Patents

Literature

1264 results about "Geopolymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Geopolymers are inorganic, typically ceramic, materials that form long-range, covalently bonded, non-crystalline (amorphous) networks. Obsidian (volcanic glass) fragments are a component of some geopolymer blends. Commercially produced geopolymers may be used for fire- and heat-resistant coatings and adhesives, medicinal applications, high-temperature ceramics, new binders for fire-resistant fiber composites, toxic and radioactive waste encapsulation and new cements for concrete. The properties and uses of geopolymers are being explored in many scientific and industrial disciplines: modern inorganic chemistry, physical chemistry, colloid chemistry, mineralogy, geology, and in other types of engineering process technologies. Geopolymers are part of polymer science, chemistry and technology that forms one of the major areas of materials science. Polymers are either organic material, i.e. carbon-based, or inorganic polymer, for example silicon-based. The organic polymers comprise the classes of natural polymers (rubber, cellulose), synthetic organic polymers (textile fibers, plastics, films, elastomers, etc.) and natural biopolymers (biology, medicine, pharmacy). Raw materials used in the synthesis of silicon-based polymers are mainly rock-forming minerals of geological origin, hence the name: geopolymer. Joseph Davidovits coined the term in 1978 and created the non profit French scientific institution (Association Loi 1901) Institut Géopolymère (Geopolymer Institute).

Geopolymer composition and application in oilfield industry

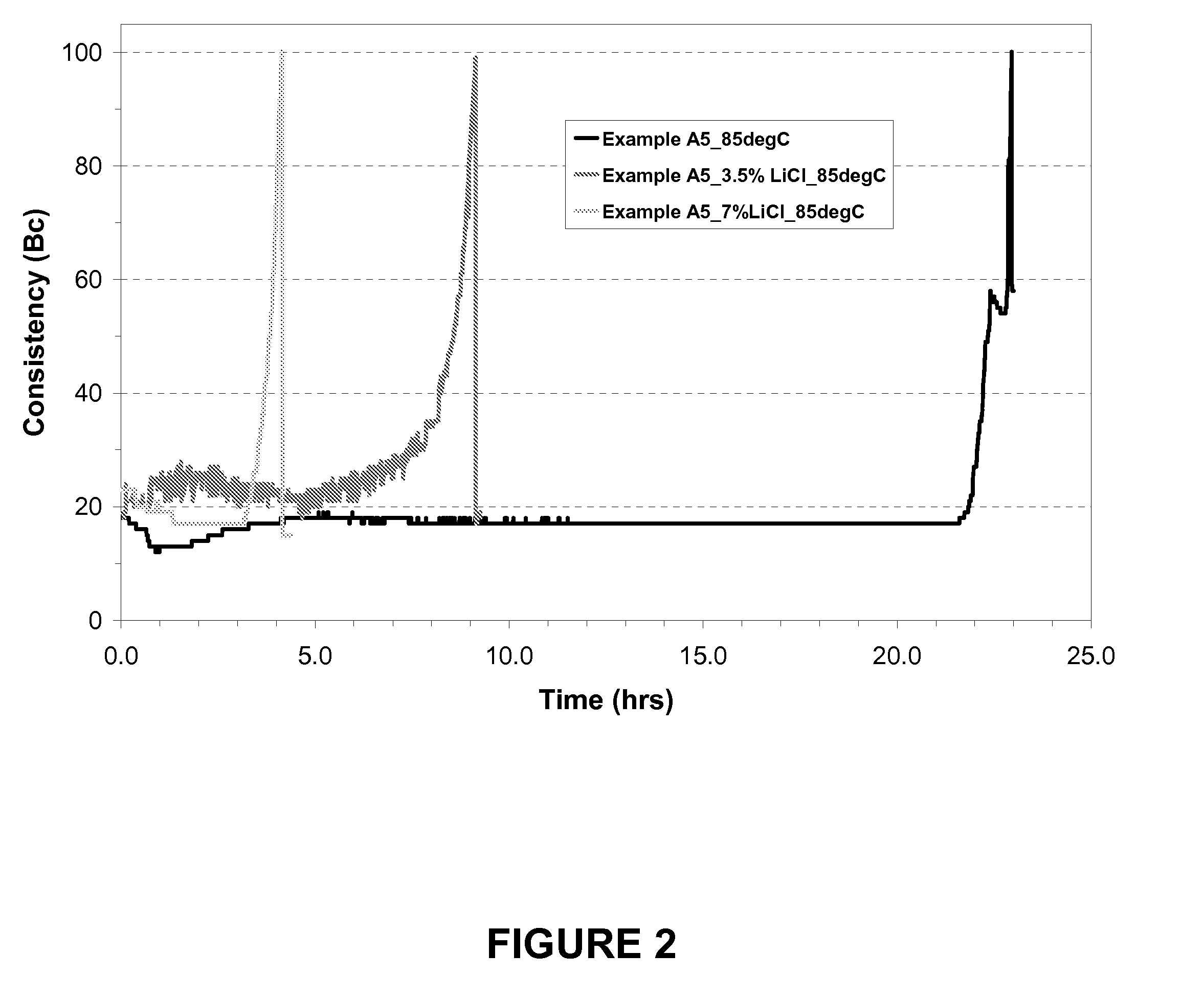

ActiveUS20080028994A1Enhanced pumpabilityImprove stabilitySolid waste managementAlkali metal silicate coatingsGeopolymerSlurry

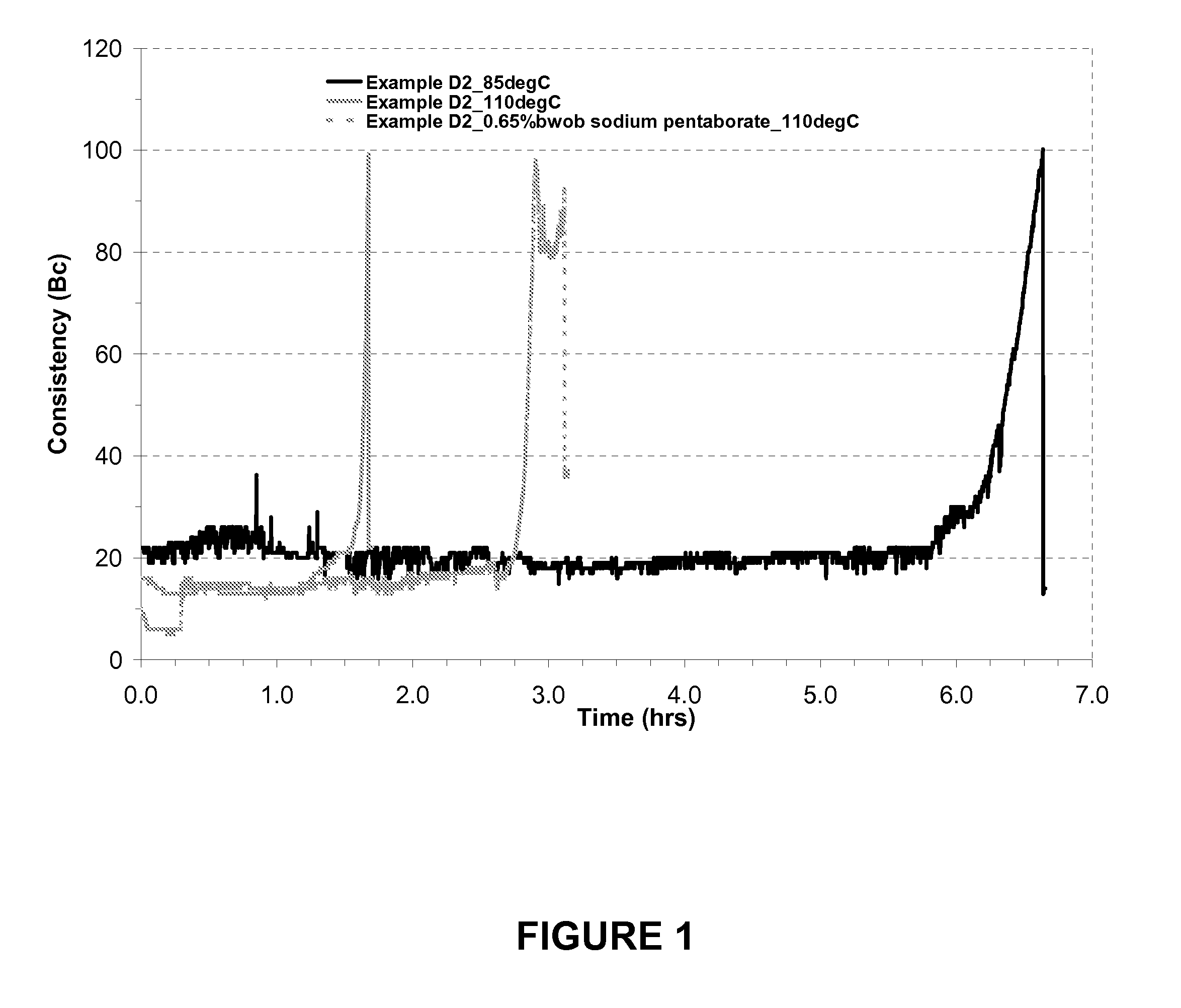

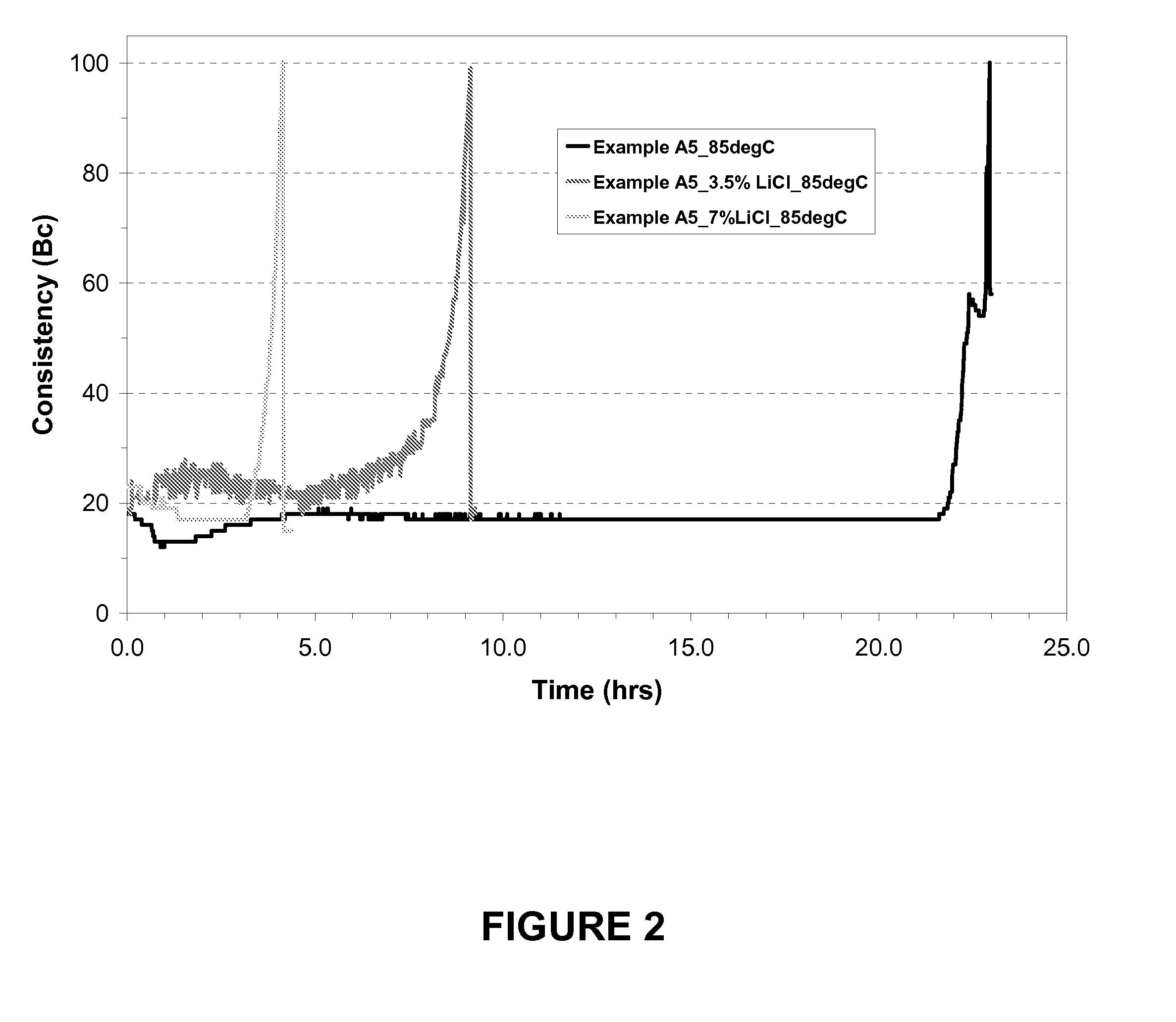

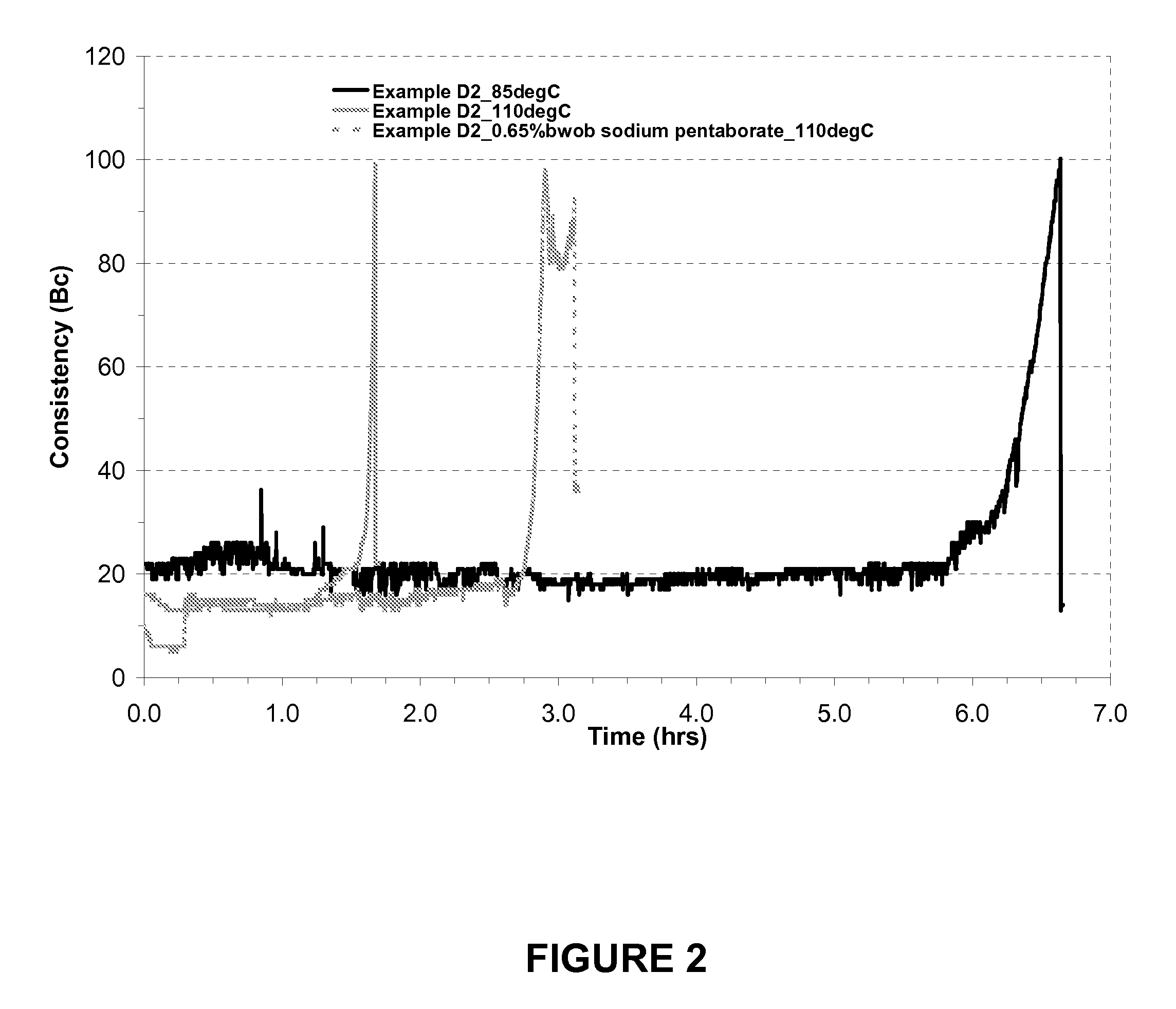

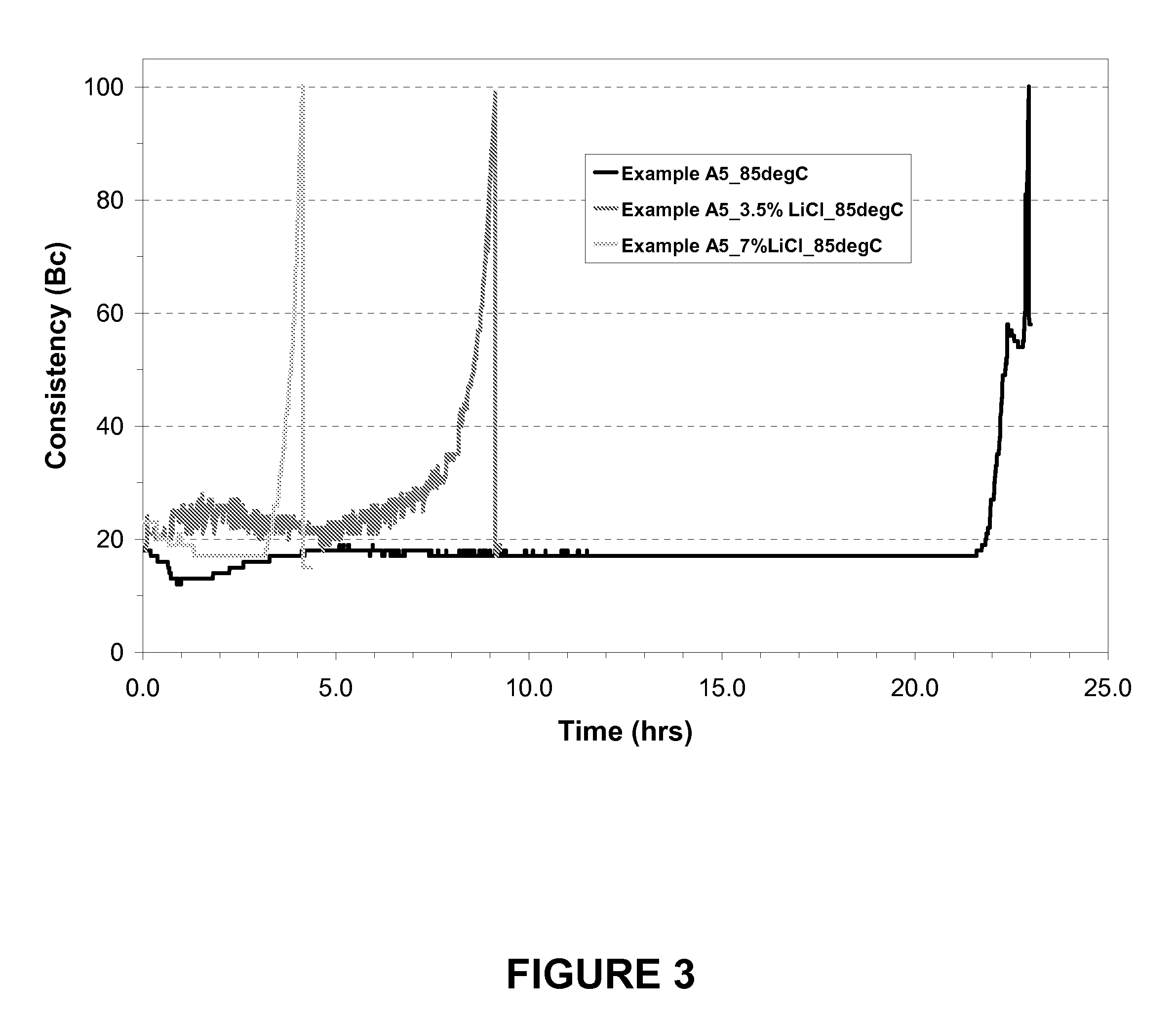

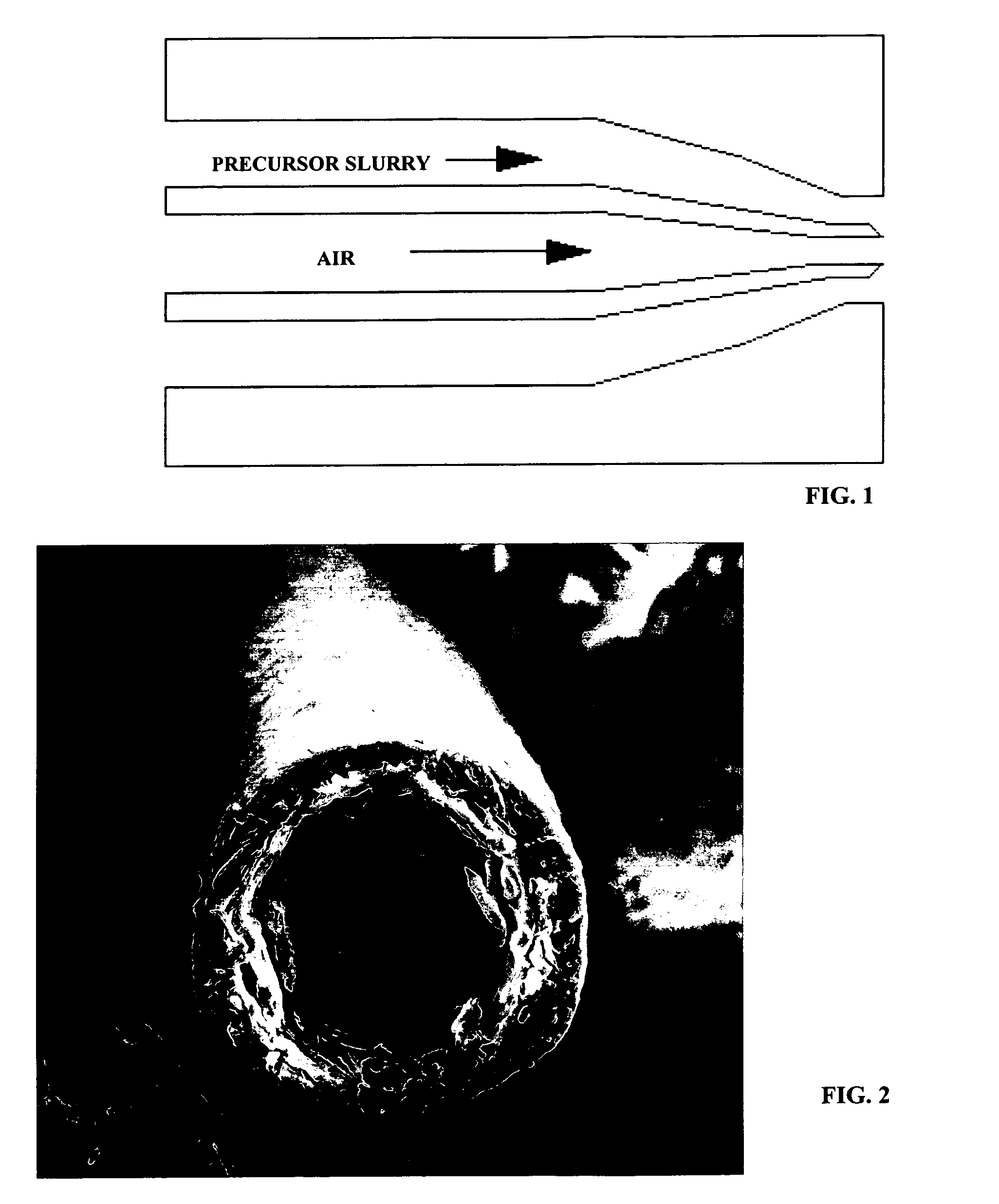

The invention provides geopolymeric compositions, which have controllable thickening and setting times for a wide range of temperatures and a large range of geopolymer slurry densities. The geopolymer slurry compositions have good mixability and pumpability, whilst the set materials develop good compressive strength and permeability. The invention discloses a method for preparing geopolymer for oilfield cementing applications. The geopolymeric compositions according to the invention comprises a suspension comprising an aluminosilicate source, a metal silicate, an alkali activator, lightweight or heavyweight fillers and a carrier fluid wherein the suspension of said geopolymeric composition is pumped in a well and allowed to set.

Owner:SCHLUMBERGER TECH CORP

Geopolymer composite for ultra high performance concrete

A geopolymer composite ultra high performance concrete (GUHPC), and methods of making the same, are provided herein, the GUHPC comprising: (a) a binder comprising one or more selected from the group consisting of reactive aluminosilicate and reactive alkali-earth aluminosilicate; (b) an alkali activator comprising an aqueous solution of metal hydroxide and metal silicate; and (c) one or more aggregate.

Owner:CATHOLIC UNIV OF AMERICA

Proppants and their manufacture

Owner:1389414 ALBERTA

Geopolymer composition and application for carbon dioxide storage

InactiveUS20080028995A1Enhanced pumpabilityImprove stabilityLiquid surface applicatorsSolid waste managementCo2 storageGeopolymer

The invention provides geopolymeric compositions intended for use in carbon dioxide injection or production wells or storage reservoirs and preferably in a supercritical carbon dioxide conditions. The geopolymeric composition is formed from a suspension comprising an aluminosilicate source, a metal silicate, an alkali activator, a retarder and / or an accelerator and a carrier fluid wherein the oxide molar ratio M2O / SiO2 is greater than 0.20 with M an alkali metal.

Owner:SCHLUMBERGER TECH CORP

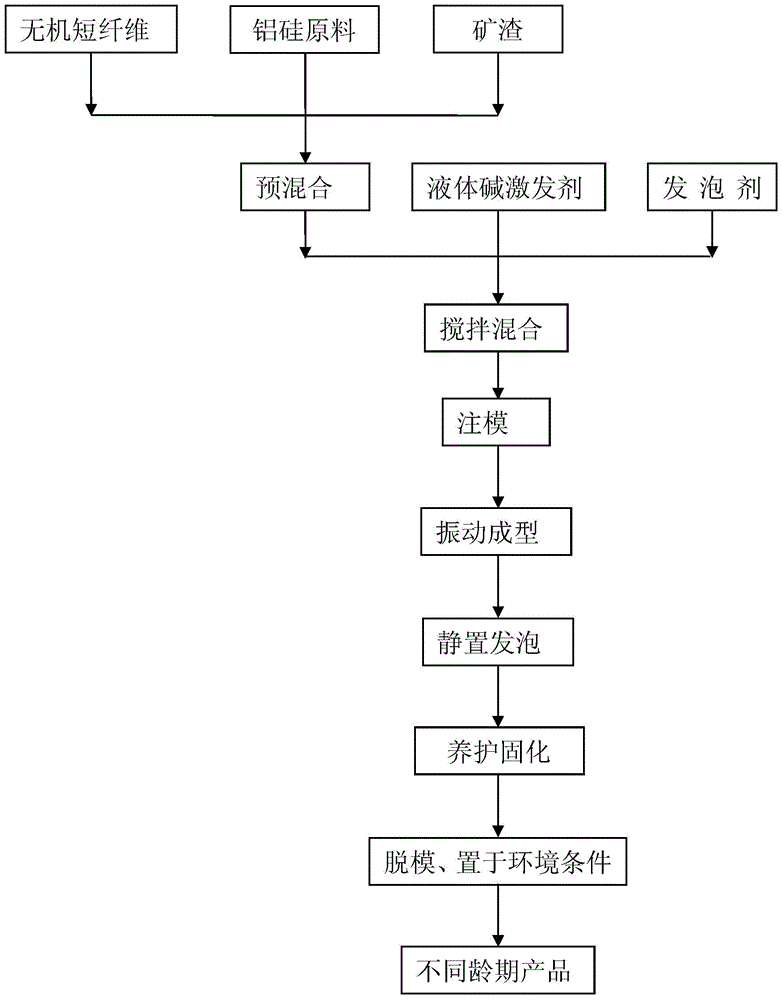

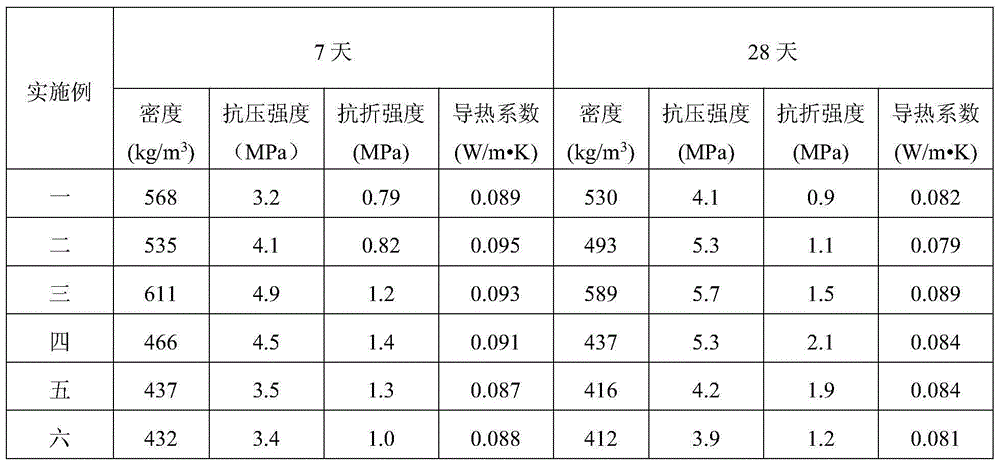

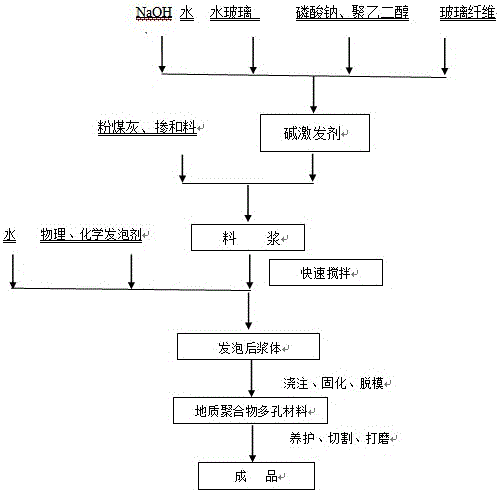

Fibre reinforced coal ash based geopolymer foam material and preparation method thereof

InactiveCN103601524ARealize high value utilizationReduce pollutionCement productionCeramicwarePolymer scienceSlag

The invention discloses a fibre reinforced coal ash based geopolymer foam material and a preparation method thereof. The fibre reinforced coal ash based geopolymer foam material disclosed by the invention comprises the following components in percentage by weight: 50-70% of aluminium silicon raw material, 5-15% of slag, 3-8% of inorganic fibre, 15-30% of liquid alkaline exciting agent, 0.2-2% of foaming agent, and 2.5-3.5% of foam stabilizer. The preparation method disclosed by the invention comprises the step of also adding the foam stabilizer while adding the foaming agent by adopting the liquid alkaline exciting agent by taking the inorganic fibre as the reinforcing agent, the slag as the Ca adjusting agent and other solid raw materials (such as coal ash, metakaolin and silica fume) as powder for providing aluminium silicon. The light foam material prepared by the invention has the characteristics of being high in intensity, small in size change rate, low in water absorption and the like in the event of having same volume weight and heat conductivity of the similar materials, and is applied to various applications.

Owner:TIANJIN UNIV

Geopolymer gel material for rush repairs and rush constructions

ActiveCN101628791AGood mechanical propertiesEasy constructionSolid waste managementCement productionSlagMetakaolin

The invention provides a geopolymer gel material for rush repairs and rush constructions, which is prepared by adding water to 13-17 percent by weight of exciting agent and 82-87 percent by weight of slag containing aluminosilicate. The slag comprises one or the combination of more of blast furnace slag, steel slag, coal ash and coal gangue, and the exciting agent comprises the following components in percentage by weight: 35-75 percent of SiO2, 0-55 percent of Na2O, 0-65 percent of K2O, 0-1 percent of CaO and 0-1 percent of SO3. The geopolymer gel material which has the characteristic of quick setting and hardening is prepared by using the industrial waste slag as a main raw material and matching the exciting agent, and the geopolymer gel material has excellent mechanical property and controllable setting time and can replace gel materials such as fast setting and hardening cement, and the like in the processes of rush repairs and rush constructions. The industrial solid wastes such as the blast furnace slag, the steel slag, the coal ash, the coal gangue, and the like containing the aluminosilicate series are used as main raw materials, metakaolin is not added and the raw materials do not need to be calcined, thus the invention has low energy consumption, less pollution, simple process, low cost, environmental protection and energy saving.

Owner:深圳市航天新材科技有限公司

Geopolymeric concrete based on recycled aggregate and preparation method of geopolymeric concrete

InactiveCN103601424AReduce consumptionImprove thermal stabilitySolid waste managementCement productionAdhesiveRoad surface

The invention relates to geopolymeric concrete based on recycled aggregate, and a preparation method of the geopolymeric concrete. The concrete is prepared by taking construction waste as aggregate and inorganic geopolymer as an adhesive through an alkali activation process. The recycled aggregate geopolymeric concrete prepared by using the method has the characteristics that the concrete can be rapidly dried, the compressive strength, particularly the early-stage compressive strength is high, the volume shrinkage in the coagulation process is extremely low, the coefficient of volume expansion is approximate to 0, and acid-base corrosion resistance is good. Due to the adoption of the method, the defects that the conventional concrete is low in early-stage strength and the coagulation time is long are overcome; a method for rapidly repairing concrete pavement is provided, and problems of recycling and reusing construction waste aggregate and environment problems caused by the construction waste aggregate are solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Burning-free geology polymer material of red mud coal ash and preparation method thereof

InactiveCN101708983AGood strength performanceHigh strengthSolid waste managementCeramic shaping apparatusRed mudCrushed stone

The invention relates to a burning-free geology polymer material of red mud coal ash and a preparation method thereof, belonging to the technical field of recycling inorganic nonmetal material and industrial solid waste. Kawazu mud powder and coal ash are taken as main substrate raw materials, building fine sands and building crushed stones are taken as aggregate, solid water glass powder is taken as alkali activator to prepare the burning-free geology polymer material of red mud coal ash. The raw materials comprise the following components based on parts by weight percent: 5-98% of the kawazu mud powder, 1-65% of the coal ash, 1-96% of the building fine sands and the building crushed stones, and 1-20% of the solid water glass powder. Counting the red mud+the coal ash+the building fine sands and the building crushed stones as 100%, the raw materials further comprise the following components based on parts by weight percent: 5-45% of water and 0.1-10% of calcium lignosulphonate. The preparation method comprises the steps of: dosing, mixing, aging, shaping, maintaining and drying, etc. The invention has the advantages of the high use ratio of industrial solid waste, the less pollution, the low energy composition and the simple operation of the preparation technology, and embodies the important meanings of environment protection, energy conservation and emission reduction.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Geopolymer grouting material

InactiveCN101712546AImprove early strengthImprove liquiditySolid waste managementCement productionSlagGeopolymer

The invention discloses a geopolymer grouting material, which is prepared from the following components in parts by weight: 10-30 parts of waste concrete powder, 5-15 parts of desulfurization gypsum, 10-20 parts of steel slag powder, 20-40 parts of scoria powder, 3-8 parts of high calcium fly ash, 20-50parts of coal ash and 5-10 parts of alkali-activator. The geopolymer grouting material has the advantages of high early strength, good flowing property, low production cost, and the like; moreover, the geopolymer grouting material has self-hardening property, can react with soil, and enable soil bodies to become a plate-shaped structure, thereby improving the bearing capacity of a soil roadbed.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Inorganic artificial combining stone and preparation method thereof

InactiveCN102557571AExpand raw material resourcesLow costCeramic shaping apparatusCement productionFiberKaolin clay

The invention discloses inorganic artificial combining stone and a preparation method thereof. The artificial combining stone uses silicon acid-base solution to arouse metakaolin to react and generate geopolymer to serve as an inorganic cementing agent, and the artificial combining stone mainly contains the metakaolin, the silicon acid-base solution, natural stone aggregate, decoration aggregate, a thickening time control agent, inorganic pigment and fibers. The preparation method is firstly enabling the thickening time control agent and the inorganic pigment to be dissolved in the silicon acid-base solution to obtain mixed serous fluid, evenly blending the metakaolin, the natural stone aggregate, the decoration aggregate, the fibers and the mixed serous fluid, preparing the artificial combining stone through model entering or material distribution, vibration under the vacuum condition, molding in a pressing mode, maintaining, cutting, polishing, burnishing and surface protection. The artificial combining stone not only has decoration features which can be equal to that of resin artificial stone, but also is non-toxic, environment-friendly, low in cost, resisting in corrosion of most majority of acid-base salts, durable in high temperature and excellent in durable performance, obviously avoids whiting and saltpetering phenomena after a long time use, and is strong in pollution resisting capability.

Owner:SOUTH CHINA UNIV OF TECH

Geopolymer grouting material and preparation method thereof

The invention discloses a geopolymer grouting material and a preparation method thereof. An inorganic silicate composite material is prepared from 71-91 parts of mineral waste residues, 66-70 parts of coal ashes, 16-28 parts of alkali-activator and 0.5-1.6 parts of retarder; and then, the inorganic silicate composite material is mixed with water according to a proportion of 0.30-0.38 to prepare the geopolymer grouting material. The geopolymer grouting material disclosed by the invention has characteristics of being good in liquidity, high in early strength, free of shrinkage, good in durability, adjustable in setting time and strength. Compared with the conventional geopolymer polymer material, the material is a composite material formed by mixing various powder materials, and can be applied by adding water and stirring on the spot; the geopolymer grouting material is simple in preparation process, low in cost, convenient to operate, capable of being widely applied to cement concrete pavement slab bottom grouting, cement concrete pavement crack repairing, foundation bolt anchoring, equipment installing, pres-stressed bridge crack pouring, engineering repairing, reinforcing, and the like.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

Geopolymer composition and application in oilfield industry

ActiveUS7794537B2Good pumpability and stabilitySolid waste managementAlkali metal silicate coatingsGeopolymerSlurry

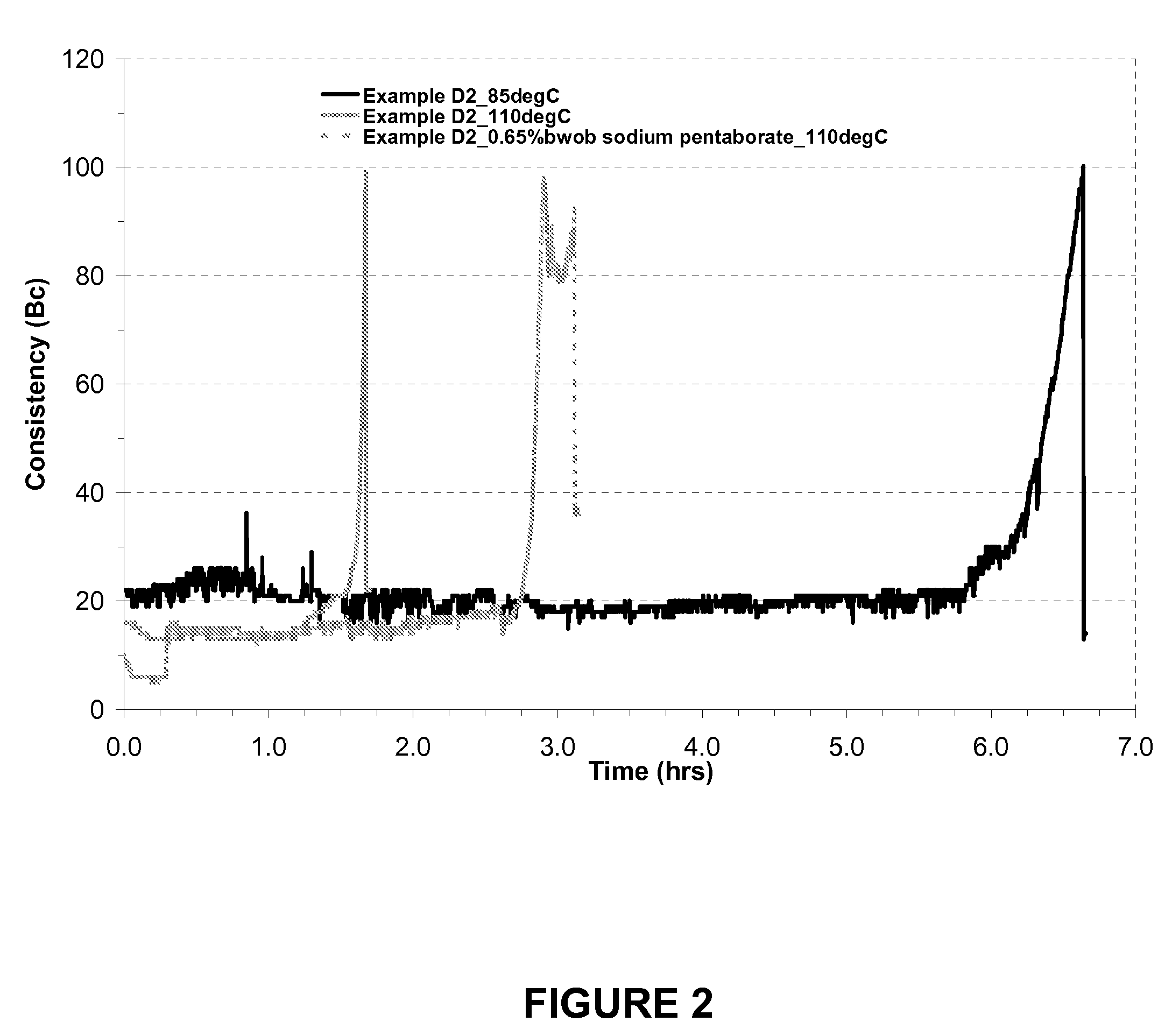

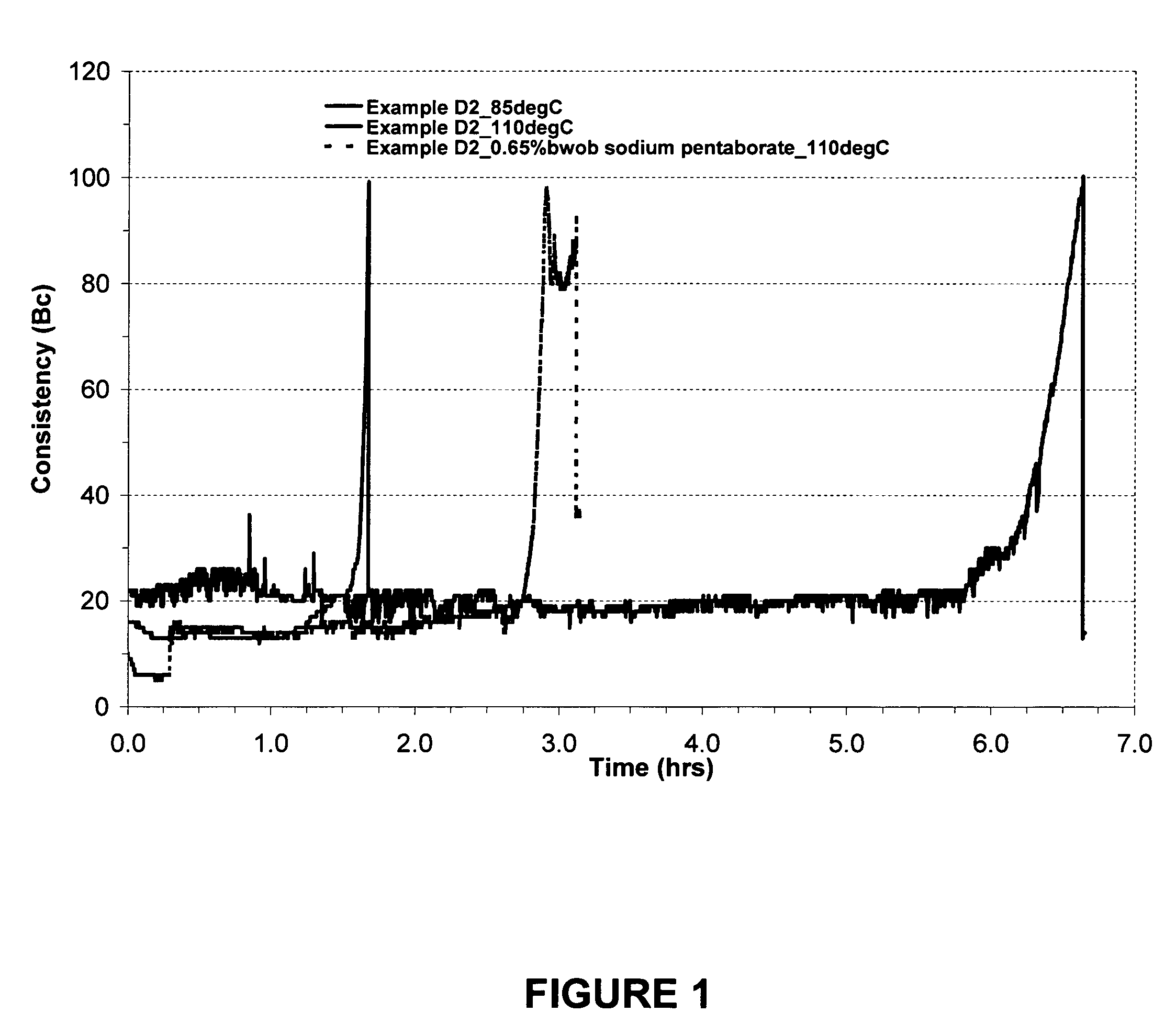

The invention provides geopolymeric compositions, which have controllable thickening and setting times for a wide range of temperatures and a large range of geopolymer slurry densities. The geopolymer slurry compositions have good mixability and pumpability, while the set materials develop good compressive strength and permeability. The invention discloses a method for preparing geopolymer for oilfield cementing applications. The geopolymeric compositions according to the invention comprises a suspension comprising an aluminosilicate source, a metal silicate, an alkali activator, lightweight or heavyweight fillers and a carrier fluid wherein the suspension of said geopolymeric composition is pumped in a well and allowed to set.

Owner:SCHLUMBERGER TECH CORP

Geopolymer composites and structures formed therefrom

InactiveUS20060251909A1Improve thermal shock resistancePromote fireAlkali metal silicate coatingsCement productionThermal expansionCordierites

Geopolymer composite materials having low coefficient of thermal expansion are disclosed. The materials are useful in high temperature applications due to their low coefficient of thermal expansion and high strength. Also disclosed is a boron modified water glass geopolymer composition that is compatible with ceramic particulate material such as cordierite and fused silica. The geopolymer composite may be extruded to form structures such as honeycomb monoliths, flow filters or used as a plugging or skinning cement and may be fired at temperatures at or below 1100° C. Both the structures and the cement have high green and fired strength, a low coefficient of thermal expansion, and good acid durability. The cost of manufacturing objects using the material of the present invention is substantially reduced, in comparison with typically production methods of cordierite based bodies, due to the substantially shortened firing times.

Owner:CORNING INC

Geopolymer precursor dry mixture, package, processes and methods

InactiveUS20110132230A1Avoid transportSatisfactory mechanical propertySolid waste managementAlkali metal silicate coatingsGeopolymerMaterials science

The present invention generally relates to a geopolymer precursor dry mixture, geopolymer precursor package, a process of preparing a geopolymer composition, and a method of providing a geopolymer composition to a geopolymer composition preparation site.

Owner:DOW GLOBAL TECH LLC

Fracturing fluid for subterranean formations

A method of fracturing a reservoir comprising the steps of pumping a geopolymer precursor fluid through a wellbore into the reservoir at a fracture pressure, the geopolymer precursor fluid at the fracture pressure generates fractures in the reservoir, wherein the geopolymer precursor fluid is comprised of an amount of aluminosilicate, an amount of alkaline reagent, and a permeability enhancer, allowing the geopolymer precursor fluid to fill the fractures in the reservoir, shutting-in the wellbore at a wellbore pressure, the wellbore pressure maintains the geopolymer precursor fluid in the fractures, allowing the geopolymer precursor fluid to harden for a hardening time to form a geopolymer in the fractures, the geopolymer has a geopolymer matrix, the geopolymer matrix has a permeability, the geopolymer has a compressive strength, and reducing the wellbore pressure allows a reservoir fluid to flow from the reservoir through the geopolymer matrix of the geopolymer to the wellbore.

Owner:SAUDI ARABIAN OIL CO

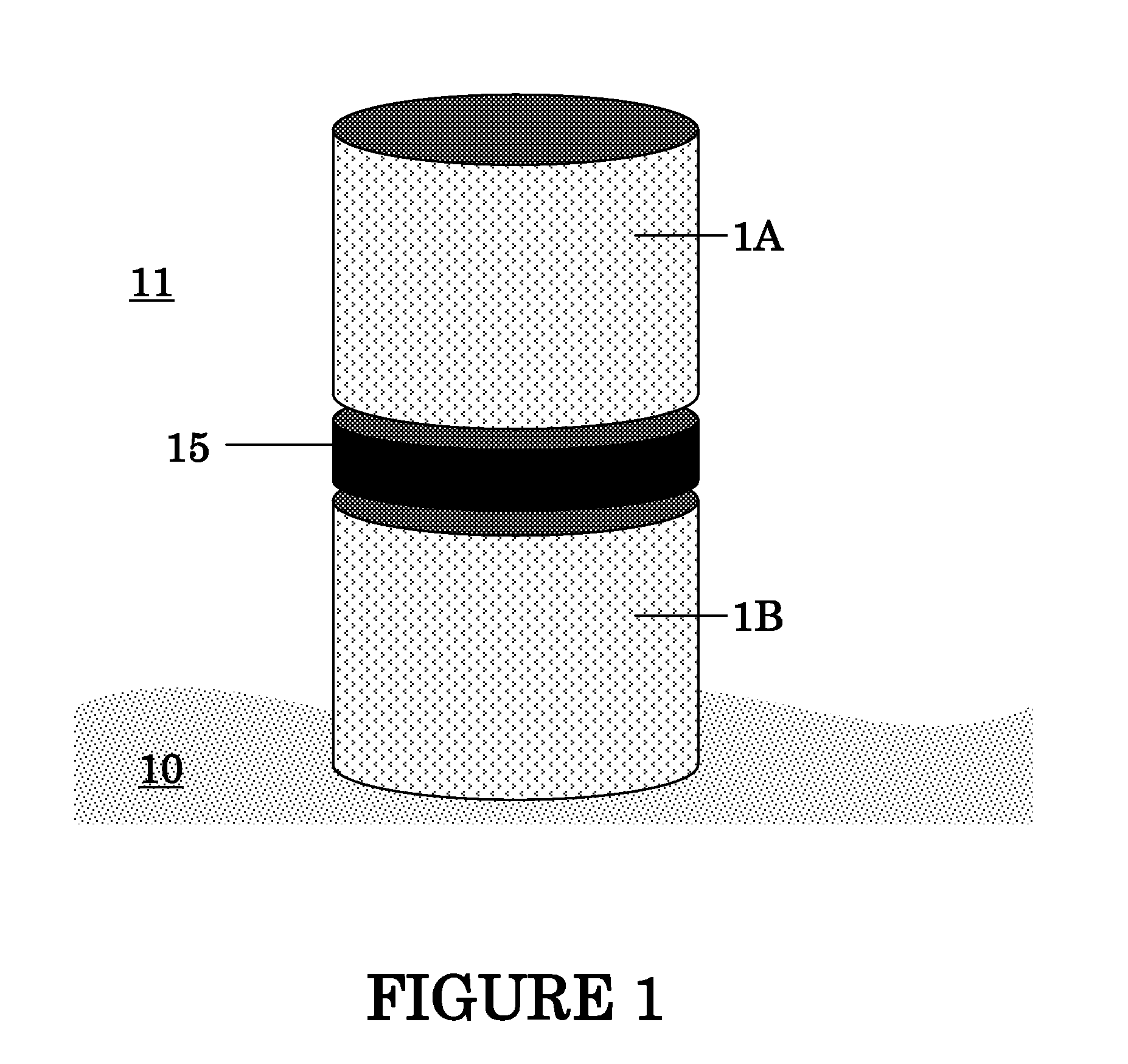

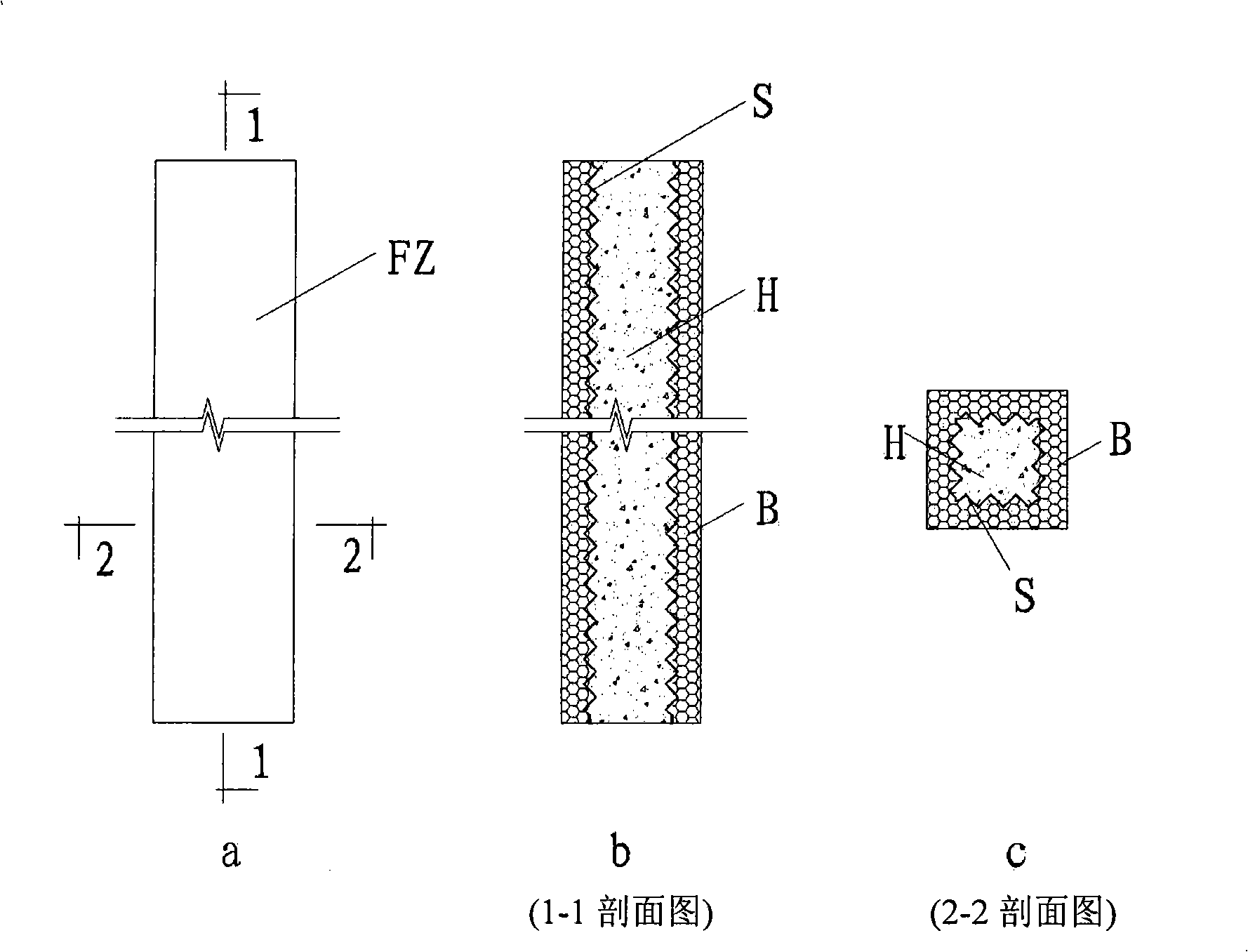

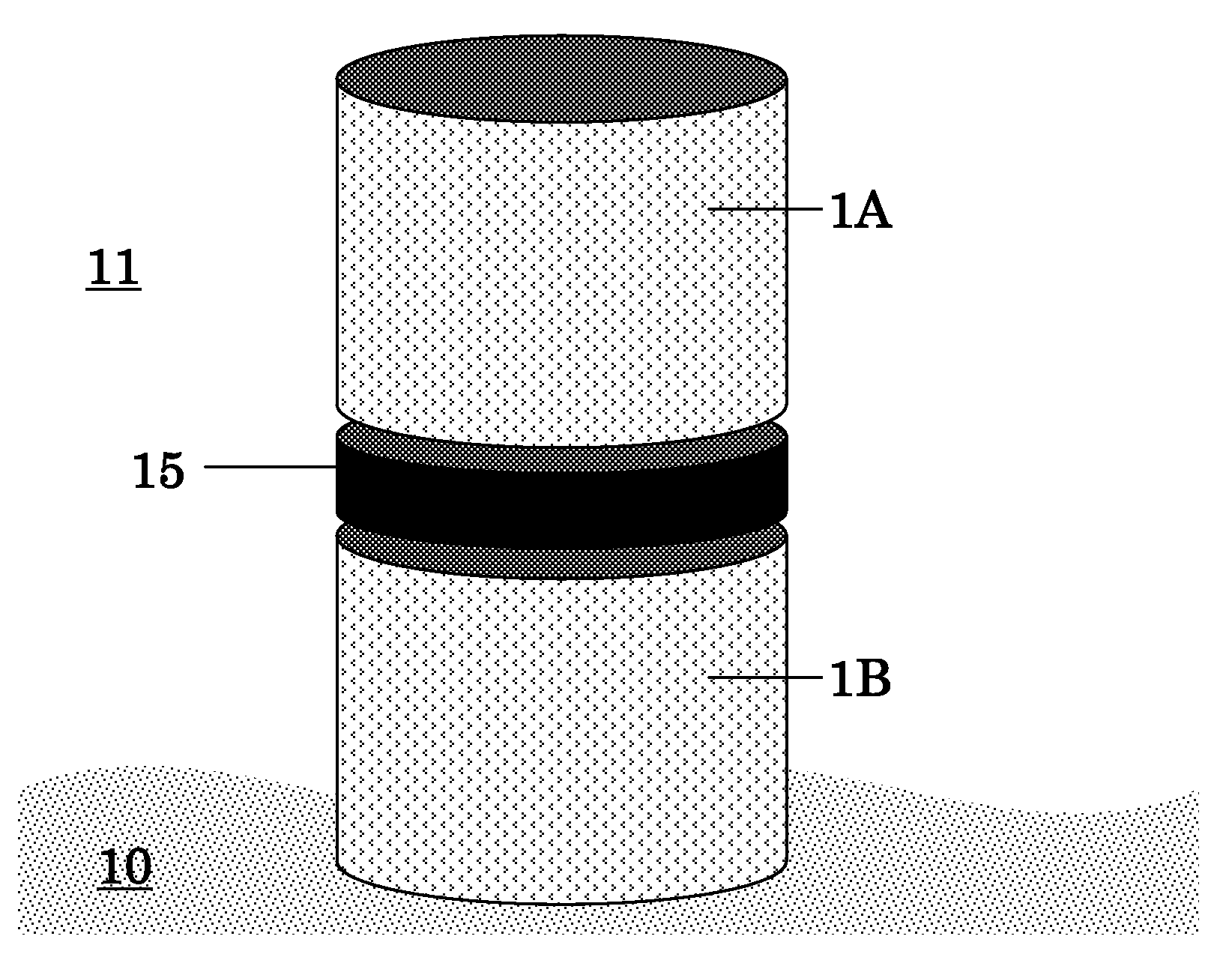

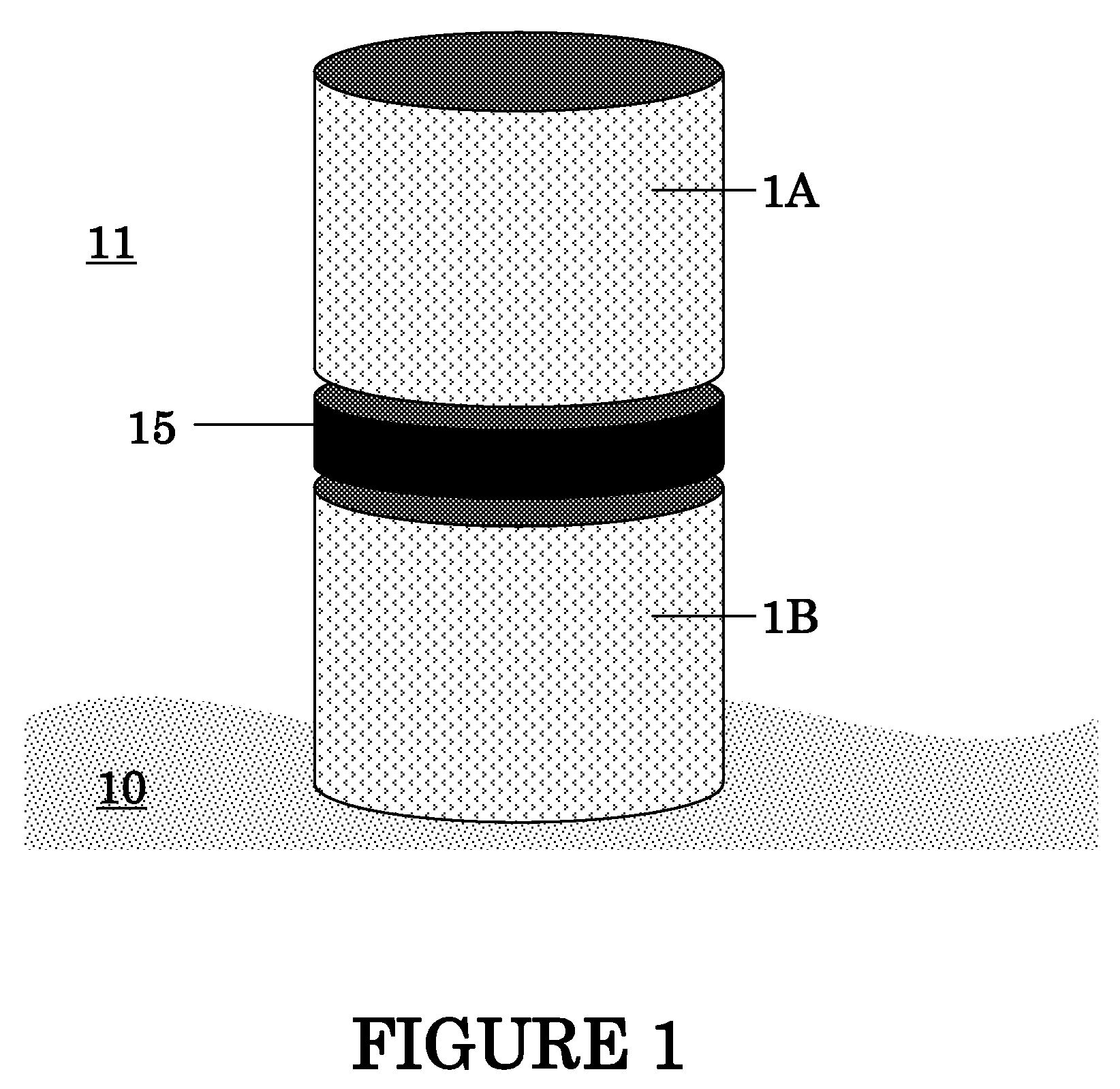

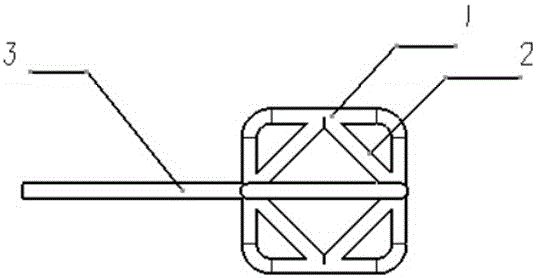

Composite pile with high permanent stability protection layer and its production and construction method

InactiveCN101343871AIncreased durabilityExtended service lifeClimate change adaptationBulkheads/pilesAlkali activatedGeopolymer

Disclosed is a high-durability protective layer compound pile. The structure of high-durability protective layer compound pile comprises: the compound pile is composed of a core bearing structure which is wrapped with a high-durability protective layer, the material of the protective layer adopts plastic or other modified products, asphalt and mortar or concrete, alkali activated material and the mortar or the concrete, geopolymer and the mortar or the concrete, reactive powder concrete, fiber reinforcement concrete base material, and resin mortar or concrete; The manufacturing and the construction can adopt six methods: firstly, site-casting can be performed to the protective layer and a core structure simultaneously; secondly, after the site-casting is performed to the protection wall of the protective layer, the site-casting is performed to the site-cast protective wall; thirdly, prefabrication is performed to the sleeve of the protective layer, and site-casting is carried out to the prefabricated sleeve of the site cast core structure of the sunk tube; fourthly, prefabrication is performed to the sleeve of the protective layer, the sleeve is taken as an outer mould plate to prefabricate the prefabricated sleeve of the core structure; fifthly, prefabrication is performed to the core structure, the core structure is taken as an inner mould plate to prefabricate the prefabricated sleeve of the core structure; and sixthly, site-casting is implemented to the protective layer and the core structure simultaneously.

Owner:BEIHANG UNIV

Process for the preparation of self-glazed geopolymer tile from fly ash and blast furnace slag

InactiveUS20070221100A1Reduce energy consumptionLow production costSolid waste managementCeramic shaping apparatusSlagHigh energy

The present invention provides a process for the preparation of self glazed geopolymer tile using fly ash and granulated blast furnace slag. In the process of the present invention, the granulated blast furnace slag is fine grounded and / or mechanically activated in conventional grinding mills or high-energy mills. The fly ash, which is found in powder form and fine powder of granulated blast furnace slag, is thoroughly mixed to make a homogenous mixture. The alkaline solution is added into the mixture to initiate the geopolymerization. The ratio of water to powder is optimised to obtain a consistent paste to be used for vibration casting. During the casting, the consistent paste flows inside the mould and the particles settles at mirror finished surface of mould, giving rise to dense and smooth surface.

Owner:COUNCIL OF SCI & IND RES

Geo-polymer recycled concrete and preparation method thereof

InactiveCN101570426ADelayed activationImprove liquiditySolid waste managementCement productionRoad engineeringSlag

The invention belongs to the fields of civil engineering and environmental material engineering, and in particular relates to geo-polymer recycled concrete and a preparation method thereof. The geo-polymer recycled concrete is prepared from raw materials of recycled coarse aggregate, recycled fine aggregate, fly ash, slag powder, water, sodium silicate, sodium hydrate, naphthalene sulfonate formaldehyde condensation compound and calcium saccharate according to certain mixing proportion by adopting a special stirring process. The product of the geo-polymer recycled concrete not only has simple preparation process, but also has good working performance, mechanical property, durability and heat-insulating property. Simultaneously, the geo-polymer recycled concrete and the preparation method can efficiently use a great deal of waste concrete and two industrial byproducts of the fly ash and blast furnace slag, are significant in saving resources, saving energy sources and protecting the environment, and accord with the sustainable development strategy of the building industry. The product of the geo-polymer recycled concrete can be widely applicable to road engineering, structural engineering and other various civil engineering constructions.

Owner:TONGJI UNIV

Fracturing fluid for subterranean formations

A method of fracturing a reservoir comprising the steps of pumping a geopolymer precursor fluid through a wellbore into the reservoir at a fracture pressure, the geopolymer precursor fluid at the fracture pressure generates fractures in the reservoir, wherein the geopolymer precursor fluid is comprised of an amount of aluminosilicate, an amount of alkaline reagent, and a permeability enhancer, allowing the geopolymer precursor fluid to fill the fractures in the reservoir, shutting-in the wellbore at a wellbore pressure, the wellbore pressure maintains the geopolymer precursor fluid in the fractures, allowing the geopolymer precursor fluid to harden for a hardening time to form a geopolymer in the fractures, the geopolymer has a geopolymer matrix, the geopolymer matrix has a permeability, the geopolymer has a compressive strength, and reducing the wellbore pressure allows a reservoir fluid to flow from the reservoir through the geopolymer matrix of the geopolymer to the wellbore.

Owner:SAUDI ARABIAN OIL CO

Geopolymer composition and application for carbon dioxide storage

InactiveUS7846250B2Good pumpability and stabilitySolid waste managementAlkali metal silicate coatingsCo2 storageGeopolymer

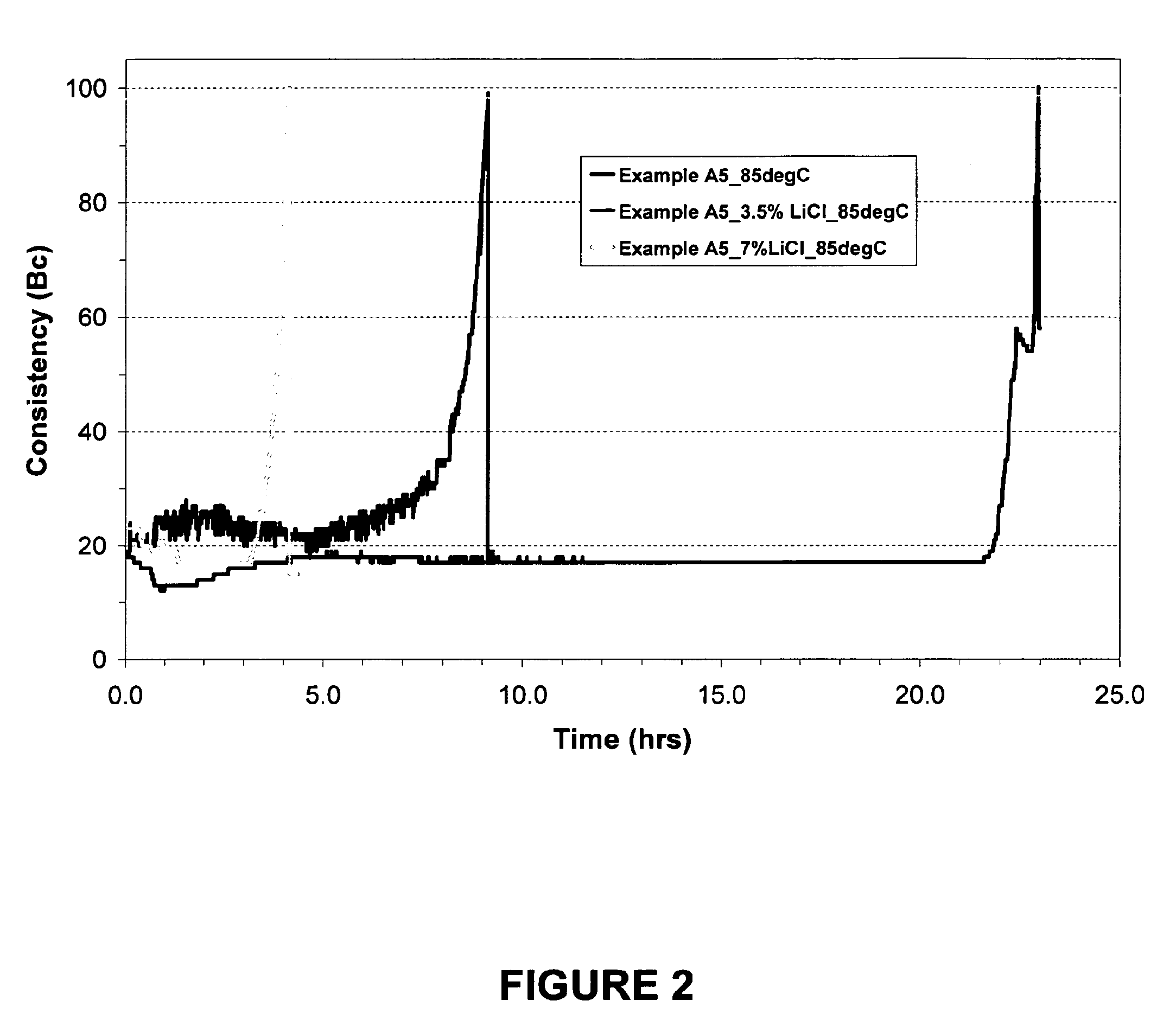

The invention provides geopolymeric compositions intended for use in carbon dioxide injection or production wells or storage reservoirs and preferably in a supercritical carbon dioxide conditions. The geopolymeric composition is formed from a suspension comprising an aluminosilicate source, a metal silicate, an alkali activator, a retarder and / or an accelerator and a carrier fluid wherein the oxide molar ratio M2O / SiO2 is greater than 0.20 with M an alkali metal.

Owner:SCHLUMBERGER TECH CORP

Pumpable geopolymer formulation for oilfield application

InactiveUS20110073311A1Enhanced pumpabilityImprove stabilityFluid removalCement productionAluminateCarrier fluid

The invention provides geopolymeric compositions, which have controllable thickening and setting times for a wide range of temperatures and a large range of geopolymer slurry densities. The geopolymer slurry compositions have good mixability and pumpability, whilst the set materials develop good compressive strength and permeability. The invention discloses a method for preparing geopolymer for oilfield cementing applications. The geopolymeric compositions according to the invention comprises a suspension made of an aluminosilicate source, a carrier fluid, an activator taken from the list constituted by: a metal silicate, a metal aluminate, an alkali activator, or a combination thereof, and an aluminum containing compound taken in the list constituted of bauxite, aluminum oxide and aluminum salt and the suspension is a pumpable composition in oilfield industry and the suspension is able to set under well downhole conditions.

Owner:SCHLUMBERGER TECH CORP

Geopolymer soil consolidation grouting material

InactiveCN101250034AImprove liquidityConvenient slurrySolid waste managementCement productionSlagGeopolymer

The invention relates to a soil consolidation grouting material of geopolymer, which is composed of fly ash, slag, steel slag, high-calcium fly ash, alkali-activator, nonpolar alkaline surface active agent and water, wherein the nonpolar alkaline surface active agent is obtained by reacting curled hair of human or animal with sodium hydroxide, and the pH value of the water is larger than 6.5. The soil consolidation grouting material of geopolymer of the invention is high in initial strength, fine in water stability, liquidity, frost-resisting property and service durability and the like, simultaneously, the soil consolidation grouting material of geopolymer has the characteristic of low manufacturing cost and reducing environmental pollution.

Owner:芮志平 +1

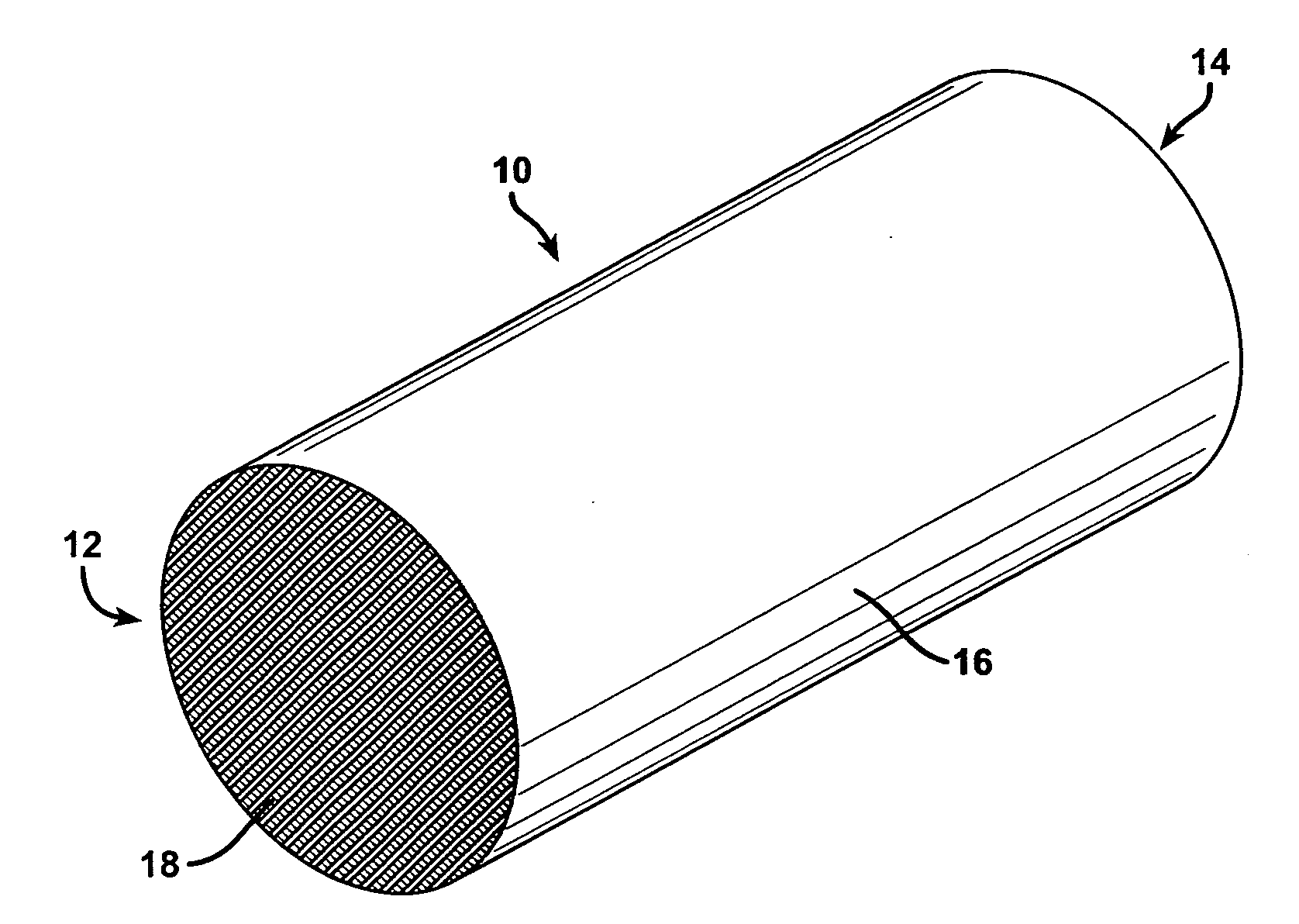

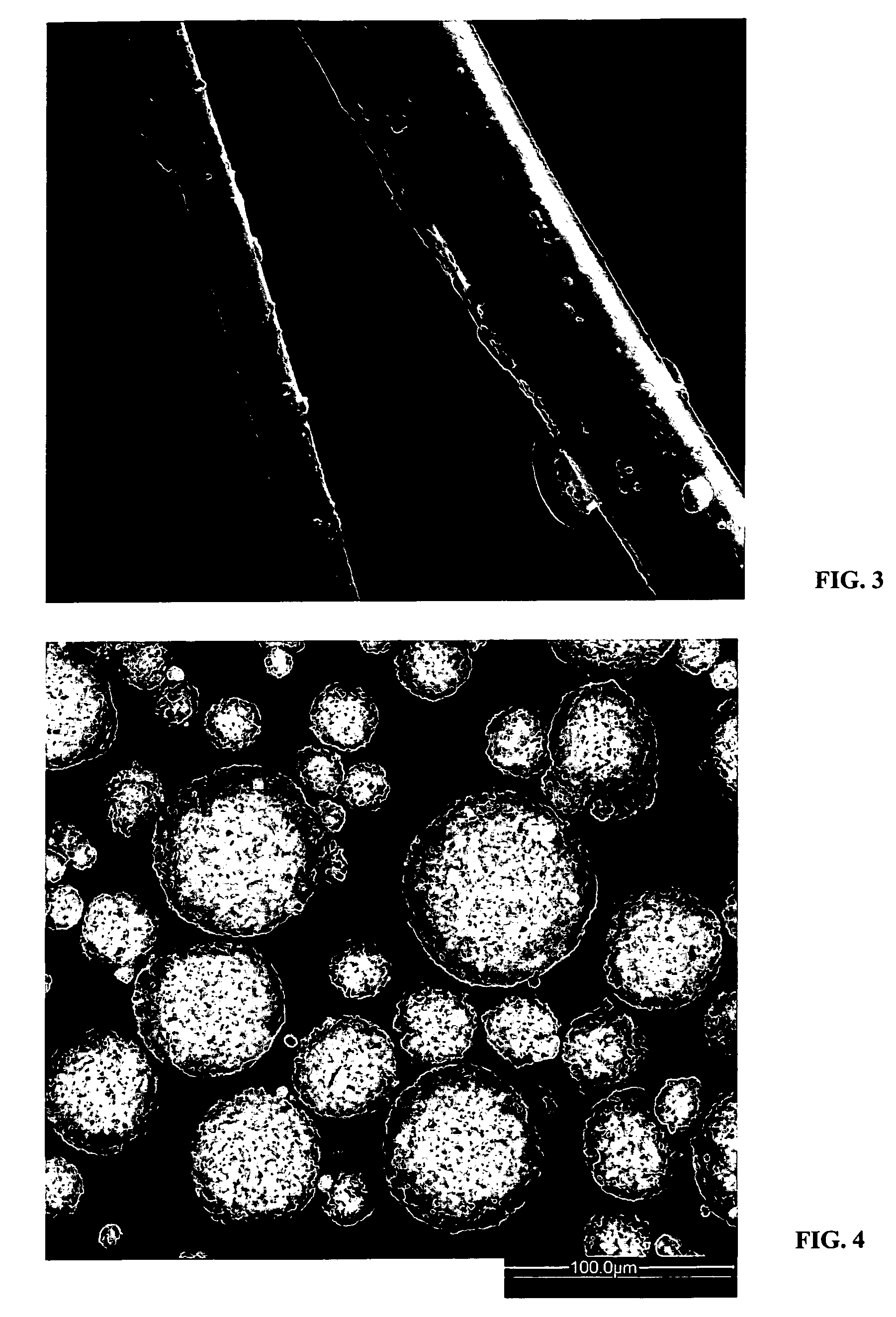

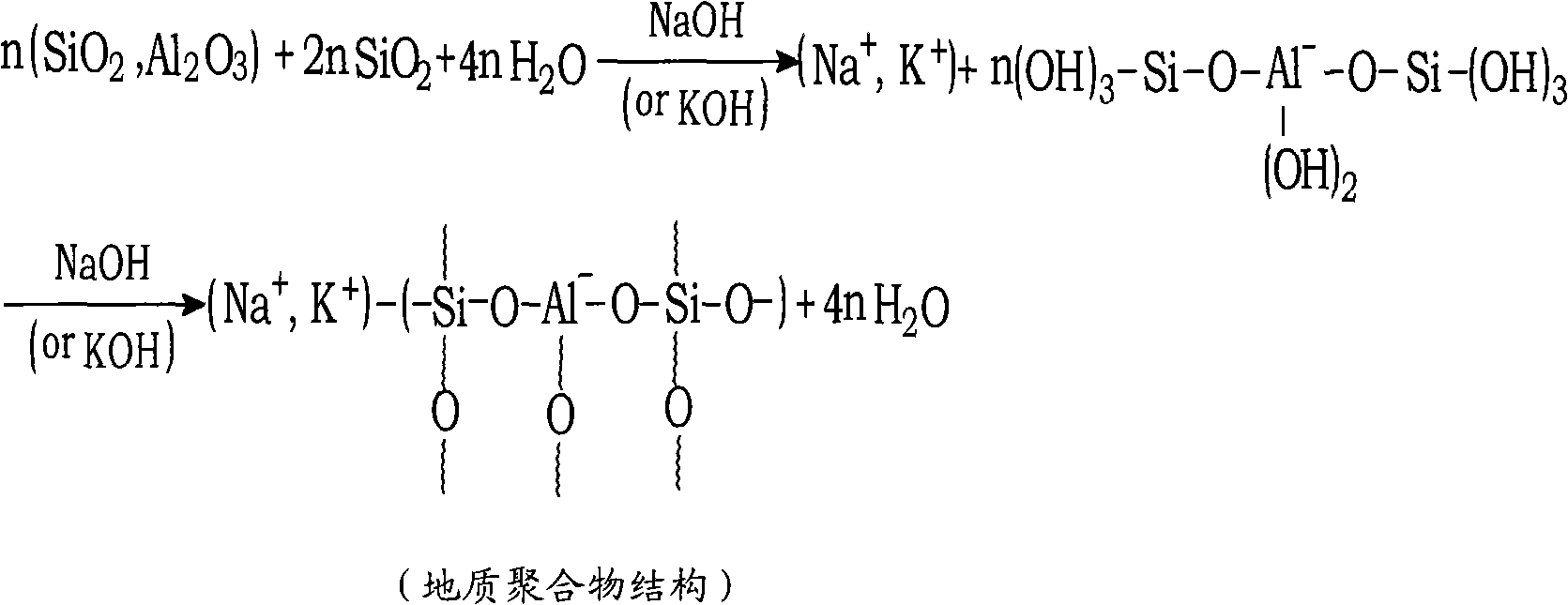

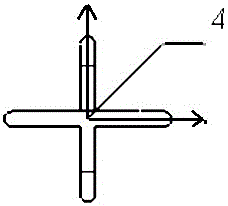

Geopolymeric particles, fibers, shaped articles and methods of manufacture

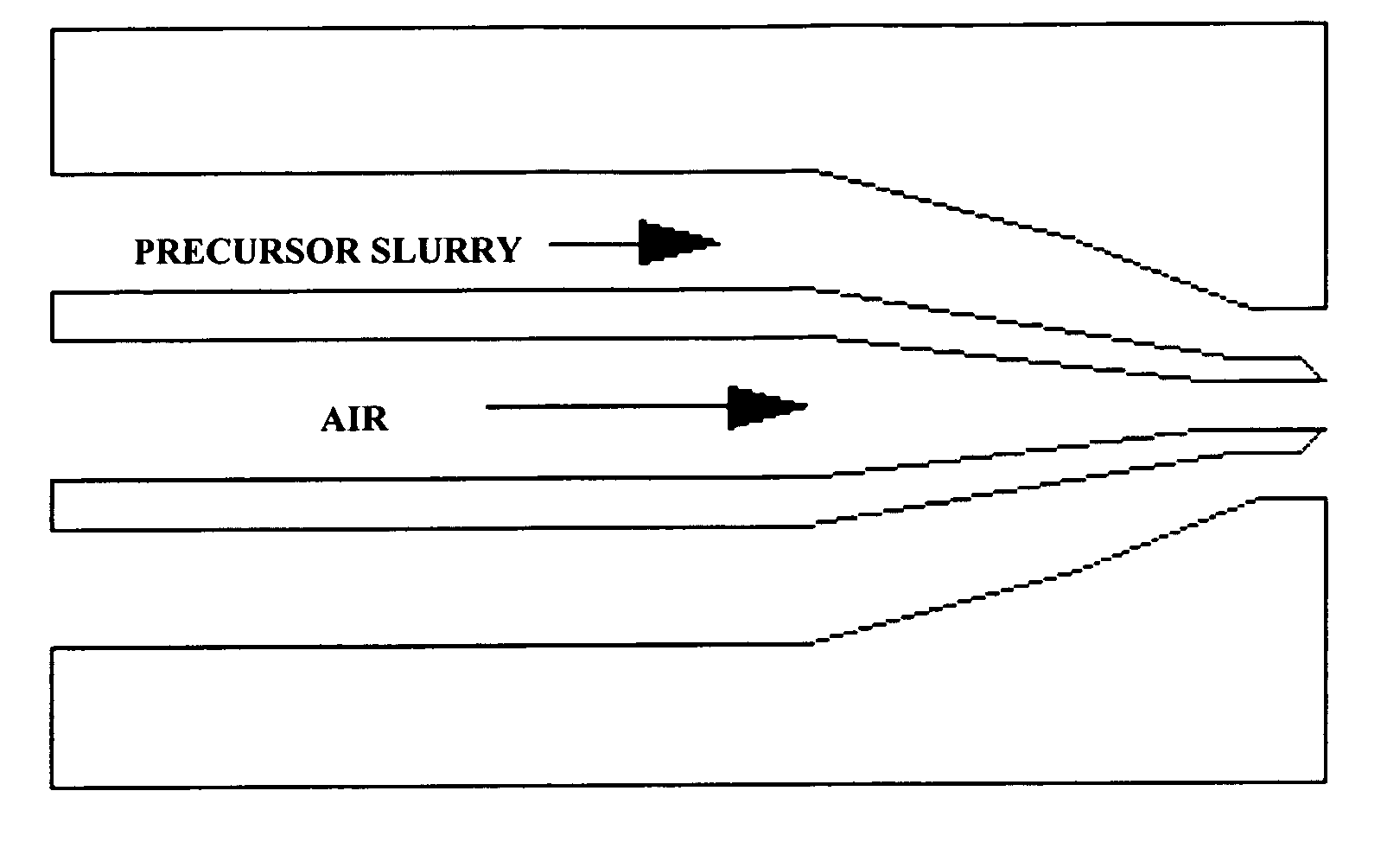

Shaped geopolymeric particles, fibers, and articles incorporating at least one geopolymer are provided; the geopolymeric particles, fibers, and articles having a structure that is solid, foamed, hollow or with one or more voids. Geopolymers are formed by alkali activation of an aluminosilicate and / or aluminophosphate material. The end-products are shaped as spheres, flakes, fibers, aggregates thereof or articles. Such products are formed at low temperatures; wherein forming includes processing using techniques such as spray drying, melt spinning, or blowing. The shaped geopolymeric particles and fibers have high chemical durability, high mechanical strength, application-targeted flowability and packing properties, and are specially suited for incorporating into composite materials, articles, and for use in cementitious, polymeric, paint, printing, adhesion and coating applications. Shaped geopolymeric particles, fibers and articles having voids, hollow or foam-like structures are formed by adding one or more blowing agents.

Owner:JAMES HARDIE TECH LTD

Preparation of manganese slag groundmass geopolymer cementing material

InactiveCN101328029ARealize environmental protectionRealize energy savingCement productionSolid componentSlag

The invention discloses a method for preparing a manganese slag-based geological polymer binder comprising: (1) the solid components of the materials are manganese slag and kaolin; the liquid components are water glass, water and activator. (2) the manganese slag is dried till the moisture content is less than 1%, and is milled in a ball mill till the specific surface is 400-600m<2> / kg, the kaolin is calcined at 900 DEG C till the kaolin becomes metakaolin, and is milled till the specific surface is 500-700<2> / kg. (3) the activator is added into the water glass solution and is mixed uniformly with water to get a water glass solution with a water glass modulus value of 1.5-3.5 and a water glass baume of 35-45 degrees. (4) the mixed solution prepared by the step (3) is added into the mixed powder of managese and metakaolin micropowder, is stirred and moulded after uniform mixture and maintenance. The preparation method has advantages of simple technology, no pollution during the preparation process, good gelling property and strong anti-seawater erosion property using industrial waste residue.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

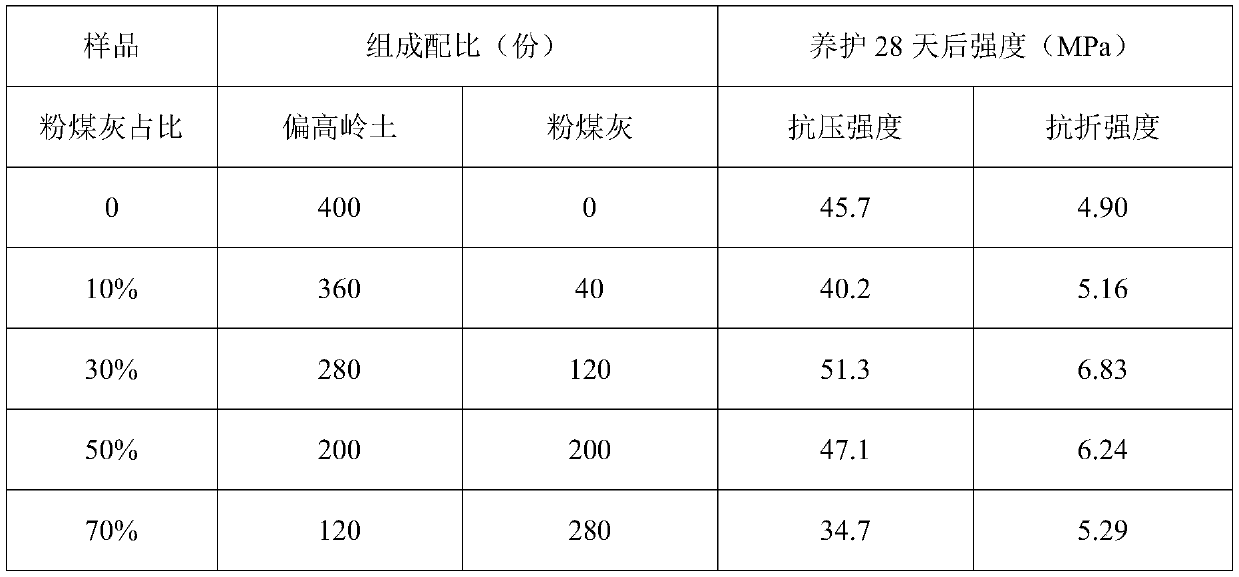

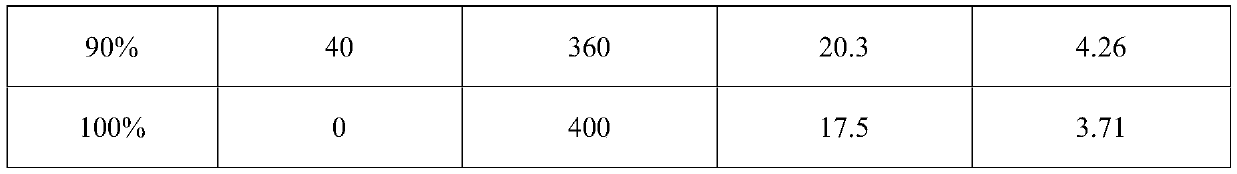

Flyash geopolymer based porous material and preparation process thereof

InactiveCN105800972APracticalSimple production processCement productionSodium phosphatesPolyethylene glycol

The invention provides a flyash geopolymer based porous material and a preparation process thereof. The porous material comprises the following components in parts by weight: 60-100 parts of flyash, 40-70 parts of alkali activator, 0-40 parts of admixtures, 0-5 parts of glass fibers, 2-8 parts of physical foaming agents and 0-0.8 part of chemical activators, wherein the alkali activator is alkaline mixed liquor containing various ions and comprises industrial water glass, sodium hydroxide, water, polyethylene glycol and sodium phosphate; the admixtures refer to levigated metakaolin, silicon micropowder and calcined coal gangue; the physical foaming agents include expired shampoo, an anionic surfactant sodium dodecyl sulfate (SDS), fatty alcohol polyoxyethylene ether sodium sulfate (AES) and disodium fatty alcohol polyoxyethylene ether monosulfosuccinate (AESS); the chemical foaming agents include aluminium powder, hydrogen peroxide, and the like. The porous material has adjustable volume density, fine and uniform pore diameter, low heat conductivity, high strength, the same life as buildings and good fireproof performance.

Owner:QINGHAI UNIVERSITY +1

Fly ash geopolymer concrete and preparation method thereof

ActiveCN110255996AImprove mechanical propertiesIncreased durabilityCement productionFiberMicrosphere

The invention discloses fly ash geopolymer concrete. The concrete is prepared by taking fly ash and metakaolin as base materials, taking one or more than two of sodium hydroxide, potassium hydroxide, sodium silicate and potassium silicate as well as water glass as alkaline activators, and adding modified ceramic microsphere particles, polymer fibers, coarse aggregates, fine aggregates and water. The fly ash geopolymer concrete has good mechanical properties, high durability and high corrosion resistance.

Owner:神木市万盛隆能源发展有限公司

Fly ash based geopolymer and preparation method thereof

InactiveCN103449744AHigh strengthImprove performanceSolid waste managementCement productionToxic industrial wastePolymer

The invention provides a fly ash based geopolymer. The fly ash based geopolymer comprises a dry powder phase and water, of which the mass ratio is 20:3, wherein the dry powder phase comprises the following components in parts by weight: 60-85 parts of fly ash, 0-25 parts of silica fume, 10 parts of solid sodium silicate, 5 parts of industrially pure sodium hydroxide and 0.05-0.12 part of sodium tripolyphosphate. The fly ash based geopolymer can replace cement to prepare engineering materials such as concrete, mortar and the like, and is expected to be applied in the fields such as utilization of high-strength thermal mortar, high temperature resistant reinforcement materials, corrosion-resistant concrete structures and industrial wastes, rapid repairing materials, high-strength and high-performance materials, and the like. Meanwhile, the industrial waste fly ash can be largely and efficiently utilized; the fly ash based geopolymer has great significance on saving of resources, saving of energy sources and protecting of the environment. A preparation method of the fly ash based geopolymer is also simultaneously provided.

Owner:WENZHOU UNIVERSITY

Porous material of phosphate-based geopolymer and preparation method thereof

The invention discloses a porous material of phosphate-based geopolymer and a preparation method thereof. The preparation method comprises the following steps of: adopting metakaolin, alumina (or aluminium hydroxide), phosphoric acid and water as raw materials, adopting aluminium powder as a foaming agent and under a lower temperature ( 50-90 DEG C) preparing the porous material which adopts geopolymer material as a skeleton and has good properties. By testing the properties of the porous material, the result shows that the porous material has compression strength of 2.0 to 15.0MPa, apparent porosity of 30 percent to 70 percent, volume density of 0.40cm to 1.0g / cm and high-temperature resistance of more than 1300 DEG C; and the porous material with different properties and porous structures can be obtained by controlling molar ratio of Al / Si and P / Al and reaction conditions. The invention has simple technique and low cost and is expected to be applied in the fields of insulating materials, waste gas absorbing materials, sewage filtering materials, energy absorbing materials, insulating and encapsulating materials, military, aerospace and the like.

Owner:GUANGXI UNIV

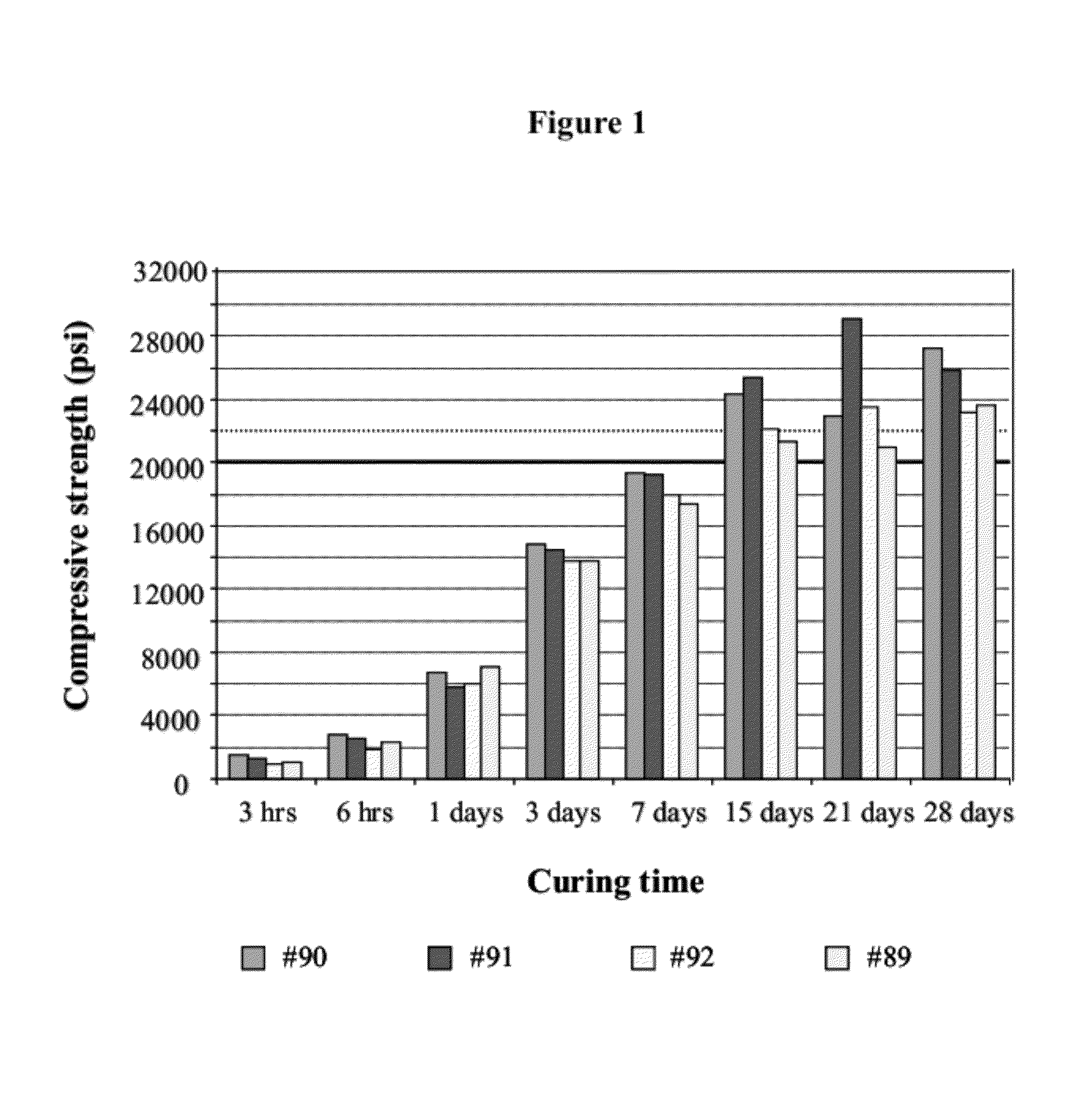

Geopolymer compositions

The present invention relates to geopolymer compositions, methods of producing the compositions, and uses thereof. The geopolymer compositions broadly are comprised of a geopolymer binder and an aggregate and, once cured, can exhibit compressive strengths in excess of that of Portland cement-based concrete formulations. The geopolymer composition of the present invention adheres to most surfaces and can b used in the formation of a mortarless building block, floor screed, bench, building block brick, support column or pre-molded column, beam, paving stone, tiles, stone accouterment for a garden, countertop, bathtub, sink, a geopolymer slab, a structural geopolymer composition, a reinforced geopolymer composition, a steel reinforced geopolymer composition, or as a substitute for structural concrete in foundations, beams, columns, or slab with the addition as necessary of steel reinforcement.

Owner:ALTER STEPHEN +1

A kind of inorganic coating with geopolymer material as film-forming substance

The invention discloses an inorganic coating using geopolymer material as a film-forming substance. It is a single-component water-based inorganic coating using alkali polymerized metakaolin geopolymer material as a film-forming substance. The coating is characterized in that It consists of solid phase S and liquid phase L. The solid phase S is metakaolin, heavy calcium carbonate powder, quartz powder, and anti-cracking additives; the liquid phase L is sodium or potassium water glass and water. The solid phase S and the liquid phase L are mixed in a weight ratio of 1:1.0 to 1.5. The invention eliminates many defects caused by organic polymer film formation. It has the characteristics of high strength, high hardness, water resistance, high temperature resistance, anti-aging, low cost, non-toxic and environmentally friendly, especially with good bonding force with cement mortar layer. It can be applied directly on the surface of buildings or products to provide decorative and protective properties.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com