130ksi steel-grade low-temperature drill rod with high toughness and corrosion resistance and manufacturing method thereof

A technology of anti-corrosion and drill pipe, applied in the direction of manufacturing tools, metal rolling, furnace types, etc., can solve the problems of material yield strength drop, impact toughness, etc., to improve the strength and toughness matching, increase the production pace, and improve the inner and outer surfaces Effects of Mass and Dimensional Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In the following, the 130ksi steel grade low-temperature high-toughness corrosion-resistant drill pipe of the present invention and its manufacturing method will be described in detail in conjunction with examples.

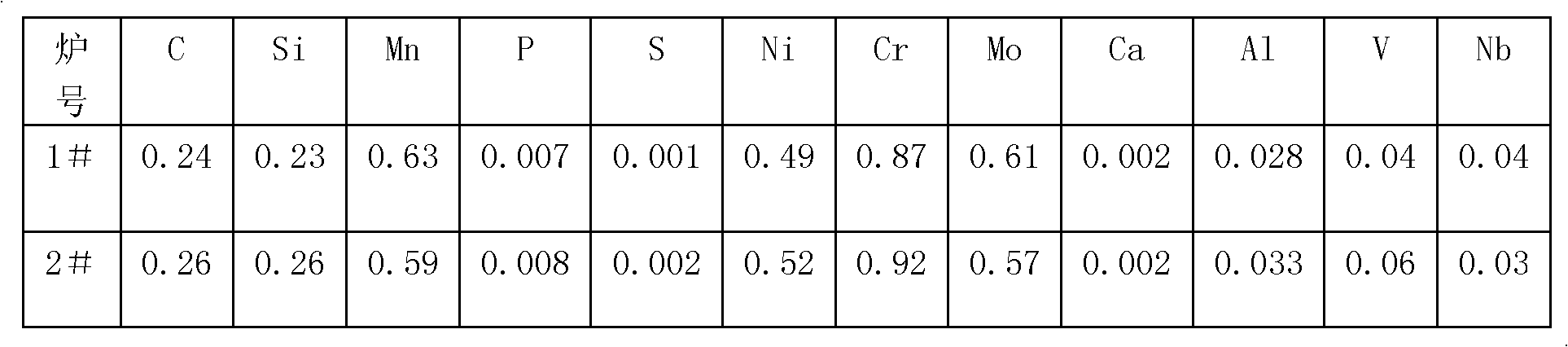

[0015] The chemical composition of the 130ksi steel-grade low-temperature, high-toughness and anti-corrosion drill pipe of the present invention contains C: 0.20-0.30%, Si: 0.15-0.40%, Mn: 0.25-0.85%, Cr: 0.45-1.25%. Mo: 0.25 to 0.85%, Ni: 0.35 to 0.85%, V: 0.03 to 0.10%, Nb: 0.01 to 0.06%, Al: 0.008 to 0.050%, Ca: 0.0015 to 0.0050%, the rest is iron, and traces of impurity elements.

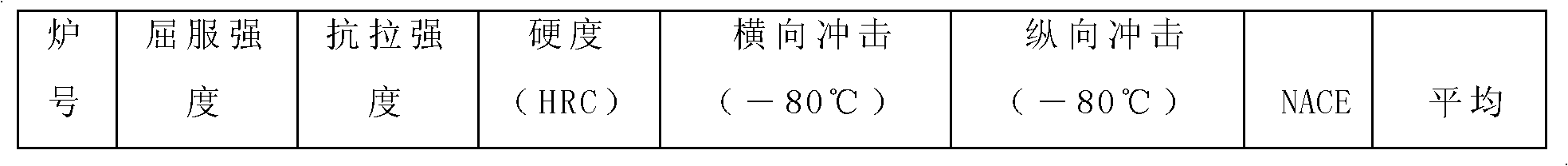

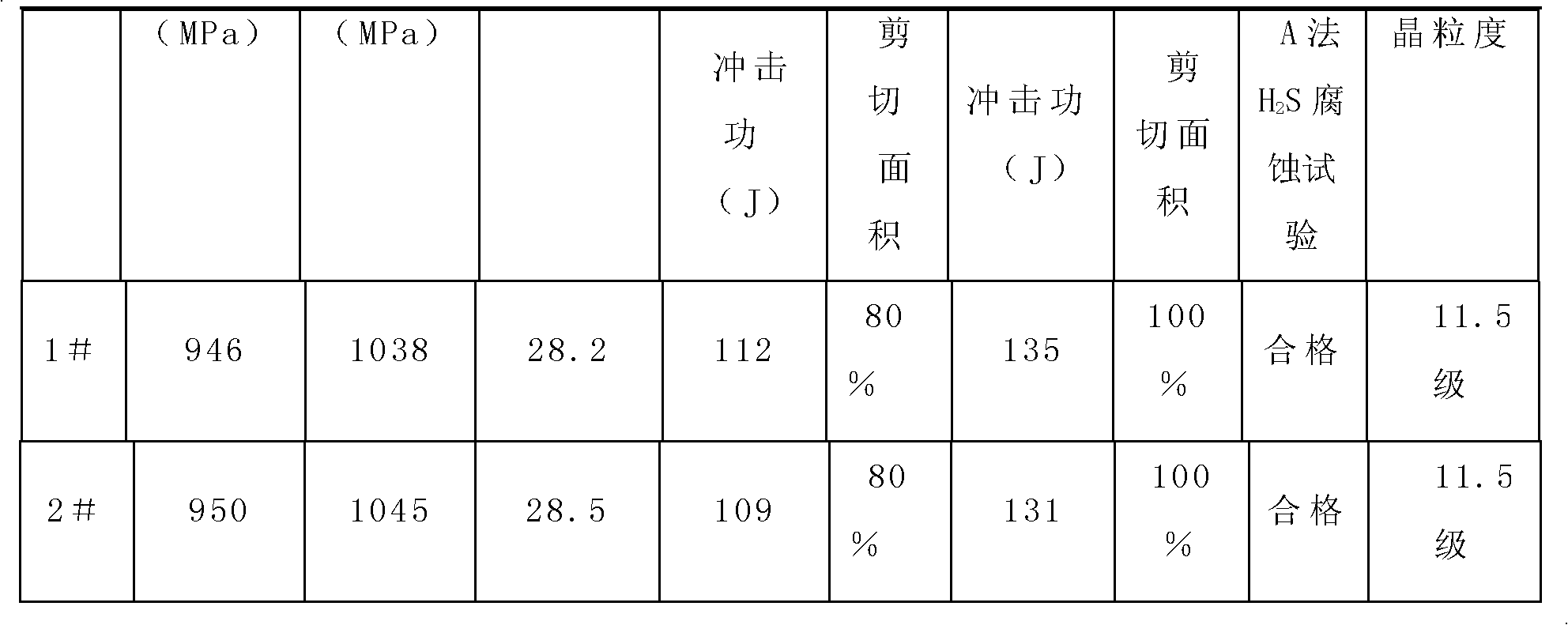

[0016] The performance index of the drill pipe is: the yield strength of the pipe at room temperature is 900-980MPa; The Charpy V-type transverse impact energy is 100-120J, and the longitudinal impact energy is 120-140J; the round bar sample of NACE test method A is under the loading force of 80% of the nominal yield strength, and is continuously exposed to saturated H for 72...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com