Patents

Literature

1058 results about "Hydrogen system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

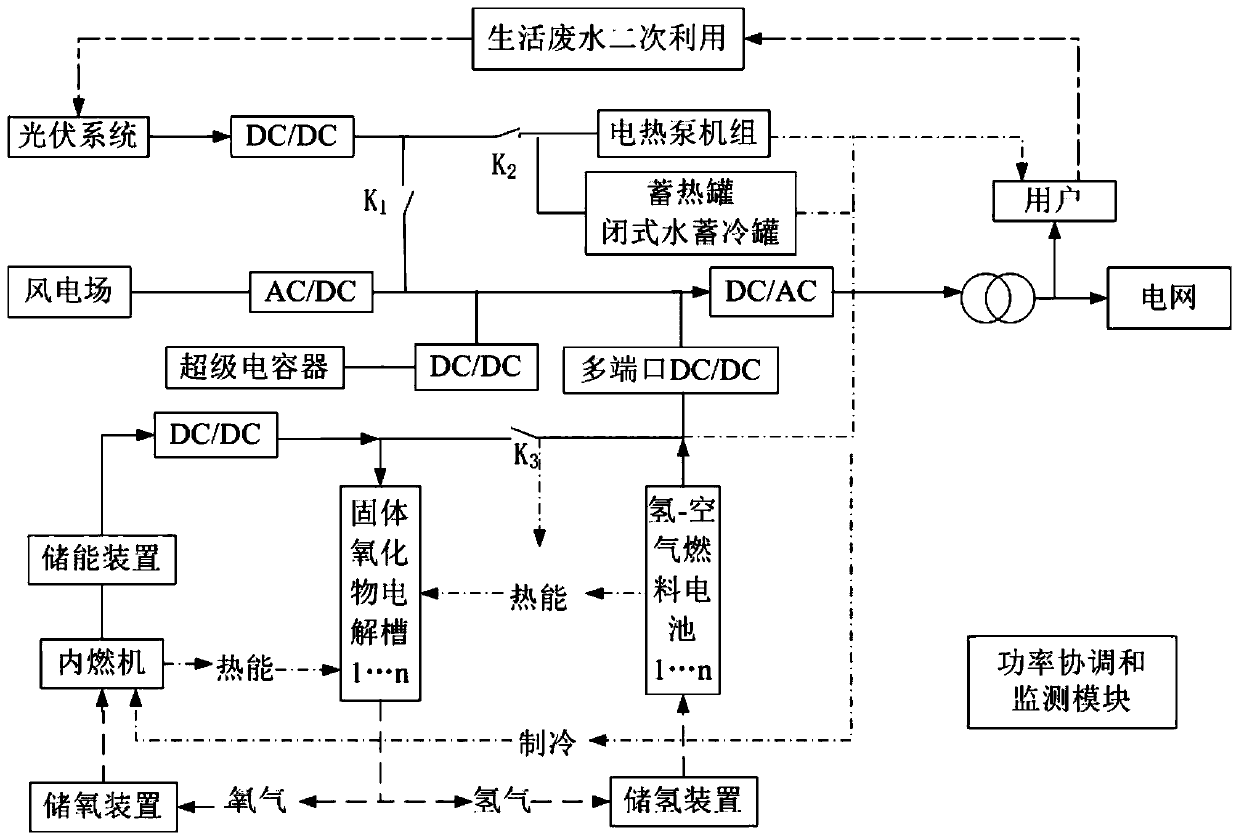

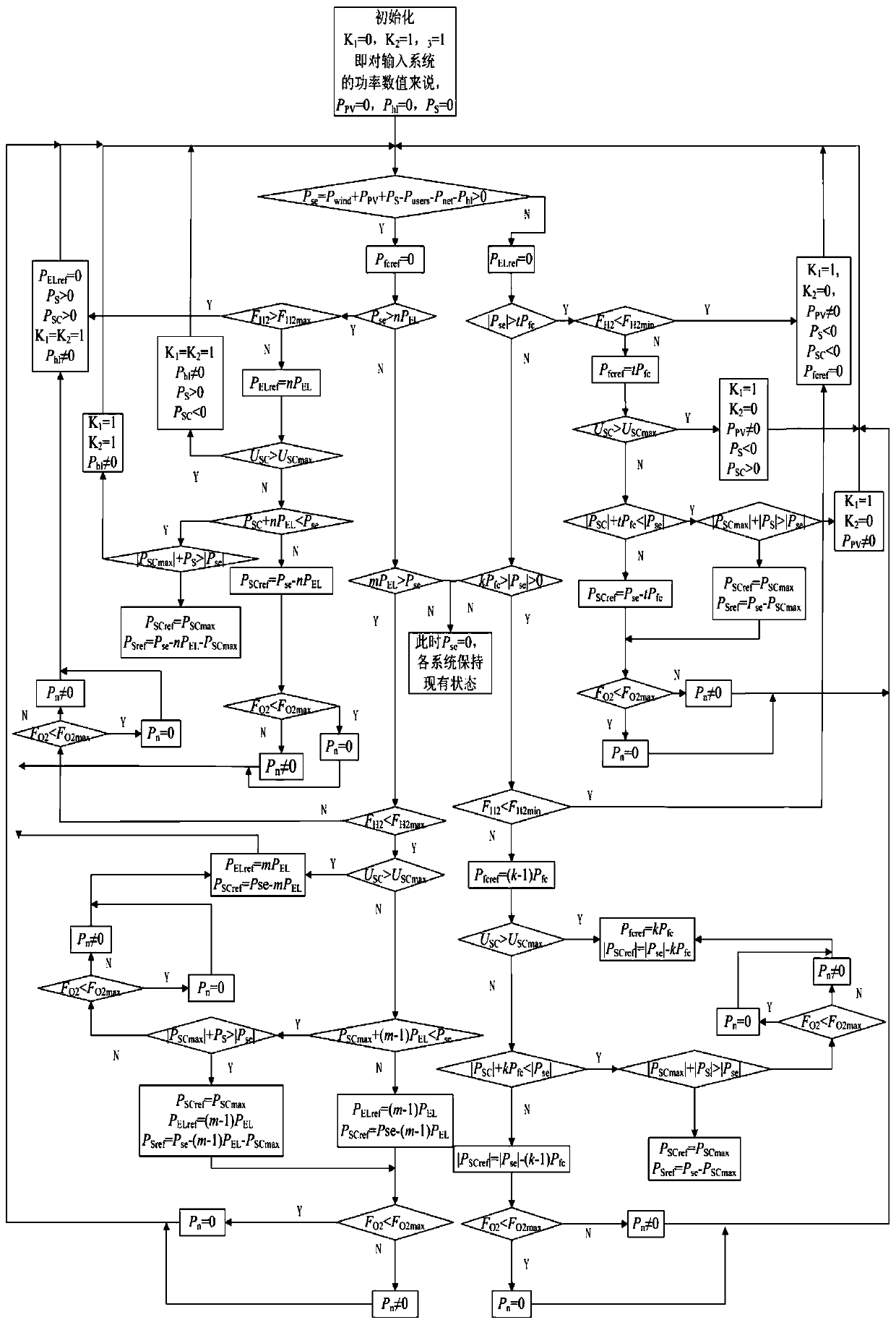

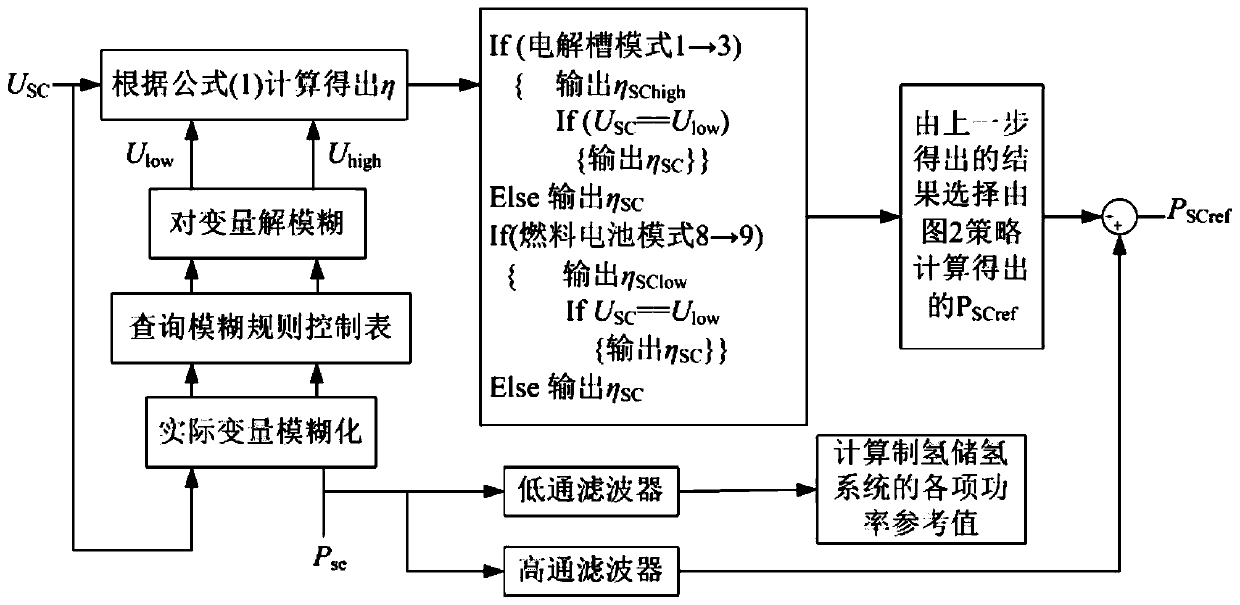

Wind-solar power generation and hydrogen-production hydrogen-storage system and operation control method thereof

ActiveCN109755965AIncrease profitSolve the requirements of evening peak loadBatteries circuit arrangementsSingle network parallel feeding arrangementsHydrogen productionGrid connection

The invention relates to a wind-solar power generation and hydrogen-production hydrogen-storage system and an operation control method thereof, and relates to the technical field of new energy wind-solar power generation and hydrogen production. According to the invention, a rectifier at a fan side of a wind power farm is connected with a grid side inverter; a DC (Direct Current) bus is connectedwith a supercapacitor of a DC / DC convertor; the rear surface of the supercapacitor is connected with a hydrogen production and hydrogen storage system; a photovoltaic system is connected with the DC bus in front of the supercapacitor by the DC / DC convertor and is used as a power compensation unit of the wind power farm; the wind-solar power generation and hydrogen-production hydrogen-storage system further comprises a power coordination control module and a monitoring module; and problems of poor peak regulation capacity, unsmooth hydrogen production, short service life of equipment and the like of a wind-solar power generation and hydrogen-production hydrogen-storage system are mainly solved. The wind-solar power generation and hydrogen-production hydrogen-storage system has the characteristics that the system is high in peak regulation capacity; the requirement of a load evening peak can be met; smooth hydrogen production can be ensured; the service life of the equipment is prolonged; flexible grid connection can be implemented in the premise of ensuring purity of produced hydrogen; and an energy utilization rate is high.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

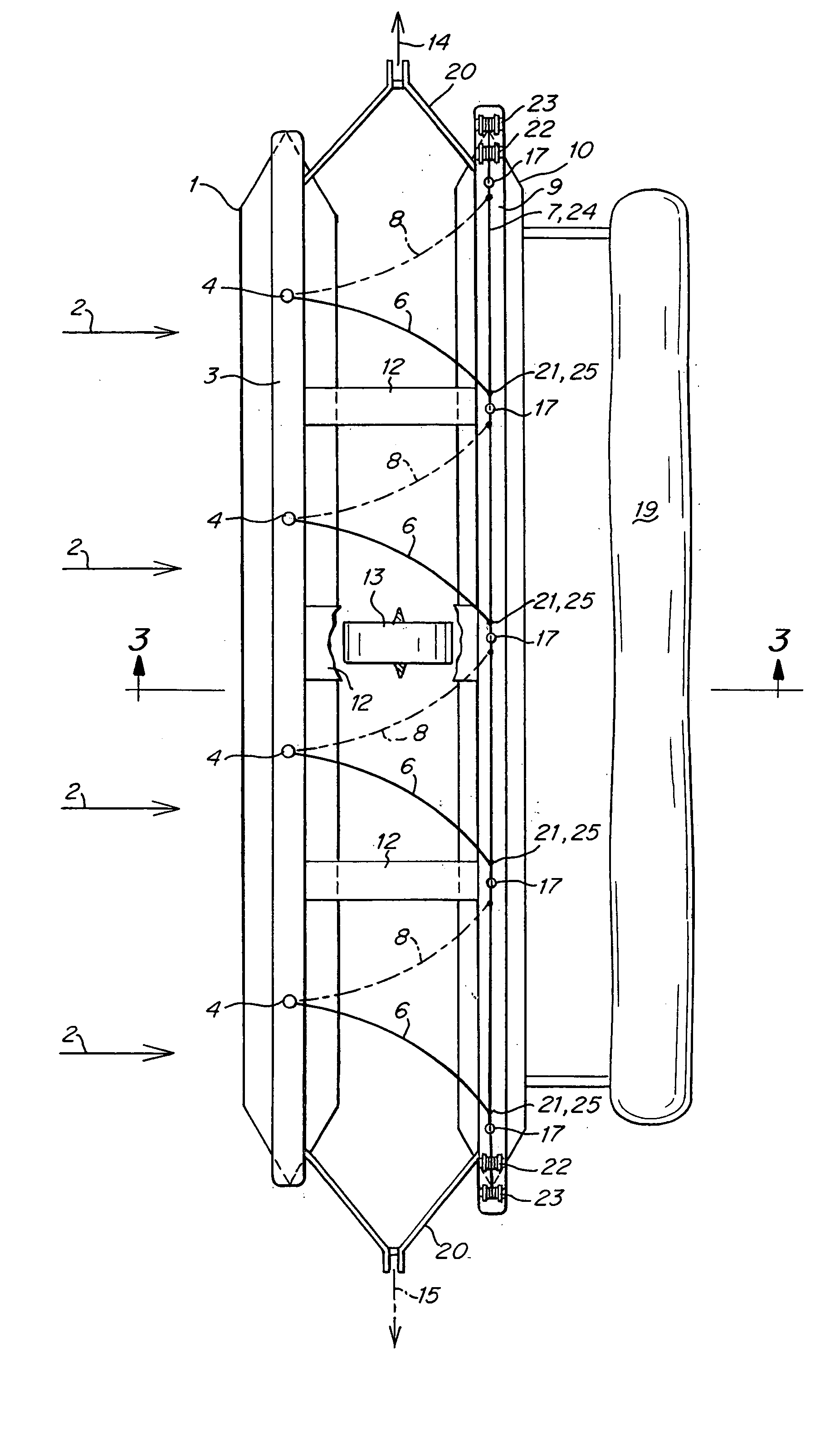

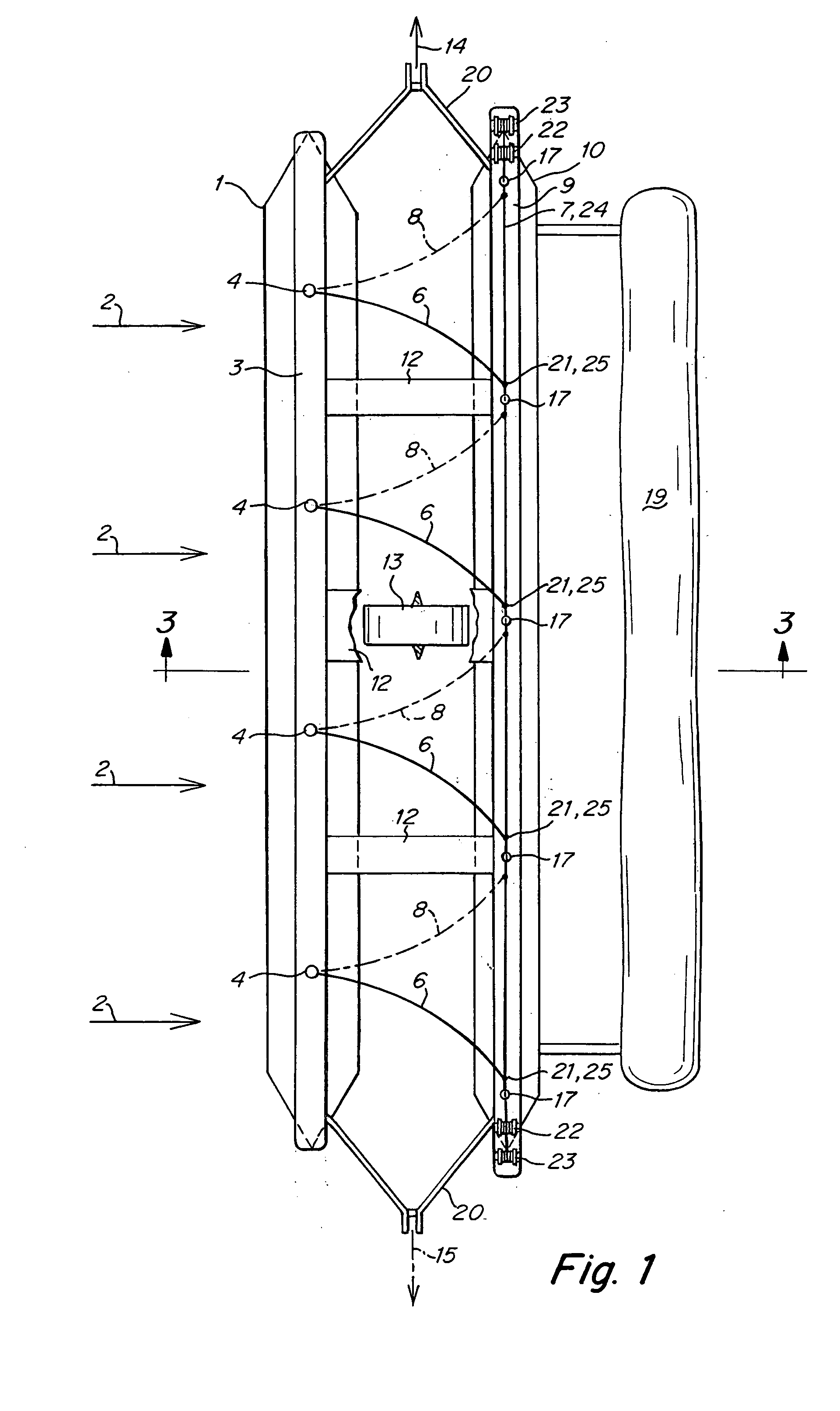

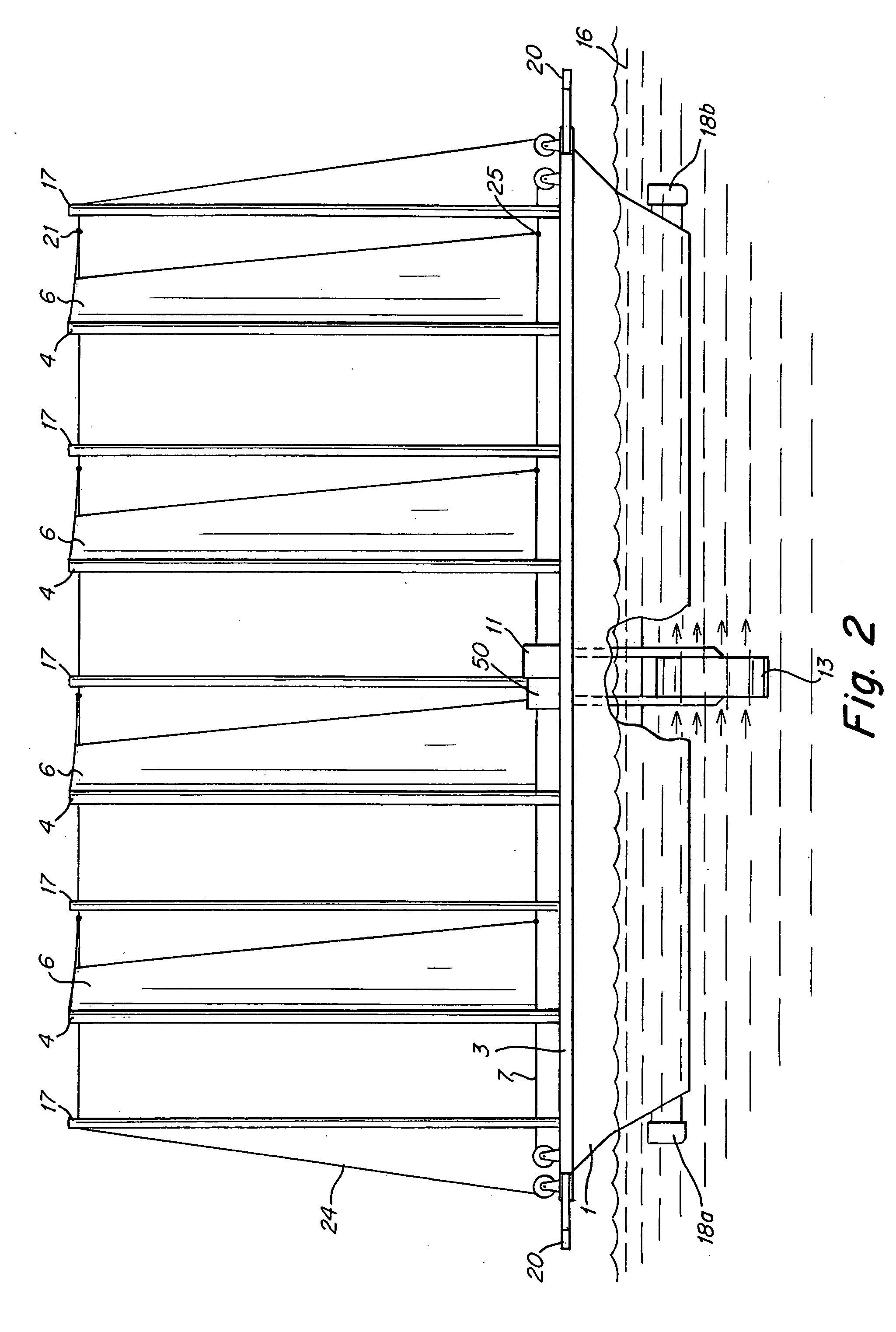

Wind-powered linear motion hydrogen production systems

InactiveUS20050252764A1Efficient use ofProduce hydrogenFinal product manufactureFuel cell auxillariesElectricityLinear motion

A system for generating hydrogen is provided which includes at least one vessel which floats in water. At least one sail for capturing wind to move the vessel reciprocally along a substantially linear path is mounted on the vessel. A power generation system is provided for converting movement of the vessel relative to the water into electricity. And an onboard hydrogen production system produces hydrogen by electrolysis using the electricity generated by the power generation system.

Owner:MELLER MOSHE

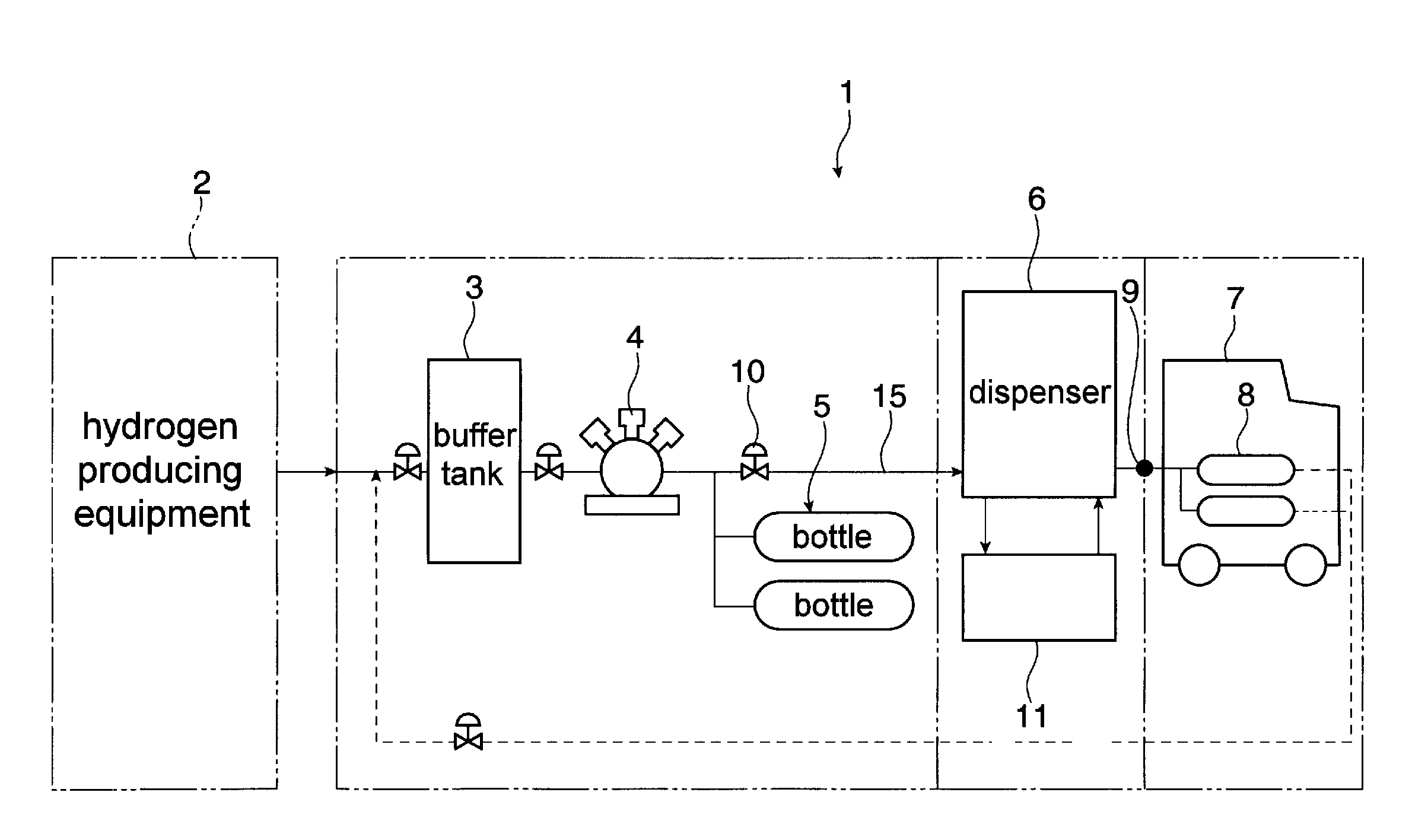

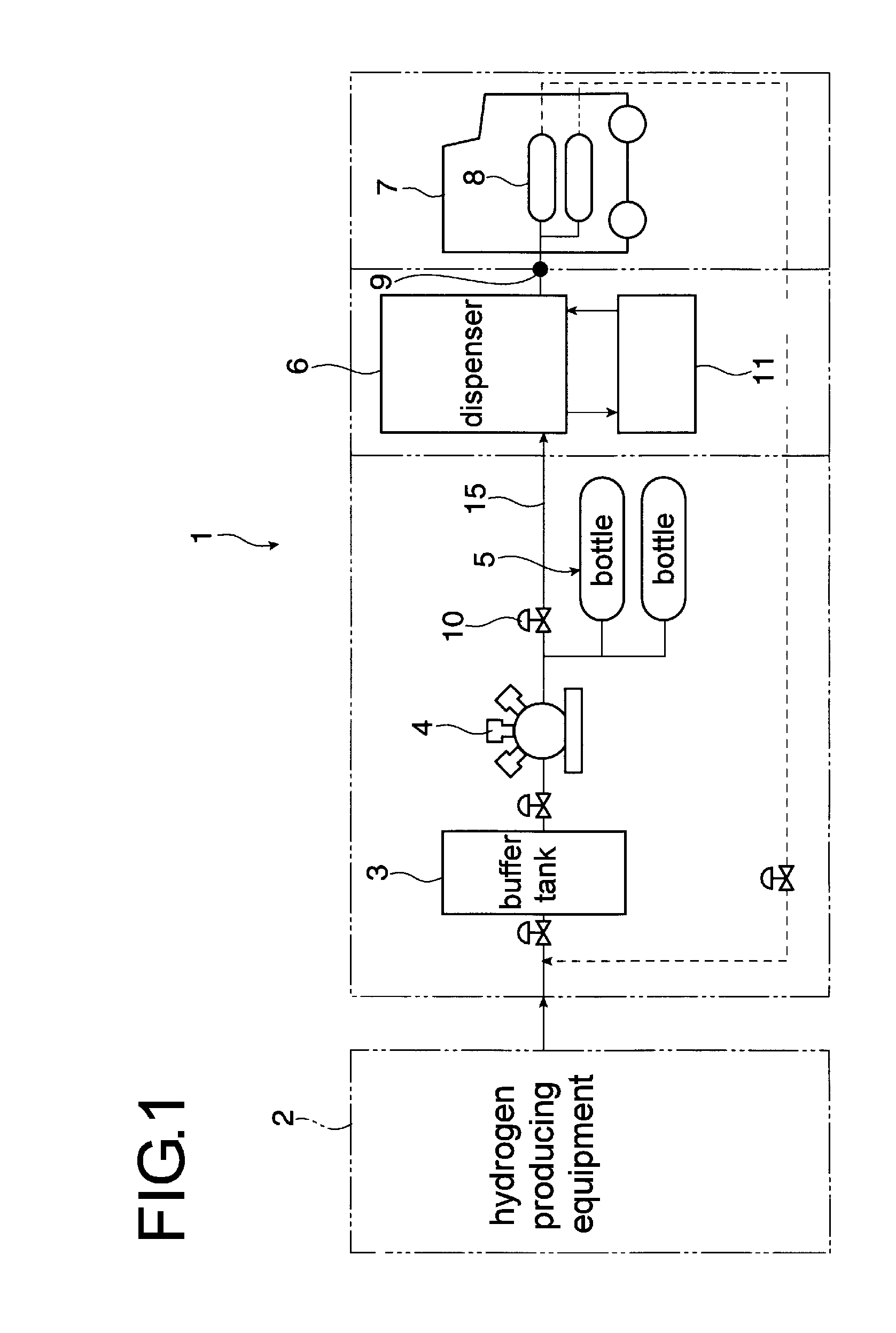

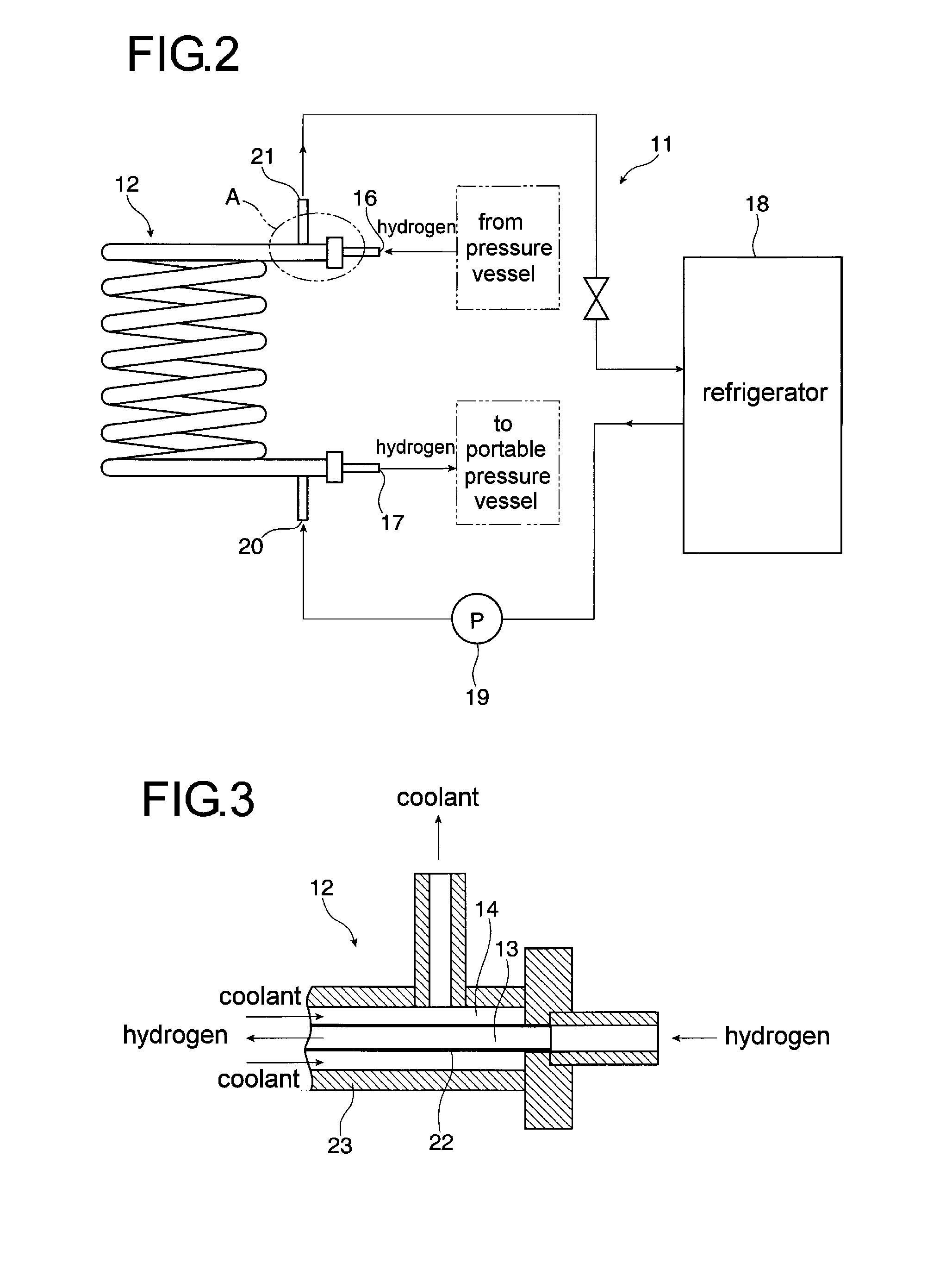

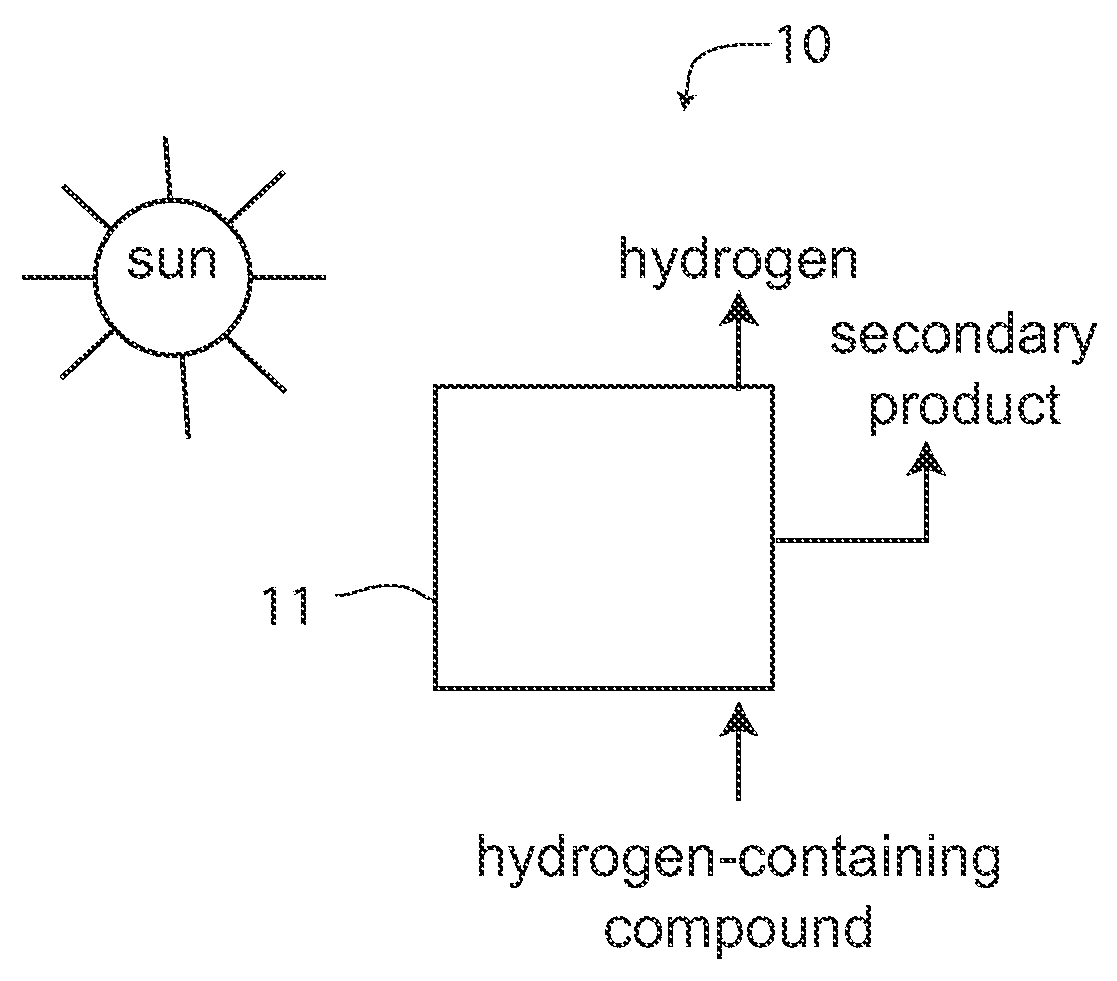

Hydrogen heat exchanger for a hydrogen filling system

InactiveUS20120216915A1Cool efficiency of cooler be raiseHeat transfer resistance be lowGas handling applicationsGas handling/storage effectsHydrogen tankHydrogen fuel

This invention has its aim in providing a hydrogen heat exchanger for a hydrogen filling system which is of a small size and has high heat transfer performance. The hydrogen filling system, in which a hydrogen tank (8) in a hydrogen fuel-cell automobile (7) is filled with pressurized hydrogen from a hydraulic accumulator (5), has a precooling apparatus (11) equipped with a heat exchanger (12) for cooling hydrogen to be filled. In the heat exchanger (12), the supply pressure in the hydrogen supplying channel (13) is substantially as high as the pressure in the coolant supplying channel (14). This allows the pipe wall of the intermediate pipe between both supplying channels to be thinner than in prior arts. Owing to this, heat transfer resistance and hydrogen pressure loss decrease, improving heat transfer performance and allowing the apparatus to be constituted in a small scale.

Owner:NAT INST OF ADVANCED IND SCI & TECH

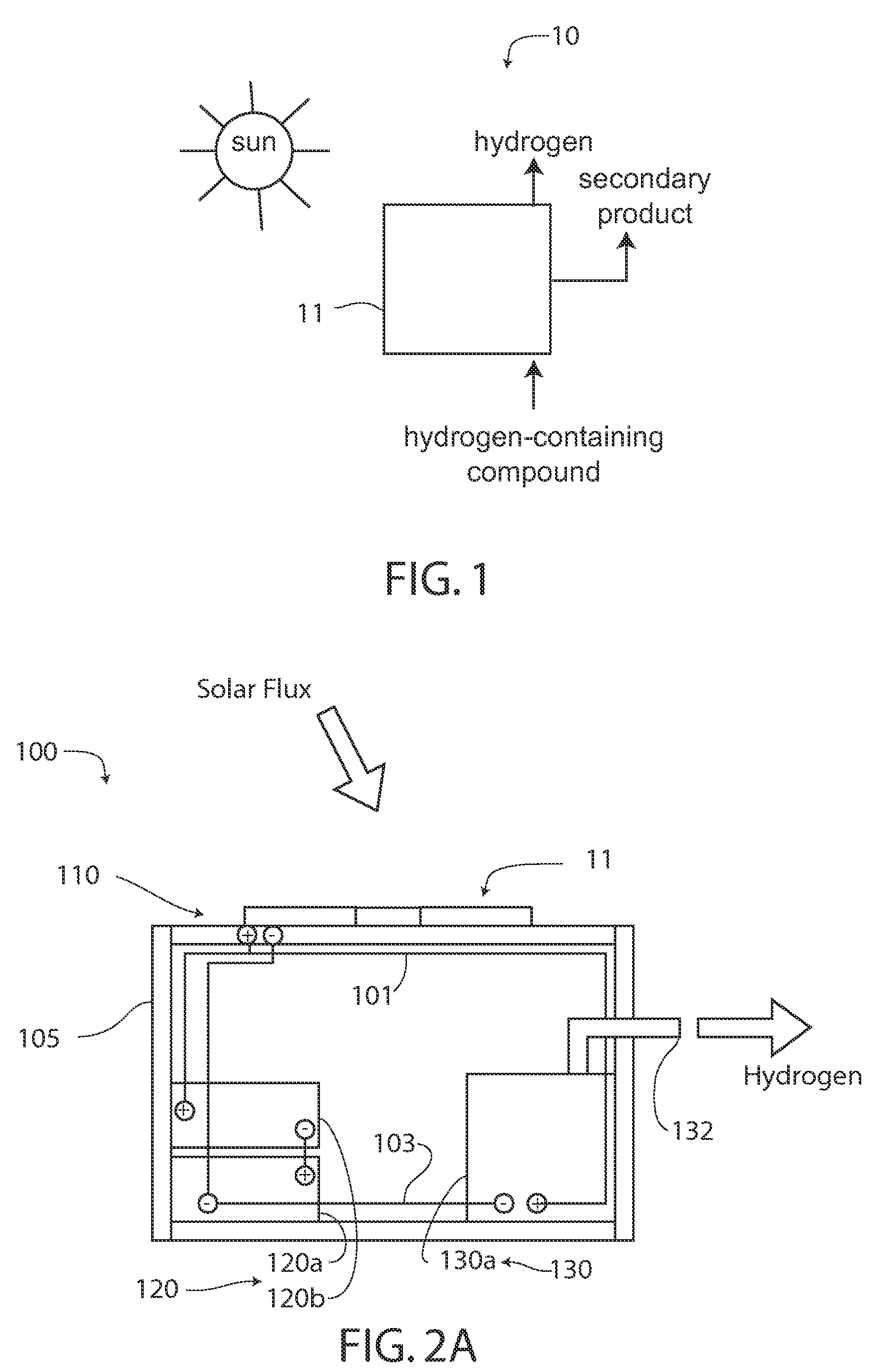

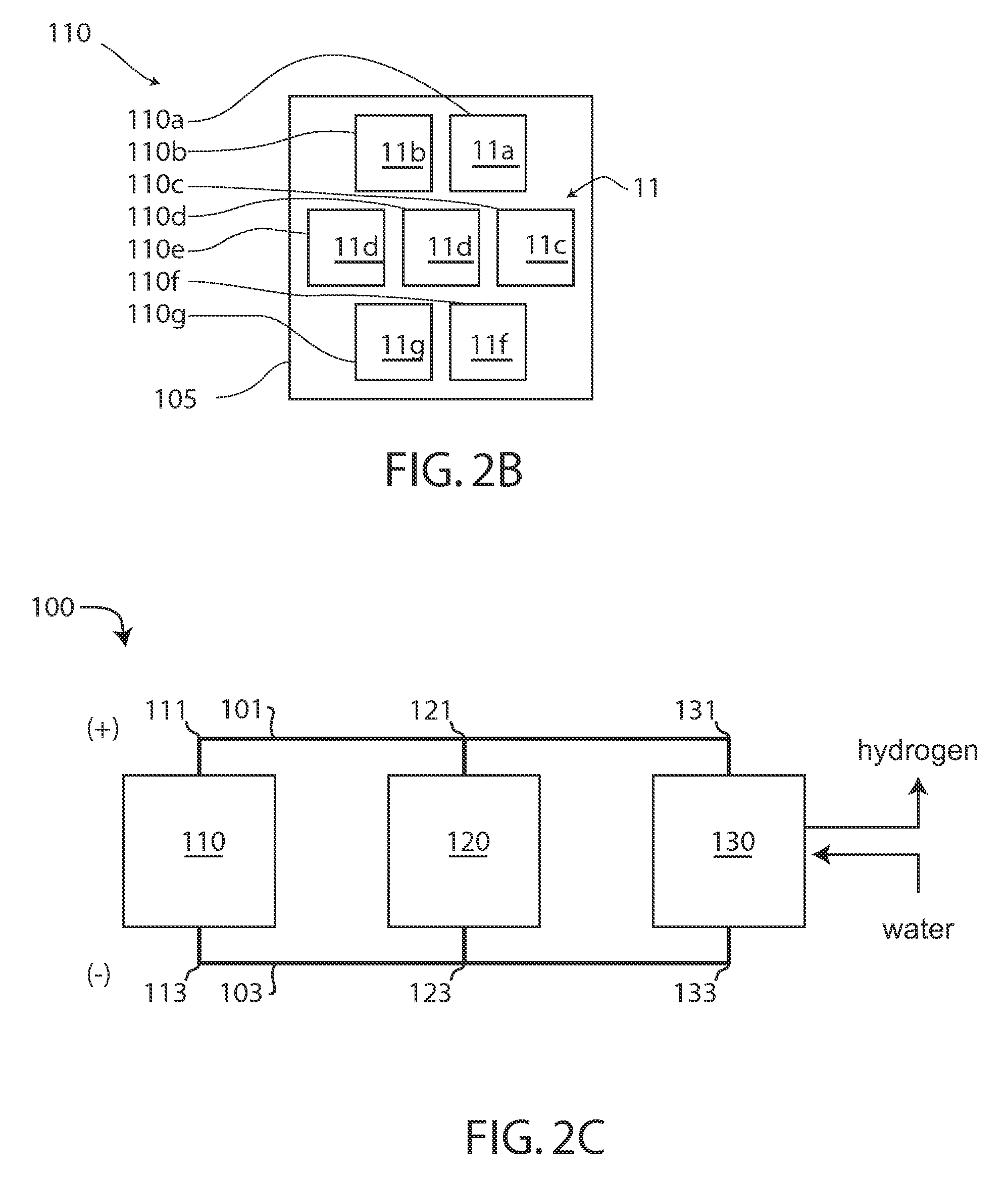

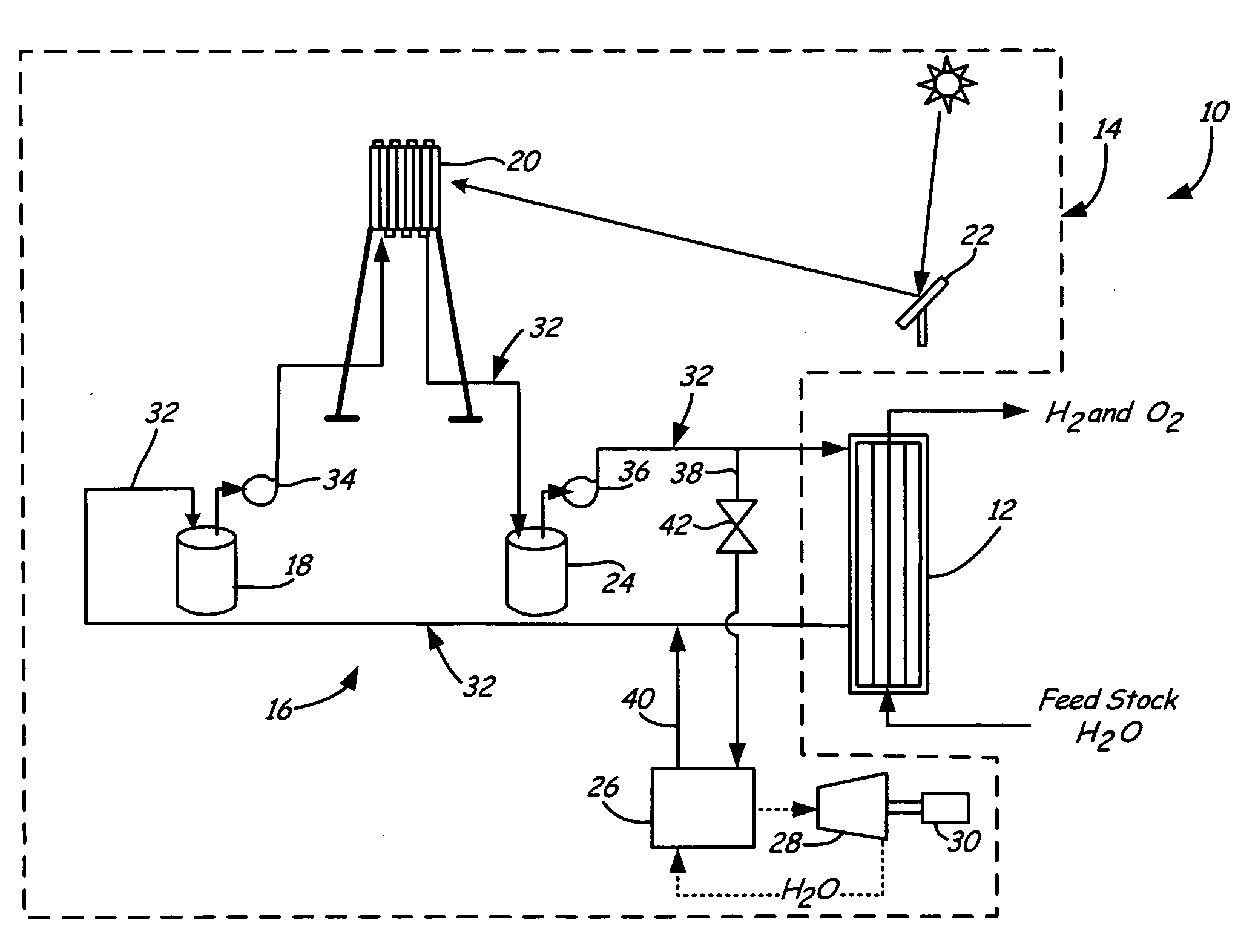

Solar hydrogen generation system

InactiveUS20070277870A1Components is relatively effectiveImprove efficiencyElectrolysis componentsPV power plantsHydrogenSolar hydrogen

A solar hydrogen generation system is disclosed that efficiently utilizes photovoltaic cells, storage batteries, and electrolyzers to generate hydrogen from the sun by direct coupling of these components. The system mutually arranges the photovoltaic cells, batteries, and electrolyzers in series, and the series components in parallel. The arrangement allows the voltages of the photovoltaic cells, batteries, and electrolyzers to match each other for optimal performance. The invention further provides for continuous hydrogen generation, even through the night or periods of low solar flux, and a system for preventing the overcharging of the batteries.

Owner:WECHSLER MARK

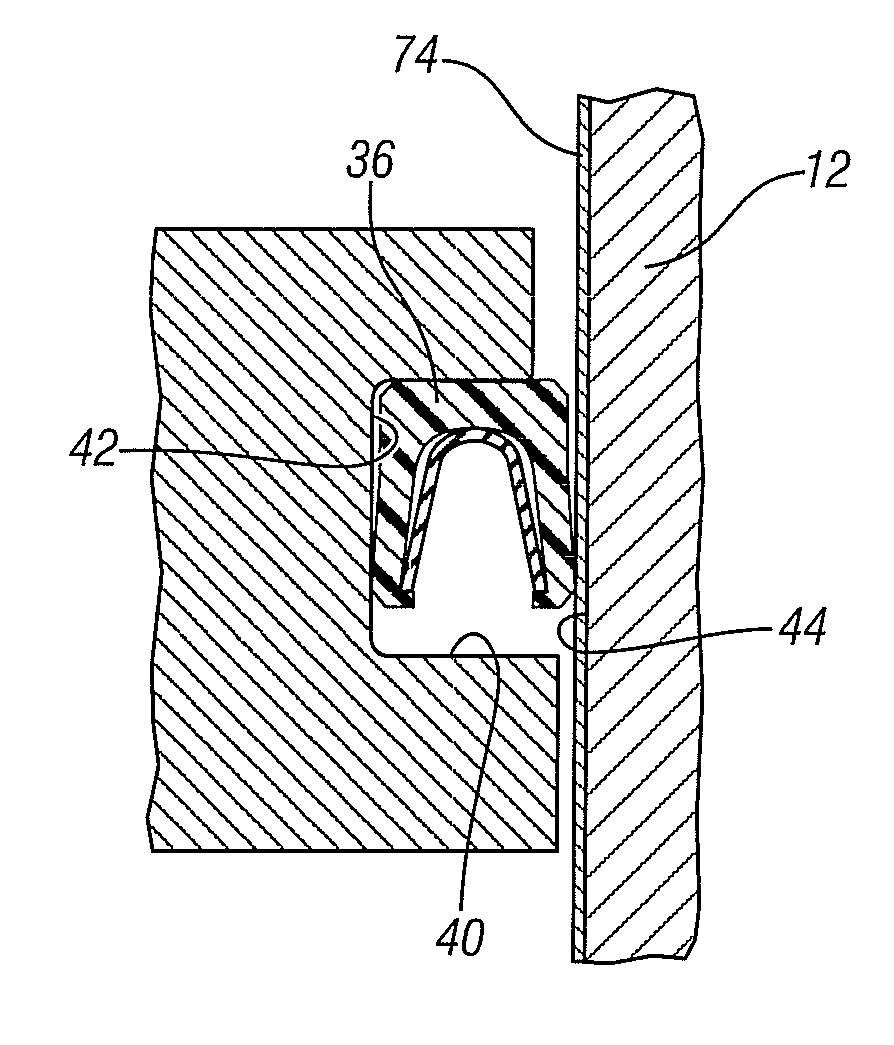

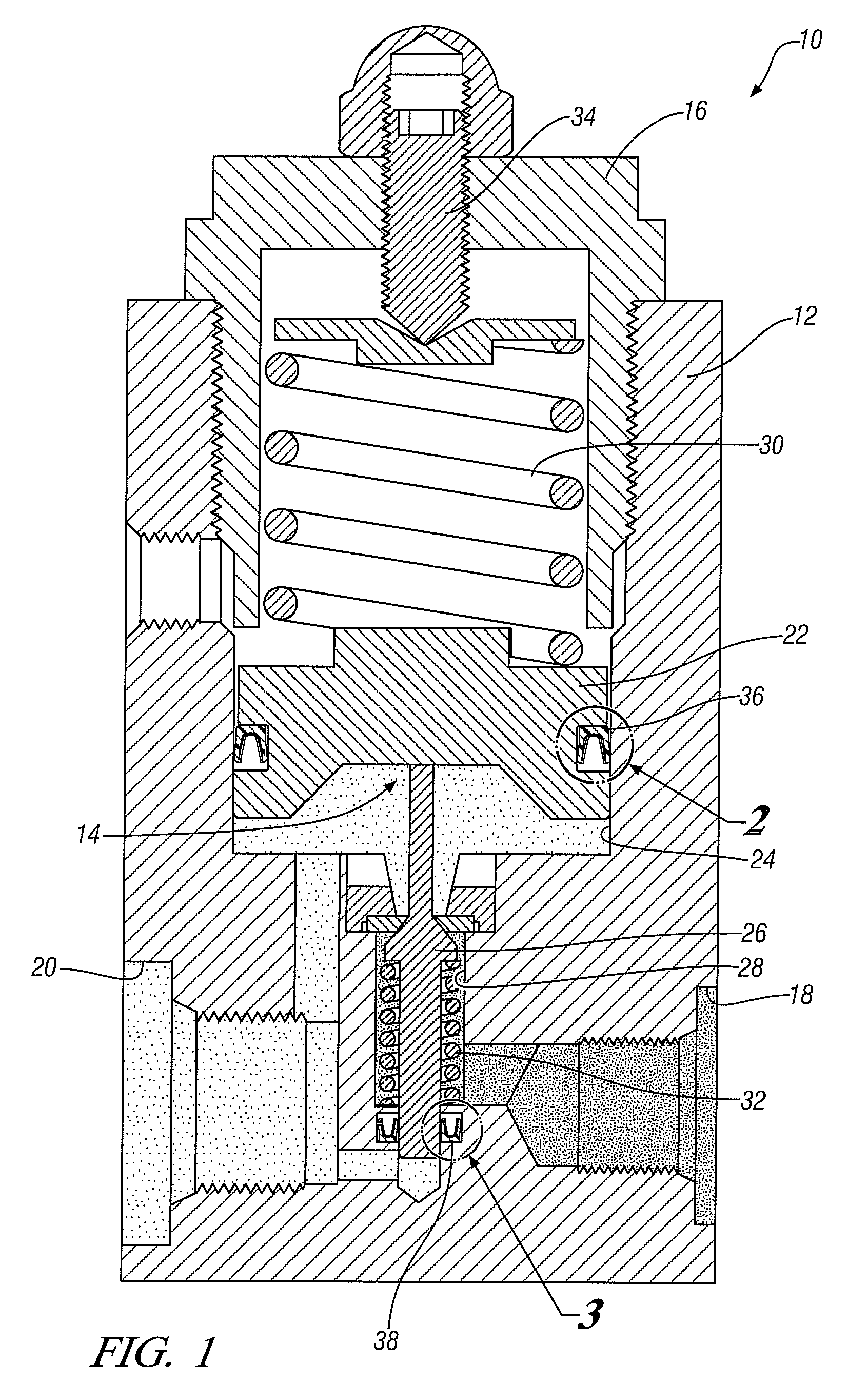

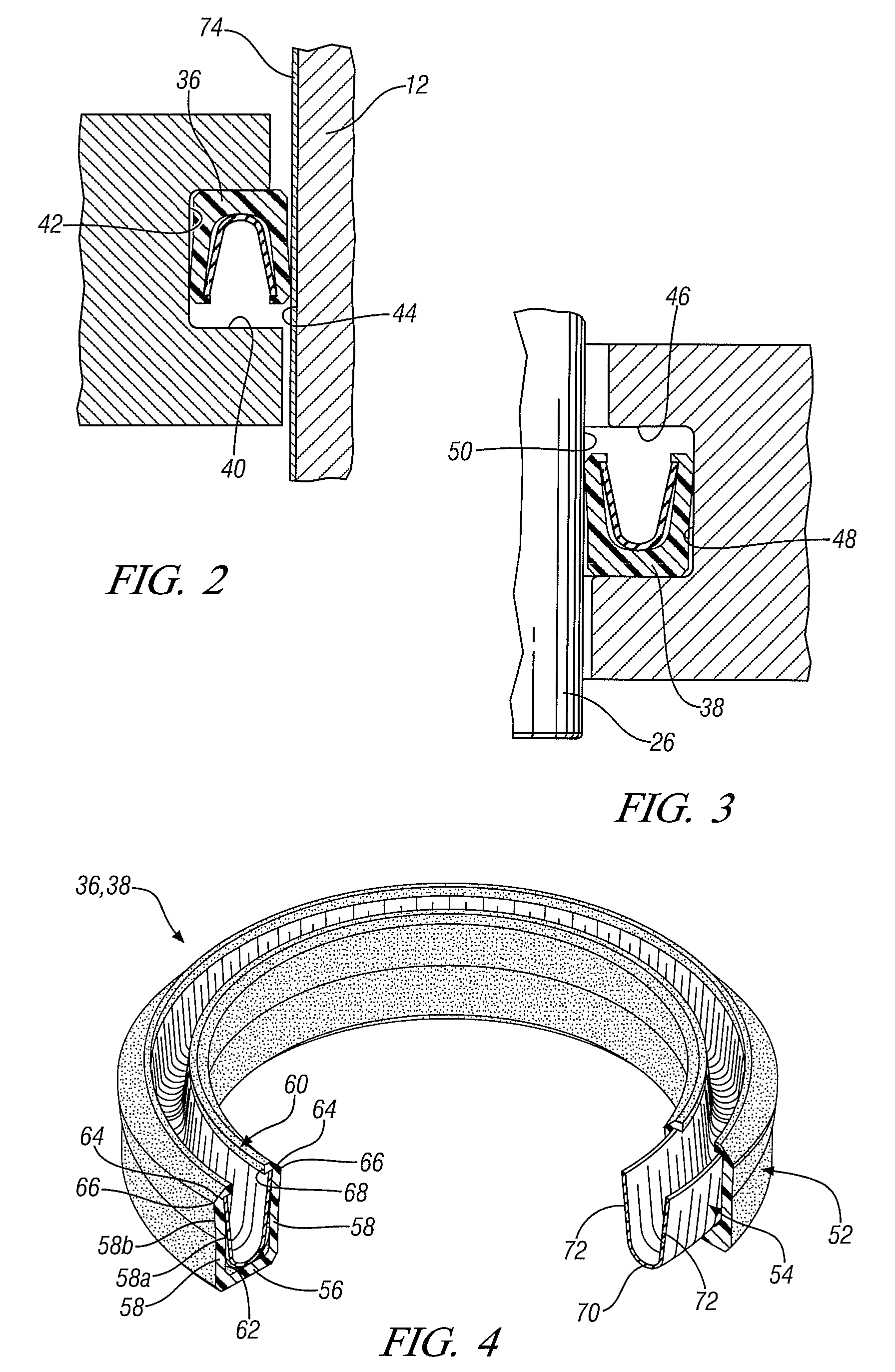

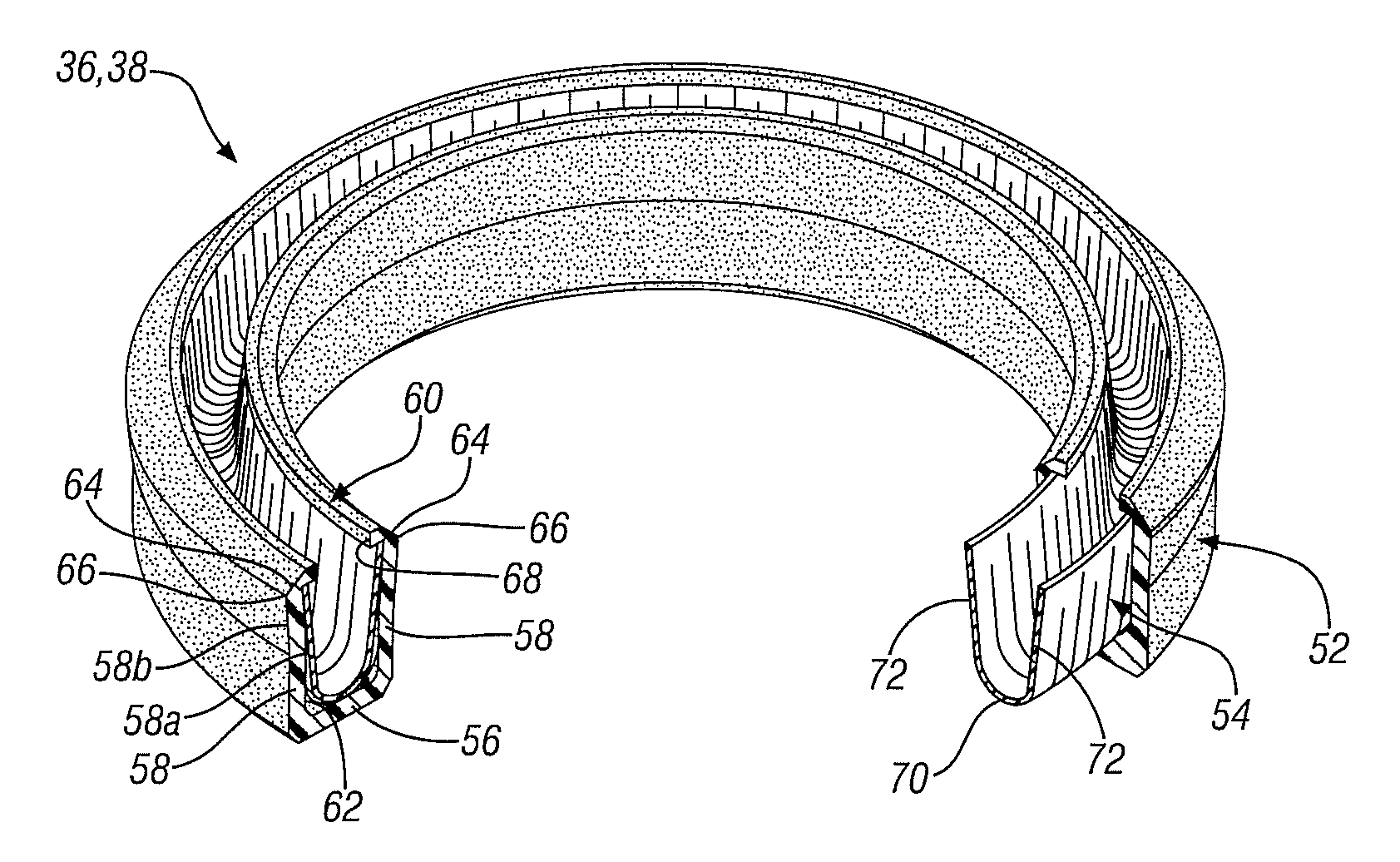

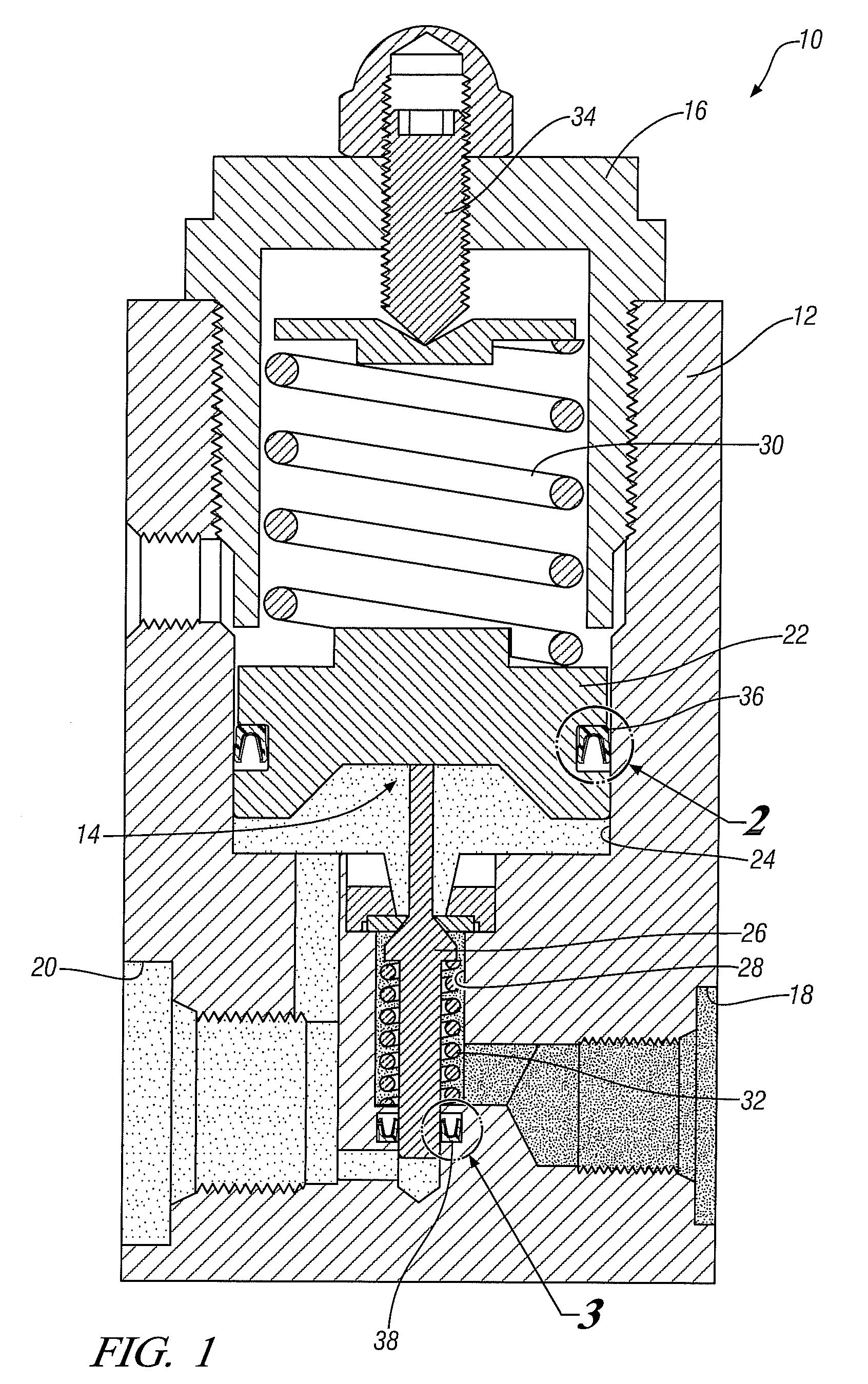

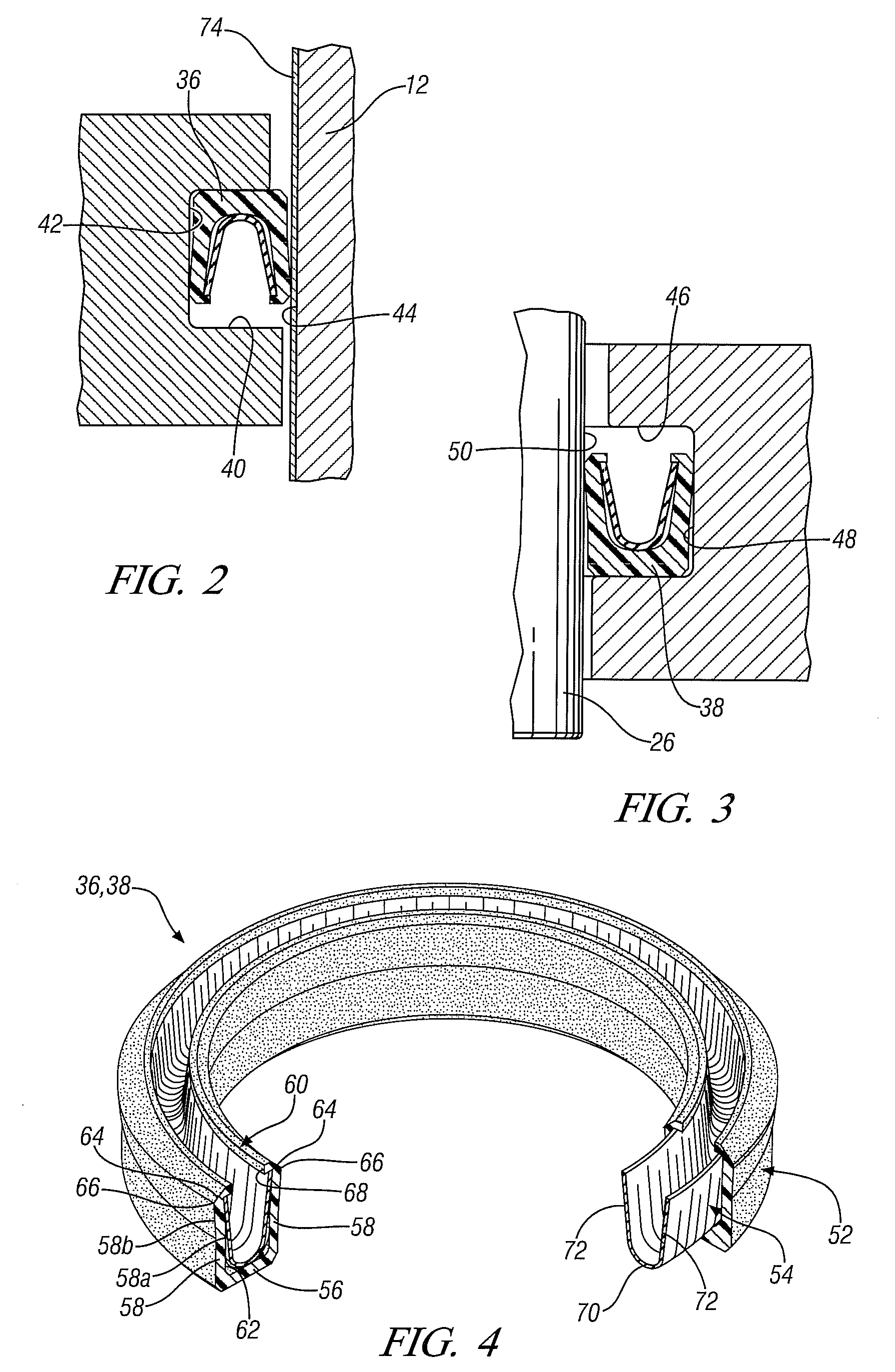

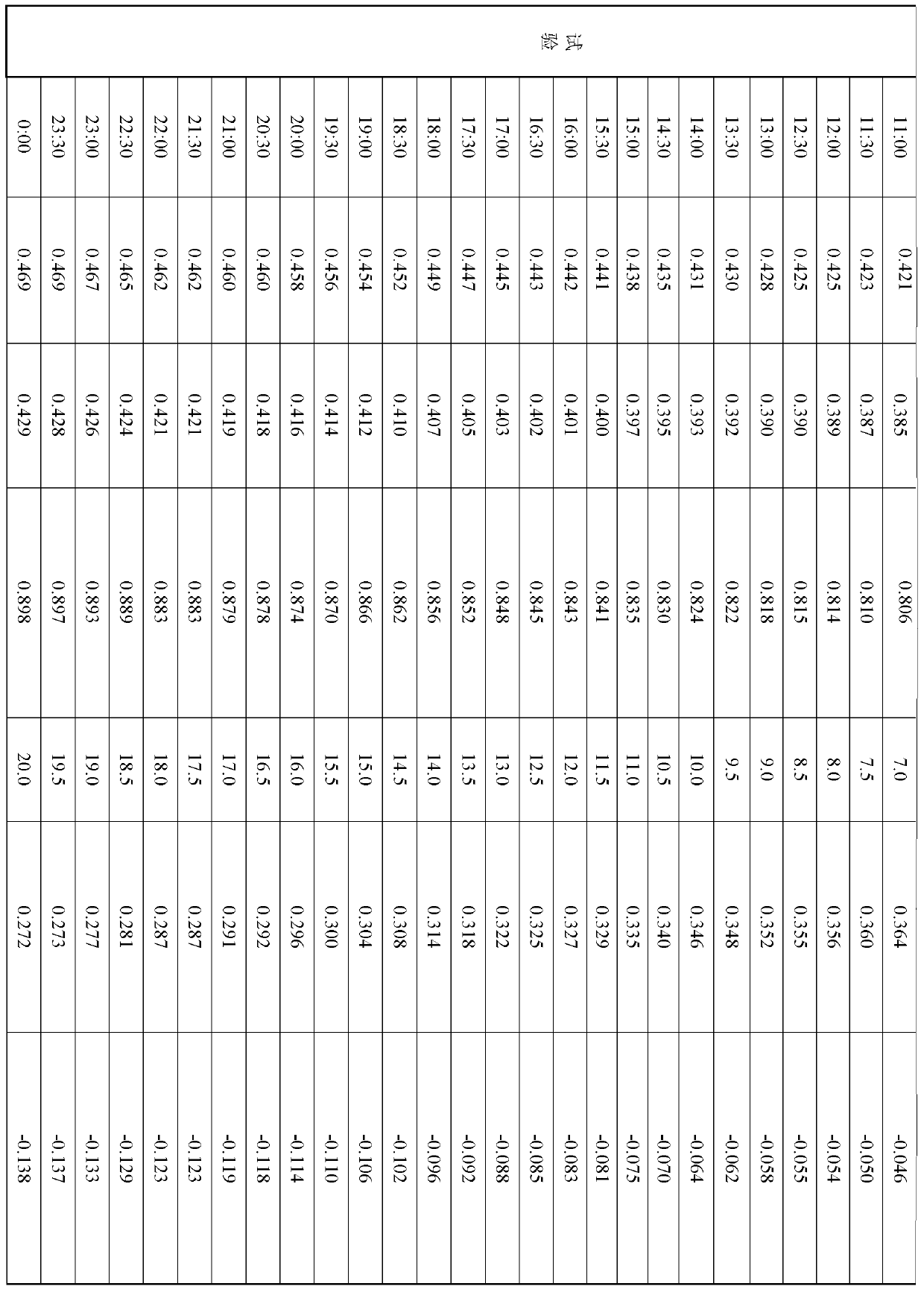

Seal performance for hydrogen storage and supply systems

InactiveUS8251373B2Increase forceImprove sealingEngine sealsElectrolysis componentsSurface roughnessElectrochemistry

The performance and durability of static and dynamic seals for hydrogen storage and supply systems has been improved by utilizing a spring-energized and plastic coated radial seal in combination with at least a mating surface that has been treated by one of a variety of procedures. These procedures include applying to the mating surface a low-friction, hard, and hydrogen impervious coating, chemically polishing the mating surface, and electrochemically polishing the mating surface. Each of these procedures significantly reduces, on a microscopic scale, the surface roughness of the mating surface. The seal can thus form a tighter and more gas-tight seal with the smoother mating surface so as to decrease the loss of hydrogen gas across the seal. The smoother mating surface can also improve seal life by reducing seal surface wear.

Owner:GM GLOBAL TECH OPERATIONS LLC

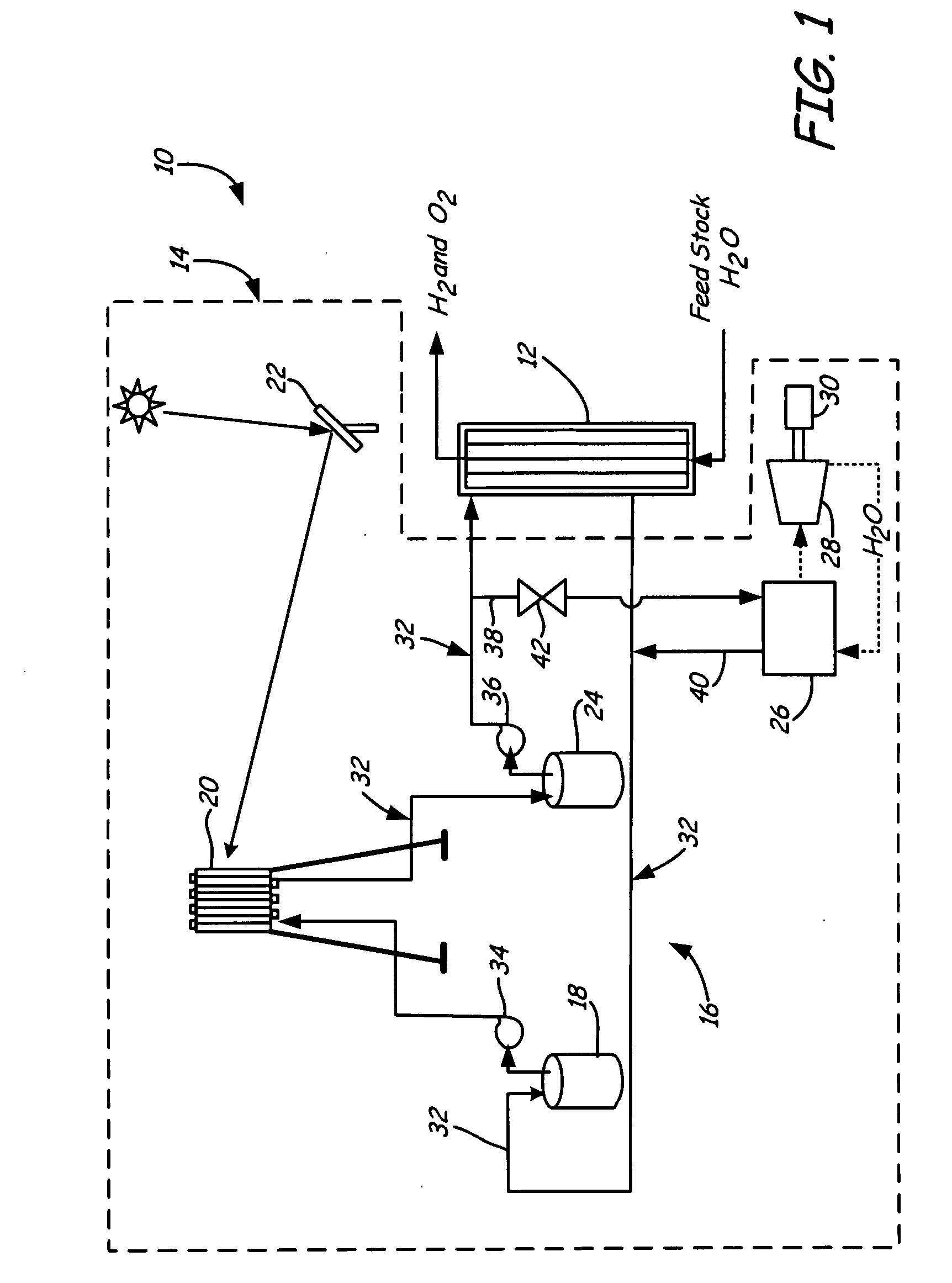

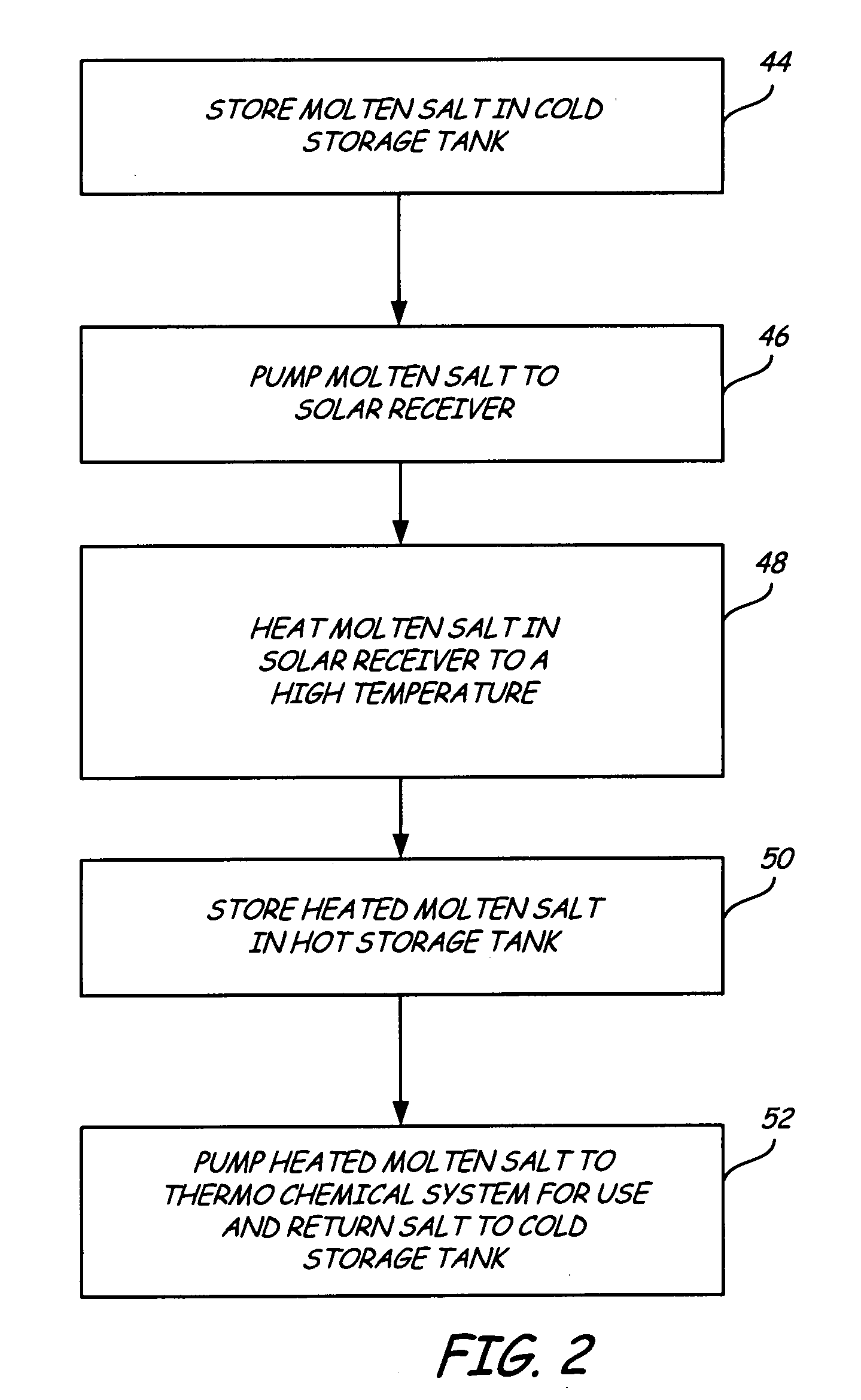

Solar power for thermochemical production of hydrogen

A solar-powered hydrogen production system includes a thermochemical system and solar heating system. The thermochemical system produces hydrogen. The solar heating system has a molten salt heat transfer medium for providing thermal energy to the thermochemical system.

Owner:SOLARRESERVE TECH

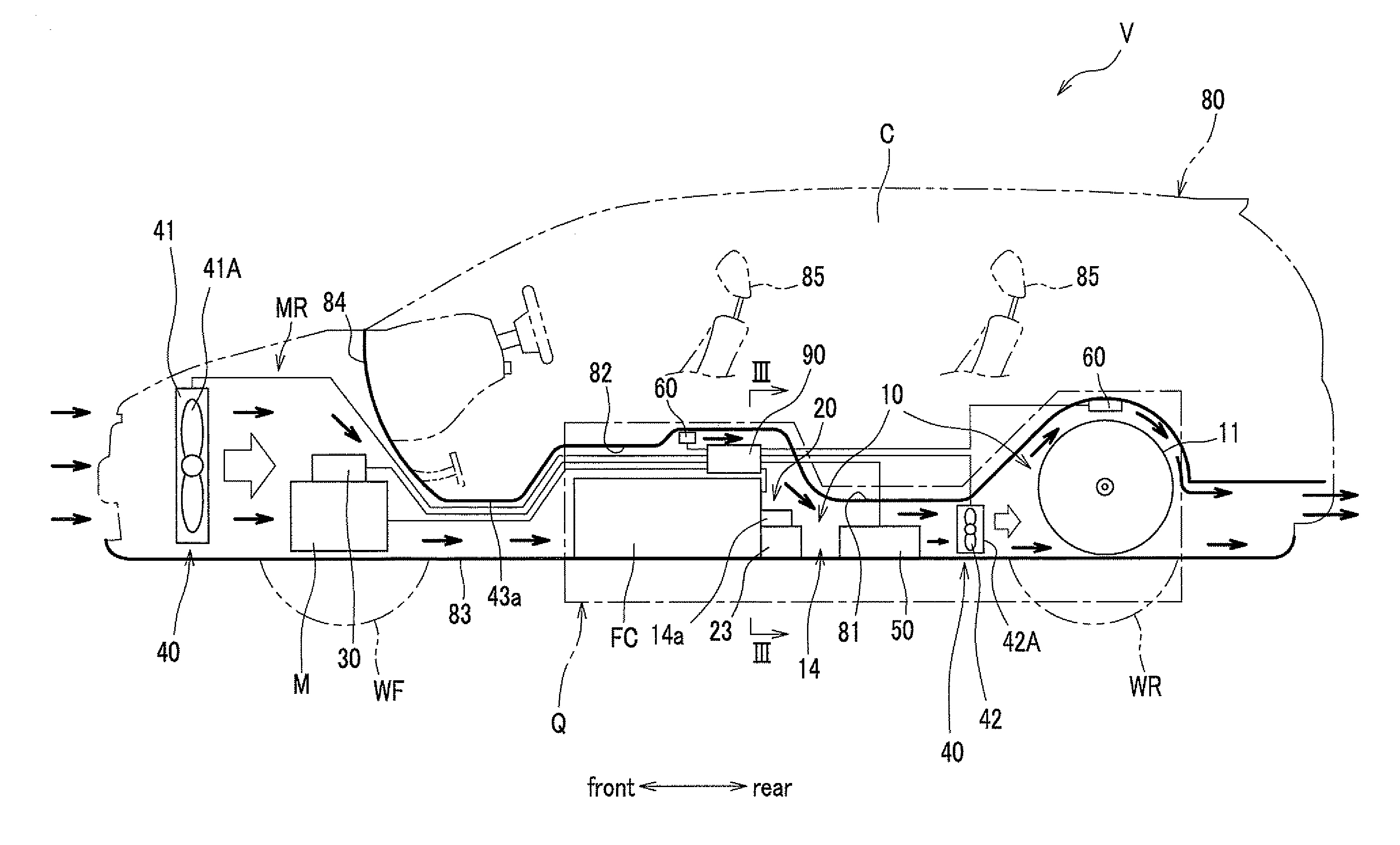

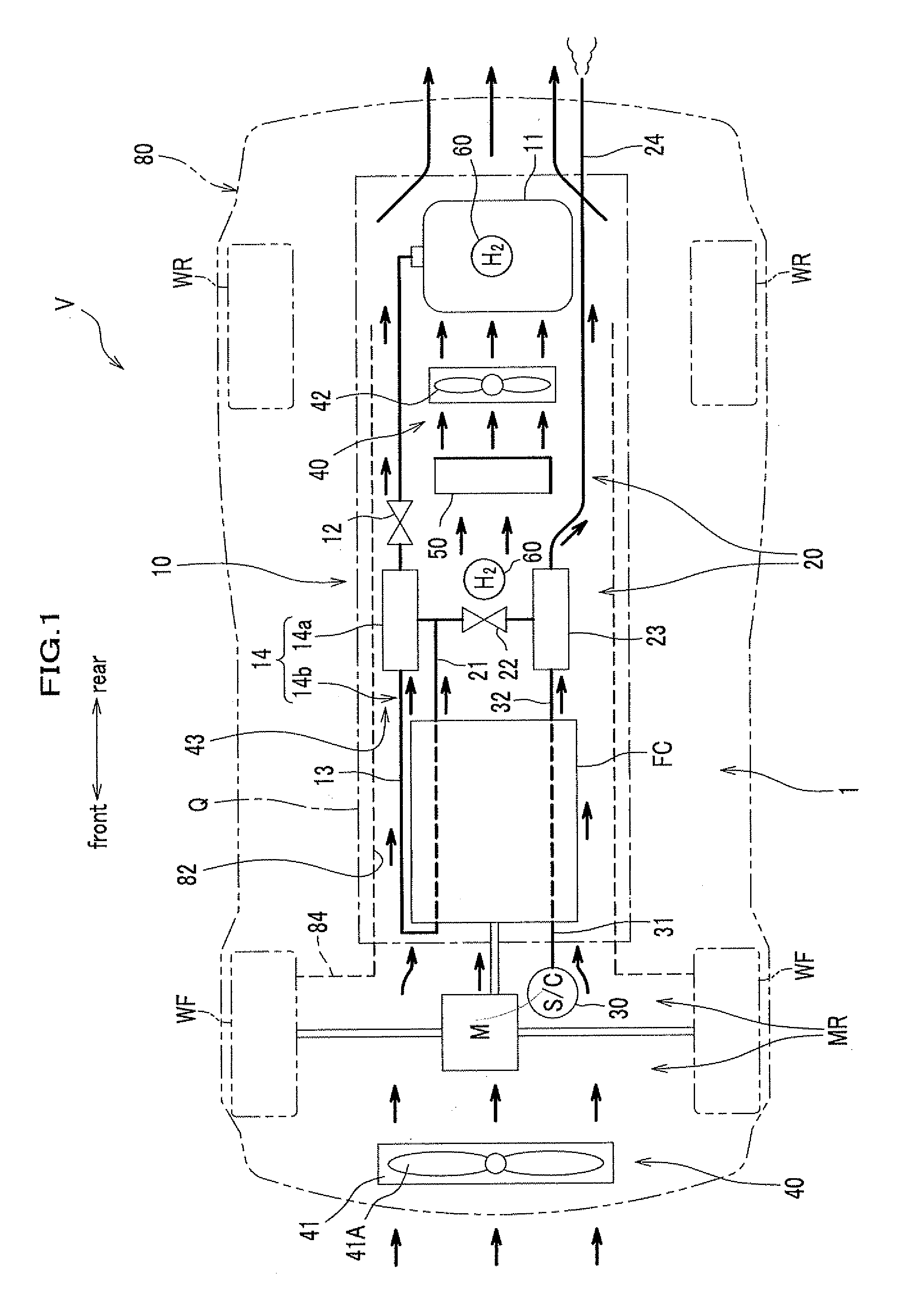

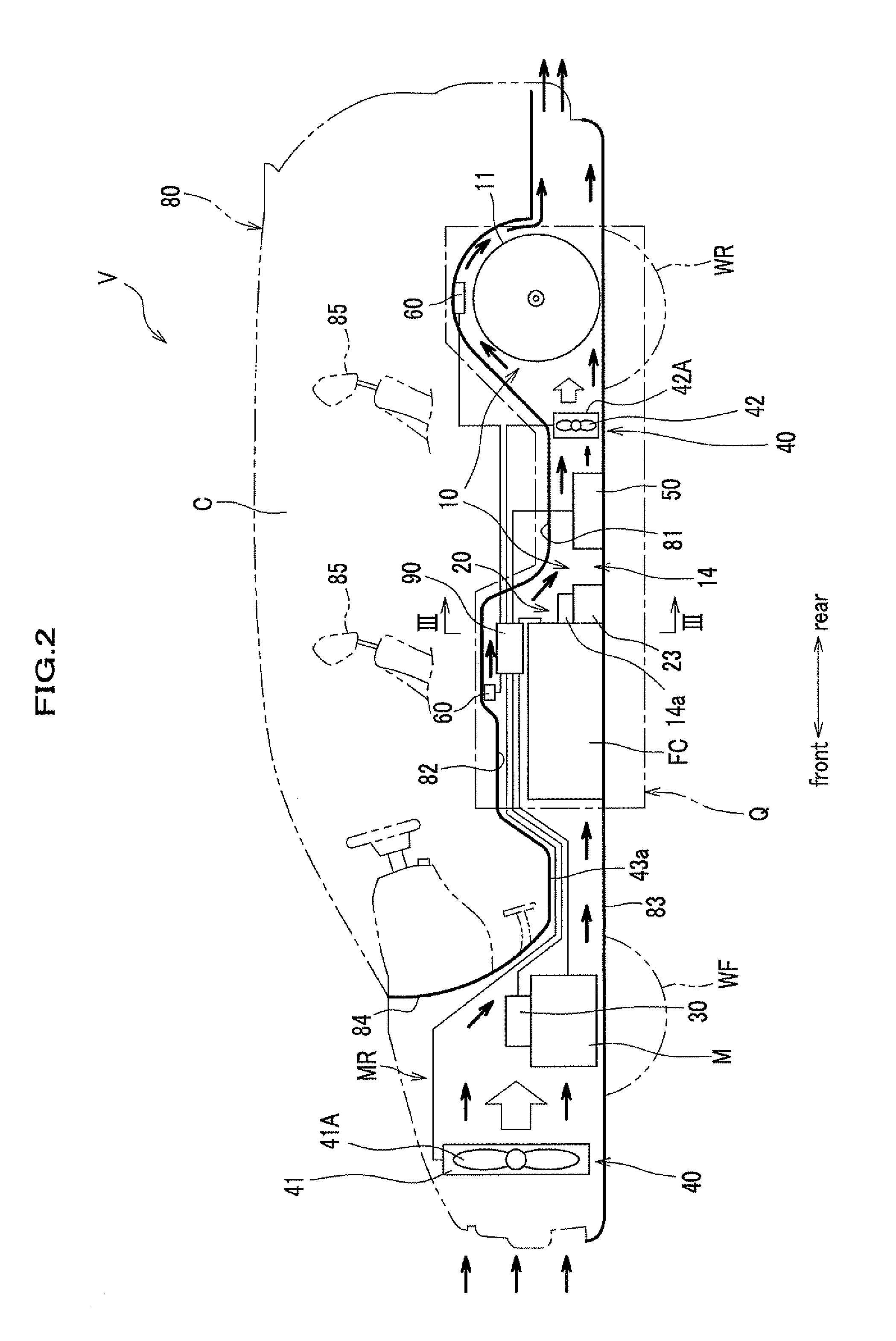

Ventilator of a fuel-cell vehicle

InactiveUS20090317692A1Improve cooling effectFlow fastAir-treating devicesFuel cell heat exchangeHydrogen supplyHydrogen system

The present invention relates to a ventilator of fuel-cell vehicles for ventilating hydrogen in the hydrogen-system unit area arranging a hydrogen circulating device in the fuel-cell vehicles boarding the fuel cell. The ventilator of fuel-cell vehicle includes a first ventilating device for taking ventilating air in from a front side of the fuel-cell vehicle to hydrogen-system unit area arranging the fuel cell, the hydrogen supply device, and the hydrogen exhaust device in the center of front and rear direction of the fuel-cell vehicle; and a second ventilating device for sucking the ventilating air taken in from the rear end of vehicle body of the fuel-cell vehicle to the hydrogen-system unit area.

Owner:HONDA MOTOR CO LTD

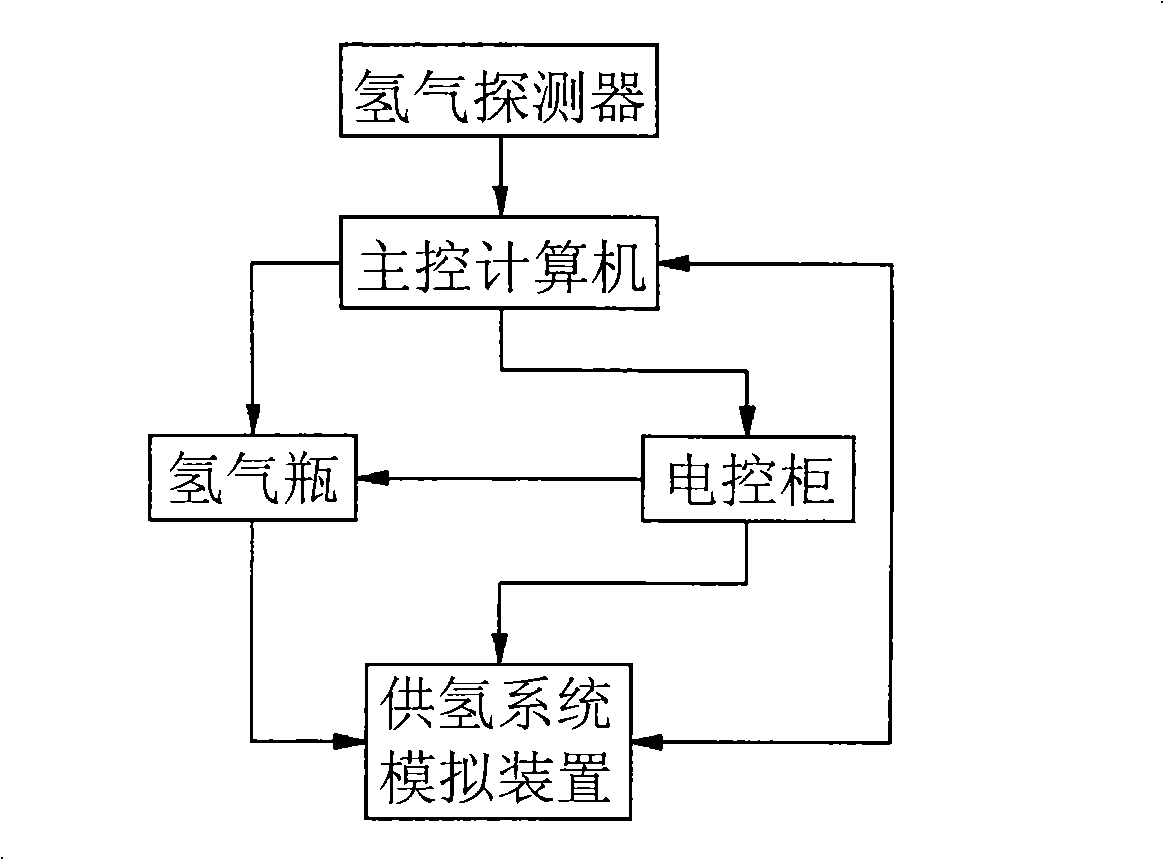

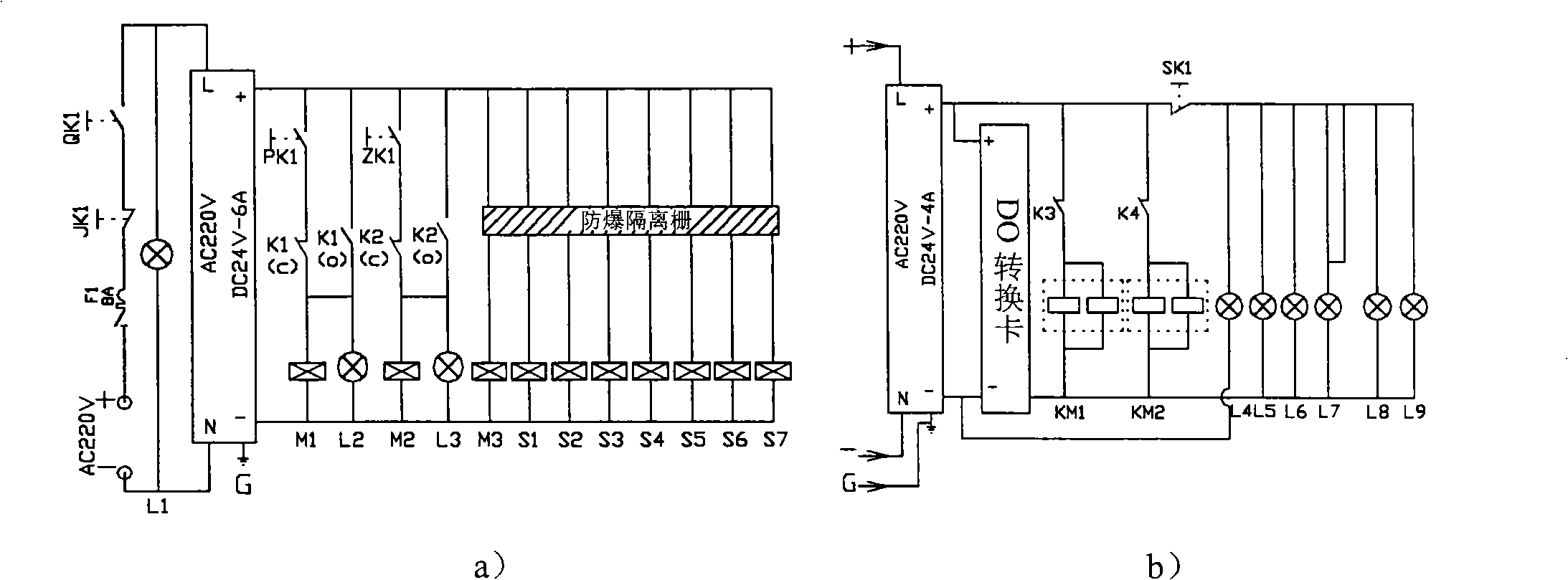

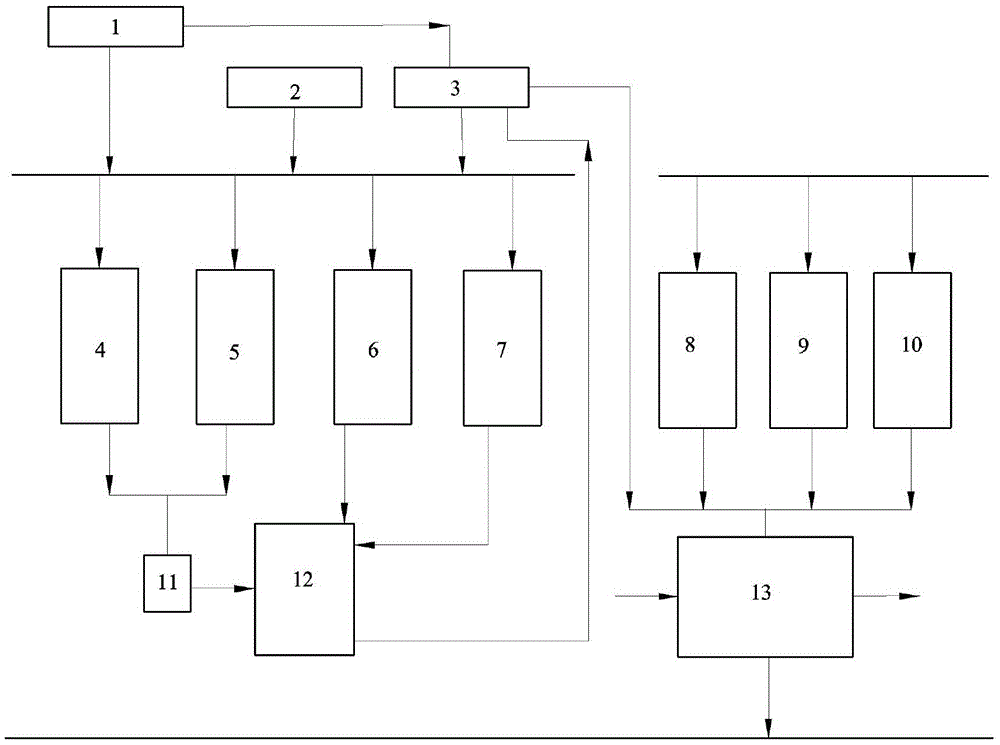

Test device and method for detecting security of fuel battery passenger car hydrogen feed system

ActiveCN101324485AImprove securityDerived performanceStructural/machines measurementHydrogen concentrationHigh pressure hydrogen

The invention relates to a test table for testing the security of a hydrogen supply system of a fuel cell bus and the test method thereof, and belongs to the security technology field of the fuel cell bus. The test table comprises a hydrogen supply system simulation device, a main control computer, an electrical control cabinet, a high pressure hydrogen bottle and a hydrogen detector, wherein the hydrogen supply system simulation device is connected with the output mouth of the high pressure hydrogen bottle, and bilaterally connected with the main control computer; the main control computer is connected with the electrical control cabinet, the high pressure hydrogen bottle and the hydrogen detector; the electrical control cabinet is respectively connected with the high pressure hydrogen bottle and the hydrogen supply system simulation device; the test table further comprises a bench for fixing and supporting the hydrogen supply system simulation device. The method comprises the following steps: a valve to be tested is connected with an identical valve in a pipeline of the hydrogen supply system simulation device in parallel; the working state of the valve to be tested is simulated; according to data such as gas pressure, flow, hydrogen concentration, etc. in an acquisition pipeline, whether the performance of the valve to be tested is qualified can be judged. The test table is used for dynamically testing the security of the key components of hydrogen supply system of the fuel cell bus.

Owner:清华大学苏州汽车研究院(吴江) +1

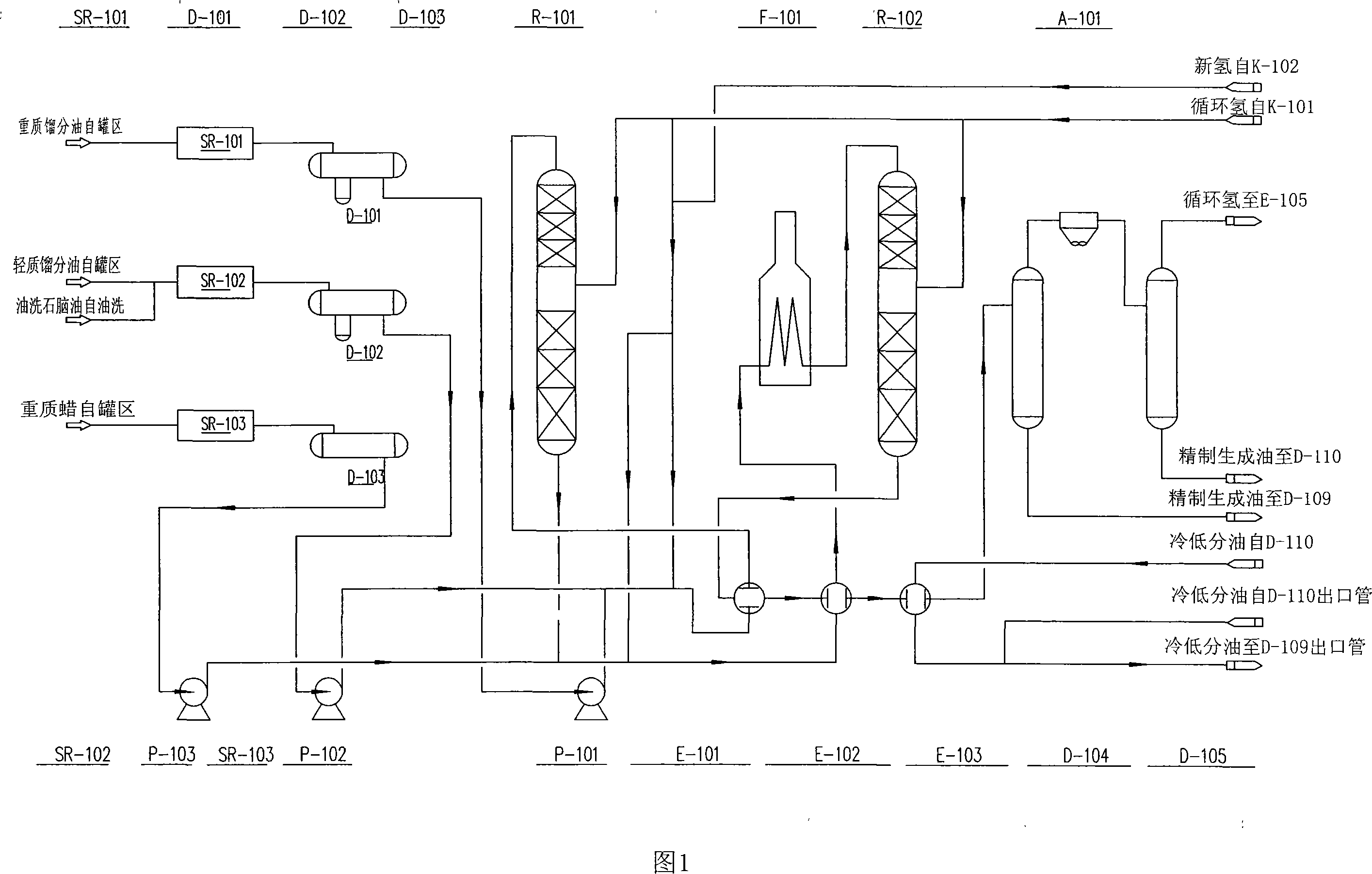

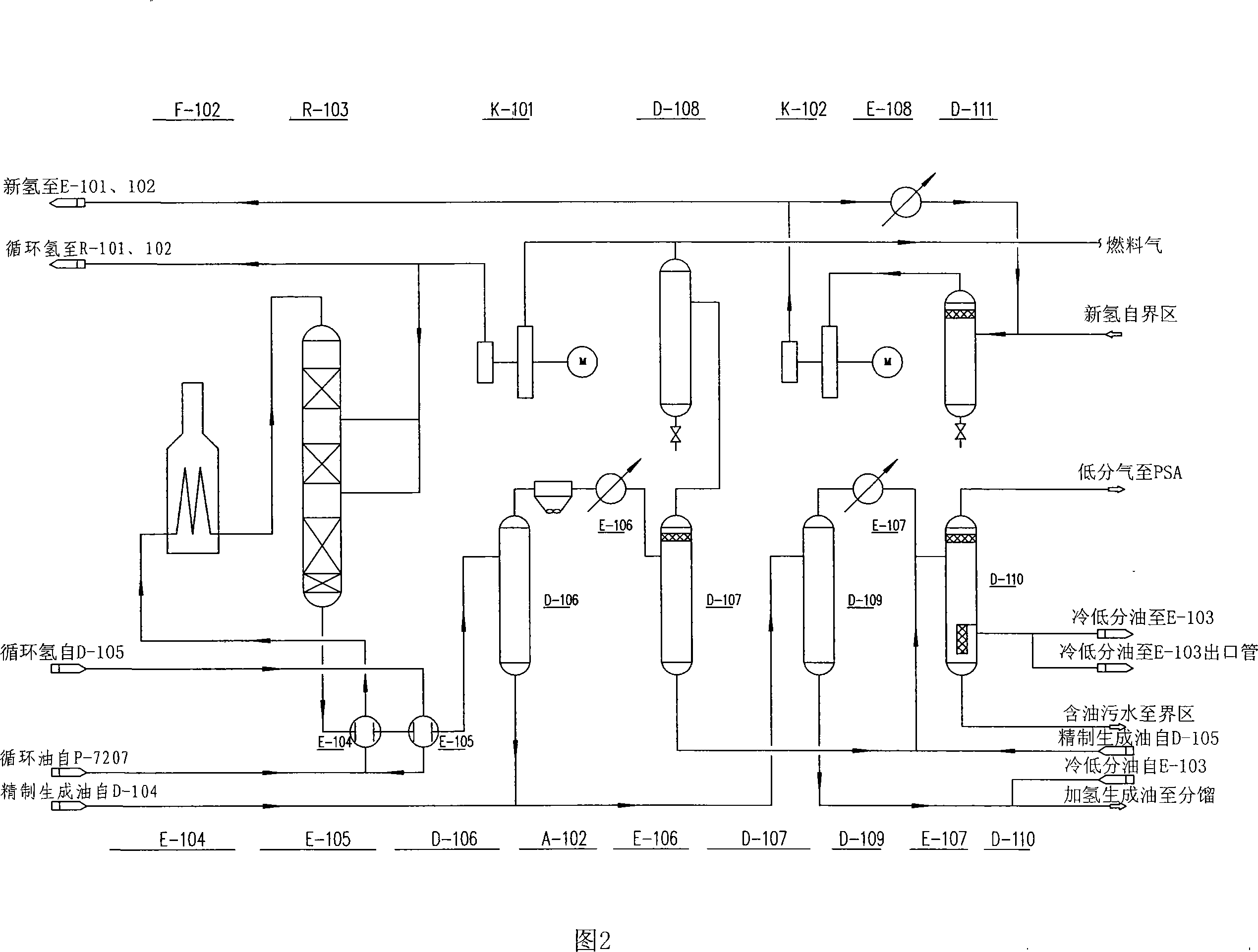

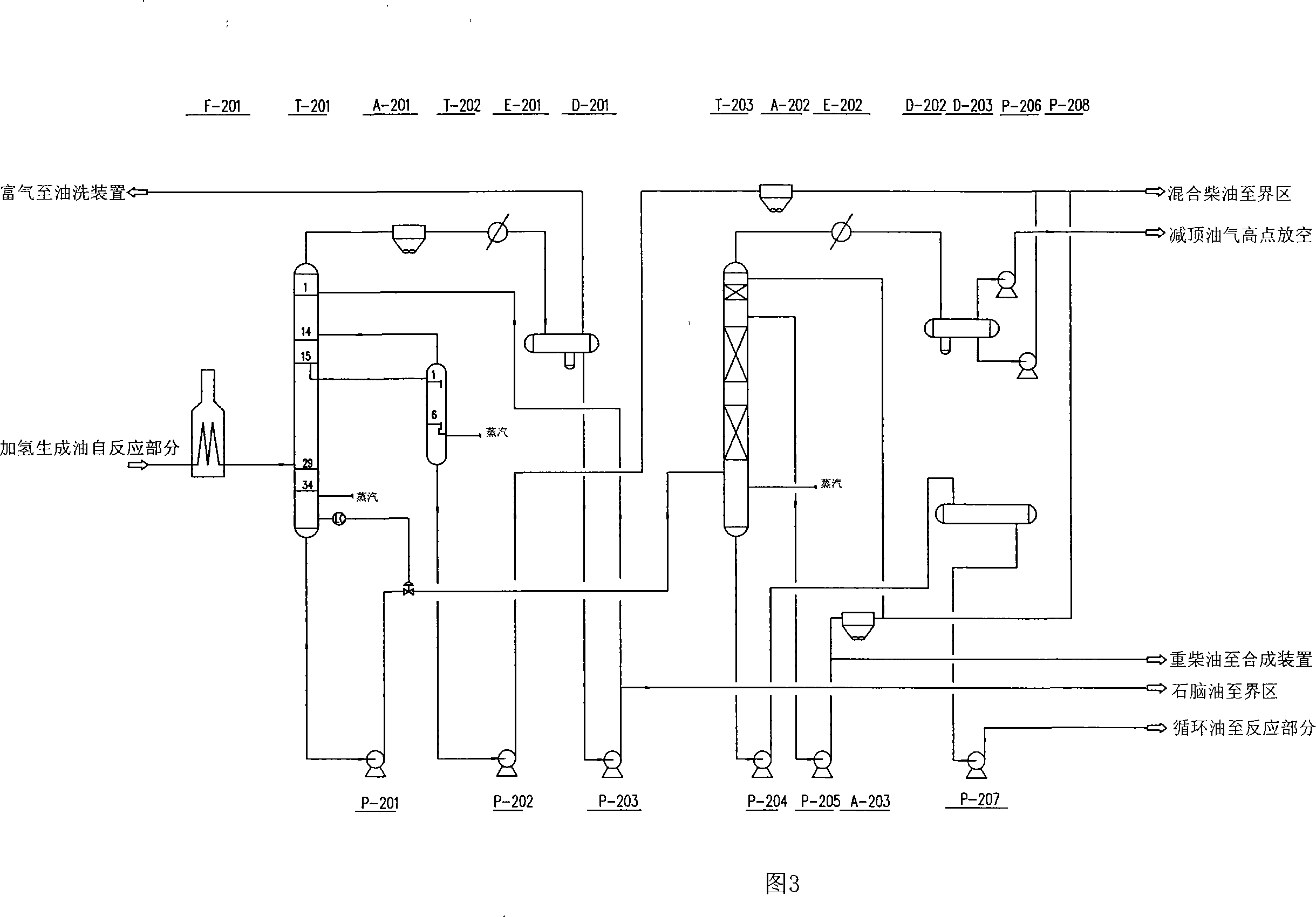

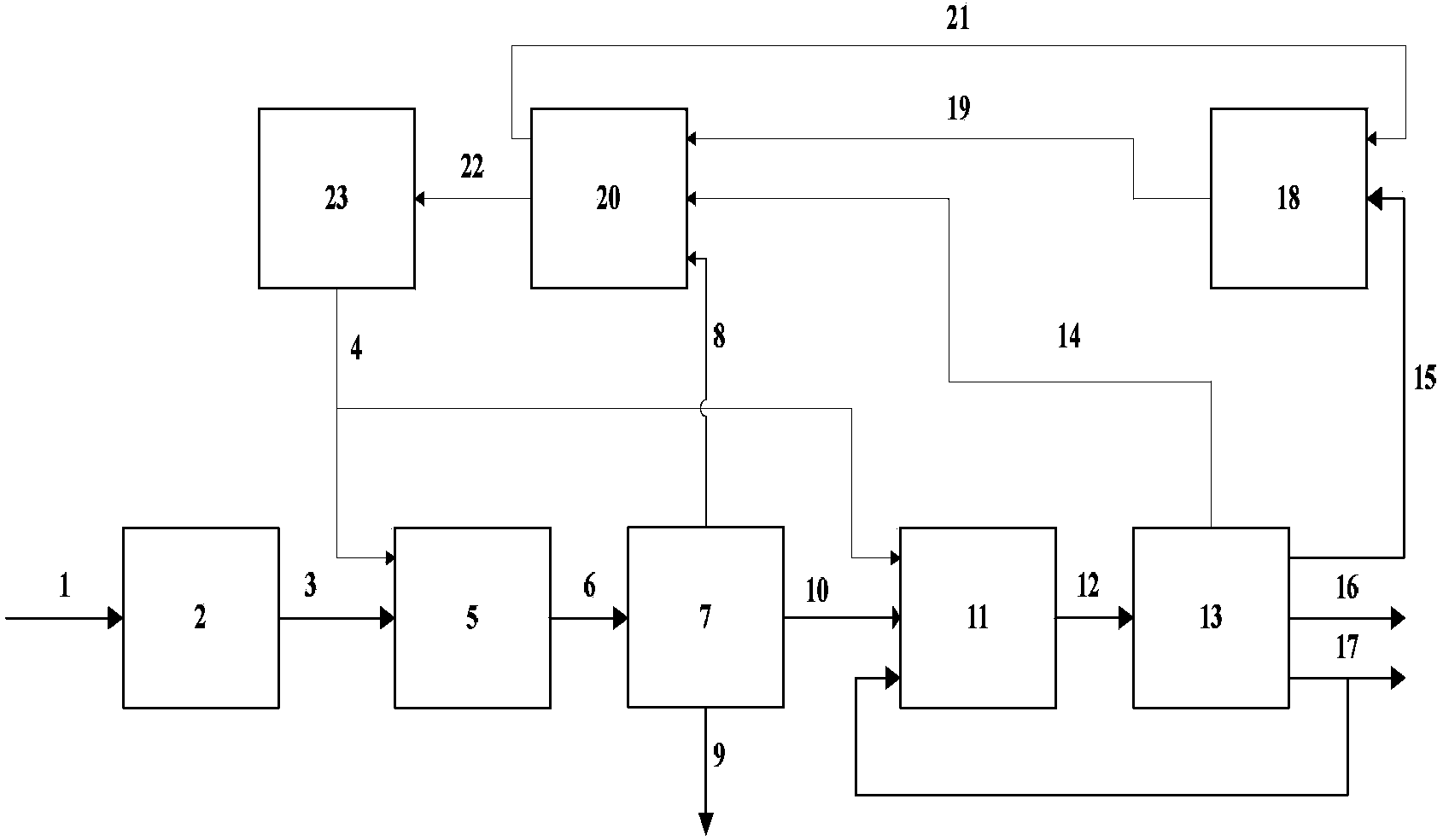

Feito synthetic oil processing line

ActiveCN101173190AReduce design flowStable temperature controlTreatment with hydrotreatment processesGas phaseMetal impurities

The invention relates to a processing flow of FT synthetic oil, which comprises hydrogenation, low-temperature oil washing, decarburization and PSA. The invention is characterized in that the synthetic oil is mixed with hydrogen via a filter, and enters a hydrogenated prerefining reactor after heat exchange, then enters a hydrogenated refining reactor after the synthetic oil is heated to 300 to 380 DEG C by a heating furnace; oxygen-containing compounds, unsaturated hydrocarbons and metal impurities in the raw material are extracted; the hydrogenated refined product enters a high thermal separator for separation of oil phase and gas phase after heat exchange, and enters a hydrocracking reactor for hydrocracking after heat exchange and heating of the heating furnace; the cracked product and the refined product are mixed to enter a fractionation system; a combined flow with two stages connected in series is adopted for the hydrogenated refining reactor and the hydrocracking reactor which share a recycle hydrogen system; a fractionation system is shared by the hydrogenated refined oil and the hydrocracked oil; and a three-column process flow is adopted for the fractionation system. The invention has the advantages of low gas consumption of the low-temperature oil washing process, high recovery of light hydrocarbons, less matching investment, and reduction of energy consumption and improvement of hydrogen recovery rate due to the decarburization process.

Owner:中国石油集团工程设计有限责任公司抚顺分公司

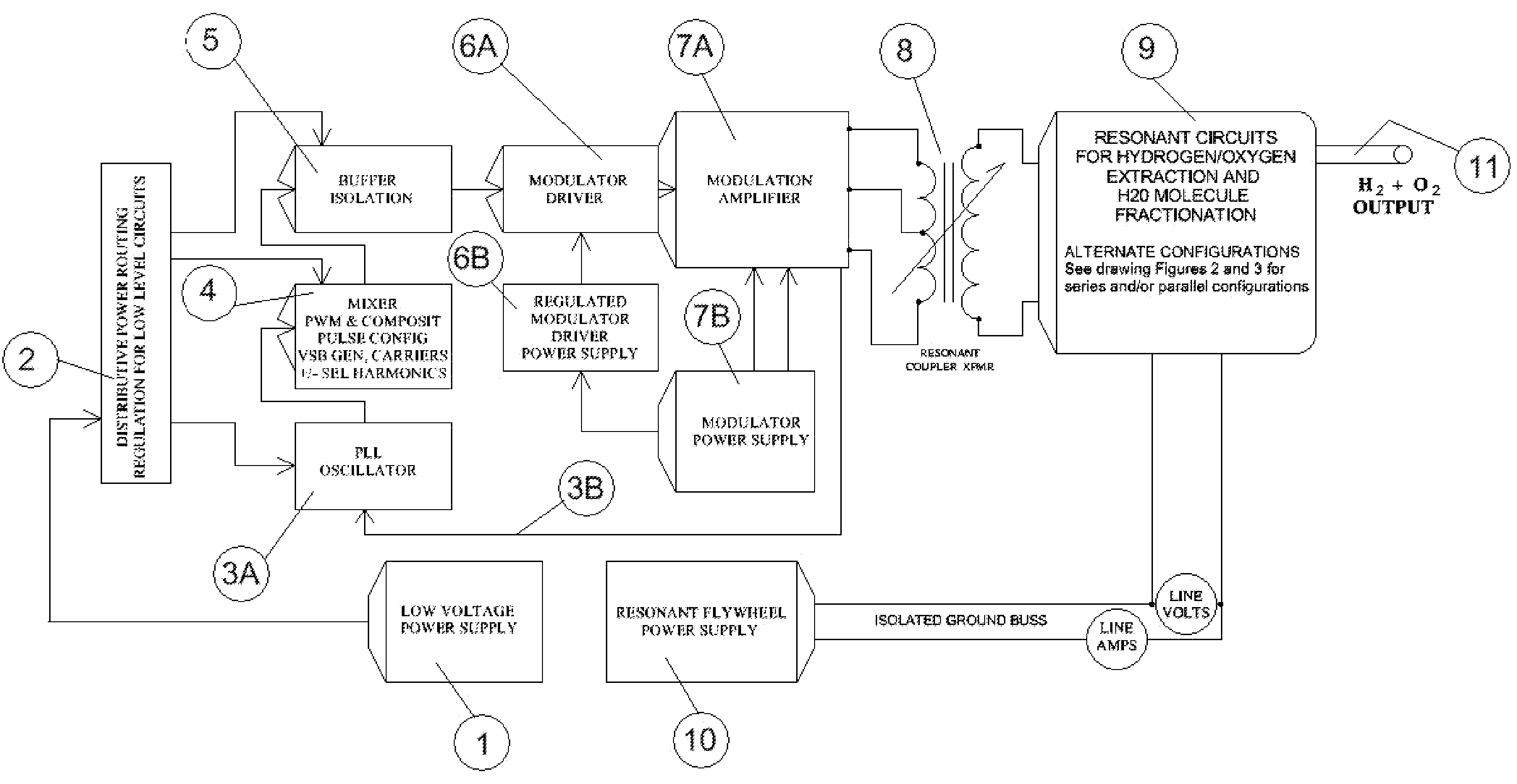

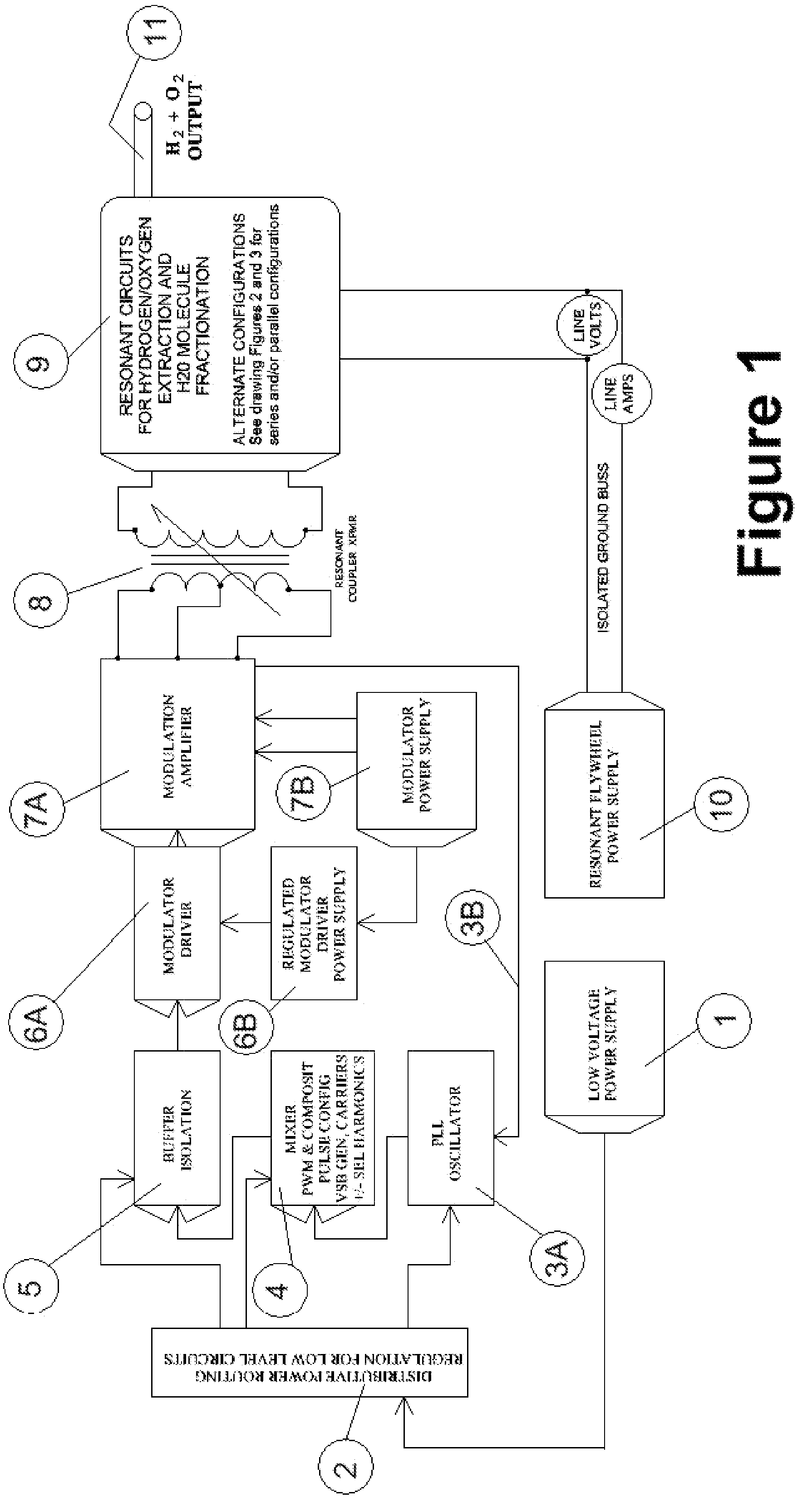

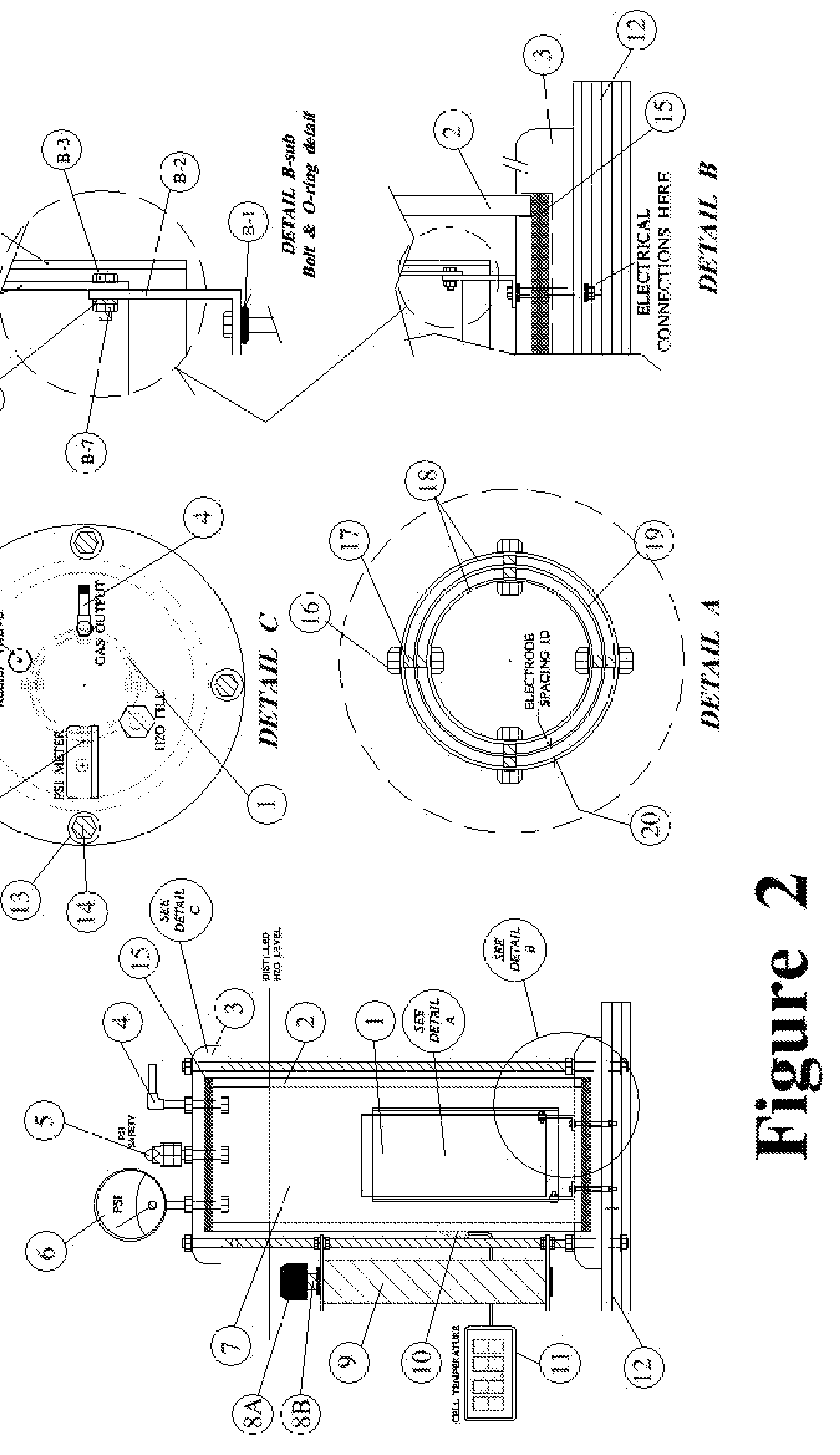

Hydrogen/Oxygen Fuel Generator

InactiveUS20090283402A1Exceeding production capabilityEliminate dangerCellsElectric circuitsHydrogen fuelHome appliance

A compact and portable system adapted for use in decomposing water and separating an oxygen rich gaseous stream and a hydrogen rich gaseous stream which produces a massive output of Hydrogen fuel, (along with the proportional amount of oxygen) capable of operating at varying levels of output, on-demand. This system can interface easily with existing technologies to power standard motor vehicles (gas, diesel, ethanol or hydrogen systems), recreational vehicles, home energy systems and home appliances, commercial / industrial power generators, smelters and much more.

Owner:OSMAN DANA CHARLES

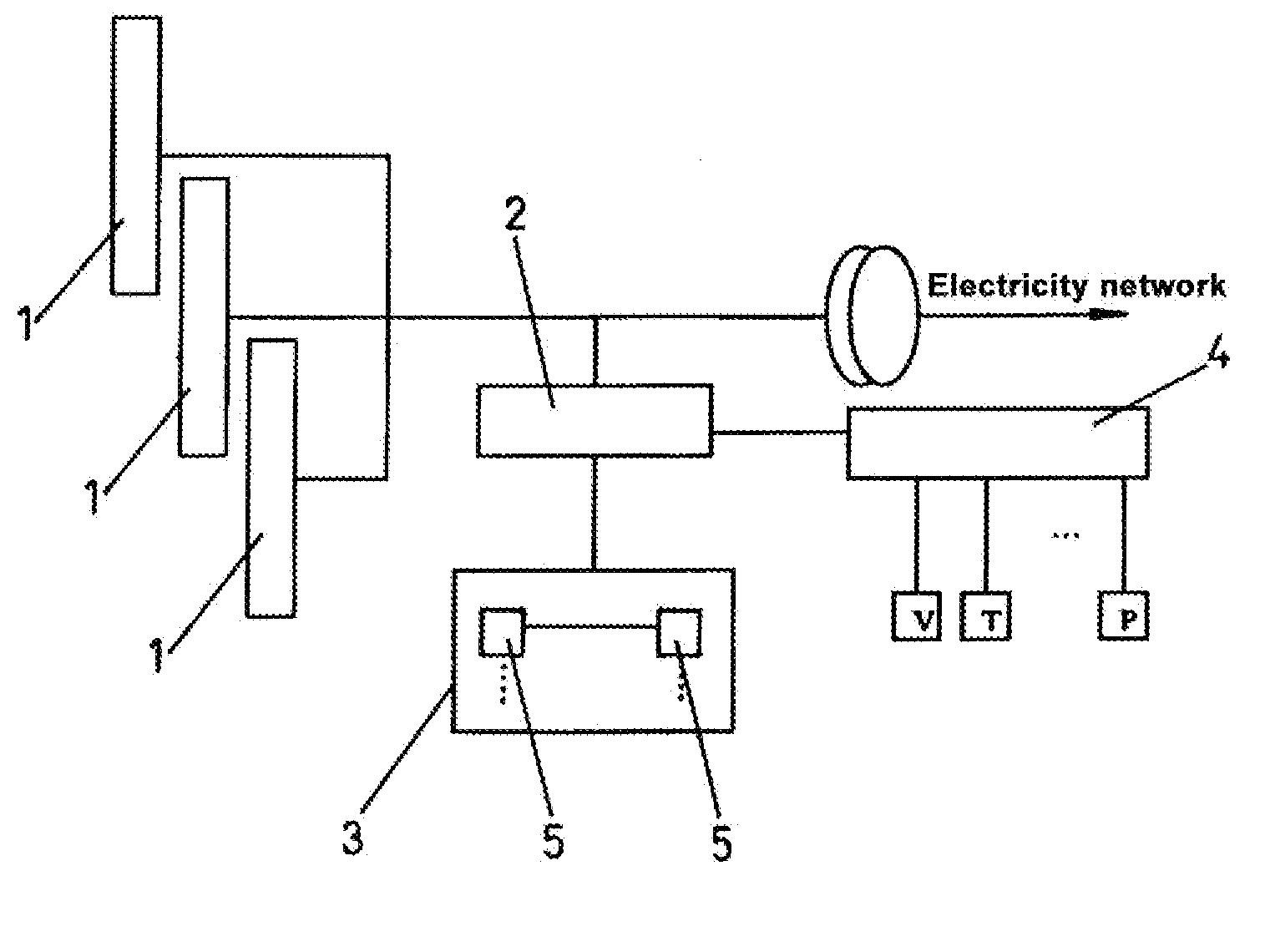

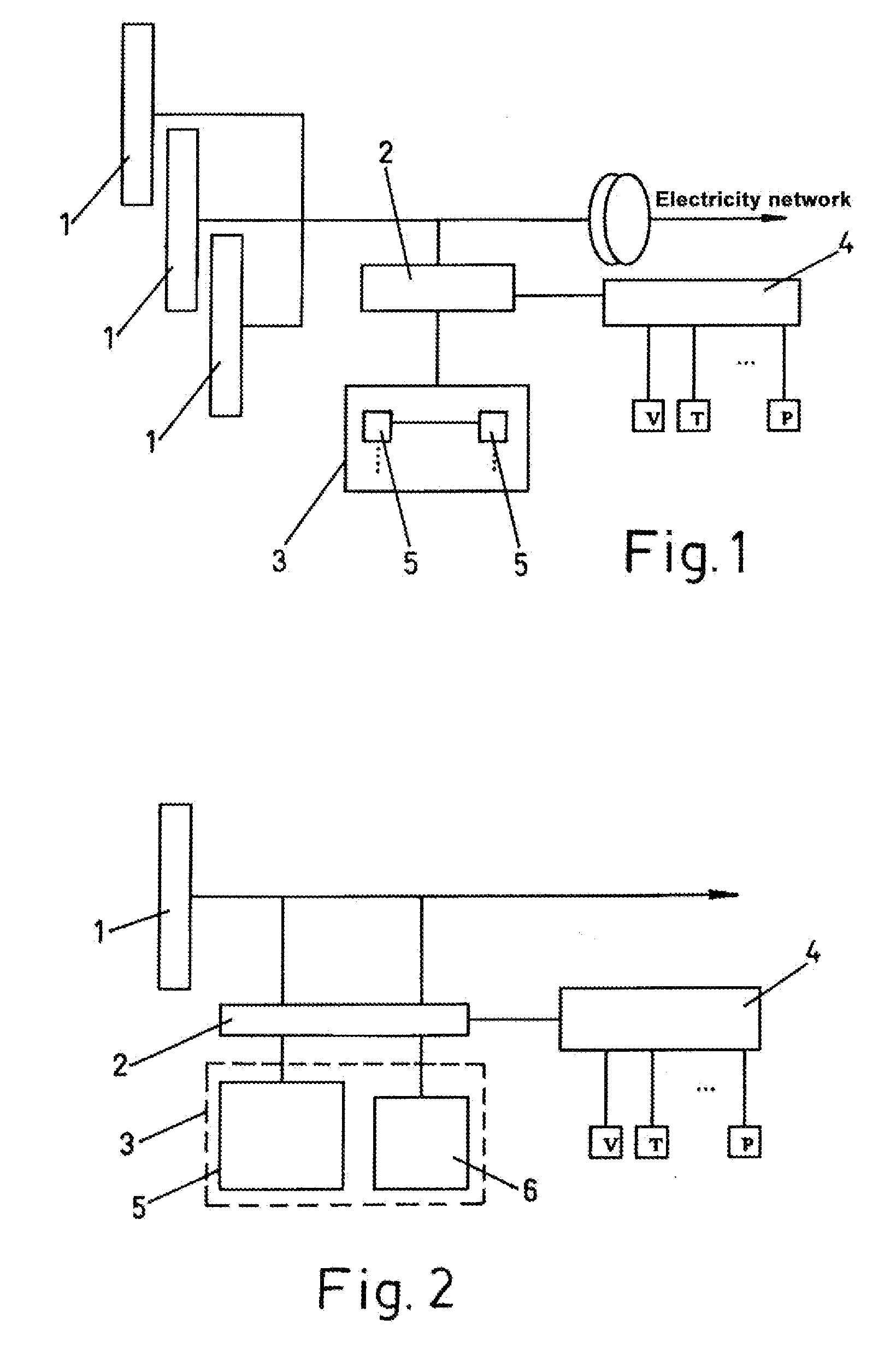

Production system for electric energy and hydrogen

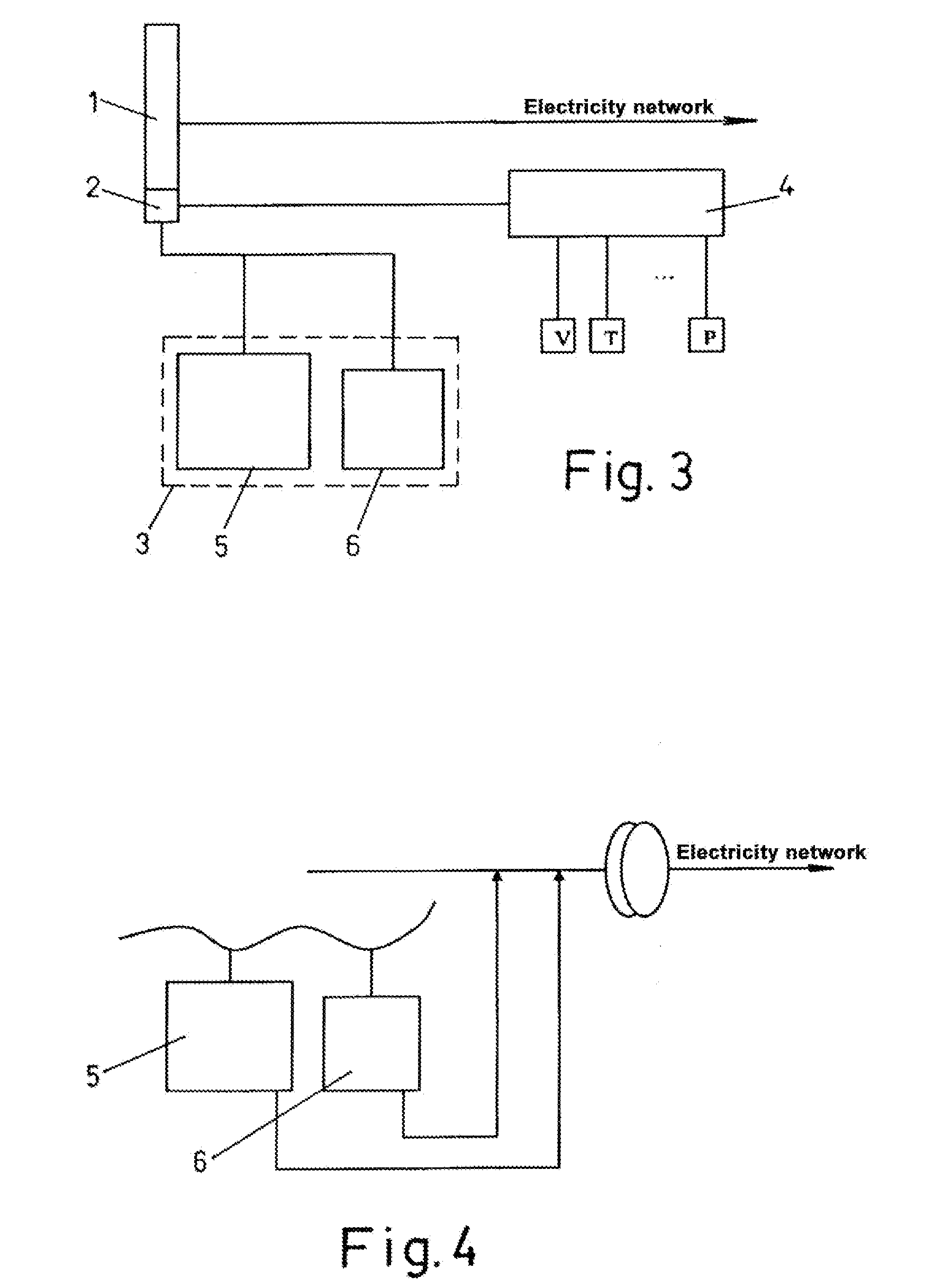

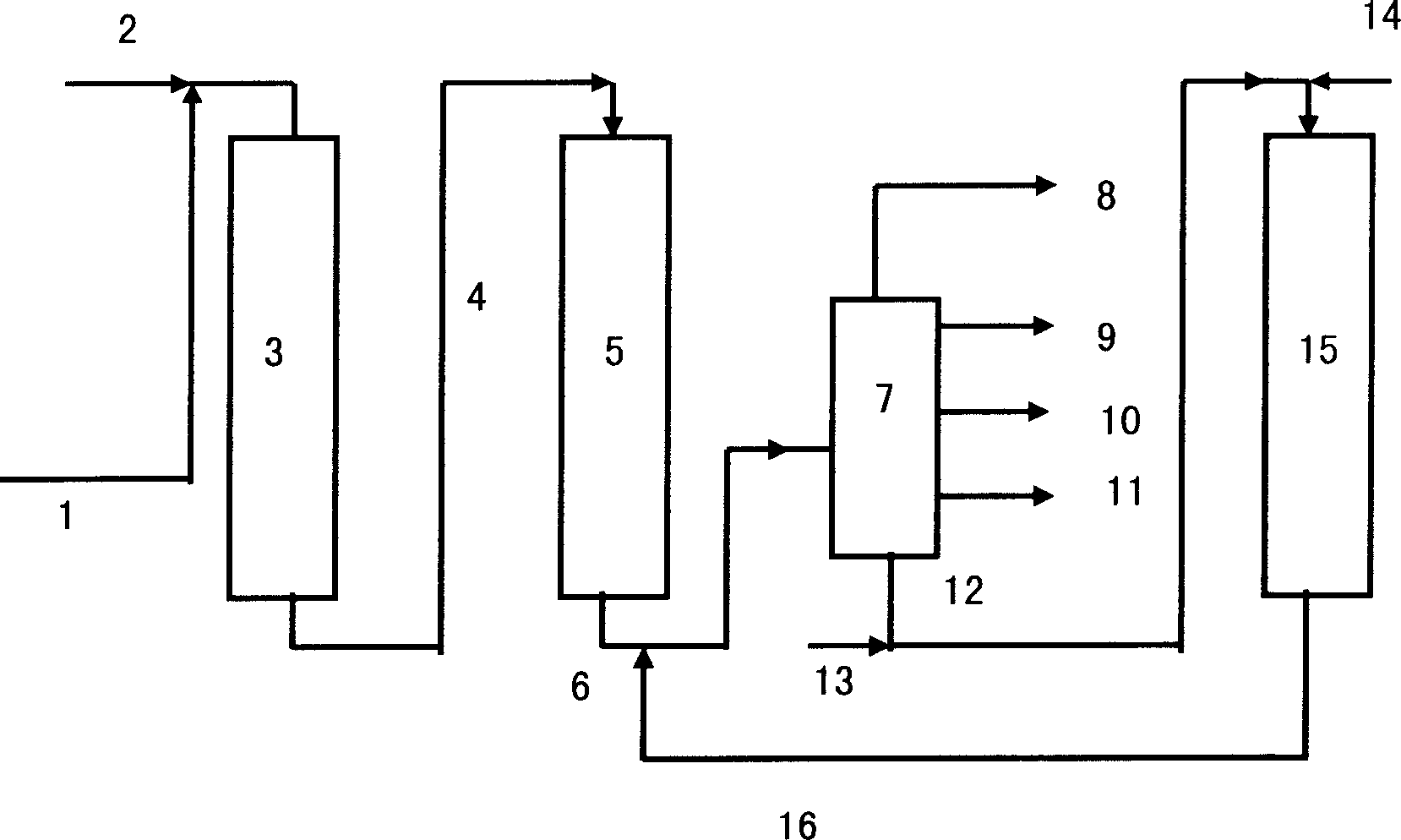

ActiveUS20100259102A1Fast response dynamicSlow response dynamicBatteries circuit arrangementsElectric circuitsElectrolysisTurbine

System for producing electric energy and hydrogen based on renewable energy sources, such as wind energy from one or several wind turbines, and incorporating means for producing hydrogen. The system comprises a hybrid electrolyzer device, which comprises a combination of at least two different electrolysis technologies and at least one control device, which manages the hydrogen production between the two electrolyzers of the different electrolysis technologies; being at least one electrolyzer of a rapid dynamics electrolysis technology type and, at least the second one of a substantially slower dynamics electrolysis technology type.

Owner:ACCIONA ENERGIA SA +1

Two-stage hydrocracking method for increasing yield of middle distillate oil

ActiveCN1766054AGood resistance to NH <sub>3<</sub> Simple processTreatment with hydrotreatment processesSeparation systemHydrogen system

The invention discloses a two-stage hydrocracking operation method to increase the production of high-grade middle distillate oil, which comprises: doping given proportion fresh feed oil in second stage feeding, inhibiting the activity of second-stage catalyst, increasing yield, and enlarging handling capacity. This invention uses one cycle hydrogen system and separation system. Compared with prior art, this inveniton has high yield, well stability, and long running period.

Owner:CHINA PETROLEUM & CHEM CORP +1

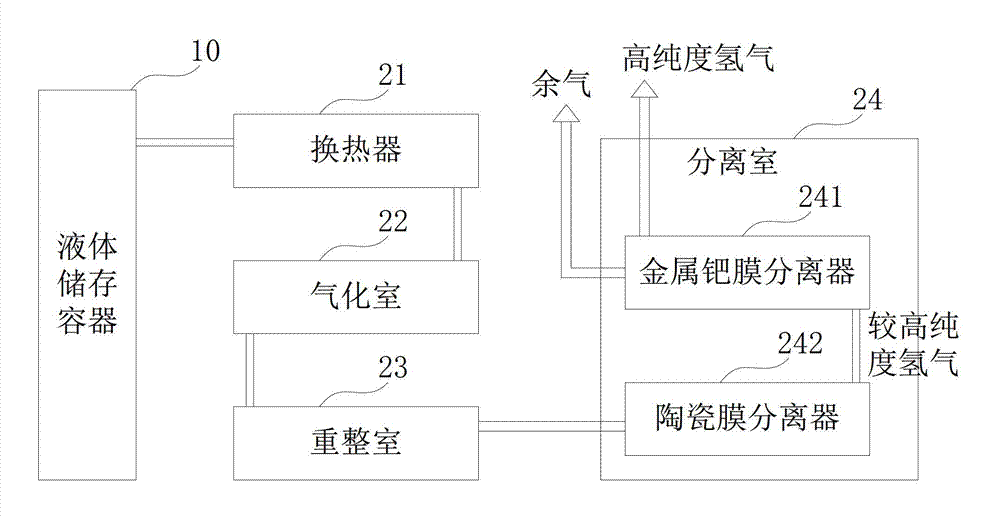

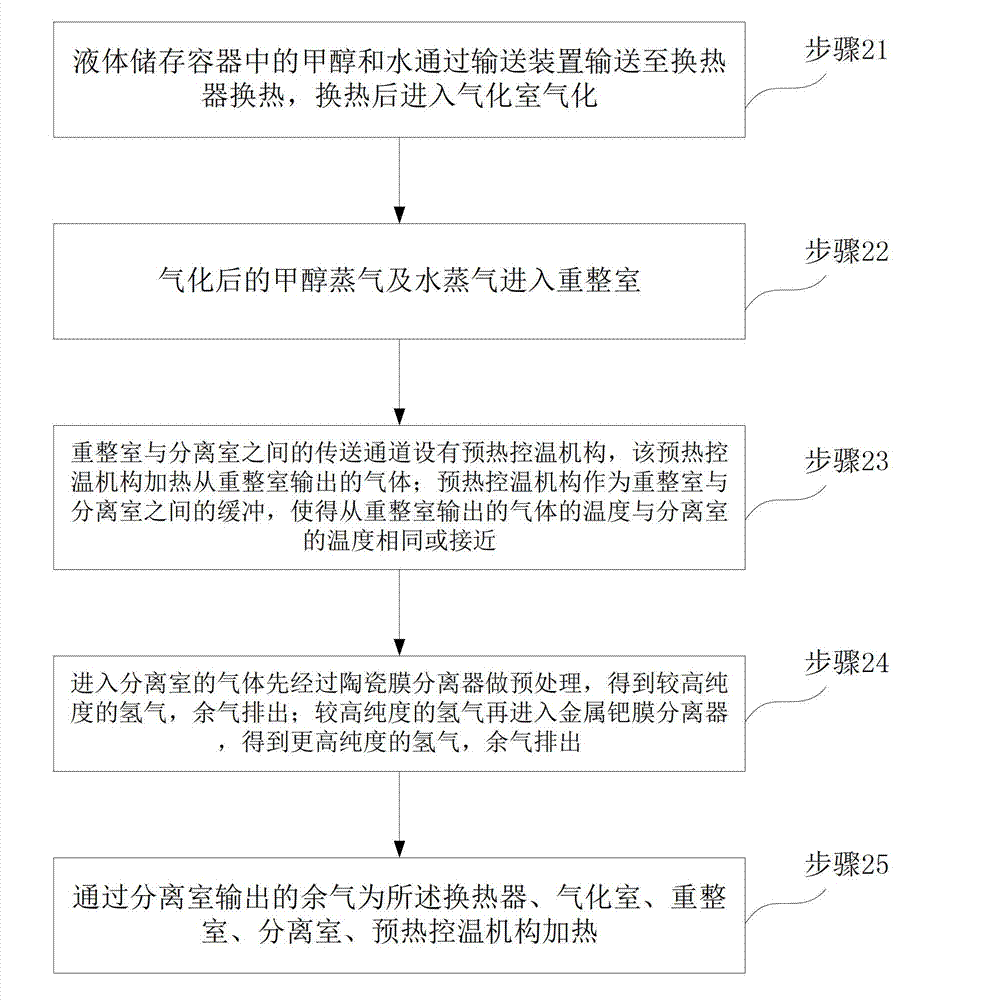

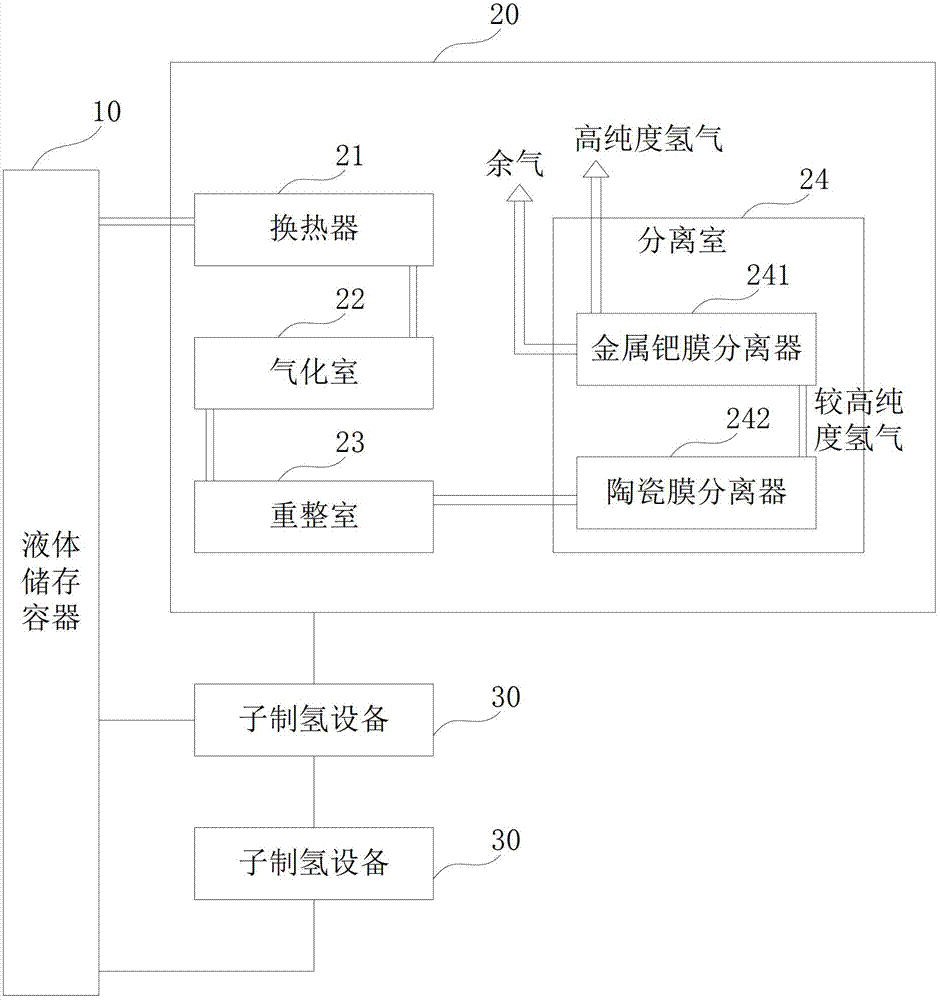

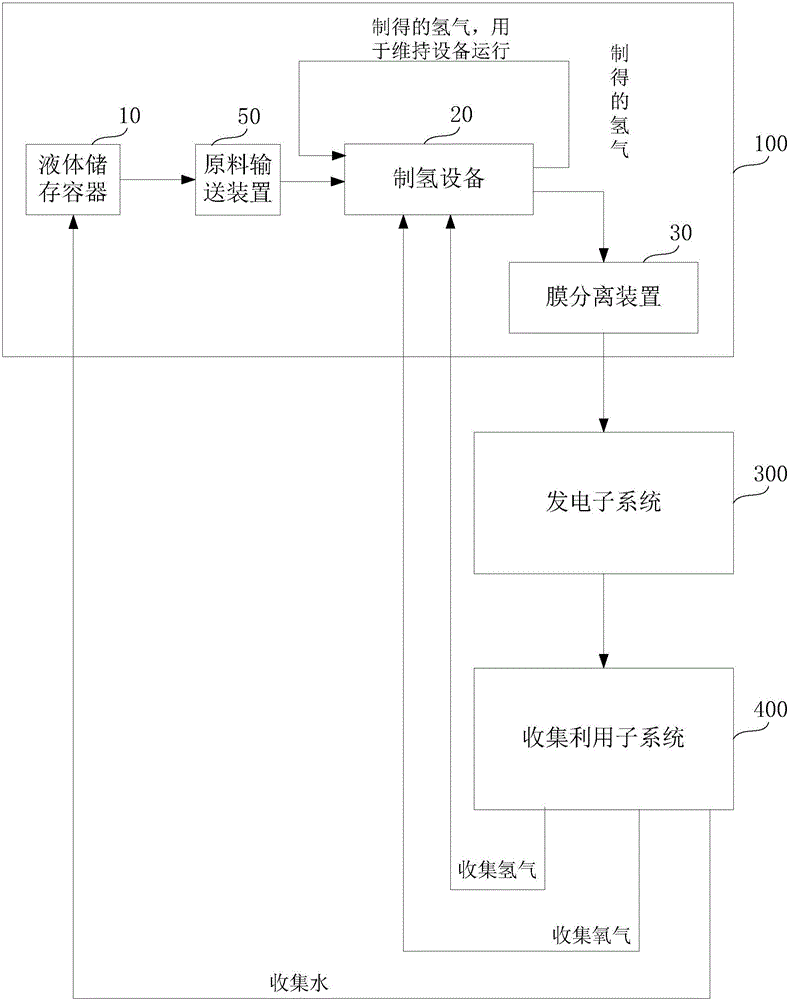

High efficiency methanol-water hydrogen production system and hydrogen production method thereof

The invention reveals a high efficiency methanol-water hydrogen production system and a hydrogen production method thereof. The system comprises a liquid reservoir vessel, a heat exchanger, a vaporizer, a reforming chamber and a separation chamber, wherein the liquid reservoir vessel, the heat exchanger, the vaporizer, the reforming chamber and the separation chamber are successively connected through pipelines, a ceramic membrane separator and a metallic palladium membrane separator are arranged in the separation chamber, gas entering into the separation chamber is pretreated by the ceramic membrane separator to obtain high purity hydrogen, and then the high purity hydrogen enters into the metallic palladium membrane separator so as to obtain hydrogen with higher purity. According to the high efficiency methanol-water hydrogen production system and the hydrogen production method thereof, the high purity hydrogen (with a purity of about 99%) is separated from reformed gas through the ceramic membrane separator at first, and then the hydrogen with higher purity (more than 99.9999%) is separated through the metallic palladium membrane separator.

Owner:广州市移电科技有限公司

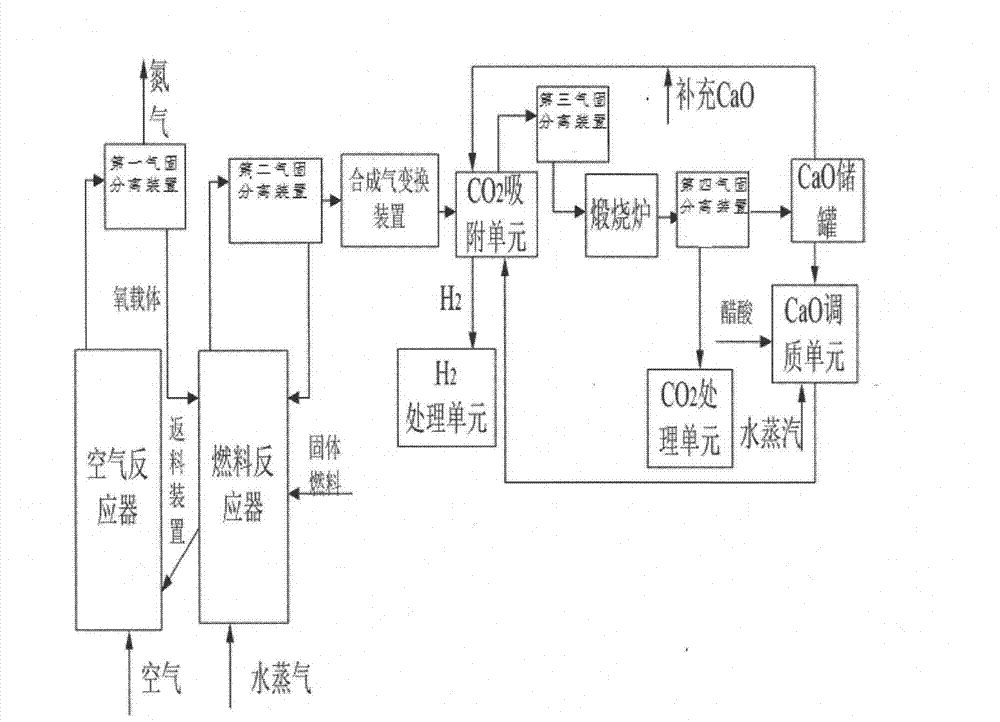

Solid fuel chemical-looping gasification hydrogen production system and method

ActiveCN103113917AEfficient separationAchieve near-zero emissionsHydrogen separation using solid contactCombustible gas productionSolid fuelProcess engineering

The invention provides a solid fuel chemical-looping gasification hydrogen production system and method. The solid fuel chemical-looping gasification hydrogen production system is characterized by comprising an air reactor, wherein the air reactor is connected with a first gas-solid separation device; the first gas-solid separation device is connected with a fuel reactor; the fuel reactor is connected with a second gas-solid separation device; a gas outlet of the second gas-solid separation device is connected with a synthetic gas converter; the synthetic gas converter is connected with a CO2 adsorption unit; a discharge port of the CO2 adsorption unit is connected with an H2 processing unit; an outlet of the CO2 adsorption unit is connected with a third gas-solid separation device; a CaCO3 solid outlet of the third gas-solid separation device is connected with a calcining furnace; the calcining furnace is connected with a fourth gas-solid separation device; a gas outlet of the fourth gas-solid separation device is connected with a CO2 processing unit; a solid outlet of the fourth gas-solid separation device is connected with a CaO storage tank; and the CaO storage tank is connected with the CO2 adsorption unit. The system can implement near zero discharge of CO2 in the hydrogen production process, and thus, reduces the influence of greenhouse gas on the environment.

Owner:SHANGHAI BOILER WORKS

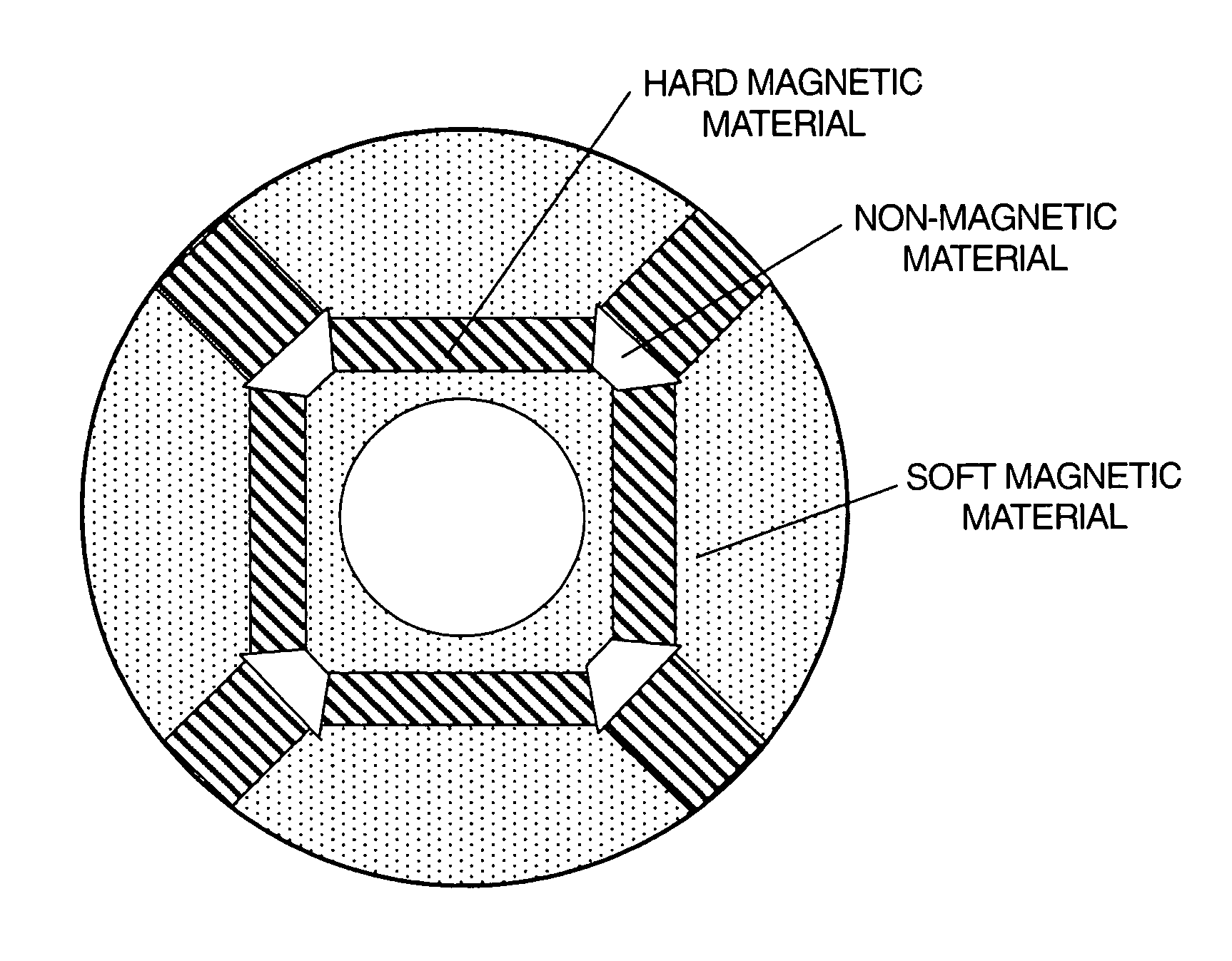

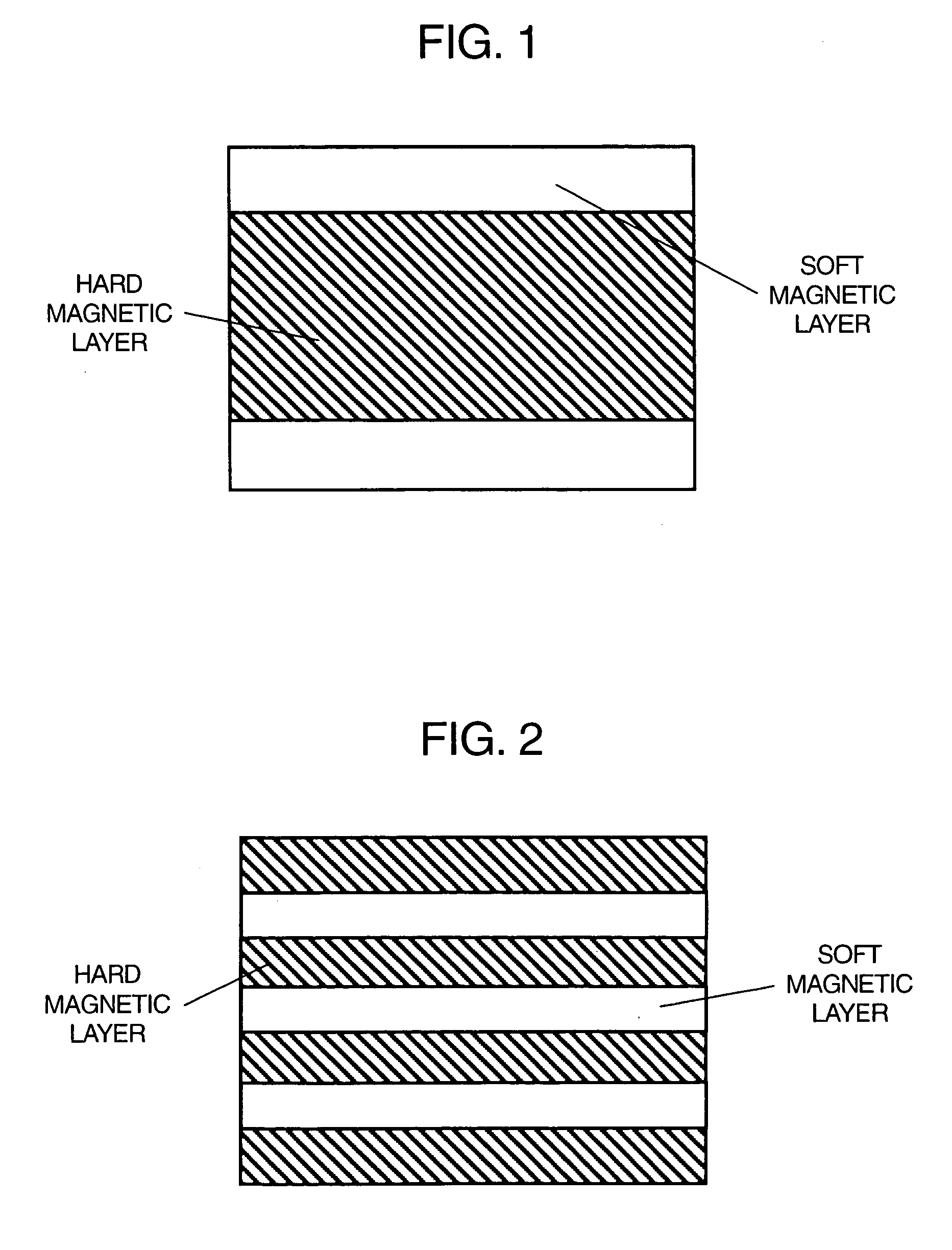

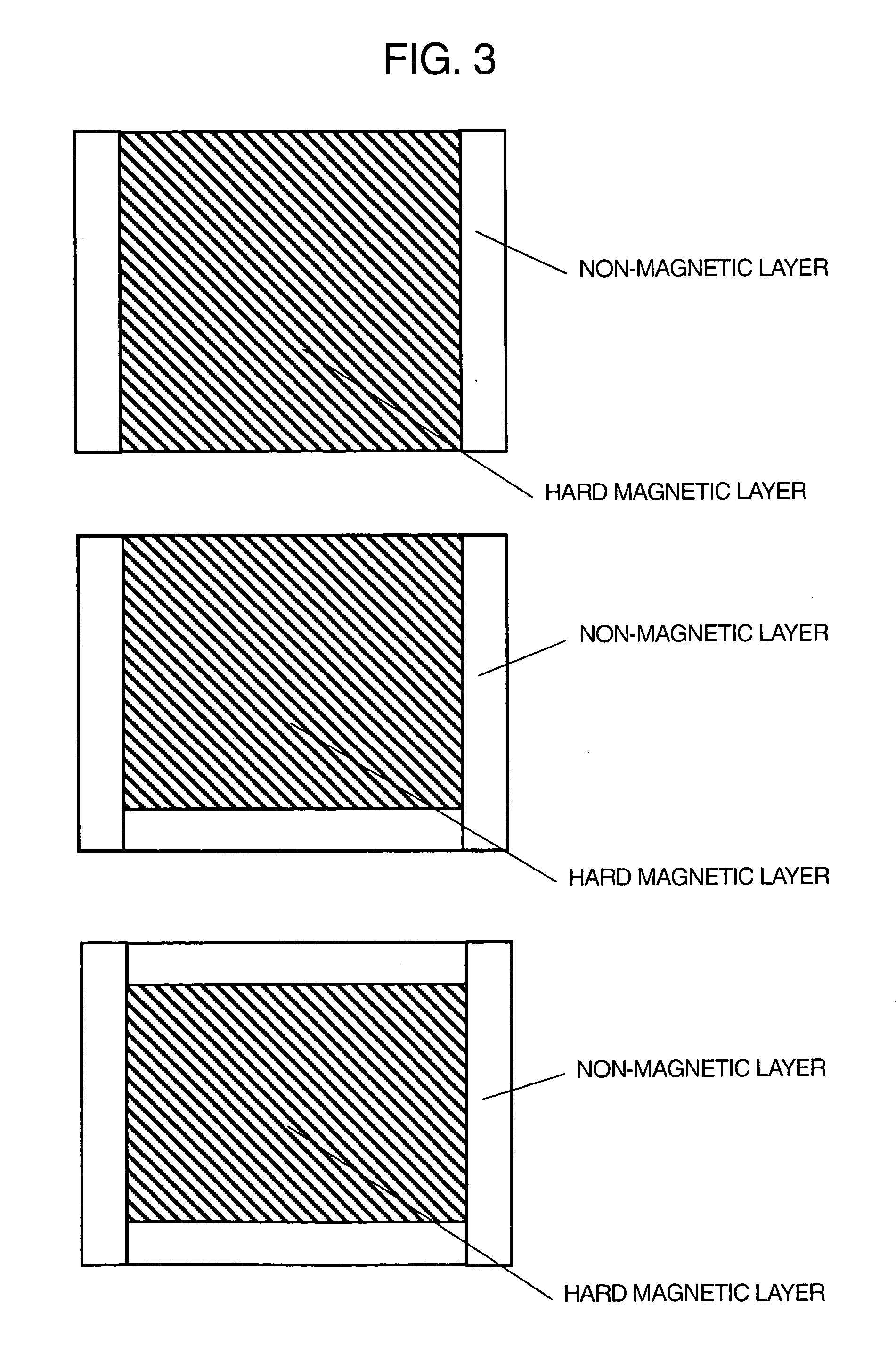

Solid material for magnet

InactiveUS20040149357A1Maintain good propertiesImprove stabilityUltra-high pressure processesInorganic material magnetismMetallurgyRare earth

Owner:ASAHI KASEI KK

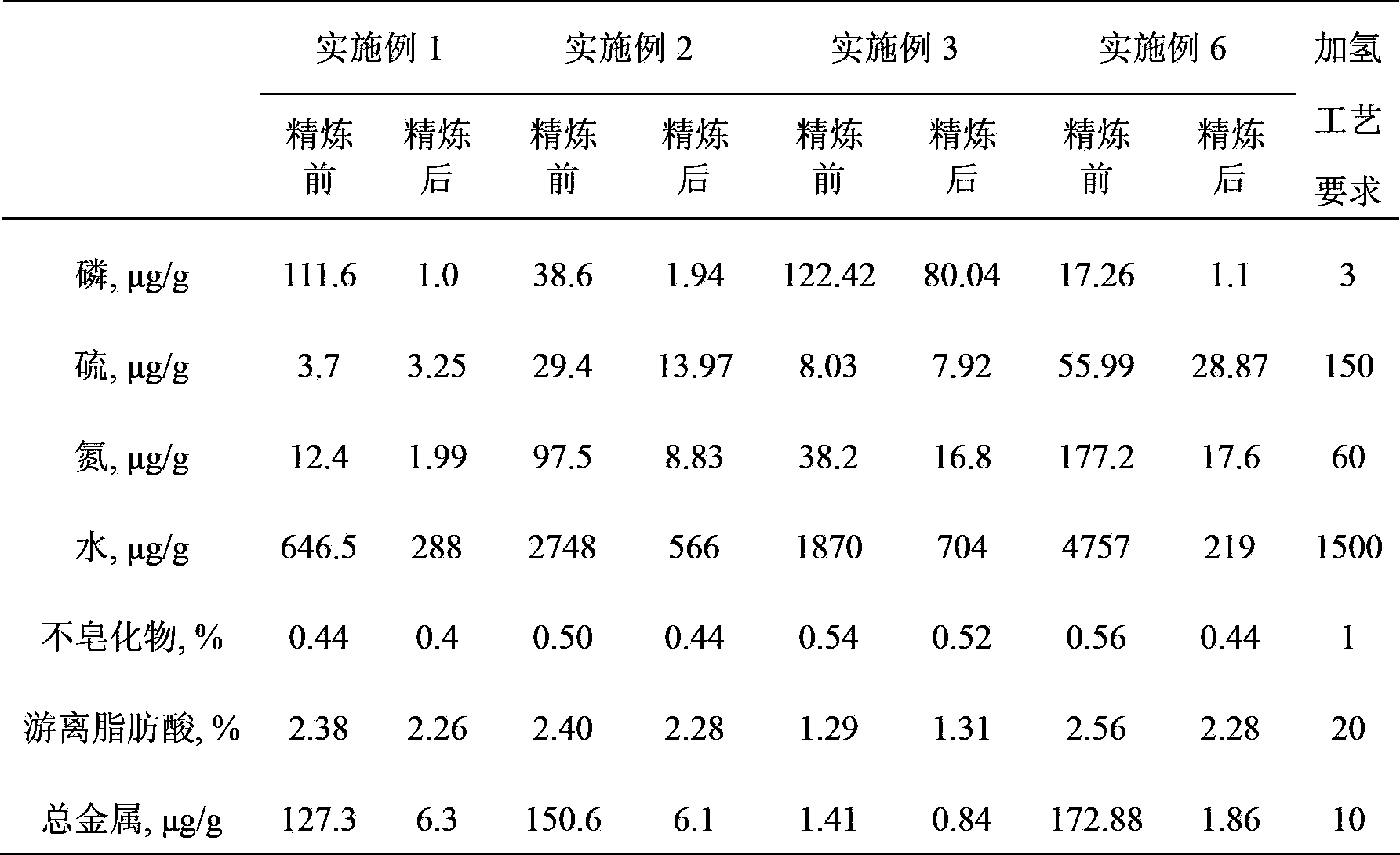

Method for production of diesel oil fraction and aviation fuel fraction by use of animal and plant oils and fats

The invention relates to a method for production of a diesel oil fraction and an aviation fuel fraction by use of animal and plant oils and fats, and the method comprises the following steps: a) performing refining processing on the animal and plant oils and fats; b) performing catalytic hydrogenation and deoxidation to obtain saturated linear alkanes and propane; c) performing hydroisomerization and hydrocracking processing to obtain an alkane material flow with higher branched chain degree; d) separating to obtain liquid hydrocarbons and gaseous hydrocarbons with the boiling point within the boiling point range of diesel oil, aviation fuels and naphtha; e) directly collecting the diesel oil fraction as a product, or cycling in whole or in part to continue isomerization and cracking reaction to increase production of the aviation fuel fraction; and f) mixing propane gaseous hydrocarbon and naphtha for steam reforming hydrogen production reaction, separating and purifying the obtained hydrogen to enter into a circulating hydrogen system; the method is used in the production of the renewable diesel oil and aviation fuels with excellent combustion performance and cold flow performance, and meanwhile efficient utilization of by-products and in-system supplement of hydrogen consumption can be realized.

Owner:PETROCHINA CO LTD

Seal performance for hydrogen storage and supply systems

InactiveUS20110012313A1Reduce surface roughnessControllably heatedEngine sealsPiston ringsSurface roughnessEngineering

The performance and durability of static and dynamic seals for hydrogen storage and supply systems has been improved by utilizing a spring-energized and plastic coated radial seal in combination with at least a mating surface that has been treated by one of a variety of procedures. These procedures include applying to the mating surface a low-friction, hard, and hydrogen impervious coating, chemically polishing the mating surface, and electrochemically polishing the mating surface. Each of these procedures significantly reduces, on a microscopic scale, the surface roughness of the mating surface. The seal can thus form a tighter and more gas-tight seal with the smoother mating surface so as to decrease the loss of hydrogen gas across the seal. The smoother mating surface can also improve seal life by reducing seal surface wear.

Owner:GM GLOBAL TECH OPERATIONS LLC

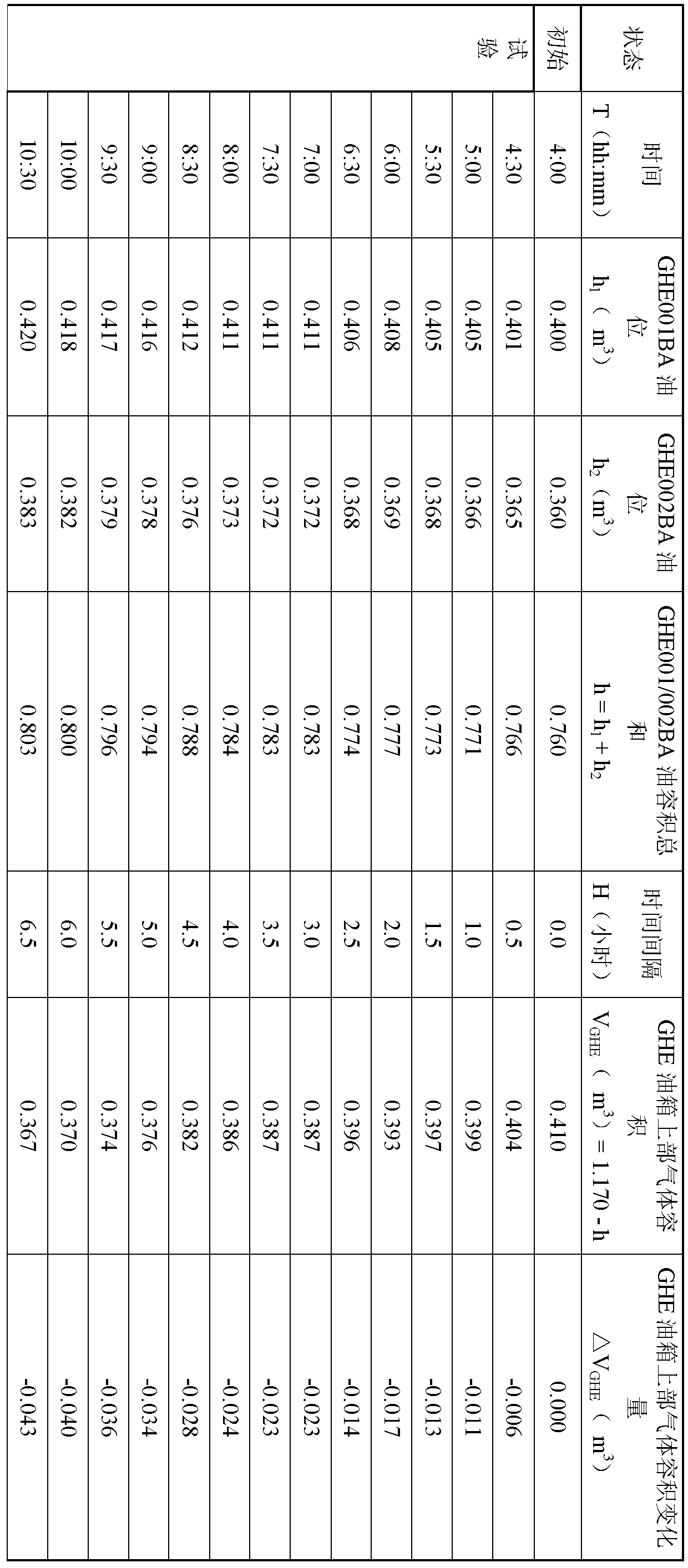

Nuclear power plant generator whole air tight test method

ActiveCN103091053AEliminate adverse factorsHigh precisionDetection of fluid at leakage pointRecording durationPressurized water reactor

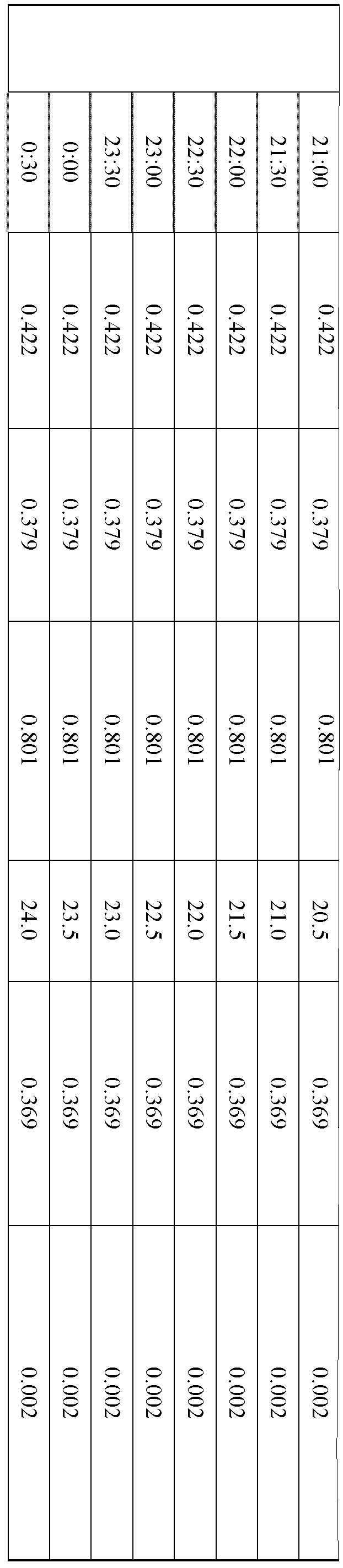

The invention belongs to the key technical field of million kilowatt level advanced pressurized water reactor nuclear power plants, and discloses a nuclear power plant generator whole air tight test method. The test method includes that gas is inflated into a generator and a hydrogen system, the pressure is increased to working pressure to be maintained, a leakage point is detected to be handled, the test can be finished when pressure maintaining time of leakage rate meets a predetermined requirement and is larger than or equal to 24 hours, and mixed gas of air and hydrogen is inflated to the generator and the hydrogen system. The test method further comprises a temperature control operating step and an anti-oil-swapping operation step, wherein the temperature control operating step is used for maintaining balanced temperature inside the generator, and the anti-oil-swapping operation step is used for controlling swapping of sealing oil on the airside and the hydrogen side not to cause gas leakage. The test method further comprises sealing oil tank liquid level monitoring step in the process of pressure maintaining. Recording duration for monitoring of gas temperature, pressure, ambient atmosphere pressure and sealing oil tank liquid level inside the generator is every 20-40 minutes in the process of the pressure maintaining. The nuclear power plant generator whole air tight test method is short in time limit for construction and high in test precision.

Owner:CHINA GENERAL NUCLEAR POWER CORP +1

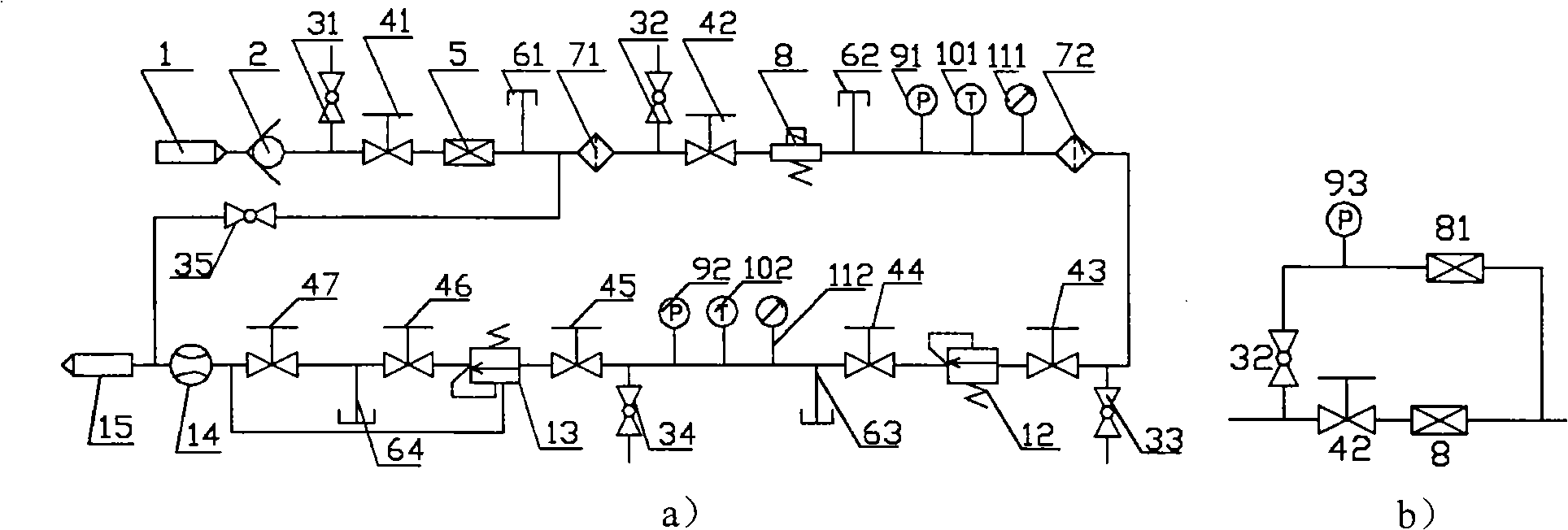

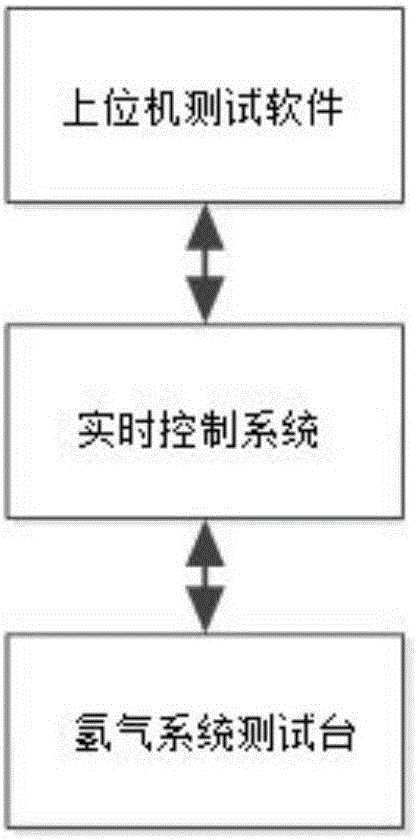

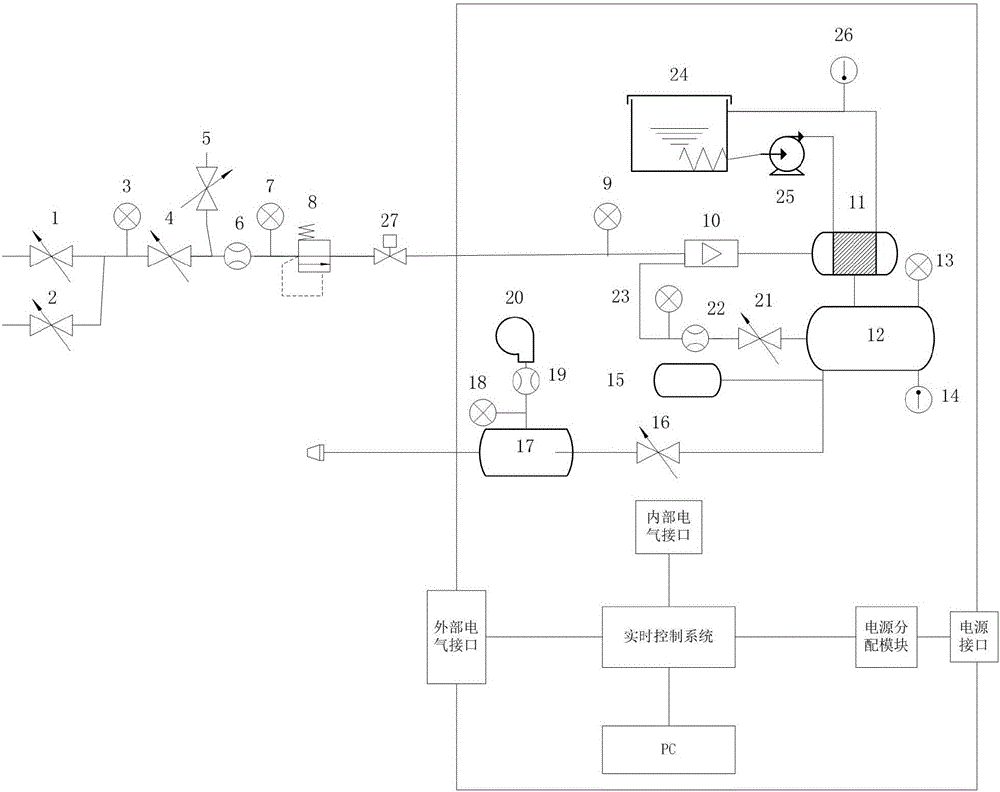

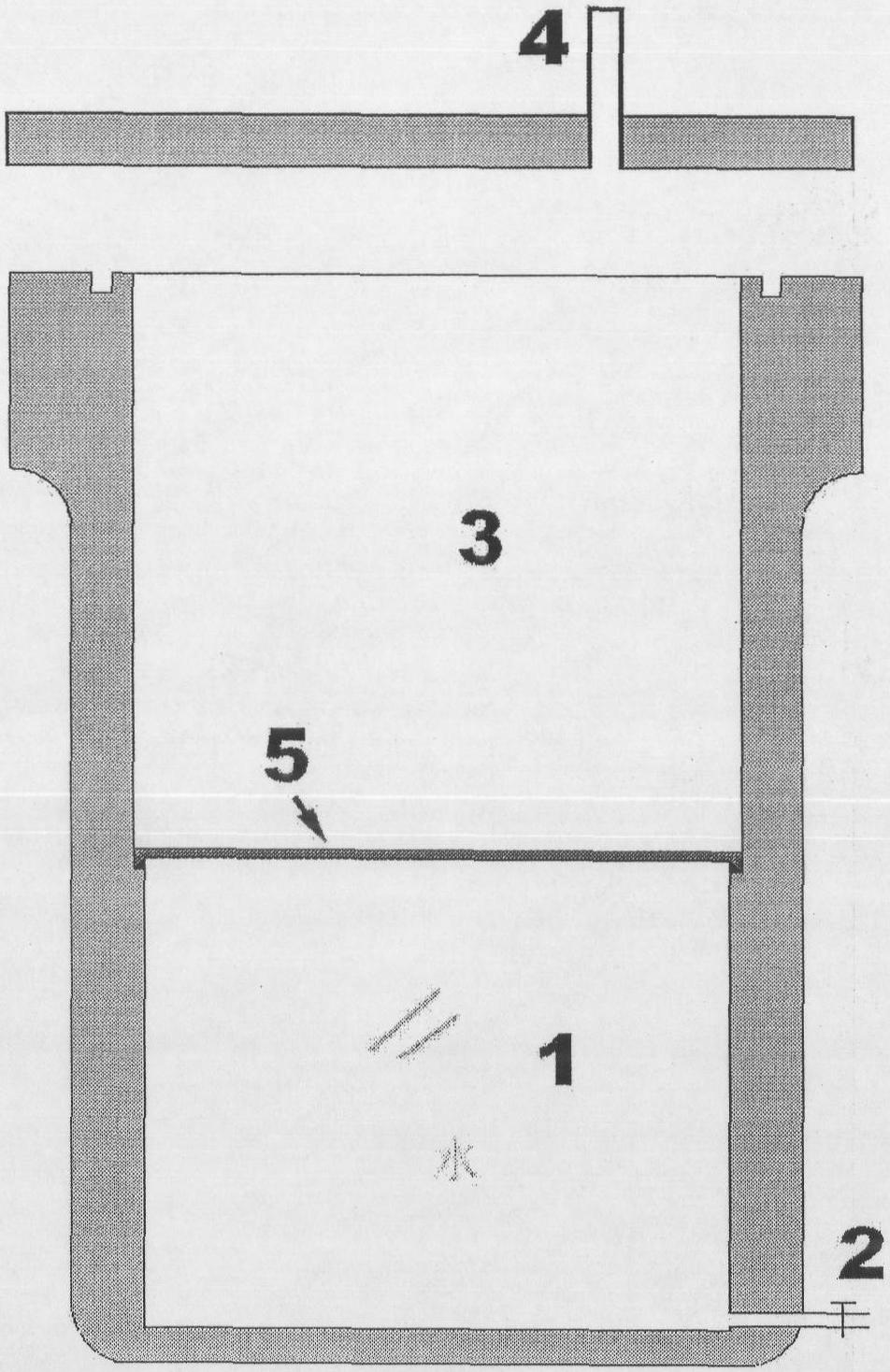

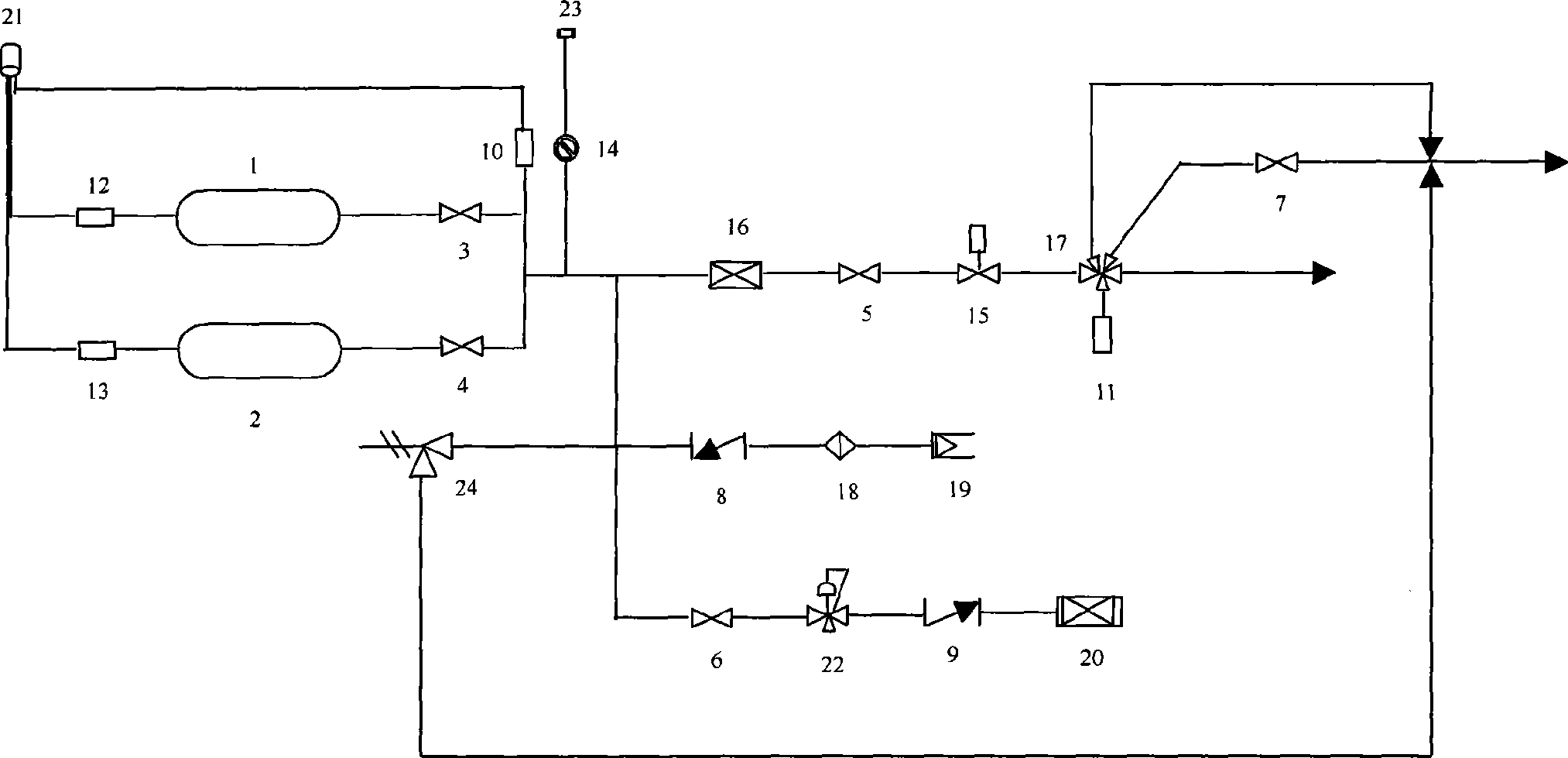

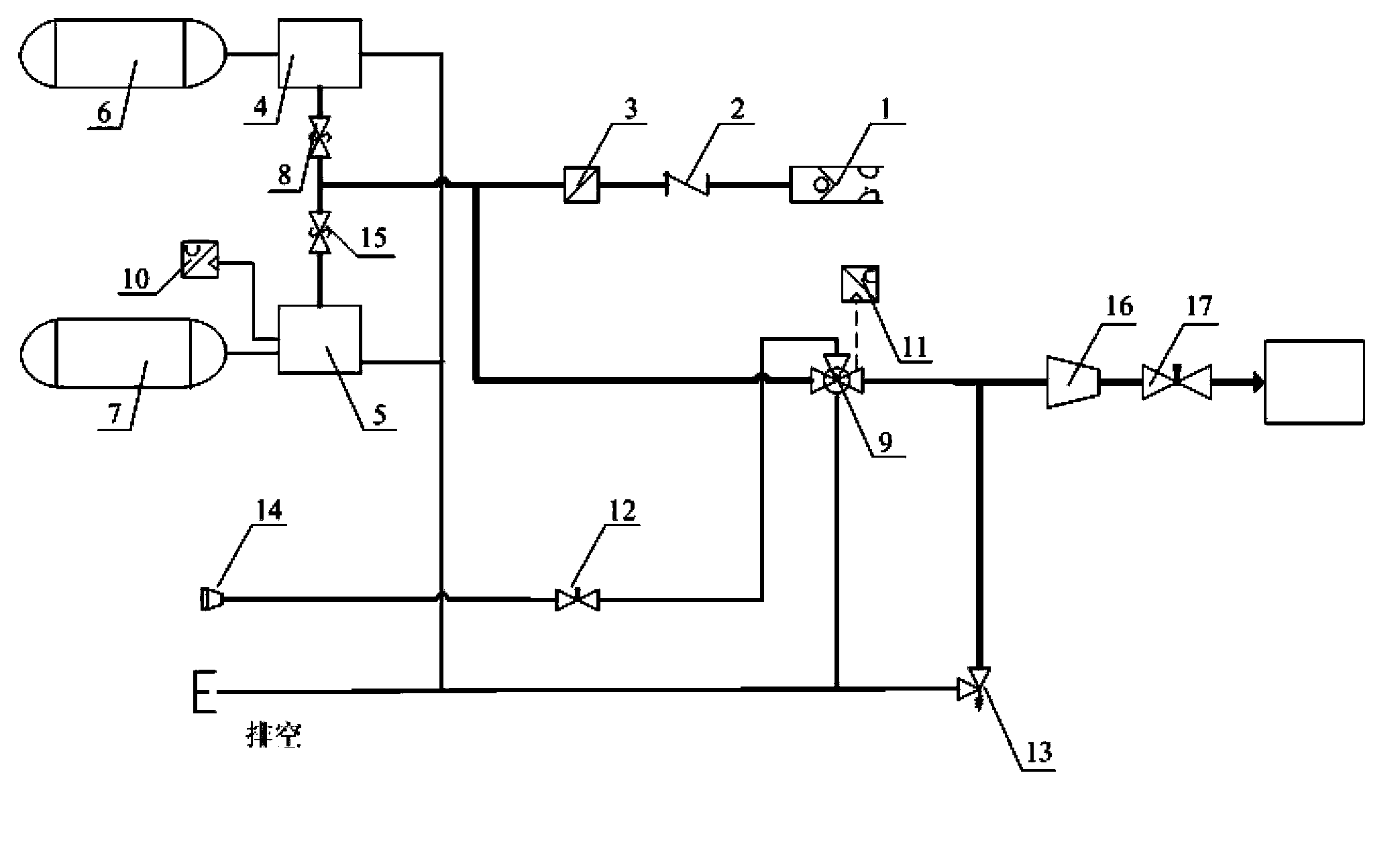

Testing platform of fuel cell hydrogen system

The invention discloses a testing platform of a fuel cell hydrogen system which comprises a real-time control system and a hydrogen system testing table.The real-time control system is connected with a hydrogen testing system and used for achieving testing control for the hydrogen testing system under the control of upper computer testing software.The hydrogen system testing table comprises a hydrogen backflow module, a hydrogen temperature control module, a galvanic pile analog module and a hydrogen tail exhaust module and is used for detecting the hydrogen system through the modules.The state of the hydrogen system can be simulated when the fuel cell system is operated, so that whether the performance and service life of all parts of the hydrogen system meet design requirements and requirements of the fuel cell system or not is tested.

Owner:上海新源动力有限公司

Method for generating hydrogen through lithium borohydride-porous carbon hydrolysis and reaction system

InactiveCN101841048AReduce volumeHigh hydrogen release efficiencyFuel cell detailsLiquid waterChemistry

The invention relates to a method for generating hydrogen through lithium borohydride-porous carbon hydrolysis, and a reaction system, which belongs to a hydrogen producing-storing technique for fuel cell hydrogen sources. The method is characterized in that hydrolysis material is prepared by mechanically ball-milling LiBH4 and porous carbon material, and the influent water rate of liquid water reacting with the hydrolysis material and the saturated steam pressure of steam are controlled so as to effectively control the hydrogen-releasing amount, hydrogen-releasing speed and the like of reaction. The method precisely combines hydrolysis hydrogen production with a hydrogen production system, and the hydrolysis hydrogen production system needs no catalyst for acceleration, can continuously and stably release hydrogen, and is convenient to control and higher in hydrogen-releasing efficiency than a NaBH4 hydrolysis hydrogen production system. The method completely meets the requirements of hydrogen fuel cells for hydrogen sources. The application of the technique of the invention has important and profound significance for promoting the progress of industries related to new energy, achieving the aim of saving energy and reducing emission and promoting economic development.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

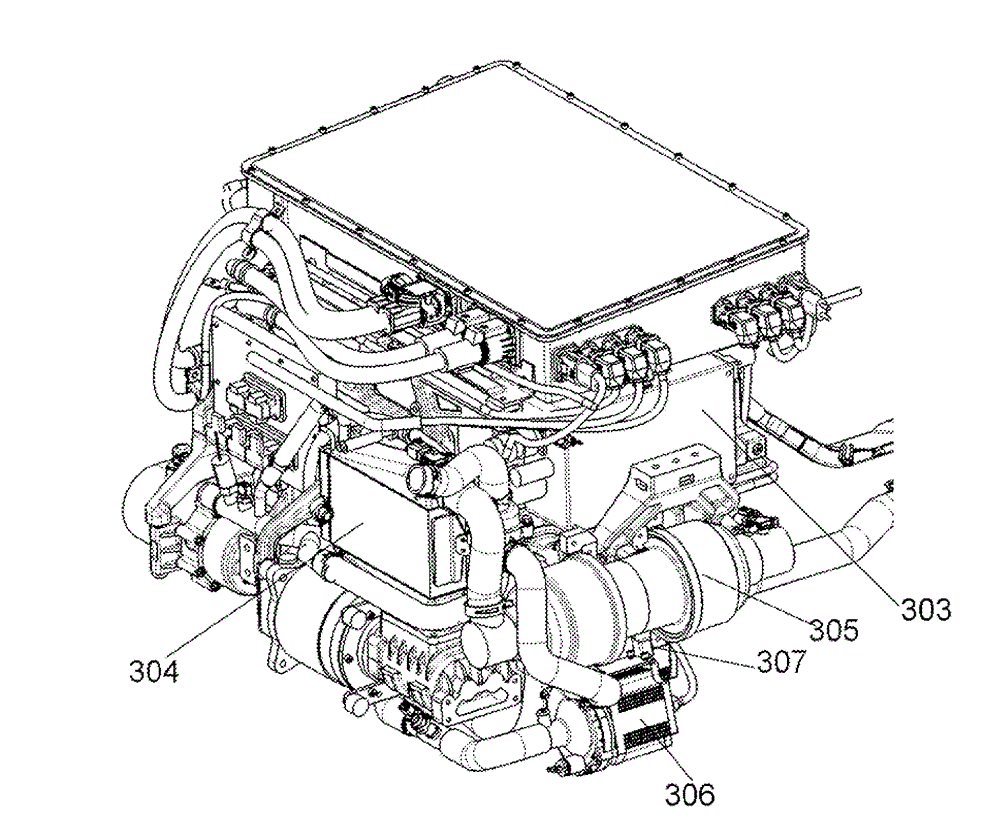

Fuel cell engine system integrated structure

The invention provides a fuel cell engine system integrated structure which includes an electric pile, an air system, a water system, a hydrogen system, a power control unit and an electro-driving system. The fuel cell engine system integrated structure also includes a framework, which is constructed in a manner that the electric pile, the air system, the water system, the power control unit and the electro-driving system can be arranged on the framework in a multilayer arrangement, wherein the electric pile is arranged at the center of the framework, the power control unit is disposed on the top layer of the framework, and the rest other parts of the fuel cell engine system are fixed on the framework in an arrangement of surrounding the electric pile. The electric pile, the power control unit and the rest other parts of the fuel cell engine system are all fixed on the framework respectively in a detachable manner. The parts in the integrated structure are easy to maintain and detach.

Owner:SAIC MOTOR +1

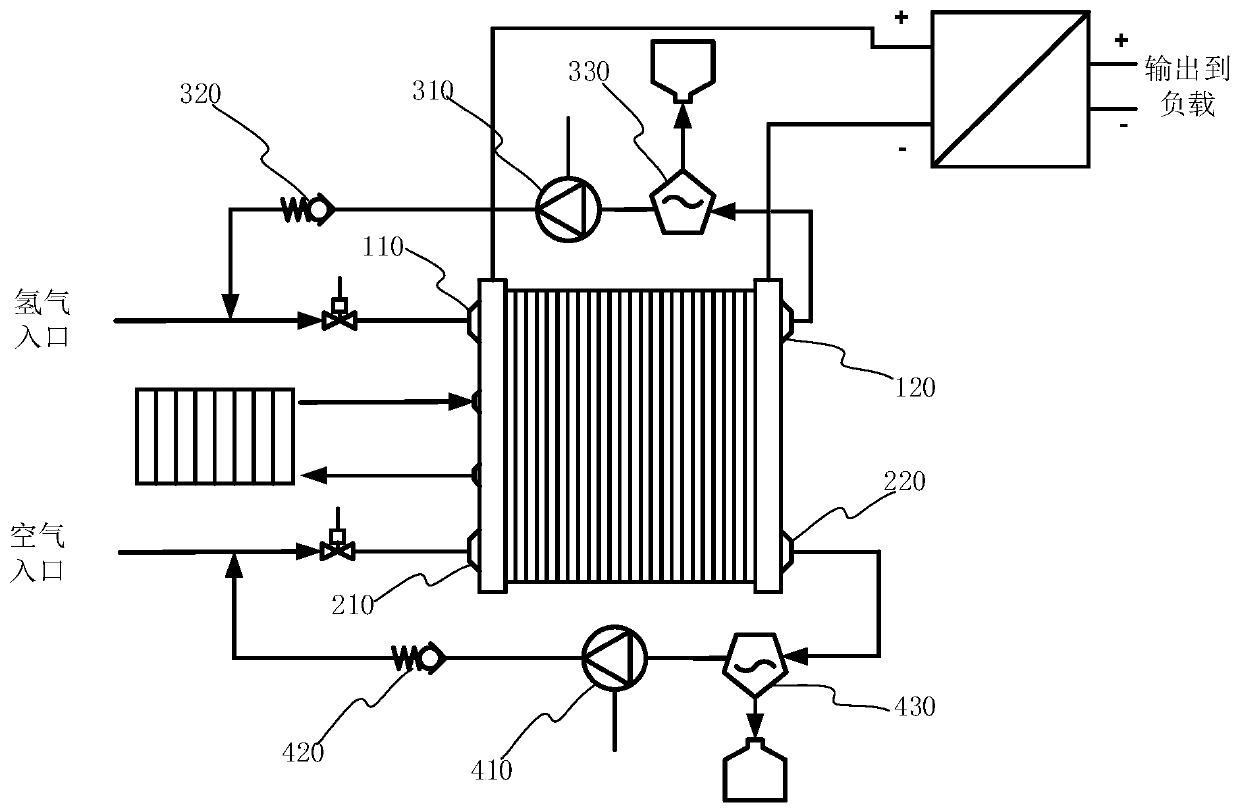

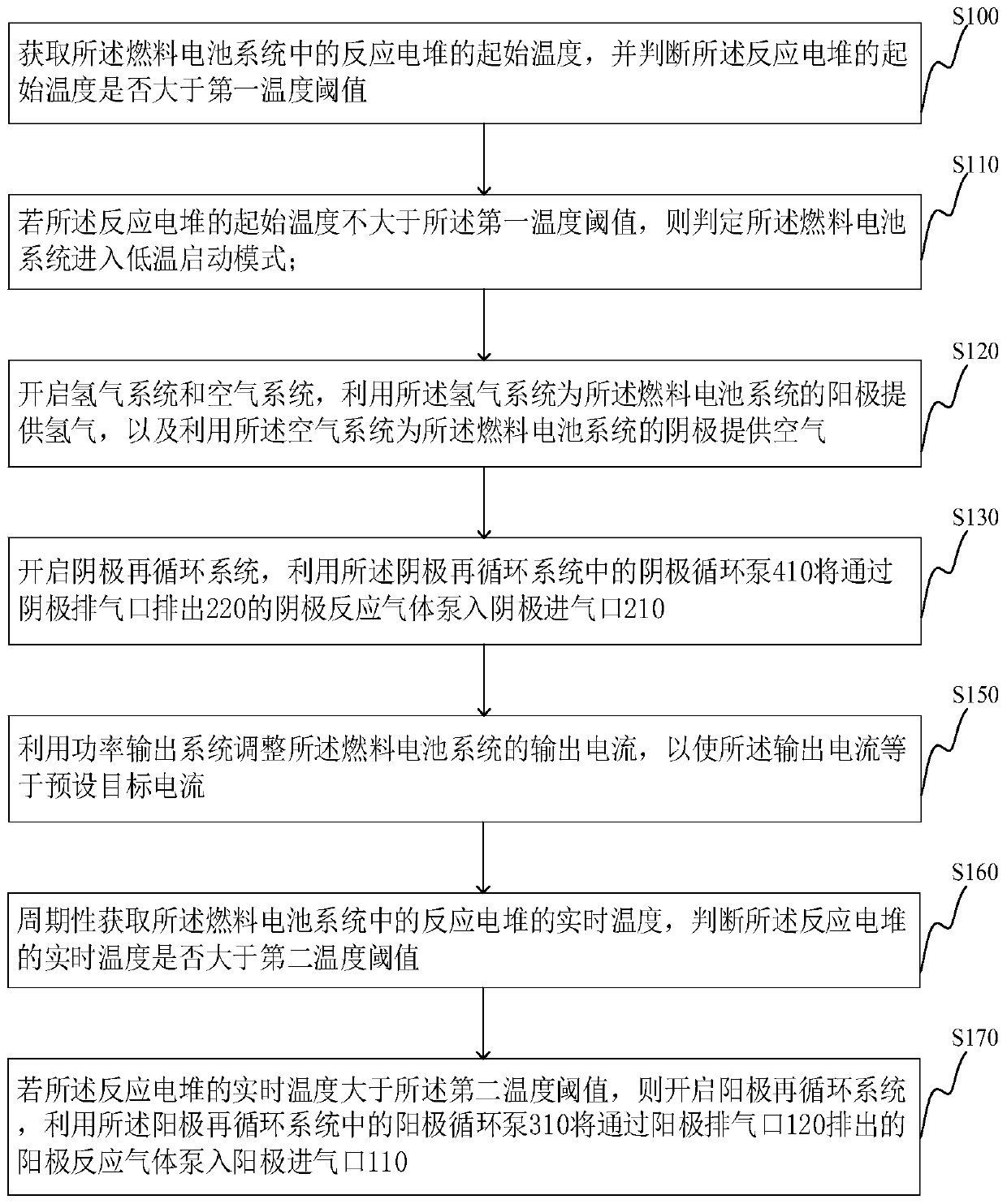

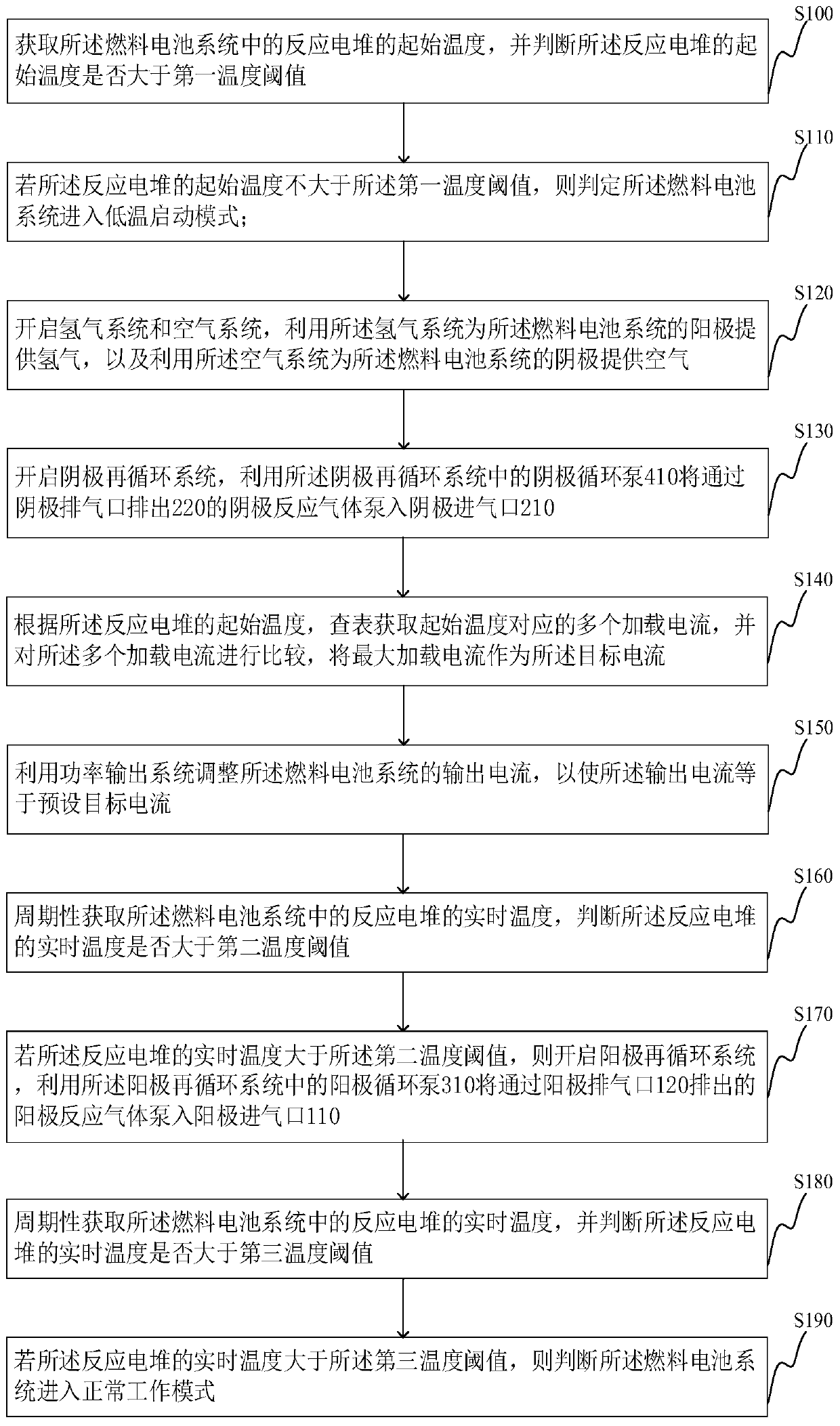

Low temperature starting methods for fuel cell system, computer equipment and memory medium

ActiveCN109904494AReduce power generation efficiencyFast heat productionFuel cell controlPower flowFuel cells

The invention provides low temperature starting methods for a fuel cell system, computer equipment and a memory medium. A low temperature starting method comprises the steps of obtaining and judging whether an initial temperature of a reaction stack in the fuel cell system is greater than a first temperature threshold or not; judging whether the fuel cell system enters a low temperature starting mode or not if the initial temperature is not greater than the first temperature threshold; providing hydrogen for an anode the fuel cell system through utilization of a hydrogen system, and providingair for a cathode of the fuel cell system through utilization of an air system; pumping cathode reaction gas exhausted from a cathode exhaust port into a cathode air inlet through utilization of a cathode circulation pump in a cathode recirculation system; adjusting an output current of the fuel cell system through utilization of a power output system, thereby enabling the output current to be equal to a preset target current; periodically obtaining and judging whether a real-time temperature of the reaction stack is greater than a second temperature threshold or not; and starting an anode recirculation system if the real-time temperature is greater than the second temperature threshold.

Owner:TSINGHUA UNIV

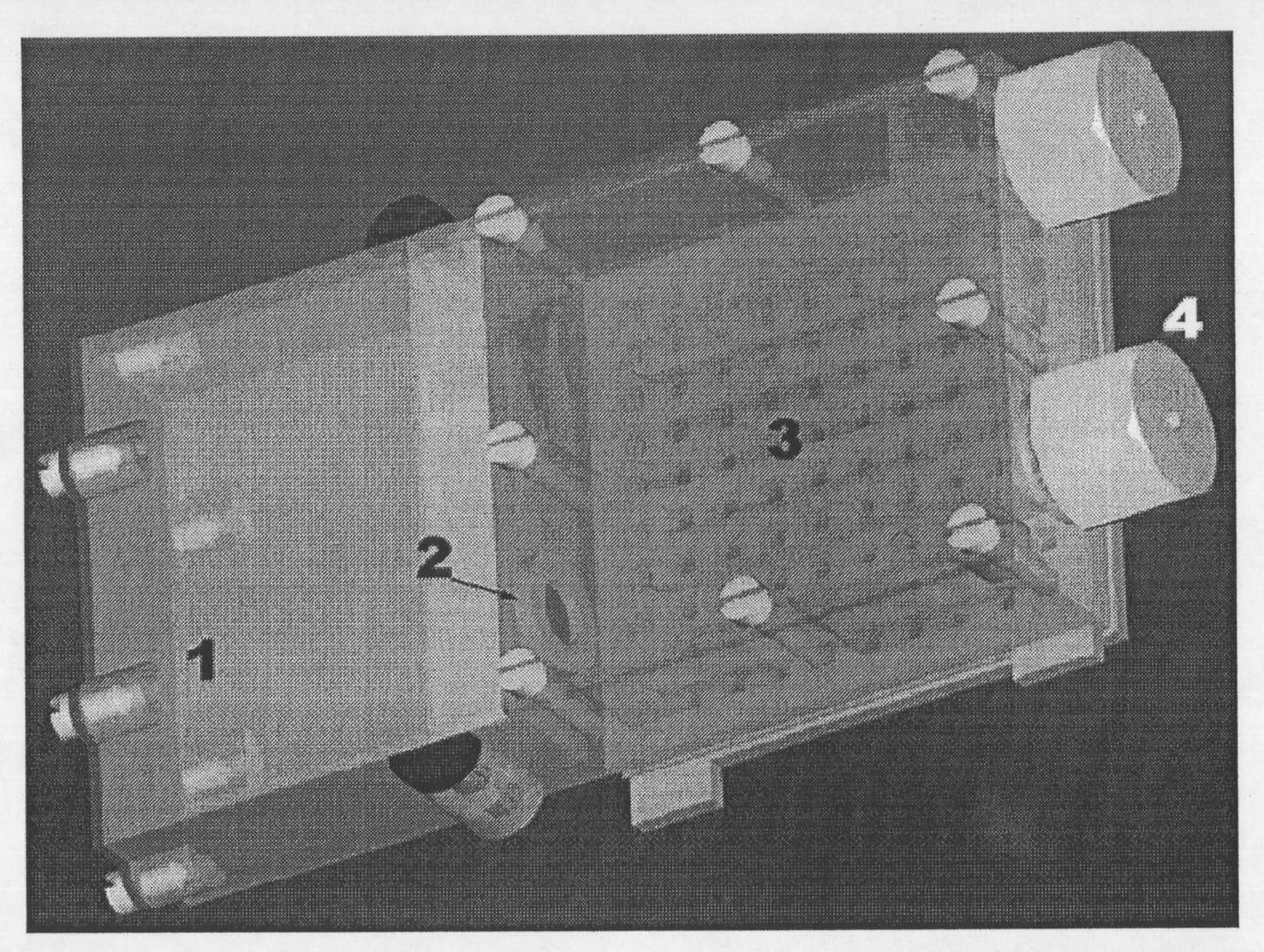

On-board hydrogen system for fuel cell automobile

InactiveCN101417603AVersatileSimple structureContainer filling methodsGas pressure propulsion mountingOn boardHigh pressure hydrogen

The invention discloses a fuel cell vehicle carriage hydrogen system; the system comprises a high-pressure hydrogen storage bottle group system, a bullied pipeline, an unloading pipeline, a hydrogen supply pipeline and a blowdown pipeline; the bullied pipeline, the unloading pipeline, and the hydrogen supply pipeline are connected to the high-pressure hydrogen storage bottle group system side by side; the blowdown pipeline is connected at the tail end for safe unloading; and the system can be applied to a hydrogen carriage hydrogen system of a fuel cell vehicle, which can receive the high-pressure hydrogen of a hydrogen filling station, can safely unload and use the carriage high-pressure hydrogen, and can provide steady pressure and flow for a fuel cell engine. The fuel cell vehicle carriage hydrogen system has the advantages of complete function, simple structure, in-place security protection measure, and high safety and reliability. When having the bullied, unloading, and hydrogen supply functions, the system also has the over-temperature, overpressure, overflow, and return protection functions.

Owner:TONGJI UNIV

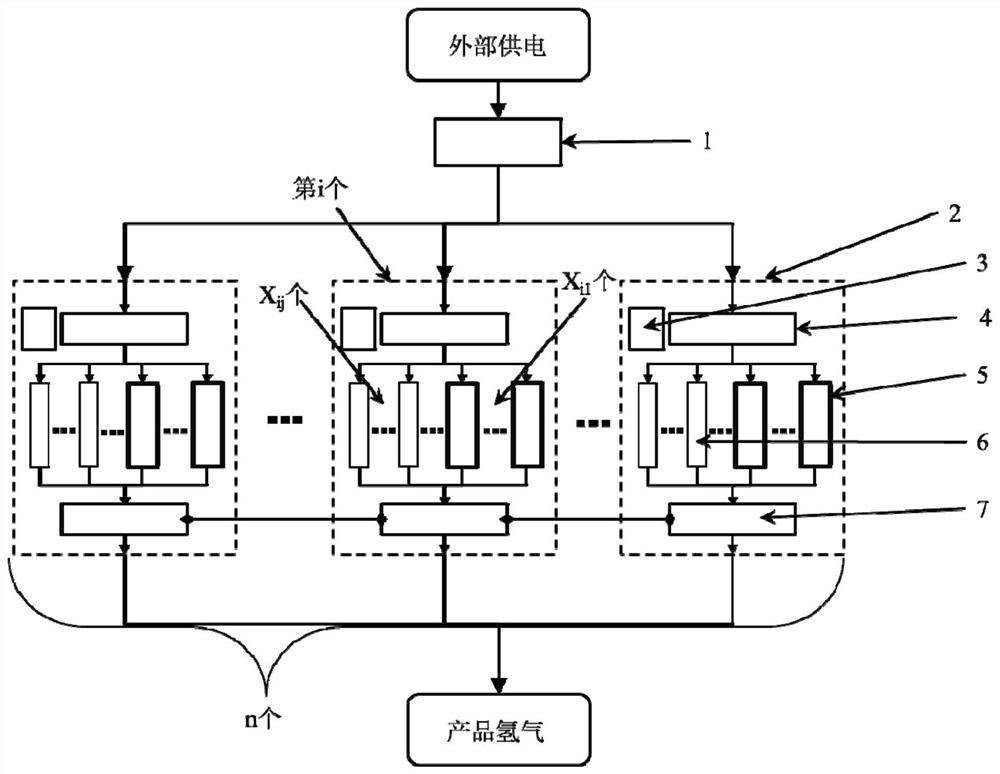

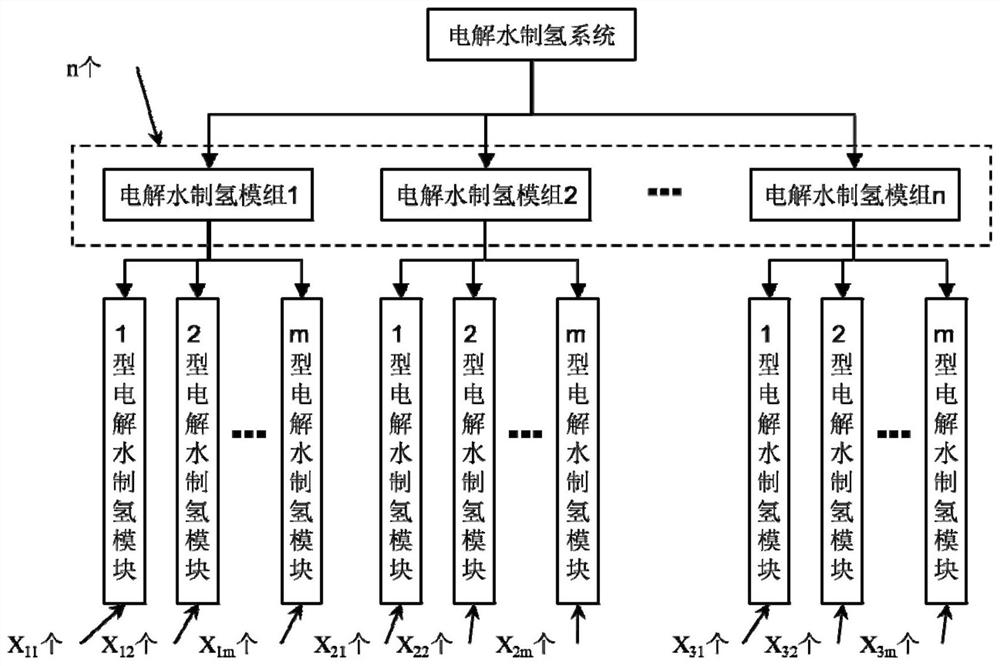

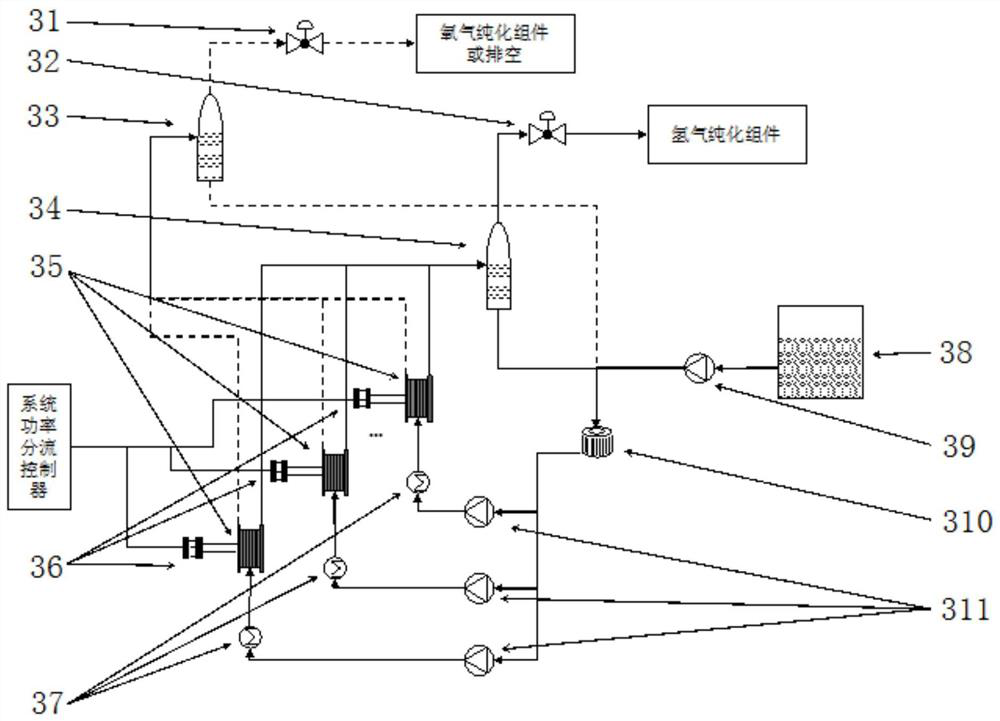

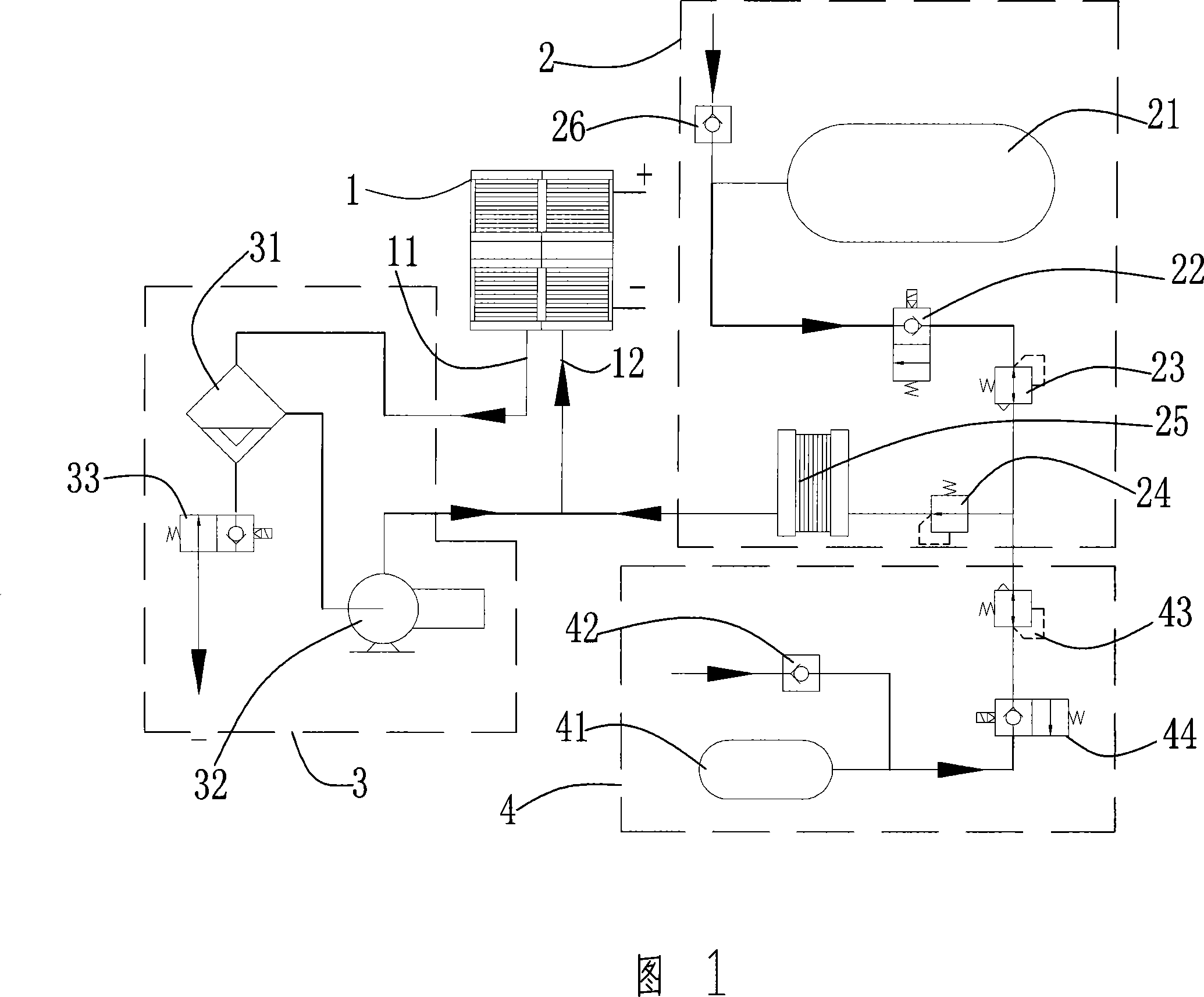

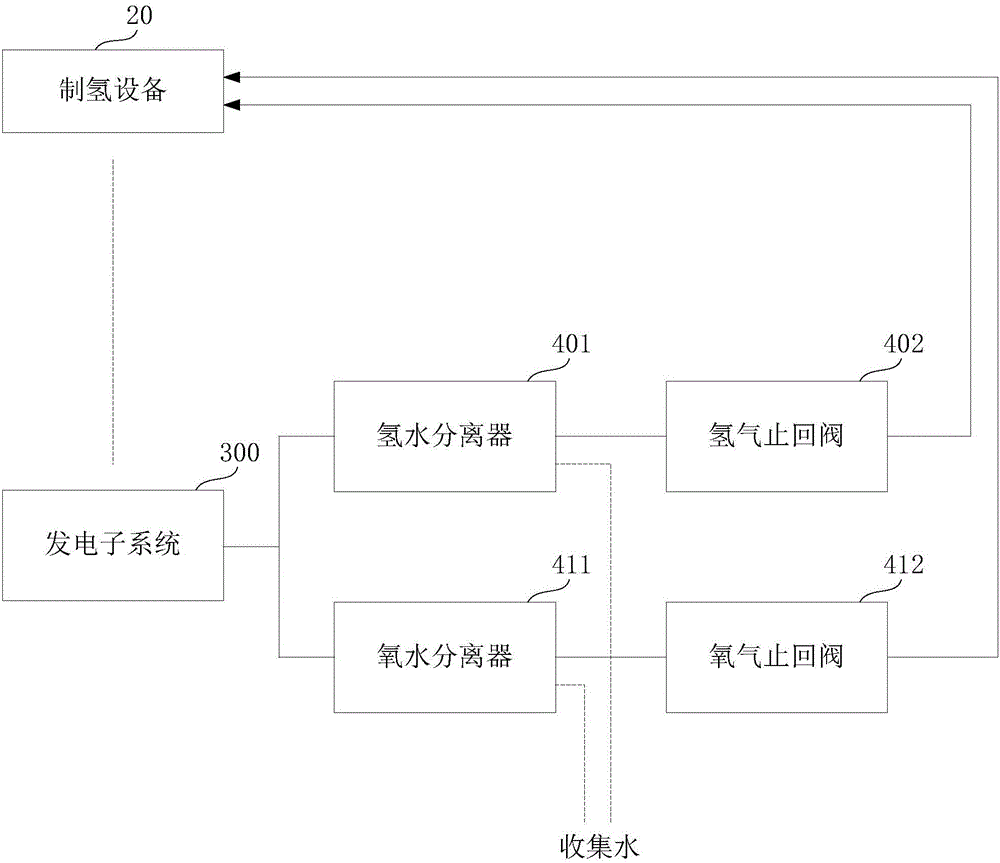

Large water electrolysis hydrogen production system with wide power fluctuation adaptability and control method

PendingCN111826669AImprove the energy consumption efficiency of hydrogen productionImprove the adaptability to wide power fluctuationsCellsThermodynamicsElectrolysed water

The invention relates to a large water electrolysis hydrogen production system with wide power fluctuation adaptability and a control method. The system comprises: a plurality of water electrolysis hydrogen production module groups which are arranged in parallel; a system power division controller, which is configured to be used for power distribution and control of the water electrolysis hydrogenproduction module groups in the water electrolysis hydrogen production system; each water electrolysis hydrogen production module group comprises a plurality of water electrolysis hydrogen productionmodules with different power levels and a module power division controller, the module power division controller is configured to be used for power diversion control of a water electrolysis hydrogenproduction module in the module group. The module power division controller is connected to the system power division controller, and the water electrolysis hydrogen production modules in the water electrolysis hydrogen production module groups share one module manager used for temperature, alkali liquor circulation and gas-liquid separation control and a hydrogen purification assembly used for hydrogen purification. Compared with the prior art, the hydrogen production energy consumption efficiency and wide power fluctuation adaptability can be improved, the instantaneous response speed is increased, and the power loading cost is reduced.

Owner:TONGJI UNIV

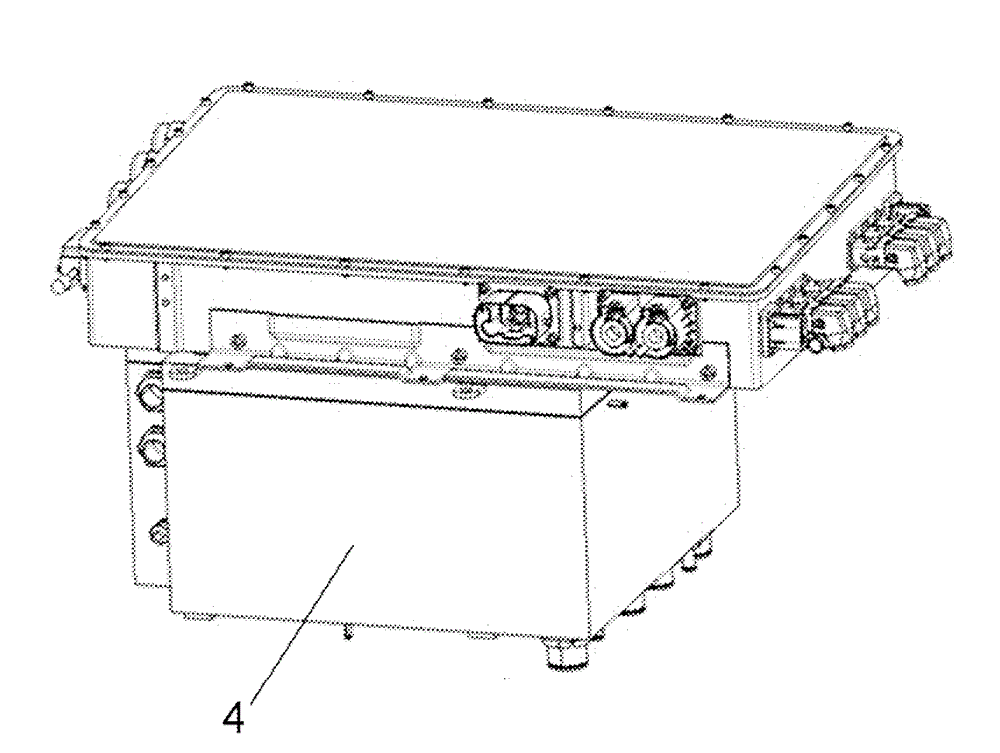

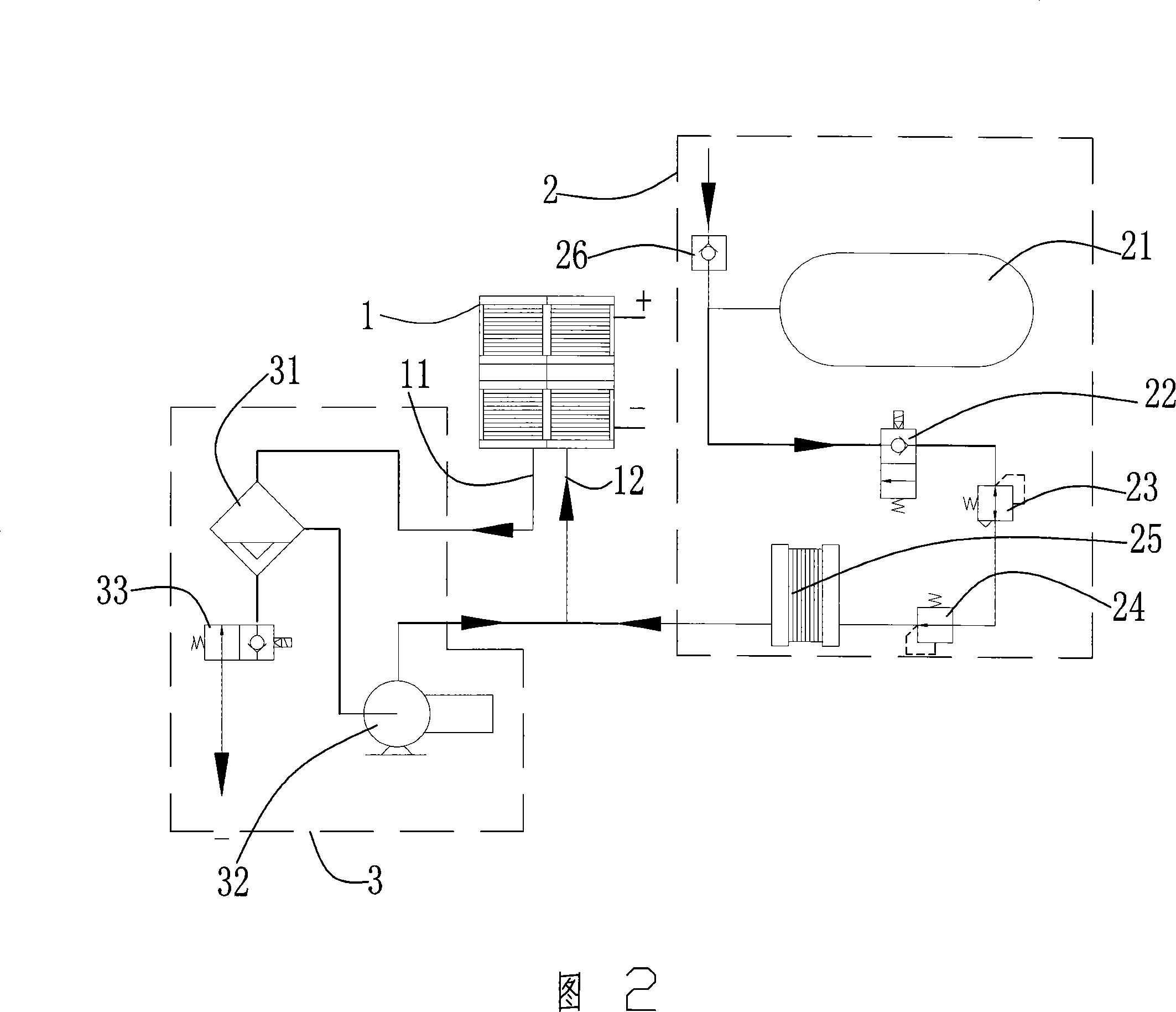

Hydrogen gas system for enhancing fuel battery service life

ActiveCN101162781AExtended service lifeSimple structureFuel cells groupingFuel cell auxillariesElectrochemical responseGas cylinder

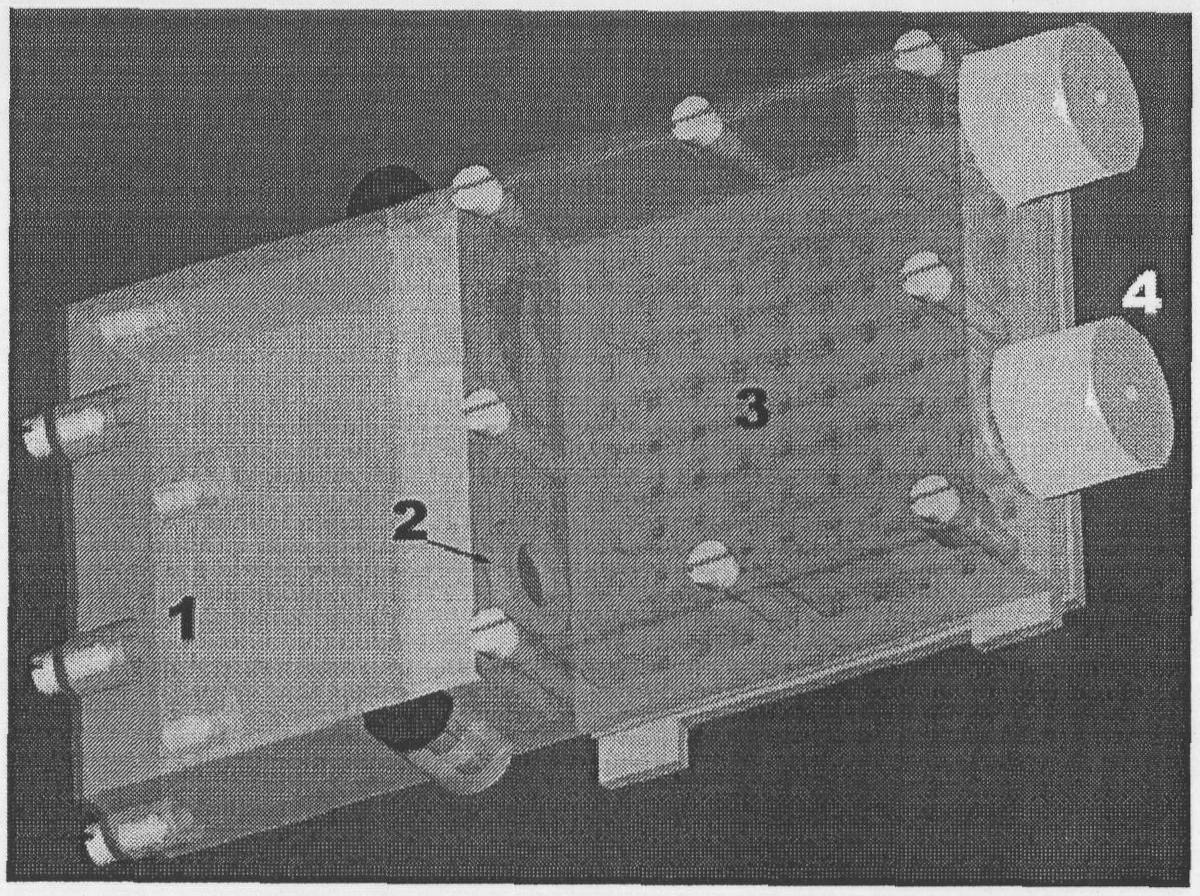

A hydrogen system for improving the operational life of a fuel cell comprises a fuel cell stack (1), a hydrogen supply part (2) and a hydrogen reflux part (3), and is characterized by also comprising a hydrogen purging part (4) which consists of a high-pressure purging gas cylinder (41) with purging gas, a purging gas control electromagnetic valve (44) connected with the purging gas cylinder, a reducing valve (43) communicated with the purging gas control electromagnetic valve (44) and a one way valve (42) connected with the purging gas cylinder (41). The residual hydrogen on the hydrogen chamber and the hydrogen channel of the fuel cell stack is removed through purging by the hydrogen purging part; the hydrogen chamber of the fuel cell membrane electrode can be effectively prevented from generating higher instant electric potential by electrochemical reactions to burn the membrane electrode when the system starts up or shuts down, thereby greatly improving the life-span of proton exchange membrane fuel cell. The invention is also characterized by simple structure, high efficiency and long life-span.

Owner:SUNRISE POWER CO LTD

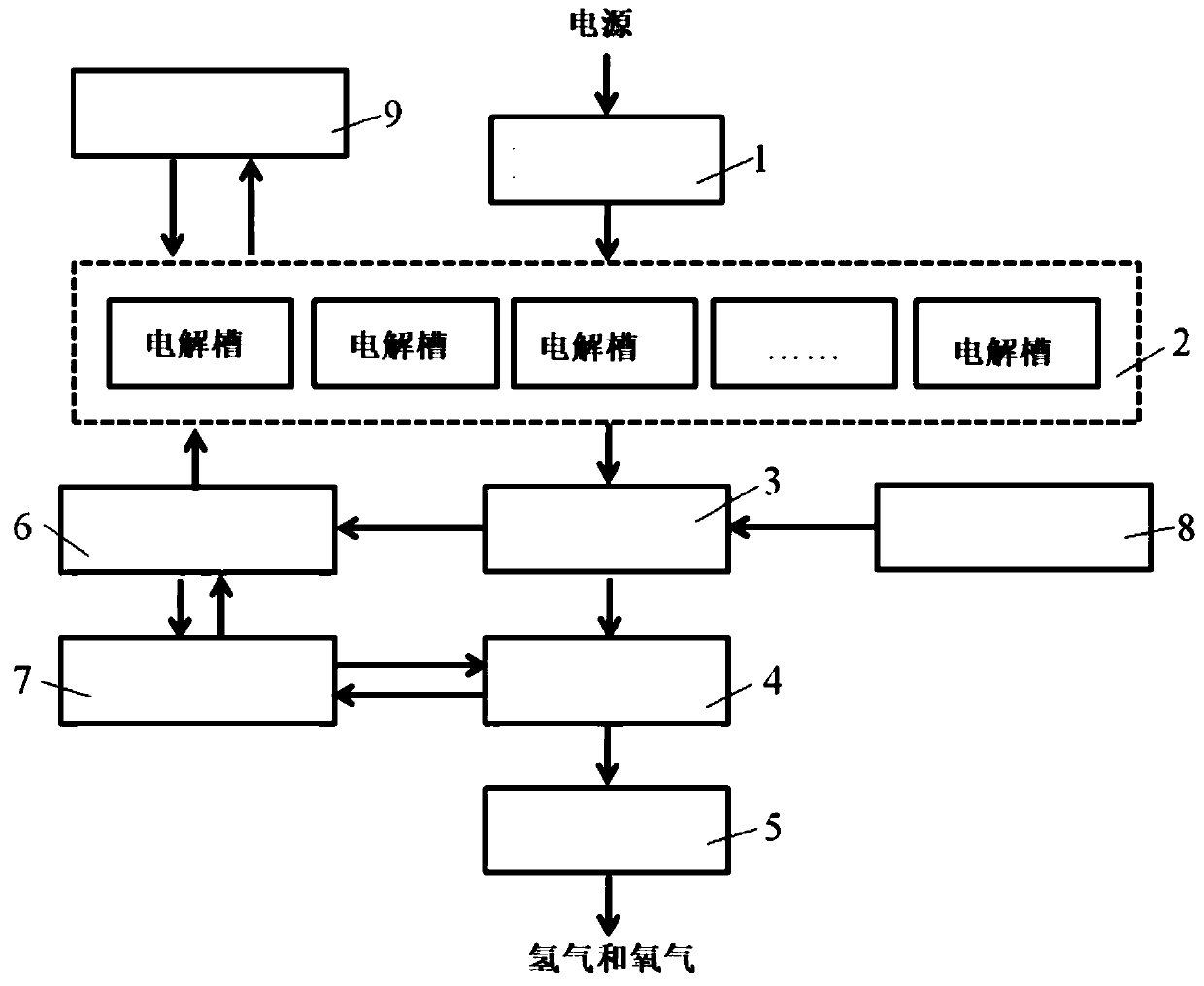

Wide-power water electrolysis hydrogen production system and method

PendingCN111364052AHigh purityReduce manufacturing costCellsGas treatmentElectrolytic agentTransformer

The invention discloses a wide-power water electrolysis hydrogen production system and method. The system comprises a rectifier transformer and an electrolytic bath, the rectifier transformer convertsAC into DC and then introduces DC into the electrolytic bath; the system further comprises a gas-liquid separator, a gas cooler and a gas drop catcher; the rectifier transformer is connected with a fluctuating power supply; the gas-liquid separator comprises a hydrogen separator and an oxygen separator; the gas cooler comprises a hydrogen cooler and an oxygen cooler; the gas drop catcher comprises a hydrogen drop catcher and an oxygen drop catcher; the cathode electrolyte outlet of the electrolytic bath is communicated with the hydrogen separator of the gas-liquid separator, and the anode electrolyte outlet of the electrolytic bath is communicated with the oxygen separator of the gas-liquid separator. The problems that a conventional water electrolysis hydrogen production system is limited in power adjustable range, and the response capacity of the system such as pressure adjustment, and the like, in the wide power fluctuation period is insufficient are solved.

Owner:HUANENG CLEAN ENERGY RES INST

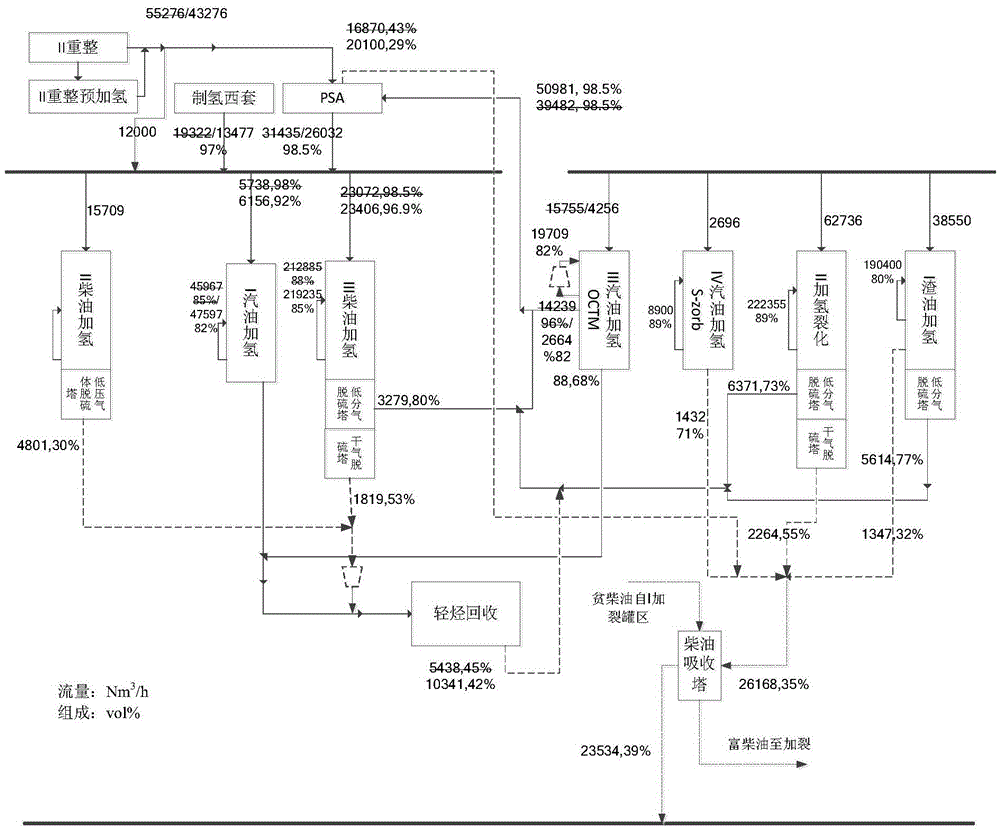

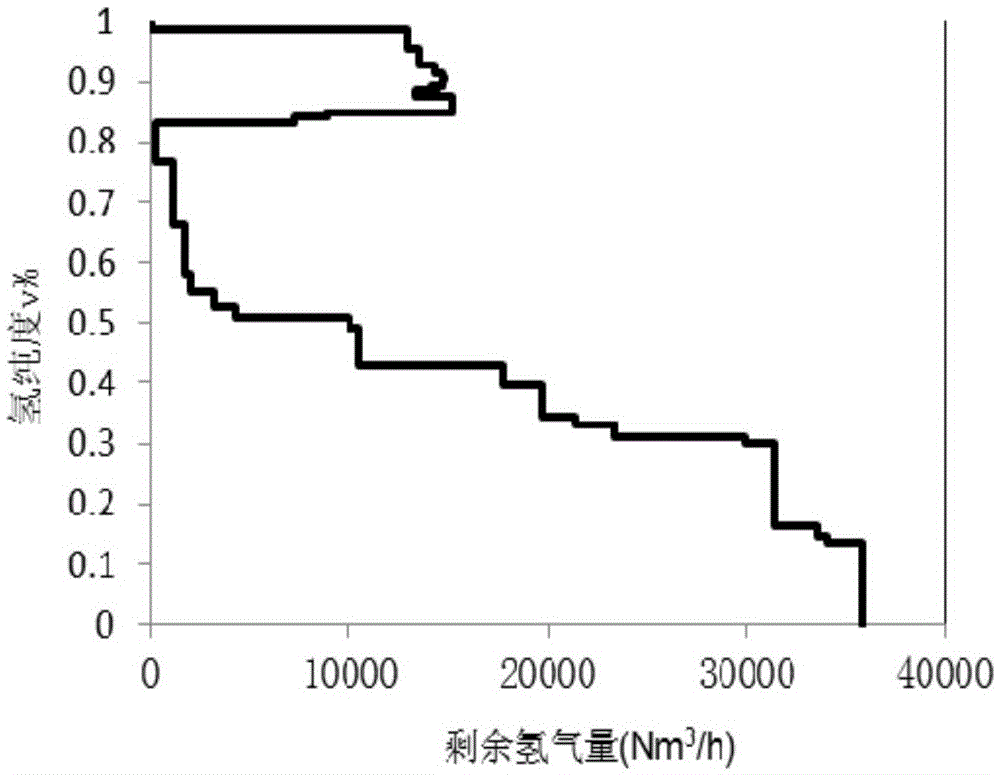

Optimization method of oil refinery hydrogen system and application thereof

ActiveCN106485341ASimple processProtect the optimization processForecastingProcess engineeringHydrogen system

The invention relates to an optimization method of an oil refinery hydrogen system. According to the system provided by the invention, the maximum benefit of the oil refinery hydrogen system is targeted, constraint conditions are optimized, and a new mathematical programming algorithm including light dydrocarbon resource optimization is formed; and compared with the mathematical programming algorithm of an existing hydrogen system, the optimization method is more suitable to actual circumstances, and more benefits can be obtained to meet the requirements of hydrogen conservation and synergy for oil refinery. The invention further provides application of the method in the optimization of the oil refinery hydrogen system, and after the method is optimized, efficient utilization of hydrogen and light dydrocarbon can be realized, so that considerable comprehensive benefit is obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

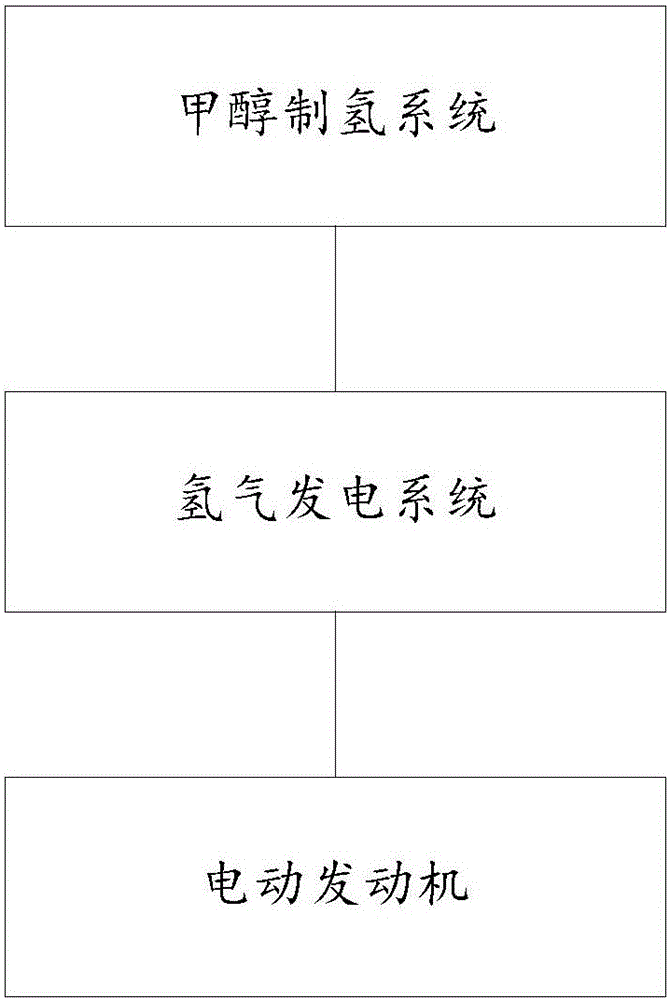

Electric methanol hydrogen transporting tool

InactiveCN104986051AEmission reductionSolve the energy crisisFinal product manufactureFuel cell auxillariesSteam reformingWater vapor

The invention discloses an electric methanol hydrogen transporting tool. The tool comprises a methanol-to-hydrogen system, a hydrogen generating system and an electric engine, wherein the methanol-to-hydrogen system, the hydrogen generating system and the electric engine are connected with each other in sequence. The methanol-to-hydrogen system is used for preparing hydrogen through methanol steam reforming; the hydrogen passes through a membrane separation device plated with a palladium silver alloy to obtain a high-purity hydrogen; the obtained hydrogen is used for generating power through the hydrogen generating system; and the generated electric power is provided to the electric engine to work. The hydrogen generating system comprises a fuell cell, wherein the fuell cell comprises a plurality of sub fuel cell modules; and each sub fuel cell module comprises at least one super-capacitor. According to the electric methanol hydrogen transporting tool disclosed by the invention, the methanol can be used as energy for the transporting tool so that problems of energy crisis and vehicle emission are solved. The electric methanol hydrogen transporting tool disclosed by the invention is advantaged in that the volume of a hydrogen preparation device is small; the prepared hydrogen is rapid, stable and highly purified because the hydrogen is purified by using a special catalyst formula and a palladium membrane; and stable input energy can be provided to the transporting tool.

Owner:SHANGHAI HYDROGEN MOBILE REFRMER INSTR

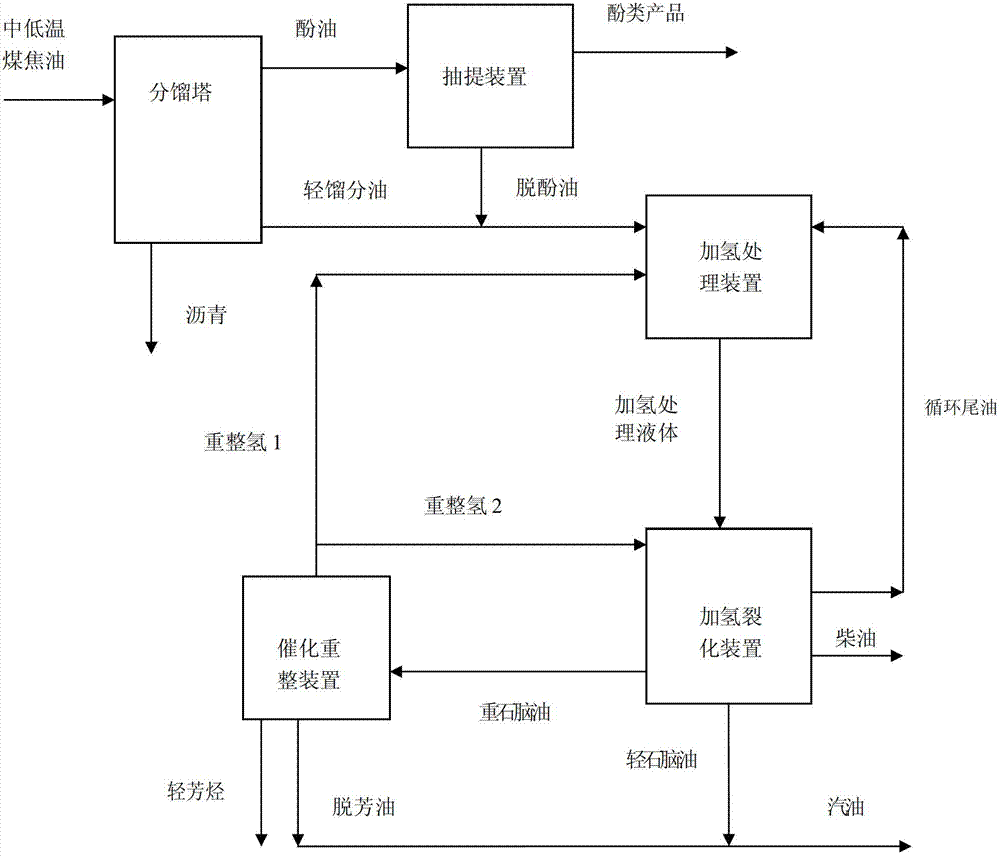

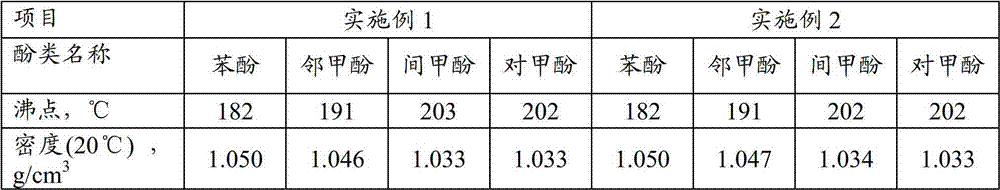

Hydrogenation method for medium and low temperature coal tar

InactiveCN102899088AReduce consumptionRaw materials are simpleTreatment with hydrotreatment processesCatalytic reformingNaphtha

The invention discloses a hydrogenation method for medium and low temperature coal tar. The medium and low temperature coal tar is pretreated and fractionated to obtain carbolic oil, light distillates and asphalt; the carbolic is subjected to dephenolization to obtain phenol products and dephenolized oil; the light distillates and the dephenolized oil are mixed and sent into a hydrotreating reaction zone; liquid generated from hydrotreatment is sent into a hydrocracking reaction zone; the liquid generated from hydrotreatment is fractionated to obtain intermediate distillate oil used as diesel; the tail oil obtained from fractionation is recycled to the hydrocracking reaction zone or the hydrotreating reaction zone; naphtha obtained from fractionation is sent into a catalytic reforming reaction zone; hydrogen obtained from catalytic reforming is used in a hydrogen system; and the obtained liquid is extracted and fractionated to obtain premium gasoline or light aromatic products. Compared with the prior art, the method provided by the invention employs a combined process comprising fractionation, dephenolization, hydrotreating, hydrocracking and catalytic reforming to obtain phenol products, light aromatic products and high-quality motor fuel, and greatly prolongs operation cycle of the device.

Owner:王小英

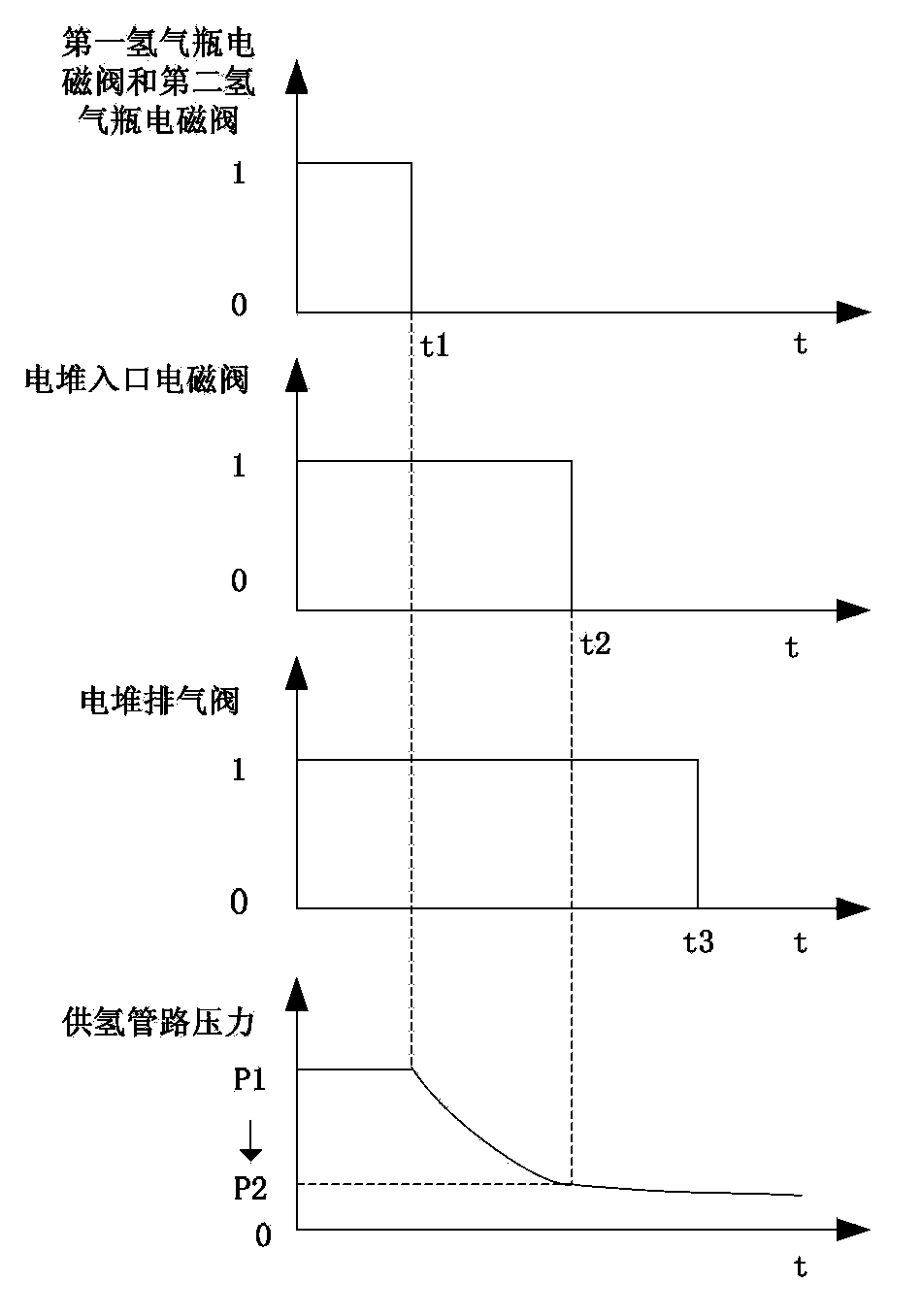

Method for managing hydrogen when hydrogen supply system of fuel cell vehicle stops working

The invention provides a method for managing hydrogen when a hydrogen supply system of a fuel cell vehicle stops working. The hydrogen supply system comprises a hydrogen bottle and a hydrogen supply pipeline, wherein the hydrogen bottle is used for supplying hydrogen to a cell stack through the hydrogen supply pipeline; a combination valve, an overflow valve, a pressure reducing valve, a secondary pressure reducer and a stack inlet electromagnetic valve are sequentially connected on the hydrogen supply pipeline between the hydrogen bottle and the cell stack; the combination valve comprises a hydrogen bottle electromagnetic valve used for connecting and disconnecting hydrogen of the hydrogen bottle; hydrogen comes from the hydrogen bottle, flows sequentially through the hydrogen bottle electromagnetic valve, the overflow valve, the pressure reducing valve, the secondary pressure reducer and the stack inlet electromagnetic valve, and finally enters the cell stack when the hydrogen supply system works; when the hydrogen supply system stops working, the hydrogen bottle electromagnetic valve is closed at first, and the stack inlet electromagnetic valve is closed after 2-3 seconds. According to the hydrogen managing method, the gas pressure in the pipeline of the hydrogen system is reduced to a low level, and the potential safety hazard of the system can be reduced.

Owner:SAIC MOTOR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com