Steam pressurized concrete composite heat insulation building blocks and its production process

A technology of autoclave gas filling and composite heat preservation, which is applied in the field of building wall materials, can solve the problems of affecting the overall performance of the wall, long production and maintenance cycle, and large drying shrinkage ratio, achieving remarkable energy saving effects, reducing product bulk density, and improving The effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

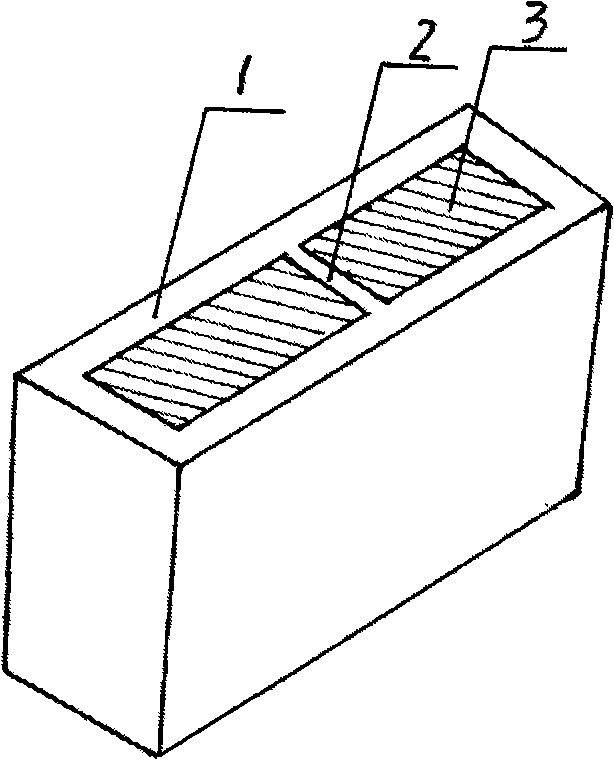

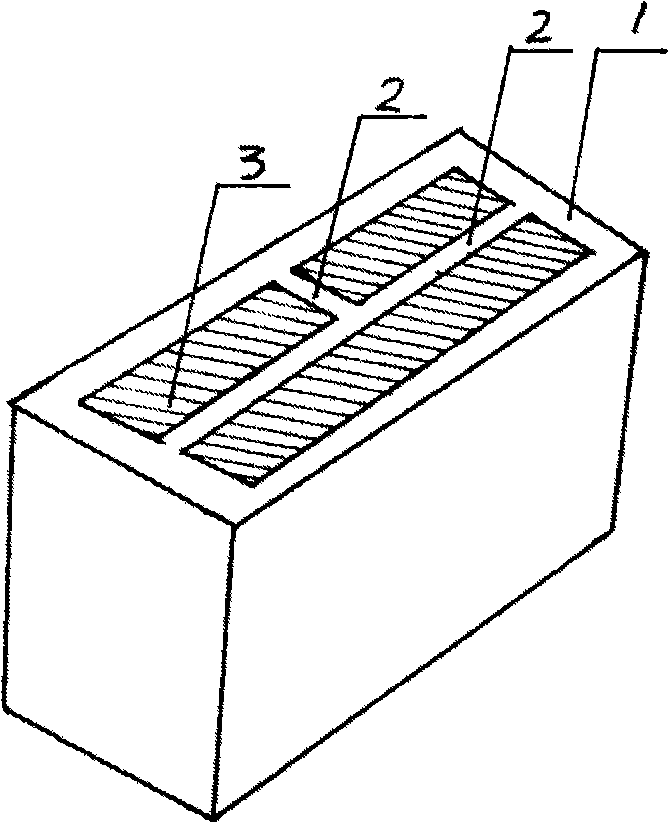

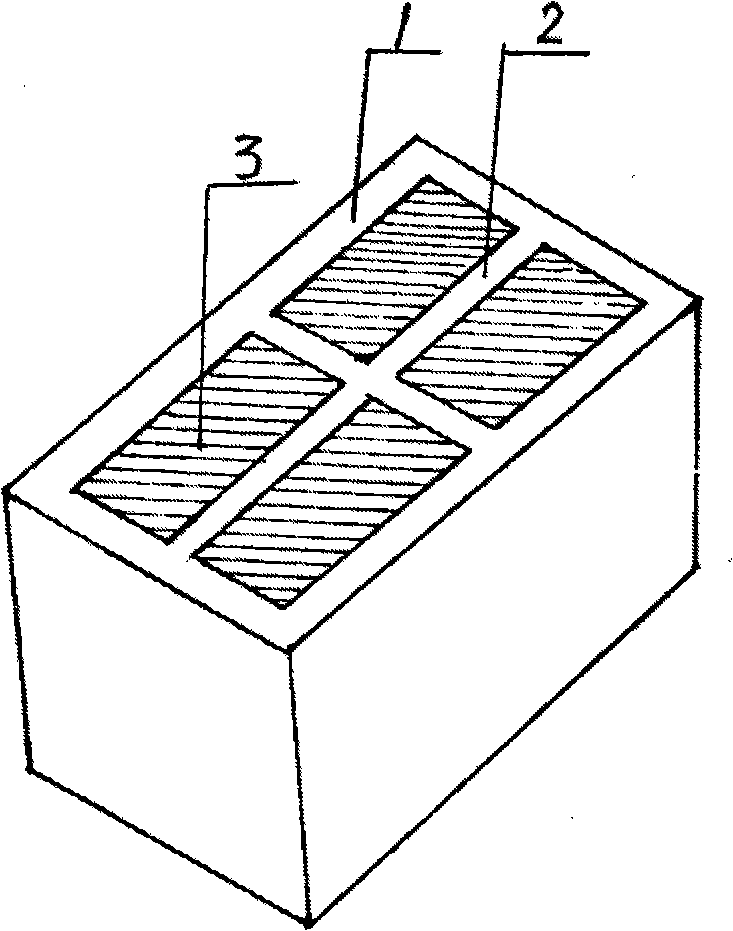

[0030] Such as Figure 1 to Figure 3 As shown, the autoclaved aerated concrete composite thermal insulation block provided by the present invention is composed of a block outer wall 1, a block rib 2 and a thermal insulation filler 3, and the block outer wall 1 and block 2 are heated by autoclaving Made of air-concrete material, the hole formed by the block outer wall 1 and the block rib 2 is filled with thermal insulation filler 3 for the second time, and the thermal insulation filler 3 can be selected from lightweight thermal insulation materials such as polyphenylene particles (boards). The block shape of this product is rectangular hexahedron (cuboid), which can be made into blocks with 2 to 4 holes, and the main specifications are 600mm×300mm×200mm, 600mm×300mm×250mm.

[0031] The production method of the autoclaved aerated concrete composite thermal insulation block comprises the following steps:

[0032] ① In terms of weight percentage, prepare materials according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com