Patents

Literature

1138results about How to "Improve volume stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightweight high-performance foam concrete and preparation method thereof

ActiveCN104108912AHigh CaO contentHigh glass bead contentSolid waste managementCeramicwareFoam concreteFiber

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

Gelatinization material gypsum-cement and producing method thereof

The invention relates to a gypsum-cement binding material and a production method thereof. The material contains gypsum binding material, active admixture, alkaline excitant, oagulation accelerator, lime, water-reducing agent, early-strength agent and gypsum hemihydrate. The weight proportions of the components are as follows: 40%-80% of gypsum binding material, 10%-45% of active admixture, 4%-15% of alkaline excitant, 0-6% of coagulation accelerator, 0-1% of early-strength agent, 0-1% of water-reducing agent, 0-5% of lime and 0-10% of gypsum hemihydrate. The production method comprises the following steps: weighing raw materials at the given ratio, mixing all raw materials, and packaging. The inventive gypsum-cement material has high strength, good water resistance and good volume stability; and can be used as masonry cement, cement mortar, gypsum plaster, jointing gypsum and heat-insulating mortar.

Owner:长沙归一新材料科技股份有限公司

Super-light foam cement concrete and preparation method thereof

The invention discloses a super-light foam cement concrete and a preparation method thereof. The super-light foam cement concrete comprises the following raw materials by weight parts: 9-36 parts of dead burnt magnesium oxides, 9-32 parts of dihydric phosphates, 0.5-7 parts of adjustable solidification agents, 6-25 parts of light burnt magnesium oxides, 0.5-7 parts of sulfur-containing components, 1-25 parts of industrial slag powder, 1-20 parts of kieselguhrs, 0.3-3.9 parts of waterproof agents, 0.2-1.7 parts of foam stabilizing agents, 1.0-8.9 parts of foaming agents and 25-90 parts of water. The preparation method of the high-performance super-light foam cement concrete comprises the following steps of: metering raw materials; preparing the slurry containing the foam stabilizing agents; uniformly mixing the foaming agents; pouring and standing by; foaming and expanding; coagulating and curing; and naturally maintaining. The super-light foam cement concrete has the advantages of light weight, high strength, heat preservation and insulation, stable volume, low production cost, energy-saving property, no environmental pollution, and the like. The super-light foam cement concrete is simple in production process and is especially suitable for the heat-insulating material of external building wall, roof and floor.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Exterior wall composite insulation heat-proof plastering material

InactiveCN101229970ARealize resource utilizationImprove protectionSolid waste managementFiberResource utilization

The invention relates to compound thermal insulation plastering material for external wall, which consists of a compound cementing material and a lightweight aggregate. The compound cementing material consists of cement, active admixture, lime powder, promoter, surfactant, anti-crack and waterproof agent, water retaining agent, flame retardant, re-dispersible emulsion powder, alkali-resistance fiber and coal flying ash cenosphere; the lightweight aggregate consists of EPS grain and expanded perlite. The invention has the advantages of low density, thermal performance, high strength, good impact resistance, bond strength and low shrinkage. The compound cementing material adopts a plurality of polymeric cementing materials, allows the insulation material to have good bond performance and simultaneously ensures falling and slipping resistance performance. The invention has good water resistance and high softening coefficient. By using cement-based cementing material as main material and organic reinforced material and waterproof component as auxiliary materials, the invention has a hydrophobic rate more than 98 percent and a softening coefficient more than 0.7. The invention can save energy and protect environment. A great deal of industrial waste residue is used in the materials, which can save a great number of energy, realize resource utilization of the waste residue and is in favor of environmental protection.

Owner:SHANGHAI TONGBIAO INSULATION TECH

High-ductility low-shrinkage anti-cracking concrete for bridge deck pavement and preparation method thereof

The invention belongs to the field of concrete structural materials, and discloses a preparation method for high-ductility low-shrinkage anti-cracking concrete for bridge deck pavement. The high-ductility low-shrinkage anti-cracking concrete for bridge deck pavement is characterized by comprising the following components in proportion: 135-155 kg / m<3> of water, a cementing material, 600-800 kg / m<3> of fine aggregate, 950-1150 kg / m<3> of coarse aggregate, 2.0-3.0 kg / m<3> of shrinkage-reducing ductility-increasing component,10-20 kg / m<3> of internal curing agent, 3.0-5.0 kg / m<3> of water reducing agent and hybrid fiber, wherein the cementing material comprises 320-380 kg / m<3> of cement and 20-40 kg / m<3> of coal ash in proportion; and the hybrid fiber comprises 0.8-1.0 kg / m<3> of organic polymer fiber and 40-50 kg / m<3> of steel fiber in proportion. According to the concrete and the preparation method for the concrete disclosed by the invention, reinforcement meshes on the bridge deck pavement layer can be cancelled.

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

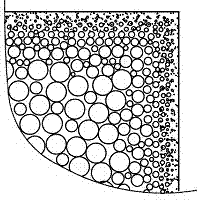

Functionally-graded cellular-concrete thermal-insulating material and preparation method thereof

ActiveCN102561532AOvercoming the Interface Breaking DilemmaImprove bending strengthHeat proofingCeramicwareFoam concreteThermal insulation

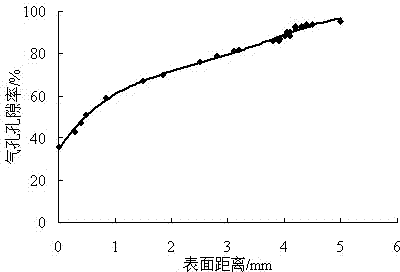

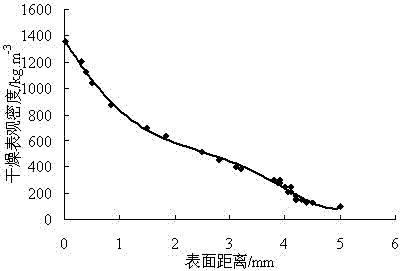

The invention relates to a functionally-graded cellular-concrete thermal-insulating material and a preparation method thereof. The functionally-graded cellular-concrete thermal-insulating material comprises a cellular-concrete thermal-insulating core, a plurality of air holes are uniformly distributed in the thermal-insulating material, and the surface of the cellular-concrete thermal-insulating core is wrapped with a functionally-graded layer; in the air holes of the functionally-graded cellular-concrete thermal-insulating material, the air hole in the cellular-concrete thermal-insulating core has a maximum diameter, then, the diameters and porosities of the air holes from the cellular-concrete thermal-insulating core to the outside are in a continuous graded change in a descending order, the thickness of the functionally-graded layer is 0.1-20 mm, the porosities of the air holes are in a continuous graded change in a range of 1- 95%, and the diameters of the air holes are in a continuous graded change in a range of 0.1-8 mm. According to the invention, the interior of the material is porous and thermal-insulating, and the surface of the material is high in density and strength, the mechanical strength of the material is gradually improved from the inside to the outside, and the thermal conductivity factor of the material is gradually reduced front the outside to the inside, thereby achieving an effect of integrating light weight, high strength, thermal insulation and fire prevention.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

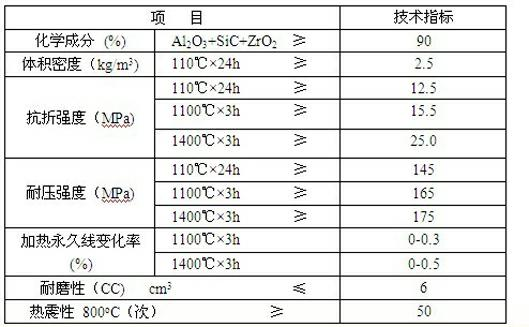

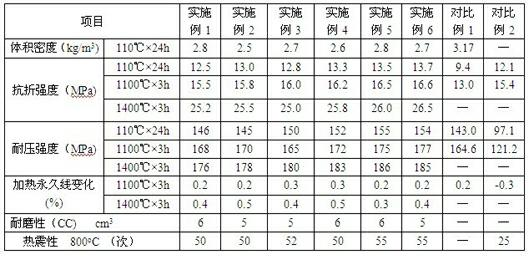

Special castable for kiln outlet

The invention discloses a special castable for a kiln outlet, which belongs to the field of refractory materials. According to the invention, the special castable comprises the following components in percentage by weight: 8-25% of silicon carbide, 10-30% of andalusite, 20-35% of corundum, 5-15% of spinel powder, 5-10% of zircon mullite powder, 1-5% of zirconium diboride, 1-5% of silicon nitride,5-15% of alumina micropowder, 3-6% of pure calcium aluminate cement, 0.5-1% of explosion-proof fiber and 0.06-0.2% of sodium tripolyphosphate, which is an additive. By using the special castable for the kiln outlet, disclosed by the invention, the phenomenon of poor wear resistance, block falling and the like in the kiln outlet can be effectively improved; the service life of the cement kiln outlet can be largely prolonged; and the special castable for the kiln outlet, disclosed by the invention, has the advantages of high temperature resistance, heat shock resistance, wear resistance, high strength, irreversible micro expansion and the like.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

Crack self-repairing concrete using aerobic basophilic microorganisms and preparation method thereof

The invention relates to crack self-repairing concrete using aerobic basophilic microorganisms and a preparation method thereof. The concrete contains expanded perlite loading an aerobic basophilic microorganism repair agent, cement, pebbles, sand, silica fume, water, calcium lactate and water reducer. The crack self-repairing concrete has the crack self-repairing function and has heat-preservation and heat-insulation functions, the aerobic basophilic microorganisms serve as a crack repairing agent, calcium lactate serves as nutritional matter for microorganism metabolism, and expanded perlite serves as a carrier of the crack repairing agent. When concrete cracks, water and air enters the cracks so that resting microorganisms can restore the metabolism function, calcium lactate is converted into calcium carbonate precipitate, and accordingly the aims of automatically diagnosing and repairing the concrete cracks, preventing expansion of the cracks and improving concrete impermeability are achieved. The microorganism crack self-repairing concrete serves as a concrete material integrating the functions of crack self-diagnosis and self-repairing, lightweight, heat preservation and heat insulation, and has large research value and application potential.

Owner:TAIYUAN UNIV OF TECH

Thermal insulation mortar

InactiveCN102010174AGood volume stabilityStrong water resistanceSolid waste managementPolystyreneTime control

The invention discloses thermal insulation mortar which comprises the following components in percentage by weight: 20 to 60 percent of caustic calcined magnesia, 1 to 25 percent of fly ash, 5 to 35 percent of thickening time control agent, 0 to 40 percent of enhanced thickener, 1 to 20 percent of kieselguhr, 5 to 35 percent of expanded aggregate, 0 to 5 percent of polystyrene foam particles, 0 to 0.2 percent of polypropylene fiber, 0.5 to 8 percent of water-resisting admixture, and 0 to 2 percent of water reducing agent. The thermal insulation mortar has the characteristics of capability of coagulating and hardening quickly and having strong binding capacity with base materials, good volume stability, capability of producing volume micro-expansion in the process of coagulating and hardening, no crack, no splitting, strong water resistance, ageing resistance, long service life, light weight, and good heat preservation and heat insulation performance, wherein the coefficient of thermal conductivity is 0.05 to 0.30 W / m.k. The thermal insulation mortar has the advantages of no toxicity, odourlessness, zero radioactivity, no harm to human bodies, no pollution to environments, energy conservation, environmental friendliness and low production cost.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +2

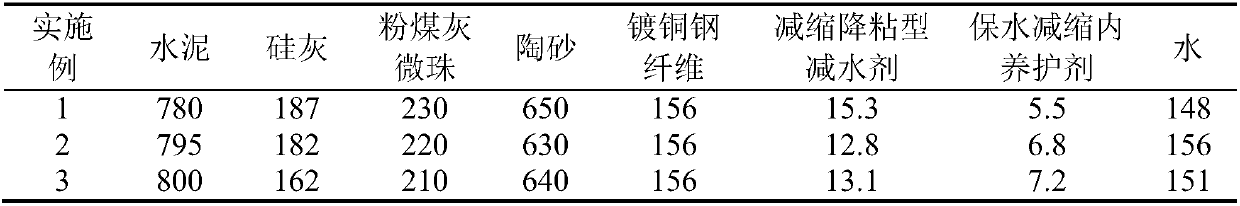

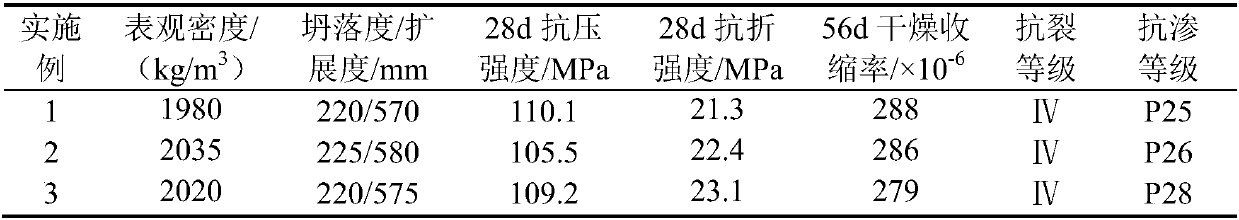

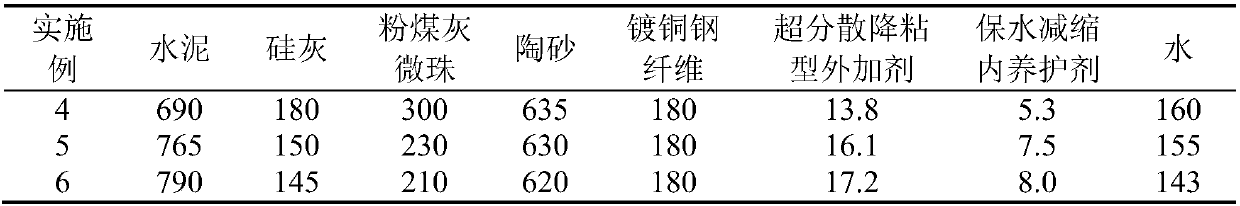

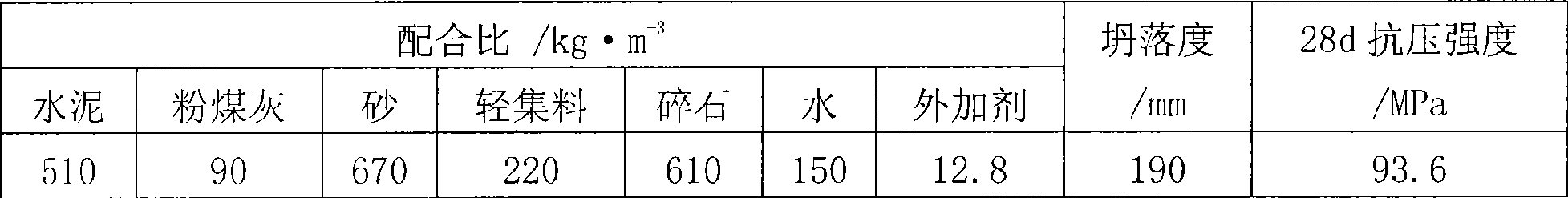

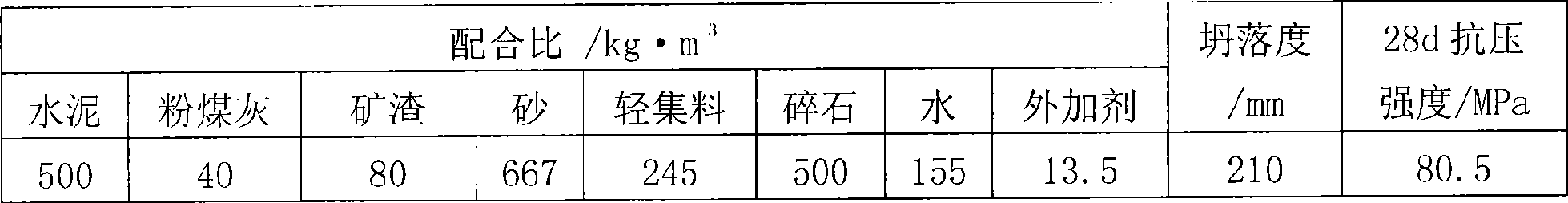

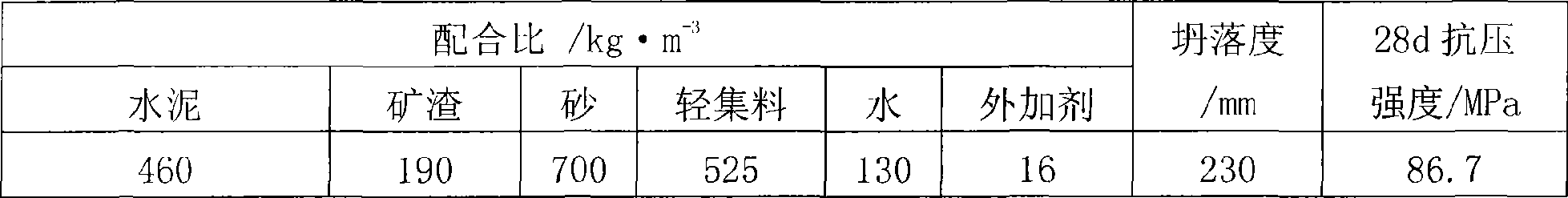

Light low-shrinkage super-high performance concrete and preparation method thereof

The invention discloses light low-shrinkage super-high performance concrete which is prepared from cement, coal ash beads, silica fume, pottery sand, a brass coated steel fiber, shrinkage and viscosity reduction type water reduction agent, a water-retention shrinkage-reduction inner curing agent and water as main raw materials. According to the concrete, the pottery sand is adopted as aggregate, the self weight of the concrete is reduced, and a high-strength and dense 'arch housing' interface area is formed on the surface of the pottery sand by using a pre-mixing process, so that the interfacestrength is improved, and the mechanical properties and the anti-penetrability performance of the concrete are improved; due to the adoption of the shrinkage and viscosity reduction type water reduction agent and the coal ash beads, the working performance and the density of the concrete are improved; due to the adoption of the pre-wetted pottery sand and the developed water-retention shrinkage-reduction inner curing agent, reduction of wetness inside the concrete is retarded, the self-shrinkage and the drying shrinkage of the concrete are reduced, and the volume stability of the concrete isimproved. While the self weight of the concrete is reduced, the light low-shrinkage super-high performance concrete disclosed by the invention is good in working performance, mechanical property, anti-penetrability and durability, and has significant practical application values.

Owner:WUHAN UNIV OF TECH

Pouring material for producing high-temperature ceramic abrasion-proof lining body

The invention relates to a castable for preparing a high-temperature ceramic wear-resistant lining, which contains 10-25% of fused mullite with a particle size of 3-5mm, and 20-45% of fused mullite with a particle size of 1-3mm. 3-7% of andalusite with a particle size of 0.1mm-1mm, 8-25% of platy corundum with a particle size of 0.1-1mm, 5-20% of fused white corundum with a particle size of 0.1-1mm, 5-20% of fused white corundum, and pure calcium aluminate with a particle size of <0.074mm 2-10% of cement, 2-6% of silicon micropowder, and 2-10% of alumina micropowder. The castable can be applied to the intersection of blast furnace hot air pipe and air supply branch pipe, etc. where thermal shock stability is high. The lining made of it has good thermal stability, high temperature air erosion resistance, good thermal shock resistance, It has the advantages of long life cycle, simple manufacturing method, short construction period, environmental protection and pollution-free, low cost, and easy industrial production.

Owner:HENAN HAOYUNXIANG REFRACTORY MATERIAL CO LTD

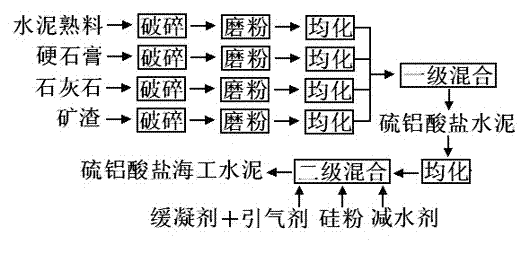

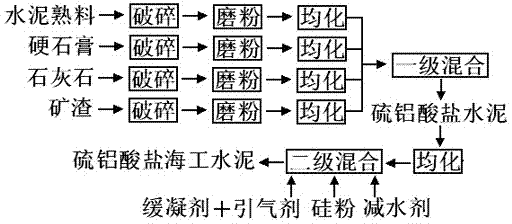

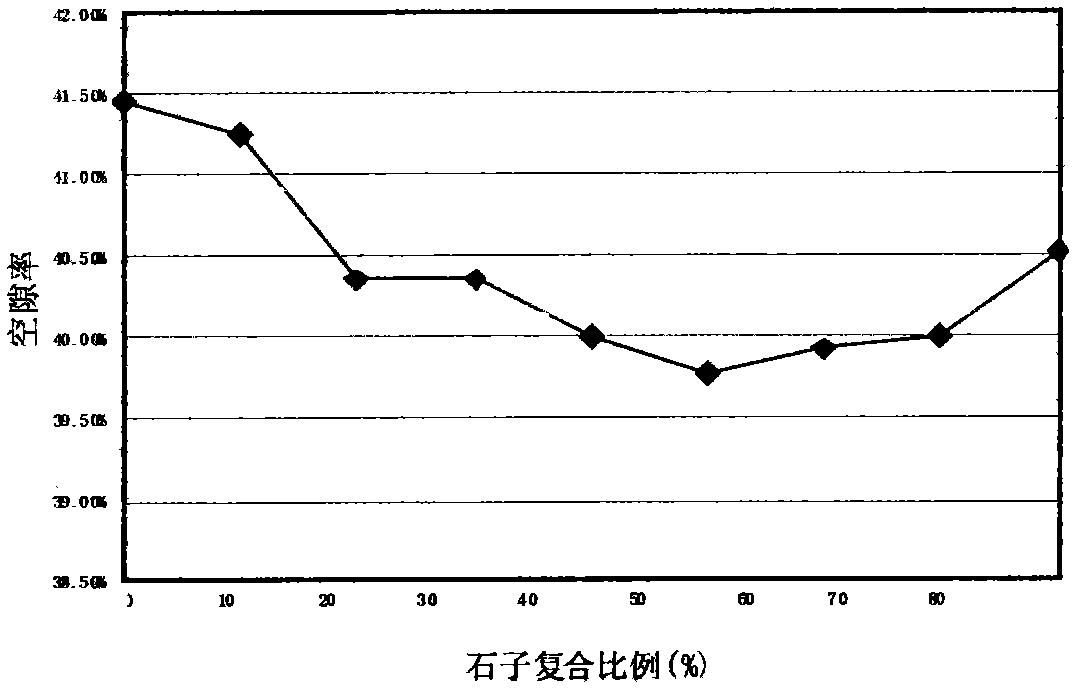

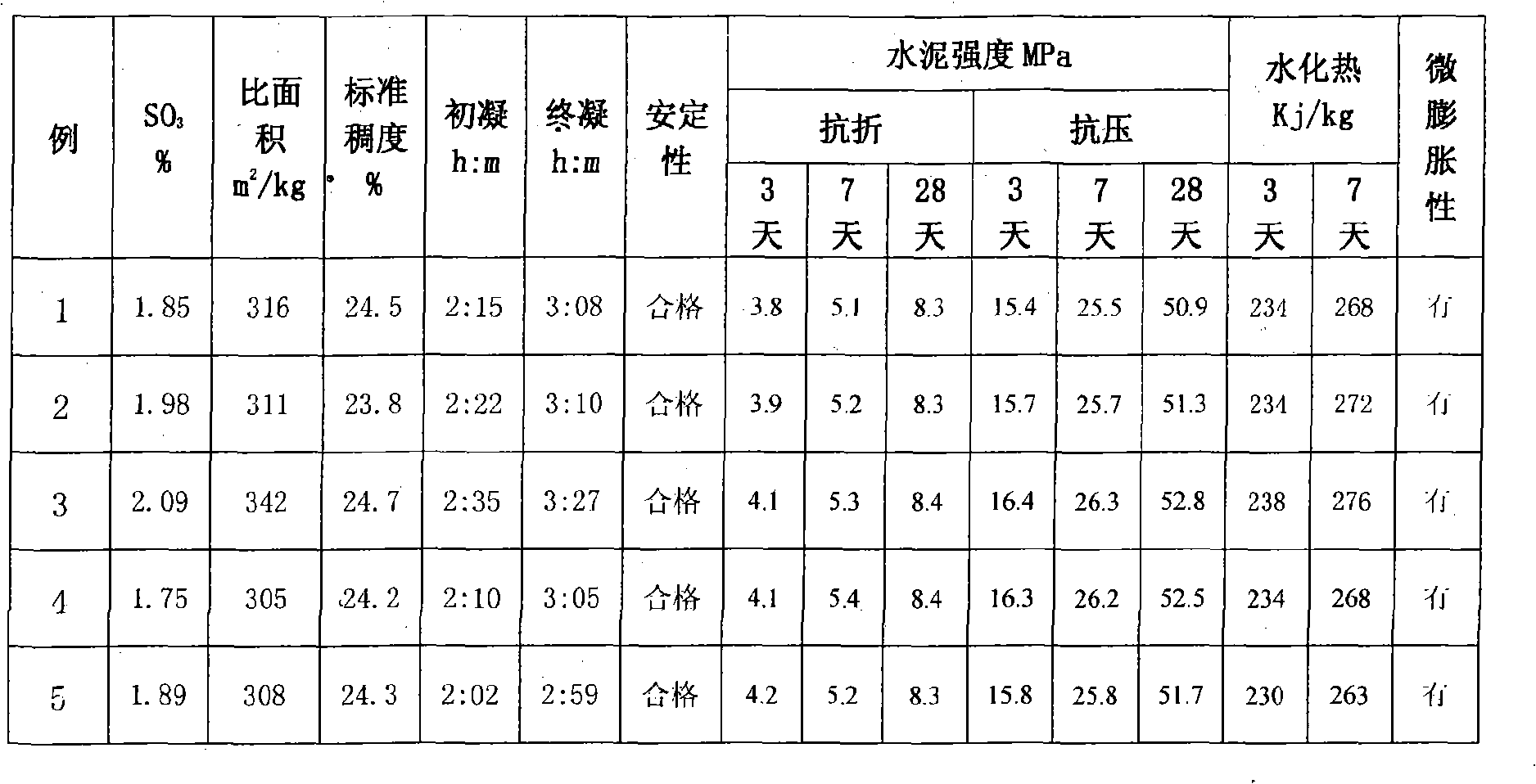

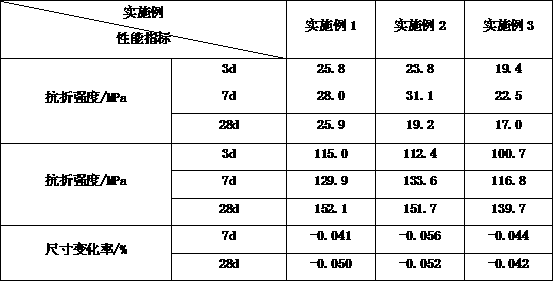

Sulphoaluminate maritime work cement and preparation method thereof

The invention discloses sulphoaluminate maritime work cement and a preparation method thereof. The sulphoaluminate maritime work cement comprises the following main raw materials in parts by weight: 50-80 parts of cement clinker, 8.0-20 parts of anhydrite, 0-30 parts of limestone, 0-30 parts of slag, 0.1-0.5 part of water reducing agent, 0.001-0.005 part of air entraining agent, 0.1-0.5 part of retarder and 2-5 parts of silicon powder. The preparation method comprises the following steps of: respectively smashing, grinding and homogenizing the sulphoaluminate cement clinker, the anhydrite, the limestone and the slag; then, burdening at a ratio, and evenly mixing; adding the water reducing agent, the air entraining agent, the retarder and the silicon powder; and mixing and homogenizing to obtain the product. The concrete mixed by the sulphoaluminate maritime work cement has the advantages of small bleeding rate and high slurry viscidity. The slurry has strong covering and supporting action on aggregate. The concrete keeps good homogeneity and has the advantages of hard and quick early strength, continuously-increased later strength, good slurry structure compactness and high volume stability and is convenient to use and operate for constructing.

Owner:广西云燕特种水泥建材有限公司

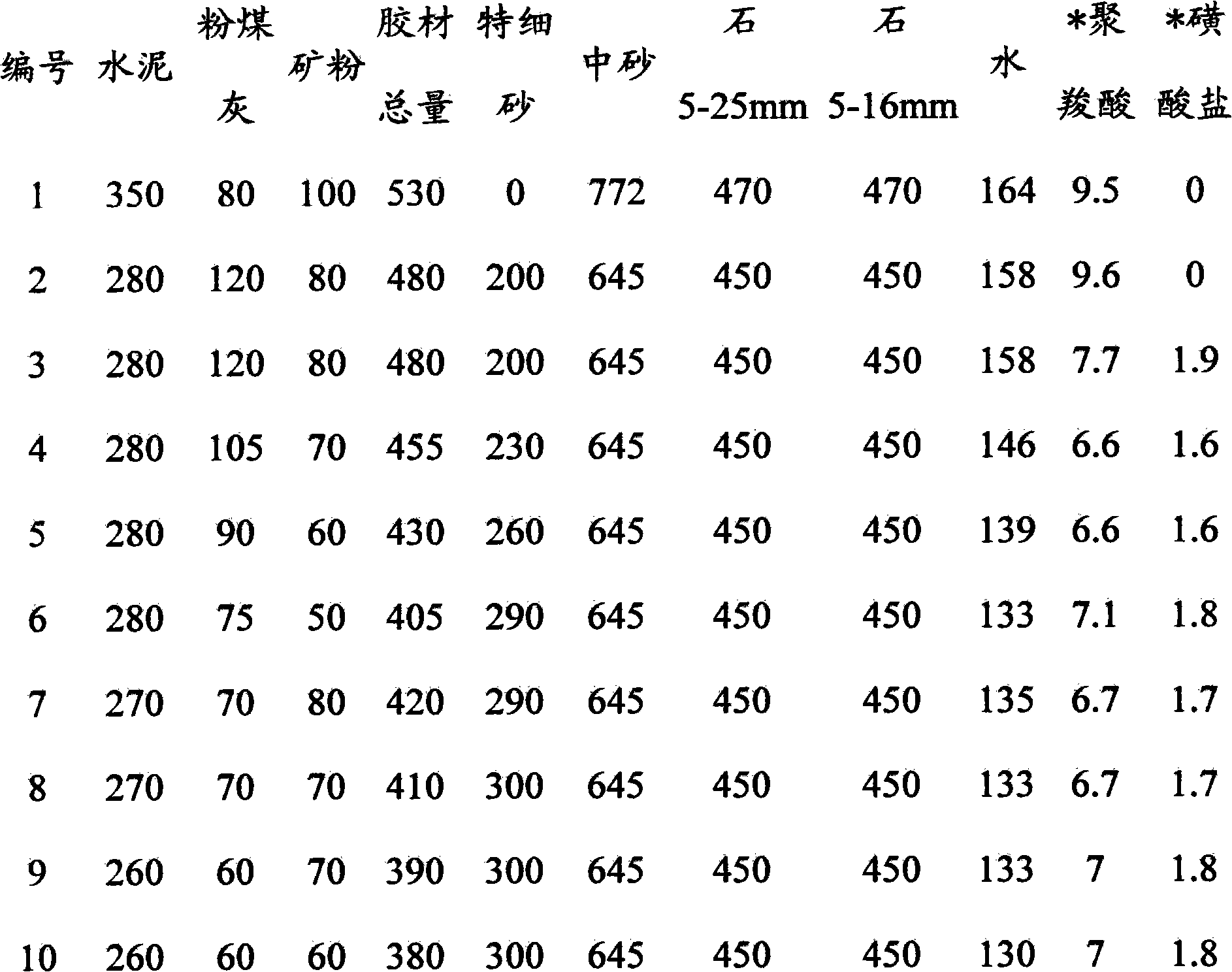

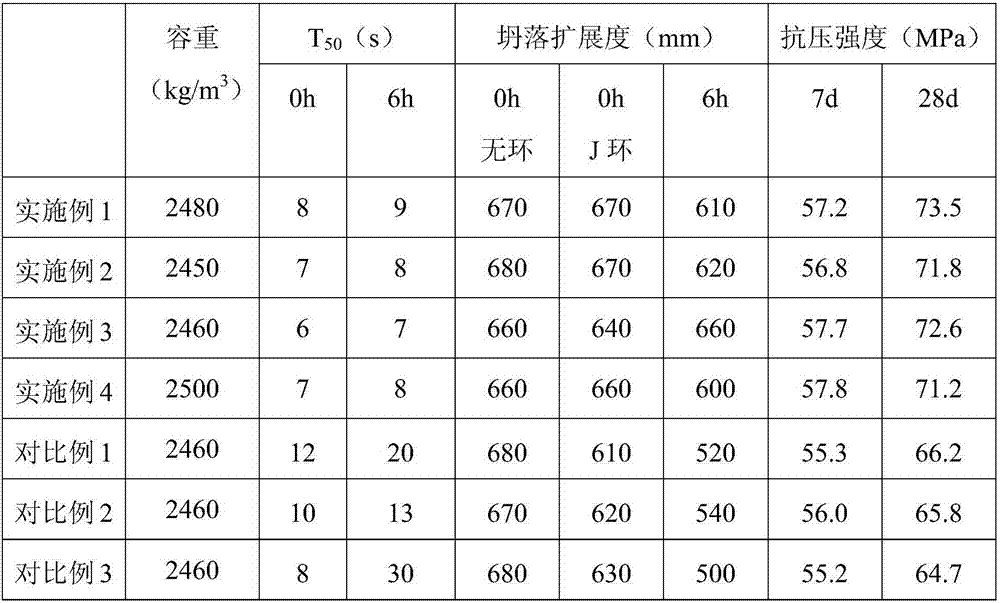

Self-compacting concrete

InactiveCN102060482AImprove volume stabilityIncreased durabilitySolid waste managementSuperplasticizerCoal

The invention relates to self-compacting concrete which is used for overcoming the contradiction between flowability and stability, early strength and delayed coagulation, contraction and expansion and the like of the self-compacting concrete in the prior art. In the invention, by means of combination of an aliphatic (hydroxyl) sulfonate superplasticizer and a polycarboxylic acid superplasticizer, selection and collocation of a cementing material and coarse and fine aggregates as well as specific mix design, the self-compacting concrete (more than C40) with low consumption of the cementing material is prepared from coal ash, mineral powder and tailings, wherein, a ketoaldehyde condensate is taken as the main component of the aliphatic (hydroxyl) sulfonate superplasticizer; and when the superplasticizer is added to cement paste, the mixed concrete has the advantages of good construction workability, less possibility of bleeding and segregation, no crystallization precipitate at low temperature and the like. Compared with the prior art, the self-compacting concrete prepared by the method provided by the invention has the advantages of lowering cement consumption by at least 70kg / m<3>, reducing consumption of the cementing material by at least 70kg / m<3>, comprehensively utilizing at least 470kg / m<3> of solid waste, and lowering concrete cost by at least **yuan / m<3>.

Owner:北京中联新航建材有限公司 +1

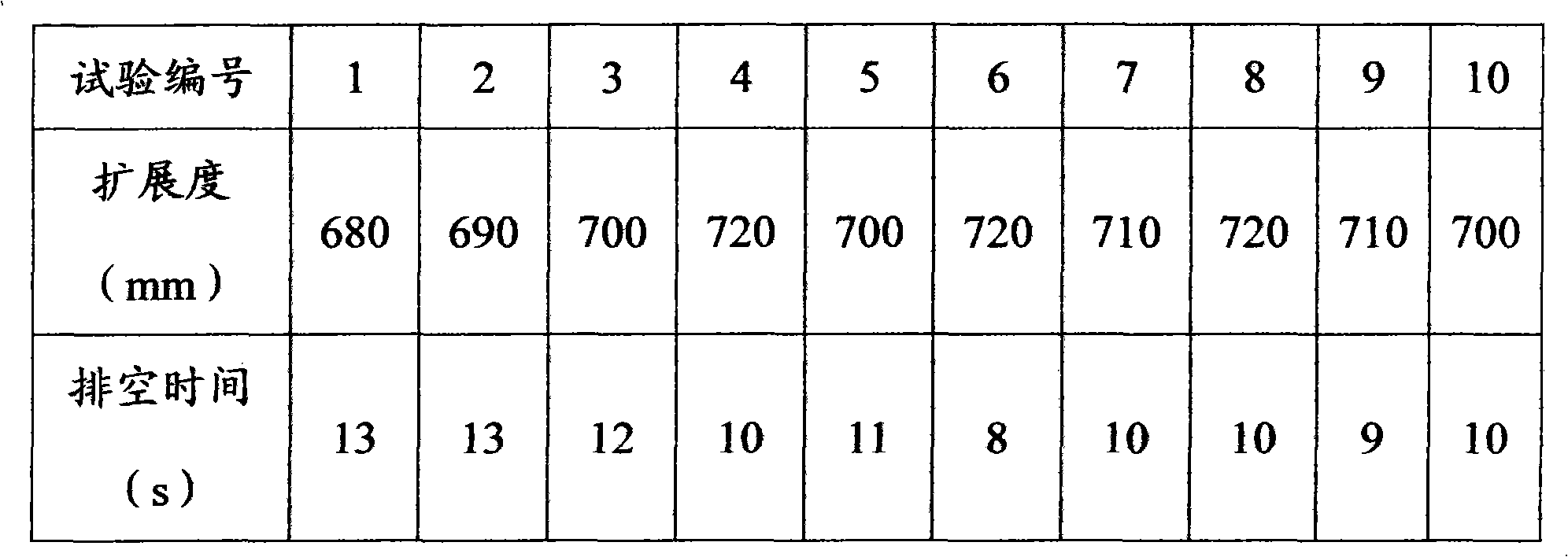

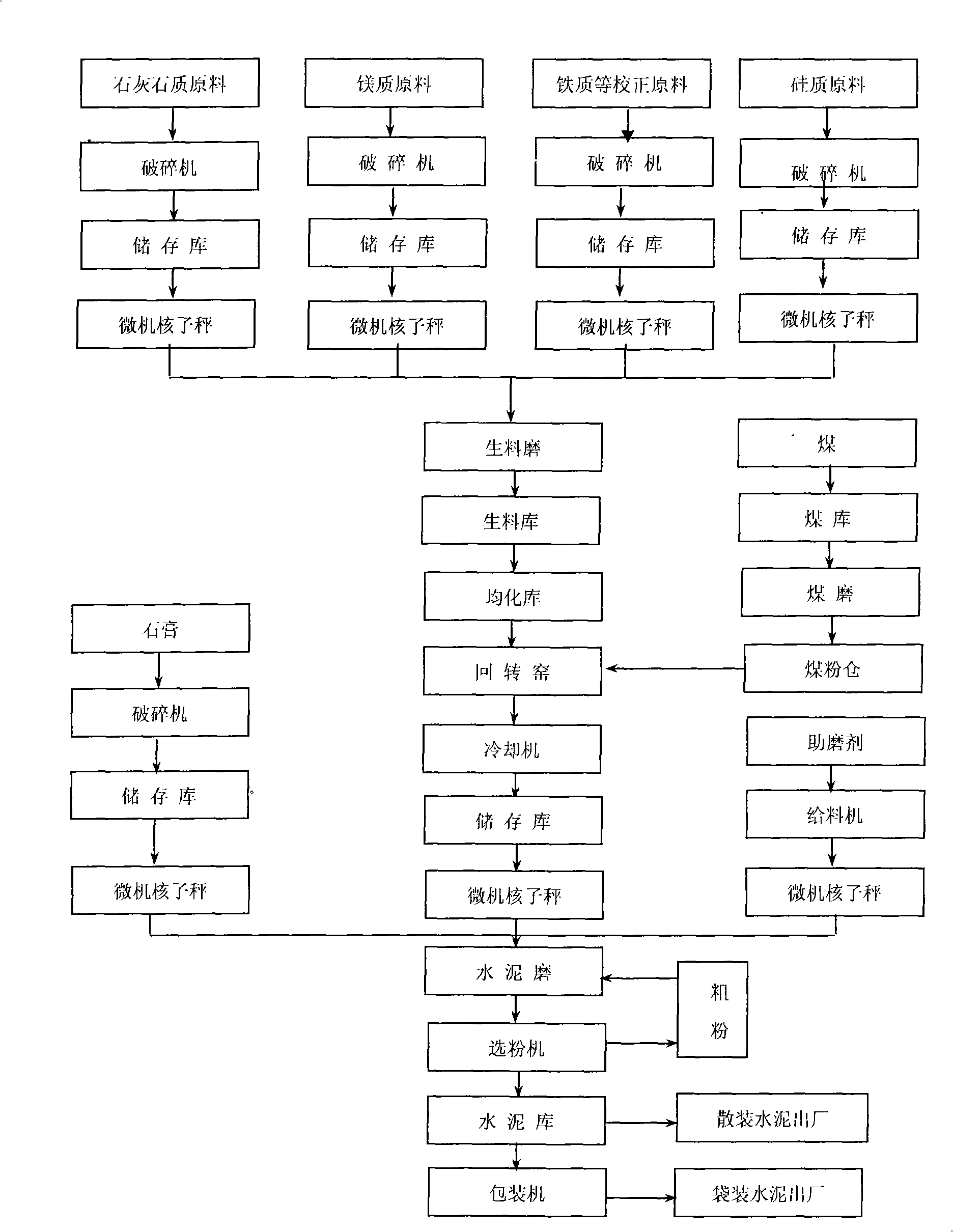

High-magnesium moderate-heat portland cement and production method thereof

InactiveCN101353231AReduce water demandThe micro-expansion property hasClinker productionHigh magnesiumPortland cement

The invention relates to a high-magnesium moderate heat portland cement, which is characterized in that (1) the contents of MgO and SO3 in the cement are 3.0-6.5% and 1.4-2.2% respectively; (2) the weight percentages of the mineral composition for grinding cement clinker are 35-55% of C3S, 15-35% of C2S, 1-6% of C3A and 10-25% of C4AF; and the content of MgO in the cement clinker is 3.0-6.5%; (3) in the raw materials for calcining the clinker, the contents of MgO, CaO and Fe2O3 are respectively controlled at a certain value within the ranges of 2.5-3.8%, 38.0-42.0% and 3.5-4.5%, and the variation ranges thereof are respectively controlled within plus or minus 0.10%, plus or minus 0.20% and plus or minus 0.15%. The production method of the cement mainly comprises three procedures of raw material milling, clinker calcining and cement grinding, namely, 'two grinding and one calcining'. The concrete made from the cement is characterized by good fluidity, low water requirement, moderate cement heat, high later strength, good durability, microdilatancy performance, and the like; compared with the conventional portland cement and moderate heat portland cement, the high-magnesium moderate heat portland cement is more favorable for realizing high performance of the concrete.

Owner:湖南石门特种水泥有限公司

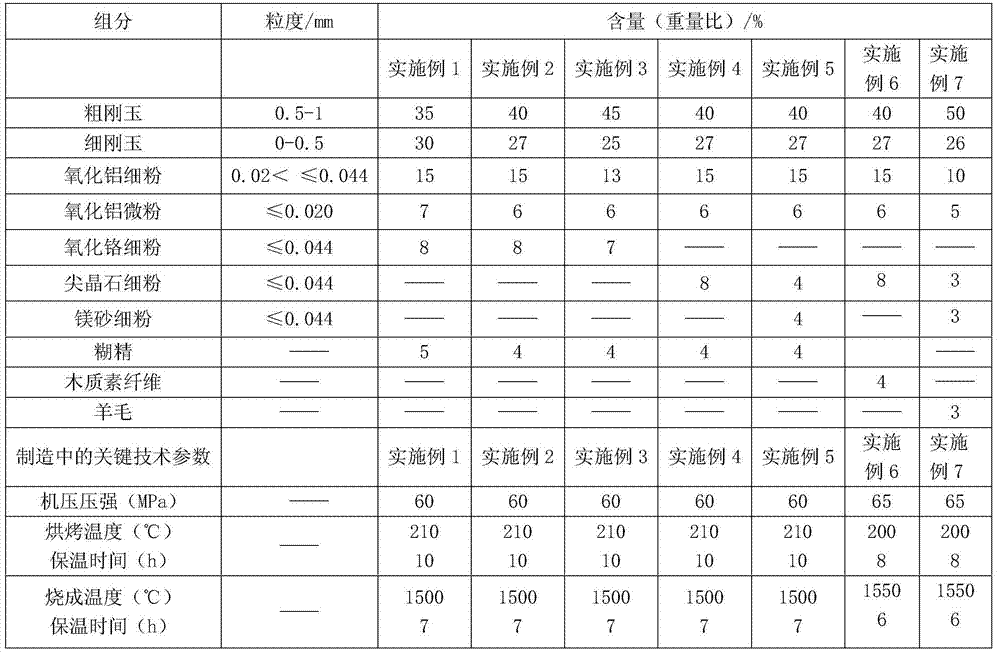

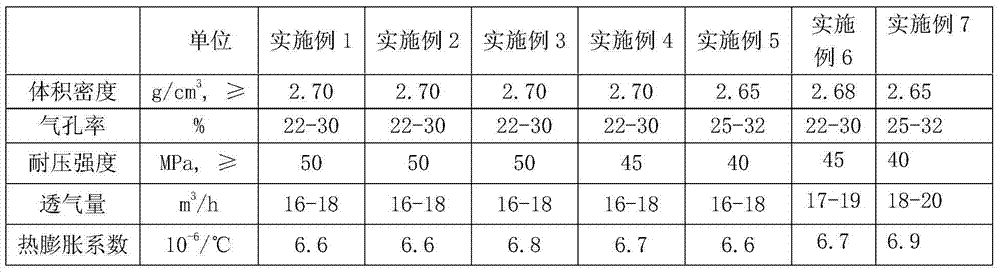

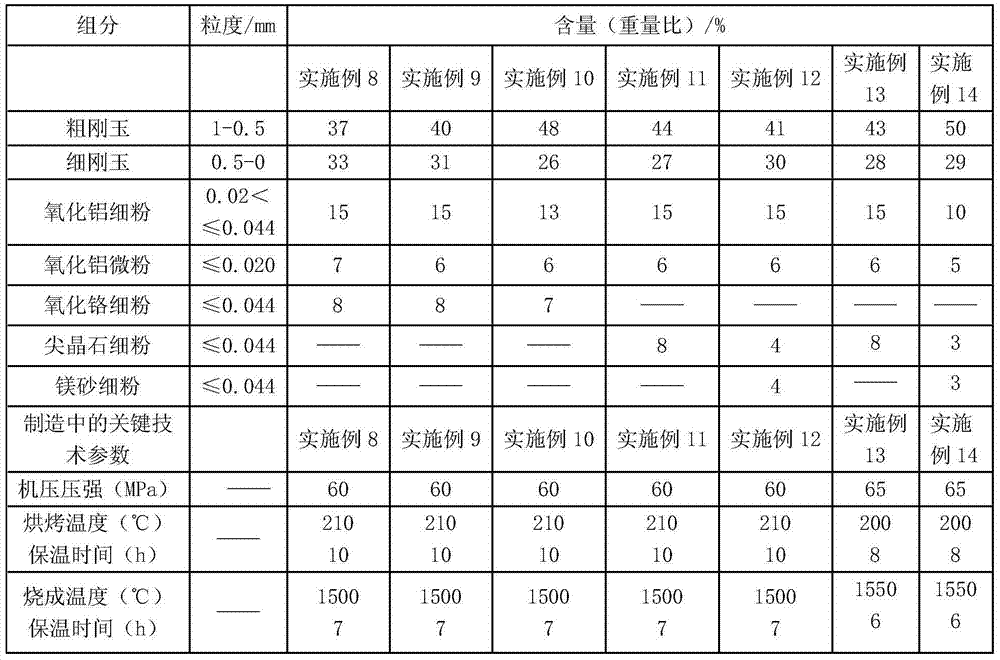

Air brick with high blowing through rate and manufacturing method thereof

The invention relates to an air brick with a high blowing through rate and a manufacturing method thereof. The air brick is composed of the following components: coarse corundum with granularity greater than 0.5mm and smaller than or equal to 1 mm and mass fraction of 35-50%; fine corundum with granularity greater than 0 and smaller than or equal to 0.5 mm and mass fraction of 25-40%; alumina fine powder with granularity greater than 0.020 mm and smaller than or equal to 0.044 mm and mass fraction of 8-15%; alumina micro powder with granularity greater than 0 and smaller than or equal to 0.020 mm and mass fraction of 5-10%. The manufacturing method comprises the procedures of mixed milling, material kneading and press forming, and further comprises the procedures of roasting, high temperature sintering, flow detecting, steel shell packaging and the like. According to the air brick provided by the invention, the particle size distribution and the machine pressing pressure are controlled, and uniformly distributed and mutually communicated micropores are formed in a brick body after high temperature sintering so as to achieve the permeability of an air brick body material.

Owner:PUYANG REFRACTORIES GRP CO LTD

Preparation method of fused silica refractory casting material unwetted by aluminum liquid

The invention belongs to the field of refractory materials and discloses a preparation method of a fused silica refractory casting material unwetted by an aluminum liquid, which comprises the following step of: enhancing a ground substance by adopting 10-20wt% of white alundum powder, 4-8wt% of calcium aluminate cement, 3-5wt% of hydrated alumina compound binding agent, 4-10wt% of silicon oxide micropowder and 3-6wt% of alumina micropowder, wherein 60-70wt% of fused silica is used as a main material, BaSO4 and Na3AlF6 is adopted as a compound aluminum liquid anti-wetting agent with the addition of 1-6wt%, and additional 0.12wt% of trimeric sodium phosphate and additional 0.03wt% of sodium hexametahposphate are adopted as dispensing agents. The casting material prepared by using the method has high strength, is unwetted by the aluminum liquid, has the highest use temperature of 1000 DEG C and can be used as the refractory materials, such as an aluminum flowing groove of an aluminum smelting furnace and the like.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

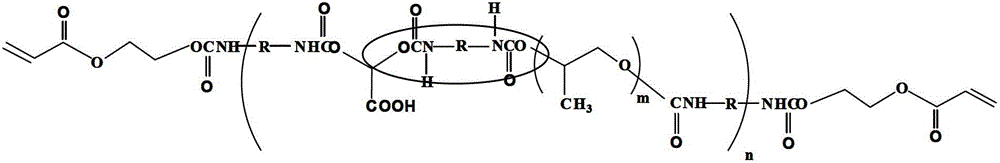

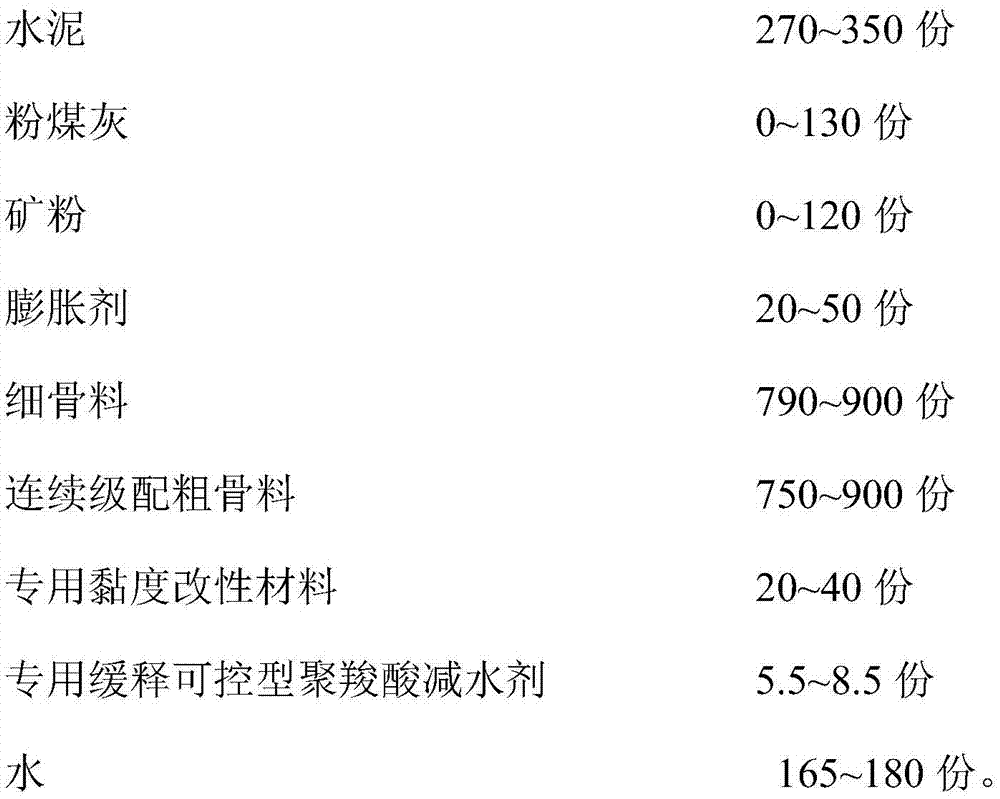

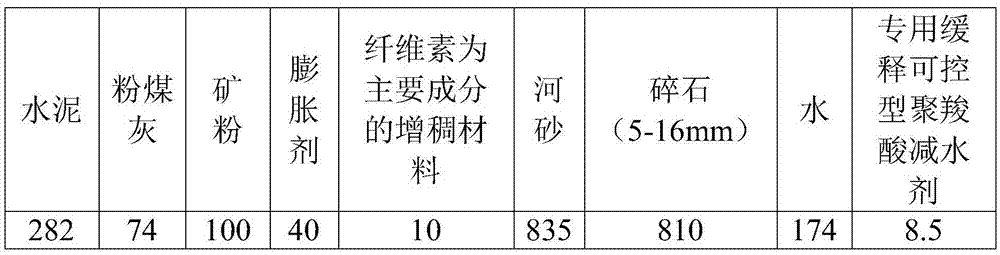

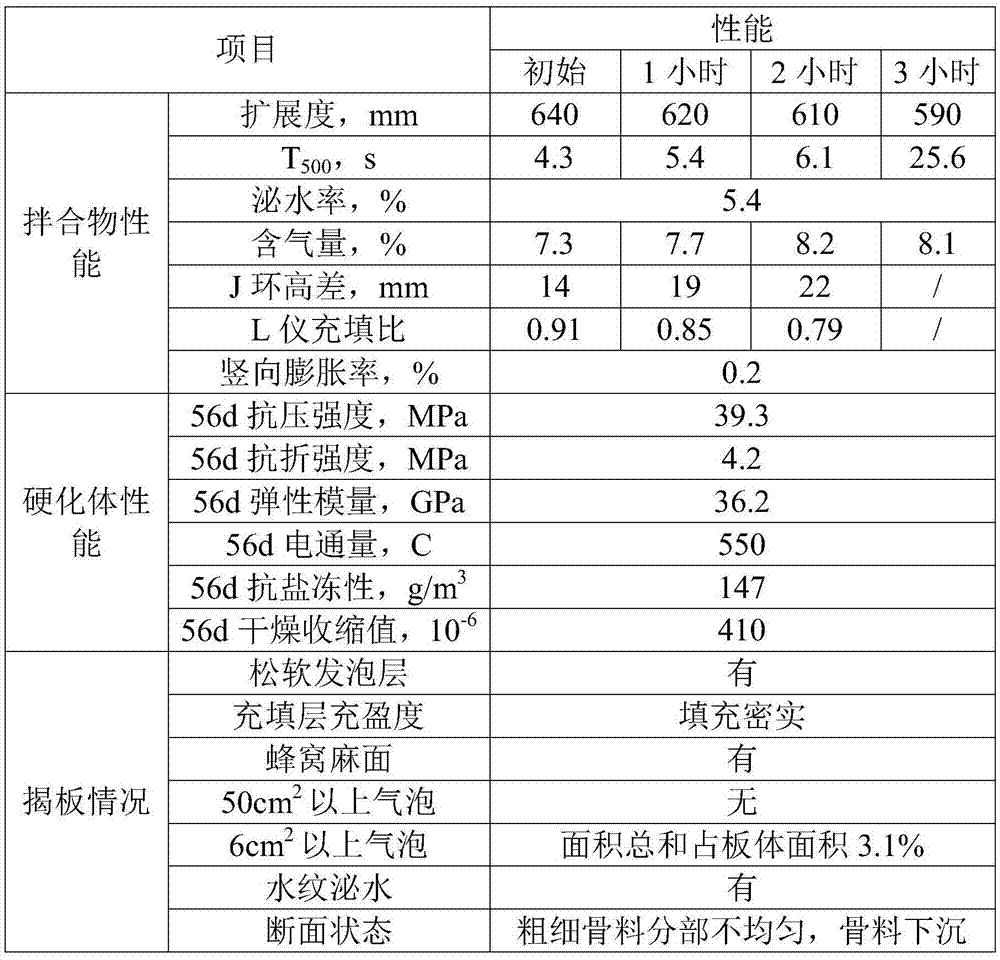

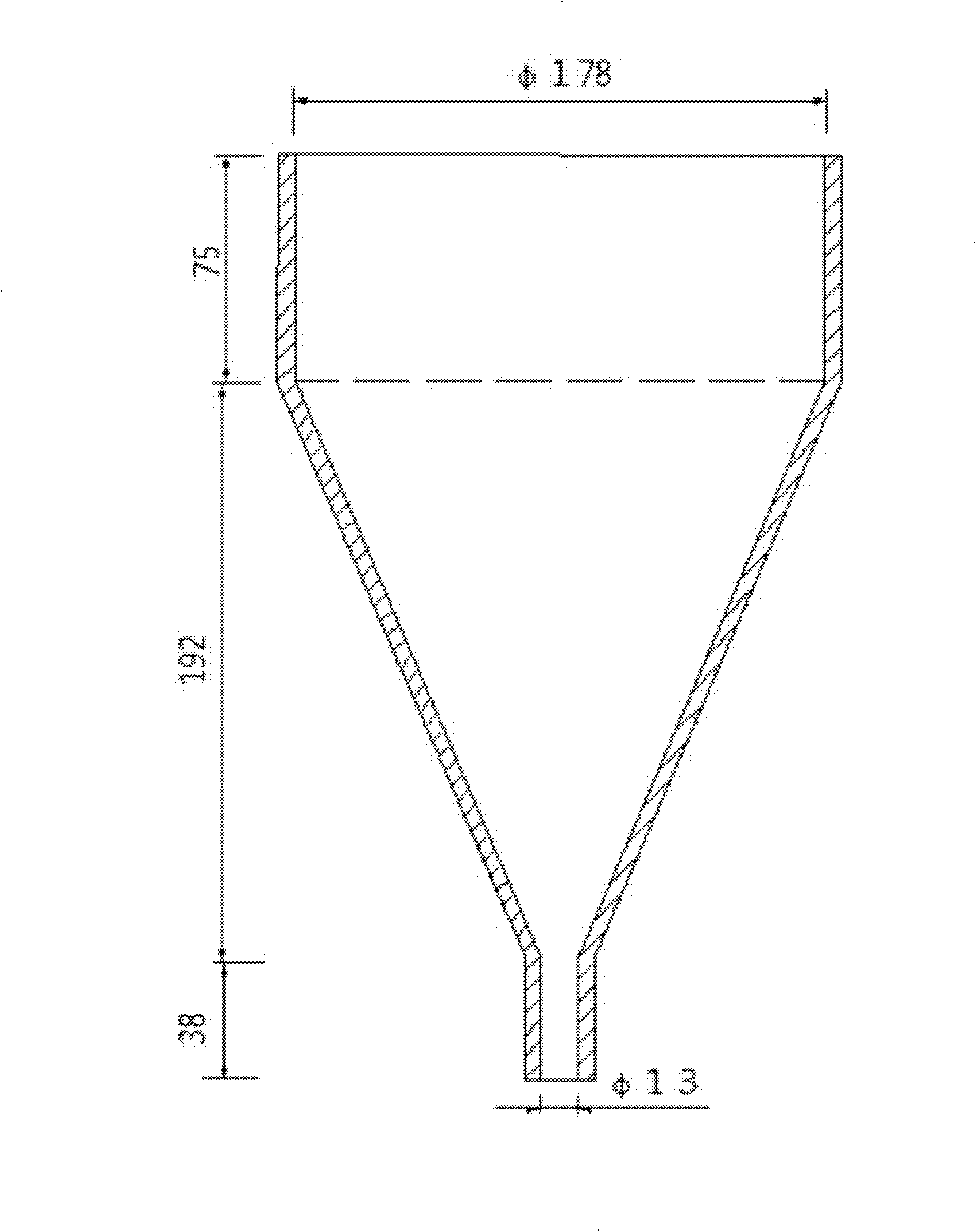

Self-compacting concrete for CRTS III plate-type ballastless track filling layer and preparation method for self-compacting concrete

The present invention discloses a self-compacting concrete for CRTS III plate-type ballastless track filling layer. The concrete is prepared from the following raw materials in parts by weight: 270-350 parts of cement, 0-130 parts of coal fly ash, 0-120 parts of mineral powder, 20-50 parts of an expanding agent, 790-900 parts of fine aggregate, 750-900 parts of continuous gradation coarse aggregate, 20-40 parts specific viscosity modified materials, 5.5-8.5 parts of a specific sustained release controllable polycarboxylic acid water reducing agent and 165-180 parts of water. According to the invention, the specific viscosity modified materials and specific sustained release controllable polycarboxylic acid water reducing agent are used in combination to prepare the specific self-compacting concrete for filling layer with good flowability, strong volume stability, low sensitivity for water consumption, small thixotropic time change, low shrinkage and good longevity, thereby reducing theconstruction difficulty of the CRTS III plate-type filling layer and prolonging the sevice life of the ballastless track structure.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

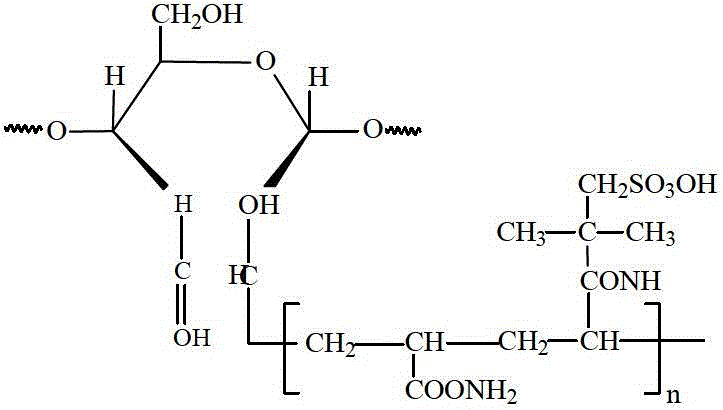

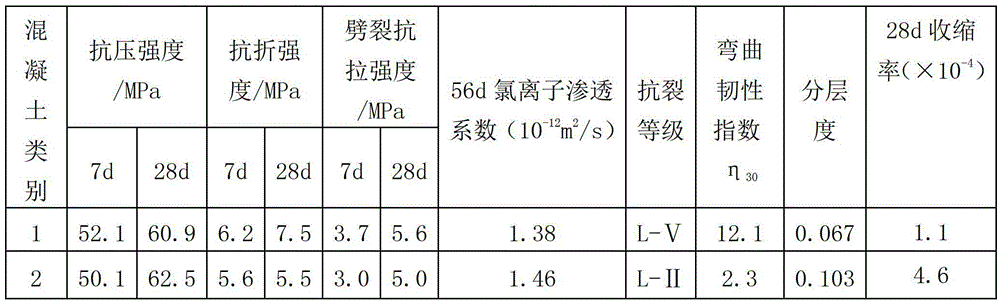

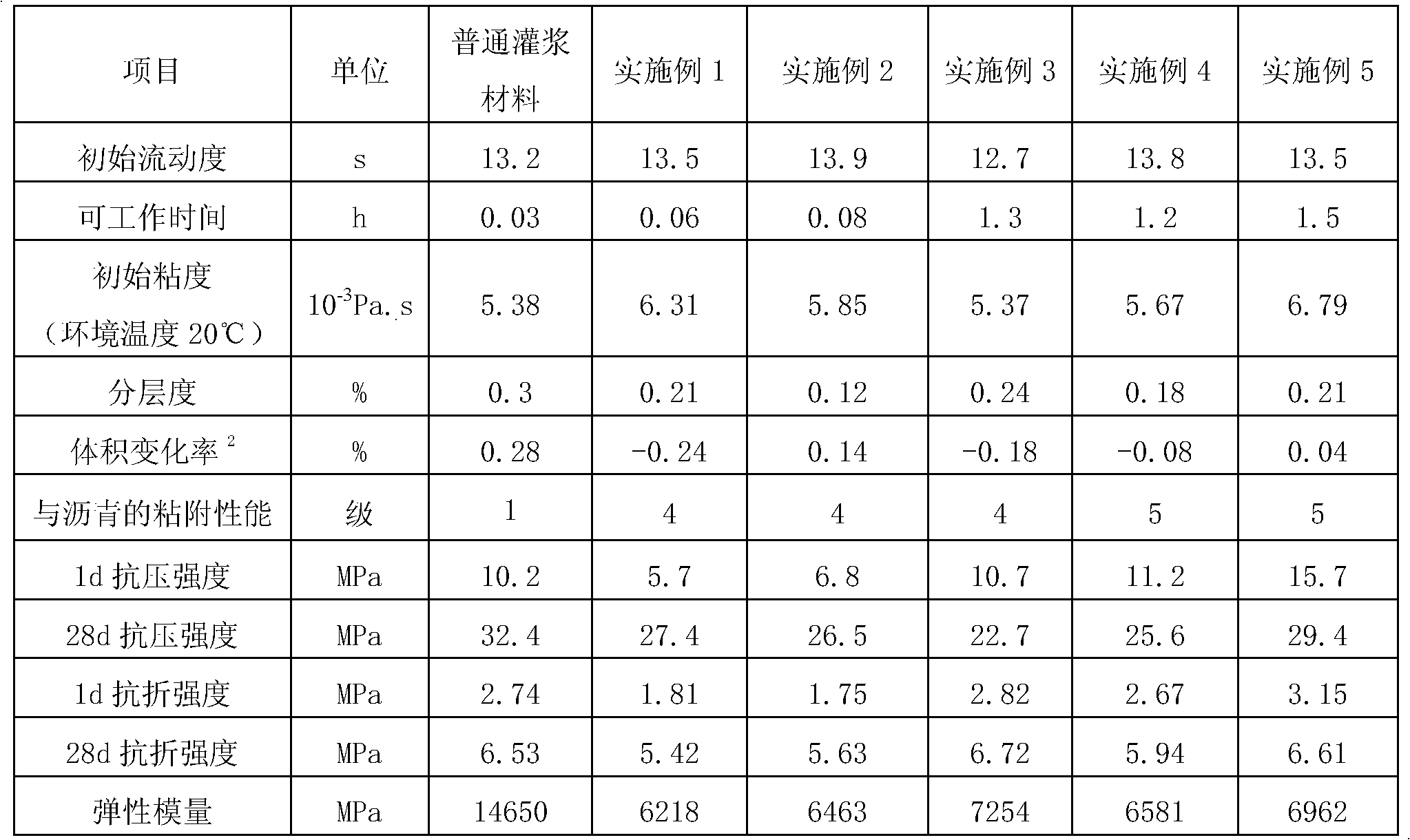

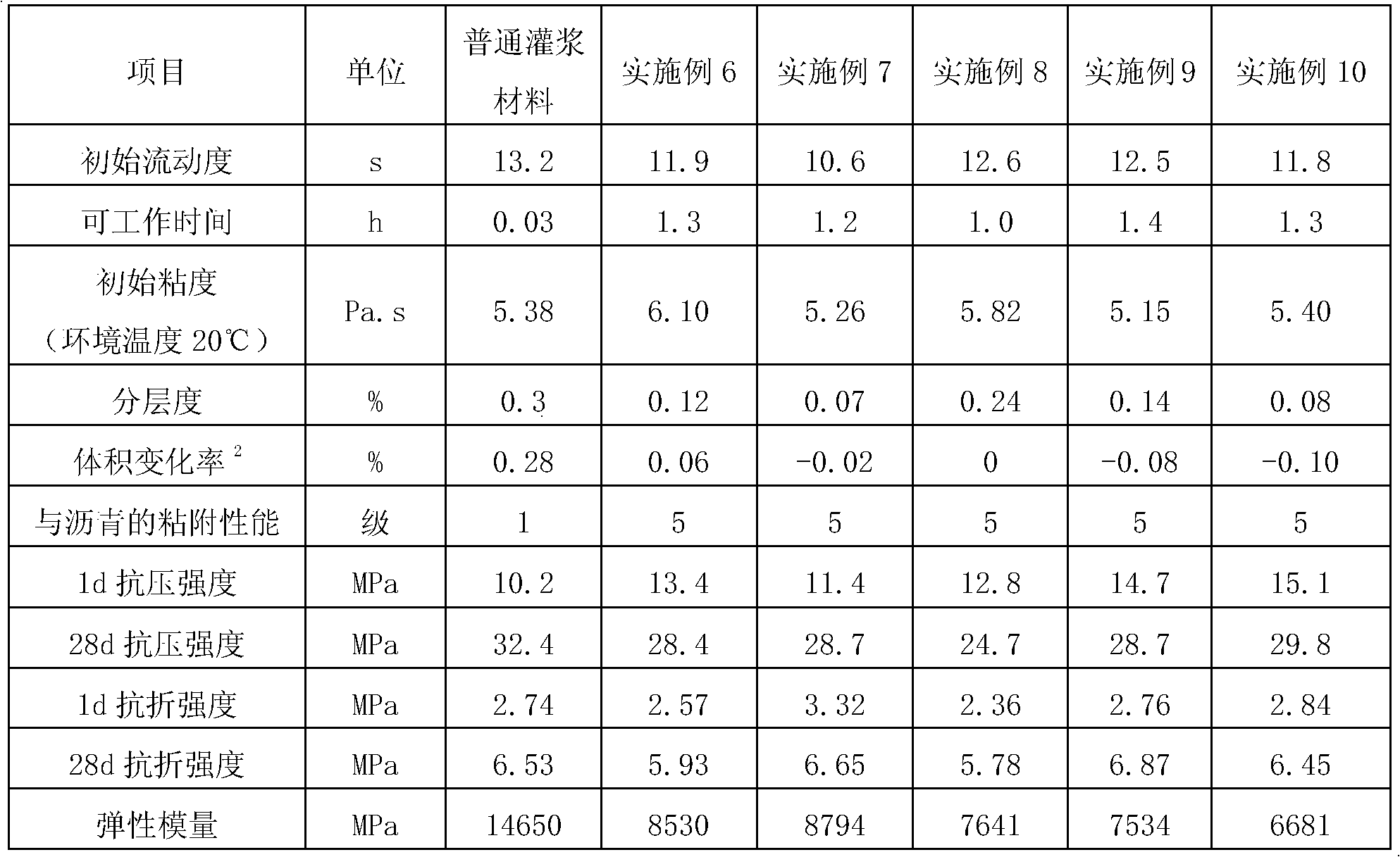

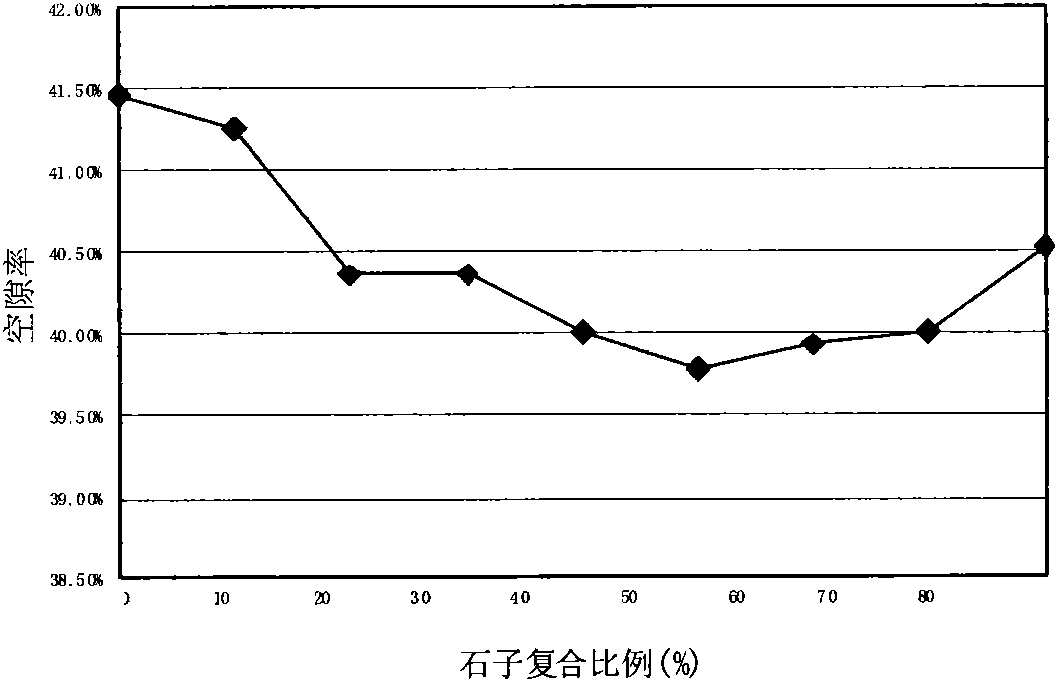

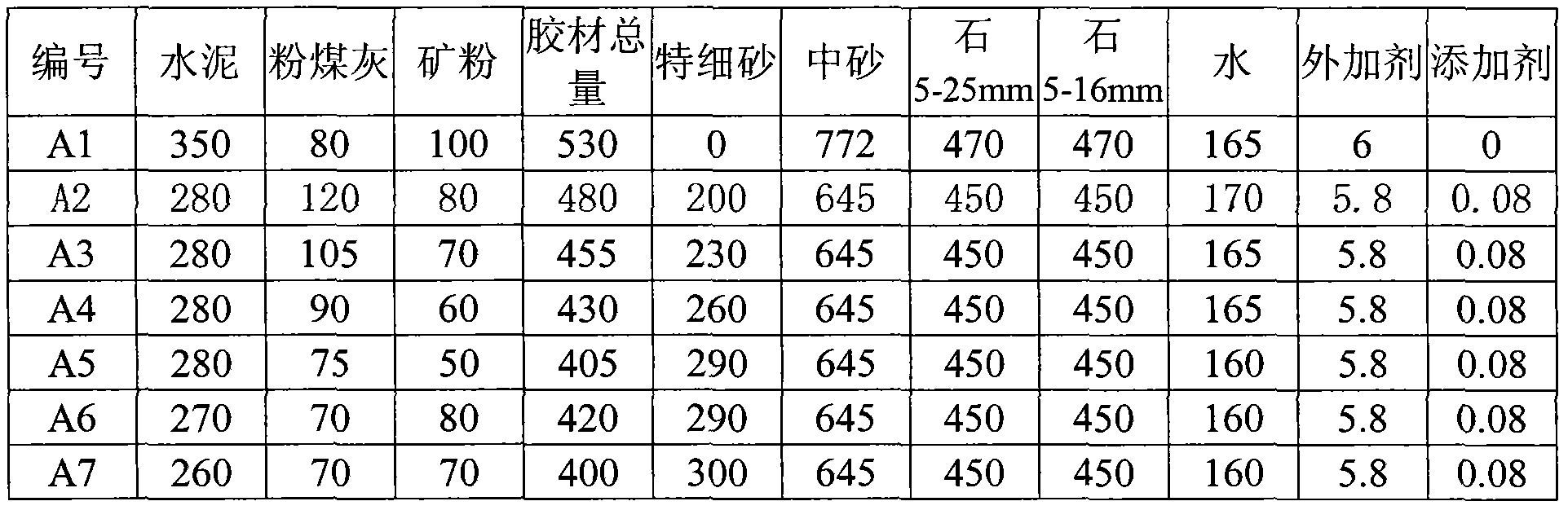

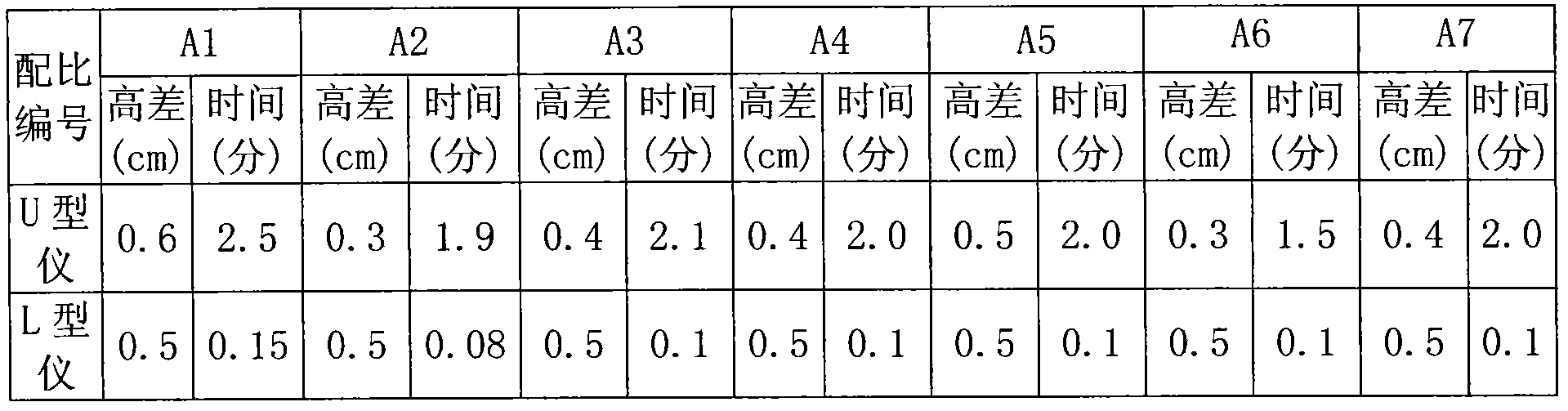

A cement-emulsified asphalt self-permeable grouting material applied to semi-flexible pavement

The invention discloses a cement-emulsified asphalt self-permeable grouting material applied to semi-flexible pavement, which comprises 100 parts of cement, 50-150 parts of mineral admixture, 15-40 parts of expansion agent, 0-80 parts of river sand, 0.5-20 parts of water agent, 60-140 parts of water, and 50-150 parts of emulsified asphalt, all of which are parts by weight. The grouting material of the present invention is low in cost, good in fluidity, long in working time, and satisfies the grouting characteristics of self-permeation of slurry; has good interfacial bonding performance with asphalt, and has a certain early strength function; the volume change rate is small, and the degree of delamination is less than 0.3%, with good volume stability; both cationic emulsified asphalt and anionic emulsified asphalt can be used, with a wide range of applications; applying this grouting material to semi-flexible pavement can greatly improve the fatigue life of flexible pavement The shear performance is effectively improved.

Owner:JIANGSU SUBOTE MATERIAL +4

Low cementitious material self-compacting concrete

ActiveCN102060481AIncrease plastic viscosityIncrease the slurry-solid ratioHigh strength concreteSelf-consolidating concrete

The invention discloses low cementitious material self-compacting concrete. Cement is a main raw material in a cementitious material of the self-compacting concrete; and if the cement consumption is high, overhigh concrete shrinkage is easily caused due to overhigh hydration heat of the cement, which is unfavorable for concrete crack control and concrete durability improvement, and problems such as disintegration, bleeding and the like easily occur. An additive XAMC is added into the concrete formula and can adsorb onto surfaces of particles to form a close adsorption layer so as to prevent the particles from flocculating and aggregating to realize the dispersion and stabilization function. Water-washing superfine sand which is rich in resources replaces partial mineral admixture, the low cementitious material self-compacting concrete can meet the basic requirement of high strength concrete by adding the XAMC under the condition of reducing cement consumption, and has obvious thickening and water retaining functions; concrete mixtures do not bleed or disintegrate, the homogenization and workability of the concrete are improved, and the concrete has important significance for saving energy and reducing emission.

Owner:北京元泰达环保科技有限公司

Ultra-high performance concrete mixed with hybrid fibers

The invention belongs to the technical field of building materials, and particularly relates to ultra-high performance concrete mixed with hybrid fibers. The concrete is prepared from ordinary Portland cement, silica fume, floating bead fly ash, slag powder, HP-CSA, quartz sand, limonite ore, titanium alloy sand, water reducing agent, defoaming agent, steel fiber, basalt fiber, cellulosic fiber and water. The ultra-high performance concrete mixed with the hybrid fibers has the advantages that the problems that the water-binder ratio is low, the usage amount of cementing material is large, andthe incorporation of the high-performance water reducing agent increases the shrinkage of the concrete can be solved, the constraint problem caused by the shrinkage on the application of the ultra-high performance concrete fabricated precast unit can be overcome, and the toughness of products is drastically improved. The ultra-high performance concrete mixed with the hybrid fibers is applicable tovarious concrete projects with special structures such as long span and super high-rise, and is suitable for various types of fabricated buildings.

Owner:TONGJI UNIV

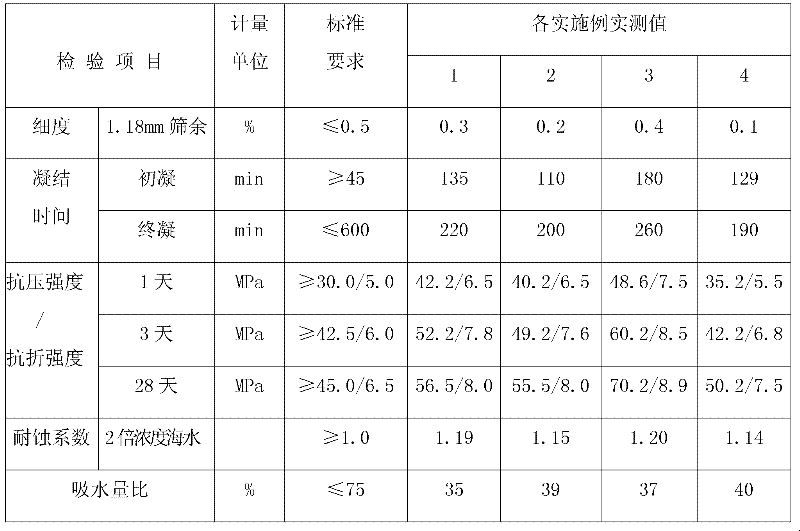

Self-compacting concrete

The invention discloses a self-compacting concrete and belongs to the technical field of concrete. The self-compacting concrete comprises the following components in parts by weight: 350-400 parts of cement, 54-80 parts of coal ash, 52-60 parts of slag powder, 50-62 parts of expanding agent, 9-13 parts of silica powder, 748-800 parts of mixed sand, 948-1020 parts of macadam, 140-165 parts of drinking water, 0-10 parts of compound additive and high-performance additive being 1-2% of the binding material in mass fraction. The concrete acquired according to the invention has excellent self-compacting property, fluidity, collapse prevention, cohesiveness and separation resistance, and meanwhile, a test proves that the compressive strength after 7 days is about 57MPa and the compressive strength after 28 days is about 70MPa, so that the concrete provided by the invention has higher compressive strength.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

Special concrete using waste and old rubber particle and steel slag particle as aggregate

InactiveCN101921087AImprove volume stabilityImprove the natural environmentSolid waste managementSlagRoad surface

The invention provides a special concrete using waste and old rubber particles and steel slag particles as aggregate, which comprises the following components in parts by mass: 100 parts of cement, 0.1-3 parts of water reducing agent, 0-50 parts of mineral admixture, 0-600 parts of sand, 200-400 parts of steel slag particle, 15-50 parts of rubber particle and 20-80 parts of water. The invention has the advantages that the two wastes of the waste and old rubber particles and steel slag are simultaneously added into concrete, the wastes can be greatly utilized, and the natural environment is improved; the expansion stress of free calcium oxide in steel slag is adsorbed by utilizing the elastic characteristic of the waste and old rubber particles, the steel slag can be utilized without special processing, and the integral volume stability of materials is high; by adding the waste and old rubber particles, the elasticity of the special concrete is higher than that of common concrete; and the special concrete can be widely applied to places in which common concrete, such as road surfaces, parking lots, buildings, and the like can be applied.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

High-strength and high performance lightweight aggregate and preparation method thereof

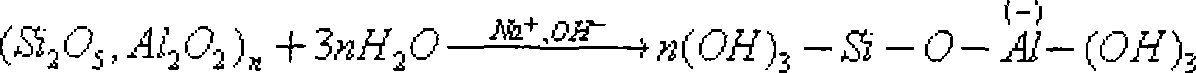

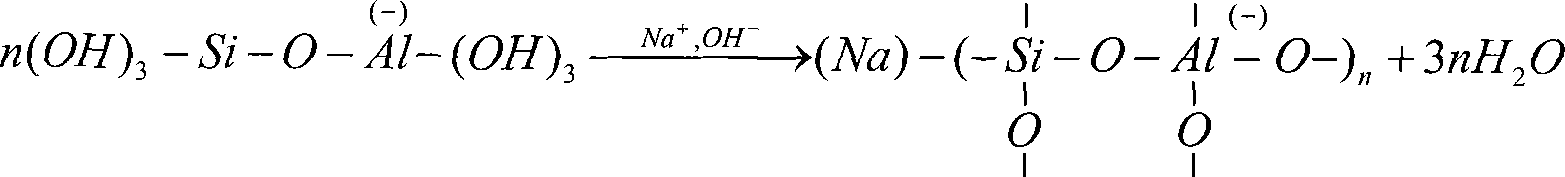

ActiveCN101456708ASimple processReduce manufacturing costSolid waste managementCement productionMetakaolinSlag

The invention belongs to the field of inorganic non-metallic material, and in particular relates to a light aggregate with high strength and high performance and a preparation method thereof. The light aggregate with high strength and high performance is characterized in that the light aggregate is prepared from solid raw materials and water glass solution, and the mass ratio of the water glass solution to the solid raw materials is 0.3-0.8:1, wherein the solid raw materials consist of metakaolin, steel slag, coal ash, mineral slag and foaming agent; each raw material in the solid raw materials by mass percentage comprises: 30 to 99.9 percent of the metakaolin, 0 to 30 percent of the steel slag, 0 to 50 percent of the coal ash, 0 to 70 percent of the mineral slag, and 0.1 to 0.5 percent of the foaming agent; and the sum of the each raw material in the solid raw materials by mass percentage is 100 percent. The method has the advantages of simple process and low production cost; and the light aggregate with high strength and high performance prepared by the method has the characteristic of high cylinder pressing strength.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

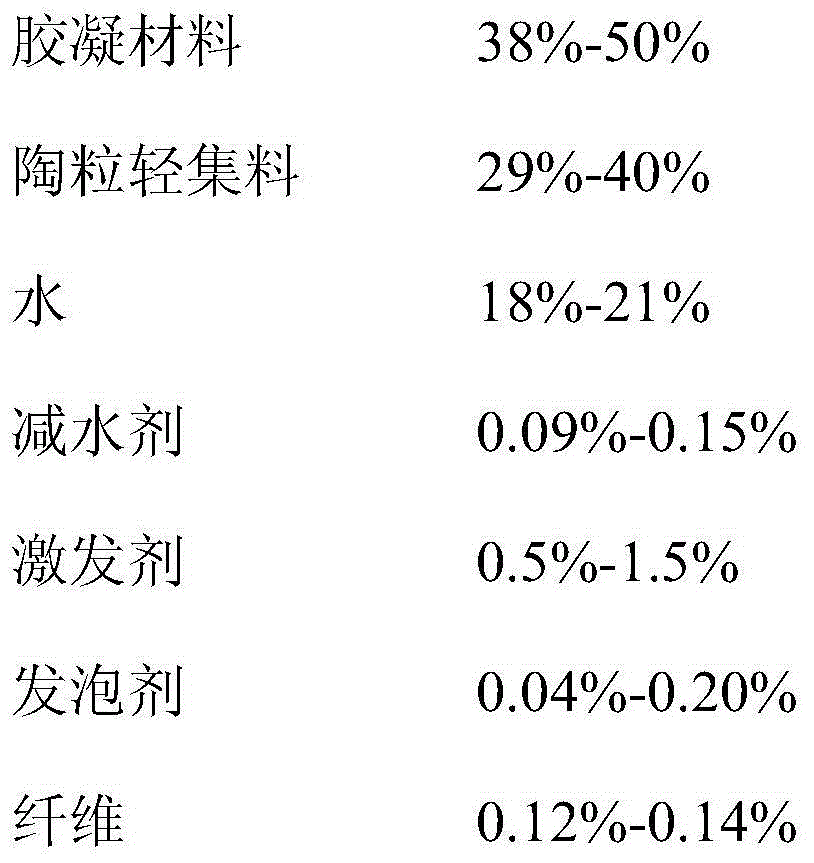

High-volume coal ash ceramsite foam concrete and preparation method thereof

The invention provides a preparation method of high-volume coal ash ceramsite foam concrete. The preparation method of the ceramsite foam concrete comprises the following steps: putting 38%-50% of a binding material, 29%-40% of ceramsite lightweight aggregates, 0.5%-1.5% of an excitant and 0.12%-0.14% of a fiber into a stirrer, and stirring evenly; simultaneously adding 0.04%-0.20% of a foaming agent and foam which is formed by a part of water in a foaming machine and has the particle sizes of 50-1,000mu m, the residual water and 0.09%-0.15% of a water reducer into the stirrer, and stirring with powder evenly to form slurry; adding the foam into the slurry, stirring evenly, and then pouring into a mold to mold; and demolding to prepare the ceramsite foam concrete of which the density is 300-800kg / m<3>. According to the formula provided by the invention, low-cost coal ashes are taken as a main raw material, and the material cost is reduced; meanwhile, the volume-weight of the concrete is reduced by adding the ceramsite lightweight aggregates with different particle sizes; and the mechanical strength and the stability of the concrete are effectively improved.

Owner:中冶武汉冶金建筑研究院有限公司

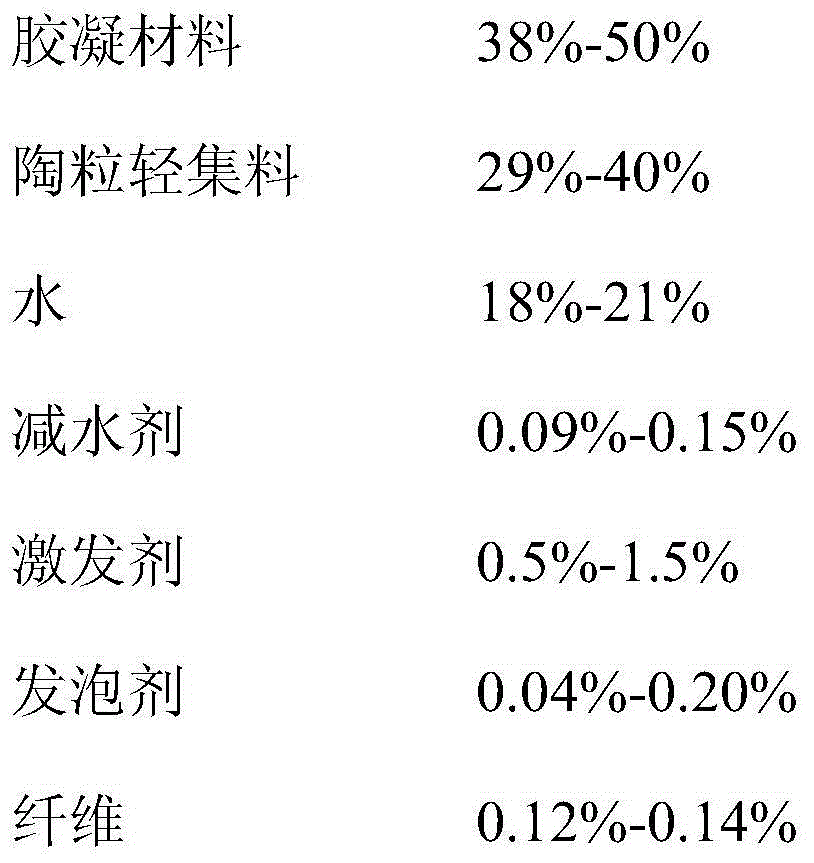

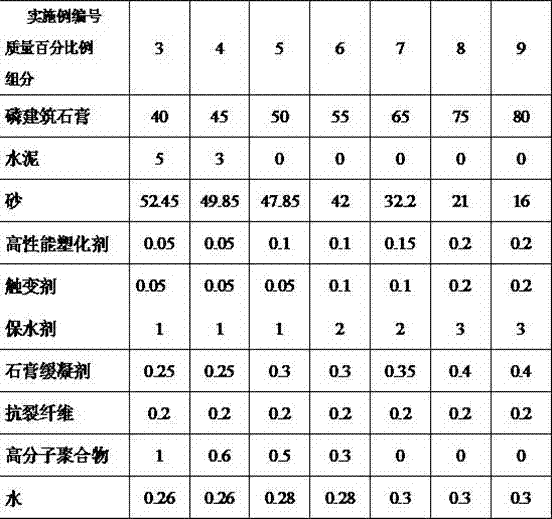

Preparation method of phosphogypsum-based anti-cracking mortar applied to interior insulation of external wall

The invention discloses a preparation method of phosphogypsum-based anti-cracking mortar applied to interior insulation of an external wall. The preparation method is characterized in that the anti-cracking mortar comprises the following components in percentage by mass: 40-80% of building phosphogypsum, 20-50% of dried sand, 0-20% of cement, 0-5% of fly ash, 0-0.2% of a high-performance plasticizer, 0-0.2% of a thixotropic agent, 0.1-0.3% of a water-retaining agent, 0.01-0.4% of a gypsum retarder, 0-3% of a micromolecular polymer and 0-0.25% of anti-cracking fiber. According to the preparation method, the building phosphogypsum prepared by washing and calcining industrial byproduct phosphogypsum is used as a cementing material, so that the problems that a cement-based material is easy to shrink, hollow and crack are solved; through full use of the characteristics of fast setting and hardening, good volume stability and low own ratio of compressive strength to flexural strength of a gypsum material, the anti-cracking mortar, of which the ratio of the compressive strength to the flexural strength is lower than 2.5, the operable time is 1-2h, the final setting time is shorter than 3h, the insulation board bonding strength is higher than 0.10MPa and breakage occurs inside an insulation board, is prepared. The anti-cracking mortar is applied to the interior insulation of the external wall and low in cost, reduces the environment pollution, and is simple in production process, low in energy consumption and good in product performance; compared with other insulation board crack resisting products, the anti-cracking mortar has higher market competitiveness and is strong in practicality.

Owner:四川华邦保和涂料有限公司

High-strength concrete mixed with low-temperature rice husk ash

InactiveCN102643060ASimple preparation processGood working performanceSolid waste managementRiver sandBuilding material

The invention belongs to the technical field of building materials, and particularly relates to high-strength concrete mixed with low-temperature rice husk ash, which comprises ordinary Portland cement, low-temperature rice husk ash, slag powder, coal powder ash, broken stones, river sand, water and water reducer. The low-temperature rice husk ash is prepared by burning rice husks at the lower temperature (600 DEG C) and grinding the burned rice husks. The specific surface area of nitrogen adsorption measurement of the high-strength concrete is 55-70m2 / g, and the high-strength concrete has ultrahigh pozzolanic activity. By means of the high-strength concrete, the problem of rice husk processing can be solved, and the production cost of the high-strength concrete can be reduced. The high-strength concrete has the advantages of high workability, high strength, rapidity in strength development, mechanical property, durability and the like by being prepared from the ordinary Portland cement serving as cementing materials, the low-temperature rice husk ash, the slag powder and the coal powder ash serving as admixture, and the broken stones and the river sand serving as aggregate and the high-efficiency water reducer. Reusability of the rice husks is effectively realized by the aid of the high-strength concrete so that energy saving, emission reduction and environmental protection are achieved. Besides, production cost of the high-strength concrete can be reduced, and economic returns are improved.

Owner:TONGJI UNIV

Geo polymer base composite material double pole plate and its preparing method

InactiveCN101051691AImprove volume stabilityReduce manufacturing costCell electrodesFuel cell detailsFiberCarbon fibers

Characters of bipolar plate of polymer based composite material are that it is produced from materials of Meta kaolin, conductance material, and solution of water glass. The conductance material is composed of graphite and carbon fiber. Doping quantity of graphite is 20-40% of mass of meta kaolin, and doping quantity of carbon fiber is 10-20%. Mass ratio between solution of water glass, meta kaolin, and conductance material 0.4-0.8:1. The said Meta kaolin is obtained by calcinating kaolin in coal series sold on market or pure kaolin at 600-850 deg.C. Modulus m of solution of water glass is equal to 2.8-3.5, and Baume degree is equal to 35-45. Features of the bipolar plate are: low cost, good corrosion resistance, high mechanical strength, light weight, good conductivity, no poison and pollution on fuel cell of proton exchange membrane.

Owner:WUHAN UNIV OF TECH

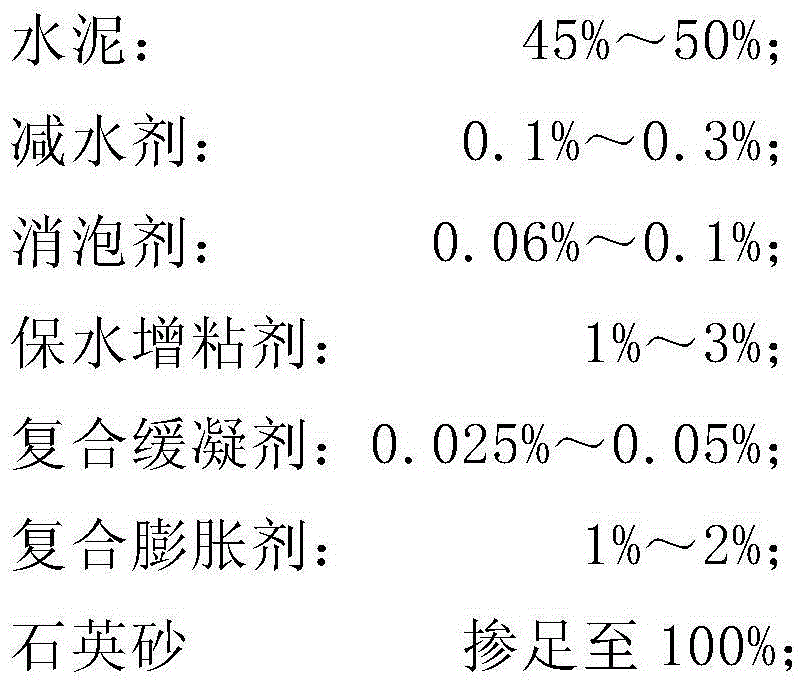

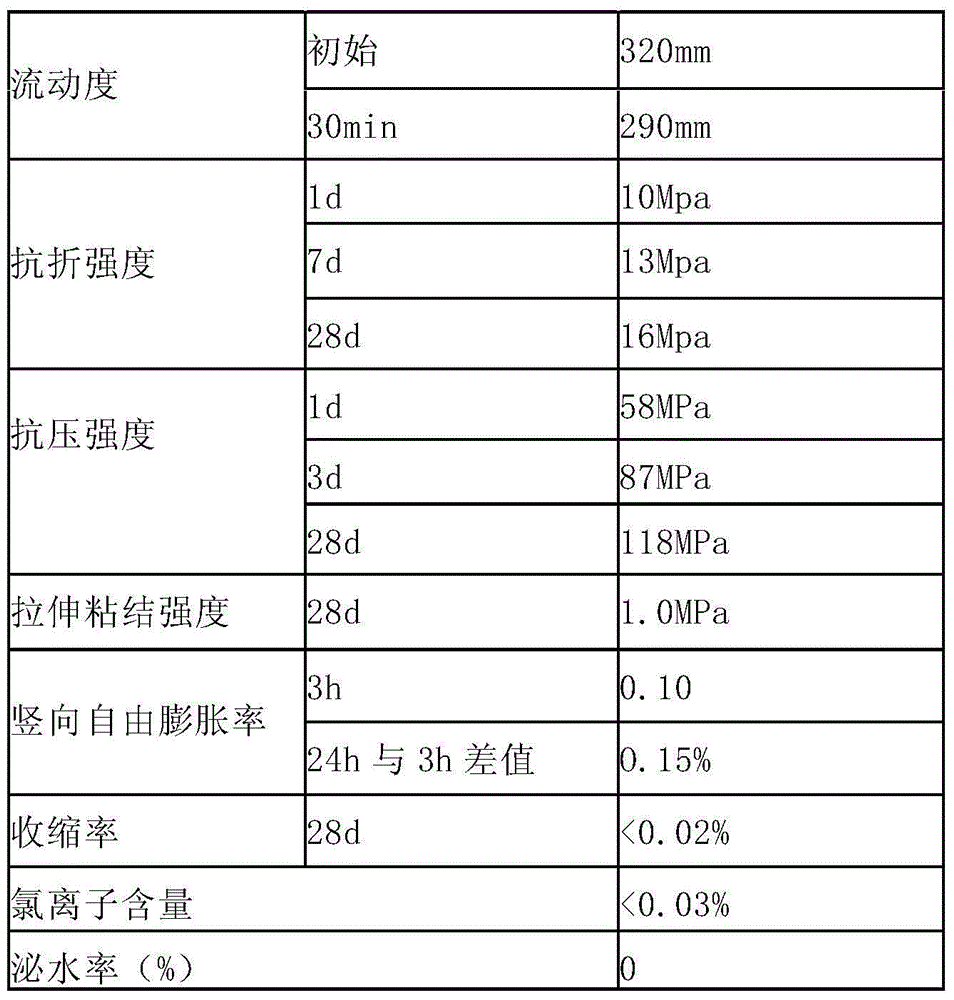

Special high strength grouting material for connecting reinforcement sleeve

The present invention discloses a special high strength grouting material for connecting a reinforcement sleeve. The special high strength grouting material for connecting the reinforcement sleeve comprises grouting material powder and water, wherein the grouting material powder is prepared from the following raw materials in percentage by weight: 45% to 50% of cement, 0.1% to 0.3% of a water reducing agent, 0.06% to 0.1% of a defoamer, 1% to 3% of a water retention tackifier, 0.025% to 0.05% of a composite retarder, 1% to 2% of a composite expansion agent; and and the balance of quartz sand, totalling 100, wherein the mass ratio of the grouting material powder to the water is 1 to (0.23-0.28). The special high strength grouting material for the connecting reinforcement sleeve provided by the present invention has the characteristics of high strength, high adhesion and slight expansion with no shrinkage; the high strength grouting material can be poured into the reinforcement sleeve to enable fixed connection formed between reinforcements and between the reinforcements and the sleeve, and has excellent durability.

Owner:SHANGHAI URBAN CONSTR MATERIAL CO LTD

Geopolymer composite material for 3D printing and preparation method and application thereof

ActiveCN106082898ASave energyEnvironmentally friendlyAdditive manufacturing apparatusSolid waste managementAdditive ingredientSlag

A geopolymer composite material for 3D printing and a preparation method and application thereof are disclosed. The geopolymer composite material comprises the following ingredients (by weight): 20-25% of water-quenched granulated blast furnace slag powder, 10-15% of ground steel slag, 0-5% of fly ash, 33-45% of tailings machine-made sand, 3-5% of a composite activator, 2.5-3% of a high-molecular polymer, 1-3% of a volume stabilizer, 1-2% of a thixotropic agent, 0.05-0.1% of an antifoaming agent and 13.9-12.45% of mixing water. The above ingredients are fully and uniformly stirred and then the mixture is subsequently pumped into a 3D printer for construction. The geopolymer composite material has good caking property, strong stability and has good pump-out morphology maintaining capability and bond property. Printed buildings have good morphology and volume stability, and houses and buildings have good overall stability and use security.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com