Method for producing high-speed mute and durable steel wire ropes for elevators

A production method and technology of steel wire ropes, which are applied in the steel application field for steel wire ropes, can solve the problems of reduced service life of steel wires, damage of steel wires, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

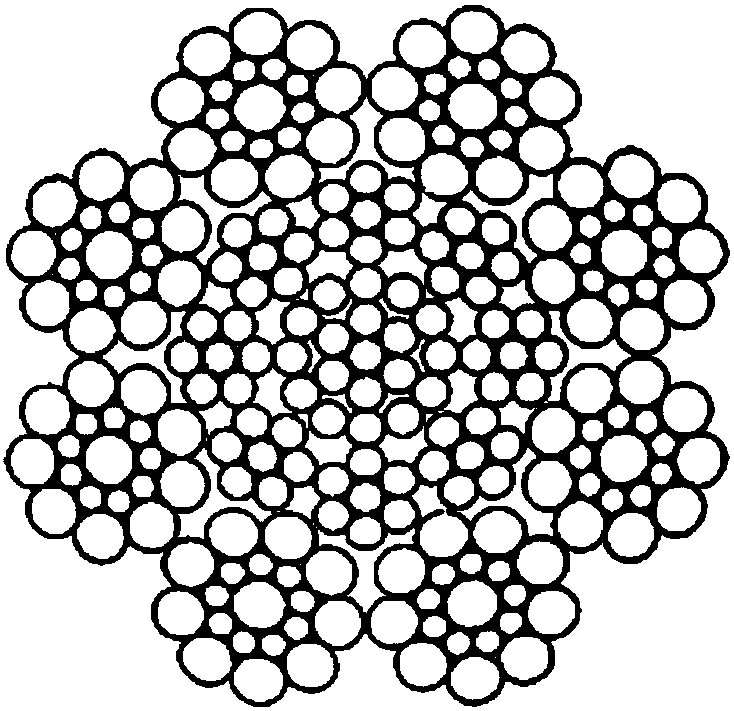

[0040] According to the requirements of steel composition, the chemical composition of molten steel is: C: 0.64%, Si: 0.30%, Mn: 0.60%, P: 0.020%, S: 0.010%. After the wire rod with a diameter of 6.5mm is dephosphorized, it is roughly drawn to a diameter of 2.5mm and annealed at a temperature of 800°C, and then drawn to a diameter of 0.9mm and annealed at a temperature of 810°C. The drawn D after the second annealing is 0.9mm, d is 0.15mm, and n is 6.

Embodiment 2

[0042] According to the requirements of steel composition, the chemical composition of molten steel is: C: 0.65%, Si: 0.25%, Mn: 0.55%, P: 0.015%, S: 0.008%. After the wire rod with a diameter of 6.5mm is dephosphorized, it is roughly drawn to a steel wire with a diameter of 2.7mm and annealed at 810°C, and the steel wire with a diameter of 0.95mm is annealed at an annealing temperature of 810°C. After the second annealing, the drawn D is 0.95mm, d is 0.16mm, and n is 6.

Embodiment 3

[0044] According to the requirements of steel composition, the chemical composition of molten steel is: C: 0.67%, Si: 0.20%, Mn: 0.50%, P: 0.010%, S: 0.007%. After the wire rod with a diameter of 6.5mm is dephosphorized, it is roughly drawn to a steel wire with a diameter of 3.0mm and annealed at 815°C, and the steel wire with a diameter of 0.98mm is annealed at an annealing temperature of 810°C. After the second annealing, the drawn D is 0.98mm, d is 0.17mm, and n is 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com