Subsynchronous damping control system for effectively inhibiting subsynchronous resonance and oscillation

A subsynchronous resonance and damping control technology, applied in the control system, control generator, AC network circuit, etc., can solve the concept and control logic without introducing subsynchronous current dynamic compensation, poor robustness, and no suppression of SSR/ The main functions of SSO, etc., can solve the multi-mode subsynchronous resonance and oscillation problems, reduce the fatigue loss of shafting torsional vibration, and improve the subsynchronous stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

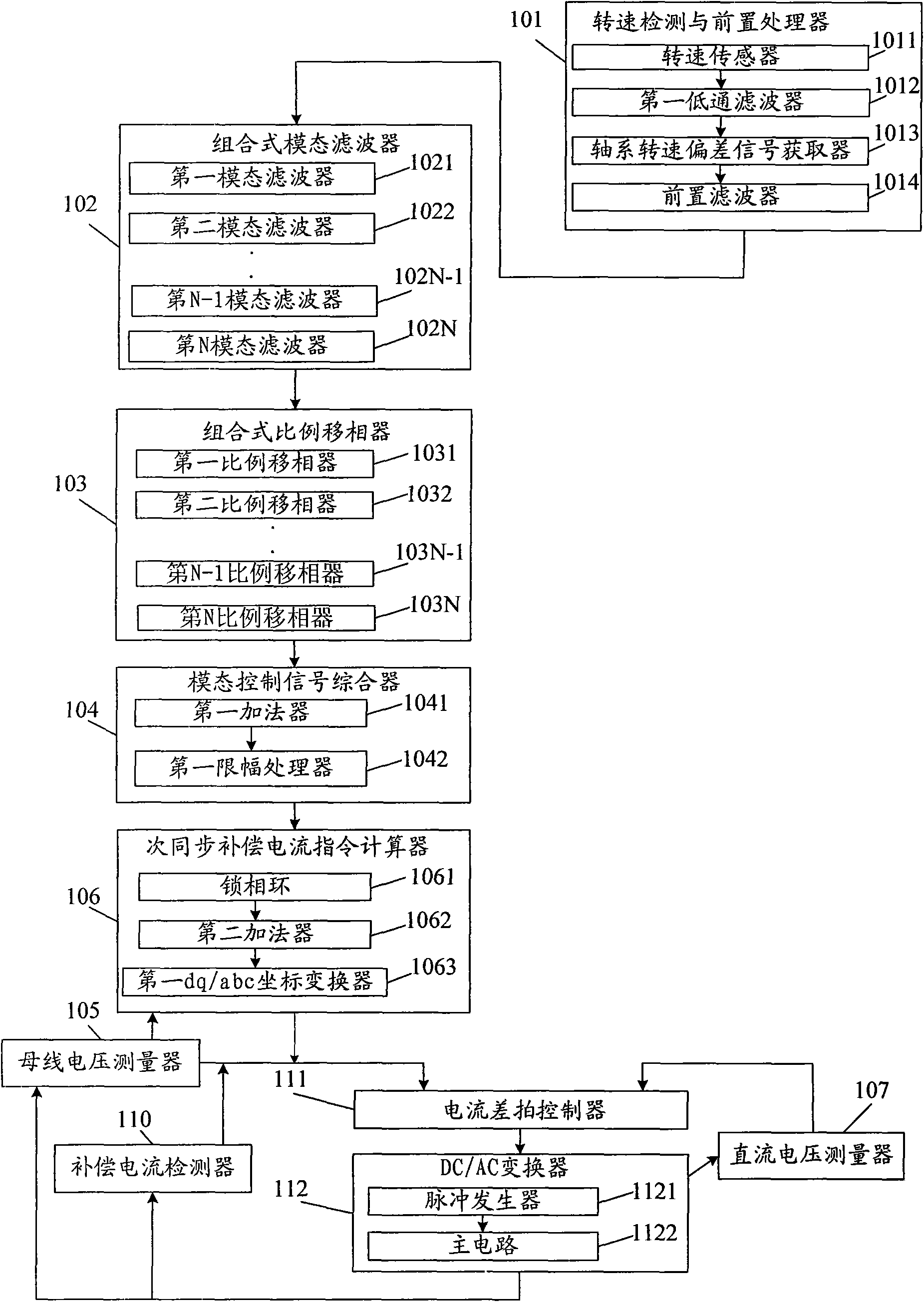

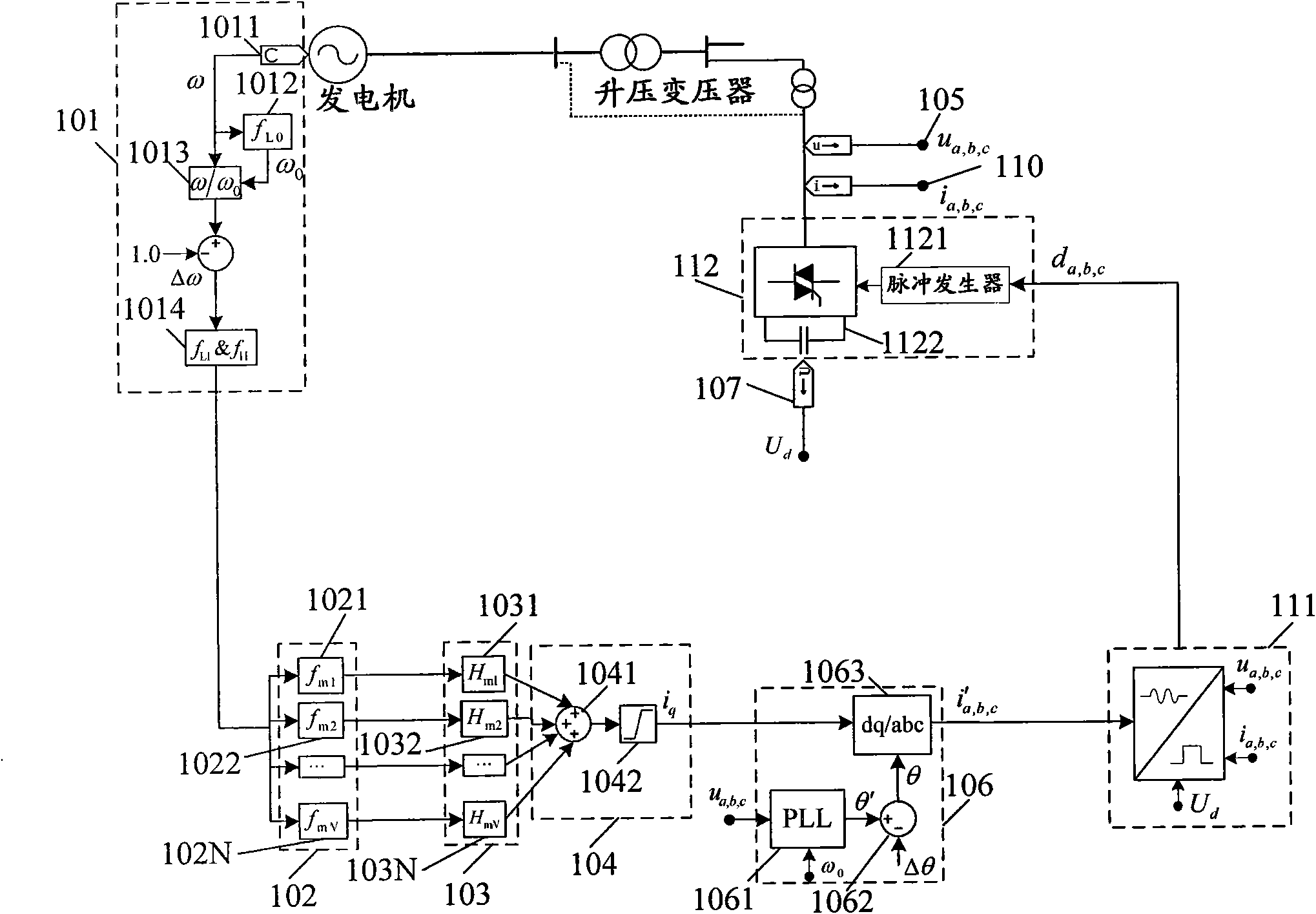

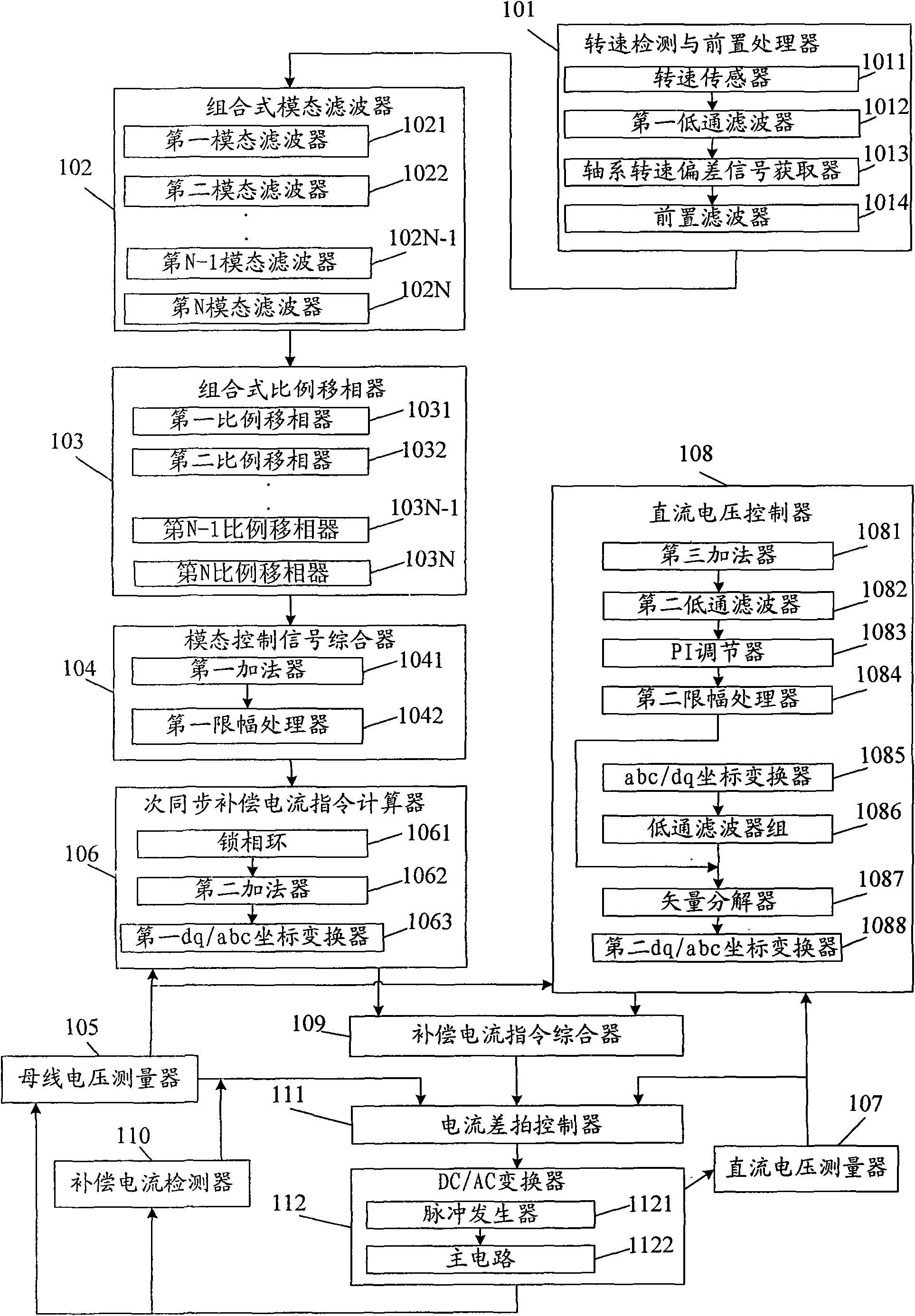

[0029] see figure 1 and figure 2 , the embodiment of the present invention provides a subsynchronous damping control system that effectively suppresses subsynchronous resonance and oscillation, specifically including: rotational speed detection and pre-processor 101, combined modal filter 102, combined proportional phase shifter 103 , modal control signal synthesizer 104, bus voltage measurer 105, subsynchronous compensation current command calculator 106, DC voltage measurer 107, compensation current detector 110, current beat controller 111 and DC / AC converter 112.

[0030] Among them, the rotational speed detection and pre-processor 101 is used to detect the rotational speed signal at the shaft end of the generator, obtain the rotational speed corresponding to the rotational speed signal and the synchronous angular velocity corresponding to the DC component in the rotational speed signal, and obtain only sub-synchronous Feedback signal for frequency components.

[0031] ...

Embodiment 2

[0173] like Figure 6 As shown, for the transmission system with SSR / SSO risk, the subsynchronous damping control system described in Embodiment 1 above will be designed and implemented according to the following steps:

[0174] 301: SSR / SSO Feature Analysis and Evaluation

[0175] On-site measurement of the characteristic parameters of the torsional vibration of the turbogenerator shafting with SSR / SSO risk. The modeling of the transmission system and the nonlinear electromagnetic transient system; the SSR / SSO characteristics of the transmission system are evaluated by using the method of eigenvalue analysis and time domain simulation, and the subsynchronous torsional vibration modes that need to be focused on are determined.

[0176] 302: Offline Parameter Design of Subsynchronous Damping Control System

[0177] For the subsynchronous torsional vibration mode determined in 301 that needs to be focused on, firstly determine the filters of the subsynchronous damping control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com