Patents

Literature

983results about How to "Meet emission standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

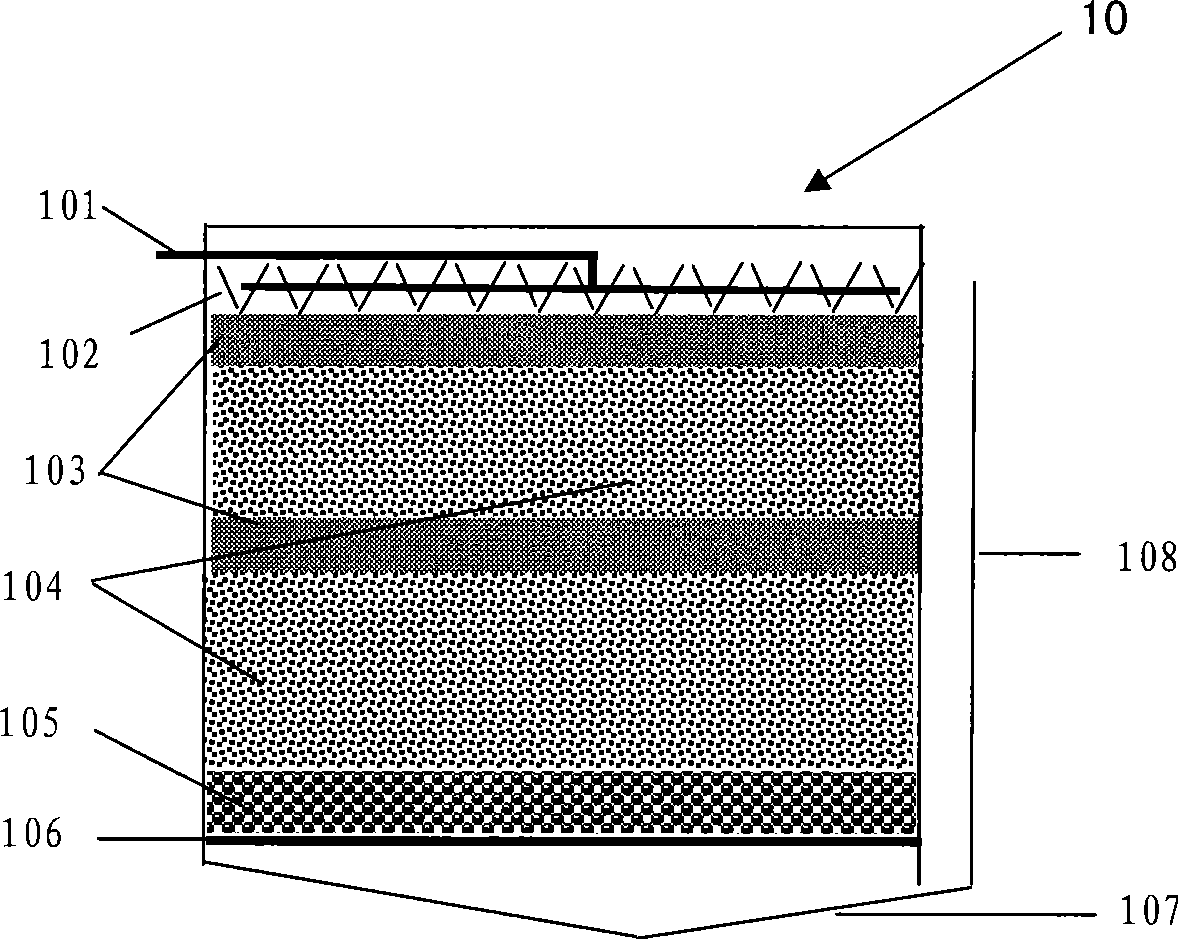

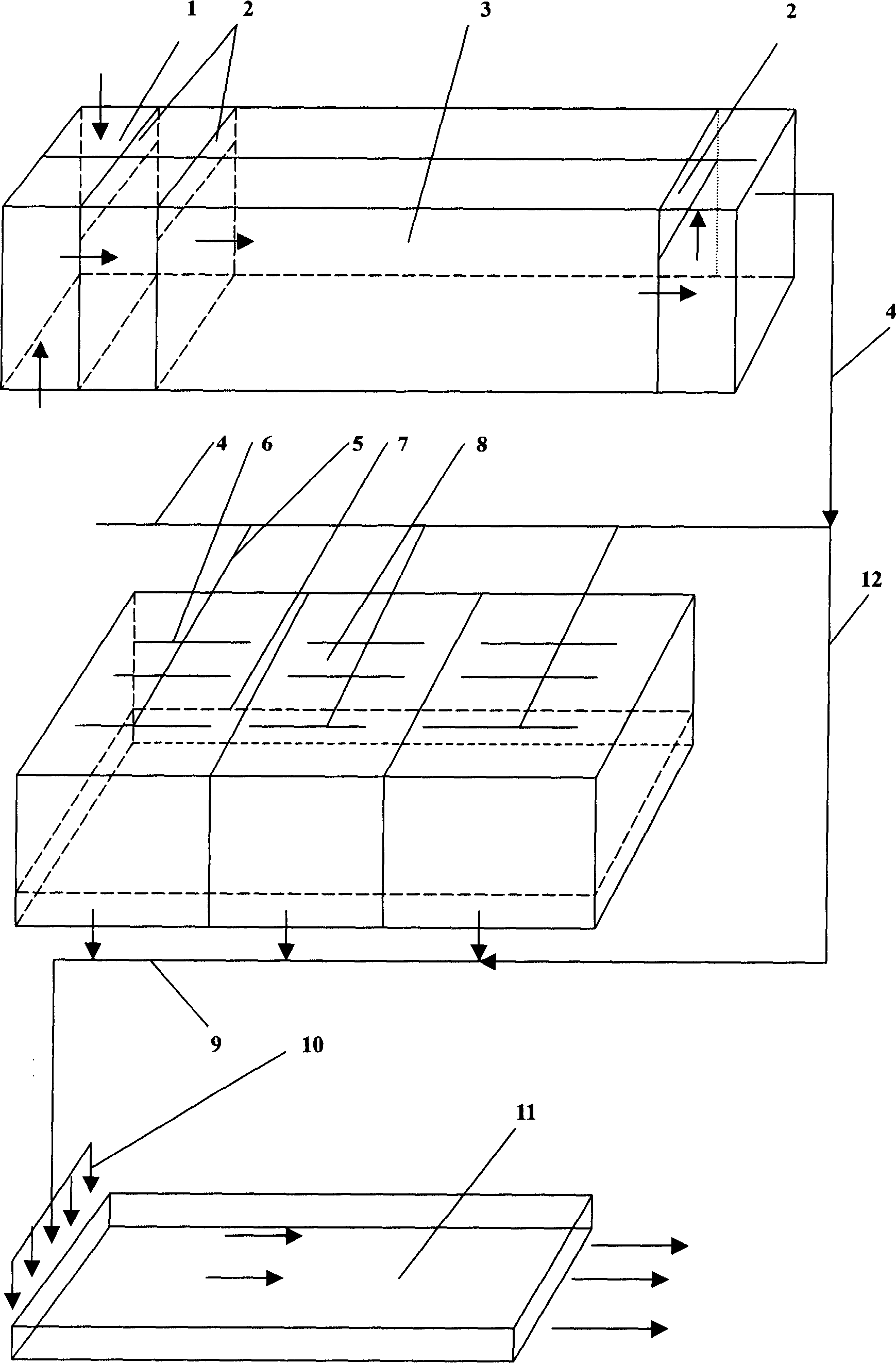

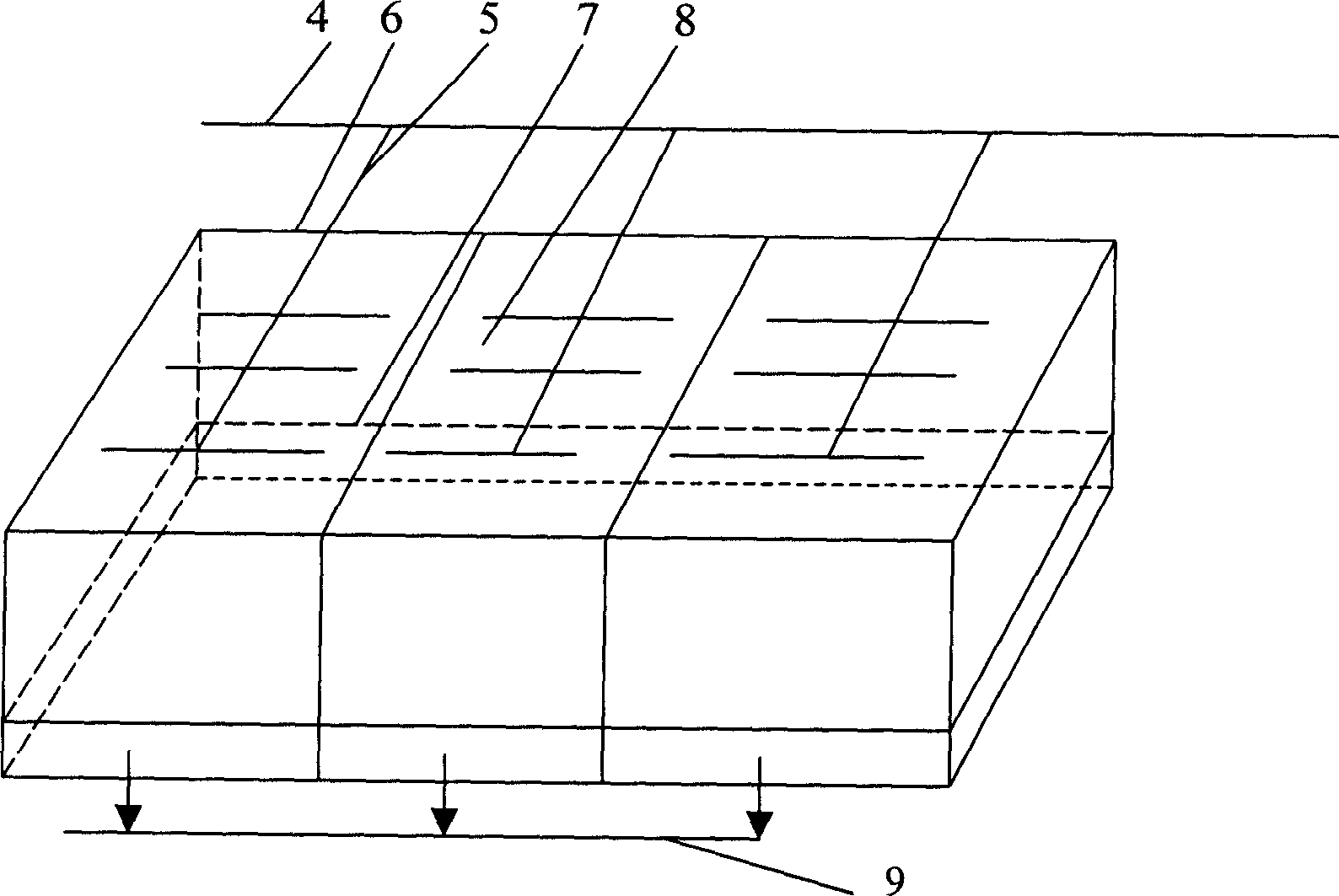

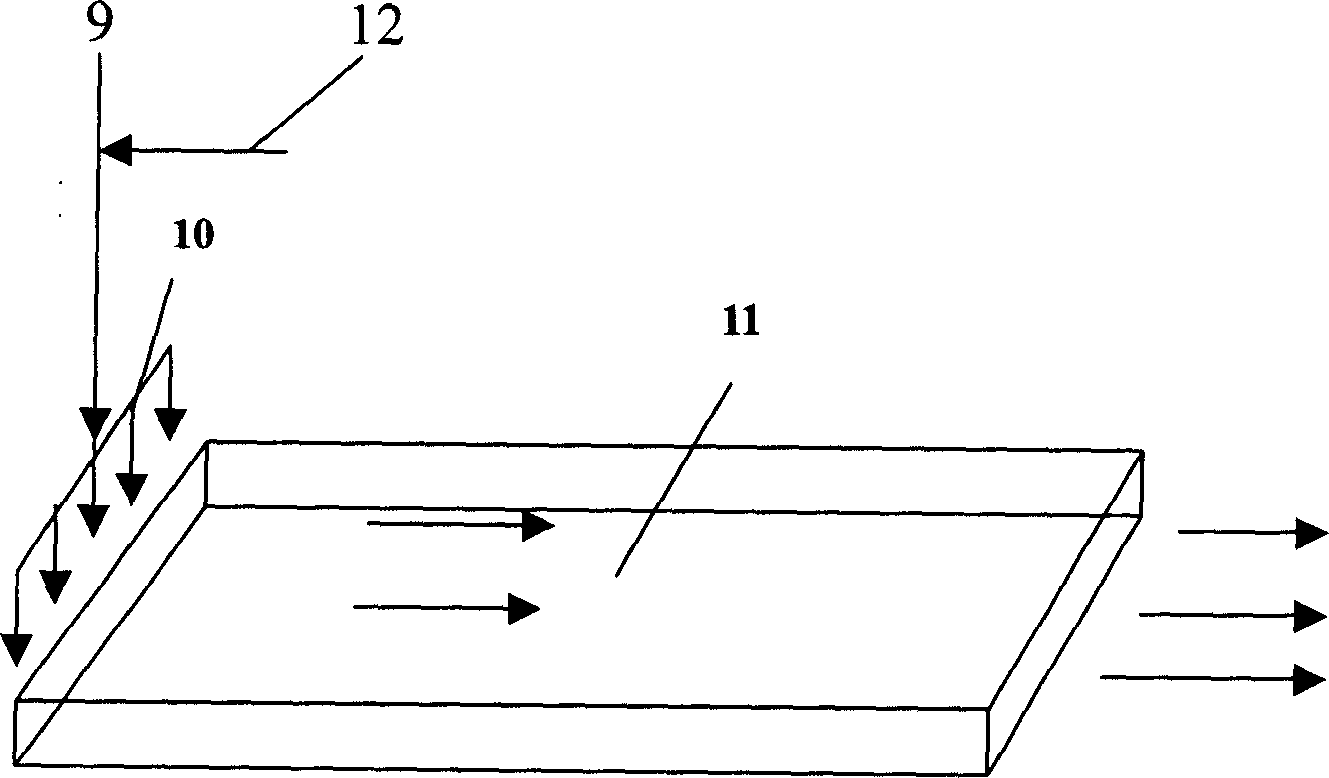

Biogas slurry ecological purification method based on microalgae cultivation

ActiveCN103396950AImprove photosynthetic efficiencyFast growthUnicellular algaeMicroorganism based processesSocial benefitsPurification methods

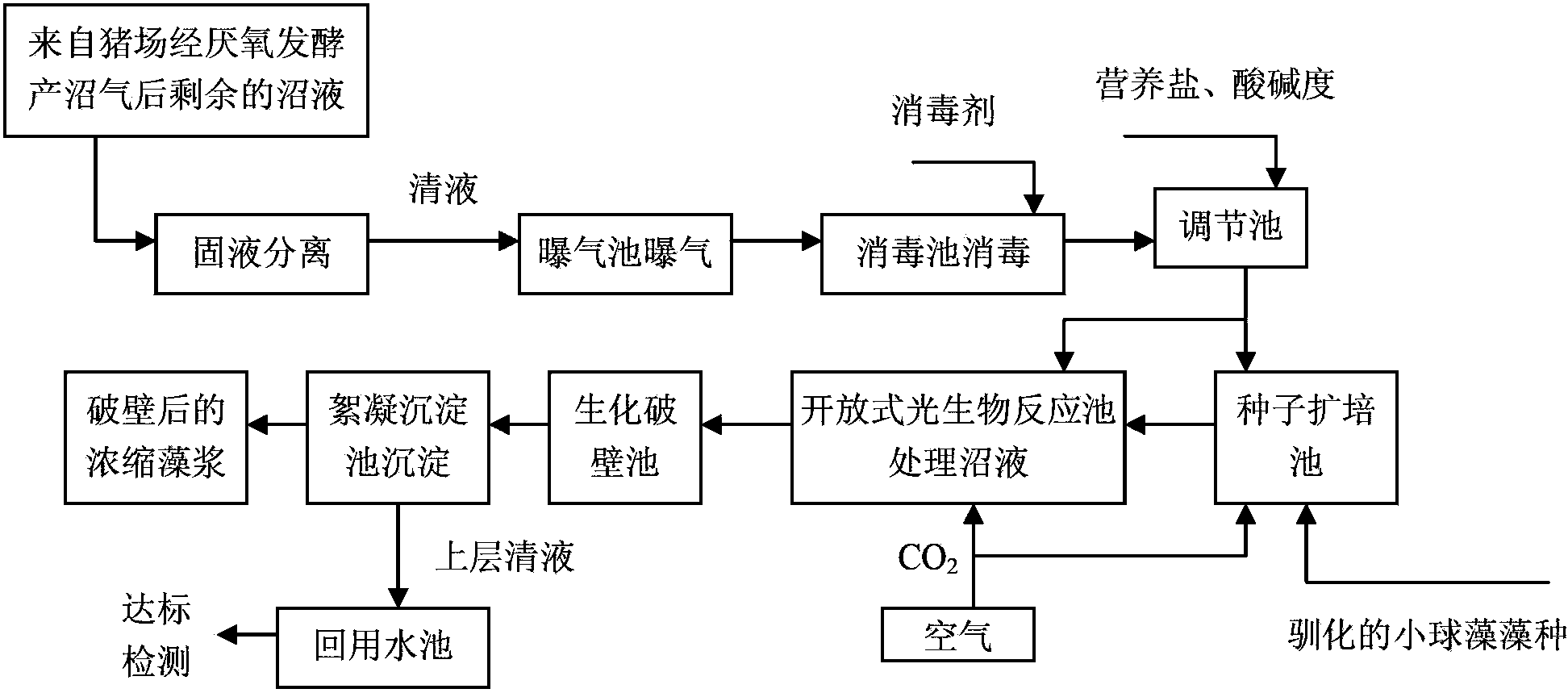

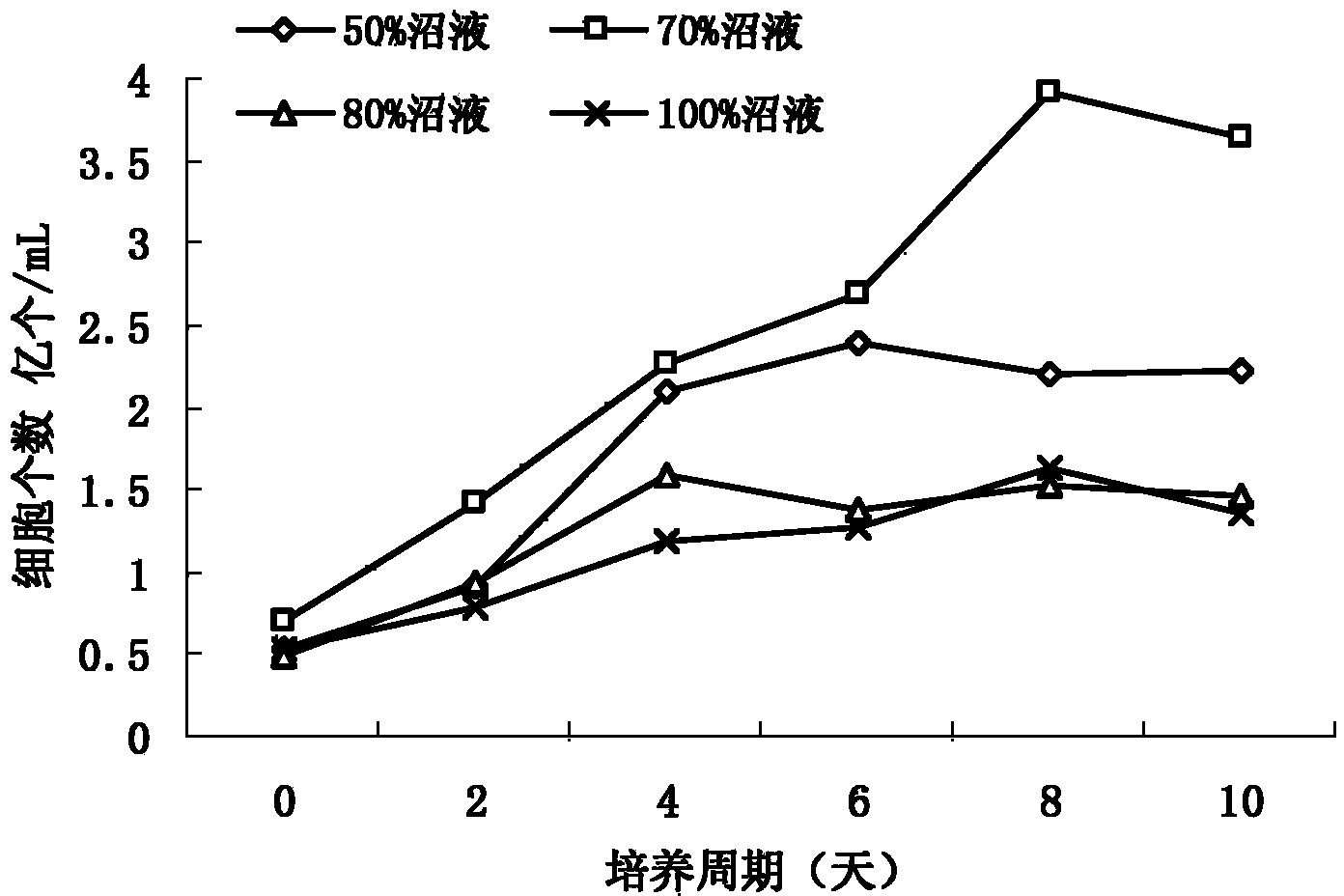

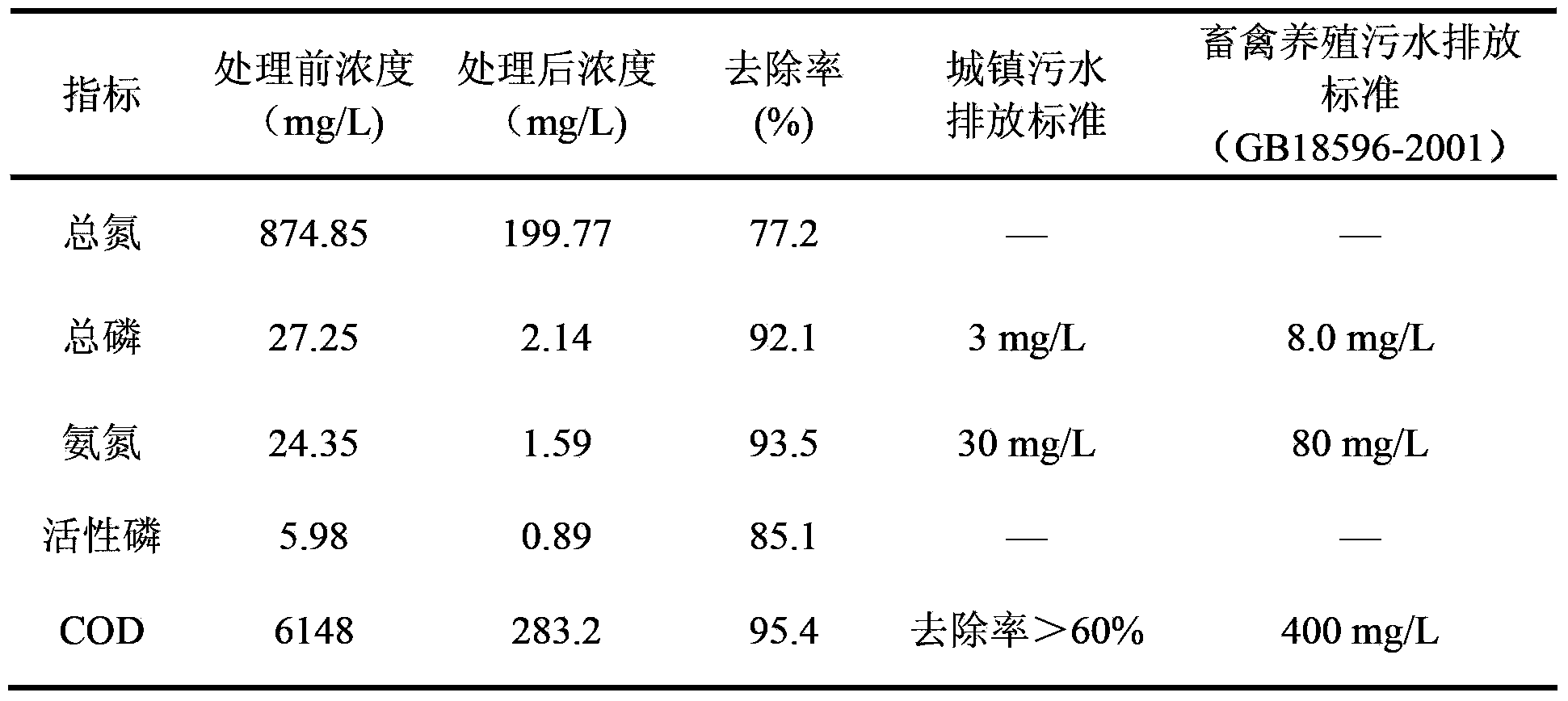

The invention discloses a biogas slurry ecological purification method based on microalgae cultivation. The method comprises the following steps: (1) biogas slurry pretreatment; (2) habituated culture of autotrophic microalgae, namely, obtaining algae strains capable of rapidly growing in 70%-100% biogas slurry; (3) preparation of a seed solution; (4) a biogas slurry purification method during growing of microalgae, namely, after expanded cultivation, inoculating the habituated algae species into an open photobioreactor for cultivation, obtaining chlorella biomass growing by high density through a semi-continuous culture method and optimized methods such as fed-batch cultivation, and purifying the biogas slurry; (5) biochemical breaking of microalgae cell walls, namely, introducing the microalgae cells into a biochemical wall breaking pool, putting freshwater fish into the pool, and obtaining algae slurry subjected to wall breaking; and (6) collection of the microalgae cells and recycling of the biogas slurry. According to the method, not only is a method provided for purifying the biogas slurry, but also the obtained algae cells and the biogas slurry can be recycled, so that ecologicalization treatment of the biogas slurry is realized, the environment is improved, and furthermore, the economic and social benefits are produced.

Owner:湖南瑞藻生物科技有限公司

Zeolite adsorbent and its preparation method

ActiveCN101007261AGood removal effectMeet emission standardsOther chemical processesWater/sewage treatment by sorptionSorbentEmission standard

The invention discloses a zeolite adsorbent and its preparation method, the zeolite adsorbent is powder particles using zeolite as main raw material; it mixes 60-95% zeolite, 30% filler, 1-30% binding agent, 0-20% hole agent and 0-20% acid to prepare colloid which solid content is 10-60%; After spray-dries it, then it roasts power particles which droplet method volume>0.5 ml / g. The exchange capacity is large, it can remove the ammonia nitrogen, calcium magnesium ion, fluorinion or heavy metallic ion in sewage water effectively and reach sewage water emission standard.

Owner:岳阳明科催化技术有限公司

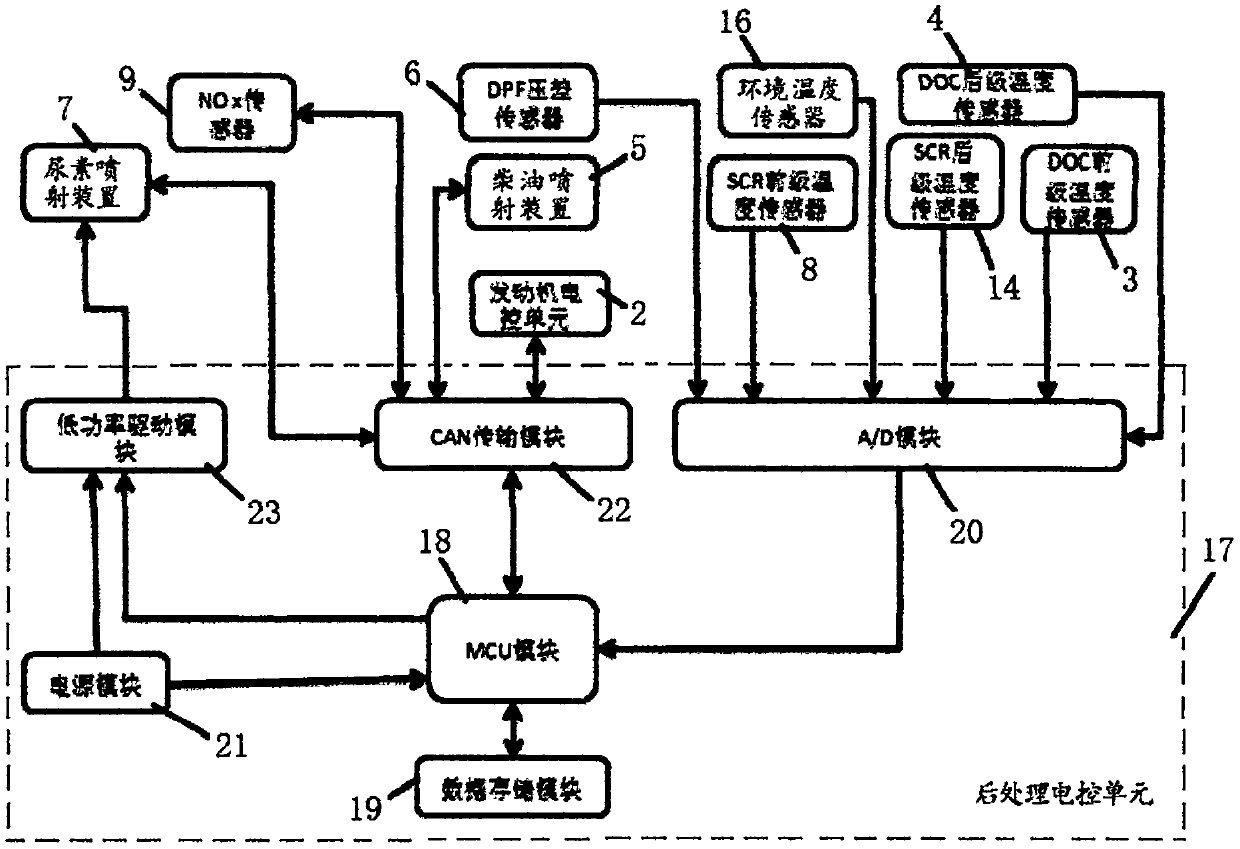

Engine tail gas after-treatment control system and control method

InactiveCN110206623AMeet emission standardsFix stability issuesInternal combustion piston enginesExhaust apparatusSoftware systemDifferential pressure

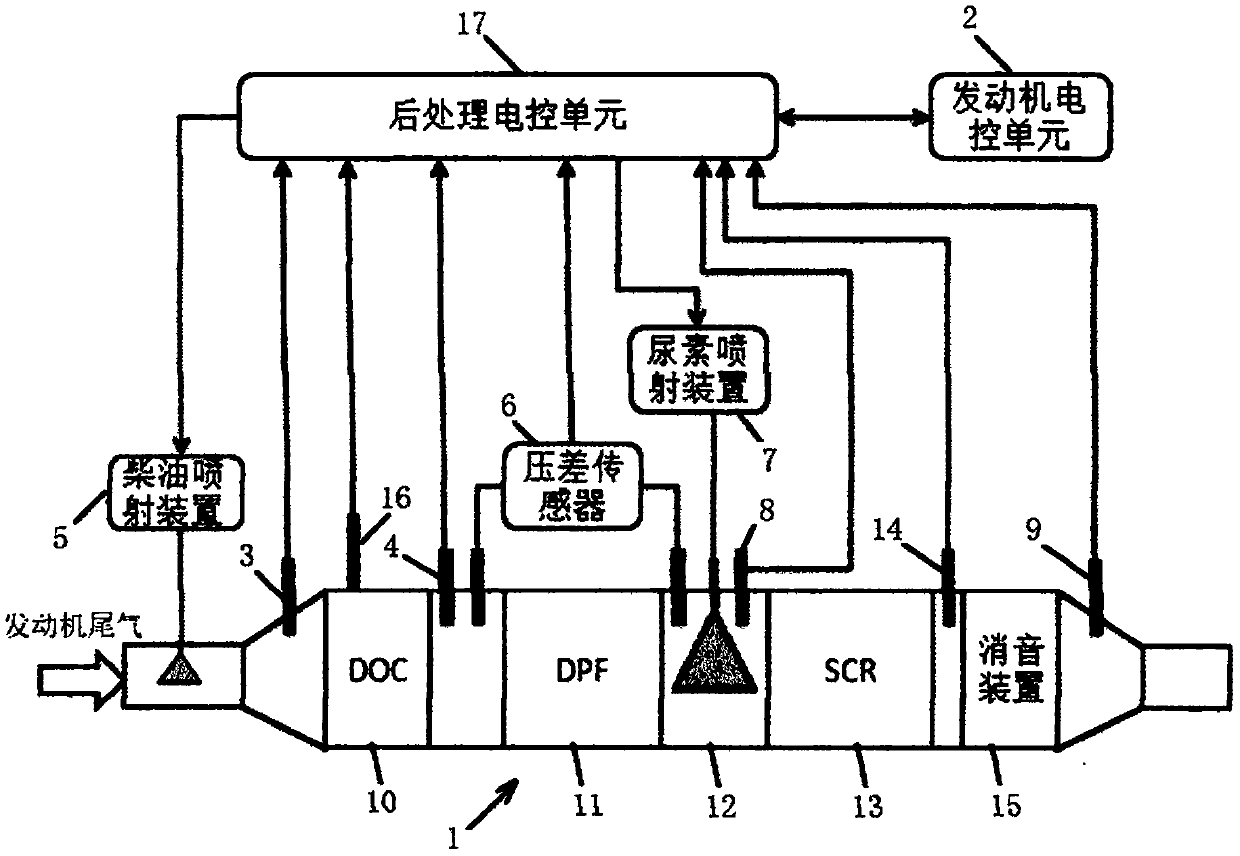

The invention provides an engine tail gas after-treatment control system and control method. The engine tail gas after-treatment control system and control method are applied to after-treatment of tail gas. The control system comprises a tail gas post-processor, an engine electric control unit, a diesel injection device, a urea spraying device and a post-treatment electric control single element.The control method is based on the measured values of different sensors and the working condition parameters of an engine, and is based on a pre-calibrated data model to complete the four functions ofDPF active regeneration controlling, DPF accumulated dust cleaning, SCR urea injection controlling and system fault diagnosing. The system is composed of a software system and a hardware system, wherein a transient segmented linear interpolation algorithm is adopted for MAP data, and the calculation precision and the execution efficiency are improved to a great extent. A DPF differential pressuresensor adopts a differential pressure dynamic integral and time-sharing comparison method, so that the condition that the differential pressure value is unstable and the fluctuation is large due to the fact that the differential pressure sensor is influenced by various factors is solved, the robustness of a control strategy of the tail gas after-treatment system is enhanced, and the misjudgment of regeneration is reduced to a great extent, so that the improper active regeneration operation is reduced, and the oil consumption is reduced.

Owner:三河市科达科技有限公司

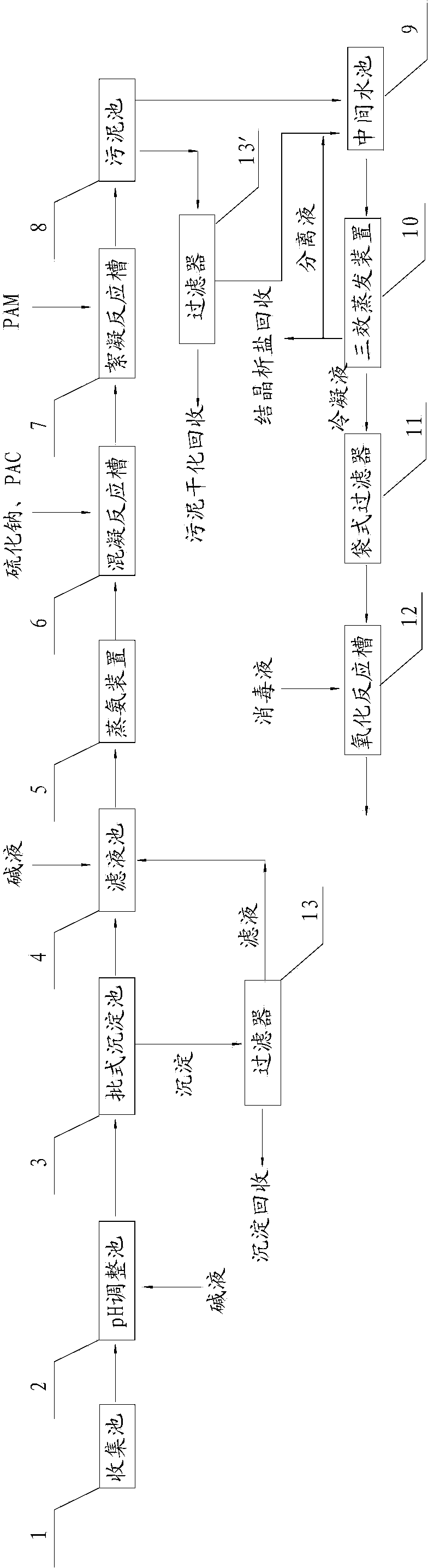

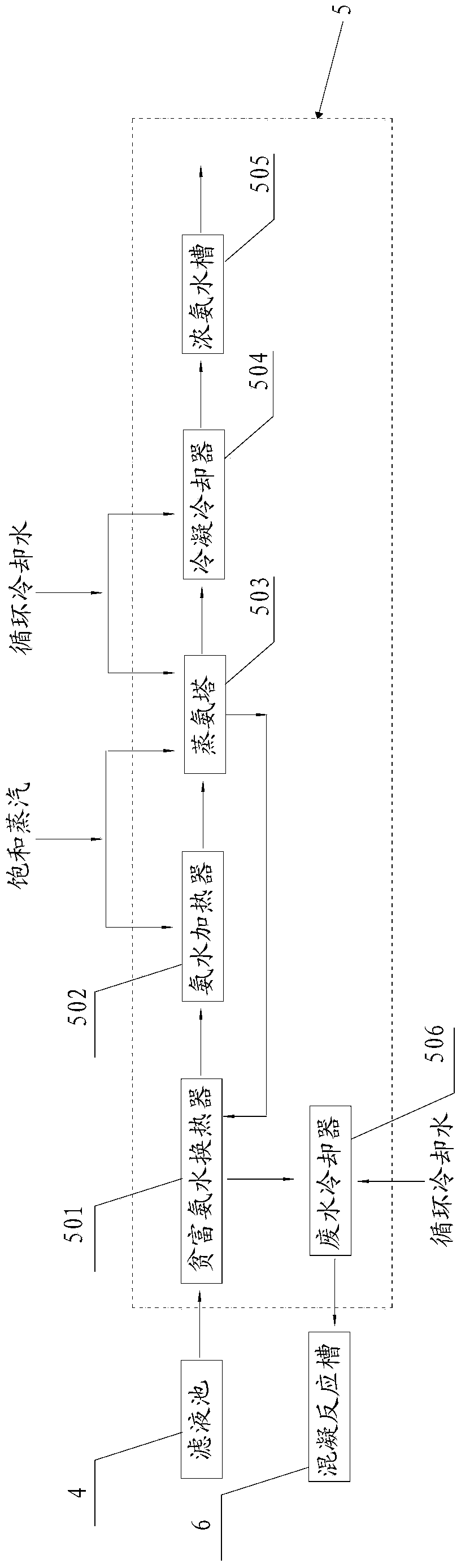

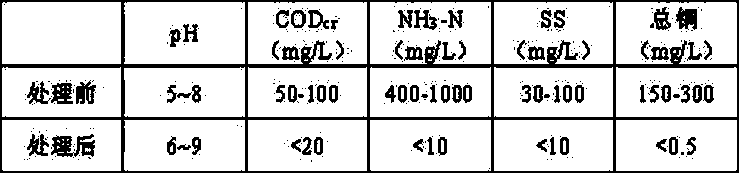

Material recovery method of wastewater containing high-concentration ammonia-nitrogen and heavy metal ions and treatment system

InactiveCN103466870AHarm reductionMeet emission standardsMultistage water/sewage treatmentAmmonia preparation/separationRecovery methodHigh concentration

The invention relates to a material recovery method of wastewater containing high-concentration ammonia-nitrogen and heavy metal ions and a wastewater treatment system. The material recovery method comprises the following steps: regulating the pH value, ammonia stilling, precipitating, evaporating and the like. The invention further relates to the corresponding treatment system. After the adoption of alkali liquor to precipitate metal ions, sodium sulfide is continuously added to further remove the metal ions left in the waste liquor to reach the emission standard; stronger ammonia water, solid precipitates and the like produced during the wastewater treatment process are recovered to reduce the environmental harm effectively and produce certain economic benefits.

Owner:SUZHOU SUJING ENVIRONMENTAL ENG

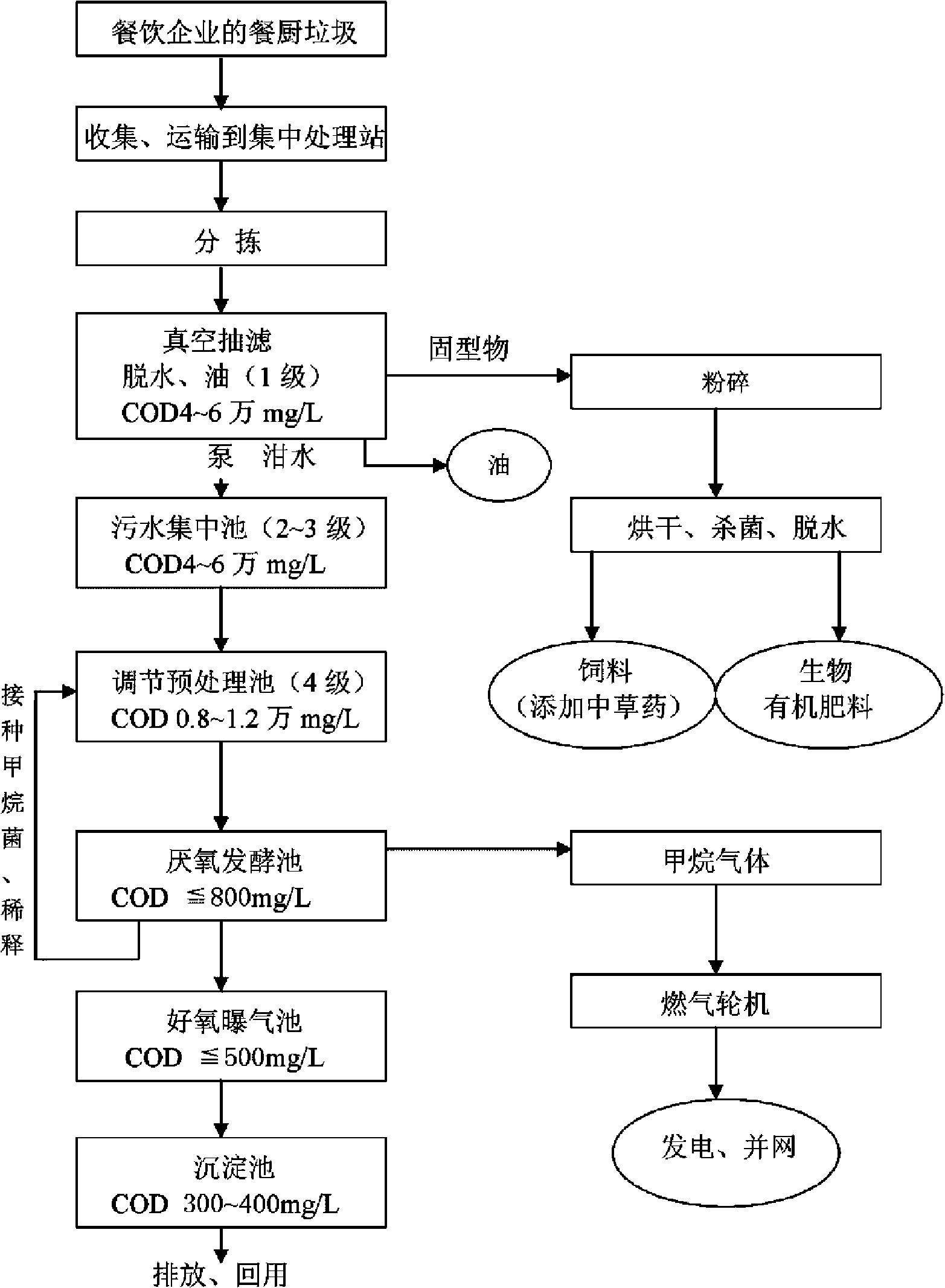

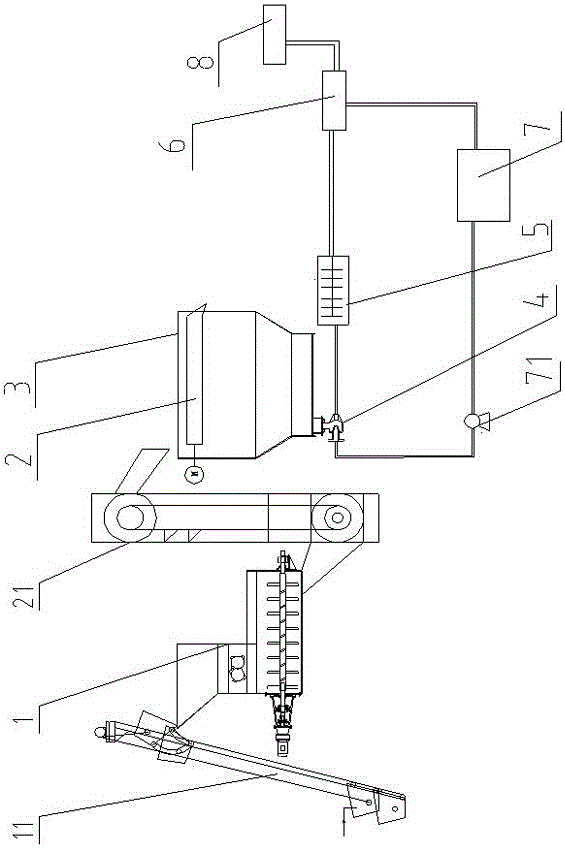

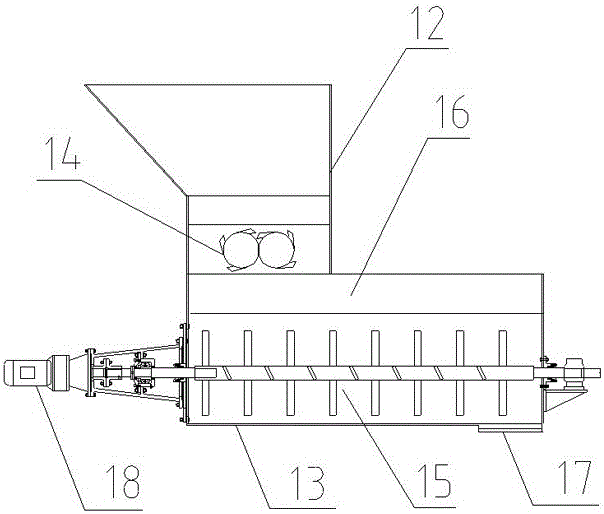

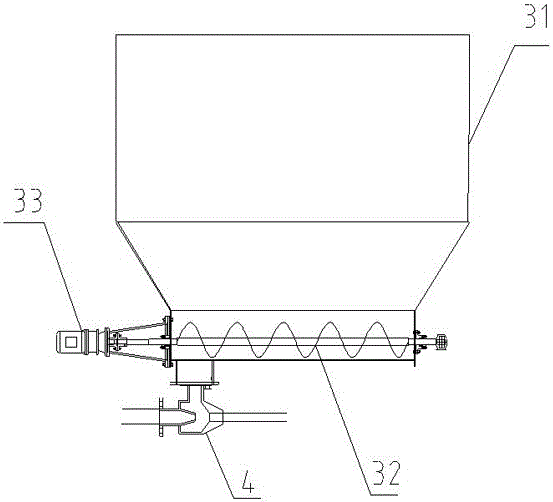

Processing method for changing restaurant and kitchen garbage into resource without environmental pollution

InactiveCN101274860AAvoid wastingEnergizeBio-organic fraction processingWaste processingThermal energyAnaerobic bacteria

The invention relates to a treating method for energy regeneration, resource recovery and pollution free of restaurant garbage, which comprises the steps that separated liquid material is pumped into a swage concentrating pool; then the concentrated liquid material is discharged into a regulating and pretreating pool, in which methane bacteria are inoculated; the pretreated liquid material is discharged into an anaerobic fermentation pool, in which anaerobic bacteria groups are added so that methane gas is generated and the overflowing liquid material from the anaerobic fermentation pool is led to enter an aerobic aerated pool for aerobic reaction; the liquid material after the aerobic reaction is discharged into a sedimentation tank for sedimentation. In the comprehensive utilization of 'swill', the disposing method of the invention carries out anaerobic fermentation and aerobic aerated biochemical treatment to transform part of the energy in the swill into bio-energy which is then transformed into heat energy and finally into electrical energy that is connected with power grid for use. The separated solid material is smashed, dried, sterilized, dehydrated and then added with Chinese herbal medicine to be processed into Chinese herbal medicine compound feeds and fertilizers; meanwhile, the treatment of energy regeneration, resource recovery and pollution free of restaurant garbage for restaurant garbage is realized.

Owner:WUXI KELUN SCI & TECH DEV

Oily sludge treatment system and treatment method thereof

PendingCN106746420AGood processing effectEasy to handleWaste water treatment from quariesSievingWater storageSludge

The invention discloses an oily sludge treatment system and a treatment method thereof. The treatment system comprises crushing equipment, a vibrating screen, a precipitation device, an ejector, a high-speed crushing device, a water storage device and separation device for separating oil, water and sludge, wherein the crushing equipment is used for primarily crushing oily sludge and is provided with an oil slick space and a first oil slick outlet which can be opened and closed; the vibration screen is located at the upper part of the precipitation device; the precipitation device is used for precipitating the screened oily sludge; the high-speed crushing device is used for crushing the oily sludge into fine particles; the precipitation device is sequentially connected with the ejector, the high-speed crushing device and the separation equipment; a water outlet of the water storage device is connected with a water inlet of the ejector. The treatment system can be applicable to dewatering of various oily sludges, meanwhile, the oil rate of the oily sludge can be reduced to below 3%, oil can be recovered to the maximal extent and secondary pollution of wastewater is not generated.

Owner:仇霞霞

Oil-containing wastewater treatment agent and preparation method thereof

ActiveCN103864177AReduce CODReduce BODFatty/oily/floating substances removal devicesLiquid separationTherapeutic effectPollution

The invention belongs to the technical field of sewage treatment agents, and in particular relates to an oil-containing wastewater treatment agent and a preparation method thereof. The oil-containing wastewater treatment agent disclosed by the invention comprises the following raw materials in parts by weight: 35-45 parts of polyacrylamide, 15-25 parts of polymeric aluminium, 12-18 parts of expanded graphite, 15-20 parts of zeolite mineral, 20-30 parts of hydrolyzed tannin, 3-5 parts of organic acid, 5-10 parts of TiO2, and 3-5 parts of chitosan-graphene composite material. The oil-containing wastewater treatment agent disclosed by the invention has the advantages of being good in treatment effect, low in production cost, high in purity, free from toxicity, influence to operators and secondary pollution after treatment; the preparation method is simple and easy for popularization.

Owner:广州小众环保科技有限公司

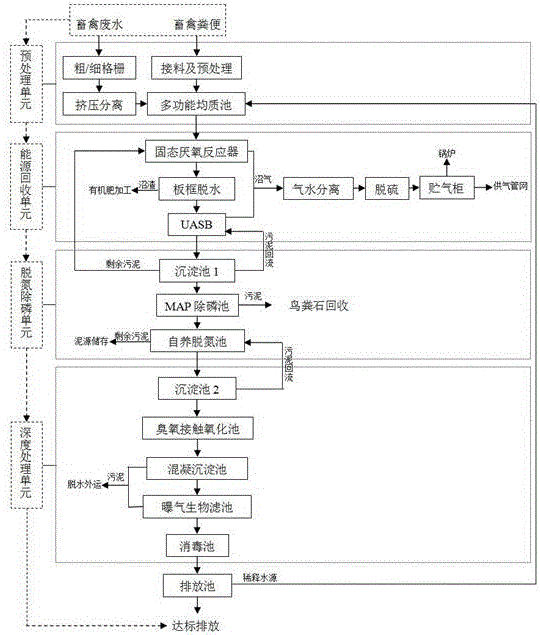

Recycling treatment method for feces and wastewater in large-scale livestock and poultry breeding farm

InactiveCN106242162ANo need to addReduce aerationSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesAnimal fecesEnergy recovery

A recycling treatment method for feces and wastewater in a large-scale livestock and poultry breeding farm includes the following steps: (1) pre-treating the feces and wastewater in the large-scale livestock and poultry breeding farm in a pretreatment unit to form slurry; (2) feeding the slurry into an energy recovery unit, and performing solid anaerobic digestion in a solid anaerobic reactor to obtain an energy gas, methane; (3) performing solid-liquid separation to the digested slurry to generate wastewater, which is then fed into a UASB reactor to perform further anaerobic fermentation to remove organic pollutants from the wastewater; (4) feeding the treated wastewater into a nitrogen and phosphorus removal unit to perform nitrogen and phosphorus removal treatment; (5) separating and purifying a precipitate, which is generated in the nitrogen and phosphorus removal unit and mainly includes magnesium ammonium phosphate, to obtain an organic fertilizer additive, wherein the nitrogen removal process is autotrophic nitrogen removal and can reduce aeration quantity by 62.5% without addition of any carbon sources, thus saving large quantity of operation cost; and (6) feeding the treated wastewater into a deep-treatment unit to remove bio-refractory substances and disinfect the wastewater so as to finally reach emission and recovery standards of wastewater.

Owner:SOUTH VENTURE TIANJIN TECH DEV CO LTD

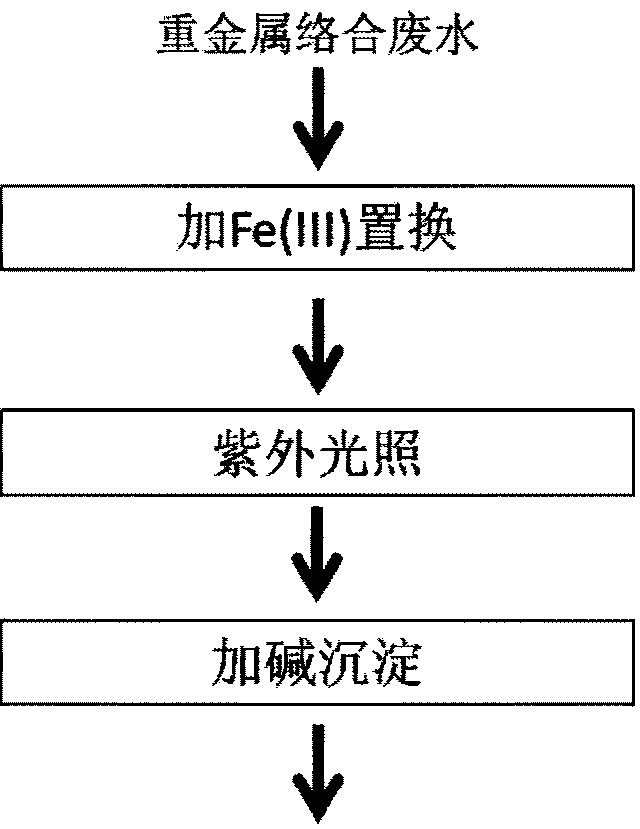

A combined process for treating heavy metal complexing waste water

ActiveCN104108819AIncrease profitReduce TOC and COD valueWater contaminantsMultistage water/sewage treatmentIonChemistry

A combined process for treating heavy metal complexing waste water is disclosed and belongs to the field of waste water treatment. The combined process includes steps of: (1) adding a ferric salt into the complexing waste water containing the target heavy metal to subject the ferric salt and the target heavy metal to a replacement reaction so as to release a target ion; (2) subjected the waste water after replacement to ultraviolet light irradiation to destroy complexes in the waste water; and (3) adjusting the pH value of the waste water to precipitate the target metal and iron, performing solid liquid separation to complete the processing process of the waste water. The combined process mainly destroys carboxyl of a complexing agent, so that the combined process has certain selectivity. Compared with methods in the prior art that degrade organic matters by utilization of hydroxyl radicals, the combined process has higher selectivity. When the content of a complexing mechanism in the total organic matters is not high, the combined process can maintain a high utilization rate.

Owner:NANJING UNIV

Method for treating container washing wastewater

InactiveCN101708935AReduce suspended solidsSave waterFatty/oily/floating substances removal devicesTreatment with anaerobic digestion processesOil separationReclaimed water

The invention relates to a method for treating container washing wastewater, comprising the pretreatment, physical and chemical treatment, biochemical treatment and advanced treatment, wherein the pretreatment comprises the step of filtering suspended matter and oil slick out by an oil separation tank and a collected water regulating reservoir so as to homogenize water quality and water quantity; the physical and chemical treatment comprises the step of removing oil substances and COD by an air flotation device; the biochemical treatment comprises the step of removing hazardous and noxious substances by an AF anaerobic filter chamber and an SBR reaction tank; and the advanced treatment comprises the steps of degrading organic matters and sterilizing by a moving bed biomembrane reactor and an ozone catalyzing oxidation pond, wherein the treated wastewater serves as washing water after reaching normal water reuse standards. The invention not only treats the container washing wastewater containing oil, poisonous substances and organic hazardous chemicals into clear water meeting the national discharging standards and discharging standards in Tianjin, but also reduces the content of the suspended matters and oils, and saves water resources because the clear water after being treated can serve as the reuse clear water.

Owner:TIANJIN TANGGU XINYU ENVIRONMENTAL PROTECTION TECH

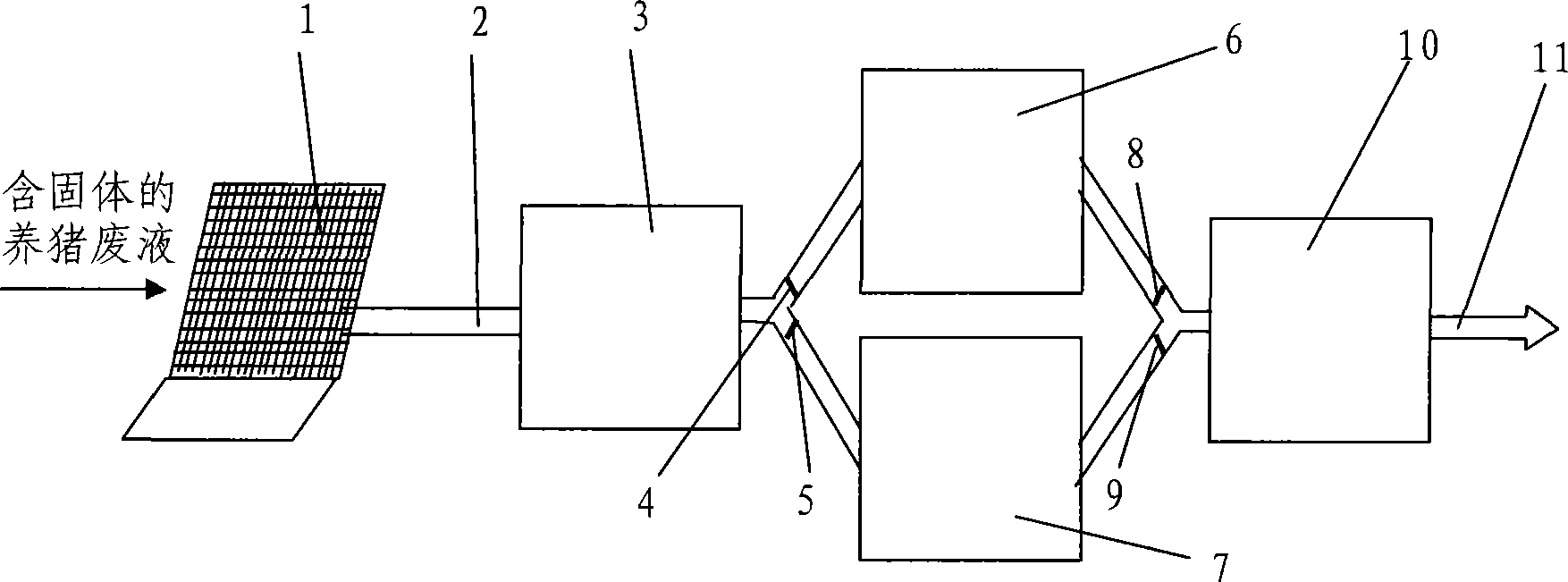

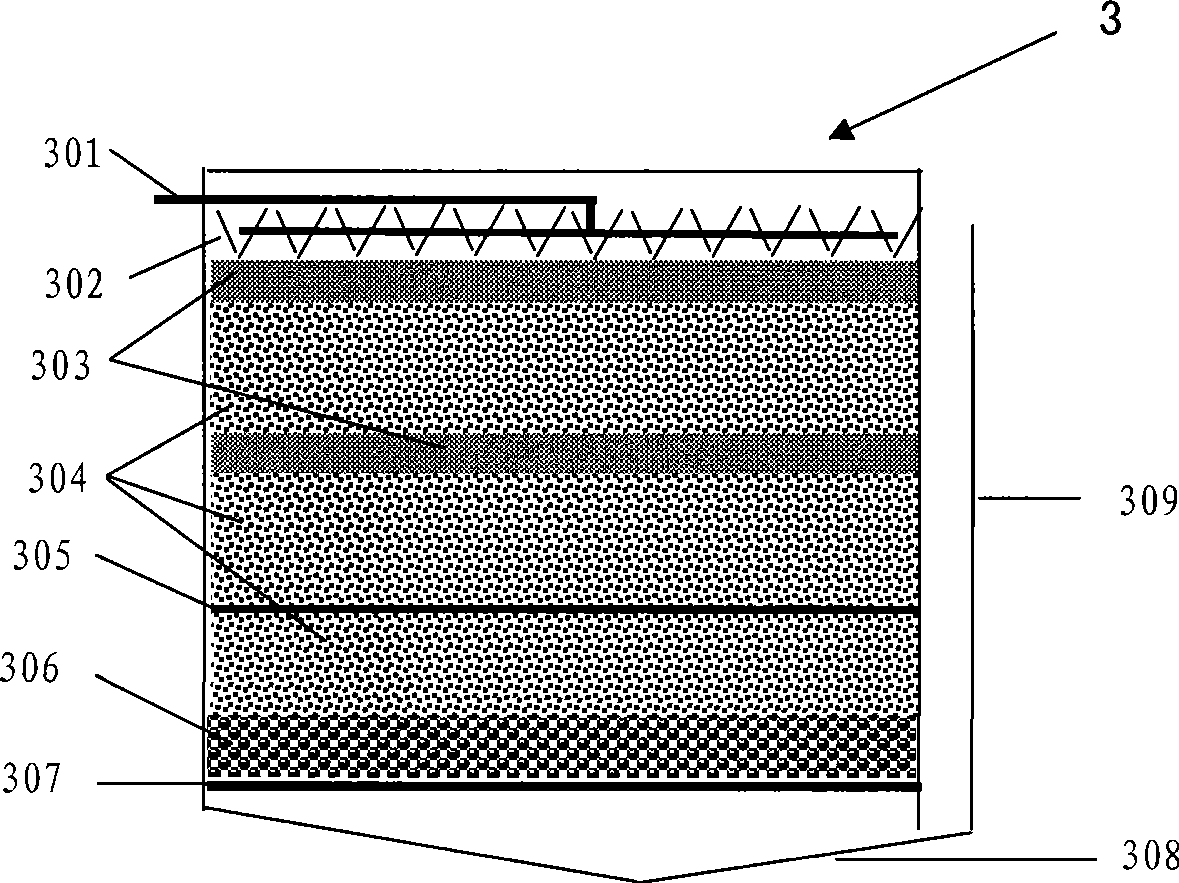

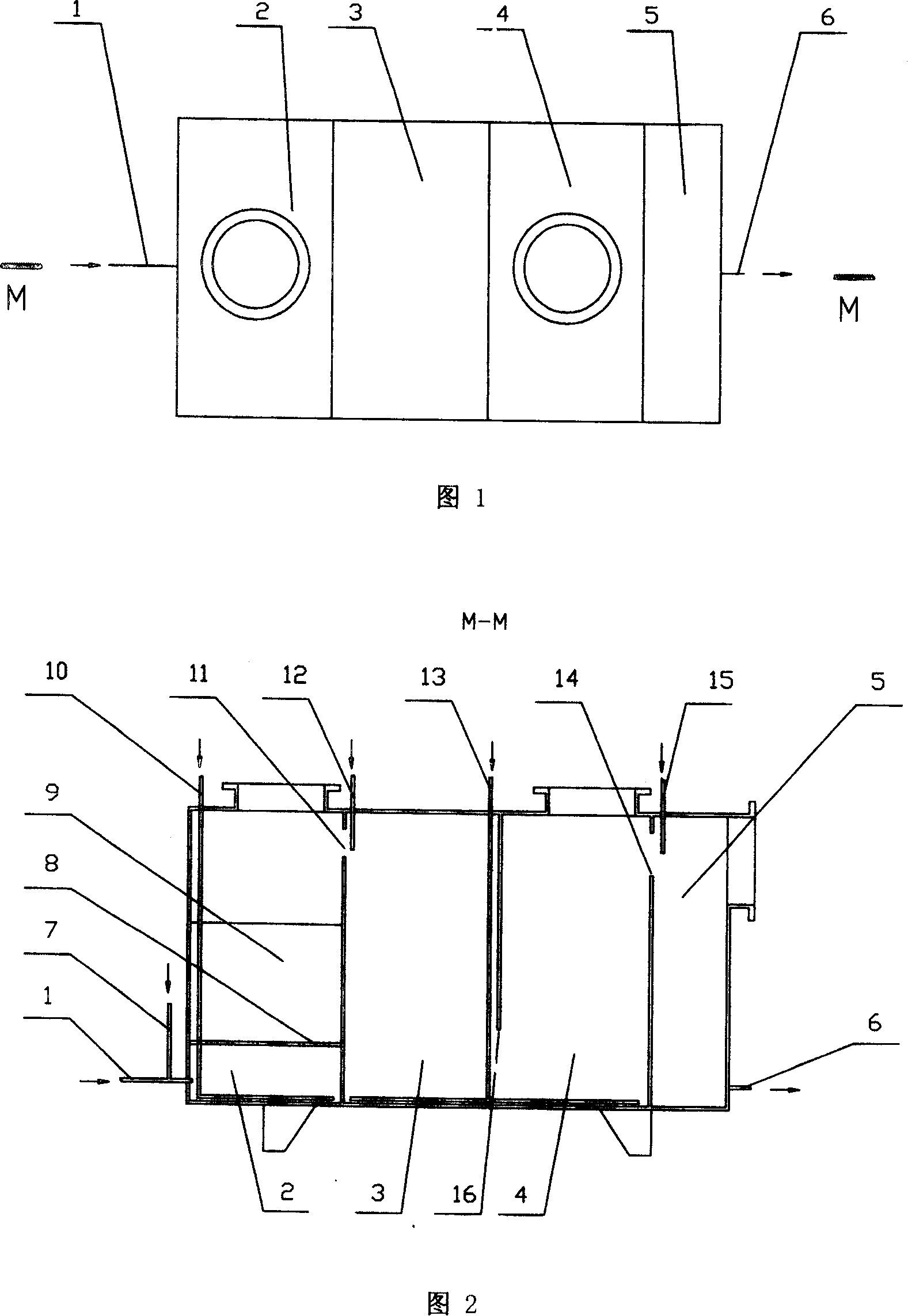

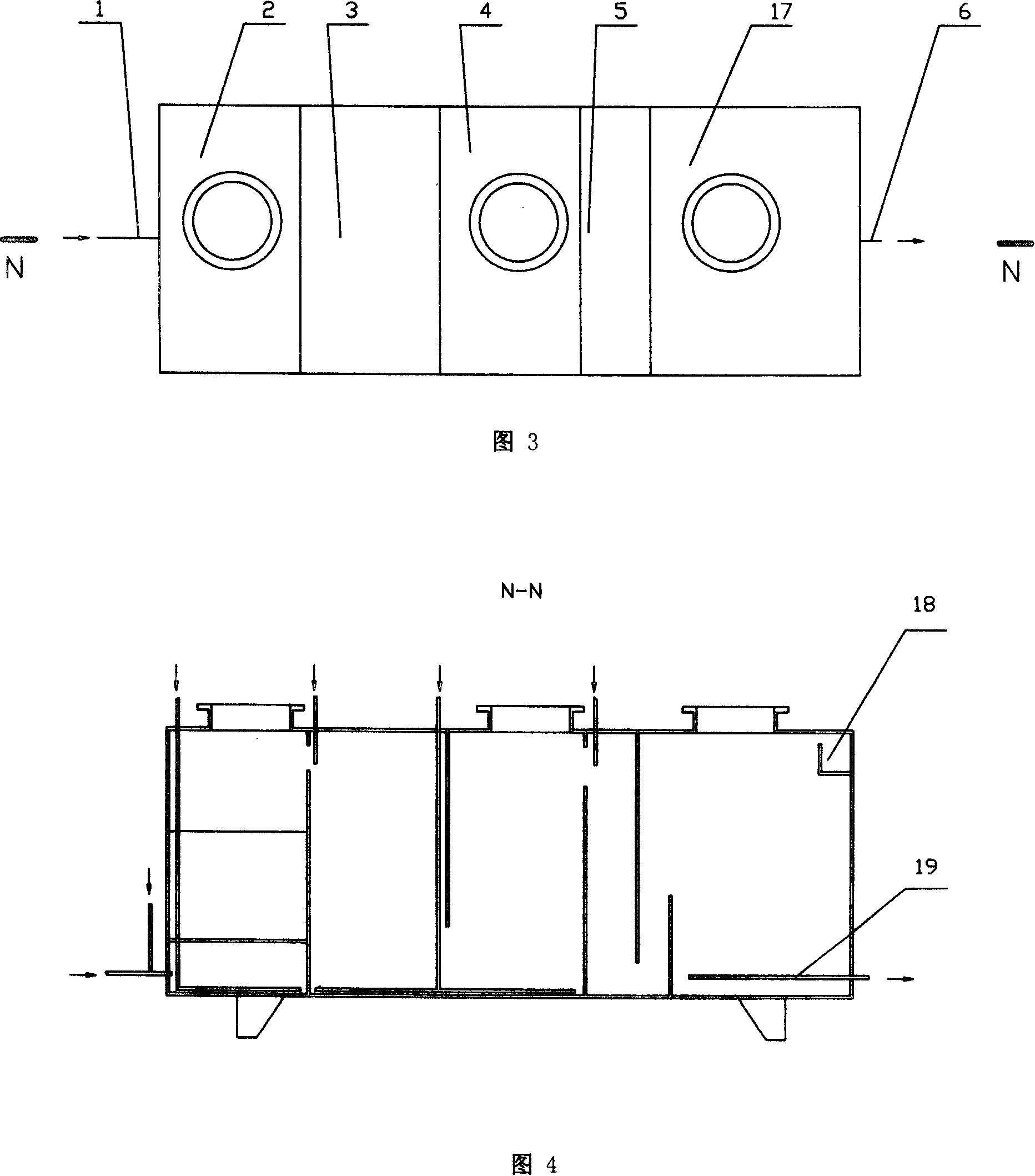

Purification treatment method and apparatus for pig raising waste liquid

InactiveCN101481180ASimple processEasy to implementClimate change adaptationExcrement fertilisersPig farmsWaste processing

The invention relates to waste processing, in particular to a method and a device for purifying waste liquid from pig cultivation, which solves the problem that the waste liquid of pig cultivation pollutes the environment. After solid and liquid waste generated by pig cultivation is separated, absorption, filtration and automatic purification technology is used for enabling the separated waste liquid from pig cultivation to enter into a first absorption pool for first absorption and filtration, then filtrated liquid enters an automatic purification depositing pool for purification depositing processing and then a second absorption pool for second absorption and filtration processing, and lastly, the processed waste water reaches the standard and is discharged. The device for purifying waste liquid from pig cultivation comprises a first absorption and filtration pool, an automatic purification depositing pool and a second absorption and filtration pool which are sequentially communicated, wherein filtration material is arranged in the absorption and filtration pools, and the filtration material is only one or a plurality of layers of furnace slag, crop stems, zeolite and gravel. The invention has simple technology, low cost and easy application, and is suitable for the purification and the standard discharge of the waste liquid from family type pig farms or small pig farms.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Method for treating home wastewater through artificial wetland combined vertical current with surface current

ActiveCN1686868ASolve shortcomings such as insufficient aerobic treatment capacityExcellent removalSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandFiltration

The present invention discloses a combined artificial wet land domestic sewage treatment method. Said combined artificial wet land is formed from front vertical-flow artificial unit land and rear surface-flow artificial wet land which are series-connected together. Firstly, the domestic sewage can be fed into precipitation tank to remove sand and large-granule suspended solids, then fed into vertical-flow artificial wet land to implement filtration treatment, in the vertical-flow artificial wet land the artificial mixed matrix can be filled and the ornamental plants can be planted, then the sewage can be fed into the surface-flow artificial wet land to make purification treatment, in the surface-flow wet land the water plants, flower plant and vegetables can be planted or the fishes can be bred.

Owner:SOUTH CHINA AGRI UNIV

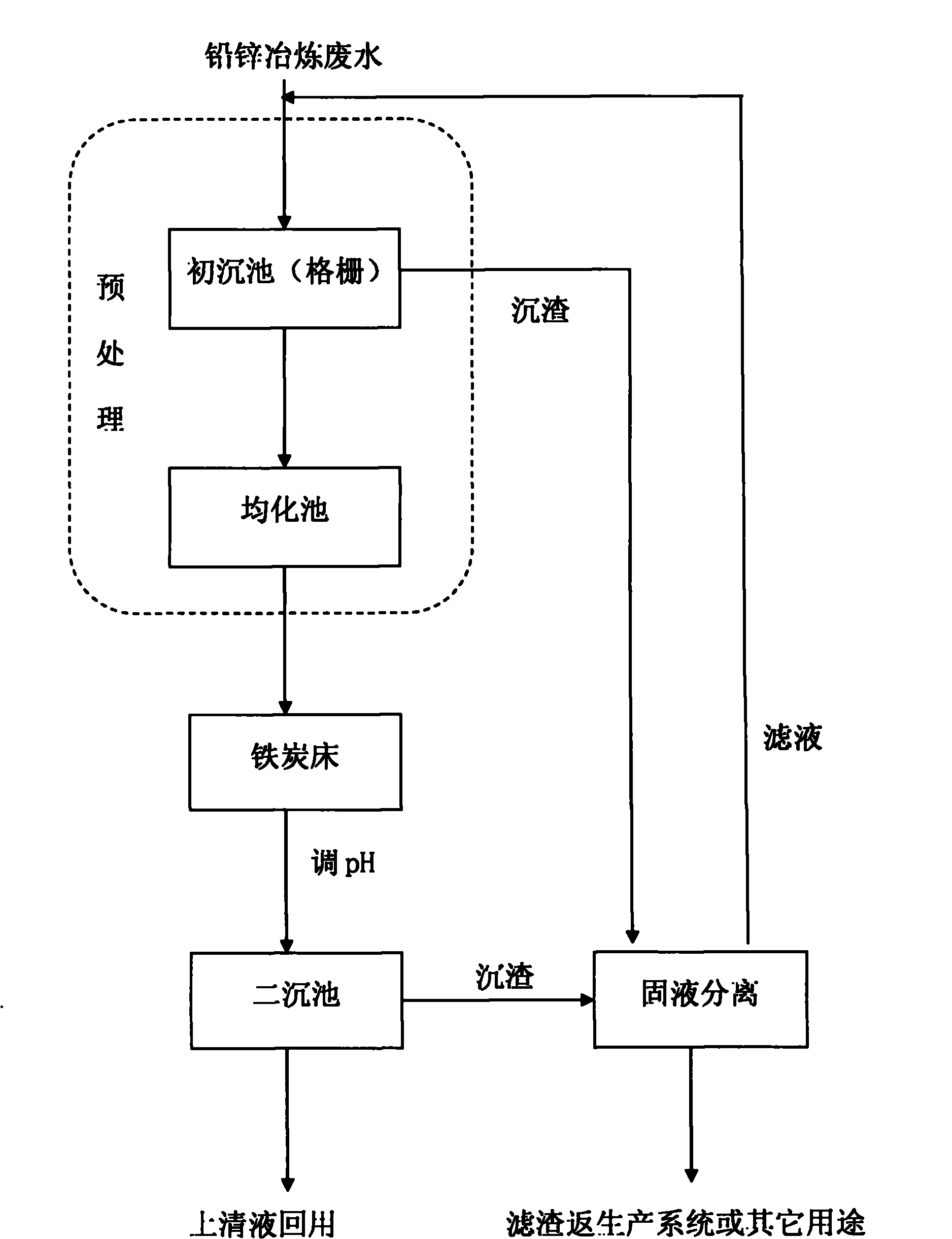

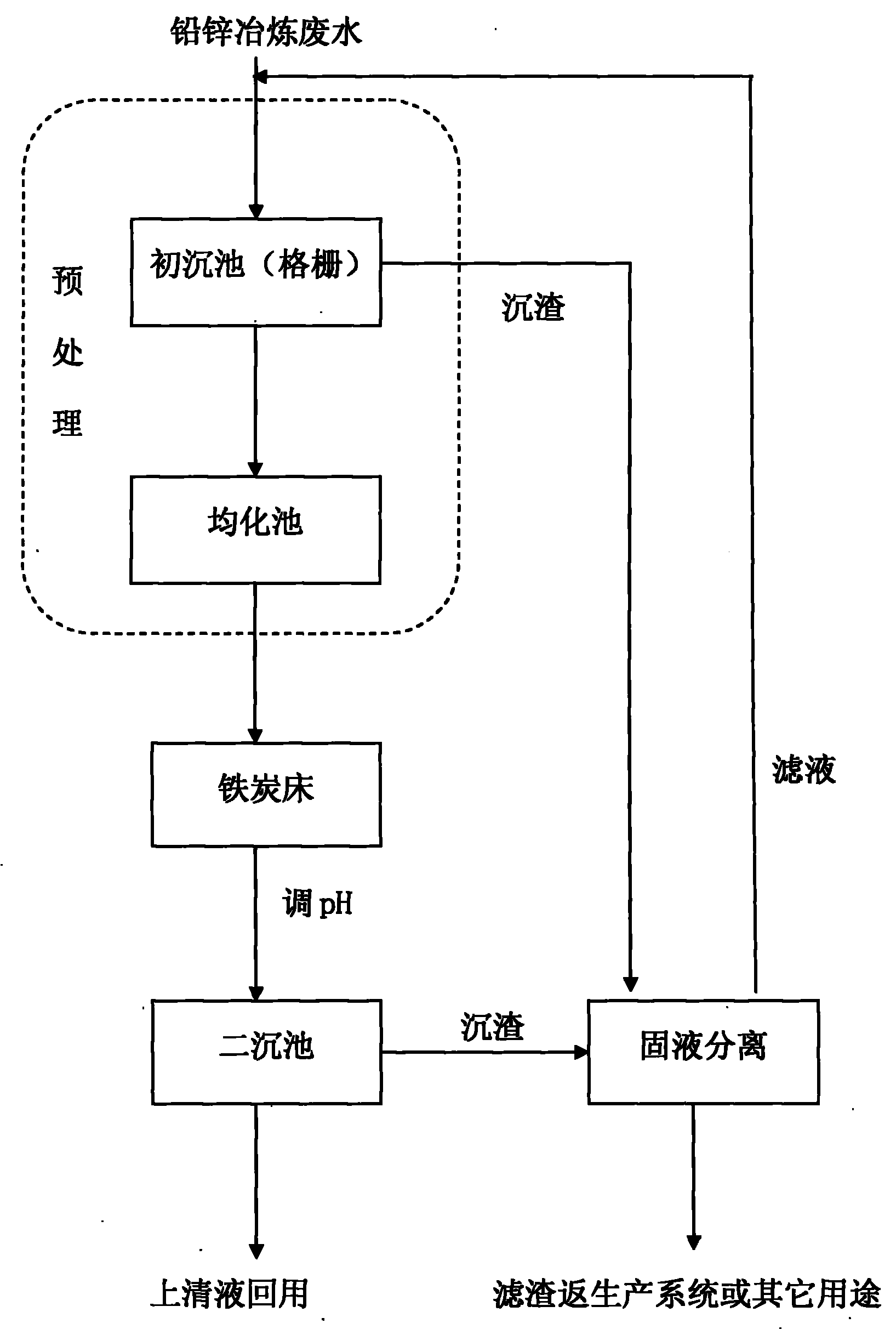

Micro-electrolysis method for lead and zinc smelting waste water

InactiveCN101928085ASimple processEasy to handleWaste water treatment from metallurgical processWater/sewage treatmentElectrolysisTherapeutic effect

The invention relates to a method for treating smelting waste water, in particular to a micro-electrolysis method for lead and zinc smelting waste water, which belongs to the technical field of environment protection. The method comprises the following steps of: pretreating lead and zinc smelting acid waste water and feeding the pretreated waste water into an iron carbon bed for reacting, wherein the mass ratio of scrap iron to active carbon is 0.5-3:1; recycling most of heavy metal pollutants by performing a micro-electrolysis reaction, wherein a pH value is increased; adjusting the pH to be between 7.5 and 9.5 and generating a flocculating constituent from Fe<2+> and Fe<3+> generated in a previous reaction; precipitating and removing remaining heavy metal ions together with arsenic and fluorine pollutants by adsorption, flocculation and co-precipitation; and recycling supernatant serving as industrial water. The method has the advantages of good treatment effect on the lead and zinc smelting waste water, low cost and capability of recycling heavy metal resources and reusing treating water.

Owner:KUNMING UNIV OF SCI & TECH

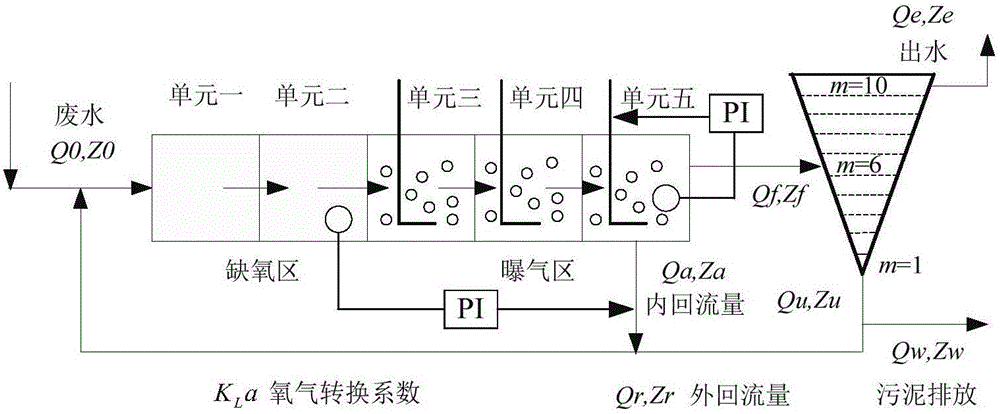

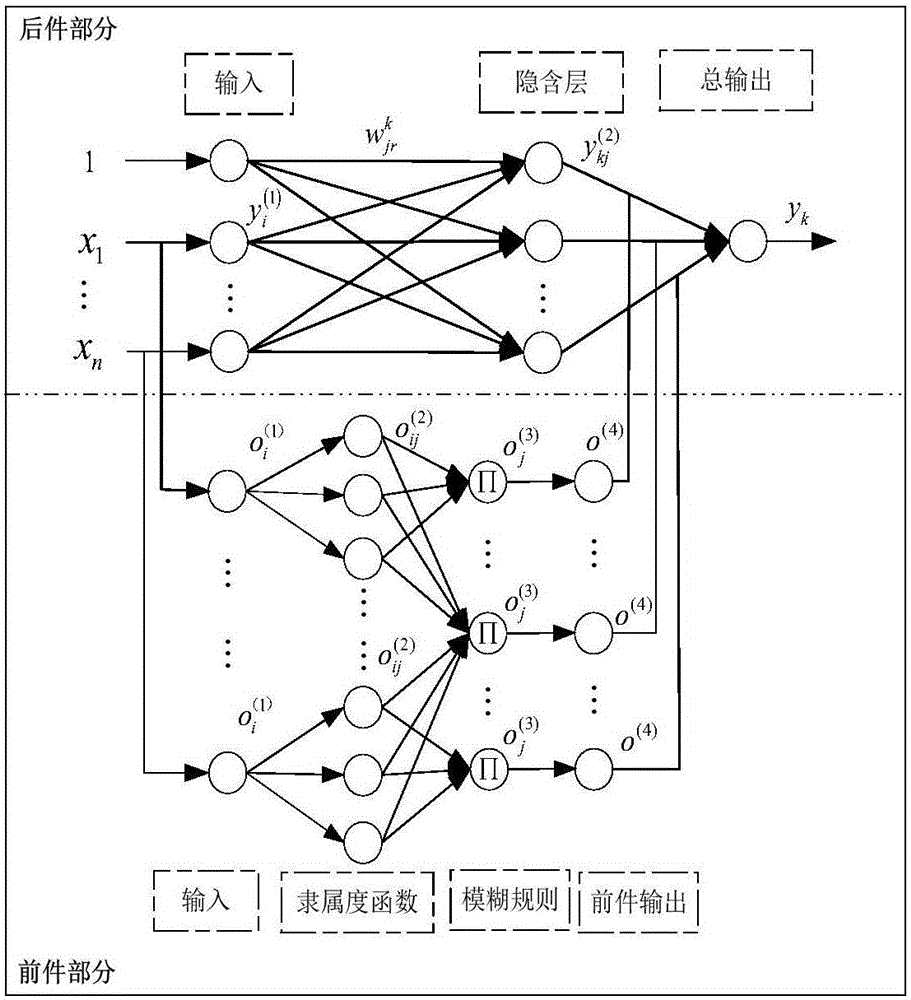

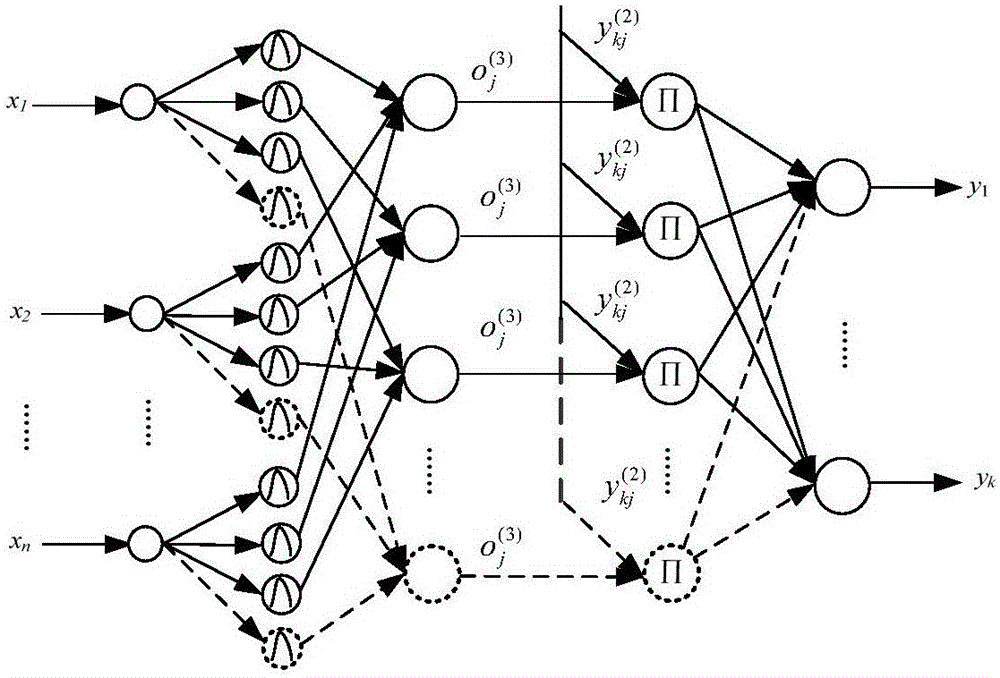

Control method for sewage treatment process based on self-organizing neural network

The invention discloses a control method for sewage processing process based on the self-organizing neural network, and belongs to the fields of water treatment and intelligent information control. The method mainly comprises adjustment for fuzzy rules by a self-organizing mechanism and self-adaptive learning control of T-S fuzzy neural network. The method comprises the steps that comparison is carried out on the basis of a T-S fuzzy neural network controller; self-organizing adjustment is carried out on the fuzzy mechanism; self-adaptive learning of the neural network is carried out; and the fuzzy rule m at the time k is obtained, and the sewage treatment process at the time k is controlled. The method can be used to adjust the internal structure of the controller in real time according to the environment state, and an object is controlled stably. The self-organizing mechanism is used to adjust the controller structure in real time so that the controller can satisfy environment requirements more effectively; the intelligent control method can be used to control the sewage treatment process stably, so that the quality of output water meet the discharge standard; and the defect that a controller of a fixed network structure is low in environment adaptability is overcome.

Owner:BEIJING UNIV OF TECH

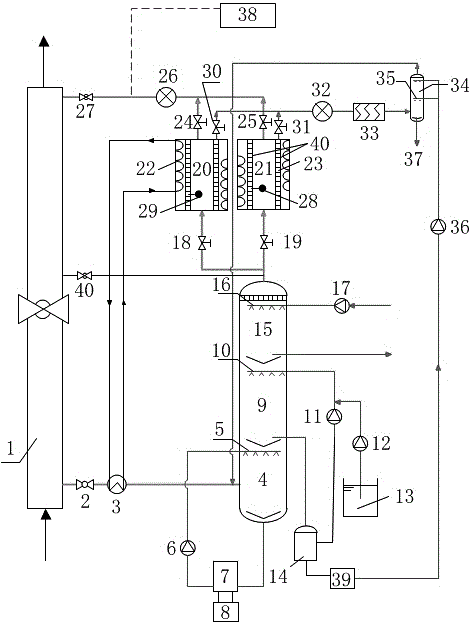

Processing technique for oil-contaminated water and equipment thereof

InactiveCN101108761AChange natureMeet emission standardsMultistage water/sewage treatmentWater/sewage treatment by neutralisationElectrolysisOil field

The oily sewage disposal process and the equipment are provided, which relates to the oily sewage disposal equipment and the process in the oil field operation. The equipment comprises a processor chamber, an acidizing fluid tank, an oxidized fluid tank, a lye tank and a controller; wherein, the processor chamber is communicated by a micro-electrolysis reactor, an Fenton reactor and a sedimentator in turns; the acidizing fluid tank is connected with a water inlet; the micro-electrolysis reactor is filled with fillers in the middle; the oxidized fluid tank and the lye tank are correspondingly connected with the Fenton reactor and the sedimentator; valves are provided at the entrance and exit of each pipeline and each valve and a water pump are separately connected with the controller. The disposal process of the invention comprises the following steps: 1) micro-electrolysis reaction; 2) Fenton reaction; 3) sedimentation; 4) sedimentator effluent input clear water tank. The invention is an ideal choice for replacing the traditional nutshell filer with unamiable disposal effects and is characterized by small investment, long life, low operation cost and simple operation, which can effectively solve the difficulty of the oil field water pollution.

Owner:YANGZHOU UNIV

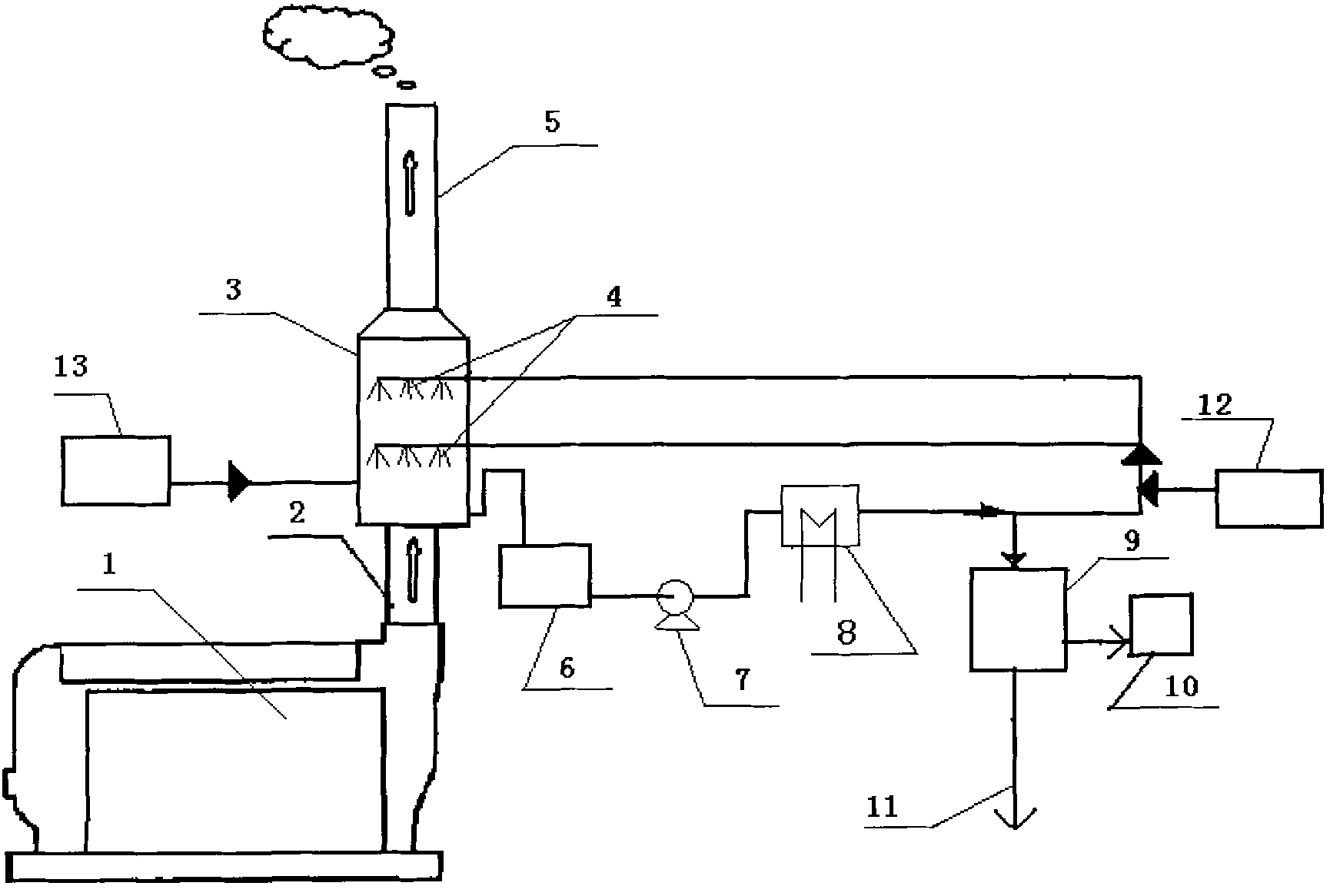

Device and method for performing alkali desulfurization and dust removal on ship exhaust fume

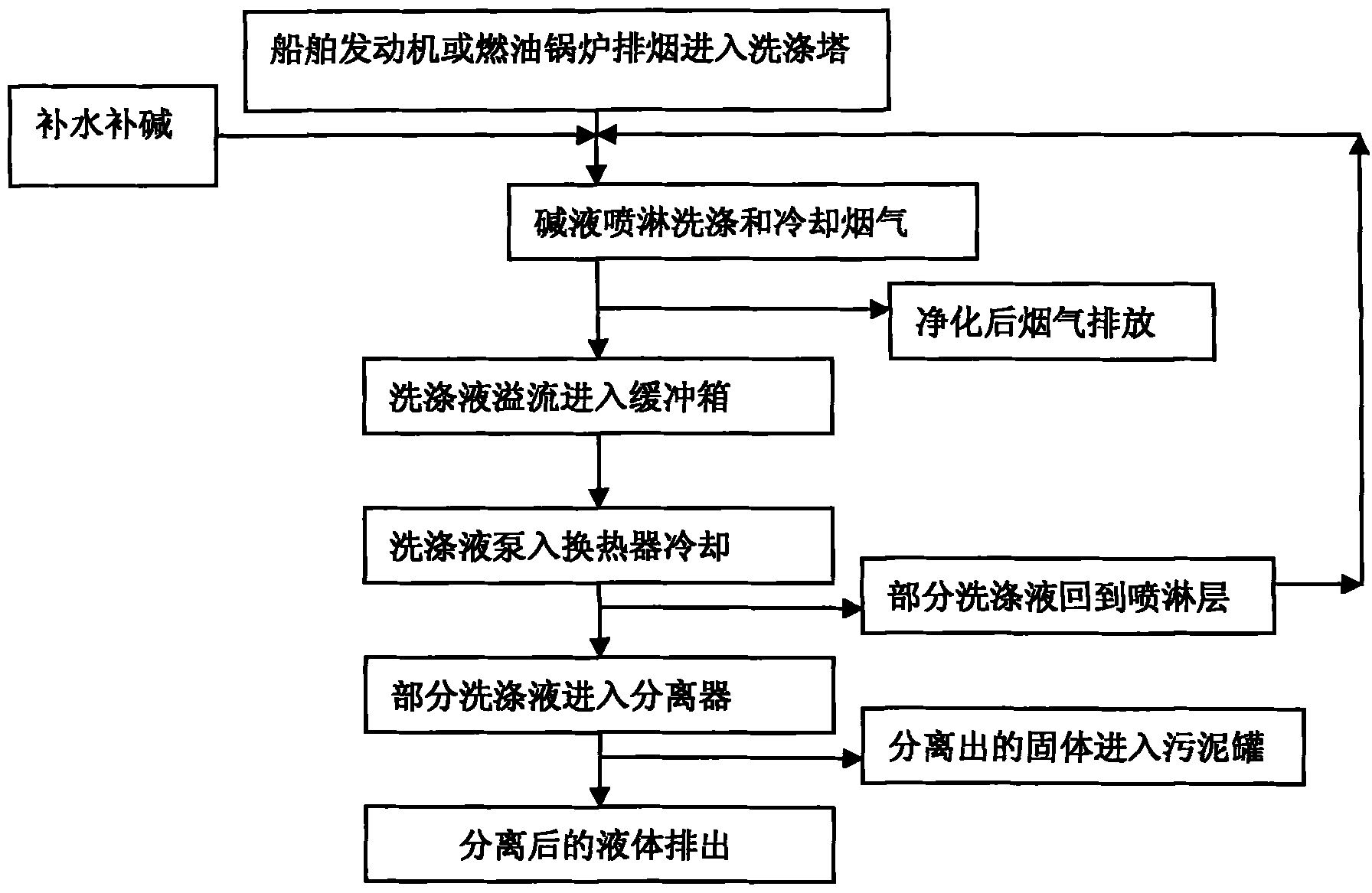

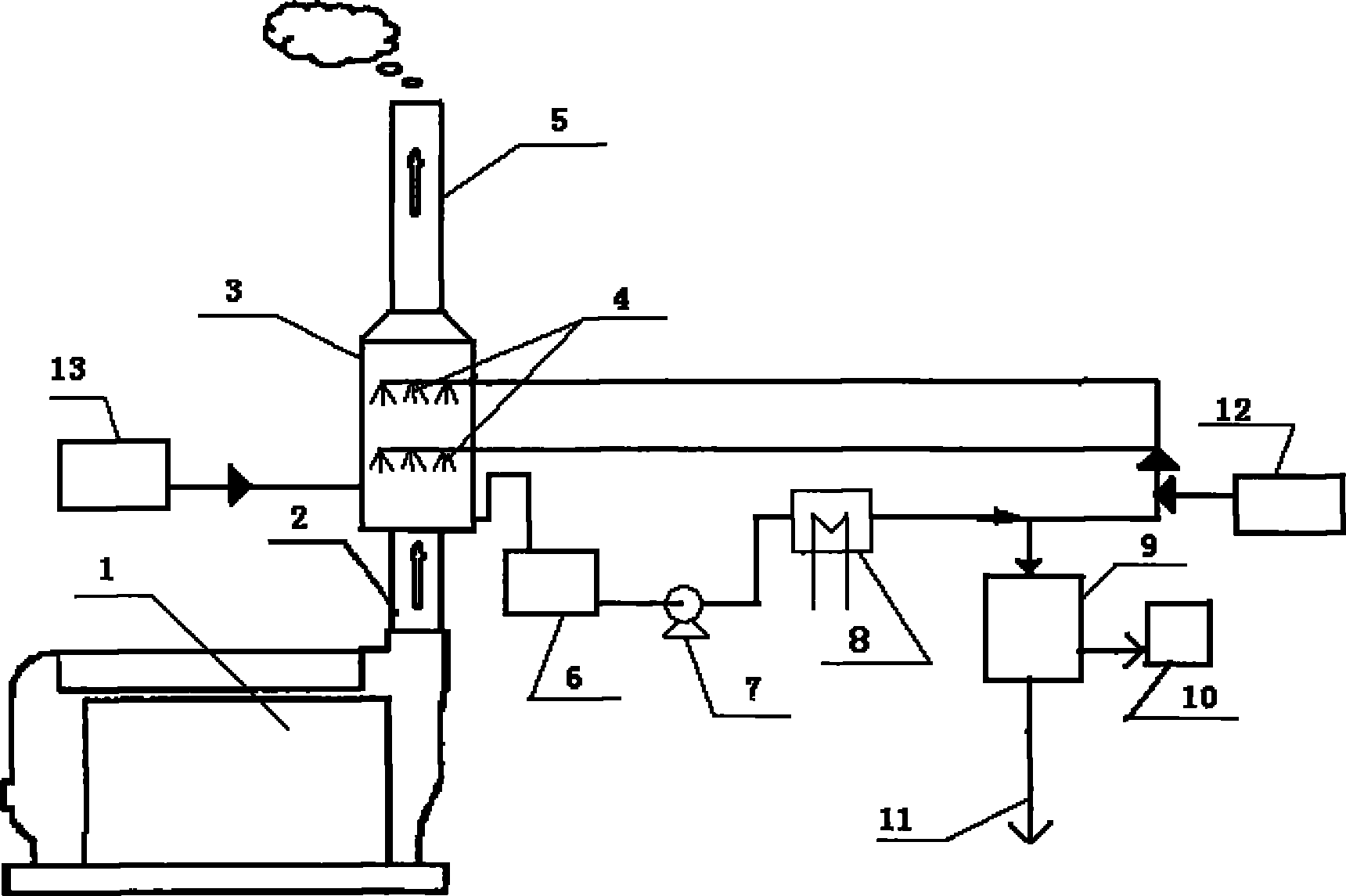

InactiveCN102309912AReduce the temperatureReduce evaporationUsing liquid separation agentSludgeAtmospheric air

The invention discloses a device and a method for performing alkali desulfurization and dust removal on ship exhaust fume, which relate to the technical field of atmospheric environment protection. The device comprises an engine / burning boiler on a ship and is characterized in that: exhausted gas of the engine / burning boiler is connected to a washing tower through a gas duct; a spraying layer connected with an alkaline liquor supplying pipe is arranged in the washing tower; a fresh water supplementing unit is connected to the lower part of the washing tower through a pipeline; an outlet at the bottom of the washing tower is connected to the alkaline liquor supplying pipe through a buffering box, a pump and a heat exchanger sequentially; an outlet of the heat exchanger is also connected with an inlet of a separator; two outlets of the separator are respectively connected with a discharge pipe and a sludge tank; and an alkaline liquor supplementing unit is connected with the alkaline liquor supplying pipe. When the device and the method are compared with the prior art, under the condition of relatively small amount of used water, very high desulfurization efficiency can be met, the device and the method have the characteristics of small occupied space and low cost, and can be applied to desulfurization of ships or burning boilers navigating in different sea areas and pollutant control regions.

Owner:TONGFANG ENVIRONMENT

Deep treatment method for printing ink wastewater by membrane method

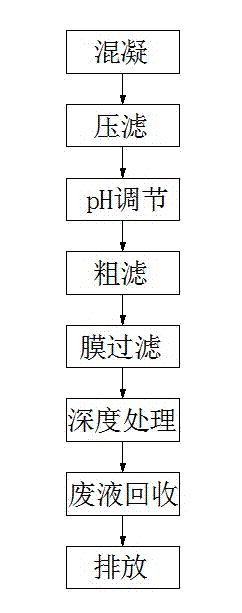

ActiveCN103043821AEasy to handleMeet emission standardsMultistage water/sewage treatmentChemical oxygen demandProcess engineering

The invention discloses a deep treatment method for printing ink wastewater by a membrane method. The method comprises the following steps: S1, coagulating; S2, filtering and pressing; S3, adjusting the pH value; S4, roughly filtering; S5, implementing the membrane filtration; S6, implementing the deep treatment; and S7, recovering waste liquid. The deep treatment method for the printing ink wastewater by the membrane method has the benefits that various composed printing ink wastewater can be treated better with stable treatment effect, most soluble and dissoluble pollutants in the printing ink wastewater are removed to enable the chromaticity and the COD (Chemical Oxygen Demand) of the printing ink wastewater to achieve the emission standard, and the method has excellent social and economic benefits.

Owner:SUZHOU FAITH HOPE MEMBRANE TECH

Basic copper chloride production method

ActiveCN103351020AImprove recycling effectSimplified processing stepsCopper chloridesAmmoniacal nitrogenTribasic copper chloride

The invention discloses a method for producing tribasic copper chloride. The method for producing the tribasic copper chloride includes the following steps of: (1) removing impurities from an acidic etching waste solution; (2) adding clean water or a tirbasic copper chloride production mother solution to a synthesis reactor, performing preheating, and then, preheating the acidic etching waste solution whose impurities have been removed and an alkaline solution of sodium hydroxide and mixing the two solutions for a reaction with the pH value and temperature of the reaction being controlled so as to gradually form the tribasic copper chloride, and discharging partial materials after a certain amount of reaction time; (3) filtering the materials discharged from the reaction system, and performing washing, suction filtration, centrifugation and drying on the filtrated residues to obtain the tribasic copper chloride; and (4) performing ammonia nitrogen removal treatment on filtrated liquid. By adopting the method for producing the tribasic copper chloride in the invention, continuous production can be achieved and the tribasic copper chloride with large particle size and high purity can be produced; further, production cost can be reduced and overall process can be integrated; and the method for producing the tribasic copper chloride is advantaged in simple ultimate steps of ammonia nitrogen removal, easiness in operation as well as reduced difficulty and cost of ammonia nitrogen treatment.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

Waste gas purifying device applicable to incinerator

The invention discloses a waste gas purifying device applicable to an incinerator. The waste gas purifying device comprises an incinerator waste gas purifying device body, and a waste gas inlet pipe communicated with the exhaust port of an incinerator body, wherein the tail end of the waste gas inlet pipe is communicated with a dust catcher; an upper dust removal baffle and a lower dust removal baffle are arranged in the dust catcher; the upper dust removal baffle and the lower dust removal baffle are arranged at intervals; the tail end of the dust catcher is communicated with a waste gas exhaust pipe; the tail end of the waste gas exhaust pipe is communicated with an exhaust chimney; a left supporting plate and a right supporting plate which are longitudinally staggered are arranged on the inner side wall of the exhaust chimney; a flue gas pre-spray heat sink is arranged on the left supporting plate; a flue gas pre-spray desulfurizer is arranged on the right supporting plate; a waste gas purifying tank is formed at the bottom of the exhaust chimney; a deslagging door is arranged at the bottom of the dust catcher; a pressure release valve is arranged at the top of the dust catcher. The waste gas purifying device can filter poisonous gas, heavy metal and dust produced during the combustion of fire coal, effectively solves the problem of waste gas pollution, and avoids the risk of explosion caused by overlarge air pressure inside the device.

Owner:广州拉斯卡工程技术有限公司

Production process of bleached chemical pulp with hemp stalk core

InactiveCN1811055ATake advantage ofEfficient use ofFats/resins/pitch/waxes removal in pulpPulp bleachingHypochloriteSulfate

The production process of bleached chemical pulp with hemp stalk core includes the following steps: 1. cutting hemp stalk core as material into 2-3 cm long sections, sieving and digesting in sulfate process to produce pulp; 2. washing and sieving the obtained pulp and oxygen delignifying; and 3. bleaching pulp with small amount of hypochlorite in a short program. Of the process, the medium concentration oxygen delignifying technology is one clean environment friendly bleaching technology with the bleached effluent being recovered and reused completely without environmental pollution, and the medium concentration hypochlorite bleaching can lower the exhausted waste water and reduce chemical and power consumption effectively. The pulp of the present invention can meet the requirement of making common paper.

Owner:SOUTH CHINA UNIV OF TECH

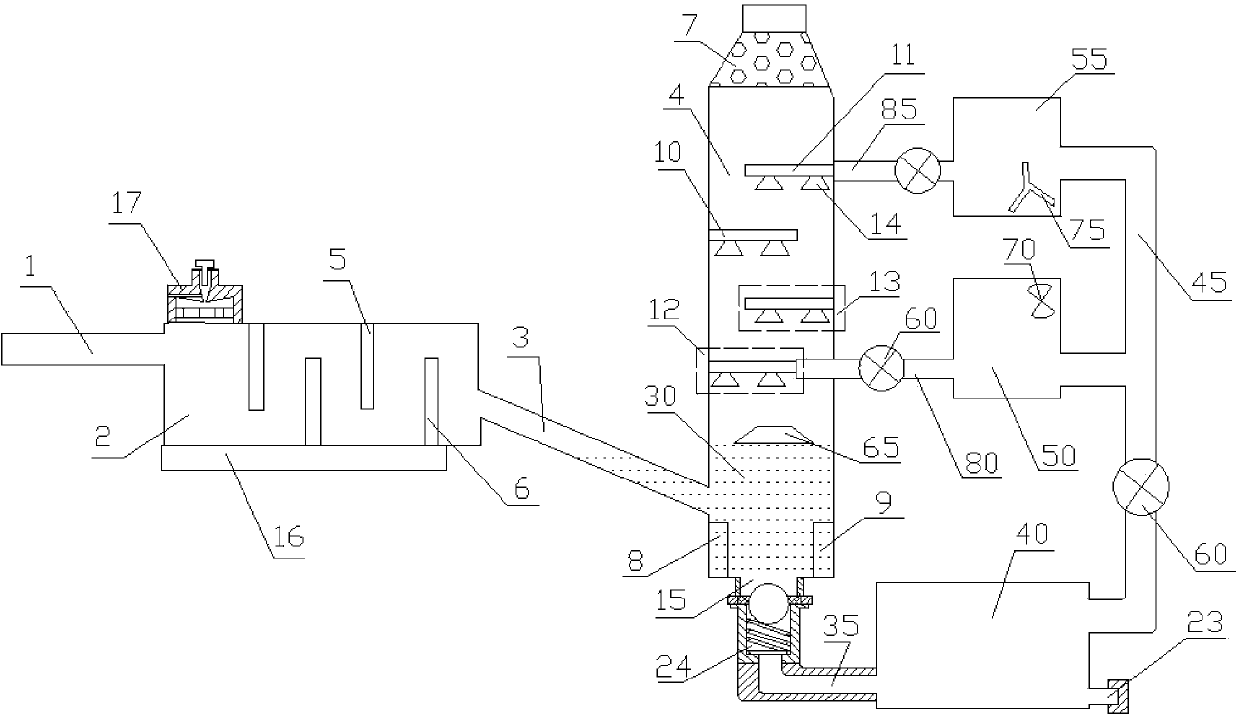

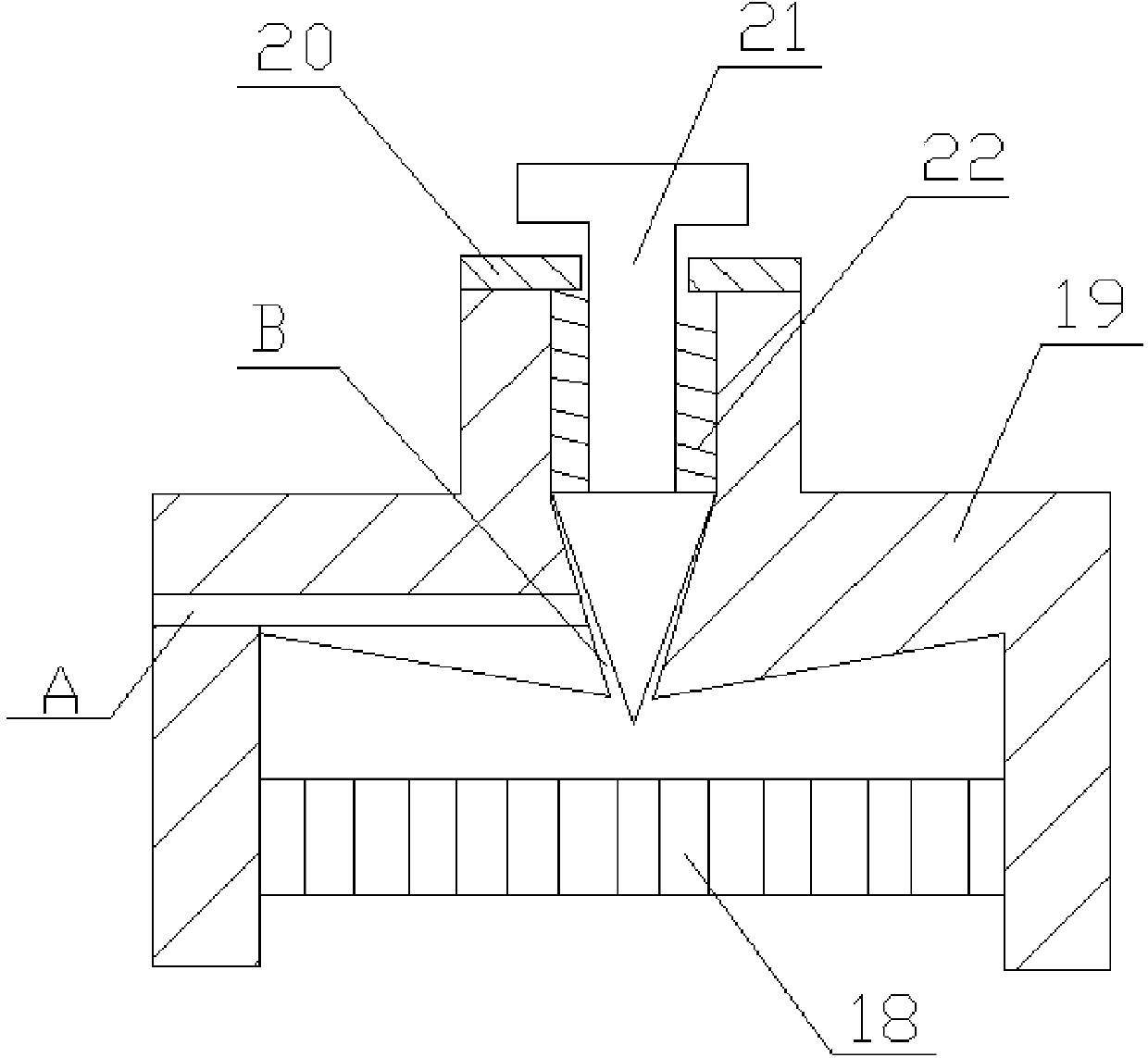

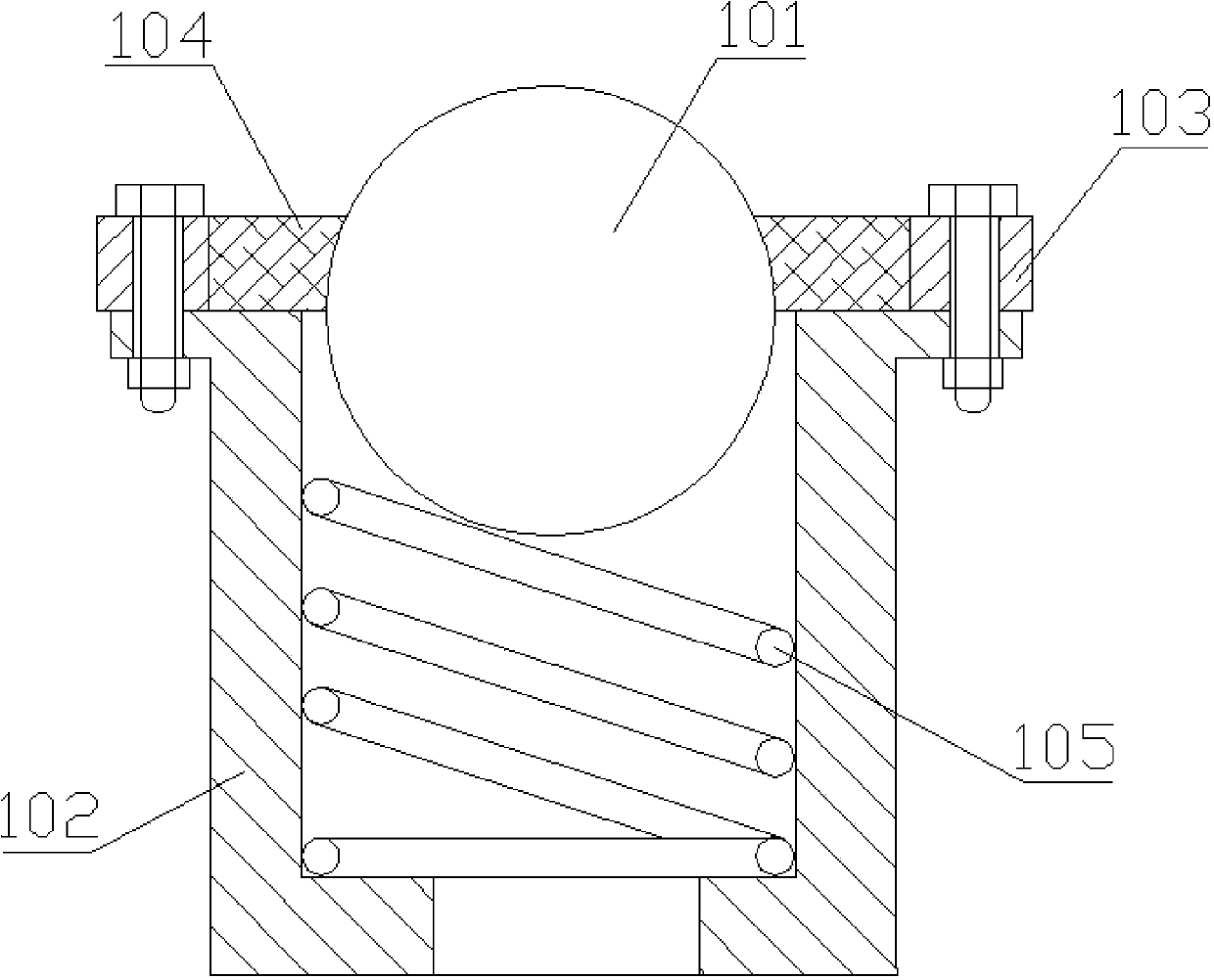

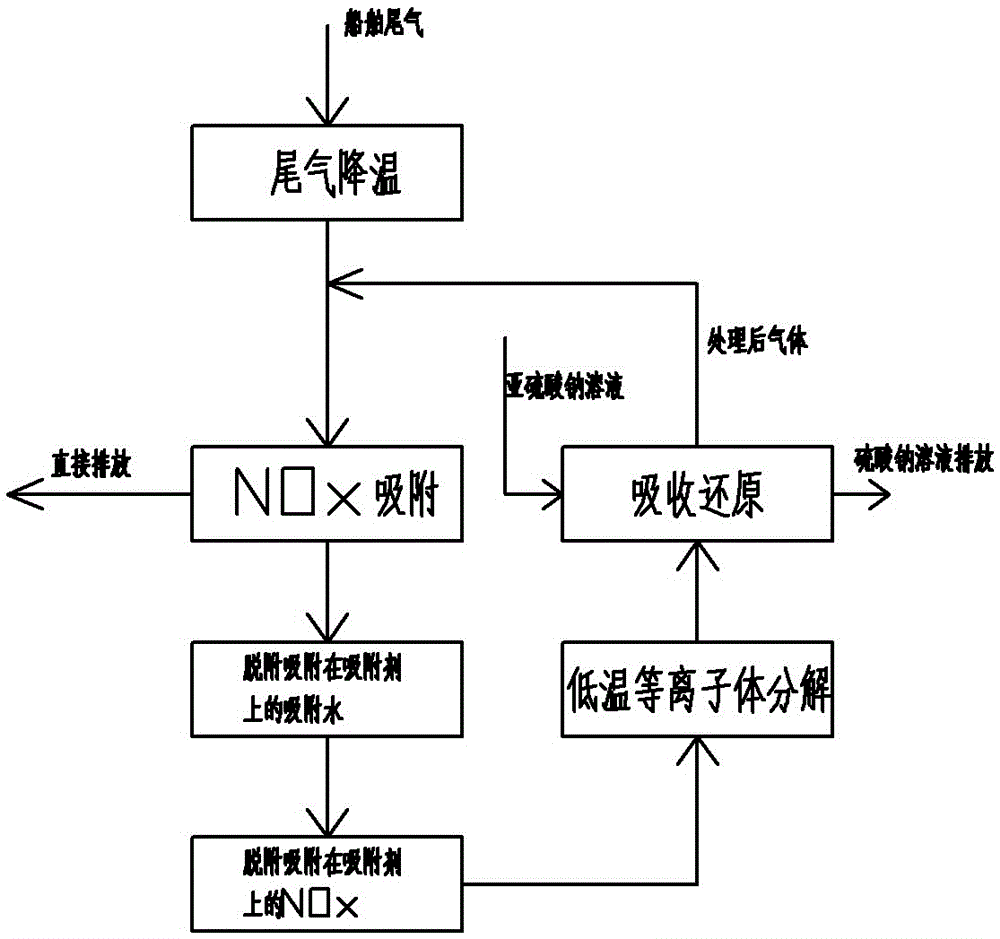

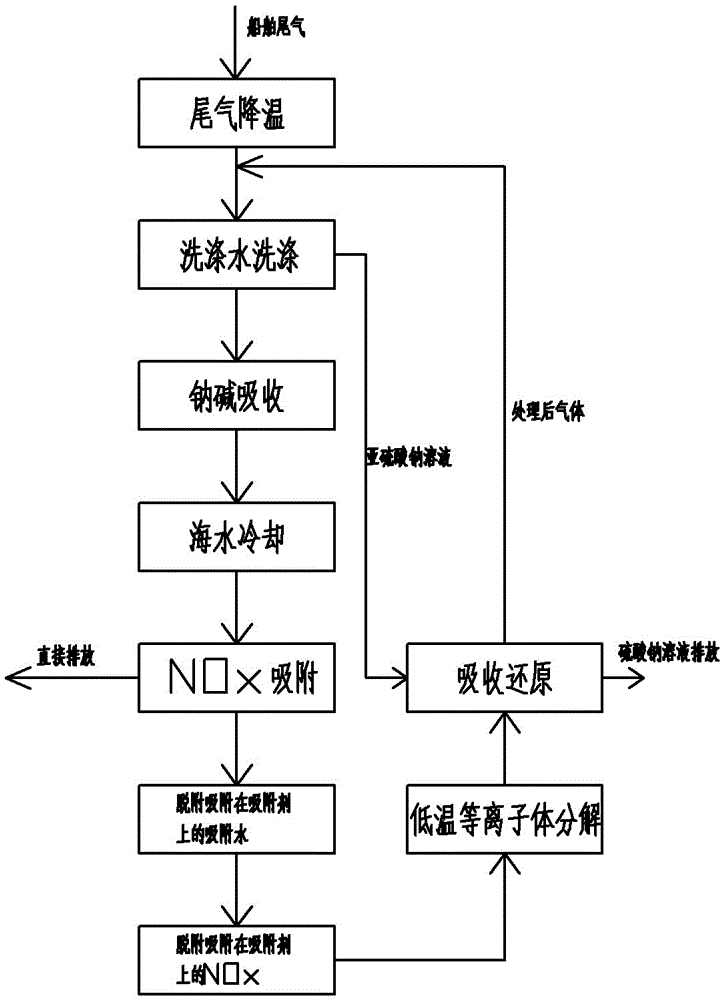

Ship tail gas denitration technology and system and desulfurization and denitrification integrated technology and system

ActiveCN105536486AEfficient use ofEfficient regenerationNitrous oxide captureGas treatmentSorbentDecomposition

The invention belongs to the field of ship tail gas treatment, energy conservation and environment protection, and particularly relates to a ship tail gas denitration technology and system and a desulfurization and denitration integrated technology and system. When low sulfur oil is used for a ship, the ship tail gas denitration technology and system can achieve high denitration efficiency and reduce energy consumption; when high sulfur content is used for the ship, desulfurization and denitration are combined together, high desulfurization and denitration efficiency is achieved, meanwhile, the cost is greatly saved, and the tail gas exhaust standards are met. The ship tail gas denitration technology comprises the steps of 1, tail gas cooling, 2, NOX adsorption, 3, desorption of NOX adsorbed on an adsorbent, 4, low-temperature plasma decomposition and 5, absorption and reduction. The ship tail desulfurization and denitration integrated technology comprises the steps of 1, tail gas cooling, 2, washing performed through washing water, 3, soda absorption, 4, NOX adsorption, 5, desorption of adsorption water adsorbed on an adsorbent, 6, desorption of NOX adsorbed on an adsorbent, 7, low-temperature plasma decomposition and 8, absorption and reduction.

Owner:张拿慧

Method for screening denitrifying bacterium

ActiveCN102041291AImprove toleranceDifferent denitrificationMicrobiological testing/measurementBiological water/sewage treatmentActivated sludgeScreening method

The invention discloses a method for screening denitrifying bacterium. The method comprises the following steps: (1) performing accumulation culture process on aerobic activated sludge by using ammonia-containing sewage; (2) separating and purifying denitrifying bacterium from accumulated flora; (3) acclimatizing the growing ability of the purified denitrifying bacterium with the water containingtarget pollutant; and (4) acclimatizing the denitrification ability of the acclimatized denitrifying bacterium under different dissolved oxygen conditions. When the denitrifying bacterium screened byusing the method disclosed by the invention is applied to denitrification treatment of sewage, the denitrifying bacterium not only can overcome the shortcomings of the traditional biologic denitrification technology, but also can be replenished into the impacted sewage treatment system as bioremediation agent so as to quickly recover the treating capability of the system and provide the conditionof synchronous nitration and denitrification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating organic wastewater by using microwave cooperated with bentonite

InactiveCN1446753AHigh removal rateEfficient adsorption purificationWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by sorptionMicrowaveWastewater

A process for treating organic sewage with microwave and organic bentone includes mixing granular organic bentone with organic sewage proportionally, microwave reaction under 200-5000W of power of decolouring and cleaning, and solid-liquid separation. Its advantages are short time, high effect and simple process.

Owner:ZHEJIANG UNIV

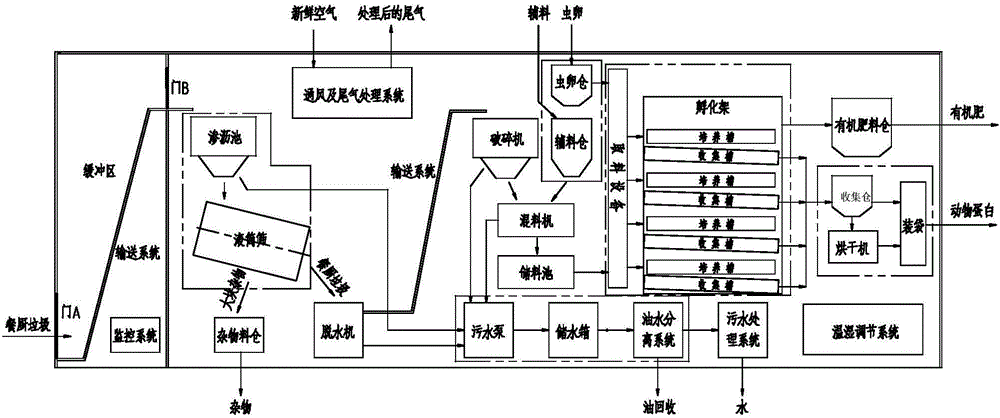

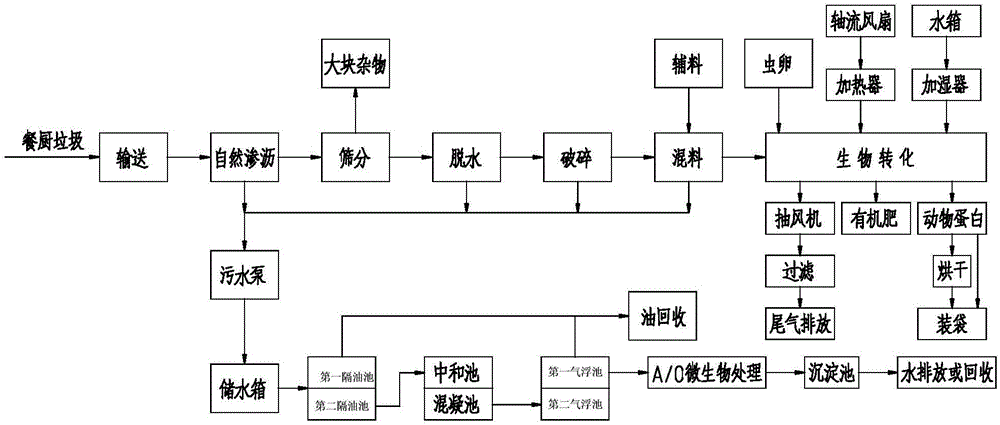

Kitchen waste treatment method based on biotransformation

InactiveCN106540951ANo secondary pollutionEfficient feedingSolid waste disposalClimate change adaptationDrug biotransformationLarva

The invention discloses a kitchen waste treatment method based on biotransformation. According to the kitchen waste treatment method based on the biotransformation, kitchen waste is treated through a concentrated incubation method based on a closed housing. The kitchen waste treatment method comprises the following steps: 1. charge: conveying the kitchen waste to an isolation buffering area of the closed housing; 2. pre-treatment comprising natural leaching, screening, dehydration, smashing and mixing; 3. biotransformation comprising spreading, inoculation and incubation, and larva collection; and 4. larva output, and treatment and discharge for waste materials and waste water. According to the kitchen waste treatment method based on the biotransformation, the kitchen waste is pre-treated and then conveyed to an incubation frame for raising insects to obtain maggots and an organic fertilizer, innocent treatment can be carried out on the kitchen waste, and economic benefits are achieved.

Owner:湖南帝星智能科技有限公司

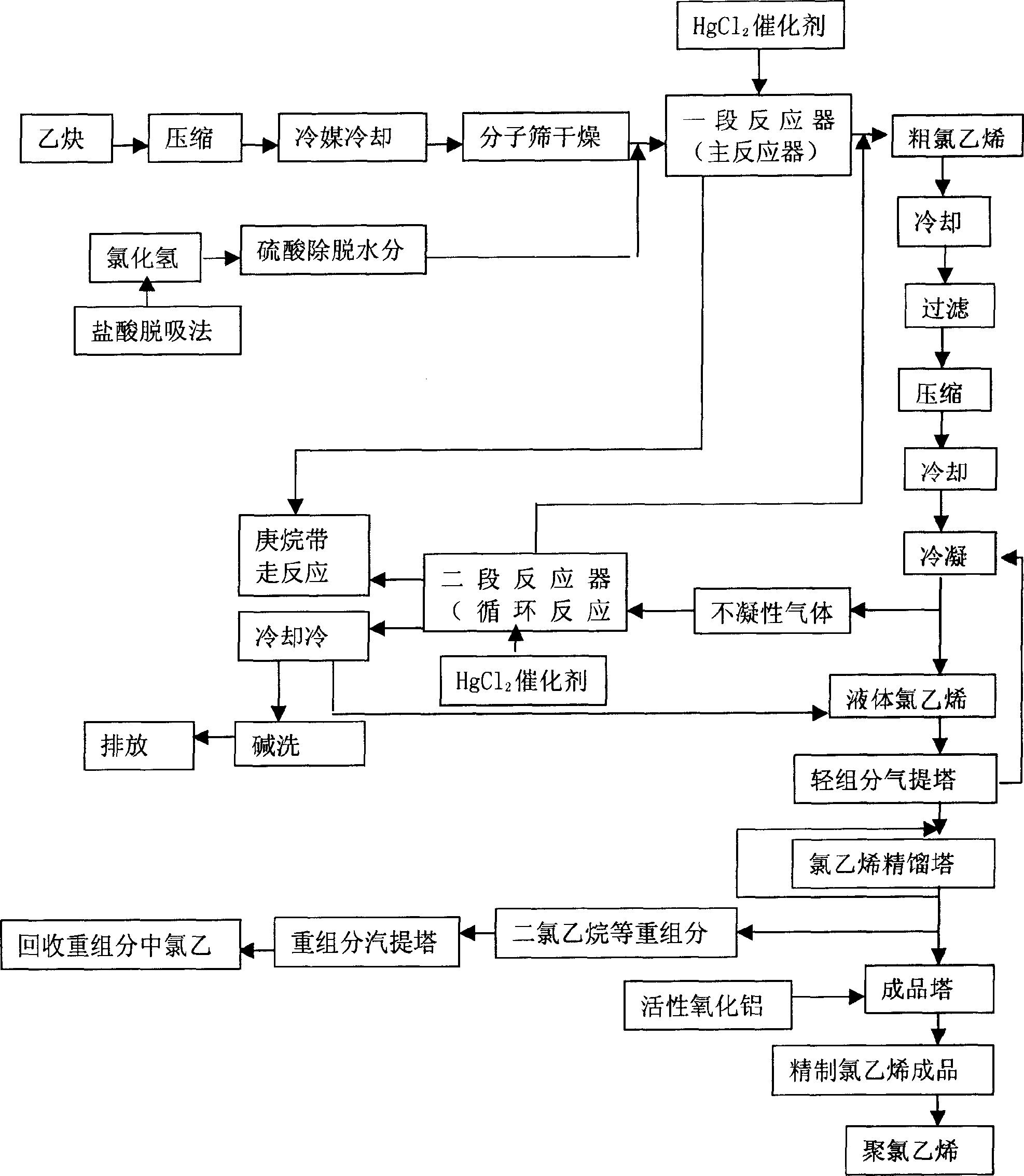

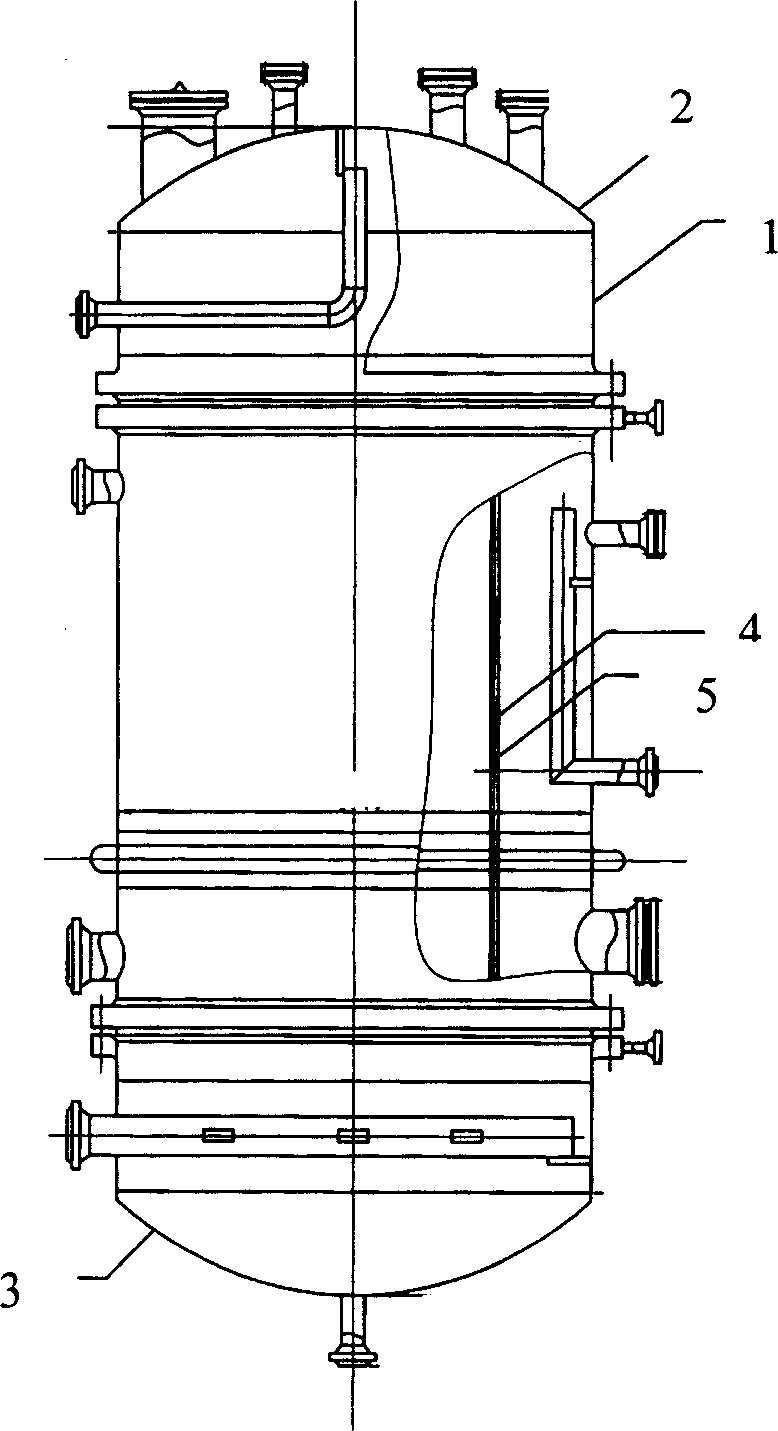

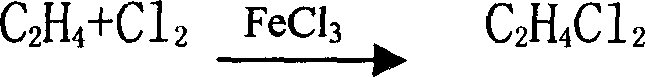

Process for producing vinyl chloride by acetylene method and dedicated device for realizing same

InactiveCN1884241ASmooth responseAvoid corrosionPreparation by halogen halide additionSewage treatmentUltimate tensile strength

The invention discloses a new method of chloroethylene through acetylene method and specific equipment, which comprises the following steps: disposing raw material gas strictly; reacting two-segment compensation; recycling heptane; cooling; radiating; providing specific catalyst and reactor to synthesize chloroethylene; disposing effluent with mercury to obtain high-purity chloroethylene monomer.

Owner:刘大军

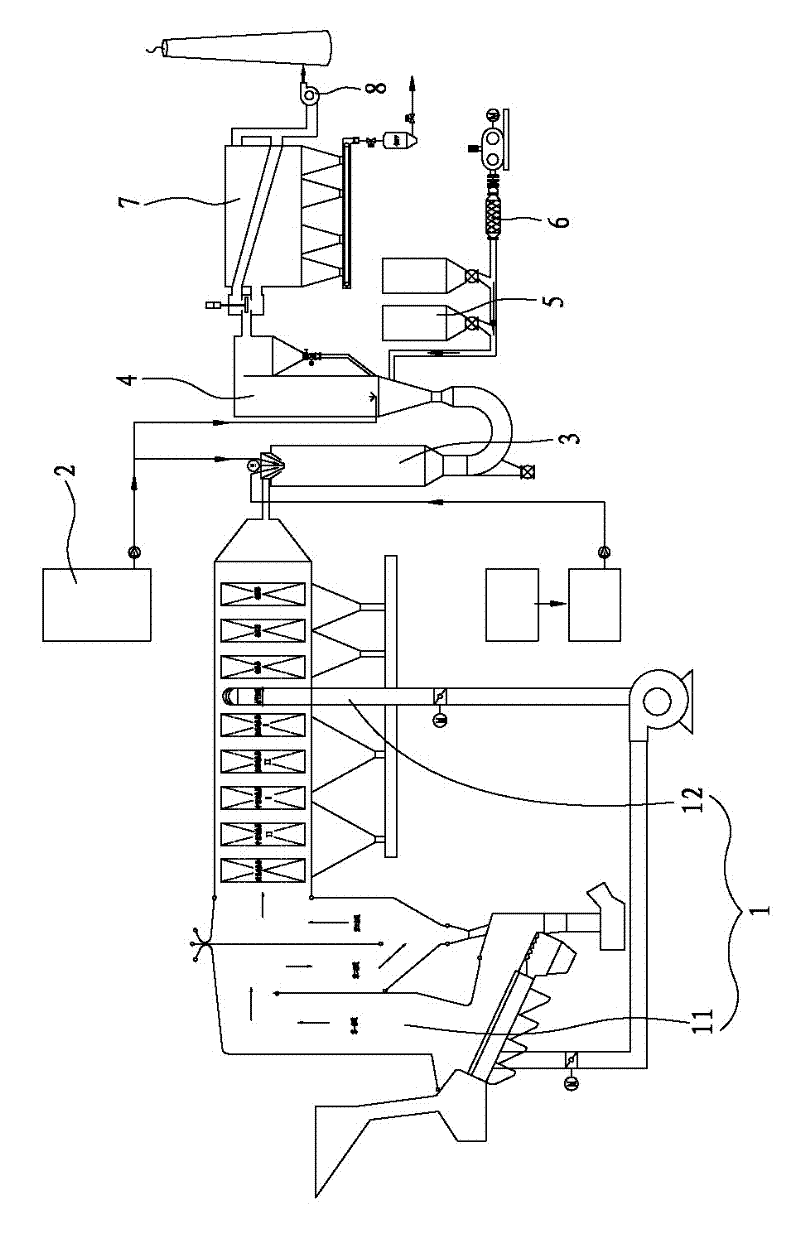

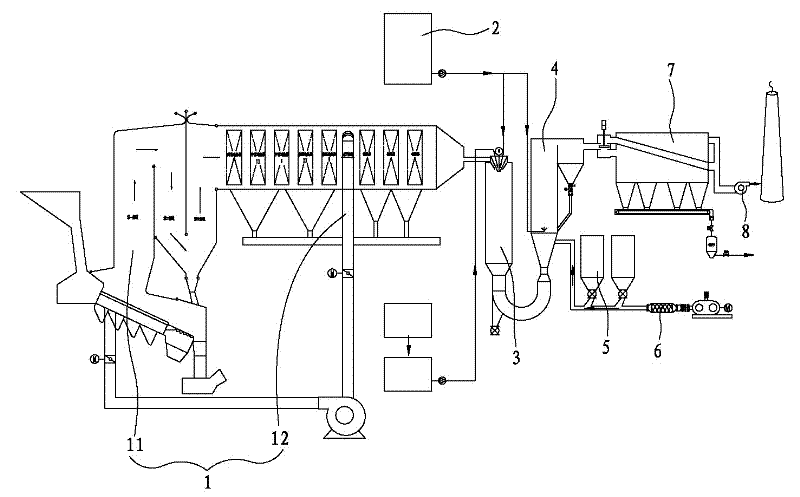

Waste burning smoke purification process and purification system

InactiveCN102233230AEmission reductionSuppress generationLighting and heating apparatusDispersed particle separationEnvironmental engineeringSpray dried

The invention discloses a waste burning smoke purification process. The process comprises a denitration step and an acid removal step. The denitration step comprises a combination step of a smoke recycling process and a selective non-catalytic reduction (SNCR) denitration process; the acid removal step comprises a primary acid removal step and a secondary acid removal step; and a spray drying method is used for removing acid in the primary acid removal step, and a suspension boiling method is used for removing acid in the secondary acid removal step. The generation of NOx is inhibited by the smoke recycling process, acidic gases in the smoke are removed by the secondary acid removal process, and the burned smoke is efficiently purified with relatively low operating cost. The deep purification effect of the smoke is achieved by organically combining several processes.

Owner:瀚蓝(厦门)固废处理有限公司 +3

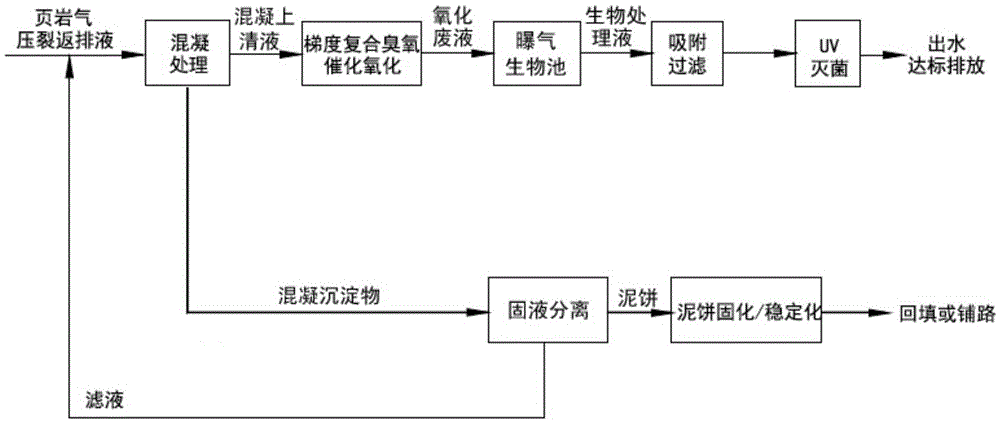

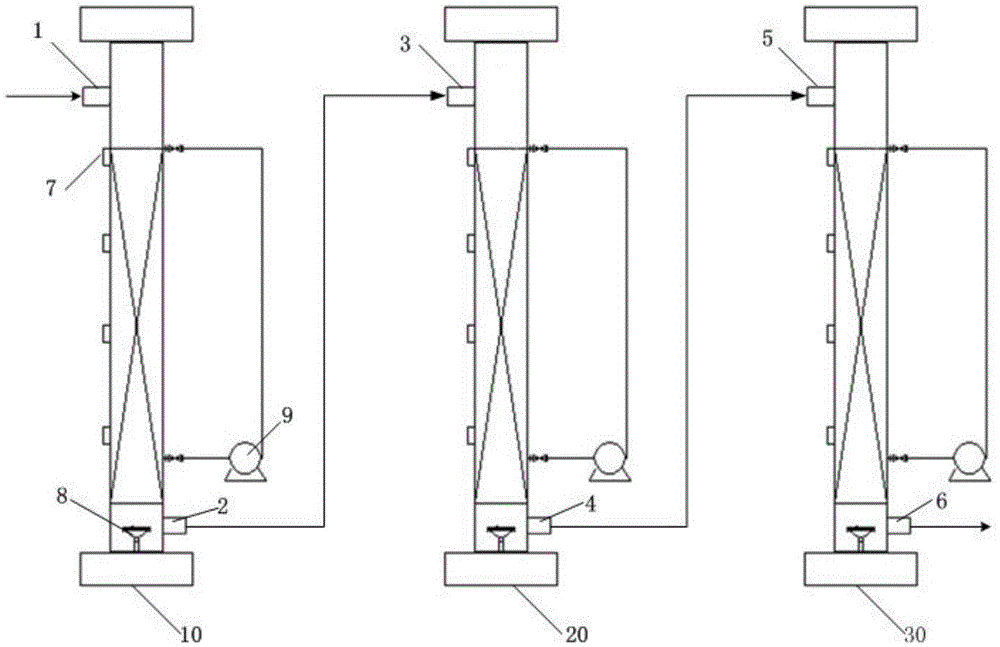

Treatment method of shale gas fracturing flowback liquid

ActiveCN105621809ARealize resource utilizationMeet emission standardsWaste water treatment from quariesTreatment using aerobic processesResource utilizationEmission standard

The embodiment of the invention discloses a treatment method of shale gas fracturing flowback liquid.The method comprises the steps that when the pH value of the shale gas fracturing flowback liquid is 5-10, an inorganic coagulant is added to the shale gas fracturing flowback liquid, stirring is conducted, a first organic coagulant and a second organic coagulant are added, stirring is continuously conducted, standing settling is conducted, filtering is conducted, and coagulation supernatant and a coagulation sediment are obtained; the pH value of the coagulation supernatant is adjusted to be 7-9 and then introduced into a gradient ozone catalytic oxidation device for gradient ozone catalytic oxidation treatment; oxidized waste liquid is treated through a biological aerated filter treatment technology; biological treatment liquid is subjected to adsorption and filtration treatment and UV sterilization treatment and then discharged; the coagulation sediment is subjected to solid-liquid separation treatment, filtrate returns back to the step for circulation treatment, and a filter cake is subjected to solidification and stabilization treatment.By means of the treatment method of the shale gas fracturing flowback liquid, pollution of the shale gas fracturing flowback liquid is removed, the treated shale gas fracturing flowback liquid meets the emission standard, the filter cake can be backfilled or be used for paving after being treated, and resource utilization of waste materials is achieved.

Owner:博慧检测技术(北京)有限公司

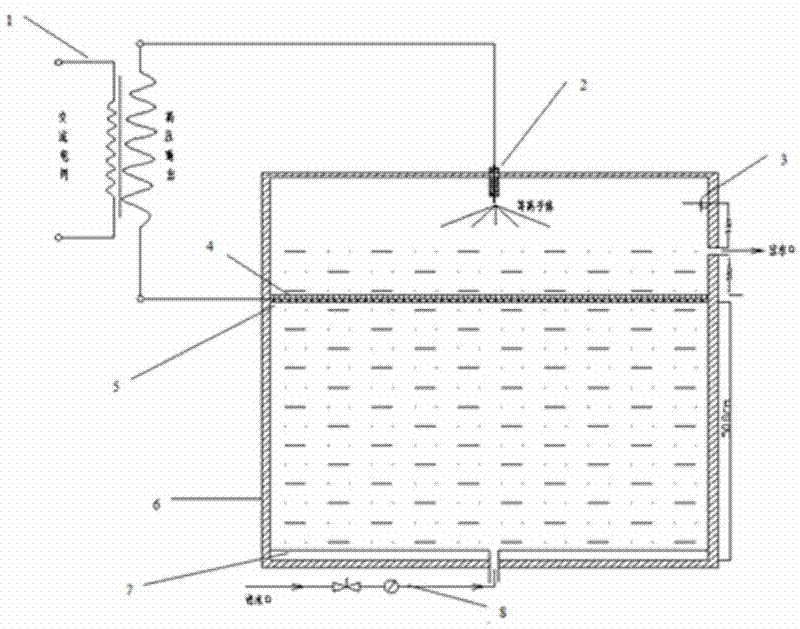

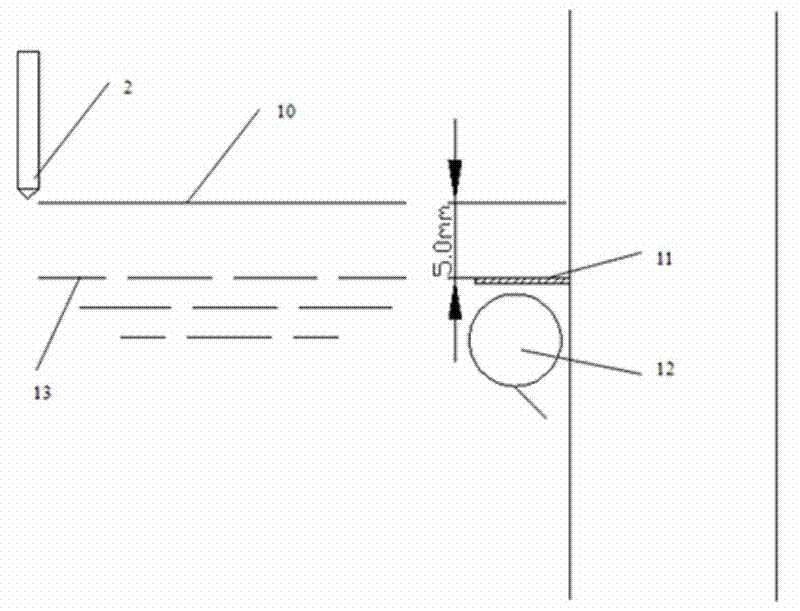

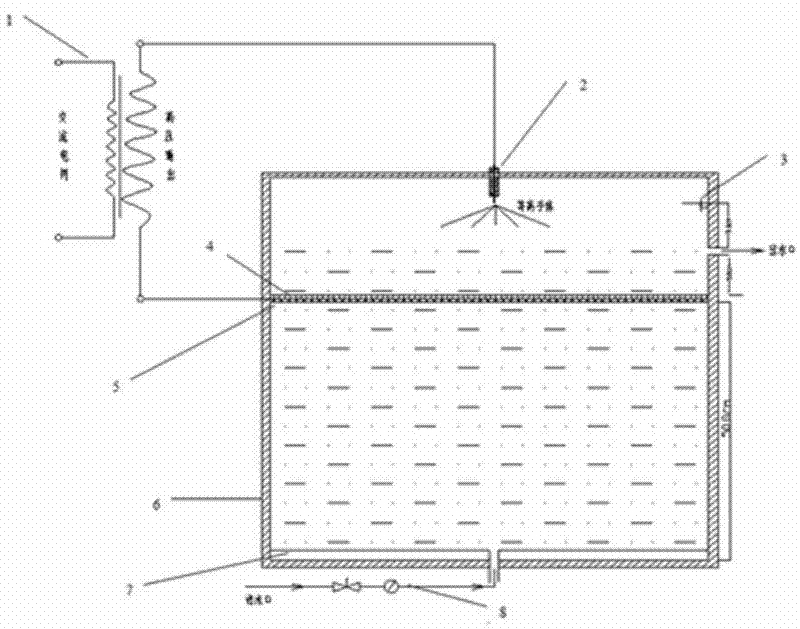

A low-temperature plasma wastewater treatment device and its treatment method

ActiveCN102267739AReduce emission concentrationMeet emission standardsWater/sewage treatment by irradiationPollutant emissionsWater level

The invention discloses a low-temperature plasma waste water treatment device and method. The method comprises the following steps of: draining waste water into a reaction groove and putting into a low-temperature plasma environment, wherein the low-temperature plasma environment is provided by using a dielectric barrier discharge low-temperature plasma device; and arranging the discharging anodeof the dielectric barrier discharge low-temperature plasma device at a position 1.0-10.0 centimeters away from a waste water level plane, charging waste water at the power / cm<2> 1.0-5.0 watts, and treating the waste water for at least more than 5 minutes. Waste water is treated at the depth of 5.0-10.0 centimeters, so that the discharging concentration of pollutants containing waste water is further lowered, and the discharging standard is increased; and the waste water treatment device has low replacement cost, and is suitable for large-scale investment.

Owner:ZHEJIANG SHUANGLIANG SUNDA ENVIRONMENTAL PROTECTION CO LTD

Sewage treating agent

InactiveCN104030377AEfficient removalLow costWater/sewage treatmentEthylene diamineSodium phosphates

The invention discloses a sewage treating agent, which comprises the following components in parts by weight: 20-40 parts of sodium phosphate, 10-15 parts of Ethylene Diamine Tetra (Methylene Phosphonic Acid), 10-20 parts of sodium phosphate, 4-8 parts of sodium tripolyphosphate, 2-4 parts of silver nitrate, and 4-8 parts of sodium polyacrylate. The sewage treating agent is capable of effectively removing pollutants in water, low in cost, and capable of reaching the emission standards.

Owner:施文康

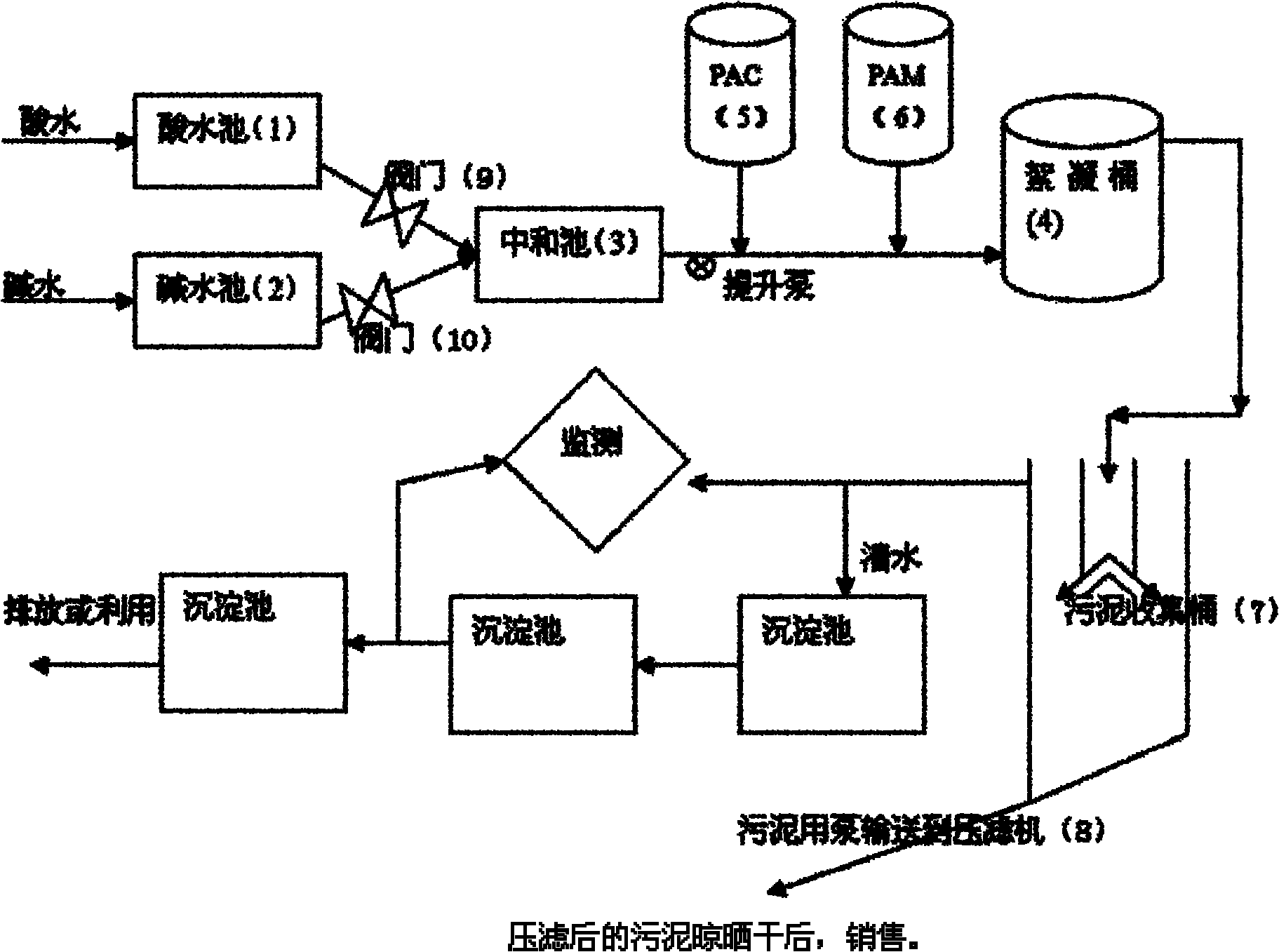

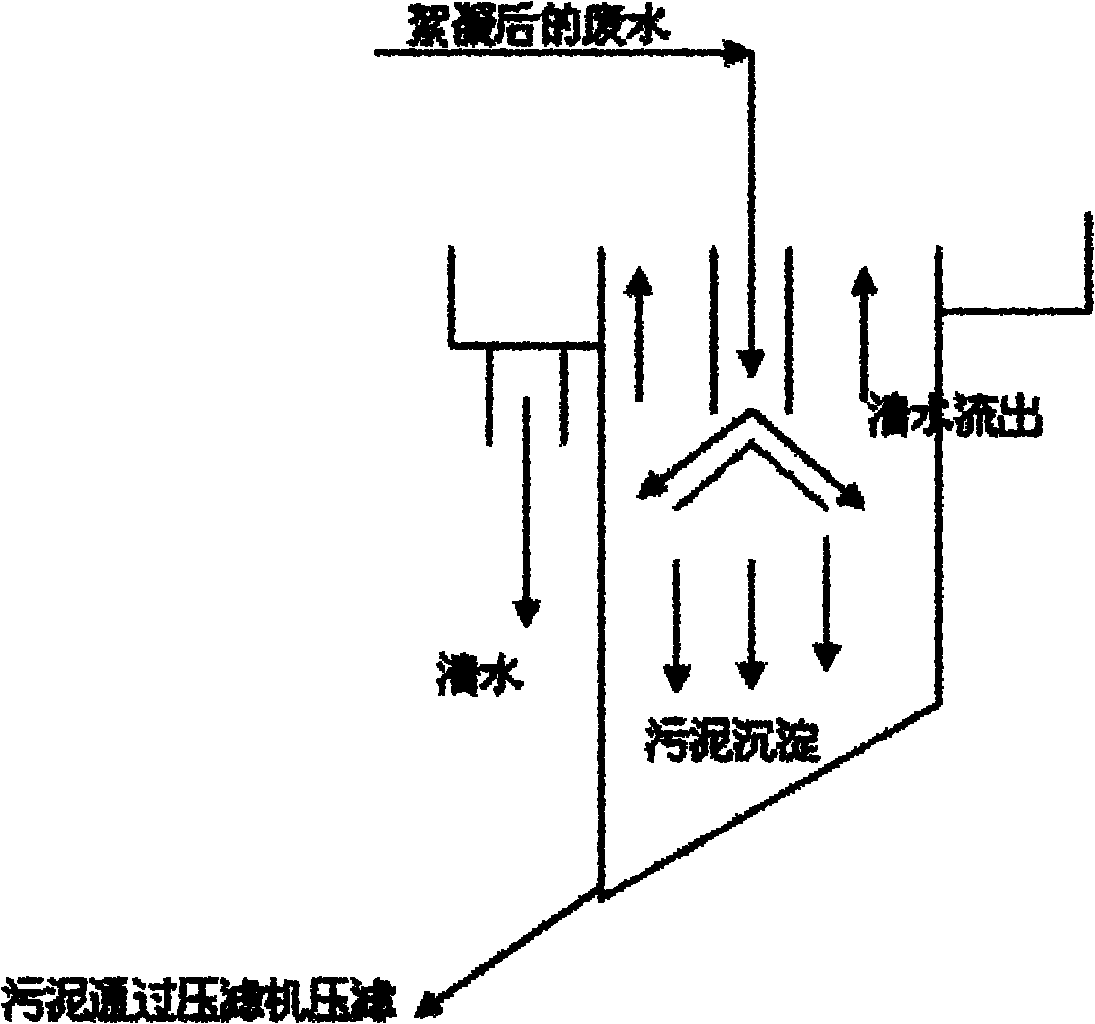

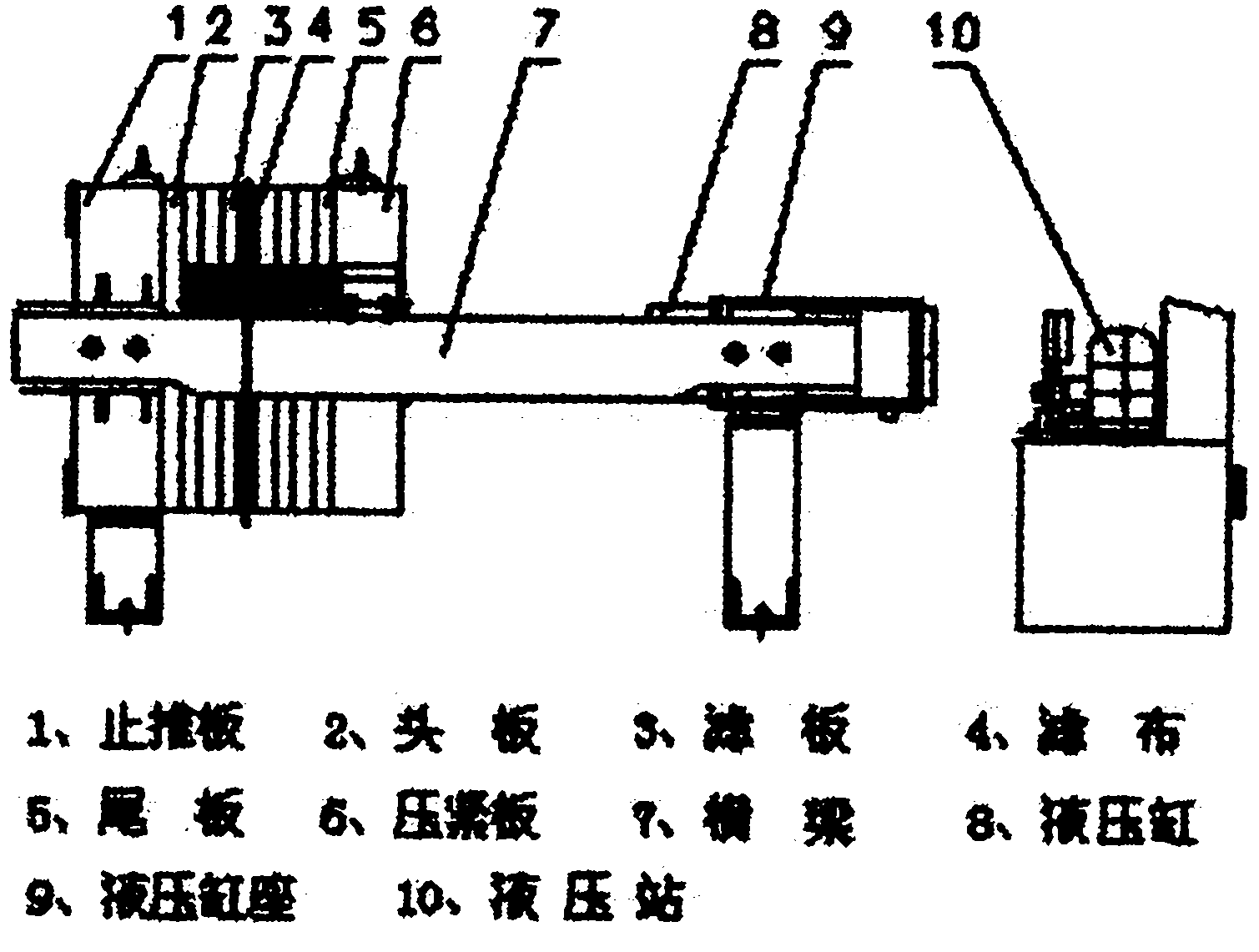

Treatment method of waste water discharged by silicon carbide micro powder production device

InactiveCN102092876AReduce in quantityReduce manufacturing costSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentAcid washingEconomic benefits

The invention discloses a treatment method of waste water discharged by a silicon carbide micro powder production device, which belongs to multi-stage treatment of the waste water. The method is characterized by comprising the following steps of: (1) collecting waste water discharged at an acid washing section and waste water discharged at an alkali washing section respectively for pH adjustment during waste water treatment; and (2) neutralizing, flocculating, performing filter pressing, separating and precipitating with a composite flocculating agent prepared from an inorganic flocculating agent A and an organic flocculating agent B, and recycling or discharged qualified waste water. Suspended matters in treated waste water reach a discharge standard. Silicon carbide micro powder is recycled from the waste water discharged by the silicon carbide micro powder production device and is sold as a byproduct, so that wastes are made profitable, the environment is protected, the economic benefits of enterprises are enhanced, and production cost is lowered.

Owner:临沂市凯祥硅粉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com