Patents

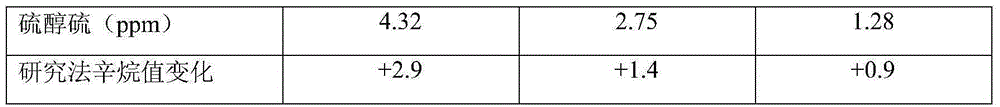

Literature

42results about How to "High desulfurization depth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

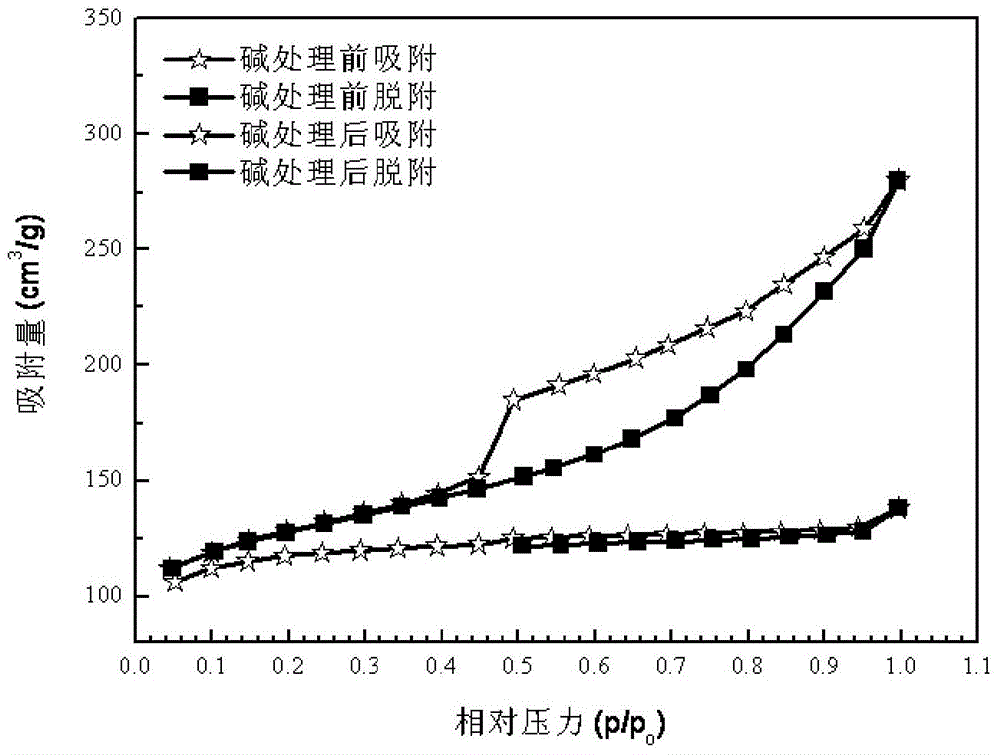

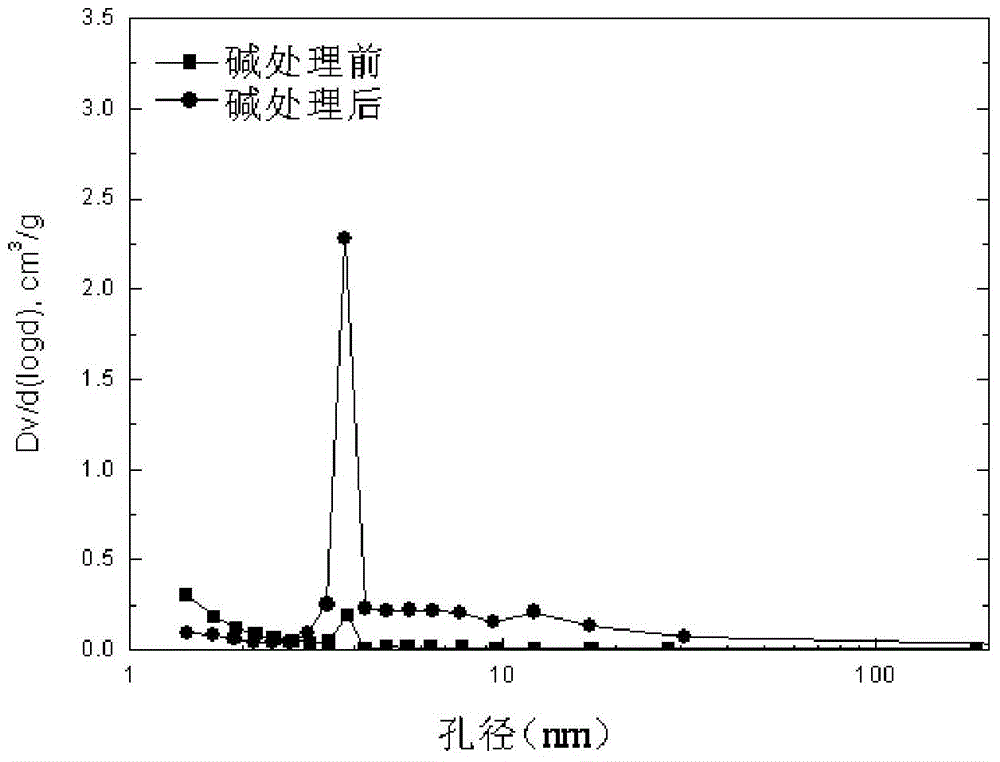

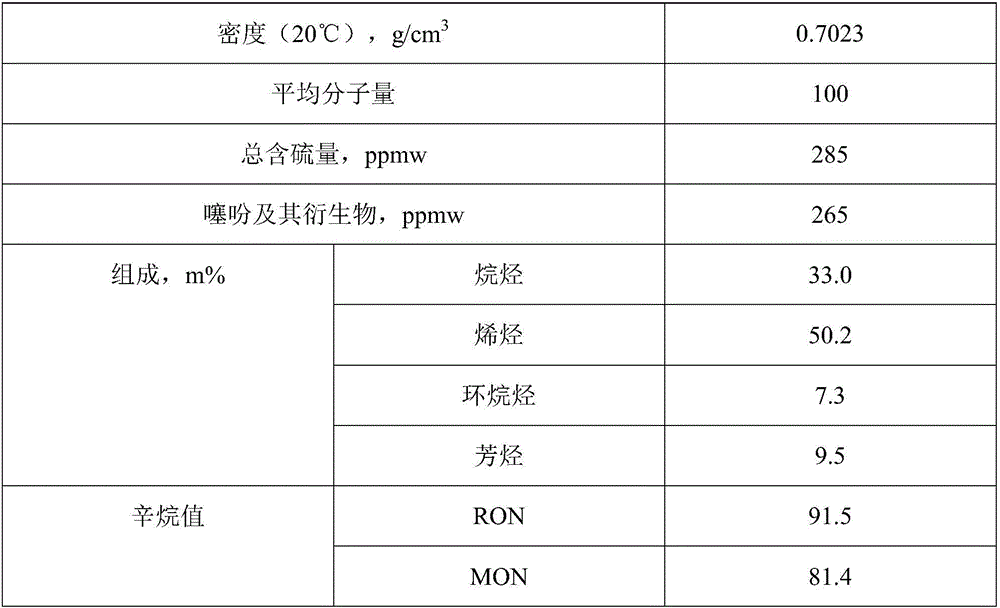

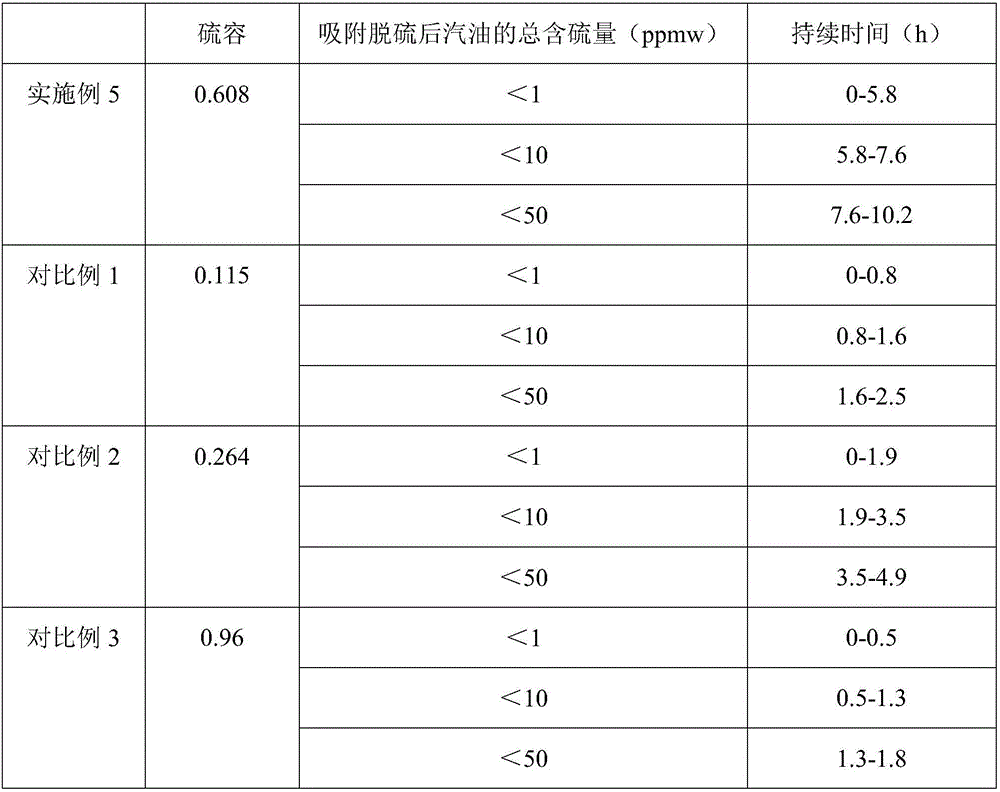

Fuel oil deep-adsorption desulfurizationn catalyst, preparation method and application thereof

ActiveCN104056632ALarge specific surface areaReduce hydrogen consumptionOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSorbent

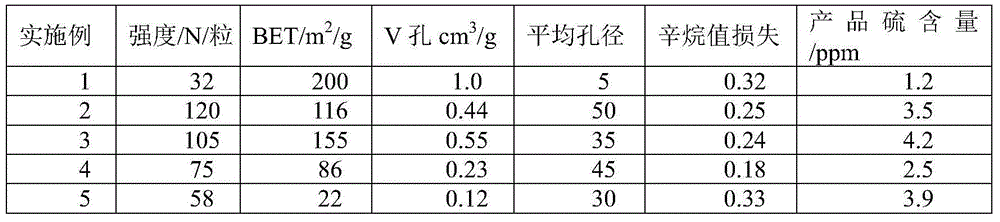

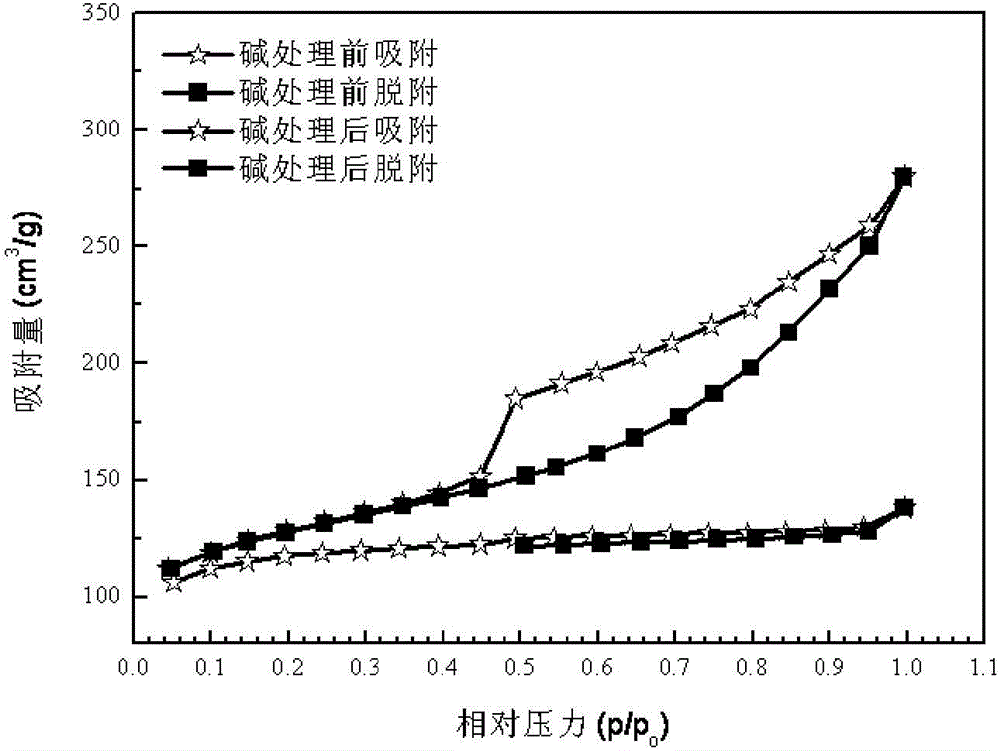

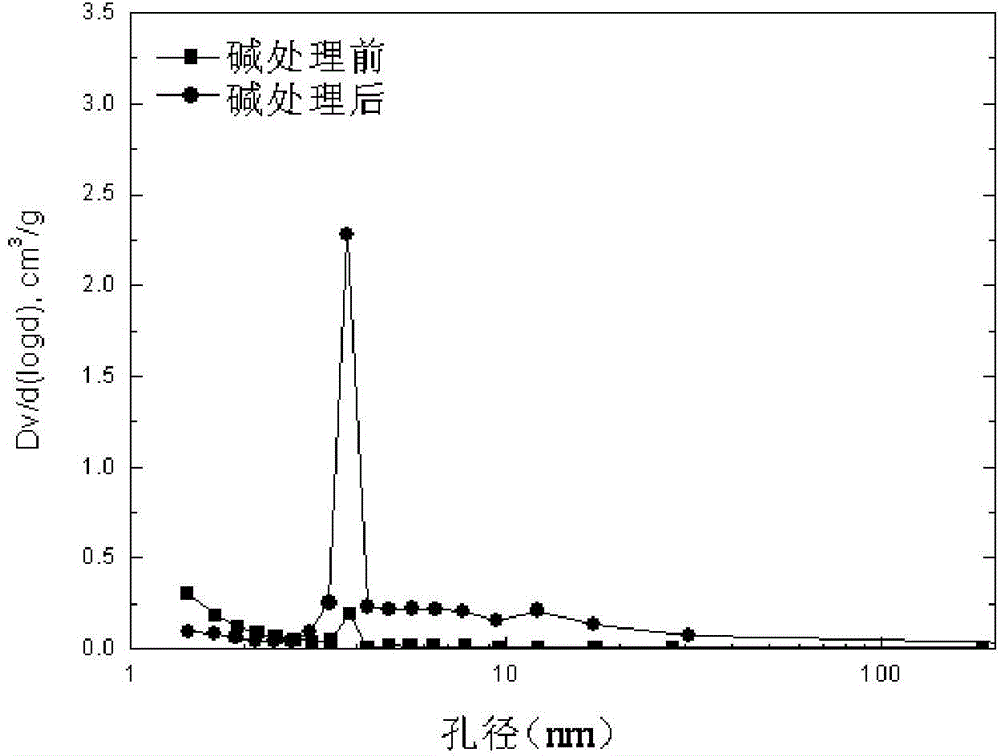

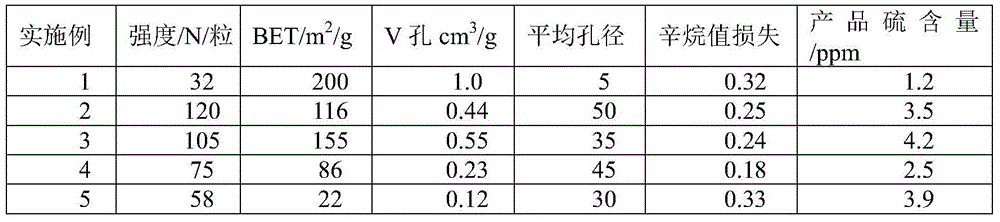

The invention discloses a fuel oil deep-adsorption desulfurizationn catalyst. The desulfurizationn catalyst is characterized by consisting of an active component, a sulfur adsorbent and an adhesion agent, wherein the active component refers to one or more of Ni, Co, Cu, W and Mo oxides; the sulfur adsorbent refers to at least one of Mg, Ca, Zn, Ce, Fe, Mn and Ti oxides; the mass percent content of the active component is 2wt%-50wt%, the mass percent content of the sulfur adsorbent is 20wt%-90wt%, and the mass percent content of the rest components is the adhesion agent. The adhesion agent is one or a mixture of more than one of aluminium oxide, pseudo-boehmite, kaolin, imvite, bentonite, Yunmeng soil, kieselguhr, silica sol, silica gel and expanded perlite. The catalyst has the advantages of high specific surface area, moderate reaction, high intensity and low hydrogen consumption.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

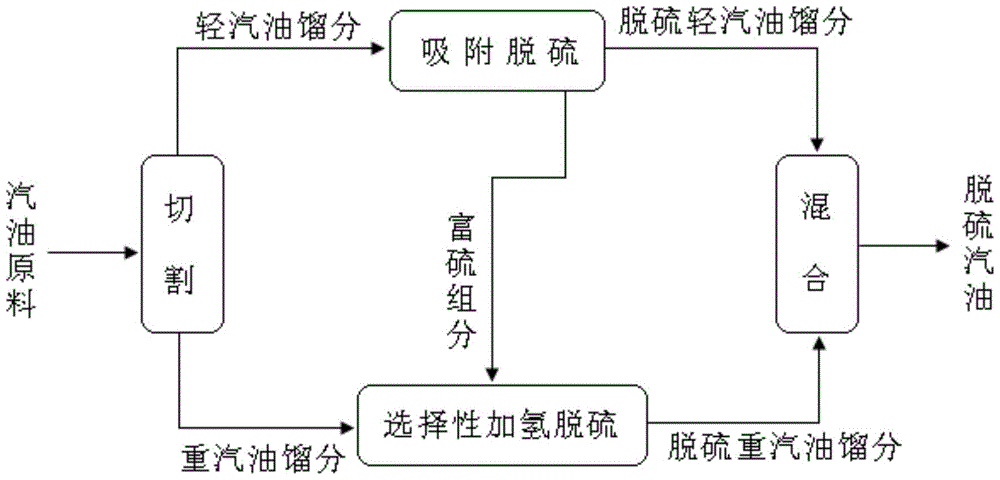

Gasoline desulfurization method

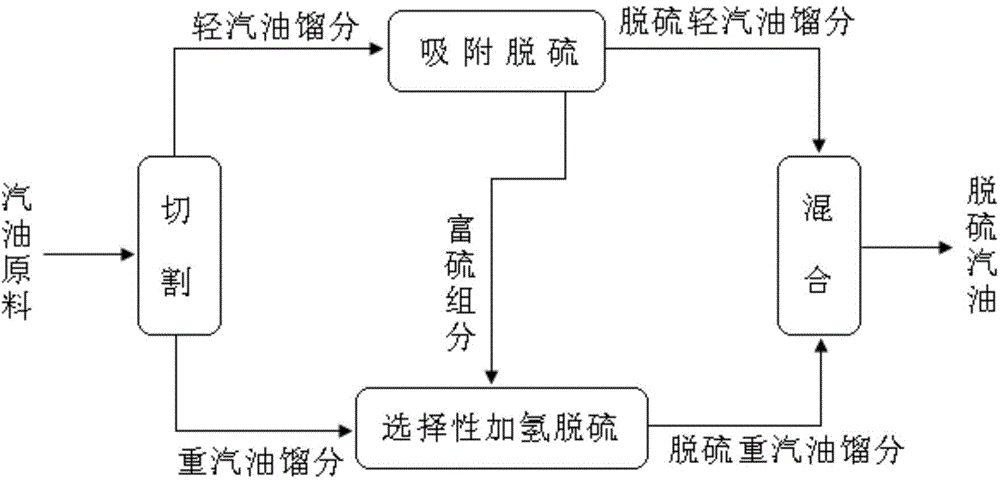

InactiveCN104673376ARealize deep desulfurizationLow component contentTreatment with hydrotreatment processesGasolineRaw material

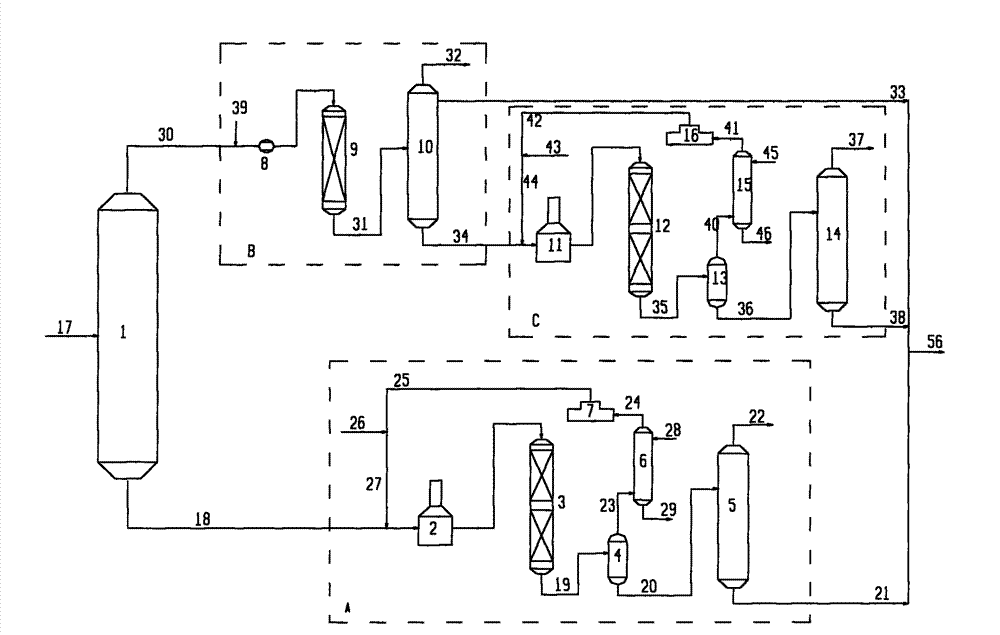

The invention provides a gasoline desulfurization method. The gasoline desulfurization comprises the following steps: cutting a gasoline raw material into a light gasoline fraction and a heavy gasoline fraction; performing adsorption desulfurization on the light gasoline fraction to obtain desulfurized light gasoline fraction; and performing selective hydrogenation desulfurization on the heavy gasoline fraction to obtain desulfurized heavy gasoline fraction, wherein the cutting temperature of the light gasoline fraction and the heavy gasoline fraction is 70-110 DEG C. By adopting the gasoline desulfurization method, not only can deep desulfurization of gasoline be realized, but also the octane loss is low.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

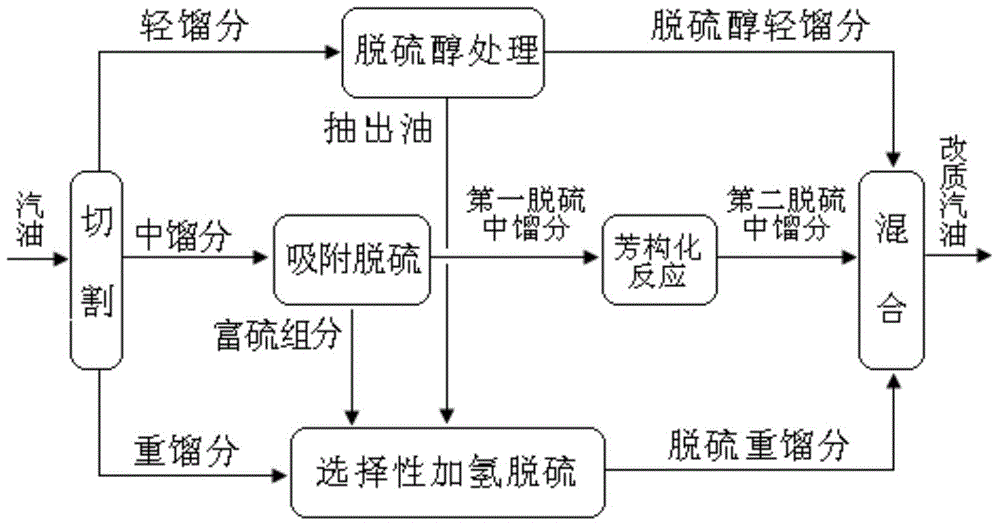

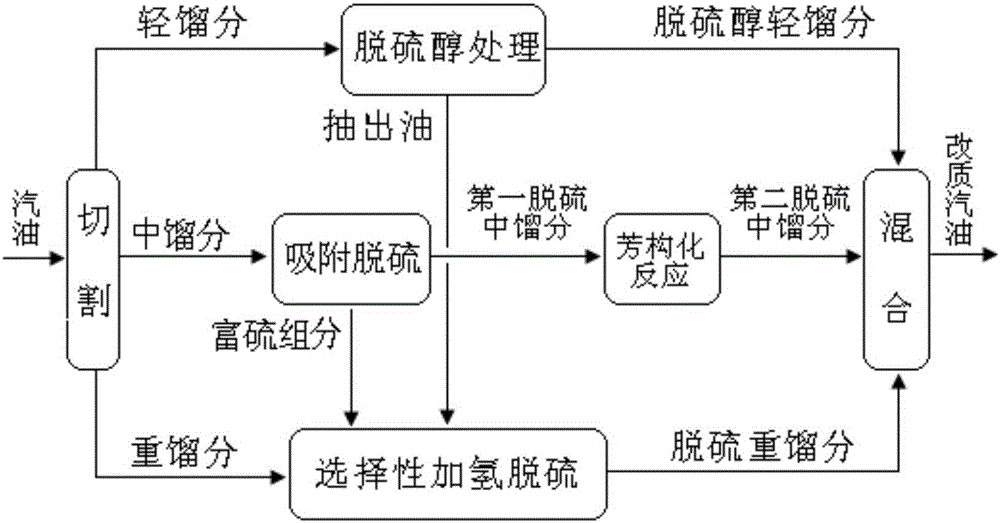

Quality improvement method of catalytic cracking gasoline

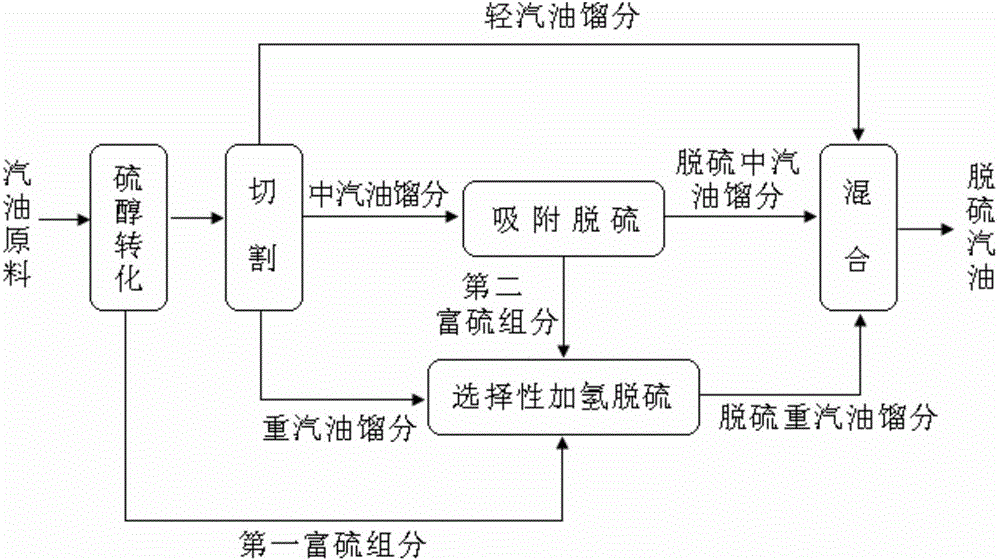

InactiveCN104673377ARealize deep desulfurizationFlexible operationTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationAromatization

The invention provides a quality improvement method of catalytic cracking gasoline. The quality improvement method comprises the following steps of: cutting a gasoline raw material into light, medium and heavy gasoline fractions; desulfurizing the medium gasoline fraction to obtain first desulfurized medium gasoline fraction; carrying out aromatization / hydroisomerization reaction on the first desulfurized medium gasoline fraction in the presence of a catalyst to obtain second desulfurized medium gasoline fraction; carrying out selective hydrodesulfurization on the heavy gasoline fraction to obtain desulfurized heavy gasoline fraction; mixing the light gasoline fraction, the second desulfurized medium gasoline fraction and the desulfurized heavy gasoline fraction to obtain quality improved gasoline, wherein the cutting temperature of the light and medium gasoline fractions is 35-60 DEG C, and the cutting temperature of the medium and heavy gasoline fraction is 70-130 DEG C. The quality improvement method provided by the invention can not only realize the deep desulfurization of the catalytic cracking gasoline, but also be used for outstandingly increasing the octane value.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

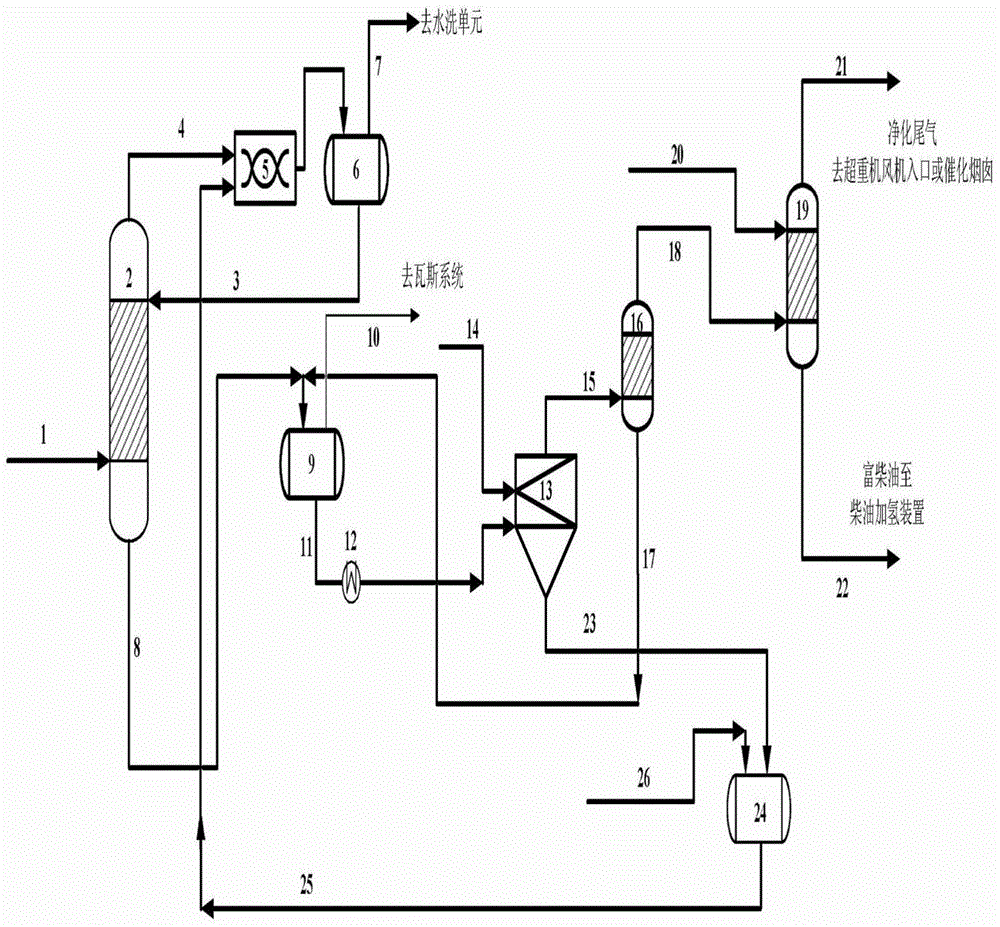

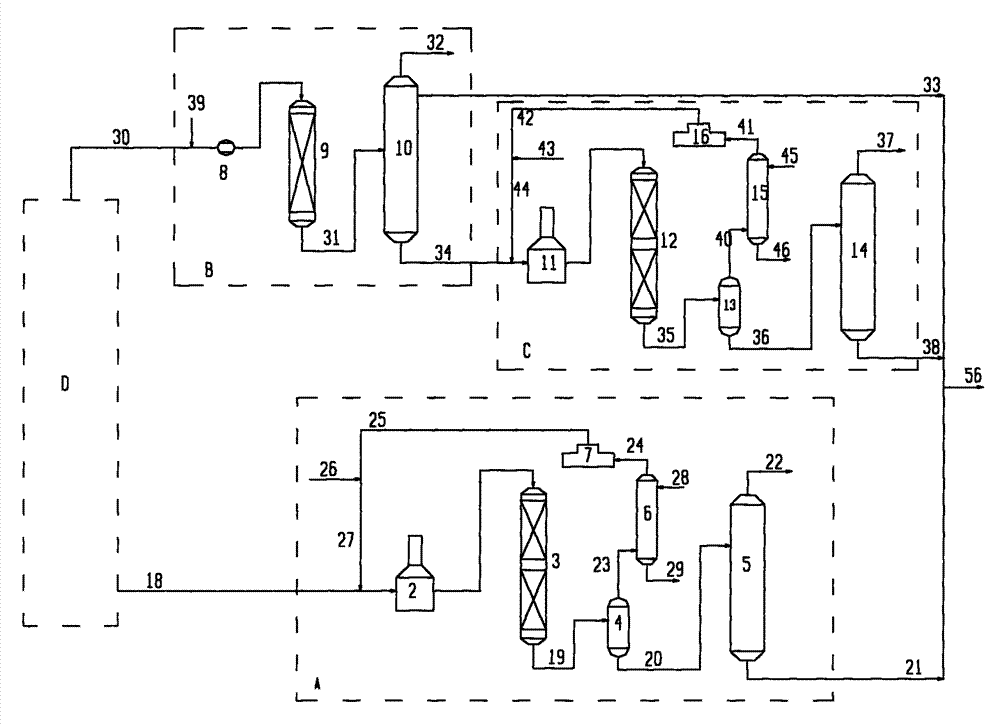

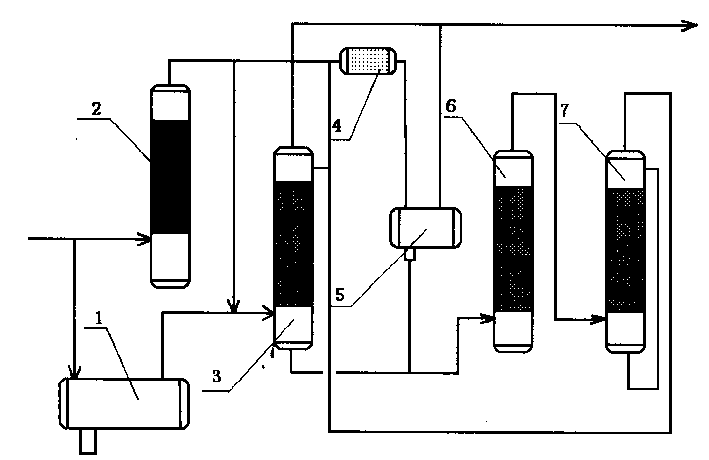

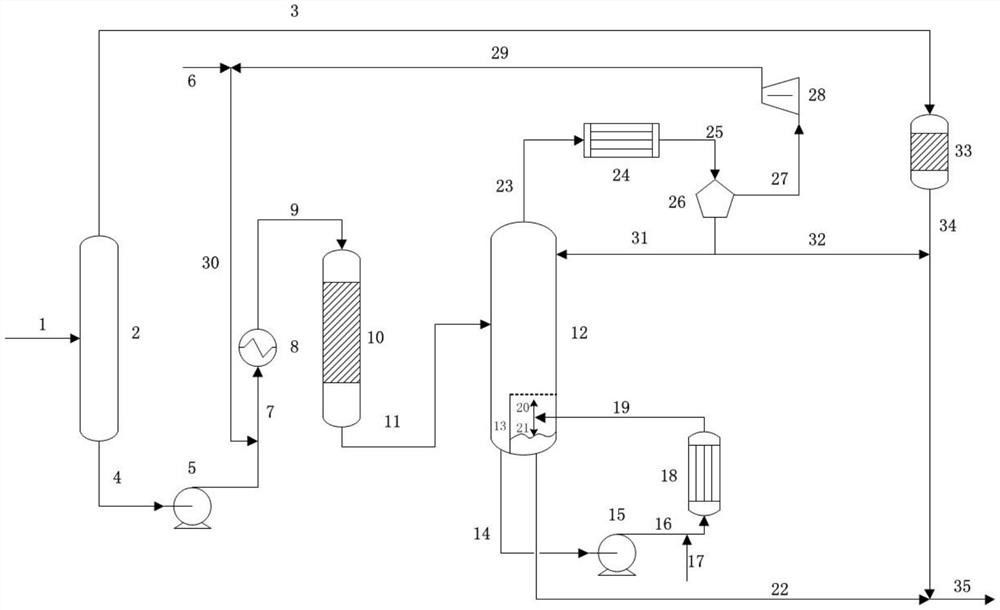

Combination method for deep desulfurization of liquefied gas

ActiveCN104624033AHigh desulfurization depthAchieve desulfurization effectGaseous fuelsDispersed particle separationStatic mixerTower

The invention relates to a combination method for deep desulfurization of liquefied gas. The method comprises the steps that liquefied gas is fed into an extraction tower to contact with an alkali liquor counter flow, desulfurized liquefied gas and regenerated alkali liquor are fed into a static mixer to be mixed and then the obtained mixture is subjected to secondary extraction, mixed liquid is separated in a liquefied gas-alkali liquor separation tank, liquid gas is fed to be subjected to water washing, alkali liquor to be generated flowing out of the bottom of the extraction tower enters a flash tank, residual liquefied gas discharged from the top of the tank is conveyed to a gas system, alkali liquor to be generated obtained at the bottom of the tank, after being heated, enters a high gravity reactor to react with non-purified air, tail gas discharged from the high gravity reactor, after being subjected to alkali liquor removal by a coalescer, is fed back to the flash tank, the tail gas subjected to alkali liquor removal is fed into a diesel oil absorption tower to contact with a diesel oil counter flow, purified tail gas discharged from the top of the tower returns to the high gravity reactor to be recycled, rich diesel oil discharged from the bottom of the tower is conveyed to a diesel oil hydrogenation device, and the obtained regenerated alkali liquor is recycled. According to the method, the desulphurization depth is large, the regenerated alkali liquor quality is high, the equipment is simple and reliable, the cost is low, the emission amount of 'three wastes' is few, and the whole process conforms to the requirements of environmental protection.

Owner:PETROCHINA CO LTD

Hydrogenation method for deeply desulfurizing gasoline

ActiveCN103087771AHigh desulfurization depthReduce lossesTreatment with hydrotreatment processesHydrogenation reactionBoiling point

The invention provides a hydrogenation method for deeply desulfurizing gasoline. The hydrogenation method comprises the steps that catalytically cracked gasoline is fractionated into light fractions and heavy fractions; the heavy fractions and hydrogen are mixed and enter into a first hydrogenation reaction zone to react to obtain low-sulfur heavy fraction oil, and the recycle hydrogen obtained through separation is recycled after desulfurization; the light fractions and hydrogen are mixed and enter into a second hydrogenation reaction zone, diene is subjected to hydrogenation saturation to obtain mono-olefin low-boiling sulfides and the mono-olefin low-boiling sulfides are converted to high-boiling sulfides; the hydrogenated light fraction oil enters a light-medium fraction fractionating tower and is divided into light fractions and medium fractions and low-sulfur light fraction oil is obtained; the medium and light fractions and hydrogen are mixed and enter into a third hydrogenation reaction zone to react to obtain low-sulfur medium fraction oil, and the recycle hydrogen obtained through separation is recycled after desulfurization; and the heavy fraction oil, the light fraction oil and the medium fraction oil are mixed to obtain the low-sulfur gasoline product. Aiming to produce the gasoline with sulfur content not more than 10mu g / g, the method provided by the invention has the characteristics of high desulfurization depth, long device running period and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

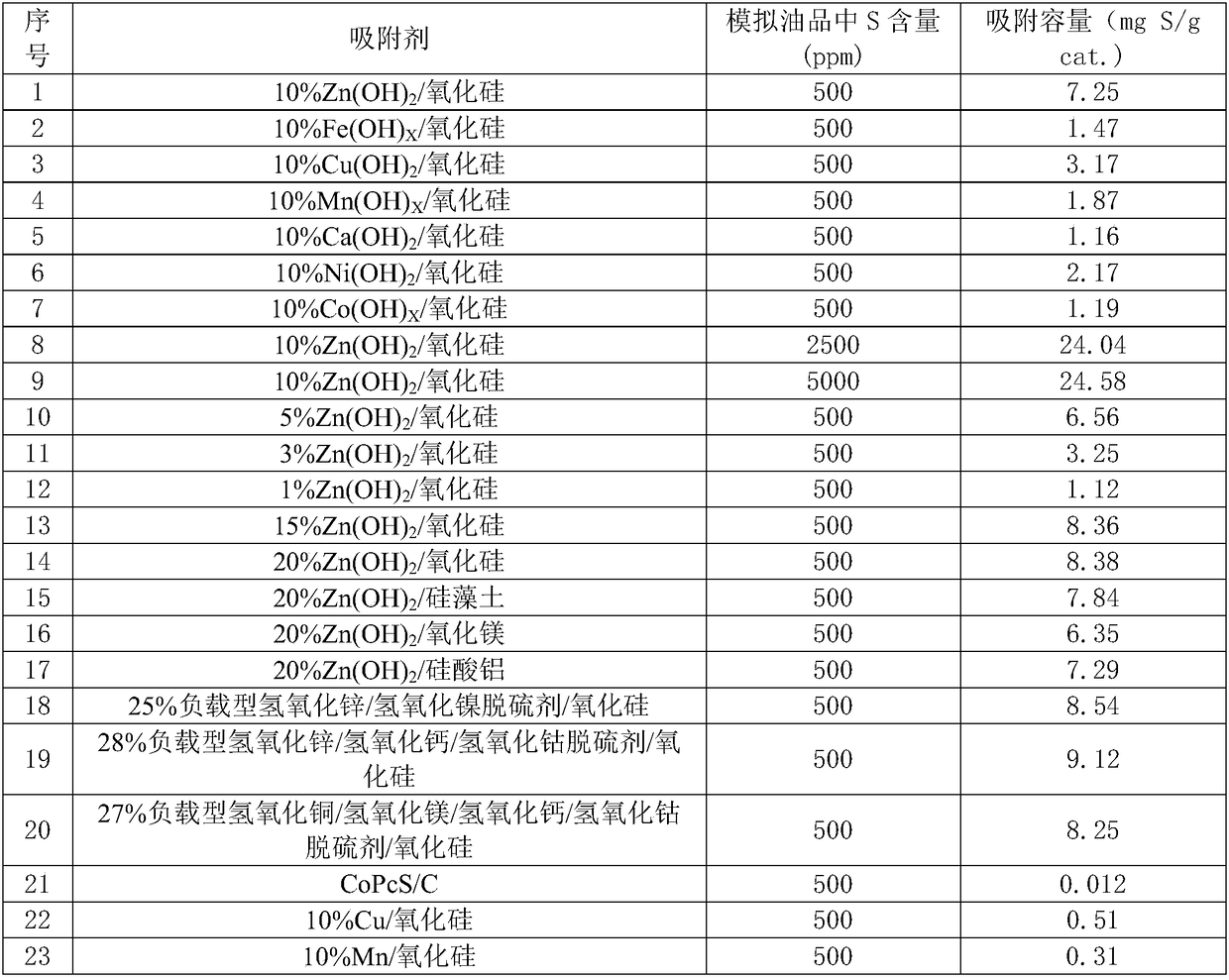

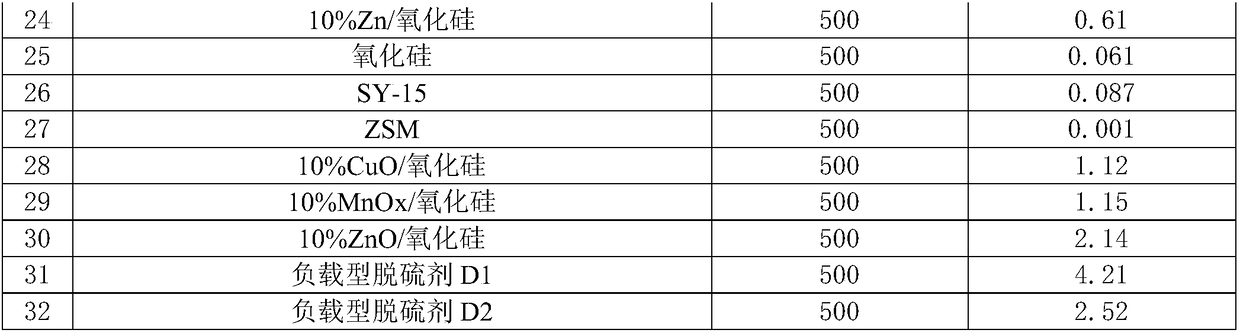

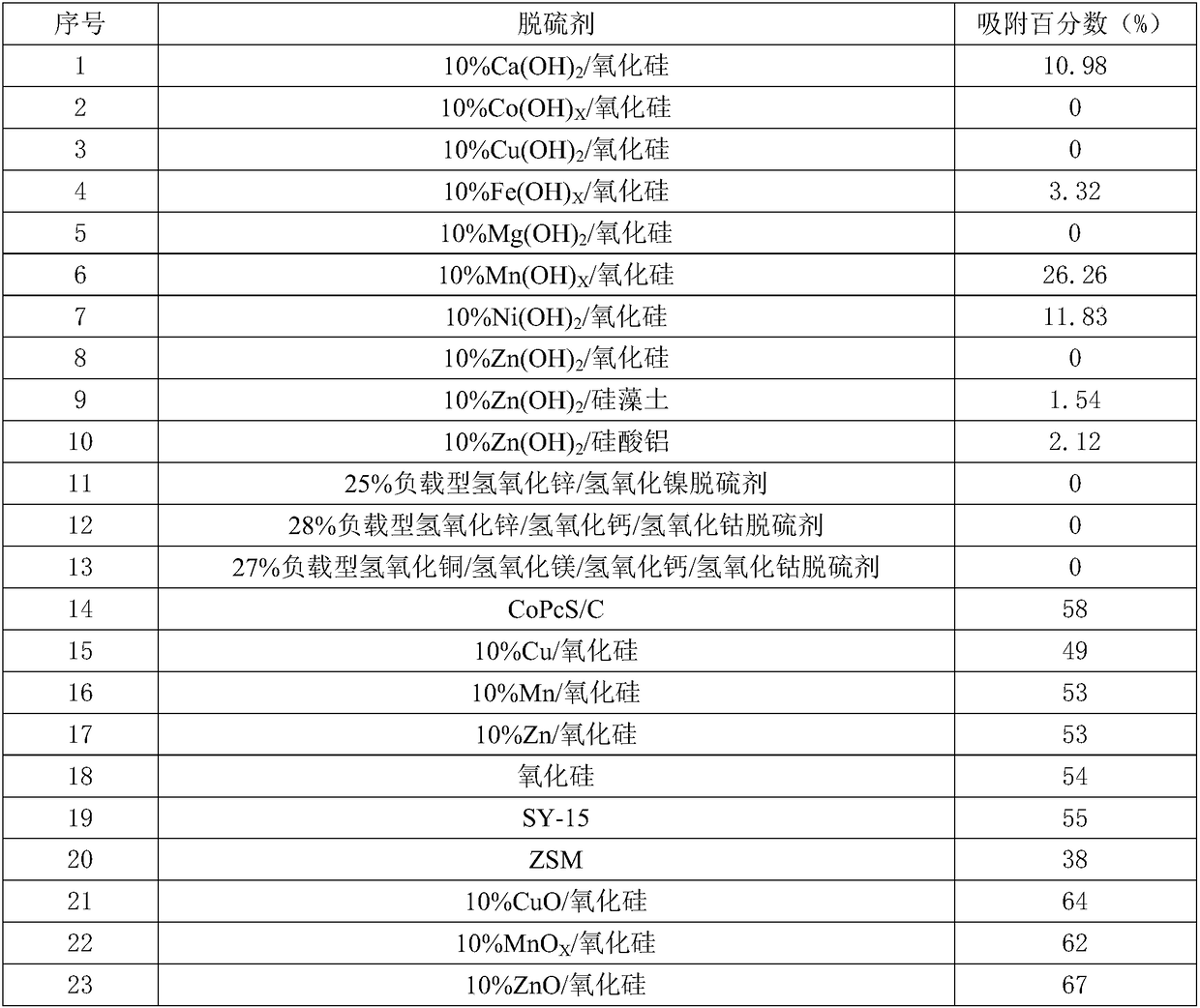

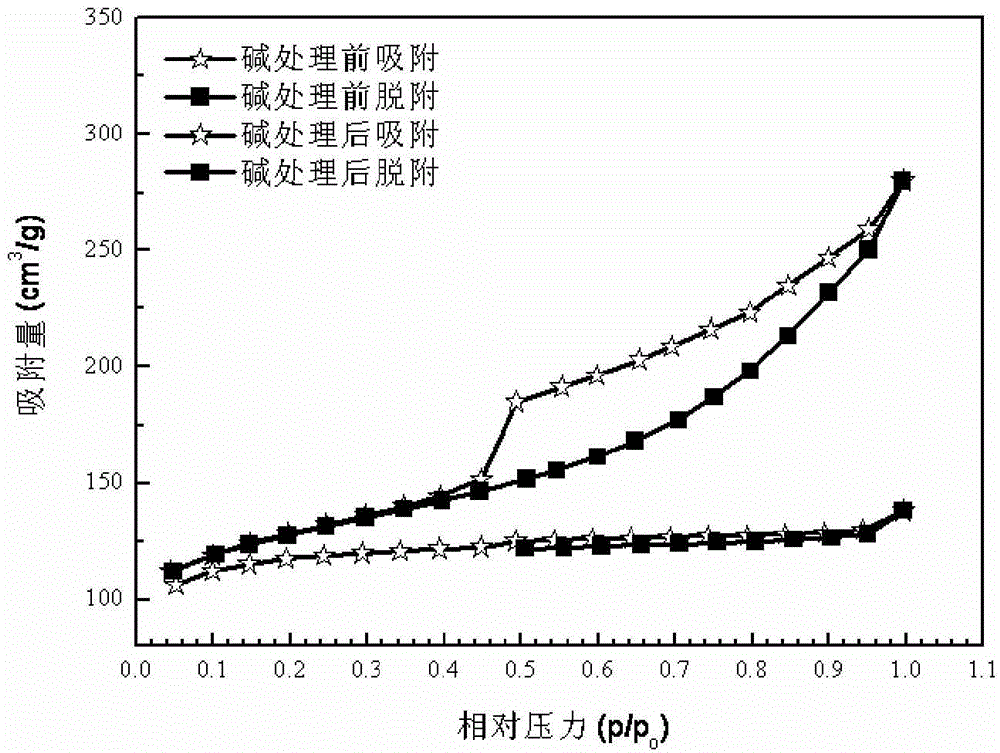

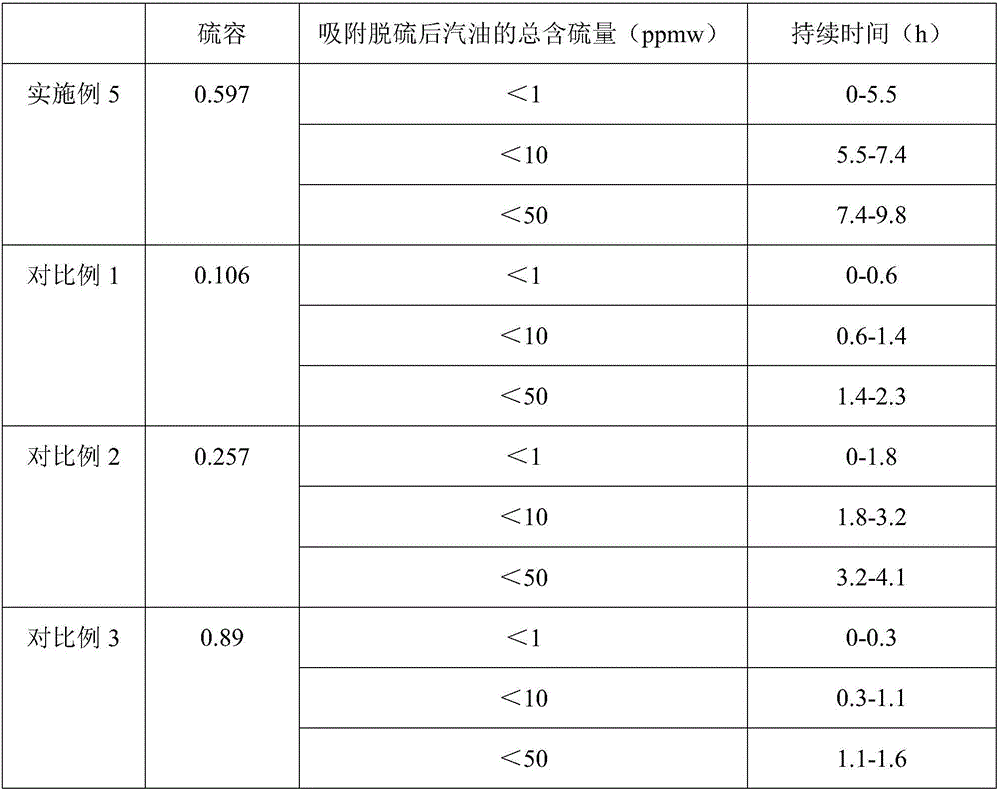

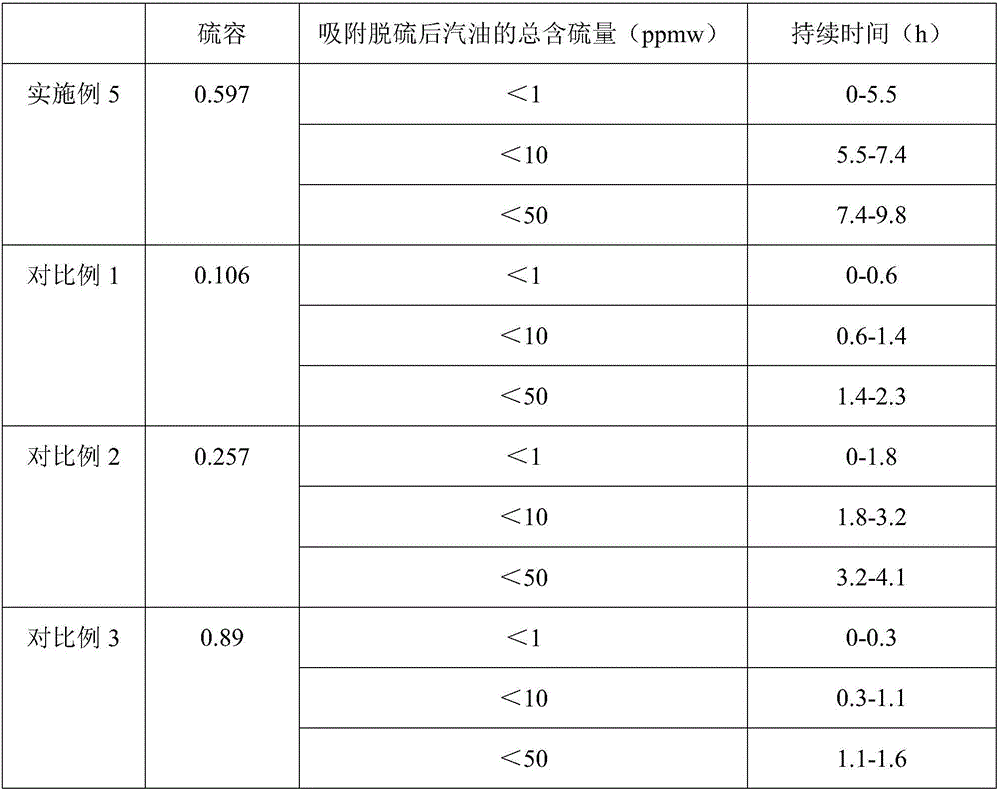

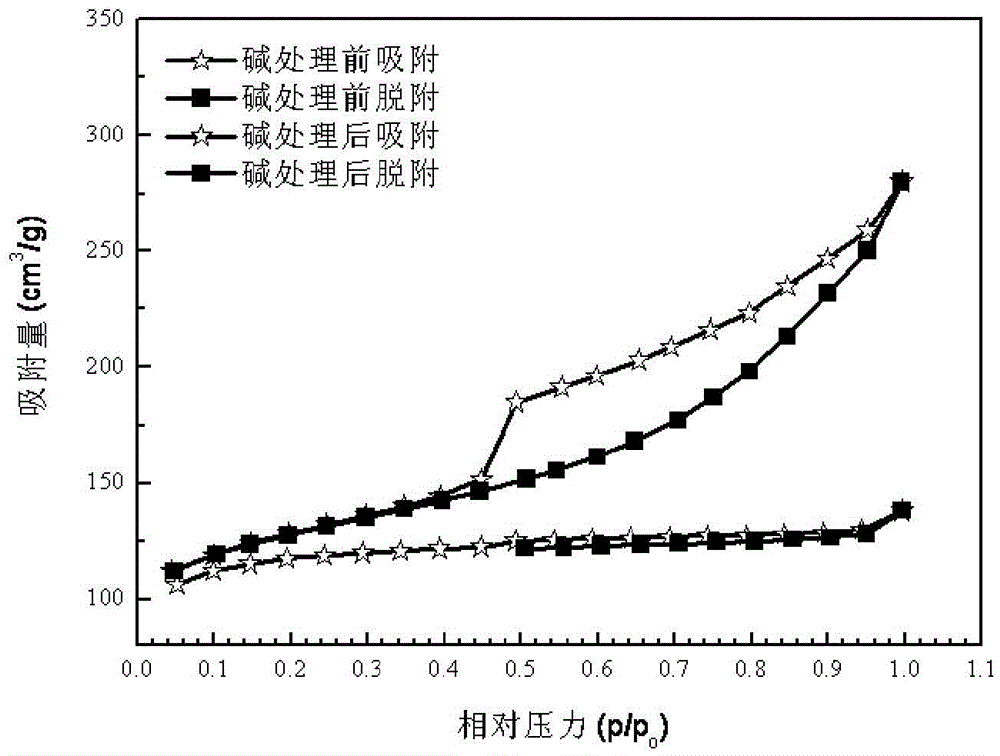

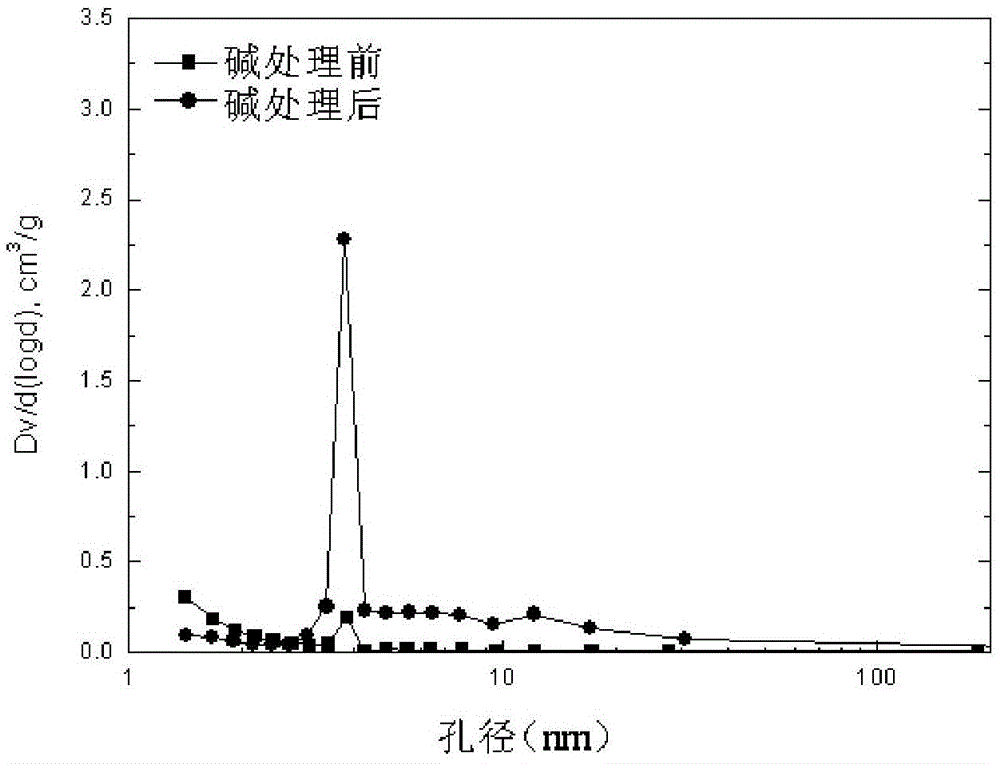

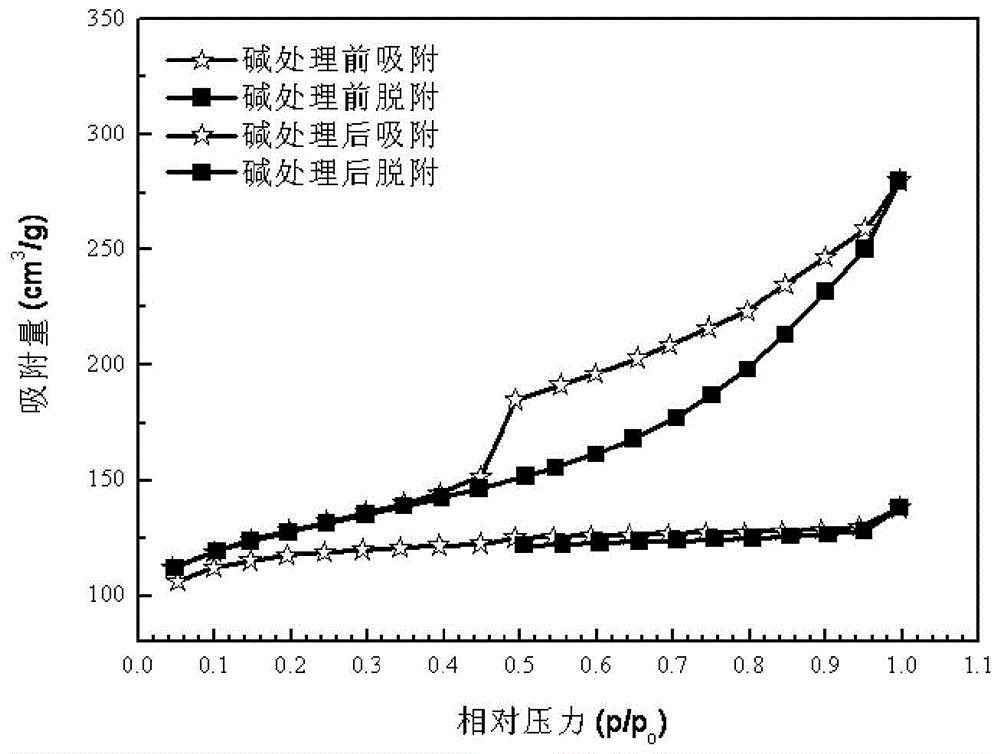

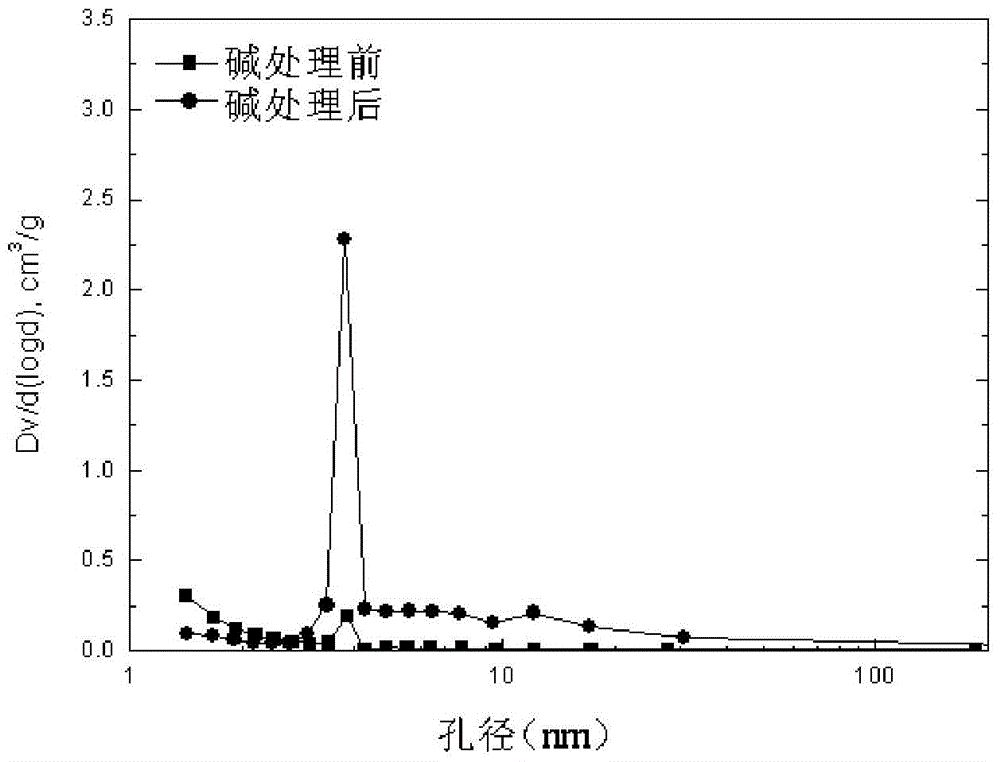

Supported hydroxide high-selectivity gasoline adsorption deep desulfurizing agent and preparation method thereof

ActiveCN108187605AHigh desulfurization depthHigh selectivityOther chemical processesHydrocarbon oils refiningChemistryHigh selectivity

The invention provides a supported hydroxide high-selectivity gasoline adsorption deep desulfurizing agent and a preparation method thereof. The supported hydroxide high-selectivity gasoline adsorption deep desulfurizing agent is prepared from a carrier and metal hydroxide supported on the carrier; the mass ratio of the metal hydroxide to the carrier is (5 to 30) to 100. The invention further provides the preparation method of the supported hydroxide high-selectivity gasoline adsorption deep desulfurizing agent. The supported hydroxide high-selectivity gasoline adsorption deep desulfurizing agent provided by the invention has the advantages of relatively high desulfurizing depth, high selectivity, no octane value loss and flexibility, simplicity and convenience for operation.

Owner:SOUTH CHINA UNIV OF TECH +1

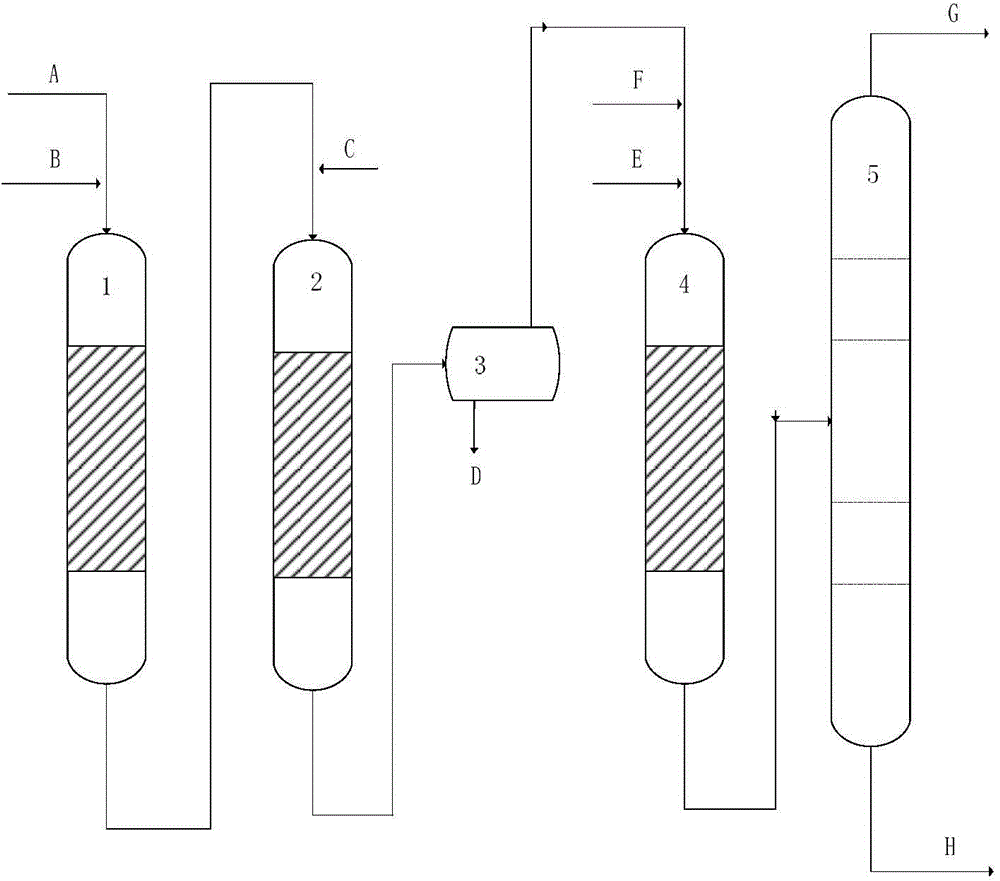

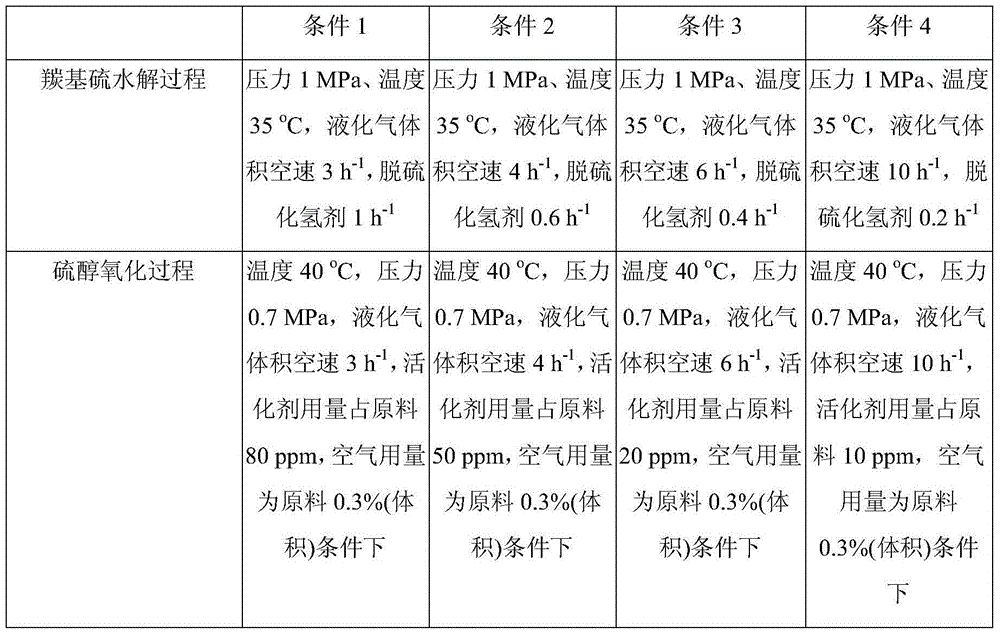

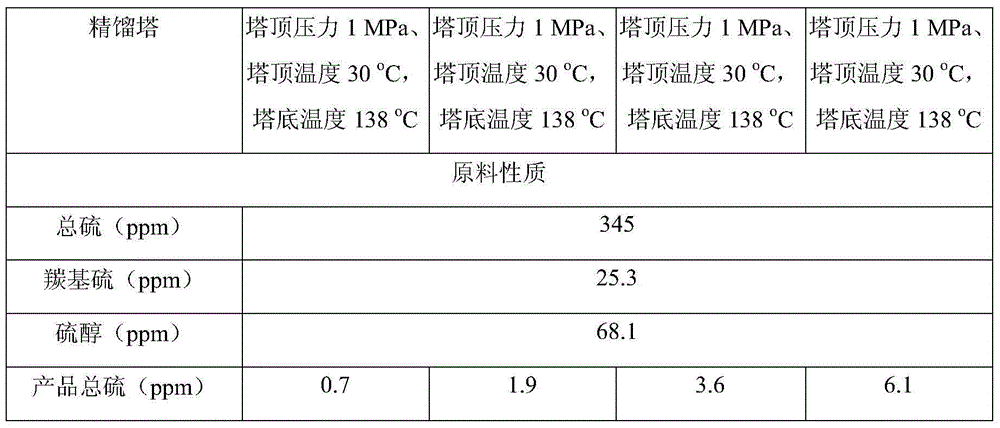

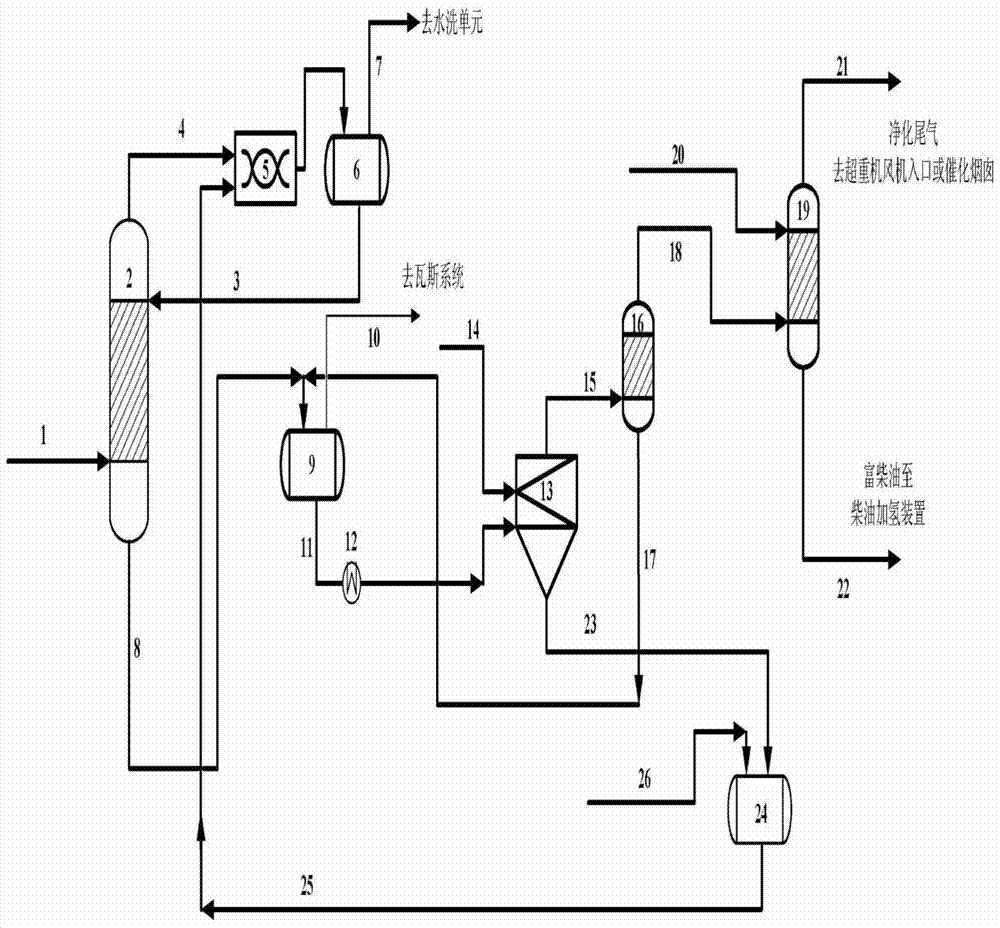

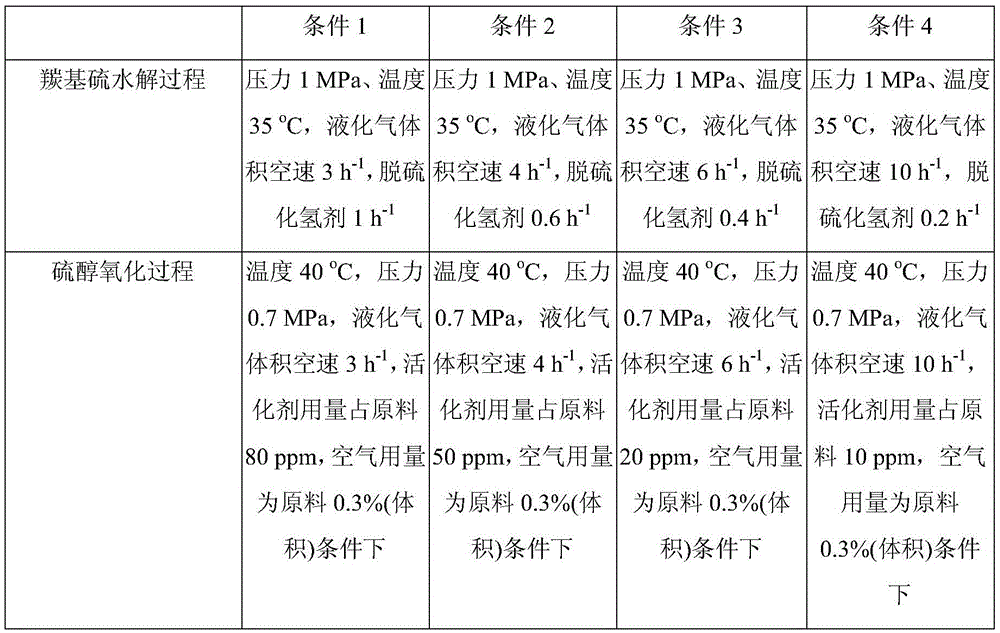

Deep desulfurization and refining combined technology for liquefied petroleum gas

InactiveCN104403688AMeet the feed requirementsReduce sulfur contentGaseous fuelsGaseous mixture working upHydrogen SulfateSulfate

The invention relates to a deep desulfurization technology for liquefied petroleum gas. A carbonyl sulfate water-washing tower is adopted to remove hydrogen sulfate and carbonyl sulfate in the liquefied petroleum gas respectively according to different nature characteristics of sulfides contained in the liquefied petroleum gas, small-molecular mercaptan in the liquefied petroleum gas is converted into disulfides with higher boiling points through an oxidation tower, then the sulfides and a liquefied petroleum gas product are separated with a rectification method, sulfur-enriched C5 or heavy C4 components are arranged at the tower bottom, and the ultra-low-sulfur liquefied petroleum gas product is arranged at the tower top. The content of sulfur in the liquefied petroleum gas is decreased to be lower than 5 mu g / g in the process, the desulfurization rate is high, and no alkali residue is discharged.

Owner:XI'AN PETROLEUM UNIVERSITY

Method for preparing catalyst for converting mercaptan in liquefied gas

ActiveCN1935377AImprove extraction efficiencyImprove oxidation effectCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventActive component

The present invention discloses a preparation method of catalyst for converting mercaptan contained in the liquefied gas. Said method has the following steps: (1), activation of carrier; (2), dissolving active component in the solvent, the described active component is phthalocyanine cobalt compound, the described solvent is simple organic solvent or organic mixed solvent or organic-inorganic mixed solvent; (3), soaking the carrier activated in step 1 in the solution obtained by step 2 so as to obtain a mixed material; and (4), making the carrier be filtered out from the mixed material obtained in the step 3, drying said carrier so as to obtain the invented catalyst.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

A kind of upgrading method of catalytic cracking gasoline

InactiveCN104673377BRealize deep desulfurizationFlexible operationTreatment with hydrotreatment processesHydrocarbon oils treatment productsHydrodesulfurizationGasoline

The invention provides a quality improvement method of catalytic cracking gasoline. The quality improvement method comprises the following steps of: cutting a gasoline raw material into light, medium and heavy gasoline fractions; desulfurizing the medium gasoline fraction to obtain first desulfurized medium gasoline fraction; carrying out aromatization / hydroisomerization reaction on the first desulfurized medium gasoline fraction in the presence of a catalyst to obtain second desulfurized medium gasoline fraction; carrying out selective hydrodesulfurization on the heavy gasoline fraction to obtain desulfurized heavy gasoline fraction; mixing the light gasoline fraction, the second desulfurized medium gasoline fraction and the desulfurized heavy gasoline fraction to obtain quality improved gasoline, wherein the cutting temperature of the light and medium gasoline fractions is 35-60 DEG C, and the cutting temperature of the medium and heavy gasoline fraction is 70-130 DEG C. The quality improvement method provided by the invention can not only realize the deep desulfurization of the catalytic cracking gasoline, but also be used for outstandingly increasing the octane value.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Desulfuration adsorbent

InactiveCN106582501AHigh sulfur capacityHigh desulfurization depthOther chemical processesHydrocarbon oils refiningChemistryEnvironmentally friendly

The invention discloses a desulfuration adsorbent. The desulfuration adsorbent is composed of the following raw materials of, by weight, 33-41 parts of nano attapulgite, 1-5 parts of cyclohexyl methyl ketone, 7-15 parts of acrylic acid, and 11-19 parts of ammonium metavanadate. According to the desulfuration adsorbent, the nano attapulgite serves as one of the raw materials and mixed with the cyclohexyl methyl ketone, grinding is conducted, and the ammonium metavanadate, the acrylic acid and the like are used for treatment, so that the desulfuration adsorbent is prepared; the desulfuration adsorbent prepared in the this way is large in sulfur capacity, good in sulfur selectivity, high in desulfuration percent and capable of reducing sulfur to 1ppmw; and in addition, the desulfuration adsorbent is long in service life, environmentally friendly and free of secondary pollution. The preparation process of the desulfuration adsorbent is simple, operation and control are easy, the performance is stable, the production cost is low, and the desulfuration adsorbent is suitable for industrialized production. When the desulfuration adsorbent is used for desulfuration of gasoline, the process operating conditions are mild, dsulfuration can be conducted under ordinary pressure and at a low temperature, accordingly energy consumption is reduced, and the operation cost is lowered.

Owner:ZHENGZHOU BEIDOU COMM TECH

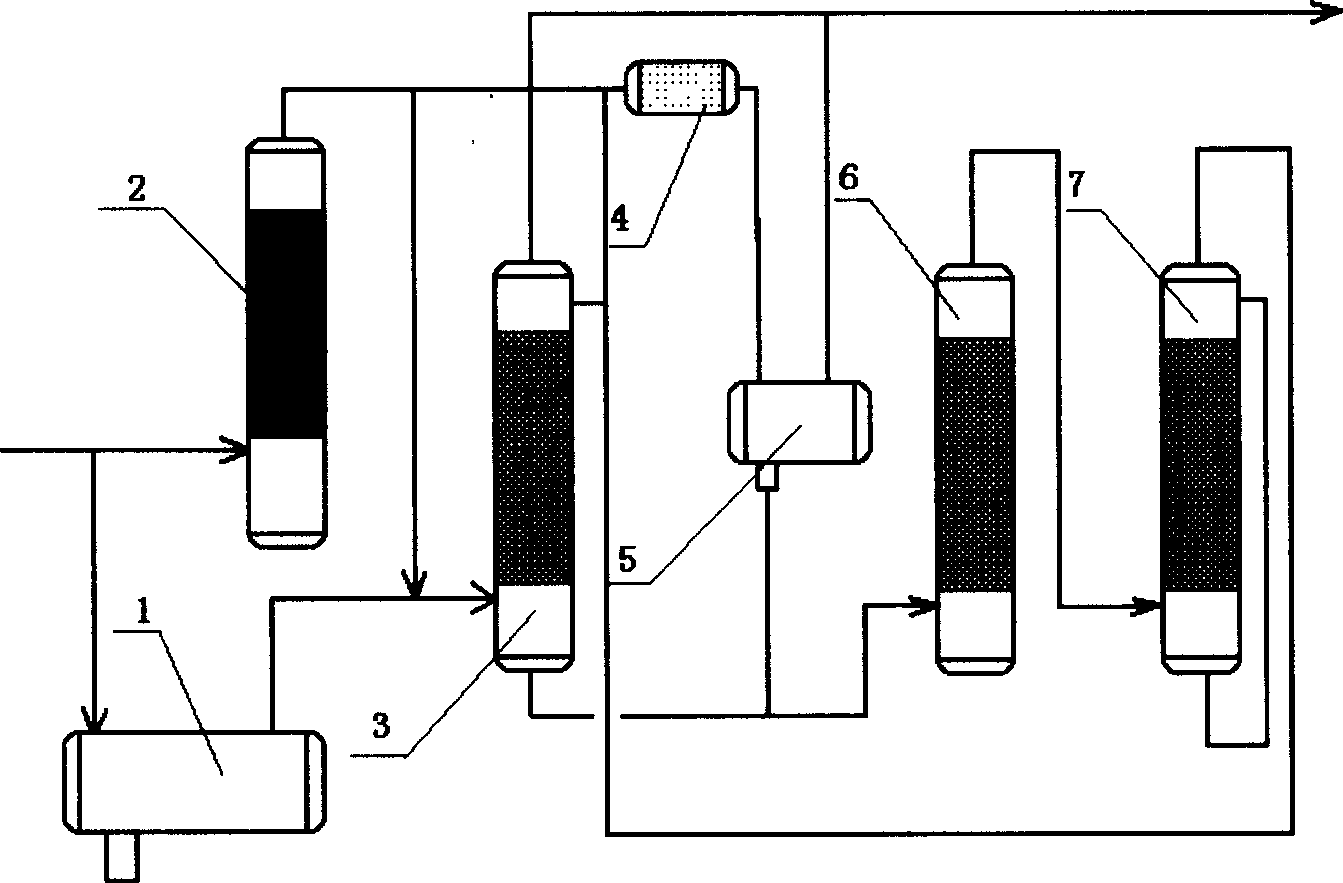

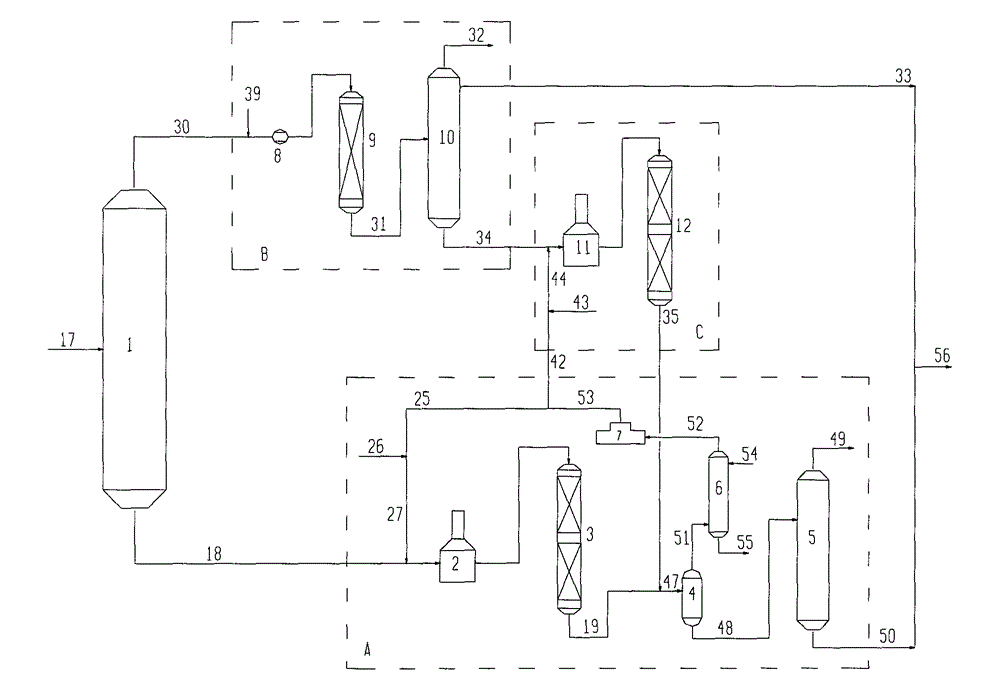

Combination process for deeply desulfurzing liquified petroleum gas and light olefin by solid alkali neutralizing agent and alkali

InactiveCN1510109AEmission reductionReduce secondary pollutionRefining with solid alkaline materialTowerLiquefied petroleum gas

A process for using solid alkali and agent-alkali to deeply desulfurizing the liquefied petroleum gas and light hydrocarbon features that the raw material to be treated passes sequentially through liquid alkali (or solid alkali) washing tank (or tower), liquid-liquid countercurrent extracting tower, and settling separation tank to separate out the refined product and extracting liquid. The agent-alkali liquid also passes through oxidizing regeneration tower and back extracting tower for cyclic use.

Owner:PETROCHINA CO LTD +1

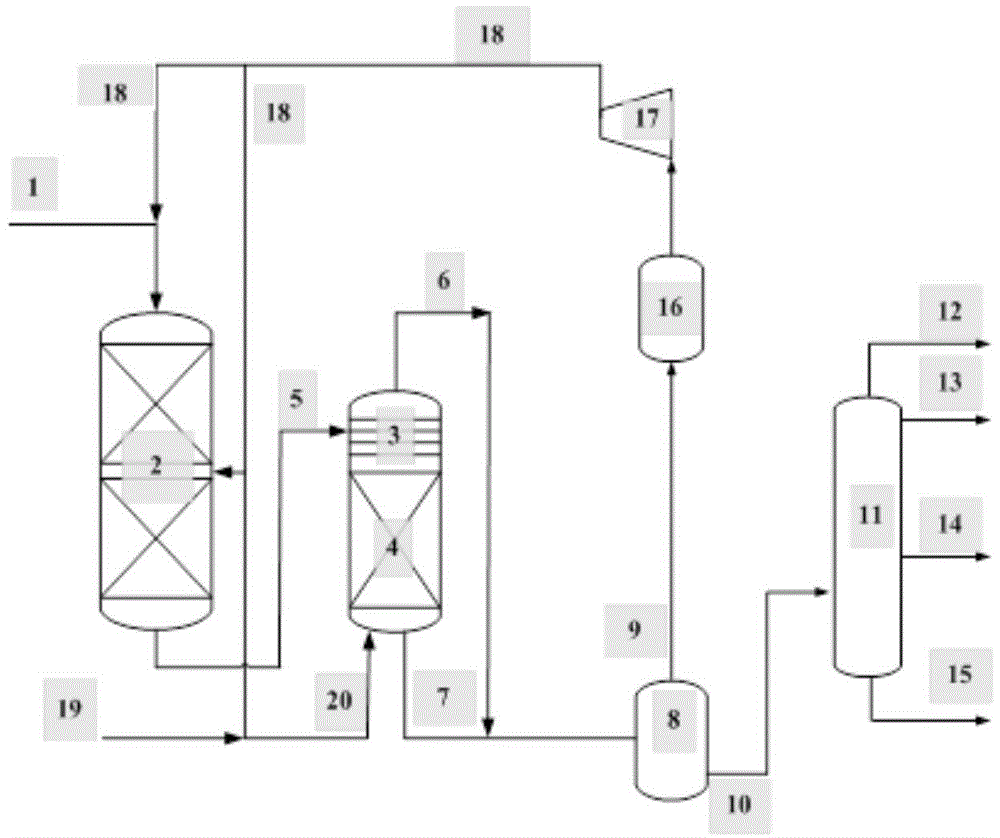

Catalytic hydrogenation method for inferior wax oil

ActiveCN105586084AExtended operating cycleImprove distributionTreatment with hydrotreatment processesWaxChemistry

The invention discloses a catalytic hydrogenation method for inferior wax oil. The method comprises the steps: (1) introducing the inferior wax oil to a first reaction zone for first hydrofining in the presence of hydrogen gas; (2) introducing effluent of the first reaction zone to a flash vaporization section for flash vaporization, so as to obtain a gas-phase component and a liquid-phase component; (3) introducing the liquid-phase component to a second reaction zone, and subjecting the liquid-phase component to countercurrent contact with hydrogen gas introduced from the bottom of the second reaction zone, so as to carry out second hydrofining; and (4) mixing effluent of the second reaction zone with the gas-phase component obtained in the step (2), and then, introducing the mixture into a gas-liquid separation system and a fractionating system sequentially. According to the method disclosed by the invention, the sulfur content and nitrogen content of high-sulfur and high-nitrogen inferior raw materials can be remarkably lowered, and the operating cycle of a catalytic hydrogenation device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

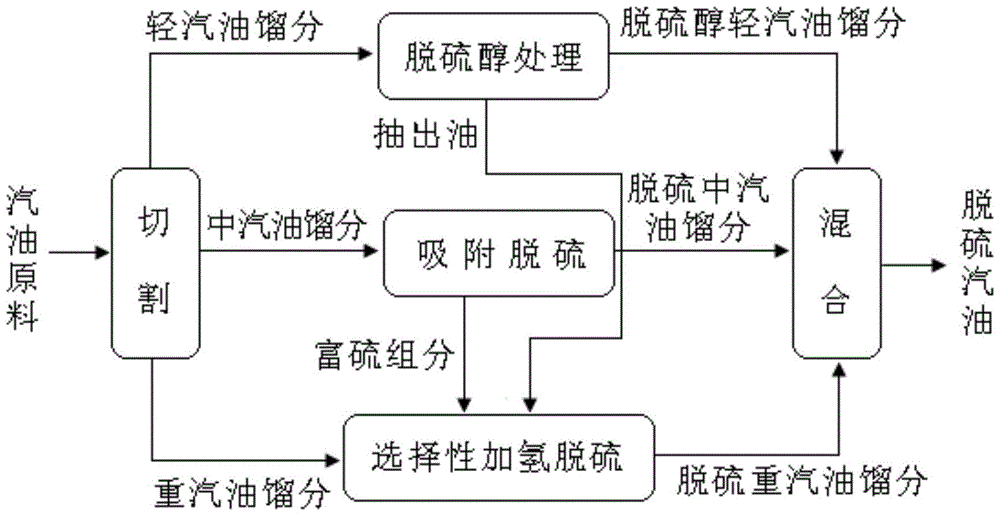

Deep gasoline desulfurization method

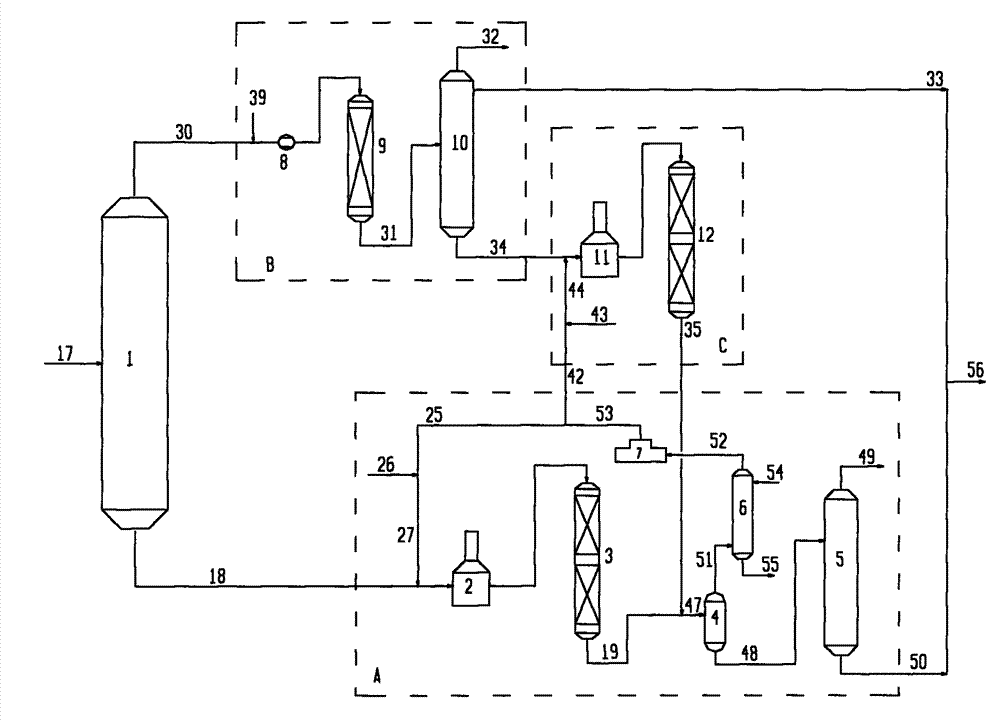

InactiveCN104673379ARealization of deep desulfurizationReduce the number of regenerationsOther chemical processesTreatment with hydrotreatment processesHydrodesulfurizationGasoline

The invention provides a deep gasoline desulfurization method which comprises the following steps of: carrying out mercaptan removing treatment on a gasoline raw material; cutting the gasoline raw material subjected to the mercaptan removing treatment into light, medium and heavy gasoline fractions; carrying out adsorption desulfurization on the medium gasoline fraction to obtain a desulfurized medium gasoline fraction; carrying out selective hydrodesulfurization on the heavy gasoline fraction to obtain a desulfurized heavy gasoline fraction; mixing the light gasoline fraction, the desulfurized medium gasoline fraction and the desulfurized heavy gasoline fraction to obtain desulfurized gasoline, wherein the cutting temperature of the light and medium gasoline fractions is 35-60 DEG C, and the cutting temperature of the medium and heavy gasoline fractions is 70-130 DEG C. The deep gasoline desulfurization method provided by the invention can not only realize the deep desulfurization of gasoline, but also has low octane value loss.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for manufacturing full-tire rubber powder high-tenacity reclaimed rubber by oligomer ester

InactiveCN108410008AImprove permeabilityIncrease productivityPlastic recyclingPolymer scienceOligomer

The invention relates to a method for manufacturing full-tire rubber powder high-tenacity reclaimed rubber by oligomer ester. The method includes the steps: matching the oligomer ester into a regeneration activator system; uniformly stirring and mixing the oligomer ester and full-tire rubber powder in a high-temperature mixing tank to obtain mixed rubber powder; recovering the mixed rubber powderby the aid of waste rubber desulphurization devices (dynamic desulphurization tank device, screw extrusion device and spiral extrusion device) to form disulfide powder; refining and packaging the disulfide powder to form high-performance reclaimed rubber products. The method solves the problem of high consumption of domestic high-tenacity reclaimed rubber.

Owner:JIANGSU ZHONGHONG ENVIRONMENT TECH CO LTD

A fuel oil deep adsorption desulfurization catalyst and its preparation method and application

ActiveCN104056632BLarge specific surface areaReduce hydrogen consumptionOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsSorbentBULK ACTIVE INGREDIENT

A fuel oil deep adsorption desulfurization catalyst, characterized in that the catalyst includes an active component, a sulfur adsorbent, and a binder, wherein the active component is one or more of Ni, Co, Cu, W, and Mo oxides, The sulfur adsorbent is at least one of Mg, Ca, Zn, Ce, Fe, Mn, Ti oxides, the mass percentage of the active component is 2wt%-50wt%, and the mass percentage of the sulfur adsorbent is 20 wt%-90wt%, the rest are binders, and the binders are alumina, pseudoboehmite, kaolin, montmorillonite, bentonite, montmorillonite, diatomaceous earth, silica sol, silica gel, One or a mixture of expanded perlite. The invention has the advantages of high specific surface area, mild reaction, high strength and low hydrogen consumption.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

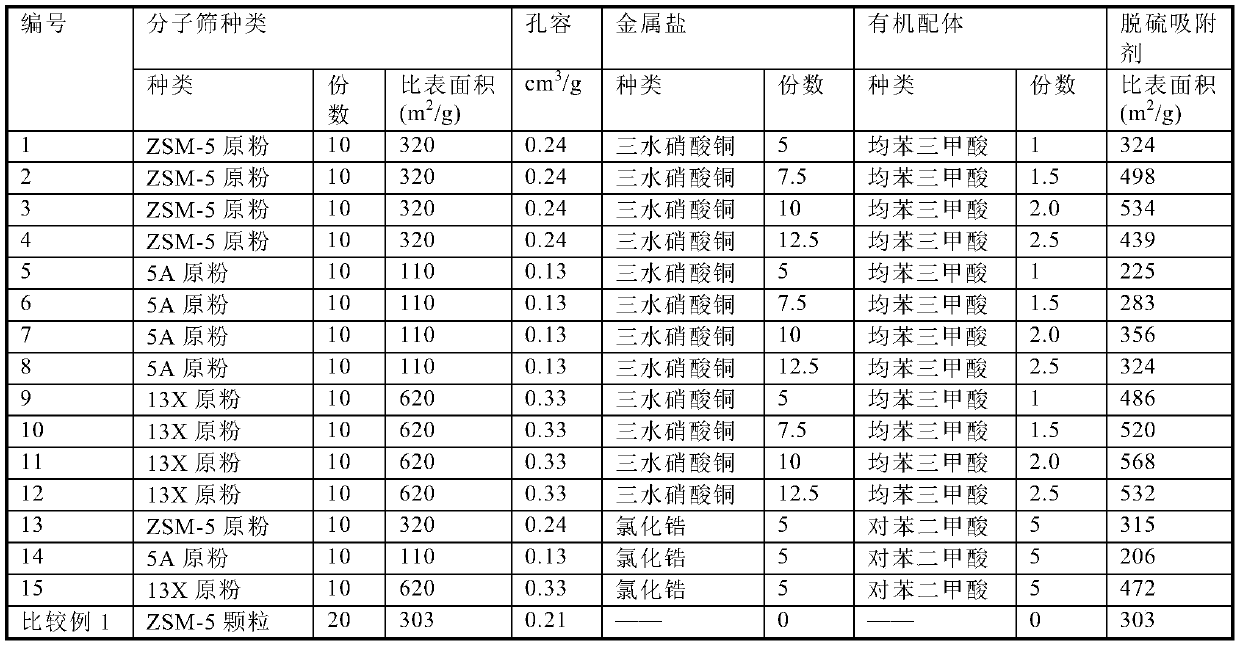

Novel composite fuel oil desulfurization adsorbent, preparation method and application thereof

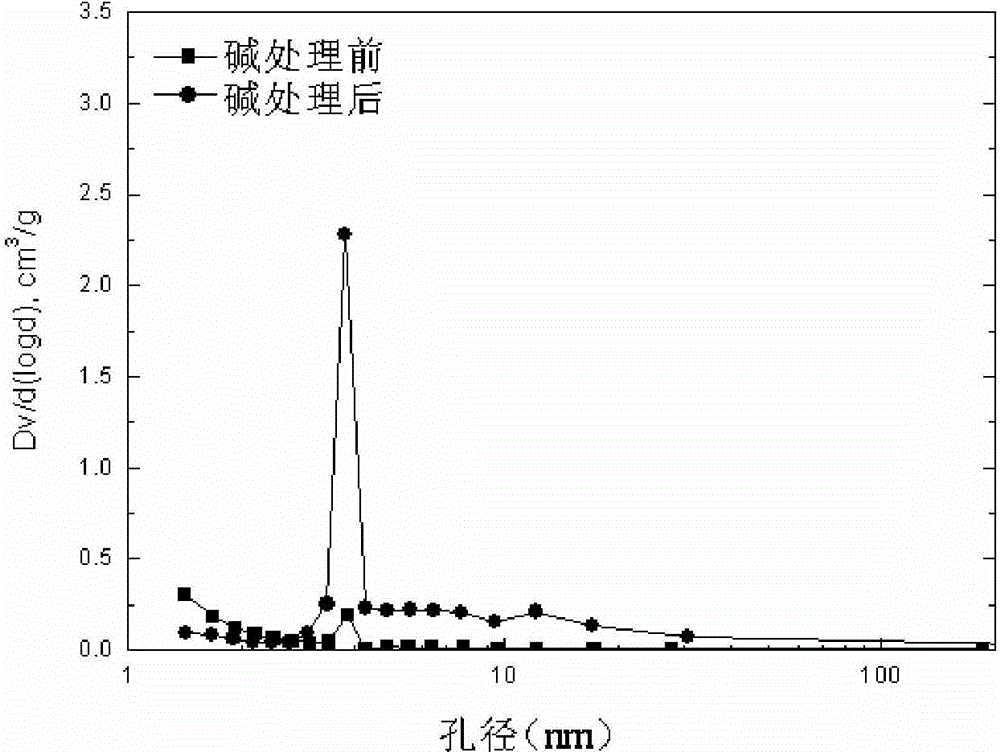

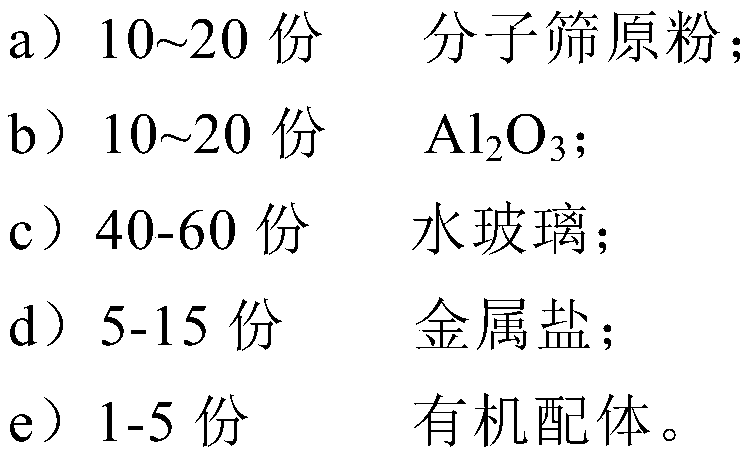

InactiveCN110898810AFacilitated DiffusionSimple structureOther chemical processesHydrocarbon oils refiningMolecular sieveSorbent

The invention provides a novel composite fuel oil desulfurization adsorbent, a preparation method and application thereof. The novel composite fuel oil desulfurization adsorbent comprises the following components by weight: 10-20 parts of molecular sieve raw powder, 10-20 parts of Al2O3, 40-60 parts of water glass, 5-15 parts of a metal salt and 1-6 parts of an organic ligand. According to the invention, integral molecular sieve particles are adopted as the carrier, on which a metal organic skeleton with high desulfurization activity is loaded, and finally an integral hierarchical pore molecular sieve@metal organic skeleton composite desulfurization adsorbent can be obtained, and the problems of low desulfurization precision, low sulfur capacity and the like in the prior art are solved. The desulfurization adsorbent provided by the invention has high removal efficiency on thiophene sulfides, has high selectivity on sulfides, is environment-friendly and has no secondary pollution. The operation can be performed under normal temperature and normal pressure, and the operation cost is saved.

Owner:DALIAN UNIV OF TECH +1

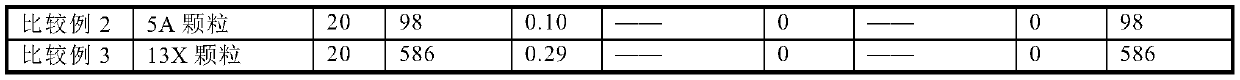

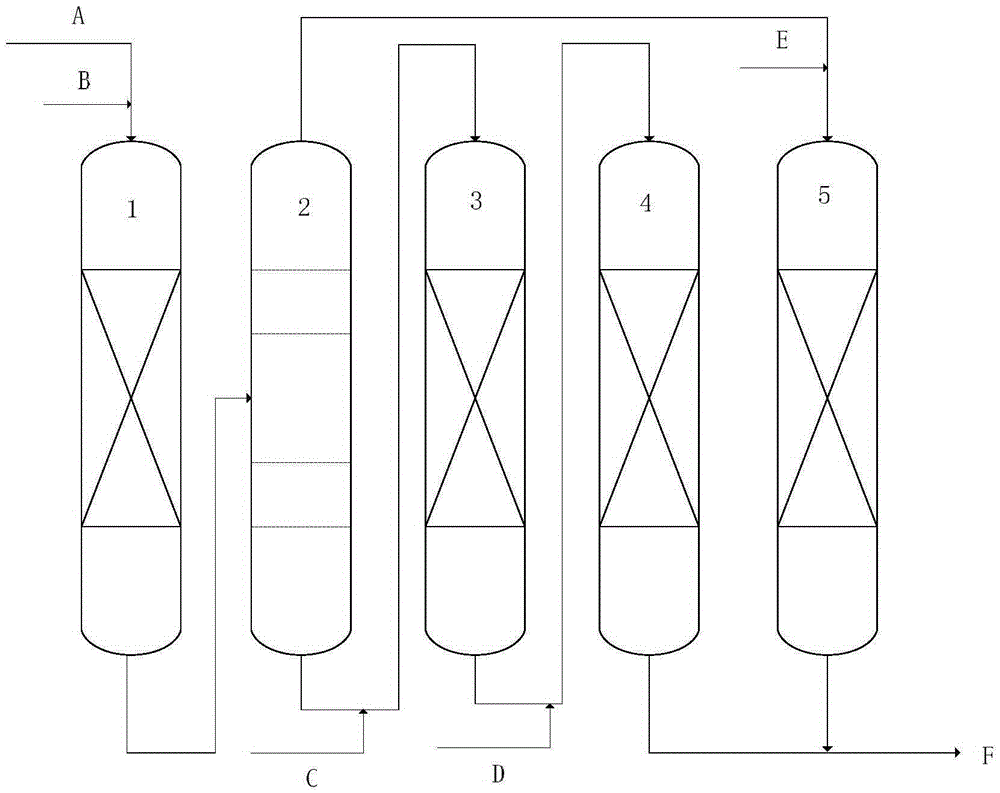

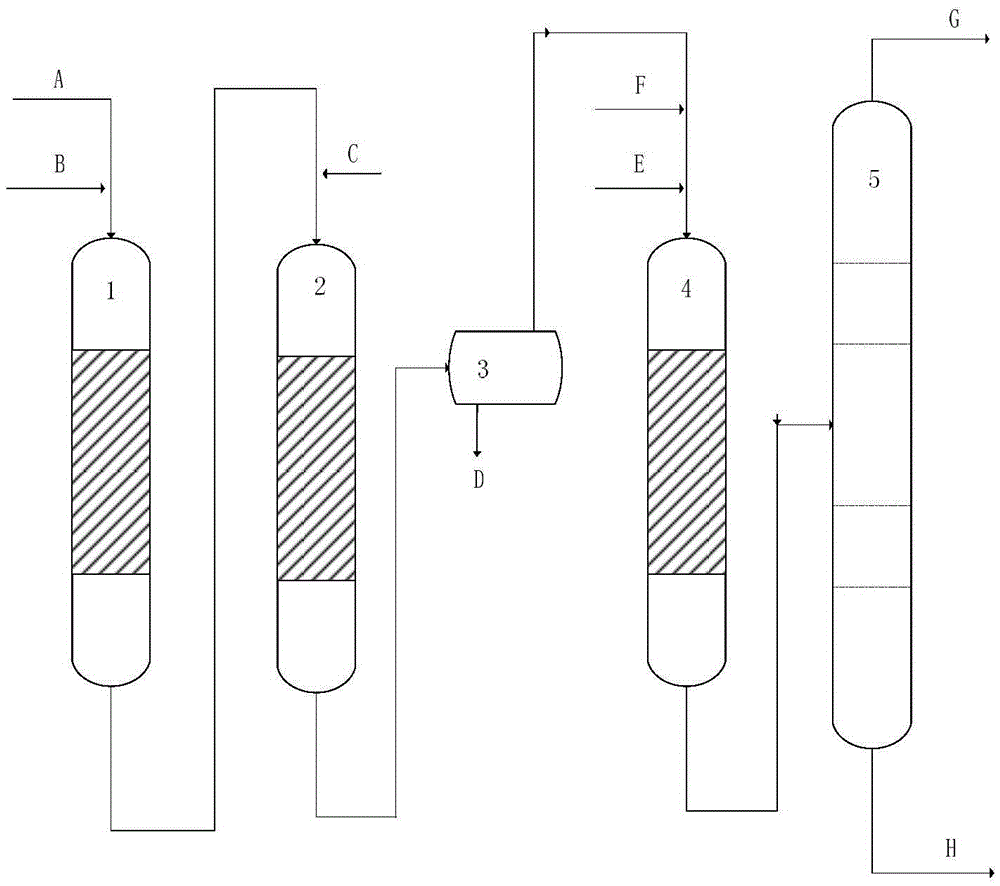

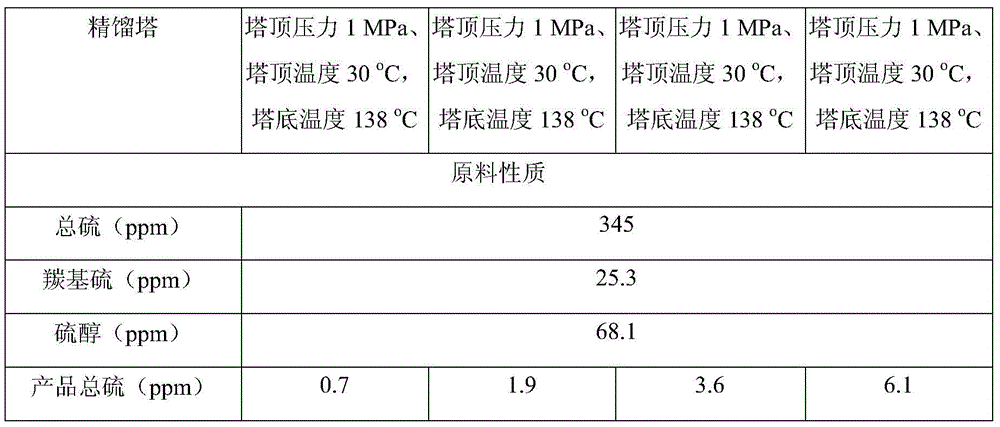

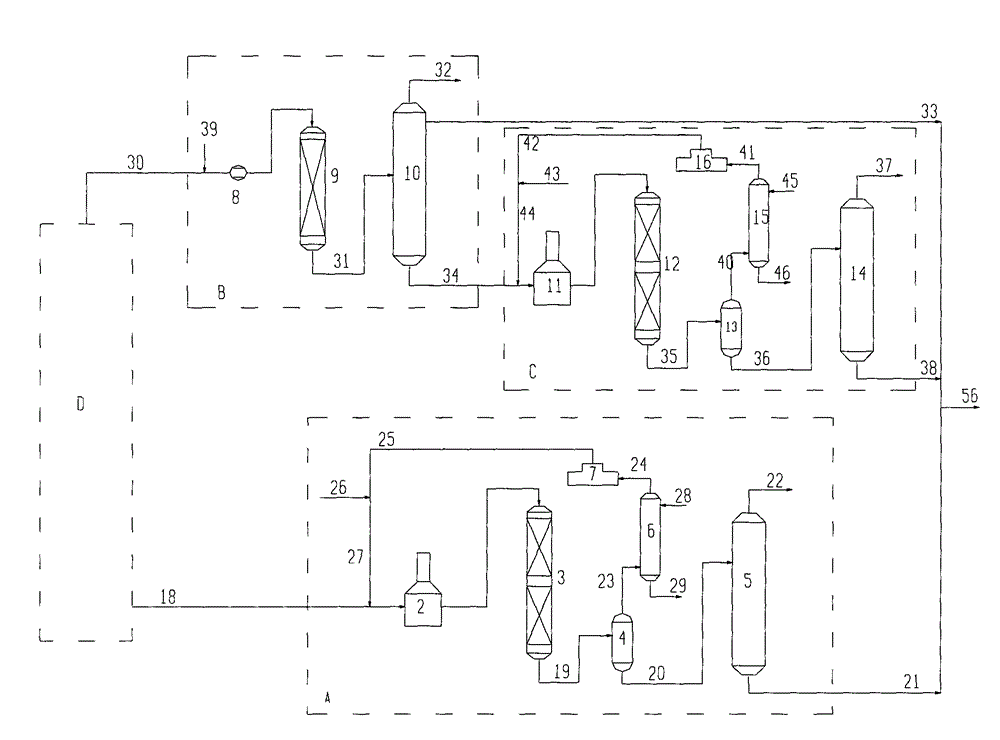

A Combined Process for Deep Desulfurization of Catalytic Cracking Gasoline

InactiveCN104479738BSolution to short lifeSimple processTreatment with hydrotreatment processesHydrocarbon oils treatment productsIsomerizationSulfur

Owner:XI'AN PETROLEUM UNIVERSITY

Gasoline fraction desulfurization method, method for producing low-sulfur gasoline and reaction system

ActiveCN112662427AEasy to removeDeinhibitionTreatment with hydrotreatment processesPtru catalystHydrodesulfurization

The invention relates to a gasoline fraction desulfurization method, a method for producing low-sulfur gasoline and a reaction system. According to the method, a gasoline fraction enters a first reactor, and contacts a first hydrodesulfurization catalyst in the presence of hydrogen to carry out a first hydrodesulfurization reaction; a product obtained after the reaction enters a steam stripping tower, hydrogen-rich gas containing hydrogen sulfide and an intermediate gasoline fraction are obtained at the top of the steam stripping tower, a descending tower bottom material enters a second reactor and contacts a second desulfurization catalyst to be subjected to a secondary desulfurization reaction, a reaction product returns to the bottom of the steam stripping tower, a liquid phase in the reaction product is extracted to serve as a desulfurized heavy gasoline fraction, and a vapor phase returns to the steam stripping section of the steam stripping tower; and the second reactor is a heat exchange type reactor, and an external heat source flows through a coil pipe or a tube nest in the heat exchange type reactor to heat reaction materials. The gasoline fraction desulfurization method provided by the invention can reduce energy consumption, and is small in octane number loss and high in desulfurization depth.

Owner:CHINA PETROLEUM & CHEM CORP +1

A combined method for deep desulfurization of liquefied gas

ActiveCN104624033BHigh desulfurization depthAchieve desulfurization effectDispersed particle separationGaseous fuelsPresent methodStatic mixer

The invention relates to a combination method for deep desulfurization of liquefied gas; the liquefied gas is fed into an extraction tower, and is contacted with incoming lye in countercurrent, and the desulfurized liquefied gas and regenerated lye enter a static mixer to mix for second-stage extraction, and the mixed liquid is liquefied The gas-alkali-liquid separation tank is separated, the liquefied gas is sent to be washed with water, the uncooked alkali solution flowing out from the bottom of the extraction tower enters the flash tank, the residual liquefied gas is discharged from the top of the tank and sent to the gas system, and the uncooked solution obtained at the bottom of the tank is heated After that, it enters the supergravity reactor and reacts with non-purified wind. The tail gas discharged from the supergravity reactor is removed from the lye by the coalescer and sent back to the flash tank. The purified tail gas is returned to the supergravity reactor for recycling, and the rich diesel oil discharged from the bottom of the tower is sent to the diesel hydrogenation unit, and the regenerated lye obtained is recycled; this method has deep desulfurization depth, high quality regenerated lye, simple and reliable equipment, and low cost. The discharge of three wastes is less, and the whole process meets the requirements of environmental protection.

Owner:PETROCHINA CO LTD

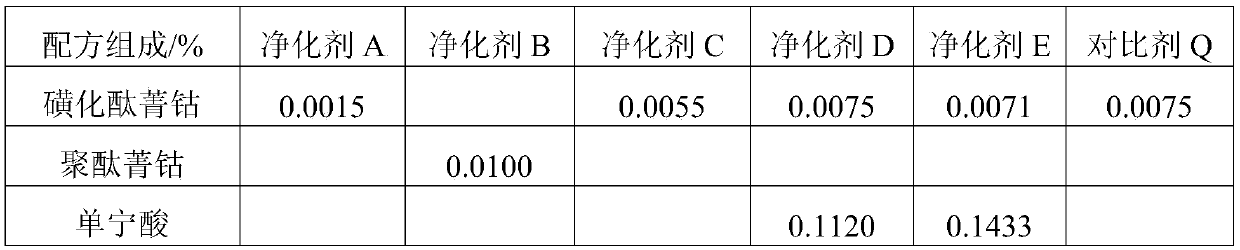

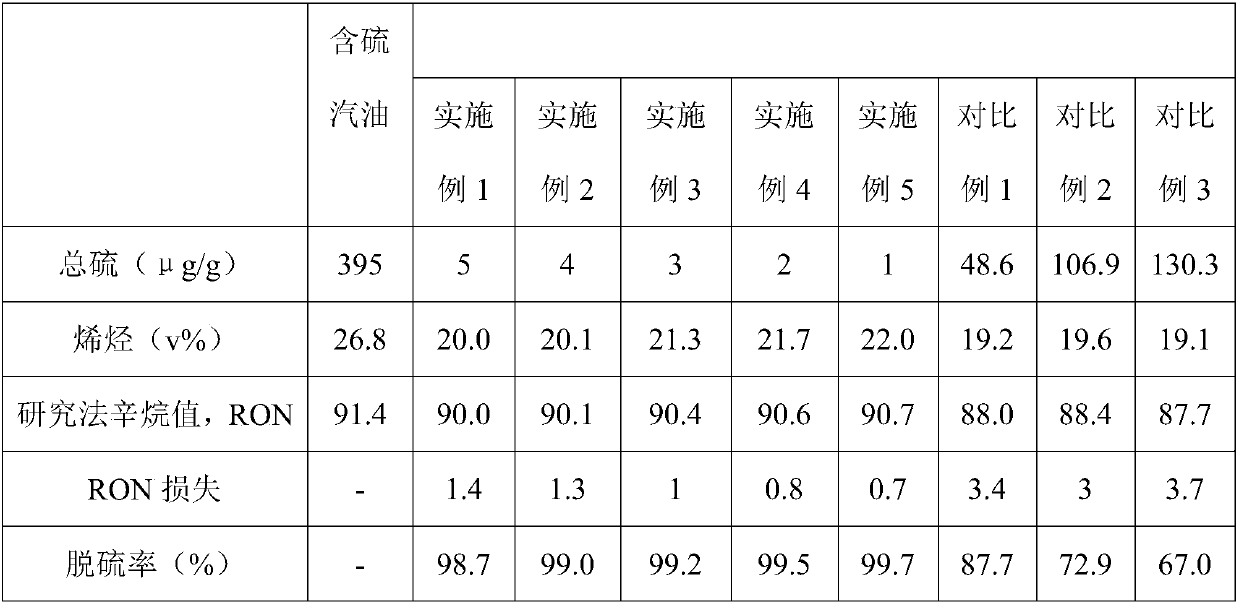

Refinery rich gas pretreatment method and dry gas and/or liquefied gas desulfurization method

ActiveCN110628475AReduce the burden onReduce consumptionGaseous fuelsDispersed particle separationPretreatment methodPre treatment

The invention provides a refinery rich gas pretreatment method and a dry gas and / or liquefied petroleum gas desulfurization method. The refinery rich gas pretreatment method comprises the step of contacting the refinery rich gas with a purifying agent. The refinery rich gas pretreatment method can reduce the desulfurization load of downstream products including dry gas and liquefied gas of the refinery rich gas, reduce the environmental protection pressure of desulfurization of the dry gas and the liquefied gas and improve the desulfurization depth of the dry gas and the liquefied gas, and particularly can break through the limit of the prior art of desulfurization of the liquefied gas. The dry gas and / or liquefied gas desulfurization method can be used to carry out deep desulfurization onthe dry gas and / or liquefied gas in order to obtain dry gas and / or liquefied gas with an extremely low sulfur content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gasoline desulfurization adsorbent, and preparation method and application thereof

InactiveCN106693883AHigh sulfur capacityHigh desulfurization depthOther chemical processesHydrocarbon oils refiningSorbentSulfur

The invention discloses a gasoline desulfurization adsorbent, and a preparation method and an application thereof. The desulfurization adsorbent is composed of the following raw materials in parts by weight: 27 to 35 parts of nanometer attapulgite, 3 to 7 parts of strontium acetate, 13 to 21 parts of acrylic acid and 5 to 13 parts of triethanolamine. The desulfurization adsorbent provided by the invention is prepared through the following steps: with the nanometer attapulgite as a raw material, carrying out mixing with strontium acetate, carrying out grinding, carrying out treatment with acrylic acid and triethanolamine, etc. The desulfurization adsorbent has large sulfur capacity, good selectivity to sulfur and high desulfurization depth, can remove sulfur to 1 ppmw, has long service life and is friendly to the environment. The preparation process provided by the invention has the advantages of simplicity, easy operation, easy control, stable performances, low production cost and applicability to industrial production. By adopting the desulfurization absorbent provided by the invention for desulfurization of gasoline, the process has mild operation conditions, and can be performed at normal pressure and low temperature, so energy consumption is saved, and the cost of operation is reduced.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

Gasoline desulfurization agent and preparation method and application thereof

ActiveCN106554803AGood choiceAvoid lostRefining with non-metalsHydrocarbon oils treatment productsSalicylic acidGasoline

The invention discloses a gasoline desulfurization agent and a preparation method and application thereof. The gasoline desulfurization agent is composed of the following raw materials of, by weight, 21-29 parts of illite, 1-5 parts of perilla alcohol, 3-7 parts of salicylic acid and 5-12 parts of triethylene diamine. The illite is smashed and added to the triethylene diamine solution to be subjected to sealing, heating and stirring treatment, then the salicylic acid is dropwise added, ultrasonic treatment is conducted, then the perilla alcohol solution is added and stirred till being dry, and the desulfurization agent is obtained after calcination. Under the situation that the RON loss of gasoline is smaller than 2.0, the ultra-low sulfur content gasoline with the sulfur content being below 6 microgram / g can be obtained. The sulfur selectivity is good, the desulfurization depth is high, the octane number loss caused by olefin hydrogenation saturation is avoided while sulfur-containing compounds in the gasoline are deeply removed, the service life is long, and the gasoline desulfurization agent is environmentally friendly, free of secondary pollution and good in regeneration performance. The preparation process is simple, the raw materials are easy to obtain, the production cost is low, and the gasoline desulfurization agent is suitable for industrial production.

Owner:NINGXIA RUIKE XINYUAN CHEM CO LTD

Desulfurization adsorbent for gasoline

InactiveCN106732460AHigh desulfurization depthHigh sulfur capacityOther chemical processesHydrocarbon oils refiningSorbentSulfur

The invention discloses a desulfurization adsorbent for gasoline. The desulfurization adsorbent is prepared from, by weight, 27-35 parts of white clay, 3-7 parts of strontium acetate, 13-21 parts of polyving akohol and 5-13 parts of ethylene glycol. According to the desulfurization adsorbent for the gasoline, the white clay serves as a row material, after the white clay is mixed with the strontium acetate, then after the processing of the polyving akohol, the ethylene glycol and the like, the desulfurization adsorbent is prepared, the sulfur capacity is large, the selection for sulfur is good, the depth of desulfurization is high, and sulfur concentration after the desulfurization can reach 1 ppmw; besides, the service life is long and the adsorbent is environmentally friendly. The desulfurization adsorbent for the gasoline is simple in preparation process, easy to operate and control, stable in performance, low in production cost and suitable for industrial production. According to the desulfurization adsorbent, when the gasoline is desulfurized, the process operation conditions are mild, the desulfurization can be carried out at a normal pressure and a lower temperature, and therefore the energy consumption is saved, and the operation cost is reduced.

Owner:ZHENGZHOU BEIDOU COMM TECH

A kind of gasoline desulfurization method

InactiveCN104673376BRealize deep desulfurizationLow component contentTreatment with hydrotreatment processesGasolineRaw material

The invention provides a gasoline desulfurization method. The gasoline desulfurization comprises the following steps: cutting a gasoline raw material into a light gasoline fraction and a heavy gasoline fraction; performing adsorption desulfurization on the light gasoline fraction to obtain desulfurized light gasoline fraction; and performing selective hydrogenation desulfurization on the heavy gasoline fraction to obtain desulfurized heavy gasoline fraction, wherein the cutting temperature of the light gasoline fraction and the heavy gasoline fraction is 70-110 DEG C. By adopting the gasoline desulfurization method, not only can deep desulfurization of gasoline be realized, but also the octane loss is low.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

A combination process for deep desulfurization and refining of liquefied petroleum gas

InactiveCN104403688BNo emissionsImprove qualityGaseous fuelsGaseous mixture working upHydrogen SulfateBoiling point

The invention relates to a deep desulfurization technology for liquefied petroleum gas. A carbonyl sulfate water-washing tower is adopted to remove hydrogen sulfate and carbonyl sulfate in the liquefied petroleum gas respectively according to different nature characteristics of sulfides contained in the liquefied petroleum gas, small-molecular mercaptan in the liquefied petroleum gas is converted into disulfides with higher boiling points through an oxidation tower, then the sulfides and a liquefied petroleum gas product are separated with a rectification method, sulfur-enriched C5 or heavy C4 components are arranged at the tower bottom, and the ultra-low-sulfur liquefied petroleum gas product is arranged at the tower top. The content of sulfur in the liquefied petroleum gas is decreased to be lower than 5 mu g / g in the process, the desulfurization rate is high, and no alkali residue is discharged.

Owner:XI'AN PETROLEUM UNIVERSITY

A kind of gasoline desulfurizer and its preparation method and application

ActiveCN106554803BGood choiceAvoid lostRefining with non-metalsHydrocarbon oils treatment productsSalicylic acidSulfur containing

Owner:NINGXIA RUIKE XINYUAN CHEM CO LTD

Pretreatment method of refinery rich gas and desulfurization method of dry gas and/or liquefied gas

ActiveCN110628475BReduce the burden onReduce consumptionGaseous fuelsDispersed particle separationPretreatment methodLiquefied petroleum gas

The invention provides a refinery rich gas pretreatment method and a dry gas and / or liquefied petroleum gas desulfurization method. The refinery rich gas pretreatment method comprises the step of contacting the refinery rich gas with a purifying agent. The refinery rich gas pretreatment method can reduce the desulfurization load of downstream products including dry gas and liquefied gas of the refinery rich gas, reduce the environmental protection pressure of desulfurization of the dry gas and the liquefied gas and improve the desulfurization depth of the dry gas and the liquefied gas, and particularly can break through the limit of the prior art of desulfurization of the liquefied gas. The dry gas and / or liquefied gas desulfurization method can be used to carry out deep desulfurization onthe dry gas and / or liquefied gas in order to obtain dry gas and / or liquefied gas with an extremely low sulfur content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gasoline desulfurization agent and preparation method and application thereof

InactiveCN108148619AGood choiceAvoid lostRefining with non-metalsHydrocarbon oils treatment productsAlcoholSalicylic acid

The invention discloses a gasoline desulfurization agent and a preparation method and application thereof. The gasoline desulfurization agent comprises, by weight, 21-29 parts of illite, 1-5 parts ofperillyl alcohol, 3-7 parts of salicylic acid and 5-12 parts of triethylene diamine. The preparation method includes: crushing the illite, adding a triethylene diamine solution, heating and stirring in a sealed manner, dropwise adding the salicylic acid, performing ultrasonic treatment, adding a perillyl alcohol solution, stirring until dryness is achieved, and calcining to obtain the desulfurization agent. The gasoline desulfurization agent has the advantages that RON loss of gasoline is allowed to be smaller than 2.0, and the ultralow-sulfur-content gasoline with the sulfur content being below 6 microgram / g can be obtained; the gasoline desulfurization agent is good in sulfur selectivity, high in desulfurization depth, capable of deeply removing sulfur-containing compounds in the gasoline and avoiding octane value loss caused by olefin hydrogenation saturation, long in service life, environmentally friendly, free of secondary pollution and good in regeneration performance. The preparation method is simple in process, easy in raw material obtaining, low in production cost and suitable for industrial production.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

Hydrogenation method for deeply desulfurizing gasoline

ActiveCN103087771BHigh desulfurization depthReduce lossesTreatment with hydrotreatment processesHydrogenation reactionBoiling point

The invention provides a hydrogenation method for deeply desulfurizing gasoline. The hydrogenation method comprises the steps that catalytically cracked gasoline is fractionated into light fractions and heavy fractions; the heavy fractions and hydrogen are mixed and enter into a first hydrogenation reaction zone to react to obtain low-sulfur heavy fraction oil, and the recycle hydrogen obtained through separation is recycled after desulfurization; the light fractions and hydrogen are mixed and enter into a second hydrogenation reaction zone, diene is subjected to hydrogenation saturation to obtain mono-olefin low-boiling sulfides and the mono-olefin low-boiling sulfides are converted to high-boiling sulfides; the hydrogenated light fraction oil enters a light-medium fraction fractionating tower and is divided into light fractions and medium fractions and low-sulfur light fraction oil is obtained; the medium and light fractions and hydrogen are mixed and enter into a third hydrogenation reaction zone to react to obtain low-sulfur medium fraction oil, and the recycle hydrogen obtained through separation is recycled after desulfurization; and the heavy fraction oil, the light fraction oil and the medium fraction oil are mixed to obtain the low-sulfur gasoline product. Aiming to produce the gasoline with sulfur content not more than 10mu g / g, the method provided by the invention has the characteristics of high desulfurization depth, long device running period and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of production method of desulfurized gasoline

InactiveCN104673378BRealize deep desulfurizationFlexible operationOther chemical processesTreatment with hydrotreatment processesHydrodesulfurizationGasoline

The invention provides a method for producing desulfurized gasoline. The method for producing the desulfurized gasoline comprises the following steps: cutting gasoline feedstock into a light gasoline fraction, a medium gasoline fraction and a heavy gasoline fraction; sweetening the light gasoline fraction to obtain the sweetened light gasoline fraction; desulfurizing the medium gasoline fraction by adsorption to obtain the desulfurized medium gasoline fraction; performing selective hydrodesulfurization of the heavy gasoline fraction to obtain the desulfurized heavy gasoline fraction; mixing the sweetened light gasoline fraction, the desulfurized medium gasoline fraction and the desulfurized heavy gasoline fraction to obtain the desulfurized gasoline, wherein the cutting temperature of the light and medium gasoline fractions is 35-60 DEG C, and the cutting temperature of the medium and heavy gasoline fractions is 70-130 DEG C. The method for producing the desulfurized gasoline disclosed by the invention not only can achieve the deep desulfurization of gasoline, but also has small octane loss.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com