Patents

Literature

61 results about "Pozzolanic activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The pozzolanic activity is a measure for the degree of reaction over time or the reaction rate between a pozzolan and Ca²⁺ or calcium hydroxide (Ca(OH)₂) in the presence of water. The rate of the pozzolanic reaction is dependent on the intrinsic characteristics of the pozzolan such as the specific surface area, the chemical composition and the active phase content.

Nano core-shell structure organic-inorganic compound concrete protective agent and preparation method and application thereof

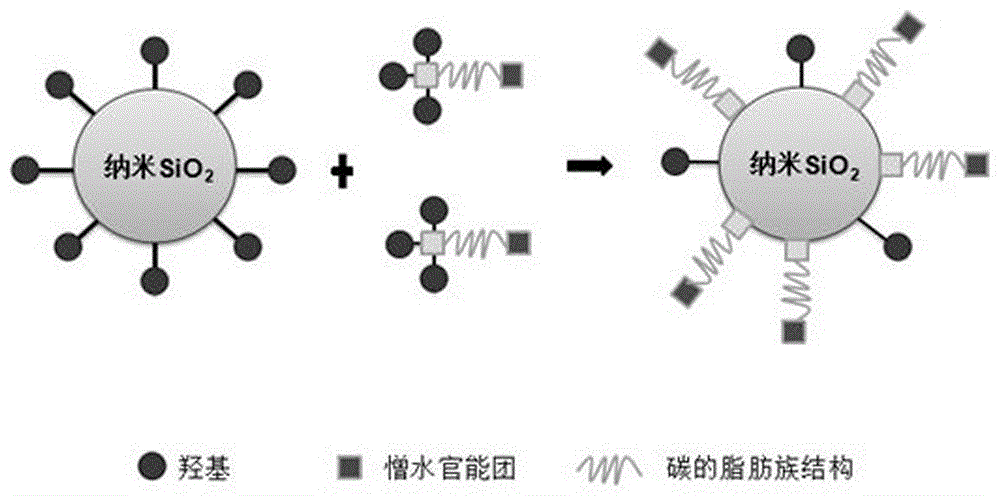

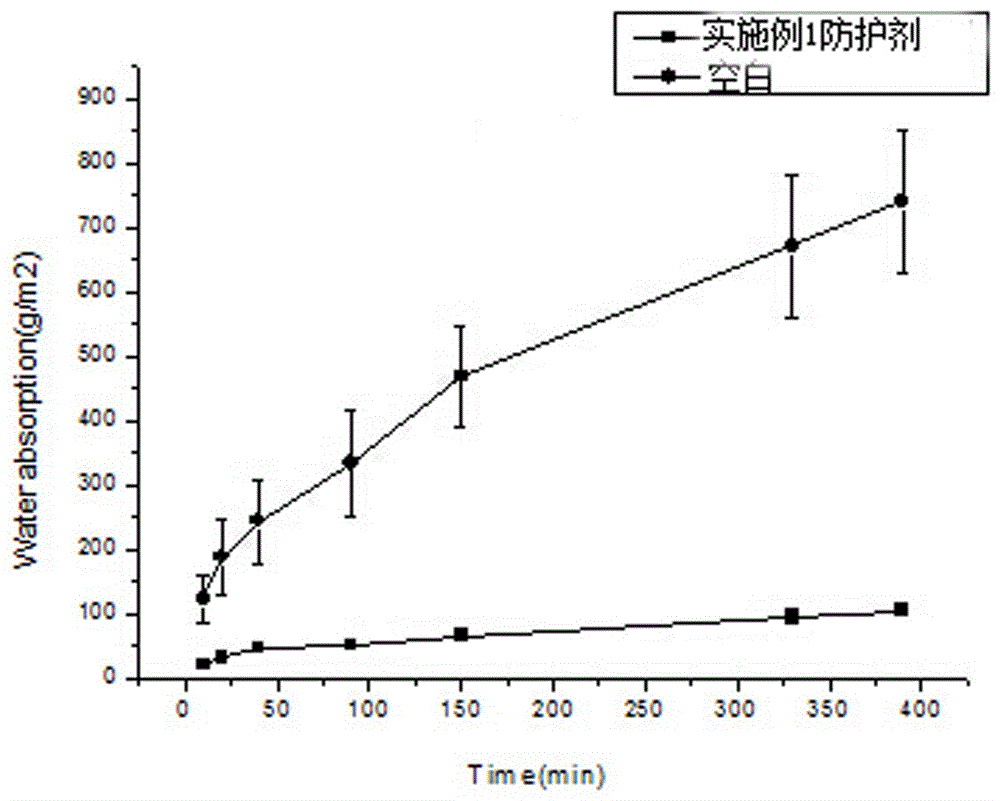

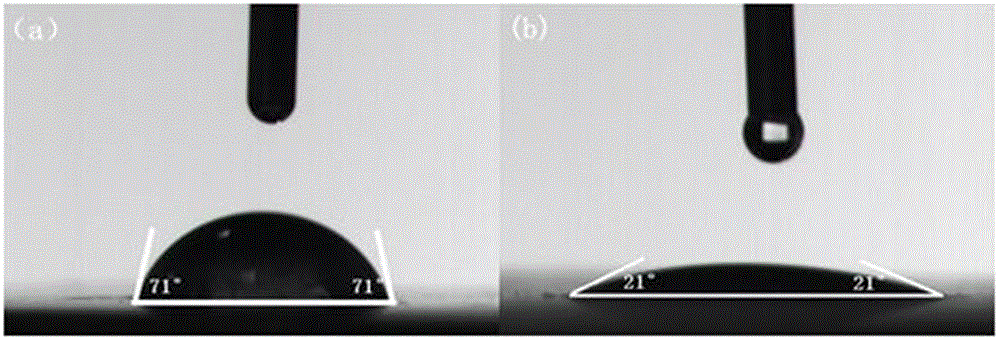

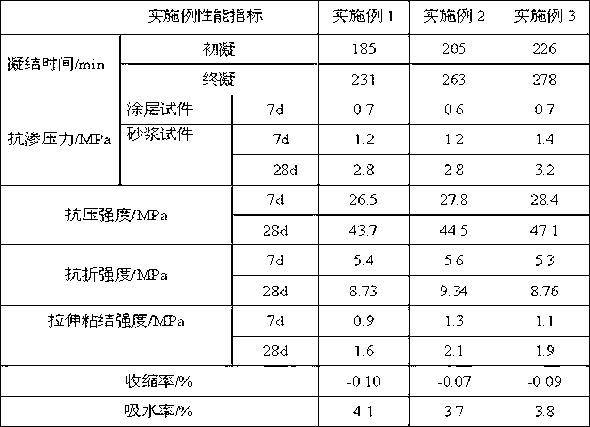

InactiveCN105712740AImprove hydrophobicityPlay the role of plugging the holeHydration reactionTectorial membrane

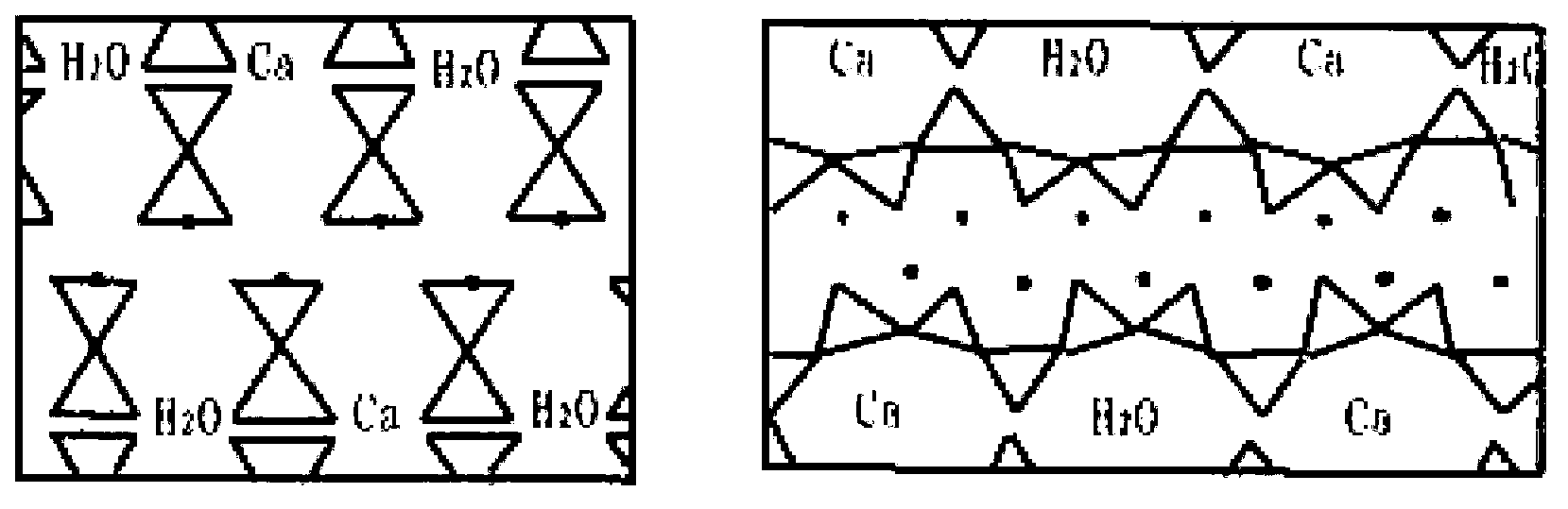

The invention discloses a nano core-shell structure organic-inorganic compound concrete protective agent and a preparation method and application therefore and belongs to the technical field of building materials. A core-shell structure material formed on the surface of nano SiO2 is wrapped in silane molecules, an organic protecting agent and an inorganic protecting agent are effectively combined, and surface layer hardened concrete is protected. The characteristic that an organic material is prone to aging is avoided, preparation and application of the material are separated, precursor hydrolysis time is saved, a dual-protection effect on a concrete structure is achieve, the advantages of the organic material and the inorganic material are integrated, on one hand, silane is laid on the surface of concrete to form a layer of protective film so that a hydrophobic effect can be achieved, and on the other hand, nano SiO2 has high pozzolanic activity and has a hydration reaction with a cement hydration product Ca(OH)2 so that hydrated gel can be generated to make the pore structure compact. The advantages of a good protective effect, easy preparation, easy construction and the like are achieved, and the nano core-shell structure organic-inorganic compound concrete protective agent can be widely applied to the field of concrete engineering.

Owner:UNIV OF JINAN

Mineral powder-doped polymer waterproof mortar and using method thereof

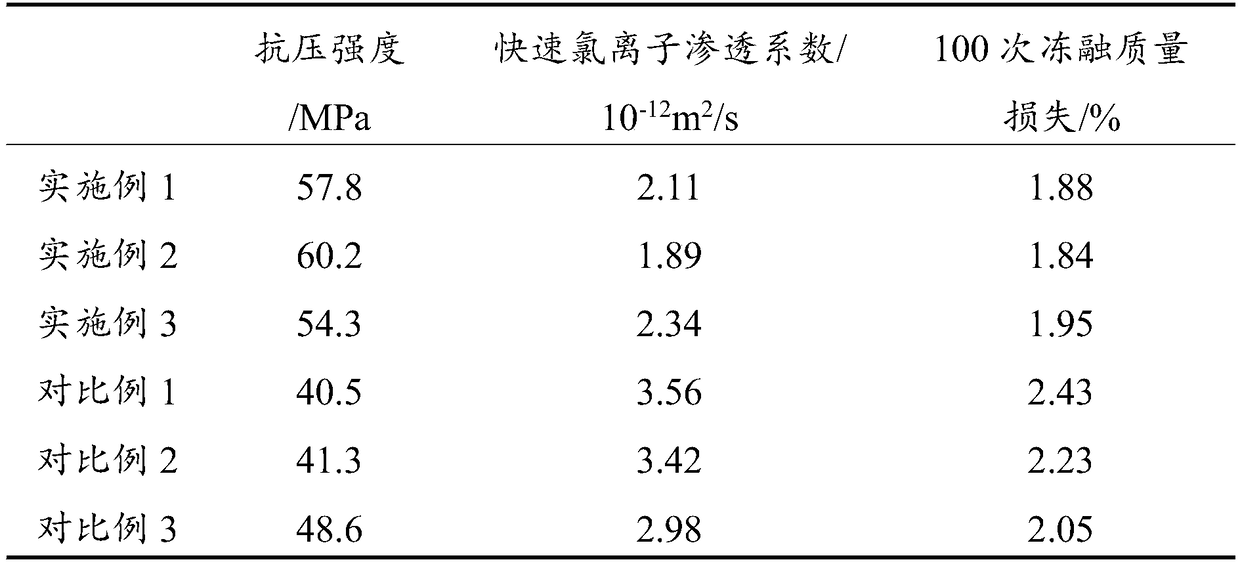

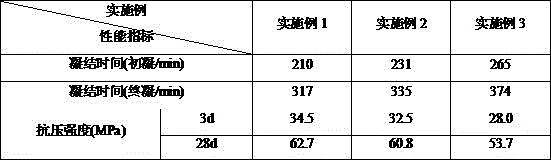

The invention relates to mineral powder-doped polymer waterproof mortar and a using method thereof. The mineral powder-doped polymer waterproof mortar comprises ordinary Portland cement, S95 mineral powder, S105 mineral powder, desulfurized gypsum, river sand, emulsion powder, fibers, a water reducing agent, a deforming agent and bentonite. According to the mineral powder-doped polymer waterproof mortar, the average grain diameter of the S105 mineral powder is 12-17mu m, the specific surface area of the S105 mineral powder, which is determined by a nitrogen adsorption method, is 600-700m<2> / kg, the quality factor K of the S105 mineral powder is 1.9-2.1, the S105 mineral powder has very high gelatinization activity, the gelatinization activity of the S105 mineral powder is nearly equivalent to and even slightly exceeds that of 52.5-grade ordinary Portland cement; and the average grain diameter of the S95 mineral powder is 45-52mu m, the specific surface area of the S95 mineral powder, which is determined by a nitrogen adsorption method, is 300-350m<2> / kg, the quality factor K of the S95 mineral powder is 1.9-2.1, and the S95 mineral powder has high pozzolanic activity. The strength of the motor is not reduced and even is slightly enhanced while the seepage prevention of the product is improved. The mineral powder-doped polymer waterproof mortar has the characteristics of high anti-permeability grade, good caking property, high strength, ageing resistance, alkali resistance, convenience in construction, low cost and the like and is suitable for waterproof treatment of general civil buildings, water resistance, corrosion prevention, seepage prevention and moisture prevention of general air-raid shelters and remediation and strengthening of general engineering.

Owner:TONGJI UNIV

Modified recycled concrete and preparation method thereof

The invention discloses modified recycled concrete and a preparation method thereof. The concrete is prepared from the following raw materials in parts by weight: 100 parts of cement, 235 to 260 partsof recycled aggregate, 145 to 165 parts of sand, 35 to 45 parts of water, 3 to 10 parts of silica fume, 0.5 to 2.5 parts of nano-silica, 0.5 to 2.5 parts of a water reducing agent, and 0.5 to 1.5 parts of cellulose ether. According to the modified recycled concrete and the preparation method thereof, the recycled aggregate is mechanically activated to remove particles and corners which can easilypeel off, so that the performance of the recycled aggregate is improved. Both nano-silica and silica fume have pozzolanic activity, can react with calcium hydroxide produced by cement hydration to form C-S-H gel, and can effectively improve the performance of the recycled aggregate concrete. The raw material components have a synergistic effect, and the obtained concrete has excellent mechanicalproperties and durability.

Owner:YOUNGWOO CHEMTECH

Self-leveling mortar doped with low-temperature rice hull ash

The invention belongs to the technical field of building materials, and particularly relates to self-leveling mortar doped with low-temperature rice hull ash. The self-leveling mortar consists of normal Portland cement, high alumina cement, low-temperature rice hull ash, slag powder, fly ash, river sand, a water reducing agent, a defoaming agent, a stabilizing agent and water. The low-temperaturerice hull ash is formed by burning rice hulls at a low temperature of 600 DEG C and grinding, has a huge surface area and super-high pozzolanic activity. According to a product provided by the invention, the problems of high cost, unsmooth hardened surface, shrinkage and crack of the normal self-leveling mortar can be solved, and meanwhile, the problem of treatment of the agricultural rice hulls can also be solved. The product provided by the invention has the characteristics of high fluidity, quickness in condensation and hardening, high early strength, smooth and flat hardened surface, solidness, wear resistance, small shrinkage, no crack and the like, is suitable for construction of a new floor, can also be used for repairing worn, dusting and damaged floor and can be used for self-leveling of various floor base courses.

Owner:TONGJI UNIV

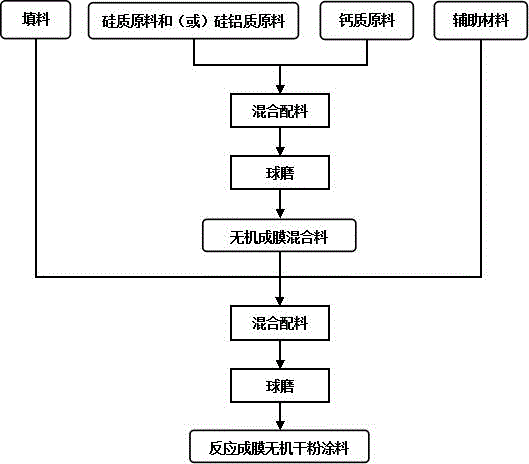

Reaction film formation inorganic dry powder coating material and production method thereof

ActiveCN104927419AShort setting timeImprove early bond strengthCoatingsInvestment materialDrying time

The invention provides a reaction film formation inorganic dry powder coating material and a production method thereof and belongs to the technical field of coating materials. The coating material is composed of, by mass, 20-50% of inorganic film formation material, 20-70% of filler and the balance auxiliary material. The inorganic film formation material is composed of a nano-scale or submicron-scale siliceous material and / or silica-aluminum material with high pozzolanic activity and a calcareous material, wherein the calcareous material has glueyness after being placed in water, the siliceous material and / or silica-aluminum material accounts for 20-50% of the total mass of the inorganic film formation material, and the balance is the calcareous material. Compared with existing coating materials, the coating material has the advantages that painting can be conducted on site after water is added to the coating material and stirred, construction is convenient, water resistance and alkali resistance are excellent, drying time is short, bonding strength is high, and scrub resistance is high.

Owner:WUHAN JIABIYUAN TECH CO LTD

Method for activating waste aerated concrete blocks

InactiveCN102838301ASolve resource reuseSolve stacking problemsCement productionCalcium silicateExperimental methods

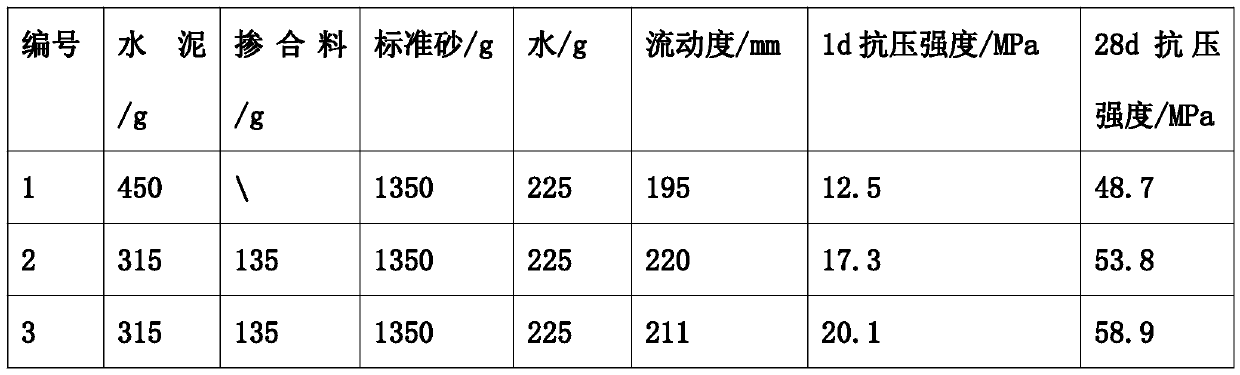

The invention discloses a method for activating waste aerated concrete blocks. The method comprises the following steps of: firstly, breaking the waste aerated concrete blocks to form aerated concrete fragments; burning the aerated concrete fragments, and cooling to normal temperature; and finally arranging the aerated concrete fragments subjected to the treatments in a ball mill and carrying out ball-milling treatment. Main hydrate tobermorite stone calcium silicate hydrate in the activated waste aerated concrete blocks is in an amorphous state and has excellent hydrolyzing property and reacting property. The activated waste aerated concrete is subjected to activity check according to provisions in a 'GB / T 12957-2005 activity experimental method for cement mixing material industrial waste residues', the data show that the activated waste aerated concrete has the activity like a pozzolanic material, the 28-day compression strength can reach about 90% of the standard cement gel sand test block. With the adoption of the method, recycling the waste aerated concrete blocks is realized and the application prospect of the waste aerated concrete blocks is expanded.

Owner:NANJING UNIV OF SCI & TECH

Mixed calcined cement admixture being produced through utilizing papermaking white mud, shale and coal gangue

The invention discloses a mixed calcined cement admixture being produced through utilizing papermaking white mud, shale and coal gangue. The cement admixture is obtained through mixing waste papermaking white mud, shale with rich reserves and coal gangue with low prices according to a certain ratio, aging, forming, drying, calcining and cooling. The pozzolanic activity of the cement admixture is equivalent to that of second-level pulverized fuel ash, and the cement admixture can be used for partially or completely substituting for pulverized fuel ash or other cement admixtures. According to the mixed calcined cement admixture produced through solid wastes of the papermaking white mud and the like, the cement performance is improved, energy is saved, emission is reduced, wastes are turned into wealth, the environmental protection is benefited, moreover, the cement admixture is low in production cost and considerable in profit, the increasing shortage situation of the cement admixture can also be relieved, and obvious social benefit and economic benefit are obtained.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Waste brick and tile recovery device for constructional engineering

The invention discloses a waste brick and tile recovery device for constructional engineering. The waste brick and tile recovery device for constructional engineering comprises a recovery tank body, afirst filtering screen, a second filtering screen and a collecting box body. A feeding inlet is installed above the recovery tank body. The first filtering screen is installed at the bottom of a smashing cavity, and the outer sides of breaking plates and hydraulic cylinders are connected with each other through piston rods. Object placement plates are welded to the left side and the right side ofthe recovery tank body, the second filtering screen is installed below the first filtering screen, the outer sides of grinding rollers are connected with motors in a rotating mode through rotating shafts, and a sliding groove is formed in the front surface of the recovery tank body. Clamping combination plates are fixedly arranged at the front end and the rear end of each grinding roller, and thecollecting box body is installed below the second filtering screen. By the adoption of the waste brick and tile recovery device for constructional engineering, waste bricks and tiles can be smashed and ground before the waste bricks and tiles are recovered, after the waste bricks and tiles are ground to form powder, the waste bricks and tiles have the pozzolanic activity and can serve as the concrete admixture to be used, and therefore resource recycling is achieved.

Owner:WUHU TIANMENG INFORMATION TECH CO LTD

Composite binding material doped with low-temperature burned clay and preparation method of composite binding material

The invention belongs to the technical field of building materials and particularly relates to a composite binding material doped with low-temperature burned clay and a preparation method of the composite binding material. The composite binding material comprises Portland cement, low-temperature burned clay, slag powder, coal ash, gypsum and an expanding agent, wherein the low-temperature burned clay is coal series kaolinite burned at the temperature of 550-600 DEG C and has very high pozzolanic activity. According to the composite binding material, the preparation process is simple, and a large amount of industrial waste can be utilized, so that the pressures of insufficient quantity and non-uniform distribution of slag powder and coal ash can be relieved, meanwhile, the proportion of mixed materials in the binding material can be increased, the proportion of cement can be decreased, and purposes of saving energy and reducing consumption are achieved; and the composite binding material can be used for preparing building mortar, pavement cushions, aerated concrete, mass concrete and the like, and therefore, the cost is lowered.

Owner:TONGJI UNIV

Hydrophobic foam concrete and preparation method thereof

The invention discloses hydrophobic foam concrete and a preparation method thereof. The concrete comprises cement, phosphorus slag powder, fly ash, phosphogypsum, modified gel and other components, wherein both the phosphorus slag powder and the fly ash contain a large amount of vitreous bodies and have high pozzolanic activity; the phosphorus slag powder, the fly ash and the phosphogypsum have density smaller than the density of the cement and can replace part of the cement to reduce mass of the concrete and facilitate lightening of the concrete; the particle distribution of each component isdifferent, and the particles with different gradations are beneficial to the increase of the compactness of the concrete. The process is reasonable in design and simple to operate. In the technical scheme, the silicon dioxide aerogel is optimized and modified to prepare the modified hydrophobic silica gel, then a fiber compound is added, the strength of the foam concrete is improved, finally, a surfactant is prepared to conduct surface treatment on the concrete, and the prepared foam concrete is excellent in hydrophobic property, excellent in mechanical property and high in practicability.

Owner:卢加贵

Concrete admixture based on iron tailing powder and preparation method of concrete admixture

The invention discloses a concrete admixture based on iron tailing powder and a preparation method of the concrete admixture. The concrete admixture is prepared from the following components specifically in percentage by weight: 59.7% of the iron tailing powder and natural gypsum, 25% of level-I coal powder ashes, 15% of S105 mineral powder, and 0.3% of a liquid functional conditioning agent. Irontailings used are prepared from the following components in percentage by weight: 62.13% of SiO2, 5.12% of CaO, 4.36% of MgO, 10.23% of Fe2O3 and 9.65% of Al2O3. According to the concrete admixture based on the iron tailing powder and the preparation method of the concrete admixture, through certain activating treatment, the pozzolanic activity of the iron tailings is shown, the iron tailings andother mineral admixtures are compounded in proportion to produce a synergistic effect, the different mineral admixtures are made to exert respective advantages, the effect of complementary to each other is reached, the iron tailings can be developed to be the concrete admixture, then the additional value of the iron tailings is improved, and the cost of cement concrete is further lowered.

Owner:江苏金木土科技有限公司

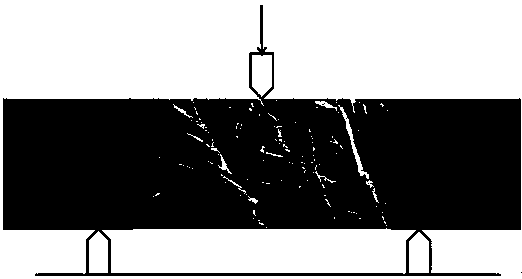

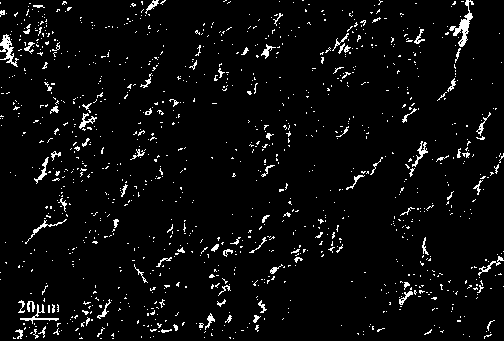

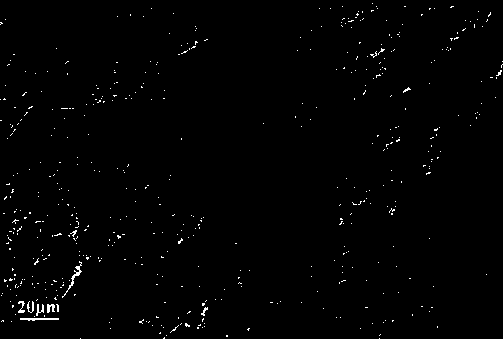

Composite modified concrete and testing method of interfacial transition zone of composite modified concrete

ActiveCN108609952AHigh activityMake up for the lack of early activitySolid waste managementMaterial strength using tensile/compressive forcesMechanical propertyMaterials science

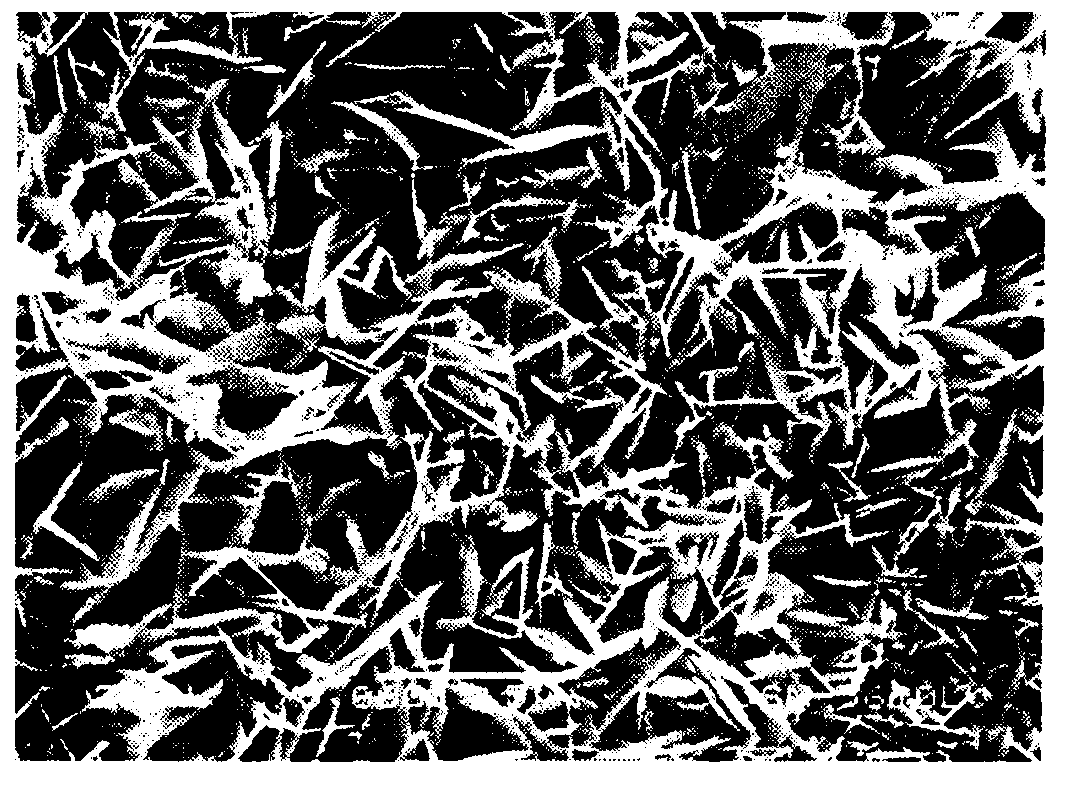

The invention discloses a testing method of an interfacial transition zone of composite modified concrete, and relates to the field of building materials. The composite modified concrete is characterized by comprising the raw materials in parts by weight: 100 parts of cement, 240 to 260 parts of pebbles, 150 to 170 parts of sands, 35 to 45 parts of water, 20 to 30 parts of fly ash, 3 to 12 parts of silicon ash, 0.5 to 2 parts of nanometer materials, and 0.5 to 1.5 parts of a high-effect water reducing agent. According to the method, calcium hydroxide enriched in the interfacial transition zoneof composite modified concrete is properly absorbed through synergism of the nanometer materials and the silicon ash with grain composition and pozzolanic activity, so that C-S-H gel with better adhesive property is produced; in addition, gaps in the interfacial transition zone are properly filled with optimized grain composition, so that the interfacial transition zone of composite modified concrete is effectively improved. Cases prove that the method can effectively improve the bonding strength of the interfacial transition zone and ensure that the interfacial transition zone is dense, thereby improving the mechanical property and chloride penetration resistance property of the concrete.

Owner:UNIV OF JINAN

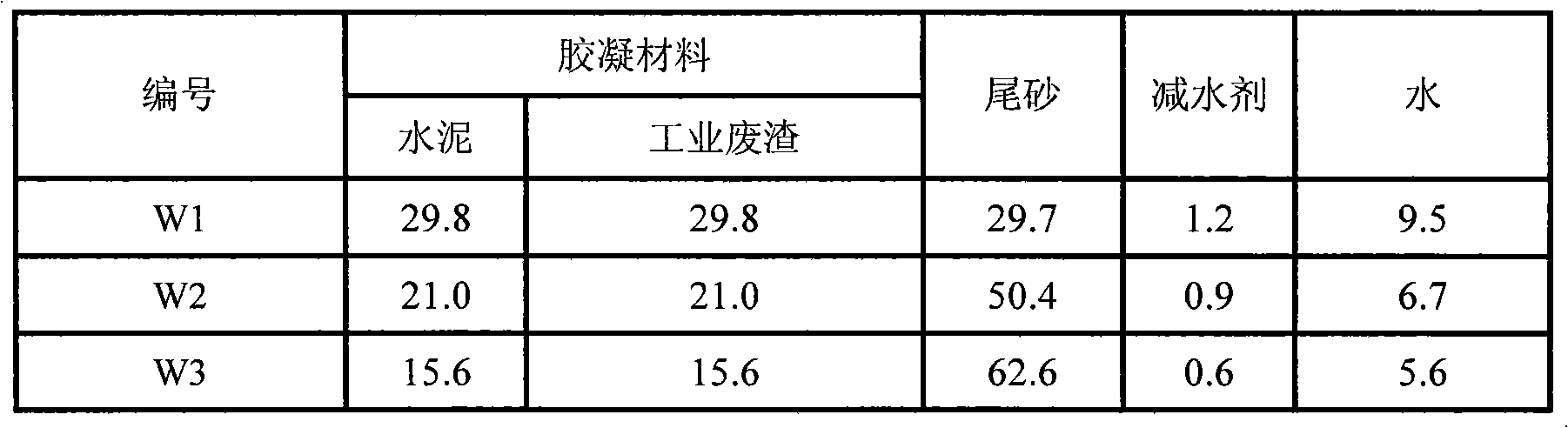

Concrete material by using tail sand to displace yellow sand and preparation method thereof

The invention discloses a concrete material by using tail sand to displace yellow sand and a preparation method thereof. The concrete material comprises the following raw materials: cement, industrial waste residue, water reducing agent, tail sand, water and reinforced fiber, wherein the industrial waste residue is one or two or more of silica fume, fly ash, fine slag powder, fine steel slag powder and other industrial byproducts with pozzolanic activity; the tail sand is the byproducts of the mining industry, with the maximum grain size of 3mm, namely the solid wastes of all types of mining enterprises. The preparation method disclosed by the invention is the improvement on preparation of common concrete; the prepared concrete product has good performances; and tail sand is fully utilized and the material and the method disclosed by the invention is environment-friendly.

Owner:NANJING UNIV OF SCI & TECH

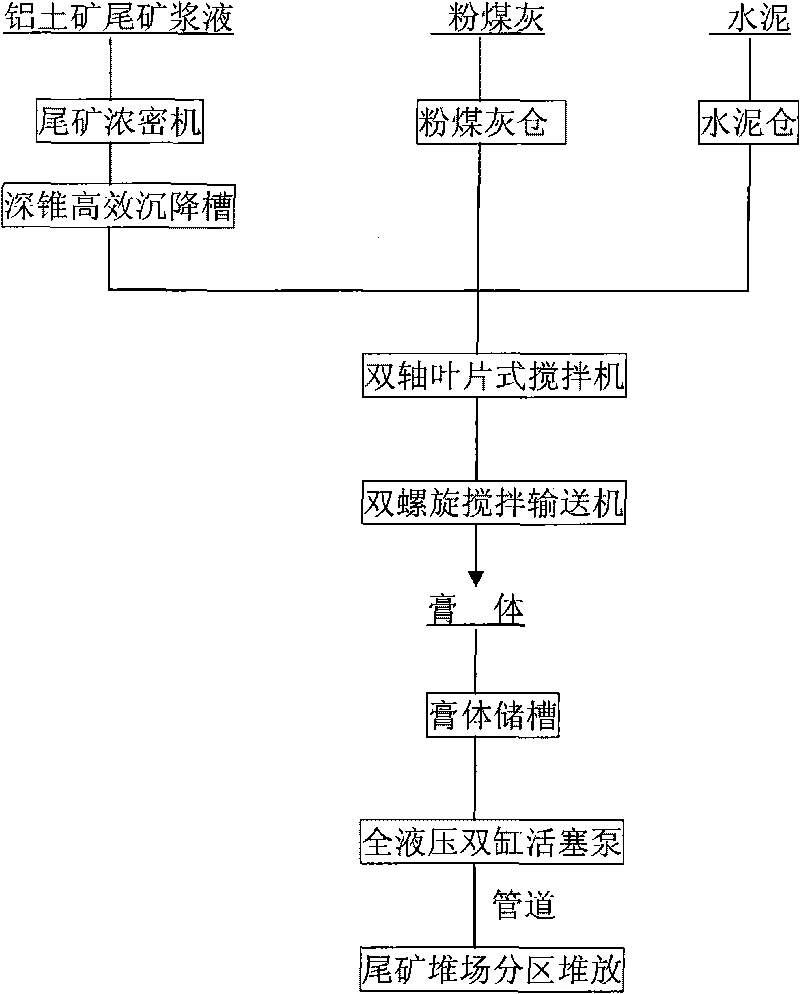

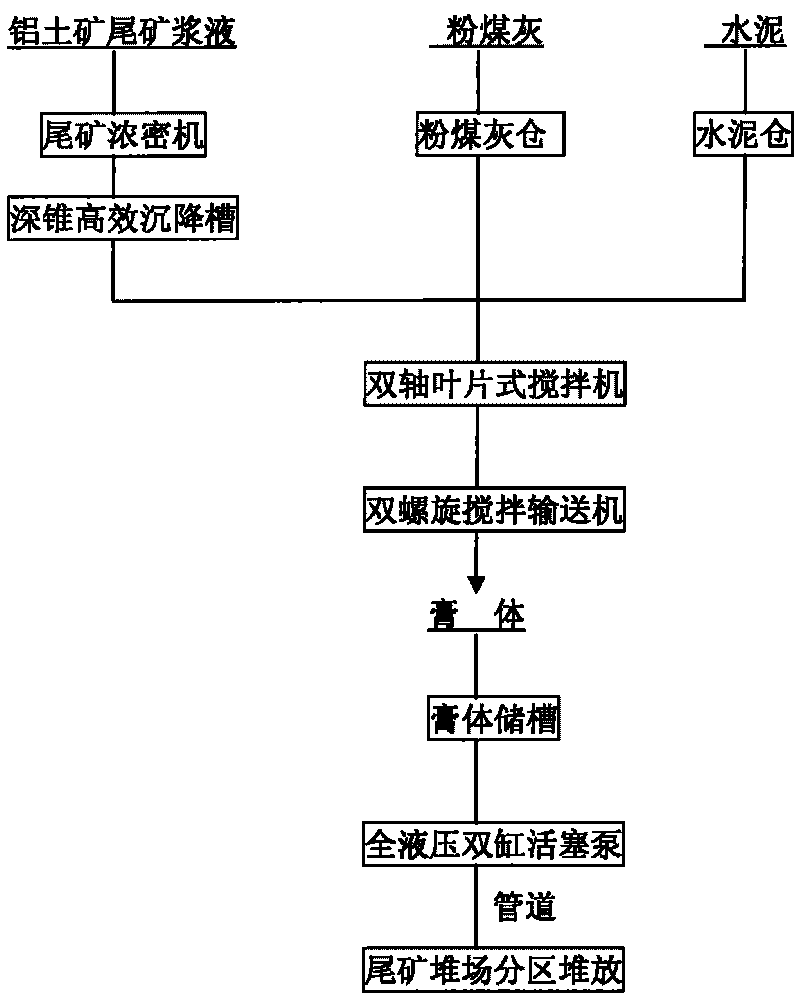

Method for stockpiling tailings from beneficiated bauxite

InactiveCN101700523ALarge-scale industrial production is easy to achieveLow running costSolid waste disposalVolcanoMaterials science

The invention relates to a method for stockpiling tailings from beneficiated bauxite, belonging to the method for stockpiling tailings from washed bauxite or beneficiated bauxite or the method for stockpiling tailings from beneficiated metal or beneficiated nonmetal. The method for stockpiling tailings from the beneficiated bauxite is characterized in that after the pulp of the tailings from the beneficiated bauxite is concentrated until the weight concentration of the solid reach 40-55 percent in the process of stockpiling the tailings from the beneficiated bauxite, base stock and gelatinous activator which have the pozzolanic activity or the latent hydraulicity are added to the pulp of the tailings from the beneficiated bauxite, then mixed with the same, and strongly stirred to the same to prepare the uniform paste with the weight concentration of the solid being 40-60 percent and the collapse degree being 20-28 cm, and the paste is transported to a stockpiling yard to be coagulated into a harden stockpiled body. The practice proves that the method for stockpiling tailings from the beneficiated bauxite is easy to realize the large-scale industrial production and has low operating cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

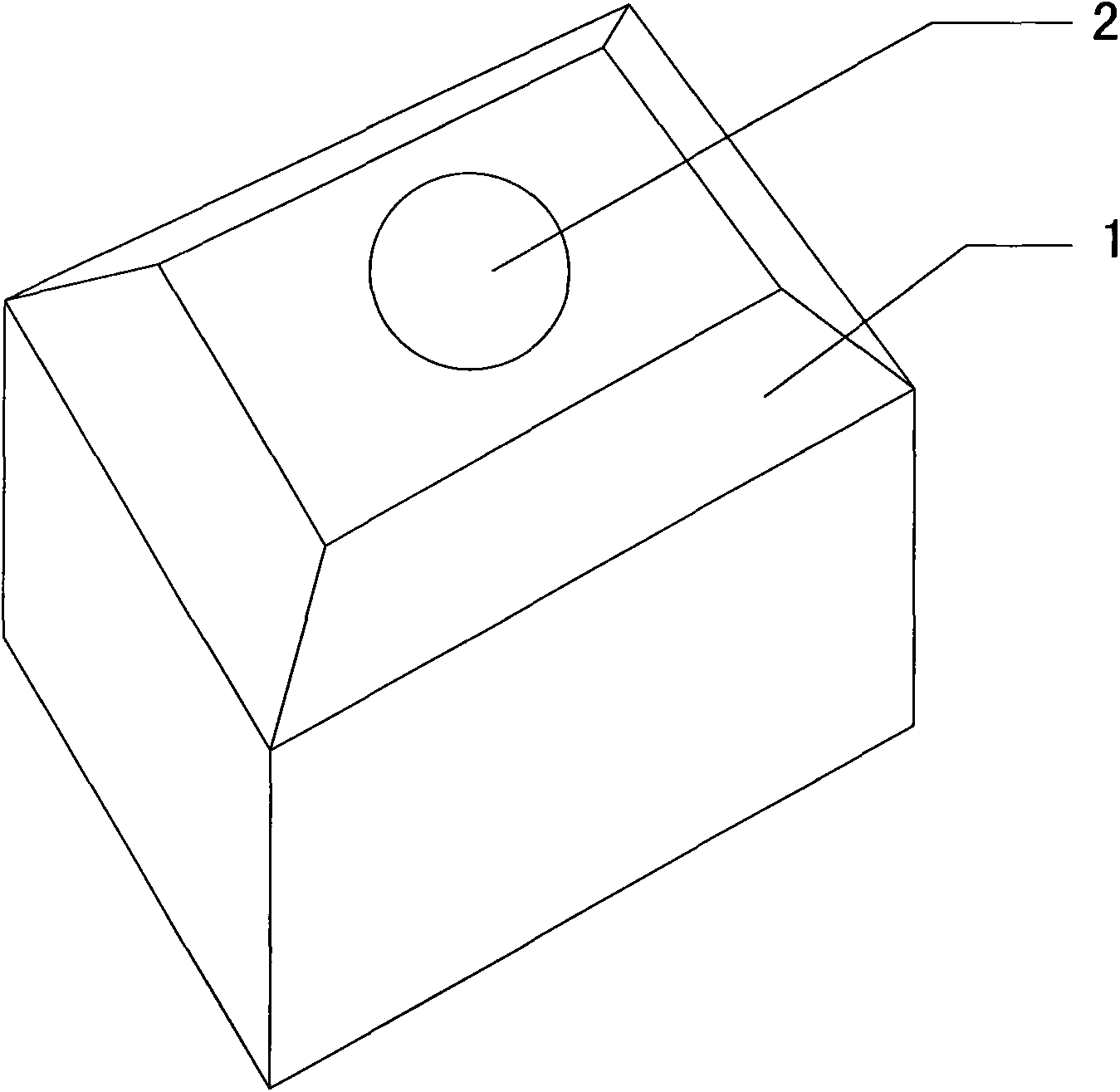

GRC inorganic non-combustible composite material lightweight box

The invention discloses the technical field of building materials, particularly relates to a GRC inorganic non-combustible composite material lightweight box, and more particularly provides an inorganic non-combustible composite material lightweight box that is light in weight, high in strength, not liable to damage, high in fireproof degree, molded in one body with a cast-in-place concrete structure, free of construction joints, beautiful and good in sound-insulation, anti-drop and anti-seepage effects. The box comprises a main box body. The main box body is formed by mold internal casting and molding with glass fibre reinforced concrete or formed by casting plates and joining. The glass fibre reinforced concrete comprises 20-30% by mass of cement, 20-25% by mass of sand, 25-30% by mass of ground perlite, 15-20% by mass of water, and 1-2% by mass of glass fiber, with the balance being polymers, additives or a pozzolanic active material.

Owner:李召水

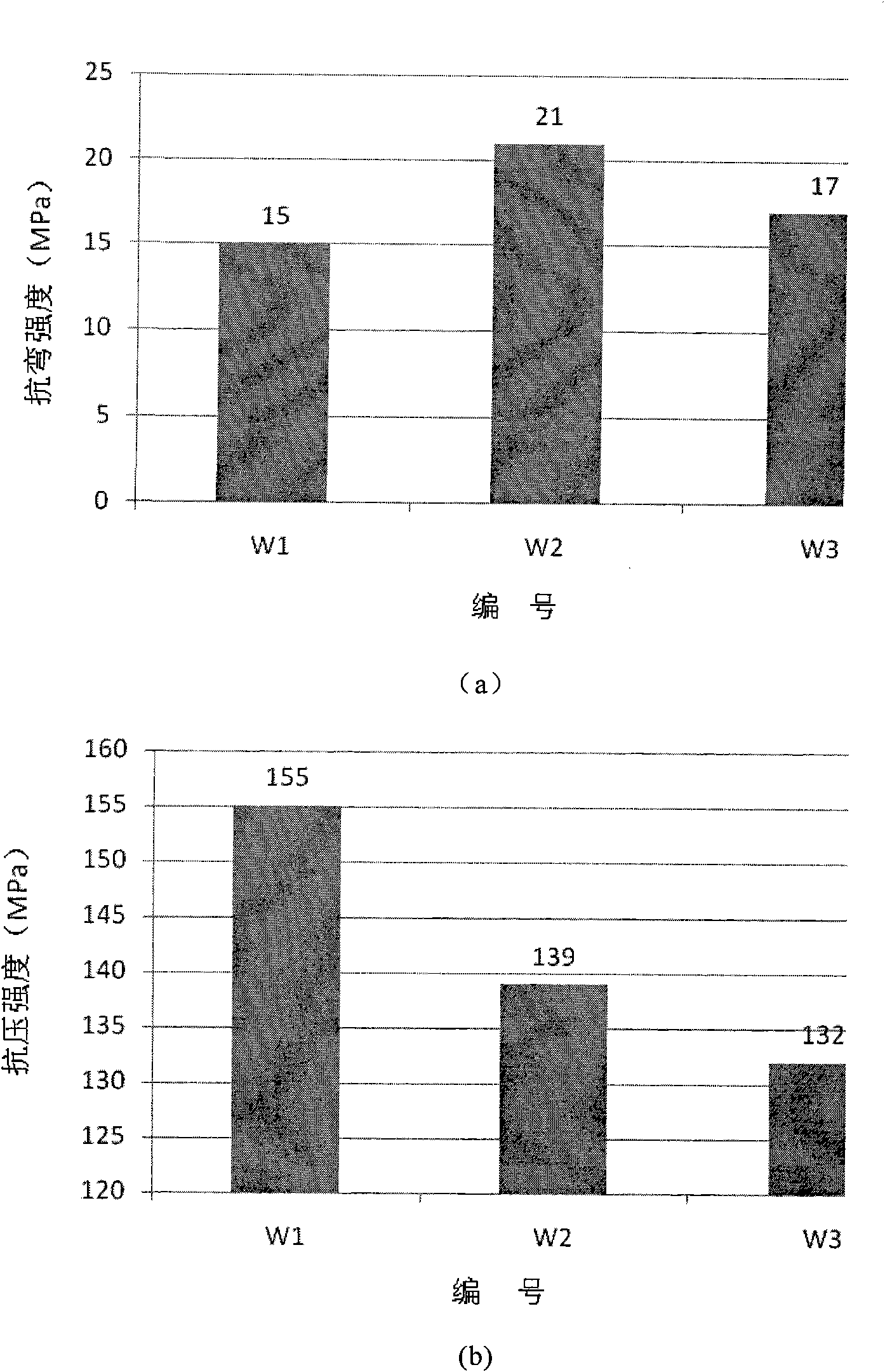

UHPC with high-volume mixed ceramic tile aggregate C160 and preparation method thereof

The invention discloses UHPC with high-volume mixed ceramic tile aggregate C160 and a preparation method thereof. The UHPC is prepared from the following components in percentage by weight: 757.5 kg / m<3> of cement, 151.4 kg / m<3> of silica fume, 37.9 kg / m<3> of fly ash, 151.0 kg / m<3> of ceramic tile powder, 46.4 kg / m<3> of a high efficiency water reducing agent, 212.2 kg / m<3> of aggregate, 848.6 kg / m<3> of quartz sand, 189.3 kg / m<3> of water and 156 kg / m<3> of steel fiber. The invention further discloses a preparation method of the UHPC. A curing method comprises the following steps: tightly wrapping a concrete test block with wet cotton cloth, and performing high-frequency intermittent watering curing or curing in water. The curing system is simplified, and evaporation of water in concretecan also be effectively prevented. The UHPC has the following technical advantages: waste ceramic tiles are recycled, consumption of natural materials is reduced, and effects of energy conservation and environmental protection are achieved; the ceramic tile powder has pozzolanic activity, and improves strength, durability, cracking resistance and flexural strength of the concrete. The ceramic tile powder with different particle sizes is added to fill gaps accumulated between quartz sand, so that the structure is more compact; the water-binder ratio and the high-efficiency water reducing agentare preferably selected, and the UHPC has the advantage of self-compacting.

Owner:XIANGTAN UNIV

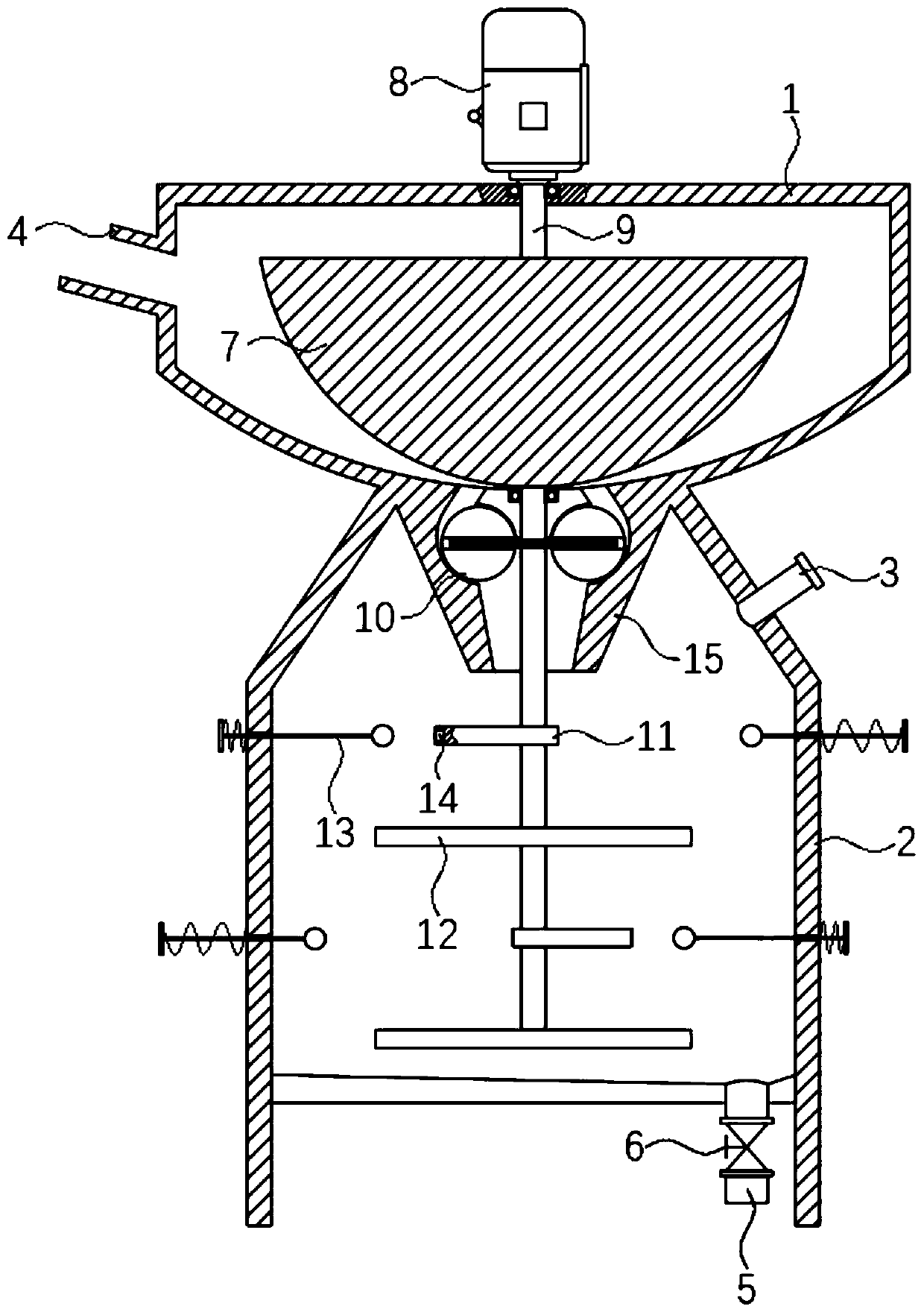

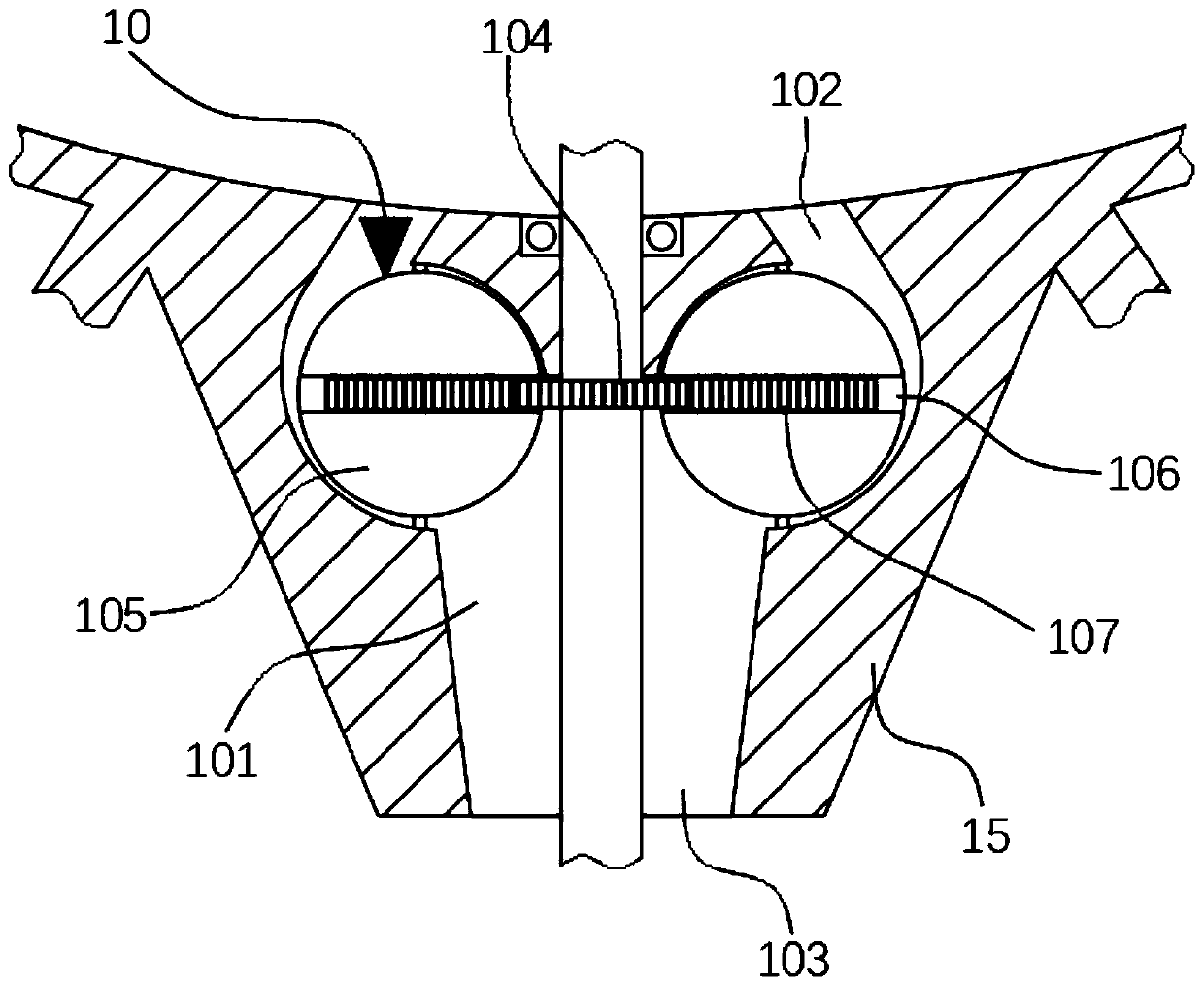

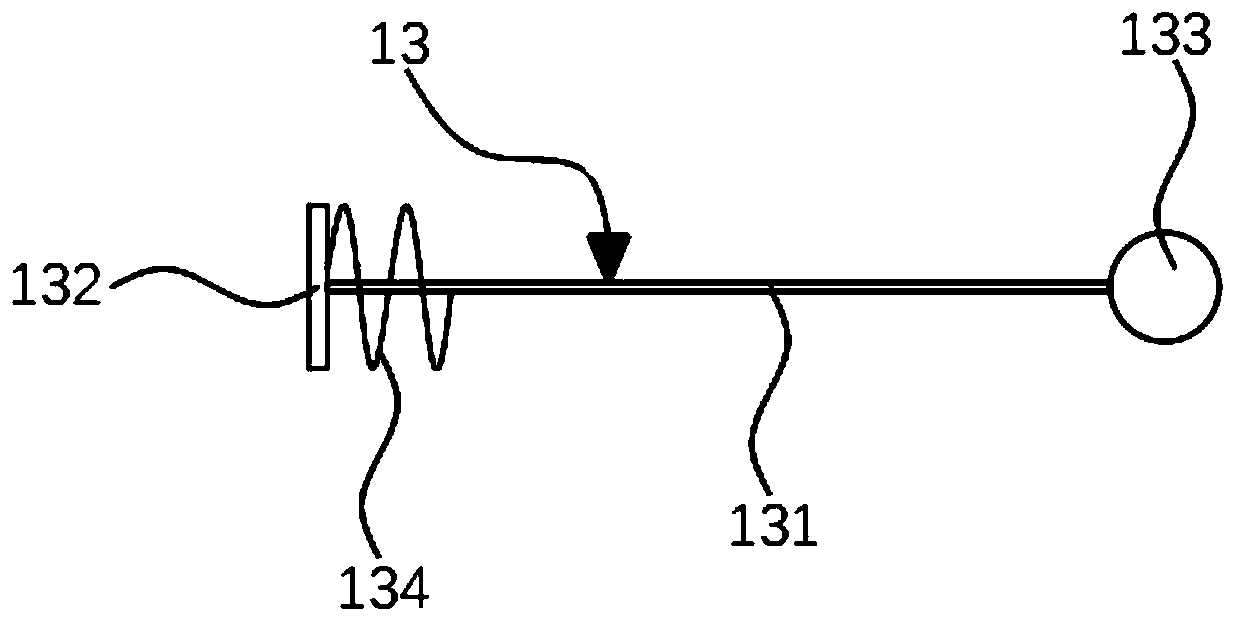

Phosphorus slag-based concrete and preparation equipment thereof

The invention discloses phosphorus slag-based concrete and preparation equipment thereof. The phosphorus slag-based concrete is prepared from the following materials in percentage by mass: 20 to 40 percent of modified phosphorus slag powder, 10 to 20 percent of pulverized fuel ash, 20 to 40 percent of cement, 5 to 15 percent of ardealite, 1 to 3 percent of an additive and the balance of slag sand,wherein the additive is prepared from one or several of sodium aluminate, sodium sulfate and sodium silicate. The phosphorus slag-based concrete disclosed by the invention has the following advantages that the phosphorus slag powder and the pulverized fuel ash contain a large amount of glass bodies and have higher pozzolanic activity, and the activity of the pulverized fuel ash is higher than that of the phosphorus slag powder; the density of the phosphorus slag powder, the pulverized fuel ash and the ardealite is smaller than that of the cement, and mixing of the phosphorus slag powder, thepulverized fuel ash and the ardealite is beneficial for lightening of concrete; the water demand of the phosphorus slag powder, the pulverized fuel ash and the ardealite is lower than that of the cement when the fluidity degrees are the same, and the using amount of water can be reduced under the situation that the flowing property is unchanged; granules are different in distribution, most of thegranules is in normal distribution, and the granules in different levels are beneficial for increasing the compactness of the concrete.

Owner:重庆砼磊混凝土有限公司

Method for preparing steam-curing building block through wet-milling waste glass

ActiveCN106587816AGive full play to the activity of volcanic ashAvoid reunion effectCeramicwareSludgeSlurry

The invention relates to a method for preparing a steam-curing building block through wet-milling waste glass. The method comprises the following steps of feeding 50 to 70 parts by weight of waste glass and 10 to 20 parts by weight of acetylene sludge into a crushing machine for crushing, then feeding into a wet type ball mill, adding water according to the proportion of 0.4 to 0.6 of weight ratio of water to material, and then adding 0.5 part of grinding aid for ball milling to obtain a slurry; and placing the slurry in a stirring machine, adding 4 to 6 parts of cement, 20 to 30 parts of coal ash, 2 to 5 parts of excitant and 1 to 2 parts of admixture for stirring and forming, carrying out four stages of standing, warming, keeping constant temperature and cooling, and obtaining the building block through steam curing. According to the method for preparing the steam-curing building block through the wet-milling waste glass provided by the invention, waste glass powder is refined through a wet-milling process, and the pozzolanic activity of the waste glass powder is fully played, so that the building block can be prepared by adopting a non-steam process, the energy consumption is low, the production cost is low, and the maintenance period can be shortened; the coal ash and the acetylene sludge are added, so that the prepared building block has excellent performances; and a large number of wastes are utilized, so that the solid waste utilization rate is improved.

Owner:HUBEI UNIV OF TECH

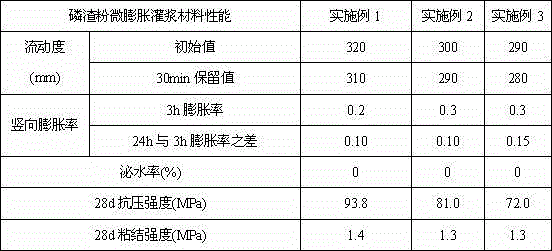

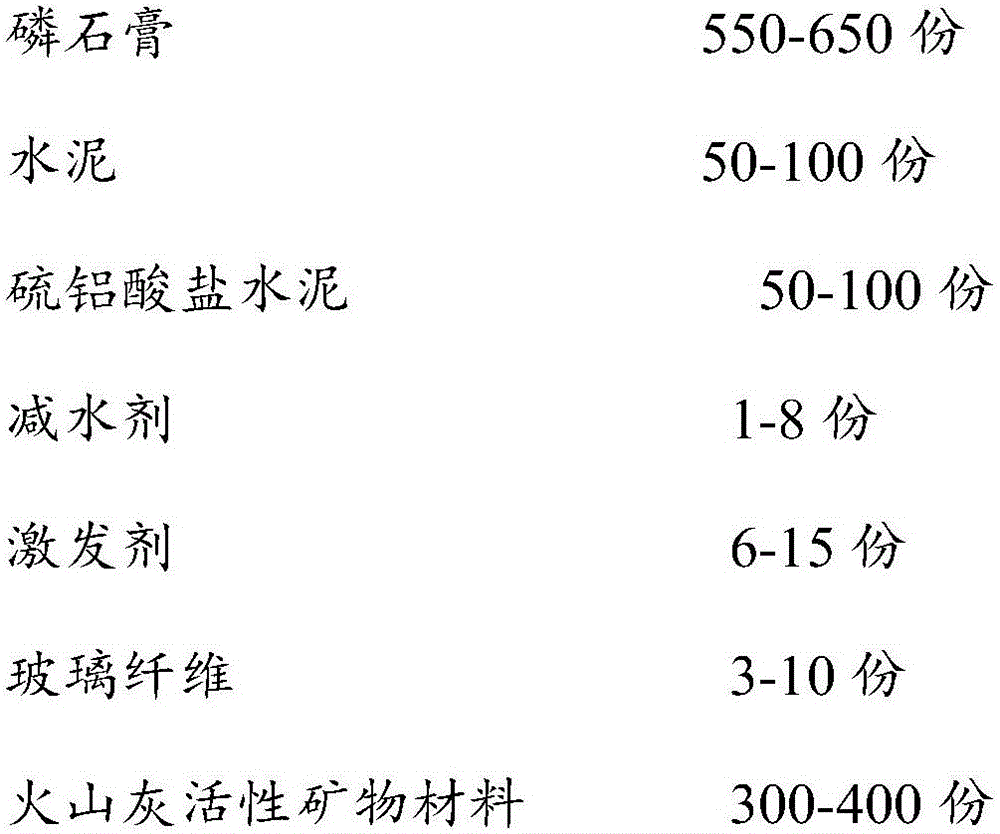

Micro-expansion phosphorus slag powder grouting material and using method thereof

InactiveCN104803646AReduce water consumptionImproved rheological propertiesCrack resistanceWater reducer

The invention belongs to the technical field of building materials, and particularly relates to a micro-expansion phosphorus slag powder grouting material and a using method thereof. The material is prepared from Portland cement, river sand, phosphorous slag powder, slag powder, a phosphorus slag powder activator, calcined magnesium oxide, lipid membrane calcium oxide, polypropylene fibers, wood fibers, modified attapulgite, an antifoaming agent and a water reducing agent. The average particle size of the phosphorous slag powder is in a range of 30-40 mu m, the specific surface area measured through nitrogen absorption is in a range of 350-400 m<2> / kg, the quality factor K is in a range of 1.3-1.4, and the phosphorus slag powder has certain potential pozzolanic activity. The micro-expansion phosphorus slag powder grouting material can be used after directly and evenly mixed with water in a construction site and has the characteristics of good liquidity, good water retention property, certain plastic expansion, high strength, micro-expansion, good crack resistance and the like. The product is applicable to secondary grouting of equipment installation foundations, reinforcement grouting of connecting positions of prefabricated reinforced concrete boards and beam columns and the like.

Owner:TONGJI UNIV

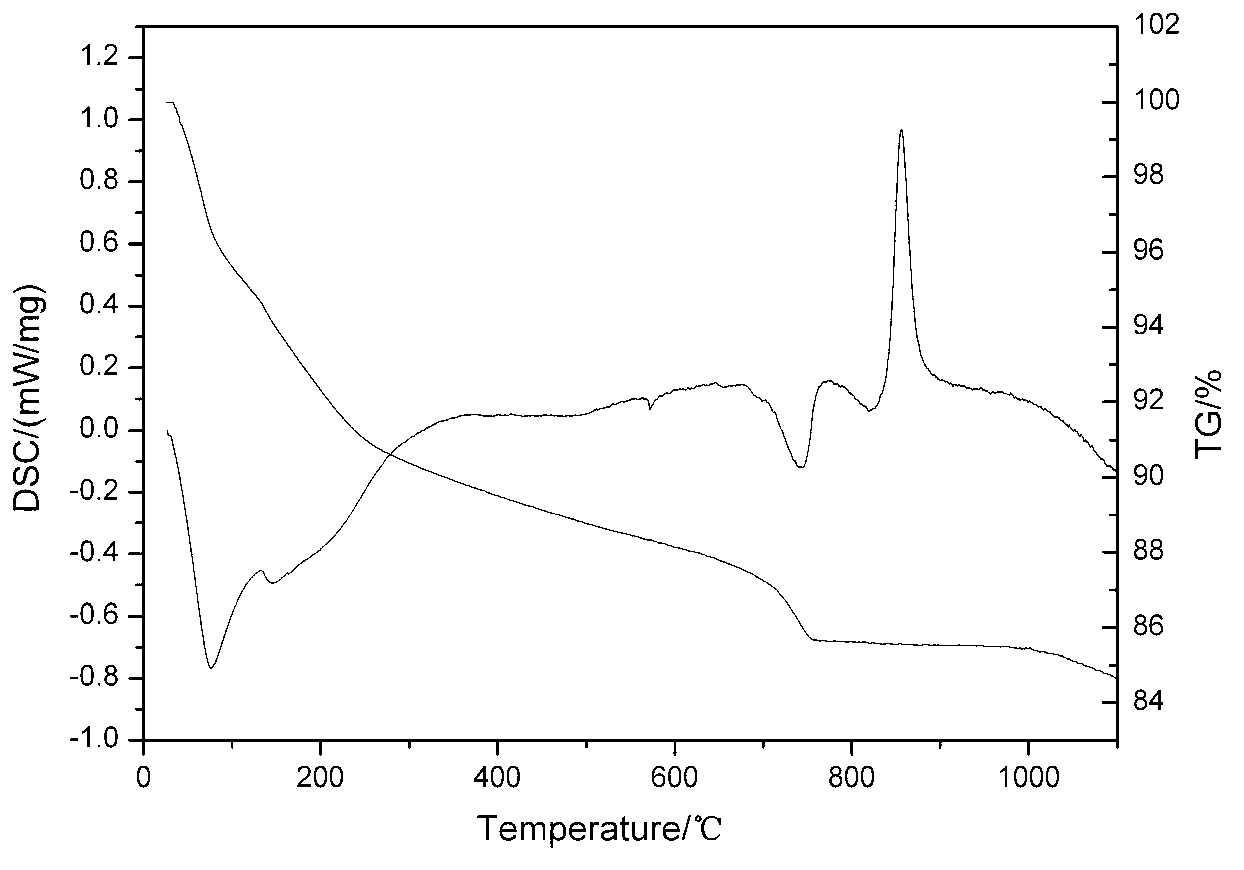

Preparation method of high-activity spherical calcined coal gangue powder

The invention discloses a method for producing a high-activity spherical calcined coal gangue powder by jointly adopting an airflow crushing-radio frequency plasma technology. The method comprises the following steps: crushing coal gangue into certain particles through an airflow crushing system to obtain ultrafine powder, and carrying out plasma high-temperature treatment on the ultrafine powder through a radio frequency plasma system to obtain the calcined coal gangue powder with high activity and high sphericity rate. The airflow crushing and calcining of the coal gangue form an integrated process flow, the energy consumption can be obviously reduced, the prepared calcined coal gangue powder has very high pozzolanic activity, the spherical particle morphology is also beneficial to reducing the water demand, and the technical effect is obvious.

Owner:FUZHOU UNIV

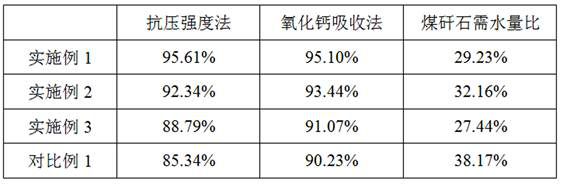

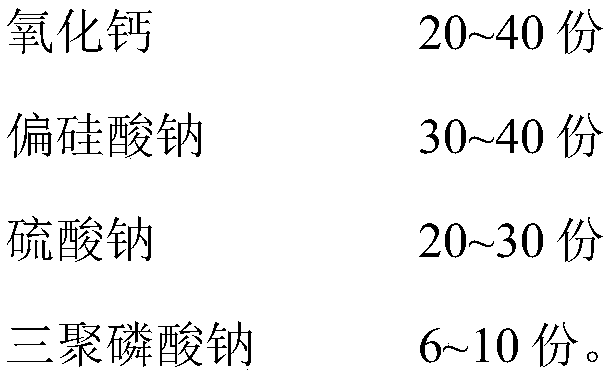

Efficient activating agent for waste copper tailings and preparation method thereof

The invention provides an efficient activating agent for waste copper tailings. The efficient activating agent is prepared by mixing the following components in parts by weight: 20-40 parts of calciumoxide, 30-40 parts of sodium metasilicate, 20-30 parts of sodium sulfate, and 6-10 parts of sodium tripolyphosphate. With the adoption of the activating agent, the pozzolanic activity of the waste copper tailing powder can be obviously improved; 1-2% of the activating agent is doped in the waste copper tailings and capable of increasing the pozzolanic activity by 35-75%, so that the technical problems of treating and recycling the waste copper tailings can be solved. The invention also provides a method for preparing the efficient activating agent for the waste copper tailings.

Owner:江西万铜环保材料有限公司

Method for preparing volcanic ash active material from building residue soil

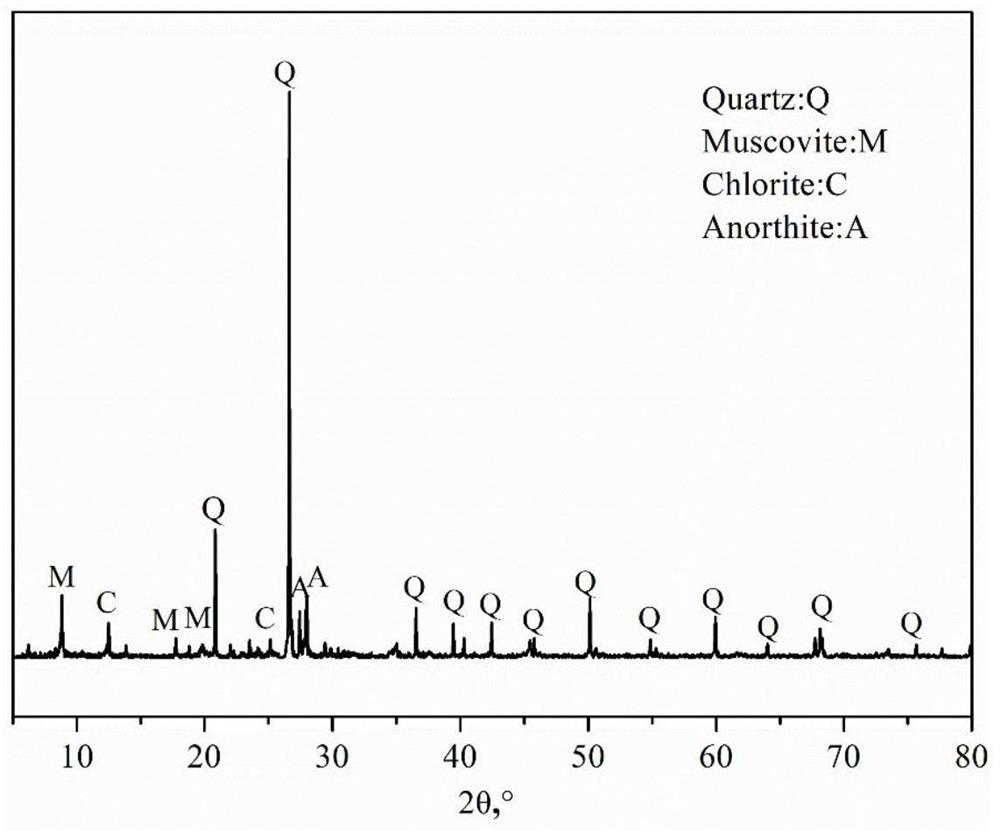

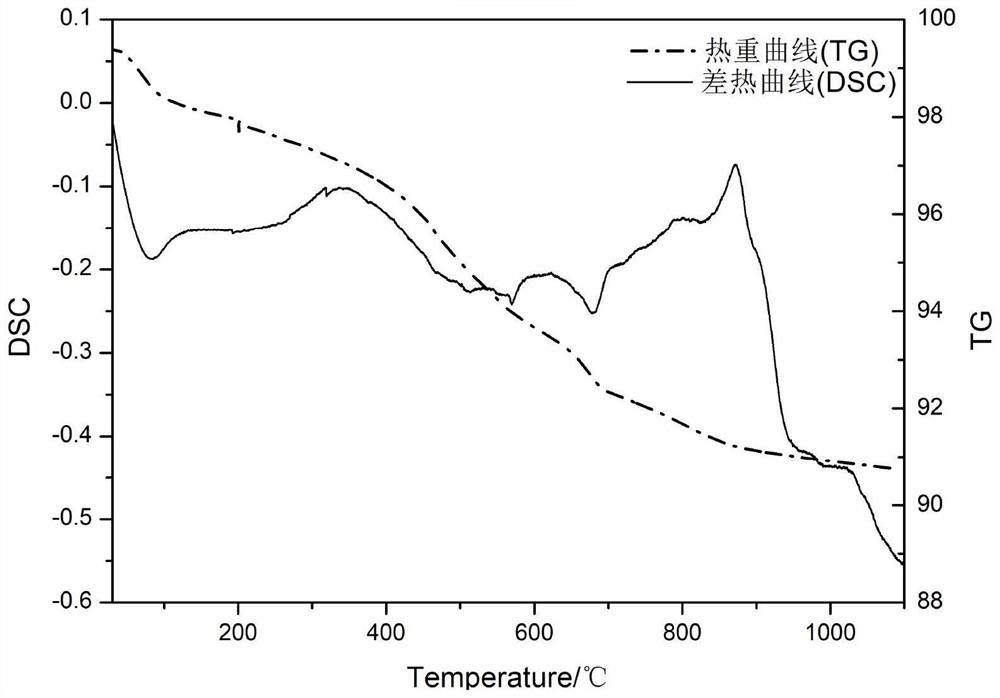

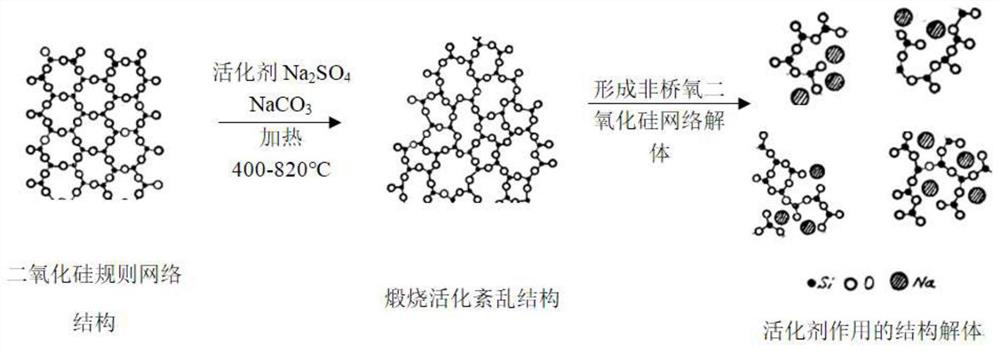

ActiveCN112979188AImprove hydrolysis effectImprove responseSolid waste managementSoil scienceEnvironmental engineering

The invention provides a method for preparing a volcanic ash active material from building residue soil, the main component of the building residue soil is a clay substance with a particle size of less than 100 [mu] m, the main mineral phases are quartz, mica and chlorite, and the method comprises the following steps: drying the building residue soil to remove moisture; doping an activating auxiliary agent into the building residue soil, calcining, and cooling to room temperature; and ball-milling to obtain the volcanic ash active material. Main minerals in the activated building residue soil are converted into an amorphous state, the activated building residue soil has good hydrolysis capacity and reaction capacity, activity inspection is carried out on the activated building residue soil, data show that the activated building residue soil has pozzolanic activity, the 28-day compressive strength can reach about 100% of that of a standard cement mortar test block, the problem of resource reutilization of the waste building muck is solved, and the application direction of the waste building muck is expanded.

Owner:NANJING UNIV OF SCI & TECH +1

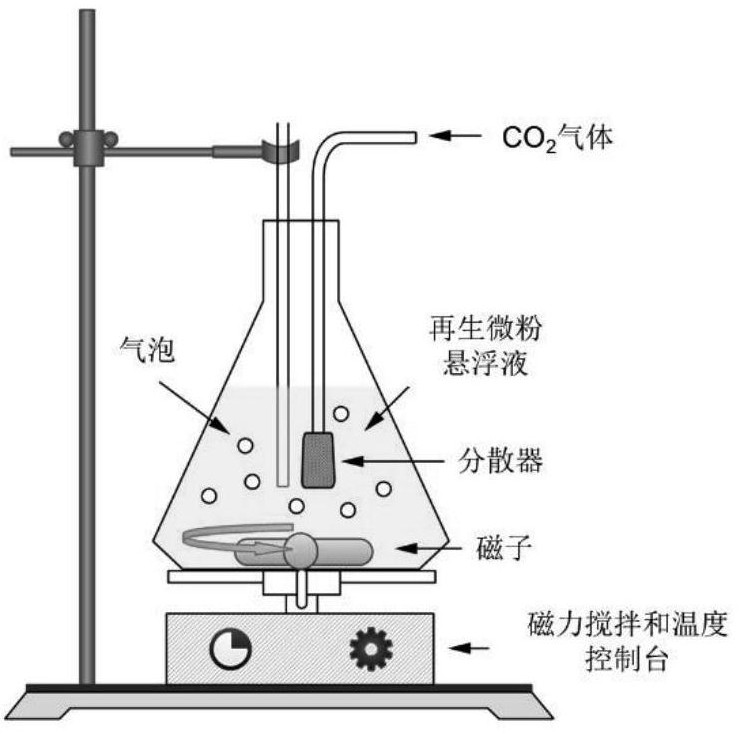

A method of wet carbonization to activate waste concrete regenerated micropowder and the application of regenerated micropowder

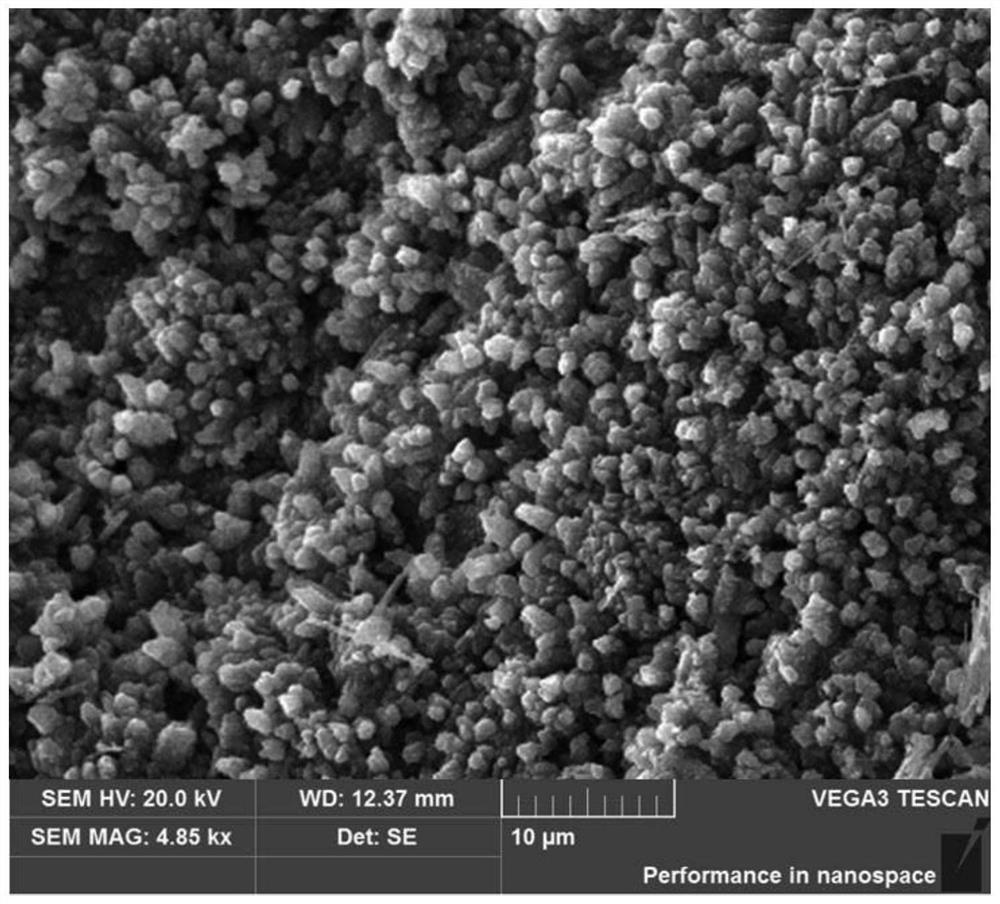

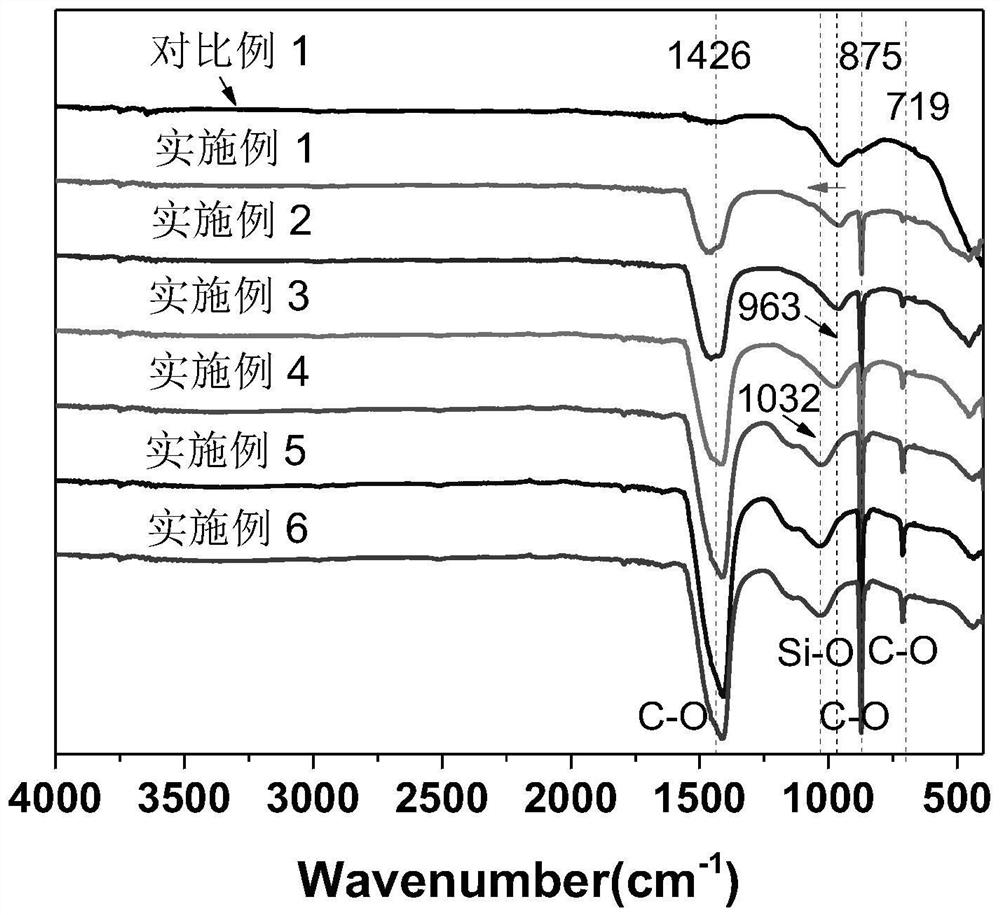

ActiveCN112125541BHigh activityEasy to achieve continuous productionCement productionCarbonizationPhysical chemistry

The present invention proposes a method for activating recycled micropowder of waste concrete by wet carbonization. The powder produced in the process of crushing waste concrete to produce recycled aggregate is used as regenerated micropowder, and the regenerated micropowder is dispersed in water to form a mixed slurry, which is mixed in the The industrial waste gas containing carbon dioxide is continuously fed into the slurry, and during this process, the carbon dioxide contained in the industrial waste gas and the regenerated micropowder undergo a carbonization reaction. In the present invention, the regenerated micropowder is subjected to carbonization reaction in an aqueous solution, and the calcium carbonate and silicon dioxide produced by carbonization have higher activity, and the pozzolanic ash activity is better than auxiliary gelling materials such as commonly used fly ash and silica fume, and can be used as auxiliary gelling materials material used.

Owner:HENAN POLYTECHNIC UNIV

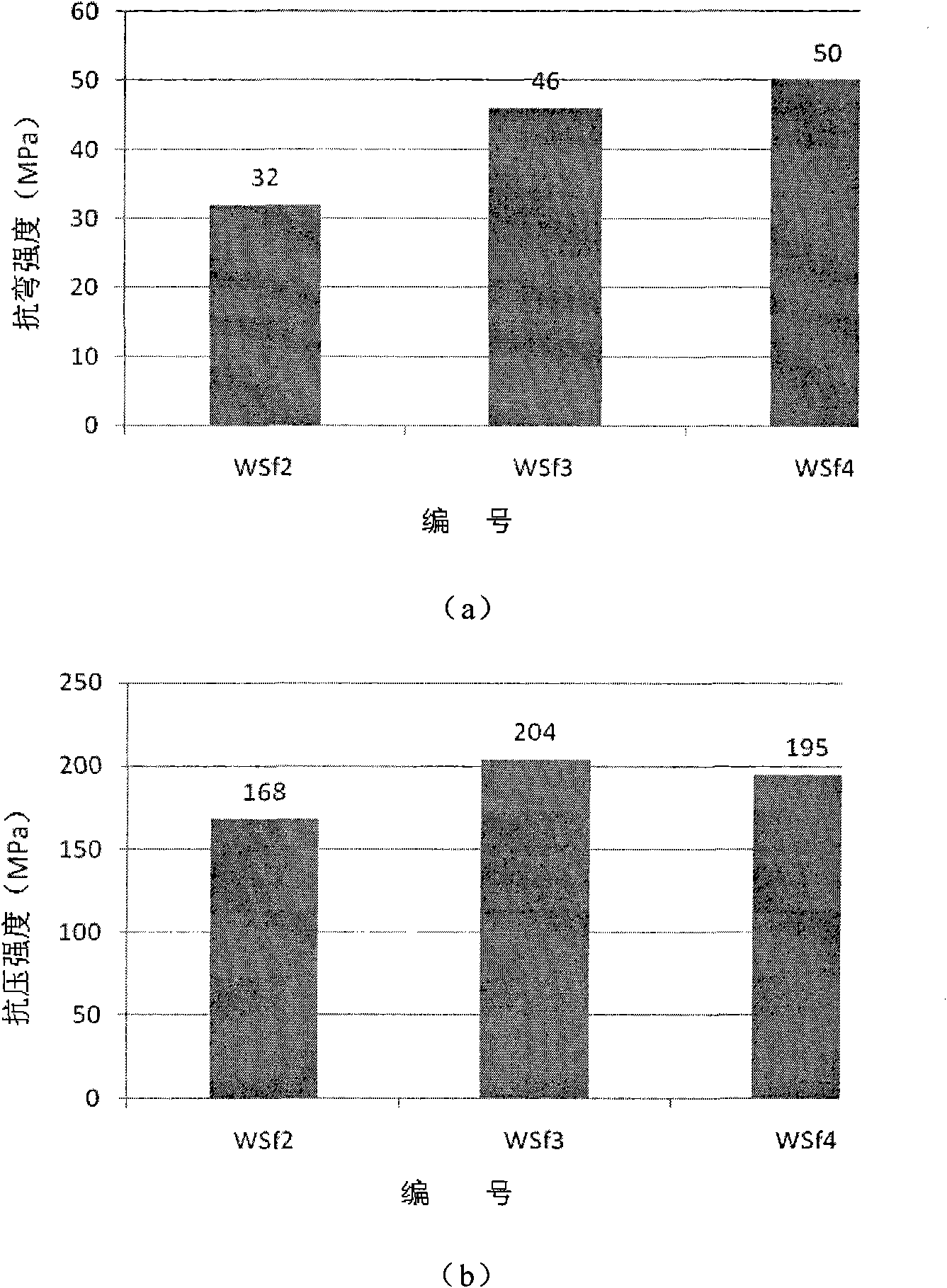

High-volume mixed glass powder C180UHPC and preparation method thereof

The invention discloses high-volume mixed glass powder C180UHPC and a preparation method thereof. UHPC of the high-volume mixed glass powder C180UHPC comprises components in the proportion as follows:cement with concentration of 770.2 kg / m<3>, silica fume with concentration of 154.0 kg / m<3>, fly ash with concentration of 38.5 kg / m<3>, fine glass powder with concentration of 154.0 kg / m<3>, a superplasticizer with concentration of 46.2 kg / m<3> and steel fiber with concentration of 156 kg / m<3>. The invention further discloses a preparation method of the UHPC. A curing way comprises steps as follows: a concrete test block is wrapped with wet cotton cloth tightly, and water is sprayed intermittently at high frequency for curing or the concrete test block is put in water for curing. Not only isthe curing mechanism simplified, but also moisture in concrete is effectively prevented from being evaporated. The high-volume mixed glass powder C180UHPC and the preparation method thereof have following technical advantages: waste glass is recycled, natural material consumption is reduced, and energy-saving and environment-friendly effects are achieved; the glass powder has pozzolanic activity,and concrete strength and durability are improved; the glass powder with different particle sizes are mixed, and accumulation gaps among quartz sand are filled, so that the structure is tighter; a water-binder ratio and the superplasticizer are preferably selected, and the UHPC has the self-compaction advantage.

Owner:XIANGTAN UNIV

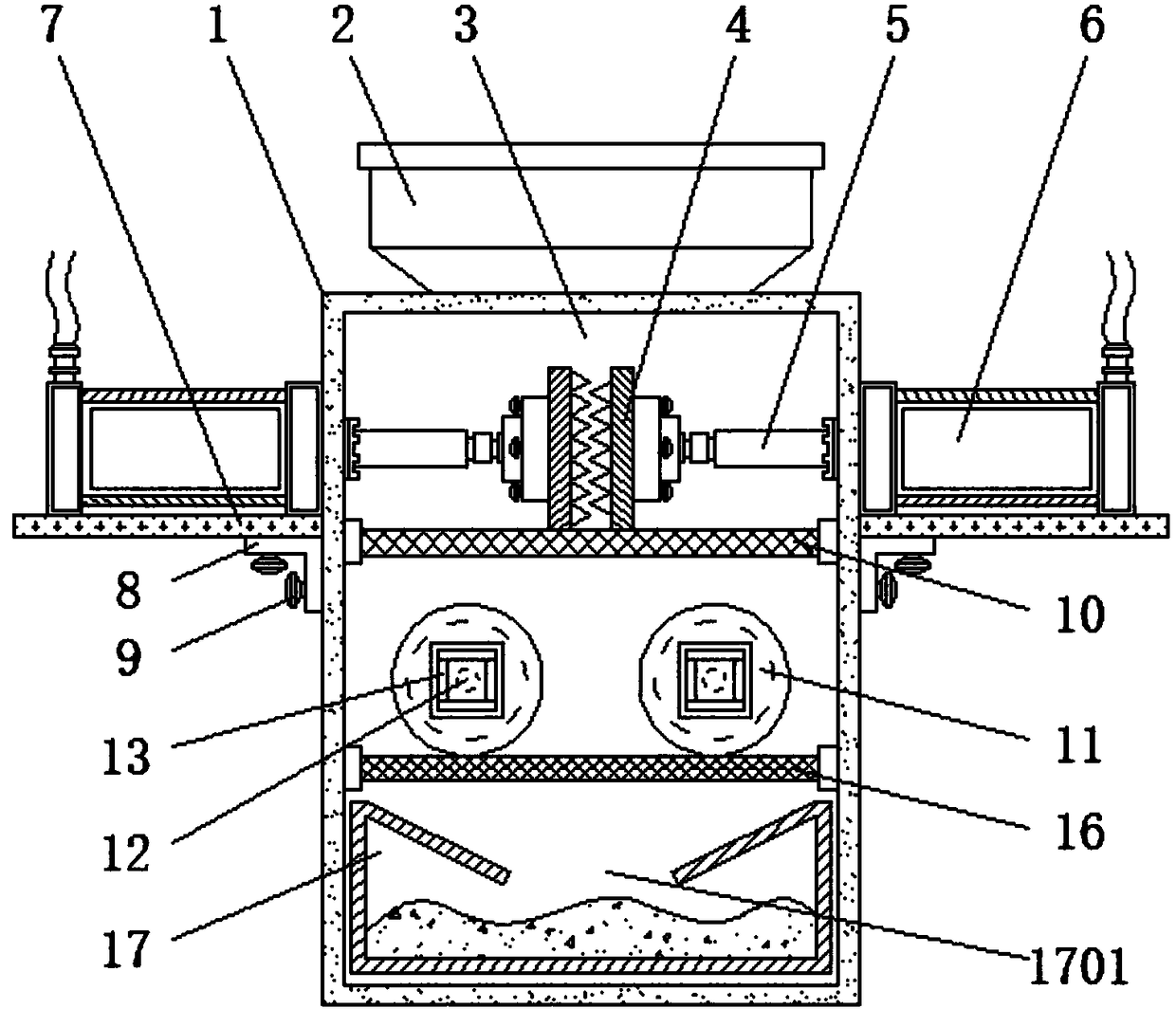

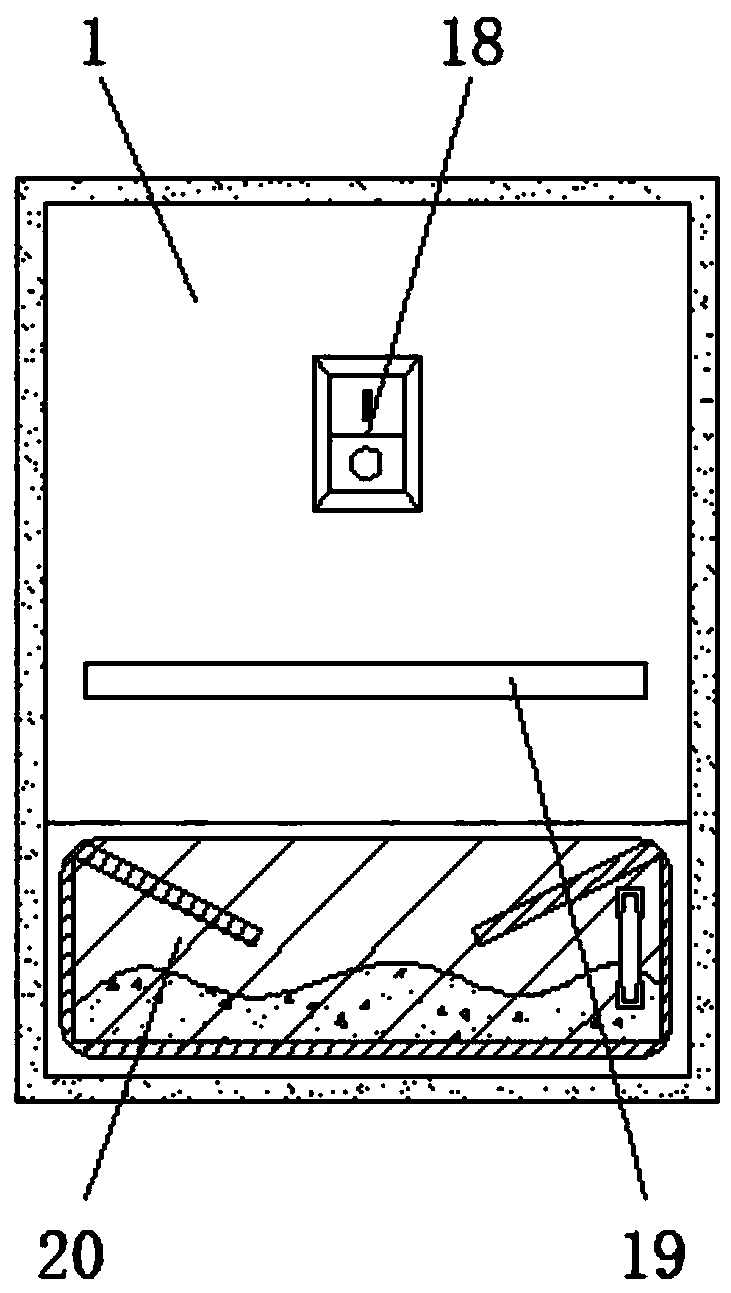

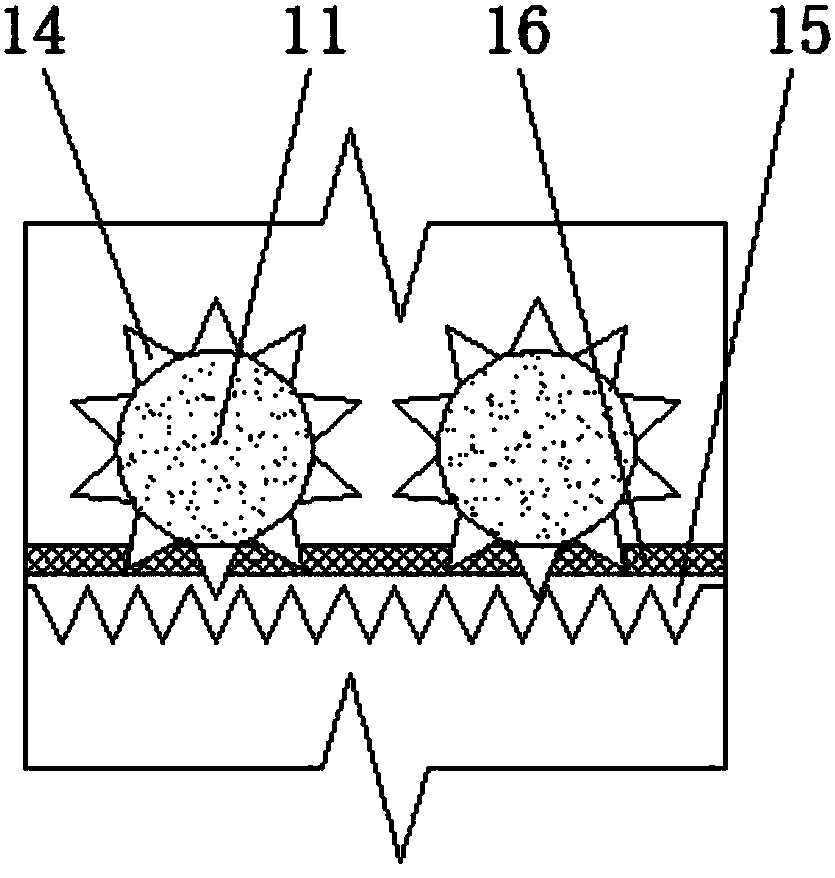

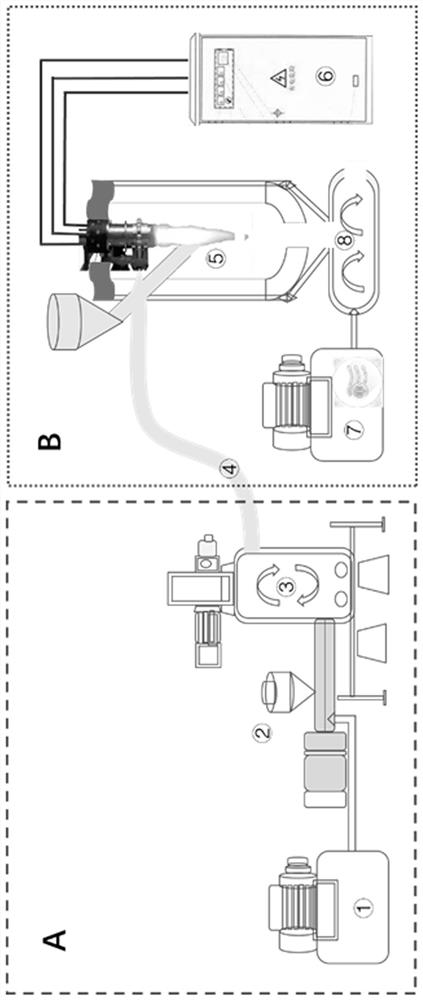

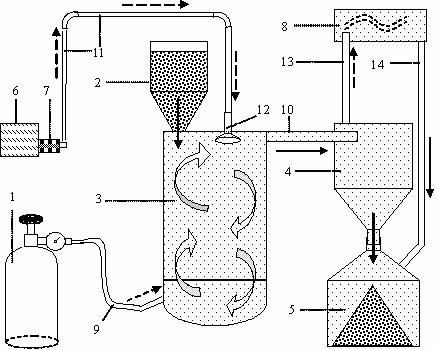

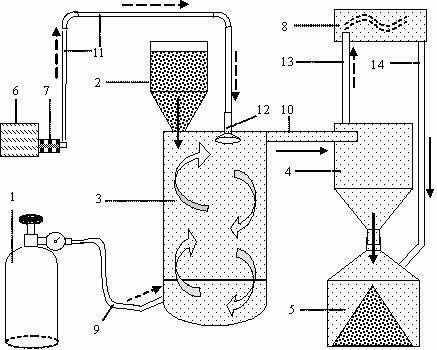

Method and apparatus for modifying pozzolanic activity of mineral material

InactiveCN102515601AReduce dosageReduce adverse effectsSolid waste managementFluidized bedMineral particles

The invention relates to a method and an apparatus for modifying the pozzolanic activity of a mineral material. The apparatus comprises devices of a gas bottle, a feeding cabin, a fluidized bed container, a pressure reduction cylinder, a finished product collection container, a modifier container, an atomizer, a nozzle, a dust collector and the like, and gas tubes, a water tube, a material tube and a heating tube for connecting the devices. The method concretely comprises the following steps: fully mixing an atomization modifier with the mineral material in the fluidized bed container, and carrying out thermal treatment by the heating tube to make modifier particles and mineral particles be tightly combined, wherein the modifier can most effectively excite the hydration activity of the mineral material. The method has the characteristics of high efficiency of the mixing of the modifier with the mineral material, and good excitation effect on the hydration activity of the mineral material.

Owner:TONGJI UNIV

Concrete reinforcement corrosion inhibitor and preparation method thereof

The invention belongs to the technical field of corrosion resistance of building materials and relates to a concrete reinforcement corrosion inhibitor and a preparation method thereof. Coal ash with pozzolanic activity is adopted for generating ettringite under the stimulation action of Ca(OH)2 to provide early-stage compactness of concrete; after complete reaction of ettringite, hydration of residual free CaO in the coal ash and CaO in an additional calcium source continues so as to realize concrete volume compactness to provide later-stage compactness of concrete, concrete volume continuous and uniform compactness can be realized, early-stage and later-stage compactness of concrete can be compensated, reinforcing steel bar erosion caused by chloride ions can be retarded, and concrete structural stability is guaranteed; by electronegativity of aromatic groups, chloride ions and the like are prevented from migrating from reinforcing steel bar bases to retard steel bar erosion caused by chloride ions; by compounding of propolis with polyhydroxy structural groups, repellence among molecules can be reduced while compactness and stability of an adsorption film are improved owing to the characteristic that hydrogen bonds can be formed among hydroxyl radicals.

Owner:王建东

High-volume mixed glass powder C190UHPC (Ultra-High Performance Concrete) and preparation method thereof

The invention discloses high-volume mixed glass powder C190UHPC (Ultra-High Performance Concrete) and a preparation method thereof. The high-volume mixed glass powder C190UHPC is prepared from the following components in proportions: 773.4kg / m<3> of cement, 154.7kg / m<3> of silica fume, 38.7kg / m<3> of pulverized fuel ash, 154.7kg / m<3> of fine glass powder, 46.4kg / m<3> of a superplasticizer, 216.6kg / m<3> of coarse glass powder, 866.2kg / m<3> of quartz sand, 193.4kg / m<3> of water and 156kg / m<3> of steel fiber. The invention also discloses the preparation method of the high-volume mixed glass powder C190UHPC. A maintenance mode is characterized by tightly coating a concrete test block by using wet cotton cloth, and intermittently spraying water at a high frequency for maintaining, or maintaining in water. Not only a maintenance system is simplified, but also evaporation of water in concrete is effectively prevented. The high-volume mixed glass powder C190UHPC disclosed by the invention hasthe following technical advantages that waste glass can be recycled, consumption of natural materials is reduced, and the effect of environmental protection is achieved; the glass powder has pozzolanic activity, so that the strength and the durability of the concrete are increased; due to the doping of the glass powder in different grain diameters, accumulation gaps between the quartz sand is remedied, and the structure is tighter; a water-glue ratio and the superplasticizer are preferably selected, so that the high-volume mixed glass powder C190UHPC has the advantage of self-compaction.

Owner:XIANGTAN UNIV

High-strength concrete mixed with low-temperature rice husk ash

InactiveCN102643060BSimple preparation processImprove work performanceSolid waste managementProcess engineeringWater reducer

The invention belongs to the technical field of building materials, and particularly relates to high-strength concrete mixed with low-temperature rice husk ash, which comprises ordinary Portland cement, low-temperature rice husk ash, slag powder, coal powder ash, broken stones, river sand, water and water reducer. The low-temperature rice husk ash is prepared by burning rice husks at the lower temperature (600 DEG C) and grinding the burned rice husks. The specific surface area of nitrogen adsorption measurement of the high-strength concrete is 55-70m2 / g, and the high-strength concrete has ultrahigh pozzolanic activity. By means of the high-strength concrete, the problem of rice husk processing can be solved, and the production cost of the high-strength concrete can be reduced. The high-strength concrete has the advantages of high workability, high strength, rapidity in strength development, mechanical property, durability and the like by being prepared from the ordinary Portland cement serving as cementing materials, the low-temperature rice husk ash, the slag powder and the coal powder ash serving as admixture, and the broken stones and the river sand serving as aggregate and the high-efficiency water reducer. Reusability of the rice husks is effectively realized by the aid of the high-strength concrete so that energy saving, emission reduction and environmental protection are achieved. Besides, production cost of the high-strength concrete can be reduced, and economic returns are improved.

Owner:TONGJI UNIV

Fly ash ceramic soilless culture substrate and manufacturing process thereof

InactiveCN103992130ALow costGood water retention and breathabilityCeramicwareGeopolymerUltimate tensile strength

The invention relates to a fly ash ceramic soilless culture substrate and a manufacturing process thereof, belonging to the technical field of material engineering. A geopolymer foamed adobe with certain strength is prepared by using the pozzolanic activity of fly ash and is then sintered so as to obtain a ceramic. The fly ash ceramic soilless culture substrate comprises the following raw materials: 80 to 98.5% of fly ash and 1.5 to 20% of a mixed exciting agent X. Sintering temperature is 1000 to 1200 DEG C. The mixed exciting agent X is an alkaline mixed liquor containing a plurality of ions and active materials. The novel fly ash ceramic soilless culture substrate has the characteristics of low cost, good water retention performance and air permeability, long service life and easy recovery processing and is very beneficial for protection of the environment since industrial waste like waste fly ash can be utilized.

Owner:张书源

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com