Foam concrete with large-dosage polystyrene particles and preparation method thereof

A technology of polystyrene particles and foam concrete, which is applied in the field of construction, can solve the problems of reduced thermal insulation performance, low compressive strength, poor durability, etc., and achieve the reduction of plastic shrinkage cracks and stress cracks, low water absorption, and distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

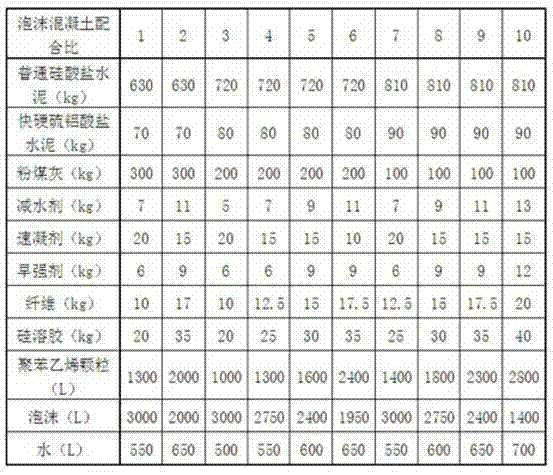

Examples

Embodiment 1

[0048] A large amount of polystyrene particle foam concrete, its components are:

[0049] Raw material parts by weight

[0050] (1) Cementitious material

[0051] Ordinary Portland cement 81 parts

[0052] Rapid hardening sulfoaluminate cement 9 parts

[0053] (2) Admixtures

[0054] Fly ash 10 parts

[0055] (3) 60 parts of water

[0056](4) Admixture

[0057] 0.8 parts of water reducer

[0058] Accelerator 1 part

[0059] Early strength agent 1 part

[0060] (5) Additives

[0061] Fiber 1.5 parts

[0062] 4 parts silica sol

[0063] (6) Light aggregate

[0064] Polystyrene pellets: volume (liter) accounts for 400% of the volume of water added.

[0065] (7) Foam: the volume (liter) accounts for 200% of the volume of the added water.

[0066] Its preparation process is:

[0067] 1. Selection of raw materials: Ordinary Portland cement is 42.5R ordinary Portland cement produced by Shenyang Jidong Cement Co., Ltd.; rapid hardening sulfoalu...

Embodiment 2

[0073] Embodiment 2 A kind of polystyrene particle foamed concrete with large dosage, its component is:

[0074]

[0075] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com