Patents

Literature

965 results about "Mass concrete" patented technology

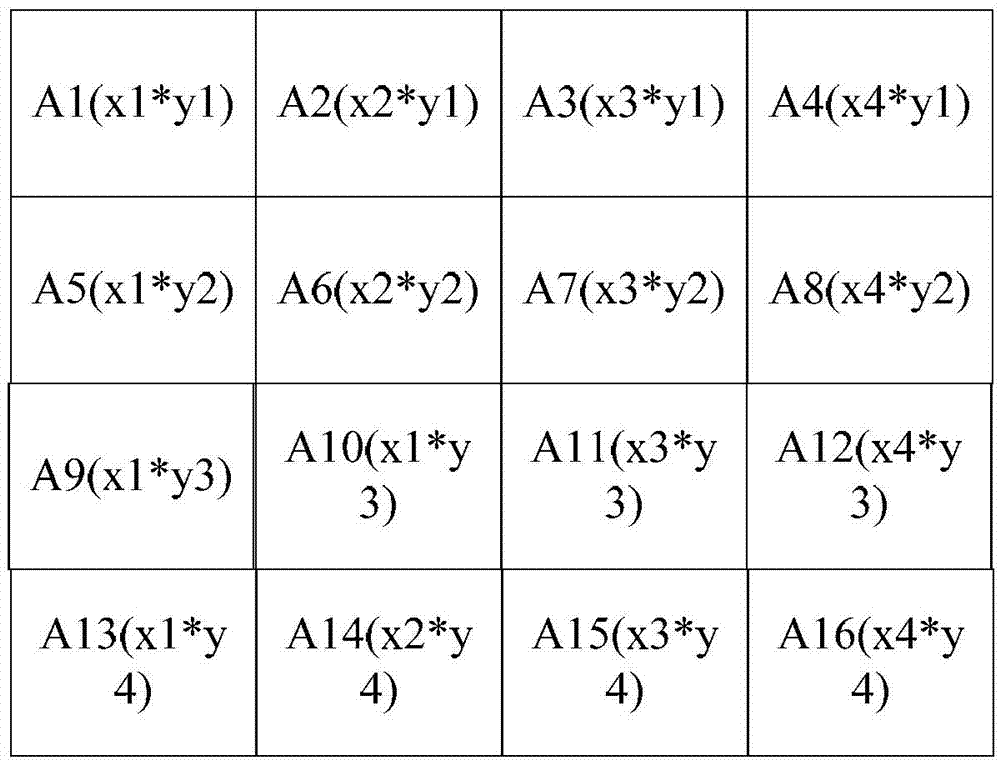

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mass concrete is defined by American Concrete Institute Committee 207 as "any volume of concrete with dimensions large enough to require that measures be taken to cope with the generation of heat from hydration of cement and attendant volume change to minimize cracking."

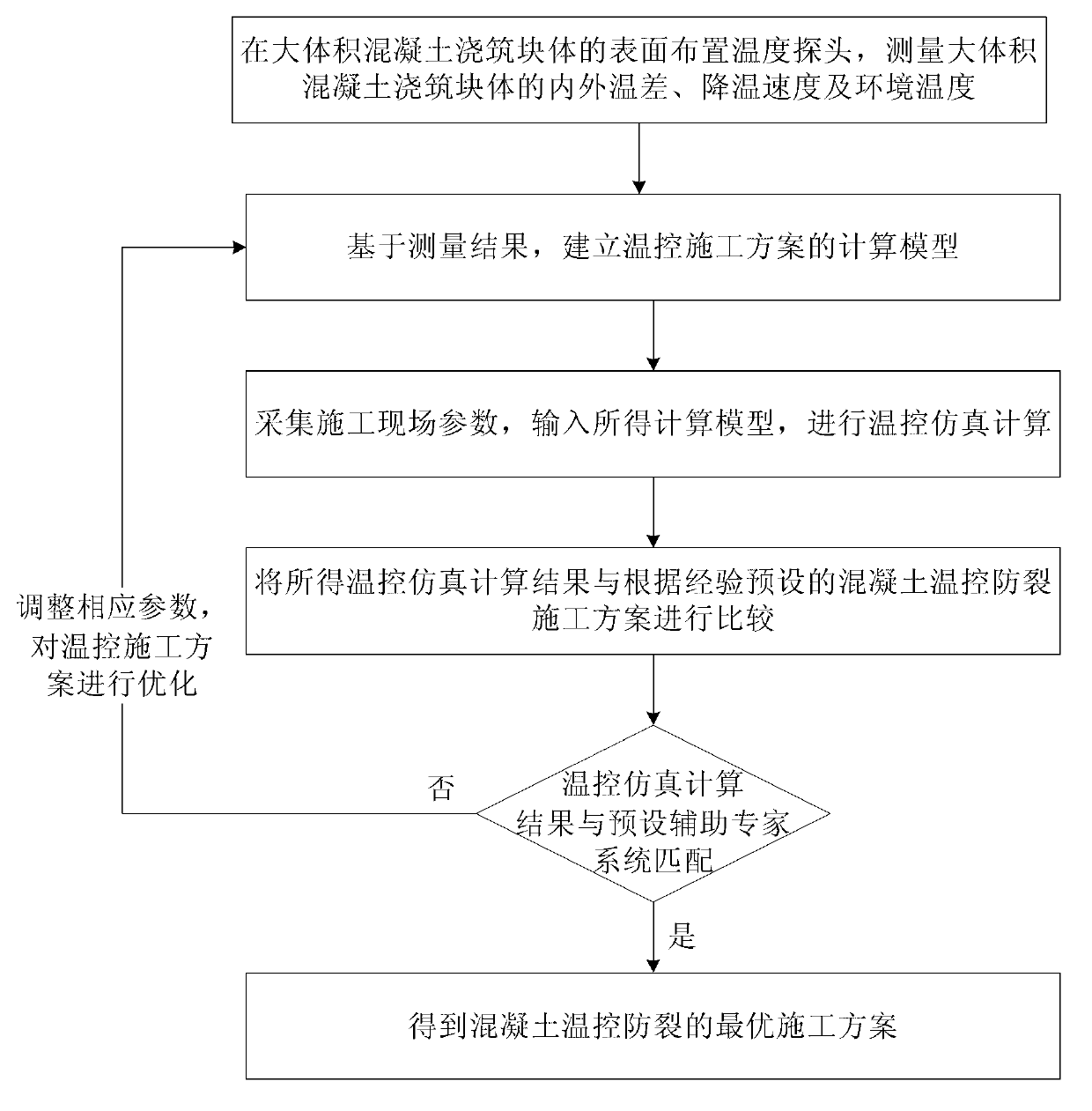

Temperature-controlled crack prevention construction method for concrete structure

ActiveCN102979307AOvercoming easy cracksOvercoming reliabilityFoundation engineeringBuilding material handlingTemperature controlTemperature difference

The invention discloses a temperature-controlled crack prevention construction method for a concrete structure. The method comprises the steps of (1) arranging temperature probes on the surface of a large-size concrete pouring block to measure the temperature difference between inside and outside, the cooling rate of the large-size concrete pouring block and the environment temperature; (2) establishing a calculation model for the temperature-controlled construction scheme based on the obtained measuring result; (3) collecting the construction site parameters, and inputting the parameters into the obtained calculation model for temperature-controlled simulation calculation; and (4) comparing the temperature-controlled simulation calculation result obtained in the step (3) with the preset auxiliary expert system, repeating the step (2) to adjust the corresponding parameters when the temperature-controlled simulation calculation result obtained in the step (3) and the preset auxiliary expert system mismatch, and optimizing the temperature-controlled crack prevention construction scheme for concrete preset based on experience until the optimal temperature-controlled crack prevention construction scheme for the concrete is obtained. The temperature-controlled crack prevention construction method for the concrete structure disclosed by the invention has the advantages that the concrete is not prone to crack, the crack prevention reliability is high, and the crack prevention commonality is good.

Owner:JINLAI CONSTR ENG TECH RES & DEV CO LTD OF THE XINJIANG PRODION & CONSTR CORPS

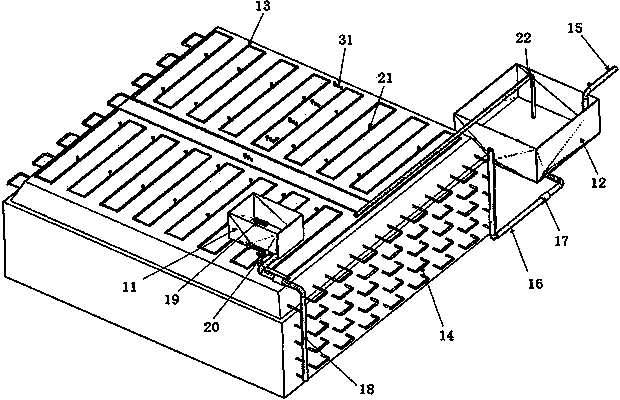

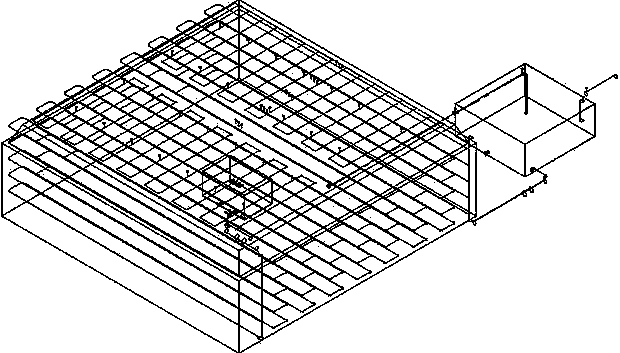

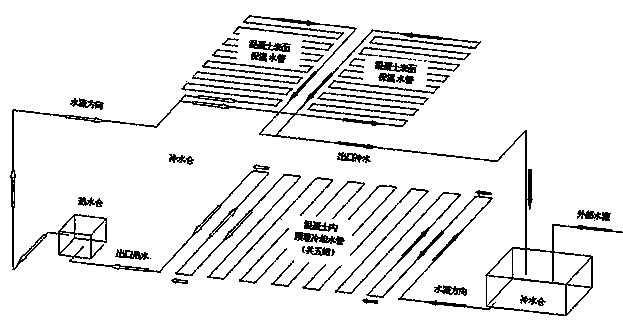

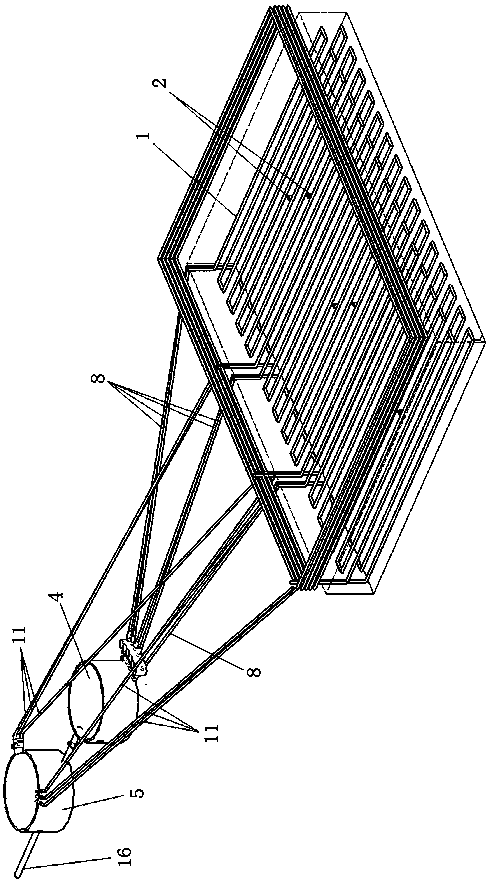

Large-sized concrete automatic temperature control and maintenance device and method

ActiveCN103526761AIncrease surface temperatureTemperature monitoring and automatic adjustmentFoundation engineeringTemperature controlSprayer

The invention discloses a large-sized concrete automatic temperature control and maintenance device and method, wherein the temperature control device comprises a water circulation system, a temperature measuring device and a temperature control system. The water circulation system comprises a hot water cabin, a cold water cabin, a heat-preservation water tube and a cooling water tube, the cold water cabin is arranged outside a concrete foundation, the cooling water tube is buried inside the concrete, the hot water cabin is arranged at the top of the concrete foundation, and a heater is arranged in the hot water cabin. The heat preservation water tube is buried in the upper portion of the concrete foundation in advance and is respectively communicated with the hot water cabin and the cold water cabin, and a sprayer is arranged on the heat preservation water tube. The temperature measuring device is buried inside the concrete foundation in advance and is connected with the temperature control system. The temperature control system is connected with the water circulation system, and the water circulation of the water circulation system is controlled according to the temperature measured by the temperature measuring system. According to the large-sized concrete automatic temperature control and maintenance device and method, the monitoring and automatic adjustment of the temperature, the flowing speed and pressure of the cooling water and heat-preservation water are achieved through the temperature control system, and the timing automatic spraying and maintenance function can also be achieved.

Owner:CHINA FIRST METALLURGICAL GROUP

Mass concrete construction method of super-thick foundation

InactiveCN101962997AQuality improvementReduce dosageFoundation engineeringBuilding material handlingDesiccationRebar

The invention discloses a mass concrete construction method of a super-thick foundation, comprising the following steps of: (1) binding the steel bars on a base plate of the foundation, and fixing cooling water pipes on a steel bar fixing frame, wherein the cooling water pipes are evenly distributed at the inside layers of the foundation; (2) blending the concrete; (3) pouring the concrete; (4) carrying out press polishing to the concrete on the surface of the foundation before the final setting of the concrete of the foundation; and (5) maintaining the foundation. The invention adopts the anti-cracking concrete so as to reduce the cement content and decrease the generation of the heat of hydration; the embedding of the cooling water pipes can shorten the emission time of the heat in the concrete and decrease the maintenance time of the concrete structure; the press polishing is carried out to the surface of the concrete structure to ensure that the desiccation fissures are prevented; and maintaining the concrete with preserved temperature and humidity can improve the quality of the concrete. The invention has the effects of at least improving the work efficiency by 4 times, greatly saving the cost, improving the work efficiency and paving the way for the advanced construction of the next process.

Owner:TIANJIN 20 CONSTR

Construction method of large-volume concrete bearing platform with one-time pouring in winter

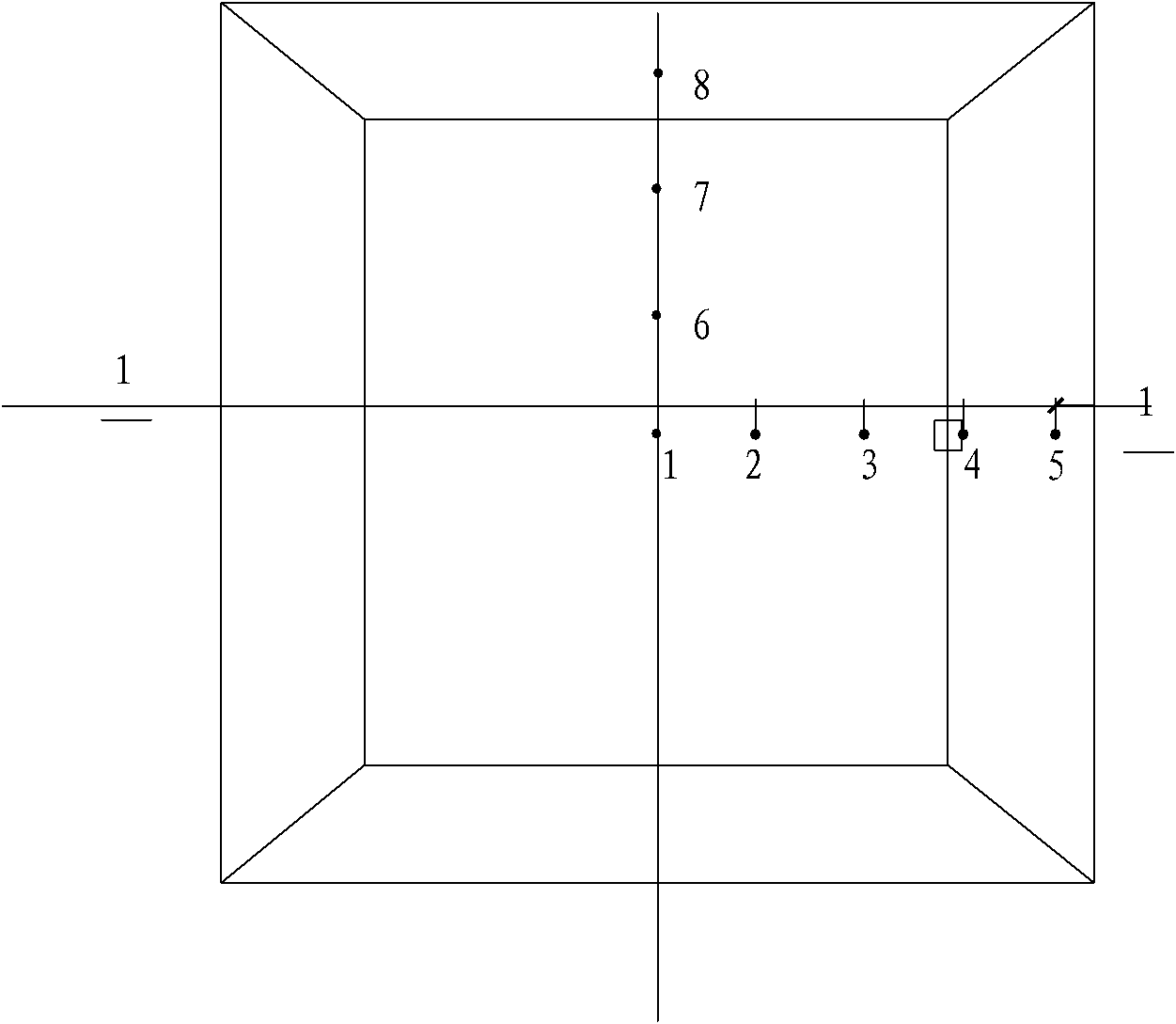

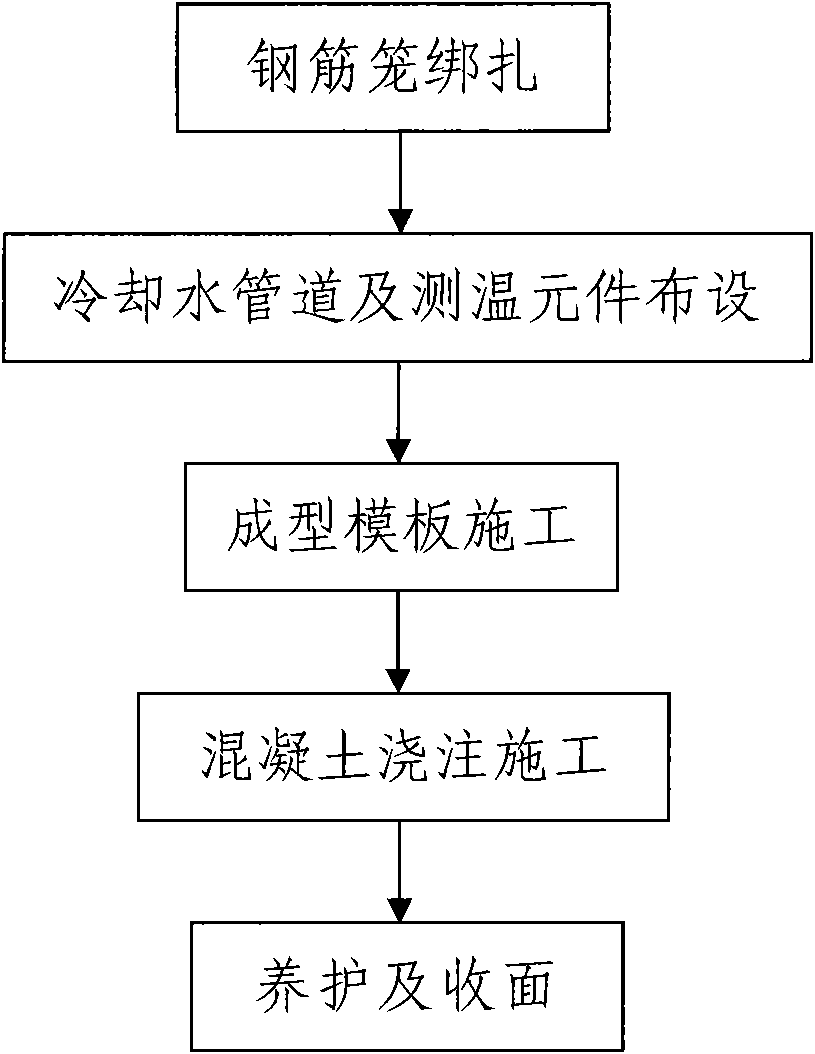

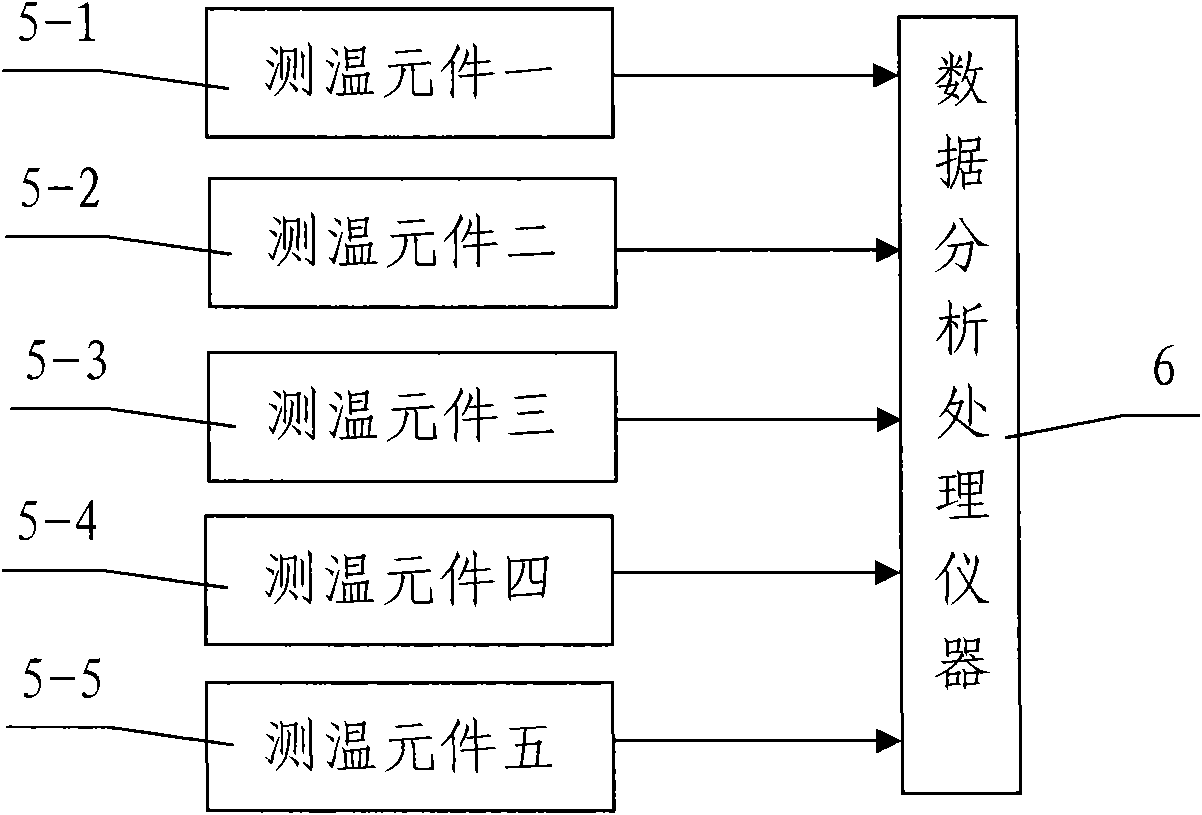

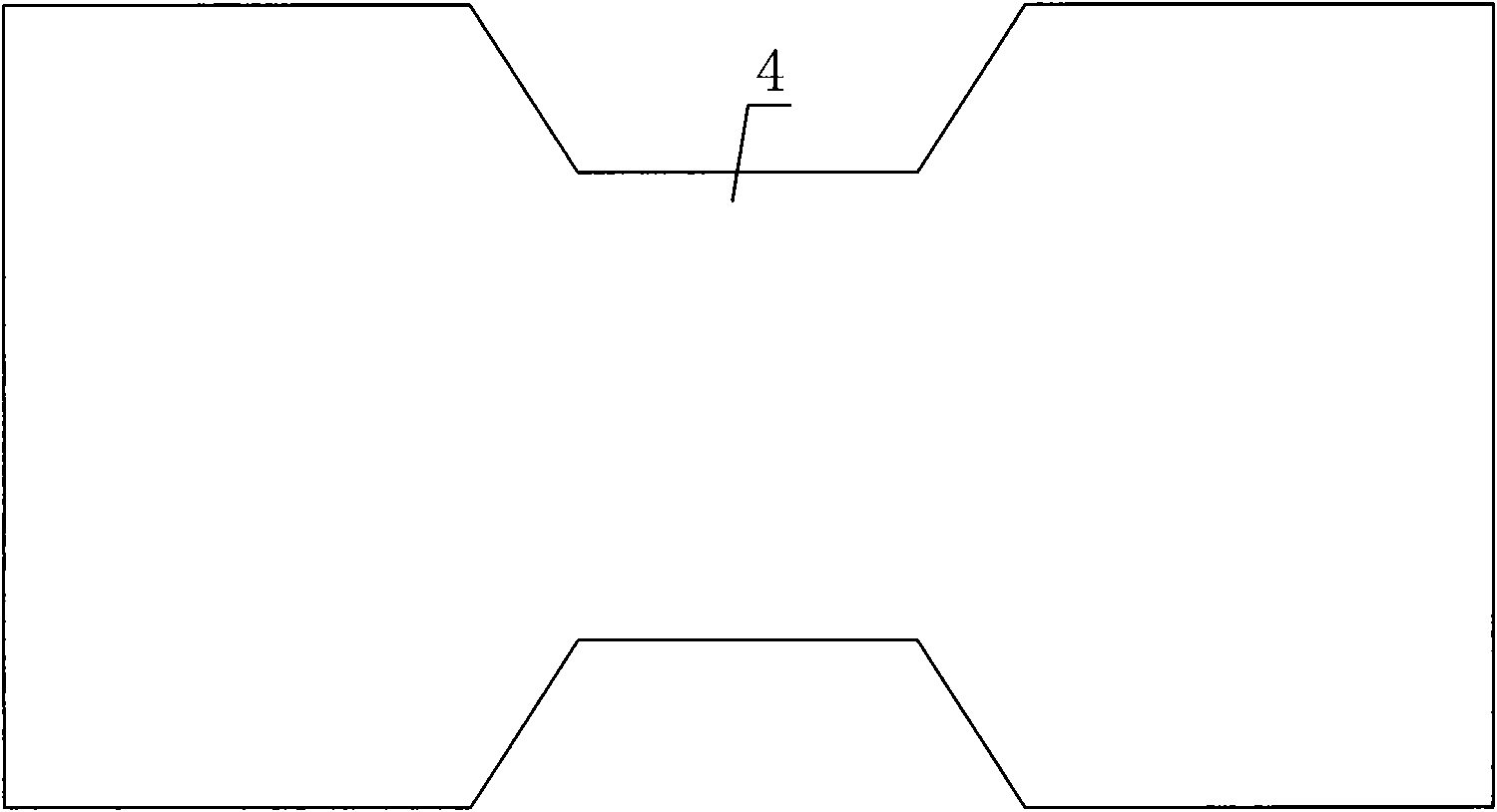

The invention discloses a construction method of a large-volume concrete bearing platform with one-time pouring in winter, comprising the following steps of: step 1, binding steel reinforcement cages; step 2, laying cooling water pipelines and temperature measuring elements; step 3, constructing formed templates, wherein the construction process comprises delimiting template lines and constructing formed brick dies; step 4, pouring concrete; and step 5, conserving and finishing surface: finishing surface in time when completing the pouring of the concrete, carrying out the surface finishing twice, carrying out the first surface finishing when pouring the concrete to the top, carrying out the second surface finishing when the concrete is initially congealed, and adopting a mode that external stores water for conserving when the concrete is initially congealed. The invention has the advantages of reasonable design, simple construction method step, convenient operation, short construction period, one-time pouring molding and strong maneuverability, the large-volume concrete bearing platform constructed for molding in winter has good quality, the poured concrete is not frozen, and the surface of the bearing platform can not have temperature cracks.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

Composite cement with large amount of coal gangue and its preparation method

InactiveCN1546410AImprove performanceFull play of water activity and hardnessSolid waste managementHigh intensityMaceral

The invention discloses a large mixing amount coal gangue composite cement comprising coal gangue, silicate cement clinker aggregate, exciting agent, gypsum coagulation regulating agent, mineral admixture by right weight portion through a finite process, wherein the content of coal gangue is 20-80% wt. The composite cement according to the invention can be used for making various concrete structure, in particular mass concrete structure.

Owner:TONGJI UNIV

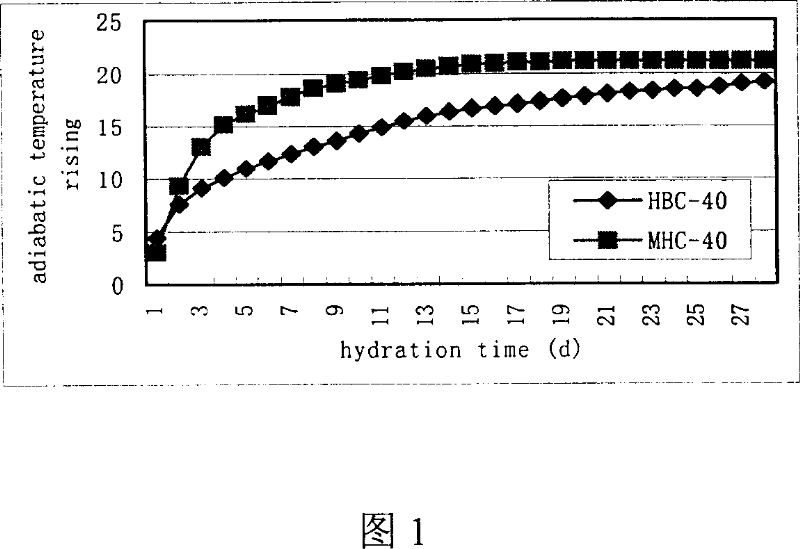

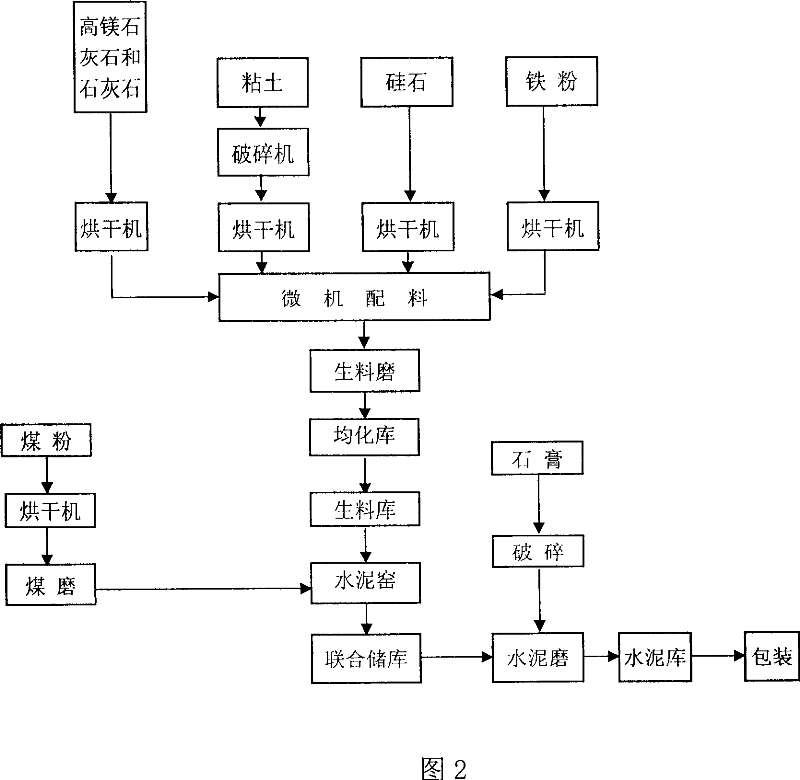

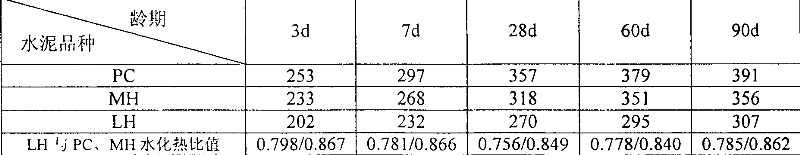

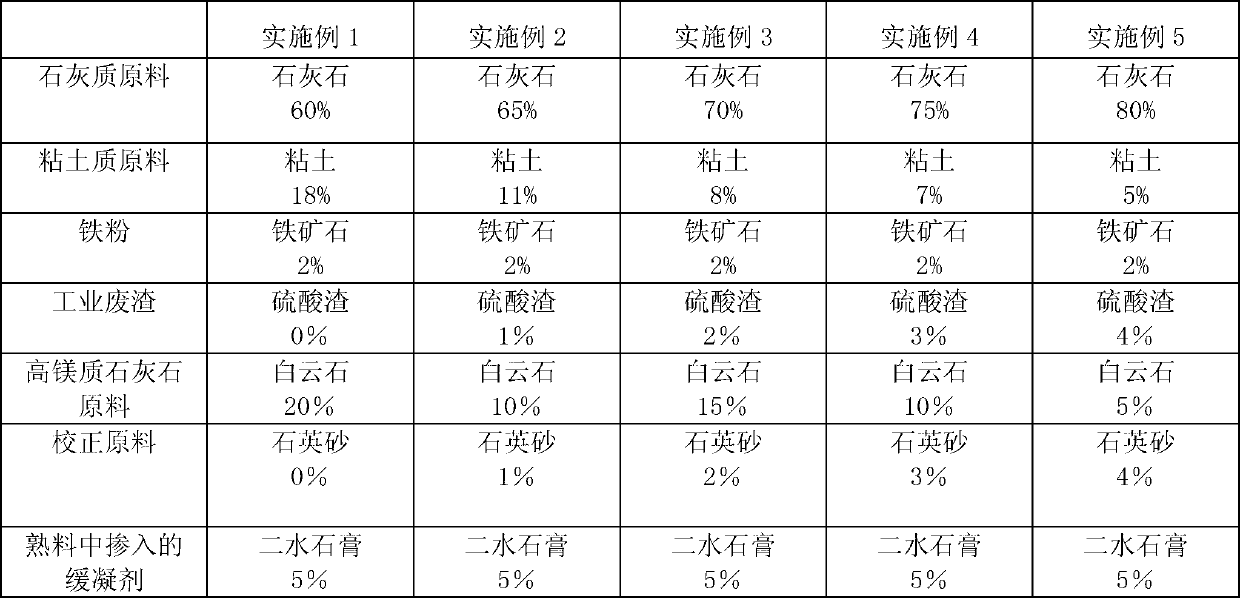

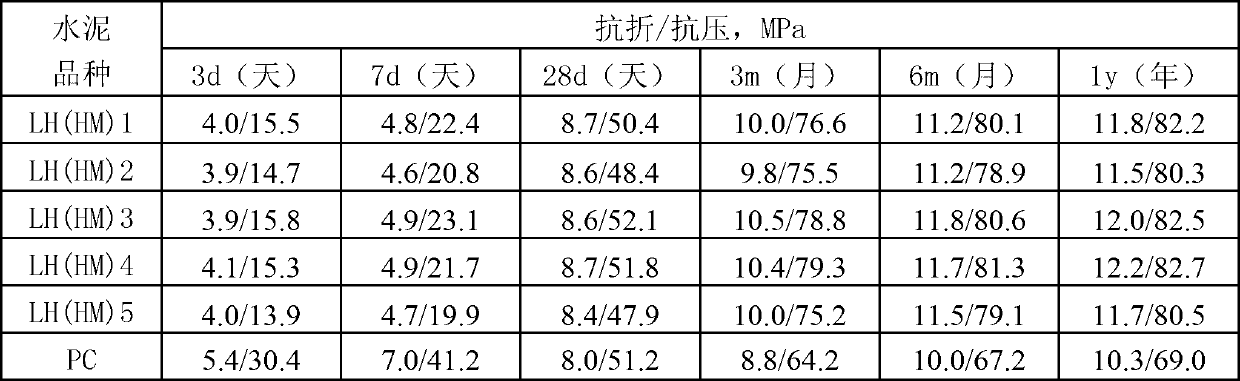

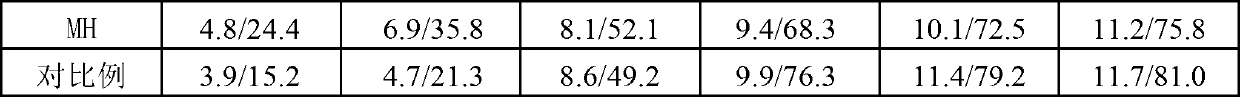

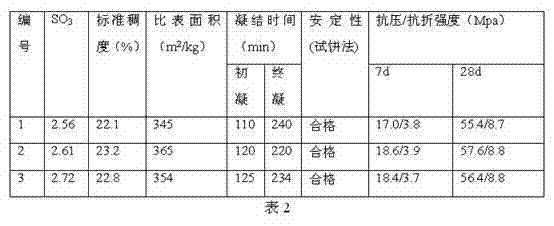

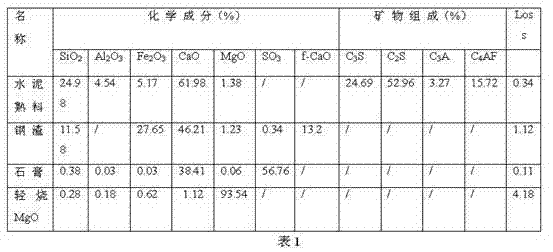

High-magnesium low-heat portland cement clinker aggregate and preparation method thereof

InactiveCN101041560AImprove crack resistanceLow heat of hydrationClinker productionHigh magnesiumPortland cement

The invention discloses a high-magnesium lower thermal silicate cement clinker, making mineralogical composition at (mass percent): 40 -65% C2S, 15-40% C3S, 1-8% C3A, 10-25% C4AF and content of MgO at 2.0-6.0%. The invention also discloses a preparing method of high-magnesium lower thermal silicate cement clinker, including indispensable steps of producing cement clinker with raw materials and controlling content of MgO of cement clinker at 2.0-6.0%.

Owner:CHINA BUILDING MATERIALS ACAD

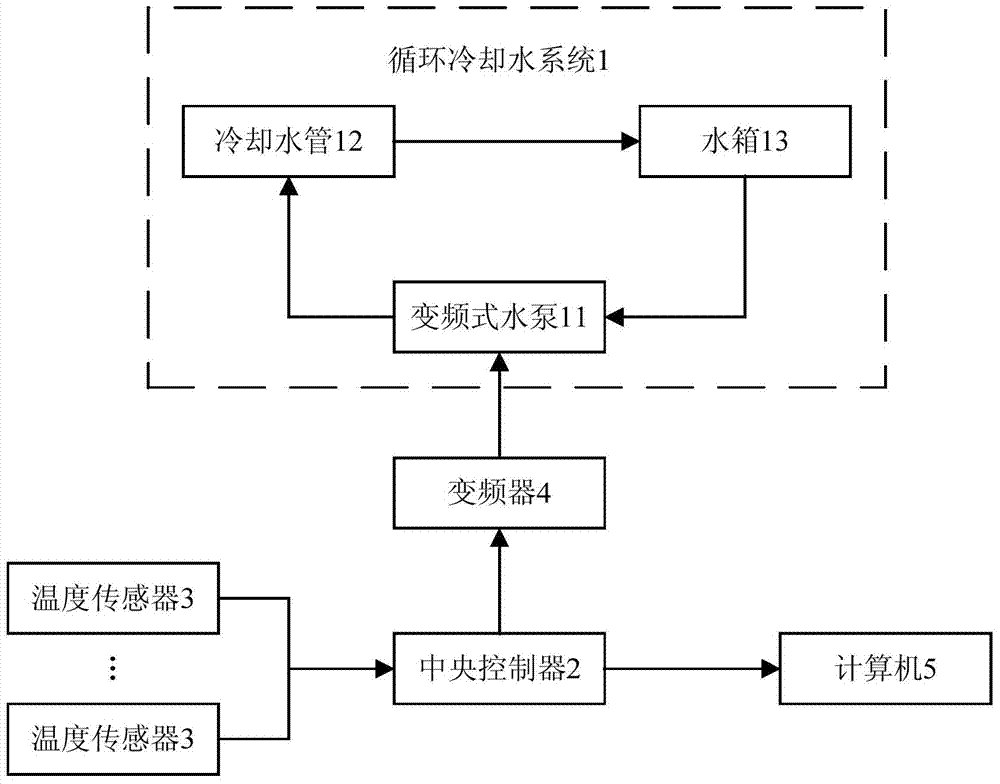

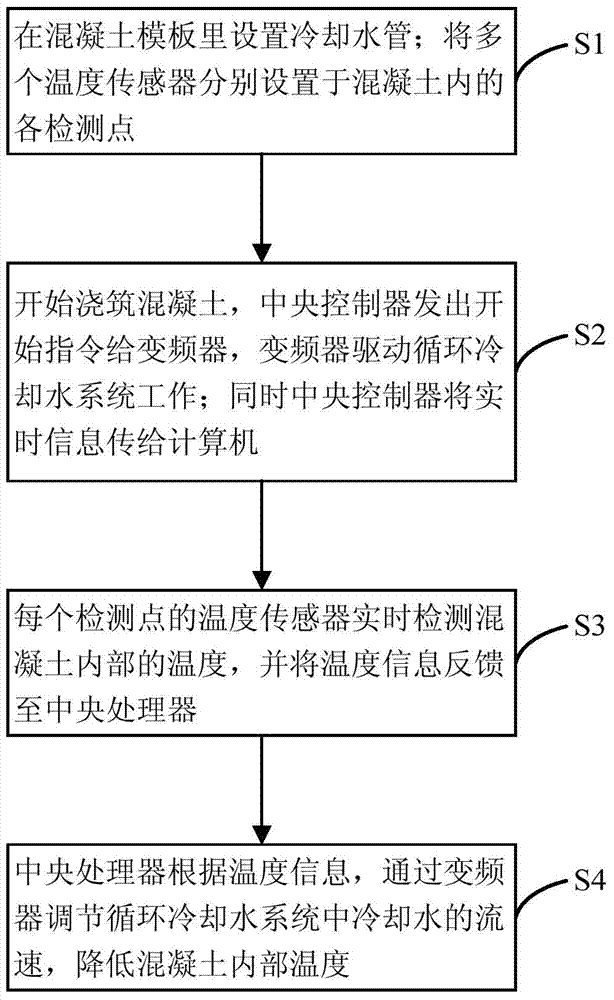

System and method for measuring and controlling hydration heat in mass concrete

InactiveCN103485542AImprove certaintyReduce labor intensityBuilding material handlingFrequency changerTime information

The invention relates to a system and a method for measuring and controlling hydration heat in mass concrete and relates to the field of automatic control systems for civil engineering construction. The system comprises a circulating cooling water system, a central control unit, a frequency converter, a plurality of temperature sensors and a computer. The central control unit is connected with the frequency converter, the computer and the temperature sensors. The frequency converter is further connected with the circulating cooling water system. The temperature sensors are disposed inside concrete and feed temperature information back to the central control unit. The central control unit sends a control command to the frequency converter according to the temperature information. The frequency converter drives the circulating cooling water system to change flow of circulating cooling water, and meanwhile, the central control unit transmits real-time information to the computer. The system and the method have the advantages that manual work is omitted, temperature changes inside concrete can be measured in real time, and work efficiency is improved; flow quantity of cooling water is automatically adjusted, so that implementation controllability is ensured; storage and subsequent analysis of data can be facilitated.

Owner:CHINA MAJOR BRIDGE ENG

Efficient retarding and water reducing agent for concrete

The present invention relates to one kind of efficient retarding and water reducing agent for concrete suitable for commercial concrete, pumped concrete and bulk concrete. The efficient retarding and water reducing agent consists of water reducing agent 0-90 wt%, retarder I 1-15 wt%, retarder II 0.5-25 wt% and shrinkage reducing agent 0.05-0.2 wt%. The efficient retarding and water reducing agent has simple preparation process, and has the effects of delaying the setting of concrete, raising early strength, reducing water, etc.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

High-magnesium minimum-inflation low-heat cement and preparation method thereof

ActiveCN102898050AWide variety of sourcesTake advantage ofCement productionHigh magnesiumPortland cement

The invention discloses high-magnesium minimum-inflation low-heat cement and a preparation method thereof. A high-magnesium minimum-inflation low-heat cement clinker comprises the following mineral compositions in percentage by weight: 10-35% of C3S, 40-65% of C2S, 1-5% of C3A, 10-20% of C4AF and 6.0-8.0% of MgO. The concrete prepared by the cement has the characteristics of good liquidity, low water requirement amount, low hydration heat, high long-term strength, good durability and minimum inflation performance, and can be used for compensating the contraction of big-volume concrete and hydraulic concrete and reducing a concrete crack. Compared with the traditional portland cement and the low-heat portland cement, the high-magnesium minimum-inflation low-heat cement is more favorable for realizing the volume stability and the safety of the concrete, and is an ideal cementing material for the major projects, especially the big-volume concrete and hydraulic concrete engineering.

Owner:CHINA BUILDING MATERIALS ACAD

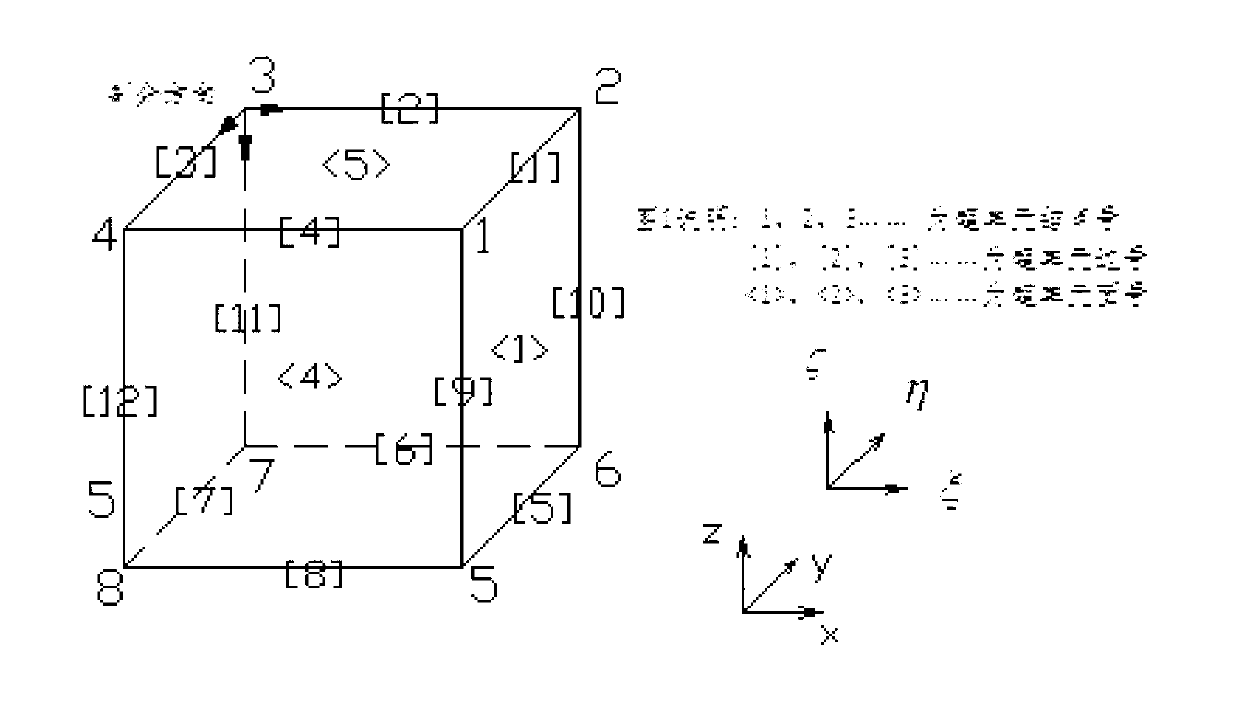

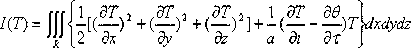

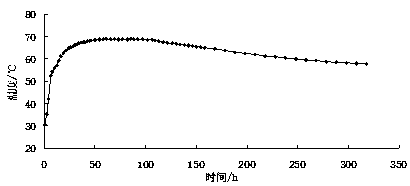

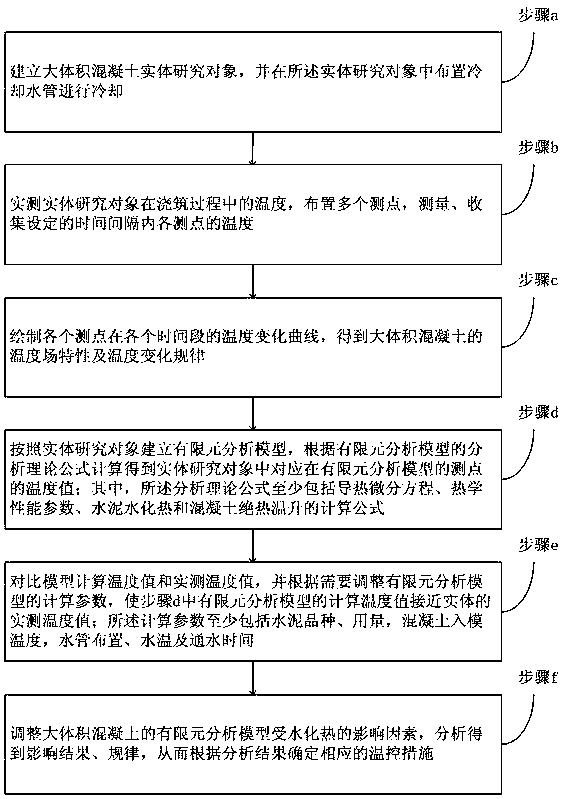

Mass concrete-based temperature field research method and temperature control method

InactiveCN108133111ANo crackImprove effectivenessGeometric CADDesign optimisation/simulationTemperature controlResearch Object

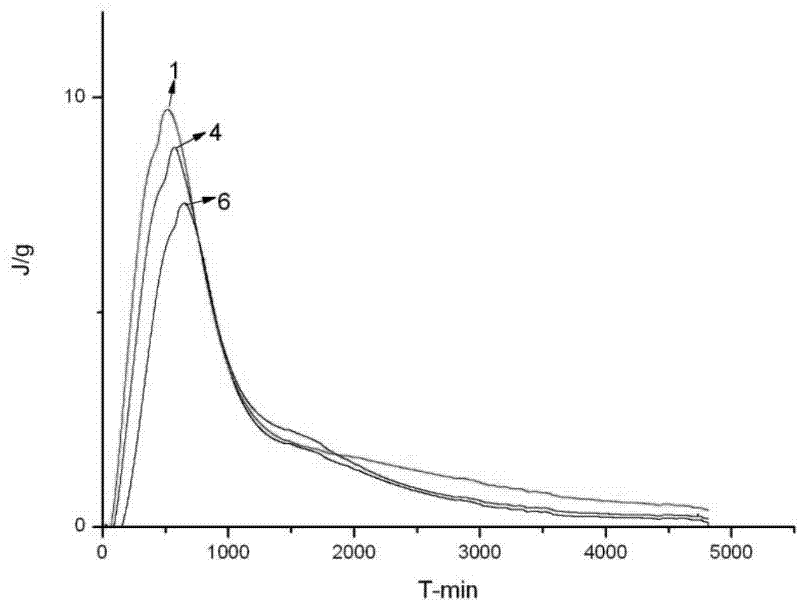

The invention discloses a mass concrete-based temperature field research method and a mass concrete-based temperature control method. The research method comprises the following steps of: establishinga mass concrete entity research object; measuring temperatures, in a pouring process, of a plurality of measurement points of the entity, and drawing corresponding temperature change curves to obtaintemperature field characteristics and a temperature change law; establishing a finite element analysis model according to the entity research object and automatically calculating temperatures of thecorresponding measurement points; adjusting temperature field calculation parameter of the model through comparing the calculated temperature values of the model with the actually measured temperaturevalues; and finally adjusting influence factors influencing hydration heat in a mass concrete model, carrying out analysis to obtain an influence result and an influence law, and adopting a corresponding temperature control method according to the result and the law. According to the mass concrete-based temperature field research method and the mass concrete-based temperature control method, fissures are prevented from occurring in mass concrete, and the pouring quality of concrete and the total quantity of projects are ensured.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

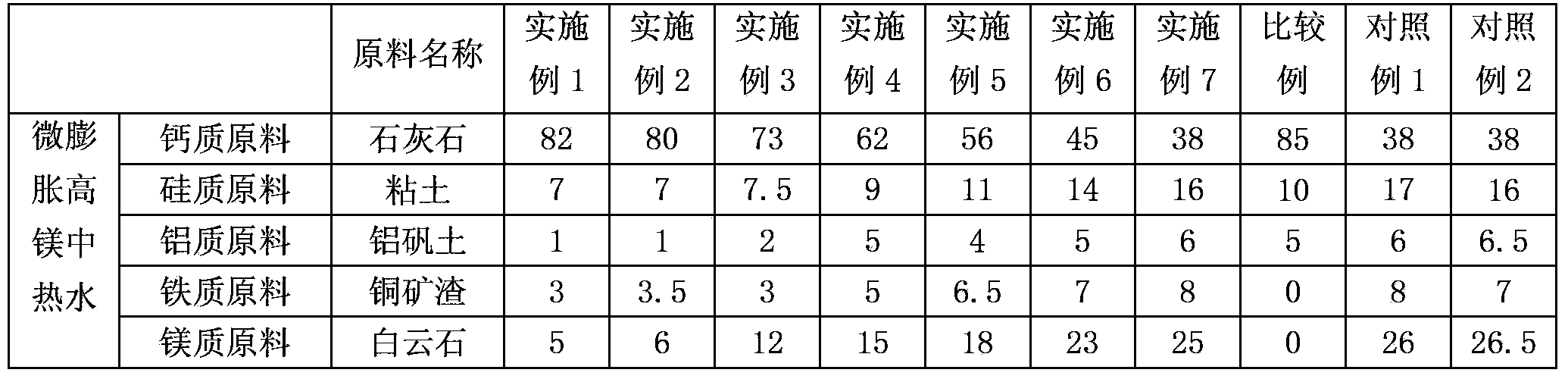

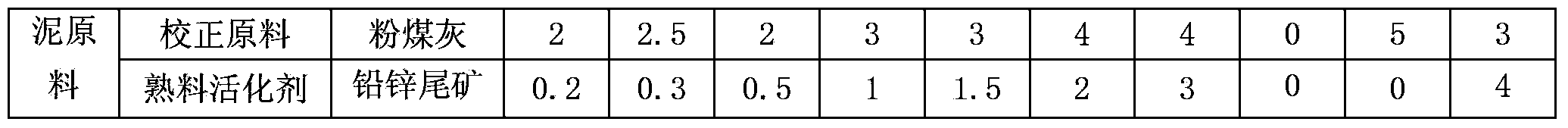

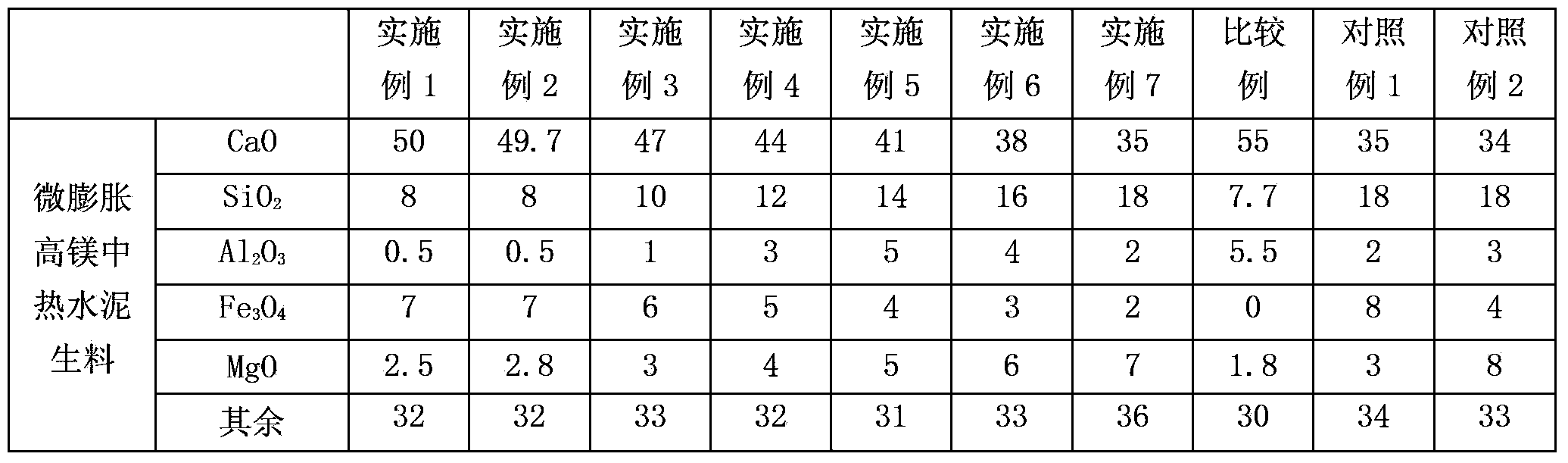

Minimum inflation high magnesium moderate heat cement, production method therefor and applications thereof

The invention discloses a kind of minimum inflation high magnesium moderate heat cement, a production method therefor and applications thereof. The cement is prepared from calcium raw materials, silicon materials, aluminum raw materials, iron raw materials, magnesium raw materials, correction raw materials and clinker activating agents through two-grinding and one-burning process. The content of MgO in the clinkers is raised to 6-9%, the content of periclase is controlled to 2-8%, the minimum inflation performance of periclase can be used fully, the contraction of mass concrete can be compensated, concrete cracks can be decreased, and therefore the volume stability and safety of concrete are raised.

Owner:CHINA BUILDING MATERIALS ACAD

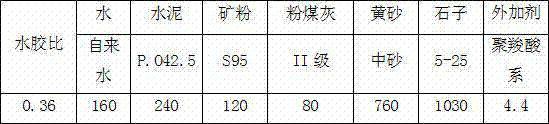

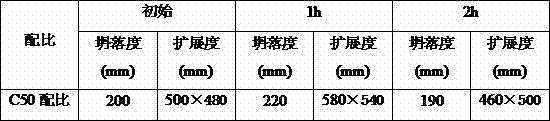

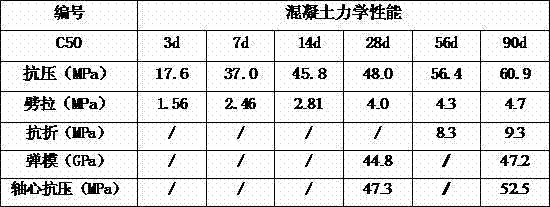

Concrete with ultra-large volume, high strength and low hydration heat

The invention relates to concrete with ultra-large volume, high strength and low hydration heat. The concrete comprises the following components in parts by weight (cube dosage kg / m3): 200-260 parts of cement, 100-160 parts of mineral powder, 80-100 parts of fly ash, 740-800 parts of fine aggregate, 1010-1050 parts of coarse aggregate, 4.0-5.0 parts of additive and 155-165 parts of water. The concrete with ultra-large volume, high strength and low hydration heat can be used to effectively reduce the hydration heat, greatly reduce the cracking risk of the large-volume concrete from the source and increase the engineering quality.

Owner:SHANGHAI CONSTR BUILDING MATERIALS TECH GRP CO LTD +5

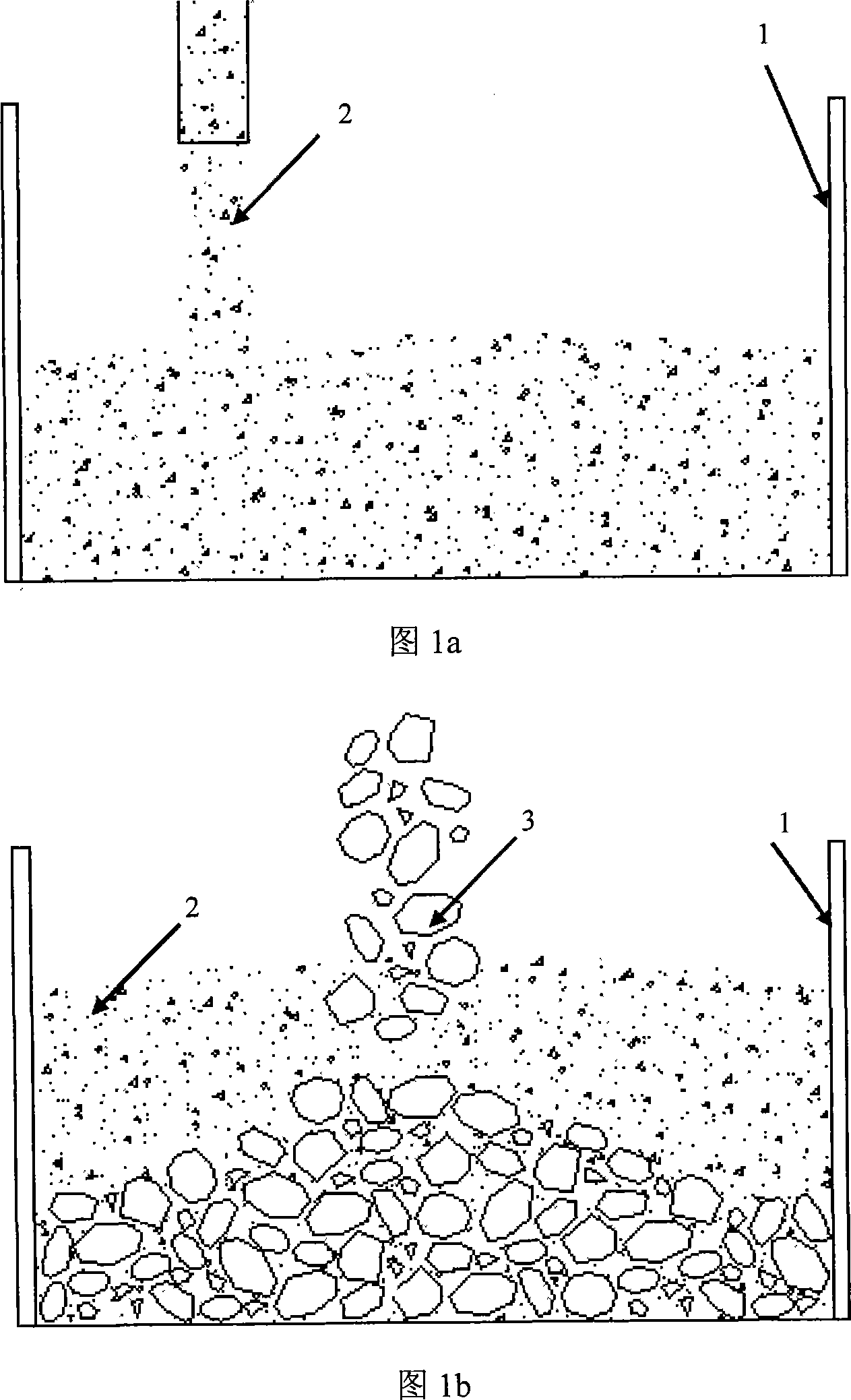

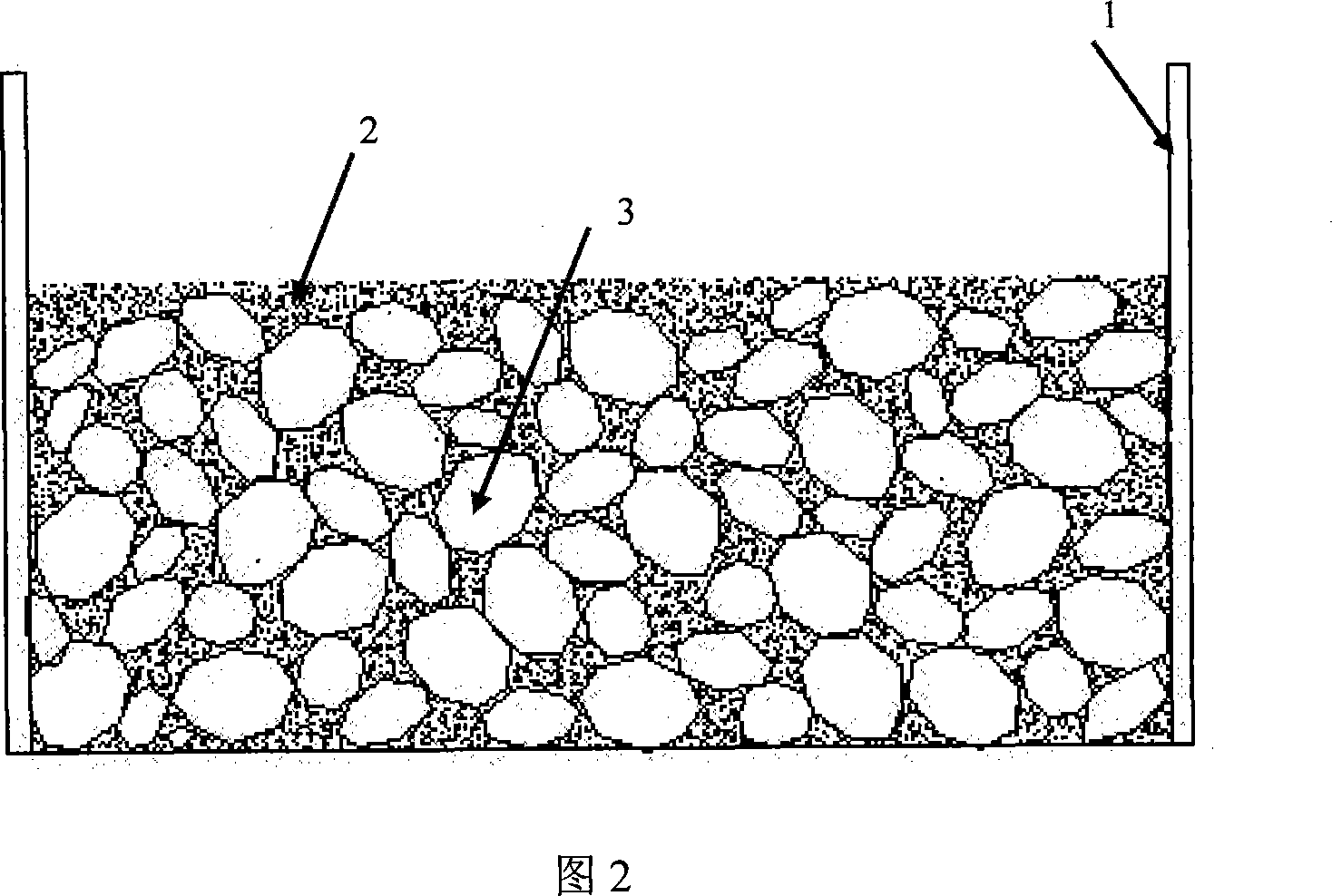

Jackstone-type rockfill concrete construction method

ActiveCN101144279APouring is flexible and fastReduce usageFoundation engineeringEarth-fill damsHigh intensityUltimate tensile strength

The present invention discloses a riprap rock-fill concrete construction method, which relates to a construction method for the large volume concrete. The present invention adopts self-compacting concrete having superior anti-segregation performance and good plasticity-retention performance, and firstly the concrete is poured into a bin, and then block stones or pebbles with the particle size smaller than 4 cm are poured into the poured self-compacting concrete in a mechanical way or a manual way, and the self-compacting concrete can fill up and compact the vacancies caused in the block stone settlement path at any time, the high anti-segregation performance ensures that the self-compacting concrete does not segregate and bleed water under the impact of the block stones, and finally the self-compacted rock-fill concrete with high intensity is formed. The method has the advantages that the construction is convenient, and the present invention has significant effects on the aspects of improving the construction efficiency and saving the construction cost, and the rock-fill concrete formed has high degree of compaction, the cement used is less, the hydration temperature rise is low, the volume stability is good, and the comprehensive performance is excellent, meanwhile, the present invention also has the advantages of energy-saving, environmental protection and being easy for continuous construction.

Owner:TSINGHUA UNIV +1

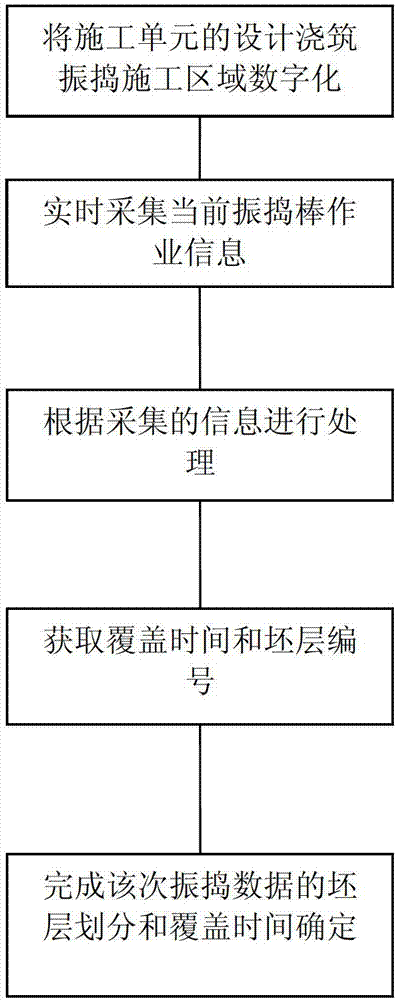

Automatic monitoring method of concrete casting vibrating blank layer

ActiveCN103195254ARealize automatic identificationAvoid vibration leakageBuilding material handlingQuality controlMaterials science

The invention relates to the field of vibrating quality control in concrete casting construction of the hydraulic and hydroelectric engineering, in particular to an automatic monitoring method of a concrete casting vibrating blank layer obtained by a laying method or a step method casting process in mass concrete vibrating quality control of the hydraulic and hydroelectric engineering. The method comprises main steps as follows: firstly, a designed casting vibrating construction area of a construction unit is digitalized; then, current operation information of a vibrating needle is acquired in real time; computing is performed according to the acquired information; cover time and a blank layer number are obtained; and accordingly blank layer dividing and cover time determining of vibrating data for the time are completed. The automatic monitoring method has the benefits that the concrete casting vibrating blank layer is automatically identified, vibration monitoring data are divided into the blank layer automatically, concrete cover time in any position can be obtained, an effective vibrating area of the blank area is judged, and accordingly quality problems caused by miss vibrating, lack vibrating, over vibrating and the like are effectively solved. The automatic monitoring method is particularly applicable to mass concrete vibrating quality control of the hydraulic and hydroelectric engineering.

Owner:POWERCHINA CHENGDU ENG

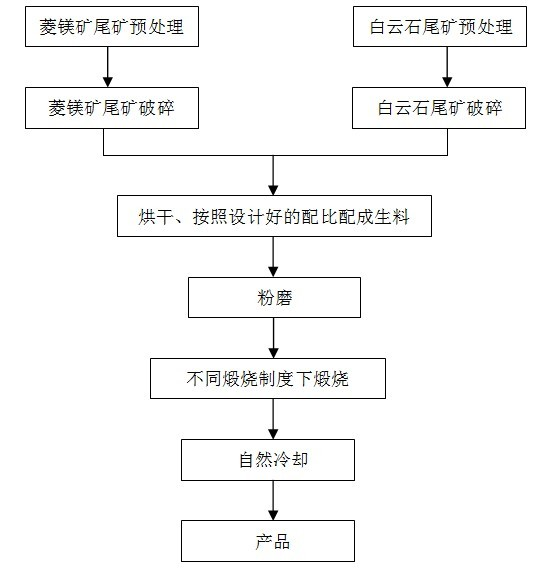

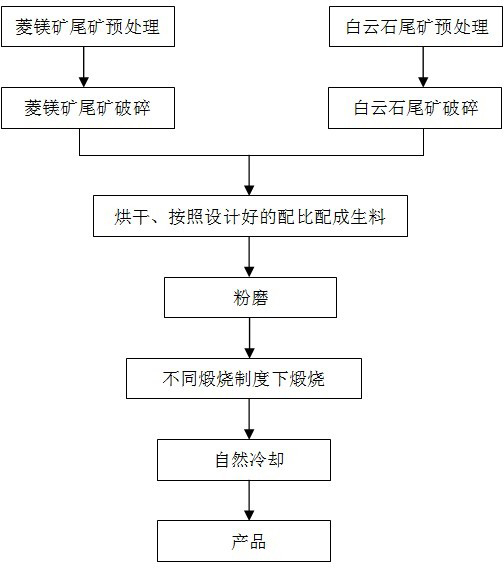

Mass eco-concrete expansive agent and preparation method thereof

ActiveCN102092976ASimple manufacturing processReduce pollutionSolid waste managementThermal expansionPre treatment

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

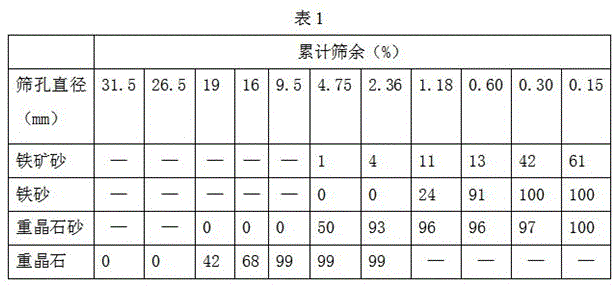

Neutron irradiation preventing low-hydration-heat barite concrete

ActiveCN104529297AImprove Radiation PerformanceReduce liquiditySolid waste managementNeutron irradiationSlag

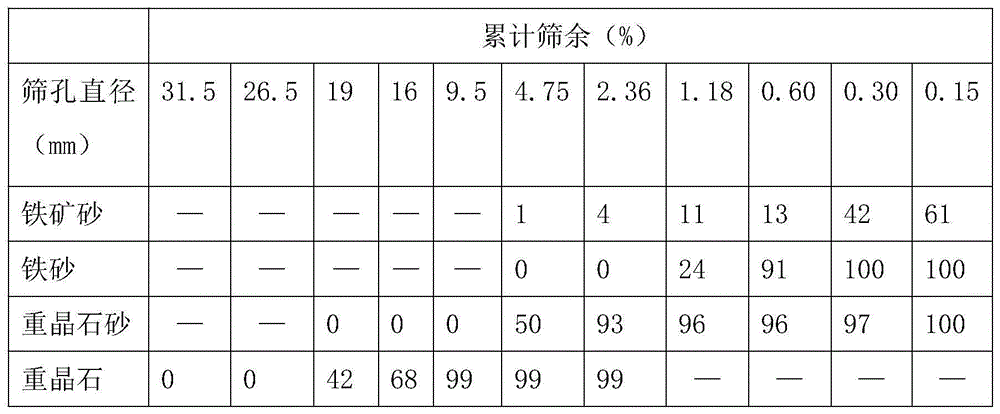

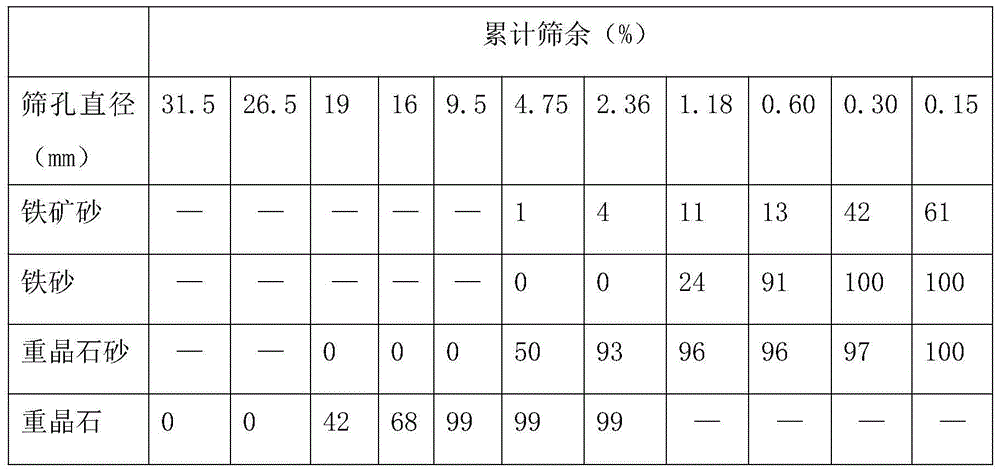

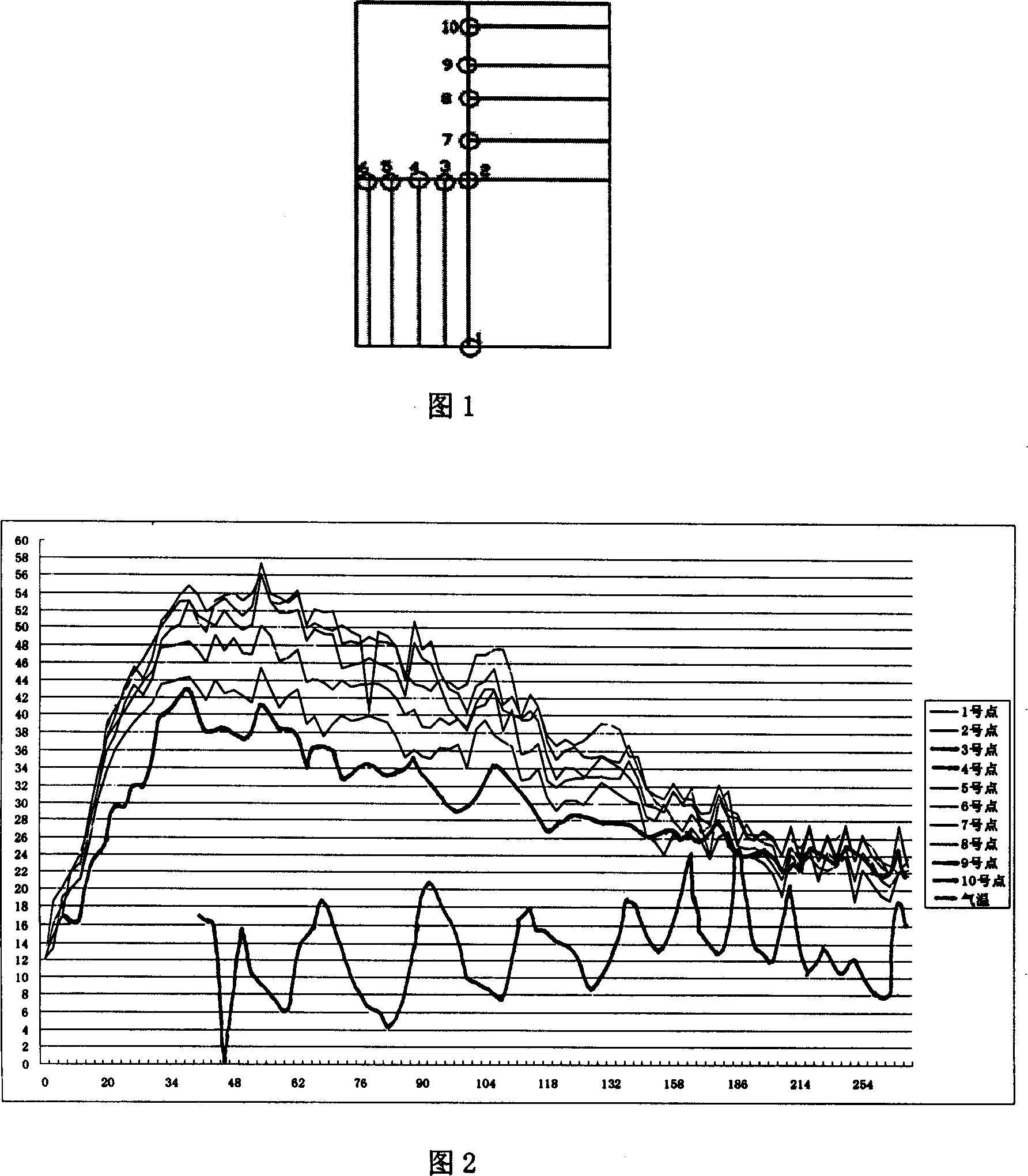

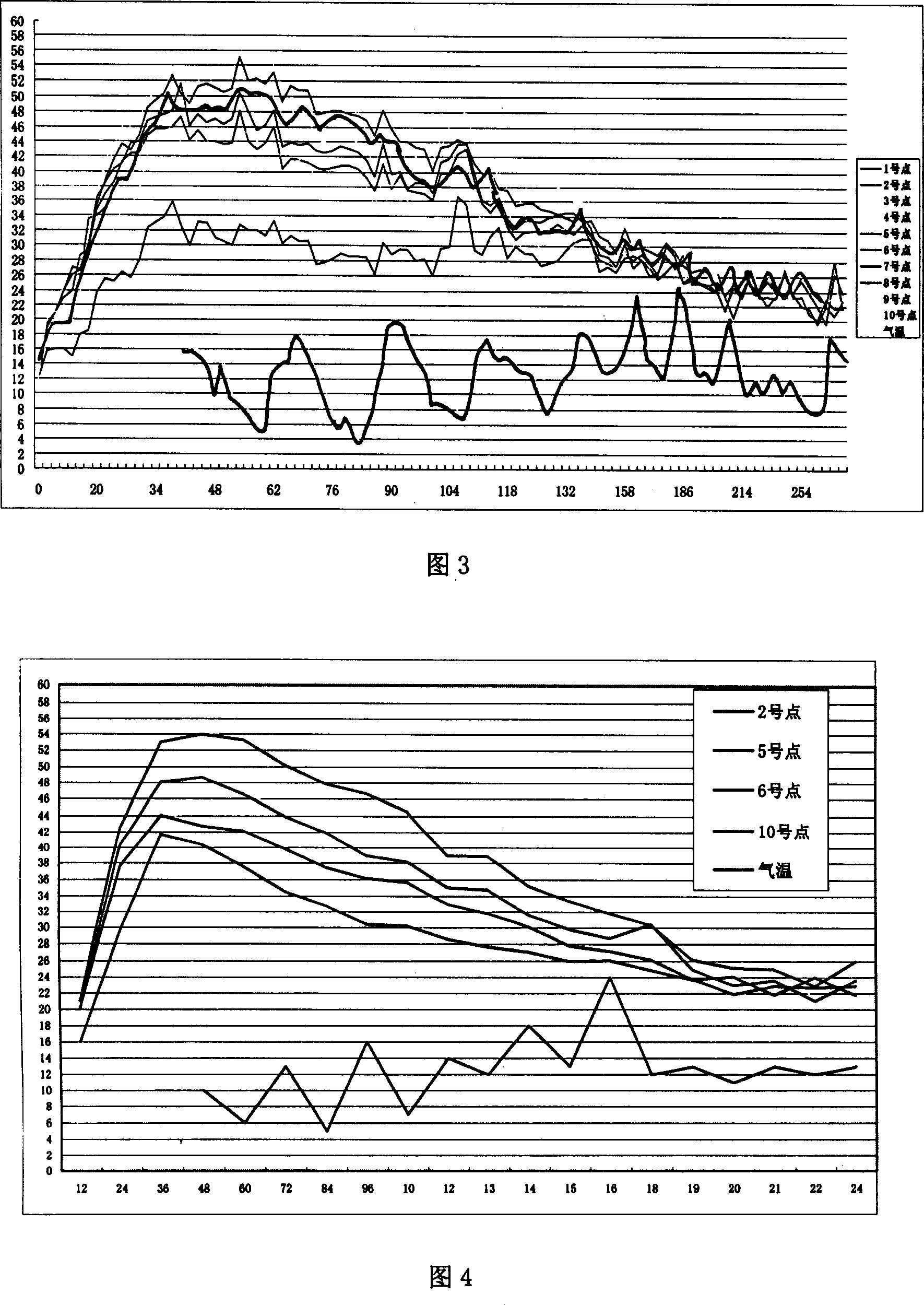

The invention relates to the technical field of concrete, and particularly relates to neutron irradiation preventing low-hydration-heat barite concrete. The neutron irradiation preventing low-hydration-heat barite concrete comprises the following components in content: 163.8-168kg / m<3> of water, 200-280kg / m<3> of cement, 90-140kg / m<3> of slag powder, 9.5-10.5kg / m<3> of boron glass powder, 850-900kg / m<3>of iron ore sand, 340-360kg / m<3> of iron sand, 1558-1600kg / m<3> of barite, 300-330kg / m<3> of barite sand, 0.85-0.95kg / m<3> of polypropylene fiber and 4% to 7% of a polycarboxylate-type water reducing agent. The neutron irradiation preventing low-hydration-heat barite concrete disclosed by the invention is larger than 3600kg / m<3> in apparent density, larger than 110kg / m<3> in retained crystal water and good in neutron irradiation prevention effect; when being applied to a large-size concrete structure of which the minimum geometric dimension is larger than 1.2m, the neutron irradiation preventing low-hydration-heat barite concrete is low in hydration heat, the internal and external temperature difference is smaller than or equal to 20 DEG C, the adiabatic temperature rise is smaller than or equal to 55 DEG C, and the neutron irradiation preventing low-hydration-heat barite concrete is applicable to a large-size radiation-proof structure. The concrete can reach relatively high requirements in aspects such as retained crystal water, fluidity, cohesiveness and water retention property and has the advantages of guaranteeing the strength and the compactness and controlling the hydration heat.

Owner:GUANGDONG PROVINCIAL ARCHITECTURAL ENG MACHINERY CONSTR +1

Large volume concrete structural solid strength detecting method

InactiveCN101021458AShorten the construction periodLow costAnalysing solids using sonic/ultrasonic/infrasonic wavesFoundation testingTime limitUltimate tensile strength

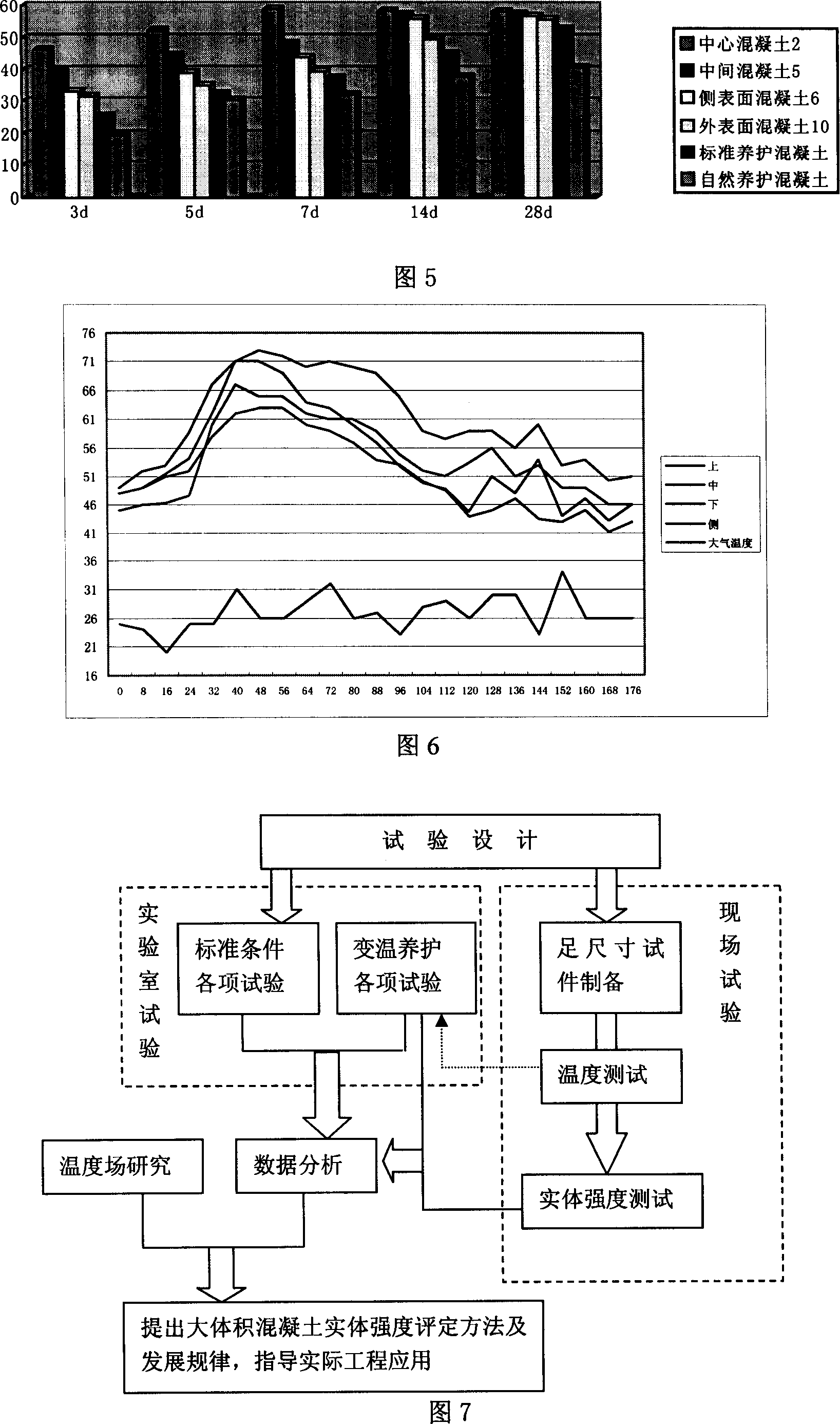

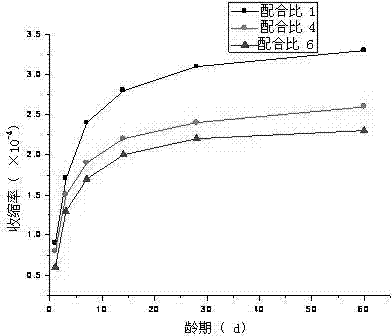

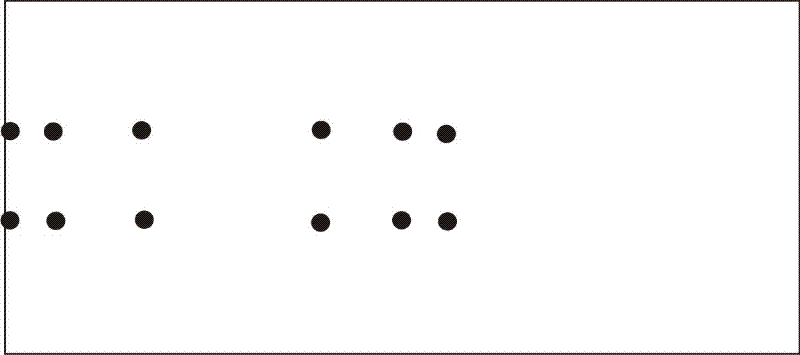

The invention discloses a method to test intensity of mass-concrete structure entity. Make sufficient-size samples according to construction entirely before the project. For changes of intensity and temperature of samples in early age, simulate in laboratory to make temperature-change curing of different samples and get their actual intensity under this temperature. When samples have striking conditions, carries intensity ultrasonic rebound and entity coring experiments for concrete quality. Hydrate cement of concrete and test in thermo temperature field to get intensity relationship of projects carried depending on early age intensity of concrete. Projects are carried according to above data. The method can test intensity of mass-concrete structure entity accurately and change the past method of assessing concrete intensity only by using strength value of same condition and standard curing coupon or rebound value of concrete, which improves accuracy, can shorten time limit of project greatly and has notable technical economic performance.

Owner:青建集团股份公司

A construction method of large-volume non-cooling tubular concrete

ActiveCN102296819AReduce temperature riseImprove crack resistanceThermometer applicationsBuilding material handlingTemperature controlCrack resistance

The invention discloses a construction method for mass pipe concrete without temperature reduction. The construction method is characterized by comprising the following steps: A. proportioning and preparation of raw materials; B. temperature control; C. construction of concrete; and D. heat preservation and curing operations. When the proportioning is designed, cement with low heat release is selected, and the cement is mixed with a large quantity of fly ash mineral mixtures and mixed with an extrusion delayed coagulation type admixture, thereby effectively reducing the temperature rise of the concrete. Based on in-situ temperature monitoring, the highest temperature of each layer of concrete is about 60 DEG C, and the maximum temperature difference is less than 25 DEG C; the crack resistance of the concrete C40 prepared by blending the fly ash and the extrusion type admixture reaches the grade II, and the concrete has excellent crack resistance; and the shrinkage rate in 60d is only 2.3*10<-4>, and the volume stability is good. In the construction of the mass concrete, the corresponding construction processes are formulated so as to effectively prevent cracks from occurring.

Owner:四川路桥建设集团股份有限公司

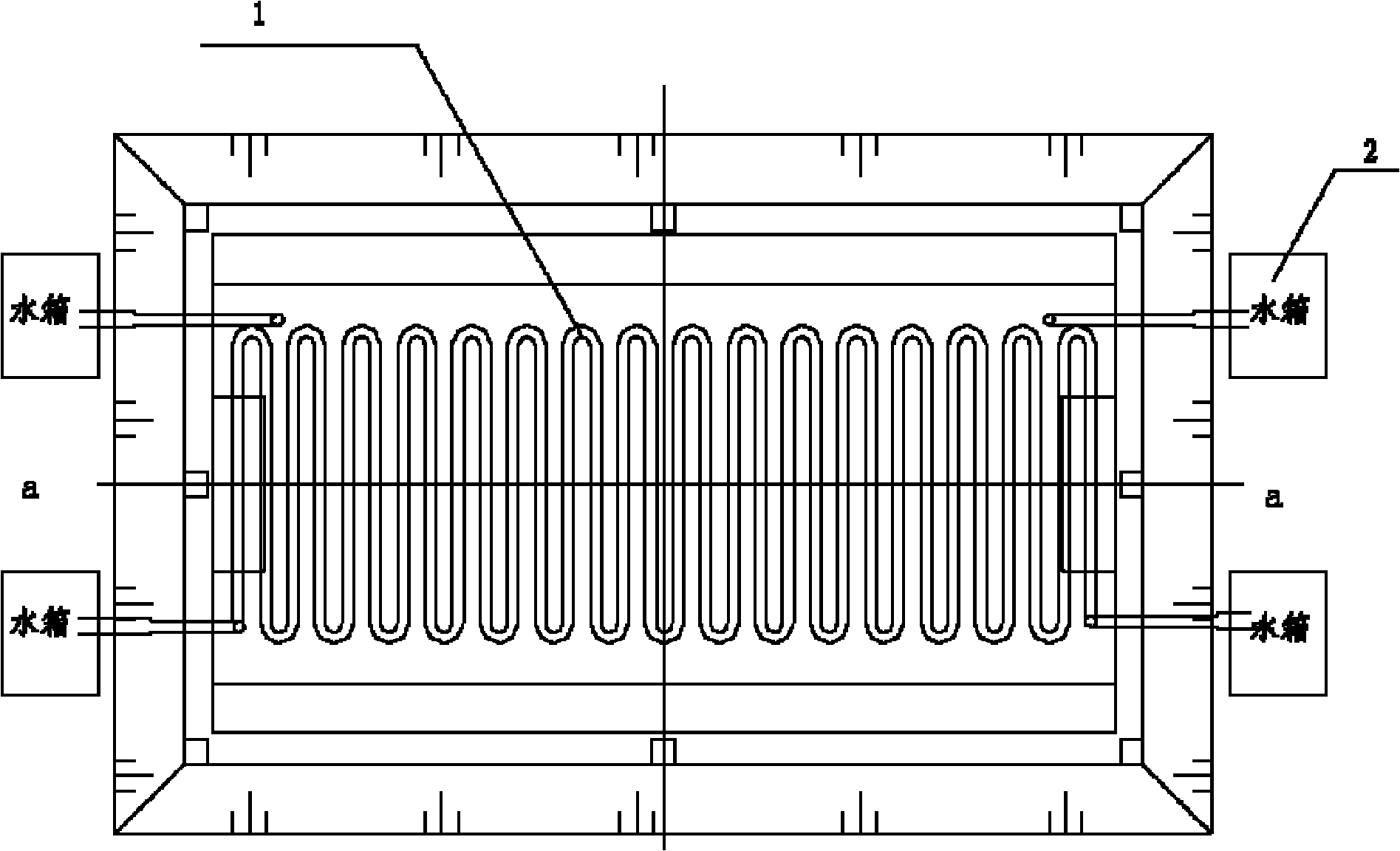

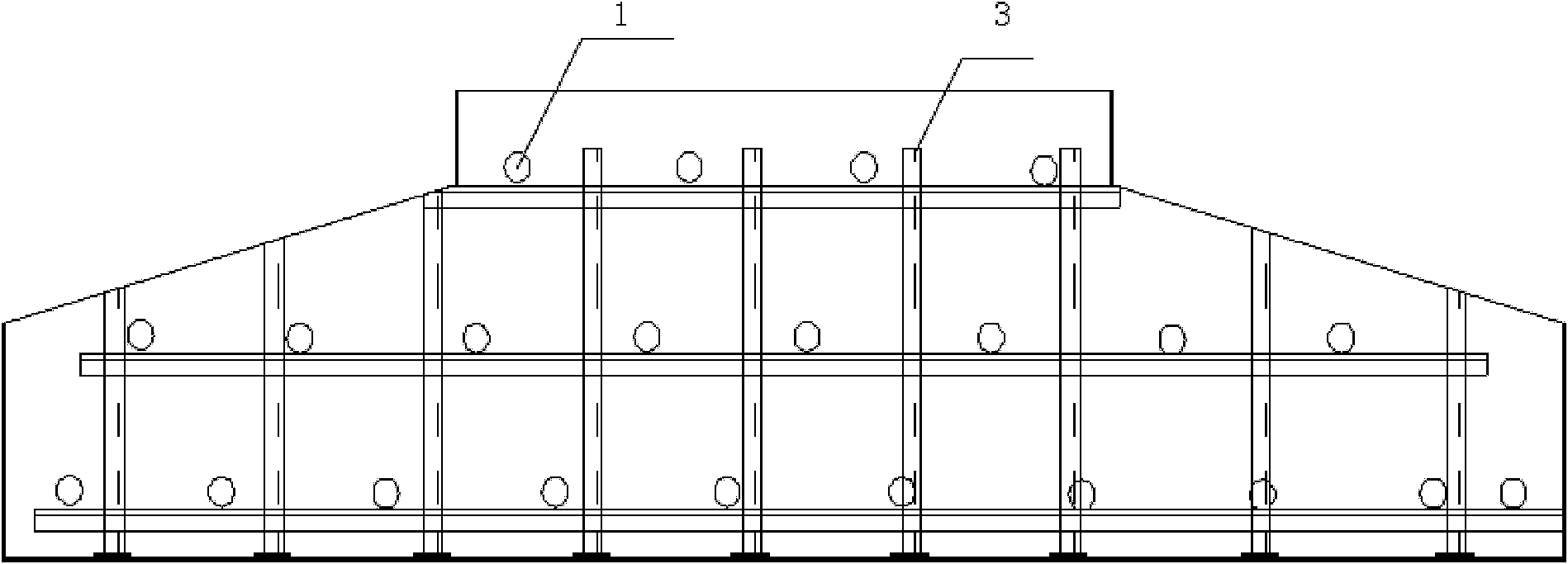

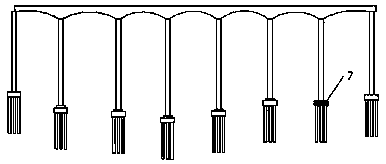

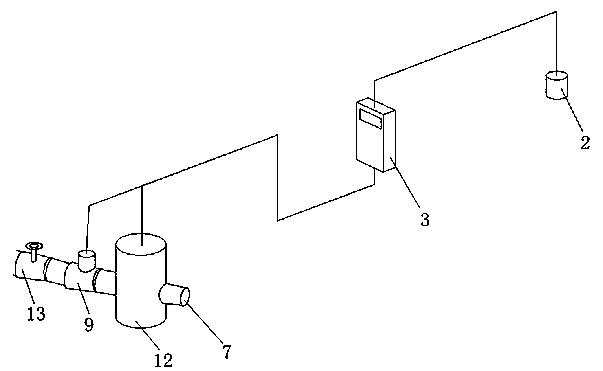

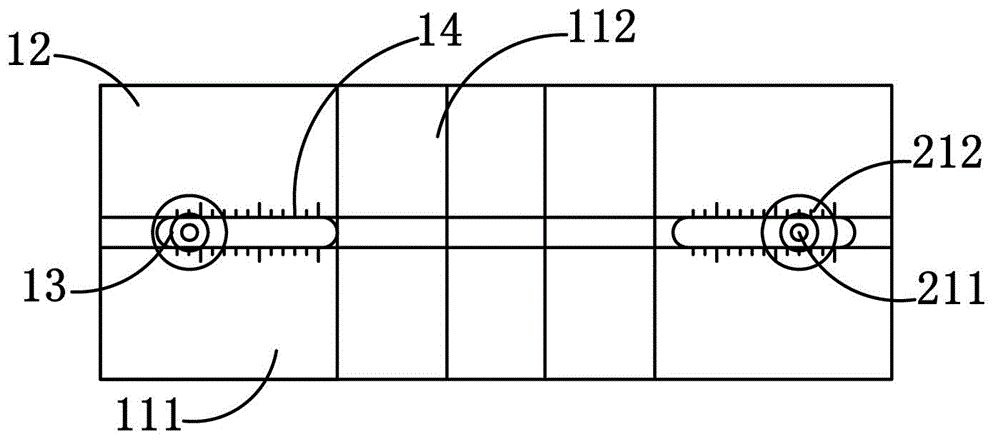

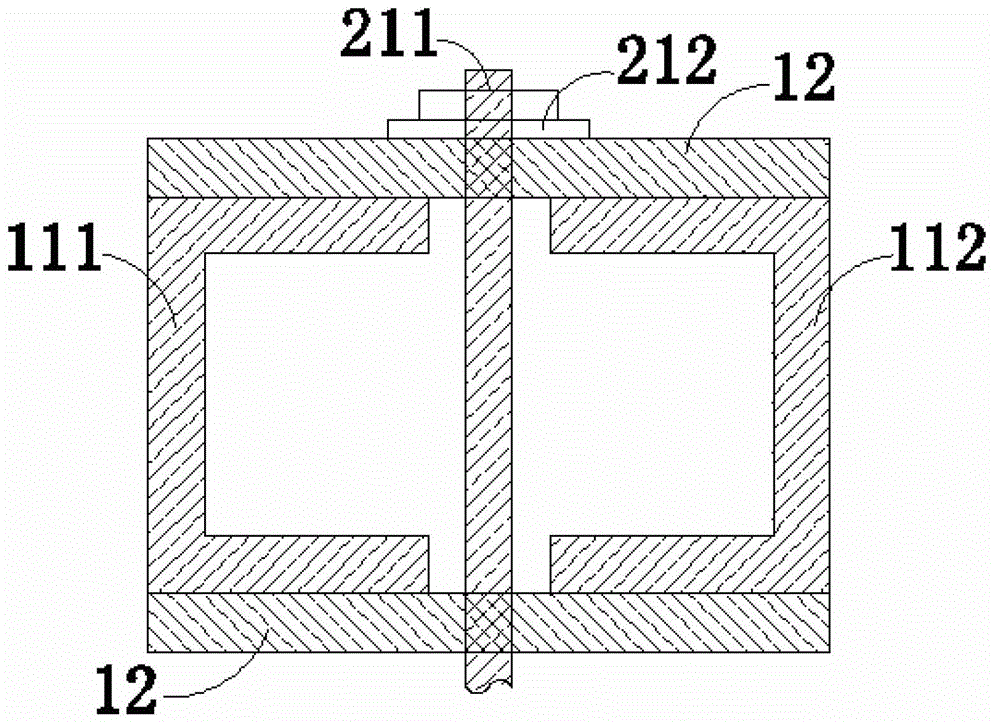

Mass concrete circulating cooling water automatic control cooling system and method

PendingCN107700489AReduce the risk of gapsReduce labor intensityFoundation engineeringBuilding material handlingTemperature controlAutomatic control

The invention discloses a mass concrete circulating cooling water automatic control cooling system and method, and belongs to the technical field of concrete cooling. The system comprises water collection boxes, cooling pipes, temperature measuring elements, a circulating mechanism connected with the water collection boxes and the cooling pipes and temperature switches connected with the temperature measuring elements and the circulating mechanism. The cooling pipes and the temperature measuring elements are pre-buried in mass concrete. The cooling pipes are pre-buried in the mass concrete ina layered manner, and each layer of cooling pipe is composed of multiple independent sub-pipes. Each sub-pipe is provided with the corresponding temperature measuring element. The temperature switchesare used for controlling the magnitude of the water conveying quantity generated after the circulating mechanism is shut down and started up according to the temperature, measured by the temperaturemeasuring elements, in the mass concrete. According to the system, zoning cooling can be carried out on the mass concrete, the temperature difference between various zones and the residual stress difference generated after hardening can be reduced, the risk that clearances appear in a concrete structure can be reduced, and the structural quality of the mass concrete structure can be improved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

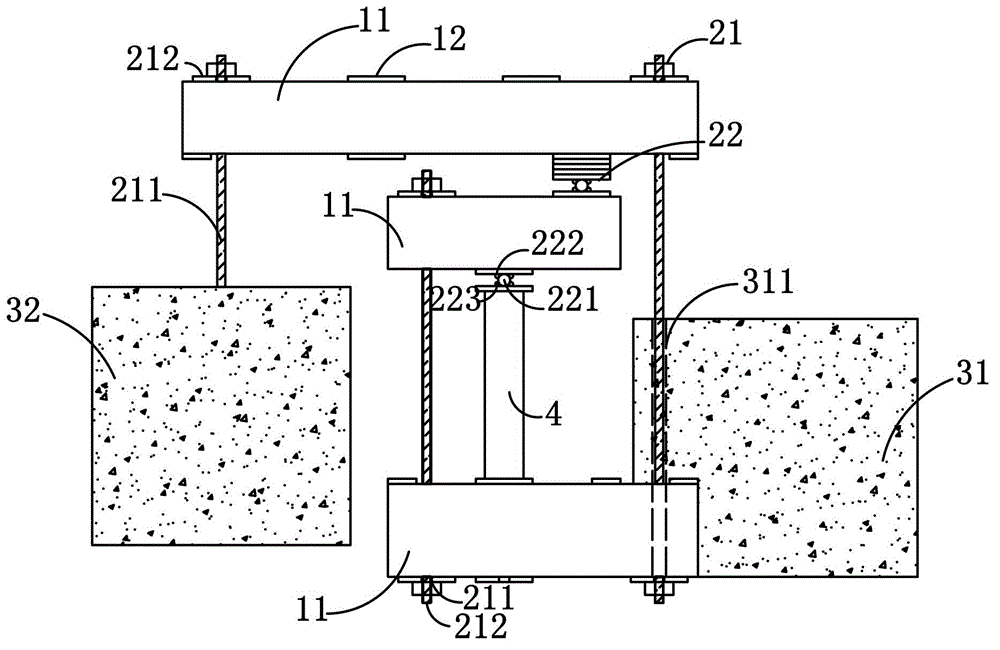

Concrete creep test apparatus and method

InactiveCN103335897AImprove loading efficiencyShorten the lengthInvestigating material ductilitySingle levelTest platform

The invention relates to a loading apparatus and a method for a concrete creep test, and aims at solving the problems of too high cost, large occupied space, complex operations and poor loading stability of a conventional creep test apparatus. The apparatus comprises a loading pedestal formed by three steel beams and a set of two-level levers, wherein the two-level levers comprise a first-level lever steel beam and a second-level lever steel beam. Compared with a conventional single-level lever test apparatus, the apparatus provided by the invention has the beneficial effects that by adopting the two-level lever loading mechanism, the lever loading efficiency for the creep test can be greatly increased, the loading lever length is shortened, the size of the balancing weight and the area of the test site can be reduced, requirements for installing hoisting equipment are lowered, and establishment for large-size concrete pedestal test platforms can be saved.

Owner:SOUTHWEST JIAOTONG UNIV

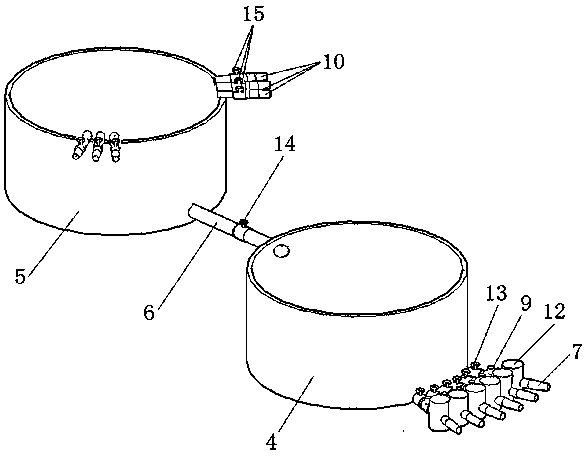

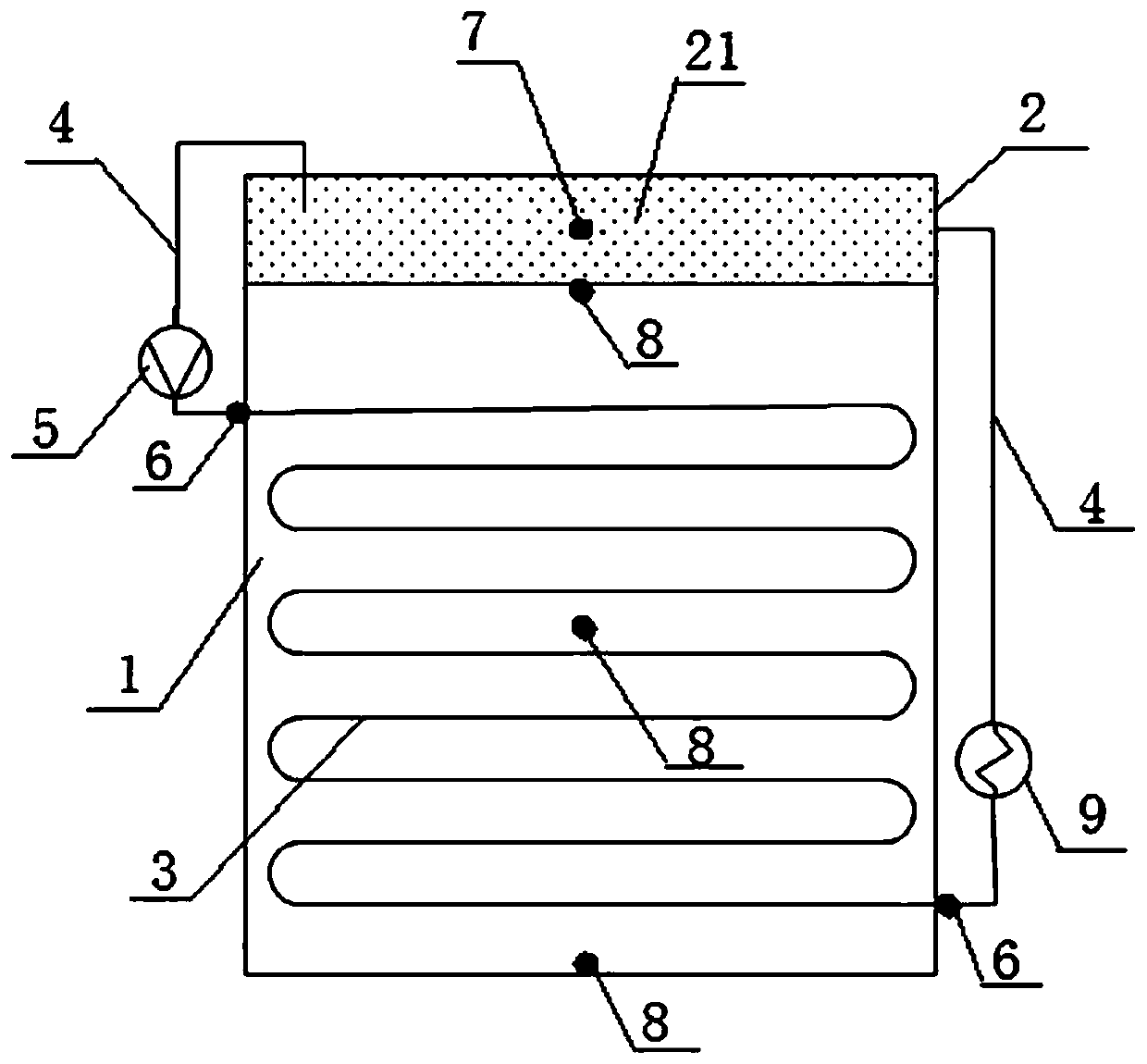

Large-volume concrete self-circulation temperature control maintenance system and method

ActiveCN110259165AIncrease surface temperatureEasy to adjust the water temperatureTemperature measurement of flowing materialsFoundation engineeringTemperature controlWater storage

The invention relates to a large-volume concrete self-circulation temperature control maintenance system and method. The large-volume concrete self-circulation temperature control maintenance system comprises a water storage frame, a cooling water pipe, a water pump, a cooling water temperature monitoring mechanism, a concrete temperature gradient monitoring mechanism and a water storage temperature sensor; the water storage frame is arranged at the top of large-volume concrete and used for forming a water storage pool; the cooling water pipe is pre-embedded into the large-volume concrete, and a water inlet and a water outlet communicate with the water storage pool through a connection pipe to form a circulation water route; the water pump is arranged on the circulation water route; the cooling water temperature monitoring mechanism is used for monitoring the temperature of cooling water; the concrete temperature gradient monitoring mechanism is used for monitoring temperature gradient distribution of the large-volume concrete; and the water storage temperature sensor is arranged in the water storage pool and used for monitoring the water storage temperature. Compared with the prior art, through water resource cyclic utilization, water is not required to be supplemented additionally in the process of maintenance temperature control, maintenance water is heated by hydration heat of binding materials, energy recycling is realized, and the temperature control cost is saved.

Owner:TONGJI UNIV

Large-volume concrete fast pouring and temperature control method

InactiveCN101994392AChange the shortcomings of large tensile stress and long construction timeGood temperature control effectBuilding material handlingTemperature controlThermal insulation

The invention discloses a large-volume concrete fast pouring and temperature control method which comprises the steps of (1) water pipe cooling and (2) surface thermal insulation. The method can lead the thickness of a pouring layer to break through 3m and lead the pouring interim period to be less than 5 days through the method of changing the material of a water pipe, the diameter of the water pipe, the thickness of the pipe wall, the spacing interval of the water pipe, the position of the water pipe, the length of the water pipe, water temperature at an inlet, flow rate of cooling water, water supply time and water flow direction during the water pipe cooling measure, and the corresponding surface thermal insulation method for assistance, thereby realizing fast pouring of large-volume concrete and simultaneously effectively preventing cracks. The method can be used for the large-volume concrete fast construction in civil and hydraulic engineering.

Owner:HOHAI UNIV

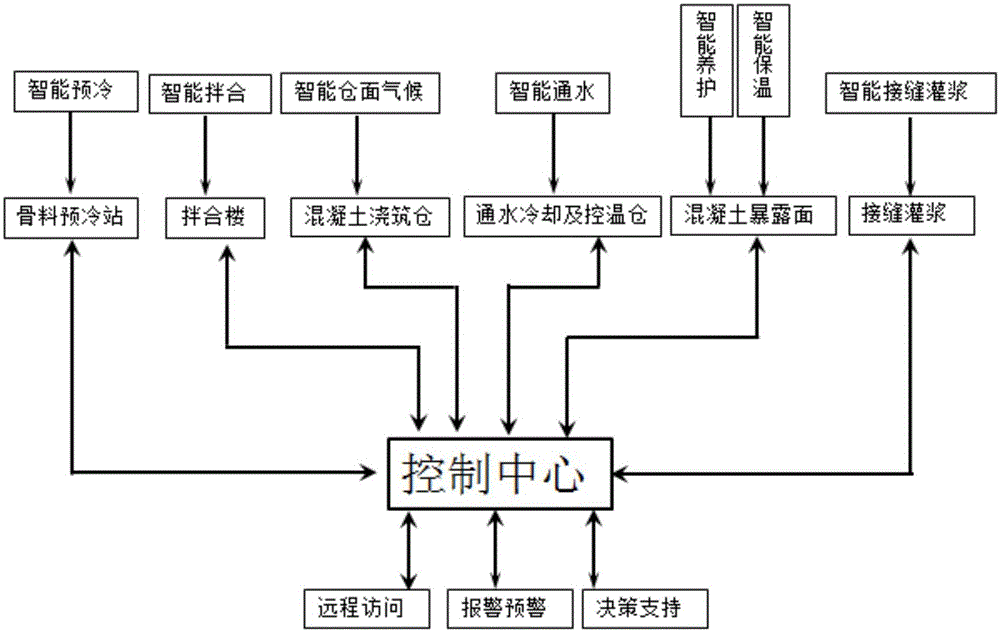

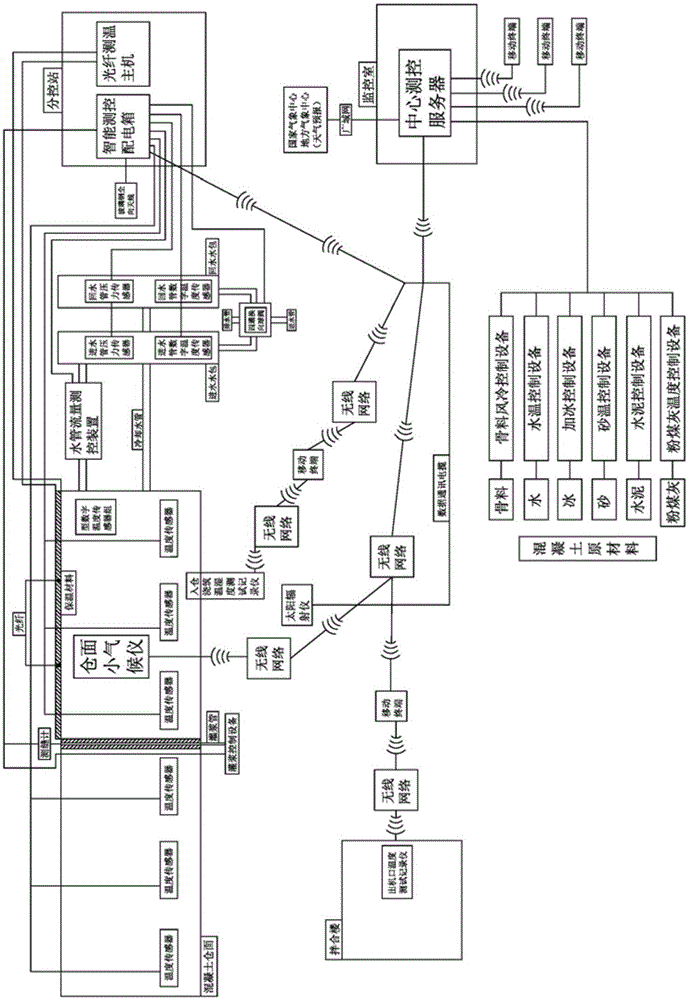

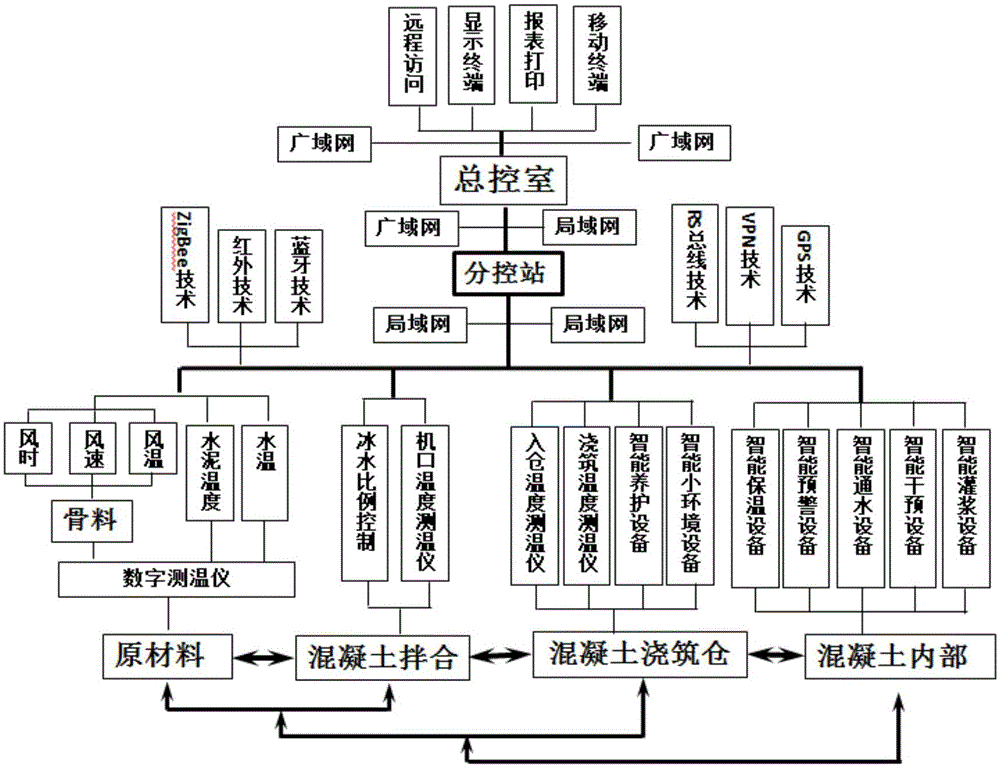

Full-process intelligent temperature control system and method for large-volume concrete

InactiveCN105045307AImprove construction qualityTemperature controlTemperatue controlTotal factory controlCrack resistanceThe Internet

The invention discloses a full -process intelligent temperature control system for large-volume concrete, and the system can achieve the automatic sensing, transmission, interconnection, sharing and control of full-process temperature control information of mixing, transportation, warehousing, closing-out, vibrating, maintaining, water cooling and joint grouting of concrete raw materials, thereby achieving the full-element and full-process management of temperature control and crack resistance based on the technologies of the Internet and Internet of Things, effectively protecting the large-volume concrete from cracking, and improving the construction quality of concrete. The system comprises an aggregate intelligent pre-cooling temperature control unit, a concrete intelligent mixing temperature control unit, a concrete pouring cabin internal small environment unit, a concrete intelligent water cooling unit, a concrete exposure face intelligent maintenance unit, a concrete exposure face intelligent heat preservation unit, an intelligent joint grouting unit, and a control center. The invention also provides a control method.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Minimum inflation low heat silicate cement

ActiveCN102173700AWith micro expansionReduce water demandSolid waste managementCement productionTemperature stressSlag

The invention discloses minimum inflation low heat silicate cement. The cement comprises the following components in percentage by weight: 75 to 95 percent of low heat silicate clinker, 1 to 10 percent of gypsum, 0.01 to 6 percent of lightly-burnt MgO, and 5 to 15 percent of steel slag. The minimum inflation low heat silicate cement can effectively reduce early concrete plastic cracking and temperature stress cracking generated by later hydrating adiabatic temperature rise, caused by adverse construction and maintenance conditions when the concrete is constructed. The prepared concrete has the advantages of high flowing performance, small dry shrinkage, little temperature contraction joint and the like, and can be applied in the fields of mass concrete, hydraulic concrete, high performance concrete engineering and the like which have high requirement on anti-cracking performance.

Owner:JIAHUA SPECIAL CEMENT

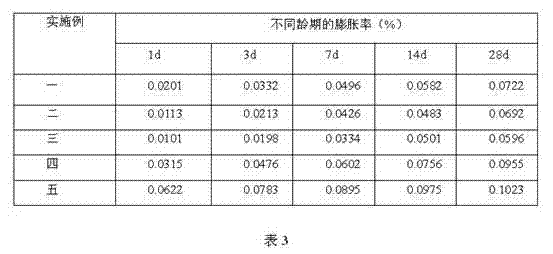

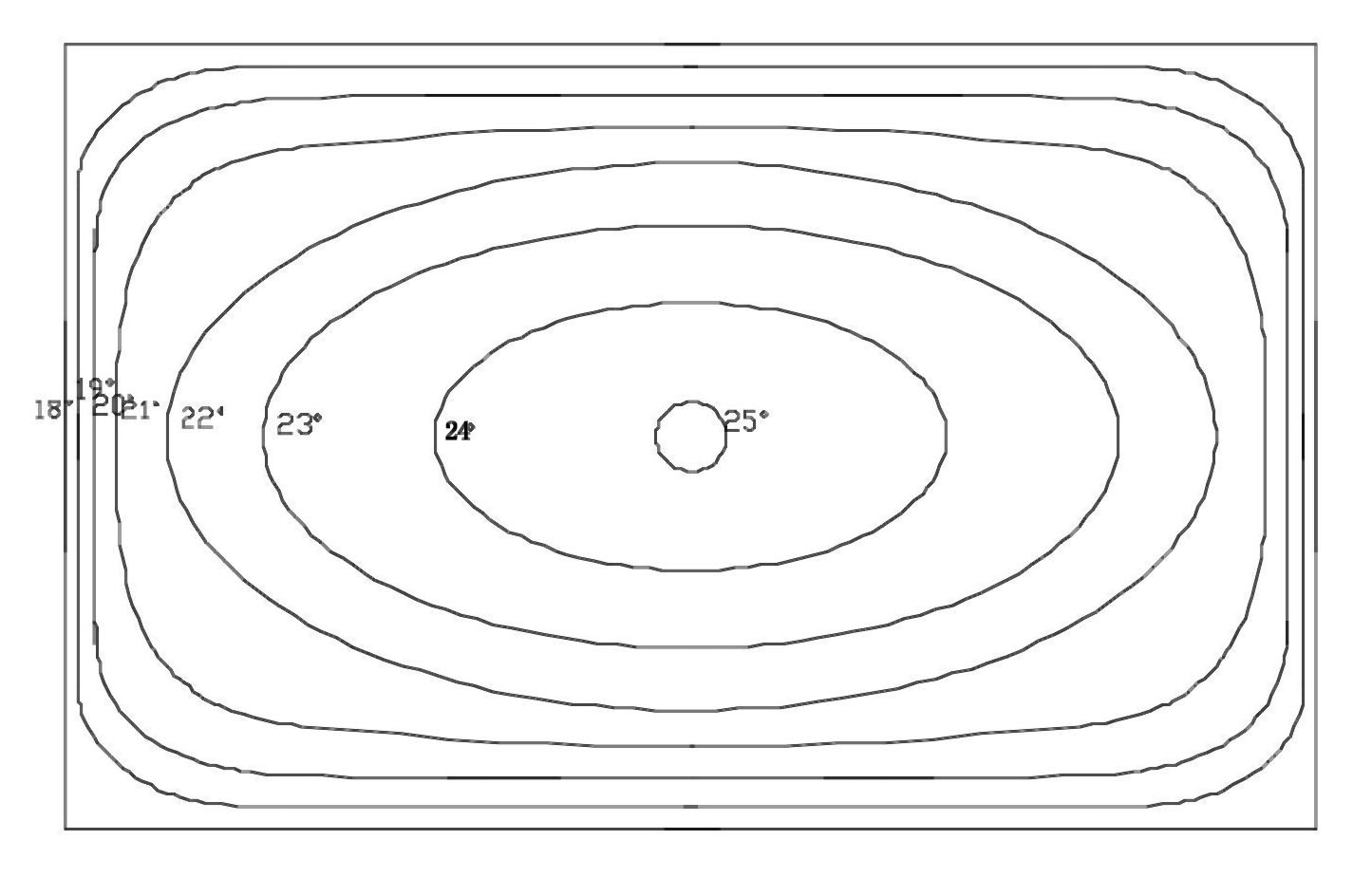

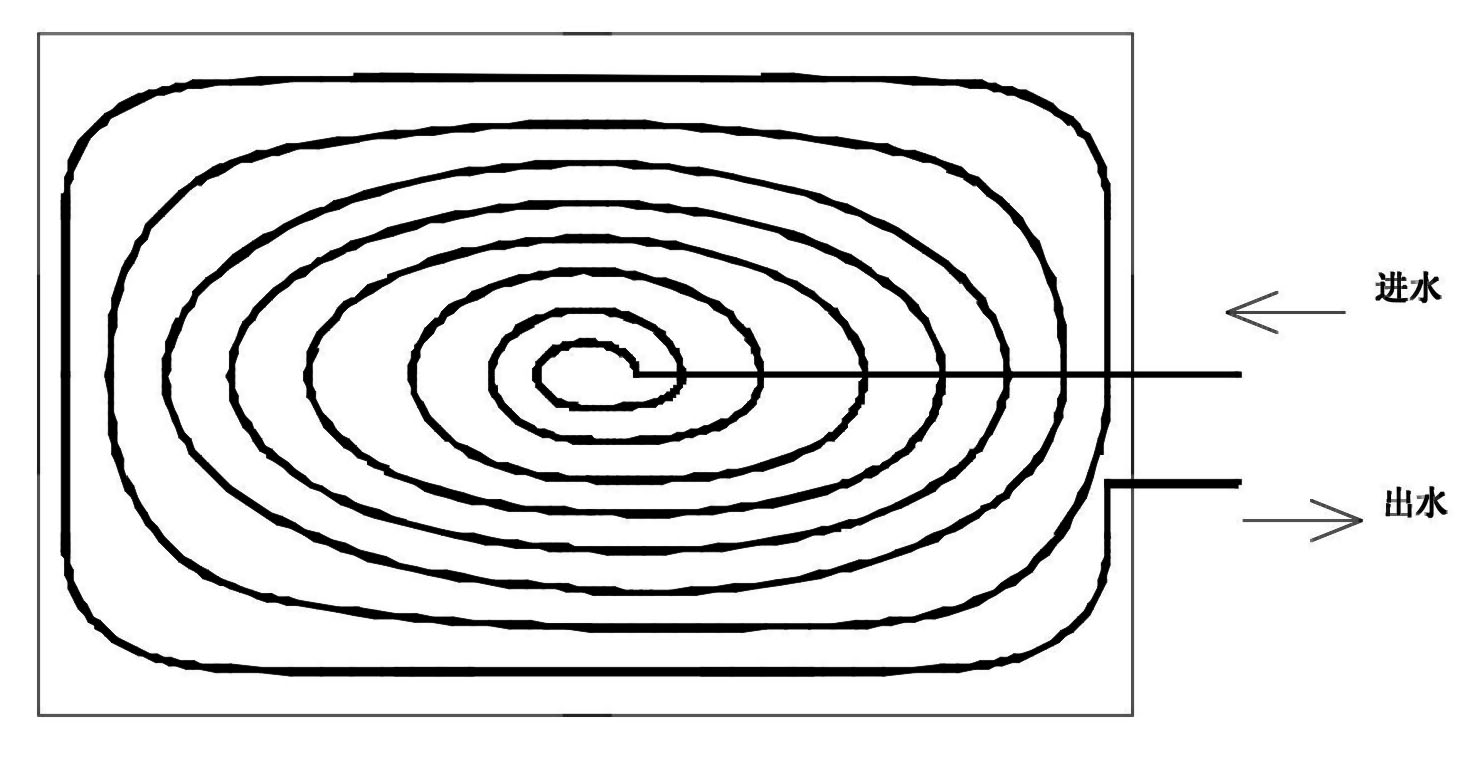

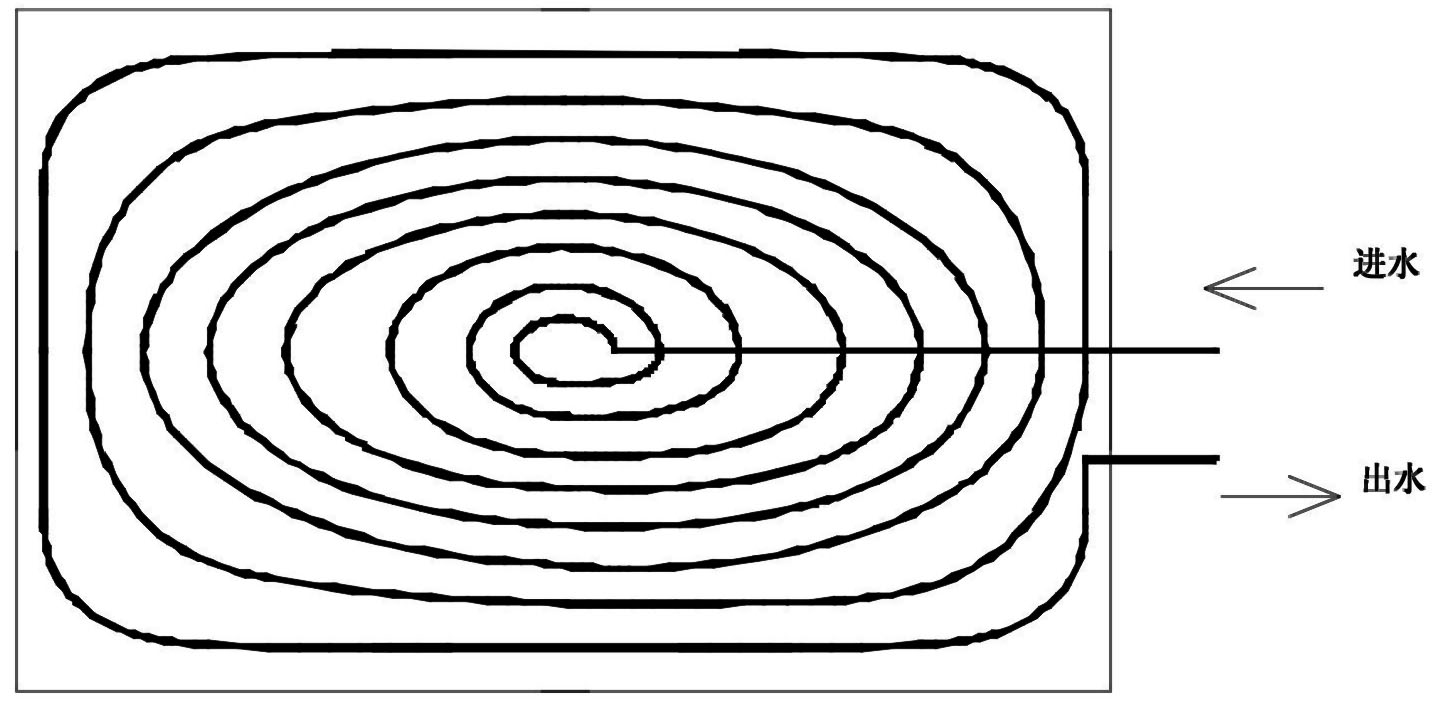

Method for arranging large-size concrete cooling water pipe

ActiveCN102094528AReduce temperature differenceReduce temperature stressFoundation engineeringBuilding material handlingTemperature stressTemperature difference

The invention discloses a method for arranging a large-size concrete cooling water pipe, comprising the following steps of: a. obtaining the temperature filed distribution condition of large-size concrete and drawing an isothermal chart of the temperature field by adopting a real-measuring or temperature field numerical simulating technology; b. arranging the cooling water pipe along an isotherm or close to the isotherm; arranging feeding water in an area with highest concrete temperature and arranging the distance between the water pipes according to the distance of the isotherm or approximate to the distance of the isotherm. According to the method for arranging the large-size concrete cooling water pipe, provided by the invention, the defect that the cooling water pipes are equidistantly arranged is overcome, the temperature difference inside the concrete can be effectively reduced, the temperature stress inside the concrete is reduced, the concrete is prevented from cracking and cracks of the concrete are limited in expanding.

Owner:中国葛洲坝集团建设工程有限公司

Concrete super retarder and preparation method thereof

InactiveCN102206057AImprove attachment functionImprove compactnessMass ratioUltimate tensile strength

The invention belongs to the technical field of civil engineering material, and relates to a novel concrete super retarder and a preparation method thereof. A technical scheme of the present invention comprises that: the concrete super retarder adopts hydroxyethylidene diphosphonic acid (HEDP), amino trimethylene phosphonic acid (ATMP) and water as raw materials, wherein a mass ratio of the three raw materials is 6:1:13. The preparation method comprises sequential adding the HEDP, the ATMP and the water into a stirring vessel, followed by slow heating to a temperature of 35-45 DEG C and uniform stirring. With the present invention, production technology of the concrete super retarder is simple, comprehensive production cost of the concrete super retarder is low, and later strength of the concrete is not reduced but is improved. An addition proportion of the concrete super retarder in the concrete is 0.05%-0.5% of mass of cementitious materials, such that the concrete can have an initial setting time of 0-120 hours, and the later strength of the concrete is unaffected after completing retarding. The concrete super retarder is widely applicable for a plurality of fields such as concrete construction in summer and mass concrete construction. According to the present invention, generations of temperature cracks are effectively prevented, slump loss is decreased, and long distance transport of the concrete is easy to be performed.

Owner:DALIAN UNIV OF TECH

High performance concrete pumping agent controlling falling degree loss type

The invention relates to a high-performance concrete pumping agent of controlling loss of concrete slump, composed of benzene solfonic acid formaldehyde condensation compound water reducer, polyvinyl alcohol, sodium lauryl sulfate, citric acid, sodium gluconate and water. It can improve the fluidity of concrete by a large margin, make the concrete slump constant basically in 2-4 hours, reduce seepage water, enhance strength and improve the durability of concrete. It is applied to the constructions (structures) of premixed concrete commodity, high-strength high-performance concrete, reinforced concrete, etc.

Owner:TONGJI UNIV

Large-volume concrete beneficial for controlling temperature and shrinkage crack and construction process thereof

ActiveCN103073240AAvoid crackingSolve the problem of shrinkage cracksBuilding material handlingCrack resistanceThin layer

The invention relates to a large-volume concrete beneficial for controlling temperature and shrinkage crack and the construction process thereof. The large-volume concrete is as follows: the weight ratio of cement, coarse aggregate, fine aggregate and water is 1.3-3.5 to 2-2.3 to 0.45-0.55; and the construction method comprises the following steps: (1) trial preparing; (2) testing cube compressive strength of concrete; (3) mixing concrete raw materials according to selected materials for trail preparation and components in the mixing ratio; (4) for the concrete, using a casting method for casting at fixed point in a sectional way, casting with one slope, casting in a thin layer, gradually advancing and casting the top at one time, and using a secondary vibrating method, wherein three vibrating gas concretes are placed in front of, in the middle of and behind each concrete layer; (5) covering a plastic film and / or covering a 1 cm thick gunny bag on the concrete after the concrete is finally set and / or a watering and curing the concrete for not less than 14 days; and (6) respectively placing temperature measuring points in the concrete casting vertical height, the edge of the concrete casting surface and the middle part of the concrete casting surface; and measuring the temperatures by using a thermocouple thermometer. The large-volume concrete beneficial for controlling the temperature and the shrinkage crack has the advantages of controllable time and high crack resistance.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD +1

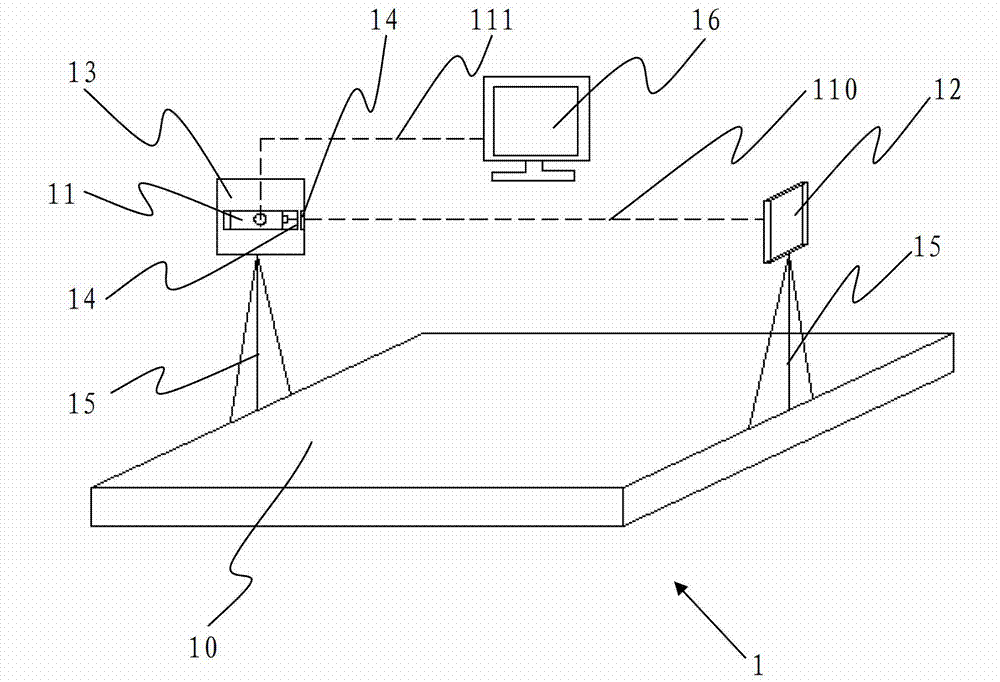

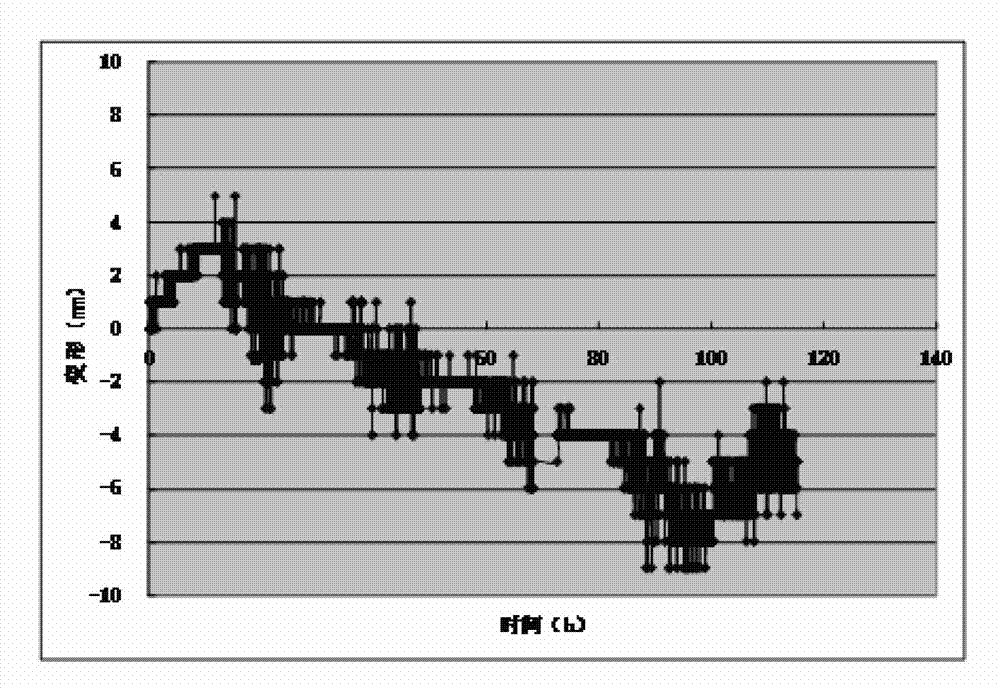

Method and device for measuring volume deformation of large-volume concrete bottom plate by using laser wireless distance meter

The invention discloses a method for measuring volume deformation of a large-volume concrete bottom plate by using a laser wireless distance meter. The method mainly comprises the following steps of after the concrete bottom plate is cast and primarily concentrated, respectively spanning the laser distance meter connected with a computer and a laser reflecting plate at the opposite positions of the two sides of the concrete bottom plate; starting the laser distance meter, radiating laser emitted by the laser distance meter onto the laser reflecting plate to generate a distance signal between the laser distance meter and the laser reflecting plate, and transmitting the distance signal to the computer, wherein when the concrete bottom plate is expanded and retracted, the distance signal generated between the laser distance meter and the laser reflecting plate is correspondingly changed; measuring and recording the distance signal to obtain the volume change of the concrete bottom plate; and measuring the deformation of the concrete bottom plate by using the laser distance meter and the laser reflecting plate.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

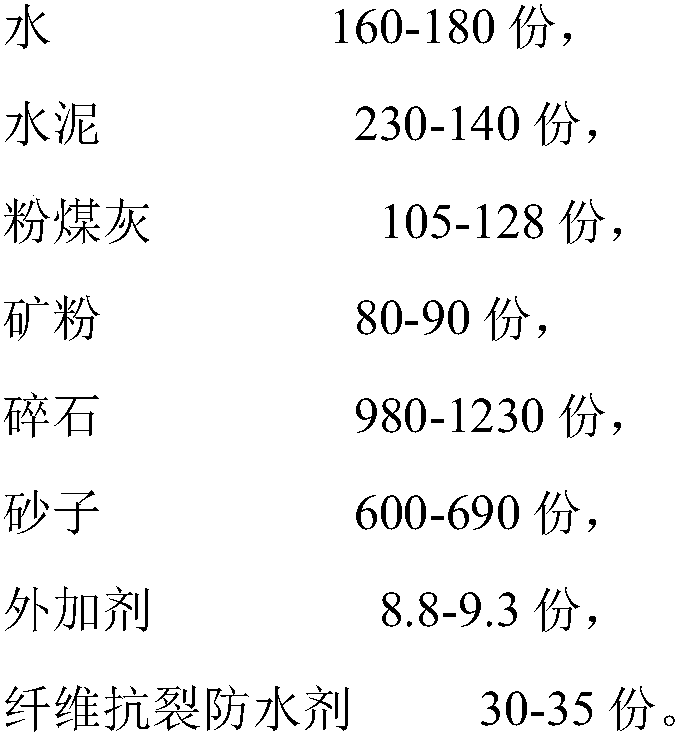

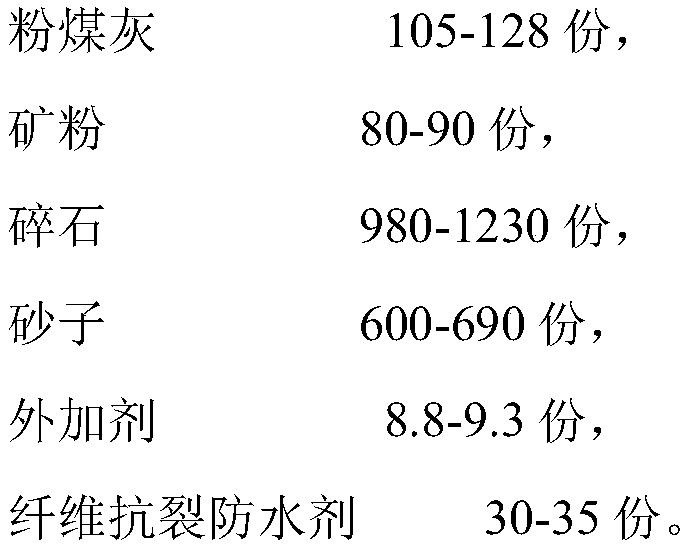

Anti-cracking mass concrete

InactiveCN107777956AMitigation of temperature cracksImprove crack resistanceCrack resistanceMaterials science

The invention discloses anti-cracking mass concrete which is characterized by comprising the following components in parts by weight: 160-180 parts of water, 140-230 parts of cement, 105-128 parts offly ash, 80-90 parts of mineral powder, 980-1230 parts of macadam, 600-690 parts of sand, 8.8-9.3 parts of an admixture and 30-34 parts of a fibrous anti-cracking water-proofing agent. The cracking resistance of the mass concrete is improved by improving the ratio of the components in the concrete.

Owner:天津顺德混凝土工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com