Patents

Literature

472results about How to "Low bulk density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing alcohols by hydrogenation of carbonyl compounds

InactiveUS6486366B1Less amountHigh strengthSugar derivativesOrganic compound preparationCobaltPt element

A method for preparation of alcohols by catalytic hydrogenation of carbonyl compounds with hydrogen or hydrogen-containing gases in the presence of a hydrogenation catalyst of Raney type, where the catalyst is used in the form of hollow bodies, Preferred as catalytically active components are nickel, cobalt, copper, iron, platinum, palladium or ruthenium.

Owner:DEGUSSA AG

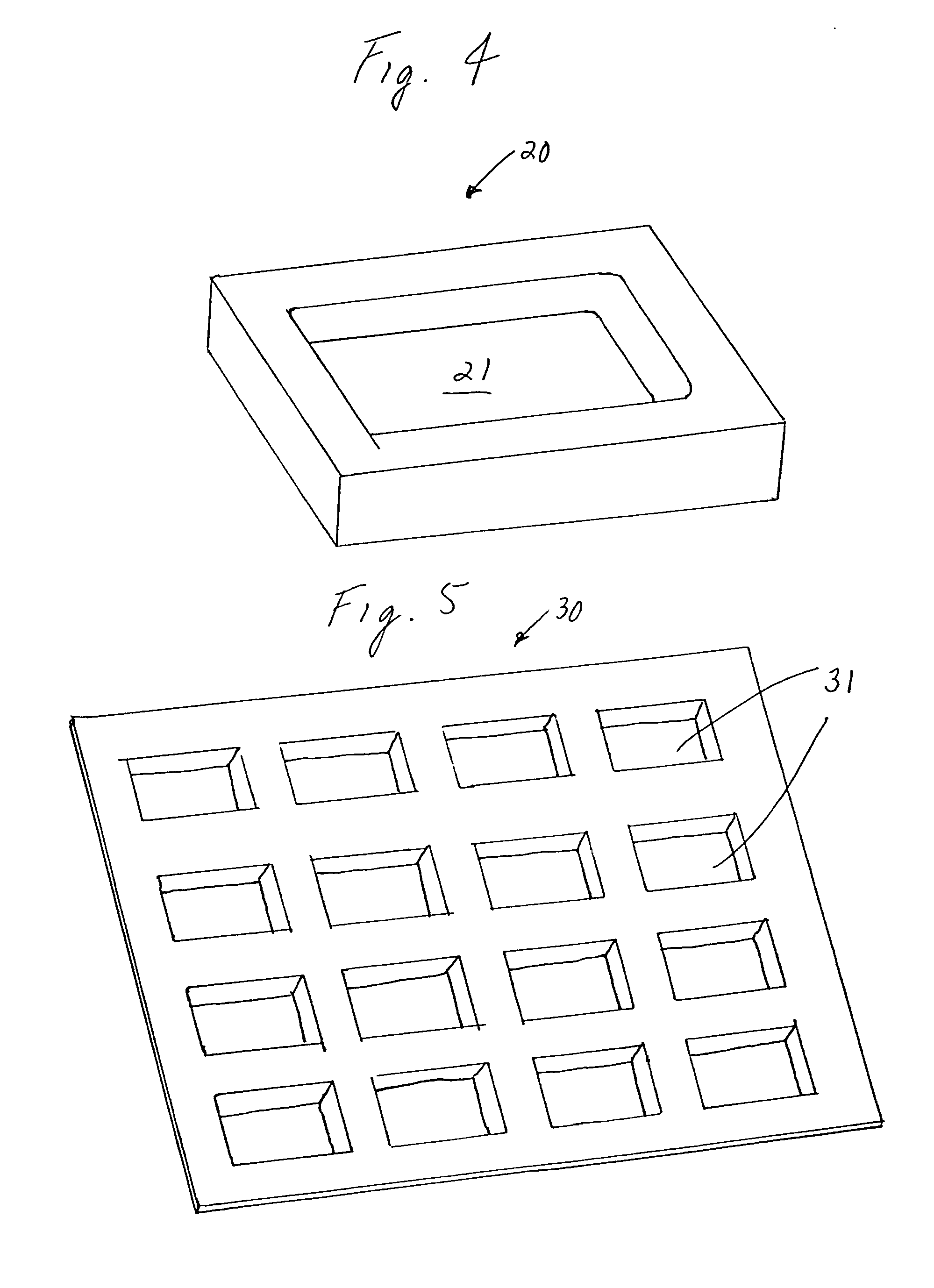

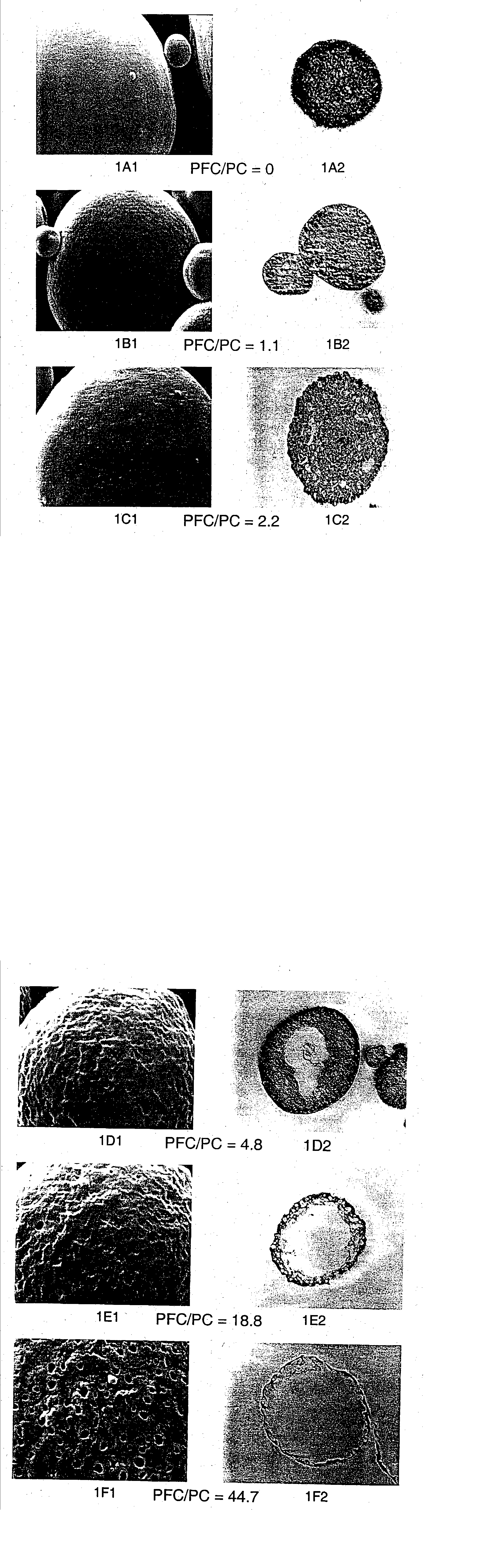

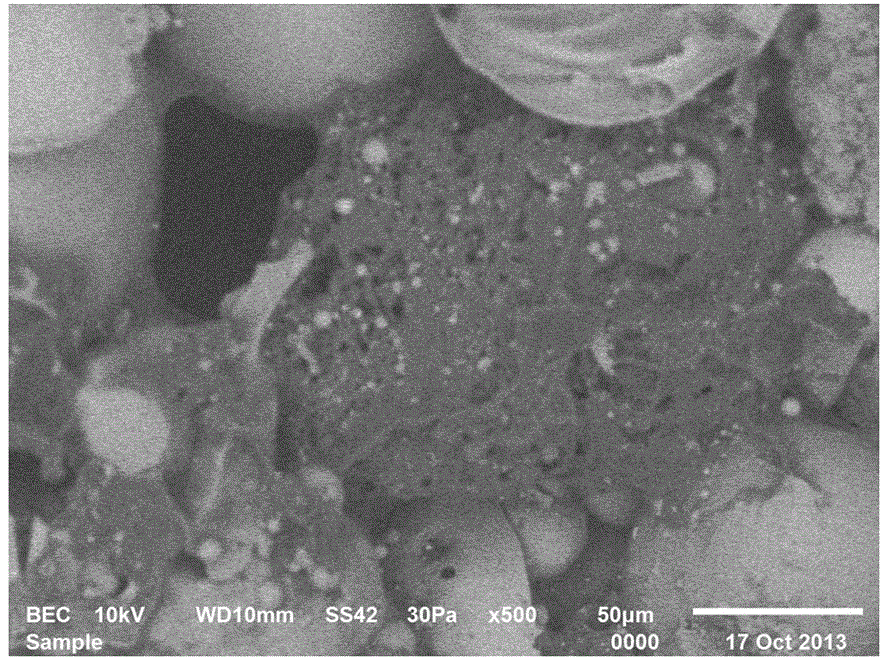

Engineered particles and methods of use

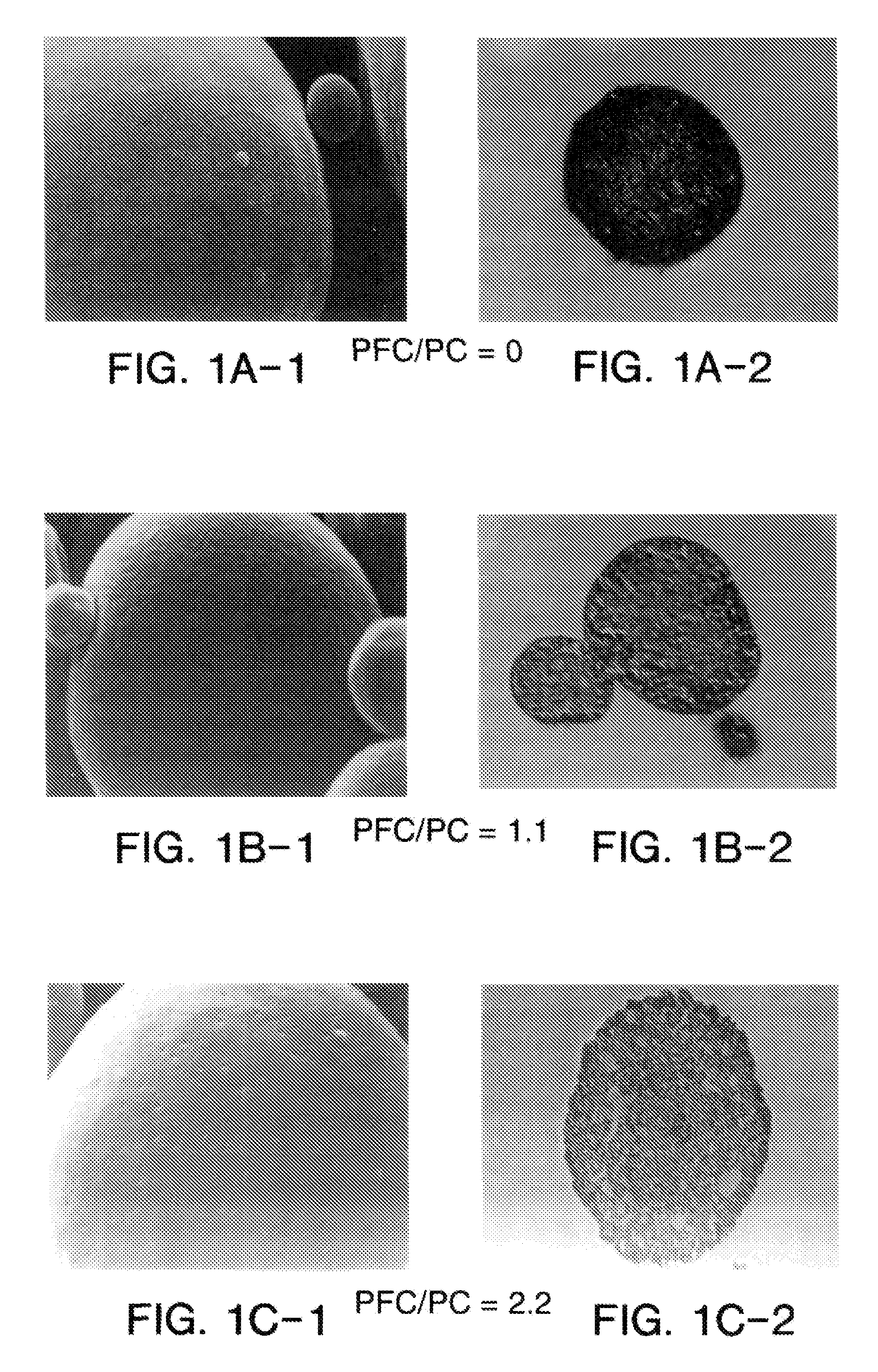

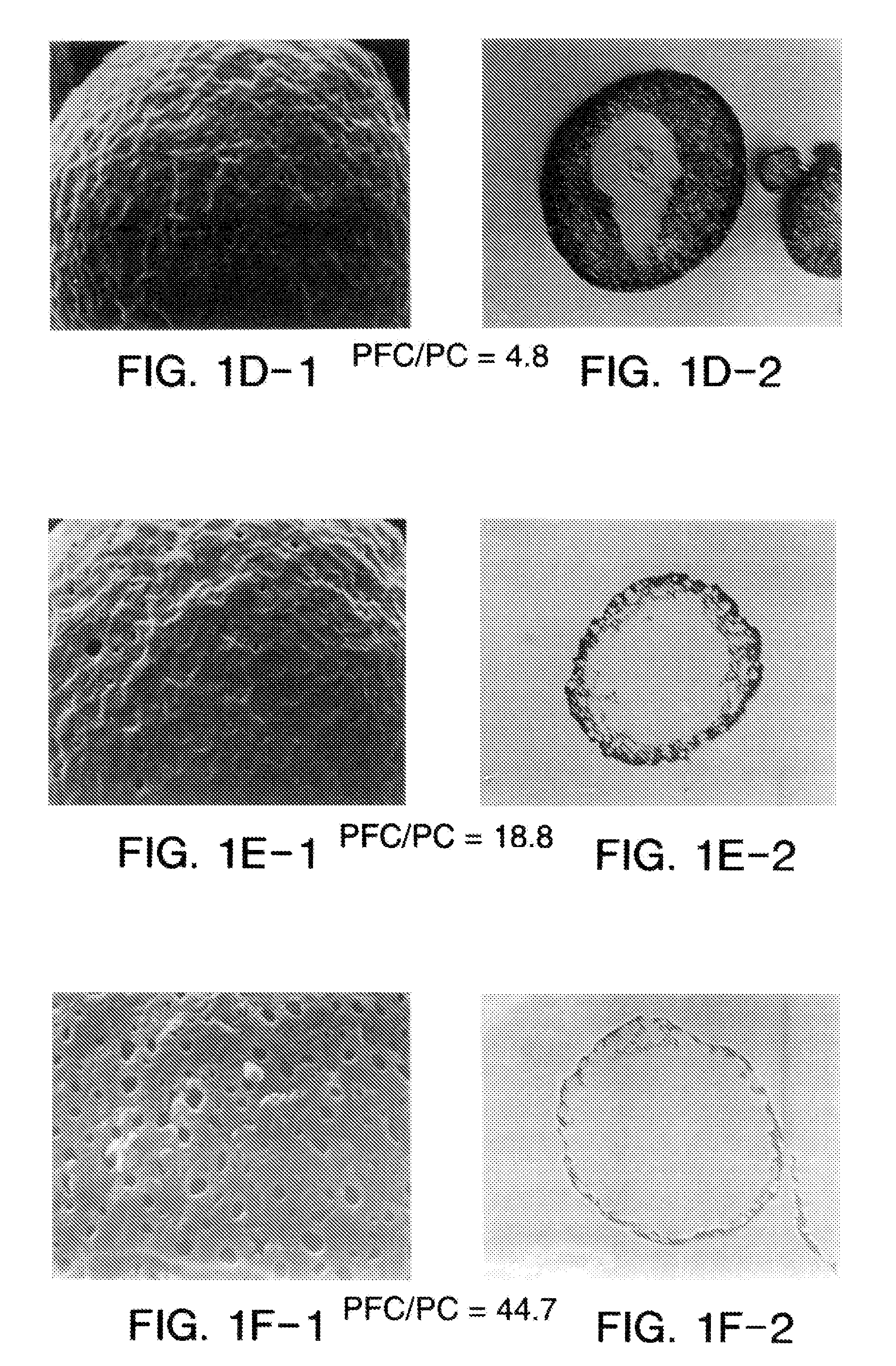

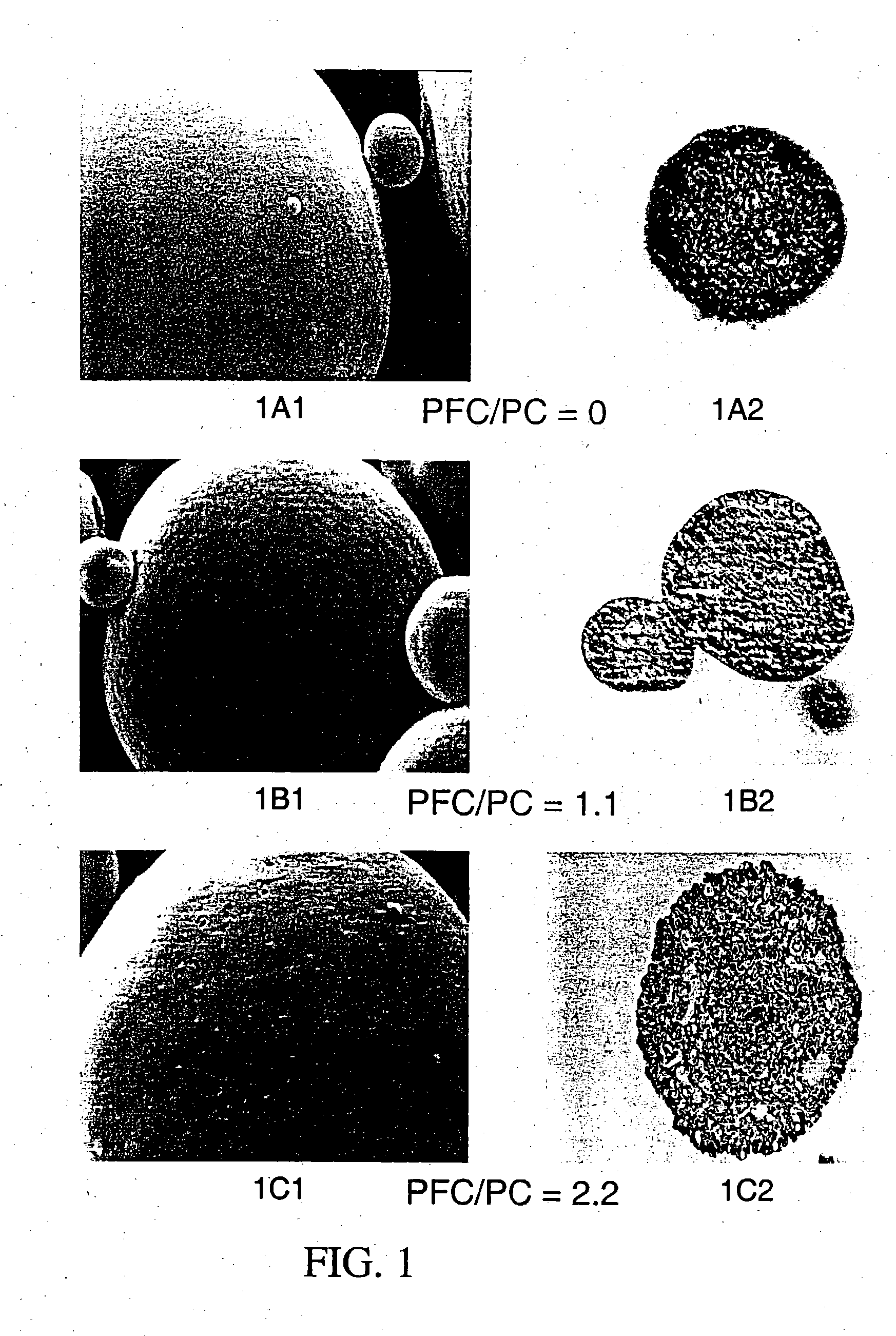

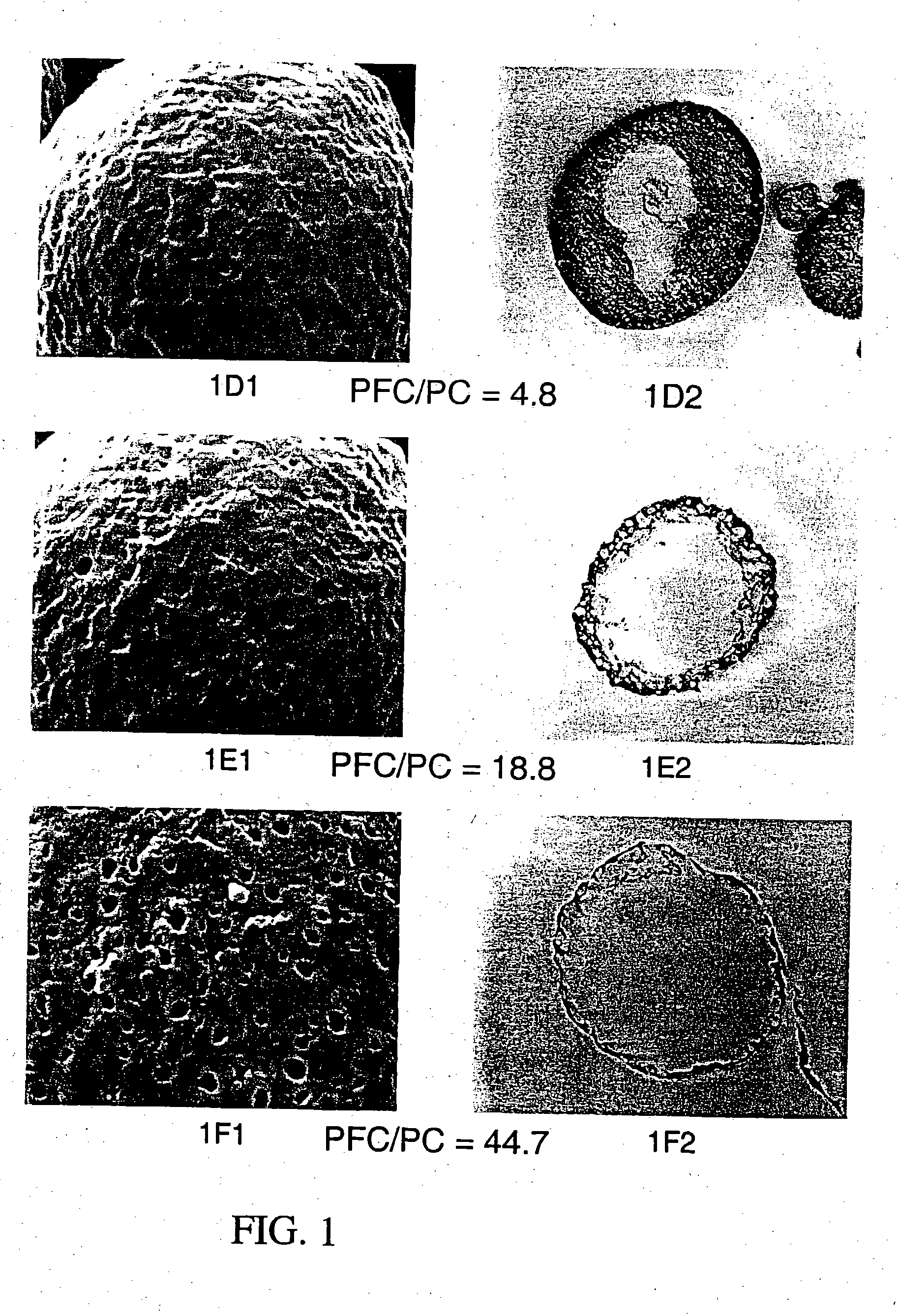

InactiveUS7306787B2Reduce deliveryLess attractivePowder deliveryOrganic active ingredientsNebulizerActive agent

Engineered particles are provided may be used for the delivery of a bioactive agent to the respiratory tract of a patient. The particles may be used in the form of dry powders or in the form of stabilized dispersions comprising a nonaqueous continuous phase. In particularly preferred embodiments the particles may be used in conjunction with an inhalation device such as a dry powder inhaler, metered dose inhaler or a nebulizer.

Owner:NOVARTIS AG

Basic magnesium carbonate, production method and use of the same

ActiveUS20050129606A1Large specific surface areaImprove featuresCalcium/strontium/barium carbonatesBiocideCarbonateMagnesium carbonate hydroxide

Owner:NITTETABU MINING CORP

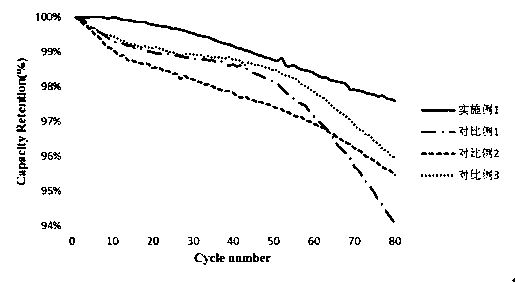

Graded high-nickel ternary anode material, and preparation method and application thereof

InactiveCN109888235AImprove compactionImprove cycle stabilityCell electrodesSecondary cellsSingle crystalMixed materials

The invention discloses a graded high-nickel ternary anode material, and a preparation method and an application thereof. The graded high-nickel ternary anode material is prepared by the following method: 1) mixing a high-nickel polycrystalline precursor with anhydrous LiOH and a doping additive, performing sintering, mixing the obtained product with a coating additive, and performing sintering toobtain a high-nickel polycrystalline material; 2) mixing a ternary monocrystalline silicon precursor with a lithium source and the doping additive, performing sintering, mixing the obtained product with the coating additive, and performing sintering to obtain a ternary monocrystalline silicon material; and 3) mixing the high-nickel polycrystalline material with the ternary monocrystalline siliconmaterial, or mixing the mixed material with the coating additive, and then performing sintering. The invention further discloses an application of the graded high-nickel ternary anode material in lithium batteries. The graded material prepared by the method provided by the invention has higher compaction and cycle stability than the single polycrystalline material, has higher capacity than the single monocrystalline silicon, and the gas production and service life problems of the battery can be effectively improved after the grading modification.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

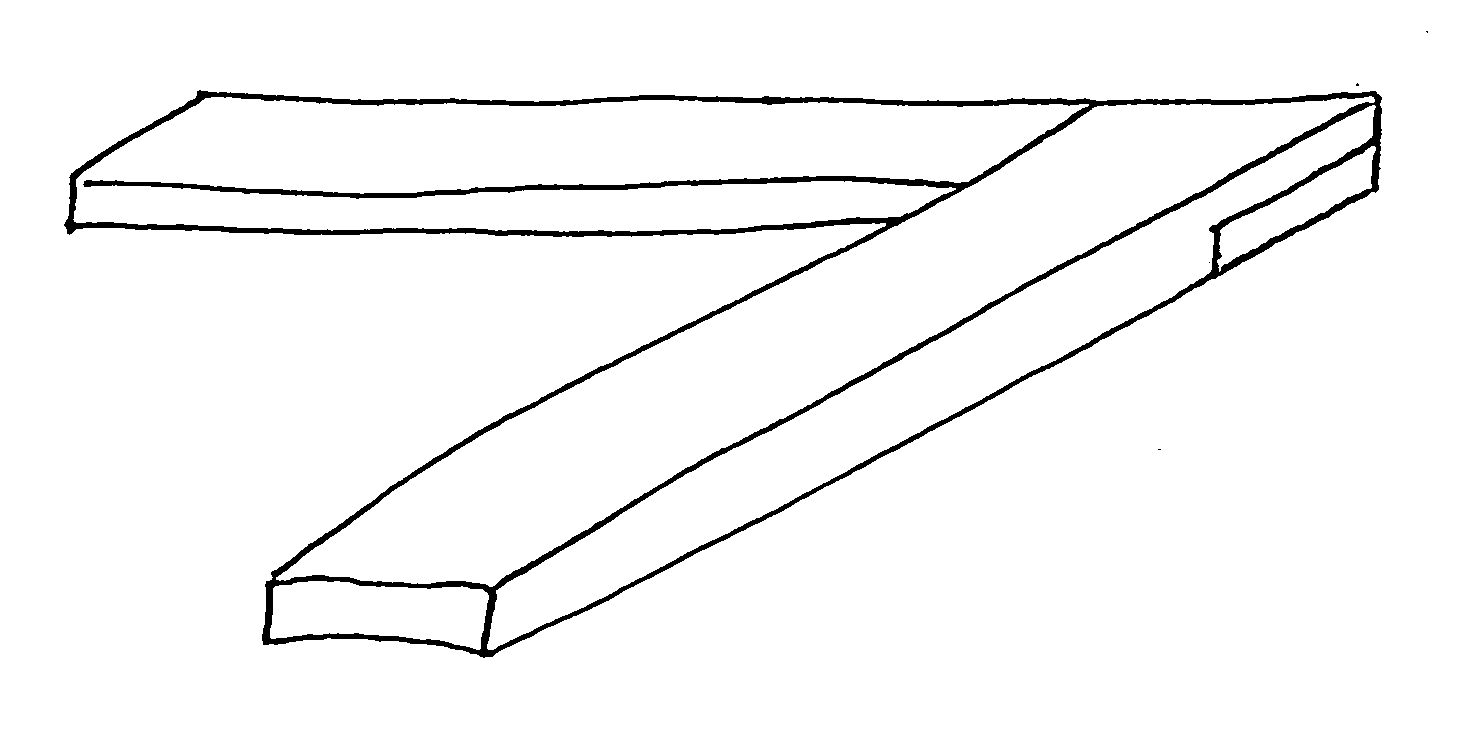

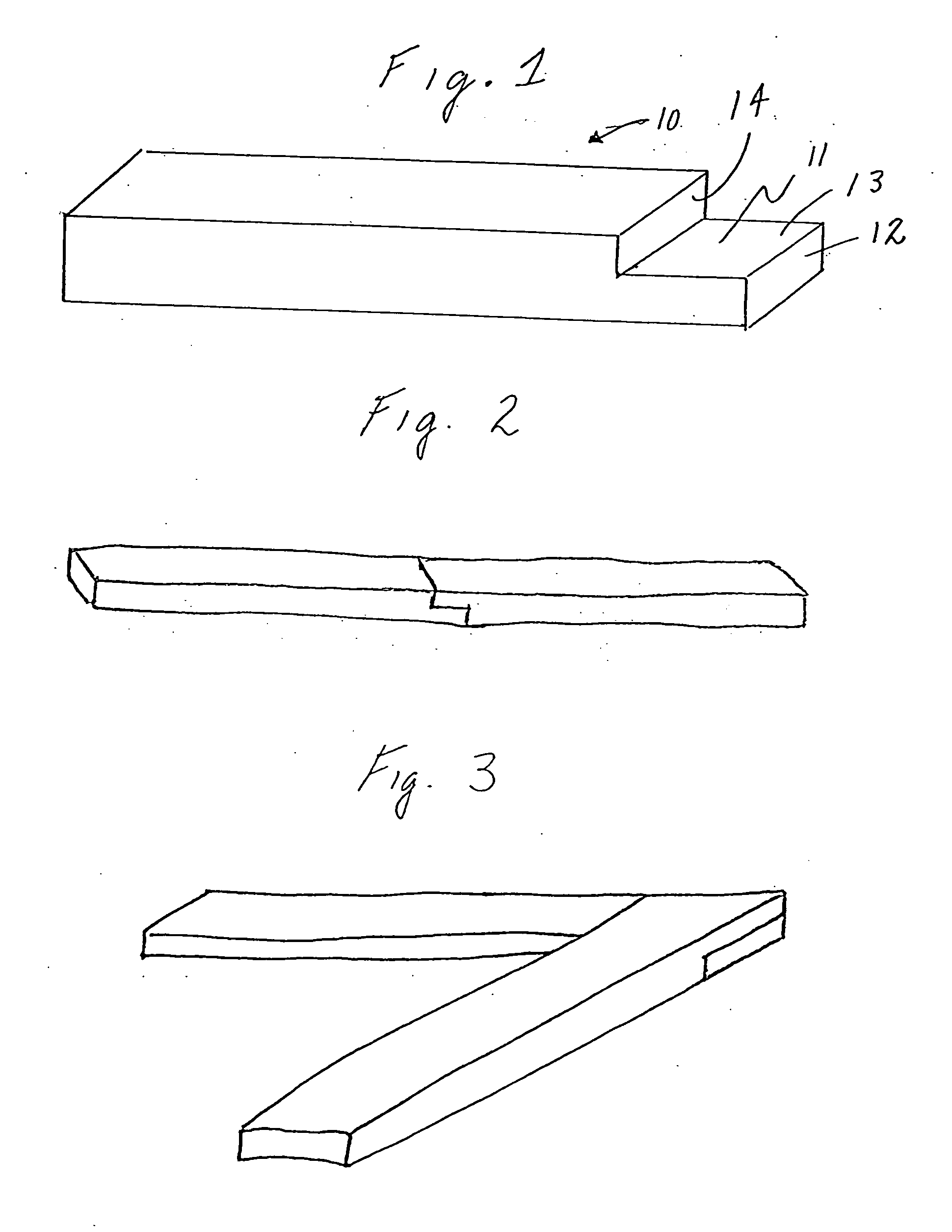

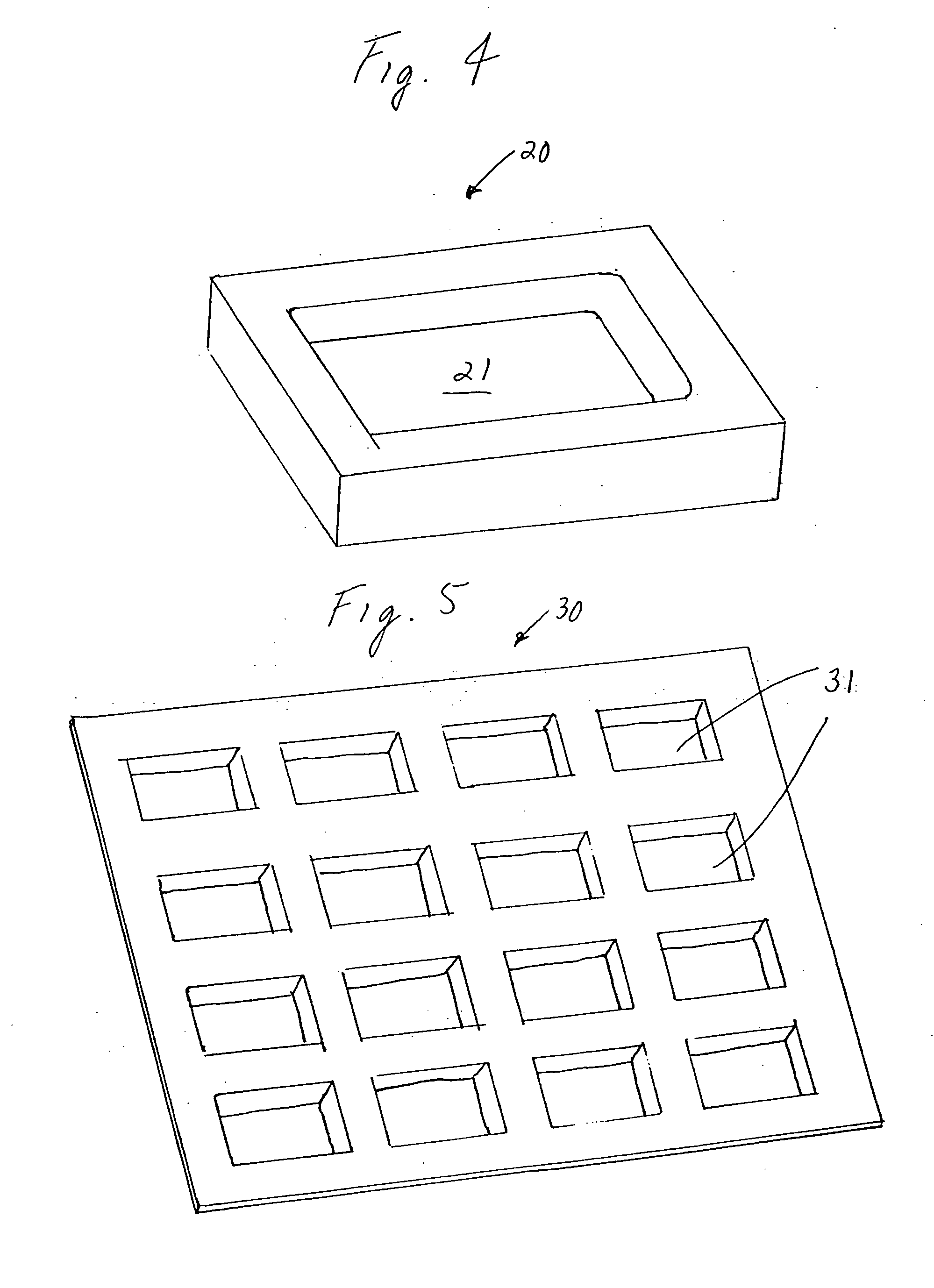

Metal catalysts

InactiveUS6747180B2Low bulk densityHigh activityOrganic compound preparationCatalyst activation/preparationHydration reactionAlkyl transfer

Owner:DEGUSSA AG +1

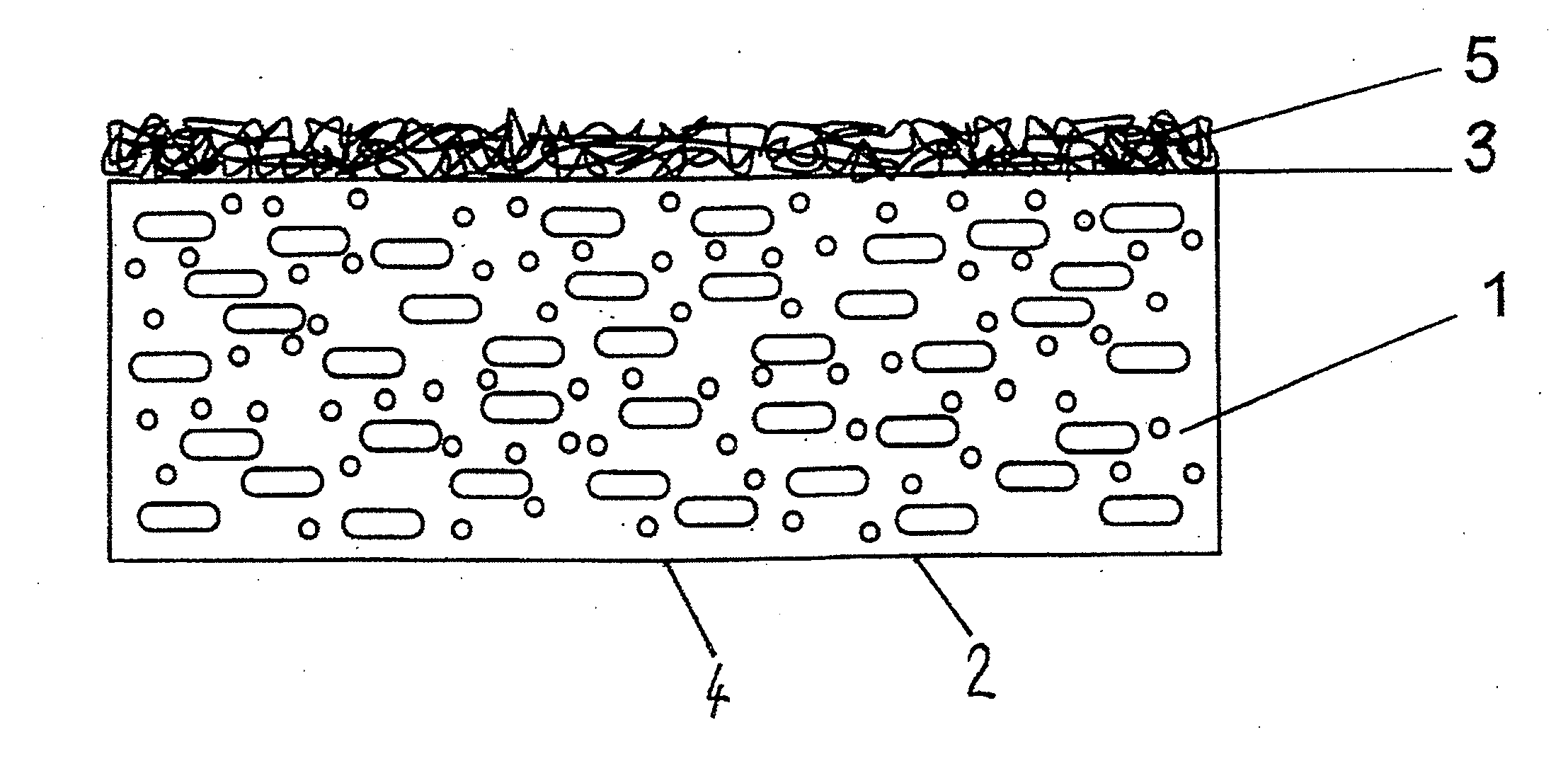

Foaming type inorganic heat insulation plate, preparation method thereof and heat insulation layer thereof

InactiveCN101798850ALow thermal conductivityImprove insulation effectSolid waste managementCeramic shaping apparatusFiberCellulose

The invention relates to a foaming type inorganic heat insulation plate, a preparation method thereof and a heat insulation layer thereof, which belongs to the technical field of a heat insulation plate and a heat insulation layer, and provides a foaming type inorganic heat insulation plate with high efficiency and energy saving, a preparation method thereof and a heat insulation layer thereof. The heat insulation plate is prepared from the following raw materials in parts by weight: 10-55 parts of composite light weight admixture, 10-55 parts of cement, 5-30 parts of lime, 3-20 parts of plaster, 1-10 parts of wollastonite, 10-55 parts of water glass, 10-60 parts of foam body which is foamed by a foaming machine through a foaming agent, 3-20 parts of fly ash, 0.1-3 parts of gel powder, 0.05-2 parts of cellulose ether, 0.01-2 parts of glauber salt, 0.1-3 parts of water reducing agent, 0.1-2 parts of hydrophobic agent, 0.01-1 part of mekarlon, 1-10 parts of bone glue, 5-30 parts of emulsion, 4-12 parts of waste slag, 1-45 parts of water and 0.02-1 part of aluminum powder. The invention is applied to the technical field of heat insulation materials.

Owner:太原思科达科技发展有限公司

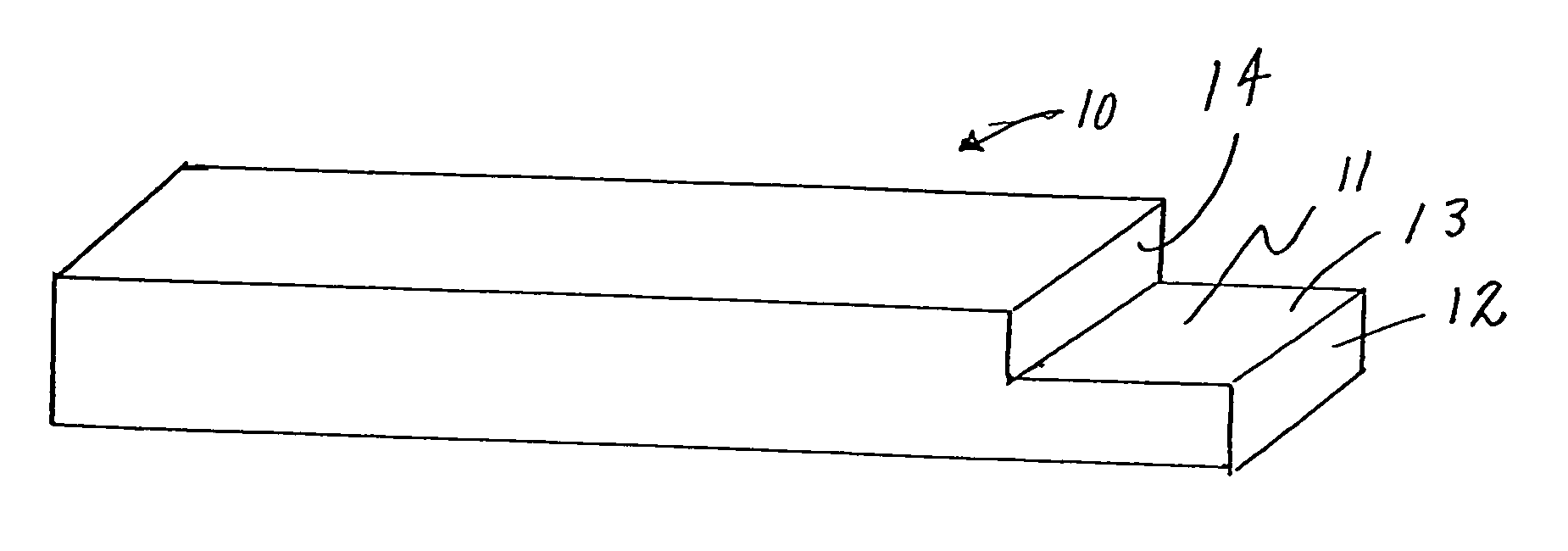

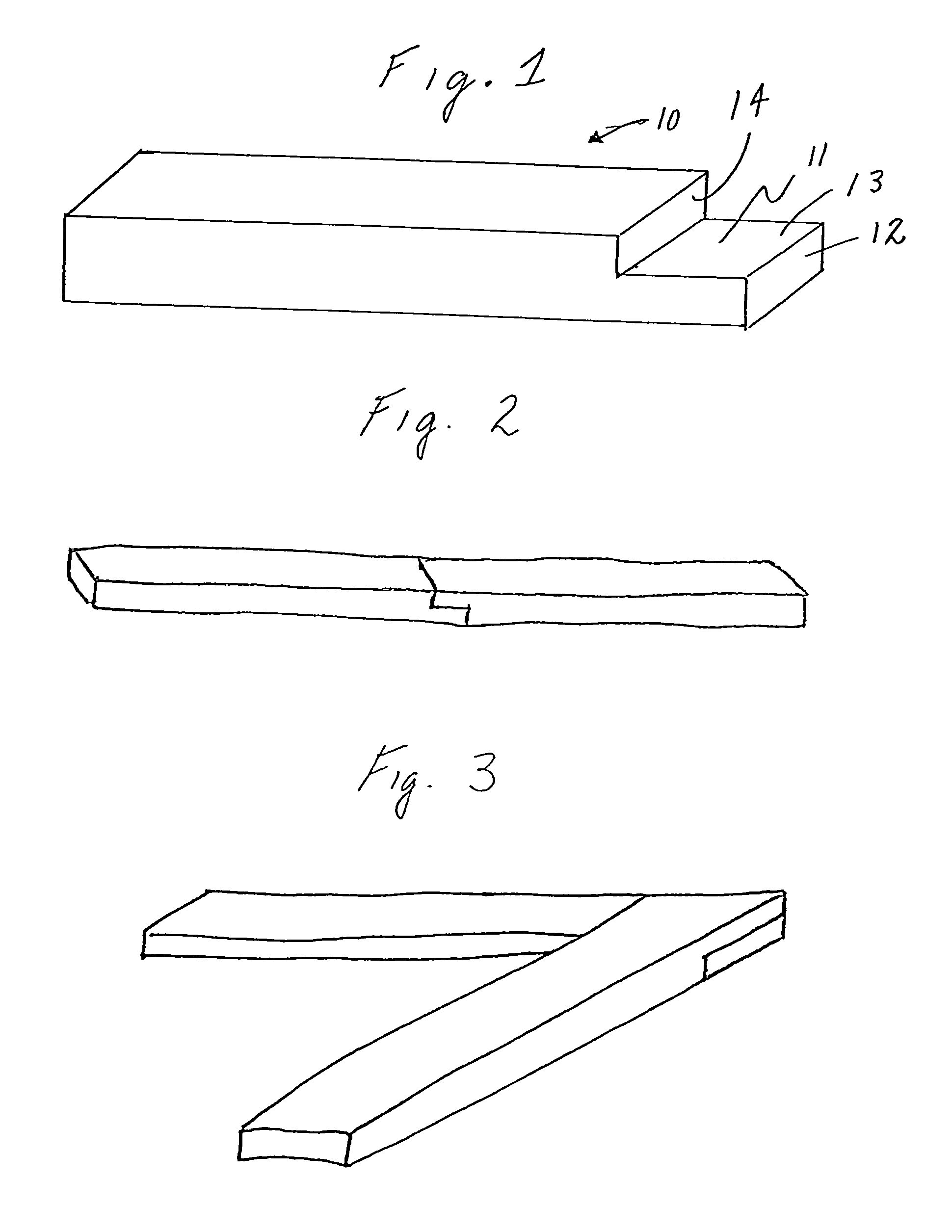

Osteoimplants and methods for their manufacture

Owner:WARSAW ORTHOPEDIC INC

Fertilizer for saline-alkali soil and preparation method of fertilizer

InactiveCN104262046AHigh in nutrientsLow bulk densitySuperphosphatesCalcareous fertilisersAlkali soilSoil organic matter

The invention relates to a fertilizer for saline-alkali soil. The fertilizer is prepared from the following raw materials in parts by weight: 5-20 parts of humic acid, 0.3-1 part of microorganisms, 6-16 parts of farmyard manure, 15-40 parts of straws, totally 5-10 parts of calcium superphosphate, ferrous sulfate, coal ash, furfural residues and flue gas desulfurization gypsum, 6-14 parts of a nitrogen fertilizer, 2-4 parts of a phosphatic fertilizer and 2-3 parts of a potassic fertilizer. The invention further relates to a preparation method of the fertilizer for saline-alkali soil. The fertilizer for saline-alkali soil, which is provided by the invention, has the beneficial effects that the fertilizer for saline-alkali soil has the characteristics of being low in cost and simple in preparation method, can be used for effectively improving the condition of saline-alkali soil, reducing the content of salt of soil and the pH value and increasing the content of organic matters in soil, and is particularly suitable for being applied to the saline-alkali soil.

Owner:瑞昊(北京)环境工程集团有限公司

Metal catalysts

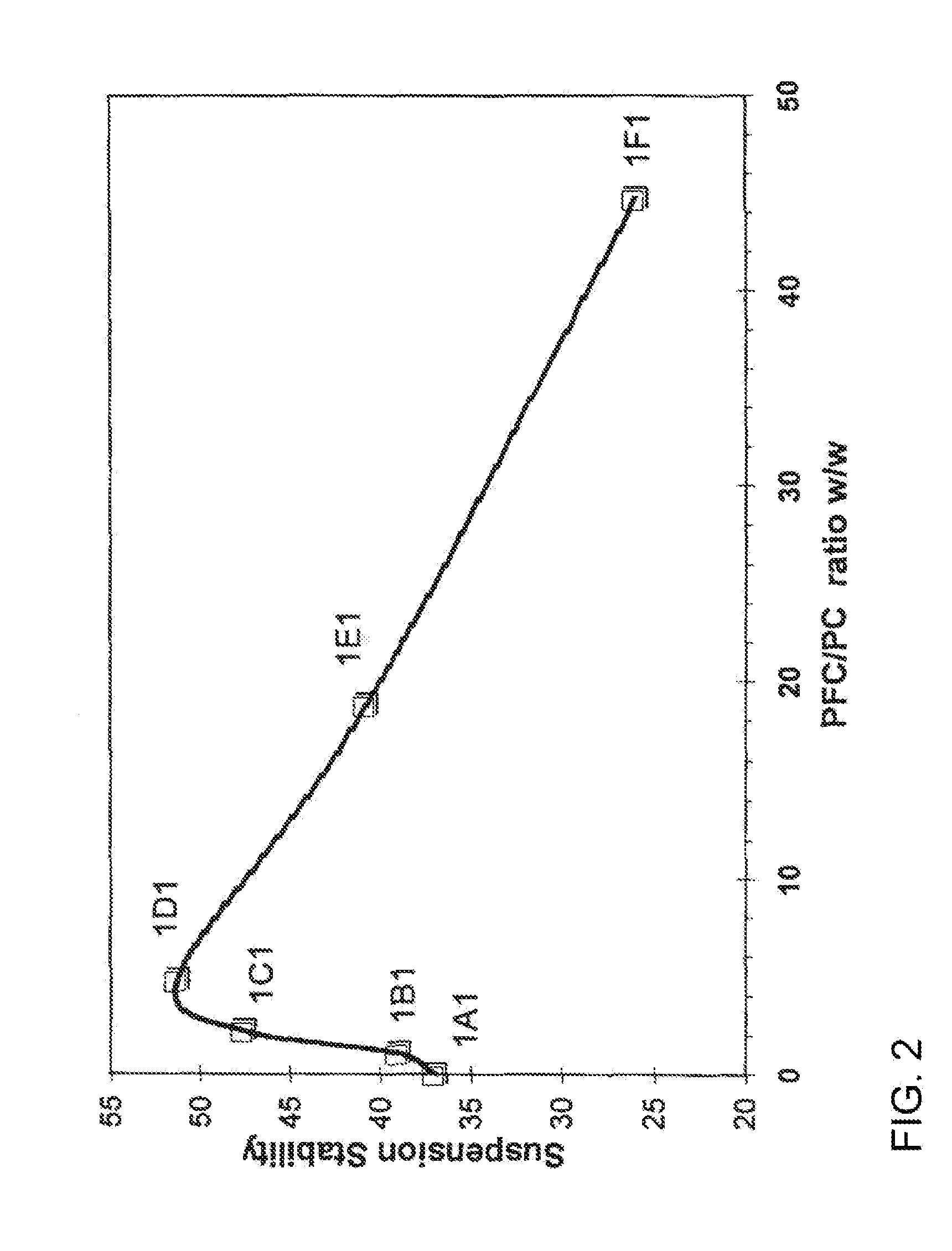

InactiveUS6573213B1Low bulk densityHigh activityOrganic compound preparationCatalyst activation/preparationHydration reactionAlkyl transfer

Metal catalysts comprising hollow forms or spheres are made of metal alloy and optionally activated. The metal catalysts can be used for the hydrogenation, dehydrogenation, isomerization reductive alkylation, reductive amination, and / or hydration reaction of organic compounds.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Engineered particles and methods of use

InactiveUS20050074498A1Reduce deliveryLess attractivePowder deliveryOrganic active ingredientsNebulizerActive agent

Engineered particles are provided may be used for the delivery of a bioactive agent to the respiratory tract of a patient. The particles may be used in the form of dry powders or in the form of stabilized dispersions comprising a nonaqueous continuous phase. In particularly preferred embodiments the particles may be used in conjunction with an inhalation device such as a dry powder inhaler, metered dose inhaler or a nebulizer.

Owner:NOVARTIS FARMA

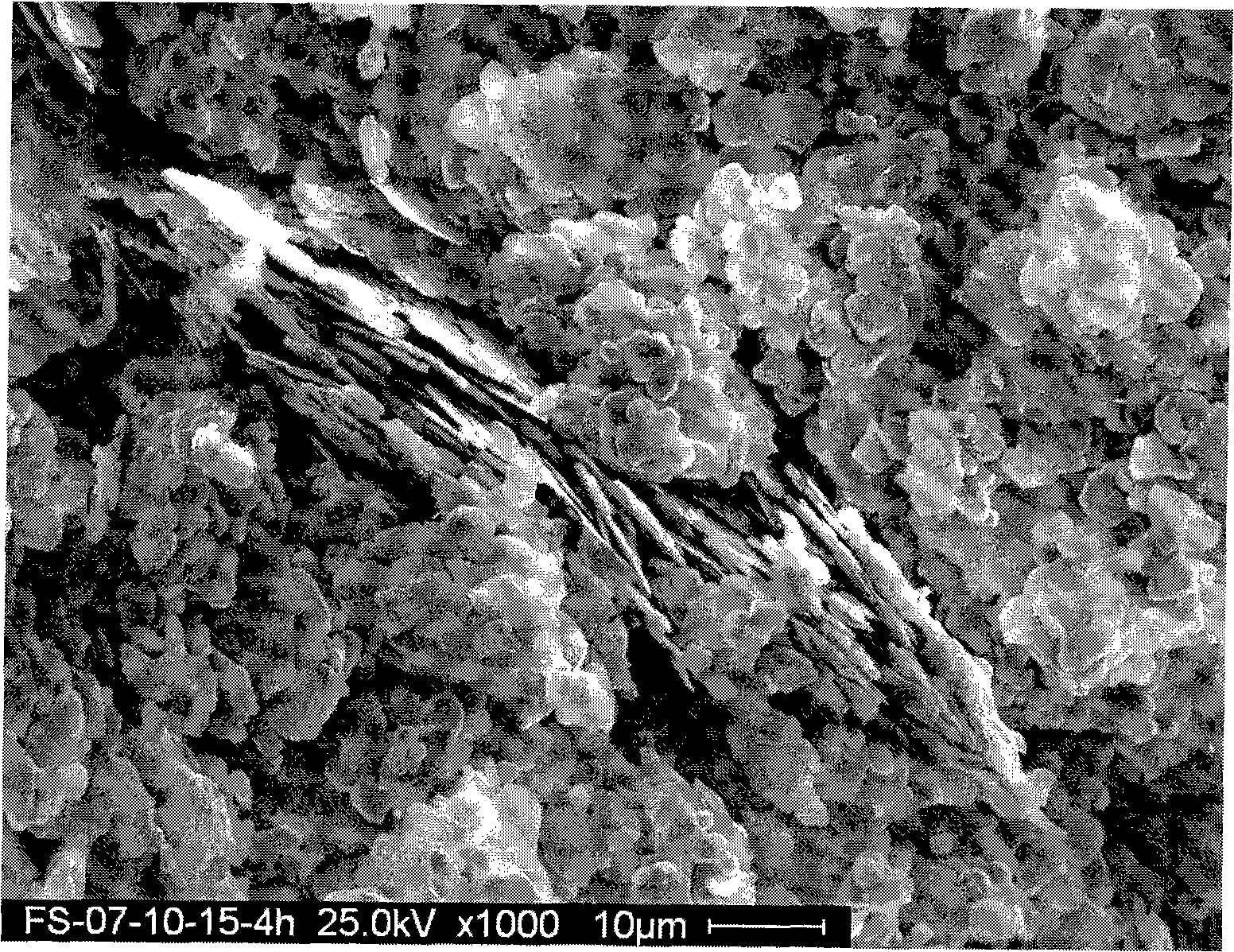

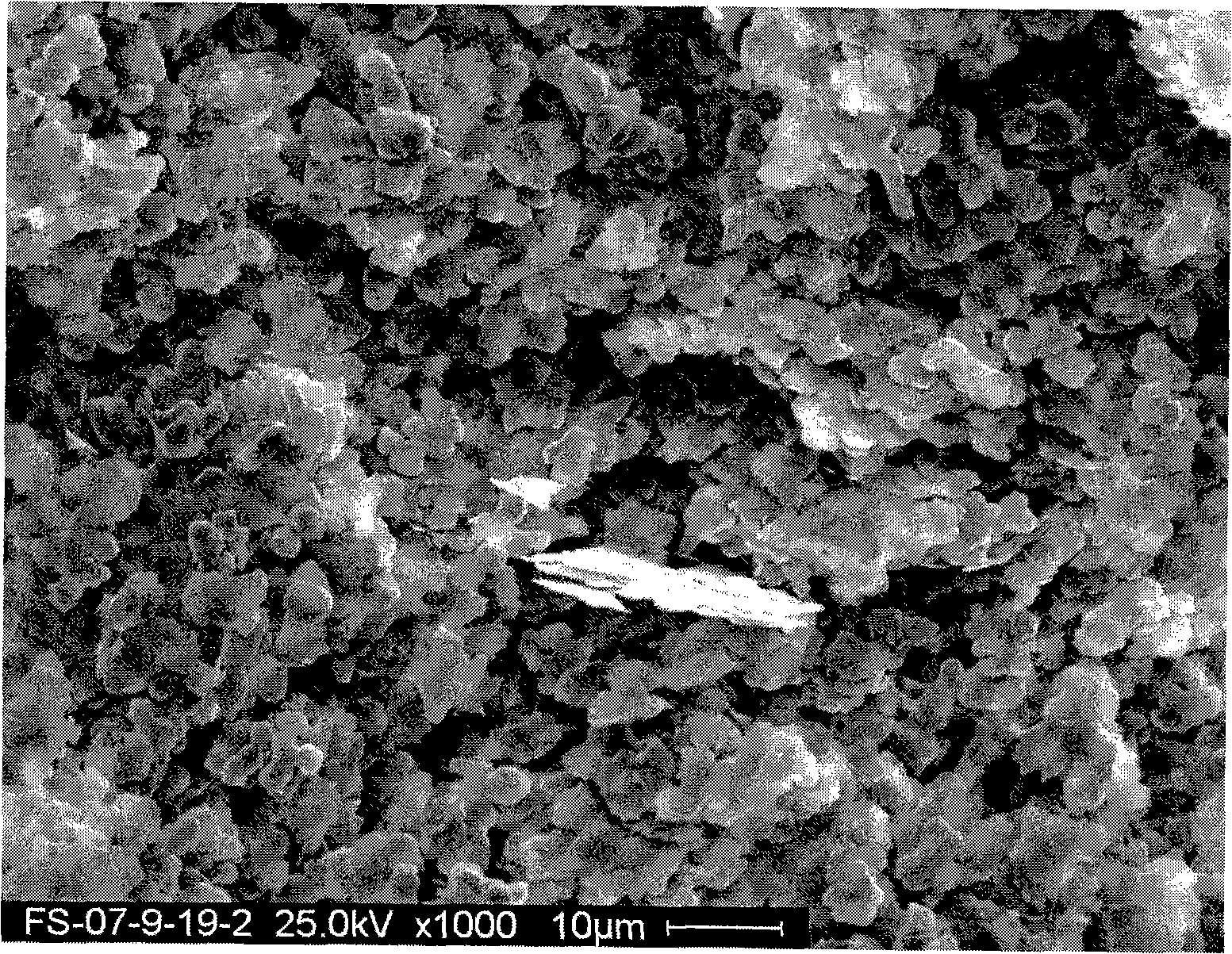

Method for preparing sheet silver powder with high dispersibility

ActiveCN101279369AGood dispersionMeet different performance requirementsShaking/oscillating/vibrating mixersApparent densityMetallurgy

The invention discloses a preparation method of high-dispersion flake silver powder, which is characterized in that spherical raw material silver powder with the1 to 3Mum of particle size D50 and the more than 99.95 percent of silver content is ground into the flake silver powder by adopting a grinding machine, the dispersion is then improved by ultrasonic dispersion and airflow dispersion, and the high-dispersion flake silver powder with the 3 to 25Mum of flake diameter D50 and the apparent density of 0.5 to 1.8g / cm<3> is obtained. The preparation process has simple process flow, which is applicable to the industrial mass production of flake silver powder.

Owner:JINCHUAN GROUP LIMITED

Silica-coated alkaline earth metal carbonate pigment

InactiveUS6136085AMaintenance economyMaintain ecological advantageCalcium/strontium/barium carbonatesPigmenting treatmentParticulatesAlkaline earth metal

A method for forming a silica coating on at least a portion of the surface of alkaline earth metal carbonate particulates in aqueous suspension and the silica-coated alkaline earth metal carbonate so produced are claimed. The claimed method consists of allowing soluble silicate ions in the aqueous phase to slowly react with the alkaline earth metal carbonate surface to form silica micro-particulates on the surface. This silica coating confers upon the composition unique properties among which are pronounced thixotropic behavior when incorporated into an aqueous suspension and increased oil absorption when dry. The pigment produced by this method is especially suited for use as a filler in paper.

Owner:CHEM PROD CORP

Method for preparing flake silver powder with low bulk density

The invention provides a method for preparing flake silver powder with low bulk density. The method comprises the following steps of reducing silver powder, i.e. adding pure water into a reaction container, and adding silver nitrate under a stirring condition to make the silver nitrate completely dissolved; adding a PH(Potential Of Hydrogen) value regulator, stirring, adding formaldehyde serving as a reducer to perform chemical reaction, washing the silver powder and drying; and ball-milling, i.e. weighing the silver powder, adding zirconia, filling in a ball-milling pot, adding a ball-milling solvent, a ball-milling aid and an emulsifier, ball-milling, sieving, washing by using a cleaning solvent, and drying to obtain the flake silver powder. The silver powder prepared in the reducing process by the method is not added with any dispersing agent, has low impurity content and high purity; and moreover, the technical process is simple, the ball-milling time is short, and the method is easily industrialized.

Owner:湘潭市泽宇新材料科技有限公司

Method for preparing film-coated ceramisite proppant by using oil shale wastes

InactiveCN101906297AEliminate hazardsLow bulk densitySolid waste disposalFluid removalFirming agentExpanded clay aggregate

The invention relates to a method for preparing a film-coated ceramisite proppant by using oil shale wastes. The method for preparing the film-coated ceramisite proppant by using the oil shale wastes is characterized by comprising the following steps of: 1) selecting raw materials which comprise the following raw materials in part by mass: 50 parts of the oil shale wastes, 50 parts of bauxite, and 1 to 4 parts of caking agent; 2) uniformly mixing the raw materials to obtain a mixture; 3) putting the mixture into a pan-type pelletizer for pelletizing to obtain raw material balls; 4) sintering the raw material balls to obtain a ceramisite aggregate; and 5) heating the ceramisite aggregate to the temperature of between 100 and 240 DEG C, adding a resin into the heated ceramisite aggregate and stirring the mixture uniformly first to ensure that the resin forms a film on the surface of the ceramisite aggregate, then adding a curing agent and other auxiliary agents, stirring the mixture uniformly, adding a lubricating agent, stirring the mixture uniformly, cooling to obtain a new mixture, crushing the new mixture and screening the crushed mixture through a 20 / 40-mesh sieve to obtain thefilm-coated ceramisite proppant. The method can extensively use the oil shale wastes and can solve the problem that the oil shale wastes harm the environment.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Polyaminoester /molecular sieve composite material and its preparation method

The invention relates to a polyurethane and inorganic porous granule composite material and method for preparation comprising the steps of, carrying out surface organic modifying treatment to the molecular screen whose grain diameter is 0.05-40 um and bore diameter is 0.3-3nm, mixing homogeneously with polyesters or polyethers polyhydric alcohol by the stirring with mechanical force, performing fabrication with polyisocyanates, chain expanded cross linking agent and auxiliary agent through the conventional polyurethane synthesizing process by one-step method or pre-aggressiveness, the mechanic property and solvent resistance of the obtained composite material are improved substantially.

Owner:TAIYUAN UNIV OF TECH +1

Thermal insulation putty for internal walls and application method thereof

The invention discloses a thermal insulation putty for internal walls, which is characterized in that the raw material at least contains the following components: component 1: 1 part by mass of solution containing polyhydroxy high-molecular compounds on the basis of polyhydroxy high-molecular compounds; component 2: 0.1-1 part of isocyanate foaming crosslinking agent; component 3: 10-20 parts of thermal insulation filler; component 4: 0.5-2 parts of silica sol; and component 5: 0.1-2 parts of inorganic powder material. The total water content in the solution containing polyhydroxy high-molecular compounds and silica sol is 8-16 parts. The method comprises the following steps: uniformly mixing the components to form a paste; plastering the paste on the surface of the internal wall of a building by a plastering construction technique, wherein the plastering thickness is 3-20 millimeters; forming distributed bubbles in the plastering layer, and crosslinking and hardening the component 1 to form the thermal insulation putty layer. The thermal insulation putty for internal walls have low volume weight and low thermal conductivity; and the foamed high polymer material is used as an adhesive and has the phase-change energy storage effect, thereby enhancing the thermal insulation property of the putty.

Owner:FUKE TECH (SUZHOU) CO LTD

Osteoimplants and methods for their manufacture

ActiveUS20070088437A1Efficient use ofReadily absorb fluidBone implantSurgeryMaterials scienceBone particle

Owner:WARSAW ORTHOPEDIC INC

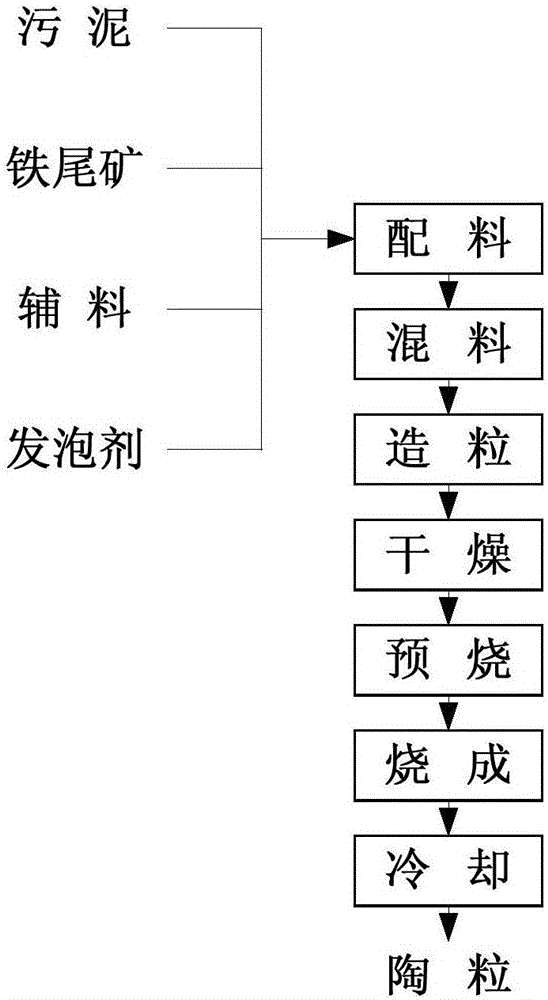

Composite solid-waste lightweight high-strength haydite and preparation method therefor

InactiveCN106242514ALightweightCorrosion resistantCeramic materials productionCeramicwareFoaming agentSludge

The invention provides composite solid-waste lightweight high-strength haydite and a preparation method therefor. The composite solid-waste lightweight high-strength haydite is mainly prepared from the following raw materials in parts by weight: 40.0-60.0 parts of iron tailings, 10.0-15.0 parts of auxiliary raw materials and 0.1-3.0 parts of foamer. The composite solid-waste lightweight high-strength haydite further contains sludge, wherein the dry sludge content of the sludge is 30.0-50.0 parts. The preparation method comprises the steps: accurately weighing the sludge, the iron tailings, the auxiliary raw materials and the foamer according to a designed ingredient proportioning ratio, and carrying out uniform mixing so as to form a uniform basic mixture; and carrying out granulating and shaping so as to obtain unburned haydite, burning the unburned haydite, and carrying out annealing and cooling, thereby obtaining municipal sludge and iron tailing cooperated haydite. The haydite is prepared from the sludge and the iron tailings, which are cooperated with each other and serve as main raw materials, so that the sludge is subjected to harmless treatment and resource-converting utilization, the sludge, which is a municipal mineral product, is used for replacing a primary mineral raw material, and thus the economic and environmental benefits are remarkable.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Aerated brick

The invention discloses an aerated brick. The aerated brick is prepared from the following raw materials by the conventional process for preparing the aerated brick: 30 to 35 weight parts of iron ore tailing, 5 to 10 weight parts of cement, 10 to 15 weight parts of quick lime, 5 to 10 weight parts of modified nano powder, 5 to 10 weight parts of broken glass powder, 3 to 5 weight parts of gypsum, 0.05 to 0.1 weight part of aluminum powder, 0.002 to 0.008 weight part of Chinese honey locust powder, 0.03 to 0.08 weight part of tea seed cake powder, 0.003 to 0.005 weight part of soda ash, 0.5 to 0.8 weight part of calcium stearate, 0.3 to 0.5 weight part of zinc stearate, 0.01 to 0.03 weight part of calcium chloride, 0.05 to 0.1 weight part of white emulsion and an appropriate amount of water. By adding nano mineral powder, the volume weight of the brick, and the energy consumption are reduced; the brick is high in thermal insulation performance and sound insulation performance; and compared with the conventional aerated brick, the aerated brick has the advantage that the thermal insulation performance and the sound insulation performance are improved obviously. Meanwhile, the raw materials are mixed according to an optimized formula; and the intensity and the freezing resistance of the brick are improved obviously.

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

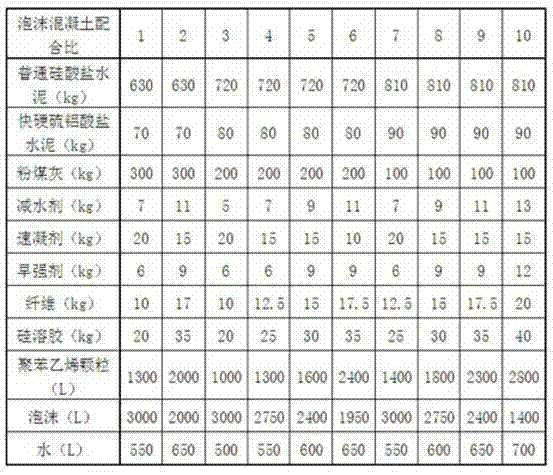

Foam concrete with large-dosage polystyrene particles and preparation method thereof

ActiveCN102503526AImprove thermal insulation performanceHigh electrical insulationCement mixing apparatusCeramicwareFoam concreteAluminate

The invention provides a foam concrete with large-dosage polystyrene particles and a preparation method thereof, which solve problems of water leakage and frost resistance of the foam concrete. The foam concrete comprises components in part as follows: 63-81 parts of ordinary portland cement, 63-81 parts of quick-hardening sulphoaluminate cement, 10-30 parts of coal ash, 0.5-1.3 parts of water reducing agent, 1-2 parts of accelerating agent, 0.6-1.2 parts of early strength agent, 1-2 parts of fiber, 2-4 parts of silica sol, and 50-70 parts of water. The percentage in volume (liter) of the polystyrene particles in added water is 200-400percent, and the percentage in volume (liter) of foam in the added water is 100-600percent. In the preparation process, the treated polystyrene particles stand for 10 min, and the foam can be added after standing uniformly-stirred cement slurry for 20 min. On the premise of ensuring the intensity, the foam cement disclosed by the invention has the advantages of higher heat preservation and heat-shielding performance, higher electric insulating performance, lower volume weight and lower water absorption. The problems of the water leakage and the frostresistance of the foam cement can be solved.

Owner:SHENYANG JIANZHU UNIVERSITY

Particulate clumpling animal litter material and process for the production thereof

InactiveUS20090308323A1High strengthLight weightAnimal housingOther apparatusParticulatesSodium Bentonite

The invention provides a particulate clumping animal litter material comprising bentonite dust, a filler material, and optionally a coagulant, wherein the material comprises 50-95 wt. % bentonite dust, wherein the particles of the particulate clumping animal litter material have a weight averaged particle size in the range of 0.25-8 mm and wherein the material has a bulk density equal to or less than 700 gram / l. The invention further provides a process for the production of the product. The product is light weight but still clumpable and scoopable. The product according to the invention eliminates odours quickly and naturally with no need for added chemicals or perfumes to mask odours. The filler material is a protein based foam.

Owner:SIVOMATIC

Method for preparing low-apparent-density copper powder through water atomization

InactiveCN101837460AReduce manufacturing costLower thermal resistanceSmelting processApparent density

The invention relates to a method for preparing copper powder. The method for preparing low-apparent-density copper powder through water atomization comprises a smelting process, which is to smelt raw materials put into a smelting furnace at the temperature of between 1,100 and 300 DEG C, constantly stir and simultaneously performing air-blowing operation. The method has the advantages of using no copper oxide and reducing production cost.

Owner:浙江旭德新材料有限公司

Single crystal nickel-cobalt-manganese lithium anode material, precursor and preparation methods for single crystal nickel-cobalt-manganese lithium anode material and precursor

The invention discloses a single crystal nickel-cobalt-manganese lithium anode material, a precursor and preparation methods for the single crystal nickel-cobalt-manganese lithium anode material and the precursor. The molecular formula of the anode material is LiNi<x>Co<y>Mn<1-x-y>M'<z>M' ' <w>O<2-delta>R<delta>(a being greater than or equal to 0.95 and smaller than or equal to 1.25, x being greater than or equal to 0 and smaller than or equal to 1, y being greater than or equal to 0 and smaller than or equal to 0.5, z being greater than or equal to 0 and smaller than or equal to 0.01, w being greater than or equal to 0 and smaller than or equal to 0.05, delta being greater than or equal to 0 and smaller or equal to 0.02). By adding a dispersant and controlling the content of a co-precipitation reaction complexing agent, the synthesis pH value and the reaction temperature, a nickel-cobalt manganese hydroxide precursor with small particles, loose shape, small density and large specific surface area is obtained. A nickel-cobalt-manganese lithium anode material with typical single crystal shape is obtained by sintering the precursor with a lithium salt and a specific melting acceleration element additive. The invention has simple process, easy process control and no need for modification or addition to original devices. The obtained precursor is easy to react and combine with the lithium salt, which reduces the sintering temperature, simplifies the sintering process and greatly improves the production efficiency.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

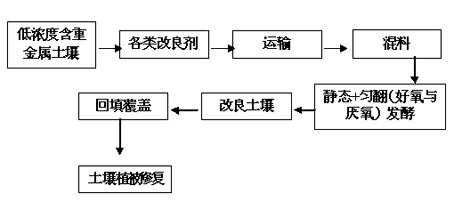

Method for comprehensively utilizing low-concentration heavy metal-containing soil improvement and repairing damaged soil by plants after detoxification of contaminated field

InactiveCN102319726AQuality improvementSimple structureContaminated soil reclamationSludgeAdditive ingredient

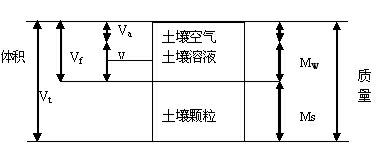

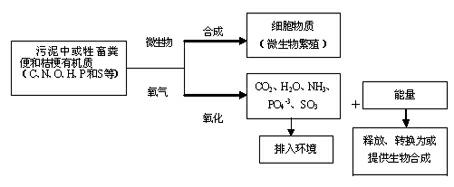

The invention relates to a method for comprehensively utilizing low-concentration heavy metal-containing soil improvement and repairing damaged soil by plants after detoxification of a contaminated field. The method comprises the following steps of: conveying of low-concentration soil after heavy metal-containing soil is detoxified, sludge and pulverized fuel ash; principal fermentation, mixing of various ingredients; primary fermentation; static state of post-fermentation (secondary fermentation); uniform turning (aerobic and anaerobic) fermentation; conveying of improved soil; and vegetation repairing (woody and herbaceous plants) planting for the contaminated soil. In the method, a modifier is added for modification, so that the content of heavy metals in the soil is reduced, the structure and pores of the damaged soil are repaired, and the permeation and air permeability of the soil are improved; and organic matters and other noxious matters in sludge and soil are decomposed and degraded in a certain condition by utilizing microbes in the sludge to reduce volume weight and compactness, so that the improved soil forms a substance similar to humus soil to serve as a biochemical process of the improved soil and fertilizer. According to the method, the planted vegetation growing environment of the land which uses the improved soil as a soil base material is ensured, so that the waste is used to treat waste, and the comprehensive utilization is improved.

Owner:姜桂荣 +1

Cast-in-situ straw/ash magnesium oxychloride cement wall and construction method

InactiveCN101818531AAvoid ignitionImprove flame retardant performanceSolid waste managementWallsSocial benefitsAdhesion process

The invention discloses a cast-in-situ straw / ash magnesium oxychloride cement wall and a construction method. The straw / ash magnesium oxychloride cement wall is obtained by processing straw, ash, light burned magnesia, magnesium chloride and the like and performing in-situ casting under the action of a modifier. The straw / ash magnesium oxychloride cement wall comprises the following raw materials in percentage by mass: 45 and 60 percent of magnesium oxide, 25 to 40 percent of solution of magnesium chloride, 2 to 20 percent of straw, 5 to 15 percent of ash and 0.5 to 2 percent of modifier. When the wall is cast in situ, the magnesium oxide, the solution of magnesium chloride, the straw, the ash and the modifier are mixed and stirred, and water is added into the mixture according to the water absorption of the straw to perform one-time forming through in-situ casting after the mixture is stirred uniformly. The wall is characterized in that the doping volume of the straw can be changed according to design requirements, and the straw can be used as inner and outer partition plates; the binding power is strong, so the adhesion process of the cast-in-situ wall materials and the conventional wall materials is avoided; due to the addition of the straw, the volume weight of products is reduced and the heat-insulating and heat-shielding performance of the products is improved; and a large amount of waste material ash, straw and the like is utilized to relieve the environmental burden effectively and reduce the cost, so the wall has great economic and social benefits.

Owner:SOUTHEAST UNIV

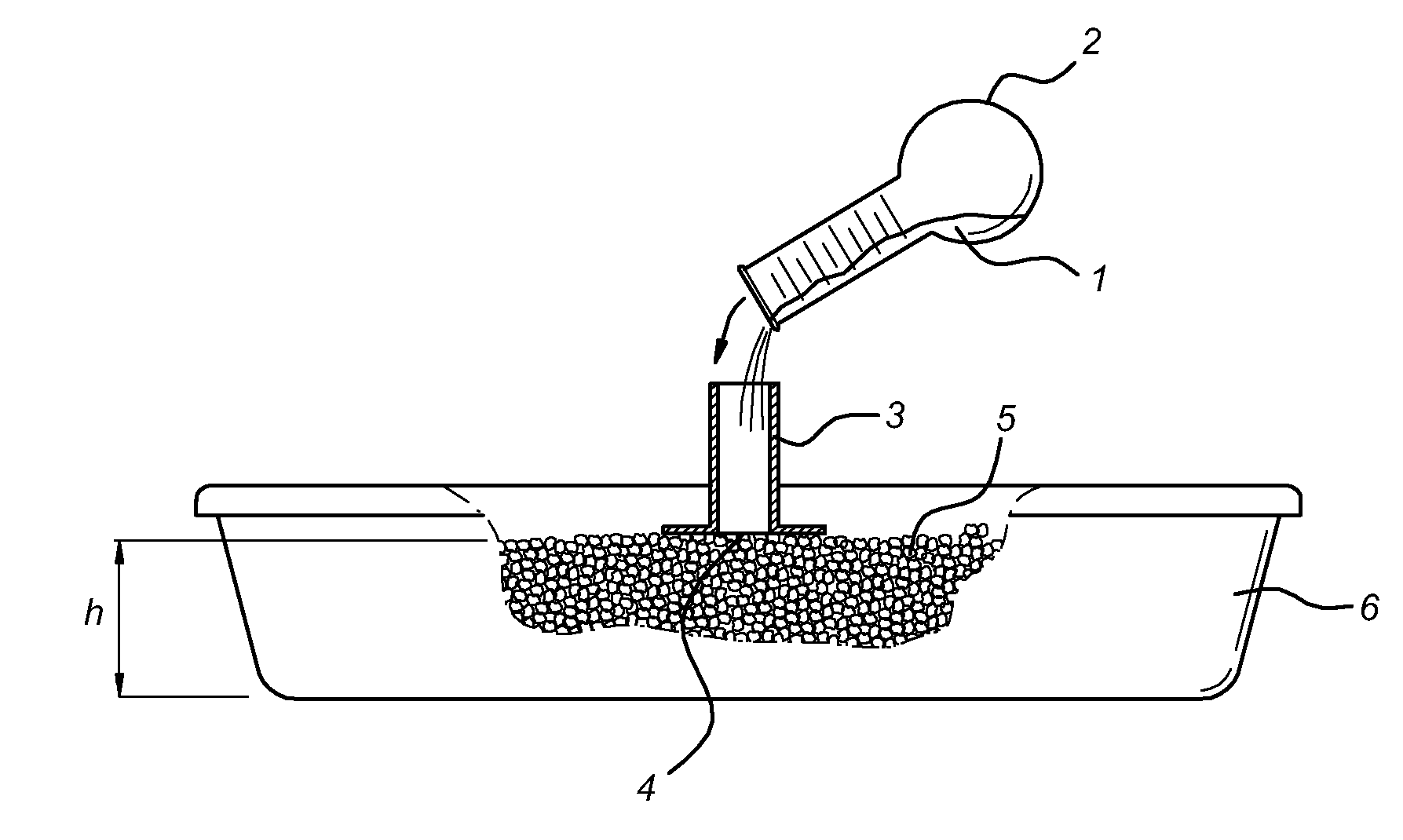

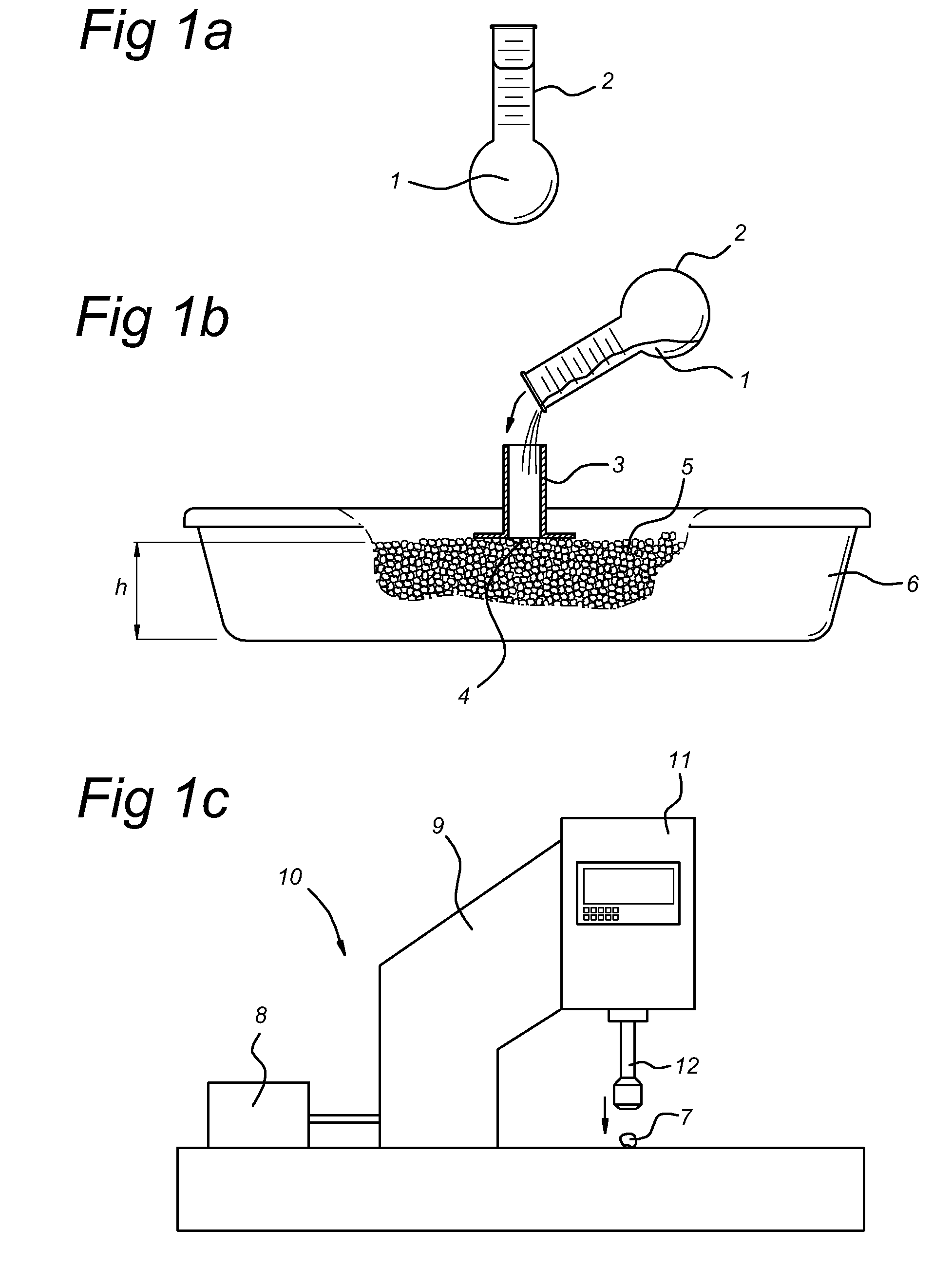

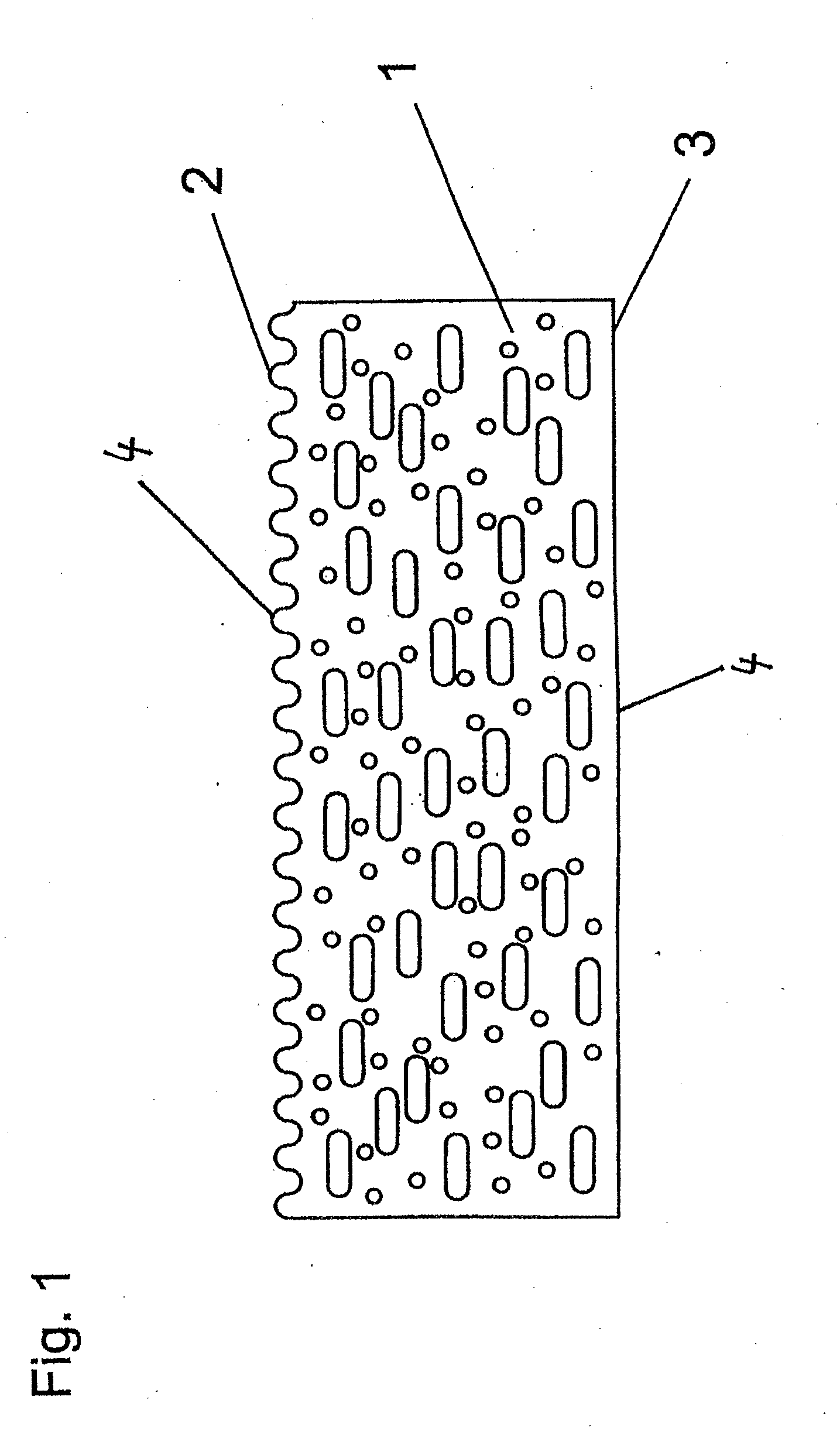

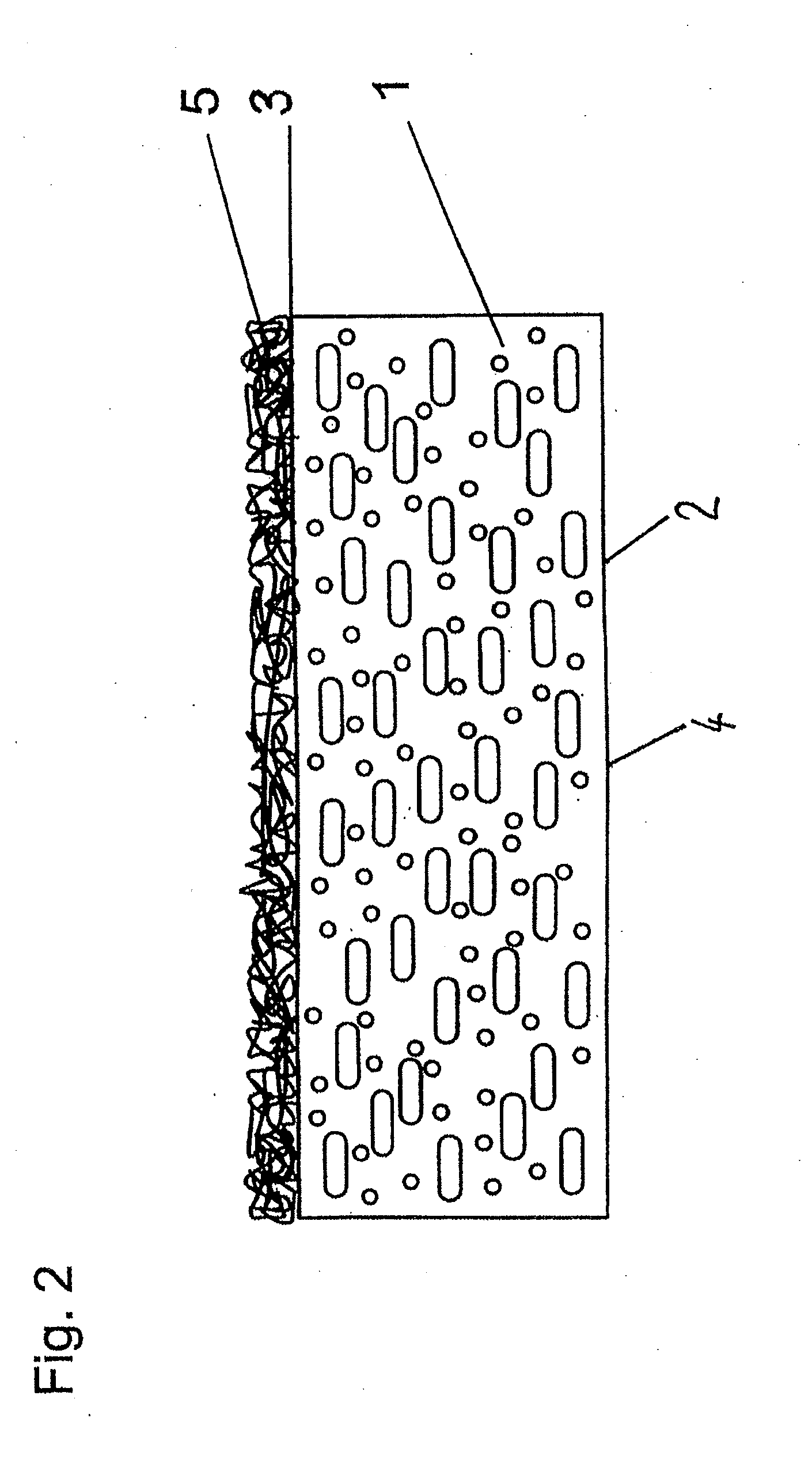

Method for continuously producing sponge bodies made of regenerated cellulose and a sponge body

InactiveUS20120023690A1Low costEffective and low-cost mannerBoard cleaning devicesCarpet cleanersEngineeringConveyor belt

A method for continuously producing sponge bodies (1) made of regenerated cellulose using at least partially agglomerated pore inducers made of sodium sulphate decahydrate is provided. First, a viscose solution is provided. A pore inducer is added to said viscose solution. The viscose solution is laid onto a conveyer belt which is continuously moving. The viscose solution is led through baths on the conveyor belt, resulting in a porous mass made of regenerated cellulose.

Owner:CARL FREUDENBERG KG

Preparation process for fluorite slag-containing aerated brick

The invention discloses a preparation process for a fluorite slag-containing aerated brick. The process comprises the following steps of: weighing blast furnace slag powder and gypsum in a weight ratio; adding an appropriate amount of water, stirring and mixing at the speed of 700 to 1,000rpm for 2 to 3 minutes, and grinding to obtain blast furnace slag powder and gypsum mixed slurry; adding fluorite slag-containing modified nano powder and other residual raw materials required by preparing the aerated brick in a weigh ratio, and stirring and mixing at the speed of 2,000 to 2,800rpm for 3 to 5 minutes; pouring the obtained mixed slurry into a mould and forming, precuring at the temperature of between 40 and 50 DEG C for 1 to 3 hours; demoulding; lifting to a cutting part and cutting to obtain a brick blank; and putting the brick blank in a reaction kettle and performing autoclaved curing, and putting in storage. The raw materials are mixed according to an optimized formula; and the intensity and the freezing resistance of the brick are improved obviously.

Owner:深圳市嘉能新型环保建材有限公司

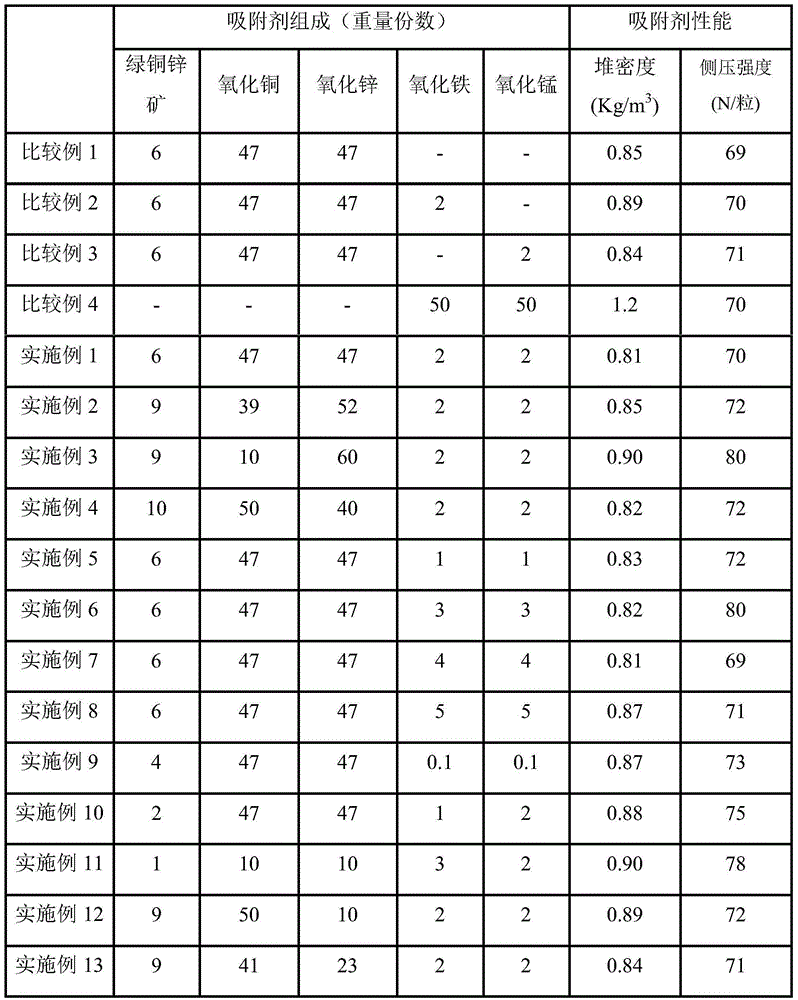

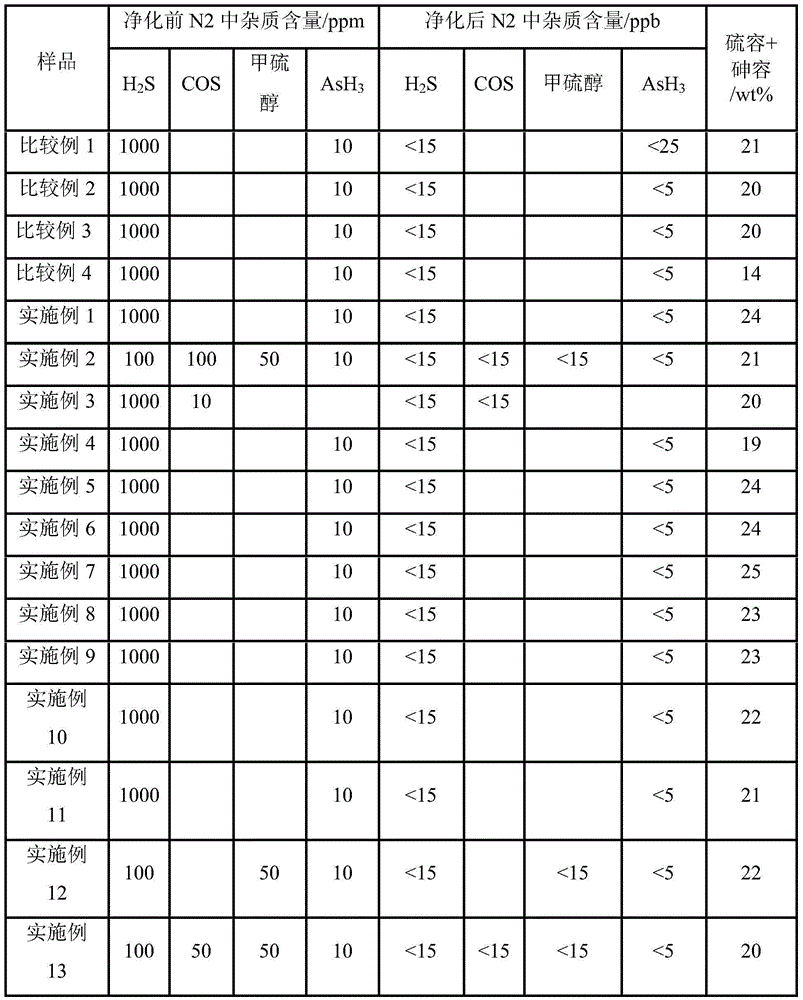

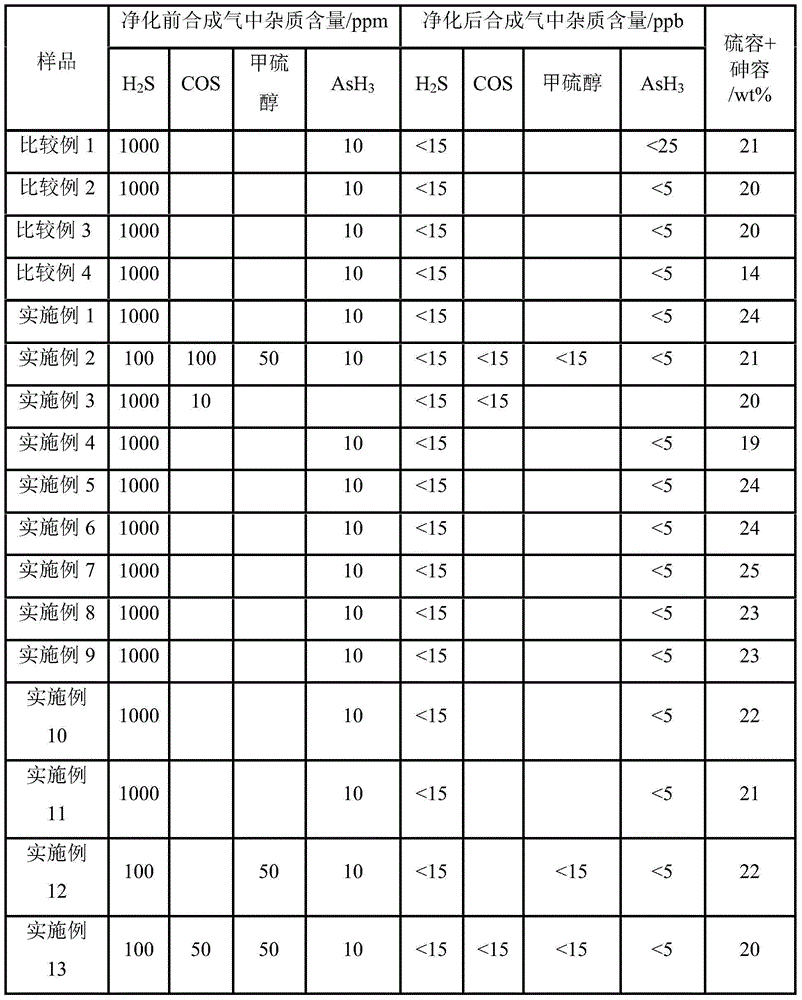

Sulfur and arsenic adsorbent and preparation method thereof

ActiveCN105214599AHigh sulfur capacityIncrease arsenic capacityOther chemical processesSorbentSulfur

The invention relates to a sulfur and arsenic adsorbent and a preparation method thereof to mainly solve the problems of high bulk density and low sulfur and arsenic capacity of sulfur and arsenic adsorbents in the prior art. The sulfur and arsenic adsorbent comprises, by weight, 1-10 parts of aurichalcite, 10-50 parts of copper oxide, 10-60 parts of zinc oxide, 0.1-5 parts of iron oxide and 0.1-5 parts of manganese oxide. The sulfur and arsenic adsorbent adopting the above technical scheme well solves the problems, and can be used to purify natural gas, synthetic gases and lightweight gas and liquid hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

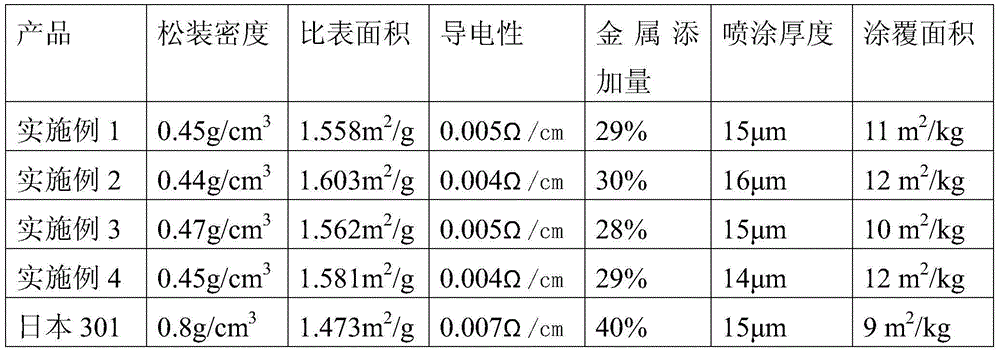

Preparation method for flake silver powder for electronic paste

The invention relates to a preparation method for flake silver powder for electronic paste, and belongs to the field of preparation of metal powder materials. The method comprises the following steps of (a) preparation of silver powder, (b) ball-milling, (c) primary surface modification and (d) secondary surface modification. The preparation method has the advantages that the flake silver powder is low in apparent density, large in specific surface area, high in dispersibility, large in coating area and low in filling amount; and the cost is greatly saved.

Owner:KUNMING SHUYANG TECH

Porous petroleum fracturing propping agent and preparation method thereof

ActiveCN105038758AGood lookingImprove water absorptionFluid removalDrilling compositionManganeseFracturing fluid

The invention provides a porous petroleum fracturing propping agent and a preparation method thereof, and belongs to the technical field of oil-gas well fracturing in oil exploitation. The porous petroleum fracturing propping agent is prepared from bauxite fine powder, bentonite, manganese powder, silicon carbide fine powder, kyanite fine powder and activated alumina fine powder. Compared with an existing medium-density petroleum fracturing propping agent, the porous petroleum fracturing propping agent has the advantages that particles of the roasted propping agent have more opening pores by adopting silicon carbide as a pore forming agent, more scale inhibitors can be accommodated in the propping agent since the porous structure is capable of providing a space structure to portability of the scale inhibitors, and generation of well scale is prevented or reduced by means of slow release of the scale inhibitors after the propping agent and fracturing fluid are pumped into the well by high pressure. Furthermore, the porous petroleum propping agent has a rather low volume density, and the low-density propping agent can be used for overcoming the defect that the fracturing fluid and the propping agent are blocked to flow deep to the rock crack since a high-density propping agent easily forms moundy accumulation at the port of the rock crack, so that the yield of an oil-gas field can be increased.

Owner:洛阳赛罗帕陶瓷科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com