On-board hydrogen system for fuel cell automobile

A fuel cell and hydrogen system technology, applied in the field of vehicle-mounted hydrogen system, can solve the problems of not considering the unloading function, not considering the utilization, not environmental protection, etc., achieving the effect of complete functions, in place security measures, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

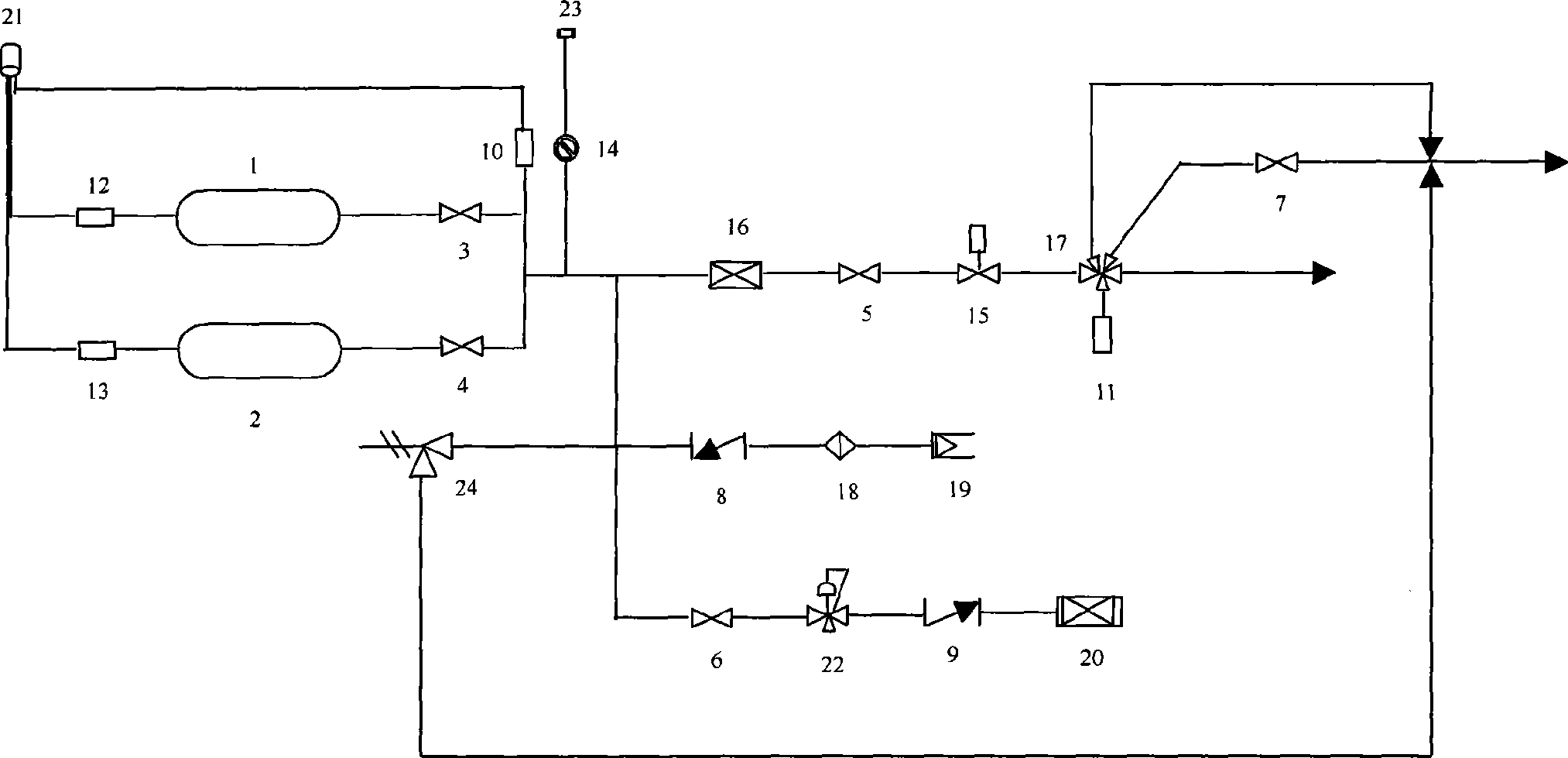

[0018] Embodiment 1 Air-receiving operation: The air-receiving operation is usually carried out when the fuel cell vehicle is turned off. Make sure needle valves 3 and 4 are fully open. Connect the vehicle communication interface to the refueling machine on the hydrogen refueling station. Insert the hydrogenation nozzle of the hydrogenation station into the gas receiver to ensure a good connection. Turn on the switches of the hydrogenation gun and gas dispenser in sequence, and the high-pressure hydrogen from the hydrogenation station will pass through the gas receiving head 19, the filter 18, the check valve 8, and the needle valves 3 and 4, and then enter the on-board hydrogen storage bottles 1 and 2. During the injection process, the temperature and pressure changes in the hydrogen storage bottle are transmitted to the hydrogenation machine through the communication interface in real time by the pressure sensor 10 and the temperature sensor 12, 13, so that the gas filling ...

Embodiment 2

[0019] Embodiment 2 Unloading operation: When the fuel cell vehicle is in the "flame off" state, connect the quick connector 20 to the external unloading system, open the needle valve 6 to the fully open state, adjust the pressure regulating valve 22 to the maximum, and the hydrogen storage bottle in the vehicle The hydrogen will enter the external unloading system through the needle valves 3, 4, 6, the pressure regulating valve 22, the one-way valve 9 and the quick connector 20 in sequence. When the hydrogen pressure in the on-board hydrogen bottle is higher than the hydrogen pressure in the storage tank of the external unloading system, the pressure difference between the two will be used to directly unload the hydrogen into the storage tank; when the hydrogen pressure in the on-board hydrogen bottle is lower than the external When the hydrogen pressure in the storage tank of the unloading system is used, the gas booster in the external unloading system will be used to pressu...

Embodiment 3

[0020] Embodiment 3 Hydrogen supply operation: After the fuel cell vehicle enters the "ignition" state, the power is turned on, the solenoid valve is automatically opened, the needle valve 5 is in the normally open state, and the hydrogen output pressure of the pressure regulating and stabilizing valve is preset. The value is transmitted to the vehicle controller by the pressure sensor 11 on board the valve. In some specific cases, such as the initial commissioning of the hydrogen system, the needle valve 7 can be opened to vent the purge gas upstream of the pressure regulating and stabilizing valve through the purge bypass, which can ensure the purity of the hydrogen that subsequently enters the fuel cell engine. After the electromagnetic valve 15 is opened, the high-pressure hydrogen in the vehicle-mounted hydrogen bottle passes through the overflow valve 16, the needle valve 5, and the electromagnetic valve 15 successively, and then flows into the pressure regulating and sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com