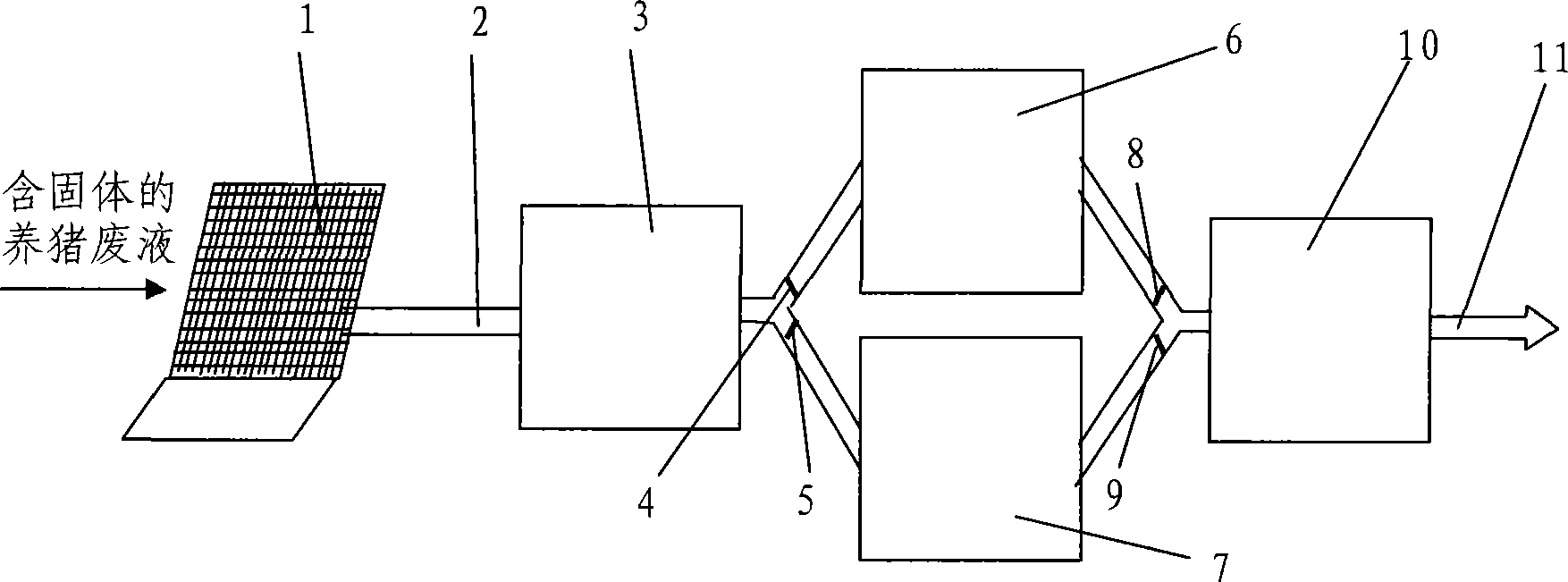

Purification treatment method and apparatus for pig raising waste liquid

A technology for purifying treatment and waste liquid, applied in chemical instruments and methods, fertilization devices, adsorption water/sewage treatment, etc., can solve problems such as environmental pollution by pig-raising waste liquid, and achieve the effects of low price, sufficient raw materials, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

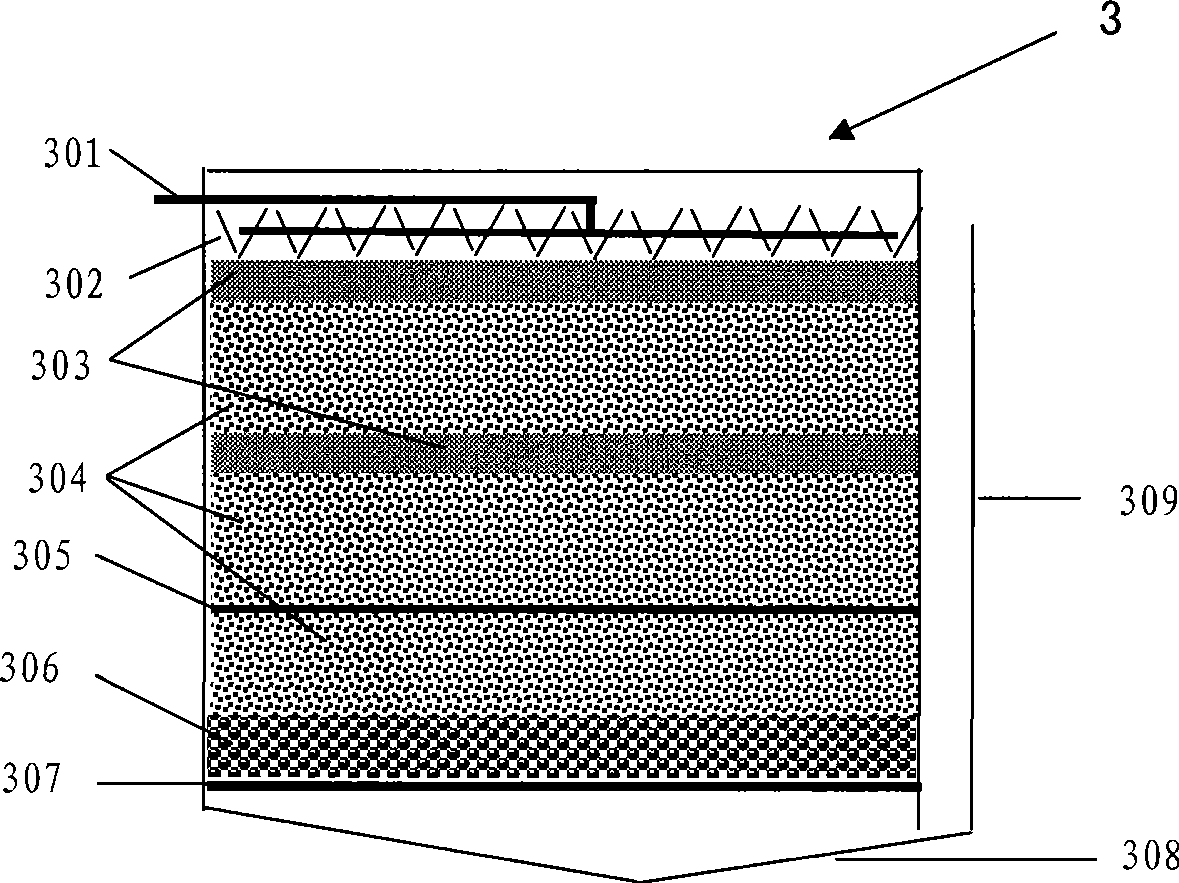

[0046] The implementation site is a 120-head family pig farm. The 90-mesh inclined plate sieve produced by Beijing Xida Agricultural Engineering Technology Group was used for solid-liquid separation; the No. 1 adsorption filter was a cuboid, the length and width of the cuboid were 1m each, and the height was 0.95m. The No. 1 water distribution horizontal pipe is 10cm from the ground, and the filter materials are No. 1 slag layer 10cm, No. 1 straw layer 20cm, No. 1 slag layer 10cm, No. 1 straw layer 20cm, No. 1 zeolite layer (1-2cm) and the lower layer. Crop straw (No. 1 straw layer 15cm) mixed with No. 1 crushed stone layer 10cm, and No. 1 seepage board under the No. 1 crushed stone layer.

[0047] The length, width and height of the self-purifying sedimentation tank are all 1m.

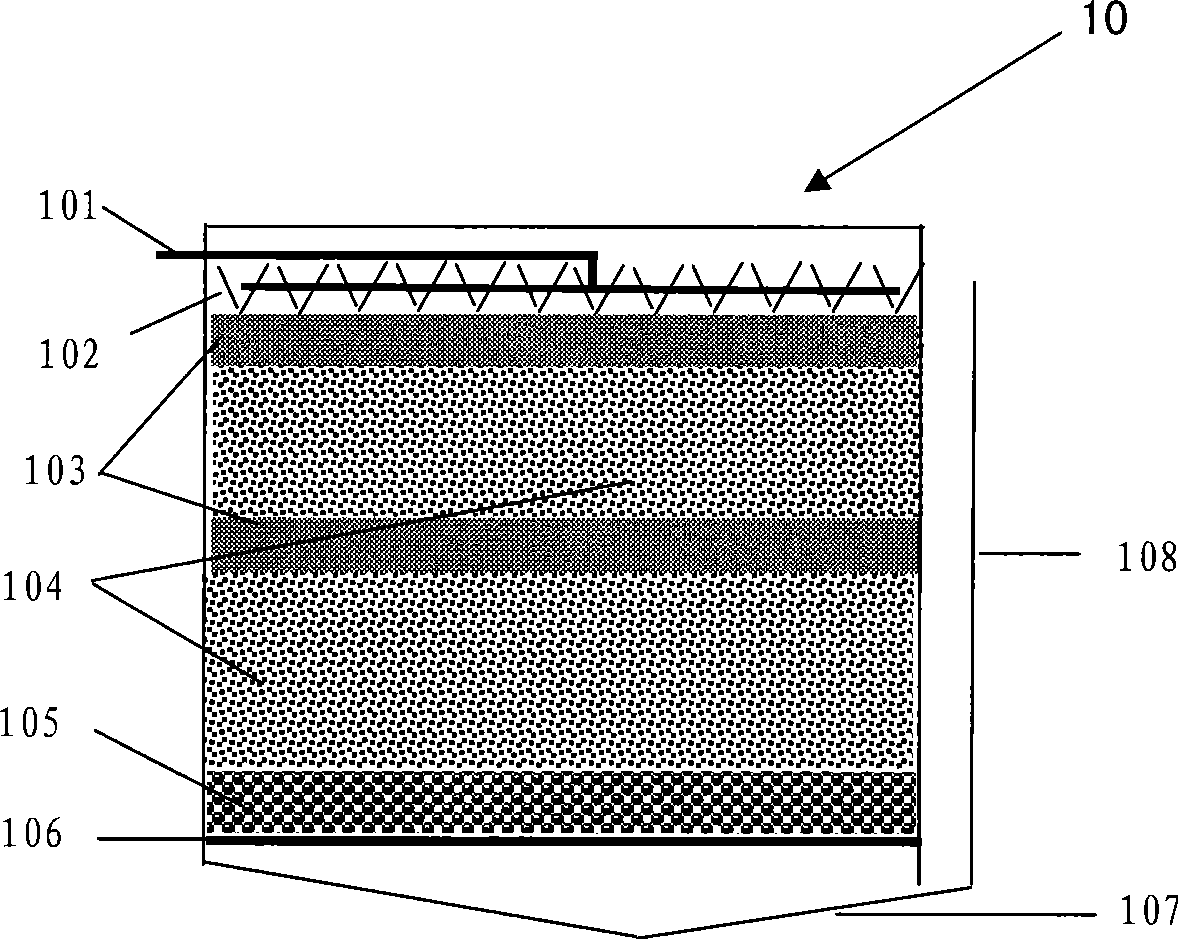

[0048] The size of the No. 2 adsorption filter pool is similar to that of the No. 1 filter pool, and the length, width and height are all 1m. No. 2 water distribution horizontal pipe is 10cm away f...

Embodiment 2

[0050] The implementation site is a 400 pig farm. The 90-mesh inclined plate sieve produced by Beijing Xida Agricultural Engineering Technology Group was used for solid-liquid separation; the No. 1 adsorption filter was a cuboid, the length and width of the cuboid were 2m each, and the height was 1.05m. The No. 1 water distribution horizontal pipe is 15cm from the ground, and the filter materials are No. 1 slag layer 10cm, No. 1 straw layer 20cm, No. 1 slag layer 10cm, No. 1 straw layer 20cm, No. 1 zeolite layer (1-2cm) and the lower layer. Crop straw (No. 1 straw layer 15cm) mixed with No. 1 crushed stone layer 15 cm, and No. 1 seepage board under the No. 1 crushed stone layer.

[0051] The size of the self-purifying sedimentation tank is 2m in length and width, and 1.05m in height.

[0052] The size of No. 2 adsorption filter tank is similar to that of No. 1 filter tank, with a length and width of 2m and a height of 1.1m. The No. 2 water distribution horizontal pipe is 15c...

Embodiment 3

[0054] The implementation site is a pig farm with about 800 pigs. The 90-mesh inclined plate sieve produced by Beijing Xida Agricultural Engineering Technology Group was used for solid-liquid separation; the No. 1 adsorption filter was a cuboid with a length and width of 2.5m and a height of 1.45m. The No. 1 water cloth is 15cm above the ground, and the filter materials are No. 1 slag layer 15cm, No. 1 straw layer 30cm, No. 1 slag layer 15cm, No. 1 straw layer 30cm, No. 1 zeolite layer (1-2cm) and the crops in the lower layer. Straw (No. 1 straw layer 20cm) mixed with No. 1 gravel layer 20cm, and No. 1 seepage board under the No. 1 gravel layer.

[0055] The size of the self-purifying sedimentation tank is 2.5m in length and width, and 1.4m in height.

[0056] The size of No. 2 adsorption filter tank is similar to that of No. 1 filter tank, with a length and width of 2.5m and a height of 1.4m. The No. 2 water distribution horizontal pipe is 15cm above the ground, and the fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com