Patents

Literature

4098results about "Railway track construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

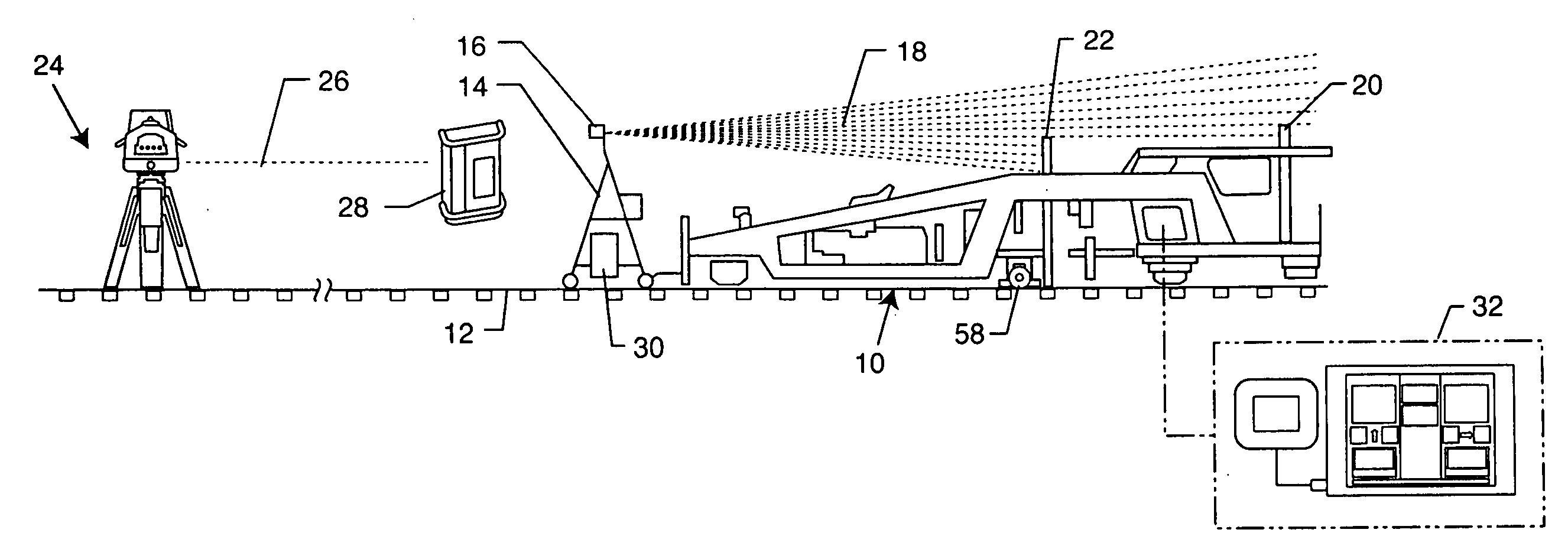

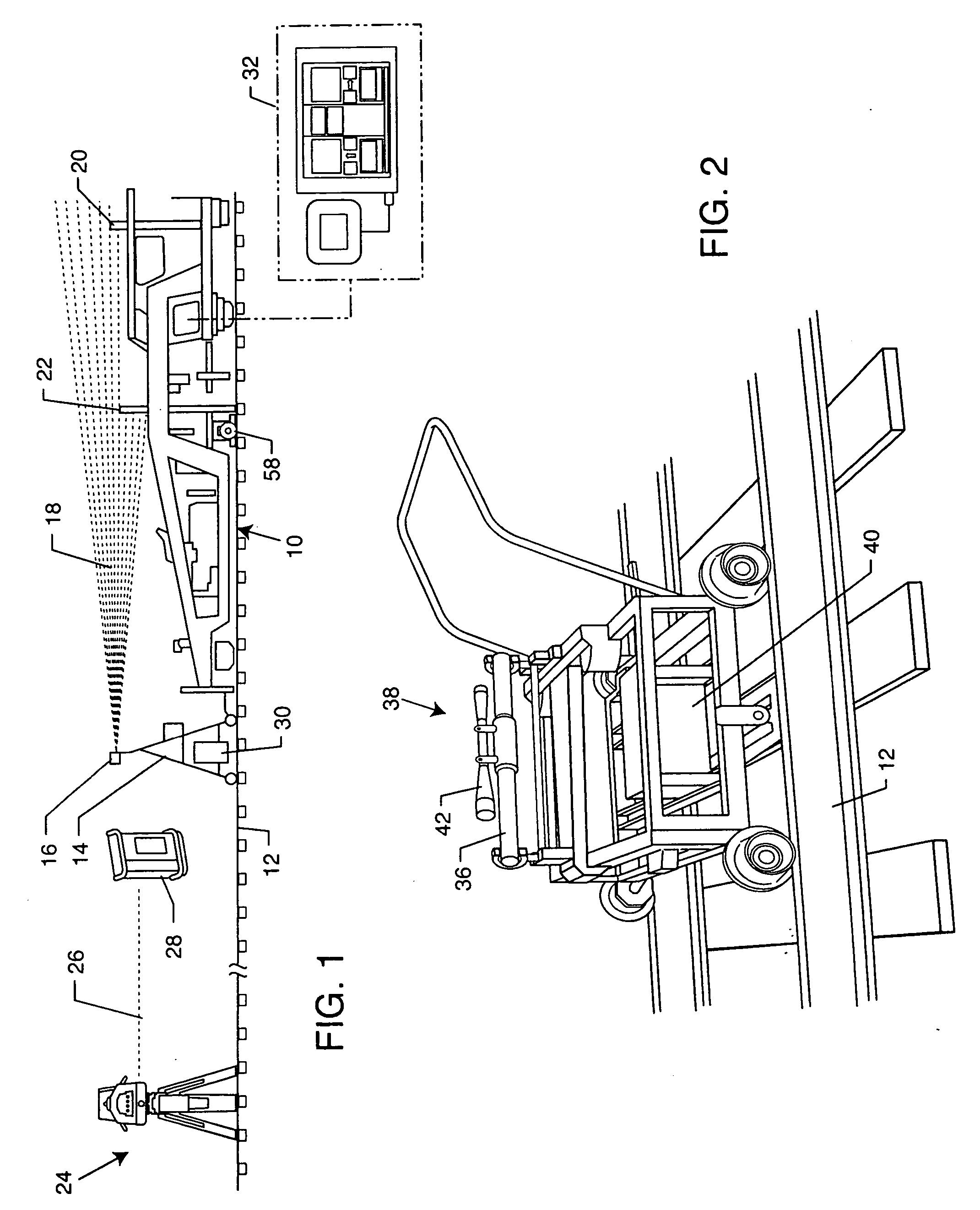

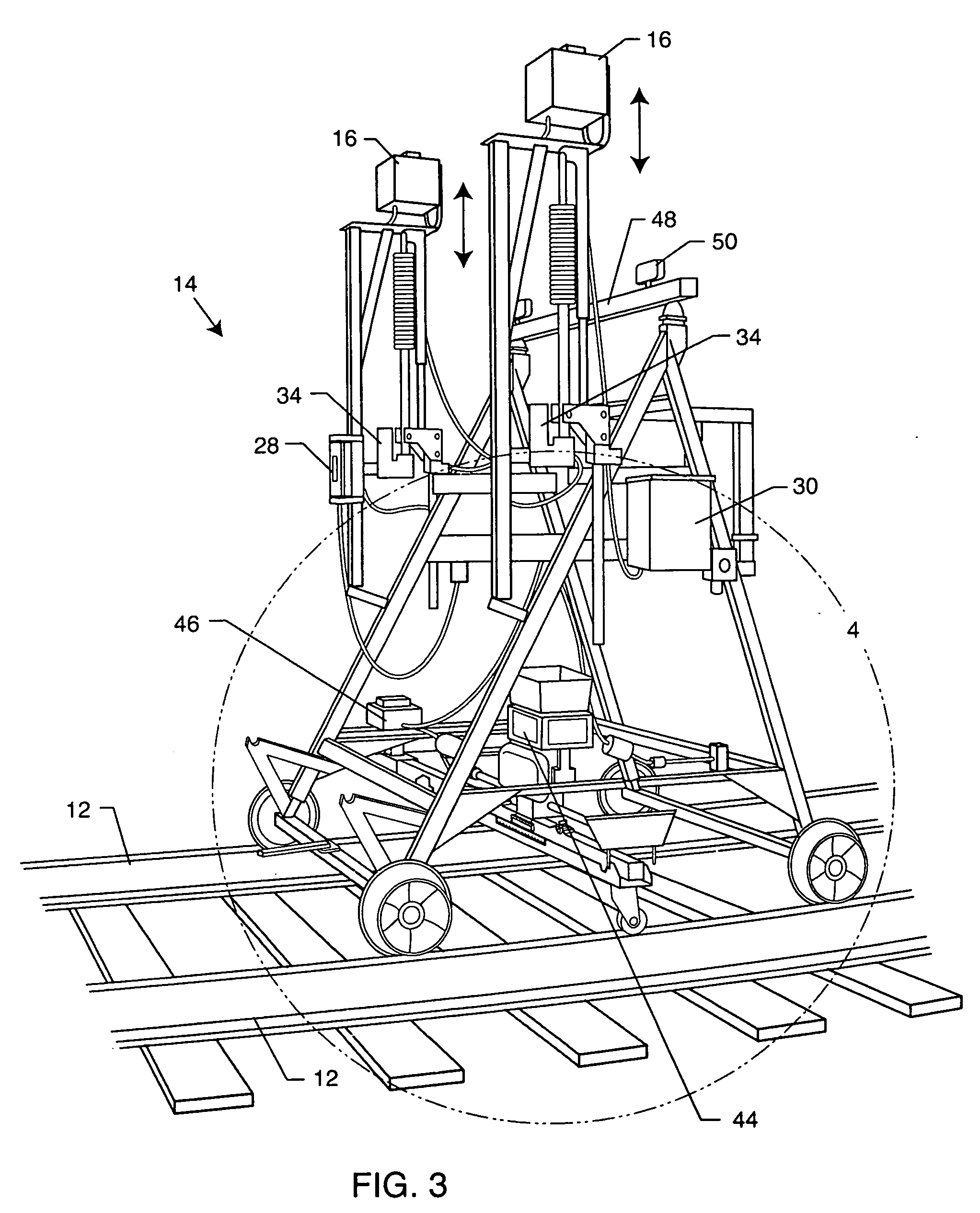

Rail vision system

InactiveUS20120192756A1Digital data processing detailsCharacter and pattern recognitionVision inspectionControl system

A vision inspection system and method for use with a railcar includes a vision device adapted to provide an image of each rail component. An image recognition component analyzes the images taken by the vision device to determine the type and condition of each rail component as the vehicle is traveling on the railroad track. A control system communicates with the vision device and the image recognition component. The control system causes workheads of the vehicle to engage respective rail components based on the input received from the vision inspection system. A method for determining the relative distance between the rail components includes comparing the position of the respective rail components of a first image to the position of the respective rail components of a second image to determine the distance between the respective components and distance the railcar has moved.

Owner:HARSCO CORP

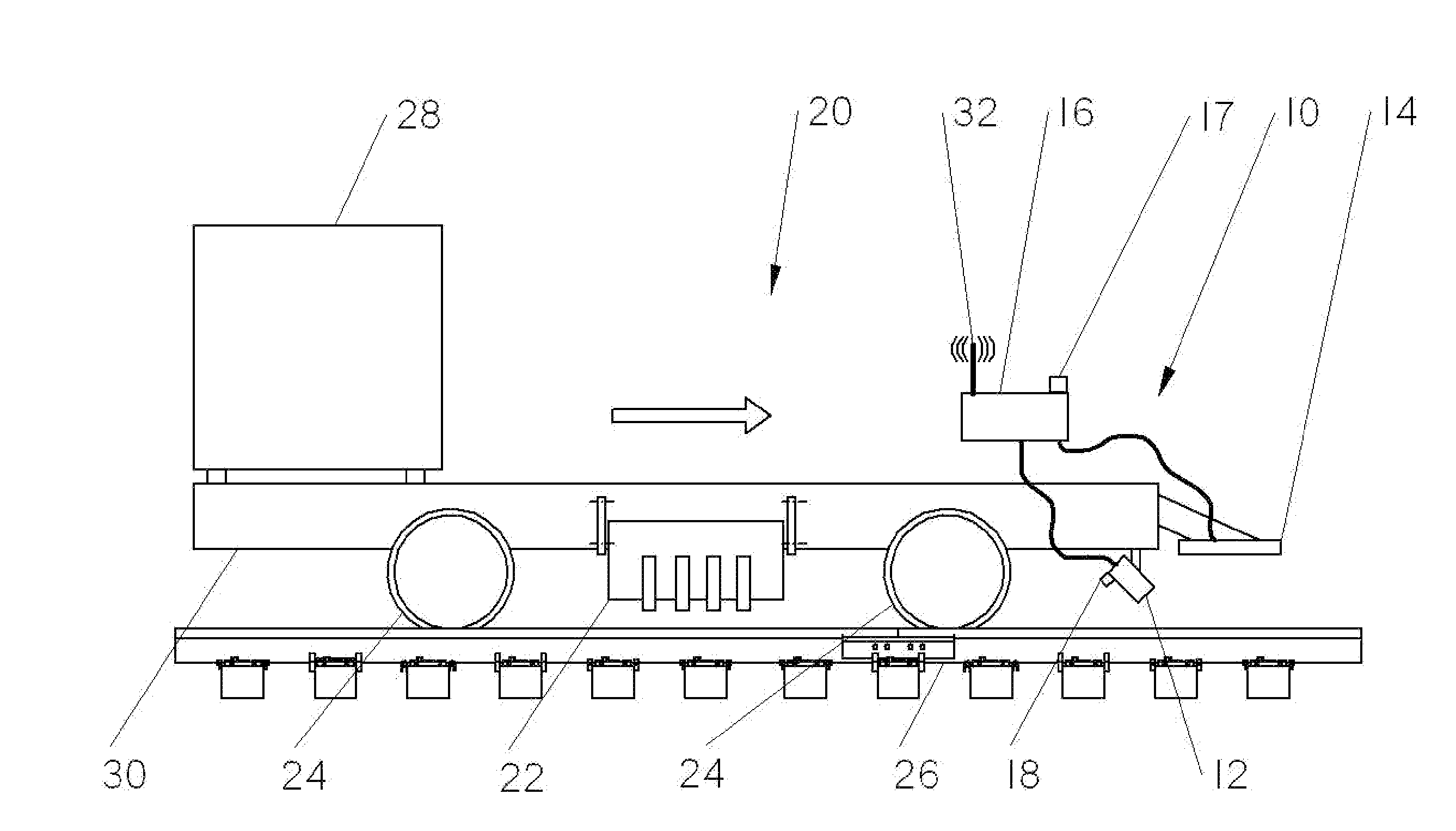

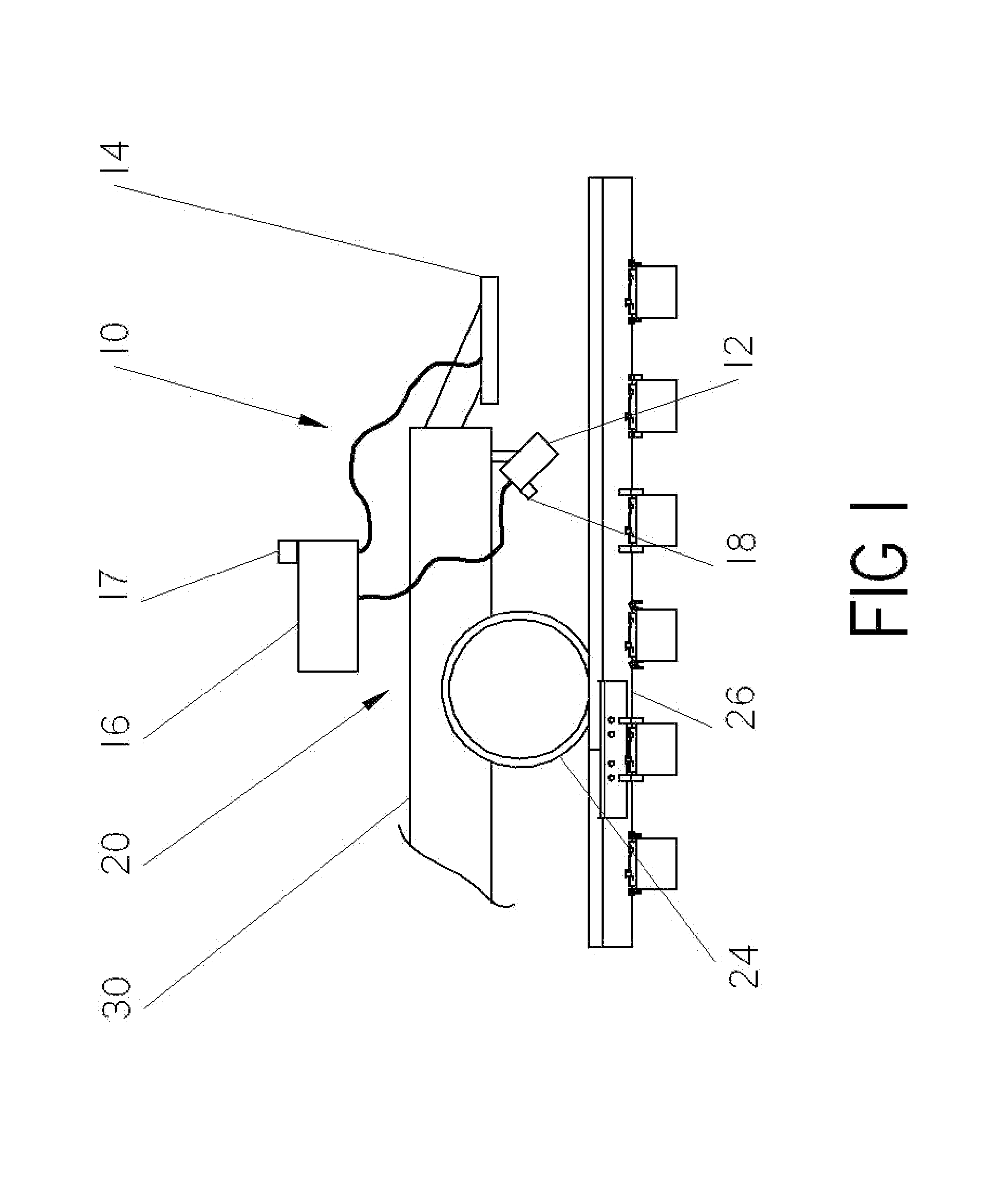

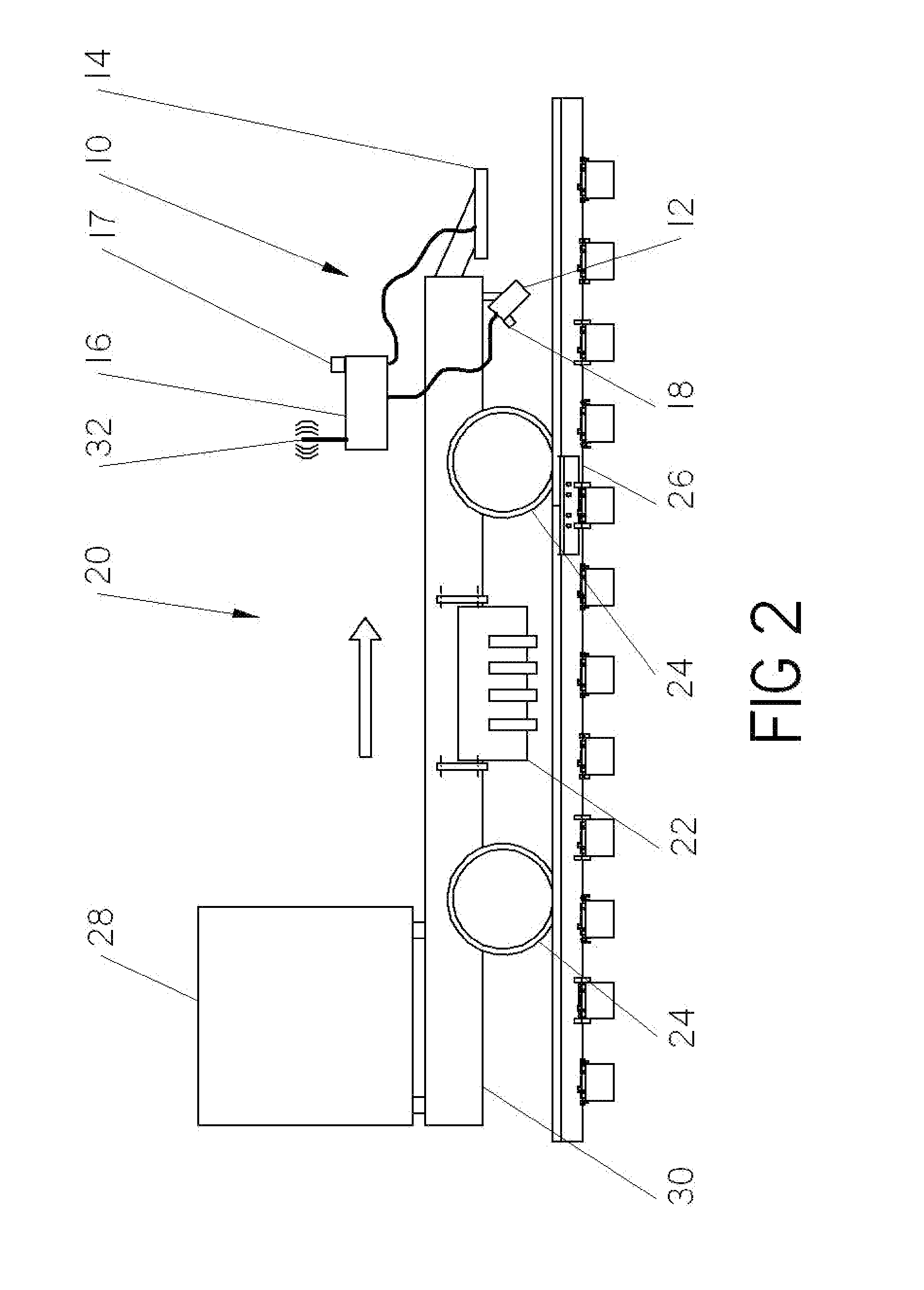

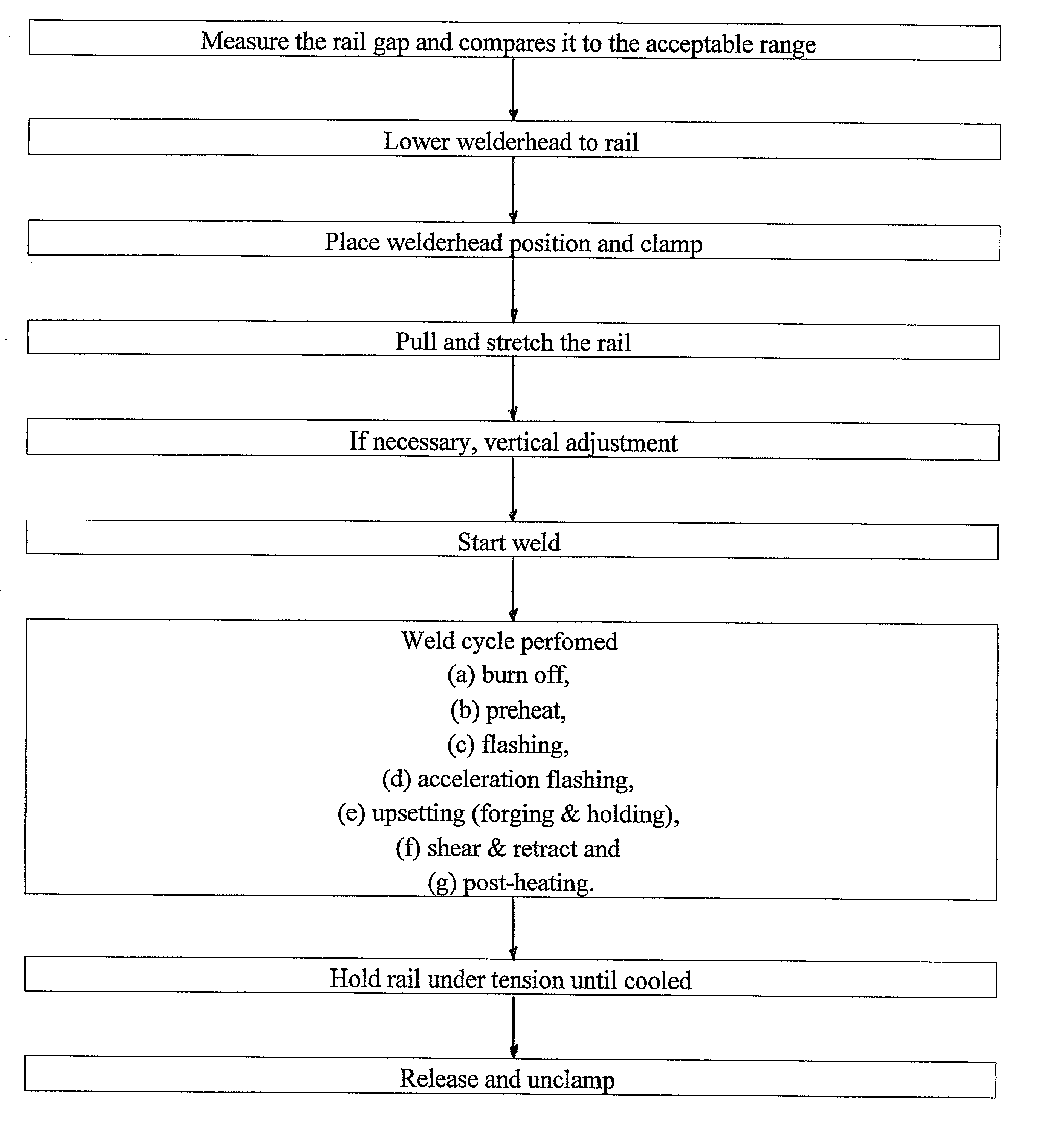

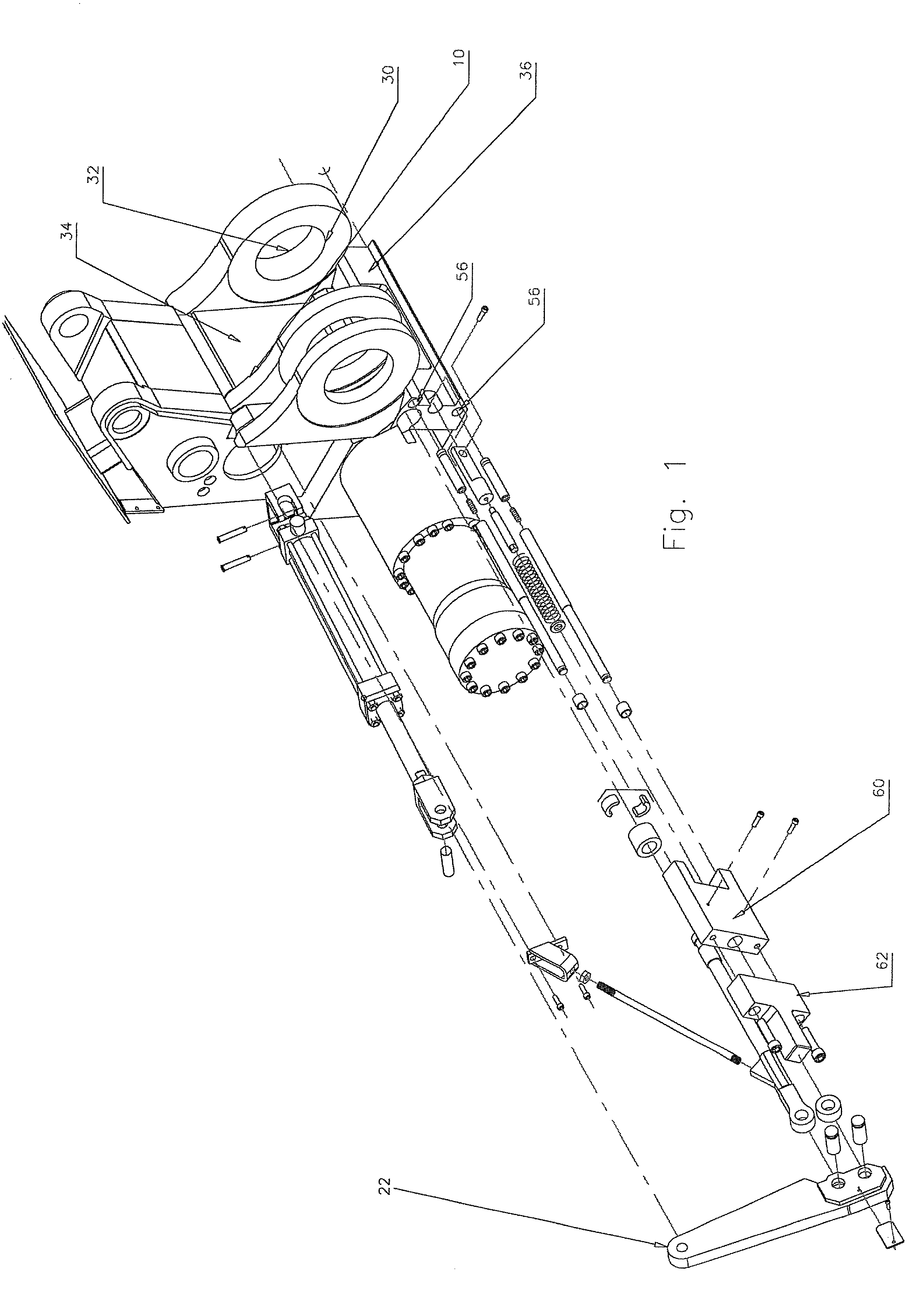

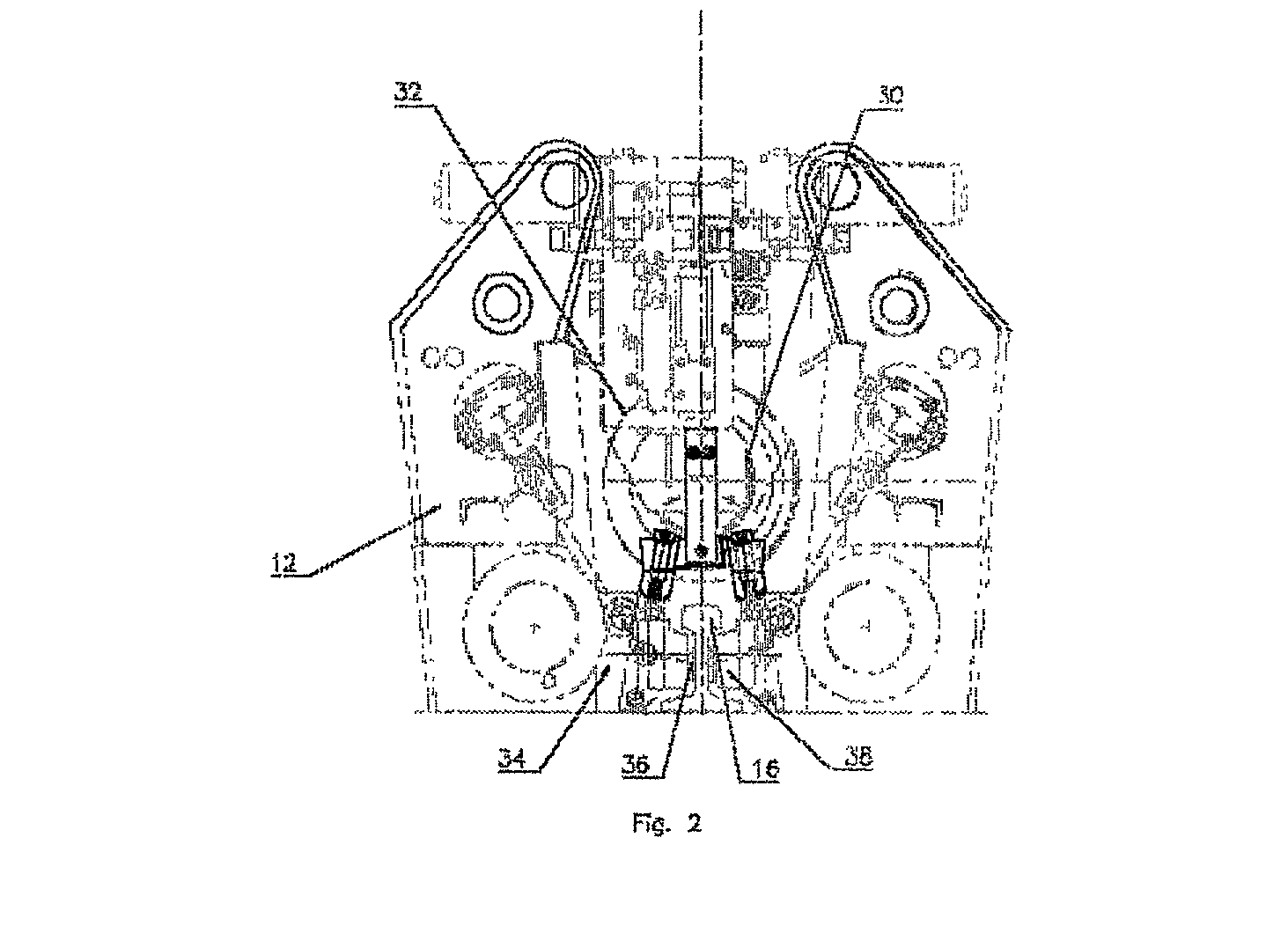

Rail welderhead shear apparatus

A flash butt rail welding welderhead combines in a single unit, the ability for the three functions of rail pulling, flash butt forging and maintaining the "after forged" displacement without any change in platen position such that shearing may be accomplished in three stages, a single stage, multiple stages or a progressive stage, all while maintaining clamping and stretching force on the rails.

Owner:HOLLAND CO

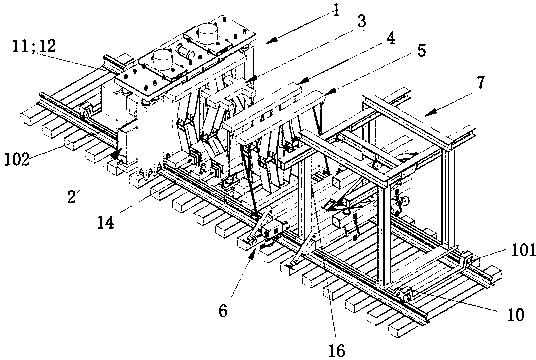

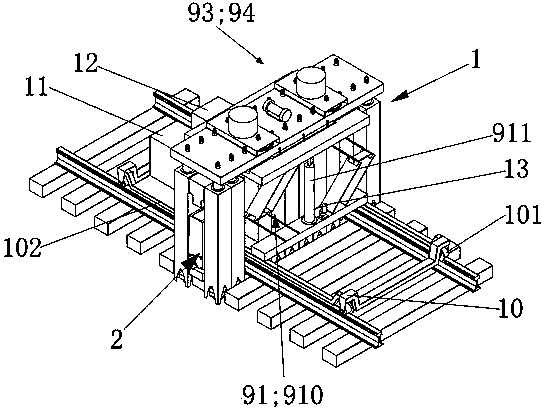

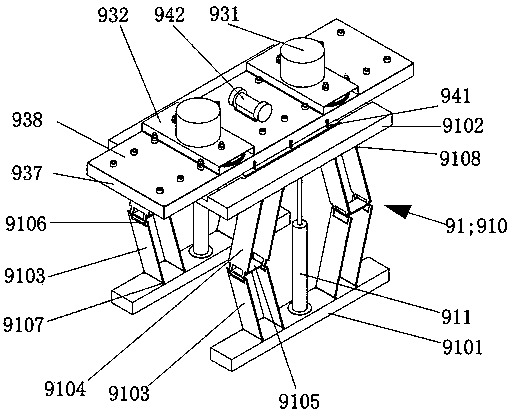

Full-mechanical rapid sleeper replacement machine

InactiveCN104195902AQuick alignmentAutomatic separation and dischargeBallastwayRailway track constructionPush and pullEngineering

The invention discloses a full-mechanical rapid sleeper replacement machine which comprises a vibration rotary excavating and ballast removing device, a ballast collecting and discharging device, a vibration ballast pushing device, a four-nut synchronous assembly and disassembly device, a sleeper lifting and rotating device, a sleeper pushing and pulling device, a sleeper hoisting device, a rail car, a power generator, a hydraulic system box, a first camera assembly, a second camera assembly, a third camera assembly, a fourth camera assembly, a fifth camera assembly, a sixth camera assembly and a monitor. A plurality of casters and two longitudinal beams are arranged on the rail car, the vibration rotary excavating and ballast removing device, the ballast collecting and discharging device, the vibration ballast pushing device, the four-nut synchronous assembly and disassembly device, the sleeper lifting and rotating device, the sleeper pushing and pulling device, the sleeper hoisting device, the power generator and the hydraulic system box are arranged on the two longitudinal beams of the rail car, and the monitor is arranged in a cab of a tow tractor. The full-mechanical rapid sleeper replacement machine is suitable for rapid sleeper replacement on straight-line and curved rail rod segments, operating time in repairing skylight through limited line can be made full and reasonable use of, and full-mechanical sleeper replacement can be achieved.

Owner:KUNMING UNIV

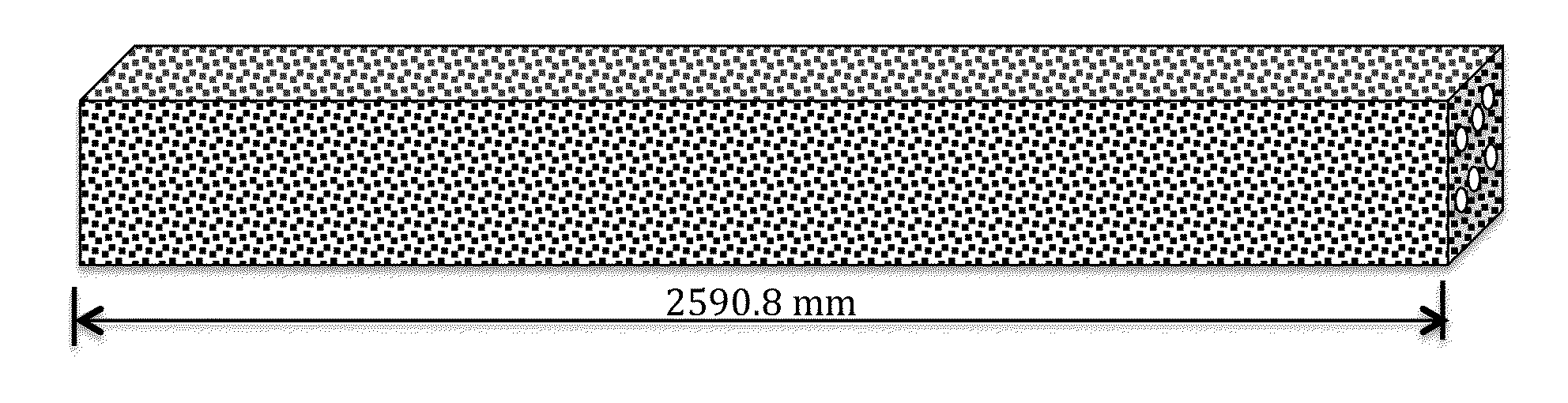

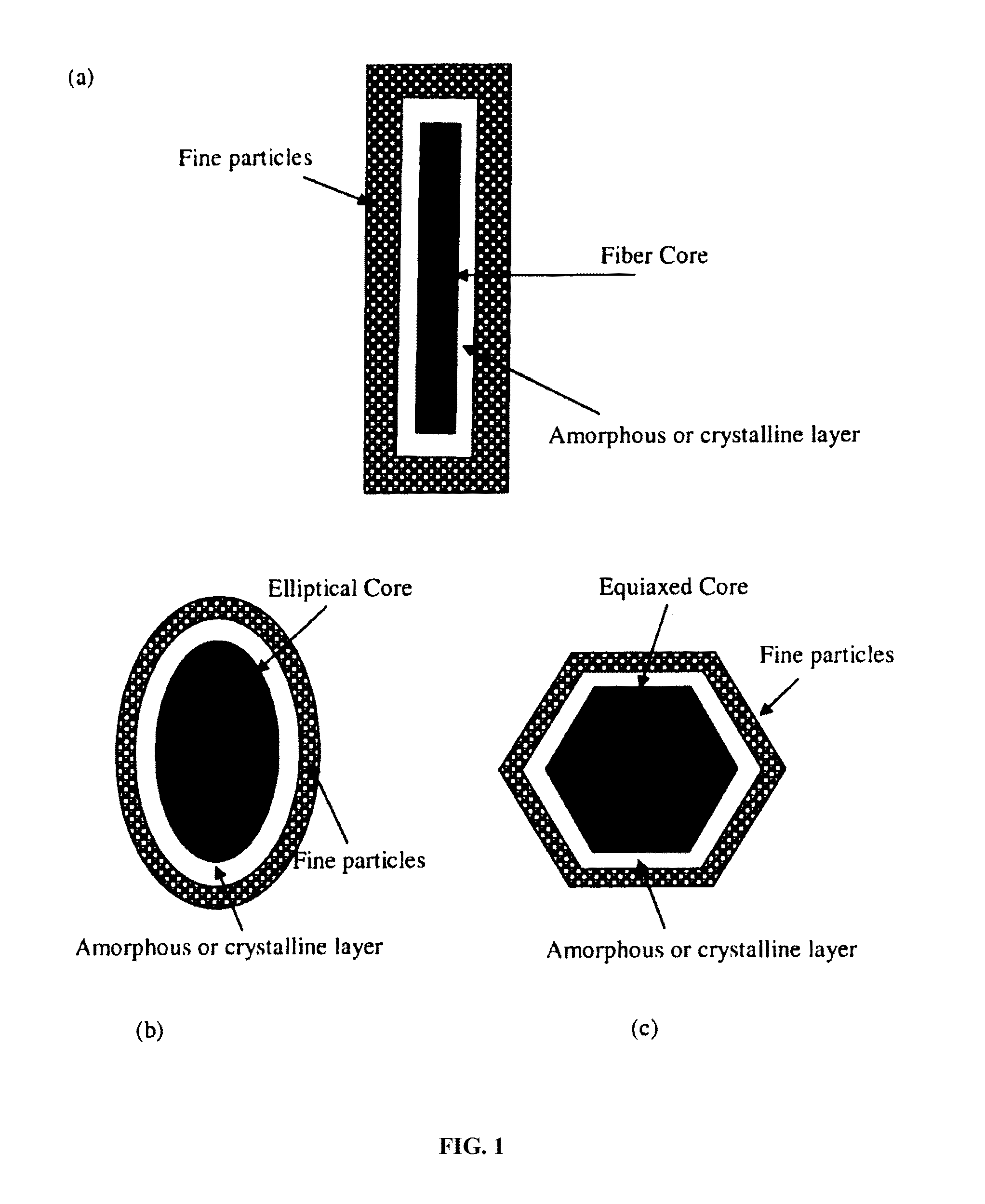

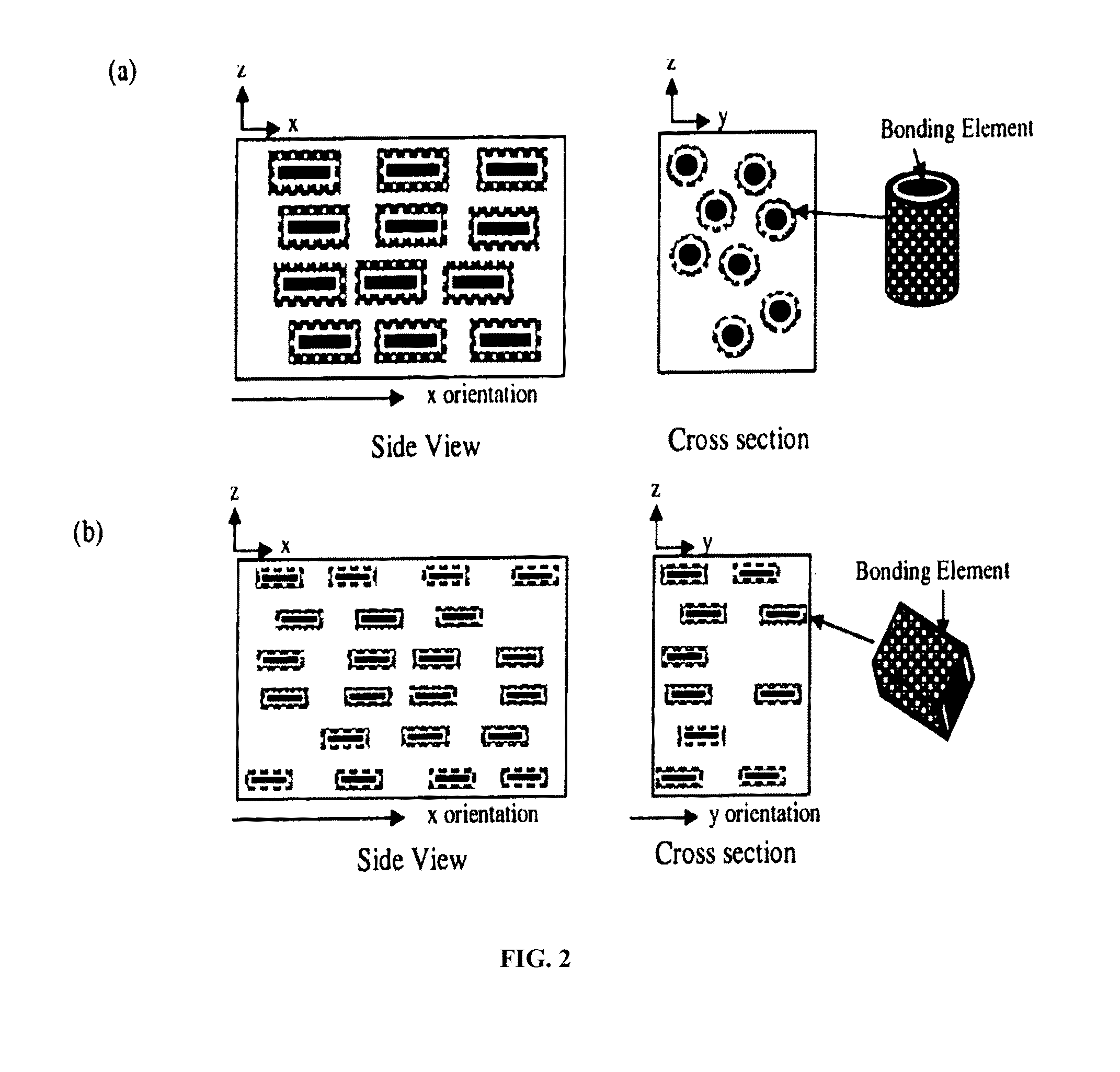

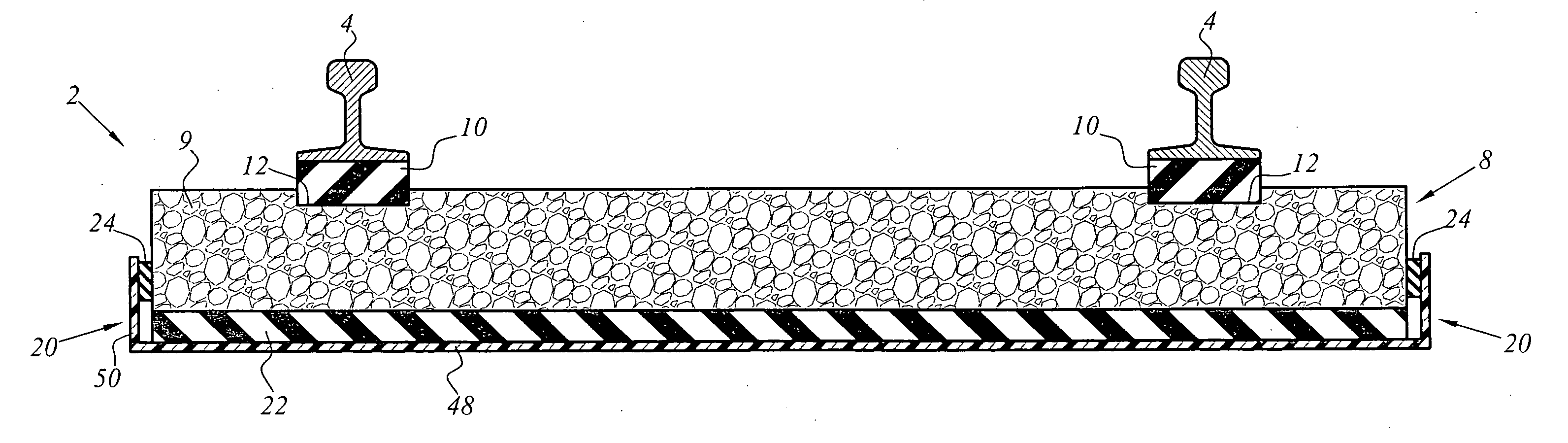

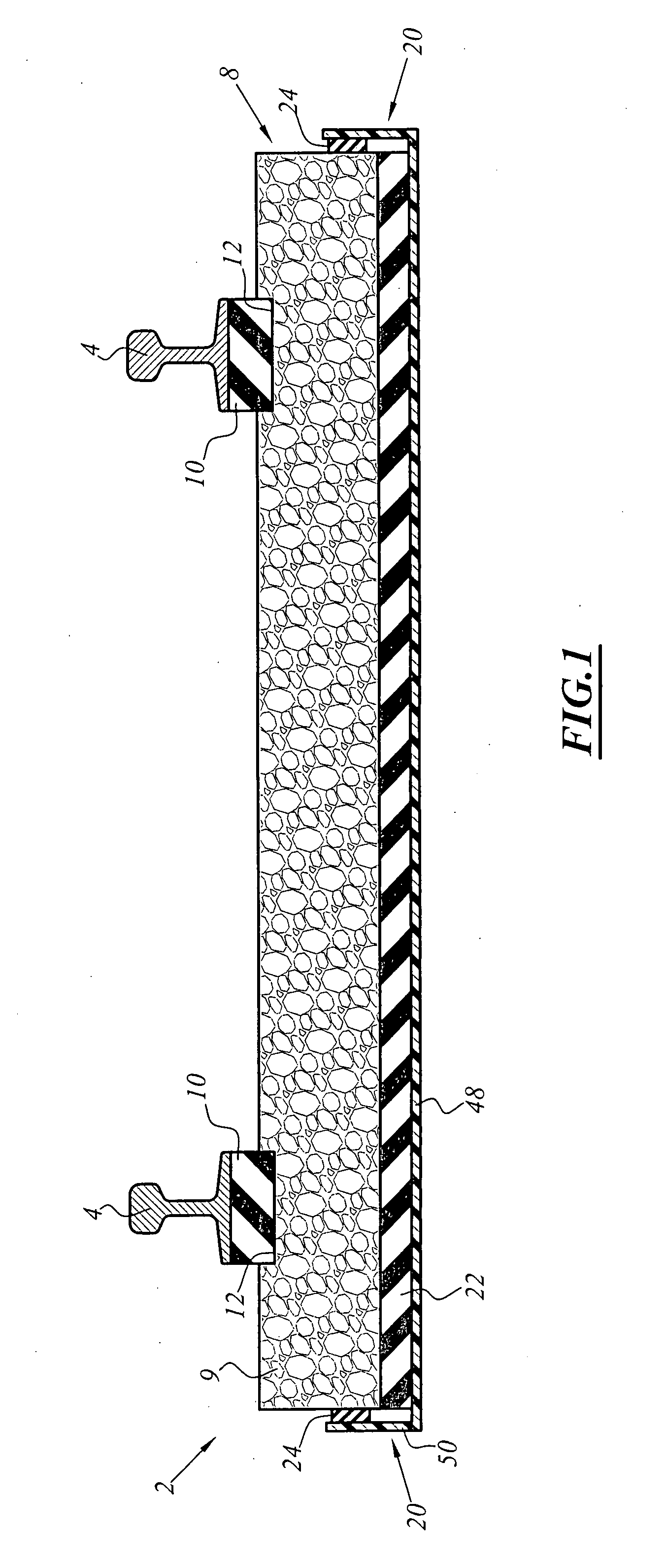

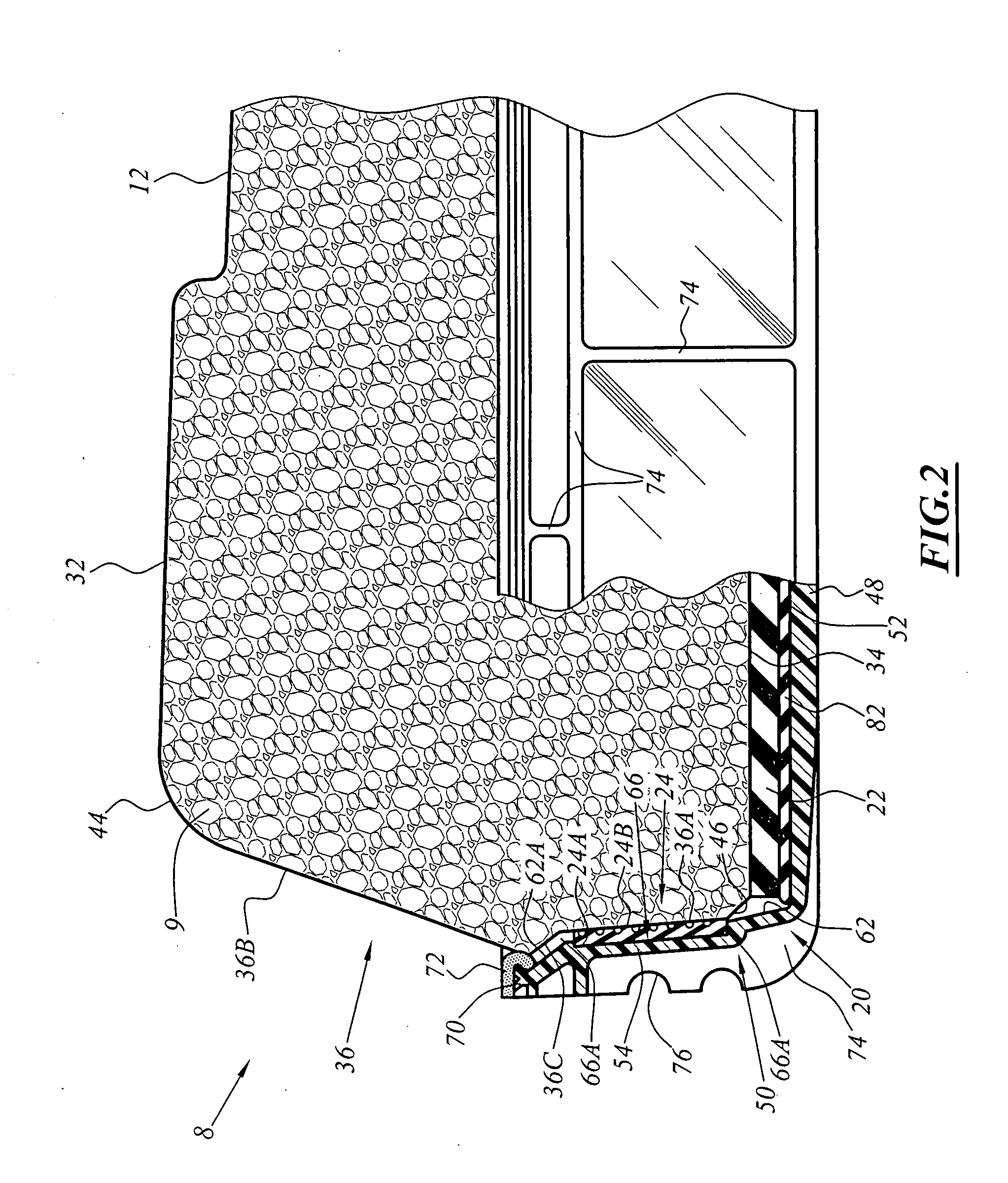

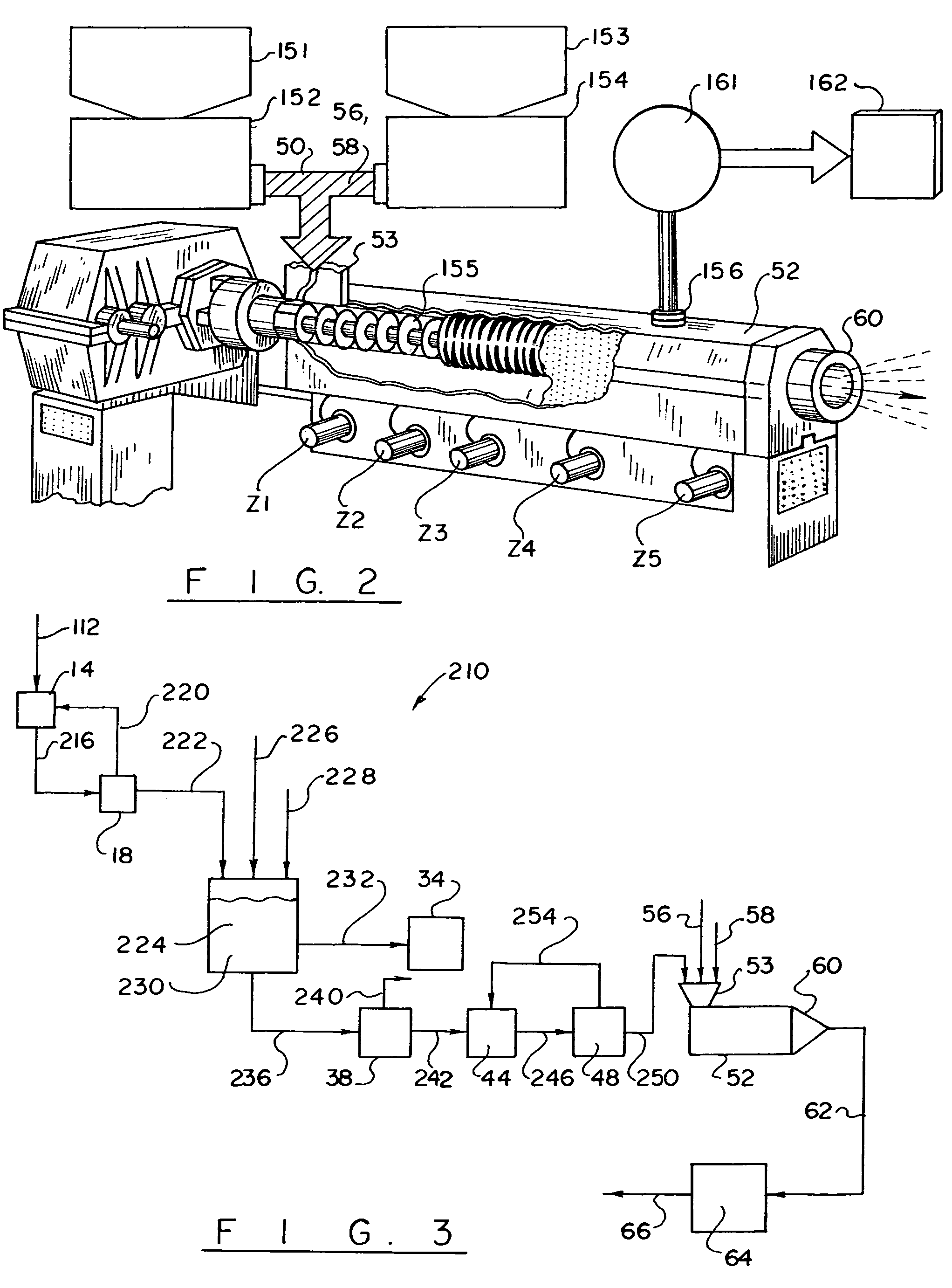

Composite railroad ties and methods of production and uses thereof

ActiveUS20140263683A1Excellent physical and performance characteristicExcellent weatherability and performance characteristicBallastwayCeramic shaping apparatusCarbon footprintMethods of production

The invention provides novel railroad ties manufactured from novel composite materials that possess excellent physical and performance characteristics matching or exceeding existing concrete RRTs. The RRTs of the invention can be readily produced from widely available, low cost raw materials by a process suitable for large-scale production with improved energy consumption and more desirable carbon footprint and minimal environmental impact.

Owner:SOLIDIA TECH

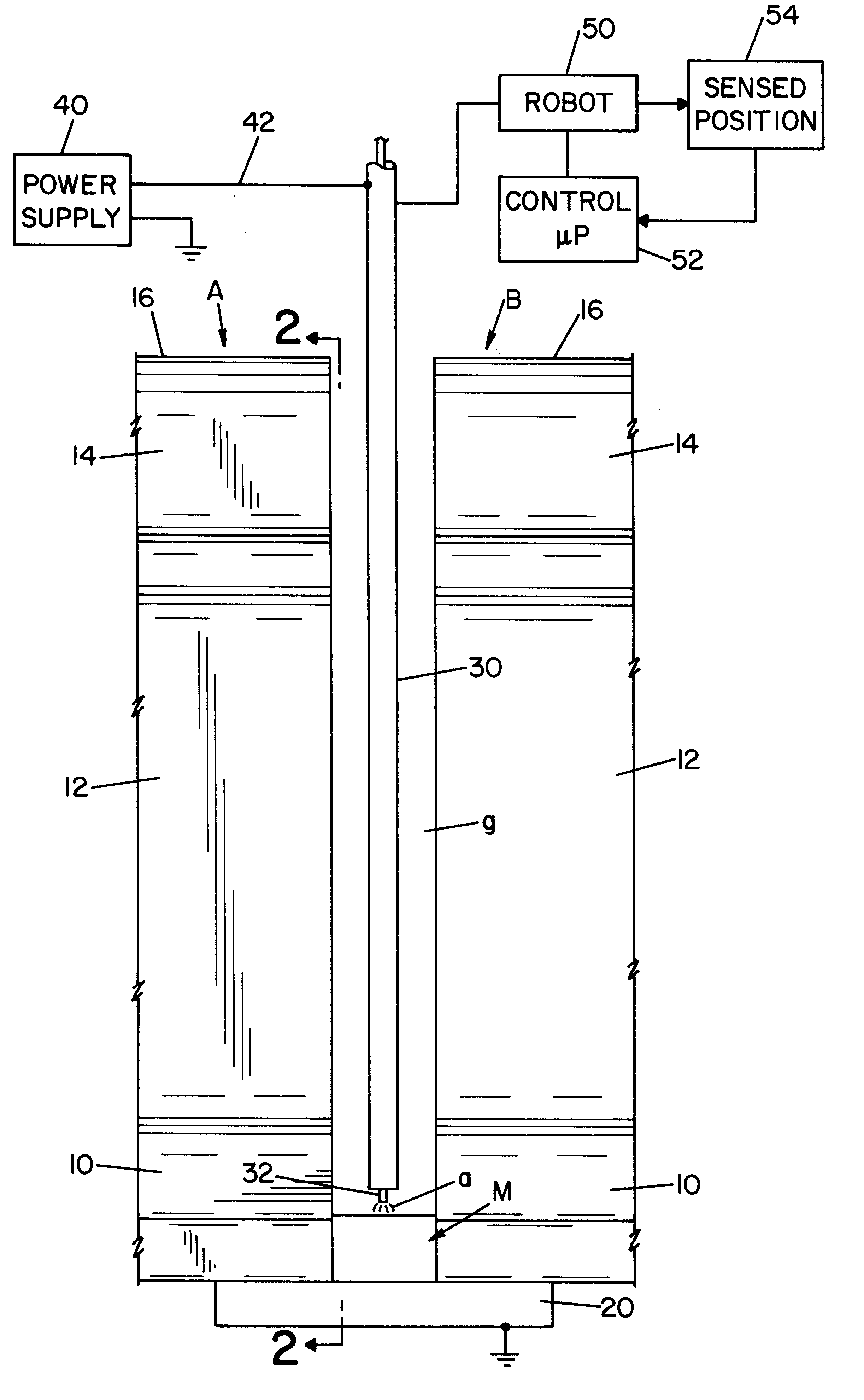

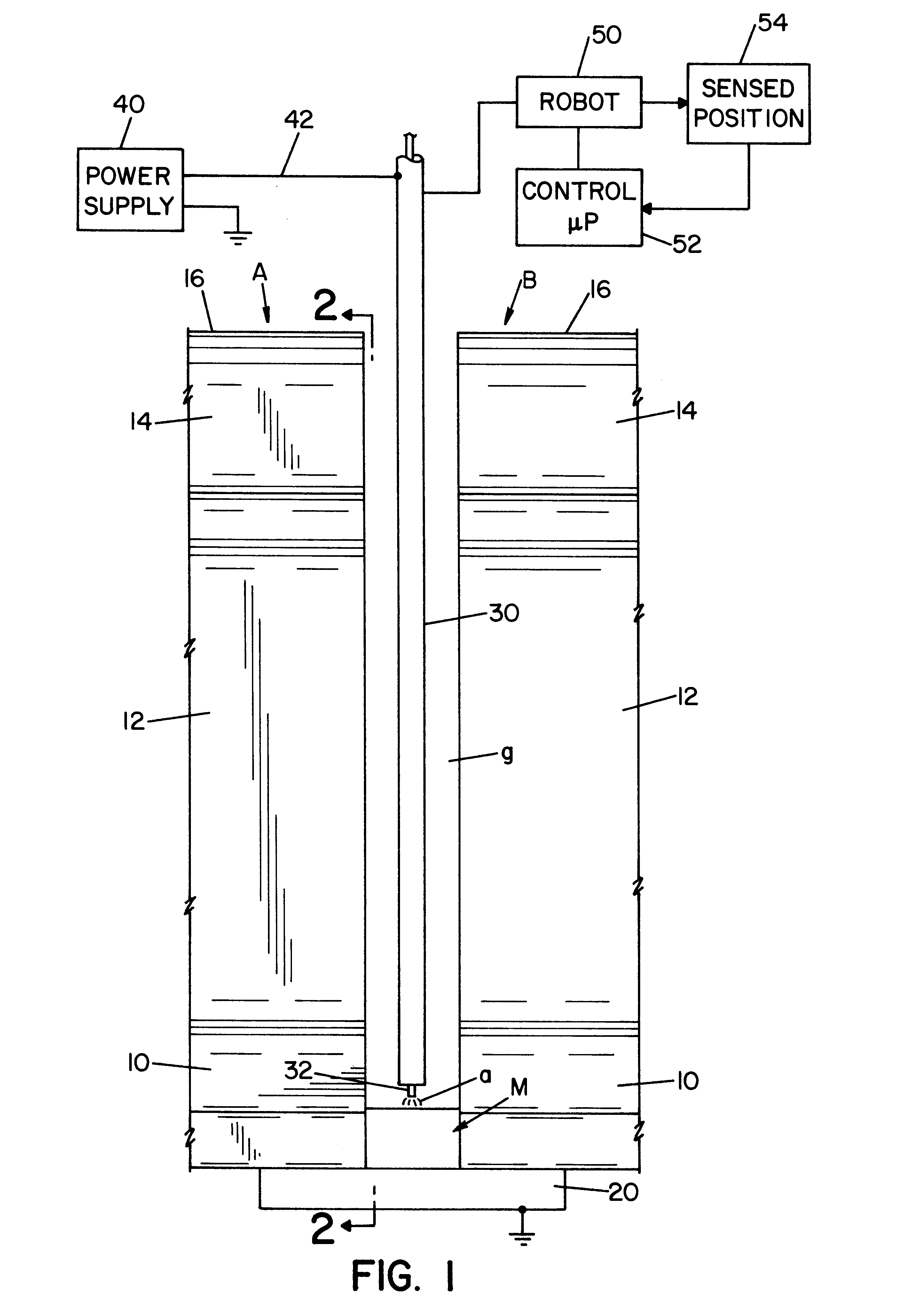

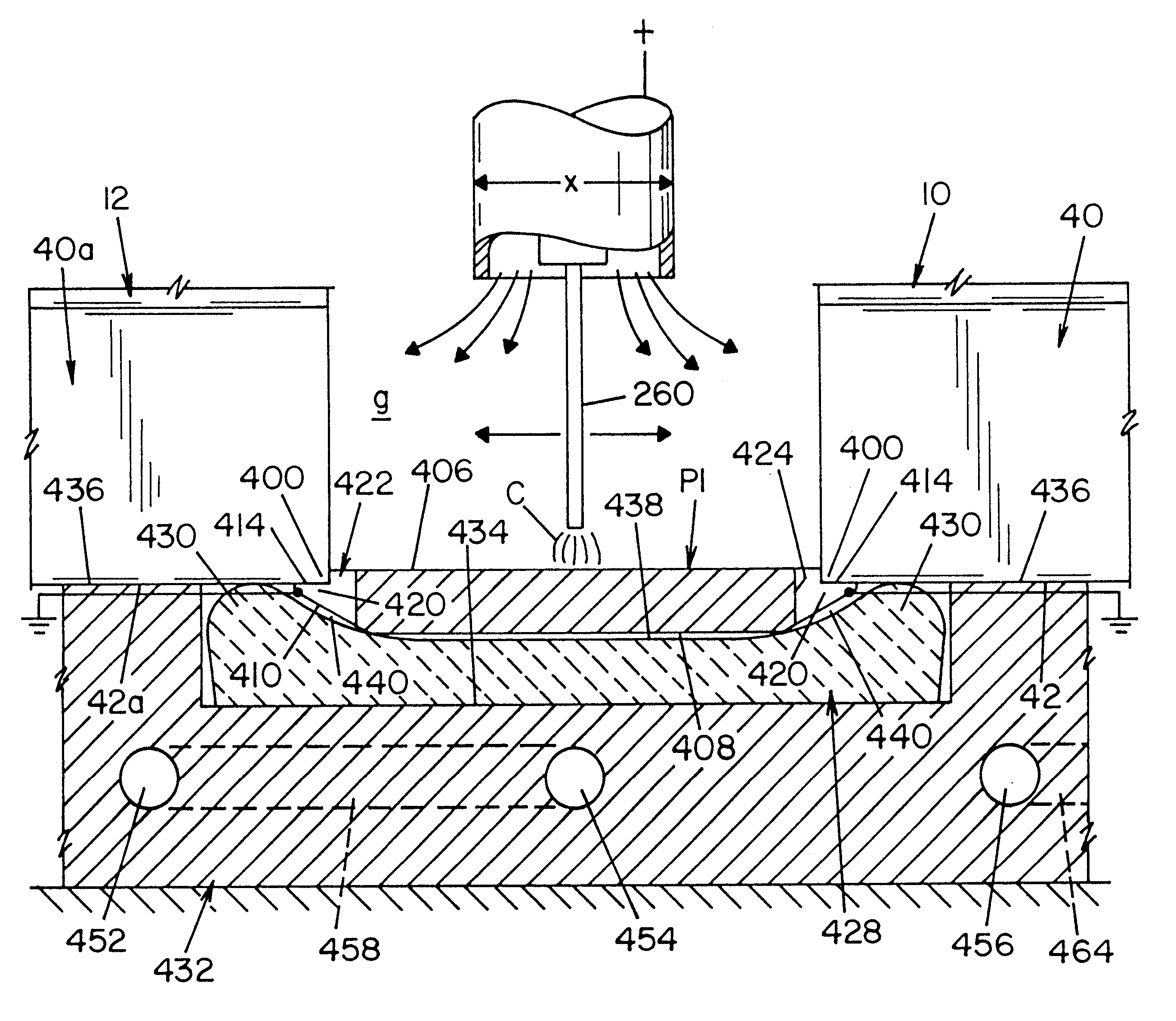

Method and system for welding railroad rails

A method and system for automatically filing the narrow gap between facing end walls of adjacent first and second railway rails by depositing vertically spaced layers of molten metal in the gap with an electric arc welding torch using a robotic mechanism that moves the torch in a pattern controlled by a low level robotic execute program from a spatial position to a next spatial position, said method and system comprising: constructing a data array for a specific gap, said array constituting a series of positions making up an idealized progression of said torch to fill said gaps in vertically spaced layers made up of multiple positions, each of said fixed positions identified by at least four coordinates, including (1) at least x, y and z, (2) the layer in which said position is a part and (3) the welding parameters to be executed while said torch moves toward the next position; outputting data relating to a specific position from said data array; processing said welding parameters associated with said outputted data using said robotic execute program; then, outputting the new fixed data relating to the next position in said series of points; processing said welding parameters associated with said new data using said robotic execute program; and, repeating said outputting and processing acts until said positions in said data array relating to a specific layer have been processed. Thereafter the method or system repeats the layer or processes the next layer comprising multiple stored positions.

Owner:LINCOLN GLOBAL INC

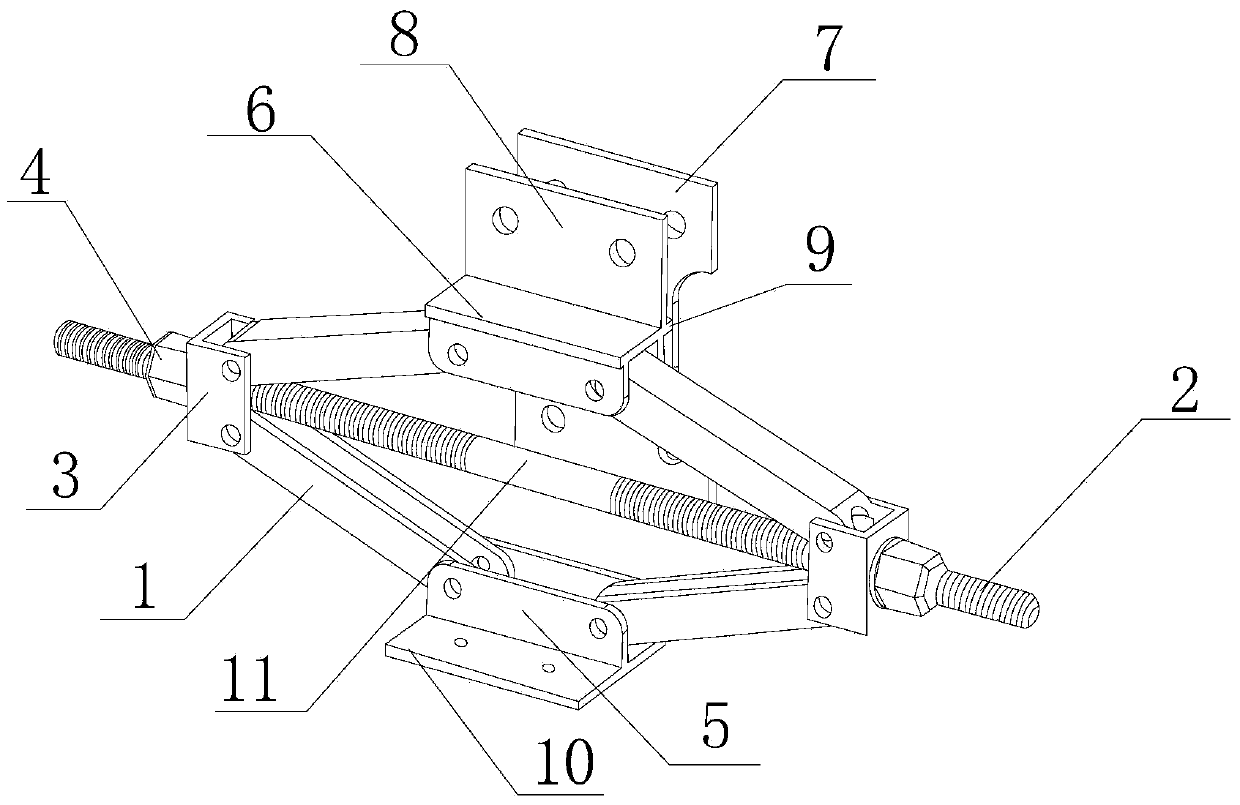

Ballastless track board lifting support

ActiveCN103434970AAvoid damageLower the altitudeLifting devicesRailway track constructionEngineeringTruck

The invention relates to the field of communication and transportation, in particular to a ballastless track board lifting support. The ballastless track board lifting support comprises a threaded rod, a plurality of buckles, two fixing nuts matched with the threaded rod, and four supporting rods made of channel steel; the ends of two adjacent supporting rods are rotationally connected with one buckle, and the four supporting rods are connected end to end in sequence to form a quadrilateral supporting frame; the lengths of two adjacent supporting rods in the supporting frame are the same; the threaded rod penetrates through two through holes in one group of the symmetrical buckles in the support at the same time to be connected with the through holes in a sleeved mode, and the two fixing nuts are arranged at the two ends of the threaded rod to be used for positioning the two buckles; in another group of vertexes, one vertex is fixed onto a base board through one buckle, and the other vertex is fixed onto a truck board through one buckle. According to the ballastless track board lifting support, concentrated stress on the damaged track board in a lifting process is reduced, and therefore the possibility that the track board is damaged in a lifting repair process is further reduced.

Owner:SOUTHWEST JIAOTONG UNIV

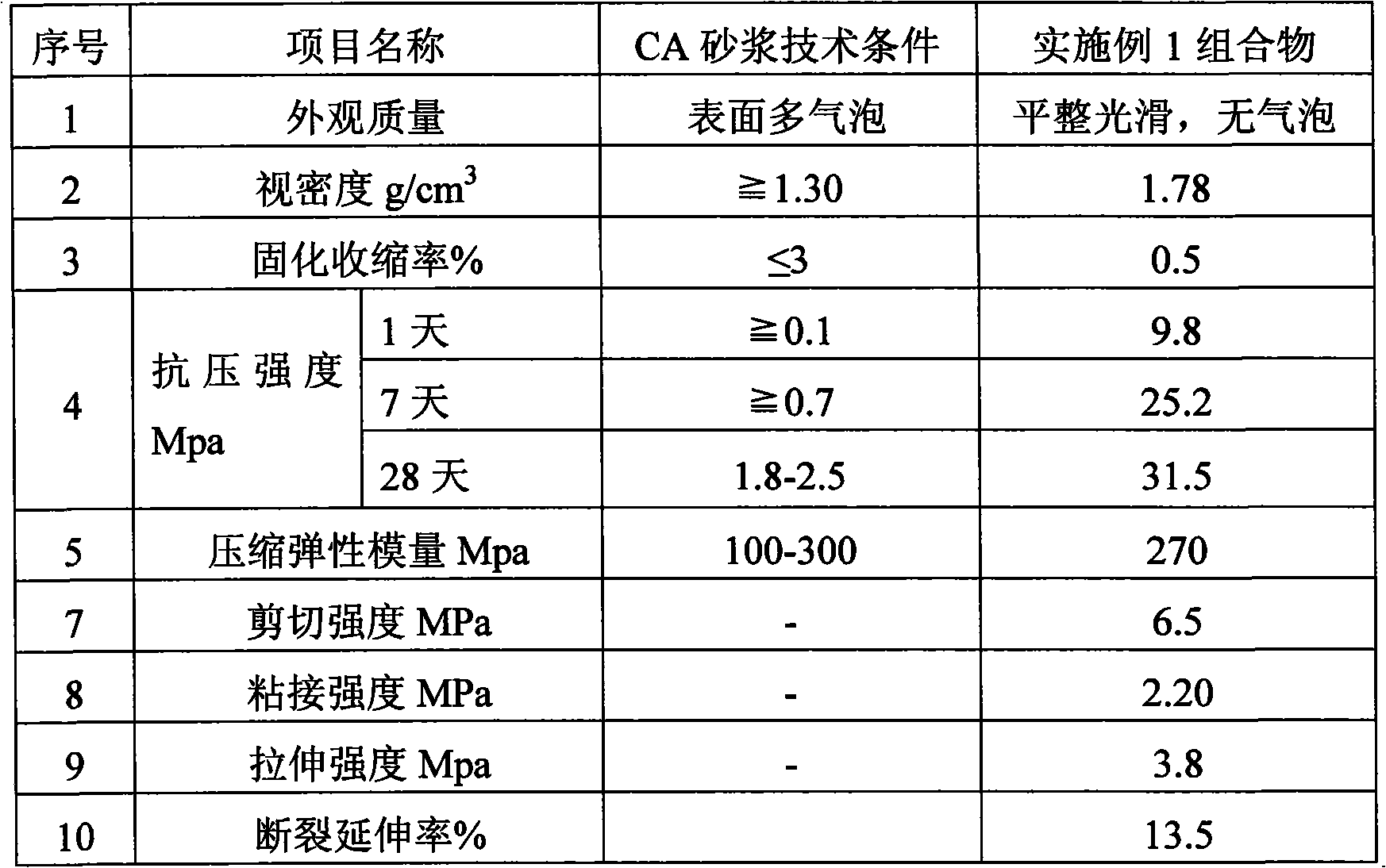

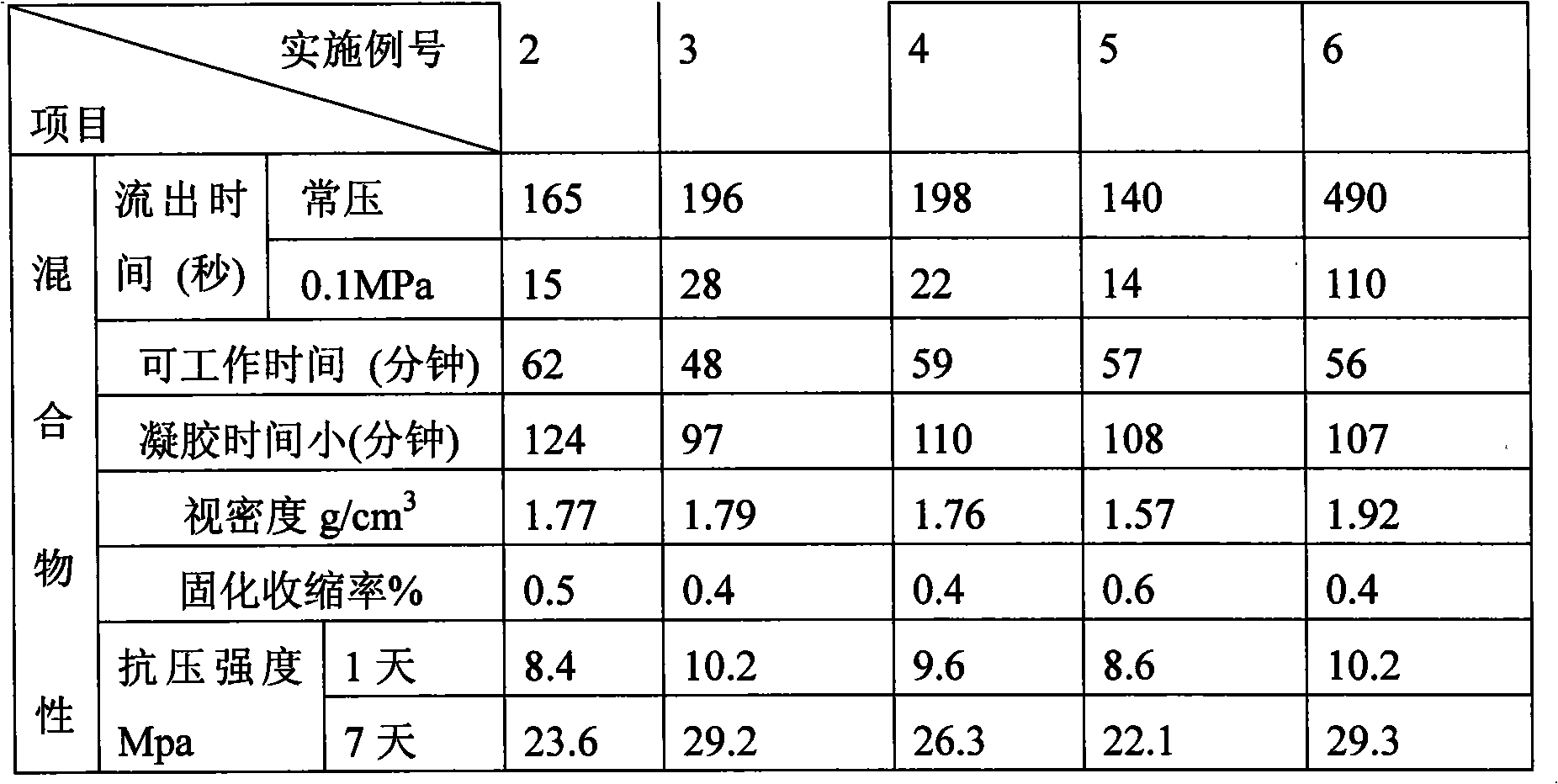

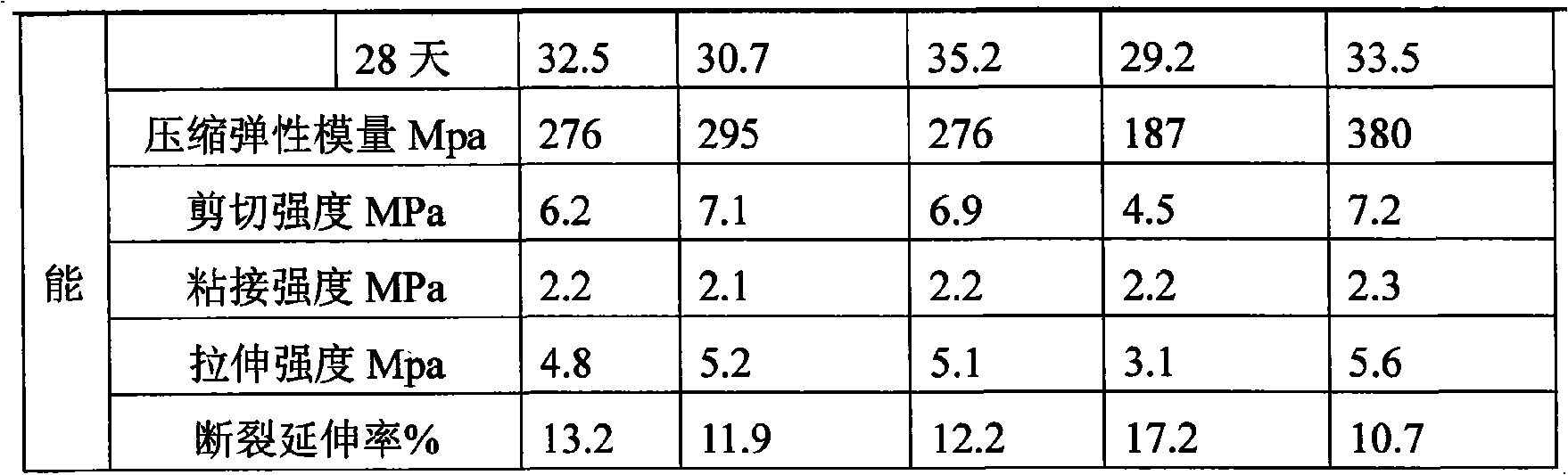

Epoxy resin mortar composite used for plate type fragment-free track

The invention discloses an epoxy resin mortar composite and an application of the composite for a filling material of railway plate type fragment-free track elastic adjusting layer, the epoxy resin mortar composite is composed of A, B and C three parts of materials, wherein part A is composed of the following materials according to parts by weight: 80-100 parts of epoxy resin, 1-10 parts of paint, 0-100 parts of diluent, 0-50 parts of toughening agent, 0-5 parts of ultraviolet absorbent, 0-5 parts of antioxidant, 0-2 parts of antifoaming agent and 0-5 parts of coupling agent; part B is curing agent; part C is filler, and the weight ratio of A, B and C parts is 80-100:5-100:50-600. Detection shows that the epoxy resin mortar composite provided by the invention has, for cement components, excellent adhesion stress, strong wet-heat aging resistance and chemical corrosion resistance and better elasticity and mechanical strength, thereby satisfying requirements of different climatic conditions and different construction conditions.

Owner:CHANGSHU JIAFA CHEM

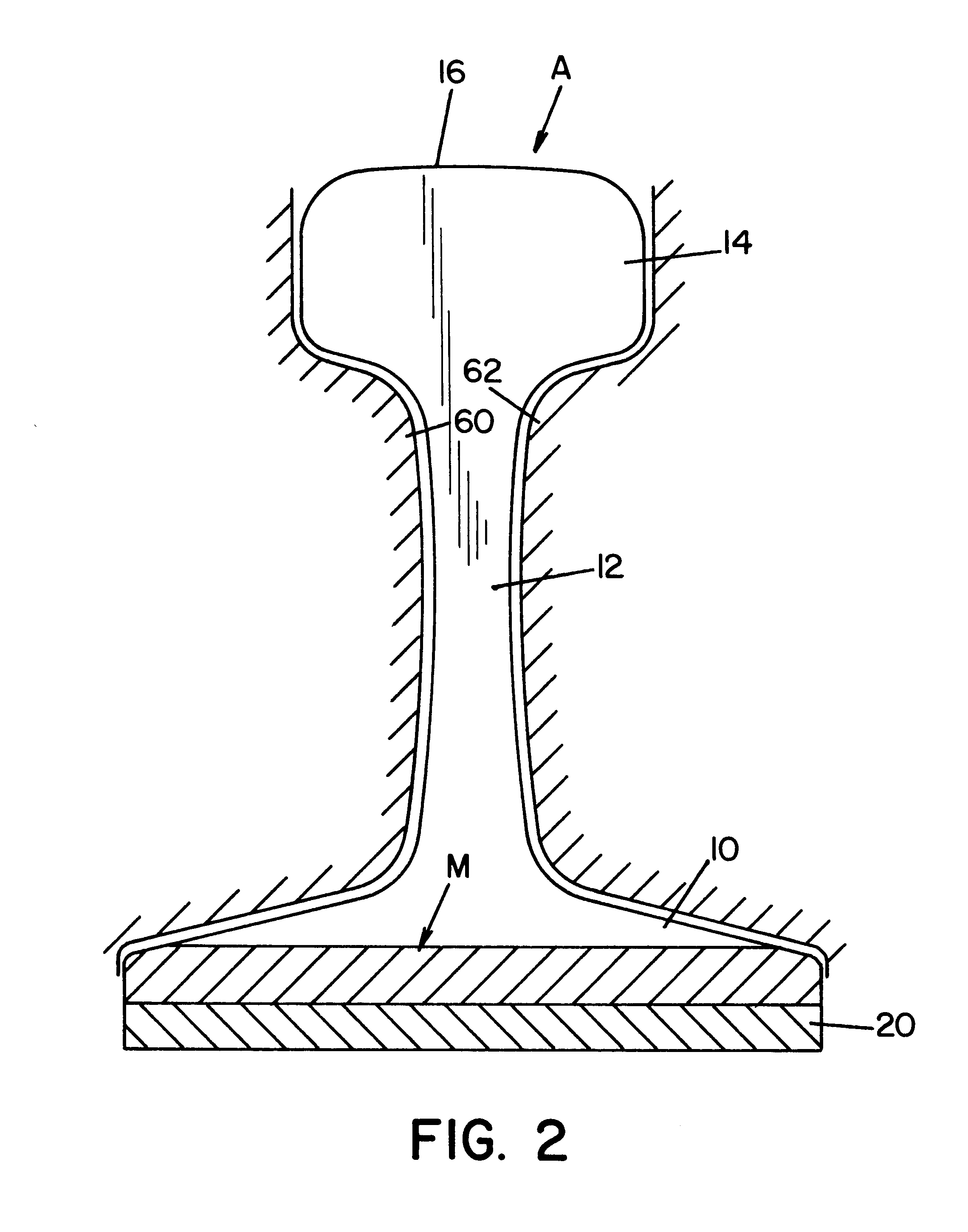

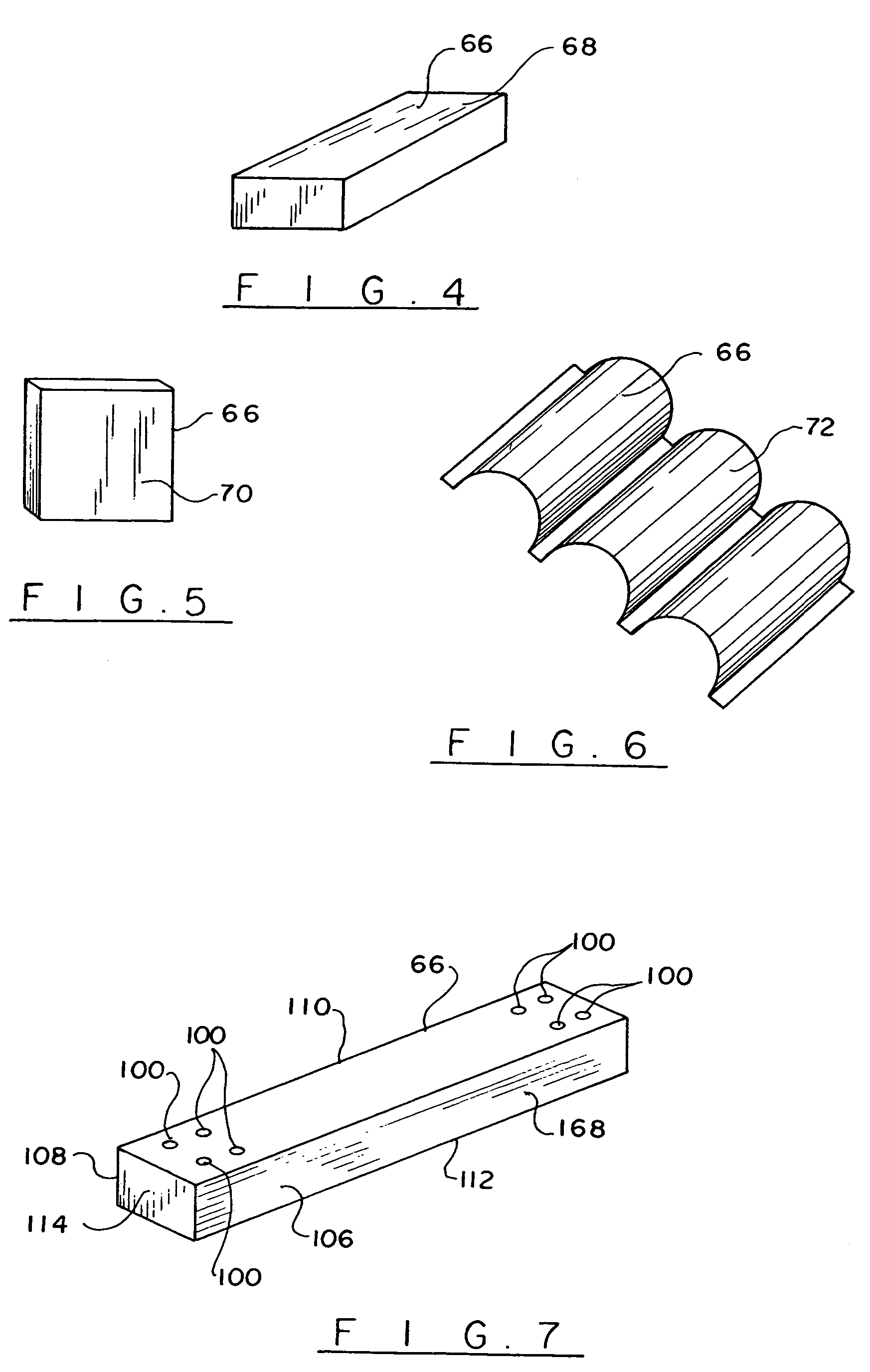

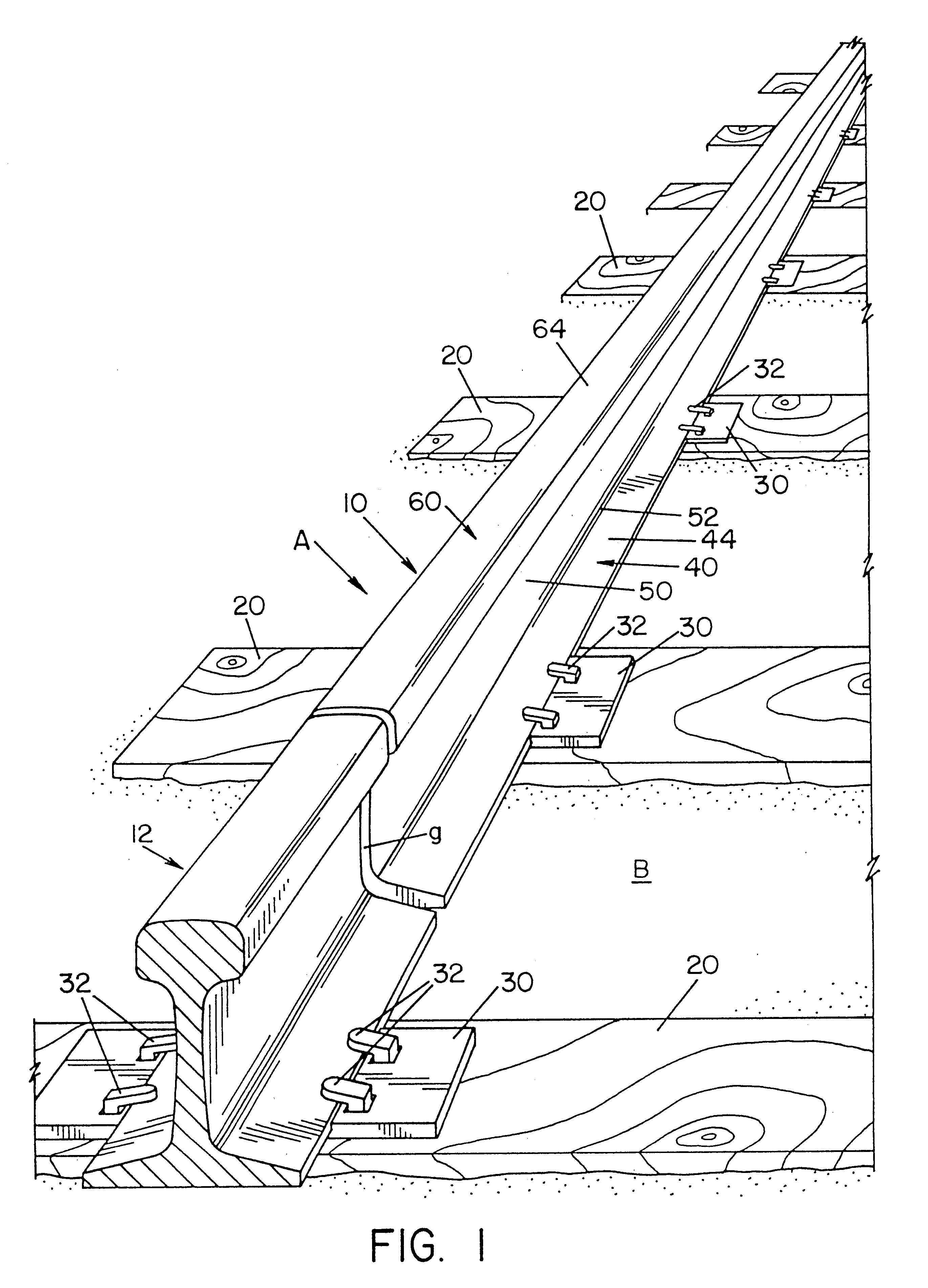

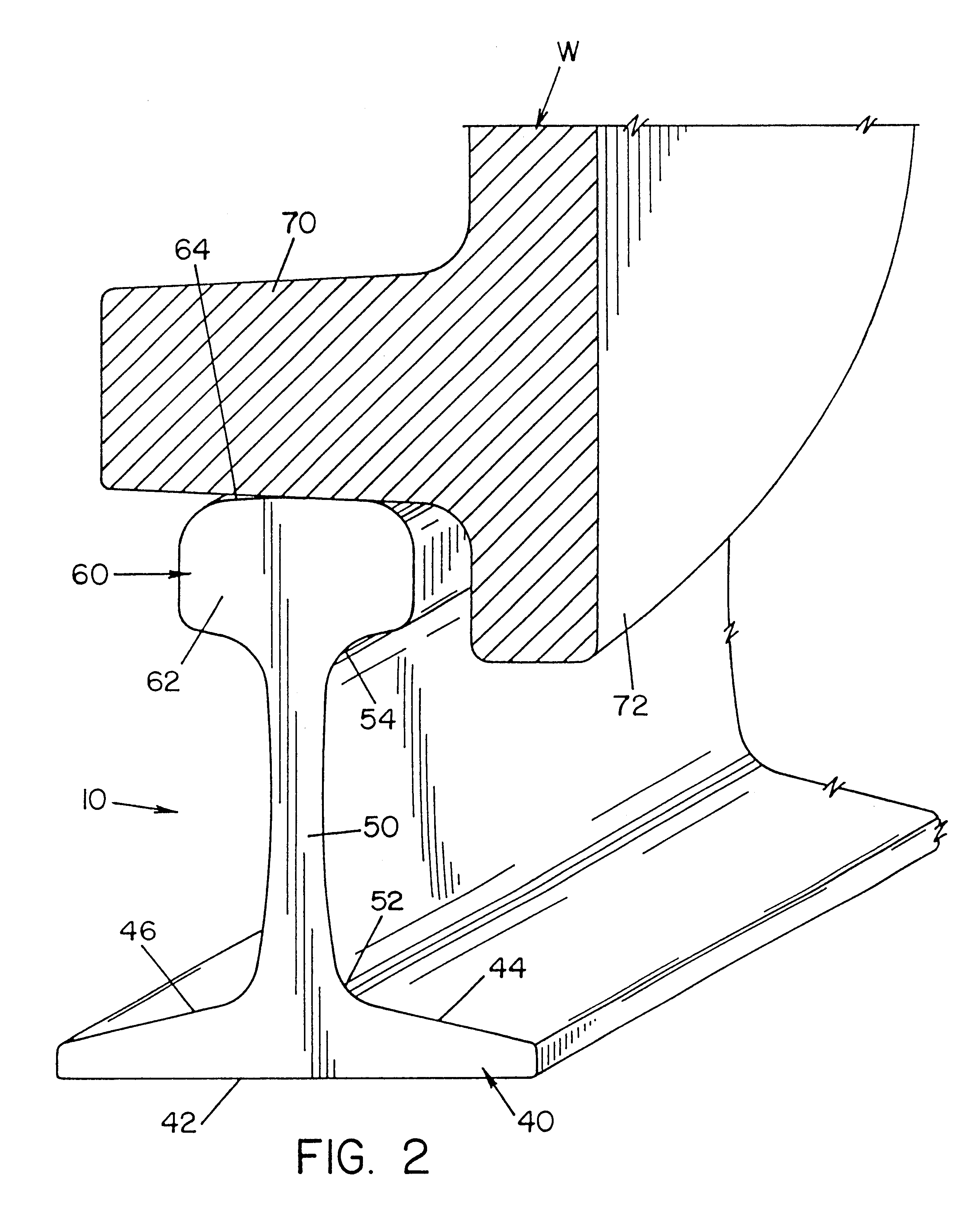

Composite railway crosstie, shaped like an I beam

InactiveUS6247651B1The implementation process is simpleBallastwayPlastic recyclingElectrical and Electronics engineeringEngineering

A railway crosstie is adapted for use in a track system having a pair of rails supported on longitudinally spaced crossties. The railway crosstie includes an I-beam member made of a combination of recycled materials.

Owner:FLANNER JR GEORGE C

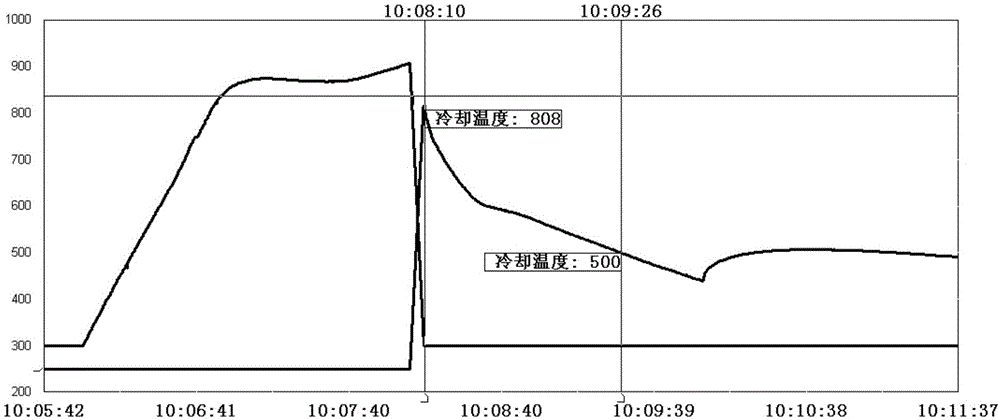

Method for post-weld heat processing of rail welded joint

ActiveCN106544933AGood toughness matchReduce internal defectsFurnace typesRailway track constructionEngineeringTread

The invention relates to the field of rail welding and discloses a method for post-weld heat processing of a rail welded joint. The method comprises the steps that first cooling is conducted to the to-be-cooled rail welded joint obtained through welding till the temperature is lower than 400 DEG C; then, the rail welded joint obtained after the first cooling is heated to a temperature between 860 DEG C and 930 DEG C; and second cooling is then conducted to the rail welded joint till a tread face temperature of the joint is between 410 DEG C and 450 DEG C, wherein the rail welded joint is a welded joint of a 75kg / m hypereutectoid steel rail and a pearlite steel rail. The method disclosed by the invention is used for the post-weld heat processing of the welded joint of the hypereutectoid steel rail and the PG4 heat-processing steel rail; and the heterogeneous rail joint has fewer internal defects and stable welding quality, and can satisfy requirements for passing tests such as a fatigue test, a stretching and impact test and a static bending test.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Fluid operated torque tool for and a method of tightening a nut on a plate on railroad crossings

A fluid operated torque tool tightens a nut through a spring washer on a plate on a railroad crossing, and has a housing, two coaxial drives applying equal turning forces in opposite directions around an axis, with one of the two coaxial drives located around the other of the two coaxial drives, a first socket attached to the one coaxial drive and configured to fit on the rectangular plate, and a second socket attached to the other coaxial drive inside the first socket and configured to fit on the nut, with the washer being not engaged by the sockets, so as to tighten the nut and to tighten up the spring washer onto the plate while the first socket and the housing stand still.

Owner:HYTORC DIV UNEX CORP

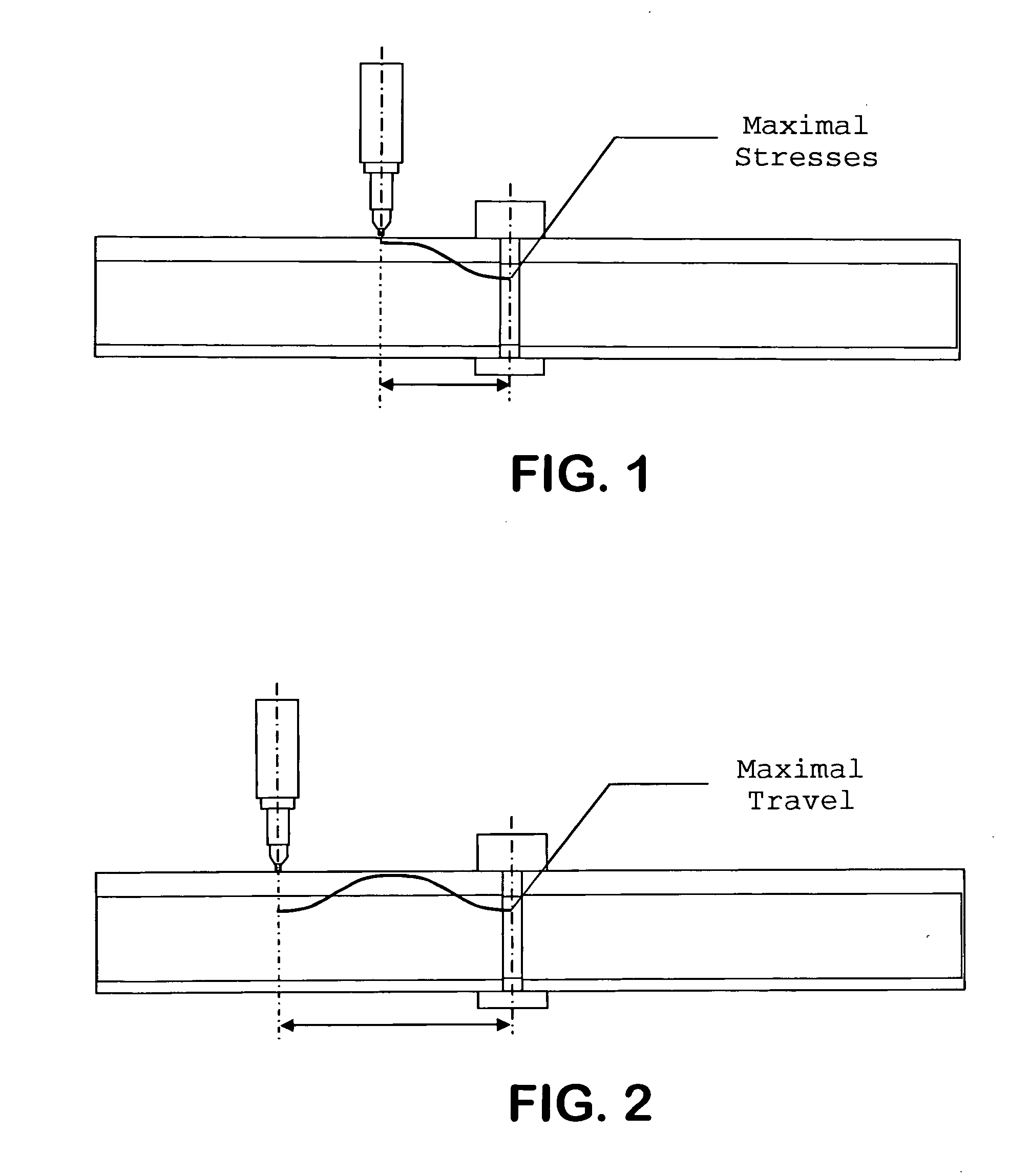

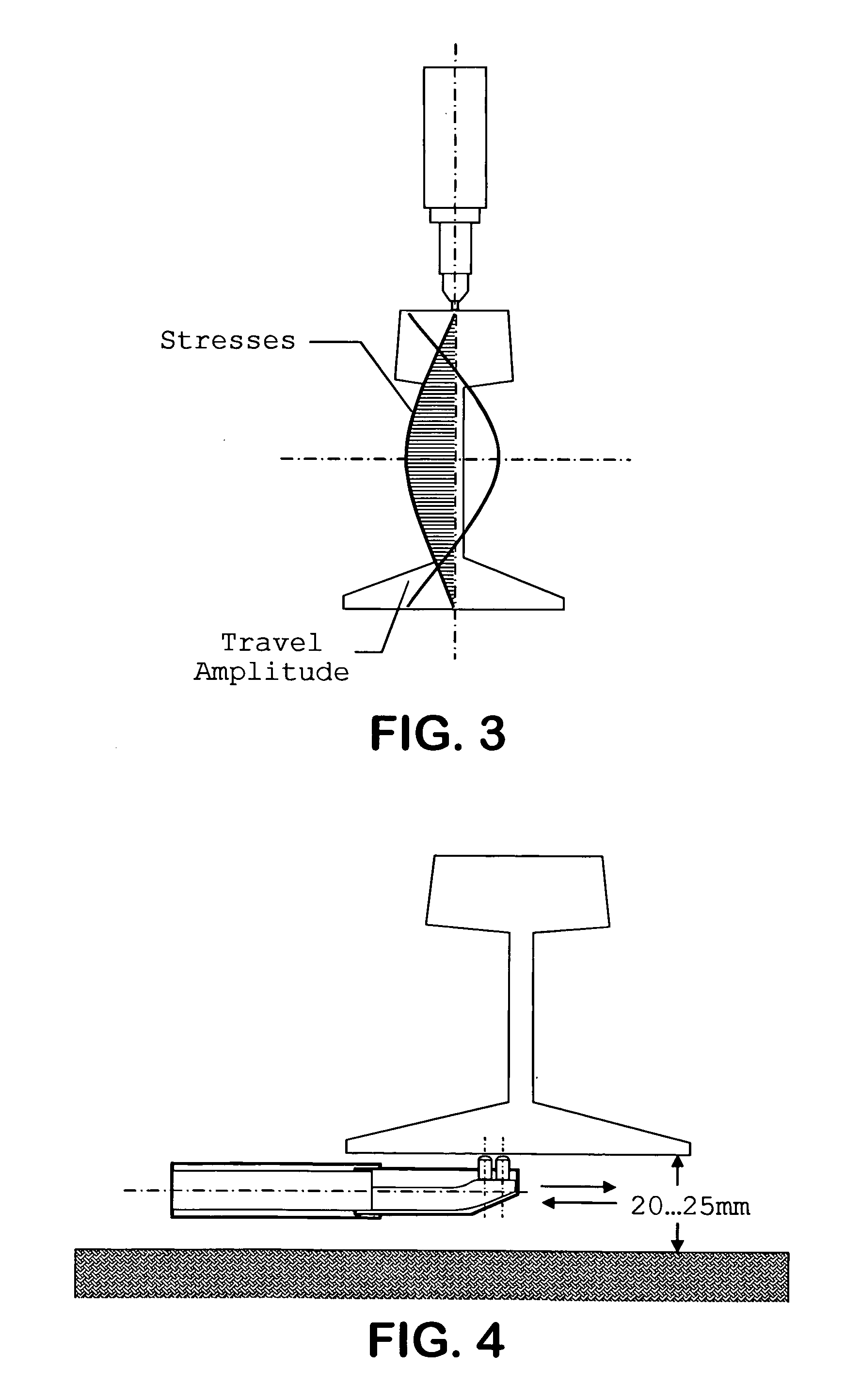

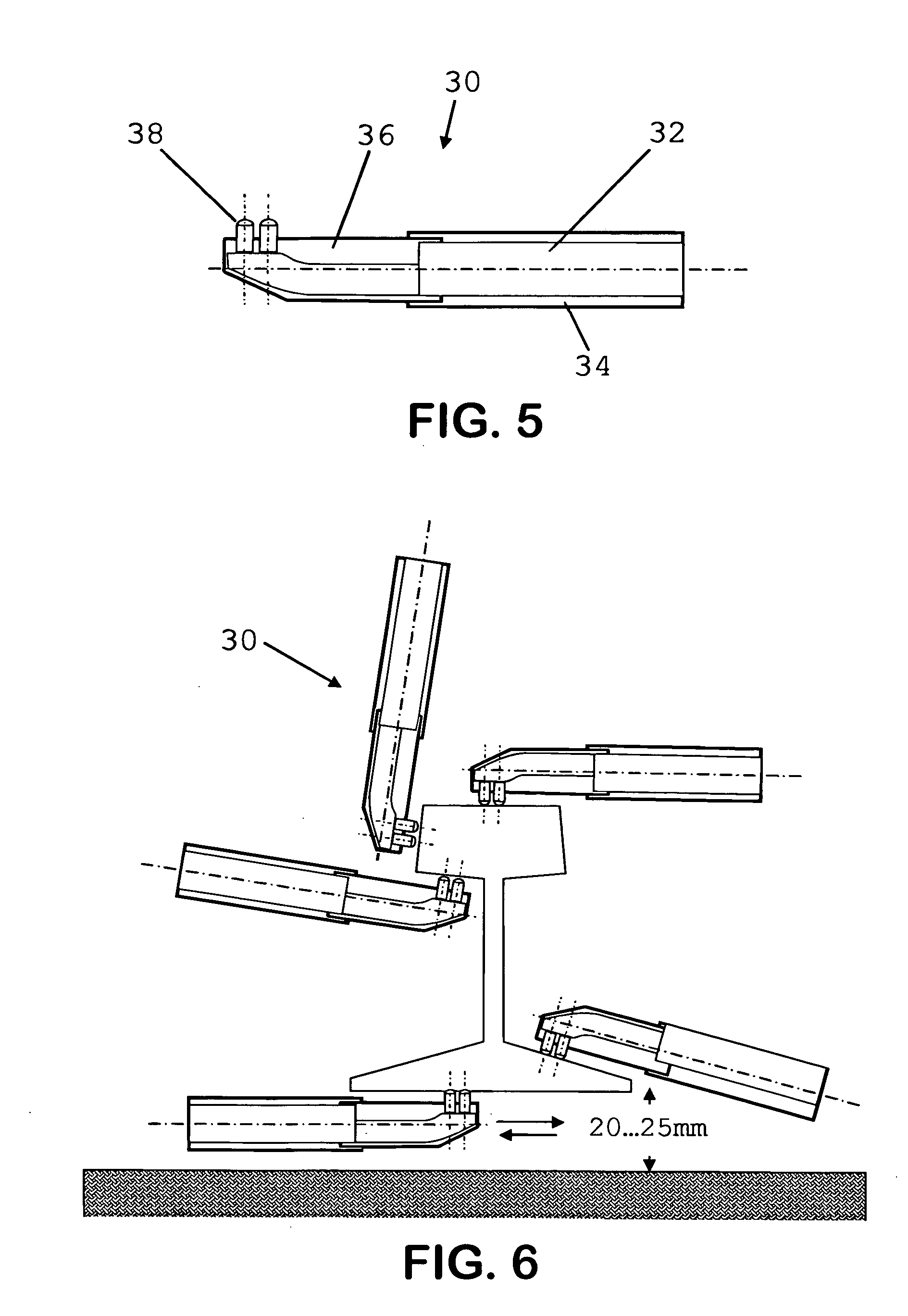

Method of improving quality and reliability of welded rail joint properties by ultrasonic impact treatment

InactiveUS20060016858A1Improving statistical reliabilitySolution to short lifeRailsCooking-vessel materialsIncreased fatiguePulse energy

A method for improving the performance of sections of rails joined together by welding by reworking welded joints utilizing an ultrasonic impact treatment (UIT) process either before welding, during welding, after welding or during repairs of used rails, including treatment of a joint, around a joint and / or length of a rail, in order to increasing fatigue life and / or other properties of welded rail sections is disclosed. The method provides reduction of stress defects and redistribution of internal stress patterns in the vicinity of weld seams of rails. The UIT provides periodic pulse energy impact treatment with surfaces in welded rails to induce internal compression waves inducing a metal plasticity state in the vicinity of the weld seam of the rail or in the rail itself.

Owner:UIT LLC

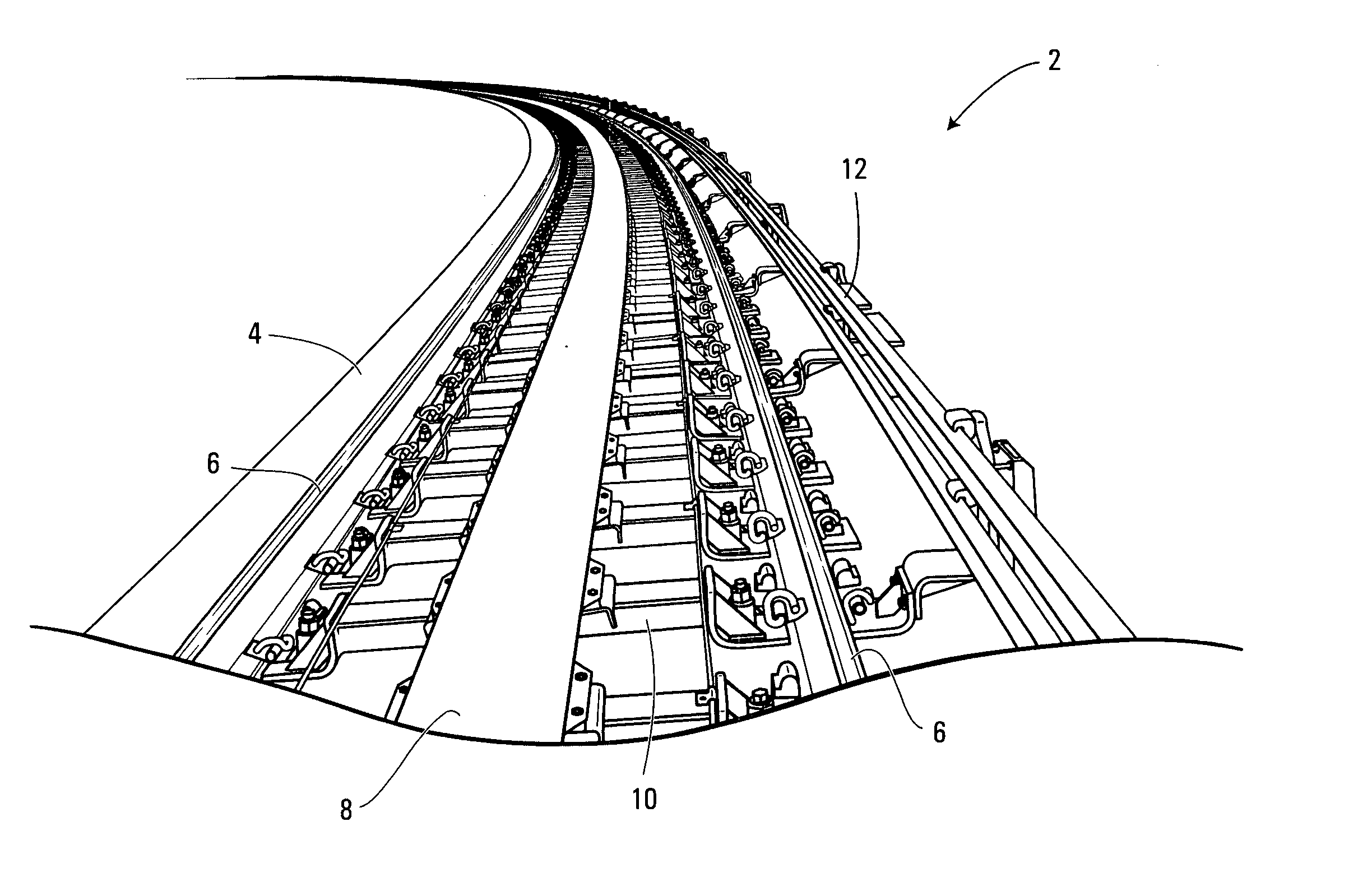

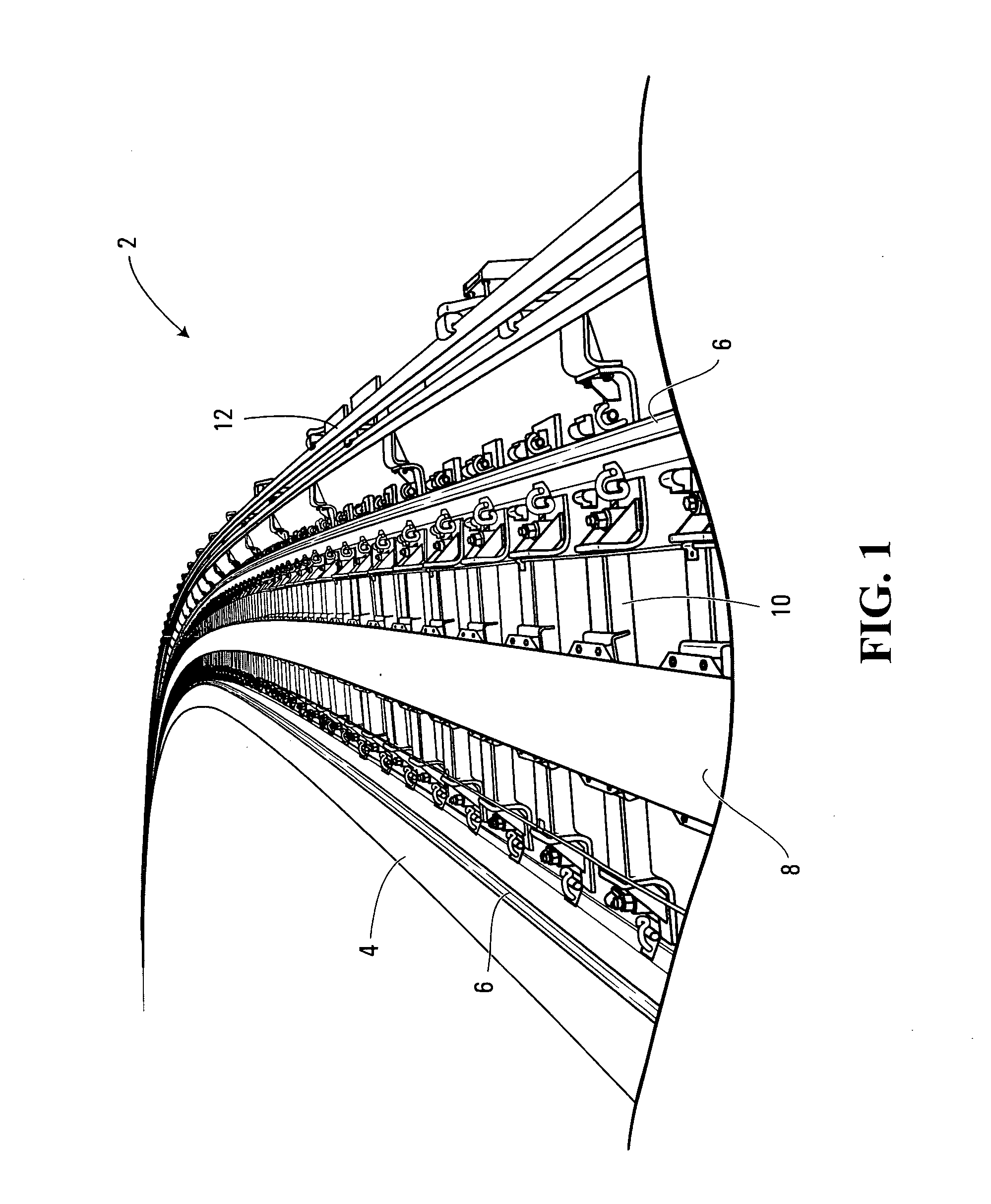

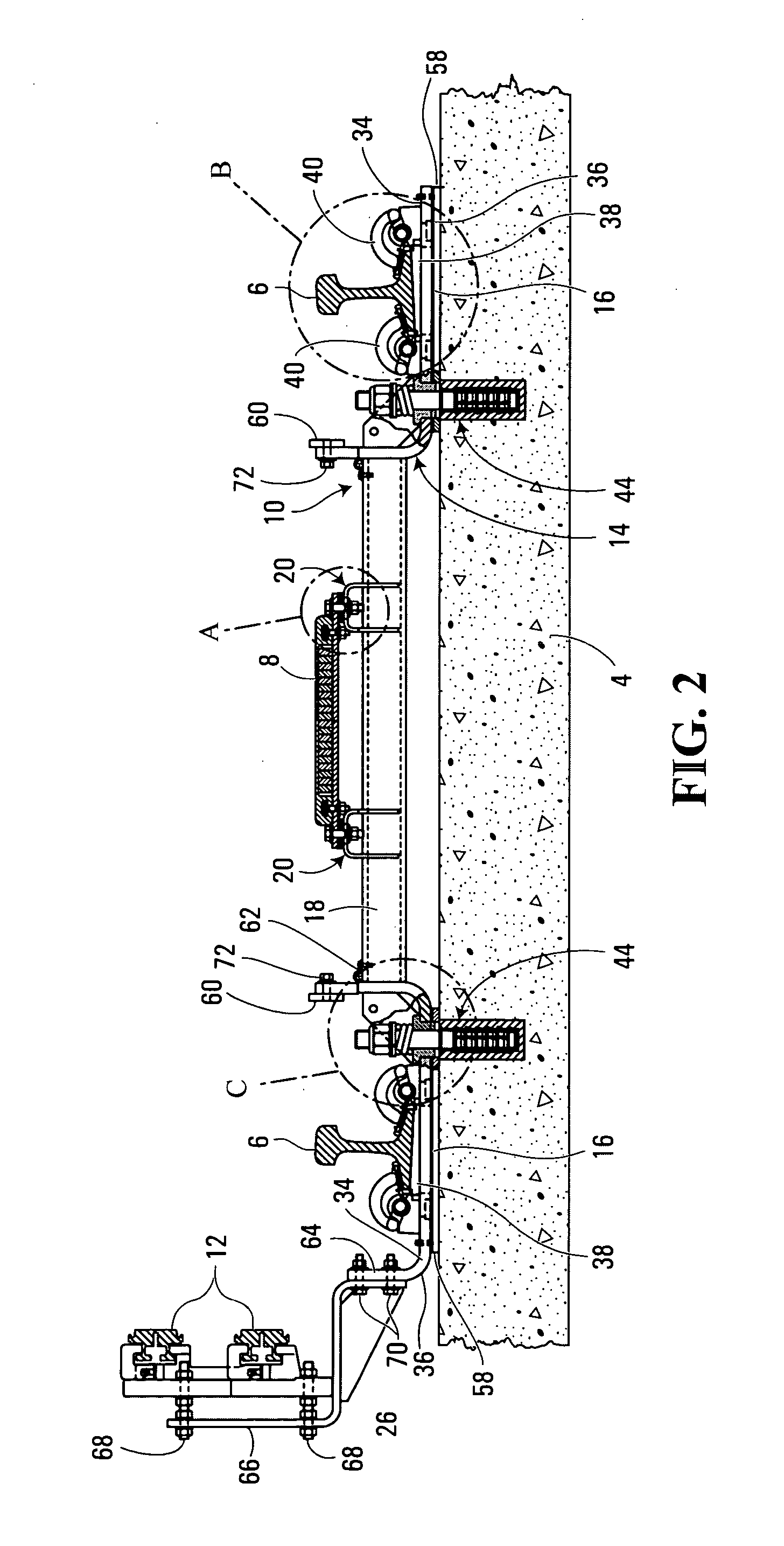

Method and system for controlling railroad surfacing

InactiveUS20060032063A1Improve accuracyImprove efficiencyBallastwayRailway track constructionControl theoryProjector

A system and method for controlling railroad surfacing is provided. A computerized controller compares desired railroad rail position values with actual railroad rail position values such that a tamper machine raises, lowers, and horizontally moves the rails to correct the alignment of the rails and ties. The system may be used in conjunction with existing shadowboard tamper systems, with the computerized controller receiving precision reference signals corresponding to desired rail position values, and moving projectors according to the difference of the railroad rail position value and desired railroad position value.

Owner:FABRICATION TECH ASSOC INC

Rail track tie

InactiveUS20080083835A1Improve vibration damping effectControl stressBallastwayRail fastenersDynamic stiffnessEngineering

The rail track tie including: a rigid block presenting a bottom face, and a top face for receiving at least one longitudinal rail; a cover for receiving the rigid block and in the form of a rigid shell including a bottom and a peripheral rim around the bottom; and a resilient soleplate disposed between the bottom face of the rigid block and the bottom of the cover. The resilient soleplate has dynamic stiffness k2 lying in the range of 6 kN / mm to 10 kN / mm, and preferably in the range of 6 kN / mm to 8 kN / mm.

Owner:ALSTOM TRANSPORT SA

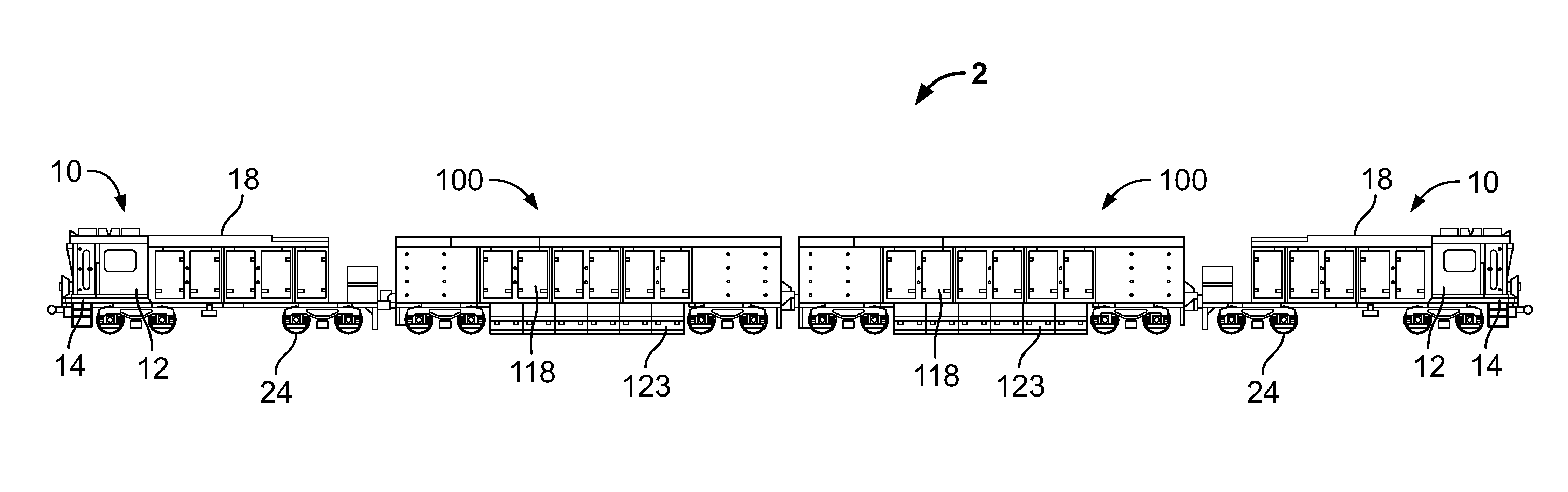

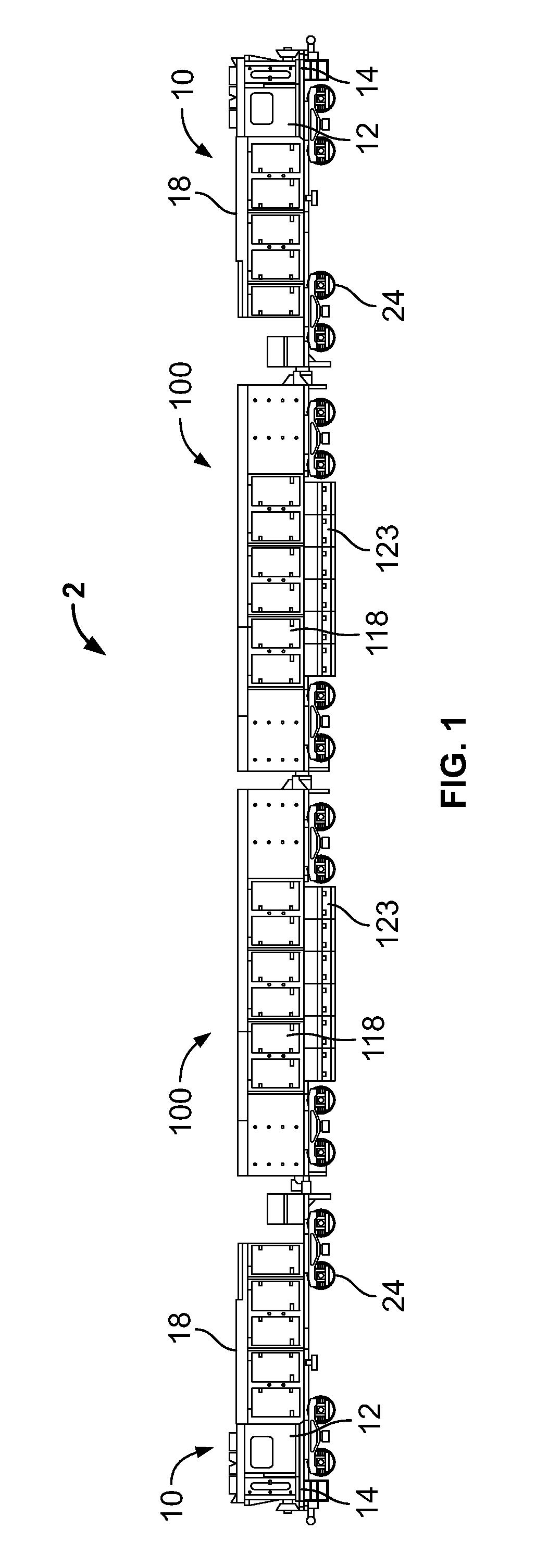

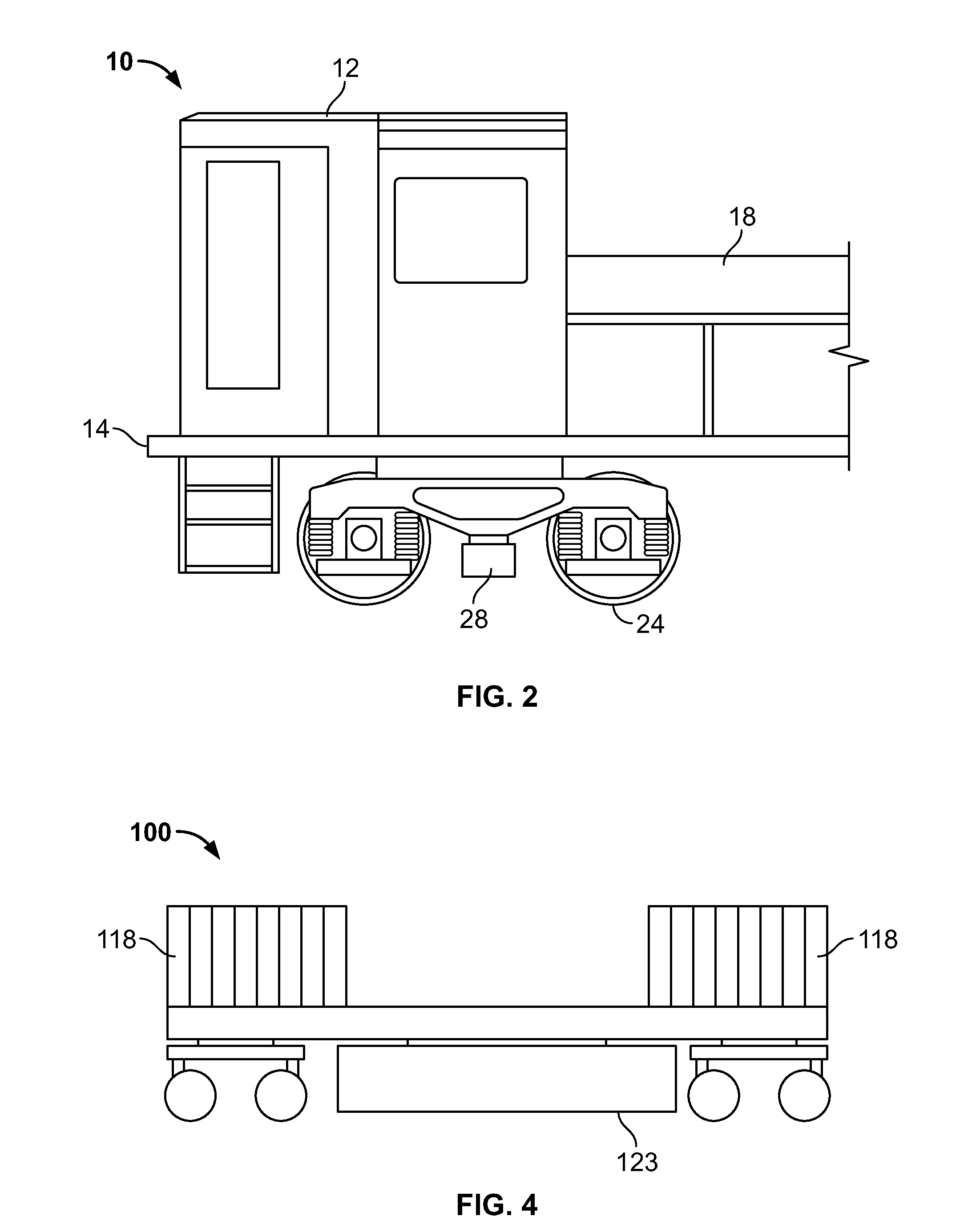

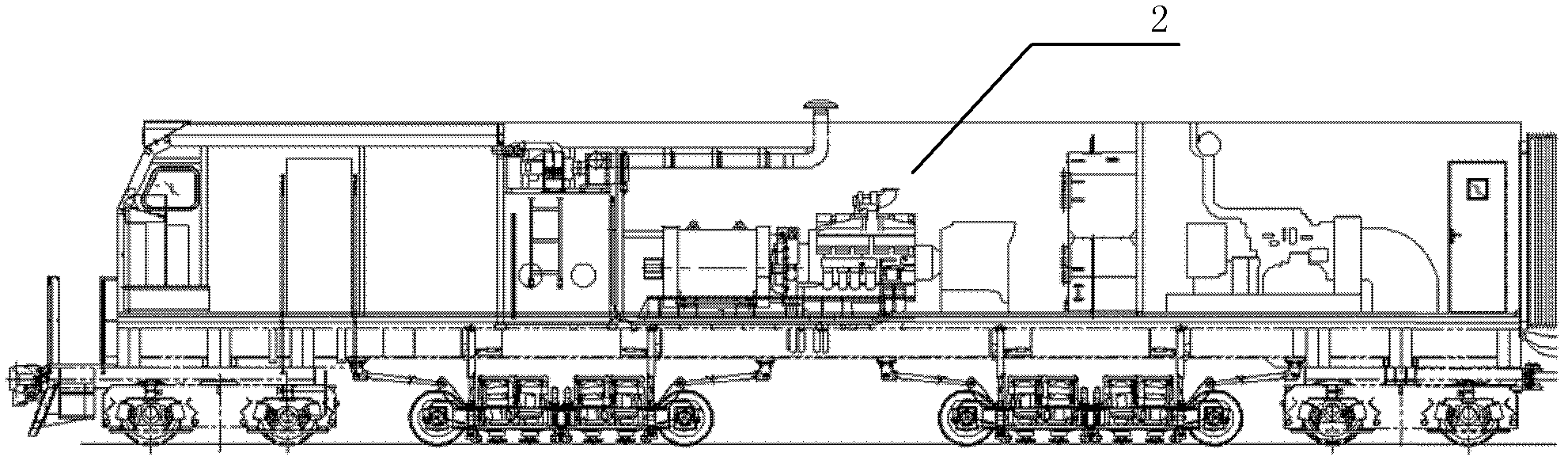

Battery-powered rail vehicle

InactiveUS20110083578A1Eliminate security concernsEliminating the associated environmental and safety issuesBatteries circuit arrangementsDc motor stoppersEnergy storageTraction motor

A rail consist having at least one propulsion car having traction motors and at least one working car having working motors. Energy storage units are provided on the consist to provide power to the traction motors and the working motors. The energy storage units provide sufficient power for work mode, travel speeds and curve characteristics of the consist. The use of the energy storage units provides safety, environmental and operational benefits.

Owner:HARSCO CORP

Cross-tie

Owner:BOMBARDIER TRANSPORTATION GMBH

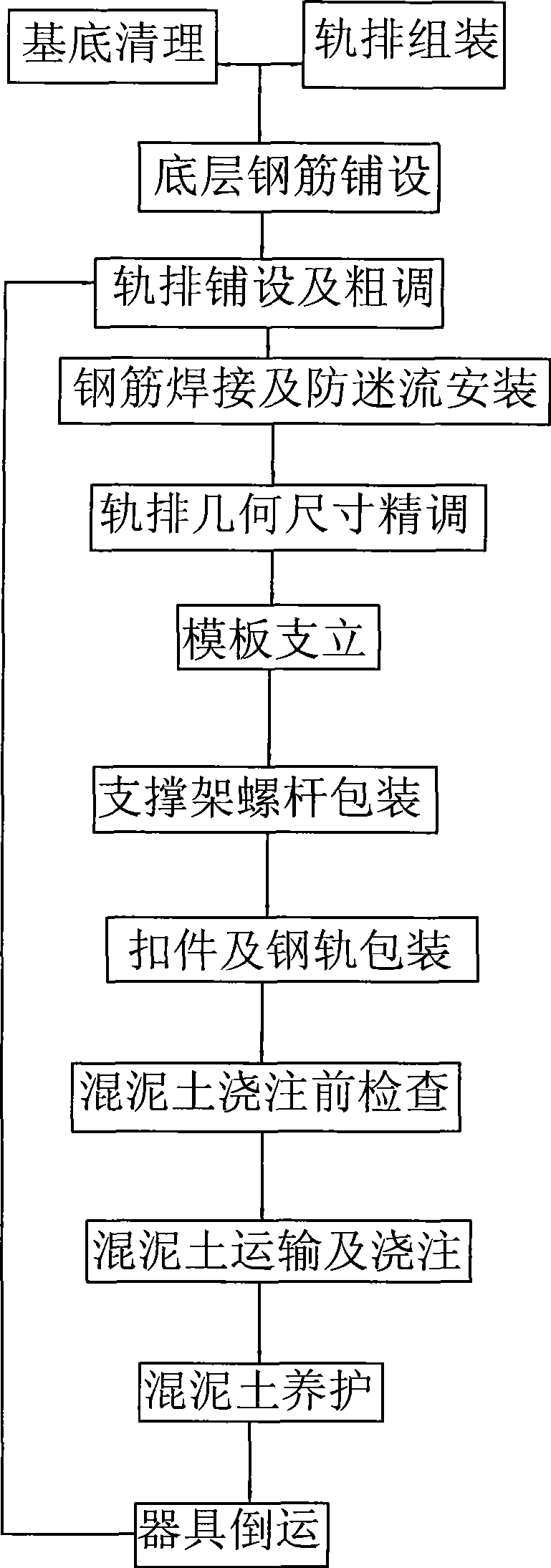

Construction method for two-block unballasted track bed board

InactiveCN101503870AAchieve precise positioningTooling system is simpleRailway track constructionEngineeringRebar

The invention relates to a construction method for a double-block-type ballastless track bed slab, which comprises the following steps: 1, clearing a base surface and performing construction lofting; 2, placing a bottom layer of reinforcing steel bars, and laying sleepers; 3, mounting a tool track and adjusting the sleepers; 4, assembling track panels; 5, coarsely adjusting the track panels; 6, binding the reinforcing steel bars and performing earthing welding; 7, mounting templates and finely adjusting the track; 8, casting concrete into the track bed slab; 9, loosening adjusting devices and fasteners, and curing the concrete; and 10, relocking the tool track and completing the measurement. The construction method has the advantages that: the tool track is adopted as a detection standard, so the precise positioning of the track is realized; a frock system is simple, is easy to process and manufacture, has wide commonality, and is not only suitable for construction of the track bed slab in a subgrade section but also suitable for construction of the track bed slab in a bridge section; the construction process is simple and quick, and various working procedures are easily carried out by flow construction; and the construction cost is low, so the construction investment is effectively saved.

Owner:THE 8TH GRP OF CHINA RAILWAY 1ST ENG CO LTD

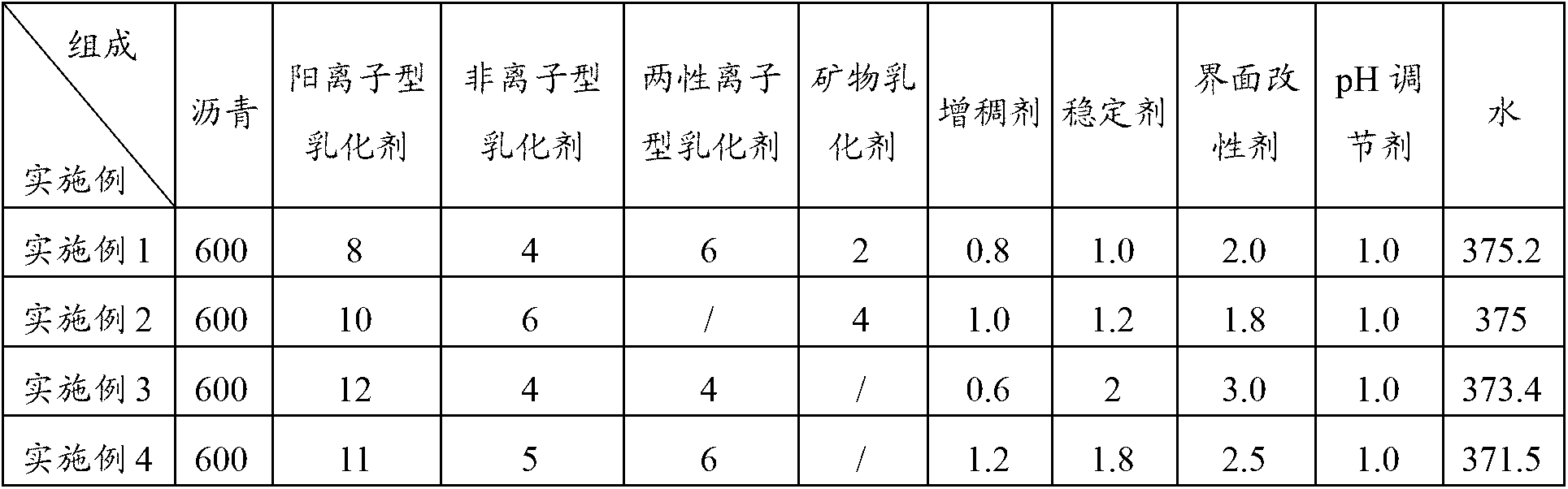

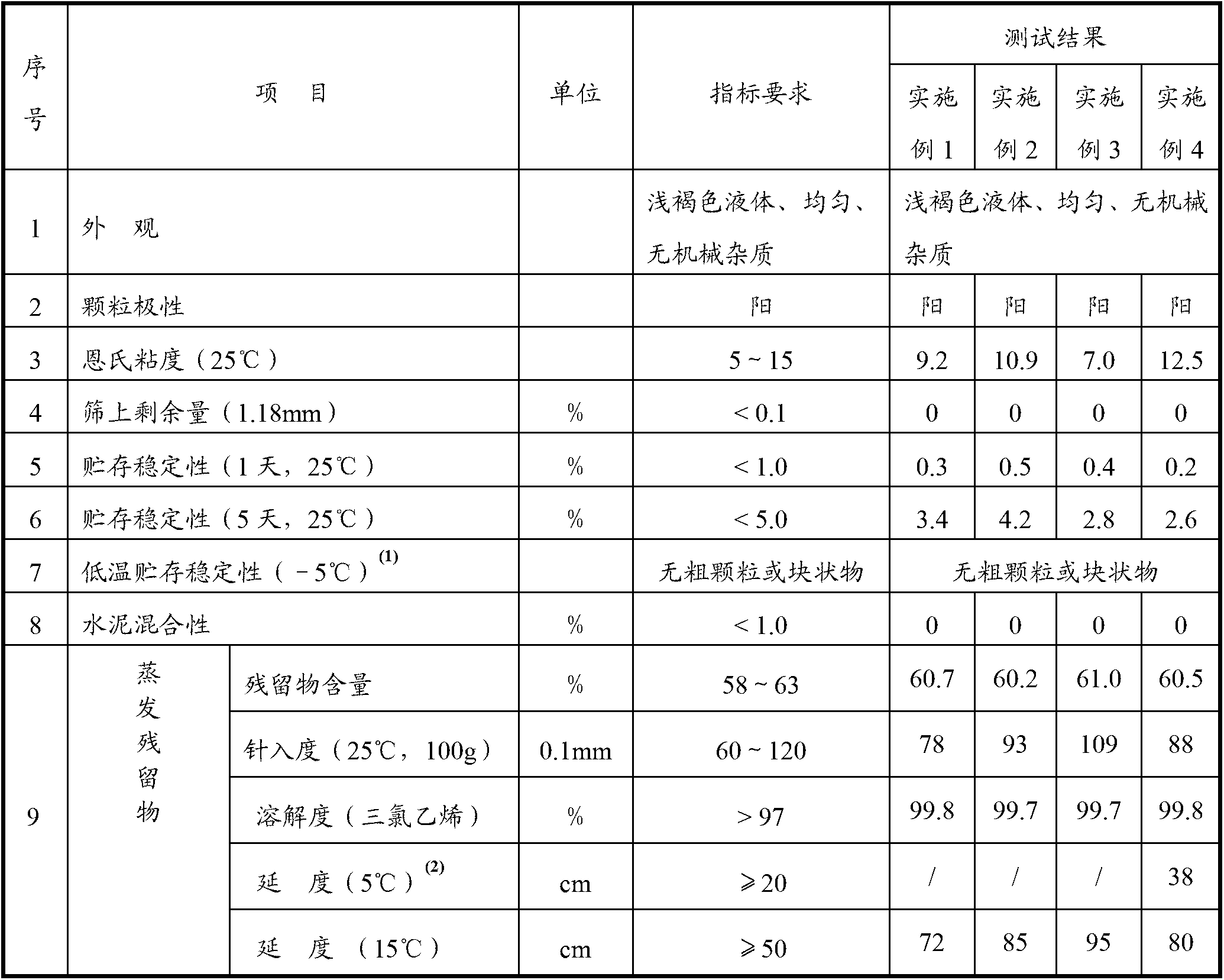

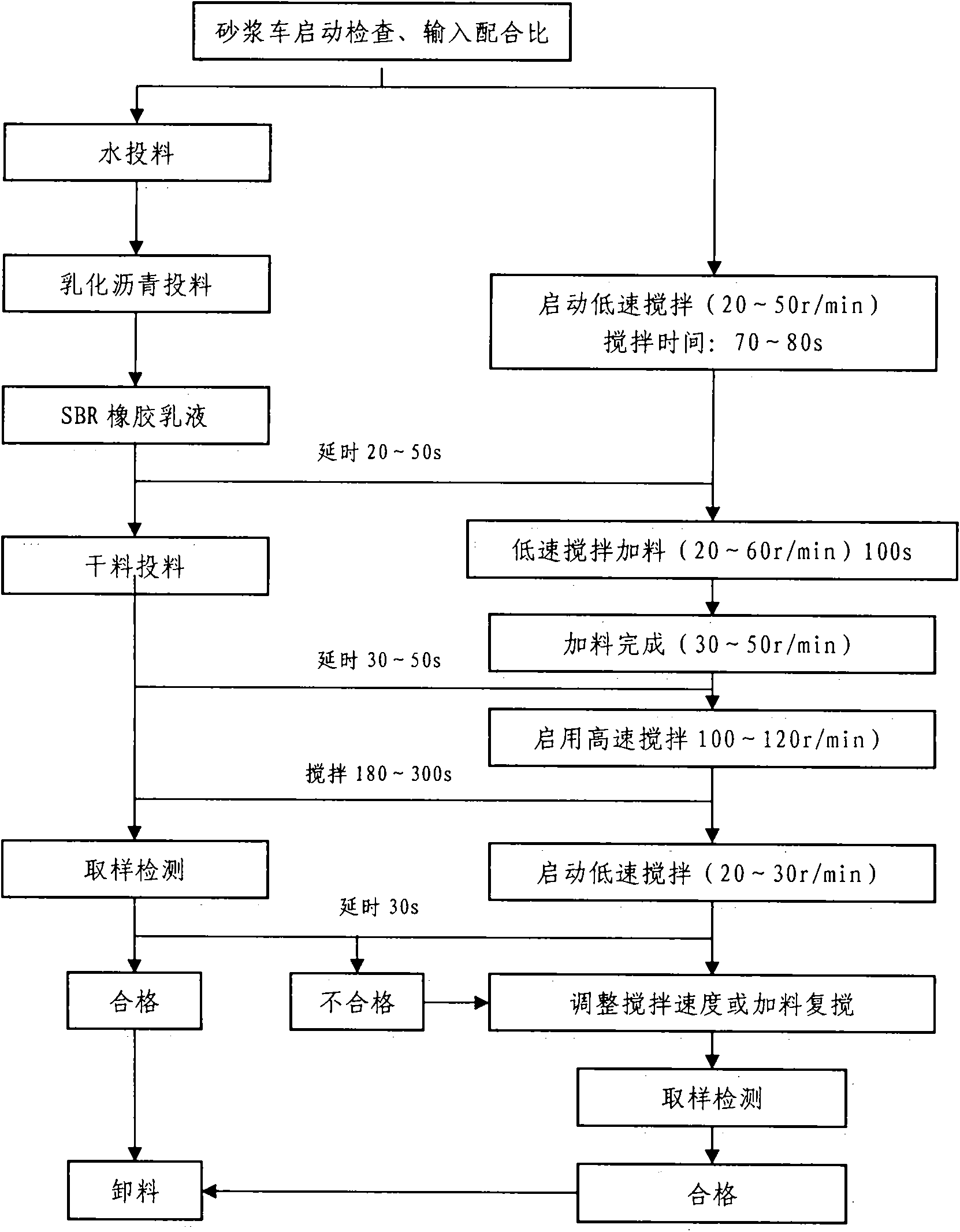

Cement-emulsified asphalt mortar for slab tracks in severe cold areas

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

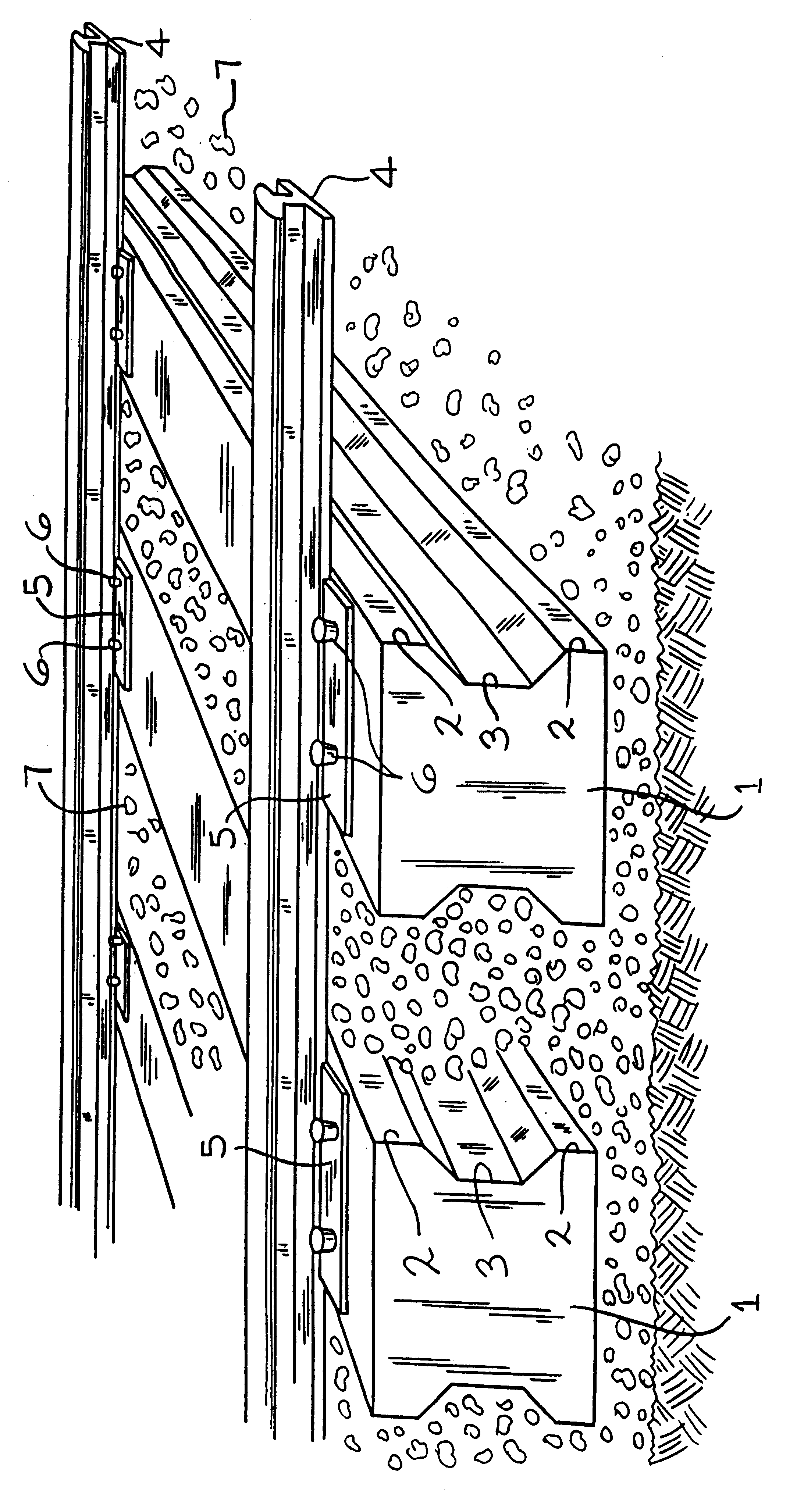

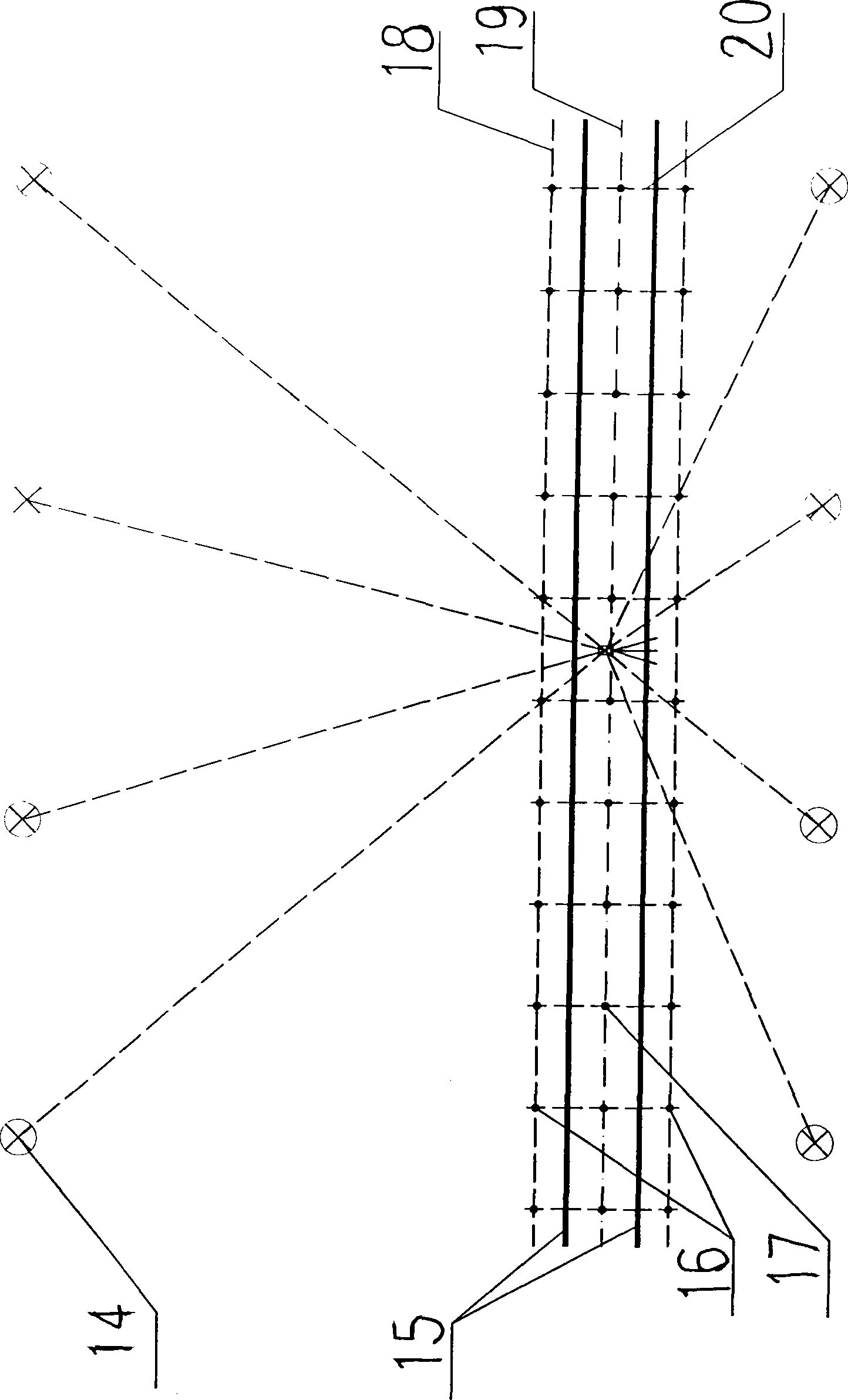

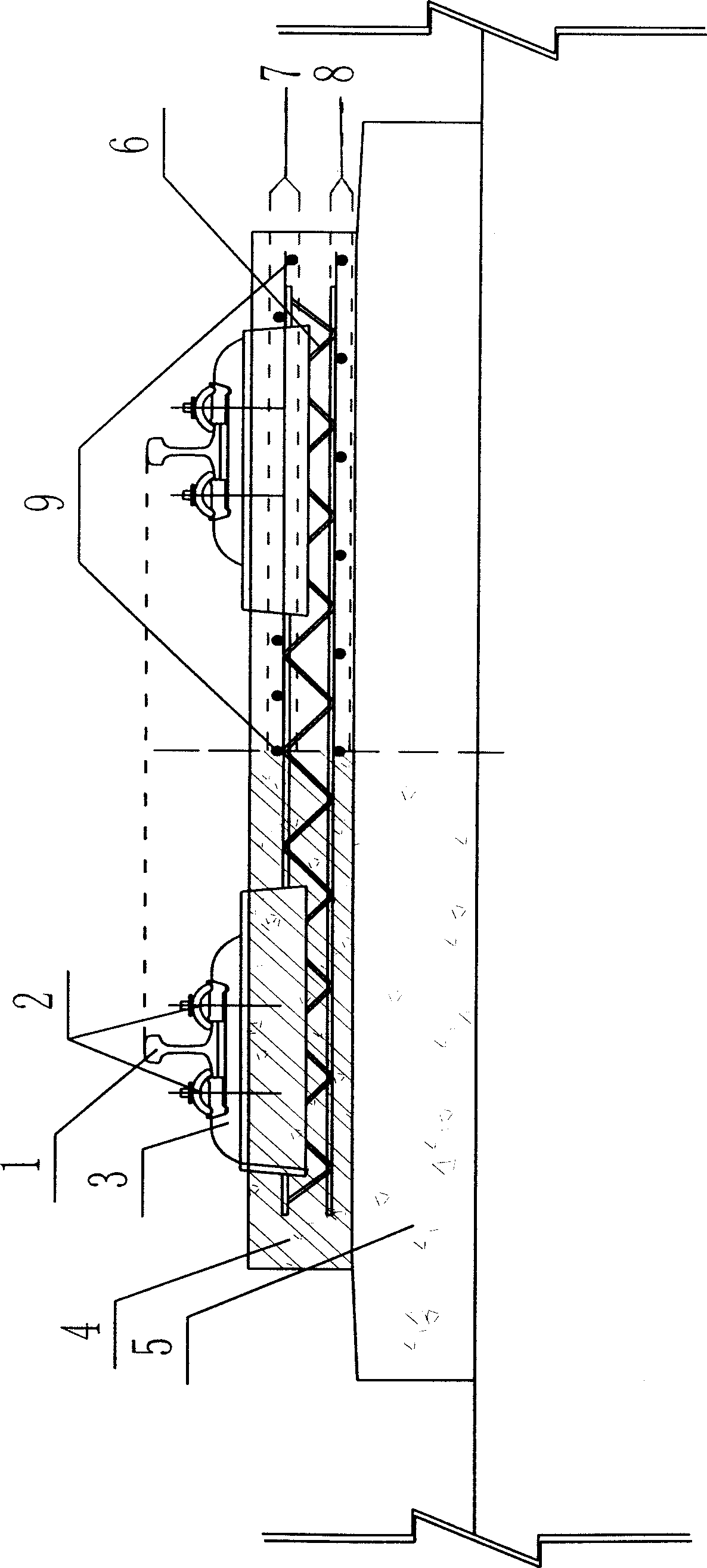

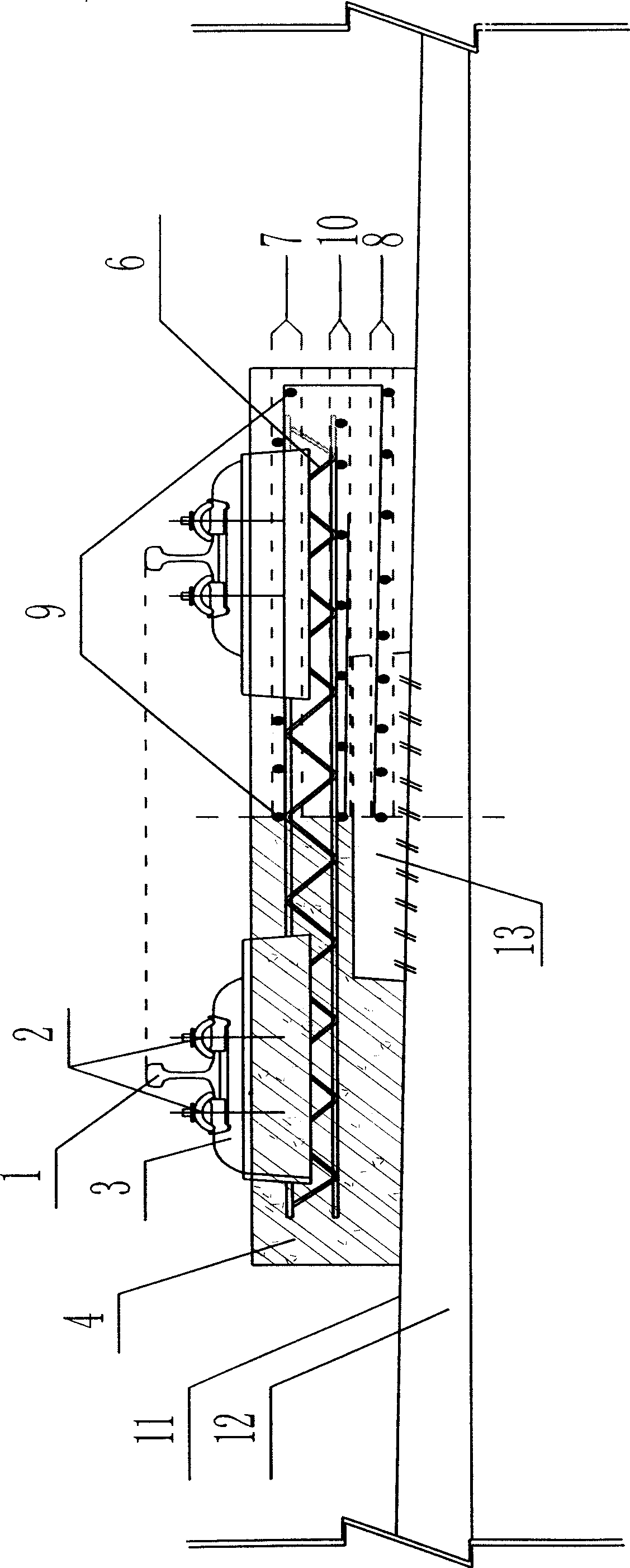

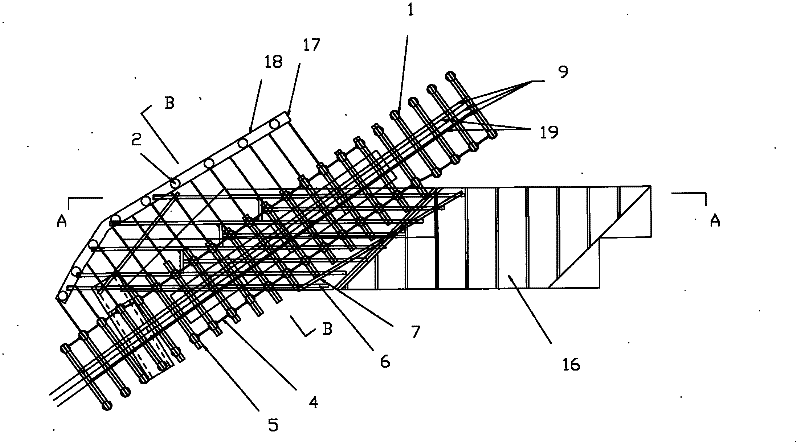

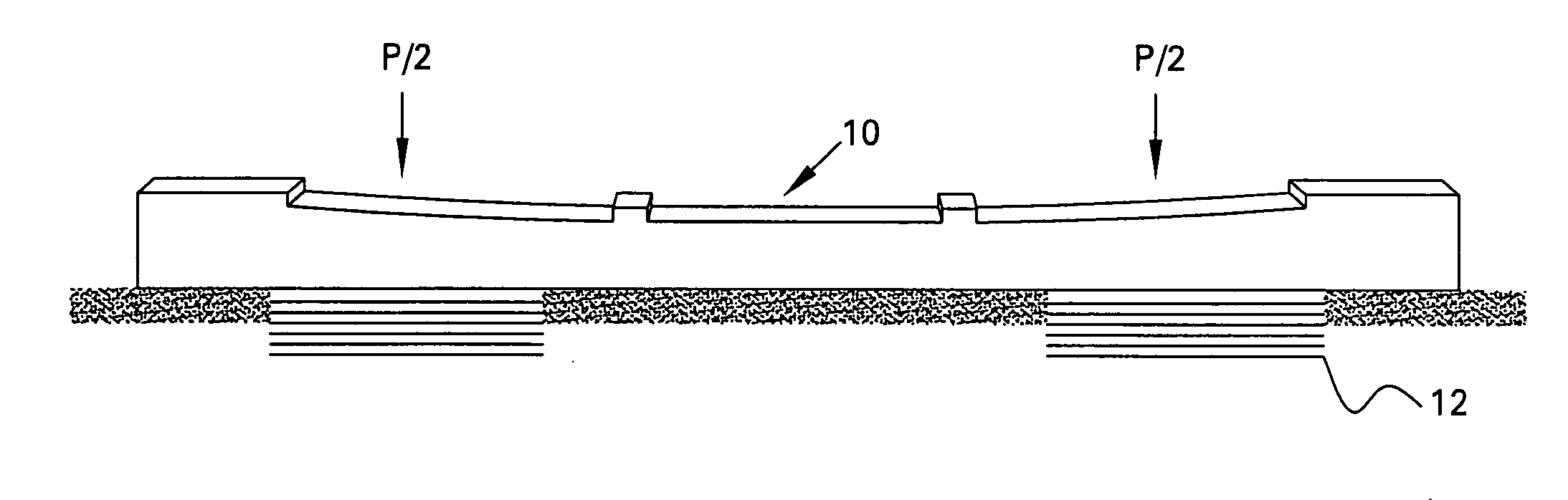

Existing line reinforcing method in under-crossing railway frame bridge small-included angle large-height inclined jacking construction

InactiveCN102359069AControl traverseEnsure stabilityBridge erection/assemblyRailway track constructionWorkloadSupport point

The invention discloses an existing line reinforcing method in under-crossing railway frame bridge small-included angle large-height inclined jacking construction. The method comprises the following steps of: reinforcing an existing line by using an overhead rail (9) along the line, and supporting the existing line by using a plurality of horizontal lifting beams (5) which are vertical to the line direction at certain intervals below the existing line, and using manual hold digging piles (1) on the lower left and right of the horizontal lifting beams (5) as support points of the horizontal lifting beams on two sides of the line; laying a steel slideway (6) between a frame top (8) and the horizontal lifting beams (5) along the jacking direction; meeting the requirements of a longitudinal slope and a cross slope of the line by using wedge-shaped wood (12) between a sleeper (20) and the horizontal lifting beams (5); and before the hole digging piles are broken, transferring the load of the pile top to the frame top (8) through the steel slideway (6), and circularly breaking the piles and jacking. By the method, the vertical and horizontal rigidity of the line are enhanced, the stability of the line during jacking is ensured, the workload for manually maintaining the line is reduced, and the driving safety is ensured.

Owner:RAILWAY NO 10 ENG GRP CO LTD

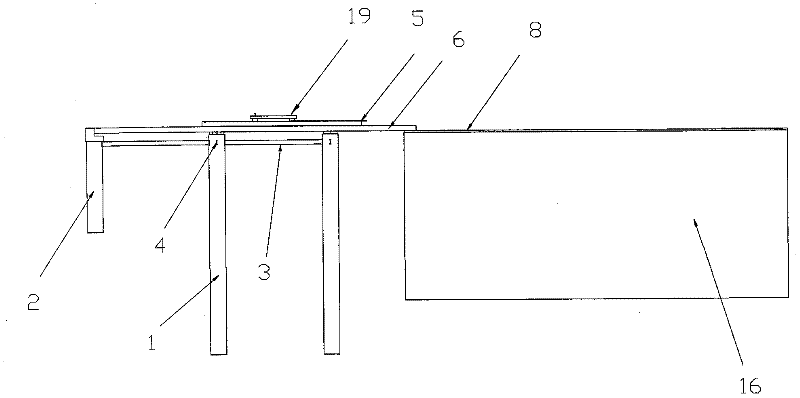

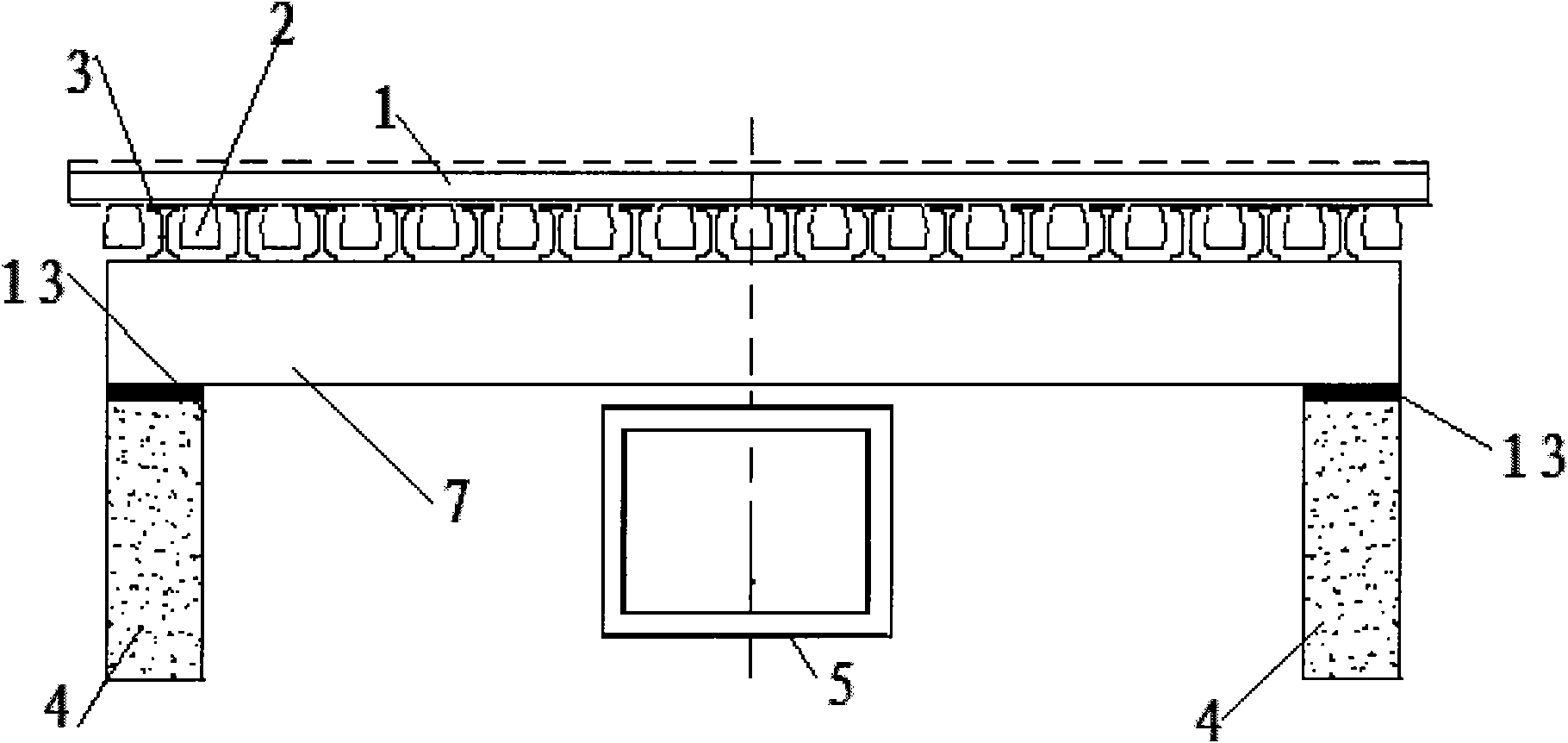

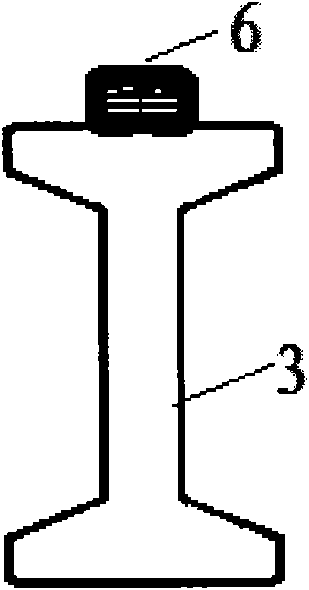

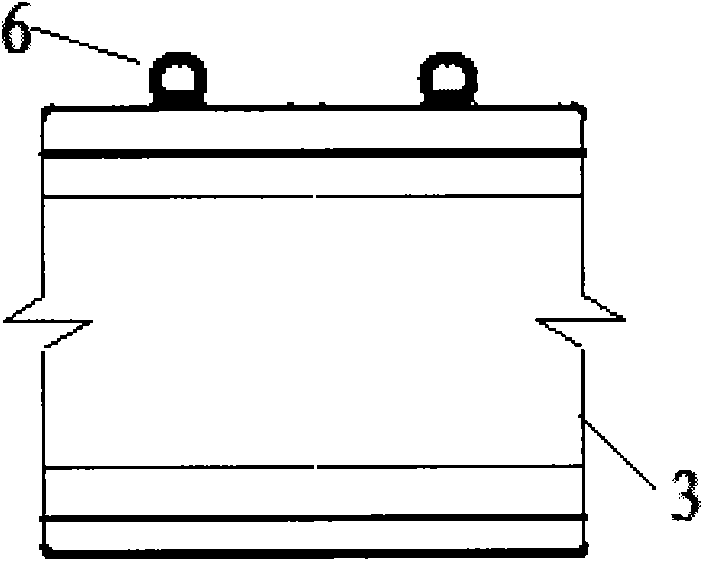

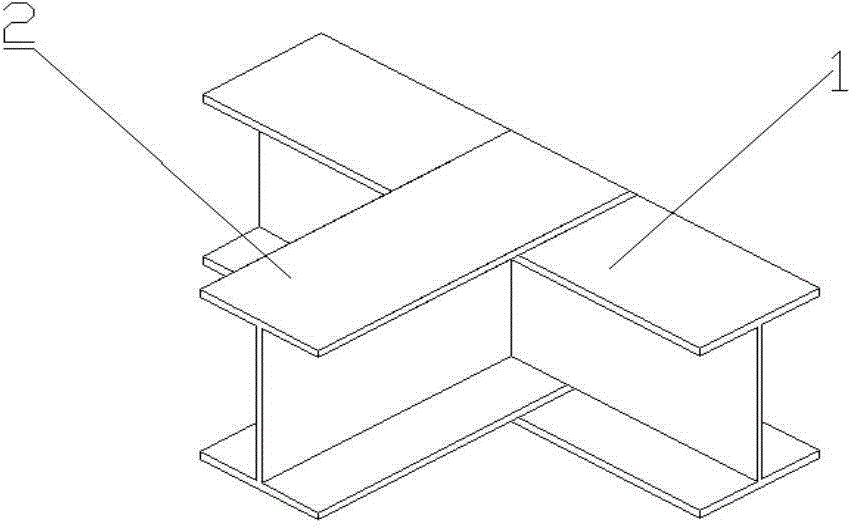

Existing line transverse lifting strengthening method and structure

InactiveCN101838955AStiffness and other effects are smallEasy to connect fastenersRailway track constructionEngineeringFastener

The invention discloses an existing line transverse lifting strengthening method and an existing line transverse lifting strengthening structure. Different from the conventional line straightening method requiring bed timber replacing and track locking, the method adopts a construction process which uses 'III'-shaped steel beams as longitudinal beams and uses I25 I-beams to perform the transverse lifting strengthening of the existing lines. The method has the advantages that: a connecting fastener is simple and consumes less material; the lines are strengthened directly, so the influences on the line rigidity and the like are light; working procedures are reduced, time is saved, and at least two window long time for replacing bed timbers and locking tracks can be saved, wherein one window is saved each day, and each window represents 1.5 hours; and the safety and quality are ensured.

Owner:CHINA RAILWAY 21TH BUREAU GROUP

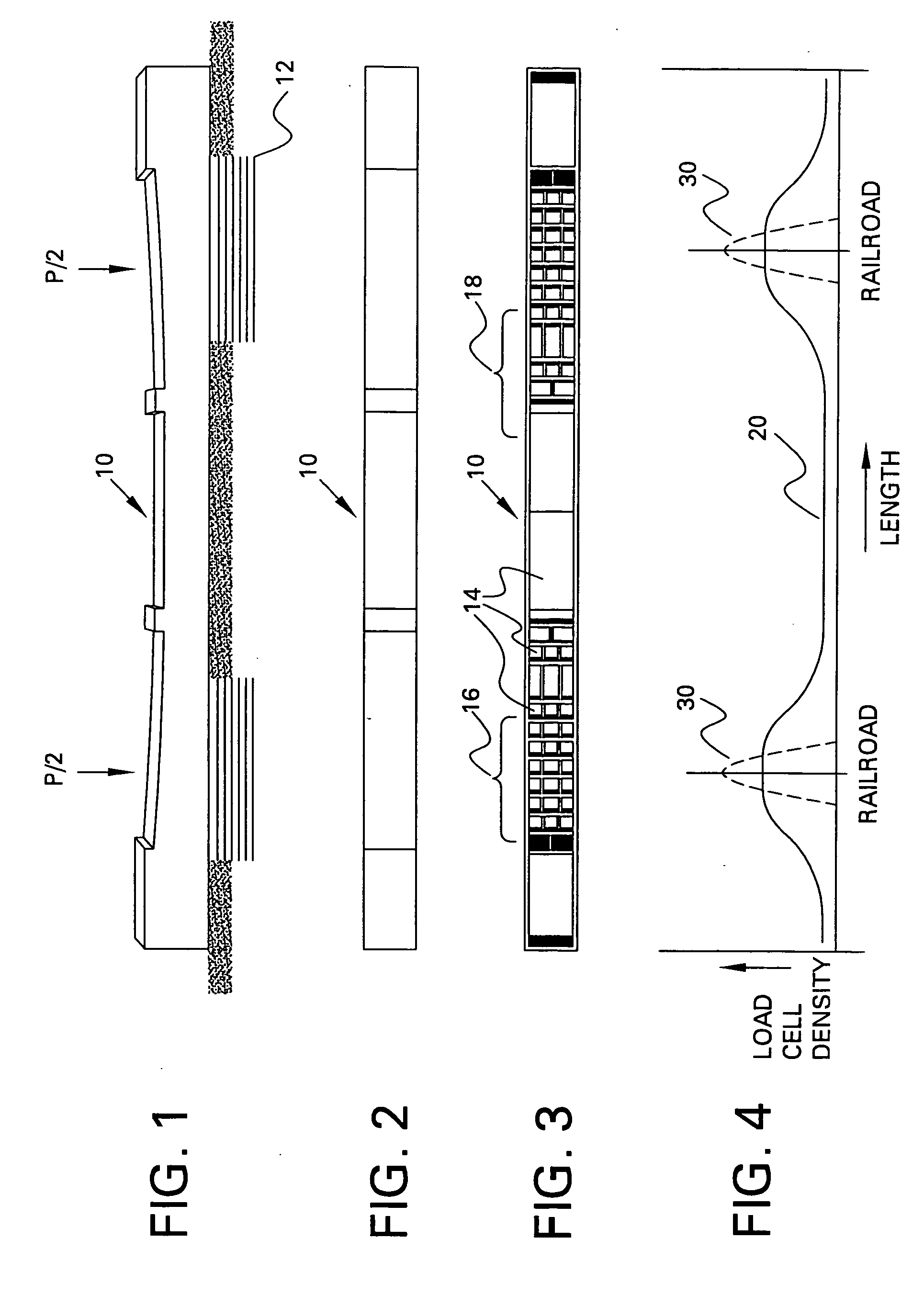

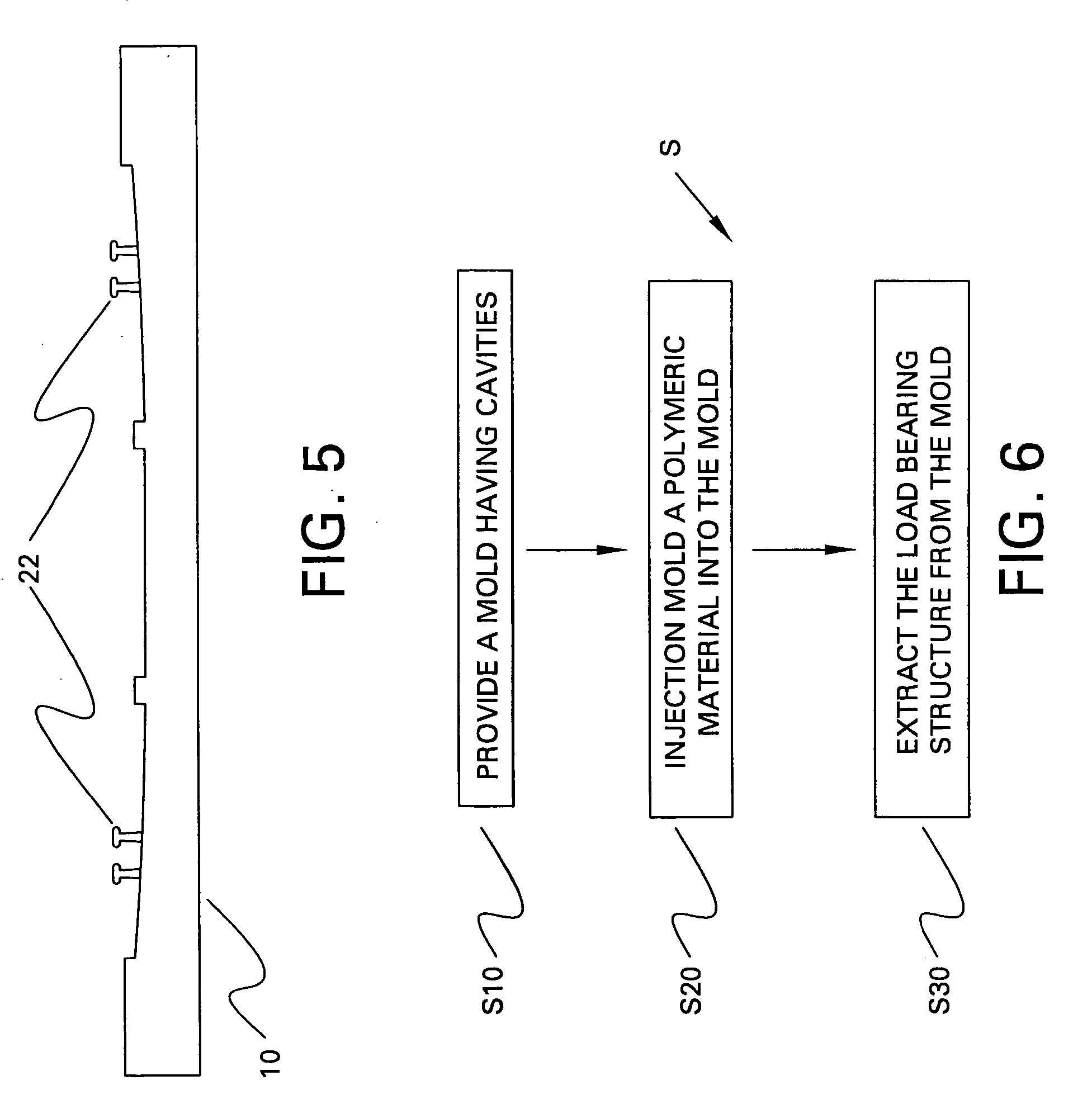

Load bearing structure and method of manufacture thereof

A load bearing structure configured to bear a load, the structure comprising a multiple cells. The load bearing structure has a length, a center, and a cell density, which varies at least along the length of the load bearing structure, which weighs at least 6 kg.

Owner:GENERAL ELECTRIC CO

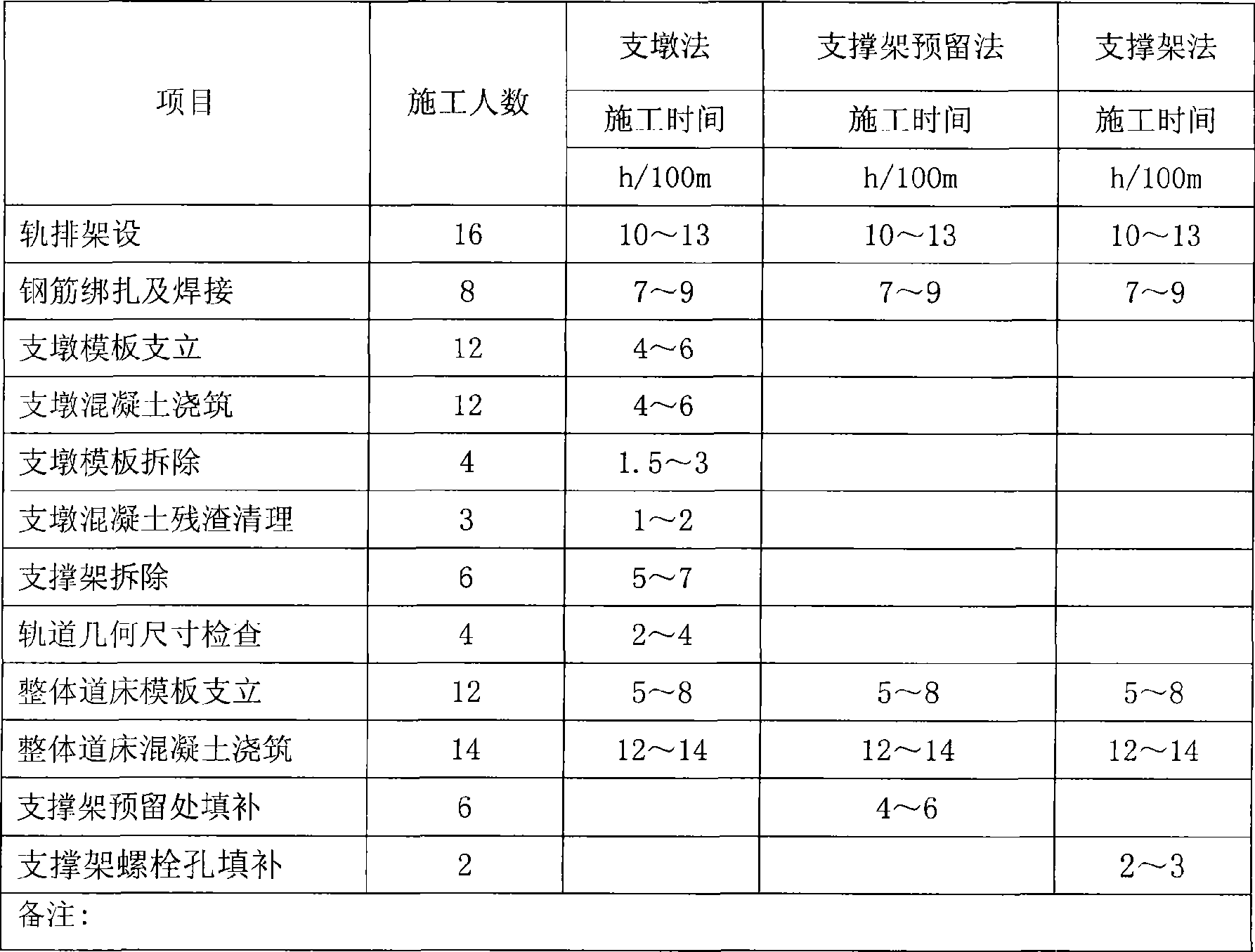

Construction method of monolithic road-bed in rail tunnel

ActiveCN101418535AReduce construction proceduresLow costRailway track constructionEngineeringLight rail

The invention discloses a method for constructing an integrated road bed of a track traffic tunnel, which is a supporting frame method for short. Firstly, a finished track panel assembled on a base is hoisted to the constructed tunnel; and the track panel of sleepers with different forms is born through adopting a supporting frame of a lower bearing type track panel; secondly, the track panel in the construction working face is hoisted to the designed elevation; the supporting frame of the track panel is mounted to support the track panel; a transverse supporting lever is utilized to approximately fix the direction of the track panel; and finally, according to fiducial mark, the elevation of track surface, the direction of the track, level and height are adjusted to the designed positions; after the binding and welding of concrete reinforcing bars and the erection of a template of the road bed are sequentially completed, and the integrated road bed is finally subjected to concrete pouring to obtain the integrated road bed; and the steps are sequentially advanced to complete the whole construction. The method reduces control links and material waste, improves construction schedule, ensures construction quality and is mainly used for the structural construction of undergrounds, light rails, tunnels, bridges, large-scale vehicle fields and other integrated road beds.

Owner:3TH ENG CO LTD OF CHINA RAILWAY CONSTR 11TH BUREAU GRP +1

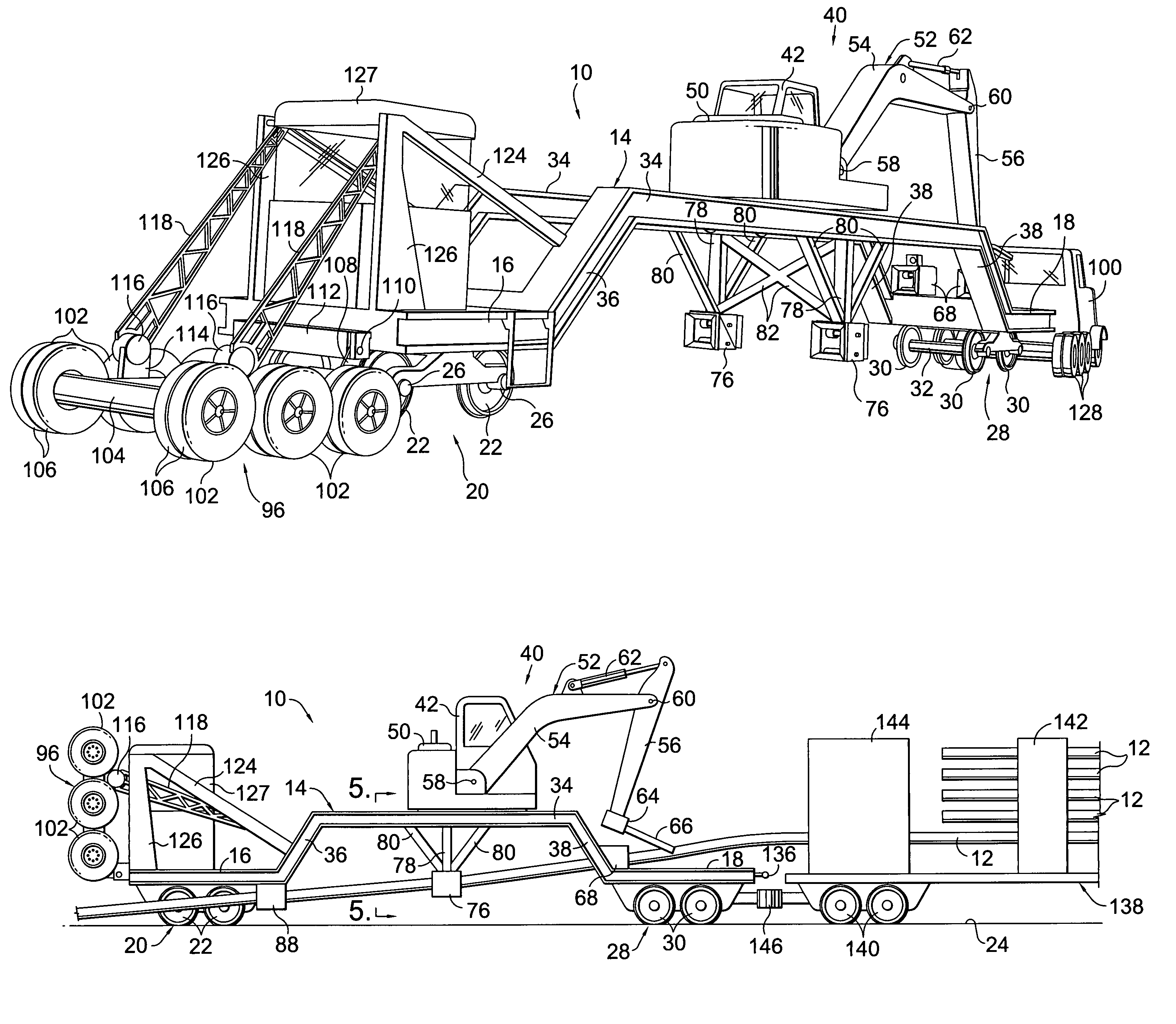

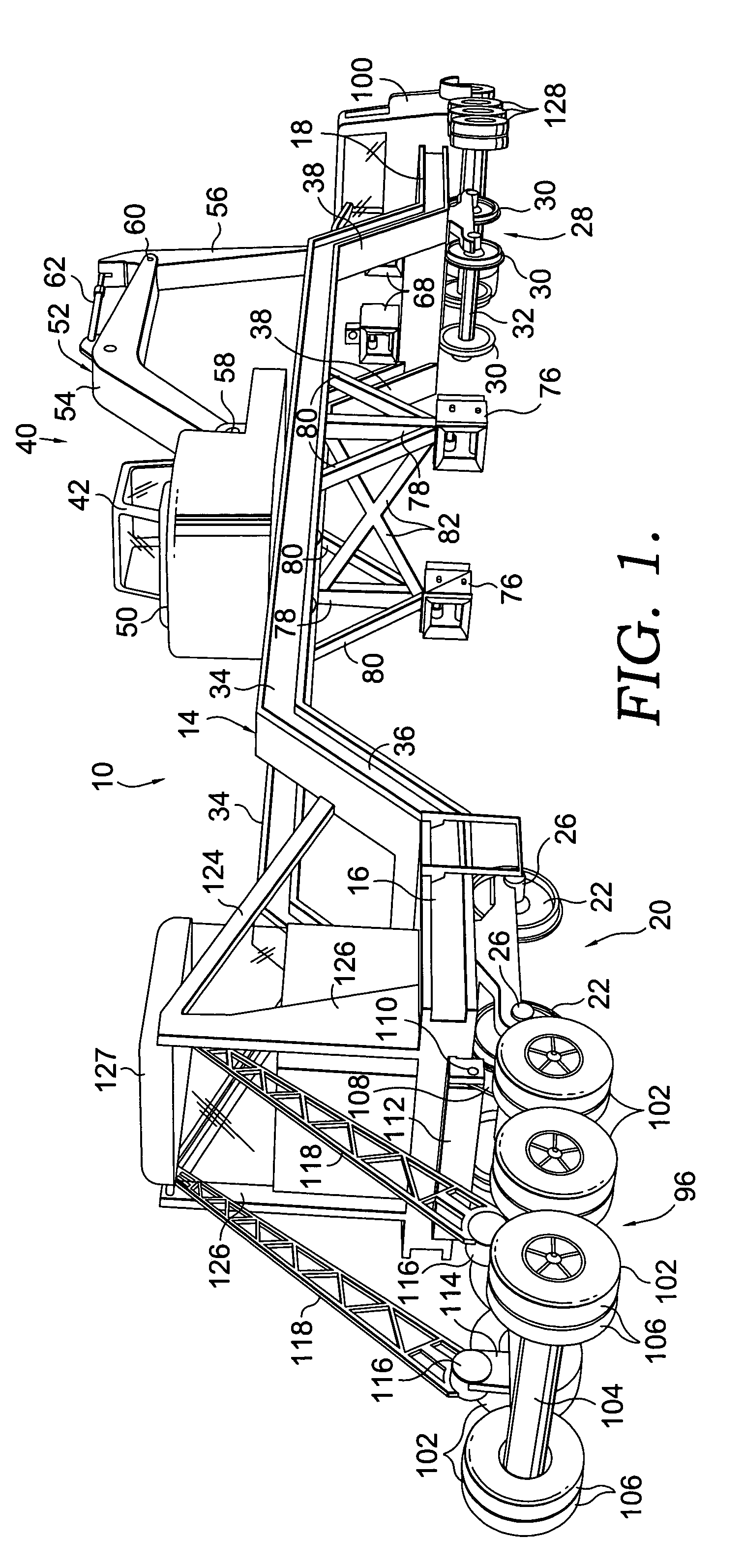

Method and apparatus for unloading ribbon rails from rail cars

ActiveUS6981452B2Reduce labor requirementsReduce riskBallastwayRefuse receptaclesEngineeringMechanical engineering

Owner:HERZOG CONTRACTING

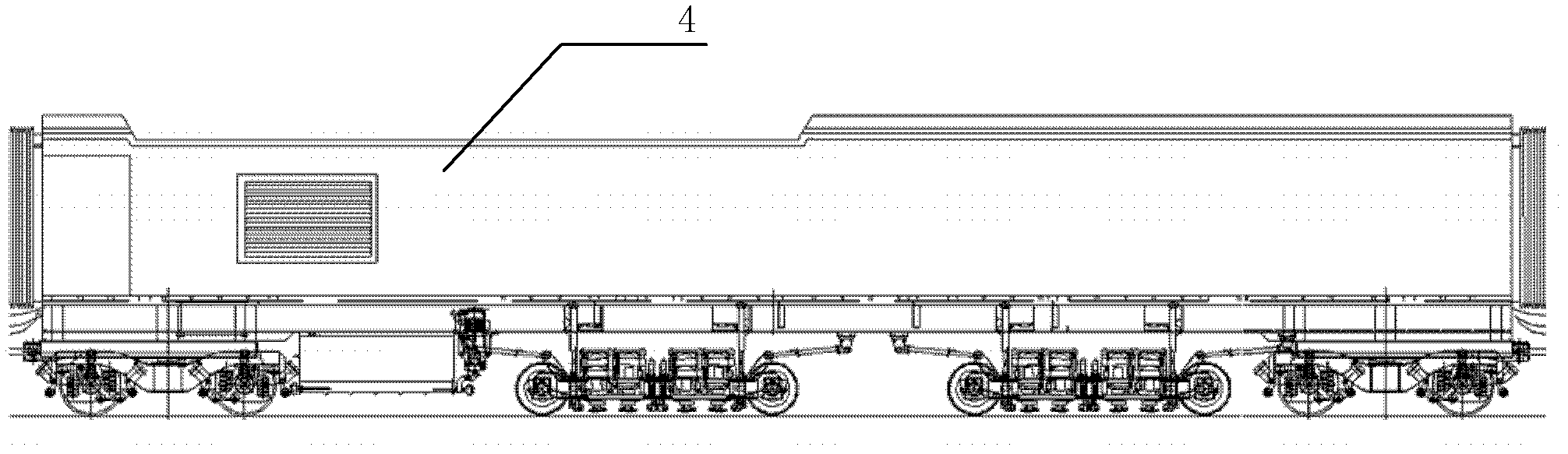

Hybrid rail grinding wagon

ActiveCN102535280AWith hybrid power sourceWork seamlesslyRailway track constructionCombustionTransformer

The invention discloses a hybrid rail grinding wagon, which is applied to operation of hybrid rail grinding trains in the field of large-sized track engineering. The hybrid rail grinding wagon comprises an internal-combustion engine driven power car, an electrically driven power car and more than one trailer, wherein a grinding device is mounted on each trailer. When the hybrid rail grinding wagon is operated in a power accessible area or tunnel area, power is taken from a contact system through a pantograph of the electrically driven power car, subjected to voltage reduction with a transformer, and subjected to rectification and inversion with an inverter to generate three-phase variable-frequency variable-voltage alternating current, which is supplied as power required by a tractor motor and the grinding devices. The hybrid rail grinding wagon switches to the internal-combustion engine and generator combined mode in the power inaccessible area, so that power required by travelling and the grinding devices of the hybrid rail grinding wagon is supplied. The technical problem that existing grinding wagons are low in operation and combustion efficiency, severe in emission pollution and high in use and maintenance cost is solved, and the hybrid rail grinding wagon can achieve full-section seamless operation in the power accessible or in accessible area and the tunnel area.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

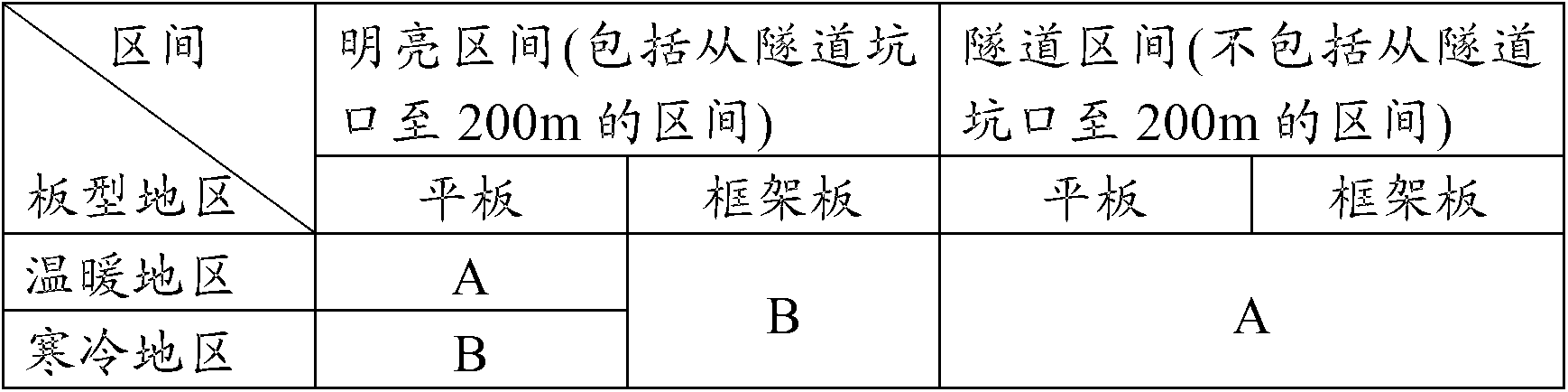

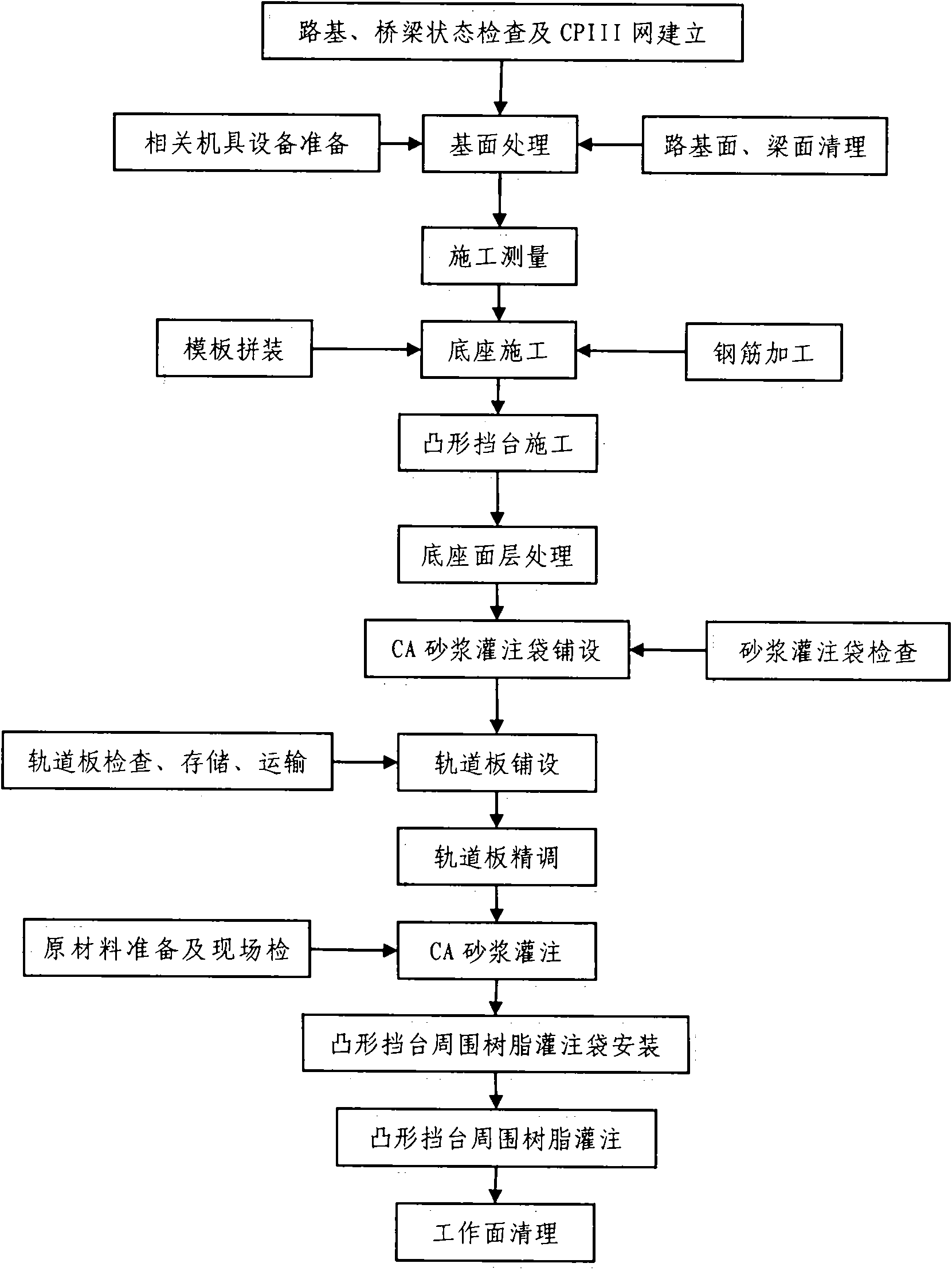

Paving method of CRTS I type plate type ballastless track slab in severe cold region

InactiveCN101851884AAdapt to climate characteristics with large annual temperature differenceHigh precisionRailway track constructionMeasuring apparatusSurface layerPrism

The invention provides a paving method of a CRTS I type plate type ballastless track slab in a severe cold region, which sequentially comprises the following steps of: building a roadbed and a CPIII control network, processing the surface of the roadbed, measuring during construction, constructing a base, constructing a convex baffling table, processing the surface layer of the base, paving a CA mortar pouring bag, paving a track slab, precisely adjusting the track slab, pouring CA mortar, arranging a resin pouring bag around the convex baffling table, pouring resin around the convex baffling table, and cleaning a work surface. The step of precisely adjusting a track slab adopts a prism frame method. The prism frame method comprises the following steps of: arranging two measuring frames at positions of screw bolt holes at the two ends of each track slab after building a CPIII control point; measuring a spherical prism on the frame after freely stationing a total station, wherein measured data represents a practical three dimensional coordinate of the track slab; counting the difference value between a theoretic three dimensional coordinate value and a practically-measured three dimensional coordinate value; precisely adjusting the track slab with a bidirectional adjustor untill that the difference value meets the criterion requirement. The CRTS I type plate type ballastless track slab which is paved with the method can meet the characteristic of the climate in the severe cold region.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

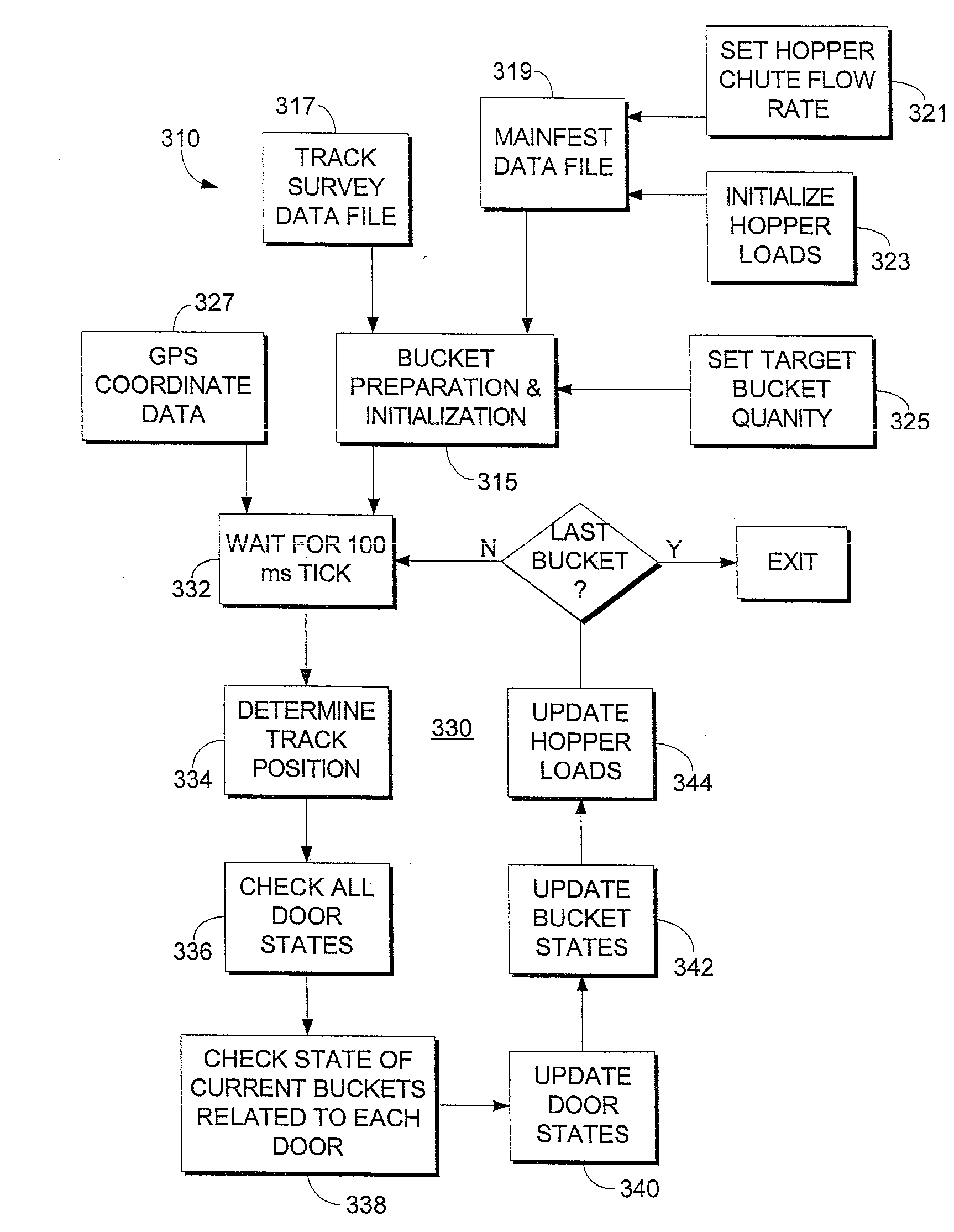

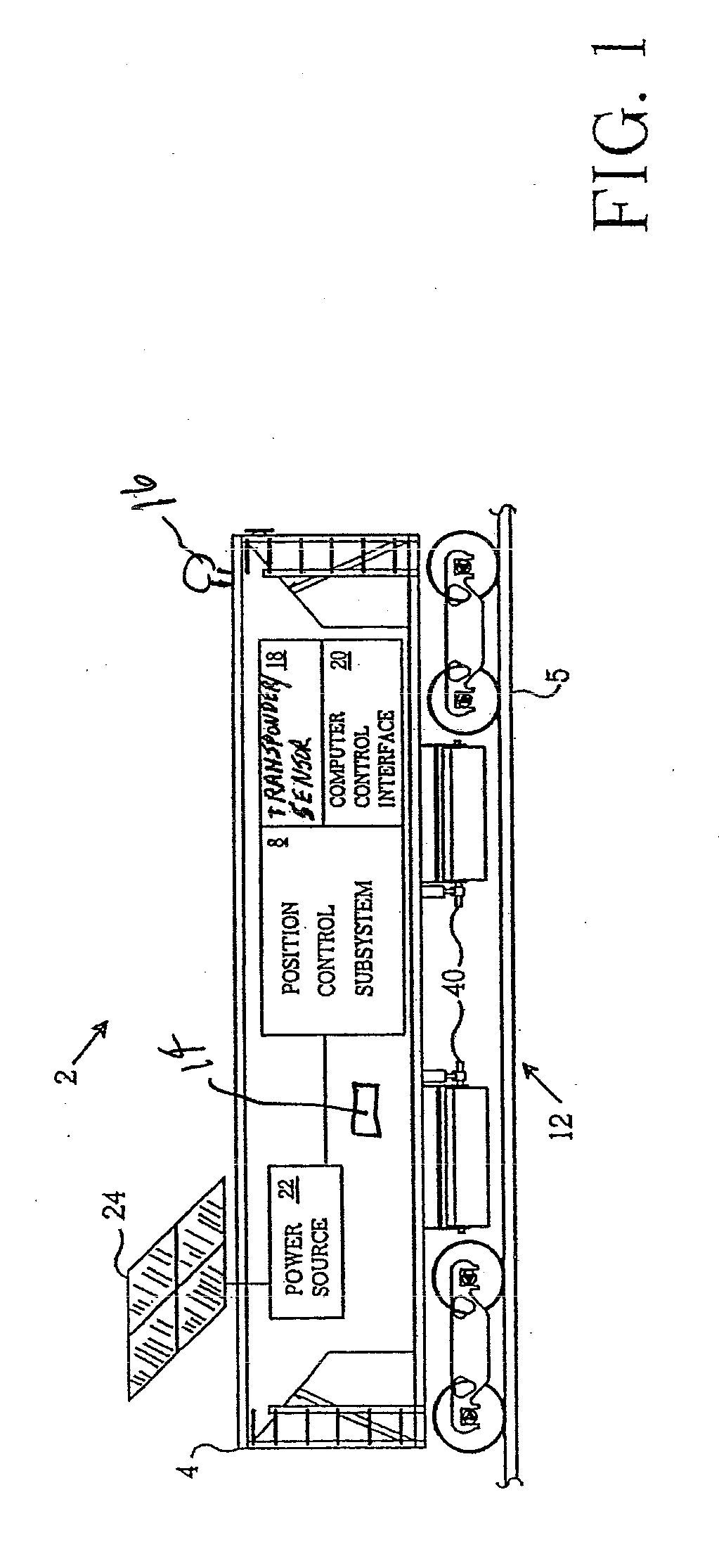

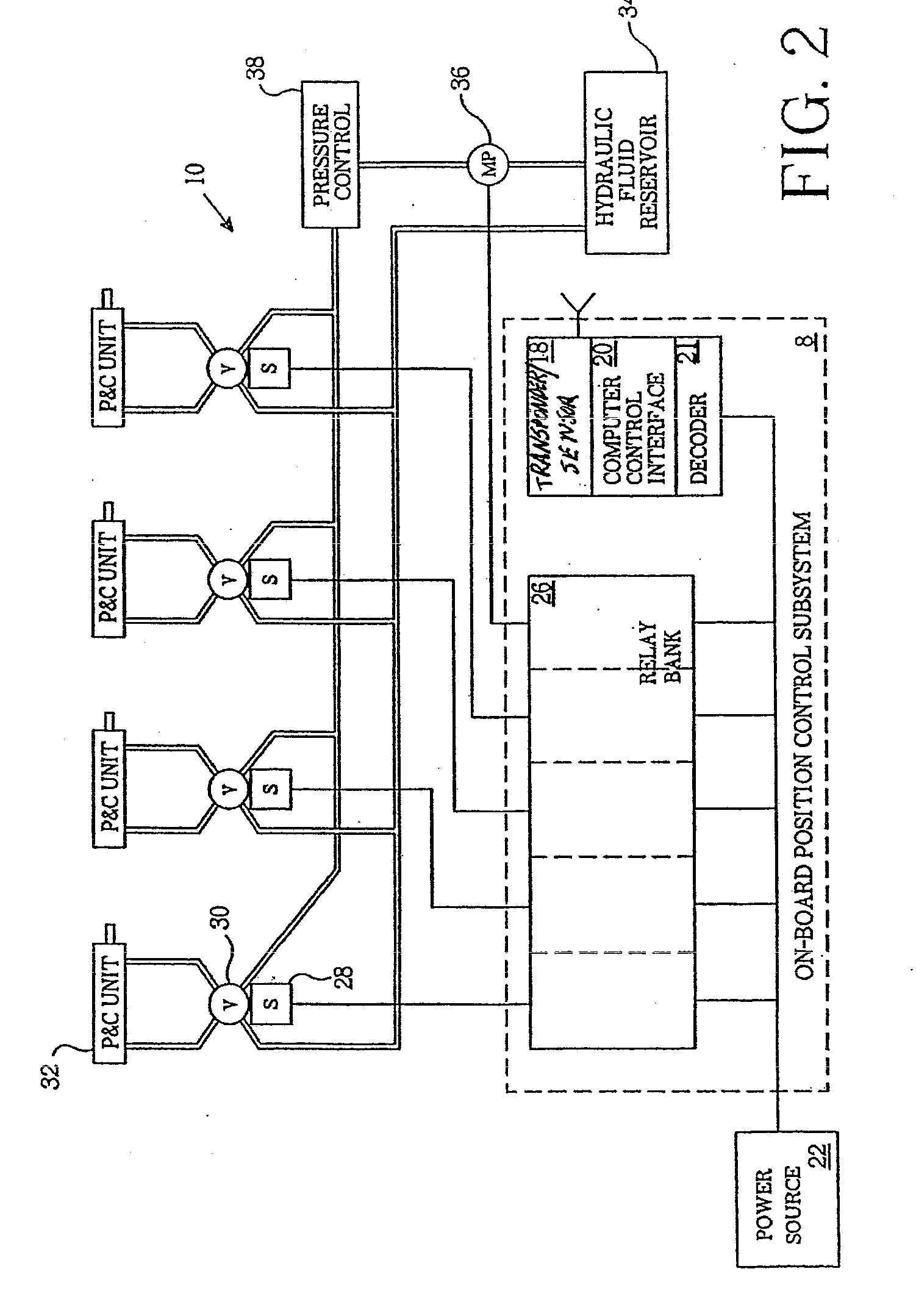

Method and apparatus for applying railway ballast

InactiveUS20070129858A1Control spreadImprove accuracyBallastwayDigital data processing detailsTerrainAviation

A method and apparatus for spreading ballast along railways makes use of an inertial measurement system to determine where to apply ballast from a hopper car. A variety of techniques can be used to determine the location and speed of the ballast spreading train, including manual or automated visual techniques, laser technology, radar technology, radio frequency transponders, magnetic sensor, thermal imaging and aerial photogrammetry. The invention also contemplates “on the fly” surveys and terrain profiling using lasers or radar.

Owner:HERZOG CONTRACTING

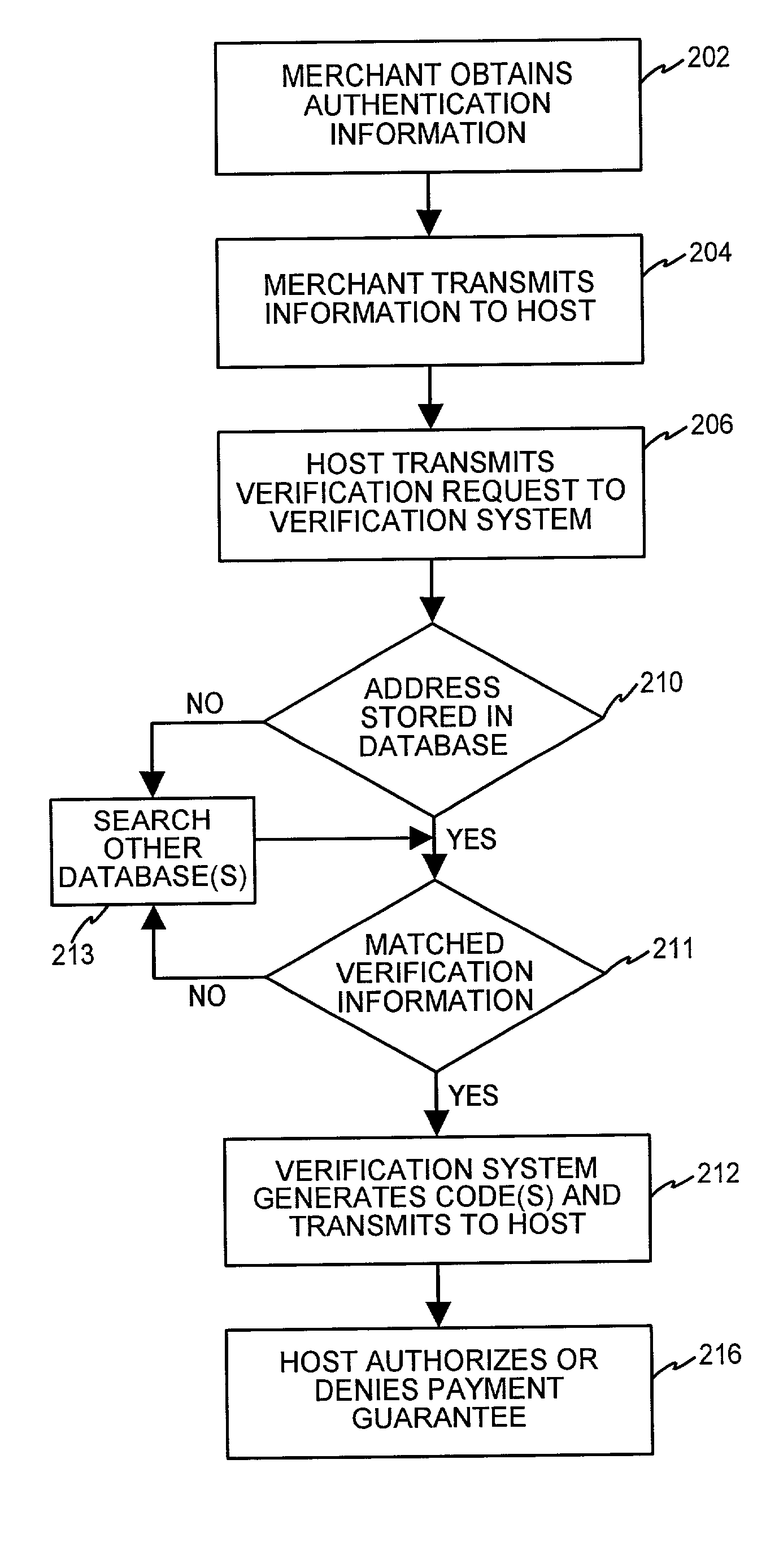

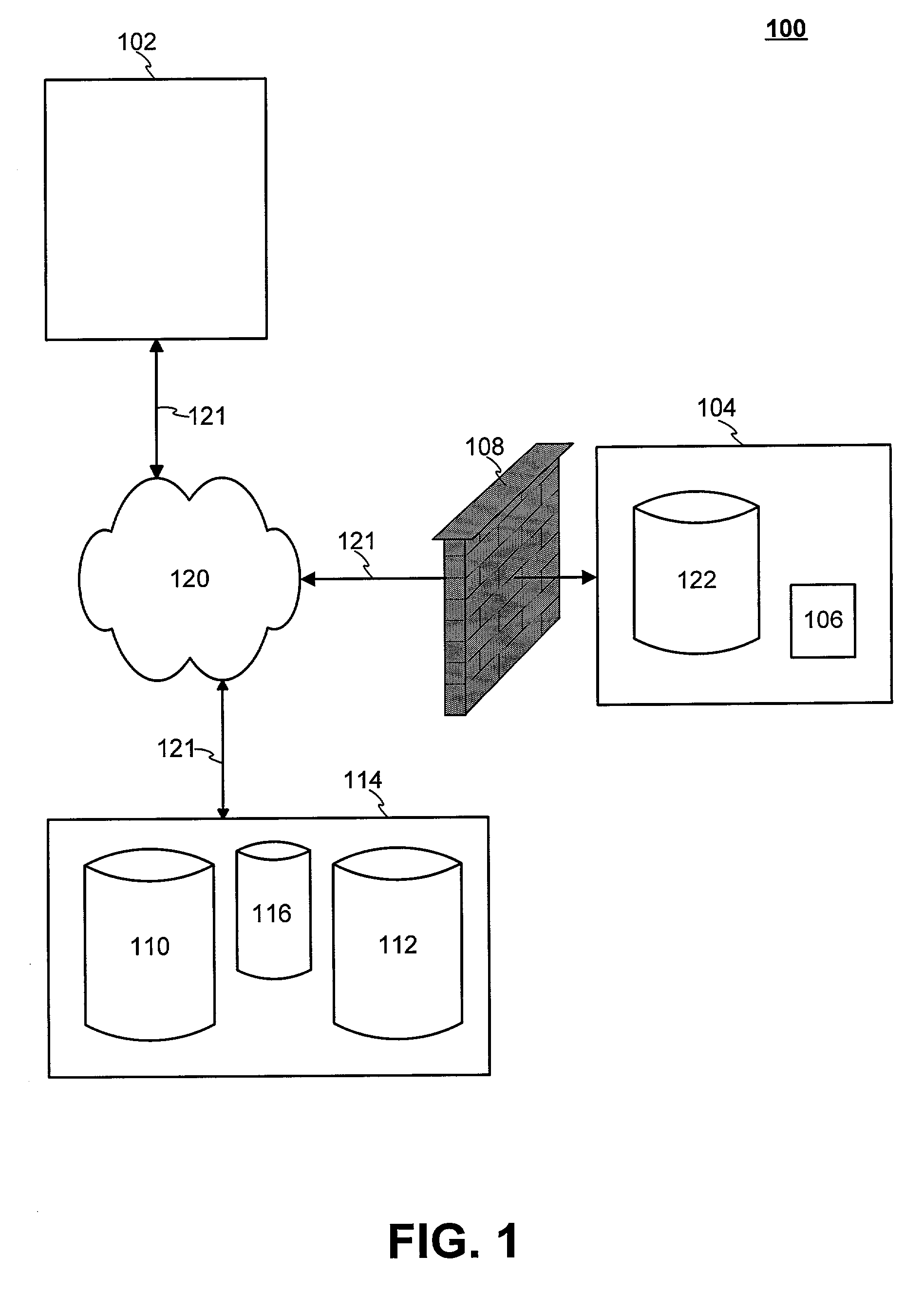

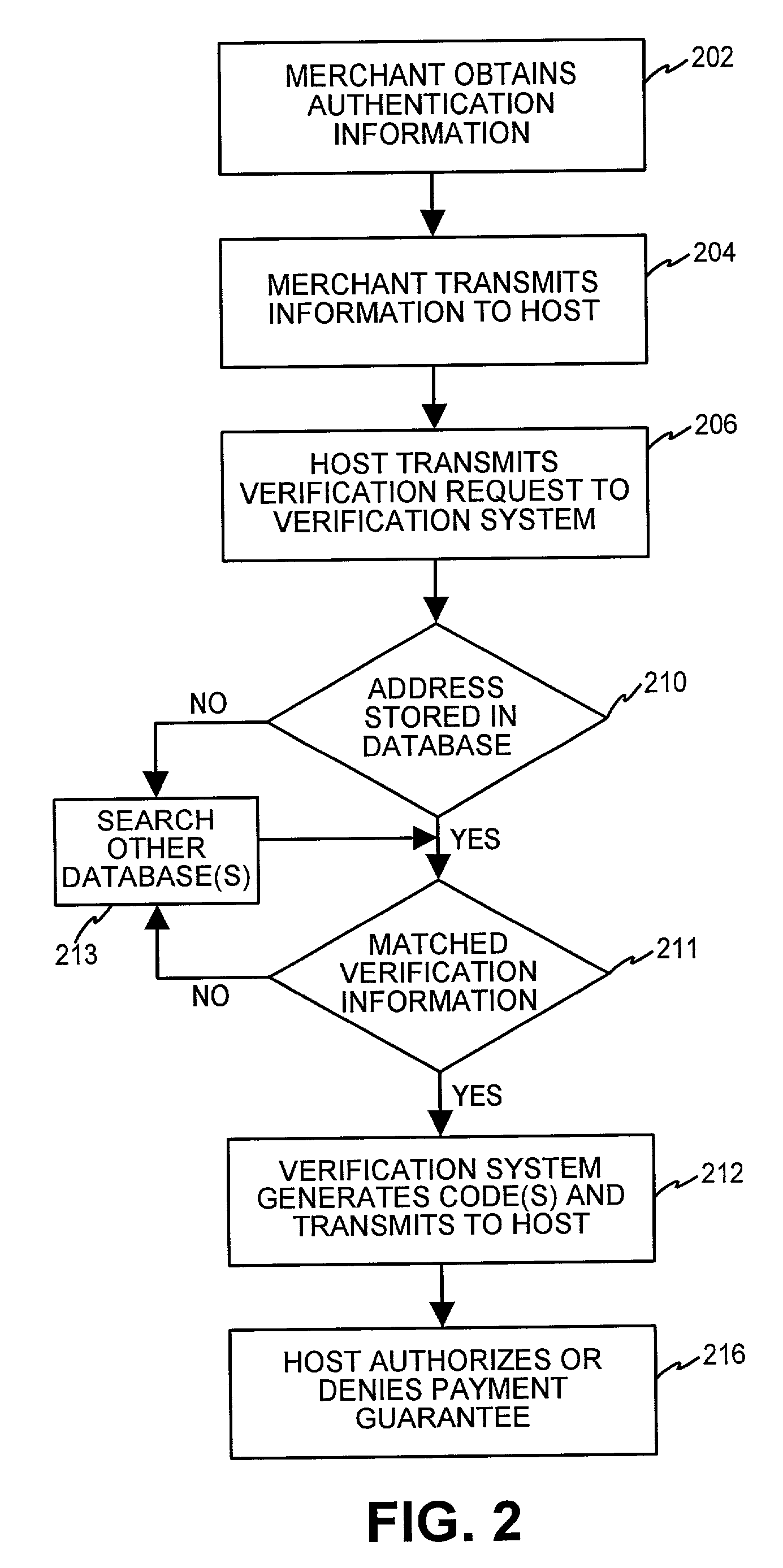

System and method for global automated address verification

The present invention provides systems and methods for global address verification of a transaction, such as a transaction card purchase. In accordance with an exemplary embodiment of the present invention, the system verifies a billing address and / or an alternate address (e.g., shipping address) in a single transaction. The billing address and / or the alternate address are associated with a transaction card purchaser. If the billing and / or alternate addresses are verified, then the transaction card issuer may offer a payment guarantee to the merchant. The merchant may choose to ship the purchased item to either a billing address or an alternate address. If the address is not verified, then the transaction card issuer may choose not to offer a payment guarantee to the merchant, and the merchant may choose not to ship the item to the alternate address.

Owner:LIBERTY PEAK VENTURES LLC

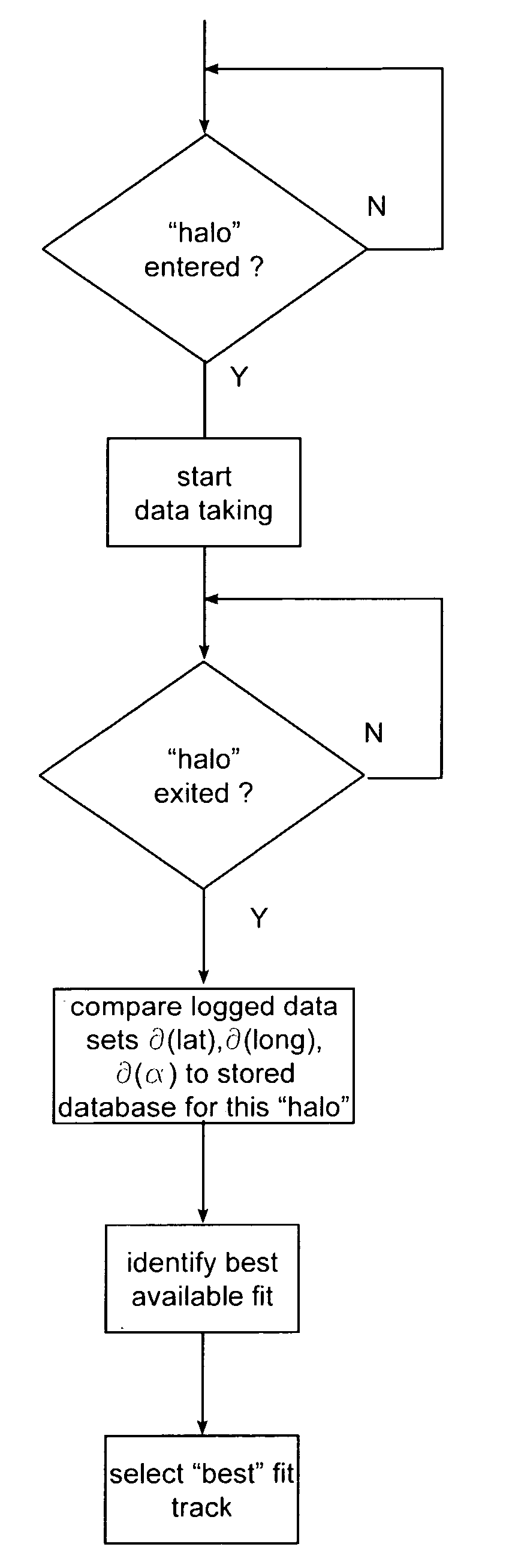

Locomotive/train navigation system and method

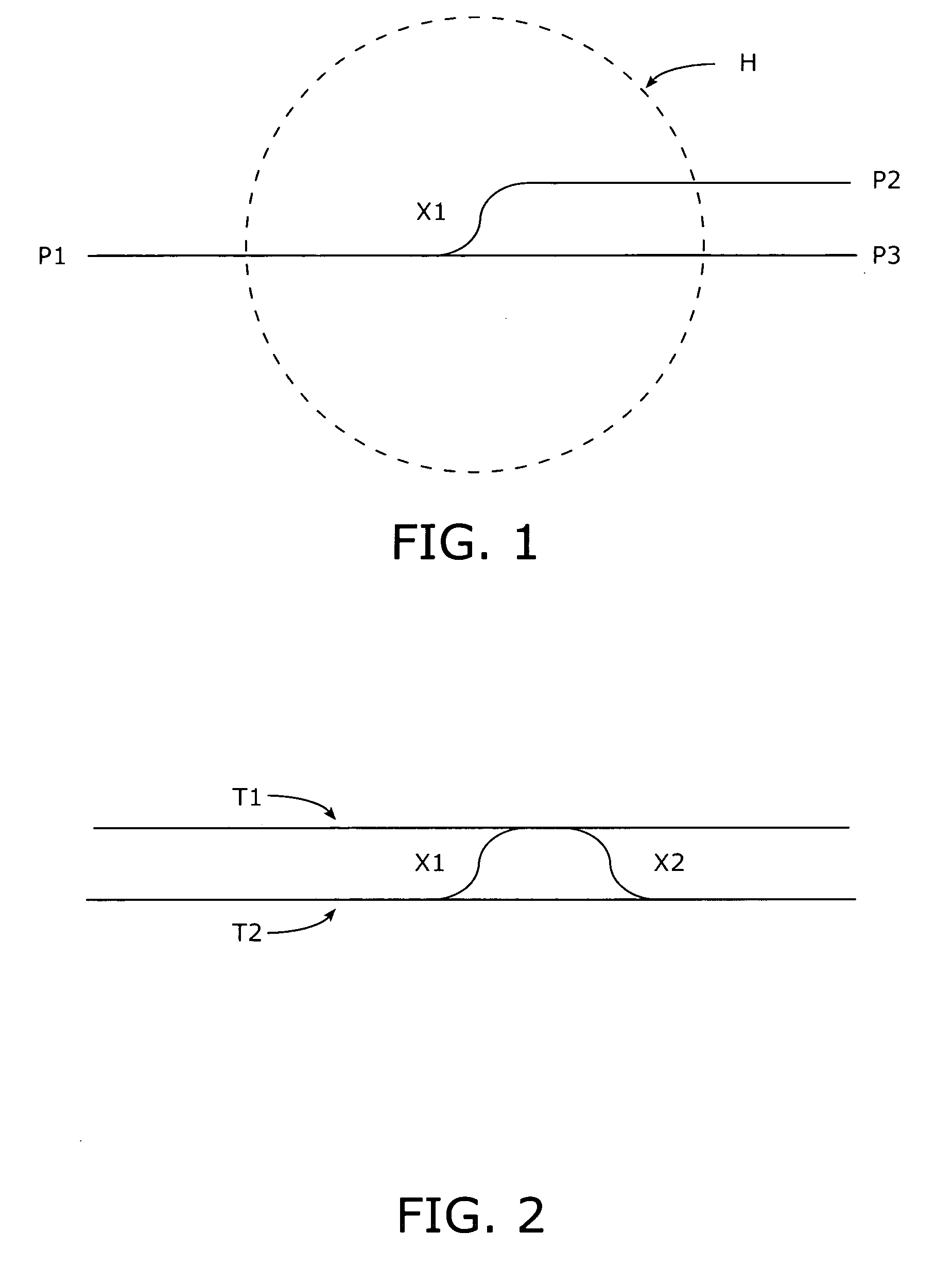

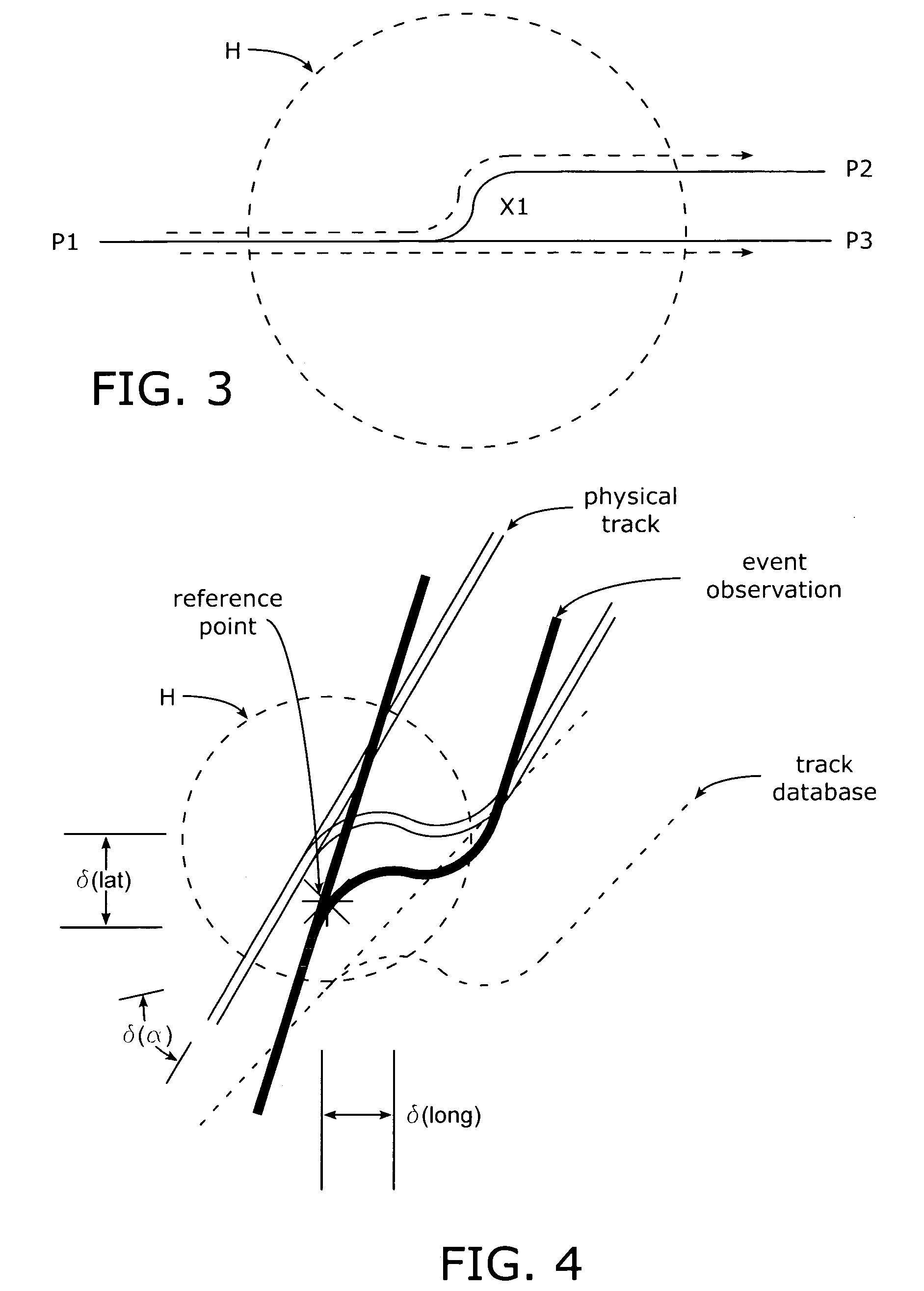

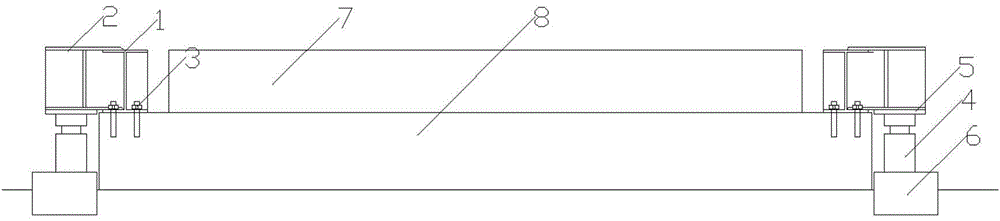

ActiveUS20060253233A1Quick fixRail switchesDigital data processing detailsEngineeringNavigation system

In a rail track system having transition points, a locomotive having a navigation system (such as a combined inertial / GPS location system) moves along an initially known track and enters the “halo” surrounding a track transition to begin data collection / logging to accumulate successive position information data points as the locomotive moves into, progresses through, and exits the “halo.” The collected data for movement within the “halo” is then subject to a best fit assessment relative to the data pre-stored in the track database.

Owner:LOCKHEED MARTIN CORP

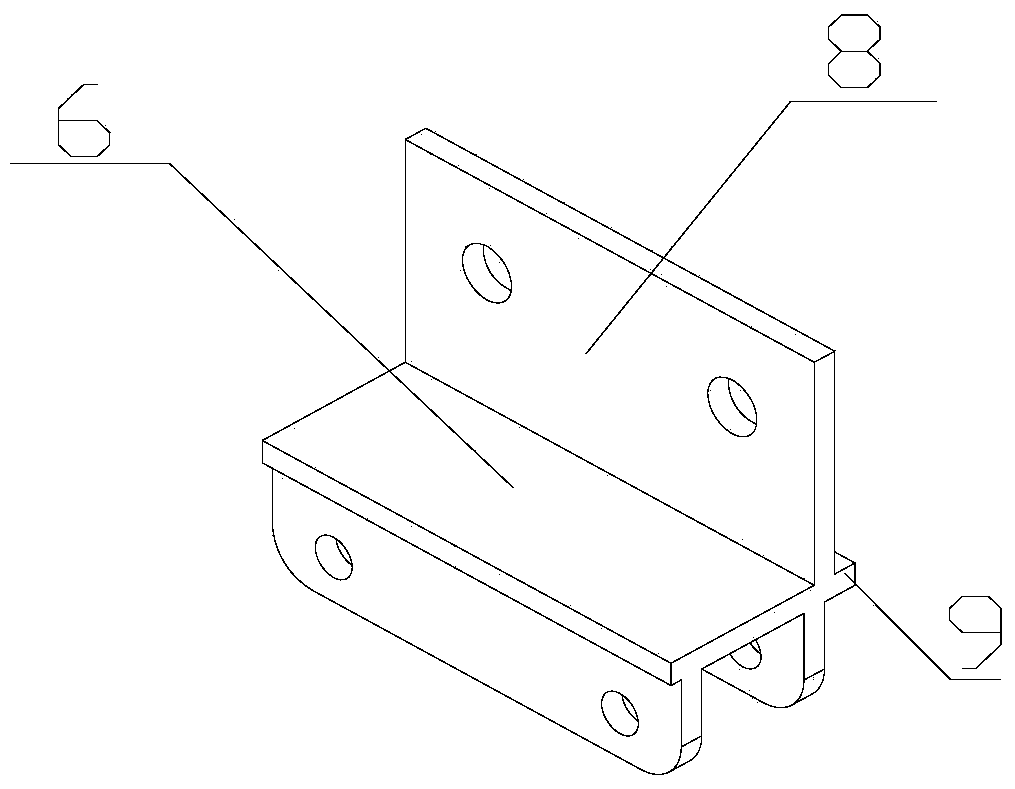

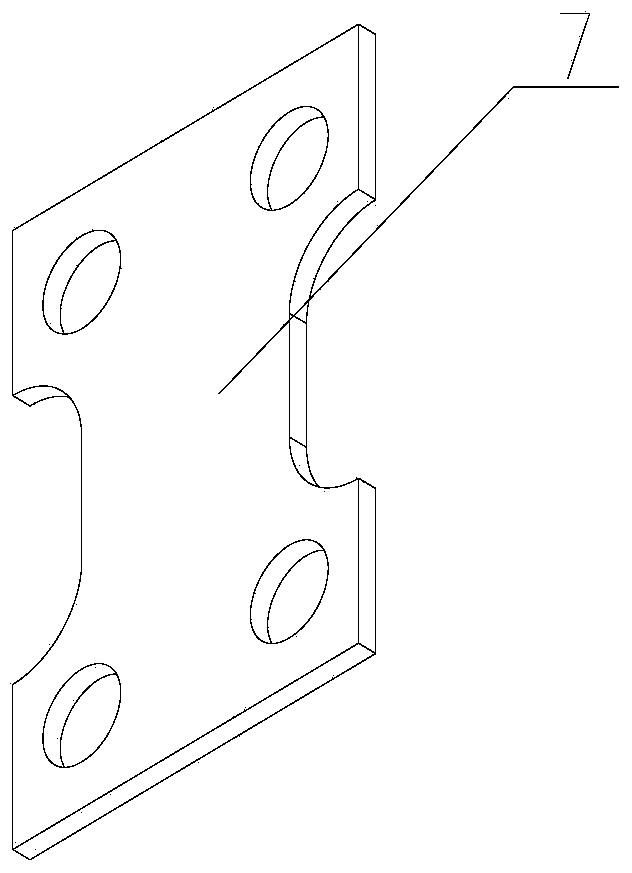

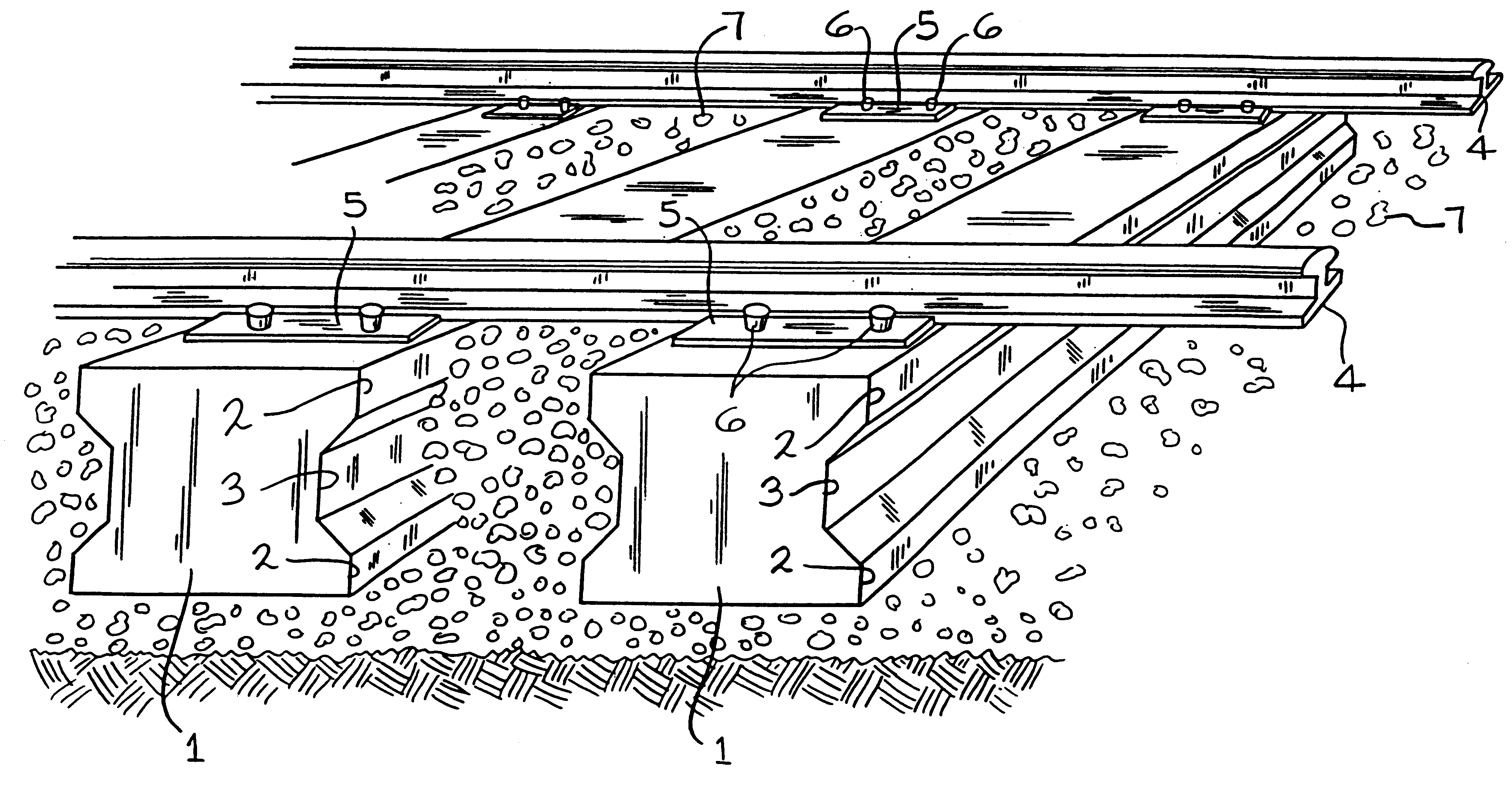

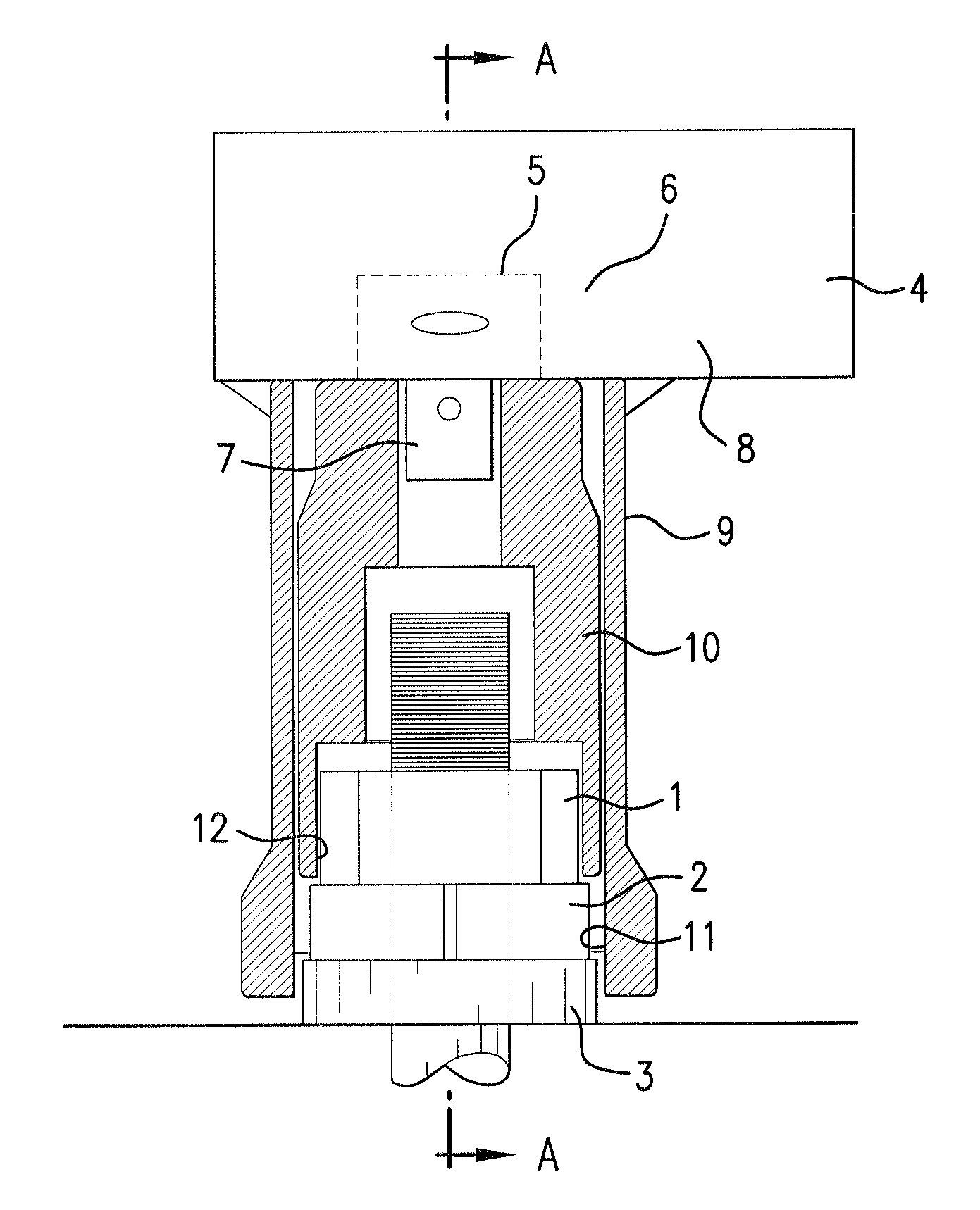

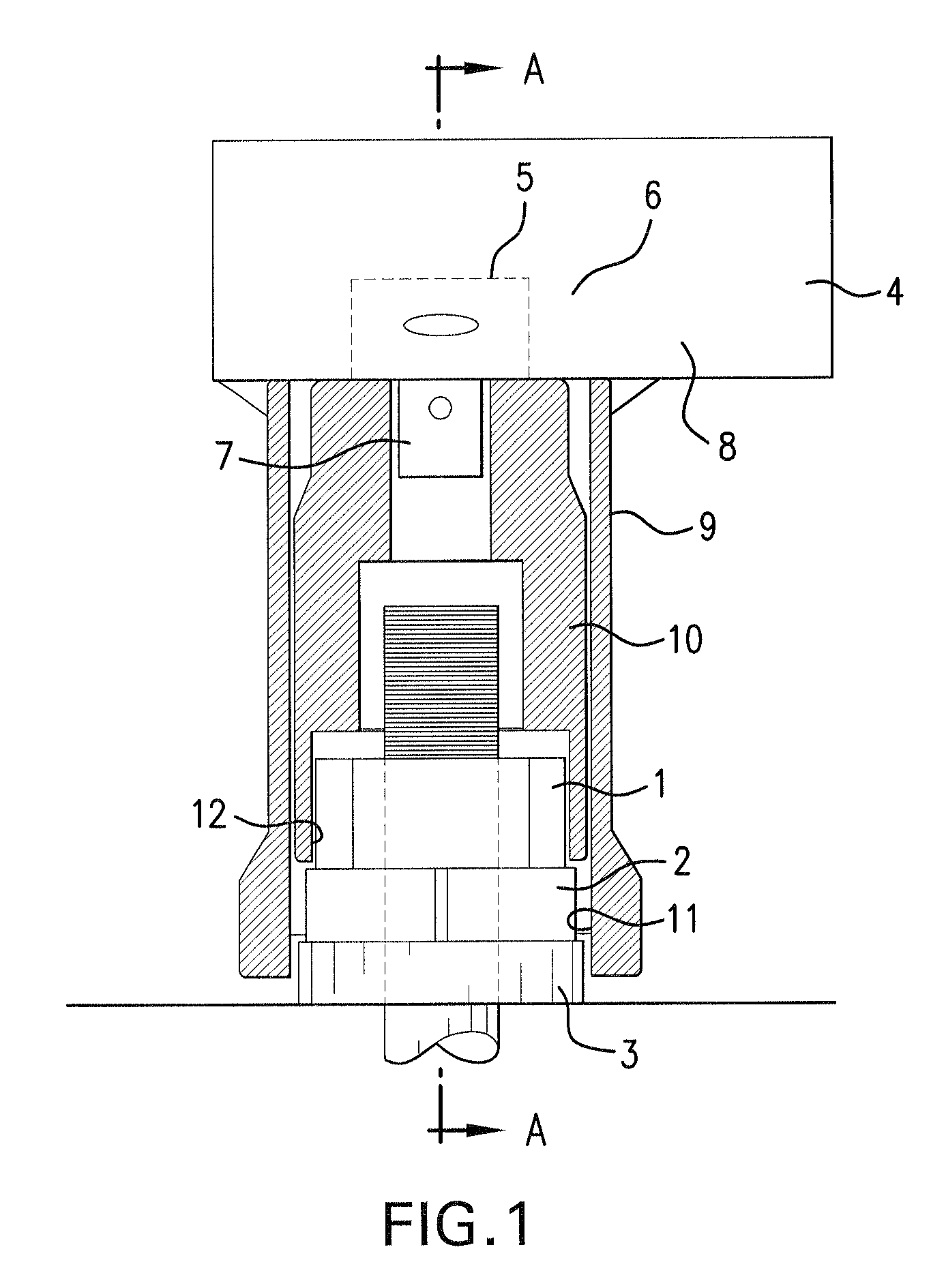

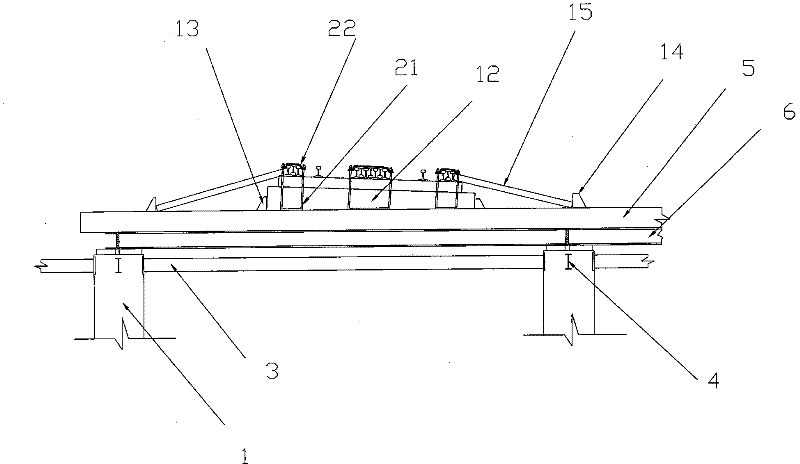

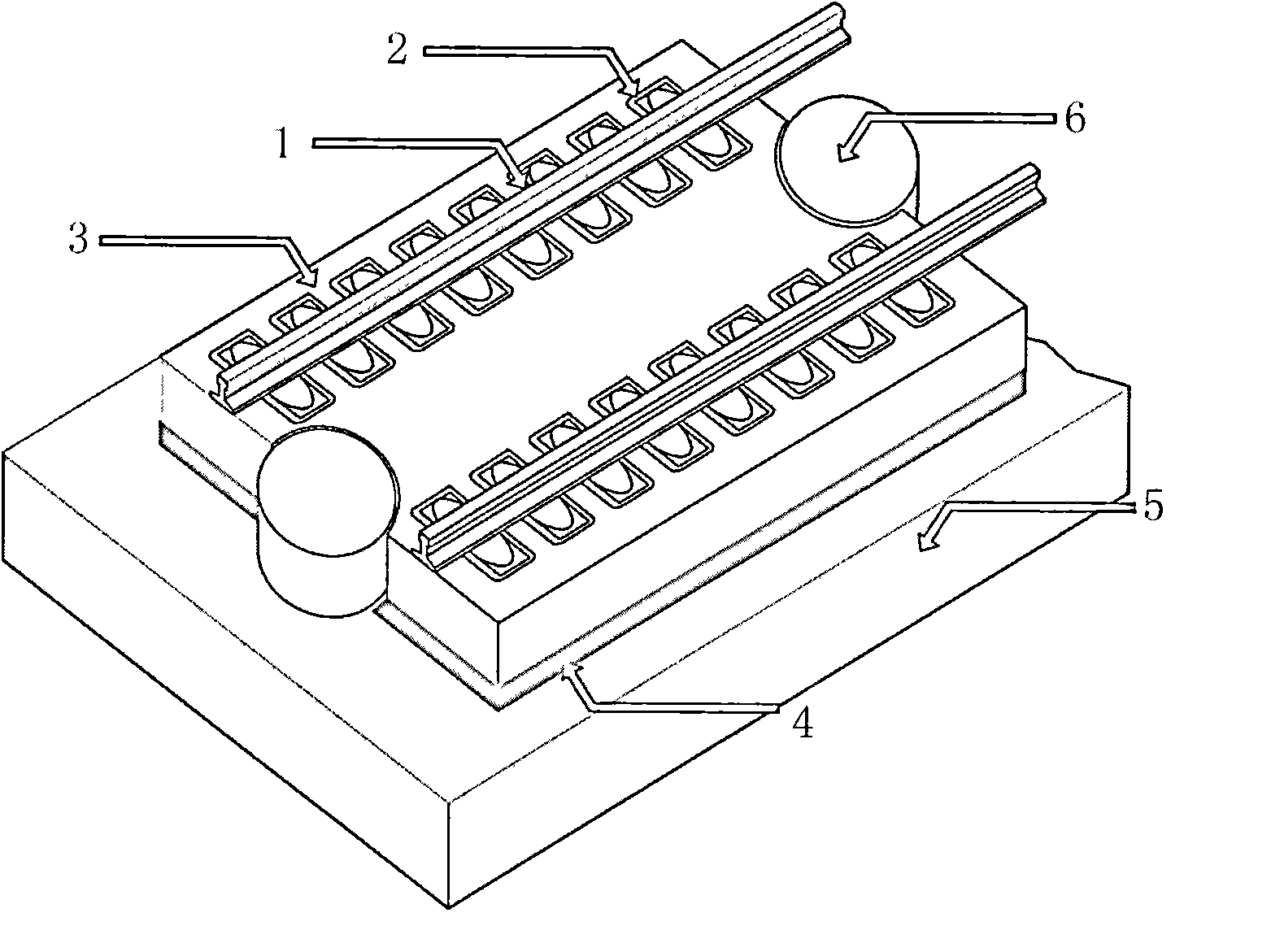

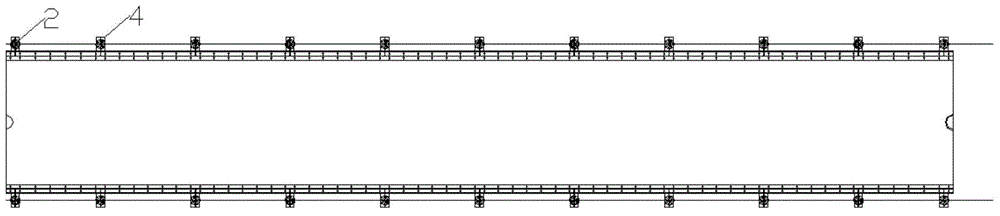

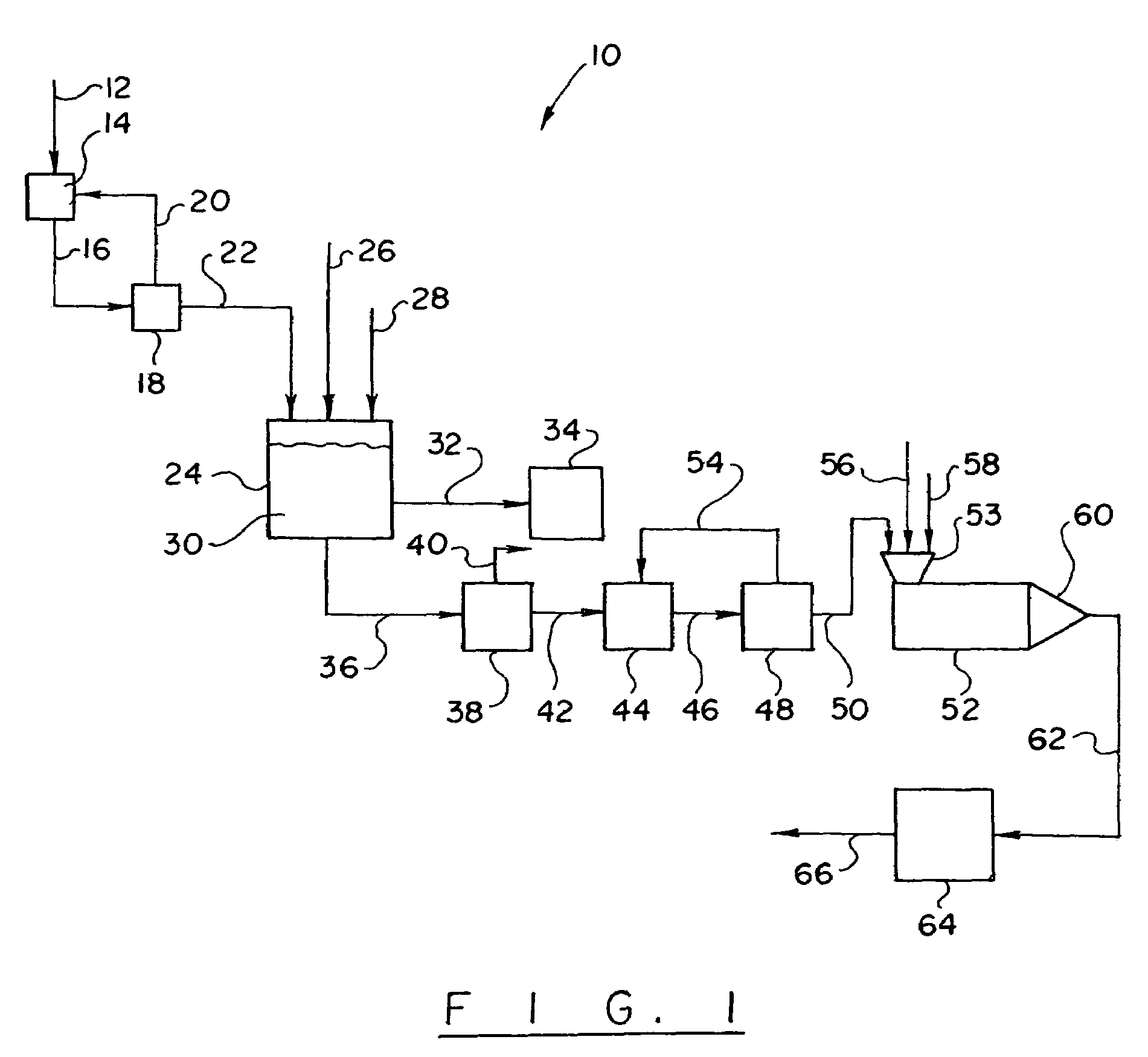

Lifting correction device and method for CRTSI mould board type ballastless track on high-speed railway roadbed

ActiveCN104928999AImprove mobilityFast constructionRailway track constructionTetrafluoroethyleneEngineering

The invention relates to a lifting correction device and method for a CRTSI mould board type ballastless track on a high-speed railway roadbed. The device comprises H-type longitudinal steel beams (1), H-type short cross beams (2), high-strength bolts (3), vertical jacks (4), tetrafluoroethylene plates (5) and vertical concrete piers (6). The H-type longitudinal steel beams (1) arranged on a base plate are fixedly connected with the base plate through the high-strength bolts (3); the H-type short cross beams (2) disposed on the outer side of the upper portion of the base plate and the H-type longitudinal steel beams (1) are directly welded and fixed; each H-type short cross beam (2) extends out of the left side and the right side of the base plate (8) for a certain distance respectively; the vertical concrete piers (6), the vertical jacks (4) and the tetrafluoroethylene plates (5) are sequentially connected on the lower sides of the H-type short cross beams (2) from bottom to top; displacement is transmitted to the base plate (8) sequentially through the tetrafluoroethylene plates (5), the H-type short cross beams (2) and the H-type longitudinal steel beams (1) by means of movement of the vertical jacks (4), and therefore the base plate (8) and a track plate (7) are lifted.

Owner:董明 +1

Thermoplastic railroad cross-ties

InactiveUS7331533B2Avoid accumulationIncrease awarenessBallastwayPlastic recyclingPolyolefinRoof tile

A process is provided for making thermoplastic-composites from recycled thermoplastics (polyolefins) together with phosphogypsum waste by-product from the phosphate fertilizer wet process or, in an equally preferred embodiment with fluorogypsum waste by-product from fluorine production wet process to produce lumber profiles. The process involves (a) admixing phosphogypsum (calcium sulfate) and / or fluorogypsum (calcium fluoride) waste byproduct and / or Flue Gas Desulfurization (FGD) gypsum and / or crude gypsum and / or calcined gypsum with thermoplastics and a functionalized compound with or without coupling agents to produce a filled thermoplastic-composite composition, and (b) melt processing the composition to produce a filled thermoplastic-composite article. The articles are preferably in the form of railroad cross ties or construction articles such as common lumber profiles, panels, tiles, poles, utility poles, crossarms for utility poles, roofing tiles, pipeline skids, pilings, marine fender-piles (including light emitting piles), bulkheads, revetments, and are useful for constructing various structures, such as oilfield board roads and equipment mats. The process avoids the accumulation of undesired phosphogypsum / fluorogypsum “stacks” and provides environmentally friendly useful products which require no chemical preservatives to prevent insect infestation or decay from the elements. Tailings from ore processing can also be used as a filler.

Owner:COMPOSITECH

Method and system for welding railroad rails

InactiveUS6207920B1Avoid lostAvoid overall overheatingRailsWelding/cutting auxillary devicesMolten steelMechanical engineering

A method of gas shielded arc welding steel rails spaced from each other to define a longitudinal gap therebetween comprises the steps of providing an elongated steel barrier plate across the gap at the bottom of the spaced rails, and filling the gap above the barrier plate with a molten steel from an advancing filler metal electrode by a gas shielded electric arc welding process. The barrier plate has a central portion received in the gap and longitudinally extending recesses laterally outwardly adjacent to the central portion and which underlie the bottoms of the rails at the bottom of the gap.

Owner:LINCOLN GLOBAL INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com