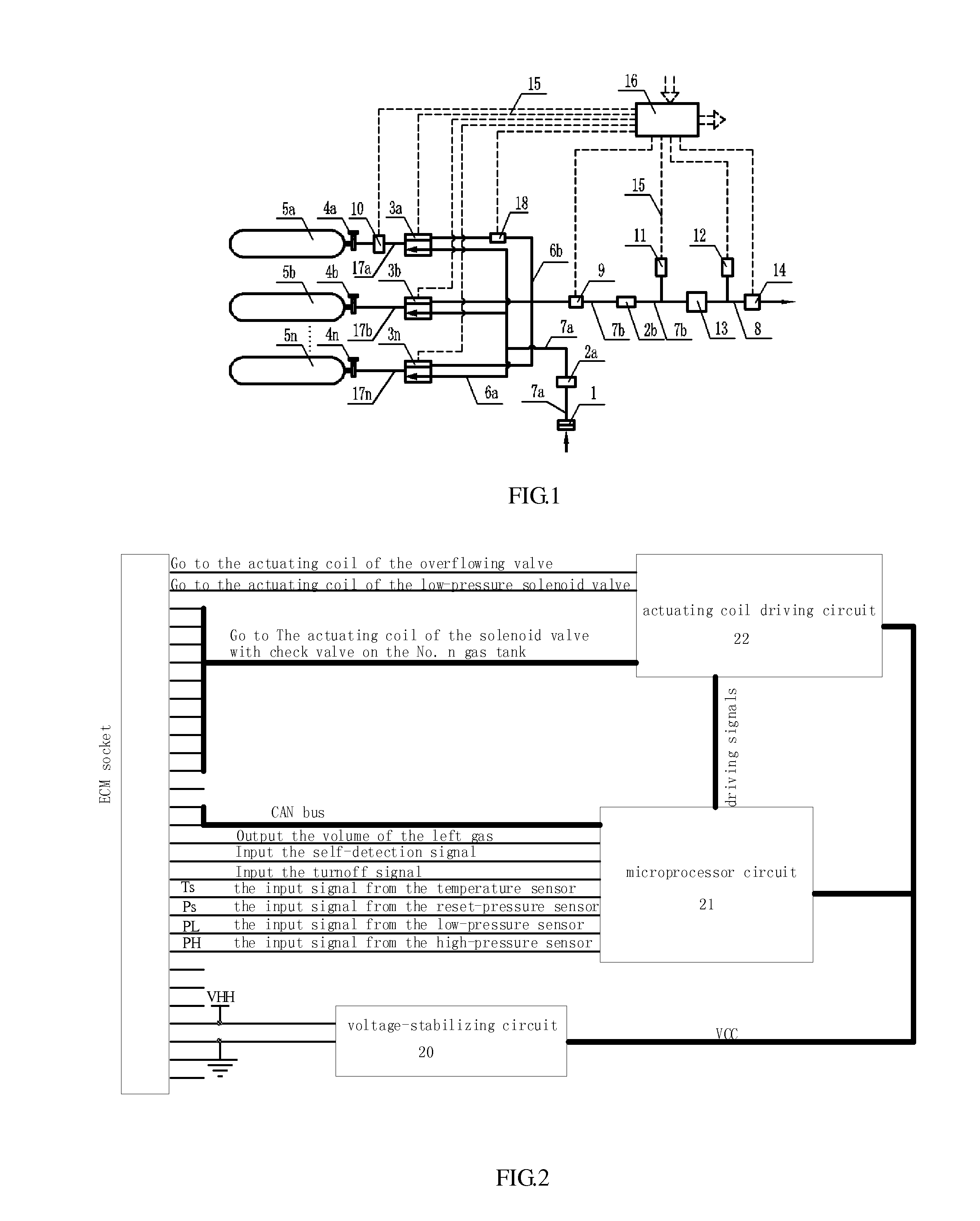

Low consumption and intelligent safe gas-supply system for gas tanks

ActiveUS20100193045A1Simple processImprove reliabilityGas handling applicationsGas handling/storage effectsSolenoid valveHigh pressure hydrogen

A low consumption and intelligent safe gas-supply system for gas tanks comprises: at least two gas tanks and gas tank valves installed on them, charge valves with check valve, at least two gas-filled parallel unit pipes, high-pressure sensor, at least two gas-supply parallel unit pipes, gas-supply main conduit, reset pressure sensor, at least two solenoid valves with check valve, and electronic control module ECM. The invention has the characteristics such as the gas tanks supply gas in sequence, intelligent control, security and reliability for use, low consumption, high display precision for gas volume, decompression transfinite alarm and convenience for installing, use and maintenance etc., and it can be used in the vehicle hydrogen supply system in the fuel cell vehicles or the vehicle compressed natural gas-supply system in the natural gas vehicles, and also the high-pressure hydrogen or natural gas-supply system for gas tanks on the ground.

Owner:BEIJING BOLKEN EQUIP

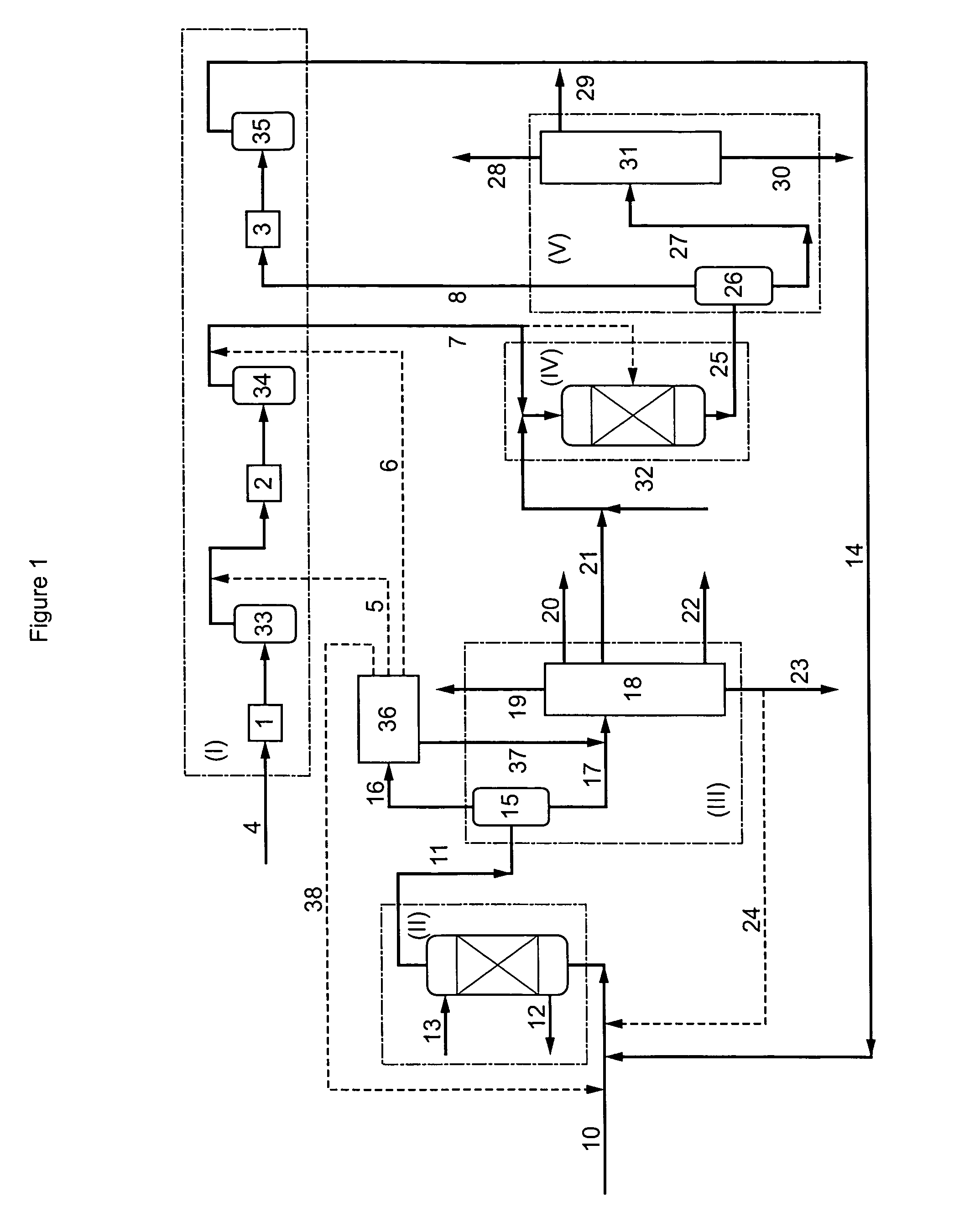

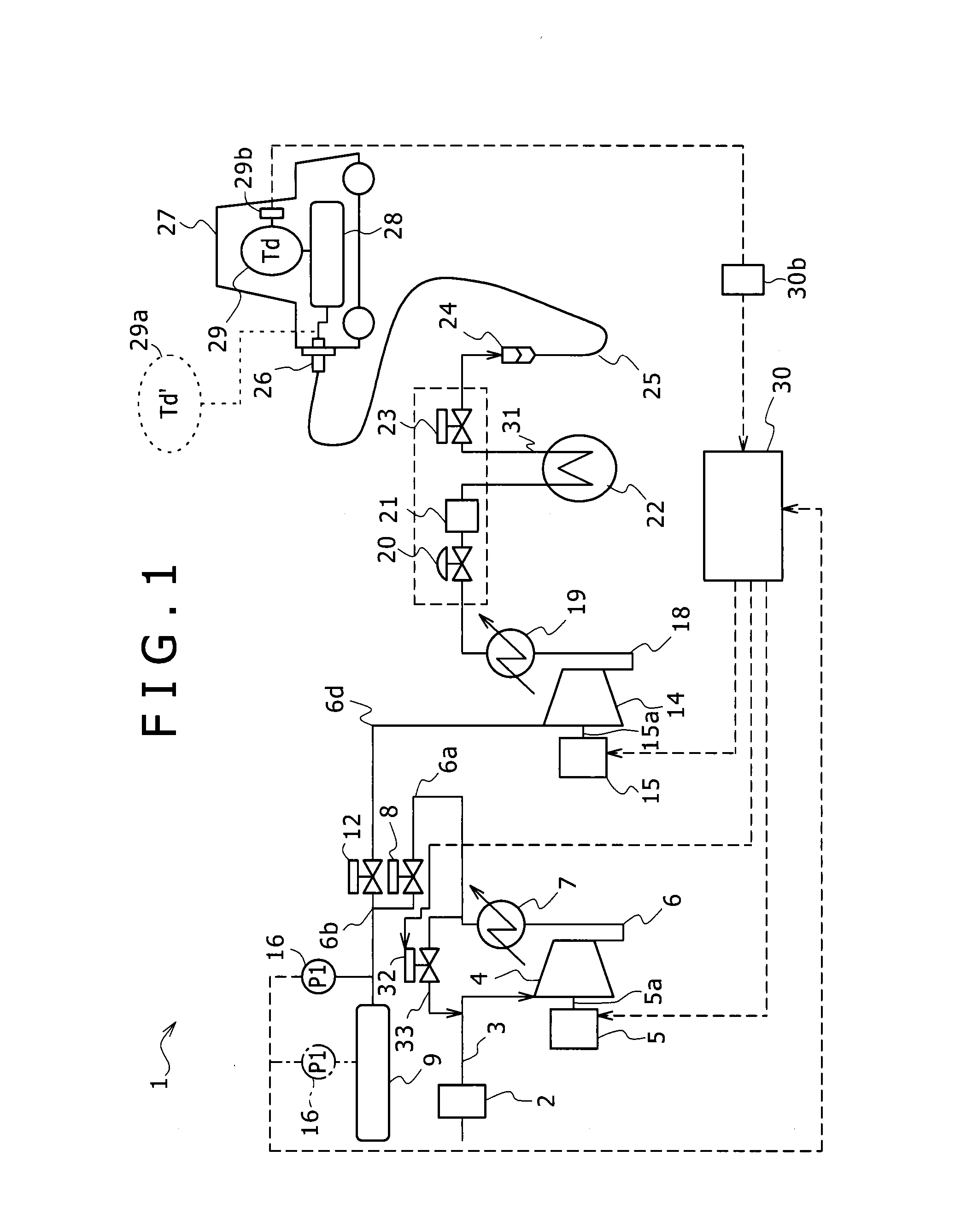

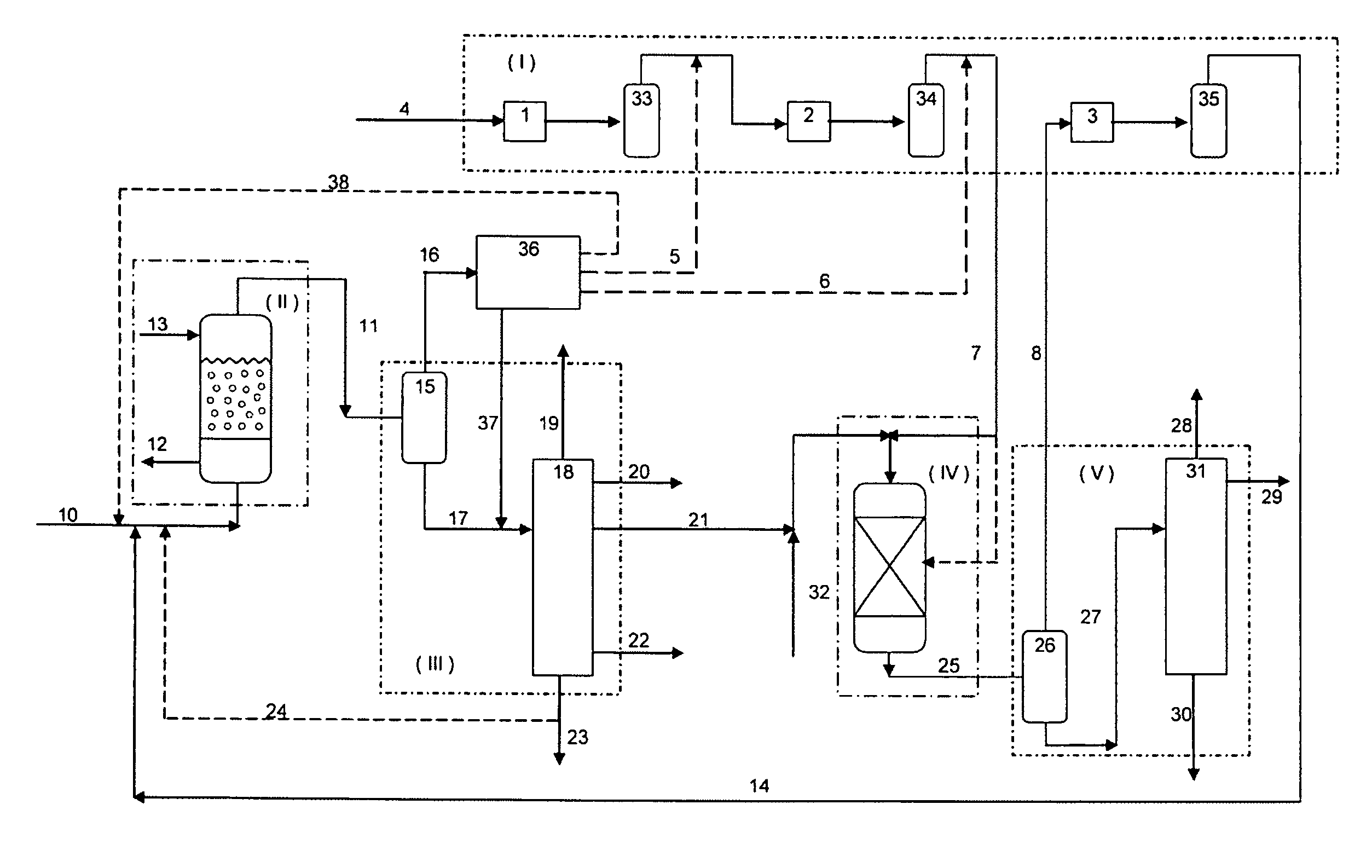

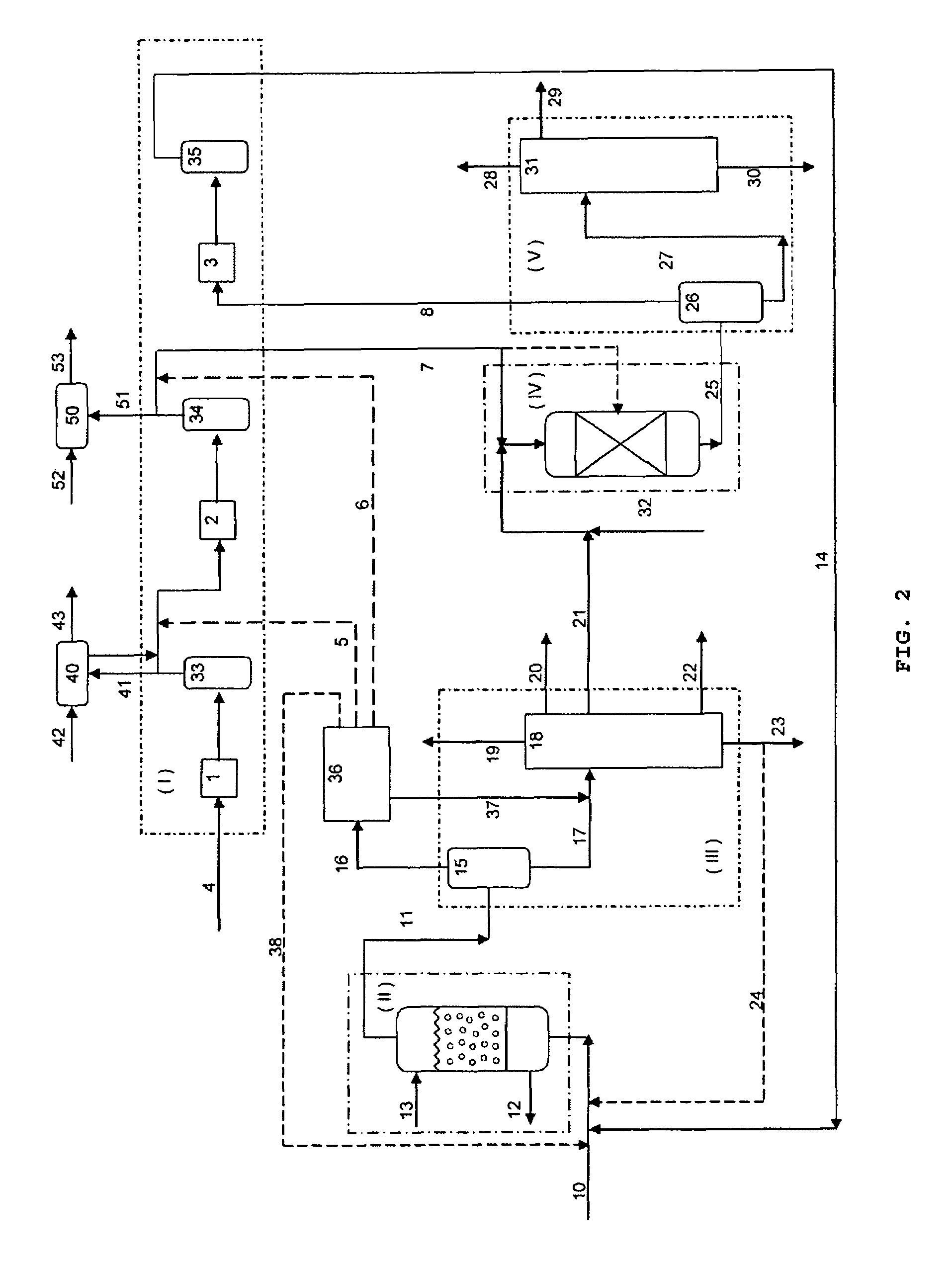

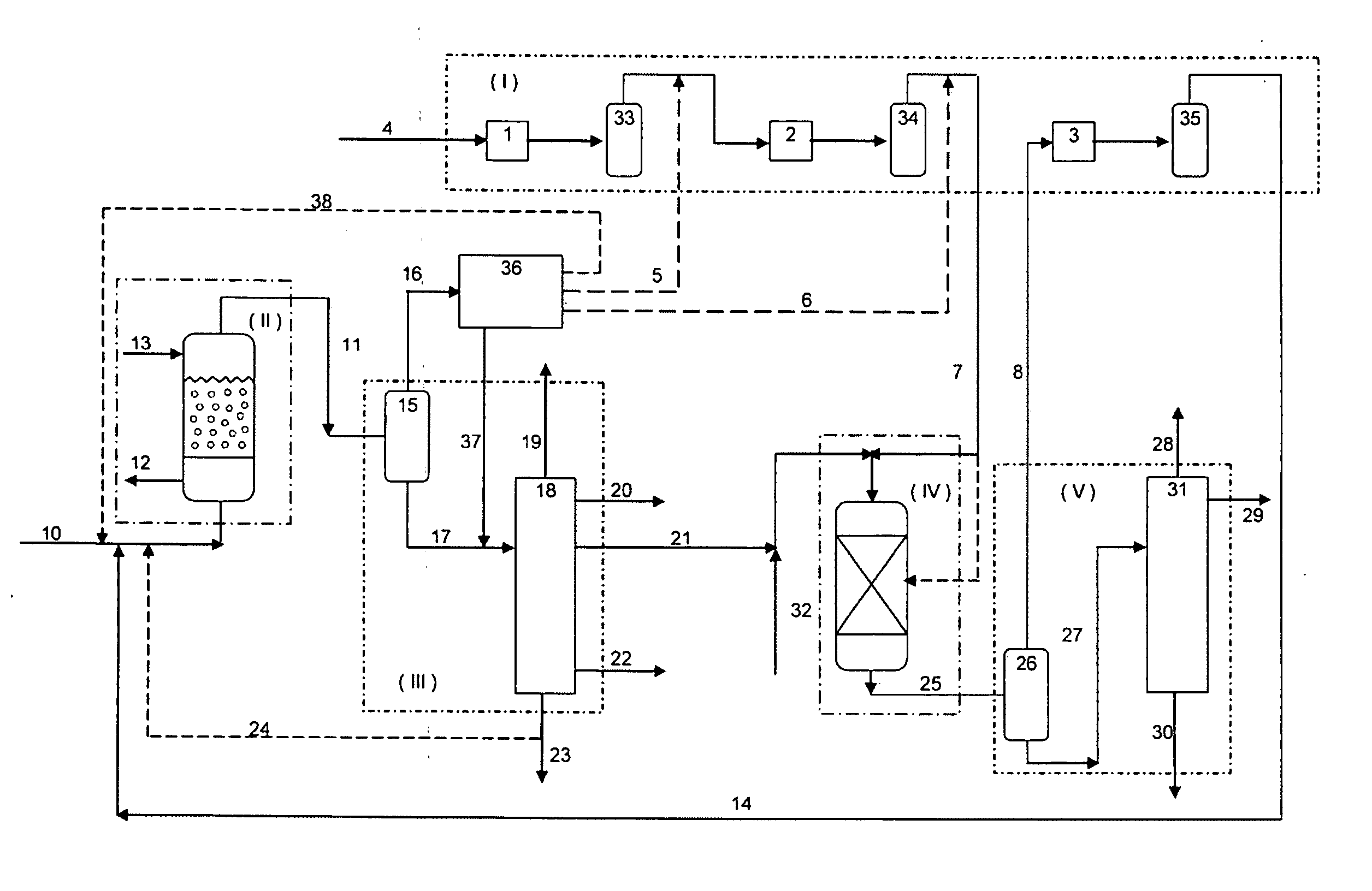

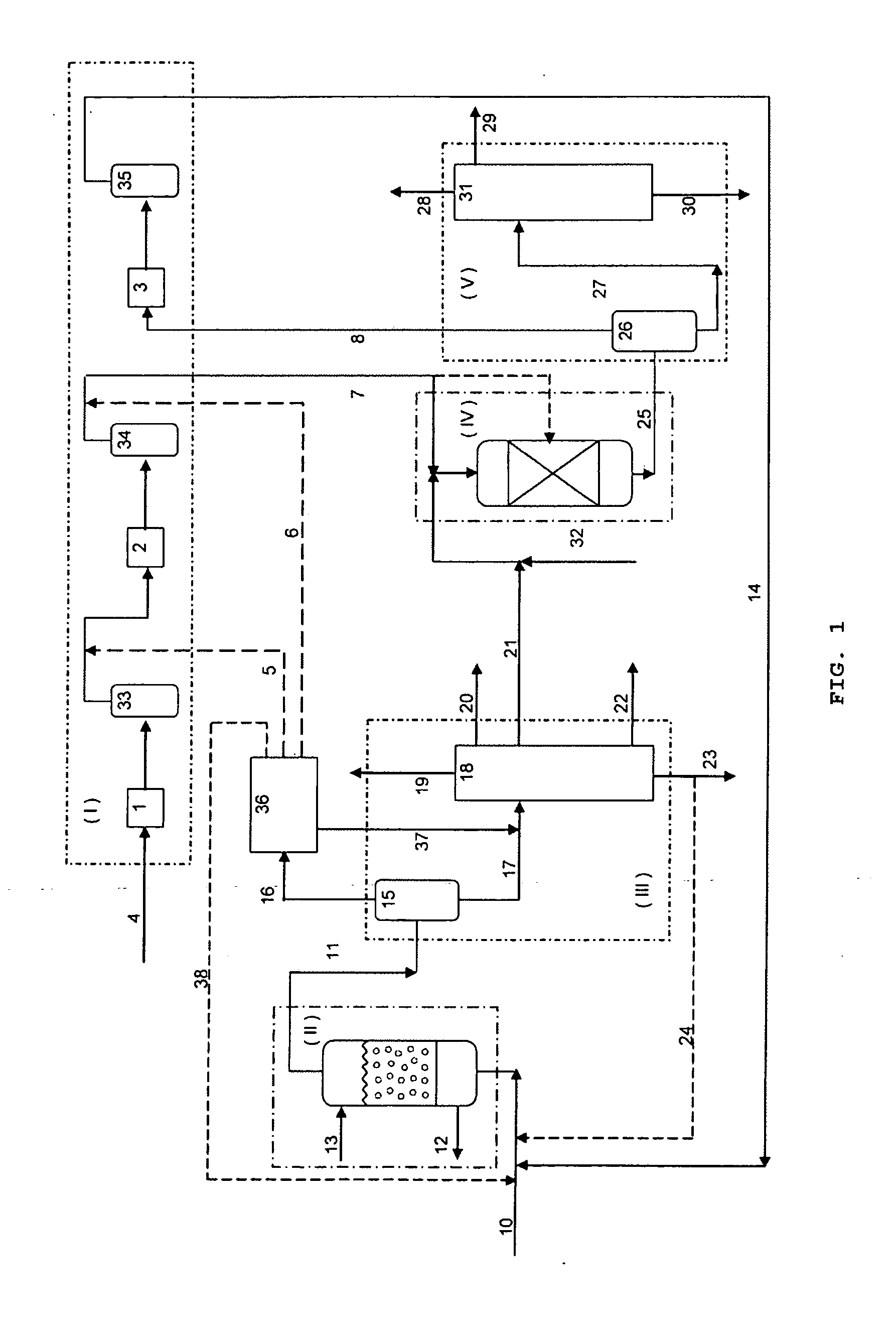

Process and installation for conversion of heavy petroleum fractions in a fixed bed with integrated production of middle distillates with a very low sulfur content

InactiveUS20080093262A1Low investment costEasy to useHydrocarbons from unsaturated hydrocarbon additionHydrocarbon oil crackingDistillates petroleumNaphtha

This invention relates to a process and an installation for treatment of a heavy petroleum feedstock, of which at least 80% by weight has a boiling point of greater than 340° C., whereby the process comprises the following stages:(a) Hydroconversion in a fixed-bed reactor operating with an upward flow of liquid and gas, whereby the net conversion in products boiling below 360° C. is from 10 to 99% by weight;(b) Separation of the effluent obtained from stage (a) into a gas containing hydrogen and H2S, a fraction comprising the gas oil, and optionally a fraction that is heavier than the gas oil and a naphtha fraction;c) Hydrotreatment by contact with at least one catalyst of at least the fraction comprising the gas oil obtained in stage (b);d) Separation of the effluent obtained at the end of stage (c) into a gas containing hydrogen and at least one gas oil fraction having a sulfur content of less than 50 ppm, preferably less than 20 ppm, and more preferably still less than 10 ppm,the hydroconversion stage (a) being conducted at a pressure P1 and the hydrotreatment stage (c) being conducted at a pressure P2, the difference ΔP=P1−P2 being at least 2 MPa, the hydrogen supply for the hydroconversion (a) and hydrotreatment (c) stages being ensured by a single compression system with n stages.

Owner:INST FR DU PETROLE

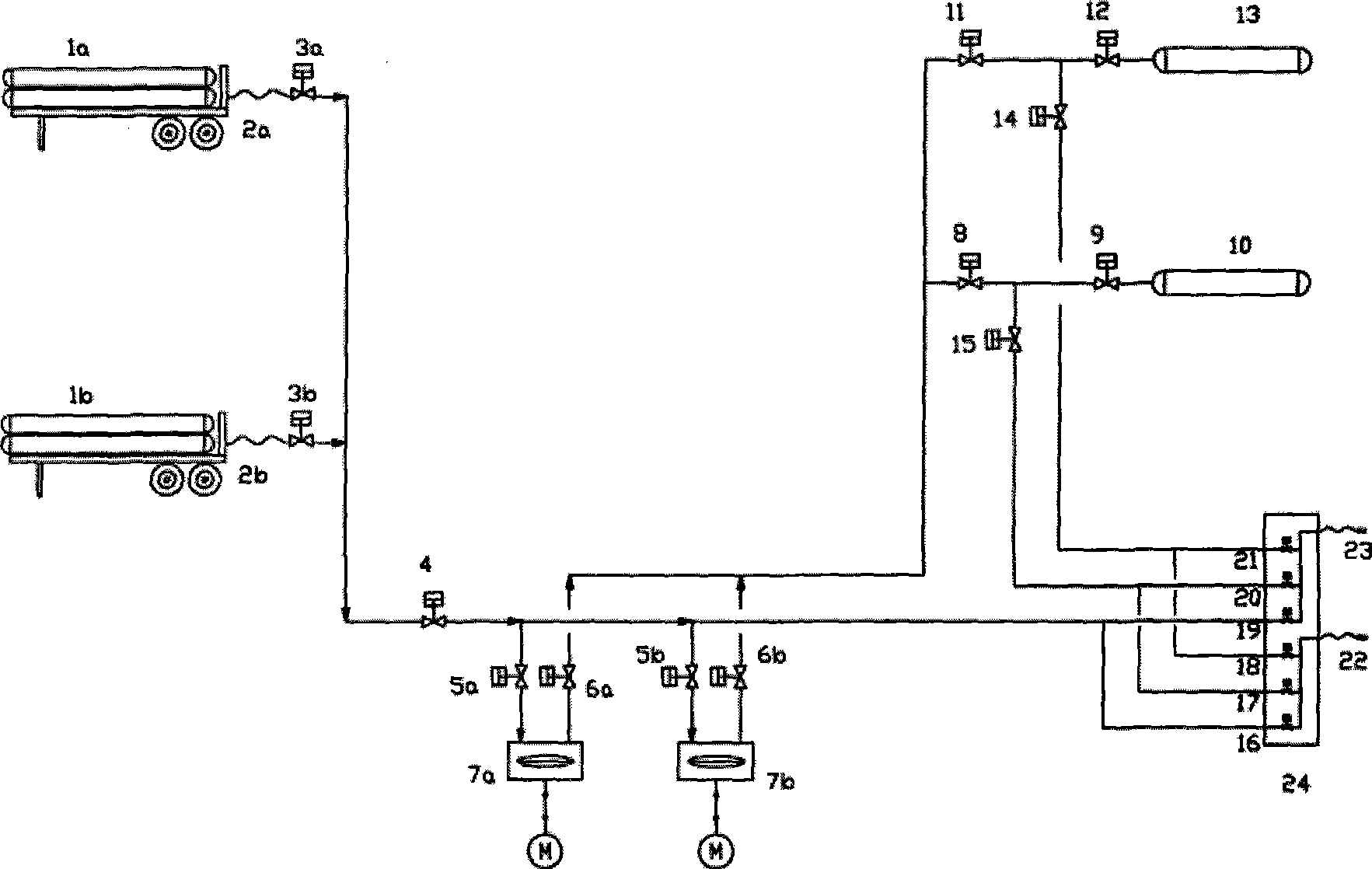

High-pressure hydrogen supply system for exterior hydrogen feeding hydrogenation stations

ActiveCN101418907ASimplified hydrogen supply processLow investment costContainer filling under pressureHigh pressure hydrogenData acquisition

The invention provides a high-pressure hydrogen supply system for an external supplying type hydrogen filling station, which can fill hydrogen fuel for fuel cell powered vehicles. The hydrogen supply system mainly comprises a pipe bundle hydrogen conveying vehicle, a fixed high-pressure hydrogen storage tank group, a parallel multi-compressor pressurizing system, a high-pressure hydrogen filling system, and a data acquiring, processing and safety monitoring system. The high-pressure hydrogen supply system takes the pipe bundle hydrogen conveying vehicle as a part of a hydrogen storage container of the hydrogen filling station and makes the pipe bundle hydrogen conveying vehicle a first stage of the staged hydrogen storage container, adopts the pressurizing system consisting of multiple compressors which are connected in parallel, and introduces the data acquiring, processing and safety monitoring system. The high-pressure hydrogen supply system has the advantages of adjustable hydrogen storage volume, large operation flexibility, cost conservation, convenient maintenance, high service efficiency and so on.

Owner:TONGJI UNIV

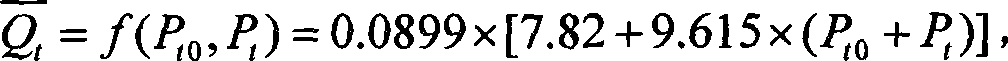

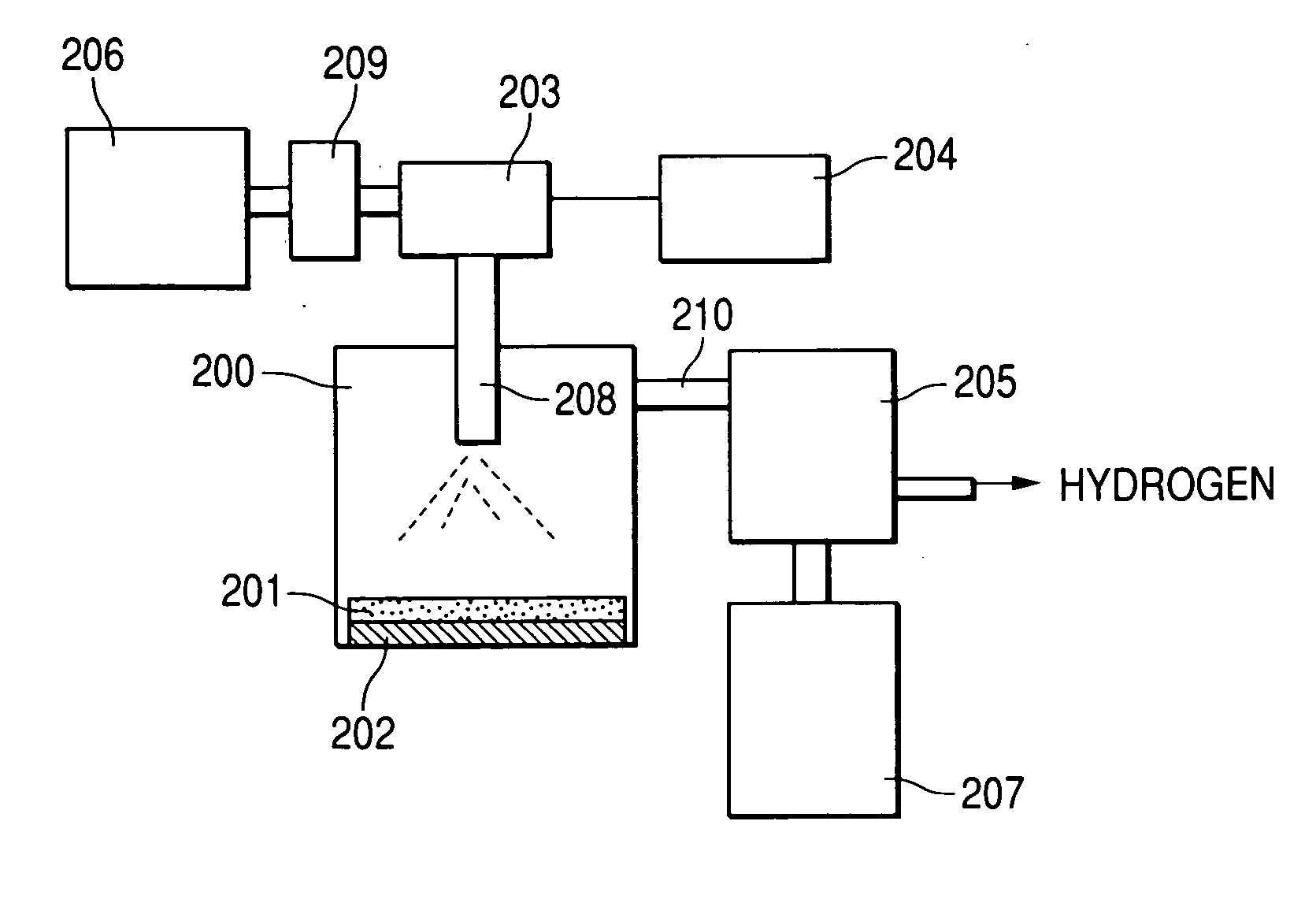

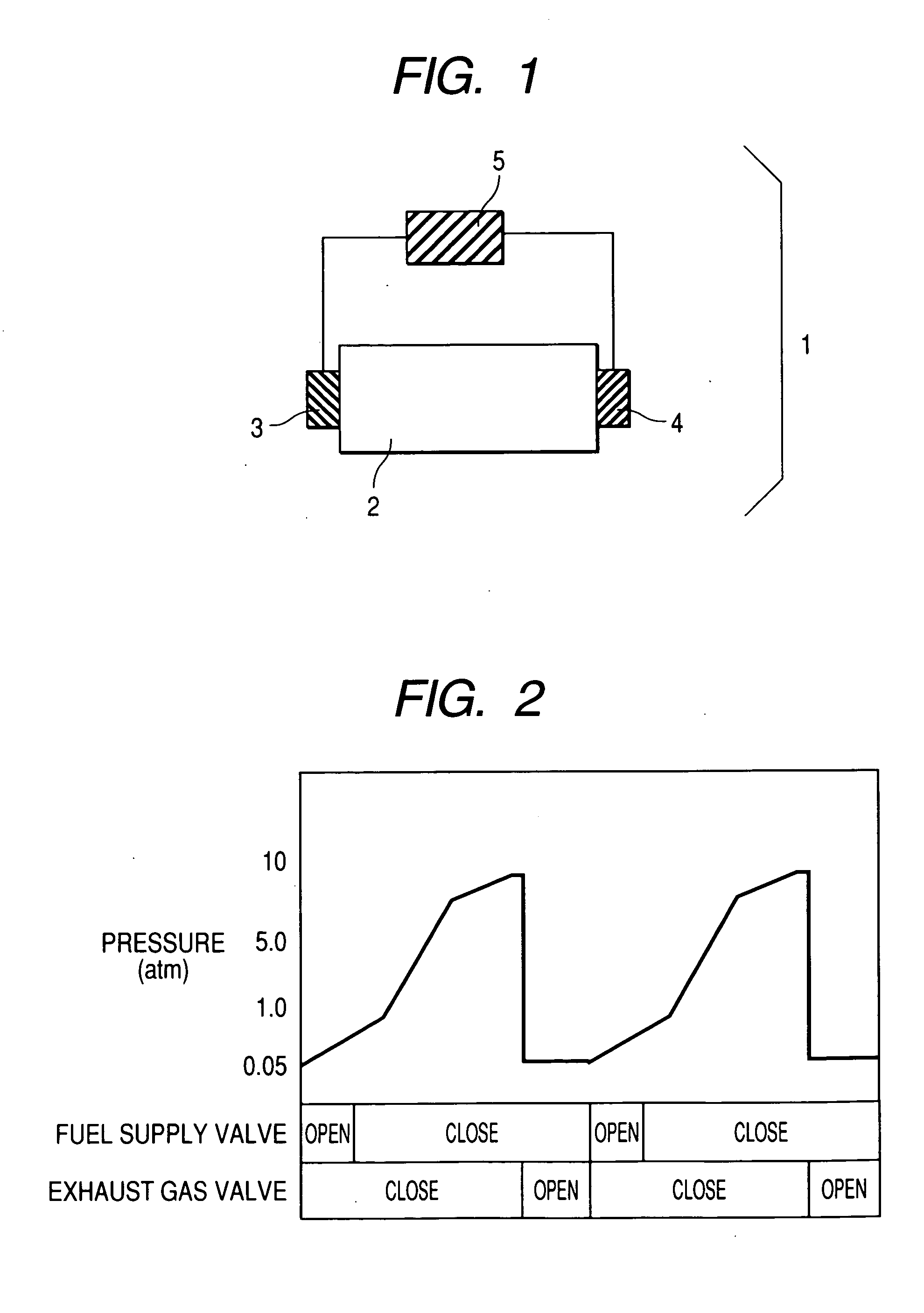

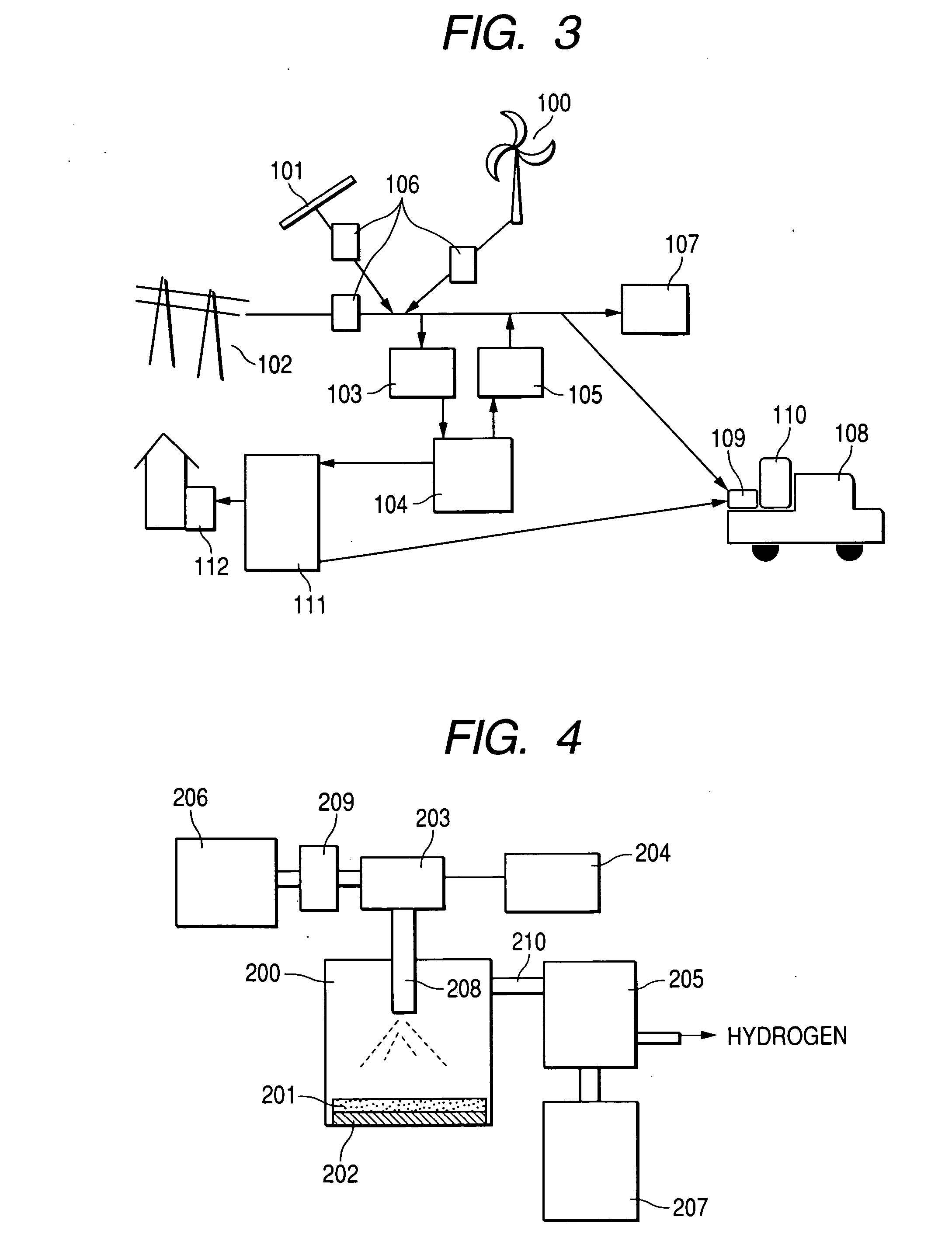

Hydrogen supply device and hydrogen supplying method

InactiveUS20060204799A1Auxillary drivesHydrogen/synthetic gas productionProcess engineeringAtmospheric pressure

A hydrogen supply device which generates hydrogen from hydrogen storing material which chemically stores hydrogen by a catalyst, wherein said device comprises valves on the fuel supply port and the exhaust port, and a valve controller which controls timing to opening and close the valves Fuel supply pressure is 2 to 20 atm. Hydrogen generation pressure is 5 to 300 atm. Exhaust pressure is atmospheric pressure to 0.01 atm.

Owner:HITACHI LTD

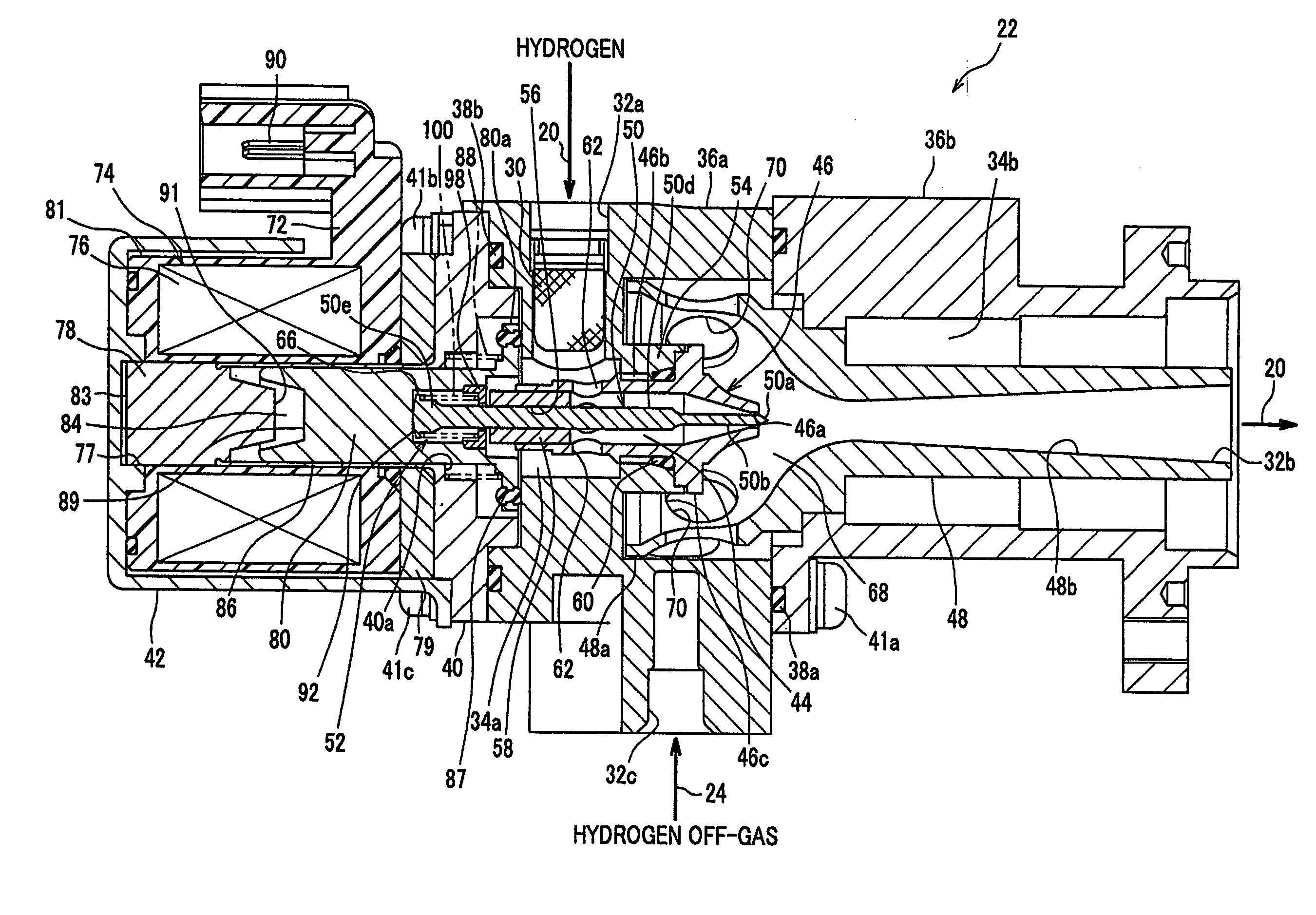

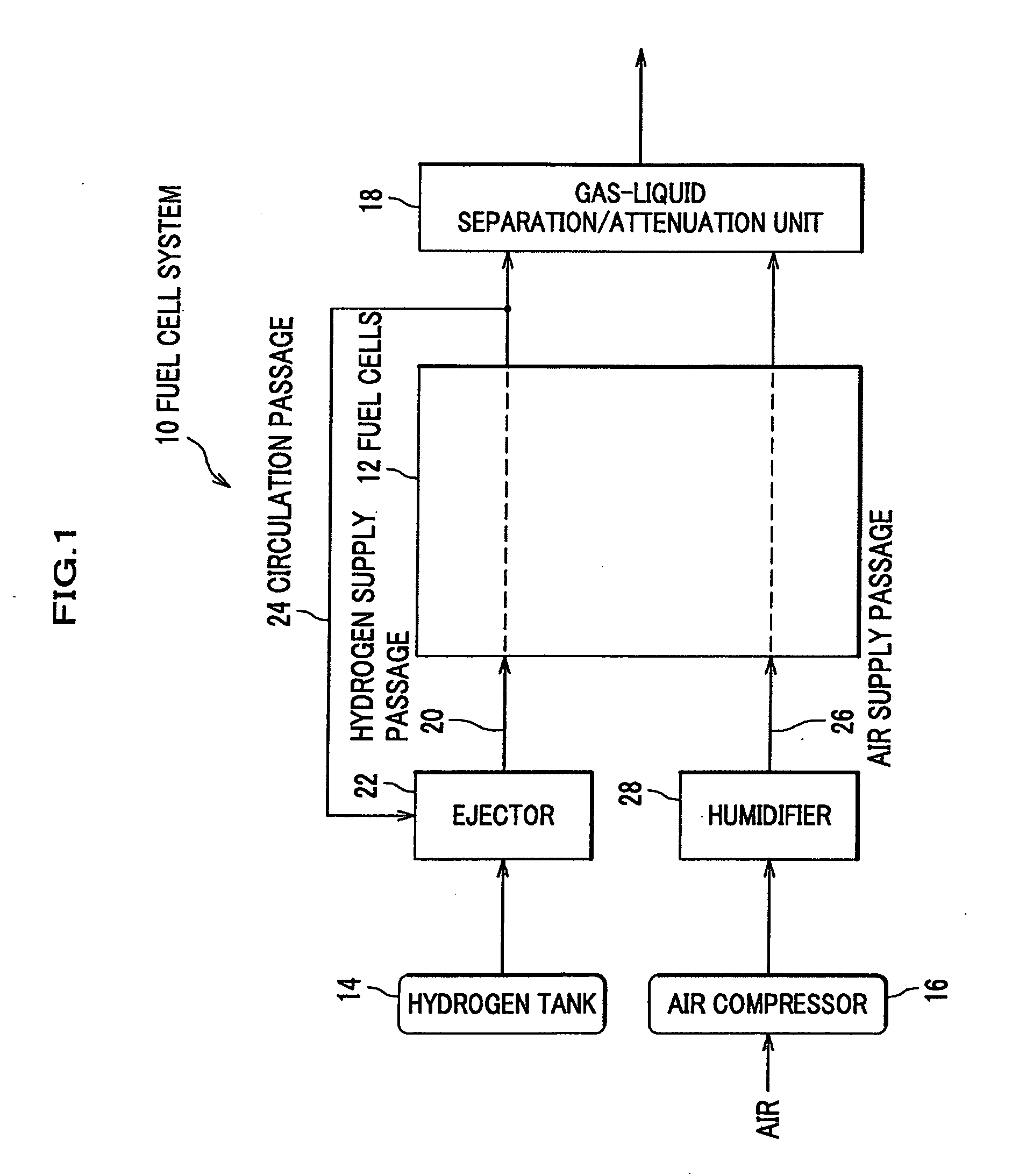

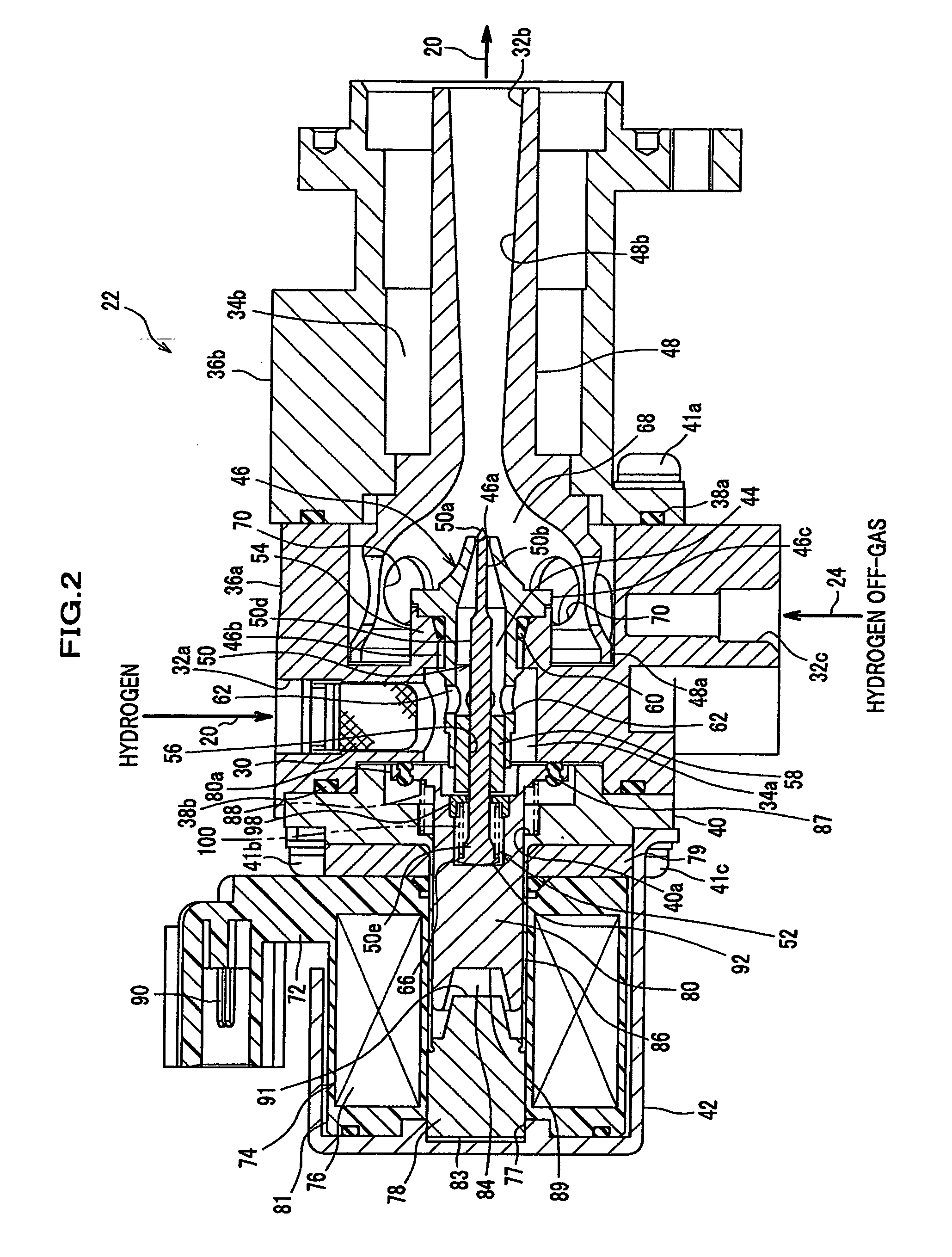

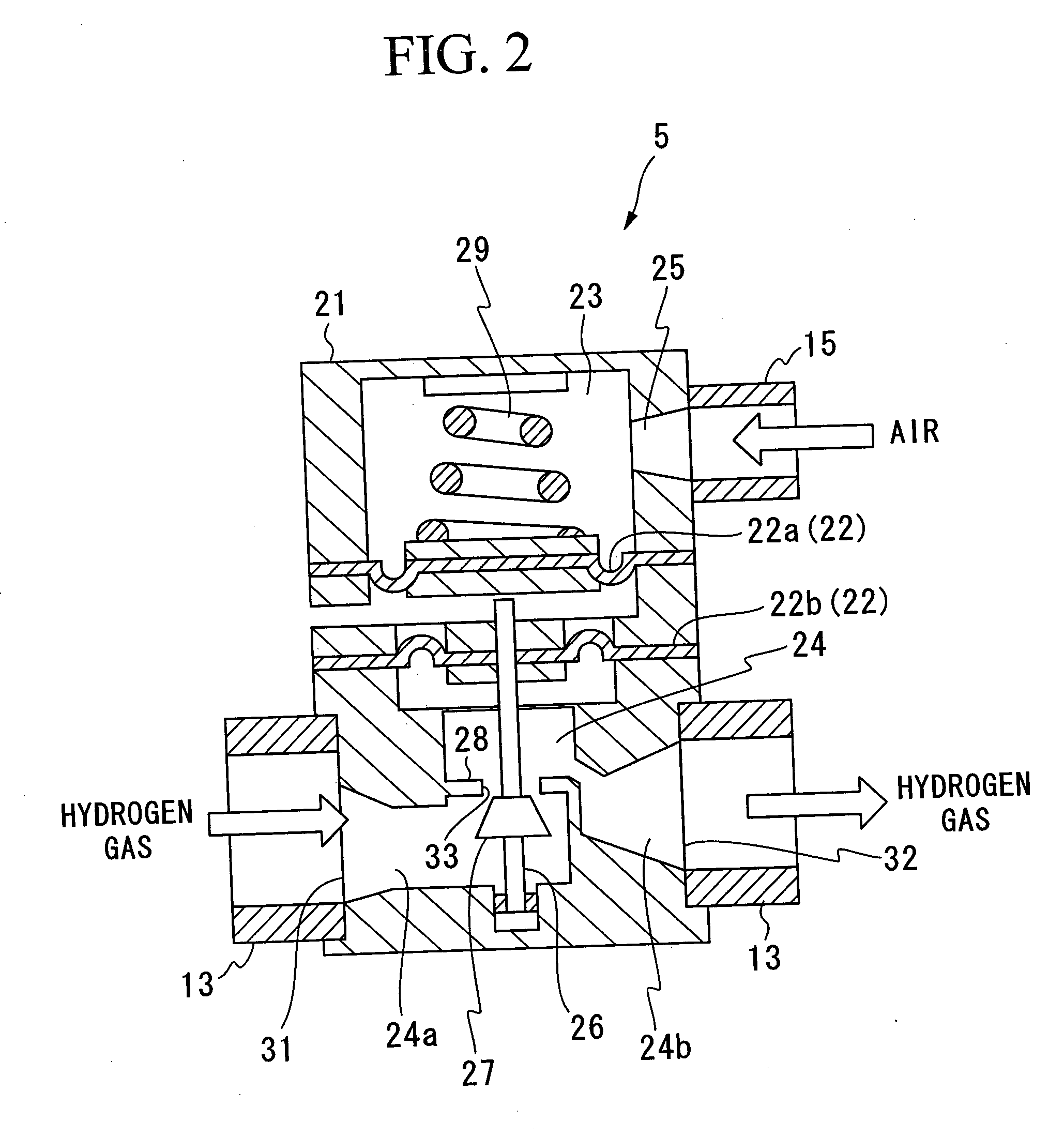

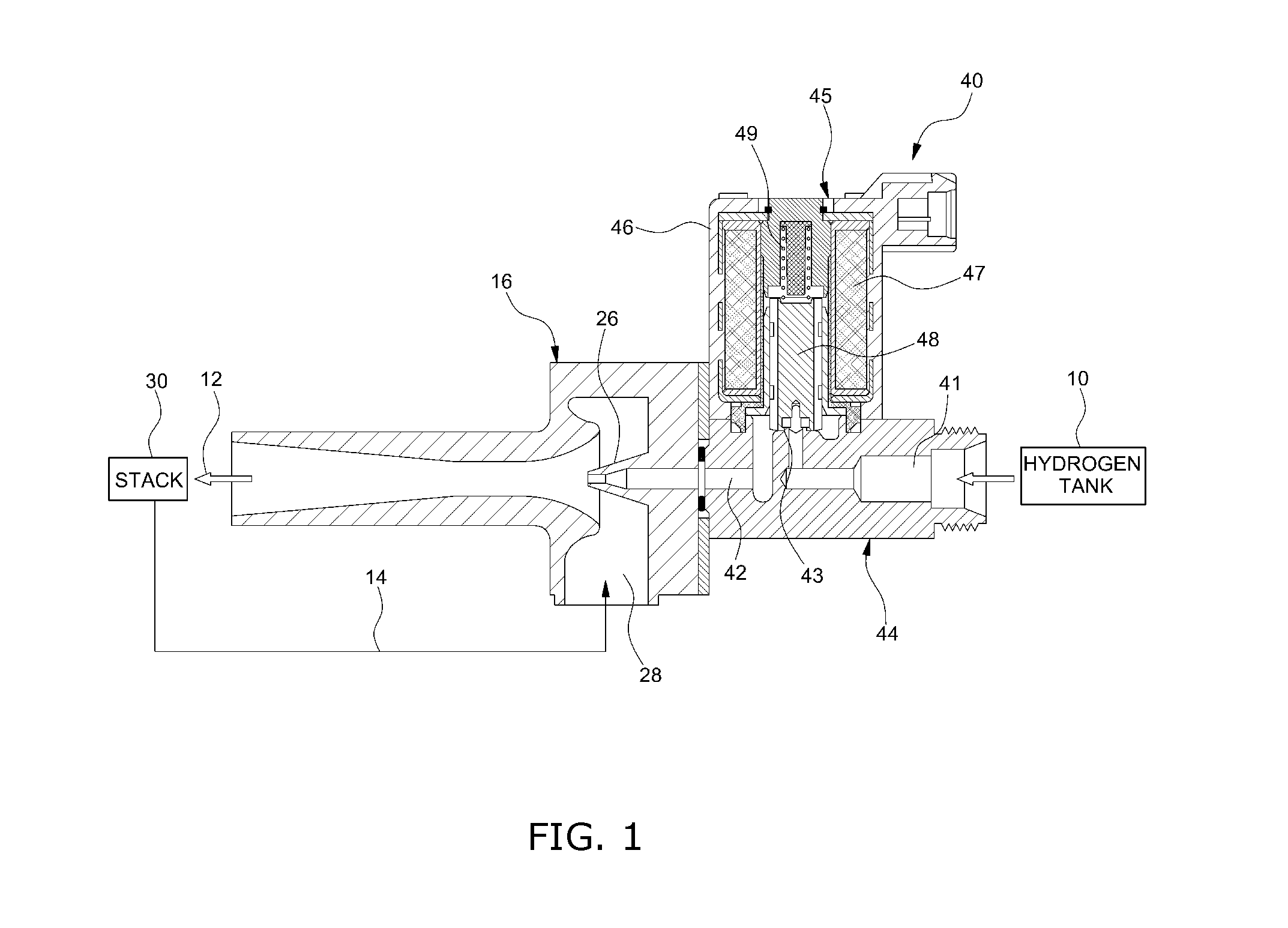

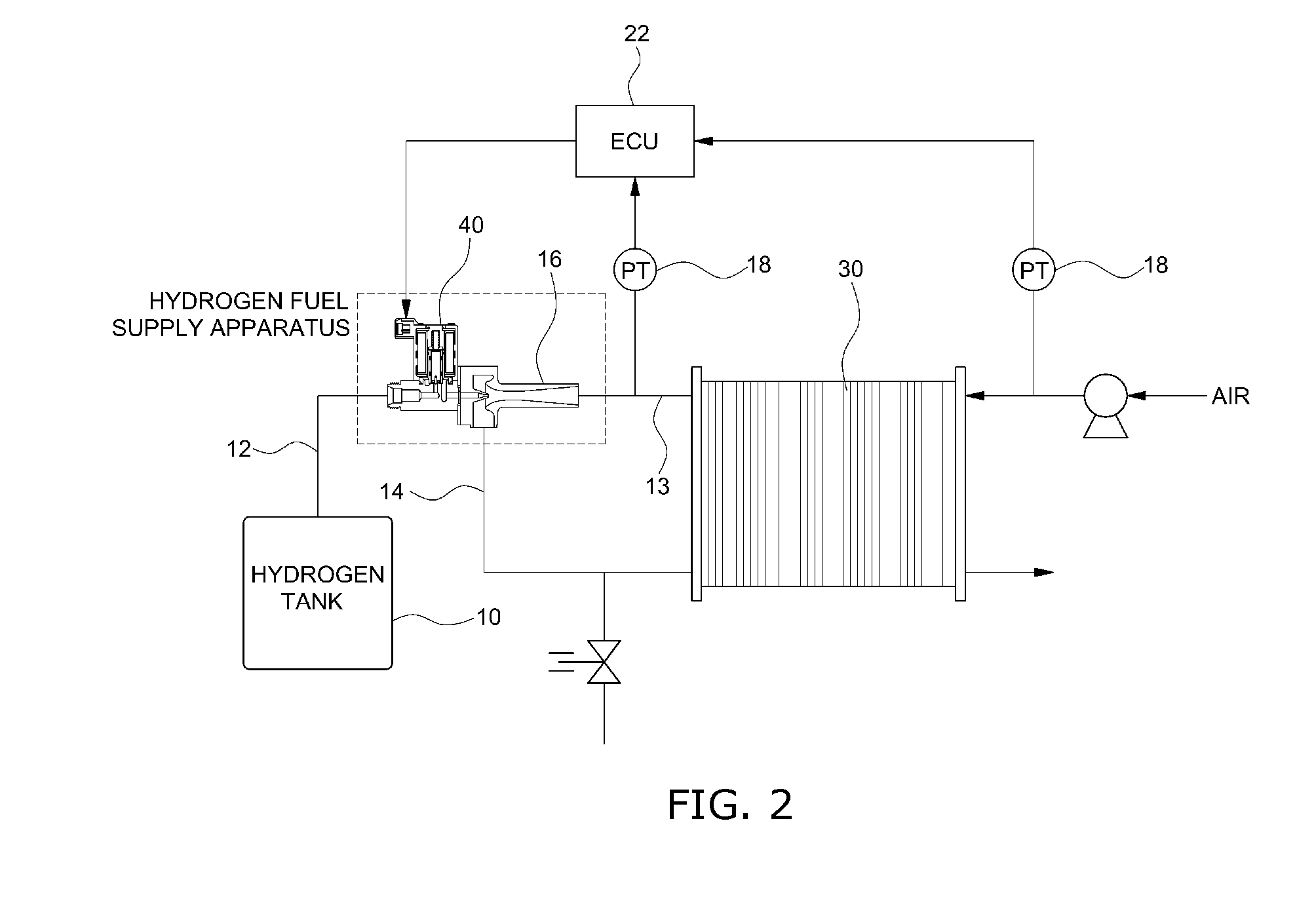

Ejector for fuel cell system

An ejector for a fuel cell system of the present invention includes a nozzle having a nozzle hole for discharging hydrogen supplied via an inlet port of an ejector body, a diffuser for mixing hydrogen discharged from the nozzle hole and hydrogen off-gas discharged and returned via a circulation passage from a fuel cell, a needle displacing in the axial direction by a driving force of a solenoid, and a bearing member held in a hollow portion of the nozzle, and having a through hole that movably supports the needle in the axial direction.

Owner:KEIHIN CORP

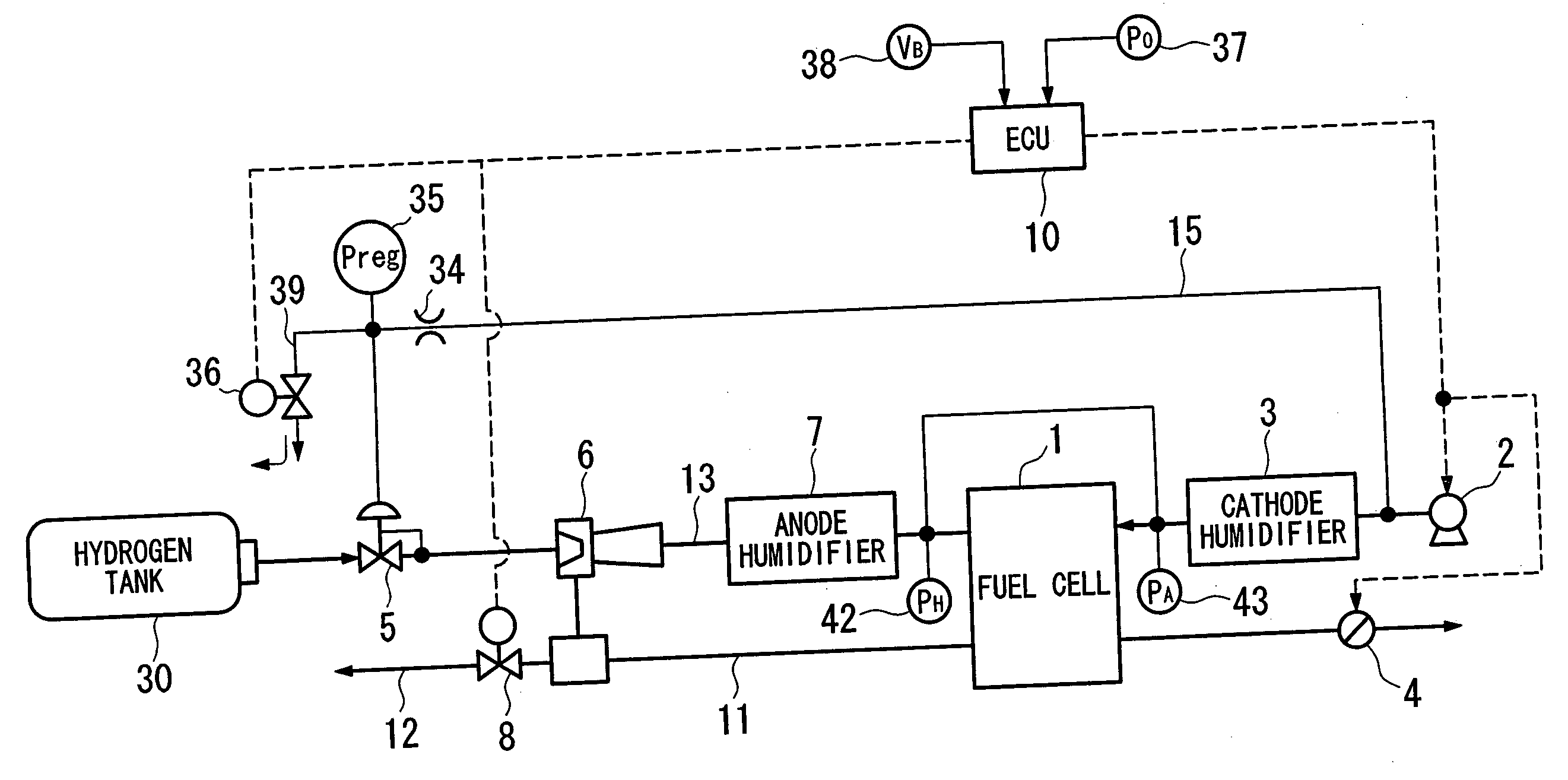

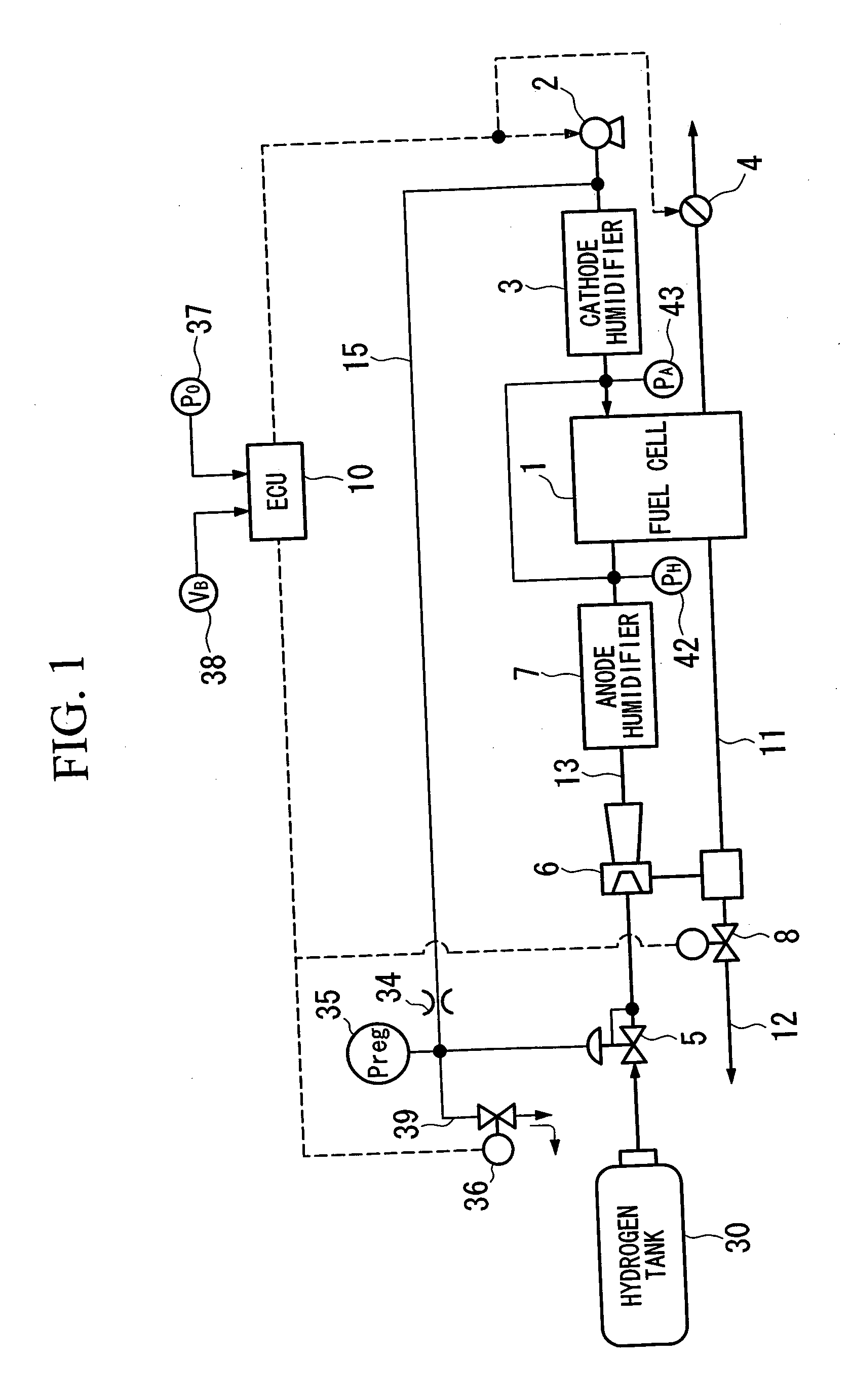

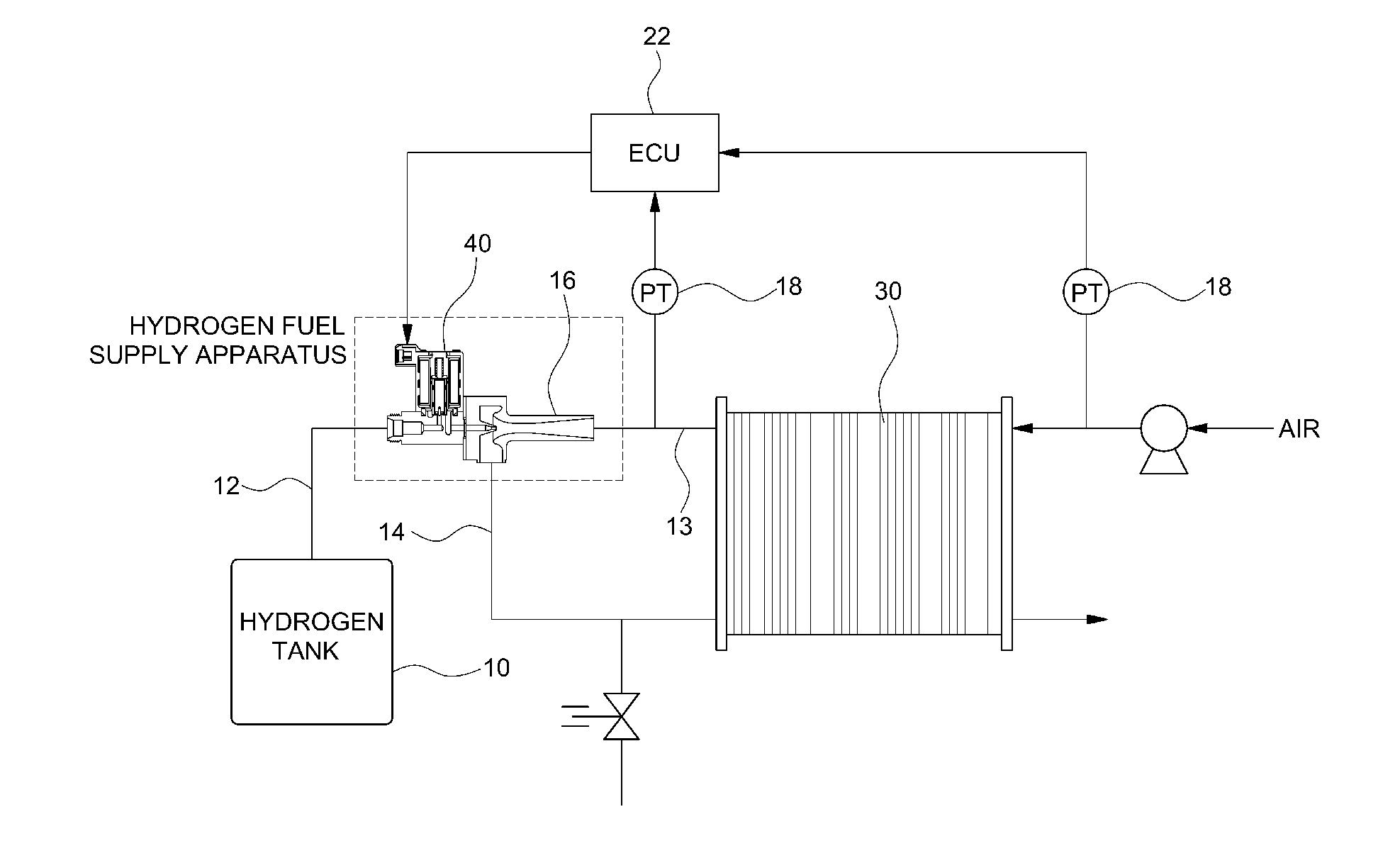

Reaction gas supply apparatus and method for fuel cell

InactiveUS20050118475A1Improve responsivenessReduce the overall diameterFuel cell auxillariesEngineeringProduct gas

A reaction gas supply apparatus for a fuel cell is able to adapt to various kinds of operating states, and can provide improved responsiveness with respect to a required output. The apparatus has: a compressor 2 that supplies pressurized air to a cathode electrode of a fuel cell 1; a hydrogen supply device 30 that supplies hydrogen to an anode electrode of the fuel cell 1; a control device 10 that regulates the pressure of the cathode electrode by controlling the compressor 2 according to an operating state of the fuel cell 1; and a regulator 5 that is applied with the air pressure of the cathode electrode as a reference pressure, and regulates the supply pressure to the anode electrode based on this air pressure. Moreover there is provided a pressure regulator 39 that is capable of regulating the reference pressure that is applied to the regulator 5, by discharging air from an air flow passage for the air pressure that is applied to the regulator 5.

Owner:HONDA MOTOR CO LTD

Hydrogen station

ActiveUS20140196814A1Easy to controlSuppresses internal temperature riseVessel mounting detailsGas handling applicationsEngineeringHydrogen supply

Provided is a hydrogen station that supplies hydrogen to an external hydrogen tank, the hydrogen station including: a reciprocating compressor that is driven by a driver of which revolution is controllable; a cooling device that is capable of cooling hydrogen supplied from the reciprocating compressor to the hydrogen tank; a temperature sensor that detects an internal temperature of the hydrogen tank or a temperature of the hydrogen supplied to the hydrogen tank; and a control unit that controls the revolution of the driver based on the temperature detected by the temperature sensor.

Owner:KOBE STEEL LTD

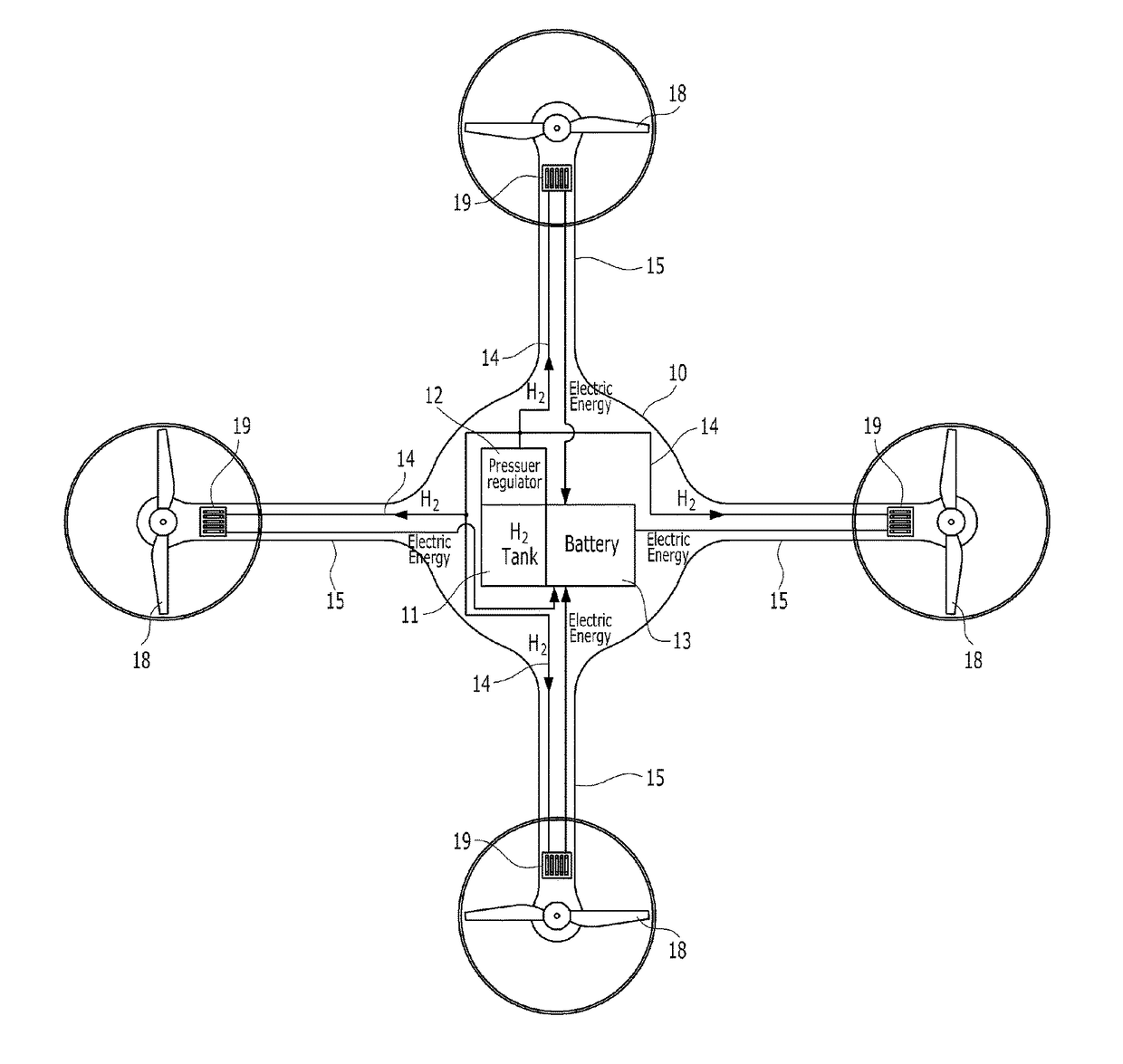

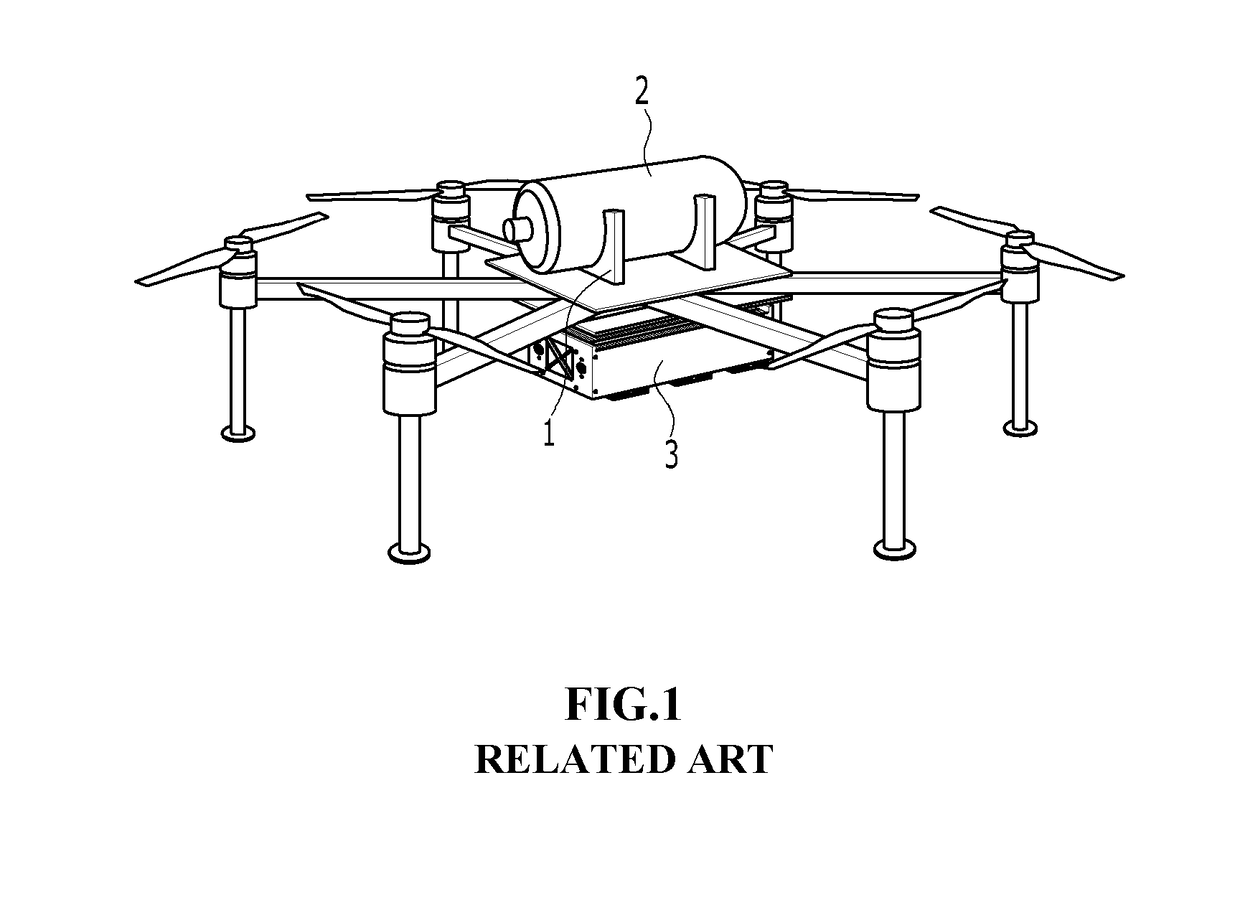

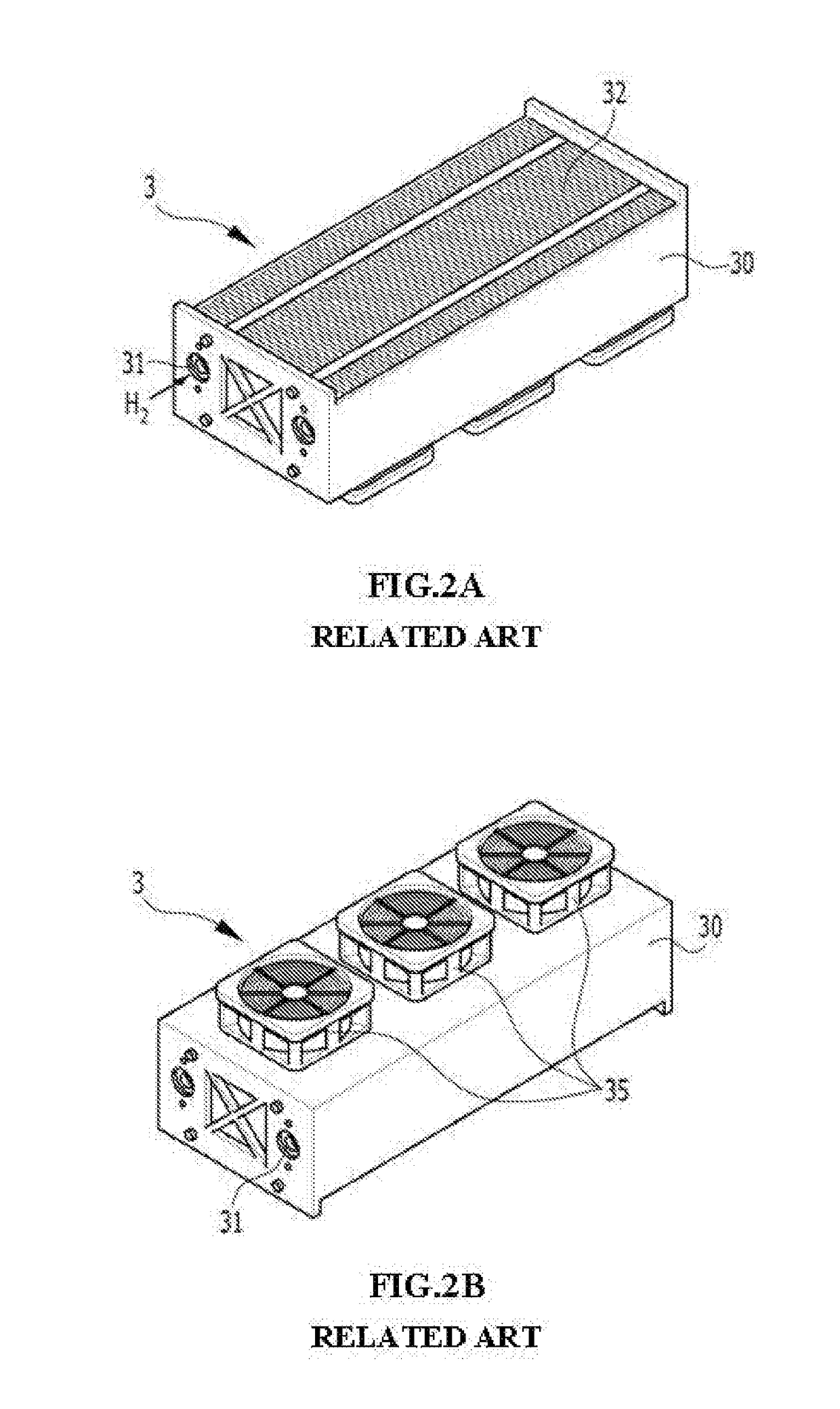

Fuel cell power pack for multicopter

InactiveUS20170240291A1Power plant cooling arrangmentsBatteries circuit arrangementsElectrical batteryFuel tank

A fuel cell power pack used as a power source in a multicopter includes a fuel tank and a fuel cell stack for producing electrical energy using hydrogen supplied from the fuel tank and supplying the electrical energy to a battery, and since the fuel cell stack is disposed at a certain point of an arm extended from the aircraft body in the radius direction (a point affected by a descending air current generated by each rotating blade), the electrical energy can be produced using the descending air current generated by the rotating blade without configuring a separate blowing apparatus.

Owner:HYLIUM IND INC

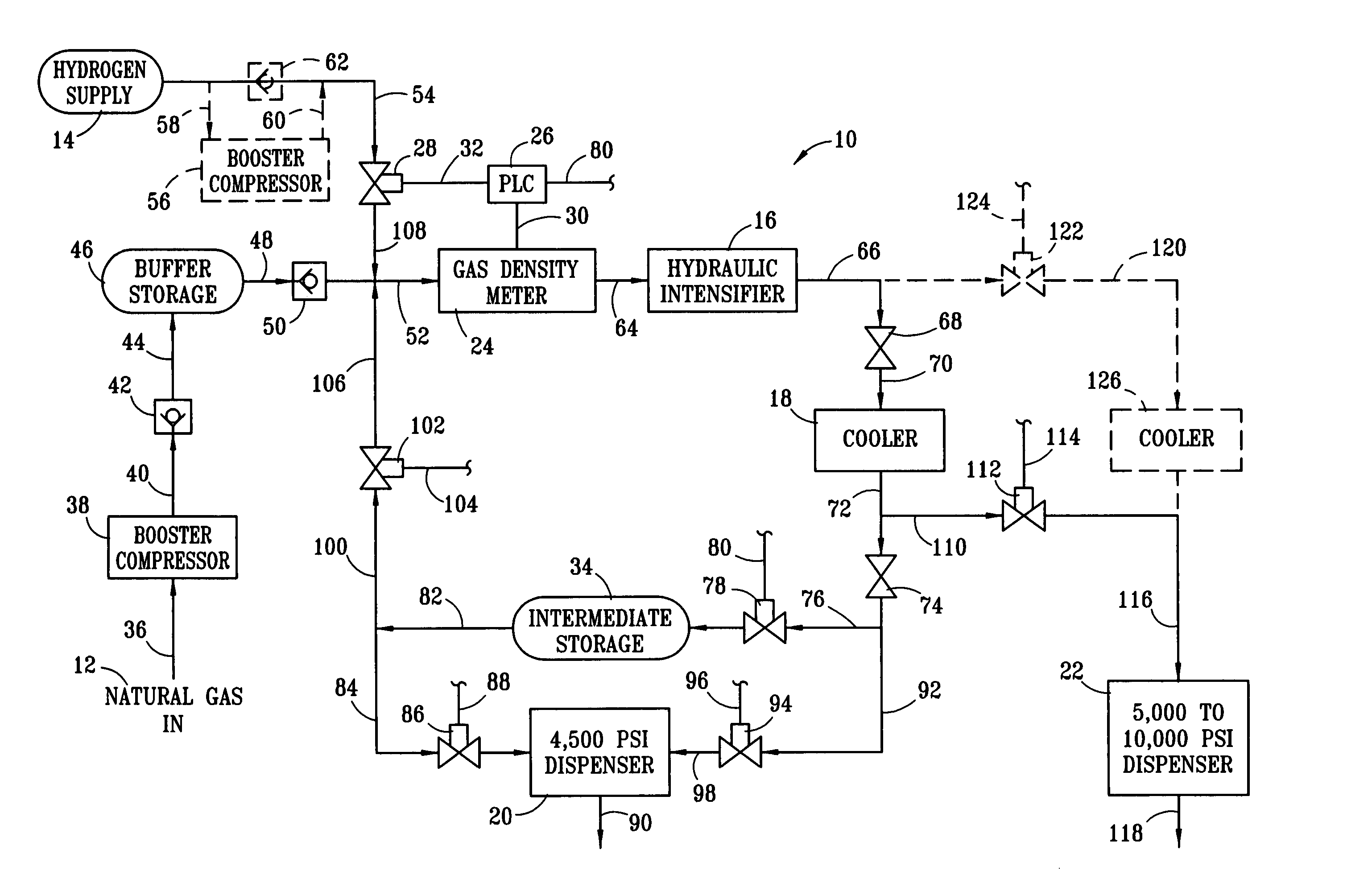

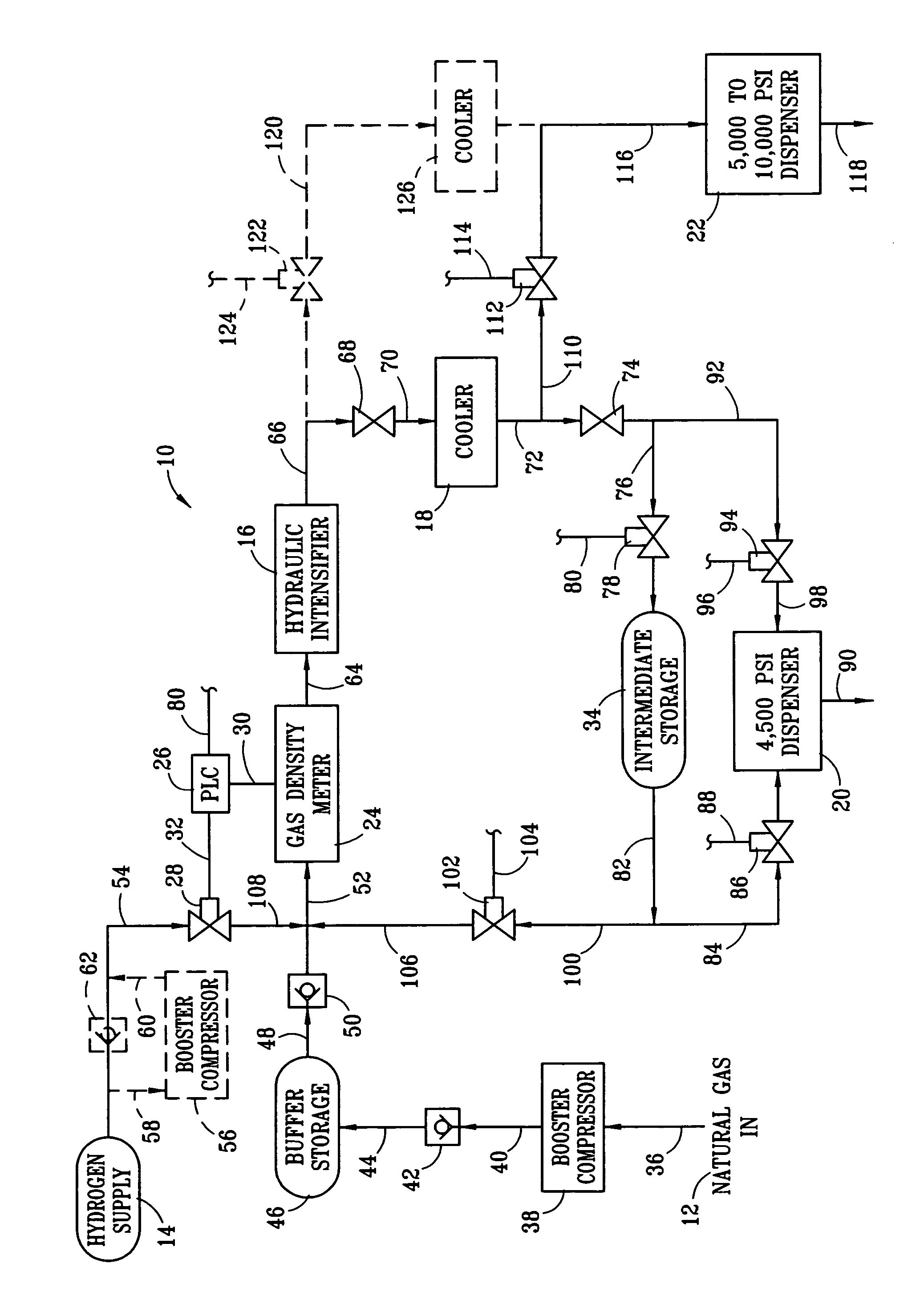

Dual-service system and method for compressing and dispensing natural gas and hydrogen

InactiveUS7168464B2Easy to switchFacilitate pressureLiquid fillingFrozen sweetsVolumetric Mass DensityGas cooler

A dual service system and method for selectively compressing and dispensing methane, hydrogen, and variable mixtures of methane and hydrogen for use as a gaseous fuel. The use of an in-line gas density meter, hydraulic intensifier, pressurized gas cooler, optional intermediate storage and multiple dispensers are disclosed. An inline gas density meter is used in combination with a programmable logic controller and a control valve on the hydrogen supply line to create a closed feedback loop for selectively controlling the hydrogen content of the resultant pressurized fuel gas.

Owner:INTEGRYS TRANSPORTATION FUELS

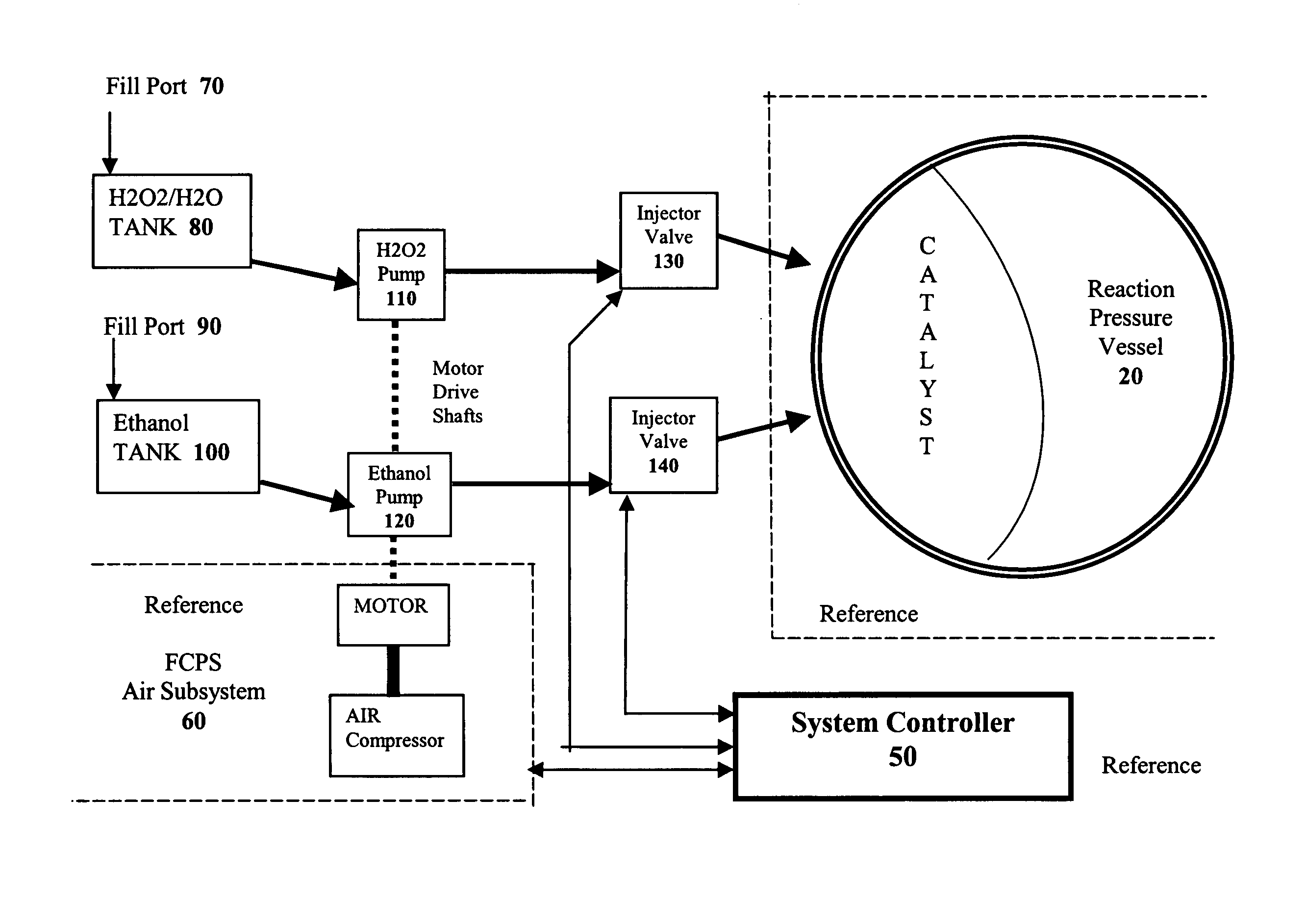

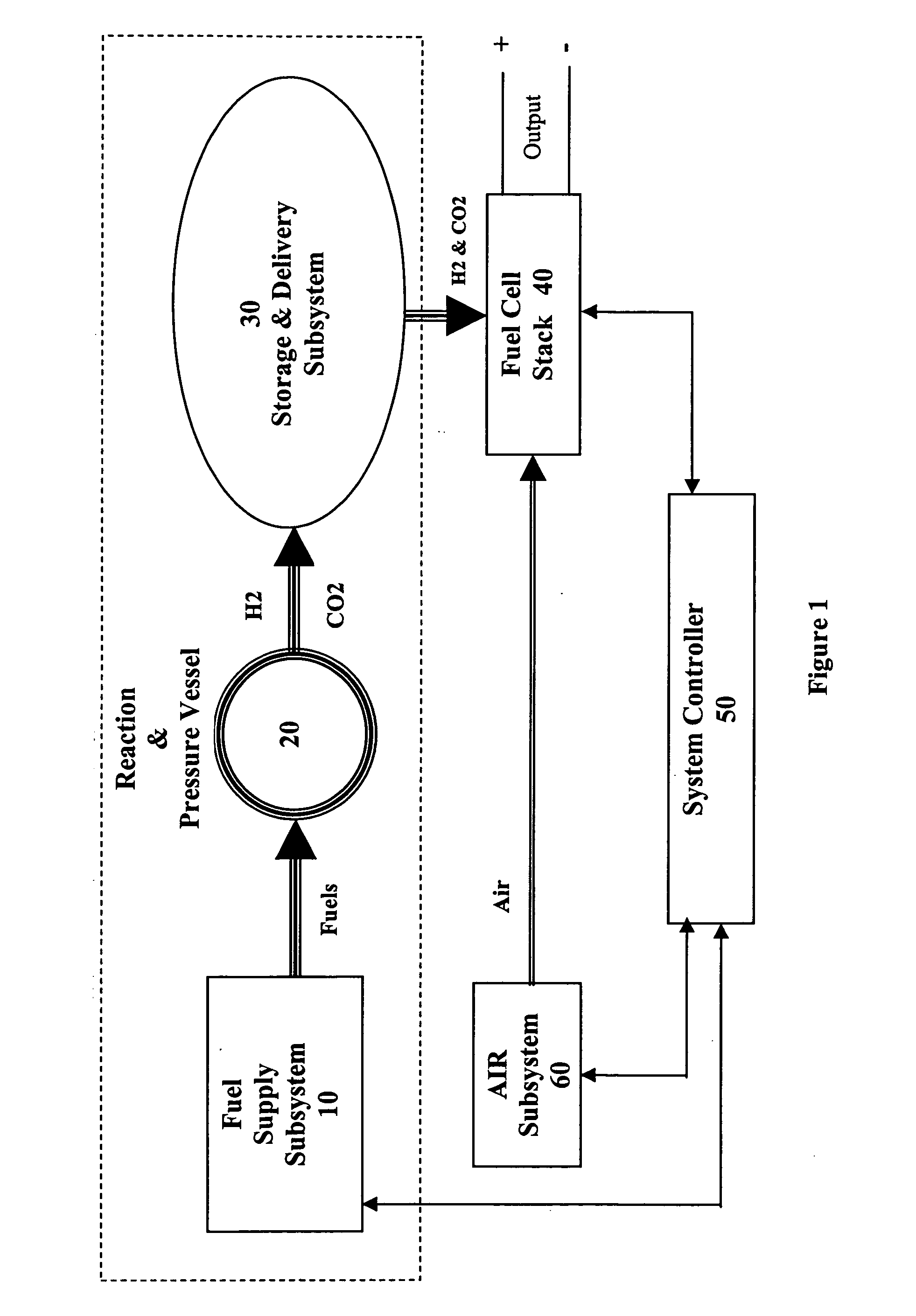

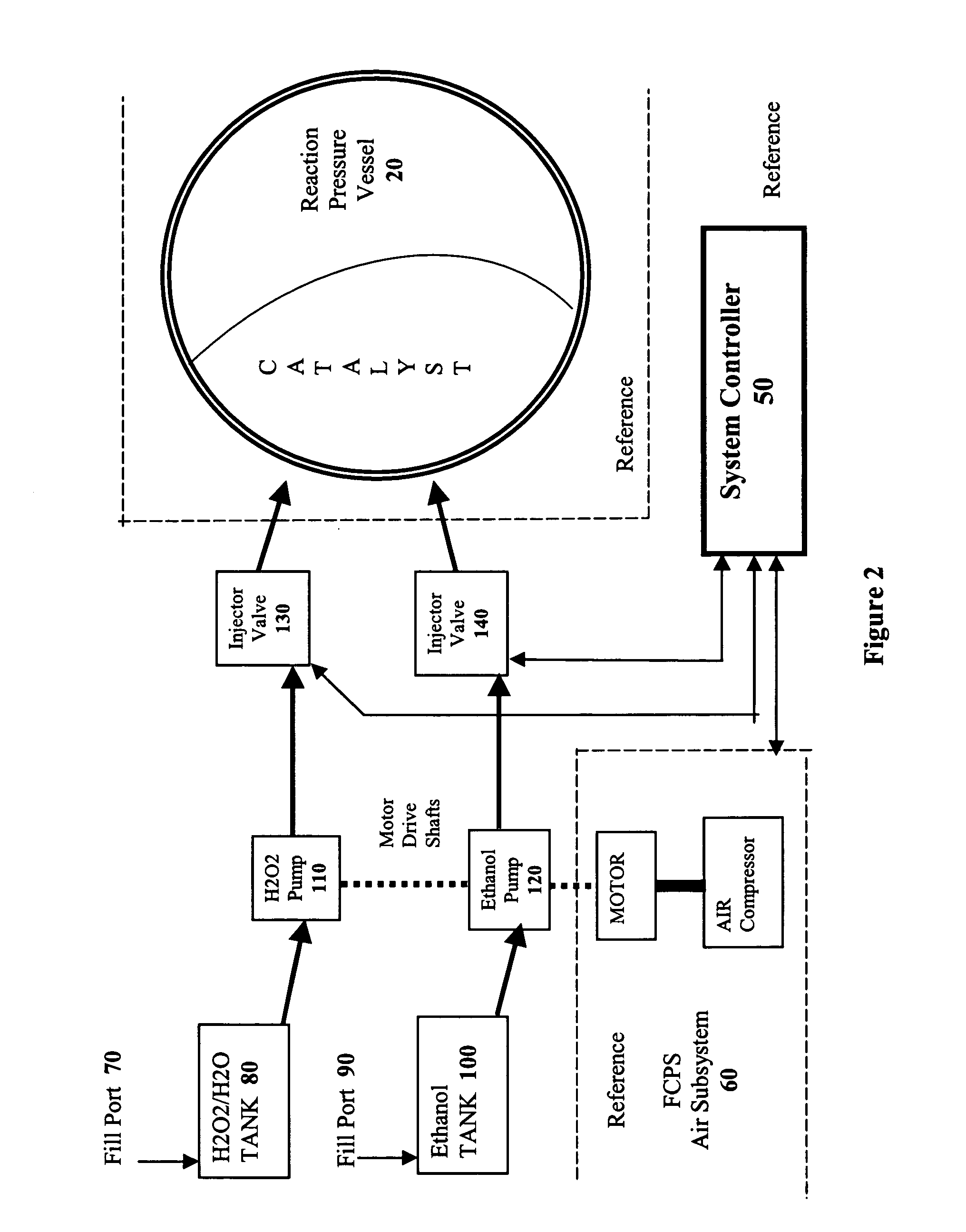

Hypergolic hydrogen generation system for fuel cell power plants

InactiveUS20050031918A1Increased electrical power densityIncrease pressureHydrogen separation using solid contactFuel cell auxillariesHydrocotyle bowlesioidesOxygen

The invention provides a controlled hypergolic approach to using concentrated hydrogen peroxide in combination with certain hydrocarbons such as ethanol, methanol, methane as well as more common fuels such as gasoline, diesel, DME, JP5, JP8 and the like to generate a gas mixture primarily composed of hydrogen and carbon dioxide. Because air is not used as the oxygen source, this novel process does not allow the formation of nitrous oxide (NOx) compounds, thereby avoiding the primary source of nitrogen contamination as well. The process is executed in a constraining system on a micro scale such that the resulting hydrogen supply is self-pressurizing. This enables the incorporation of an “on-demand” hydrogen fuel source for a variable output fuel cell power plant such as those proposed for use in automobiles, marine vessels and stationary power sources. In another embodiment of the present invention hydrogen peroxide is catalytically, or thermally reacted to provide H2O vapor and O2. When this gaseous stream is introduced to the cathode of the fuel cell, the percent concentration of oxygen is increased with no corresponding increase in the parasitic power demand made by an air-moving device. This use of H2O2 as an oxygen source may be continuous, intermittent or limited to specific instances when peak power output demands or high transient loads are placed upon the FCPS.

Owner:CBH2 TECH

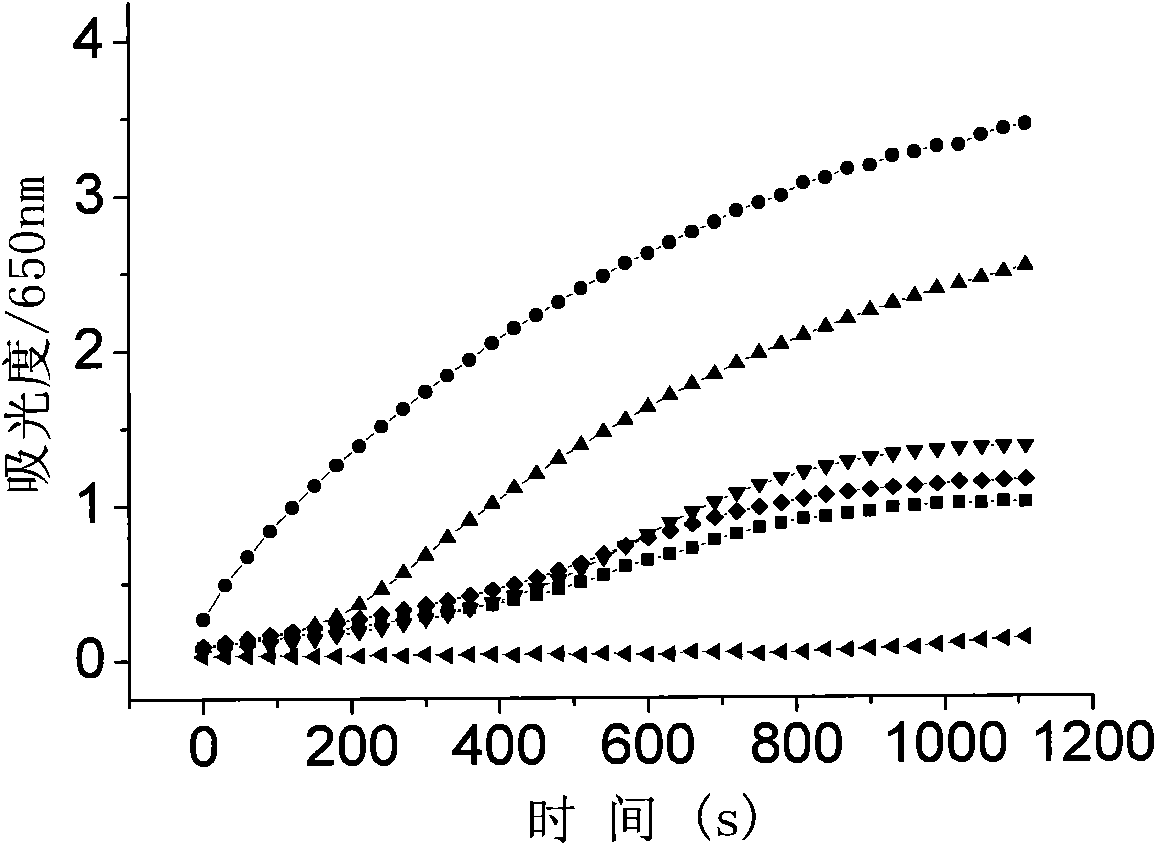

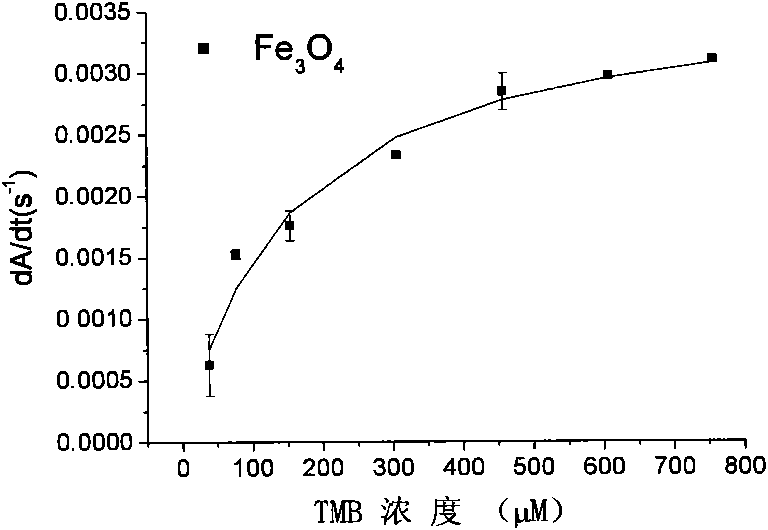

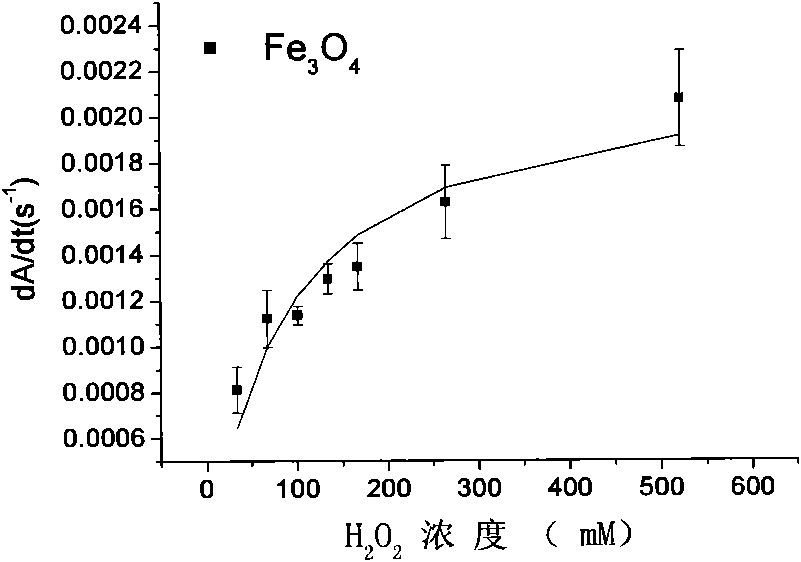

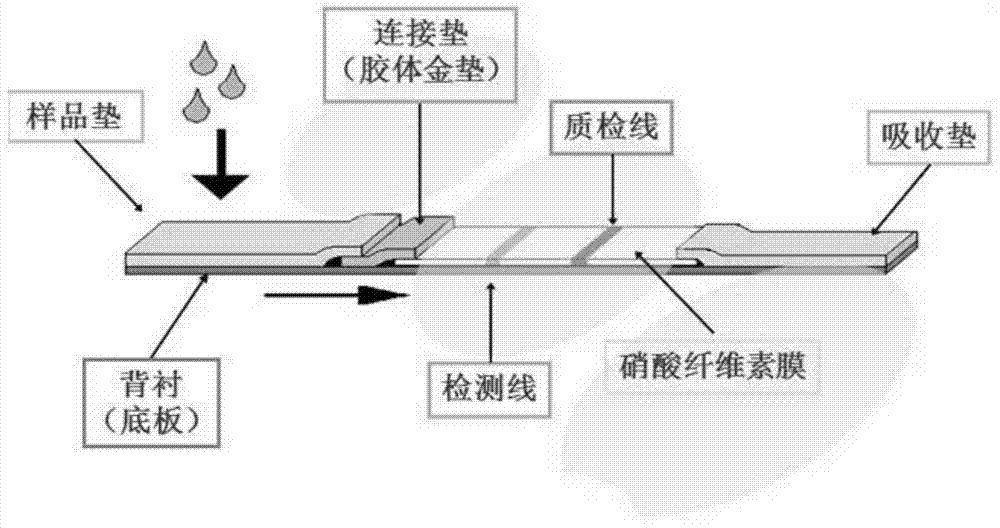

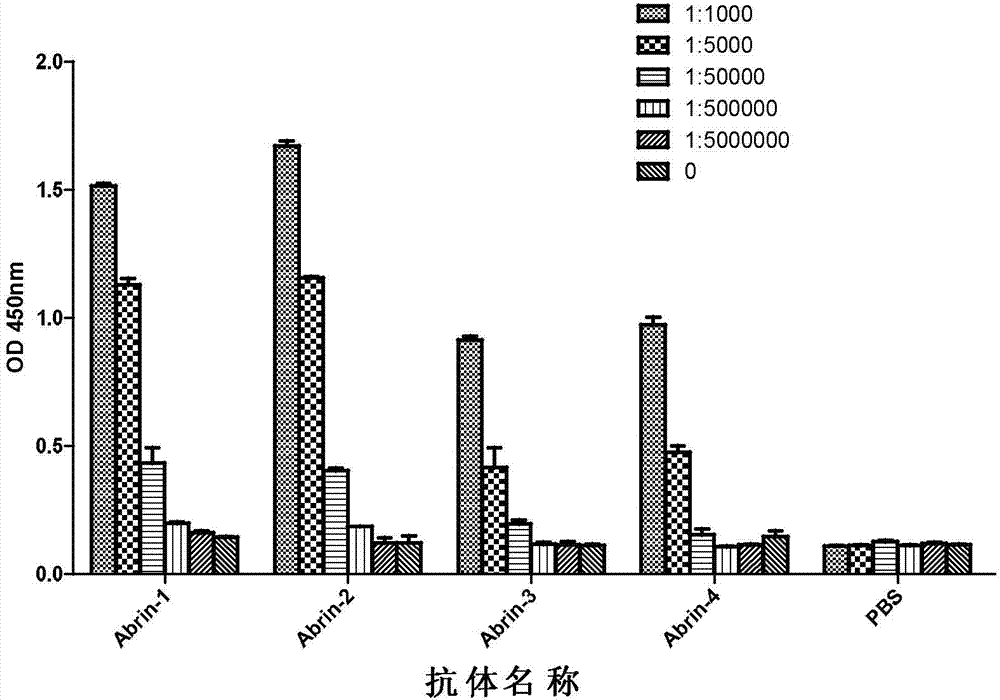

Method for applying magnetic gamma-Fe2O3 nano-particle mimetic enzyme to biological detection

InactiveCN101672771AImprove stabilityGood biocompatibilityMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsHorse radish peroxidaseHydrogen supply

The invention relates to a magnetic gamma-Fe2O3 nano-particle mimetic enzyme and provides a method for applying a magnetic gamma-Fe2O3 nano-particle mimetic enzyme to biological detection. The magnetic gamma-Fe2O3 nano-particle mimetic enzyme replaces a horse radish peroxidase (HRP) to be used in biological detection. The method comprises the following steps: coupling carboxyl groups on the surface of magnetic gamma-Fe2O3 nano-particles and a specific molecular probe to construct a specific nano probe; combining the nano probe with the specificity of the corresponding target molecules to be detected; developing by using a developer containing peroxides and hydrogen-supply zymolytes; and measuring the absorbency or carrying out the micro-observation so as to realize the qualitative and quantitative detection on target molecules.

Owner:SOUTHEAST UNIV

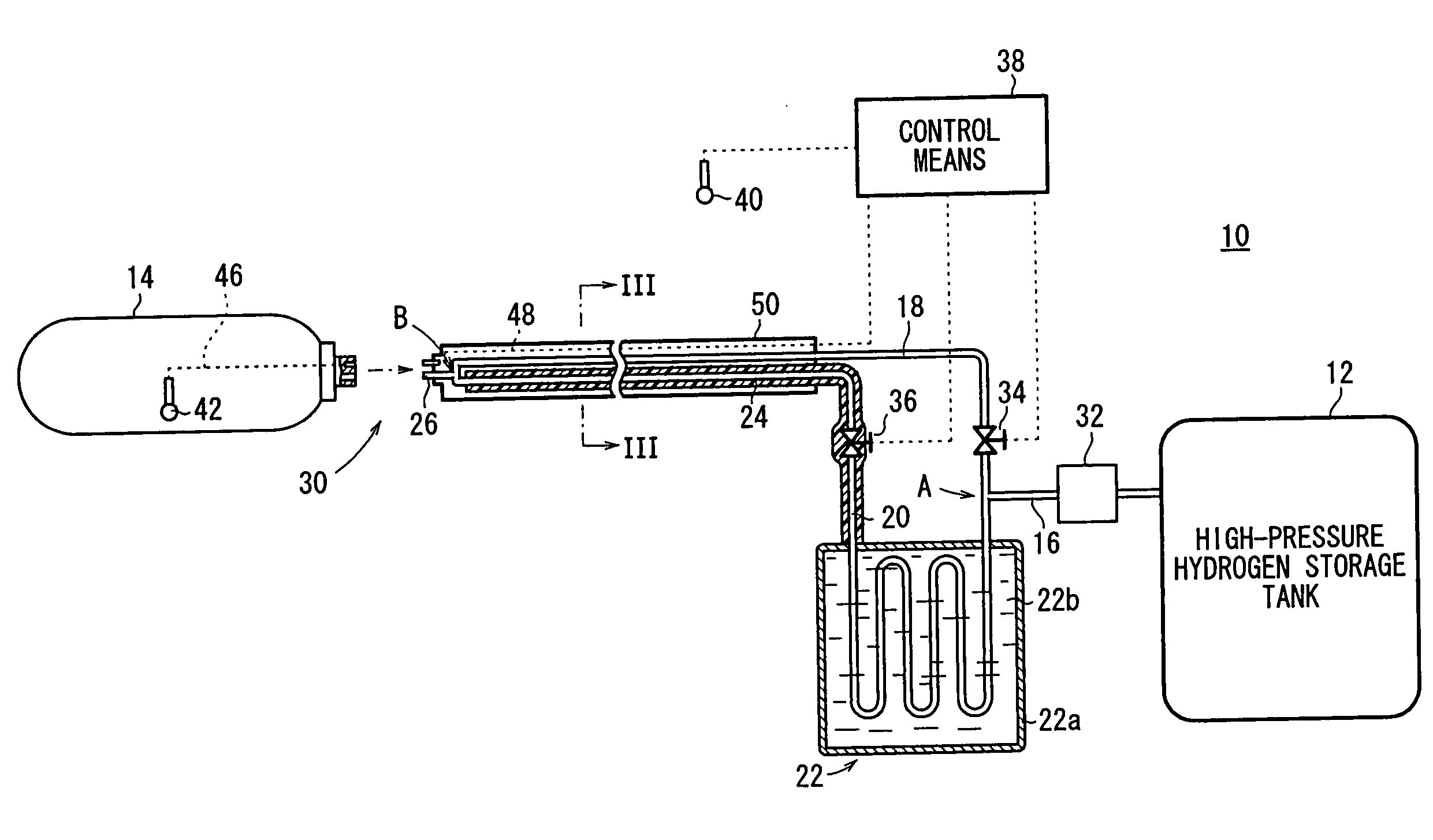

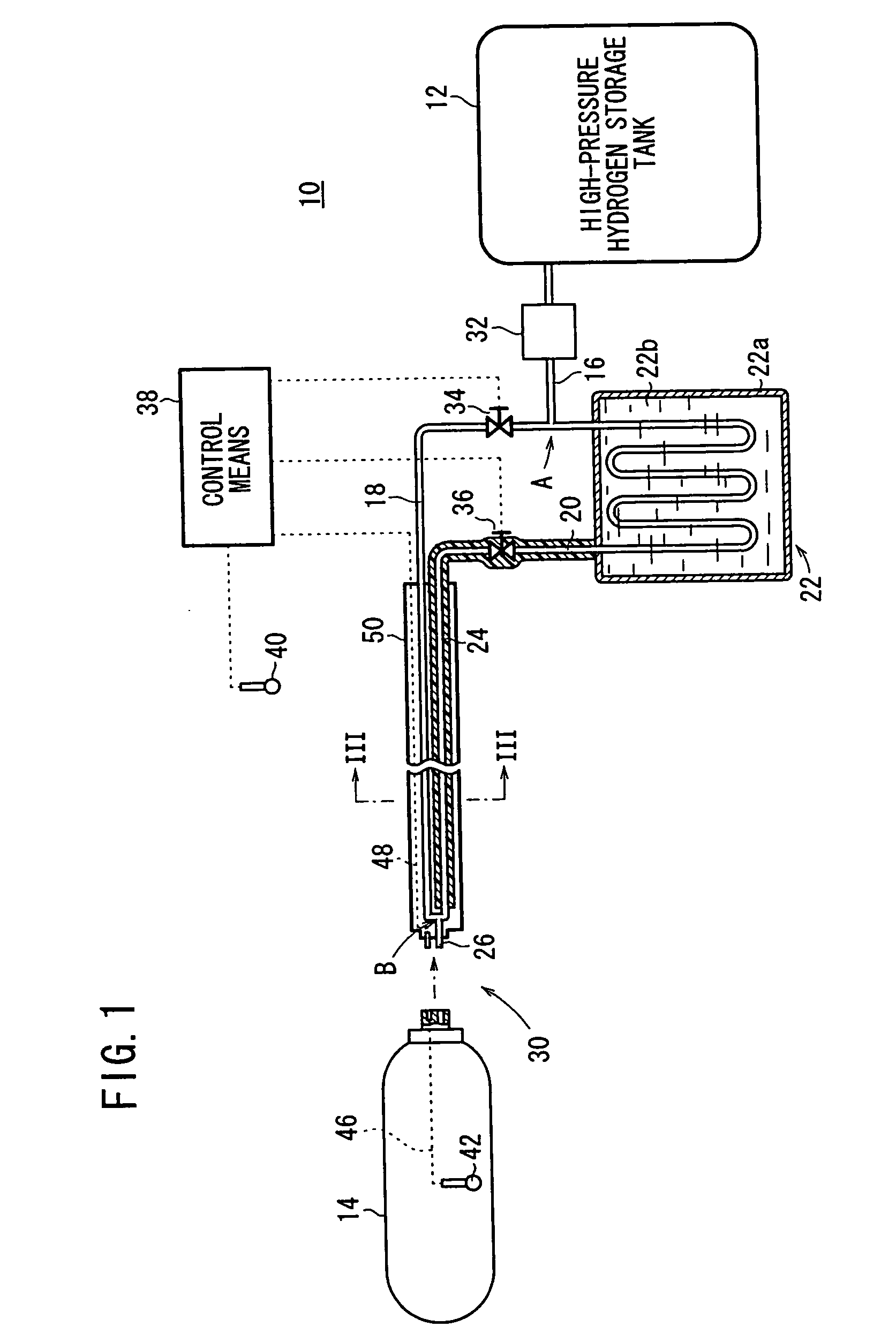

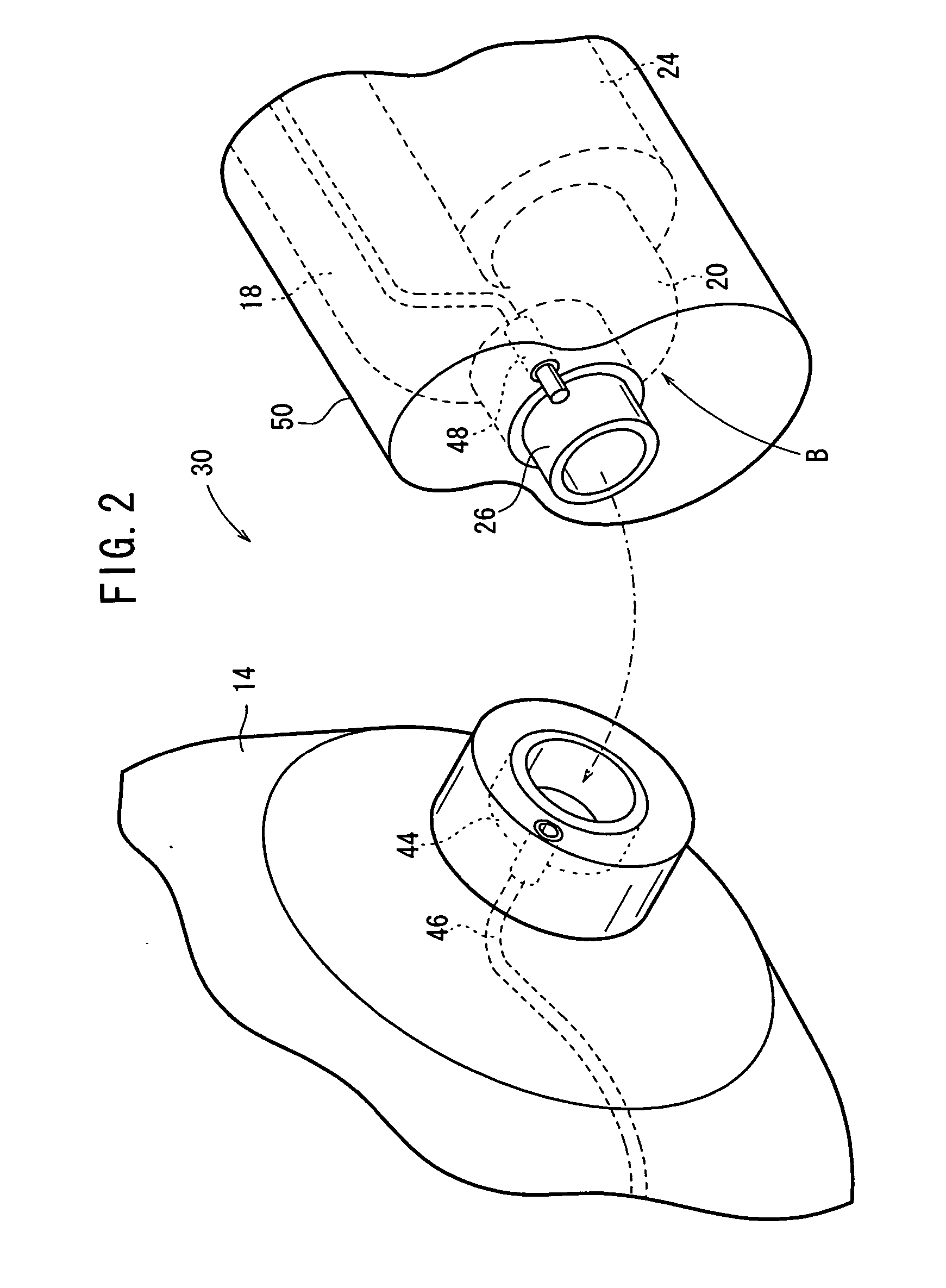

Apparatus for and method of filling hydrogen tank with hydrogen

InactiveUS20070257043A1Fast fillSuppresses temperature changesLarge containersGas handling/storage effectsHigh pressure hydrogenAtmospheric temperature

An hydrogen tank filling apparatus includes a first hydrogen supply pipe for supplying hydrogen substantially at an atmospheric temperature from a high-pressure hydrogen storage tank to a hydrogen tank, a second hydrogen supply pipe for supplying cooled hydrogen from the high-pressure hydrogen storage tank to the hydrogen tank, and an internal tank temperature measuring unit for measuring the temperature inside the hydrogen tank. The first hydrogen supply pipe and the second hydrogen supply pipe are selectively switched by a control unit, depending on changes in the temperature inside the hydrogen tank.

Owner:HONDA MOTOR CO LTD

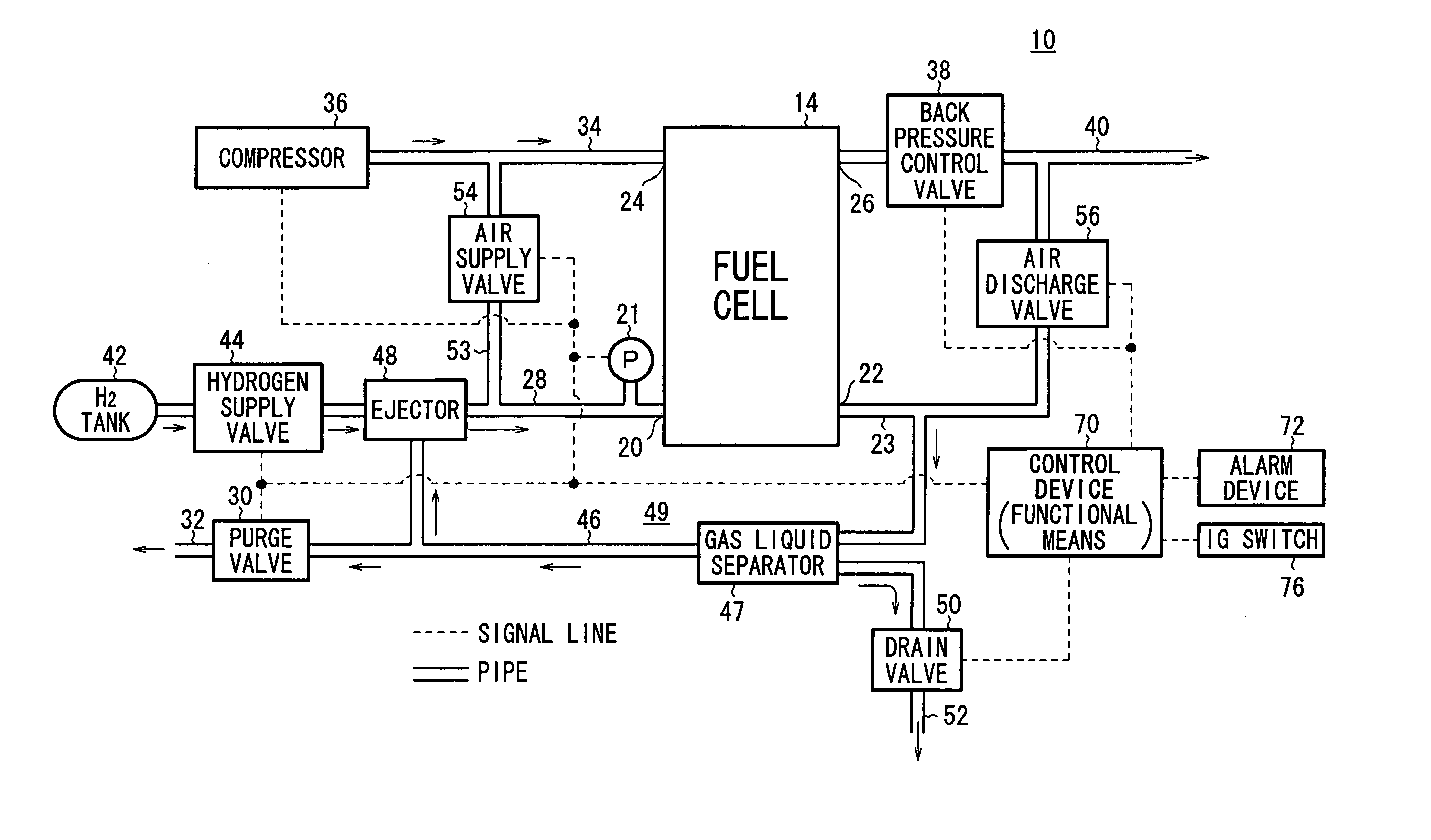

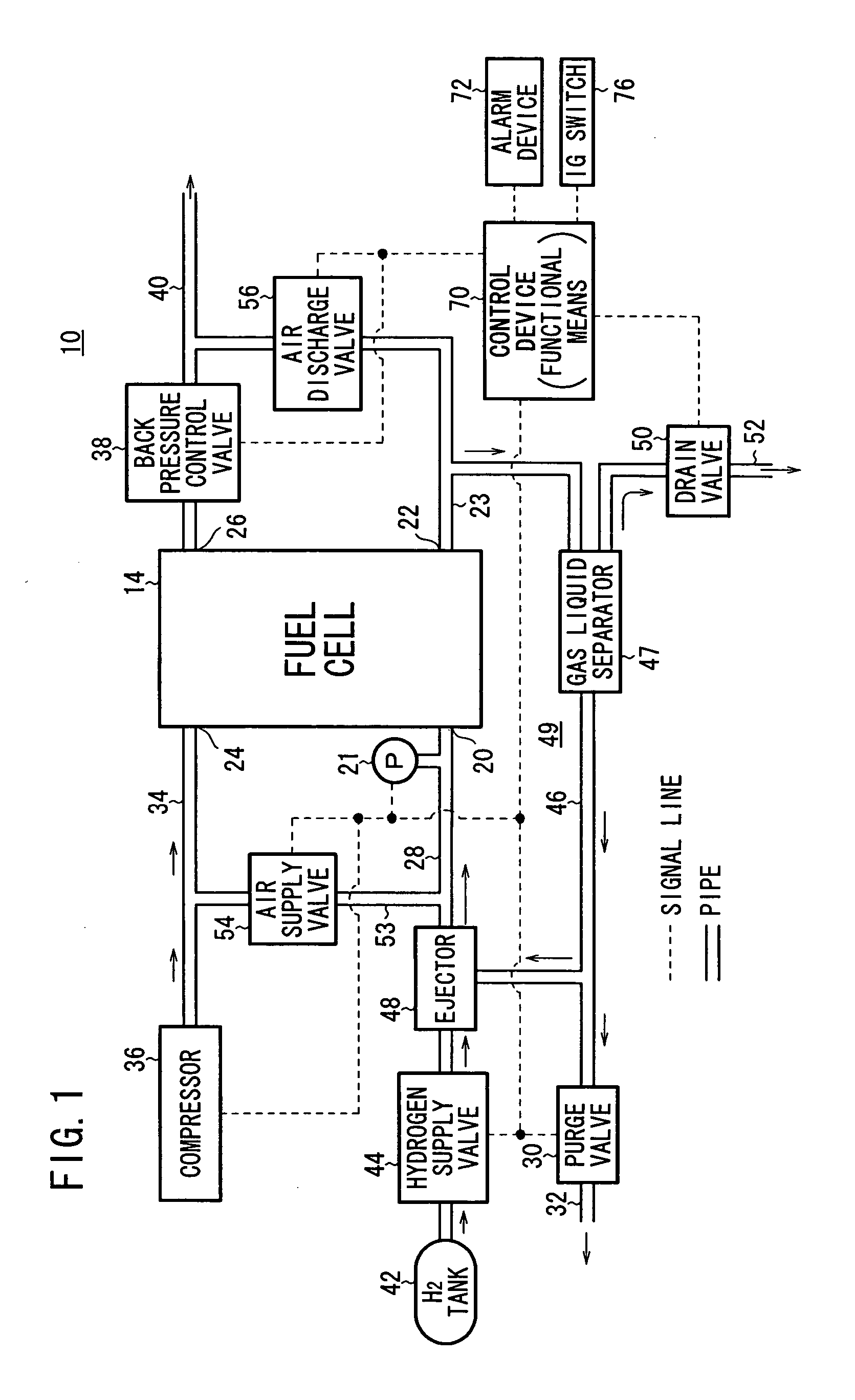

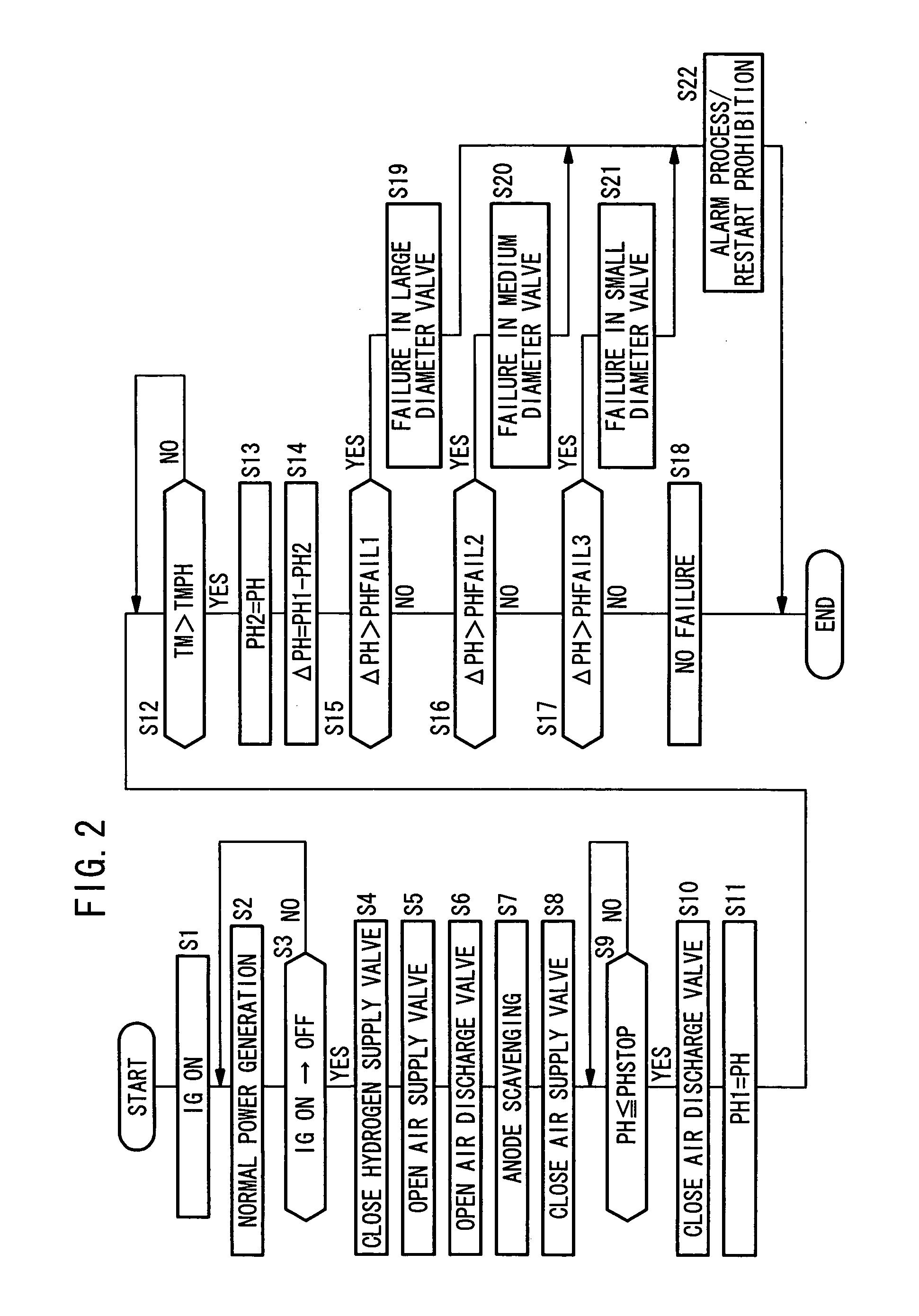

Fuel cell system and method of detecting failure in a fuel gas channel of fuel cell system

ActiveUS20060115700A1Avoid performance degradationShort processFuel cell auxillariesSolid electrolyte fuel cellsHydrogen supplyPressure difference

When an ignition switch is turned off, a hydrogen supply valve is closed. Operation of a compressor continues, and an air supply valve and an air discharge valve are opened to supply the compressed air into a fuel cell through a hydrogen supply port. The scavenging process of removing the fuel gas and the water remaining in the fuel gas channel is performed through the air discharge valve, a drain valve, and a hydrogen purge valve. Then, all the valves connected to the fuel gas channel are closed. The pressure when the valves are closed, and the pressure when a short time has elapsed after closing the valves are detected by a pressure sensor. Based on the pressure difference, a failure due to the leakage in the fuel gas channel is detected.

Owner:HONDA MOTOR CO LTD

Process and installation for conversion of heavy petroleum fractions in a boiling bed with integrated production of middle distillates with a very low sulfur content

ActiveUS7704377B2Low costTreatment with plural serial cracking stages onlyCoke ovensDistillates petroleumNaphtha

Owner:INST FR DU PETROLE

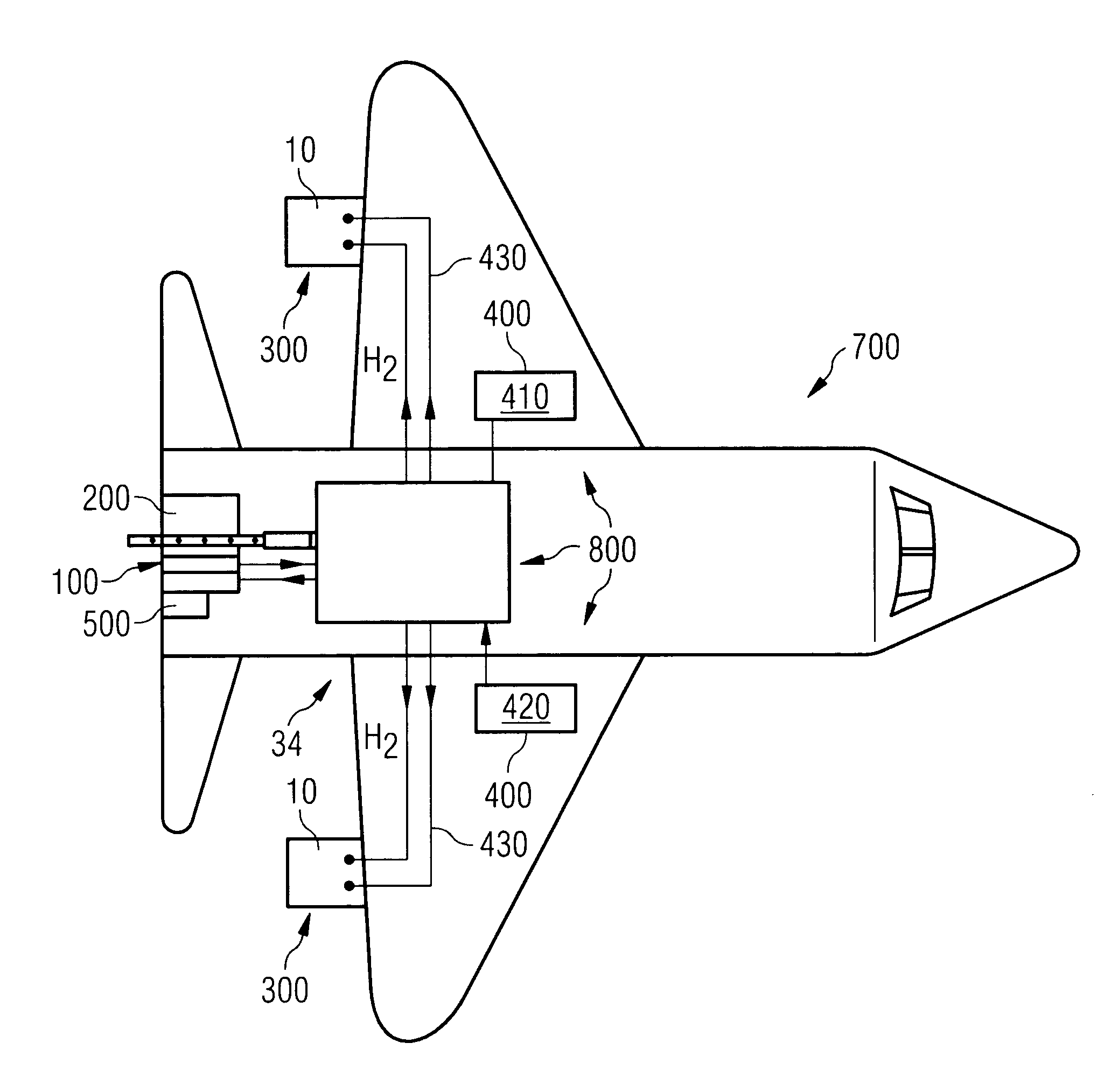

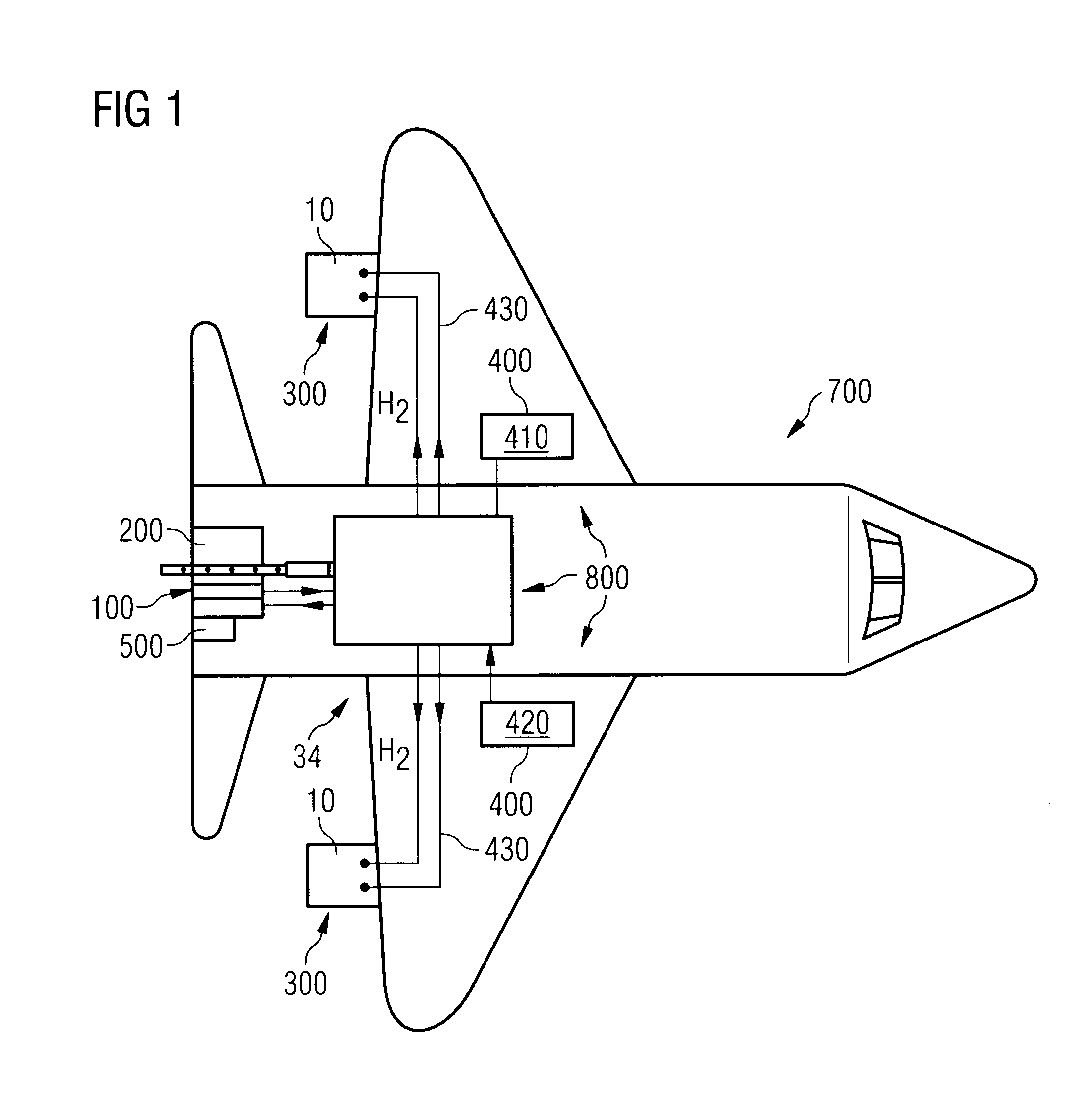

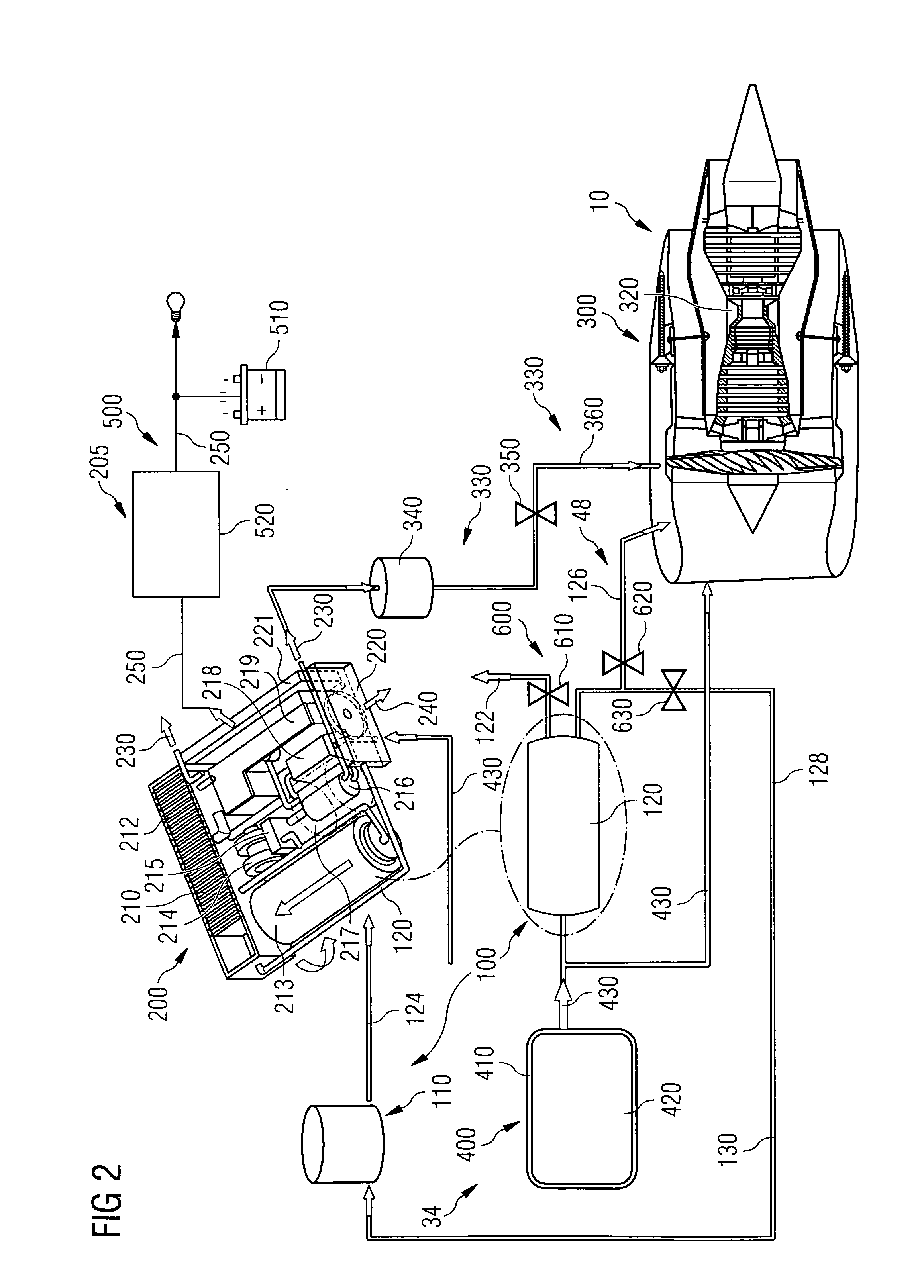

Method for Operating a Gas Turbine Engine, Power Supplying Device for Conducting such Method and Aircraft using such Method

ActiveUS20100293959A1Emission reductionReduce hydrogen consumptionContinuous combustion chamberTurbine/propulsion engine ignitionAviationCombustion chamber

A power supply device or system for aeronautics, having a hydrocarbon supply for supplying an engine with hydrocarbon fuel and a hydrogen supply having a fuel reformer for producing hydrogen from hydrocarbon fuel from said hydrocarbon supply. The hydrogen supply is connected to a hydrogen-powered fuel cell for producing electric power and to a hydrogen injecting system for injection of hydrogen into a combustion chamber of the engine. Further, the invention relates to an aircraft having an engine that can be supplied by that power supplying device or system, and to a method for operating said engine.

Owner:AIRBUS SAS

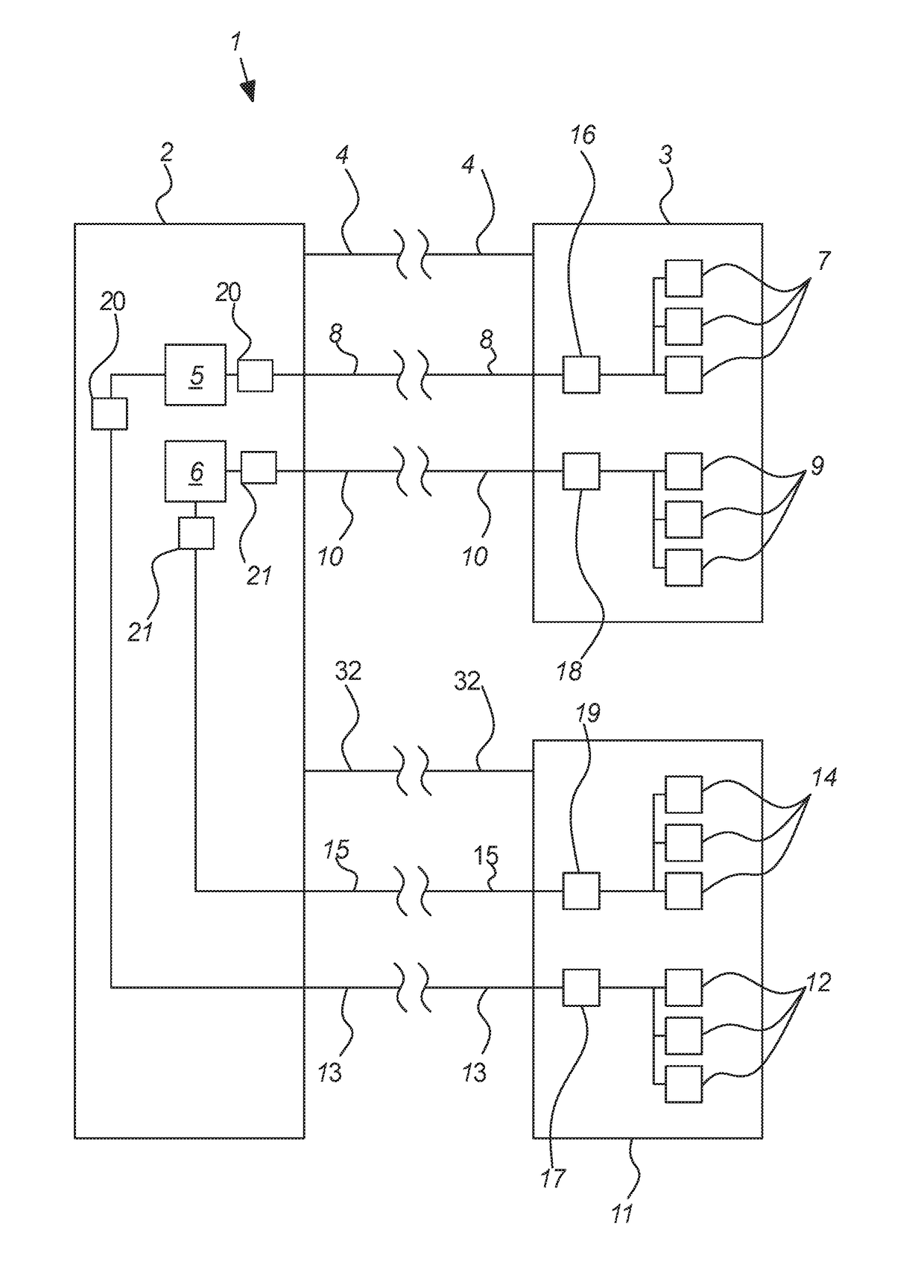

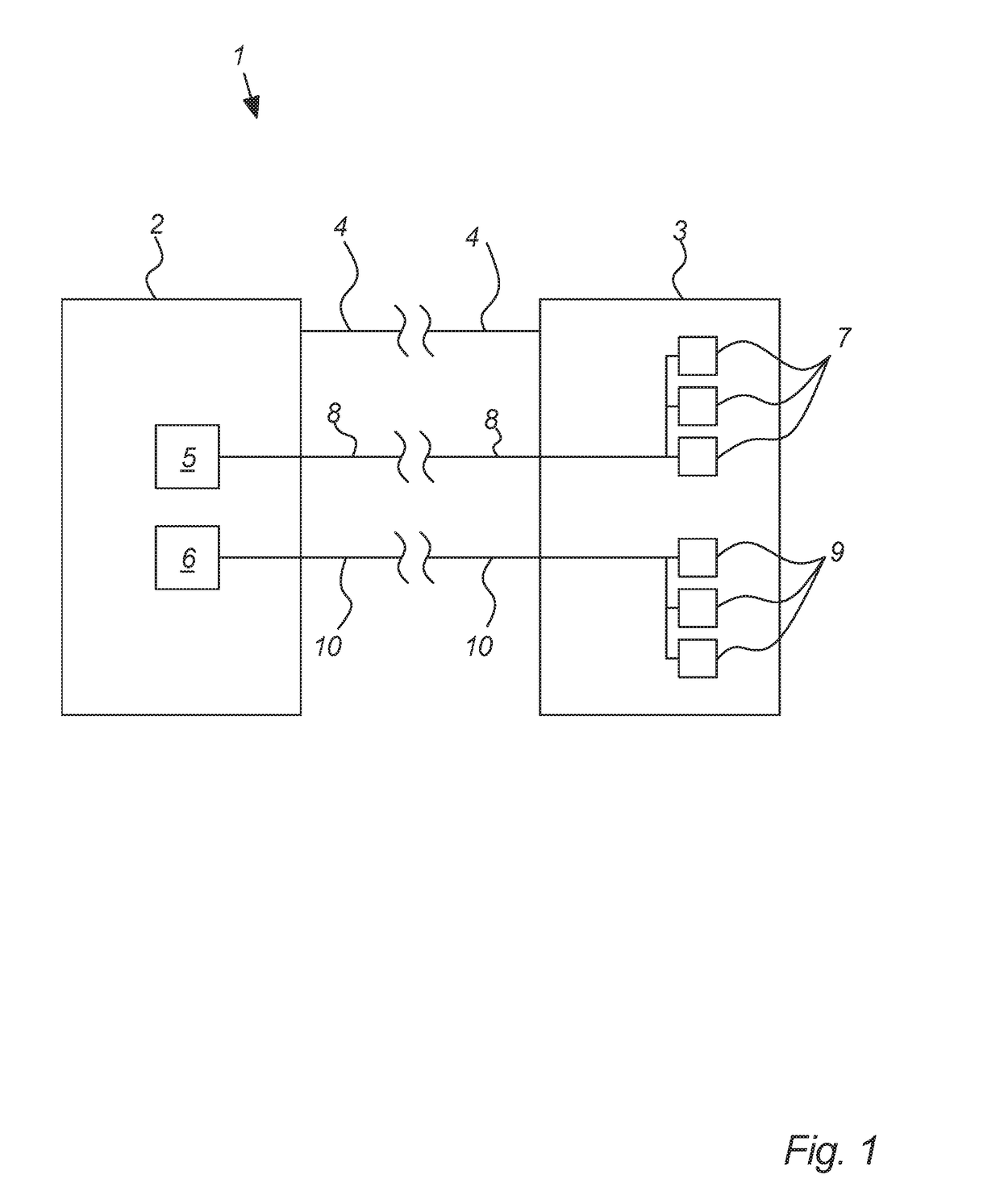

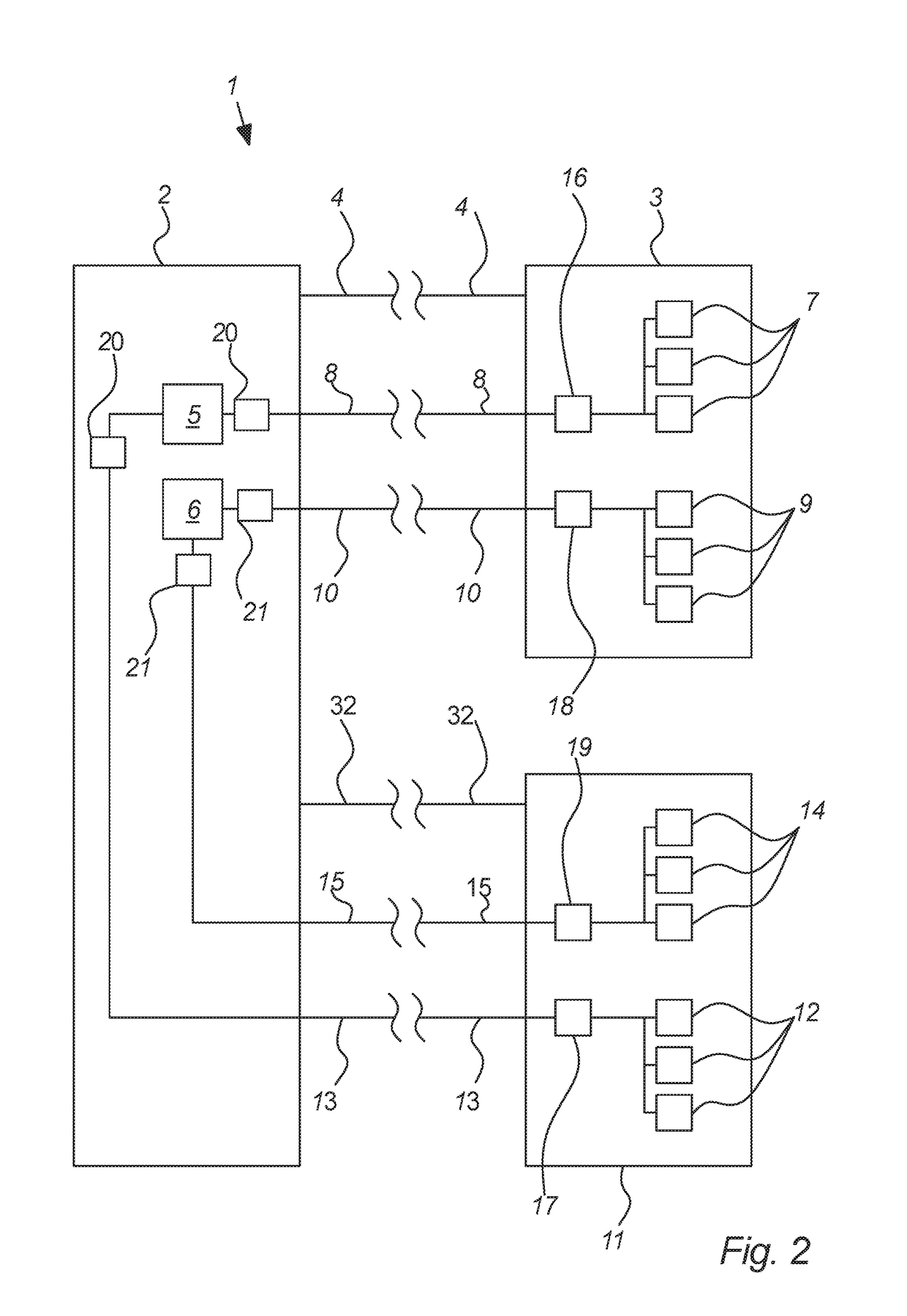

Communication system for a hydrogen refuelling system

ActiveUS20170248976A1Reduce decreaseEasy to detectFlow control using electric meansGas handling applicationsProcess engineeringHydrogen supply

A HRS comprising at least a HRS center module, a HRS dispenser module and a first hydrogen supply line facilitating flow of hydrogen between the HRS center module and the HRS dispenser module, the HRS center module comprises a safety controller and a process controller, wherein data is communicated between the safety controller and safety components of the HRS dispenser module via a safety communication channel, and wherein data is communicated between the process controller and process components of the HRS dispenser module via a process communication channel.

Owner:NEL HYDROGEN AS

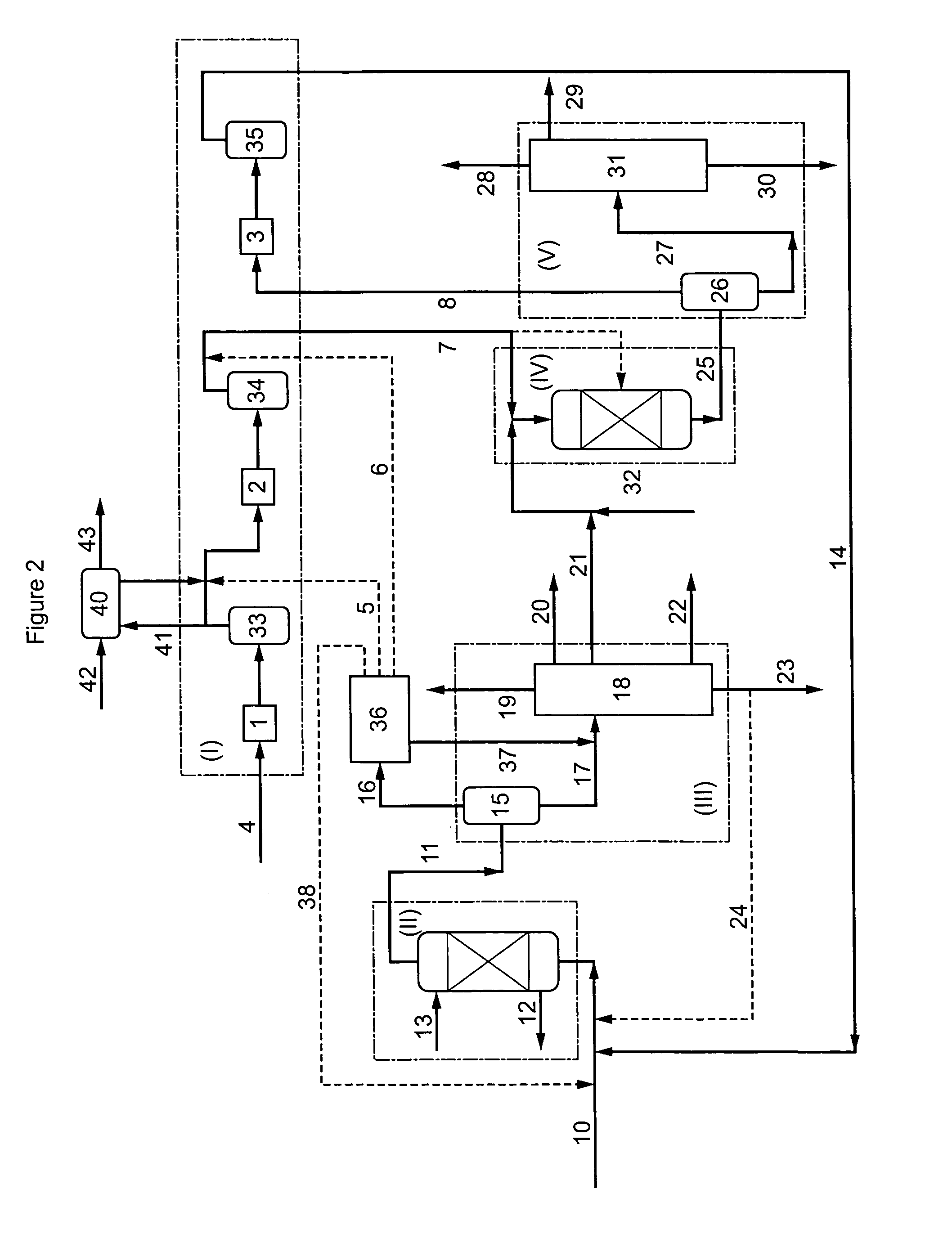

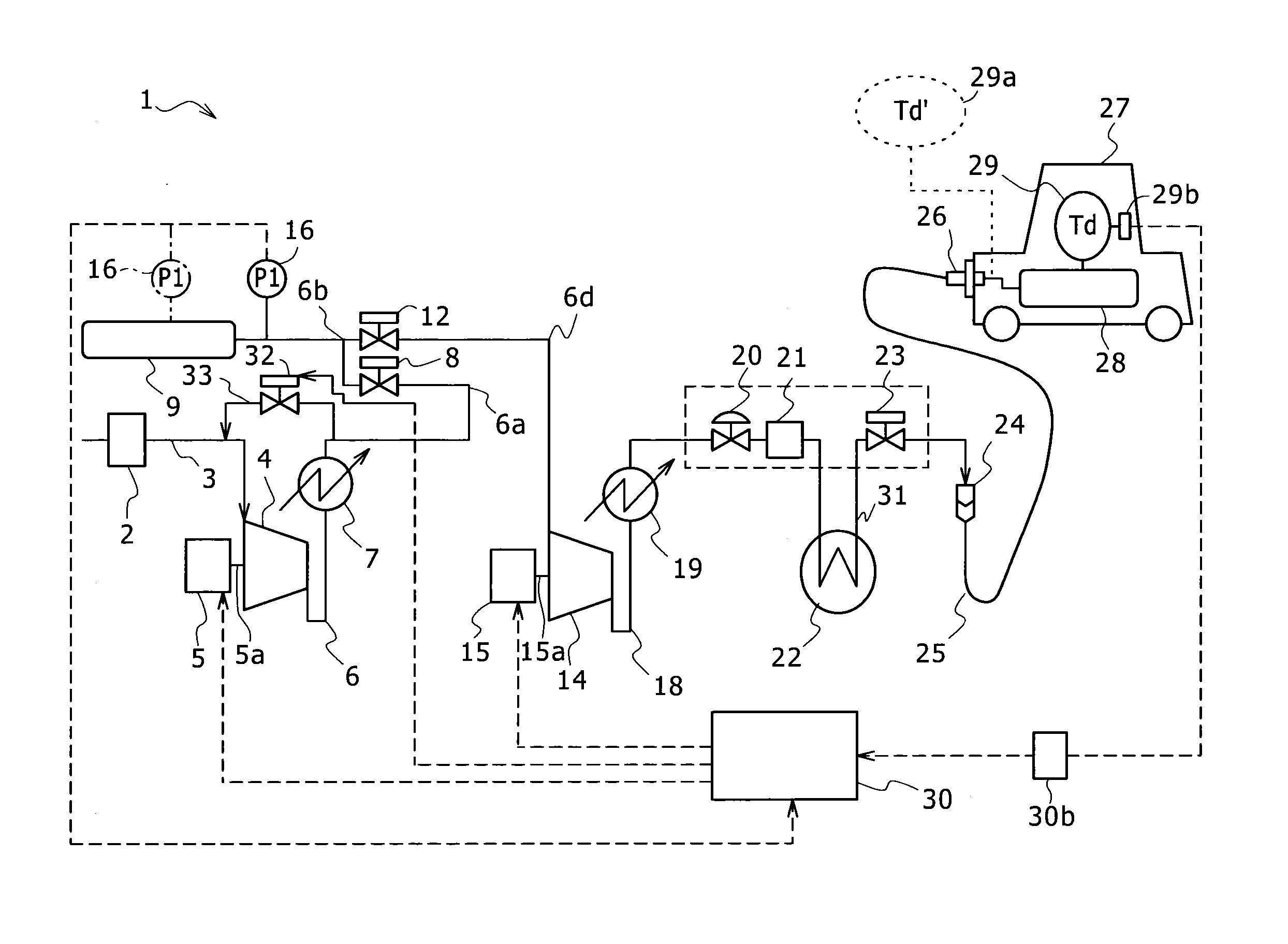

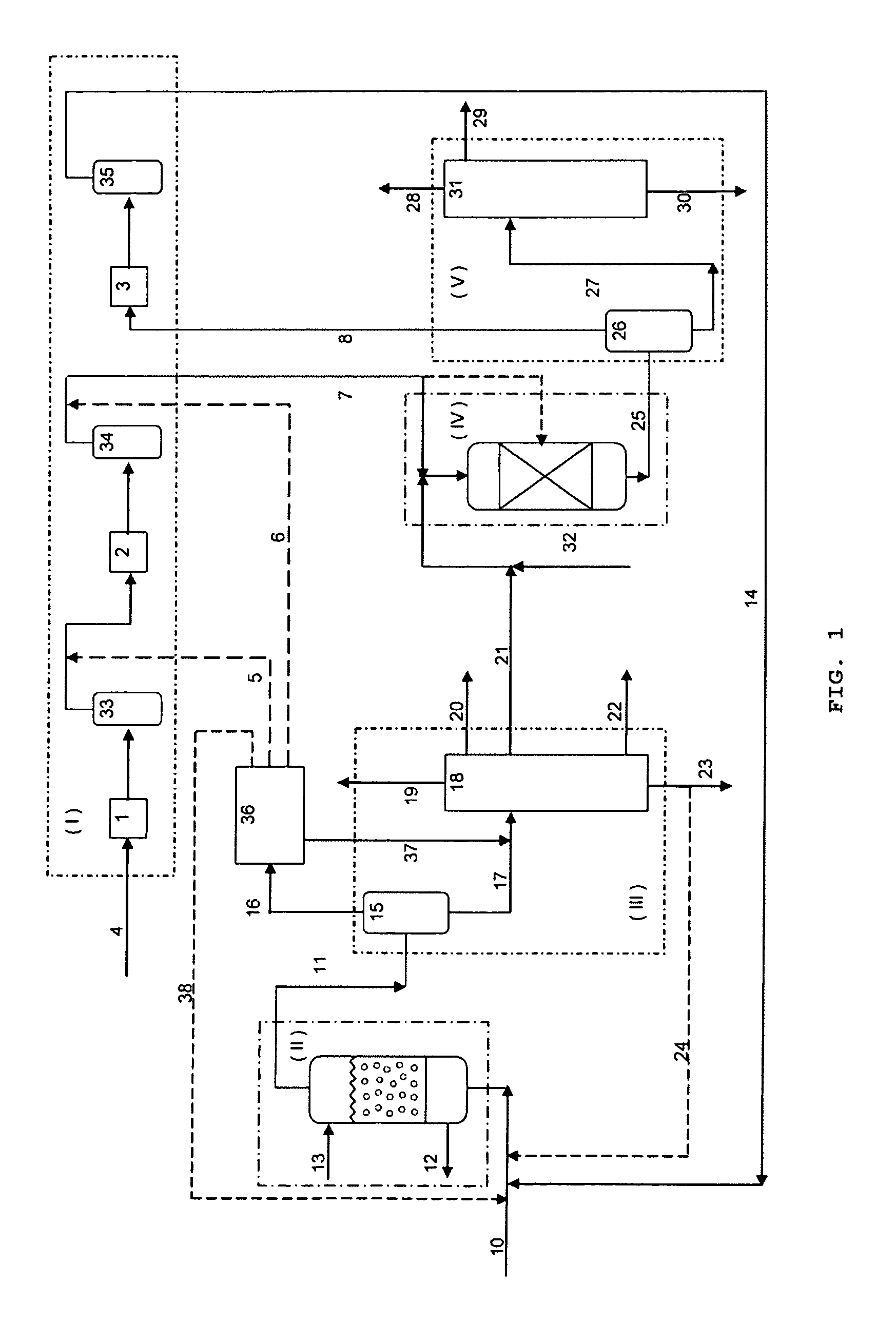

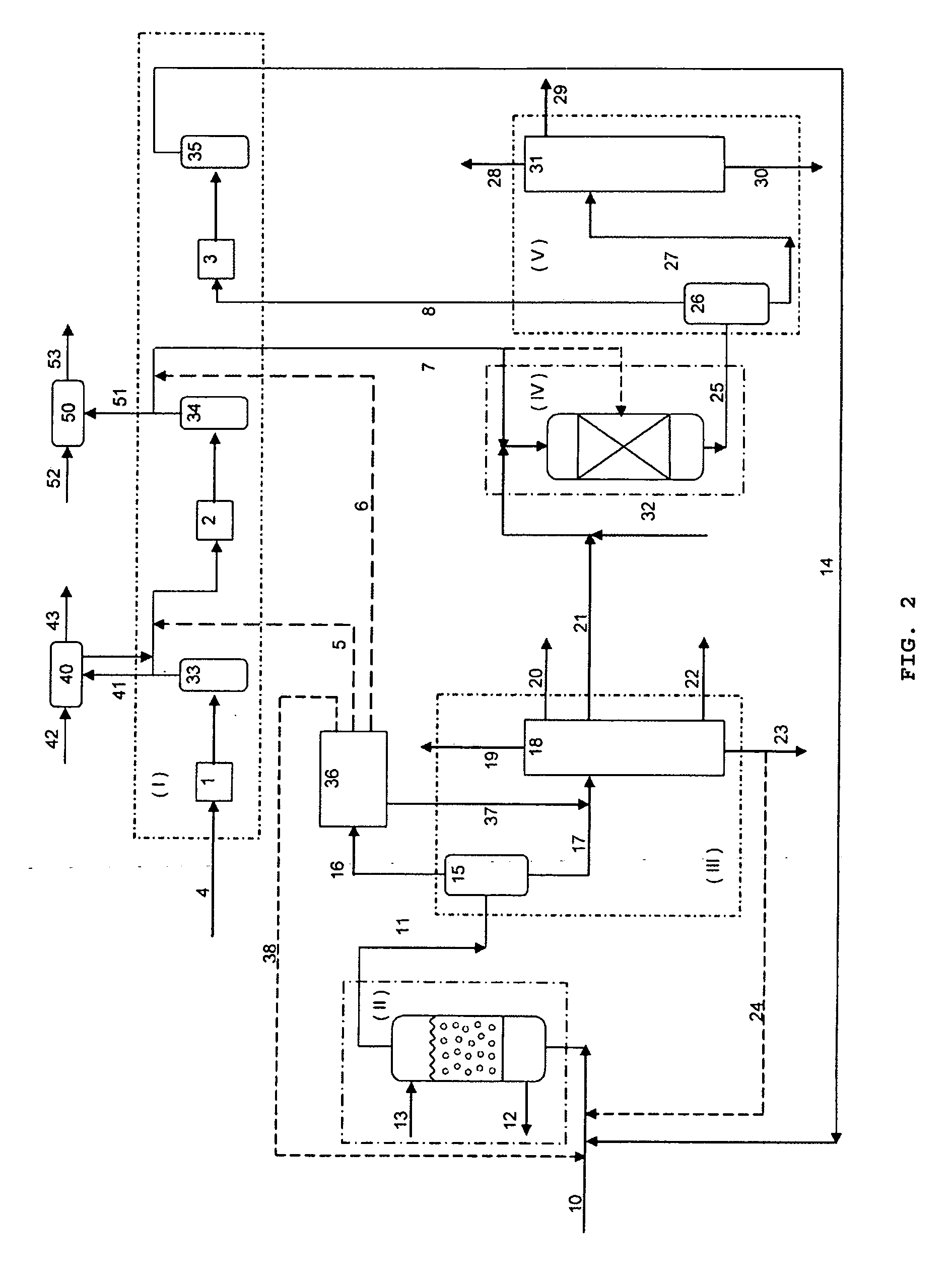

Process and installation for conversion of heavy petroleum fractions in a boiling bed with integrated production of middle distillates with a very low sulfur content

ActiveUS20070209965A1Low investment costOptimizing operating pressureTreatment with plural serial cracking stages onlyCoke ovensDistillates petroleumNaphtha

This invention relates to a process and an installation for treatment of a heavy petroleum feedstock, of which at least 80% by weight has a boiling point of greater than 340° C., whereby the process comprises the following stages: (a) hydroconversion in a boiling-bed reactor operating with a rising flow of liquid and gas, conversion in % by weight of the fraction having a boiling point of greater than 540° C. being from 10 to 98% by weight; (b) separation of the effluent obtained from stage (a) into a gas containing hydrogen and H2S, a fraction comprising the gas oil and optionally a fraction that is heavier than gas oil and a naphtha fraction; c) hydrotreatment by contact with at least one catalyst of at least the fraction comprising the gas oil obtained in stage (b); d) separation of the effluent obtained at the end of stage (c) into a gas containing hydrogen and at least one gas oil fraction having a sulfur content of less than 50 ppm, preferably less than 20 ppm, and more preferably less than 10 ppm, the hydroconversion stage (a) being conducted at a pressure P1 and the hydrotreatment stage (c) being conducted at a pressure P2, the difference ΔP=P1−P2 being at least 3 MPa, hydrogen supply for the hydroconversion (a) and hydrotreatment (c) stages being ensured by a single compression system with n stages.

Owner:INST FR DU PETROLE

Method for preparing phenolic chemicals through thermo-chemical conversion of industrial lignin

InactiveCN102173980ALow priceObvious cost advantageOrganic compound preparationBulk chemical productionCelluloseBiofuel

The invention provides a method for preparing phenolic chemicals through the thermo-chemical conversion of industrial lignin. The method is as follows: under the common functions of solid acid catalyst and hydrogen supply solvent, industrial lignin performs atmospheric thermo-chemical conversion in high boiling point organic reaction medium to prepare homogeneous low molecular weight organic matter with rich phenolic compounds such as phenol, methoxyphenol, dimethoxyphenol and 2-methoxy-4-methylphenol, and the organic reaction medium is recycled through the technologies such as vacuum distillation. The method has simple process, good stability and low production cost; and the yield of the prepared phenolic compounds is more than 54%. The method plays an important role in the high-valued comprehensive utilization of the renewable resource, namely ndustrial lignin; and the converted phenolic chemicals can be used to synthesize phenolic resin, prepare high efficiency cement water-reducing agent and further separate, purify and prepare bio-chemicals. Particularly, by adopting the method, the lignin in papermaking black liquid and preparation residue of biological fuel ethanol prepared from cellulose can be converted to phenolic chemicals; and the method has wide application prospect.

Owner:SOUTH CHINA UNIV OF TECH

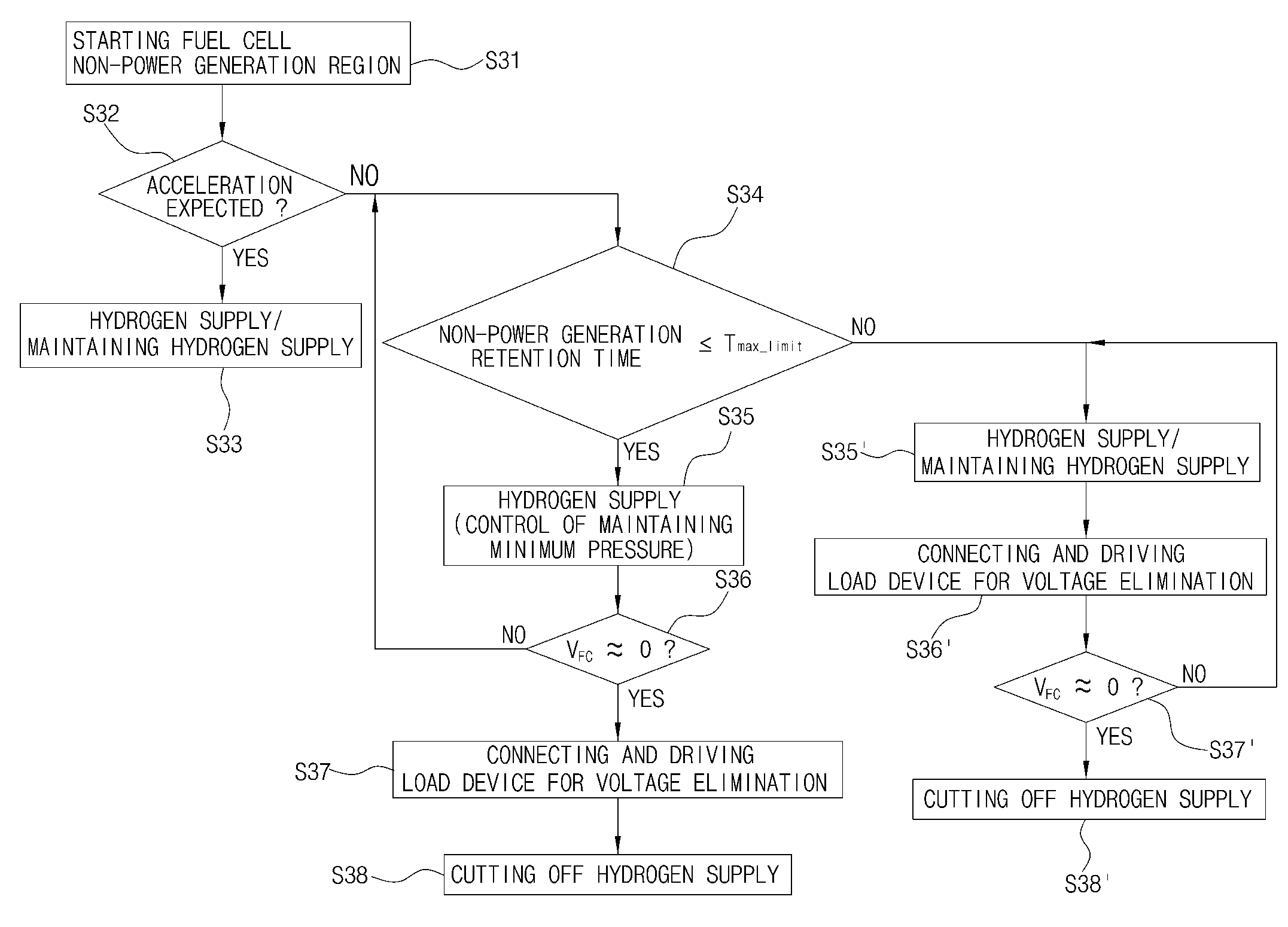

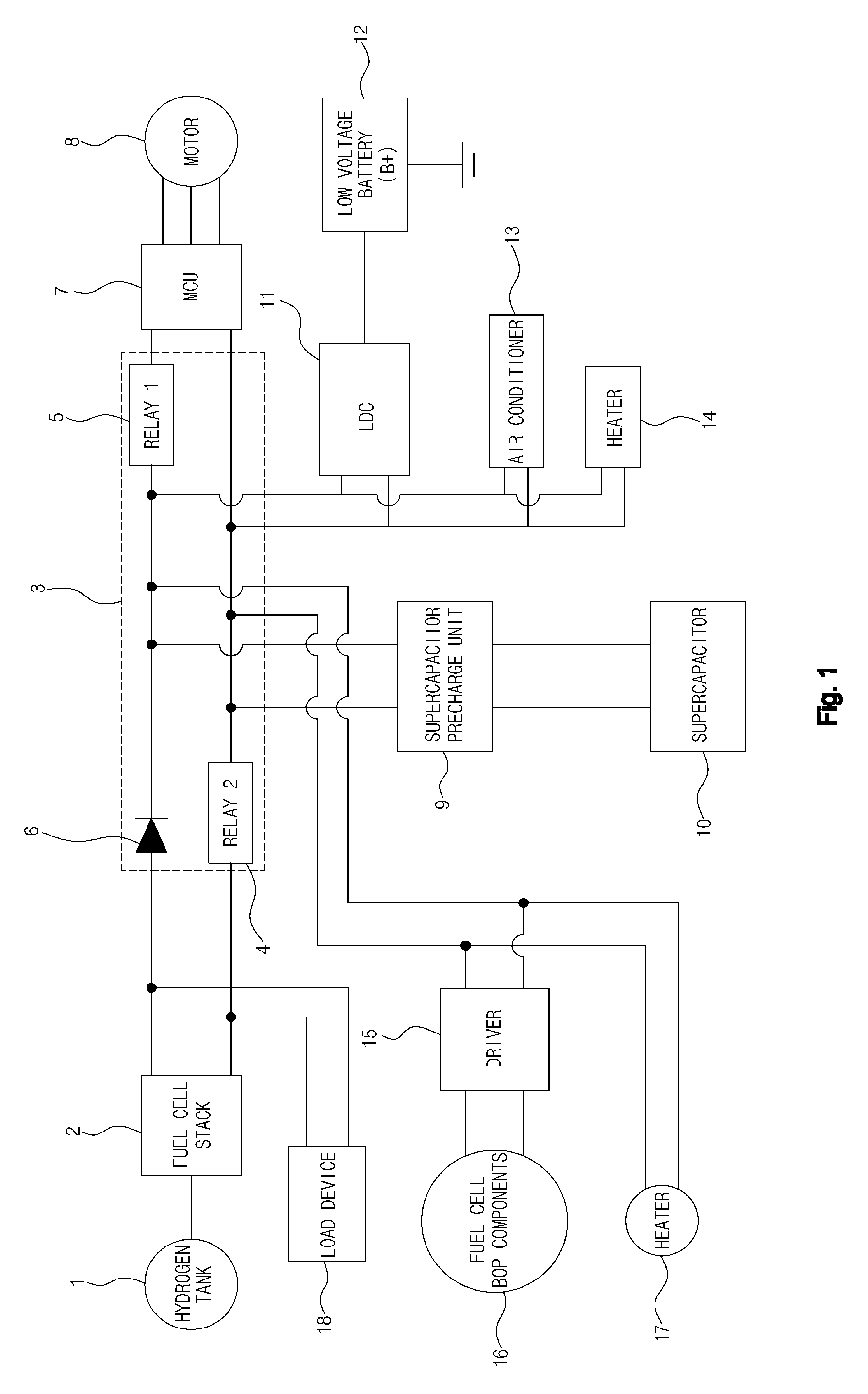

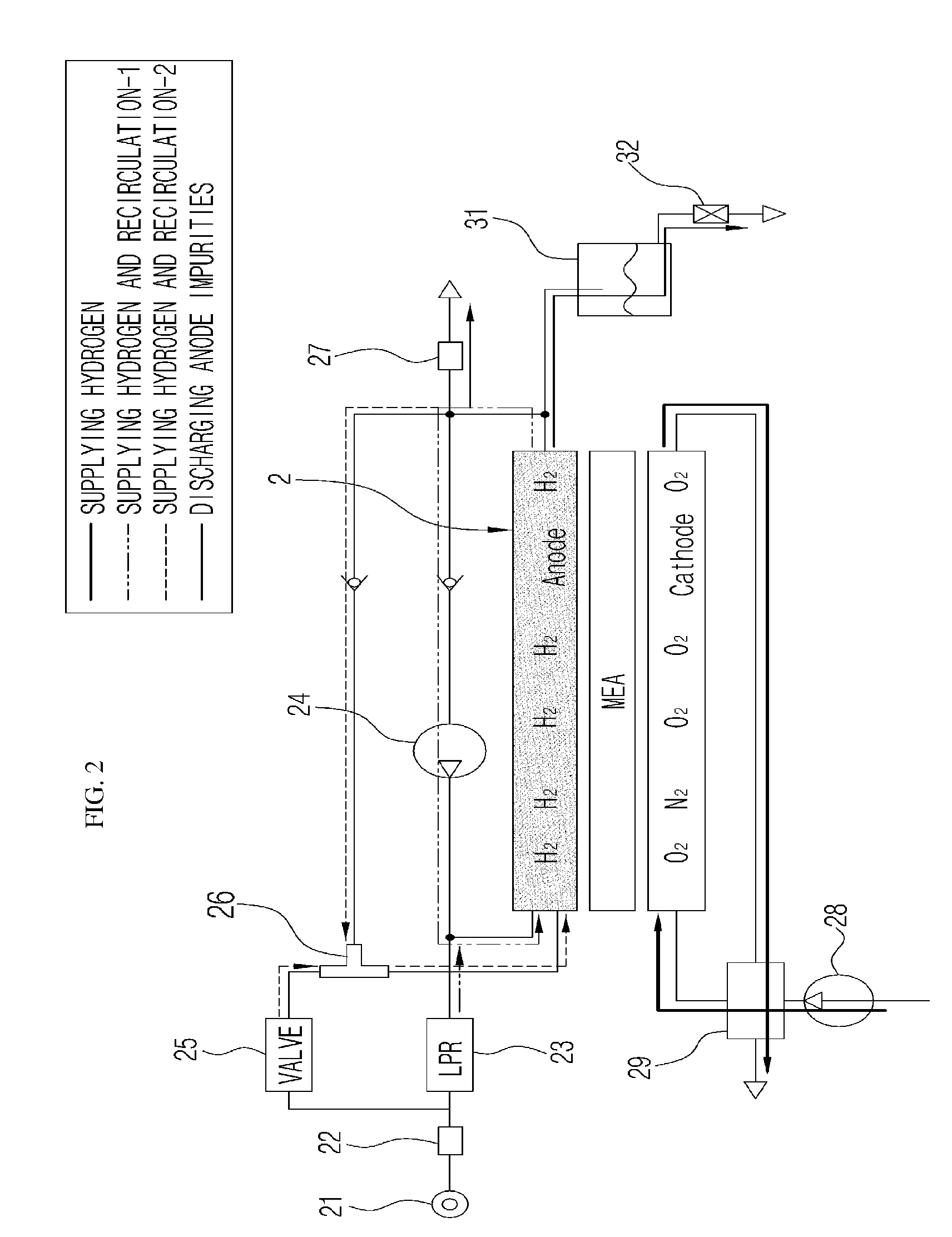

Idle stop-start control method of fuel cell hybrid vehicle

ActiveUS20100009219A1Improve fuel efficiencyIncrease volumeElectrical controlFuel cell auxillariesRegenerative brakeIdle speed

The present invention provides an idle stop-start control method of a fuel cell hybrid vehicle including a fuel cell as a main power source and a storage means as an auxiliary power source, in which air and hydrogen supply is cut off during low power operation where the efficiency of the fuel cell is low and during regenerative braking such that residual oxygen and hydrogen are consumed to drop the voltage of a fuel cell stack, thus stopping the operation of the fuel cell.

Owner:HYUNDAI MOTOR CO LTD

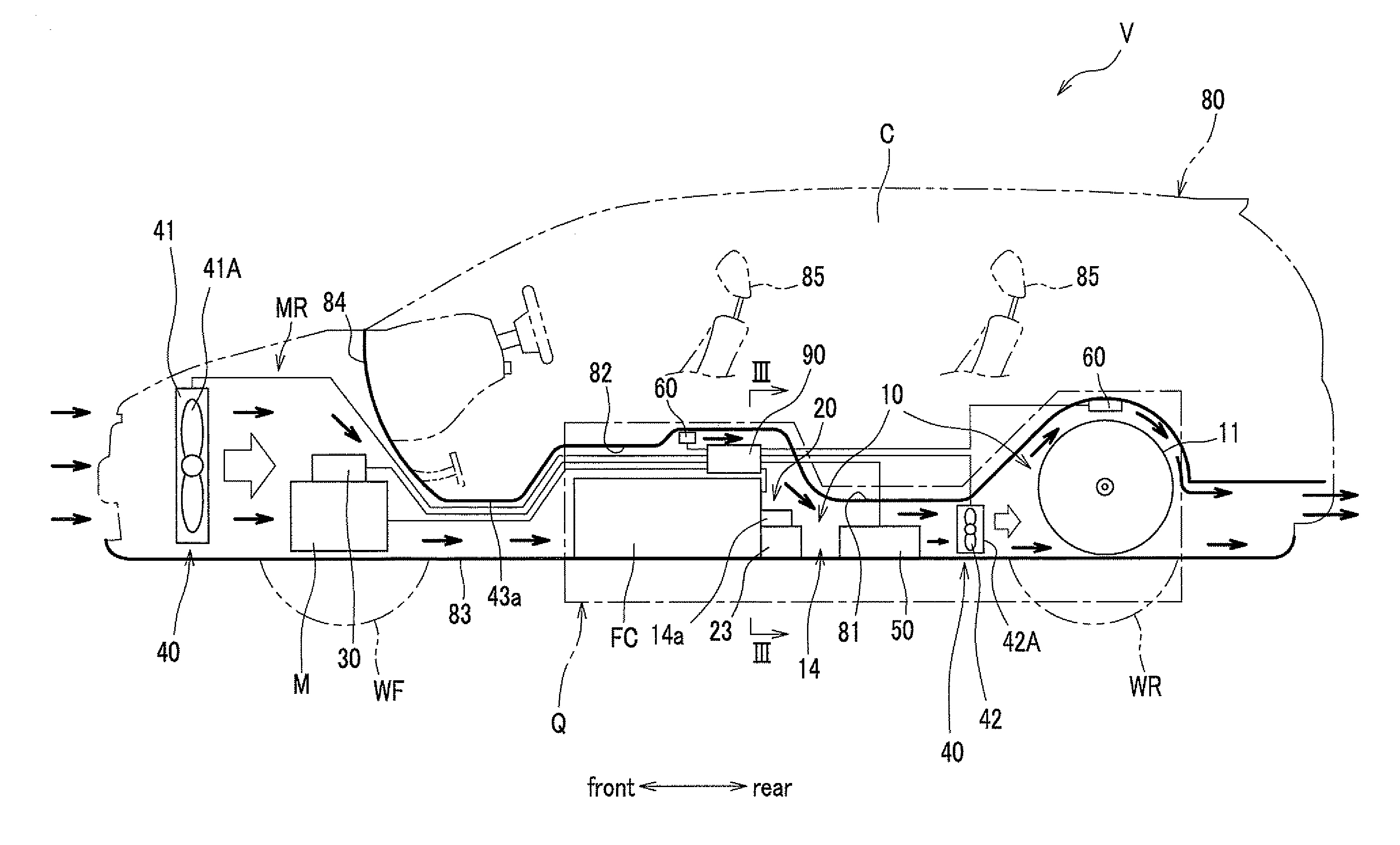

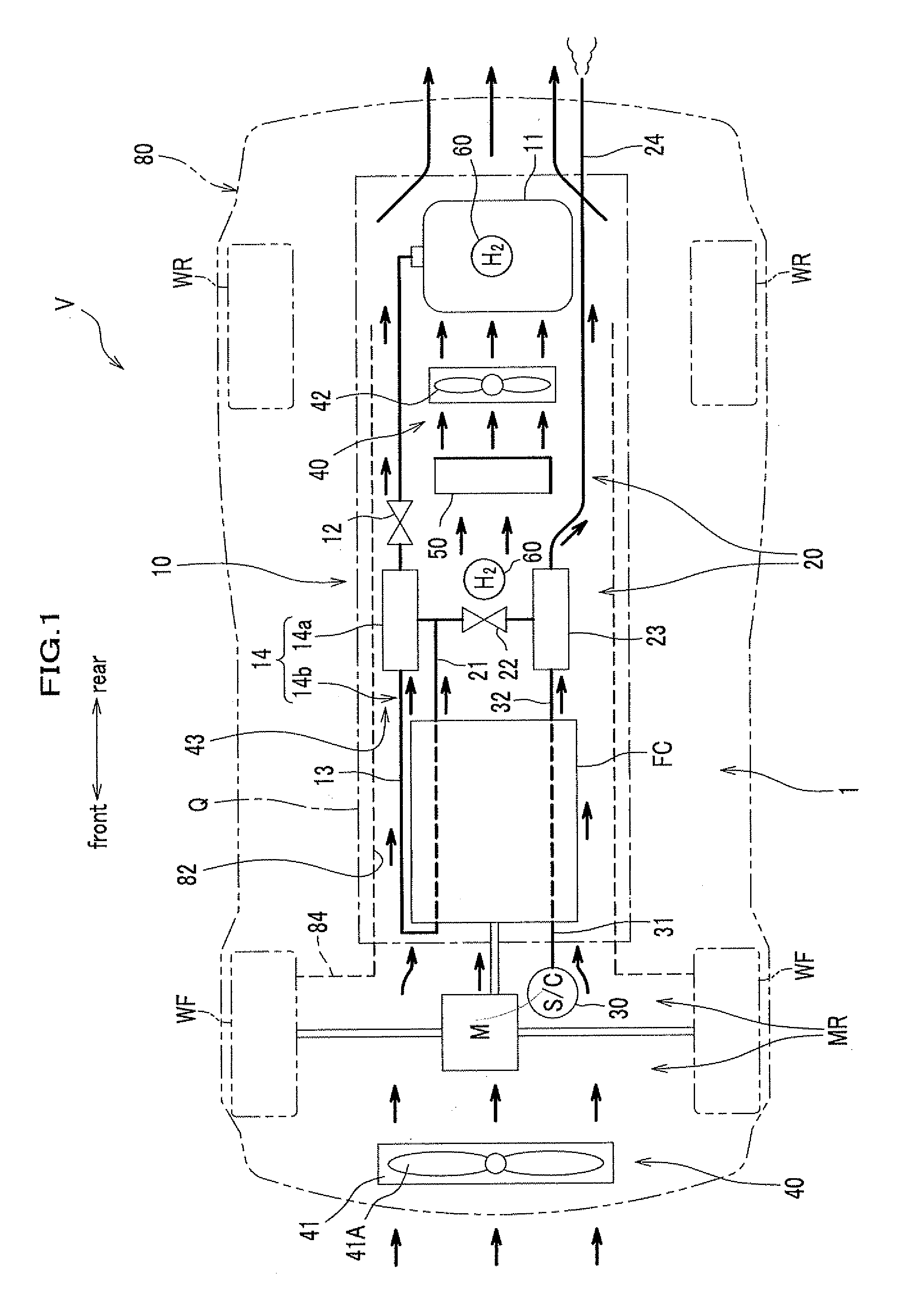

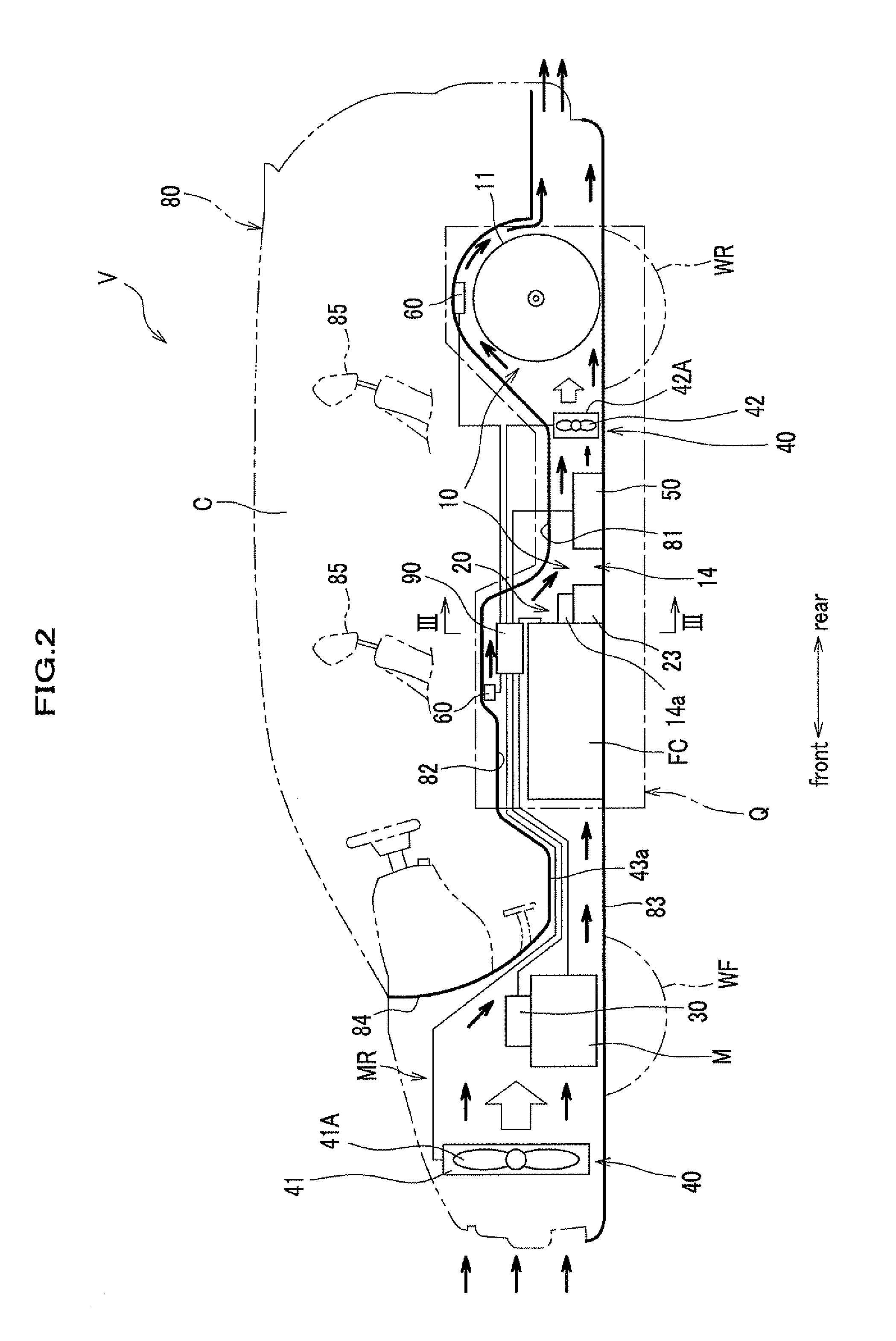

Ventilator of a fuel-cell vehicle

InactiveUS20090317692A1Improve cooling effectFlow fastAir-treating devicesFuel cell heat exchangeHydrogen supplyHydrogen system

The present invention relates to a ventilator of fuel-cell vehicles for ventilating hydrogen in the hydrogen-system unit area arranging a hydrogen circulating device in the fuel-cell vehicles boarding the fuel cell. The ventilator of fuel-cell vehicle includes a first ventilating device for taking ventilating air in from a front side of the fuel-cell vehicle to hydrogen-system unit area arranging the fuel cell, the hydrogen supply device, and the hydrogen exhaust device in the center of front and rear direction of the fuel-cell vehicle; and a second ventilating device for sucking the ventilating air taken in from the rear end of vehicle body of the fuel-cell vehicle to the hydrogen-system unit area.

Owner:HONDA MOTOR CO LTD

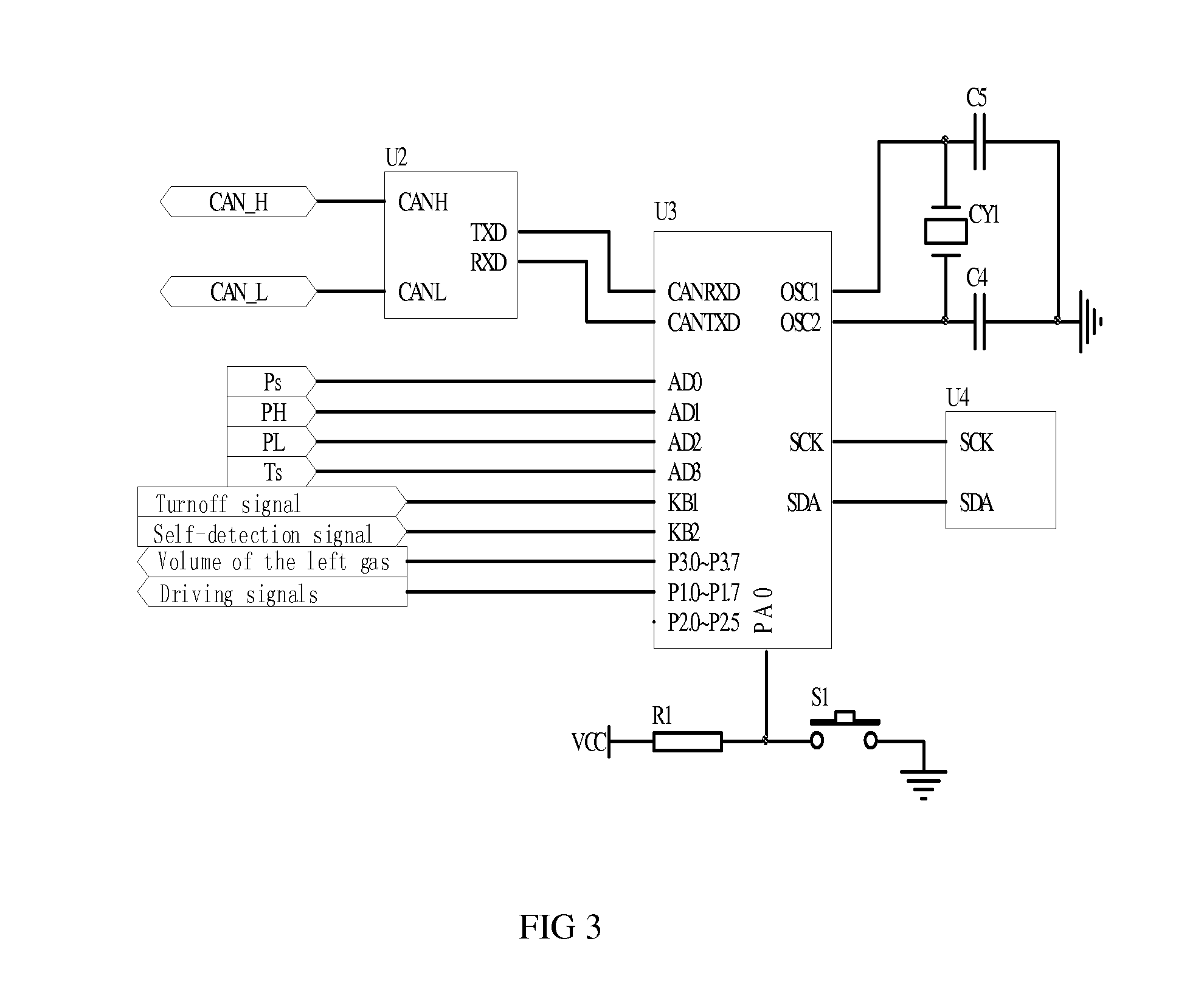

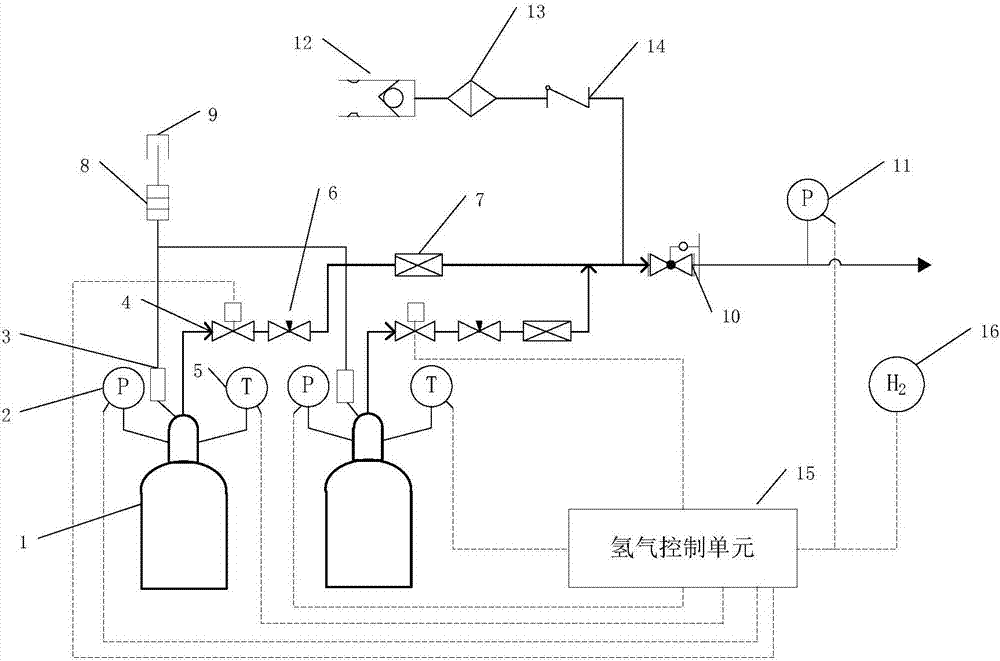

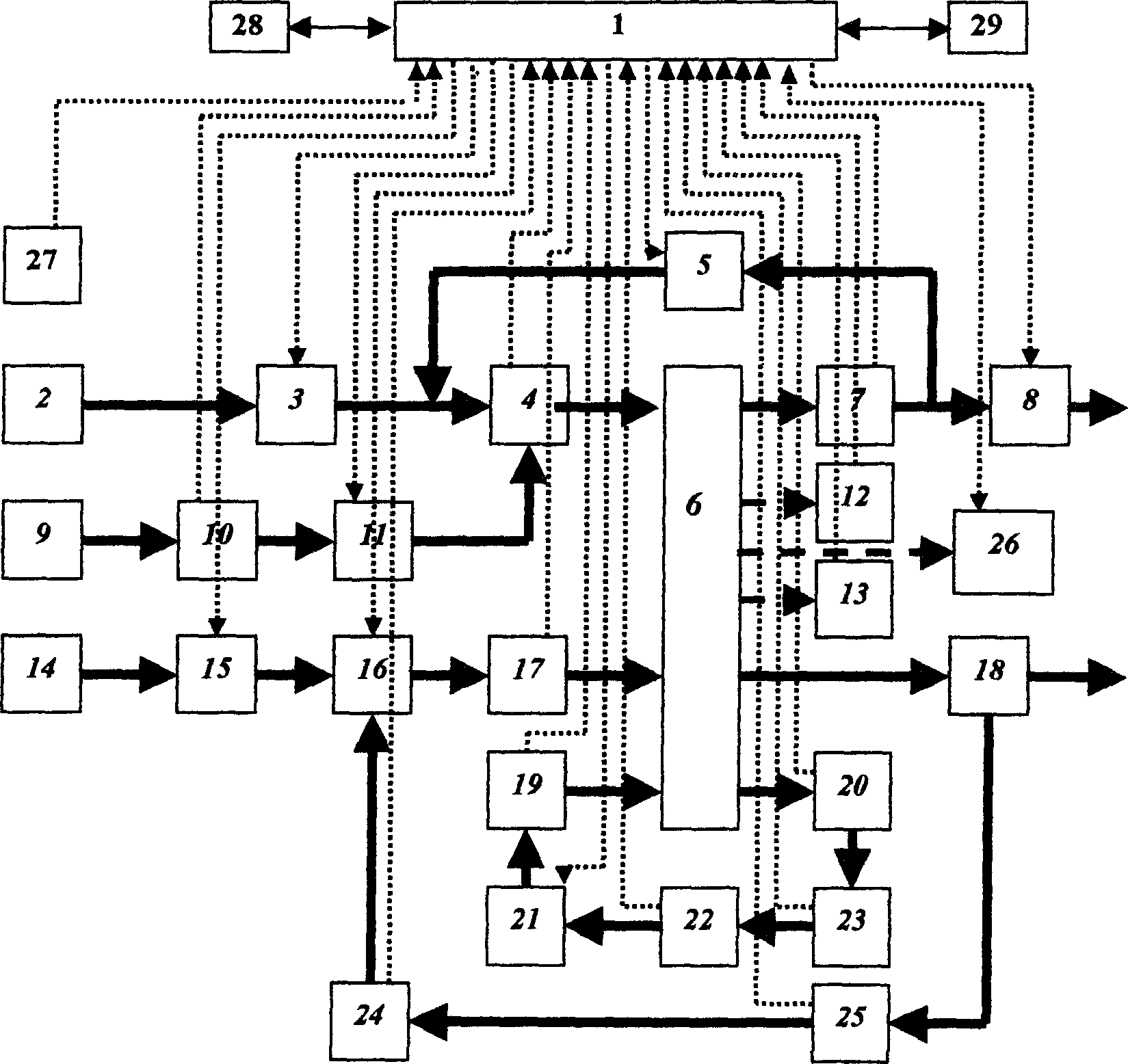

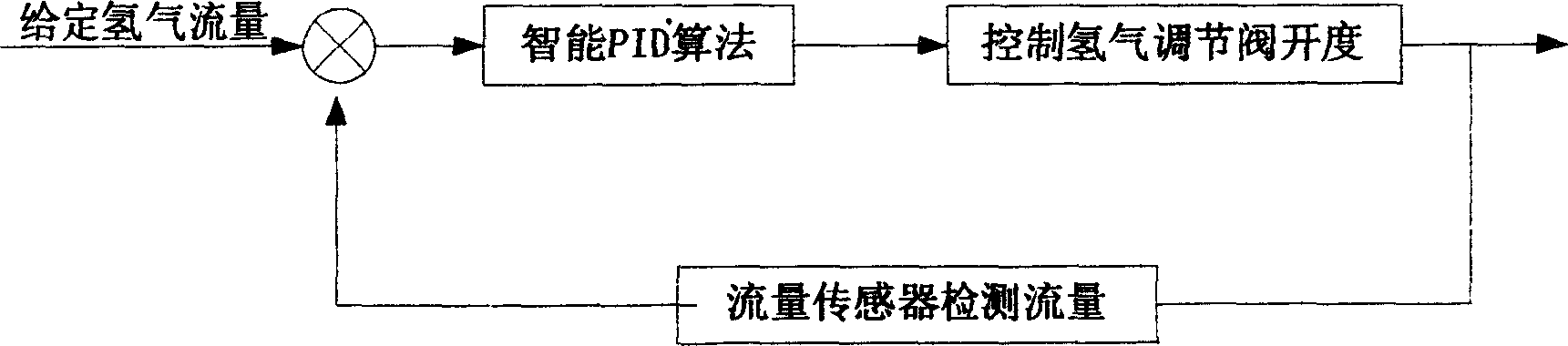

Hydrogen management system of vehicle-mounted fuel cell

PendingCN106876749AAchieve hydrogenation controlRealize hydrogen supply controlFuel cell auxillariesGas cylinderHydrogen storage system

The invention relates to a hydrogen management system of a vehicle-mounted fuel cell. The hydrogen management system comprises a hydrogen control unit (15), and a hydrogen bottle electromagnetic valve (4), a hydrogen bottle pressure sensor (2), a temperature sensor (5) and a hydrogen concentration sensor (16) which are connected with the hydrogen control unit (15) separately; the hydrogen bottle electromagnetic valve (4), the hydrogen bottle pressure sensor (2) and the temperature sensor (5) are connected with a vehicle-mounted high-pressure hydrogen bottle (1) separately; a probe of the hydrogen concentration sensor (16) is arranged in the environment above the high-pressure hydrogen bottle (1); and the hydrogen control unit (15) is in communication connection with a vehicle-mounted fuel cell controller through CAN. Compared with the prior art, the functions of hydrogen adding control, hydrogen supplying control, safety detection and the like of a vehicle-mounted hydrogen storage system can be realized, cable connection between systems is reduced, and signal missing in a signal transmission process and risk of high probability of interference are lowered.

Owner:TONGJI UNIV

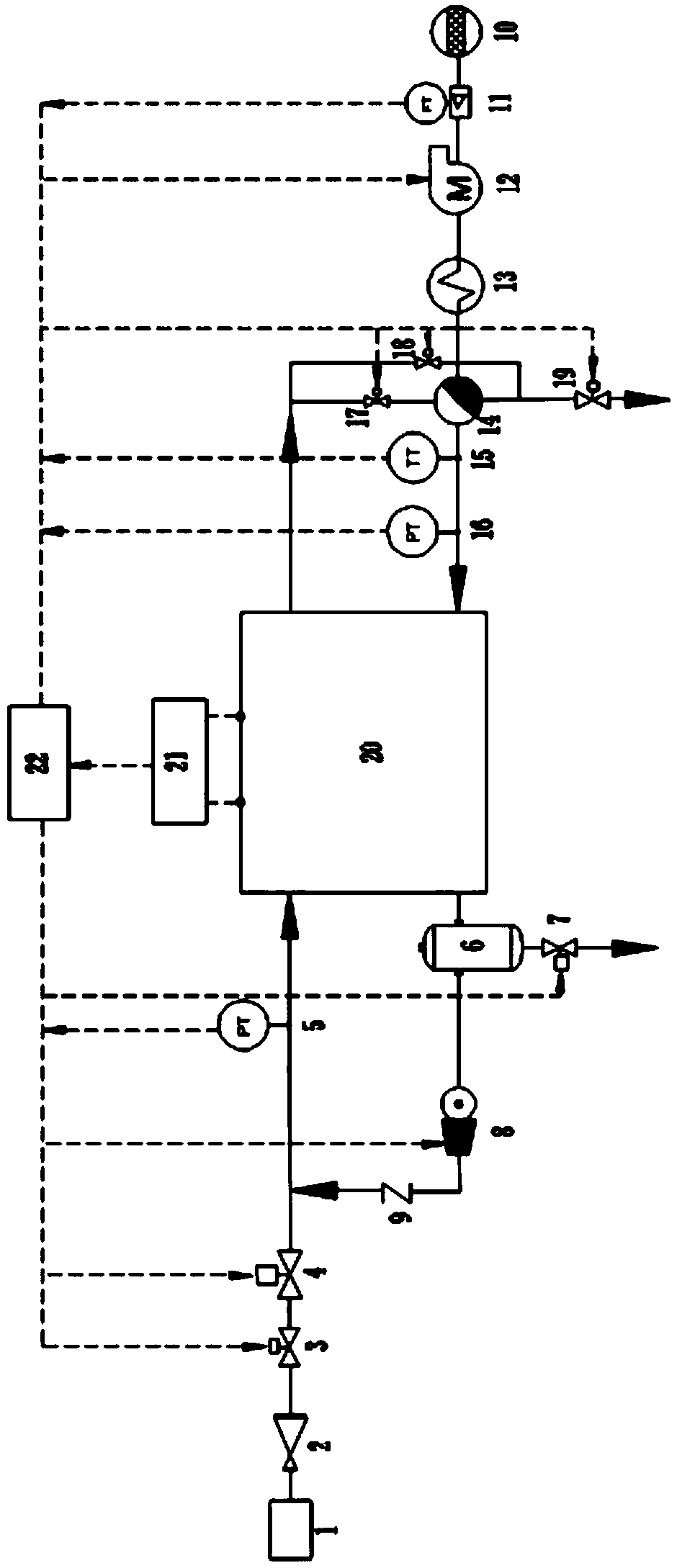

Commercial vehicle fuel cell engine air supplying system

PendingCN109411784AContinuous power generationStable power generationFuel cellsBatteriesCommercial vehicleHydrogen supply

The invention discloses a commercial vehicle fuel cell engine air supplying system. The system comprises an internal resistance detector, a controller, a fuel battery voltaic pile, a hydrogen supplying system and an air supplying system. The commercial vehicle fuel cell engine air supplying system has the advantages that the recycling of hydrogen is achieved, the supplying flow rate and pressure of the hydrogen and air can be accurately controlled, and therefore sustainable and stable power generation of a fuel cell can be ensured; the internal resistance of the fuel cell voltaic pile can be detected to judge the humidity of a proton exchange membrane, internal water management of the fuel cell is effectively conducted by adjusting the opening degree of a tail discharging valve and a humidifying valve, and the efficiency and output performance of the fuel cell are improved.

Owner:SINO TRUK JINAN POWER

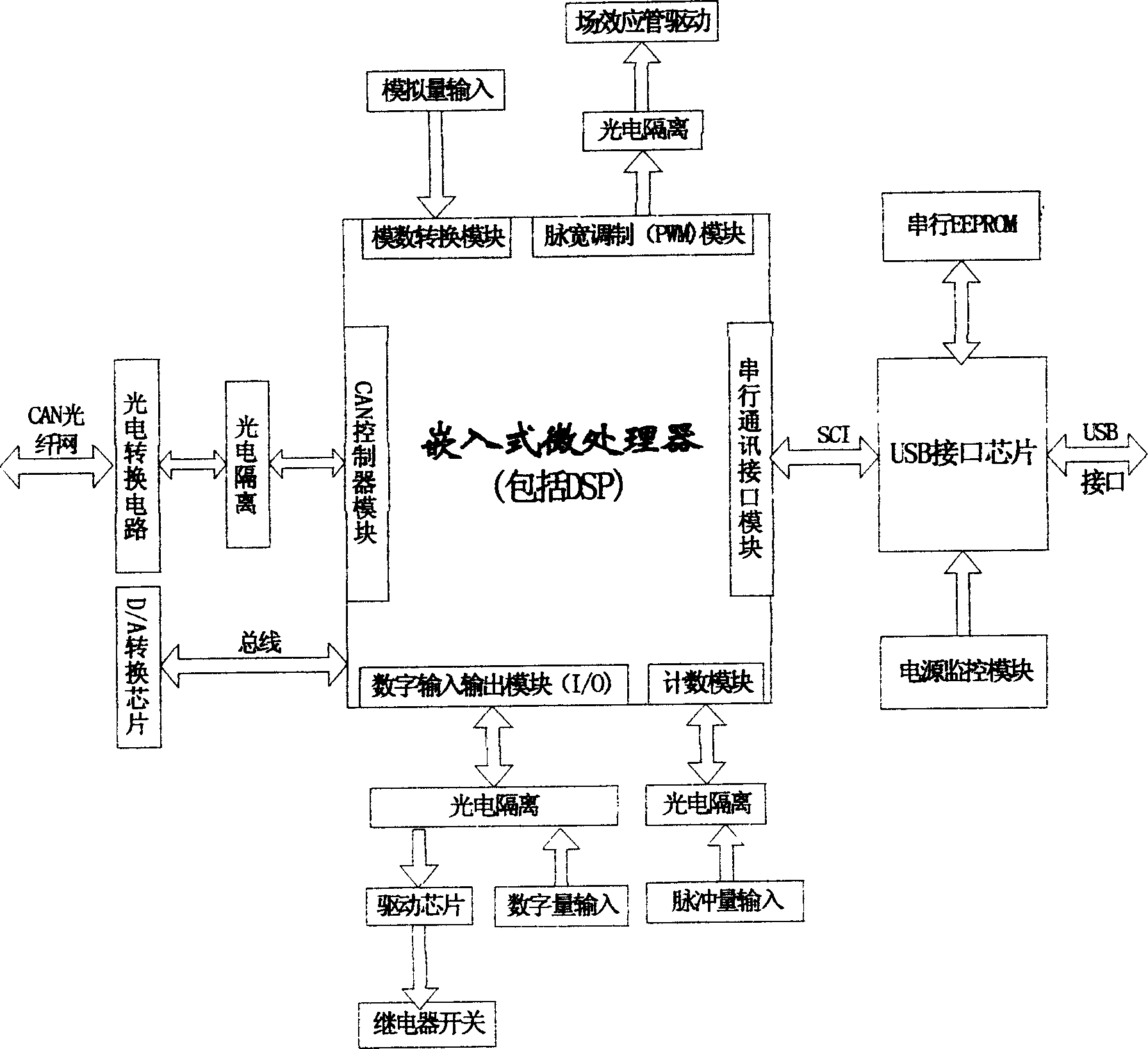

Vehicular fuel battery engine control method and apparatus

InactiveCN1632978AEnsure safe workReasonable layoutFuel cell auxillariesControl systemMotor controller

This invention relates to a car fuel battery motor control method and device, which comprises the following: fuel battery motor controller, air supply system, hydrogen supply system, cooling water recycling system, communication monitor system, fault test alarming and single battery test system. Wherein the controller controls the hydrogen supply system and adjusts the hydrogen flow and pressure according to the orders from CAN bus and current working status and adjusts air supply system and air flow and pressure and timely exchanges the data to judge the current working status is normal.

Owner:WUHAN UNIV OF TECH

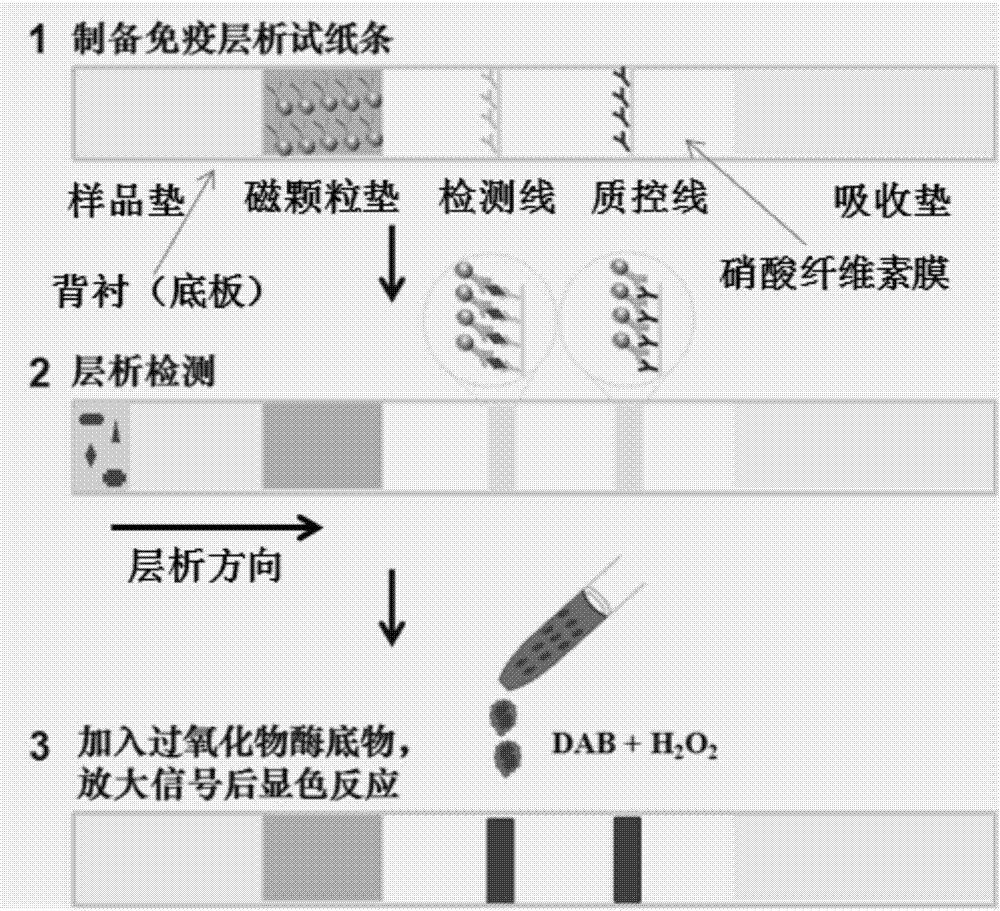

Nanometer mimic enzyme immunochromatography detection method

The invention provides a nanometer mimic enzyme immunochromatography detection method for detecting a to-be-detected object in a liquid sample. The method sequentially comprises the following steps: (1) providing a detecting probe which is prepared by coupling magnetic nanometer particles with a first molecule capable of being specifically bond with a to-be-detected object; (2) providing a capturing probe which is a fixed second molecule capable of being specifically bond with the to-be-detected object; (3) allowing the liquid sample to have contact with the detecting probe; (4) allowing the liquid sample which has contact with the detecting probe to have contact with the capturing probe; and (5) adding a hydrogen supply substrate and peroxide into the capturing probe which is subjected to the treatment in step (4) and performing a chromogenic reaction. The invention also provides a nanometer mimic enzyme immunochromatography detecting device for detecting the to-be-detected object in the liquid sample.

Owner:重庆康巨全弘生物科技有限公司

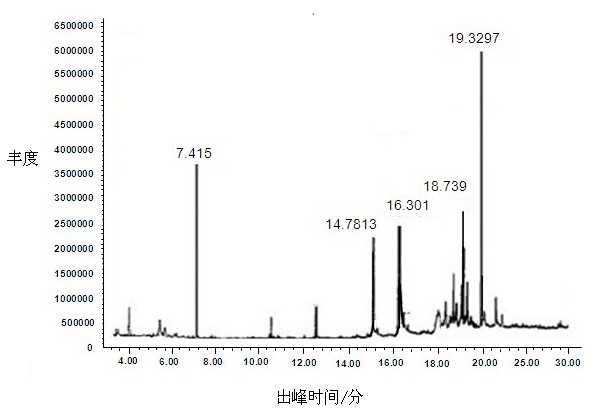

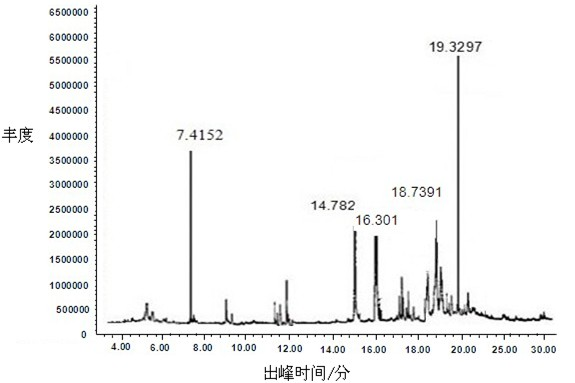

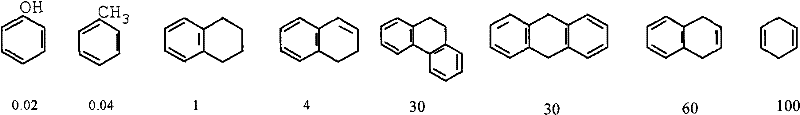

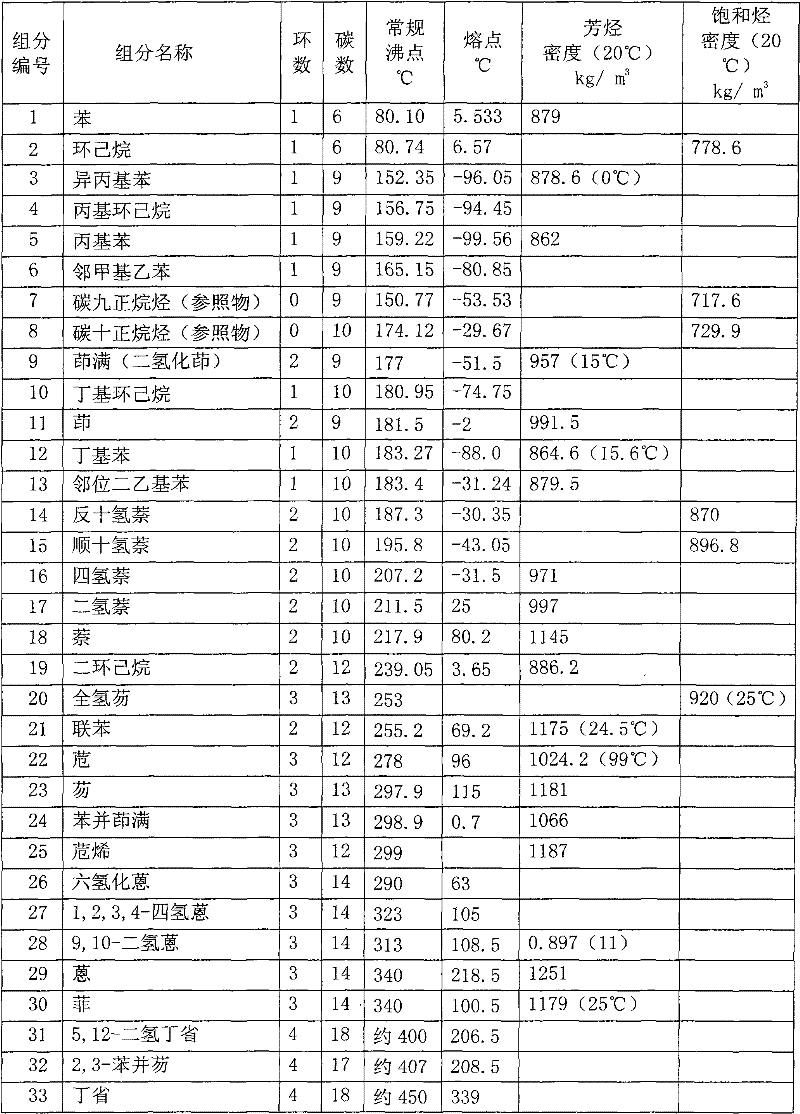

Method for conversion of low-hydrogen heavy oil to light fractions by hydrogenation with hydrogen-supplying hydrocarbons

ActiveCN102585897AImprove efficiencyShort reaction timeTreatment with hydrotreatment processesLiquid productPartial hydrogenation

The invention relates to a method for conversion of low-hydrogen heavy oil to light fractions by hydrogenation with hydrogen-supplying hydrocarbons, which is a process for conversion of heavy oil such as coal pitch by hydrogenation with hydrogen-supplying hydrocarbon stream enriched in hydrogen-supplying hydrocarbons. The method has the effects of inhibiting condensation coking speed, increasing liquid product yield in the process of conversion of coal tar heavy oil to light fractions, improving product quality, reducing reaction temperature increase and enhancing stability and safety of device operation. The hydrogen-supplying hydrocarbon stream can be hydrogenation reaction effluents in partial hydrogenation saturation process of bicyclic aromatic hydrocarbons or polycyclic aromatic hydrocarbons or oil products enriched in partial saturated aromatic hydrocarbons obtained in the separation process of bicyclic aromatic hydrocarbons or polycyclic aromatic hydrocarbons. The precursor substance of hydrogen-supplying solvent oil is coal tar fractions with boiling points of 350-450 DEG C, and the hydrogen-supplying solvent oil mainly comprises hydrocarbon components with ordinary boiling points of 350-450 DEG C. The combination of the method for conversion of coal tar heavy oil to light fractions by hydrogenation and method for conversion of coal tar light fractions by hydrogenation constitutes a novel combined process for conversion of full-range fractions of coal tar by hydrogenation.

Owner:洛阳瑞华新能源技术发展有限公司

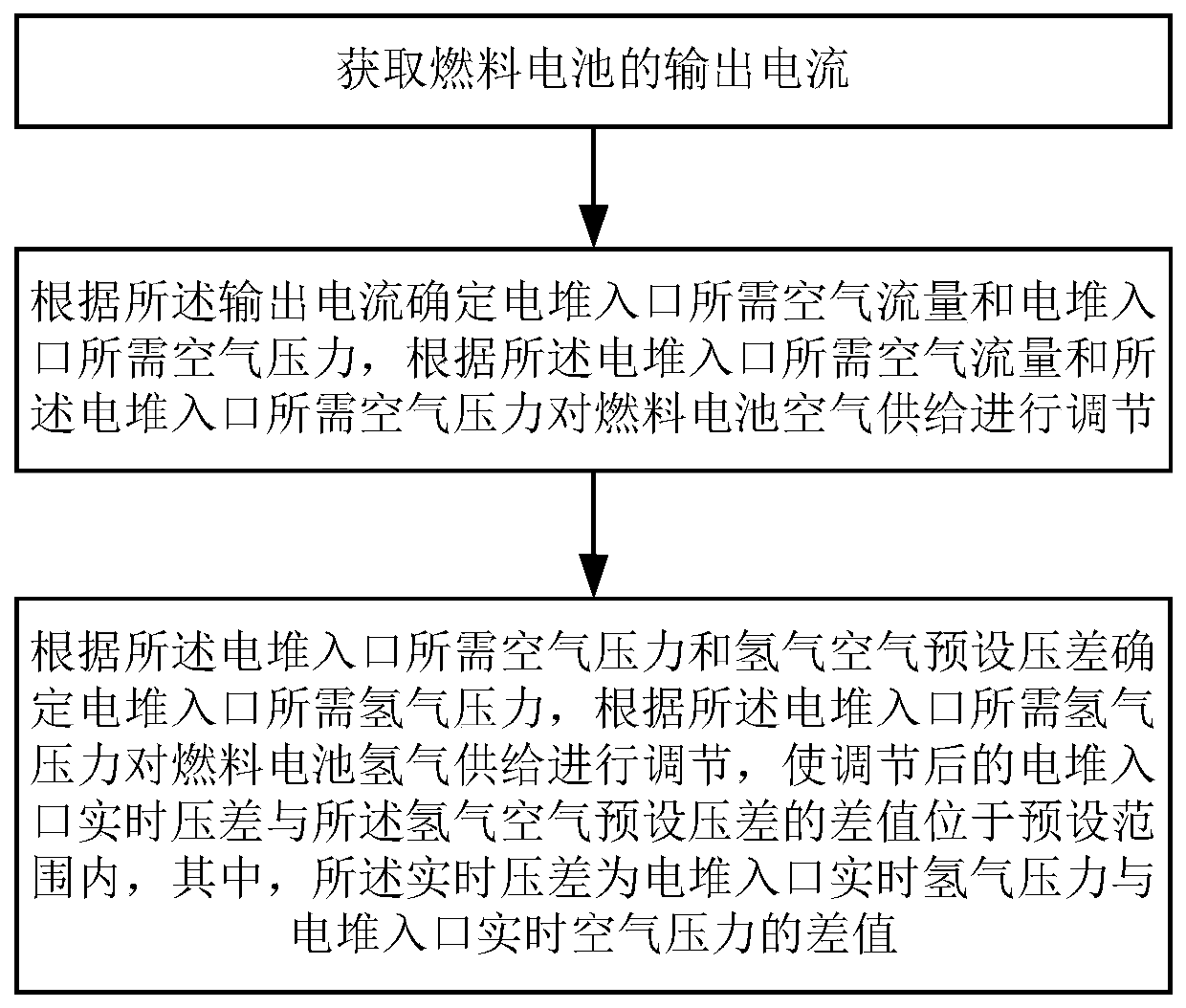

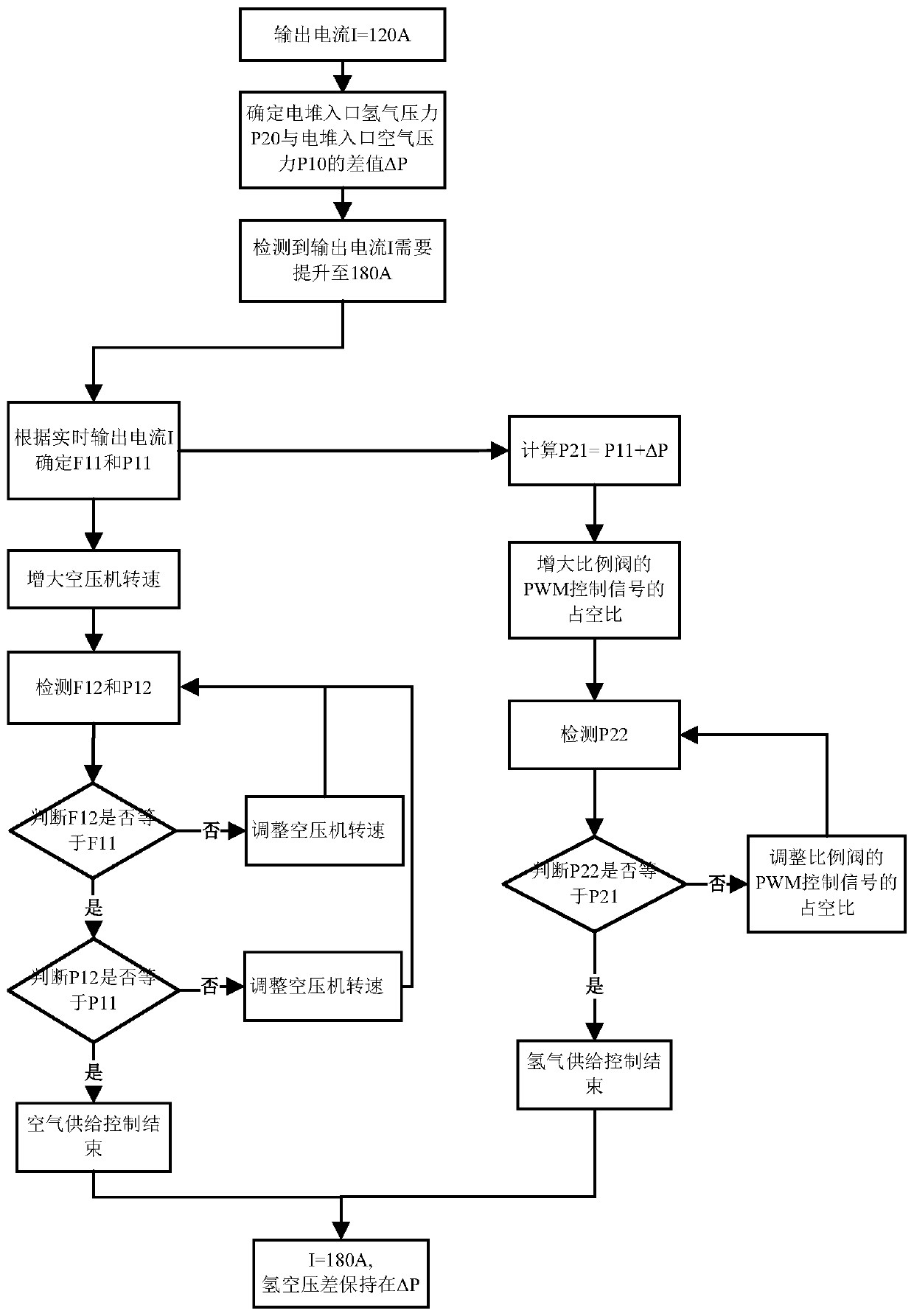

Fuel cell hydrogen and air supply control method, device and system

InactiveCN109980252AGuaranteed durabilityGuaranteed running stabilityFuel cellsHydrogen pressureEngineering

The invention relates to a fuel cell hydrogen and air supply control method, device and system. The method comprises the steps of: obtaining the output current of a fuel cell; determining an air flowand an air pressure required by a galvanic pile inlet according to the output current, and adjusting the fuel cell air supply according to the air flow and the air pressure required by the galvanic pile inlet; determining the hydrogen pressure required by the galvanic pile inlet according to the air pressure required by the galvanic pile inlet and a preset hydrogen-air pressure difference, and adjusting the fuel cell hydrogen supply according to the hydrogen pressure required by the galvanic pile inlet, so that a difference between the real-time pressure difference of the galvanic pile inlet and the preset hydrogen-air pressure difference is within a preset range, wherein the real-time pressure difference is a difference between the real-time hydrogen pressure of the galvanic pile inlet and the real-time air pressure of the galvanic pile inlet. The method can avoid great changes in pressure difference on both sides of a proton exchange membrane of the fuel cell, and ensure the performance and the service life of the fuel cell.

Owner:武汉海亿新能源科技有限公司

Apparatus for controlling hydrogen supply of fuel cell system and method for controlling the same

ActiveUS20120315559A1Secure sufficient levelSufficient level of hydrogen recirculation flowOperating means/releasing devices for valvesElectrical controlProportional controlSolenoid valve

The present invention provides an apparatus for controlling hydrogen supply of a fuel cell system and a method for controlling the same. The apparatus includes a jet pump, a proportional control solenoid valve, and a controller. The jet pump is disposed at the side of an inlet of a fuel cell stack and performs supply and recirculation of hydrogen into the fuel cell stack. The proportional control solenoid valve is connected to a hydrogen supply line and fluidly communicates with a nozzle inlet of the jet pump to control the hydrogen supply to the jet pump. The controller controls an operation of the proportional control solenoid valve according to a power of the fuel cell system. Here, the controller controls the operation of the proportional control solenoid valve according to a pulse flow control method at a low power section in which a current power is lower than a predetermined reference power.

Owner:HYUNDAI MOTOR CO LTD

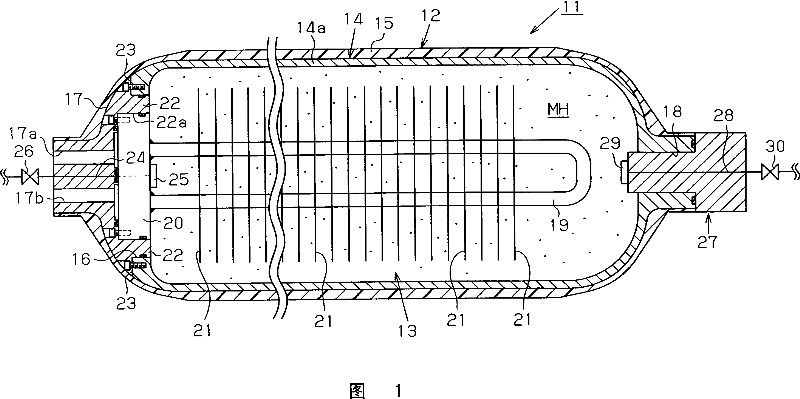

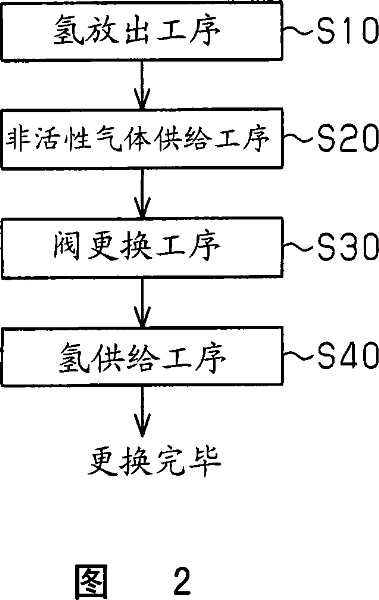

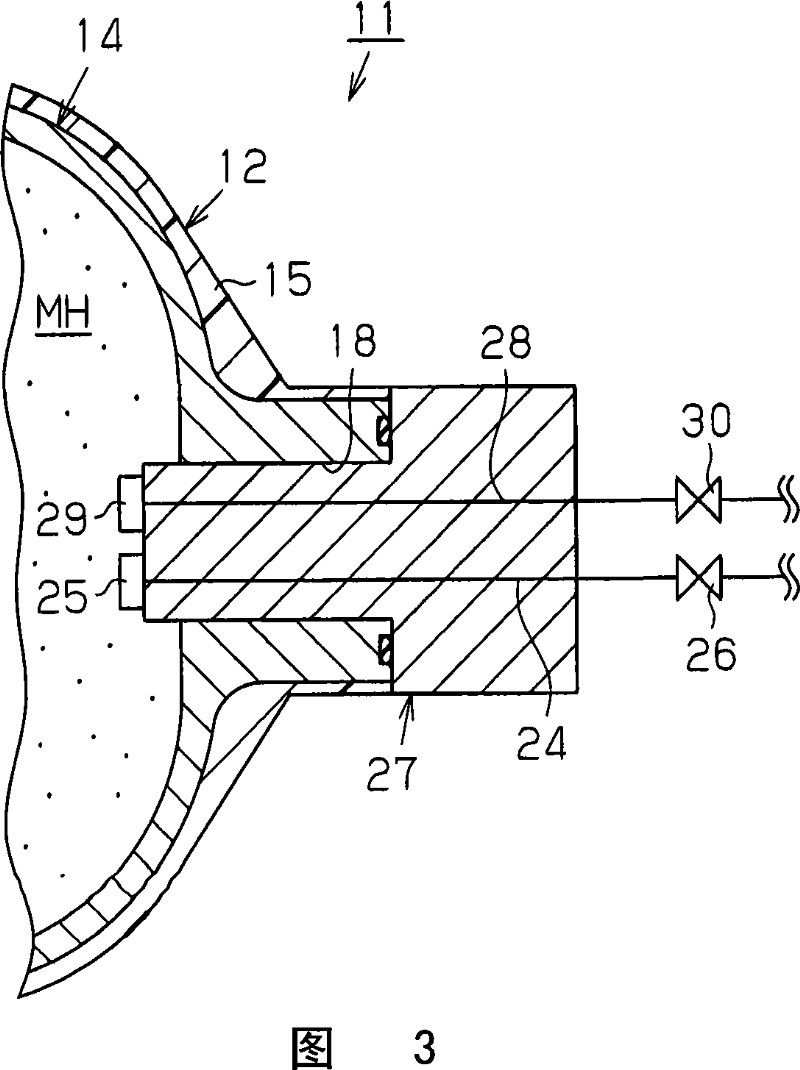

Hydrogen storage tank and replacement method for on-off valve

The present invention provides a hydrogen storage tank (11) and a replacement method for an on-off valve, in which hydrogen occluding alloy (MH) received in a tank body (12) is prevented from being oxidized in the replacement of an on-off valve (30) connected to a hydrogen supply / discharge pipe (28) extending from the tank body (12). The hydrogen storage tank (11) has the tank body (12) in which the hydrogen occluding alloy (MH) is being received, the hydrogen supply / discharge pipe (28) to which the on-off valve (30) is connected, the on-off valve (30) being used to supply hydrogen gas to the tank body (12) and discharge hydrogen gas from the tank body (12), and a gas supply pipe (24) used to supply inert gas to the tank body (12) and provided independently of the hydrogen supply / discharge pipe (28). The method of replacing the on-off valve (30) connected to the hydrogen supply / discharge pipe (28) is such that inert gas is supplied from the gas supply pipe (24) to the tank body (12) and the on-off valve (30) is replaced in a state where the inert gas can be discharged from the supply / discharge pipe (28).

Owner:TOYOTA IND CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com