Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2788results about "Sold ingredients supply apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

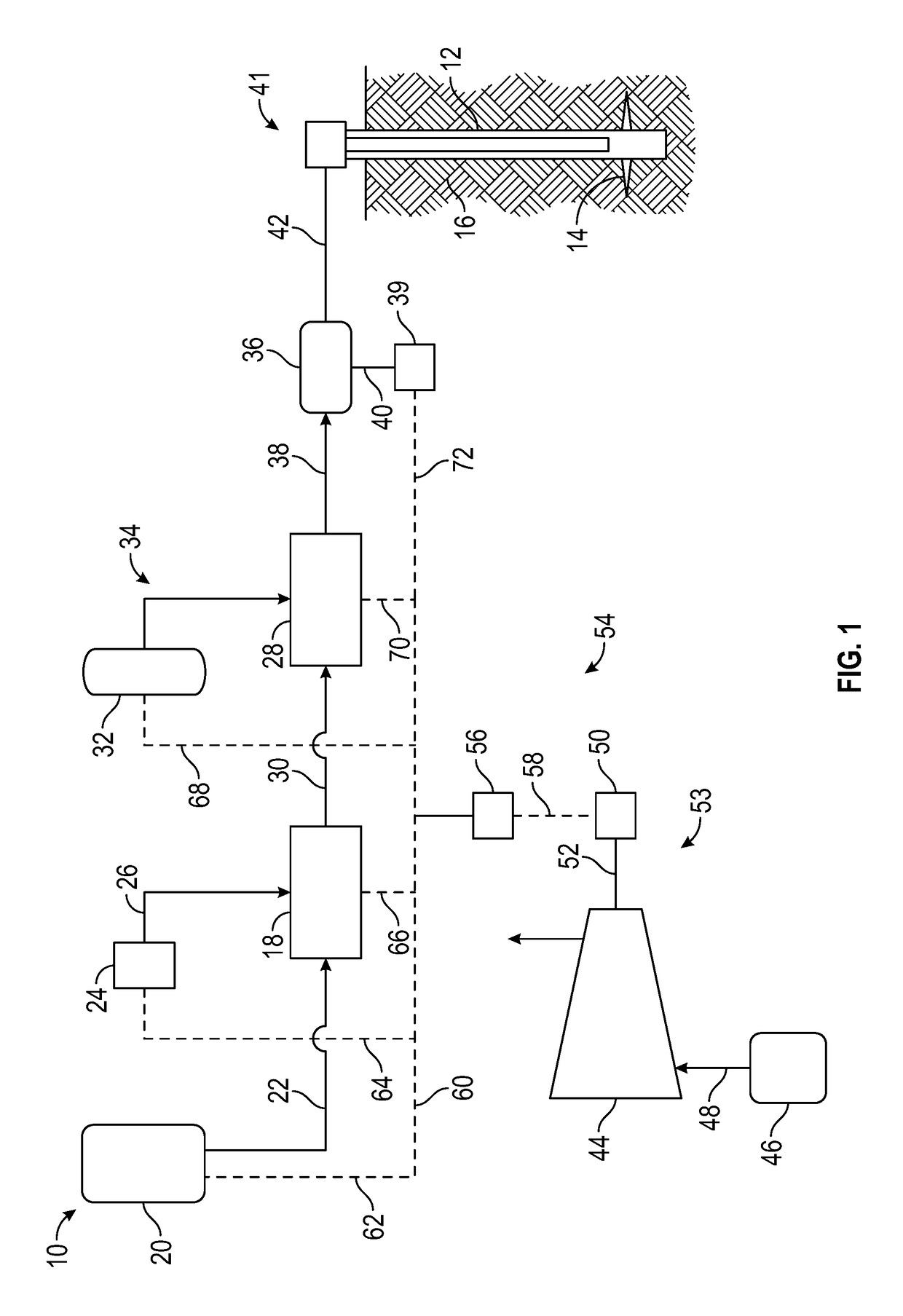

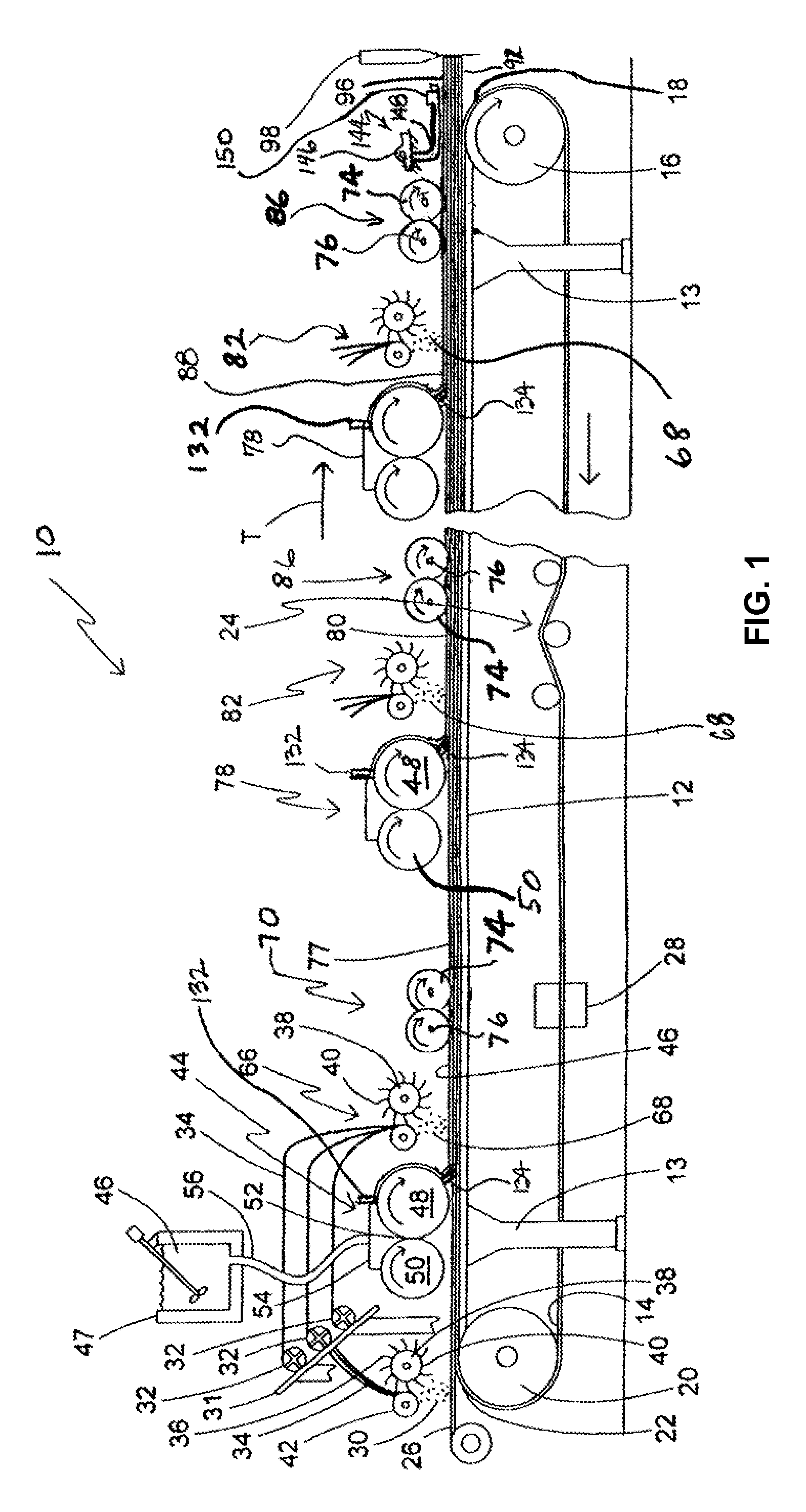

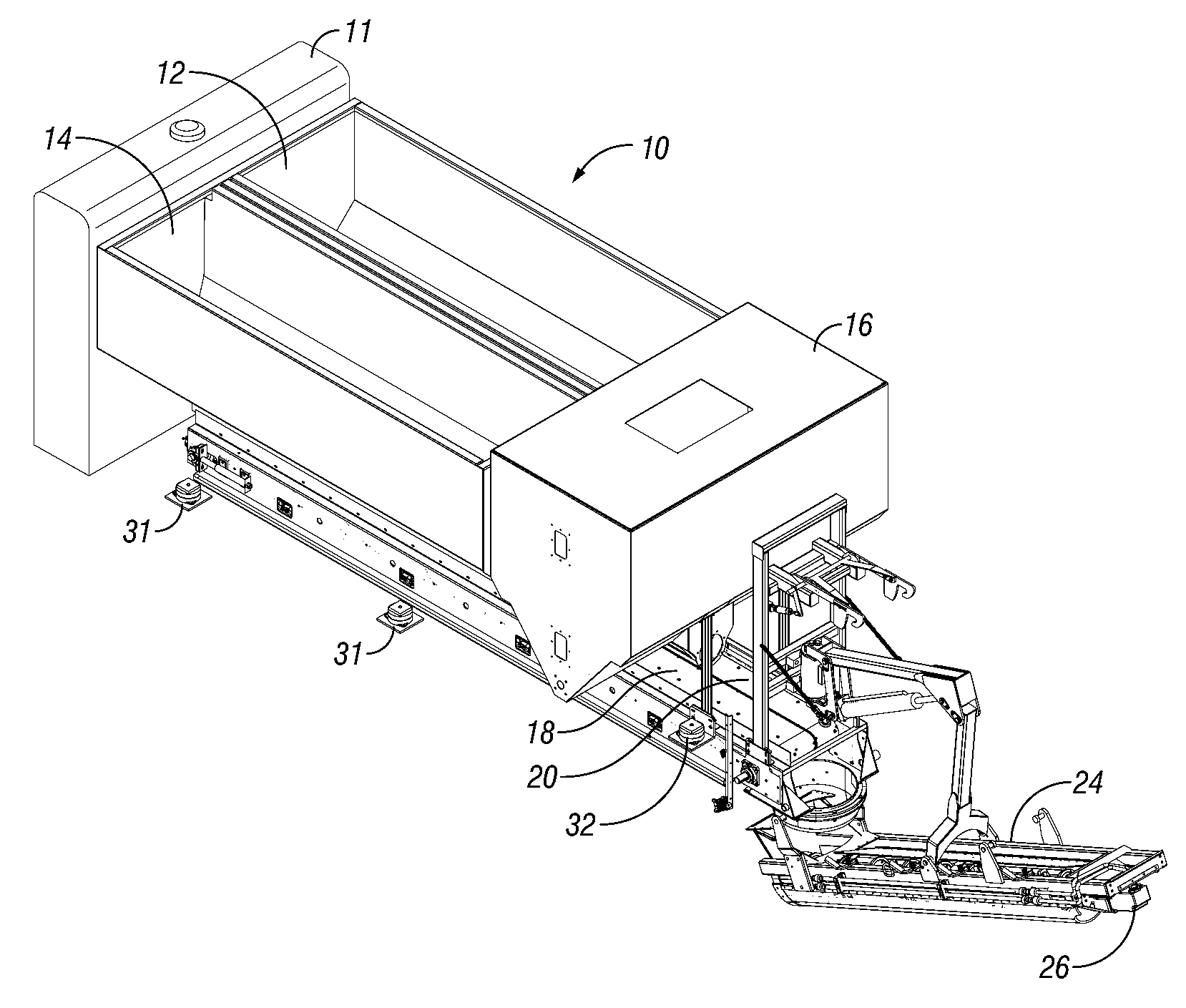

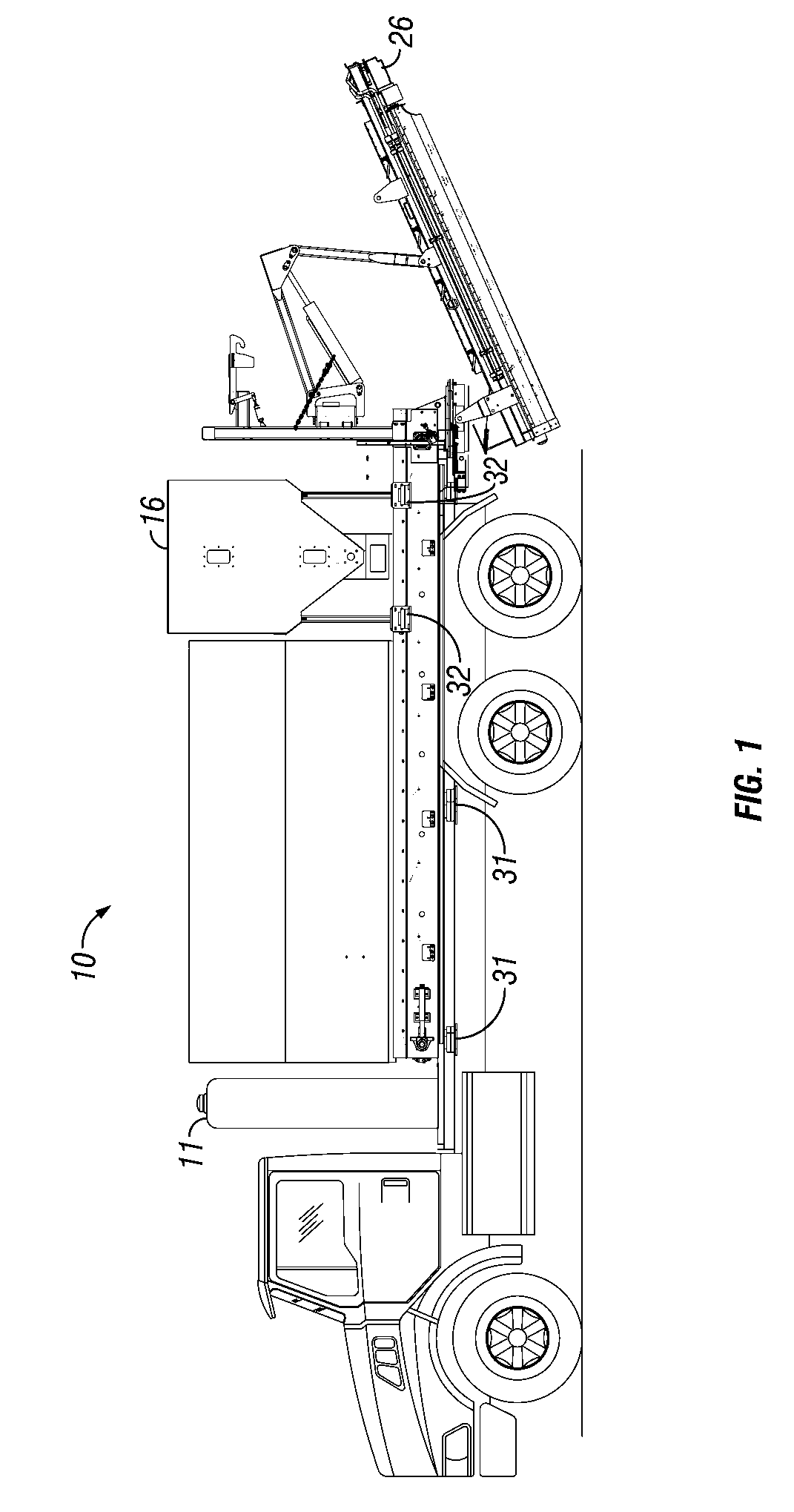

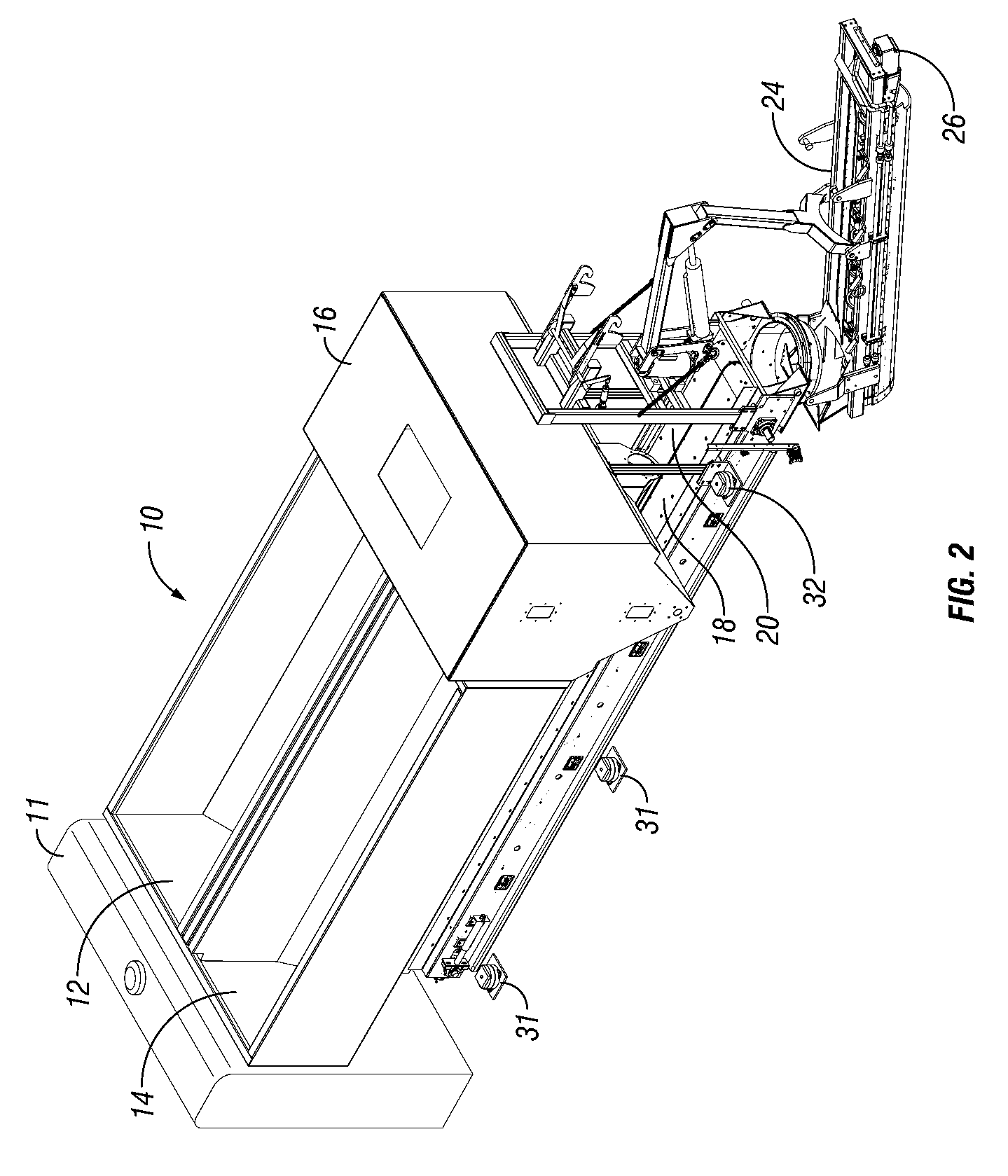

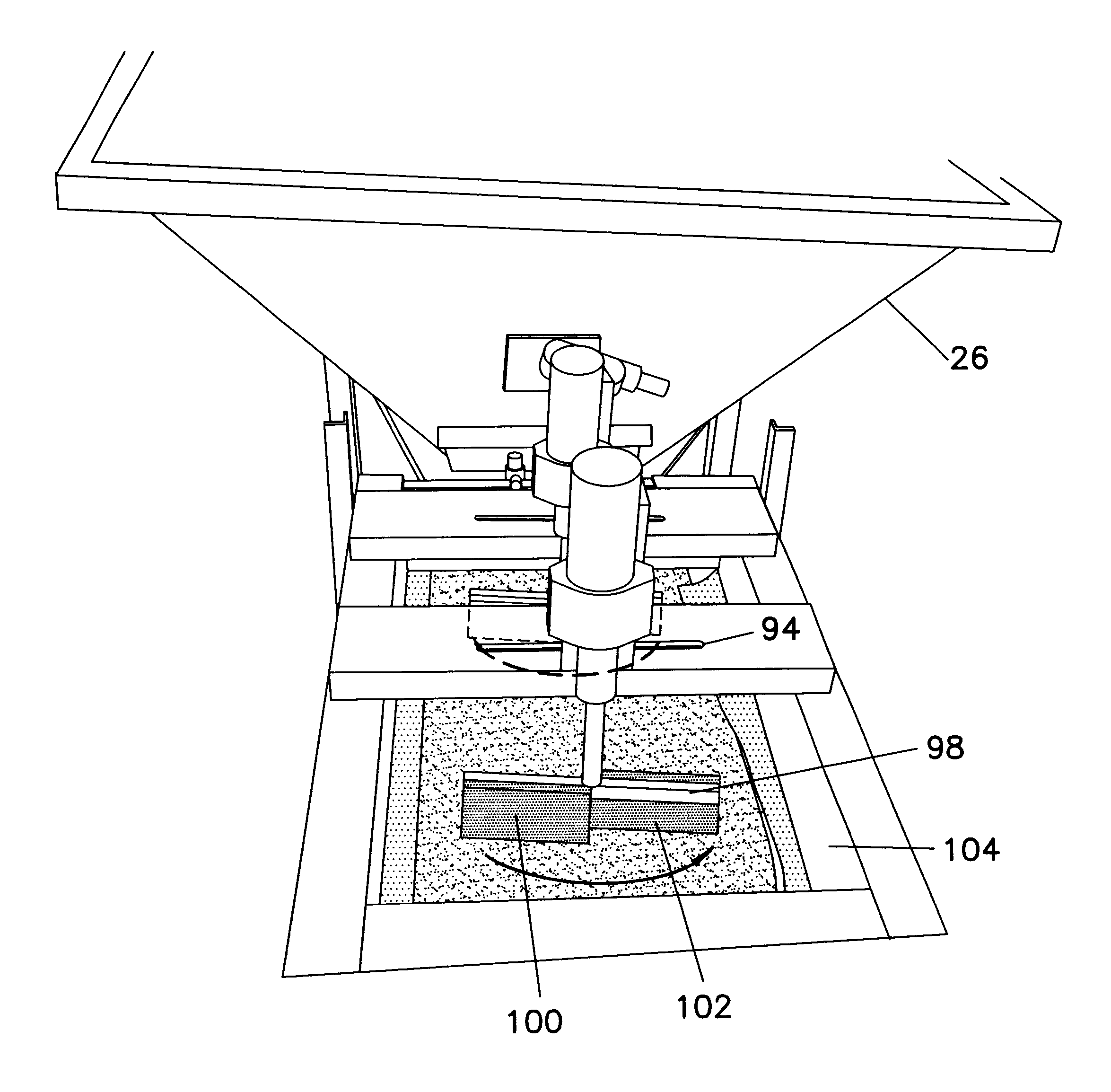

Independent control of auger and hopper assembly in electric blender system

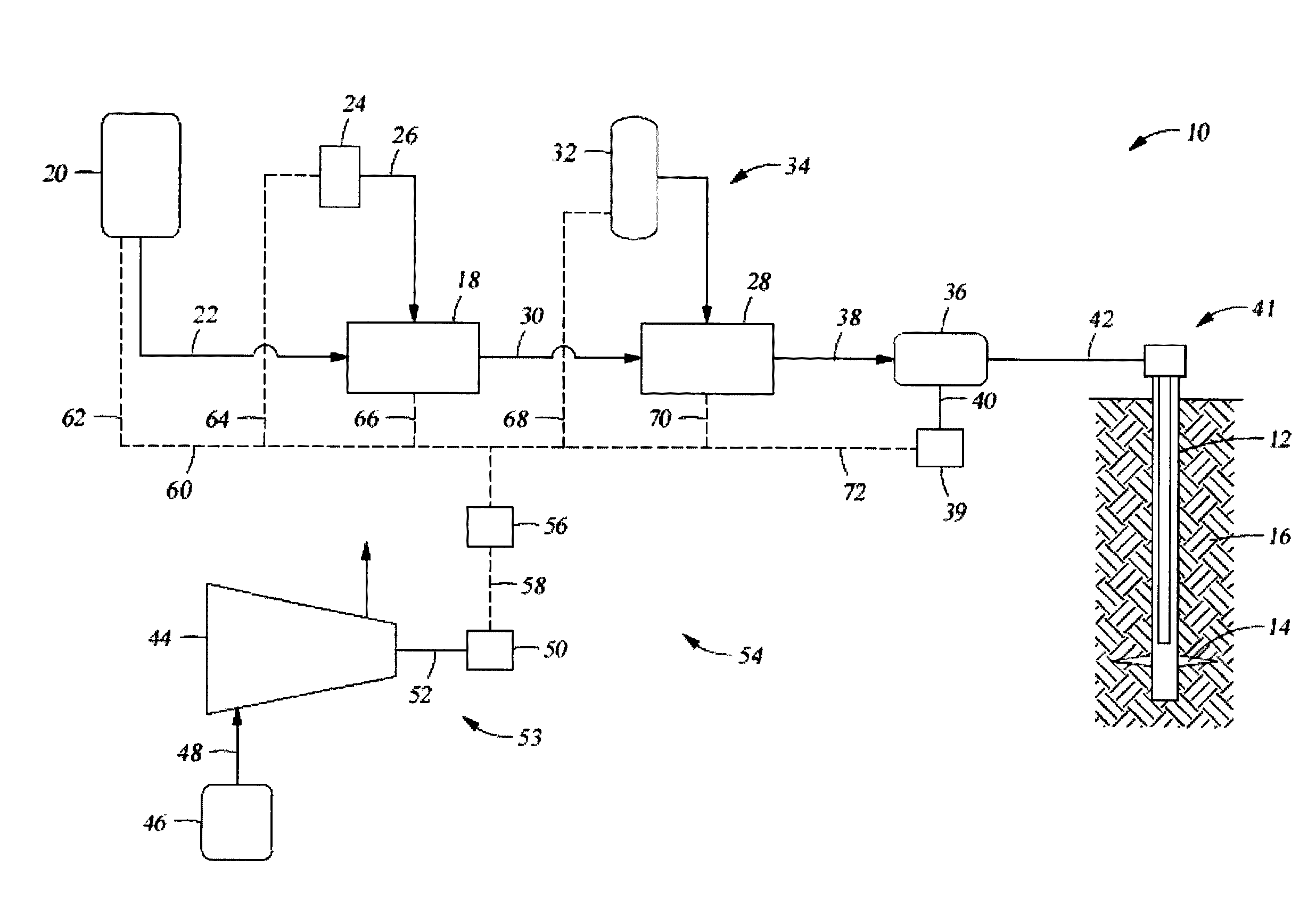

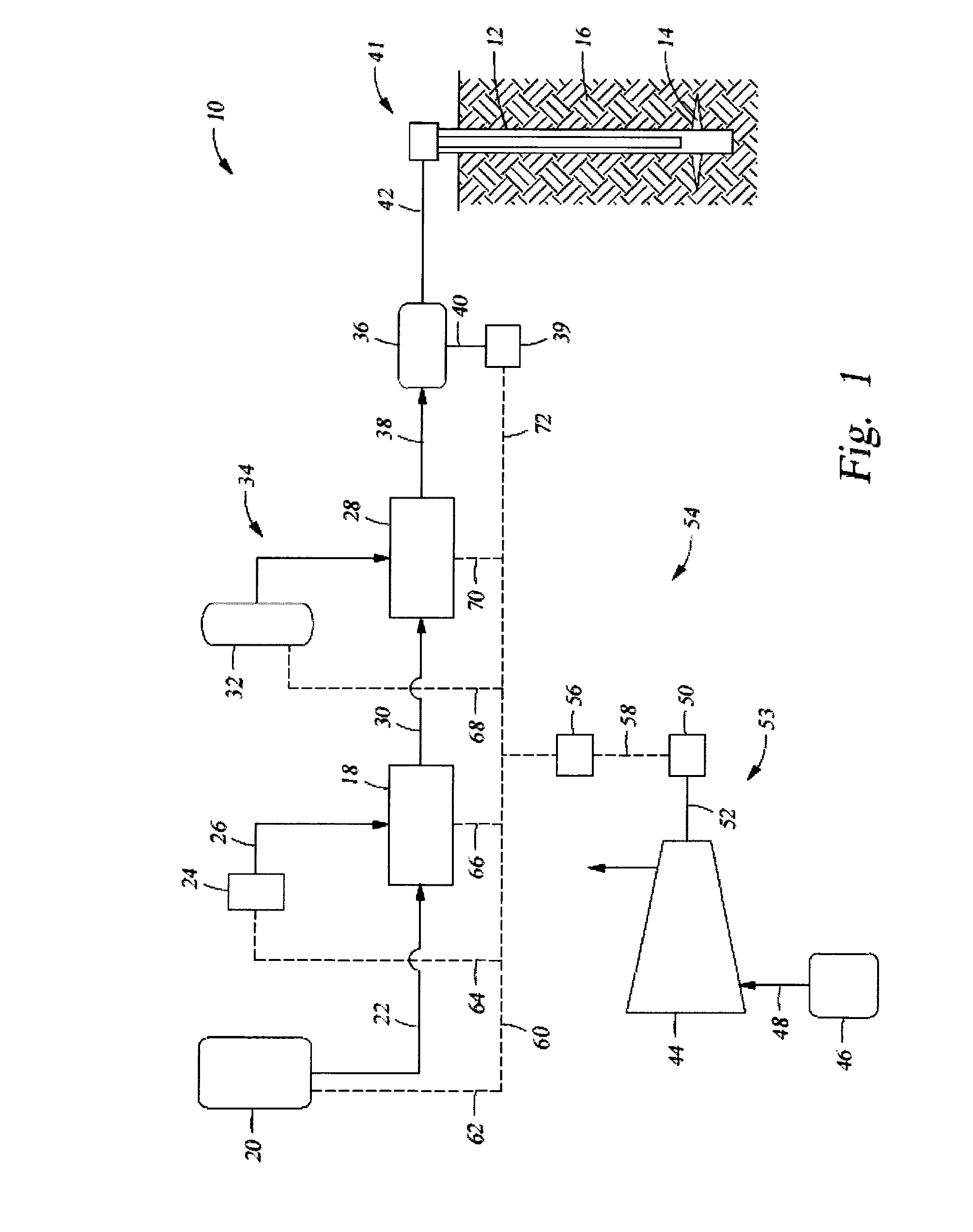

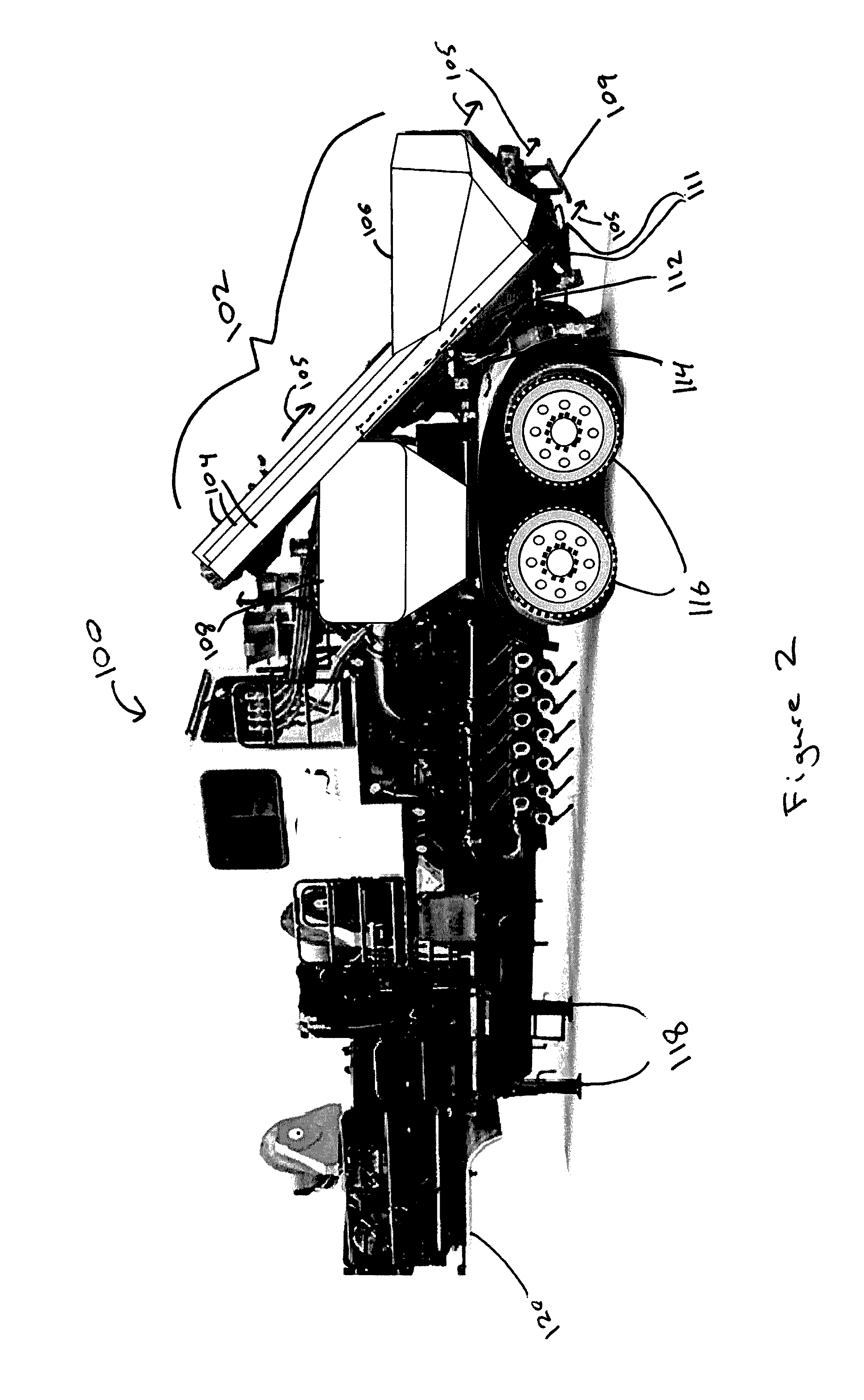

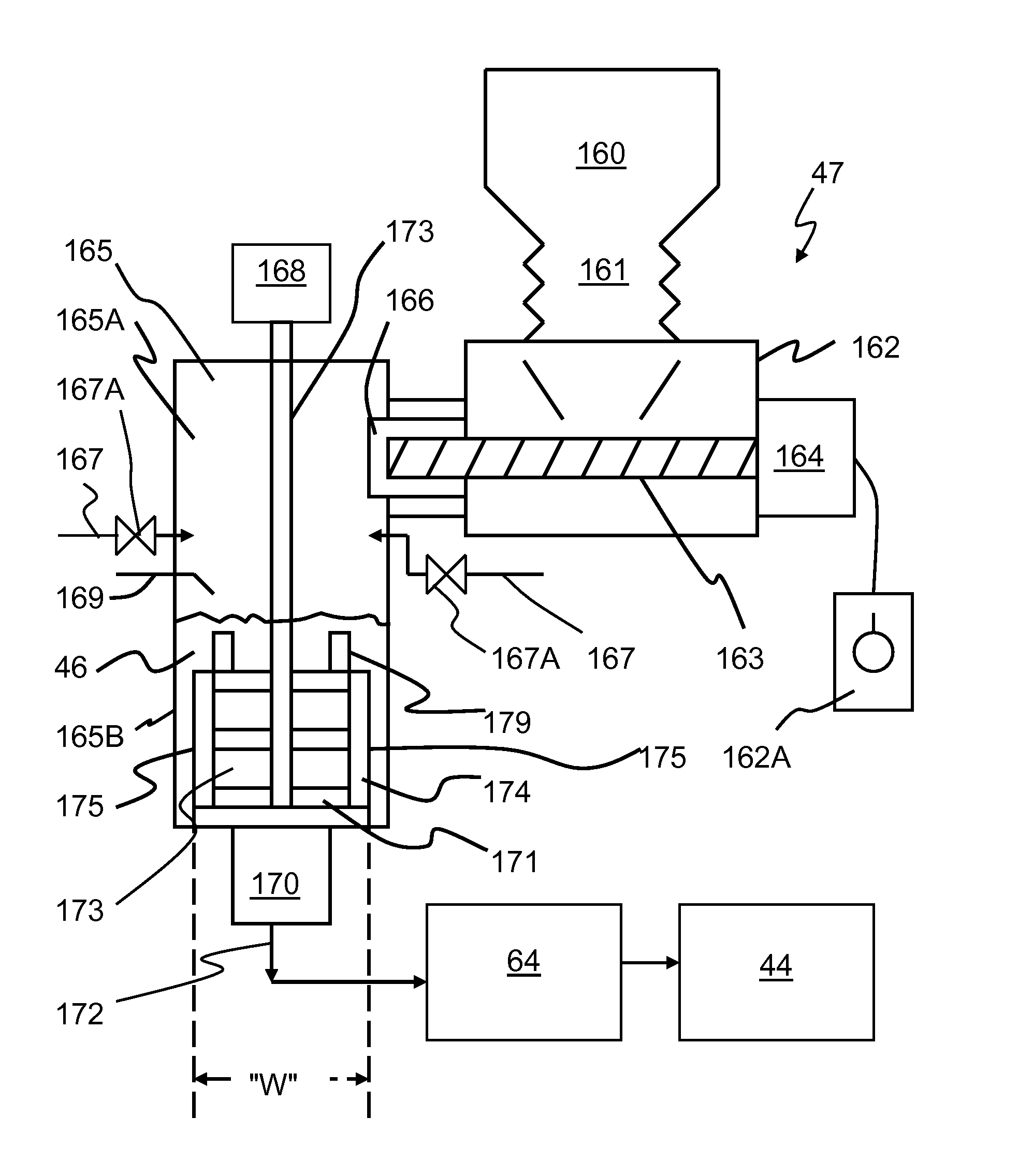

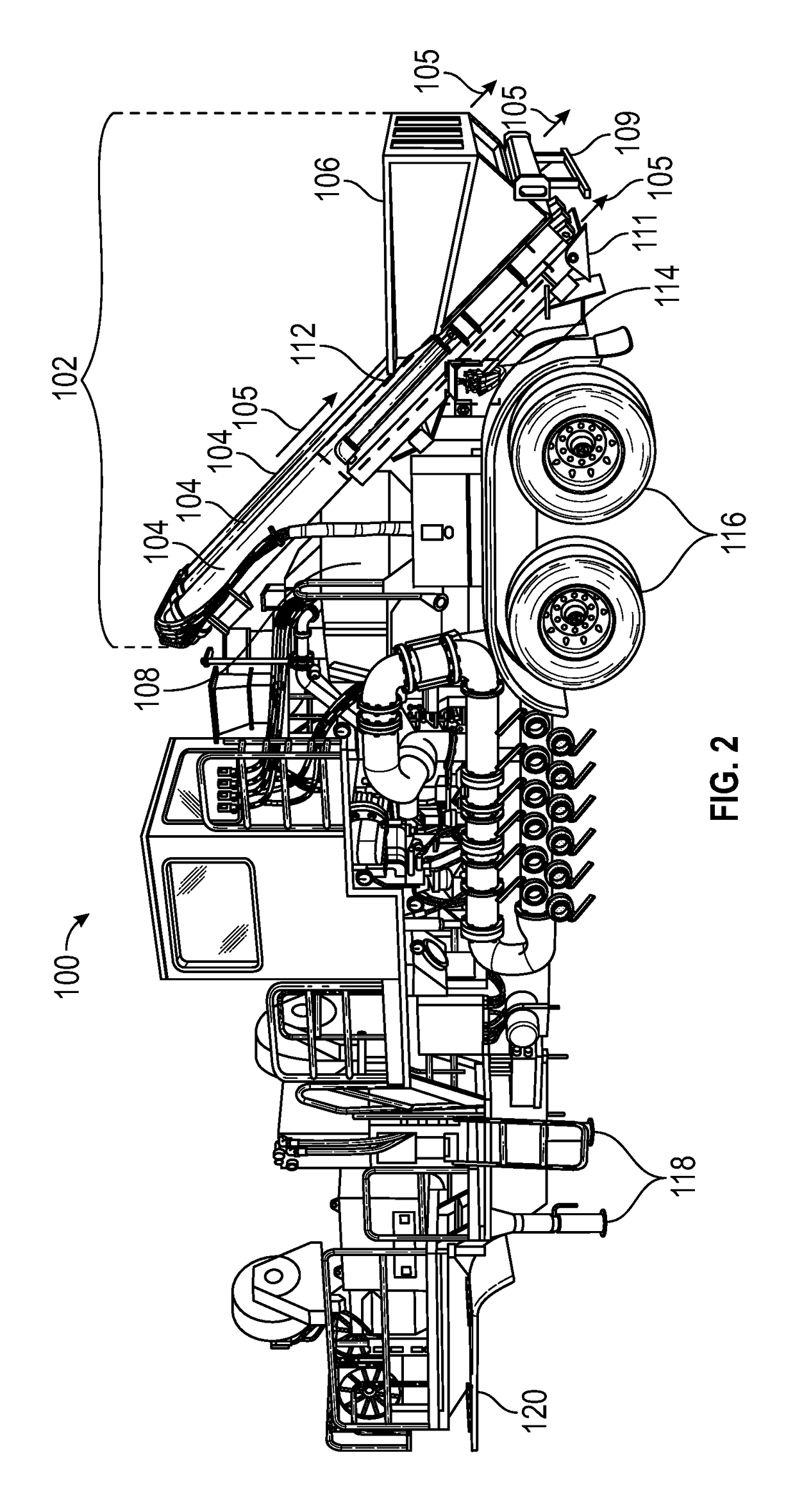

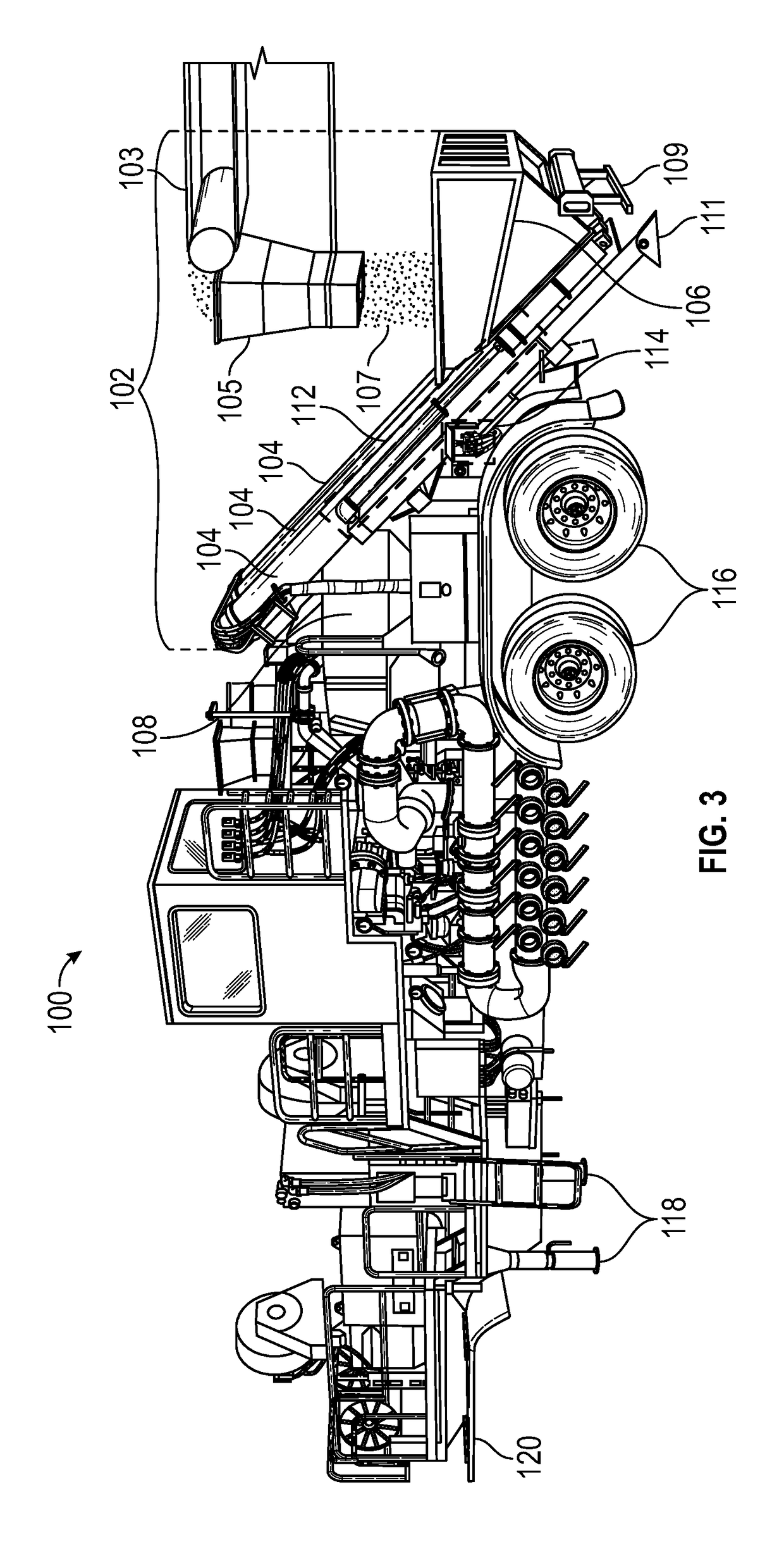

Embodiments relate to a hydraulic fracturing system that includes a blender unit. The system includes an auger and hopper assembly to receive proppant from a proppant source and feed the proppant to the blender unit for mixing with a fluid. A first power source is used to power the blender unit in order to mix the proppant with the fluid and prepare a fracturing slurry. A second power source independently powers the auger and hopper assembly in order to align the hopper of the auger and hopper assembly with a proppant feed from the proppant source. Thus, the auger and hopper assembly can be stowed or deployed without use of the first power source, which is the main power supply to the blender unit.

Owner:US WELL SERVICS LLC

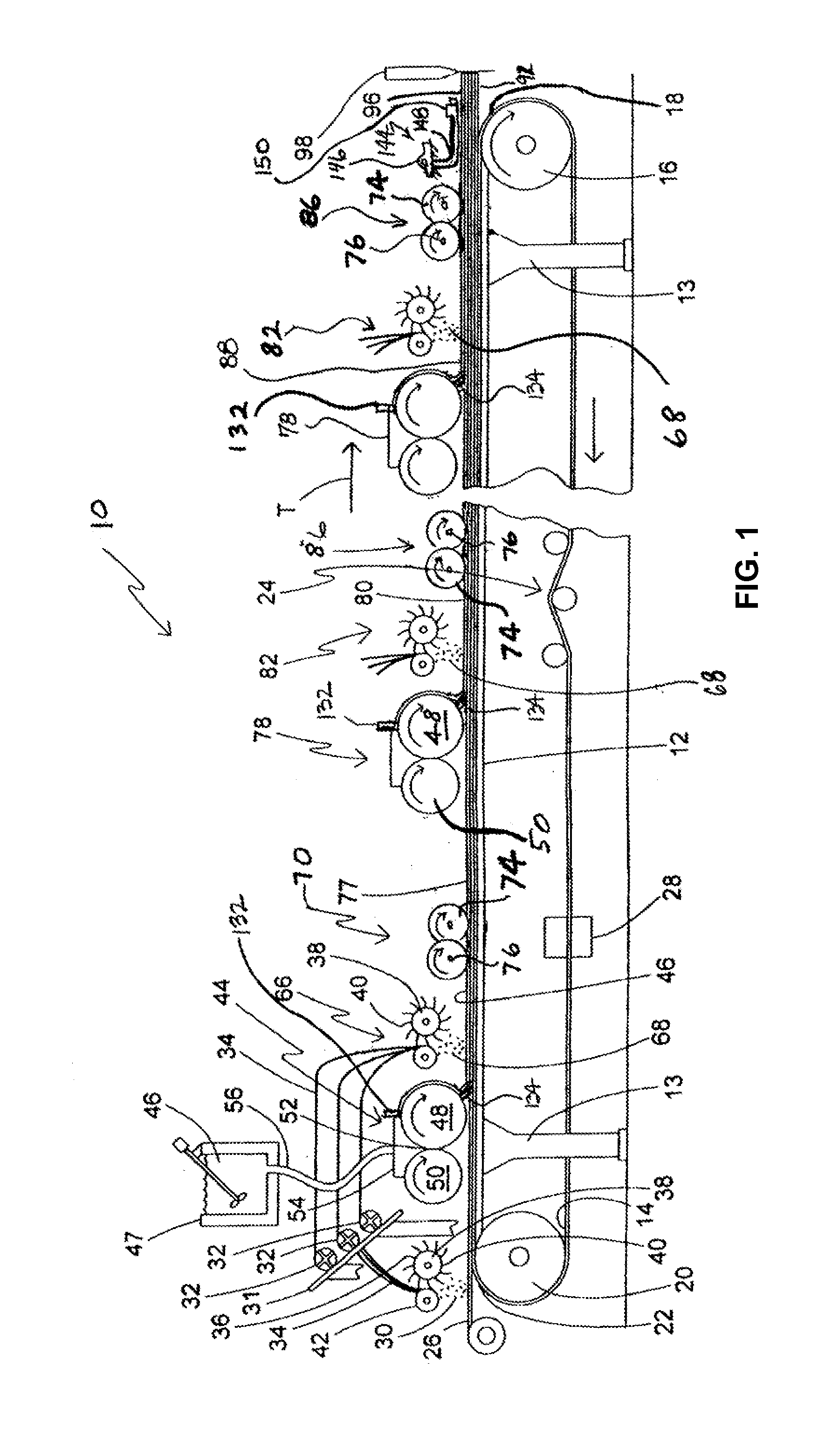

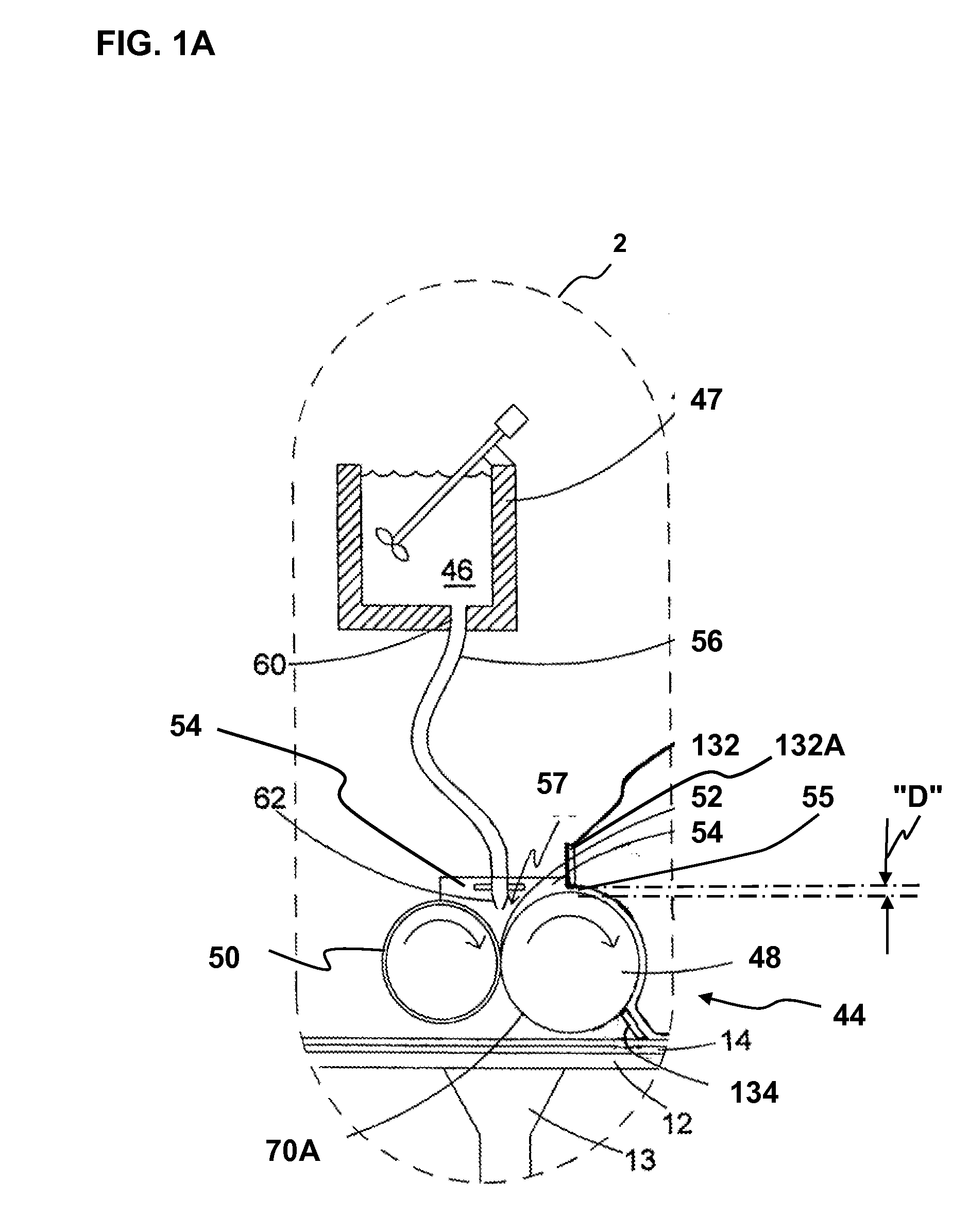

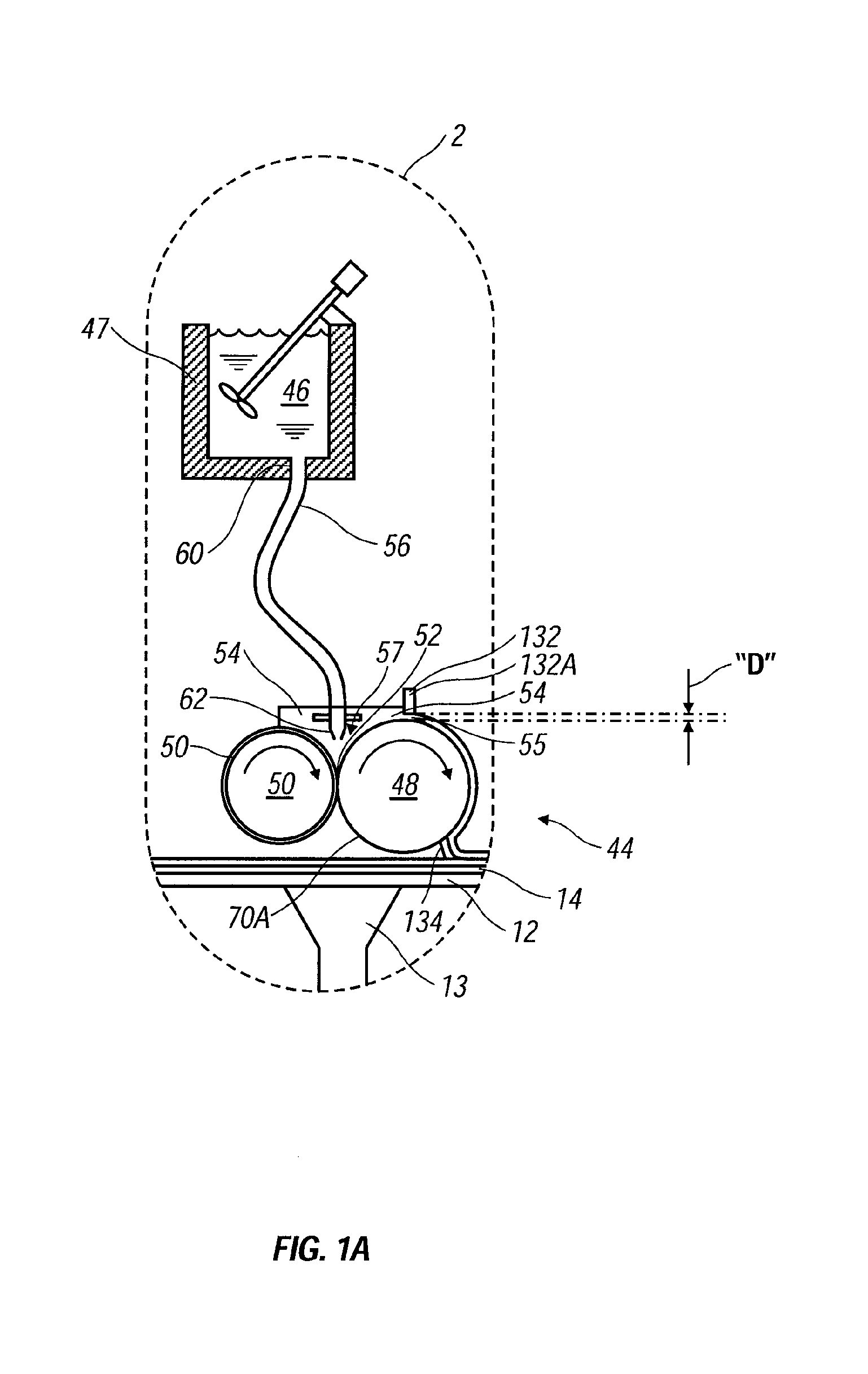

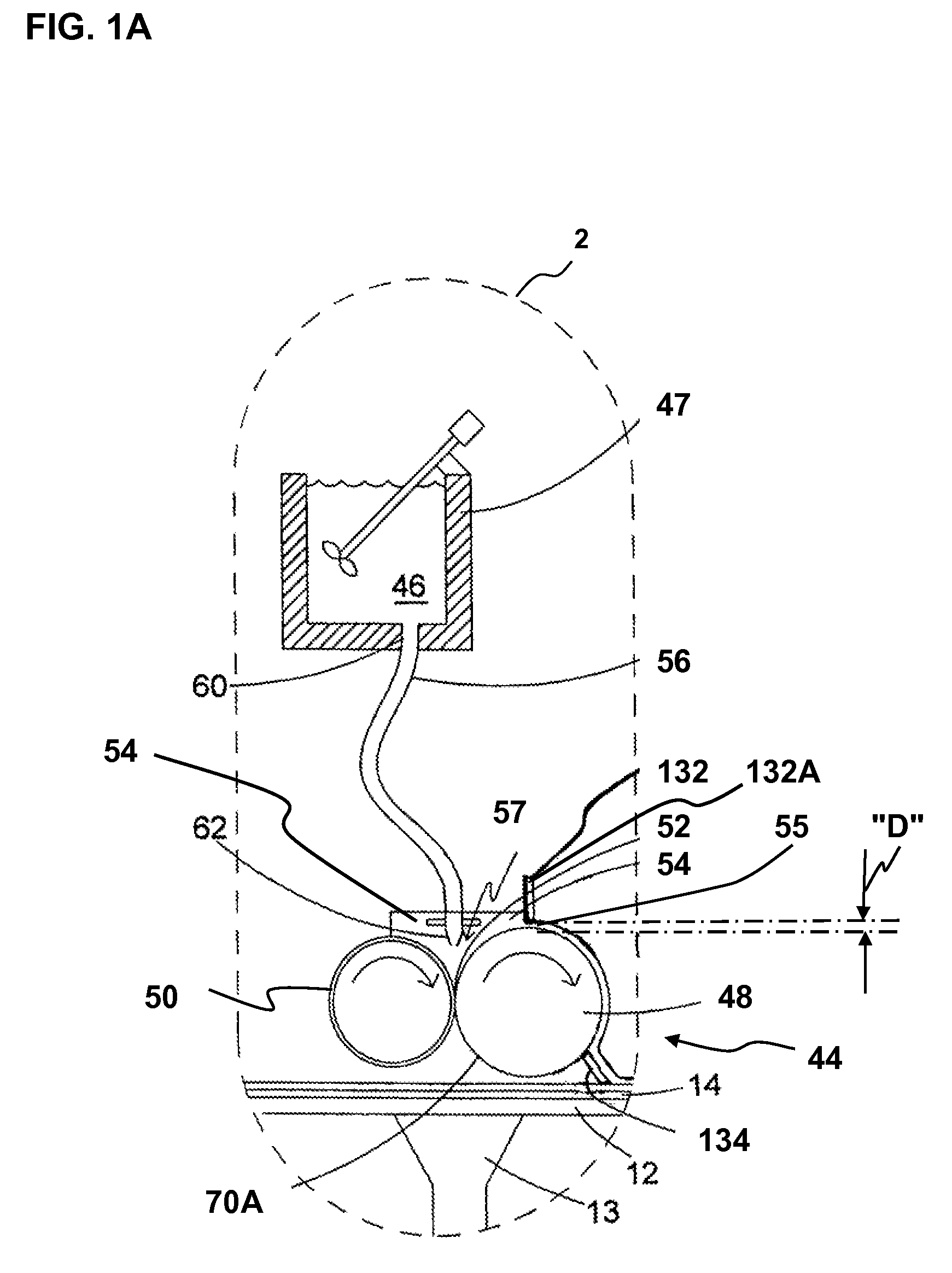

Apparatus and method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

ActiveUS20080101151A1Good strength propertiesA large amountSolid waste managementRotary stirring mixersProduction lineVertical mixing

A wet mixer apparatus and method for its use, the mixer having a vertical mixing chamber for forming a wet slurry of a cementitious slurry and water. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feeding for separate supply of cementitious powder and water to the slurry mixing area of the chamber without pre-mixing of the powder and water is also disclosed.

Owner:UNITED STATES GYPSUM CO +1

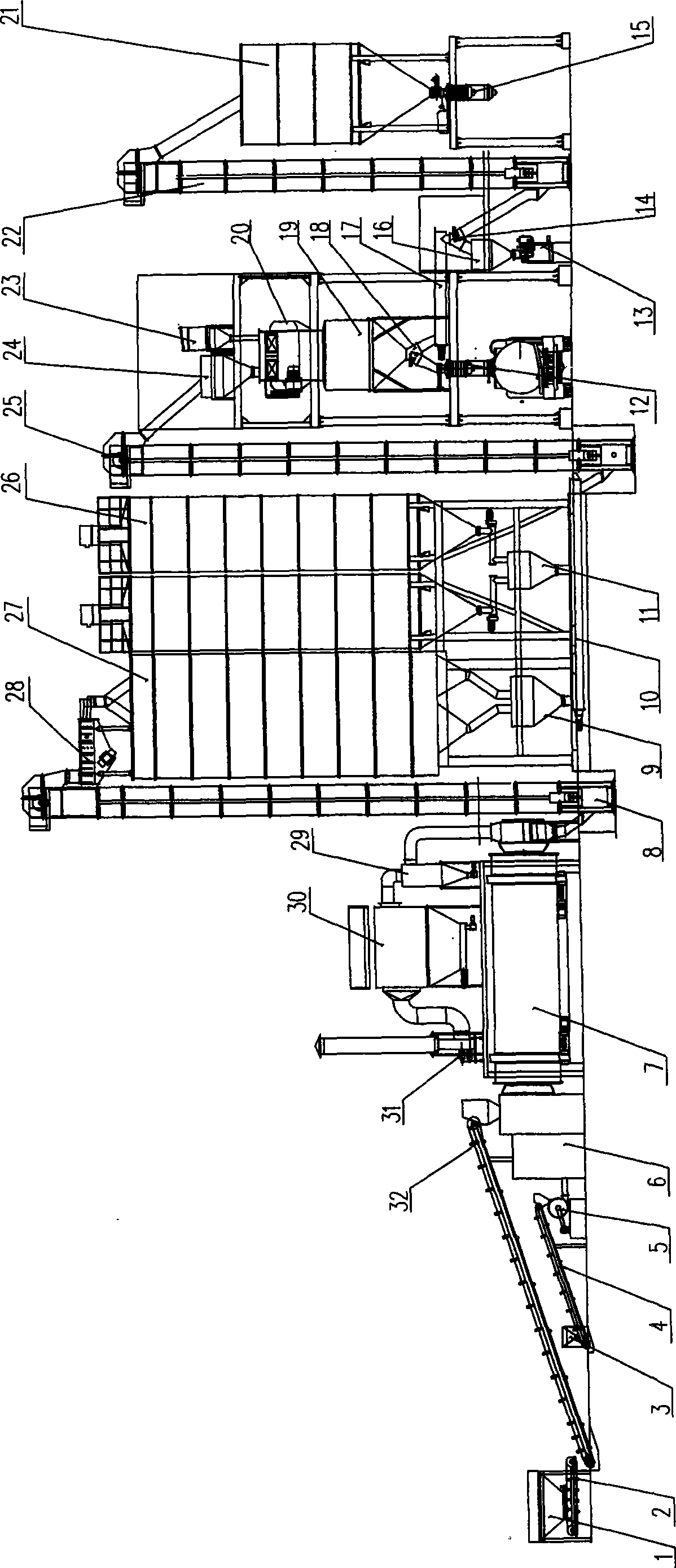

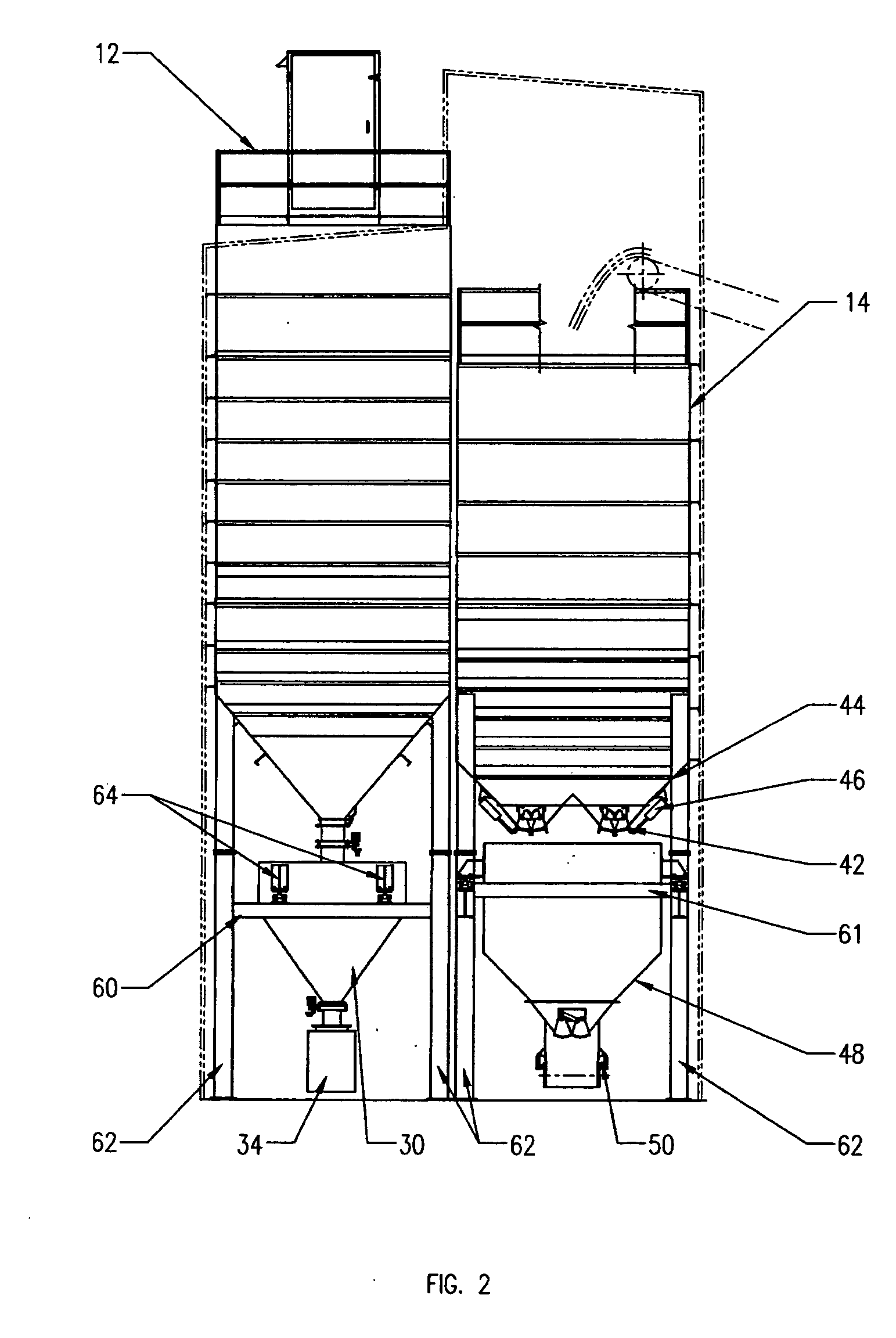

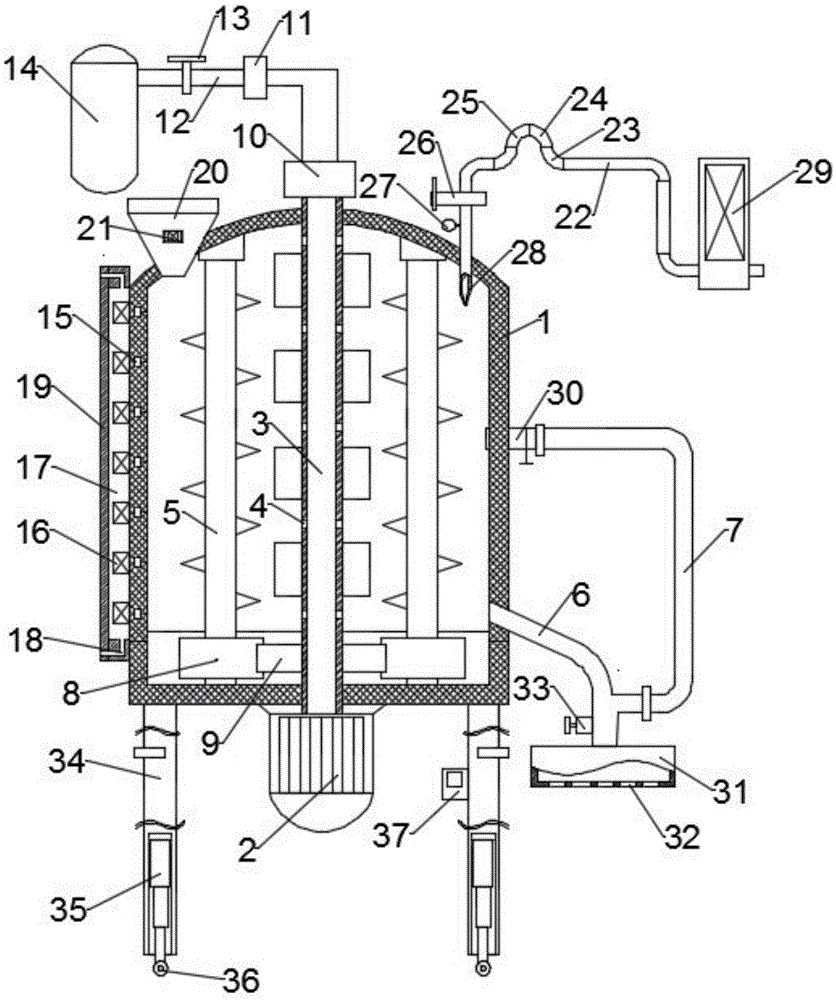

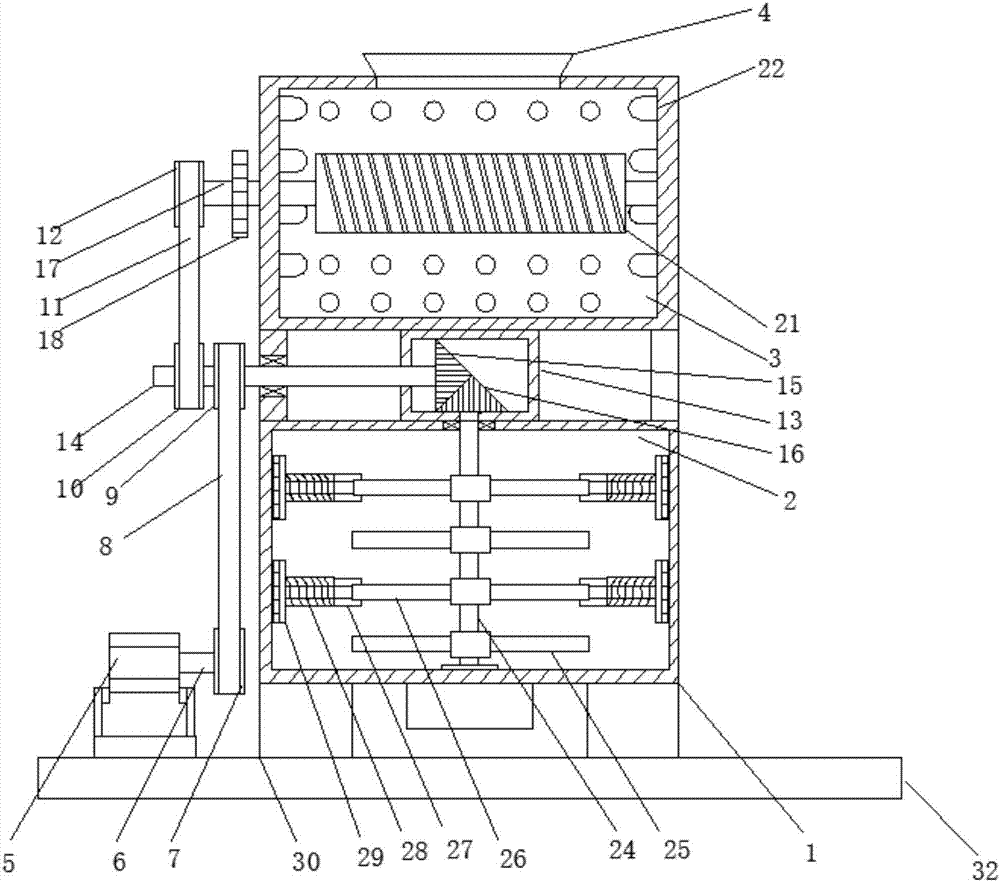

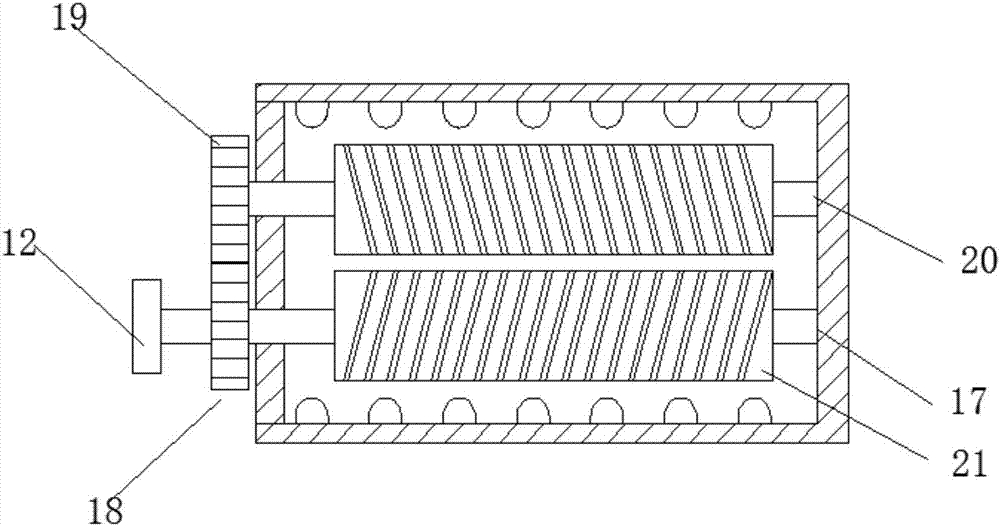

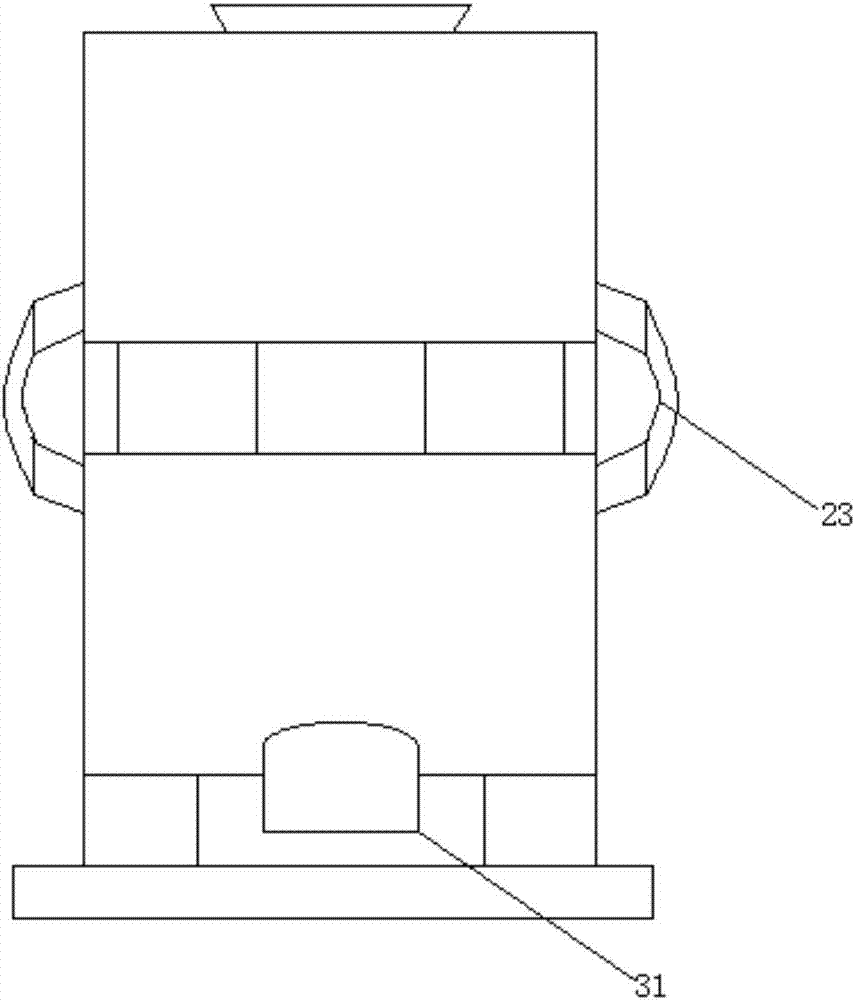

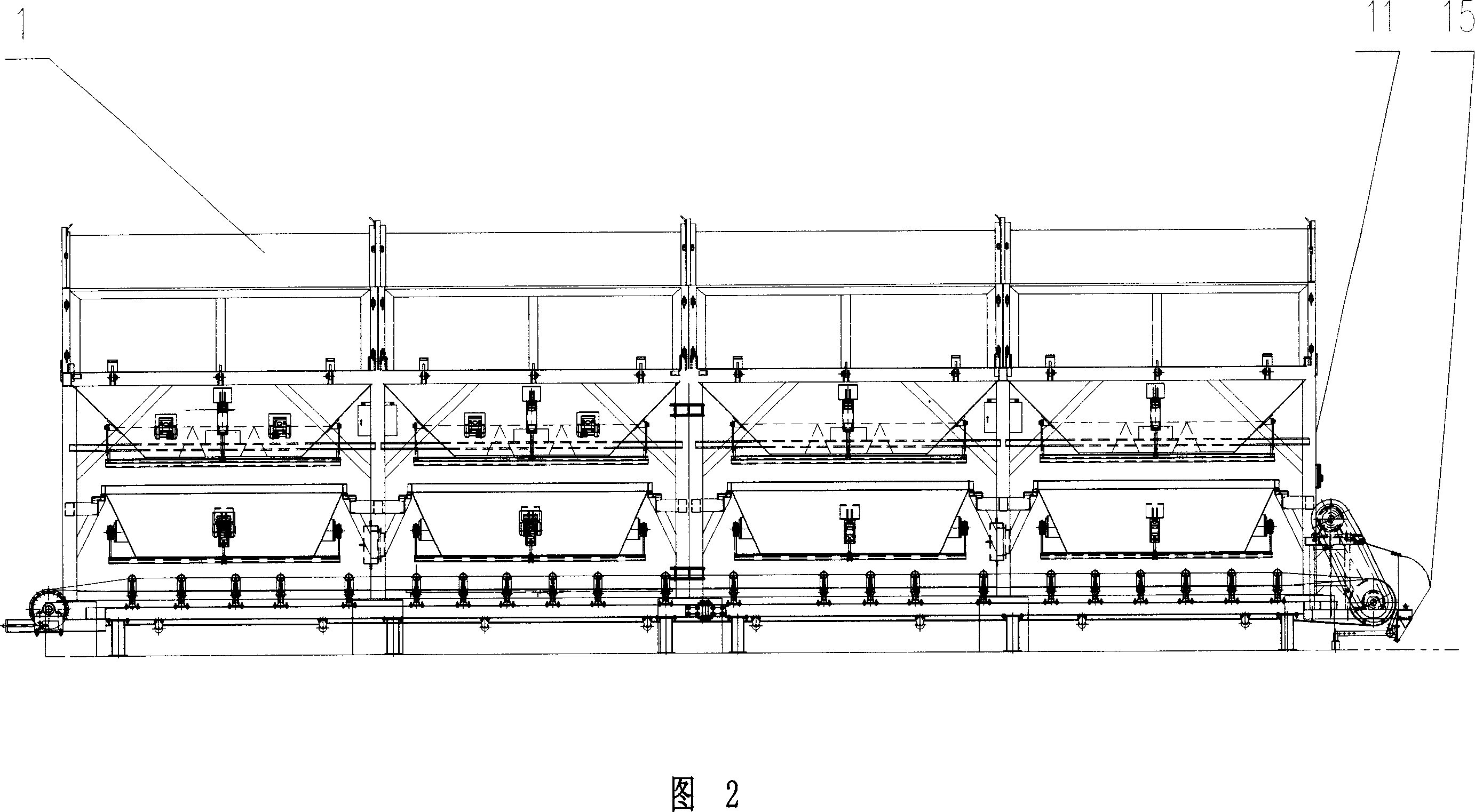

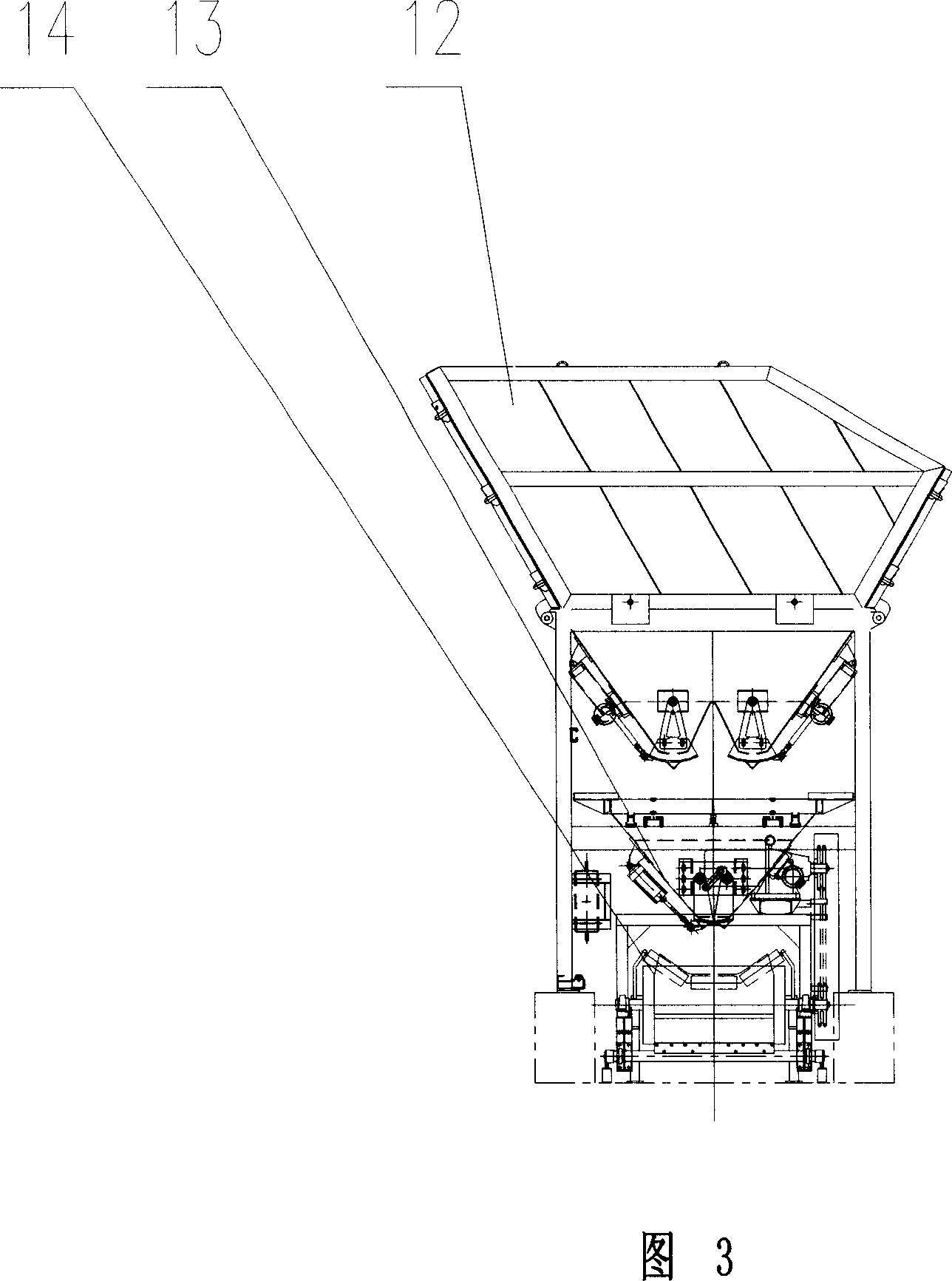

Dry-mixed mortar station

InactiveCN101462310AGood construction performanceQuality improvementMixing operation control apparatusSold ingredients supply apparatusDry sandDelivery system

The invention discloses a dry mortar mixing station, which consists of a sand conveying system, a drying system, a dust removing system, a dry sand hoisting-sieving and storing system, a powder storage system, a mixture metering and conveying system, a stirring system, and a finished product storing, conveying and packaging system. The dry mortar mixing station has good metering precision and efficient production capability; and the produced dry mixed mortar has superior construction performance and quality, is environment-friendly, can meet various construction works, and can adapt to different requirements of various novel building materials on mortar.

Owner:徐州天地重型机械制造有限公司

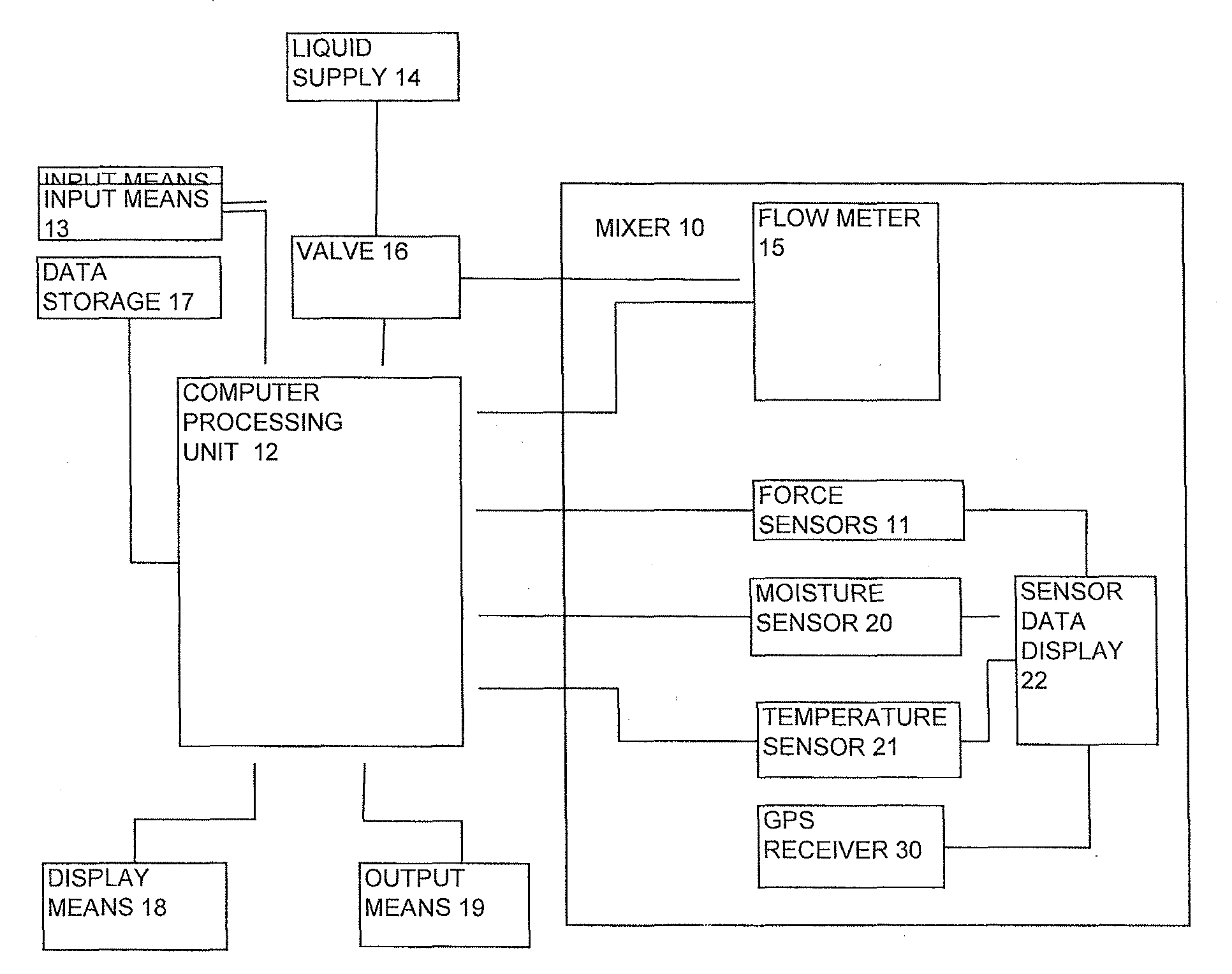

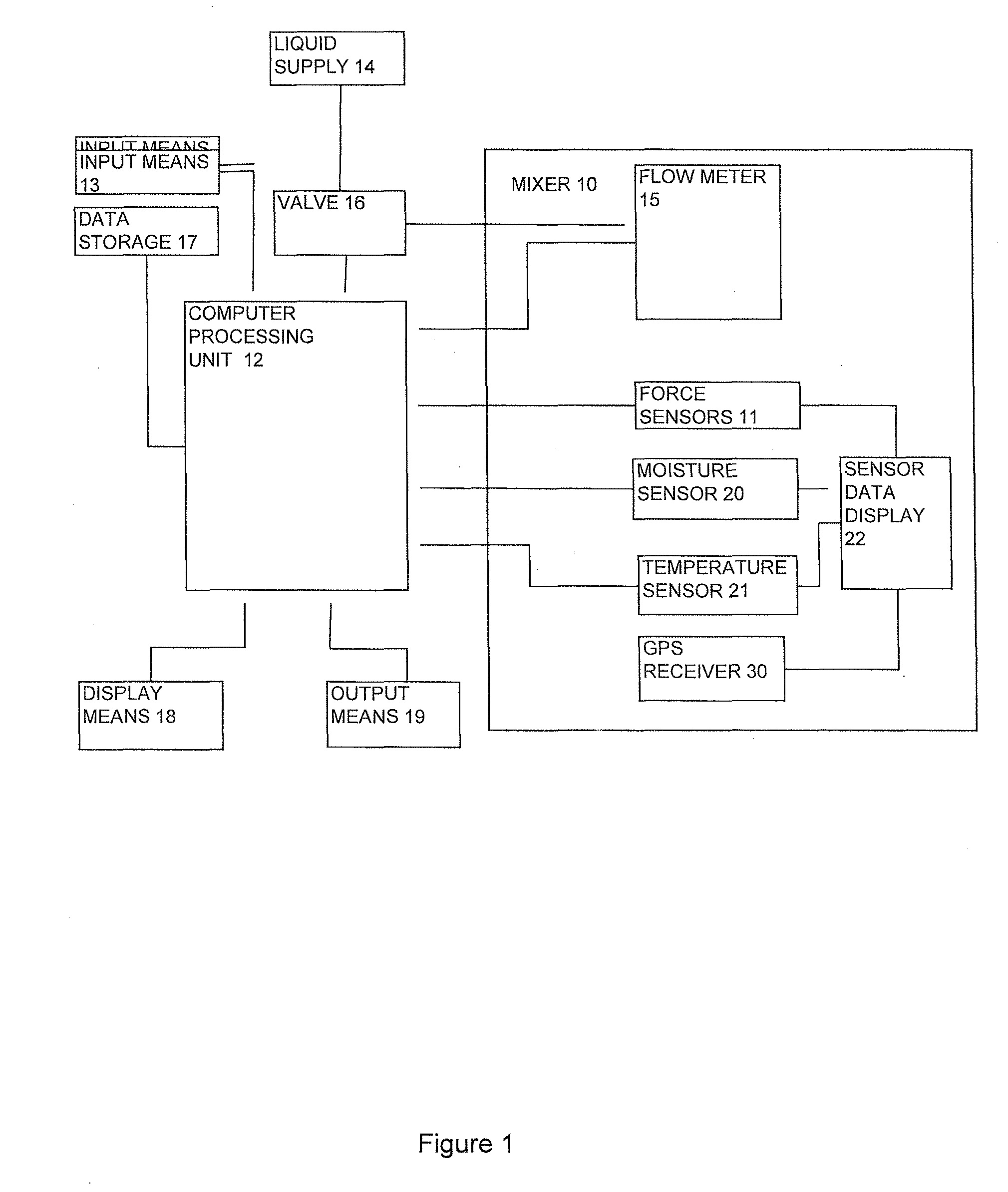

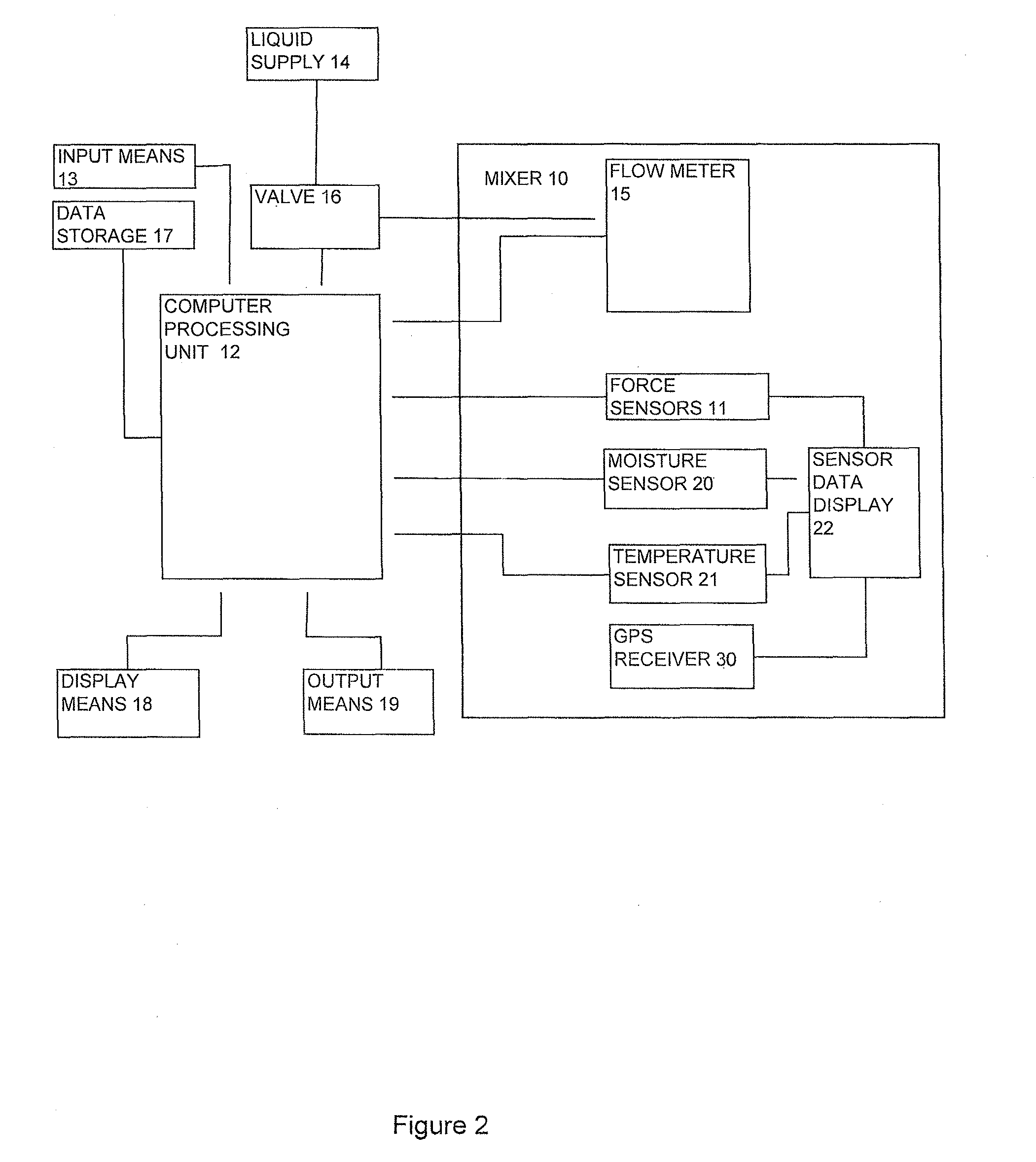

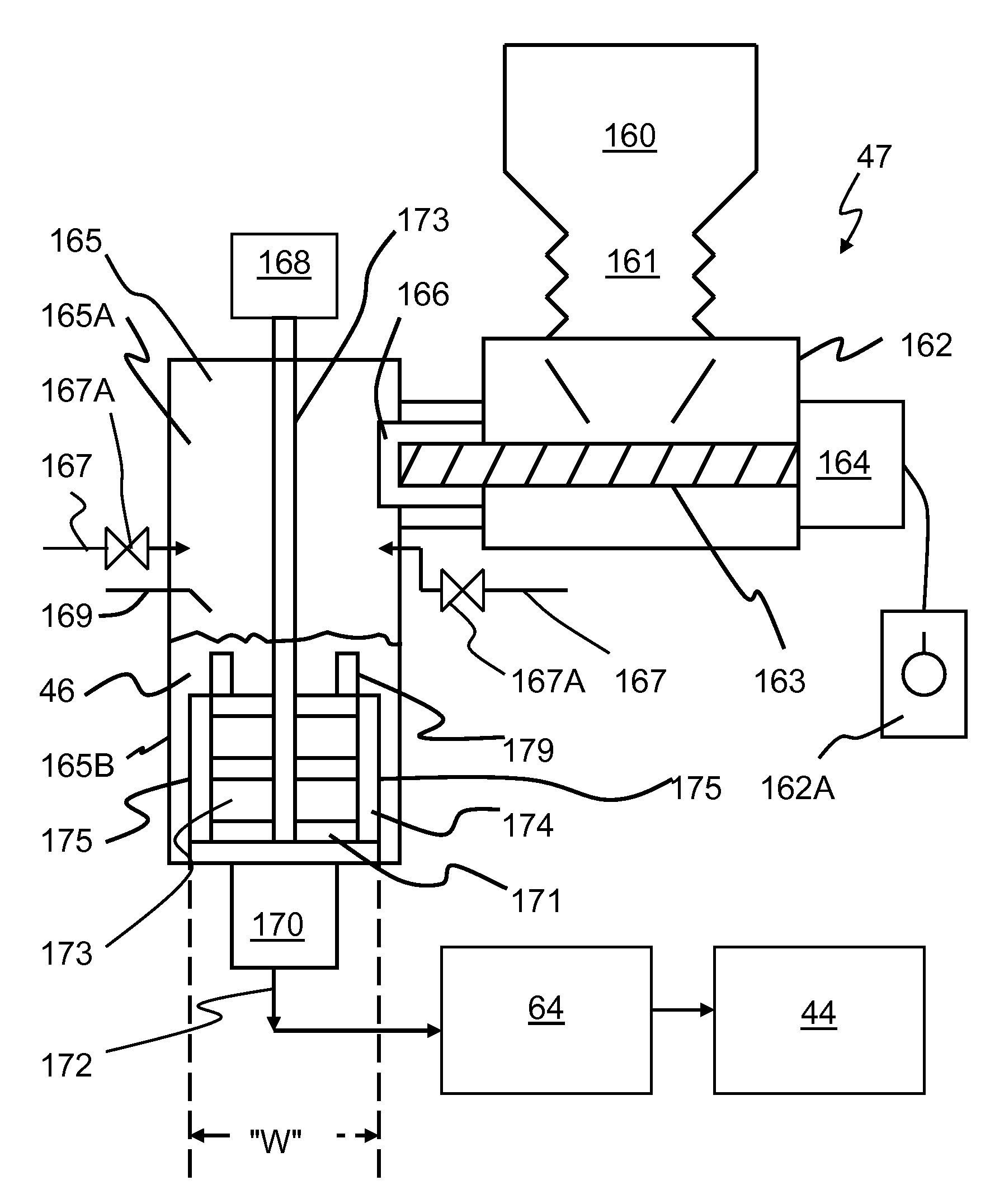

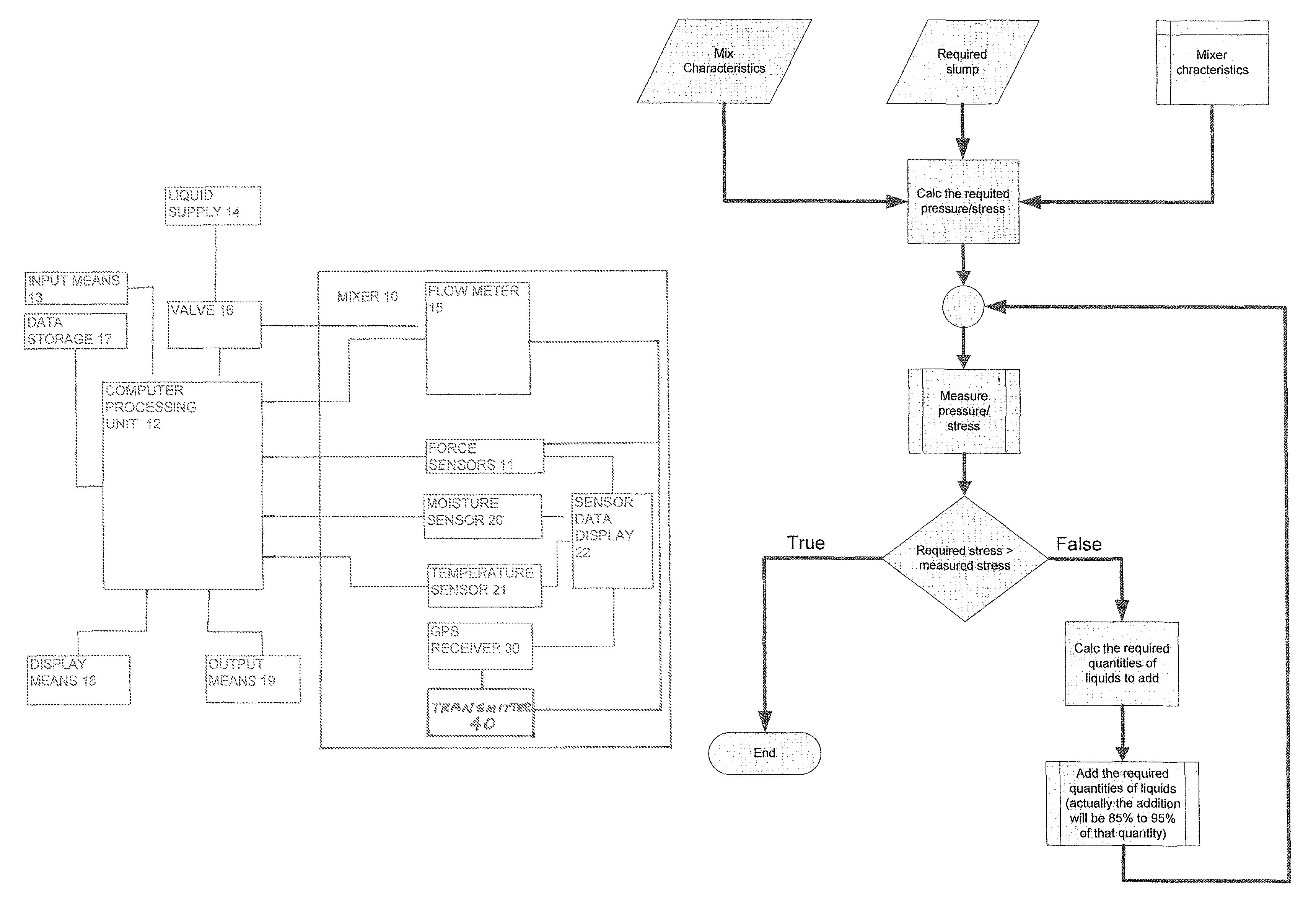

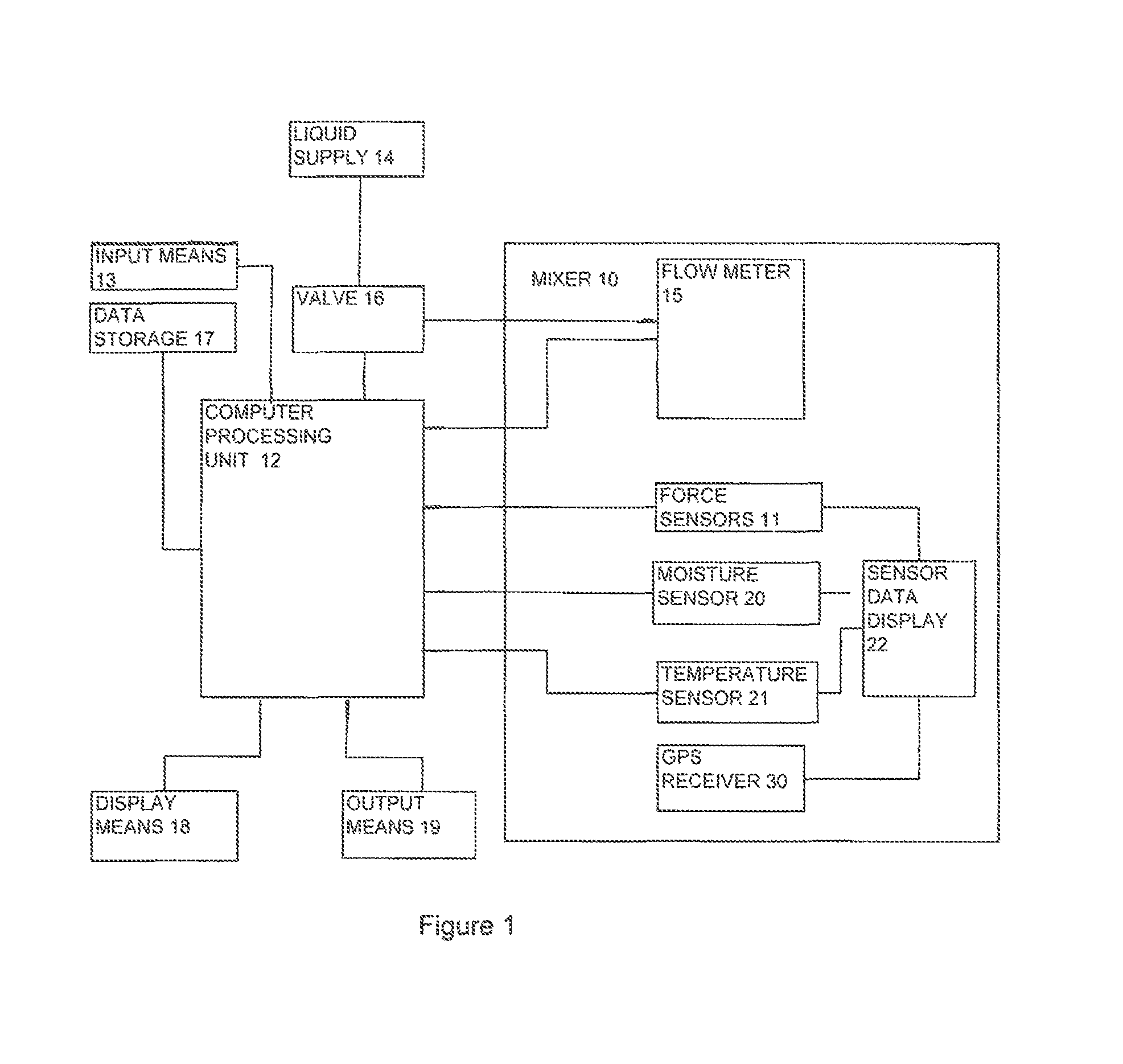

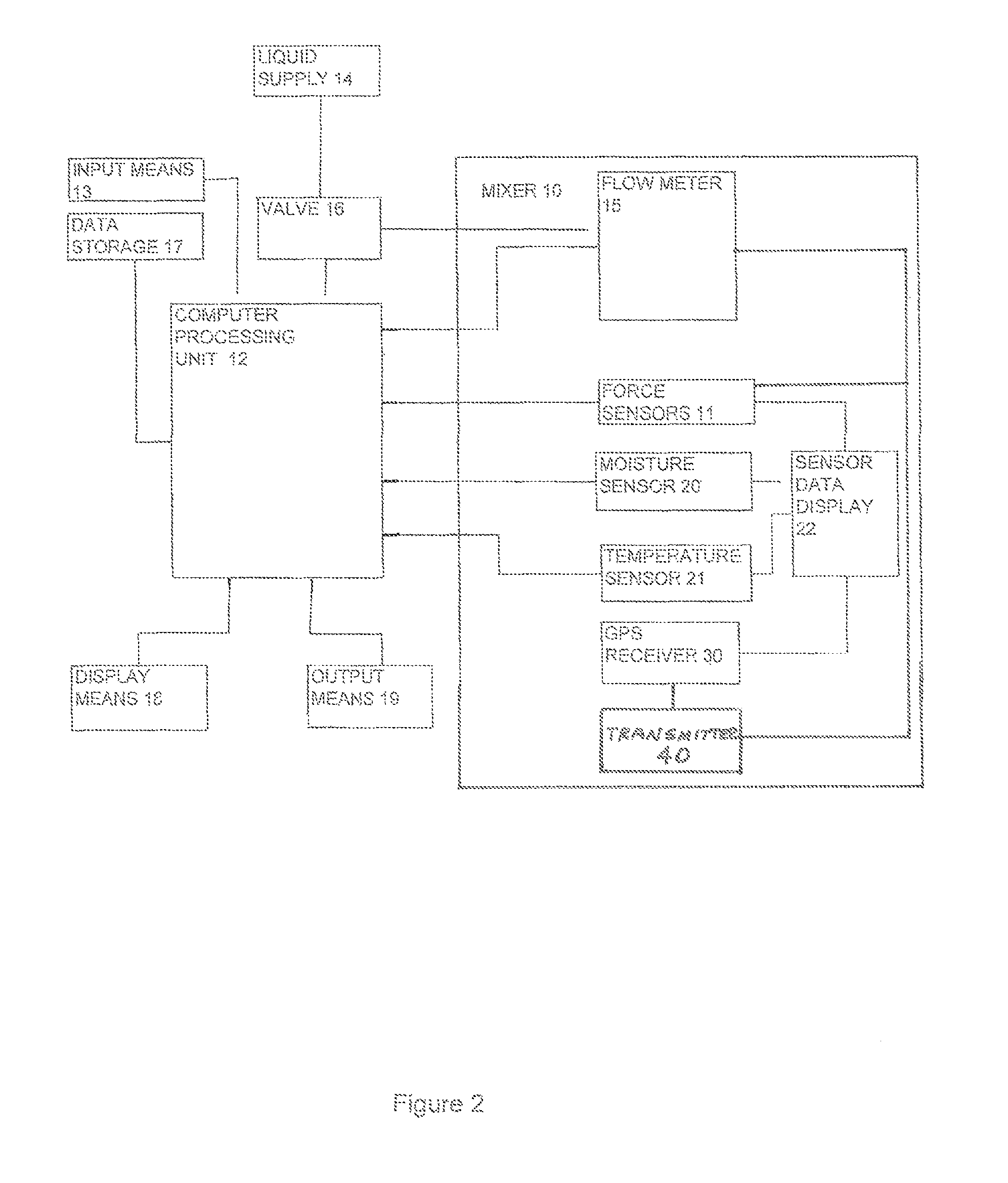

Concrete slump measurement and control system

ActiveUS20110077778A1Preventing loss through unauthorized poursSampled-variable control systemsRotating receptacle mixersControl systemEngineering

An apparatus and method to measure and control the slump of concrete by monitoring sensor within the interior surface of a concrete mixer and a liquid flow meter. Data is analyzed by a computer processing unit to determine the slump of the concrete, liquid needed the quantity of concrete within the mixer, the amount of concrete poured, and the starting and ending time of the pour.

Owner:GCP APPL TECH INC

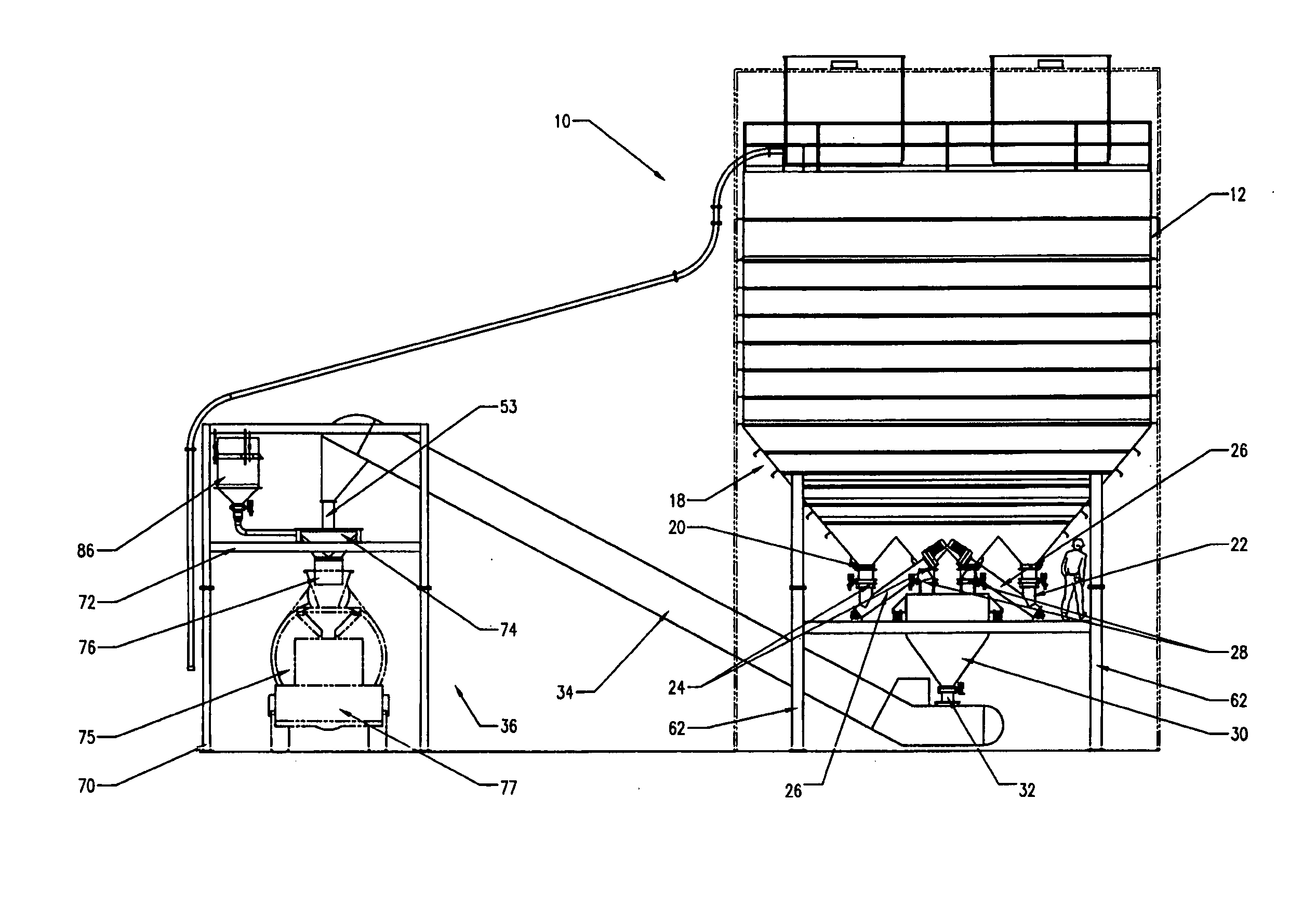

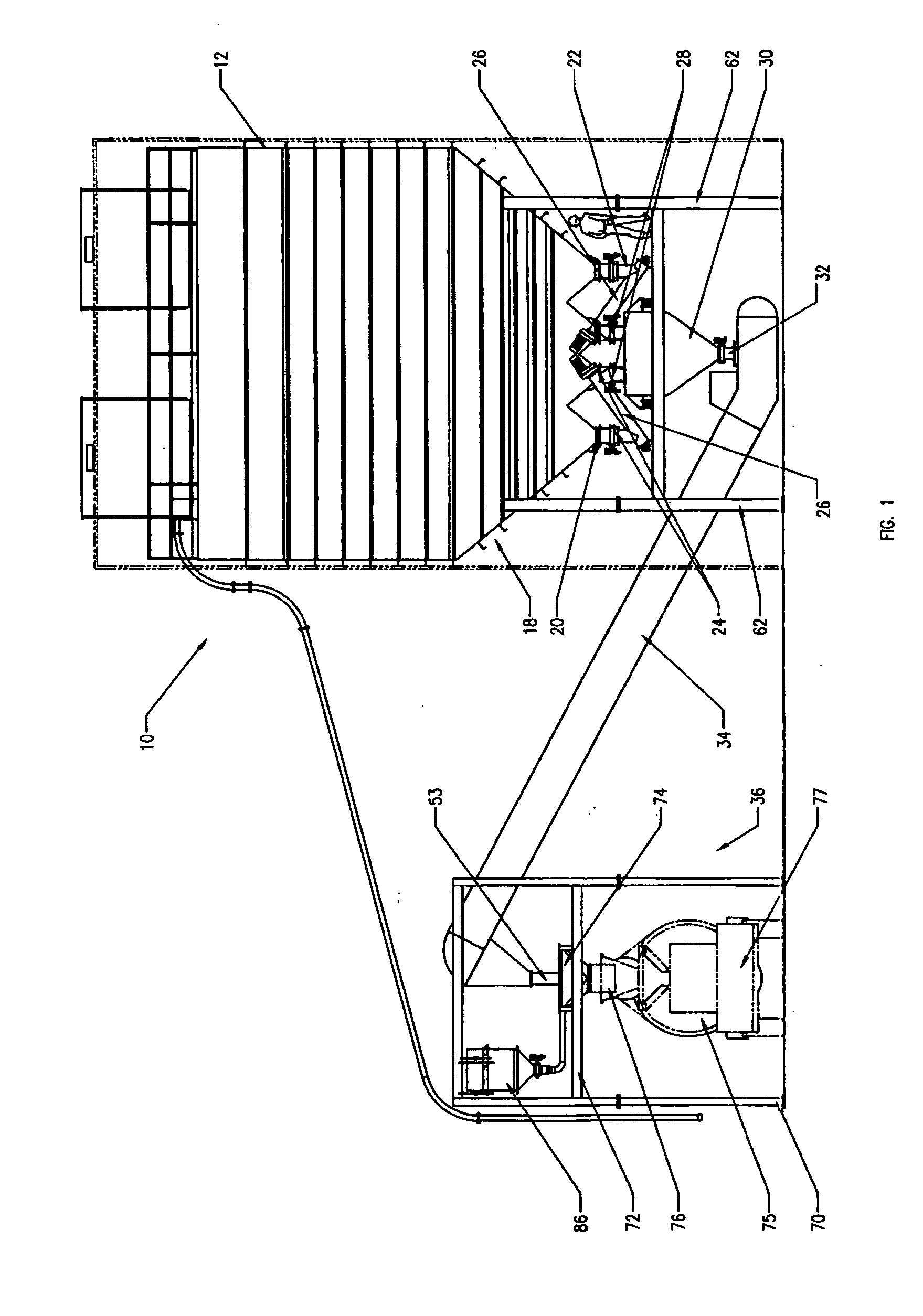

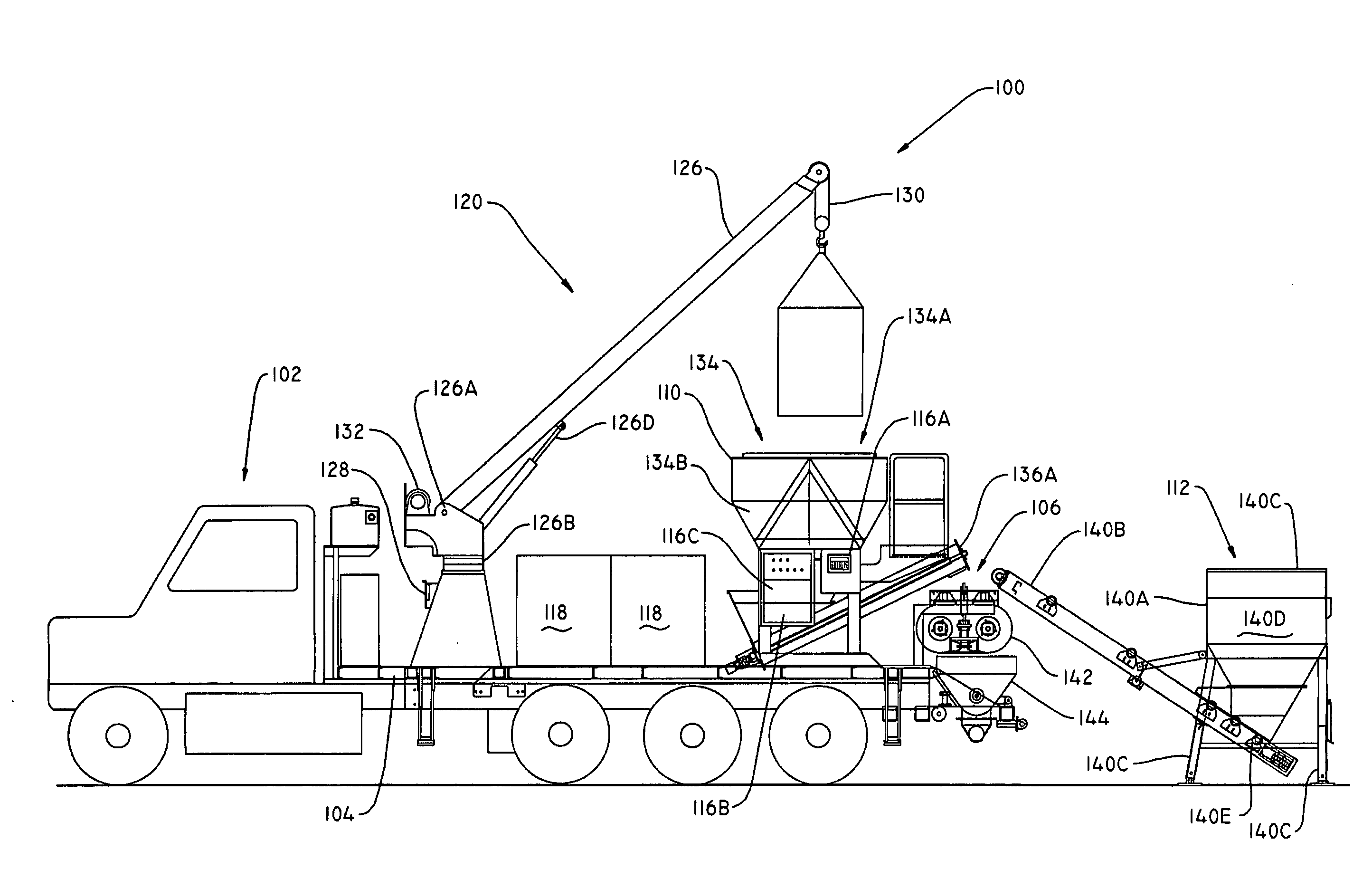

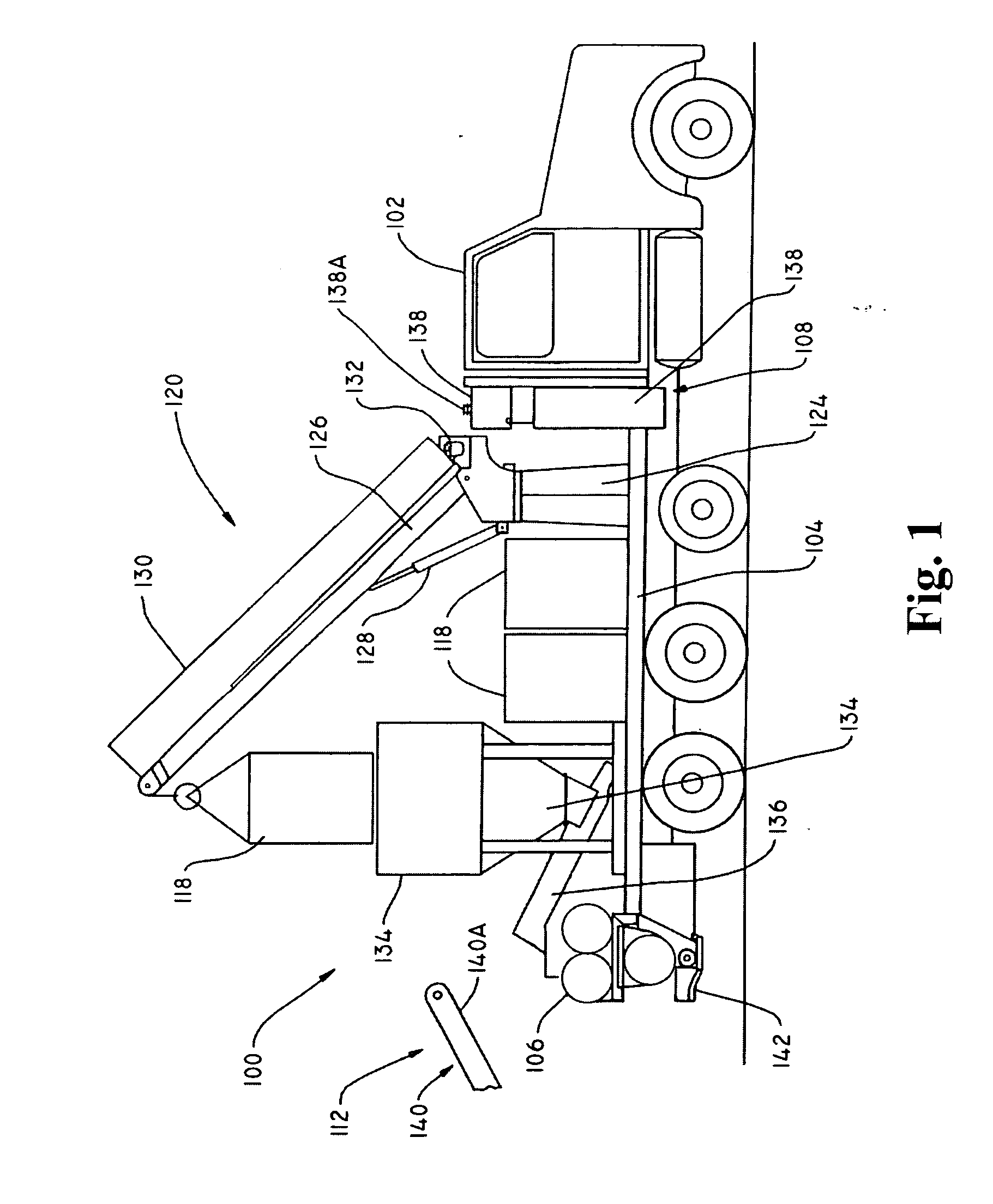

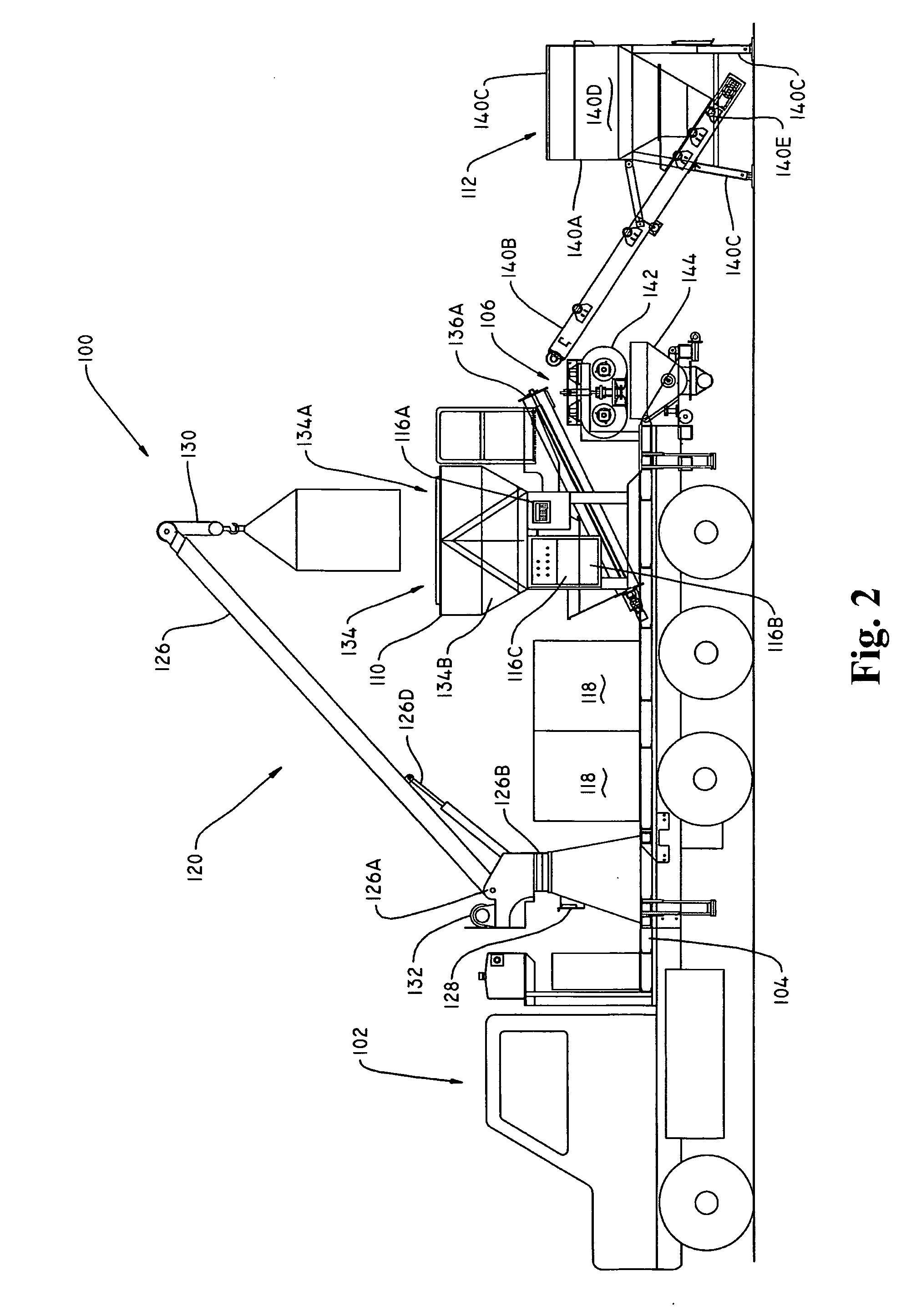

Low profile mixing plant for particulate materials

InactiveUS20050219942A1Mixing methodsMixing operation control apparatusParticulatesProcess engineering

A low profile particulate mixing plant is described. The plant is suitable for discharging the components of a particulate mixture. The plant includes a pair of storage receptacles located side-by-side. Each of the receptacles has a discharge adjacent an underside thereof to transfer a component of the particulate material mix within each receptacle to a respective conveyor at a height adjacent to ground level. The conveyor elevates the components from the discharges to a mixing station spaced from the receptacles. The plant is suitable for use as a concrete mixing plant.

Owner:WALLGREN KRIS

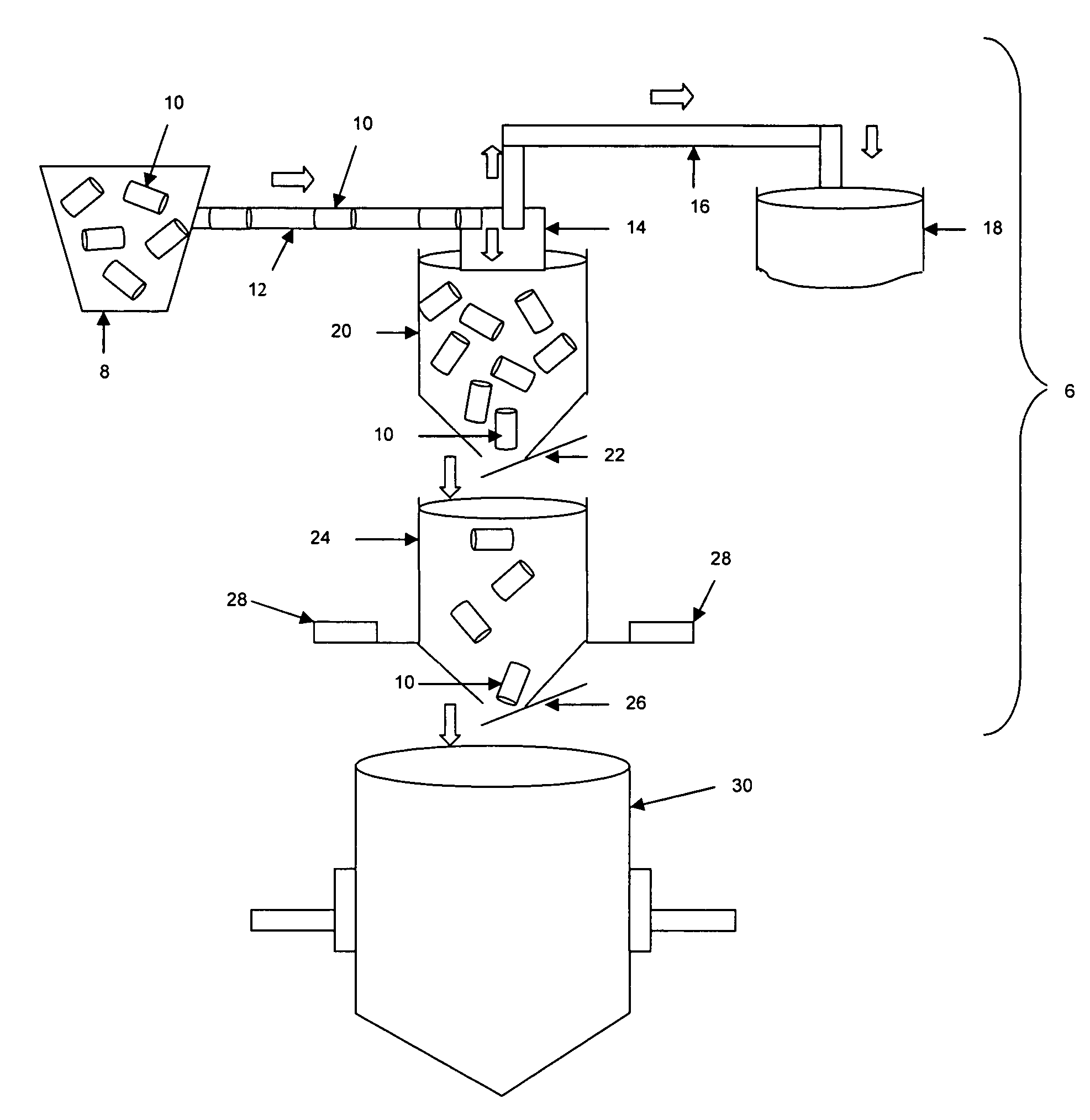

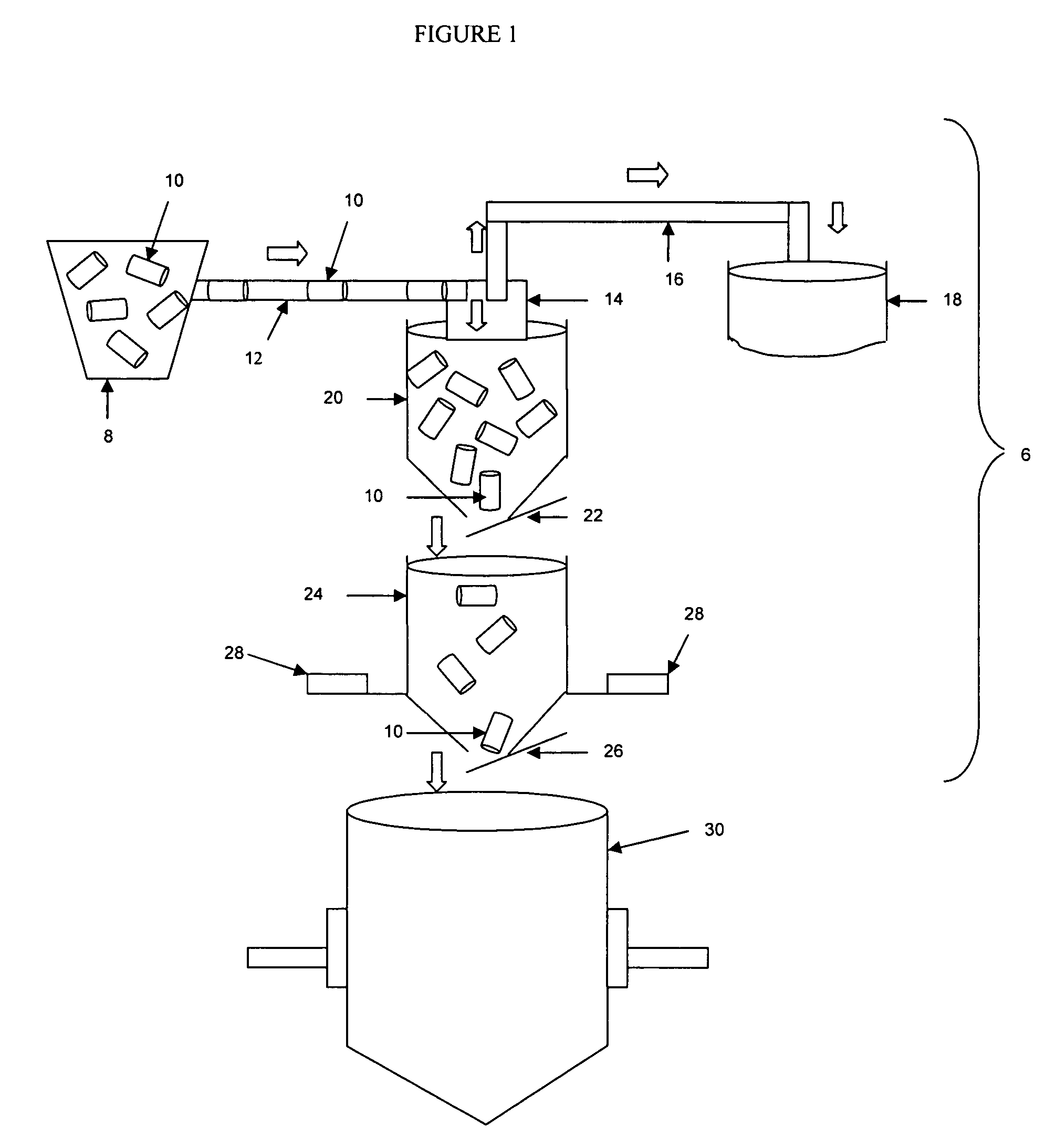

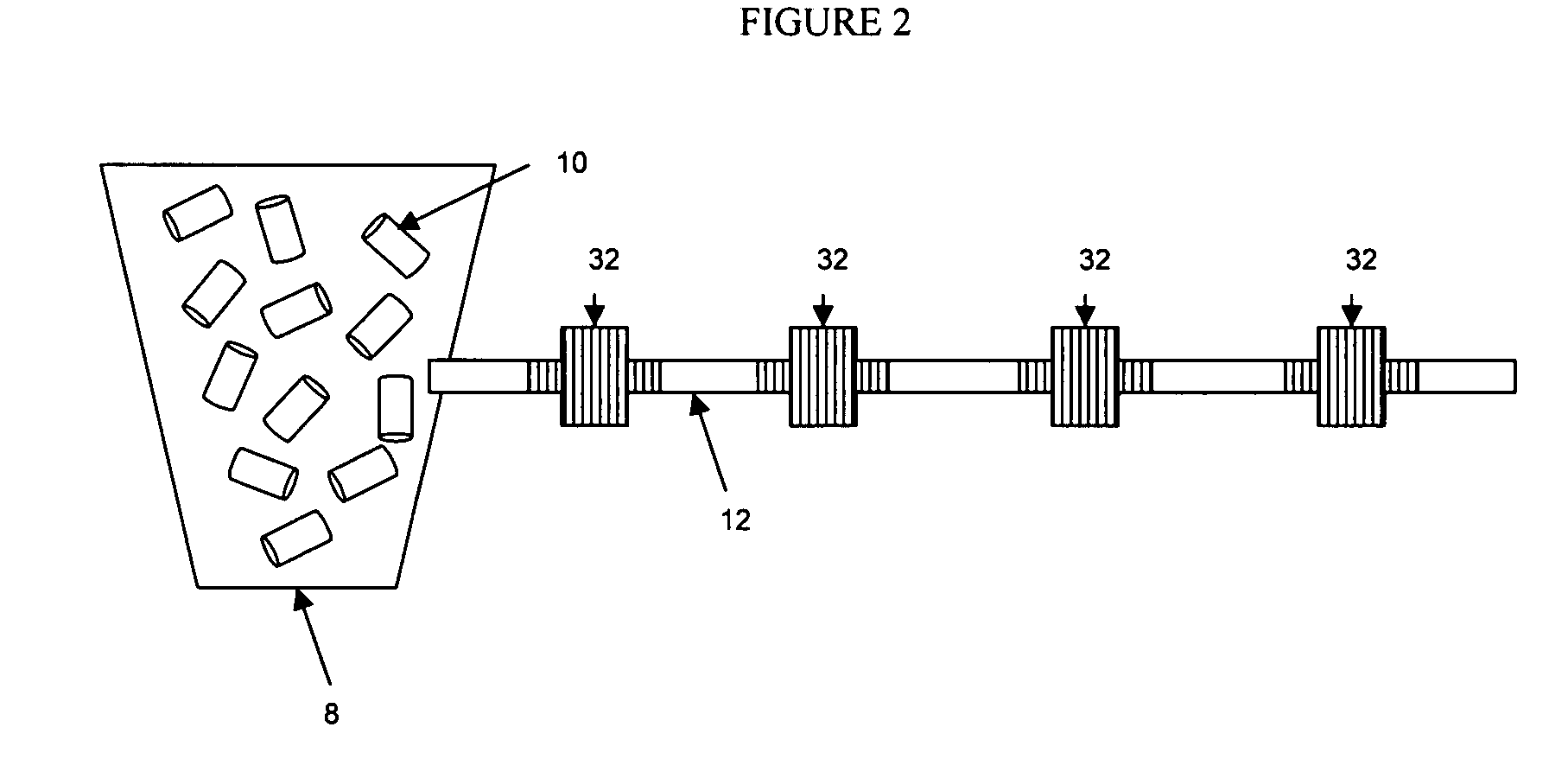

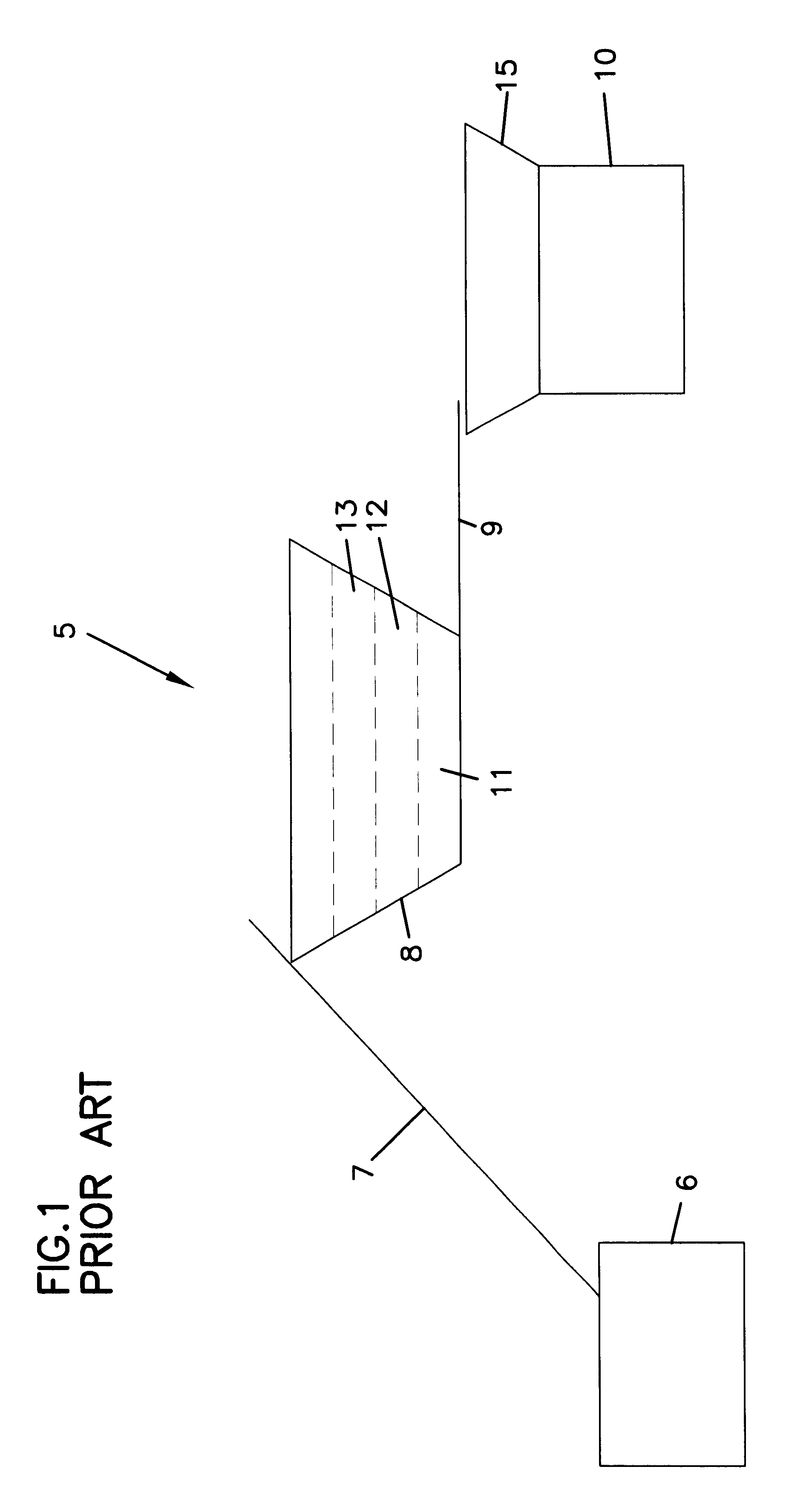

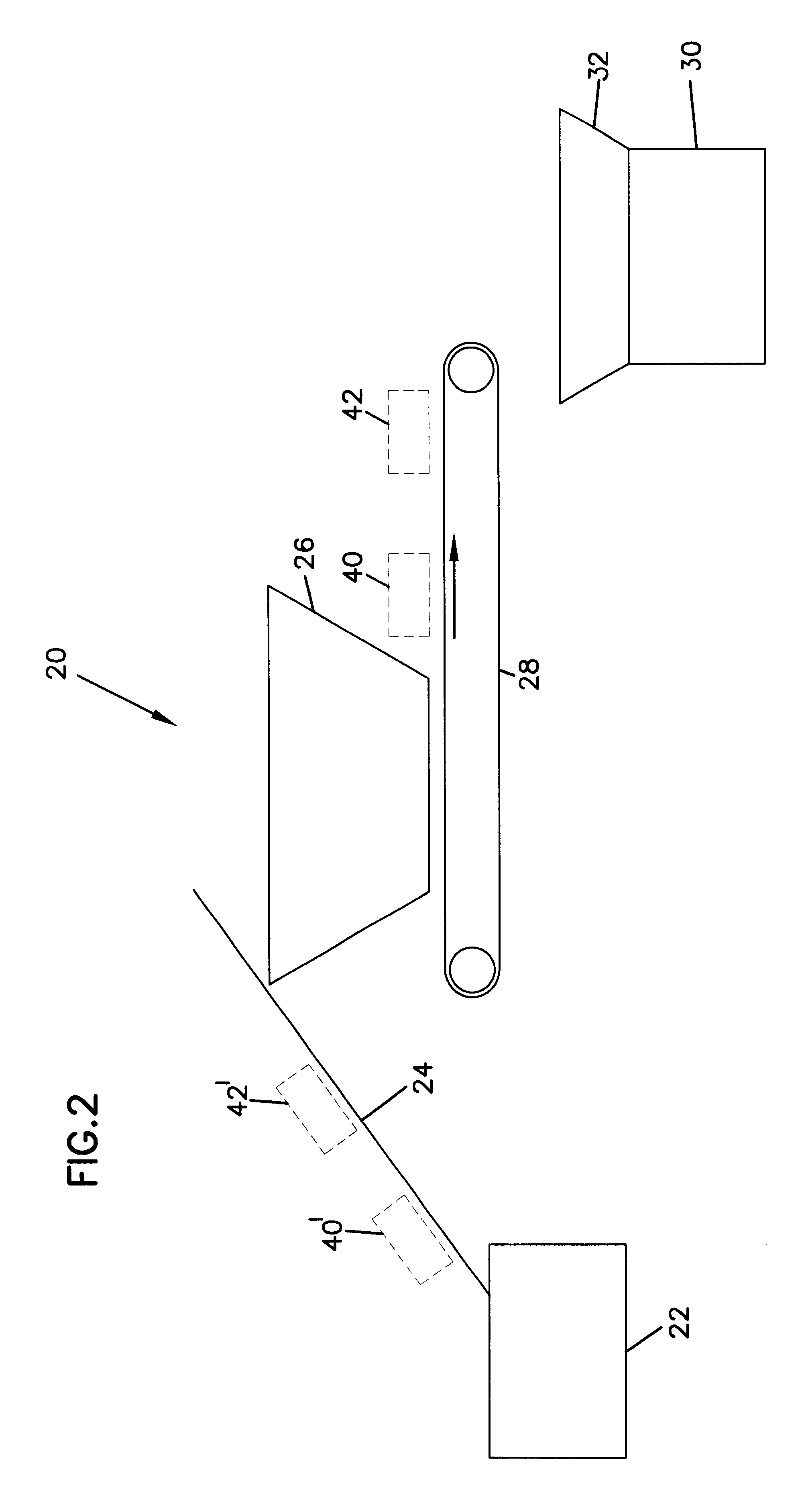

Unitized fibrous construct dispensing system

InactiveUS7228990B2Without affecting structural integrityAssist with stability of systemMixing operation control apparatusLiquid transferring devicesFiberBiomedical engineering

The present invention is directed to a method and system for transporting and dispensing fibers into an aggregate mix, and more specifically, to a method and system for transporting and dispensing unitized fibrous constructs into a mix without affecting the structural integrity of the unitized construct. The dispensing system will transport and dispense unitized fibrous constructs intact into a cementitious mixture.

Owner:FABPRO ORIENTED POLYMERS L L C

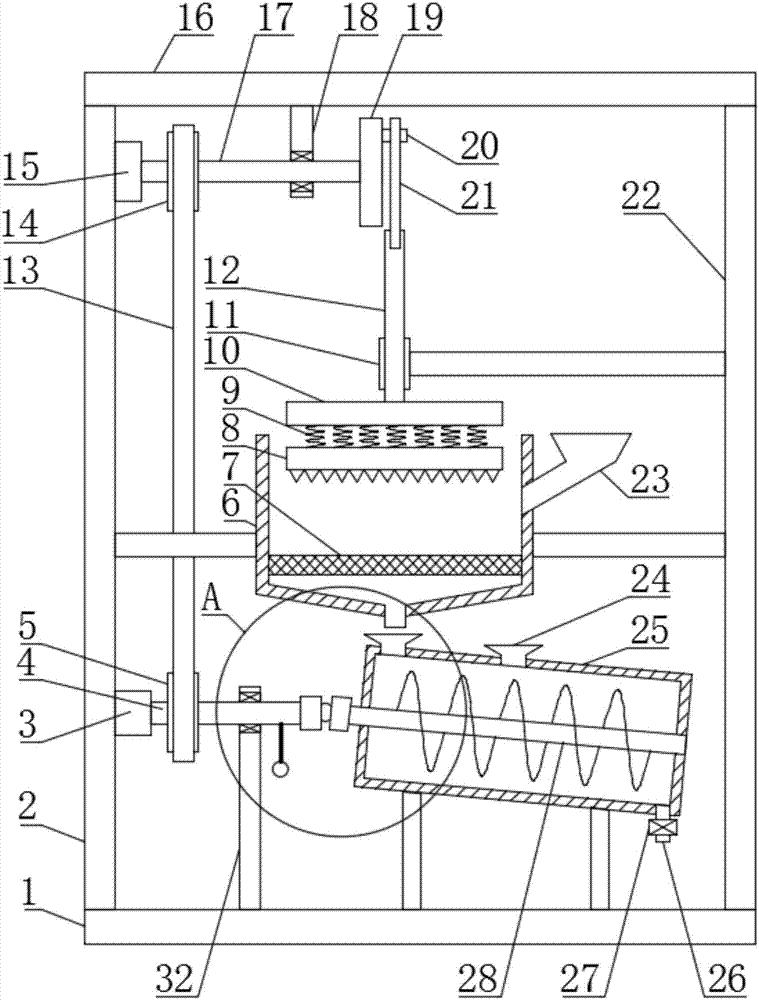

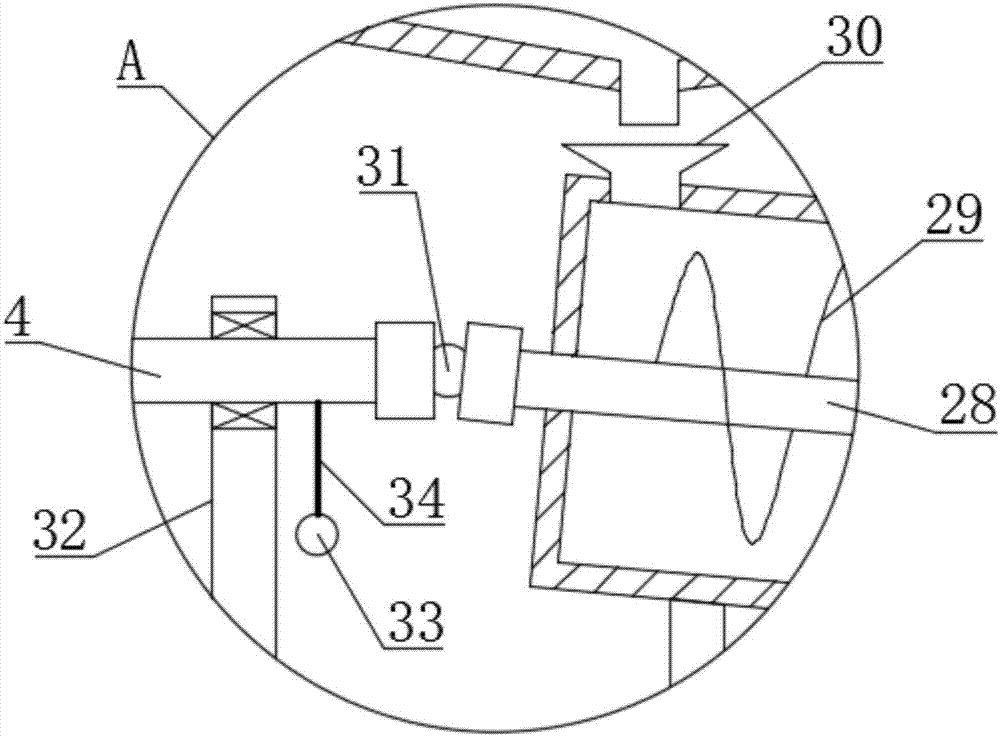

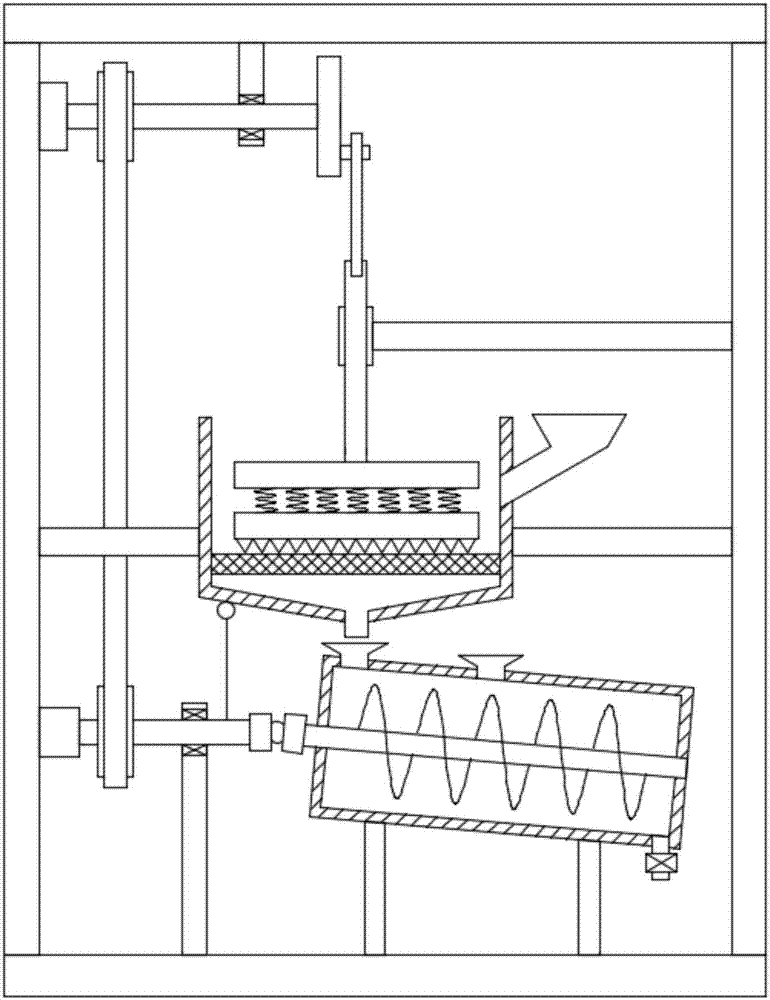

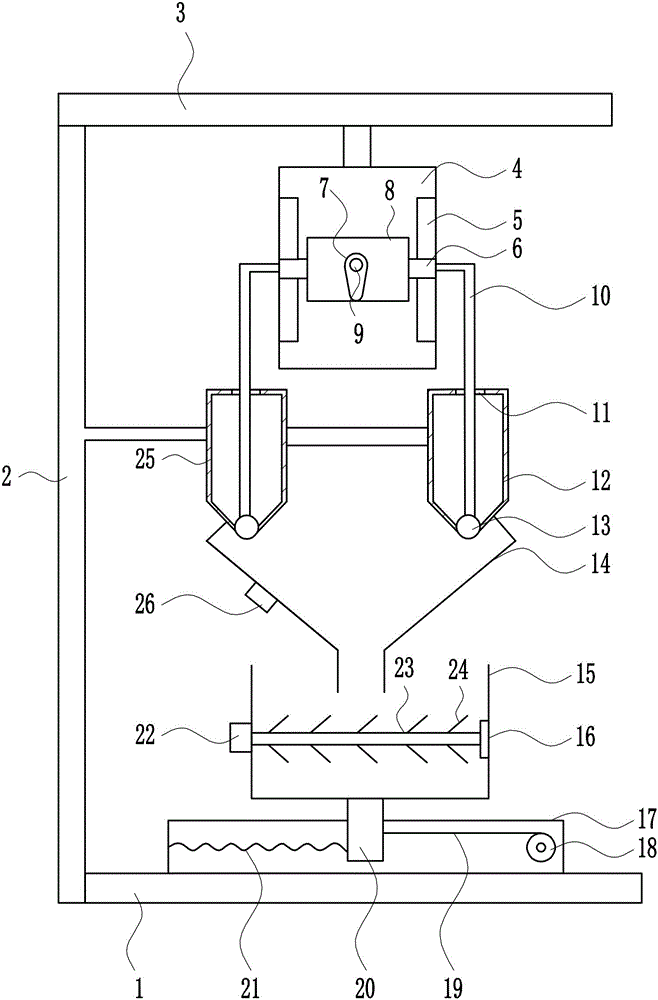

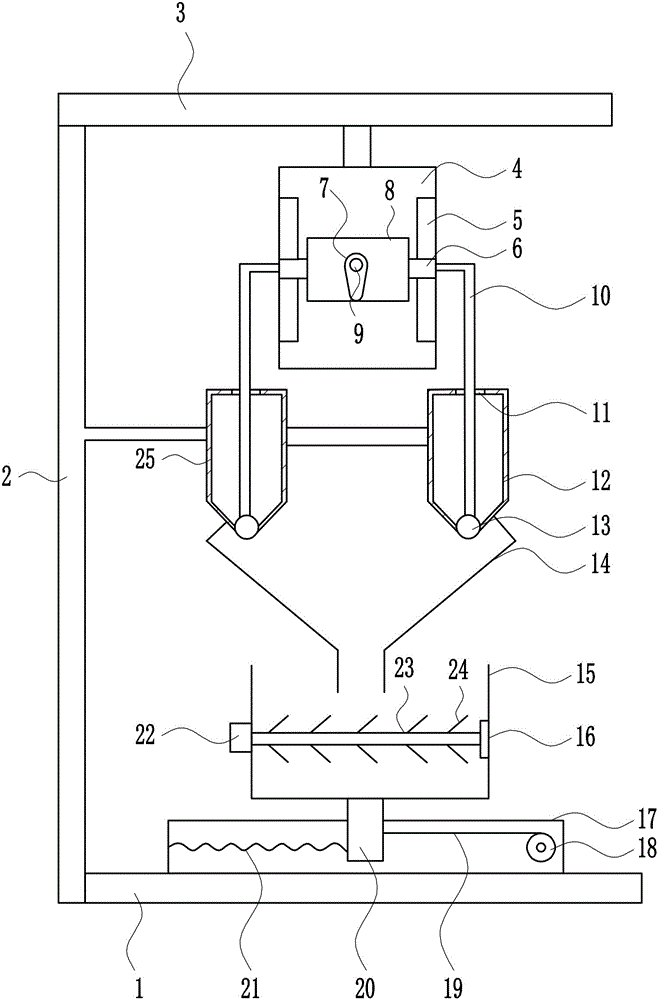

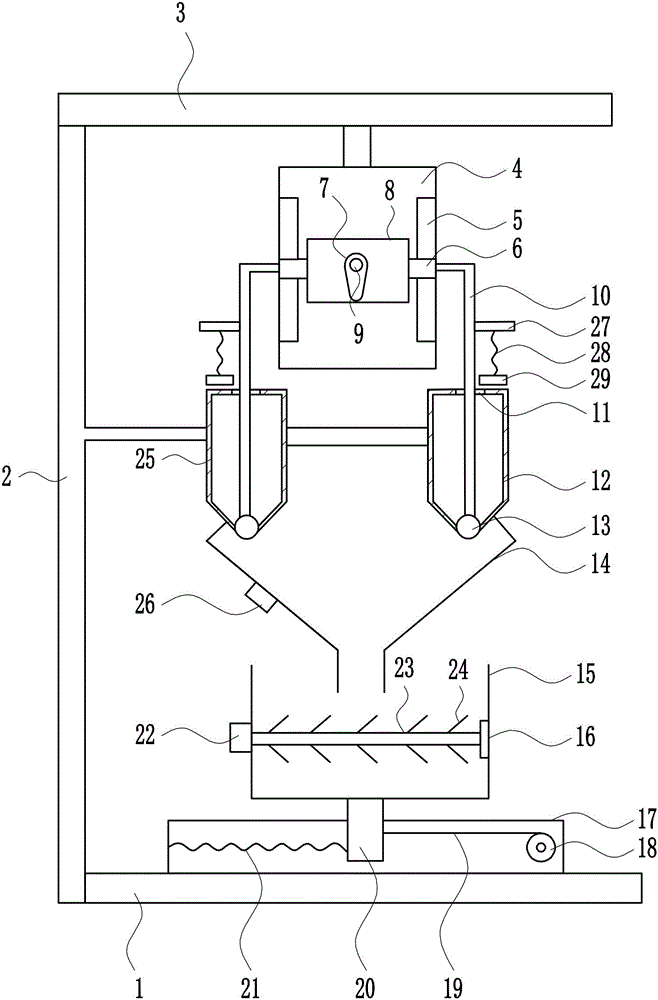

Stone-crushing concrete preparation device for buildings

InactiveCN107415049APlay a buffer roleAvoid cloggingMixing operation control apparatusPretreatment controlStone particleSpiral blade

The invention discloses a stone-crushing concrete preparation device for buildings. The stone-crushing concrete preparation device comprises a base, wherein a left supporting plate and a right supporting plate are correspondingly arranged on the left side and the right side of the base; a crushing box is fixedly arranged between the left supporting plate and the right supporting plate through a support; an extruding plate is fixedly arranged at the inner bottom of the crushing box; a marble is connected to a first rotating shaft through a snapline and positioned below the crushing box; an agitator is obliquely arranged on the base through a support, and a receiving hopper is arranged on the left side of the top of the agitator; a third rotating shaft is rotationally connected to the interior of the agitator; a spiral blade is mounted on the third rotating shaft; and the left end of the third rotating shaft penetrates the left side wall of the agitator and is connected with the right end of the first rotating shaft through a universal coupler. According to the stone-crushing concrete preparation device, the bottom of the crushing box is knocked by the marble, so that adhesion blockage is prevented; and screened stone particles directly enter the agitator to prepare concrete without manual control, so that the processing efficiency is effectively improved.

Owner:李小强

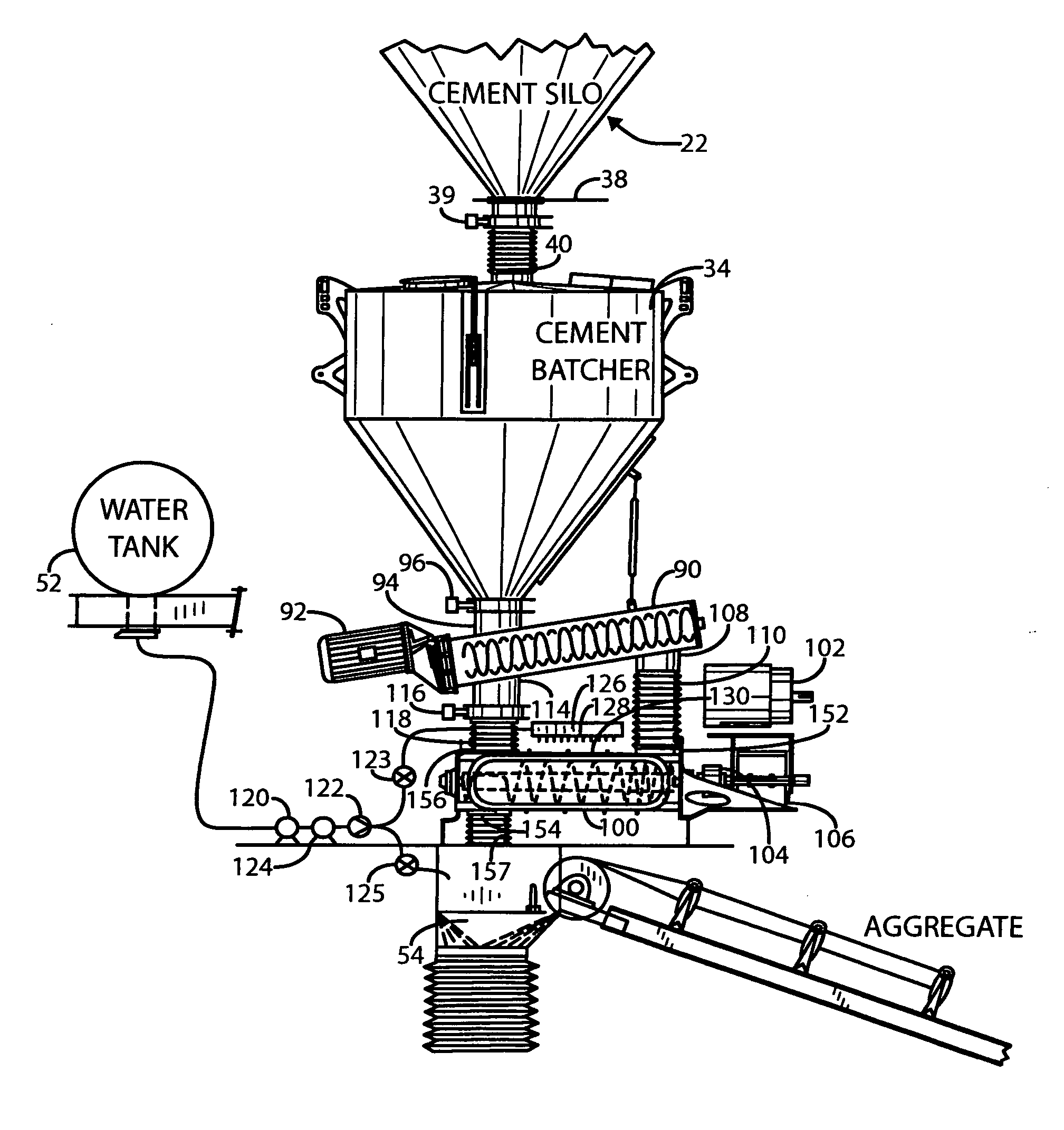

Concrete batching pre-mixer and method

InactiveUS20050219939A1Eliminate buildupWell mixedTransportation and packagingMixing operation control apparatusTruckMixed systems

A pre-mixer agglomerator and method of pre-mixing batching ingredients used to produce concrete mixes is disclosed. Specifically, this invention involves a pre-mix system which blends the wetting agents and the cementitious ingredients in relation to each other at any selected ratio in an adjustable and repeatable manner. The pre-mixer is a twin screw, preferably counter-rotating, pre-mixer agglomerator unit for pre-mixing these materials prior to combining them with aggregates in a drum of a transit mixer truck or other final mixing vessel.

Owner:MCNEILUS TRUCK & MFG INC

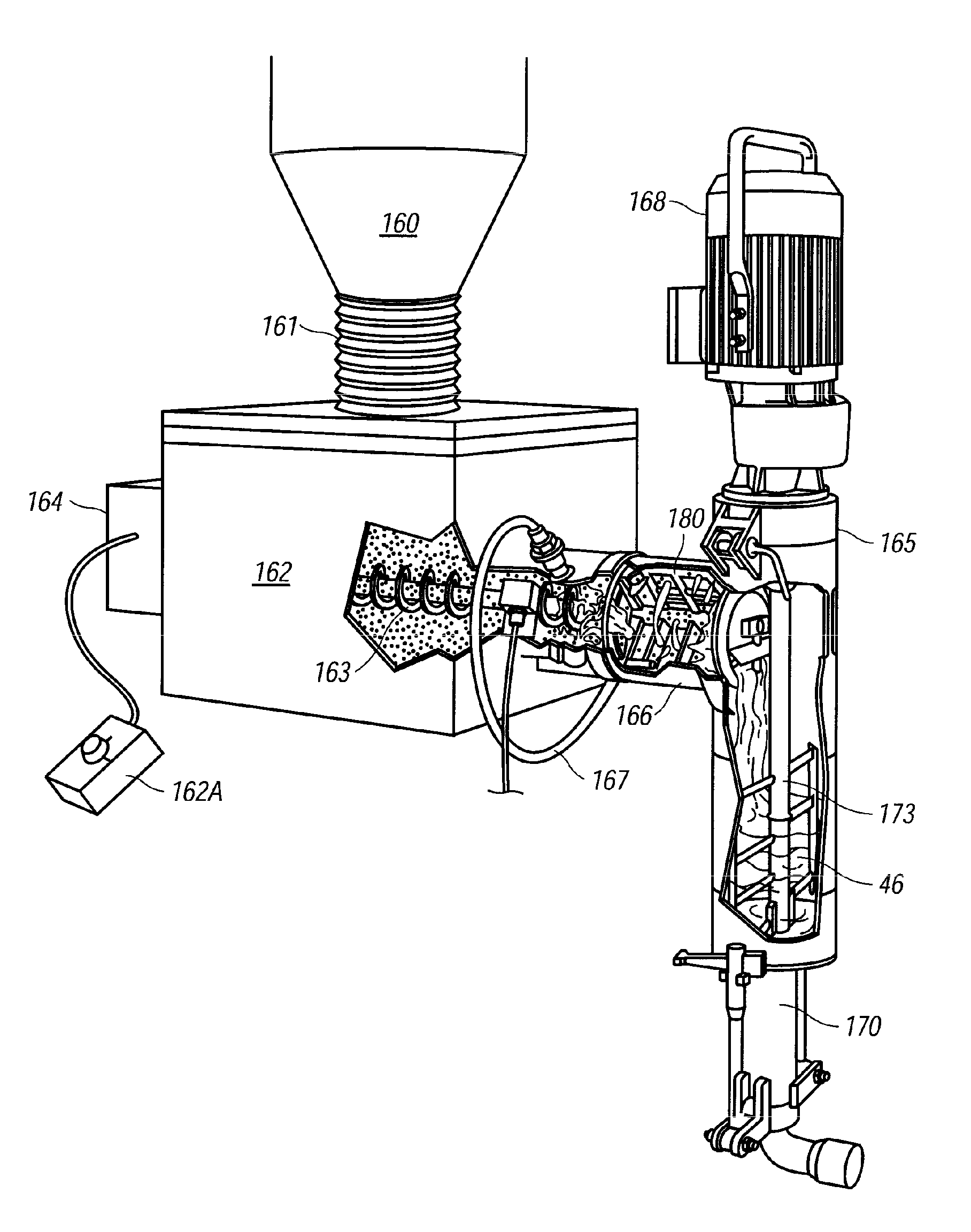

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

InactiveUS7524386B2Increase volumeSmall sizeSolid waste managementRotary stirring mixersProduction lineVertical mixing

A process employing a wet mixer having a vertical mixing chamber for forming a wet slurry of a cementitious powder and liquid. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feed for supply of cementitious powder and water to the slurry mixing area of the chamber is also disclosed.

Owner:UNITED STATES GYPSUM CO

Portable cement mixing apparatus

InactiveUS20090177313A1Sampled-variable control systemsDigital data processing detailsAdditive ingredientEngineering

A portable cement mixing system uses ingredients such as cement, water and sand in predetermined quantities. A digital controller coordinates all of the operating elements of the apparatus for the entire mixing process and stores mixing programs relative to the mixing process for a variety of cements which includes the various ingredient quantities. Separate storage containers each coupled to a conveyors from the container extend to a mixer to transfer that quantity to the mixer for each cement ingredient. The conveyors are operated in sequence by the controller to load the mixer with a predetermined quantity of each of the required ingredients prior to mixing. The mixer and its contents are weighed before and during the transfer of each ingredient to precisely determine and transfer the required amount of each ingredient. After the mixer is loaded with all of the ingredients, the mixer is operated for a predetermined length of time.

Owner:SMART BATCH SYST

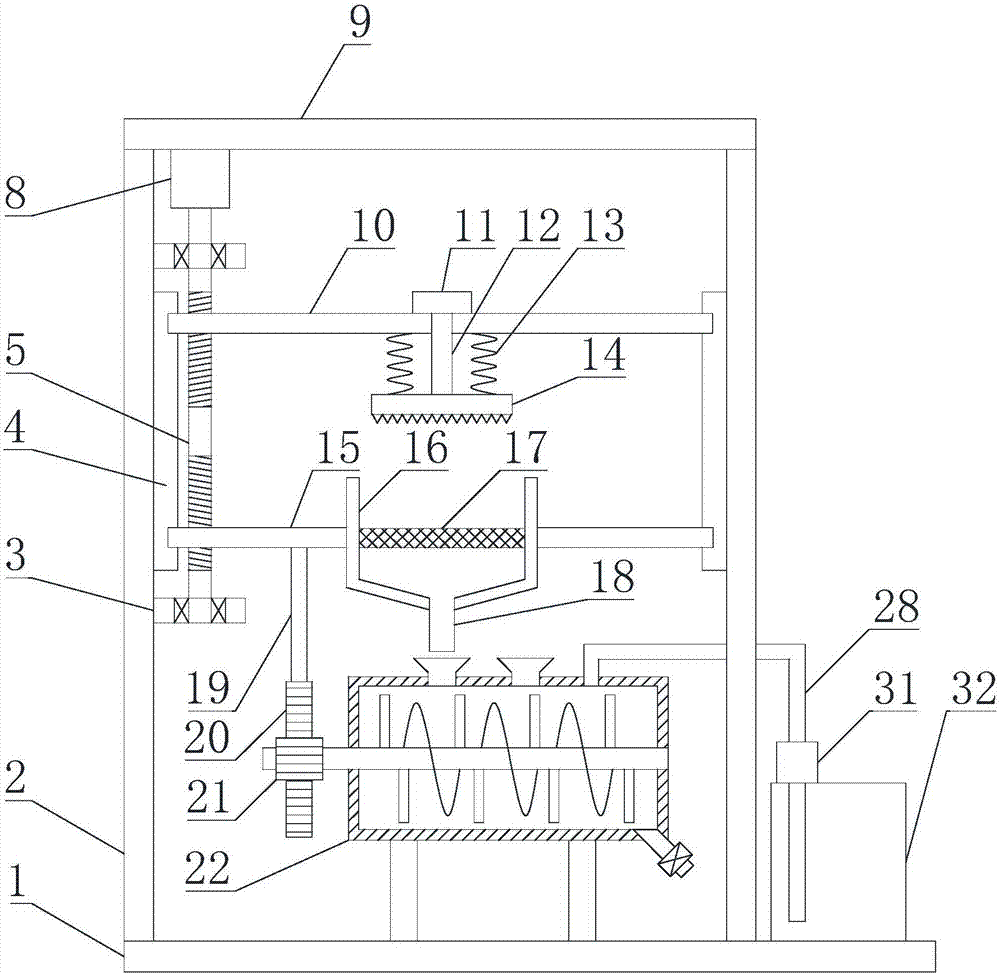

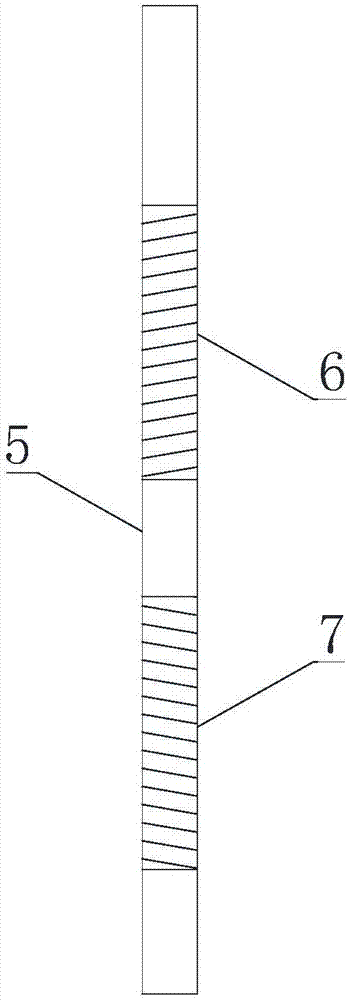

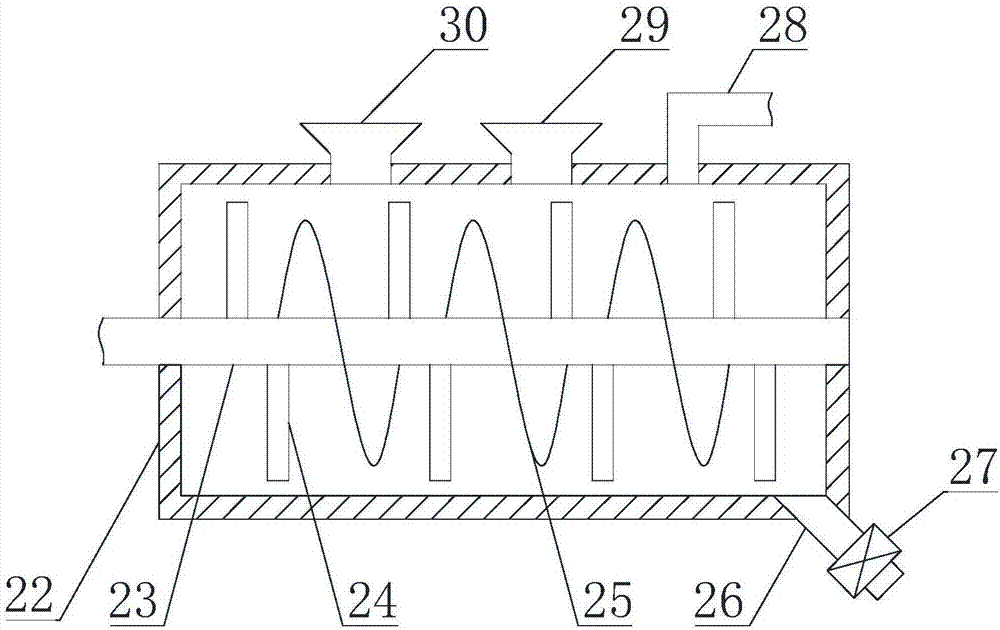

Construction refuse crushing recycling device

InactiveCN107234724AQuality assurancePlay a buffering effectSolid waste managementCement mixing apparatusArchitectural engineeringHigh pressure

The invention discloses a construction refuse crushing recycling device which comprises a base, a support and a top plate. The support is arranged on the base, and the top plate is arranged at the top of the support. A motor is arranged at the left side of the bottom of the top plate and is further connected with a lifting screw rod. The support is provided with sliding rails, and the sliding rails are connected with a first supporting plate and a second supporting plate in a sliding mode. The first supporting plate is provided with a through hole, and the through hole is connected with a first connecting rod in a sliding mode. The bottom end of the first connecting rod is fixedly connected with a pressing plate, and a high-pressure spring is arranged between the pressing plate and the first supporting plate. The second supporting plate is fixedly provided with a material crushing box, and a filtering plate is arranged inside the material crushing box. The bottom of the material crushing box is further connected with a discharging pipe. According to the construction refuse crushing recycling device, the lifting screw rod rotates to drive the pressing plate and the filtering plate inside the material crushing box to be drawn together in the middle, and thus construction refuse can be squeezed and crushed; and the crushed construction refuse is filtered through the filtering plate so as to be squeezed and crushed to be in a fine state continuously, and the phenomenon that the construction refuse is too large and thus later-period recycling cannot be facilitated is prevented.

Owner:ANHUI YIQI SOFTWARE TECH

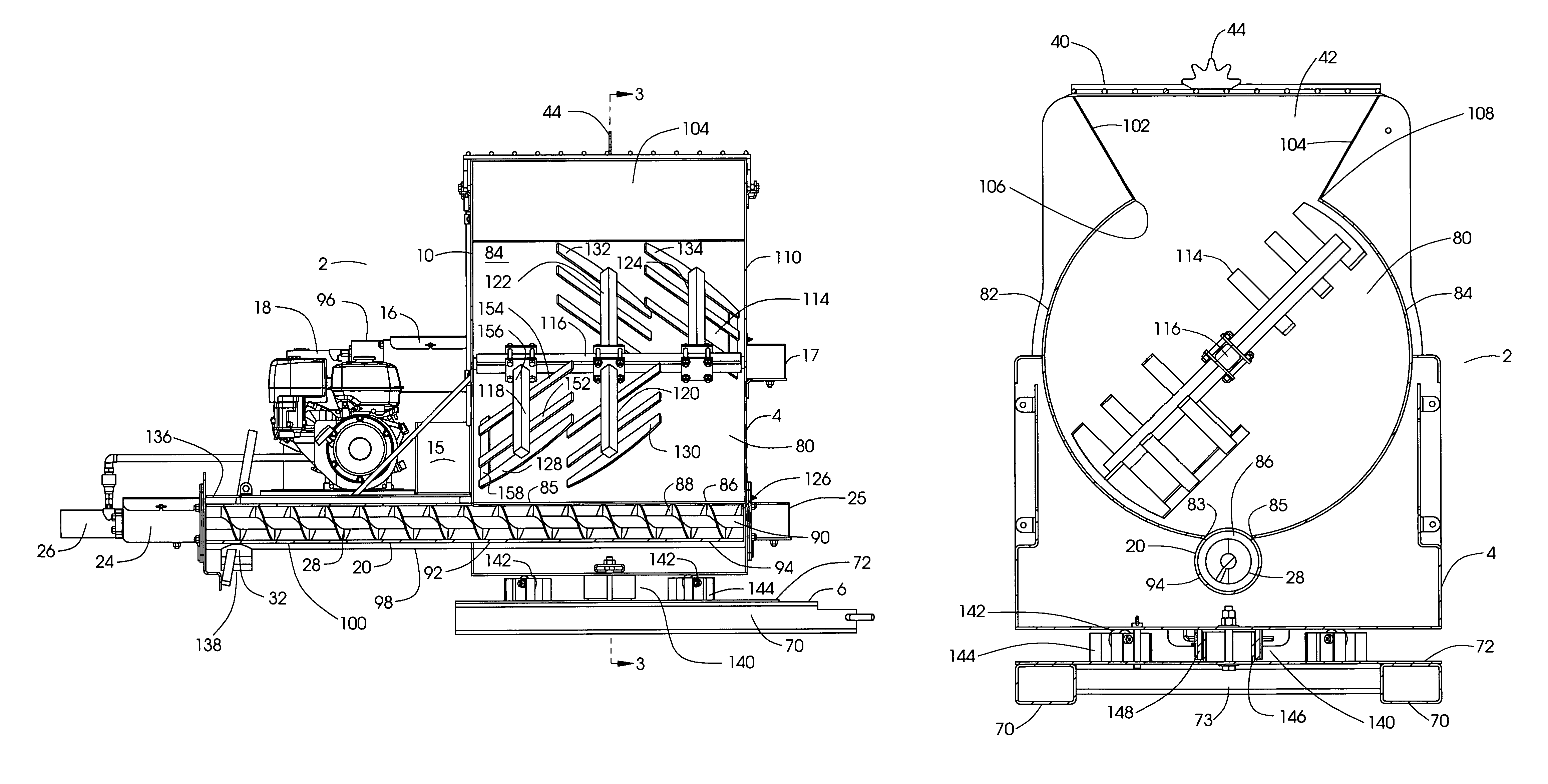

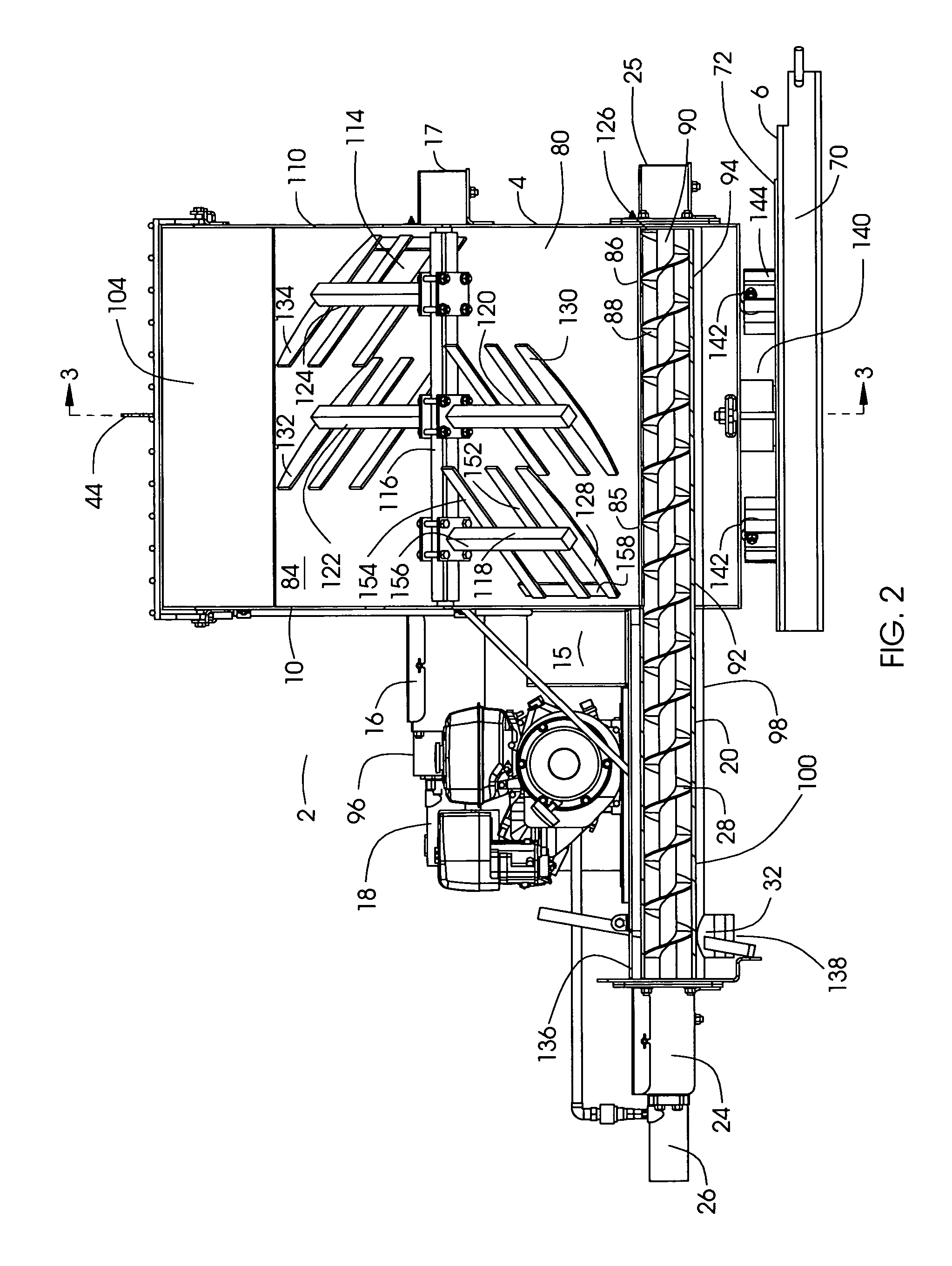

Independent control of auger and hopper assembly in electric blender system

Embodiments relate to a hydraulic fracturing system that includes a blender unit. The system includes an auger and hopper assembly to receive proppant from a proppant source and feed the proppant to the blender unit for mixing with a fluid. A first power source is used to power the blender unit in order to mix the proppant with the fluid and prepare a fracturing slurry. A second power source independently powers the auger and hopper assembly in order to align the hopper of the auger and hopper assembly with a proppant feed from the proppant source. Thus, the auger and hopper assembly can be stowed or deployed without use of the first power source, which is the main power supply to the blender unit.

Owner:US WELL SERVICS LLC

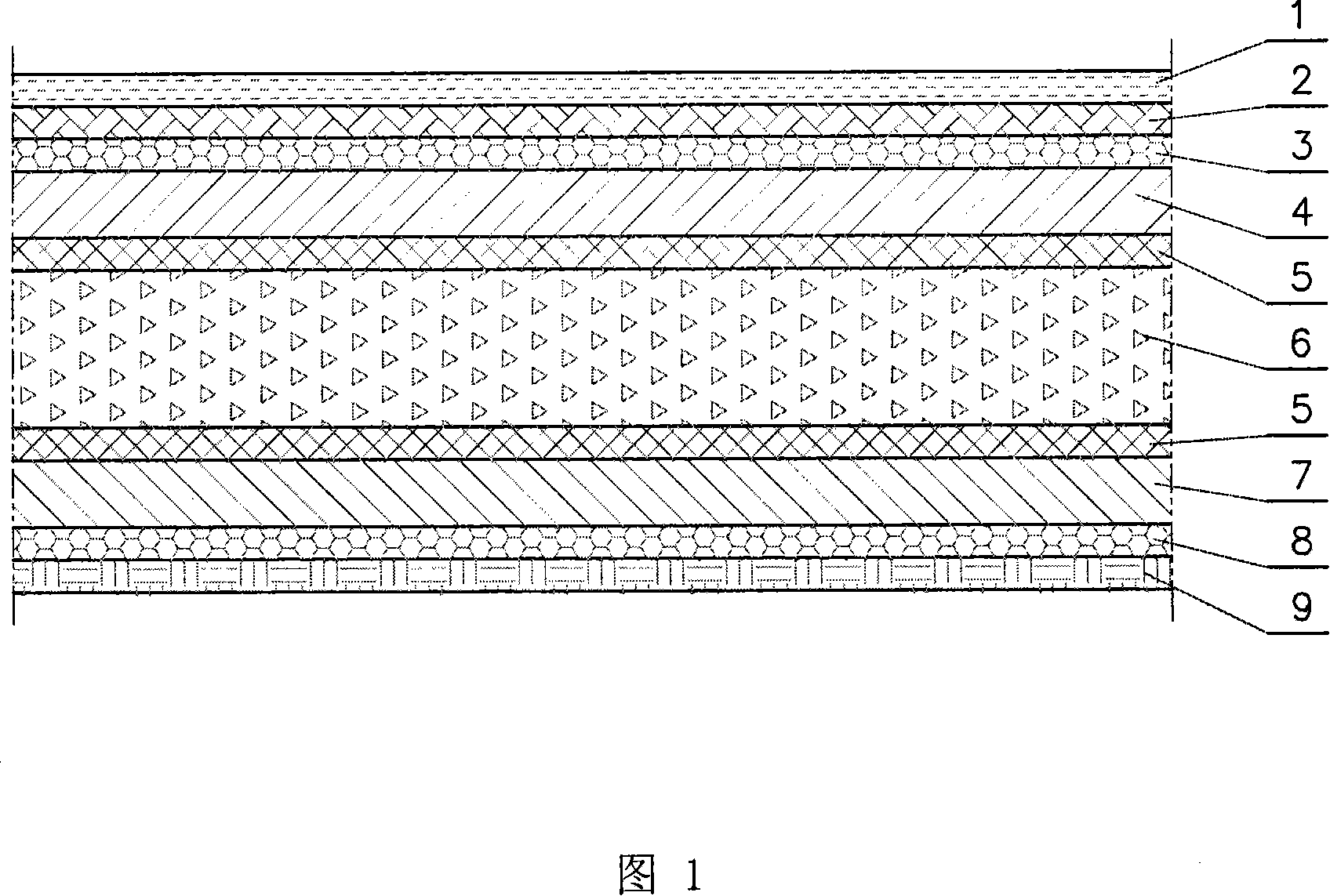

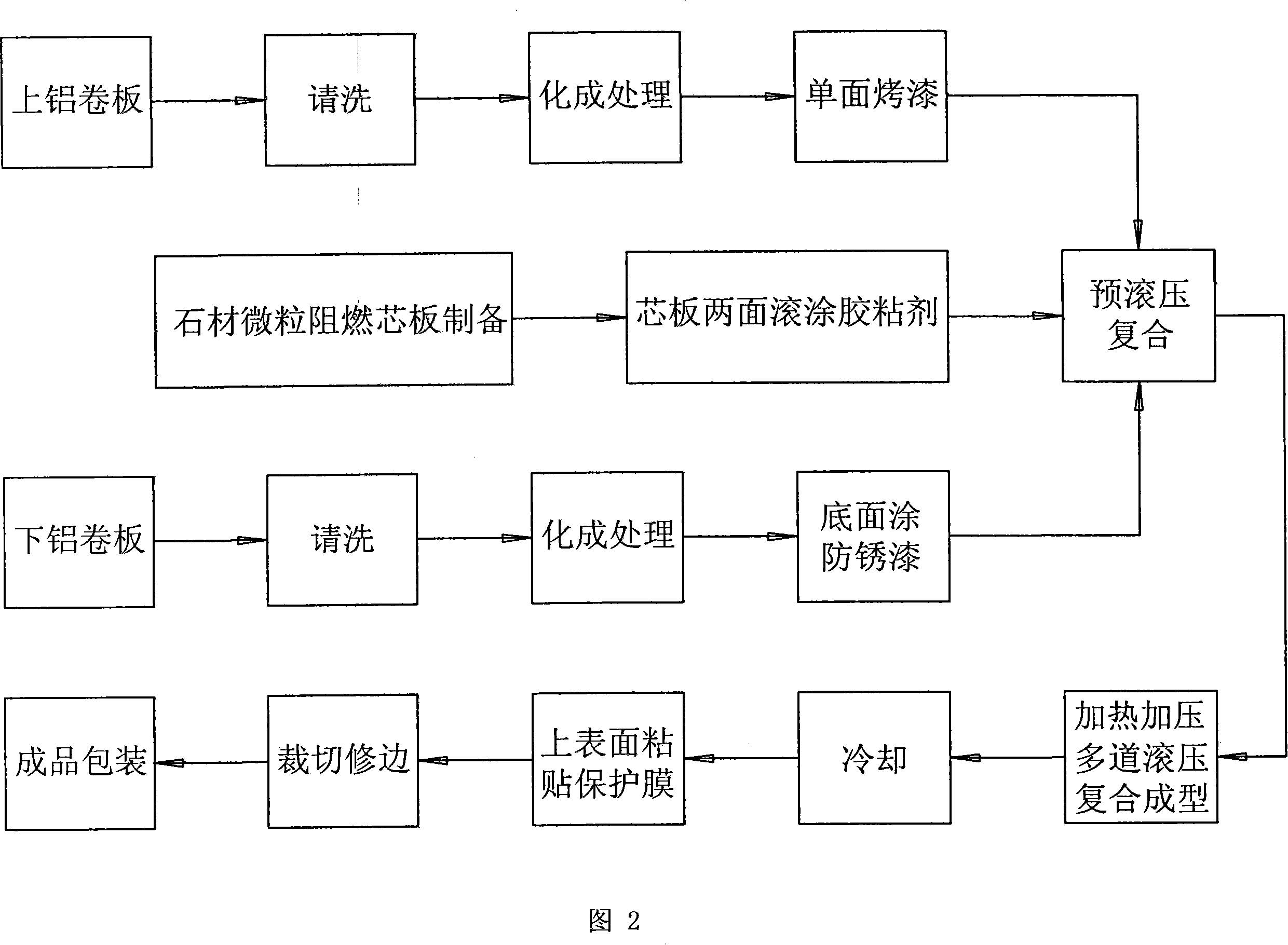

Metal composite plate with fireproof interlayer and manufacturing method thereof

ActiveCN101148936AWon't happenWith thermal insulationCovering/liningsLamination ancillary operationsTectorial membraneAdhesive

The present invention is one kind of composite metal plate with sandwiched fireproof layer and its making process. The composite metal plate with sandwiched fireproof layer consists of a protecting film layer, a baking varnish layer, a first chemically formed film layer, a first metal sheet, a first adhesive layer, a sandwiched fireproof layer, a second adhesive layer, a second metal sheet, a second chemically formed film layer and an antirust primer layer superposed successively and compounded integrally. Its making process includes the steps of: hot pressing the mixture of fine ore grains, fire retardant, coupling agent and adhesive to form the fireproof core board; treating the first metal sheet to form the first film layer and the baking varnish layer, and treating the second metal sheet to form the second film layer and the antirust primer layer; painting adhesive to two sides of the core board and hot pressing to combine the core board and two metal sheets; adhering the protecting film layer and cutting.

Owner:江阴新泓泰复合材料有限公司

Mortar mixing apparatus

A mortar mixing apparatus includes a screw conveyor disposed below the bottom of a mixing container in which a selectively operable agitator is located. An elongate opening in the bottom of the mixing container is open into the housing of the screw conveyor so that mixed mortar may flow into the screw conveyor. The screw conveyor may be rotated in a reverse direction to force materials upward into the mixing container, or it may be operated in a forward direction to convey mortar away from the mixing container. The agitator and the screw conveyor are independently driven by hydraulic motors.

Owner:CUMMER THOMAS J

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

ActiveUS7513963B2Increase volumeSmall sizeSolid waste managementTransportation and packagingProduction lineVertical mixing

A wet mixer apparatus and method for its use, the mixer having a vertical mixing chamber for forming a wet slurry of a cementitious slurry and water. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feeding for separate supply of cementitious powder and water to the slurry mixing area of the chamber without pre-mixing of the powder and water is also disclosed.

Owner:UNITED STATES GYPSUM CO +1

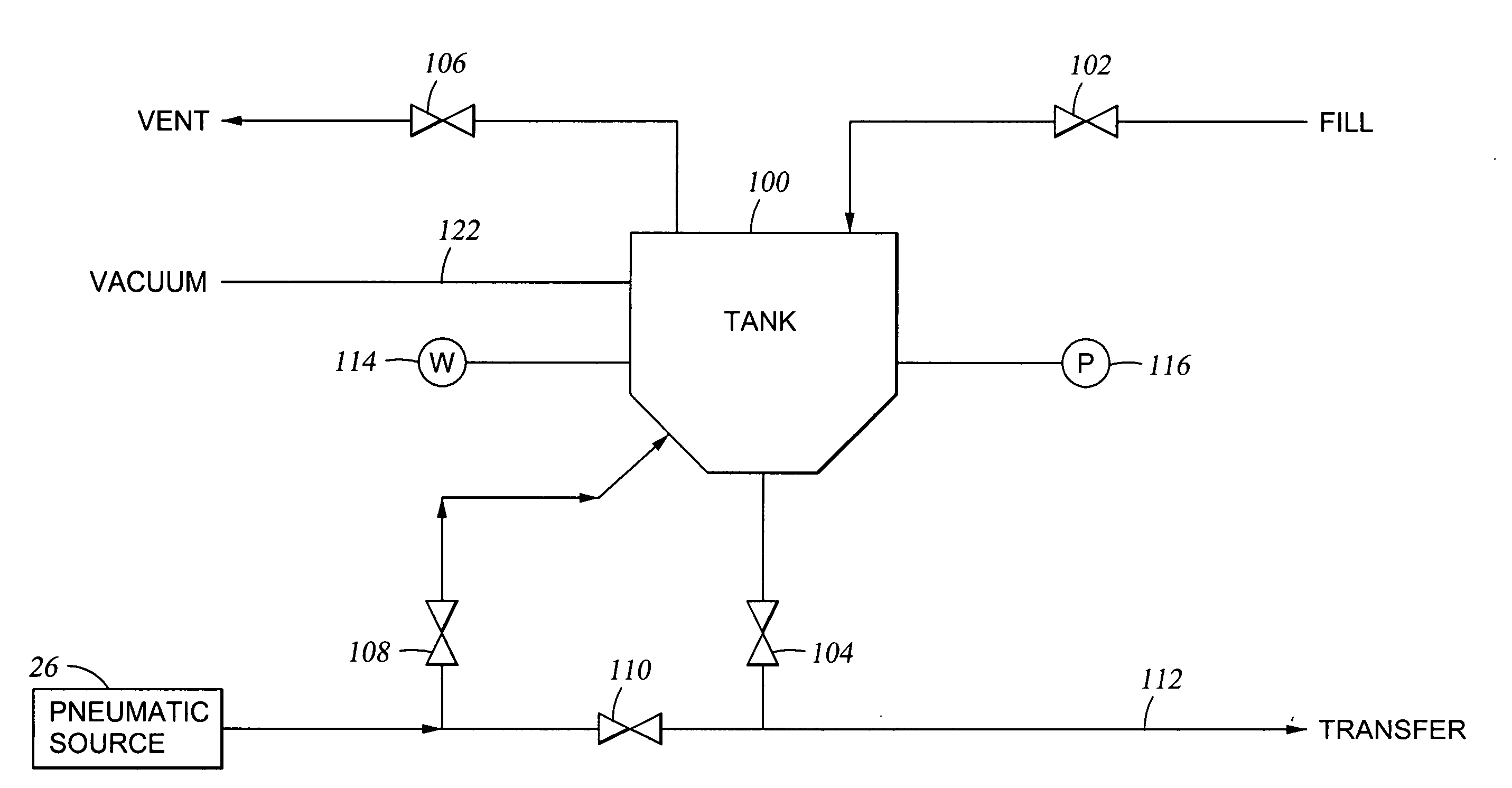

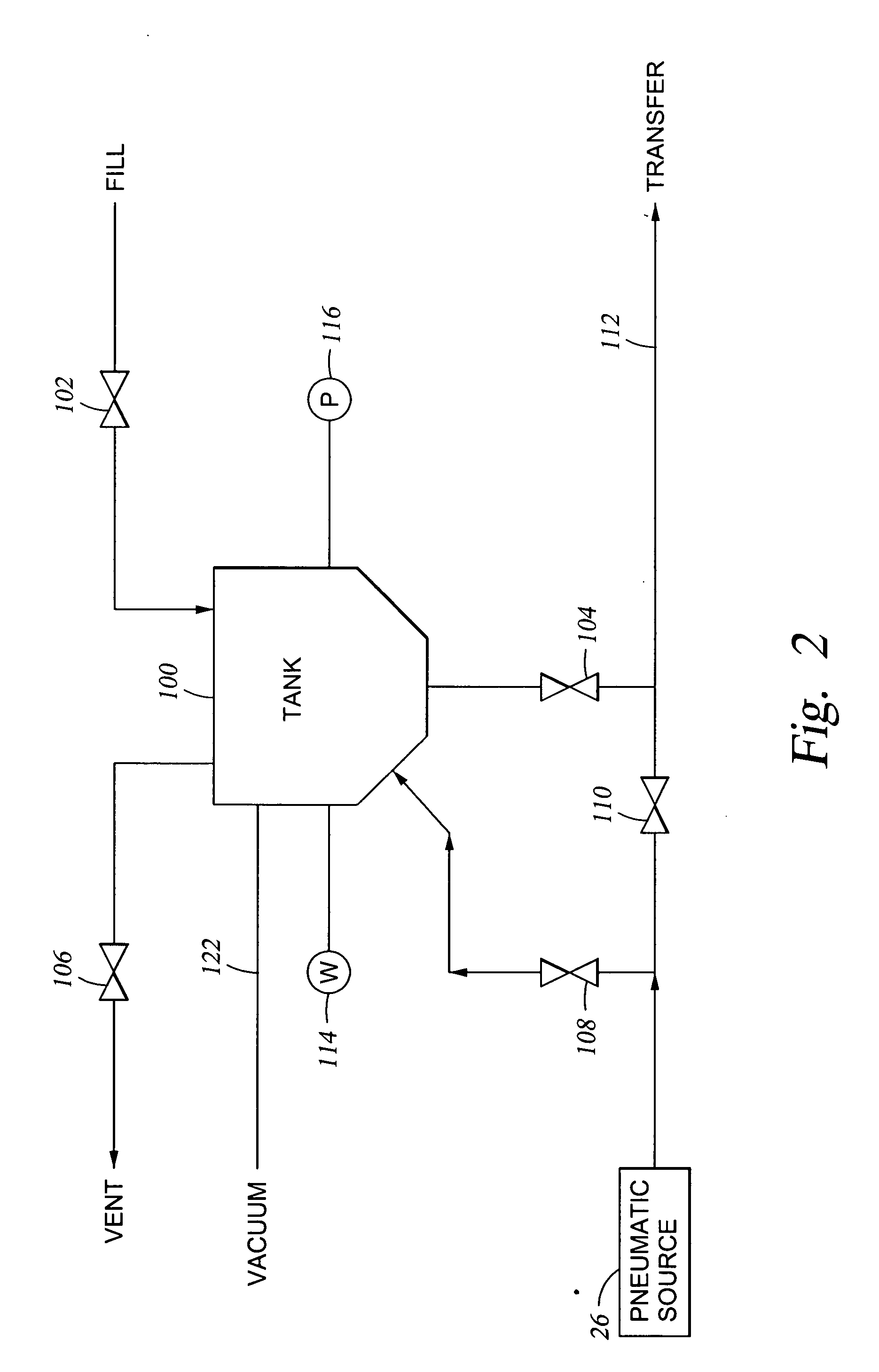

Automated control methods for dry bulk material transfer

ActiveUS20060013061A1Amount of timeMixing operation control apparatusLarge containersAutomatic controlEngineering

A method for blending dry material in a plant comprises automatically controlling fluidization of the dry material, transfer of the material, or both. In various embodiments, the automatically controlling comprises optimizing an amount of time that the dry material is fluidized prior to transfer, optimizing the transfer rate of the dry material, detecting and eliminating a developing plug of the dry material, estimating the weight of the dry material in the transfer line, minimizing dribbling during transfer of the dry material, and combinations thereof.

Owner:HALLIBURTON ENERGY SERVICES INC

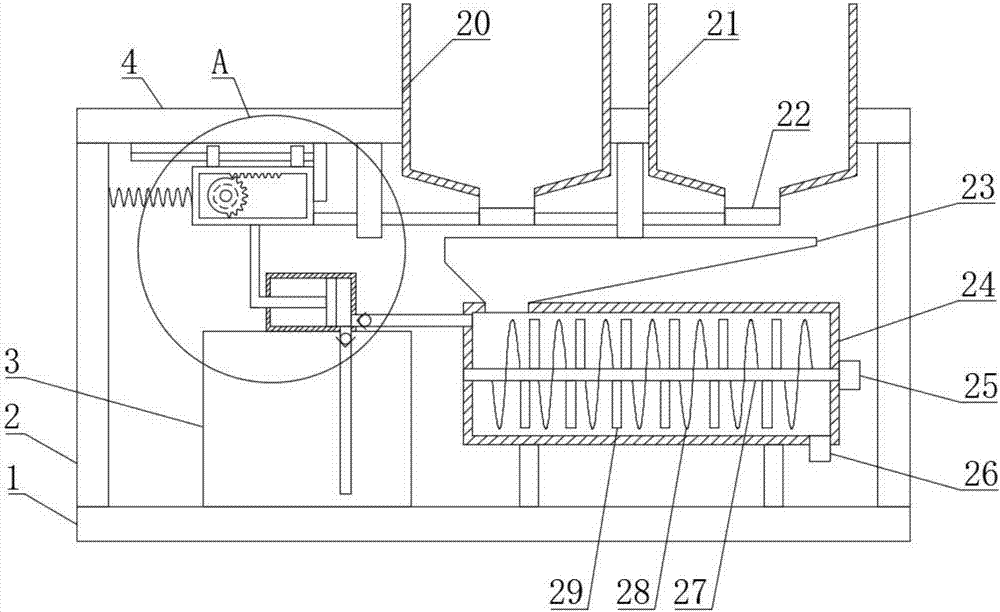

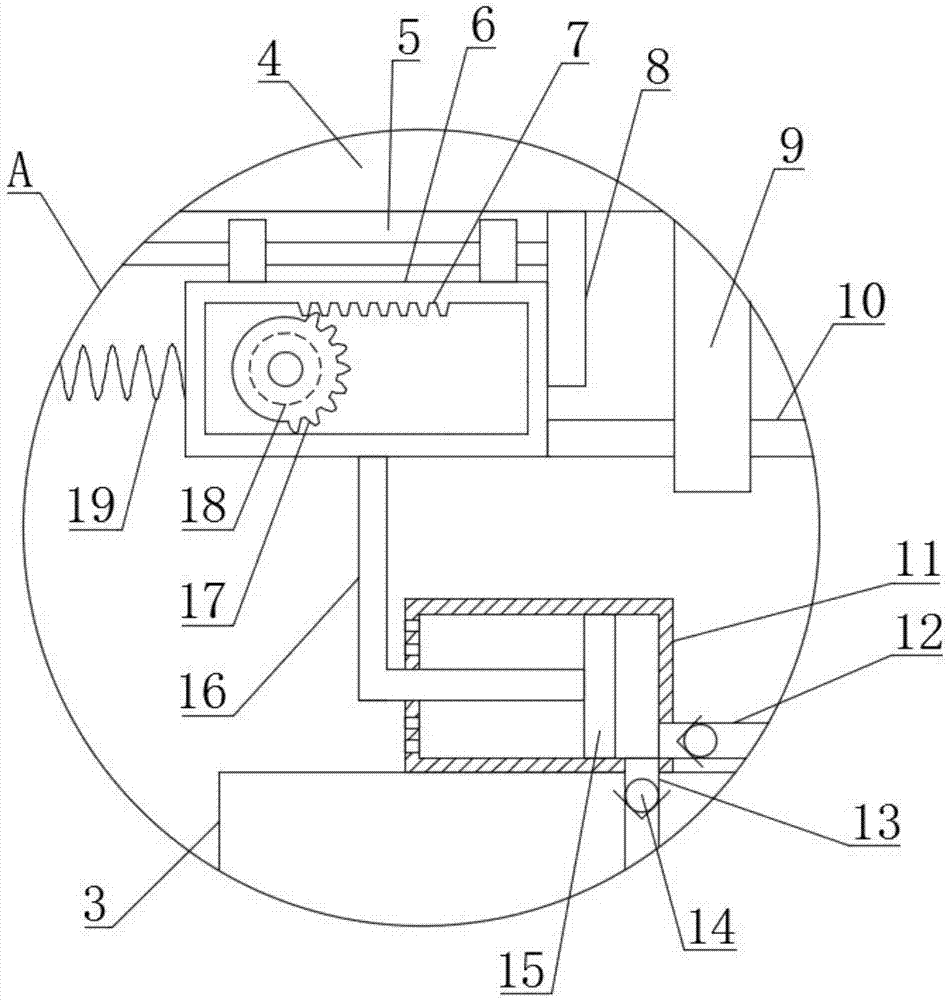

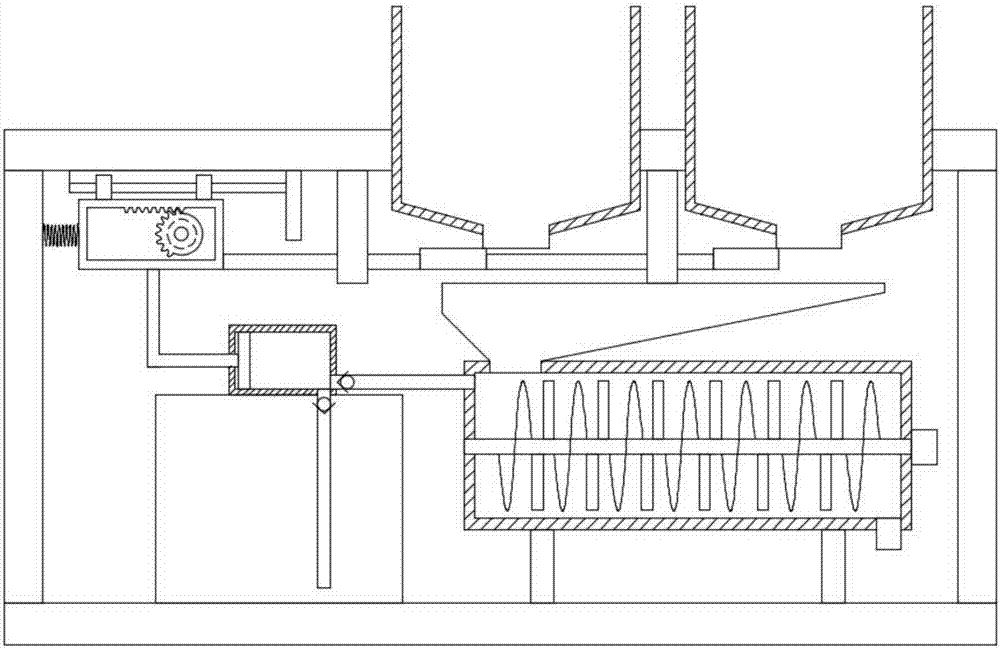

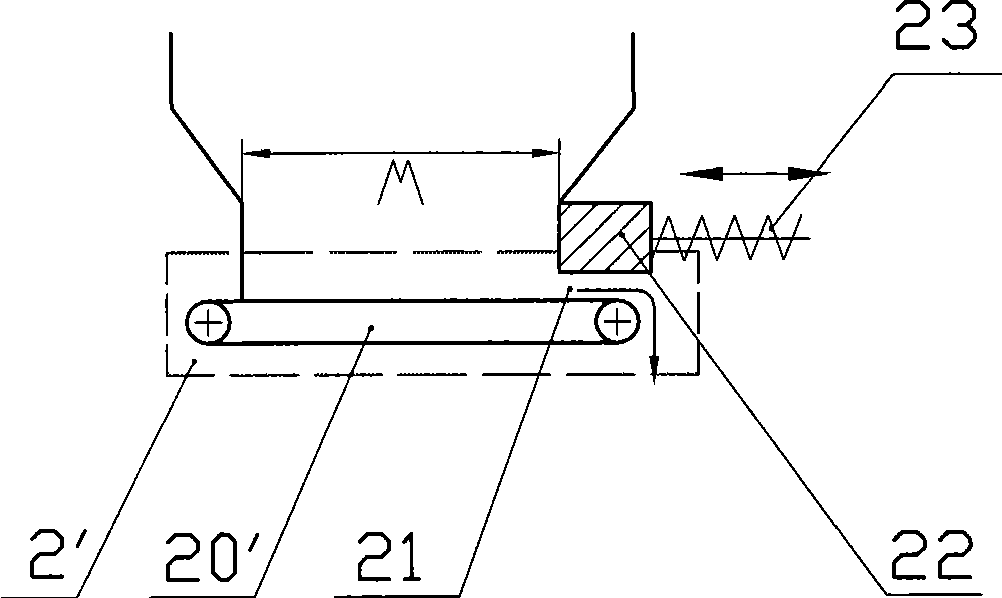

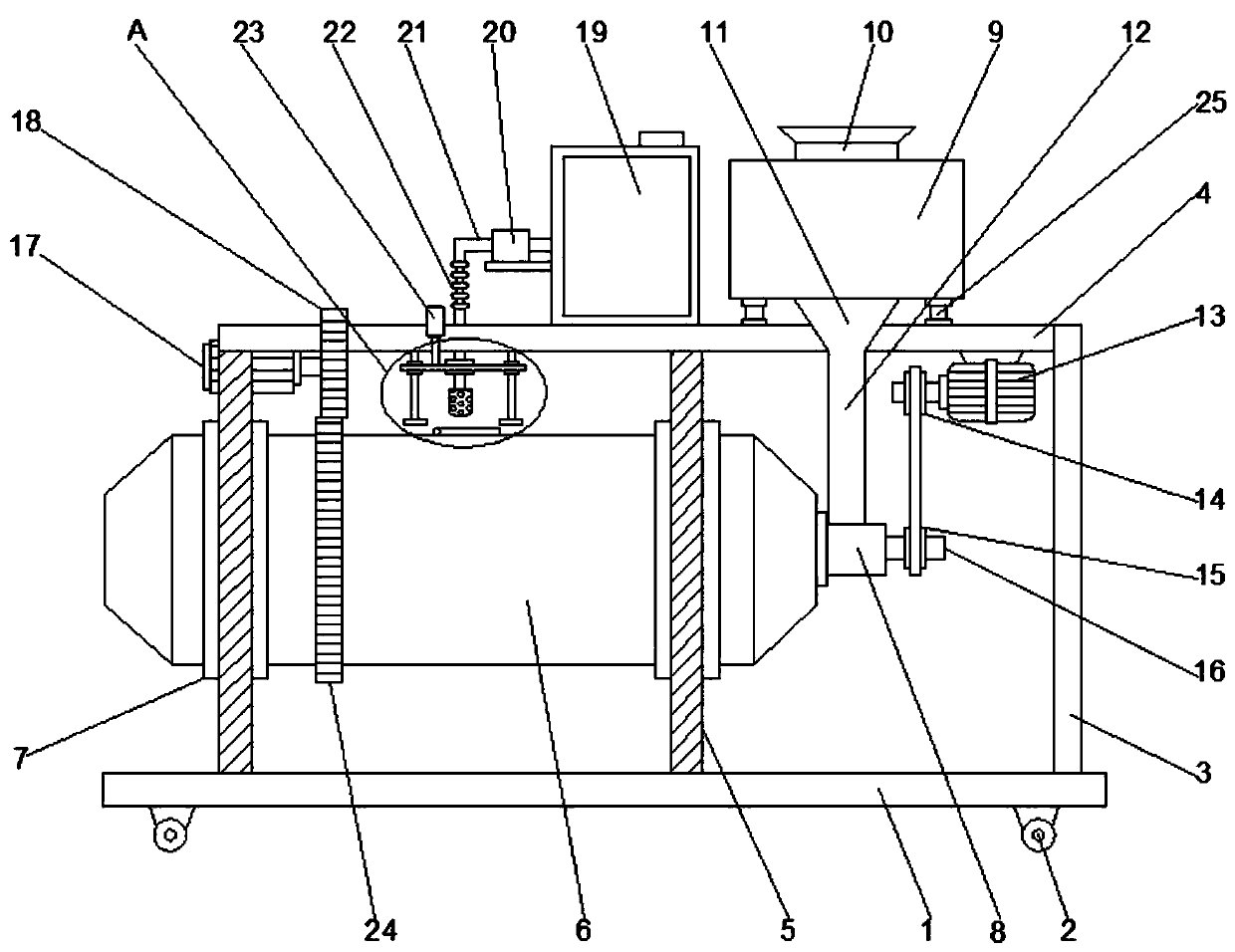

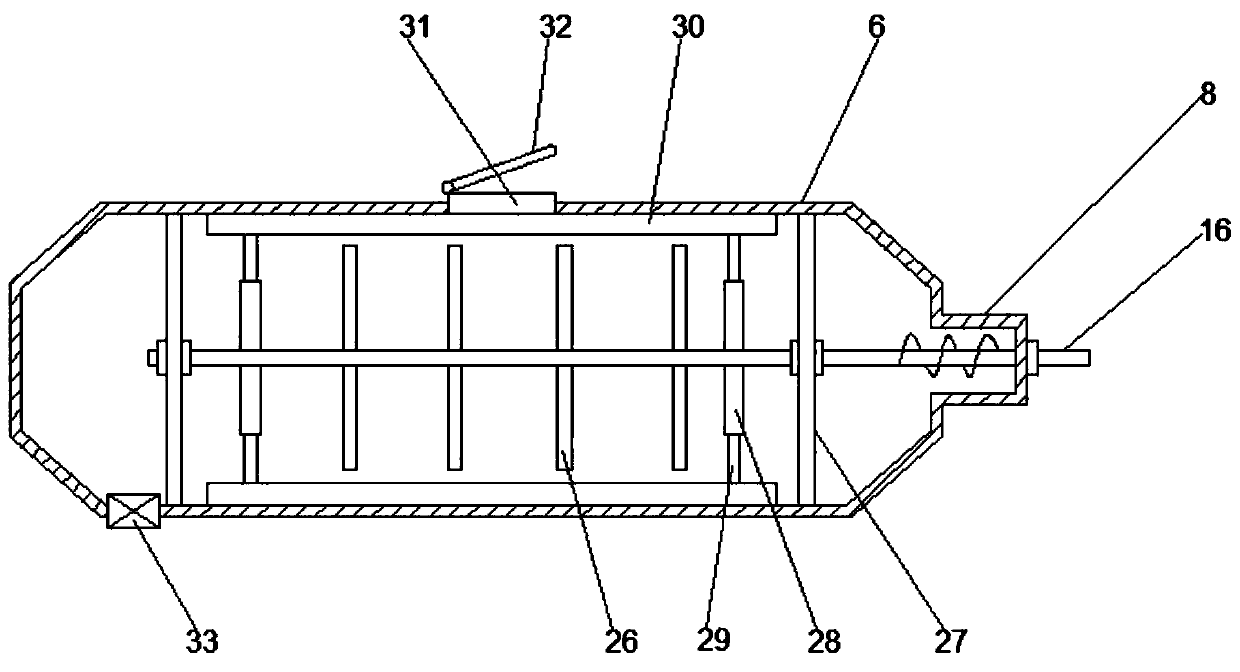

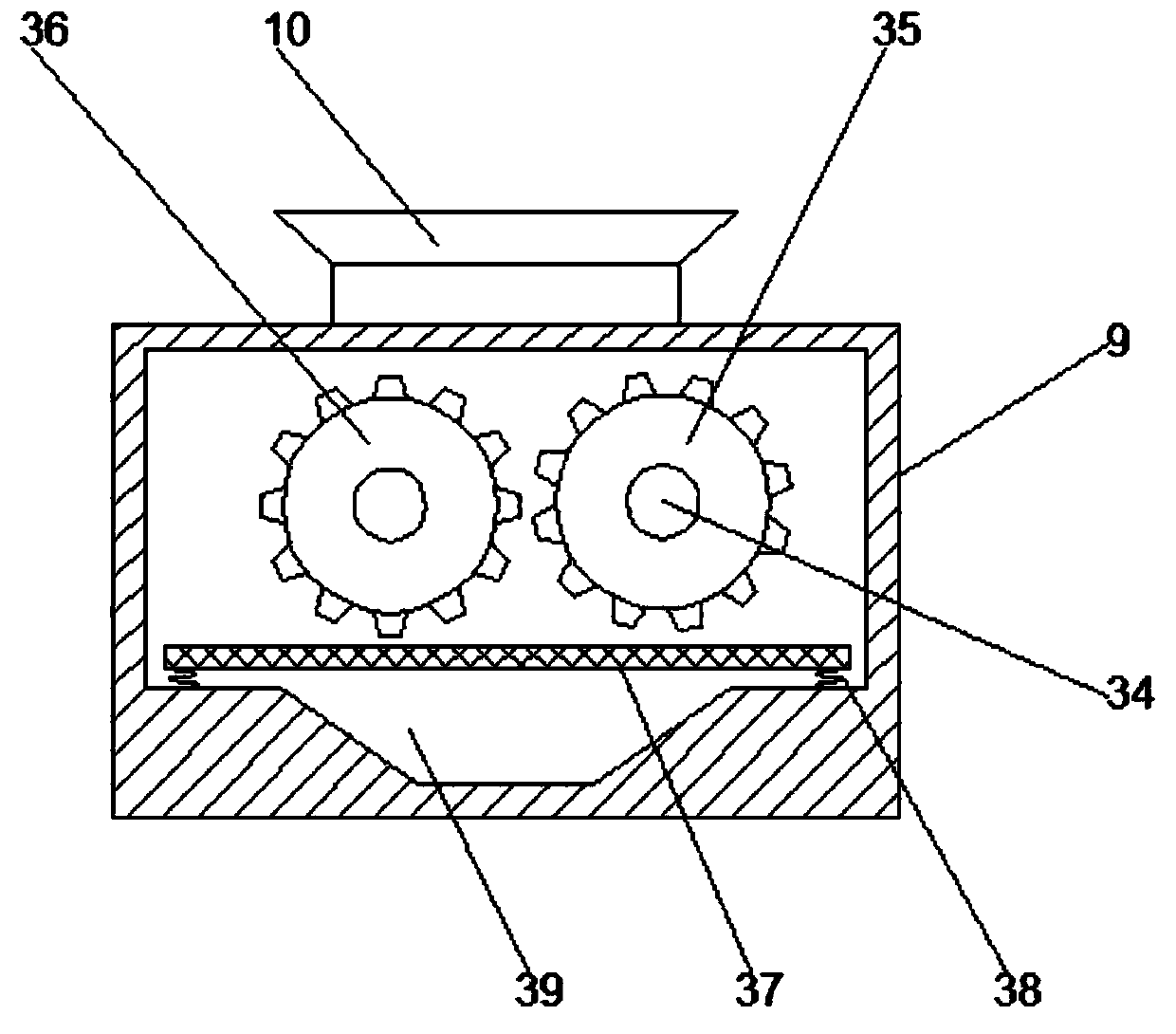

Efficient concrete quantified stirring device

InactiveCN107139328AStir wellNo manual controlDischarging apparatusCement mixing apparatusGear wheelArchitectural engineering

The invention discloses a high-efficiency concrete component mixing device, which comprises a base, a support plate is fixedly arranged at the left and right ends of the base through a support rod, a cement tank and a gravel tank are fixedly arranged on the support plate; a slide rail is arranged on the left side of the bottom of the support plate , the lower part of the slide rail is slidingly connected with the moving frame through the slider, the left end of the moving frame is connected with the left support rod through the spring, the right end of the moving frame is connected with the first moving rod, and two cover plates are arranged on the first moving rod, inside the moving frame A rack is arranged on the top, and a first motor is fixedly arranged on the top of the support plate through a bracket. The motor shaft at the top of the first motor is connected with a gear, and the gear meshes with the rack; the right side of the base is also fixed with a mixing bucket through a bracket. The invention drives the moving frame to move left and right through the cooperation of incomplete gears and springs, so that the cover plate is intermittently opened and closed, and the amount of cement and sandstone is basically the same each time, and the component stirring is carried out. The amount of stirring at one time is not much, and the stirring more fully.

Owner:童红妃

Temperature-controlled concrete stirring device

ActiveCN105643801AOvercome the problem of deviation in use effectImprove qualityDischarging apparatusMixing operation control apparatusTemperature controlStopped work

The invention discloses a temperature-controlled concrete stirring device comprising a stirring barrel body, wherein two sides of a first driving gear are meshed with second driven gears; the second driven gears are fixedly arranged on driven shafts; a plurality of temperature probes are arranged inside the left side wall of the stirring barrel body; a ceramic heating body is arranged inside a cavity; the bottom of the right side wall of the stirring barrel body is provided with a first discharging pipe; a second discharging pipe is connected with an auxiliary unloading hose; the top of the stirring barrel body is also provided with an additive introducing device; and a pipeline of a liquid control switch and an additive delivery pump is provided with a horizontal section pipeline, a first elbow pipeline, a second elbow pipeline and a third elbow pipeline. By using the temperature-controlled concrete stirring device, the temperature of inside concrete can be controlled, the automatic and quantitative addition of water is realized, the problem of deviation caused by different heights is overcome, and the retention phenomenon cannot be generated after the additive delivery pump stops working.

Owner:河南国龙矿业建设有限公司

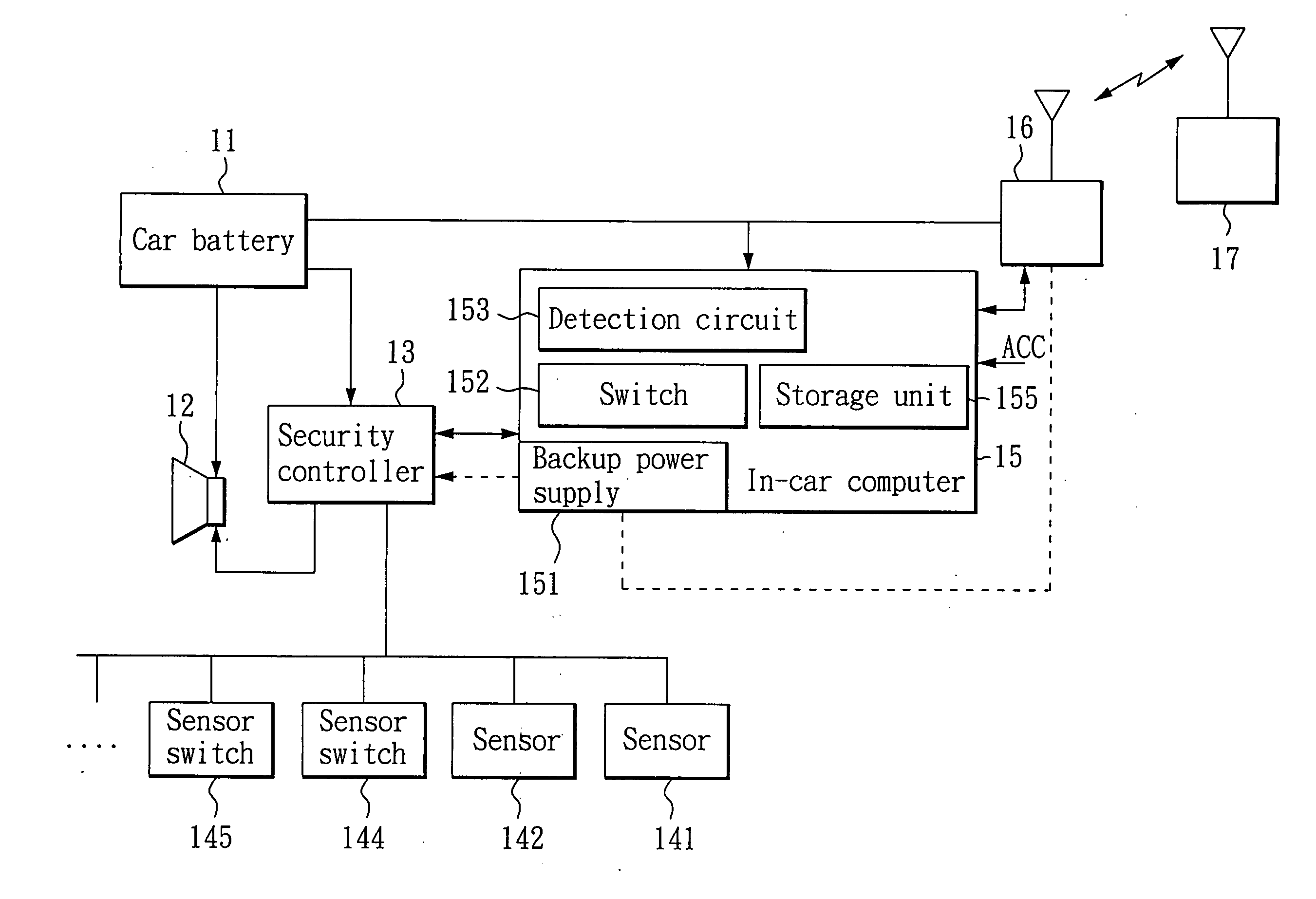

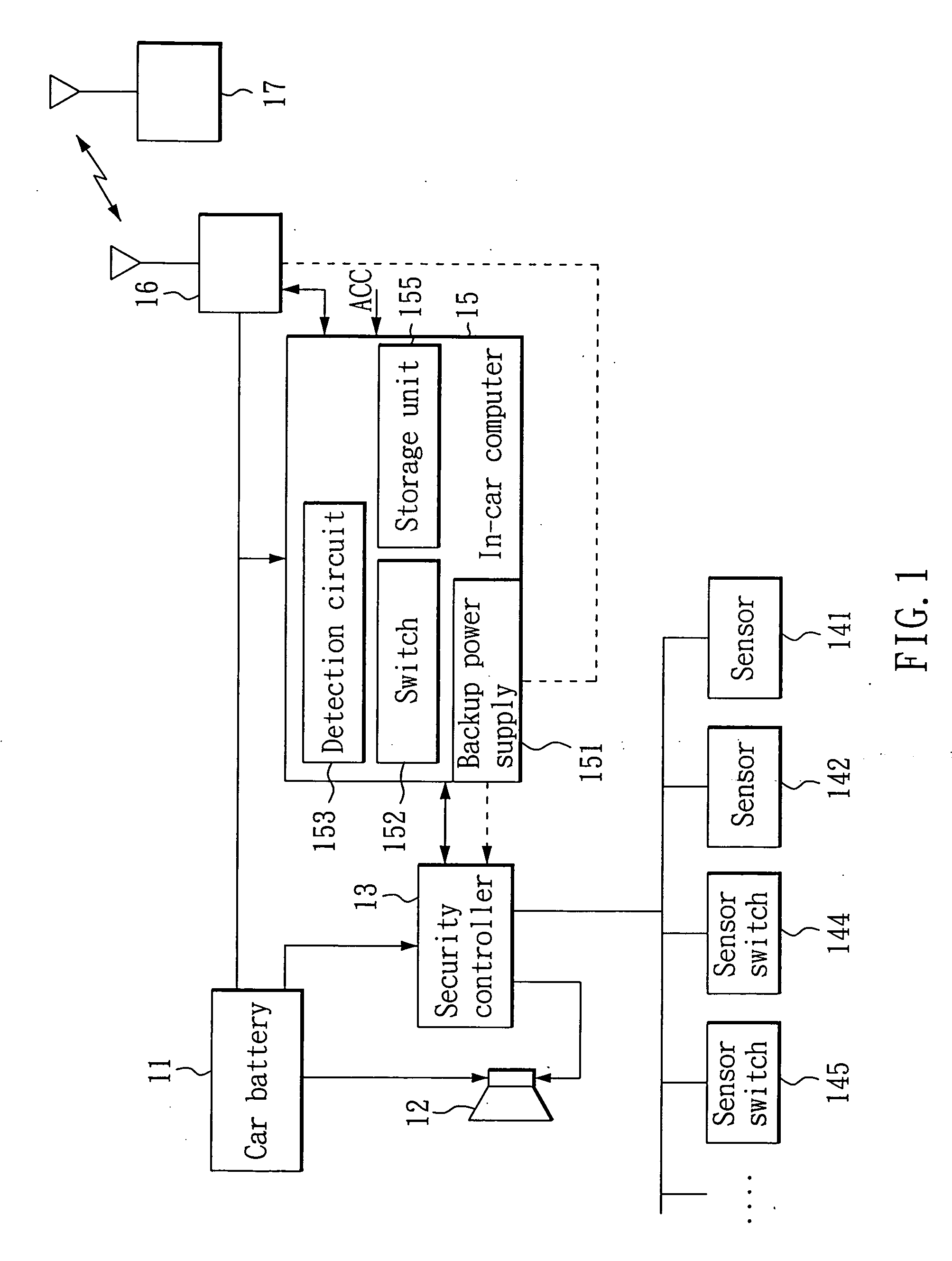

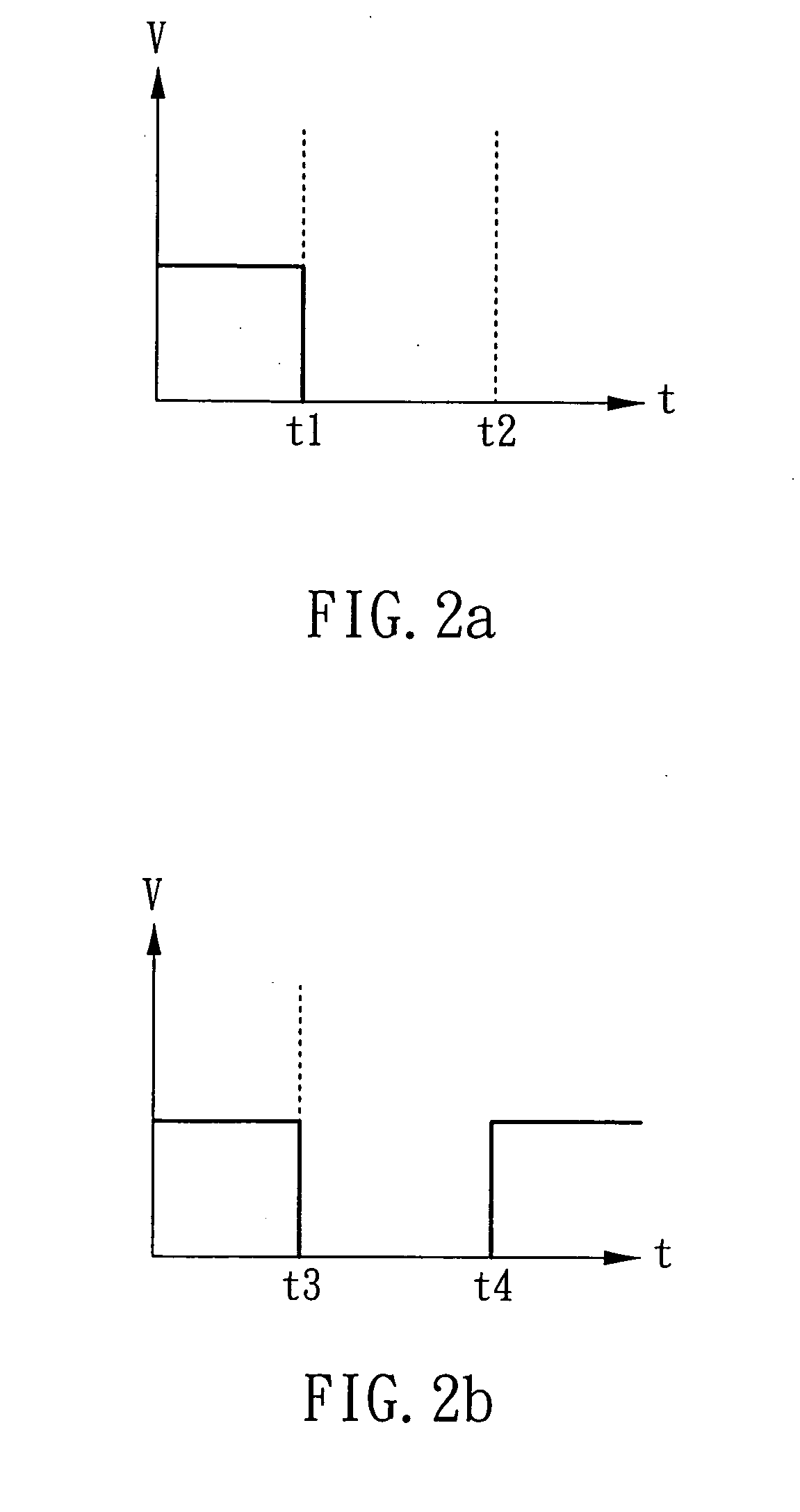

Vehicle security system

Disclosed is a vehicle security system, which uses a detection circuit to detect the supply of electric power from the car battery to the in-car computer and the status of the car ignition switch, and to start a backup power supply for the in-car computer, and drives the in-car computer to send an informing message to a remote receiver via a wireless communication module when the supply of electric power from the car battery to the in-car computer is terminated or when the car ignition switch is switched on during the alert mode of the vehicle security system.

Owner:XINGYI SCI & TECH

Crushing and stirring device for building cement

InactiveCN107297819AAvoid erectionImprove qualityMixing operation control apparatusPretreatment controlDrive wheelDrive shaft

The invention discloses a crushing and stirring device for building cement, which comprises a frame and a base. The frame includes a stirring box and a crushing box. The right end of the rotating shaft is equipped with a driving wheel, the middle position of the frame is horizontally provided with a first transmission shaft, the left end of the first transmission shaft is equipped with a primary driven wheel and a secondary driven wheel, and the driving wheel and the primary driven wheel They are connected by the first belt, the second transmission shaft and the third transmission shaft are horizontally arranged in the crushing box, the second transmission shaft and the third transmission shaft are horizontally parallel, and the left end of the second transmission shaft is installed with The third-stage driven wheel, the second-stage driven wheel and the third-stage driven wheel are connected through the second belt; the beneficial effect of the present invention is: the transmission structure of the belt and the gear is utilized, the working motor is reduced, and the operation safety is improved , fully milled and crushed to improve the quality of the material.

Owner:黄瀚

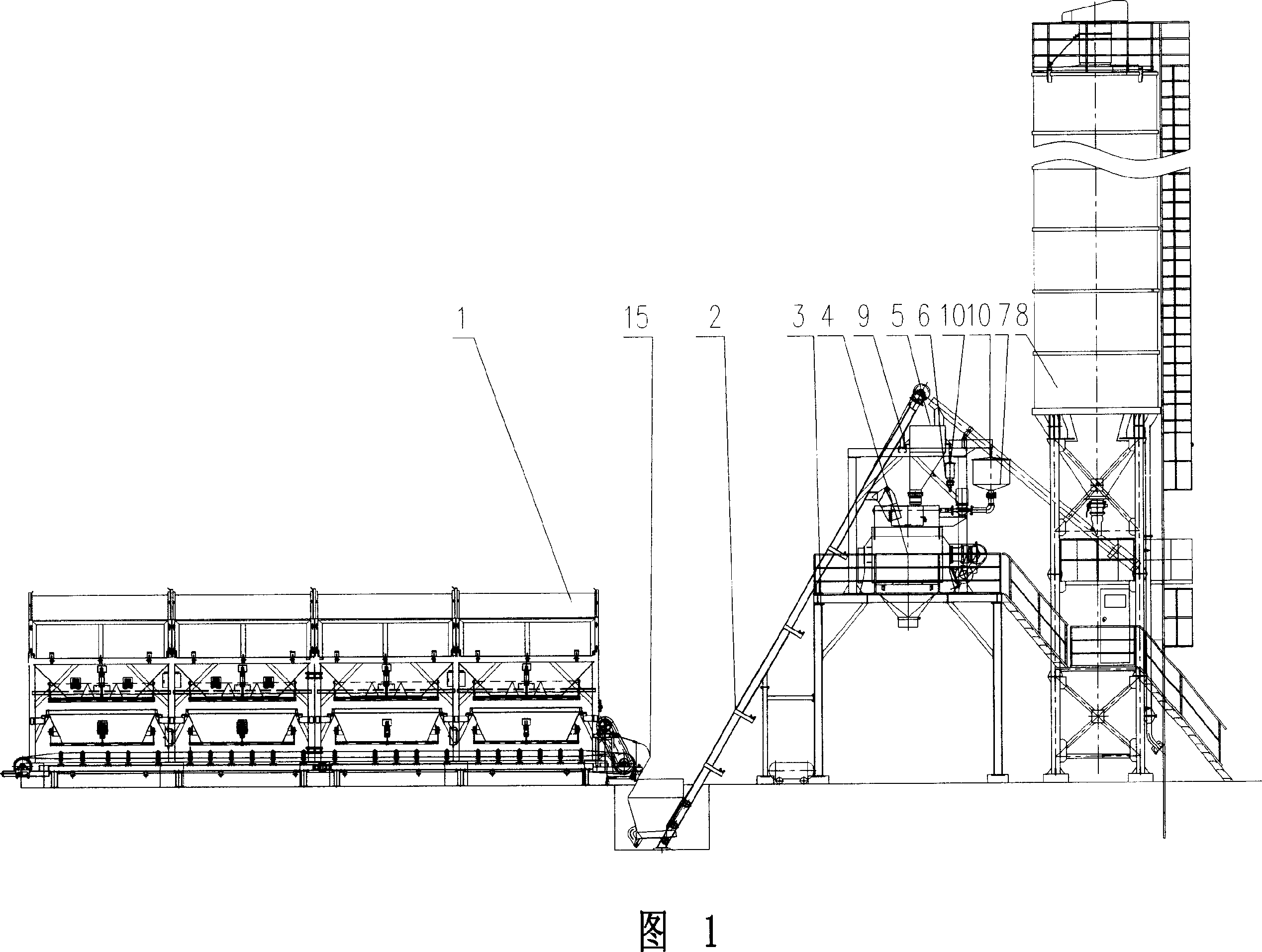

High-performance concrete mixing station

InactiveCN101011844ACompact structureHigh degree of modularityMixing operation control apparatusSold ingredients supply apparatusSmall footprintMaterials science

A high performance concrete mixer comprises the batching aggregate hoister, blender, powder weighting device, additive weighing device, water weighing device and powder storage, with one end of the aggregate hoister at the output of the batching machine, the other end above the inlet of the blender, and the weighing devices for additive, water and powder storage at the top of the inlet of the blender respectively. It is compact and simple in structure, high in modularization, small in land occupation, good in economical effect with energy saving effects.

Owner:SANY HEAVY IND CO LTD (CN)

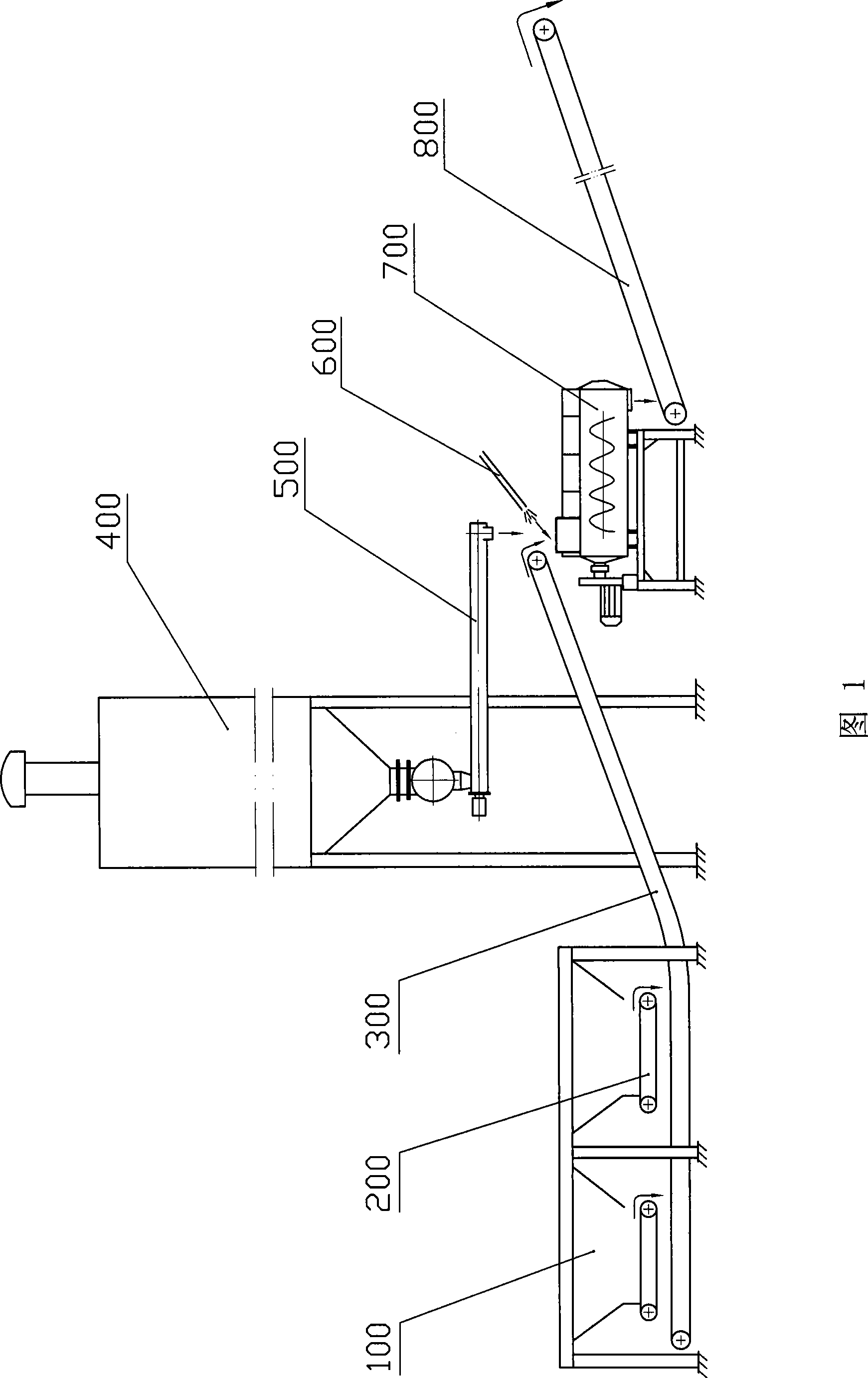

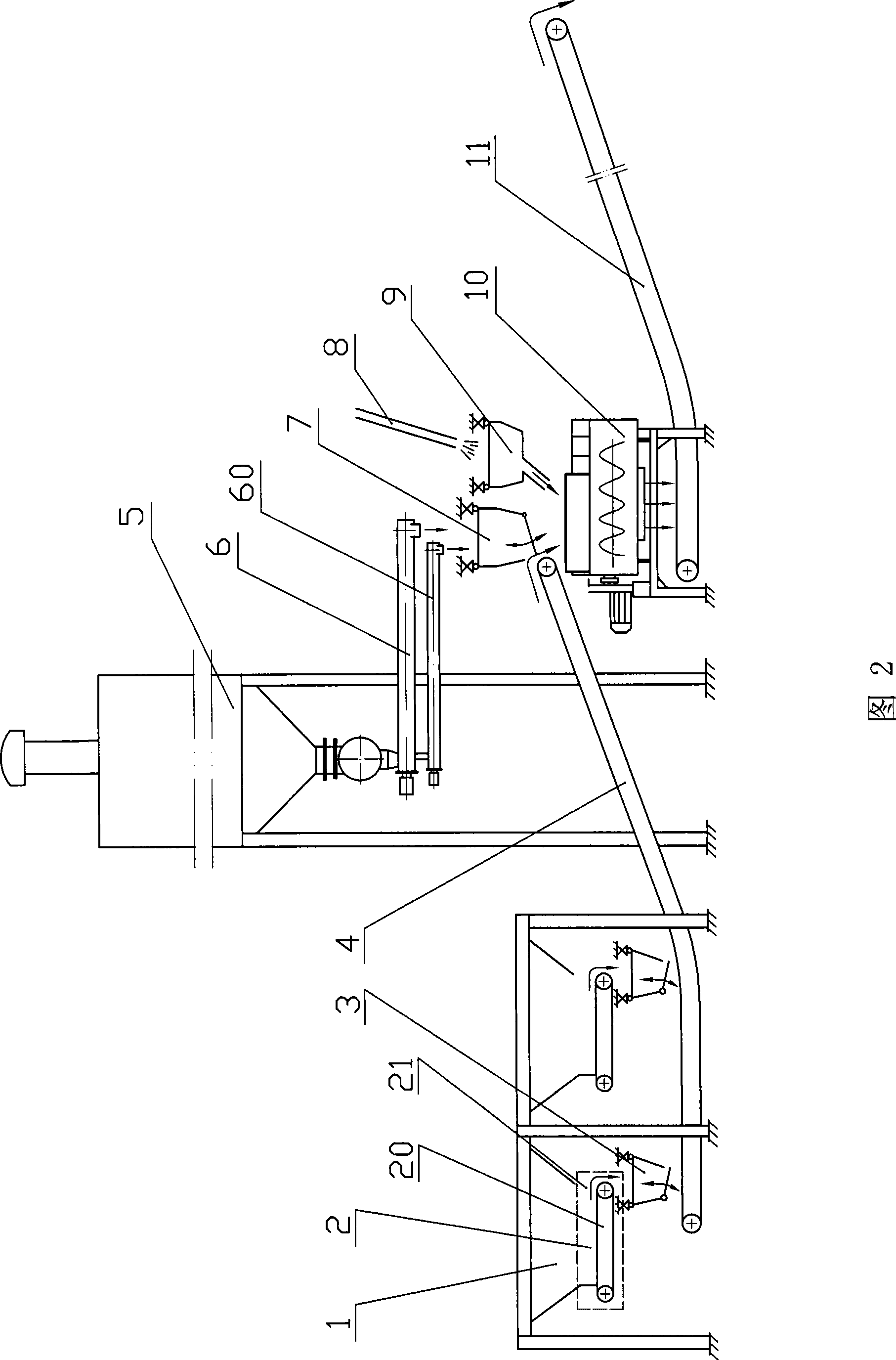

Novel stirring station

InactiveCN101456214AStir wellTwo machines in oneCement mixing apparatusControl apparatusEngineeringScrew conveyor

The invention relates to a novel stirring station, which comprises a skeletal material mixing cabin of which the bottom is provided with a material outlet, a material feeding system positioned below the skeletal material mixing cabin, a skeletal material weighting hopper positioned below the material feeding system, a material collecting belt conveyor positioned below the skeletal material weighting hopper, a stirring cylinder positioned below the material collecting belt conveyor, a cement storage bin, a cement spiral conveyor, a cement weighting hopper, a water pump and a water weighting hopper, wherein the stirring cylinder is simultaneously positioned below the cement weighting hopper and the water weighting hopper; the material feeding system is a variable material feeding system and comprises a variable feeding belt conveyor, a material outlet and a material door; and the structure of the stirring cylinder can be replaced according to different stirring materials.

Owner:陕西长大西筑路面机械科技有限公司

Self-cleaning type concrete stirring equipment for building

InactiveCN110228138AQuality improvementStir wellMixing operation control apparatusHollow article cleaningEngineeringCushion

The invention discloses self-cleaning type concrete stirring equipment for building. The self-cleaning type concrete stirring equipment comprises a base, moving wheels and a stand column, the four moving wheels are arranged at the bottom of the base, the four moving wheels are uniformly distributed in a rectangular shape, the stand column is arranged on the right side of the upper surface of the base, a top plate is arranged at the top end of the stand column, the upper surface of the top plate is correspondingly provided with a crushing box and a water tank, the four corners of the bottom ofthe crushing box are connected with the upper surface of the top plate through damping cushions, and a feeding port is formed in the top end of the crushing box. During use, sand and stones are throwninto the feeding port, a third motor is started, so that a first crushing roller and a second crushing roller rotate to crush the sand and stones, the crushed sand and stones fall on a screen, the qualified sand and stones can pass through the screen to fall into a material guiding groove, and can pass through a discharging pipe to enter a feeding pipe, due to the fact that vibrating springs arearranged at the bottom of the screen, the unqualified sand and stones can be bounced up by the vibration power to be continuously crushed.

Owner:史海军

Concrete slump measurement and control system

ActiveUS8858061B2Preventing loss through unauthorized poursRotating receptacle mixersFlow propertiesControl systemEngineering

An apparatus and method to measure and control the slump of concrete by monitoring sensor within the interior surface of a concrete mixer and a liquid flow meter. Data is analyzed by a computer processing unit to determine the slump of the concrete, liquid needed the quantity of concrete within the mixer, the amount of concrete poured, and the starting and ending time of the pour.

Owner:GCP APPL TECH INC

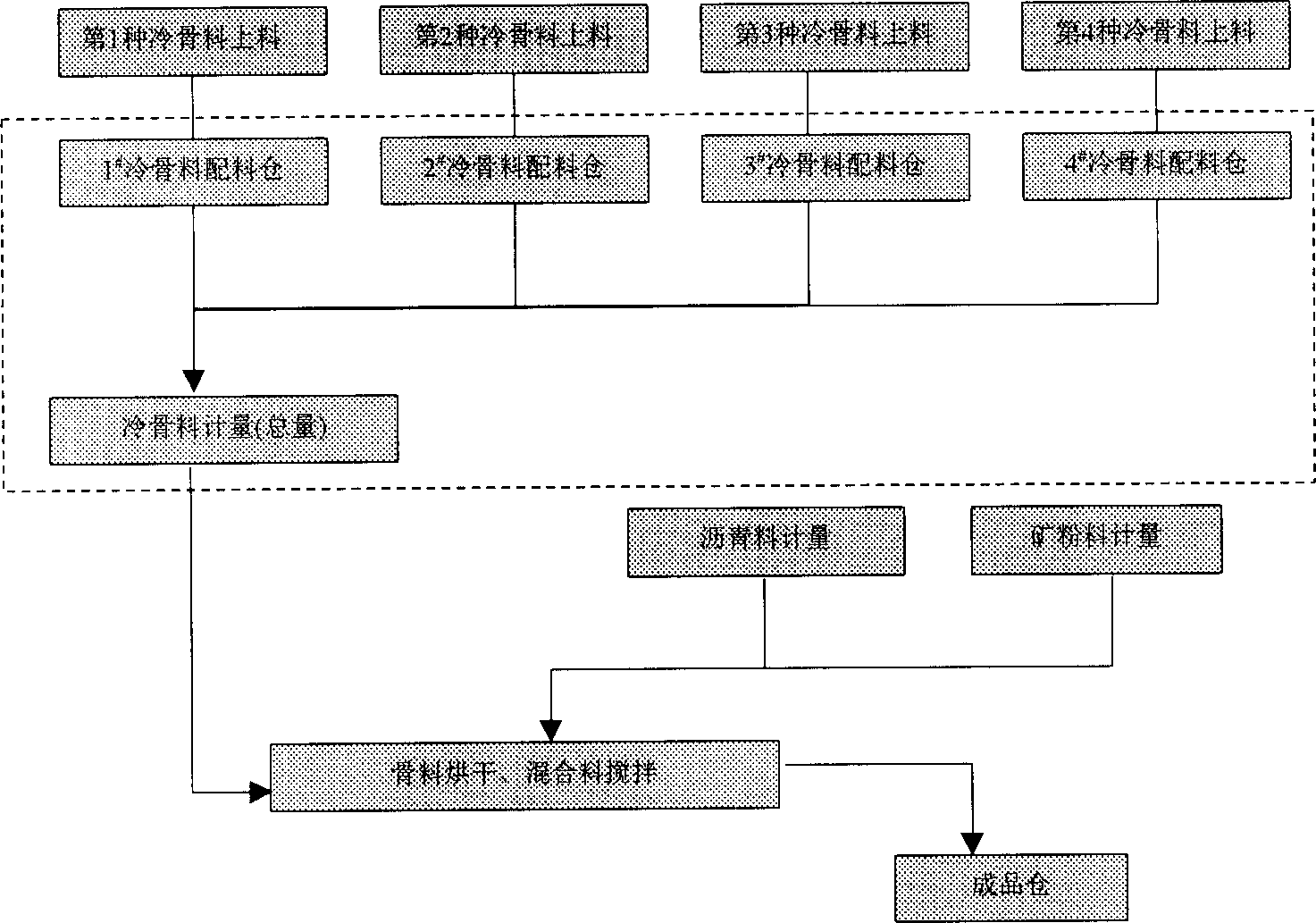

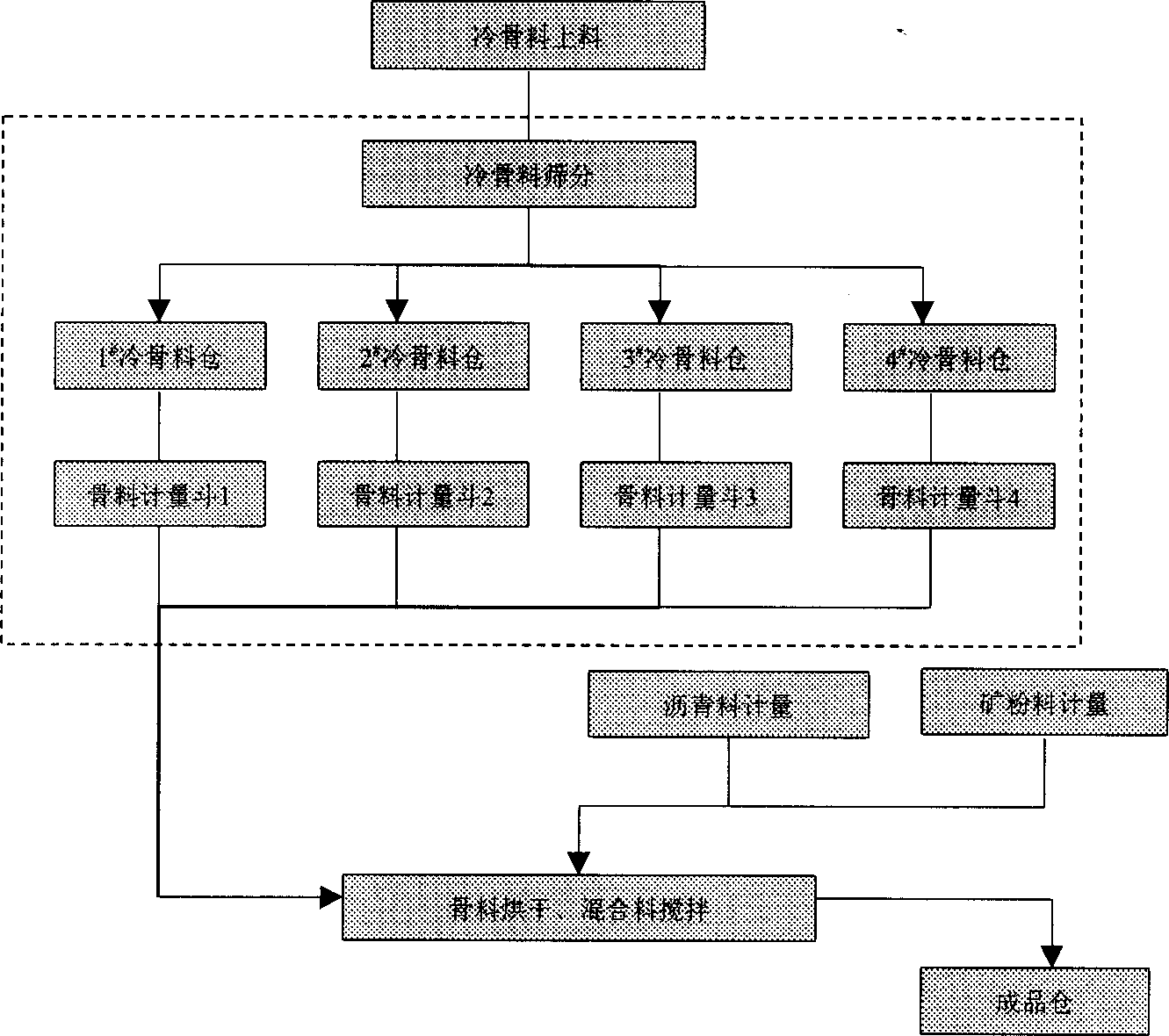

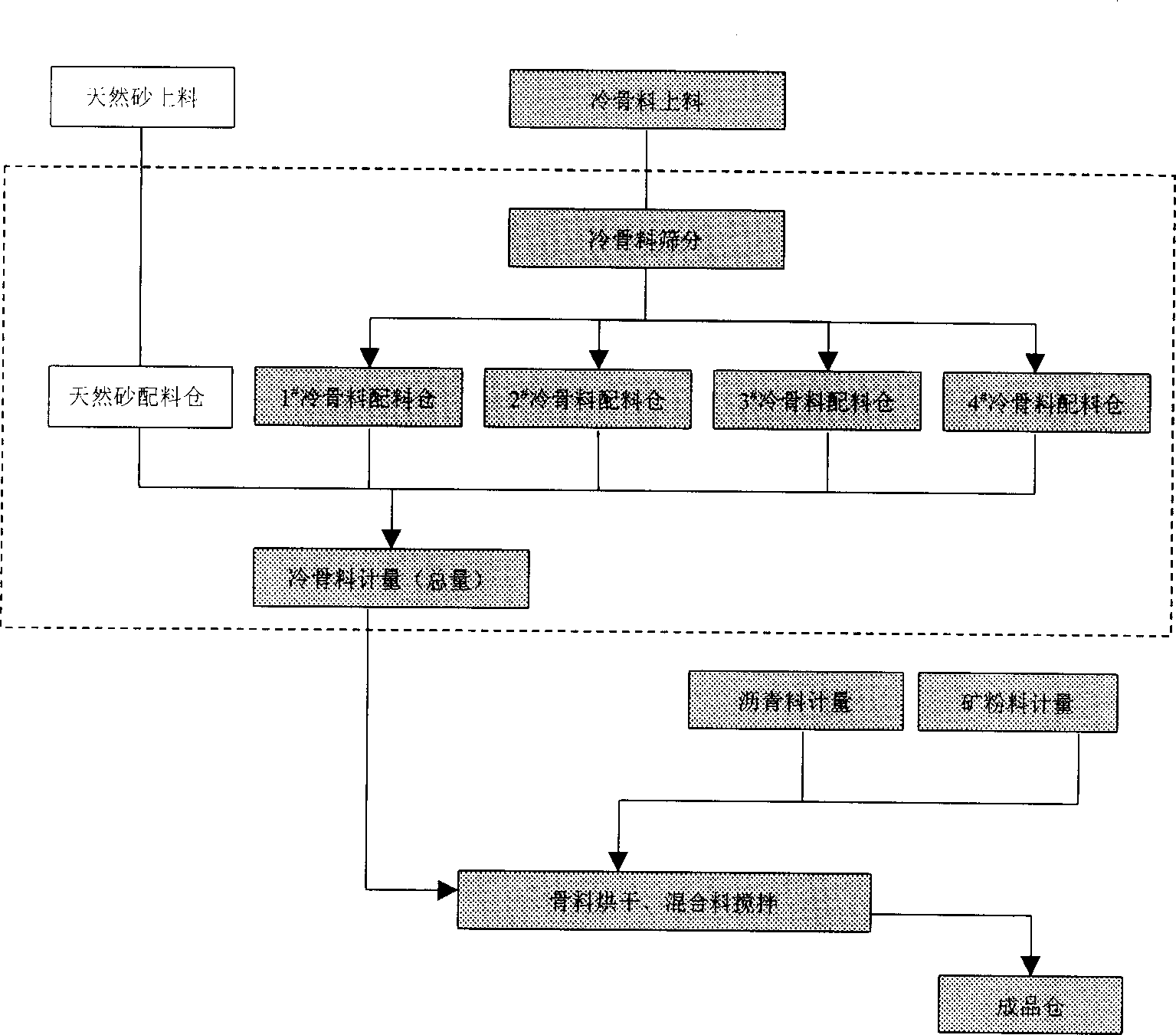

Cold aggregate batching treatment method and device for continuous bituminous concrete mixing equipment

InactiveCN1371791AQuality improvementReasonable gradationSievingScreeningSurface constructionRoad surface

The present invention relates to a cold aggregate batching treatment method for continuous-stirring equipment of bituminous concrete for highroad surface construction and asphalt parement regeneration engineering, and is characterized by that before the cold aggregate is continuously metered, firstly, said cold aggregate is passed through sieving machine to implement pregradation, then continuously metered by means of metering device then fed into continuous bituminous concrete stirring equipment and its next stoving procedure.

Owner:袁国琴

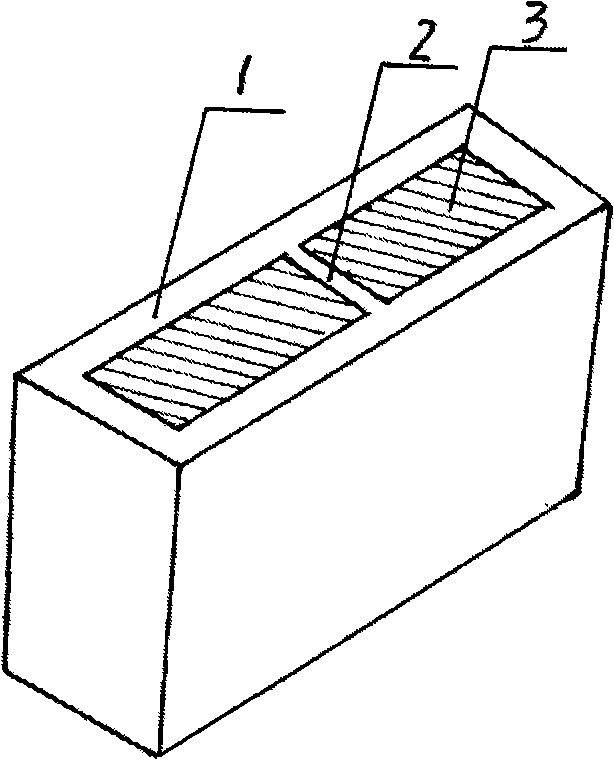

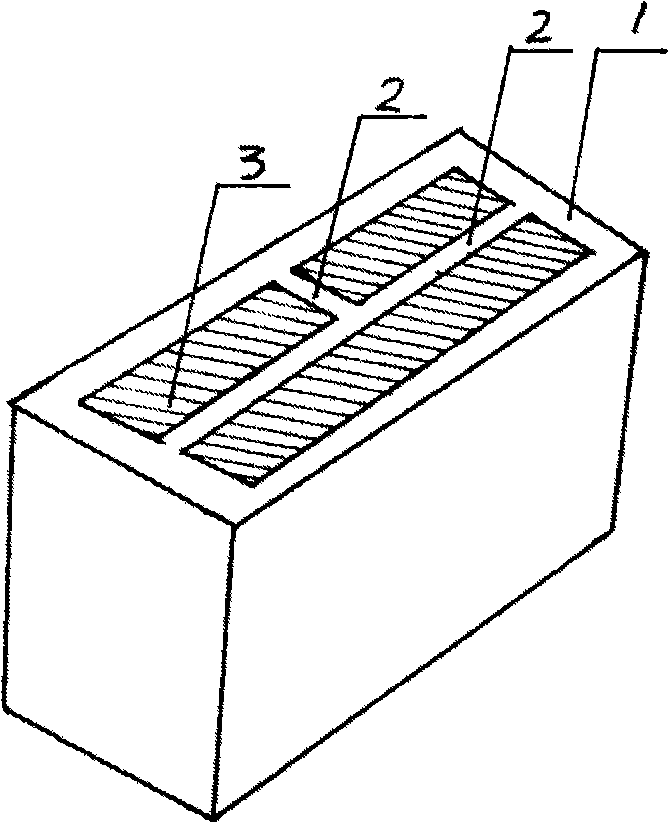

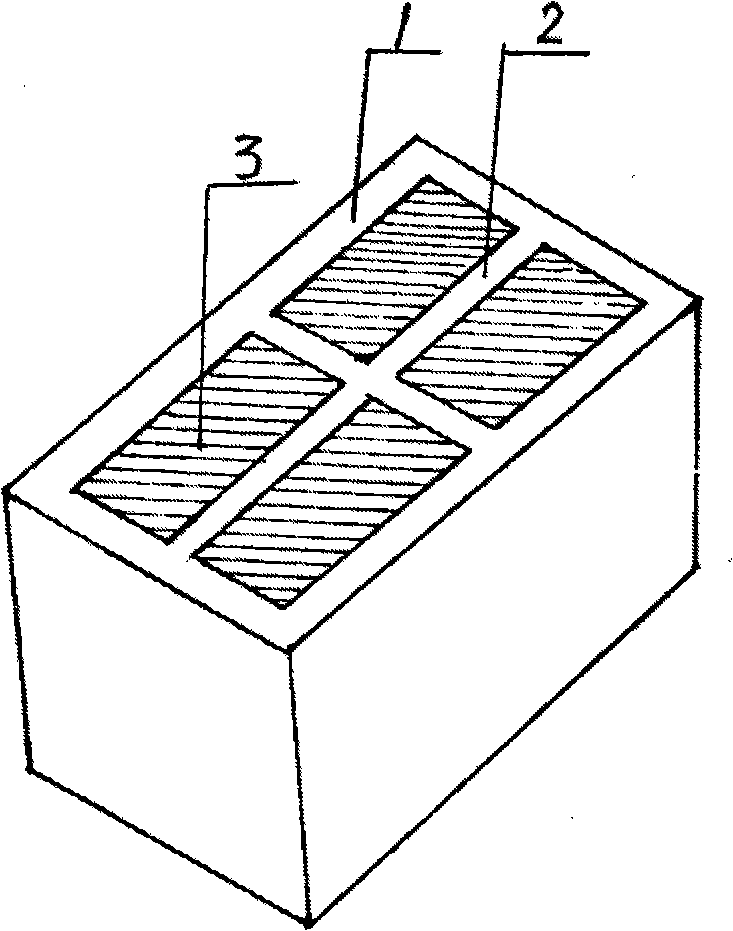

Steam pressurized concrete composite heat insulation building blocks and its production process

InactiveCN101265737AImprove thermal insulation performanceLight weightConstruction materialSolid waste managementSlurryAutoclaved aerated concrete

The invention discloses an autoclaved aerated concrete composite heat preservation building block and a production method thereof. The building block external wall and the building block are made of the autoclaved aerated concrete, the hole formed by the building block external wall and the building block rib is filled with heat preservation and insulation fillers for a second time. The building block adopts the autoclaved aerated concrete as the raw material and the preset mould core structure. The mould core is extracted after the slurry is poured so as to form a hollow structure in the building block body in the molding process, the void ratio of the hollow structure reaches 30%-70%. The light heat preservation and insulation material is filled for the second time after autoclaved curing the hollow structure block body, which reduces the production volume weight, improves the heat preservation and insulation performance of the material and facilitates the construction. Based on the application requirement, the absolute dry volume weight is adjustable in a range of 300-600kg / m<3>, the heat transfer coefficient amounts to less than 0.5W / m<2>.K, the method has a remarkable effect of energy saving, the single wall body material reaches 65% of the national building energy saving requirement, the energy-saving effect is obvious. The building block is widely applicable to industrial and civil building wall bodies.

Owner:ZHANGYE QINGTIAN BUILDING MATERIALS

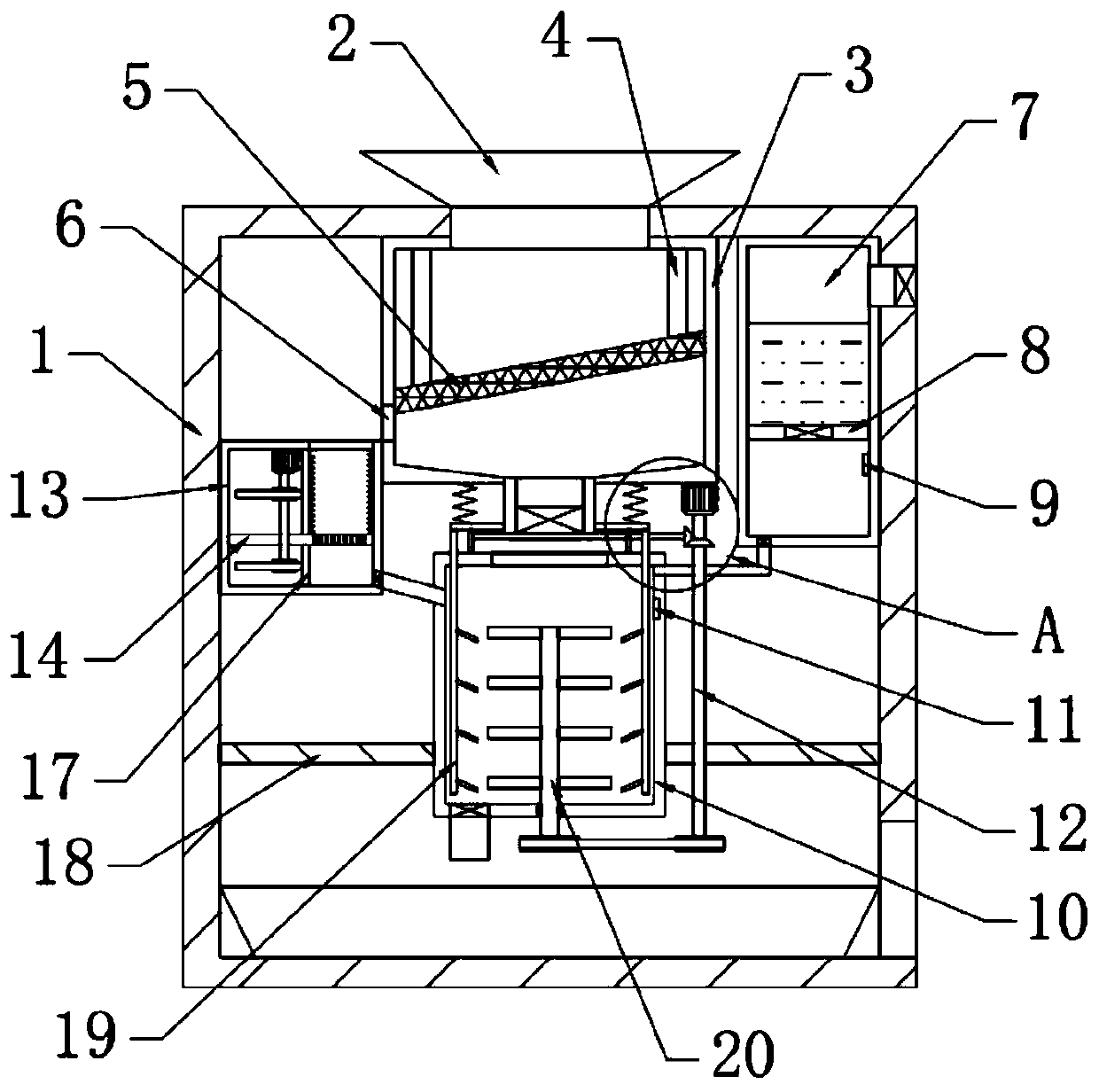

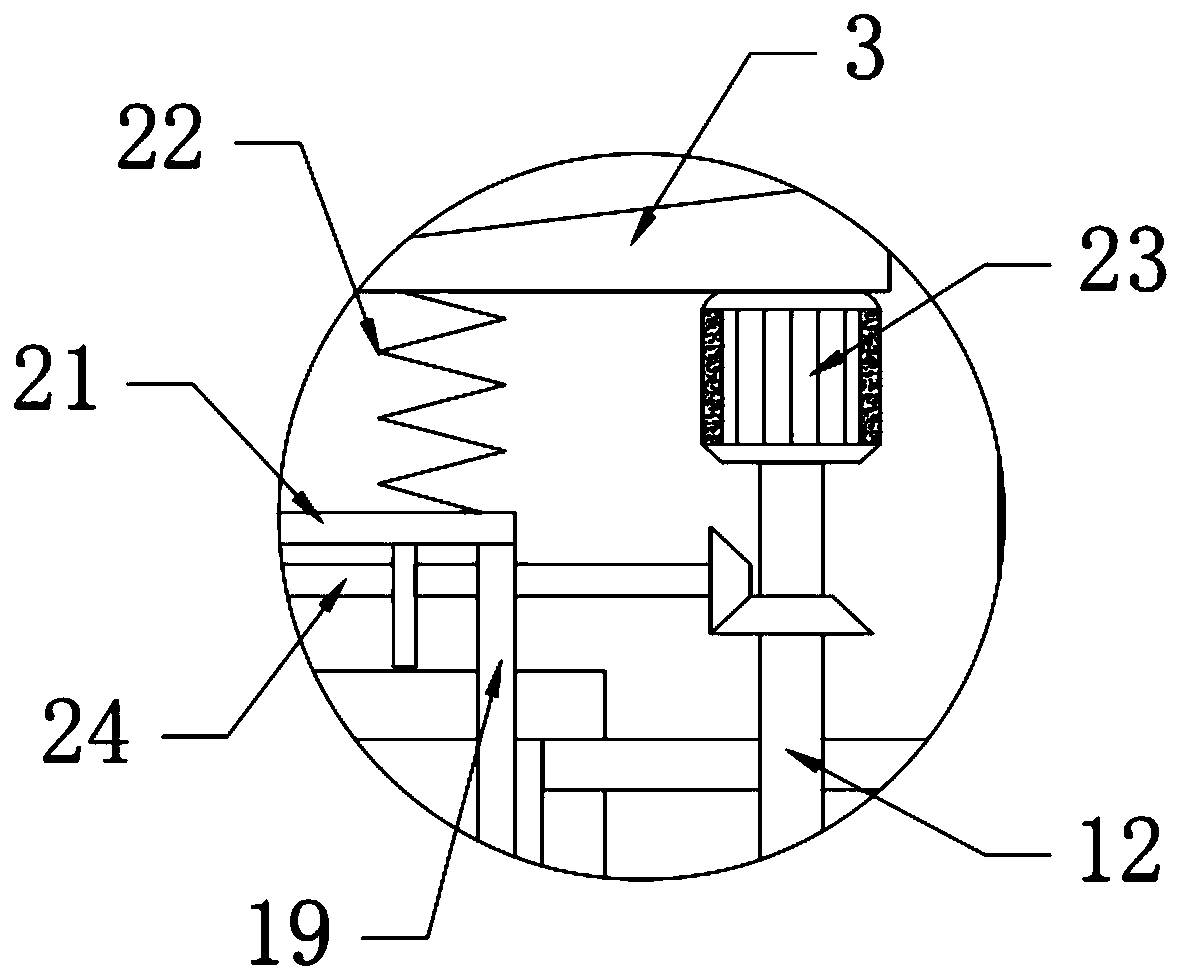

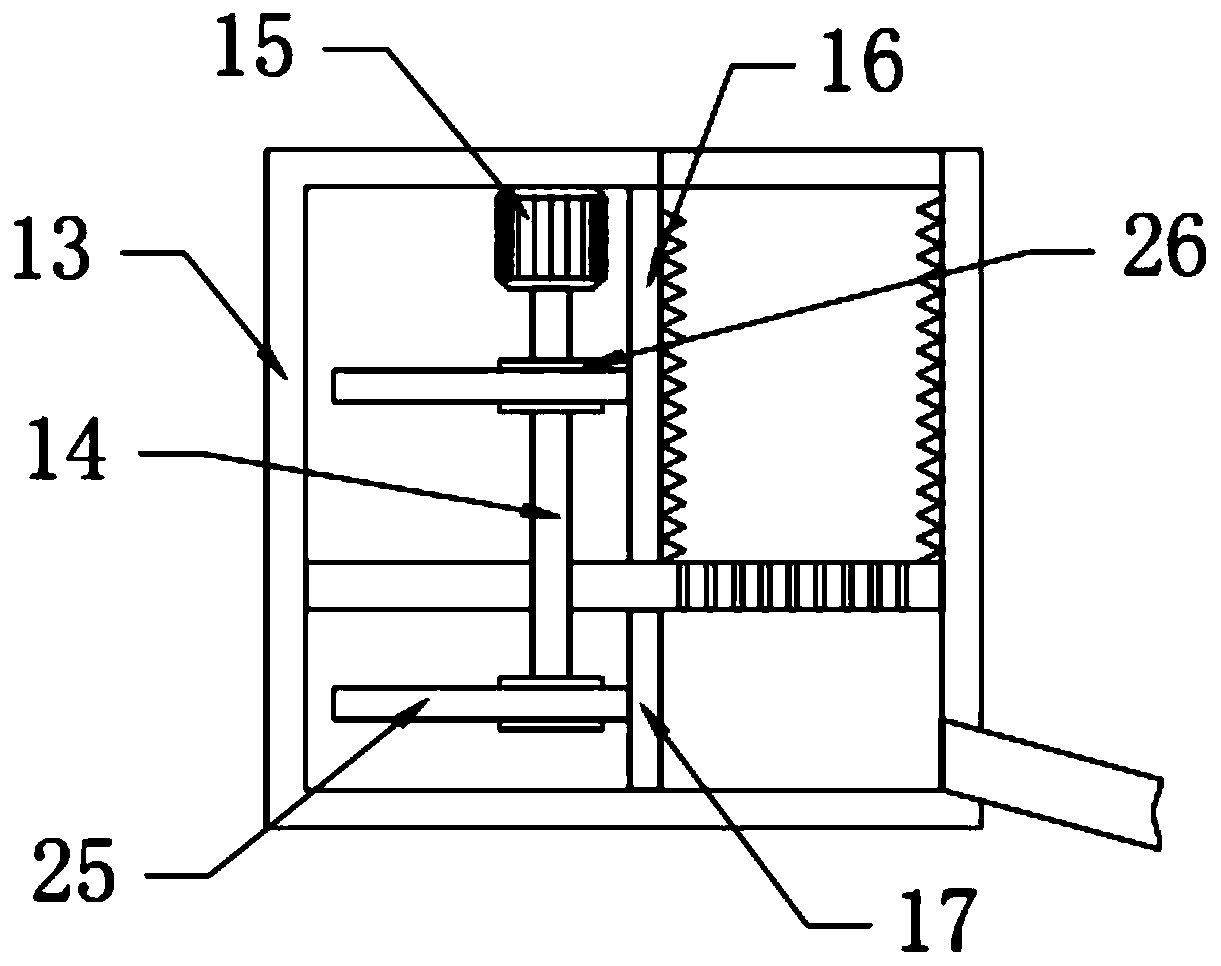

Concrete processing equipment

The invention relates to the technical field of construction, in particular to concrete processing equipment. The concrete processing equipment comprises a housing; the top of the housing is providedwith a feed hopper; the lower side of the feed hopper is provided with a screening box; the left side of the screening box is provided with a gravel processing mechanism; the lower side of the screening box is provided with a fixed plate which is fixedly connected with the housing; the fixed plate is fixedly connected with a stirring bucket; a water tank is arranged at the right side of the screening box; and a storage box is arranged at the lower side of the stirring bucket. According to the concrete processing equipment, the screening box is used for screening impurities such as gravel existing in a raw material so that the raw material falling into the stirring bucket is finer sand, the quality of the prepared concrete is beneficially improved; by arranging the gravel processing mechanism, the screened stone pieces can be crushed so that the stone pieces can be reutilized; by arranging a partition plate, a liquid level sensor and an infrared sensor, the amount of water and raw material added into the stirring bucket can be accurately controlled; and thus the ratio of the raw material to water is effectively controlled.

Owner:郭倩

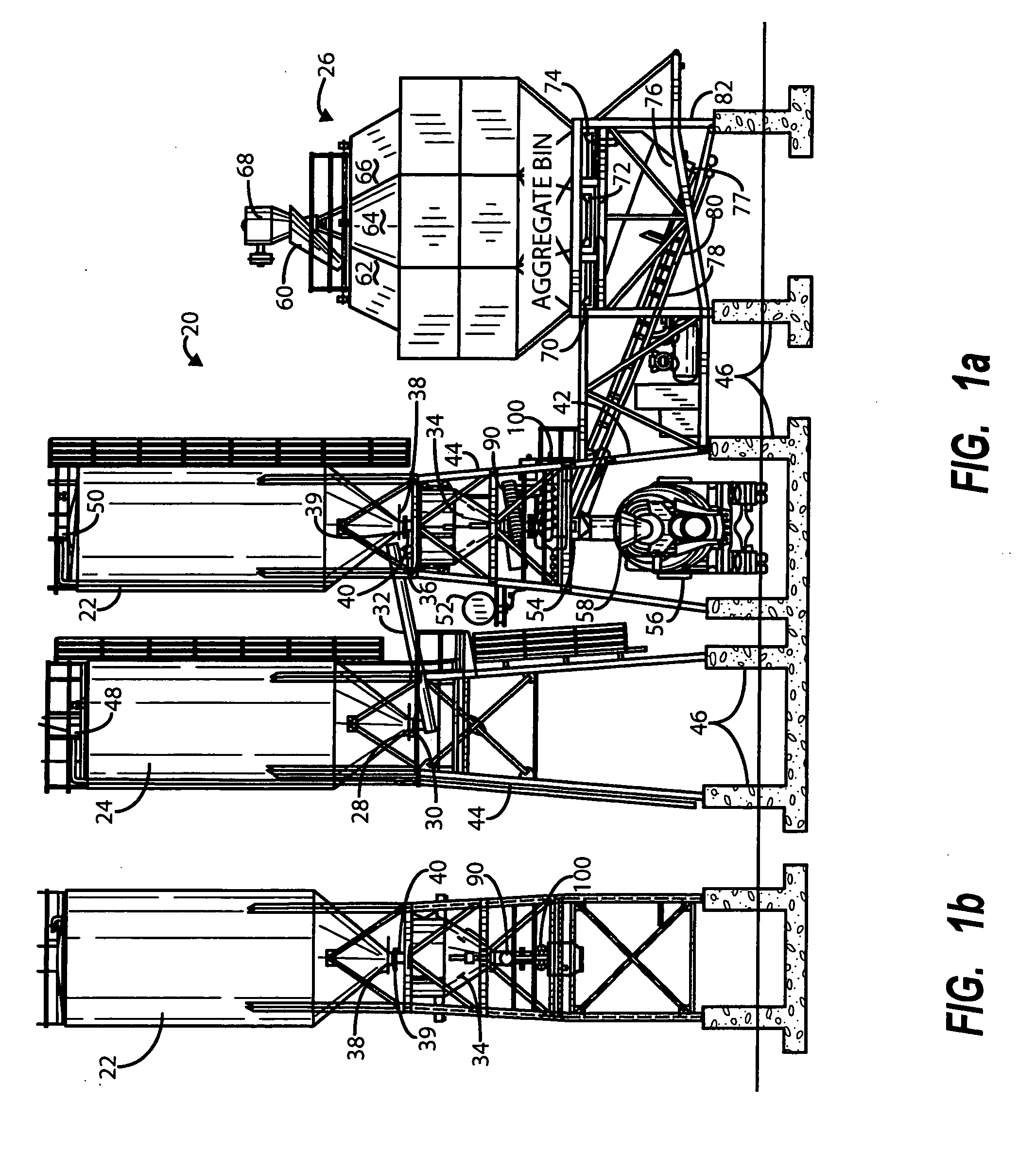

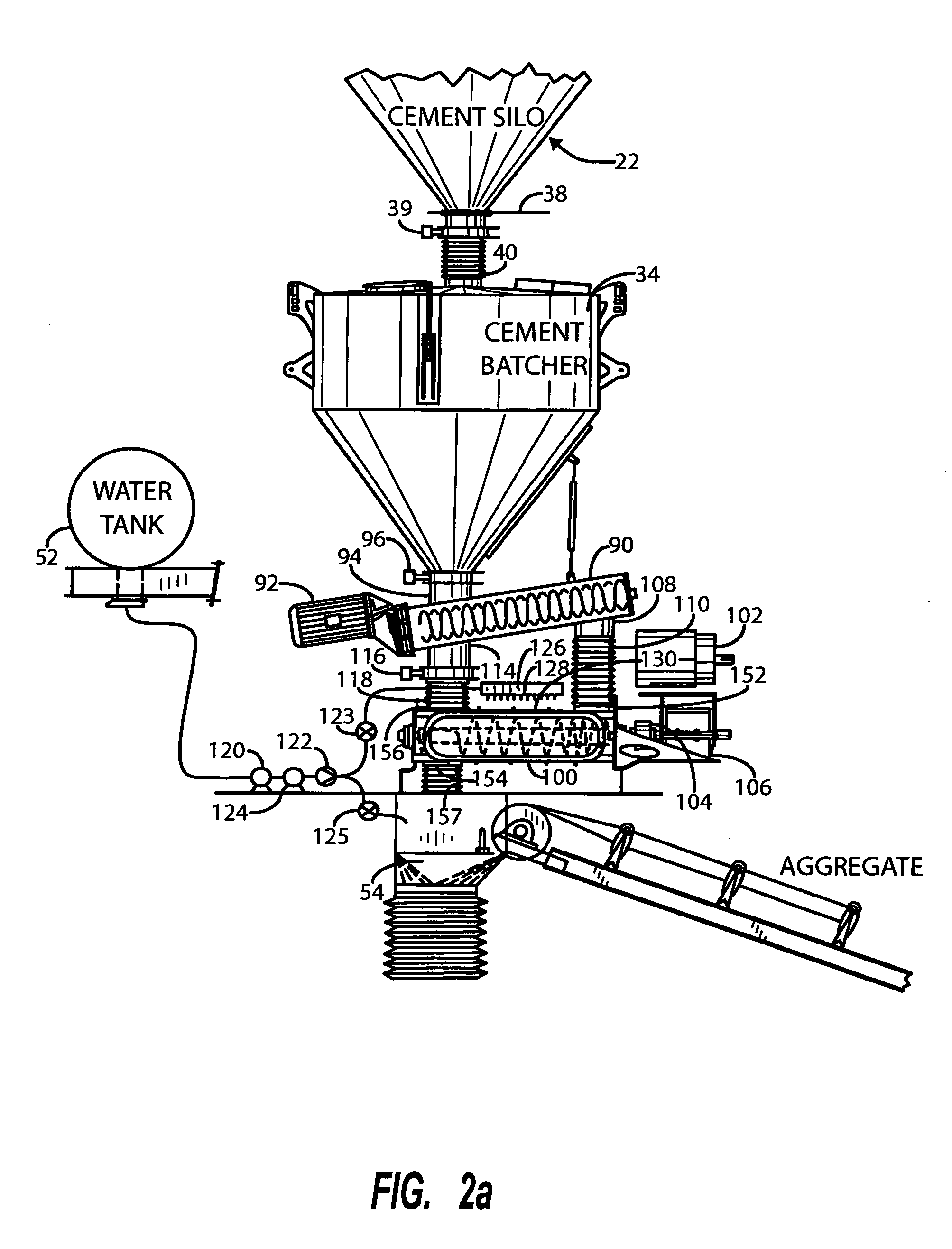

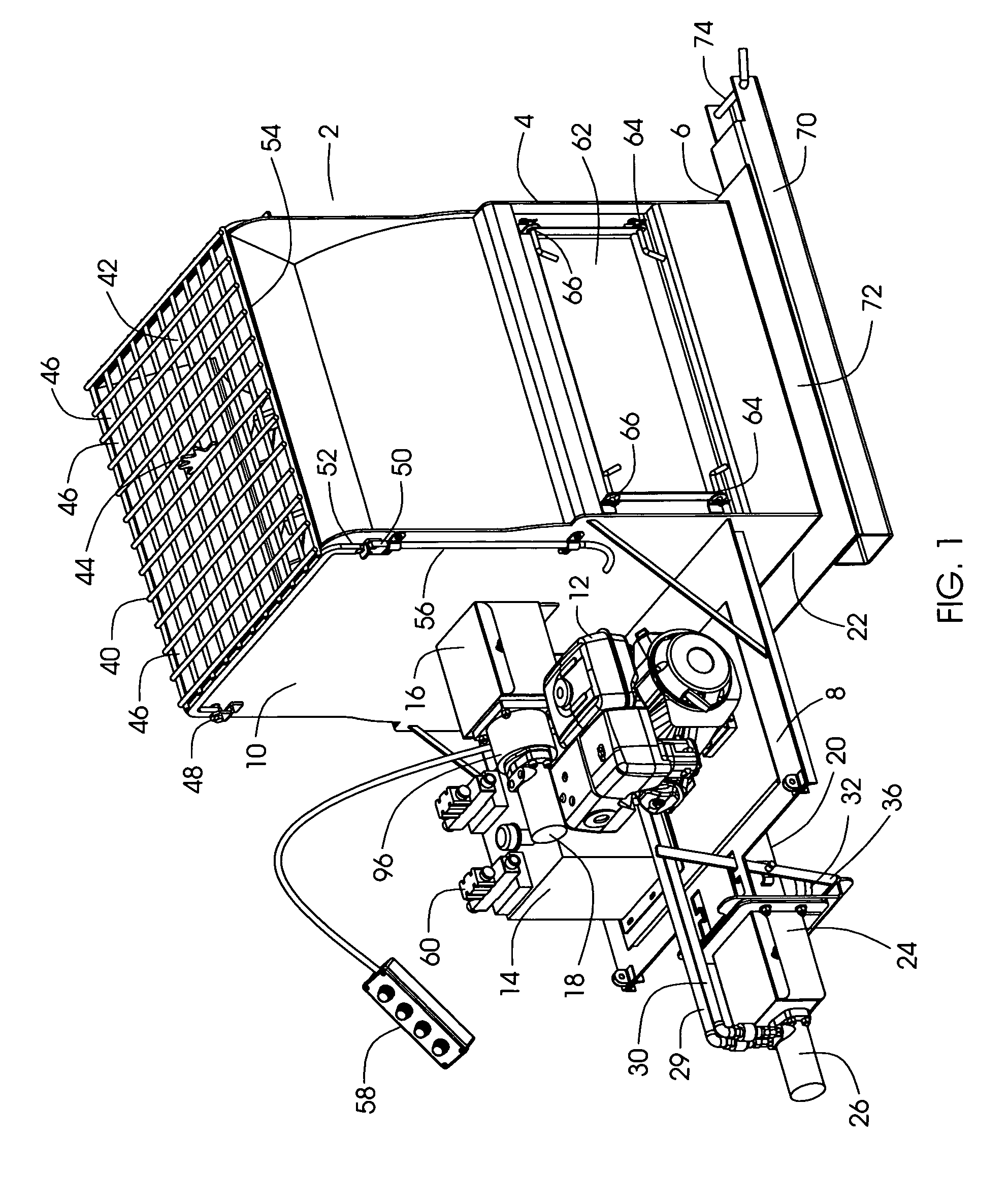

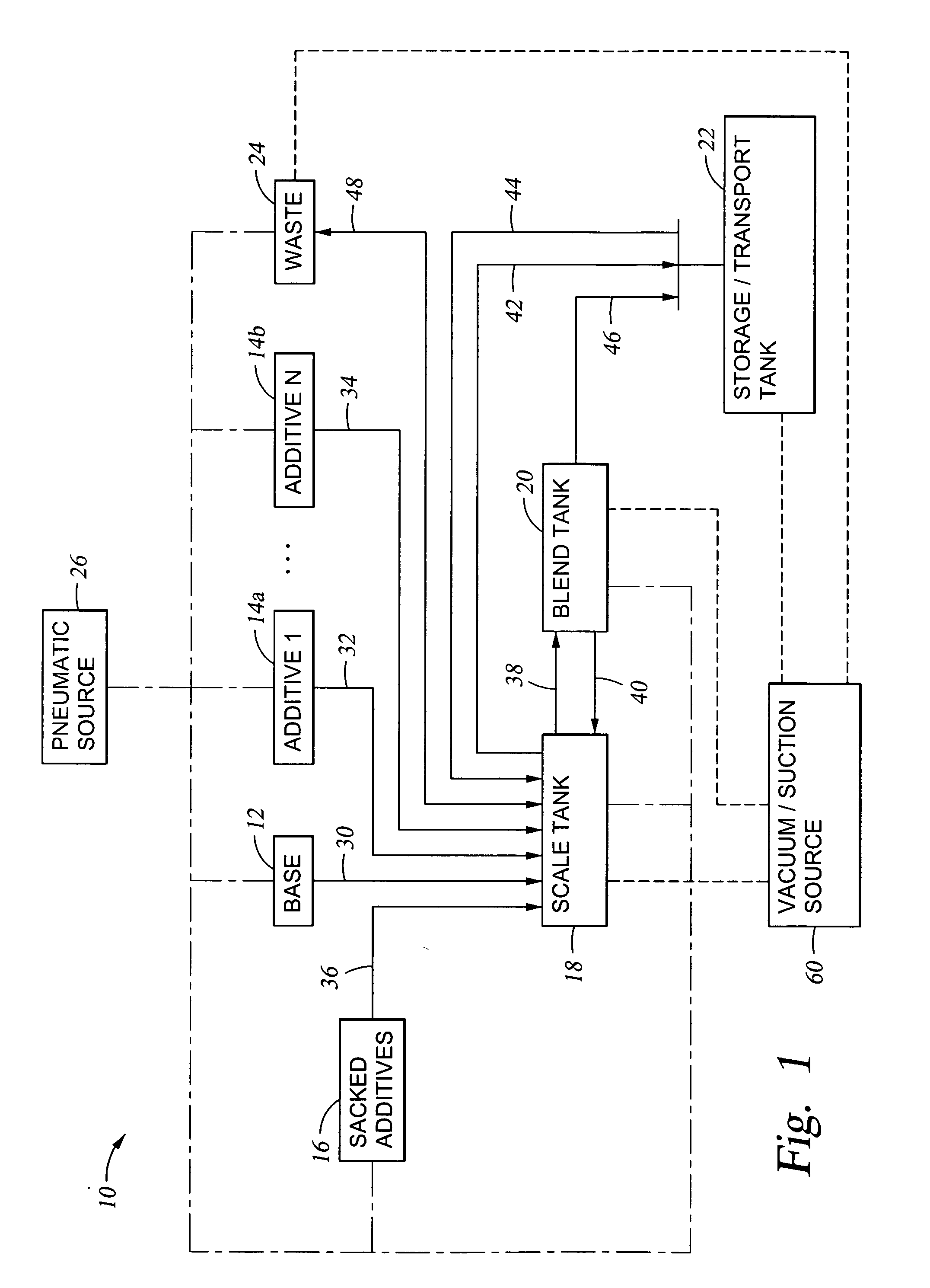

Volumetric concrete mixing method and apparatus

ActiveUS20090180348A1Mixing operation control apparatusIngredients proportioning apparatusAdditive ingredientControl theory

An improved volumetric concrete mixing system and method of the present invention utilizes load cells for measuring weight loss from the aggregate and cement bins. Load cells may also be used for measuring weight loss from the water tank. The load cells provide input data corresponding to the weight loss of each container to a controller which automatically adjusts the delivery of ingredients to a mixing boot so as to achieve a desired concrete mix ratio.

Owner:CEMEN TECH

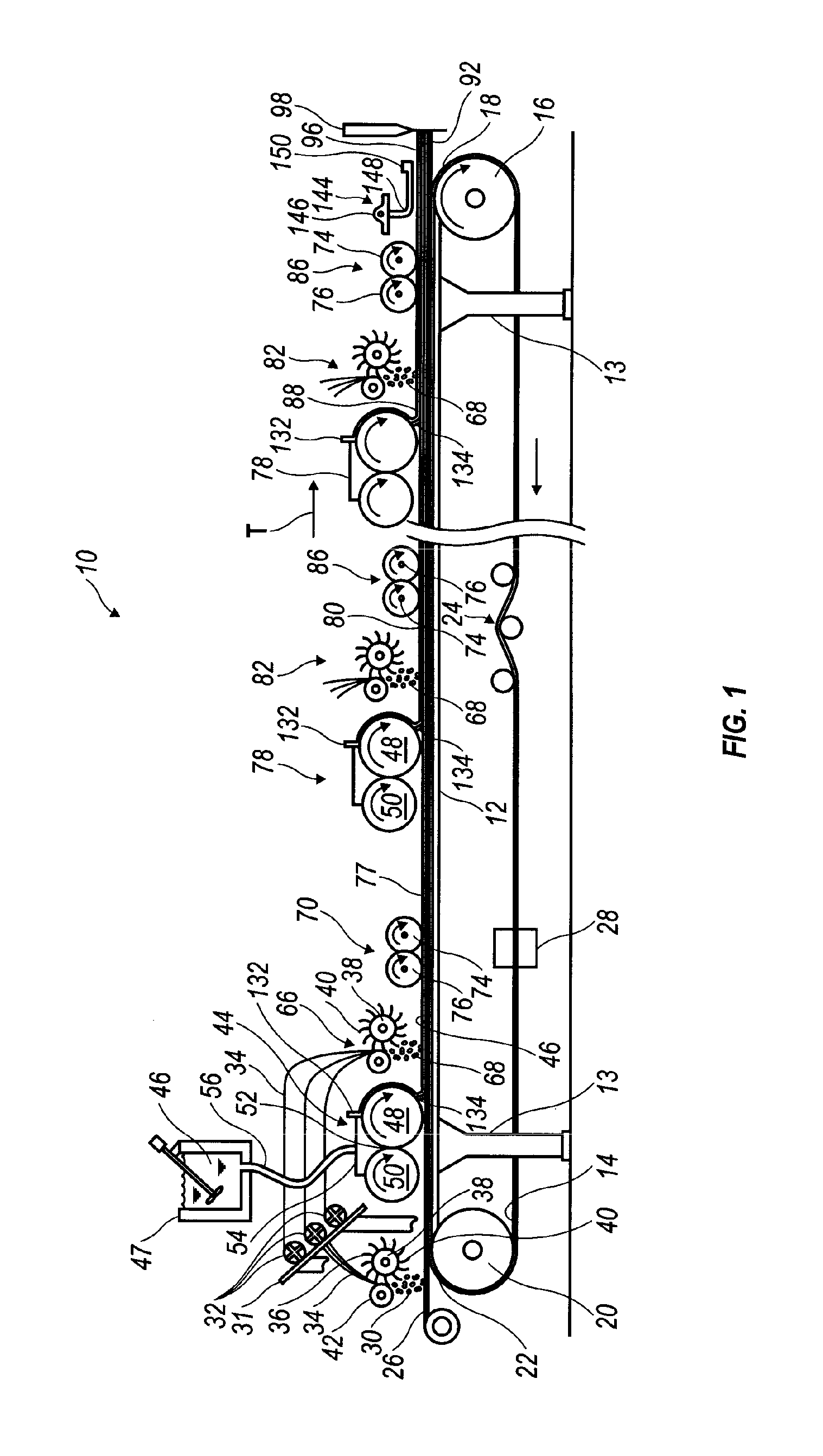

Process and equipment for producing concrete products having blended colors

InactiveUS6910796B2Easy to changeResulting appearance of the visible surfaces of the concrete products can be readily alteredFrozen sweetsConfectioneryBrickRetaining wall

A process and equipment for producing multi-color concrete products, including architectural concrete blocks, concrete bricks, modular concrete products that are suitable for use in landscaping applications, such as retaining wall blocks, concrete pavers, and concrete slabs. The invention includes a spray mechanism that sprays liquid pigment onto concrete discharged from a hopper. The concrete then proceeds to a blending mechanism which blends the pigment into the concrete to produce a multi-color concrete blend. The concrete blend is then used to produce multi-colored concrete products.

Owner:ANCHOR WALL SYST

Cement even stirring device for buildings

ActiveCN105818270AStir wellEfficient mixingMixing operation control apparatusCement mixing apparatusElectric machineArchitectural engineering

The invention relates to a cement stirring device, in particular to a cement even stirring device for buildings. The cement even stirring device for buildings aims at achieving the technical purposes of being even in stirring, high in stirring speed and easy to operate. For achieving the technical purposes, the cement even stirring device for buildings comprises a base, a left frame, a top plate, a fixed frame, a sliding rail I, a sliding block I, a cam, a movable frame, a gear motor, a supporting rod, a cement box, a blocking ball, a funnel, a stirring box, a bearing seat, a sliding rail II, an electric wheel, a pull wire, a sliding block II, a spring I, a rotating motor, a rotating rod, blades and a sand box. The sliding rail II is arranged at the top of the base, the sliding block II is arranged on the sliding rail II, and the electric wheel is arranged on the front right side of the sliding rail II. The cement even stirring device for buildings has the advantages of being even in stirring, high in stirring speed and easy to operate; by means of the device, cement can be efficiently stirred, and working efficiency can be improved.

Owner:CHINA CONSTR FIRST GRP THE SECOND CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com