Temperature self-preservation system used for temperature control of concrete in mass bearing platform and using method of temperature self-preservation system

A mass concrete, self-insulation technology, applied in the processing of building materials, infrastructure engineering, construction, etc., can solve the problems of increasing construction difficulty, difficulty in realizing, delaying construction period, etc., achieving good insulation effect, convenient construction, reducing The effect of inner surface temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

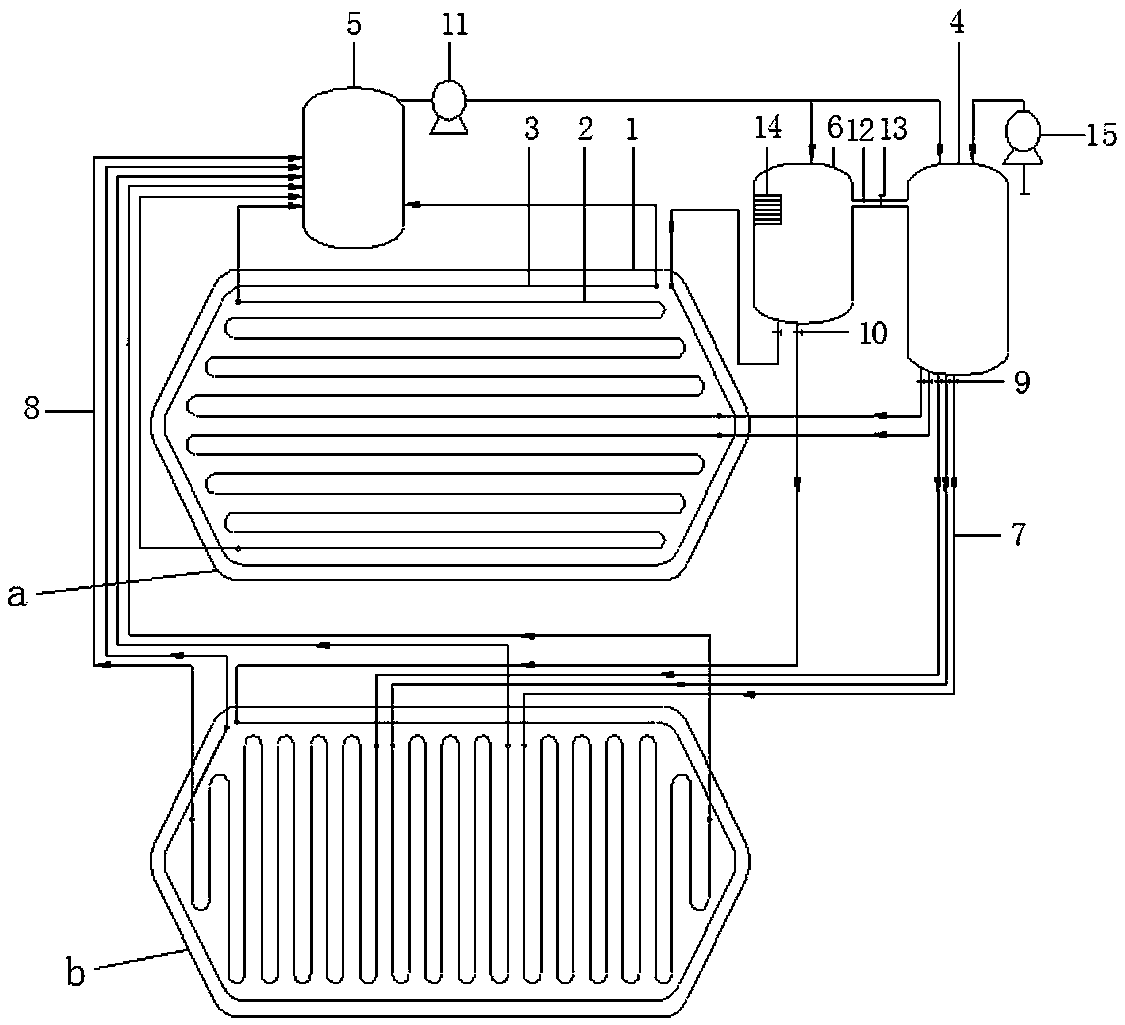

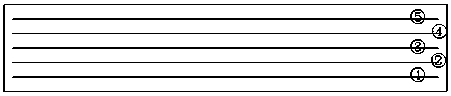

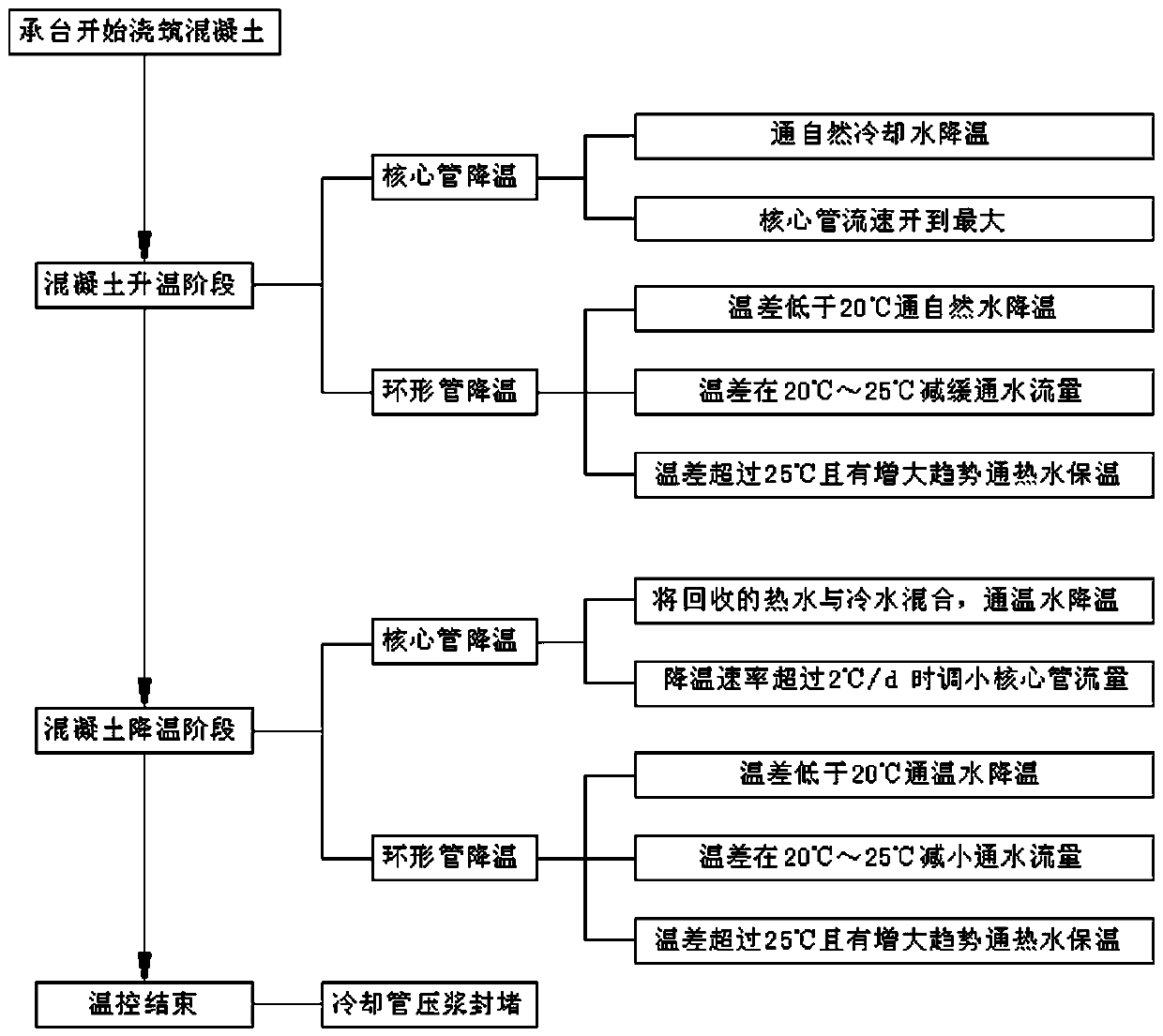

[0029] Such as figure 1 , figure 2 As shown, a self-insulation system for the temperature control of large-volume concrete caps includes five layers of cooling pipes and water delivery devices. , ②, ③, ④, ⑤; figure 1 The a and b in it are equivalent to the cooling pipes of the ① and ② layers; the layer spacing of the 5 layers of cooling pipes is 1m, and the size of the platform 1 is 36.5m×15.9m×6.0m. Each layer of cooling pipes includes an annular pipe 3 arranged around the platform 1 and a core pipe 2 arranged in the middle of the platform 1, and the annular pipe 3 and the core pipe 2 are connected by elbows; in the same layer of cooling pipes The annular tube 3 and the core tube 2 are arranged in parallel; in order to achieve uniform cooling, the core tubes 2 in the adjacent two layers of cooling tubes are vertically staggered, the annular tube 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com