Method for post-weld heat processing of rail welded joint

A technology of post-weld heat treatment and welded joints, which is applied in the field of rail welding, can solve the problems of non-eutectoid rails and PG4 heat-treated rails, and achieve the effects of good matching of joint strength and toughness, good stability, and stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment is used to illustrate the method for the post-weld heat treatment of the rail welded joint provided by the present invention

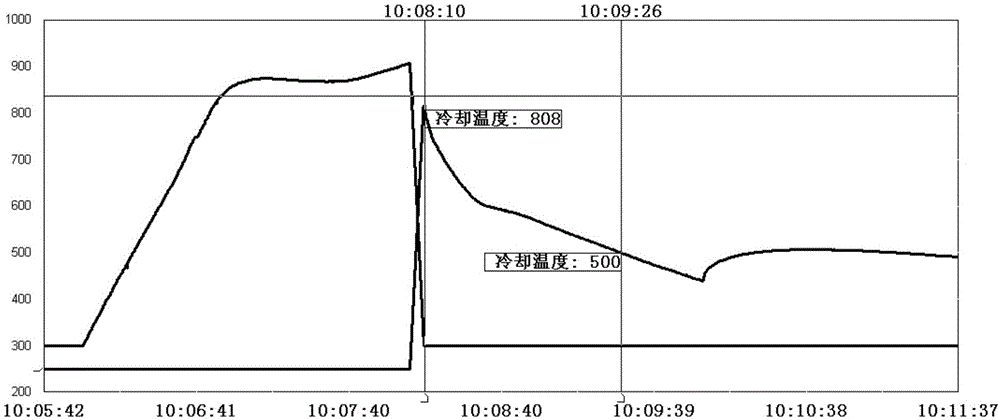

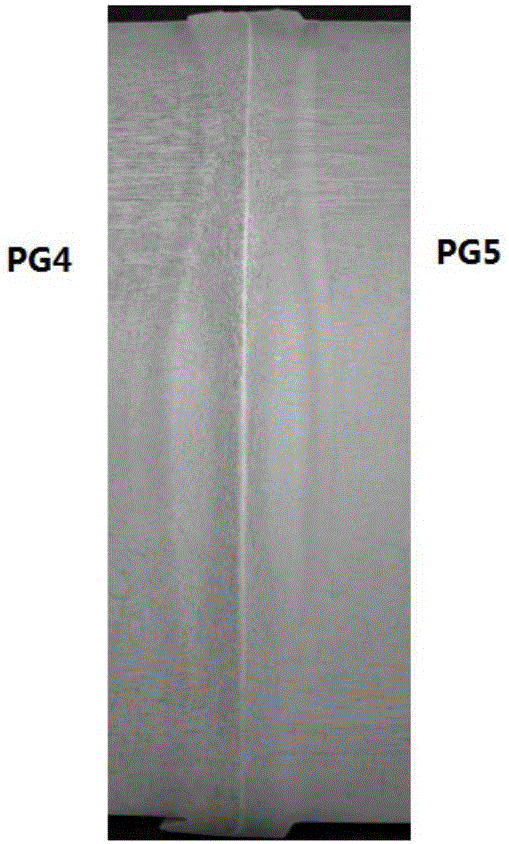

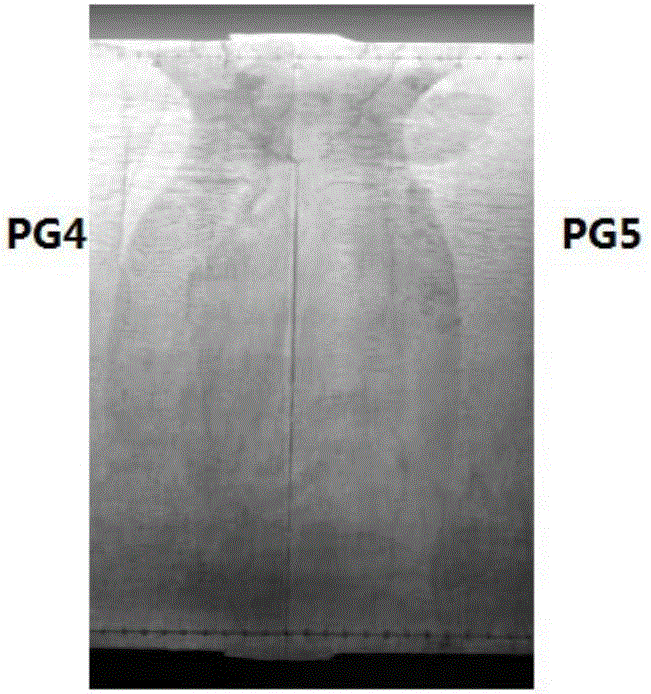

[0045] The 75kg / m PG5 hypereutectoid rail and PG4 heat-treated rail are welded by a mobile rail flash welding machine. The welding heat input in the flash flat stage is 2.5MJ, the displacement is 2.1mm, and the duration is 29s; the welding in the pulsating stage The heat input is 8.4MJ, the displacement is 10.2mm, and the duration is 81.2s; the welding heat input in the accelerated firing stage is 0.4MJ, the displacement is 11.6mm, and the duration is 26.1s; the welding heat input in the upsetting stage The displacement is 0.1MJ, the displacement is 16.9mm, and the live upsetting time is 0.4s; the holding pressure in the holding stage is 28.6t, and the duration is 15.5s. The total heat input of welding is 11.4MJ, the duration is 152.2s, the burning displacement of the rail is 40.8mm, and the welding upset is 16.9mm. The welding ...

Embodiment 2

[0057] This embodiment is used to illustrate the method for the post-weld heat treatment of the rail welded joint provided by the present invention

[0058] The 75kg / m PG5 hypereutectoid rail and PG4 heat-treated rail were welded by a mobile rail flash welding machine. The welding heat input in the flash flat stage was 2.6MJ, the displacement was 2mm, and the duration was 29s; the welding heat in the pulsating stage The input is 8.1MJ, the displacement is 10mm, and the duration is 80s; the welding heat input in the accelerated sintering stage is 0.3MJ, the displacement is 12mm, and the duration is 27s; the welding heat input in the upsetting stage is 0.08MJ, The displacement is 17.5mm, and the live upsetting time is 0.45s; the holding pressure in the holding stage is 30t, and the duration is 15s. The total heat input of welding is 11.08MJ, the duration is 151.45s, the burning displacement of the rail is 41.5mm, and the welding upsetting amount is 17.5mm. The short circuit imp...

Embodiment 3

[0063] This embodiment is used to illustrate the method for the post-weld heat treatment of the rail welded joint provided by the present invention

[0064] The 75kg / m PG5 hypereutectoid rail and PG4 heat-treated rail are welded by a mobile rail flash welding machine. The welding heat input in the flash flat stage is 2.7MJ, the displacement is 2.5mm, and the duration is 30s; the welding in the pulsating stage The heat input is 8.6MJ, the displacement is 10.5mm, and the duration is 82s; the welding heat input in the accelerated firing stage is 0.5MJ, the displacement is 10mm, and the duration is 25s; the welding heat input in the upsetting stage is 0.07 MJ, the displacement is 16.5mm, and the live upsetting time is 0.5s; the holding pressure in the holding stage is 28t, and the duration is 16s. The total heat input of welding is 11.87MJ, the duration is 153.5s, the burning displacement of the rail is 39.5mm, and the welding upsetting amount is 16.5mm. The short circuit impedan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com