Fly ash geopolymer concrete and preparation method thereof

A technology of fly ash and geopolymer, applied in cement production and other directions, can solve problems such as environmental pollution, land occupation, energy and resource waste, and achieve good mechanical properties, strong corrosion resistance and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of embodiment 1 fly ash geopolymer concrete

[0036] The metakaolin used in the present invention is prepared by calcining kaolin at 700° C. for 12 hours, and the chemical composition of metakaolin is as shown in the table below:

[0037] Table 1 Chemical composition of metakaolin

[0038] Element SiO 2

Al 2 o 3

Fe 2 o 3

CaO TiO 2

MnO K 2 o

P 2 o 5

SO 3

MgO content% 64.9 26.6 3.7 0.9 1.8 0.1 0.8 0.9 - -

[0039] The fly ash used in the present invention is a thermal power plant industrial grade F class first-level dry ash, and the chemical composition of the fly ash is shown in the following table:

[0040] Table 2 Chemical composition of fly ash

[0041] Element SiO 2

Al 2 o 3

Na 2 o

CaO Fe 2 o 3

MgO SO 3

K 2 o

TiO 2

P 2 o 5

Cl -

MnO content% 39.4 32.7 7.9 6.0 3.9 2.3 2.1 2.0 0.6 0.8 0.5...

Embodiment 2

[0047] Preparation of embodiment 2 fly ash geopolymer concrete

[0048] S1: The preparation method of modified ceramic microsphere particles is the same as that in Example 1;

[0049] S2: The preparation method of the basic activator is the same as in Example 1;

[0050] S3: first mix 200 parts of fly ash and 200 parts of metakaolin in a mixer, add the alkaline activator prepared in step S2 and 7.5 parts of polycarboxylate water reducer, stir well, and add 20 parts of polyacrylonitrile fiber , mix and stir;

[0051] S4: The preparation of geopolymer concrete is the same as in Example 1.

Embodiment 3

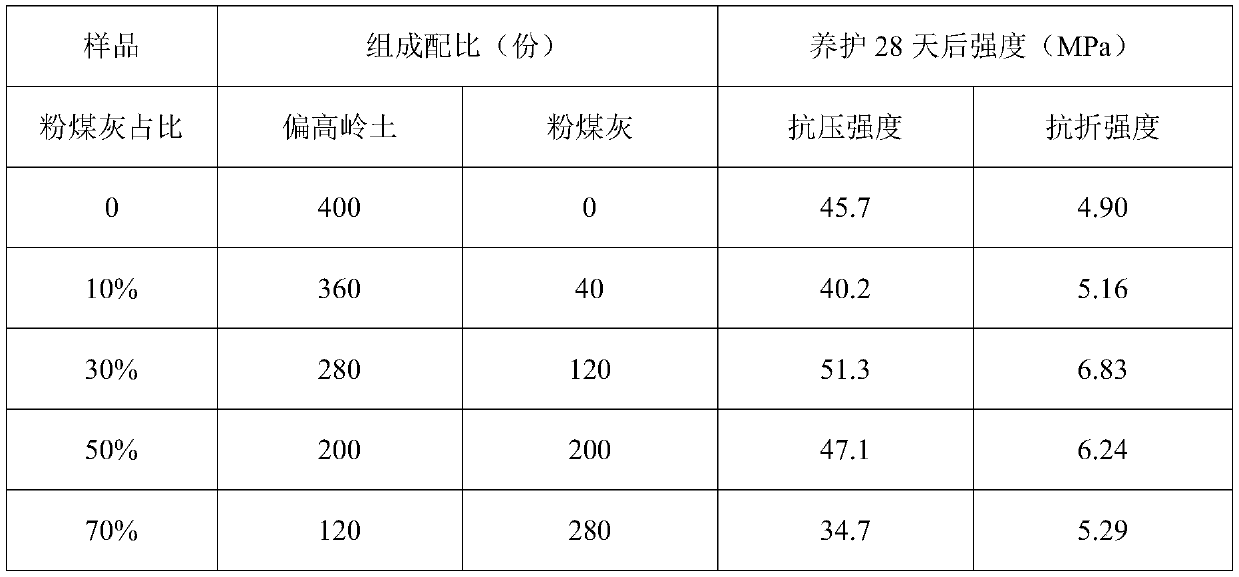

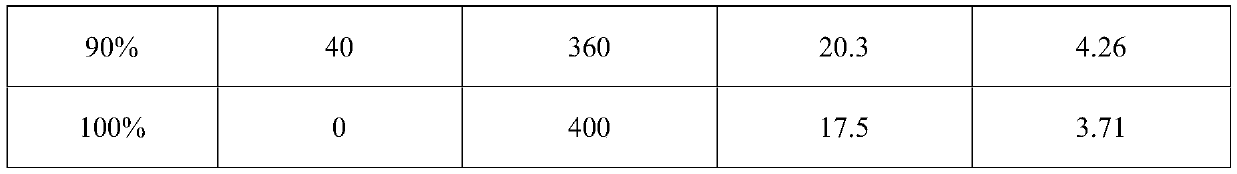

[0079] Example 3 Optimization of Fly Ash Content in Fly Ash Geopolymer Concrete

[0080] S1: The preparation method of modified ceramic microsphere particles is the same as that in Example 1;

[0081] S2: The preparation method of the basic activator is the same as in Example 1;

[0082] S3: The preparation method of the geopolymer gel material is the same as in Example 1. In order to screen the optimum amount of fly ash, a total of 400 parts of fly ash and metakaolin are used to set the proportion of fly ash to 0, 10%, and 30% respectively. %, 50%, 70%, 90%, 100%, a total of 7 groups of tests;

[0083] S4: The preparation of geopolymer concrete is the same as in Example 1.

[0084] According to GB / T 50081-2002 "Standards for Test Methods of Mechanical Properties of Ordinary Concrete", the test specimens were prepared with a size of 100mm×100mm×100mm. After 28 days of standard curing, the compressive strength of the geopolymer concrete specimens was tested. , flexural stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com