Patents

Literature

266results about How to "Control cooling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

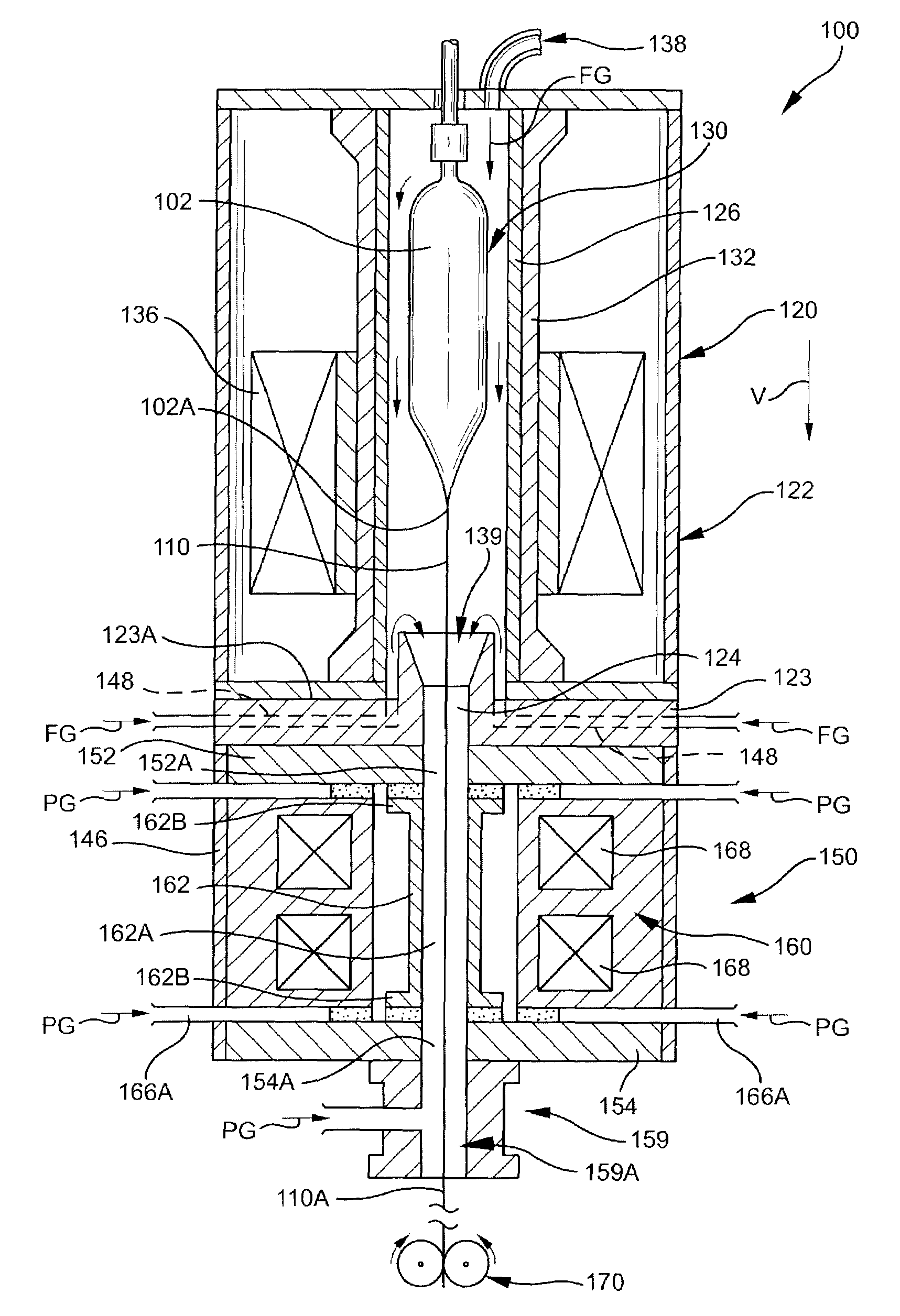

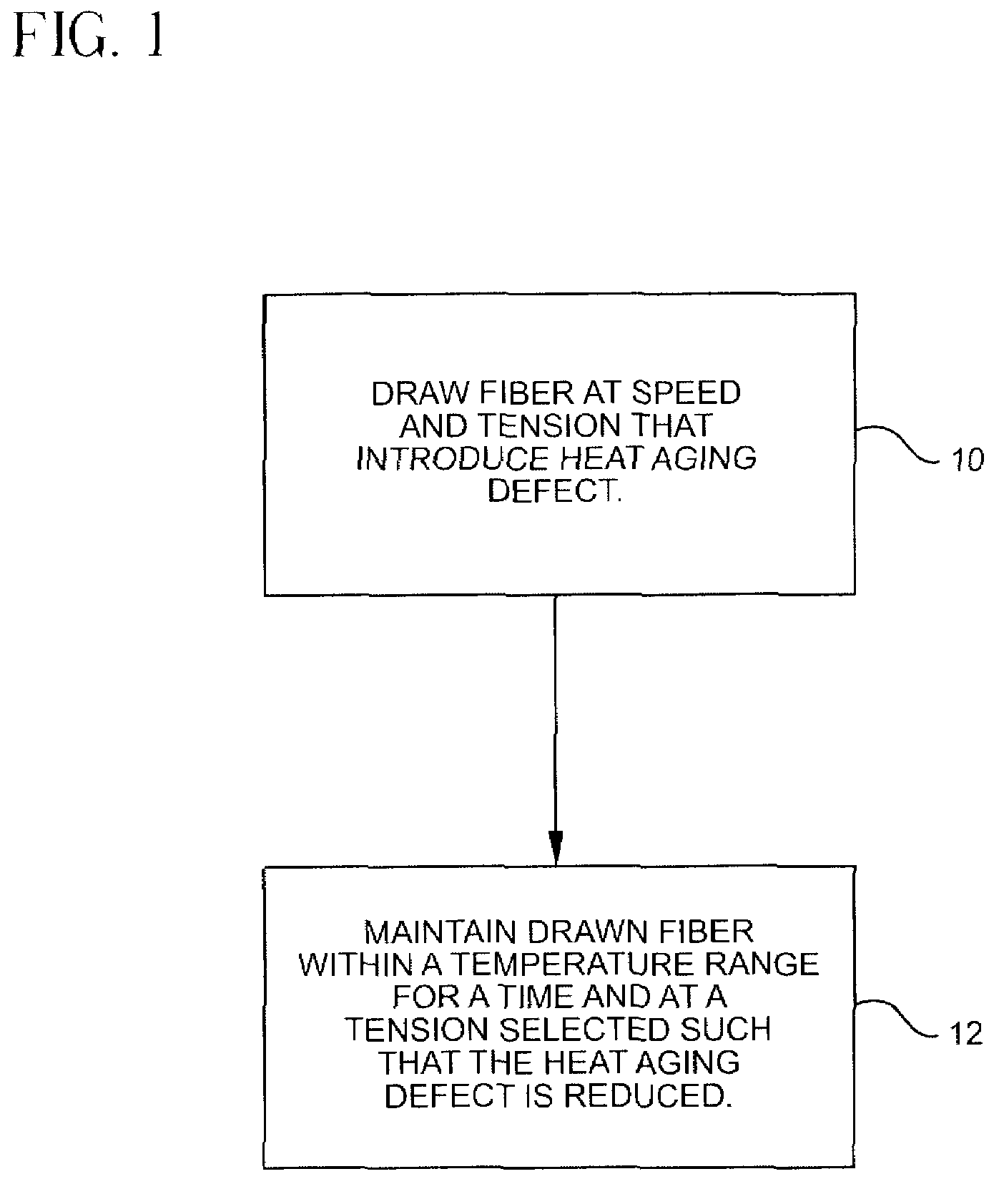

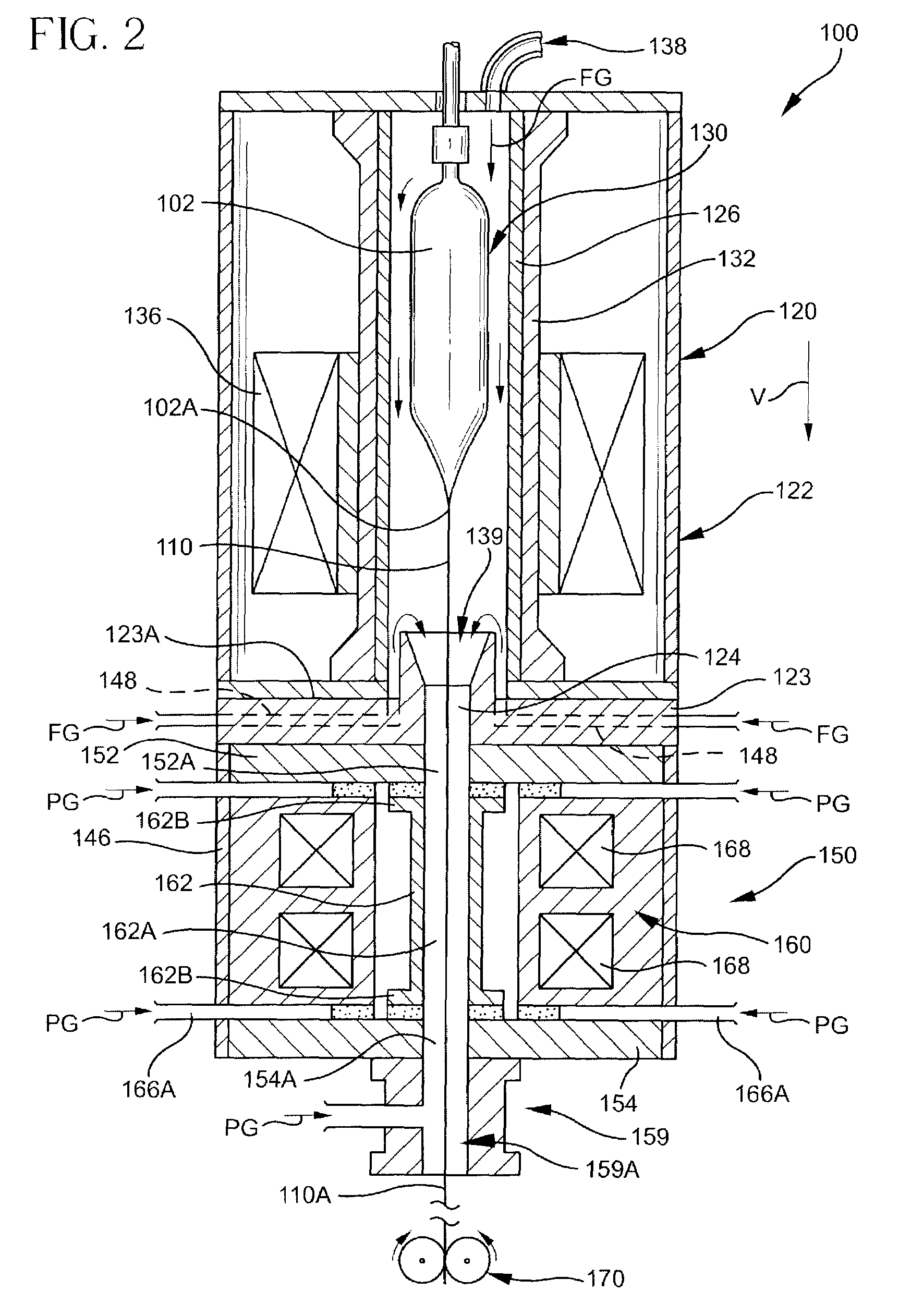

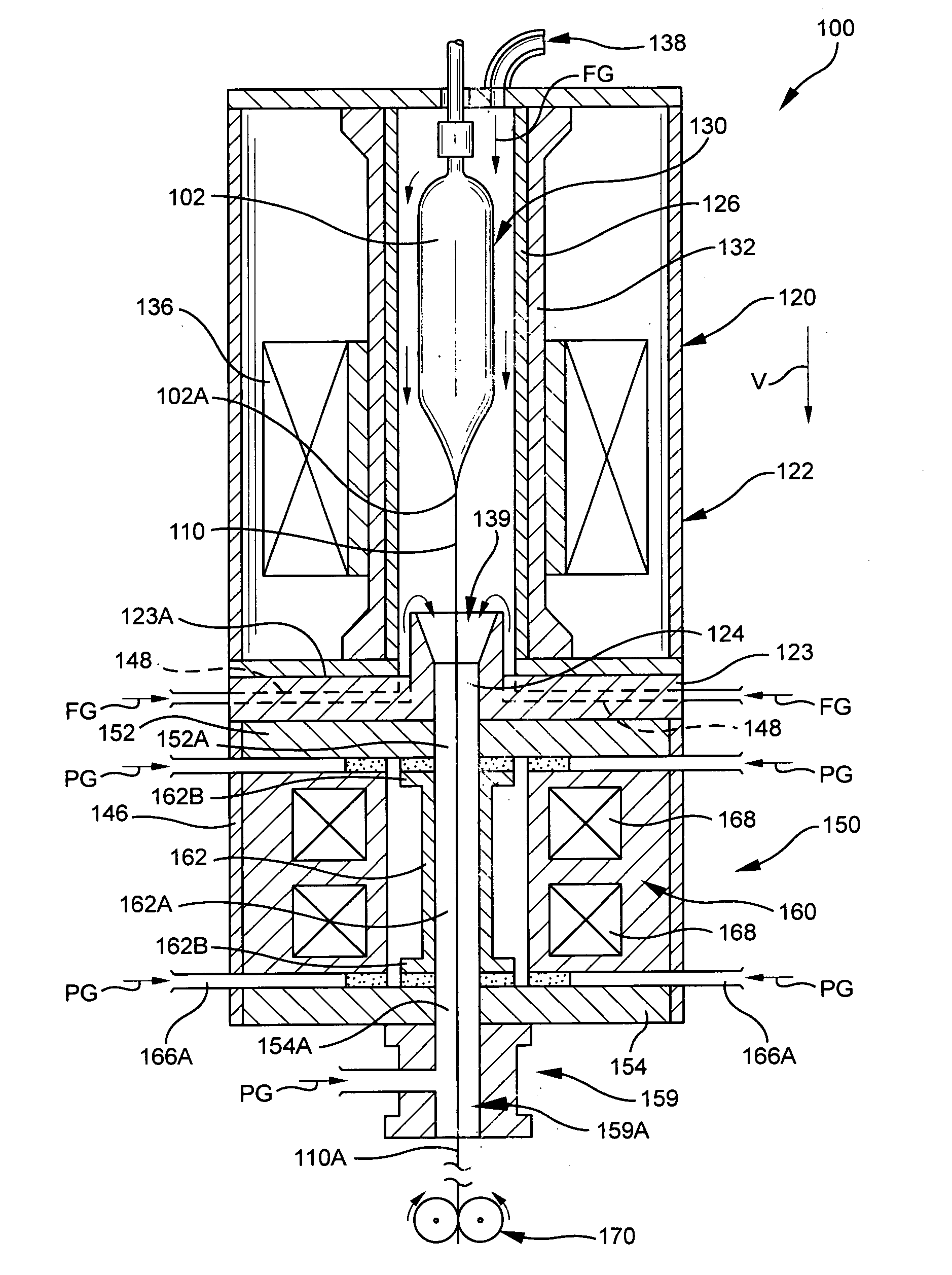

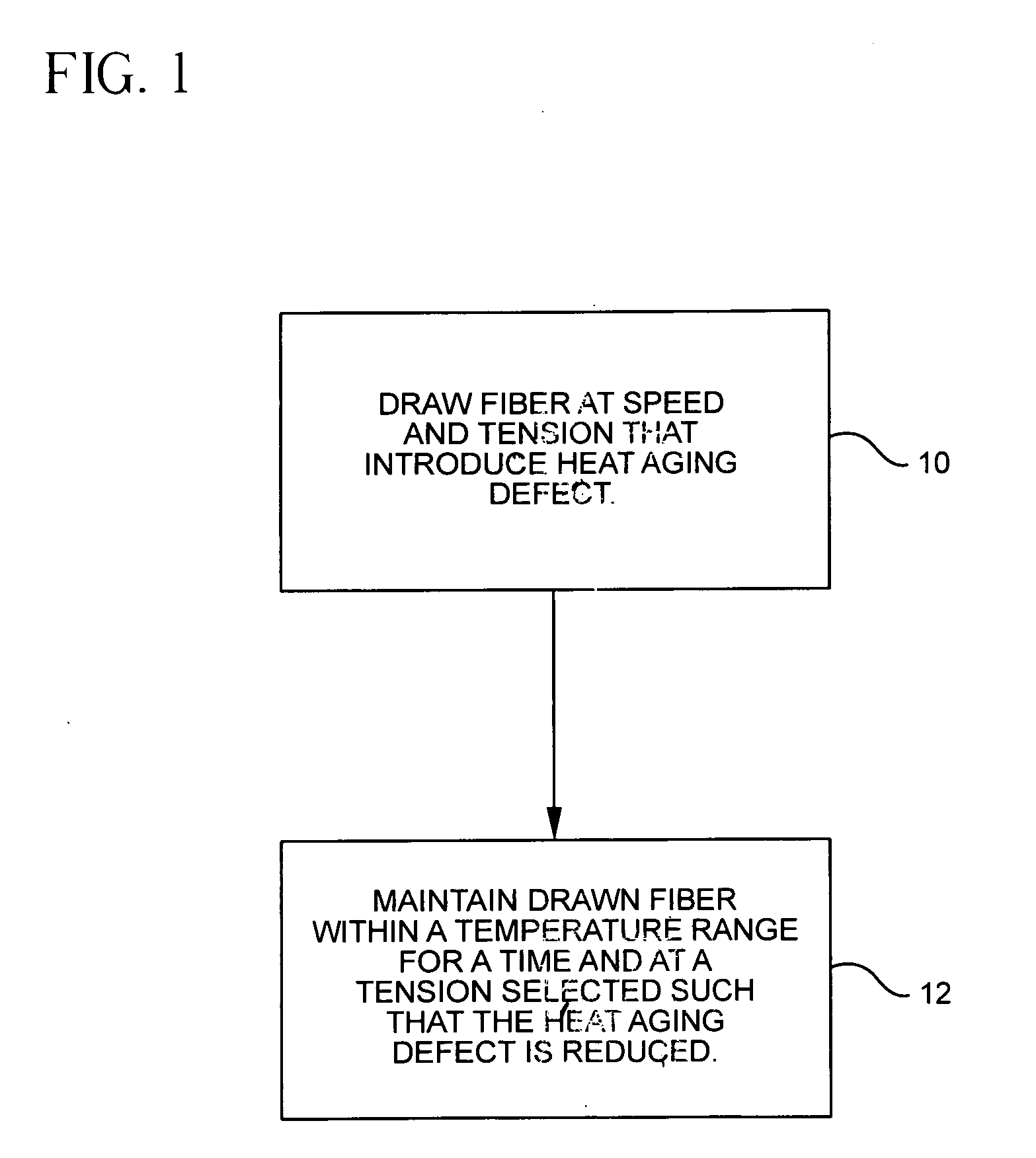

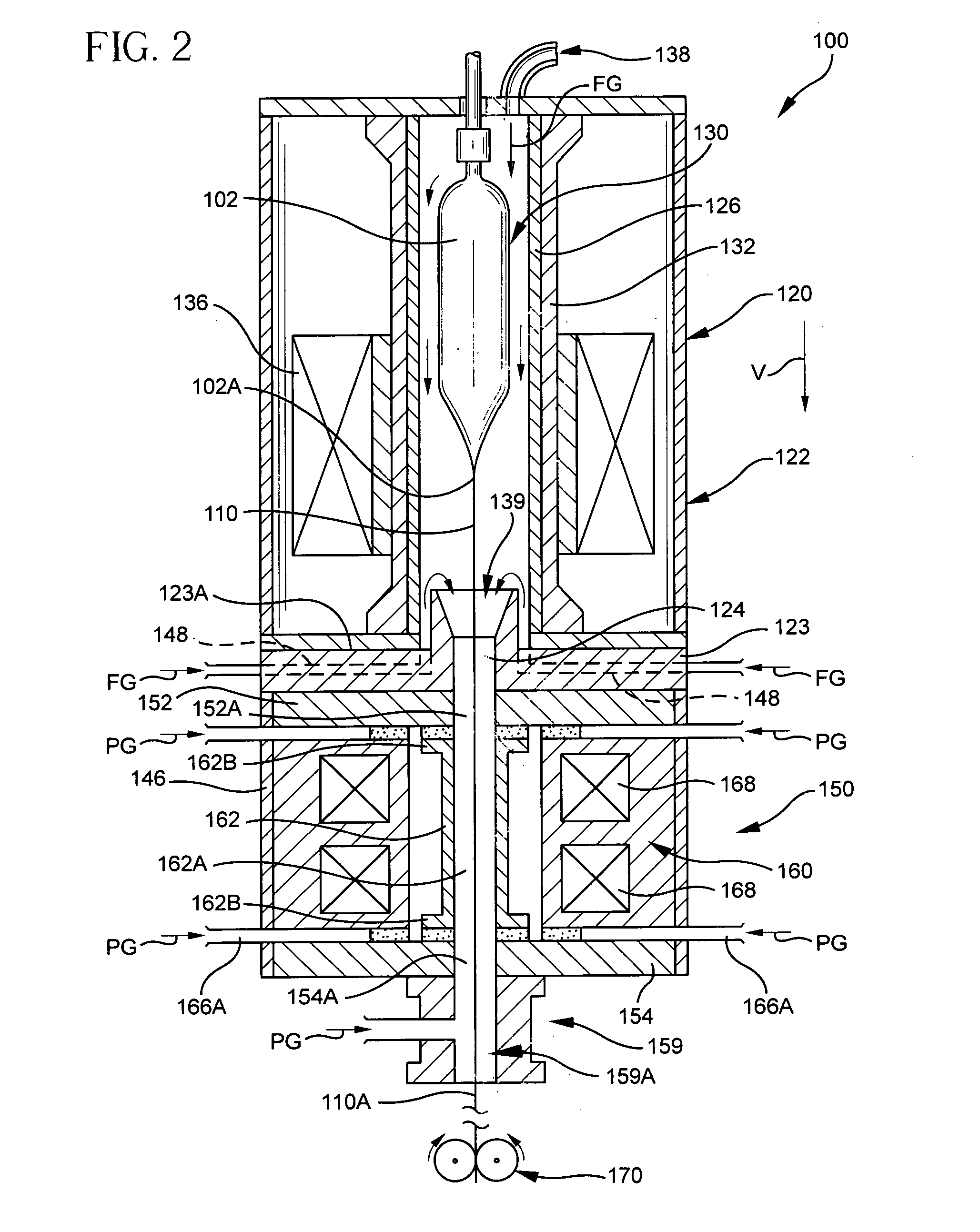

Methods and apparatus for forming heat treated optical fiber

InactiveUS7565820B2Trend downDecreases micro-density variationGlass fibre drawing apparatusNon-linear opticsUltrasound attenuationRayleigh scattering

A method for forming an optical fiber includes drawing the optical fiber from a glass supply and treating the fiber by maintaining the optical fiber within a treatment temperature range for a treatment time. Preferably also, the fiber is cooled at a specified cooling rate. The optical fiber treatment reduces the tendency of the optical fiber to increase in attenuation due to Rayleigh scattering, and / or over time following formation of the optical fiber due to heat aging. Apparatus are also provided.

Owner:CORNING INC

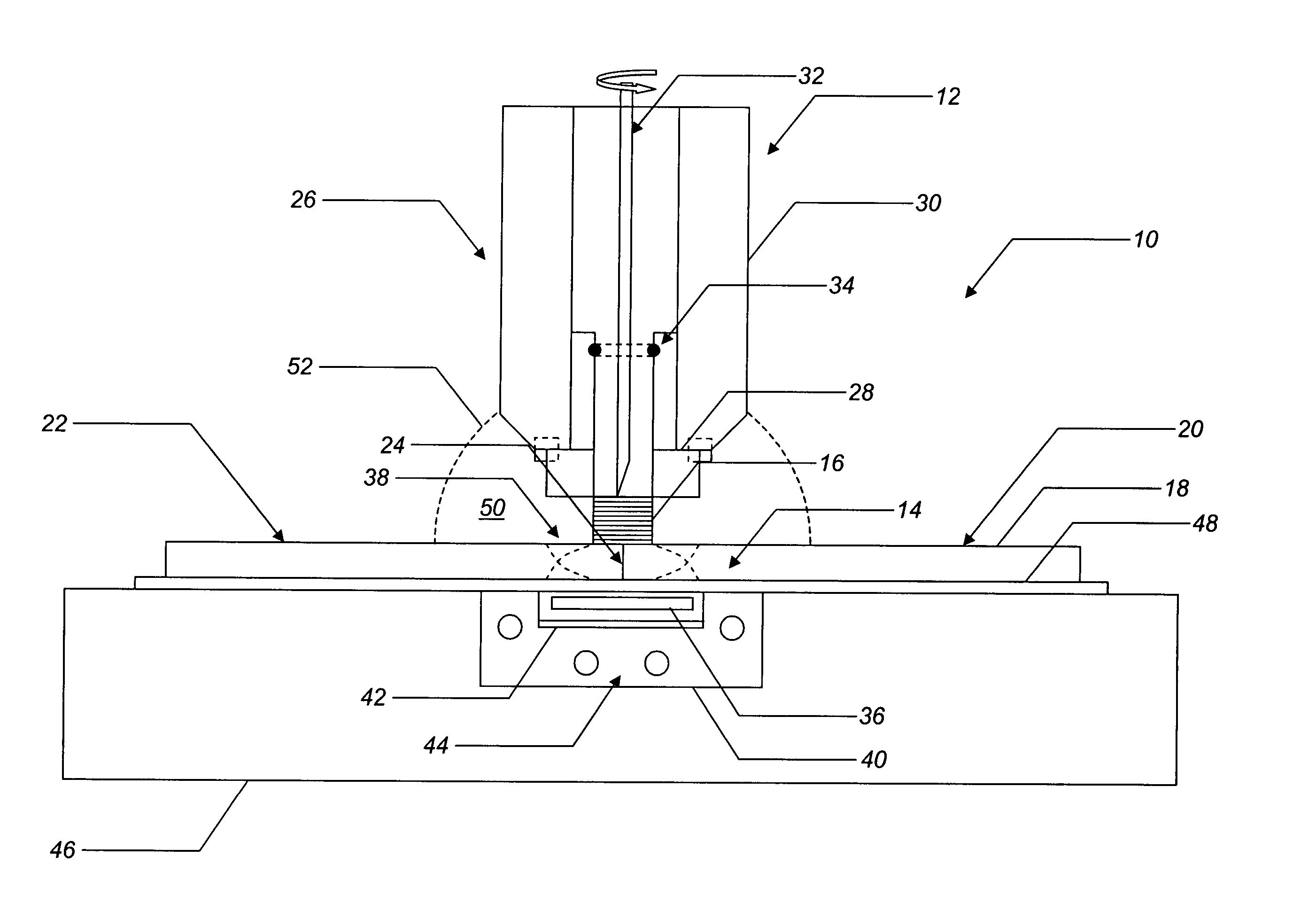

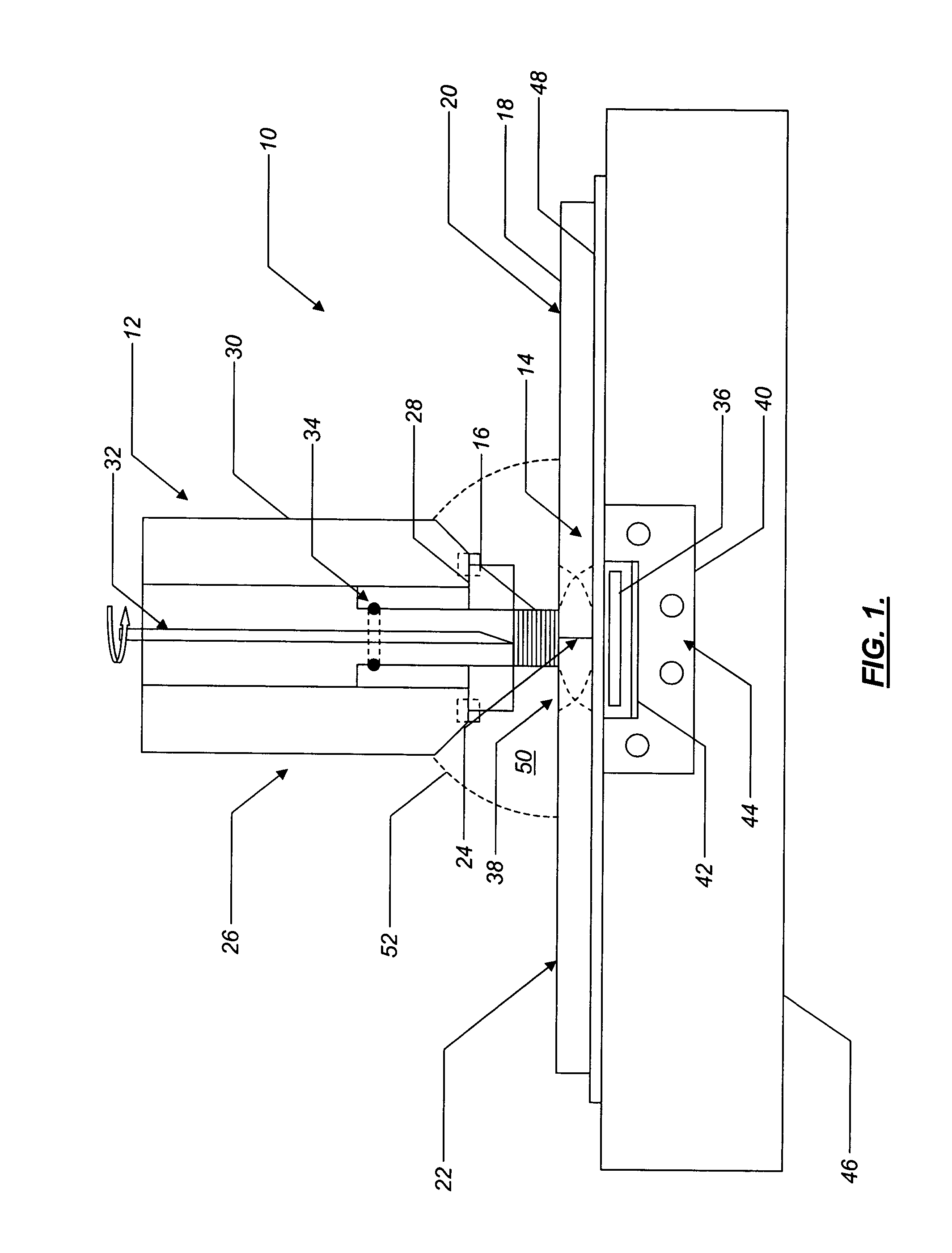

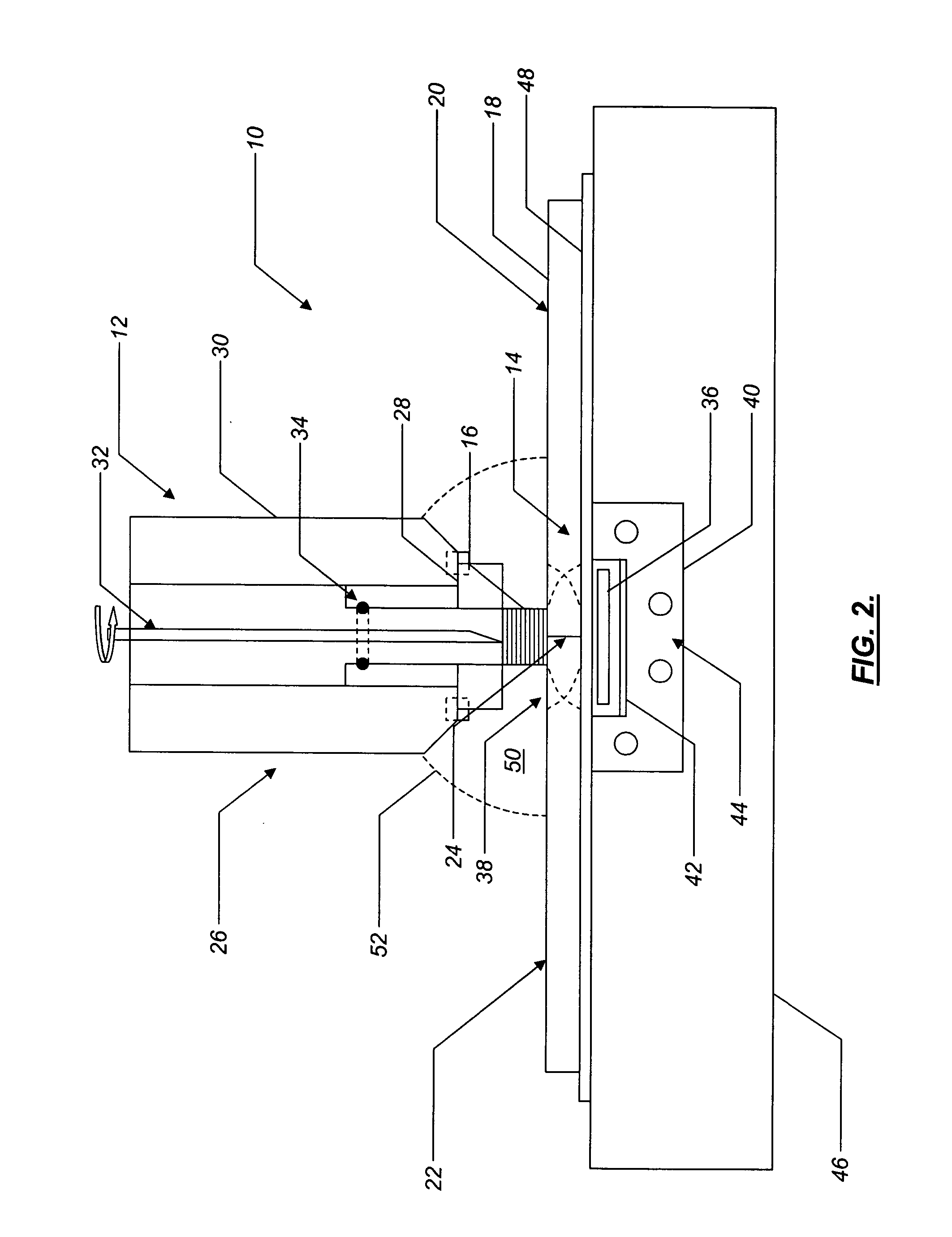

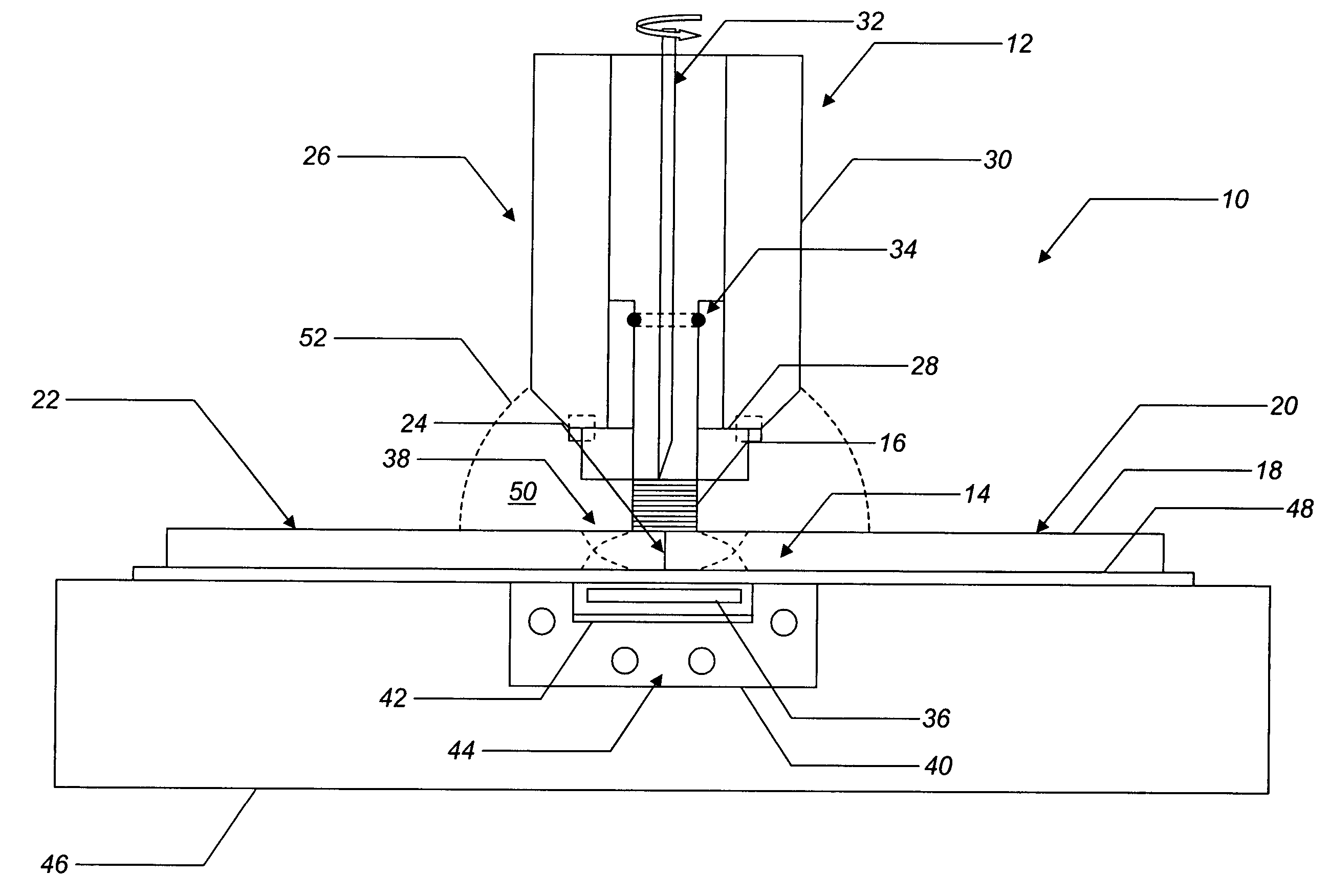

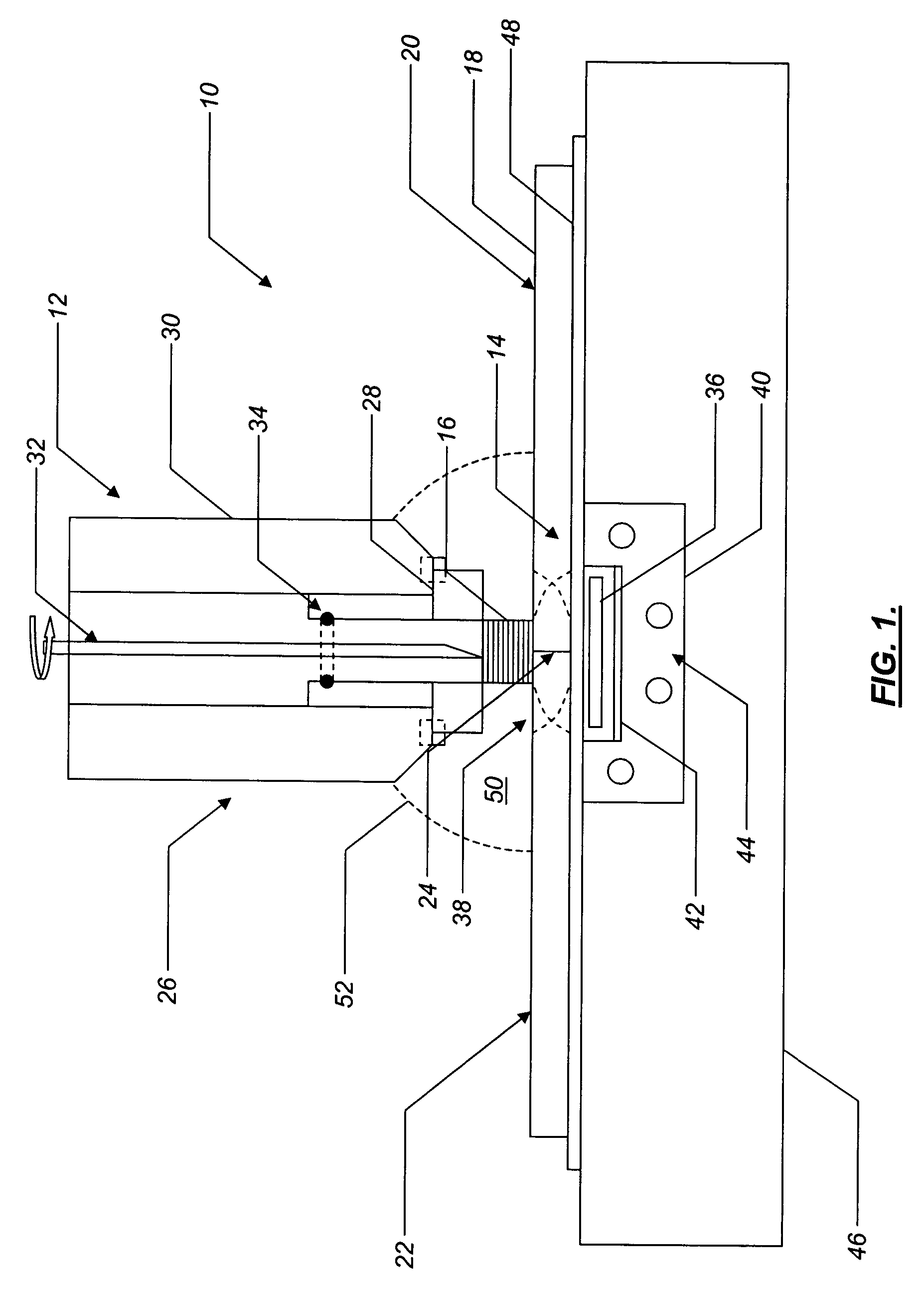

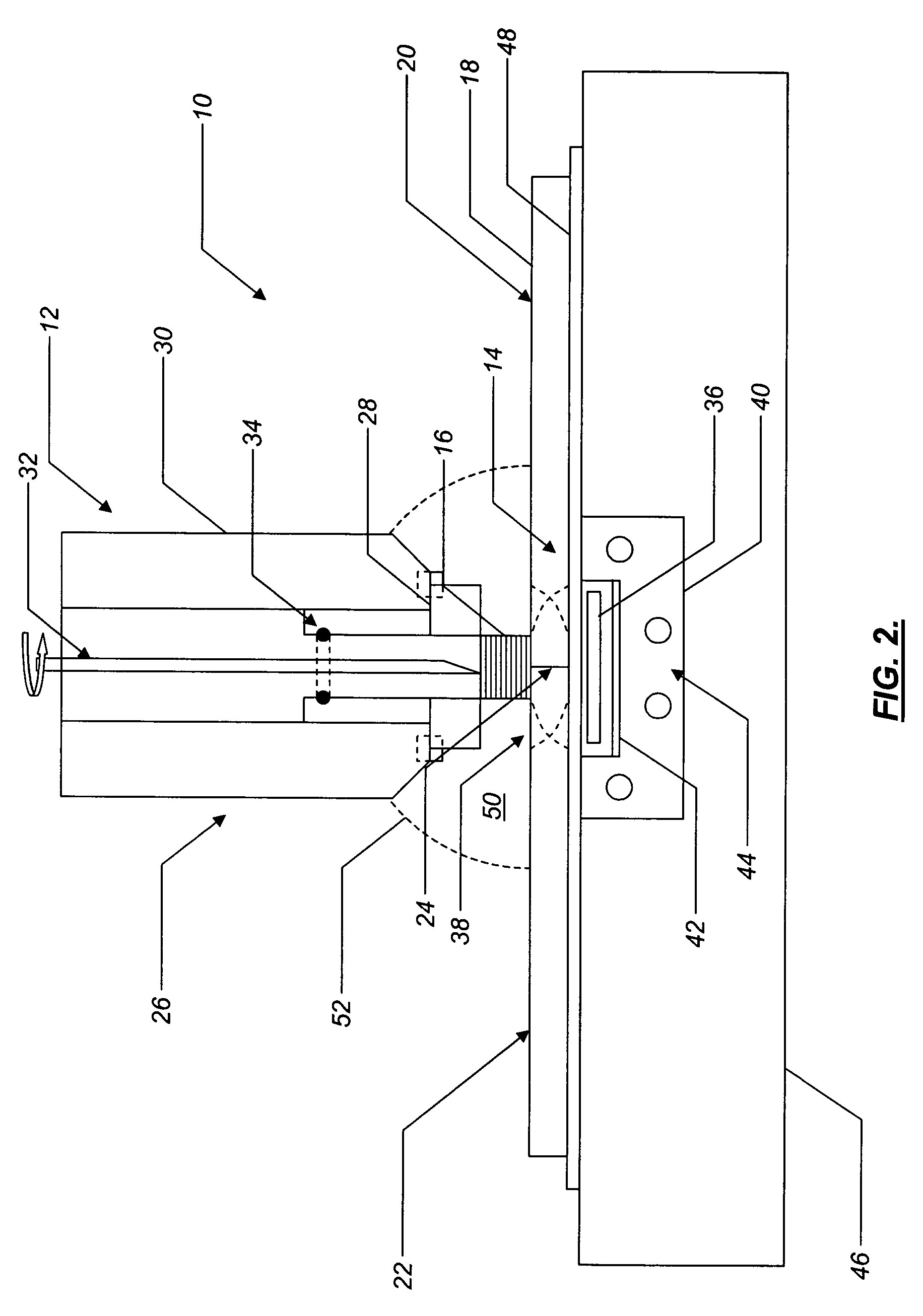

Friction stir welding apparatus and associated thermal management systems and methods

ActiveUS20050045694A1Good mechanical integrityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThermal management system

The present invention provides a friction stir welding apparatus and associated thermal management systems and methods for joining one or more similar or dissimilar materials forming a workpiece along a joint to be welded. The friction stir welding apparatus includes a pin tool apparatus selectively disposed adjacent to and in direct contact with a first surface of the workpiece along the joint to be welded and a heating member disposed adjacent to a second surface of the workpiece along the joint to be welded, the heating member operable for controllably heating at least a portion of the workpiece adjacent to the joint to be welded. The friction stir welding apparatus also includes an annular spindle having an interior portion and an axis, the interior portion of the annular spindle at least partially defining one or more cooling channels, the one or more cooling channels operable for containing a cooling fluid. The friction stir welding apparatus further includes a shoulder disposed adjacent to the annular spindle and substantially aligned with the axis of the annular spindle and a pin tool disposed adjacent to the shoulder and substantially aligned with the axis of the annular spindle. The cooling fluid is operable for cooling at least one of the shoulder and the pin tool.

Owner:GENERAL ELECTRIC CO

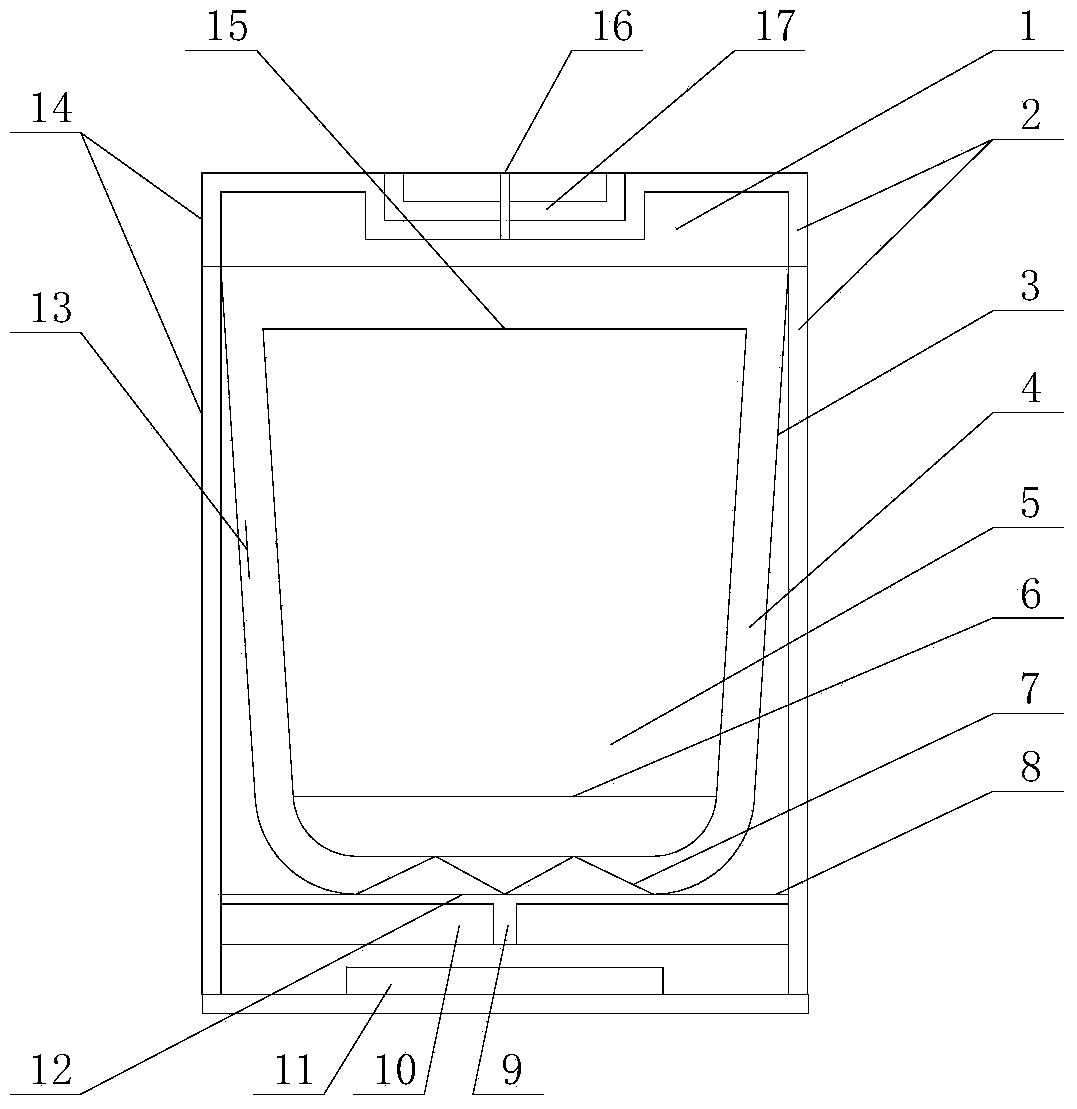

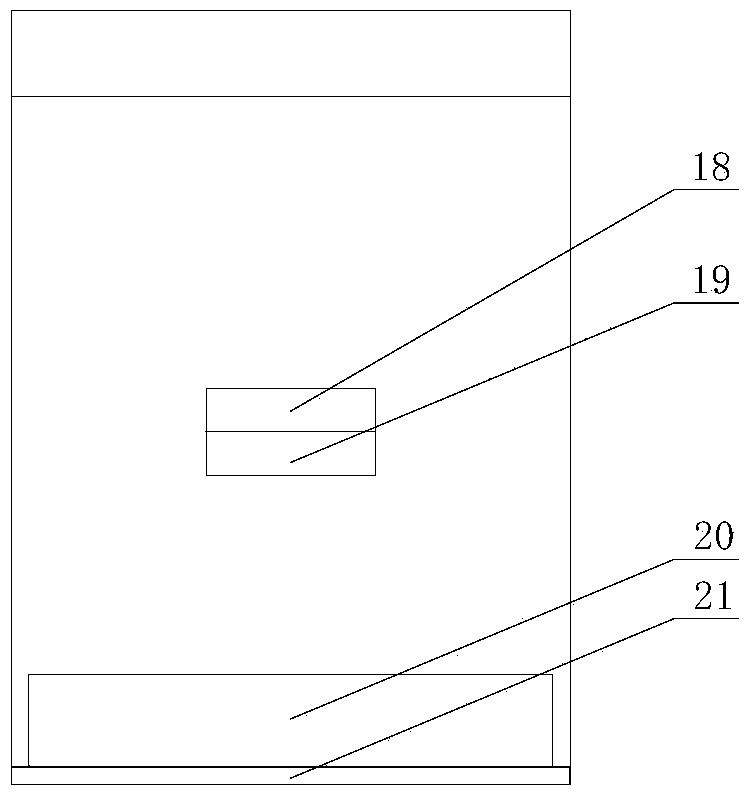

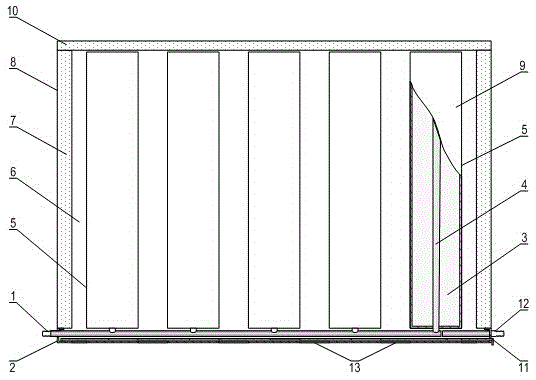

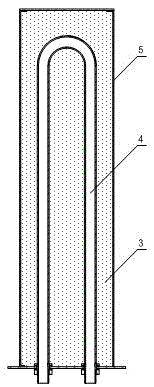

Multifunctional modularized lithium electric cooker

ActiveCN104000478AImprove cooling effectControl cooling rateTemperatue controlCooking utensils shields/jacketsElectrical engineering technologyBarrel Shaped

The invention belongs to the technical field of electric appliances and electric engineering, and relates to a multifunctional modularized lithium electric cooker. An embedded handle is embedded in an upper cover with a heat-preserving layer, the middle of the upper cover with the heat-preserving layer is provided with an air outlet hole, a lateral thermoelectric film is attached to the outer side of a barrel-shaped outer container, and a barrel-shaped inner container is arranged on the inner side of the barrel-shaped outer container; an inner container upper cover covers the top of the barrel-shaped inner container, and the lower end of the barrel-shaped inner container is provided with a strainer; the barrel-shaped outer container is arranged on an inner and outer container supporting frame, the inner and outer container supporting frame is disposed on a bottom support, the center of the bottom support is provided with a bottom cooling air hole, a bottom thermoelectric film is attached to the surface of the bottom support, and the lower portion of the bottom support is provided with a lithium battery; a power supply cover plate is disposed on the outer side of the lithium battery; the inner side of the bottom of a shell is provided with a fan, and a bottom heat-preserving pad is arranged on the outer side of the bottom of the shell; one side of the barrel-shaped outer container is provided with a temperature sensor connected with a temperature display and control unit, and the shell is provided with the temperature display and control unit and a clock displaying, timing and setting unit. The multifunctional modularized lithium electric cooker is simple in structure, multifunctional, convenient to carry, safe to use, convenient to repair and maintain, high in utilization rate and good in heat preservation.

Owner:XUZHOU FENGTONG INFORMATION TECH CO LTD

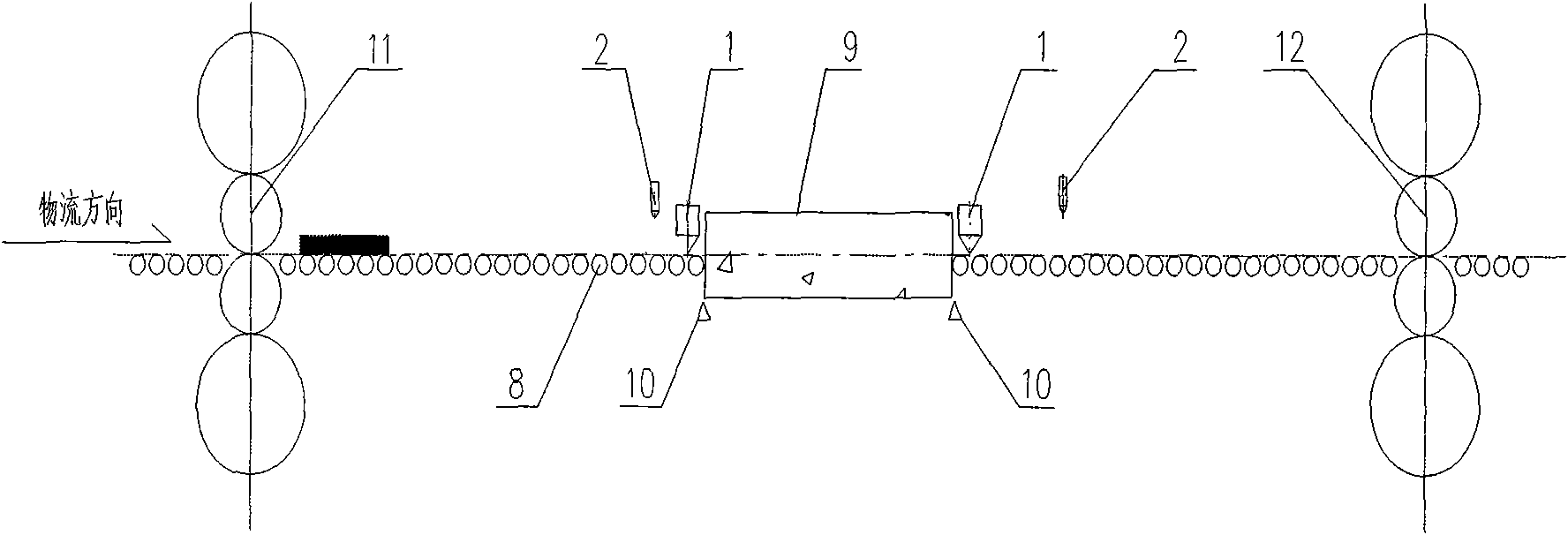

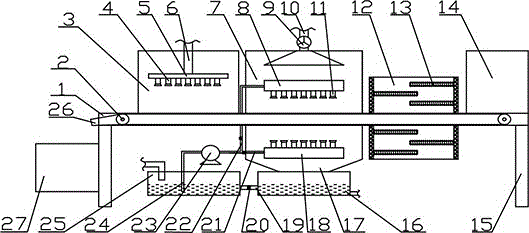

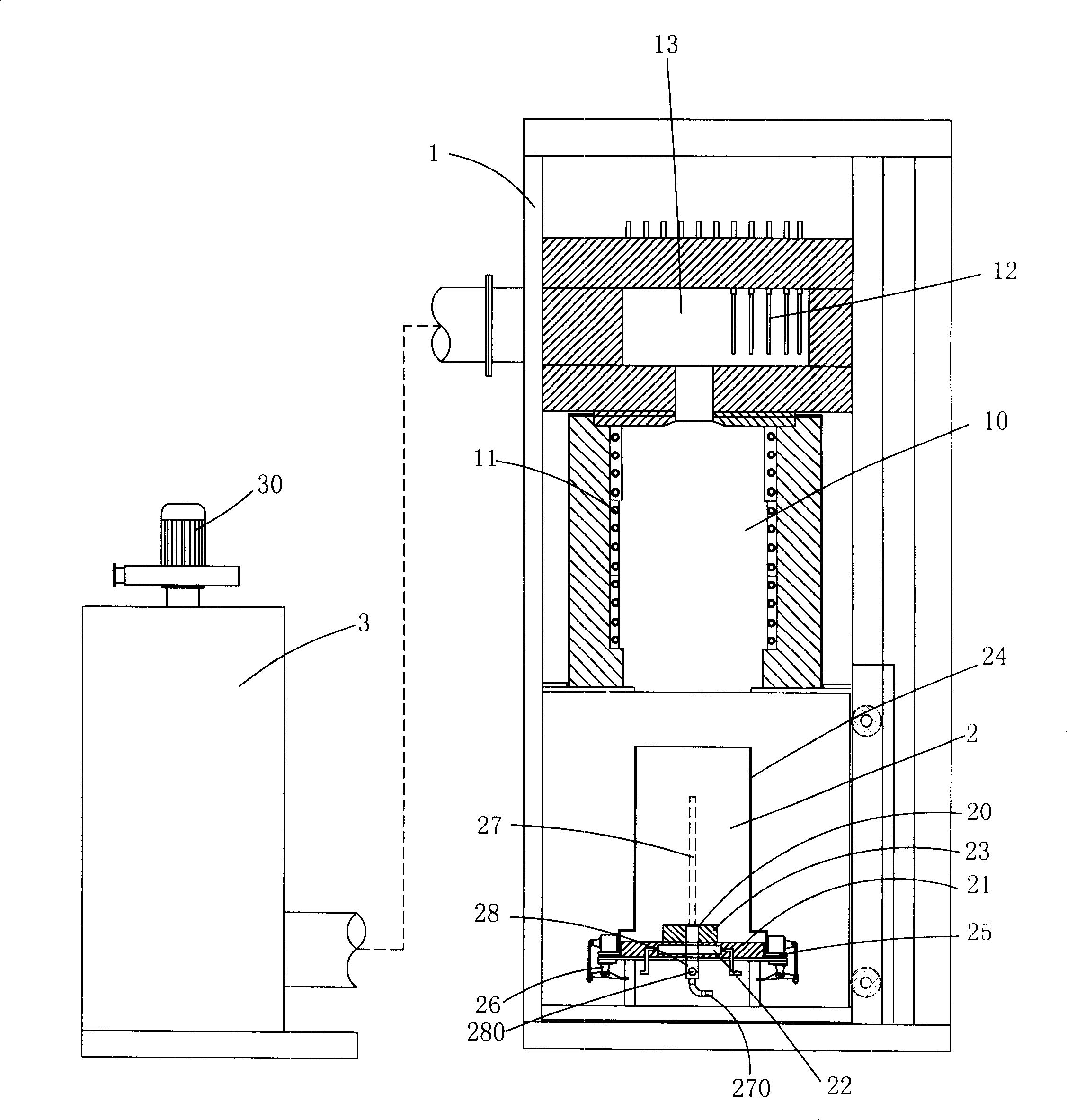

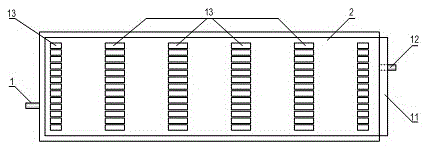

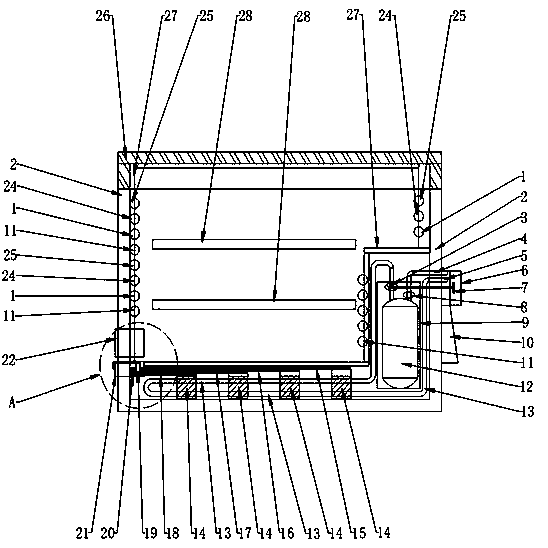

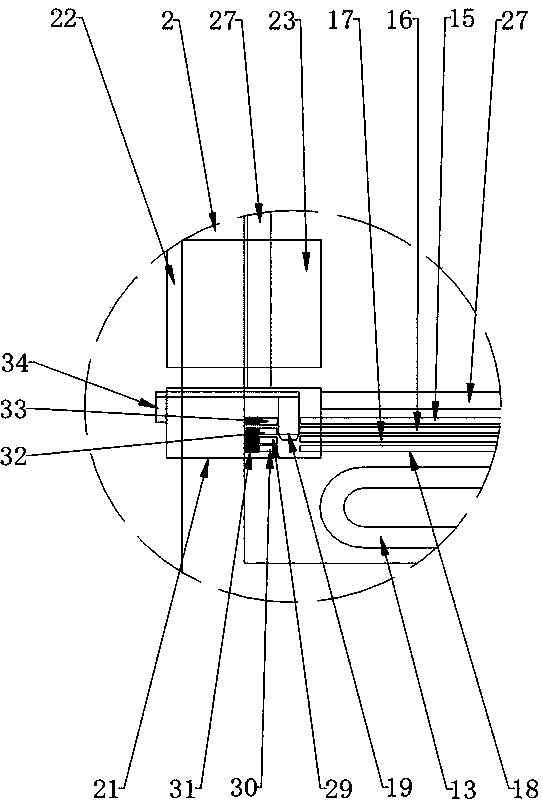

Intermediate blank cooling system and cooling control technology

ActiveCN101642780ADoes not change metal propertiesReduce difficultyTemperature control deviceWork treatment devicesProduction lineEngineering

The invention belongs to the metallurgy technical field and in particular relates to an intermediate blank cooling system and cooling control technology. The intermediate blank cooling system is characterized in that an aerial fog cooling device body is arranged between a rough mill and a finishing mill. The aerial fog cooling device body is composed of an upper cooling header and a lower coolingheader, and an aerial fog nozzle and a compression air pipe are arranged on the cooling water pipe of the upper cooling header and the lower cooling header; and the on / off control valve and flow control valve of the cooling water pipe and the compression air pipe are connected with a control valve station. The intermediate blank aerial fog cooling technology is controlled by the aerial fog controltechnology sprayed on the cooling header arranged near roller ways at the front and rear of the mills. The invention has fast cooling speed without changing metal performance, water yield regulatingrange is wide and the water yield can be regulated continuously, the cooling speed of the intermediate blank can be precisely controlled, and the invention can be widely applicable to middle and thickplate production line.

Owner:CISDI ENG CO LTD

Friction stir welding apparatus and associated thermal management systems and methods

ActiveUS7121448B2Improve integrityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

The present invention provides a friction stir welding apparatus and associated thermal management systems and methods for joining one or more similar or dissimilar materials forming a workpiece along a joint to be welded. The friction stir welding apparatus includes a pin tool apparatus selectively disposed adjacent to and in direct contact with a first surface of the workpiece along the joint to be welded and a heating member disposed adjacent to a second surface of the workpiece along the joint to be welded, the heating member operable for controllably heating at least a portion of the workpiece adjacent to the joint to be welded. The friction stir welding apparatus also includes an annular spindle having an interior portion and an axis, the interior portion of the annular spindle at least partially defining one or more cooling channels, the one or more cooling channels operable for containing a cooling fluid. The friction stir welding apparatus further includes a shoulder disposed adjacent to the annular spindle and substantially aligned with the axis of the annular spindle and a pin tool disposed adjacent to the shoulder and substantially aligned with the axis of the annular spindle. The cooling fluid is operable for cooling at least one of the shoulder and the pin tool.

Owner:GENERAL ELECTRIC CO

Methods and apparatus for forming heat treated optical fiber

InactiveUS20070022786A1Trend downDecreases micro-density variationGlass fibre drawing apparatusGlass productionFiberRayleigh scattering

A method for forming an optical fiber includes drawing the optical fiber from a glass supply and treating the fiber by maintaining the optical fiber within a treatment temperature range for a treatment time. Preferably also, the fiber is cooled at a specified cooling rate. The optical fiber treatment reduces the tendency of the optical fiber to increase in attenuation due to Rayleigh scattering, and / or over time following formation of the optical fiber due to heat aging. Apparatus are also provided.

Owner:CORNING INC

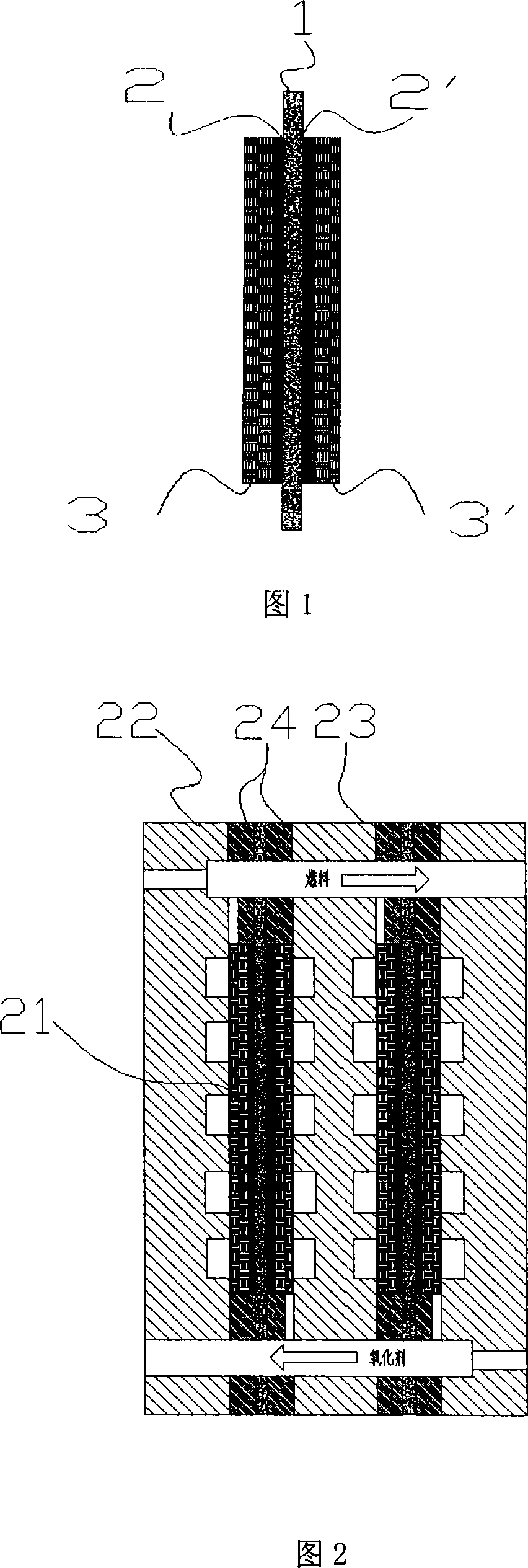

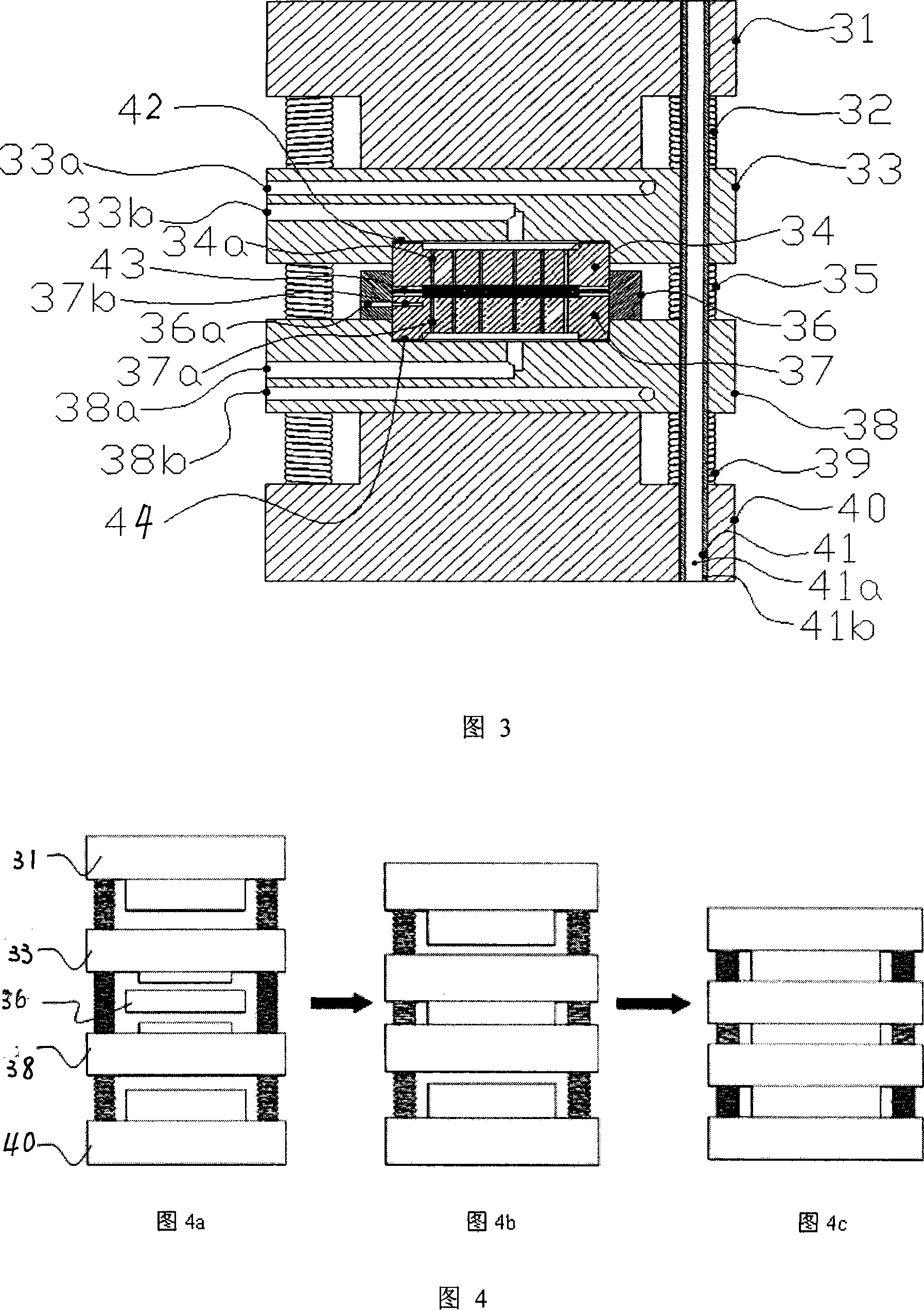

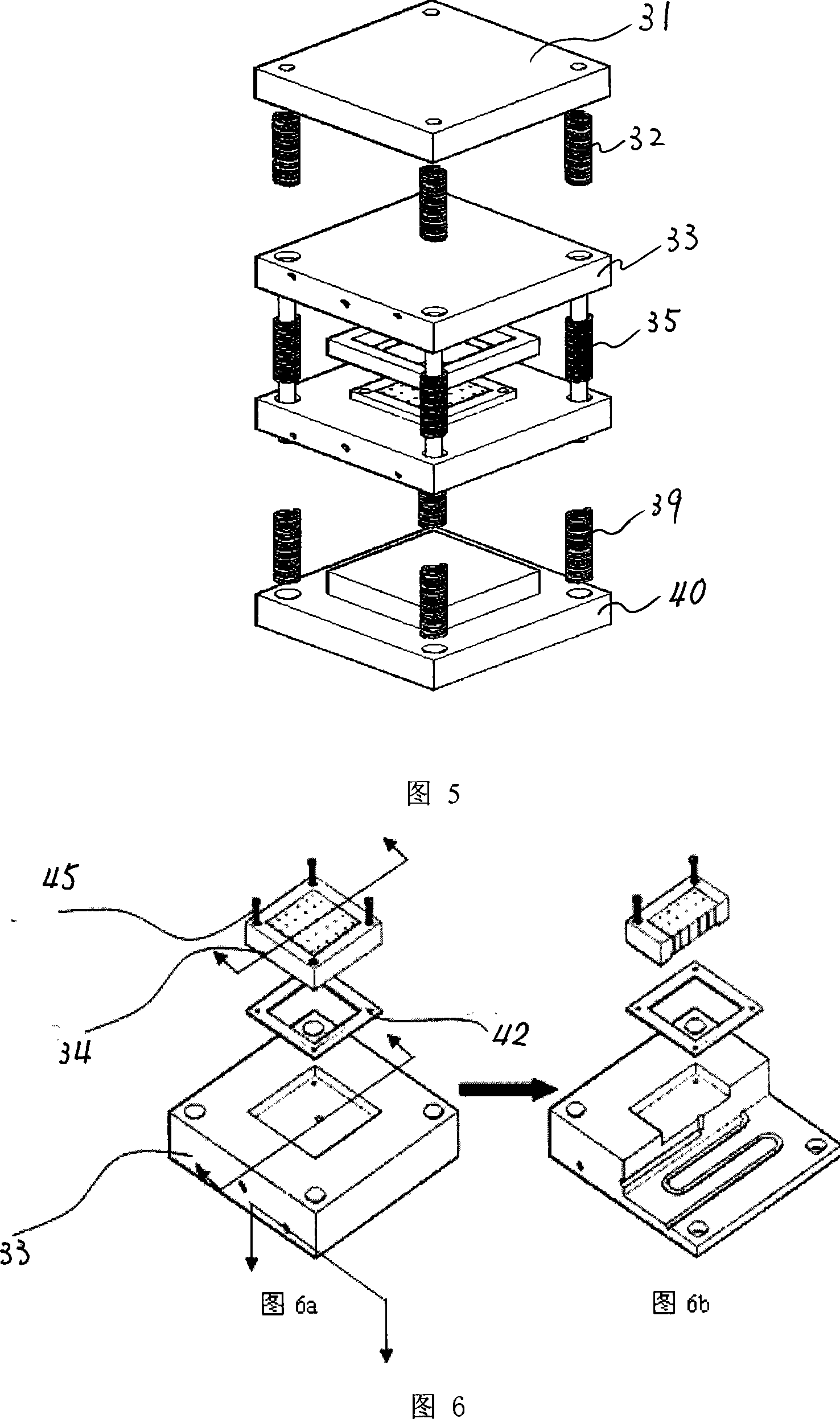

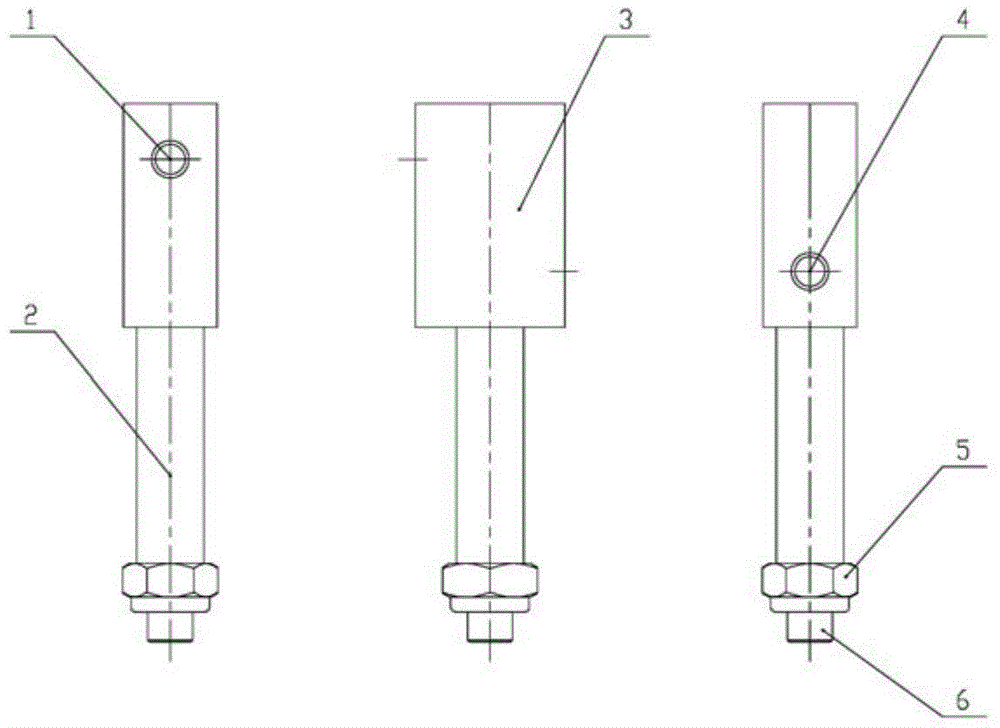

Pressing mold device for hot pressure prepared fuel cell membrane electrode

ActiveCN101183717AGuaranteed vertical alignmentImprove general performanceCell electrodesFuel cell detailsFuel cellsEngineering

The invention discloses a compound die device used in a hot pressing fuel battery film electrode, comprising a top pressing board, a top die, a positioning frame, a bottom die, a bottom pressing board, a plurality of positioning guide pillars and catapult springs; wherein the top die comprises a top die head and a top die base. A positioning groove for diffusion layers is arranged at the center ofthe contact surface between the top die head and the film electrode, so as to position the first diffusion layer of the film electrode. The bottom die comprises a bottom die head and a bottom die base, which has the same structure as the top die; wherein the bottom die head is used to position the second diffusion layer of the film electrode. The positioning frame is arranged between the top dieand the bottom die, a center bore in the positioning frame is used to position an ion exchange membrane. At least two positioning guide pillars are arranged on the bottom pressing board, aligning andpositioning the top pressing board, the top die, the positioning frame, the bottom die and the bottom pressing board in order. The catapult springs are respectively arranged between the pressing boards and the top, the bottom die, as well as between the top and the bottom die. The invention has the advantages of easy positioning and alignment, convenient, fast and energy-saving hot pressed film electrode.

Owner:雄川氢能科技(广州)有限责任公司

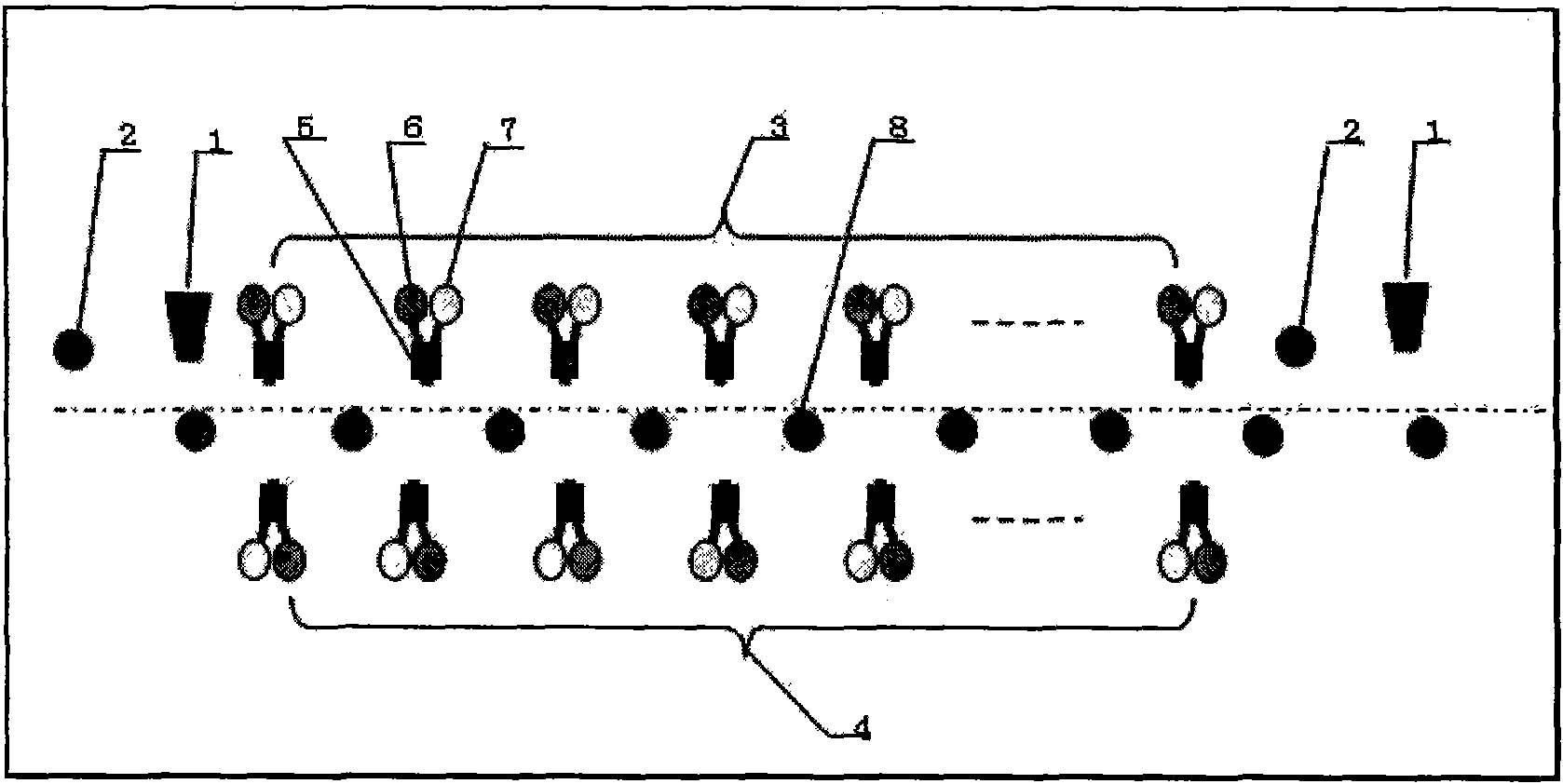

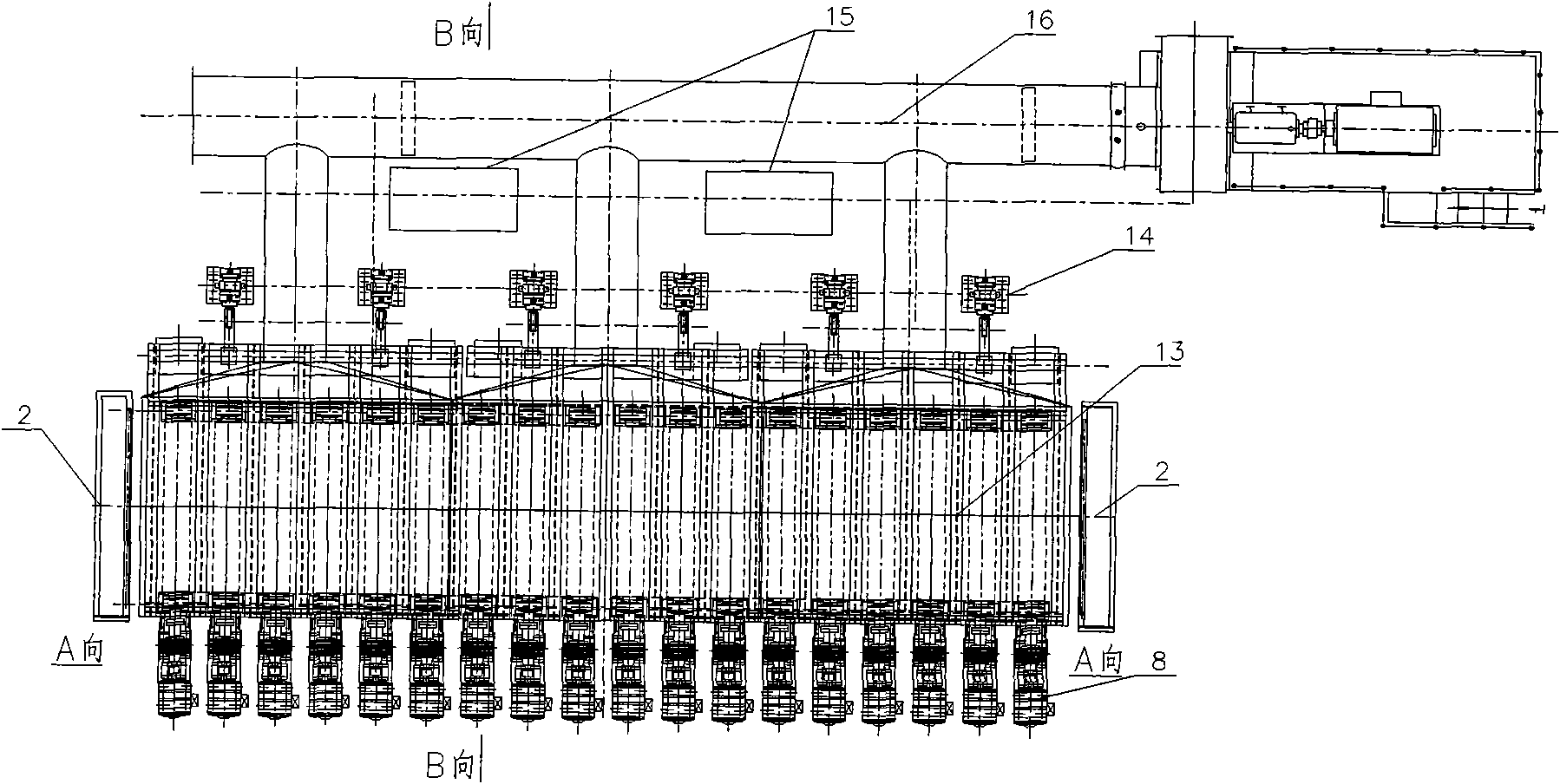

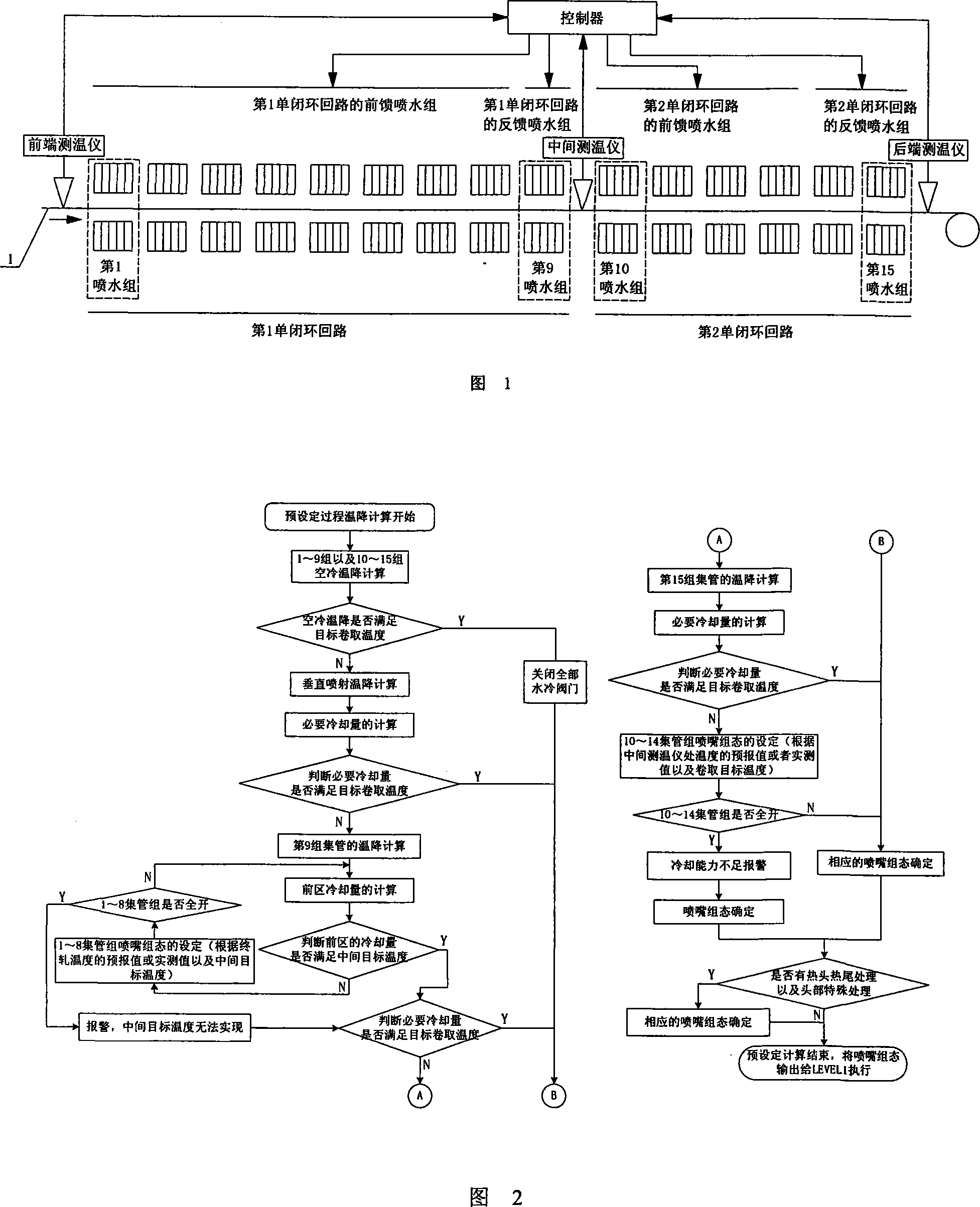

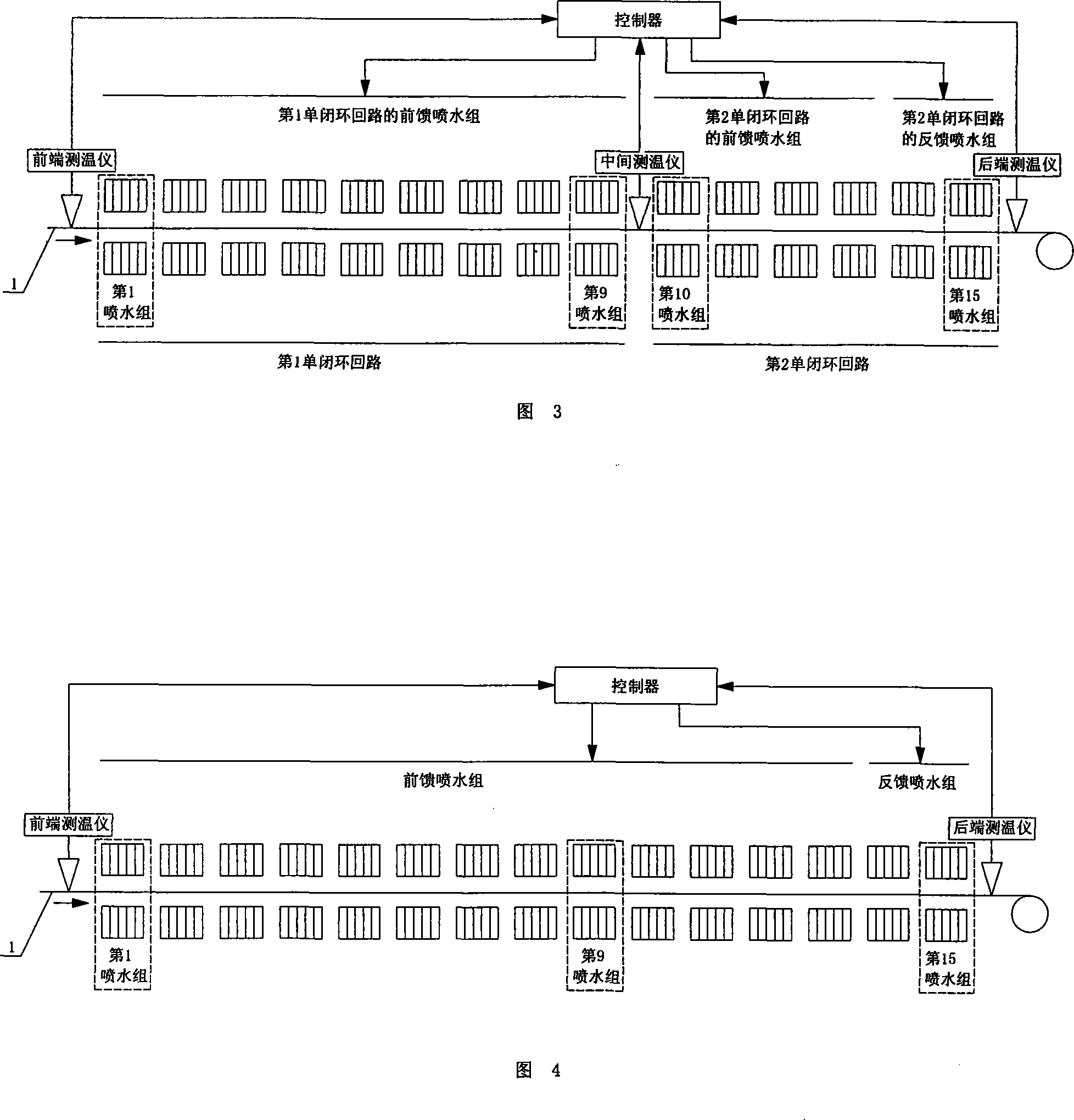

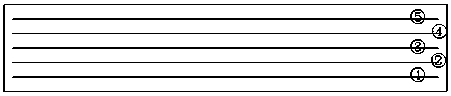

Hot rolling strip steel double-ring control laminar flow cooling system

InactiveCN101125344AControl Cooldown Time HistoryControl cooling rateTemperature control deviceControl layerMeasuring instrument

The invention relates to a laminar flow cooling system of a hot milling band steel double ring controlling layer flow. The cooling system comprises a water spraying group aligned along an output roller passage, a controller used for controlling the water spraying groups, a front end temperature measuring instrument, a back end temperature measuring instrument, an intermediate temperature measuring instrument; wherein, the output terminals of the temperature measuring instruments are connected with the controller. The control loop of the system is divided into a first single closed ring loop and a second single closed ring loop with the intermediate temperature measuring instrument as the boundary. The front end temperature measuring instrument is the feedforward temperature measuring instrument of the first single closed ring loop, and the back end temperature measuring instrument is feedback temperature measuring instrument of the second single closed ring loop. In addition, the intermediate temperature measuring instrument is the feedback temperature measuring instrument of the first single closed ring loop and the feedforward temperature measuring instrument of the second single closed ring loop. The laminar flow cooling system of the invention adopts two closed ring controlling loops, the boundaries of which are the boundary between the front end temperature measuring instrument and the intermediate temperature measuring instrument, and the boundary between the intermediate temperature measuring instrument and the back end temperature measuring instrument. The invention reasonably adopts the actual measured temperature value and the module predicted temperature value of the temperature measuring instruments to effectively control the cooling process and the cooling time as well as the cooling speed.

Owner:武钢集团有限公司

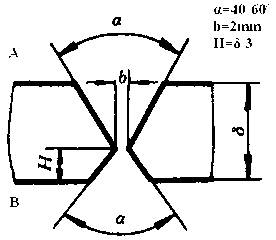

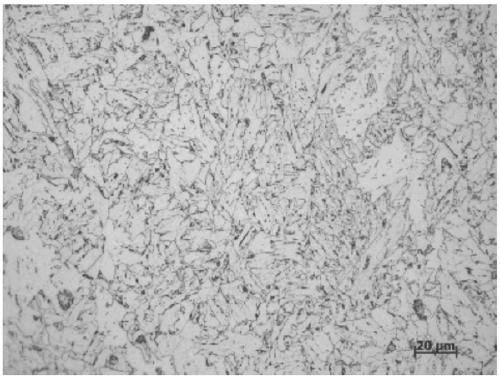

Easy-welding high-strength large-thickness steel plate preheating-free gas shielded welding process

InactiveCN103231155AImprove welding working conditionsImprove welding productivityArc welding apparatusHeat-affected zoneSemi automatic

The invention relates to an easy-welding high-strength large-thickness steel plate preheating-free gas shielded welding process which mainly comprises the following contents that: the large-thickness easy-welding 700MPa-level high-strength steel plate with the thickness of 40-80mm is matched with a high-strength high-toughness welding wire with high deoxidation element content, a 80 percent Ar+20 percent CO2 active mixed gas shielded semi-automatic or automatic welding method is adopted, due to the preheating-free treatment before welding and heating-free treatment after welding, the welding process parameters are strictly controlled, the welding sequence is reasonably arranged, the asbestos cloth coated weldment is used for heat insulation, the defect-free excellent-performance welding joint is obtained, the tensile strength of the joint is not lower than the base metal standard requirement due to mechanical performance detection, the welding line and heat affected zone are good in texture, low-temperature charpy impact absorption work (KV2) is high in surplus amount, and the application environments of the low-temperature environment can be completely met. According to the method, the production process is reduced, the labor conditions of workers are improved, the production cost is saved, and the production efficiency is improved.

Owner:JIGANG GRP

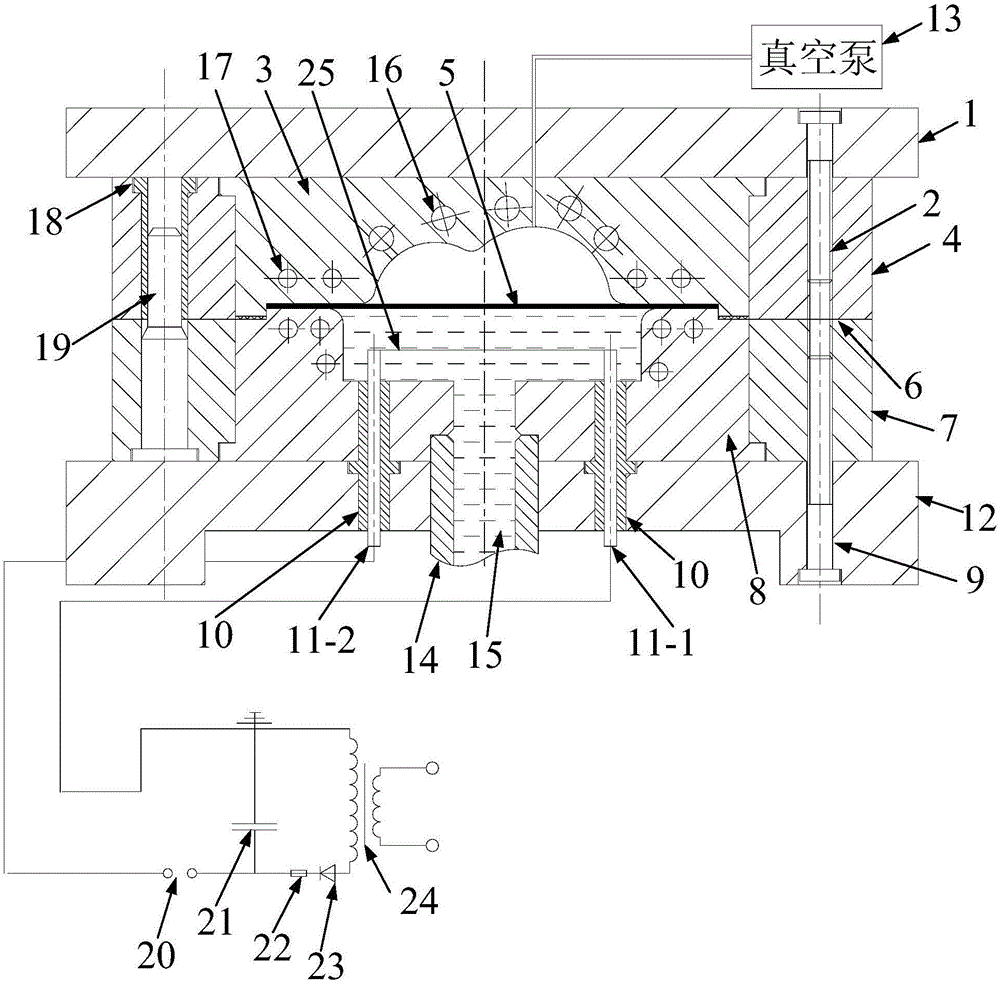

Plate warm electro-hydraulic high-speed impact-quasi static hydraulic composite forming device and plate forming method achieved by adopting device

InactiveCN106734499AGuaranteed forming qualityAvoid crackingShaping toolsElectro hydraulicEngineering

The invention discloses a plate warm electro-hydraulic high-speed impact-quasi static hydraulic composite forming device and a plate forming method achieved by adopting the device and relates to the field of metal material processing forming to solve the problems that forming of plates and complex parts is difficult, film attaching is poor, and deformation is not even. A vacuum pump is used for pumping out gas in a female die cavity; a fluid injection device is adopted for injecting high-temperature-resisting liquid to a liquid chamber; a heating device is used for heating the female die cavity, the high-temperature-resisting liquid in the liquid chamber is heated, preheating on a to-be-processed plate is completed, and heat preservation is conducted on the to-be-processed plate; an electromagnetic forming system is used for conducting discharging forming on the to-be-processed plate; high-pressure warm liquid is slowly injected into the liquid chamber under the quasi static condition, and quasi static hydraulic forming is conducted on the to-be-processed plate; and the high-pressure warm liquid in the liquid chamber is cooled to the room temperature within a period of time, waste liquid is recycled, an electro-hydraulic forming die is opened, and the to-be-processed plate is taken away. The device and the method are used for forming plates.

Owner:XIANGTAN UNIV

Aluminum profile online uniform quenching device

The invention discloses an aluminum profile online uniform quenching device. The aluminum profile online uniform quenching device comprises a base table, wherein an extrusion forming box, a thermal insulation box, a quenching box, an air cooling box and a material guide chamber are arranged on the base table in sequence. Heating elements are arranged in the thermal insulation box; an upper water injection current divider is arranged on the top of the quenching box, a lower water injection current divider is arranged at the bottom of the quenching box, and both the upper water injection current divider and the lower water injection current divider are provided with water nozzles and are connected with a water purification box through water pipes; the quenching device further comprises a backflow water tank, the water purification box is connected with the backflow water tank through a circulation water pipe, and a filter is arranged in the circulation water pipe; an exhaust fan is further arranged at the inner top end of the quenching box; an air current divider is arranged on the inner top of the air cooling box, and is provided with air nozzles; and a collection bin is arranged outside and below the material guide chamber. The aluminum profile online uniform quenching device is simple in structure, and the quenching temperature and the cooling speed can be adjusted according to the sizes and shapes of aluminum profiles, so that a better quenching effect is achieved.

Owner:四川齐飞新材料科技有限公司

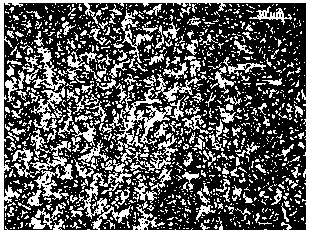

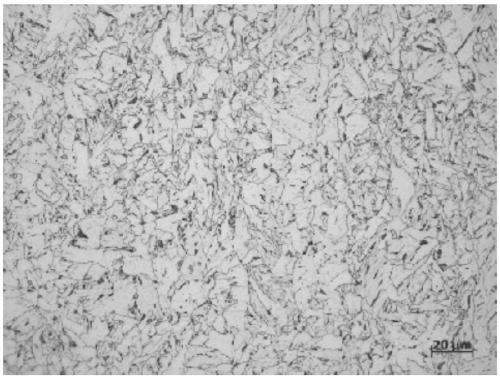

EH47 crack arrest steel for large container ship and manufacture method thereof

ActiveCN109576585AImprove corrosion resistanceAvoid negative effectsProcess efficiency improvementManufacturing technologySmallerThan

The invention relates to EH47 crack arrest steel for a large container ship. The chemical components of a steel plate comprise, by mass, 0.03%-0.06% of C, 0.15%-0.50% of Si, 1.50%-2.00% of Mn, smallerthan or equal to 0.008% of P, smaller than or equal to 0.0050% of S, 0.050%-0.080% of Nb, 0.020%-0.050% of V, 0.008%-0.020% of Ti, 0.80%-1.30% of Ni, 0.10%-0.30% of Cr and 0.10%-0.30% of Cu. The manufacture technology process of the steel plate comprises the steps of smelting, continuous casting, reheating, TMCP rolling and controlled cooling. The steel plate obtains fine and uniform acicular ferrite in the whole thickness, the strength is moderate, the toughness is excellent, the good brittle fracture resistance is achieved, namely, the CTOD characteristic value delta is larger than or equal to 0.15 mm at -60 DEG C, and the crack arrest performance is excellent, namely, Kca is larger than or equal to 6,500 N / mm<3 / 2>.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

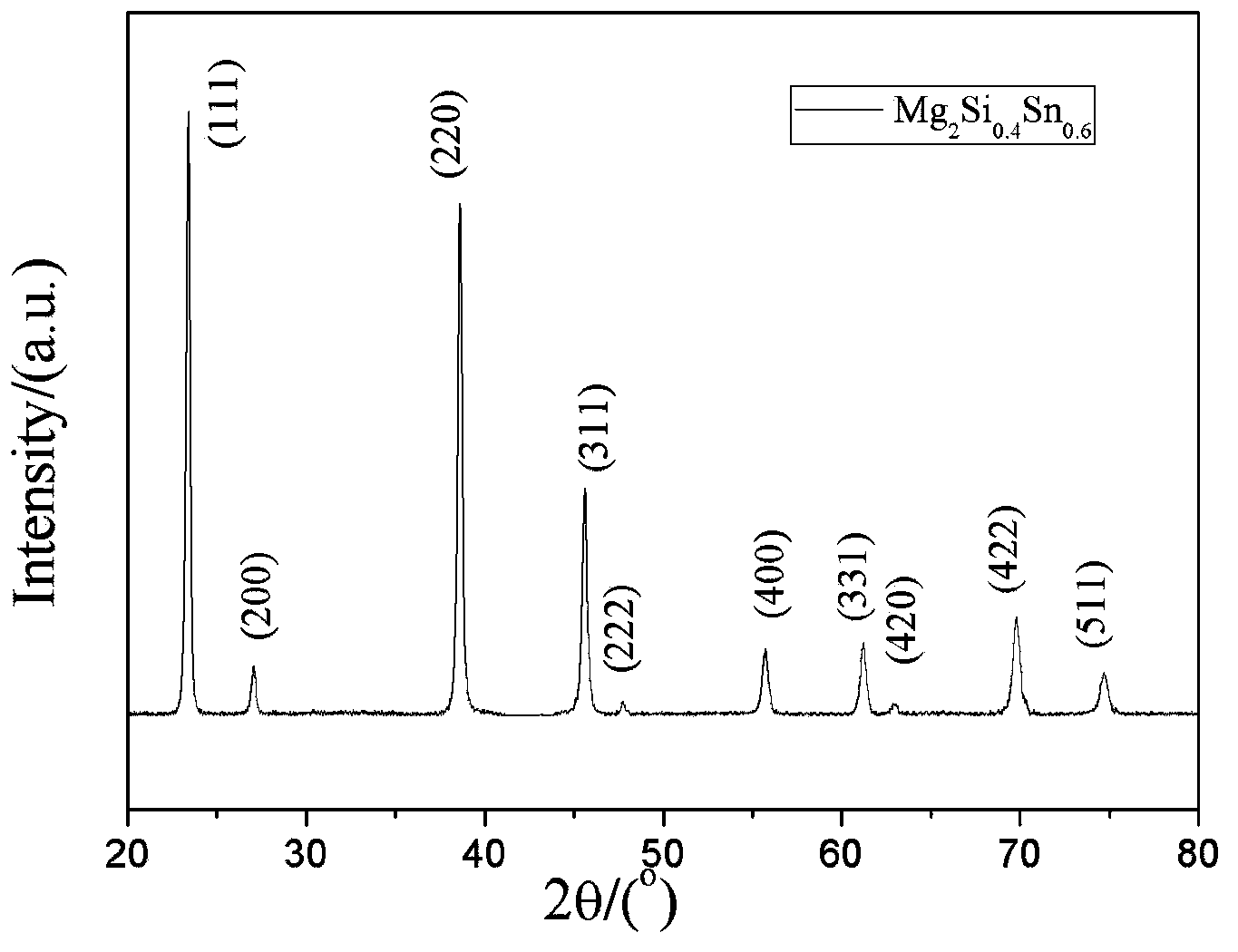

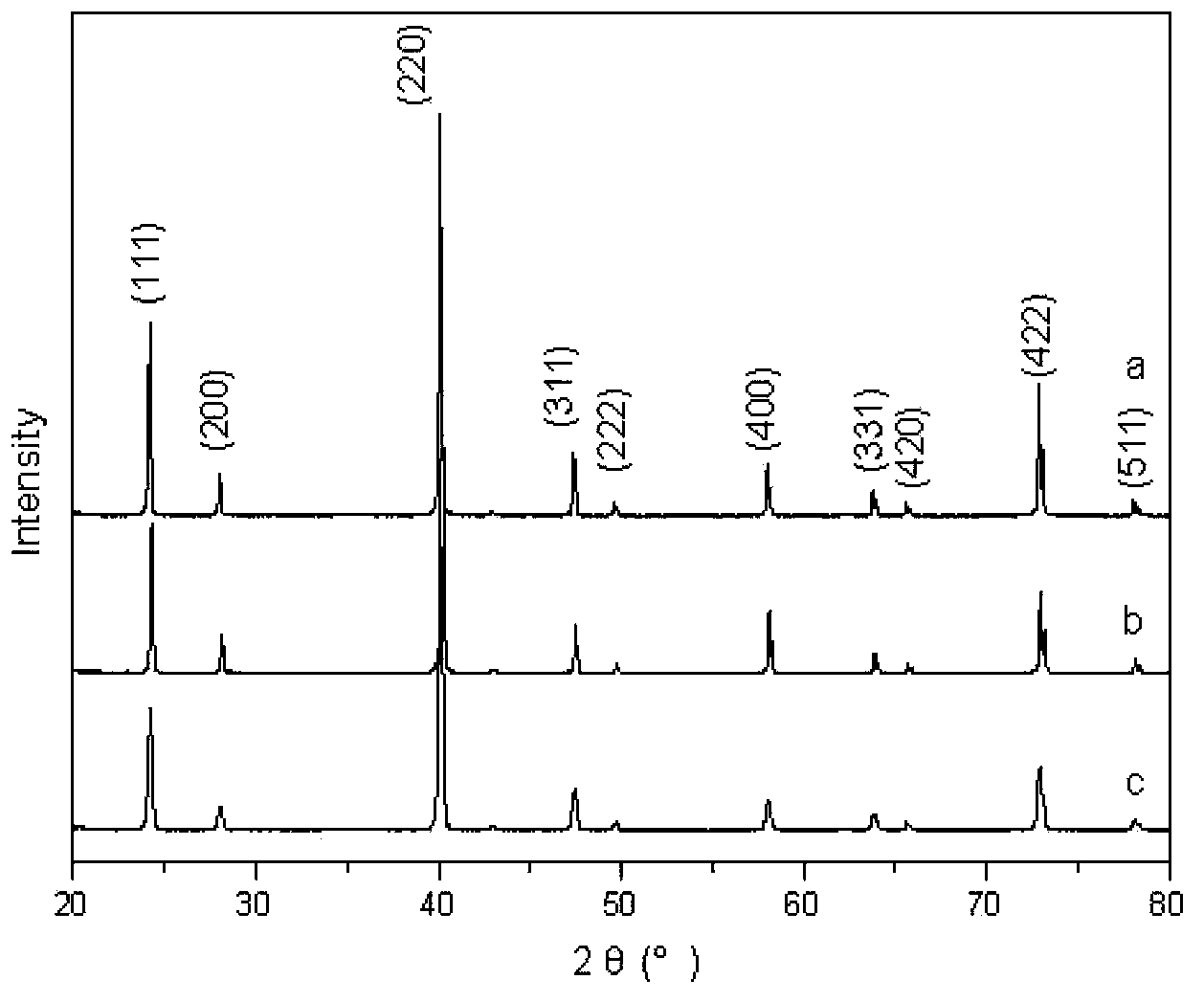

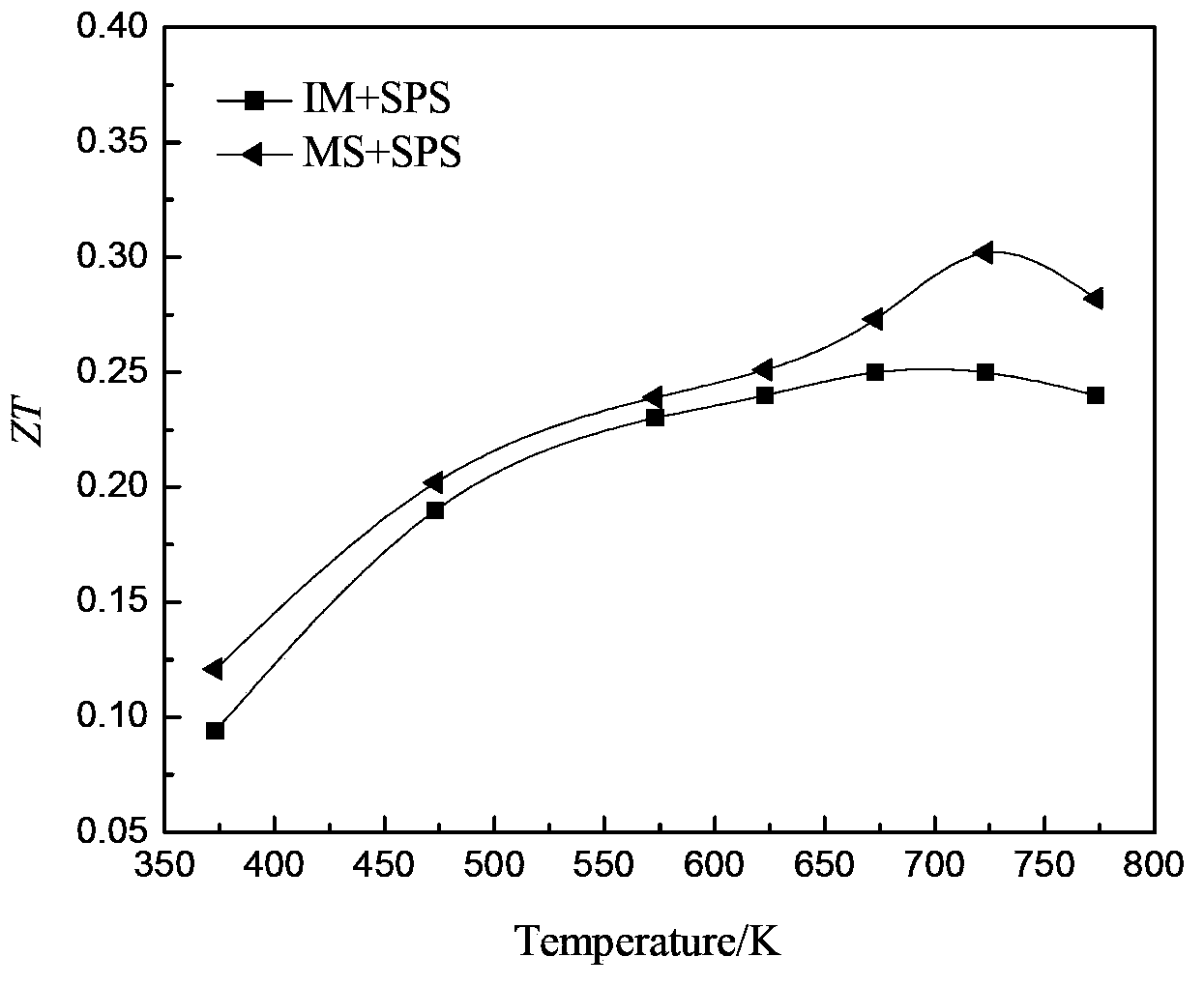

Nanocomposite structure Mg2Si-based thermoelectric material and preparation method thereof

InactiveCN103700759APrevent oxidationPrevent volatilizationThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsMolten state

The invention relates to a nanocomposite structure Mg2Si-based thermoelectric material and a preparation method thereof, and belongs to the technical field of preparation of semiconductor thermoelectric materials. The preparation method comprises the following steps: taking Mg, Si and Sn elementary substance materials according to a stoichiometric ratio and performing high-frequency induction smelting to form cast ingot; crushing the smelted cast ingots, filling into a quartz glass tube with a lower open end, vertically placing into an induction smelting coil, vacuumizing a cavity of a rapid quenching furnace, filling protective gas, performing induction smelting to enable the block to reach a molten state, spraying the melt to a copper rod, throwing out to form belt materials, and collecting the belt materials; placing the belt materials into a glove box under the argon protective atmosphere, grinding into powder, and performing spark plasma sintering into blocks. The preparation method is simple and feasible; the process flow is short; oxidation of Mg can be effectively inhibited; process parameters are easy to control. An amorphous / nanocrystalline composite structure exists in a sample, the grain size is obviously refined, the grain size distribution is controllable, scattering of electrons and phonons is increased, the Seebeck coefficient is greatly increased, and the thermoelectric property of the material is improved.

Owner:BEIJING UNIV OF TECH

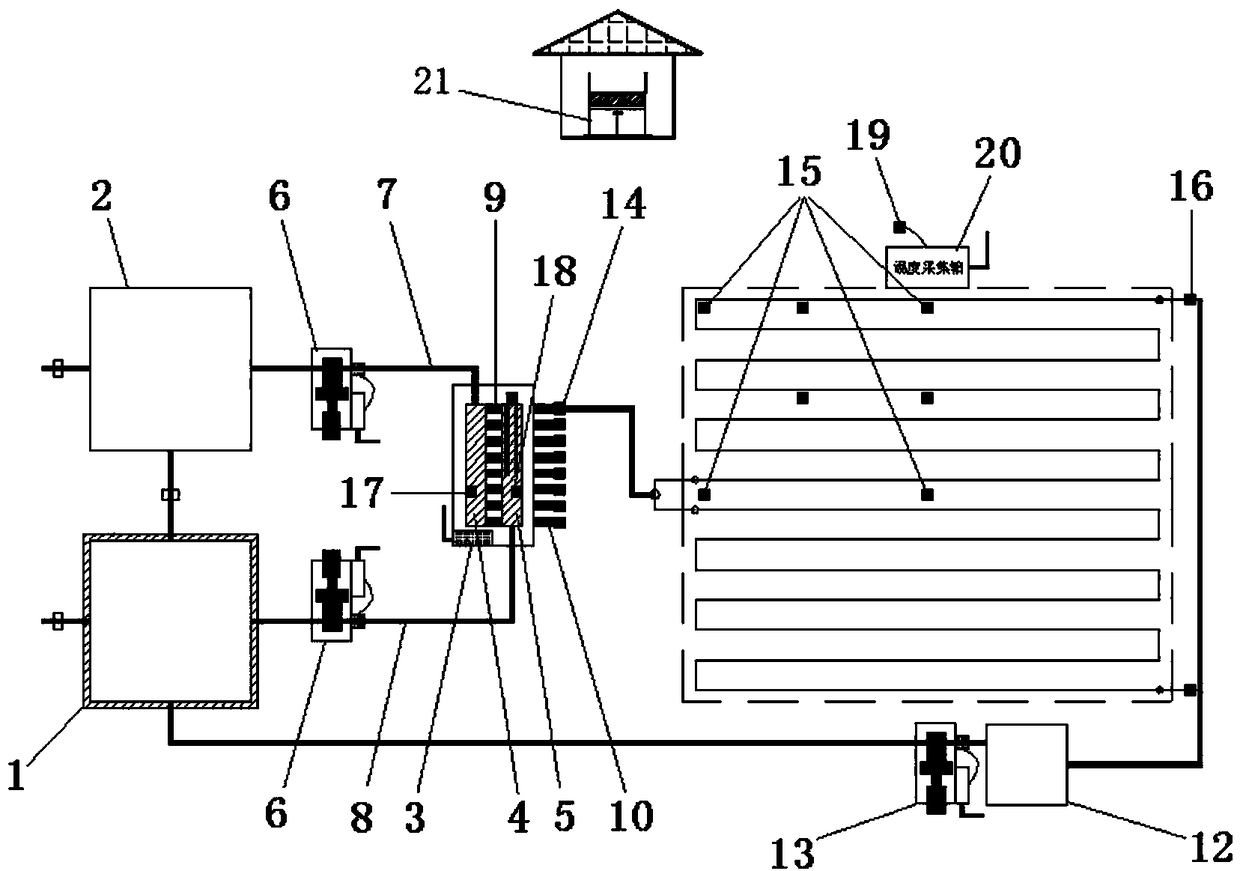

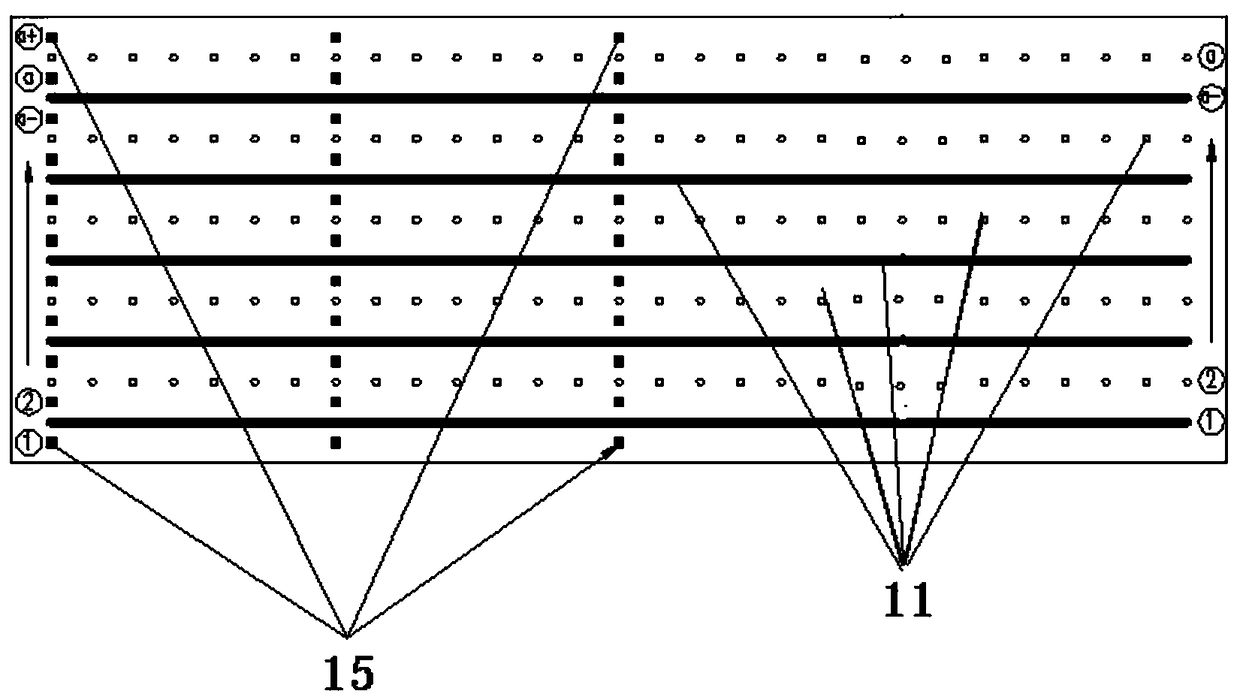

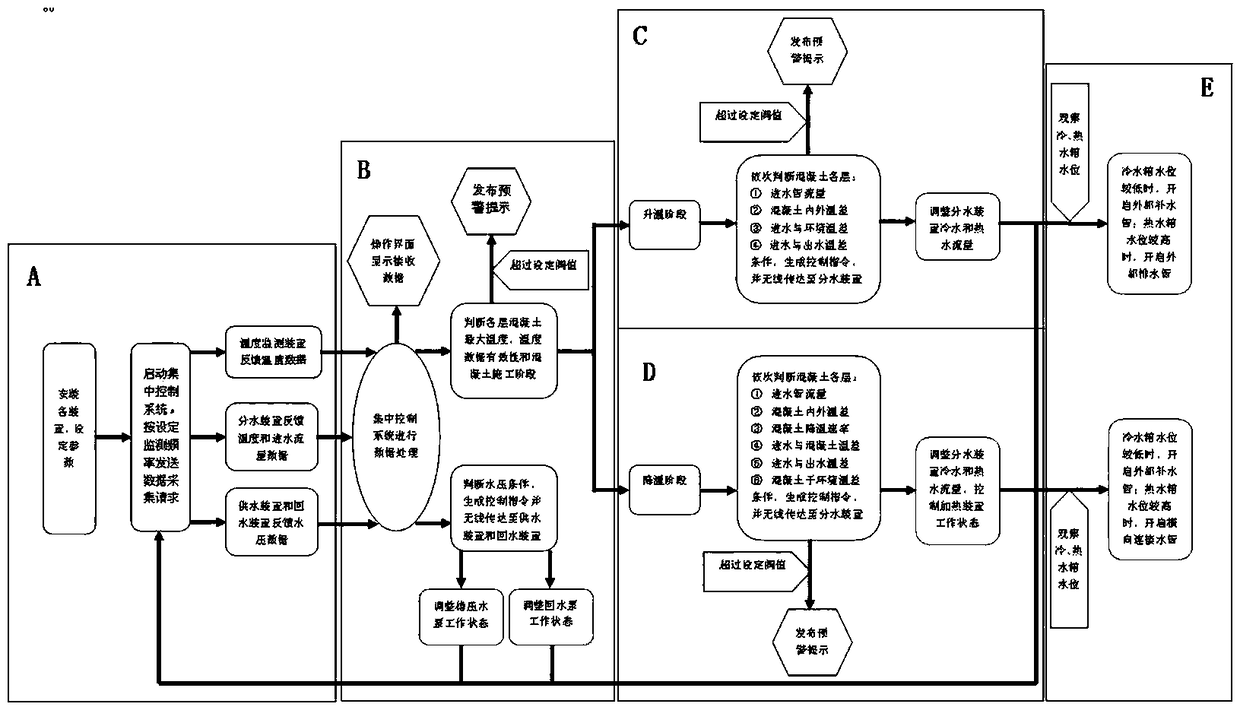

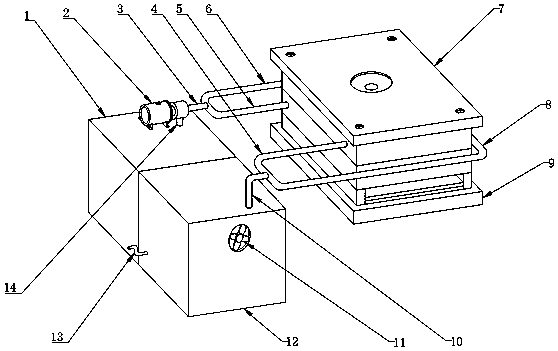

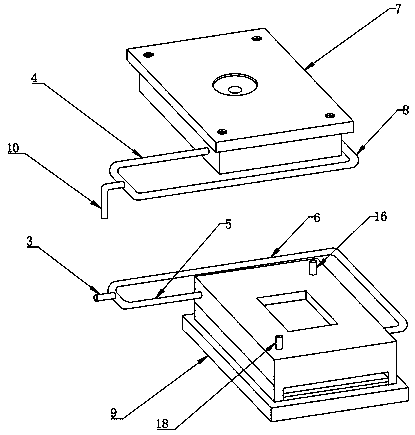

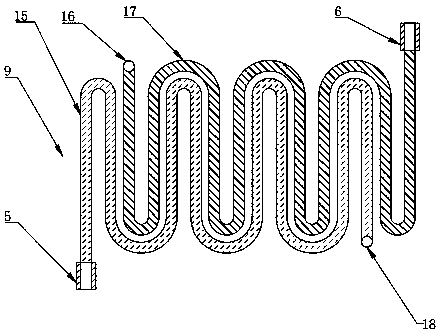

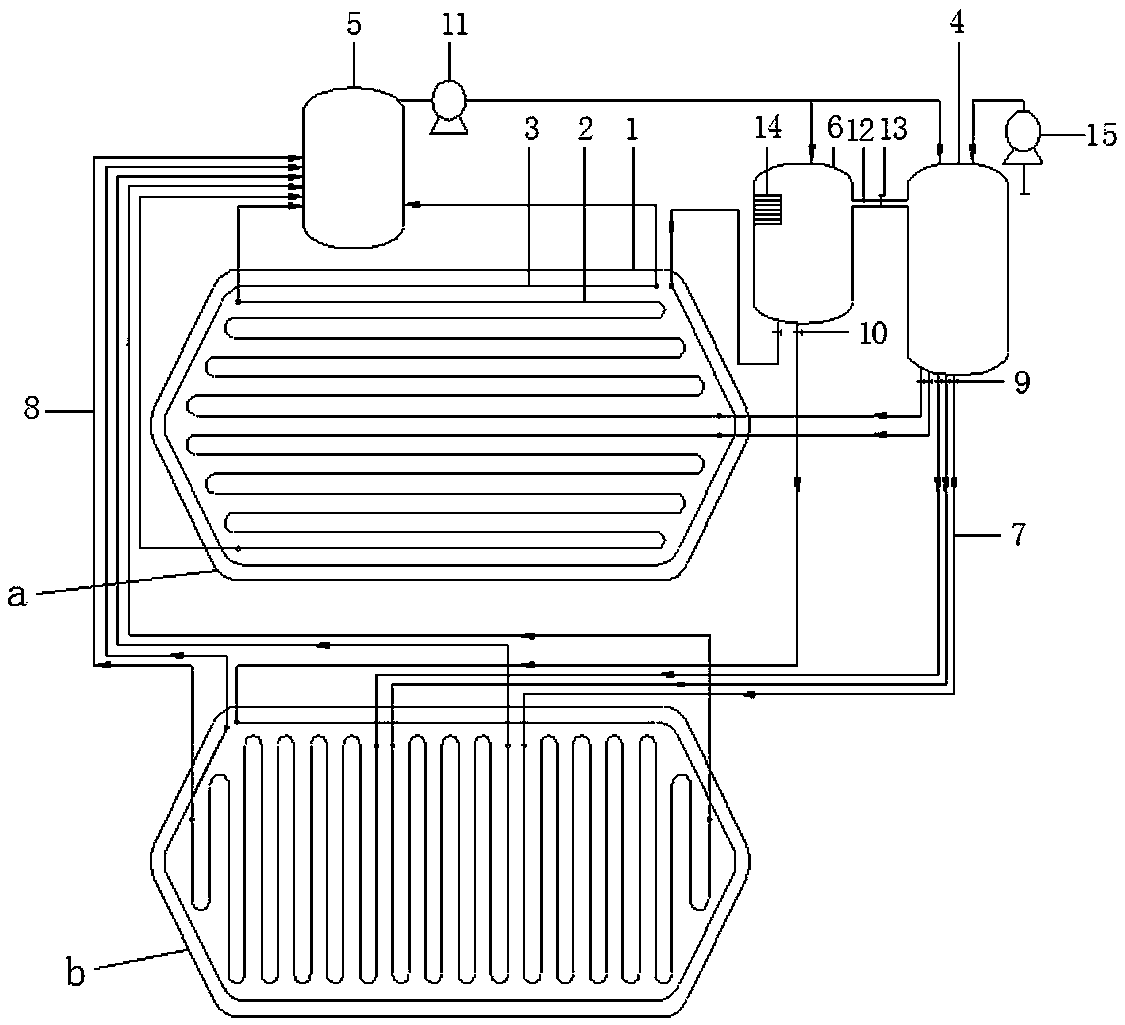

Mass concrete temperature intelligent monitoring and controlling device and method

InactiveCN109471468AControl the maximum temperatureControl cooling rateTemperatue controlPressure stabilizationData acquisition

The invention discloses a mass concrete temperature intelligent monitoring and controlling device, which comprises a circulating pipeline formed by sequentially connecting a water supply device, a water distribution device, a concrete cooling system and a water return device, wherein the concrete cooling system is internally provided with a temperature monitoring device; and a centralized controlsystem which is respectively connected with the water supply device, the water distribution device, the concrete cooling system and the water return device. The concrete cooling system comprises a cooling water pipe arranged in the concrete. Usage of the device comprises a concrete cooling system setting step, a monitoring device setting step, a water distribution device setting step, a water supply device setting step, a water return device setting step, a mass concrete construction preparation step, a data acquisition step, a water supply pressure stabilization step, an alarm step, a hot water tank drainage step and a cold water tank water replenishing step. By the adoption of the mass concrete temperature intelligent monitoring and controlling device, water supply pressure can be stabilized, different water inlet temperatures and flow rates of each layer can be dynamically adjusted, temperature field change in the mass concrete can be developed according to a target of temperature control, and an alarm function is equipped, so that the problems that a temperature difference of each region of the mass concrete is too large and cracks are easy to generate are solved.

Owner:GUIZHOU BRIDGE CONSTR GROUP +1

Method and equipment for preparing semisolid fused mass of ferrous material

An apparatus for preparing the semi-solid molten body of iron and steel is composed of a special container for molten iron or steel, temp regulator, stirrer and bottom vibrator. The linear layer of said special container contains nucleation promoter. Its method includes pouring the molten iron or steel at the temp which is 5-10 deg.C, higher than the temp of liquid-phase line into said special container, and stirring or vibrating for 1-10 min.

Owner:BEIJING JIAOTONG UNIV

High strength and high toughness as-cast-condition QT800-5 nodular cast iron and production method thereof

ActiveCN108004460AWide range of applicationsImprove production taktProcess efficiency improvementFerrosiliconBismuth

The invention relates to high strength and high toughness as-cast-condition QT800-5 nodular cast iron and a method for forming the nodular cast iron through common clay sand. According to the method,pig iron for nodular cast iron, carbon waste steel and foundry returns serve as raw materials, a proper amount of copper, molybdenum, nickel, antimony or tin or other alloys are added in, an inductionelectric furnace is adopted for smelting iron melt, a rare earth ferrosiliconmagnesium alloy serves as a nodulizing agent, ferrosilicon, bariumsili and silicon bismuth are used for performing inoculation treatment, on a micro vibration compaction modeling machine, common clay sand is used for modeling, and the high strength and high toughness as-cast-condition QT800-5 nodular cast iron can be obtained through box removing after casting is performed for 30-60 min. The high strength and high toughness as-cast-condition QT800-5 nodular cast iron can meet the requirement of the market for high strength and high toughness as-cast-condition QT800-5 nodular cast iron pieces, and especially meets the requirement of the automobile industry for lightweight castings.

Owner:WUHAN UNIV OF TECH +1

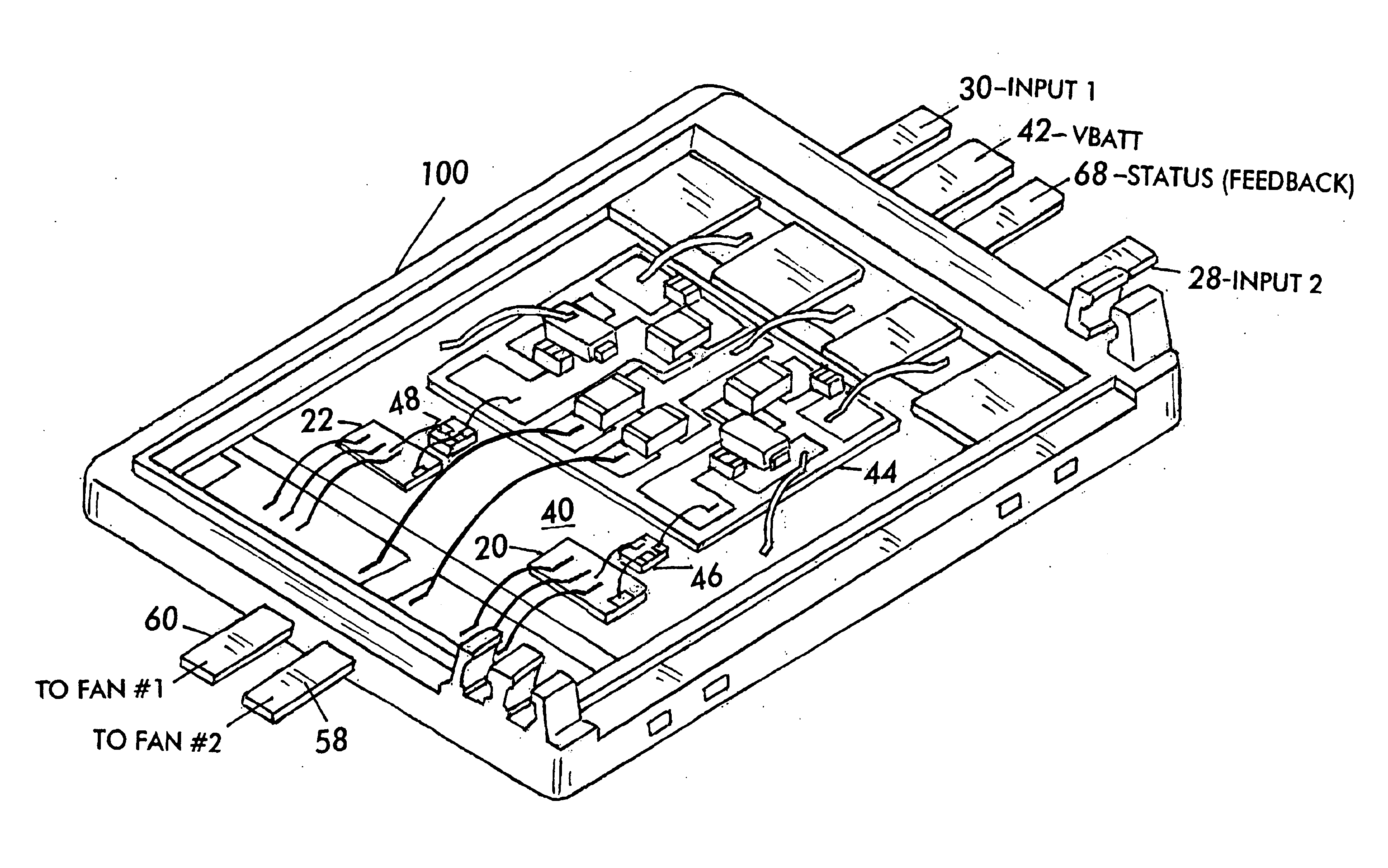

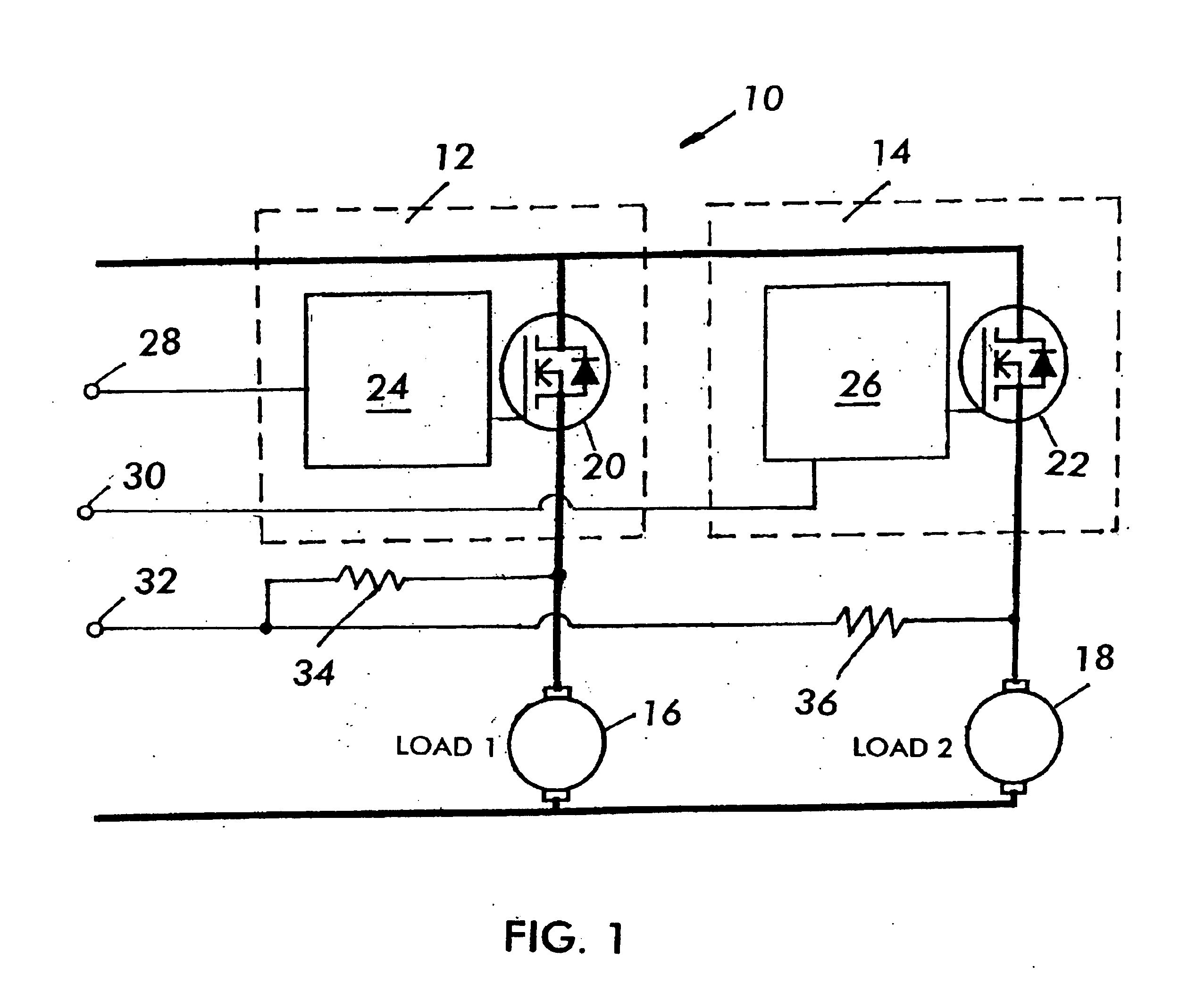

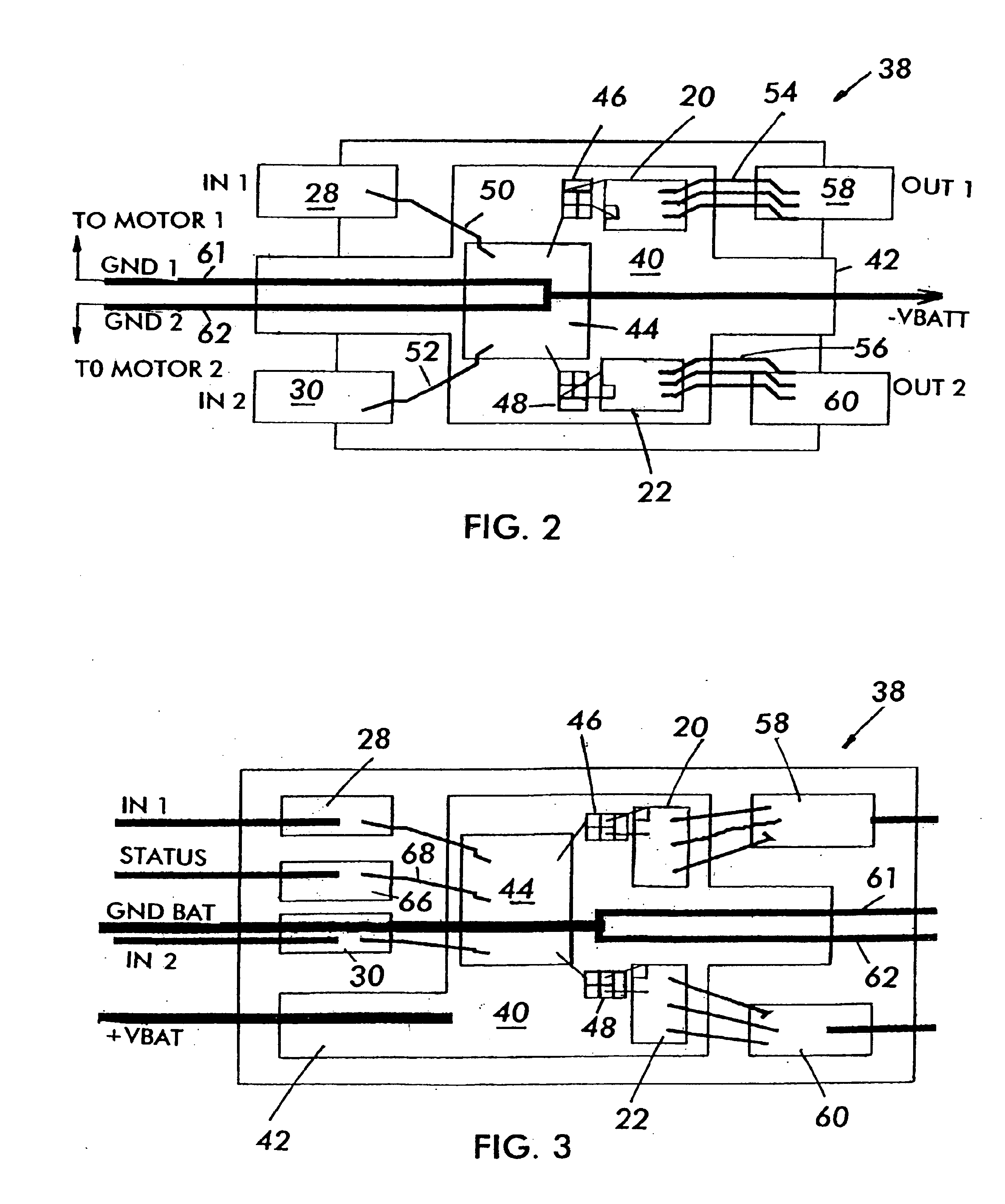

Fan control circuit and package

InactiveUS6912134B2More control over the speed of the motorsControl cooling rateSemiconductor/solid-state device detailsSolid-state devicesPower switchingEngineering

A dual output power module housing a dual output power circuit for providing variable power to two parallel connected fan motors is shown. The power module includes a pad which has disposed thereon two power switching devices, two intelligent power switches, and a power circuit board on which circuits for controlling the intelligent power switches are disposed. The module includes a power shell that surrounds the dual output power circuit, and a resilient, flexible enclosure which encapsulates the power shell and the circuit components within the power shell.

Owner:ELECTRONICS MOTION SYST HLDG

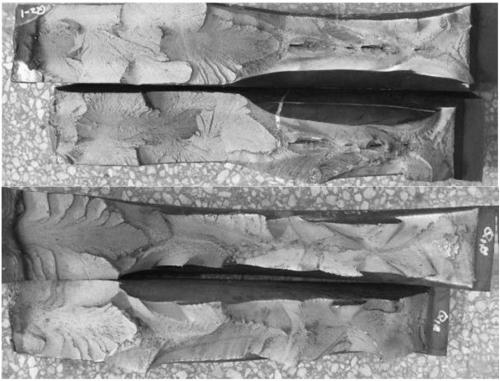

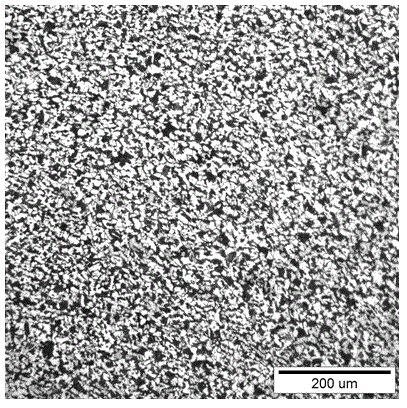

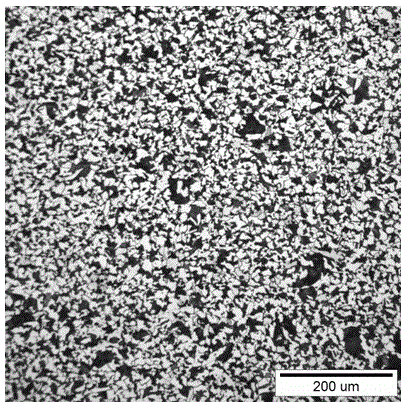

Non-annealed cold forging steel hot-rolled wire rod and production method thereof

The invention discloses a non-annealed cold forging steel hot-rolled wire rod and a production method thereof. The method comprises the steps of continuous casting, heating, rolling, spinning and cooling. The non-annealed cold forging steel hot-rolled wire rod comprises 0.29-0.38wt% of C, 0.15-0.30wt% of Si, 0.70-0.90wt% of Mn, 0.03wt% or less of P, 0.03wt% or less of S, 0.30wt% or less of Cr, 0.0008-0.0050wt% of B, and the balance of Fe and residual elements. In the heating step, continuous cast billets are heated to 1100-1190DEG C; in the rolling step, the initial finish rolling temperature is 965-995DEG C; in the spinning step, the spinning temperature is 960-990DEG C; and in the cooling step, the cooling speed is 0.5-1.5DEG C / s. The method realizes production of the non-annealed cold forging steel hot-rolled wire rod through optimally designing chemical components, controlling the heating temperature, the initial finish rolling temperature, the spinning temperature and the cooling speed and controlling the amount and the grain size of ferrite by using present devices and technologies without increasing investment or production cost, so the non-annealing production and cost reduction demands of downstream users are met, and pollution of annealing to environment is avoided.

Owner:XINGTAI IRON & STEEL

Hot roll for rolling titanium plate and manufacturing method of hot roll

The invention discloses a hot roll for rolling a titanium plate, and a manufacturing method of the hot roll. The hot roll comprises the following chemical constituents in percentage by weight: 0.30-0.50% of C, 0.60-2.00% of Si, 0.20-1.00% of Mn, 4.50-6.00% of Cr, 0.05-0.65% of Ni, 1.00-2.00% of Mo, 0.50-1.50% of V, less than or equal to 0.025% of P, less than or equal to 0.020% of S, and the balance of Fe and unavoidable impurities. The manufacturing method of the hot roll for rolling the titanium plate comprises the processing steps of steel ingot refining, roll blank forging, thermal refining, induction quenching treatment, tempering treatment and the like. Compared with the traditional hot roll made of a Cr3 material, the hot roll is good in abrasive resistance, corrosion resistance and thermal crack resistance, and the service life of the hot roll can be prolonged by above 70%.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

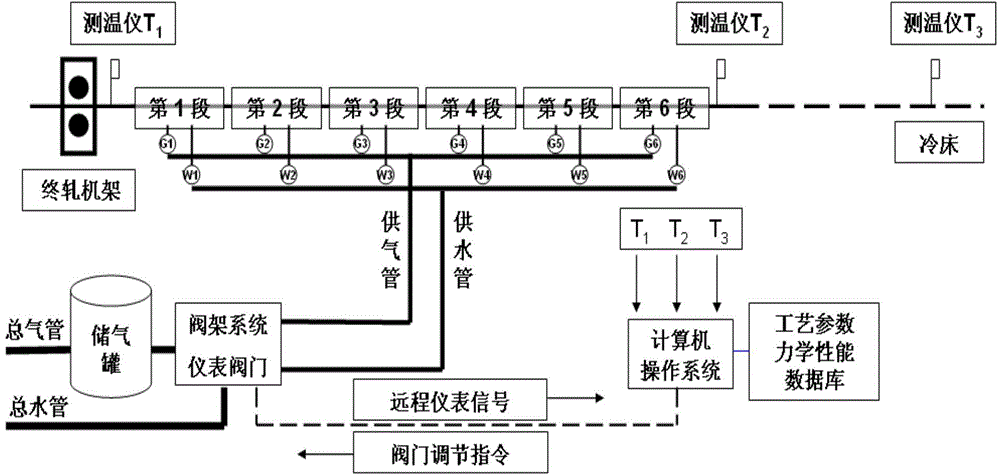

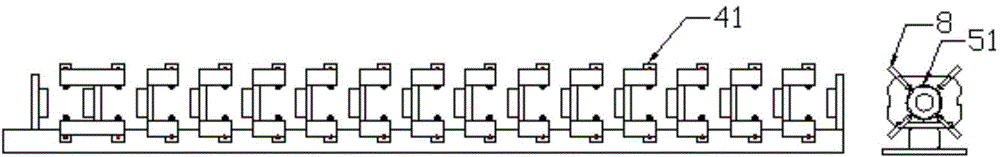

Method and device for spray evaporation cooling of hot-rolled high-strength rebar

ActiveCN104550275AEvaporative cooling high efficiencyHigh efficiency of water mist vaporization coolingTemperature control deviceWork treatment devicesEvaporationAlloy

The invention discloses a method and a device for spray evaporation cooling of a hot-rolled high-strength rebar, and belongs to the technical field of steel rolling. The device comprises a water and air supply system, six segments of a spray evaporation cooling device, infrared thermometers and a computer operating system, wherein the water and air supply system is composed of a main water pipe, a filter screen, a main air pipe, an air storage tank, a valve bracket system, a water supply pipe and an air supply pipe. Pressure gauges and flow gauges of the valve bracket system transmit pressure parameters and flow parameters of water and air supply to the computer operating system through long-distance instrument signals. According to the device for spray evaporation cooling of the hot-rolled high-strength rebar, grain refinement and bainite transformation are controlled through a grouped and segmented stepped accelerated cooling mode of spray evaporation cooling nozzles, so that strength of the hot-rolled rebar is improved remarkably and required elongation, yield strength ratio and anti-seismic property are acquired on the premise of avoiding martensite ring formation caused by conventional through water cooling, alloy content and new water consumption are reduced, and red rust on the surface of the rebar due to through water cooling is prevented.

Owner:CENT IRON & STEEL RES INST

Concentric-square-shaped cooling device for injection mold

ActiveCN109016417ALarge amount of deformation and thermal stressLow strength and toughnessSquare ShapeAerospace engineering

The invention discloses a concentric-square-shaped cooling device for an injection mold. The concentric-square-shaped cooling device comprises a cooling water tank. A heat-dissipating water tank is arranged on the front side of the cooling water tank. First concentric-square-shaped cooling grooves are formed in a movable mold and a fixed mold correspondingly, and second concentric-square-shaped cooling grooves are formed in positions, close to one sides of the first concentric-square-shaped cooling grooves, of the interiors of the movable mold and the fixed mold. A first connecting pipe is fixedly connected to the position, embedded into the bottom end of the movable mold, of the rear side of the top end of the fixed mold. An adjusting seat is arranged on the lower side of one end of the heat-dissipating water tank in an embedded mode, and a heat-dissipating fan is mounted on the front side of the heat-dissipating water tank in an embedded mode. A filtering net is arranged at the position, close to the lower side of the heat-dissipating fan, of the interior of the heat-dissipating water tank, and a fixing plate is fixedly connected to the position, close to the lower side of the filtering net, of the interior of the heat-dissipating water tank. A sealing plug is arranged in the bottom end of the fixing plate in an embedded mode. The concentric-square-shaped cooling device is reasonable in structure and safe in using, the temperature stability, the small deformation quantity, the high strength and toughness and the maximum thermal stress elimination of a product can be ensured, and the quality of the product is improved.

Owner:南京彬晨诺模具有限公司

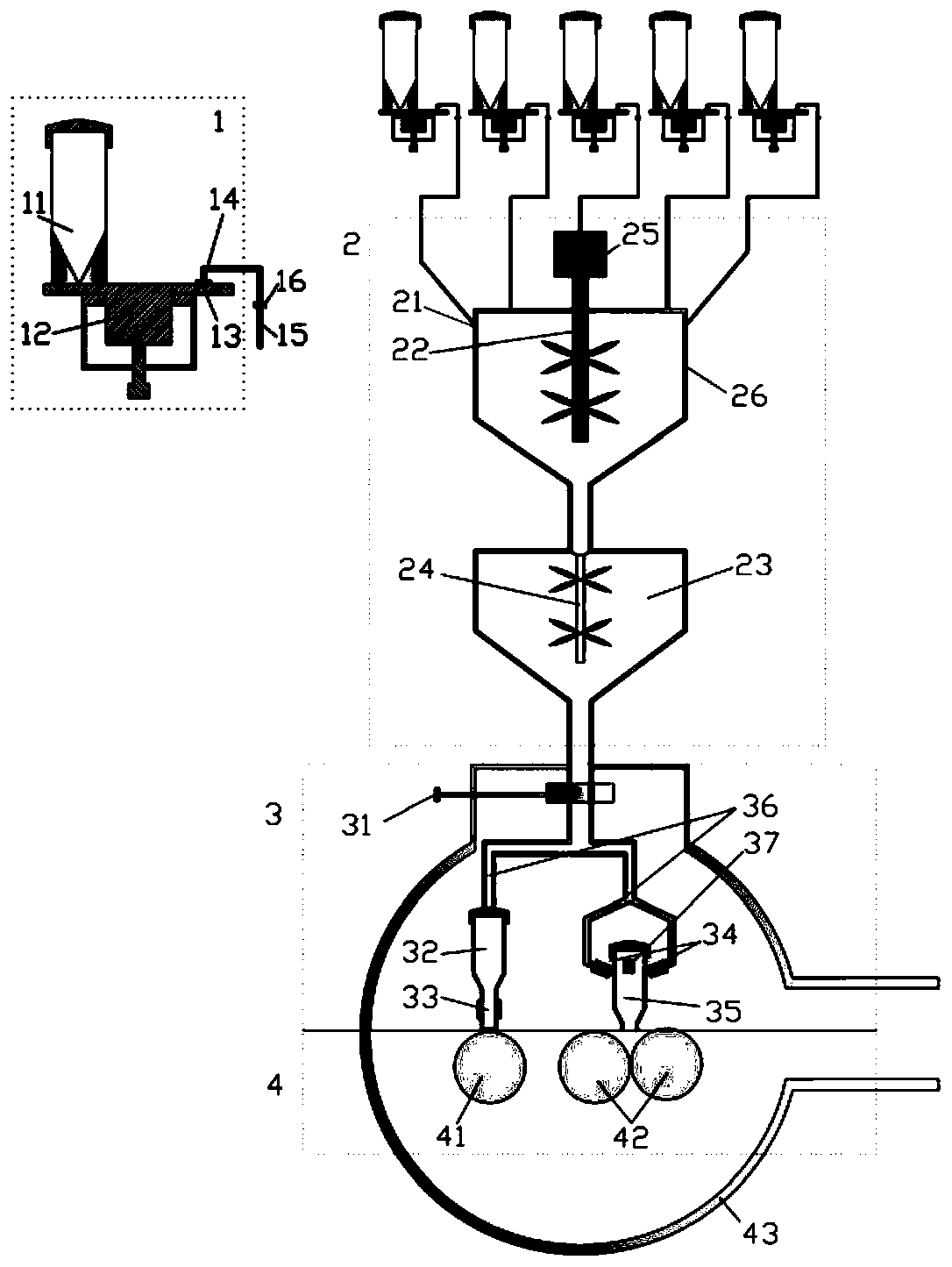

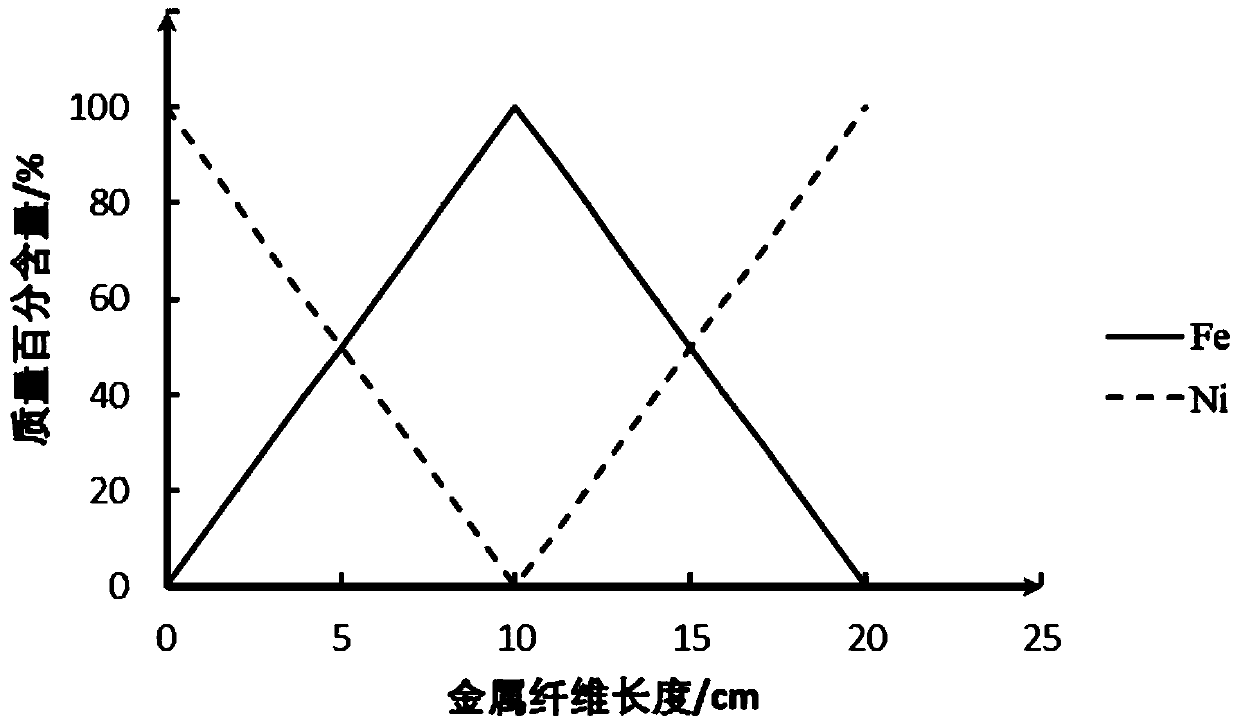

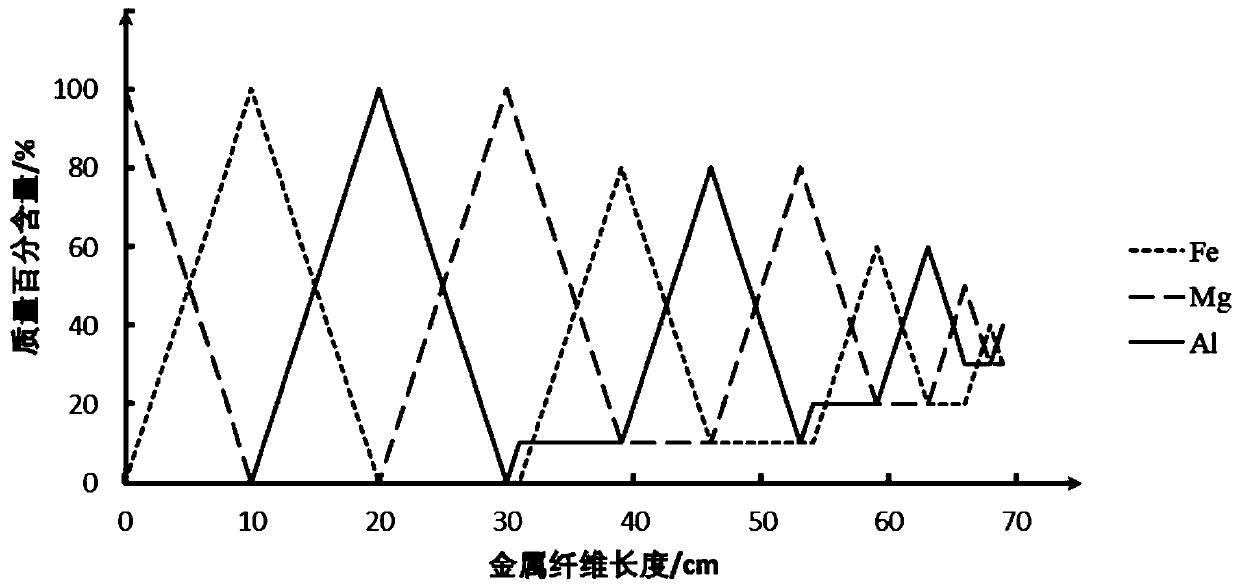

High throughput preparation device for metal fibers based on multiple powder and method of preparing metal fibers by means of same

PendingCN110722161APromote meltingRealize one-way transportAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyMetal fibers

The invention relates to a high throughput preparation device for metal fibers based on multiple powder and a method of preparing the metal fibers by means of the same. The high throughput preparationdevice comprises a metal powder conveying system, a metal powder mixing system, a metal powder smelting system and a metal fiber forming system connected successively, wherein the metal powder smelting system comprises an inductive powder smelting device and a laser powder smelting device which are arranged independently. The high throughput preparation device has the characteristics of being simple in structure, convenient to operate, wide in smelting temperature and wide in application range. The method of preparing the metal fibers by means of the high throughput preparation device comprises four steps: powder transporting, powder mixing, smelting and forming. The metal fibers, components of which are changed in gradient continuously, can be prepared by means of the preparation method,and high throughput preparation is achieved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

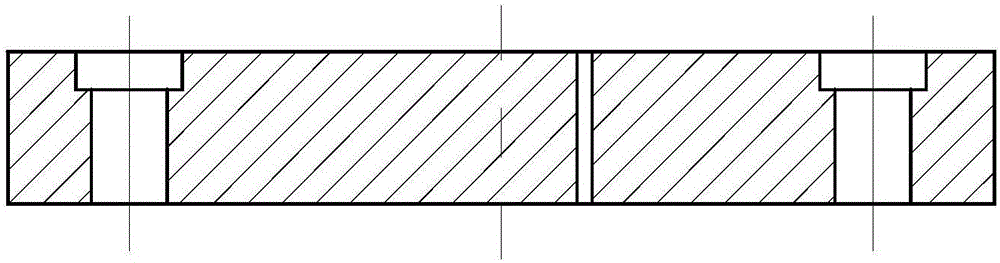

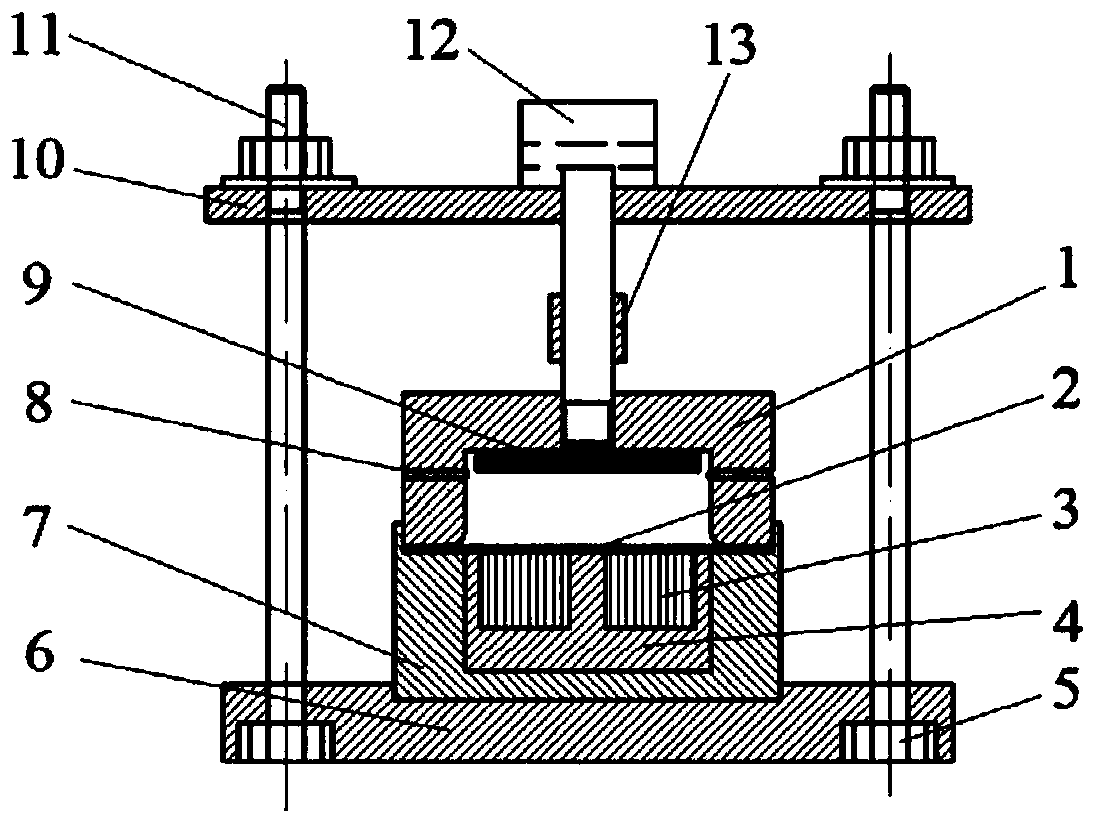

Forming device and method of thermoplasticity glass fiber reinforcement aluminum alloy laminate plate

The invention discloses a forming device and method of a thermoplasticity glass fiber reinforcement aluminum alloy laminate plate. The device comprises a sealing side pressing ring (1), a discharging coil (3), a coil frame (4), bolts (5 and 11), a lower pressing plate (6), a base (7), a resistance wire (9), an upper pressing plate (10) and a hydraulic cylinder (12). The bolts (5 and 11) and the bottom of the upper pressing plate (10) are connected in a welding mode. The hydraulic cylinder (12) is fixed on the upper pressing plate (10). A working arm of the hydraulic cylinder (12) penetrates through a center hole of the upper pressing plate (10) and extends downwards. The lower end of the working arm of the hydraulic cylinder (12) is fixedly connected with the sealing side pressing ring (1). A stroke limiting block (13) is welded to the working arm. An exhaust hole (8) is formed in the side wall of the sealing side pressing ring (1). The device can preheat the laminate plate and control the cooling speed during cooling of the laminate plate, accordingly, residual heat stress caused by different contraction rates of plate pieces is released, and cracking between layers is avoided.

Owner:HUNAN UNIV

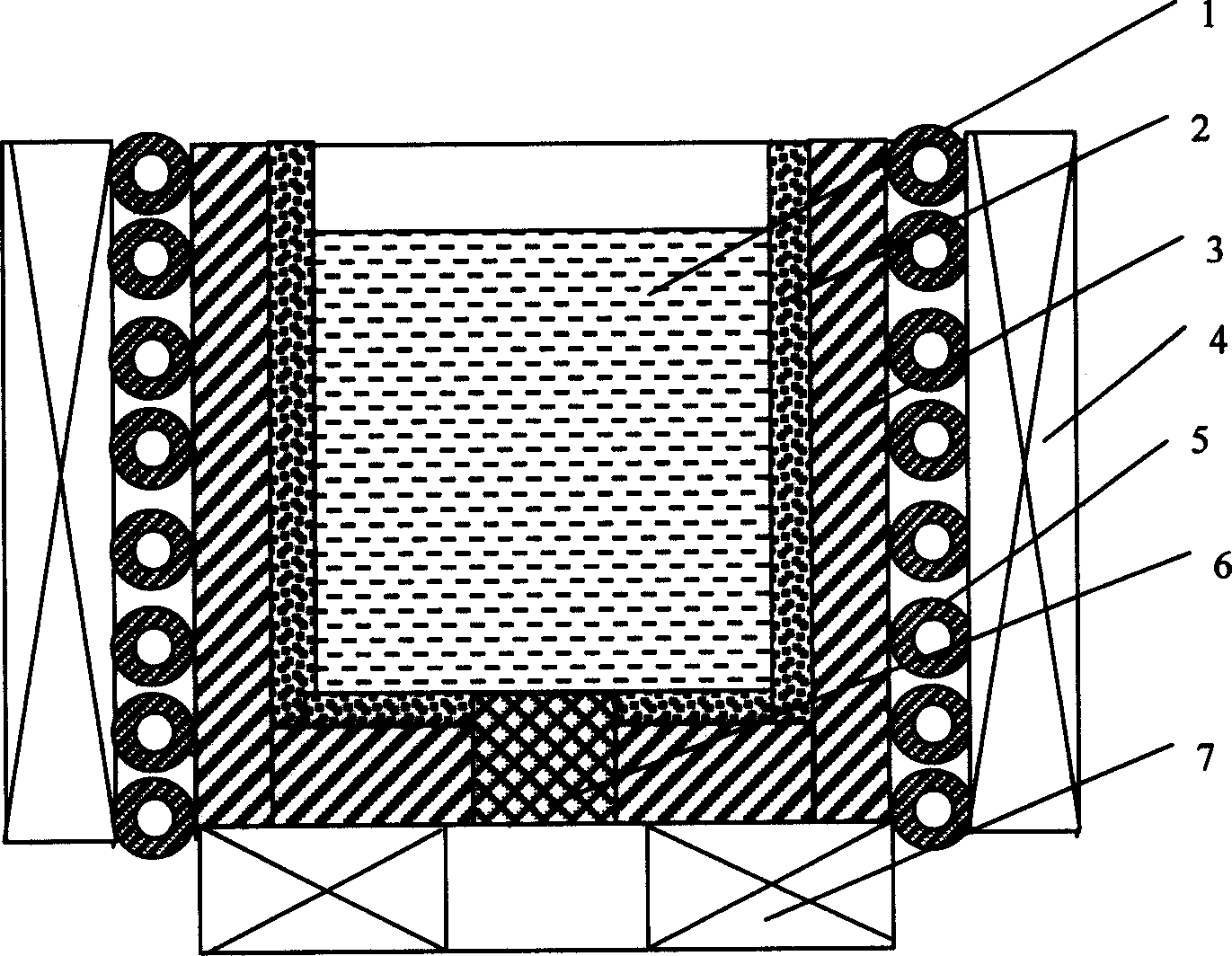

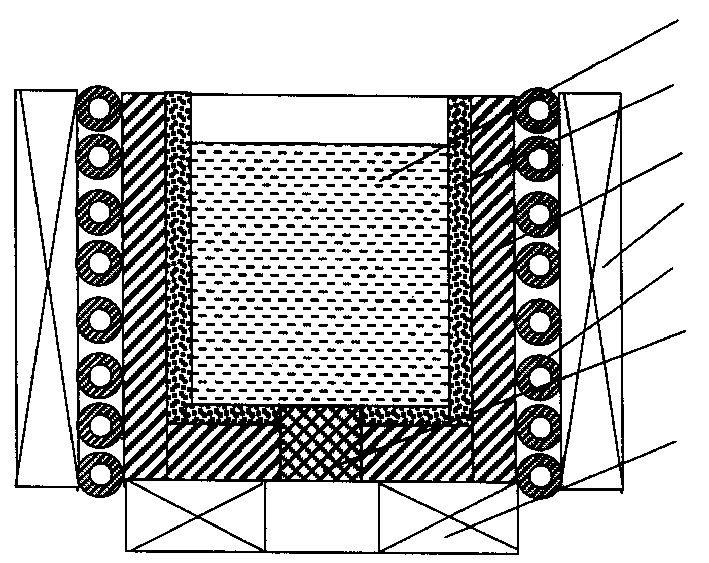

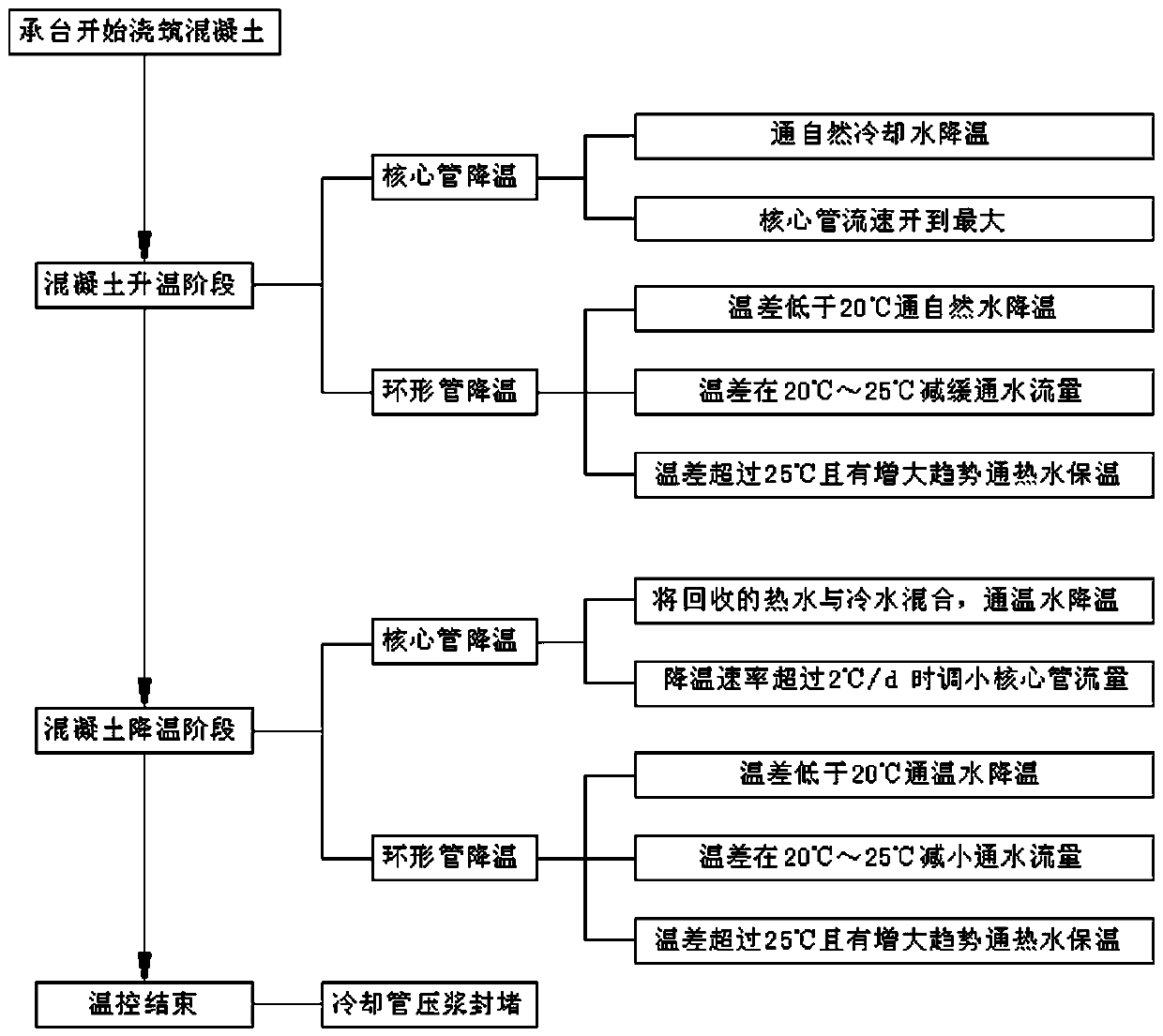

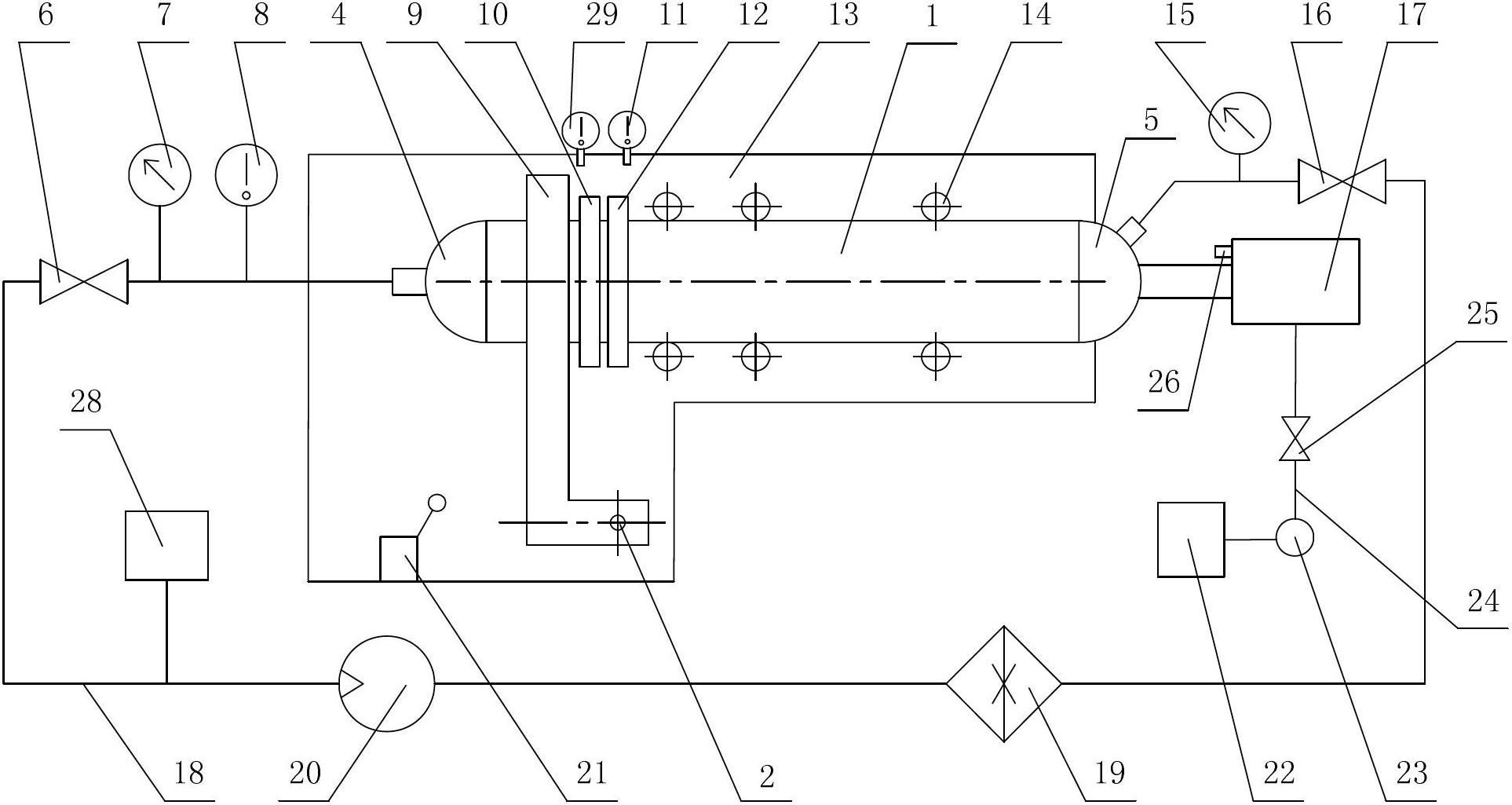

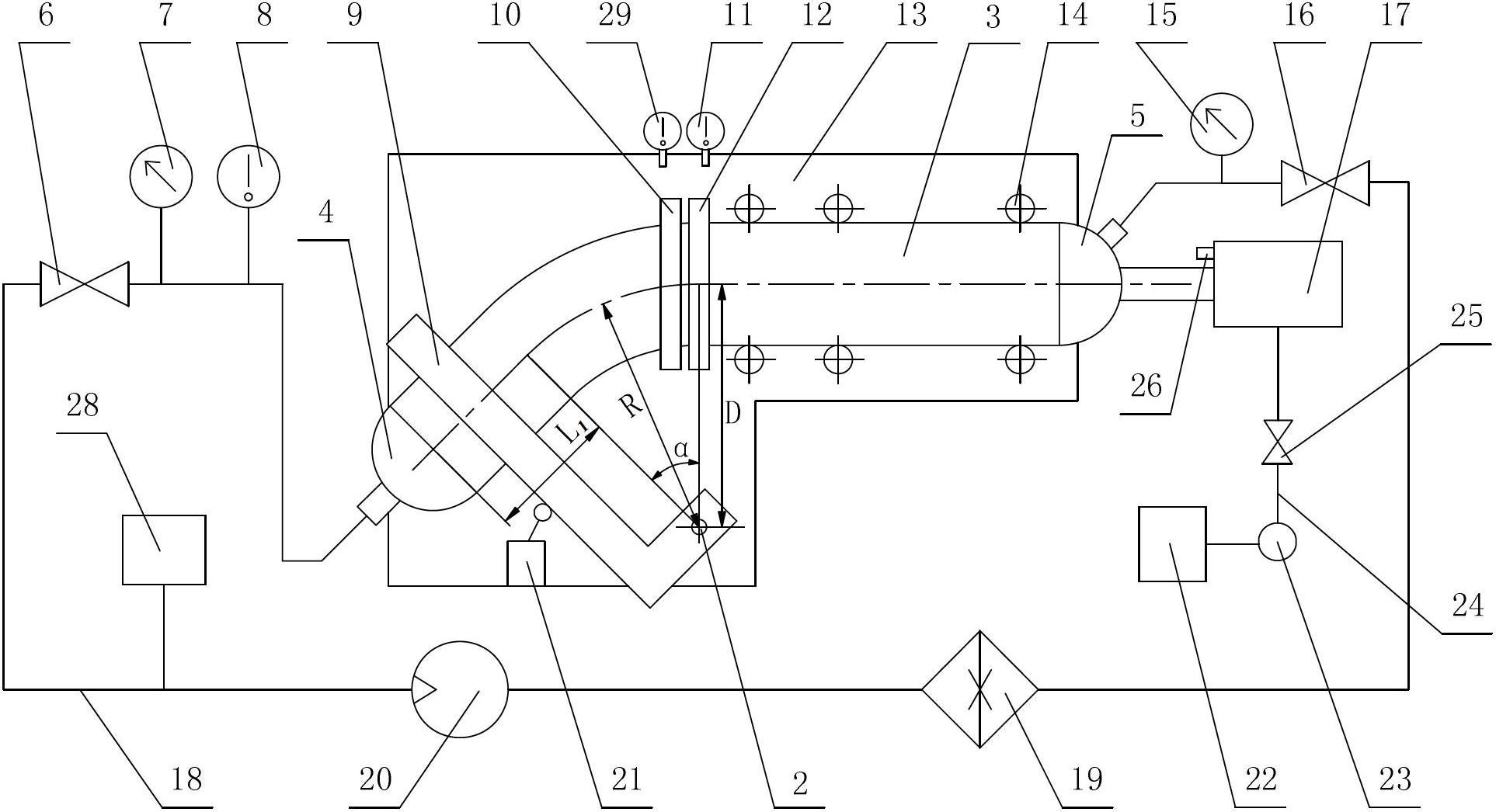

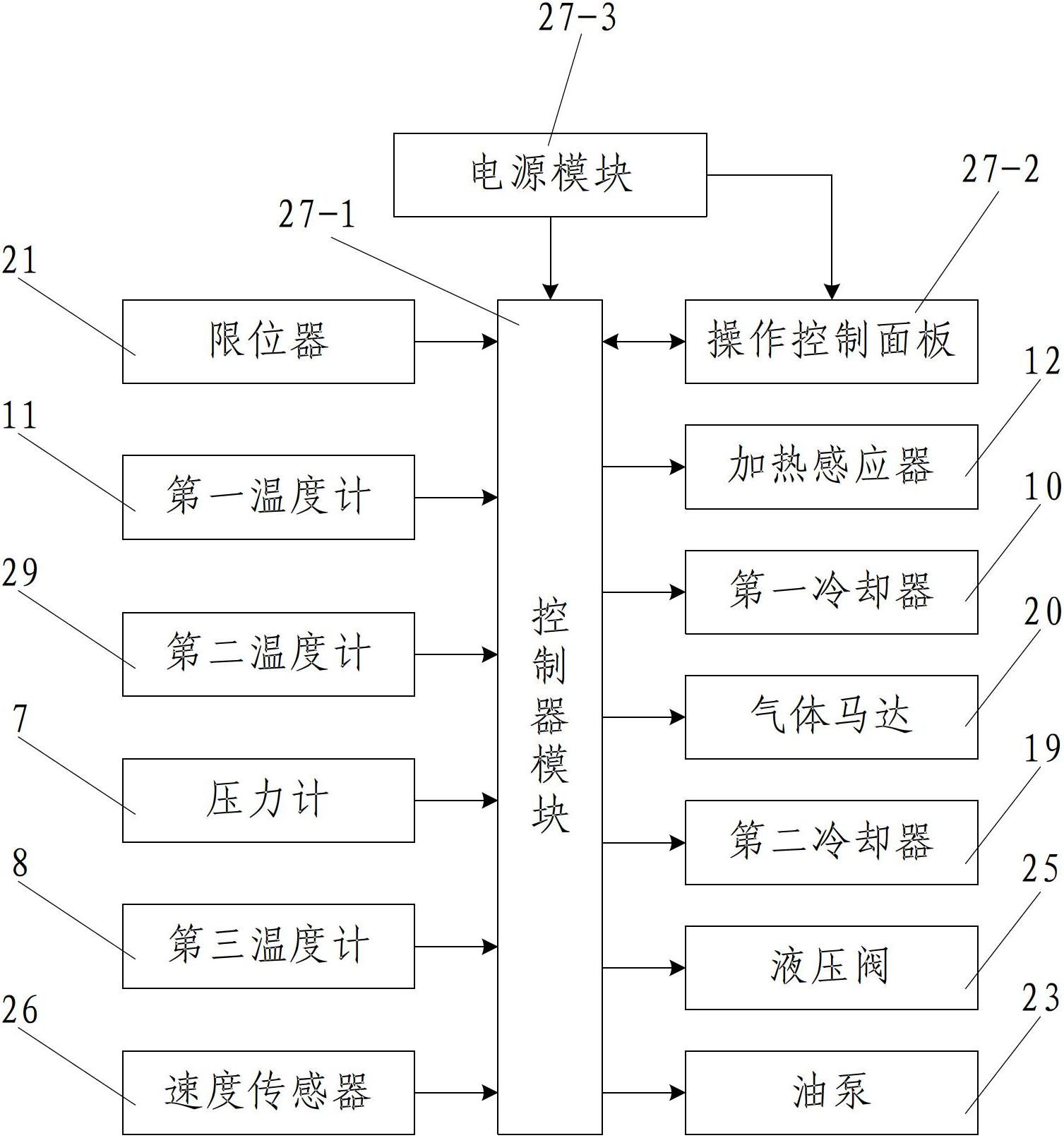

Temperature self-preservation system used for temperature control of concrete in mass bearing platform and using method of temperature self-preservation system

PendingCN109555123ASimple structureLow costFoundation engineeringBuilding material handlingEngineeringTemperature control

The invention discloses a temperature self-preservation system used for temperature control of a concrete in mass bearing platform and a using method of the temperature self-preservation system. The temperature self-preservation system comprises multi-layer cooling tubes and a water conveying device. The multi-layer cooling tubes are arranged inside the bearing platform by layers from top to bottom, each layer of the cooling tubes comprises annular tubes arranged on the periphery of the bearing platform and core tubes arranged at the center of the bearing platform, and the water conveying device is connected with the annular tubes and the core tubes. According to the temperature self-preservation system, the cooling tubes comprise the annular tubes arranged on the periphery of the bearingplatform and the core tubes arranged at the center of the bearing platform, and "cooling inside and preserve outside" is realized through the annular tubes and the core tubes, that is to say, besidestemperature cooling from inside, the temperature can further be preserved from outside; and multi-layer layout is adopted by the cooling tubes, the multi-layer cooling tubes are arranged inside the bearing platform by layers from top to bottom, and the core tubes which are arranged between adjacent two layers of the cooling tubes are perpendicularly arranged in a staggering mode so that uniformlytemperature reducing can be realized. The invention further discloses a using method of the temperature self-preservation system used for the temperature control of the concrete in mass bearing platform.

Owner:HUNAN UNIV OF SCI & TECH

Manufacturing device and method for bimetal composite hot bend

The invention discloses a manufacturing device and a method for a bimetal composite hot bend. The device comprises a thermal induction bend mechanism, an inert gas protecting system and an automatic control system, wherein the thermal induction bend mechanism comprises a rack, a hydraulic cylinder and a hydraulic control system, a rolling wheel, a heating inductor, a limiting stopper, a rotating clamp and a first cooler are arranged on the rack, the inert gas protecting system comprises a gas inlet end socket, an exhausting end socket and a gas circulating pipeline, and a gas inlet end valve, an exhausting end valve, a gas concentration tester, a gas motor and a second cooler are mounted on the gas circulating pipeline. The method includes the steps of intercepting a required bimetal composite pipe, sealing the bimetal composite pipe, installing the bimetal composite pipe on the thermal induction bend mechanism, connecting the inert gas protecting system and roasting and bending. The manufacturing device and the method for the bimetal composite hot bend are reasonable in design, high in intelligent degree, applicability, rate of finished products, product qualities and practicability, and convenient to popularize and apply.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

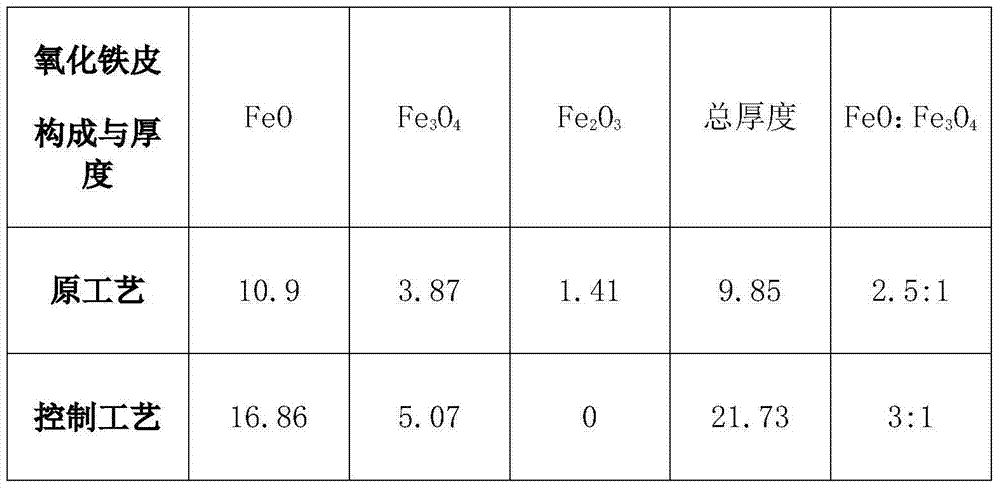

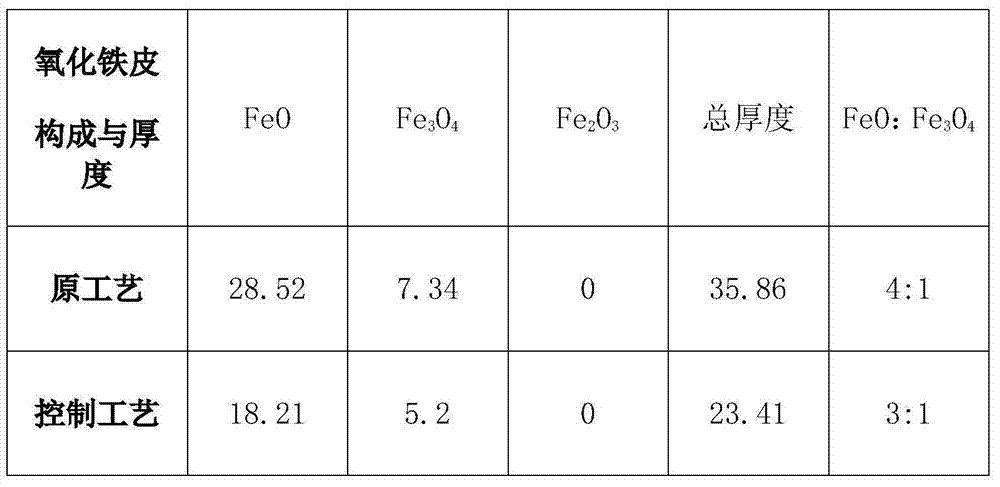

Method for controlling oxide iron scale on surface of low-carbon steel hot rolled wire rod

InactiveCN104275366AControl cooling rateGuarantee the temperature of the coverExtrusion cleaning devicesWire rodCarbon steel

Owner:NANJING IRON & STEEL CO LTD

Sapphire crystal growth method

InactiveCN101205628AAvoid melt flowControl cooling ratePolycrystalline material growthFrom solid stateLiquid stateSingle crystal

The invention discloses a growing method of sapphire crystal, which includes the steps that: alumina powder is crushed and grinded to ultra-micro powder particles; alumina particles are purified until the purity over 99.999 percent; the grinded and purified alumina with solvent is churned into pulpous state, pressed with a high pressure pump, delivered to a prilling nozzle, and sprayed into a high temperature drying tower, the pulpous state alumina which is sprayed from the prilling nozzle is dried into alumina particles and collected, and added with organic binder. The pure alumina powder particles are arranged in a mould, and added with the organic binder, and forms a body on a forcing press; the body is fired into an alumina block in half-done state in advance, arranged in a vacuum super-high-temperature furnace for preburning, thereby exhausting impure gas; the furnace is vacuumized and introduced with inert gas, and the alumina in half-done state is heated into liquid state, until the crystal growth is completed, and is solidified, cooled and contracted into monocrystal sapphire. The invention saves time for crystal growing, has low cost, is not limited in quality and size of the crystal, and fulfills the requirement of optic components, semiconductor components, communication components and other components.

Owner:庄育丰

Phase-change energy-storage radiator

InactiveCN105588165ALarge energy storage capacityReduce volumeHeat storage plantsElectric heating systemThermodynamicsHeat flow

The invention relates to a phase-change energy-storage radiator, and belongs to the field of new type energy, energy conservation and environmental protection. The phase-change energy-storage radiator is used for storage and controlled releasing of heat energy in multiple grades. The phase-change energy-storage radiator comprises an outer heat preservation box and an energy-storage unit; a natural convection radiating runner is formed between the energy-storage unit and a heat preservation shell; and the natural convection radiating runner is controlled to be opened and closed, and therefore timing accumulated storage and releasing of the energy can be achieved. Heat insulation and energy storage can be completely achieved in the energy storage process of the phase-change energy-storage radiator, and meanwhile radiating can be controlled in the storage process. The device is large in energy-storage volume and small in size. According to a specially developed and allocated mixed chlorinated paraffin low-temperature phase-change energy-storage material, the energy-storage temperature scope is appropriate, the material is non-toxic and free of chemical changes, the energy-storage temperature scope and the heat release amount are not changed after repeated utilization, undercooling and overheating phenomena are avoided, and both the physical and chemical property and the reliability are excellent.

Owner:BAOTOU BOTE TECH

Drug reagent storage device of moveable clinical diagnosis and treatment equipment

ActiveCN104192428ALight in massImprove cooling efficiencyShock-sensitive articlesPhysicsHeat conservation

The invention discloses a drug reagent storage device of moveable clinical diagnosis and treatment equipment. The drug reagent storage device comprises a cubic box and a cover which can be opened and closed and located at the upper end of the box. The box and the cover are respectively provided with a heat preservation and insulation layer, a heat-insulated storage chamber is arranged on the right side in the box, and a liquid nitrogen tank is stored in the storage chamber; a cooling pipe and a safety exhaust pipe are arranged at the upper end of the liquid nitrogen tank, the safety exhaust pipe is provided with a safety valve, and the cooling pipe is provided with a control valve used for controlling the discharge speed of nitrogen; a sliding block used for adjusting the cooling rate is arranged in the box. Liquid nitrogen serves as a cooling source, and the drug reagent storage device has the characteristics of small mass, high cooling efficiency and long refrigeration time and is convenient to move, carry and use; the refrigeration rate and the temperature in the box can be effectively controlled through adjustment of cooing pipe sets and the control valve, effective storage of drug reagents is guaranteed, and the drug reagent storage device has excellent carrying and using effects.

Owner:BEIJING BEIKEN HUAYE SCI & TECH DEV

Magnesium-chromium composite spinelle brick

The invention discloses a magnesium-chrome composite spinel brick which is made from synthetical magnesium-chrome spinel sand, magnesia, chromium concentrate and chrome oxide according the weight percentages as follows: taking 65 percent to 70 percent of MgO, 20 percent to 25 percent of Cr2O3, 0.5 percent to 1.2 percent of SiO2, 4 percent to 6 percent of Fe2O3, 2 percent to 4 percent of Al2O3 and 0.5 percent to 1.2 percent of CaO to the material of the number one synthetical magnesium-chrome spinel sand; taking 55 percent to 60 percent of MgO, 30 percent to 35 percent of Cr2O3, 0.5 percent to 1.2 percent of SiO2, 4 percent to 6 percent of Fe2O3, 2 percent to 4 percent of Al2O3 and 0.5 percent to 1.2 percent of CaO to the material of the number two synthetical magnesium-chrome spinel sand; taking 70 percent to 75 percent of MgO, 14 percent to 19 percent of Cr2O3, 0.8 percent to 1.2 percent of SiO2, 4.5 percent to 7 percent of Fe2O3, 2 percent to 4 percent of Al2O3 and 0.8 percent to 1.5 percent of CaO to the material of the number three synthetical magnesium-chrome spinel sand; taking 97 percent to 98.5 percent of MgO, 0.5 percent to 1.3 percent of SiO2, 0.5 percent to 1.3 percent of CaO and 0.2 percent to 0.5 percent of Fe2O3 to the material of the magnesia; taking 50 percent to 60 percent of Cr2O3, 9 percent to 15 percent of MgO, 0.3 percent to 1.5 percent of SiO2, 15 percent to 25 percent of Fe2O3 and 8 percent to 15 percent of Al2O3 to the material of the chromium concentrate; taking 92 percent to 96 percent of Cr2O3 and 4 percent to 8 percent of ZrO to the material of the chrome oxide. The invention has the advantage of having the characteristics of compact structure, thermal shock resistance, anti-scaling off, erosion resistance etc.

Owner:ZHENGZHOU HUAWEI REFRACTORIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com