Patents

Literature

154results about How to "Has high strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer composite high-molecular dual-network hydrogel and preparation method thereof

The invention provides a high-strength nanometer composite high-molecular dual-network hydrogel and a preparation method thereof, and belongs to the technical field of composite modification of hydrogels. The preparation method of the high-strength nanometer composite high-molecular dual-network hydrogel comprises the following steps of: firstly dissolving a first network monomer, a cross-linking agent and an initiating agent into a water dispersion liquid which contains nanometer particles, and pouring an obtained mixed solution into a mould for heating polymerization to obtain a first network hydrogel; dissolving a second network monomer, the cross-linking agent and the initiating agent into water, placing the first network hydrogel into the solution, swelling for 24 hours, and then carrying out the heating polymerization to obtain the high-strength nanometer composite high-molecular dual-network hydrogel. The high-strength nanometer composite high-molecular dual-network hydrogel provided by the invention is simple in preparation process and superior in property, can be used for enhancing the compression strength of the dual-network hydrogel and keeping higher tensile strength through nanometer enhancement and is widely applied to the fields of biological medicine, agriculture, a building industry, a chemical industry, a mining industry, and the like.

Owner:JIANGNAN UNIV

Composite foamed cement heat retaining panel using high-volume fly ash and preparation method thereof

The invention discloses a composite foamed cement heat retaining panel using high-volume fly ash and a preparation method thereof; the composite foamed cement heat retaining panel is prepared by 60-80 parts of cement, 20-40 parts of fly ash, 0.6-3.0 parts of moisture repellent, 0.12-0.30 part of a water reducing agent, 0.8-3.0 parts of an exciting agent, 0.3-0.50 part of anti-crack fiber, 30-60 parts of water and 4-8 parts of a foaming agent (by weight); the preparation method comprises the following steps: weighing each raw material; adding the water, the anti-crack fiber, the moisture repellent, the cement, the fly ash, the water reducing agent; stirring a mixture; adding the exciting agent; stirring the mixture; adding the foaming agent; stirring the mixture so as to prepare mixed slurry; then, injecting the mixed slurry into a mould; putting the mould statically for 4-5 hours; removing the mould; after 24 hours, cutting and packaging a product; and maintaining the product until age is 28 days. According to the invention, a part of the cement is substituted by fly ash; cost is low; environment pollution is reduced; and social efficiency and economic benefit are obvious.

Owner:JIANGSU NIGAO SCI & TECH +1

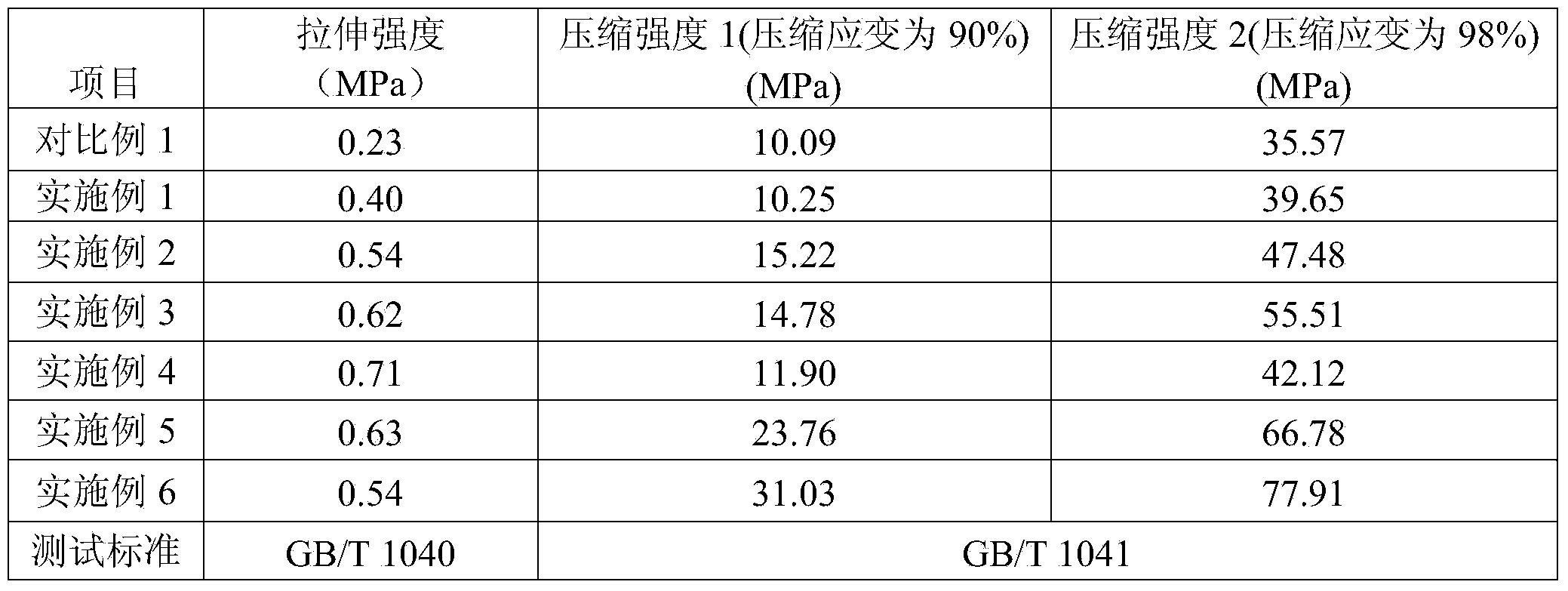

Preparation method for graphene reinforced polymer porous sponge fiber

InactiveCN103603081AExtensive sources of raw materialsEasy to getArtificial filaments from viscoseAlginate artificial filamentsSolventCvd graphene

The invention provides a preparation method for graphene reinforced polymer porous sponge fiber. The preparation method is characterized in that: the graphene reinforced polymer porous sponge fiber is prepared by subjecting an oxidized graphene solution having a certain concentration to ultrasonic processing to obtain a uniformly dispersed oxidized graphene solution; dissolving a polymer in a solvent to obtain a polymer solution with a certain concentration; adding the dispersed graphene solution into the polymer solution under stirring to obtain a graphene-polymer blend spinning solution; spraying the graphene-polymer blend spinning solution through a spinning nozzle into a coagulating bath to form fiber by utilization of a wet-method spinning device; washing with water, reducing, and washing with water again; and quickly subjecting the wet fiber to freeze drying or supercritical drying to obtain the graphene reinforced polymer porous sponge fiber. The preparation method is simple in technology and low in cost, and is suitable for large-scale production. The fiber has advantages of high strength, good antistatic performance, good elasticity, small density, large specific surface area, and the like. The fiber can be used for preparing heat insulating fabrics in the weaving field, and can be used for water treatment in the environment protection field, and the like.

Owner:QINGDAO UNIV

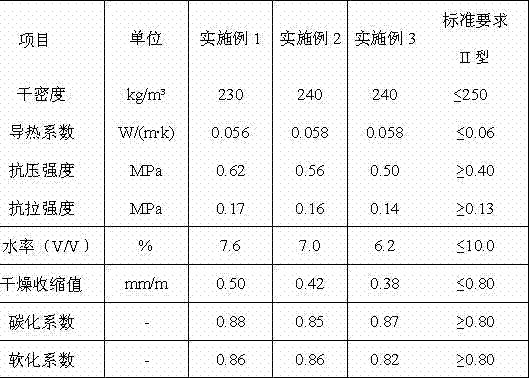

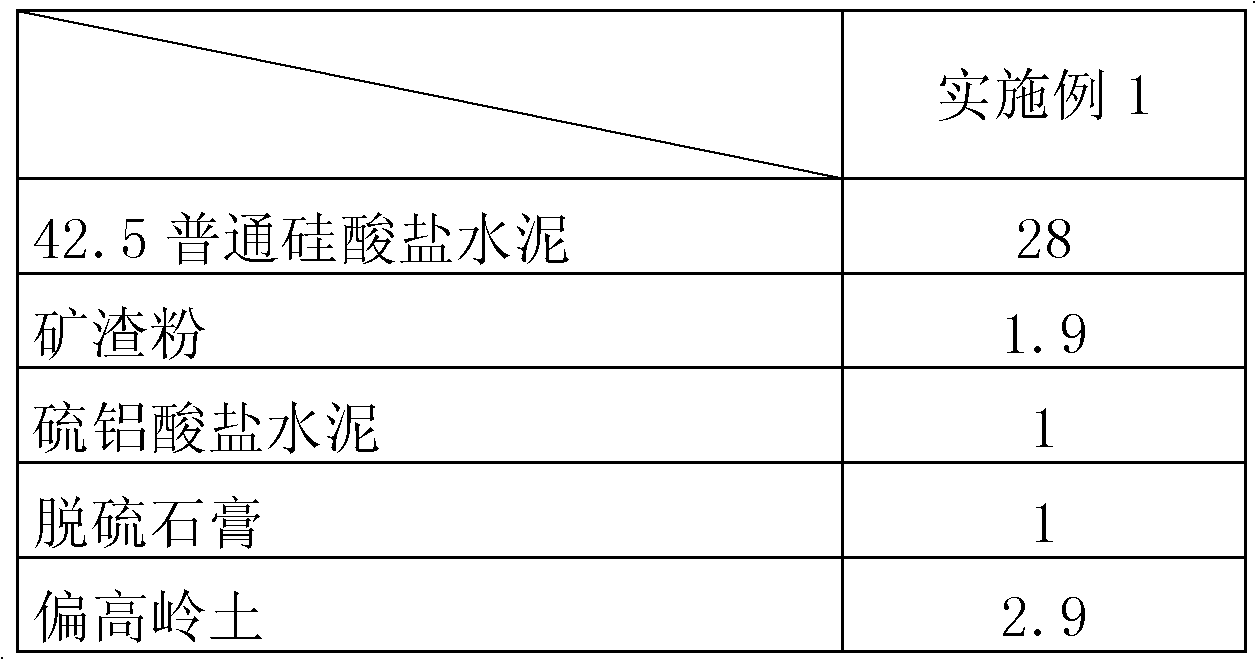

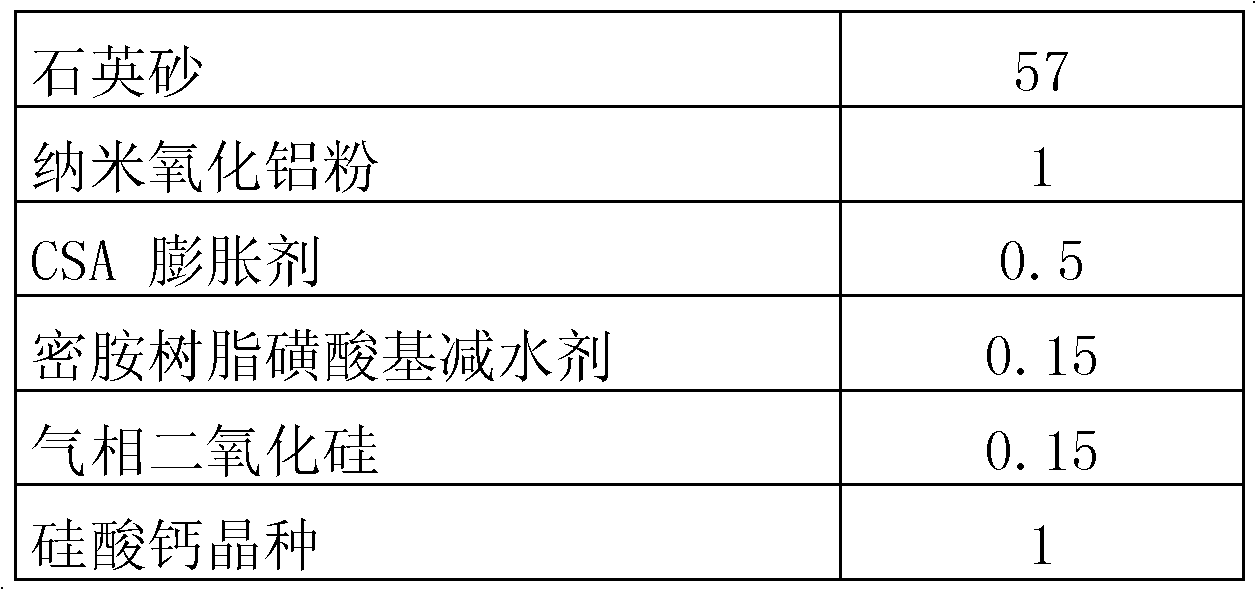

Wear-resistant cement mortar, wear-resistant floor and preparation method thereof

InactiveCN102910885AHas high strengthNon-shrinkableIn situ pavingsFlooringCalcium silicateWear resistant

The invention discloses wear-resistant cement mortar, a wear-resistant floor and a preparation method thereof, wherein the wear-resistant cement mortar is composed by mixing the following components according to a normal method, by weight, 22-40 parts of ordinary portland cement, 1.9-7.5 parts of slag powder, 1-5 parts of special cement, 1-5 parts of metakaolin, 1-5 parts of gypsum, 40-60 parts of quartz sand, 1-3 parts of calcium silicate seed crystal; 1-7 parts of nano alumina powder and 0.1-0.3 part of a water reducing agent, wherein the special cement is sulphoaluminate cement or aluminate cement. The wear-resistant cement mortar has the advantages of excellent hardness and strength. The wear-resistant floor prepared by the wear-resistant cement mortar has no micro-cracks on the surface after being grinded; good smoothness and various fresh brilliant colors can be obtained; color ordonnance can be realized on the surface with extremely high compactness; and aesthetic patterns with paint effects can be obtained.

Owner:MINGLUN BUILDING MATERIALS IND SUZHOU CO LTD

Coal gangue building thermal insulation exterior wall brick and production method thereof

The invention discloses a coal gangue building thermal insulation exterior wall brick, which is prepared by the following raw materials, by weight, 50-70% of coal gangue, 3-12% of a plasticizing agent, 3-12% of a binder, 10-30% of a vitrifying agent, 2-5% of a foaming agent, and 0.1-0.3% of a pore adjusting agent. In addition, the present invention further provides a production method for the coal gangue building thermal insulation exterior wall brick. The thermal insulation exterior wall brick of the present invention has advantages of light weight, high strength, safety, aging resistance, low cost and the like, can be directly used for beautifying modification of the building, and has a certain bearing capacity. With the present invention, the harm to the environmental and the safety due to the coal gangue is eliminated, and the performances of the building thermal insulation material in our country can be improved. Compared to the organic thermal insulation material, the thermal insulation exterior wall brick of the present invention has advantages of good safety performance, low cost, simple construction, and good durability, and the industrial waste residue is utilized by thethermal insulation exterior wall brick of the present invention so as to reduce the land occupation and the environment pollution.

Owner:CHANGAN UNIV

Pervious concrete and construction method

The invention provides pervious concrete with the characteristics of high strength, long service life and durability. According to the technical scheme adopted in the invention, the pervious concrete comprises components of raw materials in parts by weight as follows: 400-500 parts of cement, 1600-1650 parts of broken stone, 10-20 parts of a reinforcing agent, 0-10 parts of a water reducing agent and 100-130 parts of water. The cement is an ordinary portland cement with the strength grade being not lower than 42.5 grade, and the reinforcing agent adopts a silicone acrylic emulsion.

Owner:SHANDONG QUANJIAN ENG TESTING CO LTD

Method for producing high strenght flyash ceramic sand

InactiveCN1900008ALight weightHas high strengthCeramic materials productionClaywaresGranularityHigh intensity

The high strength fly ash haydite producing process belongs to the field of fly ash utilizing and new building material technology. The high strength fly ash haydite is produced with fly ash, clay, saw dust and coal powder, and through mixing in a stirrer, adding certain amount of water glass and controlling water content of about 20 %, pelletizing, sintering and cooling. The high strength fly ash haydite product has granularity of 3-5mm, bulk density of 800-900kg / cu m, and compression strength of 10-20 MPa, and may be used as aggregate of wall board.

Owner:JILIN ACAD OF AGRI MACHINERY

High-strength light Al-Mg-Zn alloy

The invention discloses a high-strength light Al-Mg-Zn aluminum alloy. The alloy comprises the following chemical components in percentage by weight: 6.0-10.0 percent of Mg, 3.0-5.0 percent of Zn, smaller than 2.0 percent of Cu, smaller than 1.2 percent of Mn, smaller than 0.3 percent of Fe and smaller than 0.3 percent of Si, wherein at least one element of Cr, Ti, Zr, Sc, Hf, La, Ce, Pr and Nd is added; the adding amount of a single element is smaller than 0.5 percent. The density of the Al-Mg-Zn alloy is smaller than 2.7 g / cm<3>; a proper homogenizing process and pressure are adopted for processing; after solid-solution hardening aging treatment is performed, the tensile strength in T6 state is greater than 530 MPa, the elongation rate is greater than 8 percent, and the hardness is greater than 170 HV.

Owner:CENT SOUTH UNIV

System and method for preparing building 3D printing material by using municipal waste and industrial solid waste

ActiveCN106904924ALow costReduce energy consumptionAdditive manufacturing apparatusSolid waste managementDry weightRed mud

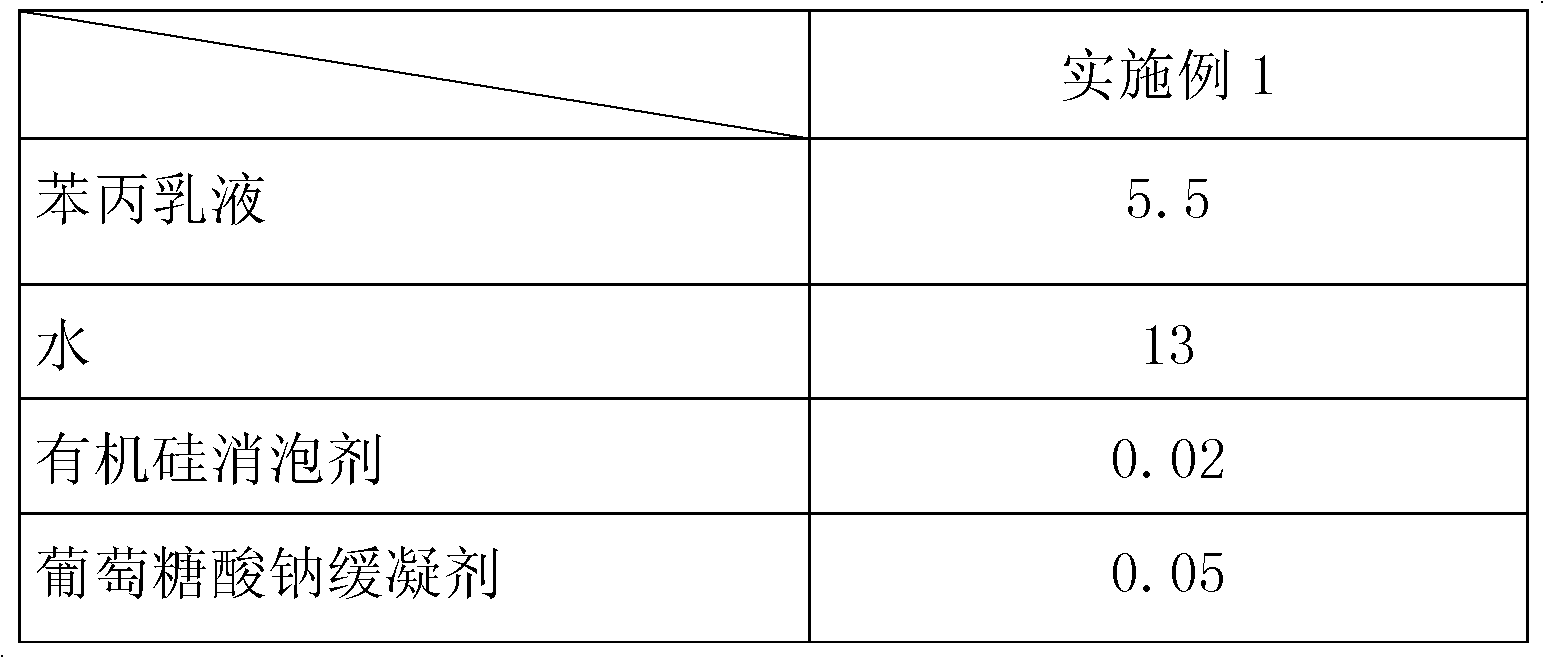

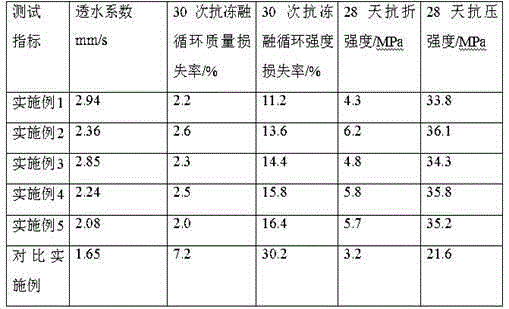

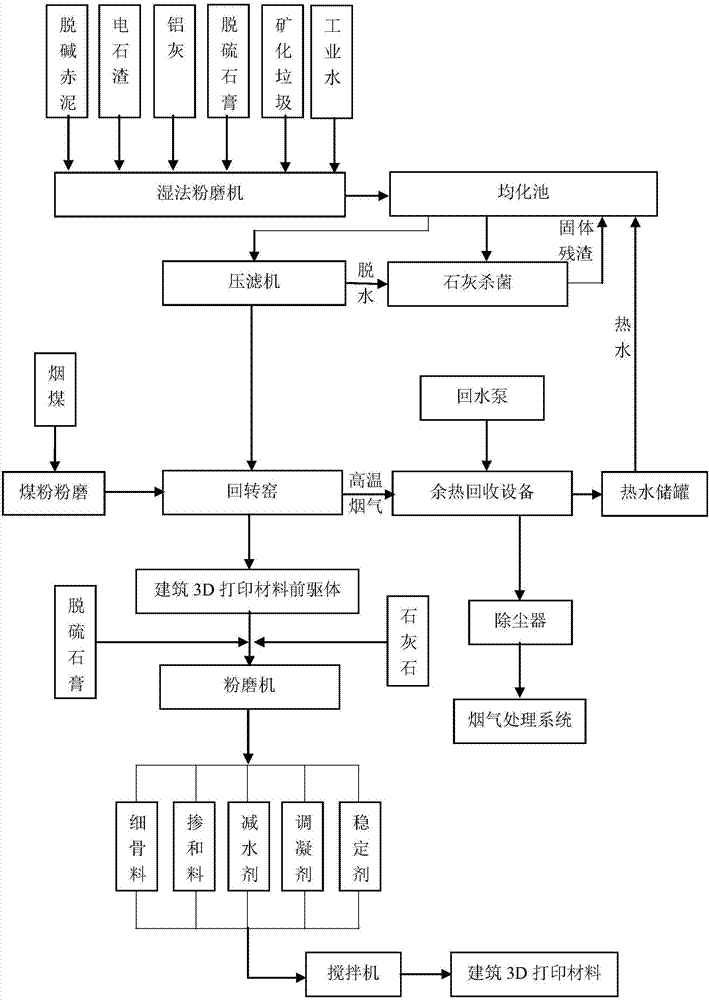

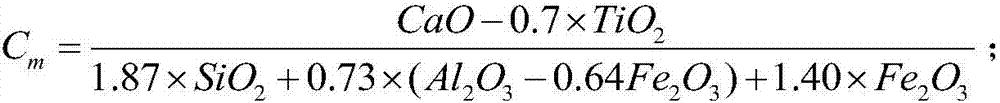

The present invention discloses a system and a method for preparing a building 3D printing material by using municipal waste and industrial solid waste. The system comprises a homogenization pool, a wet powder mill, a filter press, a rotary kiln, a powder mill and a hot water storage tank. According to the method, wet sludge produced from an urban sewage treatment plant is directly mixed with mineralized garbage, red mud, desulfuration gypsum, carbide slag and industrial water to form a mixed solution without dewatering, a dry weight ratio of the wet sludge to the mineralized garbage to the red mud to the desulfuration gypsum to the carbide slag in the mixed solution is 5-10:5-10:15-30:10-20:30-60, the solid-liquid ratio in the mixed solution is maintained at 1:3-1:4, the mixed solution is sequentially subjected to wet milling, homogenization treatment and alkali removing, the homogenization treatment temperature is 60-70 DEG C, the homogenized material is subjected to mechanical pressure filtration dehydration, and the filtered material is subjected to high temperature calcination to obtain the building 3D printing material precursor.

Owner:SHANDONG UNIV

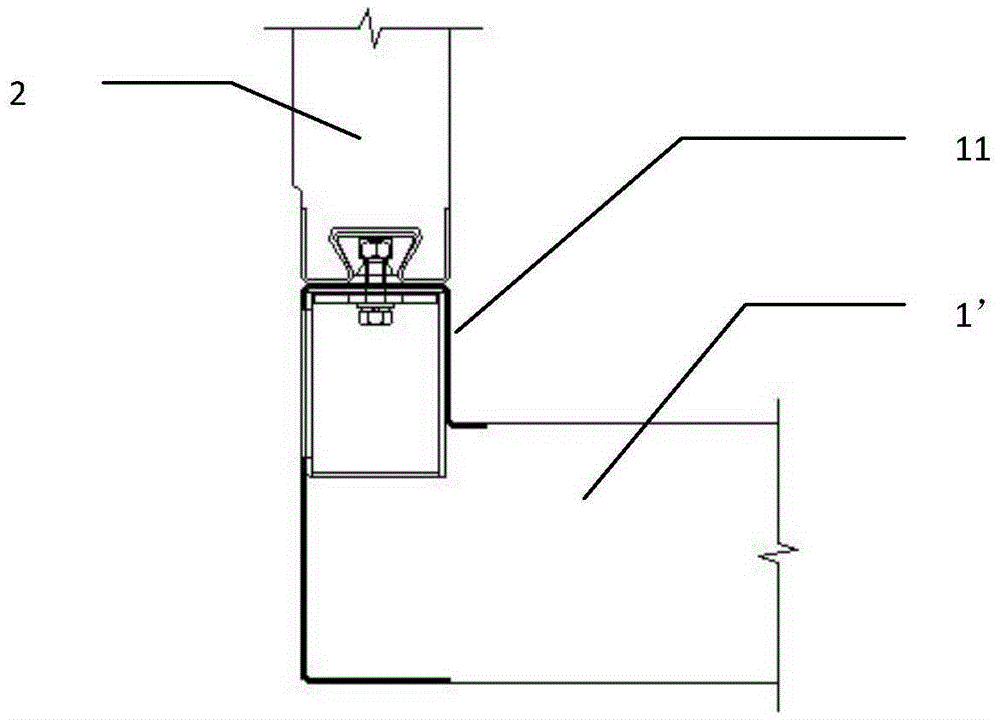

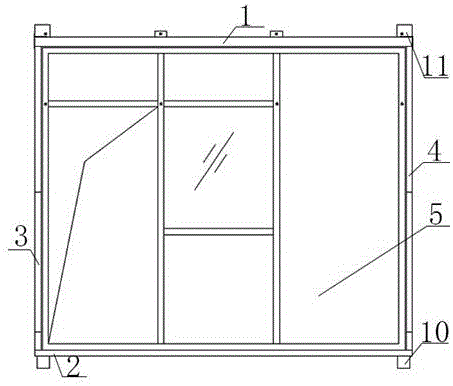

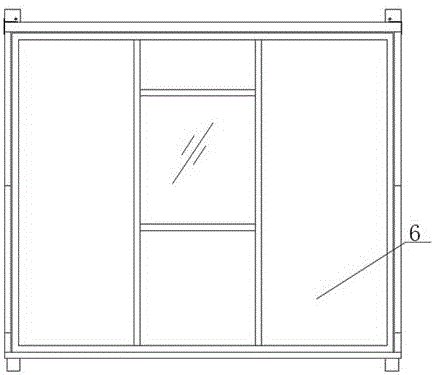

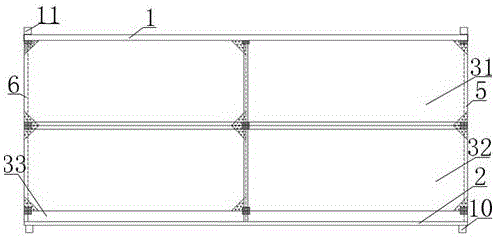

Assembly-type integrated bathroom and construction method thereof

ActiveCN105421826ARefractory hasSound insulation hasSpecial buildingBuilding constructionsThermal insulationBathroom Equipment

The invention relates to an assembly-type integrated bathroom and a construction method thereof. The assembly-type integrated bathroom comprises foaming cement composite bottom plates, foaming cement composite wall plates, foaming cement composite top plates and bathroom equipment; dovetail groove type steel frame edge ribs are arranged in the plates, and each dovetail groove type steel frame edge rib is composed of an upper wing flange, a lower wing flange and a dovetail groove edge rib groove; an embedded part wedge block is arranged in each dovetail groove edge rib groove; all the plates are fixedly connected through bolts, connecting parts and the wedge blocks arranged in the dovetail groove edge rib grooves of the plates. The assembly-type integrated bathroom has the advantages that the foaming cement composite plates obtained through industrialized production are adopted, the fire resistance duration is larger than or equal to 4 hours, the sound insulation is larger than or equal to 42 decibels, raw materials forming the plates adopt inorganic materials and are non-combustible, and the comprehensive properties of energy conservation and environment protection, bearing and thermal insulation, heat insulation, fire resistance, durability, shock resistance, small mass, high strength and the like are achieved; installing operation is easy and convenient, rapidness and firmness are achieved, and environmental pollution and noise emission caused by traditional bathroom construction are reduced. The assembly-type integrated bathroom is an energy-saving and environment-protecting green building product.

Owner:CUBIC DIGITAL TECH CO LTD +2

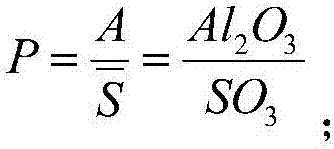

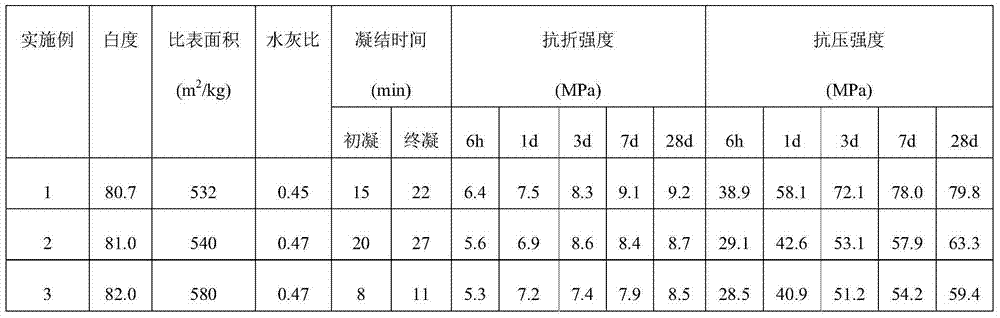

White sulphoaluminate cement and preparing method thereof

The invention provides white sulphoaluminate cement. The white sulphoaluminate cement comprises the following raw materials in parts by weight: 65-90 parts of white sulphoaluminate cement clinker, 0-20 parts of dolomite, 5-15 parts of gypsum, 0-5 parts of white silicate cement clinkers, 0-10 parts of slag and 0-2 parts of retarder. The white sulphoaluminate cement has the characteristics of rapid hardening, early strength, high strength and the like, and the clinkers also have the characteristics of low forging temperature, energy saving, environment-friendliness and the like. The invention further provides a preparing method for the white sulphoaluminate cement.

Owner:SINOMA INT ENG

Environment friendly light sound-proof refractory casting material

An environment friendly light sound-proof refractory casting material belongs to the light sound-proof refractory casting material used for a working lining or a permanent lining of medium-high temperature furnaces such as a building furnace, a building kiln, and the like. The main raw materials for manufacturing the casting material comprise volcanic, shale particles, powder pearl and aluminate cement, the weight ratio among which is 100:20-40:10-20:20-40; and the main raw materials are uniformly blended to form the casting material. The material has the beneficial effects that the environment friendly light sound-proof refractory casting material mainly uses volcanic rock abandon resources as raw materials, can be recycled after the furnace is dismantled, is beneficial to environmental protection, has the advantages of light weight, heat insulation, sound-proof, high strength, convenient construction, long service life and the like, simultaneously has the function of load-bearing, heat preservation and anti-seismic, and can be widely applied to the working lining or the permanent lining of the medium-high temperature furnaces of electricity, chemical industries, metallurgy, etc.

Owner:HENAN CHAOBEI ENG EQUIP

Titanium extraction tailing building decoration plate and production method thereof

ActiveCN108298940AWater resistantFireproofCovering/liningsSolid waste managementEcological environmentSlag

The invention provides a titanium extraction tailing building decoration plate, which is prepared from the following ingredients in percentage by weight: 35 to 45 percent of titanium extraction tailings, 15 to 25 percent of light calcined magnesia powder, 8 to 15 percent of magnesium sulfate heptahydrate, 1 to 5 percent of active filling materials, 3 to 7 percent of crop wastes, 0.5 to 2 percent of modified additives and 15 to 20 percent of water, wherein additional materials are glass fiber mesh cloth and non-woven fabric. Compared with the prior art, the titanium extraction tailing buildingdecoration plate has the beneficial effects that the industrial waste slag titanium extraction tailings obtained by the PanZhiHua Steel blast furnace slag titanium extraction process and the light calcined magnesia powder prepared from low-grade magnesite, and the magnesium sulfate heptahydrate which is byproduct of boracic acid prepared from ascharite are used as major raw materials; green and environment-friendly effects are achieved; the cost is low; the production process is simple. The addition quantity of the PanZhiHua Steel titanium extraction tailings is great; the ecological environment problem caused by the PanZhiHua Steel titanium extraction tailing stacking storage can be effectively solved; meanwhile, the titanium extraction tailing building decoration plate has the advantagesof high intensity, water resistance, fire resistance, anti-corrosion performance, no deformation, no tilting and the like.

Owner:UNIV OF SCI & TECH LIAONING +1

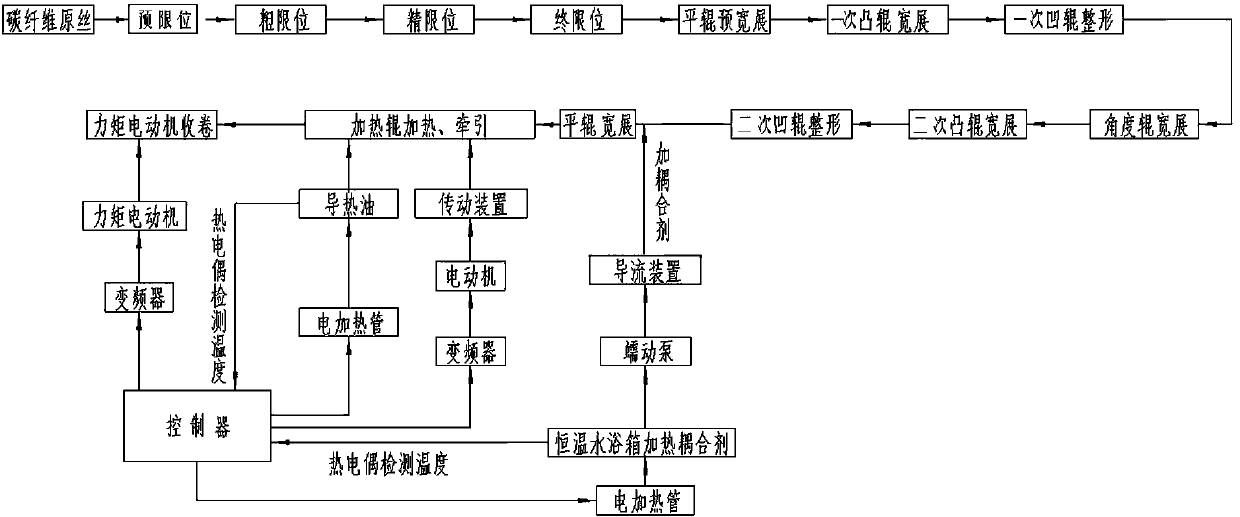

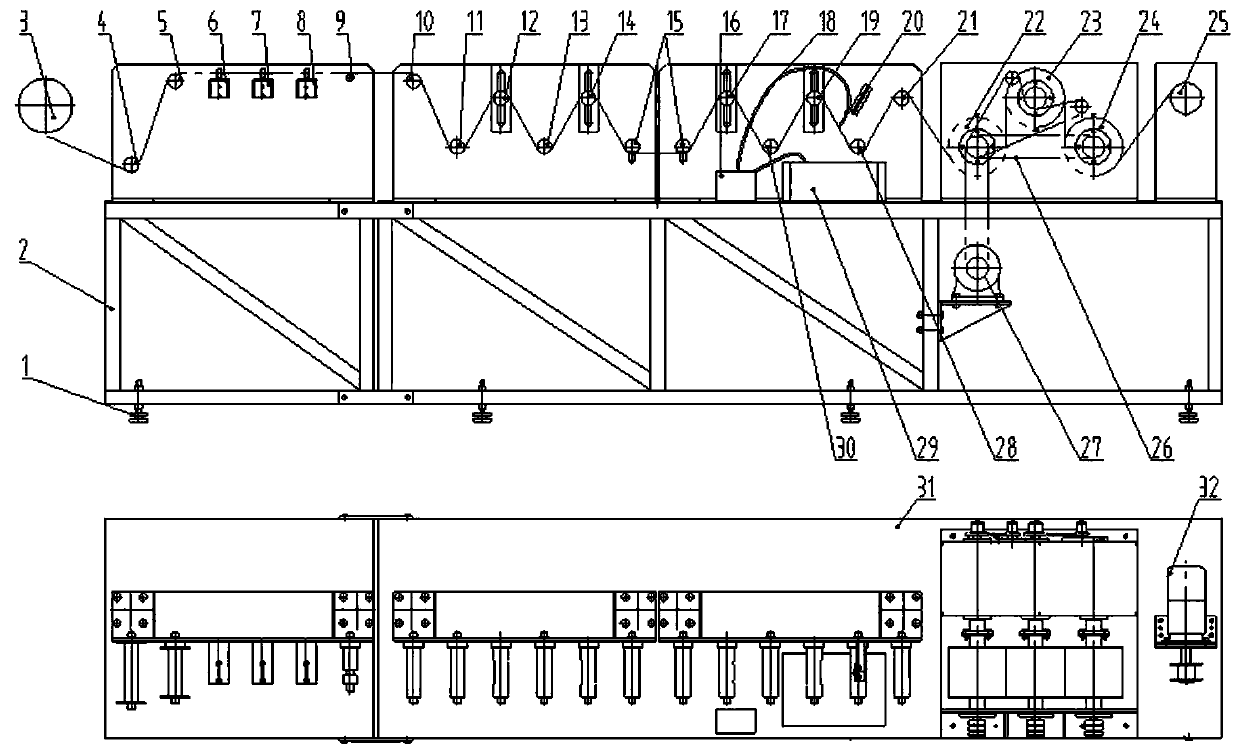

Integrated preparation process of big-tow carbon fiber spreading and curing

ActiveCN107904738ASolve hard-to-extend problemsSolve the problem of poor permeabilityLiquid/gas/vapor removalFibre chemical featuresFiberYarn

The invention provides an integrated preparation process of big-tow carbon fiber spreading and curing, which comprises the following steps: a carbon fiber precursor is precisely limited to ensure theneutrality of the carbon fiber precursor when the fiber is spread; the carbon fiber precursor is spread after the precise limiting position, and then a coupling agent is added to permeate the carbon fiber precursor before the spreading process of the carbon fiber precursor is completed; a heat curing process is carried out by traction through a heating roller on the carbon fiber precursor after being permeated; a winding process is carried out; preparation devices are provided. The invention adopts an integrated preparation process of spreading--permeating--heat curing of combination of a special-shaped multiple-roller and an angle roller. The carbon fiber becomes obviously wider and thinner and more evenly arranged after the spreading process, which effectively solves the problem of poorpermeability of the big-tow carbon fiber precursor caused by the bad spreading effect. Furthermore, the phenomena of precursor adhesion, yarn breaking, buckling and lamination angle dislocation afterspreading can be overcome during the spreading process of the big-tow carbon fiber precursor.

Owner:北京方硕复合材料技术有限公司

Preparation method of nickel-plated and silver-plated aromatic polyamide conductive fibers

Owner:SHANGHAI UNIV

Agriculture straw regeneration fire-proof heat preservation plate material and preparation method thereof

InactiveCN107186855ASolve long-term accumulation problemsLow costCeramic shaping apparatusDomestic articlesFire retardantRapid prototyping

The invention discloses an agriculture straw regeneration fire-proof heat preservation plate material. The agriculture straw regeneration fire-proof heatpreservation plate material comprises raw materials, by weight, 60-80 parts of agriculture straw, 10-15 parts of binder, 3-6 parts of metal oxide, 3-7 parts of water-proof agent, 3-5 parts of fire retardant, 15-20 parts of modified kaolin, 12-18 parts of white cement and 20-26 parts water. The agriculture straw regeneration fire-proof heat preservation plate material has the excellent properties of rapid prototyping, heat insulation and heat preservation, inflaming retarding, mould proof, deliquescence resistance, high strength and the like, the plate material is divided into a pressed inner core and an outer surface coating layer, the problems of being prone to breaking billet, sticking plate and demoulding are solved, continuous production is achieved, and the production efficiency is improved greatly; and meanwhile, the source of the main raw materials of the agriculture straw regeneration fire-proof heat insulation plate material is wide, the cost is low, the technology is simple and clear, and the high practical value and the good application prospect are achieved.

Owner:合肥市风达农业有限责任公司

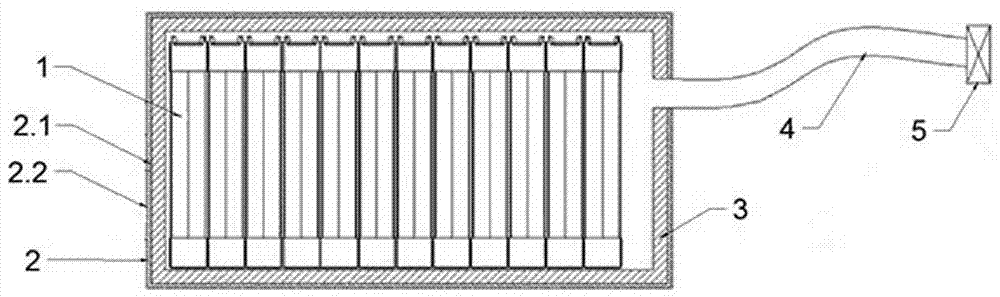

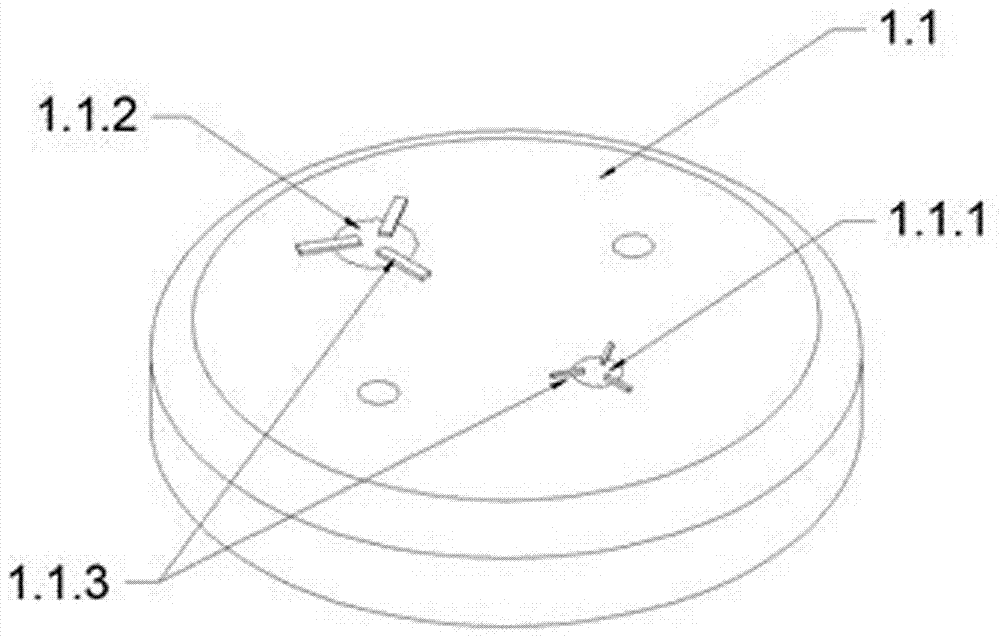

Heat-insulation, fireproof and explosion-proof battery pack

ActiveCN107507937AEnsure safetyAvoid explosion riskBattery isolationCell lids/coversLithium iron phosphateCarbon nanotube

The invention provides a heat-insulation fireproof and explosion-proof battery pack comprising a plurality of lithium ion battery cells, which are connected, in a firstly in parallel and then in series manner, to form a lithium ion battery pack. The lithium ion battery pack is arranged in a case comprising a case inner layer and a case outer layer. The case is made from phenolic resin, and the case inner layer and / or the case outer layer are coated with a heat-insulation fireproof layer, which is a melamine thermosetting foam flame retarding layer. An explosion-proof exhaust pipe is sealedly installed on the upper end of a side surface of the case. A waterproofing and breather valve is sealedly connected to an end of the explosion-proof exhaust pipe through threads. Each lithium ion battery cell includes: a top cover, a positive pole, a negative pole, an electrolyte, and a diaphragm located between the positive pole and the negative pole. The diaphragm is made from a ceramic material; the negative pole is made from carbon nano tubes; the positive pole is made from lithium iron phosphate; and the electrolyte is a polymer gel electrolyte or lithium hexafluorophosphate. The battery pack has excellent flame-retarding and explosion-proof properties, and is significantly improved in security performance.

Owner:东营悦泰技术服务有限公司

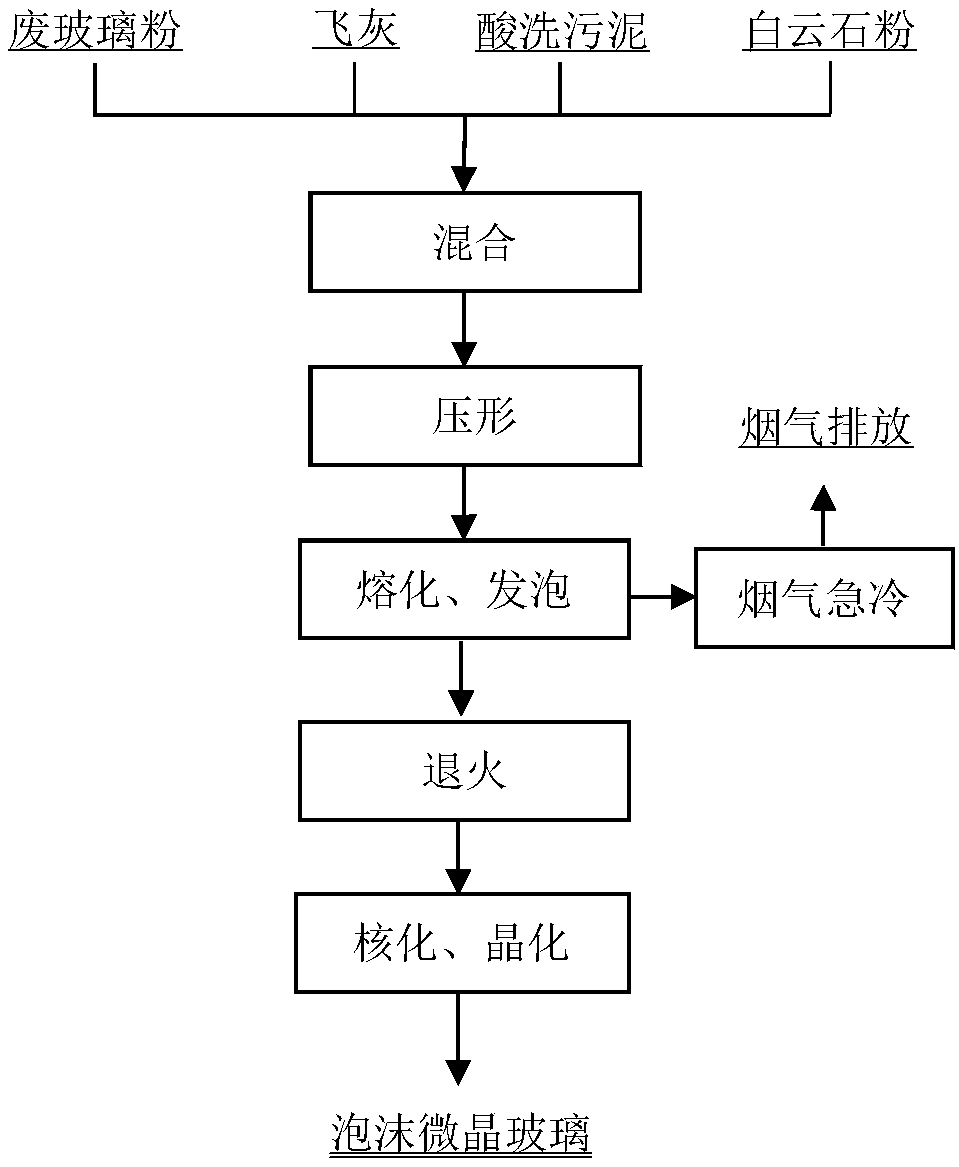

Harmless treatment method of garbage incineration fly ash dioxin

The invention discloses a harmless treatment method of garbage incineration fly ash dioxin, and belongs to the field of solid waste treatment and resource utilization. The method is characterized in that the garbage incineration fly ash is used as major raw materials to be mixed with waste glass powder, acid washing sludge and dolomite powder; shape pressing is performed; foam micro crystal glassis prepared through high-temperature fusion; meanwhile, dioxin in the fly ash is subjected to pyrolysis; chlorine atoms and alkaline earth metal oxides react to cure in the foam micro crystal glass; the generated smoke gas is fast cooled to the temperature of 200 DEG C or below through a sharp cooling device; and the synthesis of the dioxin again by residual chlorides is avoided. The harmless treatment and the high-value utilization in foam thermal insulation fireproof material of the garbage incineration fly ash dioxin can be realized; and the advantages of simple process and green and environmental-friendly effects are achieved.

Owner:UNIV OF SCI & TECH BEIJING

Semi-dull high-strength low-elongation viscose fiber as well as preparation method and application thereof

InactiveCN104846458AGood skin affinityHigh strengthArtificial filament washing/dryingArtificial filaments from viscosePolymer scienceSpinning

The invention provides a semi-dull high-strength low-elongation viscose fiber as well as a preparation method and application thereof. The viscose fiber is obtained by sequentially performing soaking, grinding, squeezing crushing, kneading, directional polymerization reduction, yellowing, dissolving, filtering, defoaming, curing, spinning drawing and after-treatment on a pulp raw material, and has an index system that the dry fracture strength is more than or equal to 3.20cN / dtex, the wet fracture strength is more than or equal to 1.70cN / dtex, the strength needed for generating 5% of the elongation in a wet state is more than or equal to 0.6cN / dtex, the dry elongation at break is 13.0-16%, and the wet elongation at break is 16.0-21.0%. The semi-dull high-strength viscose fiber provided by the invention is prepared by virtue of technical innovation, and is a novel fiber variety which has an index system different from that of ordinary viscose fibers and Modal fibers, and a product of the fiber shows high and strong fiber characteristics and also shows skin affinity stronger than that of cotton fibers, so that the semi-dull high-strength low-elongation viscose fiber can effectively replace the existing differentiation viscose fiber, the development and the industrial upgrading of downstream novel textiles can be promoted while the processability of the downstream process of the viscose fiber is improved, and the semi-dull high-strength low-elongation viscose fiber can be well applied to the field of producing underclothes and high-grade woven fabrics.

Owner:YIBIN GRACE GROUP CO LTD +2

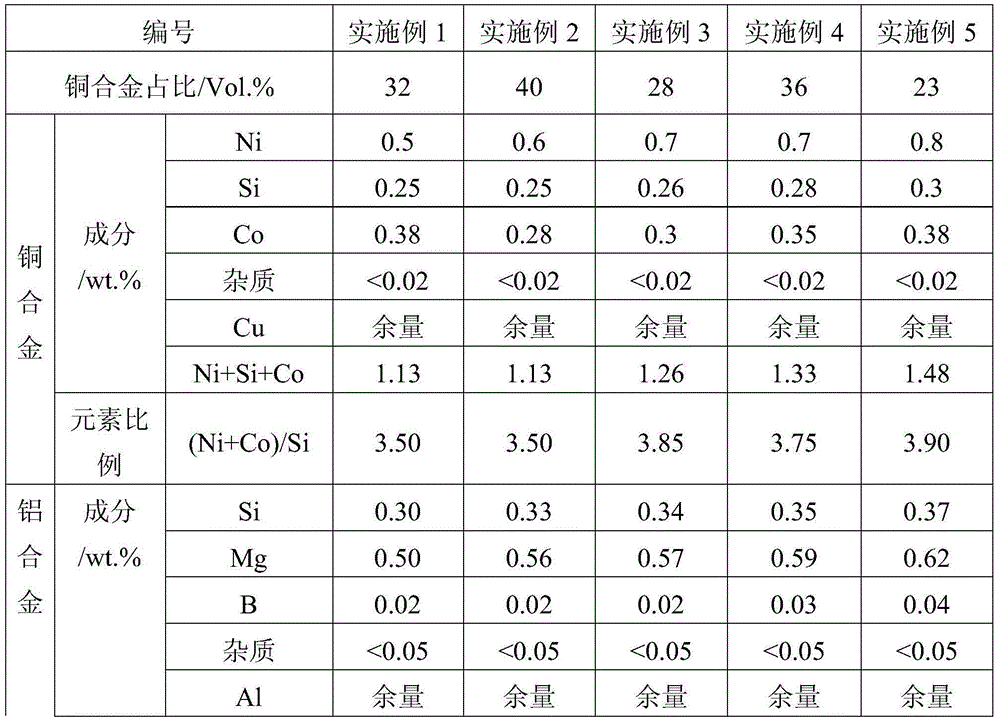

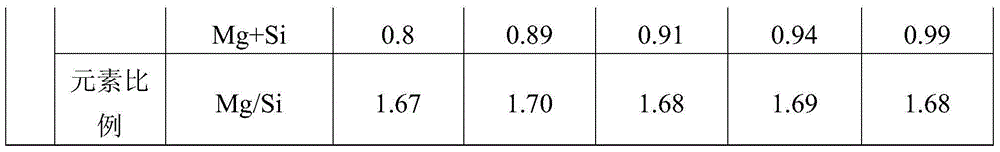

Copper alloy and aluminum alloy composite wire and preparation processing method thereof

The invention relates to a copper alloy and aluminum alloy composite wire and a preparation processing method thereof and belongs to the field of non-ferrous metal material plastic processing and heat treatment. The composite wire is of a copper clad aluminum concentric bimetallic composite structure, the outer layer is copper alloy, the core is aluminum alloy, and the copper alloy accounts for 20%-40% of the volume fraction of the composite wire. A copper alloy pipe blank and an aluminum alloy rod blank are prepared through a hot extrusion method, the copper alloy pipe blank is subjected to cold rolling, solid solution heat treatment and cold rolling once more to be made into a composite blank outer layer, the composite blank outer layer and an aluminum alloy rod core form a composite blank, and the composite blank is subjected to cold rolling (cold drawing), primary heat treatment, cold drawing once more and secondary heat treatment to be made into a finished product. The copper alloy and aluminum alloy composite wire prepared through the method has the characteristics that the strength is high, the mass is light, the good conductive capability is maintained, and meanwhile the certain elasticity is further achieved.

Owner:GRIMAT ENG INST CO LTD

Coloured floor material

The present invention relates to a building ground level material, in the concrete, it is a coloured ground level material. It raw material composition includes (by wt%) 34-45% of cement, 15-25% of refined quartz sand, 15-25% of carborundum, 2%-5% of expanding agent, 1% of water-reducing agent, 5%-10% of nano-grade pigment, 5-7% of heavy calcium carbonate, 0.5-2% of anticracking agent, 8-12% of wollastonite powder and 0.5%-2% of acid-resisting hardening agent.

Owner:SHANDONG ZERUI NEW MATERIAL TECH

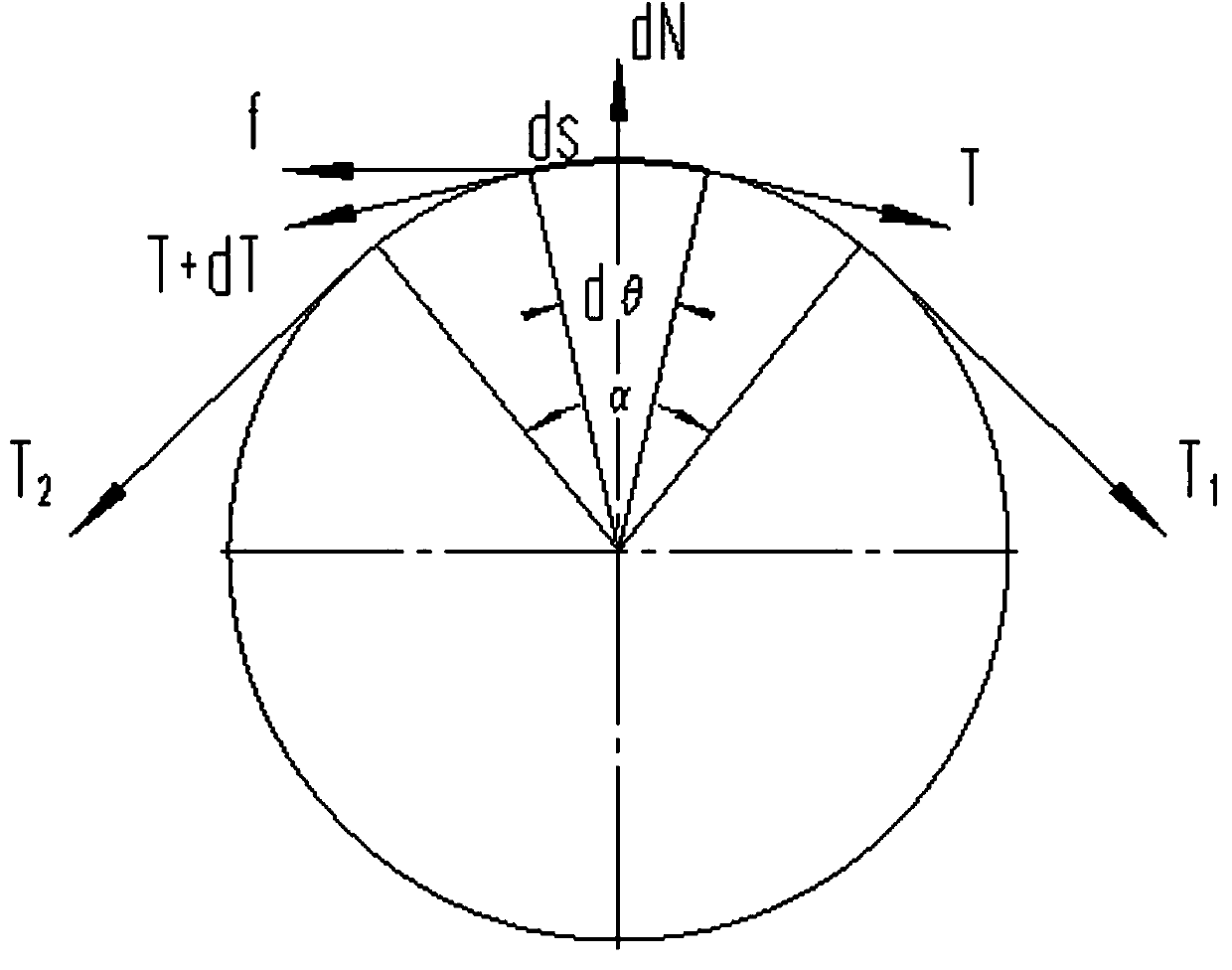

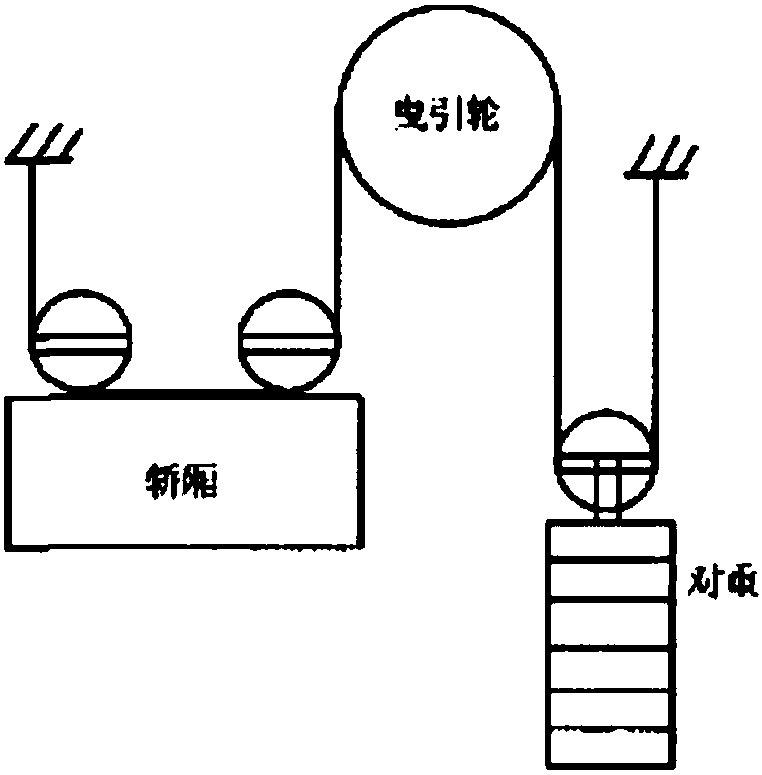

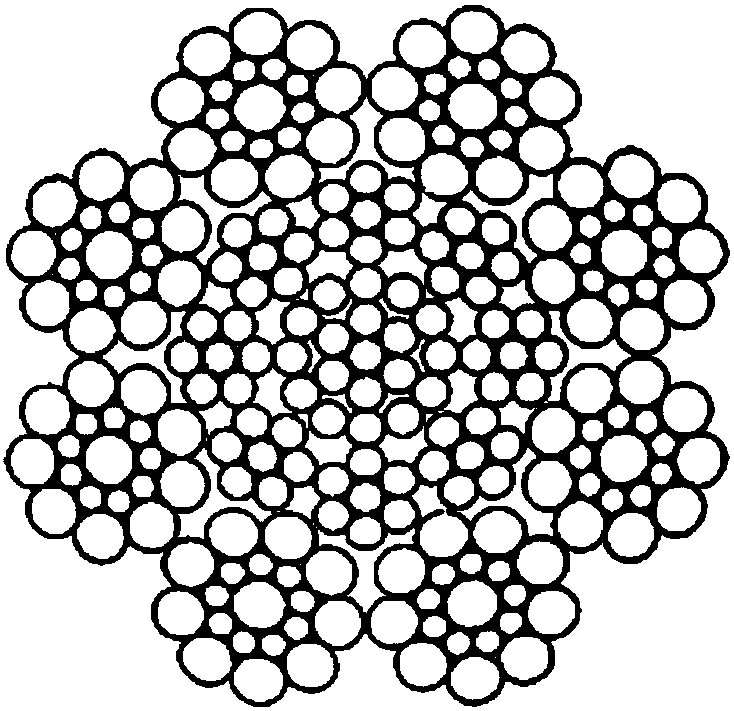

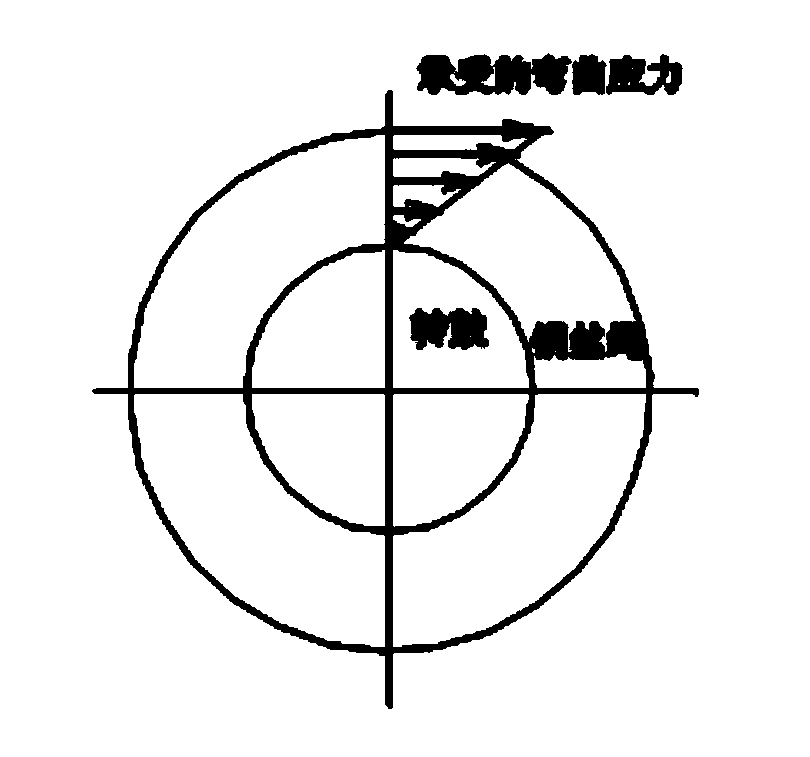

Method for producing high-speed mute and durable steel wire ropes for elevators

The invention belongs to the field of application of steel for steel wire ropes, in particular to a method for producing high-speed mute and durable steel wire ropes for elevators. The steel for the steel wire ropes comprises the chemical components in mass percentage: 0.64-0.69% of C, 0.10-0.30% of Si, 0.30-0.60% of Mn, at most 0.020% of P, at most 0.010% of S and the balance of Fe and unavoidable impurities, wherein the target mass percentage of a part of chemical components is as follows: 0.65% of C, 0.50% of Mn and 0.15% of Si; and the size of the impurities is controlled by below 8mu m. The method comprises the following steps: (1) descaling and drawing a steel wire rod prepared from the steel components for the first-time annealing, drawing again for the second-time annealing, then drawing to obtain steel wires, wherein the drawing pass after the second-time annealing is 6, and finally standing the steel wires to form a semi-finished product of steel wire rope for elevators; (2)plastic-coating the semi-finished product of steel wire rope for elevators to form a flat ribbon, wherein the thickness of the flat ribbon is 3mm, and thus obtaining the high-speed mute and durable steel wire rope for elevators. The steel wire rope for elevators produced by the method has the advantages of high strength, muteness, durability, and the method has a simple process and is suitable forproduction application.

Owner:武汉钢铁有限公司

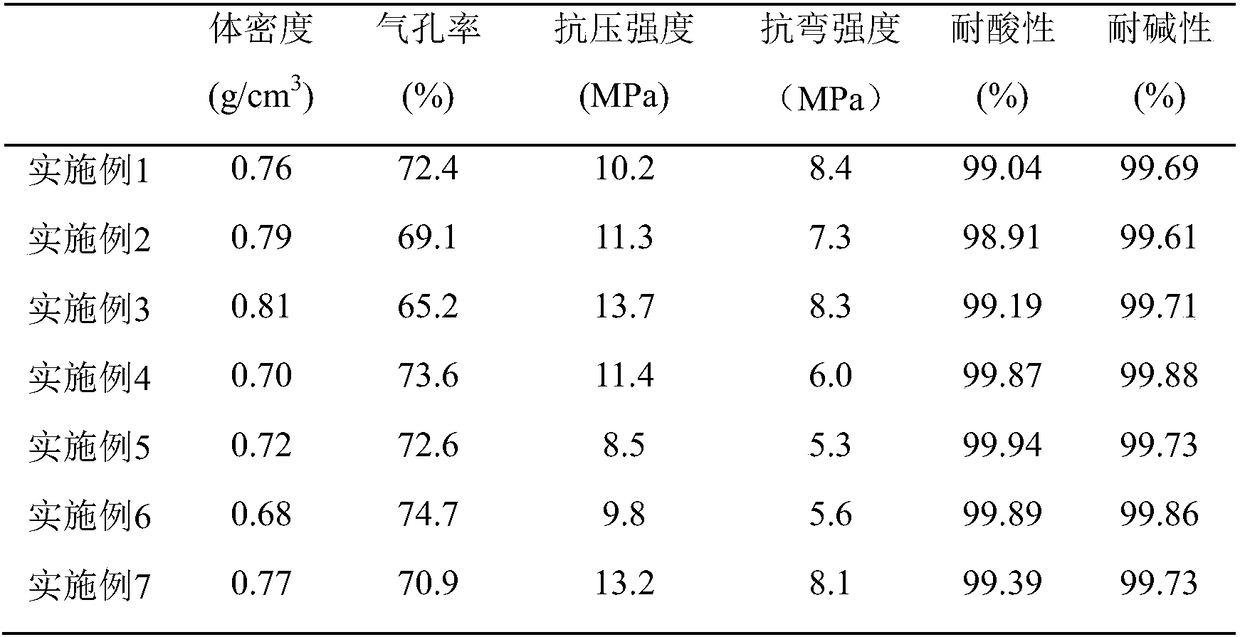

Coal gangue-pulverized fuel ash-silica sand tailing system all-waste-residue foam ceramic and preparation method thereof

InactiveCN108395271AIncrease profitLight weightCeramic materials productionCeramicwarePorosityPulverized fuel ash

The invention discloses coal gangue-pulverized fuel ash-silica sand tailings system all-waste-residue light-weight high-strength inorganic foam ceramic and a preparation method thereof. Coal gangue, pulverized fuel ash and silica sand tailings are adopted as raw materials, a bit of water is additionally added as a wetting agent, the foam ceramic is endowed with a porous structure through a gas released by reaction of inner compositions of the tailings at high temperature, and the foam ceramic with an excellent combination property is obtained. The waste residue utilization rate is high, the preparation process is simple and low in cost, a main phase is a calciclase phase, and the foam ceramic has light weight, high strength, heat insulation, heat preservation, fire protection, corrosion resistance and no secondary pollution, has the volume density being 0.68 to 0.81g.cm<-3>, the porosity being 65.2 to 74.7 percent, the compressive strength being 8.5 to 13.7MPa, the bending strength being 5.3 to 8.4MPa, the acid resistance being 98.91 to 99.94 percent, and the alkali resistance being 99.61 to 99.83 percent, and can be used as a heat-insulation heat-preservation fire-protection material for a building top layer, a nonbearing wall and inner and outer walls.

Owner:CENT SOUTH UNIV

Folding box-type board room capable of being overlapped

InactiveCN105971122AIngenious designCompact and reasonable structureHeat proofingOn boardEngineering

Owner:JIANGSU BIAOLONG CONSTR GRP CO LTD

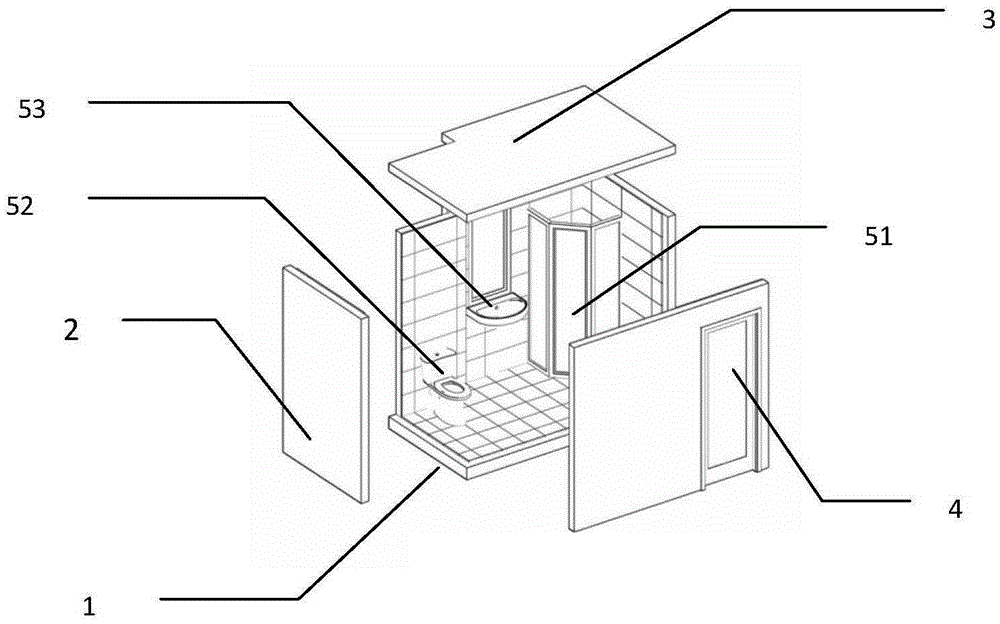

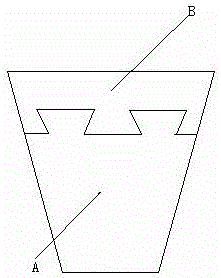

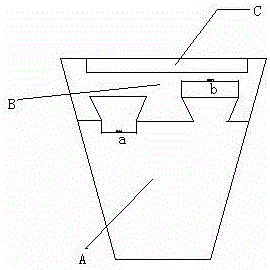

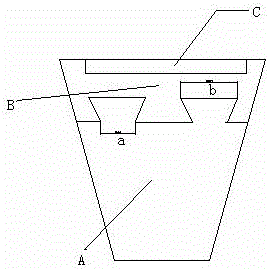

Compound brick with dovetail tenon type embedding structure and preparation method of compound brick

InactiveCN106839776AThere will be no disengagement (drawing lots)Improve insulation effectFurnace componentsInsulation layerHeavy weight

The invention is a composite brick with a dovetail mosaic structure. The heavy material and the light thermal insulation material are respectively placed at both ends of the mold, separated by a dovetail baffle in the middle, and then formed and solidified to obtain a composite brick. . A dovetail-type seam inlay structure is used between light and heavy materials. In this way, even if the combination of the two materials is not strong due to the large difference in performance, the phenomenon of separation (drawing lots) between the working layer and the insulation layer will not occur.

Owner:SHANDONG KEXIN NEW MATERIALS +1

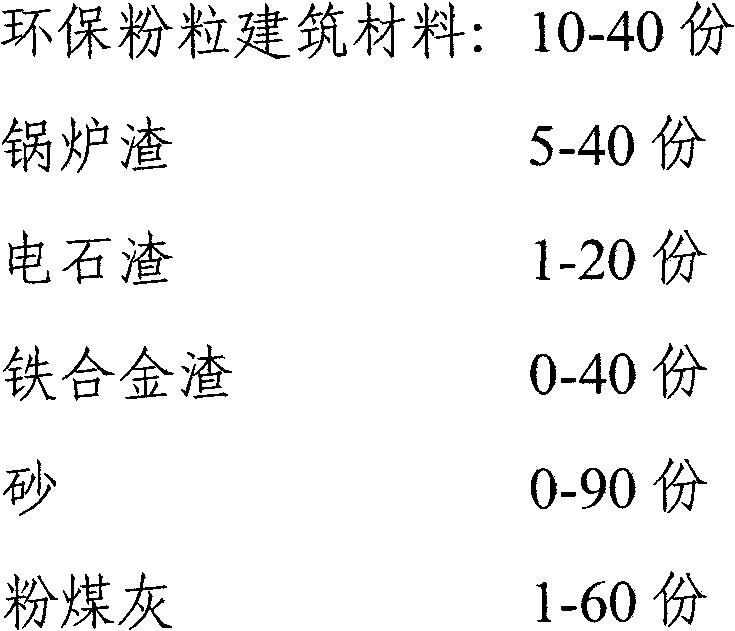

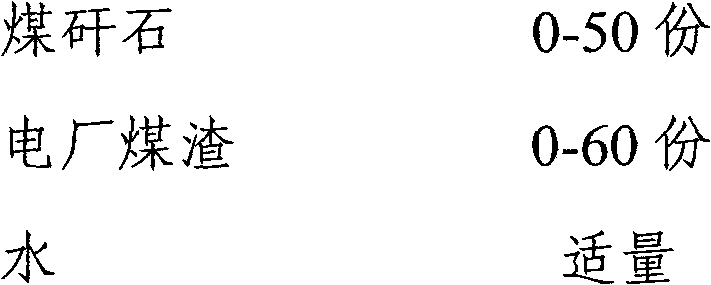

Environmentally friendly building block

The invention relates to the technical field of the environmentally friendly building block (brick). The building block is mainly composed of environmentally friendly powdery building material, fly ash, power station coal cinder, boiler clinker, iron alloy slag, carbide slag, coal gangue and sand. The environmentally friendly building block (brick) prepared from the materials is characterized in that cement is not used as gelling agent, the sources of the raw materials are wide, the slag and waste utilization proportion is high; and the environmentally friendly building block (brick) also has the advantages of low cost, wide application range, stable comprehensive product quality and the like and is easy to produce.

Owner:陈卓洋

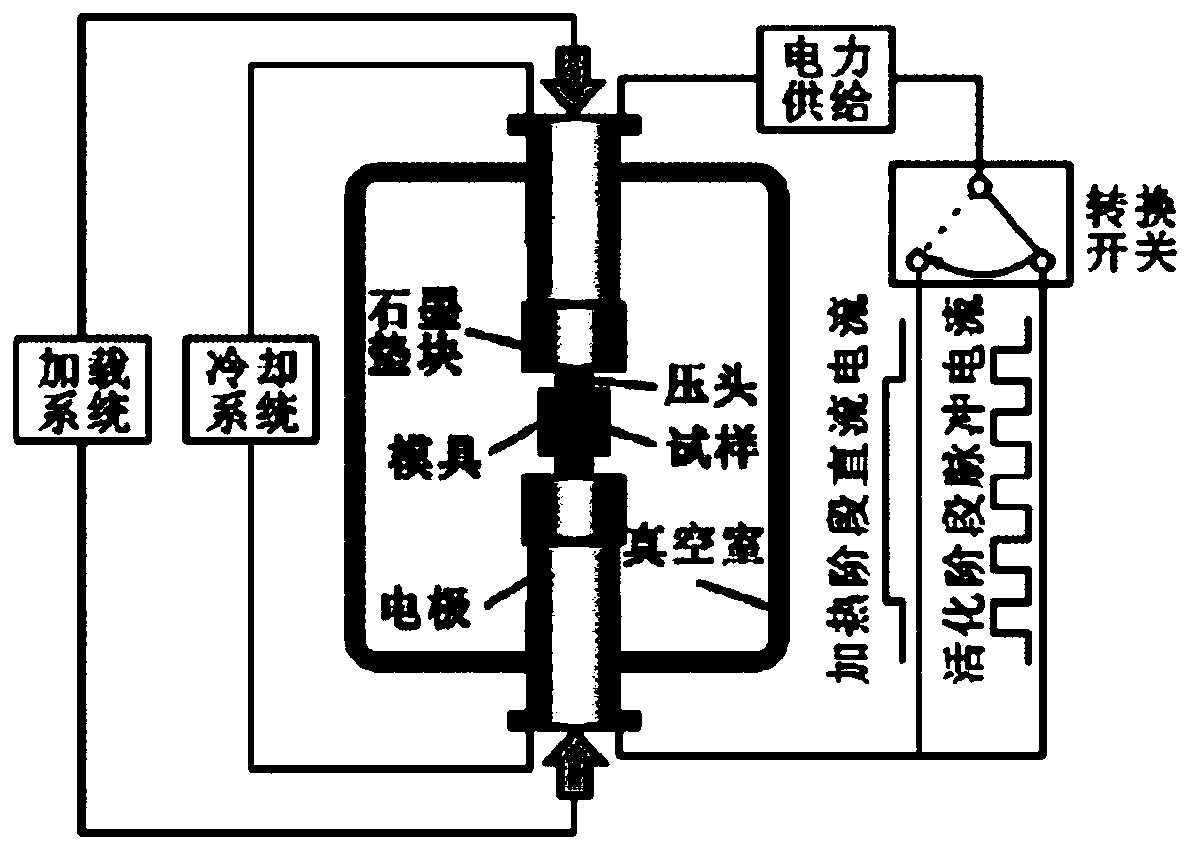

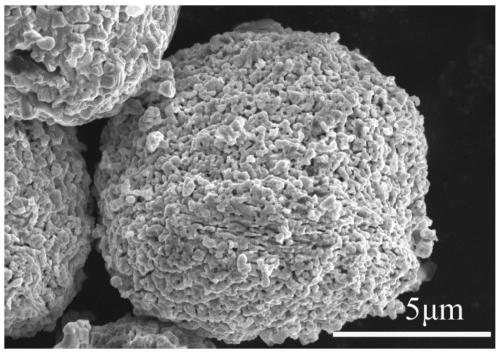

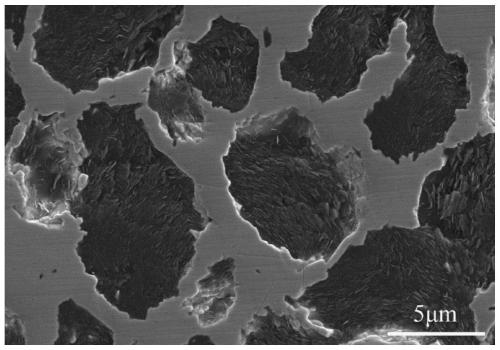

Tungsten carbide reinforced carbon matrix composite material and preparation method

The invention discloses a tungsten carbide reinforced carbon matrix composite material and a preparation method. Mesocarbon microbeads are adopted as the matrix, and tungsten carbide ceramic is adopted as the reinforcement phase and is evenly distributed among the carbon microbeads so as to form a three-dimensional network tungsten carbide skeleton reinforced isotropic structure. The preparation method includes: firstly taking tungsten oxide particles and mesocarbon microbeads as the raw materials to prepare uniform and thickness controllable tungsten carbide coating coated mesocarbon microbead powder by molten salt process, then performing pre-press molding, and conducting discharge plasma sintering at 1500-1900DEG C to form a uniform three-dimensional network tungsten carbide ceramic skeleton, which can significantly improve the strength, ablation resistance and oxidation resistance of the carbon matrix, thus forming the isotropic carbon matrix composite material characterized by lowcost, low density and excellent mechanical properties, sintering performance and ablation resistance. Because of the excellent comprehensive performance, the tungsten carbide reinforced carbon matrixcomposite material can be widely applied to aerospace, national defense and other fields, and has broad application prospects.

Owner:XI AN JIAOTONG UNIV

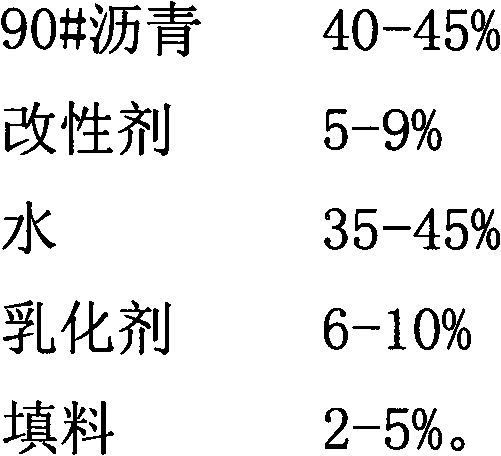

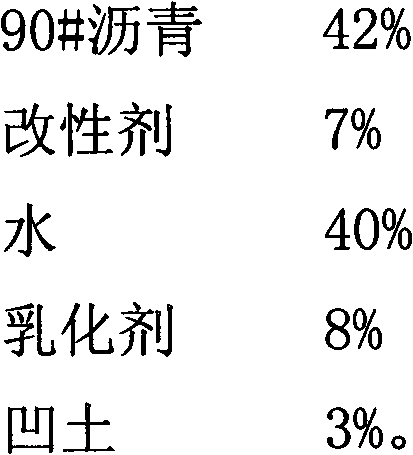

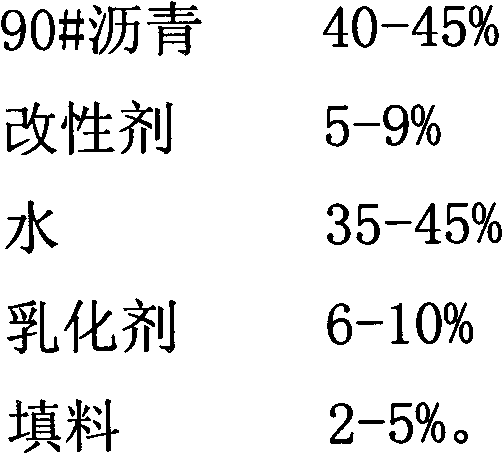

Formula and manufacturing process of water emulsion type high polymer modified asphalt waterproof paint

InactiveCN102161865AHas high strengthWith tenacityBituminous coatingsPolymer scienceBituminous waterproofing

The invention discloses a formula and a manufacturing process of water emulsion type high polymer modified asphalt waterproof paint. The formula is characterized by comprising the following components in percentage by mass: 40 to 45 percent of No.90 asphalt, 5 to 9 percent of modifier, 35 to 45 percent of water, 6 to 10 percent of emulsifier, 2 to 5 percent of attapulgite. The manufacturing process comprises: modifying the asphalt with the modifier, heating to 180 DEG C, mixing water and the emulsifier, heating the mixture to 80 DEG C, and regulating the pH value with acid to 1.5 to 2.5; emulsifying the hot asphalt and mixed emulsifier water in a special emulsification mill according to a ratio; and adding the attapulgite and filling. The invention has the advantages that: the water emulsion type high polymer modified asphalt waterproof paint can be used for civil and industrial building roof waterproofing projects, toilet and bathing room and kitchen waterproofing and seepage-proofing projects, basement, water pool and refrigeration house waterproofing and damp-proofing projects and the like and is an environment-friendly product without toxin, pollution and odor; and the coating film has high strength and toughness, water resistance, weather resistance, durability, high performance and the like.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

Method for producing environment-friendly composite building material by utilizing industrial solid wastes

InactiveCN103848595AWide range of usesLow costSolid waste managementEpoxyEnvironmental resource management

The invention relates to a method for producing an environment-friendly composite building material by utilizing industrial solid wastes. The method comprises the following steps: a, drying the industrial solid wastes and then pulverizing the industrial solid wastes by using a pulverizer until the granule diameter is less than 1mm; b, adding 10% of modified organic-inorganic composite binder taken as a binding material, 5% of chlorinated paraffin, 5% of octyl epoxy stearate and 10% of dimethyl isophthalate taken as a plasticizer into 70% of industrial solid waste granules and evenly stirring; c, plastifying the evenly-stirred materials in a rolling manner by using a plasticator so as to obtain a clinker billet, discharging the clinker billet from the plasticator and put into a prefabricated pressure mould and drying for 10 to 20 minutes under the pressure of 400 tons and at the temperature maintained within 90 DEG C to 100 DEG C, thereby obtaining the environment-friendly composite building material. The environment-friendly composite building material is wide in application range and good in economic and social benefits. When the environment-friendly composite building material is applied to the nonbearing wall of an energy-saving building, the performance of the environment-friendly composite building material is superior to the current national standard; and the friendliness of a natural environment and the recycling of resources are realized.

Owner:李永霞

Method for manufacturing thermal insulation fire-proof board with foaming ceramic fine bead and product thereof

InactiveCN101342725AHigh temperature resistantNon-deformableCeramic shaping apparatusSold ingredients supply apparatusMicrosphereThermal insulation

The invention discloses a method for manufacturing heat-insulating fire-resisting board with hollow ceramic microspheres; the method is implemented according to the following steps that A. prepare the materials according to the following weight proportions: 1000 proportion of powder hollow ceramic microspheres, not less than 100 proportion of phenolic resin or melamine resin and 10 to 30 portion of curing agents; B. evenly mix the materials and pour into a mold for smoothing; C. heat and pressurize the mixture on a hot press. The raw material used for the method is powder hollow ceramic microsphere, which belongs to the ceramic foaming product and could bear high temperature up to hundreds of degrees; the adhesive and curing agents are added and the mixture is molded after being heated and pressurized to obtain the board which has the advantages of being high temperature resistant and hard to deform, light weight and high strength. In this way, the object of the invention is fully realized.

Owner:四川威尔达节能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com