Patents

Literature

368results about How to "High sulfur capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition for a desulfurizer with a high sulfur capacity and the process of making the same

ActiveUS20080047395A1Quality improvementEasy to operateGas treatmentBlast furnace componentsActive componentLiquid state

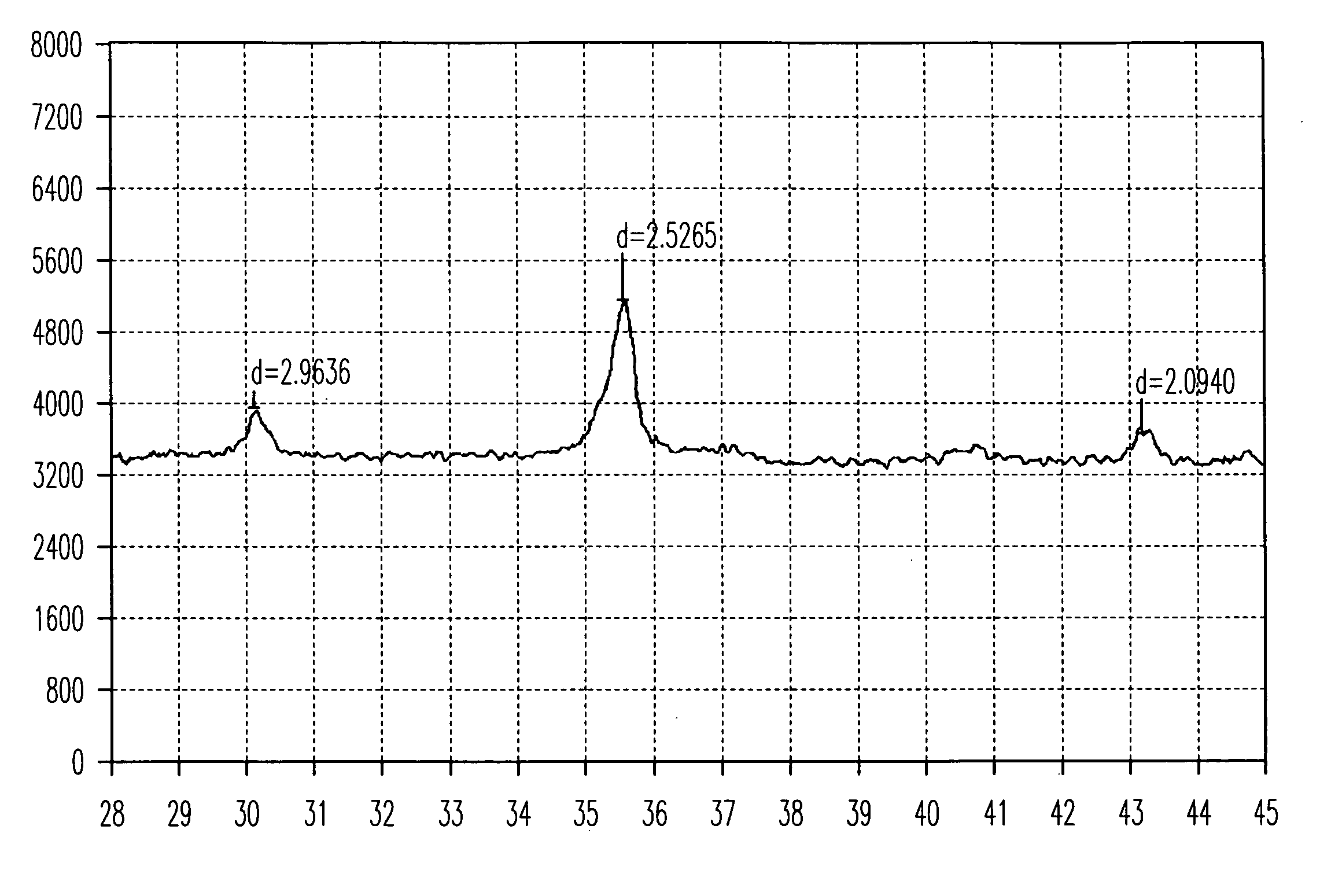

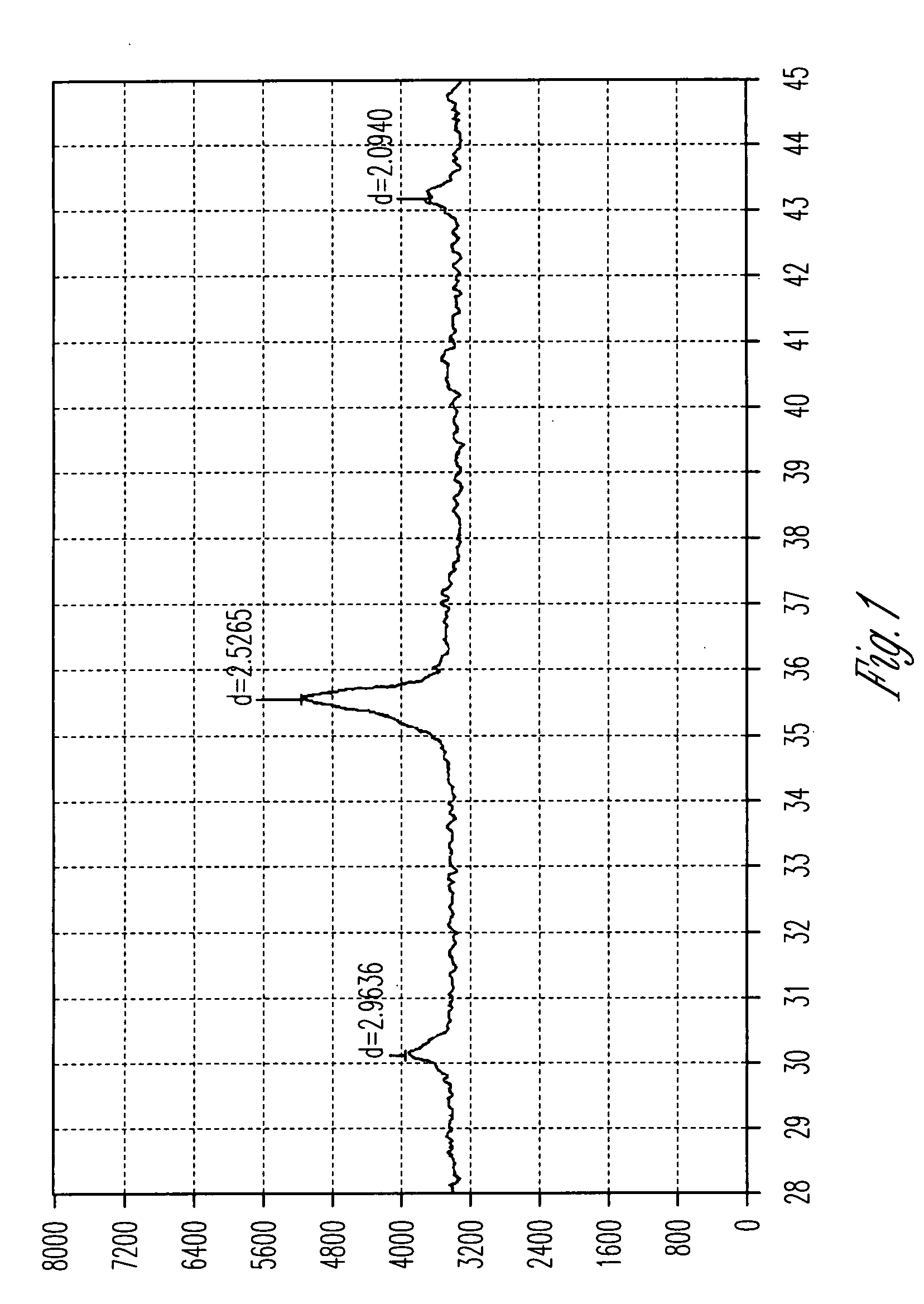

The present invention discloses a composition for a desulfurizer with a high sulfur capacity and a process for making the same. The composition comprises the active components of three kinds of iron oxides and is used in the desulfurizer to remove hydrogen sulfide from the gaseous and liquid state feed stocks. The above-mentioned composition comprises cubic ferroferric oxide in the form of crystalline phase (Fe3O4), amorphous ferric oxide (Fe2O3) and amorphous ferric oxide monohydrate (Fe2O3.H2O). The composition has a sulfur capacity of at least 40%. The process for preparing the composition comprises the following steps: (1) mixing a solid ferrous compound with a solid hydroxide at a molar ratio of iron to hydroxyl being in the range from 1:2 to 1:3; (2) kneading the mixture feeds obtained in step (1) and making them react completely; (3) drying the products obtained in step (2) in the air; (4) washing and filtering the feeds obtained in the step (3); (5) naturally drying or baking the solids obtained in step (4) to form a composition for a desulfurizer with a high sulfur capacity. The process of the present invention is simple and easy to operate, consumes less energy and produces the products with a stable quality.

Owner:BEIJING HAIXIN ENERGY TECH CO LTD

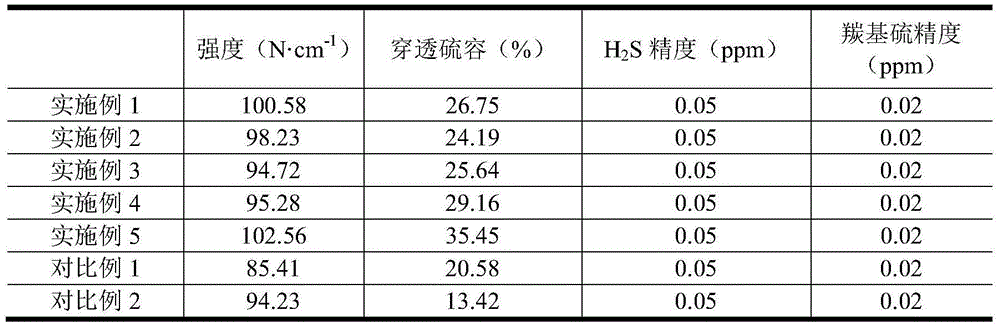

Iron-base desulfurizer for catalyzing, translating and absorbing carbonyl sulfur at middle-low temperature and preparation thereof

InactiveCN101054538AHigh breakthrough sulfur capacityHigh precisionCombustible gas purificationSyngasSecondary component

The invention relates to a preparation of catalyzing and transforming-absorbing Fe-desulphurizer by high accuracy carbonyl sulfur at medium and low temperature, which has a good hydrogenation effect to the carbonyl sulfur and absorbs the produced carbonyl sulfur. The invention can be used to accurately remove the carbonyl sulfur in the ammonia material gas, coke oven gas, natural gas and composed gas. The desulphurizer is provided with primary active components Fe2O3, CeO2, MnO2, Ni2O3, and secondary components CuO, ZnO, MgO, K2O and etc, and the carriers are Al2O3, ZrO2, and residual binding agent and expanding drilling agent, and water. The process has a reacting temperature of 150-350 DEG C, an airspeed of 500-2000h-1, a carbonyl sulfur concentration in the gas from minim to 5000ppm. The inventive desulphurizer has a high catalytic transforming capacity with a carbonyl sulfur converting ratio more than 99%.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing magnetic oxide iron and magnetic oxide iron desulfurizer prepared thereby

ActiveCN101585557AGuaranteed temperatureGuaranteed firing temperatureIron oxides/hydroxidesFerrous saltsSulfur

The invention relates to a method for preparing magnetic oxide iron Fe21.333O32, which comprises the following steps: (a) mixing solid soluble ferrous salt and solid hydroxid according to a molar ratio of iron to hydroxyl being between 1:2 and 1:3; (b) completing reaction of a mixed material prepared in step (a) by kneading, and controlling the temperature of the material not to exceed 70 DEG C in the kneading process; (c) drying a reaction product obtained in step (b) in air; (d) washing and filtering a material obtained in step (c); (e) naturally drying or baking a solid obtained in step (d); and (f) roasting a product obtained in step (e) at a temperature of between 150 and 500 DEG C. The invention further discloses a magnetic oxide iron Fe21.333O32 desulfurizer prepared by the preparation method. Tests show that the desulfurizer has high sulfur capacity reaching 62.0 percent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Absorbing desulfurizing catalyst for catalytic cracking petroleum and preparing method thereof

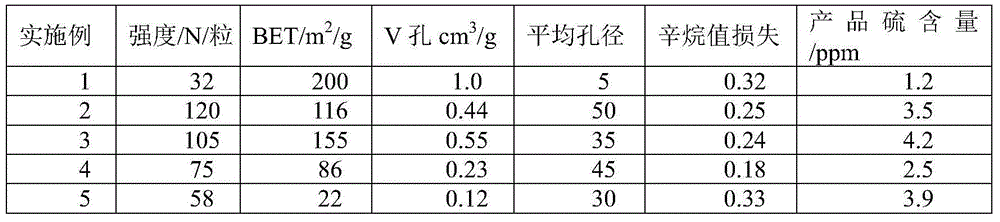

InactiveCN1583962ASuitable for desulfurizationOctane has little effectHydrocarbon oils refiningNano zinc oxidePetroleum

A kind of catalyst for Fcc gasoline's adsorption desulfuration contains in weight percent: 10-85% nano zinc oxide, the atomic diameter of which is 100-500 mu m, 5-80% silica oxide, 5-30% alumina oxide, and 4-45% nickel oxide. The method of preparation is: (1) Mix evenly the nano zinc oxide, silica oxide, alumina oxide, and nickel oxide; dry the particle of step (b); roast the dry particle of step(c); deoxidize the particle of step(d) by proper reductant. The portions of this catalyst remain mixed, and the method adopts the technology of roasting. The catalyst has a good strength, high desulfuration activity, and effective regeneration. Because of the adoption of nano zinc oxide, it causes little to octane number and applies to desulfuration of FCC gasoline. Moreover, the method of preparation is simple and the operation is easy.

Owner:SINOPEC QILU CO

Fuel oil deep-adsorption desulfurizationn catalyst, preparation method and application thereof

ActiveCN104056632ALarge specific surface areaReduce hydrogen consumptionOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSorbent

The invention discloses a fuel oil deep-adsorption desulfurizationn catalyst. The desulfurizationn catalyst is characterized by consisting of an active component, a sulfur adsorbent and an adhesion agent, wherein the active component refers to one or more of Ni, Co, Cu, W and Mo oxides; the sulfur adsorbent refers to at least one of Mg, Ca, Zn, Ce, Fe, Mn and Ti oxides; the mass percent content of the active component is 2wt%-50wt%, the mass percent content of the sulfur adsorbent is 20wt%-90wt%, and the mass percent content of the rest components is the adhesion agent. The adhesion agent is one or a mixture of more than one of aluminium oxide, pseudo-boehmite, kaolin, imvite, bentonite, Yunmeng soil, kieselguhr, silica sol, silica gel and expanded perlite. The catalyst has the advantages of high specific surface area, moderate reaction, high intensity and low hydrogen consumption.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for preparing material containing amorphous iron oxide hydroxide and methods for regenerating the same

The invention relates to a method for preparing a material containing amorphous iron oxide hydroxide and two methods for regenerating the same after being used as desulfurizer. The content of the amorphous iron oxide hydroxide in the material prepared by the invention is as high as 65% to 100%, so the sulfur capacity of the material is high; and the desulfurizer in the prior art is non-regenerative or costly for regeneration, so that the desulfurizer in a large amount cannot but be dumped as waste liquid in landfills, while the amorphous iron oxide hydroxide in the material of the invention can be repeatedly regenerated and reused after the material is used as the desulfurizer, thereby solving the problems of the waste of effective resources in the original desulfurizer and the severe environmental pollution.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Gasoline desulfurization method

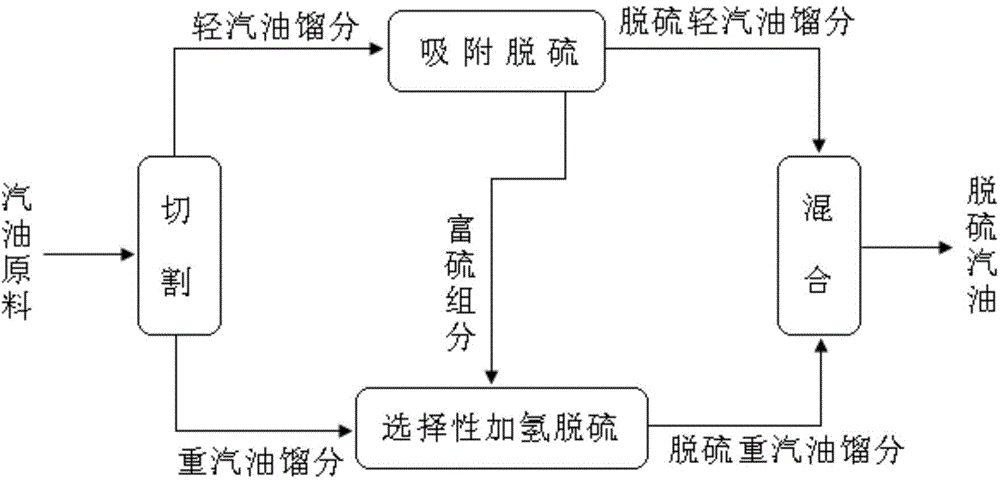

InactiveCN104673376ARealize deep desulfurizationLow component contentTreatment with hydrotreatment processesGasolineRaw material

The invention provides a gasoline desulfurization method. The gasoline desulfurization comprises the following steps: cutting a gasoline raw material into a light gasoline fraction and a heavy gasoline fraction; performing adsorption desulfurization on the light gasoline fraction to obtain desulfurized light gasoline fraction; and performing selective hydrogenation desulfurization on the heavy gasoline fraction to obtain desulfurized heavy gasoline fraction, wherein the cutting temperature of the light gasoline fraction and the heavy gasoline fraction is 70-110 DEG C. By adopting the gasoline desulfurization method, not only can deep desulfurization of gasoline be realized, but also the octane loss is low.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Method for preparing amorphous FeOOH and FeOOH desulfurizer prepared thereby

ActiveCN101585556AAvoid generatingTroubleshoot follow-up issuesIron oxides/hydroxidesFerrous saltsPhysical chemistry

The invention relates to a method for preparing amorphous FeOOH, which comprises the following steps: (a) mixing solid soluble ferrous salt and solid hydroxid according to a molar ratio of iron to hydroxyl being between 1:2 and 1:3; (b) completing reaction of a mixed material prepared in step (a) by kneading, and controlling the temperature of the material not to exceed 70 DEG C in the kneading process; (c) drying a reaction product obtained in step (b) in air; (d) washing and filtering a material obtained in step (c); and (e) naturally drying or baking a solid obtained in step (d). On the basis, the invention further discloses an amorphous FeOOH desulfurizer prepared by the preparation method, and the desulfurizer has high sulfur capacity and high desulfurization efficiency.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

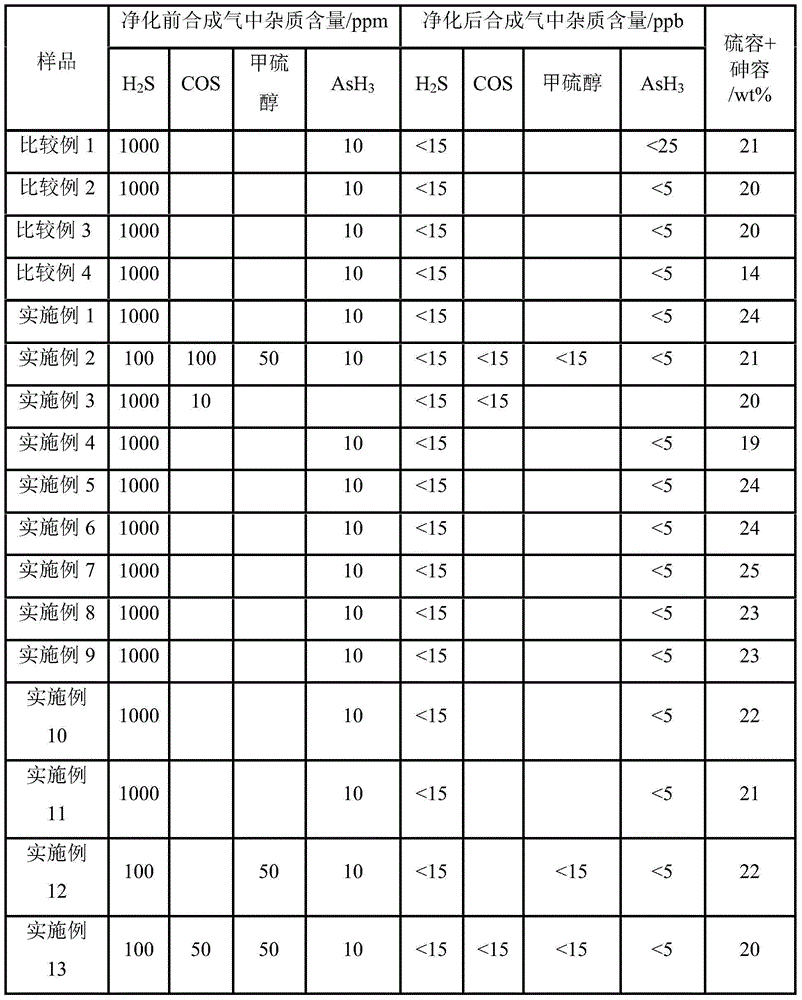

Sulfur and arsenic adsorbent and preparation method thereof

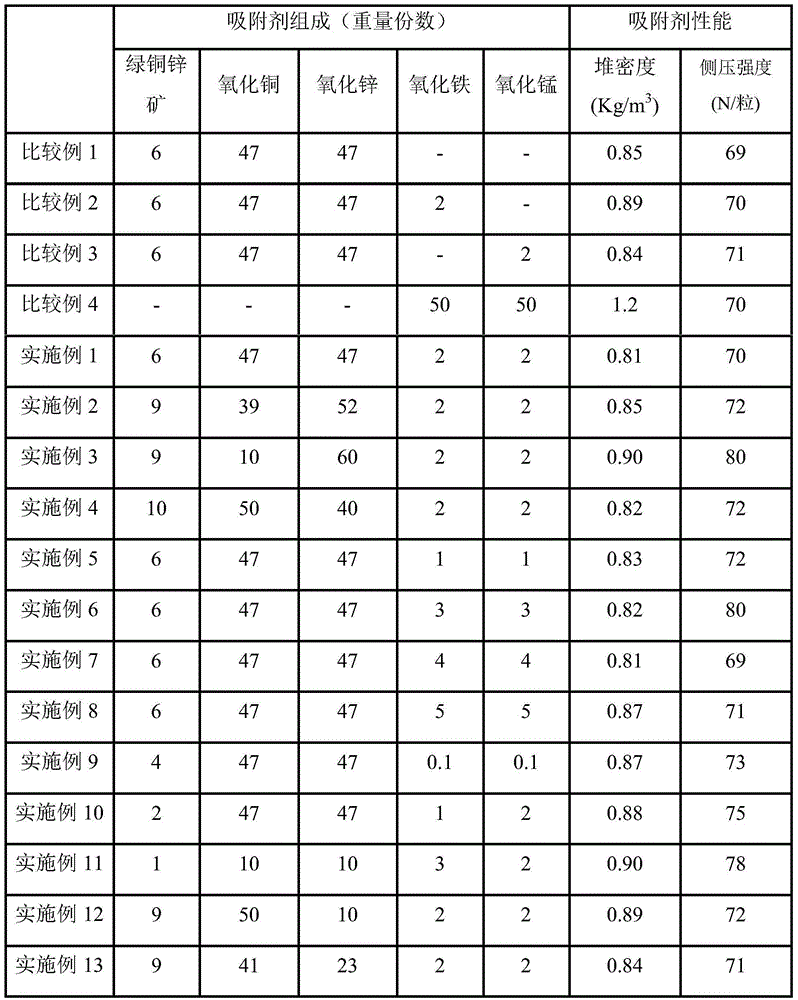

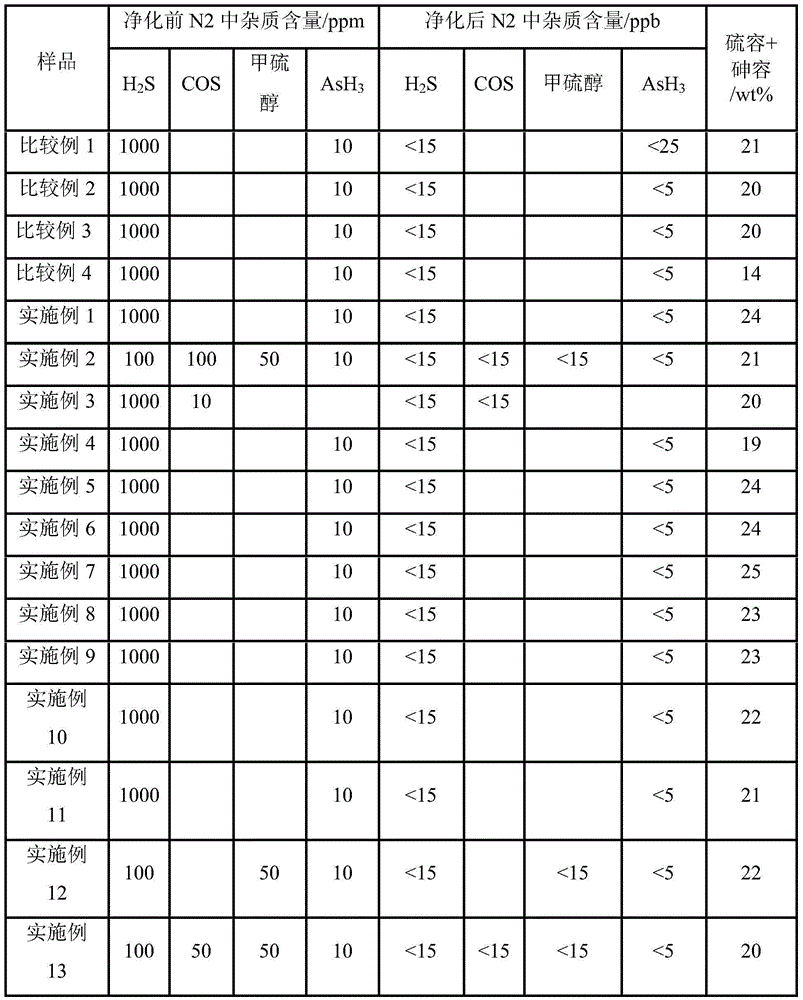

ActiveCN105214599AHigh sulfur capacityIncrease arsenic capacityOther chemical processesSorbentSulfur

The invention relates to a sulfur and arsenic adsorbent and a preparation method thereof to mainly solve the problems of high bulk density and low sulfur and arsenic capacity of sulfur and arsenic adsorbents in the prior art. The sulfur and arsenic adsorbent comprises, by weight, 1-10 parts of aurichalcite, 10-50 parts of copper oxide, 10-60 parts of zinc oxide, 0.1-5 parts of iron oxide and 0.1-5 parts of manganese oxide. The sulfur and arsenic adsorbent adopting the above technical scheme well solves the problems, and can be used to purify natural gas, synthetic gases and lightweight gas and liquid hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

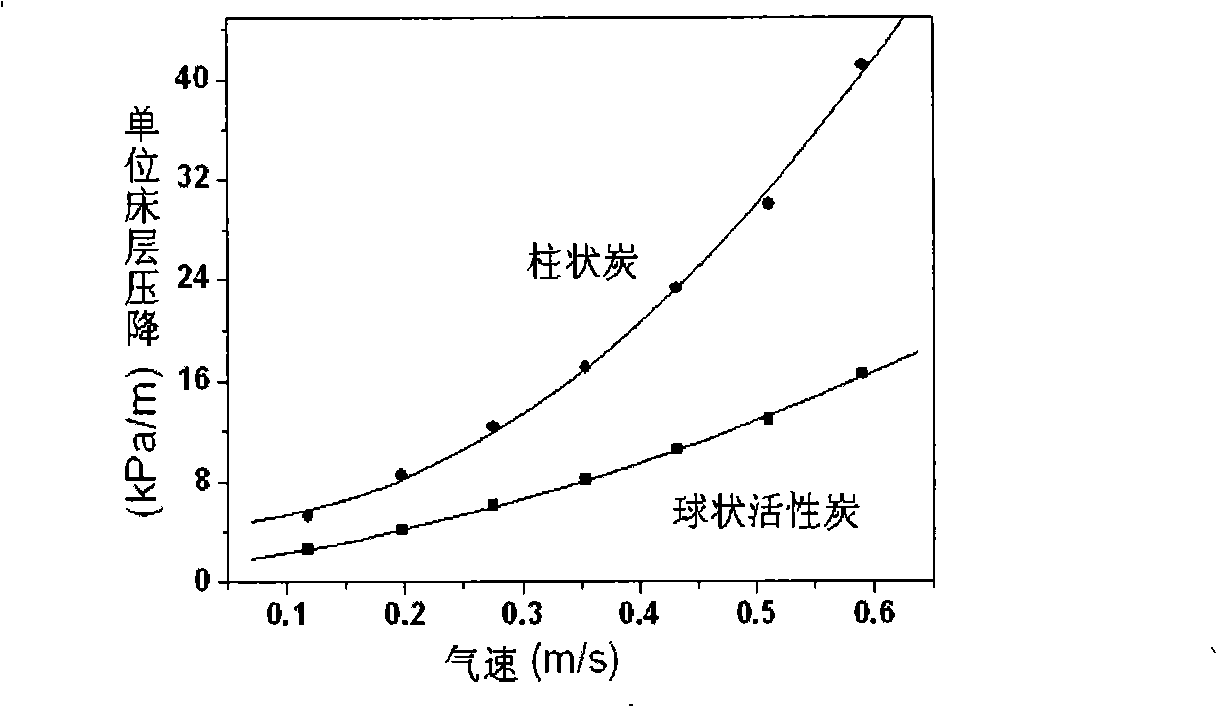

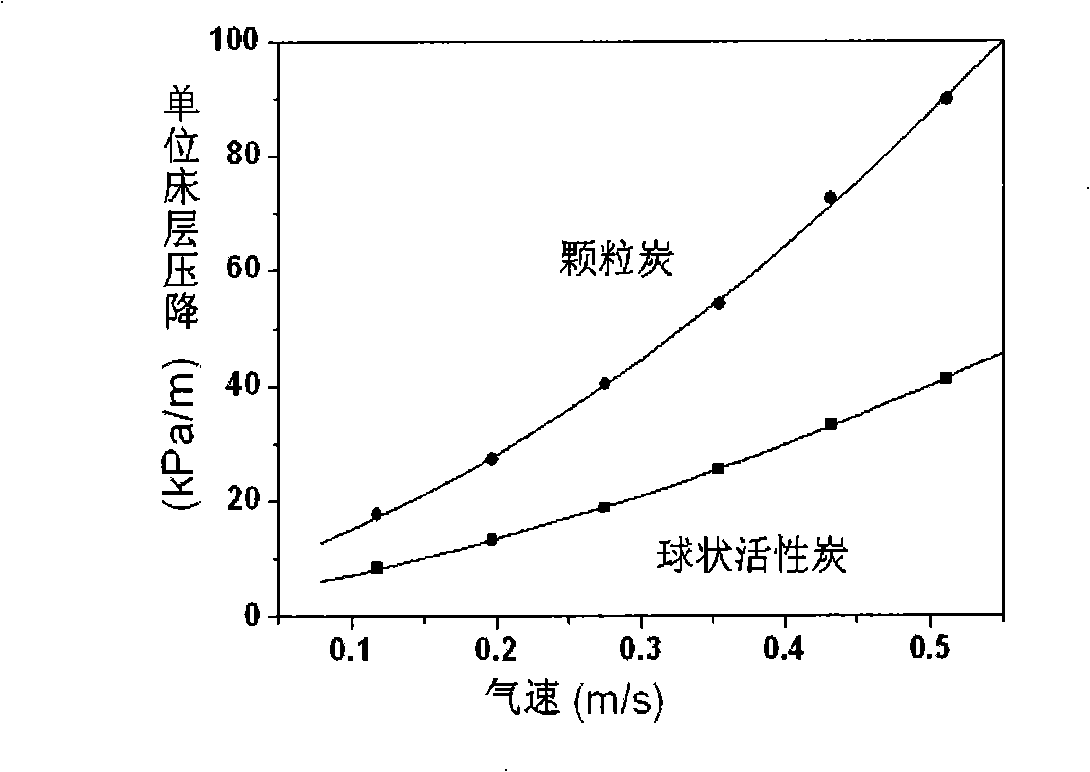

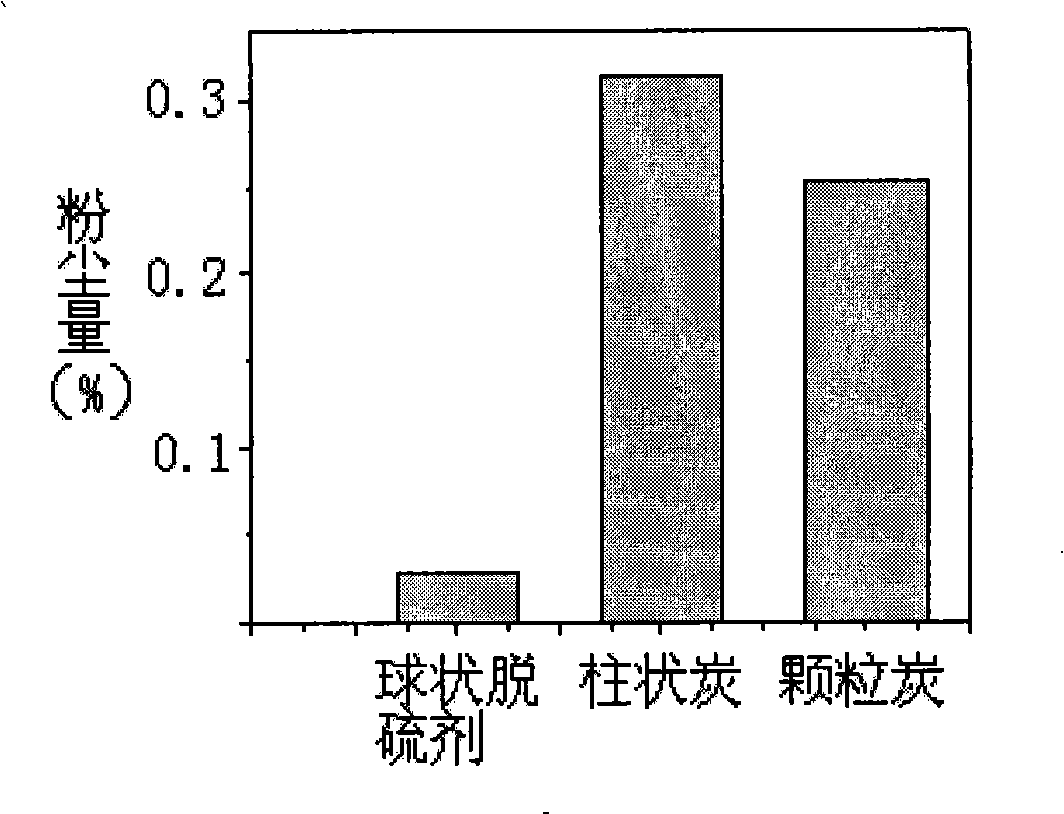

Novel globular active carbon and use in desulfuration field

InactiveCN101347718AUniform appearanceRegular structureOther chemical processesDispersed particle separationExhaust gasActivated carbon

The invention relates to novel spherical active carbon and the application thereof in the field of desulfurization. The novel spherical active carbon of the invention is prepared by carrying out equivalent volume impregnation or excessive impregnation of pitch-based spherical activated carbon or resin-based spherical activated carbon with the alkaline compound of sodium or potassium and drying the materials at 30-160 DEG C. The novel spherical active carbon of the invention can be taken as H2S desulfurizer and has the advantages of simple preparation, large breakthrough sulfur capacity, small air resistance in the application of a fixed bed, small pressure reduction and low dust capacity of active carbon. The novel spherical active carbon can be widely applied to the removal process of H2S in the tail gas of sewage treatment plants, synthesis gases, petroleum and natural gas.

Owner:EAST CHINA UNIV OF SCI & TECH

Adsorbent for deep desulfurization of refined benzene and preparation method thereof

InactiveCN103041766AHigh sulfur capacityImprove adsorption capacityOther chemical processesAdsorption purification/separationBenzeneSorbent

The invention provides an adsorbent for deep desulfurization of refined benzene and a preparation method thereof. With alumina or sodium-potassium-lanthanum modified alumina as carrier-loaded noble metal palladium, the adsorbent at least comprises the following components in percentage by weight: 0.3-1.5 % of noble metal palladium, 0-3 % of sodium, 0-3 % of potassium, 0-5 % of lanthanum and the balance of alumina carrier. A best desulfurization effect is obtained if the alumina manufactured by using an oil column molding method is used as the carrier-loaded noble metal palladium. The adsorbent provided by the invention has the advantage of strong adsorbing capacity to sulfur and large sulfur capacity; and the total sulfur in the refined benzene can be reduced from 1 ppm to less than 0.01 ppm.

Owner:YANTAI BAICHUAN HUITONG TECH CO LTD

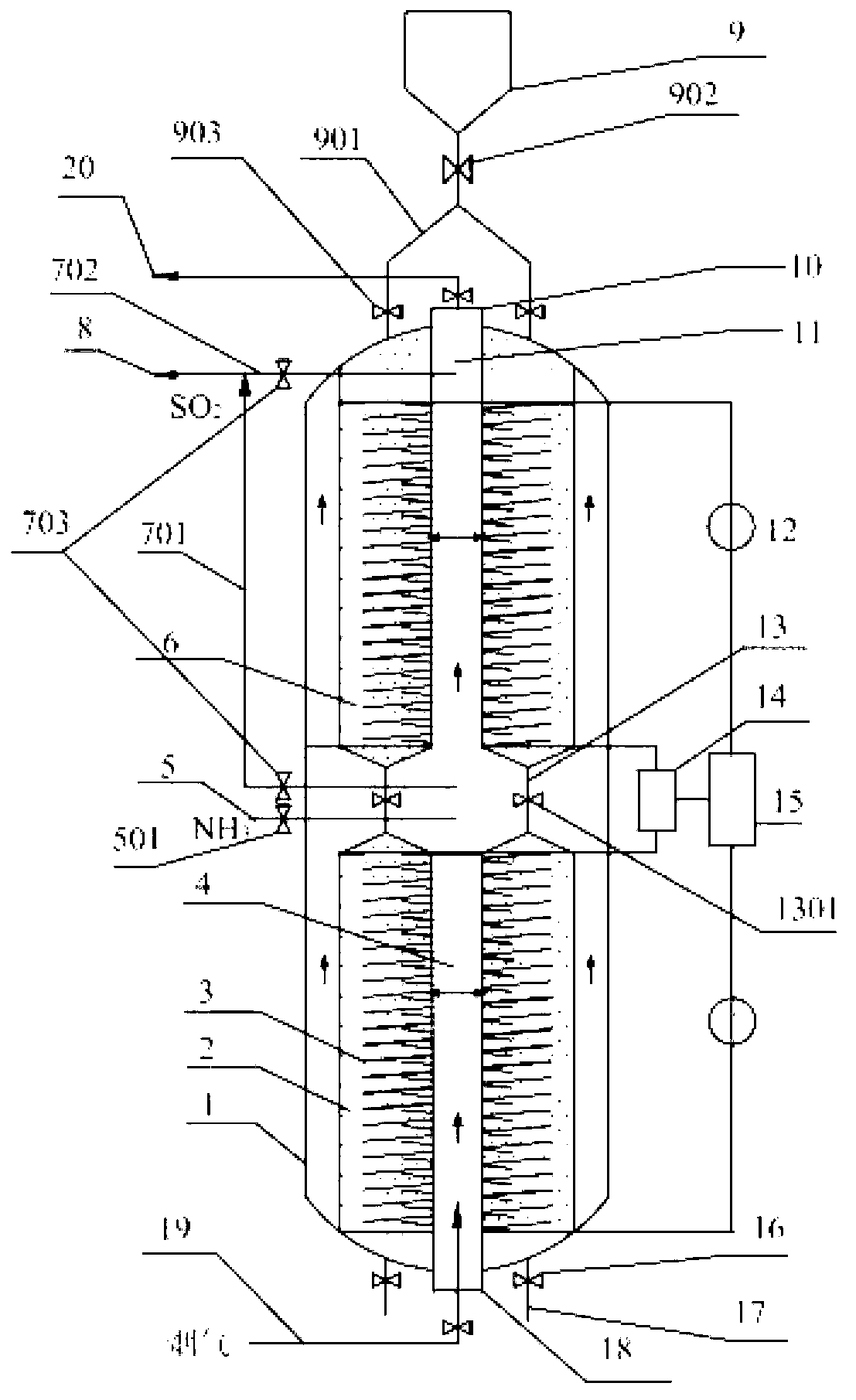

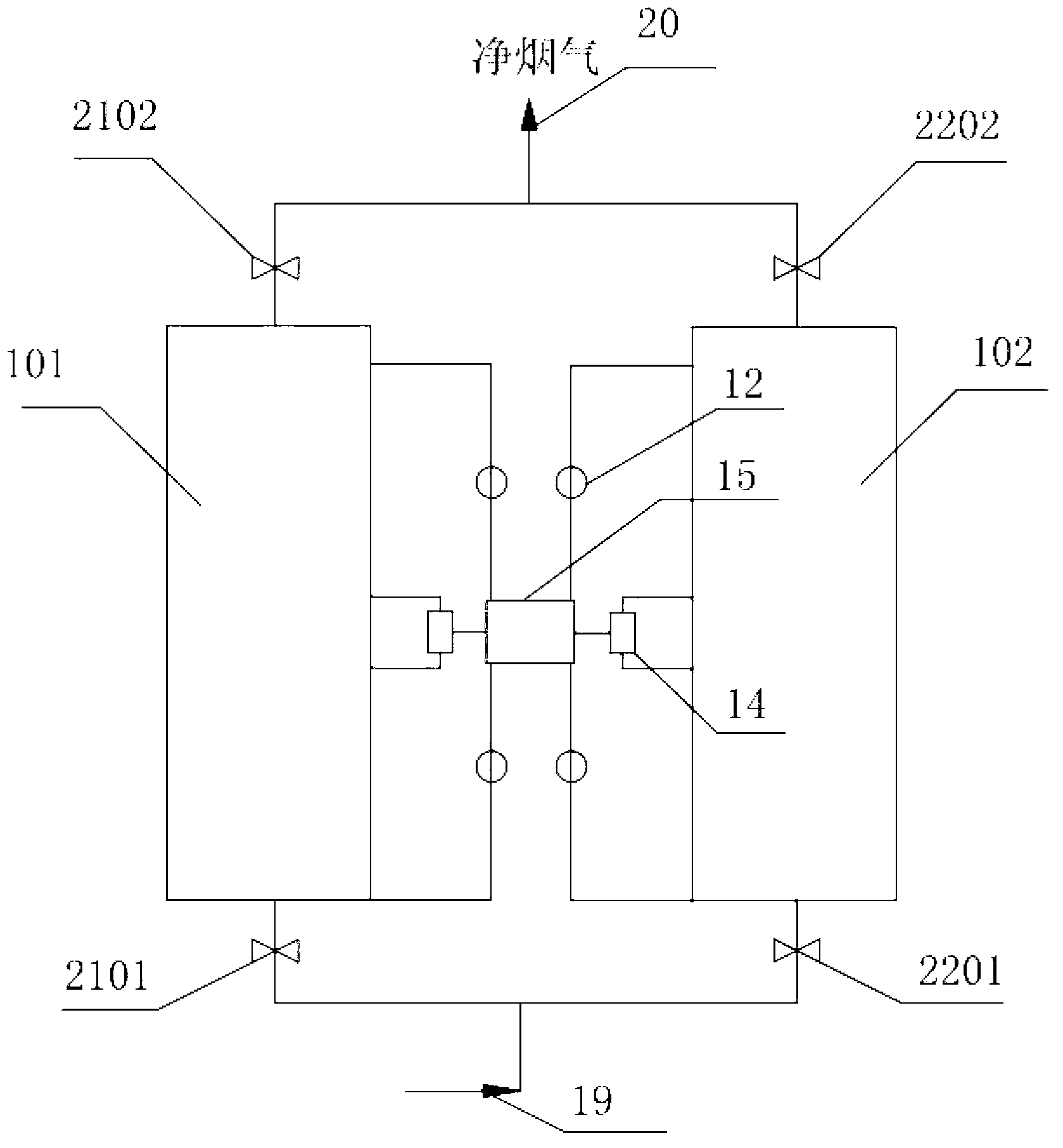

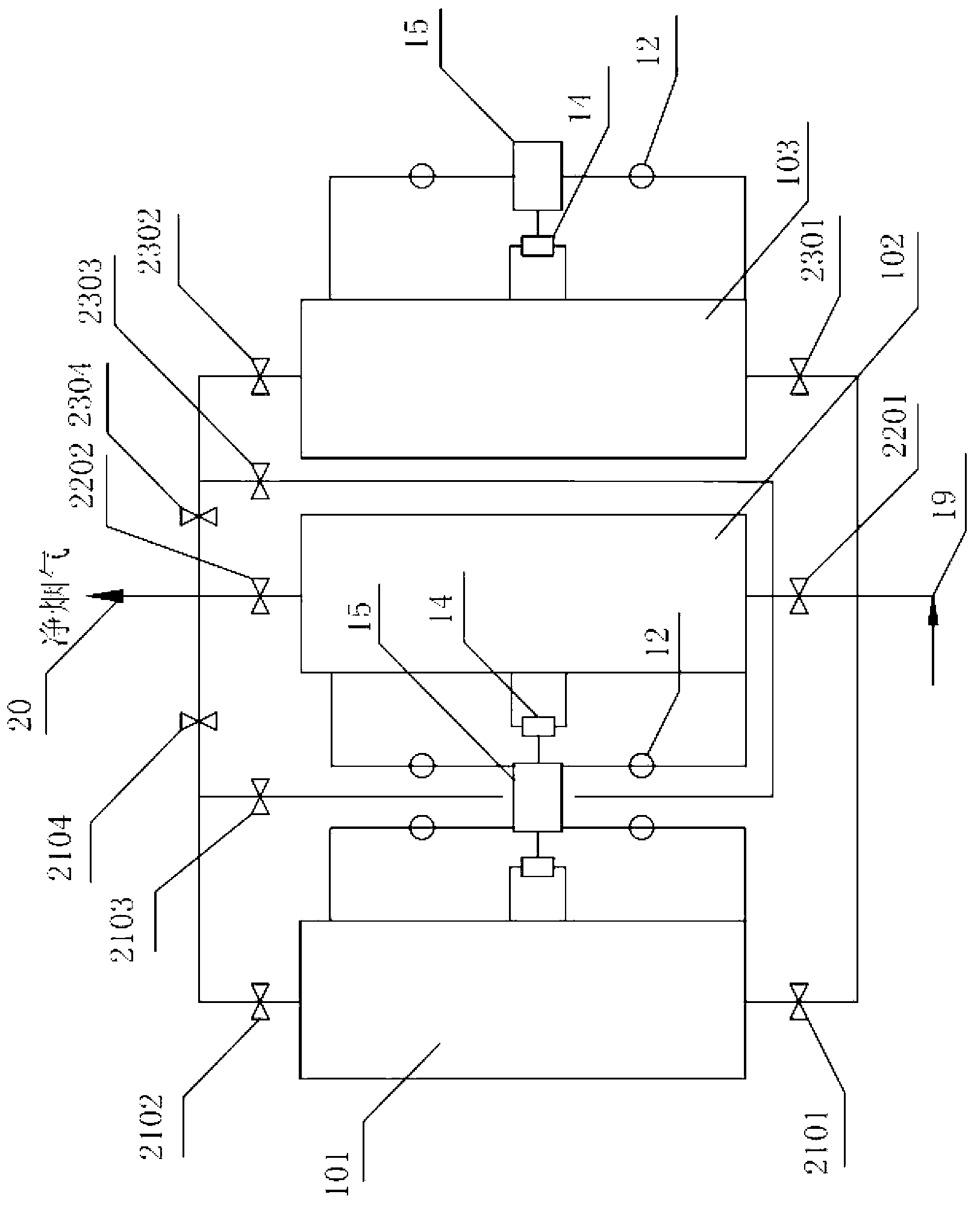

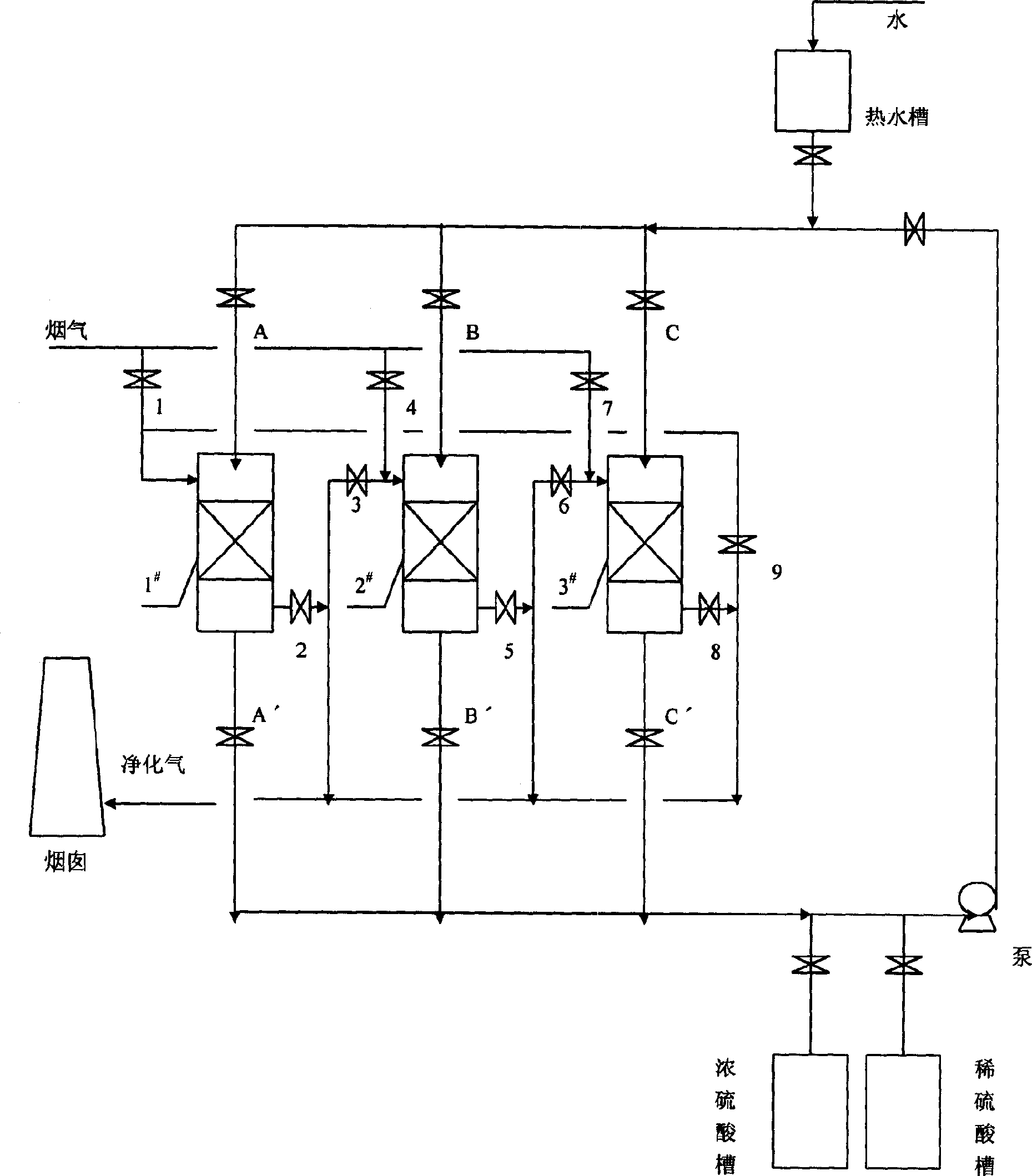

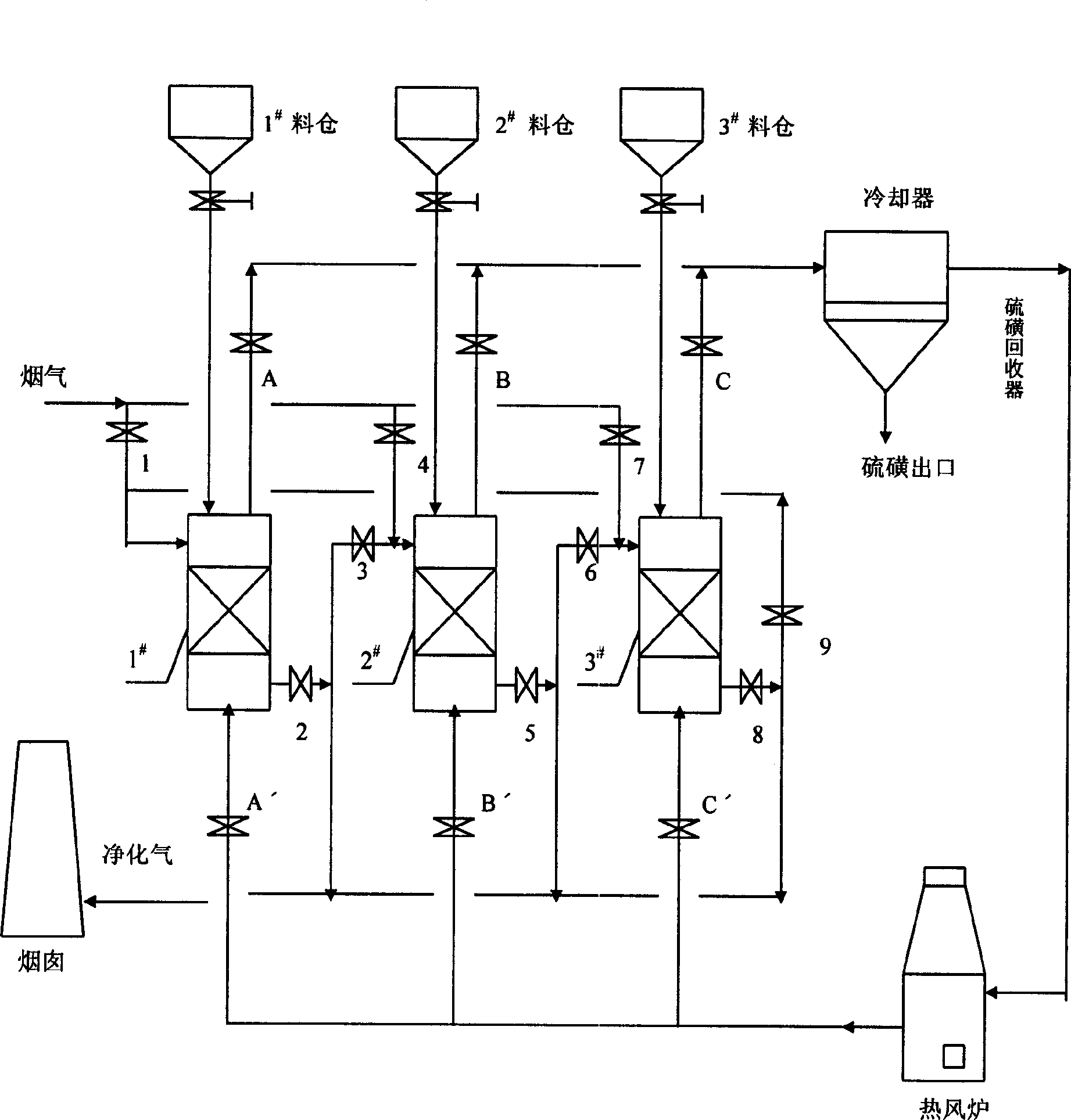

Flue gas cleaning system capable of switching pollutant desorption technology and adsorbent regeneration technology and method thereof

ActiveCN103007679AIncrease investment costNot easy to repairDispersed particle separationFlue gasDesorption

The invention provides a flue gas cleaning system capable of switching a pollutant desorption technology and an adsorbent regeneration technology. The system comprises two or more fixed bed reactors, a regenerative heating device which is used for adsorbent regeneration, and a to-be-cleaned flue gas valve and a flue gas cleaning valve which are used for controlling switching between the pollutant desorption technology and the adsorbent regeneration technology, wherein each of the fixed bed reactor is internally provided with a central tube connected with a flue gas inlet, as well as a first adsorption layer and a second adsorption layer which are used for cleaning flue gas and arranged on the outer side of the central tube; and the upper end of the central tube is connected with a flue gas outlet. The invention further discloses a flue gas cleaning method using the system. The system can be used for performing the flue gas pollutant desorption technology and the adsorbent regeneration technology in one fixed bed reactor, and achieve the switching between the pollutant desorption technology and the adsorbent regeneration technology in the different fixed bed reactors.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

Desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time

ActiveCN104437074AHigh mechanical strengthEvenly distributedDispersed particle separationCarbonyl sulfideAccelerant

The invention discloses a desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time. The desulfurizing agent is prepared through the following steps that S1, a compound containing zinc, a binder and an accelerant are mixed, kneaded and formed; S2, a mixture formed after mixing, kneading and forming in the S1 is dried, and then a dried desulfurizing carrier precursor is obtained; S3, the desulfurizing carrier precursor obtained in the S2 is calcinated, and then a desulfurizing agent carrier is obtained; S4, the desulfurizing agent carrier is impregnated in a first copper salt solution, and copper active components are loaded on the desulfurizing agent carrier, wherein the first copper salt solution is an ammonium hydroxide solution of basic cupric carbonate; S5, an impregnated sample obtained in the S4 is dried and calcinated, and then the desulfurizing agent for removing hydrogen sulfide and carbonyl sulfide at the same time is obtained. The obtained desulfurizing agent is high in strength and not prone to pulverization, the impregnation effect of the active components is better, and hydrogen sulfide and carbonyl sulfide impurities in a high-temperature industrial gas source can be efficiently removed at the same time.

Owner:SHENYANG SANJUKAITE CATALYST

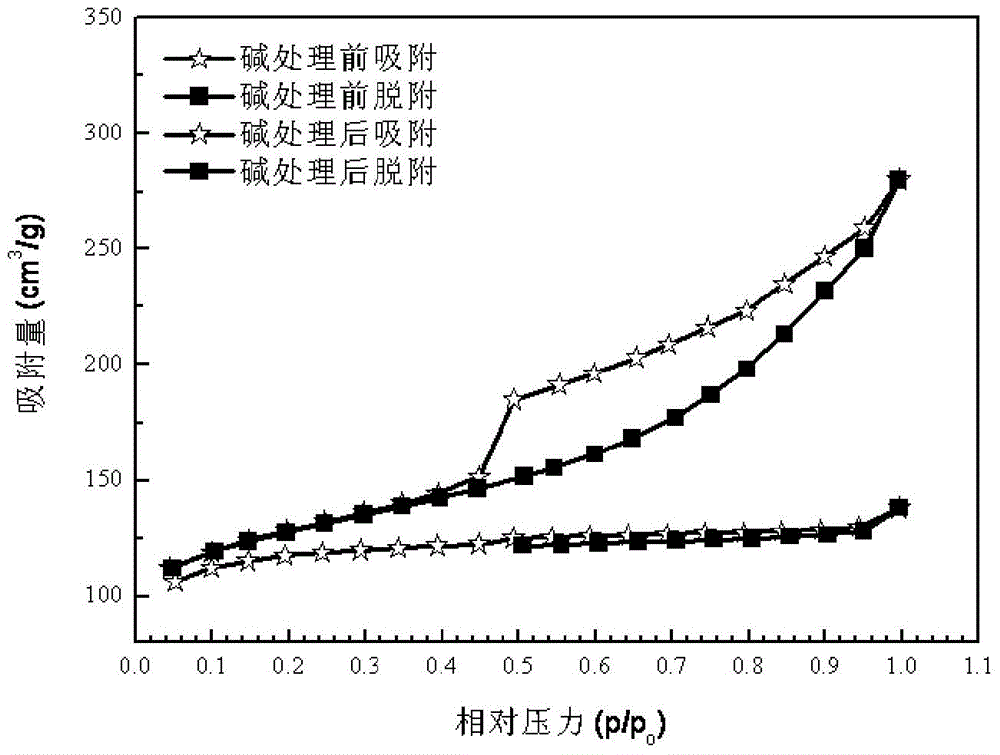

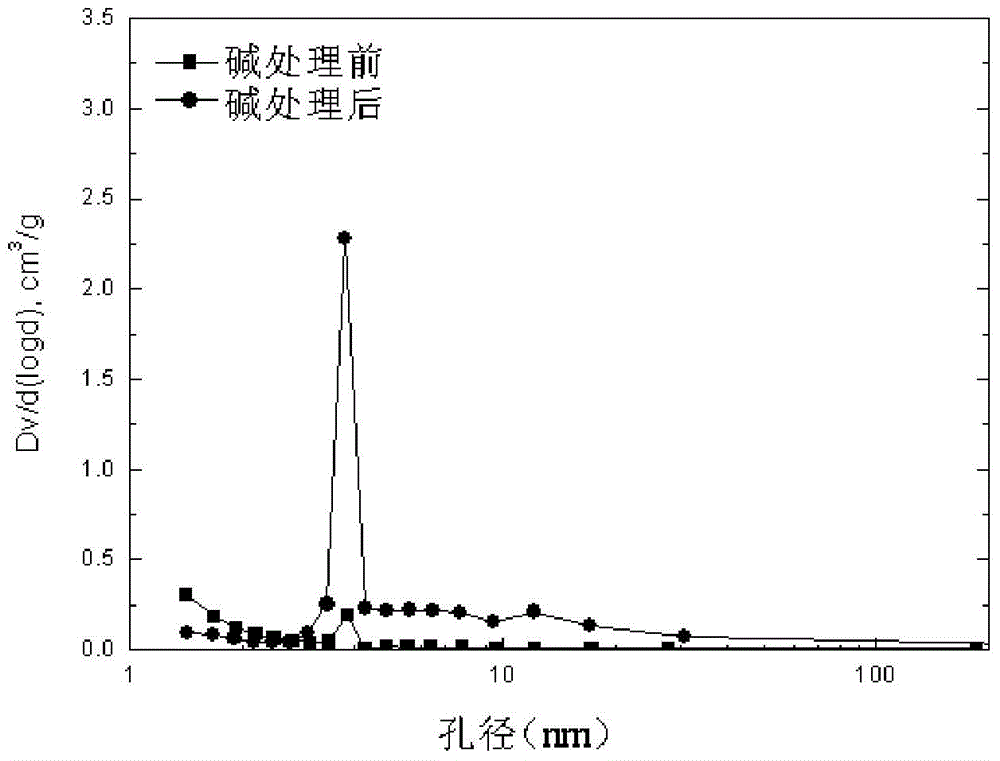

Desulfurization adsorption agent used for gasoline and gasoline desulfurization method

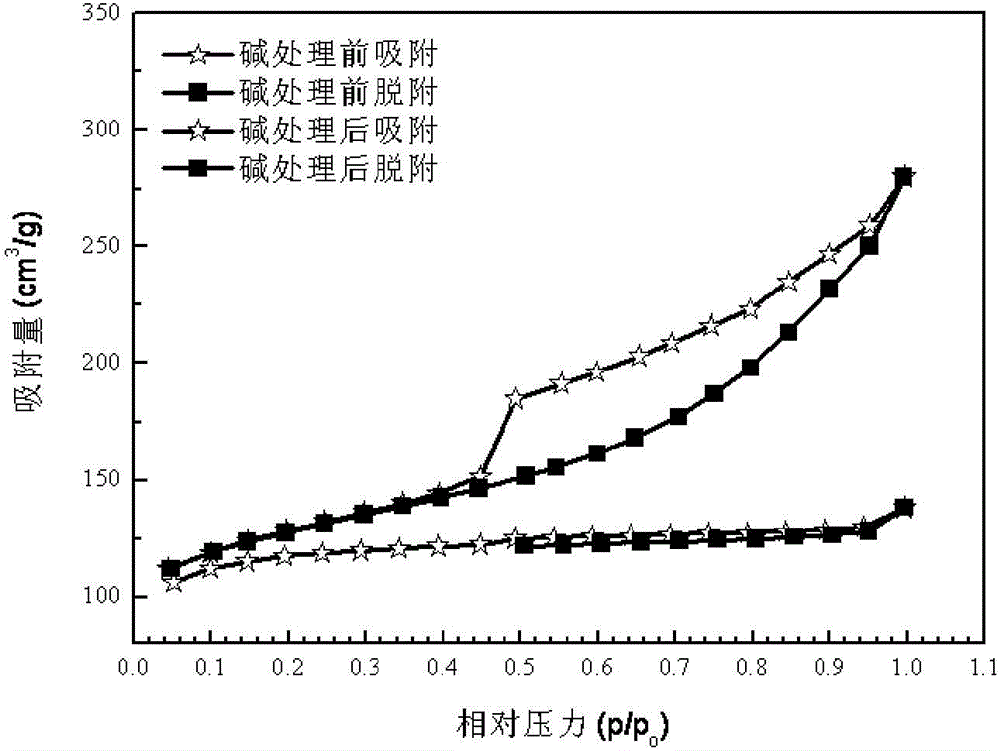

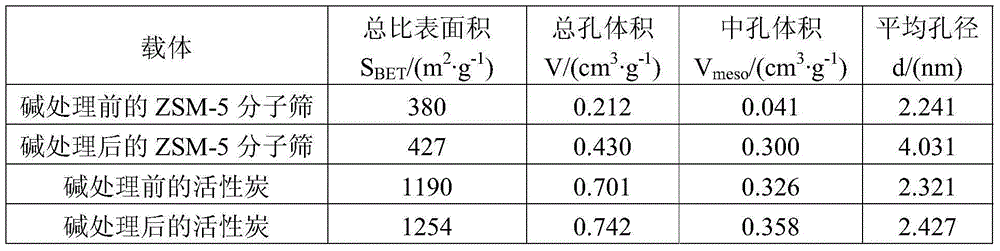

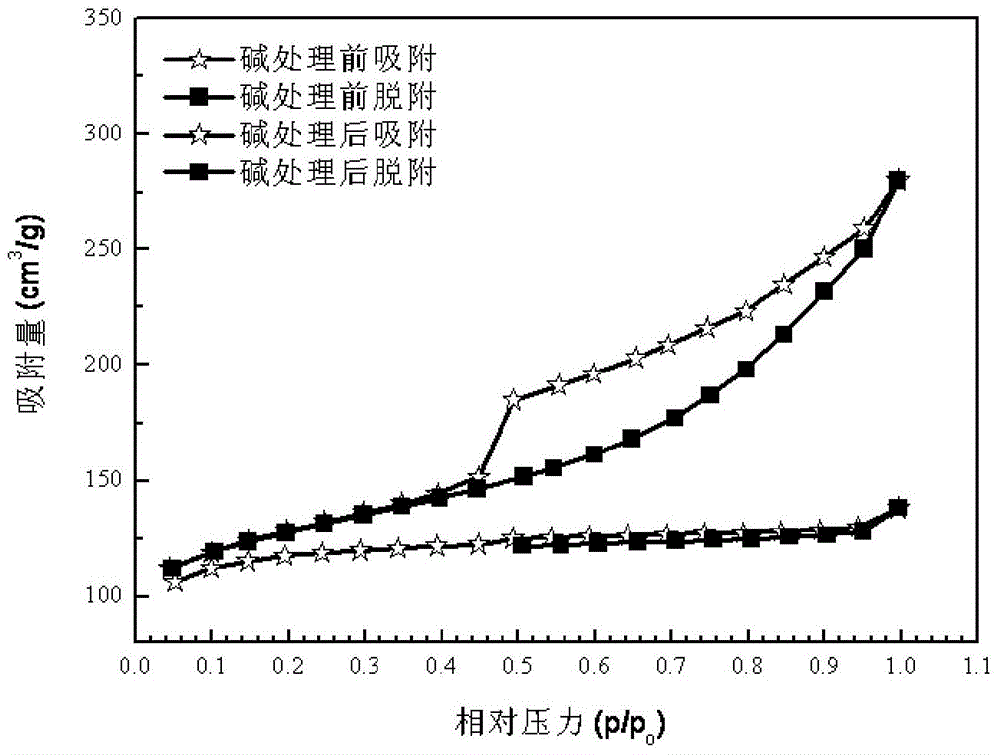

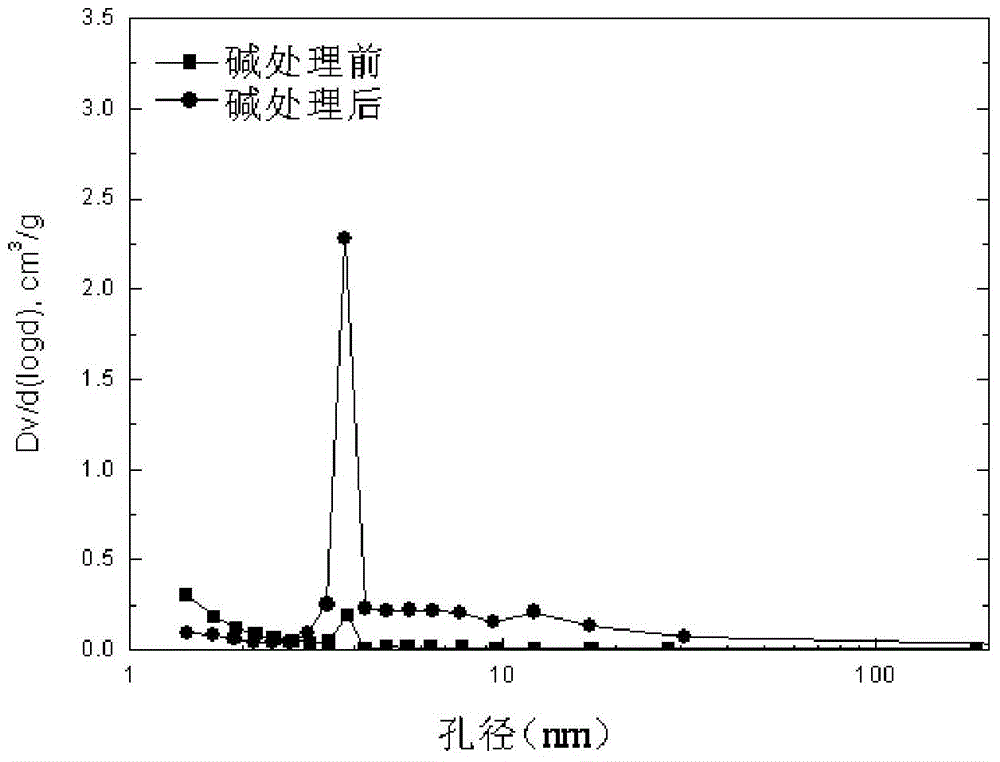

InactiveCN104667861AGood choiceHigh sulfur capacityOther chemical processesCombustible gas purificationMolecular sieveActive carbon

The invention provides a desulfurization adsorption agent used for gasoline and a gasoline desulfurization method. The desulfurization adsorption agent is obtained by taking a molecular sieve treated by an alkali and active carbon as compound carriers, and loading active metal components, wherein active metal is selected from one or more of elements in IA, IIA, VIII, IB, IIB and VIB groups in a periodic table. The desulfurization adsorption agent has a large sulfur capacity and long service life; and furthermore, a regeneration method is simple.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Desulfurizer with high sulfur capacity for eliminating sulfur alcohol, sulphide and hydrogen sulfide through catalytic oxidation, and preparation

ActiveCN101049551ASimple processLow equipment investment costDispersed particle separationCatalyst activation/preparationChemistryActivated carbon

A desulfurizing with high sulfur capacity for removing thiols, thioether and hydrogen sulfide from natural gas, petroleum gas, and other industrial gases is composed of carrier (activated carbon) and catalyzing component prepared from metallic oxide or salt (0.1-5 Wt%), modifier (2-10) and promoter (0.01-0.5). Its preparing process includes such steps as pre-treating activated carbon, impregnating the catalytic component, and drying.

Owner:DALIAN CATALYTIC ENG TECH

Quality improvement method of catalytic cracking gasoline

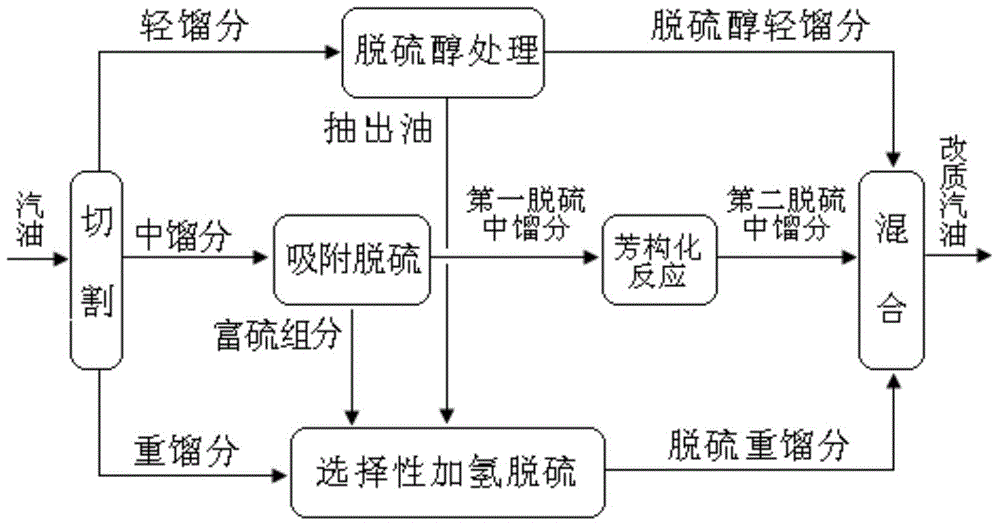

InactiveCN104673377ARealize deep desulfurizationFlexible operationTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationAromatization

The invention provides a quality improvement method of catalytic cracking gasoline. The quality improvement method comprises the following steps of: cutting a gasoline raw material into light, medium and heavy gasoline fractions; desulfurizing the medium gasoline fraction to obtain first desulfurized medium gasoline fraction; carrying out aromatization / hydroisomerization reaction on the first desulfurized medium gasoline fraction in the presence of a catalyst to obtain second desulfurized medium gasoline fraction; carrying out selective hydrodesulfurization on the heavy gasoline fraction to obtain desulfurized heavy gasoline fraction; mixing the light gasoline fraction, the second desulfurized medium gasoline fraction and the desulfurized heavy gasoline fraction to obtain quality improved gasoline, wherein the cutting temperature of the light and medium gasoline fractions is 35-60 DEG C, and the cutting temperature of the medium and heavy gasoline fraction is 70-130 DEG C. The quality improvement method provided by the invention can not only realize the deep desulfurization of the catalytic cracking gasoline, but also be used for outstandingly increasing the octane value.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation of high temperature gas desulfurizer

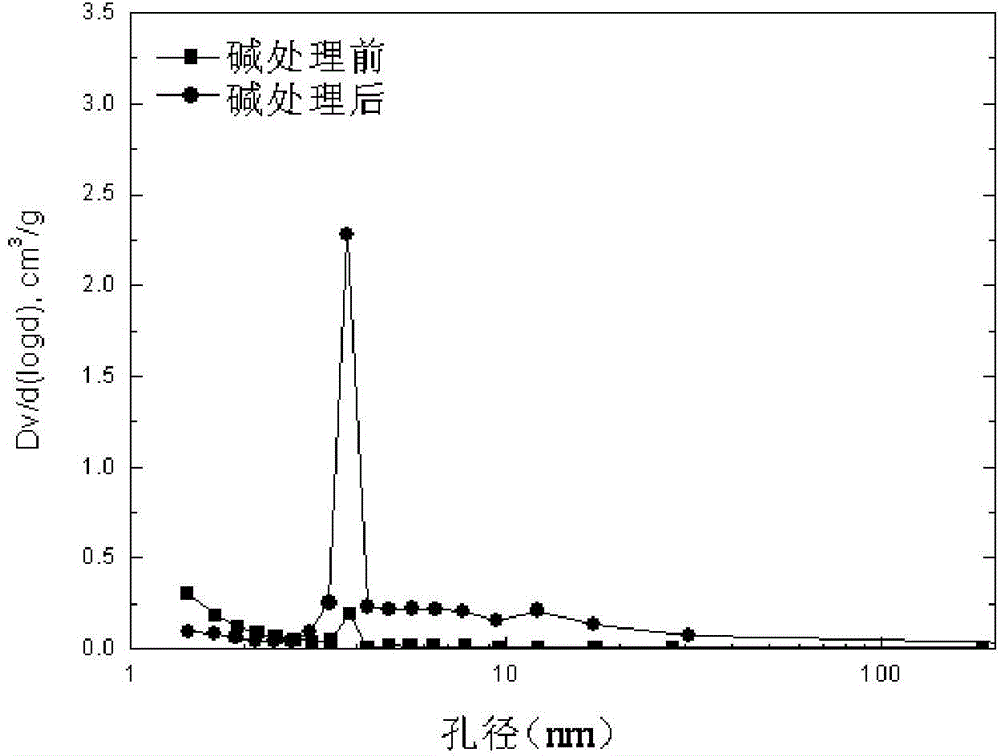

InactiveCN101475844AHigh sulfur capacityStable deliveryCombustible gas purificationPore distributionFuel cells

The invention discloses a method for preparing a high-temperature coal gas desulfurizer, which belongs to the field of preparation of desulfurizer. The method comprises the following steps that: four pore-forming agents with different pore-forming characteristics are prepared, mixed with red mud and burnt earth, ball ground to be below 200 meshes, kneaded by adding water, subjected to extruded molding, and then dried and roasted at high temperature. The specific surface area of the prepared desulfurizer is between 8 and 10m / g, the pore volume is between 0.3 and 0.5cm / g, and pores with dimensions more than 120nm account for 50 percent in the pore distribution. The desulfurizer consists of 80 to 90 weight percent of red mud, 5 to 15 weight percent of adhesive, and 5 to 10 weight percent of pore-forming agent. The desulfurizer prepared by the method has the characteristics of low cost, high sulfur capacity and good stability. The method can be used in the field of high-temperature coal gas purification-key technology of integrated gasification combined cycle power generation and fuel-cell power generation technologies, and the field of desulfurization purification of chemical raw material gas prepared by taking coal, petroleum and natural gas as raw materials.

Owner:TAIYUAN UNIV OF TECH

Desulfurizer

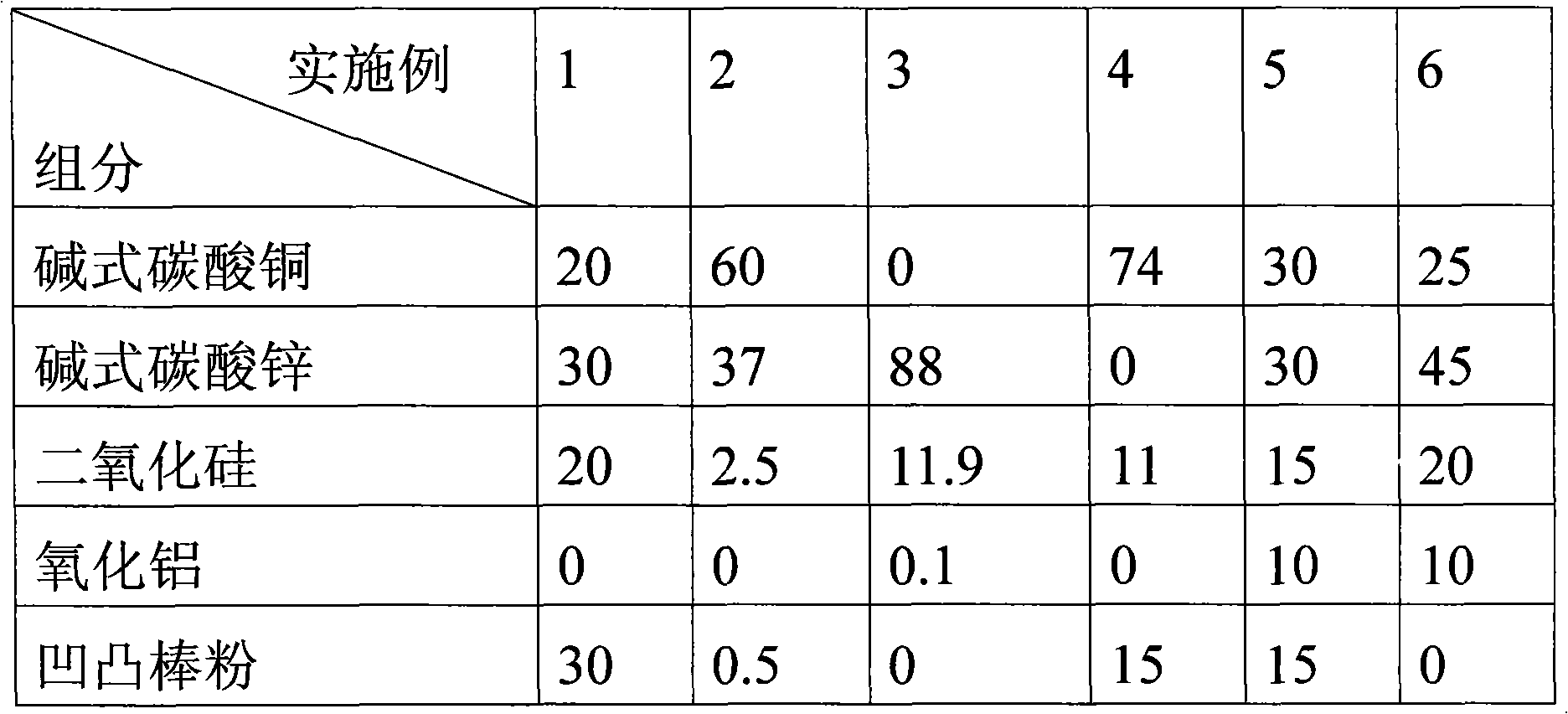

InactiveCN101961594AHigh precisionHigh sulfur capacityDispersed particle separationBASIC CUPRIC CARBONATEDecomposition

The invention discloses a desulfurizer which is composed of subcarbonate, silica and accessory ingredient. Based on the total weight of the desulfurizer, the desulfurizer comprises, in percentage by weight, 50-97 wt% of subcarbonate, 2.5-20 wt% of silica and 0.1-30 wt% of accessory ingredient, wherein the subcarbonate is at least one of basic cupric carbonate and basic zinc carbonate, and the accessory ingredient is at least one of alumina and attapulgite powder. The desulfurization (H2S) precision of the desulfurizer can be less than 0.05mg / M3, and sulphur content is about 20% (Wt / Wt). Because the raw material does not need high-temperature decomposition, energy consumption can be greatly lowered by more than 50%, thus obtaining the purpose of energy saving and emission reduction.

Owner:昆山市精细化工研究所有限公司

High-efficiency deep desulfurization active carbon and preparation method thereof

ActiveCN104667872AHigh sulfur capacityFast desulfurizationOther chemical processesActive agentFiltration

The invention discloses high-efficiency deep desulfurization active carbon and a preparation method thereof, belonging to the field of modified active carbon materials. The high-efficiency deep desulfurization active carbon is prepared through the steps of by adopting coal or a coconut shell as raw materials, crushing, screening, then adding a coal tar adhesive for extrusion forming, and calcining at 750-950 DEG C to form primary active carbon; carrying out dipping treatment on the primary active carbon, uniformly loading a hydroxide active agent and a cyclodextrin assistant active agent, carrying out secondary high-temperature calcination in the presence of excessive heat water vapors to obtain a high-efficiency desulfurization active carbon product. The active carbon prepared through the method disclosed by the invention has the advantages of high sulphur capacity, high desulfurization speed, long usage period, high strength, good abrasion resistance, good material permeability, no dust and the like, can not only be used for the large-scale deep desulfurization and purification of petrochemical products such as fuel oil, natural gas, gas, liquid hydrocarbon and synthetic ammonia, but also be used for the fields of pharmaceutical gas sterilization, solution filtration and purification, solvent recovery, water purification, gas purification and the like.

Owner:JIANGSU ZHUHAI ACTIVATED CARBON CO LTD

Desulphurization and denitration catalyst and preparation method thereof

InactiveCN101518736AWide variety of sourcesEasy accessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsParaffin waxCopper nitrate

The invention discloses a desulphurization and denitration catalyst. The catalyst comprises the following components by mass percentage: 4 to 18 percent of CuO, 80 to 95 percent of gamma-Al2O3, and 1 to 2 percent of promoter. A method for preparing the catalyst comprises the following steps: (1) adding aluminum isopropoxide into distilled water, stirring the mixture, adding a nitric acid solution into the mixture dropwise, and carrying out the evaporation in the air to obtain a boehmite sol; (2) adding the promoter into a copper nitrate solution, then adding the mixture into the boehmite sol, then adding the nitric acid solution dropwise, stirring the mixed solution for ageing, and aggregating the mixed solution into a semi-gel; and (3) adding the semi-gel dropwise into a gel pool containing ammonia water and liquid paraffin through a dropper, and obtaining the catalyst after ageing, drying and baking. The prepared catalyst can be used for synchronous desulphurization and denitration, and can be regenerated and used cyclically with low raw material cost. As the byproducts can be reutilized, the catalyst brings about no secondary pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

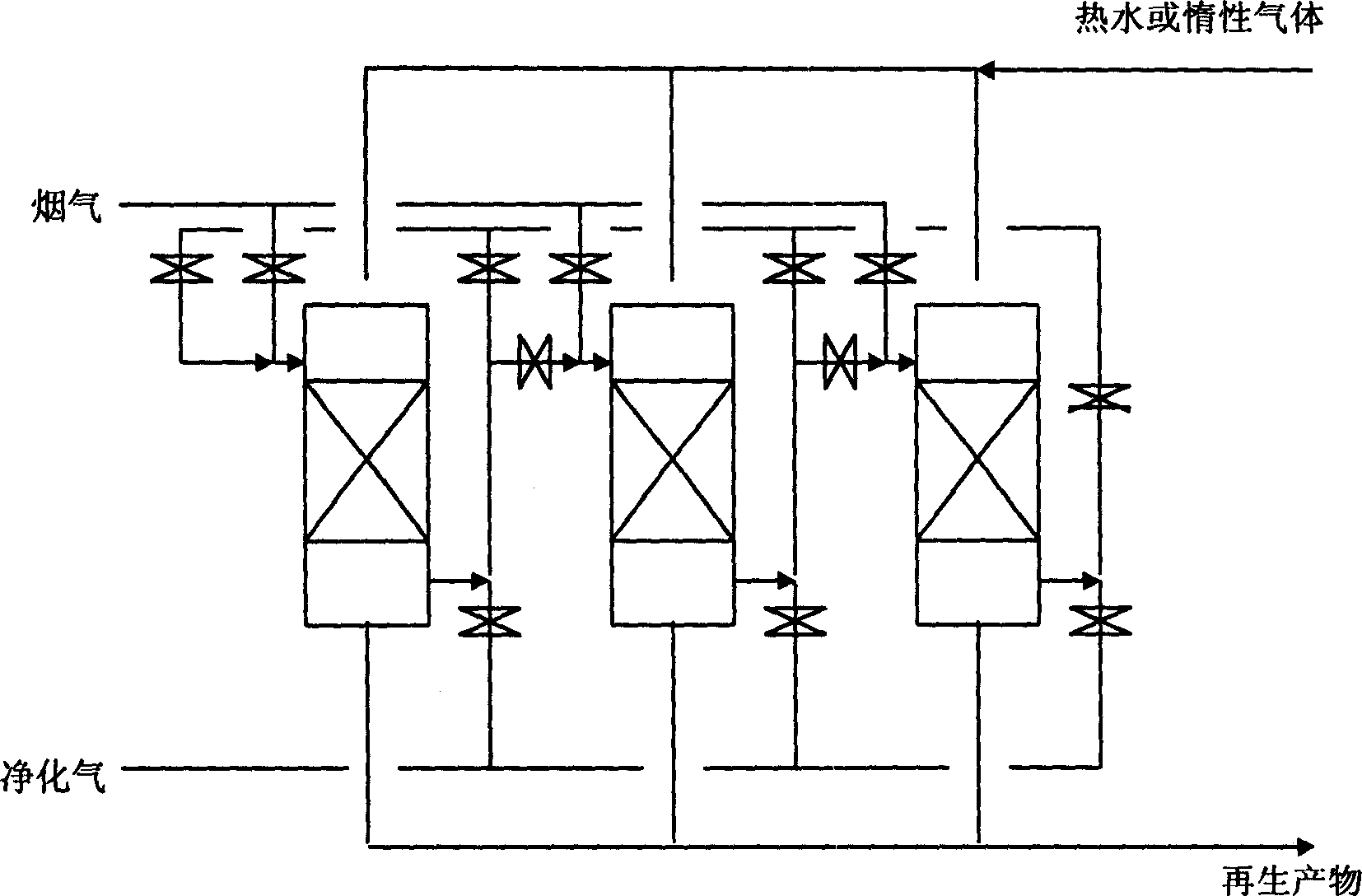

Process for eliminating SOx in flue by activated carbon based adsorbent

InactiveCN1583219AHigh sulfur capacityImprove efficiencyDispersed particle separationActivated carbonSorbent

A process for removing SO2 from fume by use of the activated carbon-based adsorbent features that the fume containing SO2 flows through the desulfurizing tower (or tank) filled by activated carbon-based adsorbent, and said adsorbent can be regenerated by hot water washing or high-temp inertial gas scavenging. Its by-product is H2SO4 or S.

Owner:OCEAN UNIV OF CHINA

Method for desulfurizing the exhaust gas containing sulfureted hydrogen and organic sulfur

A process for desulfurizing the waste gas containing HS and organic sulfur features that said waste gas is contacted with the desulfurizing agent whose active components are ZnO, TiO2 and Al2O3 at 180-320 deg.c.

Owner:CHINA PETROLEUM & CHEM CORP +1

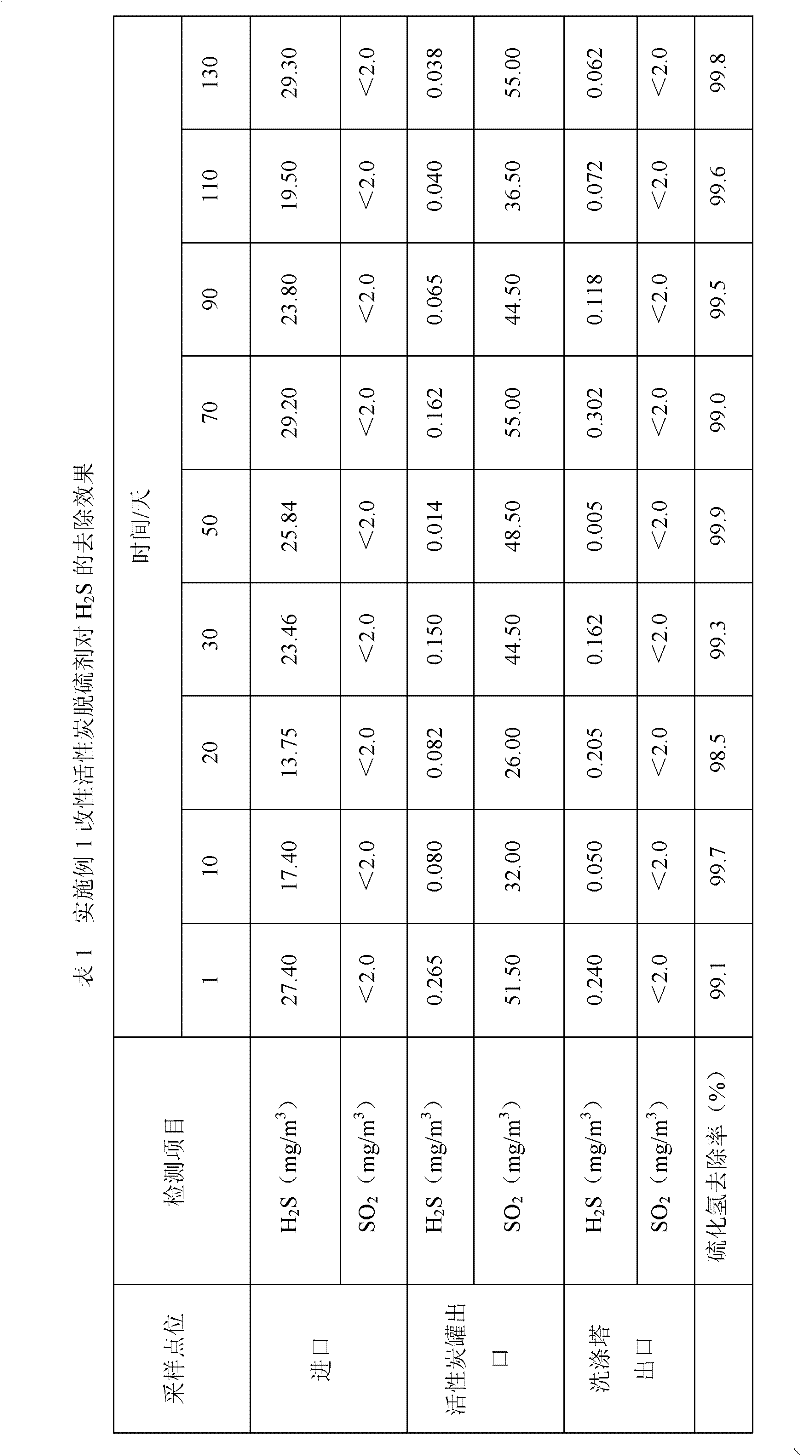

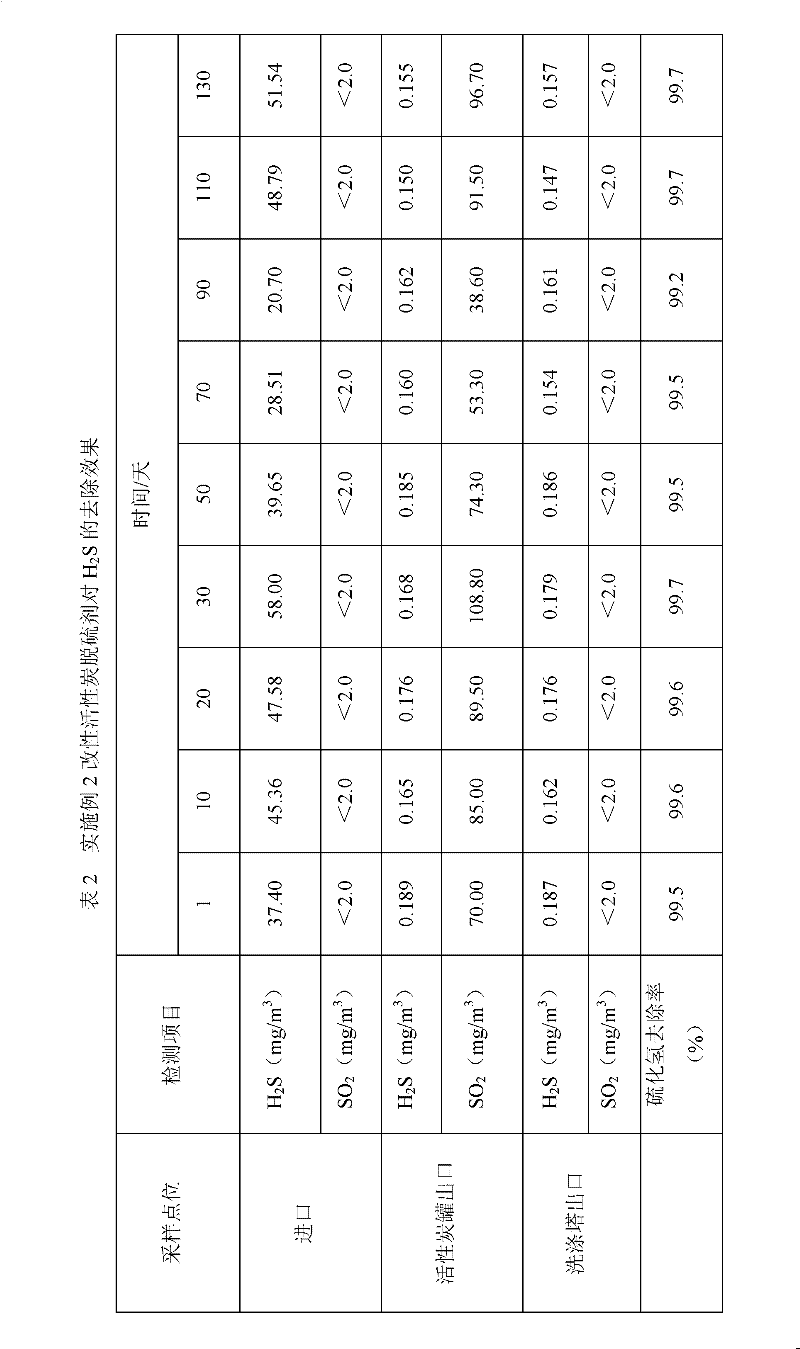

Modified active carbon desulfurizer and preparation method thereof and treatment method of hydrogen sulfide waste gas

InactiveCN102500323AEasy accessLow costPhysical/chemical process catalystsOther chemical processesActive agentCatalytic oxidation

The invention belongs to the technical field of waste gas desulfurization and purification, particularly provides a modified active carbon desulfurizer and a preparation method thereof, and a hydrogen sulfide waste gas treatment method using the desulfurizer. The modified active carbon desulfurizer is prepared from impregnating activated carbon with active agent mixed solution comprising phenol, acetone, sodium carbonate, ferric nitrate and organic solvent, and drying and roasting the mixture. The modified active carbon desulfurizer converts the hydrogen sulfide in the waste gas into sulfur dioxide at atmospheric temperature and pressure under the absorption and catalytic oxidation action, and the sulfur dioxide is converted into SO42- in water phase by washing and removed. The waste gas treatment method uses the modified active carbon desulfurizer, and prevents the defects that the desulfurizer needs to be regularly desorbed and regenerated due to blockage caused by adsorption saturation and generated elemental sulfur. Compared with an ordinary activated carbon desulfurization process, the process has the advantages of high hydrogen sulfide removal rate, long service life of the desulfurizer, low operation cost, simplicity in operation and management and the like.

Owner:北京天灏柯润环境科技有限公司

Desulfurizing agent and preparation method thereof

ActiveCN101485954AHigh sulfur capacityGood crystal structureDispersed particle separationOxidation resistantZinc

The invention relates to a desulfurizing agent, which comprises the following compositions in percentage by weight: 40 to 90 percent of nanometer-sized zinc oxide, 5 to 50 percent of cupric oxide and 0 to 20 percent of caking agent. The method for preparing the desulfurizing agent comprises the following steps: firstly, mixing the nanometer-sized zinc oxide, the cupric oxide, the caking agent, a pore creating material and water to form a mixture, wherein the weight ratio of the nanometer-sized zinc oxide to the cupric oxide to the caking to the pore creating material is 40-90:5-50:0-20:1-10; secondly, pinching and forming the mixture to obtain a formed object; and finally, drying and baking the formed object so as to obtain the desulfurizing agent. The desulfurizing agent has high sulfur capacity, can remove sulfureted hydrogen and other sulphides with high accuracy, and realize desulfurization with high accuracy at lower temperature, thereby reducing the requirement of desulfurizing equipment on thermal resistant strength, resistance of oxidation, and the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Preparation method of medium temperature ferric oxide desulfurizer

ActiveCN101590358ASimple processFew stepsDispersed particle separationCalcium hydroxideHigh volume manufacturing

The invention provides a preparation method of a medium temperature ferric oxide desulfurizer, and the active component of the medium temperature ferric oxide desulfurizer is amorphous ferric oxide of high activity. The preparation method of the medium temperature ferric oxide desulfurizer comprises the steps of directly kneading soluble ferrite, calcium hydroxide and a binder, extruding, drying and roasting. The desulfurizer obtained by using the preparation method of the invention has high content of ferric oxide, high sulphur capacity and good desulfurizing property; in addition, the preparation method of the invention has the advantages of simple process, low cost and suitability for industrialized mass production. The desulfurizer of the invention is mainly used for medium temperature desulfurization of hydrogen sulfide in chemical fertilizer industry synthesis gas.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

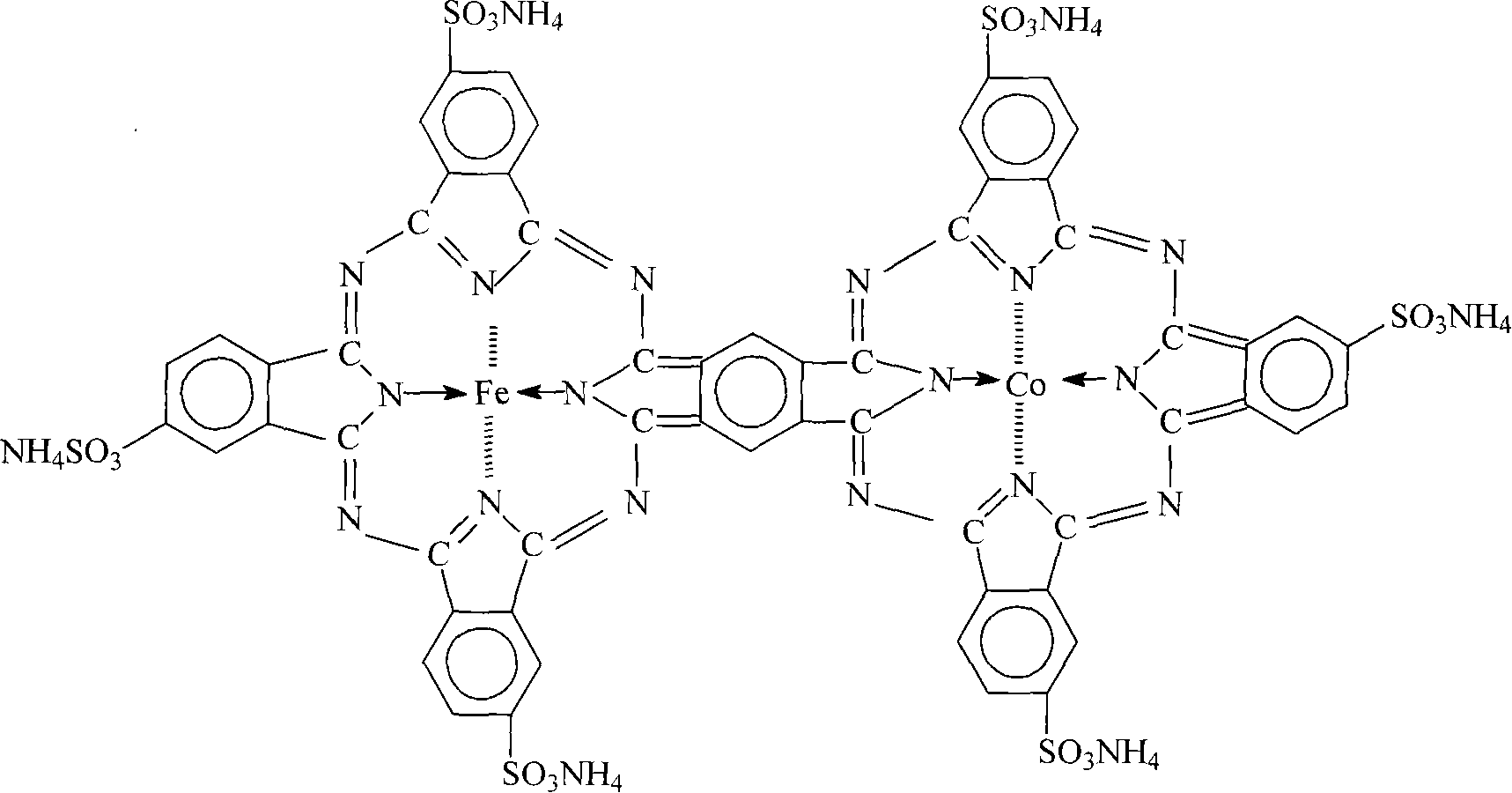

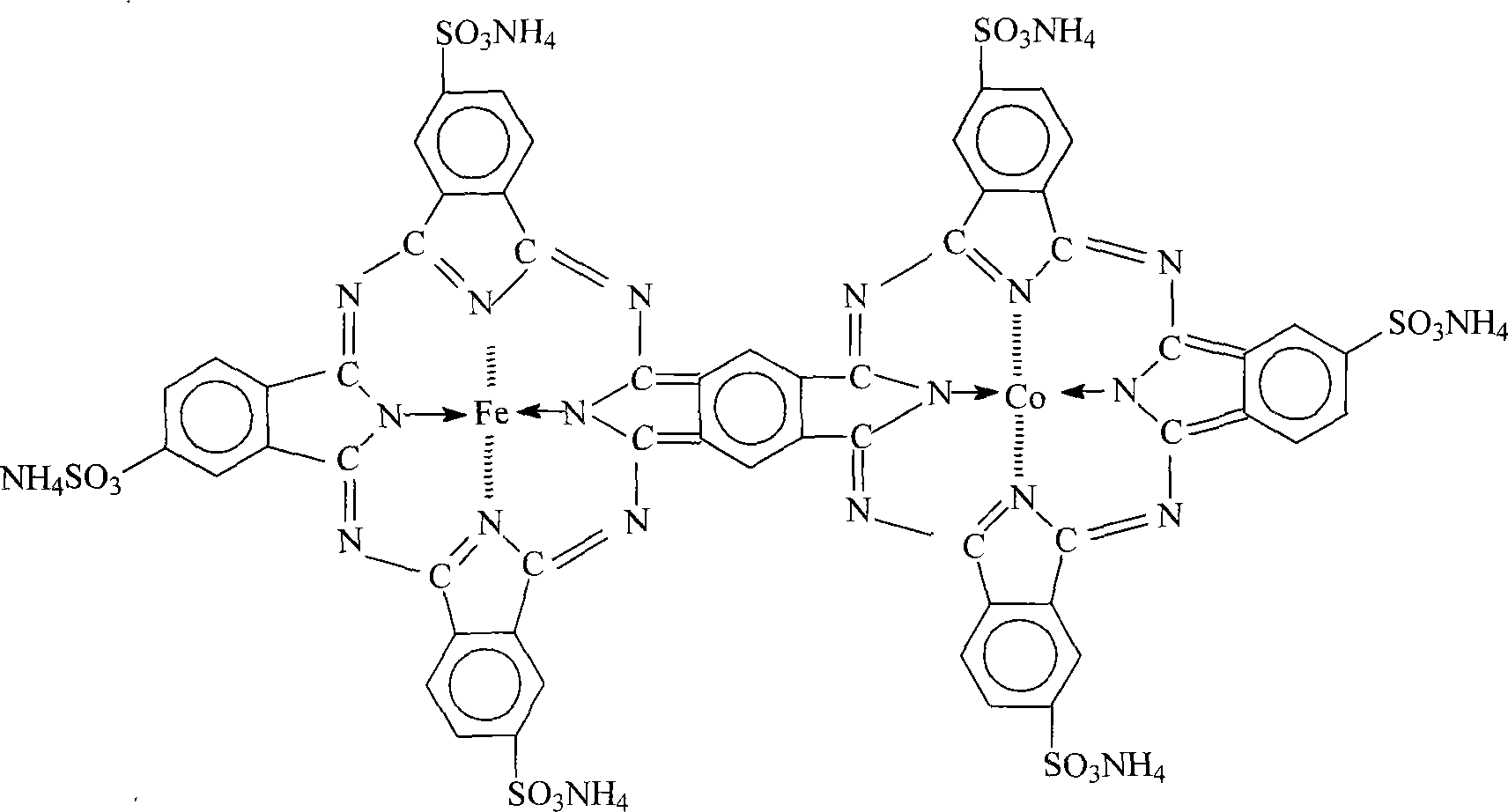

Desulphurization catalyst of sulfosalt of phthalocyanine iron cobalt, and preparation method

InactiveCN101049576AHigh catalytic activityImprove desulfurization efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationIron saltsPhthalocyanine

A phthalocyanin-iron-cobalt-ammonium sulfonate as the dsulfurizing catalyst with high catalytic activity and desulfurizing efficiency (more than 99%) is prepared through preparing the sulfonated chemical from phthalic anhydride as raw material and smoking sulfuric acid as sulfonating agent, preparing phthalocyanin-iron-cobalt- ammonium sulfonate from said sulfonated chemical, ammonium molybdate as catalyst, urea, cobalt chloride and iron salt, drying, and pulverizing.

Owner:汪晓梅

Pre-melted desulfurizing agent for refining molten steel and preparation method thereof

The invention relates to the technical field of ferrous metallurgy, in particular to a pre-melted desulfurizing agent for refining molten steel, which is characterized by comprising the following components in percentage by weight: 55 to 70 percent of calcium oxide, 10 to 25 percent of high alumina bauxite and 10 to 25 percent of aluminum ash. The aluminum ash is molten slag in aluminum production. A preparation method for the pre-melted desulfurizing agent comprises the following steps: grinding the components into powder of 0 to 2 millimeters, mixing the powder according to a proportion, melting the mixed powder at the high temperature of between 1,450 and 1,600 DEG C, discharging and cooling the melted mixture, and then crushing the mixture into granules of 0 to 70 millimeters to obtain the pre-melted desulfurizing agent. In the impurities, the content of SiO2 is less than or equal to 8 percent, the content of Fe2O3 is less than or equal to 1.5 percent, the content of MgO is less than or equal to 1.2 percent, the content of CaF2 is less than or equal to 3 percent, and the content of moisture is less than or equal to 0.5 percent. The pre-melted desulfurizing agent has the advantages that: (1) the melting point is low, and the melting speed is high; (2) the desulfurizing rate can reach over 60 percent; (3) the using amount of the desulfurizing agent is reduced by about 50 percent; (4) the desulfurizing agent can be used for desulfurizing molten steel and molten iron; and (5) the desulfurizing agent is fluorine-free or has micro-fluorine, and is favorable for environmental protection.

Owner:辽宁中汇环保科技有限公司

Normal temperature nanometer desulfurizing agent and its preparation process

InactiveCN1907544ALow requirements for processing equipmentReduce manufacturing costDispersed particle separationNitrateSulfur

The invention relates to a normal-temperature nanometer desulfurizer and a relative preparation, wherein the mol rate between nanometer ferric oxide and nanometer zinc oxide is 1:13-47; the preparation comprises: (1), dissolving the ferric nitrate into concentrated zinc nitrate solution, to make the mol rate between zinc ion and ferric ion as 100:2-5; (2), adding aquacare based on the mol rate between metal ion and aquacare as 1:3.45; (3), arranging the solution at 85-110Deg. C, to react 1-3hours; (4), filtering, washing solid and drying; (5), baking solid, to obtain the normal-temperature nanometer desulfurizer. The diameter of desulfurizer is 12.4-14nm, with high desulfurization speed, and 10-16% sulfur capacity. The invention has simple process and low cost.

Owner:HARBIN INST OF TECH

Method for preparing material containing amorphous iron oxide hydroxide and methods for regenerating the same

ActiveCN101767830AHigh sulfur capacityGood desulfurization effectIron oxides/hydroxidesIron oxideHydroxide

The invention relates to a method for preparing a material containing amorphous iron oxide hydroxide and two methods for regenerating the same after being used as desulfurizer. The content of the amorphous iron oxide hydroxide in the material prepared by the invention is as high as 65% to 100%, so the sulfur capacity of the material is high; and the desulfurizer in the prior art is non-regenerative or costly for regeneration, so that the desulfurizer in a large amount cannot but be dumped as waste liquid in landfills, while the amorphous iron oxide hydroxide in the material of the invention can be repeatedly regenerated and reused after the material is used as the desulfurizer, thereby solving the problems of the waste of effective resources in the original desulfurizer and the severe environmental pollution.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Regenerable metal oxide desulfurizer and its prepn. process

InactiveCN1375355AEasy to buyEasy to manufactureOther chemical processesDispersed particle separationAdhesiveFossil fuel

The desulfurizing agent is made from metal oxide (oxide of copper, zinc, iron, sodium, nickel and titanium, etc.) as main component, and can be divided into two types of DSO1 and DSO2. The preparation method of DSO1 includes the following steps: firstly, preparing carrier using Al2O3, ZnO, NiO, TiO2 and Na2O as component, the attaching the metal oxide to the carrier, and the preparation method ofDSO2 includes the following steps: mixing the metal oxide, activating agent, adhesive and pore-forming agent and making them undergo the one-step forming process to obtain the invented product. It can be used for desulfurizing and cleaning fuel gas and flue gas, and its desulfurizing efficiency can be up to 90%.

Owner:向军 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com