Combination process for deeply desulfurzing liquified petroleum gas and light olefin by solid alkali neutralizing agent and alkali

A technology for liquefied petroleum gas and deep desulfurization, which is applied in the refining of solid alkaline materials, etc., and can solve the problems of passive, large waste liquid discharge, and small device scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] 1. In actual design, the inventor implements the method of the present invention in the following way.

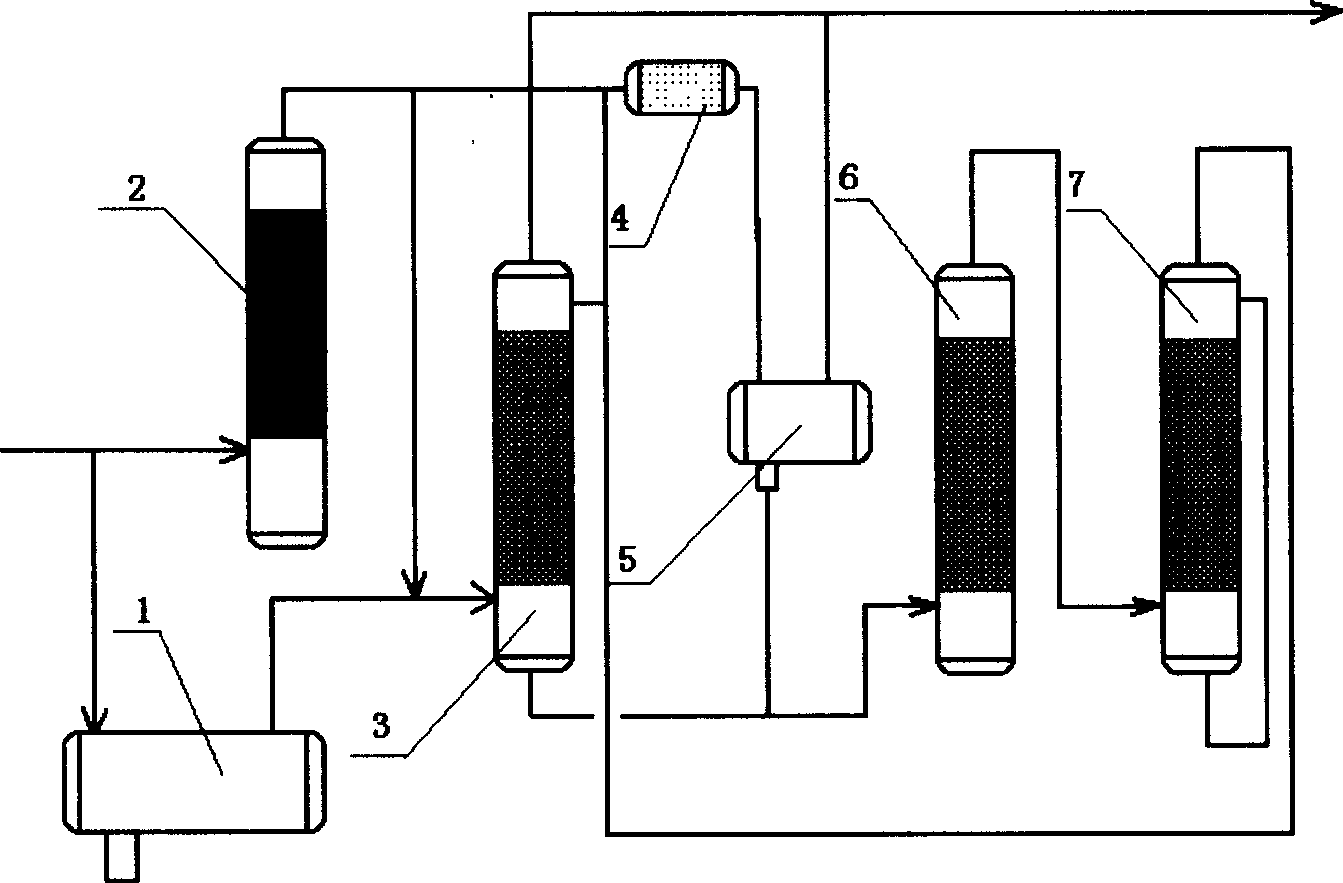

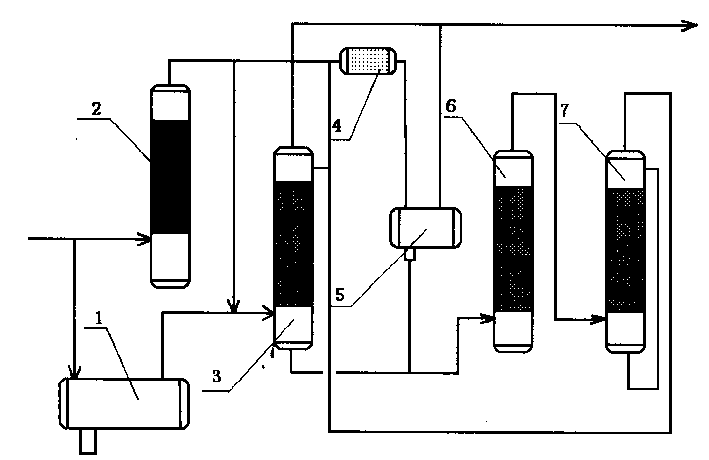

[0012] ① When the raw materials cannot meet the refining index requirements after pre-alkali washing, the desulfurization process is realized according to the following process: the raw materials enter the liquid caustic washing tank (1) or the solid caustic washing tower (2) for pre-alkali elution vulcanization The hydrogen then enters the liquid-liquid reverse extraction tower (3) to contact the recycled agent-alkali in reverse to remove mercaptan, and then enters the sedimentation separation tank (5) through the static mixer (4) for sedimentation and separation. The product is discharged from the top part of the separation tank, and the deactivator lye from the bottom part of the separation tank sequentially passes through the oxidation regeneration tower (6) and the reverse extraction tower (7), and the reverse extraction medium can be light oil.

[0013] ②When the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com