Patents

Literature

3732results about How to "Large amount of processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

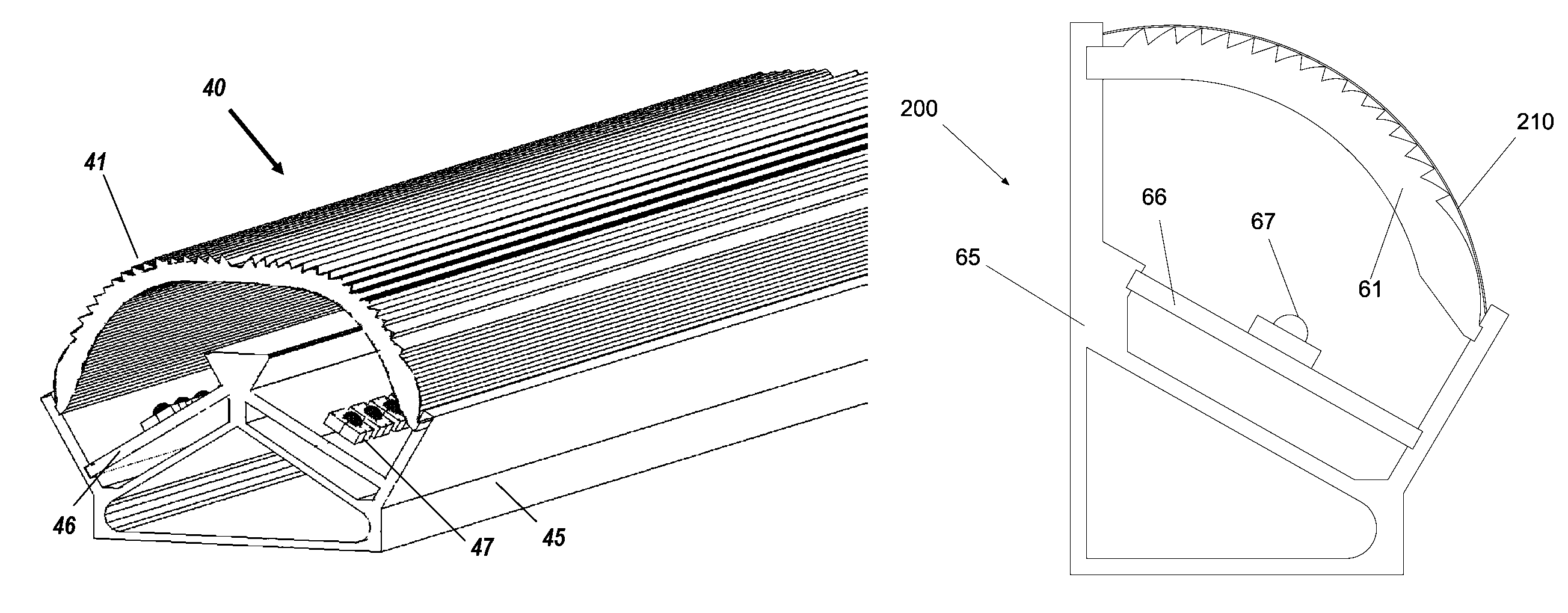

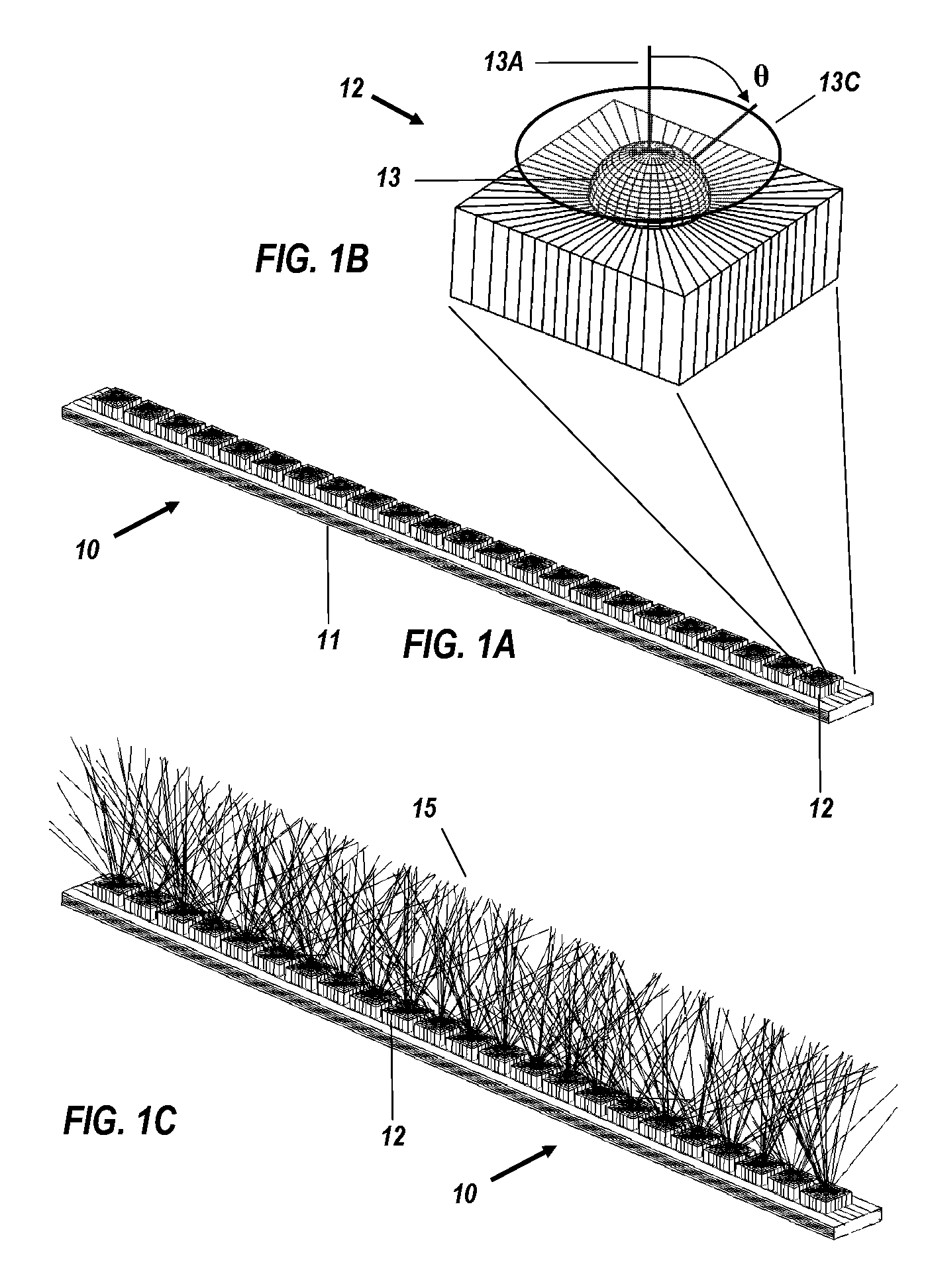

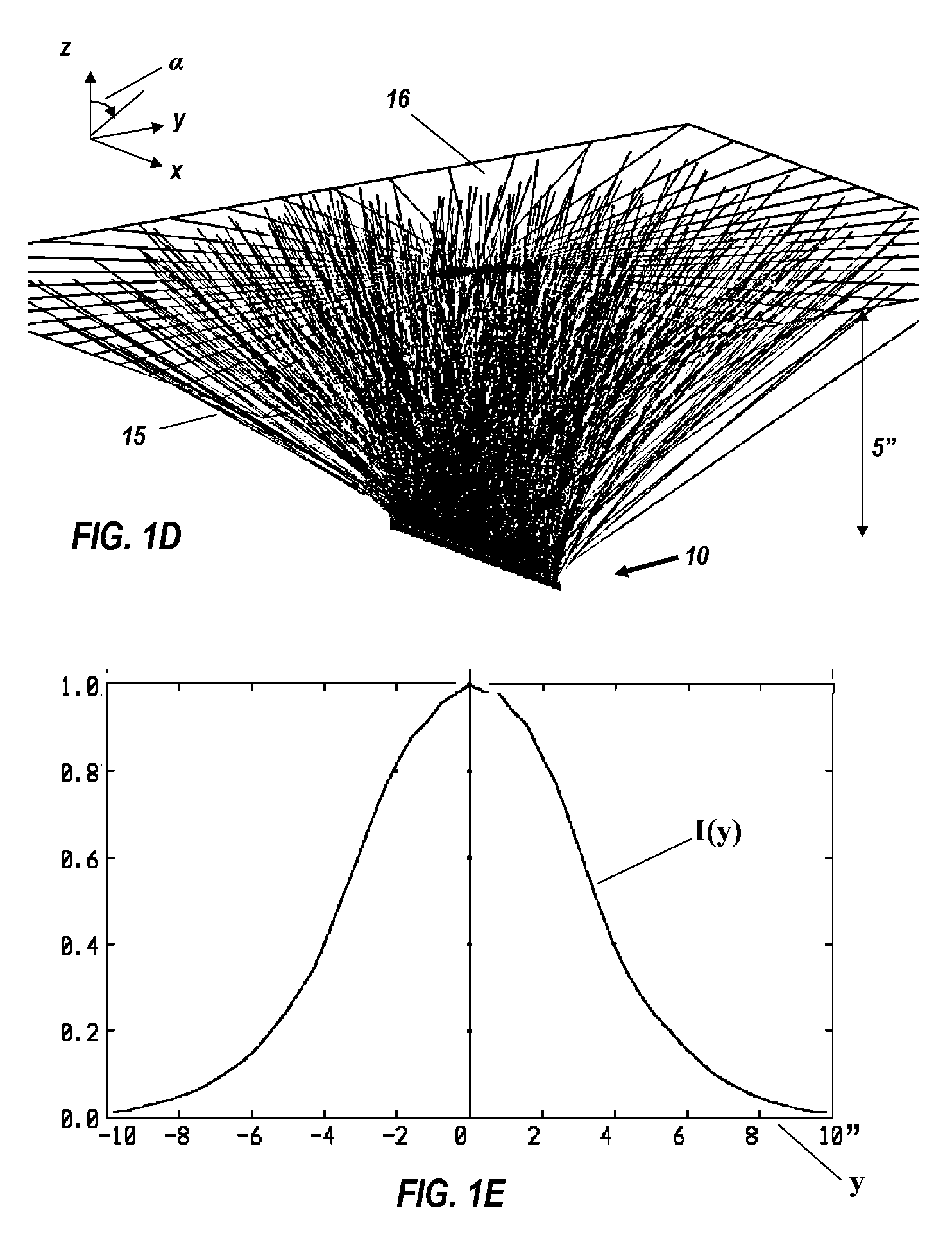

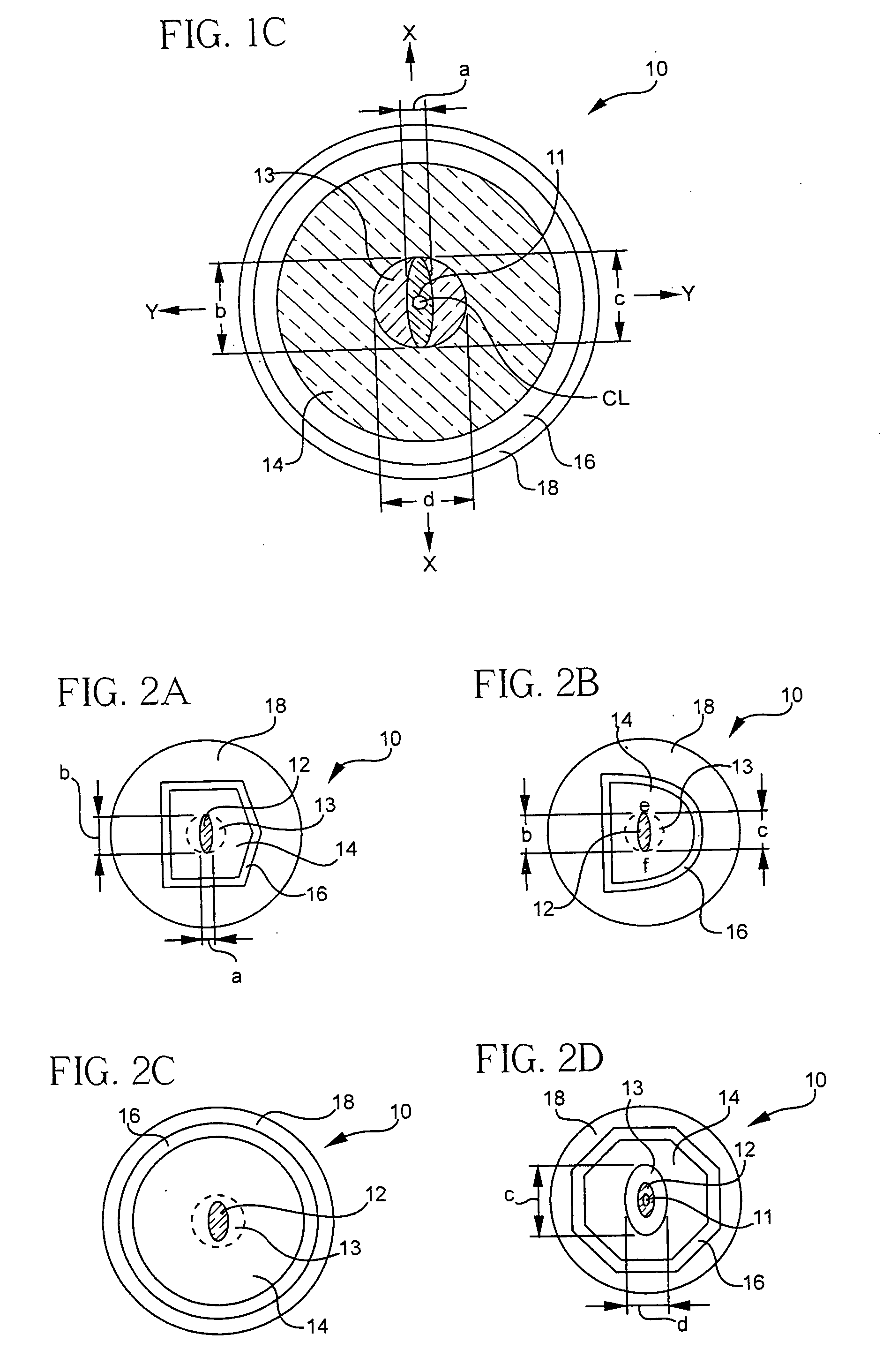

Linear illumination lens with Fresnel facets

ActiveUS7559672B1Large amount of processingImprove efficacyMechanical apparatusFurnace componentsCamera lensFresnel lens

A linear Fresnel lens for LED illumination is configured initially by using a meridional flux-assignment method and is then corrected by assessing the three-dimensional flux distribution of individual facets. The facet angles are slightly altered as required to produce uniformity. A variety of specialized lens shapes are generated, such as for illuminating shelves in commercial refrigerator food-display cases. The lens shapes are suitably thin for economical production by extrusion.

Owner:SEOUL SEMICONDUCTOR

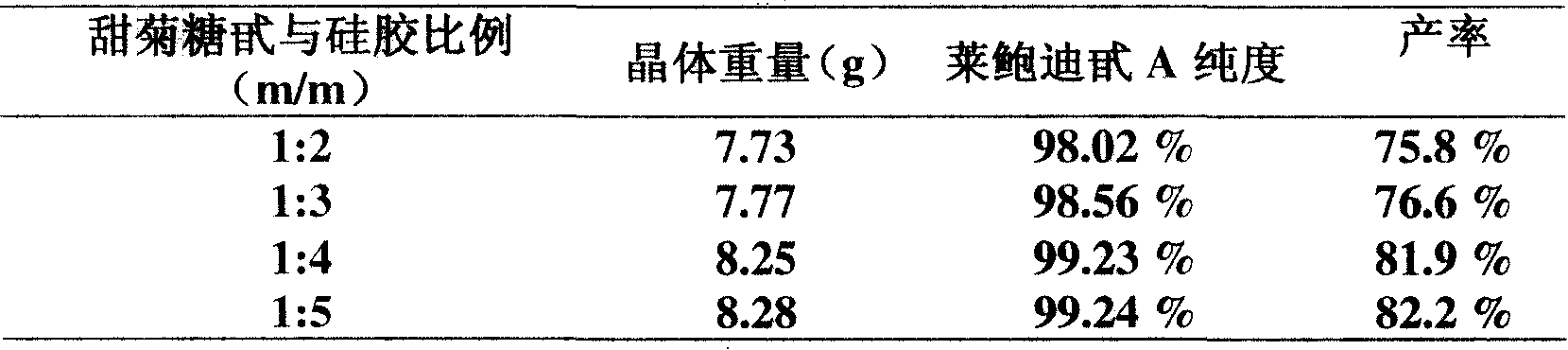

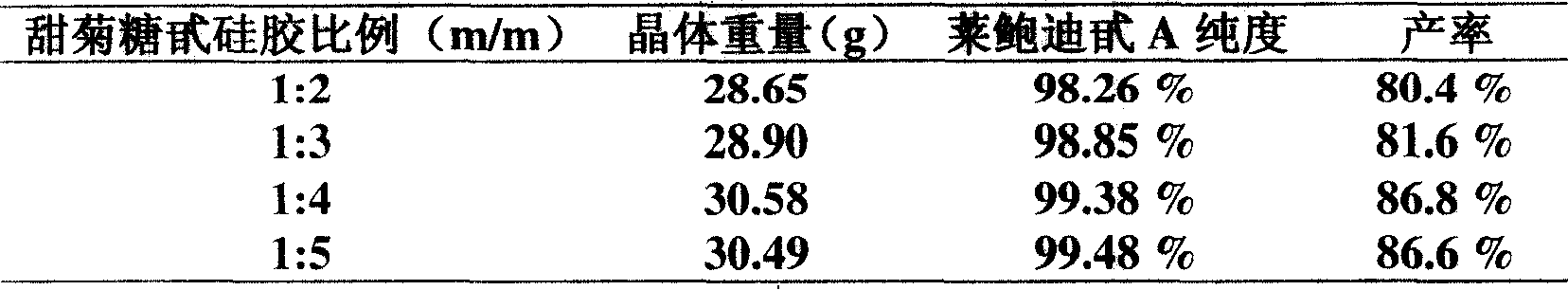

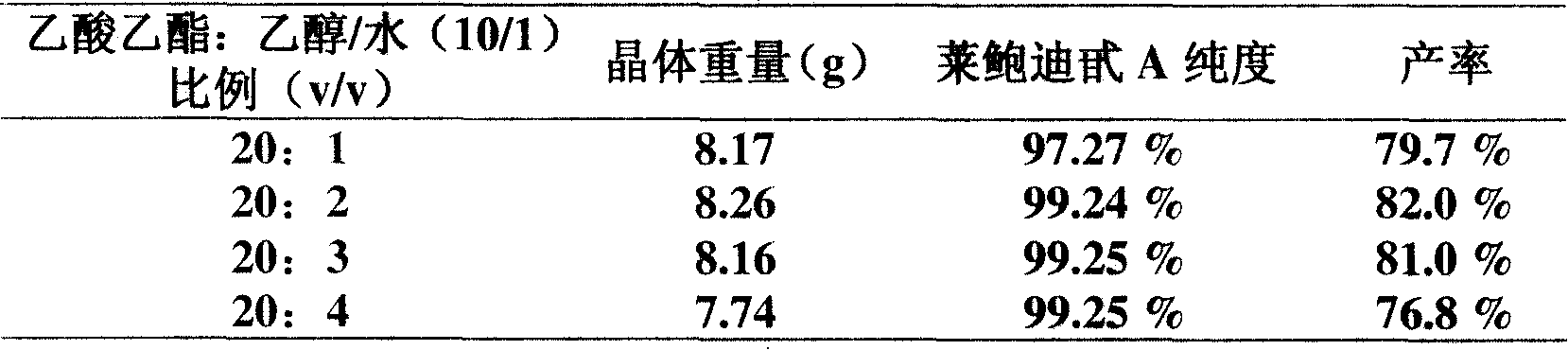

Rebaudioside A and extraction method thereof

InactiveCN101200480ALarge amount of processingLow costSugar derivativesSugar derivatives preparationExtraction methodsChemistry

Owner:CHENGDU WAGOTT RUITIAN TECH CO LTD

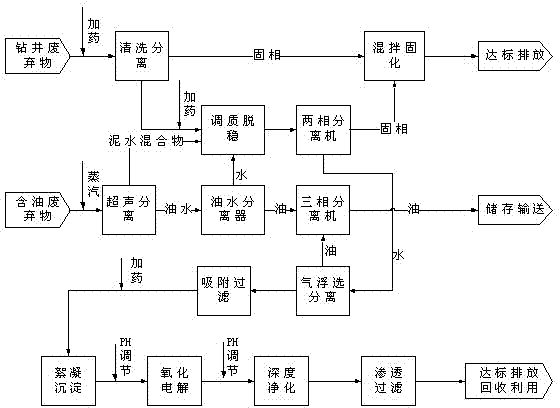

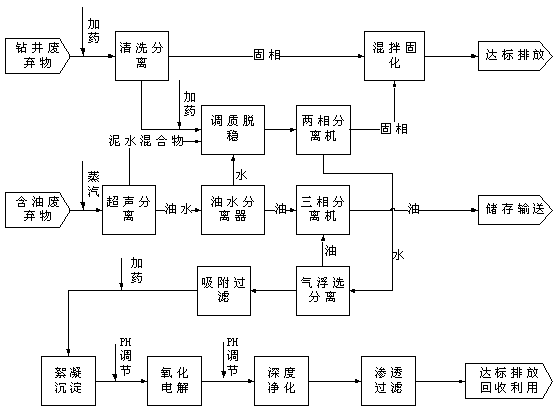

Method for comprehensive treatment of oilfield waste

ActiveCN102849880ALarge amount of processingReduce governance costsWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesSolid phasesChemistry

The invention discloses a method for comprehensive treatment of oilfield waste, which is characterized by comprising the process steps of cleaning and separation, ultrasonic separation, tempering and destabilization, oil-water separation, centrifugal separation, mixed curing, air floatation separation, adsorption filtration, flocculating settling, oxidization electrolysis, deep purification and permeable filtration. Thus, the oilfield waste is treated and utilized in a classified manner, so that sump oil is recovered, the solid phase achieves the discharge standard of oilfield sludge treatment design specifications (SY / T6851-2012) or is reutilized for construction material manufacturing, and the liquid phase achieves the sewage comprehensive discharge standard (GB8978-1996) after being subjected to water treatment.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for comprehensive treatment of oilfield waste

ActiveCN102849880BSolve the use problemMeet the actual needs of protectionWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesElectrolysisSludge

The invention discloses a method for comprehensive treatment of oilfield waste, which is characterized by comprising the process steps of cleaning and separation, ultrasonic separation, tempering and destabilization, oil-water separation, centrifugal separation, mixed curing, air floatation separation, adsorption filtration, flocculating settling, oxidization electrolysis, deep purification and permeable filtration. Thus, the oilfield waste is treated and utilized in a classified manner, so that sump oil is recovered, the solid phase achieves the discharge standard of oilfield sludge treatment design specifications (SY / T6851-2012) or is reutilized for construction material manufacturing, and the liquid phase achieves the sewage comprehensive discharge standard (GB8978-1996) after being subjected to water treatment.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

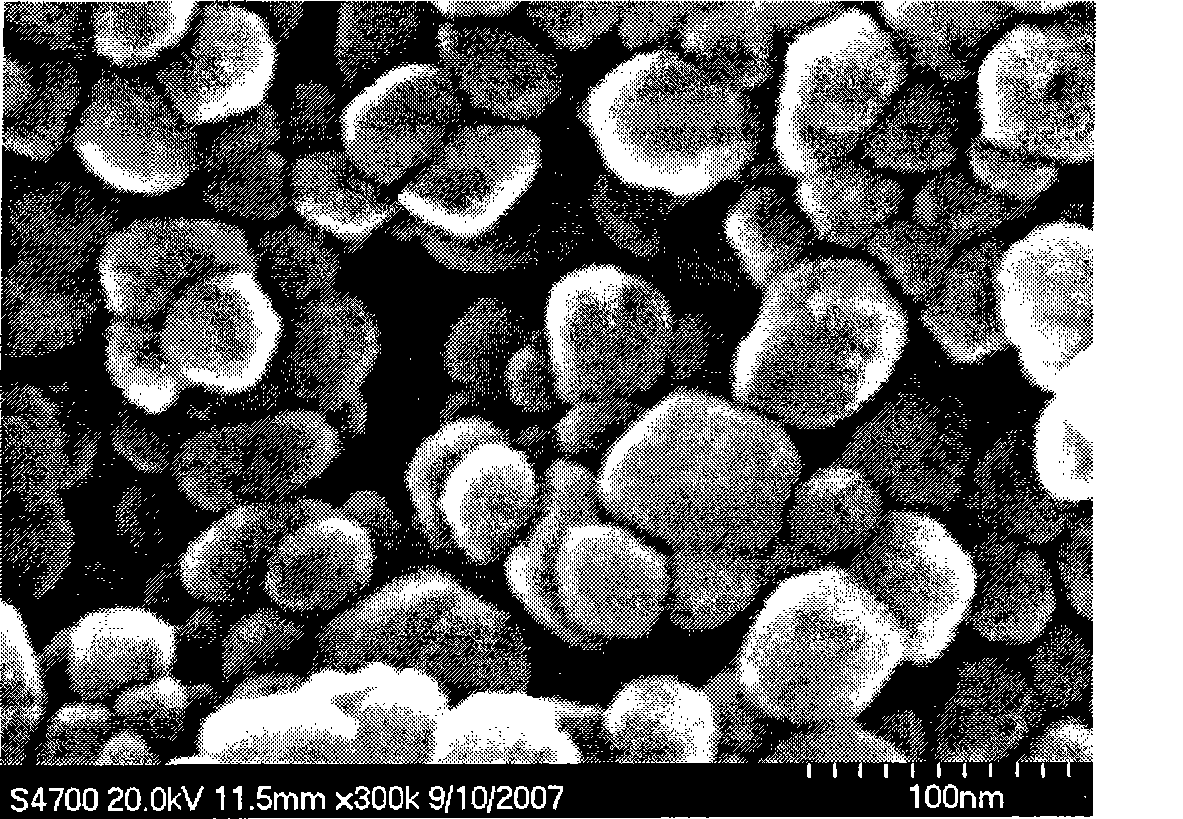

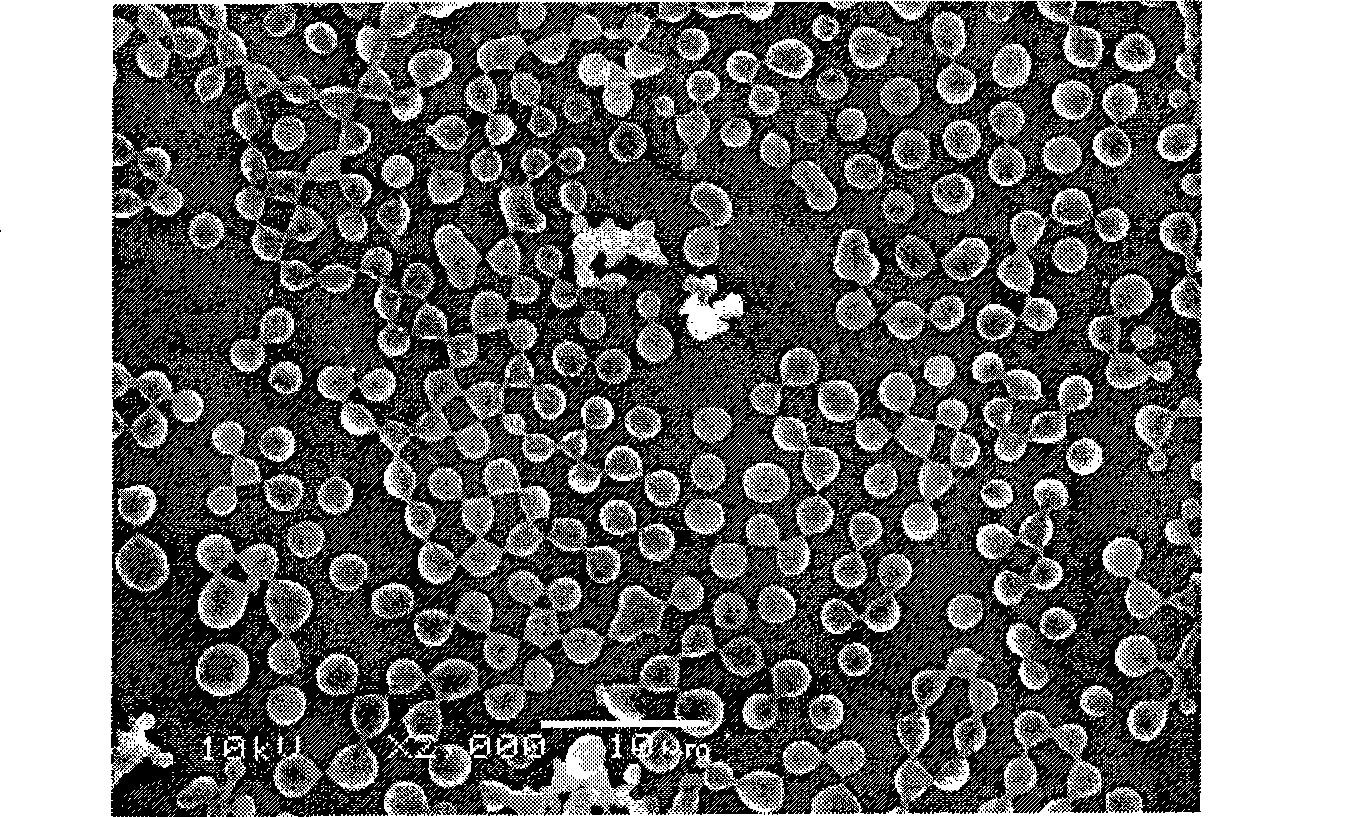

Method for preparing graphene powder

The invention relates to a method for preparing graphene powder in large scale, which is characterized by comprising the following steps of: firstly, uniformly peeling graphene oxide into a graphene oxide suspension solution; then, atomizing the graphene oxide solution by using the spray drying technology comprising spray pyrolysis drying and spray freeze drying, and removing a solvent to obtain graphene oxide powder; and finally, oxidizing grapheme by using the non-expansion heat treatment process to obtain non-agglomerative graphene powder. The continuous preparation process of the spray technology and the non-expansion heat treatment process ensure the large-scale preparation of the graphene powder. The prepared graphene powder comprising intermediate product graphene oxide powder does not have agglomeration and has good dispersivity in the solvent. The graphene powder is used as a filling material to prepare high strength composite materials, conductive composite materials, novel air-tight flame-retardant composite materials, novel nanodevices and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

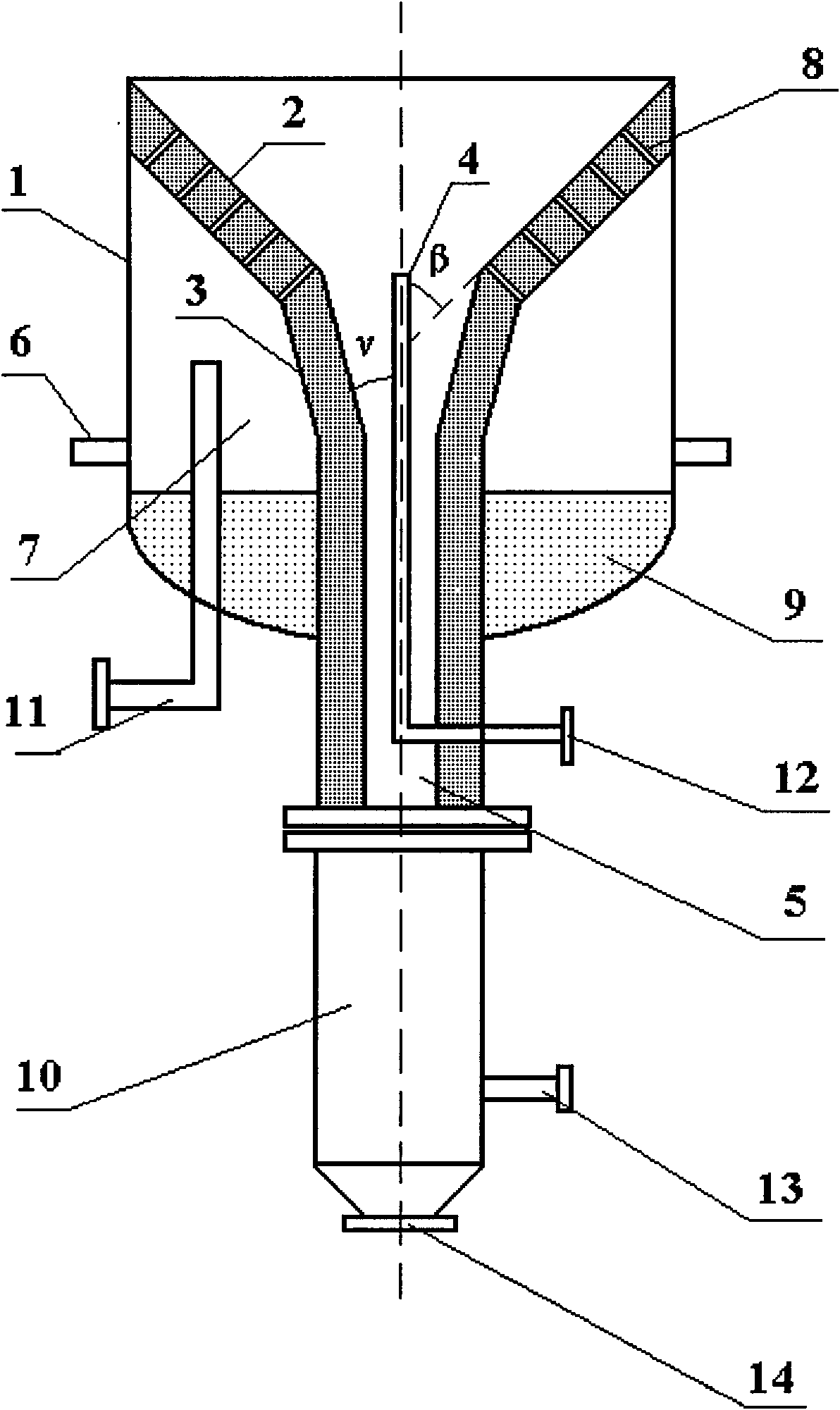

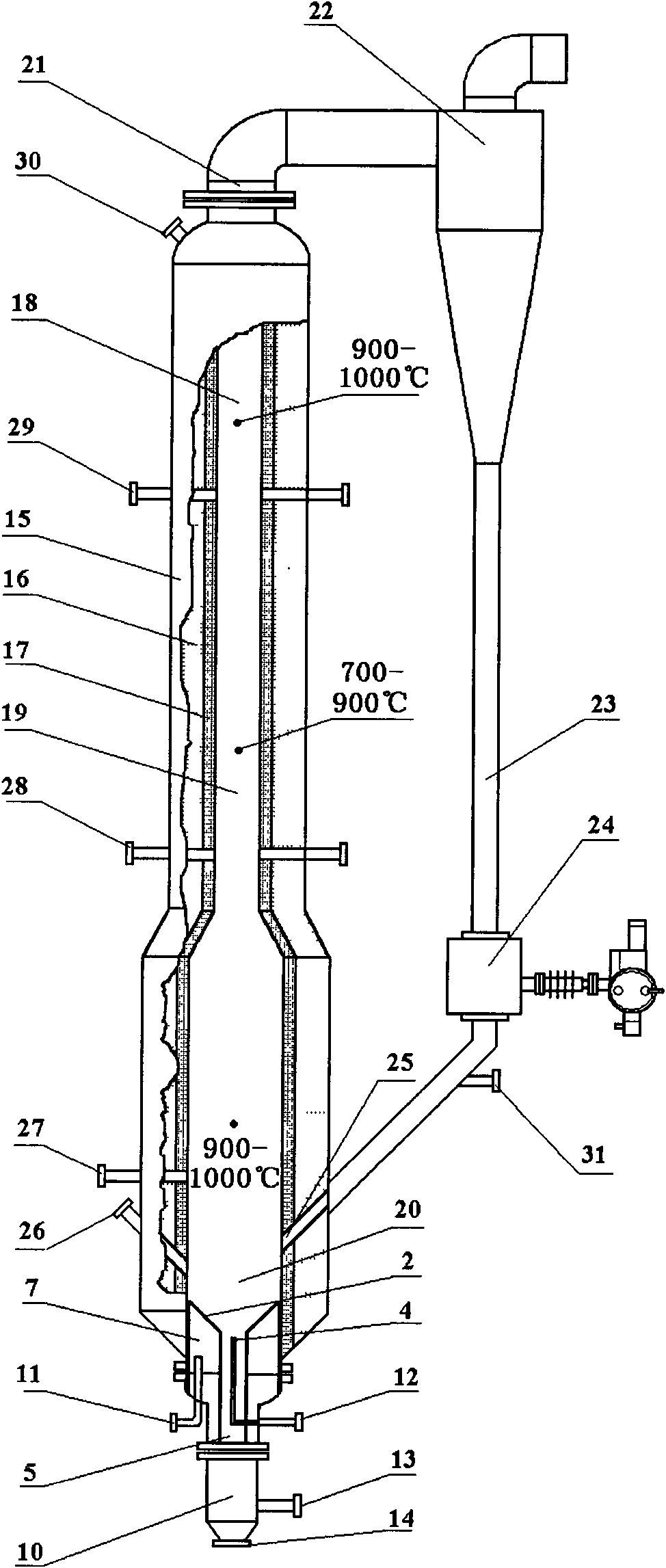

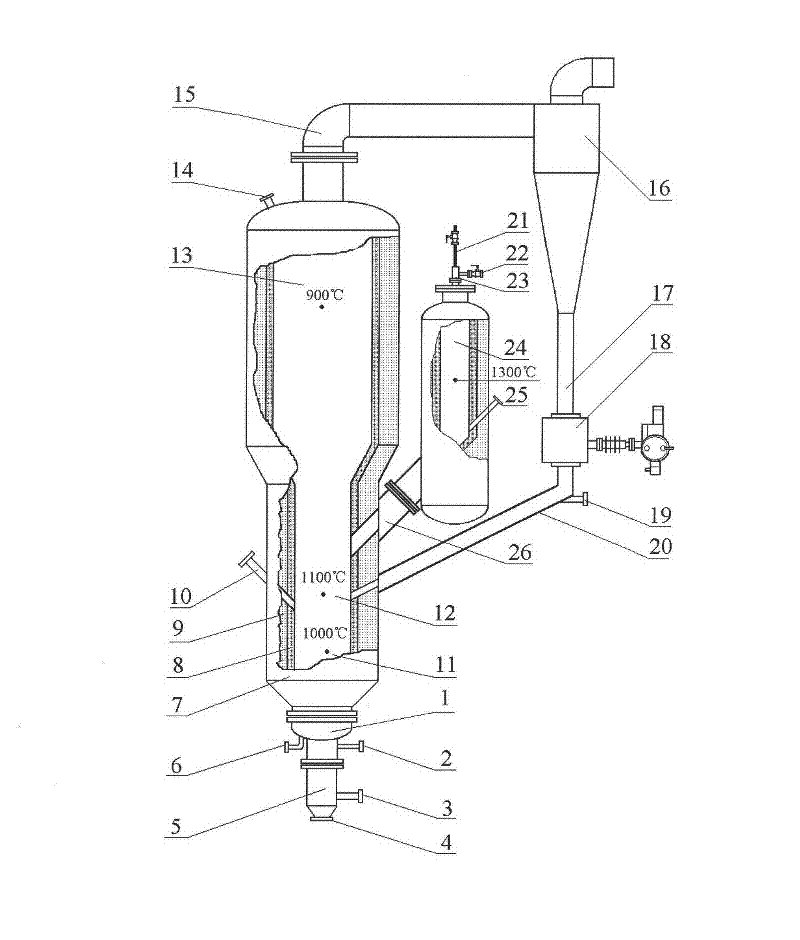

Method and device for gasifying multi-segment staged converted fluidized bed

ActiveCN101942344ALow ash carbon contentExtended stayEnergy inputCombined combustion mitigationFluidized bedProcess engineering

The invention relates to method and device for gasifying a multi-segment staged converted fluidized bed. The method comprises the following steps of: supplying coal; supplying gas; gasifying; slagging; and conveying fine powder. The device for gasifying the multi-grade staged converted fluidized bed comprises an agglomerating ash separating unit, a pyrolyzing and gasifying reactor of the multi-segment staged fluidized bed and a semicoke fine powder cyclic feeding unit. The invention has the advantages of high volume utilization rate of a gasifying oven, great handling capacity and high utilization rate of total carbon, is suitable for a coal staging and converting system and can be singly used for producing gas for mass coal-based methane synthesis and coal chemical industry.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

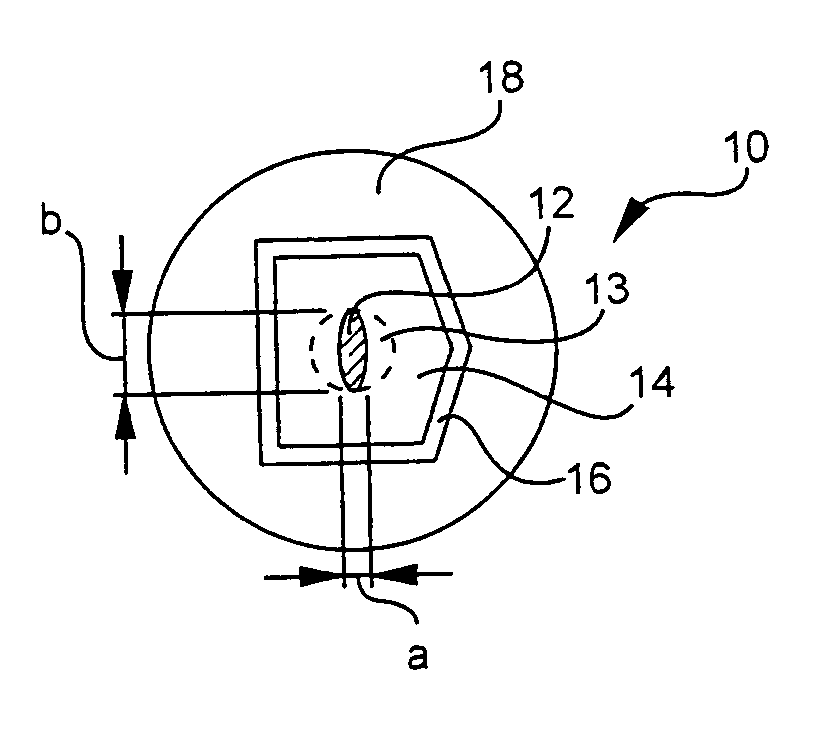

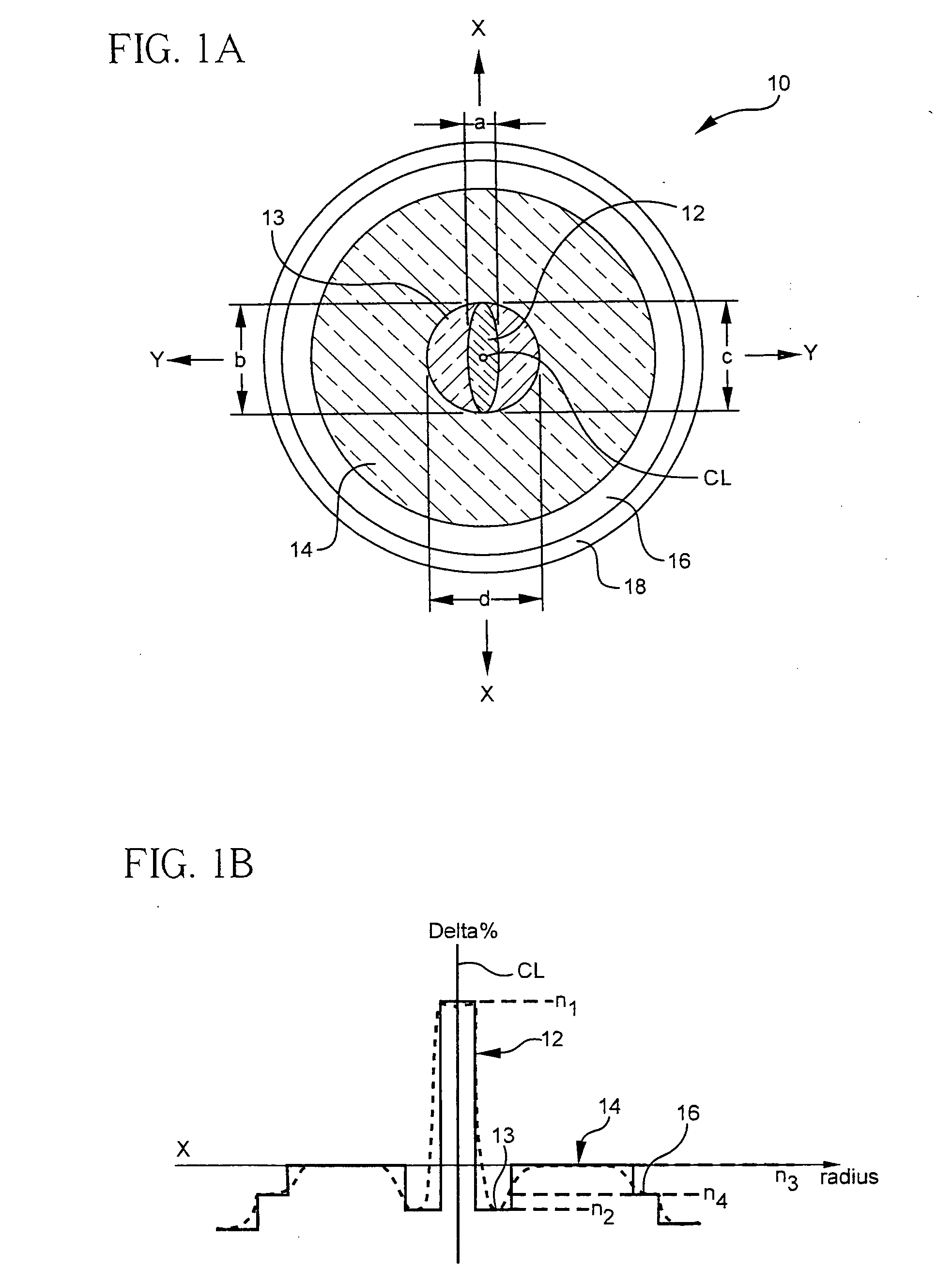

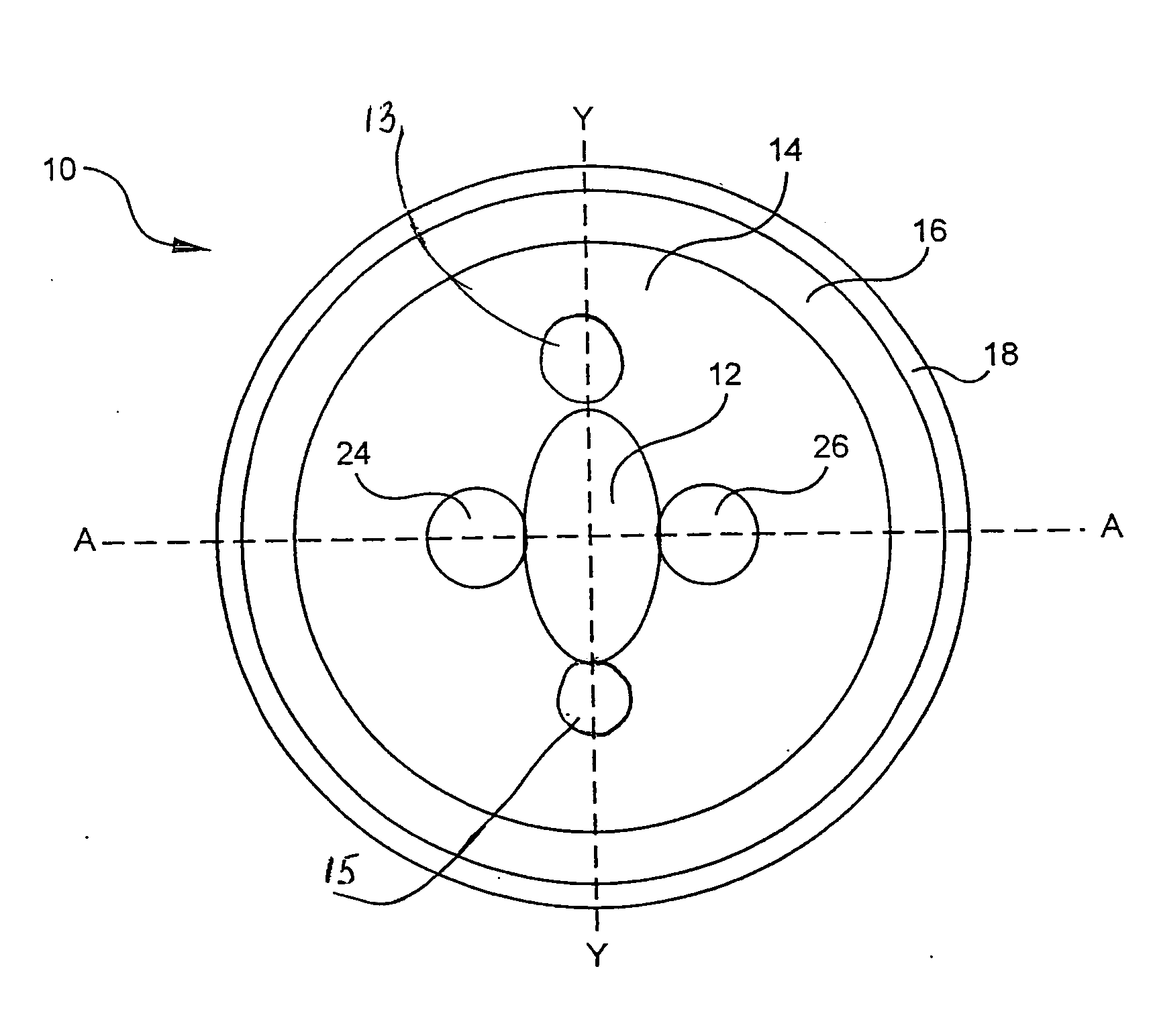

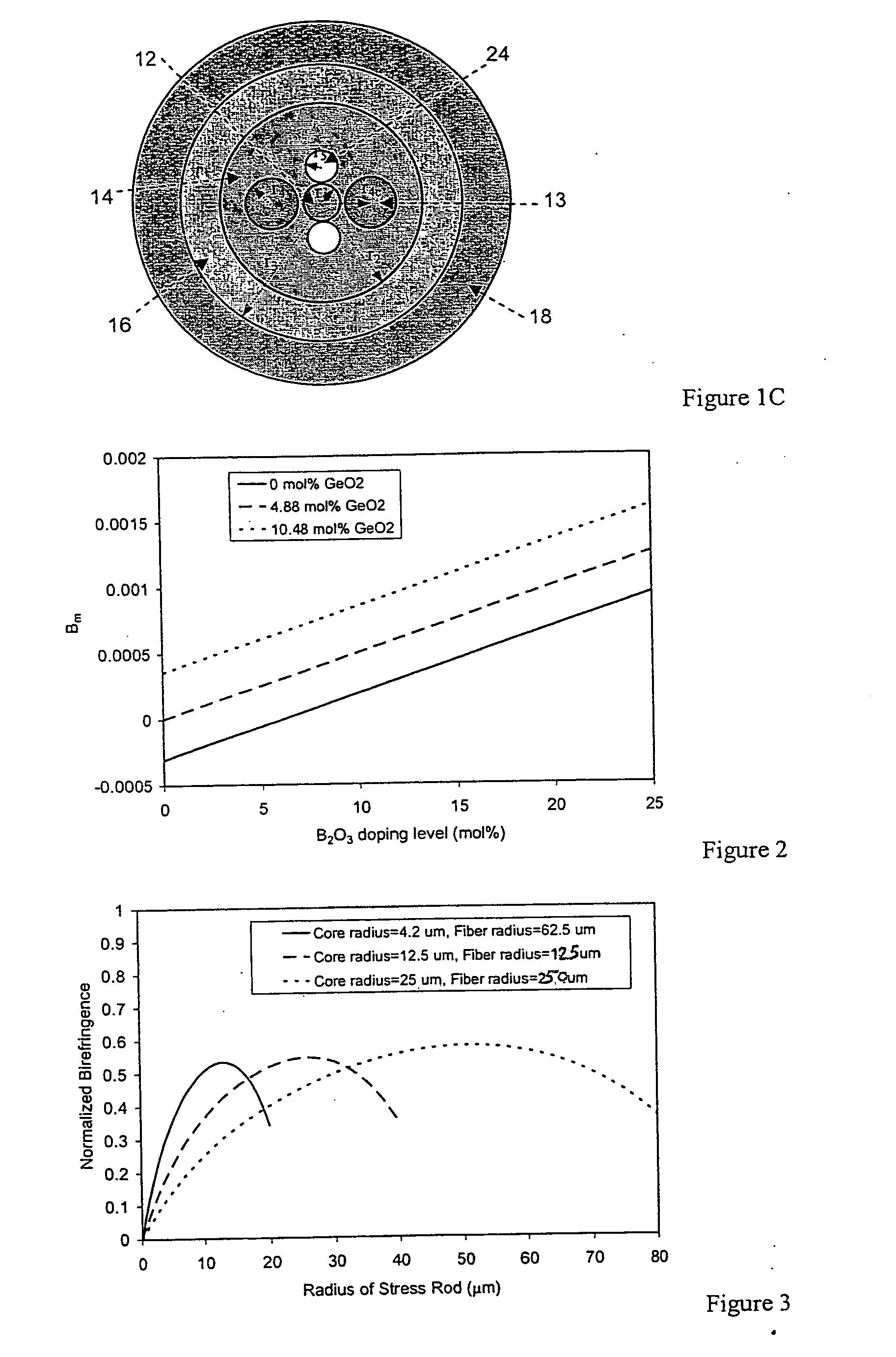

Rare earth doped single polarization double clad optical fiber and a method for making such fiber

ActiveUS20060088261A1Produced in advanceLarge amount of processingLaser detailsOptical fibre with polarisationFiberRefractive index

An optical fiber, comprising: (i) a rare earth doped silica based elongated core with a first refractive index (n1) with an aspect ratio of 1:5 to 1; (ii) a silica based moat abutting and at least substantially surrounding the core, the moat having a refractive index n2, wherein n2<n1; (iii) a silica based inner cladding surrounding the moat, the inner cladding having a third refractive index (n3), wherein n1>n3; and n3>n2; (iv) a silica based outer cladding surrounding said inner cladding, the outer cladding having a fourth refractive index (n4), such that n4<n3; the optical fiber exhibits single polarization at the operating wavelength band.

Owner:DARPA

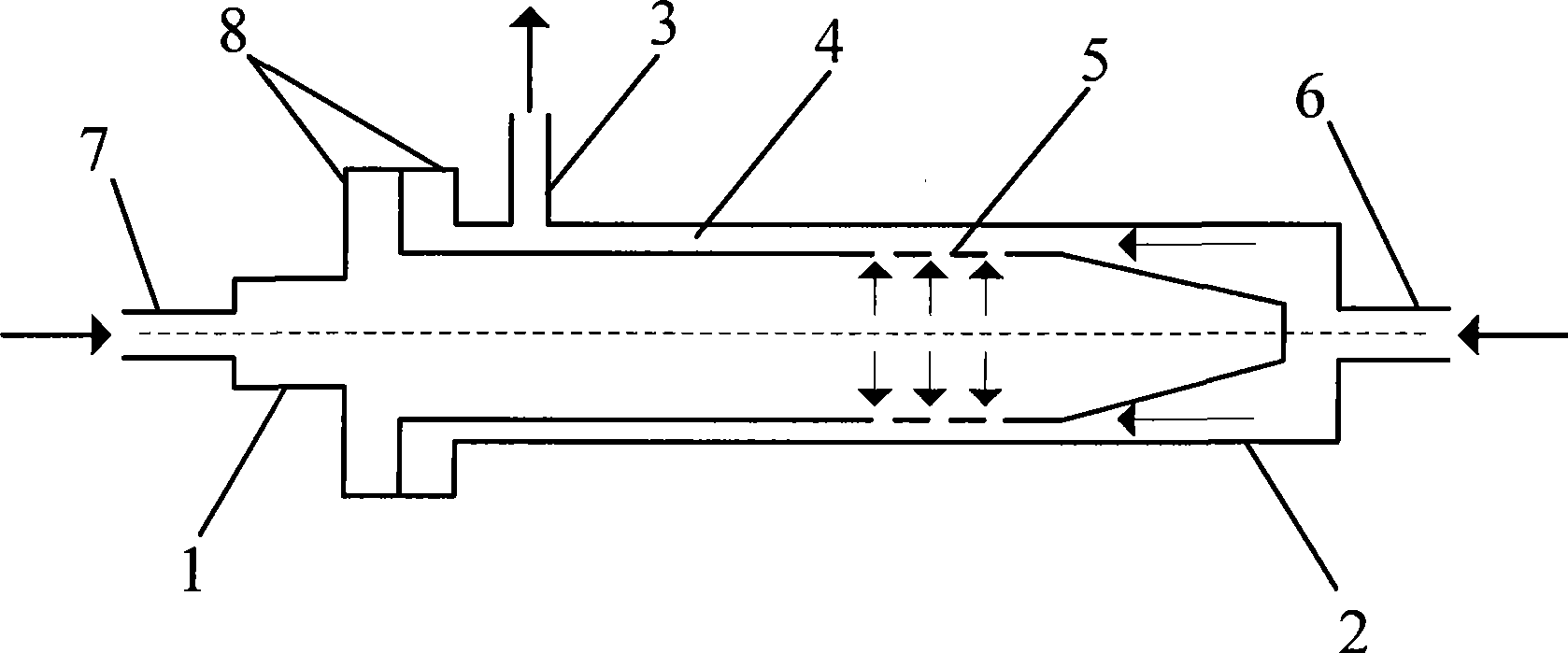

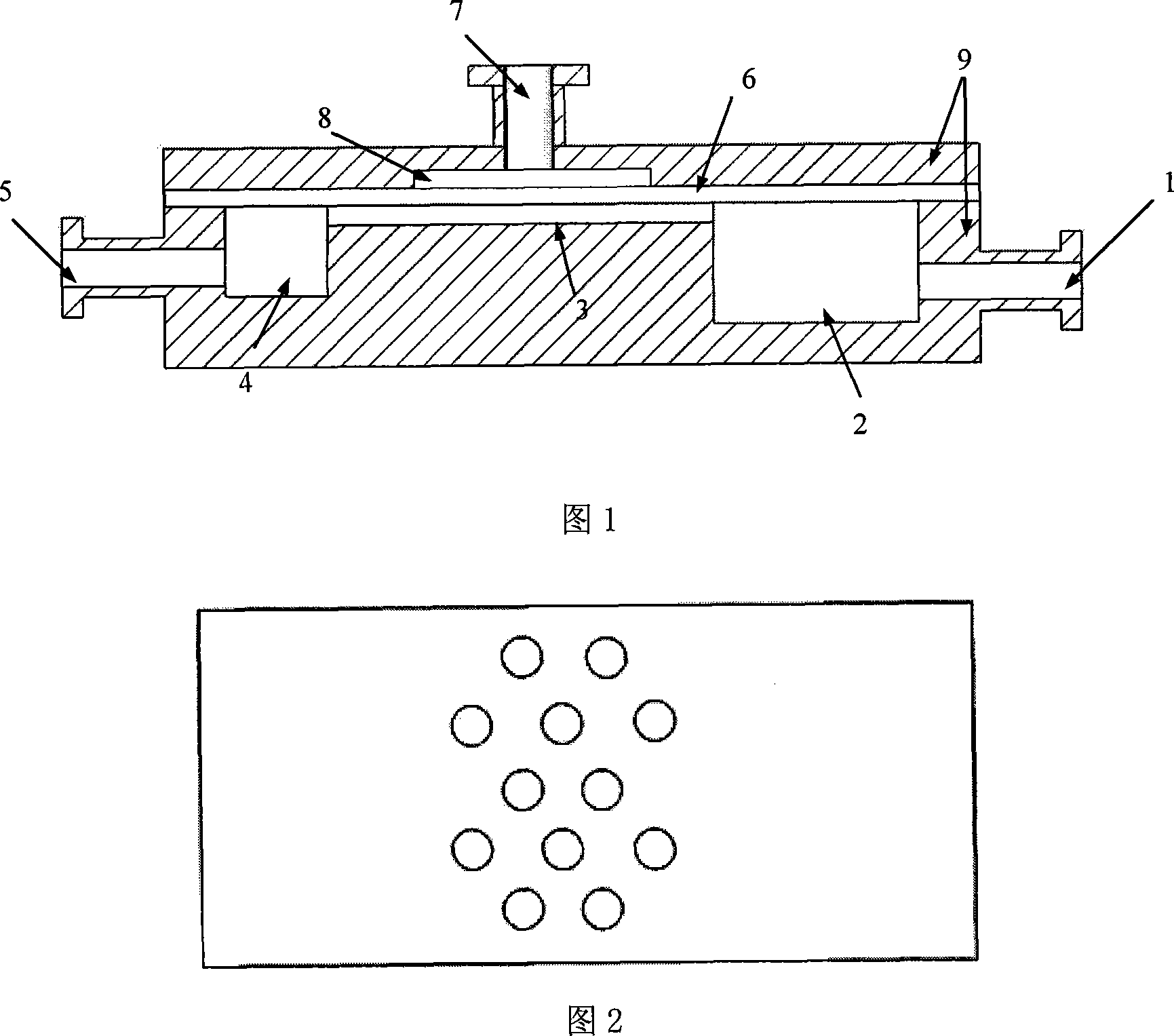

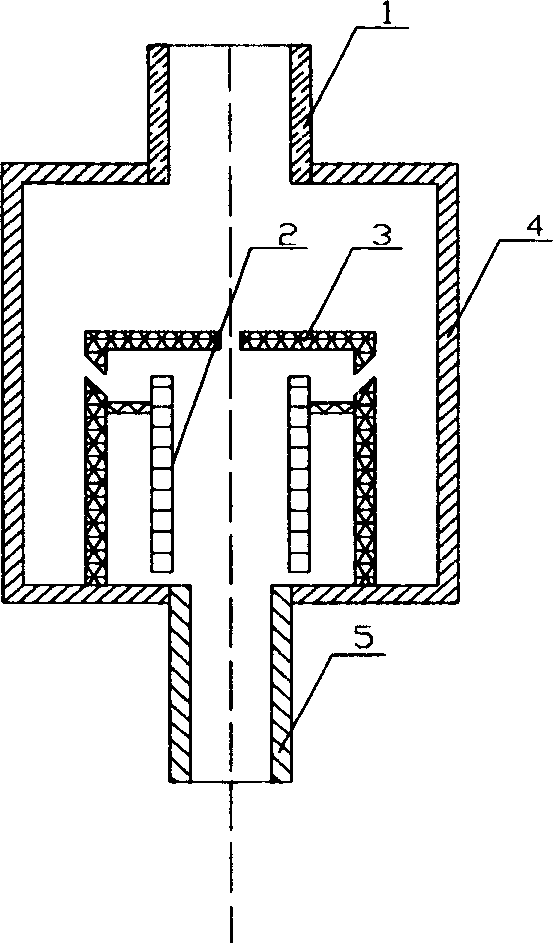

Membrane dispersion type micro-channel reactor

ActiveCN101433815ALarge amount of processingIncrease throughputChemical/physical/physico-chemical processesMembrane configurationMass transfer

The invention provides a membrane dispersion microchannel reactor. An outer pipe and an inner pipe form a bushing, an annular microchannel is formed between the inner pipe and the outer pipe, and the outer pipe is provided with a fluid inlet and a fluid outlet; and one end of the inner pipe is provided with a fluid inlet, while the other end is distributed with a micrporous membrane with a plurality of micropores along the circumferential direction of the pipe wall. Compared with the prior microchannel reactor, the cross section of the channel of the reactor is increased, and the treatment capacity is increased. The mixing and the mass transfer between fluids are strengthened. The stronger micromixing is also guaranteed when the large treatment capacity is achieved. Particularly the rapid micromixing is realized in the synthesis of nanometer particles, and barium sulfate particles with the average particle size of 37 nanometers are synthesized. The reactor has the advantages of simple operation, low operation cost, and large treatment capacity, and has good application prospect in the industrial production relating to the rapid process.

Owner:BEIJING UNIV OF CHEM TECH

Catalyst in preparation of isobutene by methyl tertbutyl ether pyrolysis

ActiveCN1853772AHigh activityImprove stabilityCatalystsHydrocarbon preparation catalystsEtherHigh selectivity

A catalyst for preparing isobutene by cracking methyl turt-butyl ether (MTBE) is prepared from the amorphous SiAl through treating by saturated steam at 100-600 deg.C for 1-10 hr. Its advantages are high conversion rate of MTBE, high selectivity to isobutene, and long service life (at least 3504 hr).

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for comprehensively treating high salt content organic industrial wastewater

ActiveCN101585620AUnique methodSimple processMultistage water/sewage treatmentWater/sewage treatment by neutralisationSocial benefitsIndustrial effluent

The present invention provides a method for comprehensively treating high salt content organic industrial wastewater, and relates to the field of the organic material preparing technique. The method of the invention mainly comprises the following steps: executing acid-alkali adjustment to the organic wastewater until pH=7-9, preheating to 30-60 DEG C; introducing the wastewater into a triple effect evaporator for executing triple effect evaporation, executing salting out to the evaporated wastewater which is condensed to a certain degree so that the solid and liquid are separated; separating the concentrated liquid for continuing the condensation; when the separated liquid satisfies a certain requirement, atomizing into an incinerator for incinerating and discharging according to the standard, and introducing the triple effect evaporation condensation water into a biochemical treating system. The method of the invention can totally dispose and remove the organic matter in the high salt content organic industrial wastewater so that the high salt content organic industrial wastewater can be charged according to the standard. The method of the invention has the advantages of unique method, simple technical process, easy operation, low operation cost, large treating capacity, low regeneration energy consumption, no easy forming of secondary pollution after abandon, better economic and social benefit, and wide application range. The method of the invention can be widely applied for the treating of the high salt content organic wastewaters of garbage penetrating fluid, dye intermediate wastewater, etc.

Owner:HEBEI JIANXIN CHEM IND CO LTD

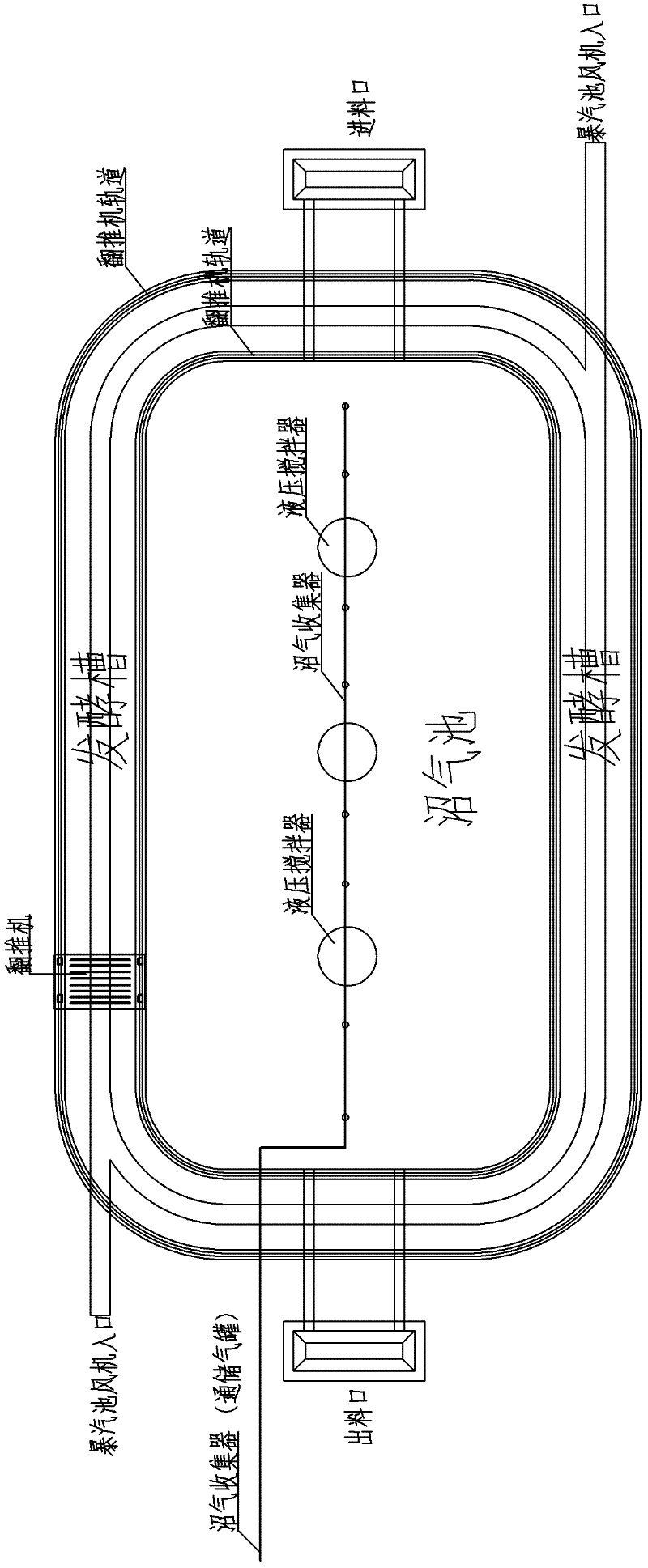

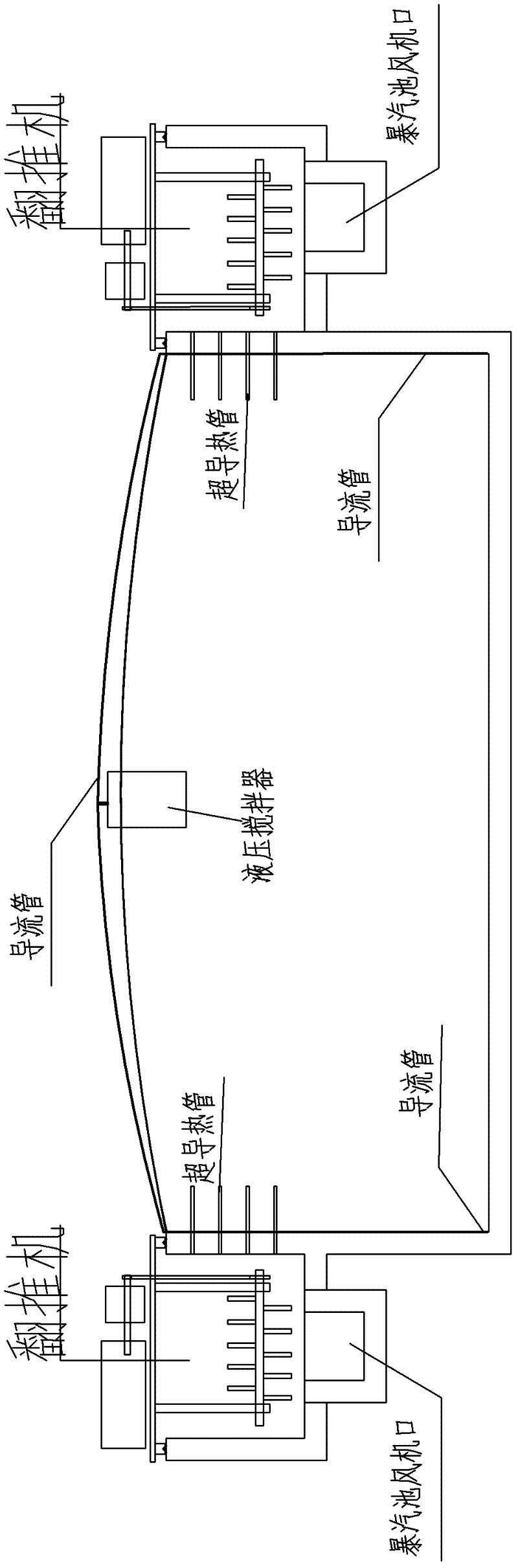

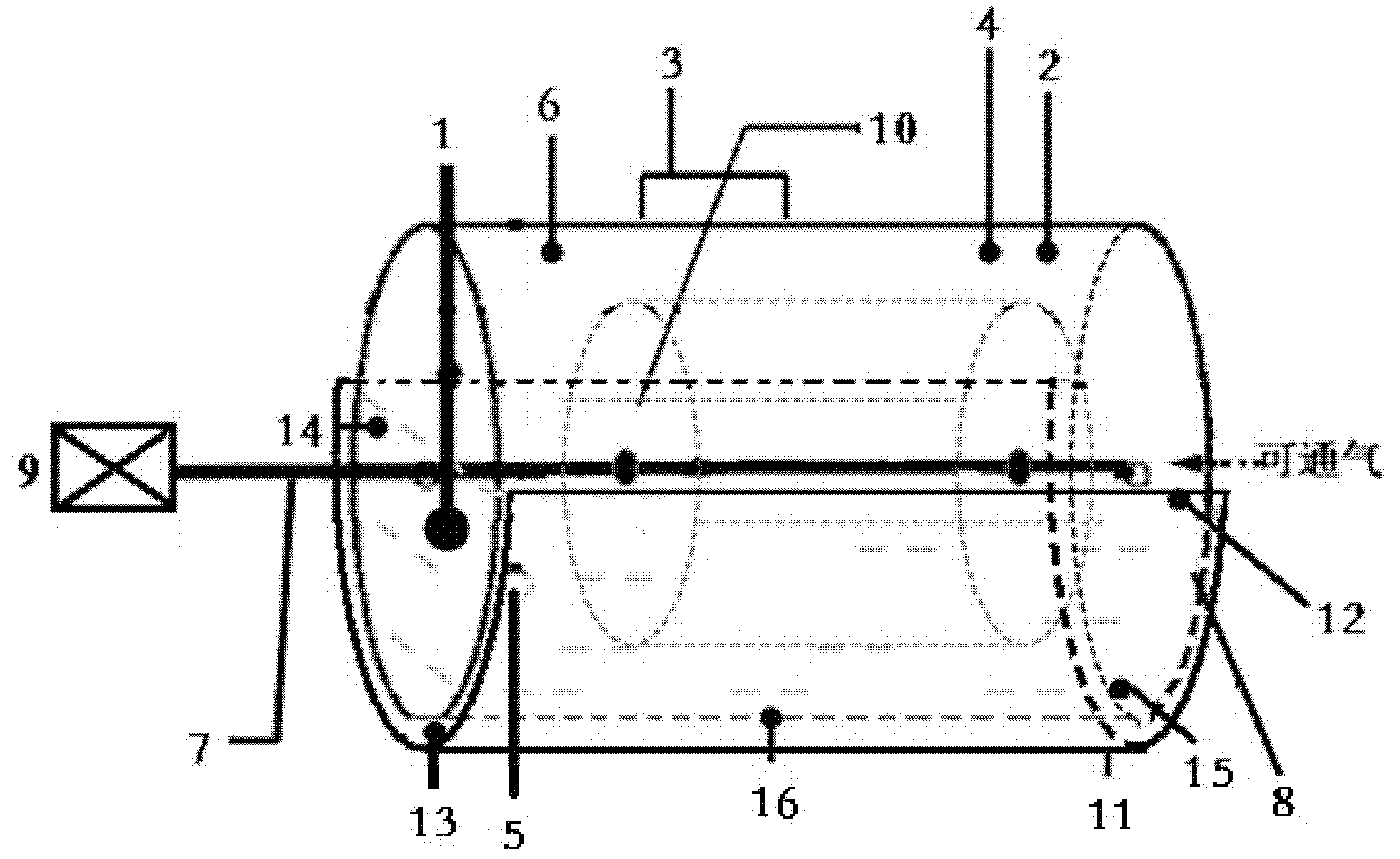

Efficient methane-generating pit using poultry excrement and methane generation process

InactiveCN102531310AReduce moisture contentEasy to produceWaste based fuelBiological sludge treatmentProcess engineeringBiogas production

The invention relates to a methane-generating pit using poultry excrement, which is integrally horizontally placed under the water plane. Partition walls are arranged in the middle of the methane-generating pit for dividing the whole methane-generating pit into a plurality of unit methane-generating pits, and medium channels arranged on the partition walls are communicated with each other. An annular fermentation tank is arranged above the periphery of the methane-generating pit, a plurality of superconductive heat pipes are arranged on the inner side of the annular fermentation tank, and the superconductive heat pipes are inserted into the methane-generating pit. A material inlet and a material outlet are respectively arranged at two ends of the methane-generating pit and under the unit methane-generating pits at two ends of the methane-generating pit, a methane collector is arranged above each unit methane-generating pit, and the methane collectors are directly communicated with a gas storage tank through pipelines. The methane-generating pit has the advantages of being high in material concentration, integrating material inlet, deslagging, methane generating, stirring, temperature controlling, regulating and the like, being high in mechanization degree, large in treating quantity, fast in digesting rate and the like and can meet requirements for scale production, and concentration of inlet materials of a continuous methane-generating pit can reach about 15%.

Owner:范立河

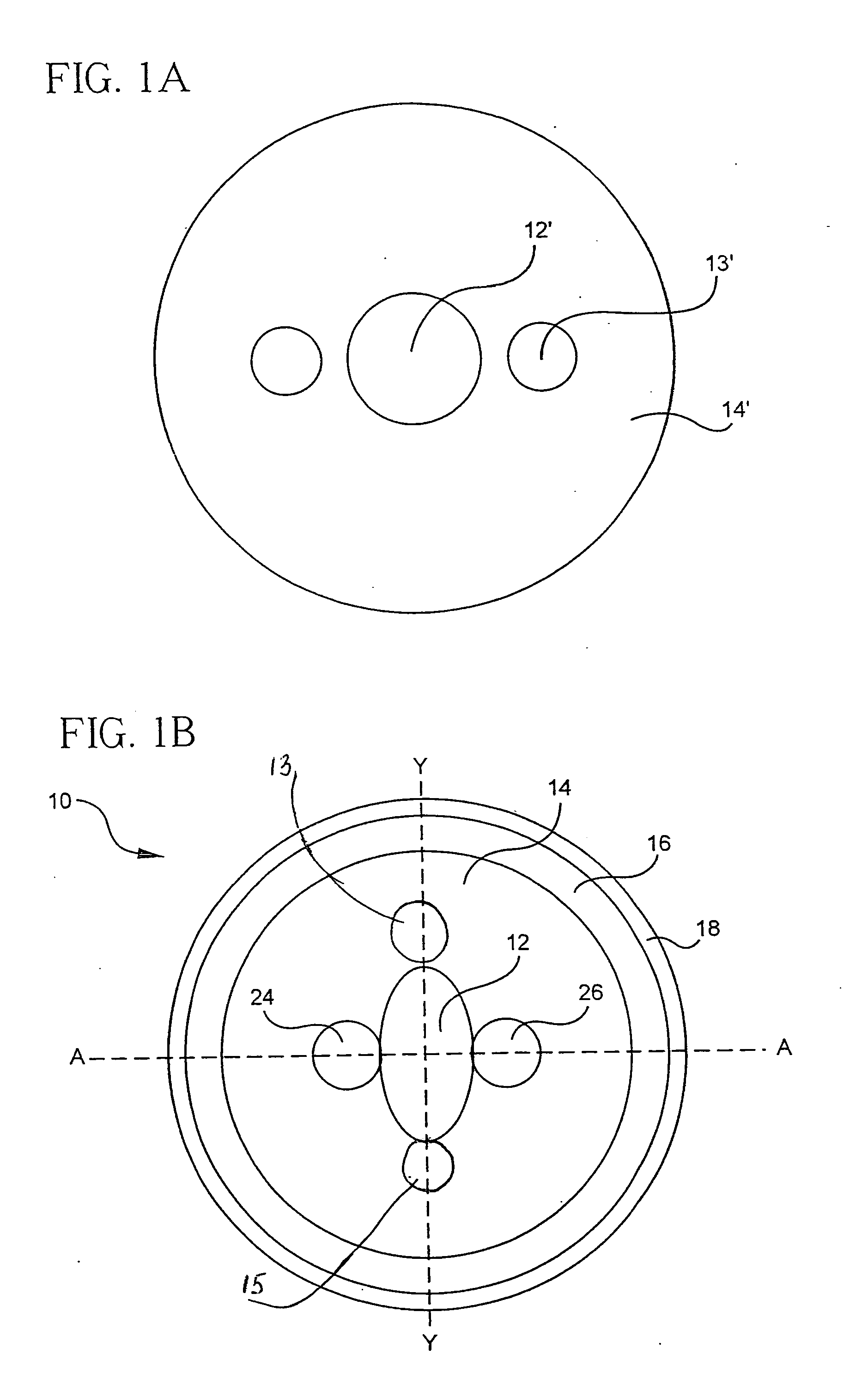

Rare earth doped double clad optical fiber with plurality of air holes and stress rods

ActiveUS20070177846A1Large mode areaProduced in advanceLaser detailsOptical fibre with polarisationSingle polarizationWavelength range

An optical fiber including: (i) a silica based, rare earth doped core having a first index of refraction n1; and (ii) at least one silica based cladding surrounding the core and having a second index of refraction n2, such that n1>n2, said cladding having a plurality of stress rods and a plurality of air holes extending longitudinally through the length of said optical fiber; wherein said optical fiber supports a single polarization mode or poses-polarization maintaining properties within the operating wavelength range.

Owner:CORNING INC

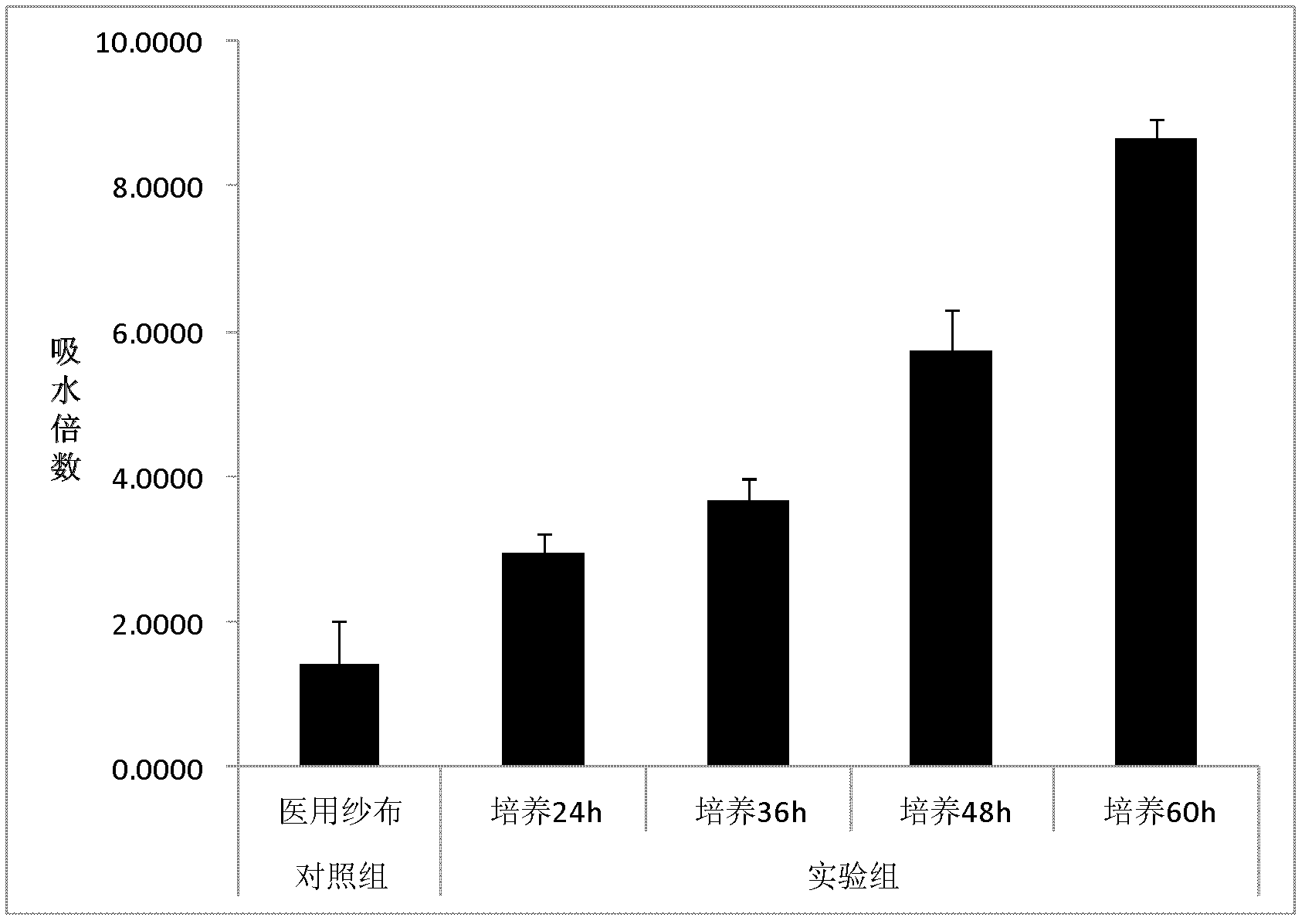

Method for preparing nano-cellulose antibacterial composite material through on-line culture

ActiveCN102552965ARealize fermentation productionImprove continuityCosmetic preparationsBacteriaWater bathsFiber

The invention relates to a method for preparing a nano-cellulose antibacterial composite material through on-line culture. The method comprises the following steps of: (1) inoculating an activated bacterial cellulose producing strain into a liquid culture medium, performing amplification culture, transferring the liquid culture medium into a bioreactor, culturing, adding an antibacterial material into the liquid culture medium, and continuing to culture to obtain an unpurified antibacterial bacterial cellulose composite material; and (2) peeling a bacterial cellulose membrane from a framework or directly soaking the composite material in a NaOH solution, treating in water bath, and washing until an obtained product is neutral to obtain the nano-cellulose antibacterial composite material. The preparation efficiency is high, and the method is simple, convenient, feasible and low in cost; and the surface of the bacterial cellulose composite material has a nanoscale three-dimensional fibrous mesh-shaped structure, the tensile strength of the material is greatly improved compared with that of a pure bacterial cellulose membrane, and the material can be widely applied to products such as facial masks, wound dressings, plasters, artificial skins and the like.

Owner:DONGHUA UNIV

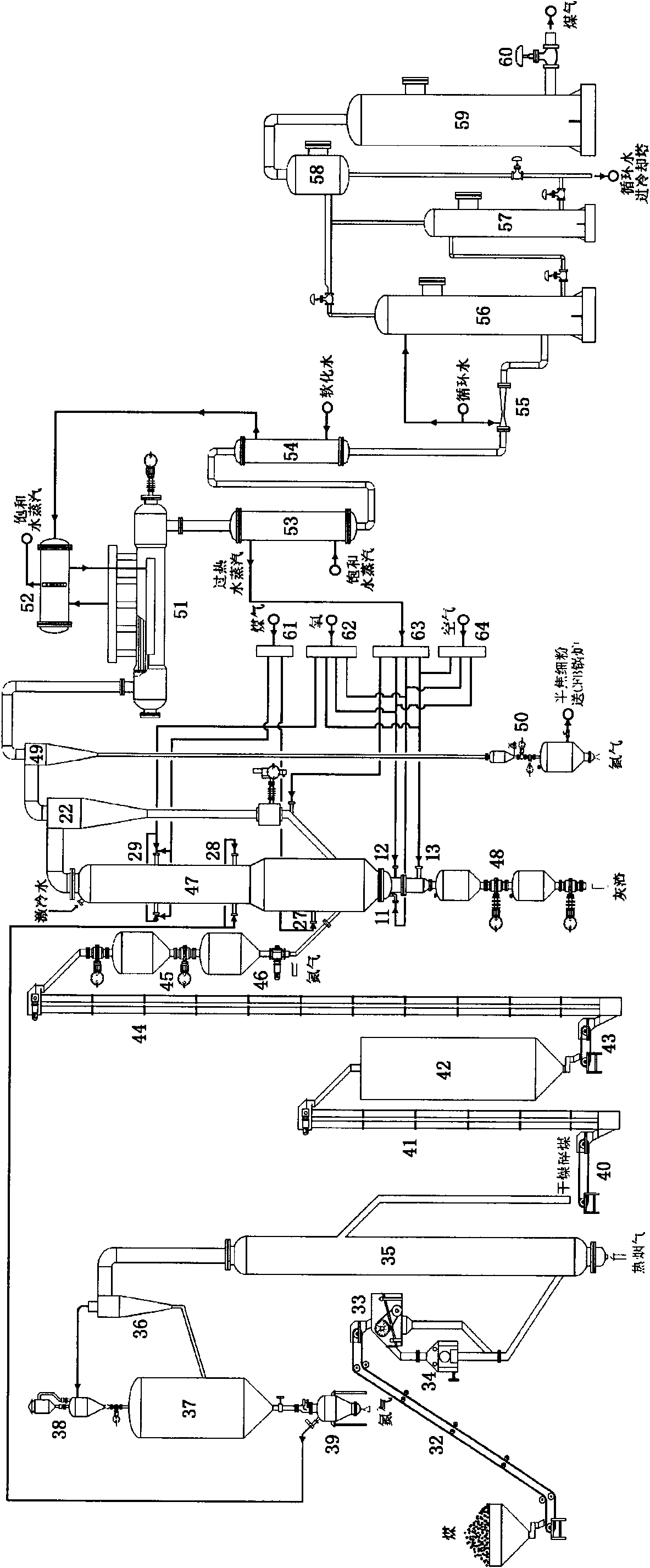

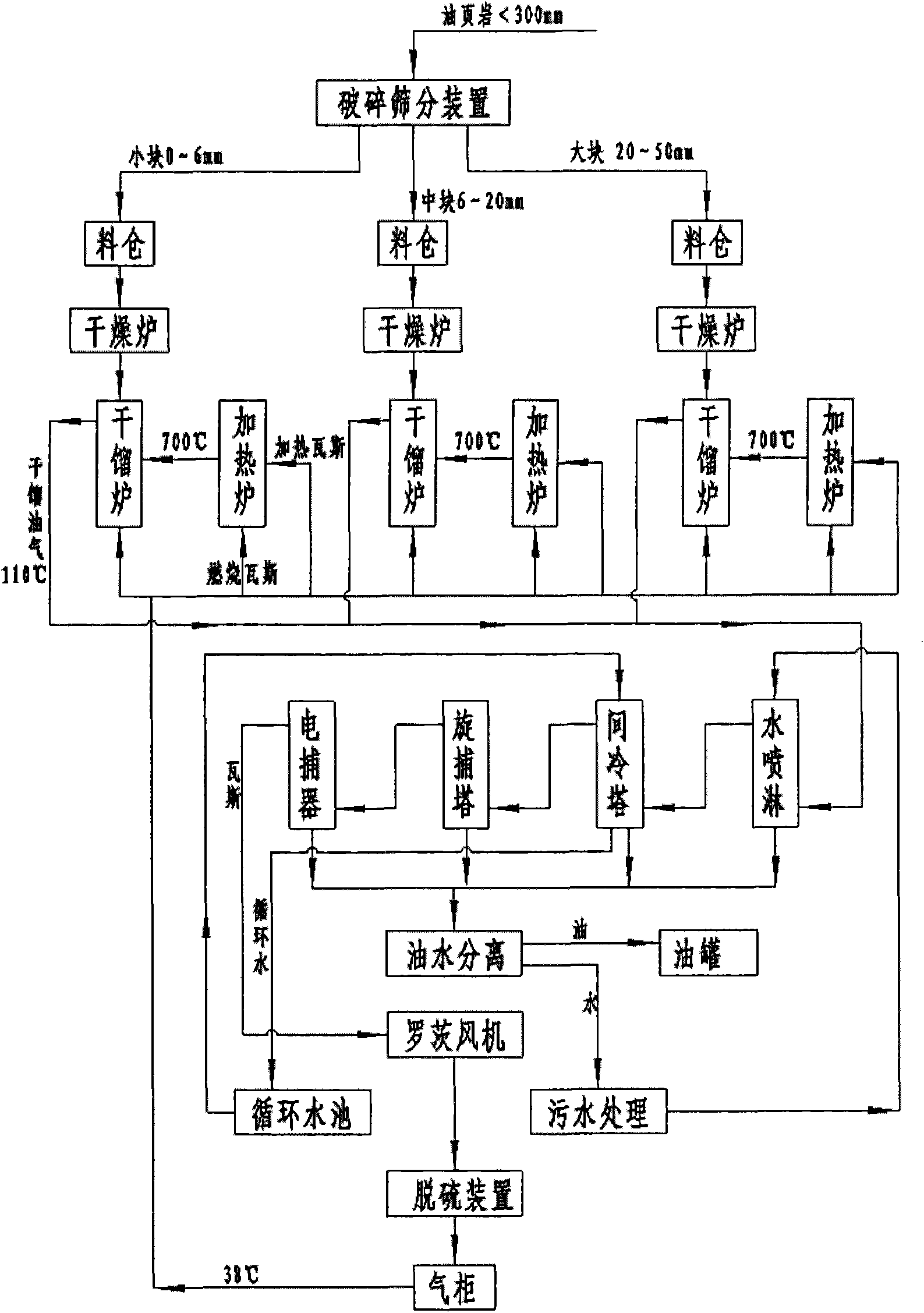

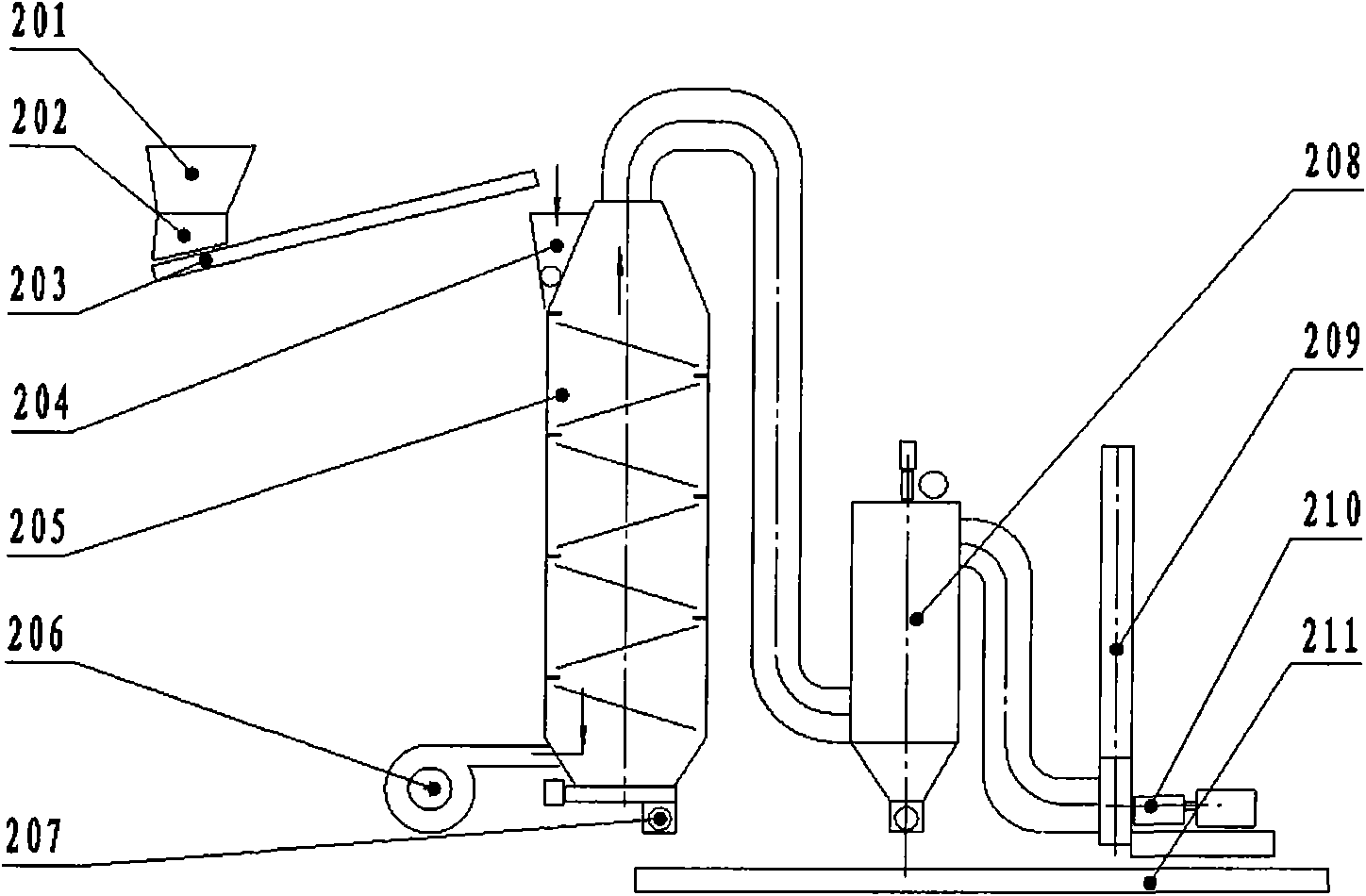

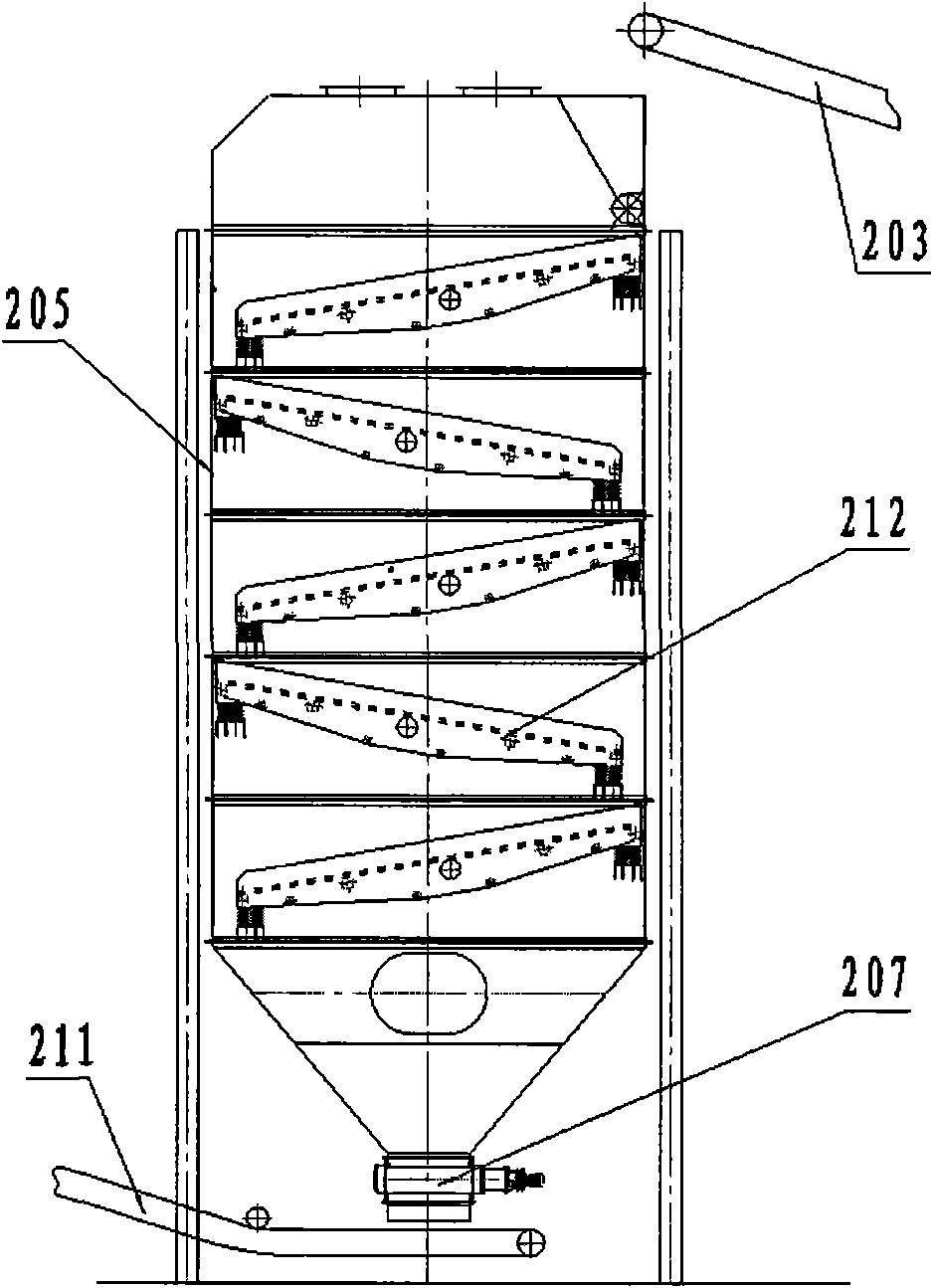

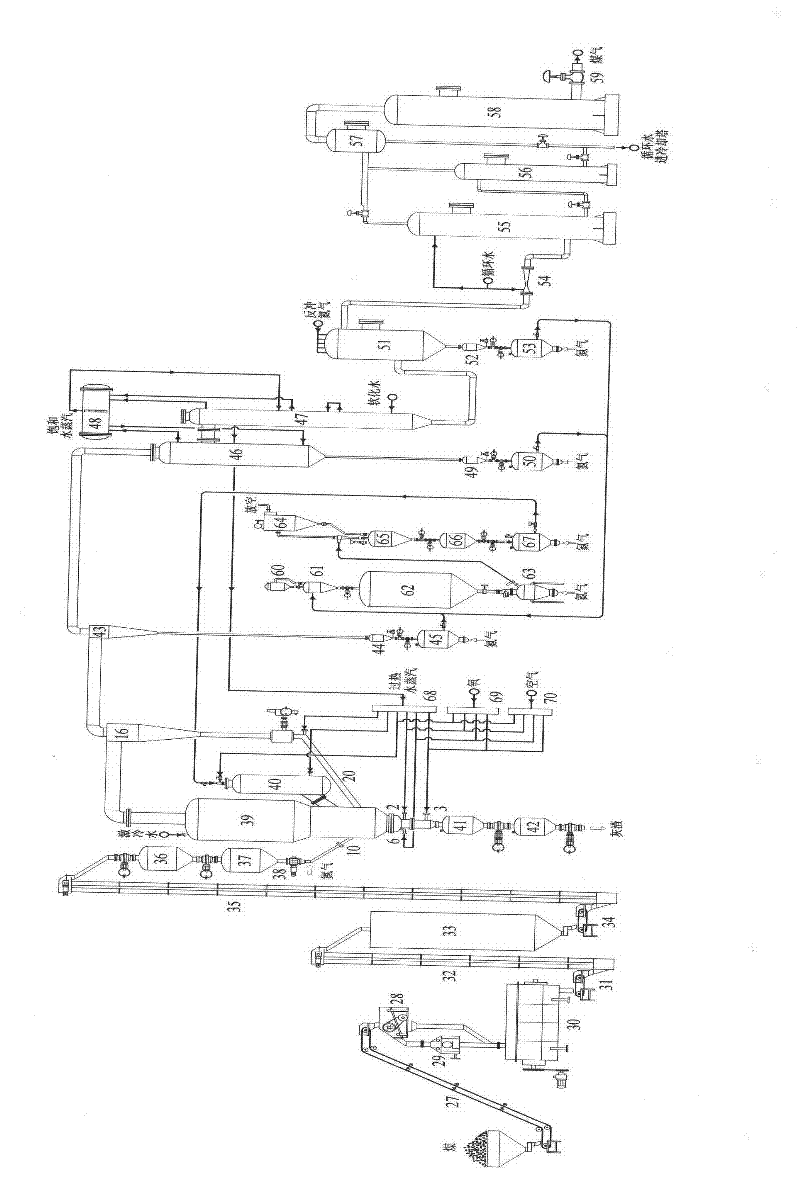

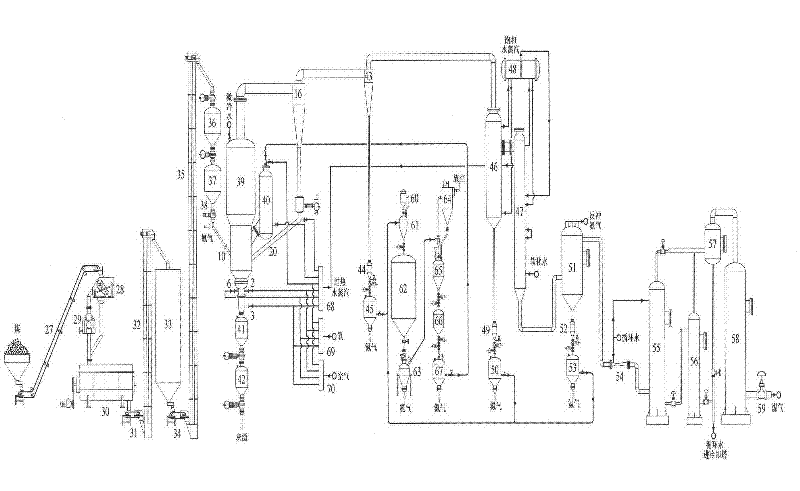

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

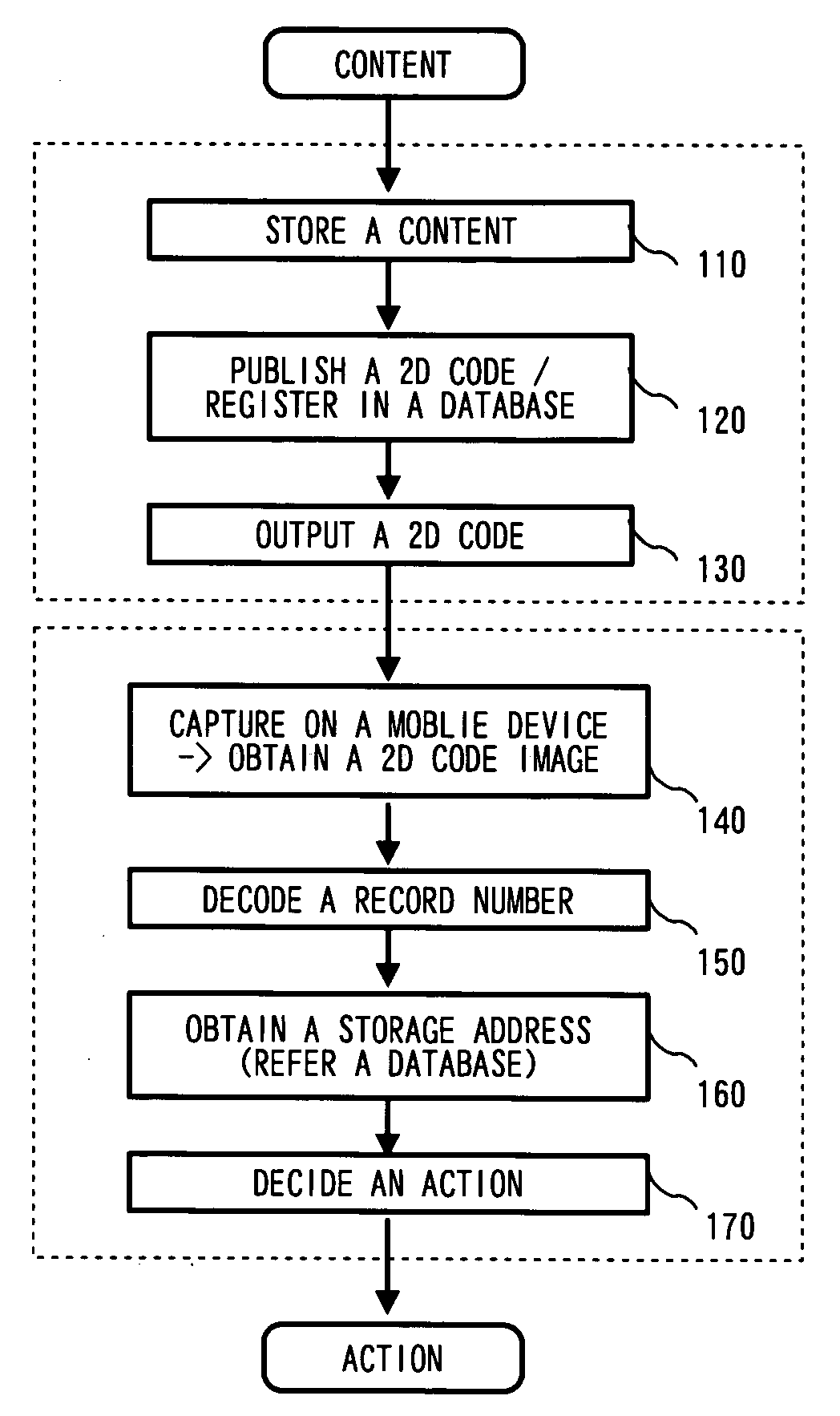

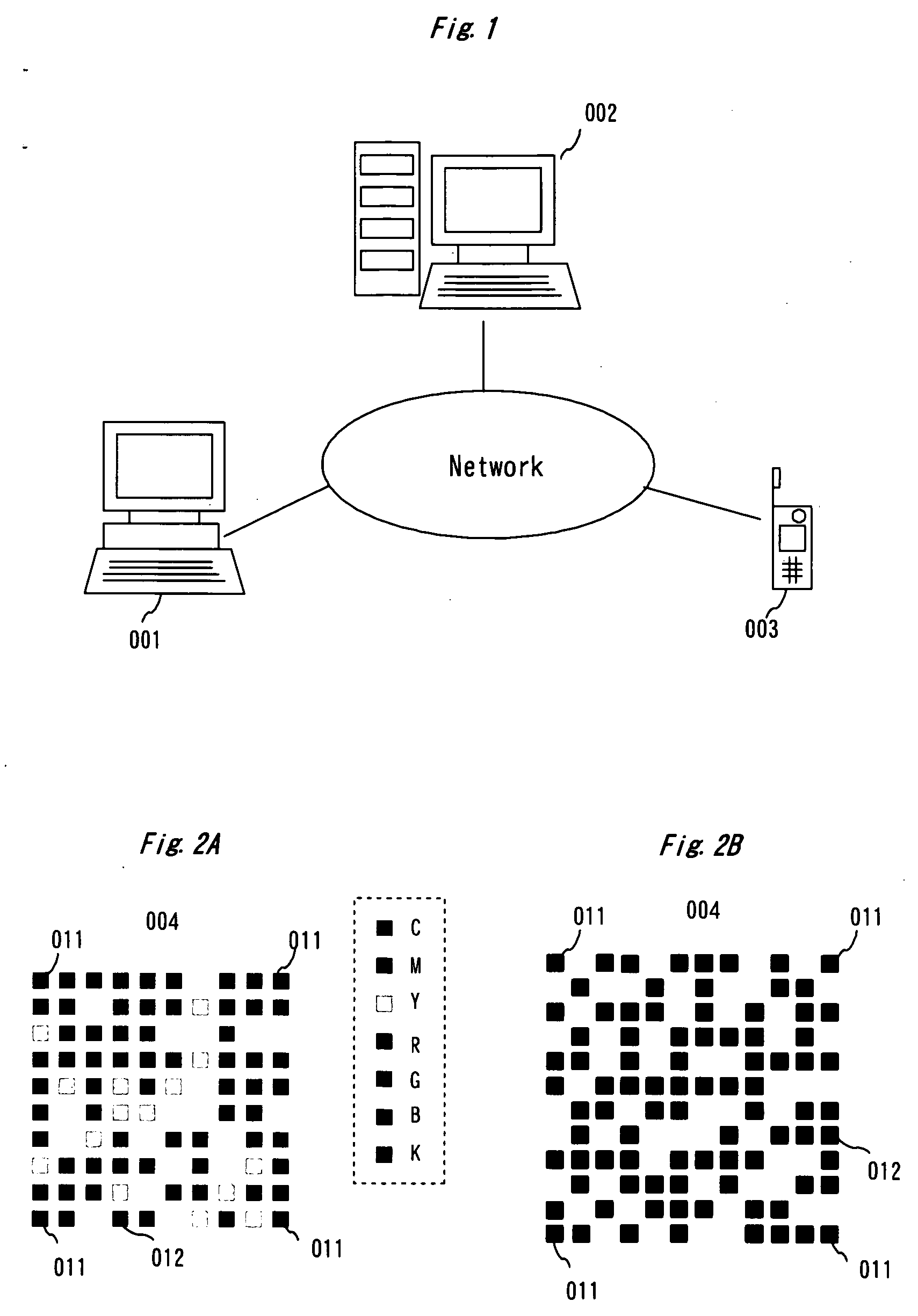

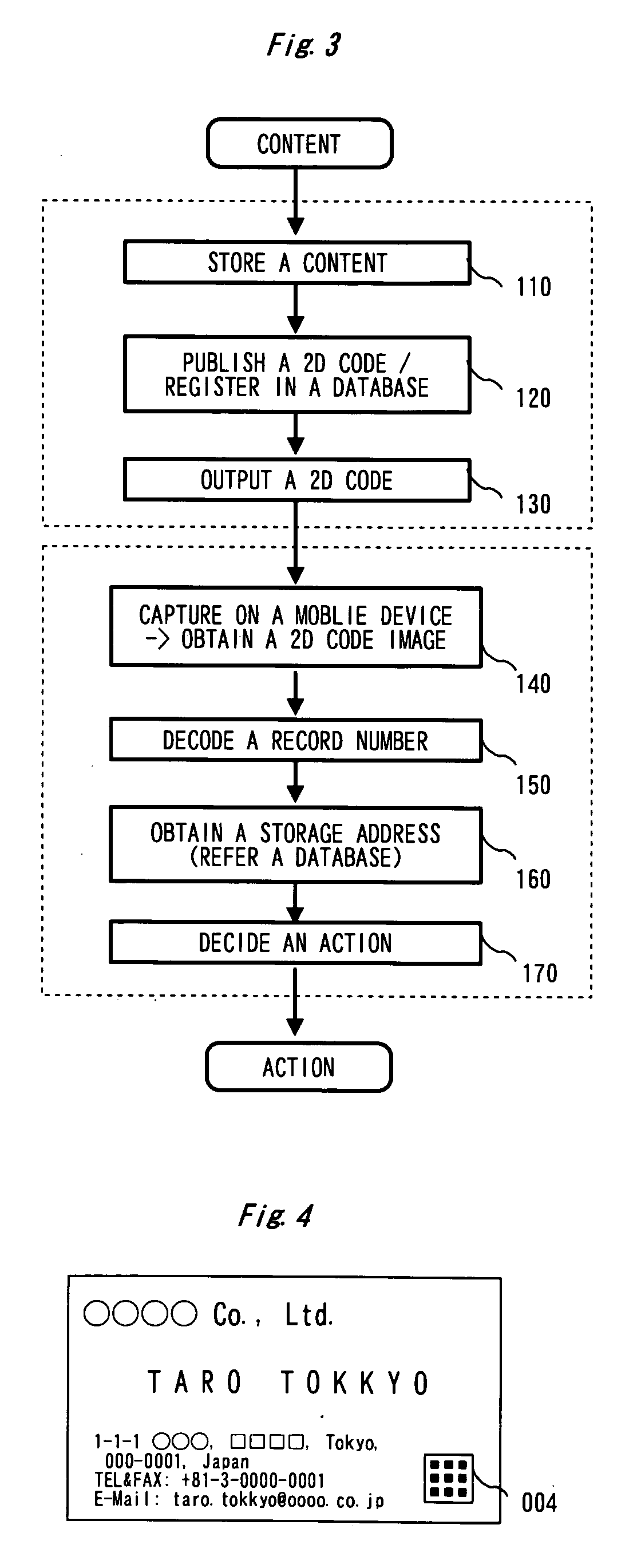

Information management method using a managing symbol and information management server

InactiveUS20060282500A1Reduce loadSmall sizeMultiple digital computer combinationsTransmissionLibrary scienceInformation management

An information management method using a managing symbol and an information management server for managing a plurality of electronic contents and automatically performing an action according to each content. Association between a bit string assigned to each content and the storage address of the content is stored, and a managing symbol representing the bit string is published. The association is referred to specify the content correspondent to the bit string. The action to be performed on the content is decided by referring to an action type selected beforehand.

Owner:KIUCHI YUTAKA +1

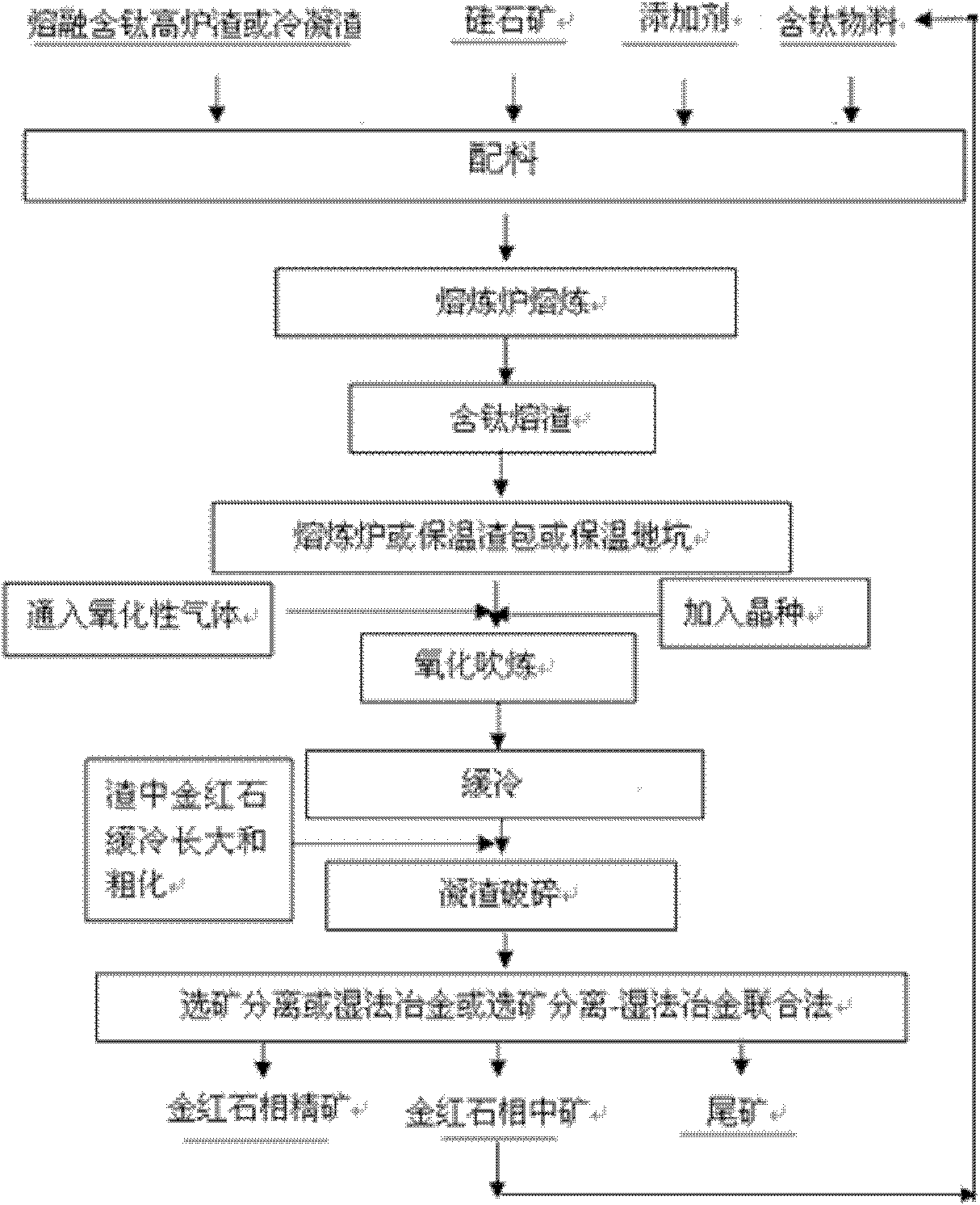

Method for producing artificial rutile from titanium-containing blast furnace slags

ActiveCN102154531ASimple compositionPromote coarseningRecycling and recovery technologiesProcess efficiency improvementTitaniumMolten slag

The invention provides a method for producing artificial rutile by taking the titanium-containing blast furnace slags as the raw material. The method has the advantages of short reaction time, high titanium recovery, low production cost, big treatment capacity and high product additional value and is environment-friendly. The method comprises the following steps: burdening: adding smelted or condensed titanium-containing blast furnace slags, a titanium-containing material, silica ores and an additive into a smelting furnace; smelting: smelting by the smelting furnace to keep the mixture underthe fusing state; oxidation: spraying and blowing an oxidizing gas into slags in the smelting furnace, or pouring the slags into a heat insulation slag tank or a heat insulation pit, spraying and blowing an oxidizing gas into slags in the heat insulation slag tank or the heat insulation pit to convert the titanium-containing substances in the slags into the rutile phase; cooling: keeping the temperature for the oxidized slags in the heat insulation slag tank or the heat insulation pit, and controlling the cooling rate to cool the slags to room temperature to cause the rutile phase to grow; and separation: and finally, breaking and levigating the oxidation modification condensed slags to separate the rutile phase to obtain the artificial rutile with high TiO2 grade.

Owner:喀左县钒钛资源综合开发利用工程技术研究中心 +1

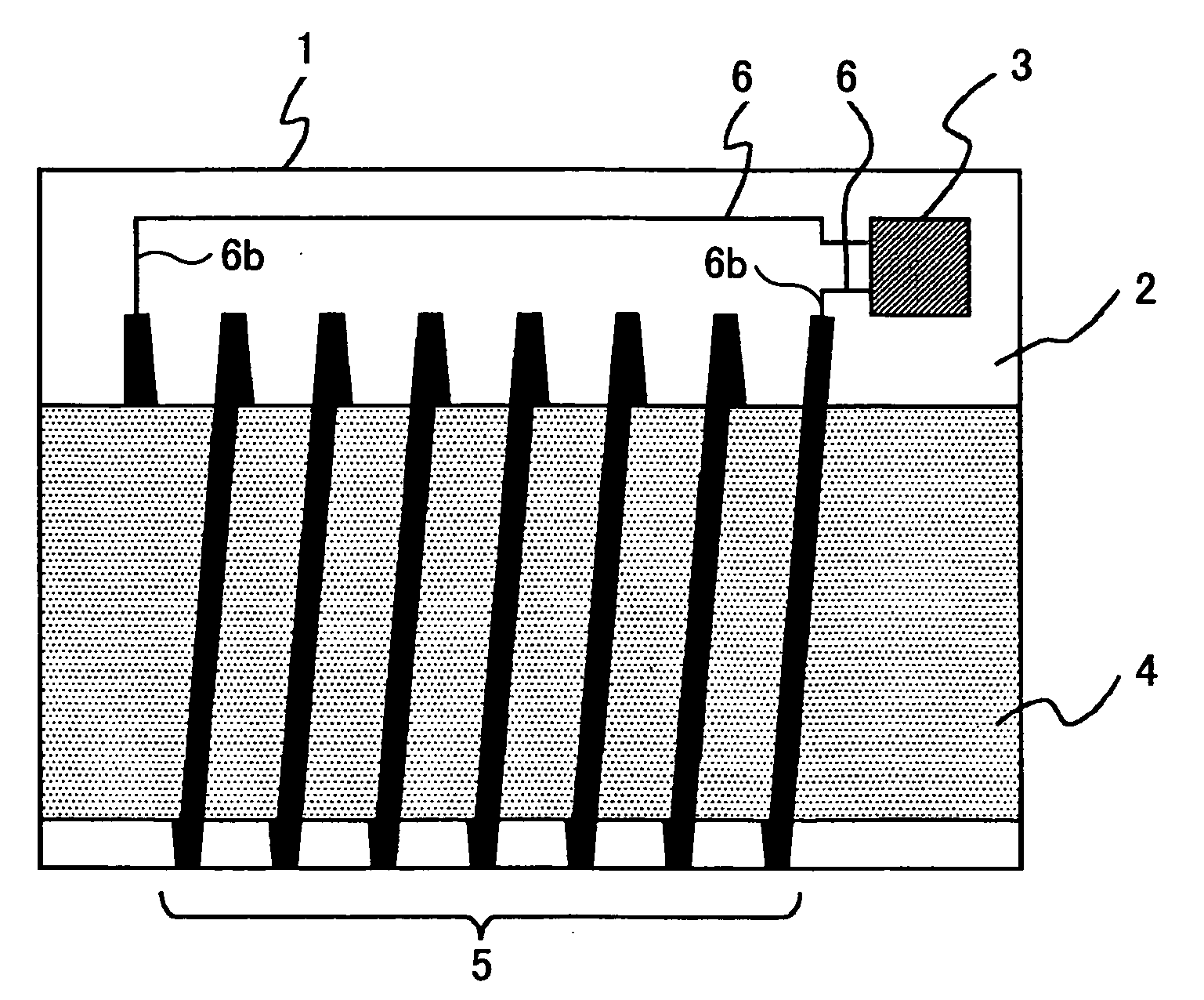

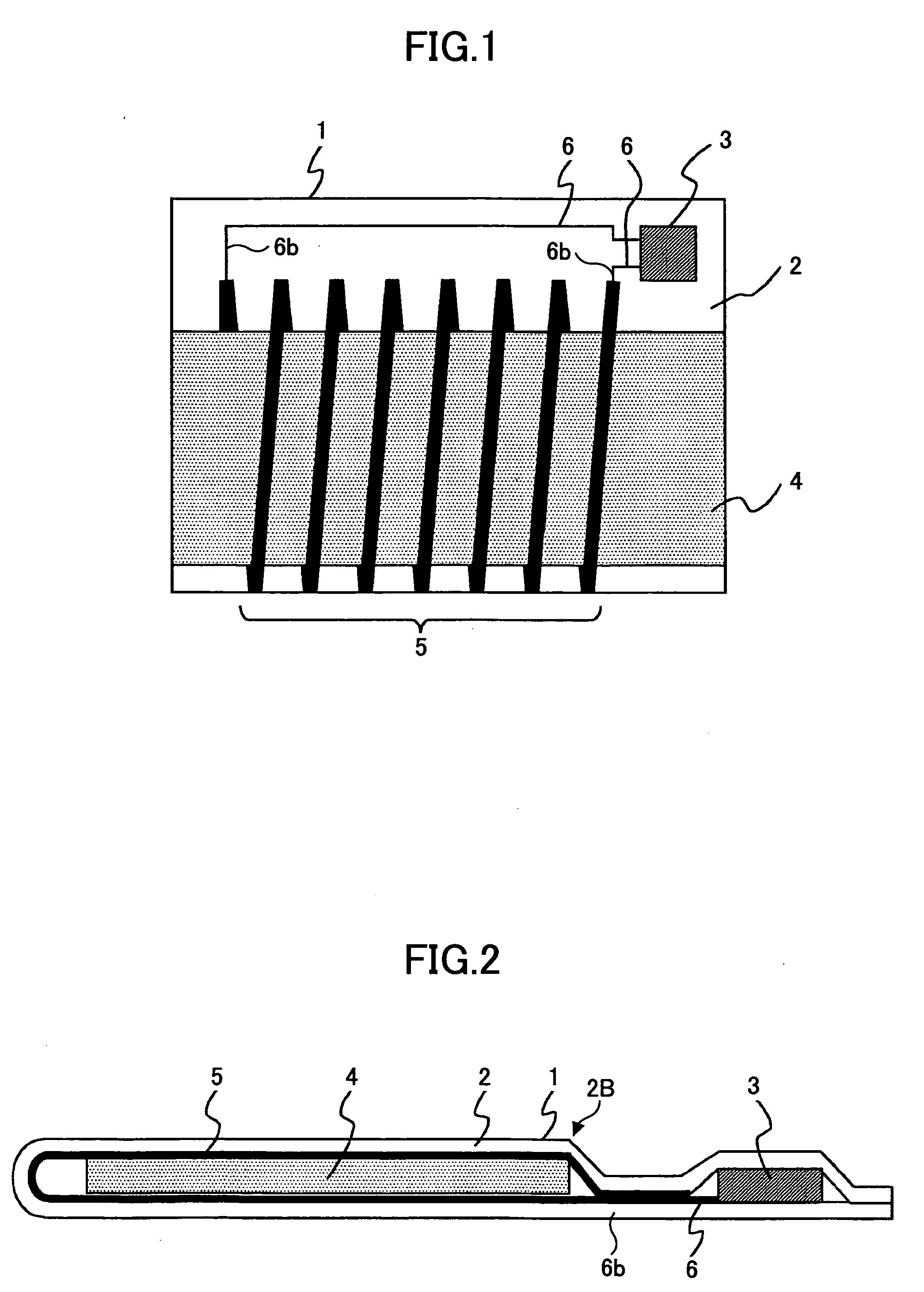

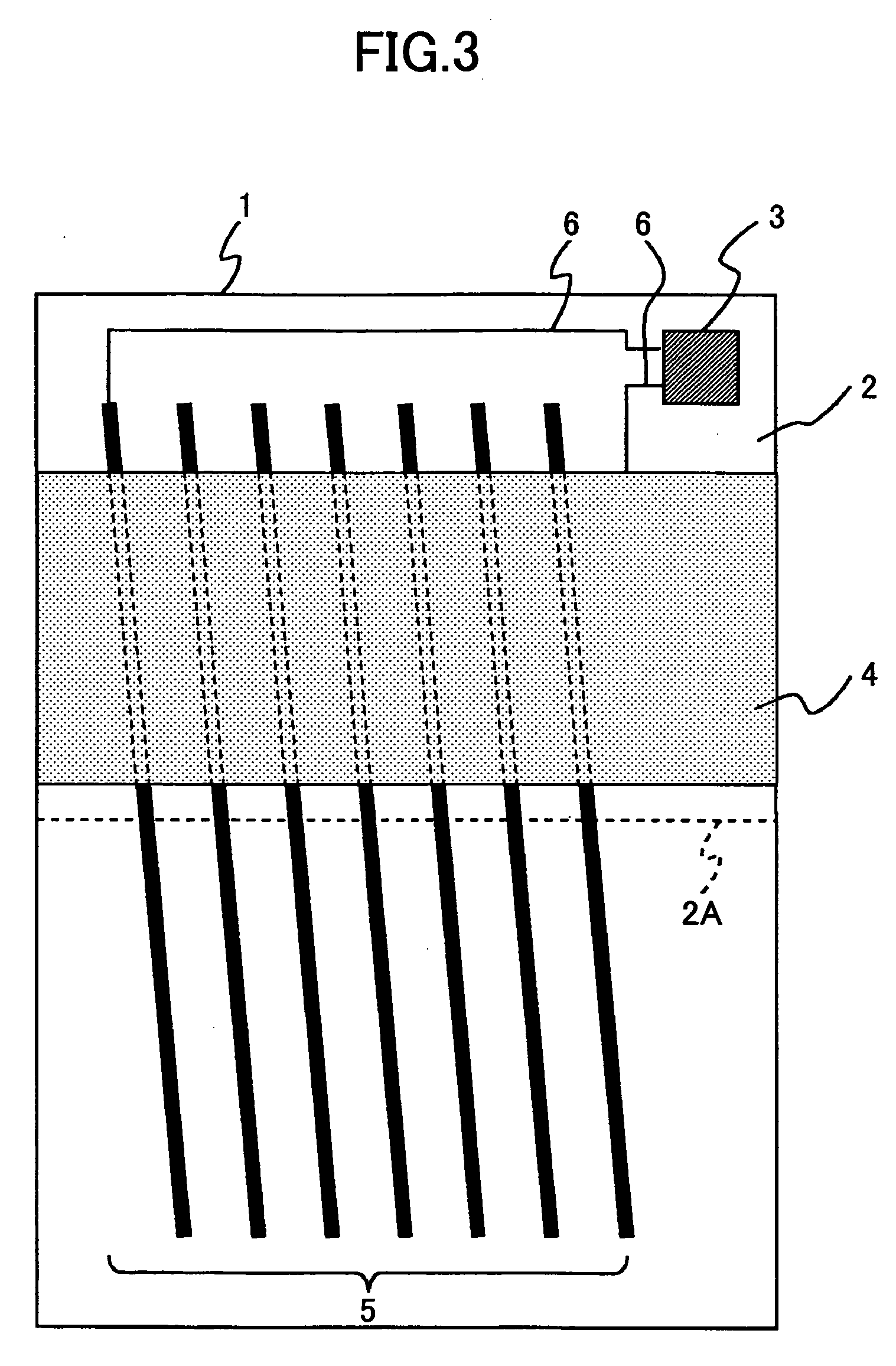

RFID tag and manufacturing process thereof

InactiveUS20070023517A1Reduce thicknessImprove reliabilitySolid-state devicesSensing record carriersElectrical conductorManufacturing technology

An RFID tag comprises a semiconductor chip storing therein information of an object to be discriminated and carrying out radio communication with a reader / writer device; and an antenna coil provided with a magnetic core member and connected electrically to the semiconductor chip. The semiconductor chip and the magnetic core member are wrapped by an insulation sheet carrying an interconnection pattern connecting a pad of the semiconductor chip and the antenna coil electrically and plural coil patterns on one side thereof. The plural coil patterns includes bar-shaped conductor patterns formed obliquely to the magnetic core member, each of the bar-shaped conductor patterns having an end connected to an end of an adjacent coil pattern, the bar-shaped conductor patterns thereby forming together a spiral coil around the magnetic core member. The coil patterns being connected with each other at a part where the coil patterns overlap with each other.

Owner:RICOH KK

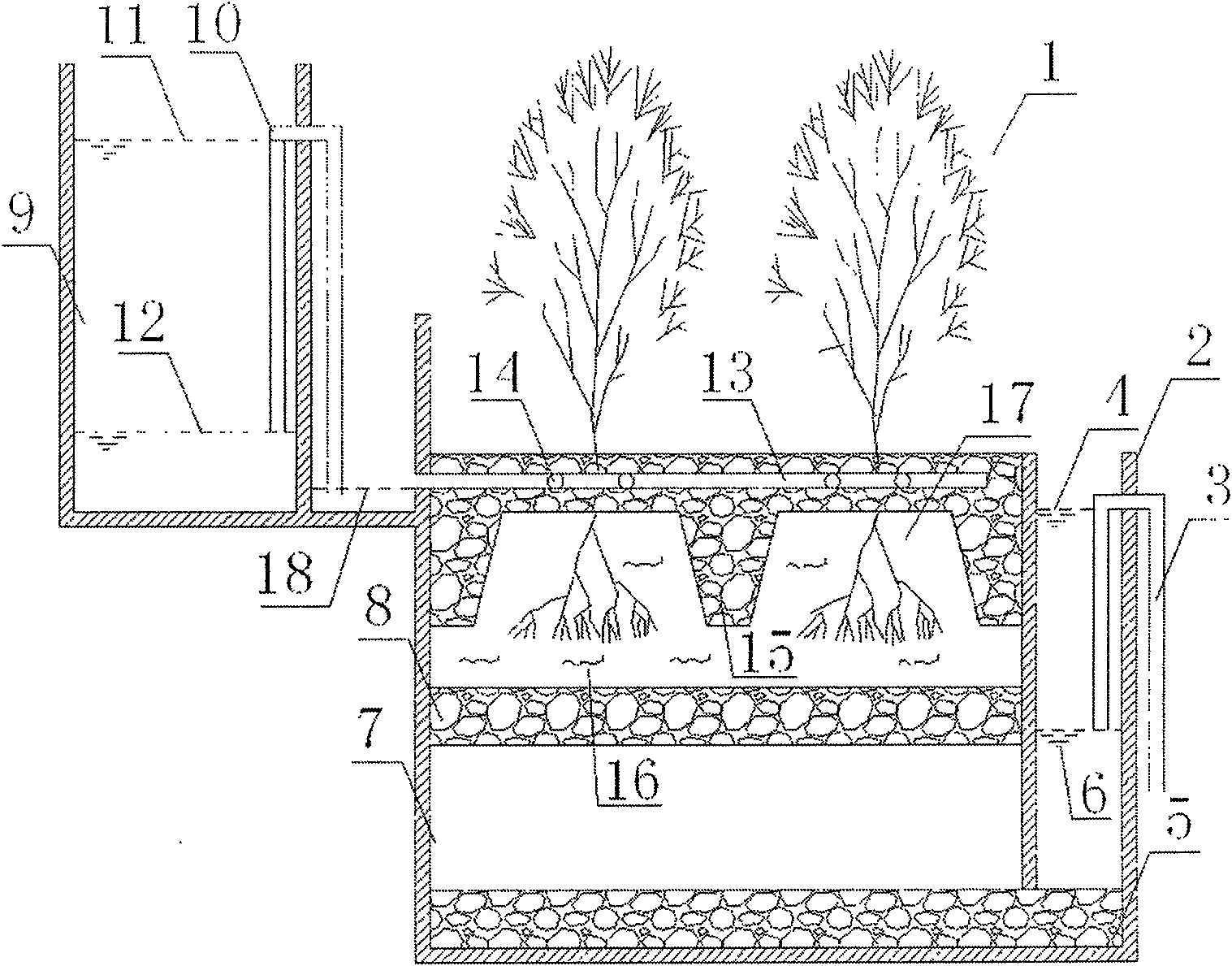

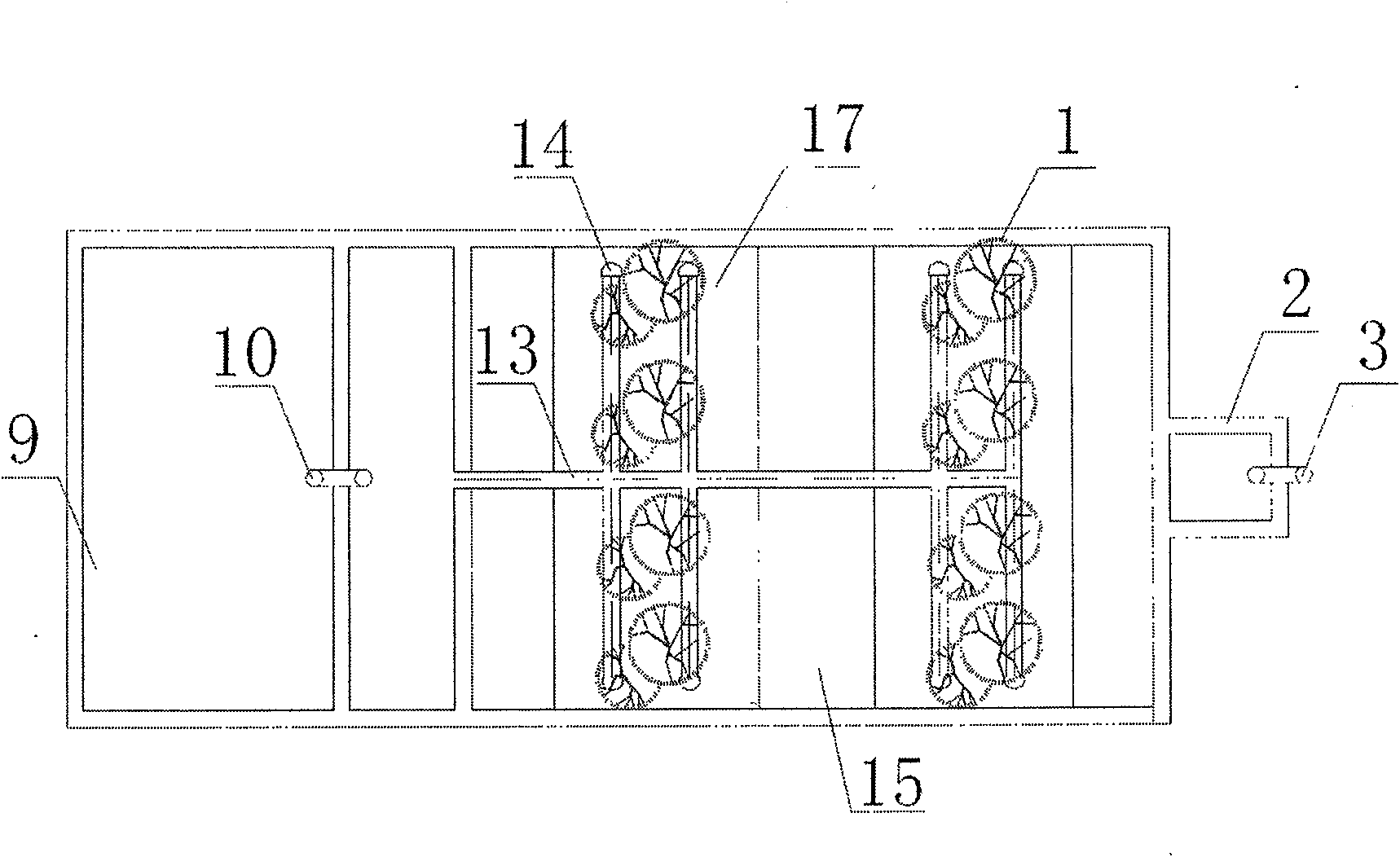

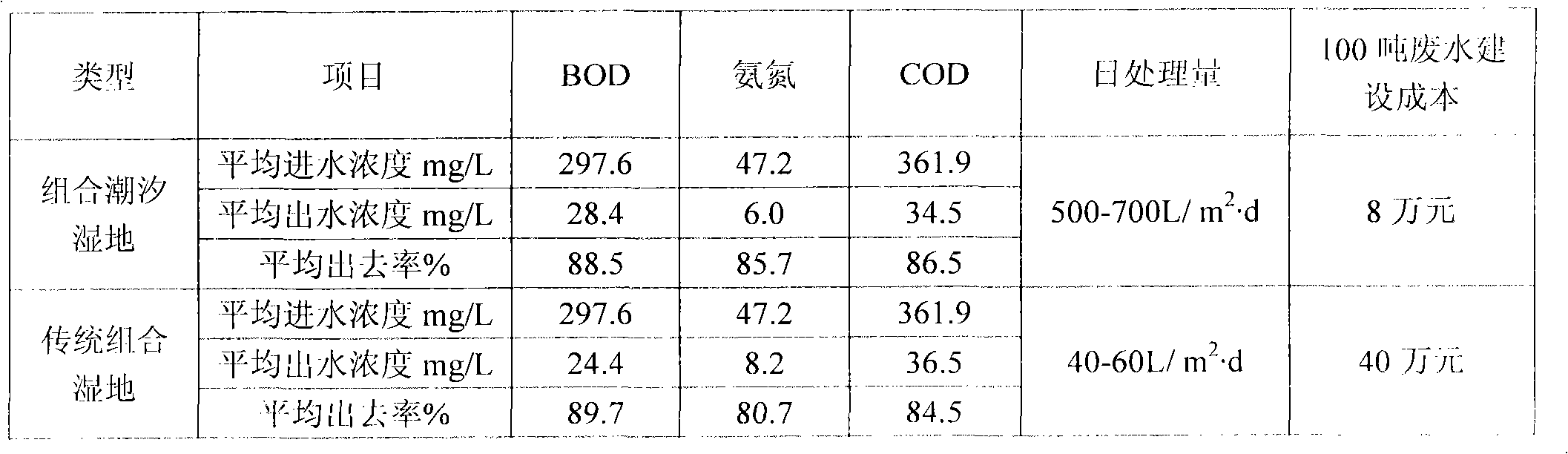

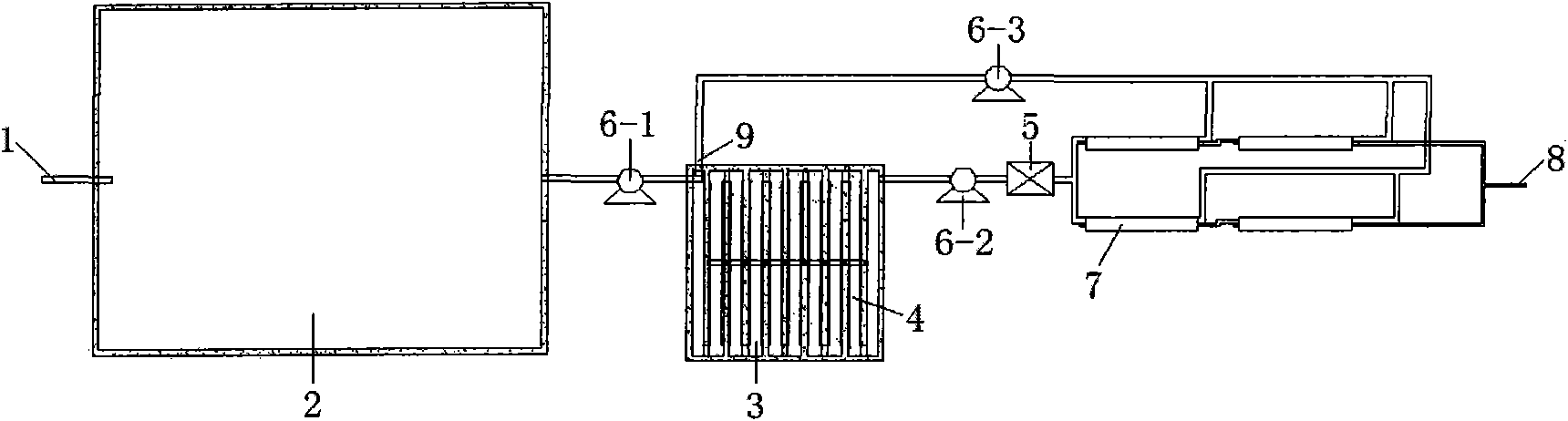

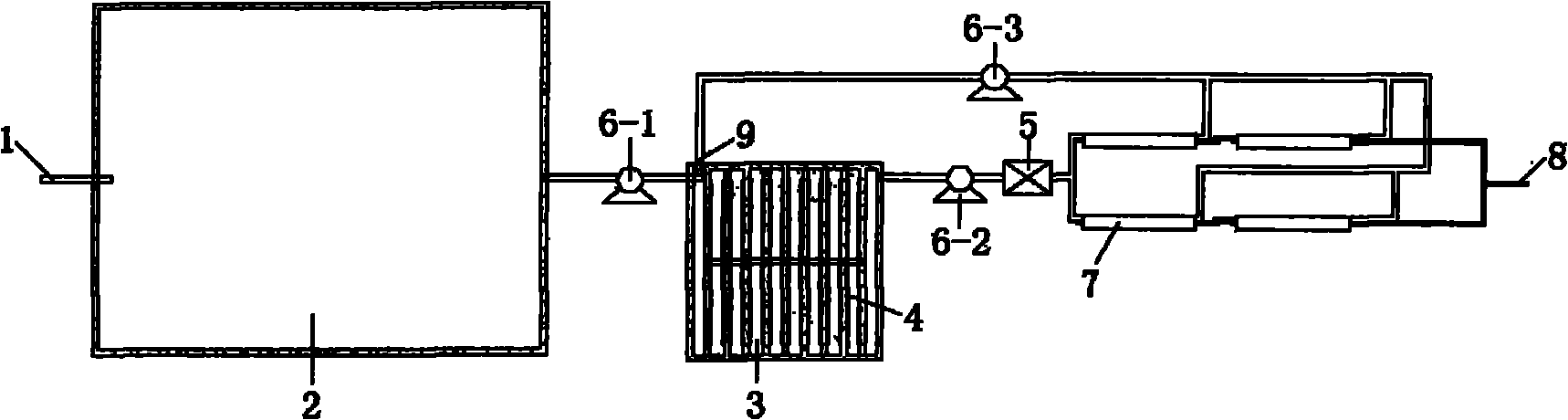

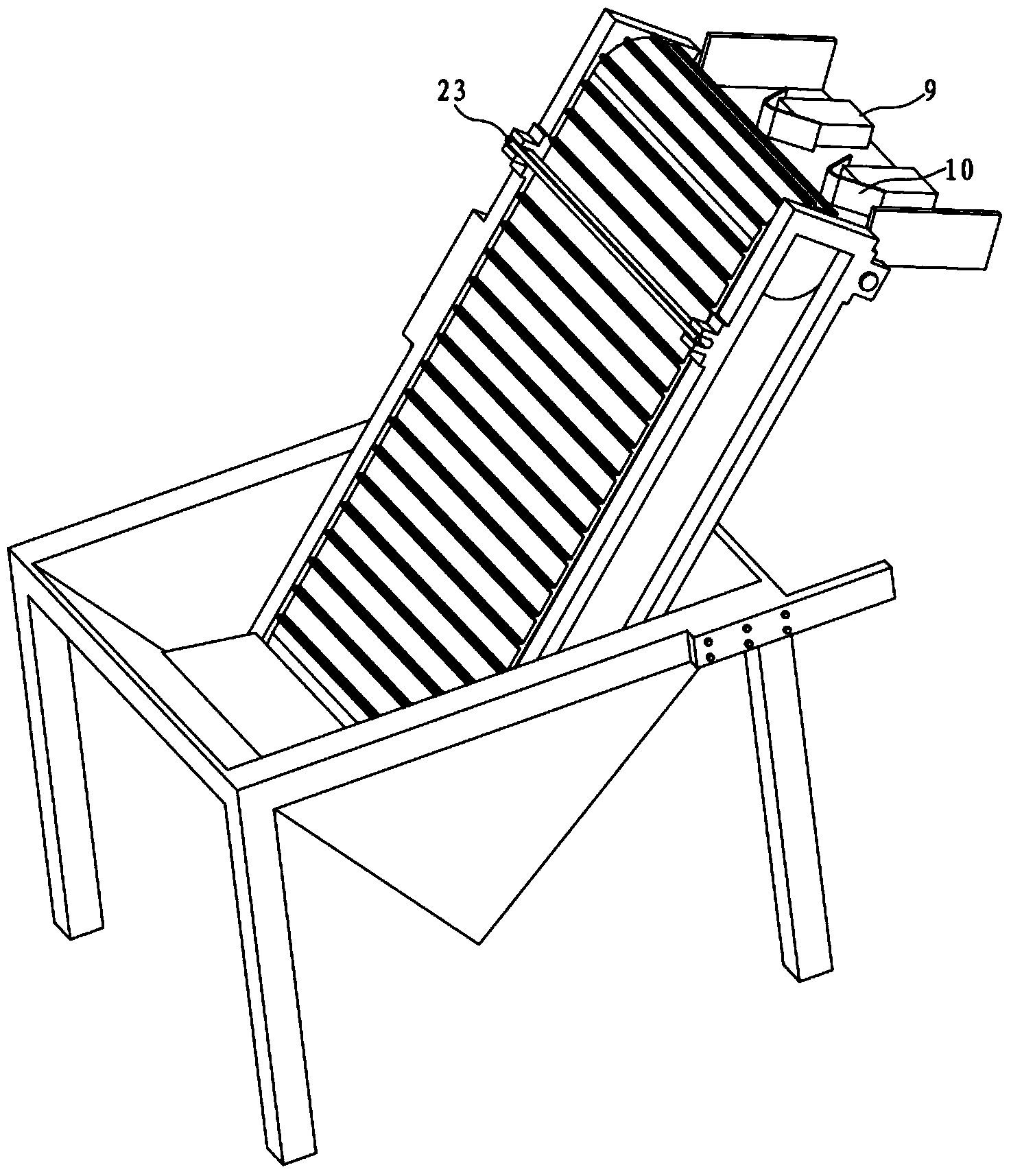

Sewage treatment system and method for combined tidal flow artificial wetland

InactiveCN101671092AGuaranteed contact areaGuaranteed timeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentConstructed wetlandSiphon

The invention discloses a sewage treatment system for combined tidal flow artificial wetland, belonging to the technical field of sewage treatment. The system comprises a non-powered automatic water charging device (9), an artificial wetland bed and a non-powered automatic water discharging device (2), wherein the non-powered automatic water charging device (9) is positioned above the artificial wetland bed and is communicated with the artificial wetland bed through a siphon water inlet pipe (10); the artificial wetland bed is provided with a water discharging layer (5), a denitrification reinforcing layer (7), a reinforcing reaeration layer (8) and an aerobic ecological sand layer (17) from the bottom up; and the non power automatic water discharging device (2) and the artificial wetlandbed form a connector and are connected with each other through the bottom water discharging layer (5). The invention further discloses a sewage treatment method using the system, comprising two stepsof waterflooding absorption and emptying reaeration. Compared with the traditional combined wetland, the sewage treatment system for the combined tidal flow artificial wetland increases daily sewage treatment amount and reduces construction cost.

Owner:CHINA AGRI UNIV

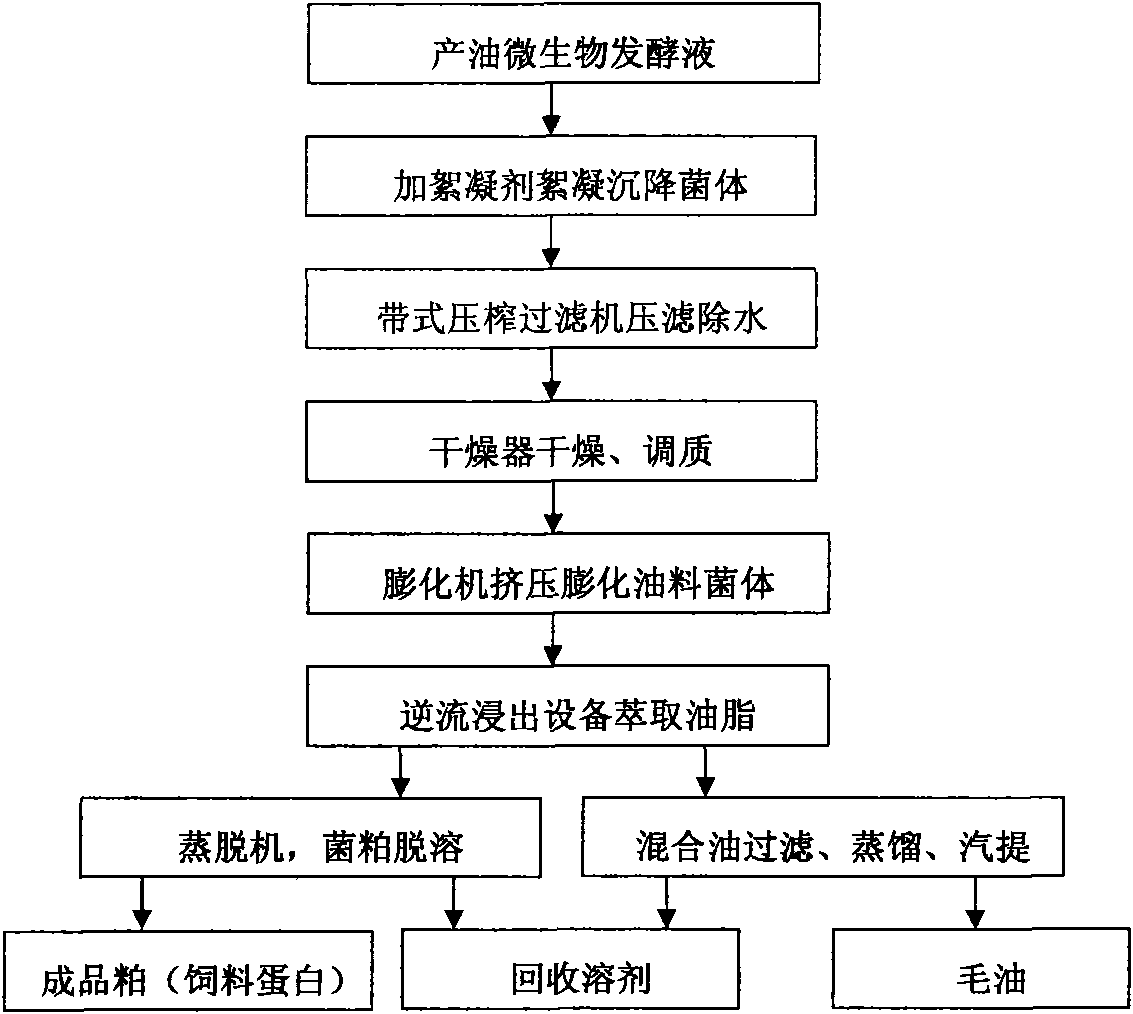

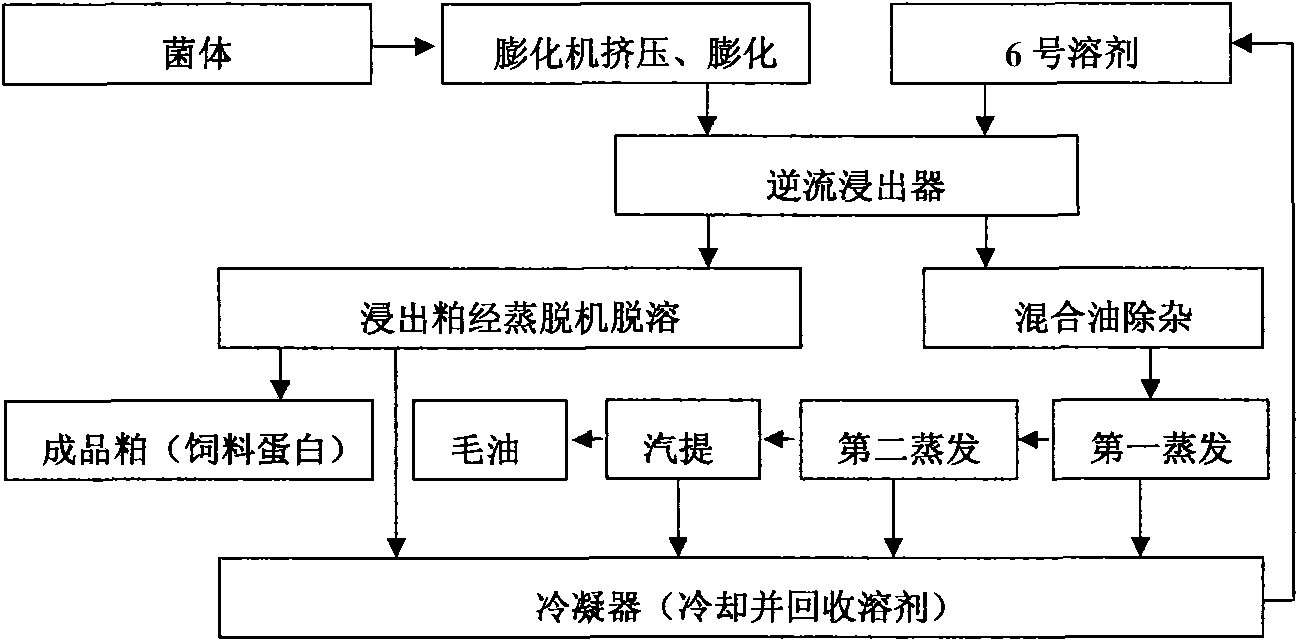

Method for preparing microbial oil and fat

InactiveCN101560440ASimple processImprove product qualityFermentationFatty-oils/fats productionOil and greaseMicrobial oil

The invention discloses a method for preparing microbial oil and fat, which comprises the following steps: (1) collecting microbial thalli; (2) performing filter pressing on the thalli obtained in the step (1) to obtain wet bacterial mud; (3) performing thermal refining, namely drying the wet bacterial mud obtained in the step (2) to remove most of free moisture and partial bound water in cells, and adjusting the temperature and the moisture content of the obtained dried thalli; (4) performing extrusion swelling, namely putting the dried thalli obtained in the step (3) into an extrusion swelling machine for extrusion and swelling; and (5) extracting and soaking the oil-bearing material dried thalli obtained in the step (4) to obtain mixed oil and soaked thalli residues. The method has the advantages of simple process, large handling capacity, low energy consumption and high product quality, and belongs to the field of oil and fat preparation.

Owner:BEIJING UNIV OF CHEM TECH

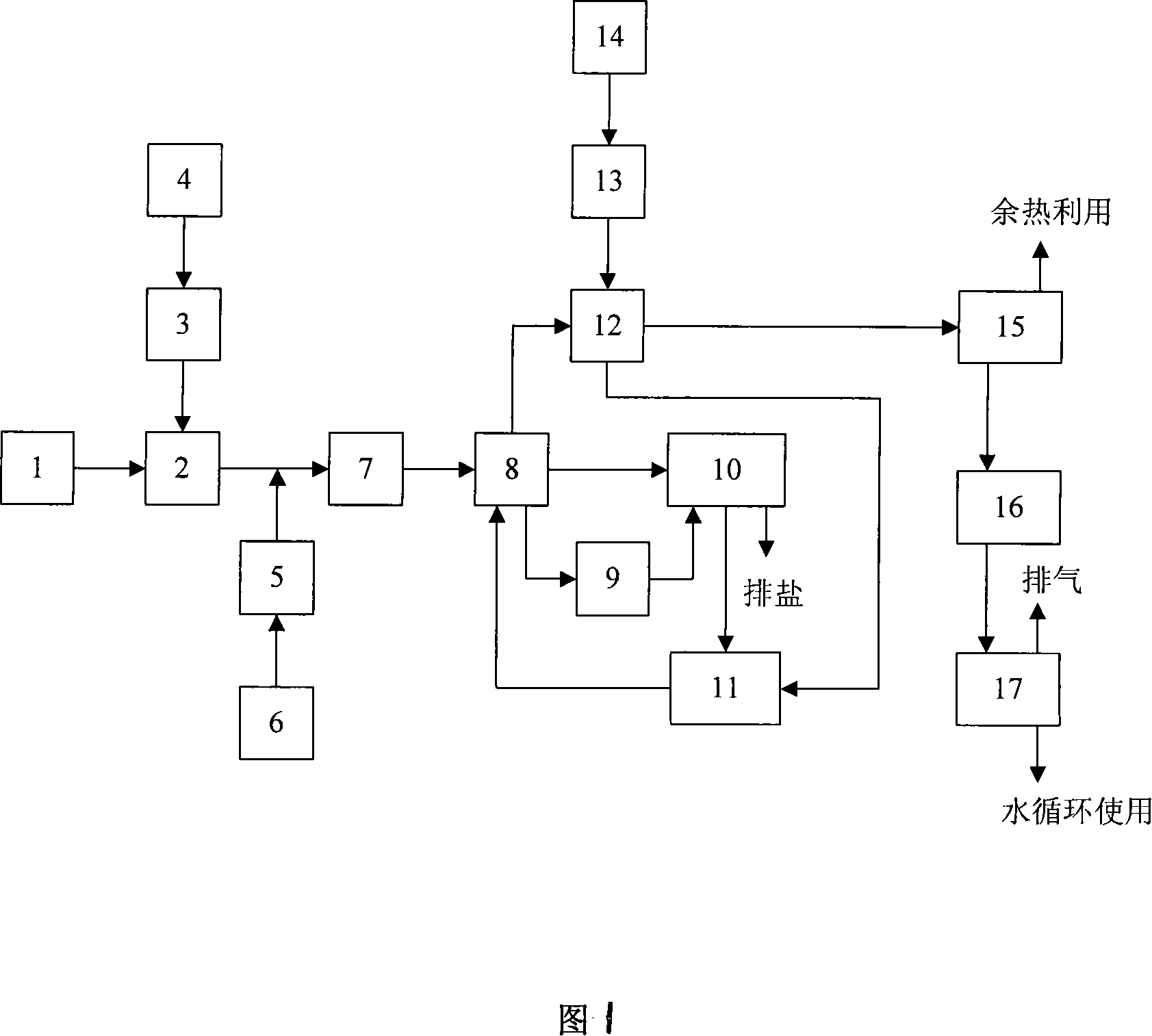

Technique for processing coking wastewater or organic wastewater by supercritical water oxidization technique

InactiveCN101209883AEmission reductionEfficient removalScale removal and water softeningMultistage water/sewage treatmentWater cyclingSolid particle

The invention relates to a process by adopting supercritical water oxidation technology to treat coking wastewater or organic wastewater. The invention is that: coking wastewater or organic wastewater is pretreated to obtain wastewater without solid granules; the wastewater is heated to 380-450 DEG C with a first interchanger and / or a supercritical boiler, and then enters demineralizing equipment to remove the salt in the wastewater by taking advantage of the property that supercritical inorganic matter is indissoluble; the wastewater after desalting is put in a reaction kettle to generate autothermal reaction with an heated and pressurized oxidant to obtain high-temperature gas-liquid mixture with higher temperature; the high-temperature gas-liquid mixture enters the first interchanger and acts as thermal medium to exchange heat with new coming coking wastewater or organic wastewater and then goes through a secondary interchanger to enter a cooler and is cooled to normal temperature, after pressure thereof is adjusted by a pressure regulation device, the high-temperature gas-liquid mixture enters a gas-liquid separator for separation, and then the air is discharged, while the liquid, namely the treated water is recycled. The organic contamination and oxidant are all dissolved in the wastewater; oxidation reaction is generated in homogeneous phase, in short reaction time, oxygenolysis of organic contamination is carried out quickly.

Owner:北京能泰高科环保技术有限公司

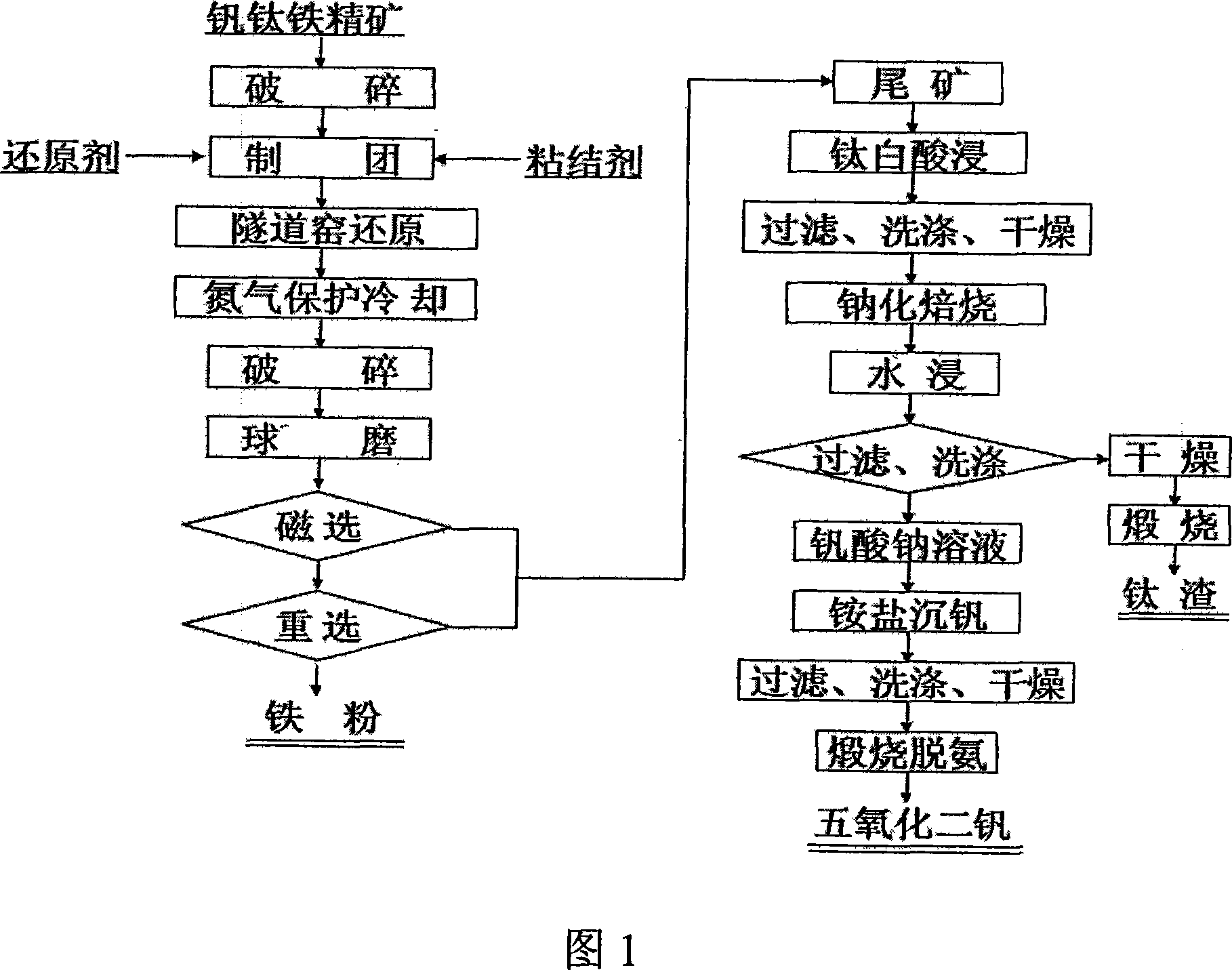

Method for comprehensive utilization of V-Ti-bearing iron ore concentrate by using tunnel kiln reduction-grinding - separation

InactiveCN101113488AAvoid defects such as loopsHigh yieldProcess efficiency improvementTunnel kilnResource utilization

The invention relates to an iron powder production method by using a tunnel kiln to reduce concentrate pellets containing carbon vanadium ferrotitanium with titanium slag and vanadium pentoxide as combined products. Concentrate pellets are made from vanadium-titanium iron concentrate through crashing and damp milling. The iron powder and tailings are obtained by putting the concentrate pellets into the tunnel kiln to be reduced, crashing, wet-grinding, magnetic separation and gravity separation. The tailings are soaked with titania waste acid to eliminate remnants magnesium and iron. Then the tailings are filtrated and dried to obtain a new material. And then the new material is added with sodium salt to do salt roast and then to be soaked by water, then titanium slag and sodium vanadate are obtained respectively after the water soaking. At last, the vanadium pentoxide is obtained by ammonium vanadate precipitating and calcination deaminase to the sodium vanadate liquid. The invention eliminates the disadvantage of high energy consumption by electric furnace smelting and bad separating effect of vanadium and titanium, difficult control of vanadium and titanium trend and low yield rate of extracting vanadium and titanium through converter blowing iron molten, etc. The invention has the advantages of high yield rate of vanadium, titanium and iron and high resources utilization rate and explores a novel practical way for comprehensive utilization of vanadium, titanium and iron concentrate ore.

Owner:攀枝花锐龙冶化材料开发有限公司

Method and device for coal gasification in combined type fluidized bed

ActiveCN102533345AImprove gasification efficiencyEasy to handleEnergy inputGranular/pulverulent flues gasificationRetention timeSlag

The invention discloses a method for coal gasification in a combined type fluidized bed, which comprises coal preparation, gas supply, gasification, slag discharge, dedusting, waste heat recovery and fine powder conveying. An ash agglomeration fluidized bed realizes gasification of large-particle coal; the non-completely converted carryover fine powder enters an entrained flow bed gasifier in a dense phase pneumatic conveying manner; secondary gasification is carried out by using a short retention time high temperature gasification manner; the produced ash slag is carried into an intersection segment of the fluidized bed and the entrained flow bed with high temperature coal gas, and rapidly mixed with ''low temperature'' large-particle partially carbonized coal in the fluidized bed and the produced ''low temperature'' coal gas; and partial ash slag is selectively discharged out of the gasifier in the form of solid. The method and the device of the invention have the advantage of being suitable for various coal types and high in carbon conversion rate.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Reactor or mixer with micromesh structure

ActiveCN101224405AShort mass transfer distanceLarge mass transfer areaFlow mixersChemical/physical/physico-chemical processesEngineeringPetrochemistry

The invention provides a reactor or a blender with micro sieve mesh structure, which relates to the fluid micro dispersion technology and equipment. The invention contains micro sieve mesh structure, a hybrid channel and a fluid distribution chamber, and utilizes the micro sieve mesh to disperse one fluid to another fluid in a form of micron-sized drop or bubble, the blending and reaction process of the drop and the bubble which have high dispersion and high specific surface are rapidly finished in the hybrid channel, so the invention is a novel microstructure reaction vessel or blender which utilizes the micro sieve mesh structure to realize the reaction or blending of homogeneous phase or non homogeneous phase fluid. The invention is characterized by simple processing, convenient operation, large treating capacity for unit volume and so on and can be widely applied to a number of fields like the chemistry, chemical engineering, petrochemistry, medicine, foodstuff, etc.

Owner:TSINGHUA UNIV

Method for deeply purifying minim phosphor in water with composite resin

ActiveCN101343093APhosphate content decreasedLarge amount of processingSpecific water treatment objectivesWater contaminantsFiltrationDesorption

The invention discloses a method for deeply purifying micro-phosphorus in water by composite resin. The pH value of water is firstly adjusted to between 5.0 and 9.0 for filtration, then the filtrate passes through an absorption tower filled with composite resin materials to make the micro-phosphorus in water be adsorbed on the composite resin; and the adsorption stops when the adsorption reaches the leakage point, a mixed solution of NaOH and NaCl serves as a desorption agent for desorption and regeneration, then a CO2 saturated solution is used to leach the absorption tower filled with composite resin materials for regenerating resin. The method takes composite resin of surface supported nano-hydrous ferric oxide or hydrous manganese oxide particles as an adsorbent to deeply purify micro-phosphorus in water. After the treatment by the method, the phosphate content (as P) in effluent can still be reduced to below 20ppb from 0.05-20ppm when the molar concentration of coexistent competing ions of Cl<->, HCO3<-> and SO4<2-> is far higher than that of phosphate ions. The method has large treatment capacity, and the materials are renewable and recyclable.

Owner:JIANGSU NJU ENVIRONMENTAL TECH

Electrolytic deposition-membrane separation combined treatment device for electrolytic zinc rinse wastewater

InactiveCN101921032AEfficient use ofLess investmentWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentElectricityElectrolysis

The invention discloses an electrolytic deposition-membrane separation combined treatment device for electrolytic zinc rinse wastewater, comprising a liquid inlet pipe, an adjusting tank, an electrolytic deposition device, a three-dimensional fixed bed device, a safety filter, three circulating pumps, a membrane assembly, a clear water outlet and a condensed liquid reflex hole, wherein the connection of various components is detailed in the description. The invention has the advantages that: by combining the electrolytic deposition technology with the membrane separation technology, the device has the advantages of less investment, high handle capacity, low energy consumption, high benefit, easy industrialization and easy implementation of the comprehensive utilization of resources; the effluent discharge after reaching standards and the recycling are realized, the heavy metal resources in the wastewater are effectively recycled; and automation degree is high and manual operation is simple and convenient, the complete recovery and zero discharge of heavy metals can be basically realized and water resources are completely recycled and the wastewater is deeply purified.

Owner:PEKING UNIV

Mineral separation process of magnetic iron ore

ActiveCN101480632AReduce energy consumptionFine Concentrate SizeSievingScreeningMagnetiteMaterials science

The invention discloses a beneficiation method for a pure magnetic iron ore. A crude ore is sequentially treated according to the steps such as first crushing, first-stage dry-type magnetic dressing, medium crushing, second-stage dry-type magnetic dressing, fine crushing and third-stage dry-type magnetic dressing, fine ore is obtained after a great amount of gangues are thrown by the third-stage dry-type magnetic dressing and sent to a grinding head sieve to be griddled and separated, granules griddled by the grinding head sieve are treated in a first-section magnetic dressing process, rough ore griddled by the grinding head sieve is treated in a first-section ball grinding and then enters the first-section magnetic dressing process; ore aggregates obtained from the first-section magnetic dressing process are treated in a second-section ball grinding after discharging gangue sands till the granularity of ore powder is -200meshes being more than or equal to 60 percent, ore powder generated from the second-section ball grinder are treated in second-section magnetic dressing, ore aggregates generated from the second-section magnetic dressing are treated in a high-frequency sieve after discharging gangue sands, products positioned on the high-frequency sieve are filtered to obtain ore concentrate, and products positioned below the high-frequency sieve are treated with desliming and then treated with floatation. The invention adopts two sections of grinding ore open-way processes and distinguishes the ore aggregates during the ore dressing process, thereby greatly reducing the energy consumption of a system, lowering the production cost and enhancing the utility ratio of equipment.

Owner:安徽大昌矿业集团有限公司

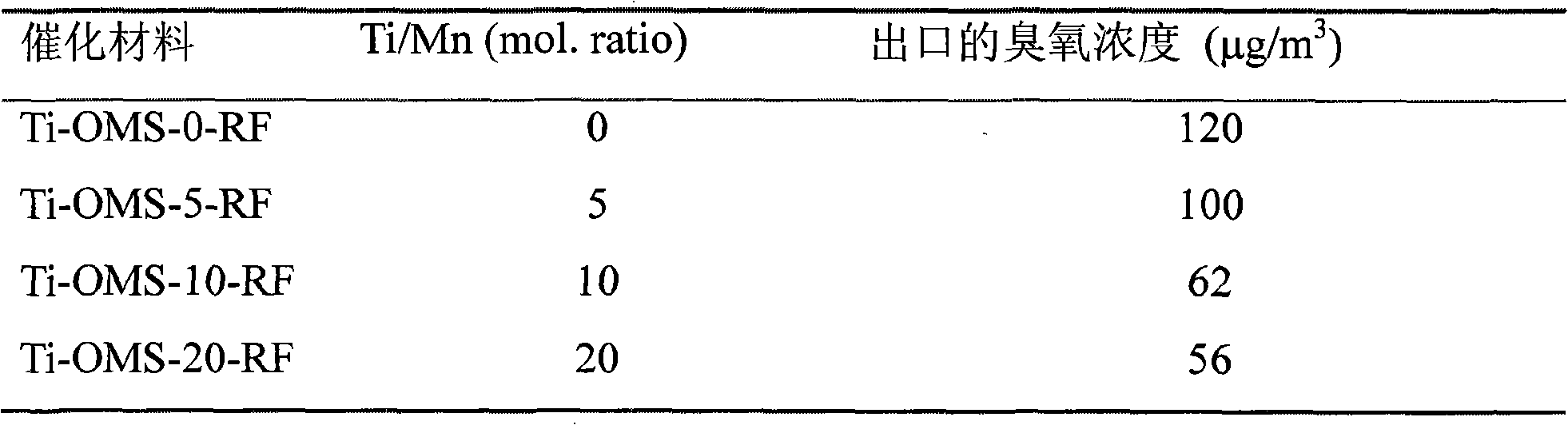

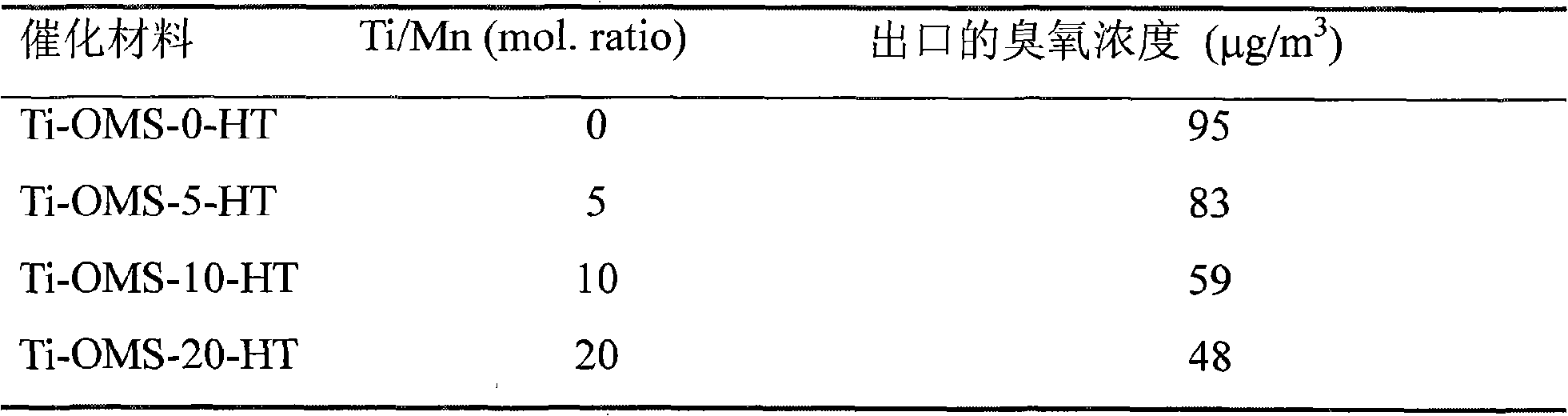

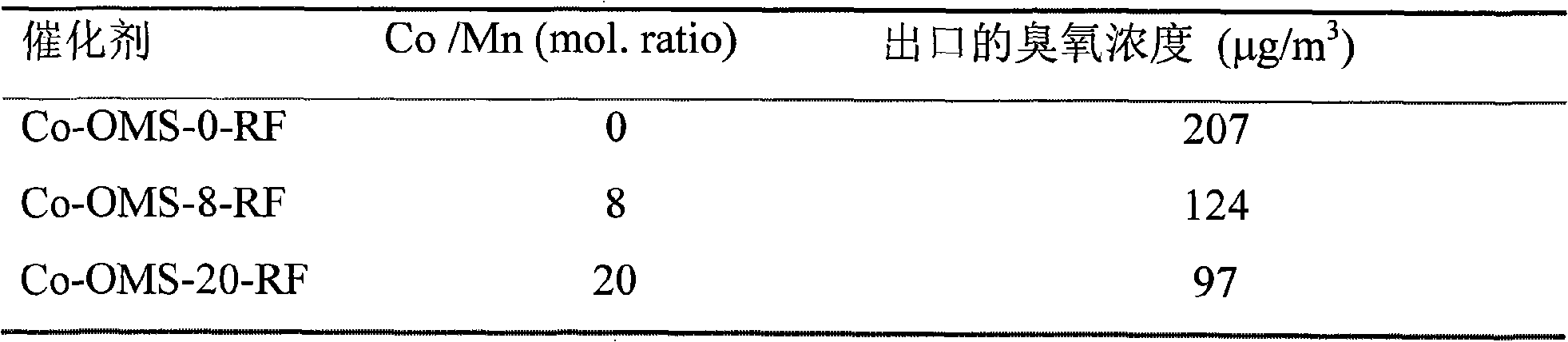

Room-temperature decomposition ozone catalysis material and preparation method thereof

InactiveCN101357331AImprove moisture resistanceImprove processing efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAir volumeDecomposition

The invention discloses a manganese oxide molecular sieve-doped monolithic catalyst for decomposing ozone (O3) at room temperature and a preparation method thereof, which relates to the fields of catalysis and environmental protection. The preparation method is characterized in that a ceramic honeycomb monolithic type or porous foam metal carrier is adopted, and the manganese oxide molecular sieve doped with cobalt or titanium is taken as an active component. The manganese oxide molecular sieve doped with the cobalt or titanium is characterized in that: 1) the manganese oxide molecular sieve has Hollandite-typed manganese oxide octahedral molecular sieves (OMS-2) structure, the pore size is about 0.46nm multiplied by 0.46nm; 2) cobalt or titanium ions are introduced on a framework of the Hollandite-typed manganese oxide octahedral molecular sieves to form the manganese oxide molecular sieve doped with cobalt or titanium. An ozone decomposition catalyst is prepared by an oxidation reduction-refluxing method or an oxidation reduction-hydrothermal synthesis method, namely, the solution with manganese salt and cobalt salt or titanium salt is added with a strong oxidizer to synthesize the ozone decomposition catalyst by refluxing at the temperature of 90-200 DEG or hydrothermal process for more than 12 hours. The monolithic catalyst is characterized in that the input of additional energy sources such as light, heat, electricity, and the like, is unnecessary, and the ozone can be stably decomposed into oxygen under the conditions of normal temperature, normal humidity and large air volume.

Owner:李永刚

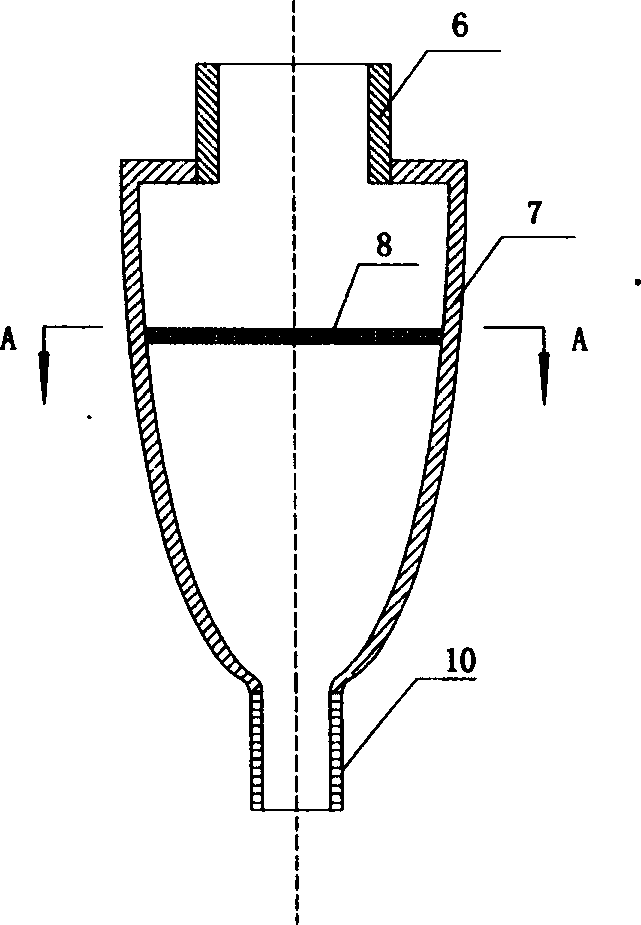

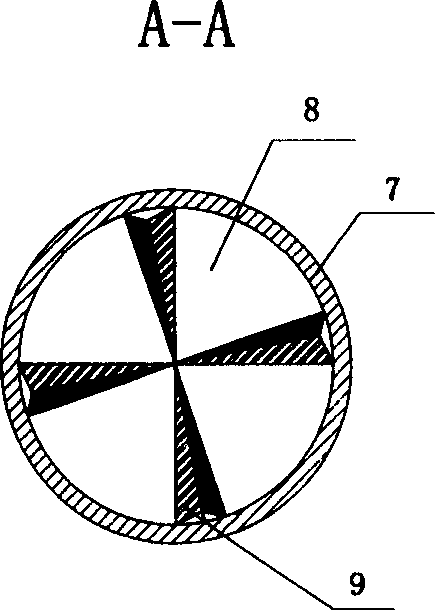

Convolution cavitation device

InactiveCN1605376ALarge amount of processingGood demulsification effectNon-miscible liquid separationHollow cylinderEngineering

The eddy cavitating unit used in the technological field of chemical separation consists of liquid inlet pipe and three coaxial cylinders including inner cylinder, middle cylinder and outer cylinder, the outer cylinder and the middle cylinder have individual tops with central inlet and common bottom, and the inner cylinder is a hollow cylinder and is connected to the middle cylinder via four radial cross beams. Or, the eddy cavitating unit consists of liquid inlet pipe, paraboloidal cone, disc with slit, flow guide plate and nozzle. Or, the eddy cavitating unit consists of liquid inlet pipe, outer paraboloidal cone, inner funnel cone and nozzle.

Owner:SHANGHAI JIAO TONG UNIV

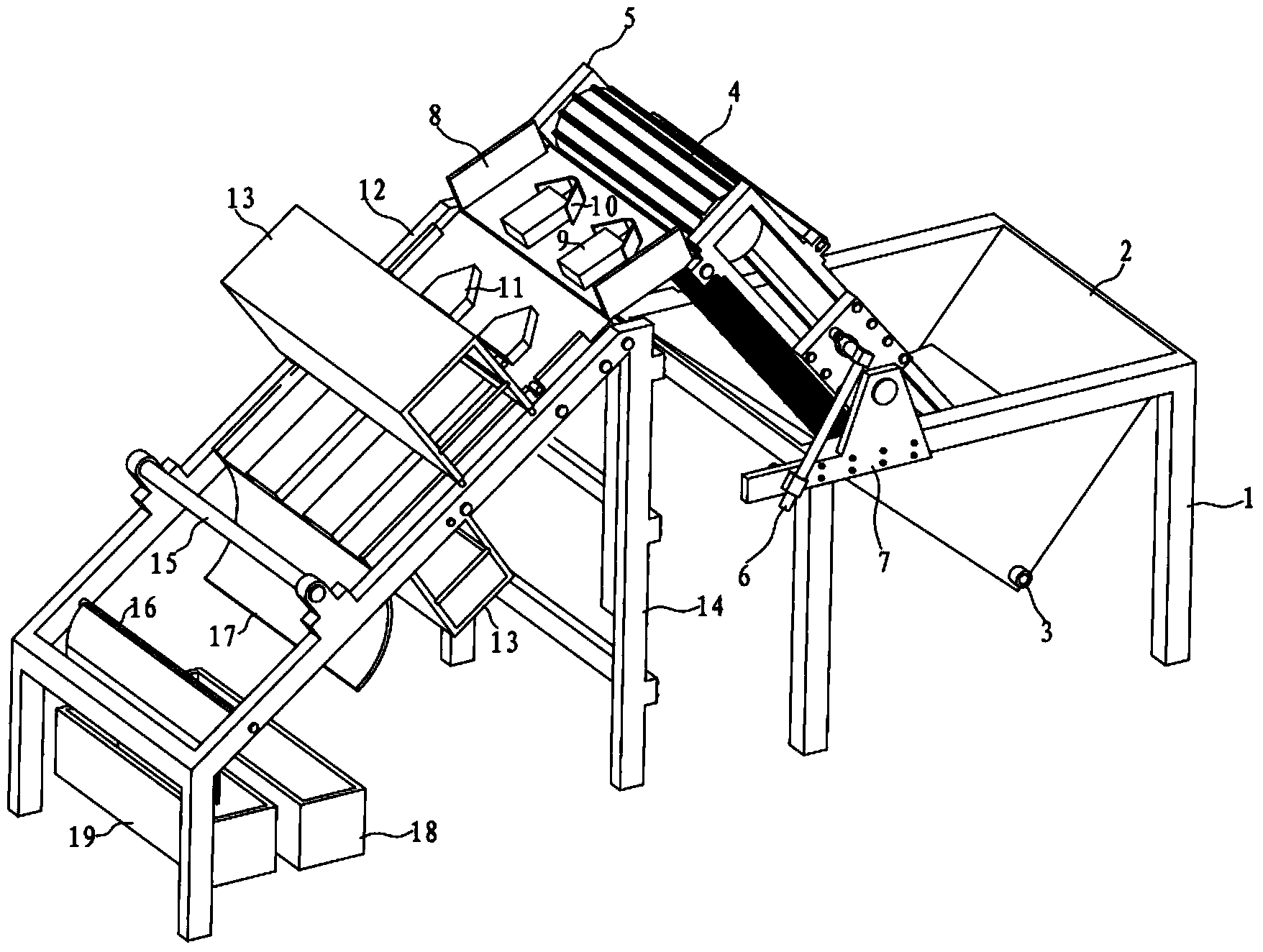

Method and device for automatically carefully sorting and grading shrimps

ActiveCN103801520ANot easy to damageAdjustable to adapt to changes in the detection objectSortingImaging processingShrimp

The invention discloses a device for automatically carefully sorting and grading shrimps. The device comprises a feeding system, a sorting channel, an image collecting system, a grading system and an image processing system; the feeding system is used for outputting to-be-sorted shrimps to the sorting channel in a single row; the sorting channel consists of a buffering channel and a sampling channel which are sequentially connected, the sampling channel is divided into a plurality of single-row channels, the buffering channel is internally provided with a plurality of direction adjusters, and used for separating raw material shrimps, output by the feeding system, into singles, and adjusting the posture of each raw material shrimp entering single-row channel; the image collecting system is used for collecting images of the raw material shrimps; the grading system comprises spray nozzles corresponding to single-row channels, and the spray nozzles are controlled by the image processing system and used for blowing the shrimps to enter different receiving tanks; the image processing system is used for analyzing the images, grading the image of each shrimp, and emitting the signal for controlling the grading system according to the graded results. The invention further discloses a method for automatically carefully sorting and grading shrimps.

Owner:ZHEJIANG UNIV

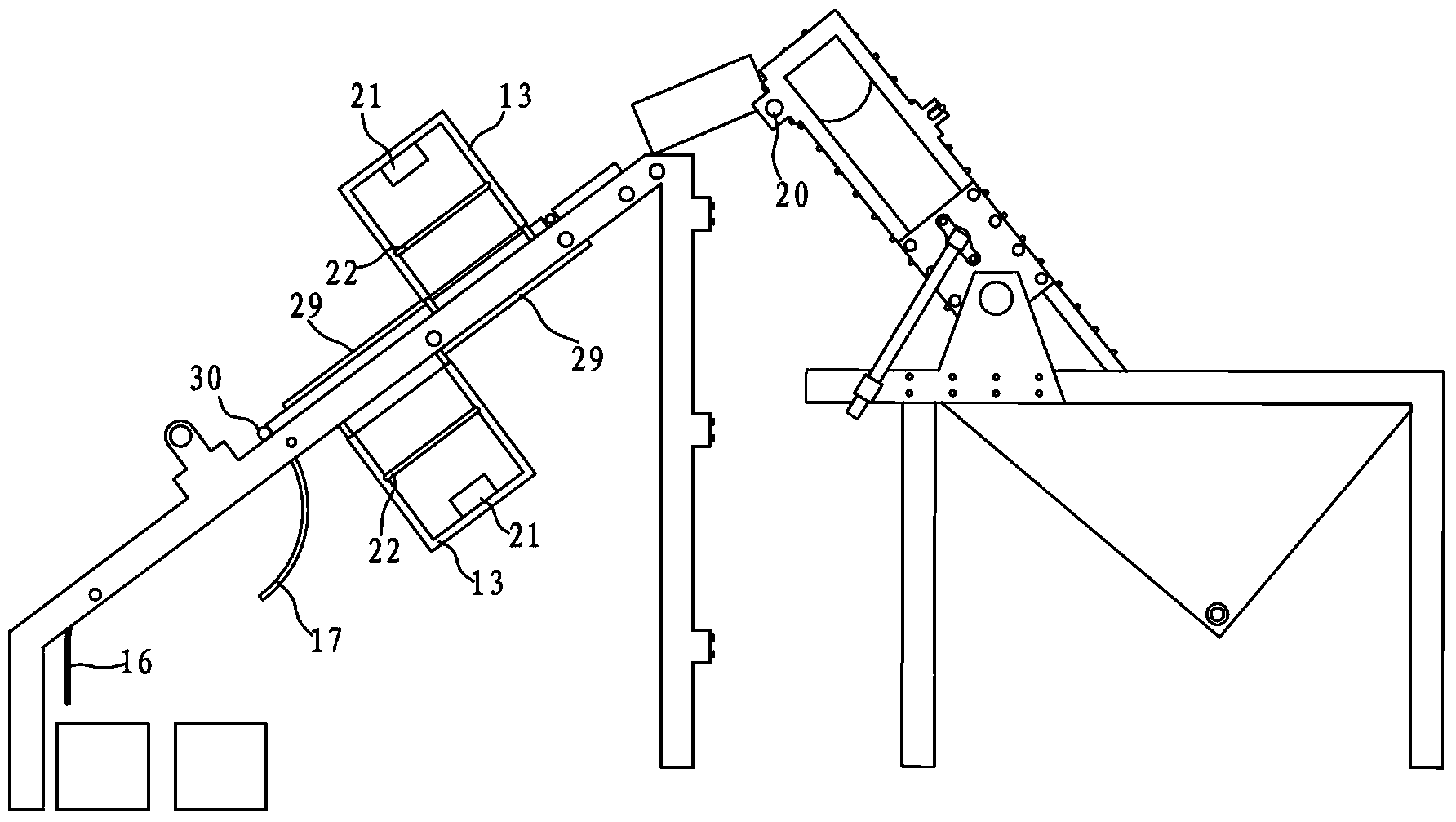

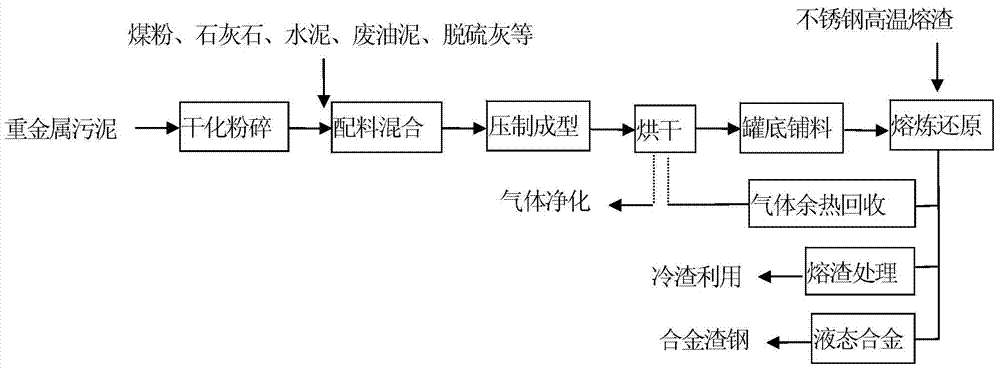

Method for treating heavy metal sludge by using stainless steel molten slag

InactiveCN104512988AIncrease productionIncrease temperatureSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeMetallurgy

The present invention discloses a method for treating heavy metal sludge by using stainless steel molten slag. The method comprises drying crushing, material matching mixing, pressing molding, drying, tank bottom material spreading, smelting reduction, gas purification, molten slag treating, metal recovery and other steps, and specifically comprises that: after heavy metal sludge is subjected to pre-treatment, a certain proportion of ingredients are matched, and the sludge agglomerate is adopted as the bottom spreading material and is placed into a stainless steel molten slag tank to carry out a harmless treatment on the sludge agglomerate. According to the present invention, the characteristics of high production amount, high temperature and rich sensible heat resource of the stainless steel molten slag are adopted, and the stainless steel molten slag is adopted to treat the heavy metal sludge, such that the harmless treatment on the hazardous components and the resource on the valuable material are achieved, the method is the new attempt crossing the industry, and the waste heat resource can be effectively utilized so as to achieve the waste treatment adopting the waste.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com