Patents

Literature

1493 results about "Metakaolin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

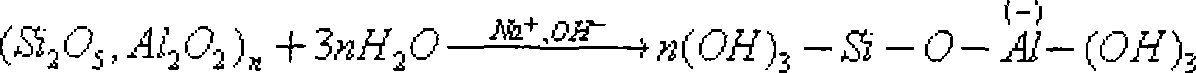

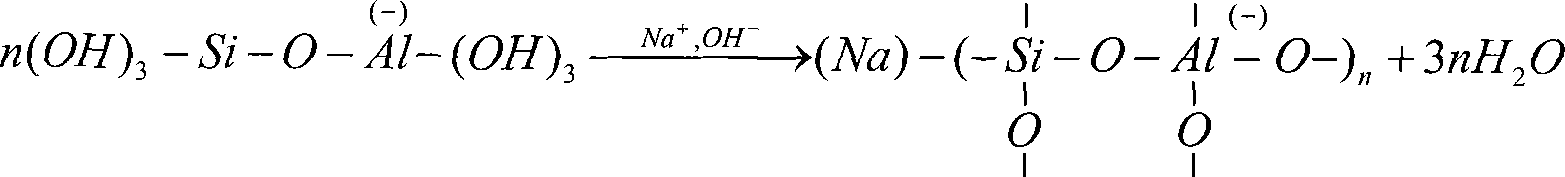

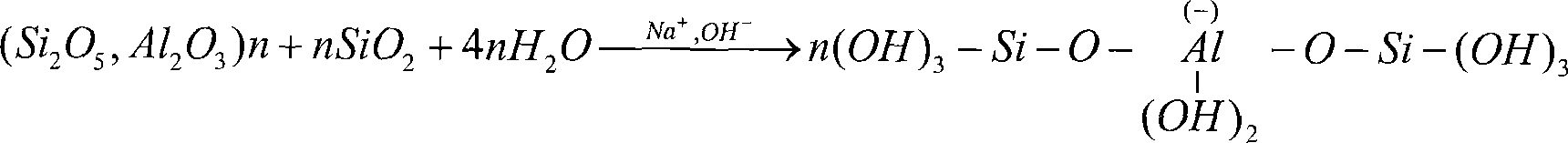

Metakaolin is the anhydrous calcined form of the clay mineral kaolinite. Minerals that are rich in kaolinite are known as china clay or kaolin, traditionally used in the manufacture of porcelain. The particle size of metakaolin is smaller than cement particles, but not as fine as silica fume.

High-tenacity crack-control impervious fiber concrete

ActiveCN101665342AEvenly dispersedFully exerted tensile strengthSolid waste managementSlagPolyvinyl alcohol

The invention relates to a fiber concrete material belonging to the field of building materials. The fiber concrete material mainly contains cement, active mineral blending materials, aggregates, fibers and water and is characterized in that the active mineral blending materials adopt coal ash, siliceous dust, pelletization blast furnace slag and metakaolin; the fibers adopt polyvinyl alcohol fibers, polyethylene fibers and aromatic polyamide fibers; the maximum particle size of the aggregates is smaller than or equal to 0.5mm, and the ratio of the weight of the aggregates to the total weightof the cement and the active mineral blending materials is 1-70 percent; and the blending volume of the fibers accounts for 1.5-2.5 percent of the total volume of fiber concrete. The fiber concrete material has the advantages of high tenacity, higher deformation capability, tensile strength and bending strength, limit tension strain of 1.8-7.5 percent, tensile strength of 4-10MPa and bending strength of 10-20MPa, can control the width of a crack lower than 0.1mm, effectively enhance the integrity and the shock resistance of a structure and ensure the permeability resistance and the durabilityof the structure.

Owner:徐世烺

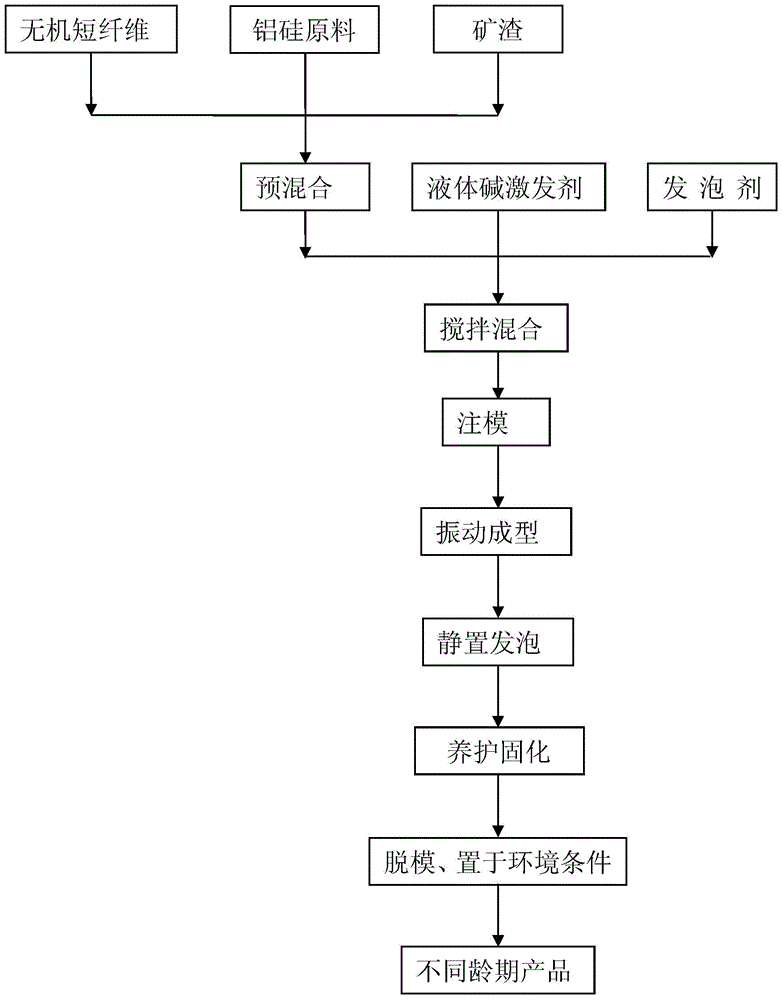

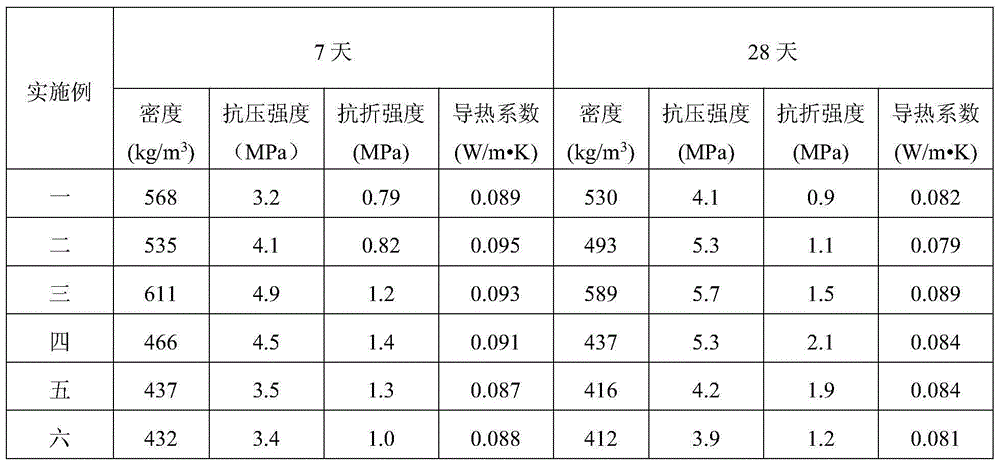

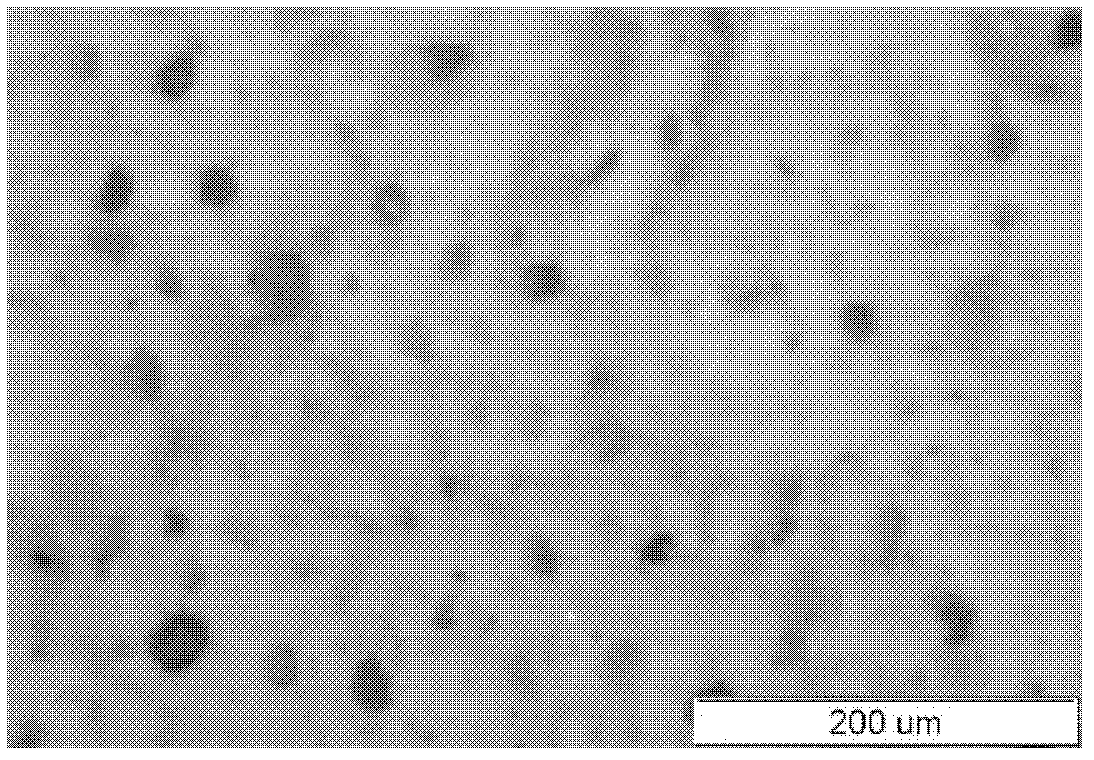

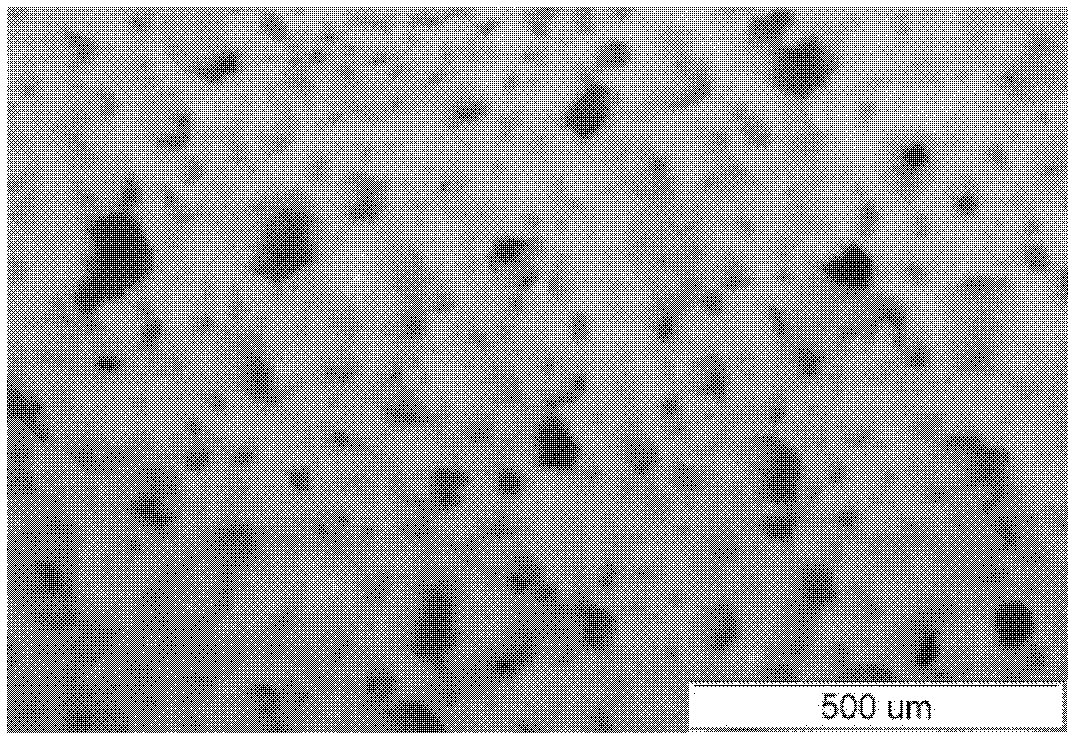

Fibre reinforced coal ash based geopolymer foam material and preparation method thereof

InactiveCN103601524ARealize high value utilizationReduce pollutionCement productionCeramicwarePolymer scienceSlag

The invention discloses a fibre reinforced coal ash based geopolymer foam material and a preparation method thereof. The fibre reinforced coal ash based geopolymer foam material disclosed by the invention comprises the following components in percentage by weight: 50-70% of aluminium silicon raw material, 5-15% of slag, 3-8% of inorganic fibre, 15-30% of liquid alkaline exciting agent, 0.2-2% of foaming agent, and 2.5-3.5% of foam stabilizer. The preparation method disclosed by the invention comprises the step of also adding the foam stabilizer while adding the foaming agent by adopting the liquid alkaline exciting agent by taking the inorganic fibre as the reinforcing agent, the slag as the Ca adjusting agent and other solid raw materials (such as coal ash, metakaolin and silica fume) as powder for providing aluminium silicon. The light foam material prepared by the invention has the characteristics of being high in intensity, small in size change rate, low in water absorption and the like in the event of having same volume weight and heat conductivity of the similar materials, and is applied to various applications.

Owner:TIANJIN UNIV

Exterior wall color surface decoration mortar and preparation method thereof

The invention relates to a building material, and in particular relates to an exterior wall color surface decoration mortar and a preparation method thereof. The exterior wall color surface decoration mortar comprises the following raw materials by weight: 20%-30% of white cement, 50%-60% of quartz sand, 0.1%-0.5% of chopped fiber, 10%-20% of heavy calcium carbonate, 0.2%-1% of latex powder, 0.3%-0.5% of cellulose ether, 1%-5% of an inorganic pigment, 0.2%-0.4% of a water repellent, 5%-10% of coal powder ash, 0.1%-0.15% of a defoaming agent, 1%-3% of metakaolin, 0.2%-0.5% of a thixotropic lubricant and 1%-2% of a water reducing agent. The exterior wall color surface decoration mortar has the advantages of crack resistance, weather resistance, good ultraviolet resistance, permanent and uniform color, good whiskering resistance, and the like, can be well combined with various inorganic base layer materials, is good in coating density, and can be widely used in the building fields such as exterior wall decoration and the like.

Owner:KUNSHAN JIANGUO CONCRETE PROD CO LTD

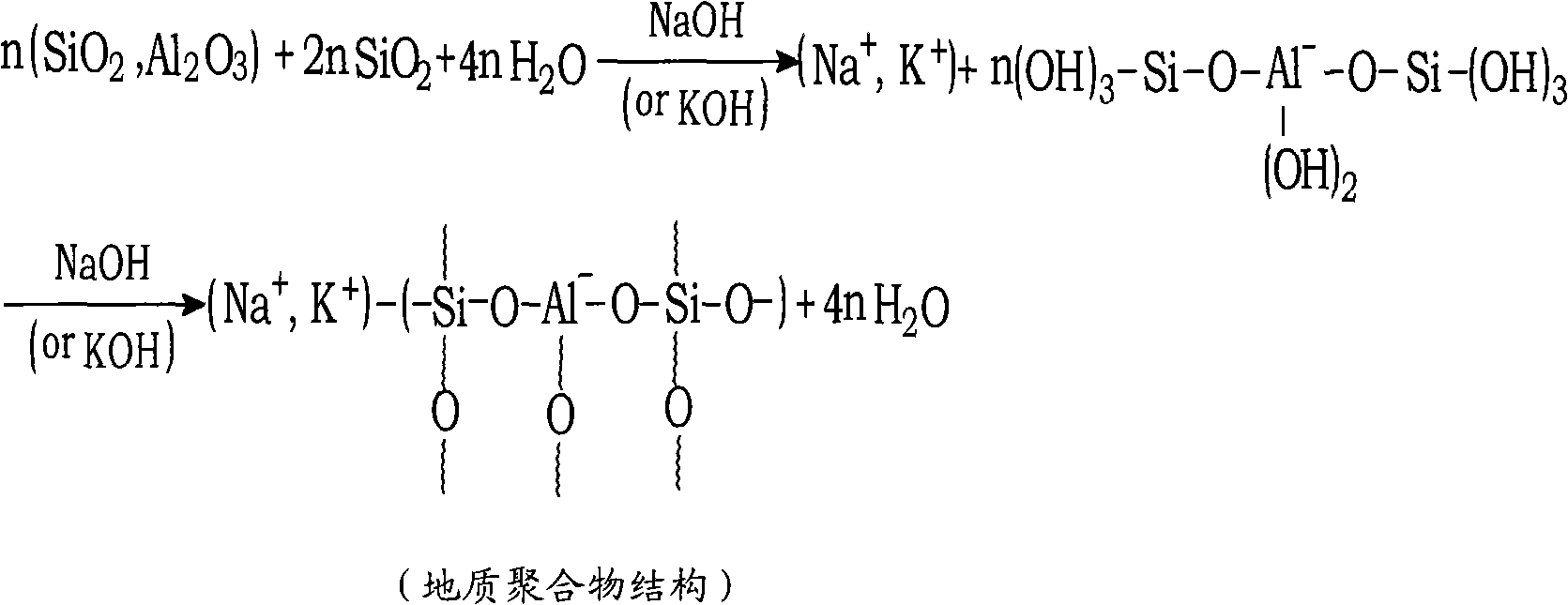

Geopolymer gel material for rush repairs and rush constructions

ActiveCN101628791AGood mechanical propertiesEasy constructionSolid waste managementCement productionSlagMetakaolin

The invention provides a geopolymer gel material for rush repairs and rush constructions, which is prepared by adding water to 13-17 percent by weight of exciting agent and 82-87 percent by weight of slag containing aluminosilicate. The slag comprises one or the combination of more of blast furnace slag, steel slag, coal ash and coal gangue, and the exciting agent comprises the following components in percentage by weight: 35-75 percent of SiO2, 0-55 percent of Na2O, 0-65 percent of K2O, 0-1 percent of CaO and 0-1 percent of SO3. The geopolymer gel material which has the characteristic of quick setting and hardening is prepared by using the industrial waste slag as a main raw material and matching the exciting agent, and the geopolymer gel material has excellent mechanical property and controllable setting time and can replace gel materials such as fast setting and hardening cement, and the like in the processes of rush repairs and rush constructions. The industrial solid wastes such as the blast furnace slag, the steel slag, the coal ash, the coal gangue, and the like containing the aluminosilicate series are used as main raw materials, metakaolin is not added and the raw materials do not need to be calcined, thus the invention has low energy consumption, less pollution, simple process, low cost, environmental protection and energy saving.

Owner:深圳市航天新材科技有限公司

Mineral polymer foaming material as well as preparation method and application of mineral polymer foaming material

The invention discloses a mineral polymer foaming material as well as a preparation method and an application of the mineral polymer foaming material. The material comprises the following ingredients in parts by weight: 50 to 100 parts of metakaolin, 0 to 50 parts of admixture, 50 to 100 parts of water glass, 0.1 to 15 parts of foaming agents, 0 to 10 parts of foam stabilizers and 10 to 90 parts of water. A physical foaming method is adopted, the foaming agents and the water are mixed to be made into foams, then, the foams are uniformly mixed with power materials adopting metakaolin powder as main structure materials, next, the water glass is added, the uniform stirring is carried out, the foaming material is manufactured through forming, and the air hole size and the product density of the foaming material are easy to control. The prepared mineral polymer foaming material has the advantages that the density is small, the air hole quantity is great, the tensile strength is higher than that of the common foaming material products, the water resistance is good, the fire resistance is good, and the resistance on high temperature of 1200 DEG C can be realized. The mineral polymer foaming material can be applied to the process fields of heat preservation and thermal insulation of buildings, heat preservation, filtering and adsorption of thermal equipment and the like.

Owner:SOUTH CHINA UNIV OF TECH

Inorganic artificial combining stone and preparation method thereof

InactiveCN102557571AExpand raw material resourcesLow costCeramic shaping apparatusCement productionFiberKaolin clay

The invention discloses inorganic artificial combining stone and a preparation method thereof. The artificial combining stone uses silicon acid-base solution to arouse metakaolin to react and generate geopolymer to serve as an inorganic cementing agent, and the artificial combining stone mainly contains the metakaolin, the silicon acid-base solution, natural stone aggregate, decoration aggregate, a thickening time control agent, inorganic pigment and fibers. The preparation method is firstly enabling the thickening time control agent and the inorganic pigment to be dissolved in the silicon acid-base solution to obtain mixed serous fluid, evenly blending the metakaolin, the natural stone aggregate, the decoration aggregate, the fibers and the mixed serous fluid, preparing the artificial combining stone through model entering or material distribution, vibration under the vacuum condition, molding in a pressing mode, maintaining, cutting, polishing, burnishing and surface protection. The artificial combining stone not only has decoration features which can be equal to that of resin artificial stone, but also is non-toxic, environment-friendly, low in cost, resisting in corrosion of most majority of acid-base salts, durable in high temperature and excellent in durable performance, obviously avoids whiting and saltpetering phenomena after a long time use, and is strong in pollution resisting capability.

Owner:SOUTH CHINA UNIV OF TECH

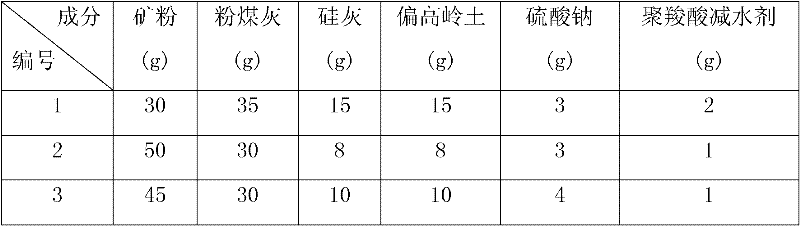

Concrete for rehabilitating historic building

The invention provides concrete for rehabilitating a historic building. The concrete comprises the following materials of cement, pebble, sand, water, mineral powder, fly ash, silica fume, metakaolin, sodium sulfate, a polycarboxylic water reducer, a cement expansive material, grace fibers, carbon fibers, glutinous rice mortar, a pumping aid, epoxy resin and a curing agent which are mixed according to a certain mass ratio. The formed concrete is short in time of coagulation, high in strength after coagulation, high in impermeability grade, high in slump characteristic as well as high in workability and plasticity effect, can prevent the problem that the concrete in a super-long concrete structure is easily cracked, and meets the requirements on toughness and seepage-proofing performance of the concrete in rehabilitation of the historic building; and the industrial residue and other materials are utilized, so that the concrete is a green and environmentally-friendly concrete.

Owner:蚌埠市兴华机械有限公司

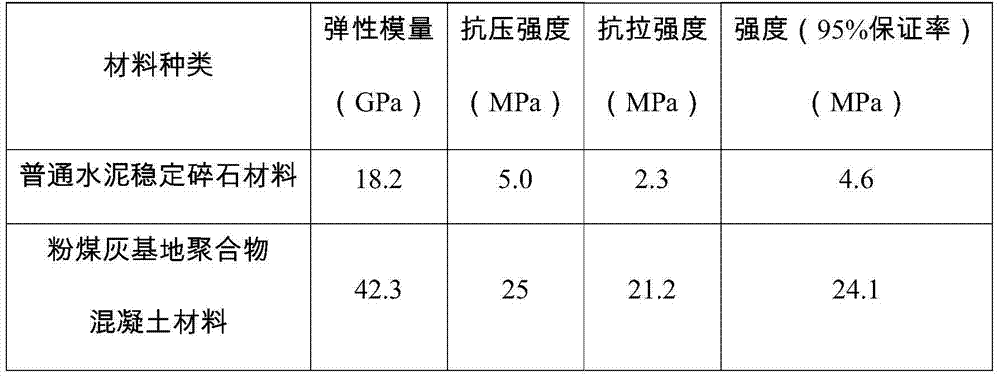

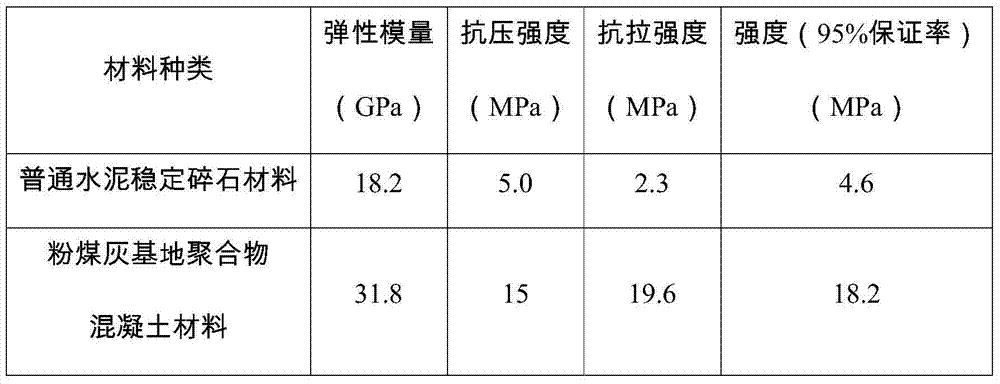

Flyash-based polymer concrete material and preparation method thereof

ActiveCN104496333APromote environmental protectionImprove mechanical propertiesPolymer sciencePolymer concrete

The invention discloses a flyash-based polymer concrete material and a preparation method and an application thereof. The flyash-based polymer concrete material comprises the following components in percentage by mass: 25%-45% of flyash, 0-15% of metakaolin, 10%-15% of cement, 0-5% of coal gangue and slag, 25%-35% of an alkali activator, 0.5%-1% of a retarder and 1%-5% of deionized water. An alkali-activated flyash-based polymer is adopted as a main gel material, so as to prepare an inorganic polymer concrete material; the polymer concrete material has the characteristics of high environmental protection property, good mechanical property and high early strength.

Owner:SHANGHAI PUDONG NEW AREA CONSTR GRP CO LTD

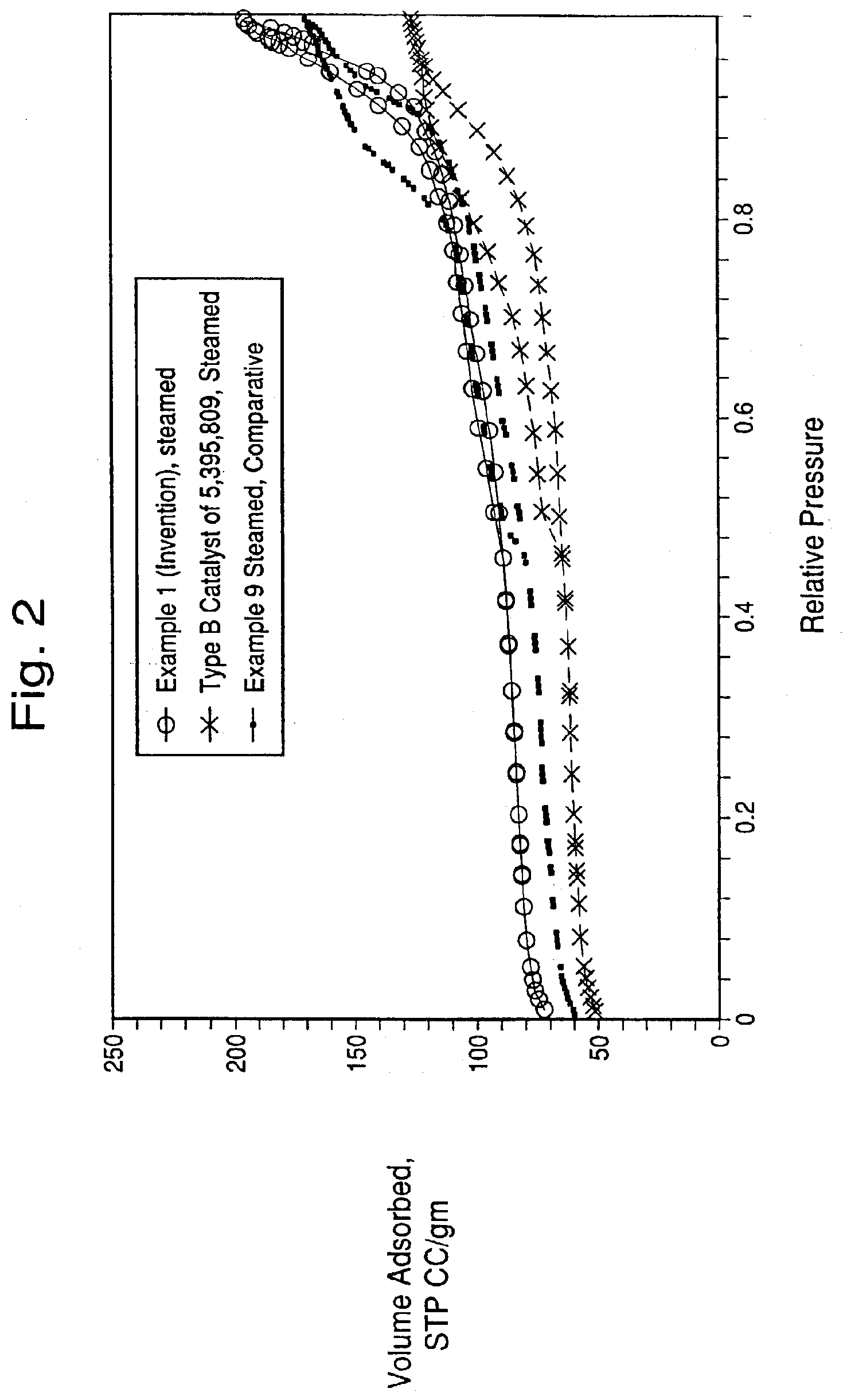

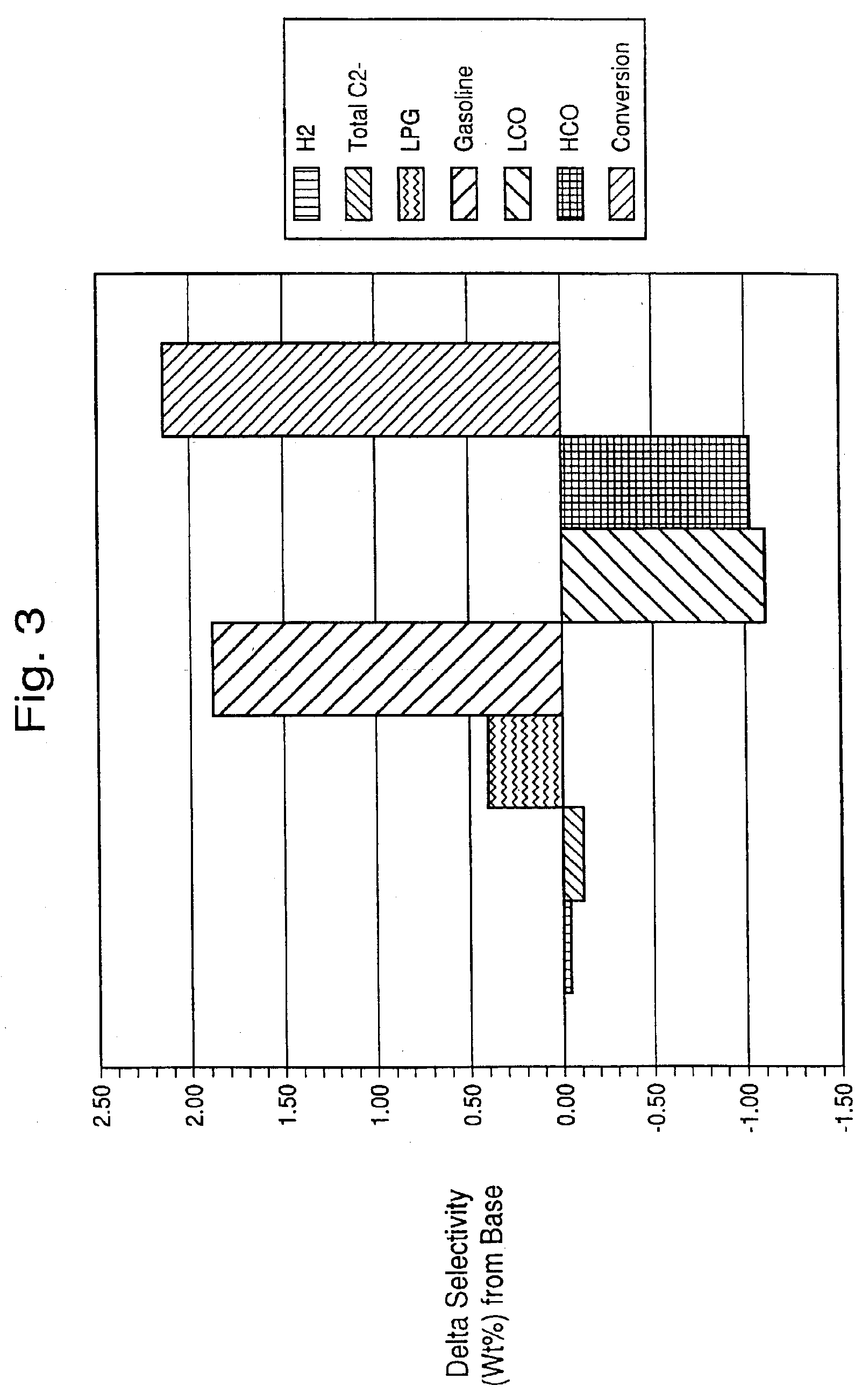

Structurally enhanced cracking catalysts

InactiveUS6943132B2Hamper accessibilityDiffusion fastCatalytic crackingMolecular sieve catalystsMicrosphereSlurry

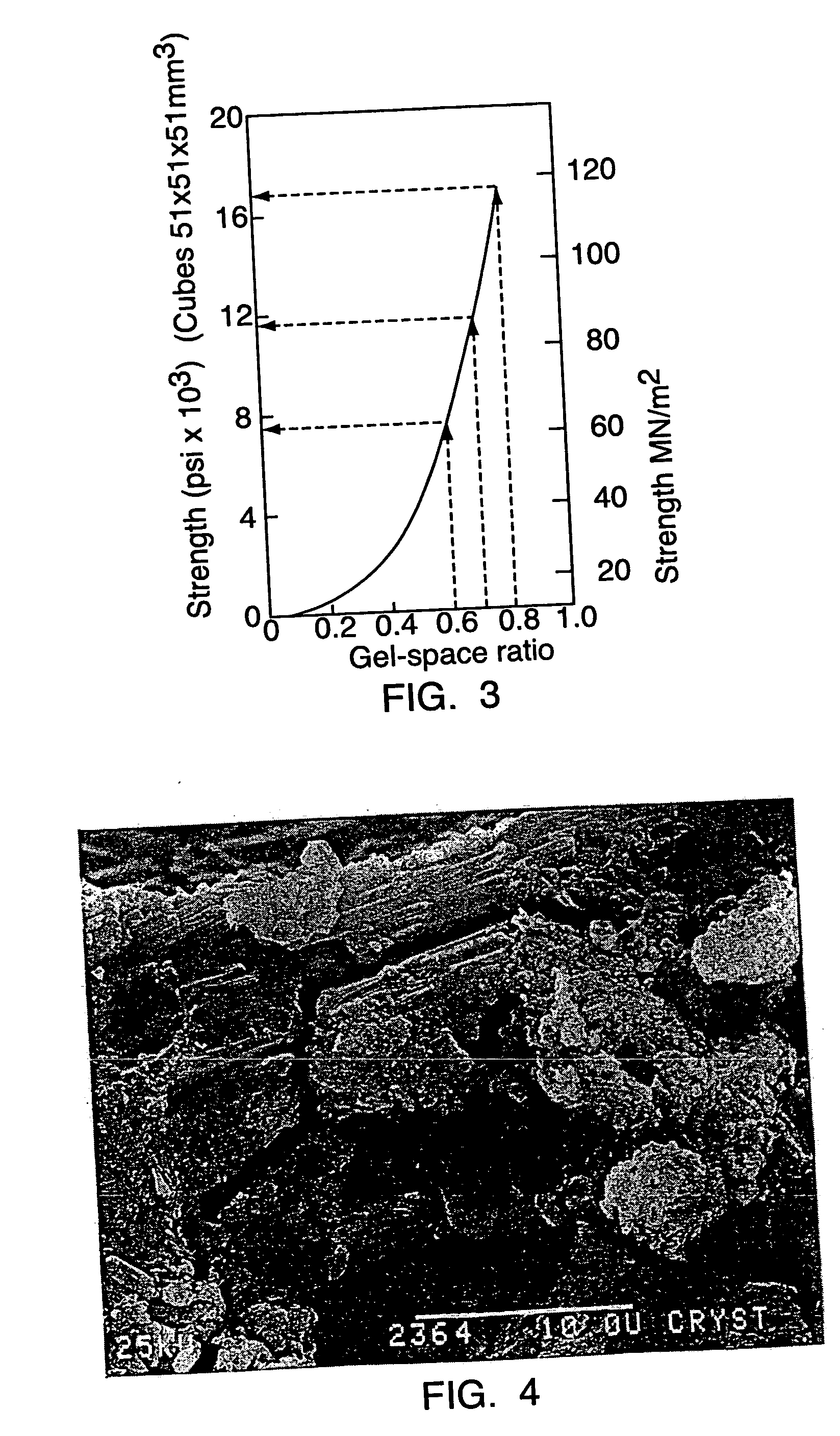

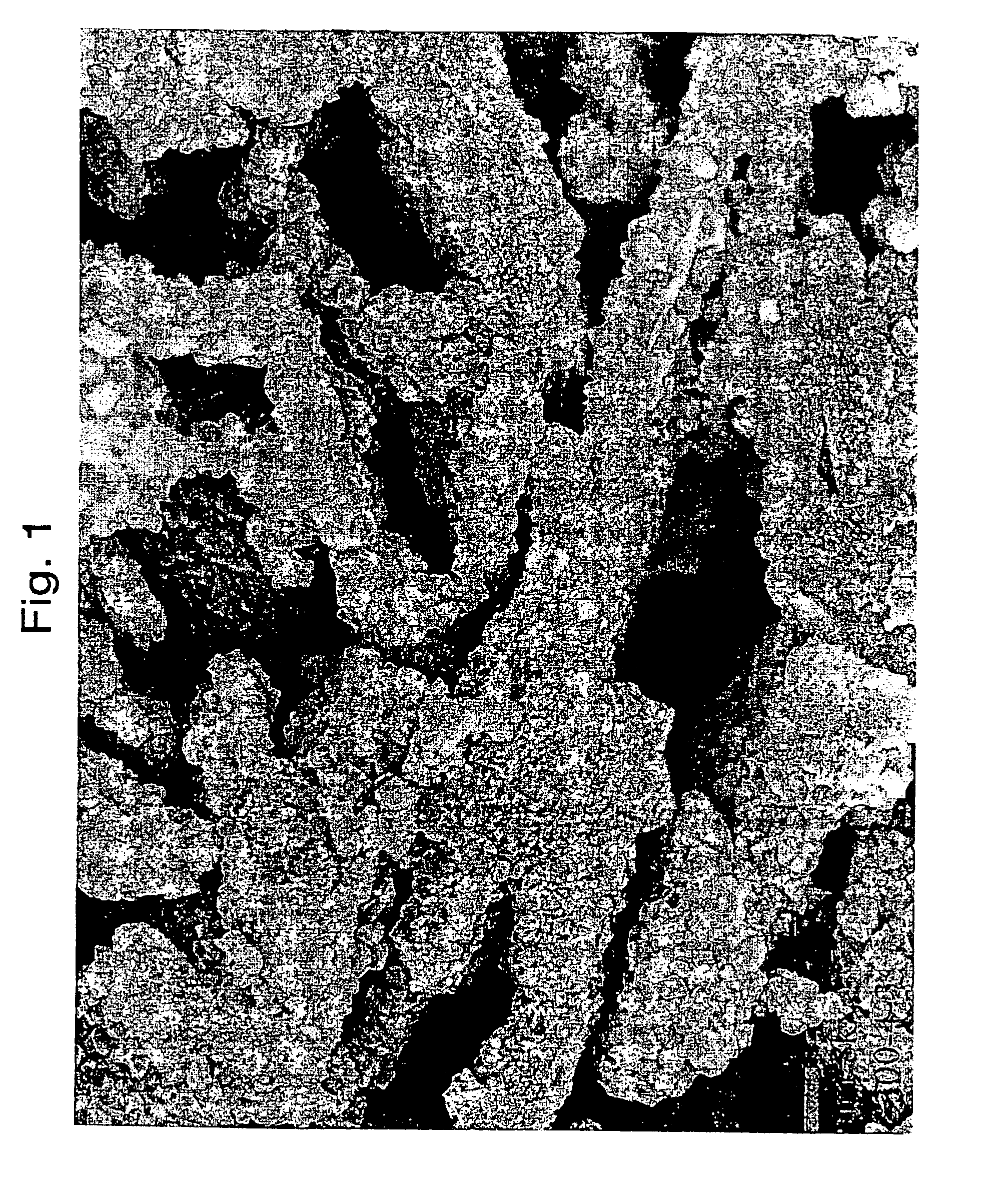

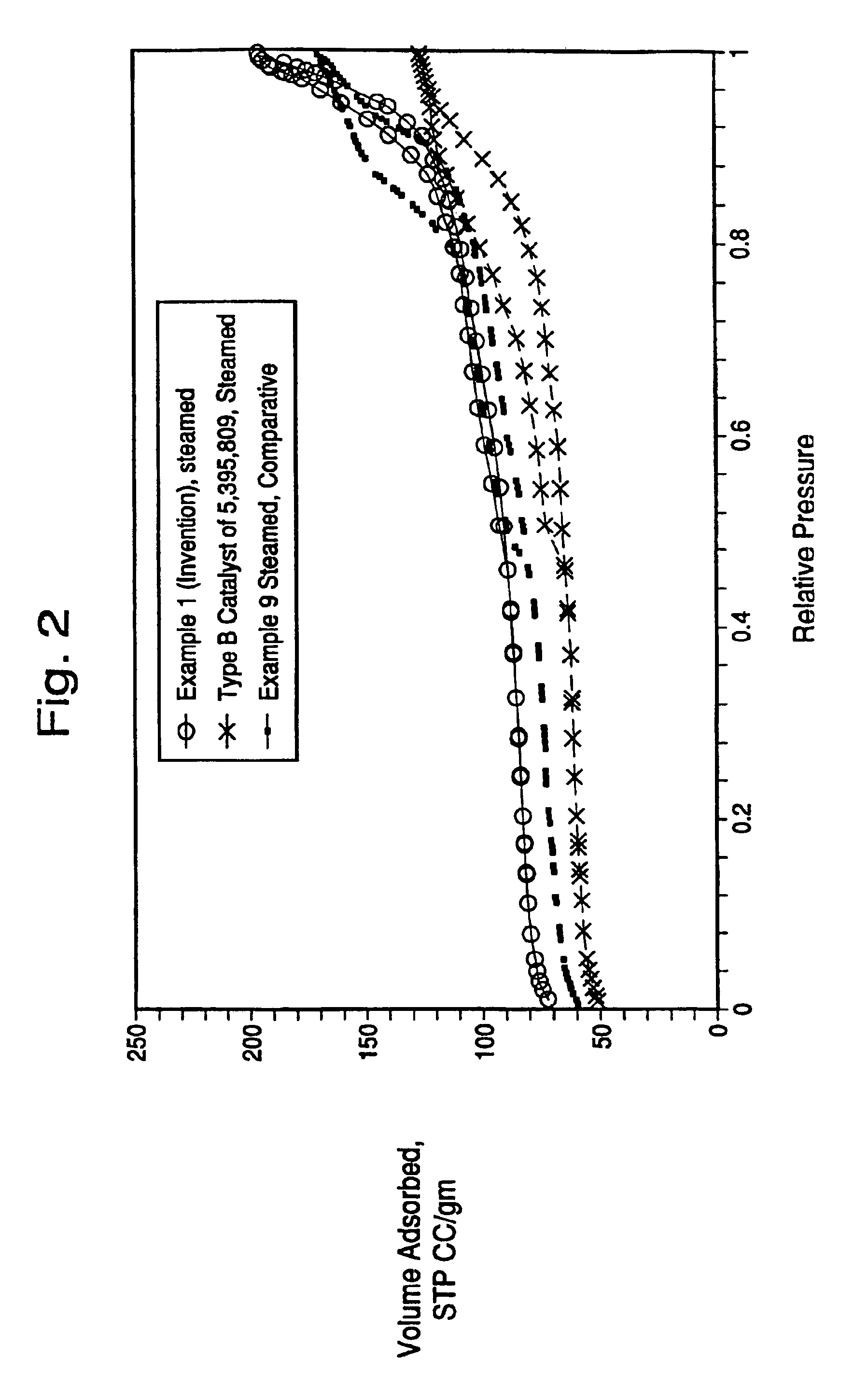

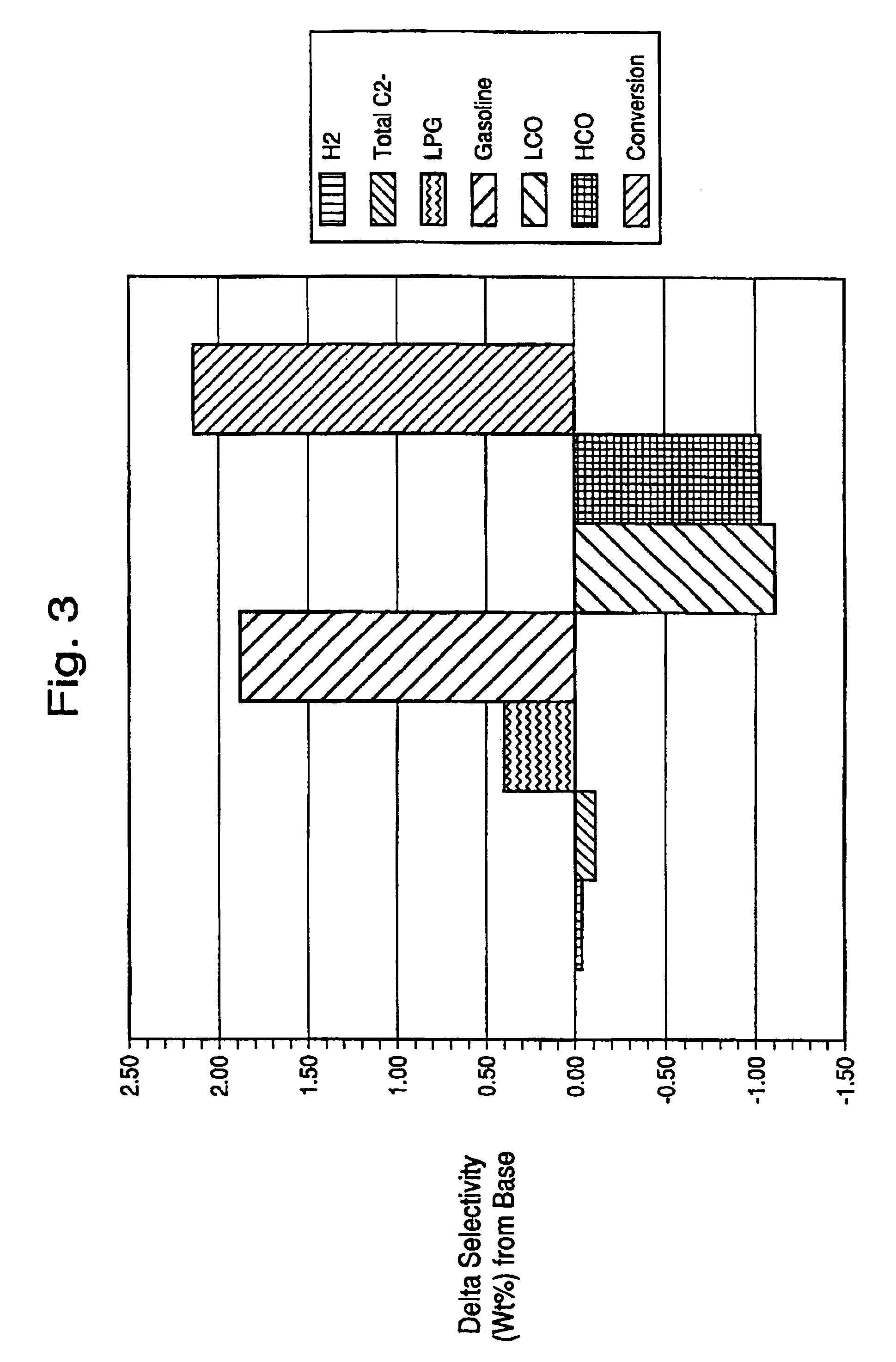

Zeolite microsphere FCC catalysts having a novel morphology comprising a macroporous matrix and crystallized zeolite freely coating the walls of the pores of the matrix. The catalysts are formed from microspheres containing a metakaolin and kaolin calcined through its exotherm, the latter calcined kaolin being derived from a kaolin having a high pore volume. Kaolin having a high pore volume can be a pulverized ultrafine kaolin or a kaolin which has been pulverized to have an incipient slurry point less than 57% solids.

Owner:ENGELHARD CORP

Preparation of manganese slag groundmass geopolymer cementing material

InactiveCN101328029ARealize environmental protectionRealize energy savingCement productionSolid componentSlag

The invention discloses a method for preparing a manganese slag-based geological polymer binder comprising: (1) the solid components of the materials are manganese slag and kaolin; the liquid components are water glass, water and activator. (2) the manganese slag is dried till the moisture content is less than 1%, and is milled in a ball mill till the specific surface is 400-600m<2> / kg, the kaolin is calcined at 900 DEG C till the kaolin becomes metakaolin, and is milled till the specific surface is 500-700<2> / kg. (3) the activator is added into the water glass solution and is mixed uniformly with water to get a water glass solution with a water glass modulus value of 1.5-3.5 and a water glass baume of 35-45 degrees. (4) the mixed solution prepared by the step (3) is added into the mixed powder of managese and metakaolin micropowder, is stirred and moulded after uniform mixture and maintenance. The preparation method has advantages of simple technology, no pollution during the preparation process, good gelling property and strong anti-seawater erosion property using industrial waste residue.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

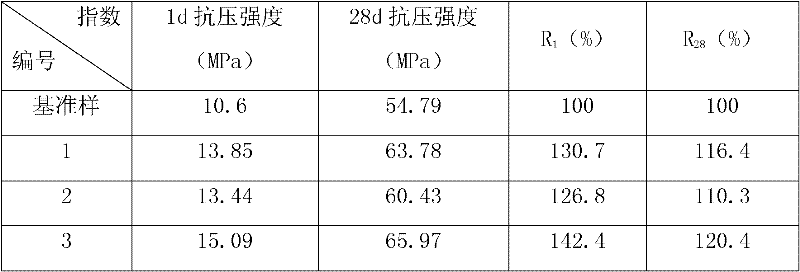

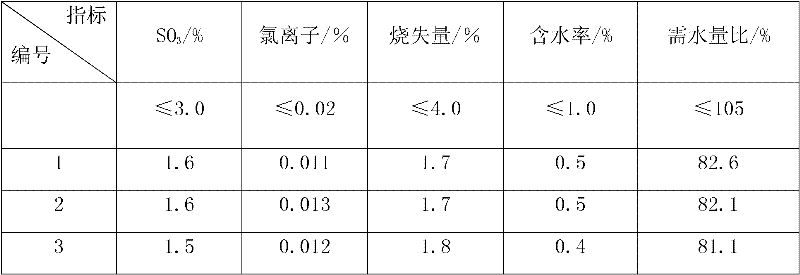

High-early-strength mineral additive for concrete

The invention relates to a high-early-strength mineral additive for concrete, which is characterized in that the high-early-strength mineral additive consists of the following ingredients which are mixed by mass percent: 30-50 percent of mineral powder, 20-35 percent of pulverized coal ash, 5-15 percent of silicon ash, 5-15 percent of metakaolin, 2-5 percent of sodium sulfate and 1-2 percent of polycarboxylate water reducing agent The high-early-strength mineral additive provided by the invention can be used for concrete prefabricated members, grouting materials, patching materials and the like. When 10 percent of high-early-strength mineral additive is added to replace cement to prepare the concrete, the water demand is small, the early activity index is high, the strength development situation is good, and compared with common cement and mineral additives, the dry shrinkage resistance is improved greatly.

Owner:赖斌

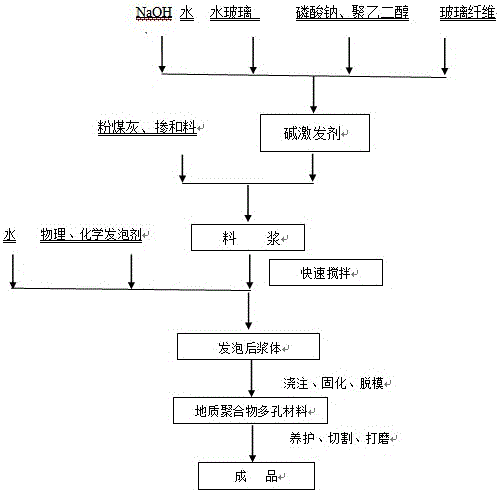

Flyash geopolymer based porous material and preparation process thereof

InactiveCN105800972APracticalSimple production processCement productionSodium phosphatesPolyethylene glycol

The invention provides a flyash geopolymer based porous material and a preparation process thereof. The porous material comprises the following components in parts by weight: 60-100 parts of flyash, 40-70 parts of alkali activator, 0-40 parts of admixtures, 0-5 parts of glass fibers, 2-8 parts of physical foaming agents and 0-0.8 part of chemical activators, wherein the alkali activator is alkaline mixed liquor containing various ions and comprises industrial water glass, sodium hydroxide, water, polyethylene glycol and sodium phosphate; the admixtures refer to levigated metakaolin, silicon micropowder and calcined coal gangue; the physical foaming agents include expired shampoo, an anionic surfactant sodium dodecyl sulfate (SDS), fatty alcohol polyoxyethylene ether sodium sulfate (AES) and disodium fatty alcohol polyoxyethylene ether monosulfosuccinate (AESS); the chemical foaming agents include aluminium powder, hydrogen peroxide, and the like. The porous material has adjustable volume density, fine and uniform pore diameter, low heat conductivity, high strength, the same life as buildings and good fireproof performance.

Owner:QINGHAI UNIVERSITY +1

Fly ash geopolymer concrete and preparation method thereof

ActiveCN110255996AImprove mechanical propertiesIncreased durabilityCement productionFiberMicrosphere

The invention discloses fly ash geopolymer concrete. The concrete is prepared by taking fly ash and metakaolin as base materials, taking one or more than two of sodium hydroxide, potassium hydroxide, sodium silicate and potassium silicate as well as water glass as alkaline activators, and adding modified ceramic microsphere particles, polymer fibers, coarse aggregates, fine aggregates and water. The fly ash geopolymer concrete has good mechanical properties, high durability and high corrosion resistance.

Owner:神木市万盛隆能源发展有限公司

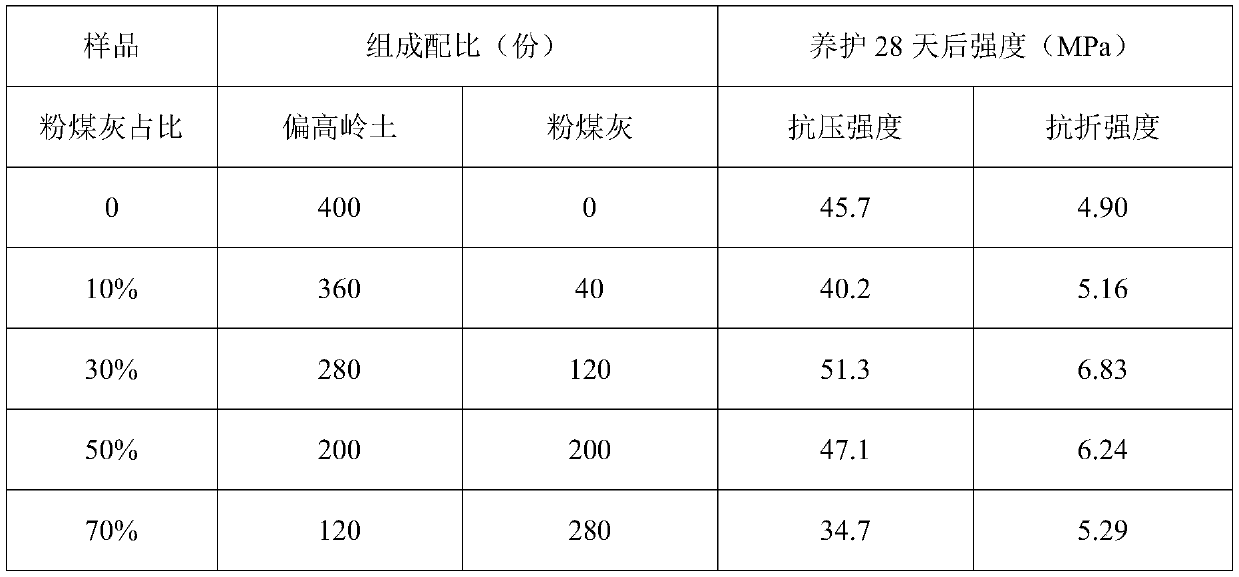

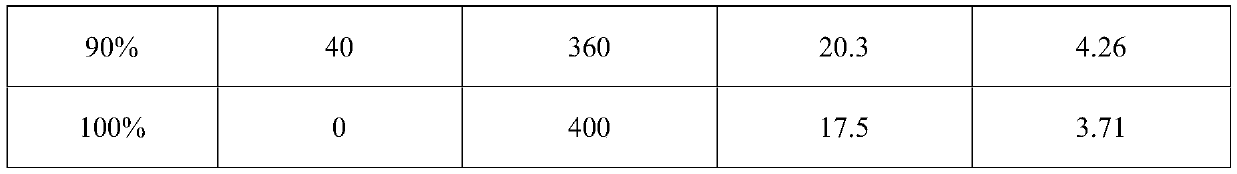

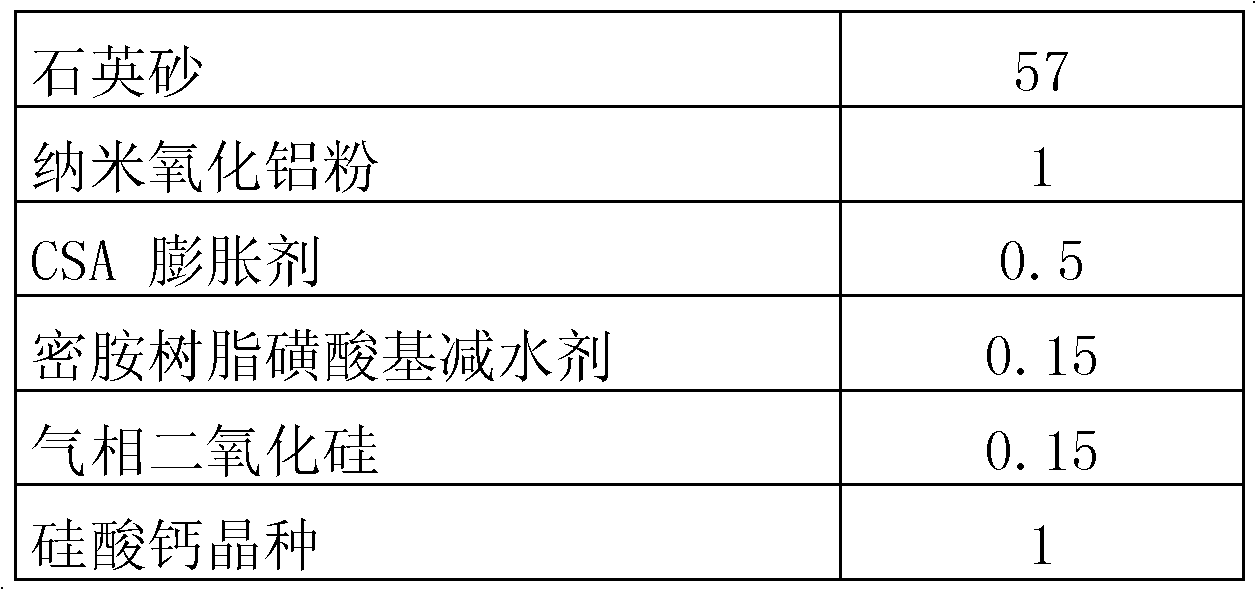

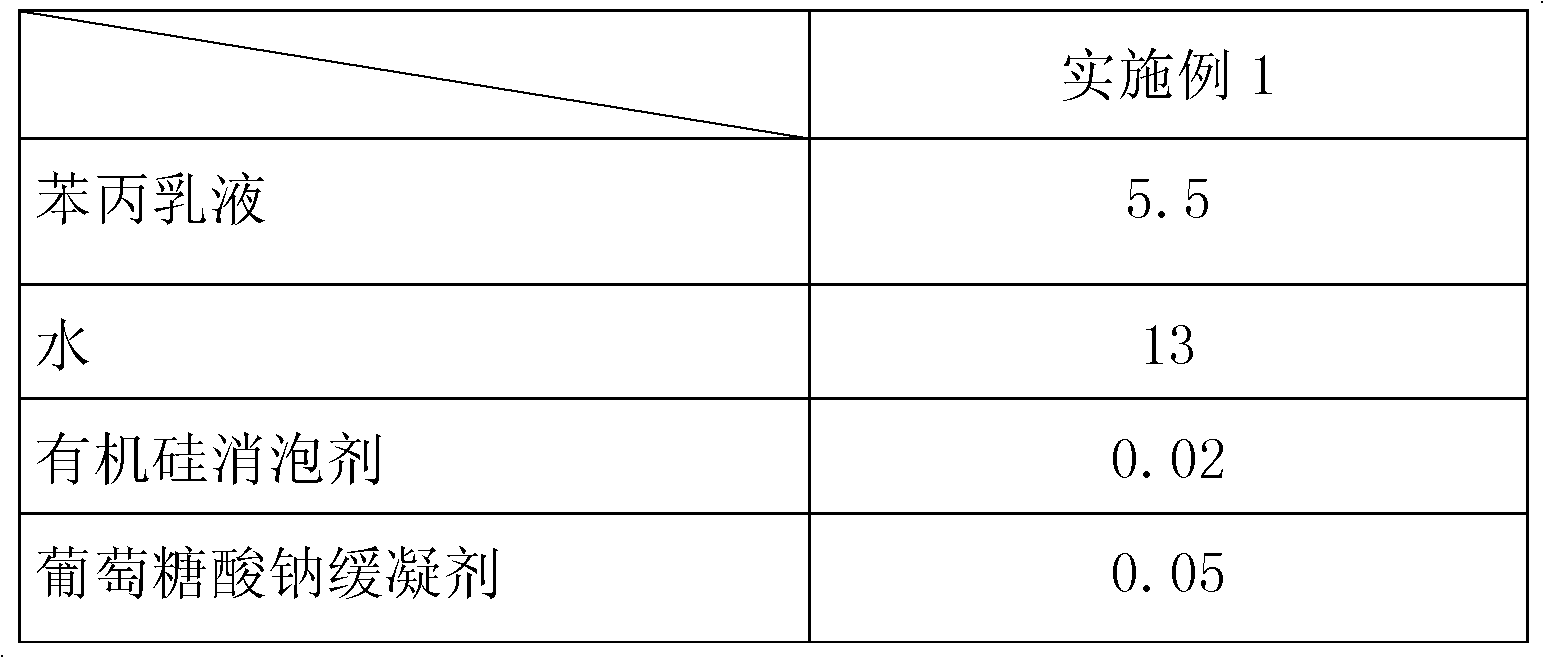

Wear-resistant cement mortar, wear-resistant floor and preparation method thereof

InactiveCN102910885AHas high strengthNon-shrinkableIn situ pavingsFlooringCalcium silicateWear resistant

The invention discloses wear-resistant cement mortar, a wear-resistant floor and a preparation method thereof, wherein the wear-resistant cement mortar is composed by mixing the following components according to a normal method, by weight, 22-40 parts of ordinary portland cement, 1.9-7.5 parts of slag powder, 1-5 parts of special cement, 1-5 parts of metakaolin, 1-5 parts of gypsum, 40-60 parts of quartz sand, 1-3 parts of calcium silicate seed crystal; 1-7 parts of nano alumina powder and 0.1-0.3 part of a water reducing agent, wherein the special cement is sulphoaluminate cement or aluminate cement. The wear-resistant cement mortar has the advantages of excellent hardness and strength. The wear-resistant floor prepared by the wear-resistant cement mortar has no micro-cracks on the surface after being grinded; good smoothness and various fresh brilliant colors can be obtained; color ordonnance can be realized on the surface with extremely high compactness; and aesthetic patterns with paint effects can be obtained.

Owner:MINGLUN BUILDING MATERIALS IND SUZHOU CO LTD

Porous material of phosphate-based geopolymer and preparation method thereof

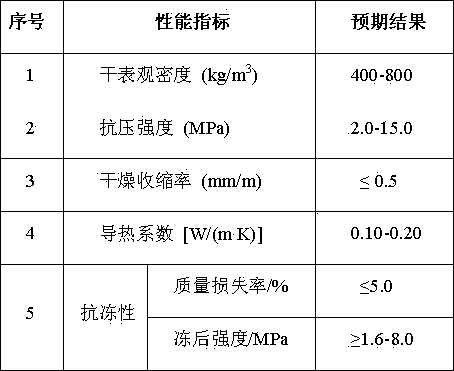

The invention discloses a porous material of phosphate-based geopolymer and a preparation method thereof. The preparation method comprises the following steps of: adopting metakaolin, alumina (or aluminium hydroxide), phosphoric acid and water as raw materials, adopting aluminium powder as a foaming agent and under a lower temperature ( 50-90 DEG C) preparing the porous material which adopts geopolymer material as a skeleton and has good properties. By testing the properties of the porous material, the result shows that the porous material has compression strength of 2.0 to 15.0MPa, apparent porosity of 30 percent to 70 percent, volume density of 0.40cm to 1.0g / cm and high-temperature resistance of more than 1300 DEG C; and the porous material with different properties and porous structures can be obtained by controlling molar ratio of Al / Si and P / Al and reaction conditions. The invention has simple technique and low cost and is expected to be applied in the fields of insulating materials, waste gas absorbing materials, sewage filtering materials, energy absorbing materials, insulating and encapsulating materials, military, aerospace and the like.

Owner:GUANGXI UNIV

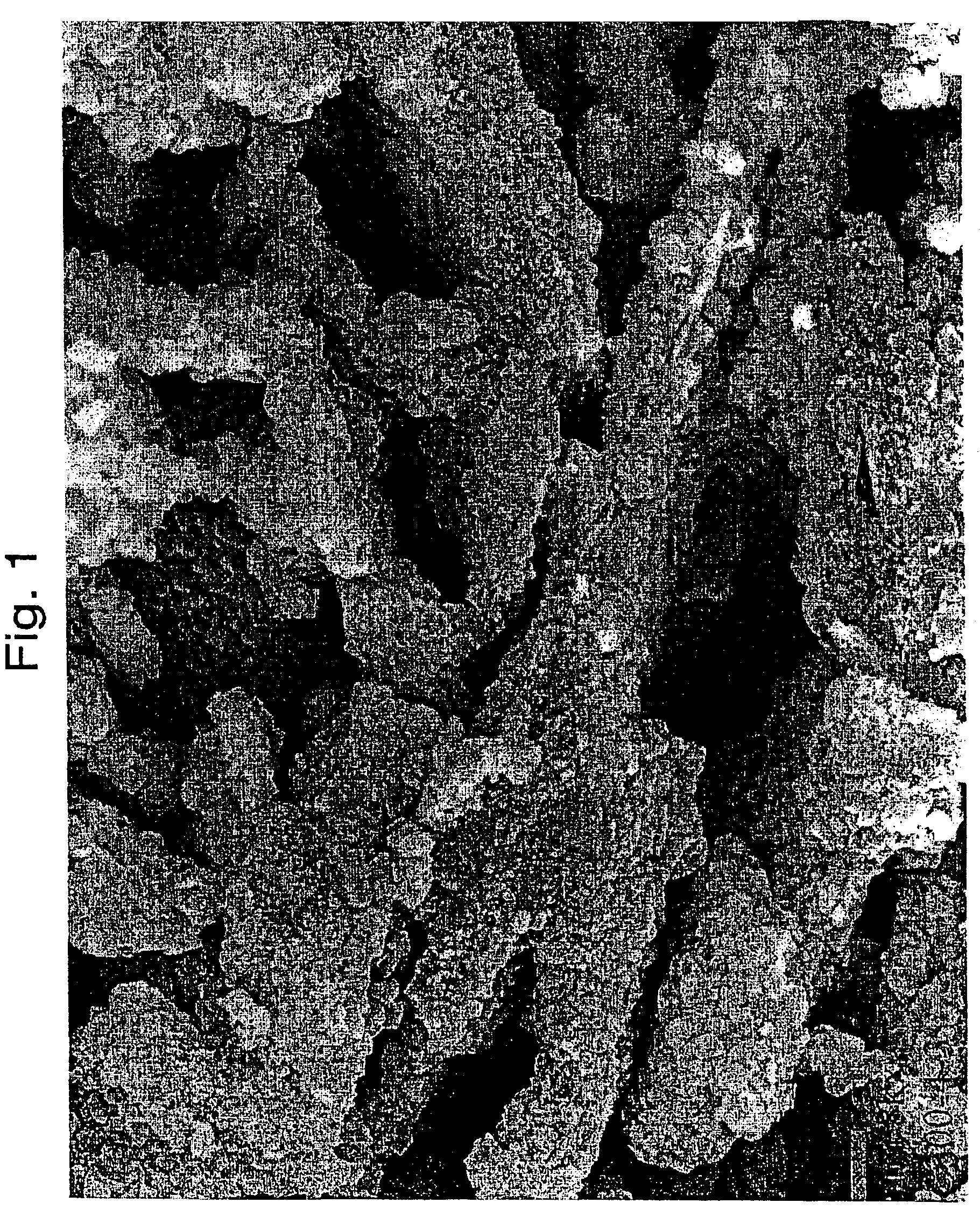

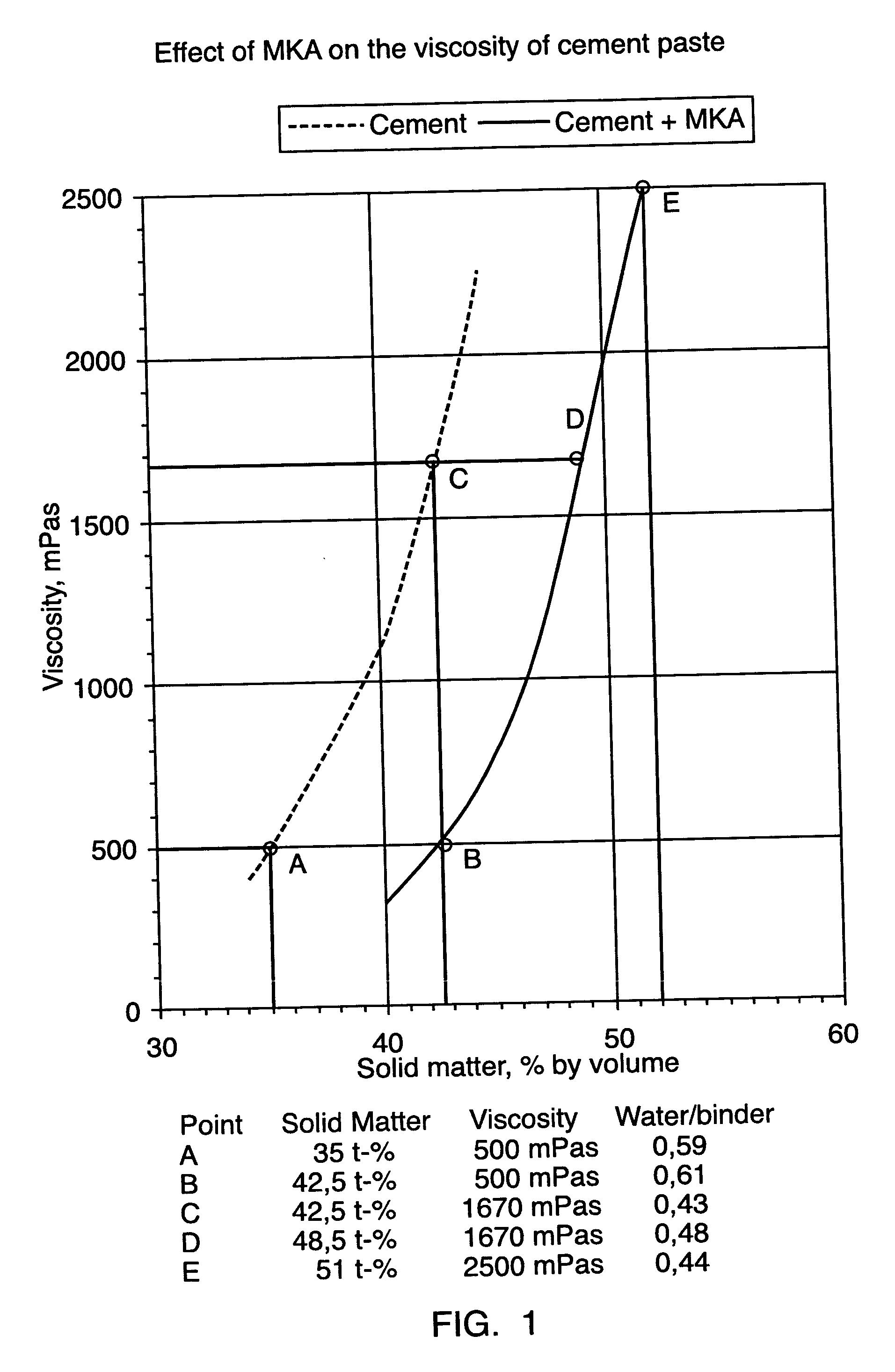

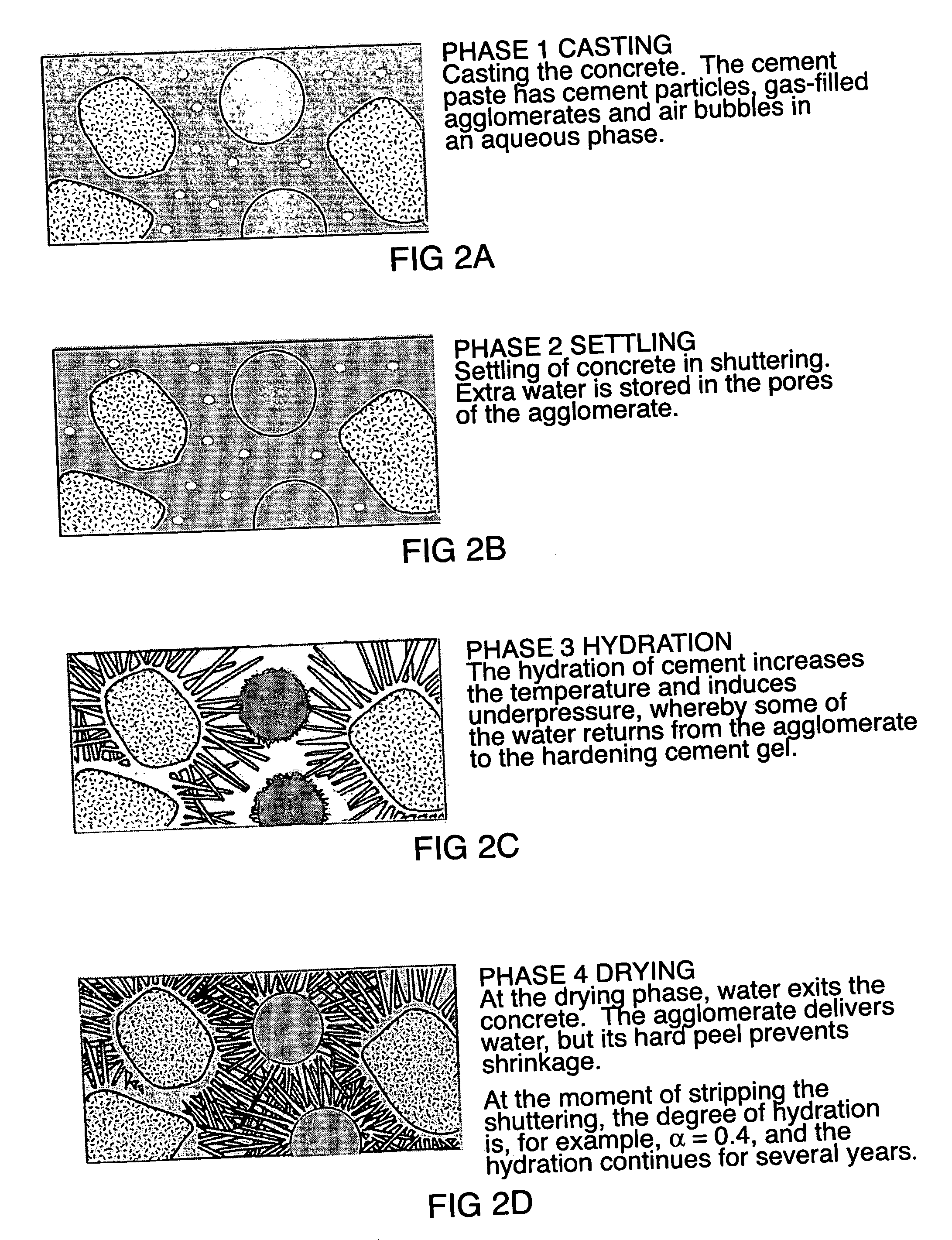

Binder admixture, kaolin product and their manufacture

InactiveUS20050000393A1Improve propertiesImprove the mixing effectClaywaresSolid waste managementFrostKaolin clay

A binder mix containing a hydraulic binding agent and an admixture mixed therewith, a process for preparing a hydraulically hardened binder mass, a calcinated kaolin product and a process for preparing the same. A paste-like composition is formed from the hydraulically hardening binding agent, a pozzolanically reacting admixture and water, which, when so desired, contains stone aggregate or similar filler, the paste-like composition is worked and the worked composition is allowed to harden to form the binder mass. The admixture comprises spherical, porous metakaolin agglomerates, the size of which is 2-200 microns and which have an open pore structure. The invention can be used to improve the manufacturing methods of cast concrete products and shorten the manufacturing times, and to provide concrete with better mechanical and chemical properties, as well as improve the fire and frost resistance of concrete.

Owner:NORDKALK AB

Structurally enhanced cracking catalysts

InactiveUS6942784B2Maximizes bottom crackingReduce contact timeCatalytic crackingMolecular sieve catalystsMicrosphereMetakaolin

Zeolite microsphere FCC catalysts having a novel morphology comprising a porous matrix and crystallized zeolite freely coating the walls of the pores of the matrix. The catalysts are formed from microspheres containing a metakaolin and an alumina source other than kaolin having a high pore volume.

Owner:ENGELHARD CORP

Dry-mixed mortar with waste stone dust in stone mining and processing plant as aggregate and filler

InactiveCN101538139APromote environmental protectionEcologically goodSolid waste managementStone dustMetakaolin

The invention belongs to the technical field of civil engineering material, specifically relates to a dry-mixed mortar with waste stone dust in stone mining and processing plant as aggregate and filler. The dry-mixed mortar is composed of 0.08-5mm of waste stone dust, 0-0.08 mm of waste stone dust, cement, fly ash, metakaolin, calcium hydroxide and water holding thickening agent; with the dry-mixed mortar of the invention adopted, the waste stone dust accounting for 55-75% of the weight of the mortar product can be recycled, thus being environmentally friendly and ecologically friendly. The dry-mixed mortar of the invention not only makes good use of waste material but also features good environmental protection; in addition, the mortar features good water retention rate, fine Constructability, high index of strength and durability, low shrinkage factor and certain crack-resistant property. With all the advantages, the product of the invention can be widely applied to plastering, masonry and land disposal of civil engineering projects of all types.

Owner:湖北昂富新型材料有限公司

A kind of inorganic coating with geopolymer material as film-forming substance

The invention discloses an inorganic coating using geopolymer material as a film-forming substance. It is a single-component water-based inorganic coating using alkali polymerized metakaolin geopolymer material as a film-forming substance. The coating is characterized in that It consists of solid phase S and liquid phase L. The solid phase S is metakaolin, heavy calcium carbonate powder, quartz powder, and anti-cracking additives; the liquid phase L is sodium or potassium water glass and water. The solid phase S and the liquid phase L are mixed in a weight ratio of 1:1.0 to 1.5. The invention eliminates many defects caused by organic polymer film formation. It has the characteristics of high strength, high hardness, water resistance, high temperature resistance, anti-aging, low cost, non-toxic and environmentally friendly, especially with good bonding force with cement mortar layer. It can be applied directly on the surface of buildings or products to provide decorative and protective properties.

Owner:GUANGXI UNIV

Double-component ceramic tile interface agent as well as preparation method and using method thereof

The invention aims at solving a ceramic tile dropping problem caused by low water absorption and a smooth interface of the existing ceramic file, especially a vitrified porcelain tile, and provides a double-component ceramic tile interface agent for improving interface performance and construction performance of a ceramic tile. The double-component ceramic tile interface agent comprises a component A and a component B, wherein the component A comprises cement, quartz sand, metakaolin and a thickener; the component B comprises a water reducing agent, a flexibilizer, a penetrating agent, a dispersing agent, an antifoaming agent, a bactericide, an accelerator, a season regulator and water. According to the invention, two strength forming materials of multiple polymers and cement are used at the same time, so that possibility of forming an interface for a second time is reduced, and bonding strength of the interface agent and the ceramic tile is improved. Besides, while construction time is ensured, setting time is shortened, construction performance is effectively improved, and long-term aesthetic sense of the ceramic tile is ensured.

Owner:湖北鲁邦建材股份有限公司

Fiber-reinforced alkali-activated cementing material and preparation method thereof

ActiveCN102910882AControl microcracksPrevention and inhibition of formationBreaking strengthPolyvinyl alcohol

The invention discloses a fiber-reinforced alkali-activated cementing material and a preparation method thereof. Polyvinyl alcohol fiber, water glass and water are added in slag and metakaolin; under the activation effect of the water glass, the slag and the metakaolin form the strength, and the polyvinyl alcohol fiber achieves the effect of enhancing the compressive strength and the breaking strength of the cementing material. The mass of polyvinyl alcohol is 0.08-0.25% of that of the slag and the metakaolin, and the mass of the water glass is 20-25% of that of the slag and the metakaolin. The preparation method comprises the steps as follows: dispersing the polyvinyl alcohol fiber in the slag and the metakaolin according to a formula amount, placing the mixture in a cement paste stirrer for stirring, and adding a water glass solution with adjusted modulus into the mixture to form uniformly mixed paste; and forming, and placing the product in a standard curing box for curing. The cementing material prepared according to the method has favorable long-term breaking strength and compressive strength after being cured and can reach the 28-d compressive strength of 83.7 MPa and the breaking strength of 11.7 MPa.

Owner:SHENYANG JIANZHU UNIVERSITY

Rapid-hardening early-strengthening wearable concrete material for road repair and its preparation method

ActiveCN1699243AHave fast hardening and early strength requirementsSmall shrinkageSolid waste managementSlagMetakaolin

The invention provides a rapid-hardening early-strengthening wearable concrete material for road repair and its preparation, wherein the material mainly comprises the following ingredients, steel slag powdered ore 40-80kg / m3, metakaolin 320-560kg / m3, alkaline exciting agent solution 200-300kg / m3, steel slag fine aggregates 630-1800kg / m3, steel fiber 62-156kg / m3, and polypropylene fiber 1kg / m3.

Owner:WUHAN MUNICIPAL CONSTR GROUP

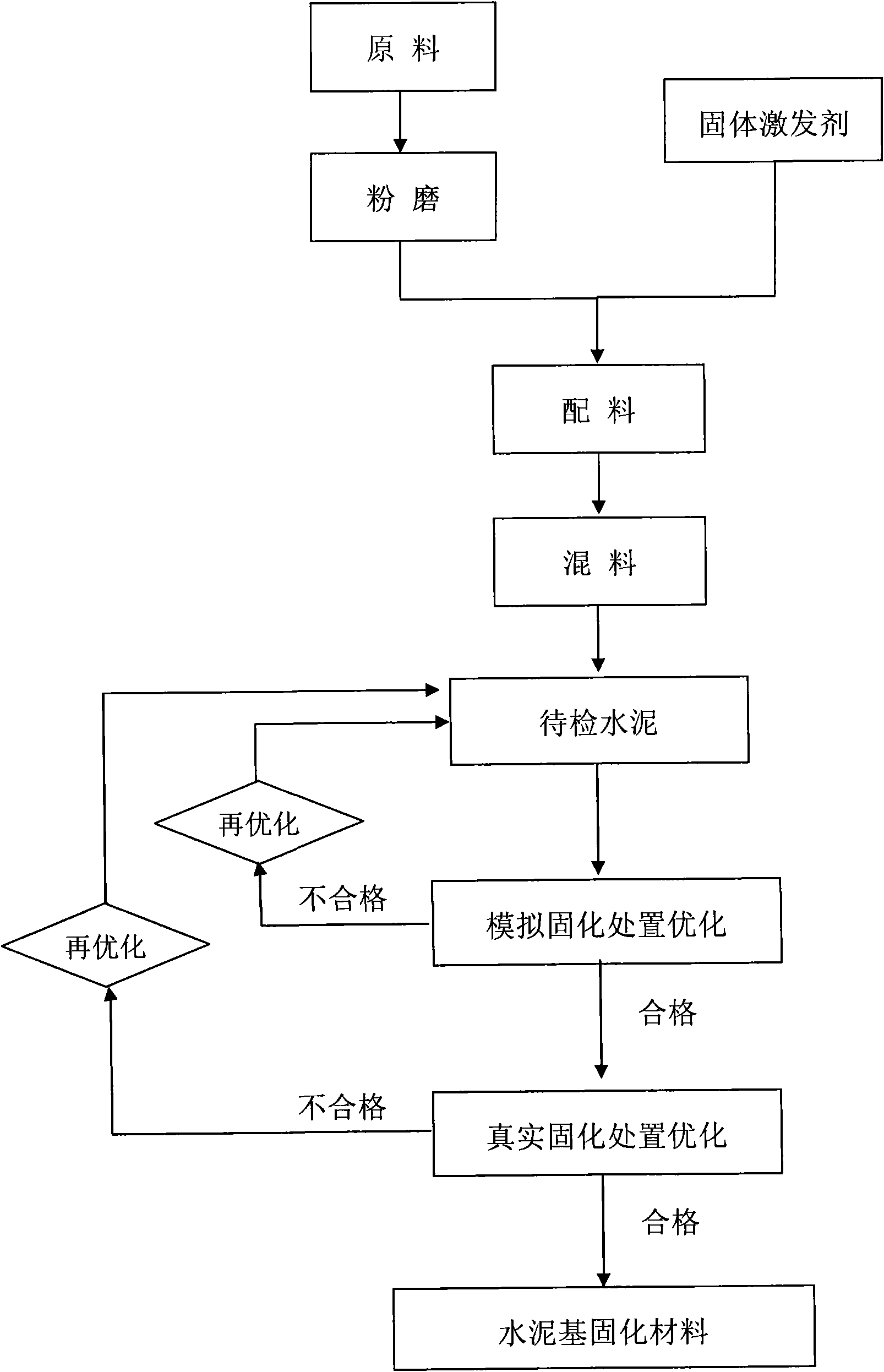

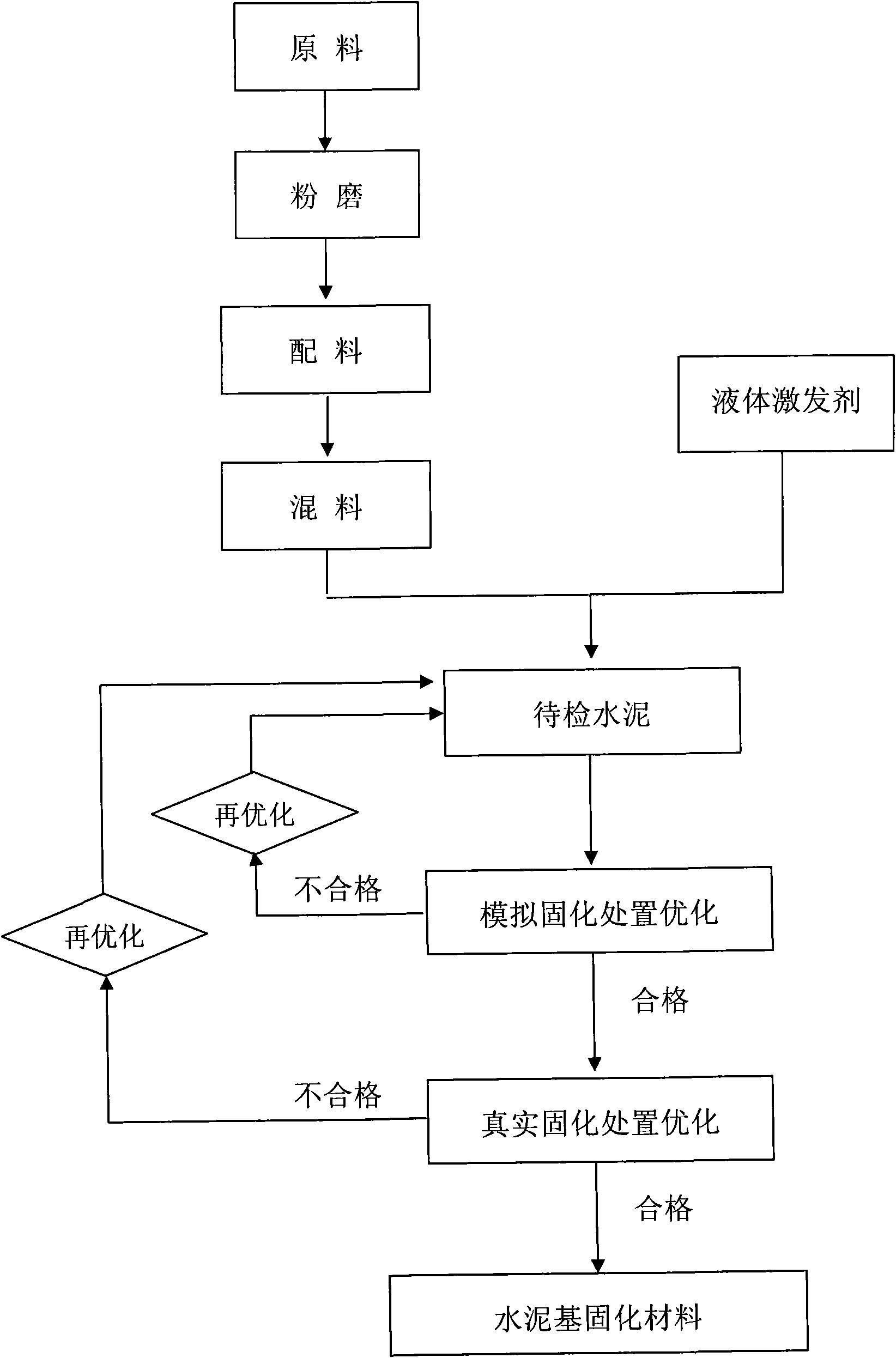

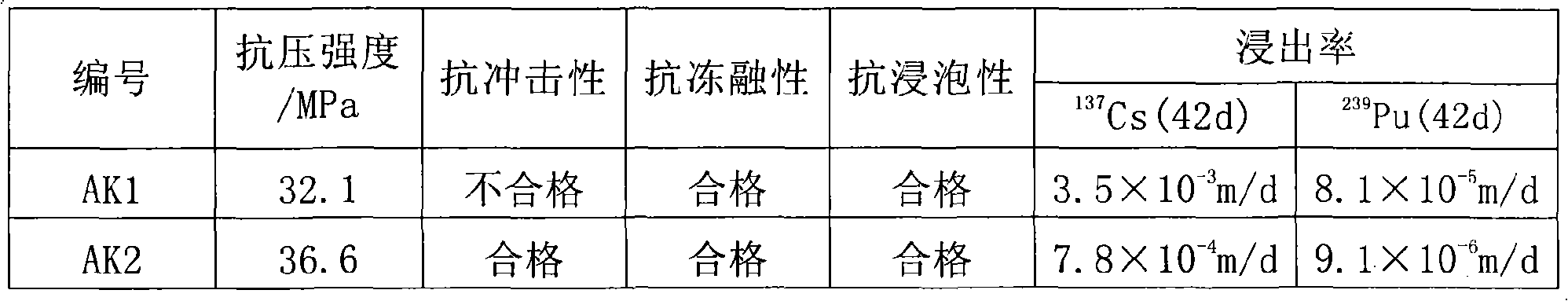

A cement-based solidified material for processing middle and low radioactive incineration ash and a method for processing middle and low radioactive incineration ash

The invention discloses a cement-based solidified material for processing middle and low radioactive incineration ash and a method for processing middle and low radioactive incineration ash. The solidified material, using the slag, fly ash, zeolite, metakaolin, cement clinker as the material to be excited, is obtained through the even mixture with activator after grinding. The liquid activator or combined solid activator can be used as the activator. Mix the material to be excited and activator together, according to the package content of 30-40%, mix with the incineration ash, stir, and maintain to solidification in light of the solidification operation. The cement-based solidified material of the invention can prepare the nuclear waste solidified body with the incineration ash package content greater than 30%, stable mechanical performance, and low leaching rate of radionuclide ion. Especially when solidifying the plutonium-containing waste, the 42-day Pu leaching rate is 10 cm / d. The invention will play an important role in the middle and low radioactive incineration ash processing with good application prospect.

Owner:浙江合力海科新材料股份有限公司

Autoclaved aerated concrete and preparation method thereof

The invention discloses an autoclaved aerated concrete and a preparation method thereof, and the autoclaved aerated concrete comprises mineral raw materials, an alkaline exciting agent, a foaming agent, a foam-stabilizing agent, a slow-release agent and the like. The mineral raw materials comprise 80-100wt.% of fly ash, and other mineral raw materials comprise mineral waste residue, metakaolin, silica fume, steel slag, circulating fluidized bed bottom ash and the like; the alkaline exciting agent mass is 40-55wt.% of the mineral raw material mass, the foaming agent mass is 0.13-5wt.% of the mineral raw material mass, the foam-stabilizing agent mass is 0.03-0.09wt.% the mineral raw material mass, and the slow-release agent mass is 2-3.5wt.% of the mineral raw material mass. The alkaline exciting agent including sodium silicate and NaOH / KOH, the mineral raw materials, the foaming agent and the foam-stabilizing agent are mixed for stirring, then are filled in a mould for prefabrication forming or casting forming, and maintained by autoclaving for 1-24h at 60-160 DEG C under 0.1-1MPa.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Geo polymer base composite material double pole plate and its preparing method

InactiveCN101051691AImprove volume stabilityReduce manufacturing costCell electrodesFuel cell detailsFiberCarbon fibers

Characters of bipolar plate of polymer based composite material are that it is produced from materials of Meta kaolin, conductance material, and solution of water glass. The conductance material is composed of graphite and carbon fiber. Doping quantity of graphite is 20-40% of mass of meta kaolin, and doping quantity of carbon fiber is 10-20%. Mass ratio between solution of water glass, meta kaolin, and conductance material 0.4-0.8:1. The said Meta kaolin is obtained by calcinating kaolin in coal series sold on market or pure kaolin at 600-850 deg.C. Modulus m of solution of water glass is equal to 2.8-3.5, and Baume degree is equal to 35-45. Features of the bipolar plate are: low cost, good corrosion resistance, high mechanical strength, light weight, good conductivity, no poison and pollution on fuel cell of proton exchange membrane.

Owner:WUHAN UNIV OF TECH

Geopolymer-like cement and preparation method thereof

ActiveCN102180606ASolve stacking problemsBroaden sources of raw materialsSolid waste managementCement productionEtchingSodium aluminate

The invention relates to geopolymer-like cement and a preparation method thereof. The geopolymer-like cement is prepared from the following components by weight percent: 62-73wt% of stone coal vanadium tailings, 5-10wt% of solid alkali metal hydroxide, 7-11wt% of solid sodium aluminate, 8-16wt% of superfine activated microsilica and 6-13wt% of metakaolin. The preparation method comprises the following steps: adding the solid alkali metal hydroxide in the stone coal vanadium tailings, stirring, performing dry ball milling and calcining; adding the solid sodium aluminate, the superfine activated microsilica and the metakaolin in the calcined mixture, stirring, and performing dry ball milling, so as to prepare the finished geopolymer-like cement; and when in use, adding water in the finishedcement, stirring and simultaneously grouting so that hardened slurry is formed at room temperature. According to the invention, the operation is simple, the cost is low, and the chemical corrosion degree on containers and human bodies is low; the hardened slurry of the prepared geopolymer-like cement has the advantages of high compression strength and folding strength, strong resistance to sulfate etching, water etching and alkali-aggregate reaction and good air shrinkage.

Owner:WUHAN UNIV OF TECH

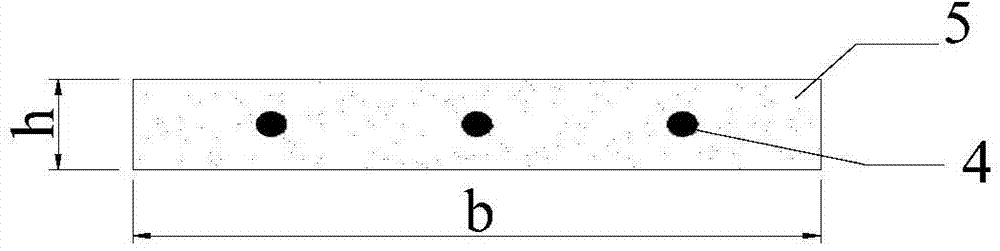

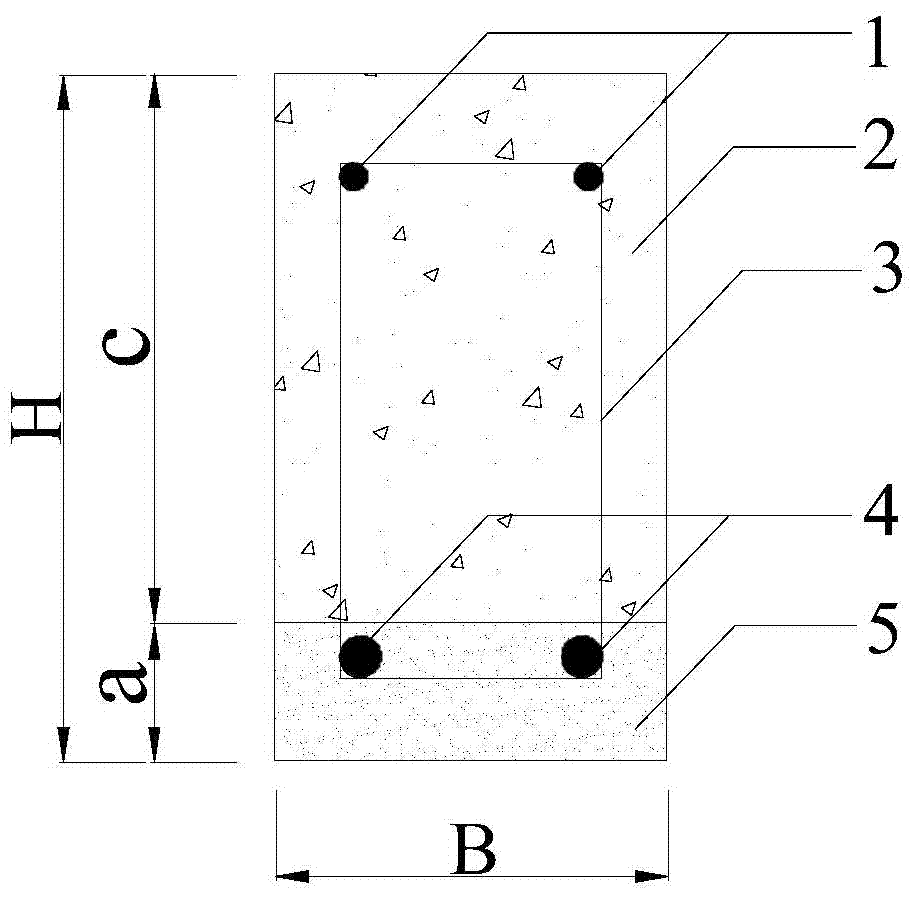

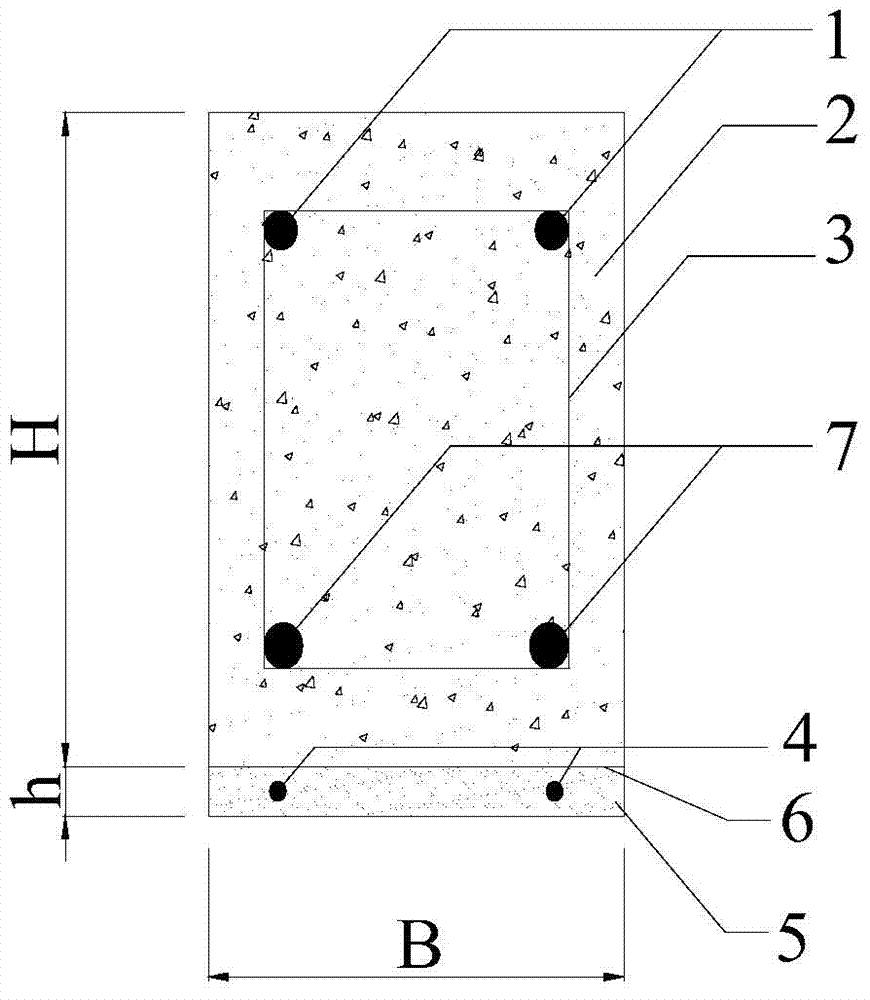

High toughness cement-based material-nonmetal fiber rib composite structure as well as application and application method thereof

InactiveCN103938803AImprove carrying capacityIncreased durabilityBuilding repairsGirdersCarbon fibersPolyvinyl alcohol

The invention discloses a high toughness cement-based material-nonmetal fiber rib composite structure. According to the structure, a high toughness cement-based material is adopted as a base material, nonmetal fiber rib is adopted as directional reinforcing rib; the high toughness cement-based material comprises the following components in percentage by weight: 35% of cement, 45-55% of fly ash, 5-10 % of silicon ash and 5-10% of metakaolin; high-strength short fiber is one or more out of polyvinyl alcohol fiber, polyethylene fiber, carbon fiber and aramid fiber; the nonmetal fiber rib is carbon fiber reinforced plastic rib, aramid fiber reinforced plastic rib, glass fiber reinforced plastic rib or basalt fiber reinforced plastic rib. The invention further discloses applications and an application method of the high toughness cement-based material-nonmetal fiber rib composite structure. The high toughness cement-based material and the nonmetal fiber rib are utilized to reinforce the reinforced concrete structure, so that the bearing capacity and the durability of the structure are increased and the aging speed of the structure is reduced.

Owner:ZHEJIANG UNIV +1

Porous geopolymer-based phase-change energy storage material

InactiveCN103641433AGood dispersionLow thermal conductivitySolid waste managementCement productionSlurryMetakaolin

The invention discloses a porous geopolymer-based phase-change energy storage material. The existing basic geopolymer-based porous materials all have no phase-change energy storage function. The porous geopolymer-based phase-change energy storage material is composed of slurry and a composite foaming agent in the weight ratio of (9-38): 1, wherein the slurry is composed of 20-50 parts of water glass, 20-50 parts of mineral waste residue, 10-20 parts of coal ash, 10-20 parts of metakaolin, 0.1-1.5 parts of polypropylene fiber, 0.3-1.0 part of redispersible latex powder, and 0.005-0.03 part of phase change microcapsule; the composite foaming agent is composed of 24-35 parts of hydrogen peroxide, 64-75 parts of water, 0.5-1 part of foam stabilizer and 1-1.5 parts of animal foaming agent. The porous geopolymer-based phase-change energy storage material provided by the invention maintains the advantages of the existing basic geopolymer-based porous materials such as even foam bore diameter, low heat conductivity coefficient, high solidification speed, high production efficiency and low cost, and wide raw material source; the porous geopolymer-based phase-change energy storage material is also capable of absorbing and releasing energy; therefore, the effects of energy saving and environmental protection can be achieved truly and the shortcomings of the similar materials are made up. The porous geopolymer-based phase-change energy storage material is a fireproof and durable basic geopolymer-based porous material which is capable of realizing phase-change energy storage.

Owner:广西启利新材料科技股份有限公司

High-ductility repair dry powder mortar and preparation method thereof

The invention discloses high-ductility repair dry powder mortar. The high-ductility repair dry powder mortar consists of a composite gel material, an additive, aggregate and fiber, wherein the composite gel material consists of sulfoaluminate cement, Portland cement, coal ash, latex powder, mineral powder, silica fume and metakaolin; the additive consists of one or more of a water-reducing agent, a defoaming agent, a solidification adjusting agent and a water-retaining agent; and the weight ratio of the composite gel material to the additive to the aggregate to the fiber is 100:(0.1-3):(30-100):(1-3). The high-ductility repair dry powder mortar has high ductility and excellent crack resistance by optimizing constitution of a mortar matrix and mixing polyvinyl alcohol fiber; the sulfoaluminate cement and the Portland cement are compounded, so that early strength and later strength are guaranteed; the latex powder is added, so that the ductility and the crack resistance are further improved; and the repair mortar dry powder materials are mixed and stirred in advance according to the ratio, so stable quality of the repair mortar is guaranteed and the construction efficiency can be improved. The high-ductility repair dry powder mortar can be widely applied to quick repair and reinforcement products of roads, bridges, water conservancy, house buildings and the like.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

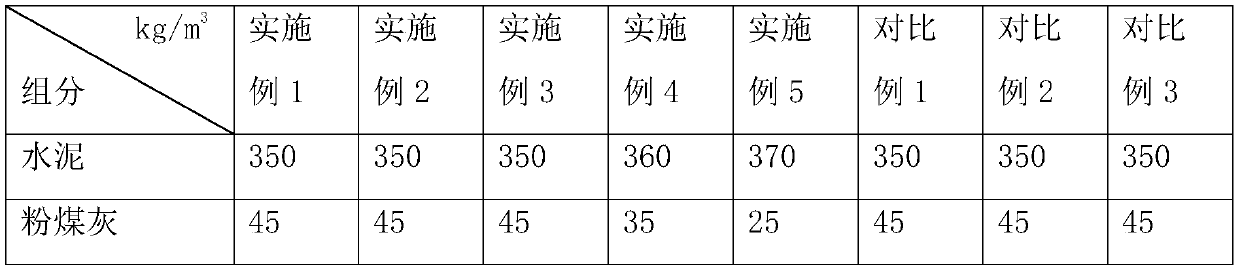

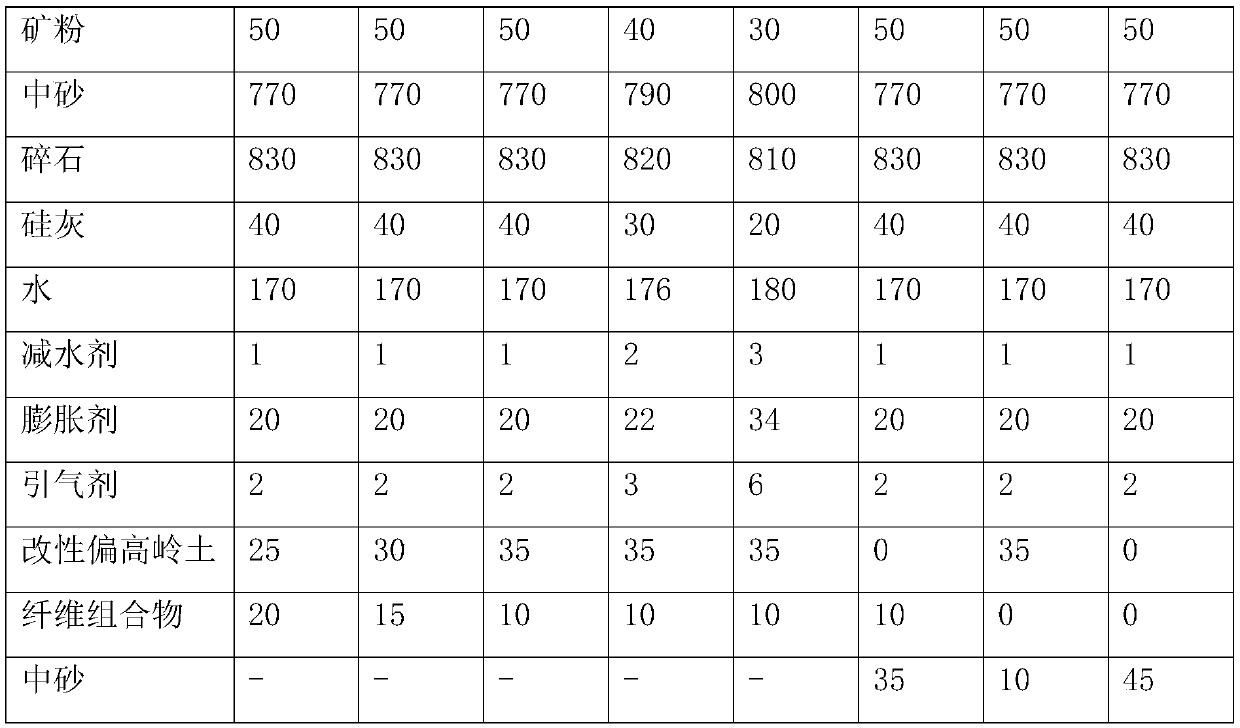

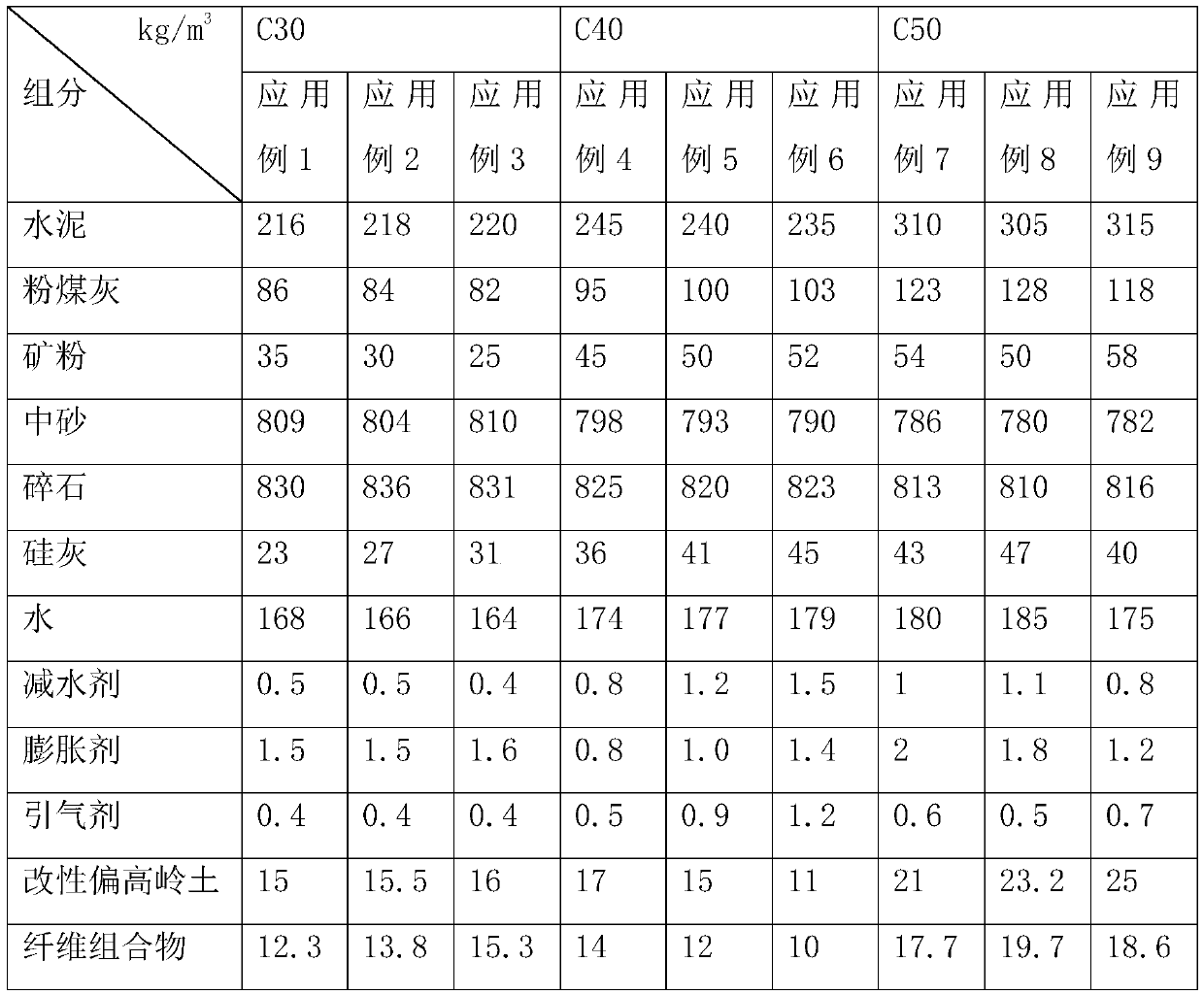

Anti-seepage, anti-freeze-thaw self-compacting concrete and preparation method thereof

The invention discloses anti-seepage, anti-freeze-thaw self-compacting concrete and a preparation method thereof. The anti-seepage, anti-freeze-thaw self-compacting concrete comprises the following components in parts by weight: 350-370 parts of cement, 25-45 parts of fly ash, 25-35 parts of modified metakaolin, 30-50 parts of mineral powder, 770-800 parts of medium sand, 810-830 parts of crushedstone, 20-40 parts of silica fume, 170-180 parts of water, 1-3 parts of a water reducing agent, 20-34 parts of an expansion agent, 2-6 parts of an air entraining agent, and 10-20 parts of a fiber composition, wherein the fiber composition is prepared by mixing a modified polyester fiber, a basalt fiber and a polyacrylonitrile fiber in a mass ratio of 1:0.6-0.9:0.3-0.6. The anti-seepage, anti-freeze-thaw self-compacting concrete has the advantages of good workability and fluidity, and excellent anti-seepage performance and anti-freezing performance.

Owner:西安新意达建筑制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com