Patents

Literature

98results about How to "Guaranteed impact toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Al-Mg-Sc series solder wire

ActiveCN1954959AImprove crack resistanceImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaChemical compositionManganese

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Duplex stainless steel and manufacturing method thereof

The invention relates to duplex stainless steel. The duplex stainless steel comprises the following chemical components in percent by weight: 0.01-0.08% of C, 0.2-1.0% of Si, 1.5-3.5% of Mn, 19.0-21.0% of Cr, 1.2-2.8% of Ni, 0.08-0.18% of N, less than or equal to 0.5% of Mo, less than or equal to 1.0% of W, less than or equal to 1.0% of Cu and the balance of Fe and inevitable impurities; PREN (Pitting Resistance Equivalent Number) is 20-24, the martensitic temperature Md formed by strain induction is 60-130 DEG C. A manufacturing method comprises the following steps of: selecting vacuum induction smelting in an electric furnace, argon oxygen decarburization (AOD) or electric furnace, argon oxygen decarburization (AOD), external refining and LF (Ladle Furnace) smelting; carrying out die casting or continuous casting on molten steel, controlling the superheat degree to be 20-50 DEG C in die casting, matching with fast cooling, preventing nitrogen from escaping, and controlling the overheat degree to be 20-50 DEG C and the plate blank casting speed to be 0.8-2m / min; and putting a die-casting blank or a continuous casting blank into a heating furnace for heating to 1100-1250 DEG C, preserving the heat for 0.5-1.5 hours, processing the die-casting blank or the continuous casting blank on a forging production line or a hot-rolling mill group to the needed thickness, then carrying out annealing at the speed of 0.5-2.5min / mm and the temperature of 1030-1150 DEG C. The obtained duplex stainless steel has excellent corrosion resistance and TRIP effect.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

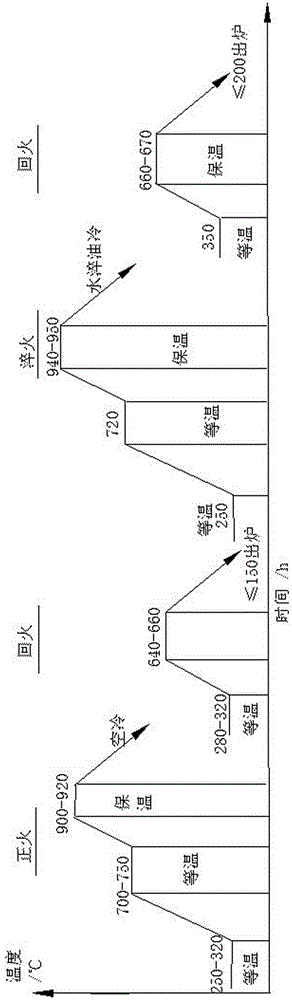

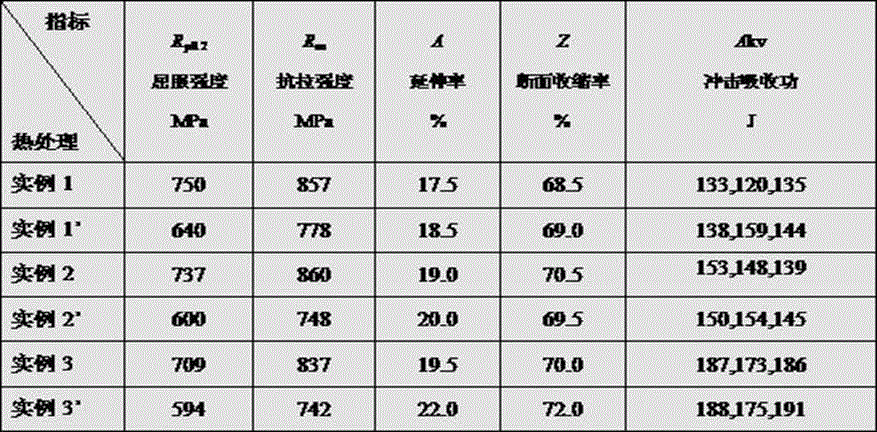

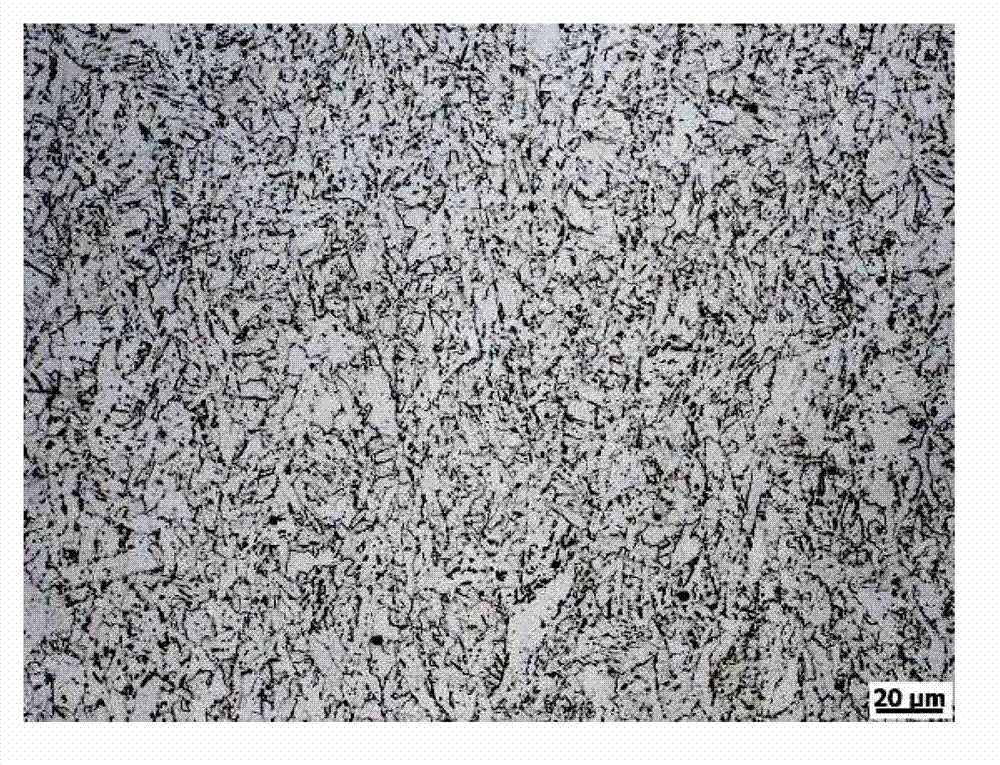

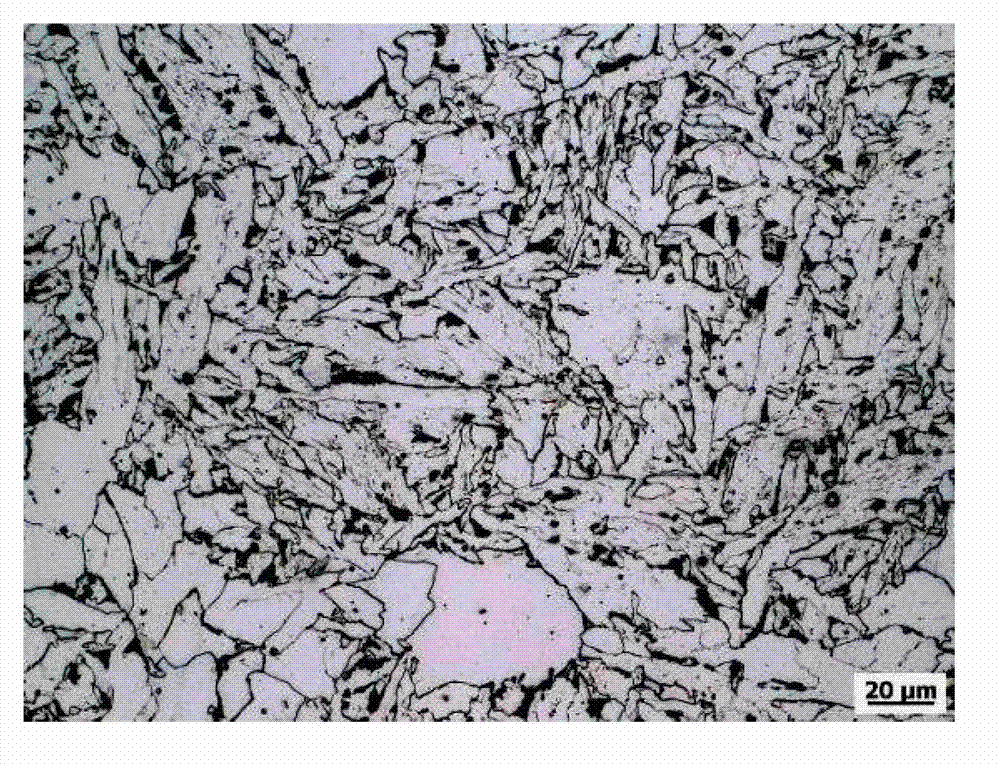

Heat treatment method for strength of 28CrMoNiV steel capable of improving industrial steam turbine rotor forge piece

A heat treatment method for strength of 28CrMoNiV steel capable of improving an industrial steam turbine rotor forge piece. The technology comprises the steps that (1), a normalizing and tempering manner is adopted in a preparation heat treatment technology and is used for refining crystalline grains and improving a material internal tissue, residual stress is reduced, and the good foundation is laid for conditioning heat treatment; a ladder heating manner is adopted in heating of normalizing and quenching, and fast heating is avoided; in the rising process, if the heating speed is too high, residual stress obtained after quenching is overlapped, and the problems that the defect of the forge piece is expanded, and even, the forge piece is cracked are possibly caused; in a quenching cooling process, a water quenching oil cooling manner is adopted, the cooling speed of a workpiece in the high-temperature stage is improved, and meanwhile, the cooling speed of a Martensite transition zone is reduced; in the water cooling initial stage, the workpiece vertically moves in a front-and-back manner in water, the quenching effect of the workpiece is fully ensured, and meanwhile, the structural stress and heat stress are reduced; in the medium heat treatment, the tempering temperature is properly reduced, impact toughness is ensured, and meanwhile, the strength of the force piece is improved.

Owner:HANGZHOU TURBINE POWER GRP +1

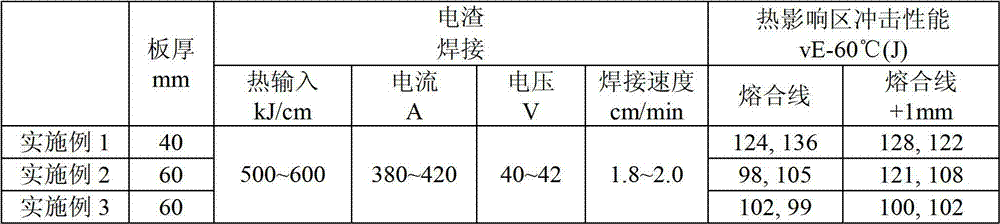

Production method of low-temperature steel plate capable of being welded by high heat input

ActiveCN102766748AImprove welding performanceImprove welding effectProcess efficiency improvementImpact energyFerrotitanium

The invention relates to a production method of a low-temperature steel plate capable of being welded by high heat input. The production method includes the steps of hot metal pretreatment, combined blown converter smelting, ladle furnace (LF) refining, RH refining, wire feeding and continuous casting, white slags are produced by LF refining, ferrotitanium is added at an RH station, vacuum breaking is performed when the temperature of molten steel reaches 1570-1600 DEG C and the content of dissolved oxygen in the molten steel reaches 20-80ppm, magnesium alloy or calcium alloy cored wires which are 200-400 meters long are fed into the molten steel at the speed of 4-6m per second and subjected to continuous casting to obtain continuous casting billets, and the continuous casting billets aresubjected to reheating and heat preservation, controlled rolling and controlled cooling to obtain the low-temperature steel plate capable of being welded by the high heat input. The steel plate is good in low-temperature toughness, Charpy impact energy of the steel plate at the temperature of -80 DEG C is larger than 47J, after the steel plate is welded by the heat input of 500-600 kJ / cm, Charpy impact energy of heat affect zones at the temperature of -60 DEG C is larger than 47J, and the steel plate can be widely applied to energy construction engineering fields of ships, low-temperature pressure containers, ocean platforms and the like.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

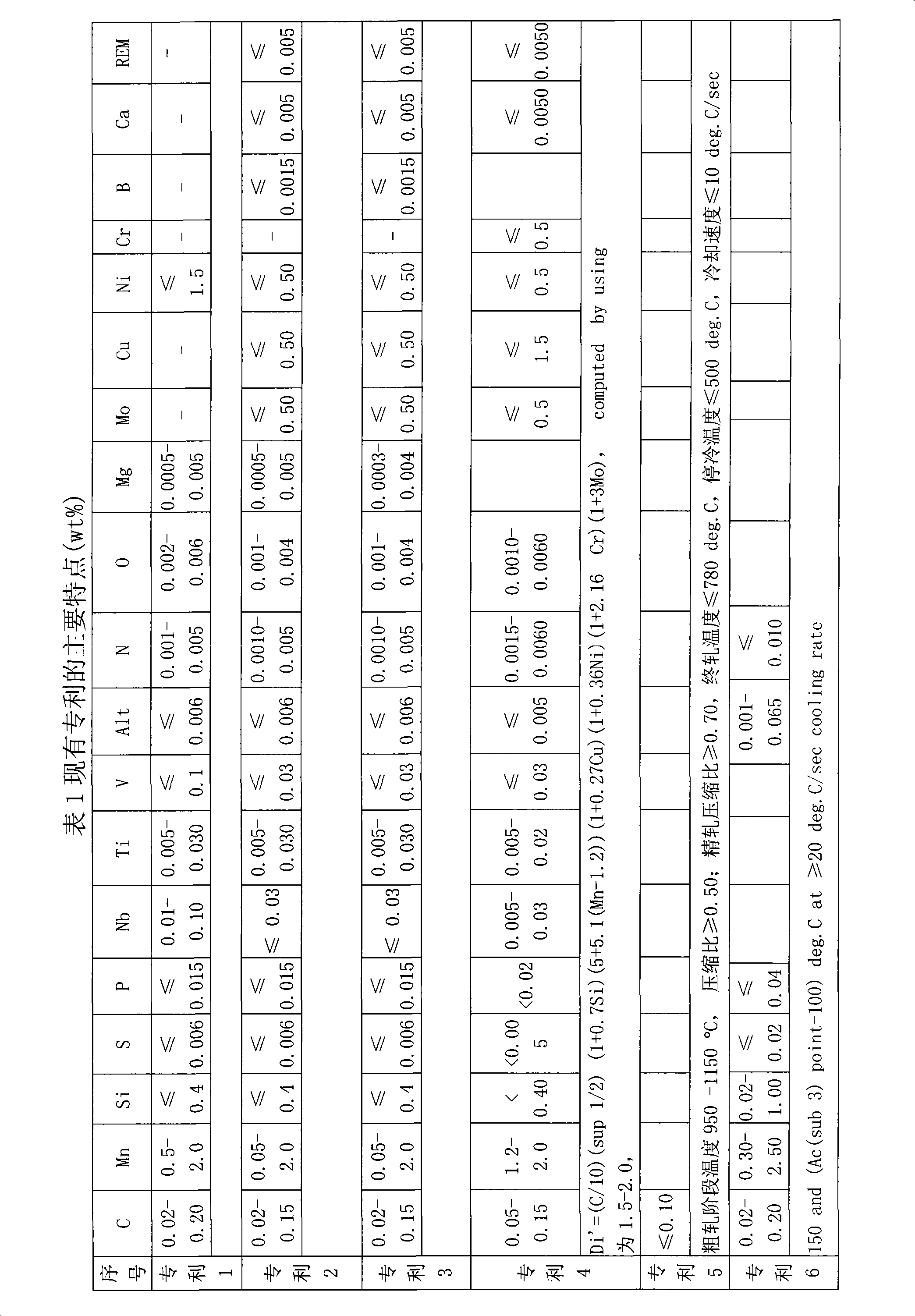

Marine 40kg heat mechanical control rolling thick plate steel and manufacturing method thereof

InactiveCN101781737ASimple configuration of ingredientsReduce manufacturing costThick plateChemical composition

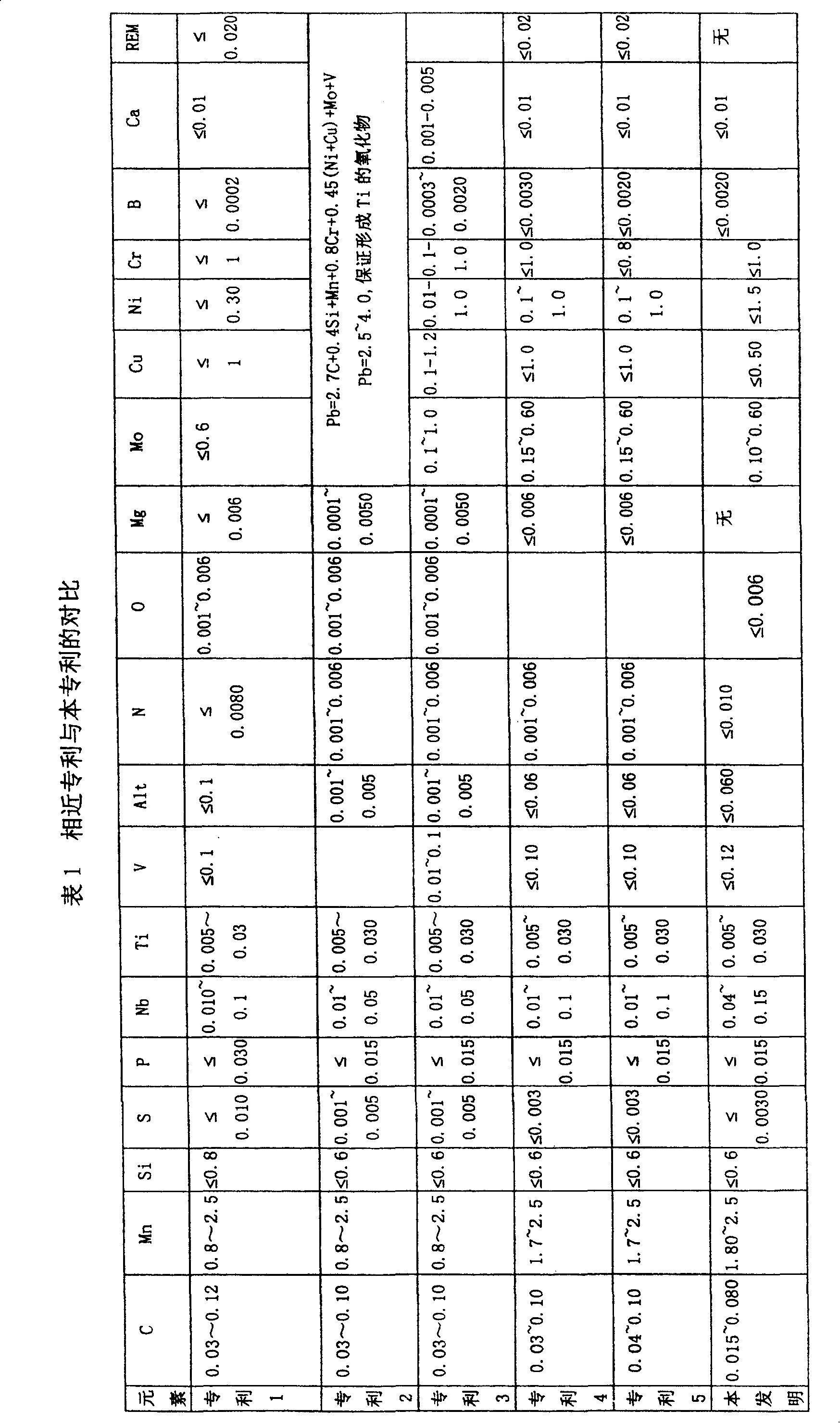

The invention discloses a TMCP-type F40 steel with excellent low-temperature toughness and a manufacturing method thereof. The TMCP-type F40 steel comprises the following chemical components in percentage by weight: 0.010-0.12 percent of C, 0.3-2.0 percent of Mn, less than 0.6 percent of Si, less than 0.0030 percent of S, less than 0.015 percent of P, 0.010-0.120 percent of Nb, 0.005-0.030 percent of Ti, less than 0.120 percent of V, less than 0.060 percent of Al, less than 0.60 percent of Mo, less than 1.2 percent of Cu, less than 1.5 percent of Ni, less than 1.2 percent of Cr, less than 0.0040 percent of B, less than 0.01 percent of Ca, 0.003-0.010 percent of N, 0.001-0.006 percent of O, less than 0.0001 percent of Mg, and the balance of Fe and other inevitable impurities. The manufacturing method comprises the steps of smelting by a revolving furnace or an electric furnace, external refining, casting, slabs reheating as well as rolling control and cooling control. The product has excellent toughness, intensity and welding performance.

Owner:BAOSHAN IRON & STEEL CO LTD

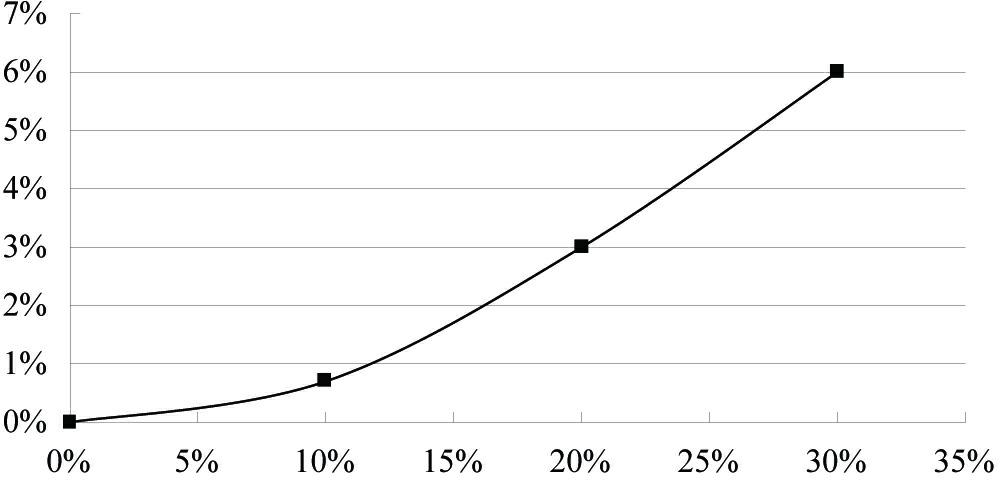

High-plasticity economical duplex stainless steel and manufacturing method thereof

The invention relates to a high-plasticity economical duplex stainless steel and a manufacturing method thereof. The high-plasticity economical duplex stainless steel comprises the following chemical components by weight part: 0.01-0.06% of C, 0.1-1.0% of Si, 0.5-4.0% of Mn, 19.5-22.0% of Cr, 1.8-3.5% of Ni, 0.1-0.18% of N, 0.5-1.3% of Mo, 0.1-1.0% of Cu and the balance of Fe and inevitable impurities. According to the invention, Ni is replaced by Mn and N, so that the cost is lowered; the contents of Cr and Mo are adjusted, so that the steel has excellent corrosion resistance, higher plasticity, excellent low-temperature toughness, and excellent welding property; the Md 30 / 50 is controlled at 50-100 DEG C; and PREN value is 23-29. Thus, the high-plasticity economical duplex stainless steel can be widely applied to an environment with higher demand on corrosion resistance and plasticity, such as heat exchanger, water tank, and the like, so that the 304 austenitic stainless steel containing 8% of nickel and the 316 stainless steel containing of 10% Ni and 2% of Mo are replaced under the conditions of room temperature and low temperature.

Owner:BAOSHAN IRON & STEEL CO LTD

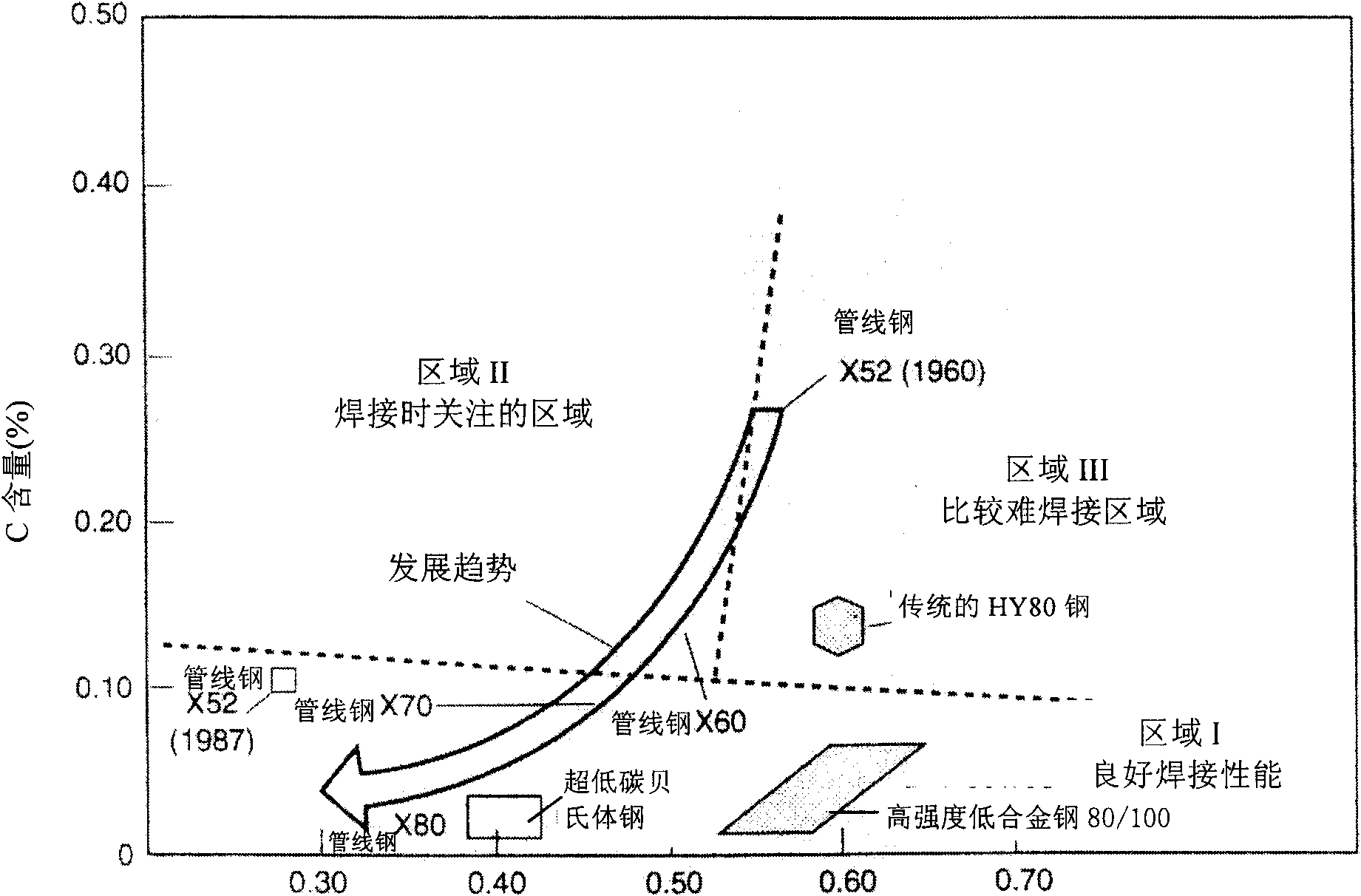

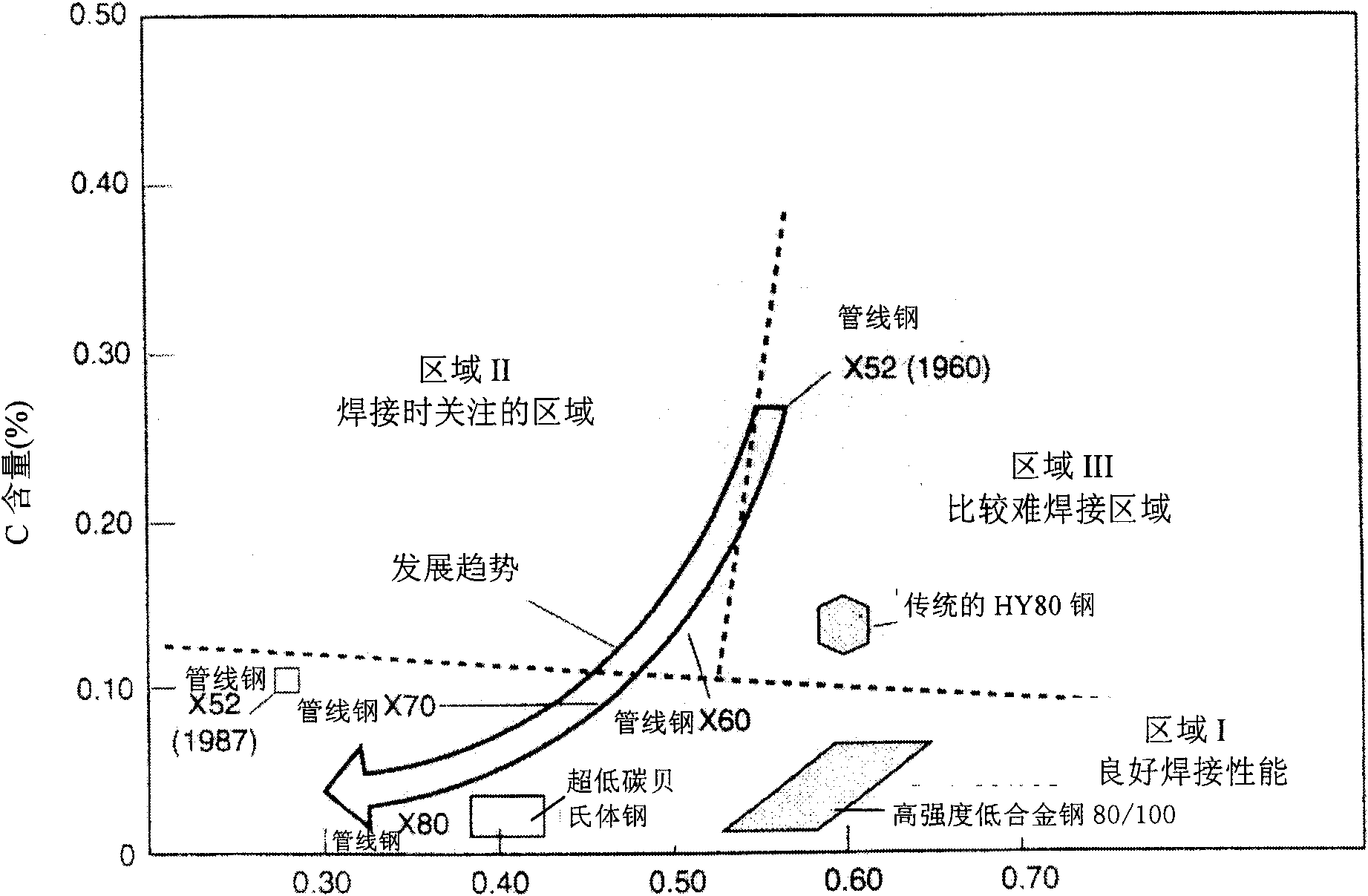

Ultrahigh-intensity high-toughness X120 pipe line steel and manufacturing method thereof

ActiveCN101165203AHas construction costsGuaranteed arrest abilityTemperature control deviceHeat treatment process controlCopperToughness

The present invention relates to one kind of high strength and high toughness X120 pipeline steel and its making process. The high strength and high toughness X120 pipeline steel consists of C 0.015-0.060 wt%, Mn 1.80-2.50 wt%, Si not more than 0.60 wt%, Ti 0.005-0.03 wt%, Al not more than 0.06 wt%, V not more than 0.15 wt%, B 0.0005-0.0030 wt%, P not more than 0.015 wt%, S not more than 0.003 wt%, Nb 0.043-0.150 wt%, N not more than 0.012 wt%, Cu not more than 0.80 wt%, Ni not more than 1.20 wt%, Cr not more than 1.20 wt%, Mo not more than 1.0 wt%, and Fe and impurity for the rest. Compared with available X80 pipeline steel, the high strength and high toughness X120 pipeline steel has 40 % higher strength and capacity of lowering pipeline constructing cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Synthesis technique of high-grade self-sharpening polycrystalline diamond

InactiveCN103521132ALow oxygenGuaranteed synthetic yieldUltra-high pressure processesIn situ polymerizationPolycrystalline diamond

The invention relates to a synthesis technique of a high-grade self-sharpening polycrystalline diamond, which comprises the following steps: metering and mixing the raw materials for synthesizing the diamond according to percentage by mass, granulating, and pressing into a synthetic stick; putting the synthetic stick into a synthesis block, and drying in a vacuum drying oven at constant temperature for later use, wherein the synthesis block is synthesized at high temperature under superhigh pressure with a cubic press; and taking out the synthetic stick, carrying out after-treatment to obtain a self-sharpening polycrystalline diamond, carrying out in-situ polymerization by a sol-gel process, and applying a zirconia coating on the diamond surface to form the high-grade self-sharpening polycrystalline diamond. The product has the advantages of favorable impact toughness, favorable thermal stability and favorable comprehensive properties, can obviously enhance the holding force of the self-sharpening polycrystalline diamond in a grinding tool, can keep the self-sharpness in the grinding process, and finally, is beneficial to prolonging the service life of th grinding tool and enhancing the machining efficiency of the grinding tool.

Owner:ZHONGYUAN ENGINEERING COLLEGE +1

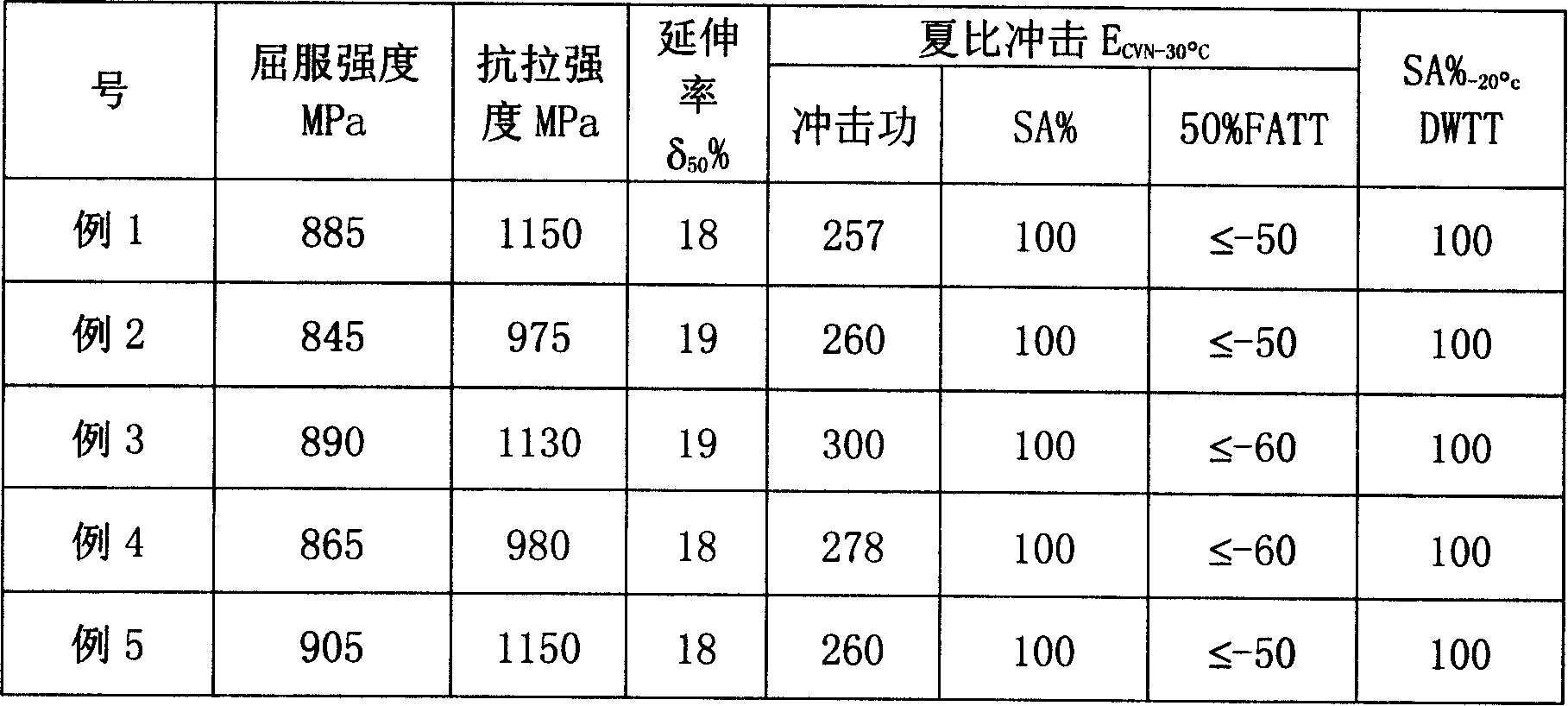

Heat treatment process of bearing ring (3m) of shield tunneling machine

InactiveCN104232875AMeet the requirements of comprehensive mechanical propertiesGuaranteed impact toughnessFurnace typesHeat treatment furnacesTemperingEngineering

The invention relates to a heat treatment process of a bearing ring (3m) of a shield tunneling machine. The method comprises the following steps: carrying out alloying design on an ordinary middle carbon alloy steel 42CrMo to obtain a steel meeting requirements of the bearing ring (3m) of the shield tunneling machine; heating a bearing ring blank produced by utilizing the steel to reach a certain temperature and carrying out heat preservation within a certain time, then carrying out oil cooling on the bearing ring blank until a room temperature reaches, carrying out high-temperature tempering on the bearing ring blank at a certain temperature and then carrying out heat preservation within a certain time, taking out the bearing ring blank and carrying out air cooling until a room temperature reaches; and carrying out induction heating on the surface of a machined bearing ring at a certain heating speed until a certain temperature reaches, and then quenching. After the experimental steel is treated by virtue of the process, the tissue of a hardening layer on the surface of the bearing ring of the shield tunneling machine is of cryptocrystalline martensite, and the matrix structure of the bearing ring is of tempered sorbite; the surface of the bearing ring is high in hardness, wherein the mean value of the hardness of the surface of the bearing ring is 57.9HRC; and the core part of the bearing ring is good in toughness and has proper hardness, wherein the mean value of the impact toughness Akv of the core part of the bearing ring at -20 DEG C is 115J, and the mean value of the hardness at the core part of the bearing ring is 293HB. Thus, the requirements of comprehensive mechanical properties of the steel for the bearing ring (3m) of the shield tunneling machine can be met.

Owner:UNIV OF SCI & TECH BEIJING

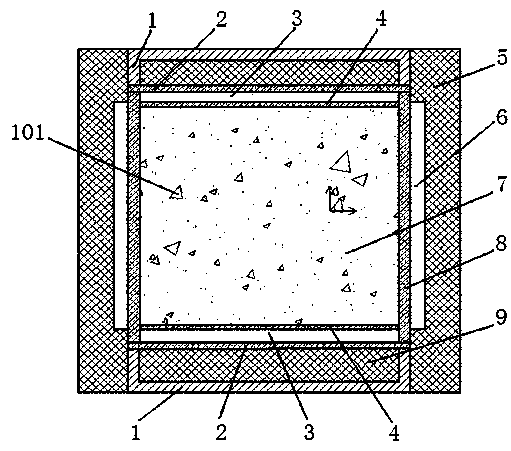

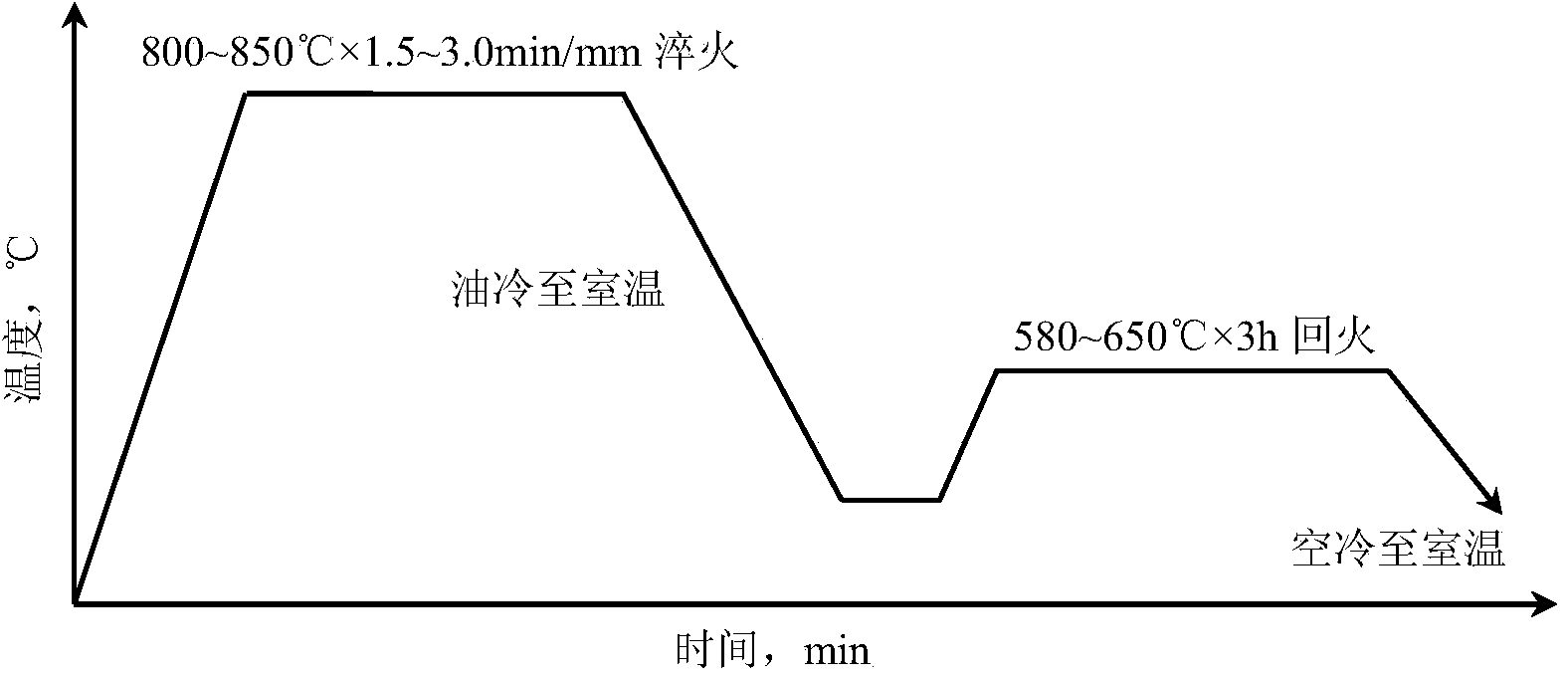

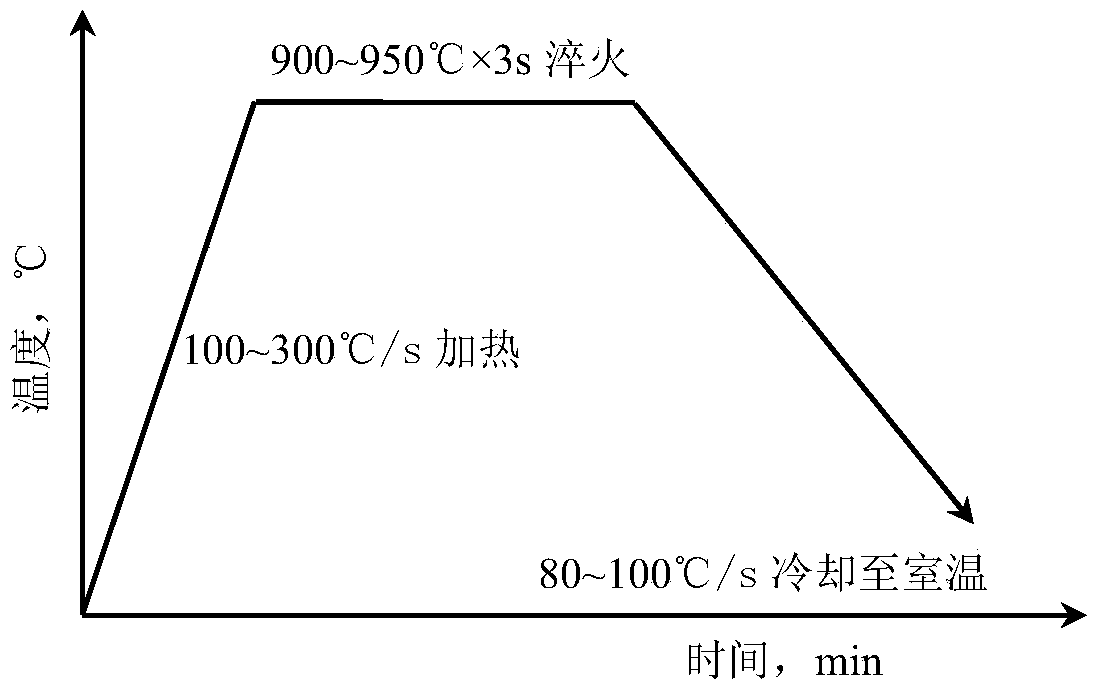

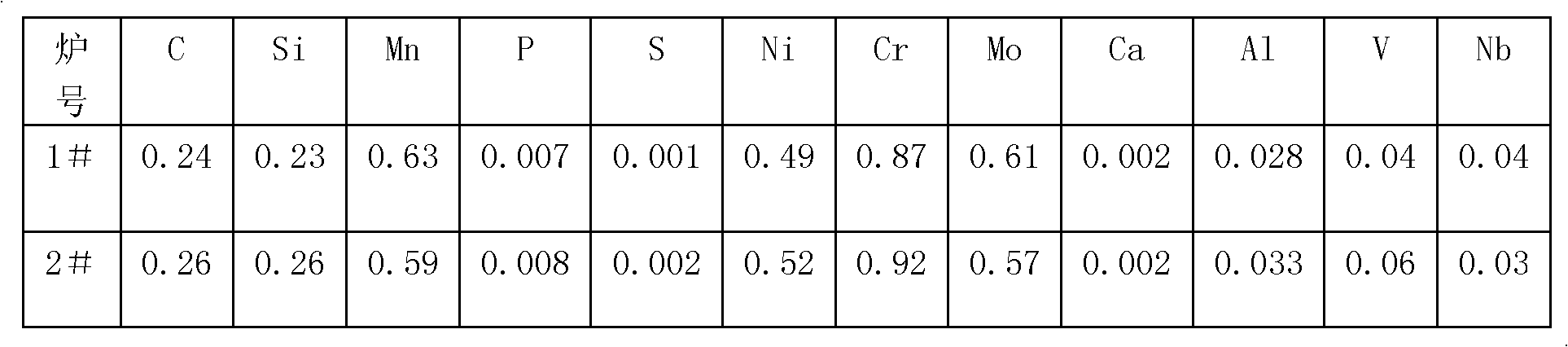

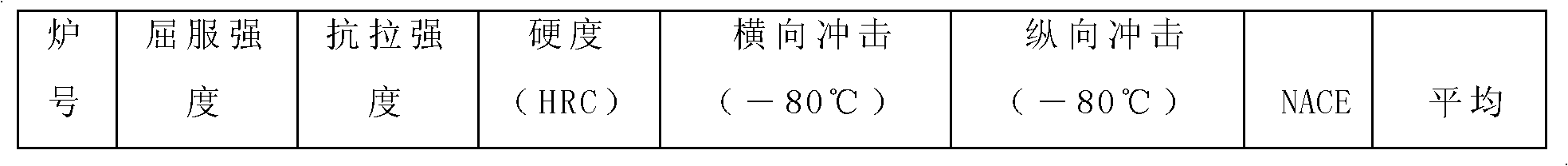

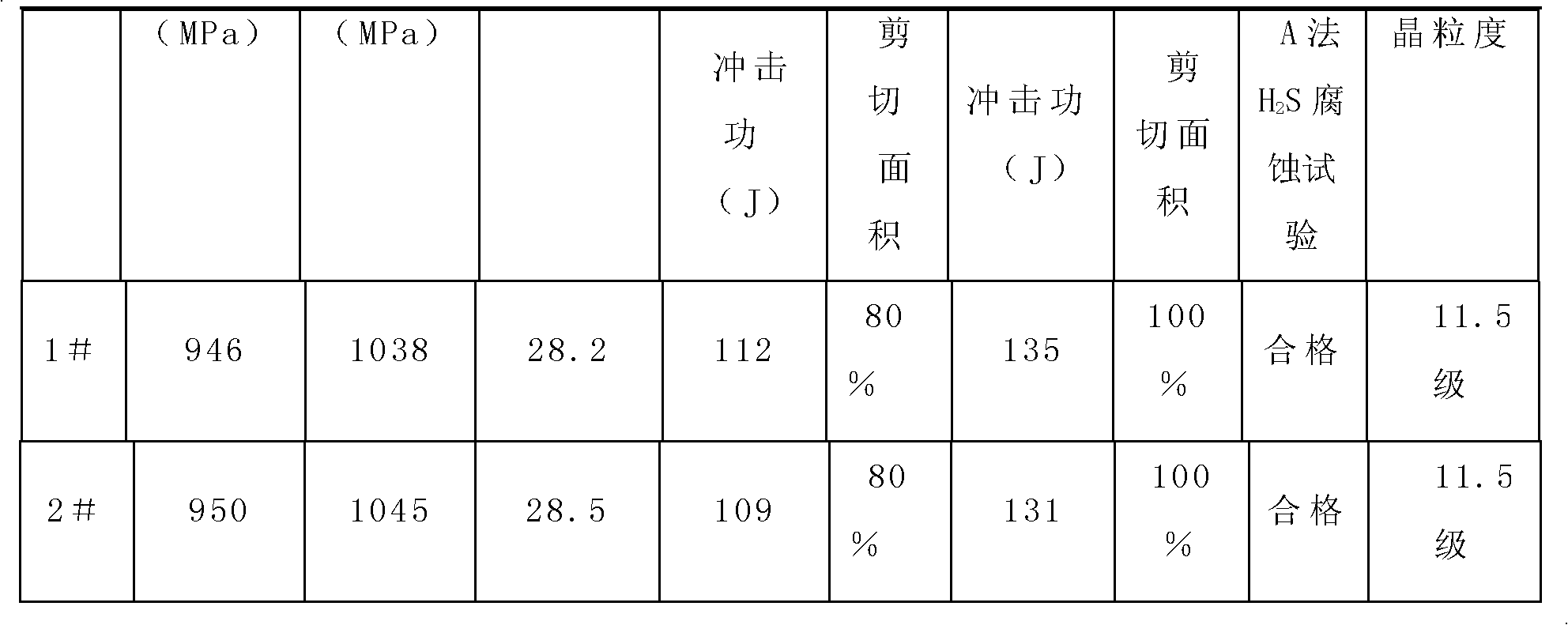

130ksi steel-grade low-temperature drill rod with high toughness and corrosion resistance and manufacturing method thereof

ActiveCN101935808AHigh strengthGood toughness matchFurnace typesMetal rolling arrangementsThermal treatmentImpurity

The invention provides a 130ksi steel-grade low-temperature drill rod with high toughness and corrosion resistance, comprising the following components in weight by percentage: 0.20%-0.30% of C, 0.15%-0.40% of Si, 0.25%-0.85% of Mn, 0.45%-1.25% of Cr, 0.25%-0.85% of Mo, 0.35%-0.85% of Ni, 0.03%-0.10% of V, 0.01%-0.06% of Nb, 0.008%-0.050% of Al, 0.0015%-0.0050% of Ca and the balance of ferrum and a trace of impurity elements. Meanwhile, the invention provides a manufacturing method of the 130ksi steel-grade low-temperature drill rod with high toughness and H2S corrosion resistance. The drill rod has the advantages that by adopting reasonable raw material components, the drill rod ensures impact toughness, favorable H2S corrosion-resistant capacity and material strength; the purity of steel is improved in a steel making process; in a rolling process, the production rhythm is improved, and the quality of the inner surface and the outer surface and the size precision of a steel tube are improved; the impact toughness and the corrosion-resistant capacity of the steel are improved by thermal treatment, and the toughness of the steel tube is improved, which is important for improving the corrosion resistance of the steel tube.

Owner:TIANJIN PIPE GROUP CORP

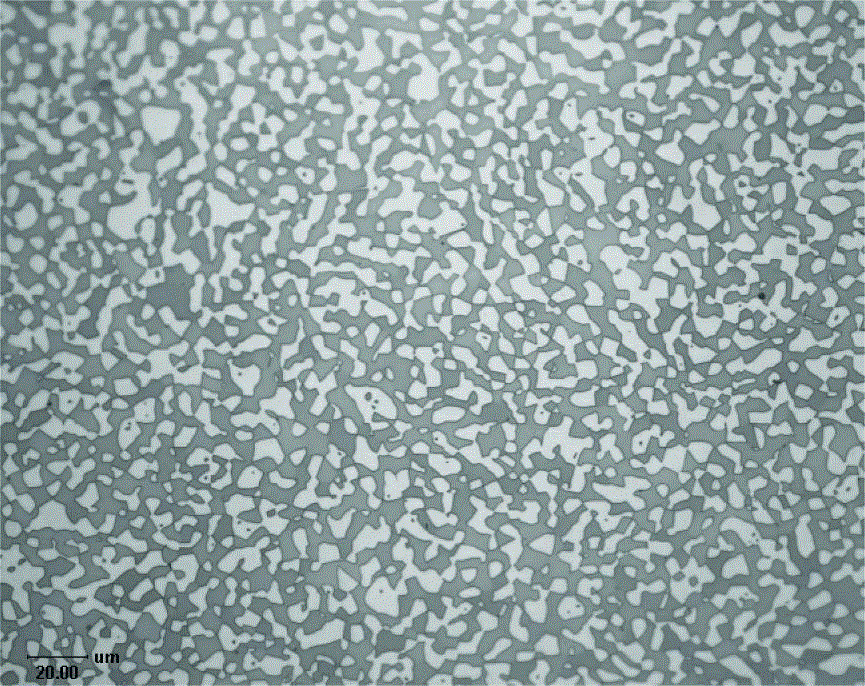

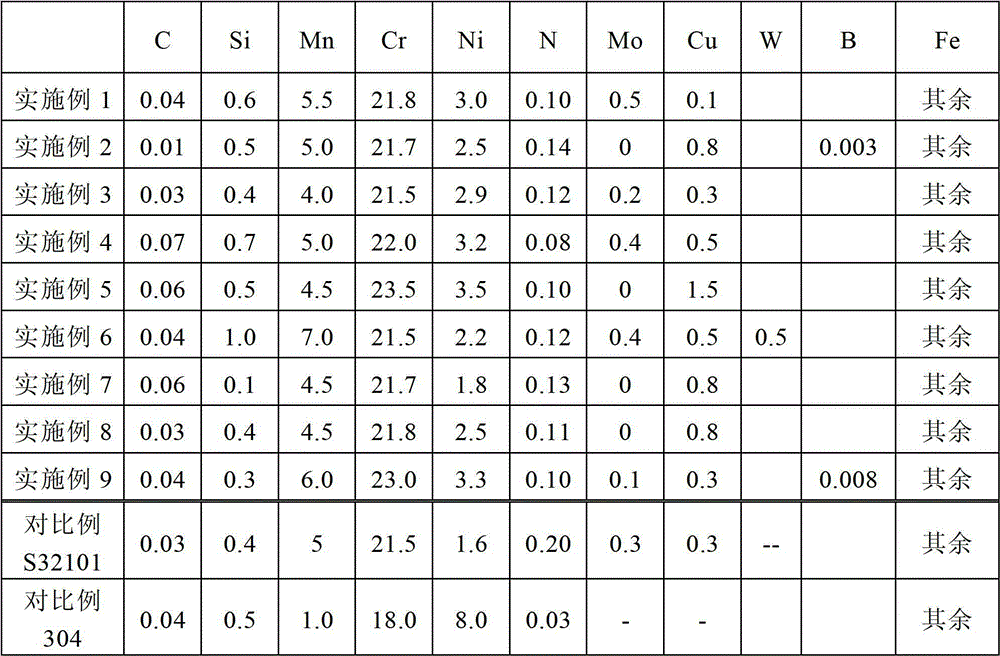

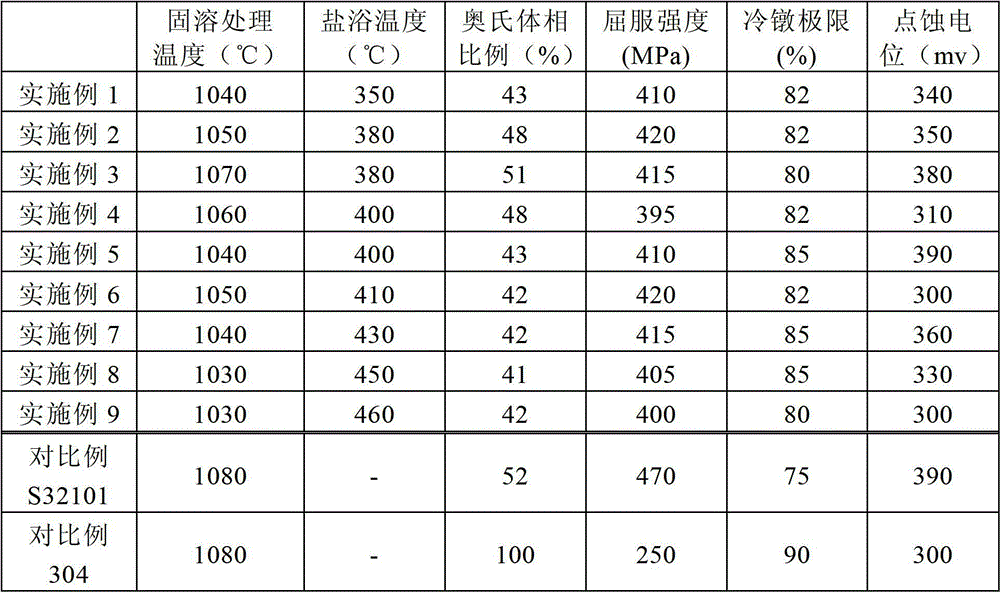

Economic duplex stainless steel with excellent cold forging performance and manufacturing method thereof

The invention discloses economic duplex stainless steel with excellent cold forging performance and a manufacturing method thereof. The economic duplex stainless steel comprises the following chemical composition in percentage by weight: 0.01 to 0.07 percent of C, 0.1 to 1.0 percent of Si, 4.0 to 7.0 percent of Mn, 21.5 to 23.5 percent of Cr, 1.8 to 3.5 percent of Ni, 0.08 to 0.15 percent of N, 0 to 0.5 percent of Mo, 0.1 to 1.5 percent of Cu and the balance of Fe and inevitable impurities. The Ni is replaced by a proper amount of Mn and N, in order to guarantee the corrosion resistance of the alloy, the Cr content is controlled to 21.5 to 23.5 percent, and 0 to 0.5 percent of Mo is added; in order to reduce the yield strength and work-hardening rate of materials and improve the cold forging performance of the materials, the N content is controlled between 0.08 and 0.15 percent, and 0.1 to 1.5 percent of Cu is added. The economic duplex stainless steel has excellent corrosion resistance and excellent cold forging performance and can be applied to stainless steel fasteners, silk screen and other industries in a large scale under the condition that the content of the Ni, Mo and other precious metals is low, and 304-austenitic stainless steel with high cost is partially substituted.

Owner:宝武特种冶金有限公司

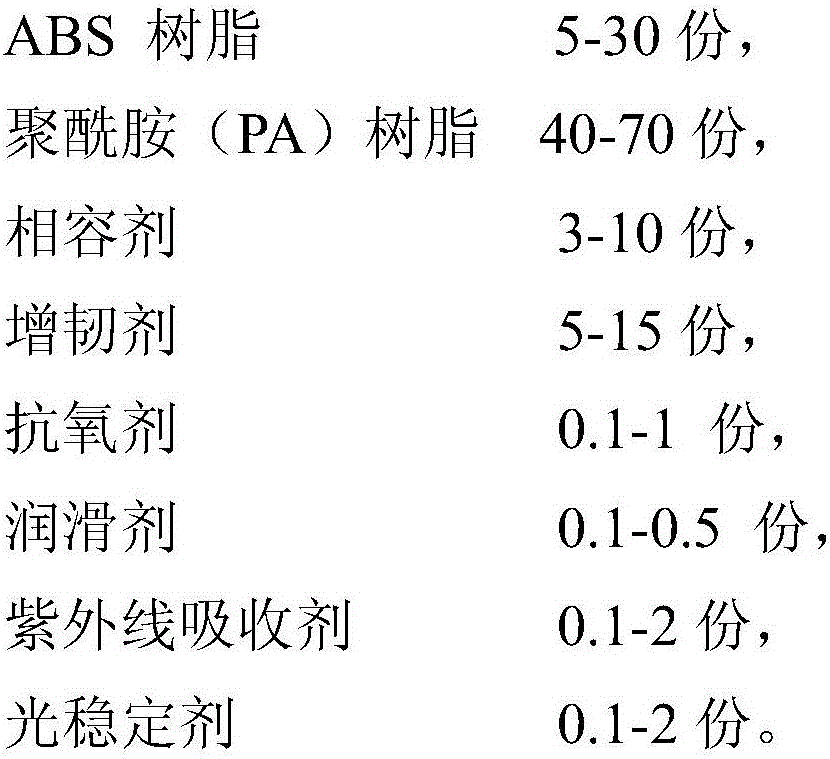

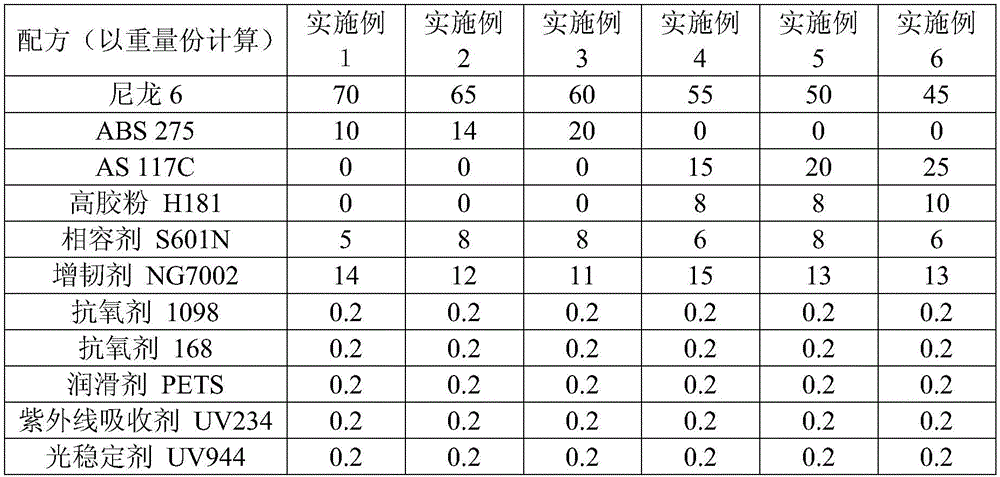

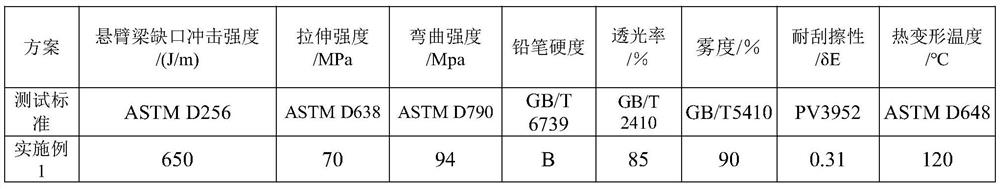

High-heat-resistance high-impact PA/ABS alloy material

InactiveCN106700524AGuaranteed CompatibilityGuaranteed impact toughnessHeat resistanceUltraviolet lights

The invention relates to the field of macromolecular materials, in particular to a high-heat-resistance high-impact PA / ABS alloy material. The high-heat-resistance high-impact PA / ABS alloy material consists of the following components in parts by weight: 5 to 30 parts of ABS resin, 40 to 70 parts of PA resin, 3 to 10 parts of a compatilizer, 5 to 20 parts of a toughening agent, 0.1 to 1 part of an antioxidant, 0.1 to 0.5 part of a lubricating agent, 0.1 to 2 parts of an ultraviolet light absorber and 0.1 to 2 parts of a light stabilizer. According to the high-heat-resistance high-impact PA / ABS alloy material, the proper compatilizer is selected to guarantee the compatibility of the PA / ABS alloy; the proper toughening agent is selected to improve the heat resistance of the material on the premise of guaranteeing the impact toughness of the material; proper PA and ABS raw materials and proportion thereof are selective to guarantee high impact and high heat resistance of the material; the Vicat temperature of high-heat-resistance alloy material can reach 140 DEG C, the notch impact toughness is 400 J / m, and the high-heat-resistance high-impact PA / ABS alloy material can be applied to the fields of electronic and electrical appliances, automobiles and the like.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

Polycarbonate resin / styryl resin non-halogen flame-retardant composite material

The invention relates to the technical field of the high polymer materials, in particular to a halogen-free flame-retardant compound material consisting of polycarbonate resin and acrylonitrile-styrene-acrylate. The halogen-free flame-resistant compound materials comprise polycarbonates (PC), acrylonitrile-styrene-acrylates, anti-flamming agents, and antioxidant additives. The invention is characterized in that the compound materials also comprise nanometer kaolin accounting for 3 per cent to 20 per cent of the total weight. The invention enhances the rigidity of the material, greatly improves the size stability of the material and maintains the impact ductility of the material simultaneously.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

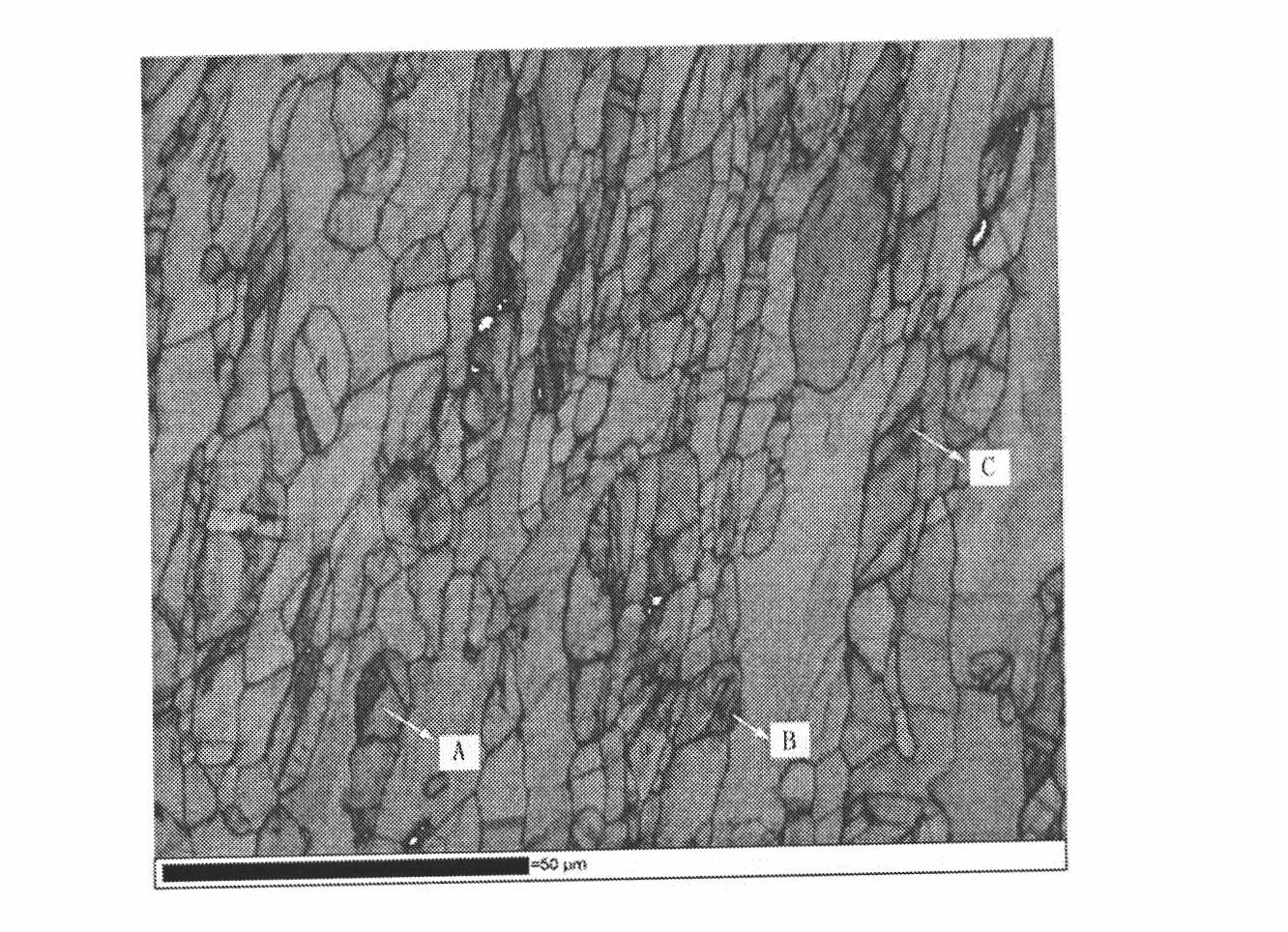

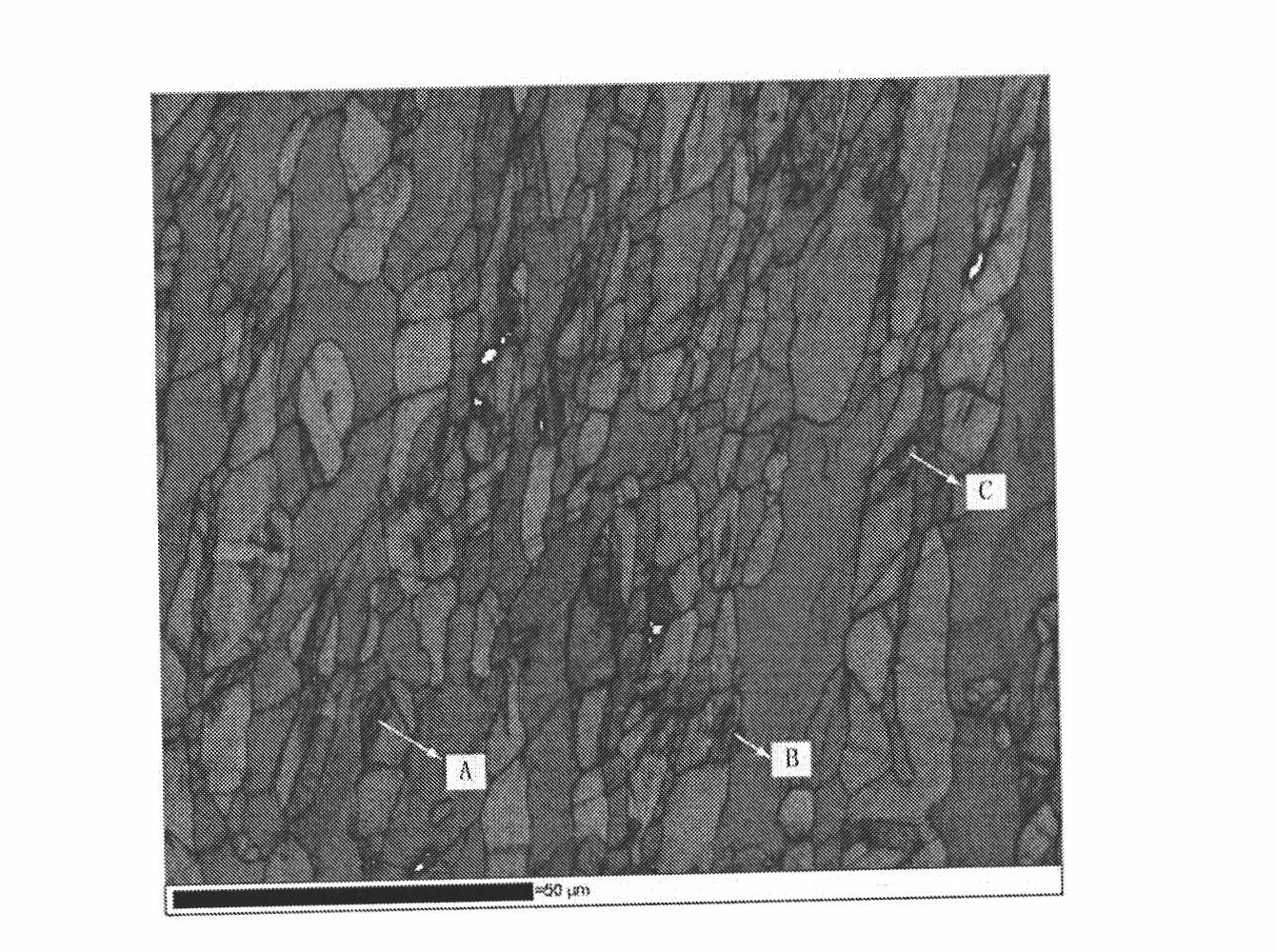

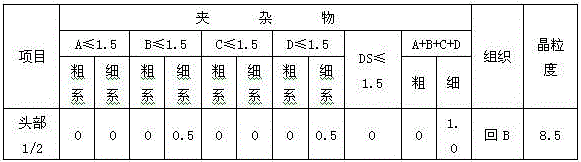

High-end bearing steel material for machine tool and production process thereof

ActiveCN110257716AImprove purityEvenly distributedProcess efficiency improvementElectric furnaceRare-earth elementNumerical control

The invention relates to a high-end bearing steel material for a machine tool and a production process of the high-end bearing steel material, and belongs to the technical field of special steel smelting. The high-end bearing steel material for the machine tool and the production process of the high-end bearing steel material aim to solve the problem that the properties such as wear resistance and contact fatigue strength of an existing bearing steel material cannot meet the requirements of a high-end numerical control machine tool, and the production process comprises electric furnace treatment, LF refining and VD process, die casting, hot delivery / cover cooling, primary heating rolling cogging, slow cooling, secondary heating rolling and spheroidizing annealing. Ni, Mo and rare earth elements are added on the basis of existing bearing steel, the content of Al and Cu is strictly controlled, and a good mechanical property index is provided for steel materials, and the produced bearing steel material has high elasticity limit, tensile strength, contact fatigue strength and wear resistance, can effectively reduce the phenomena of material fatigue flaking, clamping and the like and is applicable to manufacturing a bearing ring and a rolling body and needle with the wide size range for the machine tool.

Owner:建龙北满特殊钢有限责任公司

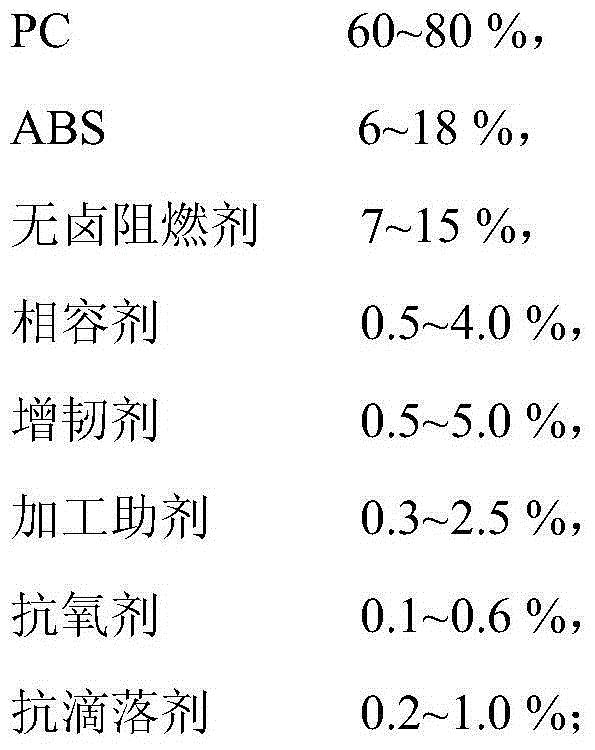

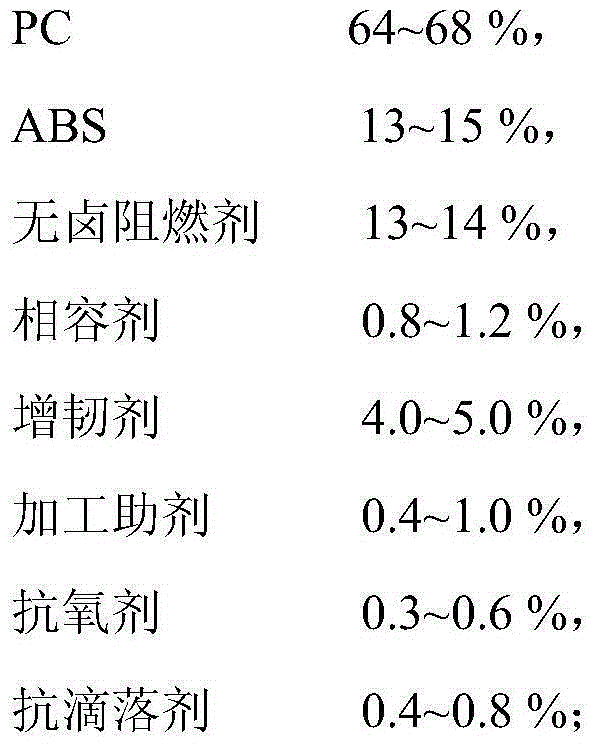

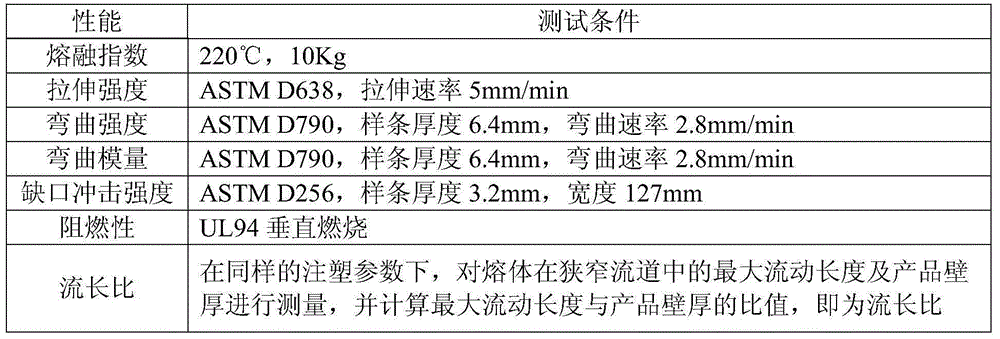

Halogen-free flame-retardant high-liquidity PC/ABS material used for shells of TV sets and preparation method of PC/ABS material

The invention provides a halogen-free flame-retardant high-liquidity PC / ABS material used for shells of TV sets and a preparation method of the PC / ABS material. The PC / ABS material is prepared from, by weight, 60-80% of PC, 6-18% of ABS, 7-15% of halogen-free flame retardants, 0.5-4.0% of compatilizers, 0.5-5.0% of toughing agents, 0.3-2.5% of machining auxiliaries, 0.1-0.6% of antioxidants and 0.2-1.0% of anti-dripping agents, wherein the PC is composed of polycarbonate with the molecular weight being 10,000-40,000 and the melt index being 20-30 g / 10min, and the ABS is acrylonitrile-butadiene-styrene copolymer with the liquidity being 20-40 g / 10min and the weight percent being 10-40%. According to the halogen-free flame-retardant high-liquidity PC / ABS material, due to the fact that the halogen-free flame retardants, the compatilizer, the toughing agents, the machining auxiliaries, the antioxidants and the anti-dripping agents are added in the selected PC and ABS base materials, the PC / ABS alloy material is good in liquidity and can meet the forming requirement of large thin-walled products, meanwhile, impacting toughness of the thin-walled products can be guaranteed, and the PC / ABS material is mainly applied to shells of TV sets, shells of printing machines and other large thin-walled electronic and electric products, can replace imported products such as Korea Sanyang PC / ABS NH-1000T and has large cost advantages.

Owner:FENGHUA XURI HONGYU

Low-alloy low-yield-ratio steel for oceaneering structure and production method thereof

Provided are a low-alloy low-yield-ratio steel for an oceaneering structure and a production method thereof. The steel contains the following chemical components by mass: 0.09-0.13% of C, 0.15-0.40% of Si, 0.80-1.50% of Mn, 0.01-0.04% of Alt, 0.02-0.04% of Nb, 0.008-0.018% of Ti, less than 0.015% of P, less than 0.005% of S and the balance, Fe and unavoidable impurities. The production method includes that thick plate slabs of 250-400mm are heated before being rolled with heating temperature as 1180-1260 DEG C, rolling is divided into two stages, start rolling temperature at an austenite recrystallization area is 1000-1100 DEG C, start rolling temperature at an austenite non-recrystallization area is 850-950 DEG C, finishing rolling temperature is 790-820 DEG C, the thick plate slabs enter a water cooling area after being rolled with cooling speed as 9-12 DEG C / s and fishing cooling temperature as 450-500 DEG C, and steel plates are cooled in heap for more than 12 hours after being taped out. The steel has the advantages of good strength, low yield ratio, good toughness and good lamellar tearing resistant performance, thereby being capable of being used in oceaneering structure construction under severe conditions.

Owner:SHOUGANG CORPORATION

Making method of lightweight rubber shock absorption member for automobile

ActiveCN103640143AAvoid degradationAvoid morphological changesDomestic articlesVulcanizationEngineering

The invention discloses a making method of a lightweight rubber shock absorption member for an automobile. The rubber shock absorption member is characterized in that the rubber shock absorption member is composed of a rubber mainspring, a plastic support and a metal insert, and the making method comprises the steps of vulcanization, gluing, drying, assembling, injection molding, cooling and moisture absorption. The method has the advantages of simple technology and low cost, and the lightweight rubber shock absorption member made through the method has a good performance and a long service life.

Owner:NINGBO TUOPU GROUP CO LTD

Bumper material with low linear expansion coefficient and preparation method of bumper material

The invention provides a preparation method of a bumper material with a low linear expansion coefficient. By means of the method, the modified bumper material has the low linear expansion coefficient and simultaneously keeps an excellent mechanical property. The bumper material comprises components in parts by mass as follows: 40-90 parts of polypropylene resin, 5-30 parts of inorganic filler, 5-30 parts of styrene elastomer without double bonds and 0.2-0.4 parts of an antioxidant. The bumper material prepared through blending and extrusion of the components has the low linear expansion coefficient and the excellent mechanical property, the size stability of the bumper can be effectively improved, the assembly accuracy of the bumper is improved, and the regional limitation to production and assembly of the bumper is overcome.

Owner:NANJING JINSHAN AUTOMOBILE ENG PLASTIC

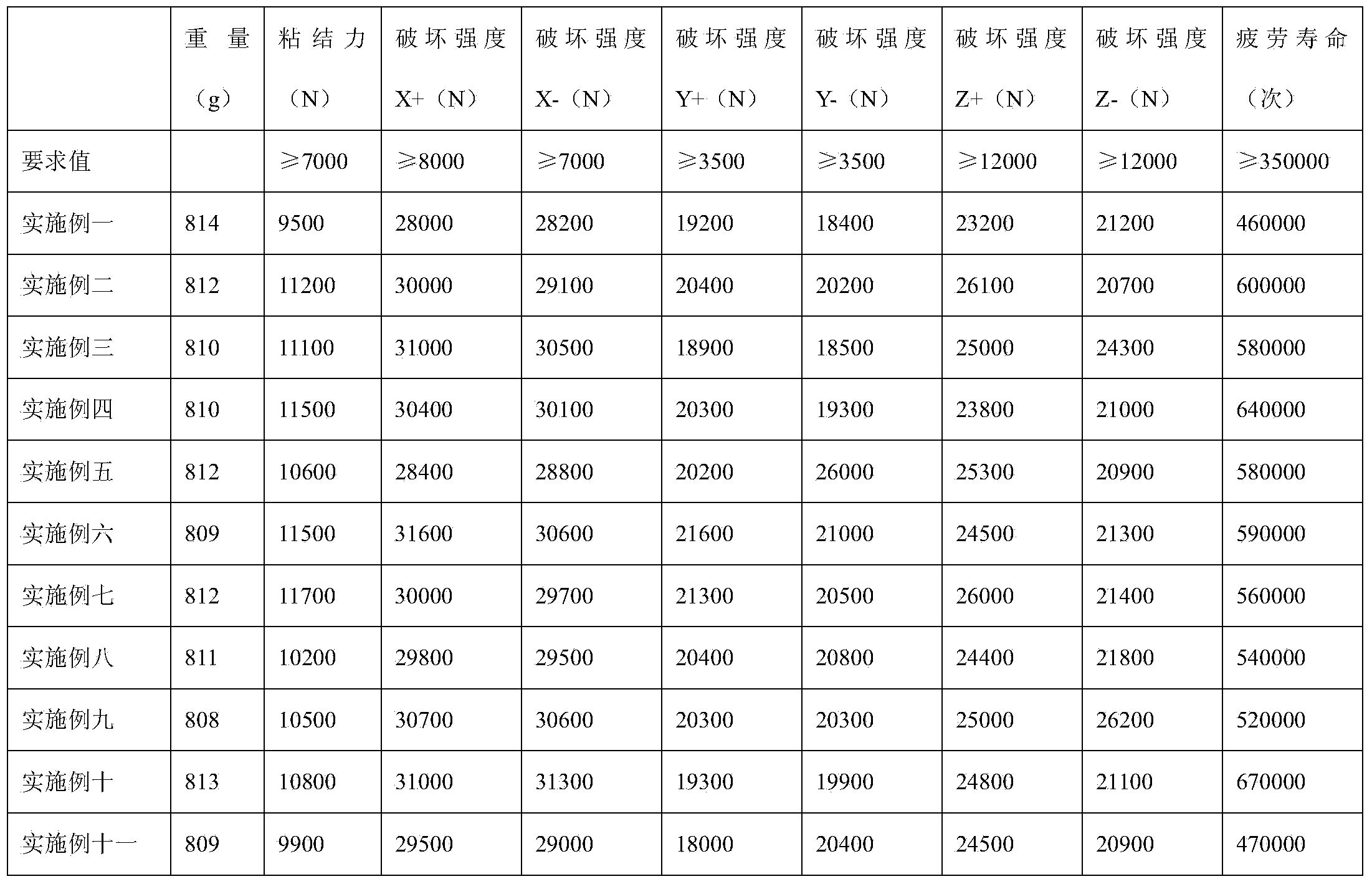

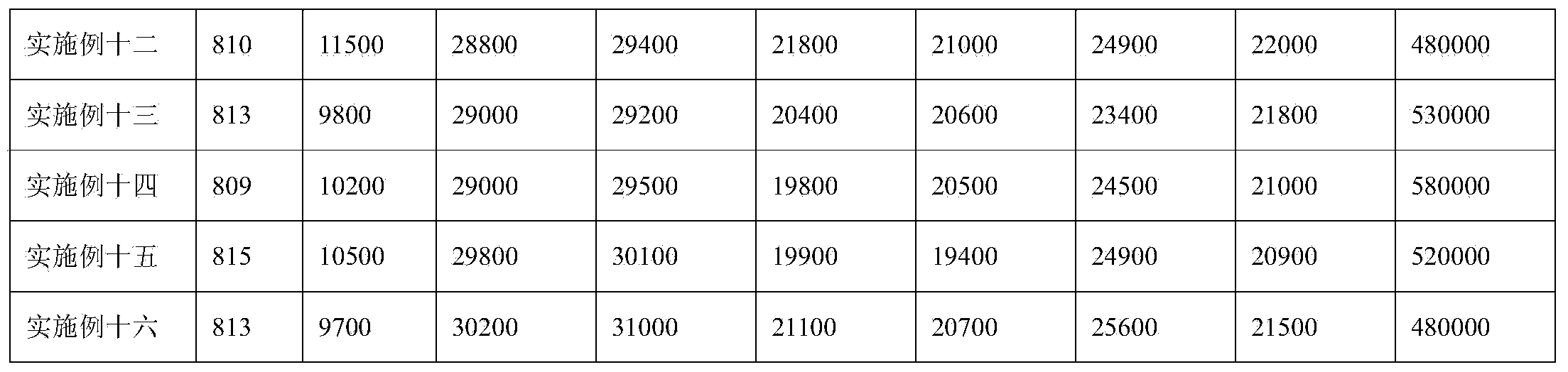

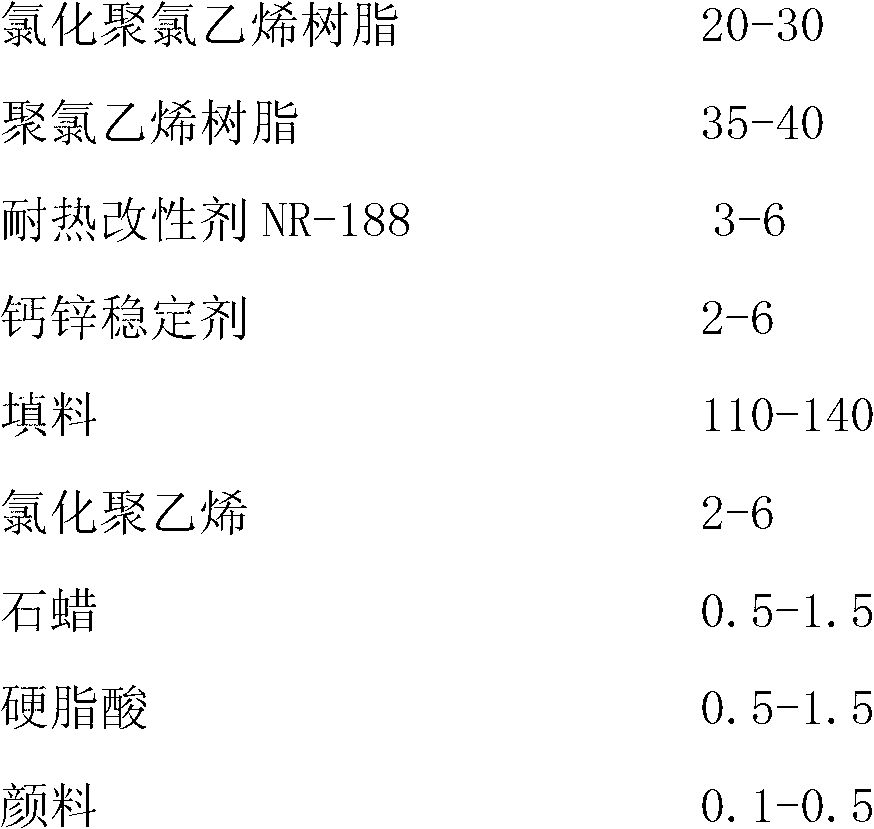

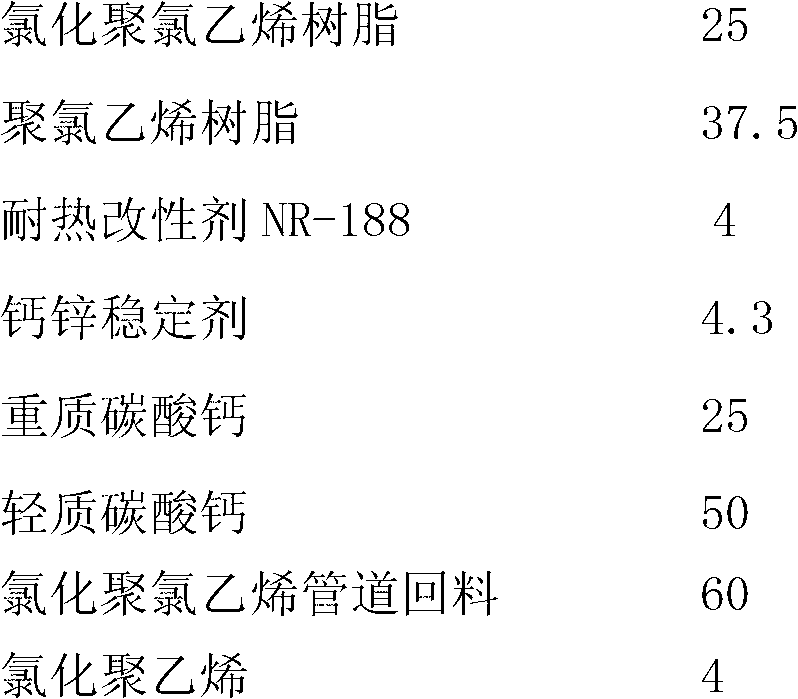

Chlorinated polyvinyl chloride pipeline

ActiveCN103012998AGuaranteed impact toughnessImprove cooling effectRigid pipesChlorinated polyvinyl chlorideChlorinated polyethylene

The invention discloses a chlorinated polyvinyl chloride pipeline for protecting cables. In order to overcome the defects of poor anti-impact toughness, high cost and poor heat dissipation of the existing chlorinated polyvinyl chloride pipeline, the pipeline disclosed by the invention is prepared from the following components: chlorinated polyvinyl chloride resin, polyvinyl chloride resin, a heat-resisting modifier NR-188, a calcium-zinc stabilizing agent, filler, chlorinated polyvinyl chloride, paraffins, stearic acid and pigment. The invention has the advantages that the vicat softening temperature is increased and the heat dissipation property of the pipeline is enhanced under the condition of guaranteeing the anti-impact toughness of the pipeline; the requirement on the anti-impact toughness of the underground pipeline is satisfied and the requirement on the heat dissipation property of the protection pipe for the cable is also satisfied; the cost is low; the special equipment is not needed to add; and the production line of the common chlorinated polyvinyl chloride pipeline is used.

Owner:HANGZHOU XINLU IND CO LTD

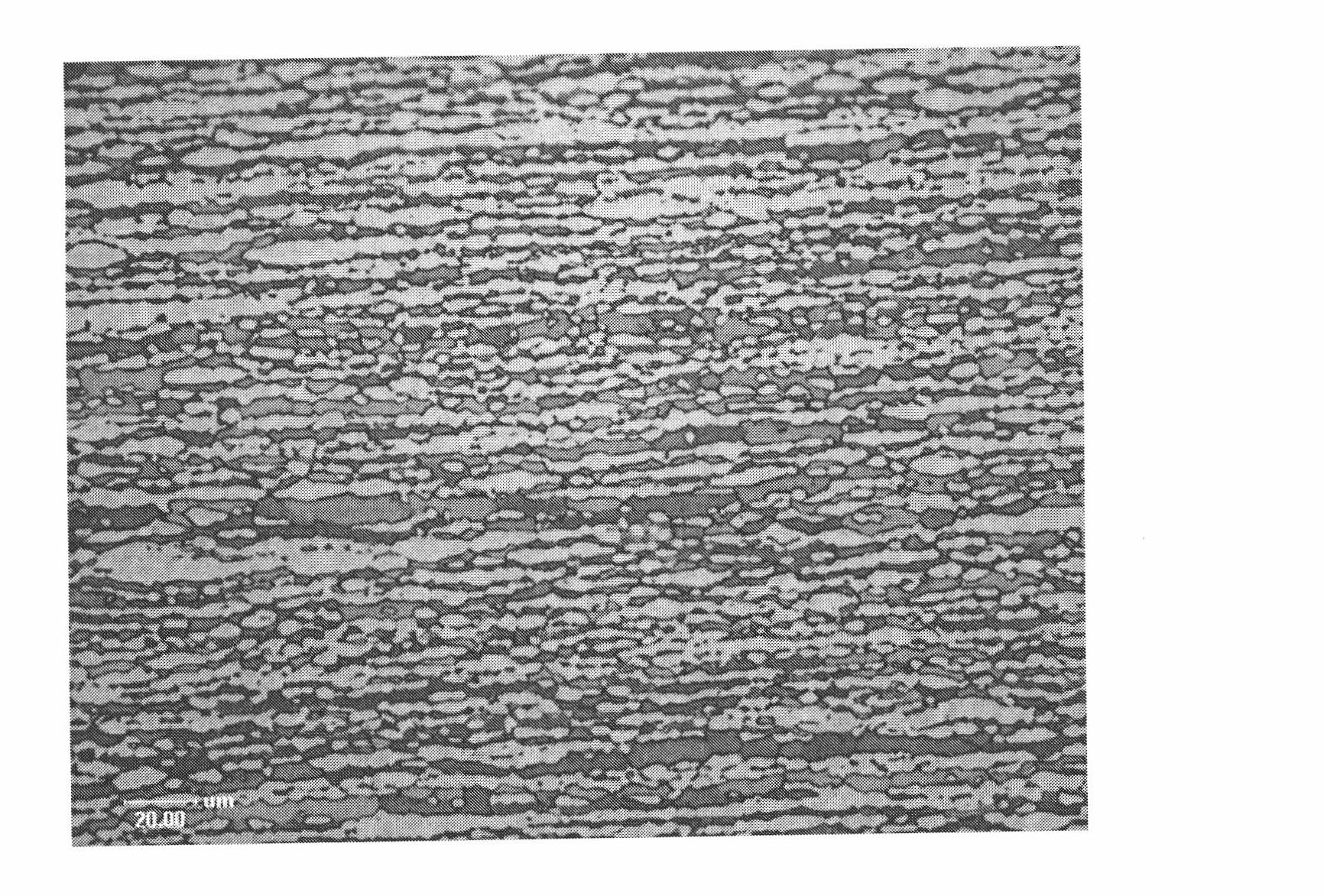

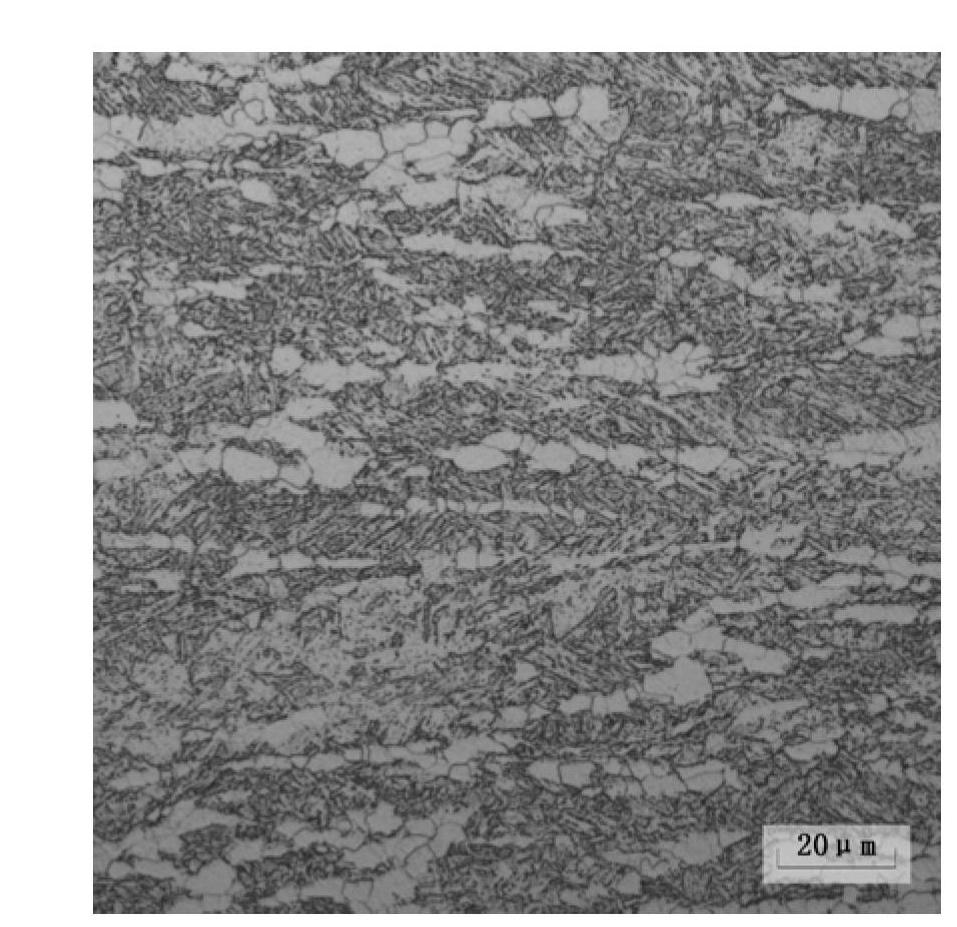

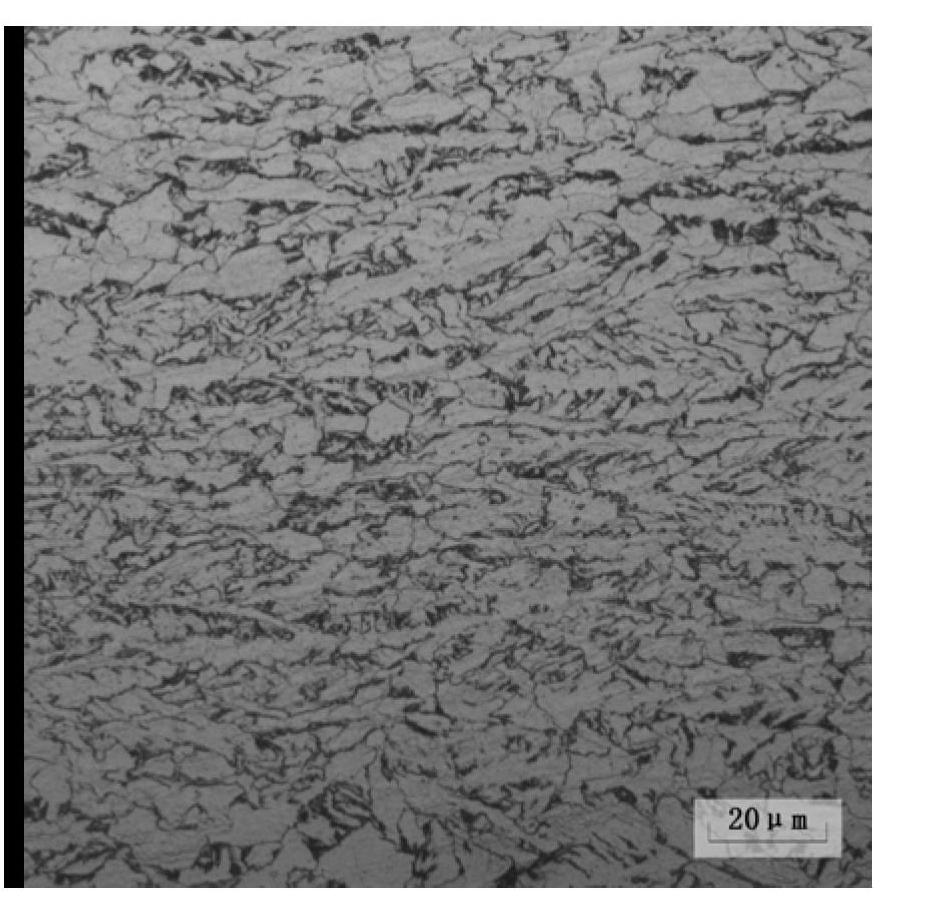

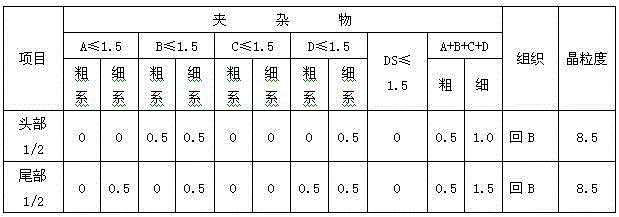

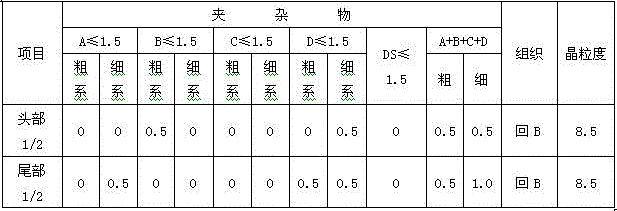

High-end bearing steel material for machine tool bearing ring and manufacturing method of high-end bearing steel material for machine tool bearing ring

ActiveCN110257717AImprove mechanical propertiesImprove purityElectric furnaceProcess efficiency improvementRare-earth elementNumerical control

The invention relates to a high-end bearing steel material for a machine tool bearing ring and a manufacturing method of the high-end bearing steel material for the machine tool bearing ring, and belongs to the technical field of special steel smelting forging. The high-end bearing steel material aims to solve the problem that the performance of the steel material cannot meet the requirement of a high-end numerical control machine tool due to the fact that the carbide inside the steel material for the bearing ring is segregated and distributed in a mesh mode, the steel material is caused not to meet the requirement of the high-end numerical control machine tool, the invention provides the high-end bearing steel material for the machine tool bearing ring and the manufacturing method of the high-end bearing steel material for the machine tool bearing ring, and comprises the following steps of electric furnace, LF refining and VD process, die casting, hot charging / cover cooling, heating rolling, slow cooling, and spheroidizing annealing. According to the steel material and the method, Ni, Mo and rare earth element are added on the basis of existing bearing steel, the content of Al and Cu is strictly controlled, and a good mechanical property index is provided for the steel material; the carbide in the manufacturing process is effectively diffused, the carbide level of the steel material is improved, the steel material for the bearing ring of the machine tool has a high elastic limit, tensile strength, contact fatigue strength and wear resistance, and can effectively reduce the phenomena of fatigue peeling, blocking and the like.

Owner:建龙北满特殊钢有限责任公司

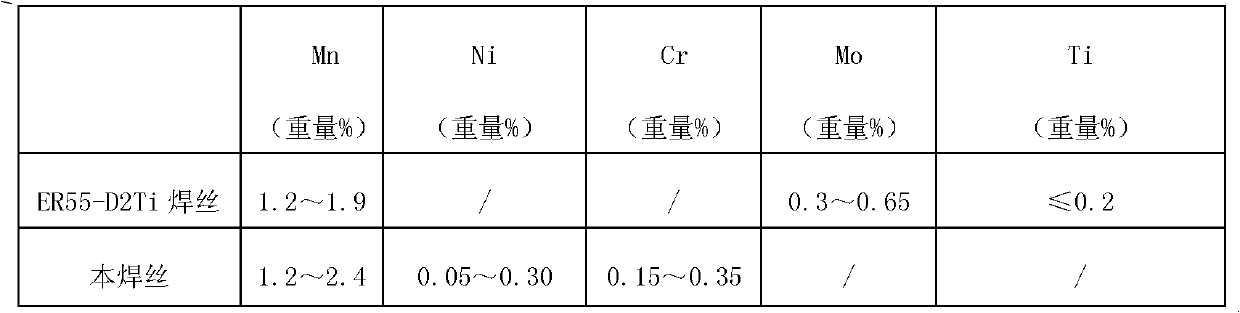

Solid welding wire for high-toughness structural steel

ActiveCN101905393AIncrease contentMeet welding requirementsArc welding apparatusWelding/cutting media/materialsChemical compositionSheet steel

The invention provides a solid welding wire for high-toughness structural steel, which comprises the following chemical components by weight percent: C: 0.06-0.12, Si: 0.4-0.8, Mn: 1.2-2.4, Ni: 0.05-0.30, Cr: 0.15-0.30, S: not more than 0.015, P: not more than 0.020 and the balance of Fe and other unavoidable impurities. As for the solid welding wire for the high-toughness structural steel provided by the invention, yield strength for deposited metal is more than 500MPa and tensile strength is more than 600MPa; after welding, welding seams have beautiful shaping, little splash and low crack sensitivity, thus meeting the welding requirement for a low-alloy high strength steel plate; and relative to an ER55-D2Ti welding wire or a 60kg of welding wire containing Ni-Mo system, the solid welding wire of the invention lowers production cost and use cost on the premise of guaranteeing intensity and impact toughness, thus being suitable for large-scale popularization and application.

Owner:YICHANG MONKEY KING WELDING WIRE

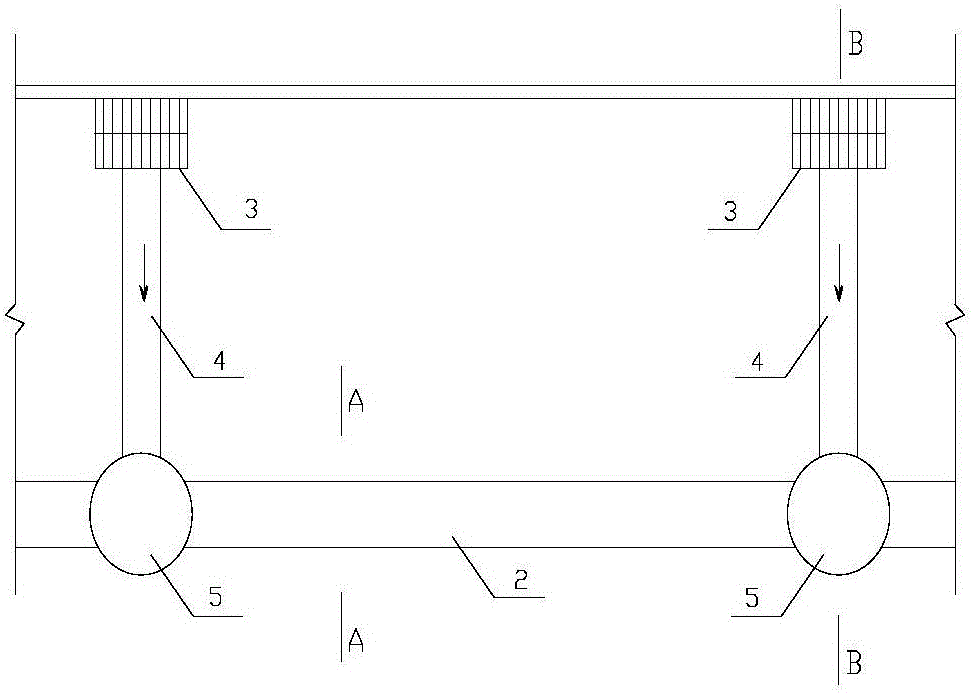

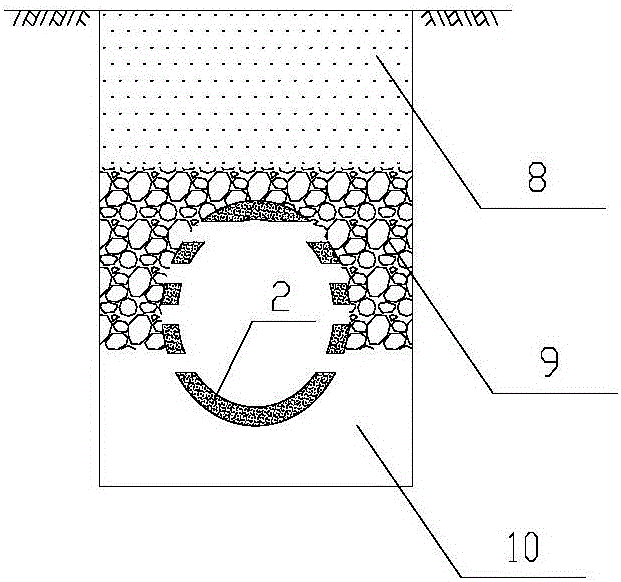

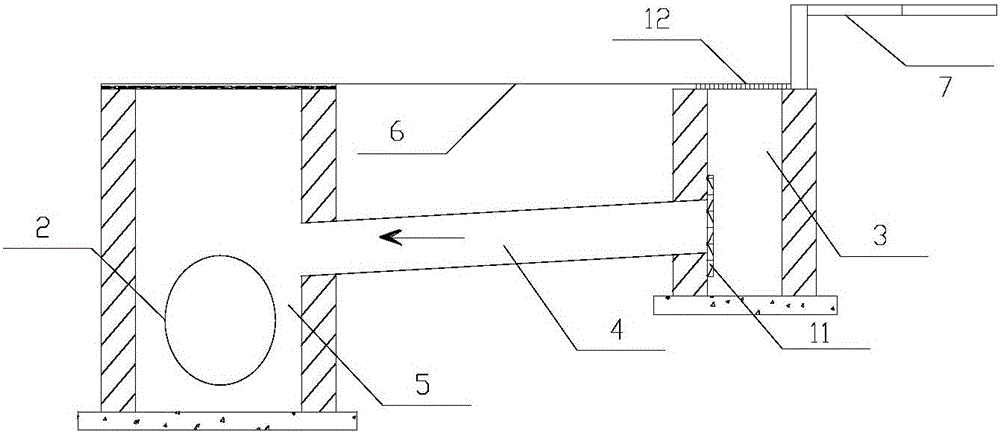

Urban rainwater pipeline system capable of effectively supplementing underground water

InactiveCN105002973AReduce water loadImprove water delivery capacityFatty/oily/floating substances removal devicesSewerage structuresEngineeringStormwater

The invention discloses an urban rainwater pipeline system capable of effectively supplementing underground water. The urban rainwater pipeline system includes a plurality of rainwater openings, filtering screens, rainwater connecting pipes and manholes which are quantitatively corresponding to the rainwater openings respectively, municipal rainwater pipes and filtering layers; each rainwater opening is provided with a first channel which is communicated with two ends of the rainwater opening; and each rainwater connecting pipe is provided with a second channel which is communicated with two ends of the rainwater connecting pipe; each municipal rainwater is provided with a third channel which is communicated with two ends of the municipal rainwater; the manholes are provided with cavities; the rainwater openings are connected with the rainwater connecting pipes; the first channels and the second channels are connected together so as to form channels which are communicated with the rainwater openings and the rainwater connecting pipes; the rainwater connecting pipes are connected with the manholes; the second channels are communicated with the cavities of the manholes; the manholes are connected with the municipal rainwater pipes; the cavities of the manholes are communicated with the third channels of the municipal rainwater pipes; the municipal rainwater pipes are provided with water seepage holes which are communicated with the interiors and the exteriors of the pipe walls of the municipal rainwater pipes; the exteriors of the municipal rainwater pipes are provided with the filtering layers; the filtering layers completely cover the water seepage holes; and the filtering screens are arranged at end portions of the rainwater connecting pipes, wherein the end portions of the rainwater connecting pipes are adjacent to the rainwater openings.

Owner:ANHUI UNIV OF SCI & TECH

Method for preparing large-specification thin-composite-layer nickel-based alloy and pipeline steel composite plate

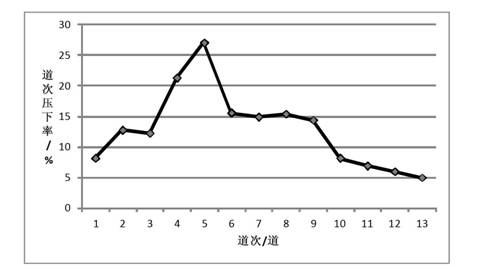

ActiveCN107185961AGuaranteed bonding strengthGuaranteed stretching effectRoll force/gap control deviceTemperature control deviceReduction ratioAlloy

The invention discloses a method for preparing a large-specification thin-composite-layer nickel-based alloy and pipeline steel composite plate. The method comprises the following steps that 1, a nickel-based alloy plate serving as a composite layer and a pipeline steel plate serving as a base layer are composited to prepare composite board blank through explosion welding; 2, a leveling treatment is carried out on the composite board blank, and then a heating treatment is carried out on the composite board blank; 3, a cooling treatment is carried out on the heated composite board blank; and 4, the composite board blank which is subjected to the cooling treatment is fed into an asynchronous rolling mill for asynchronous rolling to obtain the nickel-based alloy and pipeline steel composite plate, wherein the shearing strength of the nickel-based alloy and pipeline steel composite board is not less than 210 MPa, the total rolling reduction ratio of asymmetrical rolling is 50%-90%, and the different speed ratio of each pass of the asynchronous rolling mill is 1.05-1.30. According to the method for preparing the composite plate, the corrosion resistance of the nickel-based alloy plate serving as the composite layer is ensured, and the tensile property and the impact toughness of the pipeline steel plate serving as the base layer are ensured; and the bonding strength and other properties of the composite plate can meet the requirements specified in the NB / T47002.2 standard, and even the requirement for rolling force of the rolling mill is reduced.

Owner:XIAN TIANLI CLAD METAL MATERIALS

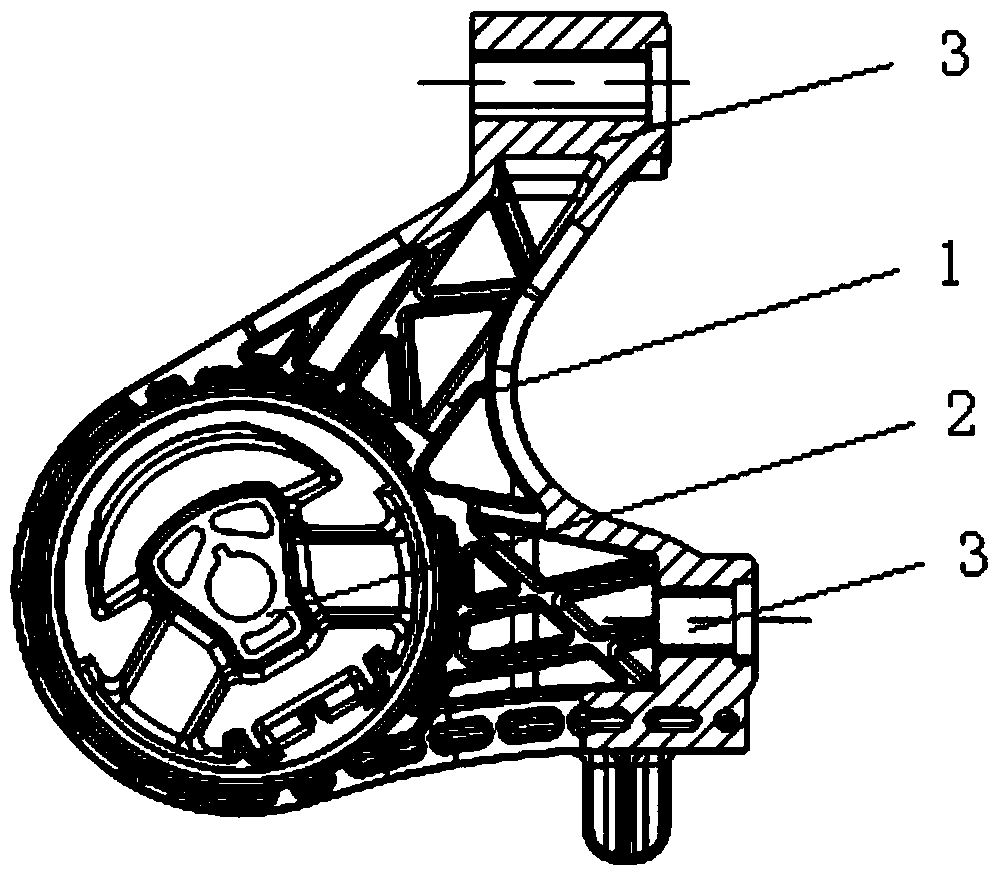

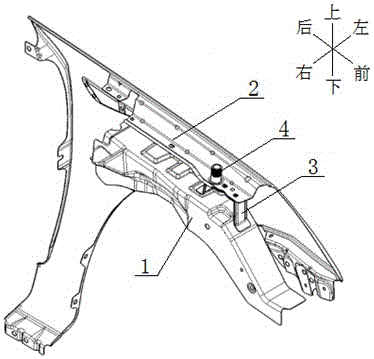

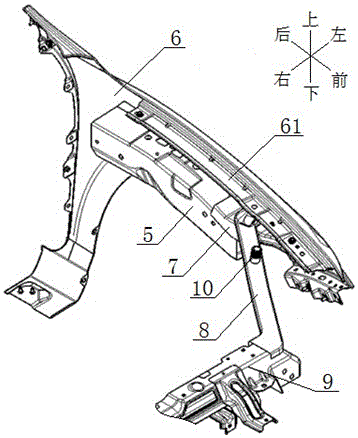

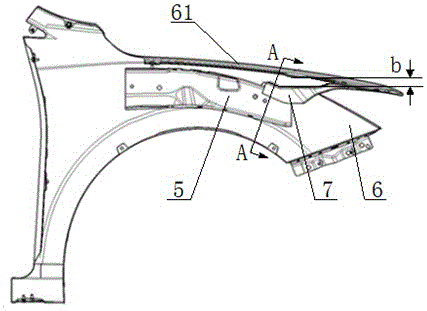

Fender mounting structure

ActiveCN105946983AGuaranteed connection stiffnessGuaranteed impact toughnessSuperstructure subunitsEngineeringPedestrian

The invention relates to a fender mounting structure which comprises a front hub strengthening beam, a fender and a fender support. The fender support is positioned between the front hub strengthening beam and the fender, is connected with the front end of the front hub strengthening beam and is used for supporting the fender. The fender mounting structure is characterized by further comprising a headlamp transverse beam and a front upper component assembly; one end of the headlamp transverse beam is connected with the fender support, and the front upper component assembly is connected with the other end of the headlamp transverse beam. The fender mounting structure has the advantages that certain impact toughness can be guaranteed while the connection rigidity of the fender is guaranteed, injury to pedestrians after the pedestrians are knocked down by automobiles can be relieved, and the life safety of the pedestrians can be protected; connection errors in the vertical directions can be reduced, and accordingly appearance gaps of the automobiles can be guaranteed.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Halogen-free flame-retarding polyamide composition

The invention relates to a halogen-free flame-retarding polyamide composition, which includes, by weight, 73-93 parts of polyamide, 7-23 parts of melamine or a derivative thereof, 0.1-3 parts of silsesquioxane, and 0.1-1 part of an antioxidant, wherein the melamine or the derivative thereof is subjected to organic treatment. Compared with the prior art, the composition has excellent flame-retarding performance. The composition reaches 0.8 mm UL 94 V-0 in flame-retarding performance and 90 J / m in notch impact strength. The composition has simple process, is convenient to produce and can be applied in the fields of electronic appliances, automobiles and the like.

Owner:上海安凸塑料添加剂有限公司

Superhigh strength X100 pipeline steel and its hot rolled plate making process

ActiveCN100398684CHas construction costsReduce construction costsTemperature control deviceCooling temperatureImpurity

The present invention relates to pipeline steel, and is especially one kind of superhigh strength X100 pipeline steel and process of making hot rolled plate of the X100 pipeline steel. The superhigh strength X100 pipeline steel consists of C 0.015-0.080 wt%, Mn 1.80-2.50 wt%, Si not more than 0.6 wt%, S not more than 0.0030 wt%, P not more than 0.015 wt%, Nb 0.04-0.15 wt%, Ti 0.005-0.030 wt%, V not more than 0.120 wt%, Alt not more than 0.060 wt%, N not more than 0.010 wt%, O not more than 0.006 wt%, Mo 0.10-0.60 wt%, Cu not more than 0.50 wt%, Ni not more than 1.50 wt%, Cr not more than 1.0 wt%, B not more than 0.0020 wt%, Ca not more than 0.01 wt%, and Fe and inevitable impurity for the rest. The rolling process of making hot rolled plate has plate blank heating temperature of 1100-1250 deg.c, final rolling temperature of 720-880 deg.c, final cooling temperature of 200-500 deg.c and cooling speed of 3-30 deg.c / s.

Owner:BAOSHAN IRON & STEEL CO LTD

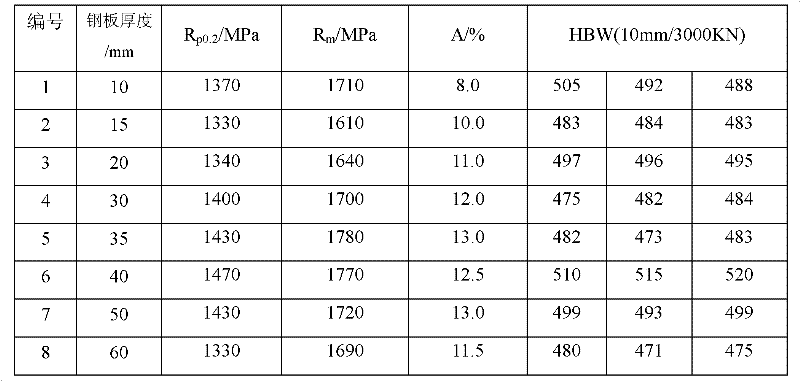

Scraper knife blade purposed steel with Brinell hardness of 470-520 and production method thereof

InactiveCN102337467AGuaranteed cold bending performanceImprove machinabilityRoll force/gap control deviceTemperature control deviceChemical compositionHardness

The invention relates to a loader and excvavtor scraper knife blade purposed steel with the Brinell hardness of 470-520 and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.26-0.35% of C, less than or equal to 0.20-0.50% of Si, 1.0-1.50% of Mn, less than or equal to 0.020% of P, less than or equal to 0.015% of S, 0.20-0.70% of Cr, 0.020-0.06% of Ti, less than or equal to 0.35% of Mo, 0.0005-0.0050% of B, less than or equal to 0.3% of Cu, less than or equal to 0.018% of As and the balance of Fe and inevitable impurities. The production method comprises the following production steps of: desulfurizing molten iron; carrying out compound blowing on the top and the bottom of the converter; carrying out RH (Ruhrstahl-Heraeus) vacuum processing to protect to be poured into a continuous casting billet in the whole flow; heating the continuous casting billet; blooming; and carrying out finish rolling for later use. The loader and excvavtor scraper knife blade purposed steel has the advantages of simple ingredient, stable technology, excellent mechanical property, high cost performance and good welding performance. A hardened and tempered steel plate can be directly welded when the hardened and tempered steel plate is not preheated, and has good cold bending performance.

Owner:武钢集团有限公司

High-chromium chromium-molybdenum steel plate and production method thereof

The invention discloses a high-chromium chromium-molybdenum steel plate and a production method thereof. The steel plate is composed of the following components in percentage by weight: 0.09%-0.15% of C, 0.5%-0.90% of Si, 0.30%-0.60% of Mn, at most 0.007% of P, at most 0.005% of S, 8.00%-10% of Cr, 0.90%-1.1% of Mo, at most 0.20% of Cu, 0.05%-0.10% of Ni, at most 0.003% of Sb, at most 0.005% of Sn, at most 0.012% of As, and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting and die casting, heating and rolling, and heat treatment. The high-chromium chromium-molybdenum steel plate satisfies the requirements of high strength, high toughness and high processability for domestic power equipment industry, and can be widely used for manufacturing of domestic power equipment. The steel plate has the advantages of favorable cold bending property, no cracking in the material manufacturing process, and favorable resilience.

Owner:WUYANG IRON & STEEL

Method for preparing automobile damping plastic

The invention discloses a method for preparing automobile damping plastic. The method comprises the following steps: mixing polycarbonate, an acrylonitrile-butadiene-styrene copolymer, polystyrene, a calcium carbonate complex, sepiolite powder, lanthanum oxide, kieselguhr and fumed silica to obtain a first material; putting epoxy soybean oil, disproportionated rosin, vinyl tri(beta-methoxyethyoxyl)silane, an antioxidant 168, an anti-aging agent DFC-34, stearic acid and acetic anhydride into the first material, mixing, heating, degumming, leaving to stand at the room temperature, further adding tert-butyl hydroperoxide and dibutyltin dilaurate, performing heating stirring, extruding, performing injection molding, and cooling, thereby obtaining the automobile damping plastic. The automobile damping plastic prepared with the method is very excellent in damping property and very high in impact resistance, the impact strength and the toughness under a high-temperature condition can be ensured, and the damping problem of a material can be remarkably improved.

Owner:无为县大江橡塑制品有限公司

PC/PMMA alloy material for LED lampshade and preparation method of PC/PMMA alloy material

PendingCN113999513AEnsure transparencyImprove impact toughnessPolymethyl methacrylateRefractive index

The invention discloses a PC / PMMA alloy material for an LED lampshade and a preparation method of the PC / PMMA alloy material. The PC / PMMA alloy material is prepared from the following materials in parts by mass: 55 to 75 parts of PC; 15 to 35 parts of PMMA (Polymethyl Methacrylate); 4 to 8 parts of MBS; 4 to 8 parts of SMA; 1 to 3 parts of an organic silicon light diffusion agent; 0.2 to 0.4 part of an antioxidant; 0.1 to 0.3 part of a light stabilizer; and 0.3 to 0.5 part of a lubricant. The refractive index of the PC ranges from 1.491 to 1.498; the refractive index of the PMMA ranges from 1.490 to 1.500; the particle size of the MBS is 220 nm to 320 nm; the content of MA in the SMA is 10%-20%; and the particle size of the organic silicon light diffusion agent is 2-10 [mu]m. According to the scheme, the light diffusion PC / PMMA material with high transparency, high surface hardness, high toughness and high rigidity is prepared from PC and PMMA base materials with a specific direct incidence rate, the composite compatilizer, the flexibilizer with a specific particle size, the light diffusion agent, the antioxidant, the weather-proof agent, the lubricant and the like based on a traditional twin-screw extrusion process, and can be applied to LED lampshades.

Owner:QINGDAO GON TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com