Hermetic compressor

a compressor and hermetic technology, applied in the direction of positive displacement liquid engines, pumps, machines/engines, etc., can solve the problems of oil lift force in the upper part of the oil feed path, the main oil feed path may not feed and the problem of hermetic compressors having the above-mentioned oil feed unit is problematic, so as to achieve efficient feeding of a sufficient amount of lubricating oil and improve the structure of the oil feed structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Reference will now be made in detail to the present preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

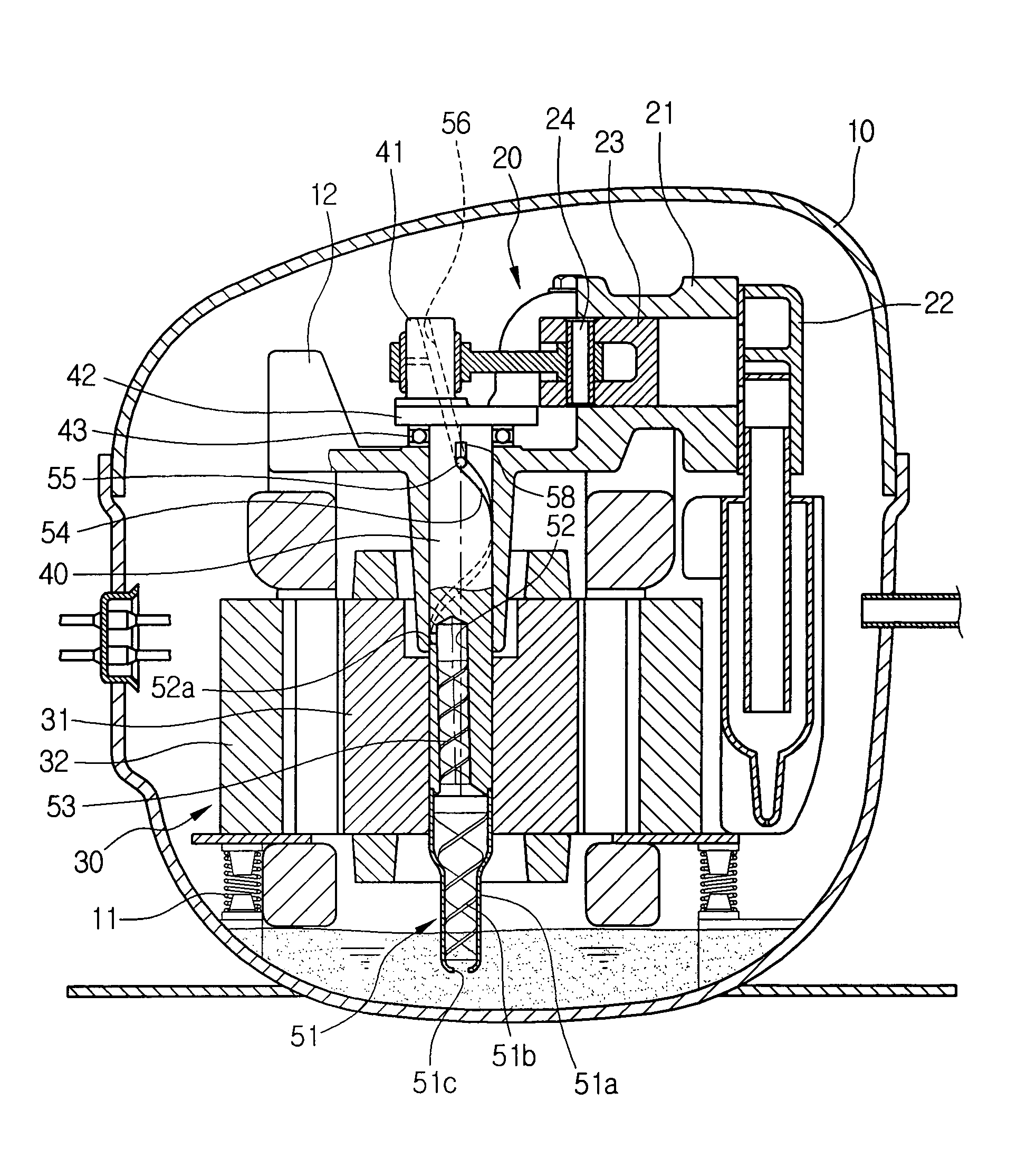

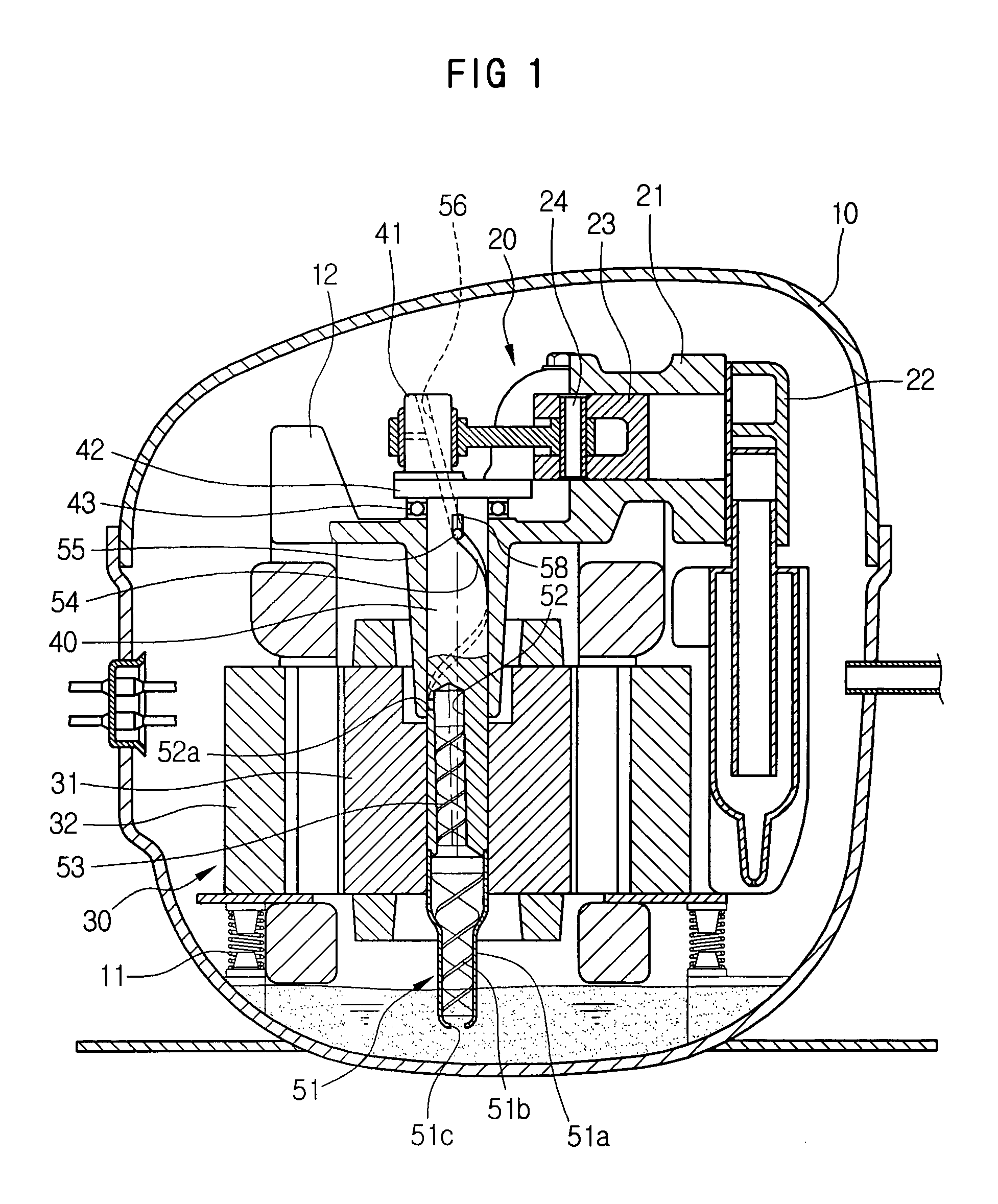

[0028] As shown in FIG. 1, the hermetic compressor according to the embodiment of the present invention has a hermetic casing 10, a frame 12 installed in the hermetic casing 10 while being supported by a plurality of damping units 11, a compression unit 20 provided on an upper portion of the frame 12, and a drive unit 30 provided in a lower portion of the frame 12 to drive the compression unit 20.

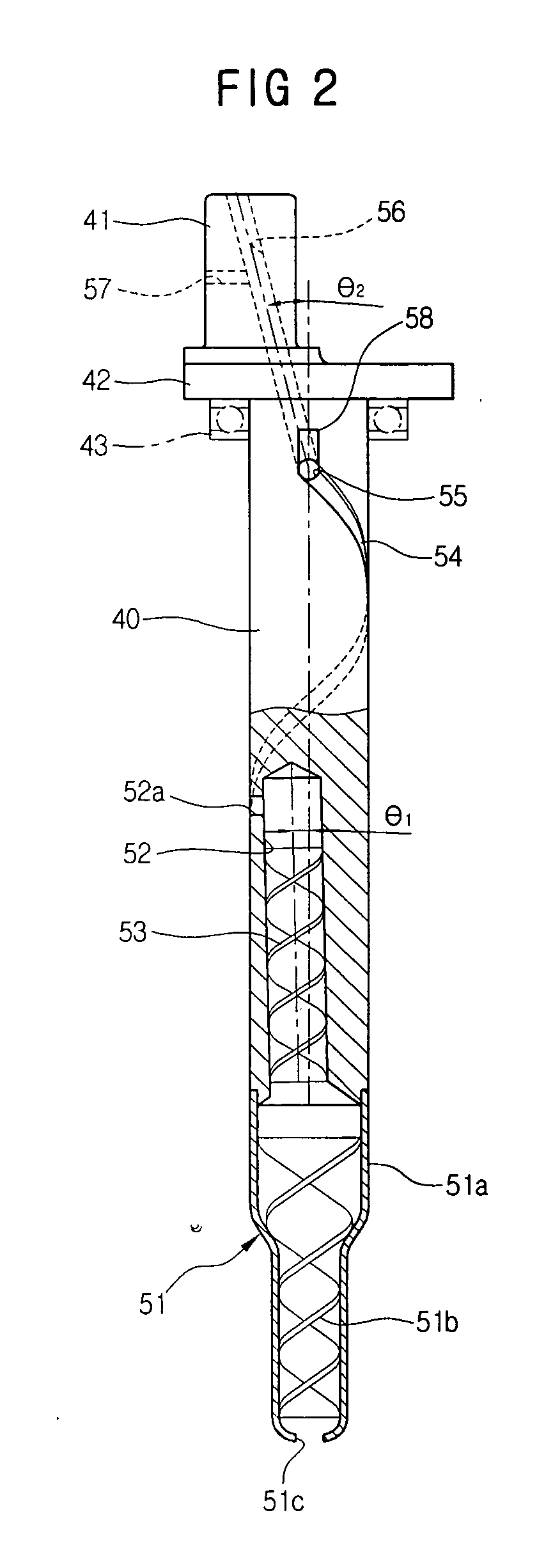

[0029] The hermetic compressor further includes a rotating shaft 40 which is vertically installed in the frame 12 while being supported by a shaft support part 13 of the frame 12 to rotate relative to the frame 12. The rotating shaft 40 transmits a ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com