Thermal insulation putty for internal walls and application method thereof

A technology of thermal insulation putty and inner wall, which is applied in the field of thermal insulation putty for the inner wall of the building and the putty for construction, can solve the problems of the dangerous outer wall of high-rise buildings, short service life, large production energy consumption, etc., and achieves guaranteed bulk density and low thermal conductivity. The effect of reducing thermal conductivity, reducing thermal conductivity, and ultra-low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

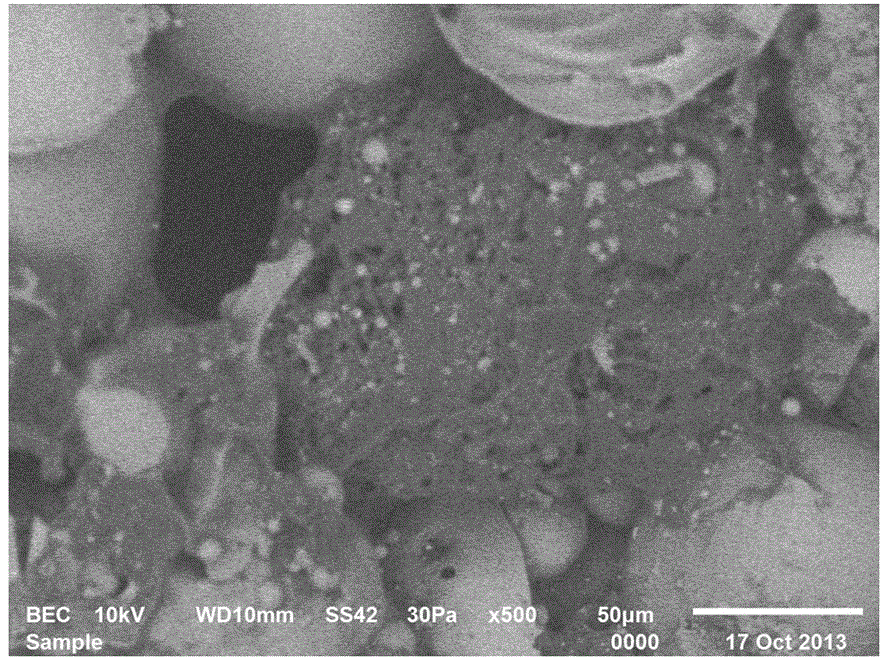

Image

Examples

Embodiment 1

[0045] Embodiment one: the preparation of thermal insulation putty:

[0046] Each component is as follows by mass:

[0047] Component A: polyvinyl alcohol aqueous solution (10% solid content): 10 parts (i.e. 1 part solid, 9 parts water);

[0048] Component B: foaming crosslinking agent 4,4-diphenylmethane diisocyanate: 0.25 parts;

[0049] Component C: 12.5 parts of 200 mesh floating beads, 120 mesh perlite: 1.25 parts;

[0050] Component D: silica sol (30% solid content): 2.5 parts (that is, 0.75 parts of solid, 1.75 parts of water);

[0051] Component E: calcium carbonate: 0.5 parts

[0052] How to use: On the construction site, weigh the component A and component B of the liquid material in proportion and pre-mix them, and use mechanical stirring to make them even. Then slowly pour components C, D, and E into the mixing pot while stirring. When mixing, use a high-speed mixer with a rotation speed of not less than 1000r / min to stir, and stir at a high speed for 5 minutes...

Embodiment 2

[0055] Example 2: Production of thermal insulation putty

[0056] The individual components are as follows by weight:

[0057] Component A: polyvinyl acetate emulsion (10% solid content): 10 parts (that is, 1 part solid, 9 parts water);

[0058] Component B: foaming crosslinking agent 4,4-diphenylmethane diisocyanate: 0.5 parts;

[0059] Component C: 6.25 parts of 200-mesh floating beads, 5.75 parts of 200-mesh vermiculite, 2 parts of 120-mesh perlite;

[0060] Component D: 3 parts of silica sol (30% solid content) (that is, 0.9 parts of solid, 2.1 parts of water).

[0061] E component: Calcium carbonate: 1 part

[0062] How to use: On the construction site, weigh the liquid material component A, component B and reinforcing agent in proportion and pre-mix them, and use mechanical stirring to make them even. Then slowly pour components C, D, and E into the mixing pot while stirring. When mixing, use a high-speed mixer with a rotation speed of not less than 1000r / min to stir...

Embodiment 3

[0063] Embodiment three: a kind of thermal insulation putty, each component is as follows by weight:

[0064] Component A: polyvinyl acetate emulsion (20% solid content): 5 parts (1 part solid, 4 parts water)

[0065] Component B: foaming crosslinking agent 4,4-diphenylmethane diisocyanate: 0.5 parts

[0066] Component C: 10.5 parts of 200-mesh floating beads, 0.85 parts of 120-mesh magnesium oxide.

[0067] Component D: 3 parts of silica sol (30% solid content) (that is, 0.9 parts of solid, 2.1 parts of water).

[0068] E component: Calcium carbonate: 1 part

[0069] Add 0.05 parts of polycarboxylate superplasticizer (40% solid content).

[0070] How to use: On the construction site, weigh the liquid material component A, component B and water reducing agent in proportion and pre-mix them, and use mechanical stirring to make them even. Then slowly pour components C, D, and E into the mixing pot while stirring. When mixing, use a high-speed mixer with a rotation speed of n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com