Vibration and oscillation composite type road roller steel wheel

A road roller and composite technology, applied in the field of road roller steel wheels, can solve the problems of not being able to meet the requirements well, the work efficiency is reduced, the compaction method is single, etc., and achieves convenient processing, production and assembly, safe working process, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

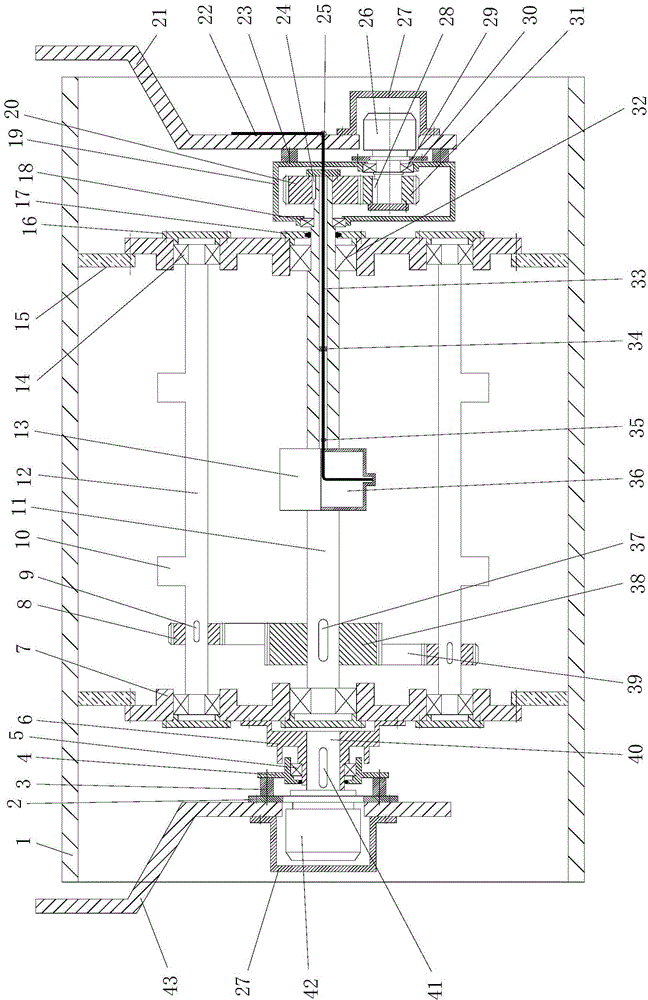

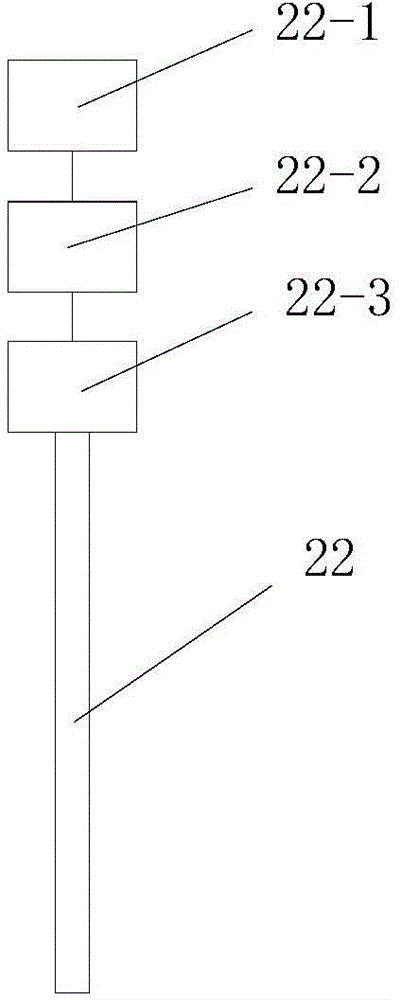

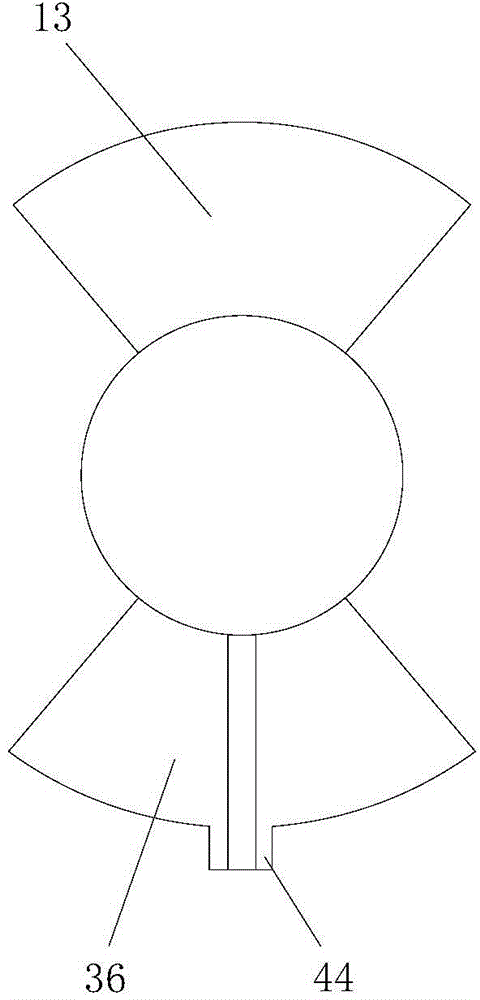

[0049] like figure 1 As shown, the present invention includes a cylindrical hollow wheel body 1, a hydraulic drive mechanism for driving the hollow wheel body 1, two wheel frames symmetrically arranged on the left and right sides of the hollow wheel body 1, and installed in the middle part of the inner side of the hollow wheel body 1. And the vibration shaft 11 arranged coaxially with the hollow wheel body 1 and the two vibration shafts 12 symmetrically arranged on both sides of the vibration shaft 11, the two vibration shafts 12 are arranged parallel to the vibration shaft 11 and both are located at Inside the hollow wheel body 1 , the two wheel frames are respectively the left wheel frame 43 and the right wheel frame 21 located on the left and right sides of the hollow wheel body 1 . An overrunning clutch 38 is installed on the vibrating shaft 11, and a driven gear 8 is coaxially installed on the two vibrating shafts 12, and the driven gear 8 installed on the two vibrating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com