Patents

Literature

374results about How to "Efficient feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

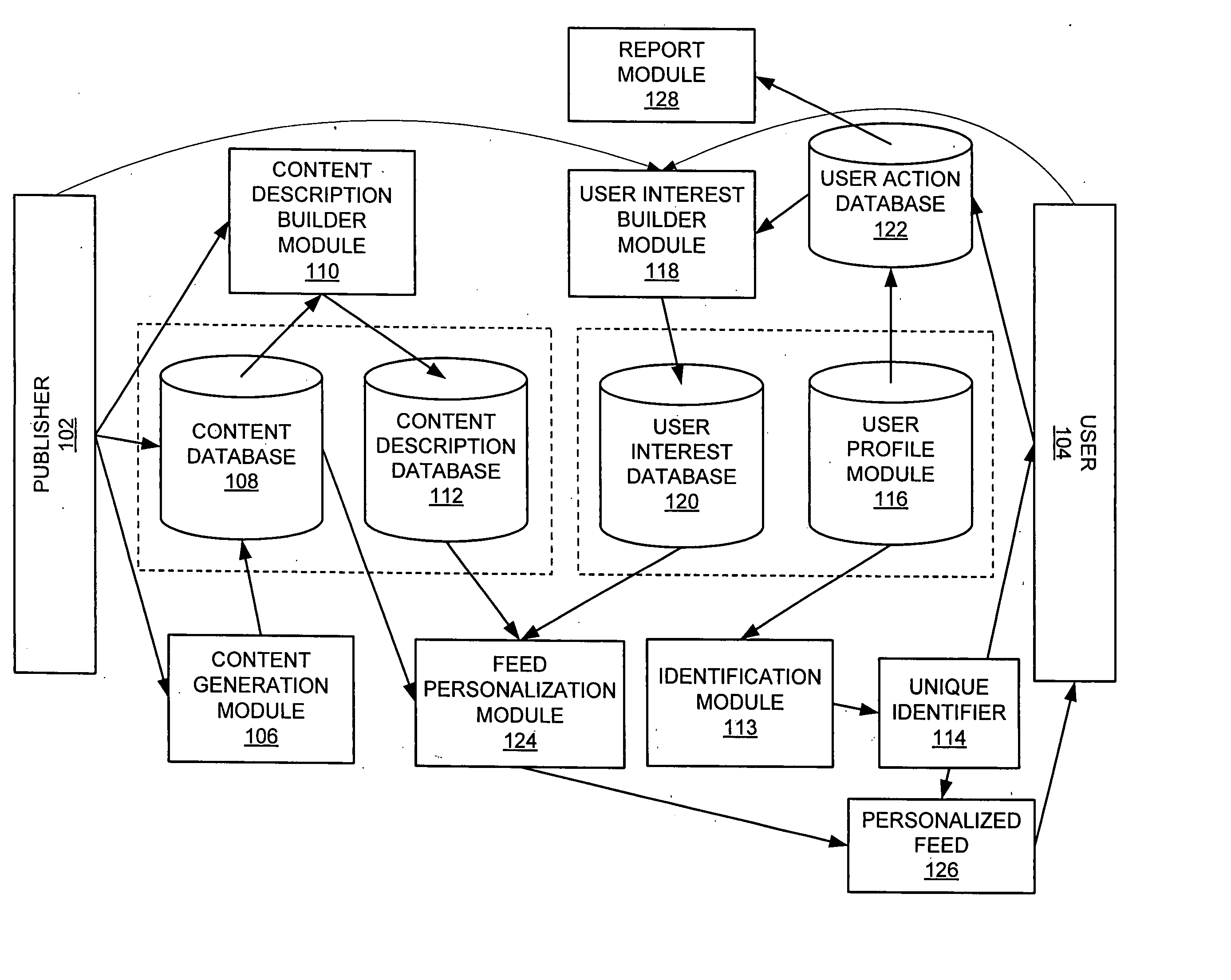

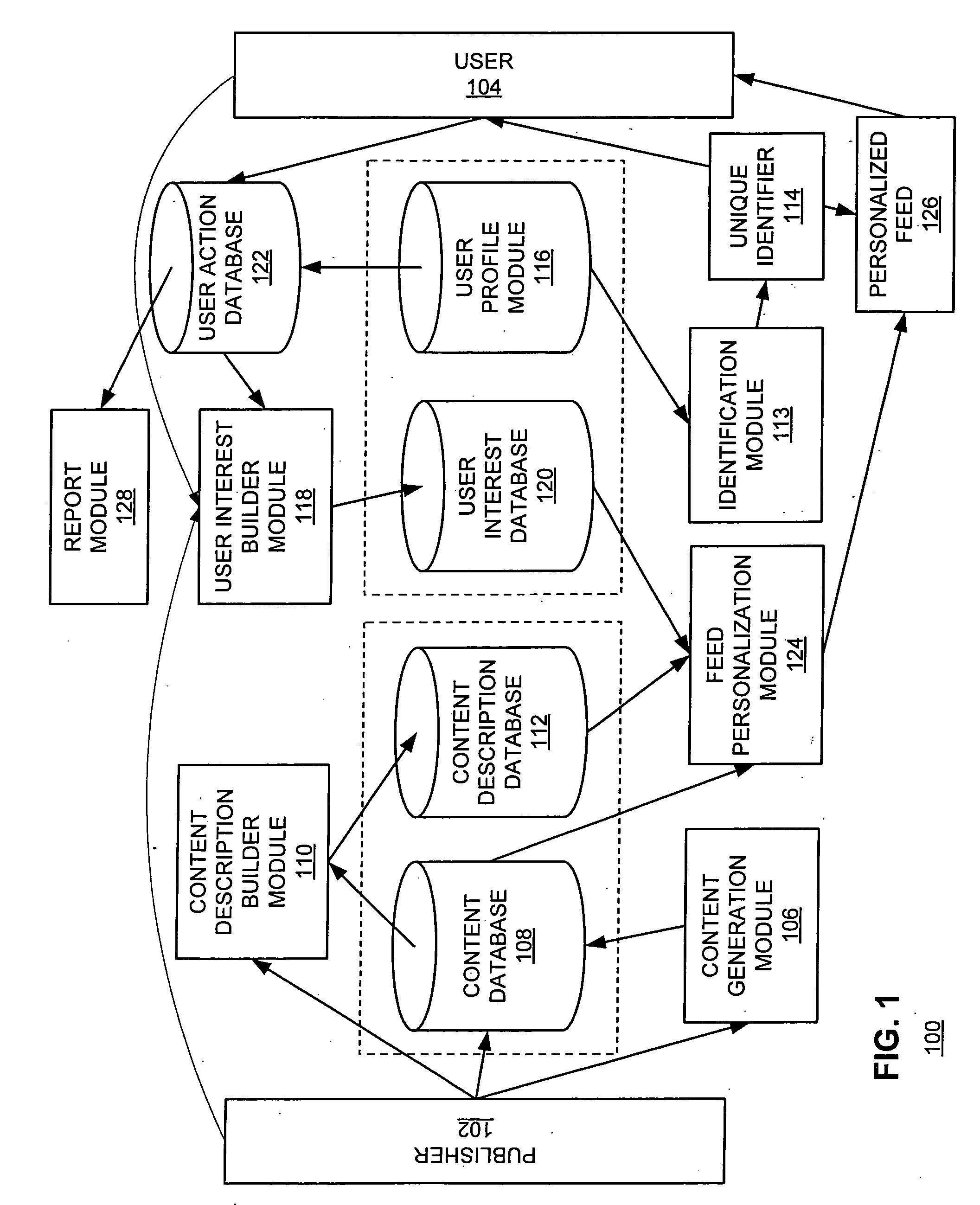

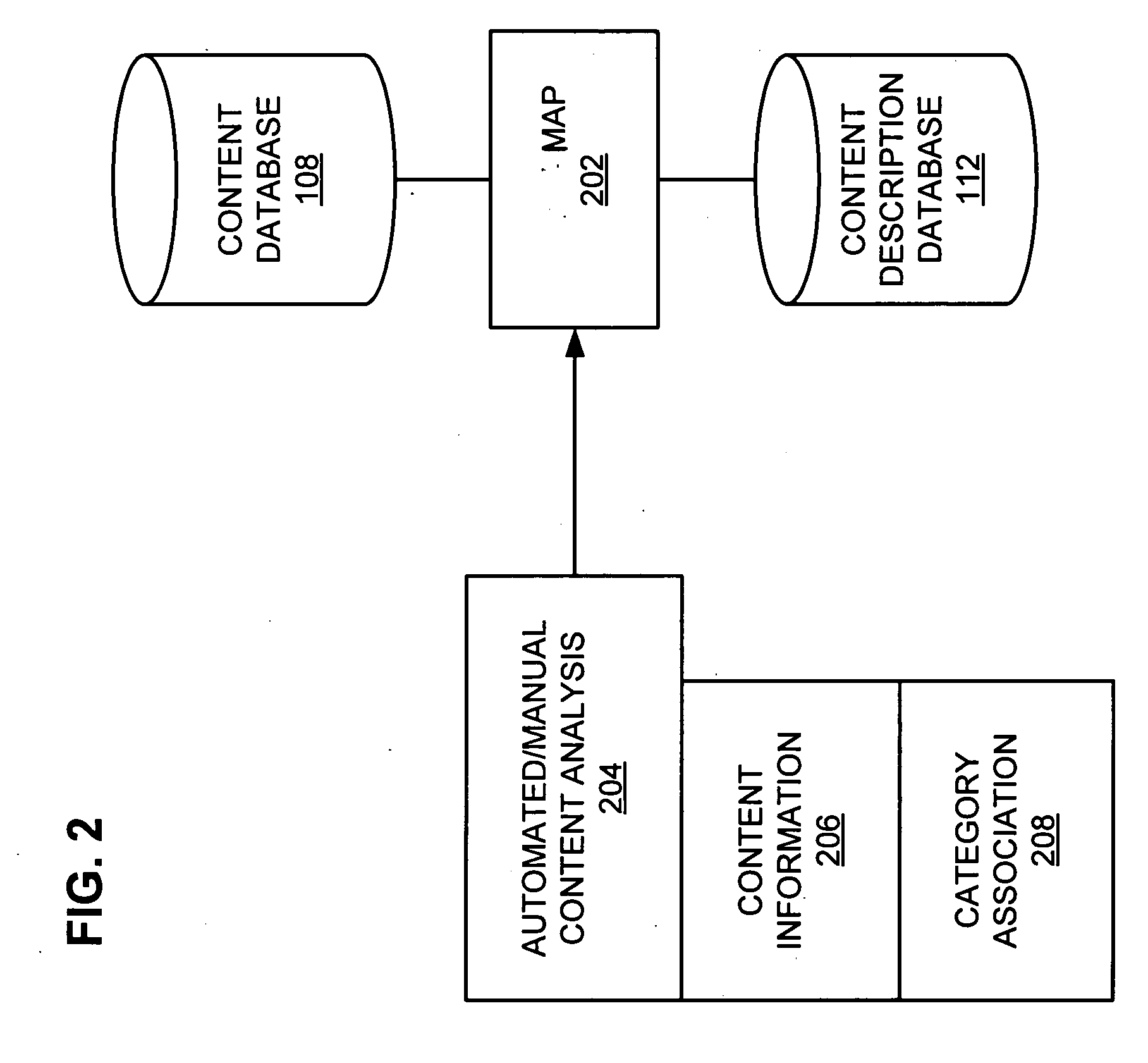

Customizable and measurable information feeds for personalized communication

ActiveUS20050267973A1Efficient feedingMultiple digital computer combinationsBuying/selling/leasing transactionsUnique identifierPersonalization

A system and a method to provide a personalized feed to a user. Information regarding the user is obtained from the user via customization content. The customization content indicates various categories of content for the user to select from. In response to the user selecting his or her categories of interest, a feed personalization module selects content pieces whose associated categories match the user selected categories. The feed personalization module then provides a personalized feed including these content pieces to the user. The personalized feed is provided to the user via a unique identifier assigned to the user. Using the unique identifier, the user's actions with respect to the provided feed is tracked. The feed is further re-personalized according to the user's actions. The feed is also re-personalized based on an input from the user indicating the relevance of the feed to the user's interests.

Owner:SIMPLEFEED

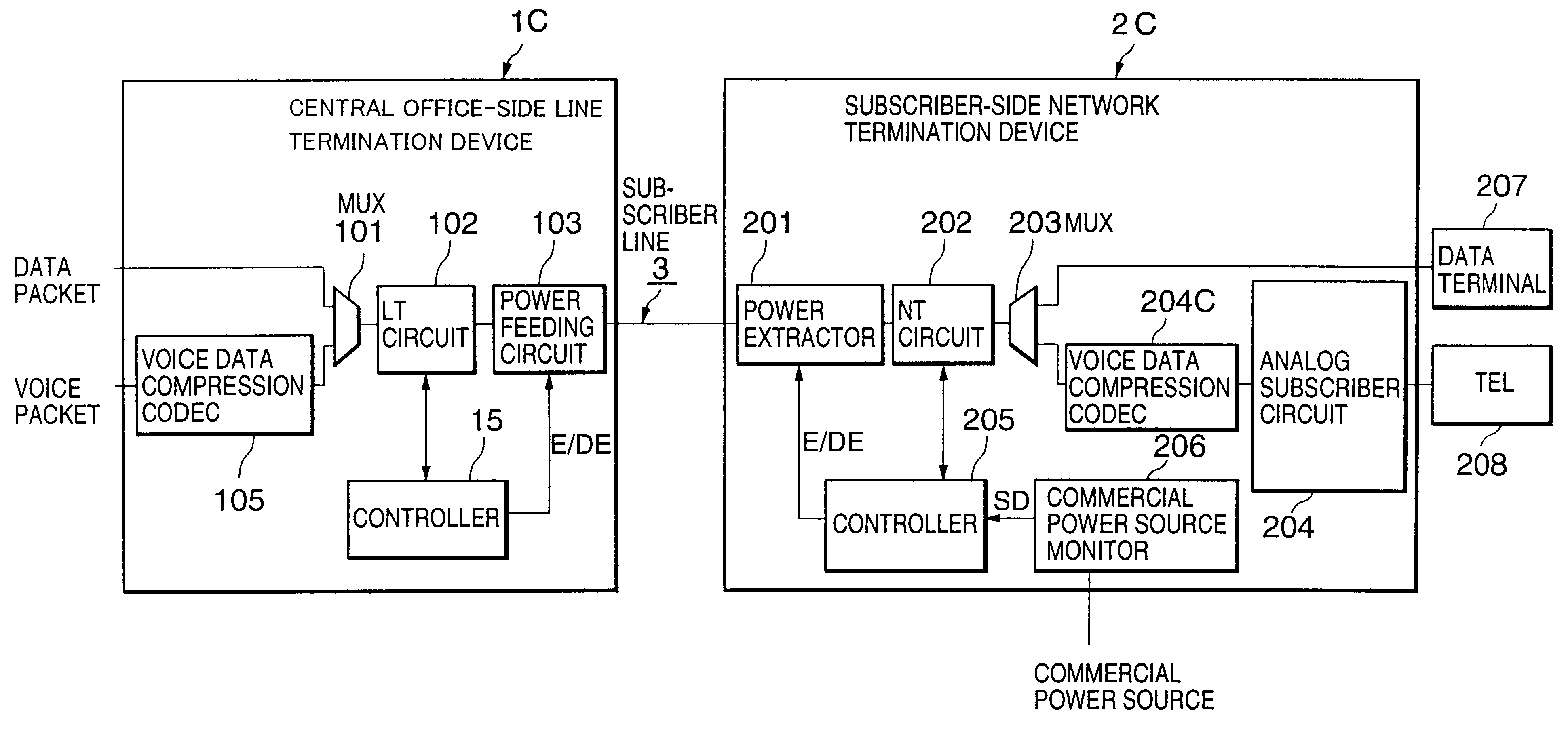

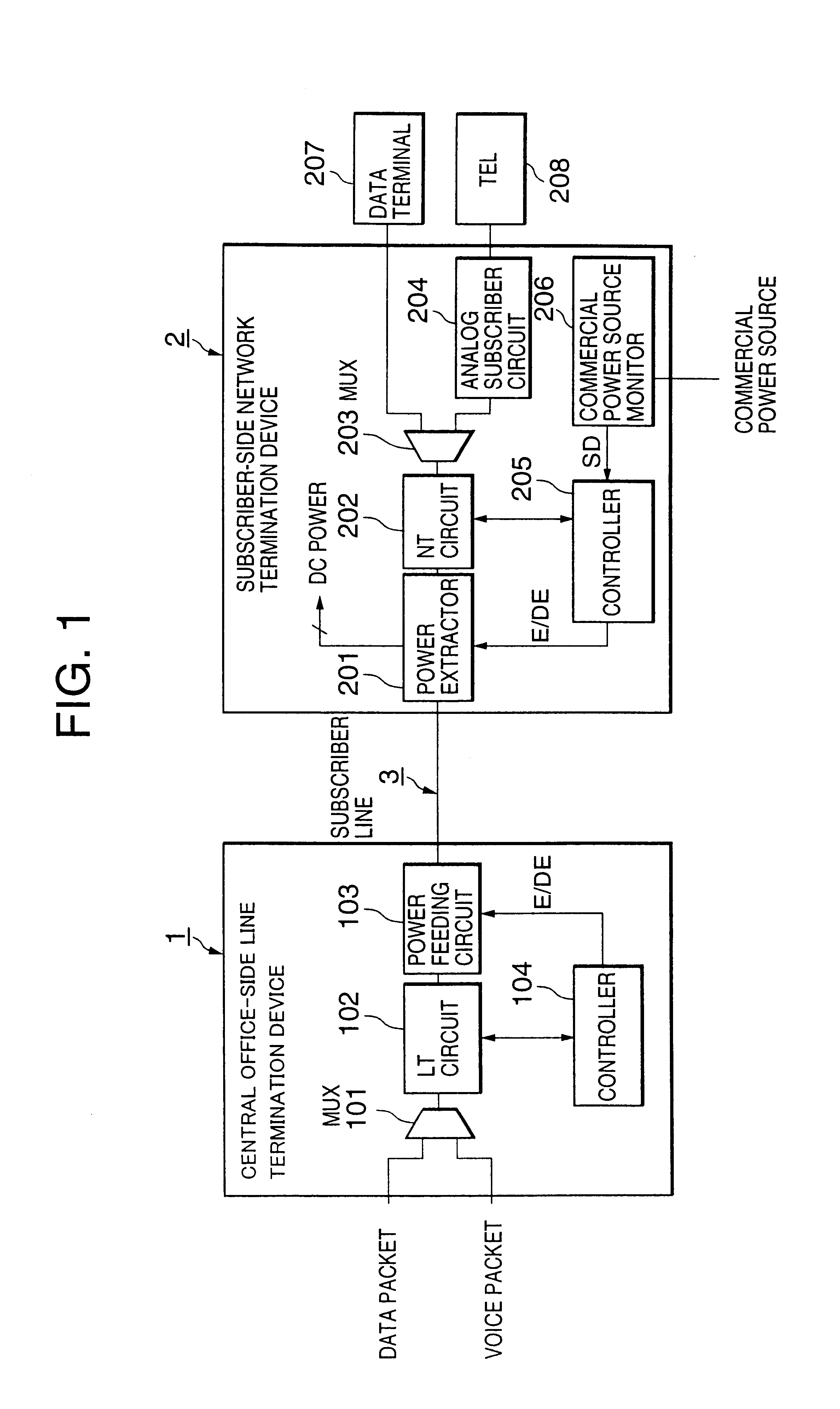

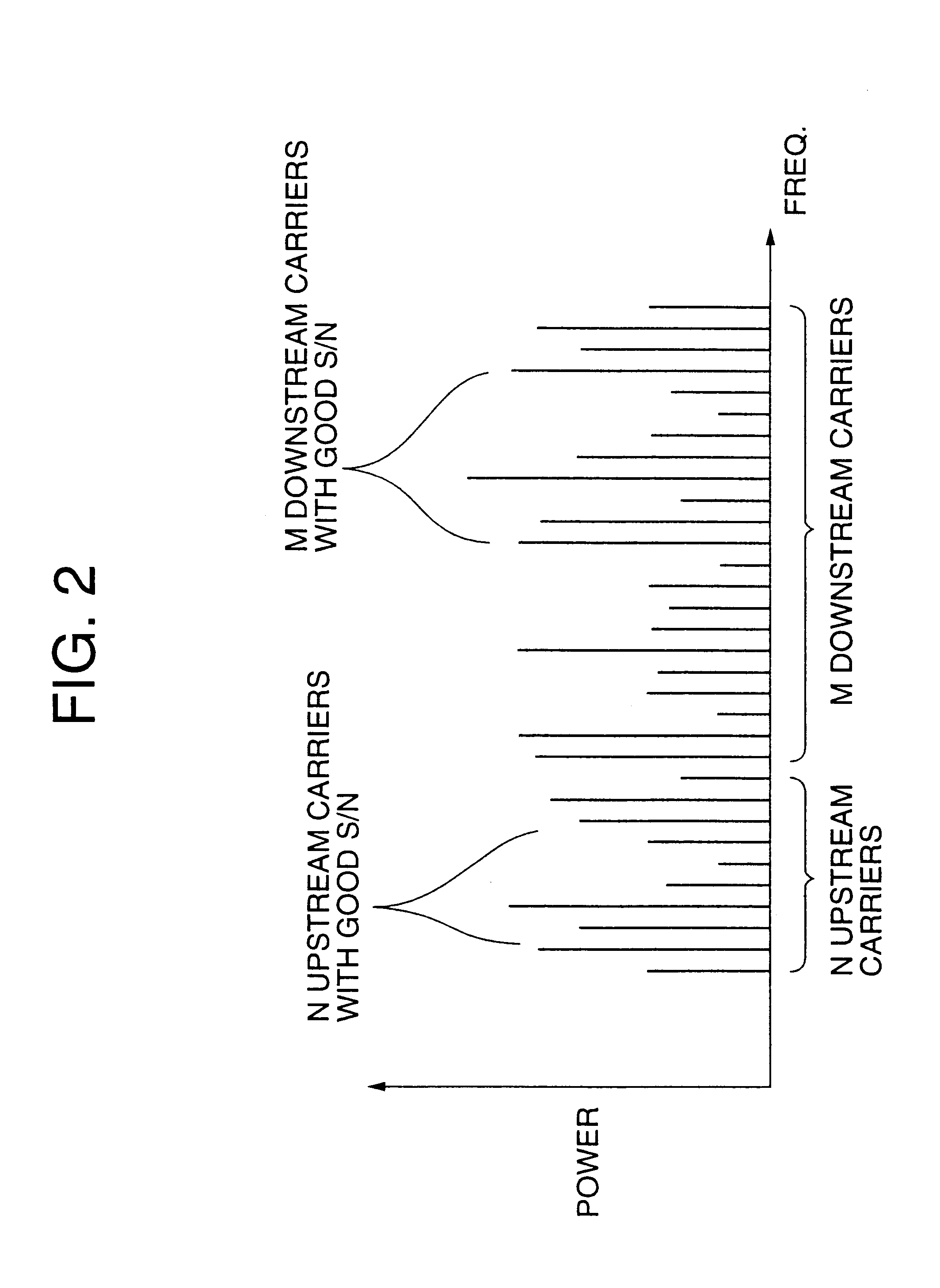

Remote power feed method and system

InactiveUS6847718B1Power feeding efficiency can be increasedImprove feeding efficiencyInterconnection arrangementsLevel controlNetwork terminationVoice communication

A remote power feeding method allowing efficient remote power feeding into a network termination device in the event of a commercial power failure at a subscriber site is disclosed. When the commercial power failure occurs, a power failure signal is transmitted from the subscriber-side network termination device to the central office-side line termination device. The central office-side line termination device, when receiving the power failure signal, starts DC power feeding to the subscriber-side network termination device via the subscriber line. During the power failure, only voice communication is permitted using previously selected good channels.

Owner:NEC CORP

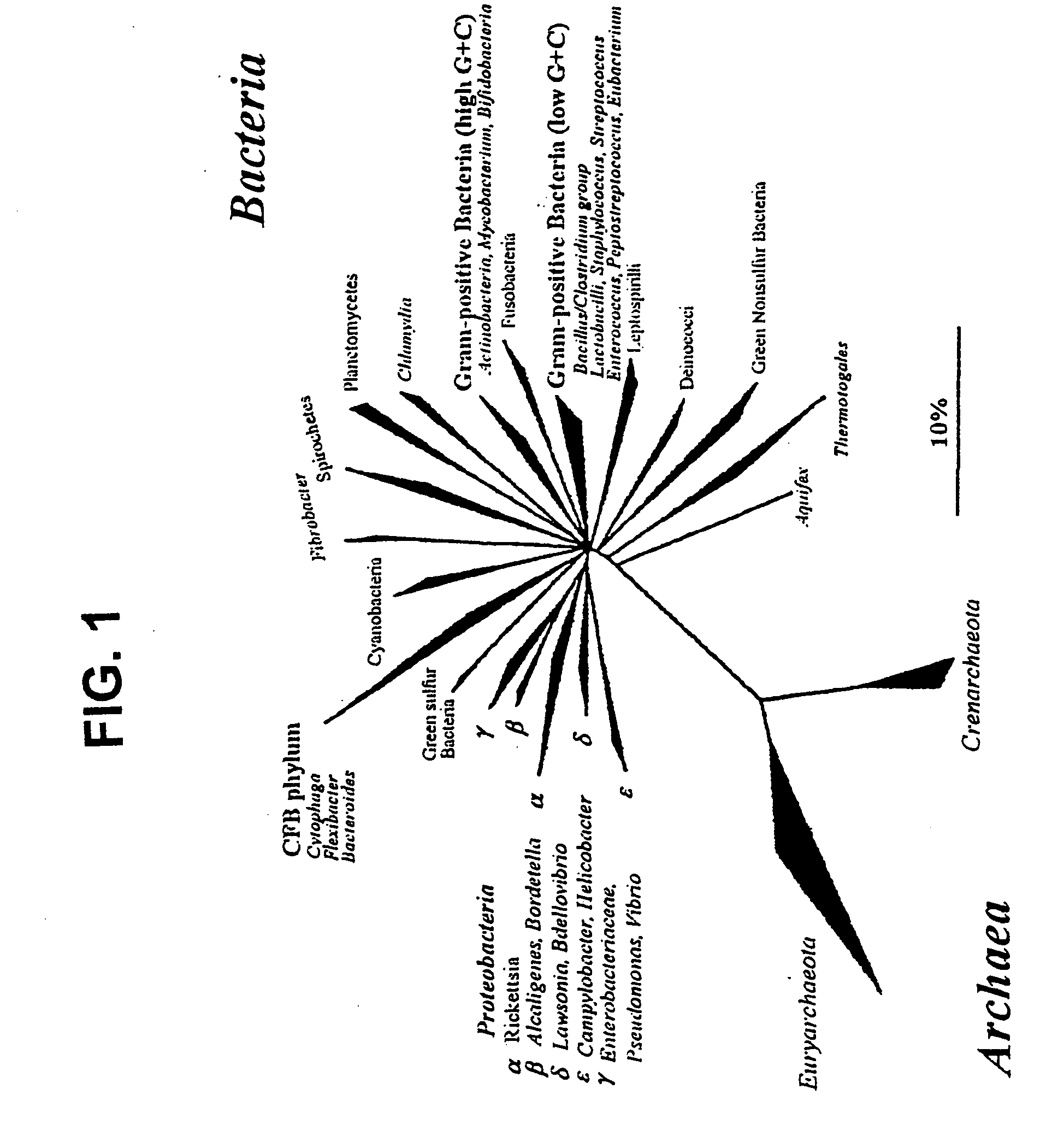

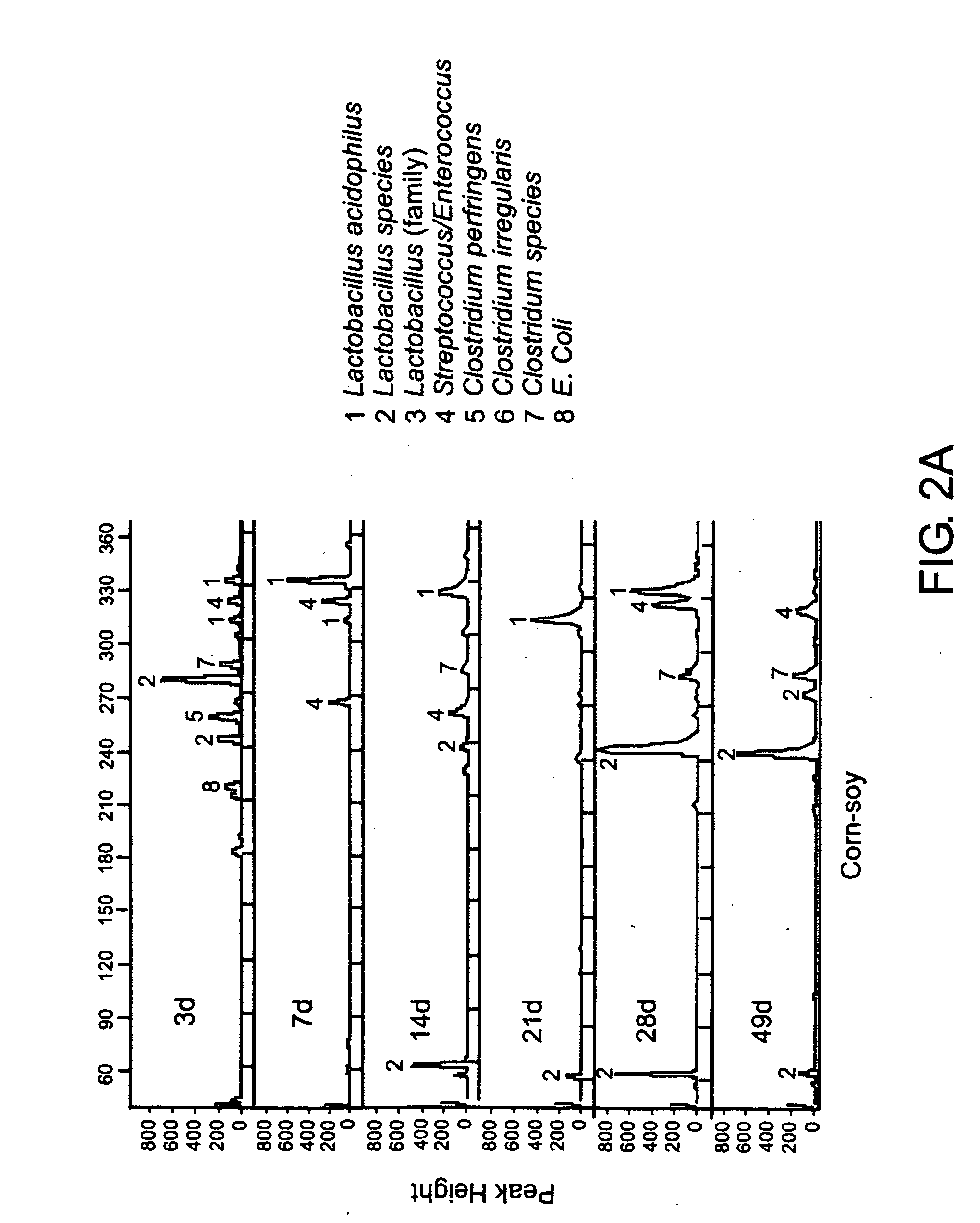

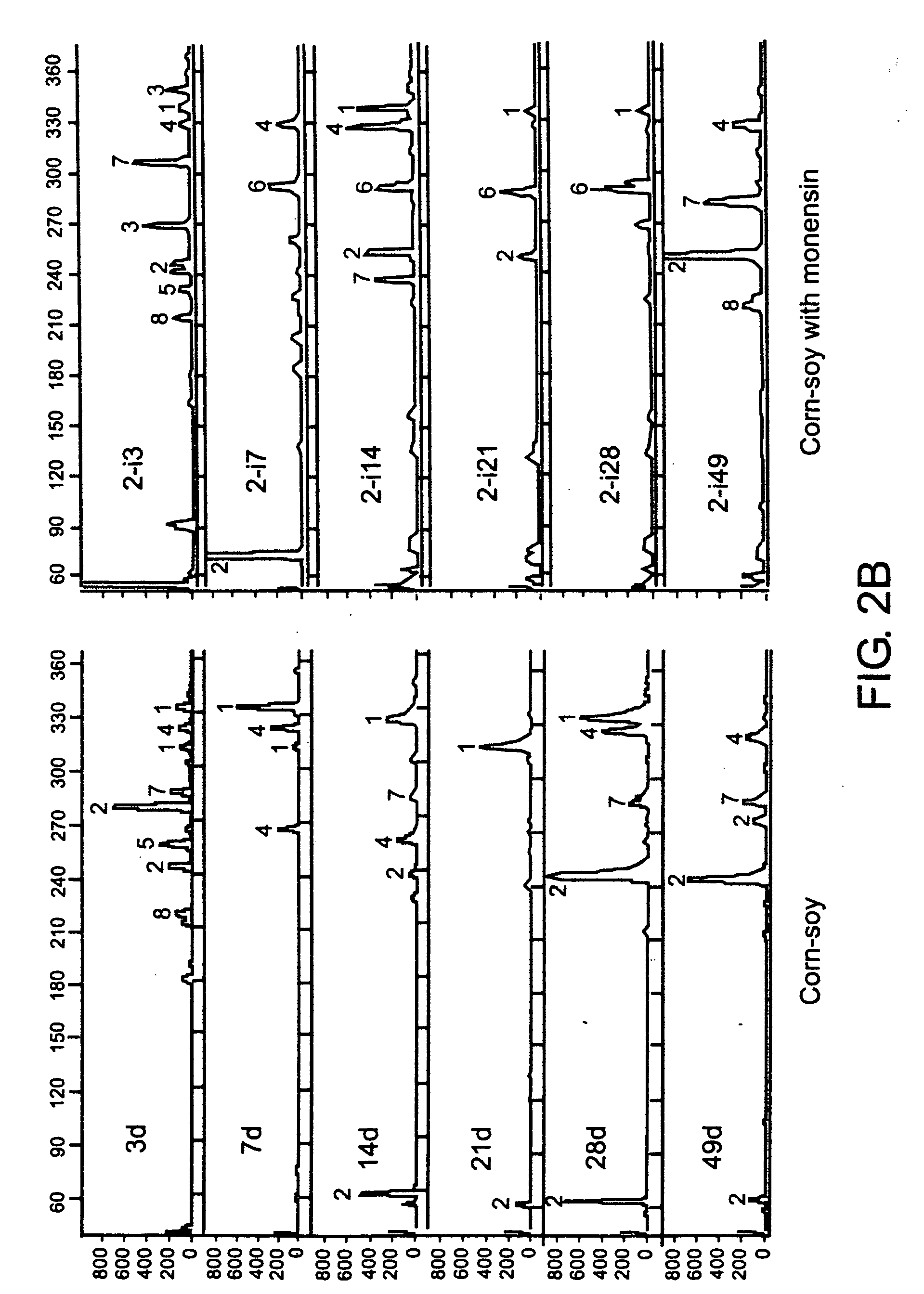

Probiotic bacteria and methods

InactiveUS20060067924A1Reduce colonizationAssess healthBiocideBacteria material medical ingredientsMicroorganismAntibiotic Y

Provided herein are molecular methods for assessing the state of gastrointestinal microflora of an animal, especially a species of poultry, and methods for identifying probiotic bacteria by comparing certain bacteria present in animals fed a diet not containing antibiotics but absent or present in significantly lower numbers in animals fed a diet containing antibiotics.

Owner:UNIV OF GEORGIA RES FOUND INC

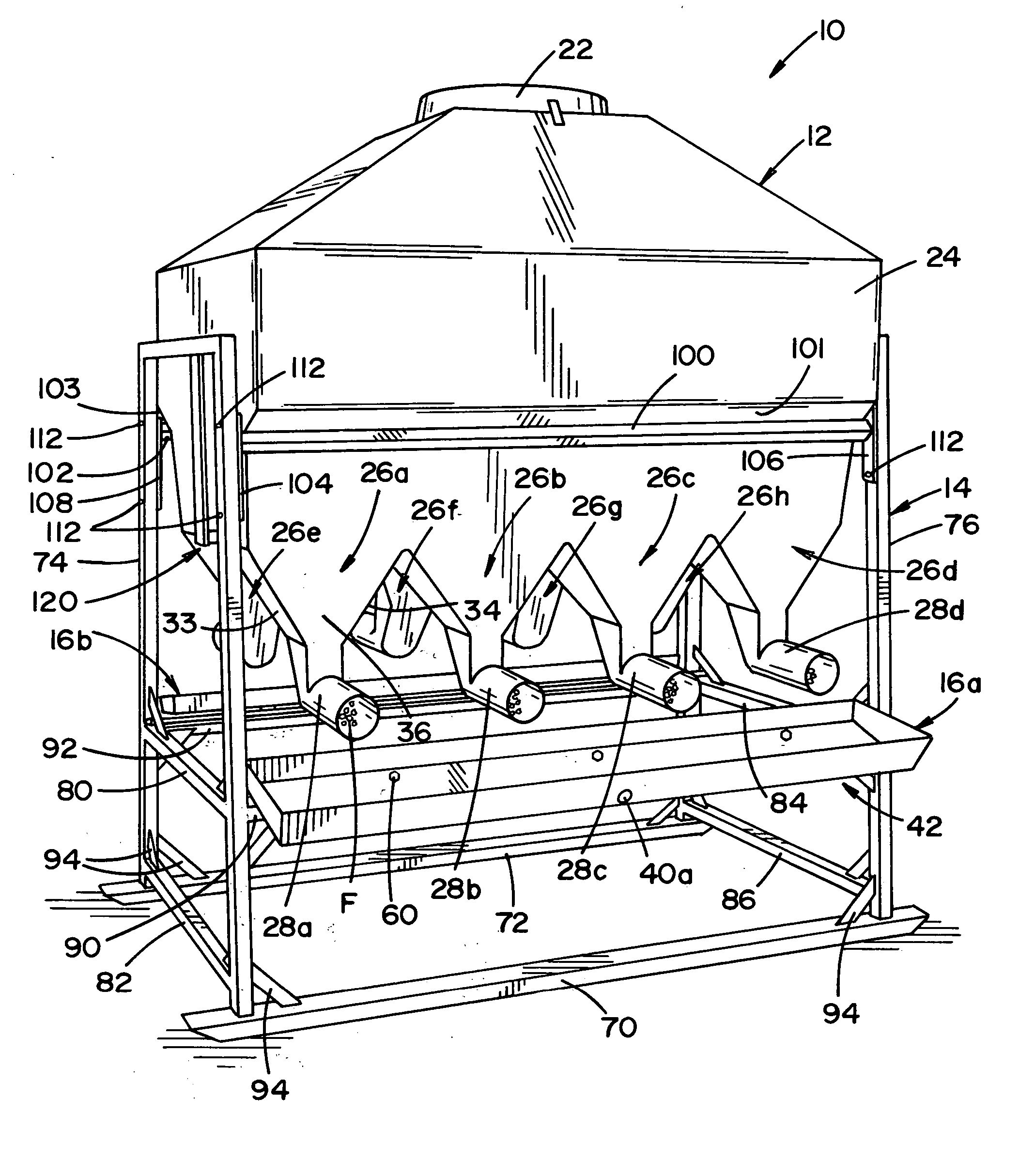

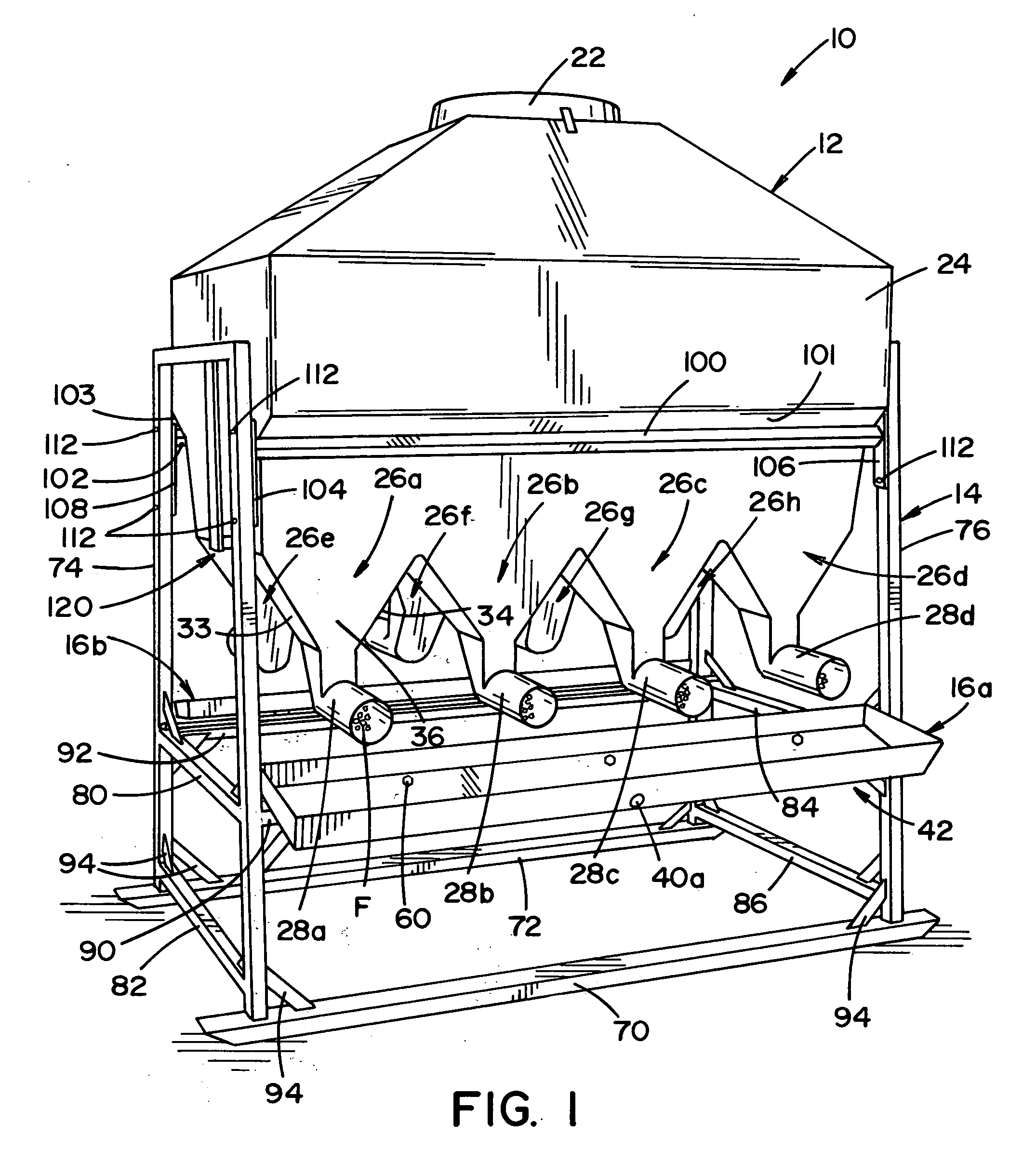

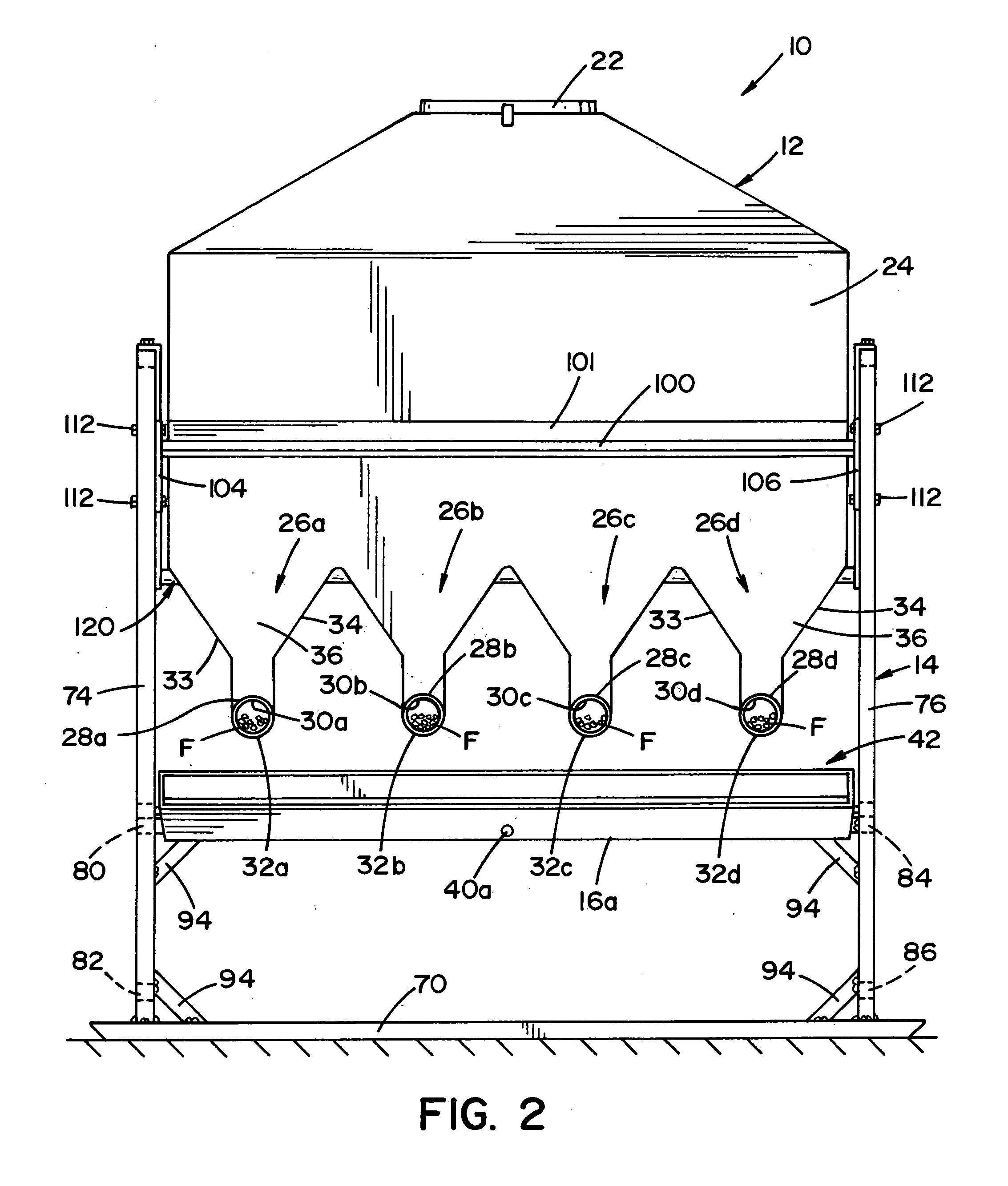

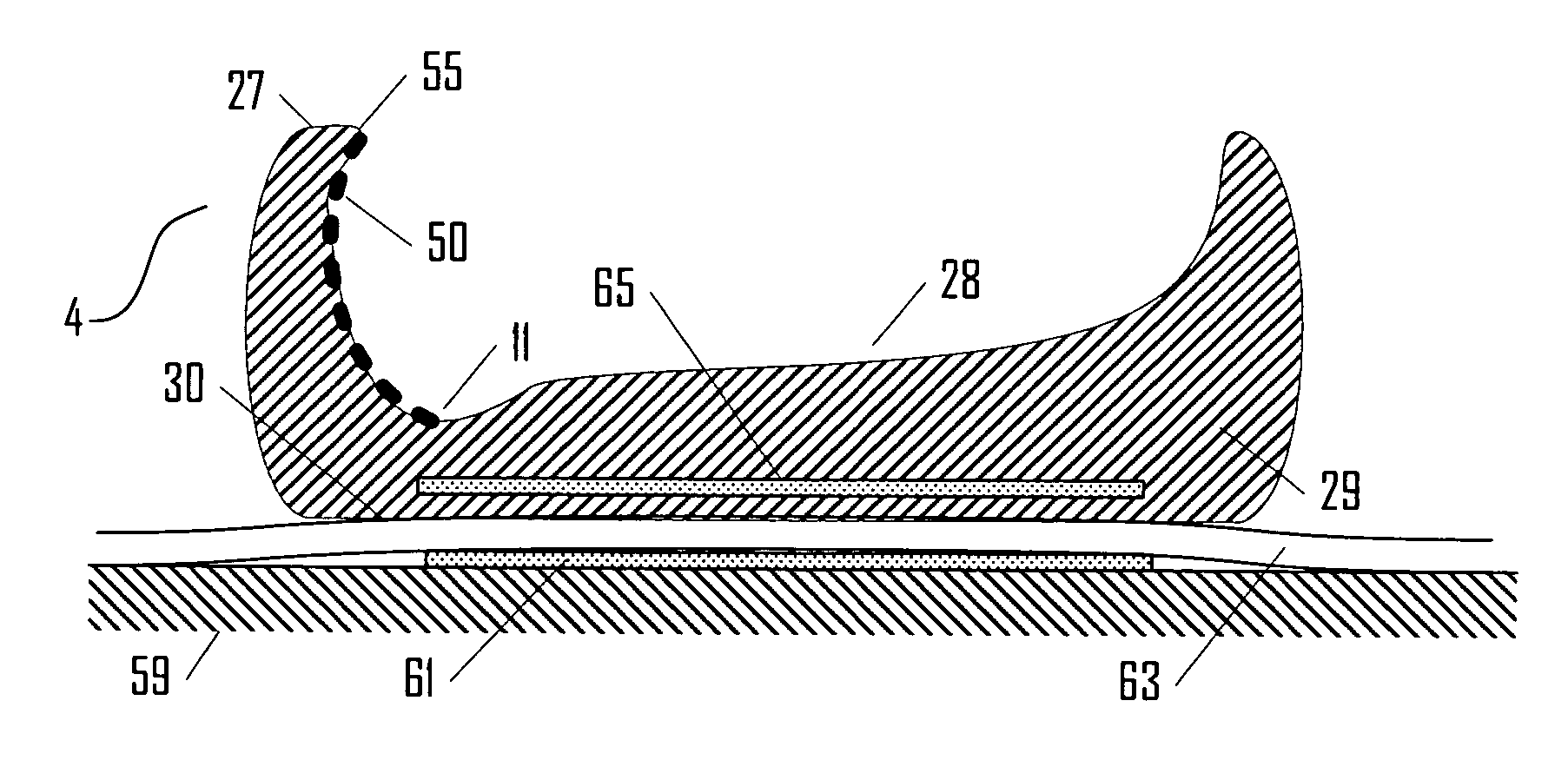

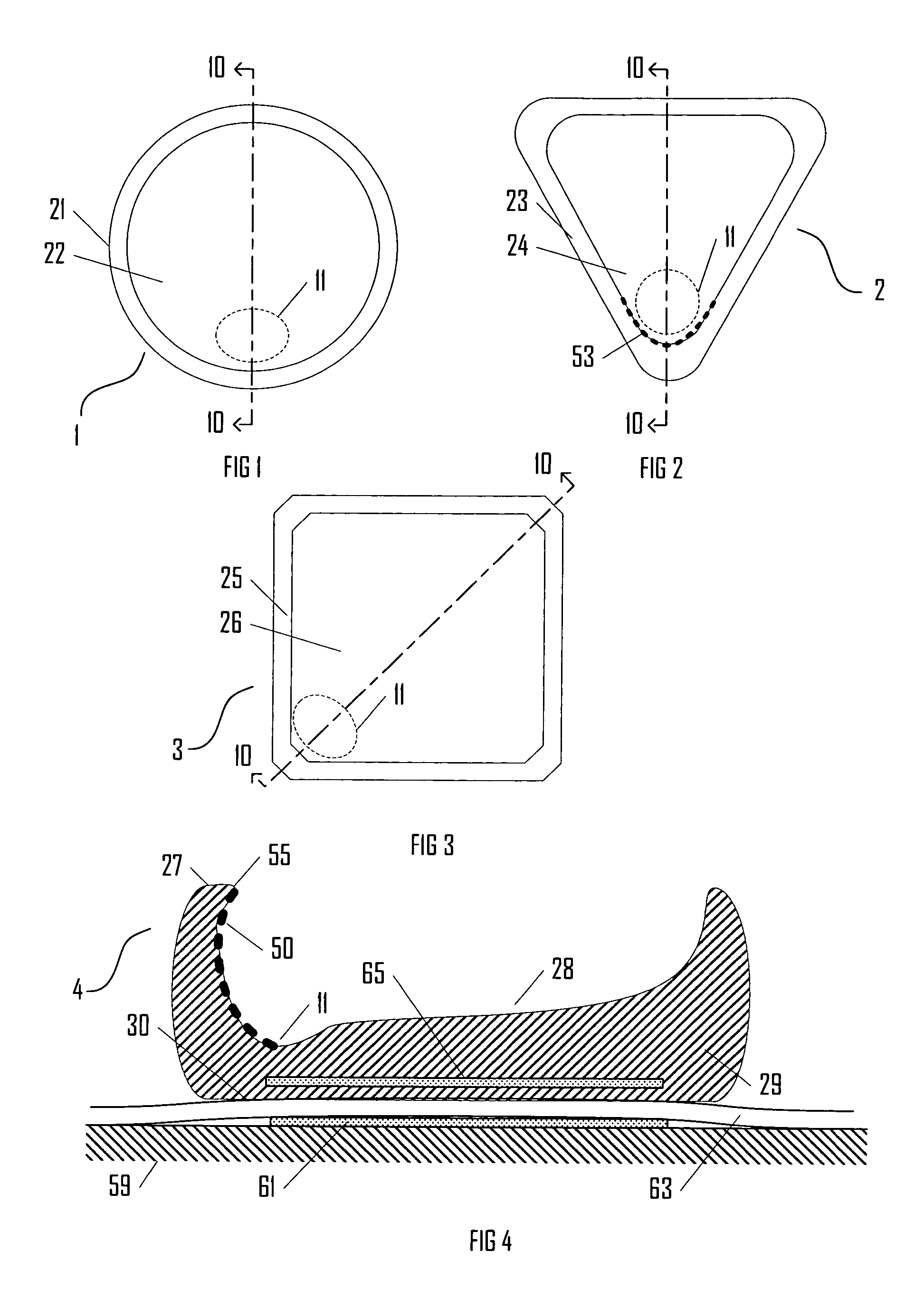

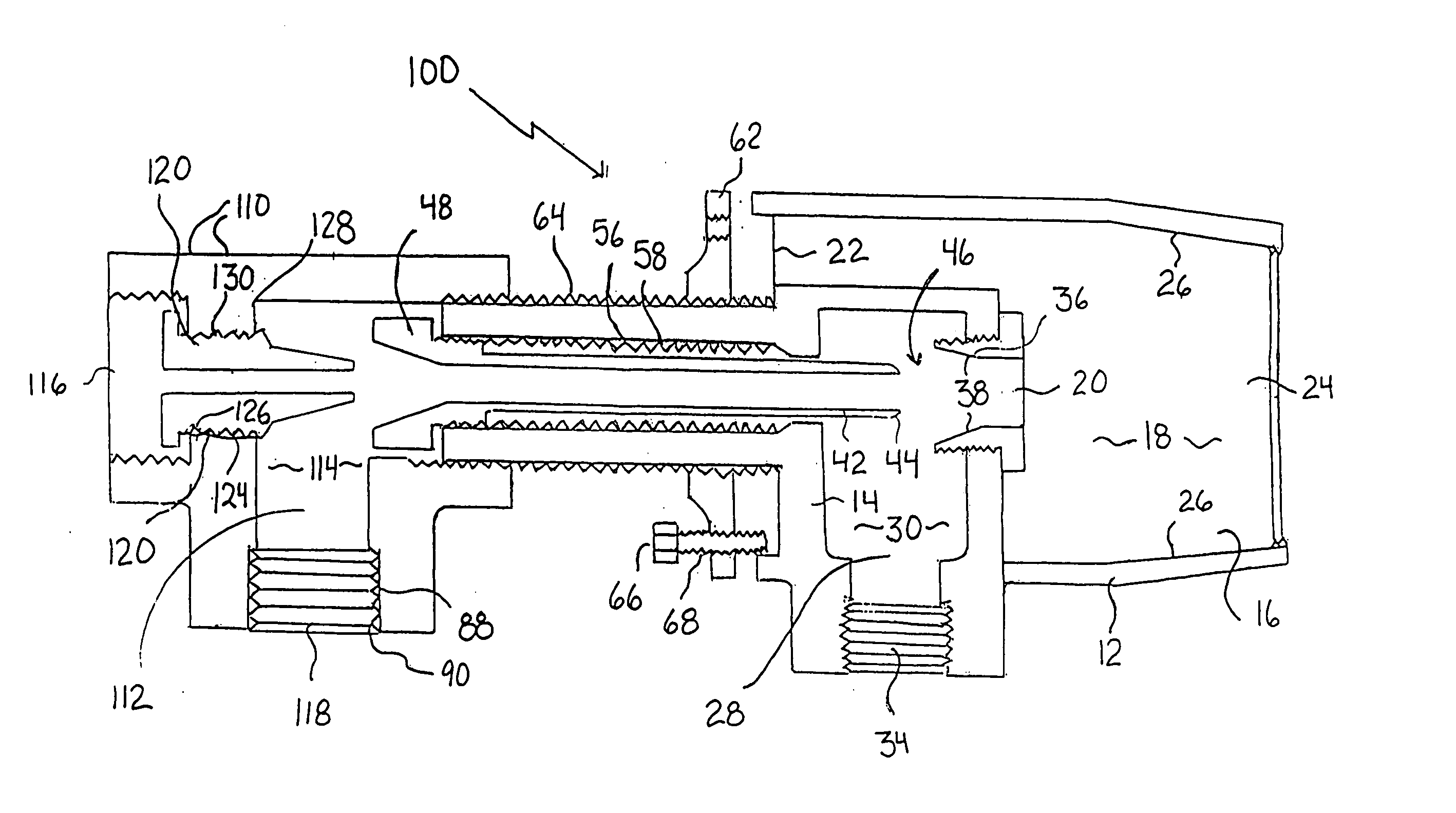

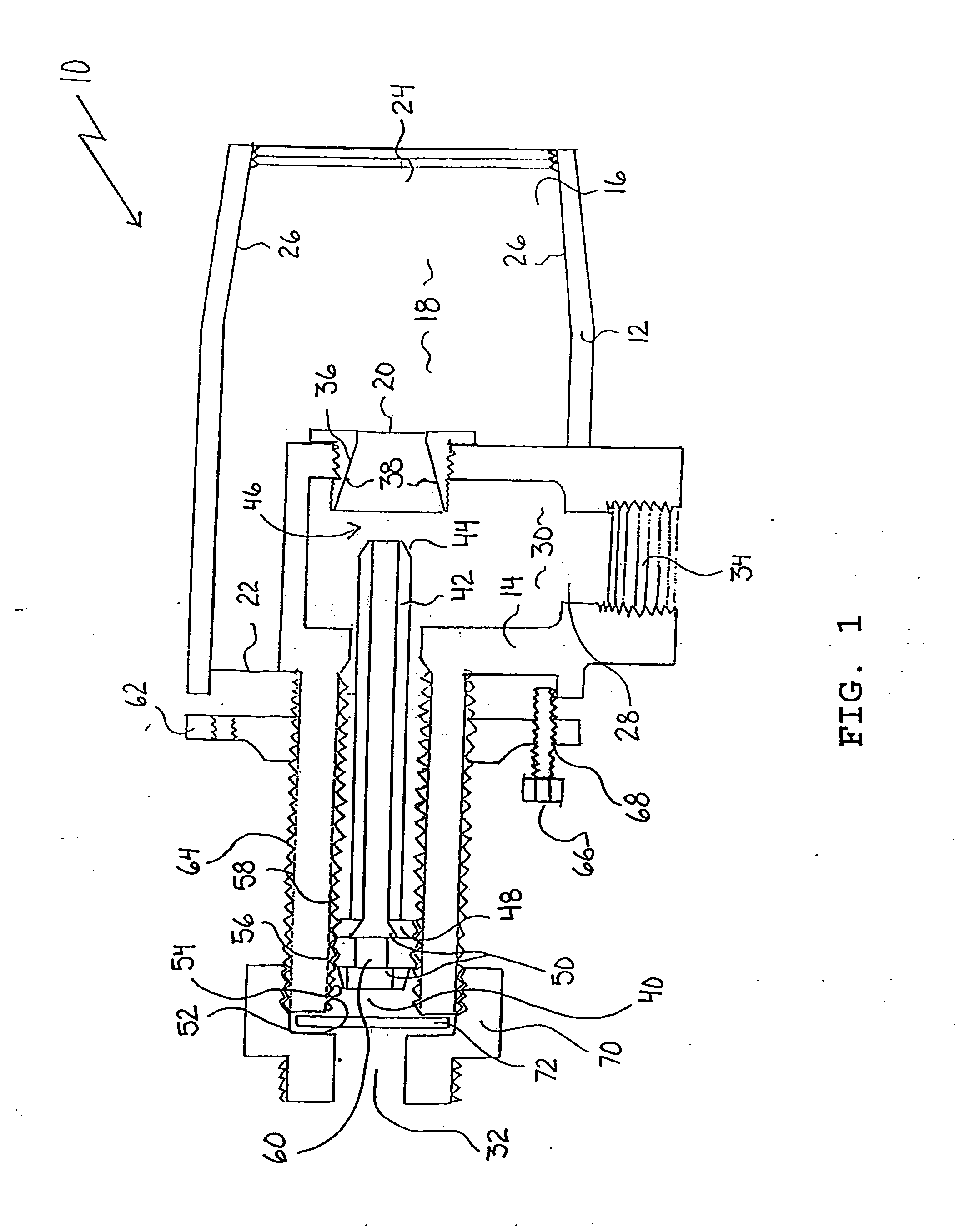

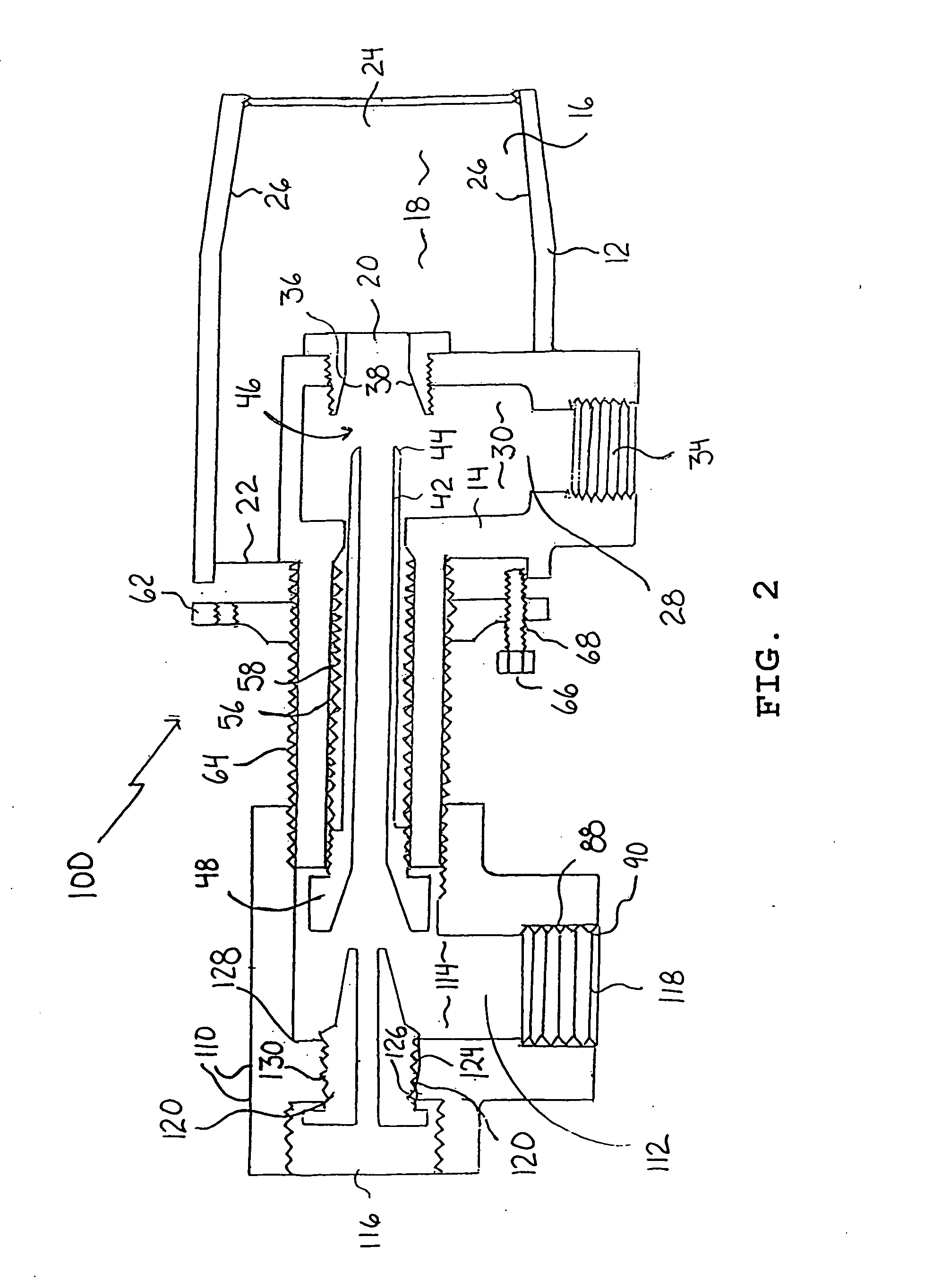

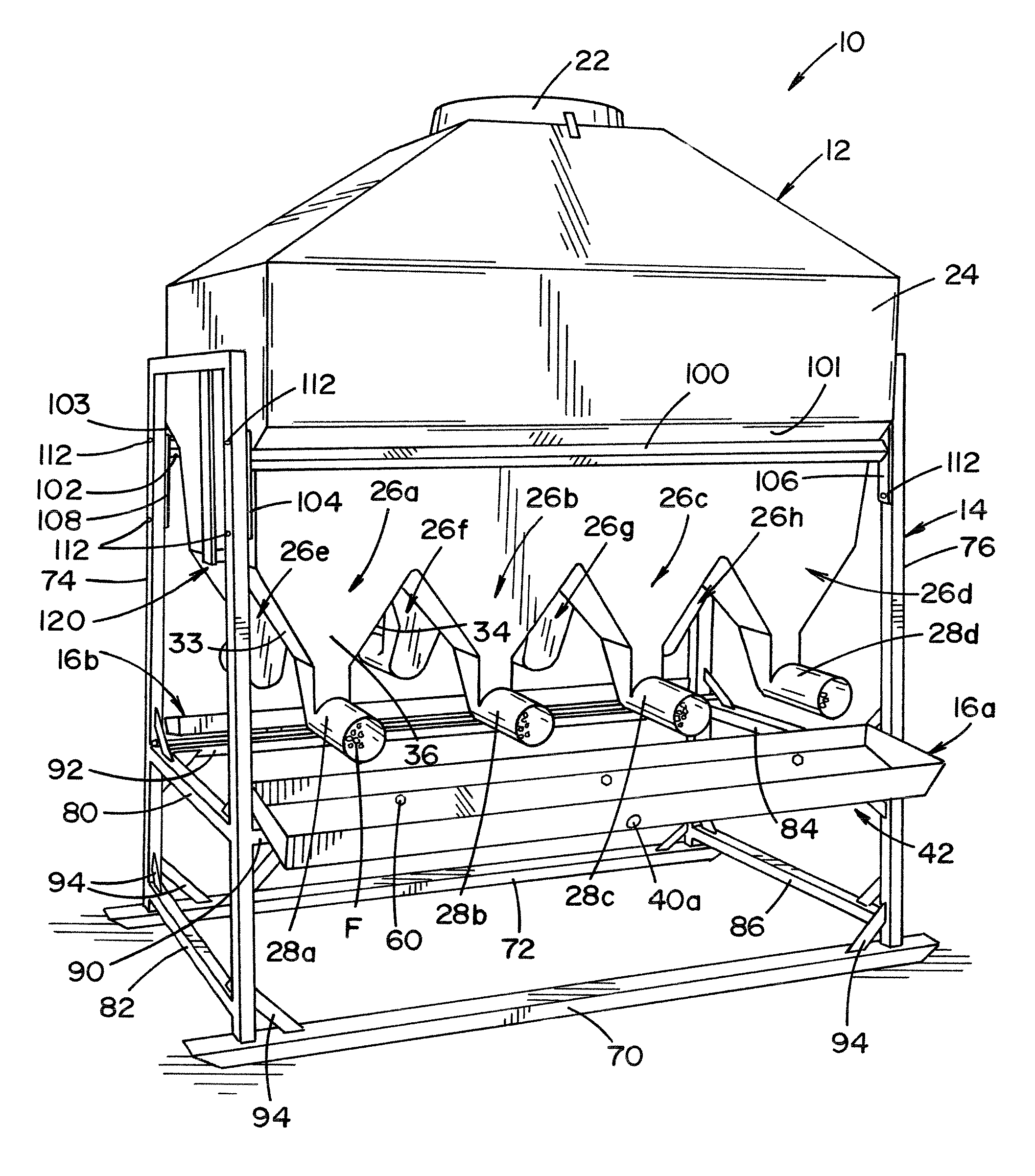

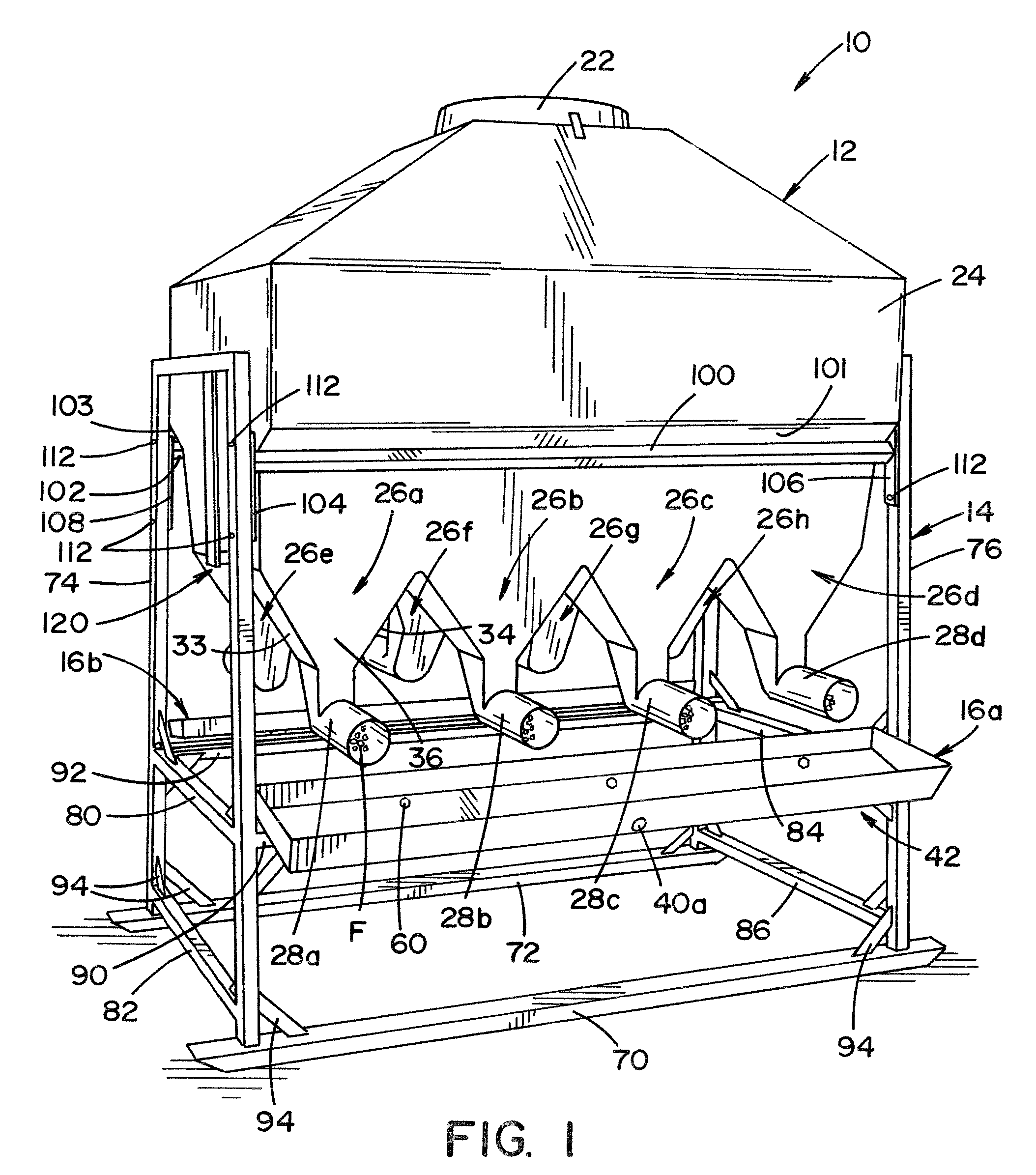

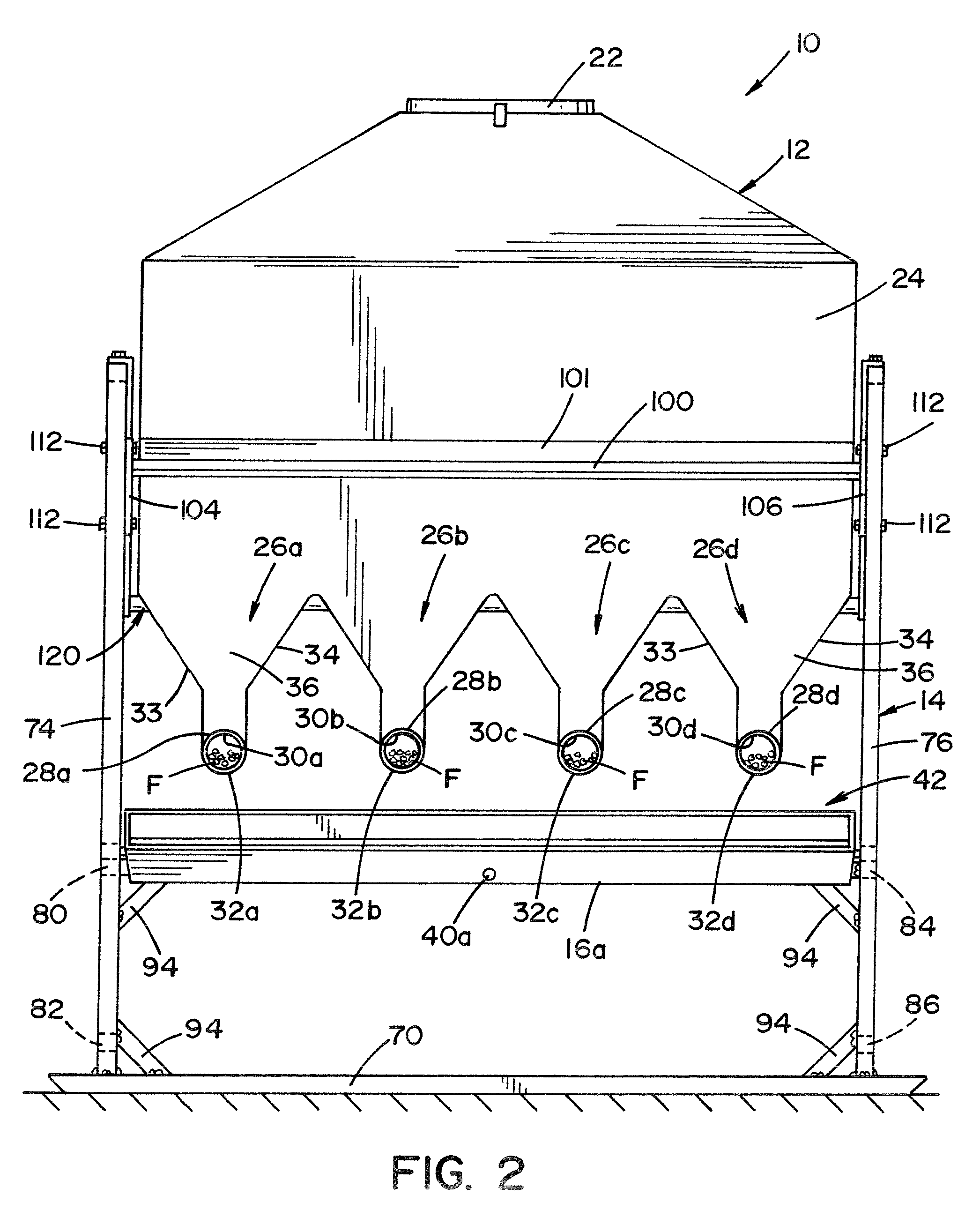

Animal feeder

InactiveUS20070028844A1Efficient feedingControl eating intervalAnimal feeding devicesPisciculture and aquariaEngineeringFodder

An animal feeder for supplying a feed to an animal of choice for feeding the animal of choice in an unprotected environment such as the outdoors. The feeder comprising a base for support the feeder on a ground surface, a support frame extending upwardly from the base and a hopper supported by the frame. The hopper having a storage reservoir for storing a supply of feed with a feed entry opening that is closeable to prevent exposure to the outdoors. The hopper further including a feed chute below the reservoir having an upper region sealingly joined to the reservoir and a lower region below the upper region that is sealingly joined to a feeding chamber. The feeding chamber having a bottom surface wherein the feed supply can move from the reservoir into the feeding chamber and rest on the bottom surface based on gravity alone. The hopper further including a horizontally extending elongated channel extending from the feeding chamber with an outer end having a feeding opening open to the outdoors wherein the feeding chamber is spaced from the opening and the feed substantially remains within the hopper and spaced from the outdoors until it is consumed by the animal of choice.

Owner:FREY HENRY H

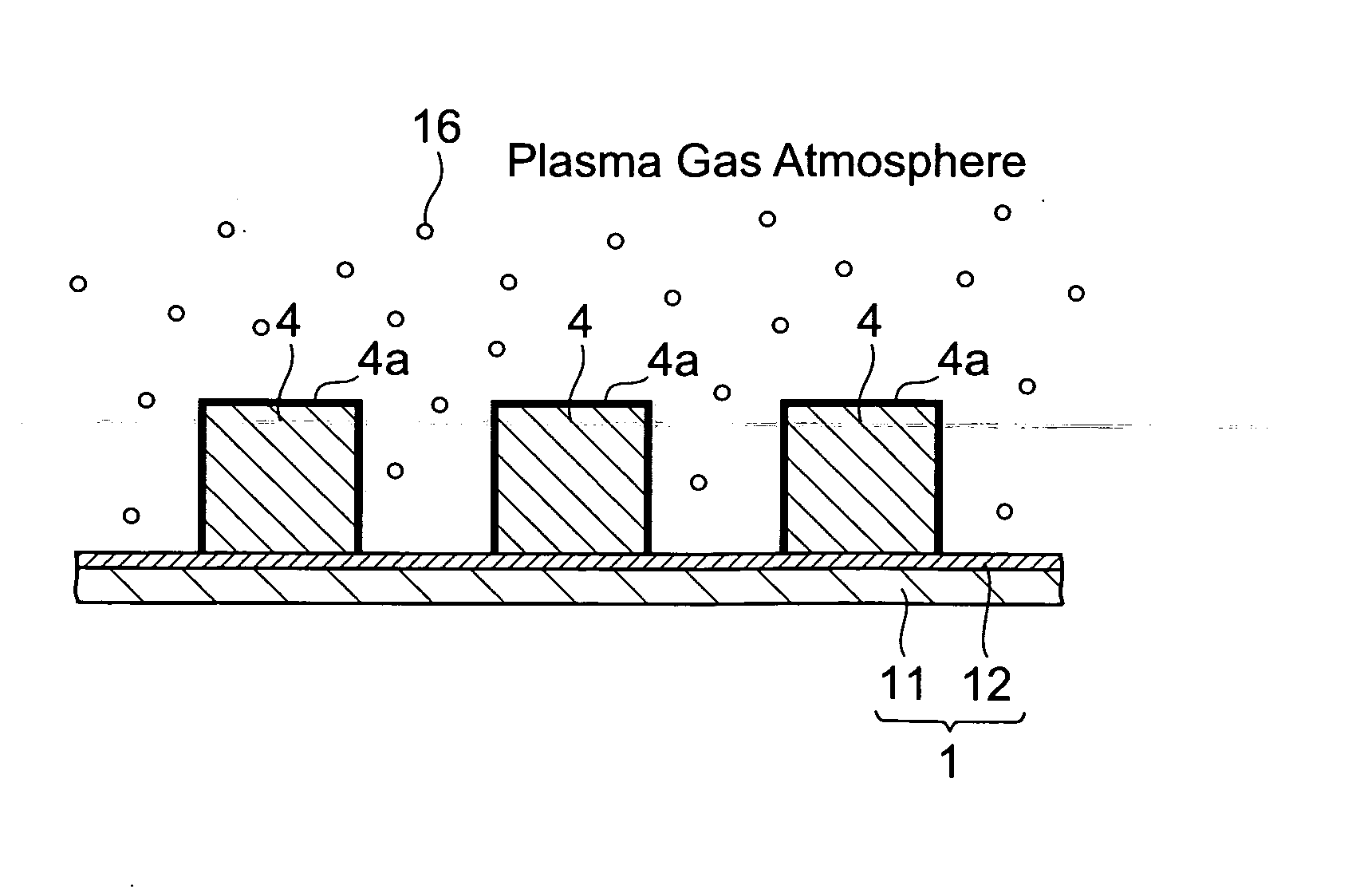

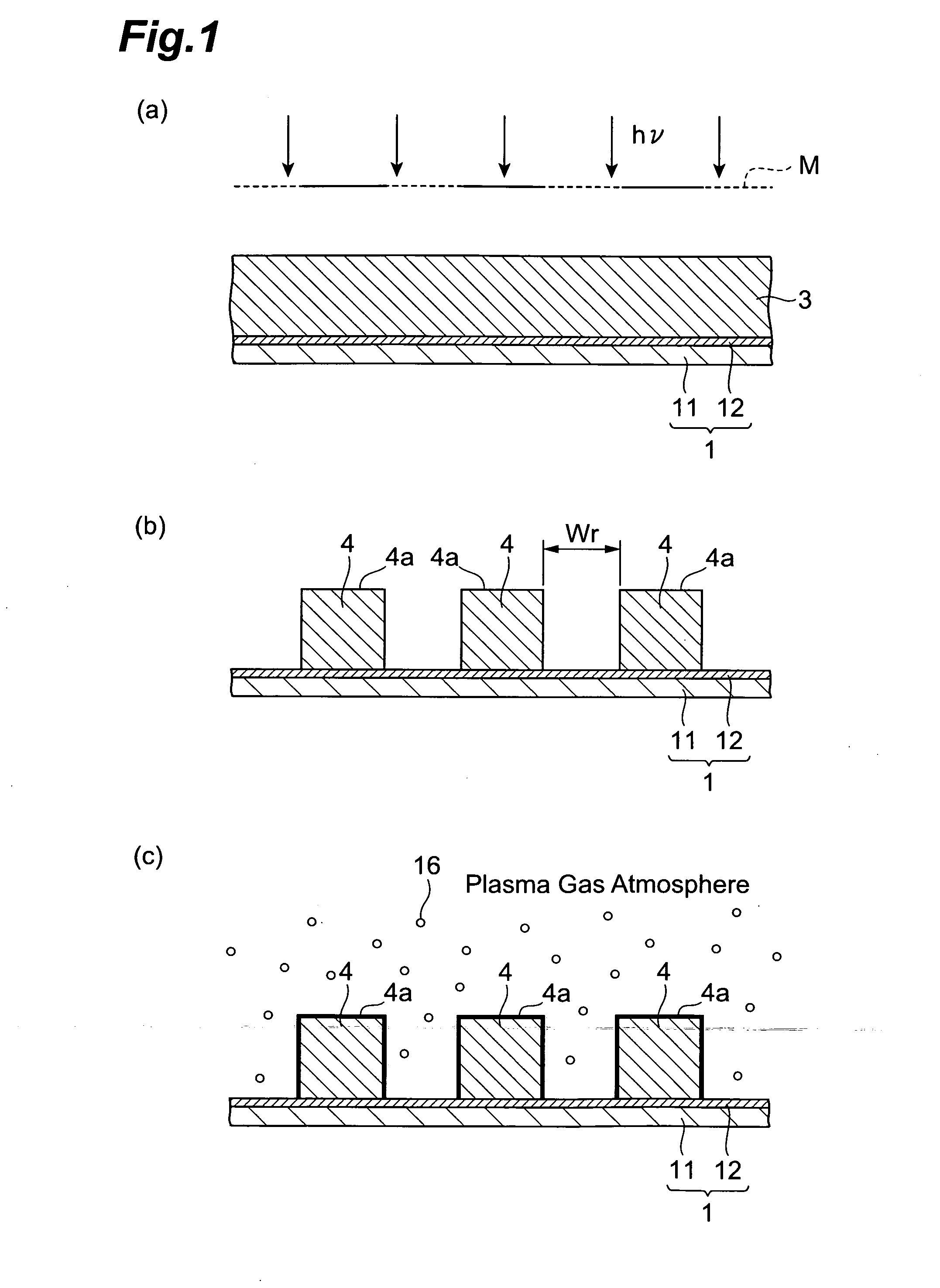

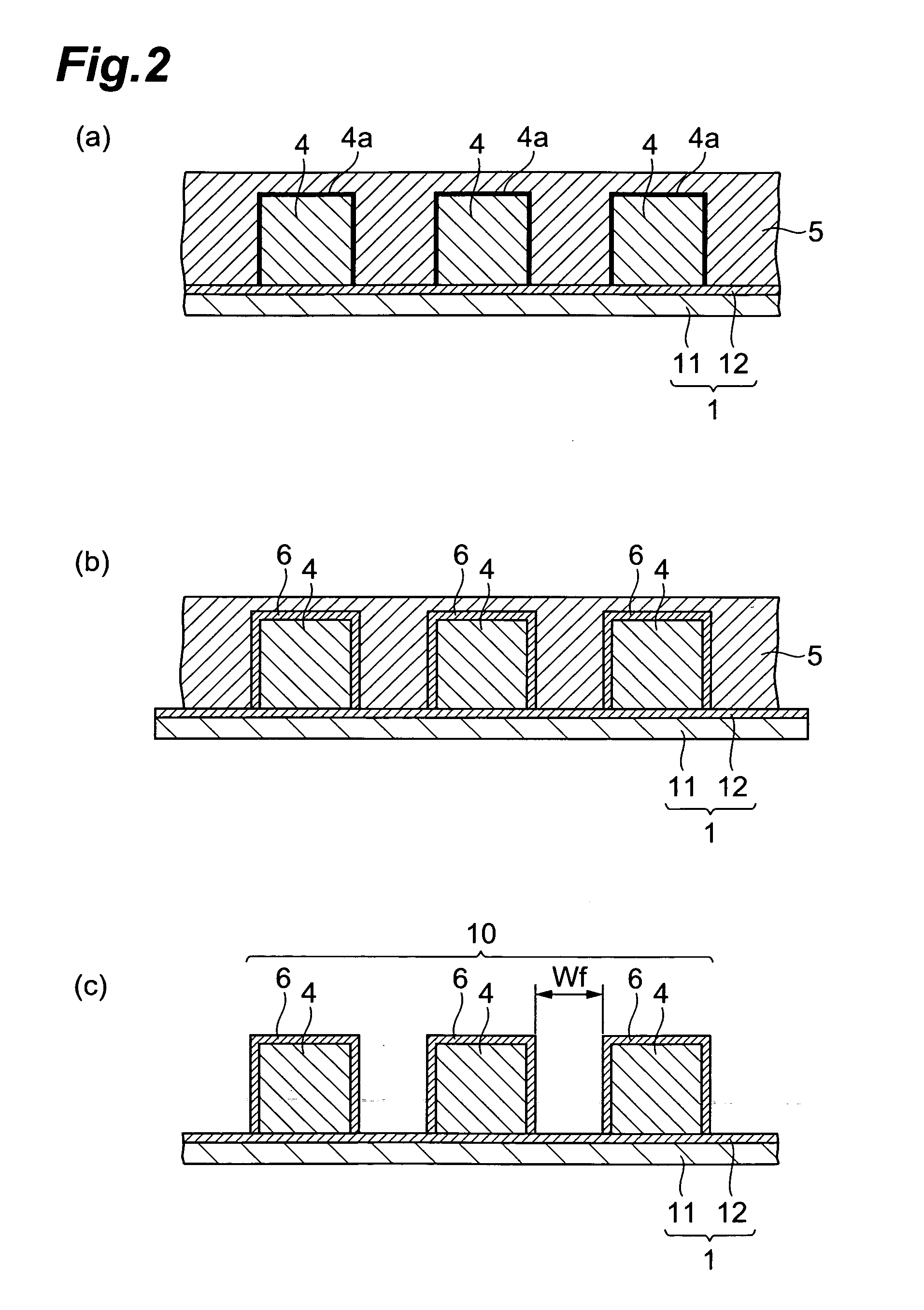

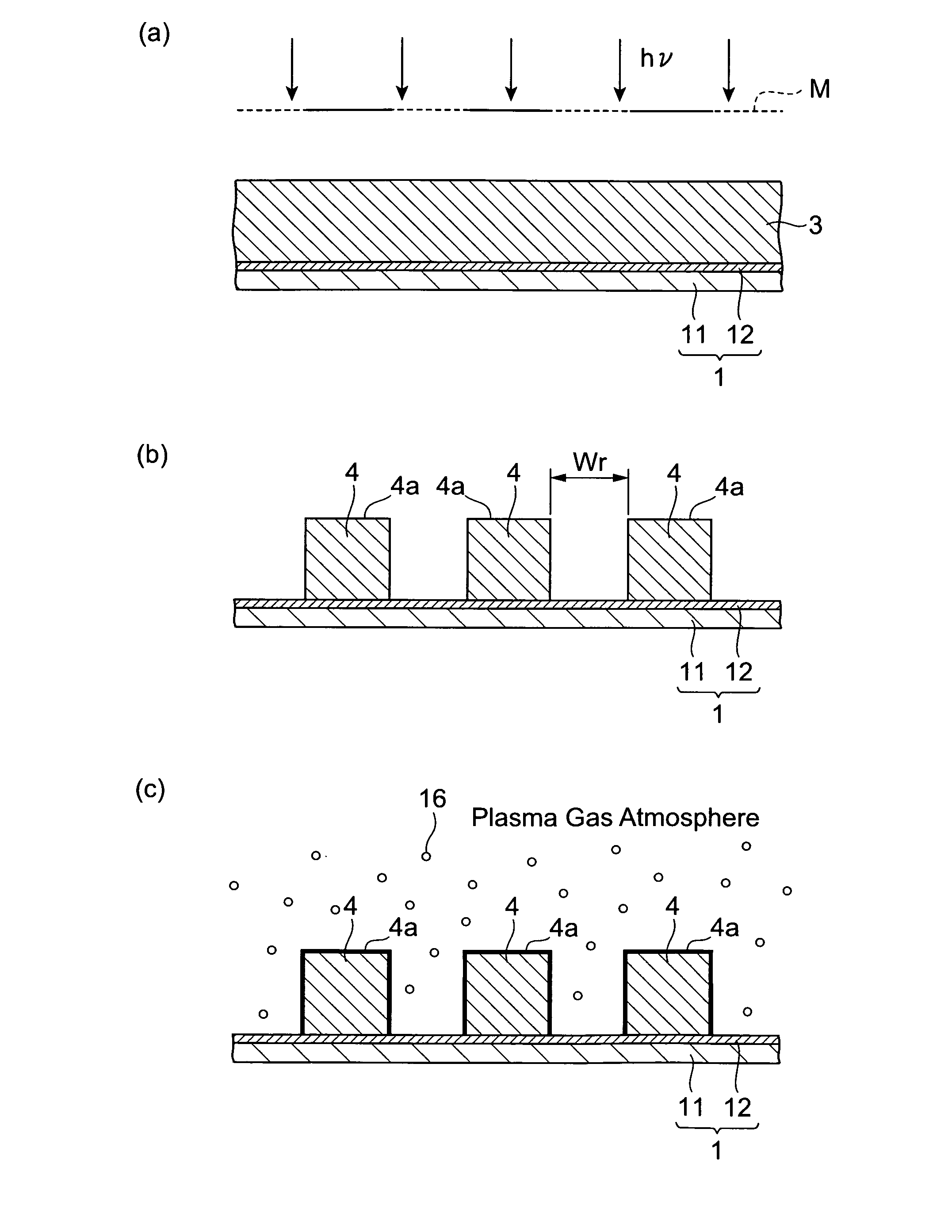

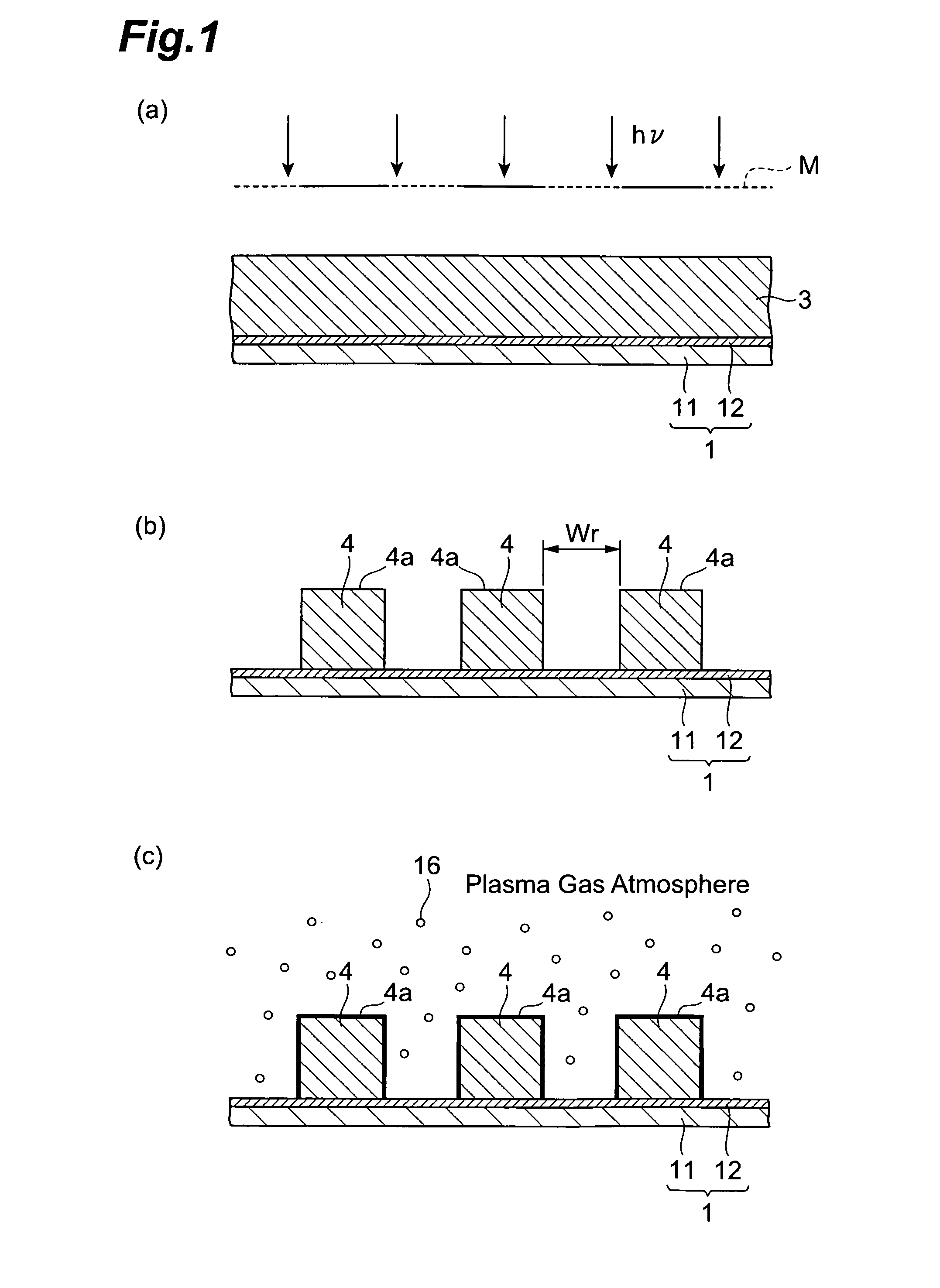

Resist pattern forming method, thin-film pattern forming method, and microdevice manufacturing method

InactiveUS20070248916A1High densityNarrow widthSemiconductor/solid-state device manufacturingRecord information storageResistFluorocarbon

A resist pattern forming method comprises the steps of plasma-processing a surface of an acid-feedable resist layer formed and patterned on a surface of a substrate in a gas atmosphere containing a fluorocarbon; attaching a resin composition crosslinkable in the presence of an acid to the plasma-processed surface of the resist layer; crosslinking the resin composition in a part in contact with the resist layer by feeding an acid from the resist layer, so as to form a crosslinked layer covering the resist layer; and removing the resin composition from a part excluding the crosslinked layer, so as to yield a resist pattern comprising the resist layer and the crosslinked layer covering the resist layer.

Owner:TDK CORPARATION

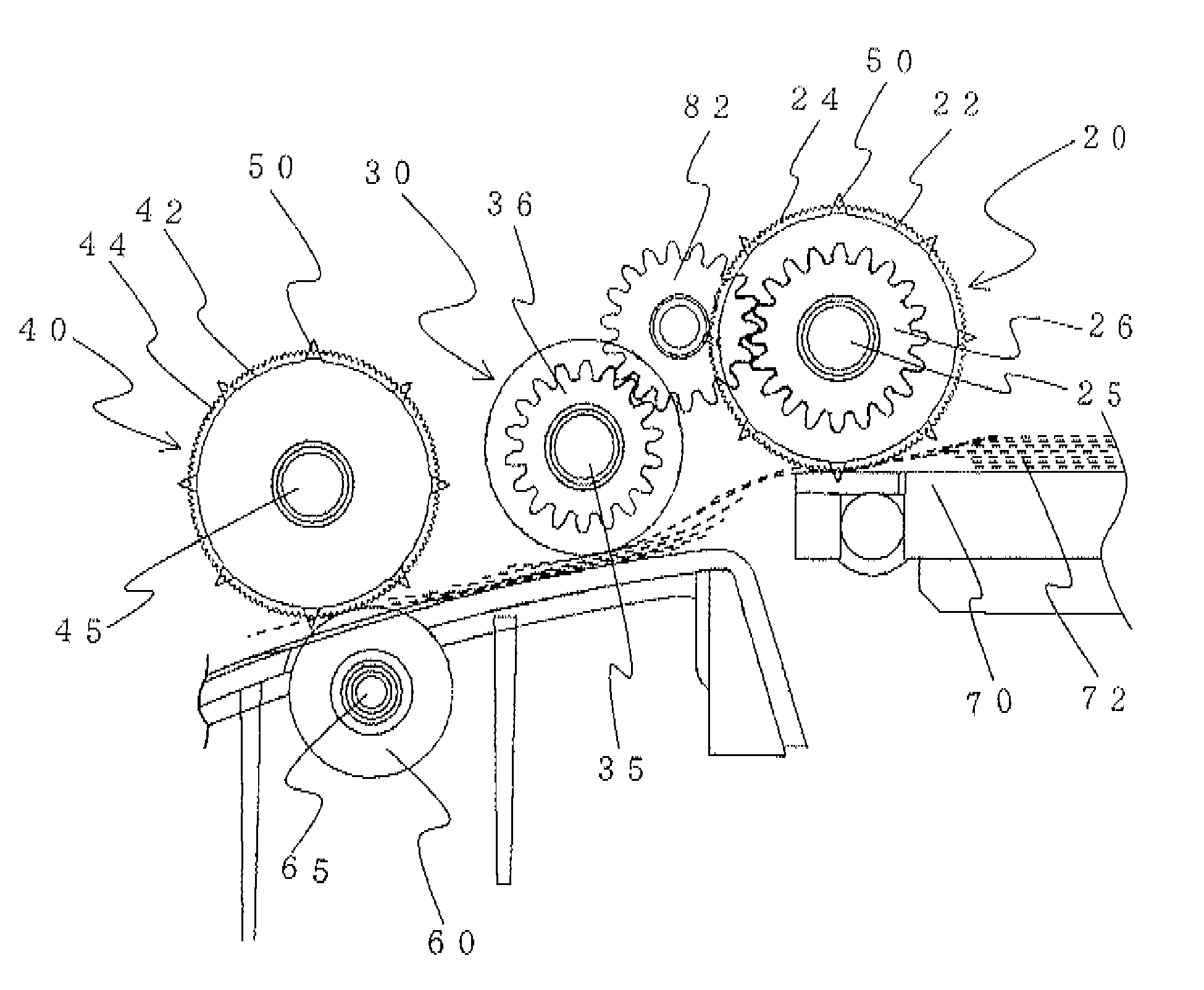

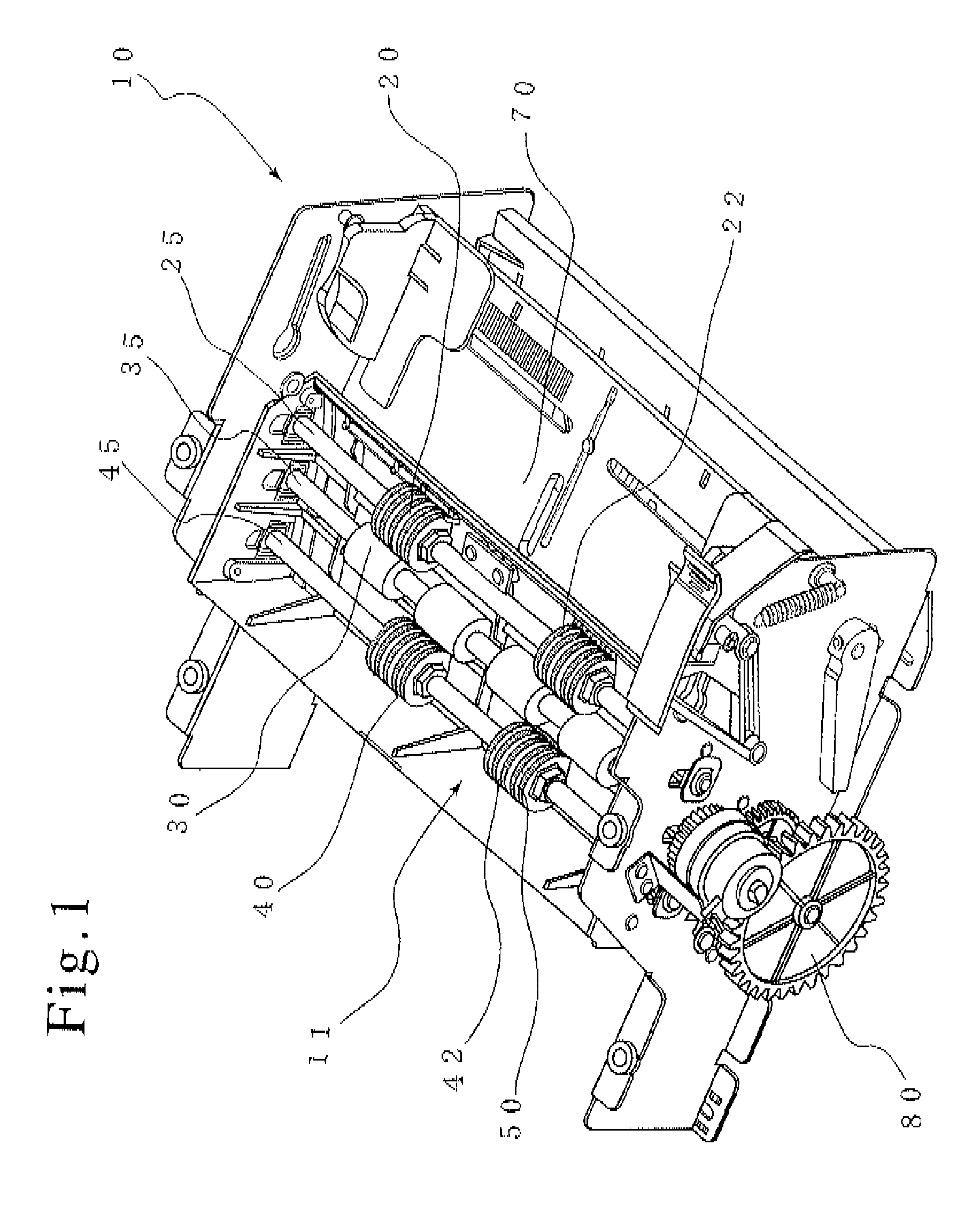

Shredder paper feed mechanism and paper feeder

InactiveUS20090008871A1Easy exitSmooth feedingGrain treatmentsArticle feedersPulp and paper industryPaper sheet

Owner:ELM INT CO LTD

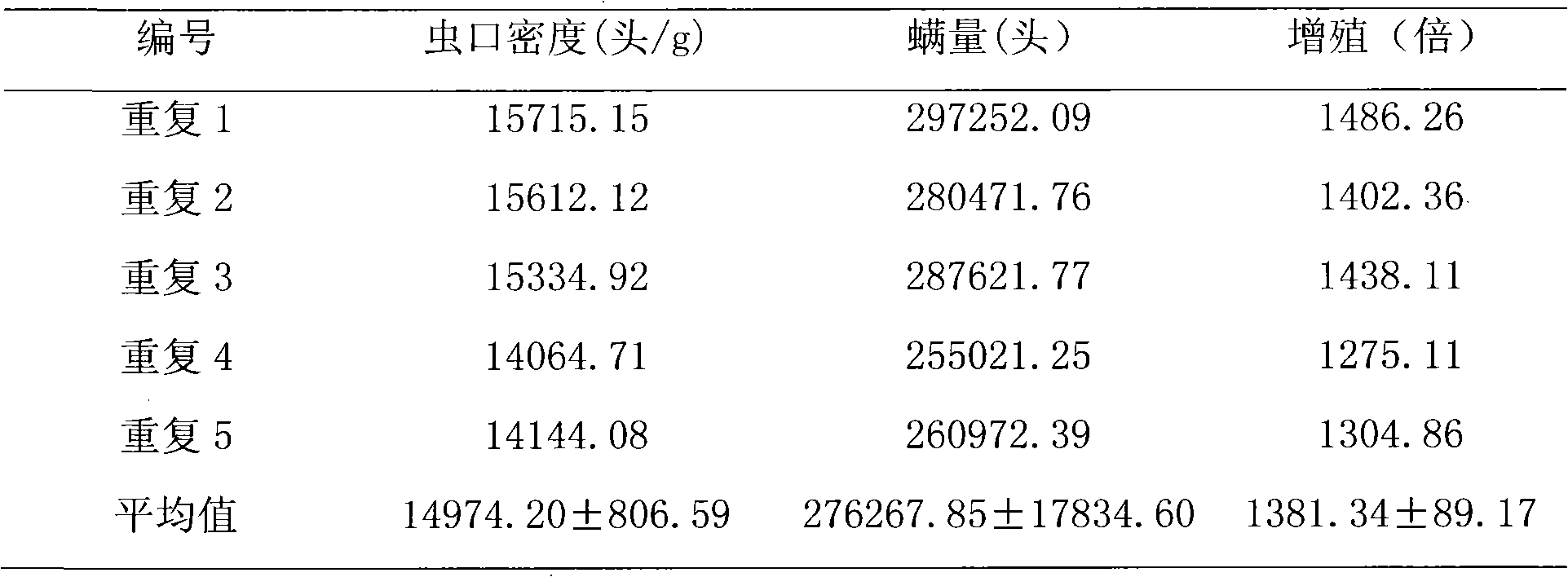

Method for artificially breeding mass Carpoglyphus lactis

ActiveCN101965822AEfficient feedingImprove nutritional statusAnimal husbandryYeastNutritional status

The invention relates to a method for artificially breeding mass Carpoglyphus lactis. In the method, the Carpoglyphus lactis is bred by 1 to 50 percent of sugar, 1 to 50 percent of yeast, 0 to 50 percent of breeding medium and 0 to 35 percent of water in an environment with the temperature of between 15 and 35 DEG C and the relative humidity of 65 to 95 percent. The method comprises the following steps of: after combining breeding materials, throwing the combined breeding materials into a breeding container; inoculating the Carpoglyphus lactis, wherein the Carpoglyphus lactis is inoculated in an amount of more than or equal to one Carpoglyphus lactis per milliliter; and breeding the Carpoglyphus lactis for 10 to 40 days to realize mass breeding. The Carpoglyphus lactis is bred by the sugar, the yeast, the breeding medium and the water, so the Carpoglyphus lactis can be efficiently bred, the method is easy to operate and has low cost, the bred Carpoglyphus lactis has the characteristics of good nutritional status, low death rate, high egg laying amount, high population density and the like, and the method is more suitable for low-cost commercial production of predatory mites.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI +2

Baby bowl

InactiveUS7637388B2Easy and efficient collectionEasy to viewDwelling equipmentLarge containersEngineeringMechanical engineering

A bowl includes non-slip means and spoon-assisted food conglomeration means. In a preferred embodiment, the bowl is transparent. Non-slip means may include a weight structure, a non-slip material affixed to the bowl bottom either substantially continuously covering the bottom or substantially discontinuously covering the bottom. Spoon-assisted food conglomeration means may include a sloped bottom, a substantially spoon-shaped locus, a steep rim, or an inward-curving rim. The bowl may further include spillage reduction means. Spillage reduction means may include an abrupt taper terminus, a steep rim, an inward-curving rim, or a chamfered or rounded bowl vertex. Alternatively the bowl may comprise a sloped bottom terminating in a substantially spoon-shaped locus and further comprise non-slip means. In alternate embodiments the bowl may further comprise spillage reduction means or be characterized by a substantial transparent region.

Owner:BABY DIPPER

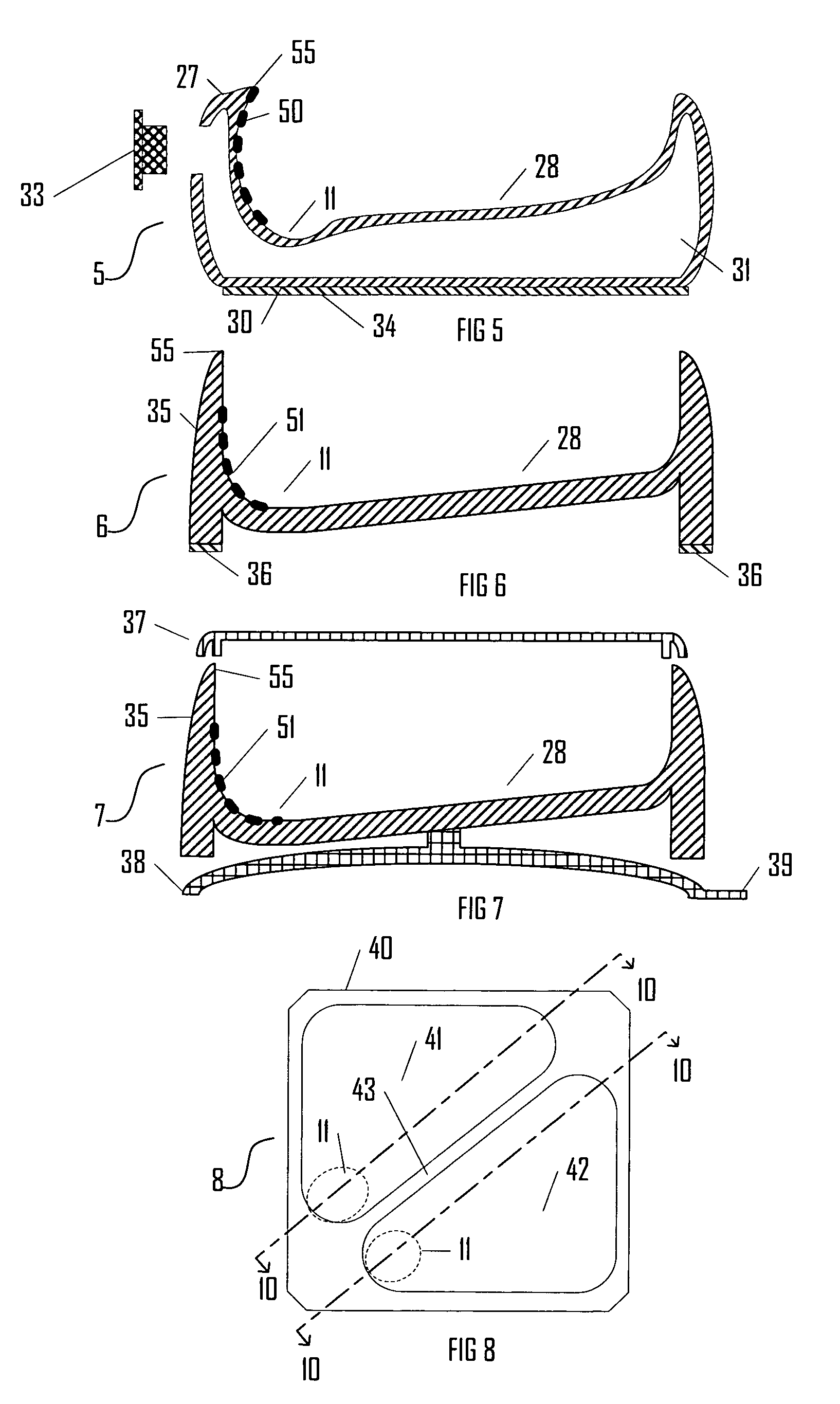

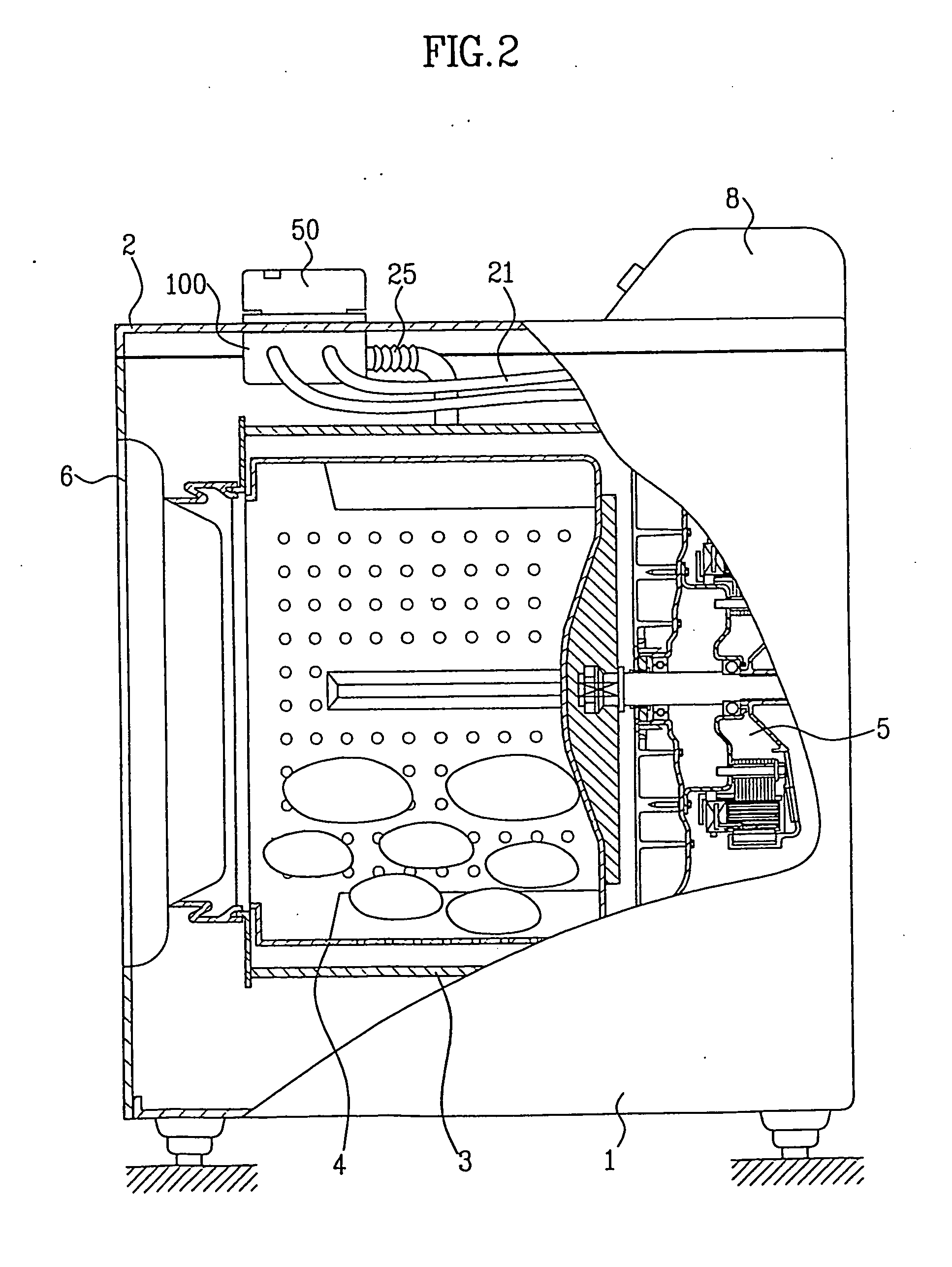

Apparatus for supplying detergent in washer

InactiveUS20050097925A1Easy constructionAccurate quantityOther washing machinesControl devices for washing apparatusEnvironmental engineeringWater discharge

The invention relates to a detergent supplying apparatus in a washer which includes a cabinet (1), a drum (4) rotatably provided in the cabinet and a tub (3) fixed outside the drum (4). The detergent supplying apparatus includes: a water feed pipe (21) for feeding water; a detergent container (100) including water storage pool (104) having water inlet opening (141) connected to the water feed pipe, for being supplied with water through the water inlet opening (141), detergent pool (101 to 103) dividedly formed at a side of the water storage pool (104 to 106) by overflow compartments (108 to 110), for storing detergent, and drain (107) provided at a passage end of the detergent pools (104 to 106), whereby the water fed to the water storage pools (104 to 106) overflows the overflow compartments (108 to 110) to be fed to the detergent pools (101 to 103), and discharges through the drain (107); and detergent discharge pipe (25) of which one end is connected to the drain of the detergent container and the other end is connected to the tub of the washer, for guiding the detergent and water discharged through the drain into the tub.

Owner:LG ELECTRONICS INC

Automatic feeding device for laser engraving machine

InactiveCN103523518AKeep it steadyEffective feedingDe-stacking articlesConveyor partsLaser engravingEngineering

The invention discloses an automatic feeding device for a laser engraving machine. The device comprises a box body, a lifting table arranged at the bottom of the box body, a material carrying device located on the lifting table and a baffle located on the top of the box body. The device is characterized in that the device further comprises a push handle located on one side of the box body and close to the baffle, the material carrying device is composed of a plurality of layers of material carrying boxes in a stacking mode, and the lower surface of the baffle is provided with a distance sensing device. The automatic feeding device has the advantages that ascending and descending of materials are controlled by means of the distance sensing device, and the push handle can be used effectively for feeding; pushing is facilitated by means of the material carrying boxes, the materials are not damaged, meanwhile stability of the materials during laser engraving can be guaranteed, and the probability of occurrence of defective products is reduced. By means of the design of notches in the material carrying boxes, the materials are convenient to take and place.

Owner:苏州市国晶电子科技有限公司

Burner fuel mixer head for concurrently burning two gaseous fuels

InactiveUS20050053887A1Efficient drawingEfficient feedingGaseous fuel burnerCombustorNuclear engineering

A burner fuel mixer head includes a primary housing and a secondary housing. The primary housing has a fuel / air mixing chamber with a mixed fuel gas inlet. The secondary housing has a fuel mixing chamber. A venturi throat with converging sidewalls is positioned in the mixed fuel gas inlet of the primary housing. A venturi nozzle communicates with a pressurized fuel gas inlet with a first end of the venturi nozzle extending into the fuel mixing chamber in axial alignment with the venturi throat. This forms a venturi, such that a pressurized flow of pressurized fuel gas through the venturi draws low pressure fuel gas from the fuel mixing chamber of the secondary housing through the mixed fuel gas inlet into the fuel / air mixing chamber of the primary housing.

Owner:THE IDEA PLACE

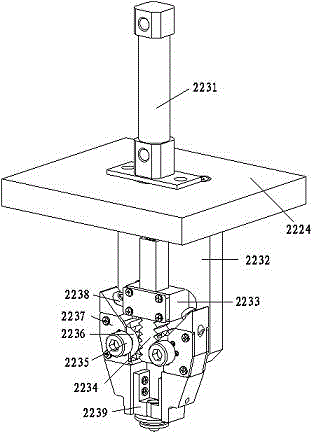

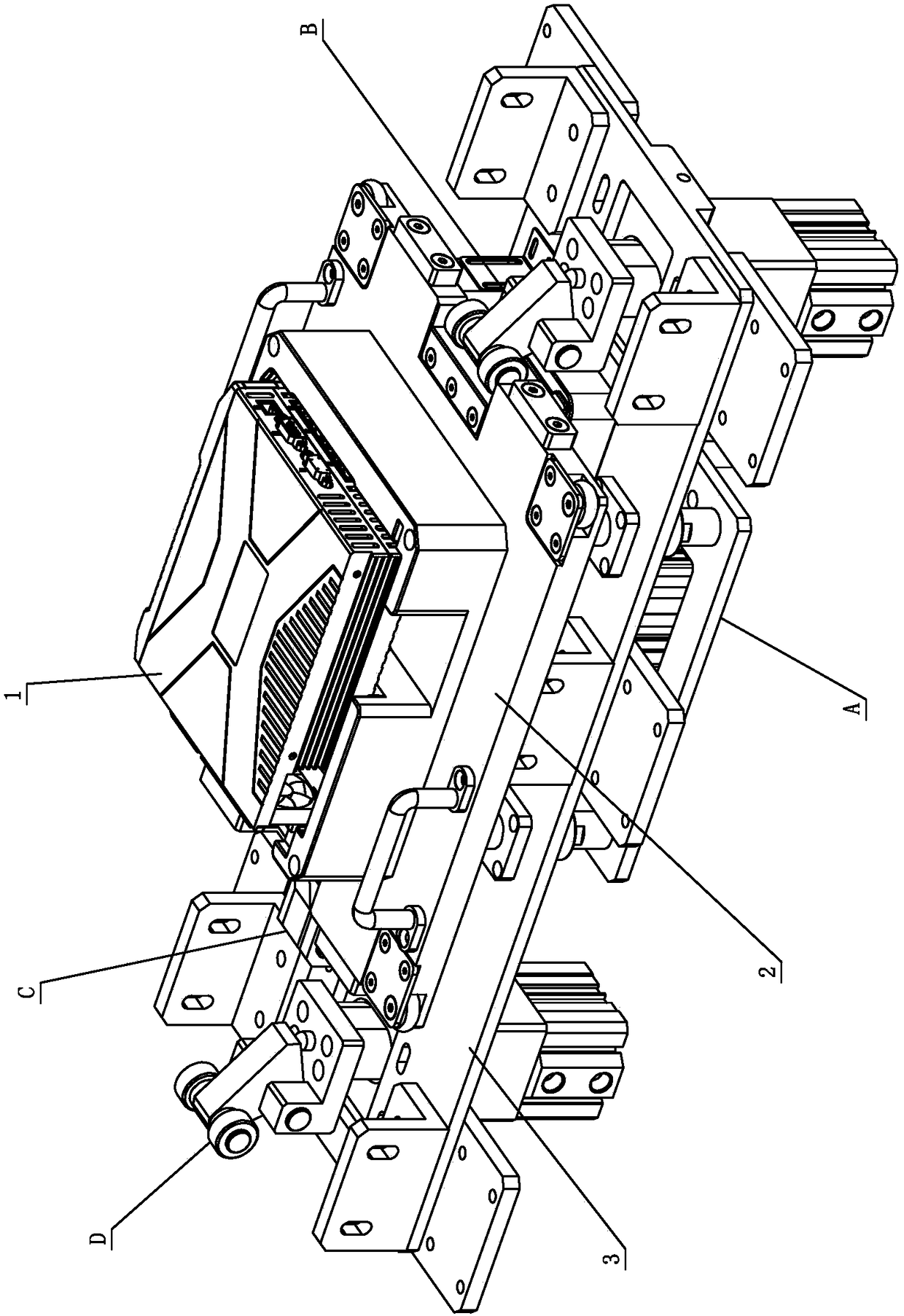

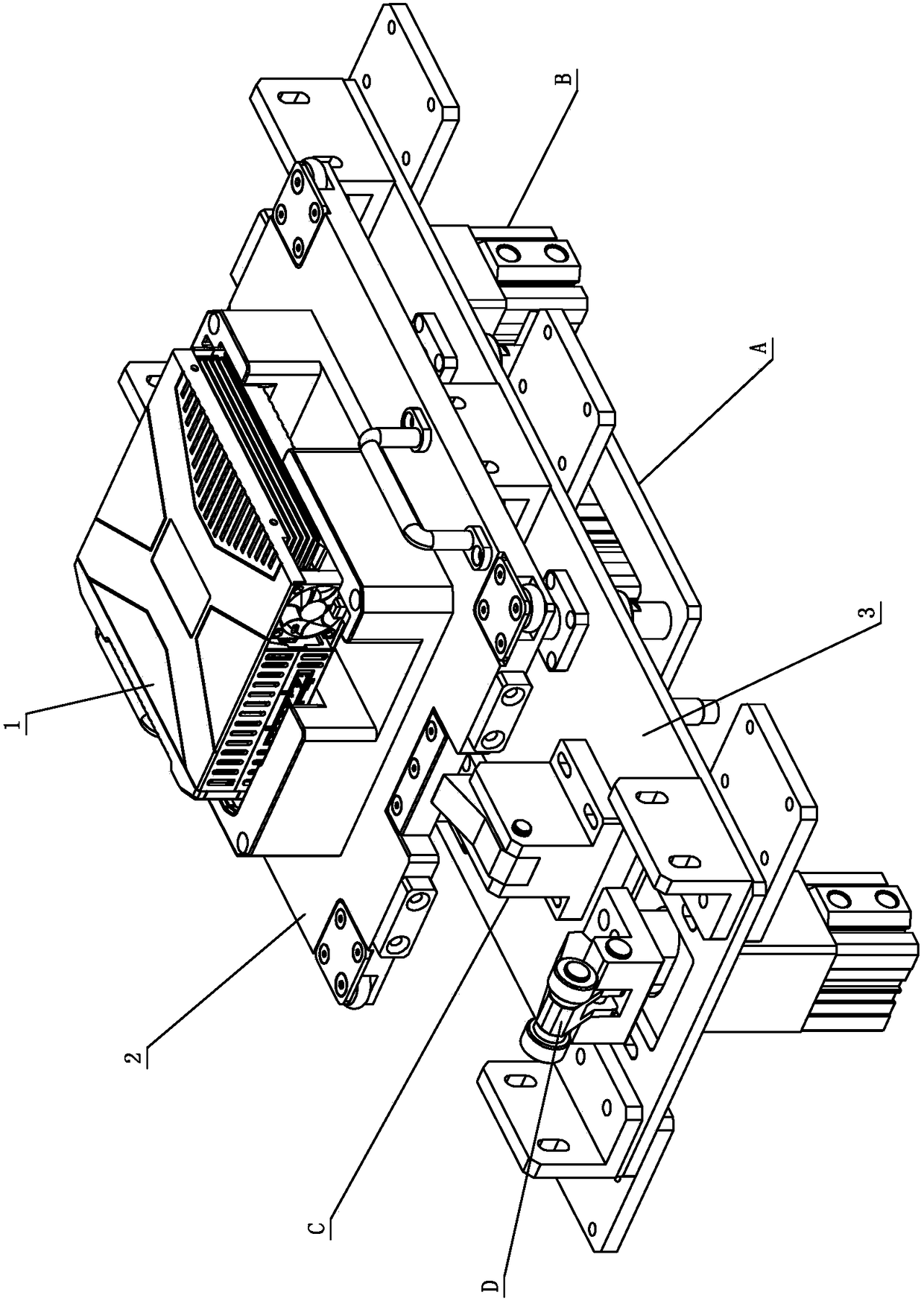

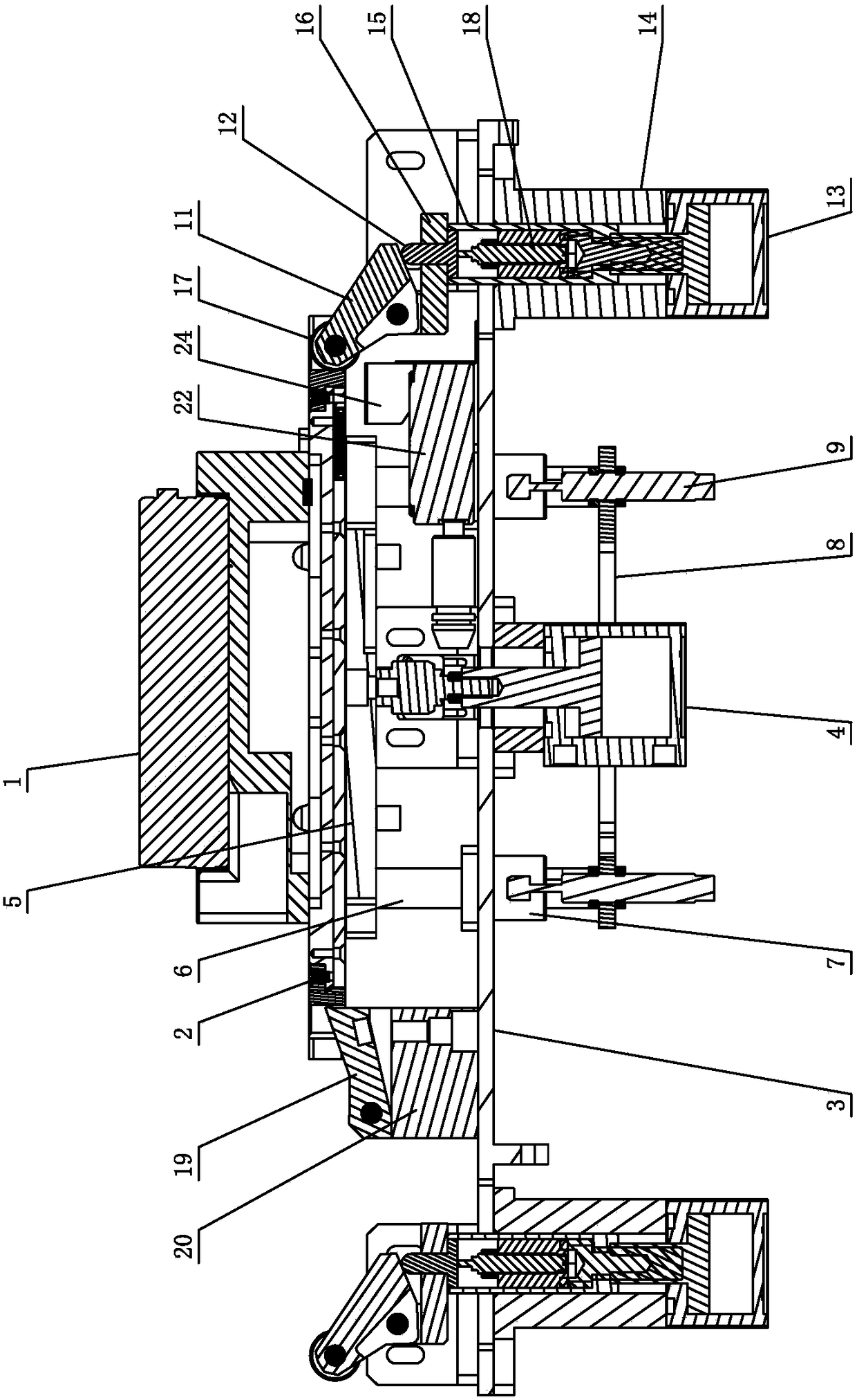

Top-plug loading manipulator of solenoid valve membrane assembling machine

InactiveCN106041472ACompact structureGuaranteed uptimeMetal working apparatusSolenoid valvePush pull

The invention discloses a top-plug loading manipulator of a solenoid valve membrane assembling machine. The top-plug loading manipulator comprises a horizontal movement unit, a vertical movement unit and a top-plug mechanical clamp; the vertical movement unit is mounted on the upper end of the horizontal movement unit; the pen-shaped air cylinder of the top-plug mechanical clamp is mounted on the vertical pushing plate of the vertical movement unit; the horizontal movement unit comprises a loading support, a horizontal slide rail, a horizontal slide block, a horizontal pushing plate, a first push-pull air cylinder, a floating joint, a horizontal connecting plate, an elevating air cylinder, an elevating plate and a guide post. By being applied with the above scheme, the top-plug loading manipulator disclosed by the invention achieves the advantages of compact structure and stable operation, and can load the top-plugs automatically, efficiently and orderly instead of manual operation, thereby saving labors.

Owner:苏州市吴中区胥口健浩五金加工厂

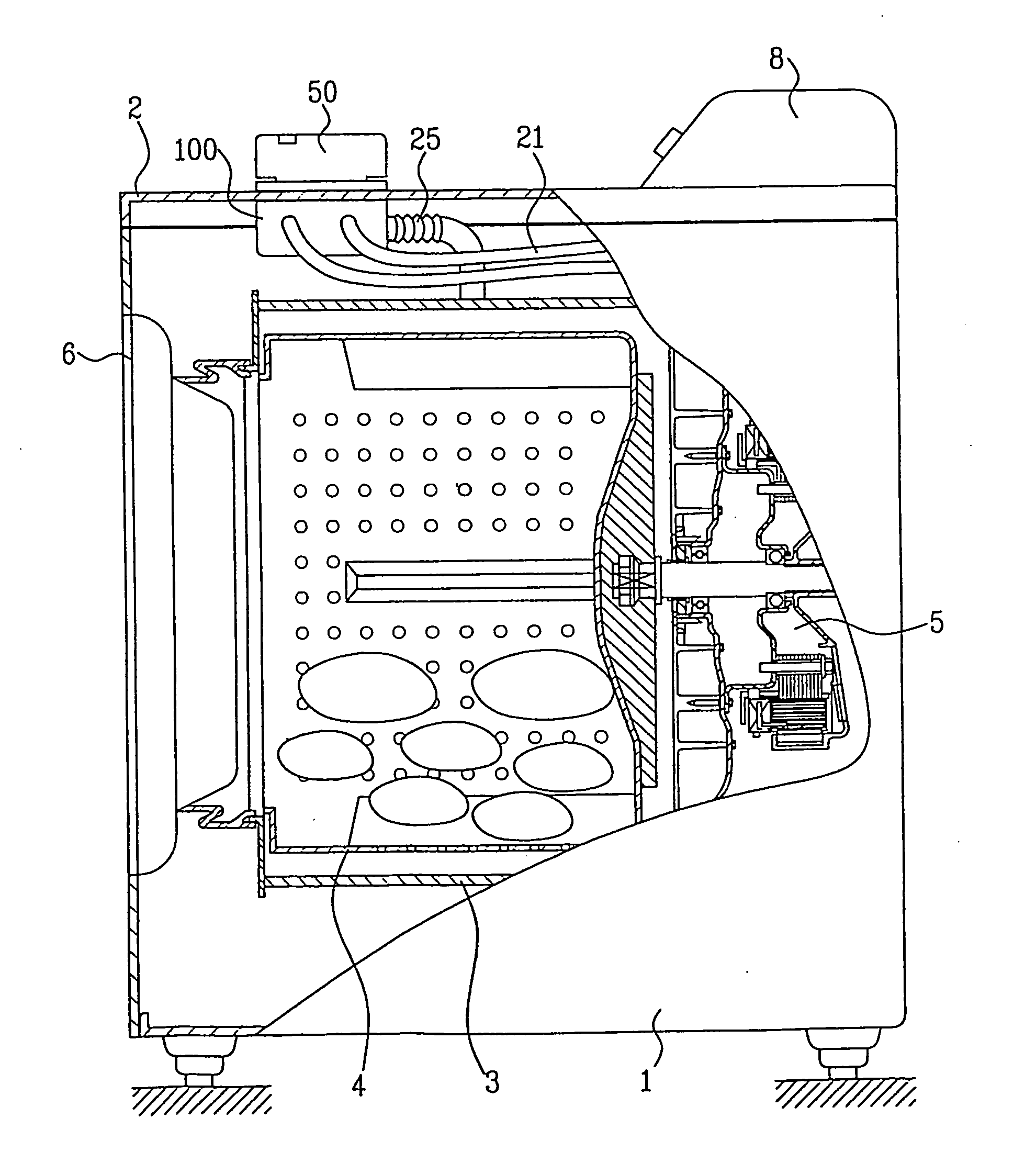

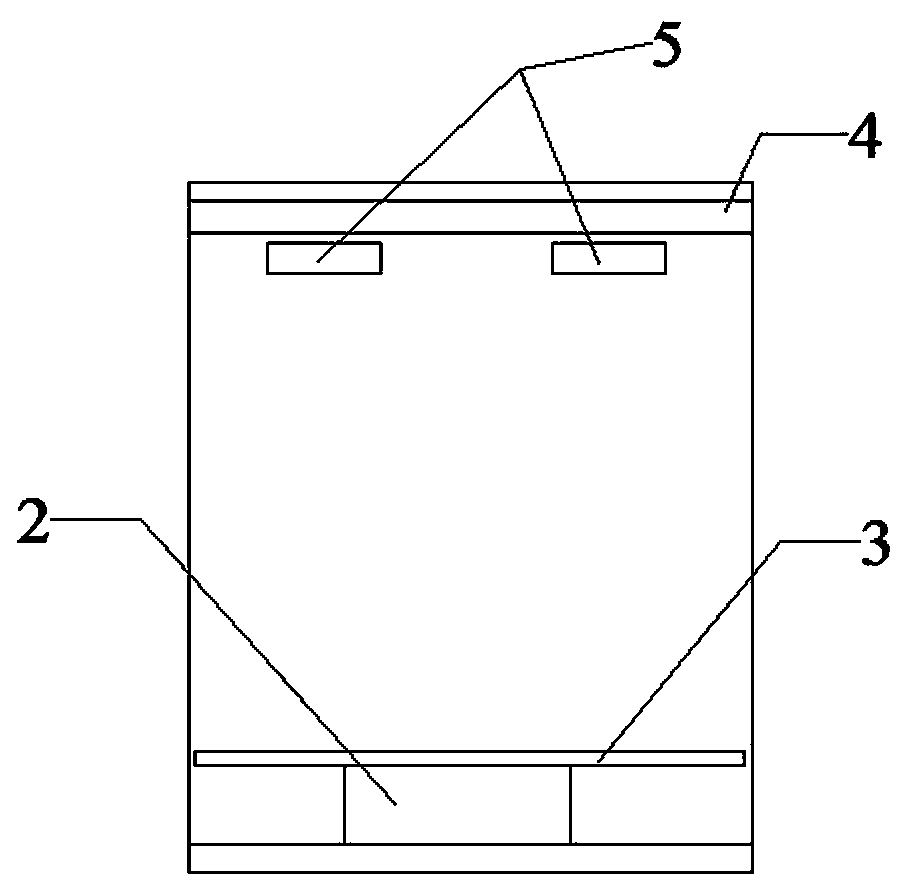

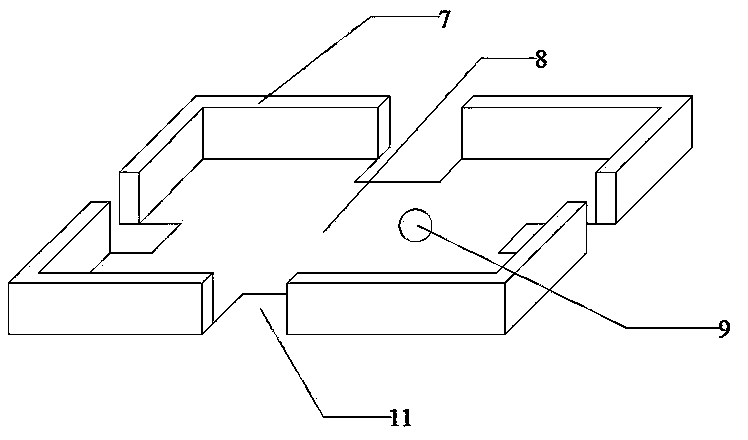

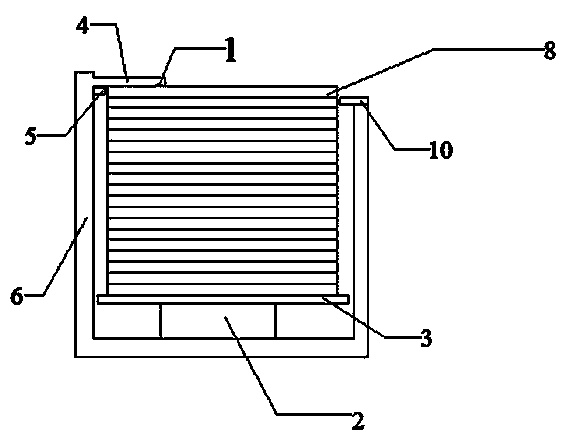

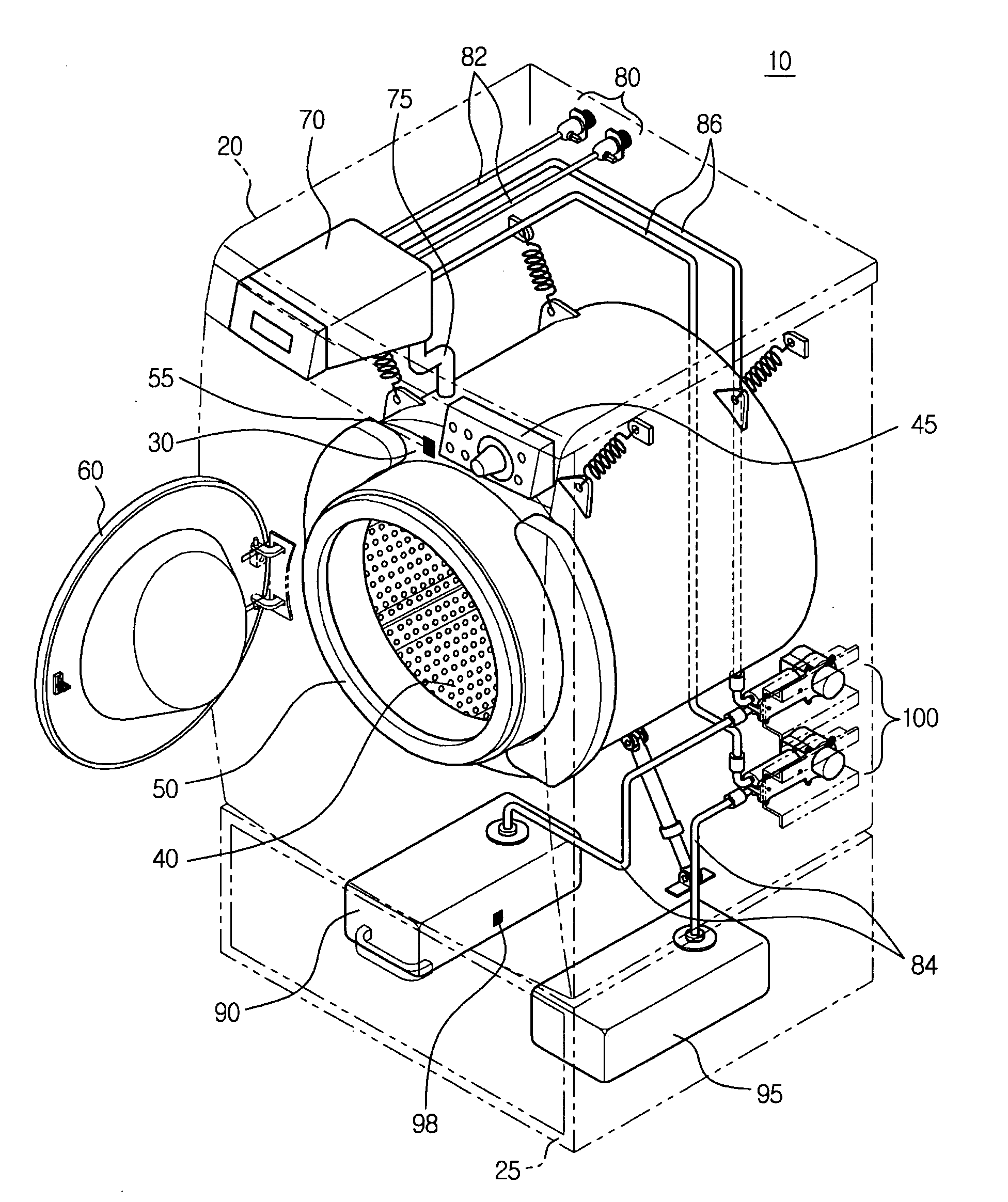

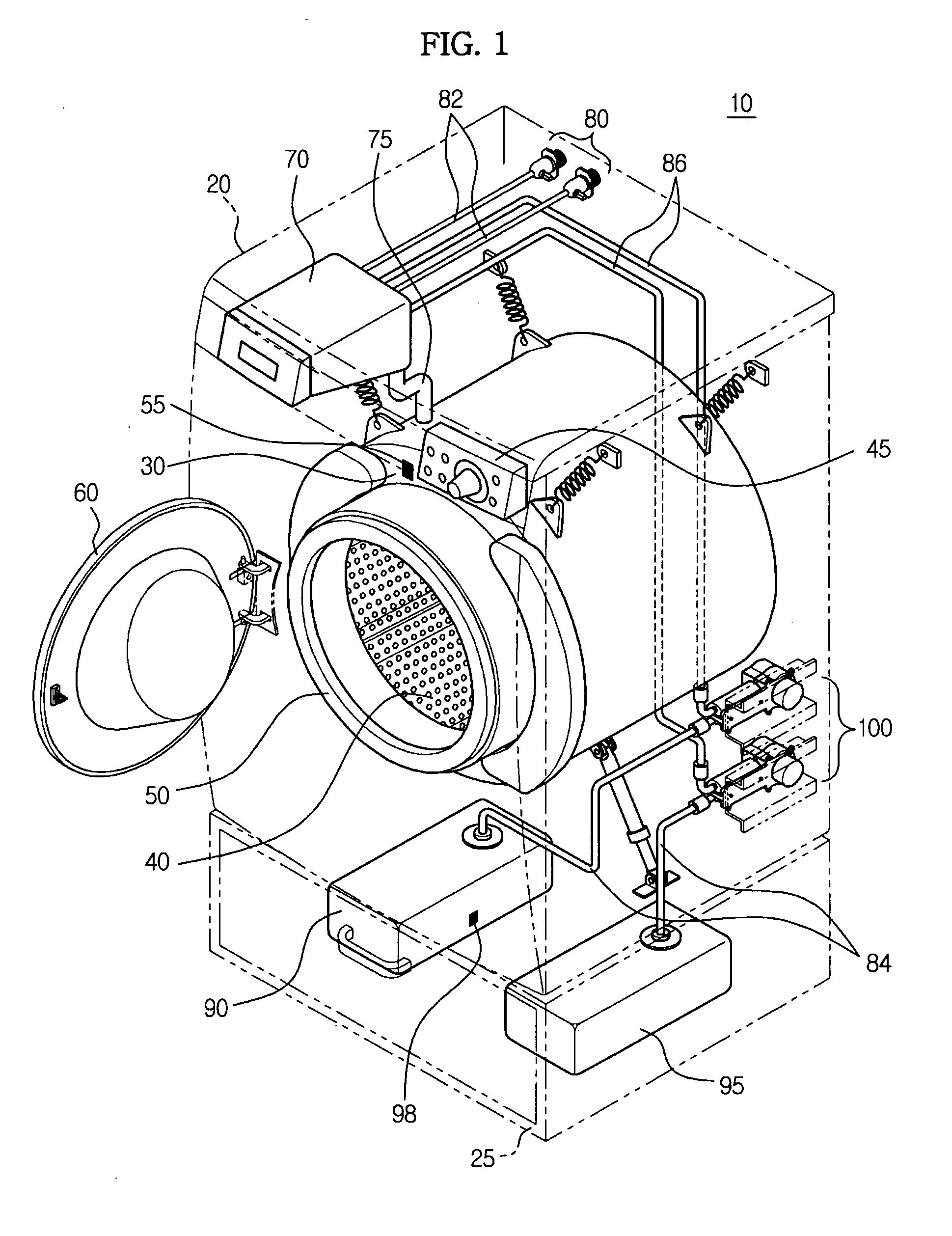

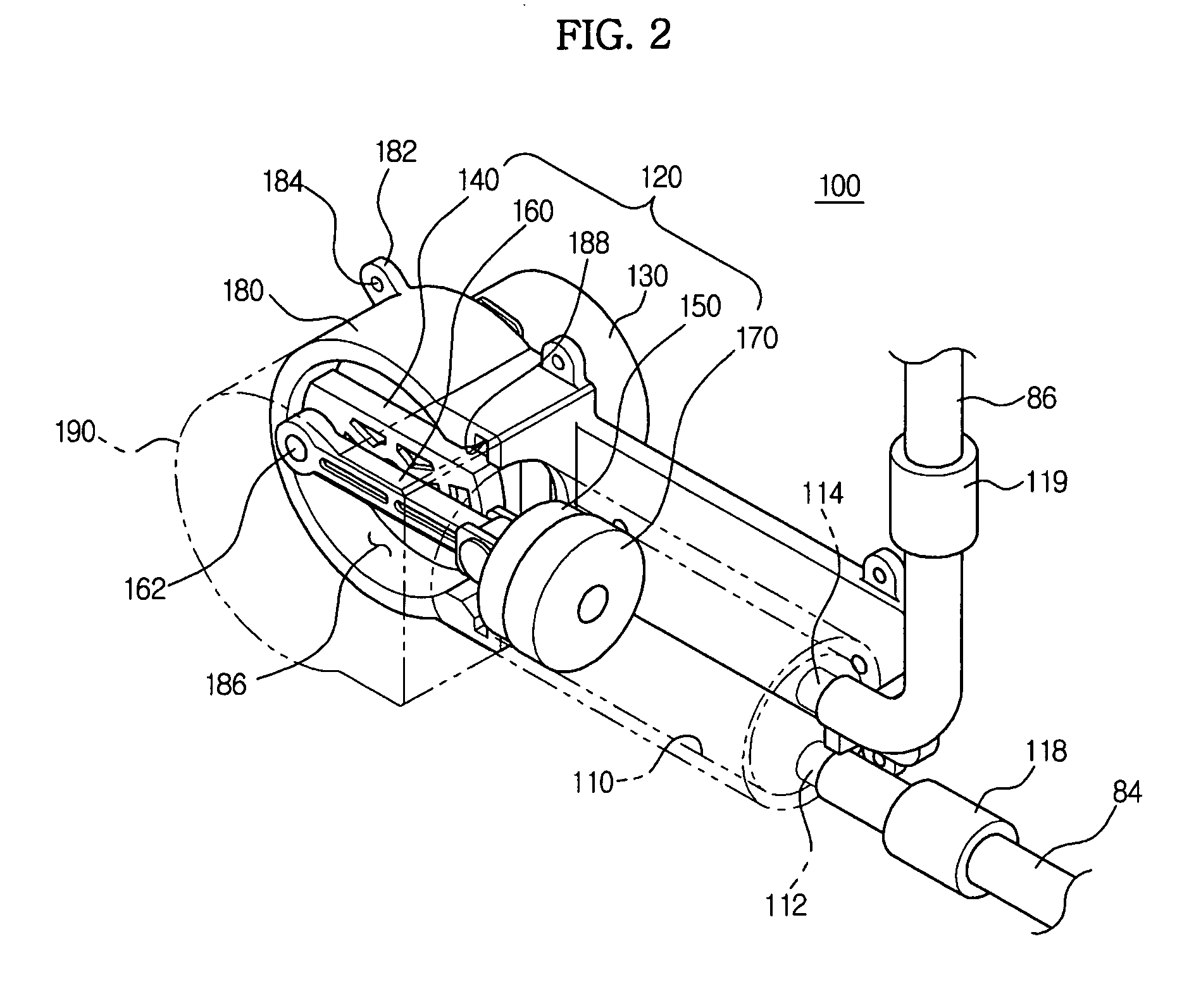

Detergent feeding apparatus and washing machine having the same

InactiveUS20120006077A1Avoid enteringEfficient feedingLarge containersOther washing machinesEngineeringLaundry

A washing machine having a detergent feeding apparatus to stably feed a required amount of liquid detergent based on the amount of laundry in an automated manner. The washing machine includes a cabinet defining an external appearance of the washing machine, a drum placed in the cabinet, a detergent box connected to the drum, a liquid detergent reservoir placed below the detergent box and to store liquid detergent therein, and a detergent feeding apparatus connected to the detergent box and the liquid detergent reservoir and to feed the liquid detergent stored in the liquid detergent reservoir to the detergent box. The detergent feeding apparatus includes a cylinder which the liquid detergent is introduced into or discharged from, and a pressure regulating unit connected to the cylinder and to introduce the liquid detergent into the cylinder or discharge the introduced liquid detergent from the cylinder.

Owner:SAMSUNG ELECTRONICS CO LTD

Resist pattern forming method, thin-film pattern forming method, and microdevice manufacturing method

InactiveUS7846646B2Narrow widthAcidifies surfaceSemiconductor/solid-state device manufacturingRecord information storageResistFluorocarbon

A resist pattern forming method comprises the steps of plasma-processing a surface of an acid-feedable resist layer formed and patterned on a surface of a substrate in a gas atmosphere containing a fluorocarbon; attaching a resin composition crosslinkable in the presence of an acid to the plasma-processed surface of the resist layer; crosslinking the resin composition in a part in contact with the resist layer by feeding an acid from the resist layer, so as to form a crosslinked layer covering the resist layer; and removing the resin composition from a part excluding the crosslinked layer, so as to yield a resist pattern comprising the resist layer and the crosslinked layer covering the resist layer.

Owner:TDK CORPARATION

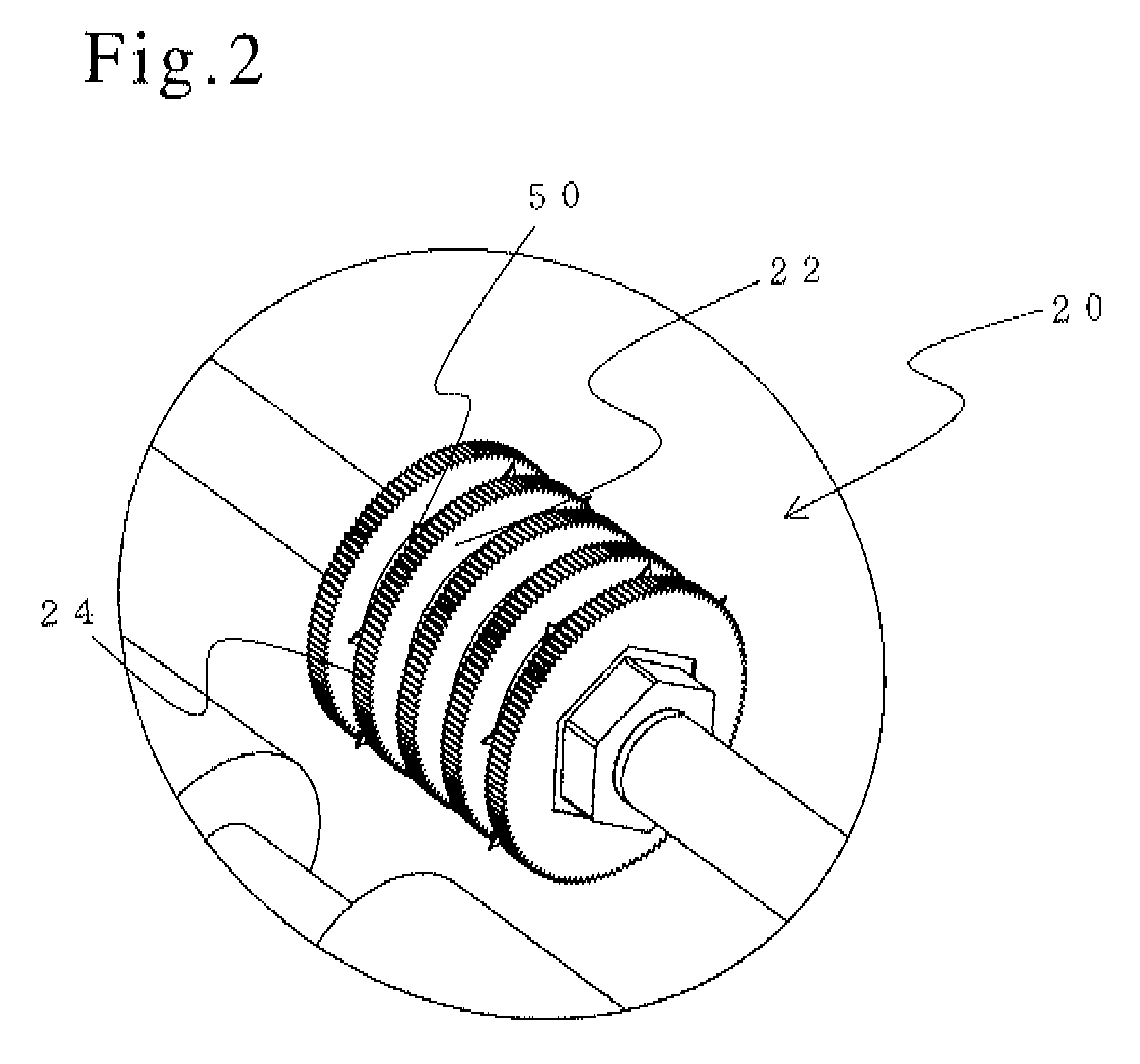

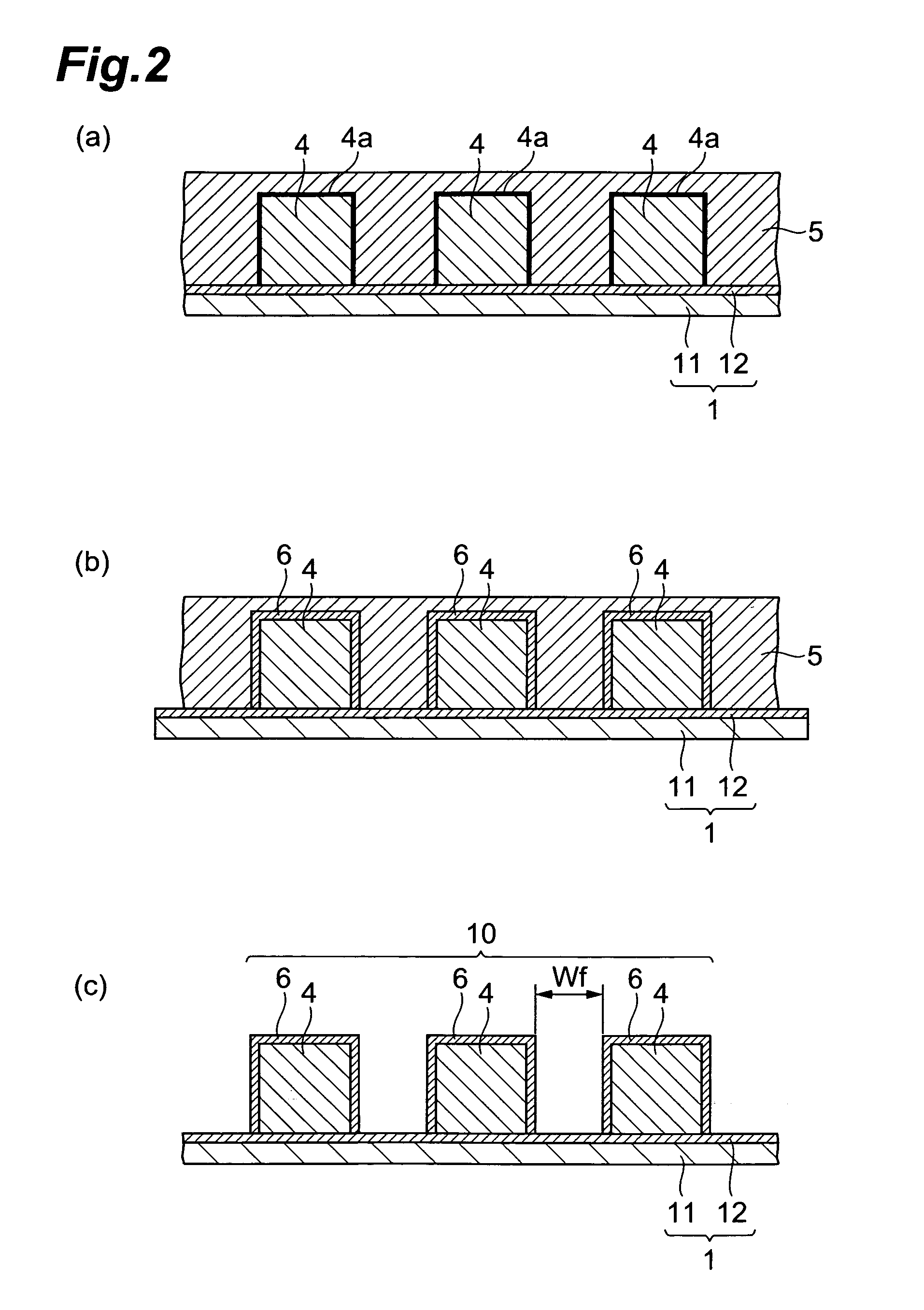

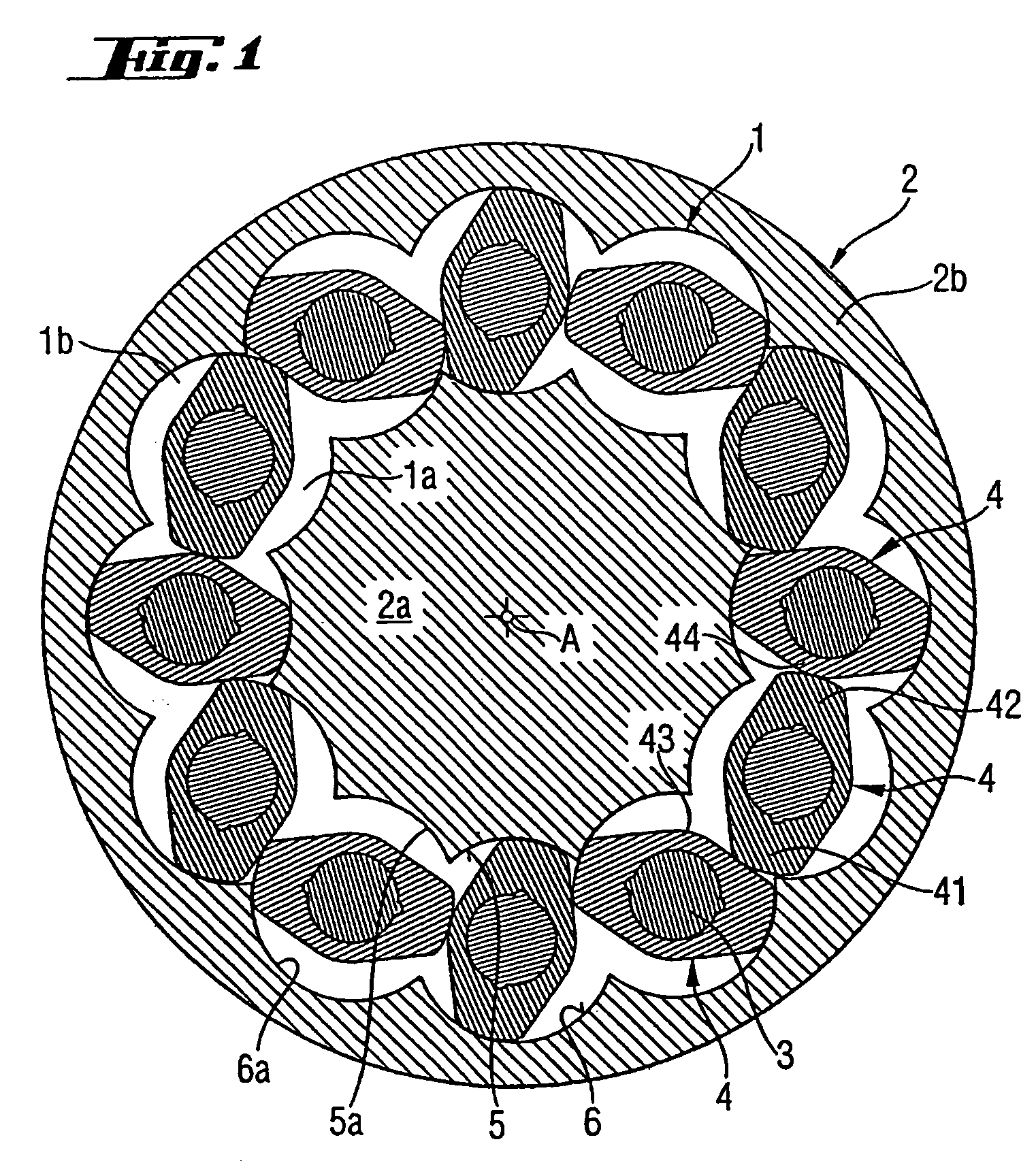

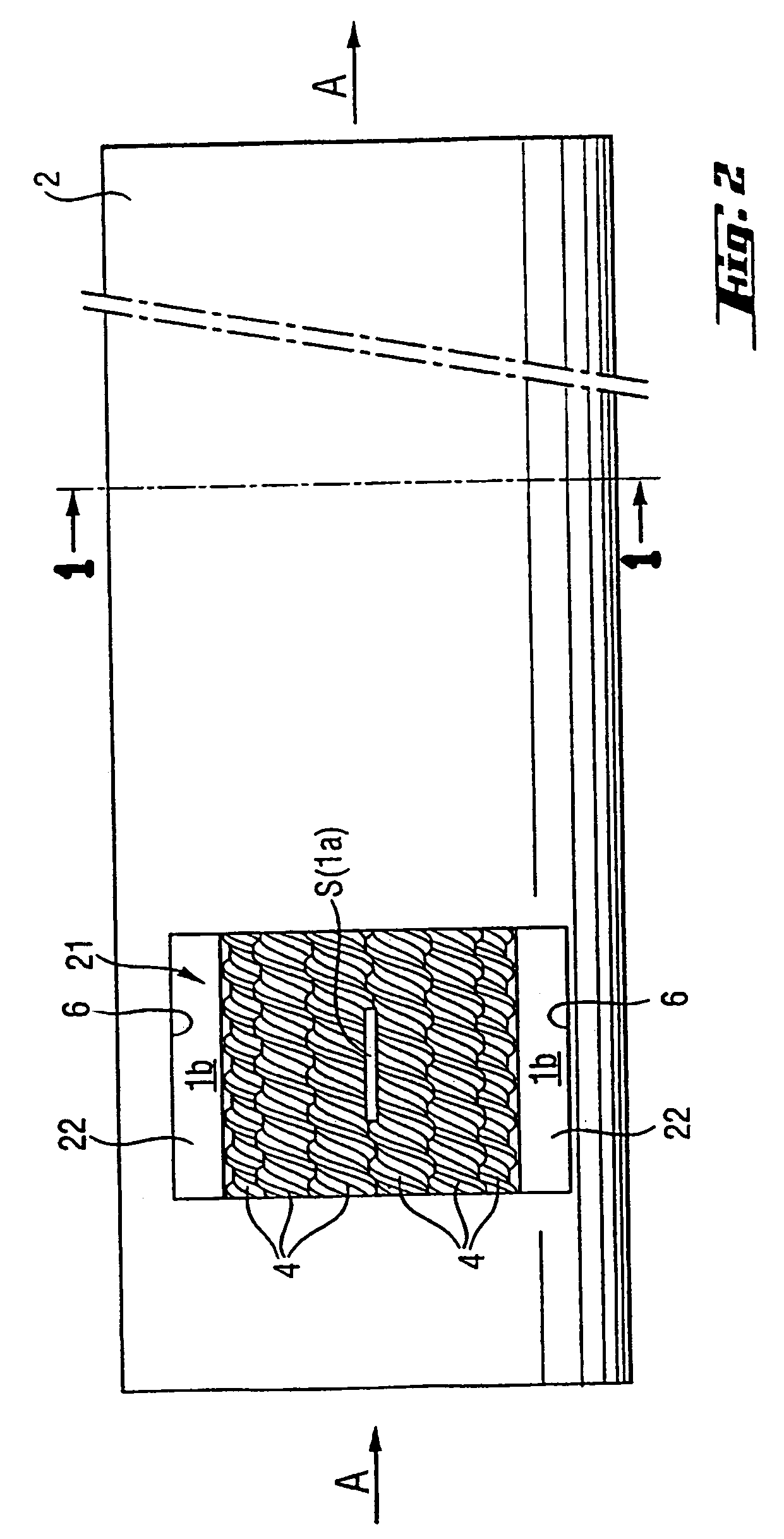

Multi-screw extruder

InactiveUS7080935B2Improve the delivery effectImprove carrying capacityRotary stirring mixersFrozen sweetsEngineeringProcessing element

The invention relates to a multi-shaft extruder for the continuous treatment and / or processing of bulk material, especially a powdery, granular or flocculent product, comprising a plurality of shafts (3) which are arranged in a crown-like manner in a cavity (1) of an extruder housing (2), said shafts extending parallel to the axial direction (A) of the extruder and forming an inner processing chamber (1a) inside the crown, and an outer processing chamber (1b) outside the crown. Each shaft carries a number of axially successive processing elements (4), at least part of the same being elements (4a; 4c; 4e) having a transporting effect, and with which adjacent shafts engage in a sealed manner at least in partial regions. At least one transporting endless screw element (4b; 4d; 4f) comprising at least one transporting screw thread (9, 10; 14, 15, 16; 19, 20) is placed in the region of the supply opening (21) in the extruder housing (2), and does not engage in a sealing manner in at least one partial region along the axial direction (A).

Owner:BUHLER THERMAL PROCESSES

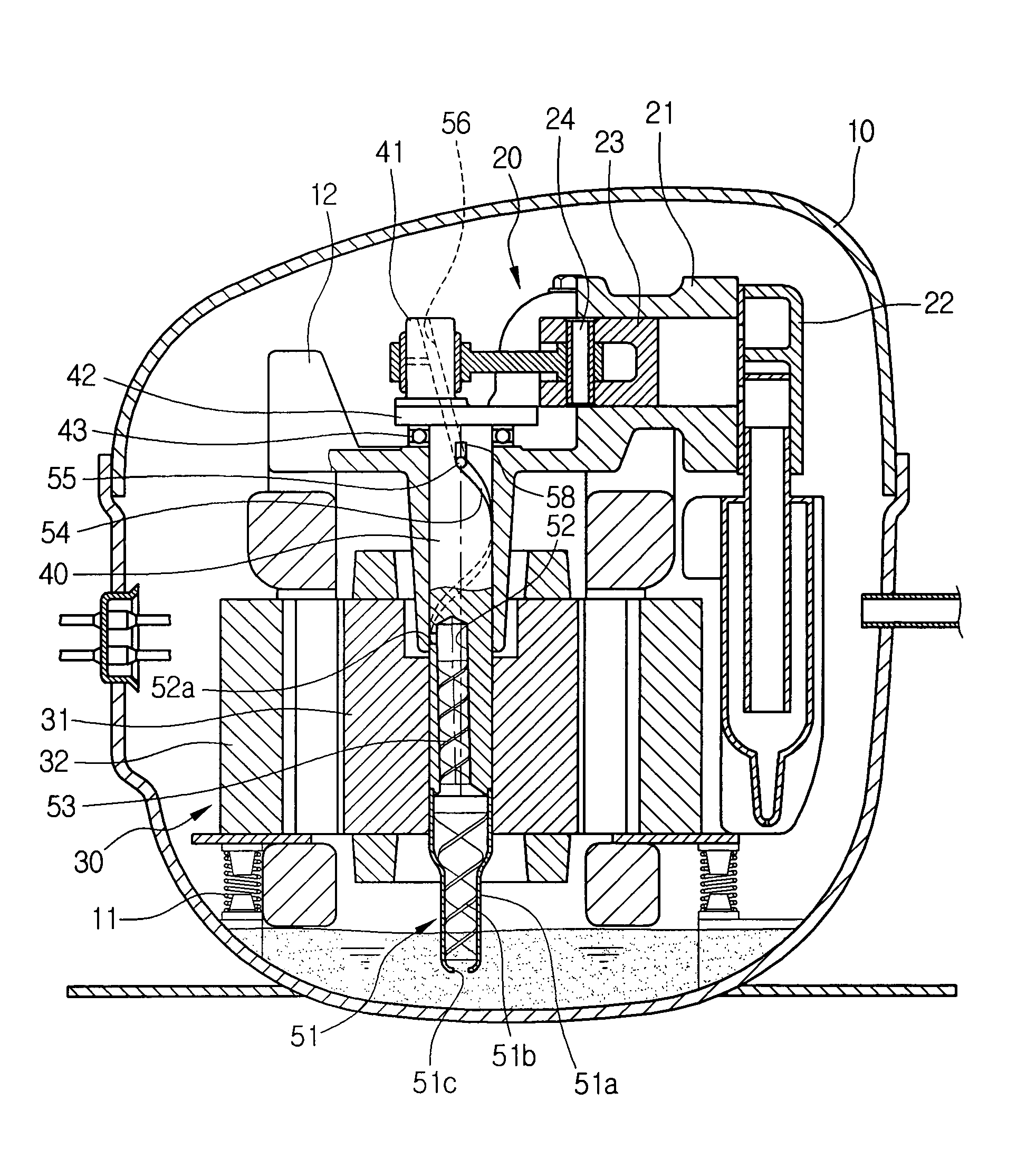

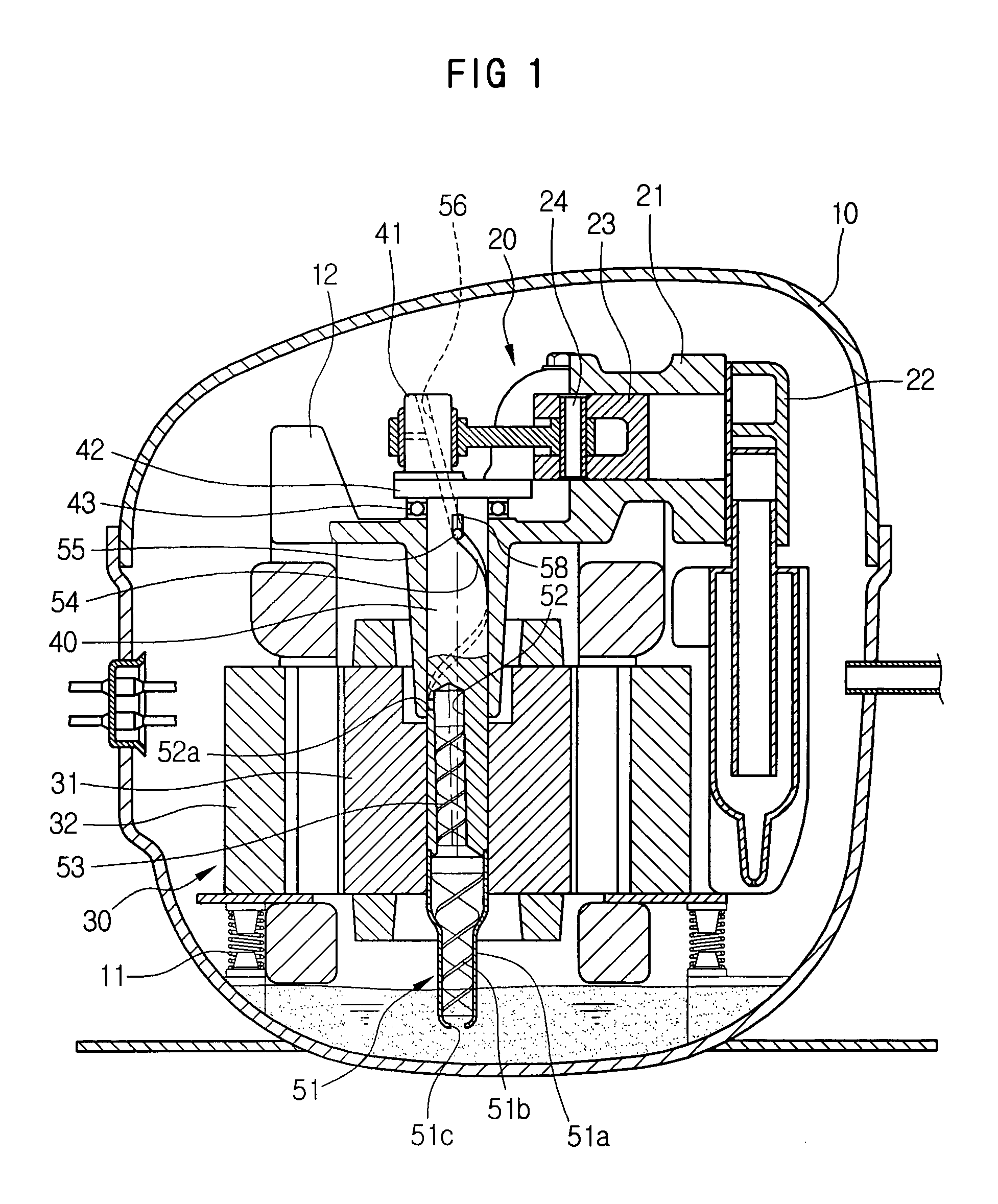

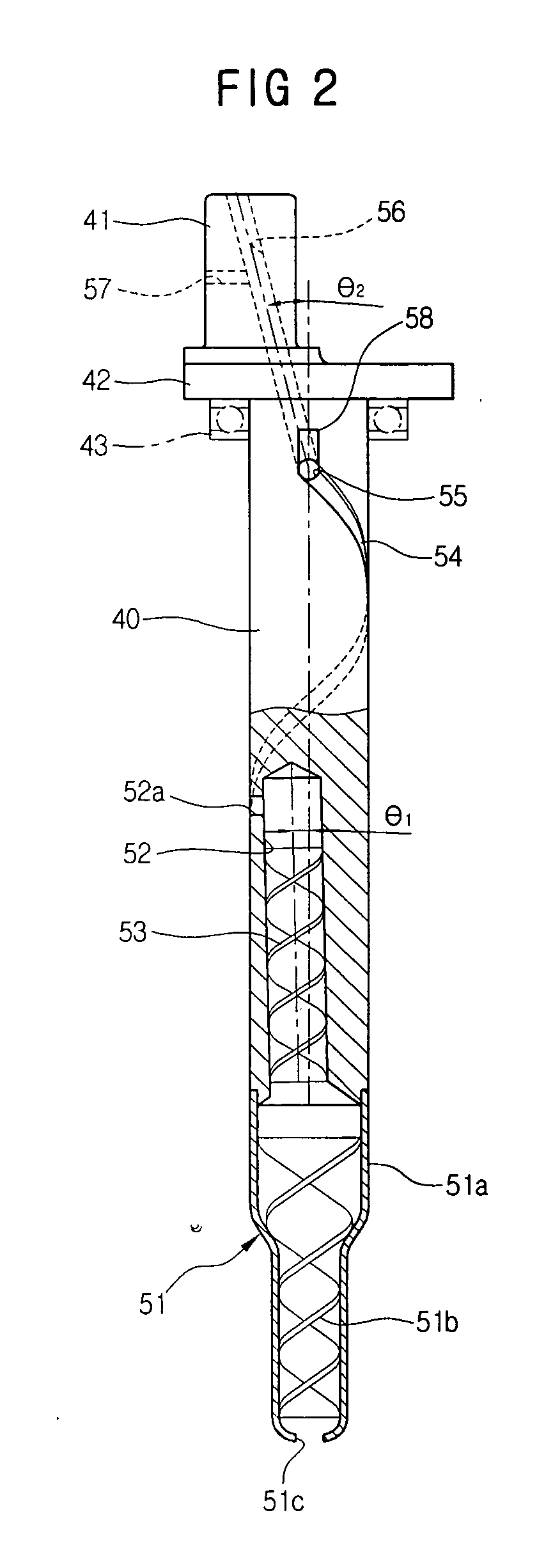

Hermetic compressor

InactiveUS20050115771A1Improved oil feed structureEfficient feedingPositive displacement pump componentsPiston pumpsPetroleum engineering

A hermetic compressor provided with an improved oil feed structure to efficiently feed lubricating oil to a plurality of drive parts. The hermetic compressor includes a hermetic casing, a frame provided in the hermetic casing, a drive unit provided in a lower portion of the frame, a compression unit provided on an upper portion of the frame, a rotating shaft vertically installed in the frame to transmit a rotating force of the drive unit to the compression unit, with an eccentric part provided on an upper end of the rotating shaft and coupled to the compression unit, and an oil feed unit provided on the rotating shaft to feed oil from a bottom of the hermetic casing to the plurality of drive parts. The oil feed unit includes a first oil pickup unit provided on a lower end of the rotating shaft to lift the oil upward from the bottom of the hermetic casing, a first oil feed path provided in the rotating shaft above the first oil pickup unit while being eccentric from a central axis of the rotating shaft, a spiral oil feed groove provided around the rotating shaft above the first oil feed path and communicating with the first oil feed path, a second oil feed path provided in the eccentric part and communicating with the spiral oil feed groove, and a second oil pickup unit provided in the first oil feed path to increase an oil lift force.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

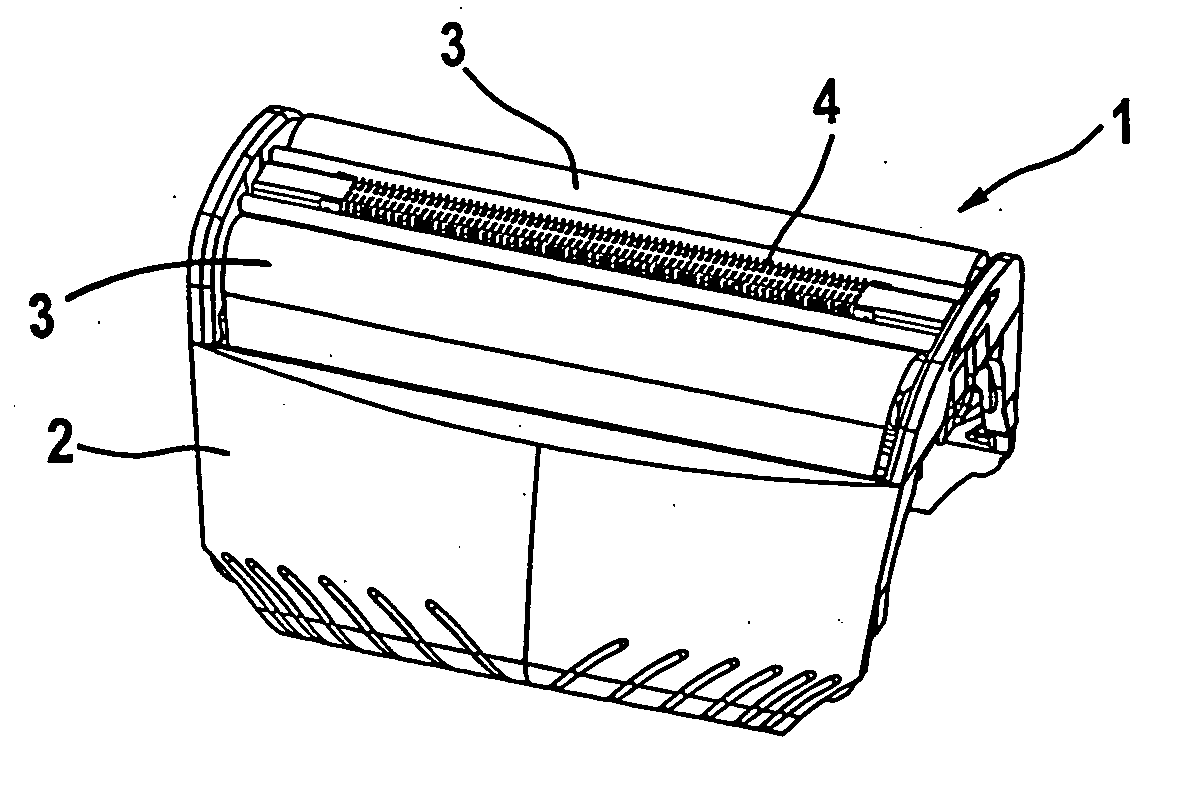

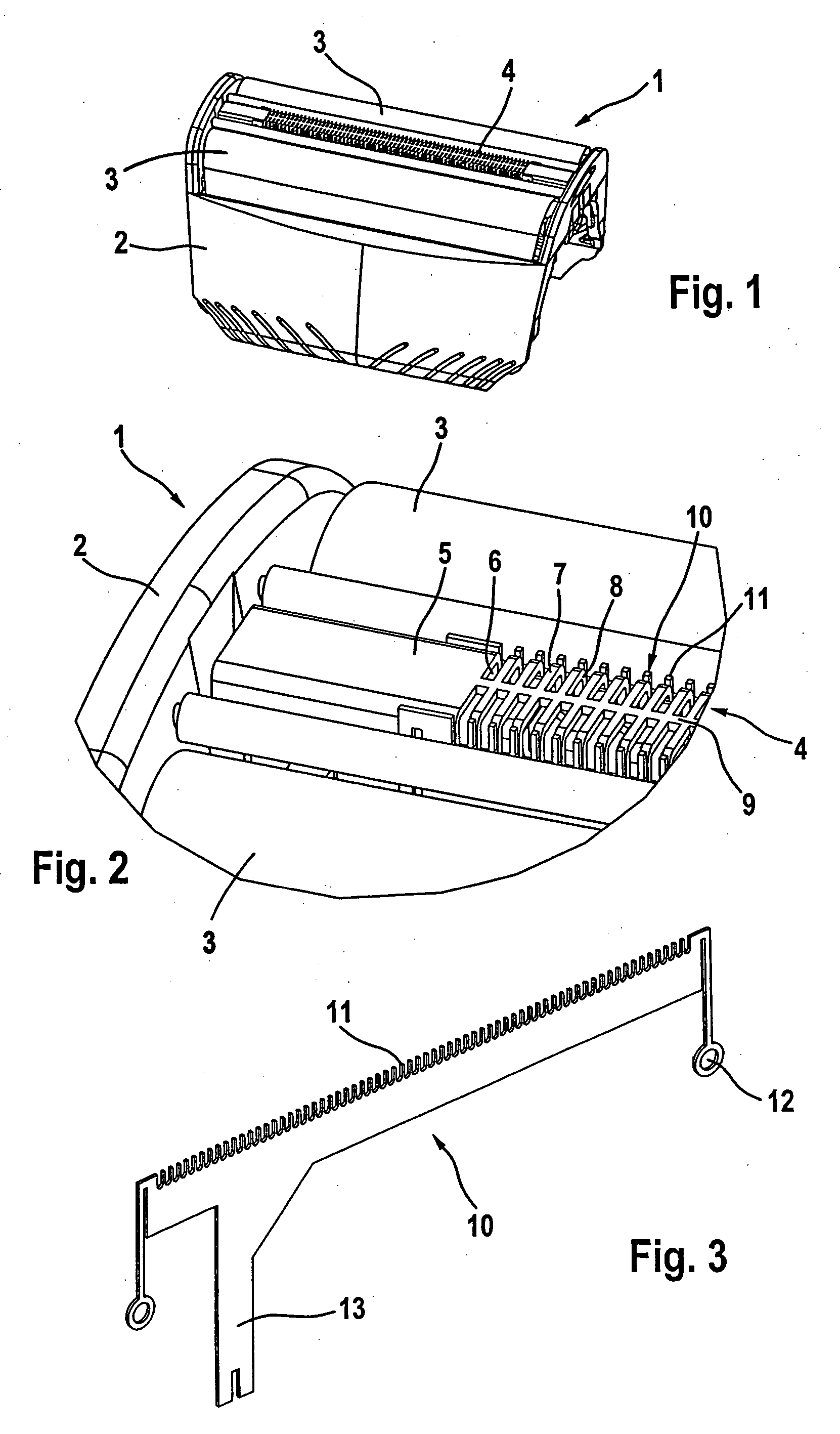

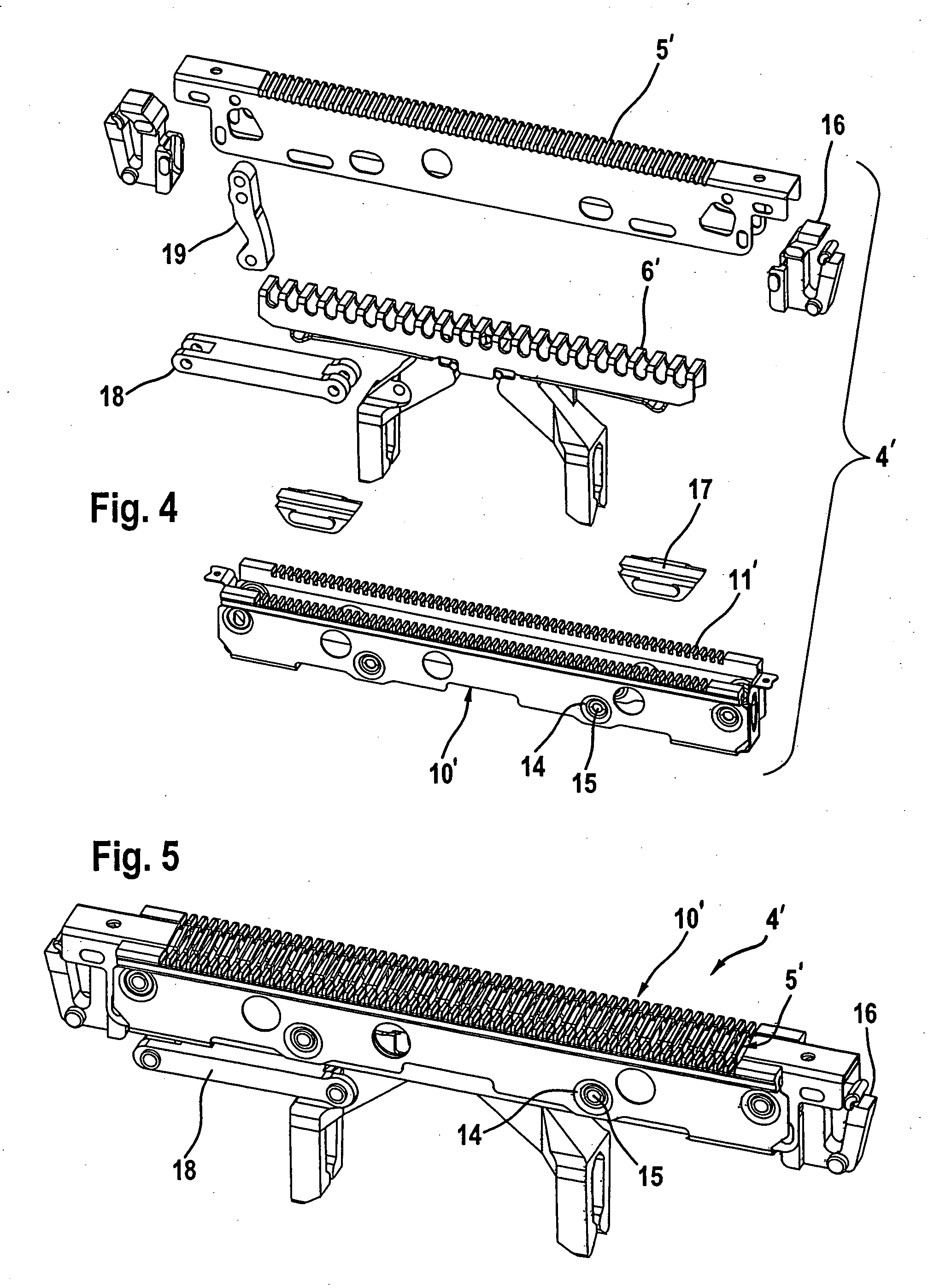

Shear system for an electric hair removing apparatus

ActiveUS20060225290A1Efficient removalIncrease probabilityMetal working apparatusRelative motionMechanical engineering

The invention is directed to a shear system for an electric hair removing apparatus, in particular for an electric shaving apparatus, including at least one shearing unit having an outer cutter and an undercutter that are set in relative motion. The shear system of the invention includes at least one feeding device arranged to precede the shearing unit and is characterized in that the feeding device is set in motion relative to the outer cutter.

Owner:BRAUN GMBH

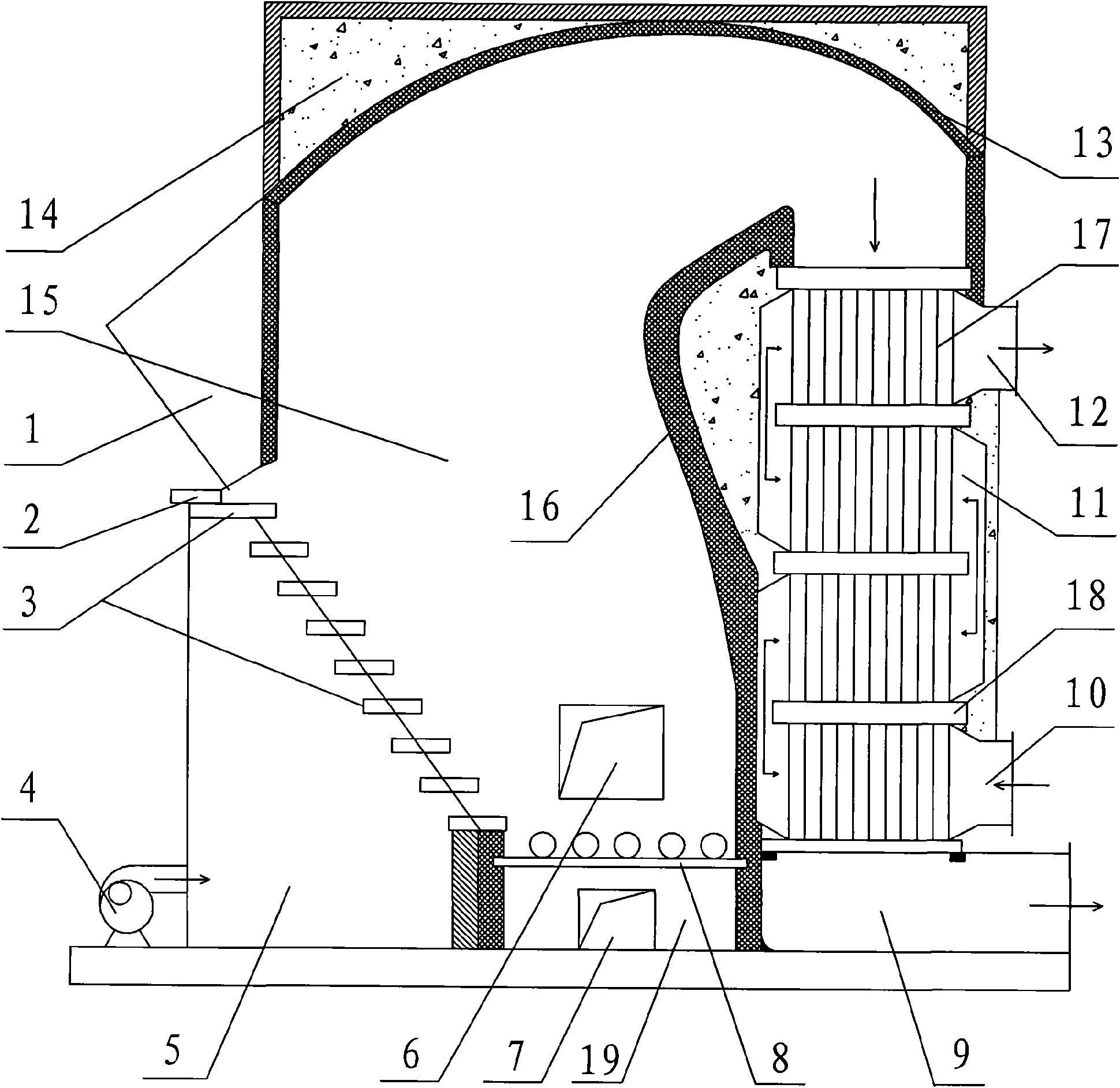

Biomass fuel hot air stove

The invention discloses a biomass fuel hot air stove, which aims to provide a biomass fuel hot air stove with simple structure, low cost, convenient repair, full fuel combustion, high heat conversion efficiency and small occupied area. The biomass fuel hot air stove comprises a stove body, a feeding system, a grate (8), a flue (9) and a curved reflex arch (16), wherein the stove body is divided into three parts including an air chamber (5), a combustion chamber (15) and a heat conversion device by the feeding system together with the curved reflex arch (16). After the biomass fuel fed by the feeding system is combusted on the grate (8), the volatile component of the biomass fuel is combusted over the combustion chamber (15) for the second time. The generated heat enters the heat conversion device together with the high-temperature smoke for heat energy conversion, then cold smoke is discharged from the flue (9), and the obtained hot air can be used for heating. The biomass fuel hot air stove can be widely used in the field of common hot air heating.

Owner:ZHUHAI HUISHENG ENERGY SOURCE TECH DEV

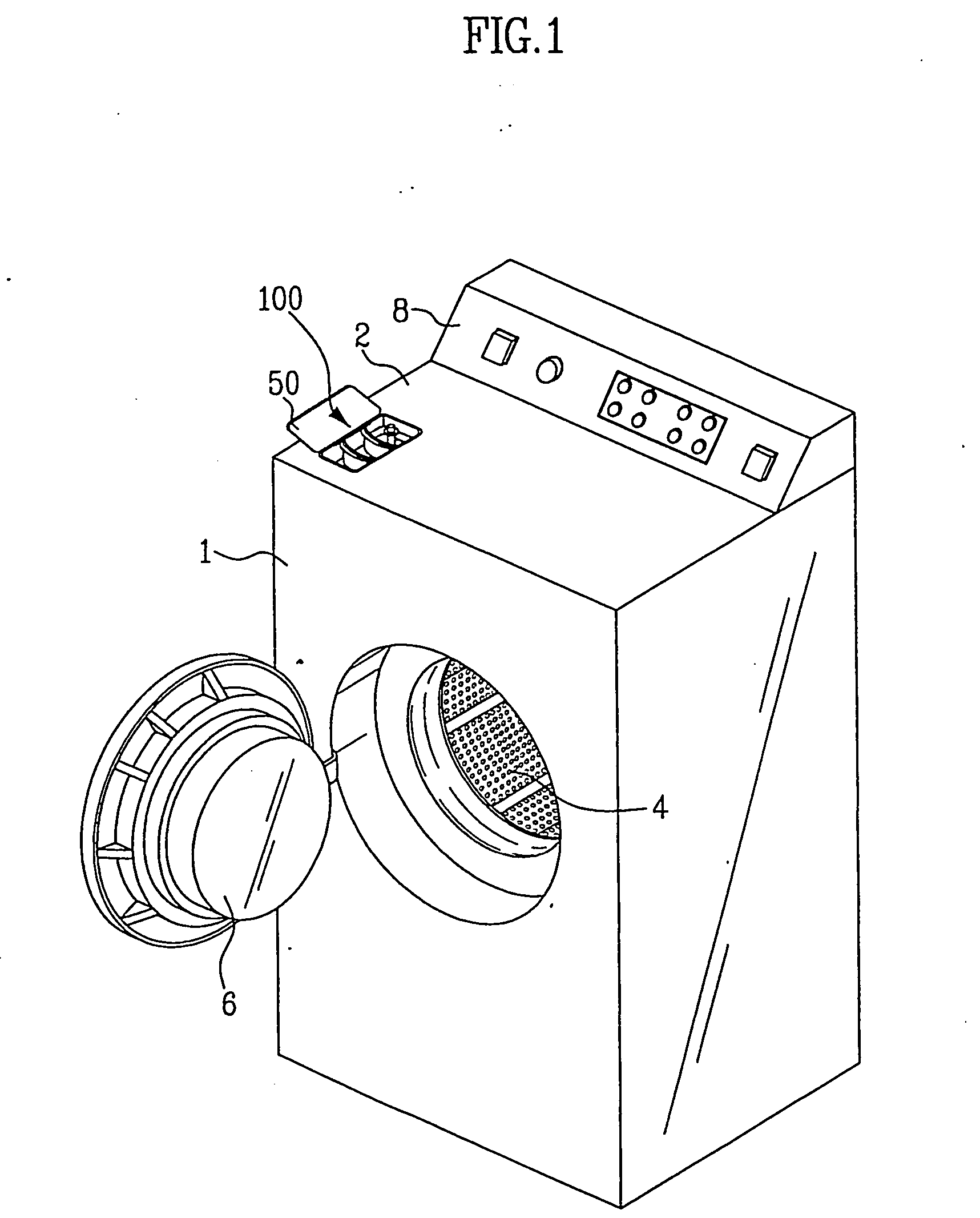

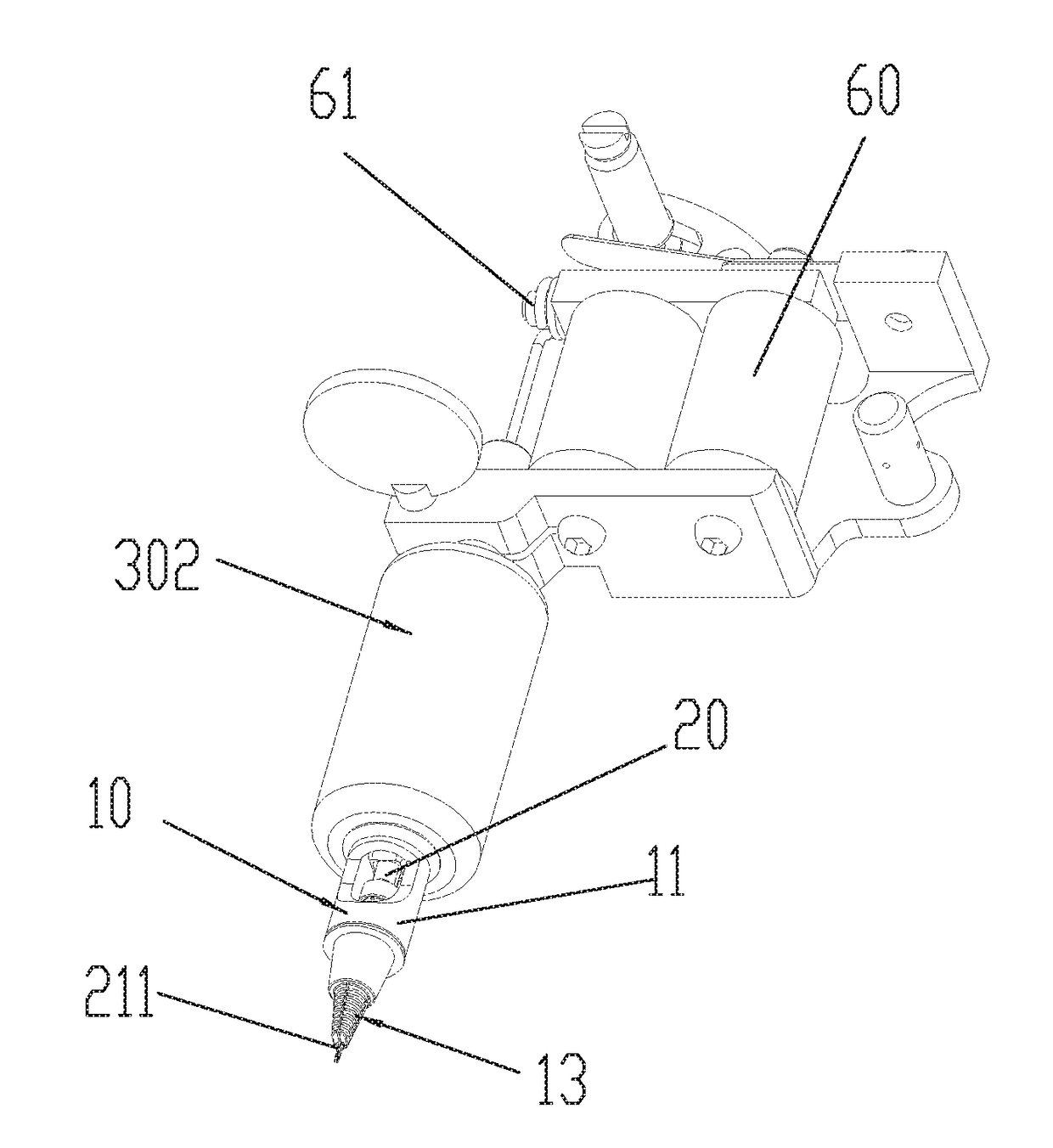

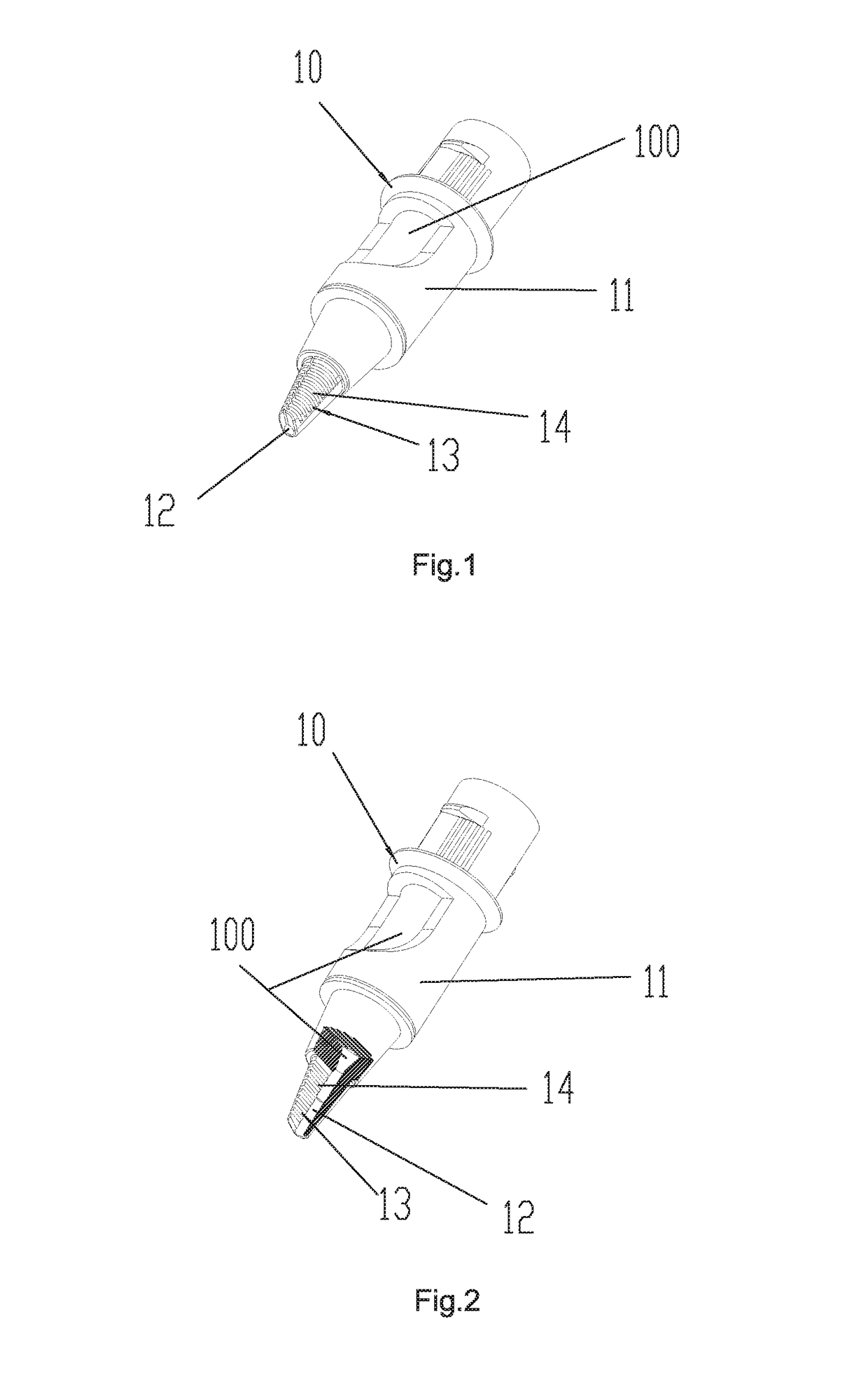

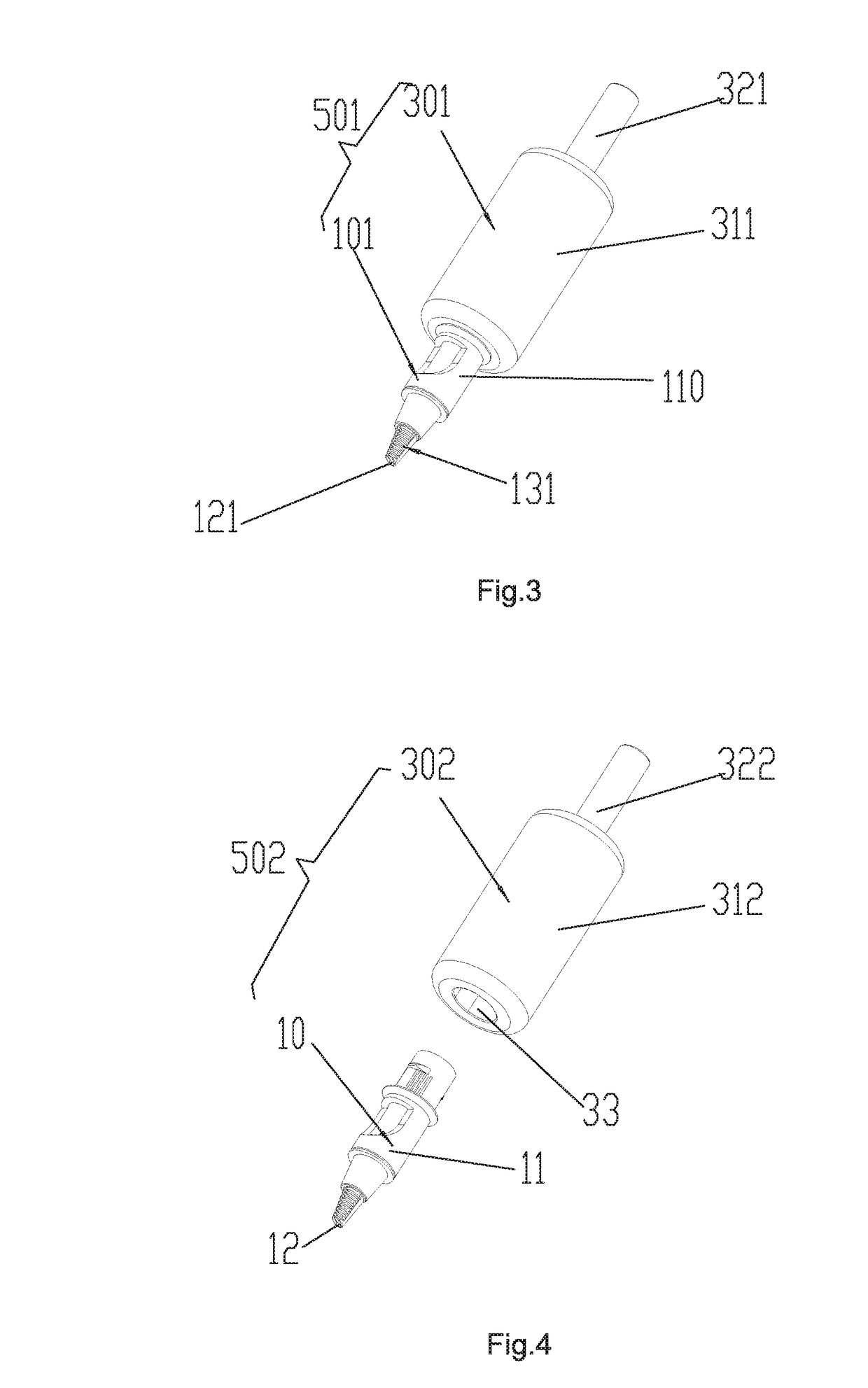

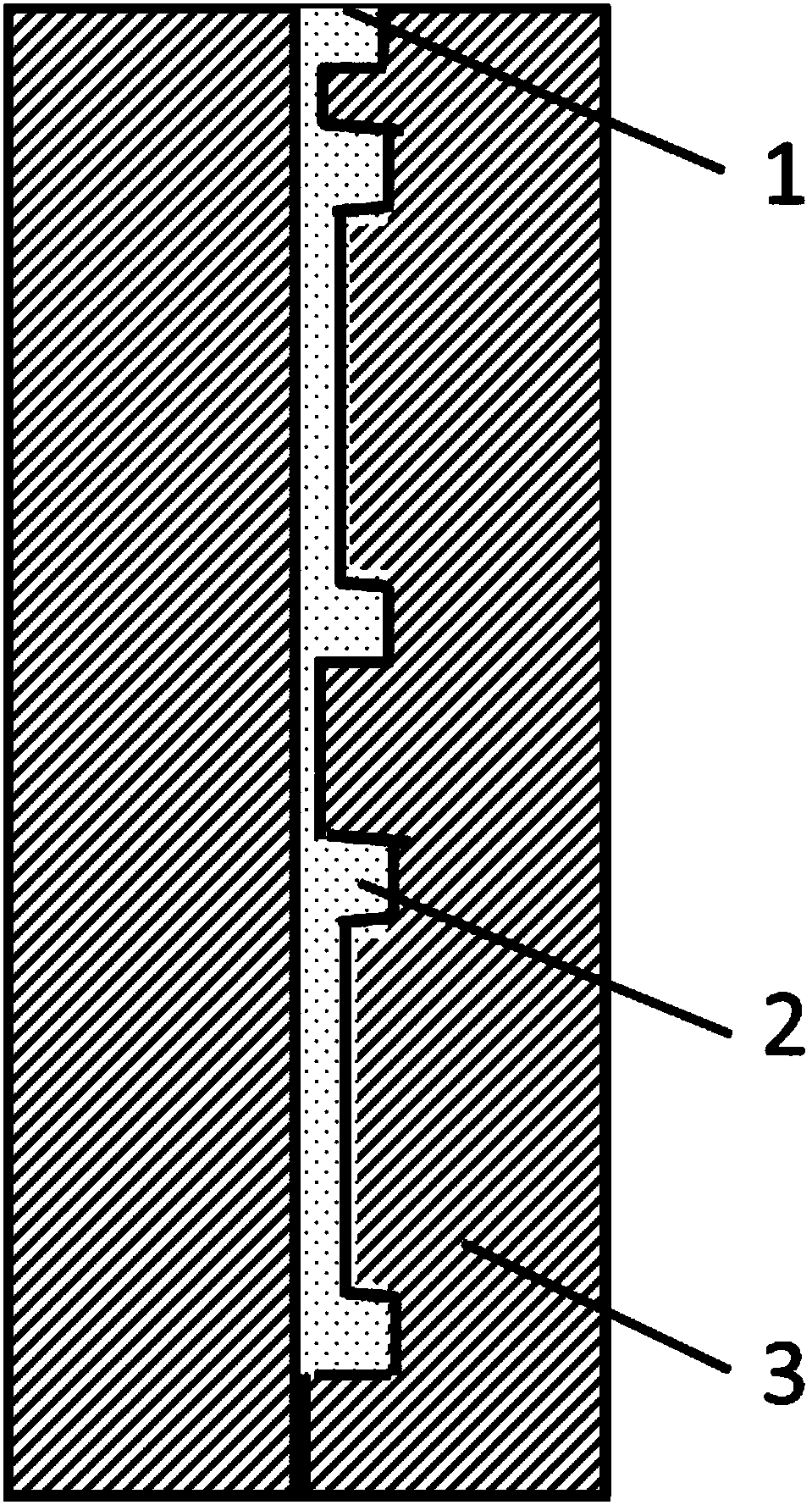

Tattoo needle tip with capillary ink reservoir and combined device thereof

ActiveUS20170072178A1Quick and easy to dipQuick and easy to and addMedical devicesTattoo needleBlood capillary

A tattoo needle tip (10) with a capillary ink reservoir (13) and combined device thereof are provided. The tattoo needle tip (10) includes a needle tip body (11). A needle passage (100) is defined inside the needle tip body (11) for placing a tattoo needle (20). The needle opening (12) is communicated with the needle passage (100). A capillary disposed ink reservoir (13) directly connected to the needle opening (12) whereby can directly feed ink to the sharp end of the tattoo needle (20).

Owner:XIAO LONG

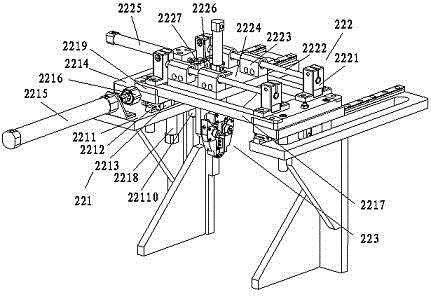

Tool plate jacking and positioning device

The invention discloses a tool plate jacking and positioning device which comprises a feeding carrier plate. A jacking module, a jacking blocking module and a non-return module are arranged on the feeding carrier plate, the jacking module comprises a jacking air cylinder and a jacking supporting plate, the jacking supporting plate is located in a jacking station, the jacking air cylinder drives the jacking supporting plate to ascend and descend, a tool bottom plate is supported on the jacking supporting plate and ascends and descends along the jacking supporting plate, the jacking blocking module comprises a jacking blocking air cylinder and a jacking blocking block, the jacking blocking air cylinder drives the jacking blocking block to do reciprocating motion, the jacking blocking block limits the front end of the tool bottom plate, the non-return module comprises a non-return elastic block doing elastic reset motion, and the non-return elastic block limits the rear end of the tool bottom plate. The structure is simple and reasonable, feeding operation is completed in a full-automatic mode, operation is convenient and fast, the labor intensity is greatly reduced, feeding work is stable and reliable, working efficiency is improved, feeding precision is effectively ensured, and safety coefficients are improved.

Owner:GUANGDONG LXD ROBOTICS CO LTD

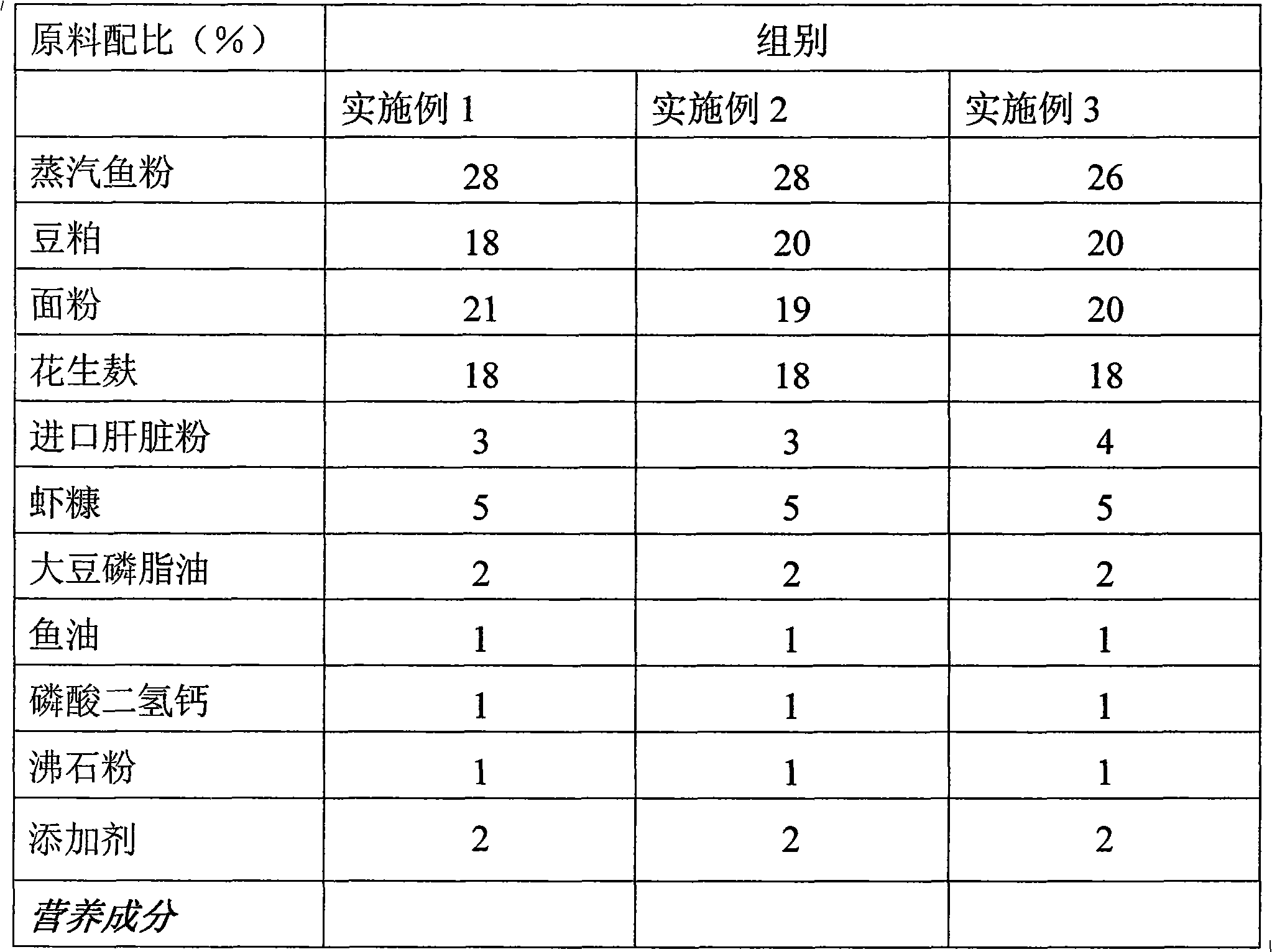

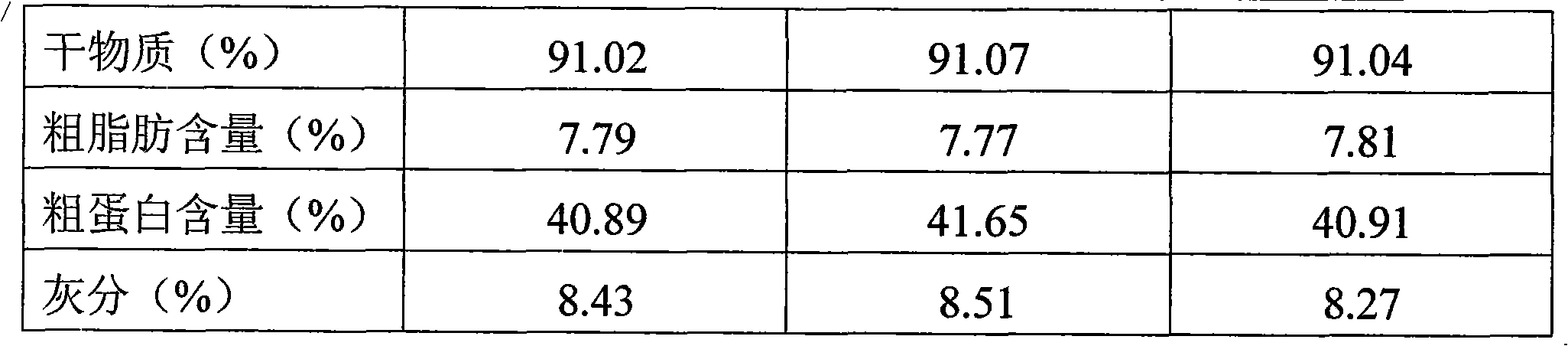

Compound feed for Penaeus vannamei Boone

ActiveCN101632417APromote growthPromote sustainable developmentFood processingClimate change adaptationAntioxidantAdditive ingredient

The invention discloses compound feed for Penaeus vannamei Boone, aiming at providing compound feed for Penaeus vannamei Boone having the advantages of low feed coefficient, balanced and comprehensive nutrition, strong palatability and high subaqueous stability. The invention is prepared, by weight percent, from the following ingredients: 25-30% of steam fish meal, 18-23% of flour, 12-20% of soybean meal, 12-20% of peanut bran, 3-5% of imported liver powder, 3-6% of shrimp crumb, 1-2.5% of soybean lecithin oil, 1-2% of fish oil, 0.8-1.2% of monocalcium phosphate, 0.5-1.2% of powdered zeolite and the balance of additives; and the additives contain complex vitamin, compound minerals, Vc organic phosphate, choline chloride, salt, mildew preventive and oxidation preventive. The compound feed for Penaeus vannamei Boone can be widely applied to the field of aquaculture of Penaeus vannamei Boone.

Owner:ZHUHAI SHIHAI FEED

Animal feeder

InactiveUS7891317B2Efficient feedingControl eating intervalAnimal feeding devicesAnimal housingEngineeringIndividual animal

An animal feeder for supplying a feed to an animal of choice for feeding the animal of choice in an unprotected environment such as the outdoors. The feeder comprising a base for support the feeder on a ground surface, a support frame extending upwardly from the base and a hopper supported by the frame. The hopper having a storage reservoir for storing a supply of feed with a feed entry opening that is closeable to prevent exposure to the outdoors. The hopper further including a feed chute below the reservoir having an upper region sealingly joined to the reservoir and a lower region below the upper region that is sealingly joined to a feeding chamber. The feeding chamber having a bottom surface wherein the feed supply can move from the reservoir into the feeding chamber and rest on the bottom surface based on gravity alone. The hopper further including a horizontally extending elongated channel extending from the feeding chamber with an outer end having a feeding opening open to the outdoors wherein the feeding chamber is spaced from the opening and the feed substantially remains within the hopper and spaced from the outdoors until it is consumed by the animal of choice.

Owner:YODER MARTY E +1

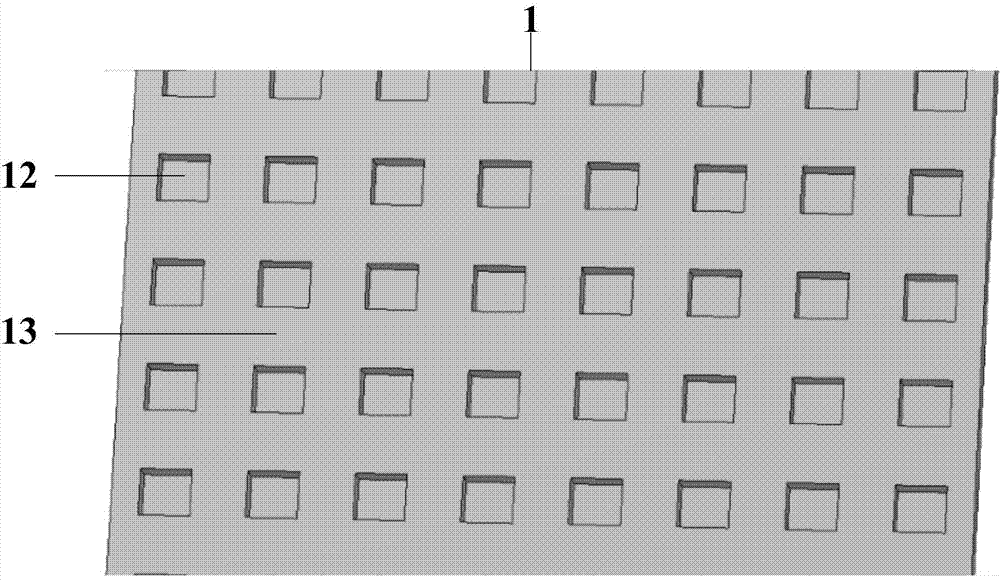

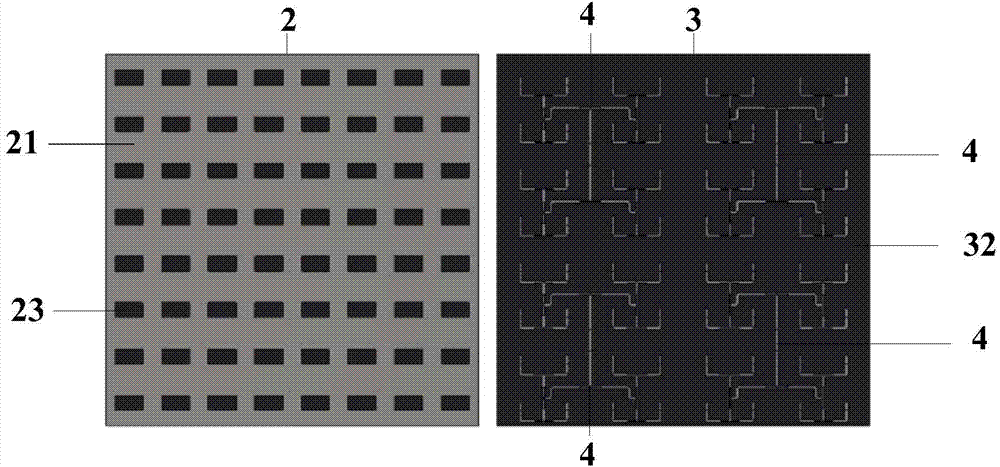

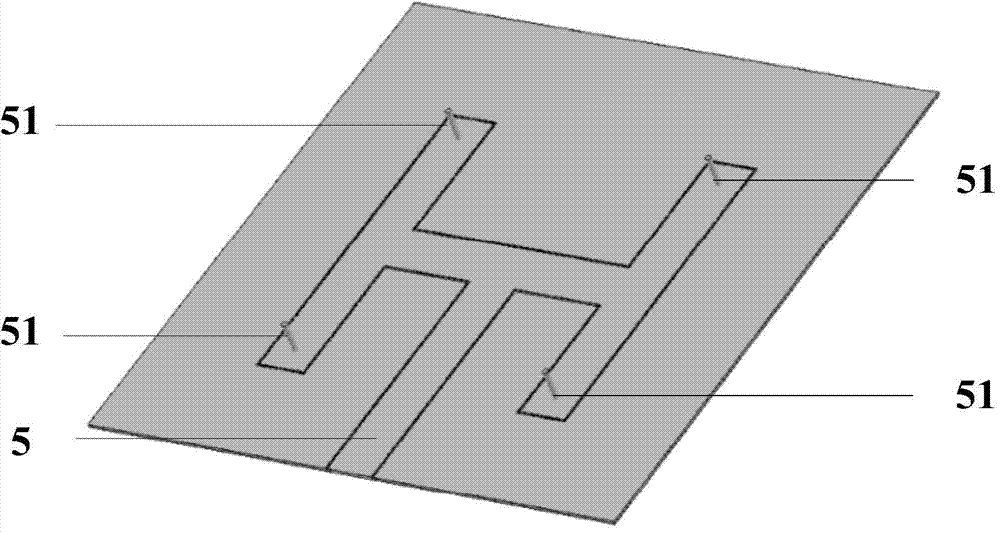

Back-cavity slot antenna array

InactiveCN104752820ABandwidthSmall structure sizeRadiating elements structural formsAntennas earthing switches associationCoaxial probeElectricity

The invention provides a back-cavity slot antenna array on the basis of SIW process and dielectric harmonic device structure. The back-cavity slot antenna array comprises a metal back cavity, two layers of dielectric substrates, an SIW feed network, a wired feed network and a plurality of dielectric harmonic device sets, the metal back cavity is of a cuboid structure, a plurality of rectangular section grooves which are identical and uniformly distributed in the surface of the metal back cavity, the SIW feed network is fixed on the lower surface of a cuboid, the dielectric substrates after being overlapped are fixed on one face, where the grooves are formed, of the metal back cavity, the wired feed network is sandwiched between the dielectric substrates and electrically connected with the SIW feed network through a coaxial probe, and each dielectric harmonic device set comprises two dielectric harmonic devices which are overlapped and fixed on the dielectric substrates. The back-cavity slot antenna array has the advantages of large bandwidth and high efficiency and can be widely applied in broadband radar systems.

Owner:NAT UNIV OF DEFENSE TECH

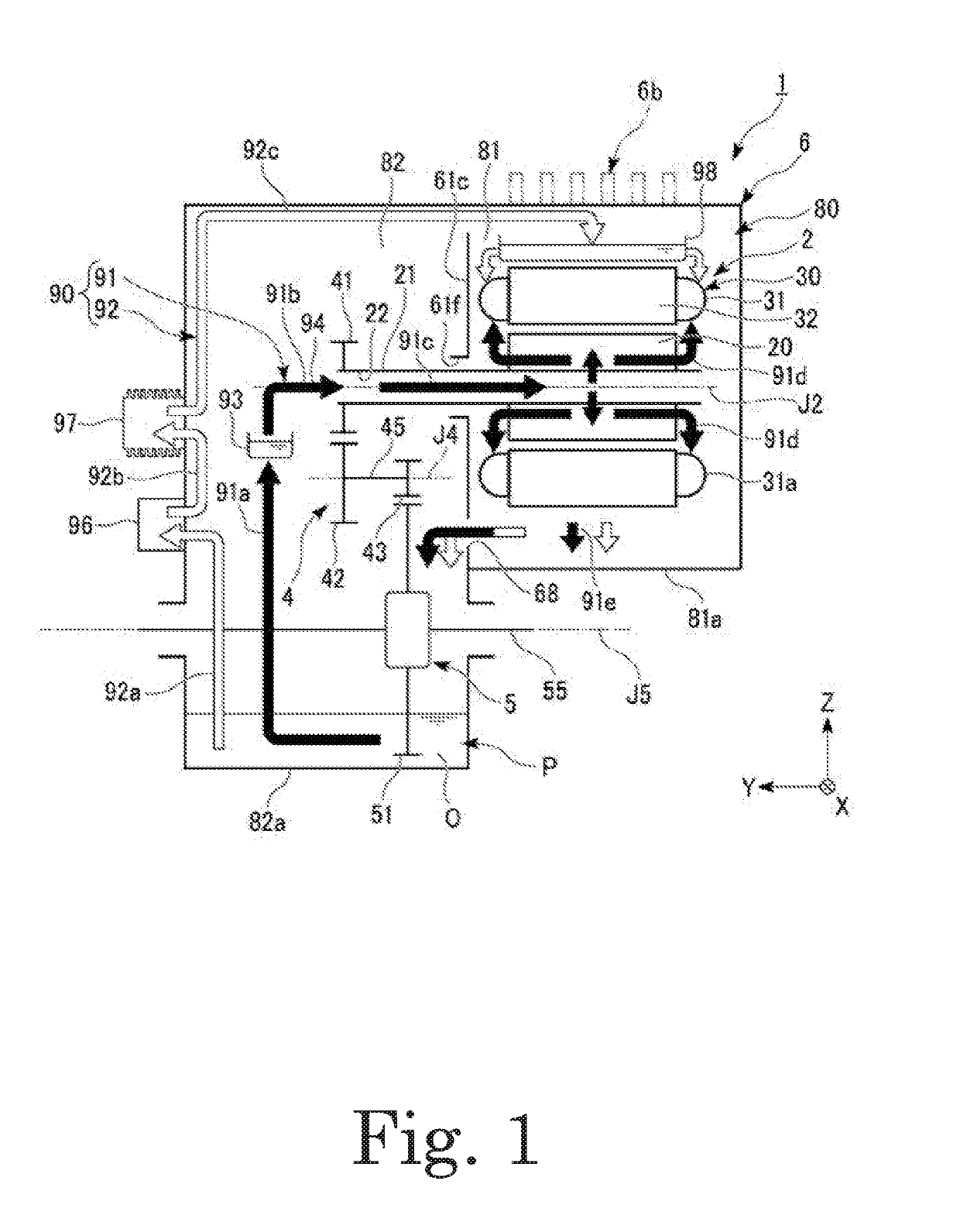

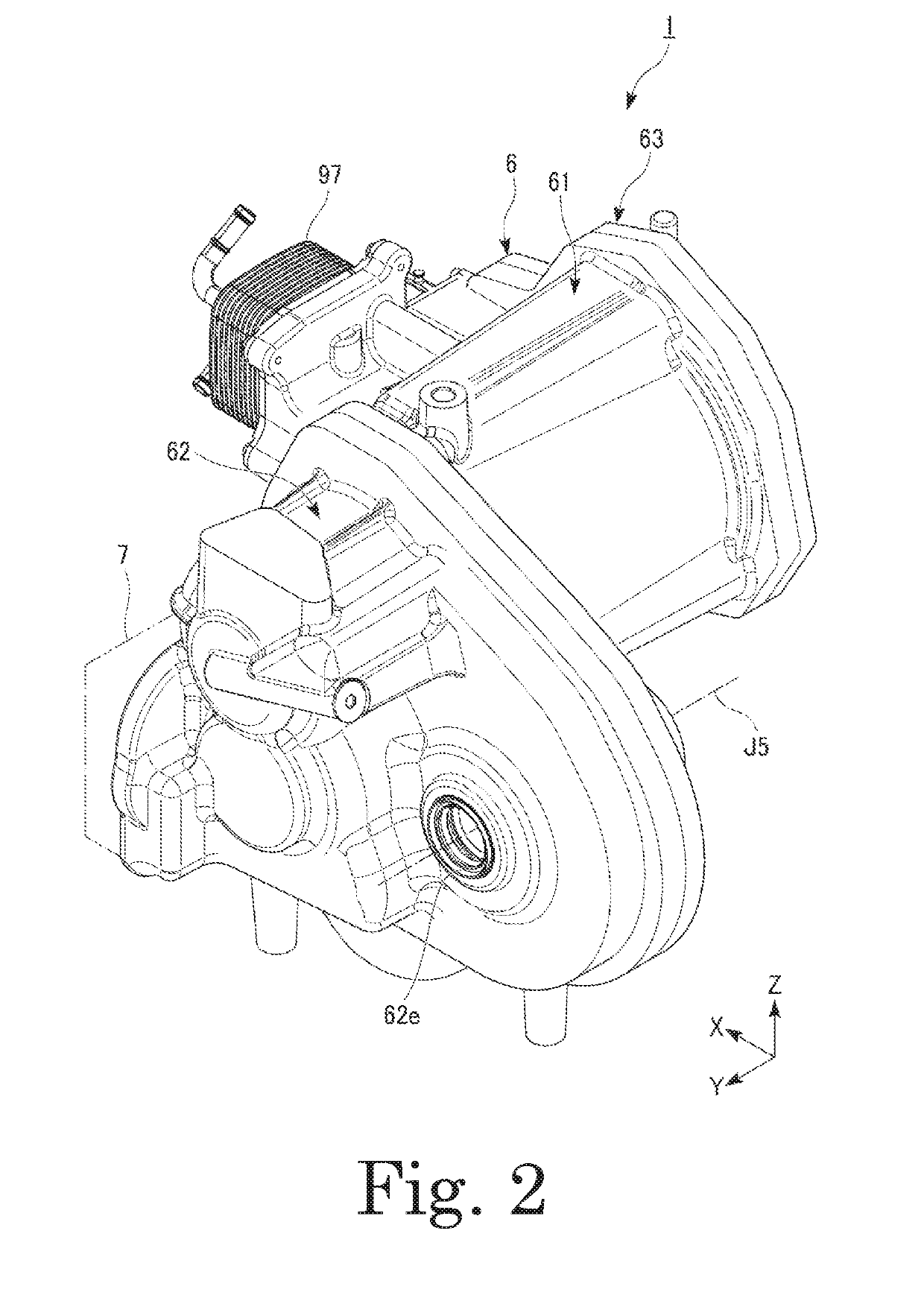

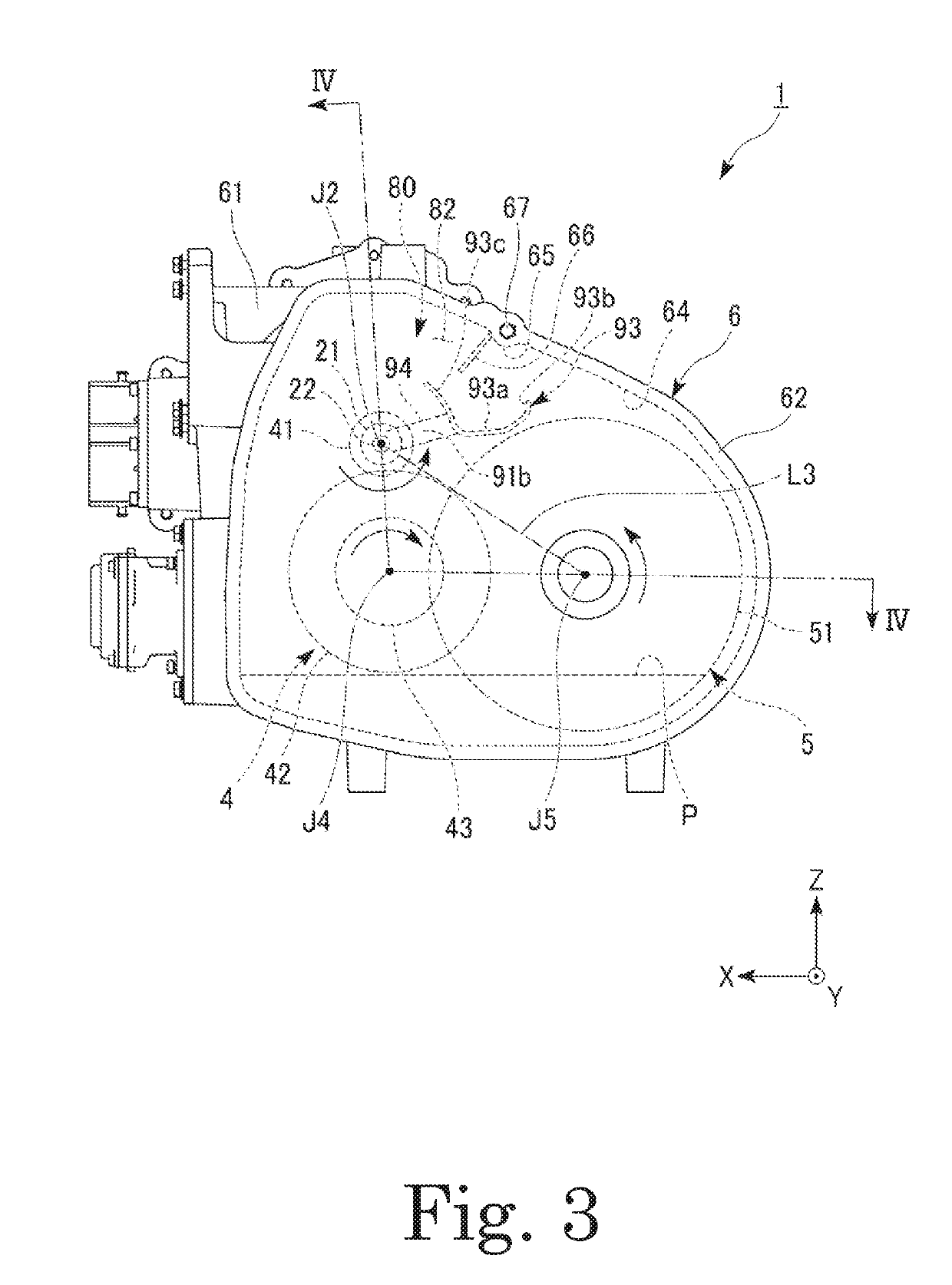

Motor unit

ActiveUS20190178365A1Efficient feedingElectric propulsion mountingGear lubrication/coolingLine segmentEngineering

A motor unit includes a motor including a rotor, a reduction gear including an intermediate gear to rotate about an intermediate axis, a differential including a ring gear arranged to rotate about a differential axis, a housing, oil in a vertically lower region of a housing space, and an oil passage to feed the oil to the motor. At least a portion of the ring gear is lower than a liquid surface of the oil in the vertically lower region of the housing space. A motor axis, the intermediate axis, and the differential axis to extend in parallel with one another in a horizontal direction. Each of the intermediate axis and the differential axis is lower than the motor axis. A line segment imaginarily joining the motor axis and the intermediate axis, a line segment imaginarily joining the intermediate axis and the differential axis, and a line segment imaginarily joining the motor axis and the differential axis when viewed in an axial direction of the motor axis are defined as first, second, and third line segments, respectively. The first line segment extends substantially along a vertical direction. The second line segment extends substantially along a horizontal direction.

Owner:NIDEC CORP

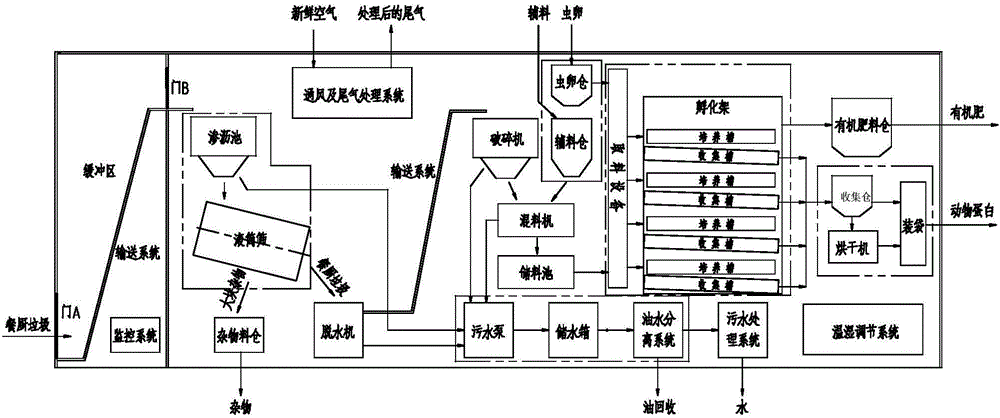

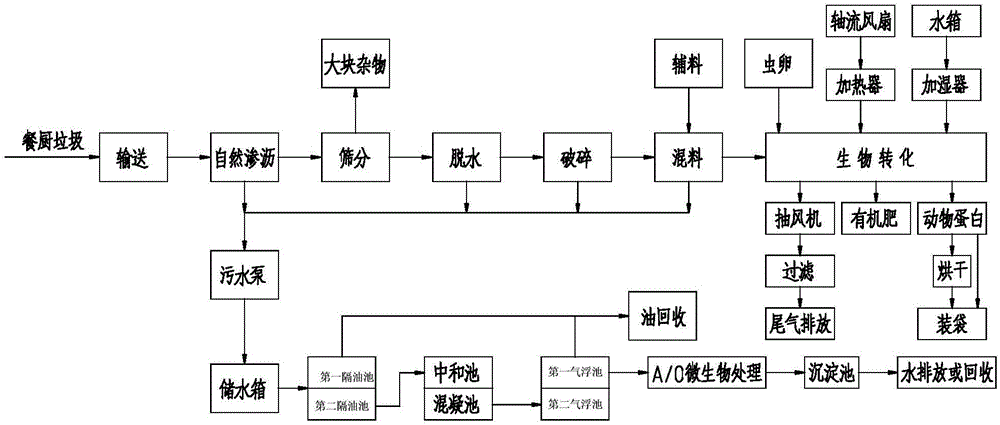

Kitchen waste treatment method based on biotransformation

InactiveCN106540951ANo secondary pollutionEfficient feedingSolid waste disposalClimate change adaptationDrug biotransformationLarva

The invention discloses a kitchen waste treatment method based on biotransformation. According to the kitchen waste treatment method based on the biotransformation, kitchen waste is treated through a concentrated incubation method based on a closed housing. The kitchen waste treatment method comprises the following steps: 1. charge: conveying the kitchen waste to an isolation buffering area of the closed housing; 2. pre-treatment comprising natural leaching, screening, dehydration, smashing and mixing; 3. biotransformation comprising spreading, inoculation and incubation, and larva collection; and 4. larva output, and treatment and discharge for waste materials and waste water. According to the kitchen waste treatment method based on the biotransformation, the kitchen waste is pre-treated and then conveyed to an incubation frame for raising insects to obtain maggots and an organic fertilizer, innocent treatment can be carried out on the kitchen waste, and economic benefits are achieved.

Owner:湖南帝星智能科技有限公司

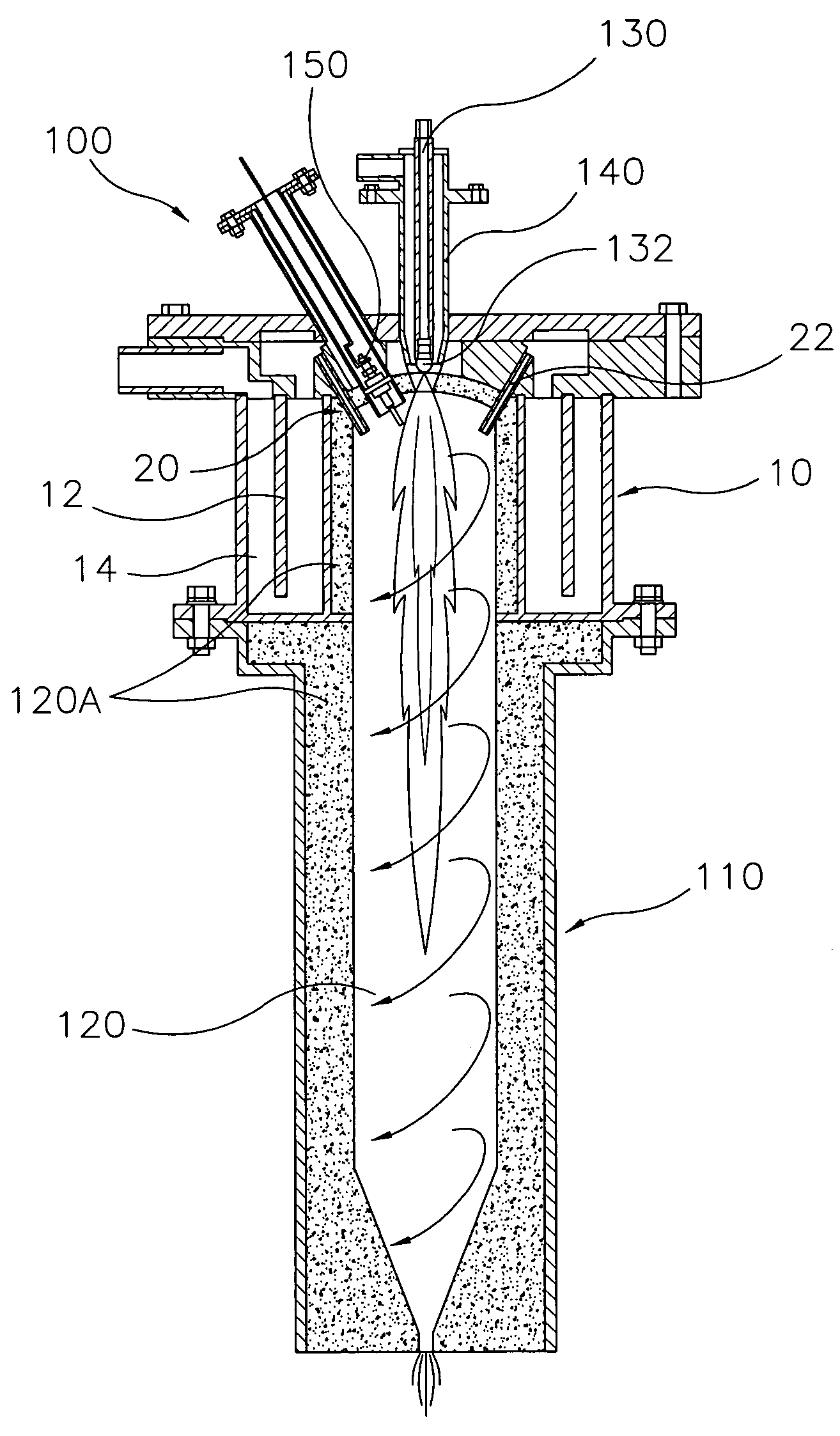

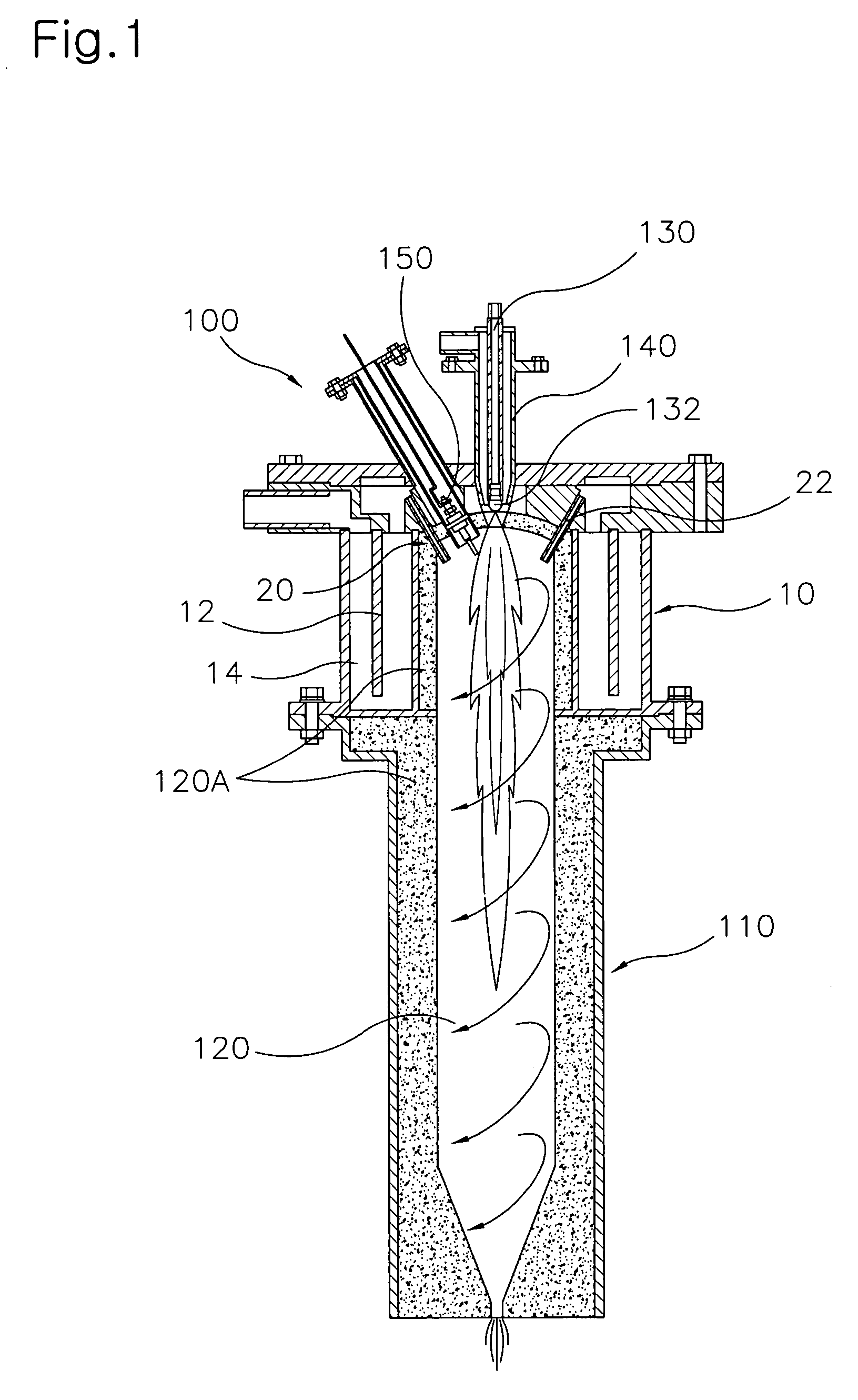

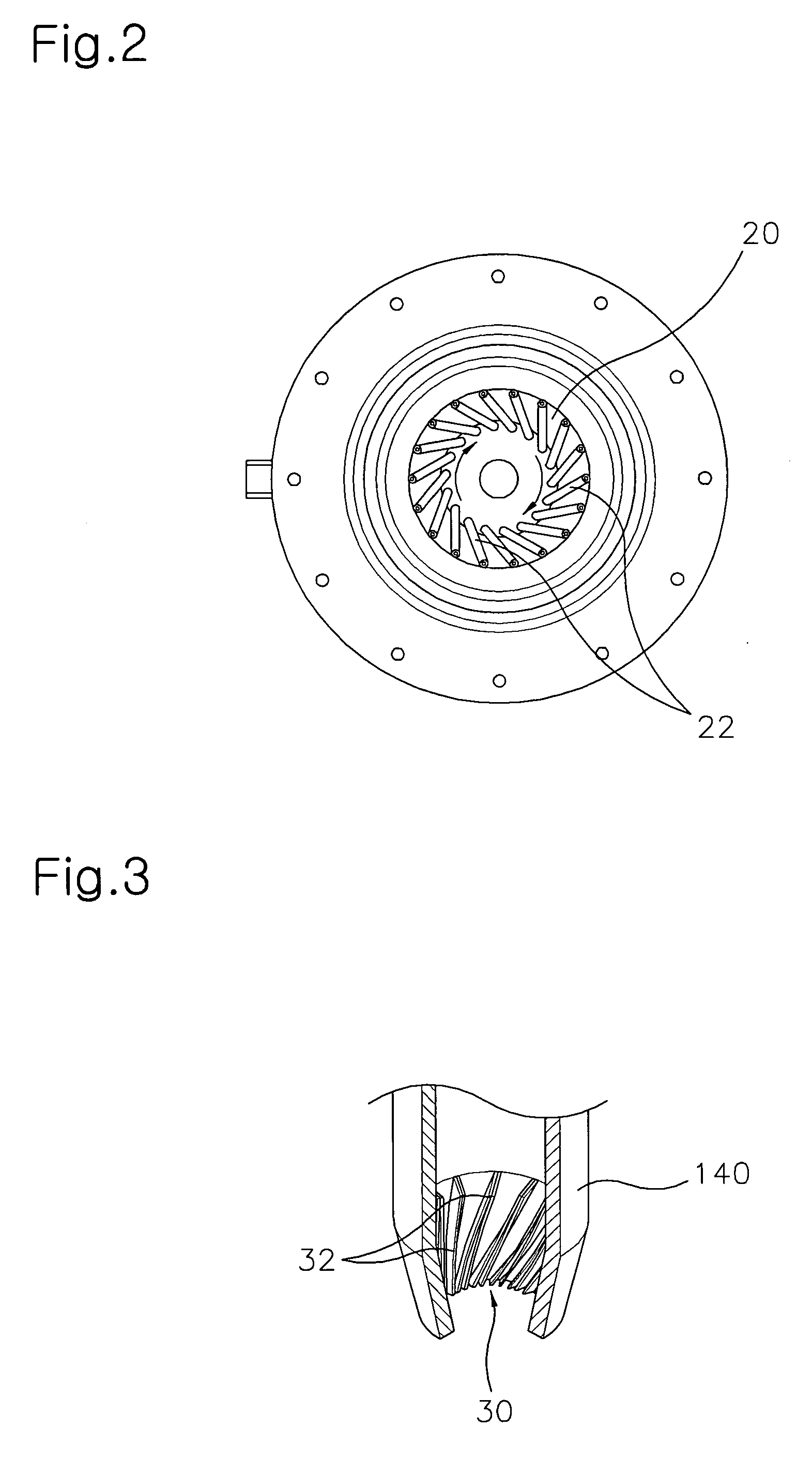

Gasification burner using high-pressure swirled air

InactiveUS20050048426A1Minimize heat conductionEmission minimizationPulverulent fuel combustion burnersLiquid fuel evaporation burnersCombustion chamberCombustor

Disclosed herein is a gasification burner using high-pressure swirled air. More particularly, the gasification burner using high-pressure swirled air is designed to enable partial cooling of a burner housing and to substantially prevent flames inside a combustion chamber from reaching an inner surface of the combustion chamber, resulting in an extension in the lifespan of the gasification burner. In the gasification burner comprising fuel feed pipe having a fuel injection nozzle, a combustion air feed pipe, an ignition plug, and a temperature sensor, which are located at one side of a combustion chamber defined in a burner housing, the gasification burner further comprises an air chamber unit, and a swirled air feeder unit. The air chamber unit is defined in an outer periphery of one end region of the housing where the fuel feed pipe and the combustion air feed pipe are mounted, and has a partition for providing the air chamber unit with a double-walled structure, defining an air feed channel. The swirled air feeder unit has a plurality of air-jet nozzles arranged along an inner periphery thereof near the fuel injection nozzle within the combustion chamber. The air-jet nozzles are obliquely disposed in a direction to communicate with the air feed channel.

Owner:REMAKE +1

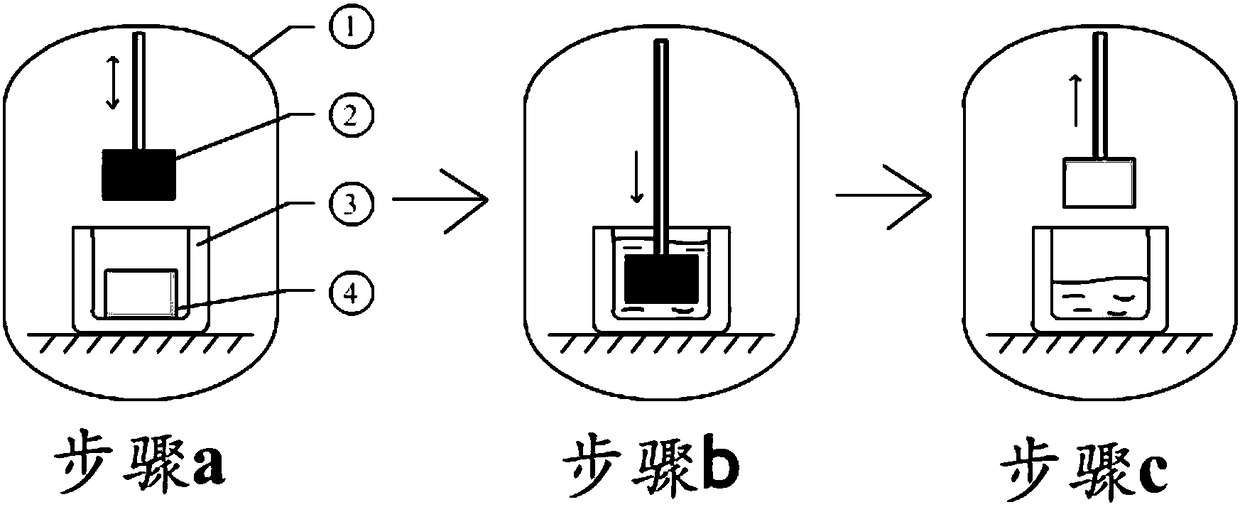

Preparation method of high-heat-conductivity diamond-copper composite

The invention discloses a preparation method of a high-heat-conductivity diamond-copper composite, and relates to a preparation method of a composite. The problems that an existing preparation methodof diamond-copper composite cannot achieve net shape forming, high quality and large batch preparation of large-size sheet samples is solved. The preparation method comprises the steps that diamond powder is placed into a die and compacted to form a precast body, the precast body is hoisted to the lower end of a lifting rod on the upper portion inside an air pressure infiltration furnace, and a crucible containing copper alloy is placed below the precast body in the furnace; vacuumizing is carried out, heating and copper melting are carried out under protection of inert gas, the lifting rod descends, pressurization infiltration is carried out, pressure is kept for cooling, pressure is released, and finally the die is removed. The preparation method has the beneficial effects that high-efficiency mass production can be achieved, the mechanical property is high, the rate of finished products is high, large-size sheet samples can be prepared, sample heat conductivity is improved, the preparation cost is low, the content of impurities is low, and the forming die and the crucible can be repeatedly used. The preparation method is applicable to preparing the high-heat-conductivity diamond-copper composite and component.

Owner:HARBIN INST OF TECH

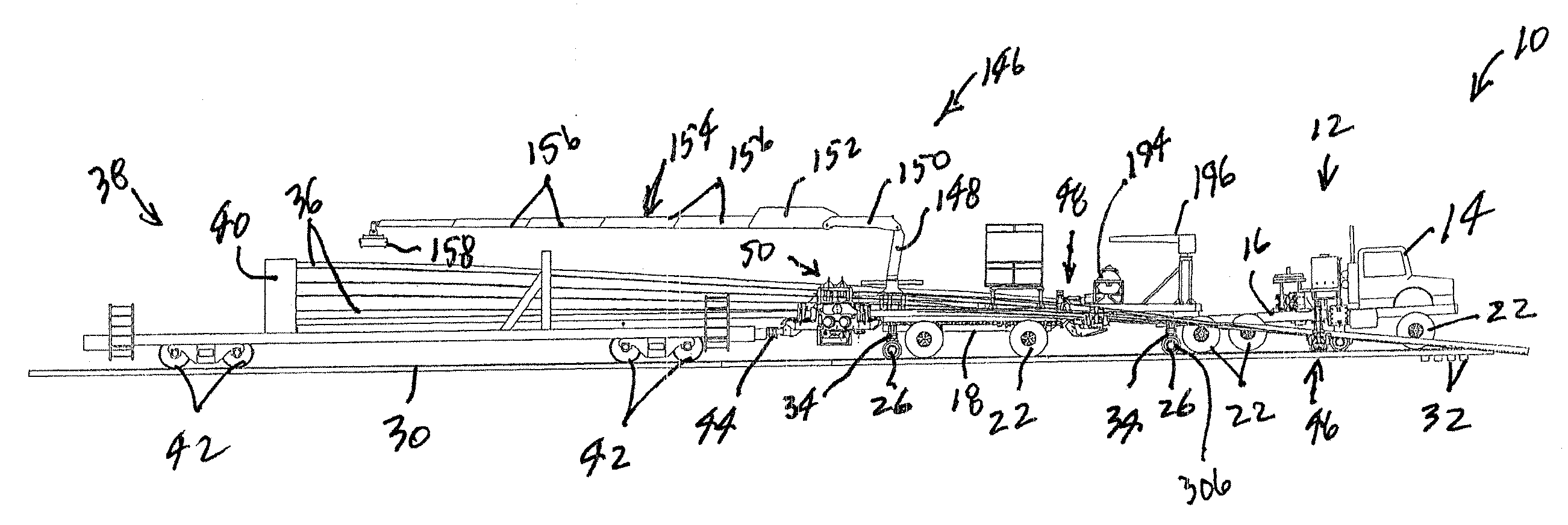

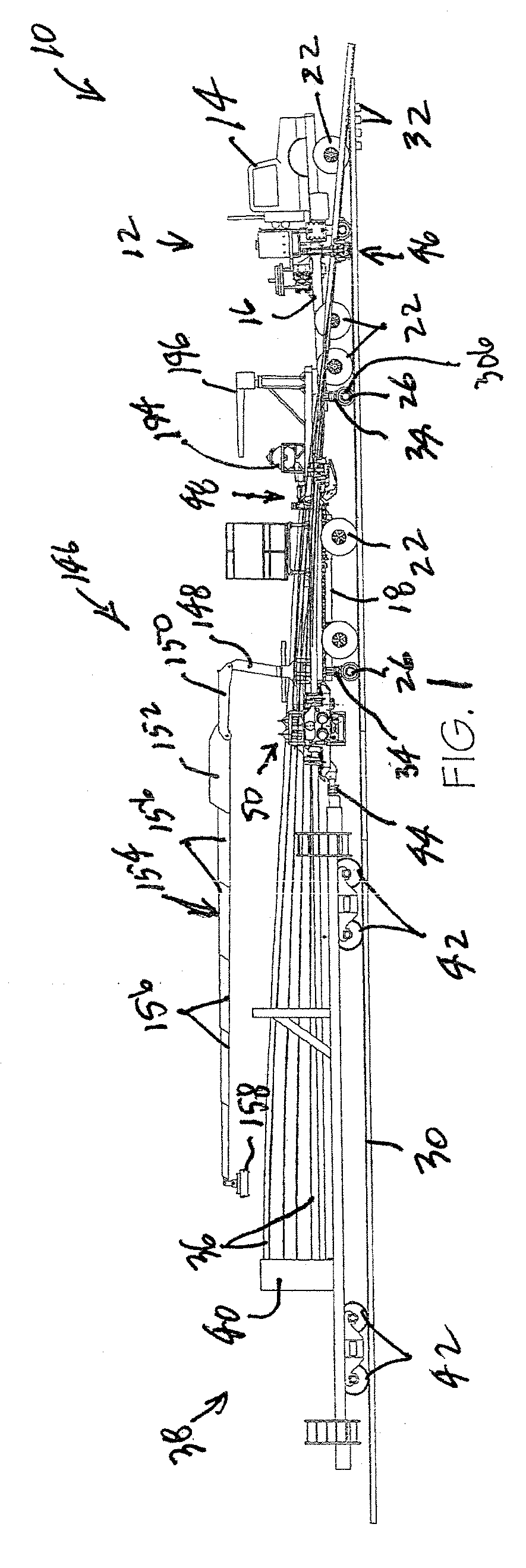

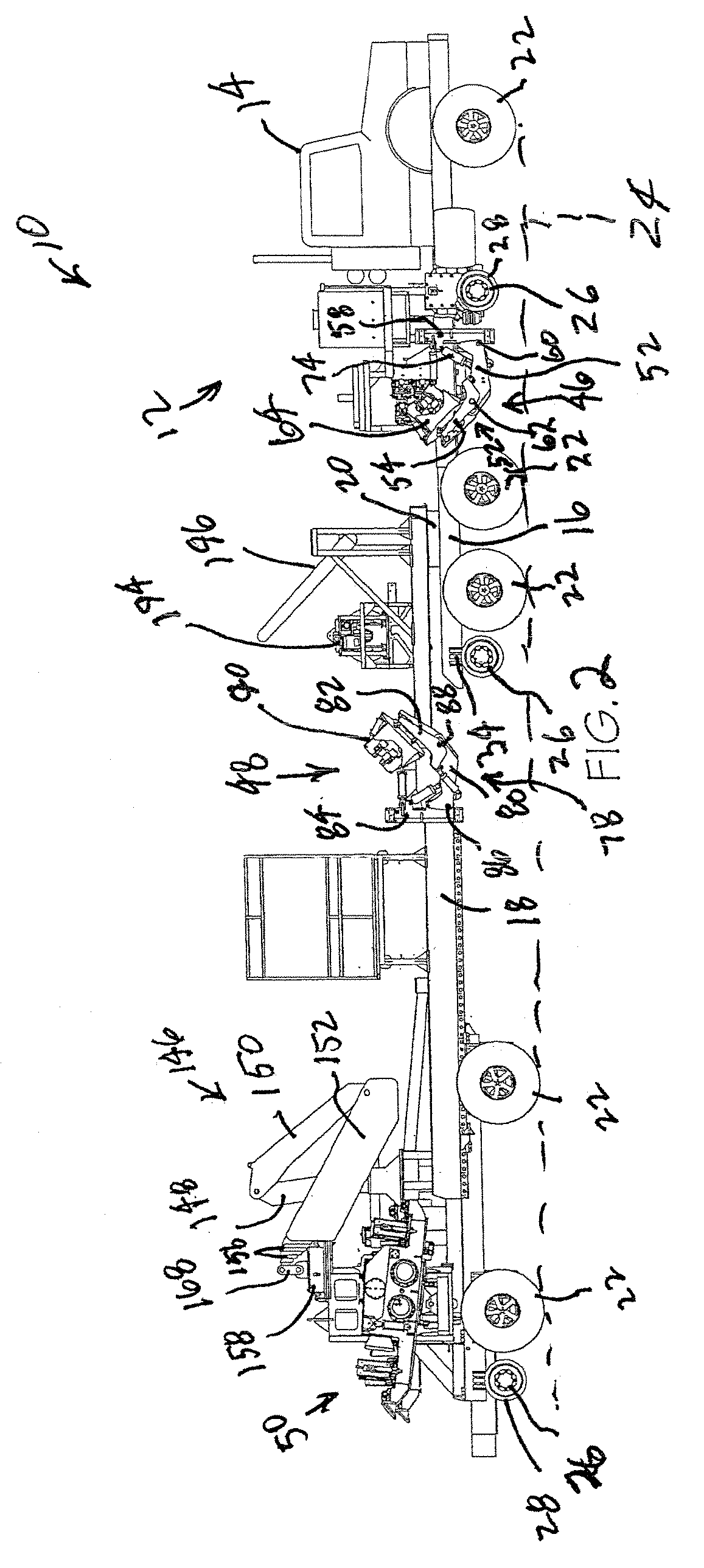

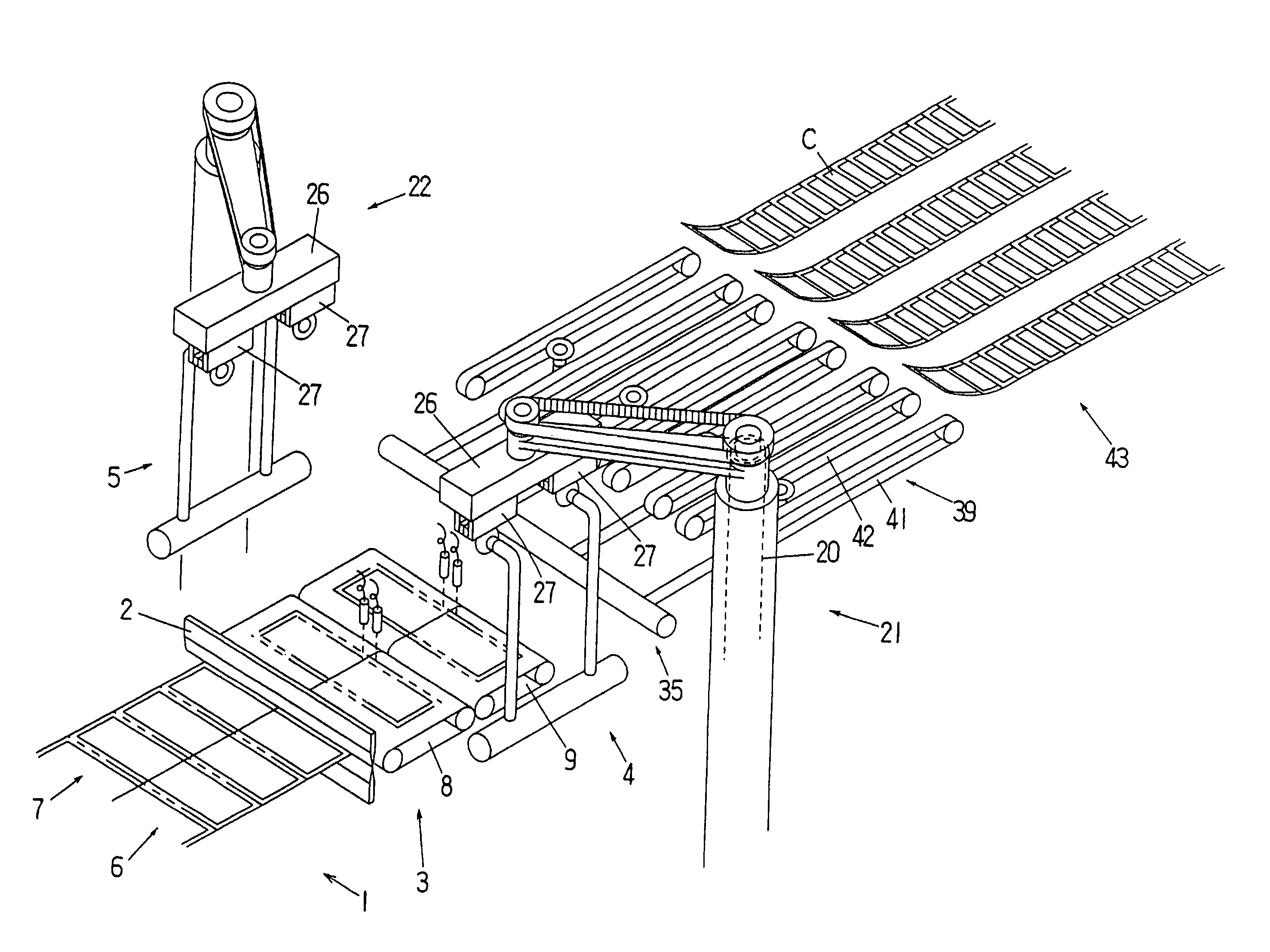

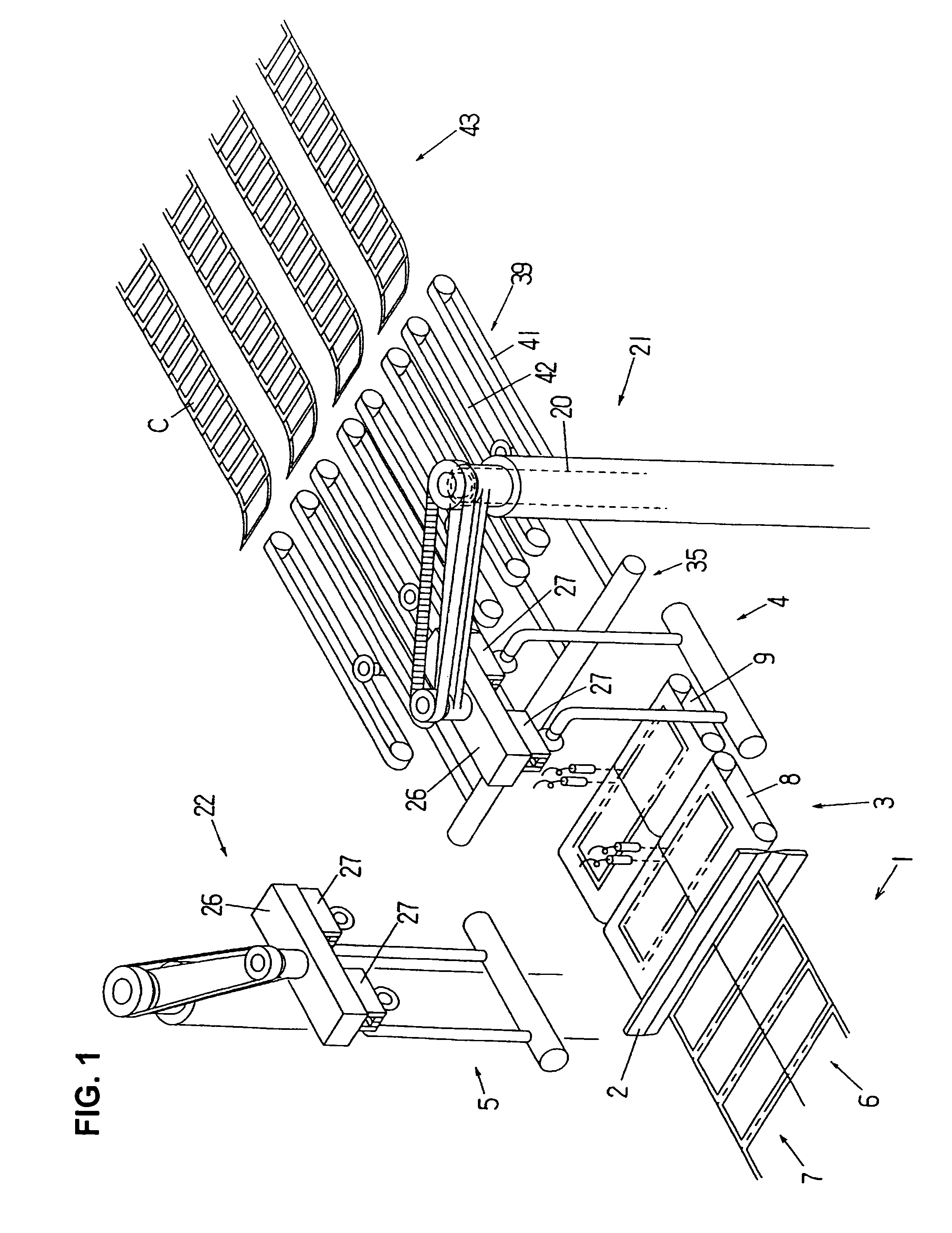

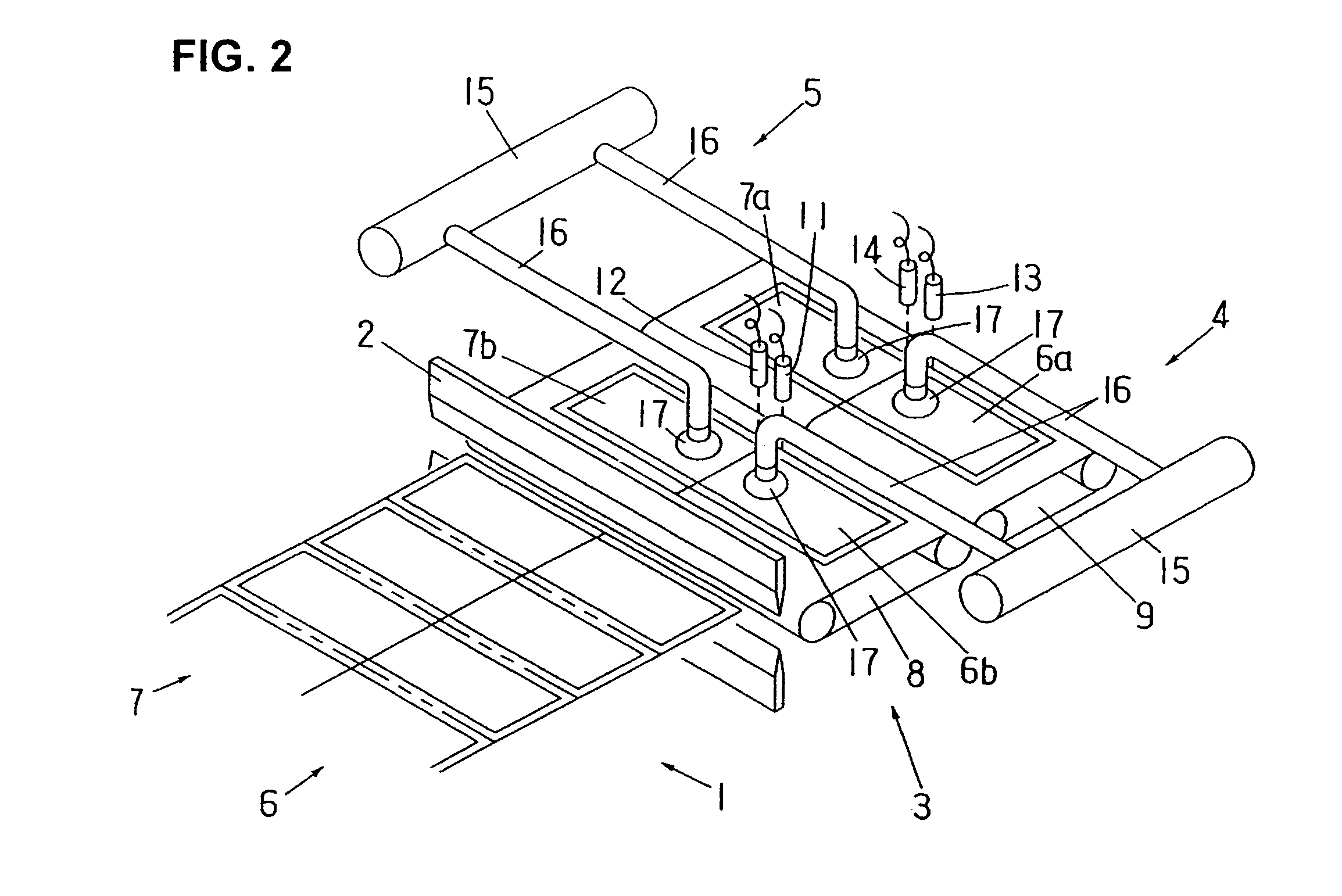

Rail Threading Mechanism

A rail threading mechanism for a rail handling vehicle includes a thread box mounted on the outer end of a manipulating arm. The thread box includes a platform and a pair of jaws pivotally connected to the platform and moveable between open and closed positions. The platform includes a support roller for rollingly engaging the flat bottom of a rail. Each jaw include a plurality of jaw rollers positioned for rollingly engaging a rail positioned on the support roller when the respective jaw is in the closed position. The jaw rollers on each jaw preferably include a pair of base rollers positioned for engaging an edge of the base of the rail, a pair of flange top rollers positioned for engaging a top surface of the top flange of the rail, and a flange side roller positioned for engaging an edge surface of the top flange of the rail.

Owner:HERZOG CONTRACTING

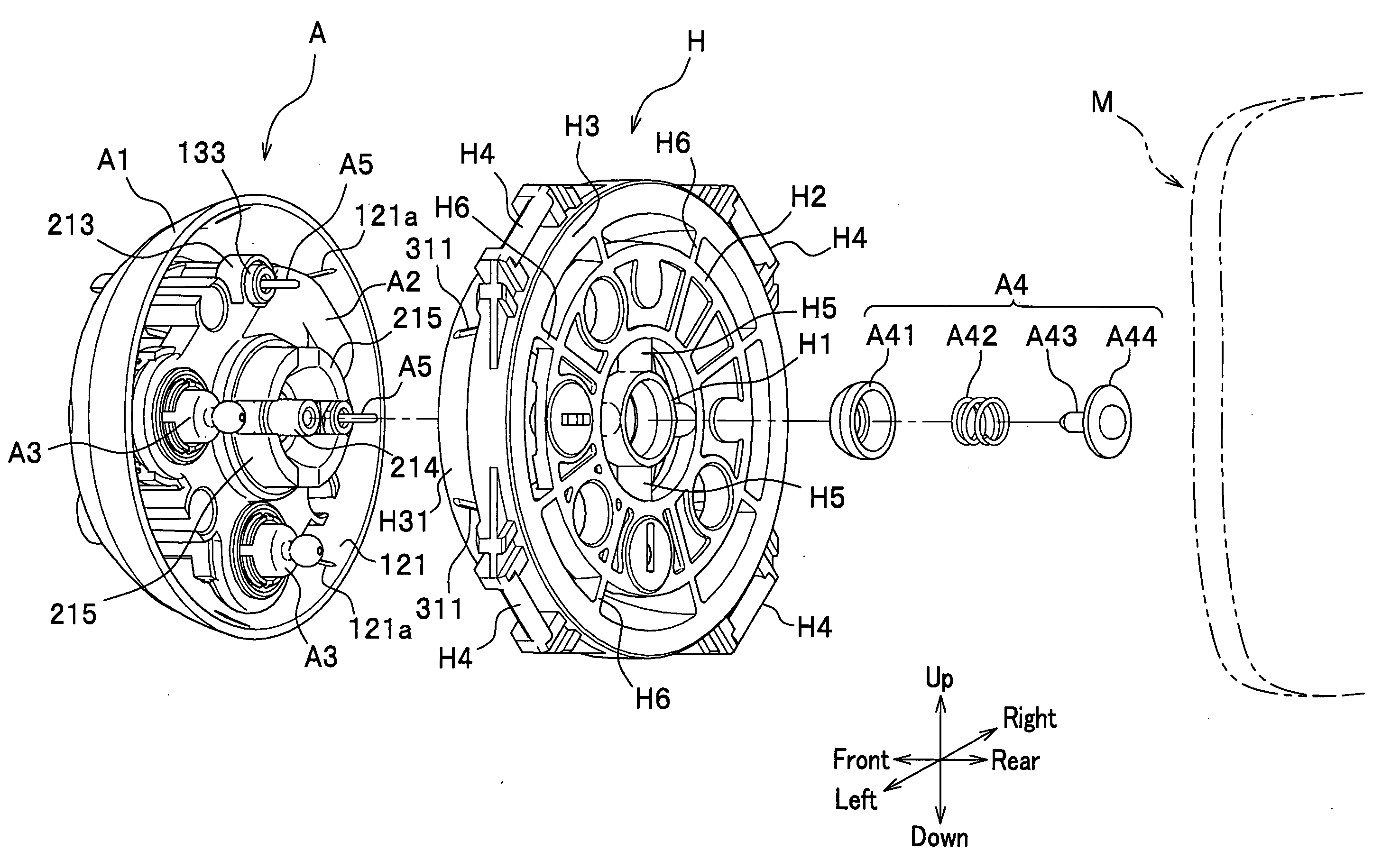

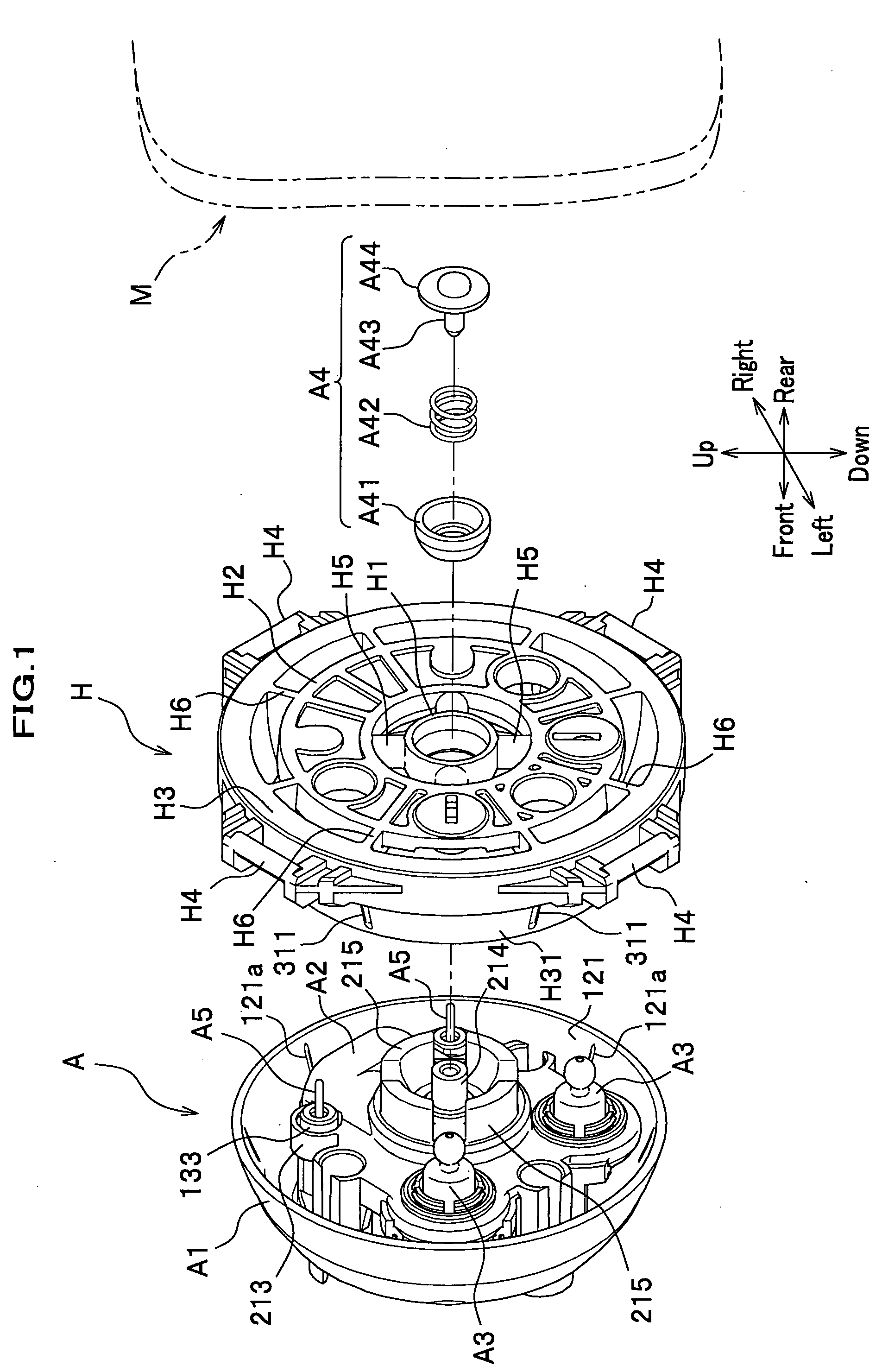

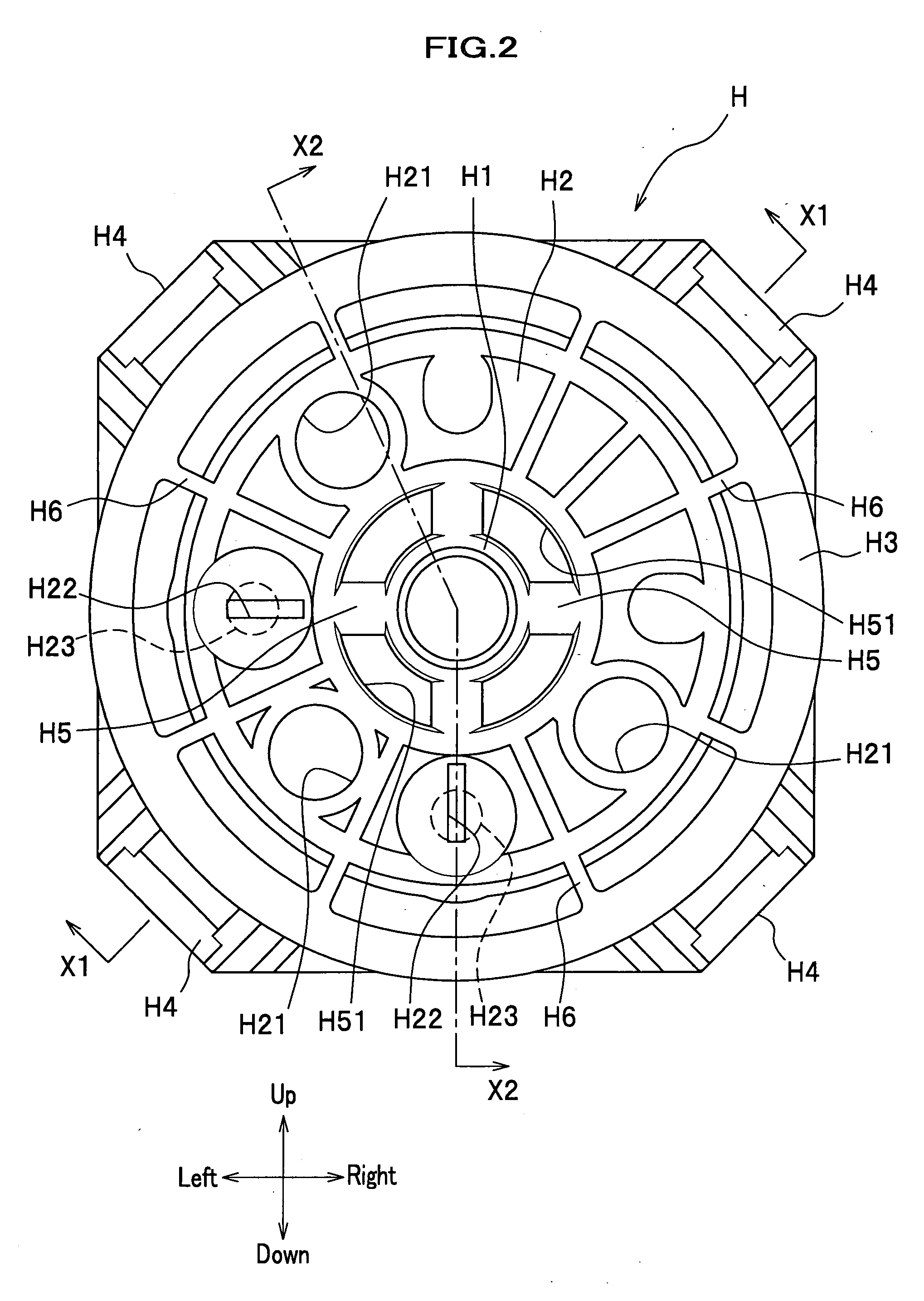

Mirror Angle Adjusting Device

InactiveUS20080310040A1Smooth slidingStably holding a pivot plateMountingsOptical viewingEngineeringActuator

A mirror angle adjusting device can stably hold a pivot plate (H), while a contact part between the pivot plate (H) and an actuator (A) smoothly slides for a long period of time. The mirror angle adjusting device includes the pivot plate (H) attached to a back side of a mirror (M), and the actuator (A) for holding the pivot plate (H). In the mirror angle adjusting device, grooves (121a) for storing a lubricant are formed on a support surface of the actuator (A), and grooves (311) for storing a lubricant are formed on a sliding surface of the pivot plate (H) which is slidably in contact with the support surface. In the mirror angle adjusting device, the contact part between the pivot plate (H) and the actuator (A) can smoothly slide for a long period of time, and the pivot plate (H) can be stably held.

Owner:MURAKAMI CORP

Method and apparatus for feeding bags to a packaging machine

ActiveUS7581370B2Packaging machineReduce the numberEnvelopes/bags making machineryBag making operationsEngineeringPackaging machine

A bag-making and packaging machine, in which a horizontal bag-making machine and a packaging machine are provided, including a positioning conveyor for positioning bags fed out from the horizontal bag-making machine, a feed conveyor for feeding the bags to the packaging machine, and first, second, and third transport mechanisms provided between the positioning conveyor and the feed conveyor. The first transport mechanism lifts up the bags up and change their attitude to a vertical attitude with the bag mouths oriented upward. The second transport mechanism receives the bags from the first transport mechanisms, transports them, and rotates the bags to orient bag surfaces in the feed direction of the feed conveyor. The third transport mechanisms receives the bags from the second transport mechanisms, changes their attitude to a horizontal attitude, and places them on the feed conveyor with the bag mouths oriented in the feed direction.

Owner:TOYO JIDOKI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com