Patents

Literature

290results about How to "Solve the pollution problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

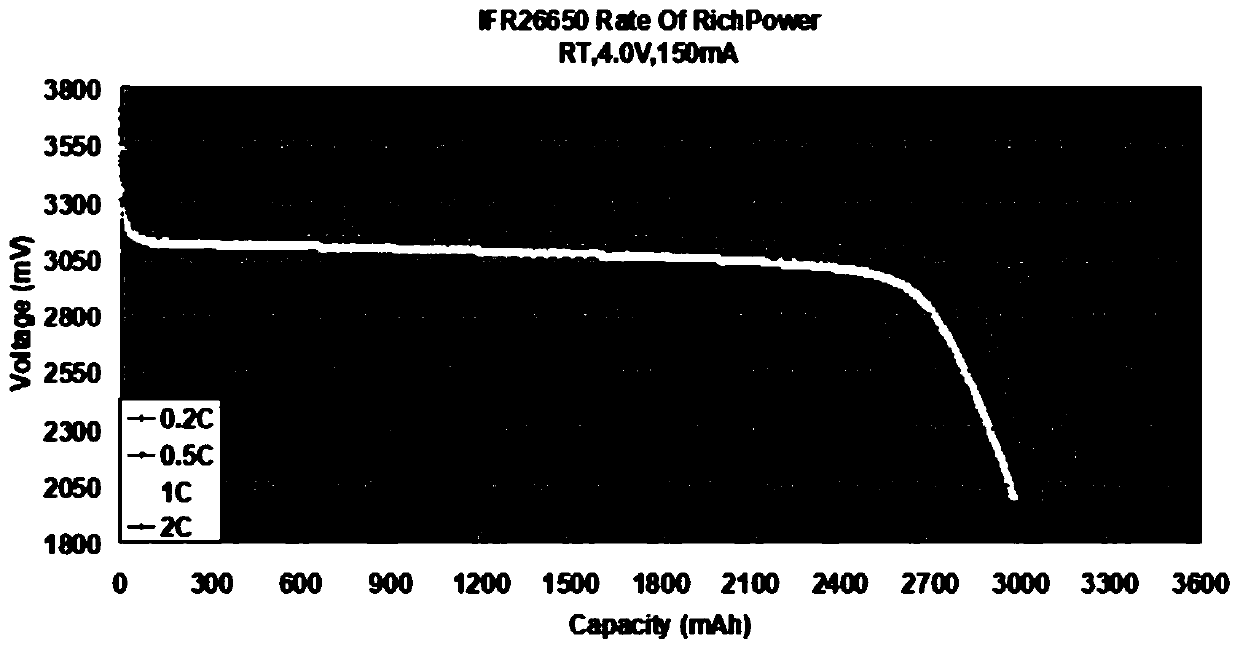

Rapidly degradable magnesium alloy material as well as manufacturing method and application thereof

ActiveCN104651691AModerate densitySolve the pollution problemFluid removalWell/borehole valve arrangementsEnvironmental resistanceSlag

The invention discloses a rapidly degradable magnesium alloy material. The material comprises the following components: elements such as Al, Li, Ca, Y, Si, Ni, Cu and Fe. The invention also discloses a preparation method and the application of the rapidly degradable magnesium alloy material. Compared with the prior art, the rapidly degradable magnesium alloy material has the advantages that the problems of failure in resisting high temperatures and failure in meeting high-temperature and high-bearing operation requirements of the existing easily degradable materials or easily degradable magnesium alloy materials and products thereof are solved, meanwhile, the material is controllable in density, the slag or the corrosion product of the material meets the requirements of flowback operations, and multiple technical effects of simplicity and high efficiency, low cost, energy conservation, environmental protection and the like can be achieved.

Owner:NINGBO HIGH NEW DISTRICT RONGCHUANG NEW MATERIAL SCI & TECH

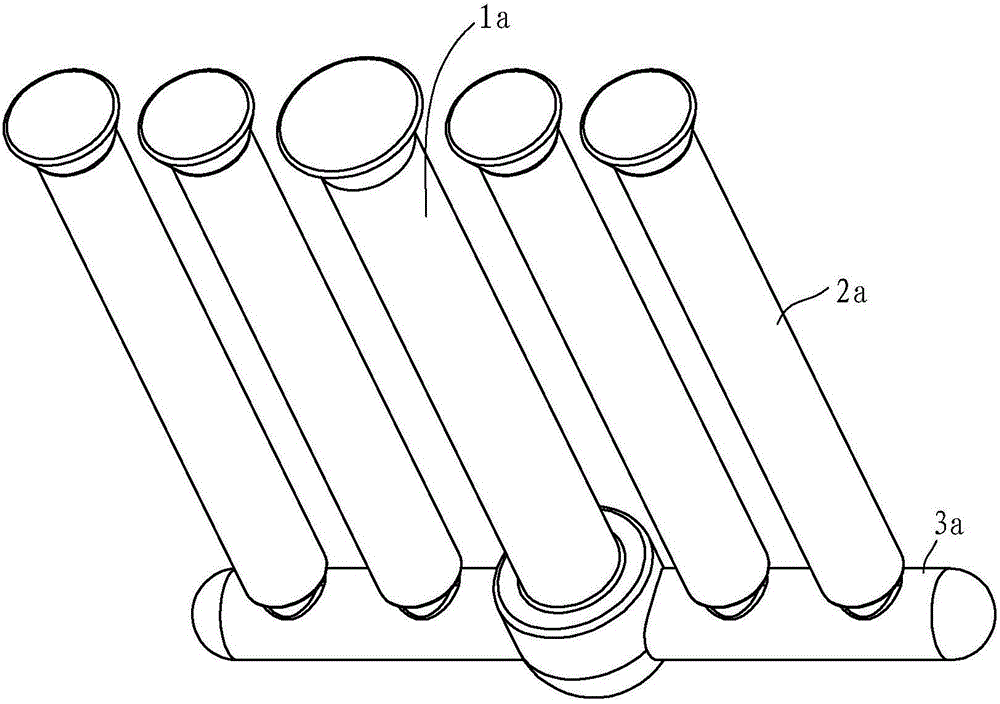

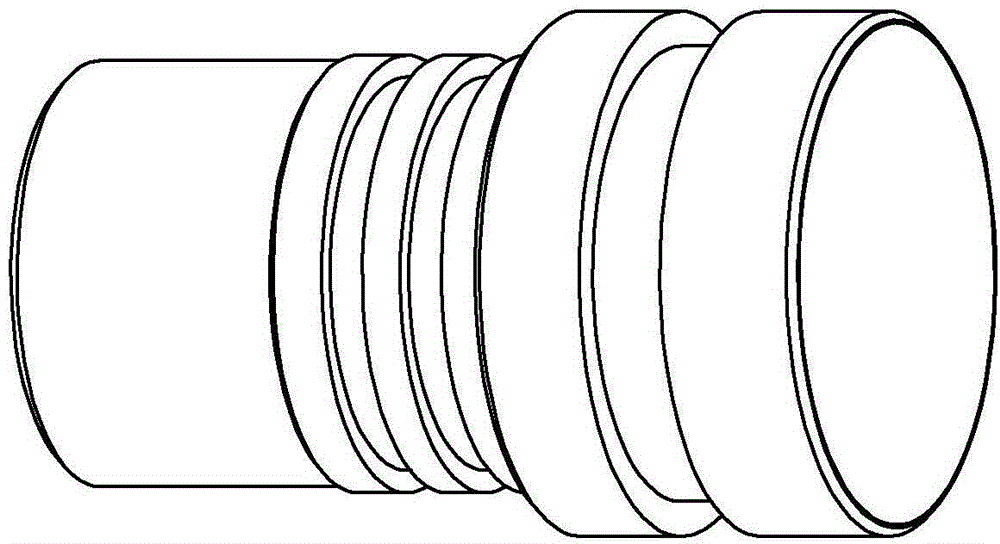

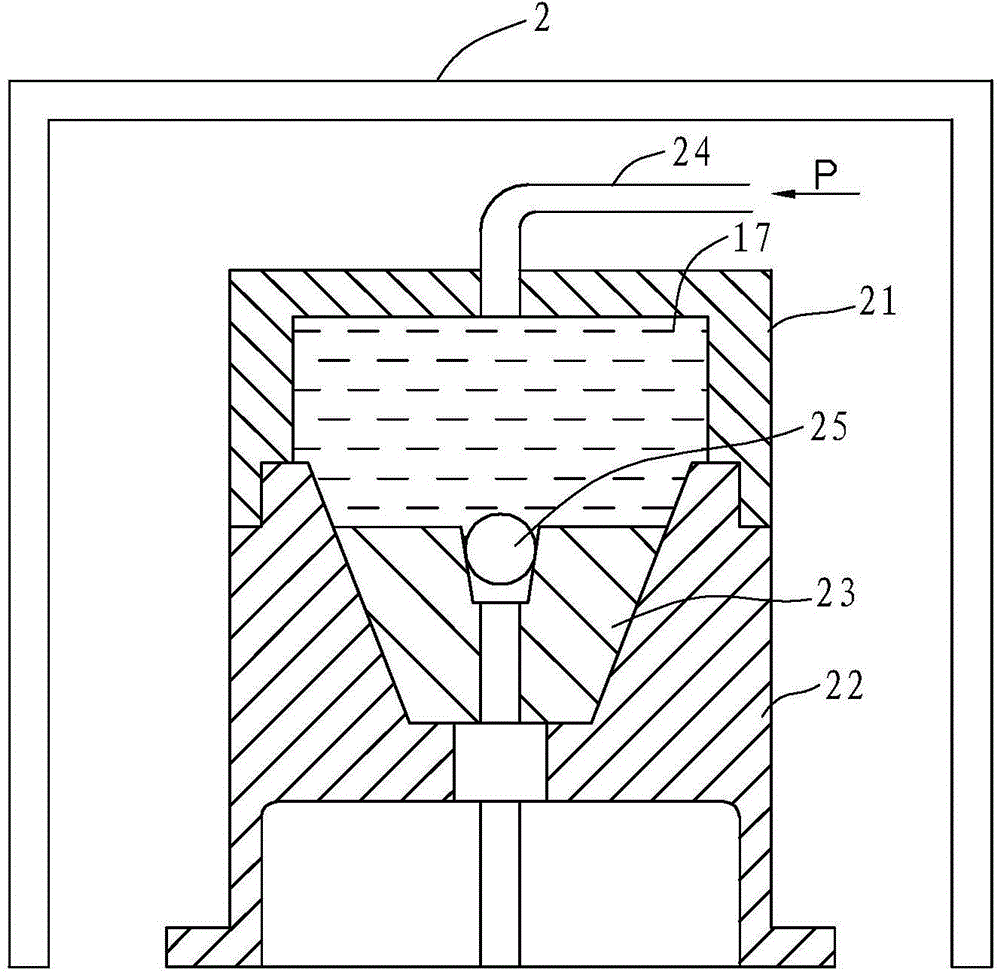

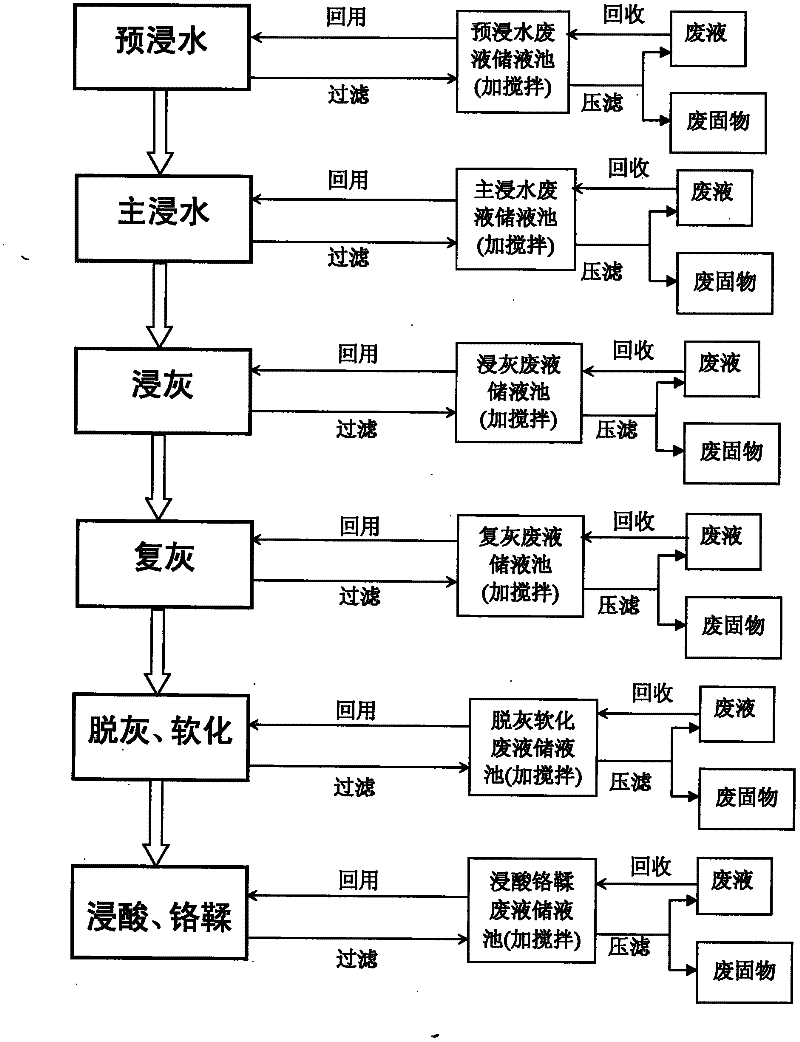

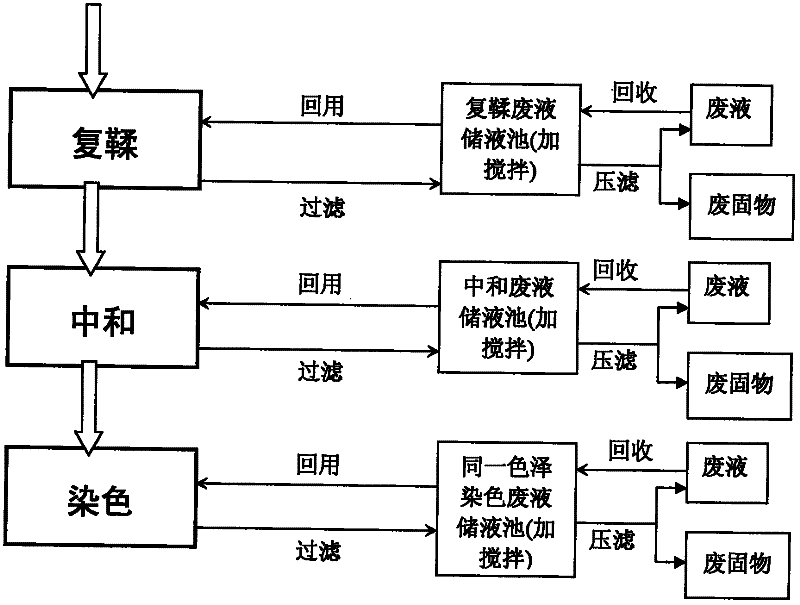

Tanning production process capable of recycling waste water repeatedly from soaking to dyeing

ActiveCN102534056AImprove firmnessHigh fullnessTanning treatmentPre-tanning chemical treatmentWastewaterSewage

The invention provides a tanning production process capable of recycling waste water repeatedly from soaking to dyeing, which is characterized in that waste liquid recycling is conducted in procedures of pre-soaking, main-soaking, liming, deliming and softening, pickling and chrome tanning, retanning, neutralizing and dyeing step by step, and waste liquid in all the procedures achieves full-closed circulation recycling. The technology is tested and verified in actual production in a tanning workshop of BIOSK (sq) Chemicals Co. Limited. The process achieves recycling of waste water from the pre-soaking to the dyeing, sewage discharging is greatly reduced, a problem of tanning pollution is solved thoroughly, quality of finished leather can be guaranteed simultaneously, loose side rate of the finished leather is effectively reduced, degree of compacting and fullness of the finished leather is improved, chemical materials can be saved by 15% to 55%, for example, chromium powder is saved by 35% to 65%, partial chemical materials can be saved by more than 90%, and exceptional chemical materials such as salt can be saved by 100%.

Owner:宝斯卡(商丘)化工有限公司

Method for linked producing ammonium acid fluoride and white carbon black

InactiveCN101028931AReduce manufacturing costSolve the pollution problemSilicon oxidesAmmonium halidesSal ammoniacCarbon black

A process for preparing ammonium hydrogen fluoride and white carbon black simultaneously includes such steps as fast reaction between fluorosilicic acid (or ammonium fluorosilicate) and ammonia water to obtain the crystal seeds of white carbon black, adding water, fluorosilicic acid (or ammonium fluorosilicate) and ammonia water, reacting while controlling pH=8-9 to obtain the slurry of white carbon black deposit and ammonium fluoride solution, filtering, washing to obtain white carbon black paste and ammonium fluoride solution, and respectively preparing white carbon black and ammonium hydrogen fluoride from them.

Owner:DO FLUORIDE CHEM CO LTD

Processing technique for oil-contaminated water and equipment thereof

InactiveCN101108761AChange natureMeet emission standardsMultistage water/sewage treatmentWater/sewage treatment by neutralisationElectrolysisOil field

The oily sewage disposal process and the equipment are provided, which relates to the oily sewage disposal equipment and the process in the oil field operation. The equipment comprises a processor chamber, an acidizing fluid tank, an oxidized fluid tank, a lye tank and a controller; wherein, the processor chamber is communicated by a micro-electrolysis reactor, an Fenton reactor and a sedimentator in turns; the acidizing fluid tank is connected with a water inlet; the micro-electrolysis reactor is filled with fillers in the middle; the oxidized fluid tank and the lye tank are correspondingly connected with the Fenton reactor and the sedimentator; valves are provided at the entrance and exit of each pipeline and each valve and a water pump are separately connected with the controller. The disposal process of the invention comprises the following steps: 1) micro-electrolysis reaction; 2) Fenton reaction; 3) sedimentation; 4) sedimentator effluent input clear water tank. The invention is an ideal choice for replacing the traditional nutshell filer with unamiable disposal effects and is characterized by small investment, long life, low operation cost and simple operation, which can effectively solve the difficulty of the oil field water pollution.

Owner:YANGZHOU UNIV

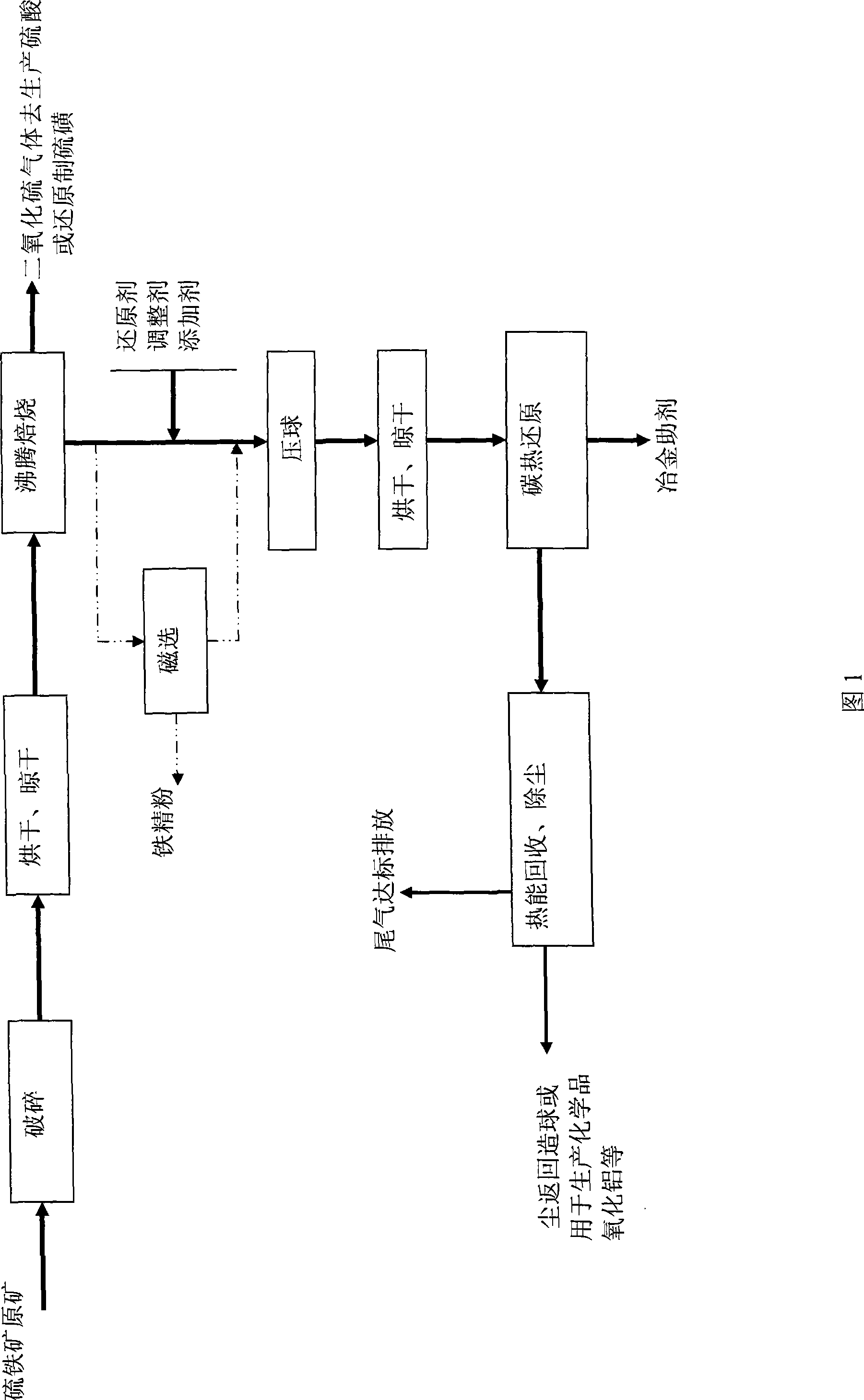

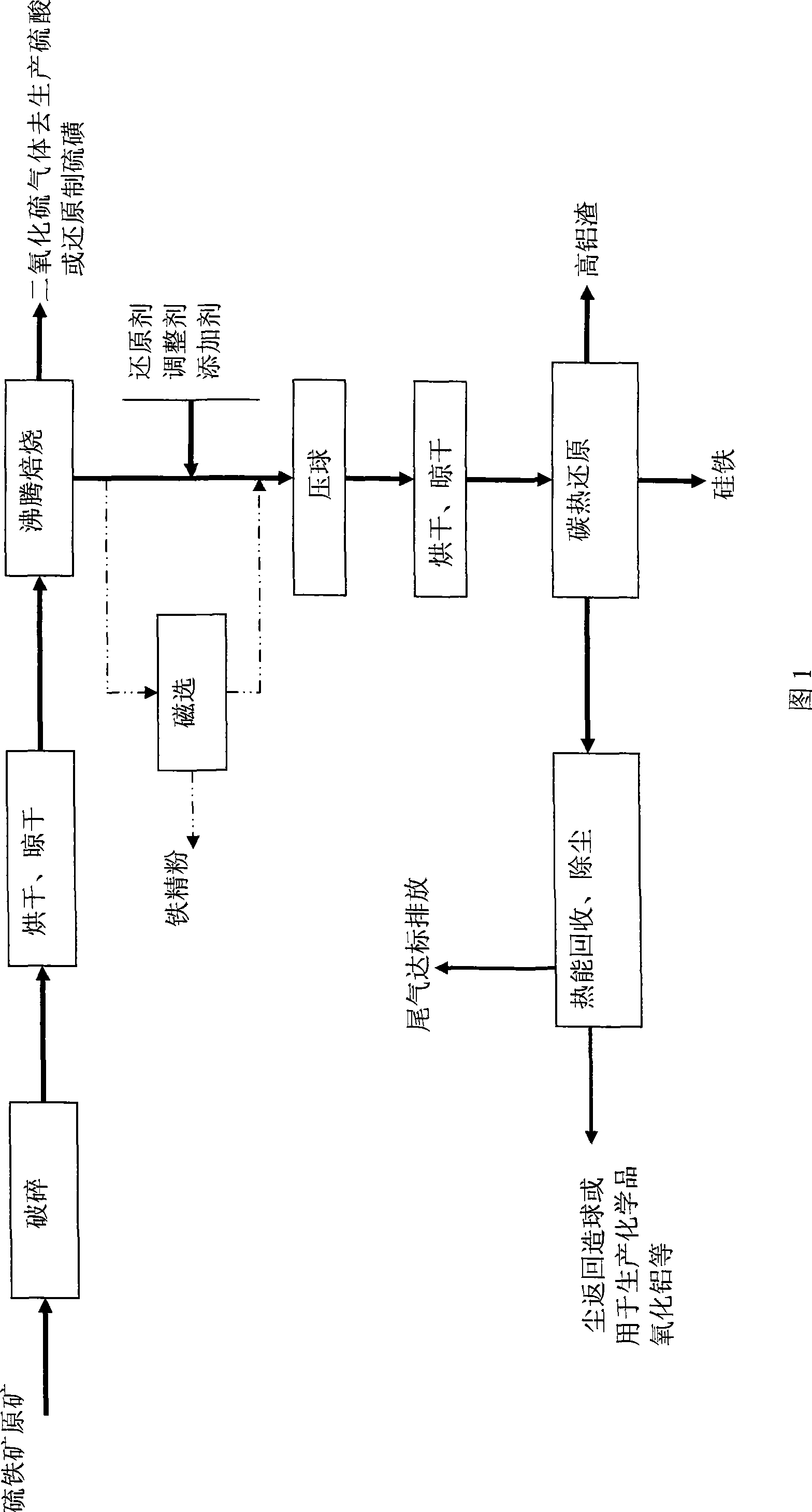

Comprehensive utilization method of middle and low grade ferro-sulphur ore

The invention discloses a comprehensive utilization method of middle-low grade pyrite. The method is characterized in that each layer of the pyrite is exploited, directly smashed and added to a fluidized bed furnace for roasting in the fluidized bed to obtain sulfur dioxide gas and cinder; the sulfur dioxide-containing gas is used for producing sulfuric acid or sulfur; component adjustment is carried out after iron ore concentrate powder is magnetically separated from the cinder, or carried out directly on the cinder by adding metallic mineral or non-metallic mineral according to the subsequent product and the fusion temperature; then, according to the mass of the monoatomic carbon which is needed to reduce each oxide in the adjusted cinder into the monoatomic metal by carbothermic reduction, a reducing agent which is 1.1-3 times of the mass is added; and a deoxidizer and a desulfurizer of high-quality metallurgical composite alloy are produced after reduction. The method solves the environmental pollution problem of the existing utilization technology and realizes each layer exploitation and cyclic comprehensive utilization of the middle-low grade pyrite.

Owner:云南常青树投资有限公司

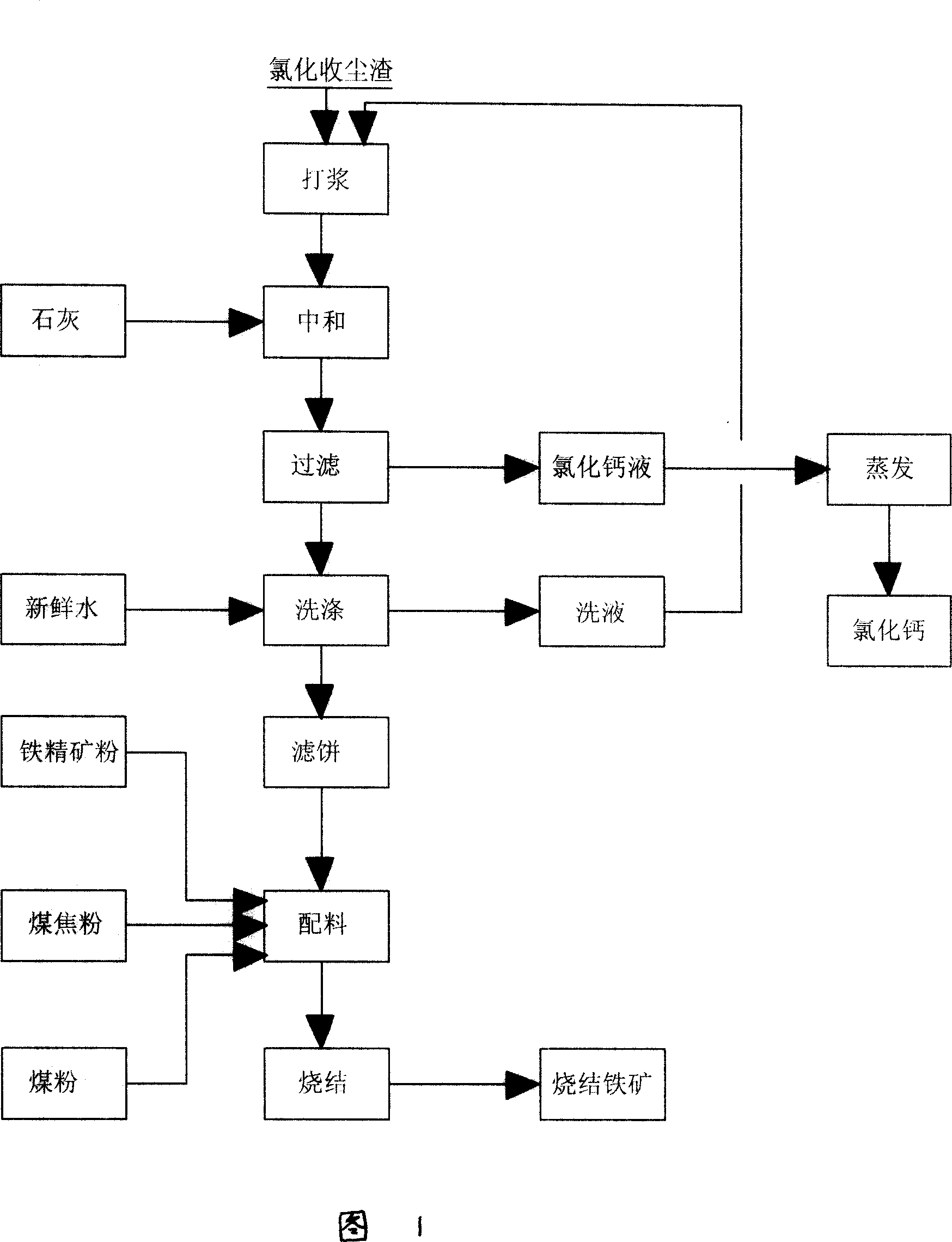

Treatment method of low grade titanium-riched material chlorination dust collecting slag

A process for treating the low-grade Ti-enriched metallic chloride dust collected in production of TiCl4 includes such steps as continuously mixing it with water while stirring to become slurry until the content of Cl radicals is 5-30%, neutralizing reacting with lime, filtering to obtain calcium chloride solution, evaporating for concentrating to obtain commodity, washing the filtered cake to obtain calcium chloride solution, and reusing it.

Owner:张清

Inorganic composite cementing material specialized for coal mine filling, and preparation method thereof

ActiveCN103553482AReduce manufacturing costReduce coal mine filling costsSolid waste managementIndustrial wasteToxic industrial waste

The invention discloses an inorganic composite cementing material specialized for coal mine filling, and a preparation method thereof. The inorganic composite cementing material is composed of the following raw materials: compound Portland cement or cement clinker, ordinary Portland cement, blast furnace slag micropowder, industrial waste gypsum, carbide slag, fly ash, an additive, citric acid and an excitant. The preparation method comprises the steps of drying all raw materials by a dryer; conveying the dried raw materials into a ball mill for milling; storing the dried raw materials in a raw material bin; conveying various raw materials to a mixer by a conveying melt; mixing uniformly; and then storing the mixture in a finished product warehouse. A filling paste provided by the invention can not be solidified or can be slightly solidified in 4 h and a slump degree is higher than 230 mm, can provide enough time for maintenance of filling equipment, prevents phenomena of tube plugging and waste tube caused by a long distance conveying pipe, can guarantee that mining work can be continuously carried out without mining column after demolding in 8 hours, increases mining output, increases resource mining rate, saves labor cost and increases production efficiency.

Owner:SHANDONG MASS ENERGY OF NEW MATERIAL

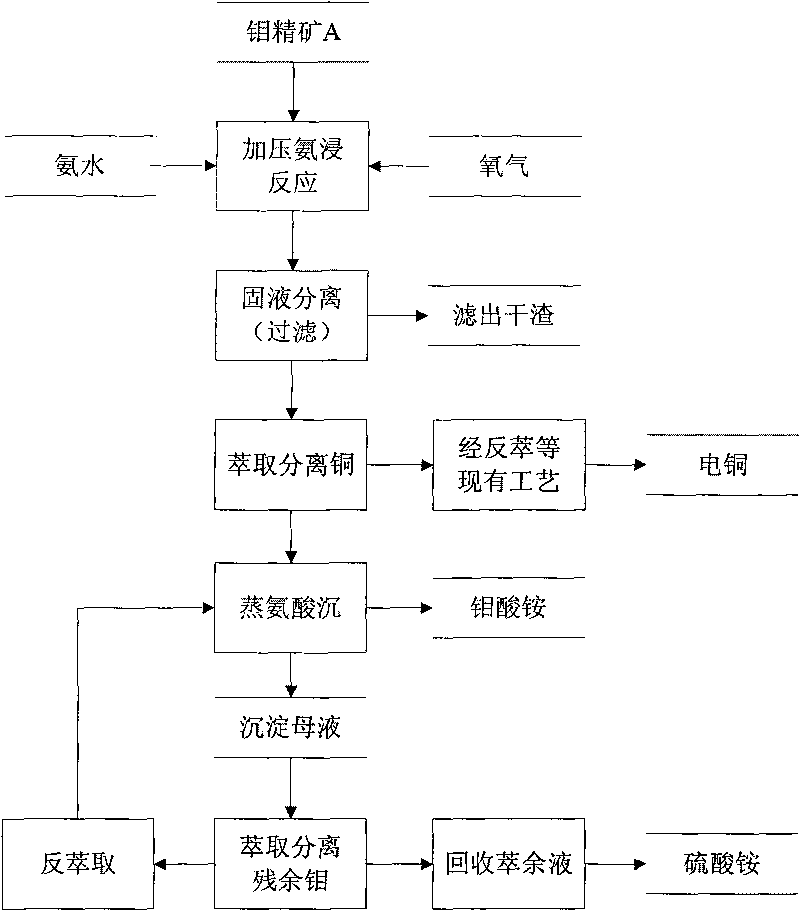

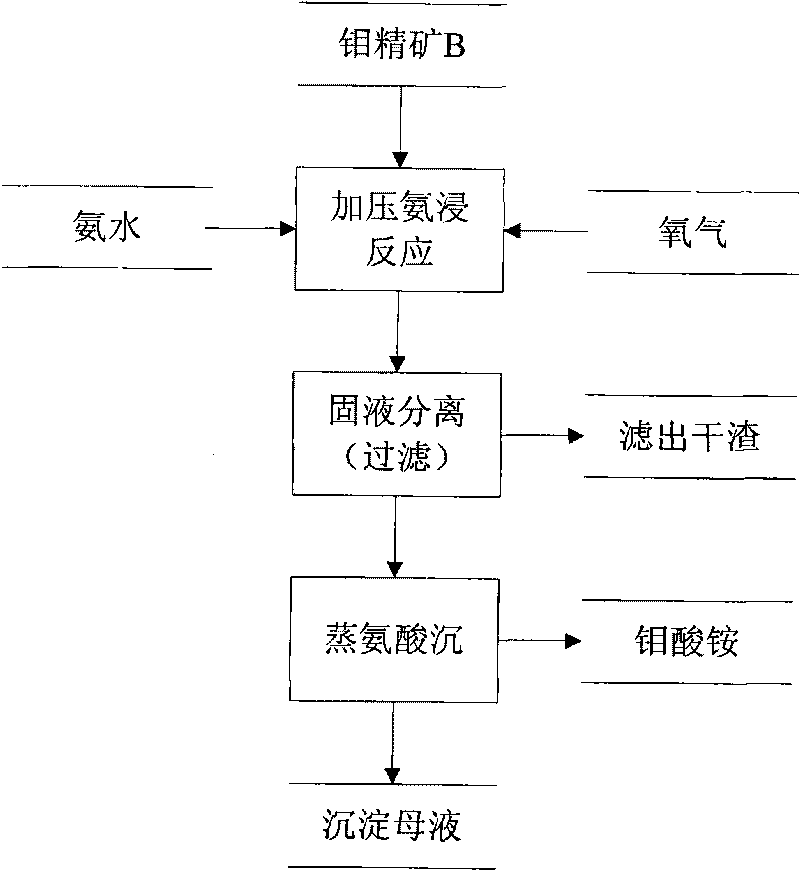

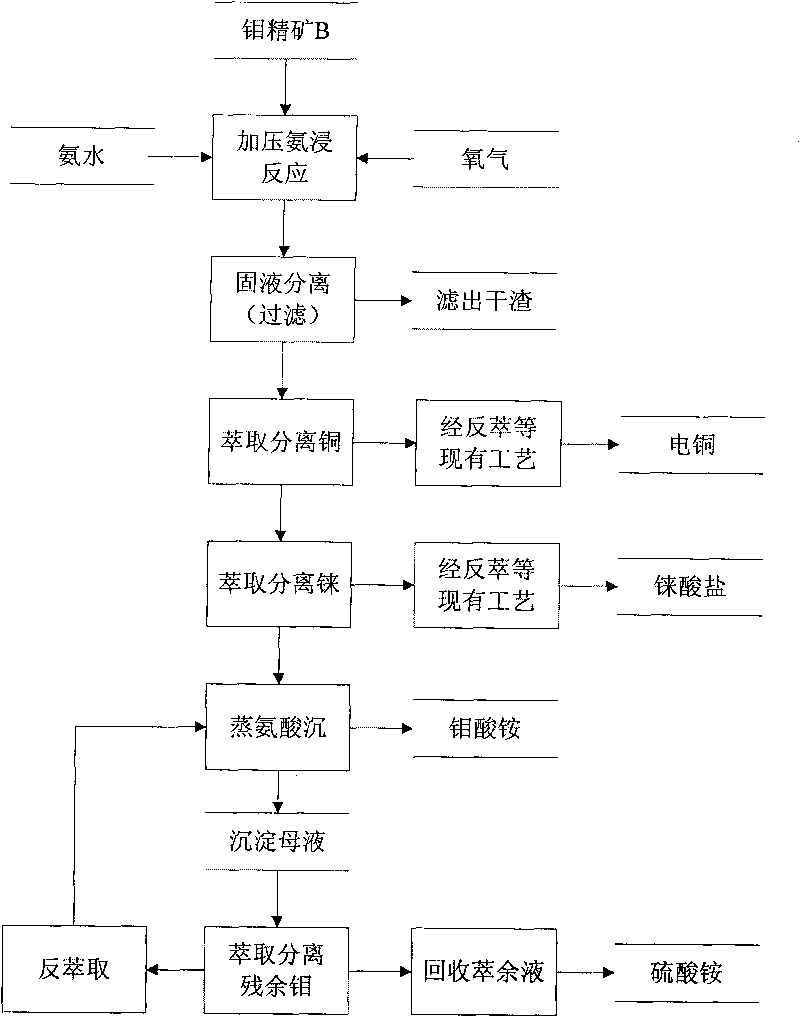

Method for extracting ammonium molybdate from molybdenum concentrate through pressure ammonia leaching

ActiveCN101736153ASolve the pollution problemConducive to the protection of the environmentPhotography auxillary processesMolybdeum compoundsSal ammoniacAmmonium molybdate

The invention discloses a method for extracting ammonium molybdate from molybdenum concentrate through pressure ammonia leaching. The method comprises the following steps: adding the molybdenum concentrate into an autoclave containing aqueous ammonia, introducing oxygen into the autoclave, performing pressure ammonia leaching reaction at the temperature of between 140 and 200 DEG C under the pressure of between 1.0 and 2.5MPa, filtering the ore pulp obtained after the reaction, evaporating ammonia from the filtered solution, acidifying and settling the filtered solution, filtering the solution and washing the sediment to obtain the ammonium molybdate. The method of the invention has the advantages of wide application range, low cost, environmental protection and safety, high comprehensive utilization rate of resources and the like.

Owner:安徽华西稀有金属材料有限公司

Method for treating 2-mercaptobenzothiazole production waste

ActiveCN102603668AChemically stableSolve the pollution problemAmino compound purification/separationSulfur compoundsEnvironmental resistanceDistillation

The invention discloses a method for treating 2-mercaptobenzothiazole production waste. The method comprises the steps of: heating the 2-mercaptobenzothiazole production waste to 90-95 DEG C, carrying out solid-liquid separation to obtain solid matter and liquid A, returning the solid matter to an accelerator M workshop, refining and purifying the solid matter to obtain a product accelerator M, distilling and separating the liquid A to obtain a fraction B and a fraction C, cooling residues in a distillation kettle to obtain asphalt-shaped matter D, absorbing hydrogen sulfide gas generated in the distillation separation process by using a sodium hydroxide solution to obtain a sodium hydrosulfide solution, concentrating the sodium hydrosulfide solution to obtain sodium hydrosulfide solids, rectifying and separating the fraction C to obtain aniline and benzothiazole. The method disclosed by the invention is capable of realizing the resourceful treatment of the 2-mercaptobenzothiazole production waste and has the advantages of various by-products, good product quality, simpleness in process flow, easiness in operation, mildness in reaction condition, low production cost and is environment-friendly.

Owner:HEBI HENGLI RUBBER PLASTIC CO LTD

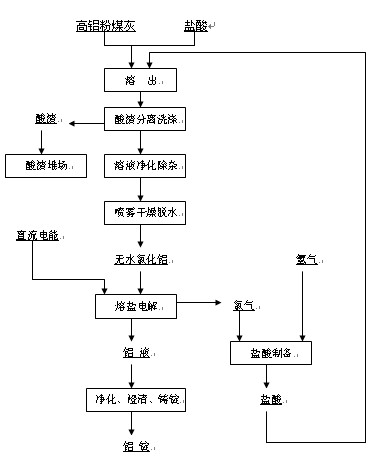

Process method for producing metal aluminium by high-alumina fly ash

ActiveCN102642857AReasonable useSolve the pollution problemAluminium chloridesProcess efficiency improvementAluminium chlorideElectrolysis

The invention discloses a process method for producing metal aluminium by high-alumina fly ash, which comprises the following process steps: firstly, dissolving fly ash out, that is, mixing high-alumina fly ash containing not less than 38% of Al2O3 with hydrochloric acid with a concentration of 20-30% to prepare raw pulp, dissolving out alumina in the fly ash at a high temperature through a continuous dissolving mode of heat insulation dissolution by a preheater and an autoclave; secondly, separating and washing acid sludge, and purifying an aluminium chloride solution for impurity removal; thirdly, performing spray drying and dehydration to obtain anhydrous aluminium chloride crystal particles; fourthly, electrolyzing the molten salts, that is, adding the anhydrous aluminium chloride into an aluminium chloride electrolytic tank, dissolving the anhydrous aluminium chloride in a molten electrolyte, wherein the temperature in the electrolytic tank is 670-700 DEG C, performing electrolyzation to obtain aluminium liquid, delivering the aluminium liquid to a casting procedure, performing purification and clarification, then preparing aluminum ingots, delivering the chlorine generated at an anode of the electrolytic tank to a hydrochloric acid preparation procedure; fifthly, preparing hydrochloric acid. The process of the invention obtains aluminum ingots by treating high-alumina fly ash, which make reasonable use of fly ash.

Owner:GUIYANG AL-MG DESIGN & RES INST

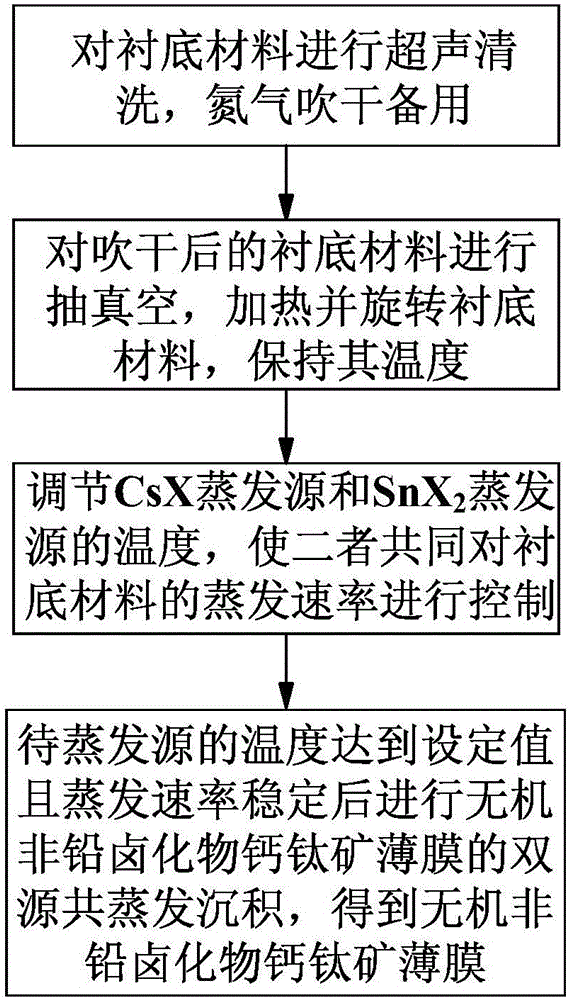

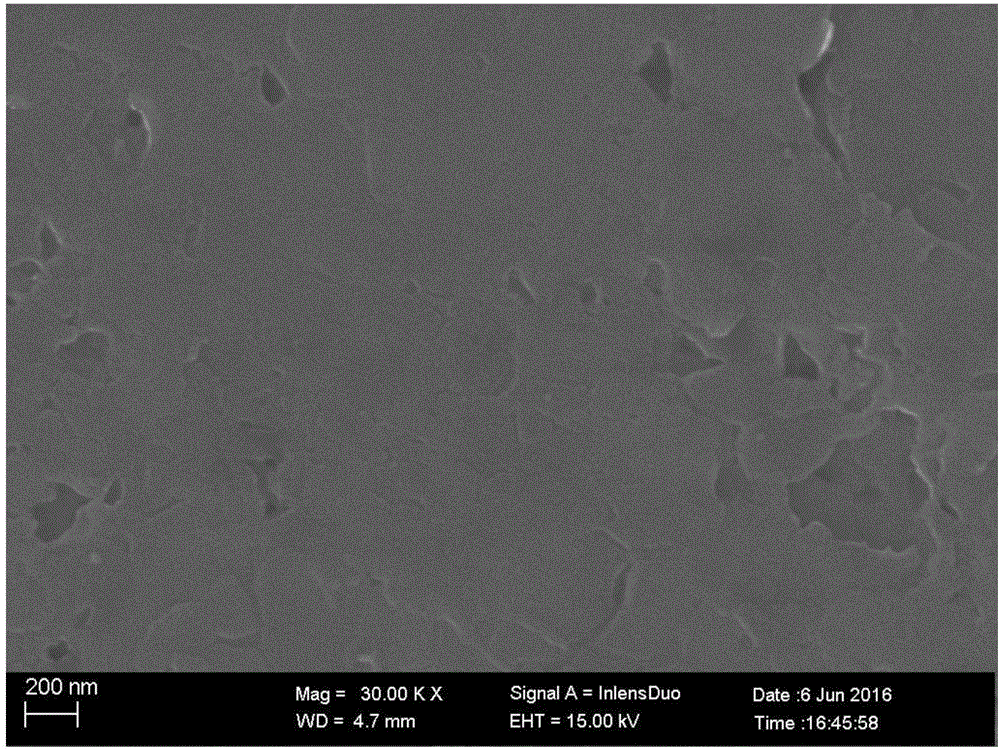

Method for preparing inorganic lead-free halide perovskite film by coevaporation

InactiveCN106282922AFix unstable performanceSolve the pollution problemVacuum evaporation coatingSputtering coatingSmooth surfaceNitrogen gas

The invention discloses a method for preparing an inorganic lead-free halide perovskite film by coevaporation. The method comprises the following steps: (1) carrying out ultrasonic cleaning on a substrate material, and blow-drying with nitrogen for later use; (2) putting the substrate material on a coevaporation plant sample holder, vacuumizing the vacuum chamber until the vacuum degree is less than 5*10<-4>Pa, heating and rotating the substrate material, and keeping the temperature; (3) regulating the temperatures of a CsX evaporation source and an SnX2 evaporation source so that the CsX evaporation source and SnX2 evaporation source control the evaporation rate of the substrate material together; and (4) after the temperatures of the evaporation sources reach the set values and the evaporation rates become stable, carrying out double-source coevaporation deposition of the inorganic lead-free halide perovskite film, and cooling to room temperature, thereby obtaining the inorganic lead-free halide perovskite film. The inorganic lead-free halide perovskite film has the advantages of high stability, low cost, smooth surface, fewer internal defects, technique repeatability, environment friendliness and no pollution, and is suitable for large-scale industrialized production.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

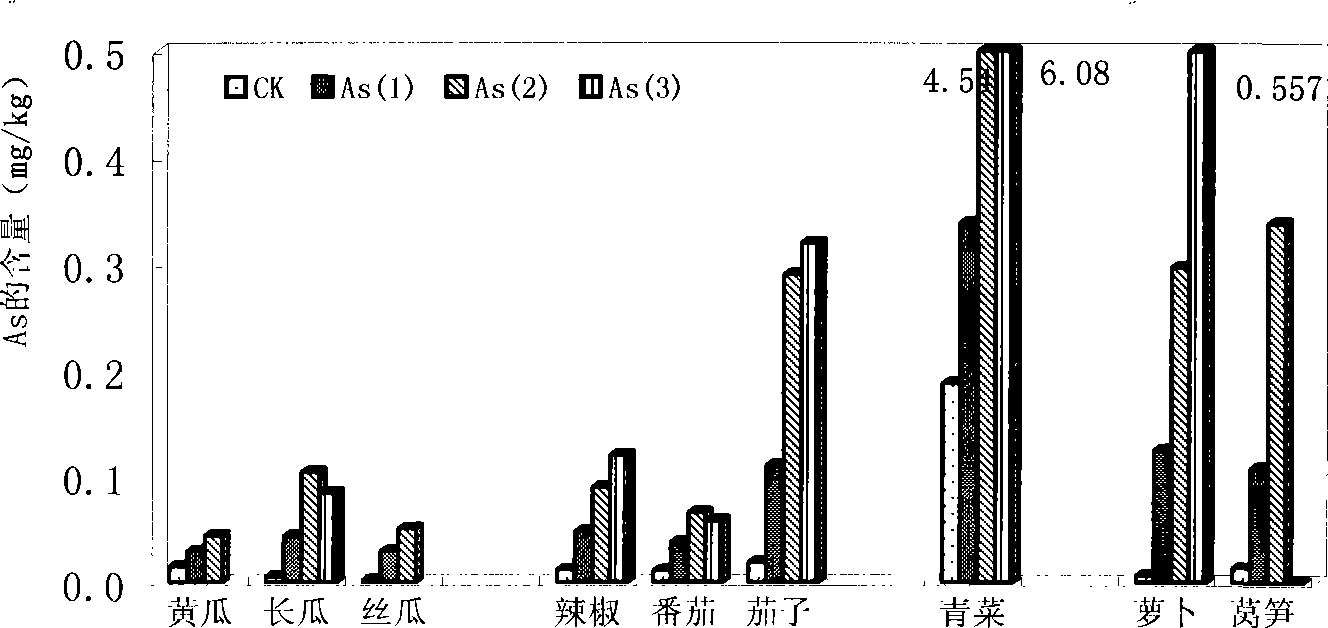

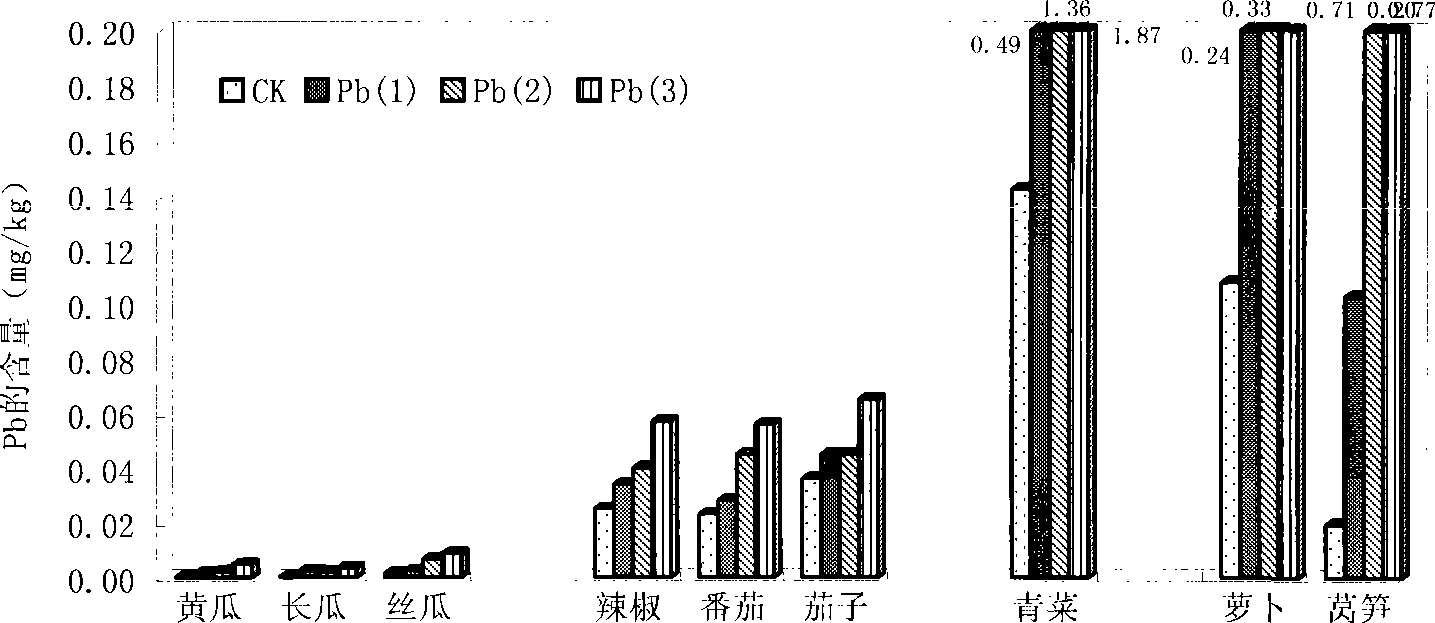

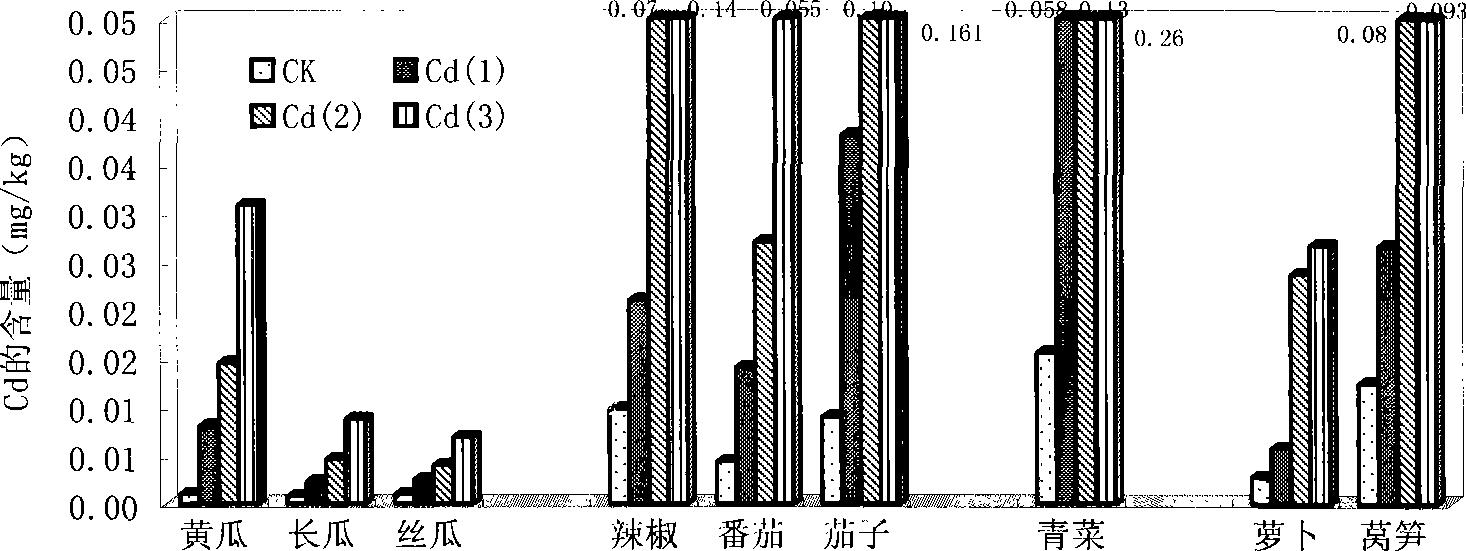

Screening method for heavy metal low accumulated and low enriched vegetable variety

The invention discloses a method for sifting a vegetable breed with low-accumulated / low-enriched heavy metals and belongs to the technical field of the quality safety of a farm product. The method comprises the following steps: (1) a potted plant mode is carried out in a greenhouse or a big shed; (2) sifting is carried out from four classes of vegetables, namely lefty vegetable, rhizome, solanaceous fruit and melon; (3) according to the limited values of the detected elements Hg, As, Pb and Cd for heavy-metal pollution in the vegetables regulated by the state and the concentration grads of 0 time, 0.5 time, 1.5 times and 4.5 times, heavy metals are added into potted soil manually; (4) vegetables are subjected to seedling, planting and management; and (5) the contents and the outputs of the heavy metals in an edible part of a product are mensurated; the product which meets the highest concentration treatment, has no marked reduction of average output per plantlet compared with the contrast and does not exceed the standard of the contents of the heavy metals is selected as the vegetable breed with low-accumulated / low-enriched heavy metals. The method has simple operation, wide applicability, economy and high efficiency, and can be popularized and applied to the departments of vegetable layout, planning and production.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Method for preparing protein filling material for leather preparation by using leather preparation chromium-containing leftover material as raw material

InactiveCN101260141ASolve the pollution problemIncrease added valueConnective tissue peptidesTanning treatmentScrapChromium

The invention provides a method for preparing protein fillers used for tanning by taking tanning chrome containing scrap materials as materials. The invention is characterized in that chrome containing scrap materials obtained from pieced wet blue are ground, and 100 portions by weight of chrome containing scrap materials are picked up and soaked in an alkali compound solution with the concentration of between 0.1 and 2wt percent, which at least submerges chrome containing scrap materials, for 10 to 48 hours, and the chrome containing scrap materials are drained, and the pretreated chrome containing scrap materials are put in a reaction kettle provided with a stirrer, a thermometer and a reflux condenser, and 6 to 20 portions by weight of alkali compounds and water at least submerging chrome containing scrap materials are added, and the reaction kettle is heated to a temperature of between 50 and 95 DEG C and keeps the temperature for 2 to 20 hours, and the thick liquids with deep color are obtained, and the pH value of the thick liquids is adjusted to between 7 and 10 by an inorganic acid after the thick liquids are cooled, and the thick liquids are filtered, and the filtrate with the solid content of between 10 and 20 percent, which is rich in containing collagen polypeptides, and the filter residues are obtained, and finally the protein fillers for tanning are obtained after the filtrate is condensed and dried; the filter residues are added with 100 to 150 portions by weight of water and has the pH value adjusted to between 2 and 3 by the inorganic acid solution, which obtains a Cr2(SO4)3 green solution used for the chroming agent.

Owner:SICHUAN UNIV +1

Furan resin for cast iron and synthesis method thereof

ActiveCN104262560AEmission reductionSolve the pollution problemFoundry mouldsFoundry coresPolymer scienceFurfuryl alcohol

The invention relates to a furan resin for cast iron and a synthesis method thereof. The invention is characterized in that the furan resin is prepared from the following raw materials in parts by weight: 60-80% of furfuryl alcohol, 5-15% of solid formaldehyde, 5-15% of urea, 0.2-1.0% of coupling agent and 5-10% of water. The solid formaldehyde is used instead of liquid formaldehyde in the synthesis process, thereby solving the problem of the sewage generated in the production process of the furan resin for cast iron; and the furan resin for cast iron has the characteristics of high strength, low viscosity, favorable molding-sand property and the like.

Owner:广西兰科资源再生利用有限公司

Fuel replacing coal of civil use and industrial use, and its prepn. process

A fuel as the substitute of coal contains X (40-80%), yellow clay (10-40%), water (5-25%), coal gangue (0-40%) and fly ash (0-40%). Said "X" is the compressed particles of biomass, organic life garbage, organic industrial dregs, or their mixture. Its preparing process is also disclosed. Its advantages are high heat value, long burning time and low cost.

Owner:范桂堂

Process for producing cement or cement products by metal tailings (skam)

InactiveCN1621378ASolve the pollution problemImprove resource utilizationSolid waste managementCement productionResource utilizationGypsum

The present invention is process of cement and cement product with skarn as one kind of metal tail ore, and converts skarn into useful resource. The cement producing process includes adding skarn in 10-35 wt% and gypsum dihydrate in 3-5 wt% into cement clinker to form mixture, and the mixture is milled to 180 mesh and to form the skarn cement. The present invention replaces skarn for partial traditional cement material to solve the pollution caused by skarn while providing cement production with new material.

Owner:河北中科环保有限公司

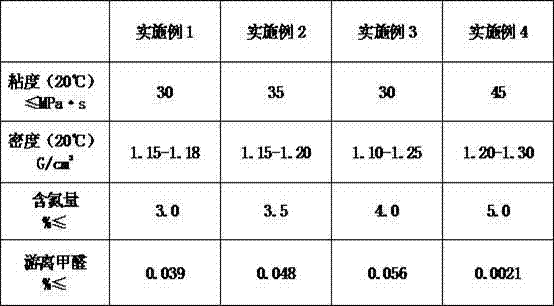

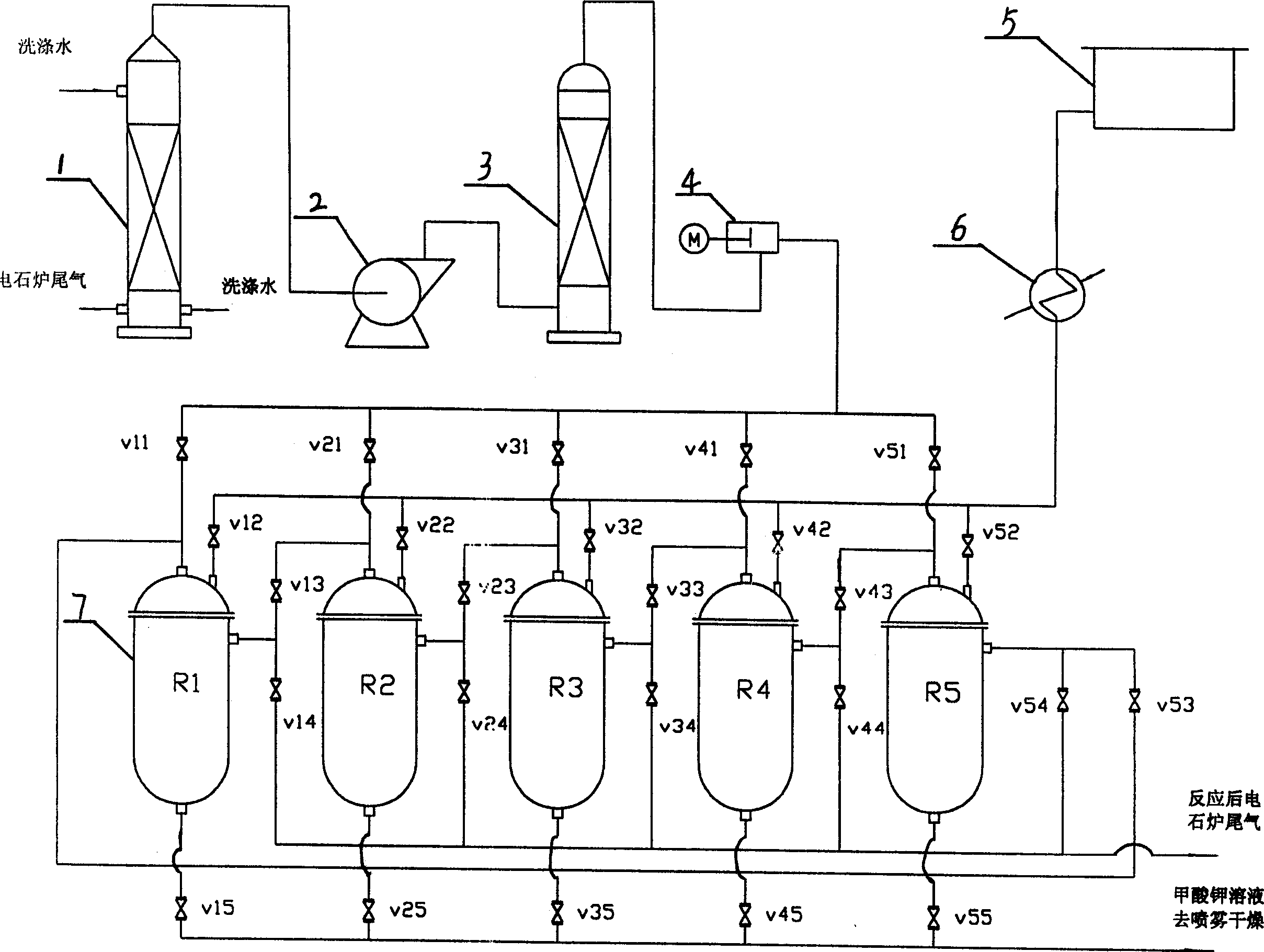

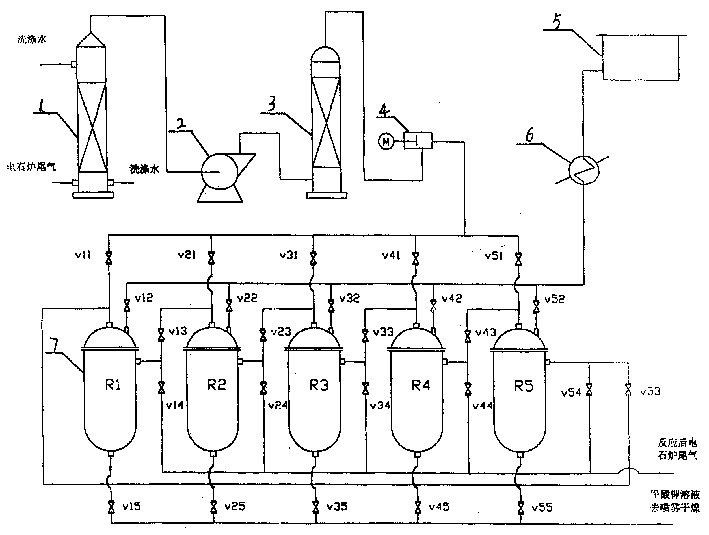

Method for preparing potassium formate and sodium formate from carbide furnace tail gas as raw material

InactiveCN1456546ASolve the pollution problemSolve pollutionCarboxylic acid salt preparationExhaust gasCalcium carbide

Owner:ALLY HI TECH

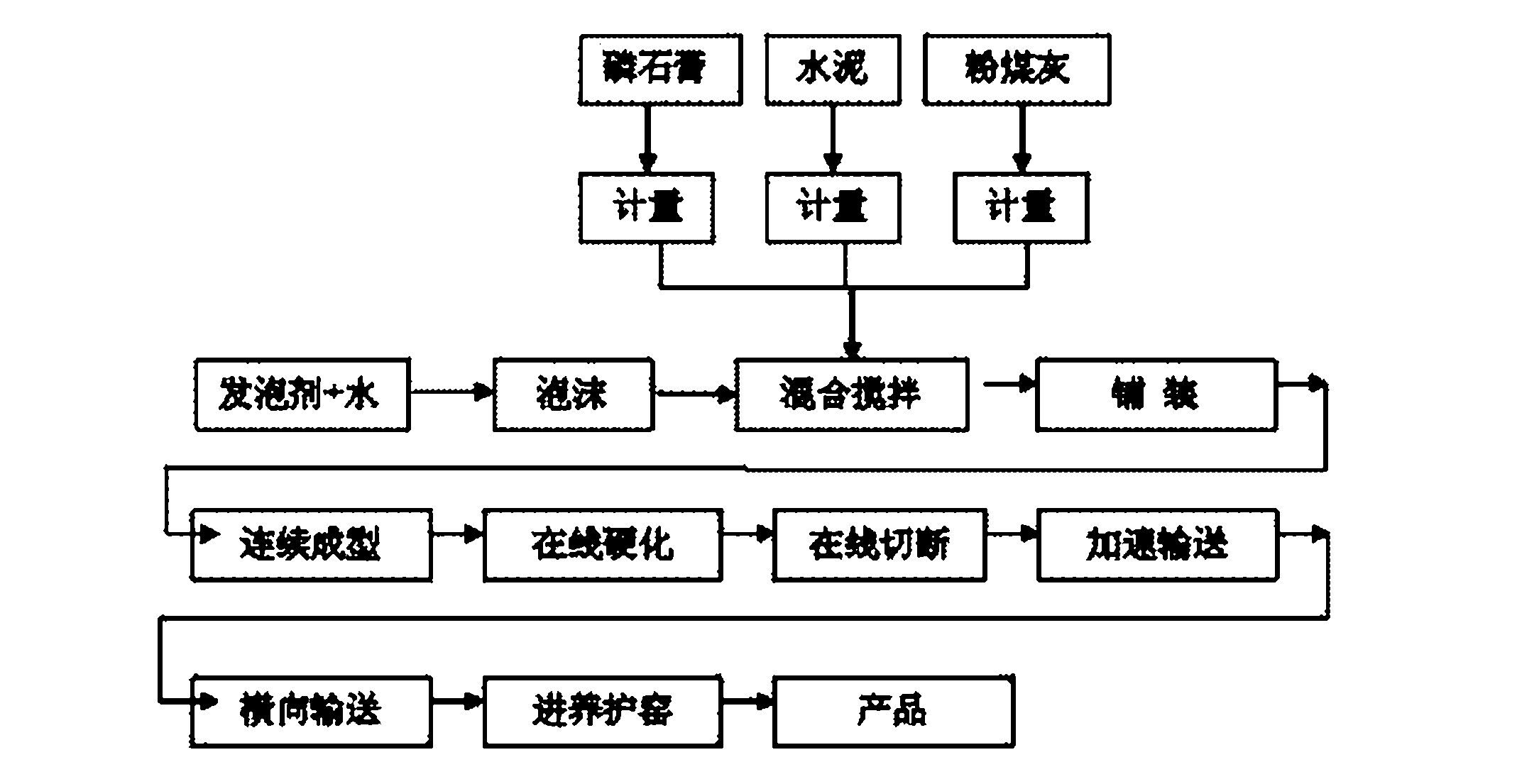

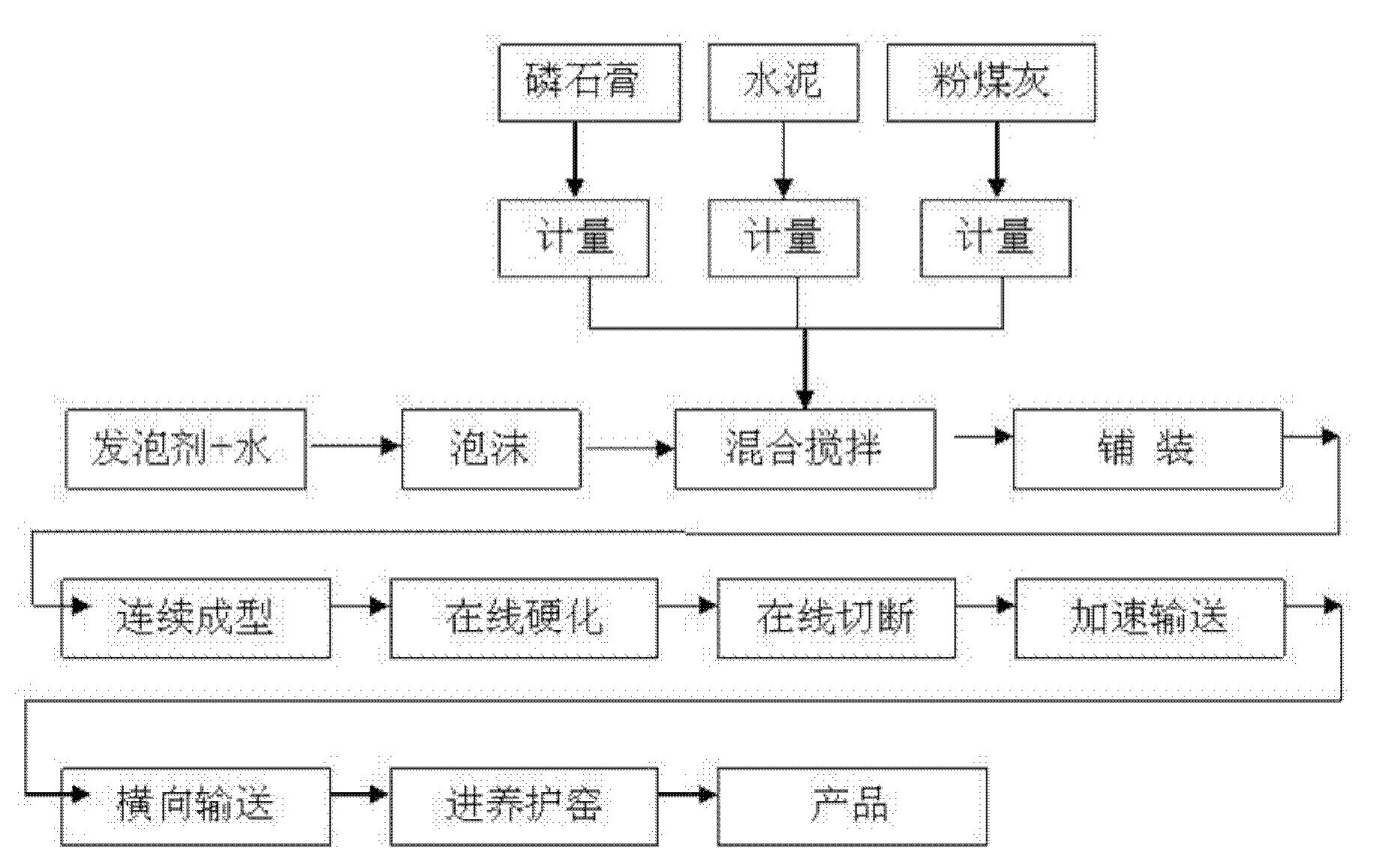

Building phosphogypsum powder thermal insulation material and preparation method thereof

ActiveCN102417369ALight weightLow thermal conductivityCeramicwareThermal insulationAdditive ingredient

The invention discloses a building phosphogypsum powder thermal insulation material and a preparation method thereof. The thermal insulation material comprises the following ingredients: 40-50 wt% of building gypsum powder, 10-15 wt% of cement, 8-13 wt% of fly ash, 1-2 wt% of foaming agent, and 30-40 wt% of water. The preparation method comprises the following steps: (1) putting building gypsum powder, cement, fly ash and other solid raw materials in a mixer for dry mixing, putting a mixture of water and foaming agent in the mixer, and stirring to form an uniform slurry; (2) injecting the prepared gypsum foamed slurry in a mould; and (3) demoulding and carrying out maintenance to obtain a finished product. The thermal insulation material has the following advantages: (1) low unit weight, low thermal conductivity, thermal insulation, and energy saving property; (2) functions of fire resistance, sound resistance, and air humidity adjustment; and (3) reduction of storage quantity of industrial waste residues.

Owner:LUXI CHEM GRP

Planting method for south ramulus mori bamboo fungus

InactiveCN104737782AFull of nutritionLong feeding periodHorticultureFertilizer mixturesNutrientShiitake mushrooms

The invention provides a planting method for a south ramulus mori bamboo fungus. The method comprises the following steps that A, ramulus mori is crushed; B, it is determined that the compost comprises 75-85 parts of ramulus mori scraps, 5-15 parts of corn flour, 2-4 parts of land plaster, 1-2 parts of magnesium sulfate, 1-2 parts of monopotassium phosphate, 1-2 parts of agar powder, 1-2 parts of vitamin B1; C, the compost is prepared; D, a greenhouse is established; E, spreading and seeding are carried out; F, planting management is carried out; G, fruiting management is carried out; H, harvesting at the right moment is carried out. Reasonable matching is carried out according to the biological characteristics of the bamboo fungus, the nutrition base prepared through the raw materials is abundant in nutrient, the constant nutrient feeding period is long, the growth and development of the bamboo fungus are facilitated, the mushroom cultivation period is shortened, the yield and quality are stable, and the ramulus mori resources are fully utilized.

Owner:象州县科学技术局

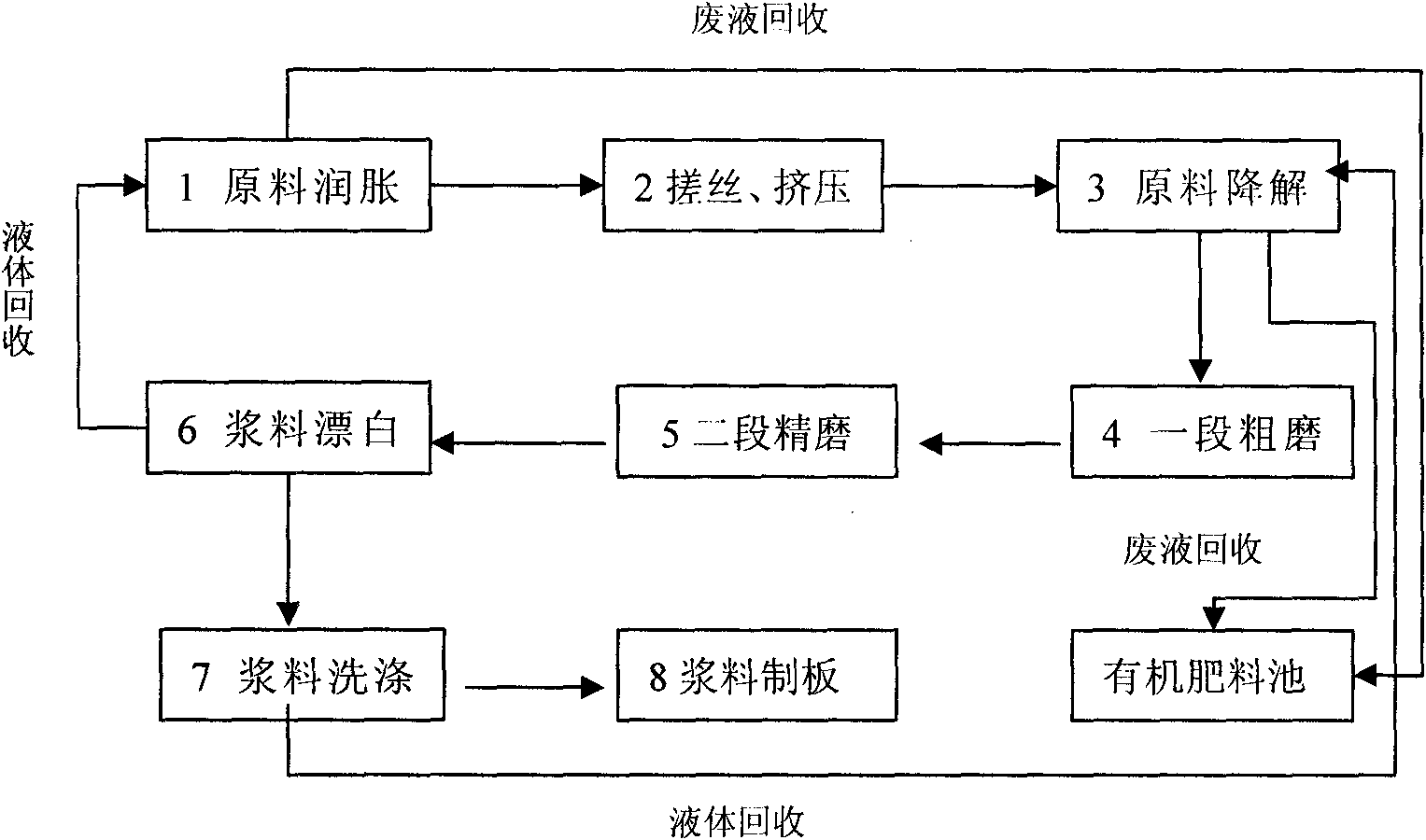

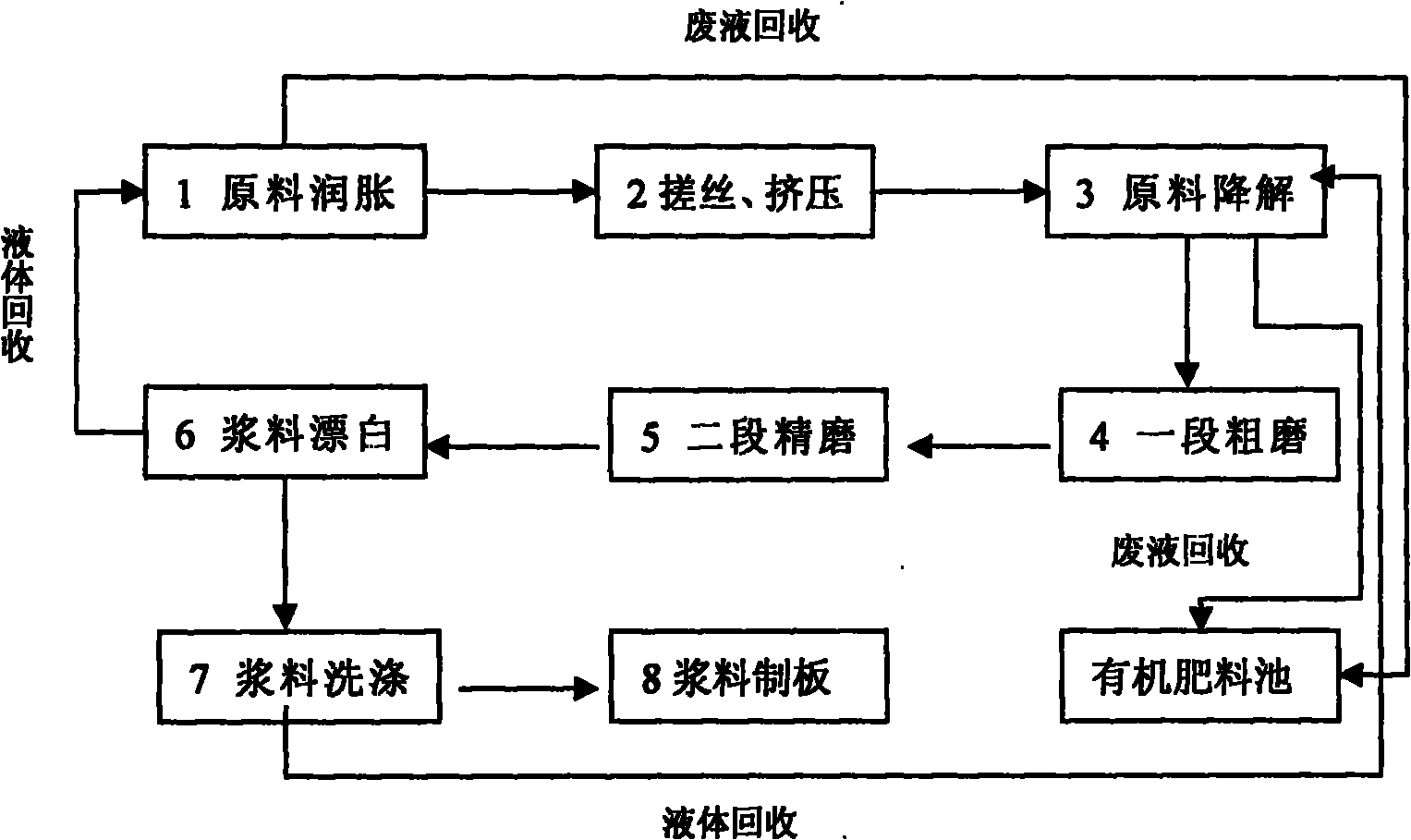

Mechanical pulping method for biological bacteria liquid

InactiveCN101792980ASuitable for productionSuitable for pollutionCellulose material pulpingRaw material divisionBiotechnologyPapermaking

The invention discloses a mechanical pulping method for biological bacteria liquid, and belongs to the field of papermaking and pulping. The main technical problem to be solved is that the waste liquor for pulping pollutes the environment. The method is that: compound bacteria serve as bacterial strains; the compound bacteria comprise white rot fungi, actinomycete, and methane bacteria in a mass ratio of 1-3: 1-3: 1; and the density of the mixed bacterial liquid is 60,000,000 / ml. The method comprises the following steps: degrading the raw materials with the mixed bacterial liquid after swelling, thread rolling and extrusion; grinding coarsely; grinding finely; bleaching or not bleaching; and washing the liquid to prepare the pulp. The method is mainly used for pulping herbal materials and has the advantages of no pollution or discharge of waste liquor in the pulping process, recyclable liquid, low production cost and simple process.

Owner:王福喜

Method for comprehensive utilization of middle and low grade ferro-sulphur ore and by-production of high-alumina slag and ferrosilicon

The invention discloses a comprehensive utilization method of byproduct high alumina slag and ferrosilicon of middle-low grade pyrite. The method comprises the following steps: each layer of the pyrite is exploited, directly smashed and added to a fluidized bed furnace for roasting in the fluidized bed to obtain sulfur dioxide gas and cinder; the sulfur dioxide-containing gas is used for producing sulfuric acid or sulfur; component adjustment is carried out after iron ore concentrate powder is magnetically separated from the cinder, or carried out directly on the cinder, by adding metallic mineral or non-metallic mineral; then, according to the mass of monoatomic carbon which is needed to reduce the ferrosilicon oxide in the adjusted cinder into the monoatomic metal by carbothermic reduction, a reducing agent which is 1.1-3 times of the mass is added; a deoxidizing agent ferrosilicon is produced after reduction; and reducing slag is discharged and cooled to obtain the high alumina slag which is used for producing chemical alumina, extracting gallium metal or being taken as a production raw material of aluminum factories. In the method, the utilization ratio of the sulfur can be improved by 40%-50% without waste slag and waste water produced by the pyrite concentrate, thereby solving the environmental pollution problem of the existing utilization technology; and all the components coexisting with the middle-low grade pyrite are fully used.

Owner:云南常青树投资有限公司

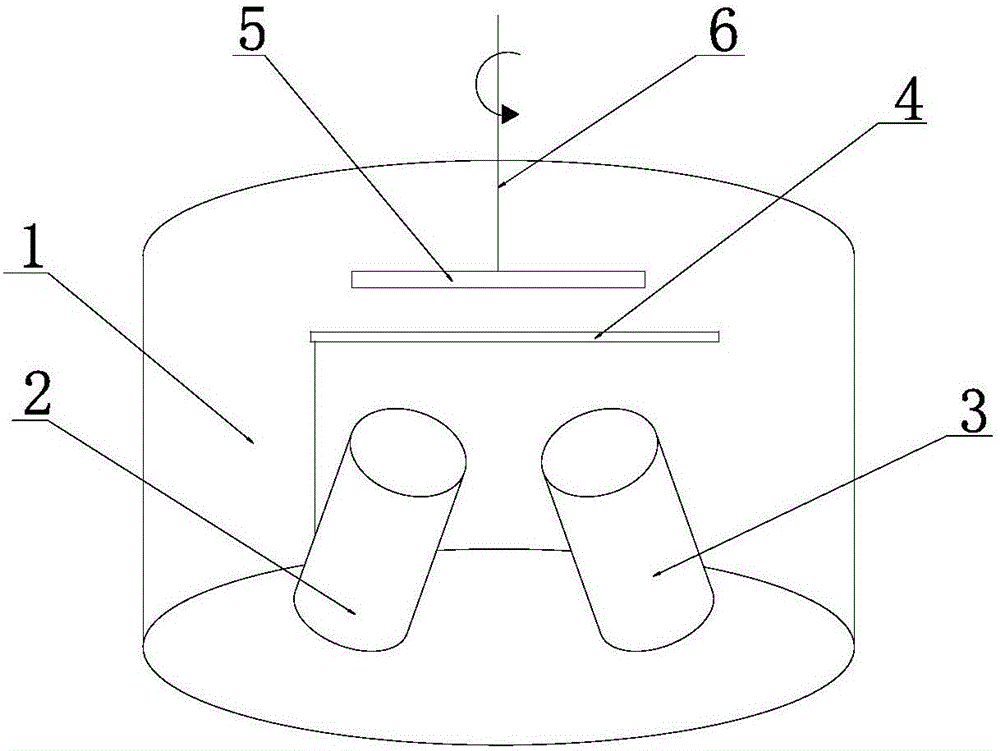

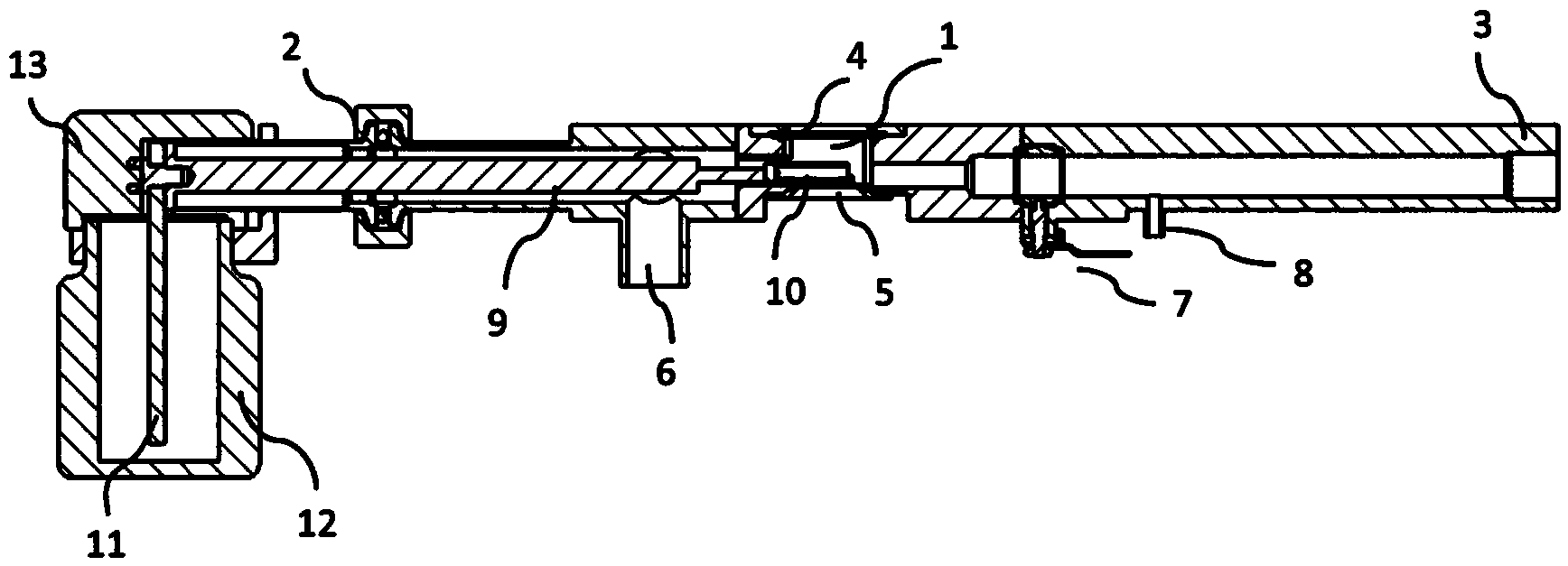

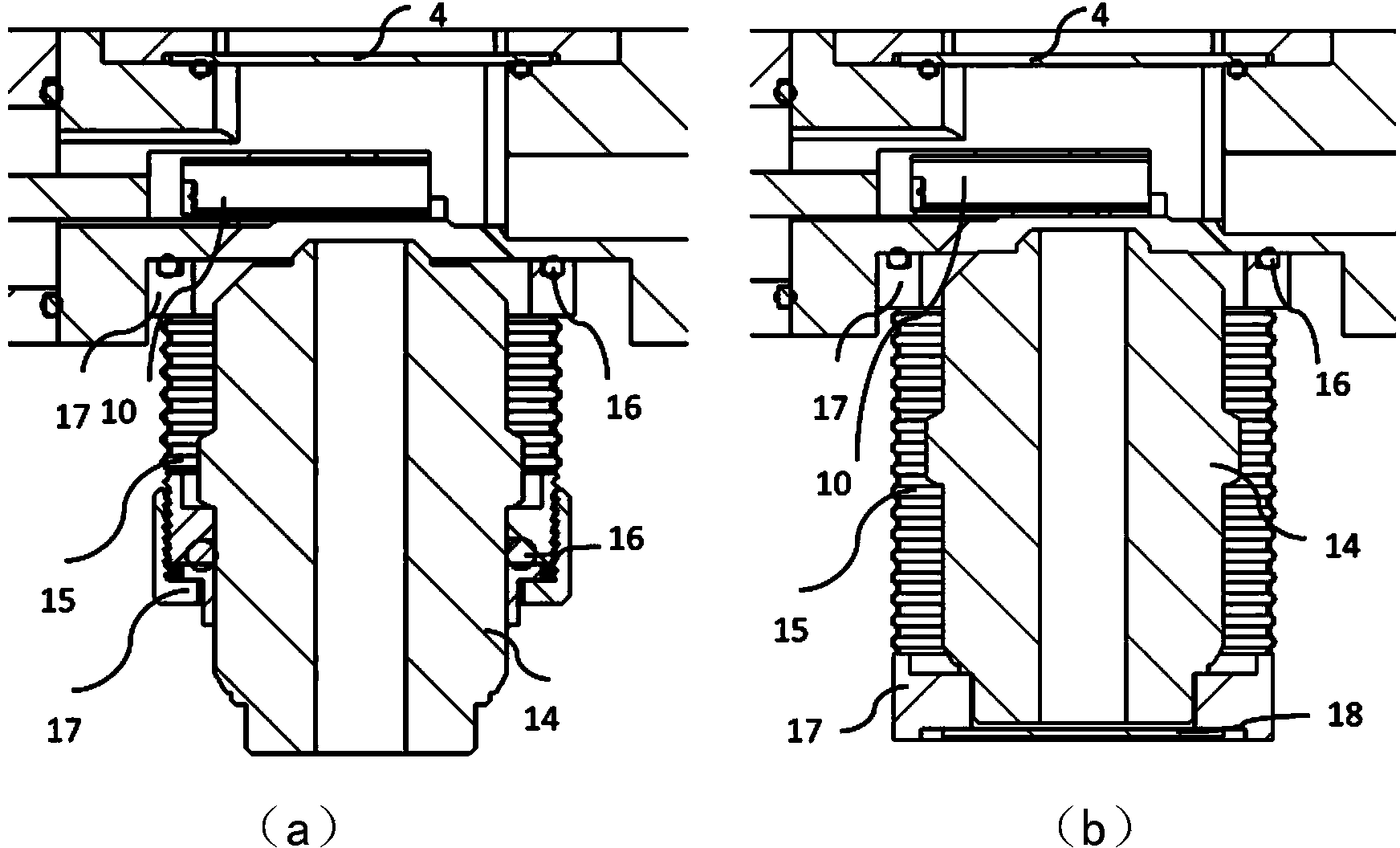

Optical vacuum cold station for light microscope and electron microscope correlated imaging

ActiveCN104142302AAvoid grid deformationSolve the pollution problemElectric discharge tubesMaterial analysis by optical meansOpto electronicMicroscope

The invention relates to an optical vacuum cold station for light microscope and electron microscope correlated imaging. The optical vacuum cold station comprises a vacuum chamber, an anti-pollution system adapter interface, an electron microscope sample lever adapter interface, an upper optical window, a lower optical window, a vacuum system adapter interface and a vacuum valve, wherein the anti-pollution system adapter interface is arranged in one end of the vacuum chamber, the electron microscope sample lever adapter interface is arranged in the other end of the vacuum chamber, the upper optical window is arranged in the upper wall of the vacuum chamber, the lower optical window is arranged in the lower wall of the vacuum chamber and opposite to the upper optical window, the vacuum system adapter interface is arranged in one side of the vacuum chamber, and the vacuum valve is arranged between the electron microscope sample lever adapter interface and the combination of the upper optical window and the lower optical window; a forvacuum channel is formed between the vacuum valve and the electron microscope sample lever adapter interface, and a forvacuum valve is arranged on one side of the forvacuum channel; vacuum seal rings are respectively arranged on the electron microscope sample lever adapter interface, the upper optical window, the lower optical window, the vacuum system adapter interface and the anti-pollution system adapter interface. The optical vacuum cold station can be widely applied to the light and electron correlated imaging and can also be applied to optical microscopic imaging independently.

Owner:INSITUTE OF BIOPHYSICS CHINESE ACADEMY OF SCIENCES

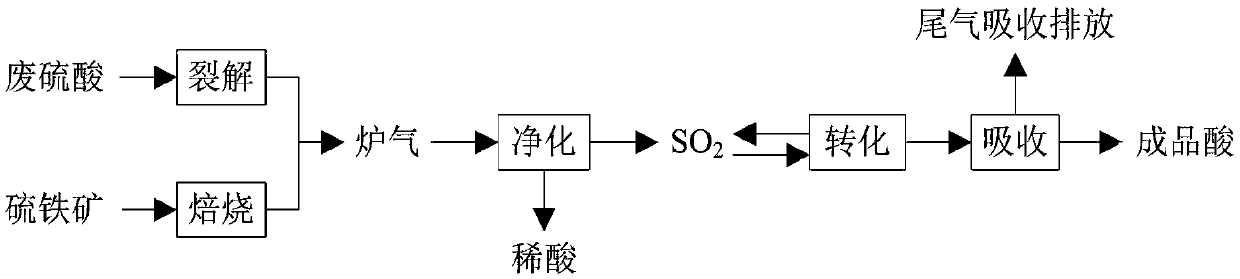

Process for processing waste sulfuric acid by virtue of pyrite acid-making roasting furnace

The invention relates to a process for processing waste sulfuric acid by virtue of a pyrite acid-making roasting furnace. The process comprises the following steps: heating the roasting furnace by virtue of external heat, adding pyrite into the roasting furnace to burn when the temperature reaches above 400 DEG C, adding alkylated waste sulfuric acid into the roasting furnace through an acid pump when the temperature reaches 850-1100 DEG C, maintaining the temperature at 850-1100 DEG C until the waste sulfuric acid cracks to produce SO2 gas at the high temperature, wherein organic matters are simultaneously burnt into CO2, and mixed gas and SO2 gas produced during the burning of the pyrite form furnace gas; cooling, washing, demisting and drying the furnace gas, so as to produce qualified SO2 furnace gas, and converting and absorbing the furnace gas, so as to obtain qualified sulfuric acid. According to the process, the cracking of waste sulfuric acid is realized by virtue of heat of materials on a boiling layer of the pyrite acid-making roasting furnace, and natural gas does not need to be used as a heating source, so that the cracking cost is greatly lowered; and by taking waste sulfur produced by peripheral factories as a combustion improver, the cracking capacity is improved.

Owner:李勇

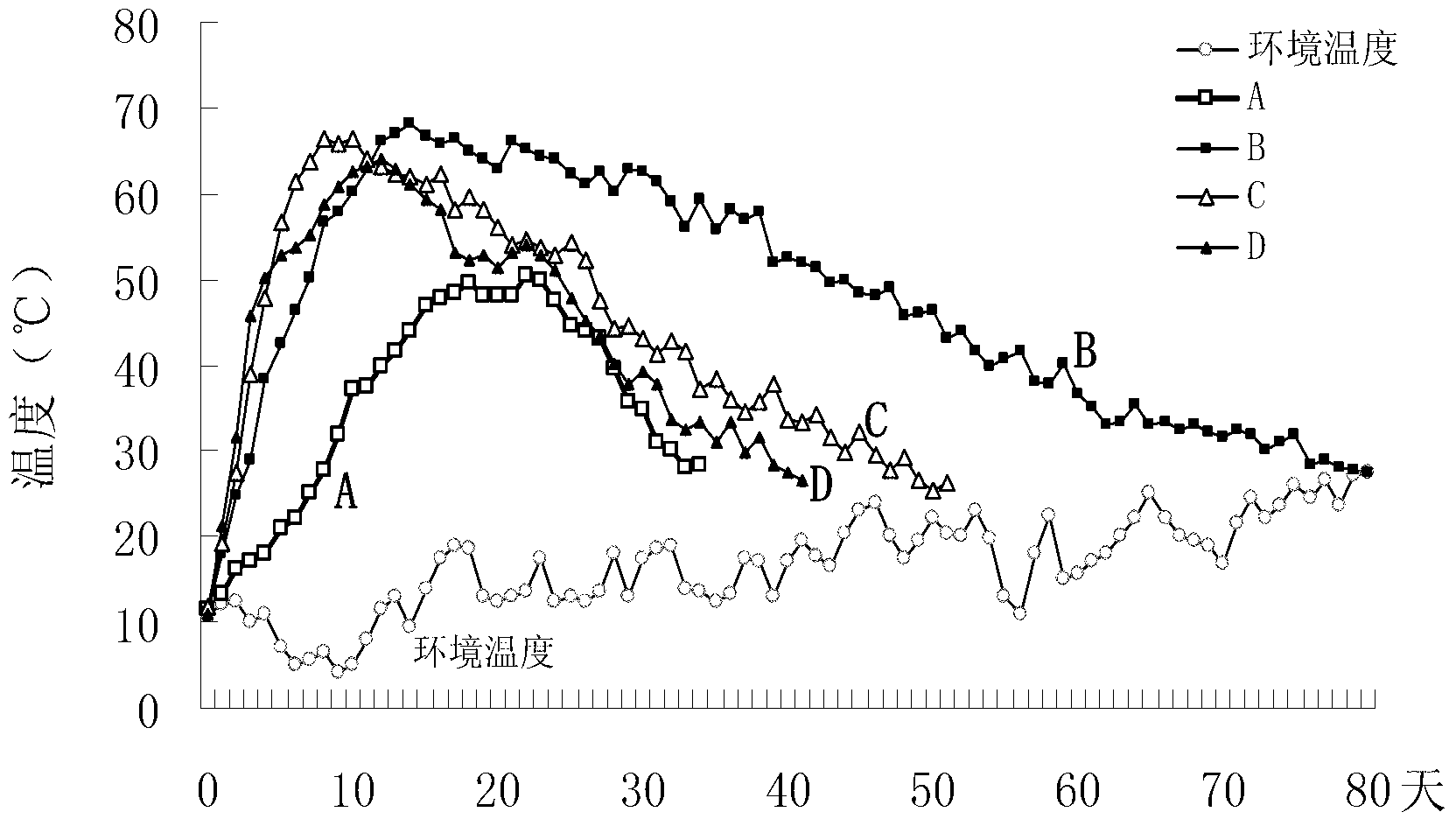

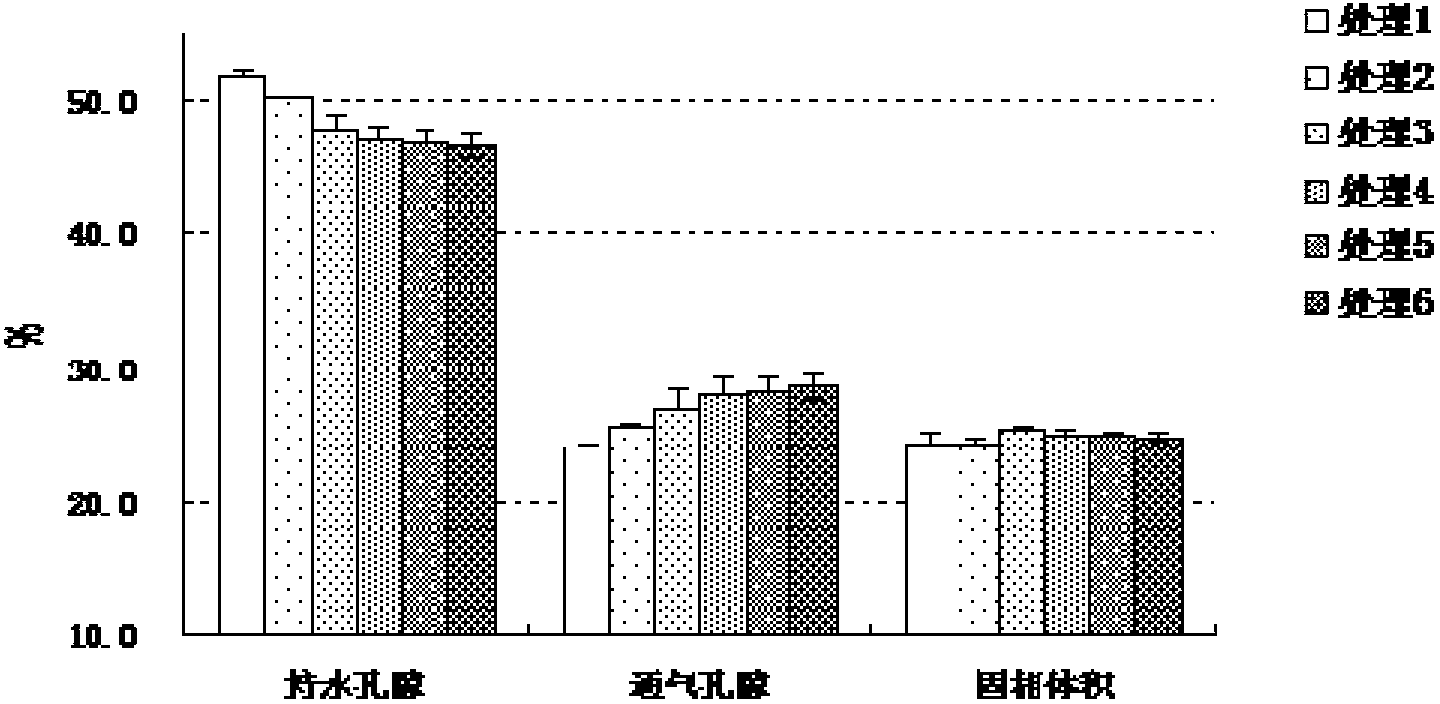

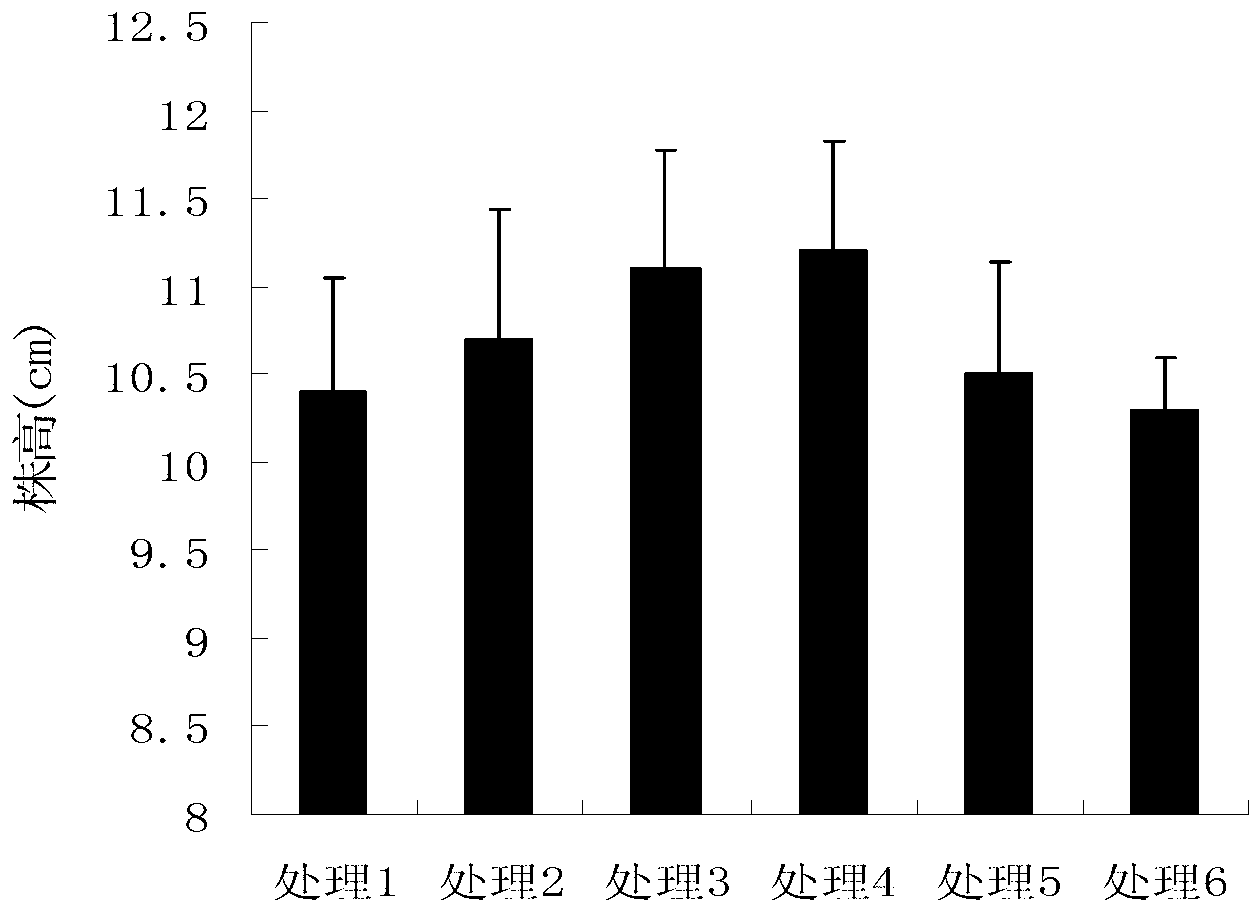

Vegetable seedling breeding matrix material made of hickory cattail husk and preparation method for vegetable seedling breeding matrix material

ActiveCN103193522AProtect peat resourcesSolve the pollution problemBio-organic fraction processingClimate change adaptationHickory nutSeedling

The invention discloses a vegetable seedling breeding matrix material made of a hickory cattail husk and a preparation method for the vegetable seedling breeding matrix material. The hickory cattail husk contains a plurality of alkaloid components and can kill or suppress survival or growth of other organisms; and the hickory cattail husk serving as the matrix material is mainly used in culture of the matrix at present. The vegetable seedling breeding matrix material made of the hickory cattail husk comprises the following raw materials in percentage by mass: 80 percent of hickory cattail husk, 5-10 percent of bean pulp and 10-15 percent of carbonized rice husk. The hickory cattail husk, the bean pulp and the carbonized rice husk are mixed and are subjected to stacking fermentation; and the obtained fermented product is subjected to solid and liquid separation by a screw extrusion method, so that alkaloid can be removed from the fermented product along with the liquid. Through fermentation, the alkaloid in the hickory cattail husk leaves out of the tissue and is removed through screw extrusion, so that the vegetable seedling breeding matrix material is formed; after the vegetable seedling breeding matrix material is mixed with other materials, a vegetable seedling breeding matrix can be formed; and the vegetable seedling breeding matrix material is suitable for large-scale production.

Owner:HANGZHOU JINHAI AGRI CO LTD +1

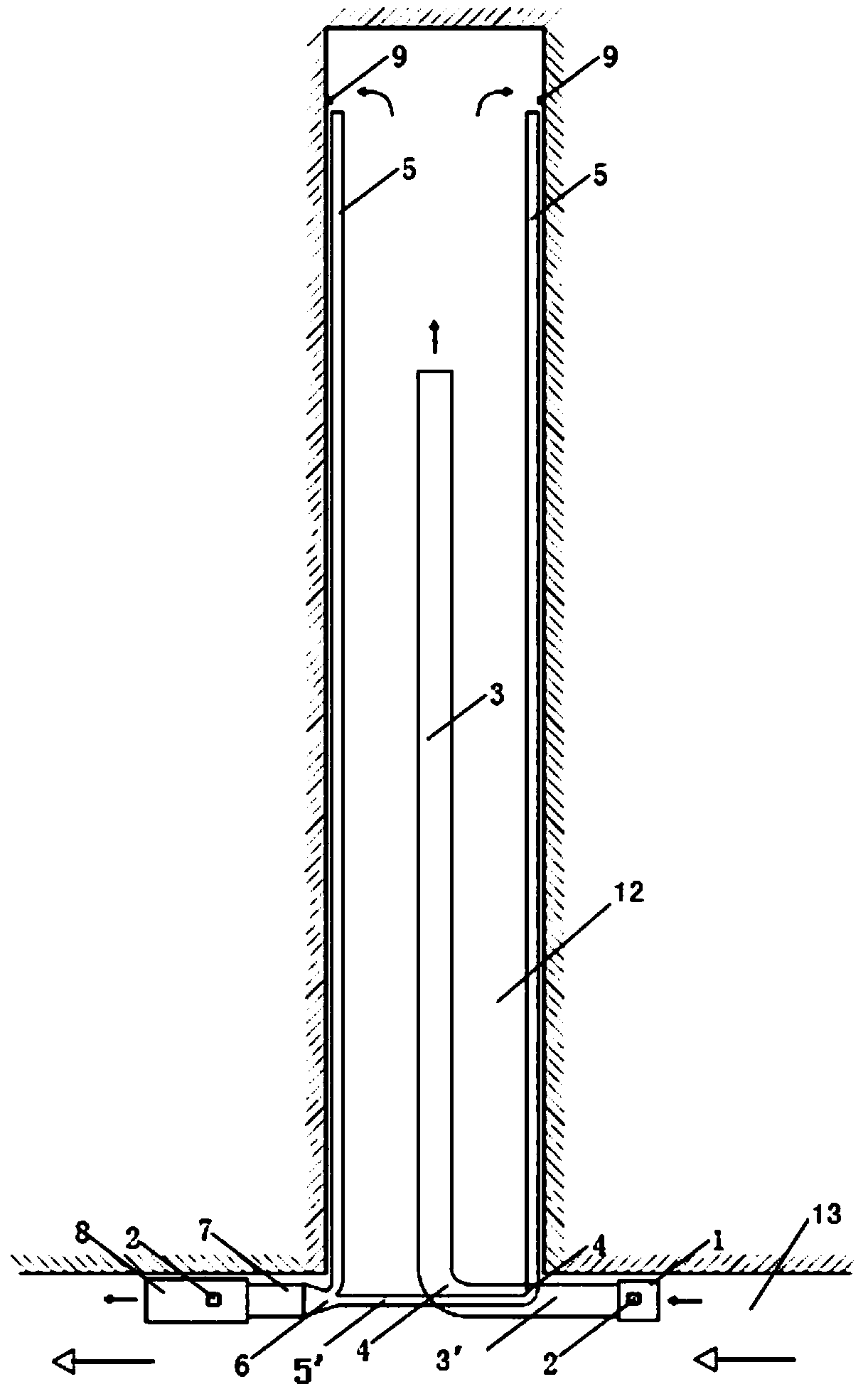

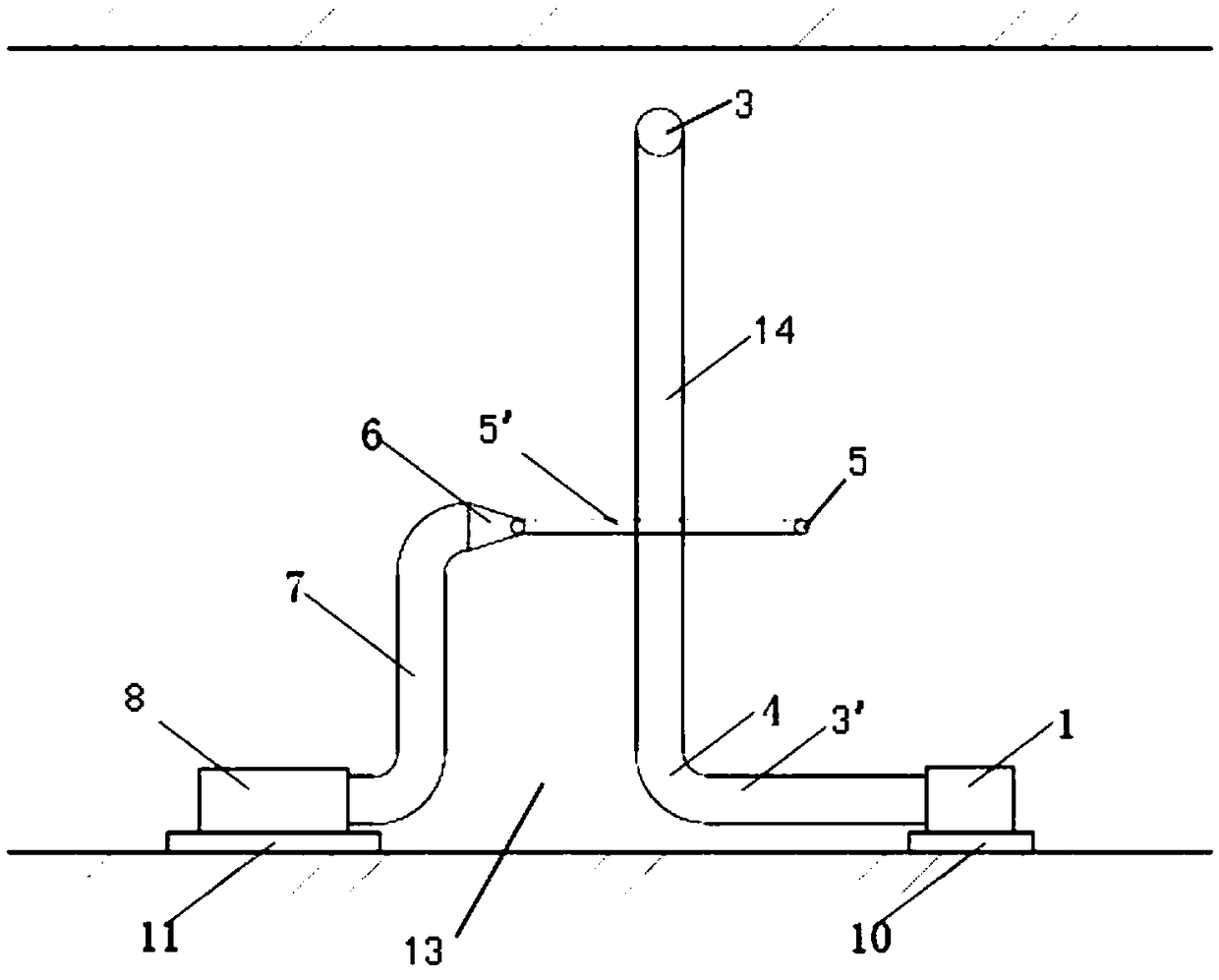

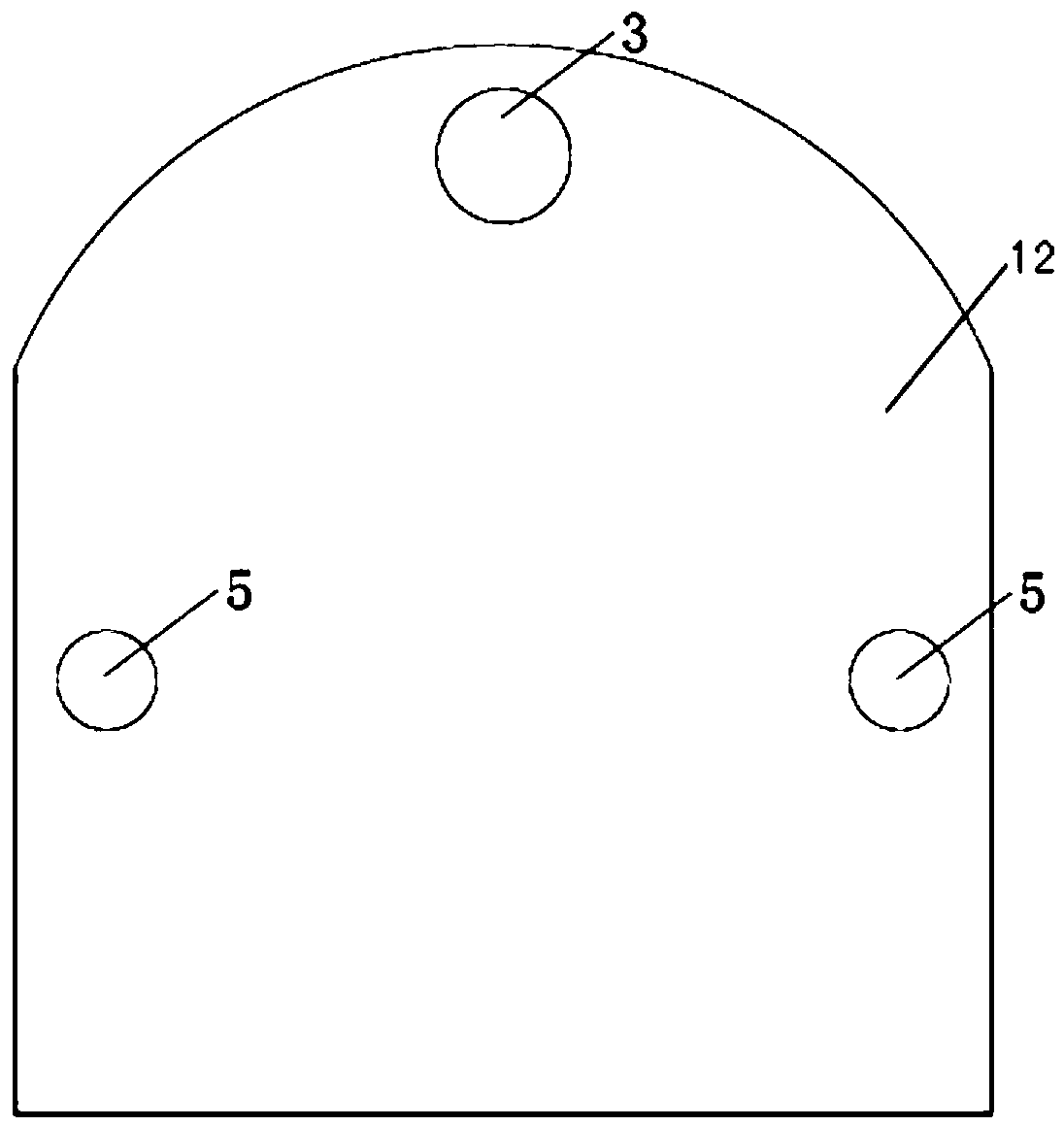

Ventilation and dust removal system for underground large-section and long-distance heading face

ActiveCN109268054AProtect healthSolve pollutionDust removalFire preventionHigh energyTunnel ventilation

The invention discloses a ventilation and dust removal system for an underground large-section and long-distance heading face. A compressed air cylinder (3) is horizontally installed at the top of a tunneling roadway, and a fan (1), an outlet connecting pipe (3), an elbow (4), a vertical connecting pipe (4) and the compressed air cylinder (3) are sequentially connected. Two air drafting cylinders(5) are arranged and are respectively arranged on two side wall faces of the tunneling roadway, the two air drafting cylinders (5) are connected with an air outlet cylinder (7) through a tee-joint pipe (6), and an air outlet of the air outlet cylinder (7) is connected with a wet-type dust removal fan (8) arranged on the leeward side of a middle-section main roadway. The ventilation and dust removal system has the advantages of being simple in operation, reliable in operation, good in practicability and the like, can prevent the problems of low operation efficiency and high energy consumption of a tunneling ventilation system, further dust contamination to underground airflow and other operation place phenomena. In addition, dust-containing airflow purified by the wet-type dust removal fancan enter the underground ventilation system for circular ventilation, and the airflow utilization efficiency of the mine ventilation system is effectively improved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

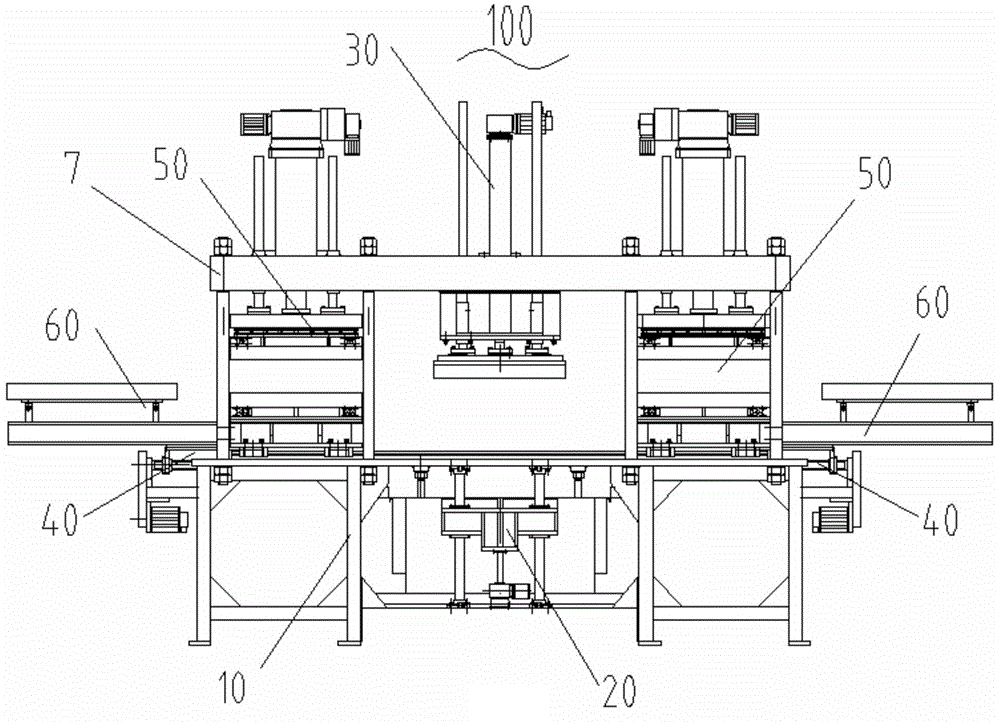

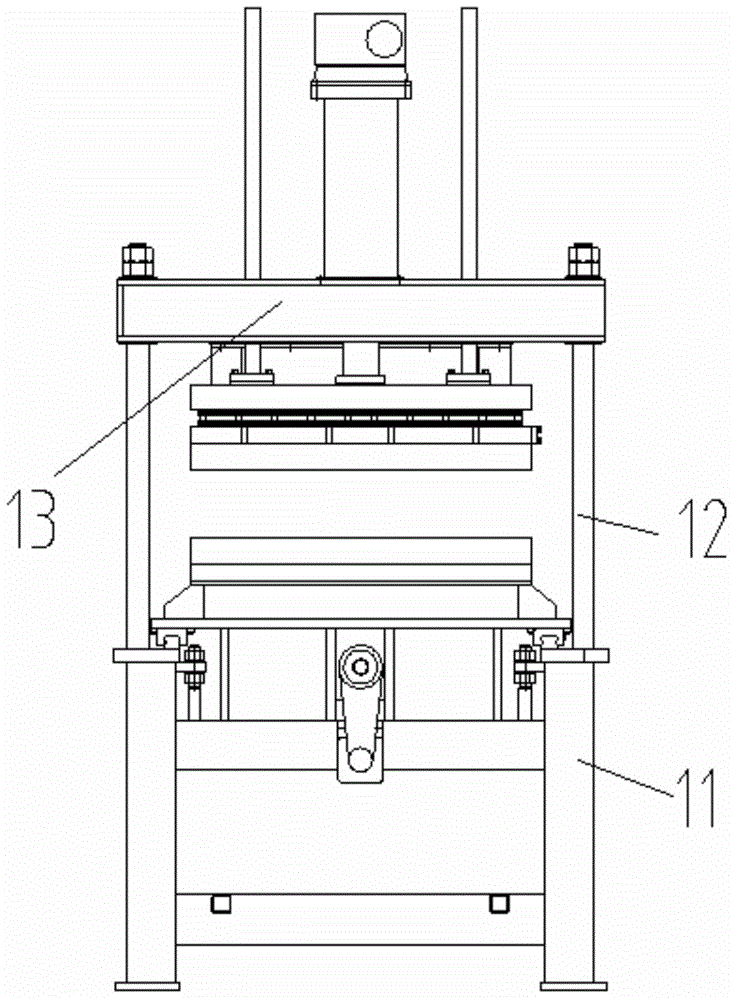

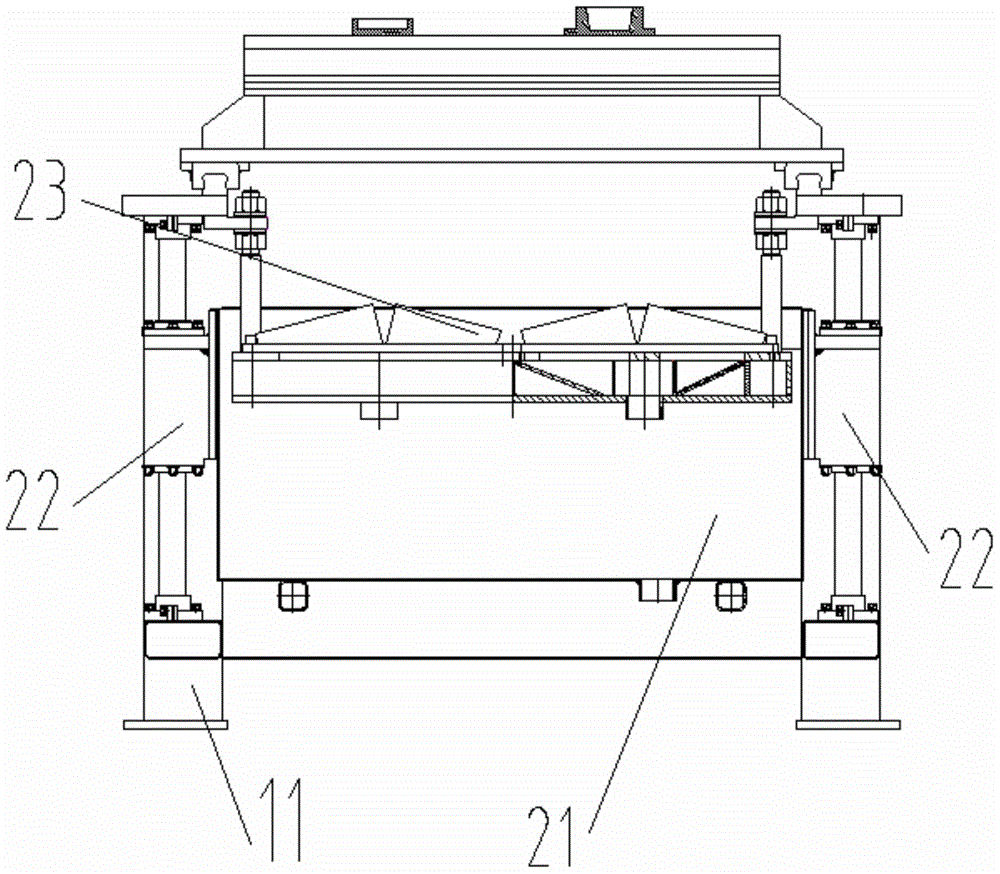

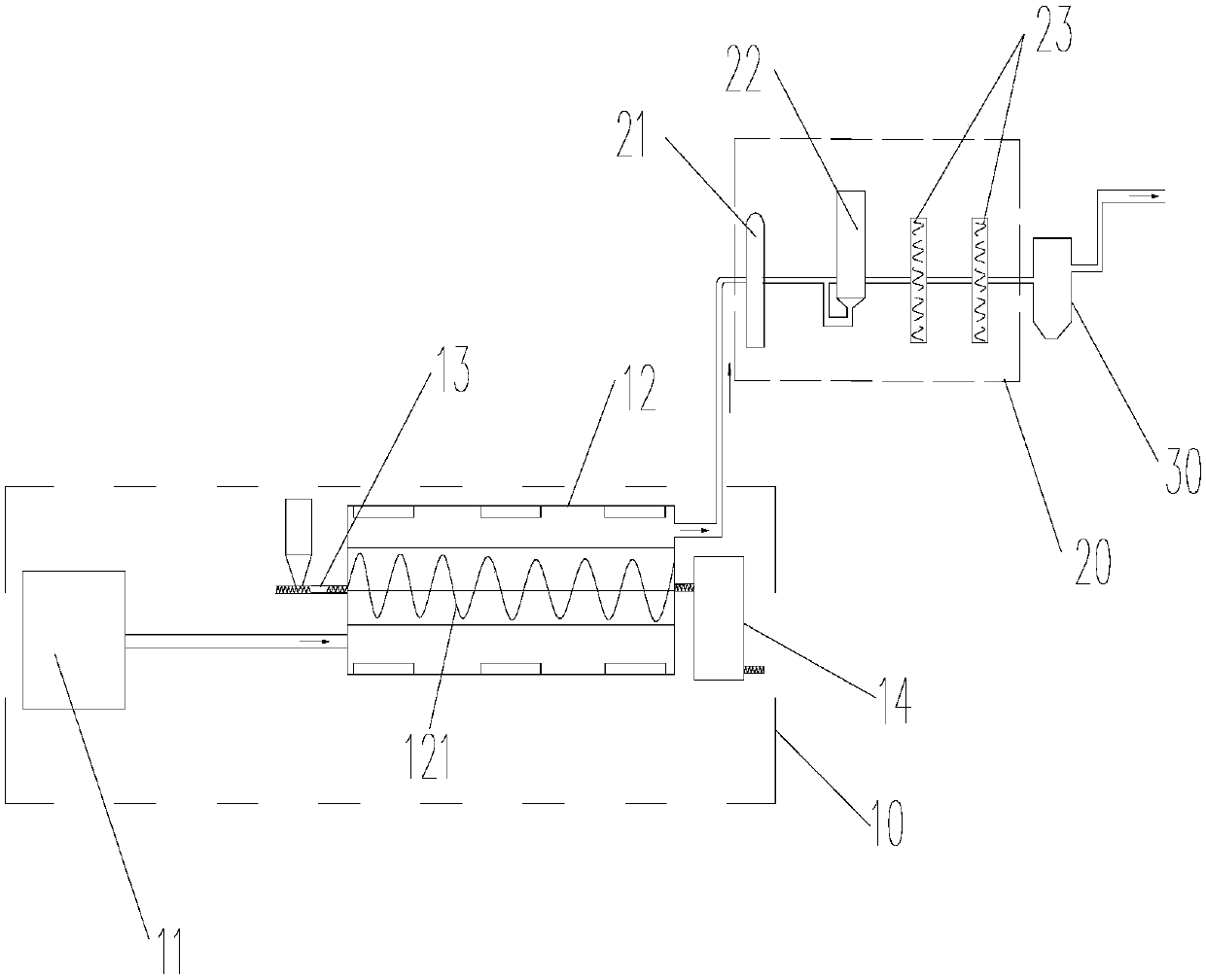

Paper pulp molding forming machine

ActiveCN104831590ASolve the pollution problemImproved accuracy and stabilityTextiles and paperMechanical drivePulp and paper industry

The invention discloses a paper pulp molding forming machine, comprising a machine body and a paper pulp slot lifting mechanism, a transfer die mechanism, a lower die moving mechanism, an upper die pressing down mechanism and a collecting mechanism which are arranged on the machine body; the paper pulp slot lifting mechanism is used for forming a paper pulp box; the transfer die mechanism is used for transferring the paper pulp box formed in the paper pulp slot lifting mechanism to the lower die moving mechanism; the lower die moving mechanism is used for sending the paper pulp box to the position of the upper die pressing down mechanism and is matched with the upper die pressing down mechanism to press and shape the paper pulp box; the upper die pressing down mechanism comprises an upper die assembly and a servo pressure cylinder for driving a lower die assembly to move up and down, and the servo pressure cylinder is of a mechanism drive structure. Mechanical drive is adopted, and the problem of pollution caused by hydraulic drive in the prior art is fundamentally solved; the precision and stability during work of the paper pulp molding forming machine are improved and the production cost is reduced while the production efficiency is improved.

Owner:ZHEJIANG SHURCON MFG

Thiophene adsorbents and application thereof

ActiveCN101890329AStrong adsorption effectSolve the pollution problemOther chemical processesWater contaminantsOxideTerthiophene

The invention provides thiophene adsorbents and a purification method for treating thiophene-containing wastewater by the same, and belongs to the technical field of water treatment. The thiophene adsorbents are a layered double hydroxide (ZnAL-CO3-LDH) and a modified product thereof (SDS-ZnAl-LDH). Experiments show that the two layered adsorbents have the thiophene removing rate of over 74 percent respectively. For example, under the meta-acid condition, the SDS-ZnAl-LDH has the thiophene removing rate of over 90 percent. The layered double hydroxide and the modified product thereof are applied to adsorbing the thiophene-containing wastewater, and can effectively remove the thiophene in the wastewater, so the invention provides feasible high-efficiency adsorbents for treating the thiophene-containing wastewater, which has valuable significance for purifying the thiophene-containing wastewater and protecting the environment.

Owner:BEIJING UNIV OF CHEM TECH

Removing system for dioxin and metallic mercury in flying ash

PendingCN108043864AEfficient removal of mercurySolve the pollution problemGas treatmentSolid waste disposalExhaust gasEnvironmental chemistry

The invention provides a removing system for dioxin and metallic mercury in flying ash. The removing system comprises a dioxin dechloridation unit, a gas-liquid separator unit and a mercury adsorptionunit. The dioxin dechloridation unit is used for carrying out a dechloridation reaction on the dioxin in the flying ash and is further provided with a flying ash inlet and a mercury-containing steamoutlet. The gas-liquid separator unit is used for cooling mercury-containing steam to obtain separated mercury-containing liquid products and mercury-containing tail gas and is further provided with amercury-containing steam inlet and a mercury-containing tail gas outlet. The mercury-containing steam inlet is connected with the mercury-containing steam outlet. The mercury adsorption unit is usedfor adsorbing the mercury-containing tail gas and is further provided with a mercury-containing tail gas inlet. The mercury-containing tail gas inlet is connected with the mercury-containing tail gasoutlet. The dioxin dechloridation unit is used for removing the dioxin in the flying ash, the gas-liquid separator unit is used for cooling the mercury-containing steam so that most of the metallic mercury can be separated out in a liquid-state mode, then remaining mercury elements in the mercury-containing tail gas are removed with the mercury adsorption unit, and therefore the efficient mercuryremoving effect can be achieved.

Owner:CHINA ENFI ENGINEERING CORPORATION

Harmless treatment method for erythrocin strain residues

InactiveCN105733970ASolve the pollution problemLow costFungiMicroorganism based processesNutrientChemistry

The invention discloses a method for treating erythromycin slag, which comprises the following steps: (1) placing the slag to be treated in a fermenter, adding other yeast fermentation medium components, and mixing to obtain slag water system, sterilized; (2) take the yeast liquid with OD value not less than 0.6, add it into the fungus residue water system in step (1) according to the inoculum amount of 2-10% (v / v), at a temperature of 30-30 Ferment for 36-72 hours at 35°C, tank pressure 0.02-0.07MPa, air flow 0.2-1.0L / min, system pH 4.5-6.5, to obtain fermentation broth; (3) Separation of solid-liquid fermentation broth , to be precipitated and dried. The method of the present invention can effectively remove the erythromycin residue in the bacteria residue, effectively solve the pollution problem of the erythromycin residue, and the bacteria residue treated per unit volume is much, the cost is low, and the solid dry yeast powder produced at the same time can be used for other products such as feed , Organic nutrients in the fermentation industry, suitable for industrial applications.

Owner:YILI CHUANNING BIOTECH CO

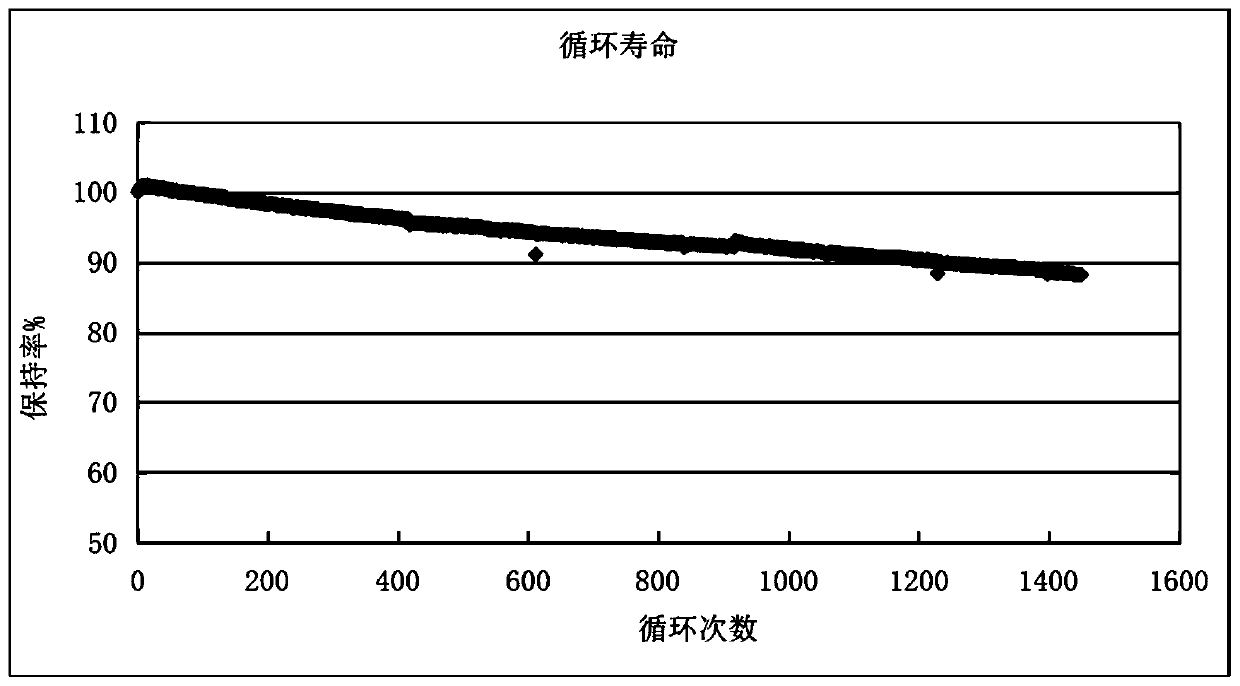

Recycling method of lithium iron phosphate waste battery

PendingCN111003700AExhaust gas treatment is simpleSolve the pollution problemCell electrodesWaste accumulators reclaimingEnvironmental chemistryElectrode material

The invention belongs to the field of resource utilization and environmental protection of waste electronic devices, and particularly relates to a recycling method of a waste lithium iron phosphate battery. The method comprises the following specific steps: high-temperature calcination, separation, burdening and grinding, and secondary calcination. According to the method, the waste lithium iron phosphate battery is subjected to high-temperature calcination in a closed environment; and the method is convenient for tail gas treatment, solves the pollution problem in the waste lithium battery disassembling process, improves the production efficiency, does not need acid, alkali and other control substances in the subsequent production process, obtains a lithium iron phosphate positive electrode material only by adding raw materials and additives for regeneration, and realizes comprehensive utilization and clean production of the waste lithium iron phosphate positive electrode material.

Owner:宁夏百川新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com