High efficiency methanol-water hydrogen production system and hydrogen production method thereof

A hydrogen production system, methanol water technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems that the equipment cannot be miniaturized, the motor takes up a large space, and the mobility is poor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

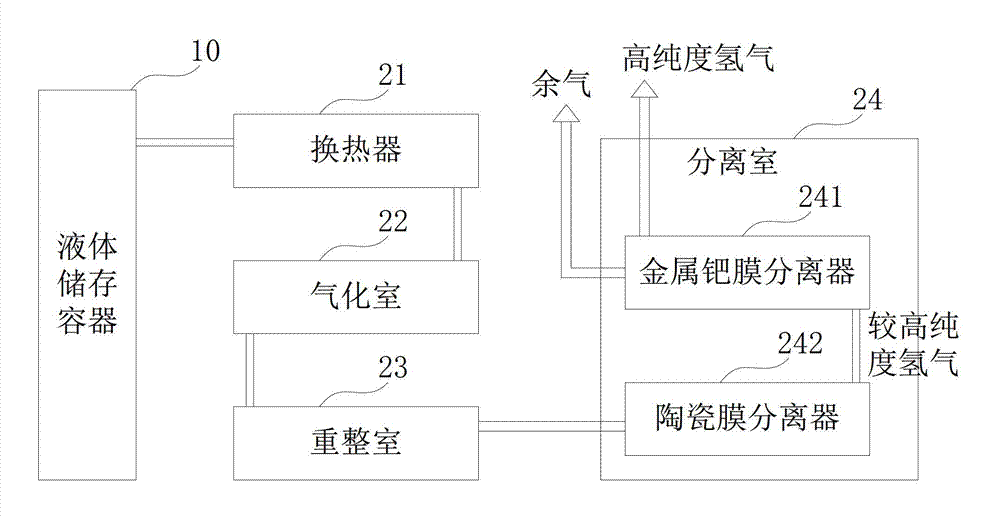

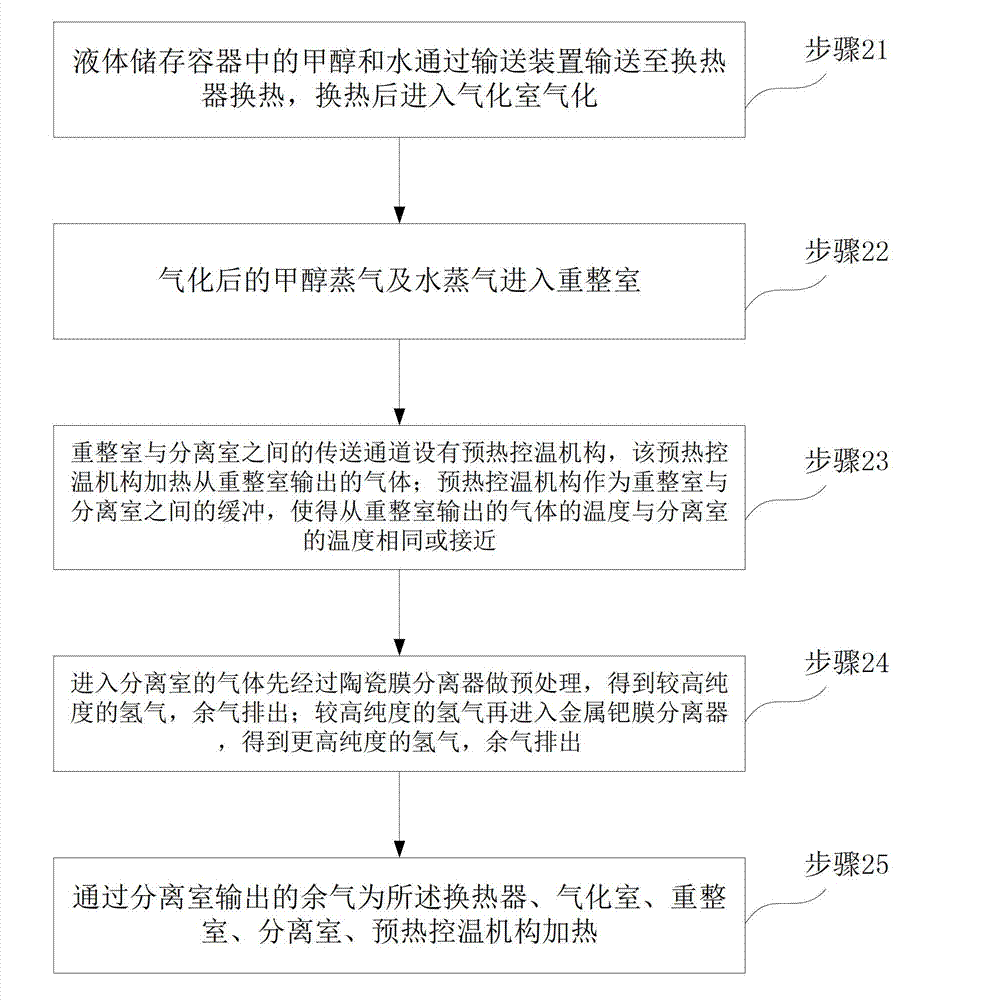

[0082] see figure 1, the present invention discloses a high-efficiency methanol water hydrogen production system, the system includes: a liquid storage container 10, a heat exchanger 21, a gasification chamber 22, a reforming chamber 23, and a separation chamber 24. The liquid storage container 10, the heat exchanger 21, the vaporization chamber 22, the reforming chamber 23, and the separation chamber 24 are connected in sequence through pipelines.

[0083] The separation chamber 24 is provided with a ceramic membrane separator 241 and a metal palladium membrane separator 242, and the gas entering the separation chamber 24 is pretreated through the ceramic membrane separator 241 to obtain higher-purity hydrogen; the higher-purity hydrogen Then enter the metal palladium membrane separator 242 to obtain hydrogen with higher purity.

[0084] Of course, the separation chamber can also be provided with a plurality of ceramic membrane separators and a plurality of metal palladium m...

Embodiment 2

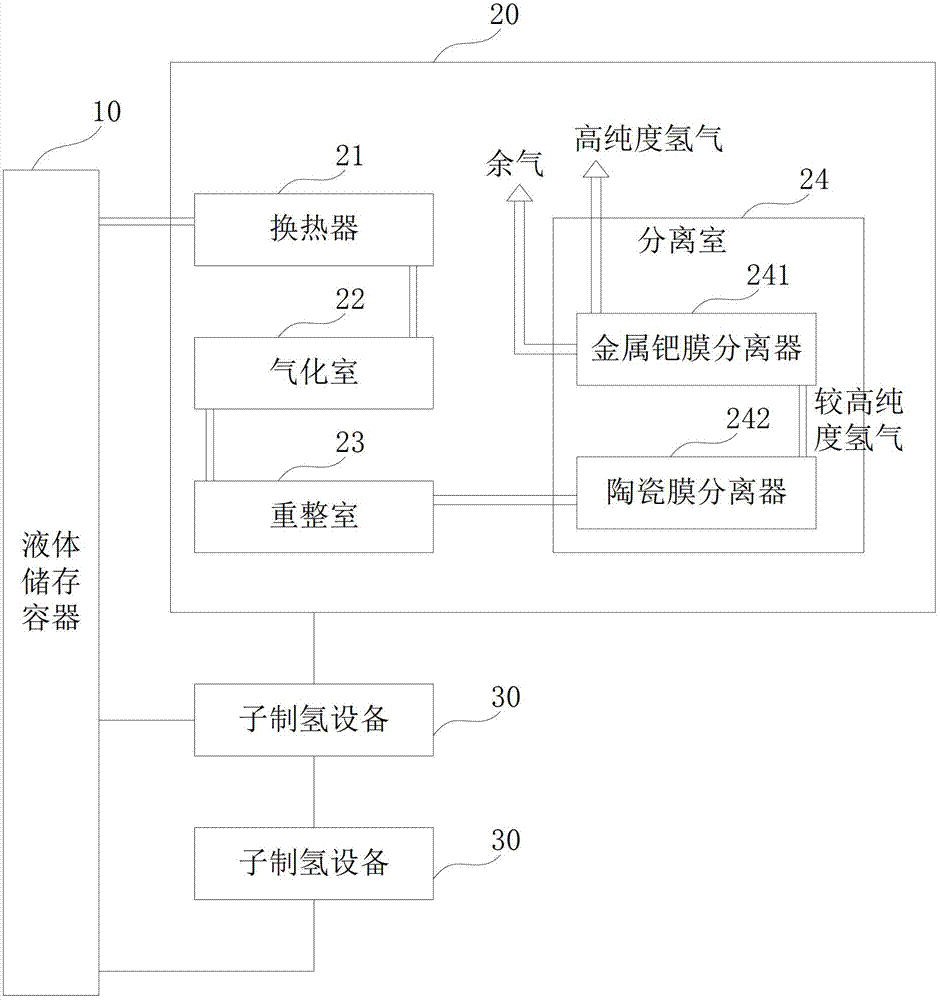

[0094] see image 3 , the present invention discloses a high-efficiency methanol water hydrogen production system, the system includes: a liquid storage container 10, a main hydrogen production equipment 20, and one or more sub-hydrogen production equipment 30. The hydrogen or / and residual gas produced by one or more sub-hydrogen production equipment 30 is finally used as the initial start-up energy of the main hydrogen production equipment 20 . When part of the hydrogen or / and residual gas produced by the sub-hydrogen production equipment 30 meets the set amount, the main hydrogen production equipment 20 is started; thereafter, the hydrogen or / and residual gas produced by the main hydrogen production equipment 20 maintains the main hydrogen production equipment 20 runs.

[0095] As mentioned above, the hydrogen production system can have one or more sub-hydrogen production equipment 30. In the case where the system includes multiple sub-hydrogen production equipment 30, each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com