Minimum inflation high magnesium moderate heat cement, production method therefor and applications thereof

A production method and micro-expansion technology, which is applied in the field of building materials, can solve the problems of inability to guarantee the deformation and shrinkage of concrete autogenous volume, and achieve the effects of improving volume stability and safety, compensating shrinkage, and reducing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation of a specific micro-expansion high-magnesium medium-heat cement may comprise the following steps:

[0029] 1) Dry the calcium raw material, silicon raw material, aluminum raw material, iron raw material, magnesium raw material, calibration raw material and clinker activator in the dryer until the water content is less than 2%, and then grind to 0.08mm The sieve residue is less than 10.0%;

[0030] 2) Uniformly mix various powders according to the ratio of raw materials to obtain cement raw meal;

[0031] 3) Put the cement raw meal into the rotary kiln, use bituminous coal with a calorific value higher than 5200kJ / kg or mix bituminous coal and anthracite as fuel, and calcine in the kiln at a calcination temperature of 1400-1450°C (excluding 1450°C), and the calcination time 20-70min;

[0032] 4) Cool the calcined cement clinker to obtain micro-expansion high-magnesium medium-heat cement clinker with periclase controlled at 2-8%;

[0033] 5) Grind micro...

Embodiment 1-7

[0037] Example 1-7, preparation of micro-expansion high-magnesium medium-heat cement with periclase controlled at 2-8%

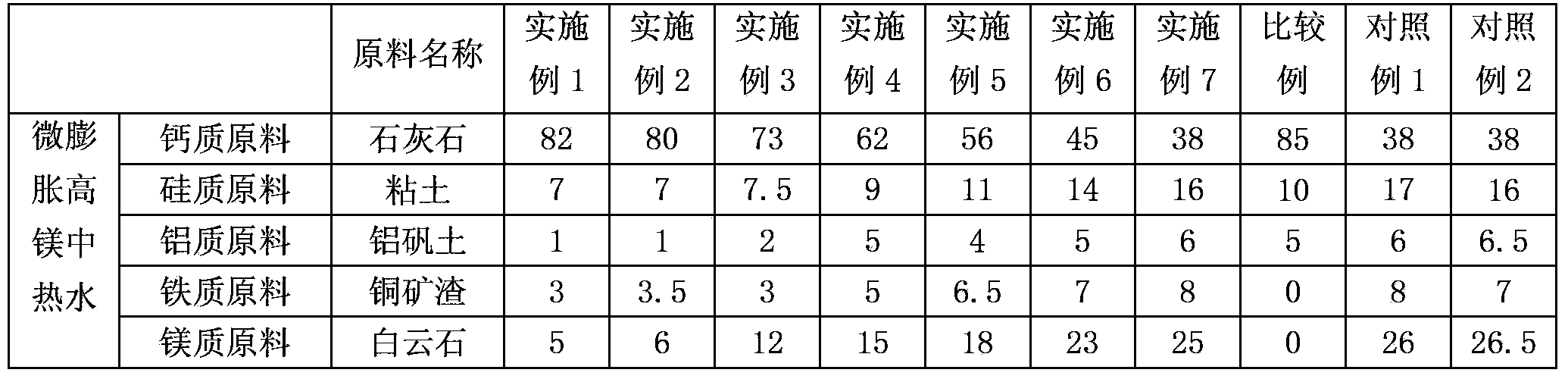

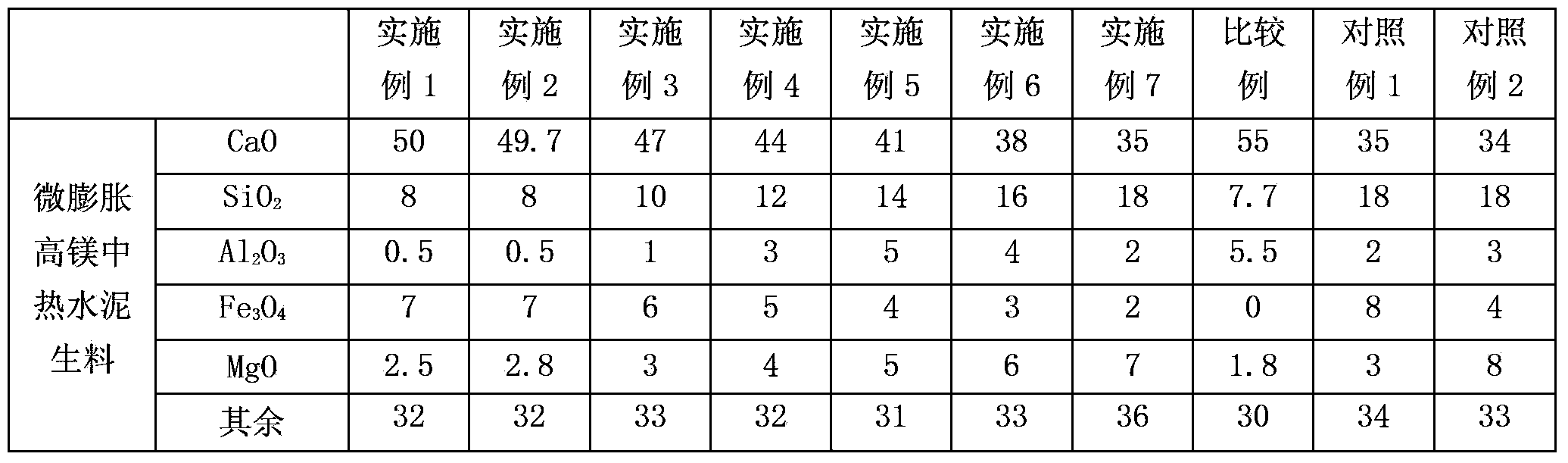

[0038] The proportioning ratio of raw materials of embodiment 1-7 and comparative example is as shown in table 1:

[0039] Table 1 Raw material proportions of micro-expansion high-magnesium medium-heat cement and comparative examples in Examples 1-7 (unit: parts by weight)

[0040]

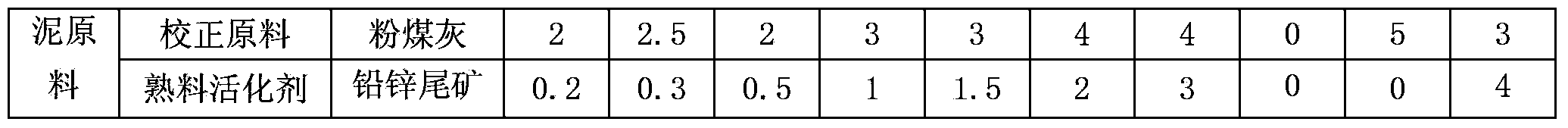

[0041]

[0042] The preparation of micro-expansion high-magnesium medium-heat cement includes the following processes:

[0043] 1) Dry the calcium raw material, silicon raw material, aluminum raw material, iron raw material, magnesium raw material, calibration raw material and clinker activator in the dryer until the water content is less than 2%, and then grind to 0.08mm The sieve residue is less than 10.0%;

[0044] 2) According to the ratio shown in Table 1, mix various powders evenly to obtain cement raw meal. After testing, the weight percentage of oxides in each co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com