Large water electrolysis hydrogen production system with wide power fluctuation adaptability and control method

A technology for power fluctuation and hydrogen production system, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the optimization method that does not consider the modular integration of a single water electrolysis device and lacks the wide power fluctuation adaptability of a large-scale electrolysis water hydrogen production system , the lack of large-scale electrolytic hydrogen production wide power fluctuation adaptability system framework and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

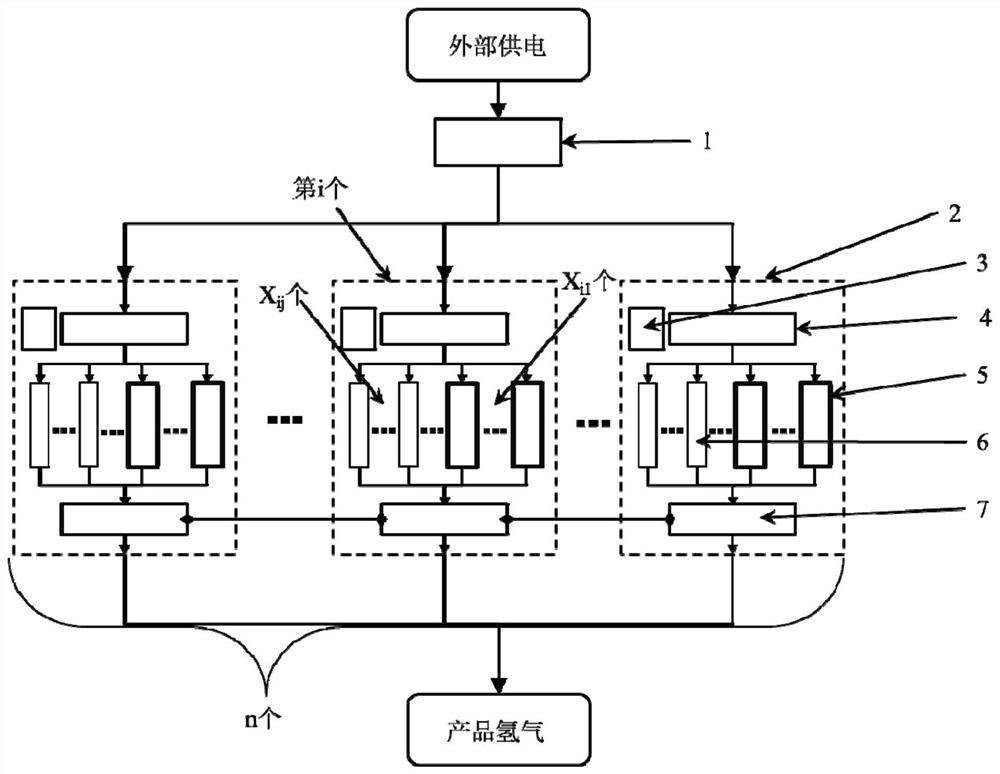

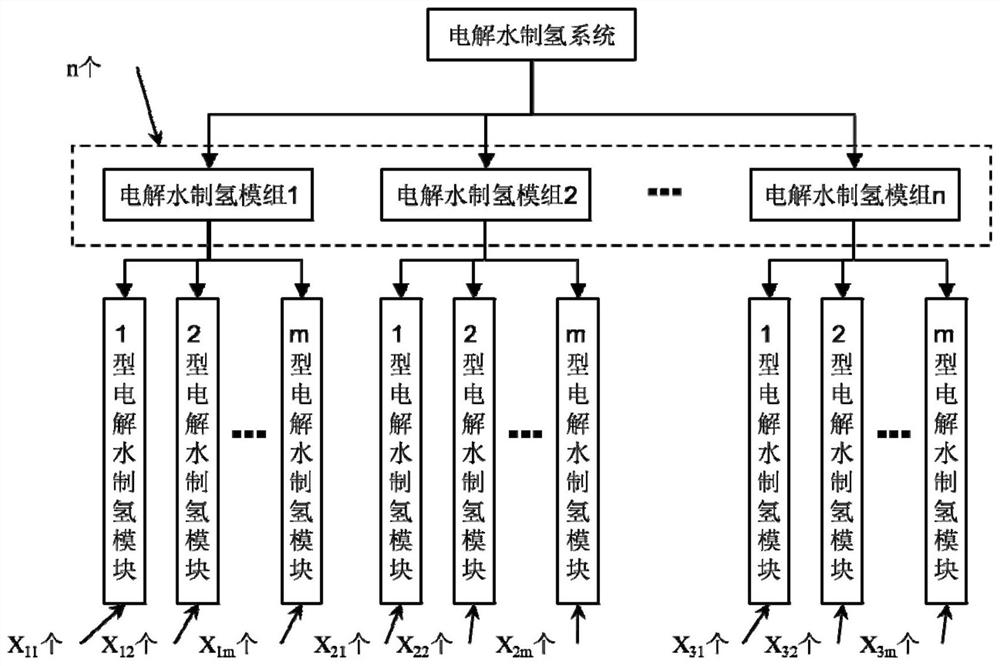

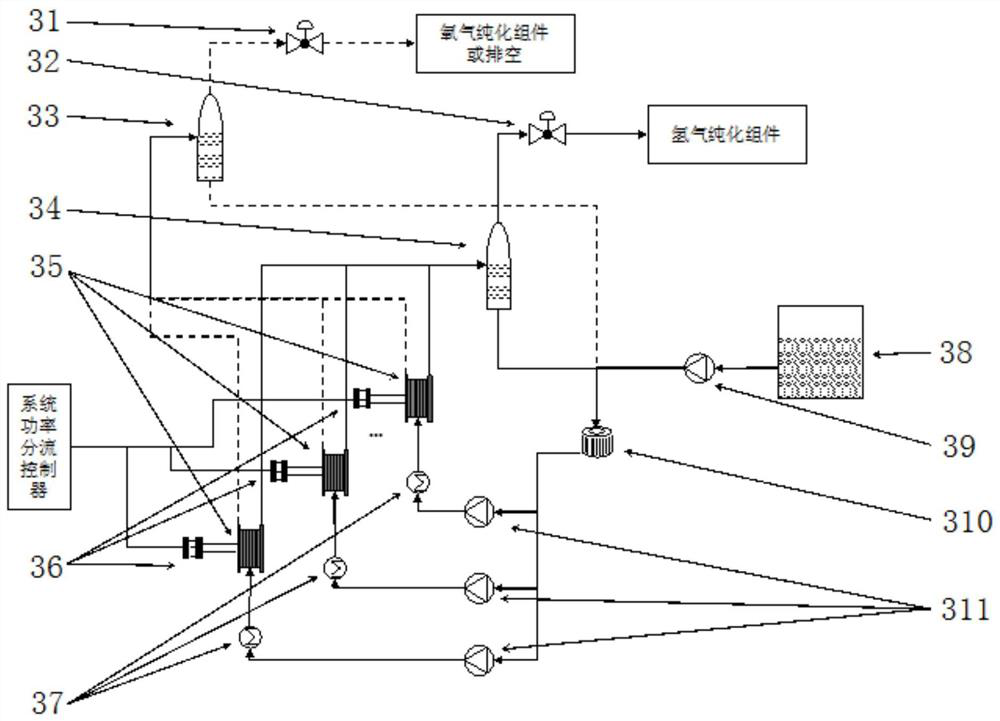

[0049] Such as figure 1 , figure 2 As shown, a large-scale electrolysis water hydrogen production system with wide power fluctuation adaptability, the system includes:

[0050] Electrolyzed water hydrogen production module 2: multiple configurations to form a parallel connection;

[0051] System power split controller 1: configured for power distribution and control of electrolyzed water hydrogen production module 2 in the electrolyzed water hydrogen production system;

[0052] Each electrolytic water hydrogen production module 2 includes a plurality of electrolytic water hydrogen production modules of different power levels and a module power split controller 4, and the module power split controller 4 is configured to be used for the electrolytic water hydrogen production module in the module. Power split control, the module power split controller 4 is connected to the system power split controller 1, and the electrolyzed water hydrogen production modules in each electroly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com