High-plasticity economical duplex stainless steel and manufacturing method thereof

A technology of duplex stainless steel and its manufacturing method, which is applied in the field of high-plasticity economical duplex stainless steel and its manufacture, can solve problems not involving material plasticity, etc., achieve the effects of reducing adverse effects, excellent corrosion resistance, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The metallographic structure of the alloy of embodiment 1 is as figure 1 shown. After the sample is ground and polished, electrolytic corrosion is performed, and the etchant is 40Gkoh+100mlH 2 O, corrosion current 0.3~0.8A / cm 2 , and finally analyzed the proportion of austenite by quantitative metallographic method under metallographic microscope. In the figure, the black structure is ferrite, the white structure is austenite, and the austenite phase accounts for about 48%.

Embodiment 2

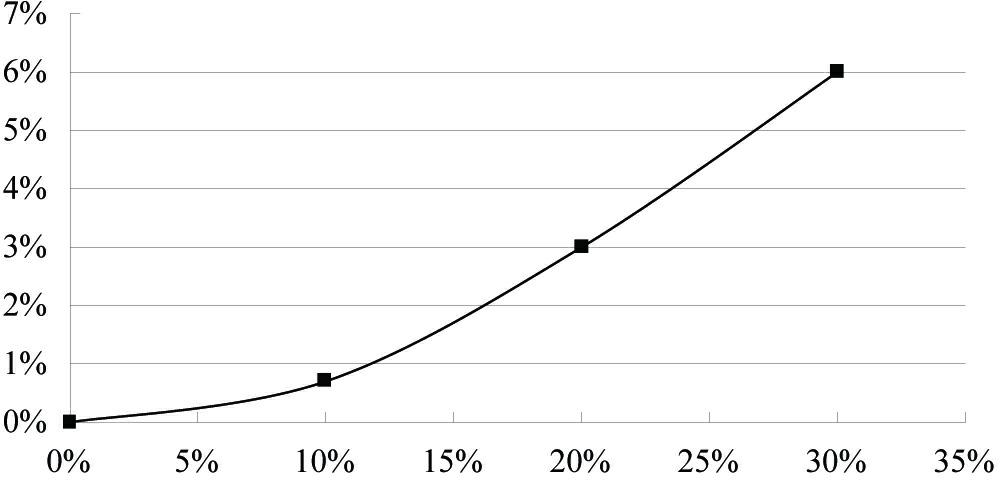

[0059] The change of martensite content in the organization in the stretching process of embodiment 2 is as follows figure 2 shown. The tensile sample is manufactured according to the JIS-13B standard. After stretching to a predetermined amount of deformation on the MTS-810 stretching machine, it stops and unloads. Then, the magnetic change before and after stretching is measured by a magnetic instrument to confirm the stretching process. Whether martensite is produced in the medium and roughly confirm the amount of martensite. figure 2 It shows that in the process of tensile deformation, part of the austenite undergoes phase transformation to form deformed martensite, which is the key reason for the improvement of its plasticity.

[0060]It can be seen from Table 1 and Table 2 that the steel of the present invention uses 0.5-4.0% Mn and 0.1-0.18% N to replace Ni, compared with 304 austenitic stainless steel containing Ni up to 8% and Ni up to 10%. And 316 austenitic stain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com