Desulfurization adsorption agent used for gasoline and gasoline desulfurization method

An adsorbent and gasoline technology, applied in the field of desulfurization adsorbent, can solve the problems of harsh operating conditions, low selectivity, complex desulfurization agent process, etc., and achieve the effects of mild process operating conditions, simple regeneration method and good desulfurization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Preparation of alkali-treated molecular sieve and activated carbon

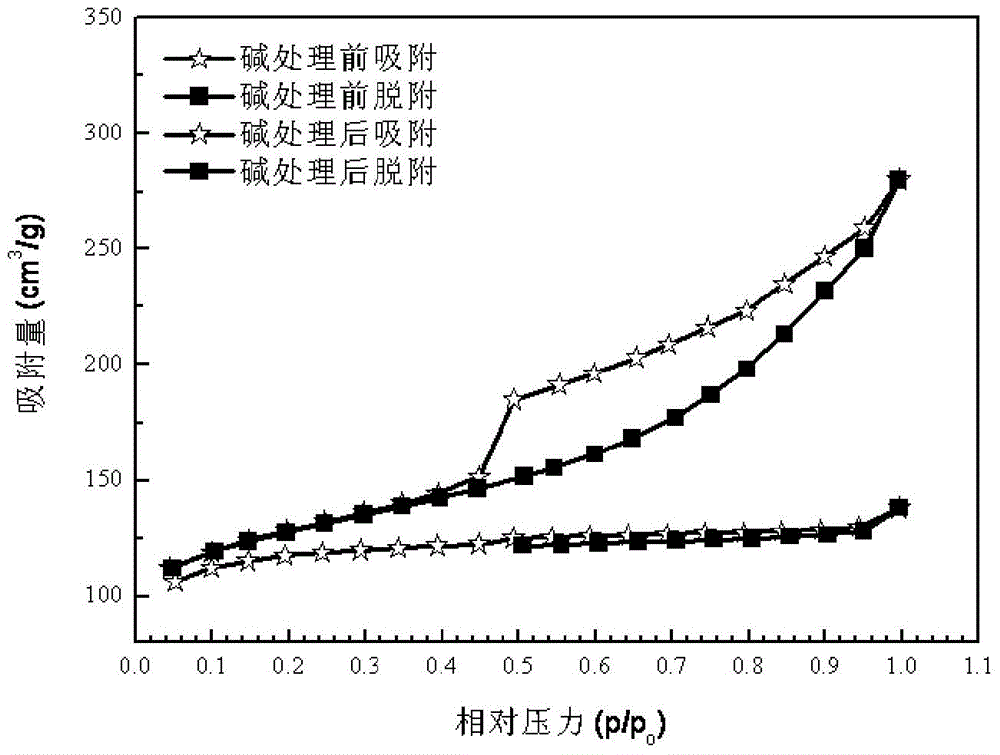

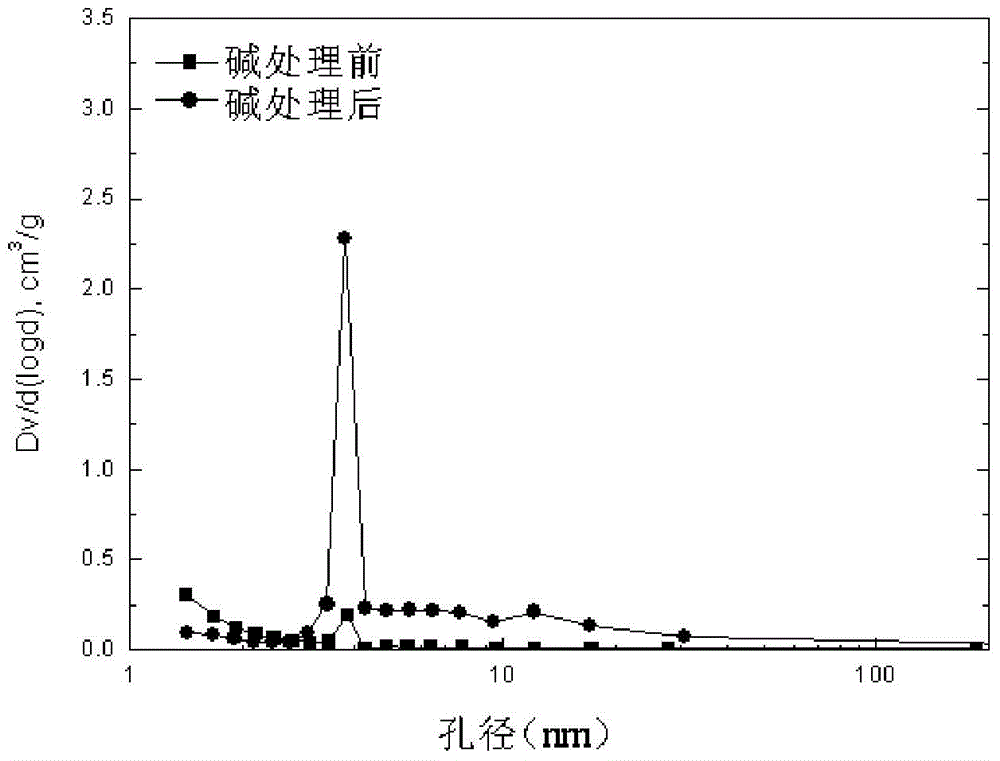

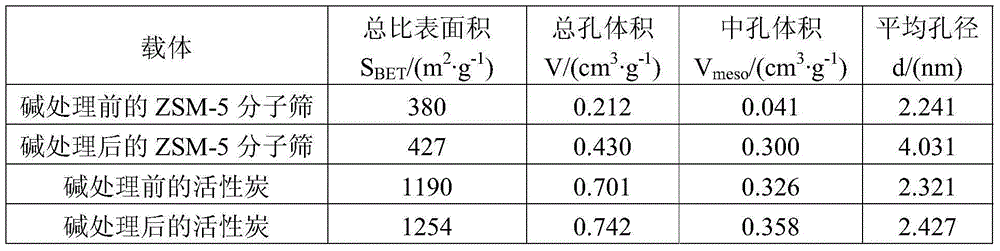

[0041] After heating two 500mL NaOH solutions with a concentration of 0.3mol / L in a water bath to about 70°C, add 25g of ZSM-5 molecular sieve and 25g of activated carbon to them respectively, stir for about 200 minutes, and immediately cool the mixture in an ice bath. to normal temperature, filter and wash the filter cake with deionized water for several times until the pH value of the filtrate is about 7, then place the obtained filter cake in an oven at 110°C for 4 hours to obtain alkali-treated ZSM- Type 5 molecular sieve and activated carbon treated with alkali; Among them, the adsorption-desorption isotherms and pore size distribution curves of ZSM-5 molecular sieve before and after alkali treatment are shown in figure 1 and figure 2 .

[0042] In addition, ASAP2000 automatic physical adsorption instrument was used to measure the specific surface area and pore size distribution of ZSM-5 mol...

Embodiment 2

[0055] 1. Preparation of alkali-treated molecular sieve and activated carbon

[0056] After raising the temperature of two 500mL NaOH solutions with a concentration of 0.2mol / L in a water bath to about 80°C, add 25g of Y-type molecular sieve and 25g of activated carbon to them respectively, stir for about 120 minutes, and immediately cool the mixture to room temperature in an ice bath , filter and wash the filter cake with deionized water for several times until the pH value of the filtrate is about 7, then place the obtained filter cake in an oven at 120°C for 3 hours to obtain alkali-treated Y-type molecular sieve and The specific surface area and pore size distribution of alkali-treated activated carbon; Y-type molecular sieve and activated carbon are shown in Table 2.

[0057] Table 2 Specific surface area and pore size of Y-type molecular sieve and activated carbon

[0058]

[0059] 2. Preparation of composite carrier

[0060] The above alkali-treated Y-type molecula...

Embodiment 3

[0066] 1. Preparation of alkali-treated molecular sieve and activated carbon

[0067] After raising the temperature of two 500mL NaOH solutions with a concentration of 0.3mol / L in a water bath to about 80°C, add 25g of X-type molecular sieve and 25g of activated carbon to them respectively, stir for about 180 minutes, and immediately cool the mixture to room temperature in an ice bath , filter and wash the filter cake with deionized water for several times until the pH value of the filtrate is about 7, then place the obtained filter cake in an oven at 100°C for 6 hours to obtain alkali-treated X-type molecular sieve and Alkali-treated activated carbon.

[0068] 2. Preparation of composite carrier

[0069] The above alkali-treated X-type molecular sieve and alkali-treated activated carbon were mixed at a mass ratio of 30:70, ground into powder in a mortar, and then dried in an oven at 120°C for 6 hours to obtain a composite carrier.

[0070] 3. Preparation of desulfurization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com